Преимущества

- Компактный дизайн Размер частотника до 40% меньше аналогичных моделей других серий

- Плотная установка Допускает плотную установку при рабочей температуре -20˚C ~ 40˚C

- Работает с различными двигателями

- Улучшенная функция торможения Режим управления энергией замедления уменьшает время замедления за счет корректировки скорости и тока двигателя, что заменяет необходимость ставить тормозные резисторы. Пример работы данного режима (цифры могут отличаться при разных нагрузках)

- Преодоление кратковременных провалов напряжения (Deceleration Energy Backup — DEB) Данная функция управляет замедлением двигателя при кратковременных провалах напряжения для избежания механических повреждений оборудования. При возврате напряжения двигатель разгоняется до прежней скорости.

- Поддерживает работу с 4 независимыми наборами параметров для асинхронных двигателей Переключение между двигателями происходит после полной остановки активного двигателя через контроллер или вручную.

- Импульсный вход Поддерживает однофазный импульсный сигнал с контроллера как частотное задание.

- Встроенный ПЛК Имеет встроенный ПЛК на 2К шагов.

- Перегрузочная способность Нормальный режим: 120% от номинального тока в течение 60 сек; 150% в течение 3 сек Тяжелый режим: 150% от номинального тока в течение 60 сек; 200% в течение 3 сек

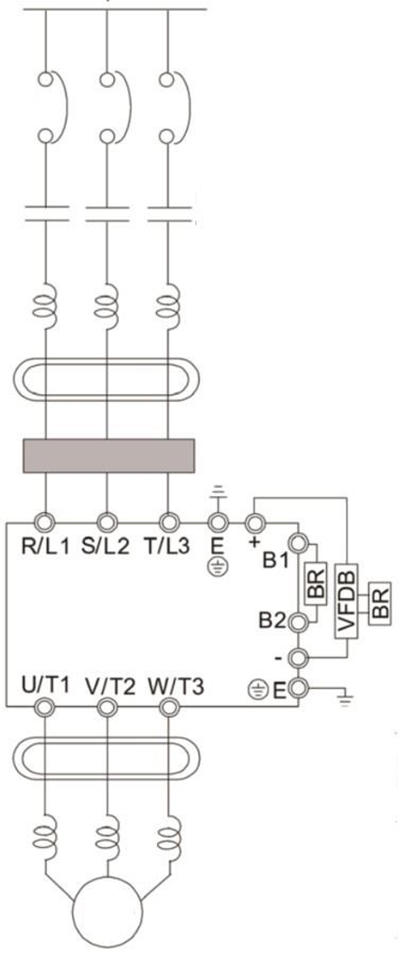

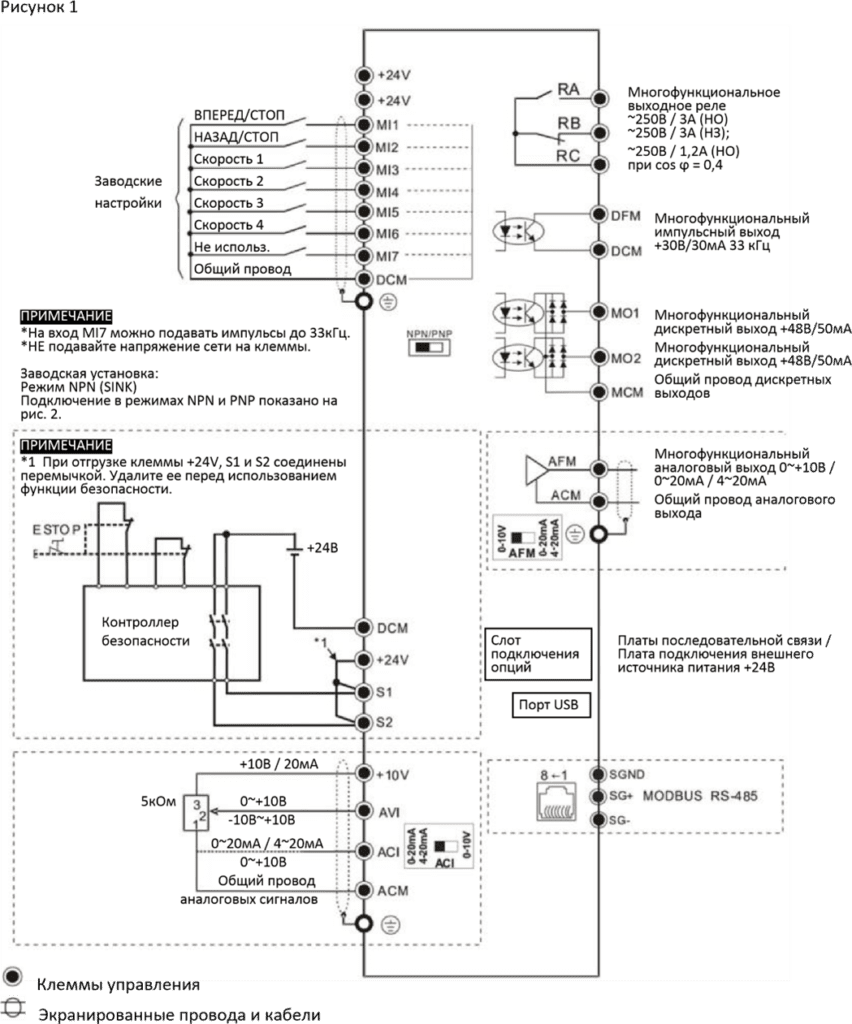

Подключение

| Сеть | Подробнее см. спецификации в таблице в Глава 9. |

| Автоматический выключатель или предохранитель | При подаче питания возможен бросок тока. Выберите нужный типоразмер автомата (глава 7-2) или предохранителя (глава 7-3). |

| Электромагнитный контактор | Включение питания чаще, чем 1 раз в час может повредить преобразователь. |

| Сетевой дроссель | Если мощность питающей сети превышает 500 кВА, или если перед преобразователем установлены конденсаторы, то мгновенные броски тока и напряжения могут повредить преобразователь. В этом случае рекомендуется устанавливать сетевой дроссель, который также повысит коэффициент мощности и снизит уровень гармонических искажений. Длина кабеля между дросселем и преобразователем не должна превышать 10 м. |

| Ферритовое кольцо | Используется для снижения излучаемых помех, особенно при наличии аудиоаппаратуры в непосредственной близости, а также снижает помехи во входных и выходных цепях. |

| Фильтр ЭМС | Используется для снижения электромагнитных помех. |

| Тормозной модуль и тормозной резистор | Используется для уменьшения времени замедления двигателя. |

| Моторный дроссель | Длина моторного кабеля влияет на величину пиковых токов коммутации. Если длина кабеля превышает величину, указанную в главе 7-4, рекомендуется устанавливать моторный дроссель. |

| Клеммы | Описание |

| R/L1, S/L2 | Клеммы подключения однофазного питания |

| R/L1, S/L2, T/L3 | Клеммы подключения трехфазного питания |

| U/T1, V/T2, W/T3 | Клеммы подключения трехфазного двигателя (асинхронного или синхронного с постоянными магнитами) |

| +1, +2 | Клеммы подключения дросселя постоянного тока, служащего для улучшения коэффициента мощности и снижения гармонических искажений. При подключении дросселя перемычку между этими клеммами нужно удалить. |

| DC+, DC | Подключение тормозного модуля (серии VFDB) Подключение общей шины постоянного тока |

| B1, B2 | Подключение тормозного резистора (опция) |

| ⏚ | Подключение заземления; руководствуйтесь действующими нормами |

Список доступных параметров

Параметры привода

| № | Описание | Значения | Заводская установка |

| 00-00 | Идентификационный код преобразователя | 102: 110 В, 1 фаза, 0.25 л.с. 103: 110 В, 1 фаза, 0.5 л.с. 104: 110 В, 1 фаза, 1 л.с. 302: 230 В, 1 фаза, 0.25 л.с. 303: 230 В, 1 фаза, 0.5 л.с. 304: 230 В, 1 фаза, 1 л.с. 305: 230 В, 1 фаза, 2 л.с. 306: 230 В, 1 фаза, 3 л.с. 202: 230 В, 3 фазы, 0.25 л.с. 203: 230 В, 3 фазы, 0.5 л.с. 204: 230 В, 3 фазы, 1 л.с. 205: 230 В, 3 фазы, 2 л.с. 206: 230 В, 3 фазы, 3 л.с. 207: 230 В, 3 фазы, 5 л.с. 208: 230 В, 3 фазы, 7.5 л.с. 209: 230 В, 3 фазы, 10 л.с. 210: 230 В, 3 фазы, 15 л.с. 211: 230 В, 3 фазы, 20 л.с. 403: 460 В, 3 фазы, 0.5 л.с. 404: 460 В, 3 фазы, 1 л.с. 405: 460 В, 3 фазы, 2 л.с. 406: 460 В, 3 фазы, 3 л.с. 407: 460 В, 3 фазы, 5 л.с. 408: 460 В, 3 фазы, 7.5 л.с. 409: 460 В, 3 фазы, 10 л.с. 410: 460 В, 3 фазы, 15 л.с. 411: 460 В, 3 фазы, 20 л.с. 412: 460 В, 3 фазы, 25 л.с. 413: 460 В, 3 фазы, 30 л.с. |

Только чтение |

| 00-01 | Номинальный ток преобразователя | Зависит от модели | Только чтение |

| 00-02 | Сброс параметров | 0: Нет функции 1: Запрет записи параметров 5: Сброс счетчика кВт-ч 6: Перезагрузка ПЛК 7: Сброс индекса CANopen (Ведомый) 9: Сброс параметров к заводским значениям (для сети 50 Гц) 10: Сброс параметров к заводским значениям (для сети 60 Гц) 11: Сброс параметров к заводским значениям (для сети 50 Гц) (с сохранением выбора пользовательских параметров 13-01~13-50) 12: Сброс параметров к заводским значениям (для сети 50 Гц) (с сохранением выбора пользовательских параметров 13-01~13-50) | 0 |

| 00-03 | Индикация при включении | 0: F (задание частоты) 1: H (выходная частота) 2: U (пользовательское значение, см. 00-04) 3: A (выходной ток) | 0 |

| 00-04 | Отображаемое пользовательское значение | 0: Выходной ток (код: A) (Единицы: A) 1: Значение счетчика (c) (CNT) 2: Выходная частота (H.) (Гц) 3: Напряжение шины постоянного тока (v) (В) 4: Выходное напряжение (E) (В) 5: Угол между векторами тока и напряжения (n) (град.) 6: Выходная мощность (P) (кВт) 7: Скорость двигателя (об/мин) 10: Обратная связь ПИД-регулятора (b) (%) 11: Сигнал на входе AVI (1.) (%) 12: Сигнал на входе ACI (2.) (%) 14: Температура силовых модулей IGBT (i.) (°С) 16: Состояние дискретных входов ВКЛ / ВЫКЛ (i) 17: Состояние дискретных выходов ВКЛ / ВЫКЛ (o) 18: Текущая фиксированная скорость (S) 19: Состояние дискретных входов на клеммах процессора (d) 20: Состояние дискретных выходов на клеммах процессора (0.) 22: Частота на импульсном входе (S.) 23: Положение на импульсном входе (q.) 25: Перегрузка (0.00~100.00 %) (o.) (%) 26: Утечка на землю GFF (G.) (%) 27: Пульсации напряжения на шине постоянного то- ка (r.) (%) 28: Данные регистра D1043 ПЛК (C) 30: Отображение пользовательского значения (U) 31: Выходная частота x 00-05 (K) 35: Режим управления: 0 = управление скоростью (SPD) 36: Текущая частота коммутации (J.) (Гц) 38: Состояние привода (6.) 41: Счетчик электроэнергии (J) (кВт-ч) 42: Задание ПИД-регулятора (h.) (%) 43: Сдвиг ПИД-регулятора (o.) (%) 44: Задание частоты на выходе ПИД-регулятора (b.) (Гц) 46: Дополнительное задание частоты (U.) (Гц) 47: Главное задание частоты (A.) (Гц) 48: Задание частоты после суммирования и вычитания главного и дополнительного заданий частоты (L.) (Гц) |

