- Manuals

- Brands

- Canon Manuals

- All in One Printer

- iR2420 series

Manuals and User Guides for Canon iR2420 series. We have 1 Canon iR2420 series manual available for free PDF download: Service Manual

Service Manual

iR2422/2420/2320/2318 Series

Apr 20 2011

Application

This manual has been issued by Canon Inc. for qualified persons to learn technical theory, installation, maintenance, and repair of products. This manual covers all localities where the products are sold. For this reason, there may be information in this manual that does not apply to your locality.

Corrections

This manual may contain technical inaccuracies or typographical errors due to improvements or changes in products. When changes occur in applicable products or in the contents of this manual, Canon will release technical information as the need arises. In the event of major changes in the contents of this manual over a long or short period, Canon will issue a new edition of this manual.

The following paragraph does not apply to any countries where such provisions are inconsistent with local law.

Trademarks

The product names and company names used in this manual are the registered trademarks of the individual companies.

Copyright

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual may not be copied, reproduced or translated into another language, in whole or in part, without the written consent of Canon Inc.

COPYRIGHT © 2001 CANON INC.

Printed in Japan

Caution

Use of this manual should be strictly supervised to avoid disclosure of confidential information.

Introduction

Symbols Used

This documentation uses the following symbols to indicate special information:

Symbol Description

Indicates an item of a non-specific nature, possibly classified as Note, Caution, or Warning.

Indicates an item requiring care to avoid electric shocks.

Indicates an item requiring care to avoid combustion (fire).

Indicates an item prohibiting disassembly to avoid electric shocks or problems.

Indicates an item requiring disconnection of the power plug from the electric outlet.

Indicates an item intended to provide notes assisting the understanding of the topic in question.

Memo

Indicates an item of reference assisting the understanding of the topic in question.

REF.

Provides a description of a service mode.

Provides a description of the nature of an error indication.

Introduction

The following rules apply throughout this Service Manual:

1.Each chapter contains sections explaining the purpose of specific functions and the relationship between electrical and mechanical systems with reference to the timing of operation.

In the diagrams,

direction of the electric signal.

The expression «turn on the power» means flipping on the power switch, closing the front door, and closing the delivery unit door, which results in supplying the machine with power.

2.In the digital circuits, ‘1’is used to indicate that the voltage level of a given signal is «High», while ‘0’ is used to indicate «Low».(The voltage value, however, differs from circuit to circuit.) In addition, the asterisk (*) as in «DRMD*» indicates that the DRMD signal goes on when ‘0’.

In practically all cases, the internal mechanisms of a microprocessor cannot be checked in the field. Therefore, the operations of the microprocessors used in the machines are not discussed: they are explained in terms of from sensors to the input of the DC controller PCB and from the output of the DC controller PCB to the loads.

The descriptions in this Service Manual are subject to change without notice for product improvement or other purposes, and major changes will be communicated in the form of Service Information bulletins.

All service persons are expected to have a good understanding of the contents of this Service Manual and all relevant Service Information bulletins and be able to identify and isolate faults in the machine.»

Contents

Contents

|

Chapter 1 Introduction |

|

|

1.1 System Construction …………………………………………………………………………………………………………………. |

1- 1 |

1.1.1Pickup/ Delivery /Original Handling Accessories System Configuration (1-cassette/Platen cover (option) model) 1- 1

1.1.2Pickup/ Delivery /Original Handling Accessories System Configuration (1-cassette/Platen cover (standard) model)1-

2

1.1.3 Pickup/ Delivery /Original Handling Accessories System Configuration (2-cassette/Duplex unit (option) model) .. 1- 3 1.1.4 Pickup/ Delivery /Original Handling Accessories System Configuration (2-cassette/Duplex unit (standard) model) .1-

