-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

User’s

Manual

Yokogawa Electric Corporation

ADMAG AXF Series

F

Fieldbus Communication Type

OUNDATION

Magnetic Flowmeter

IM01E20F02-01E

IM01E20F02-01E

3rd Edition

Related Manuals for YOKOGAWA ADMAG AXF Series

Summary of Contents for YOKOGAWA ADMAG AXF Series

-

Page 1

User’s Manual ADMAG AXF Series Fieldbus Communication Type OUNDATION Magnetic Flowmeter IM01E20F02-01E IM01E20F02-01E 3rd Edition Yokogawa Electric Corporation… -

Page 2: Table Of Contents

AI Function Block Parameters …………5-4 DI Function Block Parameters …………5-7 Integral LCD Indicator …………….. 5-8 5.6.1 Flow Data Display ……………. 5-8 5.6.2 Display Modes …………….5-10 IM 01E20F02-01E 3rd Edition: June 2012 All Rights Reserved, Copyright © 2006, Yokogawa Electric Corporation…

-

Page 3

CONTENTS IN-PROCESS OPERATION …………….6-1 Mode Transition ……………… 6-1 Generation of Alarm …………….6-1 6.2.1 Indication of Alarm …………… 6-1 6.2.2 Alarms and Events …………… 6-1 Simulation Function …………….6-2 DEVICE INFORMATION …………….7-1 DEVICE STATUS …………….7-1 Status of each parameter in failure mode ………. 7-4 PARAMETER LISTS ……………… -

Page 4

CONTENTS APPENDIX 2. INTEGRATOR (IT) BLOCK …………A-6 A2.1 Schematic Diagram of Integrator Block ……….A-6 A2.2 Input Process Section …………….. A-7 A2.2.1 Determining Input Value Statuses ……….A-7 A2.2.2 Converting the Rate …………..A-7 A2.2.3 Converting Accumulation …………. A-8 A2.2.4 Determining the Input Flow Direction ……….. -

Page 5

CONTENTS APPENDIX 5. PID BLOCK …………….A-32 A5.1 Function Diagram …………….A-32 A5.2 Functions of PID Block …………..A-32 A5.3 Parameters of PID Block …………..A-33 A5.4 PID Computation Details …………..A-35 A5.4.1 PV-proportional and -derivative Type PID (I-PD) Control Algorithm ……………. A-35 A5.4.2 PID Control Parameters …………. -

Page 6: Introduction

1. INTRODUCTION INTRODUCTION This manual is for the ADMAG AXF Series Magnetic WARNING Flowmeter Remote Converter F fieldbus OUNDATION Communication Type. The F fieldbus OUNDATION Indicates a potentially hazardous situation which, communication type is based on the same ADMAG if not avoided, could result in death or serious AXF technology used in the BRAIN/HART communi- injury.

-

Page 7: Safe Use Of This Product

• The wiring of the magnetic flowmeter must be (f) Modification performed by expert engineer or skilled personnel. • Yokogawa will not be liable for malfunctions or No operator shall be permitted to perform proce- damage resulting from any modification made to this dures relating to wiring.

-

Page 8: Warranty

— Use of the product in question in a location not conforming to the standards specified by Yokogawa, or due to improper maintenance of the installation location. — Failure or damage due to modification or repair by any party except Yokogawa or an approved representative of Yokogawa.

-

Page 9: About Fieldbus

• Switches two main inputs of different measurement the specification standardized by The Fieldbus Founda- ranges and combines the result with three auxiliary tion, and provides interoperability between Yokogawa inputs through the selected compensation function to devices and those produced by other manufacturers.

-

Page 10: Wiring System Configuration

2. ABOUT FIELDBUS 2.4 Wiring System Configuration The number of devices that can be connected to a single bus and the cable length vary depending on system design. When constructing systems, both the basic and overall design must be carefully considered to achieve optimal performance.

-

Page 11: Getting Started

3. GETTING STARTED GETTING STARTED Fieldbus is fully dependent upon digital communica- Refer to Yokogawa when making arrangements to tion protocol and differs in operation from conven- purchase the recommended equipment. tional 4 to 20 mA transmission and the BRAIN Connect the devices as shown in Figure 3.1.

-

Page 12: Host Setting

3. GETTING STARTED 3.2 Host Setting 0x00 Not used To activate Fieldbus, the following settings are 0x0F 0x10 required for the host. Bridge device 0x13 0x14 LM device V(FUN) IMPORTANT Unused V(NUN) Do not turn off the power immediately after setting.

-

Page 13: Bus Power On

59454300B Using the host device display function, check that the (594543 is the manufacturer number of Yokogawa AXF is in operation on the bus. Electric Corporation, and 000B is the AXF device The device information, including PD tag, Node number, respectively.)

-

Page 14: Continuous Record Of Values

3. GETTING STARTED 3.6 Continuous Record of Values If the host has a function that continuously records the indications, use this function to list the indications (values). Depending on the host being used, it may be necessary to set the schedule of Publish (the function that transmits the indication on a periodic basis).

-

Page 15: Configuration

4. CONFIGURATION CONFIGURATION • Terminator This chapter describes how to adapt the function and performance of the AXF to suit specific applications. Fieldbus requires two terminators. Refer to the Because multiple devices are connected to Fieldbus, it supplier for details of terminators that are attached is important to carefully consider the device require- to the host.

-

Page 16: Definition Of Combining Function Blocks

4. CONFIGURATION Table 4.2 Operation Parameter Values of the AXF to be bus control function allocated from a larger address Set to LM Devices number (247) side respectively. Place the AXF in the range of the BASIC device. When the AXF is used as Symbol Parameters Description and Settings…

-

Page 17: Setting Of Tags And Addresses

4. CONFIGURATION 4.4 Setting of Tags and A maximum of 30 ms is taken for execution of AI block. For scheduling of communications for combina- Addresses tion with the next function block, the execution is so This section describes the steps in the procedure to set arranged as to start after a lapse of longer than 30 ms.

-

Page 18: Communication Setting

4. CONFIGURATION 4.5 Communication Setting Table 4.4 VCR Static Entry Sub- Parameter Description To set the communication function, it is necessary to index change the database residing in SM-VFD. FasArTypeAndRole Indicates the type and role of communication (VCR). The 4.5.1 VCR Setting following 4 types are used for AXF.

-

Page 19: Function Block Execution Control

4. CONFIGURATION 4.6 Block Setting Sub- Parameter Description index Set the parameter for function block VFD. FasDllSubsriberTime Not used for AXF. WindowSize 4.6.1 Link Object FasDllSubscriber Not used for AXF. SynchronizationDlcep A link object combines the data voluntarily sent by the function block with the VCR.

-

Page 20: Trend Object

4. CONFIGURATION 4.6.2 Trend Object SMIB DI2 OUT (System Transducer Resource Management AI OUT It is possible to set the parameter so that the function block block DI1 OUT Information block automatically transmits Trend. AXF has seven Base) NMIB Trend objects, six of which are used for Trend in Alert (Network FBOD…

-

Page 21

4. CONFIGURATION Table 4.11 View Object for Resource Block (byte) (byte) Relative VIEW VIEW VIEW VIEW Relative VIEW VIEW VIEW VIEW Parameter Parameter Index Index ST_REV MAX_NOTIFY TAG_DESC LIM_NOTIFY STRATEGY CONFIRM_TIME ALERT_KEY WRITE_LOCK MODE_BLK UPDATE_EVT BLOCK_ERR BLOCK_ALM RS_STATE ALARM_SUM TEST_RW ACK_OPTION DD_RESOURCE WRITE_PRI… -

Page 22

4. CONFIGURATION Table 4.12 View Object for Transducer Block (byte) (byte) VIEW VIEW VIEW VIEW VIEW VIEW VIEW VIEW VIEW VIEW VIEW VIEW VIEW VIEW VIEW VIEW VIEW VIEW VIEW VIEW VIEW VIEW Relative Relative Parameter Mnemonic Parameter Mnemonic Index Index ST_REV VELOCITY_CHECK… -

Page 23

4. CONFIGURATION Table 4.13 View Object for AI Function Block Table 4.14 View Object for DI (DI1, DI2) Function Block (byte) (byte) Relative VIEW Relative VIEW VIEW VIEW VIEW VIEW VIEW VIEW Parameter Parameter Index Index ST_REV ST_REV TAG_DESC TAG_DESC STRATEGY STRATEGY ALERT_KEY… -

Page 24

4. CONFIGURATION Table 4.15 View Object for (IT1, IT2) Function Block Table 4.16 View Object for AR Function Block (byte) (byte) Relative VIEW Relative VIEW VIEW VIEW VIEW VIEW VIEW VIEW Parameter Parameter Index Index ST_REV ST_REV TAG_DESC TAG_DESC STRATEGY STRATEGY ALERT_KEY ALERT_KEY… -

Page 25: Function Block Parameters

4. CONFIGURATION Table 4.17 Indexes of View for Each Block VIEW_1 VIEW_2 VIEW_3 VIEW_4 Resourse Block 40100 40101 40102 40103 Transducer Block 40200 40201 40202 40203 AI Function Block 40400 40401 40402 40403 DI1 Function Block 40600 40601 40602 40603 DI2 Function Block 40610 40611…

-

Page 26: Explanation Of Basic Items

5. EXPLANATION OF BASIC ITEMS EXPLANATION OF BASIC ITEMS 5.1 Outline 5.2 Setting and Changing Param- eters for the Whole Process This chapter describes basic TR (Transducer block), AI, and DI function block parameter setting, displays of the integral indicator. Refer to Appendixes other IMPORTANT function blocks and LM function.

-

Page 27: Transducer Block Parameters

5. EXPLANATION OF BASIC ITEMS 5.3 Transducer Block Parameters The transducer block sets functions specific to the flow rate measurement of the ADMAG AXF. Figure5.3.1 presents the diagram of the Transducer block. PRIMARY_VALUE Dual freq. Rate limit Flow rate Lowcut (Channel1) operation damping…

-

Page 28

5. EXPLANATION OF BASIC ITEMS DISPLAY_SELECT1, 2, 3: Table 5.3.1 DISPLAY SELECT DISPLAY_SELEC T 1 DISPL AY_SELE CT 2 DISPL AY_SELE CT 3 The display content for the display The display content for the display unit’s The display content for the display unit’s first line. -

Page 29: Ai Function Block Parameters

5. EXPLANATION OF BASIC ITEMS 5.4 AI Function Block Parameters AI Function block parameters can be read or set from the host. Figure5.4.1 presents the diagram of AI Function block. Alarms IO_OPTS.Low cutoff HI,HI_HI LO,LO_LO SIMULATE.Enable LOW_CUT =1 (Enable) FIELD_VAL.Value L_TYPE PV.Value Disable…

-

Page 30

5. EXPLANATION OF BASIC ITEMS OUT: This parameter contains the current measurement value from Transducer Block or configuration adjusted engineering unit and the belonging state in AUTO MODE. OUT contains the value and status set by an operator in MAN MODE. Quality Sub-status Limit… -

Page 31

5. EXPLANATION OF BASIC ITEMS Table 5.4.1 Unit Codes Volume/ Time unit Mass unit Ml/h (65521) Ml/min (65520) kL/s (65522) Ml/d (1355) kL/d (1520) kL/h (1519) kL/min (1518) L/s (1351) L/d (1354) L/h (1353) L/min (1352) m3/d (1350) m3/ h (1349) m3/min (1348) m3/s (1347) cm3/d (1514) -

Page 32: Di Function Block Parameters

5. EXPLANATION OF BASIC ITEMS 5.5 DI Function Block Parameters DI Function block parameters can be read or set from the host. Figure5.5.1 presents the diagram of DI Function block. PV_D Simulate Optional Filter CHANNEL SIMULATE_D Invert PV_FTIME Output OUT_D FIELD_VAL_D Alarms DISC…

-

Page 33: Integral Lcd Indicator

5. EXPLANATION OF BASIC ITEMS 5.6 Integral LCD Indicator Flow Rate Flow rate is displayed together with the units set in Employing 32*132 full dot matrix backlit LCD, XD_SCALE, the maximum number of figures is six. various display can be obtained. 5.6.1 Flow Data Display — 1 2 3 .

-

Page 34

5. EXPLANATION OF BASIC ITEMS Flow Rate Unit Display on LCD Flow Rate Unit Display is shown by the following table corresponding to the XD_SCALE Units Codes. Table 5.6.1 Display Unit Codes LCD Display LCD Display LCD Display LCD Display LCD Display LCD Display LCD Display… -

Page 35: Display Modes

5. EXPLANATION OF BASIC ITEMS Arithmetic Out 1 2 3 The display is given in the same manner as Integrator l / h v e l A D H Out, decimal point is set by «AR:OUT_RANGE.Decimal_Point». F0515.eps Desimal Point AR:OUT_RANGE.Decimal_Point AR:OUT_RANGE.Decimal_Point Example Level1 : Adhesion Level2…

-

Page 36

5. EXPLANATION OF BASIC ITEMS Alarm Display 1 0 0 l / h I T 2 2 3 4 5 6 F o u n d a t i o n F i e l d b u s C O M Alarm generated P r o i p e… -

Page 37: Data Display

5. EXPLANATION OF BASIC ITEMS Category Category Alarm Message Alarm Message Countermeasure Message Countermeasure Message Alarm Description Alarm Description 10:uP Fault Microprocessor (CPU) failure 11:EEPROM Fault EEPROM failure Contact nearest office or service center 12:A/D(H) Fault 13:A/D(L) Fault A/D converter failure 14:A/D(Z) Fault 15:Coil Open Cut the power and check coil &…

-

Page 38

5. EXPLANATION OF BASIC ITEMS 9 9 9 l / h I T 1 1 2 3 4 5 6 9 9 9 l / h 2 3 5 5 6 I T 1 8 4 : 9 9 9 l / h I T 1 1 2 3 6 5 6… -

Page 39: In-Process Operation

6. IN-PROCESS OPERATION IN-PROCESS OPERATION 6.2.2 Alarms and Events This chapter describes the procedure performed when changing the operation of the function block of the The following alarms or events can be reported by the AXF in process. AXF if Link object and VCR static entry are set. Analog Alerts (Generated when a process value 6.1 Mode Transition exceeds threshold)

-

Page 40: Simulation Function

6. IN-PROCESS OPERATION 6.3 Simulation Function The simulation function simulates the input of a function block and lets it operate as if the data was received from the transducer block. It is possible to conduct testing for the downstream function blocks or alarm processes.

-

Page 41: Device Information

7. DEVICE INFORMATION DEVICE INFORMATION 7.1 DEVICE STATUS Device status for the AXF are indicated by using parameter DEVICE_STATUS_1 to DEVICE_STATUS_7 (index 1045 to 1052) in Resource Block. Table 7.1 Contents of DEVICE_STATUS_1 (Index 1045) Table 7.2 Contents of DEVICE_STATUS_2 (Index 1046) Indicator description Indicator…

-

Page 42

7. DEVICE INFORMATION Table 7.3 Contents of DEVICE_STATUS_3 (Index 1047) Table 7.5 Contents of DEVICE_STATUS_5 (Index 1049) Indicator description Indicator description 0x00000001 50:Span > 10m/s Span flow velocity setting is 11 m/s or more 0x00000001 30:Sig Overflow Input signal error 0x00000002 51:Span <… -

Page 43

7. DEVICE INFORMATION Table 7.7 Contents of DEVICE_STATUS_7 (Index 1051) Indicator description 0x00000001 130:AI Non-Schedule AI Block not scheduled 0x00000002 131:IT1 Non-Schedule IT1 Block not scheduled 0x00000004 132:IT2 Non-Schedule IT2 Block not scheduled 0x00000008 133:DI1 Non-Schedule DI1 Block not scheduled 0x00000010 134:DI2 Non-Schedule DI2 Block not scheduled… -

Page 44: Status Of Each Parameter In Failure Mode

7. DEVICE INFORMATION 7.2 Status of each parameter in failure mode Following tables summarize the value of AXF parameters and LCD display indicates an Alarm. Table 7.9 Alarm Summary BLOCK_ Primary Primary Value BLOCK_ Primary Primary Value Category Alarm ERROR Category Alarm ERROR…

