Werkstatthandbuch

1011 F

Workshop Manual

1011 F

|

0297 |

Werkstatthandbuch |

|

9765 |

1011 F |

|

0297 |

Workshop Manual |

|

9765 |

1011 F |

Manuel d’Atelier

1011 F

Manuale d’officina

1011 F

|

0297 |

Manuel d’Atelier |

|

9766 |

1011 F |

|

0297 |

Manuale d’officina |

|

9766 |

1011 F |

Werkstatthandbuch

Workshop Manual

Manuel d’Atelier

Manual de Taller 1011 F

0297 9765

V O R W O R T

Die sachgerechte Ausführung von Reparaturund Einstellarbeiten ist Voraussetzung für einen zuverlässigen Motorbetrieb.

In diesem Werkstatthandbuch sind die zweckmäßigen Arbeitsabläufe für anfallende Reparaturund Einstellarbeiten an Motor und Motorbauteilen beschrieben. Dabei wird vorausgesetzt, daß die Arbeiten von qualifiziertem Fachpersonal durchgeführt werden.

Bei der Gestaltung des Werkstatthandbuches wurden im Sinne einer schnellen Erfassung der Inhalte zusätzlich zu den knapp gehaltenen beschreibenden Texten Bildzeichen gesetzt, die den jeweils behandelten Arbeitsgang visualisieren.

Betriebsund Wartungshinweise sind der entsprechenden Betriebsanleitung zu entnehmen.

Zur Ersatzteilbestellung ist die jeweilige Ersatzteilliste zugrunde zu legen.

Das vorliegende Werkstatthandbuch unterliegt keinem Änderungsdienst. Änderungen werden jeweils bei Neuauflage eingearbeitet.

Beachten Sie bei Reparaturen die Hinweise unserer Technischen Rundschreiben.

Allgemeine Hinweise:

—Lesen und beachten Sie die Informationen dieses Werkstatthandbuches. Sie vermeiden Unfälle und verfügen über einen funktionstüchtigen und einsatzbereiten Motor.

—Stellen Sie sicher, daß dieses Werkstatthandbuch jedem an Reparaturoder Einstellarbeiten Beteiligten zur Verfügung steht und daß der Inhalt verstanden wird.

—Die Nichtbeachtung dieser Reparaturanleitung kann zu Funktionsstörungen und Motorschäden sowie Verletzungen von Personen führen, für die vom Hersteller keine Haftung übernommen wird.

—Die einschlägigen Unfallverhütungsvorschriften sowie die sonstigen allgemeinen anerkannten sicherheitstechnischen und arbeitsmedizinischen Regeln sind einzuhalten.

—Voraussetzung für die fachgerechte Reparatur ist die Verfügbarkeit aller erforderlichen Ausrüstungen, Handund Spezialwerkzeuge, sowie deren einwandfreier Zustand.

—Höchste Wirtschaftlichkeit, Zuverlässigkeit und lange Lebensdauer ist nur bei

Verwendung von Original Teilen der DEUTZ AG sichergestellt.

—Motorteile wie Federn, Klammern, elastische Halteringe etc. beinhalten bei unsachgemäßer Behandlung erhöhte Verletzungsgefahr.

—Die Instandsetzung des Motors muß der bestimmungsgemäßen Verwendung — definiert durch den Gerätehersteller — entsprechen. Bei Umbauten dürfen nur von der DEUTZ AG für den jeweiligen Verwendungszweck freigegebene Teile eingesetzt werden.

©2001 / 0297 9765

F O R E W O R D

Reliable engine operation is dependent on properly executed repairs as well as adjustment work.

This Workshop Manual describes the appropriate operations for any repair and adjustment work on the engine and engine components. It is presumed that this work will be carried out by qualified personnel.

This operation manual has been designed for quick and easy understanding. Therefore the concise text passages are accompanied by pictographs to illustrate the relevant operation.

Aspects of operation and maintenance are dealt with in the respective Operation Manual.

For spare parts orders the respective spare parts catalogue should be referred to.

This Workshop Manual is not subject to engineering change service and is valid until next issue.

Therefore please refer to the information in our Technical Circulars when carrying out repairs.

General information:

—Please read carefully and observe the instructions given in this Workshop Manual to avoid accidents and ensure that your engine always functions properly and reliably.

—Make sure that this Workshop Manual is readily available for all those carrying out repairs or adjustments and that the contents are well understood.

—Non-compliance with these repair instructions may result in malfunction and engine damage as well as personal injuries for which the manufacturer shall not accept any liability.

—The accident prevention regulations and all other generally recognized regulations on safety and occupational medicine are to be observed.

—A prerequisite for successful repair is that all required equipment, hand and special tools are available and in perfect working order.

—Optimal operation economy, reliability and durability of the engine can only be ensured when genuine parts of DEUTZ AG are used.

—Engine components such as springs, clamps, snap rings, etc. may cause injury if not handled with care.

—Engine repairs must be carried out in accordance with intended use as defined by the equipment manufacturer. For conversions, only parts approved by DEUTZ AG for a specific purpose should be used.

© 2001 / 0297 9765

P R É F A C E

Un fonctionnement fiable du moteur suppose l’exécution en bonne et due forme des travaux de réparation et de réglage.

Le présent Manuel d’atelier décrit la suite des travaux de réparation et de réglage à effectuer sur le moteur et ses éléments. Cela suppose que les travaux sont réalisés par un personnel spécialisé et qualifié.

En vue d’une compréhension rapide du contenu, le manuel d’atelier comporte, en plus des textes brefs, des symboles visualisant l’opération à réaliser.

Les indications relatives au service et à l’entretien figurent dans les instructions de service correspondantes.

Pour la commande de pièces de rechange, il convient de se baser sur la liste des pièces de rechange correspondante.

Le présent manuel d’atelier n’est soumis à aucun service de modifications. Les modifications seront incorporées à chaque réédition du Manuel.

Pour les réparations, veuillez respecter les indications de nos circulaires techniques.

Remarques générales:

—Veuillez lire attentivement les informations du présent Manuel d’ Atelier et en tenir compte. Vous éviterez ainsi des accidents et disposerez en même temps d’ un moteur fonctionnel et en parfait état de marche.

—Assurez-vous que chaque personne chargée des travaux de réparation et de mise

au point dispose bien de ce Manuel d’ Atelier et en comprenne bien le contenu.

—Le non-respect de ces instructions de réparation peut entraîner des pannes, avaries de moteur et accidents de personnes, pour lesquels le constructeur ne peut en aucun cas assumer la responsabilité.

—Il convient de respecter les consignes générales de sécurité et de prévention des accidents en vigueur.

—La condition préalable de la bonne exécution des réparations est la mise à disposition de tous les équipements, outillages manuels et spéciaux requis, en parfait état de fonctionnement.

—Seule l’utilisation de pièces de rechange d’origine DEUTZ AG garantit une rentabilité et fiabilité optimales ainsi qu’une longue durée de vie.

—Les éléments du moteur notamment les ressorts, attaches, bagues élastiques etc.,

peuvent entraîner, en cas de non-respect des prescriptions, des blessures graves.

—La remise en état du moteur doit répondre à son utilisation propre, définie par le constructeur de l’engin. En cas de modification, seules les pièces autorisées par DEUTZ AG dans le cas de l’application concernée, peuvent être utilisées.

©2001 / 0297 9765

P R O L O G O

Una ejecución competente de trabajos de reparación y ajuste es requisito fundamental para un funcionamiento seguro del motor.

En el presente manual para talleres han sido descritos los ciclos convenientes de trabajo para reparaciones y ajustes del motor y de sus componentes. Se presupone, no obstante, que los trabajos serán realizados por personal técnico especializado.

Con el fin de simplificar la comprensión del contenido del manual para talleres, se han agregado símbolos significativos a los textos explicatorios, visualizando así el trabajo a realizar.

Informaciones con respecto al manejo y al servicio de entretenimiento del motor, se encuentran en el Manual de Instrucciones de Servicio correspondiente.

Para pedidos de repuestos servirá de base el respectivo catálogo de repuestos.

El presente manual para talleres no está sujeto a un servicio continuado de modificaciones e innovaciones. Cada nueva edición incluye todas las modificaciones del caso.

Al efectuar reparaciones, aconsejamos asimismo tomar en cuenta las advertencias pertinentes de nuestras circulares técnicas.

Advertencias generales:

—Le recomendamos la detenida lectura y observancia de las informaciones contenidas en este Manual de taller. Así evitará accidentes y dispondrá de un motor que funciona perfectamente.

—Haga lo necesario para que este Manual esté a disposición de toda persona que participe en trabajos de reparación y ajuste, y cuide de que sí comprenda el contenido.

—Al no tenerse en cuenta estas instrucciones de reparación, podrán surgir perturbaciones en el funcionamiento y averías en el motor así como lesiones de personas para las cuales el fabricante no asume responsabilidad alguna.

—Se cumplirán las normas aplicables para la prevención de accidentes así como todas las demás normas de seguridad y medicina laboral generalmente aceptadas.

—Es condición para la correcta reparación que estén disponibles todos los requeridos equipos, herramientas manuales y especiales en perfecto estado.

—Máxima rentabilidad, fiabilidad y larga duración quedan garantizadas únicamente al emplearse repuestos originales de DEUTZ AG.

—Piezas del motor, tales como resortes, garras, aros de sujeción elásticos, etc. , aumentan en caso de tratamiento incorrecto el peligro de lesiones.

—El reacondicionado del motor deberá corresponder al empleo previsto definido por el fabricante del equipo. En caso de transformaciones, se deberán emplear únicamente piezas admitidas por DEUTZ AG para el respectivo uso previsto.

