Please select your preferred language

DA-50Touch numerical press brake control

Touch, making easy easier

Touch comfort for numerical CNC

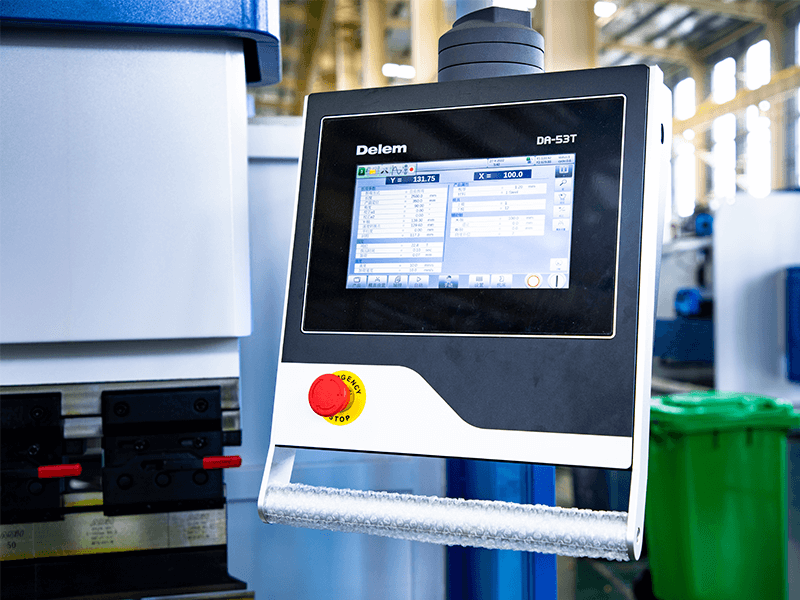

The new compact DA-53T adds a state-of-the-art complete touch control solution for synchronized press brakes. Offering easiest CNC programming based on the Delem graphical touch screen user interface.

This panel based control, standard capable of controlling up to 4 axes, can be integrated in cabinets as well as used in an optional pendulant arm housing.

Its 10.1″ wide screen high resolution colour TFT, with industrial grade multi touch technology, gives access to the proven Delem user-interface. It enables direct “hot-key” touch navigation between product programming and actual production. Functions are located where needed, offering optimised ergonomics throughout the entire application.

Machine adjustment and test bends are reduced to a minimum with a quick and easy program-to-production work sequence.

Compact solutions

The DA-53T touch CNC control provides a modern compact and versatile solution for a wide range of press brake applications without compromising machine functionality.

Compact

Fit for the purpose, enabling lean machine design with all important functionality directly at hand.

Easy-to-use

Delem touch navigation offers proven user friendliness and consistency ensuring user-efficiency.

Productive

Excellent machine behavior enabling smooth and fast bending at highest reliability.

No compromise

Machine functions and integration of partner systems, not compromising compatibility and performance.

Features

- «Hot-key” touch navigation

- 10.1″ high resolution colour TFT

- Up to 4 axes (Y1,Y2 + 2 aux. axes)

- Crowning control

- Tool / material / product library

- Servo and frequency inverter control

- Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

- TandemLink (option)

- USB memory stick interfacing

- Profile-T offline software

Technical data

| DA-53T | |

|---|---|

| Standard | |

| Display | Colour LCD display |

| Type | 10.1″ TFT, high brightness |

| Resolution | 1024 x 600 pixels, 32 bit colour |

| Touch sensor | Full touch screen control (PCT-touch) |

| Backlight | LED |

| Storage capacity | 1 GB |

| Product and tools memory | 256MB |

| Exchangeable memory | USB flash memory drive |

| Offline software | Profile-53TL |

| Options | |

| Tandem capability | TandemLink |

Images

DELEM DA53T Сенсорная цветная система ЧПУ

Сенсорное ЧПУ DA-53T предлагает современное, компактное и гибкое решение для широкого спектра задач листогибочного пресса без ущерба для функциональности станка.

10,1″ цветной TFT с высоким разрешением

Сенсорная навигация «горячими клавишами»

До 4 осей (Y1,Y2 + 2 вспомогательные оси)

Библиотека инструментов / материалов / изделий

Усовершенствованные алгоритмы управления по оси Y для клапанов как с замкнутым, так и с разомкнутым контуром.

Profile-53TL автономное программное обеспечение

СКАЧАТЬ ФЛАЕРПолучить цитату

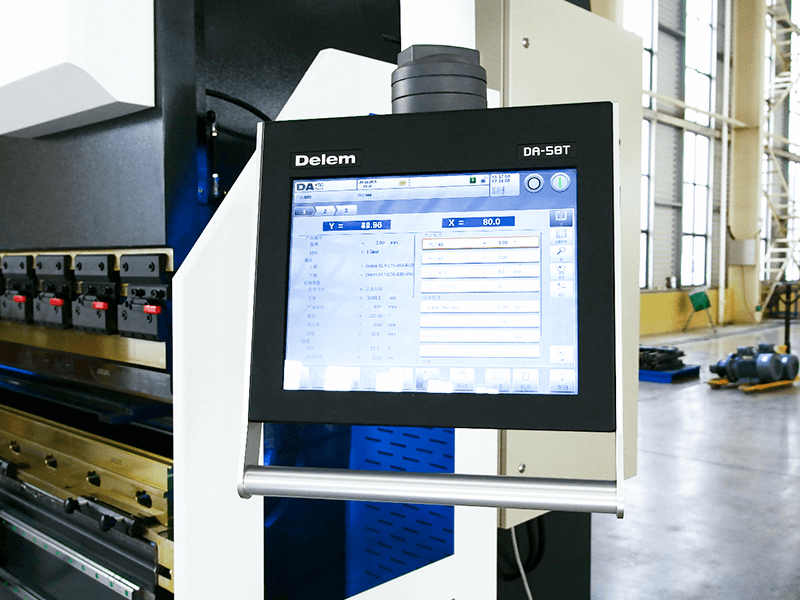

DELEM DA58T Цветная 2D графическая система ЧПУ

Сенсорное ЧПУ DA-58T — современное, компактное и универсальное решение для эффективной и экономичной работы. листогибочный пресс применения.

15″ цветной TFT с высоким разрешением

2D графическое программирование сенсорного экрана

До 4 осей (Y1,Y2 + 2 вспомогательные оси)

Расчет последовательности изгибов

Усовершенствованные алгоритмы управления по оси Y для клапанов как с замкнутым, так и с разомкнутым контуром.

USB, взаимодействие с периферийными устройствами

Profile-58TL автономное программное обеспечение

СКАЧАТЬ ФЛАЕРПолучить цитату

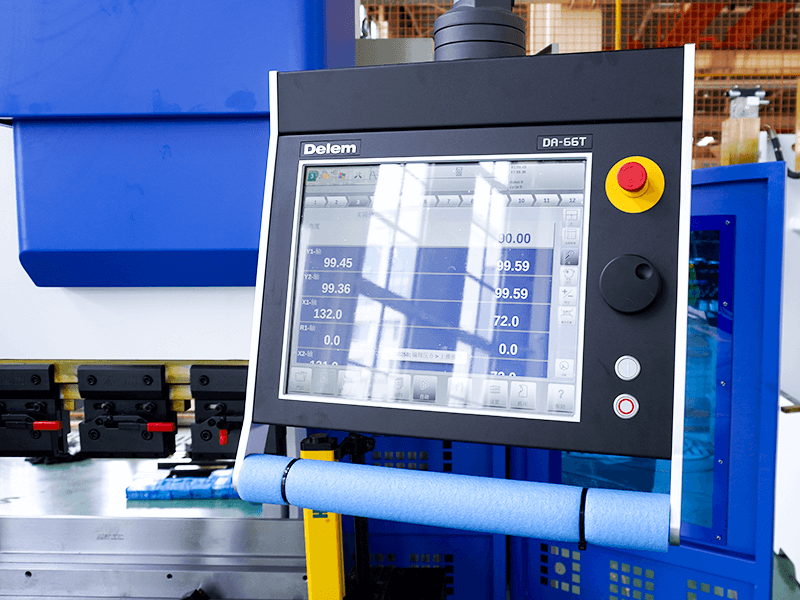

DELEM DA66T Сенсорное 2D графическое управление

Сенсорные пульты управления DA-66T Touch оснащены встроенной операционной системой Windows реального времени, что обеспечивает максимальную надежность. Плавный запуск гарантирован, даже после мгновенного отключения.