3 |

| 00-05 | Коэффициент умножения выходной частоты | 0~160.00 | 1.00 |

| 00-06 | Версия программного обеспечения | Только чтение | #.# |

| 00-07 | Ввод пароля защиты параметров | 0~65535 0~3 (количество попыток ввода пароля) | 0 |

| 00-08 | Установка пароля защиты параметров | 0~65535 0: Нет парольной защиты / введен правильный пароль (00-07) 1: Пароль установлен | 0 |

| 00-10 | Режим управления | 0: Управление скоростью | 0 |

| 00-11 | Режим управления скоростью | 0: VF (управление скоростью асинхронного двигателя (IM) по закону V/F) 1: VFPG (управление скоростью асинхронного двигателя (IM) по закону V/F + Encoder) 2: SVC (В параметре 05-33 установлено IM или PM) | 0 |

| 00-16 | Выбор типа нагрузки | 0: Нормальная нагрузка 1: Тяжелая нагрузка | 1 |

| 00-17 | Частота коммутации | Нормальная нагрузка: 2~15 кГц Тяжелая нагрузка: 2~15 кГц | 4 |

| 00-19 | Маска команды ПЛК | Бит 0: Команды управления от ПЛК Бит 1: Задание скорости от ПЛК | Только чтение |

| 00-20 | Источник главного задания частоты (режим AUTO) | 0: Пульт управления 1: RS-485 2: Аналоговый вход (03-00) 3: Клеммы UP/DOWN 4: Импульсный вход без команды направления (См. 10-16) 6: Плата CANopen 7: Потенциометр пульта управления 8: Плата связи (кроме CANopen) [Примечание]: Используется совместно с дискретным выходом MO (функция 42) или пультом KPC-CC01 | 0 |

| 00-21 | Источник команд управления (режим AUTO) | 0: Пульт управления 1: Клеммы 2: RS-485 3: Плата CANopen 5: Плата связи (кроме CANopen) [Примечание]: Используется совместно с выходом MO (функция 42) или пультом KPC-CC01 | 0 |

| 00-22 | Останов | 0: Плавный останов 1: Выбег | 0 |

| 00-23 | Направление вращения | 0: В любую сторону 1: Обратное вращение запрещено 2: Прямое вращение запрещено | 0 |

| 00-24 | Память задания частоты от пульта управления | Только чтение | Только чтение |

| 00-25 | Пользовательское отображение | Бит 0~3: Число знаков после запятой 0000b: нет 0001b: один 0010b: два 0011b: три | 0 |

| 00-26 | Максимальное пользовательское значение | 0: Отключено 0~65535 (если в 00-25 нет знаков после запятой) 0.0~6553.5 (если в 00-25 1 знак после запятой) 0.0~655.35 (если в 00-25 2 знака после запятой) 0.0~65.535 (если в 00-25 3 знака после запятой) | 0 |

| 00-27 | Пользовательское значение | Только чтение | Только чтение |

| 00-29 | Переключение режимов управления LOCAL / REMOTE | 0: Стандартная функция HOA (Ручное – 0 – Автоматическое) 1: При переключении Local / Remote привод останавливается 2: При переключении Local / Remote привод переходит в режим REMOTE 3: При переключении Local / Remote привод переходит в режим LOCAL 4: Привод переходит в режим LOCAL при переключении в Local, и переходит в режим REMOTE при переключении в Remote | 0 |

| 00-30 | Источник дополнительного задания частоты (режим HAND) | 0: Пульт управления 1: RS-485 2: Аналоговый вход (03-00) 3: Клеммы UP/DOWN 4: Импульсный вход без команды направления (См. 10-16) 6: Плата CANopen 7: Потенциометр пульта управления 8: Плата связи (кроме CANopen) [Примечание]: Используется совместно с выходом MO (функция 41) или пультом KPC-CC01 | 0 |

| 00-31 | Источник команд управления (режим HAND) | 0: Пульт управления 1: Клеммы 2: RS-485 3: Плата CANopen 5: Плата связи (кроме CANopen) [Примечание]: Используется совместно с выходом MO (функция 41) или пультом KPC-CC01 | 0 |

| 00-32 | Функция останова с пульта | 0: Кнопка STOP отключена 1: Кнопка STOP включена |

0 |

| 00-35 | Источник дополнительного задания частоты | 0: Функция основного и дополнительного задания отключена 1: Пульт управления 2: RS-485 3: Аналоговый вход 4: Клеммы UP/DOWN 5: Импульсный вход с командой направления (См. 1016) 6: Плата CANopen 8: Плата связи | 0 |

| 00-36 | Комбинация основного и дополнительного заданий частоты | 0: Основное + дополнительное 1: Основное — дополнительное 2: Дополнительное — основное | 0 |

| 00-48 | Постоянная времени дисплея (текущие значения) | 0.001…65.535 | 0.100 |

| 00-49 | Постоянная времени дисплея (пульт) | 0.001…65.535 | 0.100 |

| 00-50 | Версия программного обеспечения (дата) | Только чтение | ##### |

Базовые параметры

| 01-00 | Максимальная рабочая частота | 0.00~599.00 Гц | 60.00/ 50.00 |

| 01-01 | Номинальная частота двигателя 1 | 0.00~599.00 Гц | 60.00/ 50.00 |

| 01-02 | Номинальное напряжение двигателя 1 | Серии 110 В / 230 В: 0.0 В~255.0 В Серия 460 В: 0.0~510.0 В | 220.0 440.0 |

| 01-03 | Частота средней точки 1 двигателя 1 | 0.00~599.00 Гц | 3.00 |

| 01-04 | Напряжение средней точки 1 двигателя 1 | Серии 110 В / 230 В: 0.0 В~240.0 В Серия 460 В: 0.0 В~480.0 В | 11.0 22.0 |

| 01-05 | Частота средней точки 2 двигателя 1 | 0.00~599.00 Гц | 0.50 |

| 01-06 | Напряжение средней точки 2 двигателя 1 | Серии 110 В / 230 В: 0.0 В~240.0 В Серия 460 В: 0.0 В~480.0 В | 2.0 4.0 |

| 01-07 | Минимальная частота двигателя 1 | 0.00~599.00 Гц | 0.00 |

| 01-08 | Минимальное напряжение двигателя 1 | Серии 110 В / 230 В: 0.0 В~240.0 В Серия 460 В: 0.0 В~480.0 В | 0.0 0.0 |

| 01-09 | Пусковая частота | 0.00~599.00 Гц | 0.50 |

| 01-10 | Верхний предел выходной частоты | 0.00~599.00 Гц | 599.00 |

| 01-11 | Нижний предел выходной частоты | 0.00~599.00 Гц | 0.00 |

| 01-12 | Время разгона 1 | 01-45 = 0: 0.00~600.00 c 01-45 = 1: 0.00~6000.0 c | 10.00 10.0 |

| 01-13 | Время замедления 1 | 01-45 = 0: 0.00~600.00 c 01-45 = 1: 0.00~6000.0 c | 10.00 10.0 |

| 01-14 | Время разгона 2 | 01-45 = 0: 0.00~600.00 c 01-45 = 1: 0.00~6000.0 c | 10.00 10.0 |

| 01-15 | Время замедления 2 | 01-45 = 0: 0.00~600.00 c 01-45 = 1: 0.00~6000.0 c | 10.00 10.0 |

| 01-16 | Время разгона 3 | 01-45 = 0: 0.00~600.00 c 01-45 = 1: 0.00~6000.0 c | 10.00 10.0 |

| 01-17 | Время замедления 3 | 01-45 = 0: 0.00~600.00 c 01-45 = 1: 0.00~6000.0 c | 10.00 10.0 |

| 01-18 | Время разгона 4 | 01-45 = 0: 0.00~600.00 c 01-45 = 1: 0.00~6000.0 c | 10.00 10.0 |

| 01-19 | Время замедления 4 | 01-45 = 0: 0.00~600.00 c 01-45 = 1: 0.00~6000.0 c | 10.00 10.0 |

| 01-20 | Время разгона в толчковом режиме | 01-45 = 0: 0.00~600.00 c 01-45 = 1: 0.00~6000.0 c | 10.00 10.0 |

| 01-21 | Время замедления в толчковом режиме | 01-45 = 0: 0.00~600.00 c 01-45 = 1: 0.00~6000.0 c | 10.00 10.0 |

| 01-22 | Частота толчкового режима | 0.00~599.00 Гц | 6.00 |

| 01-23 | Частота перехода с 1-го на 4-е время разгона / замедления | 0.00~599.00 Гц | 0.00 |

| 01-24 | S-образность в начале разгона | 01-45 = 0: 0.00~25.00 c 01-45 = 1: 0.0~250.0 c | 0.20 0.2 |

| 01-25 | S-образность в конце разгона | 01-45 = 0: 0.00~25.00 c 01-45 = 1: 0.0~250.0 c | 0.20 0.2 |

| 01-26 | S-образность в начале замедления | 01-45 = 0: 0.00~25.00 c 01-45 = 1: 0.0~250.0 c | 0.20 0.2 |

| 01-27 | S-образность в конце замедления | 01-45 = 0: 0.00~25.00 c 01-45 = 1: 0.0~250.0 c | 0.20 0.2 |

| 01-28 | Верхний предел пропускаемой частоты 1 | 0.00~599.00 Гц | 0.00 |

| 01-29 | Нижний предел пропускаемой частоты 1 | 0.00~599.00 Гц | 0.00 |

| 01-30 | Верхний предел пропускаемой частоты 2 | 0.00~599.00 Гц | 0.00 |

| 01-31 | Нижний предел пропускаемой частоты 2 | 0.00~599.00 Гц | 0.00 |

| 01-32 | Верхний предел пропускаемой частоты 3 | 0.00~599.00 Гц | 0.00 |

| 01-33 | Нижний предел пропускаемой частоты 3 | 0.00~599.00 Гц | 0.00 |

| 01-34 | Режим нулевой скорости | 0: Выход отключен 1: Работа на нулевой скорости 2: Fmin (см. параметры 01-07, 01-41) | 0 |

| 01-35 | Номинальная частота двигателя 2 | 0.00~599.00 Гц | 60.00/ 50.00 |

| 01-36 | Номинальное напряжение двигателя 2 | Серии 110 В / 230 В: 0.0 В~255.0 В Серия 460 В: 0.0~510.0 В | 220.0 440.0 |

| 01-37 | Частота средней точки 1 двигателя 2 | 0.00~599.00 Гц | 3.00 |

| 01-38 | Напряжение средней точки 1 двигателя 2 | Серии 110 В / 230 В: 0.0 В~240.0 В Серия 460 В: 0.0 В~480.0 В | 11.0 22.0 |

