Руководство

пользователя

CNC Pilot 4290

Программное обеспечение NC

625 952-xx

V7.1

Русский (ru)

9/2010

Pilot

CNC PILOT 4290

Software version 6.4/7.0

English (en) 6/2003

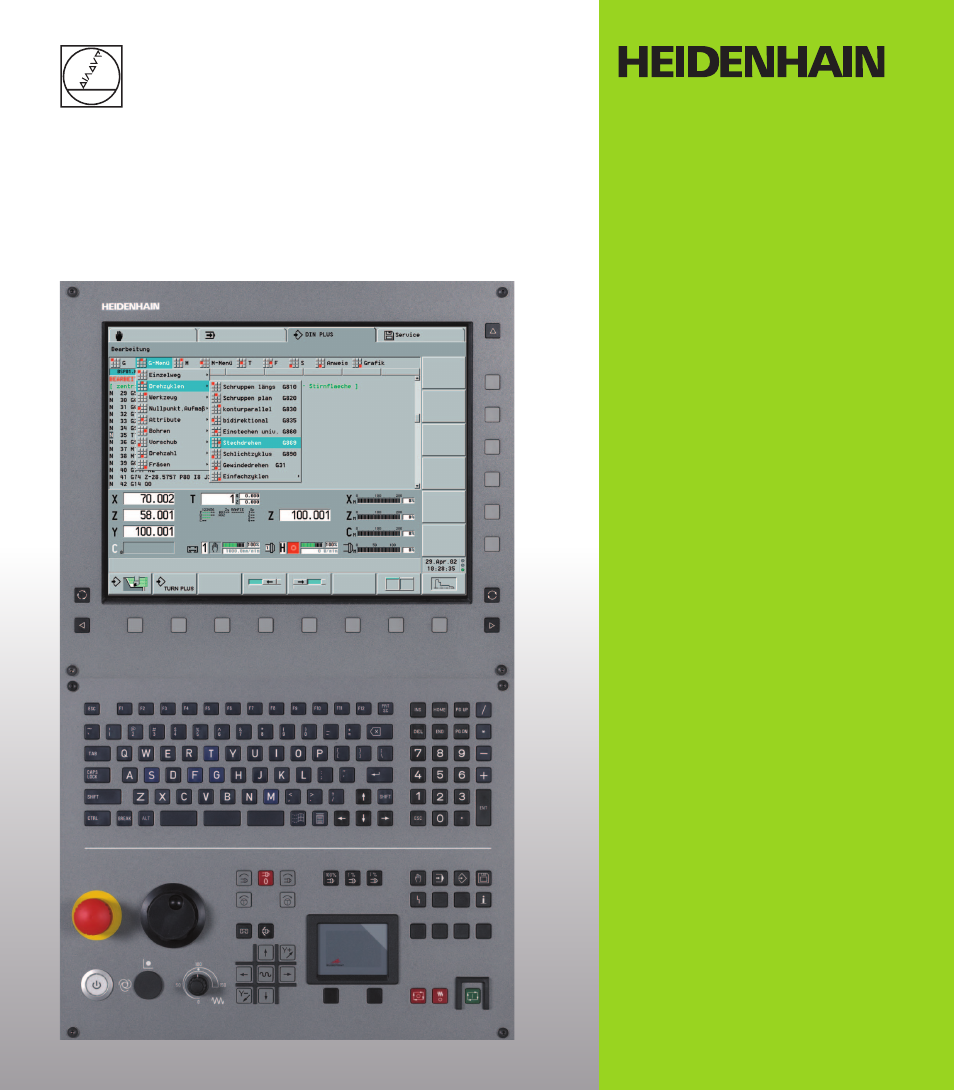

CNC PILOT 4290V7.0—Keyboard

Manual operating mode

Automatic operating mode

Programming modes (DIN PLUS, Simulation,TURN PLUS)

Organization modes (Parameter, Service,Transfer)

Display error status

Call info system

ESC (escape)

■Go back by one menu level

■Close dialog box, do not save data

“Continue key”

For special functions (e.g. marking)

DEL (delete)

■Deletes the list element

■Deletes the selected character or the character to the left of the cursor

ALT (alter)

■ Edit the list element

CNC PILOT 4290 V7.0—Keyboard

INS (insert)

■Insert list element

■Close dialog box, save data

|

Numerals (0…9) |

… |

|

For entering numbers and selecting soft keys |

Minus

For entering an algebraic sign

Decimal point

Enter

To confirm your input

Cursor keys

Moves the cursor by one position in the direction of the arrow (one character, one field, one line, etc.)

|

Page Up, Page Down |

… |

|

|

■ Go to previous/next screen page |

||

|

■ Go to previous/next dialog box |

||

|

■ Switch between input windows |

||

CNC PILOT 4290V6.4—Keyboard

Operating modes key

Call the selection of operating modes

Display error status

Call the info system

ESC

■Go back by one menu level

■Close dialog box, do not save data

>> (“continue” key)

For special functions (e.g. marking)

