Training

G u i d e

TM-1830

AVEVA Everything3D

™ (2.1)

Draw

Draw

This page is intentionally left blank

AVEVA Everything3D

™ 2.1

Migration & Interoperability Guide

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

2

www.aveva.com

AVEVA Everything3D

™ 2.1

Migration & Interoperability Guide

Revision Log

Date Revision Description

16.10.2015

26.11.2015

27.11.2015

0.1

0.2

1.0

Issued for Review

Reviewed

Released with AVEVA E3D™ 2.1

Author Reviewed Approved

SB

SB

SB

—

P.Dev

P.Dev

—

—

P.Dev

Updates

Change highlighting will be employed for all revisions. Where new or changed information is presented section headings will be highlighted.

Suggestion / Problems

This manual provides documentation relating to products to which you may not have access or which may not be licensed to you. For further information on which products are licensed to you please refer to your licence conditions.

Visit our website at

http://www.aveva.com

Disclaimer

1.1 AVEVA does not warrant that the use of the AVEVA software will be uninterrupted, error-free or free from viruses.

1.2 AVEVA shall not be liable for: loss of profits; loss of business; depletion of goodwill and/or similar losses; loss of anticipated savings; loss of goods; loss of contract; loss of use; loss or corruption of data or information; any special, indirect, consequential or pure economic loss, costs, damages, charges or expenses which may be suffered by the user, including any loss suffered by the user resulting from the inaccuracy or invalidity of any data created by the AVEVA software, irrespective of whether such losses are suffered directly or indirectly, or arise in contract, tort (including negligence) or otherwise.

1.3 AVEVA’s total liability in contract, tort (including negligence), or otherwise, arising in connection with the performance of the AVEVA software shall be limited to 100% of the licence fees paid in the year in which the user’s claim is brought.

1.4 Clauses 1.1 to 1.3 shall apply to the fullest extent permissible at law.

1.5 In the event of any conflict between the above clauses and the analogous clauses in the software licence under which the AVEVA software was purchased, the clauses in the software licence shall take precedence.

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

3

www.aveva.com

AVEVA Everything3D

™ 2.1

Migration & Interoperability Guide

Copyright Notice

All intellectual property rights, including but not limited to, copyright in this Training Guide and the associated documentation belongs to or is licensed to AVEVA Solutions Limited or its affiliates.

All rights are reserved to AVEVA Solutions Limited and its affiliates companies. The information contained in this Training Guide and associated documentation is commercially sensitive, and shall not be adapted, copied, reproduced, stored in a retrieval system, or transmitted in any form or medium by any means (including photocopying or electronic means) without the prior written permission of AVEVA Solutions Limited. Where such permission is granted, AVEVA Solutions Limited expressly requires that the Disclaimer included in this

Training Guide and this Copyright notice is prominently displayed at the beginning of every copy that is made.

Licenses issued by the Copyright Licensing Agency or any other reproduction rights organisation do not apply.

If any unauthorised acts are carried out in relation to this copyright work, a civil claim for damages may be made and or criminal prosecution may result.

AVEVA Solutions Limited and its affiliate companies shall not be liable for any breach or infringement of a third party’s intellectual property rights arising from the use of this Training Guide and associated documentation.

@AVEVA Solutions Limited 2015

Trademark Notice

AVEVA™, AVEVA Everything3D™, AVEVA E3D™, [AVEVA Tags], Tribon and all AVEVA product and service names are trademarks of AVEVA Group plc or its subsidiaries

Use of these trademarks, product and service names belonging to AVEVA Group plc or its subsidiaries is strictly forbidden, without the prior written permission of AVEVA Group plc or AVEVA Solutions Limited. Any unauthorised use may result in a legal claim being made against you.

Fluent is a trade mark of Microsoft Corporation. The Fluent user interface is licensed from Microsoft

Corporation by AVEVA and use of the Fluent trade mark is strictly forbidden

All other trademarks belong to their respective owners and cannot be used without the permission of the owner.

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

4

www.aveva.com

CONTENTS

1 Introduction ……………………………………………………………………………………………………………. 9

Introducing AVEVA Everything3D™ 2.1 …………………………………………………………………………….. 9

The Migration & Interoperability Guide ……………………………………………………………………………. 11

Using this Guide ………………………………………………………………………………………………………… 11

AVEVA Experience …………………………………………………………………………………………………………. 11

2

AVEVA Everything3D™ 2.1 ……………………………………………………………………………………. 13

Workstation Configuration ……………………………………………………………………………………………… 13

Graphics Cards ………………………………………………………………………………………………………………. 14

Graphical Performance ……………………………………………………………………………………………….. 15

Server Configuration ………………………………………………………………………………………………………. 15

Prerequisite for this Release (Products) ………………………………………………………………………….. 16

AVEVA Licensing™ 2.0.0 ……………………………………………………………………………………………. 16

AVEVA Client Cache Service™ 1.0.5 …………………………………………………………………………… 16

AVEVA Catalogue 2.1.0 ……………………………………………………………………………………………… 17

Microsoft® Software …………………………………………………………………………………………………… 17

Environment Variables ……………………………………………………………………………………………………. 18

Network ………………………………………………………………………………………………………………………….. 18

Install ……………………………………………………………………………………………………………………………… 18

AVEVA Everything3D™ – Projects 2.1 …………………………………………………………………………….. 19

AVEVA Sample Laser Data 1.1 ……………………………………………………………………………………. 19

AVEVA Everything3D™ – Documentation 2.1 ………………………………………………………………….. 20

Entering AVEVA Everything3D 2.1 ……………………………………………………………………………….. 20

3 Project Migration …………………………………………………………………………………………………… 23

Migrating projects from AVEVA PDMS or Hull & Outfitting 12.0 ……………………………………….. 23

AVEVA PDMS 12.0 AVEVA PDMS 12.1 …………………………………………………………………… 23

AVEVA Hull & Outfitting 12.0 AVEVA Hull & Outfitting 12.1 ………………………………………… 23

Preparing an AVEVA PDMS or Hull & Outfitting 12.1.SP4 Project …………………………………….. 24

Marine Projects (Hull data) in AVEVA E3D 2.1 ………………………………………………………………. 24

Preparing an AVEVA Everything3D 1.1 project ………………………………………………………………… 24

AVEVA Catalogue and AVEVA Administration …………………………………………………………………. 25

Customer PML & .NET Applications ………………………………………………………………………………… 25

4 Model Data ……………………………………………………………………………………………………………. 27

Structural ……………………………………………………………………………………………………………………….. 27

Section Conversion ……………………………………………………………………………………………………. 28

Catalogue

– Joints & Fittings ……………………………………………………………………………………….. 29

Catalogue

– Profiles …………………………………………………………………………………………………… 30

Adding Joint & Fitting Images ………………………………………………………………………………………. 32

Stairs, Ladders & Handrails …………………………………………………………………………………………. 34

Grids ………………………………………………………………………………………………………………………………. 35

Ship & Plant Grid Conversion ………………………………………………………………………………………. 35

Supports ………………………………………………………………………………………………………………………… 37

Database Updates ……………………………………………………………………………………………………… 38

Supports Application Defaults ……………………………………………………………………………………… 40

Template Data …………………………………………………………………………………………………………… 41

Model Data Upgrade ………………………………………………………………………………………………….. 47

Support Designer Access ……………………………………………………………………………………………. 47

Piping …………………………………………………………………………………………………………………………….. 48

Sloping Pipes …………………………………………………………………………………………………………….. 48

Piping & Supports ………………………………………………………………………………………………………. 50

Laser………………………………………………………………………………………………………………………………. 50

Preparing for the HyperBubble …………………………………………………………………………………….. 51

Compare / Update …………………………………………………………………………………………………………… 51

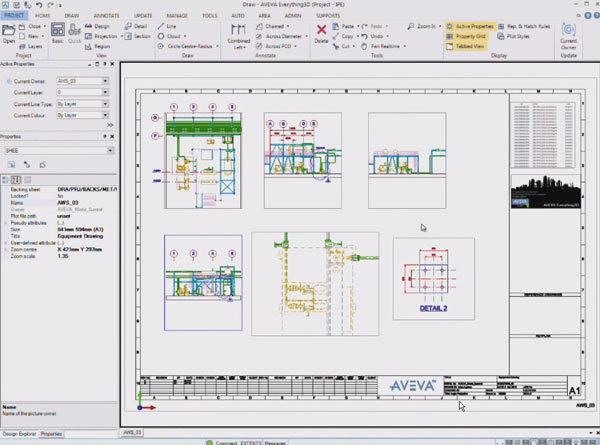

5 Draw Data …………………………………………………………………………………………………………….. 53

Module Definition ……………………………………………………………………………………………………………. 53

Draw Transformation ………………………………………………………………………………………………………. 53

Sheets ………………………………………………………………………………………………………………………. 54

Library Elements ………………………………………………………………………………………………………… 55

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

5

www.aveva.com

AVEVA Everything3D

™ 2.1

Migration & Interoperability Guide

Thumbnails ……………………………………………………………………………………………………………….. 56

Refreshing overlays ……………………………………………………………………………………………………. 57

Modification of Library elements …………………………………………………………………………………….. 58

Representation Rules & Styles …………………………………………………………………………………….. 58

Label & Symbols ………………………………………………………………………………………………………… 58

Visual Styles ……………………………………………………………………………………………………………… 59

Visual Layers …………………………………………………………………………………………………………….. 60

Plot Styles …………………………………………………………………………………………………………………. 60

Reference Grids in Draw …………………………………………………………………………………………………. 61

General ADP ……………………………………………………………………………………………………………… 61

Area-Based ADP ……………………………………………………………………………………………………….. 62

3.4.2

The Isometric ADP……………………………………………………………………………………………………… 63

Using a Marine Project with Draw ……………………………………………………………………………………. 63

Draw System Defaults ………………………………………………………………………………………………… 63

Drawing Database Storage …………………………………………………………………………………………. 63

Transformation of a Marine Drafting Drawing (incl. SDB File & Picture File) ………………………. 64

