Introduction

3

How to Use this Manual

4

Repair Procedures

4

Identification Information Engine Serial Number

6

General Repair Instructions

6

Precautions for Vehicles Equipped with a Catalytic Converter

8

Abbreviations Used in this Manual

9

Engine Mechanical

10

Description (5S-FE)

11

Description (3S-GE and 3S-GTE)

13

Troubleshooting

16

Engine Overheating

16

Hard Starting

16

Rough Idling

16

Engine Hesitates/Poor Acceleration

17

Engine Dieseling

18

After Fire, Backfire

18

Excessive Oil Consumption

18

Excessive Fuel Consumption

19

Unpleasant Odor

19

Engine Tune-Up

20

Inspection of Air Filter

20

Inspection of High-Tension Cords

20

Inspection and Adjustment of Spark Plugs (Conventional Type Only)

20

Inspection and Adjustment of Alternator Drive Belt (5S-FE)

21

Inspection and Adjustment of Alternator Drive Belt (3S-GE and 3S-GTE)

21

Inspection and Adjustment of Valve Clearance (5S-FE)

22

Adjusting Shim Selection Using Chart

24

Intake

24

Exhaust

25

Inspection and Adjustment of Valve Clearance (3S-GE and 3S-GTE)

26

Adjust Valve Clearance

27

Inspection and Adjustment of Ignition Timing (5S-FE)

31

Warm up Engine

31

Connect Tachometer

31

Further Check Ignition Timing

31

Inspection and Adjustment of Ignition Timing (3S-GE and 3S-GTE)

32

Inspection and Adjustment of Idle Speed (5S-FE)

33

Initial Conditions

33

Adjust Idle Speed

33

Further Check Idle Speed

34

Inspection of Idle Speed (3S-GE and 3S-GTE)

34

Inspection of Acoustic Control Induction System (ACIS) (3S-GE)

34

Inspection of TOYOTA-Variable Induction System (T-VIS) (3S-GTE)

35

Connect Vacuum Gauge

35

Inspect T-VIS Operation

35

Idle HC/CO Concentration Check Method (W/Twc)

36

Check Oxygen Sensor Operation

36

Check HC/CO Concentration at Idle

37

Idle Co Concentration Check and Adjustment Method (W/O TWC)

38

Compression Check

40

Check Cylinder Compression Pressure

40

Timing Belt (5S-FE)