17″ цветной TFT с высоким разрешением

2D графический режим программирования на сенсорном экране

3D-визуализация в моделировании и производстве

Полный пакет приложений для Windows

Совместимость с Delem Modusys (масштабируемость и адаптивность модулей)

USB, взаимодействие с периферийными устройствами

Profile-T2D автономное программное обеспечение

Интерфейс изгиба и коррекции датчика

СКАЧАТЬ ФЛАЕРПолучить цитату

DELEM DA69T Сенсорное 3D графическое управление

Станок DELEM DA-69T обеспечивает как 2D, так и 3D программирование, с автоматическим расчетом последовательности изгибов и обнаружением столкновений. Полная 3D-настройка станка включает в себя несколько инструментальных станций, обеспечивая точную обратную связь по выполнимости и обработке изделия.

17″ цветной TFT с высоким разрешением

2D и 3D графический режим программирования на сенсорном экране

3D-визуализация в моделировании и производстве

Полный пакет приложений для Windows

Совместимость с Delem Modusys (масштабируемость и адаптивность модулей)

USB, взаимодействие с периферийными устройствами

Profile-T2D автономное программное обеспечение

Интерфейс изгиба и коррекции датчика

СКАЧАТЬ ФЛАЕРПолучить цитату

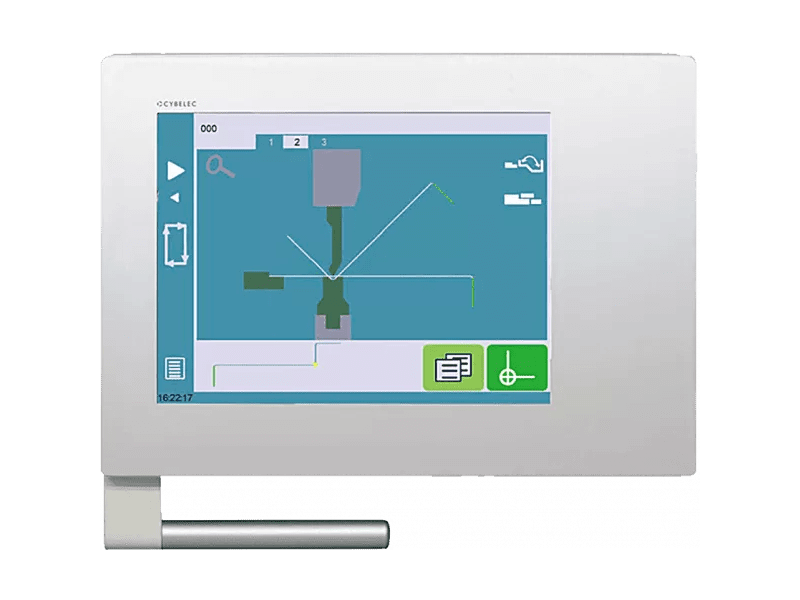

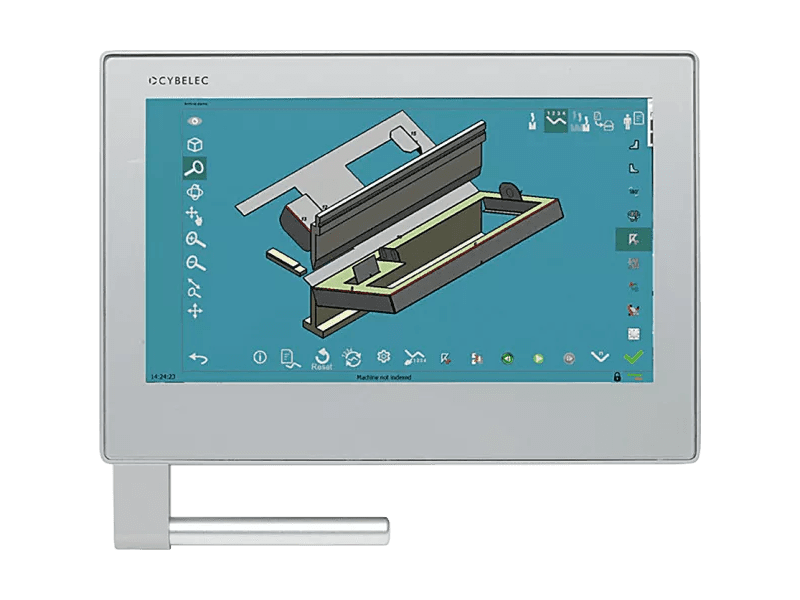

CYBELEC CybTouch 8 PS 2D графическая система ЧПУ

CybTouch 8 PS разработан специально для синхронизированных пресс-тормозов и является частью серии CybTouch. Он отличается интуитивно понятным и ярким цветным сенсорным экраном, а также высоким уровнем интеграции функций.

7-дюймовый цветной графический ЭЛТ-экран

Создание 2D графических профилей с ручной последовательностью

До 4 осей (Y1,Y2 + 2 оси)

Расчет припуска на изгиб.

Давление — расчет венцов.

Коррекция угла и заднего калибра.

Поставляется с автономным программным обеспечением PC1200.

СКАЧАТЬ ФЛАЕРПолучить цитату

CYBELEC CybTouch 12 PS 2D графическая система ЧПУ

Как и вся линейка систем числового программного управления CybTouch, CybTouch 12 PS также имеет интуитивно понятный интерфейс пользователя с сенсорным экраном, обеспечивающий высокую степень интеграции функций.

12-дюймовая цветная графика с полностью сенсорным экраном

Сенсорное создание 2D-графических деталей с ручной последовательностью

До 4 осей (Y1, Y2, X, R-оси)

Расчет припуска на изгиб.

Давление — расчет венцов.

Модулируемые инструменты для каждой детали или изгиба.

Коррекция угла и заднего калибра.

Поставляется с автономным программным обеспечением PC-ModEva.

СКАЧАТЬ ФЛАЕРПолучить цитату

CYBELEC CybTouch 15 PS 2D графическая система ЧПУ

CybTouch 15 PS — это система двухмерного числового программного управления, специально разработанная для прессовых тормозов с ЧПУ начального и среднего уровня. Она выполнена в компактном корпусе, аналогичном известной серии CybTouch, но отличается увеличенным сенсорным экраном и новым горизонтальным дизайном.

15″ цветная графика с полностью сенсорным экраном

Сенсорное 2D графическое рисование профиля и точное 2D создание программ

До 6 осей (оси Y1, Y2, X, R, Z1, Z2)

Автоматический расчет последовательности гибки

Модулируемые инструменты для каждой детали или изгиба.

Коррекция угла и заднего калибра.

VisiTouch 2D или VisiTouch MX — автономное программное обеспечение.

СКАЧАТЬ ФЛАЕРПолучить цитату

Графическая система ЧПУ CYBELEC VisiTouch 19 2D и 3D

VisiTouch 19 и VisiTouch 19 MX — это 2D и 3D графические системы числового управления для листогибочных станков с ЧПУ, разработанные для упрощения работы оператора даже при выполнении сложных задач программирования и настройки.

19″ сенсорный экран с современной обтекаемой стеклянной поверхностью

Сенсорное 2D графическое рисование профиля и точное 2D создание программ

Простое управление благодаря удобному для пользователя программируемому терминалу

Автоматический расчет последовательности гибки

Внутренние функции резервного копирования и восстановления

Модулируемые инструменты для каждой детали или изгиба.

Коррекция угла и заднего калибра.

VisiTouch 2D или VisiTouch MX — автономное программное обеспечение.