-

Page 45: Parameter Lists

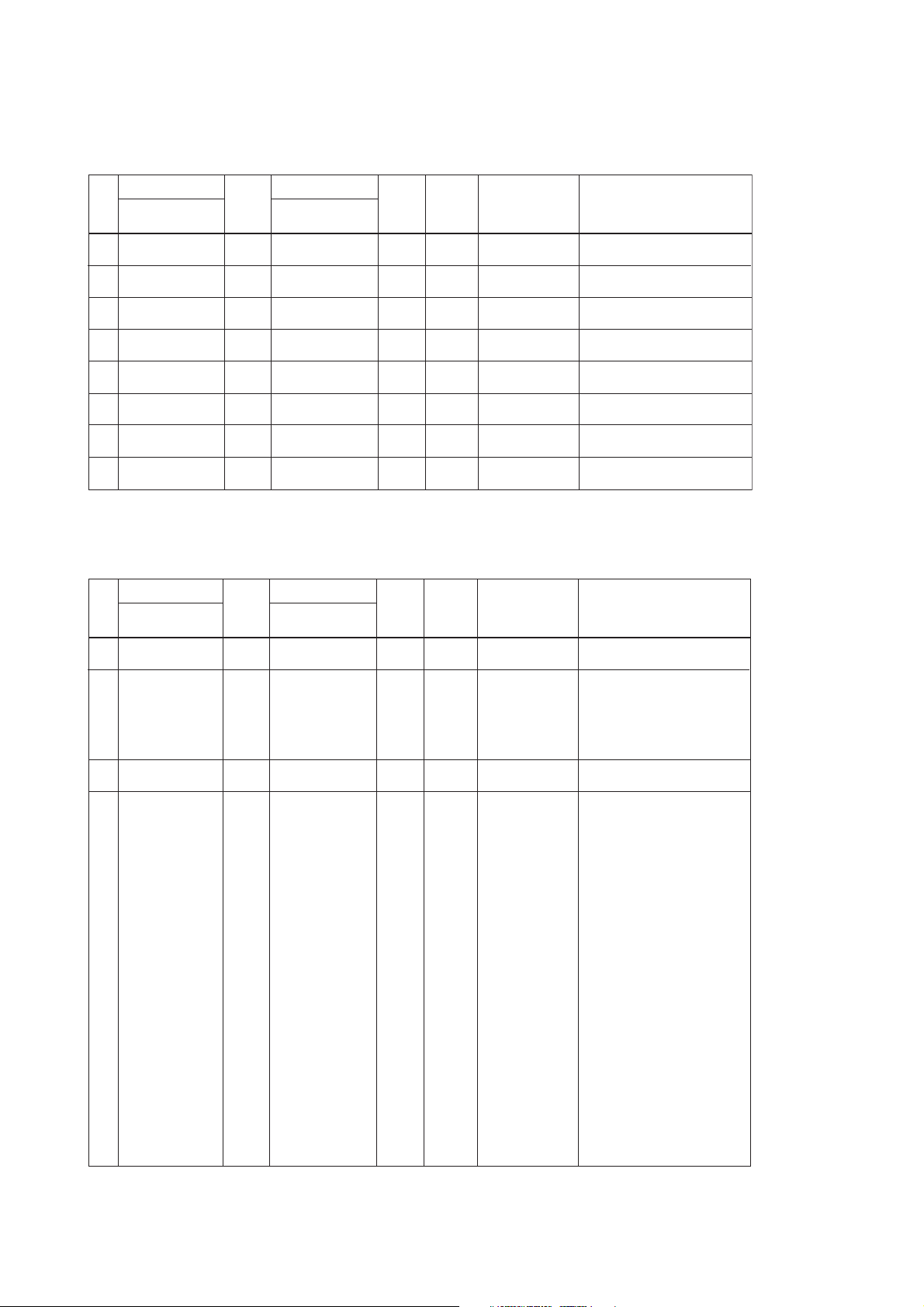

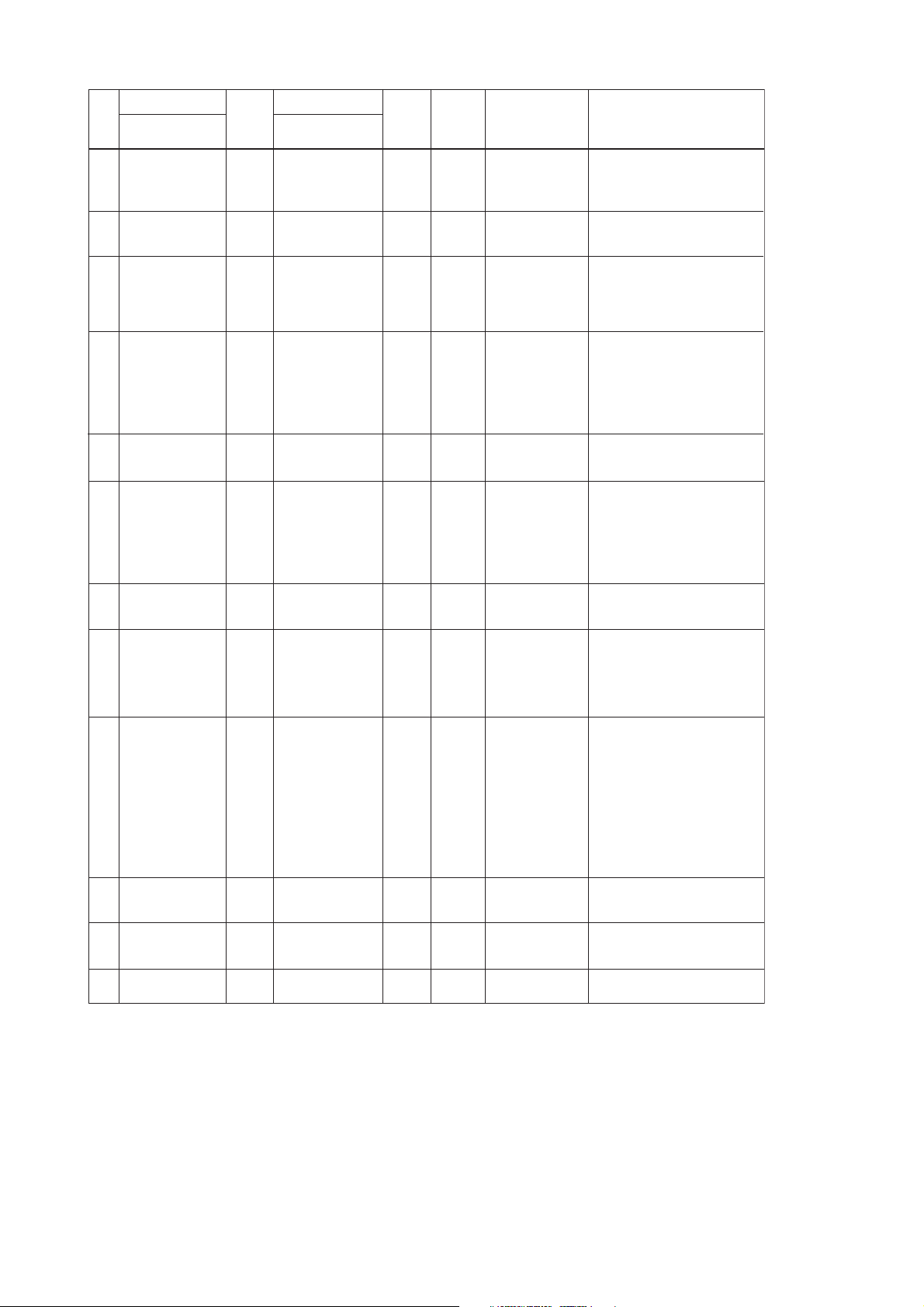

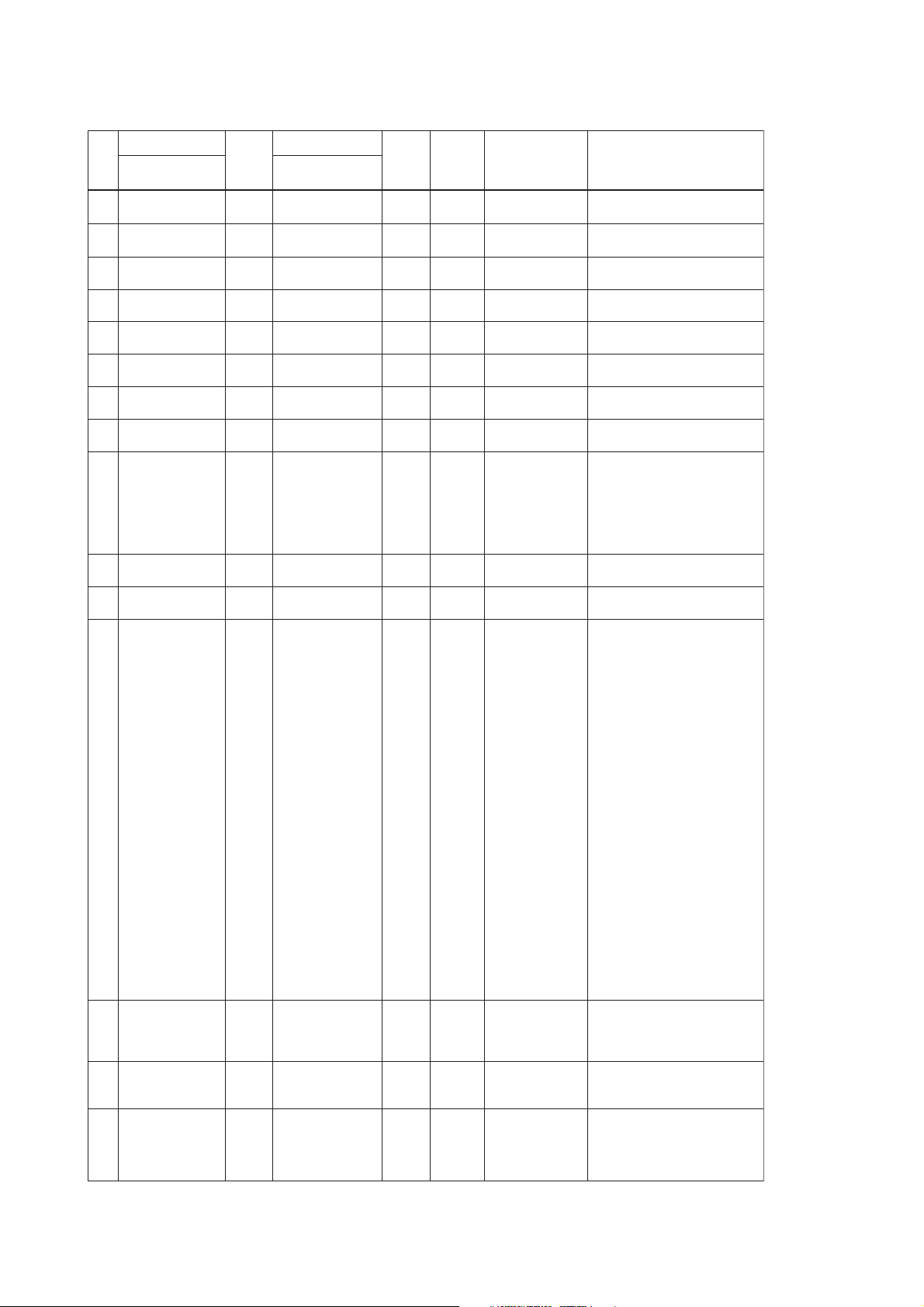

8. PARAMETER LISTS PARAMETER LISTS Note: The Write Mode column contains the modes in which each parameter is write enabled. O/S: Write enabled in O/S mode. MAN: Write enabled in Man mode and O/S mode. AUTO: Write enabled in Auto mode, Man mode, and O/S mode. Resource Block Relative Factory…

-

Page 46

This alert is generated if the write lock parameter is cleared. 1041 ITK_VER Version number of interoperability test by Fieldbus Foundation applied to AXF. 1042 SOFT_REV AXF software revision number. 1043 SOFT_DESC Yokogawa internal use. 1044 SIM_ENABLE_MSG Spaces Auto Software switch for simulation function. T0801-2.EPS IM 01E20F02-01E… -

Page 47

8. PARAMETER LISTS Relative Factory Write Index Parameter Name Explanation Index Default Mode 1045 DEVICE_STATUS_1 Device status for details, refer to Table 7.1. 1046 DEVICE_STATUS_2 Device status for details, refer to Table 7.2. 1047 DEVICE_STATUS_3 Device status for details, refer to Table 7.3. 1048 DEVICE_STATUS_4 Device status for details, refer to Table 7.4. -

Page 48: Transducer Block

METHOD Static weigh 100=volumetric 101=static weigh 102=dynamic weigh 255=other 2024 SENSOR_CAL_LOC Yokogawa Sets/indicates the location of the last sensor calibration. 2025 SENSOR_CAL_DATE 0, 0, 0, 0, 0, 0 Sets/indicates the date of the last sensor calibration. 2026 SENSOR_CAL_WHO Yokogawa Sets/indicates the name of the person responsible for the last sensor calibration.

-

Page 49

8. PARAMETER LISTS Relative Factory Write Index Parameter Name Explanation Index Default Mode 2027 LIN_TYPE 1: linear with input The linearization type of sensor output. AXF is «linear with input» 2028 SECONDARY_ N/A. For the future use. VALUE SECONDARY_ 2029 1061: m/s N/A. -

Page 50

8. PARAMETER LISTS Relative Factory Write Index Parameter Name Explanation Index Default Mode 2048 VELOCITY_CHECK This parameter is used in order to display the span velocity corresponding to PV_SCALE. E100. 2049 DENSITY_UNIT 1097: kg/m This parameter selects the units for density as required when making settings using MASS_FLOW_DENSITY. -

Page 51

8. PARAMETER LISTS Relative Factory Write Index Parameter Name Explanation Index Default Mode 2064 SWITCH_1_TARGET 1: Adhesion Alarm This parameter selects the input channel used to LIMSW_1_VALUE_D. 1: Adhesion Alarm 2: Adhesion Warning Indicate the value of switch 2, which switches ON and OFF SWITCH_2_ 2065 depending on the digital value of the target input parameter… -

Page 52

8. PARAMETER LISTS Relative Factory Write Index Parameter Name Explanation Index Default Mode 2085 ALARM_SUM Block Alarm status is shown by this parameter. Valid range is bit 0: Discrete alm, bit7: Block alarm (only bit 0 and bit 7 are effective). Initial value is Current: 0, Unacknowledged: 0, Unreported: 0, Disable: 0X0000 (all alarms are enable). -

Page 53: Ai Function Block

8. PARAMETER LISTS AI Function Block Relative Factory Write Index Parameter Name Explanation Index Default Mode 4000 Block Hedder TAG=»AI» Information on this block such as Block Tag, DD Revision, Execution Time etc. 4001 ST_REV The revision level of the static data associated with the function block.

-

Page 54

8. PARAMETER LISTS Relative Factory Write Index Parameter Name Explanation Index Default Mode Raw value of the field device in percent of the PV range, with a 4019 FIELD_VAL Bad — O/S status reflecting the Transducer condition, before signal characterization (L_TYPE), filtering (PV_FTIME), or low cut (LOW_CUT). -

Page 55: Dl Function Block

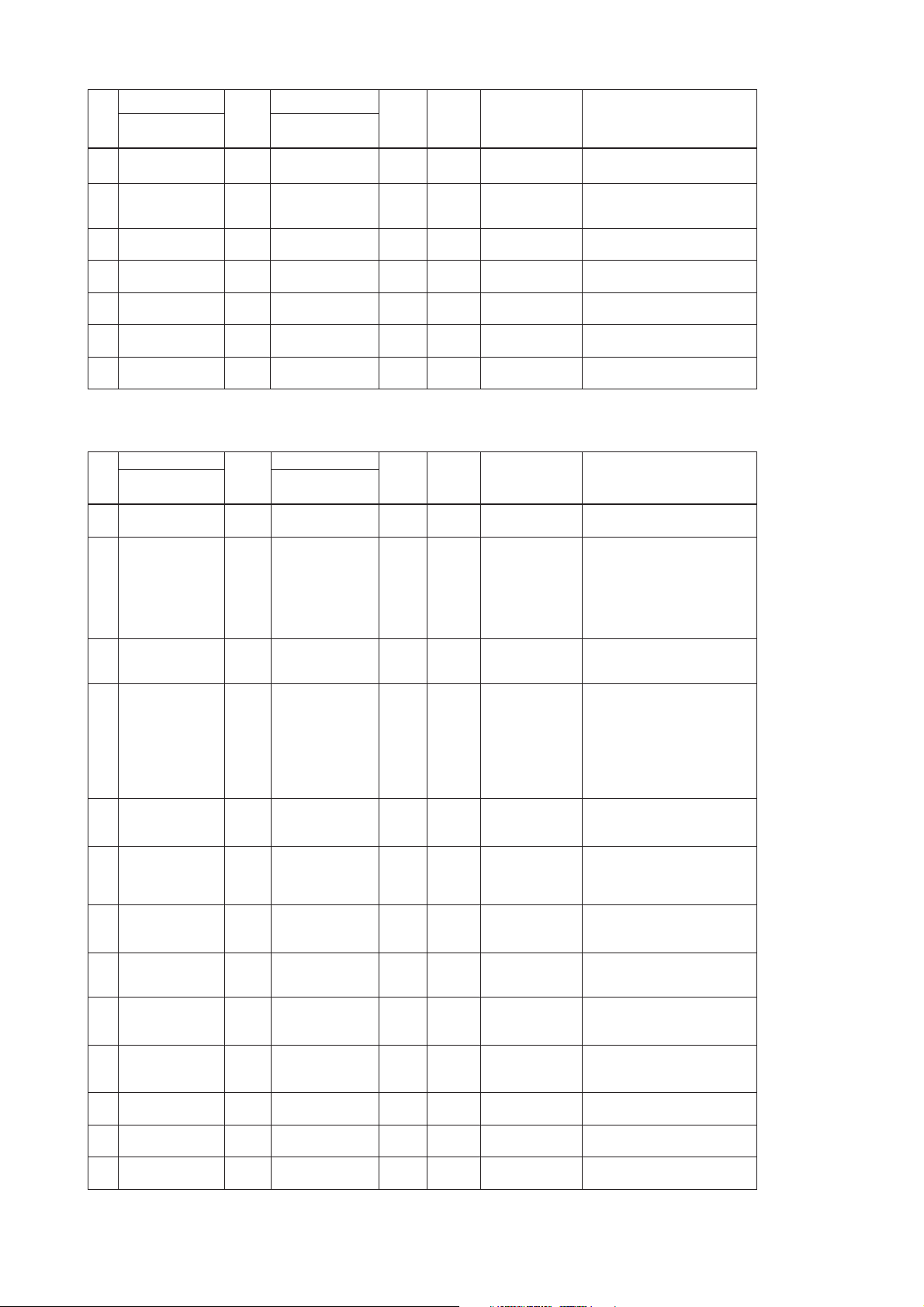

8. PARAMETER LISTS Dl Function Block Factory Write Relative Index Index Parameter Name Explanation Default Mode Index 6000 6100 Block Header Information on this block such as Block Tag, DD Revision, DI1: TAG=»DI1″ Execution Time etc. DI2: TAG=»DI2″ 6001 6101 ST_REV The revision level of the static data of the DI block.

-

Page 56: General Specifications

9. GENERAL SPECIFICATIONS GENERAL SPECIFICATIONS STANDARD SPECIFICATIONS STANDARD PERFORMANCE Accuracy: For items other than those described below, Note: The accuracy of a product before shipment is refer to IM 01E20D01-01E, IM 01E20C02-01E. defined as totalized value at the result of calibration test in our water actual flow test facility.