©2001 / 0297 9765

Inhalts-Verzeichnis

Table of Contents

Sommaire

Indice

Technische Daten / Bildzeichenerklärung

Specification data / Key to symbols

Caractéristiques techniques / Légende des symbols

Datos técnicos / Leyenda de símbolos

1

Prüfen und Einstellen

Checking and adjusting

Contrôle et réglage

Verificación y ajustes

2

Bauteile instand setzen

Repair of components

Mise en état des composants

Reparación de componentes

3

Demontage und Montage, Motor komplett

Disassembly and reassembly of complete engine

Démontage et montage moteur complet

Despiece y ensamblado conjunto de motor

4

Werkzeuge

Tools

Outils

Herramientas

© 2001 / 0297 9765

5

|

Technische Daten |

|

|

Specification data |

|

|

Caractéristiques techniques |

|

|

Datos técnicos |

1011 F |

© 2001 / 0297 9765

|

Inhalts-Verzeichnis |

Technische Daten |

|

Table of Contents |

Specification data |

|

Sommaire |

Caractéristiques techniques |

|

Indice |

Datos técnicos |

|

Deutsch |

Werkstatthandbuch 1011 F |

|

Ventilspiel |

2.00.01 — 2.00.02 |

|

Kompressionsdruck |

2.00.03 — 2.00.04 |

|

Einspritzventil |

2.00.05 — 2.00.07 |

|

Einspritzpumpe |

2.00.09 — 2.00.10 |

1

|

English |

|||

|

1. Specification data |

Page |

||

|

Specification data |

_______________________________________ |

1.00.02 -1.00.07 |

|

|

Schematic for valve clearance adjustment _______________________________ |

1.00.09 |

||

|

Tightening order for cylinder head bolts ________________________________ |

1.00.11 |

||

|

Key to symbols |

_______________________________________ |

1.00.13 |

|

|

Français |

|||

|

1. Caractéristiques techniques |

Page |

||

|

Caractéristiques techniques |

_______________________________________ |

1.00.02 — 1.00.07 |

|

|

Schéma de réglage des soupapes _____________________________________ |

1.00.09 |

||

|

Ordre à respecter lors du serrage dàpproche de définitif des fis de cul. ________ |

1.00.11 |

||

|

Explication des légendes |

_______________________________________ |

1.00.13 |

|

|

Español |

|||

|

1. Datos técnicos |

Página |

||

|

Datos técnicos |

_______________________________________ |

1.00.02 — 1.00.07 |

|

|

Esquema para el ajuste del juego de válvulas ____________________________ |

1.00.09 |

||

|

Sucesión de los trabajos al apretar los tornillos de culata ___________________ |