|

4 |

|

|

1.1.5 Reader Heater/ Cassette Heater System Configuration……………………………………………………………………………… |

1- 5 |

|

1.1.6 Printing/Transmitting Accessories System Configuration……………………………………………………………………………. |

1- 6 |

|

1.2 Product Specifications ……………………………………………………………………………………………………………….. |

1- 6 |

|

1.2.1 Names of Parts…………………………………………………………………………………………………………………………………….. |

1- 6 |

|

1.2.1.1 External View (1-cassette model) …………………………………………………………………………………………………………………………. |

1- 6 |

|

1.2.1.2 External View (2-cassette model) ………………………………………………………………………………………………………………………….. |

1- 6 |

|

1.2.1.3 Cross-Section …………………………………………………………………………………………………………………………………………………….. |

1- 7 |

|

1.2.2 Using the Machine………………………………………………………………………………………………………………………………… |

1- 7 |

|

1.2.2.1 Turning On the Power Switch (1-cassette model) …………………………………………………………………………………………………… |

1- 7 |

|

1.2.2.2 Turning On the Power Switch (2-cassette model) ……………………………………………………………………………………………………. |

1- 8 |

|

1.2.2.3 When Turning Off the Main Power Switch (1-cassette model) ………………………………………………………………………………….. |

1- 9 |

|

1.2.2.4 When Turning Off the Main Power Switch (2-cassette model) …………………………………………………………………………………. |

1- 11 |

|

1.2.2.5 Control Panel ……………………………………………………………………………………………………………………………………………………. |

1- 12 |

|

1.2.3 User Mode Items ………………………………………………………………………………………………………………………………… |

1- 13 |

|

1.2.3.1 Audible Tones …………………………………………………………………………………………………………………………………………………… |

1- 13 |

|

1.2.3.2 Common Settings ……………………………………………………………………………………………………………………………………………… |

1- 13 |

|

1.2.3.3 Copy Settings……………………………………………………………………………………………………………………………………………………. |

1- 14 |

|

1.2.3.4 Printer Settings …………………………………………………………………………………………………………………………………………………. |

1- 14 |

|

1.2.3.5 Timer Settings…………………………………………………………………………………………………………………………………………………… |

1- 15 |

|

1.2.3.6 Adjustment/Cleaning………………………………………………………………………………………………………………………………………….. |

1- 15 |

|

1.2.3.7 Report Settings …………………………………………………………………………………………………………………………………………………. |

1- 15 |

|

1.2.3.8 System Settings ………………………………………………………………………………………………………………………………………………… |

1- 15 |

|

1.2.3.9 Network Settings……………………………………………………………………………………………………………………………………………….. |

1- 16 |

|

1.2.4 Maintenance by the User……………………………………………………………………………………………………………………… |

1- 17 |

|

1.2.4.1 User Maintenance Items …………………………………………………………………………………………………………………………………….. |

1- 17 |

|

1.2.4.2 Cleaning…………………………………………………………………………………………………………………………………………………………… |

1- 17 |

|

1.2.5 Safety ……………………………………………………………………………………………………………………………………………….. |

1- 19 |

|

1.2.5.1 Safety of the Laser Light …………………………………………………………………………………………………………………………………….. |

1- 19 |

|

1.2.5.2 CDRH Regulations…………………………………………………………………………………………………………………………………………….. |

1- 19 |

|

1.2.5.3 Handling the Laser Unit ……………………………………………………………………………………………………………………………………… |

1- 19 |

|

1.2.5.4 Safety of Toner …………………………………………………………………………………………………………………………………………………. |

1- 20 |

|

1.2.5.5 Point to Note about Fire ……………………………………………………………………………………………………………………………………… |

1- 20 |

|

1.2.6 Product Specifications …………………………………………………………………………………………………………………………. |

1- 20 |

|

1.2.6.1 Product Specifications ……………………………………………………………………………………………………………………………………….. |

1- 20 |

|

1.2.7 Function List ………………………………………………………………………………………………………………………………………. |

1- 21 |

|

1.2.7.1 Printing Speed (iR2422series) …………………………………………………………………………………………………………………………….. |

1- 21 |

|

1.2.7.2 Printing Speed (iR2420/iR2320series)………………………………………………………………………………………………………………….. |

1- 23 |

|

1.2.7.3 Printing Speed (iR2318series) …………………………………………………………………………………………………………………………….. |

1- 24 |

|

Chapter 2 Installation |

|

|

2.1 Making Pre-Checks …………………………………………………………………………………………………………………… |

2- 1 |

|

2.1.1 Selecting the Site of Installation ……………………………………………………………………………………………………………… |

2- 1 |

|

2.1.2 Before Starting the Work (120VCLA) ………………………………………………………………………………………………………. |

2- 1 |

|

2.1.3 Before Starting the Work (230VCLA) ………………………………………………………………………………………………………. |

2- 3 |

Contents

|

2.1.4 Before Starting the Work (230VEUR) ………………………………………………………………………………………………………. |

2- 5 |

|

2.1.5 Before Starting the Work (230VCSPL) …………………………………………………………………………………………………….. |

2- 7 |

|

2.1.6 Before Starting the Work (230V CCN) ……………………………………………………………………………………………………… |

2- 9 |

|

2.2 Unpacking and Installation ……………………………………………………………………………………………………….. |

2- 11 |

|

2.2.1 Unpacking and Removing the Packaging Materials …………………………………………………………………………………. |

2- 11 |

|

2.2.2 Installing the Drum Unit………………………………………………………………………………………………………………………… |

2- 11 |

|

2.2.3 Installing the Toner Bottle …………………………………………………………………………………………………………………….. |

2- 12 |

|

2.2.4 Setting the Cassettes…………………………………………………………………………………………………………………………… |

2- 14 |

|

2.2.5 Checking the Image Quality………………………………………………………………………………………………………………….. |

2- 15 |

|

2.3 Flow of Accessory Installation …………………………………………………………………………………………………… |

2- 16 |

|

2.3.1 Flow of Accessary Installation……………………………………………………………………………………………………………….. |

2- 16 |

|

2.4 Installing the Heater PCB …………………………………………………………………………………………………………. |

2- 17 |

|

2.4.1 Preparing the parts ……………………………………………………………………………………………………………………………… |

2- 17 |

|

2.4.2 Preparing the Host Machine …………………………………………………………………………………………………………………. |

2- 17 |

|

2.4.3 Installing the Heater PCB……………………………………………………………………………………………………………………… |

2- 18 |

|

2.5 Installing the Reader Heater……………………………………………………………………………………………………… |

2- 21 |

|

2.5.1 Preparing the parts ……………………………………………………………………………………………………………………………… |

2- 21 |

|

2.5.2 Installing the Reader Heater Harness…………………………………………………………………………………………………….. |

2- 22 |

|

2.5.3 Removing Reader Components…………………………………………………………………………………………………………….. |

2- 25 |

|

2.5.4 Removing Parts at the Left of the Reader……………………………………………………………………………………………….. |

2- 25 |

|

2.5.5 Installing the Reader Heater …………………………………………………………………………………………………………………. |

2- 26 |

|

2.6 Installing the Cassette Heater …………………………………………………………………………………………………… |

2- 28 |

|

2.6.1 Preparing the parts ……………………………………………………………………………………………………………………………… |

2- 28 |

|

2.6.2 Installing the Cassette Heater……………………………………………………………………………………………………………….. |

2- 28 |

|

Chapter 3 Main Controller |

|

|

3.1 Construction …………………………………………………………………………………………………………………………….. |

3- 1 |

|

3.1.1 Constraction and Mechanisms………………………………………………………………………………………………………………… |

3- 1 |

|

3.2 Construction of the Electrical Circuitry………………………………………………………………………………………….. |

3- 1 |

|

3.2.1 Image processor PCB……………………………………………………………………………………………………………………………. |

3- 1 |

|

3.3 Image Processing……………………………………………………………………………………………………………………… |

3- 2 |

|

3.3.1 Overview of Image flow…………………………………………………………………………………………………………………………. |

3- 2 |

|

3.3.2 Configration of Image processing Module ……………………………………………………………………………………………….. |

3- 2 |

|

3.3.3 Reader entry Image processing………………………………………………………………………………………………………………. |

3- 3 |

|

3.3.4 Compression/extension/edit processing block…………………………………………………………………………………………… |

3- 3 |

|

3.3.5 Printer output Image processing ……………………………………………………………………………………………………………. |

3- 4 |

|

3.4 Flow of Image Data …………………………………………………………………………………………………………………… |

3- 4 |

|

3.4.1 Image data flow of copy function ……………………………………………………………………………………………………………. |

3- 4 |

|

3.4.2 Image data flow of BDL function ……………………………………………………………………………………………………………… |

3- 5 |

|

3.5 Parts Replacement Procedure ……………………………………………………………………………………………………. |

3- 6 |

|

3.5.1 Main Controller PCB ……………………………………………………………………………………………………………………………… |

3- 6 |

|

3.5.1.1 Preparation for Removing the image processor PCB ……………………………………………………………………………………………….. |

3- 6 |

|

3.5.1.2 Removing the Image Processor PCB …………………………………………………………………………………………………………………….. |

3- 6 |

|

3.5.1.3 Procedure after Replacing the Image Processor PCB………………………………………………………………………………………………. |

3- 6 |

|

Chapter 4 Original Exposure System |

|

|

4.1 Construction …………………………………………………………………………………………………………………………….. |

4- 1 |

4.1.1Specifications, Control Methods, and Functions (When the original size detection sensor is equipped for BOOK mode) 4- 1

4.1.2Specifications, Control Methods, and Functions (When the original size detection sensor is not equipped for BOOK

|

mode)……………………………………………………………………………………………………………………………………………………… |

4- 1 |

|

4.1.3 Major Components (When the original size detection sensor is equipped for BOOK mode) ……………………………. |

4- 2 |

|

4.1.4 Major Components (When the original size detection sensor is not equipped for BOOK mode) ………………………. |

4- 3 |

|

4.1.5 Control System Configuration (When the original size detection sensor is equipped for BOOK mode)……………… |

4- 3 |

|

Contents |

|

|

4.1.6 Control System Configuration (When the original size detection sensor is not equipped for BOOK mode) |

………..4- 4 |

|

4.1.7 Reader Controller PCB (When the original size detection sensor is equipped for BOOK mode)………………………. |

4- 5 |

|

4.1.8 Reader Controller PCB (When the original size detection sensor is not equipped for BOOK mode)…………………. |

4- 5 |

|

4.2 Basic Sequence………………………………………………………………………………………………………………………… |

4- 6 |

|

4.2.1 Basic Sequence at Power-on …………………………………………………………………………………………………………………. |

4- 6 |

|

4.2.2 Basic Sequence after Depression of Start Key (Book mode, One Sheet of original) ………………………………………. |

4- 7 |

|

4.3 Various Control…………………………………………………………………………………………………………………………. |

4- 8 |

|

4.3.1 Controlling the Scanner Drive System……………………………………………………………………………………………………… |

4- 8 |

|

4.3.1.1 Outline……………………………………………………………………………………………………………………………………………………………….. |

4- 8 |

|

4.3.1.2 Reader Motor Control ………………………………………………………………………………………………………………………………………….. |

4- 8 |

|

4.3.2 Contact Image Sensor (CIS) ………………………………………………………………………………………………………………….. |

4- 9 |

|

4.3.2.1 Outline……………………………………………………………………………………………………………………………………………………………….. |

4- 9 |

|

4.3.2.2 Analog Control Performed by the CIS…………………………………………………………………………………………………………………… |

4- 10 |

|

4.3.3 Enlargement/Reduction ……………………………………………………………………………………………………………………….. |

4- 11 |

|

4.3.3.1 Magnification Change in Vertical Scan Direction ……………………………………………………………………………………………………. |

4- 11 |

|

4.3.3.2 Magnification Change in Horizontal Scan Direction………………………………………………………………………………………………… |

4- 11 |

|

4.3.4 Detecting the Size of Originals ……………………………………………………………………………………………………………… |

4- 11 |

|

4.3.4.1 Outline……………………………………………………………………………………………………………………………………………………………… |

4- 11 |

|

4.3.4.2 Outline of Original Size Detection ………………………………………………………………………………………………………………………… |

4- 12 |

|

4.3.5 Dirt Sensor Control ……………………………………………………………………………………………………………………………… |

4- 13 |

|

4.3.5.1 Outline……………………………………………………………………………………………………………………………………………………………… |

4- 13 |

|

4.3.6 Image Processing……………………………………………………………………………………………………………………………….. |

4- 15 |

|

4.3.6.1 Outline……………………………………………………………………………………………………………………………………………………………… |

4- 15 |

|

4.3.6.2 CMOS Sensor Drive ………………………………………………………………………………………………………………………………………….. |

4- 16 |

|

4.3.6.3 CMOS Sensor Output Gain Correction and Offset Correction………………………………………………………………………………….. |

4- 16 |

|

4.3.6.4 CMOS Sensor Output A/D Conversion…………………………………………………………………………………………………………………. |

4- 16 |

|

4.3.6.5 Shading Correction (Outline) ………………………………………………………………………………………………………………………………. |

4- 16 |

|

4.3.6.6 Shading Adjustment…………………………………………………………………………………………………………………………………………… |

4- 16 |

|

4.3.6.7 Shading Correction ……………………………………………………………………………………………………………………………………………. |

4- 17 |

|

4.4 Parts Replacement Procedure ………………………………………………………………………………………………….. |

4- 18 |

|

4.4.1 Copyboard glass…………………………………………………………………………………………………………………………………. |

4- 18 |

|

4.4.1.1 Removing the Copyboard glass…………………………………………………………………………………………………………………………… |

4- 18 |

|

4.4.1.2 Removing the ADF Reading Glass (only for ADF equipment)………………………………………………………………………………….. |

4- 18 |

|

4.4.2 Reader Controller PCB………………………………………………………………………………………………………………………… |

4- 18 |

|

4.4.2.1 Removing the Reader Controller PCB (When the original size detection sensor is not equipped for BOOK mode)…………. |

4- 18 |

|

4.4.2.2 Removing the Reader Controller PCB (When the original size detection sensor is equipped for BOOK mode)………………. |

4- 20 |

|

4.4.3 Scanner Motor ……………………………………………………………………………………………………………………………………. |

4- 21 |

|

4.4.3.1 Removing the Scanner Motor ……………………………………………………………………………………………………………………………… |

4- 21 |

|

4.4.4 Contact sensor …………………………………………………………………………………………………………………………………… |

4- 22 |

|

4.4.4.1 Removing the Contact Image Sensor (CIS)…………………………………………………………………………………………………………… |

4- 22 |

|

4.4.4.2 Procedure after Replacing the CIS ………………………………………………………………………………………………………………………. |

4- 22 |

|

4.4.5 Copyboard Cover Open/Close Sensor …………………………………………………………………………………………………… |

4- 22 |

|

4.4.5.1 Removing the Copyboard Cover Open/Close Sensor (Front/Rear)…………………………………………………………………………… |

4- 22 |

|

4.4.6 Contact Sensor HP Sensor ………………………………………………………………………………………………………………….. |

4- 23 |

|

4.4.6.1 Removing the Contact Sensor HP Sensor (When the ADF is not installed)……………………………………………………………….. |

4- 23 |

|

4.4.6.2 Removing the Contact Sensor HP Sensor (When the ADF is installed)…………………………………………………………………….. |

4- 23 |

|

4.4.7 Original Size Sensor……………………………………………………………………………………………………………………………. |

4- 23 |

4.4.7.1Removing the Original Sensor (Vertical Scan Direction) (When the original size detection sensor is equipped for BOOK mode) 4- 23

4.4.7.2Removing the Original Sensor (Horizontal Scan Direction) (When the original size detection sensor is equipped for BOOK mode) 4- 24