-

Page 57: Optional Specifications

9. GENERAL SPECIFICATIONS MODEL AND SUFFIX CODE Integral Flowmeter AXF: Remote Converter AXFA14: AXFA14 -F — (Note1) “F” following the first dash indicates that the output is digital communication compliant with the F OUNDATION fieldbus protocol. 9.2 OPTIONAL SPECIFICATIONS For options other than below, refer to IM 01E20D01-01E and IM 01E20C02-01E (Optional codes C1, C2, C3, EM, G11 and G13 are unable to select).

-

Page 58: Terminal Connection

9. GENERAL SPECIFICATIONS 9.3 TERMINAL CONNECTION CAUTION Integral Flowmeter AXF Do not connect to these terminals which are Terminal configuration marked “CAUTION Don’t connect”. F01.EPS Terminal wiring Terminal Description Symbols Functional grounding N/– Power supply Fieldbus communication signal FB– Protective grounding (Outside of the terminal) T06.EPS…

-

Page 59: Maintenance

10. MAINTENANCE 10. MAINTENANCE For maintenance items, please refer to user’s manual IM 01E20D01-01E or IM 01E20C02-01E. 10-1 IM 01E20F02-01E…

-

Page 60

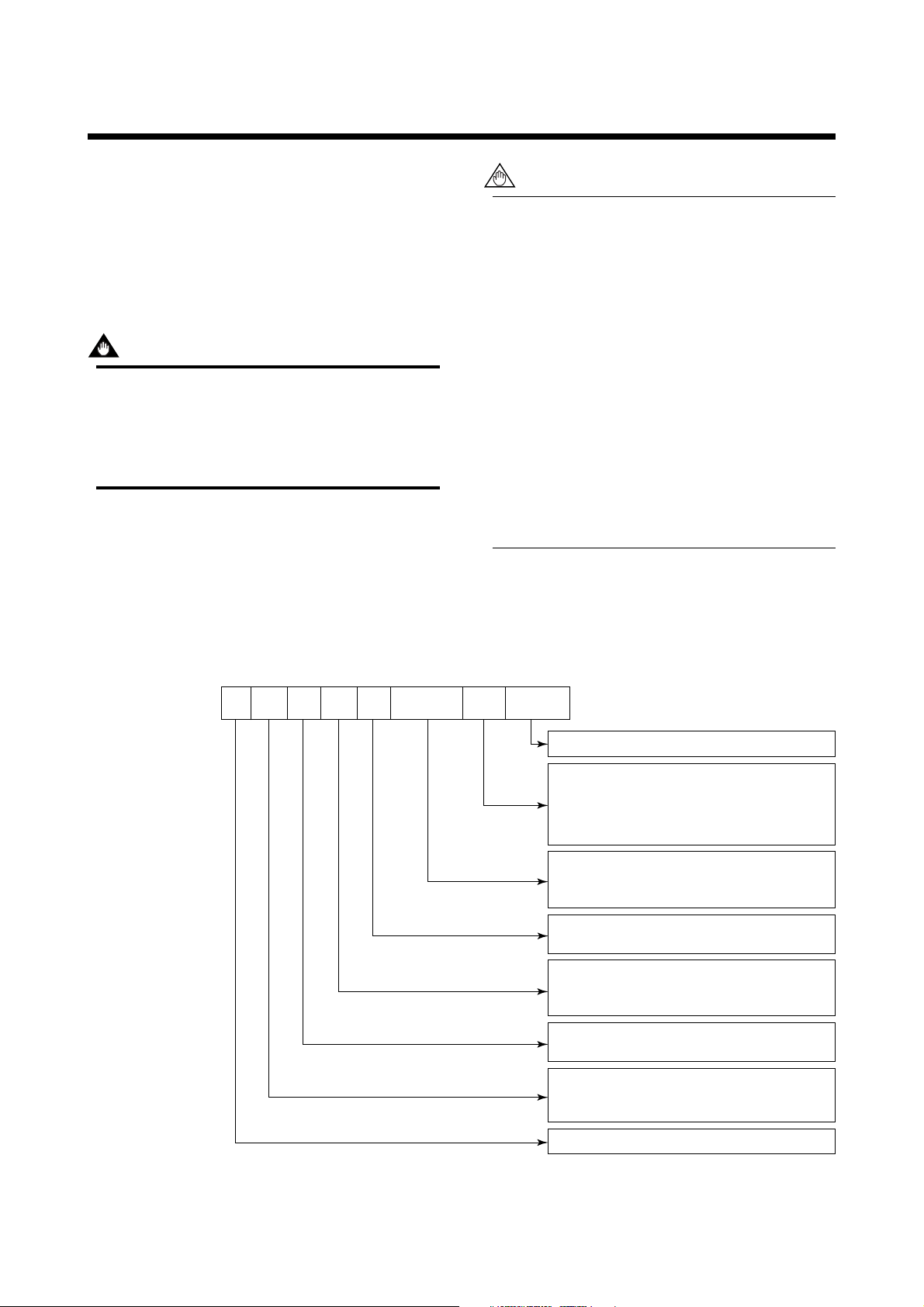

APPENDIX 1. APPLICATION, SETTING AND CHANGE OF BASIC PARAMETERS APPENDIX 1. APPLICATION, SETTING AND CHANGE OF BASIC PARAMETERS A1.1 Applications and Selection of Basic Parameters Setting Item (applicable parameters) Summary Sets PD_Tag. Up to 32 alphanumeric characters can be set. Tag No.(PD_TAG) Sets the range of input from the transducer block corresponding to the 0% and 100% points in operation within the AI function block. -

Page 61: Appendix 1. Application, Setting And Change Of Basic Parameters

APPENDIX 1. APPLICATION, SETTING AND CHANGE OF BASIC PARAMETERS A1.2 Setting and Change of IMPORTANT Basic Parameters Do not turn the power OFF immediately after This section describes the procedure taken to set and parameter setting. When the parameters are change the parameters for each block.

-

Page 62: A1.3 Setting The Ai Function Block

APPENDIX 1. APPLICATION, SETTING AND CHANGE OF BASIC PARAMETERS A1.3 Setting the AI Function (4)Simulation Perform simulation of the AI function block by setting Block the desired value and status of the input to the block. The AI function block outputs the flow rate signals. REMOTE LOOP TEST SWITCH is written to (1)Setting the flow range SIM_ENABLE_MSG(index 1044) parameter of the resource…

-

Page 63: A1.4 Setting The Transducer Block

APPENDIX 1. APPLICATION, SETTING AND CHANGE OF BASIC PARAMETERS A1.4 Setting the Transducer (4)Setting the LCD display Select the data to be displayed on the LCD indicator Block and the display refresh cycle. To access the AXF-specific functions in the transducer block, the Device Description (DD) for AXF needs to Access the DISPLAY_SELECT1-3 parameter and have been installed in the configuration tool used.

-

Page 64: A1.5 Setting The Integrator (It) Function Block

APPENDIX 1. APPLICATION, SETTING AND CHANGE OF BASIC PARAMETERS A1.5 Setting the Integrator (IT) A1.6 Setting the DI Function Function Block Block The Integrator function block output the flow totaliza- DI function blocks output limit switch signals received tion. from the transducer block. Two DI blocks (DI1 and DI2) in each AXF have (1)Setting the unit of totalization independent parameters.

-

Page 65

APPENDIX 2. INTEGRATOR (IT) BLOCK APPENDIX 2. INTEGRATOR (IT) BLOCK The Integrator (IT) block adds two main inputs and OUT.Value = Integration start value + Total integrates them for output. The block compares the Total = Total + Current Integral ∆t integrated or accumulated value to TOTAL_SP and Current Integral = (x + y) -

Page 66: Appendix 2. Integrator (It) Block

APPENDIX 2. INTEGRATOR (IT) BLOCK A2.2 Input Process Section When executed, the Integrator block first performs input processing in the order of: «Determining input status» → «Converting Rate or Accum» → «Determining the input flow direction» Switching between Convert Rate and Convert Accum is made using bit 0 (for IN_1) or bit 1 (for IN_2) of INTEG_OPTS.

-

Page 67: A2.2.3 Converting Accumulation

APPENDIX 2. INTEGRATOR (IT) BLOCK A2.2.3 Converting Accumulation This following describes an example of accumulation conversion. In accumulation conversion, the difference between the value executed previously and the value executed this time is integrated or accumulated. This conversion applies when the output of a function block used as a counter is input to the input process of the Integrator block.

-

Page 68: A2.3.2 Addition

APPENDIX 2. INTEGRATOR (IT) BLOCK A2.3.2 Addition The following three options are available for addition: • TOTAL: Adds two argument values as is. • FORWARD: Adds two argument values, regarding a negative value as «0.» • REVERSE: Adds two argument values, regarding a positive value as «0.»…

-

Page 69

APPENDIX 2. INTEGRATOR (IT) BLOCK Table A2.1 INTEG_TYPE Reset Trigger (Reset if one of the Name Integration Method Integration Range Trip Output following conditions is established) -INF< Total <TOTAL_SP • OUT reaches TOTAL_SP. 0< ATotal <+INF Counting up UP_AUTO(1) • RESET_IN = 1 Starting from «0»… -

Page 70: A2.5 Output Process

APPENDIX 2. INTEGRATOR (IT) BLOCK A2.5 Output Process A2.5.1 Status Determination The same criteria for determining the status of the There are the following three output parameters: output of the Integrator block are used in common for 1. OUT the above three parameters. 2.

-

Page 71: A2.5.2 Determining The Output Value

APPENDIX 2. INTEGRATOR (IT) BLOCK A2.5.2 Determining the Output Value Total: Total of integrated values. This value is retained even if INTEG_TYPE is changed during The value of OUT.Value is determined as follows: integration For counting up (in AUTO). OUT = integration start value (0) + Total If OUT is rewritten in the MAN mode, integration starts with the value rewritten in MAN mode after the For counting down…

-

Page 72: A2.5.3 Mode Handling

APPENDIX 2. INTEGRATOR (IT) BLOCK A2.5.3 Mode Handling Mode Action Output Automatic (AUTO) Normal action Normal output Integration calculation is stopped. You may rewrite a value in OUT. If no value is rewritten, the value just before Manual (MAN) OUT will not be updated unless you running in AUTO is held.

-

Page 73: A2.6.3 Reset Process

APPENDIX 2. INTEGRATOR (IT) BLOCK A2.6.3 Reset Process ii Carry (bit 6 of INTEG_OPTS) The basic reset process sequence is as follows: If this option is enabled while INTEG_TYPE is UP_AUTO or DN_AUTO, the value exceeding the 1.) Snapshot threshold at a reset will be carried into the next 2.) Clearing the integrated values integration.

-

Page 74: A2.7 List Of Integrator Block Parameters

APPENDIX 2. INTEGRATOR (IT) BLOCK A2.7 List of Integrator Block Parameters View Parameter Initial Write Index Definition Name Value Mode 1 2 3 4 Block Tag Information relating to this function block, such as block tag, IT1:TAG=»IT1″ BLOCK_HEADER IT2:TAG=»IT2″ =o/s DD revision, execution time ST_REV —…

-

Page 75

APPENDIX 2. INTEGRATOR (IT) BLOCK View Parameter Initial Write Index Definition Name Value Mode 1 2 3 4 CLOCK_PER 86400.0[sec] Specify the period at which a periodic reset is made. Auto PRE_TRIP 100000.0 Auto Set an allowance applied before an integrated value exceeds the setpoint. N_RESET Indicates the number of resets in the range of 0 to 999999. -

Page 76: Appendix 3. Arithmetic (Ar) Block

APPENDIX 3. ARITHMETIC (AR) BLOCK APPENDIX 3. ARITHMETIC (AR) BLOCK The Arithmetic (AR) block switches two main inputs of different measurement ranges seamlessly and combines the result with three auxiliary inputs through the selected compensation function (10 types) to calculate the output. A3.1 Schematic Diagram of Arithmetic Block The diagram below shows the Arithmetic block schematic.

-

Page 77: A3.2 Input Section

APPENDIX 3. ARITHMETIC (AR) BLOCK A3.2 Input Section PV is a parameter with status information, and PV status is determined by the value of “g.” There are five inputs: IN and IN_LO main inputs and If “g” < 0.5 → The status of IN_LO is used. IN_1, IN_2, and IN_3 auxiliary inputs.

-

Page 78: A3.2.4 Relationship Between The Main Inputs And Pv

APPENDIX 3. ARITHMETIC (AR) BLOCK A3.2.3 INPUT_OPTS · If the status of IN is anything other than “good” and that of “IN_LO” is “good” INPUT_OPTS has an option that handles an input with → PV = IN_LO IN_LO < RANGE_HI “uncertain”…

-

Page 79: A3.3 Computation Section

APPENDIX 3. ARITHMETIC (AR) BLOCK A3.3 Computation Section A3.3.2 Compensated Values In computing equations 1) to 5) in A3.3.1, the value A3.3.1 Computing Equations “f” is restricted by the COMP_HI_LIM or COMP_LO_LIM parameter. In this case, the value “f” This subsection shows computing equations used in the is treated as follows: computation section: If “f”…

-

Page 80: A3.4.1 Mode Handling

APPENDIX 3. ARITHMETIC (AR) BLOCK A3.4.1 Mode Handling A3.4.2 Status Handling The setting of INPUT_OPTS is applied to the input Mode Output status. When INPUT_OPTS is applied, there are cases Auto OUT = PRE_OUT where the PV status becomes “good” even if the status of main inputs is “uncertain”…

-

Page 81: A3.5 List Of The Arithmetic Block Parameters

APPENDIX 3. ARITHMETIC (AR) BLOCK A3.5 List of the Arithmetic Block Parameters View Relative Parameter Write Mode Valid Range Initial Value Description / Remarks Index BLOCK_HEADER TAG=“AR” Information relating to this function block, such as block tag, DD revision, and execution time Indicates the revision level of the set parameters associated with the Arithmetic ST_REV block.

-

Page 82

APPENDIX 3. ARITHMETIC (AR) BLOCK View Relative Parameter Write Mode Valid Range Initial Value Description / Remarks Index Computation algorithm identification no. Value Selection Name Description Flow compensation, linear Flow compensation (linear) Flow compensation, square root Flow compensation (square root) Flow compensation, approximate Flow compensation (approximate expression) BTU flow (*) -

Page 83: Appendix 4. Link Master Functions

APPENDIX 4. LINK MASTER FUNCTIONS APPENDIX 4. LINK MASTER FUNCTIONS A4.1 Link Active Scheduler A link active scheduler (LAS) is a deterministic, centralized bus scheduler that can control communica- tions on an H1 fieldbus segment. There is only one LAS on an H1 fieldbus segment. An AXF supports the following LAS functions.

-

Page 84: A4.3 Transfer Of Las

APPENDIX 4. LINK MASTER FUNCTIONS A4.3 Transfer of LAS LM declares itself as the LAS, then becomes the LAS. (With this procedure, an LM backs up the There are two procedures for an LM to become the LAS as shown in the following figure.) LAS: •…

-

Page 85: A4.4 Lm Functions

APPENDIX 4. LINK MASTER FUNCTIONS A4.4 LM Functions Function Description LM initialization When a fieldbus segment starts, the LM with the smallest [V(ST) × V(TN)] value within the segment becomes the LAS. At all times, each LM is checking whether or not a carrier is on the segment.

-

Page 86: A4.5 Lm Parameters

APPENDIX 4. LINK MASTER FUNCTIONS A4.5 LM Parameters A4.5.1 LM Parameter List The tables below show LM parameters. Meanings of Access column entries: RW = read/write possible; R = read only Default Factory Index Sub-parameter Name Parameter Name Access Remarks Setting (SM) (Sub Index)

-

Page 87

APPENDIX 4. LINK MASTER FUNCTIONS Index Sub-parameter Name Default Factory Access Parameter Name Remarks (SM) (Sub Index) Setting PLME_BASIC_ CHARACTERISTICS 1 ChannelStatisticsSupported 0x00 0x4900000000000000 2 MediumAndDataRatesSupported 1 (0x1) 3 IecVersion 4 NumOfChannels 1 (0x1) 5 PowerMode 0 (0x0) CHANNEL_STATES 1 channel-1 0 (0x0) 2 channel-2 128 (0x80) -

Page 88: A4.5.2 Descriptions For Lm Parameters

APPENDIX 4. LINK MASTER FUNCTIONS (5)MaxTokenHoldTimeArray A4.5.2 Descriptions for LM Parameters An 8(64 byte array variable, in which each set of 2 The following describes LM parameters of an AXF bytes represents the delegation time (set as an octet transmitter. time) assigned to a device.

-

Page 89

SchedulesPer of sub-schedules an LAS IceVersion 0x0403 IEC 4.3 is Schedule schedule can contain. (This is supported. fixed to 1 in the Yokogawa NumOf communication stacks.) Channels ActiveSchedule Indicates the version number of Power 0: Bus-powered; Version the schedule currently executed. -

Page 90: A4.6 Faqs

APPENDIX 4. LINK MASTER FUNCTIONS • 0xFF (true) to Sub- Size Element Description index [bytes] PrimaryLinkMasterFlagVariable (index 364) Version Indicates the version number of in the AXF. the LAS schedule downloaded to the corresponding domain. On a segment where an AXF works as the Macrocycle Indicates the macro cycle of the LAS, another device cannot be connected.

-

Page 91: A5.1 Function Diagram

APPENDIX 5. PID Block APPENDIX 5. PID BLOCK A PID block performs the PID control computation based on the deviation of the measured value (PV) from the setpoint (SV), and is generally used for constant-setpoint and cascaded-setpoint control. A5.1 Function Diagram The figure below depicts the function diagram of a PID block.

-

Page 92: A5.3 Parameters Of Pid Block

APPENDIX 5. PID Block A5.3 Parameters of PID Block NOTE: In the table below, the Write column shows the modes in which the respective parameters can be written. A blank in the Write column indicates that the corresponding parameter can be written in all modes of the PID block. A dash (-) indicates that the corresponding parameter cannot be written in any mode.