5.5.3.7

D …………………………………………………………………………………………………………………………… 67

Marine Transform Configuration File …………………………………………………………………………….. 70

6 Compatibility & Interoperability ……………………………………………………………………………… 73

Compatibility with other AVEVA Products ……………………………………………………………………….. 73

Interoperability — AVEVA PDMS or Hull & Outfitting 12.1.SP4……………………………………………. 74

Project Setup …………………………………………………………………………………………………………….. 74

Model Data ……………………………………………………………………………………………………………….. 75

Outfitting Applications …………………………………………………………………………………………………. 76

Hull Data …………………………………………………………………………………………………………………… 76

Reports …………………………………………………………………………………………………………………….. 76

Draw Data …………………………………………………………………………………………………………………. 76

AVEVA Administration 1.4.0 ……………………………………………………………………………………………. 77

New Database Types …………………………………………………………………………………………………. 78

Draw Module ……………………………………………………………………………………………………………… 78

Dynamic Database Sets ……………………………………………………………………………………………… 78

Multi-write Dictionary & Property Databases ………………………………………………………………….. 78

Flexible Explorer ………………………………………………………………………………………………………… 78

Unit Sets …………………………………………………………………………………………………………………… 78

AVEVA Global 3.2.1 ………………………………………………………………………………………………………… 79

AVEVA Clash Manager 12.1 …………………………………………………………………………………………….. 79

7 Customisations …………………………………………………………………………………………………….. 81

Use of PML & C# in AVEVA E3D 2.1 ………………………………………………………………………………… 81

General Considerations ………………………………………………………………………………………………….. 81

Environment Variables ……………………………………………………………………………………………….. 81

PMLLIB, PMLUI and CAF_UIC_PATH Path ………………………………………………………………….. 82

Core .dlls …………………………………………………………………………………………………………………… 83

Forms & Menus ………………………………………………………………………………………………………………. 83

Form Layout ………………………………………………………………………………………………………………. 83

Sliding Forms …………………………………………………………………………………………………………….. 83

Form Title & Icon ……………………………………………………………………………………………………….. 83

3D View Form Borders ……………………………………………………………………………………………….. 83

Modules with Ribbon Menus …………………………………………………………………………………………… 84

Customising Ribbon Menus with PML …………………………………………………………………………… 85

PML Add-in files…………………………………………………………………………………………………………. 85

Other Considerations ………………………………………………………………………………………………….. 86

Applications …………………………………………………………………………………………………………………… 86

AVEVA PDMS Draft & AVEVA Marine Drafting Customisations ………………………………………… 86

Accessing DRAW 2D Views ………………………………………………………………………………………… 86

Accessing the Draw Browser ……………………………………………………………………………………….. 87

Use of :CDLimits ………………………………………………………………………………………………………… 87

PML Object for Sections ……………………………………………………………………………………………… 87

Marine Drafting ………………………………………………………………………………………………………….. 87

Module Switching …………………………………………………………………………………………………………… 87

Writing PML code to work in both PDMS & AVEVA E3D …………………………………………………… 88

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

6

www.aveva.com

AVEVA Everything3D

™ 2.1

Migration & Interoperability Guide

The interface to main bar menu and tool bar functions ……………………………………………………. 88

Changes to environment variables ……………………………………………………………………………….. 89

Use of Lists which have been replaced by Collections in AVEVA E3D ……………………………… 89

Changes to form layout ………………………………………………………………………………………………. 89

Use of resource files for Icons ……………………………………………………………………………………… 89

PML code setting view properties …………………………………………………………………………………. 89

Changes to PML TABSET gadgets ………………………………………………………………………………. 89

Appendix A Migration from PDMS 12.0 to 12.1 …………………………………………………………….. 91

Upgrade overview …………………………………………………………………………………………………………………….. 91

DBUpgrade command……………………………………………………………………………………………………………… 91

Database Version Control ………………………………………………………………………………………………………… 92

Global ……………………………………………………………………………………………………………………………………. 92

The Upgrade Process ……………………………………………………………………………………………………………… 93

Locking the Project ………………………………………………………………………………………………………………….. 93

Extract Hierarchies ………………………………………………………………………………………………………………….. 94

International characters (Unicode) …………………………………………………………………………………………….. 94

Units of measure ………………………………………………………………………………………………………………………. 95

Schematics functions ………………………………………………………………………………………………………………. 95

Appendix B Details of Sample Project Changes ………………………………………………………….. 97

ACP Project ……………………………………………………………………………………………………………………………… 97

APS Project ……………………………………………………………………………………………………………………………. 101

AMS Project ……………………………………………………………………………………………………………………………. 106

Appendix C Forming Structural Joint & Fitting Images ………………………………………………. 109

Colours ………………………………………………………………………………………………………………………………….. 109

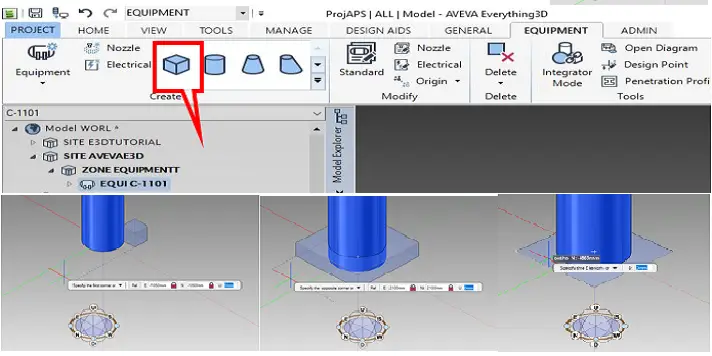

Setting up a Joint in Model ……………………………………………………………………………………………………… 110

Setting up a Section Fitting in Model ………………………………………………………………………………………. 110

Setting up the 3D View ……………………………………………………………………………………………………………. 111

Setting the Auto Colours rules and Translucencies …………………………………………………………………. 112

Taking the Screenshot ……………………………………………………………………………………………………………. 115

Naming the Image …………………………………………………………………………………………………………………… 115

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

7

www.aveva.com

This page is intentionally left blank

AVEVA Everything3D

™ 2.1

Migration & Interoperability Guide

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

8

www.aveva.com

1 Introduction

CHAPTER 1

This document is intended to provide an overview of the migration process to AVEVA Everything3D

™ 2.1 and will highlight project considerations ahead of the successful implementation of the product.

Introducing AVEVA Everything3D™ 2.1

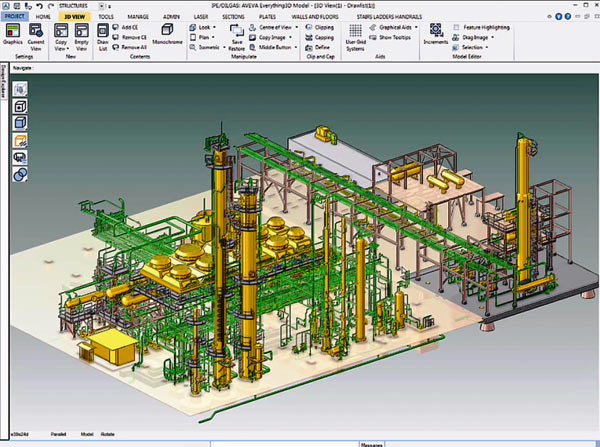

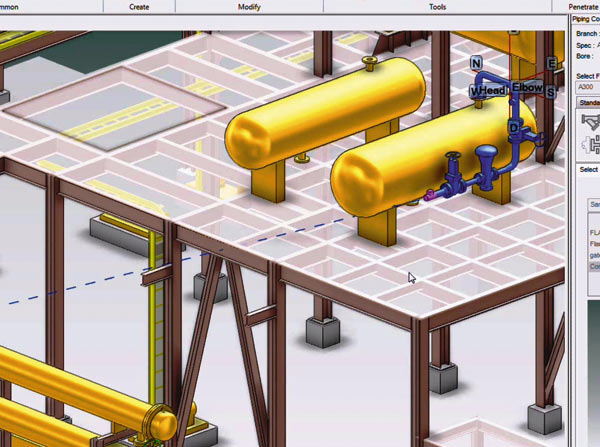

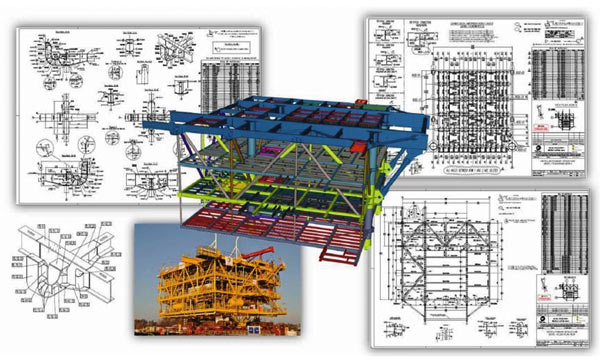

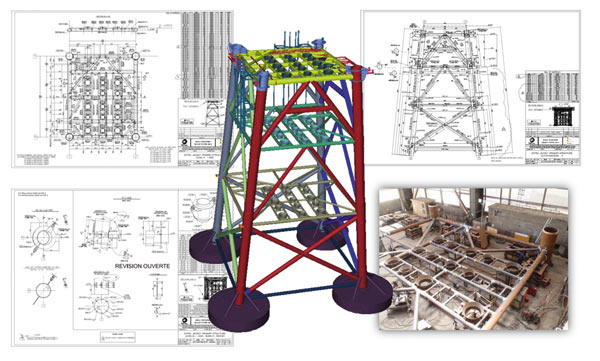

AVEVA Everything3D™ 2.1 (AVEVA E3D™ 2.1) is an innovative new flagship 3D design product from AVEVA covering the needs of Plant industries. AVEVA E3D 2.1 also introduces the capability to display, interact with and draw Hull models produced in AVEVA Marine.

AVEVA E3D 2.1 provides a platform that enables lean construction principles to be adopted, increasing quality and speed of execution throughout the entire project. This is achieved through advanced usability for all design tasks which improves productivity by utilising latest technologies and best in class User Experience to enable innovative and ever more efficient project execution processes. This is demonstrated by the clean and intuitive user interface of the product that encourages graphical centric modelling and interaction.

: Hull Model in AVEVA E3D 2.1.

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

9

www.aveva.com

AVEVA Everything3D

™ 2.1

Migration & Interoperability Guide

AVEVA E3D 2.1 is based upon a proven platform of technologies used to support a wider family of products; supporting common capabilities such as multi-user, distributed and concurrent access to the design model, and the comparison and update of information. This allows global teams to collaborate in building fully detailed models, from which construction-ready drawings and BOMs can be automatically generated

AVEVA E3D 2.1 contains the following principal modules:

Model — An interactive 3D design environment.

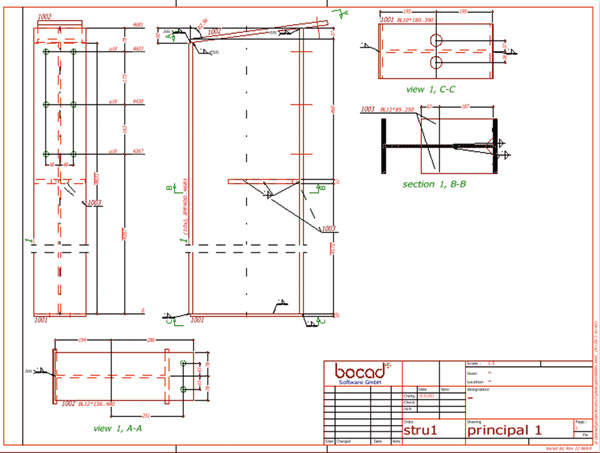

Draw — Facilitates the production of scaled, annotated drawings from the 3D Model.