СКАЧАТЬ ФЛАЕРПолучить цитату

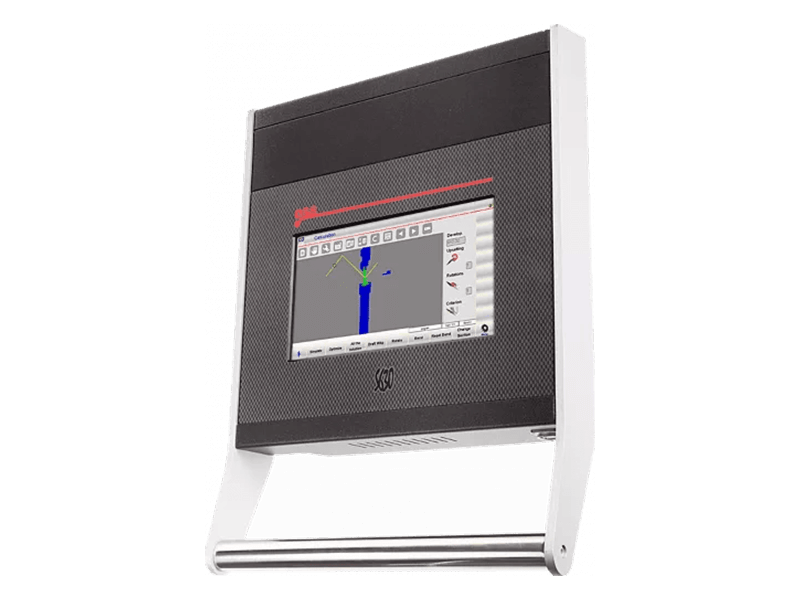

Графическая система ЧПУ ESA S630 2D

10-футовый сенсорный экран этого контроллера является самым мощным в своем классе и оснащен высокопроизводительной графикой. Этот экономичный и удобный в использовании контроллер ЧПУ предоставляет все возможности высококлассного станка.

10-дюймовый сенсорный ЖК-экран (резистивный)

Сенсорное создание 2D графических деталей с ручной последовательностью

Стандер на 4 оси (Y1Y2, X, R)

Автоматический расчет силы изгиба, расчет короны.

Модулируемые инструменты для каждой детали или изгиба.

Коррекция прямого угла, также для коронки.

Встроенный противодавление и клапан давления Amplify.

Бесплатное программное обеспечение для автономного моделирования ПК.

Управление тандемным оборудованием (опция)

Интерфейс Modbus TCP для SCADA или MES (опция)

Получить цитату

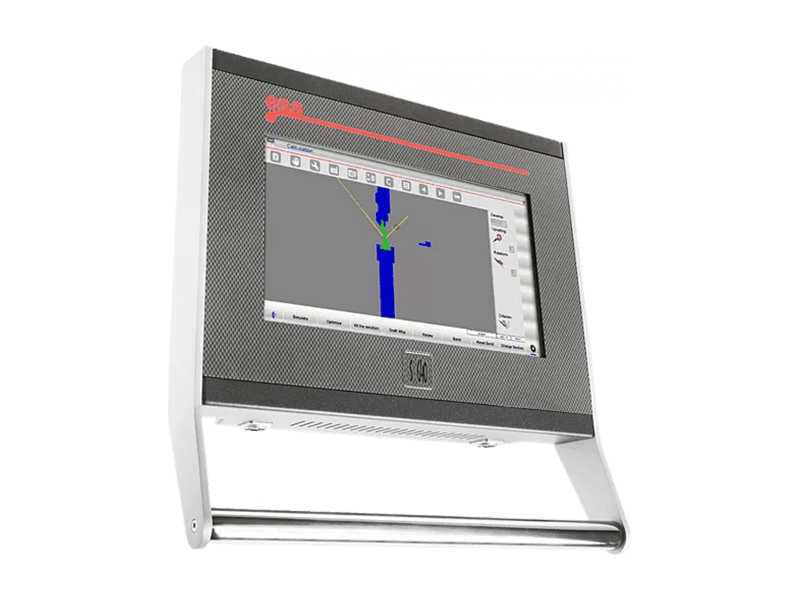

Графическая система ЧПУ ESA S640 2D

Для минимизации потерь материала доступны такие опции, как производительность высшего уровня для станков с шестью осями, автоматический расчет последовательности гибки и база данных материалов для прогнозируемой компенсации.

15-дюймовый сенсорный ЖК-экран (резистивный)

Создание сенсорных 2D графических деталей с автоматической последовательностью

Стандер на 4 оси, может достигать максимум 6 осей.

Автоматический расчет силы изгиба, расчет короны.

Модулируемые инструменты для каждой детали или изгиба.

Коррекция прямого угла, также для коронки.

Встроенный противодавление и клапан давления Amplify.

Бесплатное программное обеспечение для автономного моделирования ПК.

Управление тандемными машинами (опция, можно использовать до 4 машин)

Интерфейс Modbus TCP для SCADA или MES (опция)

Получить цитату

Графическая система ЧПУ ESA S650W 2D

— Нет ограничений как в исполнении, так и в гибкости.

— Мощный встроенный компьютер позволяет иметь на станке настоящий 3D cad cam (metallix, radan, esa).

— Конструкция заготовки для пальцев.

— Прямой импорт форм инструментов (файлы .dxf) и управление библиотекой инструментов.

— Управление держателями инструментов и штампов.

— Доступно измерение и коррекция углов со всеми существующими устройствами.

15-дюймовый сенсорный ЖК-экран (резистивный)

Импорт инструментов DXF (опции)

Создание сенсорных 2D графических деталей с автоматической последовательностью

Стандер на 4 оси, может достигать 32 осей максимум.

Автоматический расчет силы изгиба, расчет короны.

Модулируемые инструменты для каждой детали или изгиба.

Бесплатное программное обеспечение для автономного моделирования ПК.

Управление тандемными машинами (опция, можно использовать до 4 машин)

Интерфейс Modbus TCP для SCADA или MES (опция)

DataM или Iris-Plus управление угловыми измерениями (опции).

Программное обеспечение EsaBend-3D (опции)

Metalix, Radan, AutoPol 3d viewer (опции)

Получить цитату

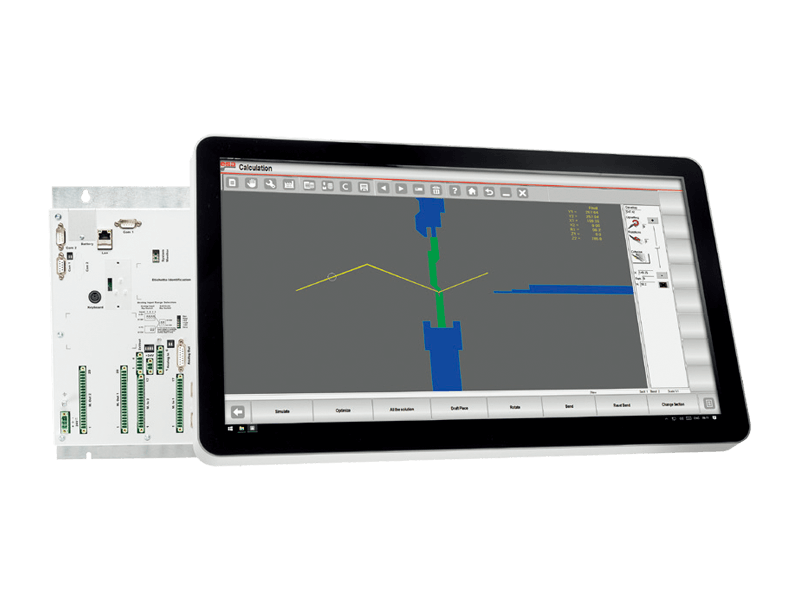

Система ЧПУ ESA S860

Новая версия промышленного ПК VIS-S860

18,5″ предназначен для мультисенсорного экрана

Поддержка мультисенсорного приложения

Без рамок, простой, но мощный

Поддержка конструкции заготовки для пальцев

Поддержка импорта форм инструментов (.dxf ifles).

Поддержка управления библиотекой инструментов

Поддержка управления держателями инструментов и штампов

Поддержка системы измерения углов datam

Поддержка программного обеспечения ESA 3D Bend

Оснащение стандартным интерфейсом Modbus TCP стандарта Industry 4.0

Получить цитату

Система ЧПУ ESA S875

Новая версия промышленного ПК VIS-S875

21,5″ предназначен для мультисенсорного экрана

Поддержка мультисенсорного приложения

Без рамок, простой, но мощный

Поддержка конструкции заготовки для пальцев

Поддержка импорта форм инструментов (.dxf ifles).