|

4.4.8 Reader Heater (option)………………………………………………………………………………………………………………………… |

4- 25 |

|

4.4.8.1 Removing the Reader Heater (Right) …………………………………………………………………………………………………………………… |

4- 25 |

|

4.4.8.2 Removing the Reader Heater (Left) (When the ADF is not installed) ………………………………………………………………………… |

4- 25 |

|

4.4.8.3 Removing the Reader Heater (Left) (When the ADF is installed) ……………………………………………………………………………… |

4- 26 |

|

Chapter 5 Laser Exposure |

|

|

5.1 Construction …………………………………………………………………………………………………………………………….. |

5- 1 |

Contents

|

5.1.1 Overview ……………………………………………………………………………………………………………………………………………… |

5- 1 |

|

5.1.2 Specifications and Control Mechanism…………………………………………………………………………………………………….. |

5- 1 |

|

5.1.3 Main Components…………………………………………………………………………………………………………………………………. |

5- 2 |

|

5.1.4 Control System Configuration …………………………………………………………………………………………………………………. |

5- 3 |

|

5.2 Various Controls……………………………………………………………………………………………………………………….. |

5- 4 |

|

5.2.1 Controlling the Laser Activation Timing ……………………………………………………………………………………………………. |

5- 4 |

|

5.2.1.1 Laser Emission ON/OFF Control …………………………………………………………………………………………………………………………… |

5- 4 |

|

5.2.1.2 Horizontal Synchronization Control………………………………………………………………………………………………………………………… |

5- 4 |

|

5.2.2 Controlling the Intensity of Laser Light……………………………………………………………………………………………………… |

5- 4 |

|

5.2.2.1 Automatic Photocurrent Control (APC) …………………………………………………………………………………………………………………… |

5- 4 |

|

5.2.3 Controlling the Laser Scanner Motor ……………………………………………………………………………………………………….. |

5- 5 |

|

5.2.3.1 Laser Scanner Motor Control………………………………………………………………………………………………………………………………… |

5- 5 |

|

5.2.4 Controlling the Laser Shutter ………………………………………………………………………………………………………………….. |

5- 6 |

|

5.2.4.1 Laser Shutter Control…………………………………………………………………………………………………………………………………………… |

5- 6 |

|

5.3 Parts Replacement Procedure ……………………………………………………………………………………………………. |

5- 7 |

|

5.3.1 Laser Scanner Unit ……………………………………………………………………………………………………………………………….. |

5- 7 |

|

5.3.1.1 Removing the Laser Scanner Unit …………………………………………………………………………………………………………………………. |

5- 7 |

|

Chapter 6 Image Formation |

|

|

6.1 Construction …………………………………………………………………………………………………………………………….. |

6- 1 |

|

6.1.1 Specifications of Image Formation System……………………………………………………………………………………………….. |

6- 1 |

|

6.1.2 Major Components of Image Formation System ……………………………………………………………………………………….. |

6- 2 |

|

6.2 Image Formation Process ………………………………………………………………………………………………………….. |

6- 3 |

|

6.2.1 Image Formation Process………………………………………………………………………………………………………………………. |

6- 3 |

|

6.3 Basic Sequence ……………………………………………………………………………………………………………………….. |

6- 4 |

|

6.3.1 Basic Sequence of Operation …………………………………………………………………………………………………………………. |

6- 4 |

|

6.4 Driving and Controlling the High-Voltage System ………………………………………………………………………….. |

6- 5 |

|

6.4.1 Outline…………………………………………………………………………………………………………………………………………………. |

6- 5 |

|

6.5 Drum Unit ………………………………………………………………………………………………………………………………… |

6- 6 |

|

6.5.1 Outline of the Drum Unit ………………………………………………………………………………………………………………………… |

6- 6 |

|

6.5.1.1 Outline……………………………………………………………………………………………………………………………………………………………….. |

6- 6 |

|

6.5.2 Charging Mechanism…………………………………………………………………………………………………………………………….. |

6- 6 |

|

6.5.2.1 Primary Charging Bias Control ……………………………………………………………………………………………………………………………… |

6- 6 |

|

6.6 Developing Unit ………………………………………………………………………………………………………………………… |

6- 7 |

|

6.6.1 Outline…………………………………………………………………………………………………………………………………………………. |

6- 7 |

|

6.6.2 Developing Bias Control ………………………………………………………………………………………………………………………… |

6- 7 |

|

6.7 Toner Container ……………………………………………………………………………………………………………………….. |

6- 8 |

|

6.7.1 Outline…………………………………………………………………………………………………………………………………………………. |

6- 8 |

|

6.8 Transfer Unit…………………………………………………………………………………………………………………………….. |

6- 8 |

|

6.8.1 Outline of the Transfer Unit…………………………………………………………………………………………………………………….. |

6- 8 |

|

6.8.1.1 Outline……………………………………………………………………………………………………………………………………………………………….. |

6- 8 |

|

6.8.2 Controlling the Transfer Bias ………………………………………………………………………………………………………………….. |

6- 9 |

|

6.8.2.1 Transfer Roller Bias Control………………………………………………………………………………………………………………………………….. |

6- 9 |

|

6.8.3 Separation Mechanism ………………………………………………………………………………………………………………………….. |

6- 9 |

|

6.8.3.1 Static Eliminator Bias Control ……………………………………………………………………………………………………………………………….. |

6- 9 |

|

6.9 Photosensitive Drum Cleaning ………………………………………………………………………………………………….. |

6- 10 |

|

6.9.1 Outline……………………………………………………………………………………………………………………………………………….. |

6- 10 |

|

6.9.2 Waste Toner Full Detection ………………………………………………………………………………………………………………….. |

6- 10 |

|

6.10 Parts Replacement Procedure ………………………………………………………………………………………………… |

6- 11 |

|

6.10.1 Drum Unit…………………………………………………………………………………………………………………………………………. |

6- 11 |

|

6.10.1.1 Removing the Drum Unit…………………………………………………………………………………………………………………………………… |

6- 11 |

|

6.10.2 Developing Assembly…………………………………………………………………………………………………………………………. |

6- 11 |

|

6.10.2.1 Removing the Developing Assembly ………………………………………………………………………………………………………………….. |

6- 11 |

|

6.10.2.2 Precautions about Installation of Developing Assembly ………………………………………………………………………………………… |

6- 11 |

|

6.10.2.3 Procedure after Replacing the Developing Assembly……………………………………………………………………………………………. |

6- 11 |

|

Contents |

|

|

6.10.3 Transfer Charging Roller ……………………………………………………………………………………………………………………. |

6- 12 |

|

6.10.3.1 Removing the Transfer Charging Roller………………………………………………………………………………………………………………. |

6- 12 |

|

Chapter 7 Pickup/Feeding System |

|

|

7.1 Construction …………………………………………………………………………………………………………………………….. |

7- 1 |

|

7.1.1 Specifications/Configuration/Operation Methods ………………………………………………………………………………………. |

7- 1 |

|

7.1.2 Locations of Main UnitsÅ@(When the duplex unit is not equipped)……………………………………………………………… |

7- 2 |

|

7.1.3 Locations of Main Units (When the duplex unit is equipped)……………………………………………………………………….. |

7- 3 |

|

7.1.4 Roller Layout Drawing …………………………………………………………………………………………………………………………… |

7- 4 |

|

7.1.5 Paper Path Drawing(Printer on its own) …………………………………………………………………………………………………… |

7- 4 |

|

7.1.6 Paper Path Drawing(Finisher-U2) …………………………………………………………………………………………………………… |

7- 5 |

|

7.1.7 Paper Path Drawing(Duplex Unit-A1(option)/Finisher-U2) ………………………………………………………………………….. |

7- 5 |

|

7.1.8 Paper Path Drawing(Duplex Unit-A1(standard)/Finisher-U2)………………………………………………………………………. |

7- 5 |

|

7.1.9 Paper Path Drawing(Duplex-A1(option)) ………………………………………………………………………………………………….. |

7- 6 |

|

7.1.10 Paper Path Drawing(Duplex-A1(standard)) …………………………………………………………………………………………….. |

7- 6 |

|

7.1.11 Paper Path Drawing(Duplex-A1(option)/Inner 2Way Tray-E2) …………………………………………………………………… |

7- 7 |

|

7.1.12 Paper Path Drawing(Duplex-A1(standard)/Inner 2Way Tray-E2)……………………………………………………………….. |

7- 7 |

|

7.1.13 Paper Path Drawing(Inner 2Way Tray-E2) ……………………………………………………………………………………………… |

7- 8 |

|

7.1.14 Sensor Layout Drawing (When the duplex unit is not equipped)………………………………………………………………… |

7- 8 |

|

7.1.15 Sensor Layout Drawing (When the duplex unit is equipped)……………………………………………………………………… |

7- 9 |

|

7.2 Detecting Jams……………………………………………………………………………………………………………………….. |

7- 10 |

|

7.2.1 Delay Jams………………………………………………………………………………………………………………………………………… |

7- 10 |

|

7.2.1.1 Delay Jam in Pickup Assembly……………………………………………………………………………………………………………………………. |

7- 10 |

|

7.2.1.2 Delay Jam in Delivery Assembly (Paper Leading Edge Jam at Delivery Sensor/Wound Paper Jam at Fixing Assembly) … |

7- 10 |

|

7.2.1.3 Duplex Paper Sensor 1 Delay Jam………………………………………………………………………………………………………………………. |

7- 10 |

|

7.2.1.4 Duplex Paper Sensor 2 Delay Jam………………………………………………………………………………………………………………………. |

7- 10 |

|

7.2.2 Stationary Jams………………………………………………………………………………………………………………………………….. |

7- 10 |

|

7.2.2.1 Stationary Jam in Pickup Assembly……………………………………………………………………………………………………………………… |

7- 10 |

|

7.2.2.2 Stationary Jam in Delivery Assembly (Paper Trailing Edge Stationary Jam at First Delivery Sensor/Stationary Jam at First |