IsoDraft — Used in the production of piping isometrics.

As part of an integrated product solution, AVEVA E3D 2.1 may integrate with AVEVA Engineering and

Schematics products. The Piping Integrator feature has been redesigned to bring the 3D Design — P&ID checking task to the daily workflow of a Piping designer. Further, AVEVA E3D 2,1 may be integrated with

AVEVA NET, epitomised by the Design in Context feature that allows the direct interrogation of the AVEVA

NET Dashboard in the Model and Draw environment.

The Model module provides enhanced access to project Design database and functions. The 3D graphics, introduced at AVEVA E3D 1.1 are based on Microsoft DirectX, delivering a faster and clear graphic. AVEVA

E3D 2.1 introduces a redesigned structural application that places the model at the centre of design workflows.

Another primary development at AVEVA E3D 2.1 is the provision of a redesigned Supports application that promotes an efficient and intuitive design workflow across different locations.

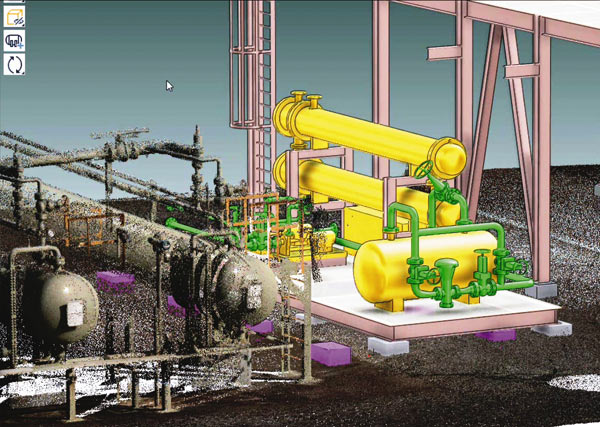

New innovation with l aser data, utilising the immersive living Point Cloud capability of AVEVA HyperBubble™ will deliver project benefits, especially in brownfield projects. Powerful 2D drafting also allows the inclusion of

Laser data, removing the need to remodel existing Digital Assets.

System administration and configuration, together with catalogue and specification capabilities, are provided by the separate AVEVA Administration™ and AVEVA Catalogue™ products respectively. AVEVA Catalogue has been updated at this latest release and introduces a new user interface that is aligned in design with

AVEVA E3D 2.1.

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

10

www.aveva.com

AVEVA Everything3D

™ 2.1

Migration & Interoperability Guide

AVEVA E3D 2.1 has been designed from the outset to be compatible with AVEVA PDMS and Hull & Outfitting

12.1.SP4 and it uses the same database and data management technology, enabling the two to be used in conjunction on operational projects.

The Migration & Interoperability Guide

The aim of the Migration & Interoperability Guide is to provide an overview of the main differences between

AVEVA E3D 2.1 and AVEVA PDMS and Hull & Outfitting 12.1.SP4. It includes the project data migration process between the two products and highlight the interoperability of the two products on a project.

This guide should be useful to administrators who wish to migrate an AVEVA PDMS or Hull & Outfitting project, including those who wish to operate on projects in a mode where both products are in use. Customers who are still using earlier releases of AVEVA PDMS and Hull & Outfitting should also read the latest editions of the

12.0 & 12.1 User Bulletins, as supplied with those releases to migrate project data to 12.1.SP4 prior to AVEVA

E3D 2.1.

Using this Guide

Certain text styles are used to indicate special situations throughout this document.

Button clicks are indicated by

bold turquoise text

.

Additional information notes and references to other documentation will be indicated in the styles below.

Additional information

Refer to other documentation

Example files or inputs will be in the courier new font.

AVEVA Experience

In addition to the migration of a project and the data to AVEVA E3D 2.1, it is also important to consider the users of the product and their adaption to the functionality provided in order to realise an efficient design workflow. This adoption is aided by an intuitive AVEVA E3D 2.1 user interface and workflows; designed with the user and the graphical model at the centre of the process.

In addition

AVEVA Experience™ ( http://www.aveva.com/experience ) provides an effective and easily accessible way to gain hands-on experience of AVEVA E3D, wherever the user is located. For employers, it makes it easier to train and upskill engineers and designers.

Once registered, the user will have the opportunity to go through an extensive set of training modules on core aspects of AVEVA E3D, including training exercises and ‘how-to’ videos. These modules will highlight the key differences between AVEVA PDMS and AVEVA E3D. The user will also be able to work with a Cloud-hosted deployment of AVEVA E3D, including a sample set of project data.

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

11

www.aveva.com

This page is left intentionally blank

AVEVA Everything3D

™ 2.1

Migration & Interoperability Guide

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

12

www.aveva.com

2 AVEVA Everything3D™ 2.1

CHAPTER 2

The AVEVA Everything3D

™ 2.1 (AVEVA E3D™ 2.1) release, usually supplied by download from a secure website, self-installs using standard Microsoft installation procedures. Please contact your local AVEVA office if a DVD installation is required. As found with other AVEVA products, the release is typically installed to individual PCs with a Microsoft Windows operating system, with the license server and file installed to a networked Microsoft Windows server. In addition, the project data is typically located on a separate server.

AVEVA E3D 2.1 is a full release that may be run alongside and in conjunction with AVEVA PDMS and Hull &

Outfitting 12.1.SP4 (Fix Release 28 onwards).

AVEVA E3D 2.1 may also be used in conjunction with other products in the AVEVA product portfolio

– please refer to Chapter 6 Compatibility & Interoperability.

AVEVA E3D 2.1 requires the use of AVEVA Catalogue and AVEVA Administration: these are distributed and installed with it, but are licensed separately and may also be used for AVEVA PDMS, Hull & Outfitting,

Engineering and Schematics products.

Workstation Configuration

The following configuration is recommended in the use of AVEVA E3D 2.1. A 64 bit operating system is required for the installation of AVEVA Everything3D™ 2.1 and for the visualisation and use of laser data in the application.

Operating System(s)

Windows® 7 Professional or Enterprise + Service Pack 1

*1

.

Windows® 8.1*

2

.

Microsoft .NET Framework 4.0*

3

.

(Supplied with AVEVA E3D 2.1 and installed if necessary).

Processor Type / Speed

Intel x86 or x64 compatible — CPU with high performance in each processor core.

Memory

8 GB of high speed RAM

Hard Disk Storage

A full installation requires approximately 1GB of drive space.

In addition, extra capacity is usually required for local storage and data; this may be used for the database cache where the Database Cache Service is employed.

The use of two SATA-300 RAID HDDs is recommended where projects are stored on the local machine. The product has also been verified with solid state HDDs.

Display

Graphics Card

File System

High resolution widescreen display recommended (1920 x 1200); dual screens also supported. Minimum resolution 1280 x 1024.

NVIDIA Quadro, AMD FirePro™ or similar.

Please refer to Section 2.2 Graphics Cards for further information.

NTFS

For information on conversion to NTFS, please see http://technet.microsoft.com/enus/library/bb456984.aspx

.

*

1

Please note that a Windows Platform Update (Windows 7 SP1 and Windows Server 2008 R2 SP1) is a pre-requisite for accurate 2D rendering (for example Text graphics) in the 3D canvas ( http://support.microsoft.com/kb/2670838 ).

*

2

AVEVA does not support the installation of E3D 2.1 software andor Projects on to disk volumes with Short8.3 file name format disabled.

Please ensure that Short8.3 file name format is enabled on all relevant volumes before installation. Please refer to Knowledge Base item

5702 for details.

13

www.aveva.com

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

AVEVA Everything3D

™ 2.1

Migration & Interoperability Guide

*

2

AVEVA E3D 2.1 has been tested with Microsoft .NET Framework 4.0 with the following fix: http://www.microsoft.com/enus/download/details.aspx?id=3556 . This fix is mandatory for the use of the Design in Context Feature.

Microsoft .NET Framework 4.5 Fix 2 has been tested with AVEVA E3D 2.1. The fix release is required to ensure the correct visualisation of AVEVA E3D Draw 2.1 print dialog.

For further information regarding IT Configuration please contact the local AVEVA Support Office.

Recommended / supported hardware and software configurations are constantly subject to review; please consult the AVEVA support web pages for the latest recommendations.

Graphics Cards

AVEVA E3D 2.1 requires 3D graphics hardware, capable of running DirectX 11, to ensure optimum performance for both design and drafting. DirectX 11 is included as an integral part of the Windows 7 & 8.1 operating systems.

AVEVA strongly recommends that appropriate hardware is used for AVEVA E3D 2.1. If appropriate graphics hardware is not detected on entry, AVEVA E3D 2.1 may still be used but a warning will be given and certain graphical effects, including use of laser data, limited.

Following extensive testing of current market Graphics Cards and AVEVA E3D 2.1, a recommended configuration is summarised in the table below.

Graphics Card

Desktop

NVIDIA® Quadro® K2000 or K2200.

AMD FirePro™ W4100.

Laptop

NVIDIA® Quadro® K2000M or K2100M.

AMD FirePro™ 4000M.

DirectX Support

DirectX 11 (Shader Model 5.0).

DirectX 11 (Shader Model 5.0).

Users using only AVEVA Catalogue or AVEVA Administration could consider a lower specification graphics card such as a NVIDIA Quadro K620 (Desktop) or NVIDIA® Quadro® K1100M (Laptop).

Where laser data is utilised, the Graphics Card memory allocation is an important consideration as this is further exploited in the visualization and manipulation of laser data (incl. HyperBubble

™). Note that the system will post an error message on entering the HyperBubble where the GPU memory is less than

1GB.

AVEVA strongly recommends that clients should test their chosen card or laptop in their own environment before purchase.

Availability and support of graphics cards changes frequently; a full updated list of graphics cards that have been verified with AVEVA E3D 2.1 is available via the IT Configuration area of the AVEVA Support

Site ( http://support.aveva.com

).

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

14

www.aveva.com

AVEVA Everything3D

™ 2.1

Migration & Interoperability Guide

To ensure the optimal performance of the graphical memory, i.e. when utilising laser data, it is recommended that the Physical Processor is altered (where employing a NVIDIA graphics card).

Using the NVIDIA Control Panel, setting a

GPU allows an increase in PhysX processing and may improve overall performance.

In the example here the PhysX processor has been set to the NVIDIA Quadro

K2100M graphics card.

