Getting Started

Requirements to install the laser imager

Unpack the laser imager.

Use a personal computer to view the documentation on

the publications disc supplied with the laser imager.

Connect a personal computer to the laser imager and

enter the network information.

Configure the laser imager to print from a modality.

Make a backup disk of the configuration.

Required tools

Required information

2011-01-05

IMPORTANT:

Task

•

Scissors

•

Straight blade screwdriver

•

Phillips screwdriver

You will need:

•

IP Address and related network information for the laser imager

•

Configuration information for each modality that will print to the laser

imager

This information should have been previously collected and recorded in

the Site Readiness manual that was provided to your site. In the Site

Readiness manual, see the sections, «Network Requirements» and

«Modality Configuration.»

If you do not have this Site Readiness manual, contact your dealer.

9G5124_en

The laser imager weighs approximately 53.52 kg (118 lb).

Two people must use safe lifting techniques to move the

laser imager. One person can complete the remaining

steps.

Recommended Skill or Knowledge

Ability to use common hand tools.

Basic personal computer skills.

Familiarity with TCP/IP network addressing

conventions.

Familiarity with DICOM protocol.

Understand personal computer file name

conventions.

1

Оплата по безналичному расчету для юридических лиц.

Счет выставляется после согласования комплектации, стоимости, условий оплаты и сроков поставки.

Выставляем счет с НДС 20%.

Доставка товаров осуществляется транспортными компаниями во все регионы России, страны Таможенного союза, СНГ.

Мы сотрудничаем с различными транспортными компаниями.

В зависимости от объема и региона поставки мы подберем для вас самый быстрый и экономичный вариант доставки.

Оплата услуг транспортной компании может быть произведена Вами самостоятельно или включена в стоимость груза, либо оформлена отдельной строкой в счете.

Обратите внимание! В обязанности работников Службы доставки не входит осуществление консультаций и комментариев относительно потребительских свойств товара.

При необходимости установки (монтажа) оборудования, вам необходимо сообщить об этом нашему менеджеру заранее.

Возможен самовывоз со склада в Санкт-Петербурге.

Для получения товара необходима доверенность или печать организации, оплатившей товар.

При самовывозе рекомендуем заранее уточнить габаритные размеры и вес получаемого товара с учетом упаковки, а также способ погрузки и убедиться, что ваш транспорт подходит для данной перевозки.

Компания «АМД» сохраняет гарантийные обязательства производителей.

Доставим оборудование в любой город России:

Абакан, Азов, Александров, Алексин, Альметьевск, Анапа, Ангарск, Анжеро-Судженск, Апатиты, Арзамас, Армавир, Арсеньев, Артем, Архангельск, Асбест, Астрахань, Ачинск, Балаково, Балахна, Балашиха, Балашов, Барнаул, Батайск, Белгород, Белебей, Белово, Белогорск (Амурская область), Белорецк, Белореченск, Бердск, Березники, Березовский (Свердловская область), Бийск, Биробиджан, Благовещенск (Амурская область), Бор, Борисоглебск, Боровичи, Братск, Брянск, Бугульма, Буденновск, Бузулук, Буйнакск, Великие Луки, Великий Новгород, Верхняя Пышма, Видное, Владивосток, Владикавказ, Владимир, Волгоград, Волгодонск, Волжск, Волжский, Вологда, Вольск, Воркута, Воронеж, Воскресенск, Воткинск, Всеволожск, Выборг, Выкса, Вязьма, Гатчина, Геленджик, Георгиевск, Глазов, Горно-Алтайск, Грозный, Губкин, Гудермес, Гуково, Гусь-Хрустальный, Дербент, Дзержинск, Димитровград, Дмитров, Долгопрудный, Домодедово, Донской, Дубна, Евпатория, Егорьевск, Ейск, Екатеринбург, Елабуга, Елец, Ессентуки, Железногорск (Красноярский край), Железногорск (Курская область), Жигулевск, Жуковский, Заречный, Зеленогорск, Зеленодольск, Златоуст, Иваново, Ивантеевка, Ижевск, Избербаш, Иркутск, Искитим, Ишим, Ишимбай, Йошкар-Ола, Казань, Калининград, Калуга, Каменск-Уральский, Каменск-Шахтинский, Камышин, Канск, Каспийск, Кемерово, Керчь, Кинешма, Кириши, Киров (Кировская область), Кирово-Чепецк, Киселевск, Кисловодск, Клин, Клинцы, Ковров, Когалым, Коломна, Комсомольск-на-Амуре, Копейск, Королев, Кострома, Котлас, Красногорск, Краснодар, Краснокаменск, Краснокамск, Краснотурьинск, Красноярск, Кропоткин, Крымск, Кстово, Кузнецк, Кумертау, Кунгур, Курган, Курск, Кызыл, Лабинск, Лениногорск, Ленинск-Кузнецкий, Лесосибирск, Липецк, Лиски, Лобня, Лысьва, Лыткарино, Люберцы, Магадан, Магнитогорск, Майкоп, Махачкала, Междуреченск, Мелеуз, Миасс, Минеральные Воды, Минусинск, Михайловка, Михайловск (Ставропольский край), Мичуринск, Москва, Мурманск, Муром, Мытищи, Набережные Челны, Назарово, Назрань, Нальчик, Наро-Фоминск, Находка, Невинномысск, Нерюнгри, Нефтекамск, Нефтеюганск, Нижневартовск, Нижнекамск, Нижний Новгород, Нижний Тагил, Новоалтайск, Новокузнецк, Новокуйбышевск, Новомосковск, Новороссийск, Новосибирск, Новотроицк, Новоуральск, Новочебоксарск, Новочеркасск, Новошахтинск, Новый Уренгой, Ногинск, Норильск, Ноябрьск, Нягань, Обнинск, Одинцово, Озерск (Челябинская область), Октябрьский, Омск, Орел, Оренбург, Орехово-Зуево, Орск, Павлово, Павловский Посад, Пенза, Первоуральск, Пермь, Петрозаводск, Петропавловск-Камчатский, Подольск, Полевской, Прокопьевск, Прохладный, Псков, Пушкино, Пятигорск, Раменское, Ревда, Реутов, Ржев, Рославль, Россошь, Ростов-на-Дону, Рубцовск, Рыбинск, Рязань, Салават, Сальск, Самара, Санкт-Петербург, Саранск, Сарапул, Саратов, Саров, Свободный, Севастополь, Северодвинск, Северск, Сергиев Посад, Серов, Серпухов, Сертолово, Сибай, Симферополь, Славянск-на-Кубани, Смоленск, Соликамск, Солнечногорск, Сосновый Бор, Сочи, Ставрополь, Старый Оскол, Стерлитамак, Ступино, Сургут, Сызрань, Сыктывкар, Таганрог, Тамбов, Тверь, Тимашевск, Тихвин, Тихорецк, Тобольск, Тольятти, Томск, Троицк, Туапсе, Туймазы, Тула, Тюмень, Узловая, Улан-Удэ, Ульяновск, Урус-Мартан, Усолье-Сибирское, Уссурийск, Усть-Илимск, Уфа, Ухта, Феодосия, Фрязино, Хабаровск, Ханты-Мансийск, Хасавюрт, Химки, Чайковский, Чапаевск, Чебоксары, Челябинск, Черемхово, Череповец, Черкесск, Черногорск, Чехов, Чистополь, Чита, Шадринск, Шали, Шахты, Шуя, Щекино, Щелково, Электросталь, Элиста, Энгельс, Южно-Сахалинск, Юрга, Якутск, Ялта, Ярославль…