|

|

Delivery Sensor)……………………………………………………………………………………………………………………………………………………… |

7- 10 |

|

7.2.2.3 Duplex Paper Sensor 1 Stationary Jam………………………………………………………………………………………………………………… |

7- 11 |

|

7.2.2.4 Duplex Paper Sensor 2 Stationary Jam………………………………………………………………………………………………………………… |

7- 11 |

|

7.2.3 Other Jams ………………………………………………………………………………………………………………………………………… |

7- 11 |

|

7.2.3.1 Door Open Jam…………………………………………………………………………………………………………………………………………………. |

7- 11 |

|

7.3 Cassette Pick-Up Unit ……………………………………………………………………………………………………………… |

7- 11 |

|

7.3.1 Overview……………………………………………………………………………………………………………………………………………. |

7- 11 |

|

7.3.2 Cassette Pickup Operation…………………………………………………………………………………………………………………… |

7- 12 |

|

7.3.3 Cassette Paper Size Detection……………………………………………………………………………………………………………… |

7- 13 |

|

7.4 Manual Feed Pickup Unit …………………………………………………………………………………………………………. |

7- 14 |

|

7.4.1 Overview……………………………………………………………………………………………………………………………………………. |

7- 14 |

|

7.4.2 Post-pickup Control after Multi Manual Feed Pickup………………………………………………………………………………… |

7- 15 |

|

7.5 Parts Replacement Procedure ………………………………………………………………………………………………….. |

7- 16 |

|

7.5.1 Pickup Roller ……………………………………………………………………………………………………………………………………… |

7- 16 |

|

7.5.1.1 Removing the Cassette Paper Pickup Roller…………………………………………………………………………………………………………. |

7- 16 |

|

7.5.2 Cassette ……………………………………………………………………………………………………………………………………………. |

7- 16 |

|

7.5.2.1 Removing the First Cassette Unit ………………………………………………………………………………………………………………………… |

7- 16 |

|

7.5.2.2 Removing the Second Cassette Unit ……………………………………………………………………………………………………………………. |

7- 17 |

|

7.5.3 Cassette Pickup Assembly …………………………………………………………………………………………………………………… |

7- 18 |

|

7.5.3.1 Removing the Cassette Pickup Assembly …………………………………………………………………………………………………………….. |

7- 18 |

|

7.5.4 Cassette Size Sensor ………………………………………………………………………………………………………………………….. |

7- 19 |

|

7.5.4.1 Removing the Paper Size Detection Switches……………………………………………………………………………………………………….. |

7- 19 |

|

7.5.5 Cassette Retry Paper Sensor……………………………………………………………………………………………………………….. |

7- 19 |

|

7.5.5.1 Removing the Retry Sensor………………………………………………………………………………………………………………………………… |

7- 19 |

|

7.5.6 Cassette Paper Sensor ……………………………………………………………………………………………………………………….. |

7- 19 |

|

7.5.6.1 Removing the Cassette Paper Presence/Absence Sensor ……………………………………………………………………………………… |

7- 19 |

|

7.5.7 Cassette Pickup Solenoid…………………………………………………………………………………………………………………….. |

7- 19 |

|

7.5.7.1 Removing the Cassette Pickup Solenoid………………………………………………………………………………………………………………. |

7- 19 |

Contents

|

7.5.8 Manual Pickup Roller…………………………………………………………………………………………………………………………… |

7- 20 |

|

7.5.8.1 Removing the Multifeeder Pickup Roller……………………………………………………………………………………………………………….. |

7- 20 |

|

7.5.9 Manual Feed Tray paper sensor……………………………………………………………………………………………………………. |

7- 20 |

|

7.5.9.1 Removing the Multifeeder Paper Presence/Absence Sensor…………………………………………………………………………………… |

7- 20 |

|

7.5.10 Manual Feed Pickup Solenoid …………………………………………………………………………………………………………….. |

7- 21 |

|

7.5.10.1 Removing the Multifeeder Pickup Solenoid …………………………………………………………………………………………………………. |

7- 21 |

|

7.5.11 Registration Roller……………………………………………………………………………………………………………………………… |

7- 21 |

|

7.5.11.1 Removing the Registration Roller ………………………………………………………………………………………………………………………. |

7- 21 |

|

7.5.12 Registration Clutch…………………………………………………………………………………………………………………………….. |

7- 22 |

|

7.5.12.1 Removing the Registration Clutch………………………………………………………………………………………………………………………. |

7- 22 |

|

7.5.13 Separation Roller ………………………………………………………………………………………………………………………………. |

7- 22 |

|

7.5.13.1 Removing the Feed and Separation Rollers ………………………………………………………………………………………………………… |

7- 22 |

|

7.5.14 Separation Pad …………………………………………………………………………………………………………………………………. |

7- 22 |

|

7.5.14.1 Removing the Separation Pad …………………………………………………………………………………………………………………………… |

7- 22 |

|

Chapter 8 Fixing System |

|

|

8.1 Construction …………………………………………………………………………………………………………………………….. |

8- 1 |

|

8.1.1 Specifications, Control Mechanisms, and Functions ………………………………………………………………………………….. |

8- 1 |

|

8.1.2 Major Components………………………………………………………………………………………………………………………………… |

8- 1 |

|

8.2 Various Control Mechanisms ……………………………………………………………………………………………………… |

8- 2 |

|

8.2.1 Controlling the Speed of the Fixing Film …………………………………………………………………………………………………… |

8- 2 |

|

8.2.1.1 Controlling the Fixing Film Speed ………………………………………………………………………………………………………………………….. |

8- 2 |

|

8.2.2 Controlling the Fixing Film Temperature…………………………………………………………………………………………………… |

8- 2 |

|

8.2.2.1 Outline……………………………………………………………………………………………………………………………………………………………….. |

8- 2 |

|

8.2.2.2 Controlling the Fixing Film Temperature…………………………………………………………………………………………………………………. |

8- 3 |

|

8.2.2.3 Target Temperatures by Mode ……………………………………………………………………………………………………………………………… |

8- 3 |

|

8.2.3 Detecting the Passage of Paper ……………………………………………………………………………………………………………… |

8- 3 |

|

8.2.3.1 Detecting the Passage of Paper ……………………………………………………………………………………………………………………………. |

8- 3 |

|

8.3 Parts Replacement Procedure ……………………………………………………………………………………………………. |

8- 5 |

|

8.3.1 Fixing Unit ……………………………………………………………………………………………………………………………………………. |

8- 5 |

|

8.3.1.1 Removing the Fixing Unit……………………………………………………………………………………………………………………………………… |

8- 5 |

|

8.3.2 Pressure Roller …………………………………………………………………………………………………………………………………….. |

8- 6 |

|

8.3.2.1 Removing the Pressure Roller ………………………………………………………………………………………………………………………………. |

8- 6 |

|

8.3.3 Fixing Film……………………………………………………………………………………………………………………………………………. |

8- 6 |

|

8.3.3.1 Removing the Fixing Film Unit ………………………………………………………………………………………………………………………………. |

8- 6 |

|

8.3.4 Fixing Delivery Sensor …………………………………………………………………………………………………………………………… |

8- 8 |

|

8.3.4.1 Removing the Fixing Delivery Sensor…………………………………………………………………………………………………………………….. |

8- 8 |

|

8.3.5 Fixing Film Sensor ………………………………………………………………………………………………………………………………. |

8- 10 |

|

8.3.5.1 Removing the Fixing Film Sensor ………………………………………………………………………………………………………………………… |

8- 10 |

|

Chapter 9 External and Controls |

|

|

9.1 Control Panel……………………………………………………………………………………………………………………………. |

9- 1 |

|

9.1.1 Overview ……………………………………………………………………………………………………………………………………………… |

9- 1 |

|

9.2 Fans ……………………………………………………………………………………………………………………………………….. |

9- 1 |

|

9.2.1 Overview ……………………………………………………………………………………………………………………………………………… |

9- 1 |

|

9.2.2 Fan Control ………………………………………………………………………………………………………………………………………….. |

9- 1 |

|

9.3 Power Supply System ……………………………………………………………………………………………………………….. |

9- 2 |

|

9.3.1 Power Supply……………………………………………………………………………………………………………………………………….. |

9- 2 |

|

9.3.1.1 Outline (When the duplex unit is not equipped) ……………………………………………………………………………………………………….. |

9- 2 |

|

9.3.1.2 Outline (When the duplex unit is equipped) …………………………………………………………………………………………………………….. |

9- 3 |

|

9.3.1.3 Rated Output of the Power Supply PCB …………………………………………………………………………………………………………………. |

9- 4 |

|

9.3.2 Protection Function ……………………………………………………………………………………………………………………………….. |

9- 4 |

|

9.3.2.1 Protective Mechanisms………………………………………………………………………………………………………………………………………… |

9- 4 |

|

9.4 Parts Replacement Procedure ……………………………………………………………………………………………………. |

9- 5 |

|

9.4.1 External Covers ……………………………………………………………………………………………………………………………………. |

9- 5 |

|

9.4.1.1 Delivery Tray………………………………………………………………………………………………………………………………………………………. |

9- 5 |

|

Contents |

|

|

9.4.1.2 Right Cover (Lower)…………………………………………………………………………………………………………………………………………….. |

9- 5 |

|

9.4.1.3 Right Cover (Upper)…………………………………………………………………………………………………………………………………………….. |

9- 5 |

|

9.4.1.4 Rear Cover…………………………………………………………………………………………………………………………………………………………. |

9- 5 |

|

9.4.1.5 Left Cover (Lower) ………………………………………………………………………………………………………………………………………………. |

9- 5 |

|

9.4.1.6 Left Cover (Rear) ………………………………………………………………………………………………………………………………………………… |

9- 6 |

|

9.4.1.7 Reader Front Cover …………………………………………………………………………………………………………………………………………….. |

9- 6 |

|

9.4.1.8 Reader Rear Cover……………………………………………………………………………………………………………………………………………… |

9- 6 |

|

9.4.2 Main Drive Assembly…………………………………………………………………………………………………………………………….. |

9- 6 |

|

9.4.2.1 Removing the Main Drive Unit ………………………………………………………………………………………………………………………………. |

9- 6 |

|

9.4.3 Fixing Drive Assembly …………………………………………………………………………………………………………………………… |

9- 8 |

|

9.4.3.1 Removing the Fixing Drive Unit …………………………………………………………………………………………………………………………….. |

9- 8 |

|

9.4.4 Power Supply Unit ………………………………………………………………………………………………………………………………… |

9- 8 |

|

9.4.4.1 Removing the Main Power Supply PCB …………………………………………………………………………………………………………………. |

9- 8 |

|

9.4.5 Control Panel……………………………………………………………………………………………………………………………………….. |

9- 8 |

|

9.4.5.1 Removing the Operation Panel Unit ………………………………………………………………………………………………………………………. |

9- 8 |

|

9.4.6 DC Controller PCB ……………………………………………………………………………………………………………………………….. |

9- 9 |

|

9.4.6.1 Removing the DC Controller PCB………………………………………………………………………………………………………………………….. |

9- 9 |

|

9.4.7 Option Power Supply PCB …………………………………………………………………………………………………………………….. |

9- 9 |

|

9.4.7.1 Removing the Option Power Supply PCB……………………………………………………………………………………………………………….. |

9- 9 |

|

9.4.8 HVT PCB …………………………………………………………………………………………………………………………………………….. |

9- 9 |

|

9.4.8.1 Removing the HVT PCB ………………………………………………………………………………………………………………………………………. |

9- 9 |

|

9.4.9 Fixing Heat Discharge Fan …………………………………………………………………………………………………………………… |

9- 10 |

|

9.4.9.1 Removing the Fan Filter (Non Duplex Unit) …………………………………………………………………………………………………………… |