Graphical Performance

To ensure optimum graphical performance, and in addition to any Graphics Card specified, the workstation used for AVEVA E3D 2.1 must conform to a reasonably high specification. To aid this specification, AVEVA

E3D 2.1 has been verified with 3DMark® ( www.3dmark.com

). A measure of overall system performance, the score includes CPU, RAM etc.

Following verification with AVEVA E3D 2.1, a recommended 3DMark score is summarised in the table below.

Please note that the rating may vary from machine to machine depending on hardware specification and software installed. The recommended scores are therefore indicative only.

Desktop Laptop

3DMark®

Combined Score

130,000 70,000

Note: Laptop score is an average score across a number of laptop hardware specifications. Desktop score based on System information:

Processor Intel(R) Xeon(R) CPU E5-1603 v3 @ 2.80GHz, Installed Memory 8.00GB, 64-bit Operating System.

Server Configuration

The following configuration is recommended in the use of AVEVA E3D 2.1 with a server configuration. A 64 bit operating system is required for the installation of AVEVA Everything3D™ 2.1.

Operating System(s)

Processor Type / Speed

Memory

Hard Disk Requirements

Windows Server 2008 R2 + Service Pack 1.

Windows Server 2012 R2.

Microsoft .NET Framework 4.0*

1

.

(Supplied with AVEVA E3D 2.1 and installed if necessary).

Intel x86 or x64 compatible — Modern architecture multiple core processors recommended (AVEVA E3D 2.1 has been verified using a Server Machine with 4 core

CPUs).

16 GB RAM.

Additional RAM increases the caching capability and thereby the performance.

The amount of disk space should be configured according to the customer’s requirement based on the number and size of projects (incl. supporting laser data).

To secure data and improve performance, the use of RAID 0+1 or 5 storage is recommended; 15k rpm drives are preferred.

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

15

www.aveva.com

AVEVA Everything3D

™ 2.1

Migration & Interoperability Guide

File System

Network

NTFS

For information on conversion to NTFS, please see http://technet.microsoft.com/enus/library/bb456984.aspx

Gigabit Ethernet (GbE) LAN. 64-bit capable network adapter. The network should provide at least 1 Gb/sec for each workstation. Two or more network cards are recommended for increased performance and redundancy.

*

1

AVEVA E3D 2.1 has been tested with Microsoft .NET Framework 4.0 with the following fix: http://www.microsoft.com/enus/download/details.aspx?id=3556 . This fix is mandatory for the use of the Design in Context Feature.

Microsoft .NET Framework 4.5 Fix 2 has been tested with AVEVA E3D 2.1. The fix release is required to ensure the correct visualisation of AVEVA E3D Draw 2.1 print dialog.

Prerequisite for this Release (Products)

The following products are required for the use of AVEVA E3D 2.1.

AVEVA Licensing™ 2.0.0

AVEVA Licensing

™ 2.0 or later and an appropriate License File is required for the operation of AVEVA E3D

2.1. AVEVA Licensing 2.0 provides the following improvements:

Support for Windows 8.1 and Windows Server 2012 thereby allowing customers to move their

Licensing Server to these later versions of the Microsoft operating systems.

Improved support facilities to help customers when reporting licensing issues. This support bundle will enable the customer to gather all relevant files and information in a zip file so that

AVEVA can investigate problems and provide an improved support response.

Error messaging has been improved to aid AVEVA Support to investigate and respond to issues reported by our customers.

As a consequence of the enhancements it is required that when migrating to AVEVA Licensing 2.0 a new format license file is installed. It is an important consideration that the new license is requested and received prior to updating the license server.

AVEVA Everything3D™ 2.1 does NOT operate with AVEVA Flexman.

If upgrading from AVEVA Licensing System 1.1.1, please install Fix release 1.1.1.3 in order to correct an uninstall defect in that release. Once this has been done version 1.1.1.3 can be uninstalled and replaced with later versions.

AVEVA Client Cache Service™ 1.0.5

The AVEVA Client Cache Service is designed for use on a LAN or WLAN network with full connectivity to the

Database files and can make a considerable improvement to Dabacon database performance. The use of the

Service is strongly recommended for all multi-user projects. The AVEVA Client Cache Service has been developed to produce an improved performance when reading data ov er ‘high’ latency networks by minimizing traffic.

The AVEVA Client Cache Service stores a copy of the read project data on the local disk which improves performance where there is repeated reading of project data across a computer network. The service operates by a data request being sent to the local Cache folder to retrieve the required Data (Database Page). If the data is not within the Cache folder, a Data Request is sent across the network to the central server to retrieve the required data. Likewise, data that is unchanged since it was previously read is retrieved from the local

Cache whereas Data that has changed in the Database must be read again from the central Database file.

Similarly, data that must be written to a Database file must still be written to that identified file.

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

16

www.aveva.com

AVEVA Everything3D

™ 2.1

Migration & Interoperability Guide

The AVEVA Client Cache Service is installed with AVEVA E3D 2.1 and may be configured or disabled using the AVEVA Cache Service Configuration application. The prompted form, seen above, enables an

Administrator to configure the caching threshold level to avoid the local hard drive being filled.

The Default is to stop caching on the Hard Drive on becoming 80% full. When full, data is continued to be delivered where already cached but no further data is cached until more space is made available. The

Cache persists data locally between sessions

– thereby, very often, the start-up will be quicker.

To ensure the performance benefits of the service are realised, Microsoft Message Queuing (MSMQ) must be enabled. This is achieved using the Windows Components feature of Windows Control Panel

> Add or Remove Programs.

For full details, please refer to the

AVEVA Everything3D™ 2.1 Installation Guide.

AVEVA Catalogue 2.1.0

AVEVA Catalogue

™ 2.1 is installed as part of the AVEVA E3D 2.1 install and is fully compatible.

Microsoft® Software

The following Microsoft products are required to support the operation of AVEVA E3D 2.1.

2.4.4.1 Microsoft Office & Fonts

Microsoft Office 2010 (and later) is required for some functions:

Optimum operation of the AVEVA Design Platform GUI requires Arial Unicode MS font, supplied with Microsoft Office and also with Microsoft Office Visio.

The layout and display of forms and the general user interface may also be adversely affected if the screen font size is not set to the smallest size.

Microsoft Office Excel import utilities in AVEVA E3D 2.1 require

“.NET Programmability Support” enabled when Office is installed. This can be found under “Advanced customization of applications” and installs the Microsoft.Office.Interop.Excel.dll.

AVEVA E3D 2.1 has been verified with Microsoft® Office 365.

Microsoft Office Visio 2010 (Standard edition, 32-bit) or later is required where AVEVA Schematic Model

Viewer is used in conjunction with AVEVA E3D 2.1.

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

17

www.aveva.com

AVEVA Everything3D

™ 2.1

Migration & Interoperability Guide

2.4.4.2 Microsoft Internet Explorer

Internet Explorer 8 or later is required to support AVEVA E3D 2.1 e.g. the Model and Draw Design in Context feature.

2.4.4.3 Microsoft .NET Framework

AVEVA E3D™ 2.1 uses Visual Studio 2010 and .NET 4.0 SP1 for .NET Customisation.

Please note that serialized settings (of the user interface configuration) are now saved in the following location on Windows 7 and 8.1:

C:Users<username>AppDataLocalAvevaAVEVA Everything3D2.1

Environment Variables

AVEVA E3D 2.1 relies on the use of environment variables for various aspects of configuration, notably the location of folders for project databases and user workspace.

When setting up a user’s environment, please bear in mind that Write access is required for folders such as

AVEVA_DESIGN_USER and AVEVA_DESIGN_WORK. The installer uses default locations, for both the program files and these data folders, that are different from those used for PDMS. These were chosen to work better on Windows 7 and 8.1; additional dialogs enable the user to control them better.

The defaults are:

Work files C:Users<username>AppDataLocalTemp

User files C:UsersPublicDocumentsAVEVAUSERDATA

Environment variables are usually set up for AVEVA E3D by the program initialisation (.INIT) file when running interactively or by using a batch (.BAT) file.

Note that at AVEVA E3D 2.1 an optional feature is available whereby a customer may remove all the

Project evars from the corresponding bat files apart from <proj>000 and ID (required to display project in

Login form). On selecting the project and entering AVEVA E3D 2.1, the start-up process will look to the project and set up any required environment variables. Where an evar is already set, the start-up process will leave that untouched, thus avoiding any unnecessary changes.

Network

AVEVA E3D 2.1 is best run on a network offering Internet access.

The system will by default be set up to access the latest online version of the documentation from the AVEVA website. It is possible instead to install the documentation locally. It may be downloaded from the AVEVA

Support website, currently: AVEVA Everything3D — Documentation 2.1

.

Install

Installations using setup.exe will install to C:Program Files (x86)AVEVAEverything3D2.1.0 by default. The individual .msi files will use the drive with most free space by default.

It is important that any files, including configuration files or sample data, that need to be updated by users are accessible for read, write etc. so they are not by default installed with the software. This is particularly important when installing in Program Files due to the introduction of User Account Control (UAC). In particular, this makes it important to ensure that files that need to be written are accessible by users without Administrator privileges. This applies to folders specified by environment variables such as AVEVA_DESIGN_WORK and

AVEVA_DESIGN_USER. The AVEVA Everything3D™ installer has been designed to allow the separate definition of suitable folders, with different defaults.

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

18

www.aveva.com

AVEVA Everything3D

™ 2.1

Migration & Interoperability Guide

It is not recommended that any combination of AVEVA products are installed in the same folder because

AVEVA does not guarantee runtime compatibility between Separate Products on different release cycles, and the uninstall of one of them subsequently damaging the other.

For further details, please refer to the

AVEVA Everything3D™ 2.1 Installation Guide. This may be accessed from the start screen of the installation process or found within the E3D210 release folder.

AVEVA Everything3D™ – Projects 2.1

As part of the install process for AVEVA E3D 2.1, a variety of standard model projects may be installed and thereafter used in the product. The projects are also available as a separate download available here: AVEVA

Everything3D™ — Projects

.

The sample projects have been extended, enhanced and renamed but wherever data matches the previous (AVEVA PDMS and Hull & Outfitting) sample model data, the same reference numbers and database numbers are used to ensure compatibility.

Note that all databases are in Unicode format (as found in the AVEVA 12.1 Series) so are not compatible with the AVEVA 12.0 series or earlier.

A file, for example APS_Project_description.pdf, is included in each project folder giving brief details of the purpose and data included in that project. The Catalogue Project (ACP) provides example component data and specifications (Component Data). All data in the projects are provided as sample data only and should be verified prior to production use.

Major project differences at AVEVA E3D 2.1 include:

The main catalogue sample project (formerly MAS) is now called ACP (AVEVA Catalogue

Project).

The main sample data projects (formerly SAM and MAR) are now called APS (AVEVA Plant

Sample) and AMS (AVEVA Marine Sample).