42

Components

42

Removal of Timing Belt

42

Remote No.2 Timing Belt Cover

43

Set No.1 Cylinder to Tdc/Compression

43

Remove Timing Belt from Camshaft Timing Pulley

43

Remove Camshaft Timing Pulley

44

Remove Crankshaft Pulley

44

Remove No.1 Timing Belt Cover

45

Remove Timing Belt Guide

46

Remove No.1 Idler Pulley and Tension Spring

46

Remove No.2 Idler Pulley

46

Remove Crankshaft Timing Pulley

46

Remote Oil Pump Pulley

47

Inspection of Timing Belt Components

47

Inspect Idler Pulleys

48

Inspect Tension Spring

48

Install Oil Pump Pulley

49

Install Crankshaft Timing Pulley

49

Temporarily Install No.1 Idler Pulley and Tension Spring

49

Temporarily Install Timing Belt

49

Install Timing Belt Guide

50

Install No.1 Timing Belt Cover

50

Install Crankshaft Pulley

50

Install Camshaft Timing Pulley

50

Install Timing Belt

51

Check Valve Timing

52

Install No.2 Timing Belt Cover

52

Install Engine Wire to Alternator Bracket and Adjusting Bar

53

Install Spark Plugs

53

Install RH Engine Mounting Bracket

53

Timing Belt (3S-GE and 3S-GTE) Components

55

Remove Timing Belt from Camshaft Timing Pulleys

56

Remove Camshaft Timing Pulleys

56

Remove No.1 Timing Belt Covers

58

Remove Timing Belt

58

Remove No.1 Idler Pulley

59

Remove Oil Pump Pulley

59

Inspect Timing Belt

60

Inspect Timing Belt Tensioner

61

Installation of Timing Belt

62

Install Camshaft Timing Pulleys

63

Install Timing Belt Tensioner

65

Adjustment of Valve Timing

68

Check Camshaft Timing Pulley Marks

68

Adjust Camshaft Timing Pulley Timing Marks

69

Adjust Valve Timing

71

Reinstall Spark Plugs

72

Cylinder Head (5S-FE) Components

73

Removal of Cylinder Head

74

Remove Alternator

74

Remove Distributor

74

Remove Exhaust Manifold and Catalytic Converter Assembly

74

Separate Exhaust Manifold and Catalytic Converter

75

Remove Water Outlet

75

Remove Water By-Pass Pipe

76

Remove EGR Valve and Vacuum Modulator

76

Remove Air Tube

77

Disconnect Engine Wire Ground Strap from Intake Manifold

77

Remove EGR VSV

77

Remove Intake Manifold

77

Remove No.3 Timing Belt Cover

78

Remove Engine Hangers

78

Remove Alternator Bracket

78

Remove Oil Pressure Switch

78

Remove Cylinder Head Cover

79

Remove Exhaust Camshaft

79

Remove Intake Camshaft

80

Disassemble Exhaust Camshaft

81

Remove Cylinder Head

82

Disassembly of Cylinder Head

83

Remove Valve Lifters and Shims

83

Remove Valves

83

Inspection, Cleaning and Repair of Cylinder Head Components

84

Clean Top Surfaces of Pistons and Cylinder Block

84

Remove Gasket Material

84

Inspect Cylinder Head

85

Clean Valves

85

Inspect Valve Stems and Guide Bushings

86

If Necessary, Replace Valve Guide Bushings

86

Inspect and Grind Valves

88

Inspect and Clean Valve Seats

89

Inspect Valve Springs

90

Inspect Camshaft for Runout

90

Inspect Cam Lobes

91

Inspect Camshaft Bearings

91

Inspect Camshaft Gear Spring

91

Inspect Camshaft Journal Oil Clearance

91

Inspect Camshaft Thrust Clearance

92

Inspect Camshaft Gear Backlash

93

Inspect Valve Lifters and Lifter Bores

93

Inspect Intake and Exhaust Manifolds

93

Assembly of Cylinder Head

94

Install Valves

94

Install Valve Lifters and Shims

95

Installation of Cylinder Head

96

Place Cylinder Head on Cylinder Block

96

Install Cylinder Head Bolts

96

Install Spark Plug Tubes

97

Assemble Exhaust Camshaft

97

Install Intake Camshaft

98

Install Exhaust Camshaft

99

Install Semi-Circular Plugs

100

Install Cylinder Head Cover

101

Install Oil Pressure Switch

101

Install Alternator Bracket

101

Install No.3 Timing Belt Cover

101

Install Intake Manifold

102

Install EGR VSV

102

Install Engine Wire Ground Strap to Intake Manifold

102

Install Air Tube

102

Install EGR Valve and Vacuum Modulator

103

Install Water Outlet

104

Assemble Exhaust Manifold and Catalytic Converter

104

Install Exhaust Manifold and Catalytic Converter Assembly

105

Install Alternator

105

Cylinder Head (3S-GE and 3S-GTE) Components (3S-GE)

107

Components (3S-GTE)

108

Cylinder Head (3S-GTE) Components

110

Removal of Cylinder Head (3S-GE)

112

Drain Engine Coolant

112

Remove RH Front Engine Hanger and No.1 Alternator Bracket

112

Remove Exhaust Manifold

113

Remove Intake Manifold Stay

115

Remove ACIS Vacuum Tank, ACIS VSV, Fuel Pressure VSV and Bracket

115

Remove Cold Start Injector

116

Remove Air Intake Chamber

116

Remove LH Engine Hanger

116

Remove ACIS Valve

117

Remove RH Rear Engine Hanger

117

Disconnect Engine Wire from Cylinder Head Cover

117

Remove Catalytic Converter

120

Remove No.2 Air Tube

121

Remove EGR Vacuum Modulator and VSV

122

Remove EGR Valve and Pipe

122

Remove Vacuum Pipe

122

Remove Intake Manifold Stays

123

Remove No.1 Air Tube

124

Remove T-VIS Vacuum Tank, T-VIS VSV, Turbocharging Pressure VSV and Bracket

124

Remove Intake Manifold and T-VIS Valve

124

Remove Camshafts

125

Clean Combustion Chambers

128

Clean Valve Guide Bushings

128

Clean Cylinder Head

129

Inspect for Flatness

129

Inspect for Cracks

129

Inspect Camshafts and Bearings

134

Inspect Camshaft Journals

135

Intake Manifold (3S-GE)