1.00.11 |

||

|

Leyenda de símbolos |

_______________________________________ |

1.00.13 |

|

© 2001 / 0297 9765

Technische Daten

Specification data

Caractéristiques techniques

Datos técnicos

Werkstatthandbuch 1011 F

|

Deutsch |

English |

Français |

Español |

||||

|

Motorgewicht |

Engine weight |

Poids du moteur |

Peso del motor |

||||

|

1 |

ohne Starter, |

without starter |

sans démarreur |

sin arrancador, |

|||

|

mit Generator |

with generator |

avec génératrice |

con generador |

||||

|

ca. kg |

approx. kg |

approx. kg |

aprox. kg |

||||

|

Gesamthubvolumen |

Engine swept volume |

Cylindrée totale |

Cilindrada total |

||||

|

cm3 |

cm3 |

cm3 |

cm3 |

||||

|

Bohrung |

Bore |

Alésage |

Calibre |

||||

|

mm |

mm |

mm |

mm |

||||

|

Hub |

Stroke |

Course |

Carrera |

||||

|

mm |

mm |

mm |

mm |

||||

|

Drehrichtung |

Direction of rotation |

Sens de rotation |

Sentido de giro |

||||

|

Nenndrehzahl |

Rated speed |

Régime nominal |

Régimen nominal |

||||

|

max. 1/min |

max. rpm |

maxi tr/mn |

máx. r/min |

||||

|

Niedrigste |

Minimum |

Ralenti extrême |

Régimen mín. |

||||

|

Leerlaufdrehzahl |

idle speed |

en vacío |

|||||

|

1/min |

rpm |

tr/mn |

r/min |

||||

|

Arbeitsweise |

Working cycle |

Principe de fonction- |

Sistema de trabajo |

||||

|

nement |

|||||||

|

© 2001 / 0297 9765 |

1.00.02 |

Technische Daten

Specification data

Caractéristiques techniques

Datos técnicos

|

Werkstatthandbuch 1011 F |

||||||||||||

|

F2 — 4L 1011 F |

BF4L 1011 F |

F3 — 4M 1011 F |

BF4M 1011 F |

|||||||||

|

F2L = 167 |

||||||||||||

|

F3L = 208 |

257 |

F3M = 200 |

249 |

1 |

||||||||

|

F4L = 250 |

F4M = 243 |

|||||||||||

|

F2L = 1366 |

||||||||||||

|

F3L = 2049 |

2732 |

F3M = 2184 |

2912 |

|||||||||

|

F4L = 2732 |

F4M = 2912 |

|||||||||||

|

91 |

||||||||||||

|

105 |

112 |

|||||||||||

|

auf Schwungrad gesehen links |

||||||||||||

|

When facing flywheel counter-clockwise |

||||||||||||

|

Vu sur volant à gauche |

||||||||||||

|

Mirándose sobre el volante a izquierdas |

||||||||||||

|

3300 |

3000 |

3000 |

2800 |

|||||||||

|

900 ±50 |

Viertakt — Diesel

Four-stroke diesel

Diesel 4 temps

Diesel a 4 tiempos

|

1.00.03 |

© 2001 / 0297 9765 |

Technische Daten

Specification data

Caractéristiques techniques

Datos técnicos

Werkstatthandbuch 1011 F

|

Deutsch |

English |

Français |

Español |

||||

|

Verbrennungs- |

Combustion |

Principe de |

Sistema de |

||||

|

1 |

verfahren |

system |

combustion |

combustión |

|||

|

Verdichtungs- |

Compression |

Taux de |

Relación de |

||||

|

verhältnis |

ratio |

compression |

compresión |

||||

|

Kompressionsdruck |

Compression pressure |

Compression |

Pressión de |

||||

|

compresión |

|||||||

|

bar |

bar |

bars |

bar |

||||

|

Zündfolge |

Firing order |

Ordre d’allumage |

Orden de |

||||

|

encendido |

|||||||

|

Abmessungen des |

Dimensions of |

Dimensions du |

Dimensiones del |

||||

|

Motors mit |

engine incl. |

moteur avec volant |

motor con |

||||

|

Anschlußgehäuse |

standard flywheel |

standard |

volante |

||||

|

(normal) |

(normal) |

||||||

|

größte Länge |

Max. length |

Longueur HT |

Longitud máx. |

||||

|

mm |

mm |

mm |

mm |

||||

|

größte Breite |

Max. width |

Largeur HT |

Anchura máx. |

||||

|

mm |

mm |

mm |

mm |

||||

|

größte Höhe |

Max. height |

Hauteur HT |

Altura máx. |

||||

|

mm |

mm |

mm |

mm |

||||

|

© 2001 / 0297 9765 |

1.00.04 |

Technische Daten

Specification data

Caractéristiques techniques

Datos técnicos

Werkstatthandbuch 1011 F

|

F2 — 4L 1011 F |

BF4L 1011 F |

F3-4M 1011 F |

BF4M 1011 F |

|||

Direkteinspritzung

Direct injection

Injection directe 1

Inyección directa

|

1 |

— 2 |

|||

|

1 |

-2 — 3 |

1 -2 — 3 |

||

|

1 -3 — 4 — 2 |

1 -3 — 4 — 2 |

1 -3 — 4 — 2 |

1 -3 — 4 — 2 |

|

|

F2L = 487 |

|||

|

F3L = 599 |

710 |

F3M = 599 |

710 |

|

F4L = 710 |

F4M = 710 |

||

|

451 |

495 |

451 |

495 |

|

F2L = 683 |

|||

|

F3L = 678 |

703 |

F3M = 678 |

703 |

|

F4L = 703 |

F4M = 703 |

||

|

1.00.05 |

© 2001 / 0297 9765 |

Technische Daten

Specification data

Caractéristiques techniques

Datos técnicos

Werkstatthandbuch 1011 F

|

Deutsch |

English |

Français |

Español |

|||||

|

Steuerzeiten ohne |

Valve timing without |

Calage distribution sans |

Cotas de reglaje sin |

|||||

|

Stößelund Ventilspiel |

valve clearance |

jeu aux culbuteurs |

juegos de válvulas y |

|||||

|

1 |

réglé |

de empujadores |

||||||

|

Einlaß öffnet |

Inlet opens |

Admission ouvre |

Admisión abre |

|||||

|

vor OT |

before TDC |

avant PMH |

a. PMS |

|||||

|

Grad |

degrees |

degrés |

grados |

|||||

|

Einlaß schließt |

Inlet closes |

Admission ferme |

Admisión cierra |

|||||

|

nach UT |

after BDC |

après PMB |

t. PMI |

|||||

|

Grad |

degrees |

degrés |

grados |

|||||

|

Auslaß öffnet |

Exhaust opens |

Echappement ouvre |

Escape abre |

|||||

|

vor UT |

before BDC |

avant PMB |

a. PMI |

|||||

|

Grad |

degrees |

degrés |

grados |

|||||

|

Auslaß schließt |

Exhaust closes |

Echappement ferme |

Escape cierra |

|||||

|

nach OT |

after TDC |

après PMH |

t. PMS |

|||||

|

Grad |

degrees |

degrés |

grados |

|||||

|

Schmieröldruck in |

Lube oil pressure at low |

Pression d’huile au bas |

Presión de aceite lubri- |

|||||

|

niedrigem Leerlauf |

idling |

ralent |

cante a marcha lenta |

|||||

|

Temperatur ca. 110° C |

Temperature approx. |

température ca. 110° C |

en vacío Tempera- |

|||||

|

Öl SAE 20W/20 |

110° C oil SAE 20W/20 |

huile SAE 20W/20 |

tura aprox. 110° C |

|||||

|

aceite SAE 20W/20 |

||||||||

|

Minimum bar |

min. bar |

mini bars |

mín. bar |

|||||

|

Absteuerventil |

Pressurestat |

Clapet régulateur |

Válvula reguladora |

|||||

|

final |

final |

|||||||

|

bar |

bar |

bars |

bar |

|||||

|

© 2001 / 0297 9765 |

1.00.06 |

Technische Daten

Specification data

Caractéristiques techniques

Datos técnicos

|

Werkstatthandbuch 1011 F |

|||||||

|

F2 — 4L 1011 F |

BF4L 1011 F |

F3 — 4M 1011 F |

BF4M 1011 F |

||||

|

1 |

|||||

|

45 |

47 |

45 |

47 |

||

|

65 |

63 |

65 |

63 |

||

|

76 |

99,5 |

76 |

99,5 |

||

|

44 |

51,5 |

44 |

51,5 |

||

|

1,4 |

|||||

|

F2 -3L = 6,5 |

7 |

F3L = 6,5 |

7 |

||

|

F4L = 7 |

F4L = 7 |

||||

|

1.00.07 |

© 2001 / 0297 9765 |

Technische Daten Specification data Caractéristiques techniques Datos técnicos

Werkstatthandbuch 1011 F

1

© 2001 / 0297 9765

Ventilspieleinstellschema

Schematic for valve clearance adjustment

Schéma de réglage des soupapes

Esquema para el ajuste de holgura de válvulas

Werkstatthandbuch 1011 F

|

English |

Français |

Español |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Crankshaft position |

1 |

Position de l’arbre à cames |

1 |

Posición del cigüeñal |

1 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Kurbelwellenstellung |

11 |

Kurbelwellenstellung |

2 |

1 |

1 |

Turn engine until valves of cylinder |

Virer le moteur jusqu’au chevau- |

Gírese el motor, hasta que las válvulas |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

No. 1 overlap. |

chement des soupapes au cylindre 1. |

del cilindro N° 1 coincidan en su |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

posición momentánea. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Motor bis zum Erreichen der Ventilüber- |

Motor um eine volle Umdrehung (360°) |

Not ready for adjustment. |

non réglable |

no ajustable |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

schneidung am Zyl. Nr. 1 durchdrehen. |

weiterdrehen. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2: |

2 |

2 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Crankshaft position |

Position de l’arbre à cames |

Posición del cigüeñal |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

nicht einstellbar |

einstellbar |

Turn engine further by one complete |

Tourner le moteur d’un tour complet |

Continuese girando el motor por una |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

revolution (360°). |

(360°) |

rotación completa (360°) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Ready for adjustment. |

réglable |

ajustable |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

© 2001 / 0297 9765 |

1.00.09 |

1.00.09 |

© 2001 / 0297 9765 |

Reihenfolge beim Anziehen der Zylinderkopfschrauben Tightening order for cylinder head bolts

Ordre à respecter lors du serrage d’approche et définitif des vis de cul. Sucesión de los trabajos al apretar los tornillos de culata