Sample drawings are in the new Draw format and Draw project libraries have been extended to support new Draw capabilities.

The catalogue has been enhanced for structural, supports and bolt holes

Additional data has been added to support the use and demonstration of Supports, Structural and Laser.

The AVEVA sample projects are regularly revised. Please check the AVEVA Support Site ( AVEVA

Everything3D™ Fix Release History

) frequently for updates.

A detailed list of changes is included in Appendix B Details of Sample Project Changes.

AVEVA Sample Laser Data 1.1

AVEVA Laser Sample Data 1.1 is available for use with AVEVA E3D 1.1 for the purpose of familiarisation with the extensive laser functionality available, including the new HyperBubble

™ technology.

The data was captured during a project to survey the Eaton Training Centre in Houston utilizing the latest laser scanning technology from Dot Product, FARO, Leica, Riegl, Trimble and Z+F. The various datasets have been prepared for consumption using LFM Software technology, the only laser scan data processing solution available that is able to combine such a broad selection of data formats into a single dataset.

AVEVA and LFM would like to thank Eaton for granting permission to utilize this data with our customers.

Eaton’s training facility focuses on industrial applications with over 5000 products installed on the mockup site and is available for a variety of training applications year-round.

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

19

www.aveva.com

AVEVA Everything3D

™ 2.1

Migration & Interoperability Guide

AVEVA Everything3D™ – Documentation 2.1

The AVEVA E3D 2.1 documentation includes the AVEVA Administration, Catalogue and Global product user guides.

Documentation is available online so that it may be continually updated and remain current for any new functionality introduced through the life of the product. AVEVA Documentation 2.1 may also be downloaded separately for local installation here.

The documentation may be accessed via the top of the main product window, via the Project tab or via the context sensitive F1 key.

The Documentation is presented via a Help Viewer, which comprises an Explorer style Contents list complete with Search function and a reading pane.

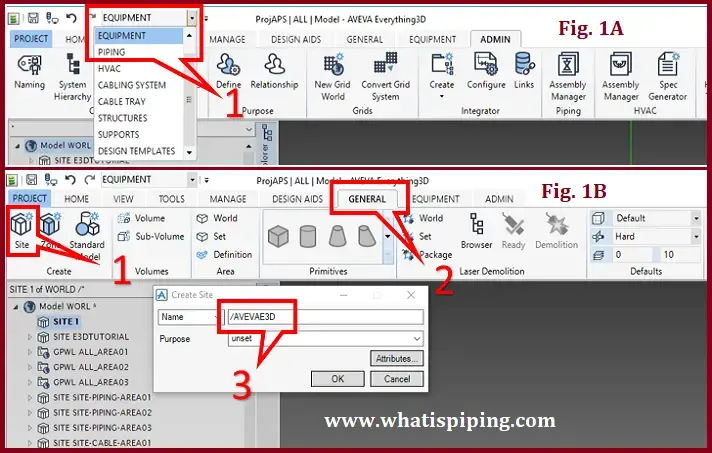

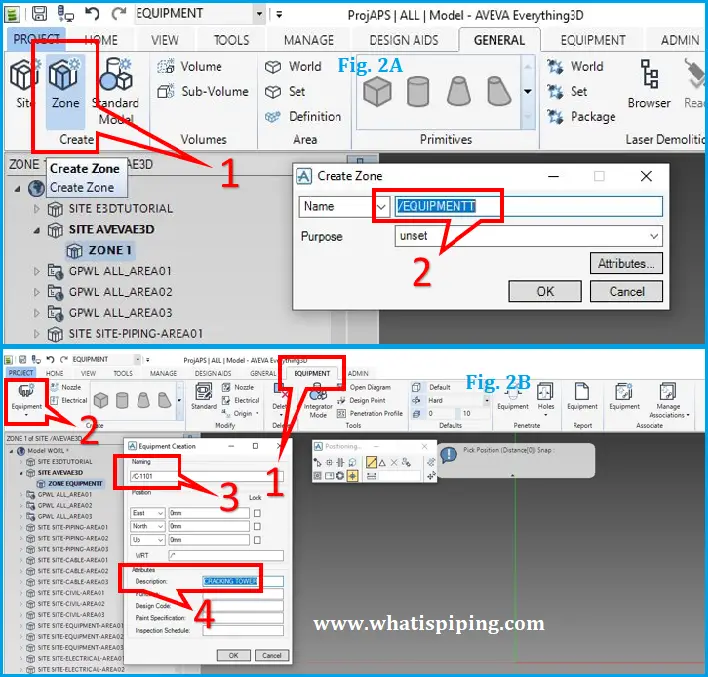

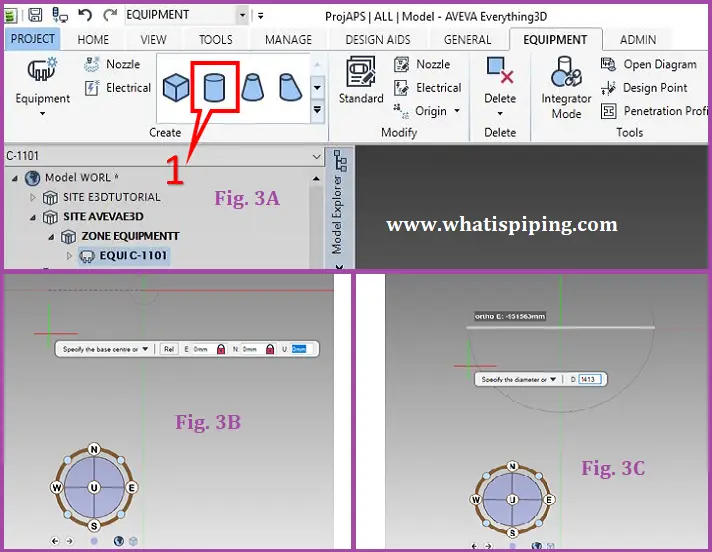

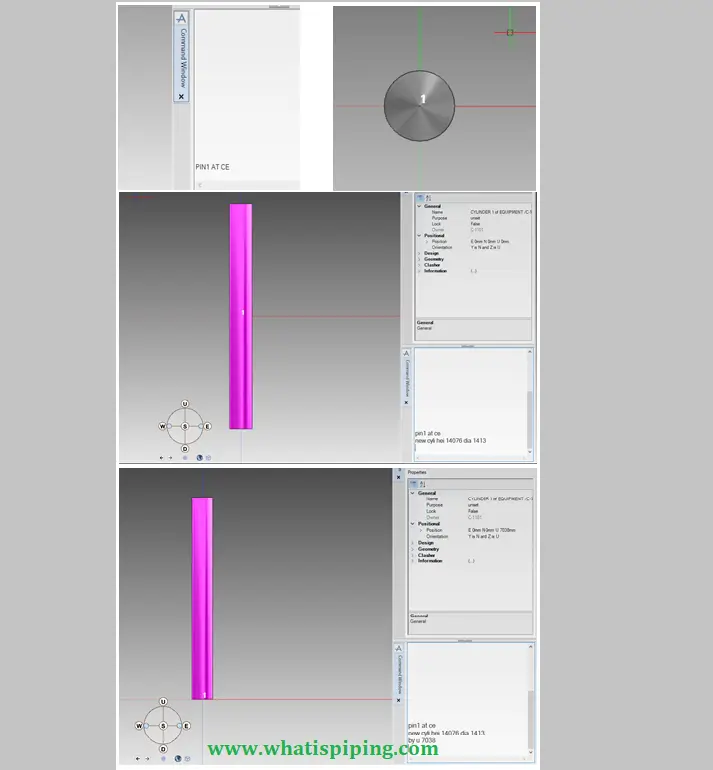

Entering AVEVA Everything3D 2.1

AVEVA Everything3D 2.1 may be accessed via the Windows Start menu or Start screen depending on the

Windows Operating System being used.

AVEVA Plant > Design > Everything3D 2.1.0

from the Windows Start Menu.

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

20

www.aveva.com

AVEVA Everything3D

™ 2.1

Migration & Interoperability Guide

The Login form is displayed.

From the Login form a project may be accessed by selecting the identified Project tile prior to entering the required login information and clicking on the desired module.

The Project search Tile allows the user to search for a project and to display masked project tiles.

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

21

www.aveva.com

This page is intentionally left blank

AVEVA Everything3D

™ 2.1

Migration & Interoperability Guide

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

22

www.aveva.com

Chapter 3

3 Project Migration

This chapter gives an overview of the process of migrating from AVEVA PDMS and AVEVA Hull &

Outfitting to the new AVEVA E3D 2.1 product.

The process is slightly different if the two products are used in conjunction on a project; in this case, it is important that a recent version (and Fix release) of AVEVA PDMS or Hull & Outfitting is used. AVEVA E3D databases are compatible with PDMS but a number of the enhancements in AVEVA E3D require a minor upgrade to the database schema; this means that PDMS must be at version 12.1.SP4 Fix.28 or later.

It is recommended that a project backup is created prior to starting any migration process.

Migrating projects from AVEVA PDMS or Hull & Outfitting 12.0

The following guidance is for those customers who currently utilise PDMS or Hull & Outfitting 12.0 on a

Project, this section can be omitted where a Project uses AVEVA PDMS or AVEVA Hull & Outfitting 12.1.

For those customers using AVEVA PDMS 11.6, please refer to the User Bulletin for PDMS 12.0 for full details on the migration process to AVEVA PDMS 12.0.

Both AVEVA PDMS 12.0 and 12.1 brought significant changes to the database, which need to be applied prior to the migration to AVEVA E3D 2.1.

The procedure for Global projects is more complex; please refer to the PDMS and Global User

Bulletins. It may be advisable to consider consolidating a project at the hub and redistributing it when the upgrade is complete.

AVEVA PDMS 12.0 AVEVA PDMS 12.1

Key developments at AVEVA PDMS 12.1 include Unicode handling, revised UKEYs and Draft Line Widths.

The upgrade process is summarised by:

Install PDMS 12.1.SP4 Fix Release 28 and use the command syntax: DBupgrade project to latest.

Is should be noted that once upgraded the Project data cannot be accessed via earlier versions of

AVEVA PDMS.

Please refer to the User Bulletin for PDMS 12.1.SP4 for full details and is further described in this guide in Appendix A: Migration from PDMS 12.0 to 12.1.

Customers’ own PML applications may need adjustment for changes in AVEVA PDMS and Hull &

Outfitting 12.1. Please refer to the relevant User Bulletins for further details.