DEL

Delete key

ALT (alter)

■ Edit the list element

INS (insert)

■Insert list element

■Close dialog box, save data

CNC PILOT 4290V6.4—Keyboard

|

Numerals (0…9) |

… |

|

For entering numbers and selecting soft keys |

Minus

For entering an algebraic sign

Decimal point

Enter

To confirm your input

Cursor keys

Moves the cursor by one position in the direction of the arrow (one character, one field, one line, etc.)

|

Page Up, Page Down |

… |

||

|

■ Go to previous/next screen page |

|||

|

■ Go to previous/next dialog box |

|||

|

■ Switch between input windows |

|||

4

The Pilot

… is your concise programming guide for the HEIDENHAIN CNC PILOT 4290 contouring control. For more comprehensive information on programming and operating, refer to the CNC PILOT User’s Manual.

Certain symbols are used in the Pilot to denote specific types of information:

Important note!

Warning: Danger for the user or the machine!

Chapter in User’s Manual. Here you will find more detailed information on the current topic.

The information in this Pilot applies to the CNC PILOT with the software number 340 340 460-xx (release 6.4) and the CNC PILOT with the software number 368 650-xx (release 7.0).

|

Contents |

|

|

DIN Programming …………………………………………………….. |

6 |

|

Overview: G Functions for Contour Description ……………. |

6 |

|

Program Section Codes …………………………………………….. |

8 |

|

G Functions for Contour Description …………………………… |

10 |

|

Front, Rear and Lateral Surface Contours …………………….. |

26 |

|

Overview: G Functions for the Machining Part ……………… |

42 |

|

Simple Linear and Circular Movements ……………………….. |

45 |

|

Feed Rate, Spindle Speed ………………………………………….. |

48 |

|

Tool-Tip and Cutter Radius Compensation (TRK) ……………. |

50 |

|

Datum Shifts, Oversizes …………………………………………… |

51 |

|

Tools, Compensation ………………………………………………… |

57 |

|

Turning, Drilling and Threading Cycles …………………………. |

59 |

|

C-Axis Machining …………………………………………………….. |

82 |

|

Other G Functions ……………………………………………………. |

90 |

|

Subprograms …………………………………………………………… |

94 |

5

DIN Programming

DIN Programming

NC blocks start with the letter “N” followed by a block number (with up to four digits).

Comments are enclosed in parentheses „[…]“.They are located either at the end of an NC block or in a separate NC block.

Instructions for operation

During editing, the CNC PILOT shows programmed contours in a maximum of two simulation windows. You can select the windows from the DIN PLUS main menu (Menu item ”Graphics—Windows”).

■The starting point of the contour will be marked with a ”small box”

■If the cursor is located on a block from ”blank or finished part”, the corresponding contour element will be indicated in red in the simulation window (”Contour display”)

•Additions/changes to the contour will only be considered if the ”Graphics” menu item is reactivated.

•Unambiguous NC block numbers are a prerequisite for the contour display!

•For programming variables, see ”CNC PILOT 4290 User’s Manual”

•For programming in the Y axis, see

”CNC PILOT 4290 with Y Axis User’s Manual”