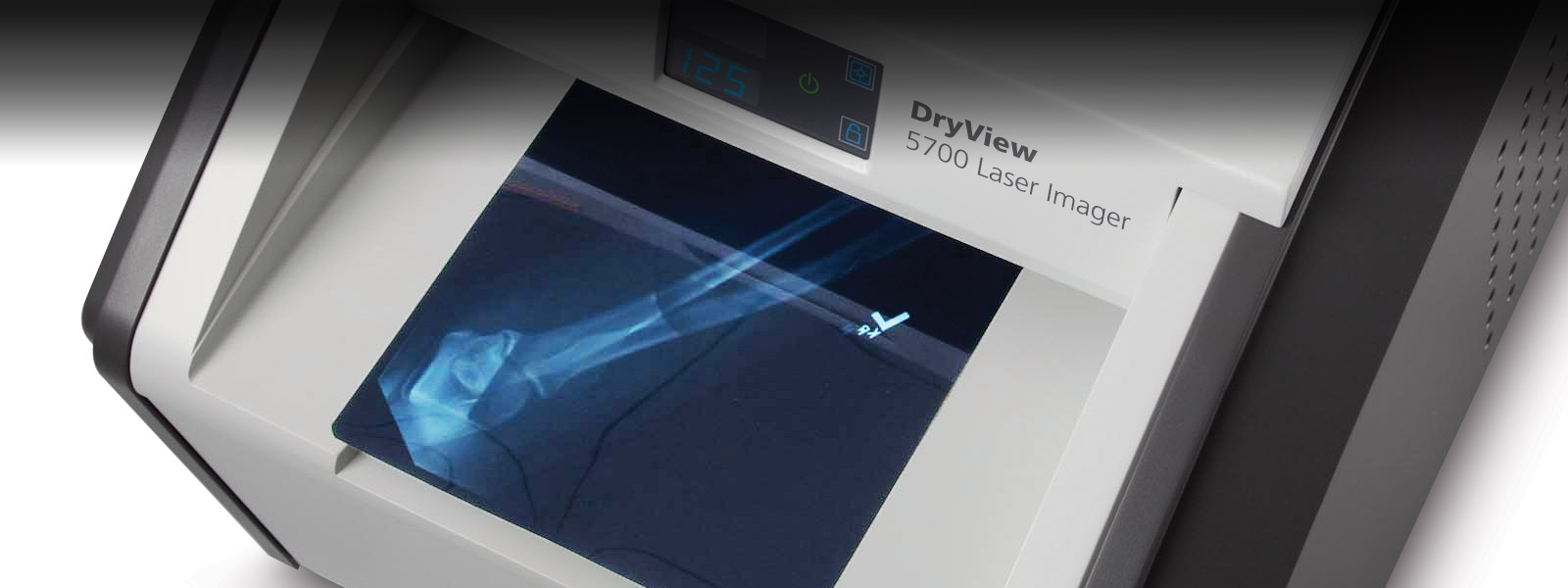

Сочетание низкой стоимости и минимальных эксплуатационных расходов делает данную мультиформатную камеру широко доступной. Быстрая и простая загрузка пленки при дневном свете.

Постоянный контроль качества при помощи системы автоматического контроля качеcтва (AIQC). Новая лазерная мультиформатная камера DryView 5700 Laser Imager — идеальное решение для получения изображений от систем компьютерной радиографии (CR), цифровой радиографии (DR), компьютерной томографии (CT) и магнитного

резонанса (MR). Компактность, производительность и надежность, которые может предложить только бренд DryView™.

Лазерная технология печати

Мультиформатная камера DryView 5700 используя современную технологию лазерного экспонирования имеет доступную цену, минимальные эксплутационные расходы и высокую производительность.

Простота и надежность

Поскольку в мультиформатной камере DryView 5700 не используются термоголовки, отсутствует необходимость ежедневного или еженедельного обслуживания. Режим ожидания экономит энергию. Сухая технология печати экологична.

Автоматический контроль качества изображения (AIQC)

В камере DryView 5700 AIQC используется встроенный денситометр, что гарантирует стандартно высокое качество печати. Технология AIQC определяет качество изображения и выполняет необходимую корректировку. Эта уникальная функция в сочетании с проверенными преимуществами технологии DryView обеспечивает отличное качество изображения для различных сфер применения. Без ручного запуска и процедур обеспечения качества. Обеспечивает стабильность показаний на протяжении длительного времени

Компактная конструкция, быстрая установка

Инновационный эргономичный дизайн и компактные размеры 66 x 61 см делают DryView 5700 Laser Imager удобным терминалом печати даже в ограниченном пространстве. Благодаря упрощенному процессу установки систему печати установить легко и быстро.

Простота обучения, удобство в эксплуатации

Интуитивно понятный пользовательский интерфейс ускоряет процесс работы, нет необходимости в специальном обучении. Пользовательская документация и интерфейс полностью на русском языке.

Характеристики

| Технология печати | Фототермографическое устройство (лазерное экспонирование) |

|---|---|

| Качество лазерного изображения | 325 пикселей на дюйм, пиксел 78 микрон |

| Шкала серого | 14-бит |

| Производительность |

До 45 пленок в час: 14 x 17 дюймов (35 x 43 см) Пленки меньшего размера печатаются быстрее |

| Пленка | Синяя или прозрачная полиэфирная подложка толщиной 7 мил |

| Картридж | 125 листов в картридже, можно устанавливать на свету |

| Форматы пленки |

14 x 17 дюймов (35 x 43 см) 11 x 14 дюймов (28 x 35 см) 10 x 12 дюймов (25 x 30 см) 8 x 10 дюймов (20 x 25 см) |

| Сетевой интерфейс | 10/100/1000 Base T Ethernet (поддержка джамбо-кадров) |

| Поддерживаемый стандарт | DICOM 3.0 |

| Габариты (ШхВхГ) | 610 x 470 x 660 мм |

| Вес | 54 кг |

| Питание | 180—264 В пер. тока; 50/60 Гц; максимум 4,5 А |

| Условия эксплуатации |

Температура: от 59 до 91°F (от 15 до 33°C) Влажность: от 20 до 80% относительной влажности, без конденсации |

Сохраняемость пленки в течение всей жизни (более 100 лет) для сфер применения с высокими требованиями (онкология, педиатрия и т.д.). Напечатанные пленочные изображения со стандартным D-max 3.0

User’s Guide

Carestream Health, Inc.

150 Verona Street

Rochester, New York 14608

© Carestream Health, Inc., 2011

Pub No. 9G3886_en

Rev. A

i

Table of Contents

1 Overview

Major internal assemblies………..……………………………………………………………………..………..……………………. 1-2

How the laser imager works ………….…………………………….………….…………..……………………..…………….……..1-3

Film sizes ………..……………………………………………………………………..………….………………………………….……..1-4

Automatic image quality and processing ……..……………………………………………………………………..………….…..1-4

Configuring and monitoring the system (using the Web Portal) ………….………………………….………………….…..1-4

Enhancing serviceability with remote monitoring ..…………………………………………………………………..………….1-5

Agency compliance …………….…………………………………………………………………….…………………………..………. 1-5

User guide conventions ….…………………………….………….…………..………….……………………..…………….………..1-5

2 Basic Operating Tasks

Understanding the display screen ………………………………………..………………………………………..…………..……..2-2

Turning the power on and off …………….……………………………………………………………………….…………….……..2-3

Working with film cartridges ……………..…………………………………………………………………………………..………..2-5

Deleting pending jobs ………………………………….………….…………..……………………..………………………..………..2-8

Making a test print ……………………………………………………….………………………….…………………………………….2-8

Calibrating the laser imager for the installed film ….…………………………..………….…………..………………………..2-9

Opening or removing a cover ………….…………………………..…………….……………………..……………………………..2-9

Using the Web Portal to access additional functionality …………..…………………………..………….………………….2-10

3 Maintenance and Troubleshooting

Overview: Status and error messages and codes ……………………………………..………………………..……..………….3-1

Preventive maintenance ………………………………..………….…………..……………………..………….…………….………..3-2

Error indicators on the display screen ………………………………………………………………….…………………………..3-4

Using the Web Portal to gain more information on errors ………….………………………….…………..………….……. 3-5

Subsystem error codes and messages ………………………………………………………………………………..………….…..3-5

Condition codes …………………………………………………………………………………….…………..……………….…………3-9

Correcting film jams ……………………………..…………………………..……………………..………….……………………….3-14

Display Screen is not functional ……………………………………………………………………………………………………..3-18

Calling for support ………….……………………………………………………….…………….…………..………………………..3-18

4 Film Technical Information

General description …….…………………………….…………..…………………………..………………..……………..………….4-1

ii

5 Specifications

Equipment Specifications ……..………………………………………………………………………………….…………..…………5-1

Operating Space Requirements ……………………………………………………………….………….……………………………5-1

Environmental Requirements ……………………….…………………………..……………………..…………..………….………5-1

Environmental Effects …….…………………………..………….…………..……………………………………………….…………5-2

Power Requirements …………………………………………………………….…………..………….………..………………………5-2

Network Requirements ……..……………………………………………………………………………………………………………5-2

Overview

2011-03-31 9G3886_en 1-1

1

Overview

The Laser Imaging System is a continuous-tone laser imager with an

internal photothermographic film processor. Heat, rather than photo

chemicals, is used to develop the film. This easy-to-use and reliable laser

imager provides high quality prints. Use the prints from this system for:

• Diagnostic purposes to determine patient treatments

• Referral, sharing, or educational purposes

The system receives and prints from image sources such as medical

electrical equipment (modalities) and workstations over the network.

You can send print jobs simultaneously from multiple image sources.

The open design lets you connect to modalities of all types and vendors.

IMPORTANT: Install the printing system in a secure location to protect

patient privacy rights if required by local regulations.