| 01-39 | Частота средней точки 2 двигателя 2 | 0.00~599.00 Гц | 0.50 |

| 01-40 | Напряжение средней точки 2 двигателя 2 | Серии 110 В / 230 В: 0.0 В~240.0 В Серия 460 В: 0.0 В~480.0 В | 2.0 4.0 |

| 01-41 | Минимальная частота двигателя 2 | 0.00~599.00 Гц | 0.00 |

| 01-42 | Минимальное напряжение двигателя 2 | Серии 110 В / 230 В: 0.0 В~240.0 В Серия 460 В: 0.0 В~480.0 В | 0.0 0.0 |

| 01-43 | Выбор характеристики V/F | 0: Задается параметрами 01-00~01-08 1: 1.5х кривая V/F 2: 2х кривая V/F | 0 |

| 01-44 | Выбор автоматического разгона / замедления | 0: Линейный разгон / замедление 1: Автоматический разгон, линейное замедление 2: Линейный разгон, автоматическое замедление 3: Автоматический разгон / замедление 4: Линейный, с переходом на автоматический для предупреждения сваливания (ограничено параметрами 01-12 ~ 01-21) | 0 |

| 01-45 | Единицы времени разгона / замедления и S-образности | 0: 0.01 с 1: 0.1 с | 0 |

| 01-46 | Быстрый останов при управлении CANopen | 01-45 = 0: 0.00~600.00 с 01-45 = 1: 0.0~6000.0 с | 1.00 |

| 01-49 | Способ замедления | 0: Обычное замедление 1: Замедление с перевозбуждением 2: Контроль передачи энергии | 0 |

| 01-52 | Максимальная рабочая частота двигателя 2 | 0.00~599.00 Гц | 60.00/ 50.00 |

| 01-53 | Максимальная рабочая частота двигателя 3 | 0.00~599.00 Гц | 60.00/ 50.00 |

| 01-54 | Номинальная частота двигателя 3 | 0.00~599.00 Гц | 60.00/ 50.00 |

| 01-55 | Номинальное напряжение двигателя 3 | Серии 110 В / 230 В: 0.0 В~255.0 В Серия 460 В: 0.0~510.0 В | 220.0 440.0 |

| 01-56 | Частота средней точки 1 двигателя 3 | 0.00~599.00 Гц | 3.00 |

| 01-57 | Напряжение средней точки 1 двигателя 3 | Серии 110 В / 230 В: 0.0 В~240.0 В Серия 460 В: 0.0 В~480.0 В | 11.0 22.0 |

| 01-58 | Частота средней точки 2 двигателя 3 | 0.00~599.00 Гц | 0.50 |

| 01-59 | Напряжение средней точки 2 двигателя 3 | Серии 110 В / 230 В: 0.0 В~240.0 В Серия 460 В: 0.0 В~480.0 В | 2.0 4.0 |

| 01-60 | Минимальная частота двигателя 3 | 0.00~599.00 Гц | 0.00 |

| 01-61 | Минимальное напряжение двигателя 3 | Серии 110 В / 230 В: 0.0 В~240.0 В Серия 460 В: 0.0 В~480.0 В | 0.0 0.0 |

| 01-62 | Максимальная рабочая частота двигателя 4 | 0.00~599.00 Гц | 60.00/ 50.00 |

| 01-63 | Номинальная частота двигателя 4 | 0.00~599.00 Гц | 60.00/ 50.00 |

| 01-64 | Номинальное напряжение двигателя 4 | Серии 110 В / 230 В: 0.0 В~255.0 В Серия 460 В: 0.0~510.0 В | 220.0 440.0 |

| 01-65 | Частота средней точки 1 двигателя 4 | 0.00~599.00 Гц | 3.00 |

| 01-66 | Напряжение средней точки 1 двигателя 4 | Серии 110 В / 230 В: 0.0 В~240.0 В Серия 460 В: 0.0 В~480.0 В | 11.0 22.0 |

| 01-67 | Частота средней точки 2 двигателя 4 | 0.00~599.00 Гц | 0.50 |

| 02-00 | 2-проводное / 3-проводное управление | 0: Нет функции 1: 2-проводный режим 1 (M1: FWD / STOP, M2: REV / STOP) 2: 2-проводный режим 2 (M1: RUN / STOP, M2: REV / FWD) 3: 3-проводный режим (M1: RUN, M2: REV / FWD, M3: STOP) 4: 2-проводный режим 1, быстрый пуск (M1: FWD / STOP, M2: REV / STOP) 5: 2-проводный режим 2, быстрый пуск (M1: RUN / STOP, M2: REV / FWD) 6: 3-проводный режим, быстрый пуск (M1: RUN, M2: REV / FWD, M3: STOP) ВАЖНО В режиме быстрого пуска силовой выход остается в режиме готовности, по команде ПУСК старт происходит немедленно. При использовании режима быстрого пуска на выходных клеммах присутствует более высокое напряжение. | 1 |

| 02-01 02-02 02-03 02-04 02-05 02-06 02-07 | Дискретный вход 1 (MI1) Дискретный вход 2 (MI2) Дискретный вход 3 (MI3) Дискретный вход 4 (MI4) Дискретный вход 5 (MI5) Дискретный вход 6 (MI6) Дискретный вход 7 (MI7) |

0: Нет функции 1: Фиксированная скорость 1 / Положение 1 2: Фиксированная скорость 2 / Положение 2 3: Фиксированная скорость 3 / Положение 3 4: Фиксированная скорость 4 / Положение 4 5: Сброс 6: Толчковый режим (с пульта KPC-CC01 или через клеммы) 7: Задержка разгона / замедления 8: Выбор времени разгона / замедления 1 / 2 9: Выбор времени разгона / замедления 3 / 4 10: Сигнал внешней неисправности (EF) 11: Гарантированное отключение (Base Block) 12: Временное отключение напряжения 13: Отключение автоматического разгона / замедления 15: Задание скорости – с AVI 16: Задание скорости – с ACI 18: Аварийный останов (07-20) 19: Команда UP (больше) 20: Команда DOWN (меньше) 21: Отключение ПИД-регулятора 22: Обнуление счетчика 23: Увеличение значения счетчика на 1 (MI6) 24: Толчковый пуск вперед 25: Толчковый пуск назад 28: Аварийный останов (EF1) 29: Подтверждение подключения в звезду 30: Подтверждение подключения в треугольник 38: Запрещение записи параметров 40: Принудительный останов выбегом 41: Переключение в ручной режим (HAND) 42: Переключение в автоматический режим (AUTO) 48: Переключение коэффициента редукции 49: Разрешение работы 50: Вход функции dEb от ведущего 51: Управление ПЛК, бит 0 52: Управление ПЛК, бит 1 53: Быстрый останов в CANopen 56: Переключение Местное / Удаленное 70: Обнуление дополнительного задания частоты 71: Отключение ПИД-регулятора, обнуление его выхода 72: Отключение ПИД-регулятора, сохранение выходной частоты 73: Обнуление и отключение интегральной части ПИД-регулятора 74: Изменение знака обратной связи ПИДрегулятора 82: Запись баланса для функции OOB 83: Выбор номера двигателя, бит 0 84: Выбор номера двигателя, бит 1 |

0 0 1 2 3 4 0 |

| 02-09 | Режим работы сигналов UP/DOWN | 0: Скорость изменения совпадает с темпом разгона/замедления 1: Постоянная скорость изменения (см. 02-10) 2: Импульсное изменение (см. 02-10) 3: Внешние клеммы UP / DOWN | 0 |

| 02-10 | Скорость изменения задания сигналами UP / DOWN | 0.001~1.000 Гц / мс | 0.001 |

| 02-11 | Фильтр дискретных входов | 0.000~30.000 сек | 0.005 |

| 02-12 | Выбор режима дискретных входов | 0000h~FFFFh (0: НО; 1: НЗ) | 0000 |

| 02-13 02-16 02-17 | Выходное реле 1 RY1 Дискретный выход 2 (MO1) Дискретный выход 3 (MO2) | 0: Нет функций 1: Работа 2: Заданная скорость достигнута 3: Желаемая частота 1 (02-22) достигнута 4: Желаемая частота 2 (02-24) достигнута 5: Нулевая скорость (задание частоты) 6: Нулевая скорость (задание частоты) или останов 7: Перегрузка по моменту 1 (06-06~06-08) 8: Перегрузка по моменту 2 (06-09~06-11) 9: Готовность 10: Предупреждение о пониженном напряжении (LV) (06-00) 11: Авария 13: Предупреждение о перегреве (06-15) 14: Электрическое торможение (07-00) 15: Ошибка обратной связи ПИД-регулятора 16: Ошибка спящего режима (oSL) 17: Достигнуто предварительное значение счетчика; без сброса на 0 (02-20) 18: Достигнуто заданное значение счетчика; со сбросом на 0 (02-19) 19: Получен внешний сигнал отключения B.B. (Base Block) 20: Предупреждение 21: Предупреждение о перенапряжении 22: Опасность опрокидывания из-за большого тока 23: Опасность опрокидывания из-за высокого напряжения 30: Частота < 02-34 31: Переключение двигателя в звезду 32: Переключение двигателя в треугольник 33: Нулевая скорость (выходная частота) 34: Нулевая скорость (выходная частота) или Стоп 35: Выбранные сигналы аварии 1 (06-23) 36: Выбранные сигналы аварии 2 (06-24) 37: Выбранные сигналы аварии 3 (06-25) 38: Выбранные сигналы аварии 4 (06-26) 40: Скорость достигнута (включая Стоп) 42: Крановая функция 43: Скорость двигателя < 02-47 44: Низкий ток (используется с 06-71~06-73) 45: Включение контактора на выходе ПЧ 46: Выход сигнала dEb ведущего 50: Управление через CANopen 52: Управление через опциональную плату 66: Выход состояния STO, логика A 67: Достигнут заданный уровень на аналоговом входе 68: Выход состояния STO, логика B 73: Перегрузка по моменту 3 74: Перегрузка по моменту 4 |