|

Program section codes |

Page |

|

|

Program section codes |

8 |

|

|

Definition of blank |

Page |

|

|

G20-Geo |

Chuck part, cylinder/tube |

10 |

|

G21-Geo |

Cast part |

10 |

|

Basic elements for contour description |

Page |

|

|

G0-Geo |

Starting point of contour |

11 |

|

G1-Geo |

Line segment |

11 |

|

G2-Geo |

Arc with incr. center dimensioning |

12 |

|

G3-Geo |

Arc with incr. center dimensioning |

12 |

|

G12-Geo |

Arc with abs. center dimensioning |

12 |

|

G13-Geo |

Arc with abs. center dimensioning |

12 |

|

Contour form elements |

Page |

|

|

G22-Geo |

Recess (standard) |

13 |

|

G23-Geo |

Recess/relief turn |

14 |

|

G24-Geo |

Thread with undercut |

15 |

|

G25-Geo |

Undercut contour |

16 |

|

G34-Geo |

Thread (standard) |

19 |

|

G37-Geo |

Thread (general) |

20 |

|

G49-Geo |

Bore hole at turning center |

22 |

6

|

Help commands for contour description |

Page |

|

|

Overview: |

Help commands for contour definition |

23 |

|

G7-Geo |

Precision stop ON |

23 |

|

G8-Geo |

Cycle stop OFF |

23 |

|

G9-Geo |

Precision stop blockwise |

23 |

|

G10-Geo |

Peak-to-valley height |

23 |

|

G38-Geo |

Feed rate reduction |

24 |

|

G39-Geo |

Attributes of superimposed elements |

24 |

|

G52-Geo |

Blockwise oversize |

25 |

|

G95-Geo |

Feed per revolution |

25 |

|

G149-Geo |

Additive compensation |

25 |

|

Superimposed contours |

Page |

|

|

G308-Geo |

Beginning of pocket/island |

26 |

|

G309-Geo |

End of pocket/island |

26 |

|

Elements of the end face contour |

Page |

|

|

G100-Geo |

Starting point of face contour |

27 |

|

G101-Geo |

Line segment on face |

27 |

|

G102-Geo |

Circular arc on face |

28 |

|

G103-Geo |

Circular arc on face |

28 |

|

G300-Geo |

Bore hole on face |

29 |

|

G301-Geo |

Linear slot on face |

30 |

|

G302-Geo |

Circular slot on face |

30 |

|

G303-Geo |

Circular slot on face |

30 |

|

G304-Geo |

Full circle on face |

31 |

|

G305-Geo |

Rectangle on face |

31 |

|

G307-Geo |

Eccentric polygon on face |

32 |

|

G401-Geo |

Linear pattern on face |

32 |

|

G402-Geo |

Circular pattern on face |

33 |

|

Elements of the lateral surface contour |

Page |

|

|

G110-Geo |

Starting point of lateral surface contour |

34 |

|

G111-Geo |

Line segment on lateral surface |

34 |

|

G112-Geo |

Circular arc on lateral surface |

35 |

|

G113-Geo |

Circular arc on lateral surface |

35 |

|

G310-Geo |

Bore hole on lateral surface |

36 |

|

G311-Geo |

Linear slot, lateral surface |

37 |

|

G312-Geo |

Circular slot on lateral surface |

37 |

|

G313-Geo |

Circular slot on lateral surface |

37 |

|

G314-Geo |

Full circle on cylindrical surface |

38 |

|

G315-Geo |

Rectangle on lateral surface |

38 |

|

G317-Geo |

Eccentric polygon on lateral surface |

39 |

|

G411-Geo |

Linear pattern, lateral surface |

40 |

|

G412-Geo |

Circular pattern, lateral surface |

41 |

Overviesw: Contour description

7

Program section codes

Program section codes

When you create a new DIN program, certain program section codes are already entered. Delete or add codes, depending on the task. A DIN program must include the codes ”MACHINING” and ”END.”

Overview of program section codes

PROGRAMMKOPF [ PROGRAM HEAD ] TURRET

CLAMPING DEVICE

ROHTEIL [ BLANK ] FERTIGTEIL [ FINISHED PART ] FRONT END

REAR END CYLINDER SURFACE AUXILIARY CONTOUR

BEARBEITUNG [ MACHINING ] ENDE [ END ]

SUBPROGRAM RETURN

PROGRAMMKOPF [ PROGRAM HEAD ]

The PROGRAM HEAD comprises:

■Organizational information (does not influence program execution)

■Setup information (does not influence program execution)

■SLIDE: NC program is only executed for the indicated slide – No input: NC program is executed for every slide (input: “$1, $2, …”)

■UNIT: unit of measurement ”metric/inches”—No input: the unit set in control parameter 1 is used

The ”Unit” can be programmed only when a new program is being created (set under PROGRAM HEAD). It is not possible to post-edit this entry.

TURRET x

contains the assignment for the tool carrier x (x: 1..6). If the tool is described in the data bank, enter the T number and the ID number. Alternately, you can define the tool parameters in the NC program.

Tool data input:

Simple tool:

■Only suitable for simple traverse paths and turning cycles (G0…G3, G12, G13; G81…G88).

■There is no regeneration of the contour.

■Cutter radius compensation is carried out.

■Data are not stored in the tool database (”Simple tools” have no ID).

Continued

8

Enhanced input: No limitations for use of the tool (data is transferred to the tool database during program conversion.)

If you do not program TURRET, the tools entered in the turret table will be used.

CLAMPING DEVICE x

Defines the type of clamping device X used on the spindle (x: 1..4).

If you do not program CLAMPING DEVICE, the machining simulation assumes there is no clamping device (see also G65).

Parameters

H: Clamping device number (reference for G65) – Range: 1 † H † 9 ID: Identification number of clamping device

X:Clamping diameter

Q:Chucking shape – defines the position of the clamping device reference point (see G65)

ROHTEIL [ BLANK ]

Program section for the definition of the blank.

FERTIGTEIL [ FINISHED PART ]

Program section for the contour definition of the finished part.

Additional program section codes within the finished part definition:

■FRONT END Z.. : Section ”Front end contour” – ”Z..” defines the position of the front contour.

■REAR SIDE Z.. : Section ”Rear side contour” – ”Z..” defines the position of the rear side contour.

■LATERAL SURFACE X.. : section ”Lateral surface contour” – ”X..”

■AUXILIARY CONTOUR: indicates further contour definitions

If you have several independent contour definitions, then repeated use of the program section codes (FRONT END, REAR END, etc.) is permitted.

BEARBEITUNG [ MACHINING ]

Program section for the machining of the workpiece. MACHINING must be included in your program.

ENDE [ END ]

Ends your NC program. The code END must be included in your program (replaces M30).