Werkstatthandbuch 1011 F

Krümmerseite,Manifold side,

Coté coudes, Lado codo

|

2-Zylinder |

|||

|

4 |

2 |

6 |

2-cylinder |

|

2-cylindres |

|||

|

5 |

1 |

3 |

2 cilindros |

Krümmerseite,Manifold side,

Coté coudes, Lado codo

|

3-Zylinder |

||||

|

7 |

3 |

4 |

6 |

3-cylinder |

|

3-cylindres |

||||

|

5 |

1 |

2 |

8 |

3 cilindros |

Krümmerseite,Manifold side,

Coté coudes, Lado codo

|

4-Zylinder |

|||||

|

8 |

6 |

4 |

5 |

9 |

4-cylinder |

|

4-cylindres |

|||||

|

10 |

3 |

1 |

2 |

4 cilindros |

|

|

7 |

1 1

Krümmerseite,Manifold side,

Coté coudes, Lado codo

|

2-Zylinder |

|||

|

4 |

2 |

6 |

2-cylinder |

|

2-cylindres |

|||

|

5 |

1 |

3 |

2 cilindros |

Krümmerseite,Manifold side,

Coté coudes, Lado codo

|

3-Zylinder |

||||

|

7 |

3 |

4 |

6 |

3-cylinder |

|

3-cylindres |

||||

|

5 |

1 |

2 |

8 |

3 cilindros |

Krümmerseite,Manifold side,

Coté coudes, Lado codo

|

4-Zylinder |

|||||

|

8 |

6 |

4 |

5 |

9 |

4-cylinder |

|

4-cylindres |

|||||

|

10 |

3 |

1 |

2 |

4 cilindros |

|

|

7 |

|

© 2001 / 0297 9765 |

1.00.11 |

1.00.11 |

© 2001 / 0297 9765 |

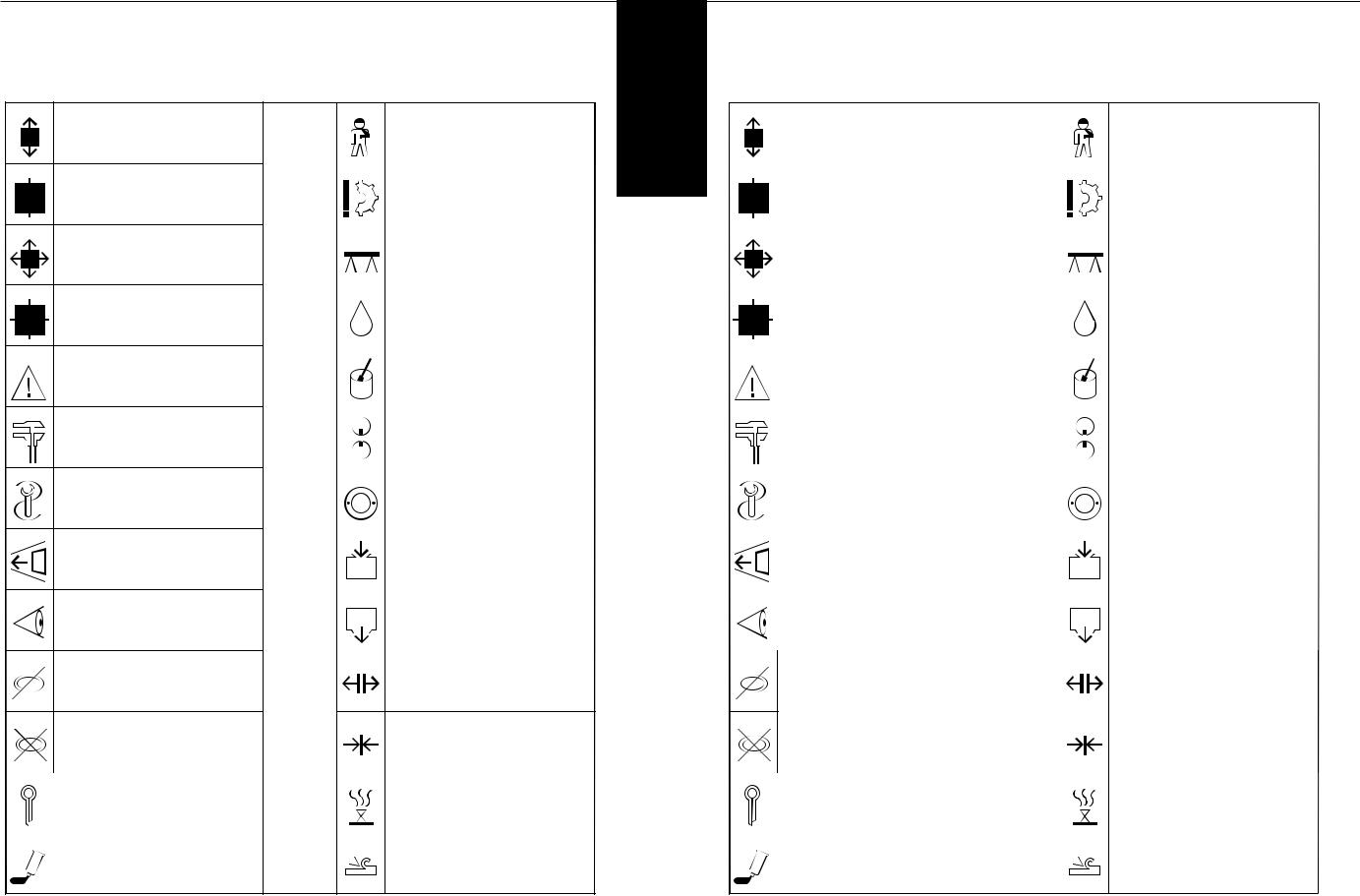

Bildzeichenerklärung

|

Werkstatthandbuch 1011 F |

|||||||||||||||

|

Bildzeichenerklärung |

Bildzeichenerklärung |

||||||||||||||

|

Zerlegen |

Personenschäden verhüten |

Zerlegen |

Personenschäden verhüten |

||||||||||||

|

von Baugruppen |

Hinweis auf Gefahrenstelle |

1 |

1 |

von Baugruppen |

Hinweis auf Gefahrenstelle |

||||||||||

|

Zusammenbauen |

Materialschaden verhüten |

Zusammenbauen |

Materialschaden verhüten |

||||||||||||

|

zu einer Baugruppe |

Teilbeschädigung |

zu einer Baugruppe |

Teilbeschädigung |

||||||||||||

|

Abbauen — Ausbauen |

Unterbauen — Abstützen — |

Abbauen — Ausbauen |

Unterbauen — Abstützen — |

||||||||||||

|

behindernder Teile |

Abfangen |

behindernder Teile |

Abfangen |

||||||||||||

|

Einbauen — Anbauen |

Einölen |

Einbauen — Anbauen |

Einölen |

||||||||||||

|

Teile, die beim Ab-/ Ausbau hinderten |

Teile, die beim Ab-/ Ausbau hinderten |

||||||||||||||

|

Achtung, wichtiger Hinweis |

Einfetten |

Achtung, wichtiger Hinweis |

Einfetten |

||||||||||||

|

Prüfen — Einstellen |

Markieren |

Prüfen — Einstellen |

Markieren |

||||||||||||

|

z. B. Drehmomente, Maße, Drücke usw. |

vor dem Zerlegen, beachten beim |

z. B. Drehmomente, Maße, Drücke usw. |

vor dem Zerlegen, beachten beim |

||||||||||||

|

Zusammenbau |

Zusammenbau |

||||||||||||||

|

Spezialwerkzeug |

Wuchten |

Spezialwerkzeug |

Wuchten |

||||||||||||

|

Ausgleichen von Unwuchten |

Ausgleichen von Unwuchten |

||||||||||||||

|

Einbaurichtung beachten |

Einfüllen — Auffüllen — Nachfüllen |

Einbaurichtung beachten |

Einfüllen — Auffüllen — Nachfüllen |

||||||||||||

|

z. B. Öl, Kühlwasser usw. |

z. B. Öl, Kühlwasser usw. |

||||||||||||||

|

Kontrollieren — Prüfen |

Ablassen |

Kontrollieren — Prüfen |

Ablassen |

||||||||||||

|

Sichtprüfung |

z. B. Öl, Kühlwasser usw. |

Sichtprüfung |

z. B. Öl, Kühlwasser usw. |

||||||||||||

|

Bedingt wiederverwendbar |

Lösen |

Bedingt wiederverwendbar |

Lösen |

||||||||||||

|

Bei Bedarf auswechseln |

z. B. Lockern einer Spanneinrichtung |

Bei Bedarf auswechseln |

z. B. Lockern einer Spanneinrichtung |

||||||||||||

|

Beim Zusammenbau immer |

Spannen |

Beim Zusammenbau immer |

Spannen |

||||||||||||

|

erneuern |

z. B. Anziehen einer Spanneinrichtung |

erneuern |

z. B. Anziehen einer Spanneinrichtung |

||||||||||||

|

Entsichern — Sichern |

Entlüften |

Entsichern — Sichern |

Entlüften |

||||||||||||

|

z. B. Splint, Sicherungsblech usw. |

z. B. Splint, Sicherungsblech usw. |

||||||||||||||

|

Sichern — Kleben |

Spanabhebende Bearbeitung |

Sichern — Kleben |

Spanabhebende Bearbeitung |

||||||||||||

|

z. B. Dichtmittel flüssig |

z. B. Dichtmittel flüssig |

||||||||||||||

|

© 2001 / 0297 9765 |

1.00.13 |

1.00.13 |

© 2001 / 0297 9765 |

Key to Symbols

|

Werkstatthandbuch 1011 F |

||||||||||||||||||

|

Key to Symbols |

Key to Symbols |

|||||||||||||||||

|

Disassembly |

Guard against personal injury |

Disassembly |

Guard against personal injury |

|||||||||||||||

|

of assembly groups |

Indication of hazard |

1 |

1 |

of assembly groups |

Indication of hazard |

|||||||||||||

|

Reassembly |

Guard against material damage |

Reassembly |

Guard against material damage |

|||||||||||||||

|

to form assembly group |

Damage to parts |

to form assembly group |

Damage to parts |

|||||||||||||||

|

Remove |

Prop up — Support — Hold |

Remove |

Prop up — Support — Hold |

|||||||||||||||

|

obstructing parts |

obstructing parts |

|||||||||||||||||

|

Reinstall — Remount |

Oil |

Reinstall — Remount |

Oil |

|||||||||||||||

|

parts which had obstructed disassembly |

parts which had obstructed disassembly |

|||||||||||||||||

|

Attention! Impartant notice! |

Grease |

Attention! Impartant notice! |

Grease |

|||||||||||||||

|

Check — Adjust |

Mark |

Check — Adjust |

Mark |

|||||||||||||||

|

e. g. torque dimensions, pressures, etc. |

before disassembly, observe marks when |

before disassembly, observe marks when |

||||||||||||||||

|

reassembling |

e. g. torque dimensions, pressures, etc. |

reassembling |

||||||||||||||||

|

Special tool |

Balance |

Special tool |

Balance |

|||||||||||||||

|

Eliminate any imbalance |

Eliminate any imbalance |

|||||||||||||||||

|

Note direction of installation |

Filling — Topping up — Refilling |

Note direction of installation |

Filling — Topping up — Refilling |

|||||||||||||||

|

e. g. oil, cooling water, etc. |

e. g. oil, cooling water, etc. |

|||||||||||||||||

|

Visual inspection |

Drain off |

Visual inspection |

Drain off |

|||||||||||||||

|

e. g. oil, cooling water, etc. |

e. g. oil, cooling water, etc. |

|||||||||||||||||

|

Possibly still serviceable |

Loosen — Release |

Possibly still serviceable |

Loosen — Release |

|||||||||||||||

|

Renew if necessary |

e. g. loosening a clamping device |

Renew if necessary |

e. g. loosening a clamping device |

|||||||||||||||

|

Renew at each reassembly |

Tighten — Clamp |

Renew at each reassembly |

Tighten — Clamp |

|||||||||||||||

|

e. g. tightening a clamping device |

e. g. tightening a clamping device |

|||||||||||||||||

|

Unlock — Lock |

Vent |

Unlock — Lock |

Vent |

|||||||||||||||

|

e. g. split pin, locking plate, etc. |

e. g. split pin, locking plate, etc. |

|||||||||||||||||

|

Lock — Adhere |

Machining process |

Lock — Adhere |

Machining process |

|||||||||||||||

|

e. g. with liquid sealant |

e. g. with liquid sealant |

|||||||||||||||||

|

© 2001 / 0297 9765 |

1.00.13 |

1.00.13 |

© 2001 / 0297 9765 |

Légende des symboles

|

Werkstatthandbuch 1011 F |

|

|

Légende des symboles |

Légende des symboles |

Déassemblage

d’un ensemble constructif

Assemblage

des composants d’un ensemble constructif

Démontage

d’eléments entravant l’accés

Remontage — Remise en place

d’eléments qui entravaient l’accés

Remarque importante!

Utilisation impérative

p. ex.: couple-moteur, cotes, pressions etc.