9- 10 |

|

9.4.9.2 Removing the Fan Filter (With Duplex Unit Type) ………………………………………………………………………………………………….. |

9- 10 |

|

9.4.10 Fixing Driver Motor ……………………………………………………………………………………………………………………………. |

9- 11 |

|

9.4.10.1 Removing the Fixing Unit Drive Motor ………………………………………………………………………………………………………………… |

9- 11 |

|

9.4.11 Left Door ………………………………………………………………………………………………………………………………………….. |

9- 11 |

|

9.4.11.1 Removing the Left Door (Non Duplex Unit Type)………………………………………………………………………………………………….. |

9- 11 |

|

9.4.11.2 Removing the Left Door (With Duplex Unit Type) …………………………………………………………………………………………………. |

9- 12 |

|

Chapter 10 Maintenance and Inspection |

|

|

10.1 Periodically Replaced Parts…………………………………………………………………………………………………….. |

10- 1 |

|

10.1.1 Overview………………………………………………………………………………………………………………………………………….. |

10- 1 |

|

10.1.2 Reader Unit………………………………………………………………………………………………………………………………………. |

10- 1 |

|

10.1.3 Printer Unit……………………………………………………………………………………………………………………………………….. |

10- 1 |

|

10.2 Durables and Consumables ……………………………………………………………………………………………………. |

10- 1 |

|

10.2.1 Overview………………………………………………………………………………………………………………………………………….. |

10- 1 |

|

10.2.2 Reader Unit………………………………………………………………………………………………………………………………………. |

10- 1 |

|

10.2.3 Printer Unit……………………………………………………………………………………………………………………………………….. |

10- 1 |

|

10.3 Scheduled Servicing Basic Procedure………………………………………………………………………………………. |

10- 2 |

|

10.3.1 Scheduled Servicing ………………………………………………………………………………………………………………………….. |

10- 2 |

|

Chapter 11 Standards and Adjustments |

|

|

11.1 Scanning System…………………………………………………………………………………………………………………… |

11- 1 |

|

11.1.1 Procedure after Replacing the CIS ………………………………………………………………………………………………………. |

11- 1 |

|

11.2 Image Formation System………………………………………………………………………………………………………… |

11- 1 |

|

11.2.1 Procedure after Replacing the Developing Assembly …………………………………………………………………………….. |

11- 1 |

|

11.3 Electrical Components……………………………………………………………………………………………………………. |

11- 1 |

|

11.3.1 Procedure after Replacing the Image Processor PCB ……………………………………………………………………………. |

11- 1 |

|

Chapter 12 Correcting Faulty Images |

|

|

12.1 Making Initial Checks……………………………………………………………………………………………………………… |

12- 1 |

|

12.1.1 Site Environment ………………………………………………………………………………………………………………………………. |

12- 1 |

|

12.1.2 Checking the Paper …………………………………………………………………………………………………………………………… |

12- 1 |

|

12.1.3 Checking the Placement of Paper ……………………………………………………………………………………………………….. |

12- 1 |

Contents

|

12.1.4 Checking the Durables……………………………………………………………………………………………………………………….. |

12- 1 |

|

12.1.5 Checking the Units and Functional Systems………………………………………………………………………………………….. |

12- 1 |

|

12.1.6 Others ……………………………………………………………………………………………………………………………………………… |

12- 2 |

|

12.2 Outline of Electrical Components …………………………………………………………………………………………….. |

12- 2 |

|

12.2.1 Clutch/Solenoid …………………………………………………………………………………………………………………………………. |

12- 2 |

|

12.2.1.1 List of Clutches/Solenoids…………………………………………………………………………………………………………………………………. |

12- 2 |

|

12.2.2 Motor ……………………………………………………………………………………………………………………………………………….. |

12- 3 |

|

12.2.2.1 List of Motors…………………………………………………………………………………………………………………………………………………… |

12- 3 |

|

12.2.3 Fan………………………………………………………………………………………………………………………………………………….. |

12- 4 |

|

12.2.3.1 List of Fans……………………………………………………………………………………………………………………………………………………… |

12- 4 |

|

12.2.4 Sensor……………………………………………………………………………………………………………………………………………… |

12- 4 |

|

12.2.4.1 List of Sensors ………………………………………………………………………………………………………………………………………………… |

12- 4 |

|

12.2.5 Switch………………………………………………………………………………………………………………………………………………. |

12- 6 |

|

12.2.5.1 List of Switches ……………………………………………………………………………………………………………………………………………….. |

12- 6 |

|

12.2.6 Lamps, Heaters, and Others ……………………………………………………………………………………………………………….. |

12- 7 |

|

12.2.6.1 List of Lamps, Heaters, and Others ……………………………………………………………………………………………………………………. |

12- 7 |

|

12.2.7 PCBs ……………………………………………………………………………………………………………………………………………….. |

12- 8 |

|

12.2.7.1 List of PCBs ……………………………………………………………………………………………………………………………………………………. |

12- 8 |

|

Chapter 13 Self Diagnosis |

|

|

13.1 Error Code Table …………………………………………………………………………………………………………………… |

13- 1 |

|

13.1.1 List of Error Codes …………………………………………………………………………………………………………………………….. |

13- 1 |

|

13.2 Error Code Details …………………………………………………………………………………………………………………. |

13- 1 |

|

13.2.1 Error Code Details……………………………………………………………………………………………………………………………… |

13- 1 |

|

13.3 Jam Code …………………………………………………………………………………………………………………………….. |

13- 3 |

|

13.3.1 Jam Codes (Related to Printer Unit) …………………………………………………………………………………………………….. |

13- 3 |

|

13.3.2 Jam Codes (Related to Finisher) …………………………………………………………………………………………………………. |

13- 4 |

|

13.3.3 Jam Codes (Related to ADF) ………………………………………………………………………………………………………………. |

13- 4 |

|

13.3.4 Jam Codes (Related to Duplex Unit)…………………………………………………………………………………………………….. |

13- 5 |

|

13.3.5 Jam Codes (Related to Inner 2-way Tray) …………………………………………………………………………………………….. |

13- 5 |

|

13.4 Finisher Error Codes ……………………………………………………………………………………………………………… |

13- 5 |

|

13.4.1 Error Code Details……………………………………………………………………………………………………………………………… |

13- 5 |

|

Chapter 14 Service Mode |

|

|

14.1 Outline …………………………………………………………………………………………………………………………………. |

14- 1 |

|

14.1.1 Outline of Service Mode……………………………………………………………………………………………………………………… |

14- 1 |

|

14.1.2 Using the Service Mode……………………………………………………………………………………………………………………… |

14- 1 |

|

14.2 Default settings……………………………………………………………………………………………………………………… |

14- 1 |

|

14.2.1 Service Mode Menus …………………………………………………………………………………………………………………………. |

14- 1 |

|

14.3 Services Choice…………………………………………………………………………………………………………………….. |

14- 3 |

|

14.3.1 Scan Setting……………………………………………………………………………………………………………………………………… |

14- 3 |

|

14.3.2 Printer Setting …………………………………………………………………………………………………………………………………… |

14- 4 |

|

14.4 Adjust…………………………………………………………………………………………………………………………………… |

14- 5 |

|

14.4.1 CIS Position Adjust ……………………………………………………………………………………………………………………………. |

14- 5 |

|

14.4.2 Reading Position Adjust……………………………………………………………………………………………………………………… |

14- 6 |

|

14.4.3 Print Position…………………………………………………………………………………………………………………………………….. |

14- 6 |

|

14.5 Counter………………………………………………………………………………………………………………………………… |

14- 6 |

|

14.5.1 Outline……………………………………………………………………………………………………………………………………………… |

14- 6 |

|

14.6 Display…………………………………………………………………………………………………………………………………. |

14- 7 |

|

14.6.1 Version Display …………………………………………………………………………………………………………………………………. |

14- 7 |

|

14.6.2 Error Code Display…………………………………………………………………………………………………………………………….. |

14- 7 |

|

14.7 Report………………………………………………………………………………………………………………………………….. |

14- 7 |

|

14.7.1 |

Outline……………………………………………………………………………………………………………………………………………… |

14- 7 |

|

14.7.2 |

Service Data List……………………………………………………………………………………………………………………………….. |

14- 8 |

|

Contents |

|

|

14.7.3 Service Label ……………………………………………………………………………………………………………………………………. |

14- 8 |

|

14.7.4 Error Log Report ……………………………………………………………………………………………………………………………….. |

14- 9 |

|

14.8 Clear Data…………………………………………………………………………………………………………………………….. |

14- 9 |

|

14.8.1 Outline …………………………………………………………………………………………………………………………………………….. |

14- 9 |

|

14.9 Test……………………………………………………………………………………………………………………………………. |

1410 |

|

14.9.1 Outline …………………………………………………………………………………………………………………………………………… |

1410 |

|

14.9.2 DRAM Test …………………………………………………………………………………………………………………………………….. |

1410 |

|

14.9.3 Scanner Test ………………………………………………………………………………………………………………………………….. |

1410 |

|

14.9.4 Printer Test …………………………………………………………………………………………………………………………………….. |

1410 |

|

14.9.5 Aging Test………………………………………………………………………………………………………………………………………. |

1411 |

|

14.9.6 Factory Test……………………………………………………………………………………………………………………………………. |

1411 |

|

14.9.7 Roller Clear Mode……………………………………………………………………………………………………………………………. |

1413 |

|

14.9.8 Video I/F Test …………………………………………………………………………………………………………………………………. |

1413 |

|

Chapter 15 Upgrading |

|

|

15.1 Outline …………………………………………………………………………………………………………………………………. |

15- 1 |

|

15.1.1 Overview of Upgrade …………………………………………………………………………………………………………………………. |

15- 1 |

|

15.2 Downloading System Software………………………………………………………………………………………………… |

15- 1 |

|

15.2.1 Downloading System …………………………………………………………………………………………………………………………. |

15- 1 |

|

15.2.1.1 Downloading Procedure……………………………………………………………………………………………………………………………………. |

15- 1 |

|

15.2.2 Downloading BOOT…………………………………………………………………………………………………………………………… |

15- 5 |

|

15.2.2.1 Downloading Procedure……………………………………………………………………………………………………………………………………. |

15- 5 |

|

Chapter 16 Service Tools |

|

|

16.1 Service Tools ………………………………………………………………………………………………………………………… |

16- 1 |

|

16.1.1 Special Tools ……………………………………………………………………………………………………………………………………. |

16- 1 |

|

16.1.2 Oils and Solvents………………………………………………………………………………………………………………………………. |

16- 1 |

Contents

Chapter 1 Introduction

Contents

Contents

|

1.1 System Construction …………………………………………………………………………………………………………………………………… |

1-1 |

|

1.1.1 Pickup/ Delivery /Original Handling Accessories System Configuration (1-cassette/Platen cover (option) model) …………….. |

1-1 |

|

1.1.2 Pickup/ Delivery /Original Handling Accessories System Configuration (1-cassette/Platen cover (standard) model) ………….. |

1-2 |

|

1.1.3 Pickup/ Delivery /Original Handling Accessories System Configuration (2-cassette/Duplex unit (option) model) ……………… |

1-3 |

|

1.1.4 Pickup/ Delivery /Original Handling Accessories System Configuration (2-cassette/Duplex unit (standard) model)…………… |