SUBPROGRAM ”12345678”

If you define a subprogram within your NC program (within the same file), it is identified with SUBPROGRAM, followed by the name of the subprogram (max. 8 characters).

RETURN

Ends your NC subprogram.

Program section codes

9

Definition of blank

Blank material for cylinder/pipe G20-Geo

G20 defines the contour of a cylinder/hollow cylinder.

Parameters

X:■ Diameter of cylinder/hollow cylinder

■ Diameter of circumference of polygonal blank

Z:Length of blank

K:Right edge (distance between workpiece datum and right edge)

I:Inside diameter for hollow cylinders

Cast part G21-Geo

G21 generates the contour of the blank part from the contour of the finished part – plus the ”equidistant allowance P.”

Parameters

P:Equidistant finishing allowance (reference: finished part contour)

Q:Bore holes yes/no – default: Q=0

■Q=0: without bore holes

■Q=1: with bore holes

10

Starting point of turning contour G0 Geo

G0 defines the starting point of a turning contour.

Parameters

X, Z: Starting point of the contour (X diameter value)

Basic elements for contour description

Line segment in a contour G1-Geo

G1 defines a line segment in a turning contour.

Parameters

X, Z: End point (X diameter value)

A: Angle to rotary axis – for angle direction see illustration

Q: Select point of intersection – default: 0 ■ Q=0: Near intersection

■ Q=1: Far intersection

B:Chamfer/rounding

■ B is undefined: Tangential transition

■ B=0: Nontangential transition ■ B>0: Rounding radius

■ B<0: Chamfer width

E:Special feed-rate factor (0 < E † 1) – default: 1 (special feed rate = active feed rate * E)

11

Basic elements for contour description

Circular arc in a contour

G2/G3-Geo – incremental, G12/G13-Geo – absolute center coordinates

G2/G3 or G12/G13 defined a circular arc in a contour. The direction of rotation is visible in the help graphic.

Parameters

X, Z: End point (X diameter value) R: Radius

Q: Selection of intersection – default: 0 ■ Q=0: Far intersection

■ Q=1: Near intersection

|

B: |

Chamfer/ rounding at end of circular arc |

|

|

■ B no entry: tangential transition |

||

|

■ B=0: no tangential transition |

||

|

■ B>0: Radius of rounding |

||

|

■ B<0: Width of chamfer |

Example: G2-Geo |

E:Special feed-rate factor (0 < E † 1) – default: 1 (special feed rate = active feed rate * E)

With G2/G3:

I:Center point incremental (distance from starting point to center

as radius)

K: Center point incremental (distance from starting point to center)

With G12/G13:

I: Absolute center (radius)

K: Absolute center

|

Recess (standard) G22-Geo |

||||

|

G22 defines a recess on an axis-parallel reference element (G1). G22 is |

||||

|

assigned to the previously programmed reference element. |

||||

|

Parameters |

elementsForm |

descriptioncontourfor |

||

|

X: |

Starting point of recess on the end surface (diameter) |

|||

|

Z: |

Starting point of recess on lateral surface |

|||

|

I, K: |

Inside corner |

|||

|

■ I for recess on front face: recess end point (diameter value) |

||||

|

■ K for recess on end face: recess base |

||||

|

■ I for recess on lateral surface: recess base (diameter value) |

||||

|

■ K for recess on lateral surface: recess end point |

||||

|

Ii, Ki: Inside corner – incremental (pay attention to sign !) |

||||

|

■ Ii for recess on end face: recess width |

||||

|

■ Ki for recess on end face: recess depth |

||||

|

■ Ii for recess on lateral surface: recess depth |

||||

|

■ Ki for recess on lateral surface: end point of recess (recess |

||||

|

width) |

||||

|

B: |

Outside radius/chamfer (at both ends of the recess) – default: 0 |

|||

|

■ B>0: Radius of the rounding |

||||

|

■ B<0: Width of the chamfer |

R:Inside radius (in both corners of recess) – default: 0

Program either X or Z.

13

Form elements for contour description

14

Recess (general) G23-Geo

G23 defines a recess on a linear reference element (G1). G23 is assigned to the previously programmed reference element. On the lateral surface the recess can be positioned on an inclined reference straight.

Parameters

H: Recess type – default: 0

■ H=0: symmetrical recess ■ H=1: free rotation

X: Center point of recess on end surface (diameter)

Z:Center point of recess on lateral surface

I:Recess depth and position

■ I>0: recess to right of reference element ■ I<0: recess to left of reference element

K: Recess width (without chamfer/rounding)

Simple recess

U: Recess diameter (diameter of recess floor) – use only if the reference element runs parallel to the Z axis.

A:Recess angle – default: 0

■ with H=0: 0° † A < 180° (angle between edges of recess)

■ with H=1: 0° < A † 90° (angle between reference straight and recess edge)

B: Outside radius/corner. Starting point near corner — default: 0 ■ B>0: Radius of rounding

■ B<0: Width of chamfer

P:Outside radius/corner. Starting point distant from corner — default: 0

■ P>0: Radius of rounding

■ P<0: Width of chamfer

R:Inside radius (in both corners of recess) – default: 0

The CNC PILOT refers the recess depth to the reference element. The recess base runs parallel to the reference element.