11 0 0 |

| 02-47 | Скорость, принимаемая за нулевую | 0~65535 об/мин | 0 |

| 02-50 | Состояние входов | Отображение состояния дискретных входов | Только чтение |

| 02-51 | Состояние выходов | Отображение состояния дискретных выходов | Только чтение |

| 02-52 | Входы, используемые ПЛК | Дискретные входы, используемые ПЛК | Только чтение |

| 02-53 | Выходы, используемые ПЛК | Дискретные выходы, используемые ПЛК | Только чтение |

| 02-54 | Память задания частоты с клемм | 0.00~599.00 Гц | Только чтение |

| 02-58 | Дискретный выход с функцией 42: Частота наложения тормоза | 0.00~599.00 Гц | 0.00 |

| 02-78 | Коэффициент торможения | 4.0~1000.0 | 200.0 |

| 02-79 | Резерв | ||

| 02-80 | Резерв | ||

| 02-81 | Включение EF при достижении заданного значения счетчика | 0: Нет индикации EF, продолжение работы 1: Сигнал EF активен | 0 |

| 02-82 | Режим задания частоты (F) после остановки | 0: Текущее задание частоты 1: Нулевое задание частоты 2: Задание 02-83 | 0 |

| 02-83 | Задание частоты (F) после остановки | 0.00~599.0 Гц | 60.00 |

Параметры аналоговых входов / выходов

| 03-00 03-01 | Аналоговый вход AVI Аналоговый вход ACI | 0: Не используется 1: Задание частоты 4: Задание ПИД-регулятора 5: Обратная связь ПИД-регулятора 6: Вход подключения термистора PTC 11: Вход подключения термистора PT100 12: Дополнительное задание частоты 13: Сдвиг ПИД-регулятора | 1 0 0 |

| 03-03 | Сдвиг аналогового входа AVI | -100.0~100.0% | 0 |

| 03-04 | Сдвиг аналогового входа ACI | -100.0~100.0% | 0 |

| 03-07 03-08 | Положительный / отрицательный сдвиг AVI Положительный / отрицательный сдвиг ACI | 0: Нет сдвига 1: Меньше чем сдвиг = сдвиг 2: Больше чем сдвиг = сдвиг 3: Абсолютное значение сдвига при 0 в середине шкалы 4: Установить сдвиг в качестве центра | 0 |

| 03-10 | Аналоговое задание для вращения назад | 0: Отрицательное задание запрещено. Направление вращения определяется сигналами с пульта или клемм управления. 1: Отрицательное задание разрешено. Положительное задание соответствует вращению вперед, отрицательное – назад. Сигналы с пульта или клемм управления на направление вращения не влияют. | 0 |

| 03-11 | Коэффициент сигнала на входе AVI | -500.0~500.0% | 100.0 |

| 03-12 | Коэффициент сигнала на входе ACI | -500.0~500.0% | 100.0 |

| 03-15 | Постоянная времени входа AVI | 0.00~20.00 с | 0.01 |

| 03-16 | Постоянная времени входа ACI | 0.00~20.00 с | 0.01 |

| 03-17 | Постоянная времени входа AVI2 | 0.00~20.00 с | 0.01 |

| 03-18 | Функция сложения аналоговых сигналов | 0: Отключена (AVI, ACI) 1: Включена (кроме входов опциональных плат) | 0 |

| 03-19 | Действия при потере сигнала на входе ACI | 0: Игнорирование 1: Продолжение работы на последней частоте 2: Плавный останов 3: Останов выбегом и индикация ACE |

0 |

| 03-20 | Аналоговый выход AFM | 0: Выходная частота (Гц) 1: Задание частоты (Гц) 2: Скорость двигателя (об/мин) 3: Выходной ток (Аrms) 4: Выходное напряжение 5: Напряжение на шине постоянного тока 6: Коэффициент мощности 7: Мощность 9: AVI 10: ACI 12: Задание тока Iq 13: Величина тока Iq 14: Задание тока Id 15: Величина тока Id 16: Задание напряжения оси Vq 17: Задание напряжения оси Vd 19: Задание частоты PG2 20: Аналоговый выход CANopen 21: Аналоговый выход RS485 22: Аналоговый выход платы связи 23: Выход постоянного напряжения | 0 |

| 03-21 | Коэффициент аналогового выхода AFM | 0~500.0% | 100.0 |

| 03-22 | Сигнал на выходе (AFM) при вращении назад | 0: Абсолютное значение 1: При вращении назад 0В; при вращении вперед 0-10В 2: При вращении назад 0-5В; при вращении вперед 5-10В | 0 |

| 03-27 | Сдвиг выхода AFM | -100.00~100.00% | 0.00 |

| 03-28 | Настройка AVI | 0: 0-10В 3: -10В ~ +10В (параметры 03-69 ~ 03-74 действуют) | 0 |

| 03-29 | Настройка ACI | 0: 4~20мА 1: 0~10В 2: 0~20мА | 0 |

| 03-30 | Аналоговые выходы, используемые ПЛК | Отображение состояния выходов ПЛК Бит 1: AFM Бит 2: AO10 Бит 3: AO11 | Только чтение |

| 03-31 | Настройка AFM | 0: 0-10В 1: 0-20мА 2: 4-20мА | 0 |

| 03-32 | Выходное напряжение AFM | 0.00~100.00% | 0.00 |

Параметры фиксированных заданий частоты

| 04-00 | Задание частоты на 1-м этапе | 0.00~599.00 Гц | 0.00 |

| 04-01 | Задание частоты на 2-м этапе | 0.00~599.00 Гц | 0.00 |

| 04-02 | Задание частоты на 3-м этапе | 0.00~599.00 Гц | 0.00 |

| 04-03 | Задание частоты на 4-м этапе | 0.00~599.00 Гц | 0.00 |

| 04-04 | Задание частоты на 5-м этапе | 0.00~599.00 Гц | 0.00 |

| 04-05 | Задание частоты на 6-м этапе | 0.00~599.00 Гц | 0.00 |

| 04-06 | Задание частоты на 7-м этапе | 0.00~599.00 Гц | 0.00 |

| 04-07 | Задание частоты на 8-м этапе | 0.00~599.00 Гц | 0.00 |

| 04-08 | Задание частоты на 9-м этапе | 0.00~599.00 Гц | 0.00 |

| 04-09 | Задание частоты на 10-м этапе | 0.00~599.00 Гц | 0.00 |

| 04-10 | Задание частоты на 11-м этапе | 0.00~599.00 Гц | 0.00 |

| 04-11 | Задание частоты на 12-м этапе | 0.00~599.00 Гц | 0.00 |

| 04-12 | Задание частоты на 13-м этапе | 0.00~599.00 Гц | 0.00 |

| 04-13 | Задание частоты на 14-м этапе | 0.00~599.00 Гц | 0.00 |

| 04-14 | Задание частоты на 15-м этапе | 0.00~599.00 Гц | 0.00 |

| 04-50 | Буфер 0 ПЛК | 0~65535 | 0 |

| 04-51 | Буфер 1 ПЛК | 0~65535 | 0 |

| 04-52 | Буфер 2 ПЛК | 0~65535 | 0 |

| 04-53 | Буфер 3 ПЛК | 0~65535 | 0 |

| 04-54 | Буфер 4 ПЛК | 0~65535 | 0 |

| 04-55 | Буфер 5 ПЛК | 0~65535 | 0 |

| 04-56 | Буфер 6 ПЛК | 0~65535 | 0 |

| 04-57 | Буфер 7 ПЛК | 0~65535 | 0 |

| 04-58 | Буфер 8 ПЛК | 0~65535 | 0 |

| 04-59 | Буфер 9 ПЛК | 0~65535 | 0 |

| 04-60 | Буфер 10 ПЛК | 0~65535 | 0 |

| 04-61 | Буфер 11 ПЛК | 0~65535 | 0 |

| 04-62 | Буфер 12 ПЛК | 0~65535 | 0 |

| 04-63 | Буфер 13 ПЛК | 0~65535 | 0 |

| 04-64 | Буфер 14 ПЛК | 0~65535 | 0 |

| 04-65 | Буфер 15 ПЛК | 0~65535 | 0 |

| 04-66 | Буфер 16 ПЛК | 0~65535 | 0 |

| 04-67 | Буфер 17 ПЛК | 0~65535 | 0 |

| 04-68 | Буфер 18 ПЛК | 0~65535 | 0 |

| 04-69 | Буфер 19 ПЛК | 0~65535 | 0 |

Параметры двигателя

| 05-00 | Автонастройка на двигатель | 0: Нет функции 1: Тест с вращением для асинхронного двигателя (IM) 2: Тест без вращения для асинхронного двигателя (IM) 13: Высокочастотный тест без вращения для синхронного двигателя | 0 |

| 05-01 | Номинальный ток асинхронного двигателя 1 | 10~120% от номинального тока ПЧ | #.## |

| 05-02 | Номинальная мощность асинхронного двигателя 1 | 0~655.35 кВт | #.## |

| 05-03 | Номинальная скорость асинхронного двигателя 1 | 0~65535 1710 (60 Гц 4 полюса); 1410(50 Гц 4 полюса) | 1710 |

| 05-04 | Число полюсов асинхронного двигателя 1 | 2~20 | 4 |

| 05-05 | Ток холостого хода асинхронного двигателя 1 | 0 ~ заводское значение 05-01 | #.## |

| 05-06 | Сопротивление статора (Rs) асинхронного двигателя 1 | 0.000~65.535 Ом | #.### |

| 05-07 | Сопротивление ротора (Rr) асинхронного двигателя 1 | 0.000~65.535 Ом | #.### |

| 05-08 | Взаимоиндукция (Lm) асинхронного двигателя 1 | 0~6553.5 мГн | #.## |

| 05-09 | Индукция статора (Lx) асинхронного двигателя 1 | 0~6553.5 мГн | #.## |

| 05-13 | Номинальный ток асинхронного двигателя 2 | 10~120% от номинального тока ПЧ | #.## |

| 05-14 | Номинальная мощность асинхронного двигателя 2 | 0~655.35 кВт | #.## |

| 05-15 | Номинальная скорость асинхронного двигателя 2 | 0~65535 1710 (60 Гц 4 полюса); 1410(50 Гц 4 полюса) | 1710 |

| 05-16 | Число полюсов асинхронного двигателя 2 | 2~20 | 4 |

| 05-17 | Ток холостого хода асинхронного двигателя 2 | 0 ~ заводское значение 05-13 | #.## |

| 05-18 | Сопротивление статора (Rs) асинхронного двигателя 2 | 0.000~65.535 Ом | #.### |

| 05-19 | Сопротивление ротора (Rr) асинхронного двигателя 2 | 0.000~65.535 Ом | #.### |

| 05-20 | Взаимоиндукция (Lm) асинхронного двигателя 2 | 0~6553.5 мГн | #.## |

| 05-39 | Сопротивление статора двигателя с постоянными магнитами | 0.000~65.535 Ом | 0.000 |

| 05-40 | Ld двигателя с постоянными магнитами | 0.00~655.35 мГн | 0.00 |

| 05-41 | Lq двигателя с постоянными магнитами | 0.00~655.35 мГн | 0.00 |

| 05-43 | Ke двигателя с постоянными магнитами | 0.0~6553.5 (Единицы: В/1000 об/мин) | 0 |

| 05-64 | Номинальный ток асинхронного двигателя 3 | 10~120% от номинального тока преобразователя | #.## |

| 05-65 | Номинальная мощность асинхронного двигателя 3 | 0~655.35 кВт | #.## |

| 05-66 | Номинальная скорость асинхронного двигателя 3 | 0~65535 1710 (60Гц 4 полюса); 1410 (50Гц 4 полюса) | 1710 |

| 05-67 | Число полюсов асинхронного двигателя 3 | 2~20 | 4 |

| 05-68 | Ток холостого хода асинхронного двигателя 3 | 0 ~ 05-64 (заводская установка) | #.## |

| 05-69 | Сопротивление статора (Rs) асинхронного двигателя 3 | 0~65.535 Ом | #.### |

| 05-70 | Номинальный ток асинхронного двигателя 4 | 10~120% от номинального тока преобразователя | #.## |

| 05-71 | Номинальная мощность асинхронного двигателя 4 | 0~655.35 кВт | #.## |

| 05-72 | Номинальная скорость асинхронного двигателя 4 | 0~65535 1710 (60Гц 4 полюса); 1410 (50Гц 4 полюса) | 1710 |

| 05-73 | Число полюсов асинхронного двигателя 4 | 2~20 | 4 |

| 05-74 | Ток холостого хода асинхронного двигателя 4 | 0 ~ 05-70 (заводская установка) | #.## |

| 05-75 | Сопротивление статора (Rs) асинхронного двигателя 4 | 0~65.535 Ом | #.### |