1-4 |

|

1.1.5 Reader Heater/ Cassette Heater System Configuration ………………………………………………………………………………………………… |

1-5 |

|

1.1.6 Printing/Transmitting Accessories System Configuration…………………………………………………………………………………………….. |

1-6 |

|

1.2 Product Specifications…………………………………………………………………………………………………………………………………. |

1-6 |

|

1.2.1 Names of Parts ……………………………………………………………………………………………………………………………………………………….. |

1-6 |

|

1.2.1.1 External View (1-cassette model) ……………………………………………………………………………………………………………………………………………… |

1-6 |

|

1.2.1.2 External View (2-cassette model) ………………………………………………………………………………………………………………………………………………. |

1-6 |

|

1.2.1.3 Cross-Section ………………………………………………………………………………………………………………………………………………………………………….. |

1-7 |

|

1.2.2 Using the Machine ………………………………………………………………………………………………………………………………………………….. |

1-7 |

|

1.2.2.1 Turning On the Power Switch (1-cassette model) ……………………………………………………………………………………………………………………….. |

1-7 |

|

1.2.2.2 Turning On the Power Switch (2-cassette model) ………………………………………………………………………………………………………………………… |

1-8 |

|

1.2.2.3 When Turning Off the Main Power Switch (1-cassette model) ……………………………………………………………………………………………………… |

1-9 |

|

1.2.2.4 When Turning Off the Main Power Switch (2-cassette model)…………………………………………………………………………………………………….. |

1-11 |

|

1.2.2.5 Control Panel…………………………………………………………………………………………………………………………………………………………………………. |

1-12 |

|

1.2.3 User Mode Items…………………………………………………………………………………………………………………………………………………… |

1-13 |

|

1.2.3.1 Audible Tones ……………………………………………………………………………………………………………………………………………………………………….. |

1-13 |

|

1.2.3.2 Common Settings …………………………………………………………………………………………………………………………………………………………………… |

1-13 |

|

1.2.3.3 Copy Settings ………………………………………………………………………………………………………………………………………………………………………… |

1-14 |

|

1.2.3.4 Printer Settings ………………………………………………………………………………………………………………………………………………………………………. |

1-14 |

|

1.2.3.5 Timer Settings ……………………………………………………………………………………………………………………………………………………………………….. |

1-15 |

|

1.2.3.6 Adjustment/Cleaning………………………………………………………………………………………………………………………………………………………………. |

1-15 |

|

1.2.3.7 Report Settings ………………………………………………………………………………………………………………………………………………………………………. |

1-15 |

|

1.2.3.8 System Settings ……………………………………………………………………………………………………………………………………………………………………… |

1-15 |

|

1.2.3.9 Network Settings……………………………………………………………………………………………………………………………………………………………………. |

1-16 |

|

1.2.4 Maintenance by the User ……………………………………………………………………………………………………………………………………….. |

1-17 |

|

1.2.4.1 User Maintenance Items………………………………………………………………………………………………………………………………………………………….. |

1-17 |

|

1.2.4.2 Cleaning ……………………………………………………………………………………………………………………………………………………………………………….. |

1-17 |

|

1.2.5 Safety ………………………………………………………………………………………………………………………………………………………………….. |

1-19 |

|

1.2.5.1 Safety of the Laser Light…………………………………………………………………………………………………………………………………………………………. |

1-19 |

|

1.2.5.2 CDRH Regulations…………………………………………………………………………………………………………………………………………………………………. |

1-19 |

|

1.2.5.3 Handling the Laser Unit ………………………………………………………………………………………………………………………………………………………….. |

1-19 |

|

1.2.5.4 Safety of Toner………………………………………………………………………………………………………………………………………………………………………. |

1-20 |

|

1.2.5.5 Point to Note about Fire ………………………………………………………………………………………………………………………………………………………….. |

1-20 |

|

1.2.6 Product Specifications …………………………………………………………………………………………………………………………………………… |

1-20 |

|

1.2.6.1 Product Specifications…………………………………………………………………………………………………………………………………………………………….. |

1-20 |

|

1.2.7 Function List ………………………………………………………………………………………………………………………………………………………… |

1-21 |

|

1.2.7.1 Printing Speed (iR2422series)………………………………………………………………………………………………………………………………………………….. |

1-21 |

|

1.2.7.2 Printing Speed (iR2420/iR2320series)………………………………………………………………………………………………………………………………………. |

1-23 |

|

1.2.7.3 Printing Speed (iR2318series)………………………………………………………………………………………………………………………………………………….. |

1-24 |

Chapter 1

1.1 System Construction

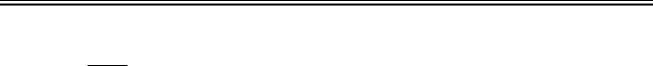

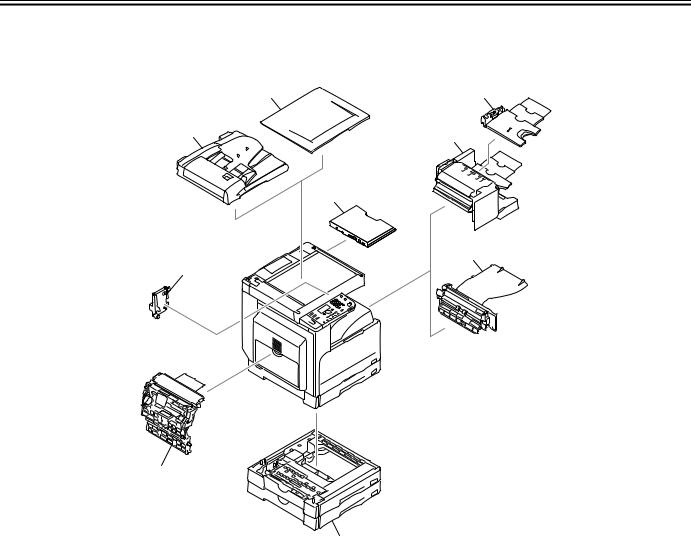

1.1.1 Pickup/ Delivery /Original Handling Accessories System Configuration (1-cassette/Platen cover (option) model)

The configuration is as shown in the following figure:

[4]

[3]

[2]

[1]

[5]

[10]

[9]

[6]

[8]

[7]

[7]

[6]

F-1-1

[1]DADF-P2

[2]Platen Cover Type J

[3]Finisher-U2

[4]Additional Finisher Tray-C1

[5]Inner 2-way Tray-E2

|

[6] |

Cassette Feeding Module-S1 |

*1 |

|

[7] |

Cassette Feeding Module-T1 |

*1 |

[8]Duplex Unit-A1

|

[9] |

Power Supply Kit-Q1 |

*2 |

[10]Document Tray-J1

*1: A Cassette feeding module-S1 can be placed on the Cassette feeding module-T1 to use these cassette units as a 3-stage cassette unit. *2: This accessory is required when the Finisher-U2, Cassette feeding module-T1 is installed.

1-1

Chapter 1

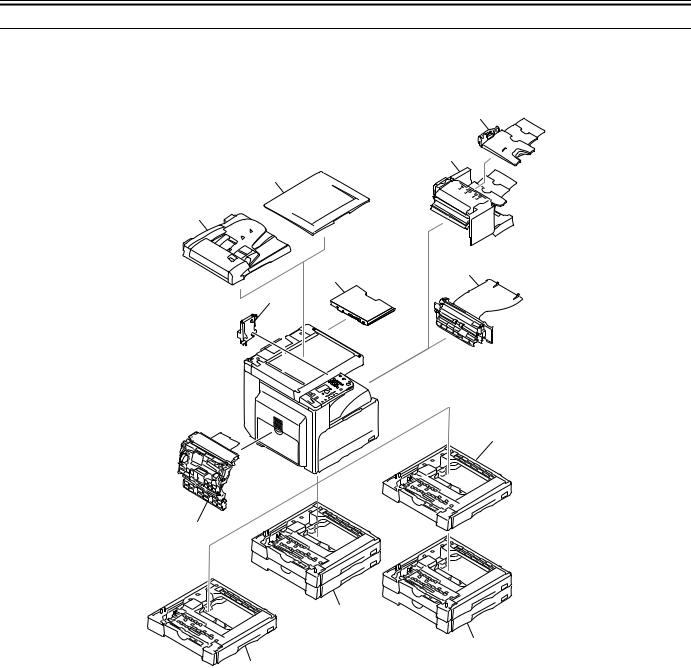

1.1.2 Pickup/ Delivery /Original Handling Accessories System Configuration (1-cassette/Platen cover (standard) model)

The configuration is as shown in the following figure:

[4]

[3]

[2]

[1]

[5]

[10]

[9]

[6]

[8]

[7]

[7]

[6]

F-1-2

[1]DADF-P2

|

[2] |

Platen Cover Type J |

*1 |

[3]Finisher-U2

[4]Additional Finisher Tray-C1

[5]Inner 2-way Tray-E2

|

[6] |

Cassette Feeding Module-S1/S2*2 |

*3 |

|

[7] |

Cassette Feeding Module-T1/T2*2 |

*3 |

[8]Duplex Unit-A1

|

[9] |

Power Supply Kit-Q1 |

*4 |

[10]Document Tray-J1

*1: This accessory comes standard.

*2: Only for China, this machine uses the cassette feeding module-S2 and the cassette feeding module-T2.

*3: A Cassette feeding module-S1 can be placed on the Cassette feeding module-T1 (A Cassette feeding module-S2 can be placed on the Cassette feeding moduleT2) to use these cassette units as a 3-stage cassette unit.

*4: This accessory is required when the Finisher-U2, Cassette feeding module-T1/T2 is installed.

1-2

Chapter 1

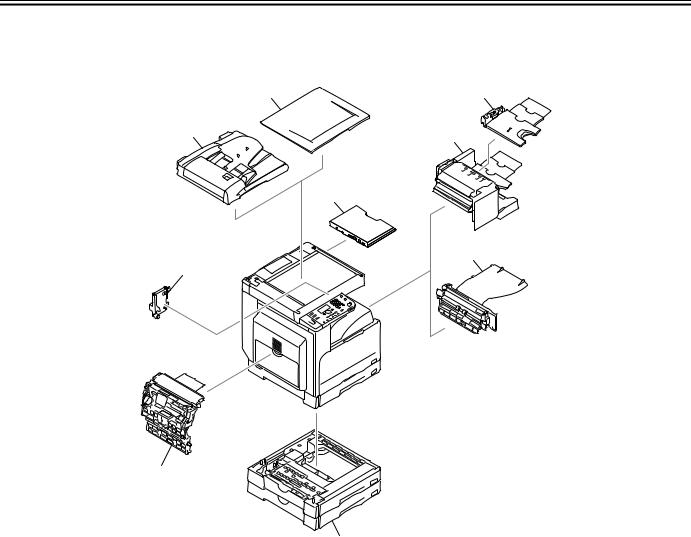

1.1.3 Pickup/ Delivery /Original Handling Accessories System Configuration (2-cassette/Duplex unit (option) model)

The configuration is as shown in the following figure:

|

[2] |

[4] |

|

[1] |

[3] |

|

[9] |

|

|

[5] |

|

|

[8] |

[7]

[6]

F-1-3

[1]DADF-P2

|

[2] |

Platen Cover Type J |

*1 |

[3]Finisher-U2

[4]Additional Finisher Tray-C1

[5]Inner 2-way Tray-E2

[6]Cassette Feeding Module-T2

|

[7] |

Duplex Unit-A1 |

*1 |

|

[8] |

Power Supply Kit-Q1 |

*2 |

[9]Document Tray-J1

*1: This accessory comes standard.

*2: This accessory is required when the Finisher-U2, Cassette feeding module-T2 is installed.

1-3

Chapter 1

1.1.4 Pickup/ Delivery /Original Handling Accessories System Configuration (2-cassette/Duplex unit (standard) model)

The configuration is as shown in the following figure:

|

[2] |

[4] |

|

[1] |

[3] |

|

[9] |

|

|

[5] |

|

|

[8] |

[7]

[6]

F-1-4

[1]DADF-P2

[2]Platen Cover Type J

[3]Finisher-U2

[4]Additional Finisher Tray-C1

[5]Inner 2-way Tray-E2

[6]Cassette Feeding Module-T1

[7]Duplex Unit-A1

|

[8] |

Power Supply Kit-Q1 |

*1 |

[9]Document Tray-J1

*1: This accessory is required when the Finisher-U2, Cassette feeding module-T1 is installed.