Recess or free rotation

Thread with undercut G24-Geo

G24 defines a linear base element, a linear thread (external or internal thread; metric ISO fine-pitch thread DIN 13 Part 2, Series 1) and a subsequent thread undercut (DIN 76).

Calling the contour macro:

N..G1 X..Z..B.. /Starting point for thread

N..G24 F..I..K..Z.. /Contours for thread and undercut

N..G1 X.. /Next surface element

Parameters

F:Thread pitch

I:Depth of undercut (radius)

K:Width of undercut

Z:End point of the undercut

• G24 can be used only if the thread is cut in the direction of contour definition.

• The thread is machined with G31.

|

Form elements |

for contour description |

15

Form elements for contour description

Undercut contour G25-Geo

G25 generates the following undercut contours in paraxial contour corners. The meaning of the parameters depends on the type of undercut.

If you program G25

■after the reference element, the undercut is turned at the end of the reference element.

■before the reference element, the undercut is turned at the beginning of the reference element.

Calling the contour macro (example):

N..G1 Z.. /Linear element as reference

N..G25 H..I..K.. .. /Undercut contour

N..G1 X.. /Next surface element

Parameters

Undercut form U (H=4)

Parameters

I:Depth of undercut (radius)

K:Width of undercut

R:Inside radius (in both corners of recess) – default: 0

P:Outside radius/chamfer – default: 0

■P>0: radius of the rounding

■P<0: width of the chamfer

Continued

H:Type of undercut – default: 0

■H=4: undercut form U

■H=0, 5: undercut form DIN 509 E

■H=6: undercut form DIN 509 F

■H=7: thread undercut DIN 76

■H=8: undercut form H

■H=9: undercut form K

Undercut DIN 509 E (H=0, 5)

Parameters

I:Depth of undercut (radius)

K:Width of undercut

R:Undercut radius (in both corners of the undercut)

W:Undercut angle

If you do not enter any parameters the CNC PILOT calculates the values from the diameter (see User’s Manual, section “Undercut Parameters DIN 509 E”).

Undercut DIN 509 F (H=6)

Parameters

I:Depth of undercut (radius)

K:Width of undercut

R:Undercut radius (in both corners of the undercut)

P:Transverse depth

W:Undercut angle

A:Transverse angle

If you do not enter any parameters the CNC PILOT calculates the values from the diameter (see User’s Manual, section “Undercut Parameters DIN 509 F”).

Continued

Undercut DIN 509 E (H=0, 5)

Form elements for contour description

|

Undercut DIN 509 F (H=6) |

17 |

Form elements for contour description

Undercut DIN 76 (H=7)

Parameters

I:Depth of undercut (radius)

K:Width of undercut

R:Undercut radius (in both corners of the undercut) – default: R=0.6*I

W:Undercut angle – default: 30°

Undercut form H (H=8)

If you do not enter W, it will be calculated on the basis of K and R. The final point of the undercut is then located at the ”final point contour.”

Parameters

K:Width of undercut

R:Undercut radius – no value: the circular element is not machined

W: Plunge angle – no value: W is calculated

Continued

Undercut DIN 76 (H=7)

Undercut form K (H=9)

Parameters

I: Undercut depth

R:Undercut radius – no value: the circular element is not machined

W: Undercut angle

A: Angle to linear axis – default: 45°

Undercut form K (H=9)

Thread (standard) G34-Geo

G34 defines a simple or an interlinked external or internal thread (metric ISO fine-pitch thread DIN 13 Series 1). Threads are interlinked by programming several G01/G34 blocks after each other.

Parameters

F:Thread pitch – no value: pitch from the standard table

•You need to program a linear contour element as a reference before G34 or in the NC block containing G34.

•The thread is cut with G31.

Form elements for contour description

19

Form elements for contour description

Thread (general) G37-Geo

G37 defines the different types of thread. Threads are interlinked by programming several G01/G34 blocks after each other.

Parameters

Q:Type of thread – default: 1

■Q=1: metric ISO fine-pitch thread (DIN 13 Part 2, Series 1)

■Q=2: metric ISO thread (DIN 13 Part 1, Series 1)

■Q=3: metric ISO taper thread (DIN 158)

■Q=4: metric ISO tapered fine-pitch (DIN 158)

■Q=5: metric ISO trapezoid thread (DIN 103 Part 2, Series 1)

■Q=6: flat metric trapezoid thread (DIN 308 Part 2, Series 1)

■Q=7: metric buttress thread (DIN 13 Part 2, Series 1)

■Q=8: cylindrical round thread (DIN 405 Part 1, Series 1)

■Q=9: cylindrical Whitworth thread (DIN 259)

■Q=10: tapered Whitworth thread (DIN 2999)

■Q=11: Whitworth pipe thread (DIN 2999)

■Q=12: nonstandard thread

■Q=13: UNC US coarse thread

■Q=14: UNF US fine-pitch thread

■Q=15: UNEF US extra-fine-pitch thread

■Q=16: NPT US taper pipe thread

■Q=17: NPTF US taper dryseal pipe thread

■Q=18: NPSC US cylindrical pipe thread with lubricant

■Q=19: NPFS US cylindrical pipe thread without lubricant

F:Thread pitch – must be entered for Q=1, 3..7, 12.