137

Intake Manifold (3S-GTE)

137

Exhaust Manifold

137

Inspect Air Intake Chamber (3S-GE)

138

Inspection of Acoustic Control Induction System (ACIS) (3S-GE)

138

Inspect ACIS Valve

138

Inspect Vacuum Tank

138

Inspection of TOYOTA-Variable

139

Induction System (T-VIS) (3S-GTE)

139

Inspect T-VIS Valve

139

Installation of Cylinder Head (3S-GE)

142

Install Cylinder Head Covers

142

Install Engine Wire to Cylinder Head Cover

142

Install RH Rear Engine Hanger

143

Install ACIS Valve

143

Install LH Engine Hanger

143

Install Air Intake Chamber

143

Install ACIS Vacuum Tank, ACIS VSV, Fuel Pressure VSV and Bracket

144

Install Intake Manifold Stay

145

Install Water By-Pass Pipe

146

Install Exhaust Manifold

146

Install No.1 Alternator Bracket and RH Front Engine Hanger

147

Installation of Cylinder Head (3S-GTE)

148

Install Camshafts

150

Install T-VIS Valve and Intake Manifold

152

Install T-VIS Vacuum Tank, T-VIS VSV, Turbocharging Pressure VSV and Bracket

152

Install No.1 Air Tube

152

Install Intake Manifold Stays

153

Install Vacuum Pipe

154

Install EGR Valve and Pipe

154

Install EGR Vacuum Modulator and VSV

154

Install No.2 Air Tube

155

Install Catalytic Converter

156

Cylinder Block (5S-FE)

159

Preparation for Disassembly

160

Disassembly of Cylinder Block

161

Remove Rear Oil Seal Retainer

161

Check Connecting Rod Thrust Clearance

161

Remove Connecting Rod Caps and Check Oil Clearance

161

Remove Piston and Connecting Rod Assemblies

163

Check Crankshaft Thrust Clearance

163

Remove Main Bearing Caps and Check Oil Clearance

164

Cylinder Block Main Journal Bore Diameter

166

Crankshaft Journal Diameter

166

Standard Sized Bearing Center Wall Thickness

166

Remove Crankshaft

166

Inspection of Cylinder Block

167

Inspect Top Surface of Cylinder Block for Flatness

167

Inspect Cylinder for Vertical Scratches

167

Inspect Cylinder Bore Diameter

167

Remove Cylinder Ridge

168

Disassembly of Piston and Connecting Rod Assemblies

168

Remove Piston Rings

168

Disconnect Connecting Rod from Piston

169

Inspection of Piston and Connecting Rod Assemblies

170

Clean Piston

170

Inspect Piston Oil Clearance

170

Inspect Piston Ring Groove Clearance

171

Inspect Piston Ring End Gap

171

Inspect Piston Pin Fit

172

Inspect Connecting Rod Alignment

172

Inspect Piston Pin Oil Clearance

173

If Necessary, Replace Connecting Rod Bushing

173

Inspect Connecting Rod Bolts

174

Inspection and Repair of Crankshaft

175

Inspect Crankshaft for Runout

175

Inspect Main Journals and Crank Pins

175

If Necessary, Grind and Hone Main Journals And/Or Crank Pins

175

Replacement of Crankshaft Oil Seals

176

Replace Crankshaft Front Oil Seal

176

Replace Crankshaft Rear Oil Seal

177

Assembly of Piston and Connecting Rod Assemblies

178

Install Piston Rings

178

Install Bearings

179

Assembly of Cylinder Block

180

Install Main Bearings

180

Install Upper Thrust Washers

180

Place Crankshaft on Cylinder Block

181

Install Main Bearing Caps and Lower Thrust Washers

181

Install Piston and Connecting Rod Assemblies

181

Install Connecting Rod Caps

182

Install Rear Oil Seal Retainer

183

Post Assembly

183

Install PS Pump Bracket

183

Install Rear End Plate

184

Install Flywheel (M/T)