-

Page 93

APPENDIX 5. PID Block Default Parameter Index Write Valid Range Description Name (factory setting) SHED_OPT Action to be performed in the event of mode shedding. SHED_OPT defines the changes to be made to MODE.BLK.target and MODE.BLK.actual when the value of RCAS_IN.status or ROUT_IN.status becomes Bad if .MODE_BLK.actual = RCas or ROut. -

Page 94: A5.4 Pid Computation Details

APPENDIX 5. PID Block A5.4 PID Computation Details A5.5 Control Output The final control output value, OUT, is computed A5.4.1 PV-proportional and -derivative based on the change in control output ∆MVn, which is Type PID (I-PD) Control Algorithm calculated at each control period in accordance with the For PID control, the PID block employs the PV- aforementioned algorithm.

-

Page 95: A5.8 Feed-Forward

APPENDIX 5. PID Block A5.8 Feed-forward Block Description Mode Feed-forward is an action to add a compensation output IMan Initialization and manual mode, in which the control signal FF_VAL to the output of the PID control action is suspended. The PID block enters this mode when the specified condition is met computation, and is typically used for feed-forward (see Section A5.14).

-

Page 96: A5.10 Bumpless Transfer

APPENDIX 5. PID Block A5.10 Bumpless Transfer A5.12 External-output Tracking Prevents a sudden change in the control output OUT at External tracking is an action of outputting the value of changes in block mode (MODE_BLK) and at switch- the remote output TRK_VAL set from outside the PID ing of the connection from the control output OUT to block, as illustrated in the figure below.

-

Page 97: A5.14 Initialization And Manual Fallback (Iman)

APPENDIX 5. PID Block A5.15 Manual Fallback Options in Description CONTROL_OPTS Manual fallback denotes an action in which a PID Bypass Enable This parameter allows BYPASS to be set. block changes mode to Man and suspends the control SP-PV Track Equalizes SP to PV when action.

-

Page 98: A5.17 Mode Shedding Upon Computer Failure

APPENDIX 5. PID Block A5.17 Mode Shedding upon NOTE: If a control block is connected as a cascade primary block of the PID block in question, a mode transition of the PID block Computer Failure to Cas occurs in the following sequence due to initialization of the cascade connection: RCas or ROut →…

-

Page 99: A5.19 Example Of Block Connections

APPENDIX 5. PID Block A5.19 Example of Block A5.20 View Object for PID Connections Function Block Relative VIEW VIEW VIEW VIEW Parameter Mnemonic Index ST_REV TAG_DESC STRATEGY ALERT_KEY MODE_BLK BLOCK_ERR BKCAL_IN CAS_IN PV_SCALE OUT_SCALE BKCAL_OUT GRANT_DENY FA0106.EPS CONTROL_OPTS When configuring a simple PID control loop by combining an AXF with a fieldbus valve positioner STATUS_OPTS that contains an AO block, follow the procedure below…

-

Page 100

APPENDIX 5. PID Block Relative VIEW VIEW VIEW VIEW Parameter Mnemonic Index SHED_OPT RCAS_OUT ROUT_OUT TRK_SCALE TRK_IN_D TRK_VAL FF_VAL FF_SCALE FF_GAIN UPDATE_EVT BLOCK_ALM ALARM_SUM ACK_OPTION ALARM_HYS HI_HI_PRI HI_HI_LIM HI_PRI HI_LIM LO_PRI LO_LIM LO_LO_PRI LO_LO_LIM DV_HI_PRI DV_HI_LIM DV_LO_PRI DV_LO_LIM HI_HI_ALM HI_ALM LO_ALM LO_LO_ALM DV_HI_ALM… -

Page 101: A6.1 Benefits Of Software Download

Class 1 devices can continue the specified how to obtain them, visit the following web site. measurement and/or control actions even while http://www.yokogawa.com/fld/fld-top-en.htm software is being downloaded to them. Upon completion of a download, however, the devices will be reset internally to make the new, down-…

-

Page 102: A6.4 Software Download Sequence

APPENDIX 6. SOFTWARE DOWNLOAD CAUTION NOTE The current dissipation of the target field device The download tool can not execute downloading increases transitorily immediately after a down- during other system connects to the system/ load due to erasing of the FlashROM’s contents. network management VFD of the device.

-

Page 103: A6.6 Steps After Activating A Field Device

APPENDIX 6. SOFTWARE DOWNLOAD The device type is “000B” for the AXF . The software name is “ORIGINAL” or “UPDATE.” The former indicates an original file and the latter an update file. Whenever performing a download to update the device revision, obtain the original file. In general, an addition to the parameters or blocks requires a device revision update.

-

Page 104: A6.7 Troubleshooting

APPENDIX 6. SOFTWARE DOWNLOAD A6.7 Troubleshooting For information on the download tool’s error messages, see also the software’s User’s Manual. Table A6.2 Problems after Software Update Symptom Cause Remedy An error occurs before starting a The selected download file is not for the Check SOFTDWN_ERROR in the resource download, disabling the selected field device.

-

Page 105

APPENDIX 6. SOFTWARE DOWNLOAD Table A6.4 Download Error Codes Error Code Detail No error 32768 Unsupported header version Abnormal header size 32769 32770 Abnormal manufacturer ID 32771 Abnormal device family Abnormal device revision 32772 32773 Abnormal vendor specification version 32774 Abnormal number of modules 32775 Abnormal number of bytes in module 1… -

Page 106: A6.9 System/Network Management Vfd Parameters Relating To Software Download

APPENDIX 6. SOFTWARE DOWNLOAD A6.9 System/Network Management VFD Parameters Relating to Soft- ware Download Table A6.5 System/Network Management VFD Parameters Write Mode: R/W = read/write; R = read only Index Default Write Parameter Name Sub-parameter Name Remarks (SM) Index (Factory Set) Mode DWNLD_PROPERTY Download Class…

-

Page 107: A6.10 Comments On System/Network Management Vfd Parameters Relating To Software Download

APPENDIX 6. SOFTWARE DOWNLOAD A6.10 Comments on System/Network Management VFD Parameters Relating to Software Download IMPORTANT Do not turn off the power to a field device immediately after changing parameter settings. Data writing actions to the EEPROM are dual redandant to ensure reliability. If the power is turned off within 60 seconds after setup, the parameters may revert to the previous settings.

-

Page 108

APPENDIX 6. SOFTWARE DOWNLOAD (2) DOMAIN_DESCRIPTOR Size Element Description (Bytes) Index Command Reads/writes software download commands. 1: PREPARE_FOR_DWNLD (instruction of download preparation) 2: ACTIVATE (activation instruction) 3: CANCEL_DWNLD (instruction of download cancellation) State Indicates the current download status. 1: DWNLD_NOT_READY (download not ready) 2: DWNLD_PREPARING (download under preparation) 3: DWNLD_READY (ready for download) 4: DWNLD_OK (download complete) -

Page 109

REVISION RECORD Title: ADMAG AXF Series F Fieldbus Communication Type Magnetic OUNDATION Flowmeter Manual No.: IM 01E20F02-01E Edition Date Page Revised Item June 2006 – New publication May 2007 Added the warning note of «Maintenance». (1-4) Deleted the ATEX documentation.

User’s

Manual

Model SE14

Magnetic Flow Converter

IM 1E10C1-E

IM 1E10C1-E

7th Edition

Yokogawa Electric Corporation

User’s

Manual

AXFA11G

Magnetic Flowmeter

Remote Converter

[Hardware Edition/Software Edition]