Параметры защиты

| 06-00 | Пониженное напряжение | 110В / 230В: 150.0~220.0В 460В: 300.0~440.0В | 180.0 360.0 |

| 06-01 | Повышенное напряжение | 0: Отключено 110V / 230В: 0.0~450.0В 460В: 0.0~900.0В | 380.0 760.0 |

| 06-02 | Защита от перенапряжения | 0: Традиционная 1: Интеллектуальная | 0 |

| 06-03 | Защита от перегрузки по току при разгоне | Нормальный режим: 0~150% (100% соответствует номинальному току преобразователя) Тяжелый режим: 0~200% (100% соответствует номинальному току преобразователя) | 120 180 |

| 06-04 | Защита от перегрузки по току при работе | Нормальный режим: 0~150% (100% соответствует номинальному току преобразователя) Тяжелый режим: 0~200% (100% соответствует номинальному току преобразователя) | 120 180 |

| 06-05 | Время разгона / замедления при защите от перегрузки по току при работе | 0: по действующему времени разгона / замедления 1: По 1-му времени разгона / замедления 2: По 2-му времени разгона / замедления 3: По 3-му времени разгона / замедления 4: По 4-му времени разгона / замедления 5: По автоматическому разгону / замедлению | 0 |

| 06-06 | Действия при перегрузке по моменту (двигатель 1) | 0: Нет действий 1: Продолжение работы при перегрузке по моменту на постоянной скорости 2: Останов при перегрузке по моменту на постоянной скорости 3: Продолжение работы при перегрузке по моменту 4: Останов при перегрузке по моменту | 0 |

| 06-07 | Уровень перегрузки по моменту (двигатель 1) | 10~250 % (100 % соответствуют номинальному току преобразователя) | 120 |

| 06-08 | Задержка сигнала перегрузки по моменту (двигатель 1) | 0.0~60.0 c | 0.1 |

Примечание:

Полный список параметров доступен в фале ниже.

Коды ошибок

| № | Индикация | Описание |

| 1 | ocA | Перегрузка по току при разгоне (Выходной ток превысил номинальный более чем в три раза) Рекомендации Короткое замыкание на стороне двигателя: Проверьте качество изоляции в выходных цепях. Время разгона мало: Увеличьте время разгона. Мала мощность преобразователя: Замените преобразователь на более мощный. |

| 2 | ocd | Перегрузка по току при замедлении (Выходной ток превысил номинальный более чем в три раза) Рекомендации Короткое замыкание на стороне двигателя: Проверьте качество изоляции в выходных цепях. Время замедления мало: Увеличьте время замедления. Мала мощность преобразователя: Замените преобразователь на более мощный. |

| 3 | ocn | Перегрузка по току при работе на постоянной скорости (Выходной ток превысил номинальный более чем в три раза) Рекомендации Короткое замыкание на стороне двигателя: Проверьте качество изоляции в выходных цепях. Резкое увеличение нагрузки. Проверьте, нет ли риска сваливания двигателя. Мала мощность преобразователя: Замените преобразователь на более мощный. |

| 4 | OFF | Если один или больше выходных клемм соединены с землей, и ток короткого замыкания превышает 50 % от номинального тока преобразователя, то силовые модули преобразователя могут быть повреждены. ВНИМАНИЕ: Защита от короткого замыкания предназначена для защиты преобразователя частоты, но не пользователя. Рекомендации Проверьте силовые выходные цепи между преобразователем и двигателем на предмет коротких замыканий и замыканий на землю. Проверьте исправность модулей IGBT. Проверьте целостность изоляции выходных цепей. |

| 6 | ocS | Перегрузка по току в режиме останова. Аппаратная неисправность измерительных цепей. Рекомендации n Верните на завод. |

| 7 | oUA | Перенапряжение на шине постоянного тока при постоянной скорости (Серия 230В: 450В; серия 460В: 900В). Рекомендации Убедитесь, что мгновенные значения входного напряжения не выходят за пределы номинального диапазона преобразователя частоты. Убедитесь в отсутствии переходных процессов в питающем напряжении. Если напряжение увеличилось в генераторном режиме привода, увеличьте время замедления или подключите опциональный тормозной резистор. |

| 8 | oUd | Перенапряжение на шине постоянного тока при замедлении (Серия 230В: 450В; серия 460В: 900В). Рекомендации Убедитесь, что мгновенные значения входного напряжения не выходят за пределы номинального диапазона преобразователя частоты. Убедитесь в отсутствии переходных процессов в питающем напряжении. Если напряжение увеличилось в генераторном режиме привода, увеличьте время замедления или подключите опциональный тормозной резистор. |

| 9 | oUn | Перенапряжение на шине постоянного тока на постоянной скорости (Серия 230В: 450В; серия 460В: 900В) Рекомендации Убедитесь, что мгновенные значения входного напряжения не выходят за пределы номинального диапазона преобразователя частоты. Убедитесь в отсутствии переходных процессов в питающем напряжении. Если напряжение увеличилось в генераторном режиме привода, увеличьте время замедления или подключите опциональный тормозной резистор. |

| 10 | ouS | Перенапряжение на шине постоянного тока в режиме останова. Аппаратная неисправность измерительных цепей. Рекомендации Убедитесь, что мгновенные значения входного напряжения не выходят за пределы номинального диапазона преобразователя частоты. Убедитесь в отсутствии переходных процессов в питающем напряжении. |

| 11 | LuA | Напряжение на шине постоянного тока ниже 06-00 при разгоне. Рекомендации Проверьте величину питающего напряжения. Убедитесь в отсутствии неожиданных нагрузок. Проверьте установку параметра 06-00. |

| 12 | Lud | Напряжение на шине постоянного тока ниже 06-00 при замедлении. Рекомендации Проверьте величину питающего напряжения. Убедитесь в отсутствии неожиданных нагрузок. Проверьте установку параметра 06-00. |

| 13 | Lun | DC BUS voltage is less than Pr. 06-00 in constant speed. Рекомендации Проверьте величину питающего напряжения. Убедитесь в отсутствии неожиданных нагрузок. Проверьте установку параметра 06-00. |

| 14 | LuS | DC BUS voltage is less than Pr. 06-00 at stop. Рекомендации Проверьте величину питающего напряжения. Убедитесь в отсутствии неожиданных нагрузок. Проверьте установку параметра 06-00. |

| 15 | orP | Обрыв фазы. Рекомендации n Проверьте наличие напряжения в цепях питания и их подключение. |

| 16 | oH1 | Температура IGBT выше уровня защиты. Рекомендации Убедитесь, что окружающая температура не выходит за допустимые пределы. Убедитесь в том, что вентиляционные отверстия свободны. Удалите посторонние предметы и грязь с радиаторов. Проверьте вентилятор и прочистите его. Обеспечьте необходимое пространство для вентиляционных потоков. |

| 18 | tH1o | Аппаратная неисправность IGBT. Рекомендации n Верните на завод. |

| 21 | oL | Перегрузка. Превышено допустимое значение выходного тока. Рекомендации Убедитесь в отсутствии перегрузки двигателя. Замените преобразователь на более мощный. |

| 33 | cd1 | Ошибка по значению тока в фазе U. Рекомендации Отключите питание и вновь включите его. Если индикация ошибки не исчезла, верните прибор на завод. |

| 34 | cd2 | Ошибка по значению тока в фазе V. Рекомендации Отключите питание и вновь включите его. Если индикация ошибки не исчезла, верните прибор на завод. |

| 35 | cd3 | Ошибка по значению тока в фазе W. Рекомендации Отключите питание и вновь включите его. Если индикация ошибки не исчезла, верните прибор на завод. |

Примечание:

Полный список ошибок доступен в фале ниже.

Скачать полную документацию.

RU

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

Related Manuals for Delta MS300 Series

Summary of Contents for Delta MS300 Series

-

Page 1

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Delta Standard Compact Drive MS300 Series User Manual CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com… -

Page 2

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com PLEASE READ PRIOR TO INSTALLATION FOR SAFETY. AC input power must be disconnected before any wiring to the AC motor drive is made. Even if the power has been turned off, a charge may still remain in the DC-link capacitors with hazardous voltages before the POWER LED is OFF. -

Page 3: Table Of Contents

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Table of Contents CHAPTER 1 INTRODUCTION ………………..1-1 1-1 Nameplate Information………………..1-2 1-2 Model Name…………………..1-3 1-3 Serial Number………………….1-3 1-4 RFI Jumper……………………1-4 CHAPTER 2 DIMENSION ………………….2-1 Frame A……………………………………………………..……………………………………2-1 Frame B……………………………………………………………..……………………………2-2 Frame C……………………………………………………………..……………………………2-3 Frame D…………………………………………………………..………………………………2-4 Frame E…………………………………………………………..………………………………2-5 Frame F…………………………………………………………..………………………………2-6 Digital Keypad…………..……………………………………………………………………….2-7 CHAPTER 3 INSTALLATION ………………..

-

Page 4: Table Of Contents

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com 7-6 EMC Filter…………………….7-26 7-7 EMC Shield Plate………………..7-30 7-8 Capacitive Filter………………….7-33 7-9 Conduit Box…………………….7-35 7-10 Fan Kit……………………7-43 7-11 Keypad Panel Mounting ……………………7-44 7-12 DIN-Rail Mounting………………..7-45 7-13 Mounting Adapter Plate………………………………….……………………………7-47 CHAPTER 8 OPTION CARDS ………………..8-1 8-1 Option Card Installation………………..8-2 8-2 CMM-MOD01 Modbus/TCP Option Card…………..8-7 8-3 CMM-PD01 PROFIBUS Option Card……………..8-10…

-

Page 5: Table Of Contents

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com 17-3 Wiring Diagram…………………..17-4 17-4 Failure Rate of the Drive Safety Function……………17-5 17-5 Reset the Parameter Settings……………….17-5 17-6 Timing Diagram Description……………….17-6 17-7 Error Code and Troubleshooting Instructions…………………………………………17-9 17-8 Test and Fault Confirmation……………………………………………………….…..17-11 Application Control Board: V 1.0 CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com…

-

Page 6: Chapter 1 Introduction

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 1 IntroductionMS300 Chapter 1 Introduction 1-1 Nameplate Information 1-2 Model Name 1-3 Serial Number 1-4 RFI Jumper CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com…

-

Page 7: Nameplate Information

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 1 Introduction MS300 After receiving the AC motor drive, please check for the following: Please inspect the unit after unpacking to ensure it was not damaged during shipment. Make sure that the part number printed on the package corresponds with the part number indicated on the nameplate.

-

Page 8: Model Name

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 1 IntroductionMS300 1-2 Model Name 1-3 Serial Number CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com…

-

Page 9: Rfi Jumper

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 1 Introduction MS300 1-4 RFI Jumper (1) In the drive there are Varistor / MOVs, which are connected from phase to phase and from phase to ground, to protect the drive against mains surges or voltage spikes. Because the Varistors / MOVs from phase to ground are connected to ground via the RFI jumper, the protection will be ineffective when the RFI jumper is removed.