184

Install Clutch Disc and Cover (M/T)

184

Cylinder Block (3S-GE and 3S-GTE)

185

Remove Rear End Plate

186

Remove RH Engine Mounting Bracket

186

Remove PS Pump Bracket

186

Remove Knock Sensor

186

Clean Cylinder Block

193

Check Fit between Piston and Piston Pin

194

Standard Oil Clearance

197

Maximum Oil Clearance

197

Ring Groove Clearance

197

Standard End Gap

198

Maximum End Gap

198

Assemble Piston and Connecting Rod

202

Install Knock Sensor

207

Turbocharger

209

Discription

210

Operation of Turbocharger

211

Waste Gate Valve

211

Intercooler

211

Precautions

214

Insufficient Acceleration, Lack of Power or Excessive Fuel Consumption

215

Abnormal Noise

216

Excessive Oil Consumption or White Exhaust

216

Inspect Intake Air System

217

Inspect Exhaust System

217

Inspect Actuator Operation

217

Check Turbocharging Pressure

217

Remove Intercooler Cool Air Inlet

219

Remove Intercooler Cool Cover

219

Remove Intercooler

219

Remove Turbocharger Heat Insulator

219

Remove Oxygen Sensor

220

Remove Heat Insulators of Turbine Outlet Elbow

220

Disconnect Hoses

220

Remove Turbocharger Stay

220

Remove Turbocharger

221

Remove Turbo Oil Pipe

221

Remove Turbo Water Pipe

221

Remove Side Bearing Housing Plate

221

Remove Turbine Outlet Elbow

222

Inspect Impeller Wheel Rotation

222

Inspect Axial Play of Impeller Wheel

222

Inspect Radial Play of Impeller Wheel

222

Install Turbine Outlet Elbow

223

Install Side Bearing Housing Plate

223

Install Turbo Water Pipe

223

Install Turbo Oil Pipe

223

Install Turbocharger

224

Install Turbocharger Stay

225

Connect Hoses

225

Install Heat Insulator of Turbine Outlet Elbow

225

Install Oxygen Sensor

225

Install Turbocharger Heat Insulator

226

Install Intercooler

226

Install Intercooler Cover

226

Install Intercooler Cool Air Inlet

226

EFI System

227

System Description

228

Air Induction System

231

Maintenance Precautions

232

Precautions When Connecting Gauge

232

In the Event of Engine Misfire the Following Precautions Should be Taken

232

(W/Twc) Precautions When Handling Oxygen Sensor

232

If Vehicle VIS Equipped with Mobile Radio System (HAM, CB, ETC.)

233

Electronic Control System

234

Fuel System

235

Troubleshooting Hints

238

Troubleshooting Procedures

239

Symptom — Difficult to Start or no Start (Engine will Not Crank or Cranks Slowly)

239

Symptom — Difficult to Start or no Start (Cranks Ok)

240

Symptom — Engine Often Stalls

242

Symptom — Engine Sometimes Stalls

244

Symptom — Rough Idling And/Missing

245

Symptom — High Engine Speed (no Drop)

247

Symptom — Engine Backfires-Lean Fuel Mixture

248

Symptom — Muffler Explosion (after Fire)-Rich Fuel Mixture-Misfire

250

Symptom — Engine Hesitates And/Or Poor Acceleration

252

Diagnosis System

254

«Check» Engine Warning Light Check

254

Output of Diagnostic Codes

254

Cancelling Diagnostic Code

256

Diagnosis Indication

256

Diagnostic Codes (5S-FE)

258

Diagnostic Codes (3S-GE)

260

Diagnostic Codes (3S-GTE)

262

Inspection of Diagnosis Circuit

264

Troubleshooting with Volt/Ohmmeter

265

Location of Fuses and Fusible Links

265

EFI System Check Procedure (5S-FE W/O ECT)