1-4

Chapter 1

1.1.5 Reader Heater/ Cassette Heater System Configuration

The configuration is as shown in the following figure:

[1]

|

[3] |

[2] |

|

|

F-1-5 |

||

|

[1] |

Reader Heater |

*1 |

|

[2] |

Cassette Heater |

*1 |

[3]Heater PCB

*1: To operate the heaters, a heater PCB is required. These parts are supplied as service parts, not the standard items.

1-5

Chapter 1

1.1.6 Printing/Transmitting Accessories System Configuration

This machine does not allow the print function and the transmission function to be added.

1.2 Product Specifications

1.2.1 Names of Parts

1.2.1.1 External View (1-cassette model)

[1]

|

[11] |

[2] |

||

|

[12] |

|||

|

[10] |

[3] |

||

|

[4] |

|||

|

[9] |

|||

|

[5] |

|||

|

[8] |

[6] |

[16] |

|

|

[7] |

[15] |

||

|

F-1-6 |

|||

|

[1] |

Copyboard cover (*1) |

[9] |

Left door |

|

[2] |

Reader front cover |

[10] |

Left cover (rear) |

|

[3] |

Control panel |

[11] |

Reader left cover |

|

[4] |

Delivery tray |

[12] |

Reader right cover |

|

[5] |

Front cover |

[13] |

Reader rear cover |

|

[6] |

Cassette 1 |

[14] |

Rear cover |

|

[7] |

Left cover (front) |

[15] |

Right cover (upper) |

|

[8] |

Manual feed tray |

[16] |

Right cover (lower) |

*1: This accessory comes optionally with the iR2320L (Latin American countries model), iR2318L (Korean model). Other models are standard.

1.2.1.2 External View (2-cassette model)

|

[1] |

||||

|

[12] |

[2] |

|||

|

[3] |

[13] |

|||

|

[11] |

||||

|

[4 ] |

||||

|

[10] |

||||

|

[5] |

||||

|

[9] |

[6] |

|||

|

[8] |

[7] |

[18] |

||

|

F-1-7 |

||||

|

[1] |

Copyboard cover |

[9] |

Left door |

|

|

[2] |

Reader front cover |

[10] |

Left cover (rear) |

|

|

[3] |

Control panel |

[11] |

Reader left cover |

|

|

[4] |

Delivery tray |

[12] |

Reader right cover |

|

|

[5] |

Front cover |

[13] |

Reader rear cover |

|

|

[6] |

Cassette 1 |

[14] |

Rear cover |

[14]

[16]

[17]

1-6

Chapter 1

|

[7] |

Left cover (front) |

[15] |

Right cover (upper) |

|

[8] |

Manual feed tray |

[16] |

Right cover (lower) |

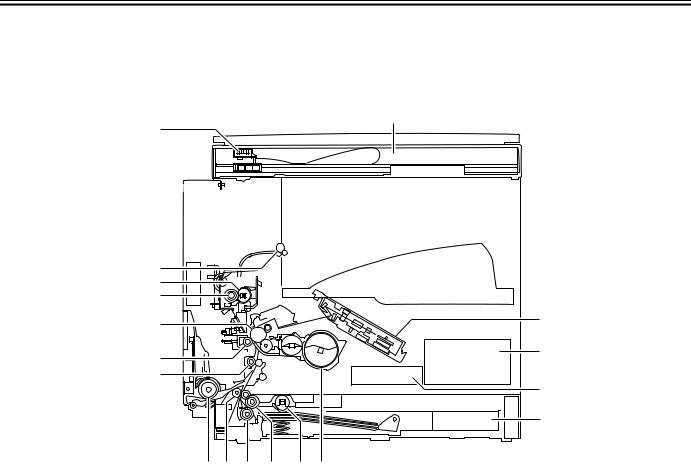

1.2.1.3 Cross-Section

[2]

[1]

[18]

[17]

[16]

[15]

[14]

[13]

|

[12] [11] [10] [9] |

[8] [7] |

||

|

F-1-8 |

|||

|

[1] |

CIS unit |

[10] |

Separation roller |

|

[2] |

Reader unit |

[11] |

Vertical path roller |

|

[3] |

Laser scanner unit |

[12] |

Manual feed pickup roller |

|

[4] |

DC power supply PCB |

[13] |

Registration roller |

|

[5] |

HVT PCB |

[14] |

Transfer roller |

|

[6] |

Cassette |

[15] |

Drum unit |

|

[7] |

Toner bottle |

[16] |

Pressure roller |

|

[8] |

Pickup roller |

[17] |

Fixing film unit |

|

[9] |

Feed roller |

[18] |

Delivery roller |

1.2.2 Using the Machine

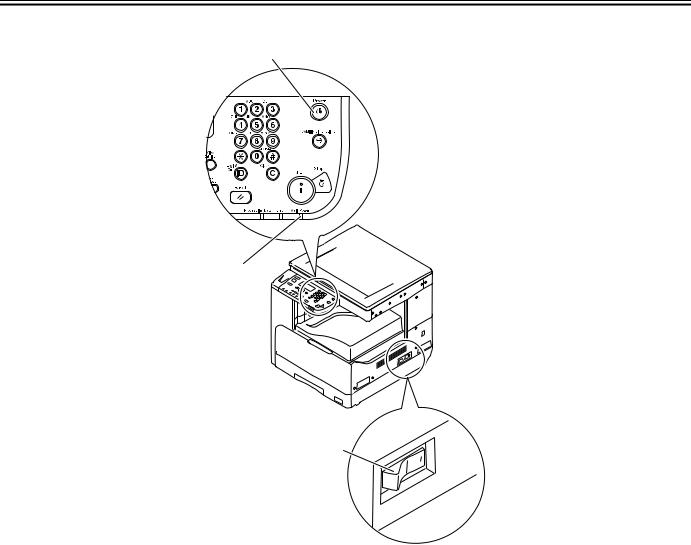

1.2.2.1 Turning On the Power Switch (1-cassette model)

1-7

Chapter 1

The machine possesses 2 power switches: main power switch and control power switch. Normally (i.e., unless the machine is in a sleep state), the machine will be supplied with power when you turn on its main power switch.

[1]

[2]

[3]

F-1-9

[1]Control panel power switch [2]Main power lamp

[3]Main power switch

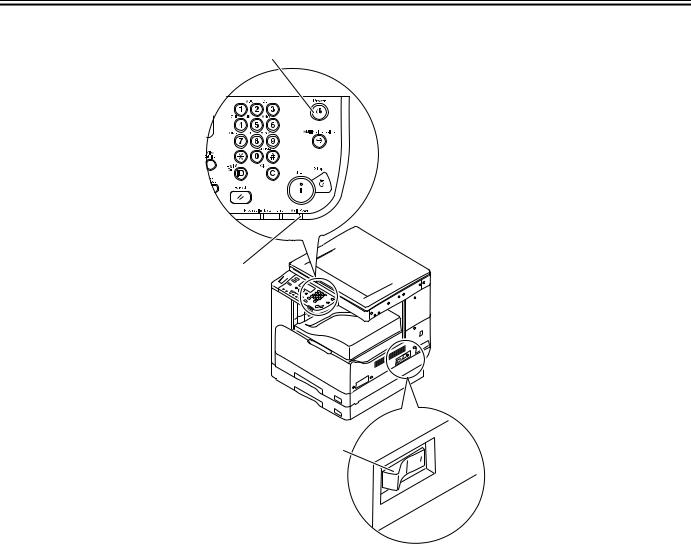

1.2.2.2 Turning On the Power Switch (2-cassette model)

1-8

Chapter 1

The machine possesses 2 power switches: main power switch and control power switch. Normally (i.e., unless the machine is in a sleep state), the machine will be supplied with power when you turn on its main power switch.

[1]

[2]

[3]

F-1-10

[1]Control panel power switch [2]Main power lamp

[3]Main power switch

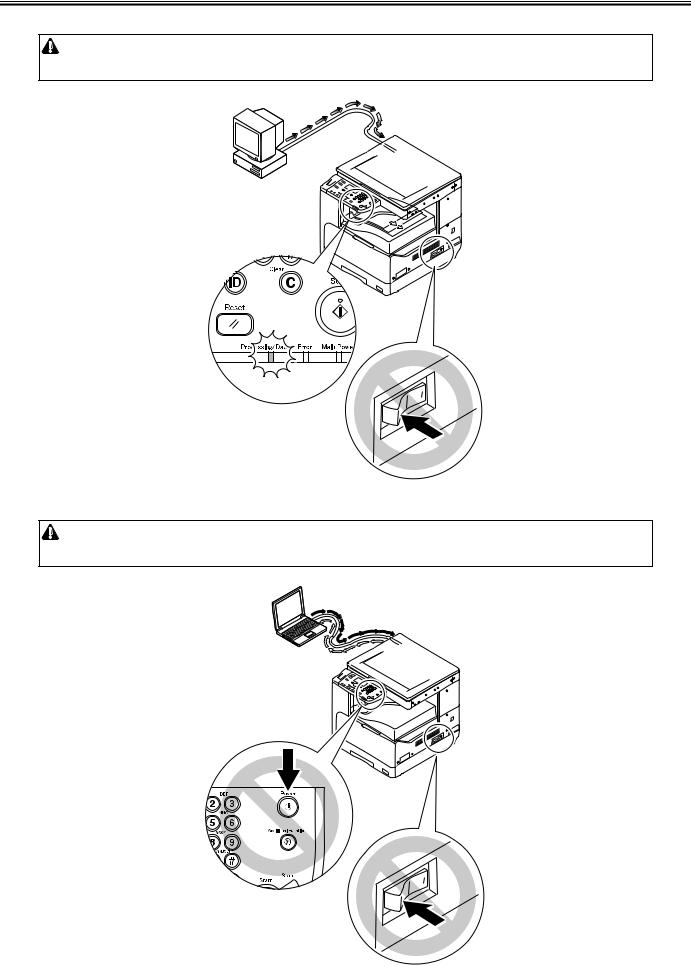

1.2.2.3 When Turning Off the Main Power Switch (1-cassette model)

1-9

Chapter 1

<During printing or fax data transmission/reception>

Be sure to operate the main power switch while the Processing/Data lamp on the control panel is not lit.

(Turning off the main switch during printing or fax data transmission/reception can erase the data being processed.)

F-1-11

<During downloading>

Do not turn off the power switch or ON/OFF switch on the control panel.

(Turning off the main power switch during downloading can make this machine inoperative.)

F-1-12

1-10

Chapter 1

1.2.2.4 When Turning Off the Main Power Switch (2-cassette model)

<During printing or fax data transmission/reception>

Be sure to operate the main power switch while the Processing/Data lamp on the control panel is not lit.

(Turning off the main switch during printing or fax data transmission/reception can erase the data being processed.)

F-1-13

1-11

Chapter 1

<During downloading>

Do not turn off the power switch or ON/OFF switch on the control panel.

(Turning off the main power switch during downloading can make this machine inoperative.)