-

Page 10

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 1 IntroductionMS300 Isolating main power from ground: When the power distribution system of the drive is a floating ground system (IT) or an asymmetric ground system (TN), the RFI Jumper must be removed. Removing the RFI Jumper disconnects the internal capacitors from ground to avoid damaging the internal circuits and to reduce the ground leakage current. -

Page 11

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 1 Introduction MS300 Asymmetric Ground System (Corner Grounded TN Systems) Caution: Do not remove the RFI jumper while the input terminal of the drive carries power. In the following four situations, the RFI jumper must be removed. This is to prevent the system from grounding through the RFI and filter capacitors, damaging the drive. -

Page 12: Chapter 2 Dimension

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 2 Dimensions MS300 Chapter 2 Dimension Frame A A1: VFD1A6MS11ANSAA; VFD1A6MS11ENSAA; VFD1A6MS21ANSAA; VFD1A6MS21ENSAA; VFD1A6MS23ANSAA; VFD1A6MS23ENSAA A2: VFD2A8MS23ANSAA; VFD2A8MS23ENSAA A3: VFD2A5MS11ANSAA; VFD2A5MS11ENSAA; VFD2A8MS21ANSAA; VFD2A8MS21ENSAA A4: VFD1A5MS43ANSAA; VFD1A5MS43ENSAA A5: VFD4A8MS23ANSAA; VFD4A8MS23ENSAA; VFD2A7MS43ANSAA; VFD2A7MS43ENSAA Unit: mm [inch] Frame 68.0 [2.68] 128.0 [5.04]…

-

Page 13

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 2 Dimensions MS300 Frame B B1: VFD7A5MS23ANSAA; VFD7A5MS23ENSAA; VFD4A2MS43ANSAA; VFD4A2MS43ENSAA B2: VFD4A8MS21ANSAA; VFD4A8MS21ENSAA B3: VFD1A6MS21AFSAA; VFD2A8MS21AFSAA; VFD4A8MS21AFSAA; VFD1A5MS43AFSAA; VFD2A7MS43AFSAA; VFD4A2MS43AFSAA Unit: mm [inch] Frame 72.0 [2.83] 142.0 [5.59] 143.0 [5.63] 60.0 [2.36] 130.0 [5.63] 6.4 [0.25] 5.2 [0.20] 72.0 [2.83]… -

Page 14

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 2 Dimensions MS300 Frame C C1: VFD4A8MS11ANSAA; VFD4A8MS11ENSAA; VFD7A5MS21ANSAA; VFD7A5MS21ENSAA; VFD11AMS21ANSAA; VFD11AMS21ENSAA; VFD11AMS23ANSAA; VFD11AMS23ENSAA; VFD17AMS23ANSAA; VFD17AMS23ENSAA; VFD5A5MS43ANSAA; VFD5A5MS43ENSAA; VFD9A0MS43ANSAA; VFD9A0MS43ENSAA C2: VFD7A5MS21AFSAA; VFD11AMS21AFSAA; VFD5A5MS43AFSAA; VFD9A0MS43AFSAA Unit: mm [inch] Frame 87.0 [3.43] 157.0 [6.18] 152.0 [5.98] 73.0 [2.87] 144.5 [5.69]… -

Page 15

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 2 Dimensions MS300 Frame D D1: VFD25AMS23ANSAA; VFD25AMS23ENSAA; VFD13AMS43ANSAA; VFD13AMS43ENSAA; VFD17AMS43ANSAA; VFD17AMS43ENSAA D2: VFD13AMS43AFSAA; VFD17AMS43AFSAA Unit: mm [inch] Frame 109.0 [4.29] 207.0 [8.15] 154.0 [6.06] 94.0 [3.70] 193.8 [7.63] 6.0 [0.24] 5.5 [0.22] 109.0 [4.29] 207.0 [8.15] 187.0 [7.36]… -

Page 16

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 2 Dimensions MS300 Frame E E1: VFD33AMS23ANSAA; VFD33AMS23ENSAA; VFD49AMS23ANSAA; VFD49AMS23ENSAA; VFD25AMS43ANSAA; VFD25AMS43ENSAA; VFD32AMS43ANSAA; VFD32AMS43ENSAA E2: VFD25AMS43AFSAA; VFD32AMS43AFSAA Unit: mm [inch] Frame 130.0 [5.12] 250.0 [9.84] 185.0 [7.83] 115.0 [4.53] 236.8 [9.32] 6.0 [0.24] 5.5 [0.22] 130.0 [5.12] 250.0 [9.84]… -

Page 17

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 2 Dimensions MS300 Frame F F1: VFD65AMS23ANSAA; VFD65AMS23ENSAA; VFD38AMS43ANSAA; VFD38AMS43ENSAA; VFD45AMS43ANSAA; VFD45AMS43ENSAA F2: VFD38AMS43AFSAA; VFD45AMS43AFSAA Unit: mm [inch] Frame 175.0 [6.89] 300.0 [11.81] 192.0 [7.56] 154.0 [6.06] 279.5 [11.00] 6.5 [0.26] 8.4 [0.33] 175.0 [6.89] 300.0 [11.81] 244.0 [9.61]… -

Page 18: Digital Keypad

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 2 Dimensions MS300 Digital Keypad KPMS-LE01 Unit: mm [inch] 68.0 [2.67] 63.8 [2.51] 45.2 [1.78] 8.0 [0.31] 46.8 [1.84] 42.0 [1.65] 26.0 [1.02] 7.5 [0.31] 30.0 [1.18] 22.7 [0.89] 2.0 [0.08] 2.2 [0.09] 1.3 [0.05] M3*0.5(2X) CALL NOW 800-985-6929…

-

Page 19

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 2 Dimensions MS300 [ This page intentionally left blank ] CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com… -

Page 20: Chapter 3 Installation

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 3 Installation MS300 Chapter 3 Installation Minimum Mounting Clearance and Installation Prevent fiber particles, scraps of paper, shredded wood saw dust, metal particles, etc. from adhering to the heat sink Install the AC motor drive in a metal cabinet. When installing one drive below another one, use a …

-

Page 21

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 3 Installation MS300 Air flow rate for cooling Power Dissipation Frame Flow Rate Flow Rate Loss External Internal Total Model No. (Unit: cfm) (Unit: m / hr) (Heat sink, unit: W) (Unit: W) (Unit: W) VFD1A6MS11ANSAA 10.0… -

Page 22

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 3 Installation MS300 Air flow rate for cooling Power Dissipation Frame Flow Rate Flow Rate Loss External Internal Total Model No. (Unit: cfm) (Unit: m / hr) (Heat sink, unit: W) (Unit: W) (Unit: W) VFD9A0MS43ENSAA VFD9A0MS43AFSAA… -

Page 23

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 3 Installation MS300 [ This page intentionally left blank ] CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com… -

Page 24: Chapter 4 Wiring

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 4 WiringMS300 Chapter 4 Wiring 4-1 Wiring 4-2 System Wiring Diagram CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com…

-

Page 25

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 4 WiringMS300 After removing the front cover, please check if the power and control terminals are clearly visible. Please read following precautions to avoid wiring mistakes. It is crucial to cut off the AC motor drive power before doing any wiring. A charge may still remain in the DC bus capacitors with hazardous voltages even after the power has been turned off a short time. -

Page 26: Wiring

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 4 WiringMS300 4-1 Wiring CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com…

-

Page 27

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 4 WiringMS300 Figure 1 CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com… -

Page 28

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 4 WiringMS300 Figure 2 SINK (NPN) / SOURCE (PNP) Mode S i n k Mo d e S o u r ce Mo d e wi th i n te r n a l p o we r ( +2 4 V d c) wi th i n te r n a l p o we r ( +2 4 V d c) i n te rn a l i n te rn a l… -

Page 29: System Wiring Diagram

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 4 WiringMS300 4-2 System Wiring Diagram CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com…

-

Page 30: Chapter 5 Main Circuit Terminals

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 5 Main Circuit TerminalsMS300 Chapter 5 Main Circuit Terminals 5-1 Main Circuit Diagram 5-2 Main Circuit Terminals CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com…

-

Page 31

U/T1, V/T2, W/T3 of the AC motor drive. DO NOT use phase-compensation DANGER capacitors or L-C (Inductance-Capacitance) or R-C (Resistance-Capacitance), unless approved by Delta. DO NOT connect brake resistor directly to +1/DC+ to DC-, +2/B1 to DC- to prevent damage to the drive. -

Page 32: Remove The Front Cover

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 5 Main Circuit TerminalsMS300 Terminals for connecting DC reactor, external brake resistor and DC circuit These are the terminals for connecting the DC-reactor to improve the power factor and harmonics. At delivery they are shorted by a jumper. Please remove it before connecting the DC reactor.

-

Page 33: Main Circuit Diagram

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 5 Main Circuit TerminalsMS300 5-1 Main Circuit Diagram Terminals Descriptions R/L1, S/L2 Mains input terminals 1-phase R/L1, S/L2, T/L3 Mains input terminals 3-phase U/T1, V/T2, W/T3 Motor output terminals for connecting 3-phase IM and PM motors. Connections for DC reactor to improve the power factor and harmonics.

-

Page 34: Main Circuit Terminals

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 5 Main Circuit TerminalsMS300 5-2 Main Circuit Terminals It needs following additional terminal when wiring. The additional terminal dimension should comply with the following figure 1. After crimping the wire to the ring lug (must UL approved), UL and CSA approved R/C (YDPU2) heat shrink tubing rated min 600Vac insulation shall be install over the live part.

-

Page 35

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 5 Main Circuit TerminalsMS300 Frame A Main circuit terminals: R/L1, S/L2, T/L3, U/T1, V/T2, W/T3, ,DC-, DC+/+1, +2/B1, B2, Note: 1-phase model with no T/L3 terminal Max. Min. Wire Torque Models Wire Screw Gauge (±10%) Gauge… -

Page 36

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 5 Main Circuit TerminalsMS300 Frame B Main circuit terminals: R/L1, S/L2, T/L3, U/T1, V/T2, W/T3, ,DC-, DC+/+1, +2/B1, B2, Note: 1-phase model with no T/L3 terminal Max. Wire Min. Wire Torque Models Screw Gauge Gauge (±10%) -

Page 37

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 5 Main Circuit TerminalsMS300 Frame C Main circuit terminals: R/L1, S/L2, T/L3, U/T1, V/T2, W/T3, ,DC-, DC+/+1, +2/B1, B2, Note: 1-phase model with no T/L3 terminal Max. Wire Min. Wire Torque Models Screw Gauge Gauge (±10%) -

Page 38

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 5 Main Circuit TerminalsMS300 Frame D Main circuit terminals: R/L1, S/L2, T/L3, U/T1, V/T2, W/T3, , DC-, DC+/+1, +2/B1, B2, Max. Wire Min. Wire Torque Models Screw Gauge Gauge (±10%) VFD25AMS23ANSAA 8 AWG [8.4mm VFD25AMS23ENSAA VFD13AMS43ANSAA… -

Page 39

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 5 Main Circuit TerminalsMS300 Frame E Main circuit terminals: R/L1, S/L2, T/L3, U/T1, V/T2, W/T3, , DC-, DC+/+1, +2/B1, B2, Max. Wire Min. Wire Torque Models Screw Gauge Gauge (±10%) VFD33AMS23ANSAA 6 AWG 6 AWG VFD33AMS23ENSAA [13.3 mm… -

Page 40

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 5 Main Circuit TerminalsMS300 Frame F Main circuit terminals: R/L1, S/L2, T/L3, U/T1, V/T2, W/T3, , DC-, DC+/+1, +2/B1, B2, Max. Wire Min. Wire Torque Models Screw Gauge Gauge (±10%) VFD65AMS23ANSAA 2 AWG [33.6 mm VFD65AMS23ENSAA VFD38AMS43ANSAA… -

Page 41

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 5 Main Circuit TerminalsMS300 [ This page intentionally left blank ] 5-12 CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com… -