Поддержка управления библиотекой инструментов

Поддержка управления держателями инструментов и штампов

Поддержка системы измерения углов datam

Поддержка программного обеспечения ESA 3D Bend

Оснащение стандартным интерфейсом Modbus TCP стандарта Industry 4.0

Получить цитату

Учебное пособие по листогибочному прессу:

Руководство по эксплуатации листогибочного пресса Genius

https://www.harsle.com/Genius-Press-Brake-Operation-Tutorial-DA-66T-and-DA-69T-id40611677.html

Учебное пособие по работе с листогибочным прессом Smart

https://www.harsle.com/Smart-Press-Brake-Operation-Tutorial-For-DA-53T-id44813667.html

Руководство по эксплуатации контроллера:

Руководство по эксплуатации DA-69T

htts://www.harsle.com/DELEM-DA-69T-Operation-Manual-For-Your-Press-Brake-id401 18767.html

Руководство по эксплуатации DA-66T

https://www.harsle.com/DELEM-DA-66T-operation-manual-for-CNC- Press-brake-machine-Important-passwords-id3758861.html

Руководство по эксплуатации DA-58T

https://www.harsle.com/DELEM-DA-58T-Operation-manual-and-Introduction-for-CNC Press-brake-machine-lmportant-passwords-id3105862.html

Руководство по эксплуатации DA-53T

https://www.harsle.com/DELEM-DA-53T-Руководство по эксплуатации для листогибочного станка с ЧПУ- Пароли-Автономная загрузка программного обеспечения-id3319162.html

DA-41S/T Руководство по эксплуатации

https://ww.harsle.com/DELEM-DA-41S-эксплуатация-руководство-и-введение-как-использовать-DA-41S-контроллер-для-пресс-тормоза-id598360.html

E21 Руководство по эксплуатации

https://www.harsle.com/E21-Operation-Manual-for-Press-Brake-Machine-Inclusive-lmportant-Passwords-id3525783.html

Автономное программное обеспечение:

Профиль-53ТL

https://www.harsle.com/Profile-53TL-Offtine- Software — Tutorial — for Press — Brake- id43893867.html

Профиль-TL

https://www.harsle.com/CNC Press-brake-DELEM- Profile- T-Offline- Software- 2D- 3D-Metal-sheet-bending-programming-id3896875.html

Профиль-T3D

https://www.harsle.com/How-to-lmport-DXF-File-From-U-disk-to-DELEM-Controller-id44484977 .html

Дополнительное оборудование :

Гидравлический зажим инструмента.

https://www.harsle.com/How-to-Operate-The-Hydraulic-Clamping-System-For-Your-Press-Brake -id40577867.html

Лазерная безопасная защита

https://www.harsle.com/How-to-Use-DSP-Laser-Protection-For-Your-Press-Brake-id44591077.html

Многофункциональный ножной переключатель

https://www.harsle.com/Multifunctional-Pedal-Switch-For-CNC-Press-Brake-Machine-id41825867.html

Безопасный световой занавес

https://www.harsle.com/Safety-Light-Curtain-For-CNC-HydraulicPress-Brake-id42935867.html

Устранение неполадок листогибочного пресса:

Как изменить оснастку V?

https://www.harsle.com/Trouble-shooting-How-to-change-the-bending-channels-on-Multi-V-die. -для-гидравлического-гибочного пресса-id3404795. HTML

Как исправить угол изгиба?

https://www.harsle.com/Trouble-shooting-How-to-correct-the-bending-angles-on-one-line-for-NC-press-brake-machine-id3666795.html

Что нужно сделать перед запуском листогибочного пресса?

https://www.harsle.com/Preparing-steps-before-starting-hydraulic-press-brake-machine-id66341 16.html

Как настроить Y1 и Y2?

https://www.harsle.com/How-to-adjust-Y1-and-Y2-axis-for-CNC-Press-brake-machine-if-both-цилиндры-на-разных-уровнях-id6554646.html

Как повысить точность гибки?

https://www.harsle.com/How-to-lmprove-Your-Bending-Accuracy-id3656319.html

Как очистить гидравлический клапан листогибочного пресса?

https://www.harsle.com/Disassembly-and-cleaning-process-of-hydraulic-valve-group-of-hydraulic-bending-machine-id3347323.html

Что делать, если баран не может спуститься?

https://www.harsle.com/Trouble-shooting-E21-Hydraulic-press-brake-machine-ram-can-not-come-down-id3594795.html

DA-53T

Reference Manual

Operation of Version 1.5

English

Preface

This manual describes the operation of the Delem control type DA-53T and is meant for operators who are instructed for operation of the total machine.

Delem Limited warranty

• This manual does not entitle you to any rights. Delem reserves the right to change this

manual without prior warning.

• All rights reserved. The copyright is held by Delem. No part of this publication may be

copied or reproduced without written permission from Delem BV.

Version history

The control software is updated regularly to increase performance and add new functionality.

This manual is also updated as a result of changes in the control software. The following over-

view shows the relation between software and manual versions.

| Software version | Manual version | Description |

| V1.5 | V0817 | first issue V1 |

This manual is valid for software version 1.5 and higher.

Table of contents

1. Operation overview and general introduction . . . . . . . . . . . . . . . . . . . . 1.1

1.1. The control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.1

1.2. Front control elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.2

1.3. USB connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3

1.4. Operation and programming modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.4

1.5. Getting started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.7

1.5.1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.7

1.5.2. Preparations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.7

1.5.3. Modifying a program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.7

1.5.4. The Auto menu and Manual menu, production modes . . . . . . . . . . . . . . . . . . 1.7

1.5.5. Back-up data, external storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.8

1.6. Programming aids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.9

1.6.1. Listbox functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.9

1.6.2. Parameter zoom functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.10

1.6.3. Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.11

1.6.4. Text input and editing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.11

1.6.5. Typing alphanumeric characters vs. special characters . . . . . . . . . . . . . . . . 1.12

1.6.6. Messages centre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.13

1.6.7. Key-lock function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.13

1.6.8. Manual positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.15

1.6.9. Software versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.16

2. Products, the product library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.1

2.1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.1

2.1.1. The main view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.1

2.1.2. Product selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2

2.1.3. New Program, starting a numerical program . . . . . . . . . . . . . . . . . . . . . . . . . 2.3

2.1.4. Edit, Copying and Deleting a product or program . . . . . . . . . . . . . . . . . . . . . 2.4

2.1.5. Product Rename . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.5

3. Tool configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.1

3.1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.1

3.2. Standard procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.1

3.3. Tool selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.2

4. Product programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.1

4.1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.1

4.2. Program mode, parameter explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.3

4.2.1. Bend parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.3

4.2.2. Force . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.5

4.2.3. Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.6

4.2.4. Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.6

4.2.5. Product properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.7

4.2.6. Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.7

4.2.7. Auxiliary axes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.7

4.3. Edit / view modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.8

4.3.1. All Bends . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.8

4.3.2. Change tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.10

4.3.3. Product properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.11

4.3.4. Add bend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.14

4.3.5. Bumping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.15

4.4. Programming parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.17

5. Automatic mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.1

5.1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.1

5.1.1. Auto mode, parameter explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.2

Corrections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.2

General corrections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.3

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.3

5.2. View modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.4

5.2.1. Main . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.5

Bend selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.5

5.2.2. All bends . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.6

5.2.3. Macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.7

5.2.4. Manual positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.8

5.2.5. Corrections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.9

Calculate corrections, programming of measured angles . . . . . . . . . . . . . . . . 5.10

5.2.6. Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.11

5.3. Bumping correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.12

6. Manual mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.1

6.1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.1

6.1.1. Manual mode, parameter explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.2

Bend parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.2

Force . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.4

Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.4

Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.4

Product properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.4

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.5

Auxiliary axes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.5

6.1.2. Tool setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.6

6.2. Programming parameters & Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.7

View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.7

6.3. Macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.9

6.4. Manual movement of the axes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.10

6.4.1. Movement procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.10

6.4.2. Teach . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.11

6.5. Corrections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.12

6.6. Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.13

6.6.1. IO status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.14

Zoomed IO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.15

7. Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.1

7.1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.1

7.2. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.2

7.3. Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.4

7.4. Backup / restore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.7

7.4.1. Product backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.8

7.4.2. Product restore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.10

7.4.3. Tool backup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.12

7.4.4. Tool restore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.13

7.4.5. Backup and restore for Tables and Settings . . . . . . . . . . . . . . . . . . . . . . . . . 7.13

7.4.6. Directory navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.14

7.5. Program settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.15

7.6. Default values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.18

7.7. Computation settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.20

7.8. Production settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.22

7.9. Time settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.25

8. Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.1

8.1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.1

8.2. Programming of Punches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.2

8.2.1. Create a new punch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.3

8.2.2. Standard punch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.4

8.2.3. Hem bend punch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.7

8.2.4. Air + hem bend punch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.8

8.2.5. Big radius punch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.10

8.3. Programming of bottom dies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.11

8.3.1. Create a new die . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.12

8.3.2. Standard die . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.13

8.3.3. Hem bend die . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.16

8.3.4. Inside hem bend die . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.17

8.3.5. Air + hem bend U die . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.20

8.4. Backgauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.21

8.5. Position corrections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.24

8.6. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.25

8.7. System information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.26

A. Parameter index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A.1

1. Operation overview and general introduction

1.1. The control unit

The control looks as follows:

The precise appearance of your control may differ.