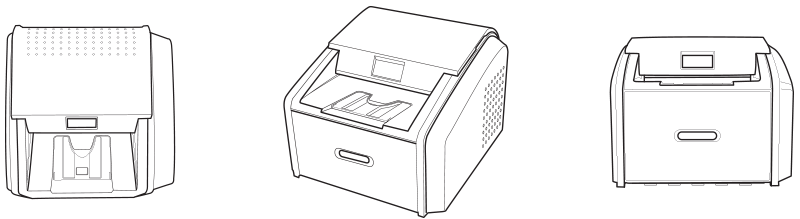

1Top cover. Covers the processor rollers. The top cover is interlocked.

2 Display screen. Your interface to the laser imager. Provides status and

error information.

3Right cover. Protects sensitive electronic equipment. The right cover

is interlocked and is only accessed by service personnel.

4 Film supply. Install film cartridges here. Supports four film sizes.

5 Left cover. You might remove the left cover to clear an occasional

film jam. The left cover is interlocked.

6 Power switch. The power switch is on the back.

7 Exit tray. Extend the exit tray to hold large film (35 x 43 cm, or

14 x 17 in.) as it finishes printing. It can hold up to 50 processed sheets

of film.

1-2 9G3886_en 2011-03-31

Overview

Major internal assemblies

1Exposure transport. Moves the film past the scanning laser beam.

2Transport guides. Orient and center the film while moving the film from the supply to the imaging

portion of the laser imager.

3DICOM Raster Engine (DRE). A computer board that receives, processes, and manages the images.

4Feed rollers. Move the film through the laser imager.

5Processor rollers. The processor uses heat to develop the image written onto the film by the laser in the

optics module. The rollers move the film through the processor assembly, holding the film against the

processor drum.

6Processor drum. Provides the heat that processes the image on the film.

7Airflow manifolds. Remove heat and processing odors from the processor assembly.

8Pickup assembly. Lifts a single sheet of film from the supply cartridge and feeds it into the rollers.

9Exit rollers. Moves the film from the processor area to the exit tray.

10 Rollback assembly. Rolls the film cartridge cover back so the pickup assembly can lift the film. When

the laser imager is not printing, the cover is closed over the film cartridge to protect the film from light.

11 Charcoal filter. Absorbs the odors caused by heat processing.

12 Optics module. Writes the image onto the film while the film is moved through the exposure transport.

13 Accumulator. The film feeds into the accumulator as it is imaged. When imaging is complete, the film

is sent from the accumulator up to the processor assembly where the heat is applied to process the image.

H210_1012HC

1

2

3

4

5

678

9

10

11

12

13

Overview

2011-03-31 9G3886_en 1-3

How the laser imager works

The laser imager receives, processes, manages, and prints the images on

film. The laser imager has limited storage to hold a small number of

digital images. As images are received for printing, they are stored in

memory, placed in a sequential print queue, and are printed in order. The

laser imager can continue to accept incoming print jobs even if

temporarily unable to print (if the film supply is empty, etc).

During normal operation, the laser imager requires very little attention. It

prints automatically in response to print requests from the configured

image sources. Information sent with the images by the image source,

such as film type and size and image quality settings, is applied unless

you set the laser imager to override information that comes from the

image source.

Print sequence

Each time the laser imager receives a print request, the following print

sequence occurs. The blue arrows show the film path.

1. Suction cups in the pickup area lift a single sheet of film out of the

supply cartridge and feed the film into the transport rollers.

2. The transport rollers move the film down into the exposure transport

area.

3. The film moves down during imaging (as the optics module writes

the image onto film), reverses direction at the conclusion of

imaging, and then the film moves up into the processor.

4. As the film passes over the processor drum, the heat generated by

the drum develops the film.

5. The exit rollers move the developed film to the exit tray.

1-4 9G3886_en 2011-03-31

Overview

Film sizes

The laser imager supports four sizes:

• 35 x 43 cm (14 x 17 in.)

• 28 x 35 cm (11 x 14 in.)

• 25 x 30 cm (10 x 12 in.)

• 20 x 25 cm (8 x 10 in.)

For the specific films that are supported, see the Publications Cover

Page.

Automatic image quality and processing

An internal densitometer enables the laser imager to automatically adjust

image processing parameters (Automatic Image Quality Control, or

AIQC) to produce an optimal image. The laser imager adjusts these

parameters each time it prints a calibration film.

A calibration film is printed when:

• The film tray is inserted in the laser imager with film of a new lot

number.

• You request a calibration film at the display screen or the Web

Portal. For more information, see “Calibrating the laser imager for

the installed film” on page 2-9.

• A film cartridge is inserted into the laser imager for which a current

calibration is not stored.

Configuring and monitoring the system (using the Web

Portal)

The Web Portal is your interface to additional features. In addition to

the installation and setup of your system, you can view and manage the

laser imager’s connections over the network, configure features, view

error messages, and access general status information at the Web Portal.

You can also check film count, film size, and film type.

For more information, see “Accessing the Web Portal” on page 2-10.

Overview

2011-03-31 9G3886_en 1-5

Enhancing serviceability with remote monitoring

Remote Management Services is set up through the Web Portal, and is

designed to enhance efficient system serviceability and simplify

analytical and service processes through the monitoring of your

equipment. Additionally, this simplifies the service process by providing

qualified service personnel with faster, easier, and more complete access

to the operational history of each system.

Remote Management Services provides the following for the laser

imager:

• Ability to monitor and diagnose error conditions without

introducing “downtime”

• Firewall-safe, Internet transmission of machine data, while

complying with patient confidentiality regulations

• Minimal effort to set up communication

• Flexibility to facilitate specific configurations at each site

Agency compliance

See the Safety Manual.

User guide conventions

The following special messages emphasize information or indicate

potential risks to personnel or equipment.

NOTE: Notes provide additional information, such as expanded explanations,

hints, or reminders.

IMPORTANT: Important notes highlight critical policy information that

affects how you use this guide and this product.

Cautions point out procedures that you must follow precisely to

avoid damage to the system or any of its components, loss of

data, or corruption of files in software applications.

DANGER: DANGER IDENTIFIES PROCEDURES THAT YOU

MUST FOLLOW PRECISELY TO AVOID INJURY TO

YOURSELF OR OTHERS.

Laser warnings warn personnel that access to laser radiation is

possible and all personnel must avoid direct exposure to the

beam.

Basic Operating Tasks

2011-03-31 9G3886_en 2-1

2

Basic Operating Tasks

During normal operation, the laser imager receives and automatically

prints images sent by modalities over a network. Very little interaction is

required. You may do the following:

• Turn the power on (|) and off (0).

• Load film cartridges.

• Monitor the display screen for status and operating conditions.

Sometimes it will be necessary to perform preventive maintenance, filter

replacement, and other corrective actions such as a restart. (See

“Chapter 3 Maintenance and Troubleshooting”.)

You also may access the Web Portal to perform additional configuration,

optimize image quality, or do troubleshooting tasks. (See page 2-10.)

2-2 9G3886_en 2011-03-31

Basic Operating Tasks

Understanding the display screen

The display screen communicates the status of the laser imager.

Symbol or code Description

Top left of the

display screen:

Error or status code. The 3-digit code displays when the error or status condition is present.

See “Chapter 3 Maintenance and Troubleshooting” for a complete list of the codes and how

to resolve them. If the laser imager is on and a 3-digit code does not display, the laser

imager is operating normally.

If a different film size has been requested than what is installed, the requested film size

displays. See “Loading a different film size to match a print request” on page 2-7.

Lower left of the

display screen:

Film count. Displays the number of films that are remaining in the film cartridge.

The loaded film size also displays in this location.

Power When the symbol is green, the power is on and the laser imager is ready to print. The

symbol flashes while the laser imager is processing.

When the symbol is yellow, the laser imager is not ready to print. Examples are when the

laser imager is warming up or when the film cartridge is empty.

Calibrate Press to initiate film calibration. The symbol flashes while the calibration is in process. See

“Calibrating the laser imager for the installed film” on page 2-9.

Pause During normal operation, the symbol is off. When the film cartridge cover is open, the

symbol is on. To avoid exposing the film to light, do not open the film supply until the

symbol is off.

If the Pause symbol is on, you can press the symbol to temporarily pause printing. Any

jobs in progress finish printing, then the film cartridge cover closes.

Wait until the Pause symbol is off for cartridge replacement, etc.

Film Size When the symbol appears, the requested job requires a different film size. See “Loading a

different film size to match a print request” on page 2-7.

You can also delete a print request. See “Deleting pending jobs” on page 2-8.

Restart Restart the laser imager. An error code also displays. See “Restarting the laser imager” on

page 2-4.

Film Jam Film is jammed. The error code confirms the film jam and gives direction on where to find

the film inside the laser imager. See “Film jams” on page 3-4.

Maintenance Preventive maintenance is required. Check the error code to learn what action to take. See

“Preventive maintenance” on page 3-2.