AVEVA Hull & Outfitting 12.0 AVEVA Hull & Outfitting 12.1

Further to above there was an optional database upgrade (no 12010301) between AVEVA Hull & Outfitting

12.1.SP2 and 12.1.SP3. This should be considered as the upgrade item 2931 Storing of coordinate

system entities under a GENPRI element is relevant to AVEVA E3D 2.1 where there is a wish to make use of this feature.

Please refer to the AVEVA Hull & Outfitting 12.1.SP3 User Bulletin

– Chapter 2 Upgrading from

Previous Release for further information.

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

23

www.aveva.com

AVEVA Everything3D

™ 2.1

Migration & Interoperability Guide

Preparing an AVEVA PDMS or Hull & Outfitting 12.1.SP4 Project

There are no major database changes between PDMS 12.1 and AVEVA E3D 2.1. However, if PDMS 12.1 is to be used on the same project as AVEVA E3D, it is important that PDMS 12.1.SP4 (Fix 28 or later) is used.

Chapter 6 Compatibility & Interoperability outlines the use AVEVA E3D 2.1 alongside AVEVA

PDMS or AVEVA Hull & Outfitting 12.1.SP4.

A project that uses only AVEVA PDMS or AVEVA Hull & Outfitting 12.1 and/or AVEVA E3D has no need for legacy text formats so all databases could be migrated to the current Unicode database format.

However, this is not mandatory.

The encoding of a database can be checked using the command Q DBTEncoding.

It is of course necessary to ensure that the AVEVA E3D environment variables are set up to access the

PDMS project; this can be achieved by adding a call to the project in custom_evars.bat.

In order to secure legacy data, projects may continue to reference 12.0 databases (in read mode) as foreign databases. However, customers are recommended to validate this in their domain as AVEVA is unable to replicate the wide variety of customer data configurations.

Marine Projects (Hull data) in AVEVA E3D 2.1

When using AVEVA E3D 2.1 in a marine context there are two alternatives for the project environment.

AVEVA E3D 2.1 can be started with either:

A project marked as ‘Plant’ with Hull 12.1.SP4 databases included as foreign databases.

The Hull databases are read-only in this alternative, providing a visual Hull context for the modelling of Outfitting elements.

In this scenario hull settings must be made available to AVEVA E3D 2.1. This is achieved via a function in the Inithull utility found in AVEVA Hull & Outfitting 12.1.SP4 Fix 23 onwards. The function transfers the Hull System Defaults to the Hull database.

Drawing databases should not be included as foreign databases. Drawings stored in a 12.1 format will be transformed when opened in AVEVA E3D 2.1 Draw and this requires write access to the PADD database.

A project marked as ‘Marine’.

This is a full marine environment, including the project setup d065 file and a number of default files controlling settings for Hull modelling and drafting.

A marine project environment, including these settings, is required for the marine specific AVEVA

E3D 2.1 Draw functionality such as the creation and modification of Hull Symbolic Views.

Please note that spaces in their pathnames should be avoided for AVEVA Marine (Hull) 12.1.SP4 projects.

Preparing an AVEVA Everything3D 1.1 project

An AVEVA E3D 1.1 project may be used with AVEVA E3D 2.1 without any project migration or restriction.

It should be noted that the use of AVEVA E3D 1.1 and AVEVA E3D 2.1 on the same project is not a supported setup.

Please refer to Chapter 4 Model Data for further information on the migration of Model data to support the new Model functionality found in AVEVA E3D 2.1.

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

24

www.aveva.com

AVEVA Everything3D

™ 2.1

Migration & Interoperability Guide

AVEVA Catalogue and AVEVA Administration

AVEVA E3D 2.1 is released alongside and supported by AVEVA Catalogue 2.1 and AVEVA Administration

1.4.

In a project scenario where AVEVA E3D 2.1 is used in conjunction with AVEVA PDMS 12.1.SP4 for example, it is strongly recommended (and is mandatory for some operations) that the latest AVEVA

Administration and AVEVA Catalogue products are used rather than the (PDMS) versions of those modules.

In regards to the migration process, the use of AVEVA Administration 1.4.0 on an AVEVA PDMS or Hull &

Outfitting 12.1.SP4 project will automatically define the necessary Module Definition for the E3D Draw module. A user will be unable to access the Draw module until this administrative action has been completed.

The use of AVEVA Catalogue 2.1 is essential in supporting the migration process of PDMS and Outfitting model data to AVEVA E3D 2.1.

For further information regarding the use of AVEVA Catalogue 2.1 in supporting model data migration please refer to Chapter 4 Model Data.

Customer PML & .NET Applications

Before considering the migration of any customisations to AVEVA E3D 2.1 it is important to assess the extensive functionality and redefined workflows found therein. After consideration, it may be found that previous customisations have been rendered redundant or require adapting to ensure the most efficient workflow is promoted.

The majority of customisations should operate as expected in AVEVA E3D 2.1 but may require adjustment where the customisation is called from, or accessed via, a menu bar or toolbar as these do not exist in the

Model or Draw modules. Further, aspects of AVEVA E3D Draw that differ somewhat from PDMS Draft and

Marine Drafting will necessitate changes to customisations.

For more details, please see Chapter 7 Customisations.

As Draw is a new module at AVEVA E3D, any changes made to the module definition for PDMS Draft may also be required for Draw.

It should be noted that Users can no longer define new modules in AVEVA Administration.

As module switching between AVEVA Administration or Catalogue modules and AVEVA E3D modules

is no longer possible, any macro doing this will need to be re-structured. In addition, some forms may need adjustment to their layout for best presentation.

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

25

www.aveva.com

This page is intentionally left blank

AVEVA Everything3D

™ 2.1

Migration & Interoperability Guide

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

26

www.aveva.com

Chapter 4

4 Model Data

The following chapter outlines the key migration considerations where model data from an AVEVA PDMS or AVEVA Marine 12.1.SP4 project is to be used with AVEVA E3D 2.1.

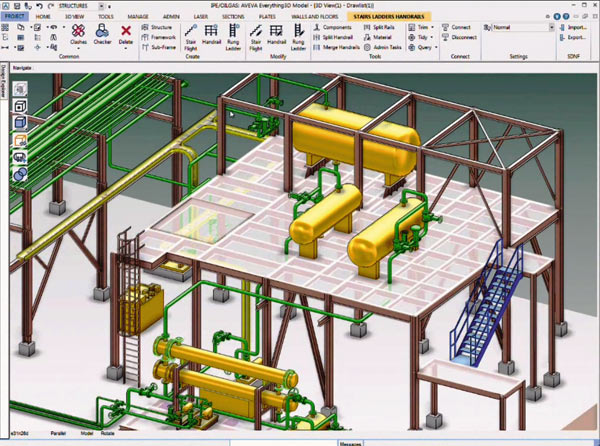

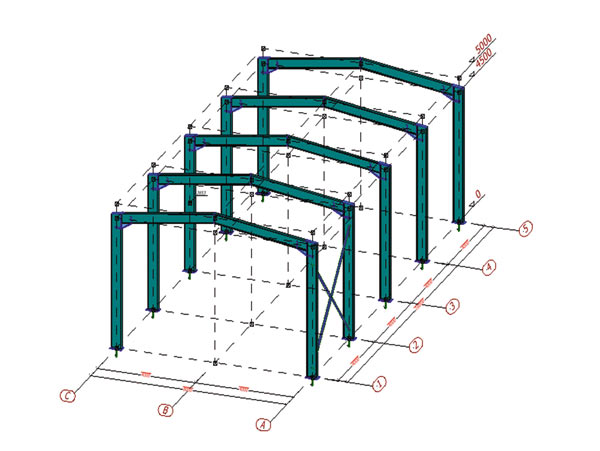

Structural

A key feature of the AVEVA E3D 2.1 product, the structural application places the model at the centre of design workflows.

Highlights of the structural application include the following:

Less reliance on forms and menus with direct graphic input and interaction; supported by a gesture based PowerWheel

™ and powerful Properties Grid.

Automated storage of elements and a grid allied structural model reduces the reliance on the

Model Explorer.

Preservation of user input to ensure data persists and is easily retrieved.

Automatic connection between elements at creation and a connectivity model that is dynamically maintained.

New and more comprehensive Structural Catalogues based on the latest National Standards.

Please refer to the AVEVA E3D 2.1 User Bulletin for an outline of the key structural concepts and available structural functionality in the E3D 2.1 Model module.

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

27

www.aveva.com

AVEVA Everything3D

™ 2.1

Migration & Interoperability Guide

Section Conversion

To enable the use of the AVEVA E3D 2.1 structural application functionality to modify existing model data, it is necessary to convert all Section (SCTN) elements to GENSEC elements.

It is recommended that this action is the first step taken in the conversion process for a structural model and that the process is completed in manageable hierarchy segments i.e. STRUs or FRMWs depending on the complexity of the model.

It is recommended that where the conversion of MDS Template data is required, the SCTN to

GENSEC conversion process should be undertaken using the Support Convert Template utility and not the Structural Conversion utility. Please refer to Section 4.3.3 Template Data.

As part of the conversion process:

Fitting (FITT) and Joint (SJOI) elements are converted to Fitting (FIXING) and Joint (FIXING) elements.

Primary Node (PNODE) and Primary Joint (PJOI) elements are converted to End Datum

(ENDATU) elements that own a Joint (FIXING) with the referenced joint.

A utility,

Convert Sections

, is provided in the Structures group of the

ADMIN tab in AVEVA E3D 2.1.

The conversion of SCTN elements to GENSEC elements is an administration task; access is only available to users with administration rights (member of the STRUADMIN team) or a free user.

The Convert SCTN/GENSEC form allows the

Administrator to select and convert SCTN elements to the required GENSEC elements.

When the SCTN to GENSEC conversion is complete, the GENSEC elements are updated and displayed in the Model Explorer.

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

28

www.aveva.com

AVEVA Everything3D

™ 2.1

Migration & Interoperability Guide

The Model Explorer highlights the result of the conversion process:

The utility converts SCTN elements to straight GENSECs i.e. the

GENSEC’s SPINE (only) owns two POINSP elements.

Any connections, i.e. SNOD/SJOI elements, are converted to the equivalent GENSEC elements of JLDATU/PLDATU/FIXING, and all connectivity remains, as are all joints and fitting Specification References.

PNOD/PJOI elements, say for baseplate joints on the bottom of columns, are converted to the new ENDATU element and the SpecRef maintained.

The utility presents a conversion summary and maintains a log file to which any errors in the conversion process are written.

Catalogue

– Joints & Fittings

A new profile catalogue, based on the latest National standards, has been developed for AVEVA Catalogue

2.1. Translation of Joints and Fittings is required to ensure compatibility with the P-line and Profile parameter of the new profile catalogue.

Where joint and fitting catalogues are to be translated, this should be done prior to updating the

Specification Reference of existing GENSECs to use the new catalogue profiles. This is due to the Profile

Catalogue update referring to the updated Joints & Fittings in the update process.