Operation of the control is mainly done over the touchscreen. A description of the functions

and available touch controls is given in the next sections of this manual, aside of the

description of the specific functions.

1.2. Front control elements

The Start and Stop button, integrated in the touch screen user interface:

Stop button + Start button

1.3. USB connectors

At the right side of the control a USB port is available for

connection of external devices, such as a memory stick

or an external keyboard or mouse.

1.4. Operation and programming modes

The control’s main screen looks as follows:

Depending on the navigation button which is active, the screen will differ. The above main

screen will appear having the Products function active.

Just by tapping the various modes, the specific mode will be selected.

The structure of the main screen is as follows:

Title panel

In the top the title panel is always shown. In this area you can find logo information, which

product is loaded and (when activated) the service row. Also machine indicators can be found

here.

Information panel

In the information panel all functions and visualisation related to the selected modes are

displayed and can be found.

Command panel

The command panel is part of the Information panel and is the location where the controls

related to the Information panel can be found.

Navigation panel

The Navigation panel is the area where all the major modes can be found. This area is always

visible. The controls, large buttons with icons, can be used to directly switch from one mode to

the other.

Explanation of the main modes / navigation buttons

To make a new program and select a program out of the product

library.

To setup the machine and modify existing tool setups.

To create a new CNC-program or edit an existing CNC- program

numerically.

To start production of the selected program.

To program all settings for making one single bend, not related to a program.

User settings and preferences applicable to the programming of

new programs. Also the required material properties can be

programmed in the Material library.

User settings and preferences applicable to the machine, tooling

library including the tool editor, backup/restore of data, software

version info etc.

1.5. Getting started

1.5.1. Introduction

In order to obtain a bend program for a product, the control offers the possibility to create a

program bend by bend and adjust specific parameters for each bend independently.

This is done with the following steps:

1 Go to the Products mode in the navigation panel and start a new program by tap-

ping New Program.

2 Enter the program’s basic properties and continue by pressing Accept.

3 Automatically the next menu is switched to, Tool-setup, to select the desired tool-

ing. Check the tooling, modify upon desire and one can continue to the Program

menu.

4 In the Program menu one can start programming the bend specific parameters for

the first bend. To add the next bendstep to the program the function Add bend can

be used. This cycle can be repeated upon choice.

5 Tap Auto and press the Start button in order to produce the programmed product.

1.5.2. Preparations

Before product programming can be started, the following preparations must be made.

• The correct material properties must have been programmed in the Materials library.

You can find this on the Materials page in the Settings mode.

• The correct tools must be programmed in the Tool Library. Tools are necessary to

create a CNC program. You can find the libraries for the different types of tools in the

Machine mode.

1.5.3. Modifying a program

The Program menu gives access to the numerical program and values of the active product.

Existing programs can be modified via this menu. The independent bendsteps can be

selected and the programmed values can be monitored and modified if required.

Axes positions, if applicable, are calculated according to the machine configuration.

1.5.4. The Auto menu and Manual menu, production modes

A product program can be executed via the Auto mode. In Automatic mode, a complete

program can be executed bend after bend. In the Auto mode the Step mode can be selected

to have each bend started separately.

The Manual mode of the control is an independent production mode. In this mode, one bend

can be programmed and executed. It is typically used to test the behaviour of the bend

system.

More information about this can be found in chapters 5 and 6.

1.5.5. Back-up data, external storage

Both product and tool files can be stored externally. These files can be stored on a USB stick.

This facilitates a back-up of important data and the possibility to exchange files between

Delem controls.

More information about this can be found in chapter 7.

1.6. Programming aids

1.6.1. Listbox functionality

Several parameters on the control have a limited number of possible values. When selecting

such a parameter, by tapping the parameter line on the screen, the list of options will open up

near the position where you tapped the line, and the desired value can be selected.

To undo the selection and the opened listbox, tapping outside the box will make it close

without changing the selected parameter.

1.6.2. Parameter zoom functionality

To improve the focus on parameters, and to ease the use while programming, the parameter

zoom function will enlarge specific parameterlines when being programmed. When selecting

e.g. force in Program mode, the force lines will expand giving them better focus while fine

tuning.

When selecting any other parameterline, the previous selection will be reduced and zoomed

out again, as the newly selected parameterline will be zoomed in at.

1.6.3. Navigation

Within some modes, the program screens are divided into tabs.

The tabs can easily be selected by just tapping them. When a tab is not completely visible or

not visible at all, just by dragging the tab row horizontally, the desired tab can be «pulled» in

sight and be selected.

1.6.4. Text input and editing

The cursor can be used to enter a specific value or text within an existing input. Just tap at the

desired position to do so. The cursor will appear and input will be added there.

1.6.5. Typing alphanumeric characters vs. special characters

Both alphanumeric characters and special characters can be used throughout the control. A

full on-screen alphanumerical keyboard will pop up when required.

When editing a field which is pure numeric, the alphanumeric characters will be hidden. For

fields which enable to use alphanumerical strings, the keyboard is completely available.

Special characters as ? % — can be found using the special character button on the left-lower

side of the keyboard.

Special characters (like á, à, â, ã, ä, å, æ) are supported by the on screen keyboard by

keeping a character (like ‘a’) pressed.

1.6.6. Messages centre

When messages are displayed coming from PLC, Safety systems or the Sequencer, these

messages can be ‘send’ to the ‘Messages centre’. When a message is displayed

simultaneously the message centre symbol is shown in the top row of the page header, next

to e.g. the key lock symbol. When tapping this message centre symbol the messages are taken

from the screen, giving way for normal programming and editing. When tapping again the

actual messages are shown.

When messages are in the background, the message centre symbol has an extra indicator to

show new incoming messages which are not yet shown.

1.6.7. Key lock function

To prevent for changes to products or programs, the key lock function offers the possibility to

lock the control.

There are two levels of locking the control. Program Lock and Machine Lock.

• In Program Lock, only a product can be selected and executed in Automatic mode.

• In Machine Lock, the machine is locked and the control can not be used.

To lock a control just tap the lock symbol in the top of the screen. Depending on the code

which is used, the control will be in Program Lock or Machine Lock. Program Lock will show a

closed lock in grey. Machine lock will show the same lock but colored (red).

Lock symbols when Program Lock is active will also appear behind parameters to show the

lock is active and modification is not possible.

To unlock the control, tap the lock symbol and enter the appropriate code. After entering, the

lock symbol will show it is unlocked and the lock symbols behind parameters will disappear.

Codes can be changed upon desire. The procedure to manages codes can be found in the

Installation manual.

1.6.8. Manual positioning

On the manual positioning page in Manual mode and Automatic mode a slider at the bottom of

the screen can be used to position the axis. The distance moved with the slider determines

the speed of the axis. When the slider is released, the axis stops. The buttons at each end of

the slider can be used to fine-tune the axis position. When «sliding» the beeper gives feedback

that the axis is moving.

1.6.9. Software versions

The version of the software in your control is displayed at the System Information tab in the

Machine menu.

Example of version number:

V 1.2.3

V stands for version

V 1.x.x is the major version number

V x.2.x is the minor version number

V x.x.3 is the update version number

The major version number is increased when new major features are added to the software.

These software changes require additional introduction and could change the normal working

order. The minor version number is increased when new features and enhancements are

integrated which do not change the working order. The update version number solely is used

for software changes when corrections are needed in the existing software version.

2. Products, the product library

2.1. Introduction

In the Products mode, existing, previously produced products can

be selected to start production or for modification in order to make a

similar product. To start making a new program New Program can

be used from this mode.

2.1.1. The main view

In Products mode an overview is given of the program library on the control. In this mode a

product program can be selected (loaded). After that a program can be modified or executed.

Each item in the list consists of its Product ID, the Product Description, the Number of bends

in the product and the Date it was last used or modified.

If a product program is already active its ID is shown in the top of the screen. A program can

be loaded by tapping the product ID or any other part of the product’s line.