Basic Operating Tasks

2011-03-31 9G3886_en 2-3

Turning the power on and off

To start the laser imager, press the power switch on the back of the laser

imager to on (|). Wait as the laser imager warms up. The warm-up period

might last up to 30 minutes. The display screen shows the progress as the

laser imager becomes ready to print.

Warming up

The warm-up period varies depending on the amount of time the laser

imager has been off and the ambient temperature. During warm-up, the

laser imager can receive and store images but cannot print films.

When the laser imager reaches operating temperature, the display screen

changes to show that the system is ready to print, and the laser imager

prints images that were received during the warm-up period.

Ready to print

Emergency shutdown

or power loss In the event of a power loss, or if an emergency requires an immediate

shutdown of the laser imager, films in process will not be completed.

However, when power is restored, the laser imager will restart. After

warming up, the laser imager automatically reprints any films that were

in process when the power was interrupted.

The power symbol is

yellow and flashing

while the laser

imager warms up

A countdown to zero (0) indicates

how soon the laser imager will be

ready to print

Film count

Green power symbol means «ready»

You can

calibrate the film

cartridge if

necessary

2-4 9G3886_en 2011-03-31

Basic Operating Tasks

Restarting the laser

imager If the laser imager encounters an error that is usually corrected with a

restart, the display screen shows the Restart symbol.

1. Press the power switch on the back of the laser imager off (0).

2. Press the power switch on (|).

If the error does not clear with after the restart, it might be necessary

to contact a qualified service provider.

Restart

The error code indicates

the error condition. You

may want to check the

“Troubleshooting” chapter

or the Quick Reference

Card to identify the error.

Basic Operating Tasks

2011-03-31 9G3886_en 2-5

Working with film cartridges

Checking film count The film count displays on the laser imager display screen.

Checking the size of

the loaded film The film size displays in the same location as the film count. The display

screen alternates between the film count and the size of the loaded film.

Film count is flashing

«0» When the film cartridge is empty, the film count flashes «0» and the

power symbol is yellow, which indicates that the laser imager cannot

print. Replace the film cartridge with a new one with the appropriate size

film. See page 2-6.

Film count

125 indicates a full cartridge

Film size

«35» indicates the 1st dimension of the

film cartridge. For example, «35» then

«43» appears if 35 x 43 cm film is

loaded. Then the film count displays

again.

When the film count is «0», you

must replace the film cartridge

before you can print again

2-6 9G3886_en 2011-03-31

Basic Operating Tasks

Inserting a new film

cartridge Before you insert a new film cartridge, make sure that the Pause symbol

is off. During normal operation, the symbol is off. When the film

cartridge cover is open, the symbol is on. To avoid exposing the film to

light, do not open the film supply until the Pause symbol is off.

If the Pause symbol is on, press the symbol to close the film cartridge

cover.

1. Open the film supply. Hold the edges of the film cartridge and lift

the empty cartridge out of the film supply.

2. Discard the removed cartridge.

3. Insert the new film cartridge. Align the cartridge with the label

facing up and the perforations to the front. Set the leading edge on

the cartridge guides, and then slide the film cartridge into the laser

imager to engage the detents in the bottom of the cartridge.

4. Close the film supply.

5. Check that the display screen changes to reflect the new film count.

Make sure the Pause symbol is off (not illuminated)

before you insert a new film cartridge.

Pause symbol is on Pause symbol is off

H210_1020AC

H210_1020ACA

Leading Edge

Detents

Perforations

Cartridge

Guide

Basic Operating Tasks

2011-03-31 9G3886_en 2-7

Loading a different

film size to match a

print request

If a print request requires a different film size, the requested film size

flashes on the display screen. Change the installed film to match the print

request.

1. If the Pause symbol is on, press it and wait until it goes off.

2. Open the film supply. Hold the edges of the film cartridge and lift

the cartridge out of the film supply.

3. Store the removed film cartridge.

4. Insert the new film cartridge. Align the cartridge with the label

facing up and the perforations to the front. Set the leading edge on

the cartridge guides, and then slide the film cartridge into the laser

imager to engage the detents in the bottom of the cartridge.

5. Close the film supply.

6. Check that the display screen changes to reflect the new film size.

The requested film

size flashes. In this

example, load

35 x 43 cm

(14 x 17 in.) film.

The Film Size symbol

indicates that you

must change the film size.

Screen 1: «35» flashes Screen 2: «43» flashes

In most cases, the Pause symbol is off. Do not open the film

supply if the Pause symbol is on. The Pause symbol indicates

that the film cartridge is open.

H210_1020AC

H210_1020ACA

Leading Edge

Detents

Perforations

Cartridge

Guide

2-8 9G3886_en 2011-03-31

Basic Operating Tasks

Deleting pending jobs

To cancel all print requests, press and hold the Film Size symbol for five

seconds. All print requests are deleted from the queue.

NOTE:

• A print request that cannot be printed is automatically deleted

from the laser imager. This situation could be caused by

invalid parameters from the modality, etc.

• If a job is not printable, the laser printer will eject a blank

film into the exit tray.

Making a test print

NOTE: You can make additional test prints at the Web Portal. For more

information, see “Accessing the Web Portal” on page 2-10.

Make a SMPTE test from the laser imager to check that you can print.

Press and then release the Calibration and Pause symbols. The symbols

flash until the test print is complete.

Press this symbol

for five seconds

Press these

two symbols at

the same time

for five

seconds

Basic Operating Tasks

2011-03-31 9G3886_en 2-9

Calibrating the laser imager for the installed film

In normal operating conditions, it is not necessary to calibrate the laser

imager for the film. Run a calibration when:

• Code 001 appears on the display screen.

• A calibration error occurs, indicated by codes 624, 631, or 632 on

the display screen.

• A «Not Calibrated» message appears on the Web Portal Home

screen.

The calibration initiates a test print with a step wedge pattern. The

pattern has a series of 21 step wedges of increasing optical density.

1. Press the symbol to start the calibration. The Calibration and Power

symbols both flash while the calibration is in progress.

2. When the symbols stop flashing, the calibration is complete.

NOTE: If the Calibration symbol turns from blue to yellow, there was a

problem with the calibration process. See “Calibration error” on

page 3-3.

Opening or removing a cover

You can open or remove the laser imager’s top cover, left cover, and film

supply. The covers are protected with an interlock mechanism to keep

the laser imager from printing when they are open, to keep you safe.

Code 701 alerts you that a cover and an interlock are open, and internal

power to the laser imager is turned off.

You might open the top or left cover to search for film jams. For more

information, see “Correcting film jams” on page 3-14.

Press to calibrate the laser

imager for the installed film

2-10 9G3886_en 2011-03-31

Basic Operating Tasks

Using the Web Portal to access additional functionality

The Web Portal is your interface to additional features. In addition to

the installation and setup of your system, you can view and manage the

laser imager’s connections over the network, configure features, view

error messages and access general status information at the Web Portal.

You can also check film count, film size, and film type.

Troubleshooting tools include:

• Optimization of image quality for modalities.

• Retrieval of logs, statistics, and system status.

• Diagnostic utilities, including backup and restore.

The Web Portal provides an online Help system and a user’s guide to

assist you.

Accessing the Web

Portal To access the Web Portal, use a desktop or laptop computer that is

connected to the network.

1. On a desktop or laptop computer, start WINDOWS Internet

Explorer (version 6, 7, or 8).

2. In the address field, type: http://<laser imager’s IP address>

NOTE: If you do not know the IP address, check with your network

administrator or the person who installed the laser imager.

3. Click Go.

The main window for the Web Portal shows the general status, the

number of print jobs queued, the number of jobs waiting for film,

and the film count.

The center panel displays the screens where you view and perform

tasks. Online help is available by selecting Documentation from

the left panel, and the Help icon provides context-sensitive Help for

fields and pages.

The left panel also provides the links to all other screens.

NOTE: If you are using WINDOW Internet Explorer 8, place the

Internet Explorer window into compatibility view. After you

have opened the IE8 window, click the Compatibility View

toolbar button. This will correct some potential viewing issues

with IE 8. If the icon is not on the toolbar, select Compatibility

View from the Tools menu.

Maintenance and Troubleshooting

2011-03-31 9G3886_en 3-1

3

Maintenance and

Troubleshooting

Use the information in this chapter to keep the laser imager in the best

condition and to correct minor problems.