Page 42

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 6 Control TerminalsMS300 Chapter 6 Control Terminals Analog input terminals (AVI, ACI, ACM) Analog input signals are easily affected by external noise. Use shielded wiring and keep it as short as possible (<20 m) with proper grounding. If the noise is inductive, connecting the shield to terminal ACM can bring improvement. -

Page 43

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 6 Control TerminalsMS300 Specifications of Control Terminal Specifications of RELAY Terminal Wire Gauge: 20~18AWG [0.519~0.82 mm Wire Gauge: 24~16 AWG [0.205~1.3 mm Torque: 5 kg-cm / [4.3 Ib-in.] / [0.49 Nm] DATAMATRIX Safety function 32637012 RELAY RS485… -

Page 44

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 6 Control TerminalsMS300 Terminals Terminal Function Factory Setting (NPN mode) Digital control signal common +24V +24V ± 10 % 100 mA (Source) Refer to parameters 02-01~02-07 to program the multi-function inputs MI1~MI7. Source Mode ON: the activation current is 3.3 mA ≧… -

Page 45

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 6 Control TerminalsMS300 Terminals Terminal Function Factory Setting (NPN mode) +10V Potentiometer power supply +10.5 ± 0.5 Vdc / 20 mA Analog voltage input Programmable analog input, see Pr. 03-00 Impedance: 20kΩ internal circuit Range 0~Max. -

Page 46

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 6 Control TerminalsMS300 Terminals Terminal Function Factory Setting (NPN mode) Factory setting: S1/S2 shorted to +24V Rated voltage: 24VDC ±10%; Max. voltage: 30VDC ±10% S1,S2 Activation current: 6.67 mA ±10% STO activation mode Input voltage level: S1-DCM>0VDC or S2-DCM <… -

Page 47

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 6 Control TerminalsMS300 [ This page intentionally left blank ] CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com… -

Page 48: Chapter 7 Optional Accessories

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional AccessoriesMS300 Chapter 7 Optional Accessories All Brake Resistors and Brake Units Used in AC Motor Drives Non-fuse Circuit Breaker Fuse Specification Chart AC/DC Reactor Zero Phase Reactor EMC Filter EMC Shield Plate Capacitive Filter Conduit Box 7-10 Fan Kit…

-

Page 49: All Brake Resistors And Brake Units Used In Ac Motor Drives

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional Accessories MS300 The optional accessories listed in this chapter are available upon request. Installing additional accessories to your drive would substantially improve the drive’s performance. Please select an applicable accessory according to your need or contact the local distributor for suggestion. 7-1 All Brake Resistors and Brake Units Used in AC Motor Drives 115V 1-phase Applicable…

-

Page 50

Resistors of 1000W and above should be fixed on a surface with temperature below 350°C NOTE Please select the resistance value, power and brake usage (ED %) acc. to Delta rules. Definition for Brake Usage ED% Explanation: ED (%) is defined to allow enough time for the brake unit and brake resistor to dissipate the heat generated by braking. -

Page 51

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional Accessories MS300 Take the safety of the environment into consideration when installing the brake resistors. If the minimum resistance value is to be used, consult local dealers for the calculation of the power. When using more than 2 brake units, equivalent resistor value of parallel brake unit can’t be less than the value in the column “Minimum Equivalent Resistor Value for Each AC Drive”… -

Page 52: Non-Fuse Circuit Breaker

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional AccessoriesMS300 7-2 Non-fuse Circuit Breaker Comply with UL standard: Per UL 508, paragraph 45.8.4, part a. Current Input / Output (Max.) Breaker rating Input (A) Voltage / 1-phase Model (3-phase) Normal duty Heavy duty Normal duty Heavy duty…

-

Page 53

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional Accessories MS300 Current Input / Output (Max.) Breaker rating Input (A) Voltage / 1-phase Model (3-phase) Normal duty Heavy duty Normal duty Heavy duty VFD2A7MS43ANSXX 4.2 A / 3.0 A 3.7 A / 2.7 A 8.58 VFD2A7MS43ENSXX… -

Page 54: Fuse Specification Chart

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional AccessoriesMS300 7-3 Fuse Specification Chart The fuse specifications lower than below table is allowed. For installation in the United States, branch circuit protection must be provided in accordance with the National Electrical Code (NEC) and any applicable local codes. To fulfill this requirement, use the UL classified fuses.

-

Page 55

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional Accessories MS300 Current Input / Output (Max.) Voltage/ 1-phase Branch Circuit Fuses Output Model (3-phase) Normal duty Heavy duty 79.2 VFD33AMS23ANSXX 43.2 A / 36.0 A 39.6 A / 33.0 A VFD33AMS23ENSXX Class T JJS-80 112.2… -

Page 56: Ac/Dc Reactor

Saturation Rated Current Input/ Output Input Reactor DC Reactor DC Reactor Model ND / HD ND / HD (A Reactor (mH) Delta Part # (mH) Delta Part # Current (A VFD1A6MS11ANSAA 1.8 / 1.6 2.7 / 3.2 5.857 DR005D0585 5.857…

-

Page 57

Saturation Rated Current Input/ Output Input Reactor DC Reactor DC Reactor Model ND / HD ND / HD (A Reactor (mH) Delta Part # (mH) Delta Part # Current (A VFD4A8MS21ANSAA 5 / 4.8 7.5 / 9.6 3.66 DR008D0366 3.66… -

Page 58

Rated Saturation Current Input/ Output Input Reactor DC Reactor DC Reactor Model ND / HD ND / HD Reactor (mH) Delta Part # (mH) Delta Part # Current (A VFD2A7MS43ANSAA 3 / 2.7 4.5 / 5.4 6.077 DR004A0607 18.709 DR003D1870… -

Page 59

Screw Location Torque Terminal 5.32~7.09 kg-cm / [6.12~8.16 lb-in.] / [0.6~0.8 Nm] PE bolt 8.86~10.63 kg-cm / [10.2~12.24 lb-in.] / [1.0~1.2 Nm] Input AC reactor D1*D2 PE D Delta part # DR005A0254 DR008A0159 6*12 80.5 DR011A0115 6*12 80.5 DR017AP746 6*12 80.5… -

Page 60

Email: info@deltaacdrives.com Chapter 7 Optional AccessoriesMS300 Screw Location Torque Terminal 10.63~12.4 kg-cm / [12.24~14.28 lb-in.] / [1.2~1.4 Nm] Input AC reactor D1*D2 PE D Delta part # DR049AP215 6*12 1.2~1.4 DR065AP163 6*12 2.5~3.0 Unit:mm 7-13 CALL NOW 800-985-6929 http://www.deltaacdrives.com… -

Page 61

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional Accessories MS300 Input AC reactor D1*D2 Delta part # DR075AP170 7*13 20*3 Unit:mm 7-14 CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com… -

Page 62

Screw Location Torque Terminal 5.32~7.09 kg-cm / [6.12~8.16 lb-in.] / [0.6~0.8 Nm] PE bolt 8.86~10.63 kg-cm / [10.2~12.24 lb-in.] / [1.0~1.2 Nm] Input AC reactor D1*D2 PE D Delta part # DR003A0810 DR004A0607 6*12 80.5 DR006A0405 6*12 DR009A0270 6*12 DR010A0231… -

Page 63

Email: info@deltaacdrives.com Chapter 7 Optional Accessories MS300 Screw Location Torque Terminal 10.63~12.4 kg-cm / [12.24~14.28 lb-in.] / [1.2~1.4 Nm] Input AC reactor D1*D2 PE D Delta part # DR038AP639 6*12 1.2~1.4 DR045AP541 7*13 1.2~1.4 Unit:mm 7-16 CALL NOW 800-985-6929 http://www.deltaacdrives.com… -

Page 64

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional AccessoriesMS300 Input AC reactor D1*D2 Delta part # DR060AP405 7*13 20*3 Unit:mm 7-17 CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com… -

Page 65

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional Accessories MS300 DC reactor can also, improve power factor, reduce input current, and reduce interference generated from motor drive. A DC reactor stabilizes the DC-bus voltage. Compared to an AC input reactor, the advantages are smaller size, lower price and lower voltage drop (lower power dissipation) Installation DC reactor is installed between terminals +1 and +2. -

Page 66

Chapter 7 Optional AccessoriesMS300 DC reactor dimension and specification: The length of screw should keep away from the hole. DC reactor Rated Current Saturation current DC reactor Dimension Delta Part # (Arms) (Arms) (mH) (mm) (mm) (mm) (mm) (mm) (mm) DR005D0585 8.64… -

Page 67

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional Accessories MS300 DC reactor Rated Current Saturation current DC reactor Dimension Delta Part # (Arms) (Arms) (mH) (mm) (mm) (mm) (mm) (mm) (mm) DR012D0467 19.8 4.677 119 128 DR018D0311 30.6 3.119… -

Page 68

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional AccessoriesMS300 Without AC reactor With AC reactor 230V 1-phase Rated current Shielded Cable Non-shielded Shielded Cable Non-shielded (ND) (Arms) Model (meter) cable (meter) (meter) cable (meter) VFD1A6MS21ANSAA VFD1A6MS21ENSAA VFD1A6MS21AFSAA VFD2A8MS21ANSAA VFD2A8MS21ENSAA VFD2A8MS21AFSAA VFD4A8MS21ANSAA VFD4A8MS21ENSAA… -

Page 69

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional Accessories MS300 Without AC reactor With AC reactor 460V 3-phase Rated current Shielded Cable Non-shielded Shielded Cable Non-shielded (ND) (Arms) Model (meter) cable (meter) (meter) cable (meter) VFD1A5MS43ANSAA VFD1A5MS43ENSAA VFD1A5MS43AFSAA VFD2A7MS43ANSAA VFD2A7MS43ENSAA VFD2A7MS43AFSAA… -

Page 70: Zero Phase Reactor

Interferences can also be suppressed by installing a zero phase reactor at the mains input or the motor output of the drive, depending on where the interference is. Delta provides two types of zero phase reactors to solve interference problems.