When there are more products than can be visualised in the screen simply drag the list in the

upward direction until the product is visible. From then again a single tap on the product

selects the product and activates it in the control.

2.1.2. Product selection

To select a product a single tap will do. The product will be selected and loaded into the

memory. From here production can be started by tapping Auto. Also navigation can start

through the Tool Setup and the numerical Program.

2.1.3. New Program, starting a numerical program

To start a new numerical program tap New Program.

After New Program is chosen, the programming starts with its general details like e.g. Product

ID, Thickness and Material.

2.1.4. Edit, Copying and Deleting a product or program

To delete a product in the Products mode select a product by tapping it. It will be selected.

After that tap Edit and use Delete. To finally delete it confirm the question. To delete all

programs at once, tap Delete All.

To copy a product select a program and tap Edit and use Copy. After this the name of the

product can be programmed and the copy will be done. The copied product will be an exact

copy including tool setup.

2.1.5. Product Rename

Products can also be renamed.This can be done in one single step: Rename allows the user

to give it a new name.

To rename a product select a program and tap Edit and choose Rename from the list. For

Rename a new name can be given.

3. Tool configuration

3.1. Introduction

To edit or modify a tool setup for the product, select the product

from the library and use Tool Setup

3.2. Standard procedure

When the function Tool Setup has been activated, the screen shows the active machine set-

up. Both punch and die can be selected from the tool library.

The Upper and Lower tool, resp. Punch and Die, in the machine are shown and can be

changed.

3.3. Tool selection

When selecting tools, both upper and lower tool (resp. punch and die) can be selected from

the tool library.

Tap Select Punch or Select Die to change tools to the configuration.

4. Product programming

4.1. Introduction

With the back gauge finger dimensions the R-axis movement and related X-axes movement is

taken into account. Also the workpiece / back gauge collision are computed using the

dimensions.

To edit an existing CNC program, select a product in the Products overview and select the

navigation button Program. When starting a new program, select New Program and after

giving in the main product properties and tool setup, the system will automatically switch to

Program.

In both cases, a screen as shown above should appear. Programming and changing data is

done in the same way in both cases.

The main screen shows the existing numerical program or, when starting a new program, the

first to be programmed bend. The bend selector in the top of the screen can be used to

navigate thru the bends. The indicated bends can be tapped to easily select the desired bend

data.

At the side of the main screen views and functions are indicated with command buttons.

Functions

Following modes / functions are available:

Main, numerical bend data.

All Bends, shows all bend data in a table.

Change Tools, enables the change of tools for this specific bend

step or all bend steps.

Product Properties, gives access to product properties which are

general for the product, not bend specific.

Add Bend, adds a new bend to the existing program.

Bumping, changes a single bend step into a bumping bend.

4.2. Program mode, parameter explanation

The main screen shows the available bends and from this main screen, from every available

bend, specific parameters can be viewed and edited.

The product ID and product description are displayed in the top row on the screen.

4.2.1. Bend parameters

Method

Select the required bending method. The control supports the following standard

methods:

• air bend

• bottoming

• hemming

• hemming & bottoming

| air bend | The sheet is bent to the programmed angle by bringing the punch to the required depth.The control calculates the required Y-axis position to obtain the programmed angle. |

| bottoming | The sheet is bent by pressing the sheet between the punch and the die. The control assumes the bottom of the die as required Y- axis position. |

| hemming | The sheet is folded in two. This is possible after the sheet has been bent into a sharp angle in a previous bend. The control calculates the precise Y-axis position for this action: the surface of the die plus twice the sheet thickness.Y-axis positioning can be adjusted byprogramming a ‘hem opening’. |

| hemming &bottoming | The same as hemming, but now the control assumes the top of the die as required Y-axis position. The folded sheet is pressing between punch and die. |

Product position

The absolute position value of the product in the Z-direction. Left machine side is

reference position zero.

Angle

The required angle of this bend. This parameter only appears if angle programming is

selected with the parameter ‘Angle sel.’ and the bend method is an air bend.

Hem opening

The hem bend can be made with a certain opening distance between the 2 flanges. The

hem opening value will be used calculating the beam position in the hemming process.

By default this parameter has the value of the Settings mode parameter Default Hem

Opening.

Y-axis (Bend position)

The required Y-axis position for this bend. This parameter only appears if absolute

programming is selected with the parameter ‘Angle sel.’ This parameter also appears if

the bend method is bottoming and/or hemming.

Mute

Sequence point at which the Y-axis is switched from fast closing speed to pressing

speed. The value programmed here is the distance of the mute point above the sheet.

By default, the mute value from the programmed die is used.

Whether or not this parameter is present depends on machine settings.

Parallel

Difference of left- and right hand side cylinder (Y1 and Y2). When positive, right hand

side lower. When negative, right hand side higher. The programmed value is active

below the clamping point.

Opening

This parameter results in a certain gap opening between the punch and the die after the

bend. A positive value is the gap opening above Mute, a negative value below Mute.

When you want to limit the handling time of the product you can program a small

positive or a negative value.

4.2.2. Force

Force

Maximum adjusted force during pressing (automatically computed).

Dwell time

Holding time of punch at bending point.

Decompression

Decompression distance after the bending to release the working pressure from the

system.

4.2.3. Speed

Speed

Working speed (pressing speed). Initially, the value for this parameter is copied from the

parameter Default Pressing Speed in the Settings mode.

Decomp speed

The decompression speed is the programmable speed of the beam during the

decompression distance.

4.2.4. Functions

Repetition

0 = bending is skipped

1 through 99 = the number of times this bending will be repeated.

Wait for retract

In case of a retract, let the Y-axis wait until the retract is finished, yes or no.

No: the retract is started when the Y-axis passes the clamping point, the Y-axis does not

stop.

Yes: when the Y-axis reaches the clamping point, the Y-axis is stopped and the retract

is started. When the retract is completed, the Y-axis moves on.

Code

Programmable step change code parameter which determines when the parameter

values for the next bending will be active. The following settings are possible:

0 = ER: Bending number change (step change) at end of decompression (next bend

parameters active).

1 = MUTE: Step change at muting position when the beam moves in opening direction.

2 = UDP: Step change at upper dead point.

3 = UDP STOP: Step change at upper dead point without movement of any axis and the

control goes to «stop».

4 = EXTERNAL: Step change if C-input signal becomes active, without movement of the

beam. When you still have a beam movement there will be no retract function of the

back gauge performed. See also code 5.

5 = UDP EXTERNAL: Step change if C-input signal becomes active and the beam is in

the upper dead point. Now you may move the beam and the retract function of the

back gauge will be performed.

Delay time

Programmable delay time before step change (0-30sec)

4.2.5. Product properties

Thickness

The thickness of the sheet.

Material

The material of the product.

4.2.6. Tools

The set tools are displayed and can be modified from the Tool Setup menu. If required the

tools per bend can be specifically selected for that bend using Change Tools.

Punch

The name (ID) of the selected punch. Tap Change Tools to modify or select from the

punch library.

Die

The name (ID) of the selected die. Tap Change Tools to modify or select from the die

library.

Press the Change Tools button to get an overview of the available tools in the library.

4.2.7. Auxiliary axes

Auxiliary axis

The position of the selected axis.

Retract

Retract distance of the selected axis in the current bend. The «backgauge retract» is

started when the beam is pinching the sheet.

Speed

Speed of the selected axis in the current bend. Speed can be programmed in a

percentage of the maximum possible speed.

Lay-on

Toggle between lay surface on finger or not. This option is only selectable in case you

have an R-axis in your machine.

4.3. Edit / view modes

4.3.1. All Bends

When the function All Bends has been pressed, a complete overview of the bends appears.

From within this screen, the complete CNC program can be edited. All bend parameters can

be edited within the table and bends can be swapped, moved, added and deleted.

The available columns can be scrolled by finger movement / swipe.

Functions

Edit

Edit the program with one of the following commands:

• insert bend

• mark bend

• delete bend

When the function Edit has been pressed a new, temporary button bar appears with additional

functions:

+Insert Bend

To insert a new bend between one of the bends. When pressed, the current bend is copied

and added before the current bend.

+Mark Bend

Mark the current bend, in order to prepare it for another action, like move or swap. See

description below.

+Delete Bend

To delete the bend that is currently selected.