•“Overview: Status and error messages and codes” on page 3-1

•“Preventive maintenance” on page 3-2 — Learn how to respond to the

Maintenance symbol when it appears

•“Error indicators on the display screen” on page 3-3 — Learn about

the yellow and red error symbols

•“Using the Web Portal to gain more information on errors” on

page 3-5 — Learn how and why to access the Web Portal

•“Subsystem error codes and messages” on page 3-5 — A reference

section with all error codes and messages

•“Condition codes” on page 3-9 — A reference section with all

condition codes

•“Correcting film jams” on page 3-14 — Provides instructions to

locate and correct jammed films

•“Display Screen is not functional” on page 3-18 — Instructions if the

display screen is not responding

•“Calling for support” on page 3-18

Overview: Status and error messages and codes

The laser imager detects errors and other conditions and reports them to

you in multiple ways. Some conditions require your action. This section

provides a list of the codes, explains the condition, and provides

recommended actions where appropriate. View the codes:

• At the laser imager’s display screen, on the top left. The display

screen reports 3-digit codes.

Some codes are associated with symbols on the display screen, such

as the Film Jam symbol, to help you quickly understand the

condition.

• At the Web Portal. Access the Web Portal using your personal

computer, keyboard, and mouse to gain more information about the

errors and conditions. Using the Web Portal is optional but you may

find it useful. The Web Portal can report more information than the

laser imager’s display screen due to the limited size of the display

screen. See “Using the Web Portal to gain more information on

errors” on page 3-5.

3-2 9G3886_en 2011-03-31

Maintenance and Troubleshooting

Preventive maintenance

NOTE: These conditions are also reported at the Web Portal.

Replacing the filter

In the U.S., exhausted filters are considered to be

non-hazardous waste according to the US Environmental

Protection Agency Resource Conservation Recovery Act

(RCRA). Municipality owned and licensed solid waste

management facilities are an appropriate disposal option.

Contact your local or state solid waste authorities to determine

if additional disposal requirements apply. In other regions,

contact local or regional solid waste authorities for proper

disposal guidance.

The charcoal filter controls processing odors in the laser imager. The

filter in the laser imager must be replaced after 7500 prints. Keep at least

one filter available to be ready to replace it when needed.

When the filter must be replaced, the display screen shows the error code

and the Maintenance symbol:

1. Open the film supply.

2. Remove the charcoal filter by lifting it up and pulling it forward.

Code 449 indicates that the filter

must be replaced

The system requires maintenance

H210_1016AC

H210_1016ACA

Charcoal

Filter

Maintenance and Troubleshooting

2011-03-31 9G3886_en 3-3

3. Install a new charcoal filter.

4. Close the film supply.

5. To reset the laser imager for the new filter and to clear the

Maintenance symbol, press and then release the Maintenance and

Calibrate symbols at the same time.

550 code and

Maintenance symbol If the laser imager needs a preventive maintenance service call, the 550

code and Maintenance symbol appear:

When the 550 code displays, contact a qualified service provider.

Error indicators on the display screen

The laser imager can detect errors and other conditions that require a

response. Some errors or abnormal conditions are reported on the display

screen in the form of condition codes and symbols.

NOTE: These errors are also reported at the Web Portal.

Calibration error When the calibration has failed, the display screen shows a 624, 631, or

632 error and the Calibrate symbol is yellow:

The most common cause is a film-related problem. Depending on the

cause, you may be able to keep printing, but the laser imager may not be

optimally calibrated.

The system requires maintenance

Code 550 indicates that the laser

imager requires a service call

Yellow symbol

indicates that the

calibration failed

3-4 9G3886_en 2011-03-31

Maintenance and Troubleshooting

Required restart When the Restart symbol appears, you must restart before the laser

imager can continue to print.

1. Press the power switch on the back of the laser imager off (0).

2. Press the power switch on (|).

3. If the error does not clear, contact a qualified service provider.

Film jams When the Film Jam symbol appears, you must clear the jam before the

laser imager can continue to print.

See “Correcting film jams” on page 3-14 for instructions.

Maintenance and Troubleshooting

2011-03-31 9G3886_en 3-5

Using the Web Portal to gain more information on errors

The Web Portal is your interface to additional functions on the laser

imager. You can view and correct error messages and access general

status information at the Web Portal.

To access the Web Portal, see “Using the Web Portal to access additional

functionality” on page 2-10.

Understanding the

codes on the Web

Portal and the Display

Screen

The 3-digit error and status codes on the display screen are reported at

the Web Portal as 5-digit codes. The last three digits on the Web Portal

codes match the three digits on the display screen. For example, code

701 on the display screen is the same as code 20701 on the Web Portal.

Use the information in this section to understand the information at the

display screen and/or at the Web Portal and to respond appropriately.

Subsystem error codes and messages

Use the information in this section to interpret the codes and messages

that appear on the display screen and at the Web Portal.

DICOM (Digital

Imaging and

Communications in

Medicine)

In response to a DICOM printer N-GET status request from a modality, a

printer status message and a printer status info message are returned to

the requesting service class user (SCU). Every error has an associated

printer status info message. If more than one error exists when a printer

N-GET request is received, a status message is sent in response,

according to an established priority. The table shows the DICOM printer

status and info message.

Printer Status Printer Status Info Printer Status Printer Status Info

FAILURE ELEC DOWN

PRINTER DOWN

PROC DOWN

WARNING BAD SUPPLY MGZ

CALIBRATION ERR

CHECK PRINTER

COVER OPEN

EMPTY MEDIASZ MEDIATP

FILM JAM

FILM TRANS ERR

PROC INIT

PRINTER INIT

PRINTER OFFLINE

3-6 9G3886_en 2011-03-31

Maintenance and Troubleshooting

Printer

Printer

Status Display Screen Web Portal DICOM Status Description

Cover is open Code: 701

Power symbol is yellow 20701: Cover

Open WARNING / COVER

OPEN The top cover is open or one of

the side panels may be off. The

laser imager is not ready to

print.

Failed Power symbol is yellow Failed See Condition Code An error has occurred that

prevents printing.

Cartridge

closure is

requested

Power symbol is green

and/or flashing

Pause symbol is on

Not Ready Not Applicable The laser imager completes

any prints in progress before

closing the cartridge cover.

Offline Power symbol is yellow 20704: Printing

Disabled WARNING /

PRINTER OFFLINE The laser imager has been

disabled and does not have a

network connection.

Printing Power symbol is green

and flashing Printing NORMAL The laser imager is currently

printing films.

Ready Power symbol is green

Film count displays Ready NORMAL The laser imager is online and

the processor has reached

operating temperature.

Self-test Power symbol is yellow

and flashing

Code and film count are

replaced by dashes

Self-test WARNING /

PRINTER INIT This occurs when power is

first applied to the laser

imager.

Service Mode Status code: 700

Power symbol is yellow 20700: Service

Mode WARNING /

PRINTER OFFLINE The service switch is enabled.

The laser imager is not ready

to print.

Warming Power symbol is yellow

and flashing

Number of minutes count

down until ready

Warming=xx WARNING / PROC

INIT The processor is warming up

and will not be ready to print

for xx minutes.

Maintenance and Troubleshooting

2011-03-31 9G3886_en 3-7

Film Cartridge

Film

Cartridge

State

Display Screen Web Portal Description

Failed Power symbol is yellow

Pause and Calibrate symbols are off

Film count is replaced by dashes

Failed An error has occurred that affects

normal operation. This film

cartridge is currently not usable.

Reinsert the cartridge. If error

reoccurs, insert a new film

cartridge.

Calibrating Power symbol is green and flashing

Pause symbol is on

Calibrate symbol is blue and flashing

Calibrating A calibration is in progress for the

film cartridge.

Film cartridge is

empty Power symbol is yellow

Pause and Calibrate symbols are off

Film count is flashing «0»

Empty and/or sheet

count of 0 The film cartridge is inserted but the

sheet count is 0. Insert a new

cartridge.

Manual mode Status code: 002

Power symbol is green

Calibrate symbol is yellow

AIQC Off (with

normal tray

information)

The film in this cartridge does not

meet AIQC standards. However, the

laser imager prints if ready.

Invalid film

cartridge Power symbol is yellow

Pause and Calibrate symbols are off

Film count is replaced by dashes

Invalid Film Tray There is a film cartridge in the film

supply but it does not contain a

liner/RF tag. Install a new film

cartridge.

Ready Power symbol is green

Calibrate symbol is on Normal Tray Info The film cartridge is ready for use.

Requires

calibration Power symbol is yellow

Calibrate symbol is on Requires

Calibration The film cartridge must be

calibrated before the laser imager

can print. See “Calibrating the laser

imager for the installed film” on

page 2-9.

Film cartridge is

not detected Power symbol is yellow

Pause and Calibrate symbols are off

Film count is blank

No Film Tray The film cartridge is not fully

inserted in the laser imager. Insert

the cartridge.

Not ready Various Not Ready When the conditions are corrected,

the laser imager can print.

3-8 9G3886_en 2011-03-31

Maintenance and Troubleshooting

Job Manager

Cartridge closure

is pending Power symbol is green

Calibrate symbol is off

Pause symbol is on

Pause Requested You pressed the Pause button, but

the rollback has not started because

films are still moving through the

laser imager. When the closure is

complete, the Pause symbol is off. At

this time, you can remove the film

cartridge.