IM 01E20C01-01E

Yokogawa Electric Corporation

IM 01E20C01-01E

7th Edition

CONTENTS

Contents

1. INTRODUCTION ……………………………………………………………………………………… 1-1

1.1 Using the Magnetic Flowmeter Safely ………………………………………………….. 1-2

1.2 Warranty ……………………………………………………………………………………………. 1-2

1.3 Combination Remote Flowtubes …………………………………………………………… 1-3

2. HANDLING PRECAUTIONS ……………………………………………………………………. 2-1

2.1 Checking Model and Specifications ……………………………………………………… 2-1

2.2 Accessories ………………………………………………………………………………………… 2-1

2.3 Storage Precautions …………………………………………………………………………….. 2-1

2.4 Installation Location Precautions ………………………………………………………….. 2-1

3. INSTALLATION ………………………………………………………………………………………. 3-1

3.1 Installation Location ……………………………………………………………………………. 3-1

3.2 Mounting …………………………………………………………………………………………… 3-1

4. WIRING ……………………………………………………………………………………………………. 4-1

4.1 Wiring Precautions ……………………………………………………………………………… 4-1

4.2 Cables ……………………………………………………………………………………………….. 4-1

4.3 Wiring Ports ………………………………………………………………………………………. 4-3

4.4 Wiring Connections ……………………………………………………………………………. 4-5

4.4.1 Removing Cover ………………………………………………………………………….. 4-5

4.4.2 Terminal Configuration …………………………………………………………………. 4-5

4.4.3 Precautions for Wiring of Power Supply Cables ………………………………. 4-6

4.4.4 DC Power Connection ………………………………………………………………….. 4-6

4.4.5 Grounding …………………………………………………………………………………… 4-7

4.4.6 Wiring the Remote Flowtube with the AXFA11 Converter………………… 4-7

4.4.7 Connecting to External Instruments ……………………………………………….. 4-8

5. BASIC OPERATING PROCEDURES (USING THE DISPLAY UNIT) …….. 5-1

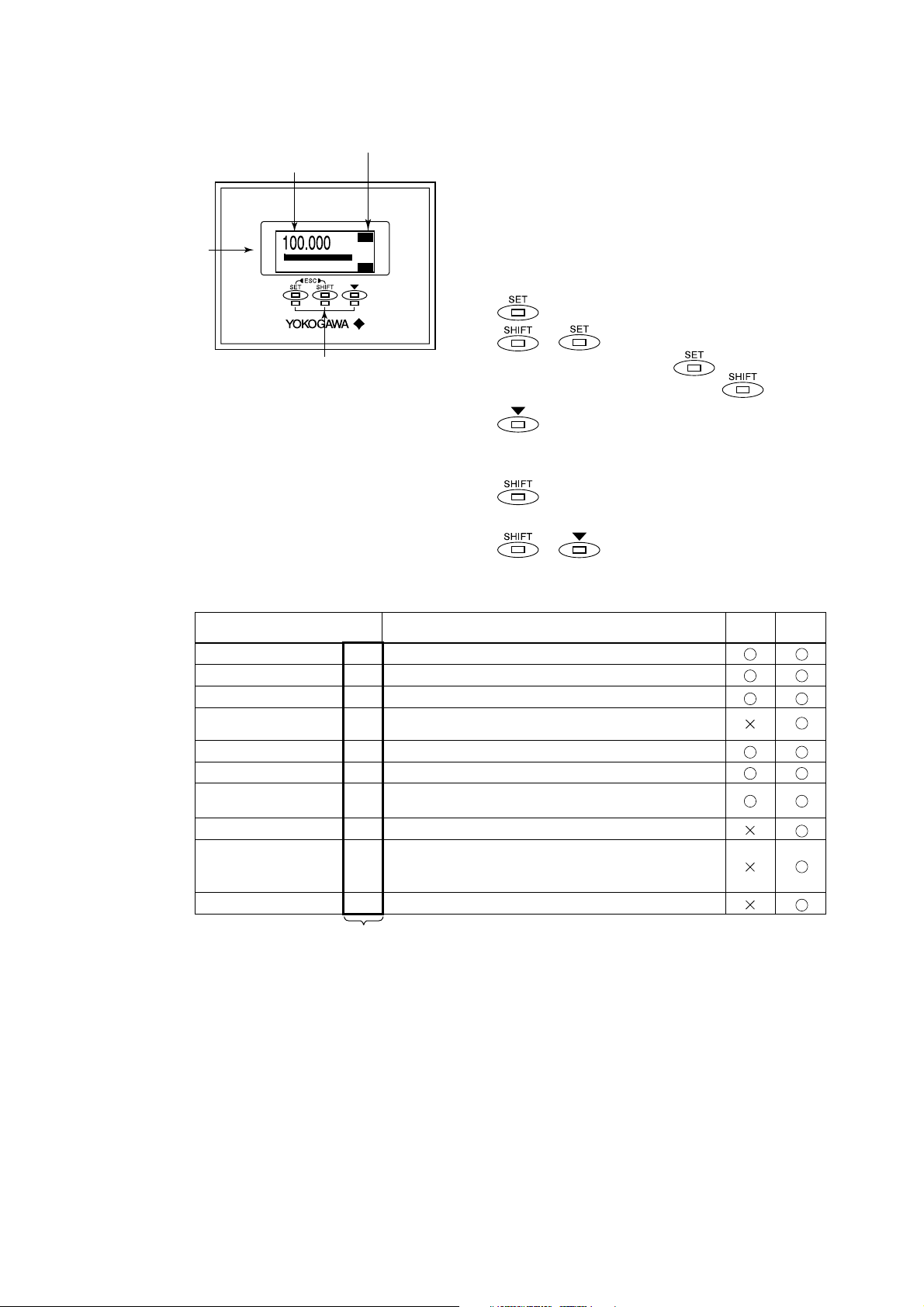

5.1 Operating Panel Configuration and Functions ……………………………………….. 5-2

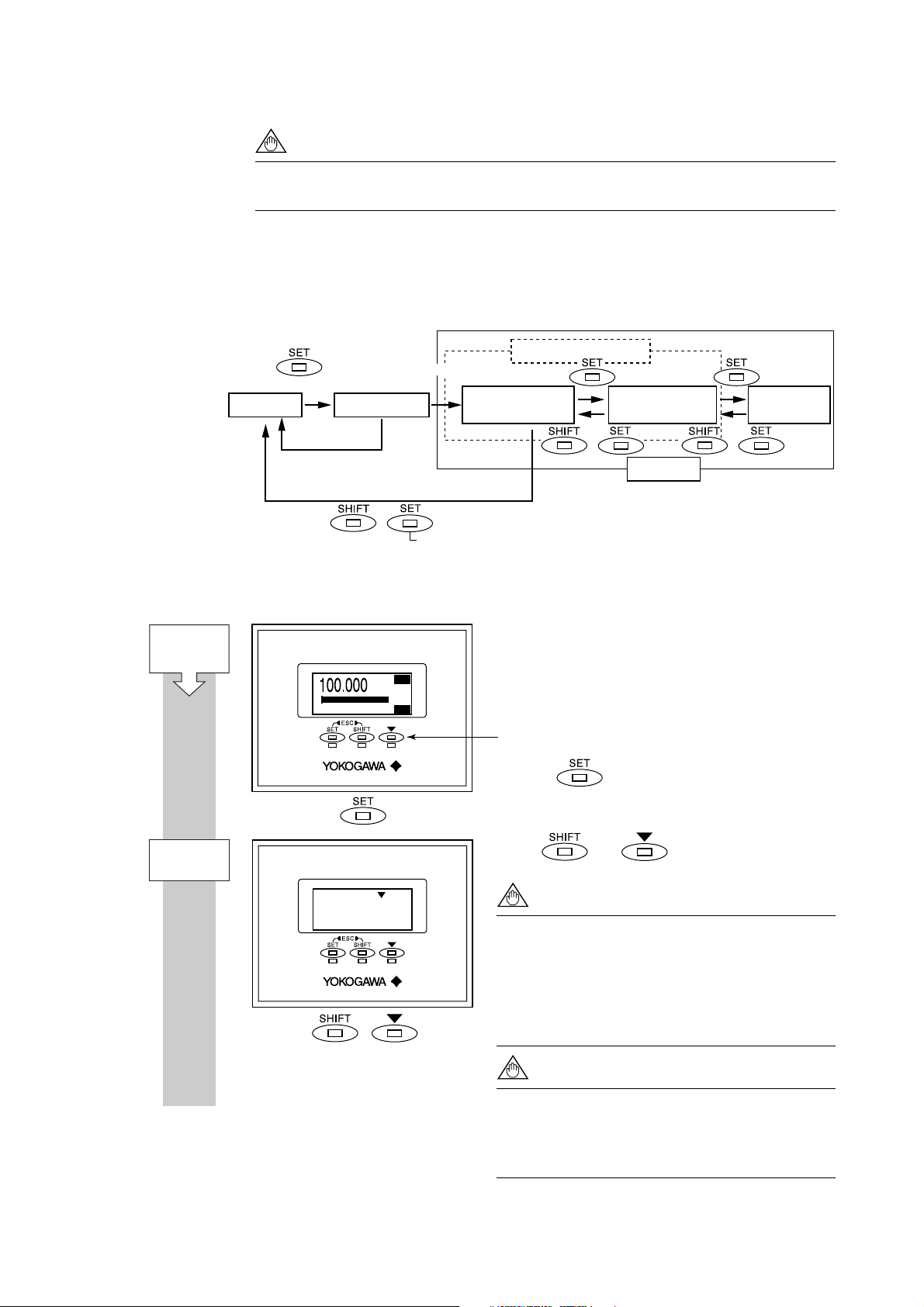

5.2 Display Unit Setting Methods………………………………………………………………. 5-3

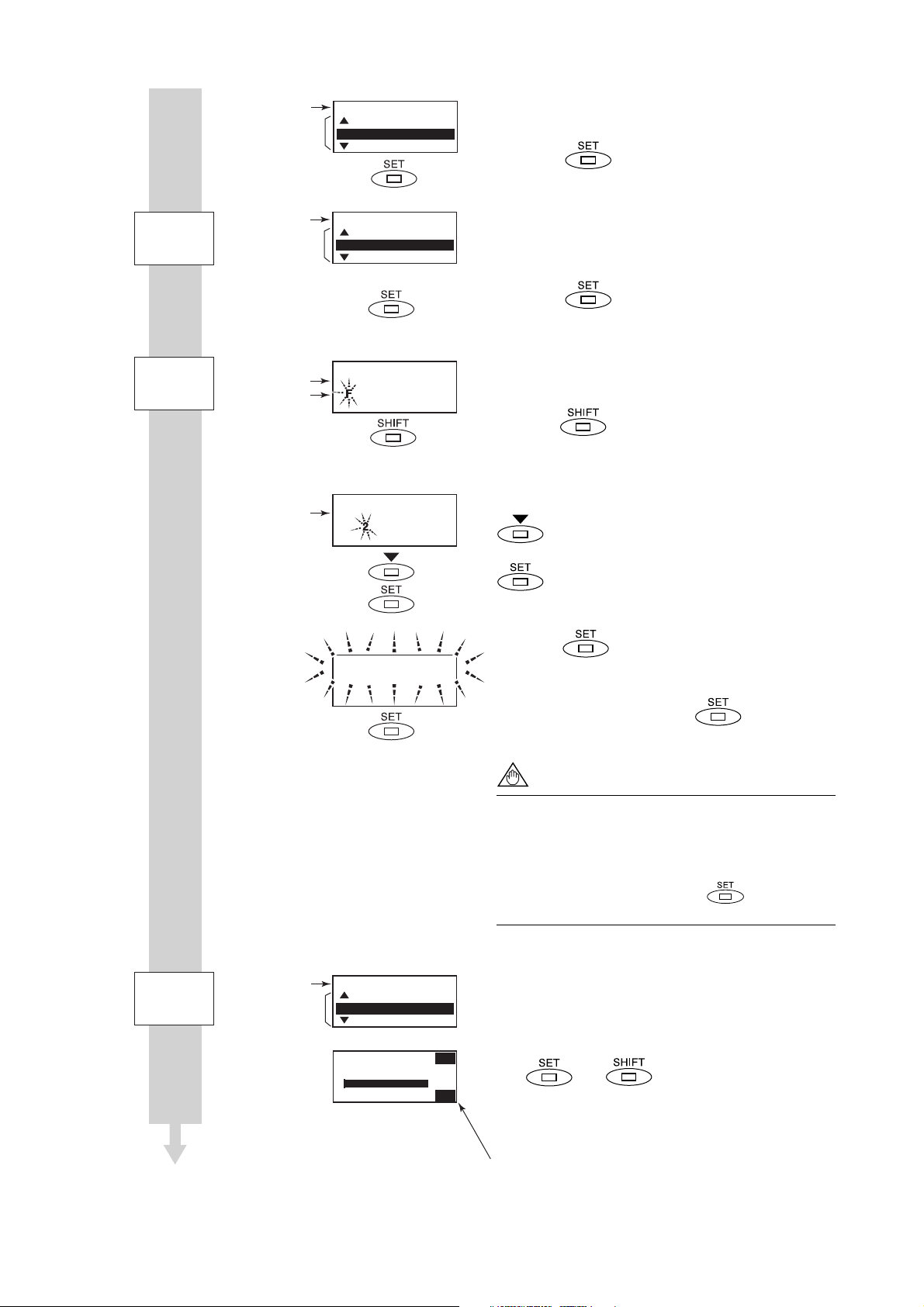

5.2.1 Display Mode Æ Setting Mode ……………………………………………………… 5-3

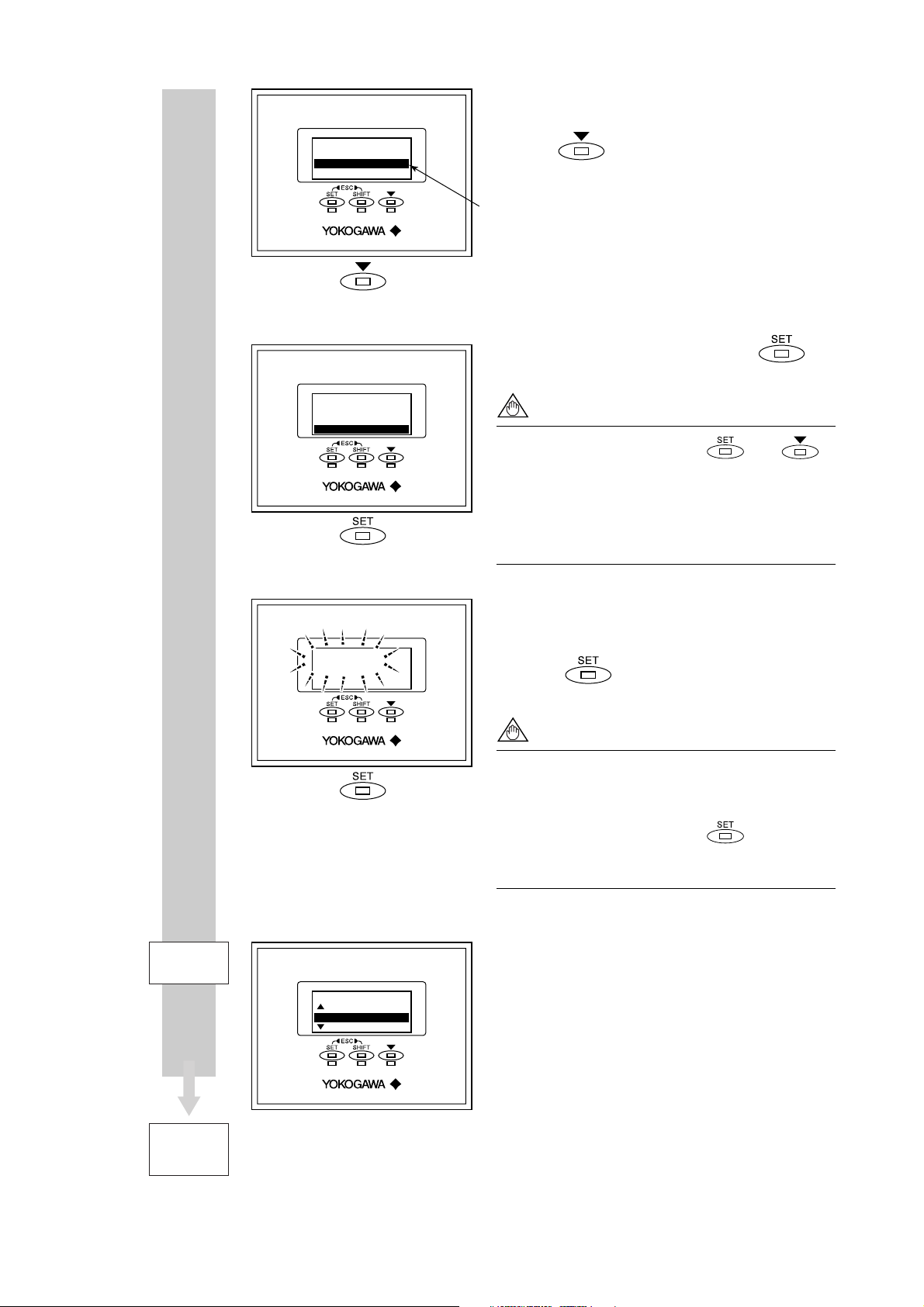

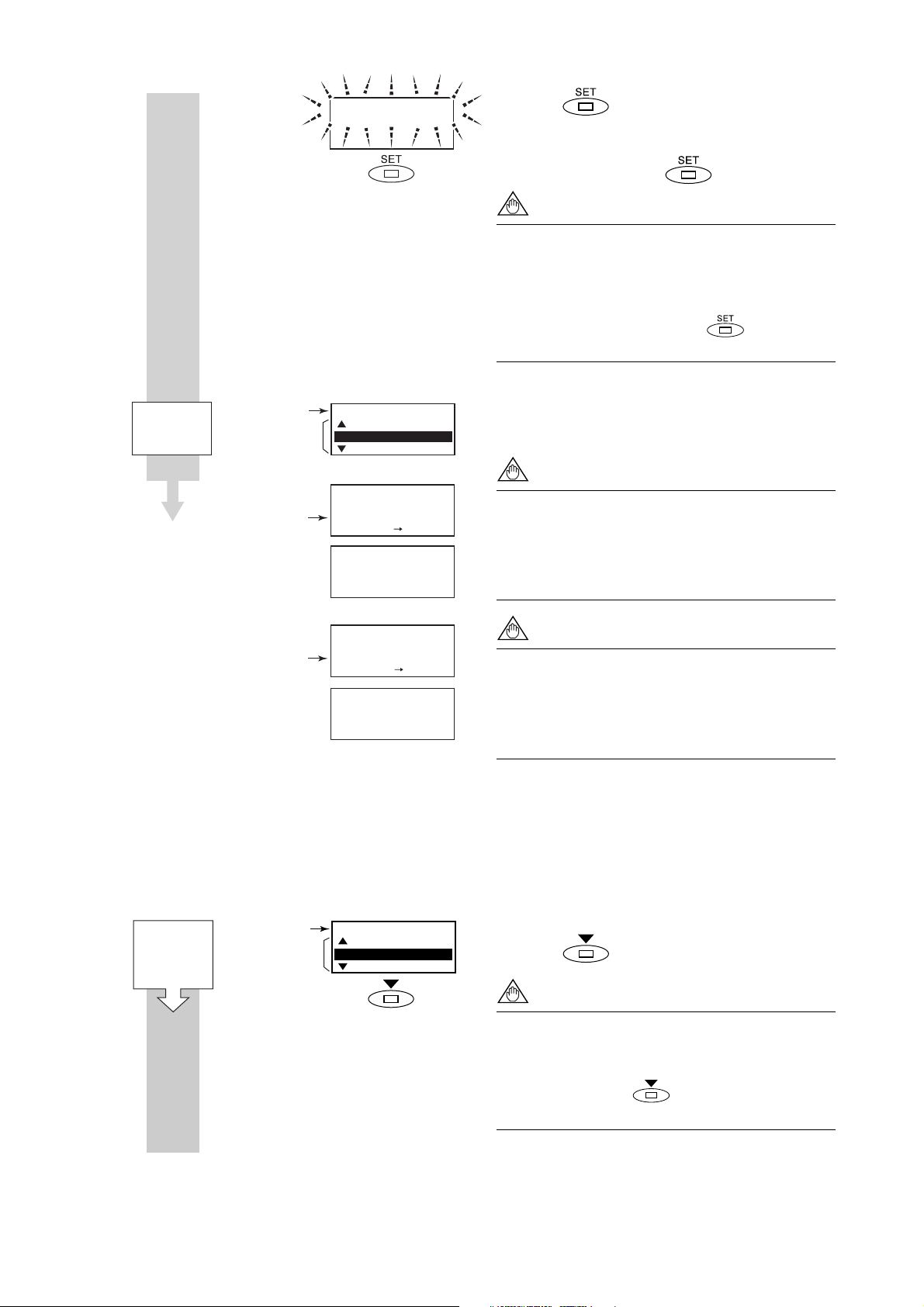

5.2.2 Setting Mode ……………………………………………………………………………….. 5-5

5.3 Parameter Setting Procedure ………………………………………………………………… 5-5

5.3.1 Setting Example for Selection-Type Data: Flow rate units ………………… 5-5

5.3.2 Setting Example for Numeric-Type Data: Flow rate span ………………….. 5-7

5.3.3 Setting Example for Alphanumeric-Type Data: Tag number ……………… 5-8

7th Edition: June 2012

All Rights Reserved, Copyright © 2003, Yokogawa Electric Corporation

i

IM 01E20C01-01E

CONTENTS

6. PARAMETER DESCRIPTION …………………………………………………………………. 6-1

6.1 Parameters …………………………………………………………………………………………. 6-1

6.2 Parameter Lists …………………………………………………………………………………… 6-1

6.3 Parameter List Overview …………………………………………………………………….. 6-2

6.4 Parameter Description ……………………………………………………………………….. 6-12

(1) Menu B: Easy Setup items ………………………………………………………………… 6-12

(2) Menu C: Basic Setting items……………………………………………………………… 6-15

(3) Menu D: Total Setting items ……………………………………………………………… 6-17

(4) Menu E: Pulse Setting items ……………………………………………………………… 6-19

(5) Menu F: Status Functions Setting items ……………………………………………… 6-20

(6) Menu G: Alarm Setting items ……………………………………………………………. 6-25

(7) Menu H: Display Setting items ………………………………………………………….. 6-30

(8) Menu J: Auxiliary Function Setting items …………………………………………… 6-30

(9) Menu K: Diagnostic Function Setting items ………………………………………… 6-33

(10) Menu M: Automatic Zero Adjustment Function Setting items ……………… 6-33

(11) Menu N: Loop Test Setting items …………………………………………………….. 6-33

(12) Menu P: Parameter Protection items…………………………………………………. 6-34

6.5 Alarm Functions ……………………………………………………………………………….. 6-36

6.5.1 Alarm Levels……………………………………………………………………………… 6-36

6.5.2 Alarm Selection …………………………………………………………………………. 6-36

6.5.3 Alarms & Warning Messages ………………………………………………………. 6-39

7. OPERATION VIA BRAIN TERMINAL (BT200) ………………………………………. 7-1

7.1 BT200 Basic Operations ……………………………………………………………………… 7-1

7.1.1 Key Layout and Display ……………………………………………………………….. 7-1

7.1.2 Key Descriptions………………………………………………………………………….. 7-1

7.2 AXFA11 Operation Using a BT200 ……………………………………………………… 7-3

7.2.1 BT200 Connection ……………………………………………………………………….. 7-3

7.2.2 The data update and upload/download function of BT200…………………. 7-3

7.2.3 BT200 Screens & Flow Rate Data Display ……………………………………… 7-4

7.3 Parameter Setting Using a BT200 ………………………………………………………… 7-4

7.3.1 BT200 Setting of Selection-Type Data: Flow rate units …………………….. 7-5

7.3.2 BT200 Setting of Numeric-Type Data: Flow rate span ……………………… 7-6

7.3.3 BT200 Setting of Alphanumeric-Type Data: Tag number ………………….. 7-7

8. OPERATION VIA HART COMMUNICATOR TOOL (HART 5)……………… 8-1

8.1 Matching of instrument (AXFA11) DD and HART

Configuration Tool’s DD …………………………………………………………………….. 8-1

8.2 Interconnection between AXFA11 and HART

Configuration Tool ……………………………………………………………………………… 8-2

8.3 Basic Setup ………………………………………………………………………………………… 8-3

8.4 Parameters …………………………………………………………………………………………. 8-3

8.4.1 Parameter configuration………………………………………………………………… 8-3

8.4.2 Data Renewing…………………………………………………………………………….. 8-3

8.4.3 Self-diagnostic …………………………………………………………………………….. 8-4

8.4.4 HART Specific Functions ……………………………………………………………… 8-4

8.4.5 Other operations for the HART configuration tool ……………………………. 8-6

8.4.6 Menu Tree for DD (HART 5) ………………………………………………………… 8-7

8.4.7 Menu Tree for DTM (HART 5) ……………………………………………………. 8-12

ii

IM 01E20C01-01E

CONTENTS

9. ACTUAL OPERATION …………………………………………………………………………….. 9-1

9.1 Pre-operation Zero Adjustment …………………………………………………………….. 9-1

9.1.1 Zero Adjustment Using Display Unit Switches………………………………… 9-2

9.1.2 Zero Adjustment via External Status Input………………………………………. 9-3

10. MAINTENANCE …………………………………………………………………………………….. 10-1

10.1 Maintenance …………………………………………………………………………………….. 10-1

10.1.1 Fuse Replacement ………………………………………………………………………. 10-1

10.2 Setting of Switches …………………………………………………………………………… 10-1

10.2.1 Lifting of display unit …………………………………………………………………. 10-1

10.2.2 Setting of Burnout Switch …………………………………………………………… 10-2

10.2.3 Setting of Write Protect Switch ……………………………………………………. 10-2

10.3 Troubleshooting ………………………………………………………………………………… 10-3

10.3.1 No Indication …………………………………………………………………………….. 10-3

10.3.2 Unstable Zero…………………………………………………………………………….. 10-4

10.3.3 Disagreement Between Indication and Actual Flow ………………………… 10-5

11. OUTLINE………………………………………………………………………………………………… 11-1

REVISION RECORD …………………………………………………………………………………………… 1

iii

IM 01E20C01-01E

1. INTRODUCTION

1. INTRODUCTION

This instrument has been adjusted at the factory before

shipment.

To ensure correct use of the instrument, please read

this manual thoroughly and fully understand how to

operate the instrument before operating it.

Regarding This User’s Manual

• This manual should be provided to the end user.

• Before use, read this manual thoroughly to comprehend its contents.

• The contents of this manual may be changed

without prior notice.

• All rights are reserved. No part of this manual may

be reproduced in any form without Yokogawa’s

written permission.

• Yokogawa makes no warranty of any kind with

regard to this material, including, but not limited to,

implied warranties of merchantability and suitability

for a particular purpose.

• All reasonable effort has been made to ensure the

accuracy of the contents of this manual. However,

if any errors or omissions are found, please inform

Yokogawa.

• Yokogawa assumes no responsibilities for this

product except as stated in the warranty.

• Please note that this user’s manual may not be

revised for any specification changes, construction

changes or operating part changes that are not

considered to affect function or performance.

• If the customer or any third party is harmed by the

use of this product, Yokogawa assumes no responsibility for any such harm owing to any defects in the

product which were not predictable, or for any

indirect damages.

ments. If this instrument is used in a manner not

specified in this manual, the protection provided by

this instrument may be impaired.

• Yokogawa will not be liable for malfunctions or

damage resulting from any modification made to this

instrument by the customer.

• The following safety symbol marks are used in this

user’s manual and instrument.

WARNING

A WARNING sign denotes a hazard. It calls

attention to procedure, practice, condition or the

like, which, if not correctly performed or adhered

to, could result in injury or death of personnel.

CAUTION

A CAUTION sign denotes a hazard. It calls

attention to procedure, practice, condition or the

like, which, if not correctly performed or adhered

to, could result in damage to or destruction of

part or all of the product.

IMPORTANT

An IMPORTANT sign denotes that attention is

required to avoid damage to the instrument or

system failure.

NOTE

Please refer to manual IM 01E20D01-01E for

information of the AXF Remote Flowtube.

Safety and Modification Precautions

• The following general safety precautions must be

observed during all phases of operation, service, and

repair of this instrument. Failure to comply with

these precautions or with specific WARNINGS

given elsewhere in this manual violates safety

standards of design, manufacture, and intended use

of the instrument. Yokogawa assumes no liability for

the customer’s failure to comply with these require-

A NOTE sign denotes information necessary for

essential understanding of operation and features.

Protective grounding terminal

Functional grounding terminal

(This terminal should not be used as a protective

grounding terminal.)