Utilisation impérative

d’un outil specialise

Respecter l’ordre de montage

Vérification — Contrôle

à vue

Réutilisation sous certaines conditions

à remplacer,si besoin est

|

Prévention aux accidents profession |

Déassemblage |

Prévention aux accidents profession |

||||

|

attirer l’attention sur un risque eventuel |

1 |

1 |

d’un ensemble constructif |

attirer l’attention sur un risque eventuel |

||

|

d’ accident |

d’ accident |

|||||

|

Prévention à la détérioration de |

Assemblage |

Prévention à la détérioration de |

||||

|

matériels |

matériels |

|||||

|

Risque d’endommager des piéces |

des composants d’un ensemble constructif |

Risque d’endommager des piéces |

||||

|

Monter sur tréteaux — freiner par |

Démontage |

Monter sur tréteaux — freiner par |

||||

|

sabots — immobiliser par un moyen |

sabots — immobiliser par un moyen |

|||||

|

quelconque |

d’eléments entravant l’accés |

quelconque |

||||

|

Huiler |

Remontage — Remise en place |

Huiler |

||||

|

d’eléments qui entravaient l’accés |

||||||

|

Graisser |

Remarque importante! |

Graisser |

||||

|

employer lubrificant plastique |

employer lubrificant plastique |

|||||

|

Repérage en cours de démontage |

Utilisation impérative |

Repérage en cours de démontage |

||||

|

permet un remontage correct! |

p. ex.: couple-moteur, cotes, pressions etc. |

permet un remontage correct! |

||||

|

Equilibrer |

Utilisation impérative |

Equilibrer |

||||

|

éliminer le balourd |

d’un outil specialise |

éliminer le balourd |

||||

|

Premier garnissage — remplissage — |

Respecter l’ordre de montage |

Premier garnissage — remplissage — |

||||

|

garnissage d’appoint |

garnissage d’appoint |

|||||

|

p. ex.: Huile eau de refroidissement etc. |

p. ex.: Huile eau de refroidissement etc. |

|||||

|

Vidanger — soutirer |

Vérification — Contrôle |

Vidanger — soutirer |

||||

|

p. ex.: Huile eau de refroidissement etc. |

à vue |

p. ex.: Huile eau de refroidissement etc. |

||||

|

Desserrer |

Réutilisation sous certaines |

Desserrer |

||||

|

p. ex.: desserrage d’un dispositiv |

conditions |

|||||

|

à remplacer,si besoin est |

p. ex.: desserrage d’un dispositiv |

|||||

|

A remplacer systématiquement |

Serrer |

A remplacer systématiquement |

Serrer |

|||||

|

lors de remontage |

p. ex.: serrage entre un dispositif |

lors de remontage |

p. ex.: serrage entre un dispositif |

|||||

|

Arracher la goupille — goupiller |

Faire la purge d’air |

Arracher la goupille — goupiller |

Faire la purge d’air |

|||||

|

freiner par tôle-arrétoir |

freiner par tôle-arrétoir |

|||||||

|

Freiner — coller |

Usinage par enlèvement de copeaux |

Freiner — coller |

Usinage par enlèvement de copeaux |

|||||

|

p. ex. avec páte hermétique, ou frein liquide |

p. ex. avec páte hermétique, ou frein liquide |

|||||||

|

© 2001 / 0297 9765 |

1.00.13 |

1.00.13 |

© 2001 / 0297 9765 |

Leyenda de símbolos

|

Werkstatthandbuch 1011 F |

|||||||||||||||

|

Leyenda de símbolos |

Leyenda de símbolos |

||||||||||||||

|

Desarmar |

Evitar accidentes |

Desarmar |

Evitar accidentes |

||||||||||||

|

grupos de construcción |

indica puntos de peligro |

1 |

1 |

grupos de construcción |

indica puntos de peligro |

||||||||||

|

Rearmar |

Evitar daños materiales |

Rearmar |

Evitar daños materiales |

||||||||||||

|

un grupo de construcción |

averia de piezas |

un grupo de construcción |

averia de piezas |

||||||||||||

|

Desmontar |

Calzar — Apoyar |

Desmontar |

Calzar — Apoyar |

||||||||||||

|

partes que puedan estorbar |

partes que puedan estorbar |

||||||||||||||

|

Montar — Incorporar |

Aceitar |

Montar — Incorporar |

Aceitar |

||||||||||||

|

partes que puedan estorbar en |

partes que puedan estorbar en |

||||||||||||||

|

el desmontaje |

el desmontaje |

||||||||||||||

|

!Atención! Indicación importante |

Engrasar |

!Atención! Indicación importante |

Engrasar |

||||||||||||

|

Verificar — Graduar — Ajustar |

Marcar |

Verificar — Graduar — Ajustar |

Marcar |

||||||||||||

|

(p. ej. pares, medidas, presiones) |

antes del desmontaje — controlar la marcación |

antes del desmontaje — controlar la marcación |

|||||||||||||

|

en el remontaje |

(p. ej. pares, medidas, presiones) |

en el remontaje |

|||||||||||||

|

Herramienta especial |

Equilibar |

Herramienta especial |

Equilibar |

||||||||||||

|

Aeliminar desequilibros o excentricidad |

Aeliminar desequilibros o excentricidad |

||||||||||||||

|

Observar la dirección de montaje |

Lienar — Rellenar — Completar |

Observar la dirección de montaje |

Lienar — Rellenar — Completar |

||||||||||||

|

p. ej. aceite, agua refrigerante, etc. |

p. ej. aceite, agua refrigerante, etc. |

||||||||||||||

|

Control |

Evacuar — Vaciar |

Control |

Evacuar — Vaciar |

||||||||||||

|

verificación visual |

p. ej. aceite, agua refrigerante, etc. |

verificación visual |

p. ej. aceite, agua refrigerante, etc. |

||||||||||||

|

Re-utilización condicional |

Soltar |

Re-utilización condicional |

Soltar |

||||||||||||

|

sustituir en caso necesario |

p. ej. un sistema de fijación o tensado |

sustituir en caso necesario |

p. ej. un sistema de fijación o tensado |

||||||||||||

|

Sustituir en cada montaje |

Tensar — Apretar |

Sustituir en cada montaje |

Tensar — Apretar |

||||||||||||

|

p. ej. un sistema de fijación o tensado |

p. ej. un sistema de fijación o tensado |

||||||||||||||

|

Desafianzar — Afianzar (mecánicamente) |

Purgar el aire |

Desafianzar — Afianzar (mecánicamente) |

Purgar el aire |

||||||||||||

|

(p. ej. pasador de aletas, chapa de seguridad, |

(p. ej. pasador de aletas, chapa de seguridad, |

||||||||||||||

|

etc.) |

etc.) |

||||||||||||||

|

Afianzar — Pegar |

Mecanización con arranque de |

Afianzar — Pegar |

Mecanización con arranque de |

||||||||||||

|

p. ej. con medio liquido |

virutas |

p. ej. con medio liquido |

virutas |

||||||||||||

|

© 2001 / 0297 9765 |

1.00.13 |

1.00.13 |

© 2001 / 0297 9765 |

Prüfen und Einstellen

Checking and adjusting

Contrôle et réglage

Verificación y ajustes 1011 F

© 2001 / 0297 9765

|

Inhalts-Verzeichnis |

Prüfen und Einstellen |

||

|

Table of Contents |

Checking and adjusting |

||

|

Sommaire |

Contrôle et réglage |

||

|

Indice |

Verificación y ajustes |

||

|

Deutsch |

Werkstatthandbuch 1011 F |

||

|

2. Prüfen und Einstellen |

Seite |

||

|

Ventilspiel _______________________________________________________ |

2.00.01 — 2.00.02 |

||

|

Kompressionsdruck ________________________________________________ |

2.00.03 — 2.00.04 |

||

|

Einspritzventil |

____________________________________________________ |

2.00.05 — 2.00.07 |

|

|

Einspritzpumpe ___________________________________________________ |

2.00.09 — 2.00.10 |

||

|

English |

|||

|

2. Checking and adjusting |

Page |

||

|

Valve clearance ___________________________________________________ |

2.00.01 — 2.00.02 |

2 |

|

|

Compression pressure ______________________________________________ |

2.00.03 — 2.00.04 |

||

|

Injector _________________________________________________________ |

2.00.05 — 2.00.07 |

||

|

Injection pump ___________________________________________________ |

2.00.09 — 2.00.10 |

||

Français

|

2. Contrôle et réglage |

Page |

Jeu aux soupapes _________________________________________________ 2.00.01 — 2.00.02 Taux de compression ______________________________________________ 2.00.03 — 2.00.04 Soupape injectrice _________________________________________________ 2.00.05 — 2.00.07 Pompe d’injection _________________________________________________ 2.00.09 — 2.00.10

Español

|

2. Verificación y ajustes |

Pagina |

Juego de válvulas _________________________________________________ 2.00.01 — 2.00.02 Presión de compresión _____________________________________________ 2.00.03 — 2.00.04 Inyector _________________________________________________________ 2.00.05 — 2.00.07

Bomba de inyección _______________________________________________ 2.00.09 — 2.00.10

© 2001 / 0297 9765

|

Prüfen und Einstellen |

Ventilspiel |

|

Checking and adjusting |

Valve clearance |

|

Contrôle et réglage |

Jeu de soupapes |

|

Verificación y ajustes |

Juego de válvulas |

|

English |

Français |

|||

|

The standard valve clearance can be |

Le réglage standard du jeu des |

|||

|

adjusted: |

soupapes est possible |

|||

|

with engine cold or warm after cooling |

sur moteur froid ou chaud après une |

|||

|

down for at least 0.5 h. |

période de refroidissement d’au moins |

|||

|

30 minutes. |

||||

|

Oil temperature ≤ 80°C. |

Température de l’huile ≤ 80˚C. |

|||

|

Note: The valve clearance is to be in- |

Nota: à chaque changement du joint de |

|||

|

creased by 0.1 mm at every cy- |

culasse augmenter le jeu aux |

|||

|

linder head gasket renewal. |

soupapes de 0,1 mm. |

|||

|

The standard valve clearance is |

Après 500 heures de marche |

|||

|

to be adjusted after completion |

procéder au réglage standard du |

|||

|

of 500 hours of operation. |

jeu des soupapes. |

|||

|

2 |

Cylinder head cover has been removed. |

Le cache-culbuteurs a été déposé. |

||

|

1. Turn engine until valves of cyl. No. |

1. Virer le moteur jusqu’à ce que les |

|||

|

1 overlap. |

soupapes soient en bascule, cyl. no. 1. |

|||

|

For valve clearance adjustment |

Schéma de réglage du jeu aux |

|||

|

schematic see Specification Data. |

soupapes voir caractéristiques |

|||

|

techniques. |

||||

|

Note: Valves overlapping means: |

Nota: le chevauchement des soupapes |

|||

|

Exhaust valve about to close. |

signifie: soupape d’échappement |

|||

|

Inlet valve about to open. |

pas encore fermée et soupape |

|||

|

Neither pushrod can be turned |

d’admission commence à |

|||

|

in this position. |

s’ouvrir. Les deux tiges de |

|||

|

culbuteurs ne peuvent plus |

||||

|

tourner. |

|

2. |

Adjust valve clearance on respec- |

2. |

Régler le jeu des soupapes au |

||

|

tive cylinder with feeler gauge. |

cylindre correspondant avec une |

||||

|

jauge d’épaisseur. |

|||||

|

Note: Inlet valve clearance: |

0.3 mm |

Nota: Jeu soupape ADM: |

0,3 mm |

||

|

Exhaust valve clearance: 0.5 mm |

Jeu soupape ECH: |

0,5 mm |

|||

|

3. |

Tighten locknut. |

3. |

Serrer le contre-écrou |

||

|

Tightening specification: 20 ±2 Nm |

Consigne de serrage 20 ± 2 Nm |

||||

|

Recheck the adjustment with feeler |

Effectuer un nouveau contrôle du |

||||

|

gauge. |

serrage avec une jauge d’épaisseur. |

Español

El ajuste del juego estándar de válvulas es posible:

Con el motor frío o con el motor caliente después de un período de enfriamiento de por lo menos media hora.

Temperatura del aceite: ≤ 80°C.

Nota: El juego de válvulas debe aumentarse por 0,1 mm a cada cambio de la junta de culata,. Tras 500 horas de servicio se ajustará el juego estándar.

La tapa de culata está desmontada.

1.Girar el cigüeñal hasta que se crucen las válvulas en el cilindro 1.