Film

Cartridge

State

Display Screen Web Portal Description

Job

Manager

Status

Display Screen Web Portal Description

Active Not Applicable Shows how many

print requests have

been initiated.

The laser imager is accepting DICOM job

requests and film is available for all current jobs.

No Media Power symbol is green

Film Size symbol is

yellow

The required film size

is shown on the display

screen

Shows how many jobs

with this status are in

the job queue.

The laser imager is accepting DICOM job

requests but film of the correct size and type is

not available for at least one current job. See

“Loading a different film size to match a print

request” on page 2-7.

Offline Status code: 704

Power symbol is green DICOM Offline The laser imager cannot accept any DICOM job

requests. Restart the laser imager.

Maintenance and Troubleshooting

2011-03-31 9G3886_en 3-9

Condition codes

Condition codes are shown on the display screen in the order in which

they are generated. If there is more than one code associated with the

current condition of the laser imager, the first code is shown on the

display screen for six seconds, while other codes in the list display for

three seconds as the list is cycled. You can also view these codes and

messages at the Web Portal.

Display

Screen Web

Portal Web Portal

Message Action

004 01004 MIM Core: Internal

Software Error Restart the laser imager. See page 2-4.

If the error persists, call for service.

200 04200 MIM Core: Disk Full Load the requested film type and size for jobs that are waiting

for media. See “Loading a different film size to match a print

request” on page 2-7.

If the error persists, call for service.

400 06400 MIM Core: Image Page

Error Resend the print job from the image source.

If the error persists, call for service.

410 06410 MIM Core: Image

Rendering Error Resend the print job from the image source.

If the error persists, call for service.

411 06411 MIM Core: Image Data

Error Resend the print job from the image source.

If the error persists, call for service.

420 06420 MIM Core: Internal

Software Error Resend the print job from the image source.

If the error persists, call for service.

430 06430 MIM Core: Internal

Software Error Resend the print job from the image source.

If the error persists, call for service.

001 10001 MIS: Internal Software

Error Restart the laser imager. See page 2-4.

If the error persists, call for service.

003 10003 MIS: Image Buffer Error Restart the laser imager. See page 2-4.

If the error persists, call for service.

015 10015 MIS: Database Error Restart the laser imager. See page 2-4.

If the error persists, call for service.

910 10910 MIS: MCS Communication

Failure Restart the laser imager. See page 2-4.

If the error persists, call for service.

006 20006 Disconnected or faulty

network cable Check and reconnect the network cable on both ends.

If the error persists, call for service.

3-10 9G3886_en 2011-03-31

Maintenance and Troubleshooting

154 20154 MCS: Internal

Communications Failure Restart the laser imager. See page 2-4.

If the error persists, call for service.

155 20155 Incompatible MCS Printer

Configuration for Hardware Restart the laser imager. See page 2-4.

If the error persists, call for service.

156 20156 Incompatible Software

Versions Installed Restart the laser imager. See page 2-4.

If the error persists, call for service.

209 20209 Laser Imager Opened

During Self Test Close the cover.

Restart the laser imager. See page 2-4.

If the error persists, call for service.

449 20449 none Change the charcoal filter. See “Replacing the filter” on

page 3-2.

550 20550 none Call service for preventive maintenance. See “550 code and

Maintenance symbol” on page 3-3.

700 20700 none The laser imager is inoperable.

If the error persists, call for service.

701 20701 none Close the cover.

704 20704 none The network connection to the laser imager has been lost.

Restart the laser imager.

705 20705 none The laser imager is restarting (for example, during a software

update). Wait until the restart is complete.

706 20706 none A shutdown that was initiated remotely is complete. Restart the

laser imager.

915 20915 Internal Image Data

Transfer Failed Restart the laser imager. See page 2-4.

If the error persists, call for service.

919 20919 Internal Image Data Render

Failed Restart the laser imager. See page 2-4.

If the error persists, call for service.

002 21002 none No action. The error may remain until the film cartridge is

empty. The film cartridge is operating in manual mode and

AIQC is off.

116 21116 Film Jam in Area 1 See “Film jam code 116 / Jam in Area 1” on page 3-15.

Display

Screen Web

Portal Web Portal

Message Action

Maintenance and Troubleshooting

2011-03-31 9G3886_en 3-11

118 21118 Film Supply: Internal

Hardware Failure If the Pause symbol is on, press it to cover the film cartridge.

When the Pause symbol stops flashing, remove the film

cartridge from the laser imager. Then reinsert the film cartridge

into the laser imager.

If the error persists, call for service.

119 21119 Film Supply: Internal

Hardware Failure If the Pause symbol is on, press it to cover the film cartridge.

When the Pause symbol stops flashing, remove the film

cartridge from the laser imager. Then reinsert the film cartridge

into the laser imager.

If the error persists, call for service.

125 21125 Film Supply: Internal

Hardware Failure If the Pause symbol is on, press it to cover the film cartridge.

When the Pause symbol stops flashing, remove the film

cartridge from the laser imager. Then reinsert the film cartridge

into the laser imager.

If the error persists, call for service.

139 21139 Film Supply: Unable to

Identify Film Cartridge If the Pause symbol is on, press it to cover the film cartridge.

When the Pause symbol stops flashing, remove the film

cartridge from the laser imager. Insert a different film cartridge

into the laser imager.

If the error persists, call for service.

145 21145 Film Supply: Unsupported

Film Type The laser imager does not support the loaded film type. Install

a cartridge with a supported film type.

If the error persists, call for service.

146 21146 Film Supply: Unsupported

Film Size The laser imager does not support the loaded film size. Install a

cartridge with a supported size.

If the error persists, call for service.

175 21175 Rollback Failed to Engage

Cartridge If the Pause symbol is on, press it to cover the film cartridge.

When the Pause symbol stops flashing, remove the film

cartridge from the laser imager. Insert a different film cartridge

into the laser imager.

If the error persists, call for service.

177 21177 Film Cartridge Failed to

Close Open the film supply. Manually close the film cartridge, using

the manual rollback knob, to prevent the film from fogging. See

page 3-15.

If the error persists, call for service.

Display

Screen Web

Portal Web Portal

Message Action

3-12 9G3886_en 2011-03-31

Maintenance and Troubleshooting

178 21178 Rollback Failed to Leave

Home If the Pause symbol is on, press it to cover the film cartridge.

When the Pause symbol stops flashing, remove the film

cartridge from the laser imager. Insert a different film cartridge

into the laser imager.

If the error persists, call for service.

624 21624 Film Supply: Film

Calibration Failure Calibrate again. See “Calibrating the laser imager for the

installed film” on page 2-9.

If the error still displays, install a new film cartridge.

If the error still displays, restart the laser imager. See page 2-4.

If the error persists, call for service.

631 21631 Film Supply: Film

Calibration Failure — Dmin

Outside Target

The minimum density of the film is too high. Calibration results

for this film are outside the normal range. Printing will continue

with these parameters.

If the prints are not optimal, do the calibration procedure again

(see page 2-9) or install another film cartridge.

632 21632 Film Supply: Film

Calibration Failure — Dmax

Outside Target

The maximum density of the film is lower than the target density.

Calibration results for this film are outside the normal range.

Printing will continue with these parameters.

If the prints are not optimal, do the calibration procedure again

(see page 2-9) or install another film cartridge.

922 25922 RF Tag: Internal Diagnostic

Failure Restart the laser imager. See page 2-4.

If the error persists, call for service.

323 26323 Film Jam in Area 2 See “Film jam code 323 / Jam in Area 2” on page 3-16.

324 26324 Film Jam in Area 2 See “Film jam code 324 or 325 / Jam in Area 2” on page 3-16.

325 26325 Film Jam in Area 2 See “Film jam code 324 or 325 / Jam in Area 2” on page 3-16.

326 26326 Film Jam in Area 2 or 3 See “Film jam code 326 / Jam in Area 2 or 3” on page 3-17.

543 26543 Film Jam in Area 3 See “Film jam code 543 / Jam in Area 3” on page 3-18.

544 26544 Film Jam in Area 3 See “Film jam code 544 / Jam in Area 3” on page 3-18.

123 27123 Optics: Internal Hardware

Failure Restart the laser imager. See page 2-4.

If the error persists, call for service.

601 27601 Optics: Calibration Failed Restart the laser imager. See page 2-4.

If the error persists, call for service.

604 27604 Optics: Calibration Failed Restart the laser imager. See page 2-4.

If the error persists, call for service.

Display

Screen Web

Portal Web Portal

Message Action

Maintenance and Troubleshooting

2011-03-31 9G3886_en 3-13

607 27607 Optics: Calibration Failed Restart the laser imager. See page 2-4.