Alternating current

Direct current

1-1

IM 01E20C01-01E

1. INTRODUCTION

1.1 Using the Magnetic

Flowmeter Safely

WARNING

(1) Installation

• Installation of the magnetic flowmeter must be

performed by expert engineer or skilled personnel. No operator shall be permitted to perform

procedures relating to installation.

• The magnetic flowmeter is a heavy instrument.

Be careful that no damage is caused to personnel through accidentally dropping it, or by

exerting excessive force on the magnetic

flowmeter. When moving the magnetic flowmeter, always use a trolley and have at least two

people carry it.

• When the magnetic flowmeter is processing hot

fluids, the instrument itself may become extremely hot. Take sufficient care not to get

burnt.

• Where the fluid being processed is a toxic

substance, avoid contact with the fluid and

avoid inhaling any residual gas, even after the

instrument has been taken off the piping line for

maintenance and so forth.

• Do not apply excessive weight, for example, a

person sttepping on the magnetic flowmeter.

• All procedures relating to installation must

comply with the electrical code of the country

where it is used.

(2) Wiring

• The wiring of the magnetic flowmeter must be

performed by expert engineer or skilled personnel. No operator shall be permitted to perform

procedures relating to wiring.

• When connecting the wiring, check that the

supply voltage is within the range of the voltage

specified for this instrument before connecting

the power cable. In addition, check that no

voltage is applied to the power cable before

connecting the wiring.

• The protective grounding must be connected

securely at the terminal with the mark to

avoid danger to personnel.

(3) Operation

• When opening the cover, wait for more than 10

minutes after turning off the power. Only

expert engineer or skilled personnel are permitted to open the cover.

• Be sure to set parameters as «Protect» on the

write protect function after finish of parameter

setting work.

Under extremely rare case, the infra-red

switches may respond unexpectedly in such

conditions as sticking ball of water or

extraneous substances on the surface of

display panel glass according to the principle of

infra-red switch operation.

Its probability rises in such cases as sticking

rain water by storm or other similar situation

and washing up work near flowmeter installation place.

Either to illuminate or stop illuminating the infrared switches by the flashlight may cause the

mis-reaction.

Refer to Chapter 6 «Menu P: Parameter Protection Items» and section «10.2.3» how to use the

write protect function in detail.

(4) Maintenance

• Maintenance of the magnetic flowmeter should

be performed by the trained personnel having

knowledge of safety standard. No operator

shall be permitted to perform any operations

relating to maintenance.

• When opening the cover, wait for more than 10

minutes after turning off the power.

• Always conform to maintenance procedures

outlined in this manual. If necessary, contact

Yokogawa.

• Care should be taken to prevent the build up of

dirt, dust or other substances on the display

panel glass or data plate. If these surfaces do

get dirty, wipe them clean with a soft dry cloth.

1.2 Warranty

• The terms of this instrument that are guaranteed are

described in the quotation. We will make any repairs

that may become necessary during the guaranteed

term free of charge.

• Please contact our sales office if this instrument

requires repair.

• If the instrument is faulty, contact us with concrete

details about the problem and the length of time it

has been faulty, and state the model and serial

number. We would appreciate the inclusion of

drawings or additional information.

• The results of our examination will determine

whether the meter will be repaired free of charge or

on an at-cost basis.

The guarantee will not apply in the following

cases:

• Damage due to negligence or insufficient maintenance on the part of the customer.

1-2

IM 01E20C01-01E

1. INTRODUCTION

• Problems or damage resulting from handling,

operation or storage that violates the intended use

and specifications.

• Problems that result from using or performing

maintenance on the instrument in a location that

does not comply with the installation location

specified by Yokogawa.

• Problems or damage resulting from repairs or

modifications not performed by Yokogawa or

someone authorized by Yokogawa.

• Problems or damage resulting from inappropriate

reinstallation after delivery.

• Problems or damage resulting from disasters such as

fires, earthquakes, storms, floods, or lightning strikes

and external causes.

Trademarks:

ADMAG, AXF and ADMAG AXF are registered

trademarks of Yokogawa Electric Corporation.

Company names and product names used in this

material are registered trademarks or trademarks of

their respective owners.

maintenance, and repair are strictly restricted,

and non-observance or negligence of these

restriction would result dangerous condition.

1.3 Combination Remote

Flowtubes

IMPORTANT

• The AXFA11 Magnetic Flowmeter Converter

should be used in combination with the following remote flowtubes:

AXFA11G ⇔AXF002-N to AXF26L-N

Contact Yokogawa before using it in combination with flowtubes other than those listed

above.

• The model AXFC remote flowtube with

optional code JF3 (TIIS flame proof type)

cannot be combined with the AXFA11 converter. In this case, use the AXFA14 converter.

• If the converter combined with the AXF magnetic flowmeter remote flowtube is changed

from the AXFA11 to AXFA14 or vice versa, the

meter factor of the remote flowtube must be

readjusted according to its flow calibration.

CAUTION

In case of combination with the explosion proof

type remote flowtube (AXFC-N) for

ATEX, FM, and CSA certification, please see the

manual IM 01E20D01-01E. The construction of

the instrument, installation, external wiring,

1-3

IM 01E20C01-01E

2. HANDLING PRECAUTIONS

2. HANDLING PRECAUTIONS

This instrument has been inspected carefully at the

factory before shipment. When the instrument is

delivered, visually check that no damage has occurred

during transportation.

Read this section carefully as it contains important

information on handling this instrument. Refer to the

relevant sections for information not contained in this

section. If you have any problems or questions, please

contact Yokogawa sales office.

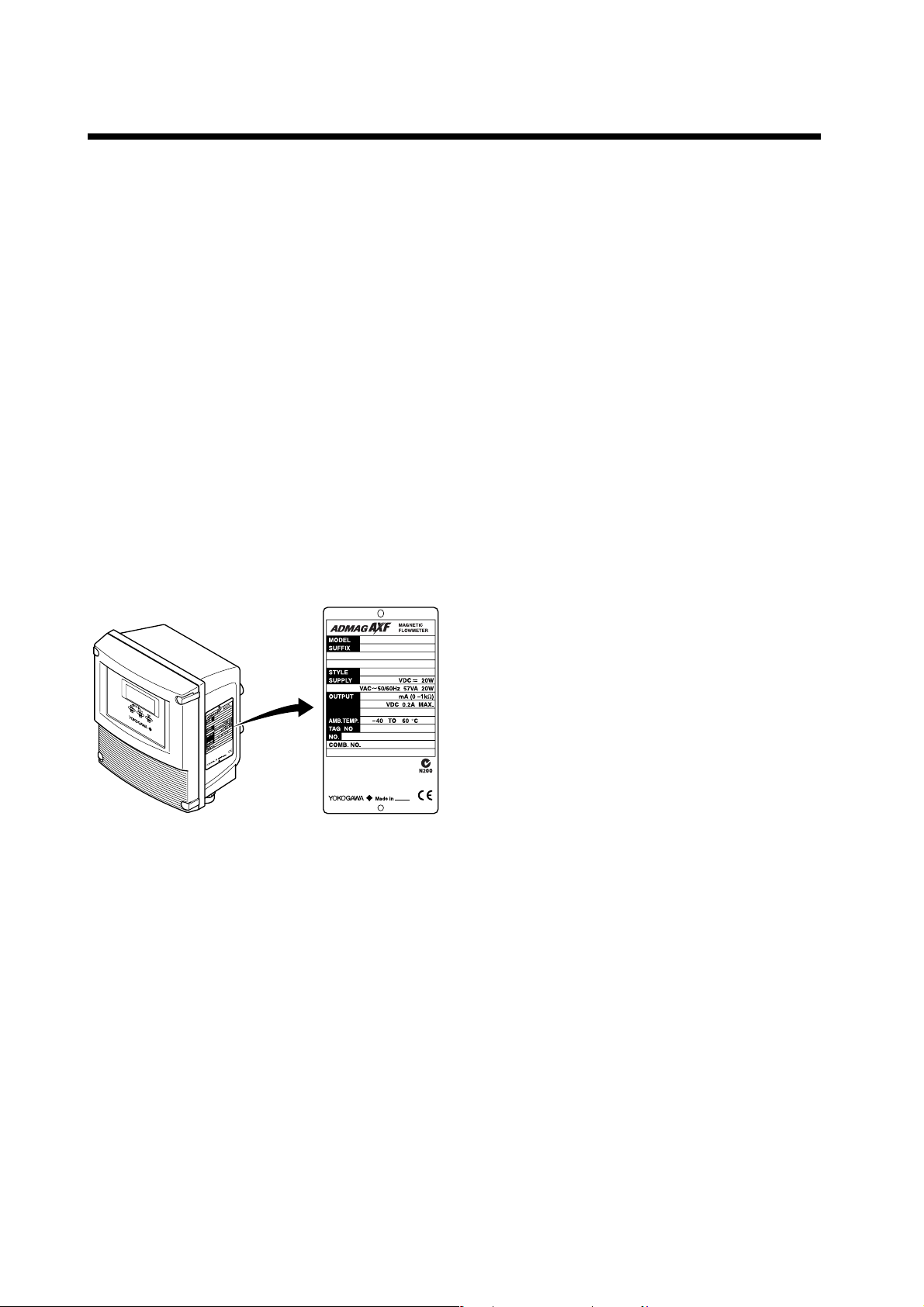

2.1 Checking Model and

Specifications

The model code and specifications are found on the

data plate located on the outside of the case. Check

that the model code and specifications match what you

have ordered.

Be sure you have your model number and serial

number available when contacting Yokogawa.

2.3 Storage Precautions

If the instrument is to be stored for a long period of

time after delivery, observe the following points.

The instrument should be stored in its original

packing condition in the storage location.

Select a storage location that fulfils the following

conditions:

• A place where it will not be exposed to rain or

water

• A place subject to minimal vibrations or shocks

• Temperature and humidity levels should be as

follows:

Temperature: -30 to 70°C

Humidity: 5 to 80% RH (no condensation)

The preferred ambient temperature and

humidity levels are 25°C and approximately

65% RH.

If the AXFA11 is transferred to the installation site

and stored without being installed, its performance

may be impaired due to the infiltration of rainwater

and so forth. Be sure to install and wire the

AXFA11 as soon as possible after transferring it to

the installation location.

F0201.EPS

2.2 Accessories

Check that the parts shown below are included in the

package:

Mounting hardware: 1 set

2.4 Installation Location

Precautions

Select the installation location with consideration to the

following items to ensure long-term stable operation of

the instrument.

Ambient Temperature:

Avoid installing the instrument in locations with

constantly fluctuating temperatures. If the location is

subject to radiant heat from the plant, provide heat

insulation or improve ventilation.

Atmospheric Condition:

Avoid installing the instrument in a corrosive

atmosphere. In situations where this is unavoidable,

consider ways to improve ventilation and to prevent

rainwater from entering and being retained in the

conduit pipes.

Vibrations or Shocks:

Avoid installing the instrument in a place subject to

shocks or vibrations.

2-1

IM 01E20C01-01E

3. INSTALLATION

3. INSTALLATION

WARNING

Installation of the magnetic flowmeter must be performed by expert engineer or skilled personnel. No

operator shall be permitted to perform procedures relating to installation.

3.1 Installation Location

IMPORTANT

Install the instrument in a location where it is not exposed to direct sunlight. For ambient temperature,

refer to Chapter 11 “OUTLINE”.

The instrument may be used in an ambient humidity where the RH ranges from 0 to 100%. However,

avoid long-term continuous operation at relative humidity above 95%.

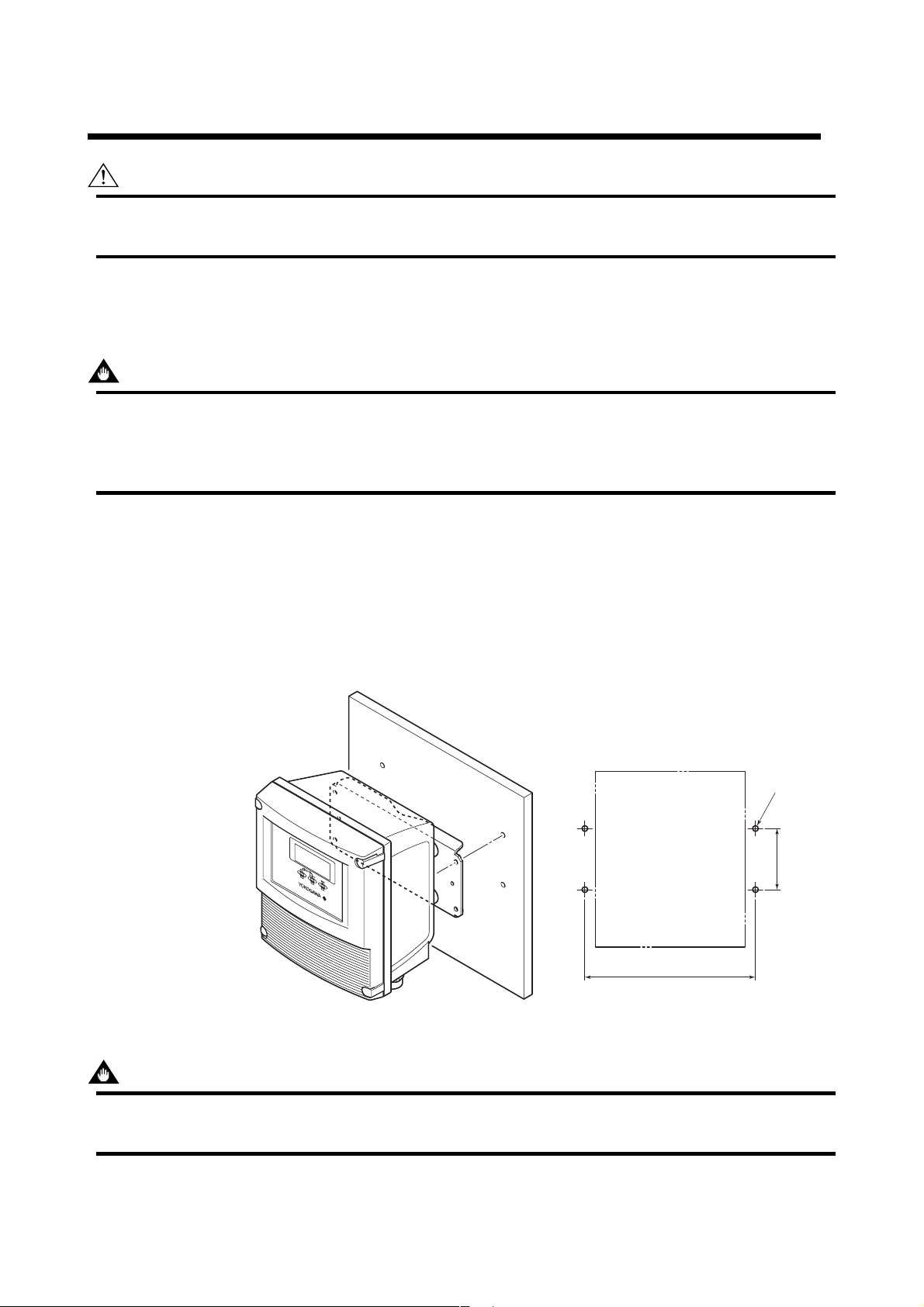

3.2 Mounting

This instrument can be mounted using surface mounting, 2-inch pipe mounting, or panel

mounting.

Surface Mounting (Wall Mounting)

Unit: mm

(approx. inch)

For surface mounting, use the mounting

fixture provided, using M6 screws.

These M6 screws must be provided

by the user.

194 (7.64)

4-6 Hole or

M6 Screw

65

(2.56)

F0301.EPS

Figure 3.2.1 Surface Mounting

IMPORTANT

Mounting fixture on equipment intended to be mounted on a wall or ceiling shall withstand a force of four

times the weight of the equipment (AXFA11: 3.3kg (7.3 lb)).

3-1

IM 01E20C01-01E

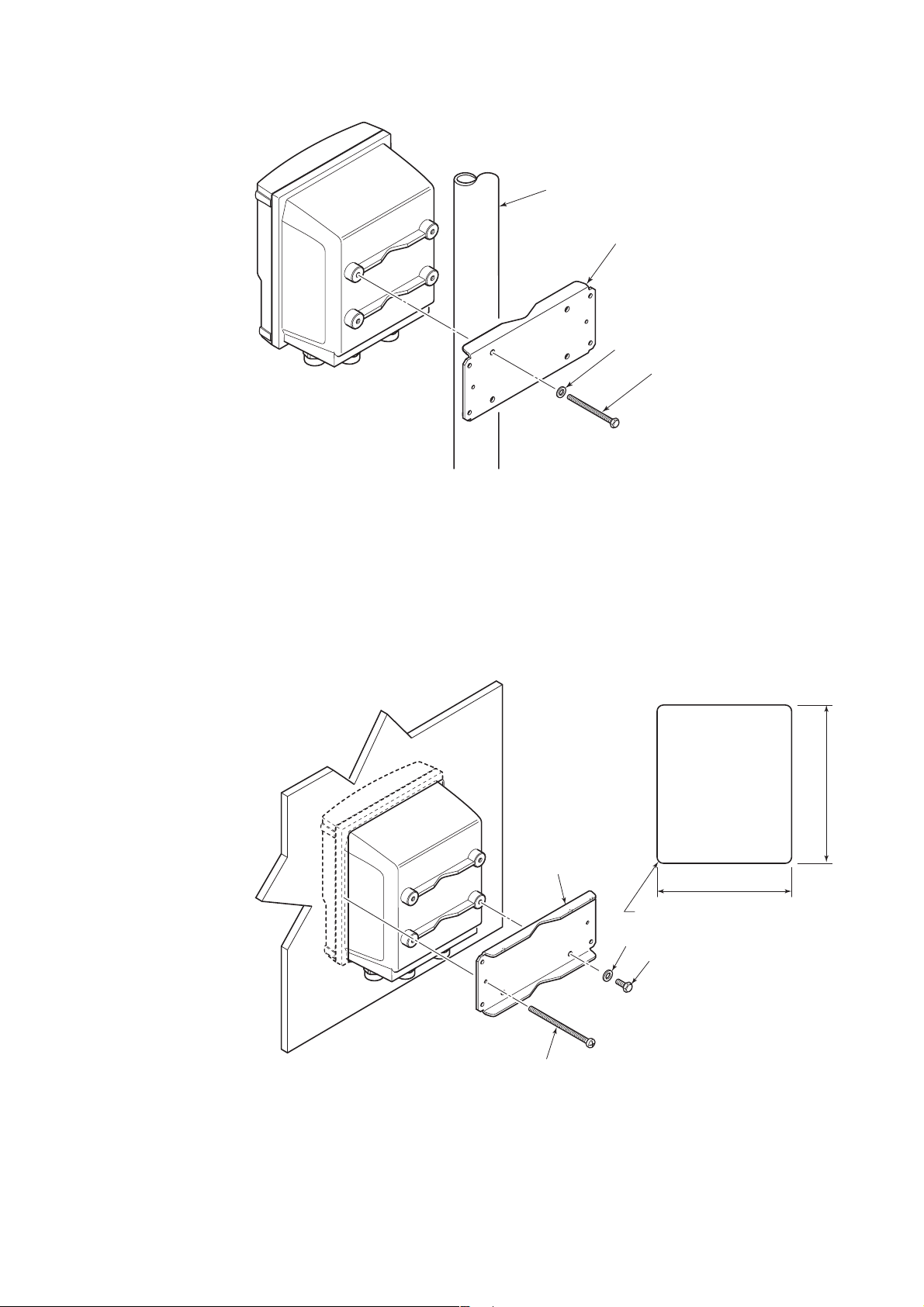

2-inch Pipe Mounting

2-inch pipe

Mounting fixture

Washer

Clamp screw

Pass the four clamp screws through the mounting fixture, position it on the 2-inch pipe,

and then fasten the AXFA11 in place.