F-1-14

1.2.2.5 Control Panel

|

[1] [2] [3] |

[4] [5] |

[6] [7] [8] |

[9] |

[10][11] |

|||||||||||||||||||||||||||||||||||

|

[30] [29] [28] [26][25] [23][22] [19] [17] [15] [14] [13] [12] |

|||||||

|

[27] |

[24] |

[18] |

[16] |

||||

|

[21] [20] |

|||||||

|

F-1-15 |

|||||||

|

[1] |

System Monitor key |

[16] |

Clear key |

||||

|

[2] |

SCAN key |

[17] |

Processing/Date Indicator |

||||

|

[3] |

COPY key |

[18] |

ID key |

||||

|

[4] |

Back key |

[19] |

Reset key |

||||

|

[5] |

Upper/Lower/Left/Right arrow key |

[20] |

Tone key |

||||

|

[6] |

OK key |

[21] |

Paper Select key |

||||

|

[7] |

LCD display |

[22] |

Frame Erase key |

||||

|

[8] |

View Settings key |

[23] |

Copy Ratio key |

||||

|

[9] |

Numeric keys |

[24] |

2-Page Separation key |

||||

|

[10] |

Control Panel Power Switch |

[25] |

Image Quality key |

||||

|

[11] |

Additional Functions key |

[26] |

Finishing key |

1-12

Chapter 1

|

[12] |

Stop key |

[27] |

Density key |

|

[13] |

Start key |

[28] |

Different Size Originals key |

|

[14] |

Main Power Indicator |

[29] |

Image Combination key |

|

[15] |

Error Indicator |

[30] |

2-Sided key |

Key names may be different depending on the countries or area of destination.

1.2.3 User Mode Items

1.2.3.1 Audible Tones

|

Additional Functions |

Settings |

|

Entry Tone |

Off, ON(*) |

|

Error Tone |

Off, ON(*) |

|

Scan Done Tone |

Off, ON, For Error Only(*) |

|

Print Done Tone |

Off, ON, For Error Only(*) |

* Factory setting (It may be different depending on the countries or region of destination.)

1.2.3.2 Common Settings

|

Additional Functions |

Settings |

|

|

Initial Function |

Copy(*), Scan |

|

|

Contrast |

-2 to +2; -/+0(*) |

|

|

Invert Screen Colors |

Off(*), On |

|

|

Auto Clear Setting |

Initial Function(*), Selected Function |

|

|

Toner Save Mode |

Off(*), Low, High |

|

|

Print Density |

-4 to +4; -/+0(*) |

|

|

Auto Drawer Select. |

Copy: Stack Bypass (Off(*), On), Drawer 1 (Off, On(*)), Drawer 2 (Off, On(*)), |

|

|

Drawer 3 (Off, On(*)), Drawer 4 (Off, On(*)) |

||

|

Printer: Drawer 1 (Off, On(*)), Drawer 2 (Off, On(*)), Drawer 3 (Off, On(*)), |

||

|

Drawer 4 (Off, On(*)) |

||

|

Other: Stack Bypass (Off(*), On), Drawer 1 (Off, On(*)), Drawer 2 (Off, On(*)), |

||

|

Drawer 3 (Off, On(*)), Drawer 4 (Off, On(*)) |

||

|

Register Paper Type |

Drawer 1: Plain(*), Recycled, Color, 3-hole punch, Bond, Heavy Paper 1 |

|

|

Drawer 2: Plain(*), Recycled, Color, 3-hole punch, Bond, Heavy Paper 1 |

||

|

Drawer 3: Plain(*), Recycled, Color, 3-hole punch, Bond, Heavy Paper 1 |

||

|

Drawer 4: Plain(*), Recycled, Color, 3-hole punch, Bond, Heavy Paper 1 |

||

|

Tray Designation |

Tray A: Copy (Off, On(*)), Printer (Off, On(*)), |

Other (Off, On(*)) |

|

Tray B: Copy (Off, On(*)), Printer (Off, On(*)), |

Other (Off, On(*)) |

|

|

Stand. Stack Bypass. |

Off(*), On: |

|

|

Paper Size (LTR(*), LTRR, LGL, STMT, STMTR, EXEC, 11 x 17, Custom Size, |

||

|

COM10, Monarch, DL, ISO-C5, ISO-B5, A4, A4R, A3, A5, A5R, B4, B5, B5R) |

||

|

Paper Type (Plain(*), Recycled, Color, 3-hole punch, Bond, Heavy Paper 1, Heavy |

||

|

Paper 2, Heavy Paper 3, Transparency, Labels) |

||

|

Paper Size (LTR(*), LTRR, LGL, STMT, STMTR, EXEC, 11 x 17, Custom Size, |

||

|

COM10, Monarch, DL, ISO-C5, ISO-B5, A4, A4R, A3, A5, A5R, B4, B5, B5R) |

||

|

Paper Type (Plain(*), Recycled, Color, 3-hole punch, Bond, Heavy Paper 1, Heavy |

||

|

Paper 2, Heavy Paper 3, Transparency, Labels) |

||

|

Paper Feed Switch |

Stack Bypass (Speed Priority(*), Print Side), Drawer 1 (Speed Priority(*), Print |

|

|

Side), Drawer 2 (Speed Priority(*), Print Side), Drawer 3 (Speed Priority(*), Print |

||

|

Side), Drawer 4 (Speed Priority(*), Print Side) |

||

|

Language Switch |

Chinese (Simplified), English(*), French, Japanese, Korean, Portuguese, Spanish |

|

|

Dirty Feeder Error |

Off, On(*) |

|

|

Remote Scan Compress |

High Ratio, Normal(*), Low Ratio |

|

|

Remote Scan Gammma |

1.0, 1.4, 1.8(*), 2.2 |

|

|

K/B Size Originals*1 |

Use 8K/16K Format, Use B4/B5 Format(*) |

1-13

Chapter 1

|

Additional Functions |

Settings |

|

Inch/Millimeter Switch |

mm, inch(*) |

|

Paper Size Group |

AB, Inch(*), A |

|

Initialize Common |

Select <Yes> or <No>. |

* Factory setting (It may be different depending on the countries or region of destination.) *1 This item may be omitted depending on the countries or area of destination.

1.2.3.3 Copy Settings

|

Additional Functions |

Settings |

|

Image Orientation |

Off(*), On |

|

Auto Orientation |

Off, On(*) |

|

Standard Settings |

|

|

No. of Copies |

1(*) — 99 |

|

Density |

Auto(*), Manual (-4 to +4) |

|

Image Quality |

Text(*), Text/Photo, Photo |

|

2-Sided |

Off(*), 1 -> 2-Sided, 2 -> 2-Sided, 2 -> 1-Sided, |

|

Book -> 2-Sided, Layout Settings |

|

|

Copy Ratio |

Zoom (25 — 400%), MAX. (400%), STMT -> 11 x 17 (200%), LTR -> 11 x 17 |

|

(129%), LGL -> 11 x 17 (121%), 1:1 (100%)(*), LGL -> LTR (78%), 11 x 17 -> |

|

|

LGL (73%), 11 x 17 -> LTR (64%), 11 x 17 -> STMT (50%), MIN. (25%) |

|

|

Paper Select |

Auto(*), Stack Bypass, Drawer 1, Drawer 2, Drawer 3, Drawer 4 |

|

Image Combination |

Off(*), 2 on 1, 4 on 1, ID Card Copy |

|

Differ. Size Orig |

AB/inch Size group selected: |

|

Off(*), Same Width, Different Width |

|

|

A Size group selected: |

|

|

Off(*), On |

|

|

Finishing |

Collate, Rotate + Collate, Group(*), Rotate + Group, Offset + Collate, Offset + |

|

Group, Staple |

|

|

2-Page Separation |

Off(*), On |

|

Frame Erase |

Off(*), Org. Frame Erase, Book Frame Erase, Binding Erase, Options |

|

Sharpness |

Lowest (leftmost) to Highest (rightmost), Middle (center)(*) |

|

Initialize Copy Set. |

Yes(*), No |

* Factory setting (It may be different depending on the countries or region of destination.)

1.2.3.4 Printer Settings

|

Additional Functions |

Settings |

|

Default Papersize |

LTR(*), LTRR, LGL, STMTR, EXEC, A4, A4R, A3, A5R, B4, B5, B5R, |

|

COM10, Monarch, DL, ISO-C5, ISO-B5 |

Default Papertype

2-Sided Print Quality

Image Refinement

Density

Toner Saver

Page Layout

Binding

Margin

Finishing

Error Time Out

Auto Size Detection

Initialize Printer

Plain(*), Recycled, Color, 3-hole punch, Bond, Heavy Paper, Tracing Paper, Transparency, Labels

Off(*), On

On(*), Off

-4 to +4; -/+0(*) Off(*), On

Long Edge(*), Short Edge

Inch: -01.97″ to +01.97″; 00.00″ mm: -50.0 mm to +50.0 mm; 0.0 mm

Collate, Rotate + Collate, Group(*), Rotate +Group, Offset +Collate, Offset + Group, Staple

On(*)(1 to 300 sec), Off; 15 sec(*)

Off(*), On

Select <Yes> or <No>.

* Factory setting (It may be different depending on the countries or region of destination.)

1-14

Chapter 1

1.2.3.5 Timer Settings

|

Additional Functions |

Settings |

|

Auto Sleep Time |

Off, On ( 3 to 30 minutes; 5 min(*) in one minute increments) |

|

Auto Clear Time |

Off, On ( 1 to 9 minutes; 2 min(*) in one minute increments) |

* Factory setting (It may be different depending on the countries or region of destination.)

1.2.3.6 Adjustment/Cleaning

|

Additional Functions |

Settings |

|

Clean Trans. Roller |

Select <Yes> or <No>. |

|

Drum Cleaning |

Select <Yes> or <No>. |

|

Fixing Unit Cleaning |

Select <Yes> or <No>. |

|

Feeder Cleaning |

Select <Yes> or <No>. |

|

Bond Sp. Processing |

Off(*), On |

|

Special Mode M |

Low, Standard(*), High |

|

Special Mode N |

Off(*), On |

|

Special Mode O |

Stack Bypass: Off(*), On |

|

Drawer: Off(*), On |

|

|

Special Mode P |

Off(*), On |

|

Special Mode S |

Off(*), Speed Priority1, Speed Priority 2 |

|

Rotate Collate Adj. |

Speed Priority 1(*), Speed Priority 2, Image Priority |

|

Dirty Feeder Adj. |

Off(*), On |

* Factory setting (It may be different depending on the countries or region of destination.)

1.2.3.7 Report Settings

|

Additional Functions |

Settings |

|

Print List |

User’s Data List: Select <Yes> or <No>. |

1.2.3.8 System Settings

|

Additional Functions |

Settings |

|

System Manager Set. |

System Manager ID, System Manager |

|

Device Info Settings |

Device Name, Location |

|

Dept. ID Management |

Off(*), On: |

|