If the error persists, call for service.

611 27611 Optics: Internal Hardware

Failure Restart the laser imager. See page 2-4.

If the error persists, call for service.

646 27646 Optics: Internal Hardware

Failure Restart the laser imager. See page 2-4.

If the error persists, call for service.

650 27650 Optics: Internal Hardware

Failure Restart the laser imager. See page 2-4.

If the error persists, call for service.

501 28501 Processor: Internal

Hardware Failure Restart the laser imager. See page 2-4.

If the error persists, call for service.

509 28509 Processor Warm-up Failure Restart the laser imager. See page 2-4.

If the error persists, call for service.

510 28510 Processor: Internal

Hardware Failure Restart the laser imager. See page 2-4.

If the error persists, call for service.

551 28551 Processor Heater Failure Restart the laser imager. See page 2-4.

If the error persists, call for service.

554 28554 Processor Over

Temperature Restart the laser imager. See page 2-4.

If the error persists, call for service.

924 29924 Densitometer: Internal

Diagnostic Failure Restart the laser imager. See page 2-4.

If the error persists, call for service.

925 29925 Densitometer: Internal

Diagnostic Failure Restart the laser imager. See page 2-4.

If the error persists, call for service.

931 29931 Densitometer: Internal

Communications Failure Restart the laser imager. See page 2-4.

If the error persists, call for service.

935 36935 Local Panel: No

Communications from MCS Restart the laser imager. See page 2-4.

If the error persists, call for service.

Display

Screen Web

Portal Web Portal

Message Action

3-14 9G3886_en 2011-03-31

Maintenance and Troubleshooting

Correcting film jams

When film is jammed, the display screen indicates a jam and an error

code that provides guidance on where to check for the jammed film.

NOTE: These errors are also reported at the Web Portal.

Film Jam Areas

Film Jam symbol

Check the code to

know where to find

the jammed film

Jam Areas Description Interlocks Description

A1 Film supply I1 Film supply

A2 Film path I2 Left cover

A3 Processor / densitometer I3 Top cover

Maintenance and Troubleshooting

2011-03-31 9G3886_en 3-15

For some jams, you can remove the film by turning a knob to move the

film out of the laser imager. See details in the film jam instructions.

Knobs for manual film removal

Film jam code 116 /

Jam in Area 1 NOTE: This error displays as code 21116 at the Web Portal.

1. If the Pause symbol is on, press it and wait until it goes off.

2. Open the film supply and remove the film cartridge from the laser

imager.

3. Look in Area 1 (the film supply) and remove any film. See

page 3-14 for the film jam areas.

4. Reinsert the film cartridge in the laser imager.

H210_1013HAB

Exit Roller Knob

Exposure Transport Knob

Front of laser imager

Manual rollback knob

3-16 9G3886_en 2011-03-31

Maintenance and Troubleshooting

Film jam code 323 /

Jam in Area 2 NOTE: This error displays as code 26323 at the Web Portal.

1. If the Pause symbol is on, press it and wait until it goes off.

2. Open the film supply.

3. Check that the film cartridge is closed. If it is not closed, carefully

close the cartridge cover.

4. Remove any loose film near, in, or partially in the film cartridge.

5. Close the film supply.

Film jam code 324 or

325 / Jam in Area 2 NOTE: This error displays as code 26324 or 26325 at the Web Portal.

1. If the Pause symbol is on, press it and wait until it goes off.

2. Remove the left cover:

a. Open the film supply.

b. Remove the top cover.

c. Turn the knurled knobs by hand.

3. Reach into Area 2 and remove any film. See page 3-14 for the film

jam areas.

4. If the film is not loose, carefully turn the exposure transport knob

clockwise to remove the film from the rollers. See page 3-15 for the

location of the knob.

5. Reinstall the covers.

H210_1017AC

H210_1017ACA

2 Screws

Remove the top

cover to gain

access

Open the film supply

to gain access

Left cover

2 Knurled knobs

Maintenance and Troubleshooting

2011-03-31 9G3886_en 3-17

Film jam code 326 /

Jam in Area 2 or 3 NOTE: This error displays as code 26326 at the Web Portal.

1. If the Pause symbol is on, press it and wait until it goes off.

2. Remove the top cover.

3. Remove the left cover:

a. Open the film supply.

b. Remove the top cover.

c. Turn the knurled knobs by hand.

4. Rotate the exit roller knob clockwise until a film exits the laser

imager. See page 3-15 for the location of the knob.

5. If a film does not exit:

a. Reach into Area 2 and remove any film. See page 3-14 for the

film jam areas.

b. If the film is not loose, carefully turn the exposure transport knob

clockwise to remove the film from the rollers. See page 3-15 for

the location of the knob.

6. Reinstall the covers.

H210_1017AC

H210_1017ACA

2 Screws

Remove the top

cover to gain

access

Open the film supply

to gain access

Left cover

2 Knurled knobs

3-18 9G3886_en 2011-03-31

Maintenance and Troubleshooting

Film jam code 543 /

Jam in Area 3 This error displays as code 26543 at the Web Portal.

1. If the Pause symbol is on, press it and wait until it goes off.

2. Open the top cover.

3. Remove the left cover:

a. Open the film supply.

b. Remove the top cover.

c. Turn the knurled knobs by hand.

4. Rotate the exit roller handle clockwise until a film exits the laser

imager. See page 3-15 for the location of the knob.

5. Reinstall the covers.

Film jam code 544 /

Jam in Area 3 This error displays as code 26544 at the Web Portal.

1. Remove any film that is jammed in the exit tray. See page 3-14 for

the film jam areas.

2. If the Pause symbol is on, press it and wait until it goes off.

3. Open the top cover and remove any films.

4. Close the top cover.

Display Screen is not functional

If the display screen is not responding, use the power switch on the laser

imager to turn power off, and then on. If the display screen is still

non-responsive, turn the laser imager off and contact a qualified service

provider.

Calling for support

If you cannot correct a condition and need help, call for support. Have

the following information ready when you call:

• Model number

• K-number

• Error code from the display screen and/or code and error message

from the Web Portal

Film Technical Information

2011-03-31 9G3886_en 4-1

4

Film Technical Information

General description

This section describes the characteristics of Laser Imaging Film, not the

operation of the laser imager. The Laser Imaging Film is a

high-resolution, infrared-sensitive, photothermographic film designed

specifically for the Laser Imager.

Spectral sensitivity The Laser Imaging Film is infrared sensitive and has been sensitized to

the infrared laser diode of the laser imagers. When handled according to

instructions on the daylight-load film package, safelights are not needed.

If you remove undeveloped film from the daylight-load package, you

will need a darkroom setting and a green safelight.

Relative Log Exposure (Example)

Image quality The Laser Imaging Film delivers diagnostic-quality, continuous-tone

images along with sharp alphanumerics and optimum contrast. This

high-quality, silver-based film provides health care providers with the

same diagnostic information they are accustomed to viewing —

including the spatial resolution, contrast, and gray levels. Because it is a

totally dry imaging process, there is no image quality variability due to

wet chemistry.

0 0.5 1 1.5 2 2.5 3

0

0.5

1

1.5

2

2.5

3

3.5

4-2 9G3886_en 2011-03-31

Film Technical Information

Environmental impact Tests show that the Laser Imaging Film is not considered hazardous to

the environment. As a result, you can develop, recycle, and dispose of

film with less impact on the environment than if you were using

wet-developed silver halide films.

Storing and handling

undeveloped film

To achieve consistent results up to the expiration date indicated on the

film package, the Laser Imaging Film must be stored in a cool, dry

place (5° to 25° C, or 41° to 77° F) and protected from radiation and

chemistry fumes.

The film can withstand short-term temperature spikes

(up to 35° C, or 95° F) for several hours during transit without any

significant effect on film quality or performance. Transit temperatures

above 35° C (95° F) will gradually diminish shelf life.

Handling developed film Handling the Laser Imaging Film requires reasonable care. Spills,

humidity, and other moisture typically have no significant effect on

developed films. However, prolonged exposure to intense light or

excessive heat (54.4° C or 130° F) for more than three hours may cause

some gradual darkening of images. Leaving films in vehicles in hot

climates for extended periods of time is not recommended.

For best results, store film in sleeves when not being reviewed. The

Laser Imaging Film can be left on a light box for more than 24 hours. In

extreme cases in which light boxes are exceptionally hot

(49° C, or 120° F), the manufacturer recommends removing them prior

to eight hours of continuous exposure.

Laser Imaging Film

US Environmental Regulations Comparison

Wet (Silver Halide) Film Dry Film

Developer Fixer Wash Film Film

Product Regulations

OSHA MSDS Required Required Not required Not required Provided

DOT Hazardous Hazardous No limits No limits No limits

Use permits Local Local None None None

Disposal* Regulations

EPA Hazardous Hazardous No No No

DOT Hazardous Hazardous No No No

There is no SUPERFUND liability with dry Laser Imaging Film.