Please refer to the AVEVA E3D 2.1 User Bulletin for an outline of the key changes to the structural catalogue at AVEVA Catalogue 2.1.

It is not necessary to update to the new catalogue as AVEVA E3D 2.1 will function correctly with the

‘old’ catalogue data, however, images on the joint and fitting selection forms will not be available.

A utility is provided in AVEVA Catalogue 2.1 to translate joint and fitting catalogues, and specifications that work with the previous catalogue to work with the new catalogue.

The utility,

Translate Joints/Fittings Catalogue

in the

Tools group of the SPECIFICATION tab in Paragon, copies the former specifications and then interrogates the reference data to translate it to the ‘new’ catalogue

The Translate Joints and Fittings Specifications form is displayed, as shown on the following page, and allows the selection of the Specification World (SPWL) or Specification (SPEC) to be validated and translated.

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

29

www.aveva.com

AVEVA Everything3D

™ 2.1

Migration & Interoperability Guide

It is important to consider that if the catalogue joints or fittings do not comply with the way the AVEVA samp le joints and fittings in the ‘old’ catalogue are constructed, or the parameter order/Dkey attributes of the profiles that they relate to have been changed, then the translation process will be unsuccessful and the translation must be done manually.

It should also be noted that template joints and fittings cannot be translated automatically. They must be translated manually.

Catalogue

– Profiles

As indicated in the previous section, a new profile catalogue has been introduced alongside the AVEVA

E3D 2.1 structural capability. The new profiles have common Gtype geometry and P-line sets, together with a common data set. Therefore joints and fittings, developed for and used with the previous profile catalogue

(AVEVA PDMS and Hull & Outfitting 12.1.SP4 / AVEVA E3D 1.1) will not work with the new catalogue at

AVEVA E3D 2.1.

In addition, Angle profiles have been re-orientated to conform to National Standards and to be aligned with the typical orientation used by other software packages.

The profile specification of GENSEC and FIXING elements must be converted for compatibility with the most recent profile specification catalogue.

It is not necessary to update to the new catalogue as AVEVA E3D2.1 will function correctly with the

‘old’ catalogue data, however, images on the joint and fitting selection forms will not be available.

SCTN, FITT and SJOI elements must be converted to GENSEC and FIXING elements prior to conversion of the profile specification. Joints and fittings applied to GENSECs where the SpecRef is from the previous catalogue will not work with the new catalogue due to the change in profile parameter order and the Dkey attributes.

A utility,

Update Profile

, is provided in the Structures group of the ADMIN tab. The utility updates profiles from the catalogue previously used to the new catalogue.

The profile specification conversion of GENSEC and FIXING elements is an administration task, access is only available to users with administration rights (member of the STRUADMIN team) or a free user.

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

30

www.aveva.com

AVEVA Everything3D

™ 2.1

Migration & Interoperability Guide

The Convert Profile Sprefs form allows the

Administrator to convert the profile specification of

GENSEC and FIXING elements.

When the conversion is complete, the Attempted and

Succeeded columns are populated with the number of profile specifications that were attempted for conversion and the number that were successfully converted.

The conversion utilises a mapping file,

%AVEVA_DESIGN_DFLTS%profilelist.pmldat, to convert the

Specification references, Gtypes, justification lines, etc.

The

Browse

…

button adjacent to the Mapping File text box allows the Administrator to navigate to a required location and select an alternative mapping file.

It should be noted that whilst the new catalogue contains many more profiles compared to the old catalogue, for some profiles in the old catalogue there are no equivalent profiles in the new catalogue. This is because the National Standards have been updated and the profiles have been deleted from the standards.

Similarly, customer profile catalogues or profiles where the Spref name has been changed will not be updated by this utility unless the mapping file is updated manually.

The example below is an extract of a mapping file that indicates the old and new profile specifications.

# File to define profile translation

# to new AVEVA structural catalogue

# <old spco> <new spco>

/AISC/C15x50 /US-C15x50

/AISC/C15x40 /US-C15x40

/AISC/C15x33.9 /US-C15x33.9

/AISC/C12x30 /US-C12x30

/AISC/C12x25 /US-C12x25

/AISC/C12x20.7 /US-C12x20.7

On clicking

Apply

to convert the profile specifications, a Confirm message is displayed.

The message informs the Administrator that the catalogue specifications must be translated before the conversion of the profile specifications.

It should be noted that Angle profiles are automatically re-orientated to the new catalogue orientation during the process.

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

31

www.aveva.com

AVEVA Everything3D

™ 2.1

Migration & Interoperability Guide

The utility presents a conversion summary and maintains a log file to which any errors in the conversion process are written.

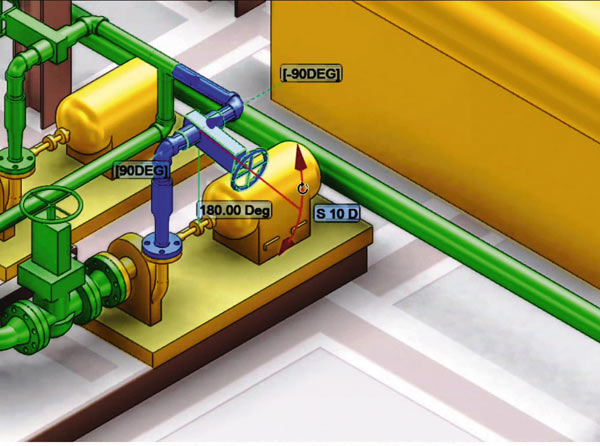

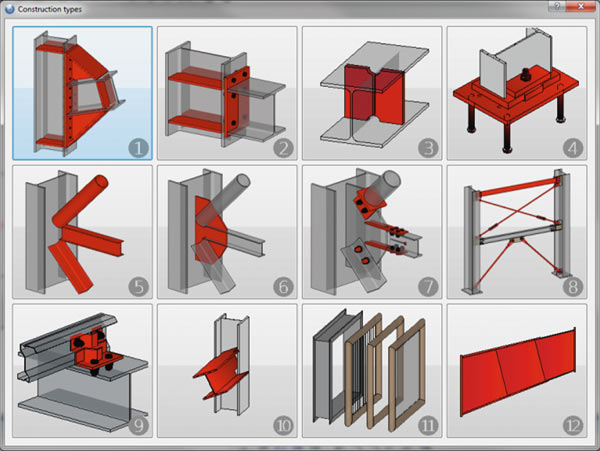

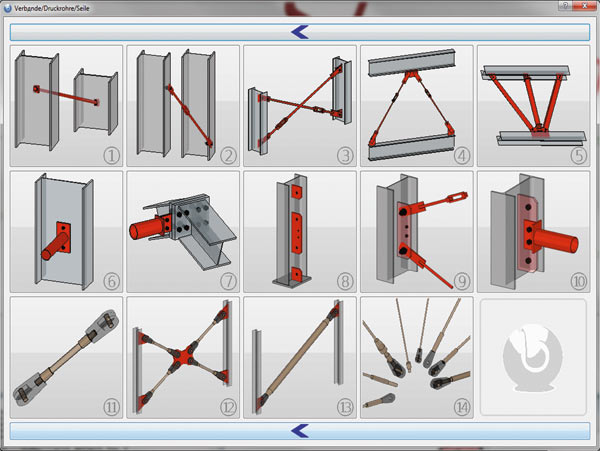

Adding Joint & Fitting Images

The use of the AVEVA E3D 2.1 structural application and workflows therein are greatly aided by the available images (.png) for joints and fittings.

: The Section Fitting / Modify Joints forms include a selection gallery displaying all available joints and fixings that may be applied within the current specification.

All icons and help files are available for the standard Joints and Fittings catalogue. These are

.png files which are stored in the file:

Aveva.Interaction.Structural.Resource

s.resources.

: In addition a sketch of the joint or fitting including the defining Parameters of the joint or fitting can be opened via the Detail button on the Create Fixing / Modify Joints forms.

In regards to the migration process, an important consideration is the inclusion of user-defined, customer images of Project Joints and Fittings to complement those already found in the structural application.

The following will describe how to create icons (.png format) for a customer joint and fitting catalogue and the process to follow in the naming and storing of them.

Please refer to Appendix C. Forming Structural Joint & Fixing Images for further information and a recommended workflow for the creation of quality images.

4.1.4.1 Naming

All joint and fitting specification components (SPCO elements) within the AVEVA Sample Catalogue are named following a simple naming convention. For example:

Joint SPCO: J1S1-WEL-PFC-PFC-001, J1S2-SNS-PFI-PFI-001 and J2S4-FEP-PFI-CTUB-

002.

Fitting SPCO: F1-CIR-CTUB-4H-STIFF, F3-PLT-PFI-001 and F2-FLS-PFI-VAR.

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

32

www.aveva.com

AVEVA Everything3D

™ 2.1

Migration & Interoperability Guide

The reciprocal image must be named as per the SPCO with the exception that any forward slash is replaced by a hyphen.

In addition, SELE elements also require an image with a similar naming convention used.

In AVEVA Catalogue Paragon, SPCO and SELE elements have an attribute Icon which is the full name of the icon file stored in the resource file.

The ‘ID_’ prefix is added to all icon names.

In determining the help sketch image, the file name is based upon the name of the STCA element (owning the Catref of the SPCO) where a Catalogue joint/fitting or, alternatively, the Template name (Tmpref of

SPCO) is used where a Template joint/fitting.

The image names are case sensitive so it is advised to use only upper case in icon names. Indeed, when files are added to resource files the names are all upper case.

When adding .pngs files to a resources file with the Resource Editor the prefix is added automatically so the prefix is not required on the png file itself.

4.1.4.2 Storage of User-defined Images

Customised images (icons or help sketch) may be added to the default resource file

Aveva.Interaction.Structural.Resources.resources in the AVEVA E3D 2.1 installation folder but it is recommended to create a new Resource file to store customer images.

Please note that the Joint/Fitting forms must be prompted in AVEVA E3D 2.1 to first populate the

Resource Editor.

To create a new Resource file, the Resource Editor can be utilised from the installation folder of AVEVA

E3D 2.1.

A new Resource File is added on clicking the

+

icon.

A new image is added to the resource file by clicking the

Add New Resource File

from the Bitmaps tab and then selecting the required .png file to be added.

A png file can also be added to the Resource Editor window by a Drag and Drop action.

The file is to be saved with an easily identifiable name, for example: Company.Resources.resources.

The next step is to open the Aveva.Interaction.Structural.Resources.resources file and edit the string

ID_FILE_STRU_IMAGE_FILE to refer to the created resources file.

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

33

www.aveva.com

AVEVA Everything3D

™ 2.1

Migration & Interoperability Guide

This reference operation must be done for each installation of the application.