P:Thread depth – enter only for Q=12.

K:Runout length (for threads without undercut) – default: 0

•Program a linear contour element as a reference before G37.

•The thread is cut with G31.

•For standard threads, the parameters P, R, A and W are defined by the CNC PILOT.

•Use Q=12 if you wish to use individual parameters.

The thread is generated to the length of the reference element. For the machining of threads without an undercut, it is necessary to program an additional linear element so that the overrun can be executed by the CNC PILOT without danger of collision.

D:Reference point (position of thread runout) – default: 0

■D=0: runout at end of reference element

■D=1: runout at beginning of reference element

H:Number of grooves – default: 1

A:Edge angle left – enter only for Q=12.

W:Edge angle right – enter only for Q=12.

R:Thread width – enter only for Q=12.

E:Variable pitch (increases/reduces the pitch per revolution by E) – default: 0

|

Form elements |

for contour description |

21

Form elements for contour description

Bore hole (centered) G49-Geo

G49 defines a single bore hole with countersink and thread at the turning center (front or end face).

Parameters

Z:Starting position for hole (reference point)

B:Bore hole diameter

P:Depth of hole (excluding point)

W:Point angle – default: 180°

R:Countersinking diameter

U:Countersinking depth

E:Countersinking angle

I:Thread diameter

J:Thread depth

K:Thread runout length

F:Thread pitch

V:Left-hand or right-hand thread — default: 0

■V=0: Right-hand thread

■V=1: Left-hand thread

A:Angle (position of bore hole) – default: 0

■A=0: front end

■A=180: tail end

O:Centering diameter

• G49 is programmed in the FINISHED PART section (not in the FRONT or REAR SIDE section).

• The contour defined with G49 is machined with G71…G74.

22

Overview: Help commands for contour description

G7 Accurate stop ON

G8 Accurate stop OFF

G9 Accurate stop blockwise

G10 influences finishing feed rate for total contour

G38 influences finishing feed rate for basic contour elements block by block

G39 Only for form elements:

■influences finishing feed rate

■additive compensation values

■equidistant finishing allowances

G52 Equidistant finishing allowances – blockwise

G95 defines finishing feed rate for total contour

G149 additive compensation values for total contour

Accurate stop ON G7-Geo

G7 switches the ”precision stop” on modally. In a ”precision stop,” the CNC PILOT does not start the next block until the ”tolerance window” around the end point is reached (for tolerance window, see machine parameters 1106, 1156, …).

• The NC block containing G7 is also executed with a precision stop.

•”Precision stop” is used for basic contour elements that are executed with G890 or G840.

Precision stop OFF G8-Geo

G8 switches the precision stop off. The block containing G8 is executed without a precision stop.

Blockwise accurate stop G9-Geo

G9 activates a precision stop for the NC block in which it is programmed (see also ”G7 Geo”).

Peak-to-valley height (surface texture) G10-Geo

G10 influences the finishing feed rate of G890 and thus determines the surface roughness of the workpiece.

Basics of programming

■The peak-to-valley height activated with G10 is modal.

■G10 without parameters deactivates peak-to-valley height.

■G95 Geo deactivates peak-to-valley height.

■G10 RH… (without ”H”) overwrites the valid peak- to-valley roughness block by block.

■G38 Geo overwrites the valid peak-to-valley roughness block by block.

Parameters

H:Type of surface texture (see also DIN 4768)

■H=1: general roughness (profile depth) Rt1

■H=2: average roughness Ra

■H=3: mean roughness Rz

RH: Peak-to-valley roughness (in µm, inches: µinch)

The peak-to-valley height applies only for basic contour elements.

Help commands for contour description

23

Help commands for contour description

Feed rate reduction factor G38-Geo

G38 defines a special feed rate for G890.

Parameters

E:Special feed-rate factor (0 < E † 1) – default: 1 (special feed rate = active feed rate * E)

Attributes for superimposed elements G39-Geo

G39 influences the machining of G890 for the superimposed elements (form elements):

■ Chamfers/rounding arcs (for connecting base elements)

■Undercuts

■Recesses

Influence on machining:

■Special feed rate

■Peak-to-valley height

■Additive D compensation

■Equidistant oversizes

Parameters

F:Feed per revolution

V:Type of surface texture (see also DIN 4768)

■V=1: general roughness (profile depth) Rt1

■V=2: average roughness Ra

■V=3: mean roughness Rz

RH: Peak-to-valley height (µm, inch mode: µinch)

D:Number of the additive compensation (901 † D † 916)

Basics of programming

■G38 is a non-modal function.