When a bend has been marked with the function key Mark Bend several other functions

become available:

+Move Bend

In the table overview of the bend sequence, it is possible to change the order of bends simply

by moving a bend to another place. Select the bend that must be moved. Then press the

button Mark Bend and the bend is highlighted. Now select the right place in the sequence.

When the correct bend is highlighted, press Move Bend. The bend will be inserted on the

current place.

+Swap Bends

With this command, two bends can change place in the bend sequence. Move the cursor to

one of the required bends and press the Mark Bend button. Then move the cursor to the bend

with which it must be swapped and press Swap Bends. If for any reason the action must be

cancelled, press the function Abort Mark during the procedure.

+Abort Mark

Remove the mark from the currently marked bend.

A bend is no longer marked when the mark is aborted, when an action is finished or when this

menu is left.

Copy Column

Copy the value of the currently selected parameter in the current bend to all other bends.

Chain Bendsteps

Chaining of bend steps is possible by just setting the number of steps in the chain (Repetition)

and the back gauge position offset (X offset). The relative offset value can be positive as well

as negative for flexible chaining.

4.3.2. Change tools

To change the tools the Tool Setup menu can be used. If the tool setup needs to be changed

for just one bend step, the Change Tools button can be used. The control will always ask if the changes are to be done on the whole setup or just for one bend. If the whole tool setup is

required, automatically the Tool Setup menu will be switched to.

4.3.3. Product properties

To change the main product properties tap Product Properties. These parameters of the

program are the same for every bend of the program (main data of program).

Parameter explanation

Product ID

A unique name to identify a product program. The maximum length is 25 characters.

The product ID may contain letters and numbers.

Product description

A number or description of this program. The maximum length is 25 characters. The

product description may contain letters and numbers.

Angle sel.

Selection of the programming mode for the Y-axis.

0 = absolute: program the absolute Y-axis position for a bend.

1 = program the angle to bend. The required Y-axis position is computed.

Depending on this parameter, either the parameter Angle or the parameter Bend

Position will appear in a bend step.

Thickness

Thickness of the sheet.

Material

Selection of one of the programmed materials, which are used to calculate the bending

depths. The control contains 6 pre-programmed materials. In total, 99 materials can be

programmed on the control. The materials can be programmed on the Materials page in

the Settings mode.

| Tensile strength(N/mm²) | E-module (N/mm²) |

Strain hardening exponent | |

| 1 = Steel | 470 | 210 | 0.23 |

| 2 = Aluminium | 250 | 210 | 0.26 |

| 3 = Zinc | 200 | 94 | 0.2 |

| 4 = Stainless steel | 750 | 210 | 0.32 |

Functions

Connect

The function Connect is to have a possibility to connect certain programs to each other. This

option can be used to produce 3-dimensional products out of two programs.

+Connect program

With the function Connect it is possible to create a 3-dimensional product. The control

automatically executes the bend sequences in the different directions in succession. You

program the control as follows:

1 Create the product in one direction.

2 Create the product in the other direction.

There are now two bend programs of one product in two directions. You connect these

programs as follows:

1 Select the program with the bend sequence in the direction which you want to

execute in the first place. You select the program of the product via the ’product

library’.

2 Go to the Program mode and select Product properties.

3 In the Product properties window you select the function Connect and Connect

program.

4 Select the product ID of the product in the other direction.

5 Select the second program as in step 1. Repeat steps 2 to 4. If you want to connect two programs, as in this example, you enter the product ID of the first program. The cycle is closed.

When you want to execute more than two programs in succession (not necessarily to create a

3-dimensional product) the second program must refer to the third. The third program to the

fourth and so on. The final program of the cycle must always refer to the first program.

To produce products with connected programs the next four actions are necessary.

1 Select the first program

2 Select the Automatic mode

3 Program the amount of products you want to produce with the ’stock count’ parameter.

4 Push the Start key.

When the first program has been finished the second program starts automatically. The

program counter indicates the remaining amount of repeats.

+Disconnect program

To stop the sequence of connected programs.

Save as

Copy the current product. When pressed, you must enter a new product ID for the copy

program.

4.3.4. Add bend

To add a new bend after the last bend. When pressed, the last bend is copied and added after

the last bend.

4.3.5. Bumping

From pure numerical programs a single bend step can be changed into a bumping bend.

When Bumping has been selected in the Main view, a pop-up window is shown on which the

following parameters can be programmed:

Bumping

disabled => Air bend as normal bend with a defined angle and preferred radius.

enabled => Large radius in different steps of airbending.

Angle

The angle value to bend.

Radius

The intended radius which is programmed.

Number of segments

The number of segments in which the radius will be divided. The number of bends in this

radius is the number of segments plus 1.

The more segments you select, the more bends will be used to create the programmed

radius within a smaller tolerance. With a high number of segments you will need a

smaller V-die opening to be able to bend in a proper way.

Equal bumping-segments

When a product has a radius bend, the segment size is computed from the number of

segments, which has been defined by the user. Standard the first and last segment are

calculated half the size of the mid segments to obtain a better result. However, it can be

a problem selecting a die suitable to bend these small segments. Therefore the control

can calculate an equal size for all segments. This can be defined with this parameter.

• Disabled (no equal sizes)

• Enabled (equal sizes)

When Enabled all segments will have an equal size.

When Disabled the calculation is including half size segments. If in this case a problem

with the size of the V-die opening is detected in the bend sequence determination, the

user is asked whether or not to select a re-calculation with equally sized segments.

Bumping corrections can be found in Automatic mode where the user is helped in distributing

the correction over the related bends.

4.4. Programming parameters

Parameters in program mode can be programmed one by one. The effect of the parameter on

other parameters is automatically computed.

The relation between parameters is visualized with a symbol and a background color.

When an information symbol is shown with parameters after an edited value, this parameter

was changed due to the last changed input.

A star symbol is shown with parameters if the value of the parameter differs from the

calculated value by the control. This can be helpful if a value is intentionally programmed

different or if the value of a parameter is limited by the parameters limits.

An error symbol is shown with parameters if the value cannot be correct according to the

currently programmed values. This, e.g. when a hemming bend is programmed with no

hemming tools programmed.

5. Automatic mode

5.1. Introduction

By tapping the navigation button Auto the control is switched to the

automatic production mode.

In auto mode with the active program, production can be started. After entering Auto, the Start

button can be pressed and production can begin.

The automatic mode executes the program automatically bend by bend after pushing the Start

button. When selecting a different product in Products mode, which is in the library and has

already been used for production, one can immediately switch to Auto and start production.

Every time after a different bending program is selected you must check your tools and tool

positions in your machine. This is also indicated with a ‘check tools’ warning message when

you enter the automatic mode.

In the header of the Auto mode screen the selected product is displayed along with the

product description. At the top of the screen the bend selector shows the available bends in

the program. By tapping the preferred bend the bend can be selected. The start button can be

pressed to start from this bend. The details of the selected bend are shown in the available

views.

The repetition of a bend and the connected programs, when applicable, are shown in the

header of the screen. A connected program is also indicated in the bend selectors last

position.

5.1.1. Auto mode, parameter explanation

Following is a list of the available parameters in Auto mode.

Corrections

Angle 1 / Angle 2

Corrections on angle values in this bending.

Angle corrections can be programmed for both sides of the machine, Y1 and Y2. When

correction Angle 1 is entered for one side, this value is automatically copied to the

correction Angle 2 for the other side. The correction for the other side can then be

changed. When both angle corrections have been entered, the resulting corrections for

Y-axis and parallelism are calculated. The corrections will be saved in the active

bending program.

The angle correction should be entered as following examples indicate:

Programmed value of 90 degrees. Measured value of 92 degrees.

-> Then it is required to program of correction of -2.

Programmed value of 90 degrees. Measured value of 88 degrees.

-> Then it is required to program a correction of +2.

In case the angle correction database has been switched on, the control checks whether a

correction exists for this type of bend in the database. The result of this check is prompted in

the entry field:

• No stored correction.

No correction has been found for this bend • Stored correction.

A correction that matches the current bend has been found

• Interpolated correction.

A correction has been calculated (interpolated) based on other existing corrections

If a correction is entered, it will be stored in the database. At each next bend with the same

properties, this same correction will be offered.

The angle correction database can be found on the Program Settings page in the Settings

mode.

Y1 / Y2

Corrections on the Y-axis positions, in case absolute programming is used or bottoming

is selected for a bend.