On opening the Joints or Fitting forms, the application will first look within the Company.Resources file and if no image is found, will proceed to look in the default AVEVA Resource file.

If no image is found in a resource file a default image will be displayed (blank image).

Stairs, Ladders & Handrails

It should be noted that there is no utility provided to update SLH Defaults or Assemblies to use the new structural catalogue due to the complex cross referencing of elements.

Therefore, it is recommended that if it is desired to use the new profile catalogue with SLH, new Defaults and Assemblies should be created. It is possible to manually modify Defaults and Assemblies but this should be approached with caution and contact with AVEVA Support made to go through the process.

Specifications associated with the old AVEVA Catalogue have been disabled. If the old AVEVA

Catalogue is to be used for new SLH elements, the relevant Specification will be required to be reactivated by setting the PURP attribute for the SPEC to STL. This will display the identified Profiles in the appropriate SLH forms.

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

34

www.aveva.com

AVEVA Everything3D

™ 2.1

Migration & Interoperability Guide

Grids

A principal aid to the AVEVA E3D 2.1 Model Designer is the provision of new Grid elements called

Reference Grids. Reference Grids are formed in the Model Database, may be used across an entire project and added, with automated annotation, to project drawings in AVEVA E3D 2.1 Draw.

: Clipped Model Graphic along a Grid Plane with Model annotation (Elevations and Grid

Labels).

:Isometric view of Grid (with associated Structure) in

Draw with automated annotation (Elevations and

Grid Labels).

Please refer to the AVEVA E3D 2.1 User Bulletin for an outline of available Grid functionality and how they may be utlilised and incorporated into both Draw and Model alike.

Ship & Plant Grid Conversion

To facilitate use across a project, Plant and Ship Grids are stored in a Design (DESI) database. In AVEVA

PDMS and Hull & Outfitting 12.1.SP4 and AVEVA E3D 1.1 the Grid is stored beneath a Grid System

(GRDSYS) element, while in AVEVA E3D 2.1 the Grid is stored below a Reference Grid (REFGRD).

A conversion tool is available in AVEVA E3D 2.1 Model to convert Grids from GRDSYS to REFGRD elements.

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

35

www.aveva.com

AVEVA Everything3D

™ 2.1

Migration & Interoperability Guide

The conversion is considered an administrative task and is available via the

Convert Grid System

button in the Grids group of the ADMIN tab.

The Convert Grid System process is an administrative task; access is only available to users with administration rights or as a free user.

The Convert GRIDSY/REFGRD form allows the Administrator to select

GRIDSY elements for conversion by defining all elements, selected elements or named elements within the project.

The utility presents a conversion summary and maintains a log file to which any errors in the conversion process are written.

When the GRIDSY to REFGRD conversion is complete, the REFGRD elements are displayed in the Model Explorer.

All Grid Axis (GRIDAX) and Grid Line (GRIDLN) elements are converted to

Grid Face (GRIDFA), Grid Elevation (GRIDEL) and Grid Plane (GRIDPL) elements.

The original GRIDSY elements are not deleted as part of the conversion and can be deleted manually.

For Hull users, please note that Hull Grid Elements (GENTAB) are not visible in the Model Hierarchy; having been converted to GRIDSYS elements in AVEVA Hull & Outfitting 12.1.SP4.

The following naming rules apply to the conversion of GRIDSY elements:

If the original GRIDSY element is named, the suffix ‘_REF’ is added to the name of the new

REFGRD element.

If the GRIDSY element is not named and the Purpose property is SHIP, the new REFGRD element is named ‘SHIP_GRID_REF’.

If the GRIDSY element is not named and the Purpose property is set to be other than SHIP, the REFGRD element is not named.

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

36

www.aveva.com

AVEVA Everything3D

™ 2.1

Migration & Interoperability Guide

The following naming rules apply to the conversion of GRIDAX elements:

If the GRIDAX element is named, the suffix ‘_FA’ or ‘_EL’ is added to name of the new

GRIDFA and GRIDEL elements respectively.

If the GRIDAX element is not named and the Purpose property of the owning GRIDSY element is SHIP, the new GRIDFA and GRIDEL elements are named ‘SHIP_X_FA’,

‘SHIP_Y_FA’ and ‘SHIP_Z_EL’ respectively.

If the GRIDAX element is not named and the Purpose property of the owning GRIDSY element is set to be other than SHIP, the new GRIDFA and GRIDEL elements are not named.

Auto naming rules can be applied to Grid Planes.

An auto naming file providing Grid Plane names for the Ship Grid, in the same format as in AVEVA

Hull & Outfitting 12.1SP4, is installed with AVEVA E3D 2.1.

Supports

A key development in AVEVA E3D 2.1, the Supports application enables users to create multi-discipline supports using an efficient and intuitive workflow that does not require write access to Piping, Cable, HVAC or connecting Steelwork elements. Extending existing configuration capabilities, AVEVA E3D 2.1 allows the user to configure various support types available within the Supports application to meet project requirements.

Please note that AVEVA Outfitting Supports is not available in AVEVA E3D 2.1.

In order to use the new Supports application with AVEVA PDMS or Hull & Outfitting 12.1.SP4 or AVEVA

E3D 1.1 version model data, a number of conversion steps are necessary to make existing model data compatible with the new application.

Before project data can be successfully upgraded to function within the AVEVA E3D 2.1 environment the

Administrator must ensure that all product updates have been performed to align it with the update

Copyright © 2015.

AVEVA Solutions Limited and its subsidiaries.

All rights reserved.

37

www.aveva.com

AVEVA Everything3D

™ 2.1

Migration & Interoperability Guide requirements for AVEVA E3D 2.1. The conversion process requires that the customer project utilises either

AVEVA PDMS or Hull & Outfitting12.1.SP4 Fix.28 (earliest compatible fix with AVEVA E3D 2.1) or AVEVA

E3D 1.1.

Database Updates

In using the Supports application at AVEVA E3D 2.1 it is important to consider that many of the default

AVEVA maintained database libraries used previously have been updated for AVEVA E3D 2.1 and will need to be included or replaced within customer projects.

The databases used by the MDS application are split into two classes

AVEVA controlled reference libraries i.e. those databases that are maintained by AVEVA and generally regarded as being non-user definable.

User definable template and configuration databases i.e. those databases that contain client/project specific customised supports data.

AVEVA controlled reference library updates:

The following library databases are required by the new Supports application and the existing user references to these items must be reset to the AVEVA ACP project versions:

MDS/CATA

MASTER/MDSDICT

DB 7320

DB 7325

User definable template & configuration databases

These are user defined database items that may already exist within customer versions of AVEVA PDMS or Hull & Outfitting 12.1.SP4 or AVEVA E3D 1.1. For example:

MDS/APPDEFAULTS

MDS/DESITMPL-BS

MDS/DESITMPL-BS-ORI

MDS/DESI-SPECIAL-TMPL-BS

MDS/DESITMPL-PSL

In such cases were existing user/corporate versions of these databases exist then such databases can either be included within the working project by either foreign reference or by a direct copy into the working project.

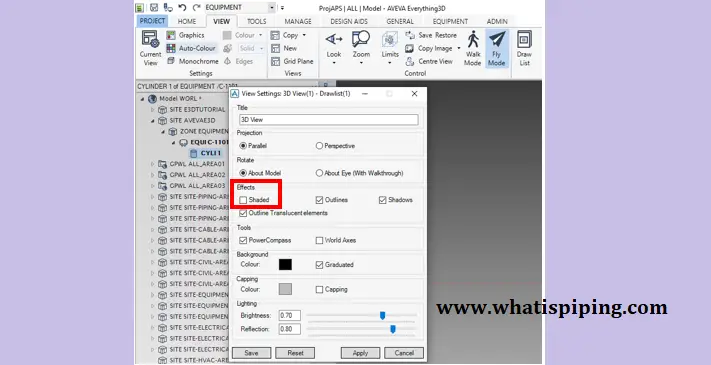

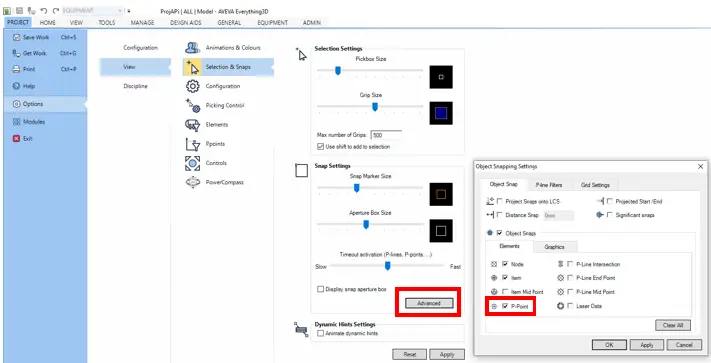

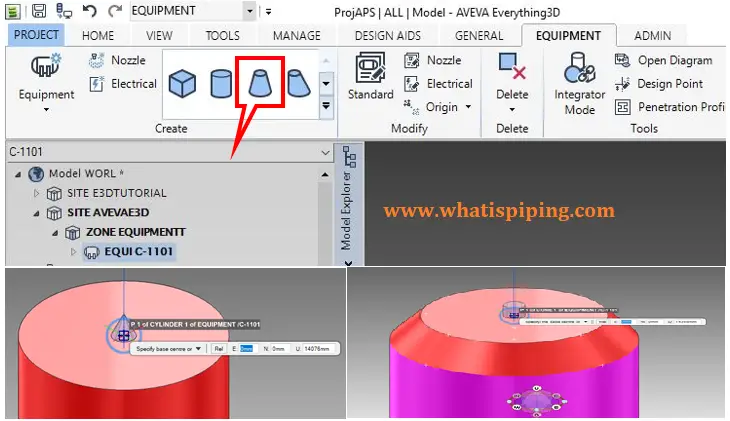

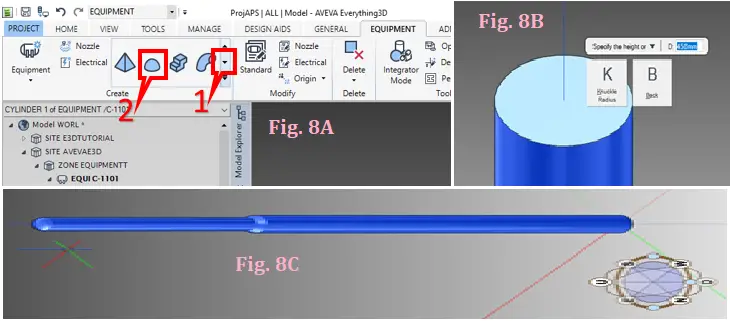

Further information regarding project setup is located in the Supports Customization guide.