■G38 is programmed before the contouring element for which it is destined.

■G38 replaces another special feed rate or a programmed peak-to-valley height.

The ”special feed rate” applies only for basic contour elements.

P:Finishing allowance (radius)

H:(Translation of P) absolute / additive – default: 0

■H=0: P replaces G57/G58 allowances

■H=1: P is added to G57/G58 allowances

E:Special feed-rate factor (0 < E † 1) – default: 1 (special feed rate = active feed rate * E)

Basics of programming

■G39 is a non-modal function.

■G39 is programmed before the contour element for which it is destined.

■G50 before a cycle (MACHINING section) switches

G39 oversizes for this cycle off.

Only use peak-to-valley height (”V, RH”), finishing allowance (”F”) and special feed rate (”E”) alternately!

24

Blockwise finishing allowance G52-Geo

G52 defines an equidistant finishing allowance which is taken into consideration in G810, G820, G830, G860 and G890.

Basics of programming

■G52 is a non-modal function.

■G52 is programmed in the NC block containing the contour element for which it is destined.

■G50 before a cycle (MACHINING section) switches G52 oversizes for this cycle off.

Parameters

P:Finishing allowance (radius)

H:(Translation of P) absolute / additive – default: 0

■H=0: P replaces G57/G58 allowances

■H=1: P is added to G57/G58 allowances

Feed rate per revolution G95-Geo

G95 influences the finishing feed rate of G890.

Basics of programming

■G95 is a modal function

■G10 switches the G95 finishing feed rate off.

Parameters

F:Feed per revolution

• Use peak-to-valley height and finishing feed rate alternatively.

• The G95 finishing feed rate replaces a finishing feed rate defined in the machining program.

Additive compensation G149-Geo

The CNC PILOT manages 16 tool-independent correction values.

To activate the additive correction function, program G149 followed by a „D number“ (for example, G149 D901). ”G149 D900” resets the additive compensation function.

Basics of programming

■Additive compensation is effective from the block in which G149 is programmed.

■An additive compensation remains active until:

•the next ”G149 D900”

•the end of the finished part description

Parameters

D:Additive compensation — Default: D900 Range: 900 to 916

Note the direction of contour description!

Help commands for contour description

25

Overlapped contours

Start of pocket/island G308-Geo

G308 defines a new reference level/reference diameter for hierarchically nested front face or lateral surface contours.

Parameters

P:Depth for pocket, height for islands

The algebraic sign of ”Depth P” defines the position of the milling contour:

■P<0: Pocket

■P>0: Island

|

Section |

P |

Surface |

Milling floor |

|

FRONT END |

P<0 |

Z |

Z+P |

|

FRONT END |

P>0 |

Z+P |

Z |

|

REAR END |

P<0 |

Z |

Z–P |

|

REAR END |

P>0 |

Z–P |

Z |

|

CYLINDER SURFACE P<0 |

X |

X+(P*2) |

|

|

CYLINDER SURFACE P>0 |

X+(P*2) |

X |

|

The milling cycles machine from the ”surface” toward the ”milling floor.”

X:Reference diameter from the section code

Z:Reference plane from the section code

P:”Depth” from G308 or from the cycle parameters

End pocket/island G309-Geo

G309 ends a reference level. Every reference plane defined with G308 must be ended with G309!

•Note with ”P”: the addition of a negative number reduces the result, and the subtraction of a negative number increases the result.

•Island: The area-milling cycles machine the complete area specified in the contour definition. Islands that are defined within this area are not considered.

26

Starting point of end face contour G100-Geo

G100 defines the starting point of an end face contour.

Parameters

X, C: Starting point in polar coordinates (diameter, starting angle) XK,YK: Starting point in Cartesian coordinates

Linear segment in end face contour G101-Geo

G101 defines a line segment in an end face contour.

Parameters

X, C: End point in polar coordinates (diameter, end angle) XK,YK: End point in Cartesian coordinates

A:Angle to positive XK-axis

B:Chamfer/rounding

■B is undefined: Tangential transition

■B=0: Nontangential transition

■B>0: Rounding radius

■B<0: Chamfer width

Q:Select point of intersection – default: 0

■Q=0: Near intersection

■Q=1: Far intersection

Base elements for front/end face contour

27

Base elements for front/end face contour

28

Circular arc in front end contour G102-/G103-Geo

G102/G103 defines a circular arc in a front/end face contour. The direction of rotation is visible in the help graphic.

Parameters

X, C: End point in polar coordinates (diameter, end angle)

XK,YK: End point in Cartesian coordinates

R:Radius

I, J: Center in Cartesian coordinates

Q:Selection of intersection – default: 0

■Q=0: Far intersection

■Q=1: Near intersection

|

B: |

Chamfer/ rounding at end of circular arc |

|

|

■ B no entry: tangential transition |

||

|

■ B=0: no tangential transition |

||

|

■ B>0: Radius of rounding |

G102-Geo |

|

|

■ B<0: Width of chamfer |

||

|

The end point may not be the same as the starting point (not a |

||

|

full circle). |

||

|

G103-Geo |

Bore hole on end face G300-Geo

G300 defines a bore hole with countersink and thread on the front/end face.