-

Page 71

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional Accessories MS300 Installation During installation, please pass the cable through at least one zero-phase reactor. Use a suitable cable type (insulation class and wire section) so that the cable passes easily through the zero-phase reactor. -

Page 72

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional AccessoriesMS300 Recommended max. wiring gauge when installing zero phase reactor Max. Wire Gauge AWG Max. Wire Gauge AWG Model # of Zero Max, Wire Gauge (1Cx3) (1Cx4) Phase Reactor or LUG width 75 °C 90 °C 75 °C… -

Page 73: Emc Filter

Recommended model of cable length Input zero-phase reactor Frame Model # Current Filter model # 100m 100m Position to place zero phase reactor DELTA VFD1A6MS11ANSAA EMF11AM21A RF008X00A T60006L2040W453 VFD1A6MS21ANSAA EMF11AM21A RF008X00A T60006L2040W453 ✓ ✓ ✓ ✓ VFD2A8MS21ANSAA EMF11AM21A RF008X00A T60006L2040W453 ✓…

-

Page 74

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional AccessoriesMS300 Filter Dimension EMF11AM21A EMF10AM23A EMF6A0M43A Screw Torque M5 * 2 16~20 kg-cm / [13.9~17.3 lb-in.] / [1.56~1.96 Nm] M4 * 2 14~16 kg-cm / [12.2~13.8 lb-in.] / [1.38~1.56 Nm] 72.0 [2.83] M5 screw TORQUE:16-18kgf-cm 54.0 [2.13]… -

Page 75

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional Accessories MS300 EMF27AM21B; EMF24AM23B EMF33AM23B; EMF12AM43B EMF23AM43B Screw Torque M5 * 4 16~20 kg-cm / [13.9~17.3 lb-in.] / [1.56~1.96 Nm] 109.0 [4.29] M5 screw 94.0 [3.70] TORQUE:16-18kgf-cm 76.0 [2.99] 28.0 [1.10] 29.1 [1.14] 5.5 [0.22] 5.5 [0.22]… -

Page 76

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional AccessoriesMS300 TDK B84143D0050R127 (50A) TDK B84143D0075R127 (75A), TDK B84143D0090R127 (90A) 7-29 CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com… -

Page 77: Emc Shield Plate

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional Accessories MS300 7-7 EMC Shield Plate EMC Shield Plate (for use with use shielded cable) EMC Shield Plate model Reference figure Frame MKM-EPA MKM-EPB MKM-EPC MKM-EPD MKM-EPE MKM-EPF 7-30 CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com…

-

Page 78

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional AccessoriesMS300 Installation (Frame A model as an example) 1. As on the right, fix the iron plate on the AC motor drive. Torque value: Frame Screw Torque M3.5 6~8 kg-cm / [5.2~6.9 lb-in.] / [0.59~0.78 Nm] 6~8 kg-cm / [5.2~6.9 lb-in.] / [0.59~0.78 Nm] 6~8 kg-cm / [5.2~6.9 lb-in.] / [0.59~0.78 Nm] 4~6 kg-cm / [3.5~5.2 lb-in.] / [0.39~0.59 Nm]… -

Page 79

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional Accessories MS300 Recommended wire mounting method Frame Model of EMC Shield Plate Reference figure MKM-EPA MKM-EPB MKM-EPC MKM-EPD MKM-EPE MKM-EPF 7-32 CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com… -

Page 80: Capacitive Filter

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional AccessoriesMS300 7-8 Capacitive Filter diagram Installation The capacitive filter (CXY101-43A) is a simple filter which can support basic filtering and noise interference reduction. Capacitor Filter Grid Motor Capacitive filter and drive wiring figure: R/L1 S/L2 T/ L3 Specification:…

-

Page 81

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional Accessories MS300 Dimension: CXY101-43A Unit:mm [inch] 77 .5 [3 .05 ] 77 .5 [3 .05 ] 86 .5 [3 .41 ] 4.0 [ 0.1 6] 31 .6 [1 .24 ] 7-34 CALL NOW 800-985-6929 http://www.deltaacdrives.com… -

Page 82: Conduit Box

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional AccessoriesMS300 7-9 Conduit Box Conduit box are in compliance with protection level NEMA 1 / UL Type 1 Frame A (A1~A2) Frame A (A3~A5) Model of conduit box: MKM-CBA0 Model of conduit box: MKM-CBA 71 5 2 81 .

-

Page 83

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional Accessories MS300 Frame B Model of conduit box: MKM-CBB 87 7 3 45 . [ . 71 9 2 83 . [ . Unit : mm [inch.] 7-36 CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com… -

Page 84

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional AccessoriesMS300 Frame C Model of conduit box: MKM-CBC 89 2 3 51 . [ . 87 0 3 43 . [ . Unit : mm [inch.] 7-37 CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com… -

Page 85

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional Accessories MS300 Frame D Model of conduit box: MKM-CBD 8 8 5 3 48 . [ . 103 7 4 08 . [ . Unit mm inch Unit : mm [inch.] 7-38 CALL NOW 800-985-6929 http://www.deltaacdrives.com… -

Page 86

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional AccessoriesMS300 Frame E Model of conduit box: MKM-CBE 8 7 1 3 43 . [ . 1 24 5 4 90 . [ . Unit m m inch Unit : mm [inch.] 7-39 CALL NOW 800-985-6929 http://www.deltaacdrives.com… -

Page 87

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional Accessories MS300 Frame F Model of conduit box: MKM-CBF 168 7 6 64 . [ . 90 8 3 57 . [ . Unit : mm [inch.] 7-40 CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com… -

Page 88

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional AccessoriesMS300 Installation: Recommended screw torque: M3: 4-6 kg-cm / [3.5-5.2 lb-in.] / [0.39-0.59 Nm] M3.5: 4-6 kg-cm / [3.5-5.2 lb-in.] / [0.39-0.59 Nm] M4: 6-8 kg-cm / [5.2-6.9 lb-in.] / [0.59-0.78 Nm] Frame A 7-41 CALL NOW 800-985-6929… -

Page 89

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional Accessories MS300 Frame B~F 7-42 CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com… -

Page 90: Fan Kit

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional AccessoriesMS300 7-10 Fan Kit Frame Fan Model Fan Kit MKM-FKMA MKM-FKMB MKM-FKMC MKM-FKMD MKM-FKME MKM-FKMF Fan Removal 1. As shown in figure on the right, press the tabs on both sides of the fan to remove it. 2.

-

Page 91: Keypad Panel Mounting

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional Accessories MS300 7-11 Keypad Panel Mounting KPMS-LE01 Method 1: Direct installation on a plate (unit: mm [inch]) Torque: 8~9 kg-cm [6.94~7.81 lb-in.] [0.78~0.88 Nm] Method 2: Mounting through a plate (unit: mm [inch]) Thickness = 1.2 [0.05] or 2.0 [0.08] ※…

-

Page 92: Din-Rail Mounting

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional AccessoriesMS300 7-12 DIN-Rail Mounting MKM-DRB (applicable for Frame A and Frame B) 72.0[2.83] 8.0[0.31] Screw Torque 8~10 kg-cm M4*2PCS [6.9~8.7 lb-in.] [0.7 ~0 98 Nm] 4.6[0.18] (M4 NUT) unit: mm[inch] MKM-DRC (applicable for Frame C) Screw Torque 87.0[3.43]…

-

Page 93

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional Accessories MS300 Installation Screw Torque 8~10 kg-cm MKM-DRB M4*P0.7*2PCS [6.9~8.7 lb-in.] [0.78~0.98 Nm] 10~12 kg-cm MKM-DRC M5*P0.8*4PCS [8.7~10.4 lb-in.] [0.98~1.18 Nm] MKM-DRB: for frame A. B MKM-DRC: for frame C 7-46 CALL NOW 800-985-6929 http://www.deltaacdrives.com… -

Page 94: Mounting Adapter Plate

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional AccessoriesMS300 7-13 Mounting Adapter Plate This mounting adapter accessory is to change the wiring way of MS300/MH300 series to provide flexible installation. It changes the wiring from mains input/motor output at the bottom to mains input from the top and motor output from the bottom.

-

Page 95

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional Accessories MS300 MKM-MAPB: Applicable for Frame A and B Installation L 1 L 2 L 3 Unit: mm [inch] Screw Torque 14~16 kg-cm / [12.2~13.9 lb-in.] / [1.37~1.56 Nm] 16~20 kg-cm / [13.9~17.4 lb-in.] / [1.56~1.96 Nm] 7-48 CALL NOW 800-985-6929 http://www.deltaacdrives.com… -

Page 96

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional AccessoriesMS300 MKM-MAPC: Applicable for frame C Installation Unit: mm [inch] Screw Torque 14~16 kg-cm / [12.2~13.9 lb-in.] / [1.37~1.56 Nm] 16~20 kg-cm / [13.9~17.4 lb-in.] / [1.56~1.96 Nm] 7-49 CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com… -

Page 97

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 7 Optional Accessories MS300 [ This page intentionally left blank ] 7-50 CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com… -

Page 98: Chapter 8 Option Cards

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 8 Optional Cards MS300 Chapter 8 Option Cards Option Card Installation CMM-MOD01 Modbus/TCP option card CMM-PD01 PROFIBUS option card CMM-DN01 DeviceNet option card CMM-EIP01 Modbus TCP/EtherNet IP option card CMM-COP01 CANopen option card EMM-BPS01 Back-up Power Supply card CALL NOW 800-985-6929 http://www.deltaacdrives.com…

-

Page 99: Option Card Installation

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 8 Optional Cards MS300 The option cards mentioned in this chapter are optional items. Please select applicable option cards for your drive or contact your local distributor for suggestion. The option cards can improve the performance of the drive significantly.

-

Page 100

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 8 Optional Cards MS300 NOTE Wiring after the option card fixed fitting is clipped with the holes (see Fasten the screw to fix the option card before wiring (shown in Fig. 8-3). Torque:4~6 kg-cm [3.5~5.2 lb-in] / [0.39~0.59 Nm]. -

Page 101

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 8 Optional Cards MS300 Fasten the screw after the option card fixed fitting is clipped with the holes. (shown in Fig. 8-5) Torque: 4~6 kg-cm [3.5~5.2 lb-in.] [0.39~0.59 Nm] Fig. 8-5 Installation is completed (shown in Fig. 8-6). Put the front cover back on. Fig. -

Page 102

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 8 Optional Cards MS300 NOTE The option cards listed below must connect to ground when wiring. The ground terminal is enclosed with option card as shown in Fig. 8-7. 1. CMM-MOD01 2. CMM-PD01 3. -

Page 103

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 8 Optional Cards MS300 Frame F Fig. 8-11 Torque (±10%) Frame F: 7 kg-cm [6.1 Ib-in.] [0.69 Nm] CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com… -

Page 104: Cmm-Mod01 Modbus/Tcp Option Card

Category 5e shielding 100 M Transmission speed 10 / 100 Mbps Auto-Detect Network protocol ICMP, IP, TCP, UDP, DHCP, SMTP, MODBUS OVER TCP / IP, Delta Configuration Electrical Specification Power supply voltage 5 VDC (supplied by AC motor drive) Insulation voltage…

-

Page 105

Setting for source of The operation command is controlled by 00-21 communication card operation command Decoding method for 09-30 Decoding method for Delta AC motor drive communication 09-75 IP setting Static IP(0) / Dynamic distribution IP(1) 09-76 IP address -1 IP address 192.168.1.5… -

Page 106

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 8 Optional Cards MS300 LED Indicator & Troubleshooting LED Indicators Status Indication Processing Methods POWER Green Power supply in normal status No action is required POWER Green No power supply Check the power supply Network connection in normal No action is required status… -

Page 107: Cmm-Pd01 Profibus Option Card

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 8 Optional Cards MS300 8-3 CMM-PD01 PROFIBUS option card Features 1. Supports PZD control data exchange. 2. Supports PKW polling AC motor drive parameters. 3. Supports user diagnosis function. 4. Auto-detects baud rates; supports Max. 12 Mbps. …

-

Page 108

CALL NOW 800-985-6929 http://www.deltaacdrives.com Email: info@deltaacdrives.com Chapter 8 Optional Cards MS300 Environment ESD (IEC 61800-5-1, IEC 6100-4-2) EFT (IEC 61800-5-1, IEC 6100-4-4) Noise immunity Surge Test (IEC 61800-5-1, IEC 6100-4-5) Conducted Susceptibility Test (IEC 61800-5-1, IEC 6100-4-6) Operation: -10ºC ~ 50ºC (temperature), 90% (humidity) Operation / Storage Storage: -25ºC ~ 70ºC (temperature), 95% (humidity) International standards:… -

Page 109: Cmm-Dn01 Devicenet Option Card