Para el esquema de ajuste del juego de válvulas, véanse los Datos Técnicos.

Nota: Cruce de válvulas significa: La válvula de escape aún no está cerrada y la de admisión comienza a abrirse. En esta posición, no es posible girar las dos varillas de empuje.

2.Ajustar el juego de válvulas en el cilindro correspondiente mediante la galga de espesores.

|

Nota: Juego de válvulas |

|

|

— admisión: |

0,3 mm |

|

— escape: |

0,5 mm |

3.Apretar la contratuerca.

Prescripción de apriete: 20 ± 2 Nm.

Comprobar nuevamente el ajuste efectuado, mediante la galga de espesores.

|

© 2001 / 0297 9765 |

2.00.01 |

|

Ventilspiel |

Prüfen und Einstellen |

|

Valve clearance |

Checking and adjusting |

|

Jeu de soupapes |

Contrôle et réglage |

|

Juego de válvulas |

Verificación y ajustes |

|

Deutsch |

Werkstatthandbuch 1011 F |

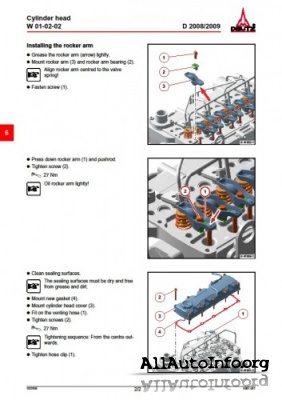

Die Standard-Ventilspieleinstellung ist möglich:

Am kaltenoder am warmen Motor nach einer Abkühlzeit von mindestens 0,5 h. Öltemperatur ≤ 80° C

Hinweis: Bei jedem Zylinderkopf-Dichtungswech- sel ist das Ventilspiel um 0,1 mm zu erhöhen.

Nach 500 Bh ist das Standard-Ventil- spiel einzustellen.

Zylinderkopfhaube ist abgebaut

1.Motor durchdrehen bis zum Erreichen der

Ventilüberschneidung, Zyl. Nr. 1.

Ventilspieleinstellschema siehe Techn. Daten

Hinweis: Ventilüberschneidung bedeutet: Auslaßventil ist noch nicht geschlossen, Einlaßventil beginnt zu öffnen. Dabei sind beide Stoßstangen nicht drehbar.

2.Ventilspieleinstellung am entsprechenden Zylinder mit Fühlerlehrenblatt einstellen.

|

Hinweis: Ventilspiel Einlaß: |

0,3 mm |

|

Ventilspiel Außlaß: |

0,5 mm |

3.Kontermutter festdrehen.

Anziehvorschrift: 20 ± 2 Nm

Einstellung nochmals mit Fühlerlehrenblatt überprüfen.

9

2

9

5

6

5

|

2.00.01 |

© 2001 / 0297 9765 |

|

Prüfen und Einstellen |

Ventilspiel |

|

Checking and adjusting |

Valve clearance |

|

Contrôle et réglage |

Jeu de soupapes |

|

Verificación y ajustes |

Juego de válvulas |

Werkstatthandbuch 1011 F

4

0

Deutsch

4. Dichtung aufsetzen.

5.Zylinderkopfhaube montieren. Schrauben festdrehen.

Anziehvorschrift: 8,5 Nm

|

© 2001 / 0297 9765 |

2.00.02 |

|

Ventilspiel |

Prüfen und Einstellen |

||||

|

Valve clearance |

Checking and adjusting |

||||

|

Jeu de soupapes |

Contrôle et réglage |

||||

|

Juego de válvulas |

Verificación y ajustes |

||||

|

English |

Français |

Español |

|||

|

4. Put gasket in place. |

4. Mettre en place le joint. |

4. Colocar la junta. |

|

5. Fit cylinder head cover. Tighten |

5. Monter le cache-culbuteurs. |

5. Montar la tapa de culata. Apretar |

|

bolts. |

Bloquer les vis. |

los tornillos. |

|

Tightening specification: 8.5 Nm |

Consigne de serrage: 8,5 Nm. |

Prescripción de apriete: 8,5 Nm. |

2

|

2.00.02 |

© 2001 / 0297 9765 |

|

Prüfen und Einstellen |

Kompressionsdruck |

|||||||

|

Checking and adjusting |

Compression pressure |

|||||||

|

Contrôle et réglage |

Taux de compression |

|||||||

|

Verificación y ajustes |

Presión de compresión |

|||||||

|

English |

Français |

Español |

||||||

|

Commercial tools required: |

Outillage usuel: |

Herramientas comerciales: |

||||||

|

Compression tester __________ 8005 |

Compressiomètre ___________ 8005 |

Compresímetro _____________ 8005 |

||||||

|

Torx tool kit ________________ 8189 |

Jeu d’outils Torx ____________ 8189 |

Juego de herramientas Torx |

___ 8189 |

|||||

|

Special tools required: |

Outil spécial: |

Herramientas especiales: |

||||||

|

Connector ______________ |

100 120 |

Pièce de raccordement ____ |

100 120 |

Pieza de empalme ________ |

100 120 |

|||

|

Special wrench |

Clé spéciale pour |

Llave especial para |

||||||

|

for injection line __________ |

110 490 |

conduite d’injection _______ |

110 490 |

tubo de inyección ________ |

110 490 |

|

Injectors have been removed, valve |

Les injecteurs ont été déposés et le |

Los inyectores están desmontados y |

|

|

clearance has been checked. |

jeu des soupapes contrôlé. |

el juego de válvulas está controlado. |

|

|

2 |

1. Insert connector with new special |

1. Mettre en place la pièce de |

1. Introducir la pieza de empalme con |

|

seal. |

raccordement avec un joint spécial |

la junta especial nueva. |

|

|

neuf. |

2. Fit clamping pad. Tighten bolt.

2.Placer la griffe de serrage et serrer le boulon.

2.Colocar la garra de sujeción. Apretar el tornillo.

3.If necessary, screw on adapter for connector.

3.Si nécessaire mettre en place l’adaptateur de la pièce de raccordement.

3.De ser necesario, enroscar el adaptador para la pieza de empalme.

|

© 2001 / 0297 9765 |

2.00.03 |

|

Kompressionsdruck |

Prüfen und Einstellen |

|

Compression pressure |

Checking and adjusting |

|

Taux de compression |

Contrôle et réglage |

|

Presión de compresión |

Verificación y ajustes |

Deutsch

Handelsübliche Werkzeuge:

Kompressionsdruckprüfer ___________ 8005 Torx-Werkzeugsatz ________________ 8189

Spezialwerkzeuge:

Anschlußstück _________________ 100 120 Spezialschlüssel für Einspritzleitung __ 110 490

Einspritzventile sind ausgebaut, Ventilspiel ist kontrolliert.

1.Anschlußstück mit neuer Spezialdichtung einsetzen.

Werkstatthandbuch 1011 F

4

0

|

2. Spannpratze aufsetzen. Schraube festdrehen. |

4 |

|

3. Falls notwendig Adapter für Anschlußstück |

4 |

|

aufschrauben. |

|

2.00.03 |

© 2001 / 0297 9765 |

|

Prüfen und Einstellen |

Kompressionsdruck |

|

Checking and adjusting |

Compression pressure |

|

Contrôle et réglage |

Taux de compression |

|

Verificación y ajustes |

Presión de compresión |

Werkstatthandbuch 1011 F

4

6

|

9 |

|||

|

2 |

5 |

||

Deutsch

4.Kompressionsdruckprüfer anschließen. Motor mit Starter durchdrehen. Kompressionsdruck:

|

F 1011 F |

25-30 bar |

|

BF 1011 F |

22-27 bar |

Der gemessene Kompressionsdruck ist abhängig von der Anlaßdrehzahl während des Meßvorganges und der Höhenlage des Motoraufstellortes.

Grenzwerte sind daher nicht genau festlegbar. Empfohlen wird die Kompressionsdruckmessung nur als Vergleichsmessung aller Zylinder eines Motors untereinander anzusehen. Sind mehr als 15% Abweichung ermittelt worden, sollte durch die Demontage der betroffenen Zylindereinheit die Ursache ermittelt werden.

Hinweis: Einspritzventil mit neuer Spezialdichtung einsetzen und festdrehen.

Anziehvorschrift: 21 Nm

Einspritzleitungen festdrehen.

Anziehvorschrift: 22 + 2 Nm

Die Leckölleitung ist grundsätzlich zu erneuern.

|

© 2001 / 0297 9765 |

2.00.04 |

|

Kompressionsdruck |

Prüfen und Einstellen |

|

Compression pressure |

Checking and adjusting |

|

Taux de compression |

Contrôle et réglage |

|

Presión de compresión |

Verificación y ajustes |

English

4.Connect compression tester. Turn engine with starter.

Compression pressure:

|

F engine |

25-30 bar |

|

BF engine |

22-27 bar |

The measured compression pressure is dependent on the starting speed during the measuring process and also on the altitude of the engine site. Therefore it is difficult to specify precise limit values. It is recommended to use the compression pressure measurement only for comparison of compression pressures of all cylinders in one engine. If a difference in pressure in excess of 15 % is determined, the cylinder unit concerned should be dismantled to establish the cause.

Note: Fit injector with new special seal and tighten.

Tightening specification: 21 Nm

Tighten injection lines.

Tightening specification: 22 + 2 Nm

The leakage fuel line must always be renewed.

Français

4.Brancher le compressiomètre. Virer le moteur au démarreur Pression de compression

|

Moteur F |

25-30 bars |

|

Moteur BF |

22-27 bars |

Le taux de compression mesuré dépend de la vitesse de démarrage durant le relevé des mesures, et de l’altitude du lieu d’implantation du moteur.