Parameters

XK,YK: Center of hole

B:Hole diameter

P:Depth of hole (excluding point)

W:Point angle – default: 180°

R:Countersinking diameter

U:Countersinking depth

E:Countersinking angle

I:Thread diameter

J:Thread depth

K:Thread runout length

F:Thread pitch

V:Left-hand or right-hand thread — default: 0

■V=0: Right-hand thread

■V=1: Left-hand thread

A:Angle (reference: Z-axis)

■Front end – default: 0° (range: –90° < A < 90°)

■Rear end – default: 180° (range: 90° < A < 270°)

O:Centering diameter

Use G71…G74 to machine bore holes defined with G300-Geo.

Figures on end face contour

29

Вы здесь

Каталог инструкций » H » HEIDENHAIN » Оборудование HEIDENHAIN » HEIDENHAIN CNC Pilot 4290 V7.1 » Страница инструкции 1

-

1

-

2

-

3

-

4

-

5

-

6

-

7

-

8

-

9

-

10

-

11

-

12

-

13

-

14

-

15

-

16

-

17

-

18

-

19

-

20

-

21

-

22

-

23

-

24

-

25

-

26

-

27

-

28

-

29

-

30

-

31

-

32

-

33

-

34

-

35

-

36

-

37

-

38

-

39

-

40

-

41

-

42

-

43

-

44

-

45

-

46

-

47

-

48

-

49

-

50

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- …

- ››

Распечатать

Страница 1 из

- << Предыдущая

- Следующая >>

Cnc pilot 4290, Руководство пользователя в инструкции по эксплуатации HEIDENHAIN CNC Pilot 4290 V7.1

Руководство пользователя

CNC Pilot 4290

Программное обеспечение NC

625 952-xx

V7.1

Русский (ru)

9/2010

- << Предыдущая

- Следующая >>

User’s Manual

CNC Pilot 4290

NC Software

625 952-xx

V7.1

English (en)

4/2010

CNC Pilot 4290 Pilot

HEIDENHAIN CNC Pilot 4290 Pilot Benutzerhandbuch,

94 pages

CNC Pilot 4290 Pilot

HEIDENHAIN CNC Pilot 4290 Pilot User Manual,

94 pages

CNC Pilot 4290 Pilot

HEIDENHAIN CNC Pilot 4290 Pilot Manuel d’utilisation,

94 pages

CNC Pilot 4290 Pilot

HEIDENHAIN CNC Pilot 4290 Pilot Manuale d’uso,

94 pages

CNC Pilot 4290 Pilot

HEIDENHAIN CNC Pilot 4290 Pilot Manual del usuario,

94 pages

CNC Pilot 4290 Description of the Y axis

HEIDENHAIN CNC Pilot 4290 Description of the Y axis Benutzerhandbuch,

64 pages

CNC Pilot 4290 Description of the Y axis

HEIDENHAIN CNC Pilot 4290 Description of the Y axis User Manual,

65 pages

CNC Pilot 4290 Description of the Y axis

HEIDENHAIN CNC Pilot 4290 Description of the Y axis Manuel d’utilisation,

64 pages

CNC Pilot 4290 Description of the Y axis

HEIDENHAIN CNC Pilot 4290 Description of the Y axis Manuale d’uso,

64 pages

CNC Pilot 4290 Instructions for engraving cycles

HEIDENHAIN CNC Pilot 4290 Instructions for engraving cycles Benutzerhandbuch,

12 pages

CNC Pilot 4290 Instructions for engraving cycles

HEIDENHAIN CNC Pilot 4290 Instructions for engraving cycles User Manual,

12 pages

CNC Pilot 4290 Description of the Y axis

HEIDENHAIN CNC Pilot 4290 Description of the Y axis Manual del usuario,

64 pages

TNC 310 (286 040)

HEIDENHAIN TNC 310 (286 040) Manuale d’uso,

205 pages

TNC 128 (77184x-02)

HEIDENHAIN TNC 128 (77184x-02) Benutzerhandbuch,

518 pages

TNC 128 (77184x-02)

HEIDENHAIN TNC 128 (77184x-02) Manuel d’utilisation,

513 pages

TNC 128 (77184x-02)

HEIDENHAIN TNC 128 (77184x-02) User Manual,

513 pages

TNC 128 (77184x-02)

HEIDENHAIN TNC 128 (77184x-02) Manuale d’uso,

518 pages

TNC 128 (77184x-01)

HEIDENHAIN TNC 128 (77184x-01) Benutzerhandbuch,

509 pages

TNC 128 (77184x-02)

HEIDENHAIN TNC 128 (77184x-02) Manual del usuario,

491 pages

TNC 128 (77184x-01)

HEIDENHAIN TNC 128 (77184x-01) User Manual,

505 pages