* State and local laws vary. Consult appropriate regulations or authorities prior to disposal.

Film Technical Information

2011-03-31 9G3886_en 4-3

Take care when using spotlight viewing for more than 30 seconds

because temperatures near the light source may exceed 82.2° C

(180° F). Use in slide projectors is not recommended due to the high

temperatures generally found in these devices.

With dry technology, a small amount of final development occurs when

the film exits the laser imager and is initially exposed to ambient or

view-box lighting. This is virtually undetectable and has no effect on

image quality (typically 0.02 change in density). This small density

increase is uniform and permanent upon full exposure of the film under

normal handling conditions (room light or view box).

Archiving developed

film

The Laser Imaging Film has been tested and can be archived for more

than 100 years when stored at American National Standards Institute

(ANSI) recommended storage conditions (25° C or 77° F). Developed

films may be stored at higher temperatures; however, that may reduce

the number of years the film can be stored. For example, storing films at

a constant elevated temperature of 32.2° C (90°F) may reduce archive

capability to 30 years.

Exposing to moisture The Laser Imaging Films typically withstand humidity, spills, and other

forms of water without any significant effect on image quality or film

integrity. If needed, film can be cleaned with a clean, damp cloth.

Dissipating odor Dry technology eliminates virtually all unpleasant odors. While some

low-level odors are produced during the development process, they pose

no known adverse health risks. Processing odor levels are further

reduced by a non-hazardous, recyclable filter in the laser imager. This

filter traps most low-level odors and prevents them from dissipating into

the work environment. To help maintain optimum performance, the

filter requires periodic replacement. The laser imagers require no special

venting.

Dissipating heat The laser imagers use controlled heat to develop the Laser Imaging

Film. The heat has virtually no effect on the air temperature of the work

area. The amount of heat dissipated into an area during a day is typically

less than the heat generated by two to four 100-watt light bulbs.

Recycling film According to the Environmental Protection Agency (EPA) standards, the

Laser Imaging Film is not considered hazardous and requires no special

disposal procedures. However, the film does contain silver and polyester

that may be recovered by using one of several recycling processes.

2011-03-31 9G3886_en 5-1

5

Specifications

Equipment specifications

Operating space requirements

Allow 5 cm (2 in.) clearance around the top, sides, and back of the laser

imager. This space is required to let the laser imager perform normal

operator functions. For service functions, allow 15 cm (6 in.) clearance

around the laser imager.

Environmental requirements

Temperature • Operating: 15° to 33° C (59° to 91° F)

• Storage: -40° to 55° C (-40° to 131° F)

Relative humidity • Operating: 20% to 85% RH, noncondensing

• Storage: 10% to 90% RH, noncondensing

Altitude • 30 m (100 ft) below sea level to 3,048 m (10,000 ft) above sea level

Surface levelness • The countertop/floor must be level within 1°.

Environmental effects

• Acoustical Noise:

– Less than 55 dB at 1.5 m during idle or standby

– Less than 75 dB momentary at 1 m during normal operation

Unpacked Packed

Height 47 cm (19 in.) 74 cm (29 in.)

Width 61 cm (24 in.) 79 cm (31 in.)

Depth 66 cm (26 in.) 85 cm (34 in.)

Weight 54 kg (120 lbs) 73 kg (160 lbs)

5-2 9G3886_en 2011-03-31

Specifications

Power requirements

A power cord is provided with this equipment. All countries must use an

Agency-approved power cord with a plug type suitable for the country of

use. Contact a qualified dealer for help.

Connect the equipment to a power source that is suitable for the voltage

and current ratings shown on the rating label. The single-phase power

source, with grounding, must be provided within 2.5 m (8 ft) of the laser

imager.

The wire must be insulation-rated for 600 V (ac). A dedicated line is

recommended.

Network requirements

The laser imager receives digital images from medical imaging devices

(modalities) over a 10/100Base-T or 1000Base-T Ethernet Network.

Publication History

Revision Date Reason for Change

A2011-03-31 First release

Описание

Даже ограниченный бюджет не помешает вашему лечебному учреждению использовать преимущества лазерной технологии печати. Это возможно благодаря новой системе лазерного экспонирования CARESTREAM DryView 5700.

Сочетание низкой стоимости и минимальных эксплуатационных расходов делает данную мультиформатную камеру широко доступной. Быстрая и простая загрузка пленки при дневном свете.

Постоянный контроль качества при помощи системы автоматического контроля качеcтва (AIQC). Новая лазерная мультиформатная камера DryView 5700 Laser Imager — идеальное решение для получения изображений от систем компьютерной радиографии (CR), цифровой радиографии (DR), компьютерной томографии (CT) и магнитного

резонанса (MR). Компактность, производительность и надежность, которые может предложить только бренд DryView™.

Лазерная технология печати

Мультиформатная камера DryView 5700 используя современную технологию лазерного экспонирования имеет доступную цену, минимальные эксплутационные расходы и высокую производительность.

Простота и надежность

Поскольку в мультиформатной камере DryView 5700 не используются термоголовки, отсутствует необходимость ежедневного или еженедельного обслуживания. Режим ожидания экономит энергию. Сухая технология печати экологична.

Автоматический контроль качества изображения (AIQC)

В камере DryView 5700 AIQC используется встроенный денситометр, что гарантирует стандартно высокое качество печати. Технология AIQC определяет качество изображения и выполняет необходимую

корректировку. Эта уникальная функция в сочетании с проверенными преимуществами технологии DryView обеспечивает отличное качество изображения для различных сфер применения.

Компактная конструкция, быстрая установка

Инновационный эргономичный дизайн и компактные размеры 26 x 24 дюйма (66 x 61 см) делают DryView 5700 Laser Imager удобным терминалом печати даже в ограниченном пространстве. Благодаря упрощенному процессу установки систему печати установить легко и быстро.

Компактная конструкция, быстрая установка

Инновационный эргономичный дизайн и компактные размеры 26 x 24 дюйма (66 x 61 см) делают DryView 5700 Laser Imager удобным терминалом печати даже в ограниченном пространстве. Благодаря упрощенному процессу установки систему печати установить легко и быстро.

Простота обучения, удобство в эксплуатации

Интуитивно понятный пользовательский интерфейс ускоряет процесс работы, нет необходимости в специальном обучении.

Описание

- Лазерная мультиформатная камера для печати изображений Carestream DryView 5700

Технология

- Фототермографическое устройство (лазерное экспонирование)

Качество лазерного изображения DryView

- 325 пикселей на дюйм, пиксел 78 микрон

- Шкала серого 14-бит

Производительность

До 45 пленок в час: 14 x 17 дюймов (35 x 43 см)

- Пленки меньшего размера печатаются быстрее

Пленка для лазерного экспонирования DryView

- Синяя или прозрачная полиэфирная подложка толщиной 7 мил

- Пленка в картриджах для зарядки на свету

- 125 листов в картридже

- Сохраняемость пленки в течение всей жизни (более 100 лет) для сфер применения с высокими требованиями

(онкология, педиатрия и т. д.) - Напечатанные пленочные изображения со стандартным D-max 3.0

Выбор формата пленки

Лазерная камера DryView 5700 позволяет обрабатывать следующие форматы пленок:

- 14 x 17 дюймов (35 x 43 см)

- 11 x 14 дюймов (28 x 35 см)

- 10 x 12 дюймов (25 x 30 см)

- 8 x 10 дюймов (20 x 25 см)

Автоматический контроль качества изображения (AIQC)

- Без ручного запуска и процедур обеспечения качества

- Обеспечивает стабильность показаний на протяжении длительного времени

Возможность сетевого подключения

- Интегрированный интерфейс DICOM поддерживает печать с диагностических устройств DICOM

Подключение к сети

- Подключение к камере 10/100/1000 Base T Ethernet (поддержка джамбо-кадров)

Размеры/вес

- Высота: 19 дюймов (47 см)

- Ширина: 24 дюйма (61 см)

- Глубина: 26 дюймов (66 см)

- Вес: 120 фунтов (54 кг)

Питание

- 180—264 В пер. тока; 50/60 Гц; максимум 4,5 А

Условия эксплуатации

- Температура: от 59 до 91°F (от 15 до 33°C)

- Влажность: от 20 до 80% относительной влажности, без конденсации

- Магнитное поле: < 50 Гс

- Высота над уровнем моря: от -30,5 до 3 048 м

Интерфейс пользователя

- Упрощенная панель пользователя

- Пользовательская документация и поддерживаемые языки: русский

Помогите другим пользователям с выбором — будьте первым, кто поделится своим мнением об этом товаре.

Как купить

Гарантия

Видео

Инструкции