Des valeurs limites précises ne peuvent donc pas être fixées. Il est conseillé de considérer la mesure du taux de compression uniquement comme mesure comparative pour tous les cylindres d’un moteur. En cas d’écart supérieur à 15 %, la cause pourra être déterminée en démontant l’unité cylindre concernée.

Nota: monter l’injecteur avec un joint spécial et serrer.

Consigne de serrage: 21 Nm.

Serrer les tuyauteries d’injection.

Consigne

de serrage 22 + 2 Nm.

Toujours remplacer la tubulure de retour de fuites.

Español

4.Conectar el compresímetro. Girar el motor con ayuda del arrancador. Presión de compresión:

|

Motor F |

25 — 30 bar |

|

Motor BF |

22 — 27 bar |

El valor de compresión medido depende de la velocidad de arranque durante la medición y de la altitud del lugar de instalación del motor.

Por tanto, no es posible fijar valores 2 límite exactos. La medición de

compresión se aconseja solamente como una medida de comparación entre todos los cilindros de un mismo motor. Si se verifican diferencias superiores al 15%, es conveniente buscar la causa, desmontando la unidad de cilindro afectada.

Nota: Montar el inyector con una junta especial nueva y apretar.

Prescripción de apriete: 21 Nm.

Apretar las tuberías de inyección.

Prescripción

de apriete: 22 + 2 Nm.

La tubería de combustible sobrante deberá ser sustituida, en todos los casos, por otra nueva.

|

2.00.04 |

© 2001 / 0297 9765 |

|

Prüfen und Einstellen |

Einspritzventil |

|

Checking and adjusting |

Injector |

|

Contrôle et réglage |

Soupape injectrice |

|

Verificación y ajustes |

Inyector |

English

Commercial tools required:

Nozzle tester _______________ 8008

Long socket a/flats 15 ________ 8021

Special tool required:

Retainer for injector _______ 110 110

|

Note: Utmost cleanliness must be en- |

|

|

sured when working on the in- |

|

|

jection equipment. For testing |

|

|

2 |

the injector use only pure test oil |

|

to ISO 4113 or clean diesel fuel. |

|

Caution!

Beware of injection nozzle fuel jet. The fuel penetrates deeply into the skin tissue and may cause blood poisening.

1.Connect injector to nozzle tester.

2.Checking opening pressure

With pressure gauge switched on, slowly press down lever of nozzle tester. The pressure at which the gauge pointer stops or suddenly drops, is the opening pressure.

Opening pressure for initial setting:

Genset engines = 250 + 8 bar

Automotive engines = 210 + 8 bar

© 2001 / 0297 9765

Français

Outillage usuel:

Banc d’essais d’injecteurs _____ 8008 Clé à douille longue de 15 _____ 8021

Outillage spécial:

Dispositif d’immobilisation

pour injecteur ___________ 110 110

Nota: tous les travaux à effectuer sur les injecteurs doivent être réalisés dans de parfaites conditions de propreté. Pour contrôler les injecteurs n’utiliser que du gazole d’essai pur selon ISO 4113 ou du combustible diesel parfaitement propre.

Attention!

Tenir les mains à l’écart des jets de gazole, la force de pénétration de ceuxci est telle qu’ils peuvent créer des blessures graves et amener un empoisonnement du sang.

1.Monter l’injecteur sur la pompe d’essais d’injecteurs.

2.Contrôle de la pression d’ouverture

Le manomètre étant branché, appuyer lentement sur le levier de la pompe d’essai d’injecteurs. La pression à laquelle l’aiguille s’arrête ou chute brusquement, est la pression maxi ou pression d’ouverture.

Valeur de contrôle de pression d’ouverture pour nouveau tarage : Moteurs de groupe: 250 + 8 bars Moteurs de véhicule: 210 + 8 bars

2.00.05

Español

Herramientas comerciales:

Comprobador para inyectores __ 8008 Llave de vaso largo de 15 _____ 8021

Herramientas especiales:

Soporte de inyectores _____ 110 110

Nota: Al trabajar en el equipo de inyección, se deberá observar máxima limpieza. Para la prueba de los inyectores sólo se utilizará aceite de ensayo puro según ISO 4113 o combustible diesel limpio.

Atención:

No acercar nunca las manos a los chorros del inyector, pues el combustible se introduce en la carne y destruye los tejidos. Si llega a la sangre, produce grave intoxicación.

1.Empalmar el inyector al comprobador.

2.Comprobación de la presión de apertura

Con el manómetro conectado, empujar la palanca del comprobador lentamente hacia abajo. La presión a la que la aguja

se detiene o cae repentinamente, es la presión de apertura.

Presión de apertura para el nuevo ajuste en motores:

para grupos

electrógenos = 250 + 8 bar. para vehículos = 210 + 8 bar.

|

Einspritzventil |

Prüfen und Einstellen |

|

Injector |

Checking and adjusting |

|

Soupape injectrice |

Contrôle et réglage |

|

Inyector |

Verificación y ajustes |

Deutsch

Handelsübliche Werkzeuge:

Düsenprüfgerät ____________________ 8008 Lange Stecknuß SW 15 ______________ 8021

Spezialwerkzeug:

Halter für Einspritzventil __________ 110 110

Hinweis: Bei Arbeiten an der Einspritzausrüstung auf größte Sauberkeit achten. Zur Prüfung der Einspritzventile nur reines Prüföl nach ISO 4113 oder sauberen Dieselkraftstoff verwenden.

Achtung !

Hände weg vom Düsenstrahl. Der Kraftstoff dringt tief in das Fleisch ein und kann zur Blutvergiftung führen.

1.Einspritzventil an das Düsenprüfgerät anbauen.

2.Prüfung des Öffnungsdruckes

Hebel des Düsenprüfgerätes bei zugeschaltetem Manometer langsam niederdrücken. Der Druck bei dem der Zeiger stehen bleibt oder plötzlich abfällt, ist der Öffungsdruck.

Öffnungsdruck für die Neueinstellung: Aggregat — Motoren = 250 + 8 bar Fahrzeug — Motoren = 210 + 8 bar

Werkstatthandbuch 1011 F

5

2

e

4

6

|

2.00.05 |

© 2001 / 0297 9765 |

|

Prüfen und Einstellen |

Einspritzventil |

|

Checking and adjusting |

Injector |

|

Contrôle et réglage |

Soupape injectrice |

|

Verificación y ajustes |

Inyector |

Werkstatthandbuch 1011 F

1

7

|

8 |

|||

|

2 |

r |

||

6

6

Deutsch

3.Einstellen des Öffnungsdruckes am Einspritzventil

Überwurfmutter abschrauben, alle Teile ausbauen.

Folge der Einzeldemontage

1.Überwurfmutter

2.Einspritzdüse

3.Zwischenstück

4.Druckbolzen

5.Druckfeder

6.Ausgleichscheiben

4.Durch Auswahl der erforderlichen Scheibe Druck einstellen. Stärkere Scheibe ergibt höheren Öffnungsdruck. Einspritzventil zusammenbauen. Überwurfmutter festdrehen.

Anziehvorschrift: 45 ± 5 Nm

Einspritzventil auf dem Düsenprüfgerät erneut prüfen.

5.Prüfung auf Dichtheit

Düse und Düsenhalter abtrocknen — mit Luft trockenblasen. Handhebel des Prüfgerätes langsam niederdrücken, bis ca. 20 bar unterhalb des vorher abgelesenen Öffnungsdruckes erreicht werden.

|

© 2001 / 0297 9765 |

2.00.06 |

|

Einspritzventil |

Prüfen und Einstellen |

|

Injector |

Checking and adjusting |

|

Soupape injectrice |

Contrôle et réglage |

|

Inyector |

Verificación y ajustes |

English

3.Adjusting the opening pressure on the injector

Unscrew cap nut and remove all parts

Sequence of parts disassembly

1.Cap nut

2.Injection nozzle

3.Adapter

4.Thrust pin

5.Compression spring

6.Shims

4.Adjust pressure by selecting appropriate shim. A thicker shim increases the opening pressure. Reassemble injector. Tighten cap nut.

Tightening specification: 45 ± 5 Nm

Recheck injector on nozzle tester.

5.Checking for tightness

Dry nozzle and nozzle holder — blow out with compressed air. Press down handlever of nozzle tester slowly until a pressure of about

20 bar below the previous opening pressure reading is attained.

Français

3.Tarage de la pression d’ouverture sur injecteur

Dévisser l’écrou-raccord et déposer toutes les pièces.

Suite du démontage des pièces

1.Ecrou-raccord

2.Injecteur

3.Pièce intermédiaire

4.Tige poussoir

5.Ressort de pression

6.Rondelles d’épaisseur

4.Régler la pression en prenant le nombre de rondelles nécessaires. Des rondelles plus épaisses entraînent une pression d’ouverture plus grande. Remonter l’injecteur et serrer l’écrou-raccord.

Consigne de serrage: 45 ± 5 Nm

Contrôler à nouveau l’injecteur

à l’aide de la pompe d’essai d’injecteurs.

5.Contrôle de l’étanchéité

Sécher l’injecteur et le porteinjecteur par jet d’air. Appuyer lentement sur le levier de la pompe d’essai jusqu’à obtention d’environ 20 bars en-dessous de la pression d’ouverture lue auparavant.

Español

3.Ajuste de la presión de apertura en el inyector

Desenroscar la tuerca de unión y desmontar todas las piezas.

Secuencia del despiece

1.Tuerca de unión

2.Inyector propiamente dicho

4.Perno de presión

5.Muelle de presión

6.Arandelas de reglaje

4.Ajustar la presión eligiendo la arandela adecuada. Una arandela más gruesa da una presión de apertura más elevada. Rearmar el inyector. Apretar la tuerca de unión.

Prescripción

de apriete: 40 ± 5 Nm.