3. INSTALLATION

Figure 3.2.2 2-inch Pipe Mounting

Panel Mounting

F0302.EPS

Unit: mm

(approx. inch)

Panel cutout

203 (8.0)

Mounting fixture

172 (6.8)

R3MAX

Washer

Screw

Fit the AXFA11 into the panel. Then attach the mounting fixture to the AXFA11 using the screw and the

washer, and secure the instrument with the two clamp screws.

Figure 3.2.3 Panel Mounting

3-2

Clamp screw

F0303.EPS

IM 01E20C01-01E

4. WIRING

4. WIRING

This section describes the wiring on the converter side

only. For information relating to wiring on the

flowtube side, refer to the user’s manual of the AXF

Remote Flowtube (IM 01E20D01-01E).

WARNING

The wiring of the magnetic flowmeter must be

performed by expert engineer or skilled personnel. No operator shall be permitted to perform

procedures relating to wiring.

CAUTION

Once all wiring is complete, check the connections before applying power to the instrument.

Improper arrangements or wiring may cause a

unit malfunction or damage.

4.1 Wiring Precautions

Be sure to observe the following precautions when

wiring:

four-core cables are used for wiring. Keep

conduits or flexible tubes watertight using

sealing tape.

• Ground the remote flowtube and the converter

separately.

• Cover each shield of the signal cable with vinyl

tube or vinyl tape to avoid contact between two

shields or between a shield and a case.

• When waterproof glands or union equipped

waterproof glands are used, avoid tightening

the glands with an excessive torque.

• Be sure to turn power off before opening the

cover.

• Before turning the power on, tighten the cover

securely.

4.2 Cables

(1) Dedicated Signal Cable (AXFC)

Conductors (A and B)

Shields (SA and SB)

Tape

Outer jacket

10.5 (0.413″)

CAUTION

• In cases where the ambient temperature

exceeds 50°C (122°F), use external heatresistant wiring with a maximum allowable

temperature of 70°C (158°F) or above.

• Do not connect cables outdoors in wet weather

in order to prevent damage from condensation

and to protect the insulation.

• Do not splice the cable between the flowtube

terminal and the converter if it is too short.

Replace the short cable with a cable that is the

appropriate length.

• All the cable ends must be provided with round

crimp-on terminals and be securely wired.

• The signal cables must be routed in separate

steel conduit tubes 16 (JIS C 8305) or flexible

conduit tubes 15 (JIS C 8309).

• Always route the power and output signal

cables in separate steel conduit tubes, except

when the power supply voltage is 24 V and

Shield (C)

Insulation

Insulation

Figure 4.2.1 Dedicated Signal Cable AXFC

F0401.EPS

The flow signal is transmitted via this dedicated cable.

The cable is constructed with double shielding over the

two conductors, and heat-resistant vinyl is used for the

outer jacket material.

Finished diameter: 10.5 mm (0.413″)

Maximum length: 200 m (660 ft)

Maximum temperature: 80°C (176°F)

IMPORTANT

If the cable is longer than required, cut off any

extra length rather than coiling it up, and terminate the conductors as shown in Figure 4.2.2.

Avoid using junction terminal boards to extend

the cable length, as this will interrupt the shielding.

4-1

IM 01E20C01-01E

4. WIRING

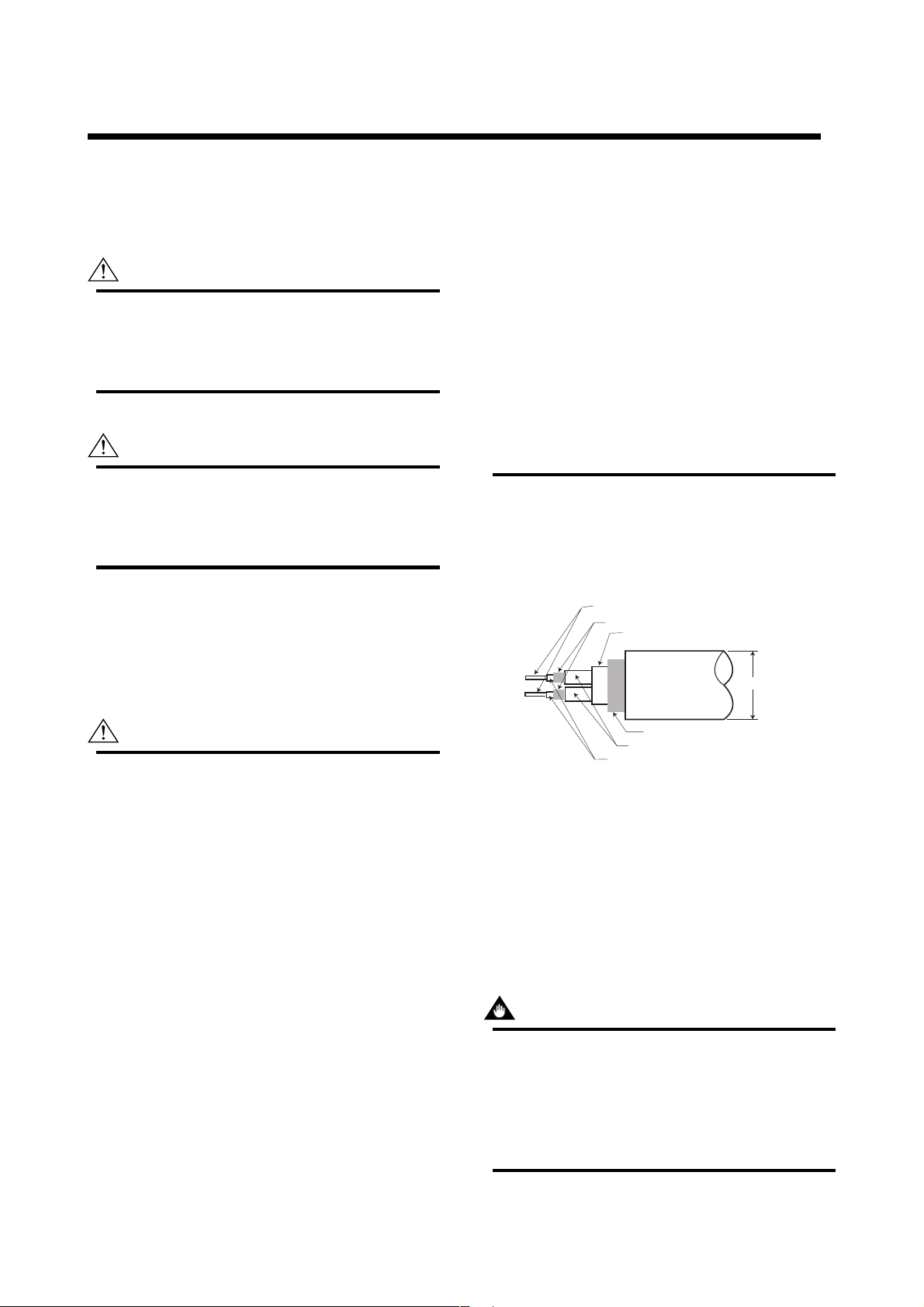

Unit : mm

(approx. inch)

ACB

SA

White Black

On the

converter

side

25 (0.98)

5

150

8(0.3) max.

(5.9)

20 (0.8)

SB

50 (1.97)

Red

60 (2.36)

70 (2.76)

L (Specified Dimensions)

AXFC

ACB

55 (2.17)

90 (3.54)

White Black Red

8 (0.3) max.

5

On the

(5.9)

150

flowtube

side

10.5 (0.4)

F0402.EPS

Figure 4.2.2 Treatment of Dedicated Signal Cables

CAUTION

• As crimp terminals A, B, SA, SB and C have

their own electrical potentials, securely insulate

them so as not to come in contact with one

another.

• To prevent a shield from coming in contact with

another shield or the case, cover each shield

with a vinyl tube or wrap it in vinyl tape.

90 (3.54)

With gland options EG, EU and EW;

• Excitation cable;

10.5 or 11.5 mm (0.41 or 0.45 in.)

• Power and output cable;

7.5 to 12 mm (0.30 to 0.47 in.)

With gland options EP;

6 to 12 mm (0.24 to 0.47 in.)

Nominal Cross Section:

Single wire; 0.5 to 2.5 mm

Stranded wire; 0.5 to 1.5 mm

2

2

In case of power cable, Green/Yellow covered conductor shall be used only for connection to PROTECTIVE

CONDUCTOR TERMINALS. Conform to IEC227,

IEC245 or equivalent national authorization.

Unit : mm

(approx. inch)

Crimp Terminal

EX2

EX1

85 (3.35)

On the converter side

85 (3.35)

On the flowtube side

EX1

EX2

NOTE

Conductors A and B carry the signal from the

electrodes, and C is at the potential of the liquid

(signal common). Shields SA and SB are kept

at the same potentials as the individual electrodes (these are actively driven shields.) This is

done to reduce the effect of the distributed

capacitance of the cable at long cable length.

Note that, since the signals from the individual

electrodes are impedance converted inside the

converter, errors will result if they come in

contact with any other component. Great care

must be taken in the cable end treatment.

(2) Excitation Cable/Power Cable/Output

Cable

JIS C3401 control cable equivalent

JIS C3312 power cable equivalent

14 AWG Belden 8720 equivalent

Outer Diameter:

With no gland option;

6.5 to 12 mm (0.26 to 0.47 in.)

F0403.EPS

Figure 4.2.3 End Treatment of Excitation Cable

• For excitation and power cables, always use a

crimp terminal with an insulation cover.

• Use crimp tools from the manufacturer of the

crimp terminal you want to use to connect the

crimp terminal and cable.

• Use crimp tools that are appropriate for the

diameter of the cable to be connected.

4-2

IM 01E20C01-01E

4. WIRING

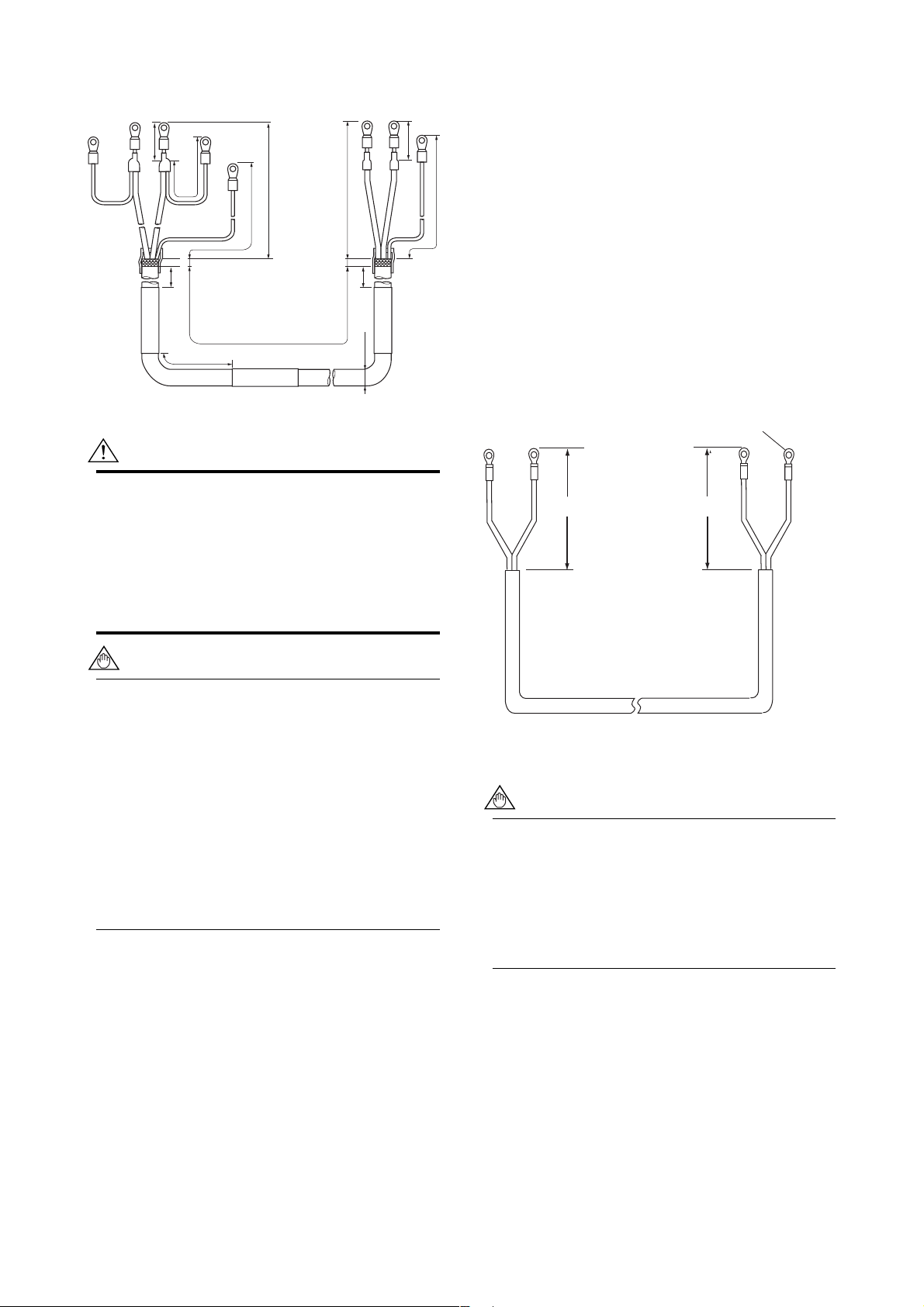

4.3 Wiring Ports

This instrument is of watertight construction as

stipulated in JIS C0920. It is shipped with a wiring

bracket (waterproof gland or waterproof gland with

union) or a plastic gland attached, only in cases where

an optional specification is selected for the wiring port.

IMPORTANT

The wiring port is sealed with a cap (not waterproof). Do not remove the cap from the unused

wiring port. If waterproof property is necessary,

please use waterproof glands.

(1) When waterproof property is unnecessary

(When there are no particular optional

specifications)

The wiring port is sealed with a cap (not water-proof)

that must be removed before wiring. At this time,

handle the wiring port in accordance with the JIS

C0920 mentioned above. Do not remove the cap from

the unused wiring port.

For working on the electric wire tubes or the flexible

tubes (PF1/2), remove the waterproof gland and attach

them directly to the wiring port.

Washer

PF1/2

Gasket

Tightening gland

Cable

When working on conduit pipes or flexible pipes (PF1/2 only)

F0405.EPS

Figure 4.3.2 Waterproof Gland with Union Joint

(Optional Code EU)

(2) When waterproof property is necessary

(Wiring using waterproof glands)

IMPORTANT

To prevent water or condensation from entering

the converter housing, waterproof glands are

recommended. Do not over-tighten the glands or

damage to the cables may result. Tightness of

the gland can be checked by confirming that the

cable is held firmly in place.

Washer

Gasket

Waterproof gland

Cable

F0404.EPS

Plastic gland

Figure 4.3.3 Plastic Gland (Optional Code EP)

PF1/2

PF3/4

Extension plug (x2)

Conversion plug (x5)

Cable

When working on electric wire tube or flexible tube (PF3/4)

* When connecting PF1/2, remove the conversion plug and

connect directly to wiring port.