Auxiliary axis

Corrections on auxiliary axis positions in this bending. In case bend allowance is

activated (see the Settings mode) and a program has been entered in Program mode,

the X-axes correction values are the result of bend allowance calculation. The corrections will be saved in the active bending program.

The auxiliary axis correction should be entered as following examples indicate:

Programmed value of 200 millimetres. Measured value of 202 millimetres.

-> Then it is required to program a correction of -2.

Programmed value of 200 millimetres. Measured value of 198 millimetres.

-> Then it is required to program a correction of +2.

deflect

Correction on the crowning device.

Only available if a crowning device is present

General corrections

Thickness

General correction on the product thickness, valid for each bend of the program.

Angle / Angle 2

General correction of the angle, valid for each bend of the program. The value should be

programmed in the same manner as for the correction per bend.

Depth

General correction on the Y-axis position, in case ’absolute programming’ is used and

’air bend’ is selected for a bend. This correction is valid for each bend of the program.

X-axes

General correction of the X-axis position, valid for each bend of the program. The value

should be programmed in the same manner as for the correction per bend.

deflect

General correction on the crowning device.

Only available if a crowning device is present.

General

Stock

The stock counter is incremented or decremented after each end of a program cycle.

Repetition

Selection of one of the repeated steps of one bend. Useful if a bend has a repetition

value larger than 1. This parameter is visible when the parameter Repetition in Program

mode has been set to a value larger than 0.

Step mode

Select to use either Auto mode (no) or Step mode (yes). In Step mode you have the

same possibilities as in Auto mode. There is only one difference. After each bend cycle,

the control will stop. To continue working, you must start the control again by pressing

the Start button on the front panel of the control.

5.2. View modes

The auto mode screen is offering a diversity of views which, depending on ones production

method, can be chosen. When selecting auto mode for the first time, the main screen will

appear. On the right side of the screen the available view modes can be selected.

Following view modes are available:

Main, numerical bend data. See for details paragraph 7.2.1

All bends, shows all bend data in a table. See for details paragraph

7.2.2

Macro, large visualisation of axes values shown in a list. See for

details paragraph 7.2.3

Manual positioning, large visualisation of axes values with the

possibility to move axes from their position and teach the axis value in

the selected bend. See for details paragraph 7.2.4

Corrections, all correction values for angle as well as axes positions.

See for details paragraph 7.2.5

Diagnostics, special information on the axes positioning and I/O

status of the control system. This view mode is meant for service

purposes. See for details paragraph 7.2.6

The appropriate view can be switched from and to, not changing the bend data. The Start will

not jump to Stop while switching view modes.

5.2.1. Main

Main view shows the numerical data of the bend along with the corrections. The corrections

can be programmed here.

Both columns can be scrolled to see all data.

Bend selector

The bend selector in the top of the screen can be used to navigate thru the bends. The

indicated bends can be tapped to easily select the desired bend data.

5.2.2. All bends

The all bends view mode shows a table including all bend data. The bends are shown row

wize and the columns display all bend parameters.

5.2.3. Macro

With macro view mode, the control switches to a view with only large axes values on the

screen. This view can be used when working a little remote from the control, still able to read

the axes values.

Next to the target position (programmed) also the actual position of all axes can be followed.

5.2.4. Manual positioning

In manual positioning view mode the axes values are shown at large. Axes can be selected

and while selected the position can be controlled by moving the slider, on the bottom of the

screen, out of its middle position. When releasing the slider it will return to its middle position

automatically.

The teach indicator:

When the teach indicator arrow is pressed, standing in between actual value and programmed

value, the value is taught to the program step.

5.2.5. Corrections

In this view mode all corrections of all bends are shown. You can browse through all

corrections and change them as you see fit. If a correction for 1 is entered then this value is,

dependent on the settings parameter ‘Angle correction programming’, copied to the correction for 2, or keeping the delta between both corrections, or not influencing the correction for 2.

Different corrections for 2 can be entered in the field itself.

The column ‘Stored correction’ is only available when the Angle correction database has been

activated. When activated, the column ‘Stored correction’ shows for each bend the correction

value that is present in the database. A blank entry in this column means the database does

not have a correction value for this type of bend. When a new correction is entered, it will be

copied to the database automatically.

The markers ‘>’ indicate bends that have the same value.

All From Stored serves to copy corrections in the database to the current program: corrections

in all bends are adjusted according to database values.

Calculate corrections, programming of measured angles

To calculate the corrections from measured angle values, one can use the “calculate

corrections” function in the correction window. Calculate corrections will open a separate

window in which, upon choice, the measured angle(s) can be programmed.

From the programmed value the control will determine a correction. The proposed result can

be seen in the window itself. In the top of the window the programmed angle is shown, in the

bottom of the window the resulting corrections are shown. When selecting accept, these

values will be transferred to the main corrections screen.

When only one measured angle value is entered, the other values will be copied equally. If

there are separate left, right or even middle values, these can be entered as well. The

appropriate correction values will be determined from the entered values. The middle

measured angle, if applicable, is transferred to an absolute crowning correction.

Axes corrections can also be edited in the main screen. When there are multiple axes

available this special view mode can be switched to for all axes corrections.

5.2.6. Diagnostics

The diagnostics view mode is meant for service purpose mostly. In diagnostics the activities of

independent axes can be monitored. I/O on the control system can be followed. In rare

situations this information can be helpful to diagnose operation during the bending process.

5.3. Bumping correction

In case of a selected bumping bend a general correction for a bumping bend can be entered.

This function is only available if a product is loaded that contains a bumping bend.

With Bumping Corr. a new window appears in which the correction can be entered.

When the general correction of an angle is altered, all individual corrections are recalculated.

When any of the individual corrections is altered, the general correction is recalculated.

Bumping corrections can be programmed independently for both sides, 1 and 2.

If a bumping correction for 1 is entered then this value is, dependent on the settings

parameter ‘Angle correction programming’, copied to the bumping correction for 2, or

keeping the delta between both bumping corrections, or not influencing the bumping

correction for 2. Subsequently all separate corrections for 2 are recalculated. To change

correction values of 2, use bumping correction 2 or one of the separate corrections of 2.

6. Manual mode

6.1. Introduction

By tapping the navigation button Manual the control is switched to

the manual production mode.

In manual mode you program the parameters for one bending. This mode is useful for testing,

for calibration and for single bends.

Manual mode is independent from Automatic mode and can be programmed independently of the programs in memory.

In the top of the Manual mode screen you can find the Y-axis and the main X-axis current

position. All other axes and functions are listed one by one in the two columns below.

When these Y-axis value and X-axis value are highlighted it means that the reference markers

of these axes have been found and that they are positioned correctly referred to their

programmed values.

6.1.1. Manual mode, parameter explanation

Following is a list of the available parameters in Manual mode.

Bend parameters

Method

Select the required bending method. The control supports the following standard

methods:

• Air bend

• Bottoming

• Hemming

• Hemming & bottoming

The bend methods have been explained in more detail in the Program mode.

Bending length

Program the bending length of the sheet.

Product position

The absolute position value of the product in the Z-direction. Left machine side is

reference position zero.

Angle

Angle to bend.

Corr. 1, Corr. 2

Correction on angle to bend.

The angle correction should be entered as following examples indicate:

Programmed value of 90 degrees. Measured value of 92 degrees.

-> Then it is required to program Corr. with -2.

Programmed value of 90 degrees. Measured value of 88 degrees.

-> Then it is required to program Corr. with +2.

Hem opening

The hem bend can be made with a certain opening distance between the 2 flanges. The

hem opening value will be used calculating the beam position in the hemming process.

By default this parameter has the value of the Settings mode parameter Default Hem Opening.

Corr.Y

Correction on the Y-axis position, in case bottoming has been selected.

Y-axis

The programmed or calculated Y-axis value to realise a certain angle.

Mute

Sequence point where the Y-axis is switched from fast closing speed to pressing speed.

It is programmed here as a Y-axis position value. The programmed value is the Y-axis

point above the sheet.

Parallel

Difference of the left- and right hand side cylinder (Y1 and Y2). When positive, the right

hand side is lower. When negative, the right hand side is higher. The programmed value

is active below the clamping point.

Opening

This parameter results in a certain gap opening between the punch and the die after the

bend. A positive value is the gap opening above Mute, a negative value below Mute.

When you want to limit the handling time for the product you can program a small

positive or a negative value.

Force

Force

The programmed force applied during pressing.

Dwell time