Volver a ensayar el inyector sobre el comprobador.

5.Comprobación de estanqueidad

Secar el inyector y el portainyector, soplándolos con aire comprimido. Empujar la palanca de mano del comprobador lentamente hacia abajo hasta alcanzar un valor de aprox. 20 bar por debajo de la presión de apertura leída previamente.

|

2.00.06 |

© 2001 / 0297 9765 |

|

Prüfen und Einstellen |

Einspritzventil |

|

Checking and adjusting |

Injector |

|

Contrôle et réglage |

Soupape injectrice |

|

Verificación y ajustes |

Inyector |

English

6.Nozzle is tight if there is no dripping within a period of 10 seconds.

7.In case of a drip, the injector must be dismantled and cleaned to remedy the leak. If this does not cure the leak, the injector must be replaced.

2

Reworking is not permissible.

8.Buzzing and spray pattern test

Switch off pressure gauge of tester.

The buzzing test permits an audible check of the ease of movement of the nozzle needle in the nozzle body. New injectors emit a different buzzing sound as compared to used injectors. It deteriorates due to wear in the needle seat area. If an injection nozzle does not buzz despite cleaning, it must be renewed.

A used injector should buzz clearly during rapid actuation of the handlever, while exhibiting a well atomized spray pattern. The spray pattern may differ noticeably from that of a new injector.

Français

6.L’injecteur est étanche lorsqu’il ne goutte plus durant 10 secondes.

7.Si l’injecteur goutte, le déposer et le nettoyer pour supprimer le manque d’étanchéité. En cas d’échec, remplacer l’injecteur.

Ne jamais rectifier l’injecteur.

8.Contrôle du crissement caractéristique de l’injecteur

Débrancher le manomètre de la pompe d’essai.

Le contrôle du crissement permet un contrôle audible de l’injecteur dont l’aiguille doit retomber d’ellemême dans son logement. Les injecteurs neufs présentent par rapport aux injecteurs usagés un crissement différent. L’usure se produisant au niveau du siège de l’aiguille entraîne une dégradation du crissement. Si, après nettoyage, l’injecteur refuse de crisser, il faut le remplacer.

Un injecteur usagé doit, après actionnement rapide du levier de commande, émettre un crissement audible et pulvériser de manière bien homogène. La forme du jet peut alors, à la différence d’un injecteur neuf, être tout à fait différente.

Español

6.El inyector es estanco si, pasados 10 segundos, no sale ni una gota de líquido.

7.Si cae una gota, el inyector debe ser desarmado y limpiado para eliminar la falta de estanqueidad. Si esto no surte efecto, es necesario reemplazar el inyector.

No están permitidos trabajos de repaso.

8.Comprobación del ronquido y chorro

Desconectar el manómetro del comprobador.

La comprobación del ronquido permite controlar acústicamente la facilidad de movimiento de la aguja dentro del cuerpo del inyector. Inyectores nuevos tienen un ronquido diferente de los usados. El desgaste en la zona de asiento de la aguja lo empeora. Si el inyector no produce el ronquido característico del mismo a pesar de su limpieza anterior, es necesario sustituirlo por otro nuevo.

Un inyector usado tiene que roncar de forma audible y producir un chorro bien pulverizado si se acciona la palanca rápidamente. La forma del chorro puede diferir, en tal caso, claramente de la producida por un inyector nuevo.

|

© 2001 / 0297 9765 |

2.00.07 |

|

Einspritzventil |

Prüfen und Einstellen |

|

Injector |

Checking and adjusting |

|

Soupape injectrice |

Contrôle et réglage |

|

Inyector |

Verificación y ajustes |

Deutsch

6.Düse ist dicht, wenn innerhalb 10 Sekunden kein Tropfen abfällt.

7.Fällt ein Tropfen ab, ist das Einspritzventil zu zerlegen und die Undichtigkeit durch Reinigen zu beseitigen. Ist das nicht erfolgreich, muß die Einspritzdüse erneuert werden.

Nacharbeit ist nicht zulässig.

8.Schnarrund Strahlprüfung

Manometer des Prüfgerätes abschalten.

Die Schnarrprüfung ermöglicht eine hörbare Prüfung der Leichtgängigkeit der Düsennadel im Düsenkörper. Neue Einspritzventile haben gegenüber gebrauchten ein geändertes Schnarrverhalten.

Durch Verschleiß im Nadelsitzbereich verschlechtert es sich. Schnarrt eine Einspritzdüse trotz Reinigung nicht, muß sie durch eine neue ersetzt werden.

Ein gebrauchtes Einspritzventil muß bei schneller Hebeltätigkeit hörbar schnarren und dabei gut zerstäubt abspritzen. Das Strahlbild kann dabei gegenüber dem eines neuen Einspritzventils deutlich unterschiedlich sein.

Werkstatthandbuch 1011 F

9

9

2

9

|

2.00.07 |

© 2001 / 0297 9765 |

|

Prüfen und Einstellen |

Einspritzpumpe |

|

Checking and adjusting |

Injection pump |

|

Contrôle et réglage |

Pompe d’injection |

|

Verificación y ajustes |

Bomba de inyección |

English

Commercial tool required:

Injection pump tester _________ 8006

Special tool required:

Special wrench

for injection line __________ 110 490

The following inspection for injection pumps with parts no 0417 9573 and

0417 9981 (with con-stant pressure valve).

The injection pump is tested on the engine to make sure that the delivery valve and pump element are not leaking. For the test, it is essential that the fuel feed system is operating properly and that there is no air in the fuel system.

2

Injection lines have been removed.

1.Connect injection pump tester to delivery valve holder.

2.Turn crankshaft via V-belt pulley, while bleeding tester at the screw plug.

Français

Outillage usuel:

Appareil de contrôle de la pompe d’injection _________________ 8006

Outillage spécial:

Clé spéciale pour

conduite d’injection ________ 110490

Dans le cas des pompes à injection portant le numéro de pièce 0417 9573 et 0417 9981

(avec soupape de pression constante), il est impossible d’effecteur le contrôle décrit ciaprès.

Le contrôle de la pompe d’injection se fait sur le moteur même au niveau de l’étanchéité de la soupape de refoulement et de l’élément de pompe. Ce contrôle suppose une alimentation en combustible irréprochable et l’absence d’air dans le système d’injection.

Les conduites d’injection sont déposées.

1.Raccorder l’appareil de contrôle de la pompe d’injection au support de la soupape de refoulement.

2.Virer le vilebrequin par la poulie à gorge et purger l’appareil de contrôle par le bouchon obturateur.

Español

Herramienta comercial:

Comprobador de bombas

de inyección _______________ 8006

Herramienta especial:

Llave especial para

tuberías de inyección ______ 110 490

Si se tatra de bombas de inyección con el N° de pieza 0417 9573 y 0417 9981 (con válvula de presión constante) no es posible

Ilevar a cabo la siguiente prueba.

La bomba de inyección es ensayada sobre el motor en cuanto a estanqueidad de la válvula de presión y del elemento de bomba.

Condición previa para la comprobación es que el abastecimiento del combustible sea impecable y no exista aire en el sistema de combustible.

Las tuberías de inyección están desmontadas.

1.Conectar el comprobador de bombas de inyección al soporte de la válvula de presión.

2.Girar el cigüeñal a través de la polea de correa trapezoidal, purgando de aire el comprobador en el tapón roscado.

3.Turn crankshaft until a pressure of 150 bar is applied to the delivery valve. The pressure may drop by 10 bar within one minute.

3.Virer le vilebrequin jusqu’à obtention d’une pression de 150 bars à la soupape de refoulement. Cette pression peut tomber de 10 bars en l’espace d’une minute.

3.Girar el cigüeñal hasta que la válvula de presión cuente con una presión de 150 bar, admitiéndose una caída de presión de 10 bar dentro de un minuto.

|

© 2001 / 0297 9765 |

2.00.09 |

Deutz Engines 912, BF4M2012, F4M2011, BF4M2011, 1011F operators, service and maintenance manuals, error codes list, DTC, spare parts manuals & catalogues, wiring diagrams, schematics free download PDF

Deutz logo

Deutz engine manuals free download are available for free download.

| Title | File Size | Download Links |

| Deutz 2008-2009 Parts Manual [PDF] | 3.1Mb | Download |

| Deutz 2008-2009 Service Manual [PDF] | 4.4Mb | Download |

| Deutz 226B Operation Manual [PDF] | 8.5Mb | Download |

| Deutz 413 Parts Manual [PDF] | 4.5Mb | Download |

| Deutz Accessories Catalogue [PDF] | 5.2Mb | Download |

| Deutz BF4M1013C Spare Parts Catalogue [PDF] | 3Mb | Download |

| Deutz BFM 1015 Series – BF6M 1015 C, BF8M 1015, BF8M 1015 C, BF8M 1015 CP, BF6M 1015 CP Workshop Manual [PDF] | 12.3Mb | Download |

| Deutz D 2008-2009 Workshop Manual [PDF] | 4.6Mb | Download |

| Deutz D 909 / 910, B / FL 1011 / F / 2011, B / FL 912 / 913 / 914 / C, B / FL 413 F / 513 / C / CP, B / FM 1011 F 2011 Installation Manual [PDF] | 7.8Mb | Download |

| Deutz Engine D2008 2009 Workshop Manual PDF [PDF] | 3.8Mb | Download |

| Deutz Engine Fire Protection – Operation Manual [PDF] | 21.2Mb | Download |

| Deutz Engine S-BV6-8-9M628 Operation Manual [PDF] | 10Mb | Download |

| Deutz FL 411 Service Manual [PDF] | 8.7Mb | Download |

| Deutz FL 413 Service Manual [PDF] | 8.7Mb | Download |