Figure 4.3.4 PF3/4 Waterproof Gland (Optional Code EW)

F0406.EPS

Gasket

Washer

Figure 4.3.1 Waterproof Gland (Optional Code EG)

4-3

IM 01E20C01-01E

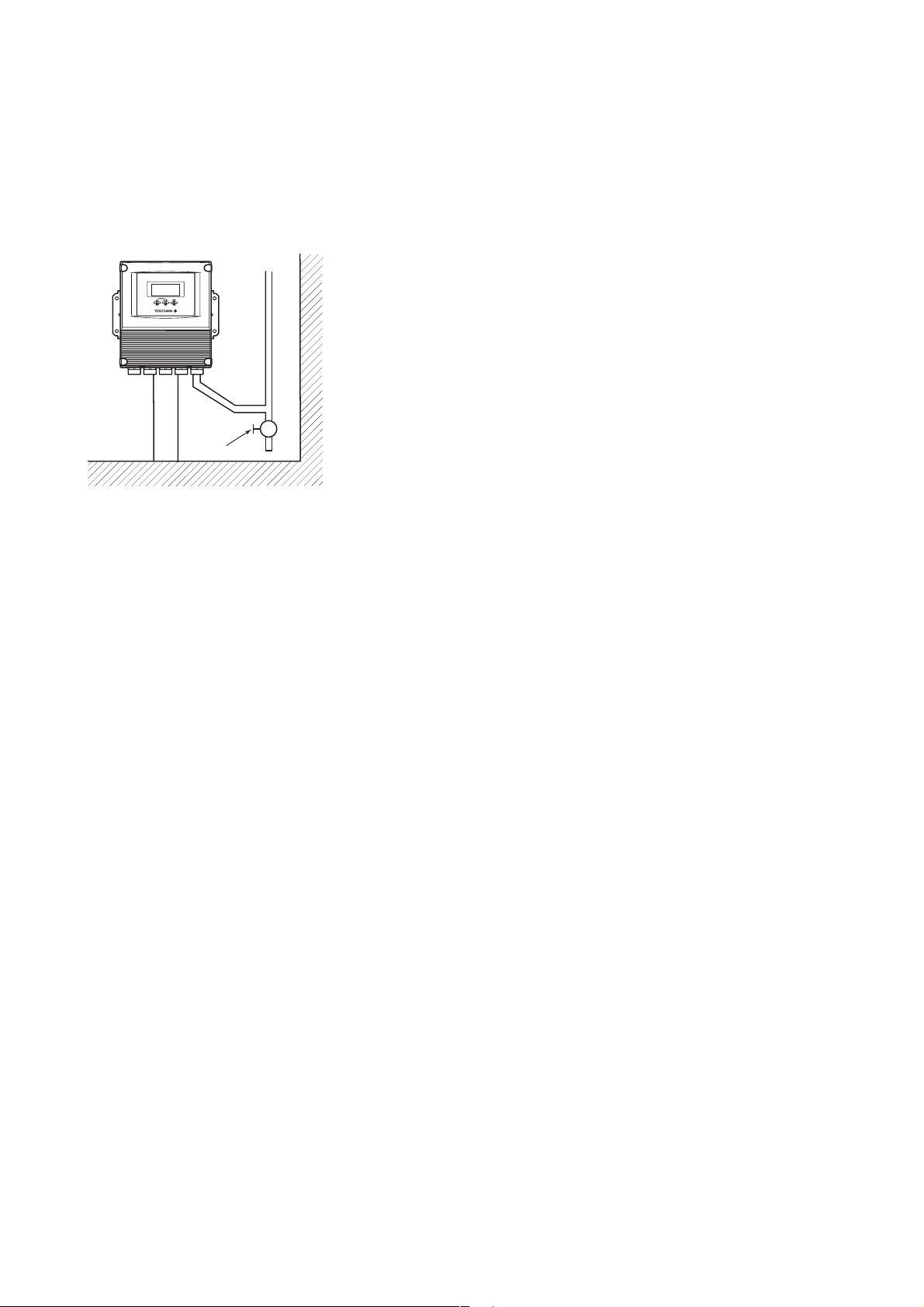

(3) Conduit Wiring

When wiring the conduits, pass the conduit through the

wiring connection port, and utilize the waterproof

gland to prevent water from flowing in. Place the

conduit pipe on an angle as shown in Figure 4.3.5.

Install a drain valve at the low end of the vertical pipe,

and open the valve regularly.

Drain valve

F0408.EPS

Figure 4.3.5 Conduit Wiring

4. WIRING

4-4

IM 01E20C01-01E

4.4 Wiring Connections

4.4.1 Removing Cover

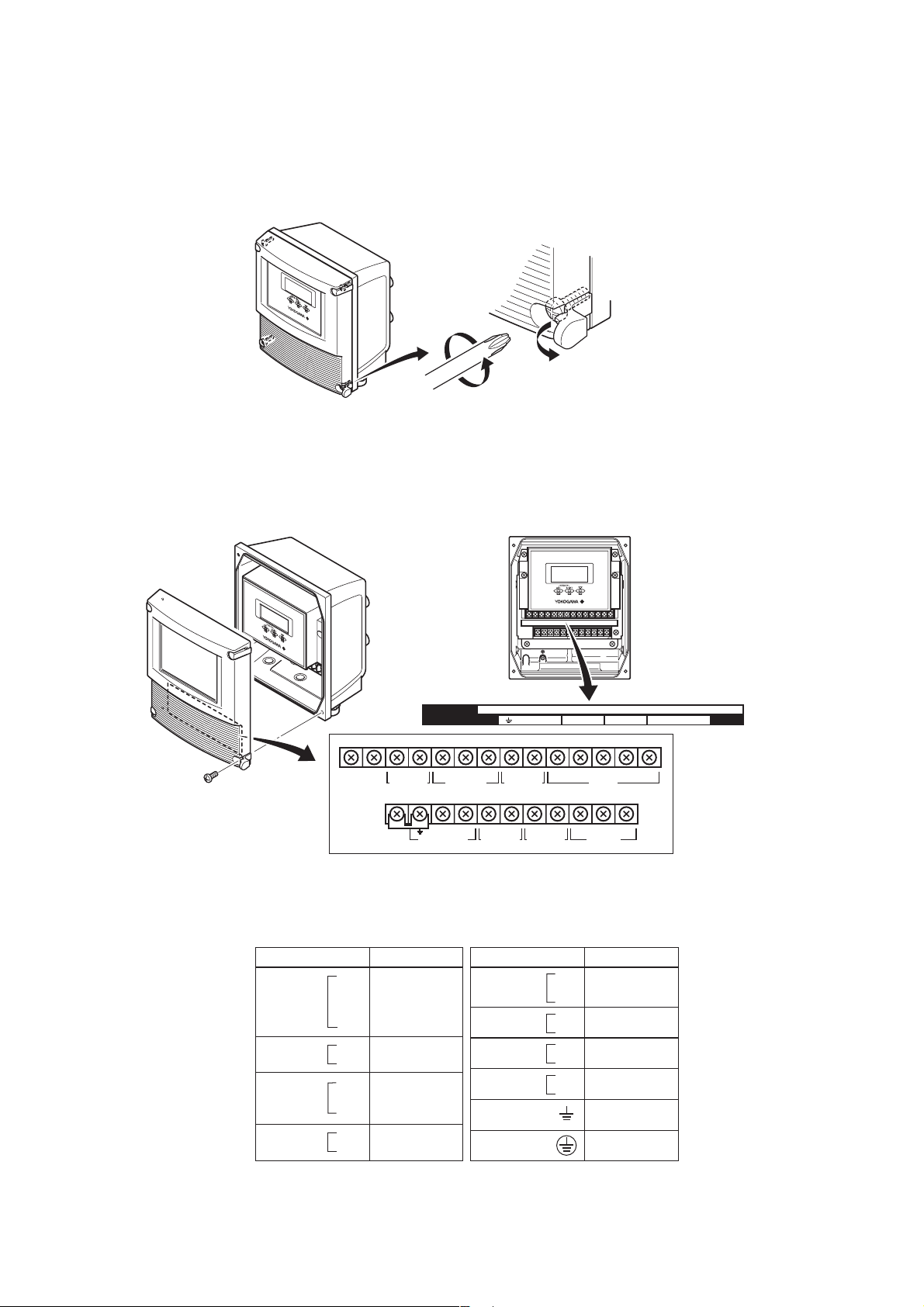

While supporting the front of the cover with your hand, flip the connecting screw protective cover over, and remove the four connecting screws.

Figure 4.4.1 Removing the Front Cover

4.4.2 Terminal Configuration

When the cover is removed, the connection terminals will be visible. The terminal configuration labels are attached in the position shown in Figure 4.4.2.

4. WIRING

F0409.EPS

SO2+

N/– L/+ EX2EX1 P– SI1+ SI2+ COMP+

AL+ AL– C SA A B SB

ALARM OUT

EX2EX1

PULSE OUT STATUS IN

SIGNAL

P– SI1+ SI2+ COMP+

I+ I–

CURRENT OUT

POWER SUPPLY

SO1+ COMSO2+

STATUS OUT

N/– L/+

I+ I– AL+ AL– C SA A B SBSO1+ COM

EXCIT ATION

Figure 4.4.2 Terminal Layout Labels Position

The description of the terminal symbols is shown in Table 4.4.1.

Table 4.4.1 Terminal Symbols

Terminal Symbols

SIGNAL

ALARM OUT

STATUS OUT

CURRENT OUT

C

SA

A

B

SB

AL+

AL-

SO1+

SO2+

COM

I+

I-

Description

Flow signal input

Alarm output

Status output

(Two output)

Current output

4 to 20mA DC

Terminal Symbols

STATUS IN

PULSE OUT

EXCITATION

POWER SUPPLY

Description

Sl1+

Status input

Sl2+

(Two input)

COM

P+

Pulse output

P-

Excitation current

EX1

EX2

output

L /+

Power supply

N/-

Functional grounding

Protective grounding

(Outside of the terminal)

T0401.EPS

F0410.EPS

4-5

IM 01E20C01-01E

4. WIRING

IMPORTANT

Do not wire the terminal without terminal symbols in terminal layout labels.

4.4.3 Precautions for Wiring of Power

Supply Cables

When connecting to the power supply, observe the

points below. Failure to comply with these warnings

may result in an electric shock or damage to the

instrument.

WARNING

• Ensure that the power supply is OFF in order to

prevent electric shocks.

• Ensure the protective grounding terminal is

grounded before turning the power on.

• Use insulating sleeve crimp terminals (for 4-mm

screws) for the power supply wiring and protective grounding wiring.

• To prevent electric shocks, ensure the electrical

wiring cover (transparent) is attached.

• Install an external switch or circuit breaker as a

means to turn the powe off (capacitance; 15A,

conforming to IEC947-1 and IEC947-3). Locate

this switch either near the instrument or in other

places facilitating easy operation. Affix a

“Power Off Equipment” label to this external

switch or circuit breaker.

4.4.4 DC Power Connection

When using DC power as the power supply for the

converter, give attention to the following points.

(1) Connecting Power Supply

IMPORTANT

Do not connect power supply with reversed

polarities.

L/+ terminal: connect +

N/– terminal: connect

IMPORTANT

Do not connect power supply with 100 to 240 V

AC or 100 to 120 V DC in the case of a 24 V

power supply version (power supply code 2).

It will give a damage to the converter.

(2) Required Power Supply Voltages

IMPORTANT

When using a 24 V power supply, the specification for the supply voltage is 24 V (–15% to

+20%), but the input voltage of the converter

drops due to cable resistance therefore it must

be used within the following ranges.

Supply Voltage and Cable Length

–

Wiring Procedure

1. Turn the instrument’s power off, and remove the

wiring cover (transparent).

2. Wire the power supply cable and the functional

grounding cable to the power supply terminals.

CUR OUT STATUS OUT ALARM OUT SIGNAL

Functional

grounding cable

Figure 4.4.3 Electric Cable Wiring

POWER SUPPLY EXCITER

P–P+

PULSE OUT STATUS IN

Power supply cable

SBBASACAL–AL+COMSO2+SO1+I+ I–

COMSI2+SI1+EX2EX1L/+N/–

F0411.EPS

3. Reattach the electrical wiring cover (transparent).

420 (1380)

280 ( 920)

200 ( 660)

100 ( 330)

Allowable cable length m(ft)

0

20.4 22 24 26 28.8

Usable range E (V)

Cable cross section area: 1.25 mm

Cable cross section area: 2 mm

(3) Setting Power Supply Frequency

IMPORTANT

Set the local commercial power frequency in

order to eliminate the effect of induction noise

from the commercial power supply.

Refer to “Chapter 6: Parameter Description” in

this manual. Parameter No. J30 and J31.

4-6

2

2

F0411-2.EPS

IM 01E20C01-01E

4. WIRING

4.4.5 Grounding

CAUTION

Be sure to connect the protective grounding of

the AXFA11 with a cable of 2mm2 or larger cross

section in oder to avoid electrical shock to the

operators and maintenance engineers and to

prevent the influence of external noise. Connect

the grounding wire to the mark (100 or

less).

IMPORTANT

When optional code A (lighting protector) is

selected, the ground should satisfy Class C

requirements (grounding resistance, 10 or

less).

• The protective grounding terminals are located

on the inside and outside of the terminal area.

Either terminal may be used.

• Use 600 V vinyl insulation wires as the grounding

wires.

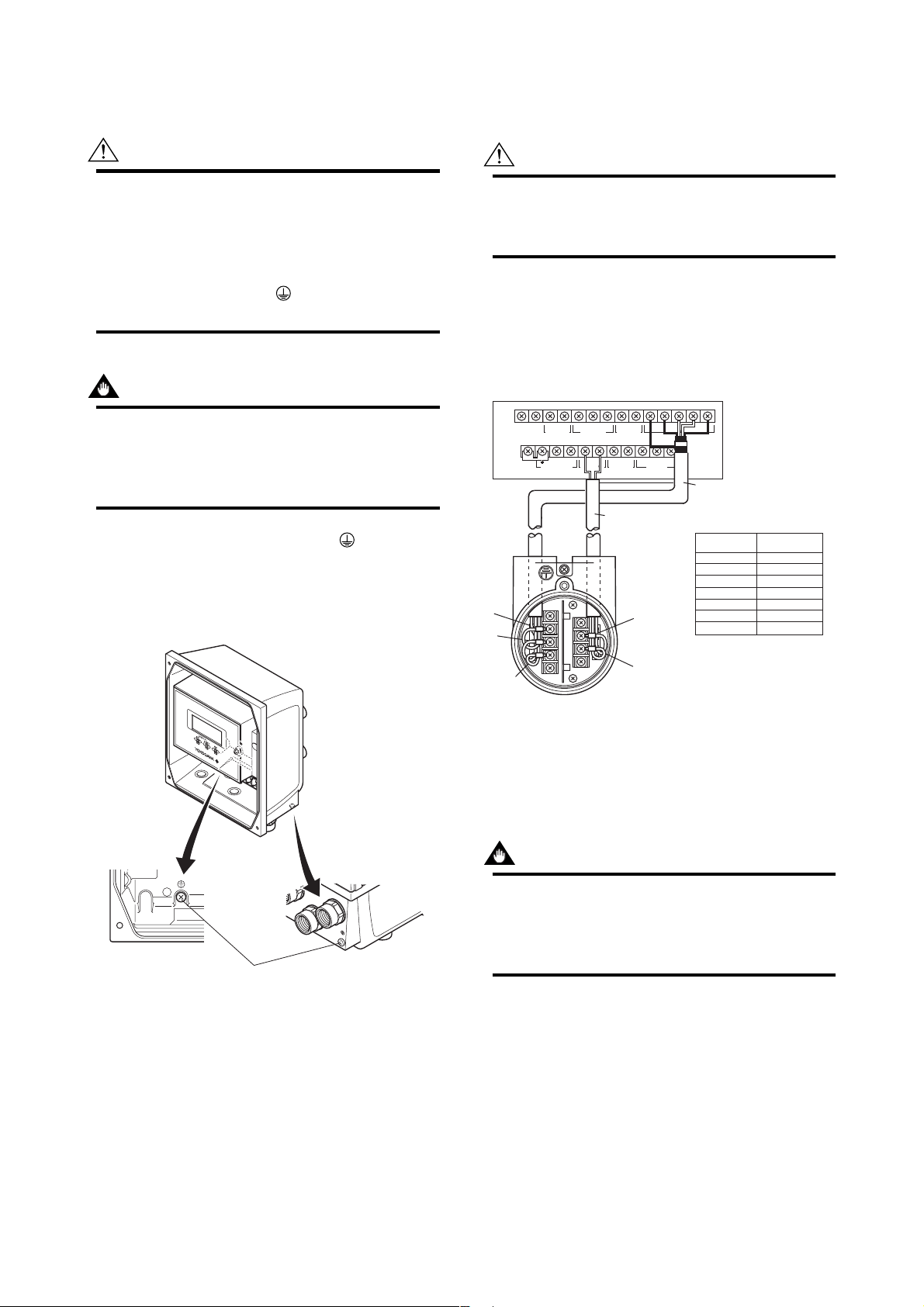

4.4.6 Wiring the Remote Flowtube

with the AXFA11 Converter

WARNING

Before wiring, be sure that the power supply for

AXFA11 converter has been turned off to

prevent an electrical shock.

(1) Connection with the Remote Flowtube

(General-Purpose Use, Submersible Type,

Sanitary Type, Size 2.5 to 400 mm (0.1 to

16 in.))

Connect wiring as shown in the figure below.

I+ I–

CURRENT OUT

N/– L/+

POWER SUPPLY

A

B

C

Figure 4.4.5 Wiring Diagram

AL+ AL– C SA A B SB

SO1+ COMSO2+

ALARM OUT

STATUS OUT

EX2EX1

P– SI1+ SI2+ COMP+

EXCIT ATION

PULSE OUT STATUS IN

Excitation cable

Remote flowtube

EX2

EX1

SIGNAL

AXFA11 Converter

AXFC Dedicated signal

cable

Converter

SA

A

B

SB

C

EX1

EX2

* Individually tape and insulate the

shields corresponding to SA and

SB on the remote flowtube side.

Remote

flowtube

Taping*

A

B

Taping*

C

EX1

EX2

F0415.EPS

Protective grounding terminals

F0414.EPS

Figure 4.4.4 Protective Grounding Terminal Location

(2) Connection with the Remote Flowtube

(Explosion proof Type, Size 2.5 to 400 mm

(0.1 to 16 in.))

IMPORTANT

In case of TIIS Flame proof type, a remote

flowtube cannot be combined with AXFA11

converter. In this case, use the AXFA14 converter.

4-7

IM 01E20C01-01E

4. WIRING

In case of explosion proof type for ATEX, FM, and

CSA certification, connect wiring as shown in the

figure below.

In case of the explosion proof type, the protective

grounding

of remote flowtube must be connected to

a suitable IS grounding system. In that case,

(functional grounding terminal) need not be connected.

I+ I–

CURRENT OUT

N/– L/+

POWER SUPPLY

A

B