267

Terminals of Engine ECU

267

Voltage at Engine ECU Wiring Connectors (5S-FE W/O ECT)

268

Engine ECU Terminals

268

EFI System Check Procedure (5S-FE W/Ect)

282

Terminals of Engine and ECT ECU (5S-FE W/Ect)

282

Voltage at Engine and ECT ECU Wiring Connectors (5S-FE W/Ect)

283

Engine and ECT ECU Terminals

283

EFI System Check Procedure (3S-GE)

298

Terminals of Engine (and ECT) ECU (3S-GE)

298

Voltage at Engine (and ECT) ECU Wiring Connectors (3S-GE)

299

Engine (and ECT) ECU Terminals

299

W/Twc Only

313

EFI System Check Procedure (3S-GTE)

314

Terminals of Engine ECU (3S-GTE)

314

Voltage at Engine ECU Wiring Connectors (3S-GTE)

315

Fuel Pump

331

5S-FE and 3S-GE

331

On-Vehicle Inspection (5S-FE)

333

Check Fuel Pump Operation

333

Check Fuel Pressure

333

On-Vehicle Inspection (3S-GE and 3S-GTE)

336

Removal of Fuel Pump (2WD)

339

Remove Floor Service Hole Cover

339

Disconnect Fuel Pipe and Hose from Fuel Pump Bracket

340

Remove Fuel Pump Bracket Assembly from Fuel Tank

340

Disassembly of Fuel Pump

341

Assembly of Fuel Pump

341

Installation of Fuel Pump

342

Removal of Fuel Pump (4WD)

343

Remove Fuel Evaporation Bent Tube

343

Remove Fuel Pump from Fuel Pump Bracket

344

Remove Fuel Pump Filter from Fuel Pump

344

Install Fuel Pump Filter to Fuel Pump

344

Install Fuel Pump to Fuel Pump Bracket

344

Install Fuel Pump Bracket Assembly to Fuel Tank

345

Install Fuel Evaporation Bent Tube

345

Install Fuel Tank

345

Removal of Fuel Pump

346

Disconnect Cable from Negative Terminal of Battery

347

Disconnect Fuel Pump Connector and Fuel Sender Gauge Connector

347

Remove Parking Brake Intermediate Lever and No.1 Center Floor Crossmember

348

Disconnect A/C Hoses from Body

348

Disconnect Radiator Pipes from Body

348

Remove Fuel Tank Heat Insulators

348

Disconnect Fuel Hoses and Tube

349

Remove Fuel Tank

349

Remove Fuel Pump from Fuel Tank

349

Install Fuel Pump to Fuel Tank

351

Install Radiator Pipes to Body

351

Install A/C Hoses to Body

352

Install Parking Brake Intermediate Lever and No.1 Center Floor Crossmember

352

Connect Fuel Pump Connector and Fuel Sender Gauge Connector

352

Install Fuel Tank Heat Insulators

352

Cold Start Injector (5S-FE)

353

On-Vehicle Inspection

353

Inspect Resistance of Cold Start Injector

353

Remove Cold Start Injector Pipe

353

Inspection of Cold Start Injector

354

Inspect Injection of Cold Start Injector

354

Inspect Leakage

355

Installation of Cold Start Injector

355

Cold Start Injector (3S-GE)

356

Connect Cold Start Injector Pipe

358

Cold Start Injector (3S-GTE)

359

Fuel Pressure Regulator (5S-FE)

362

Removal of Fuel Pressure Regulator

362

Disconnect Vacuum Sensing Hose from Fuel Pressure Regulator

362

Disconnect Fuel Return Pipe from Fuel Pressure Regulator

362

Remove Fuel Pressure Regulator

363

Installation of Fuel Pressure Regulator

363

Connect Fuel Return Pipe to Fuel Pressure Regulator

363

Connect Vacuum Sensing Hose to Fuel Pressure Regulator

363

Fuel Pressure Regulator (3S-GE)

364

Fuel Pressure Regulator (3S-GTE)

366

Disconnect Fuel Inlet Hose from Delivery Pipe

366

Remove Injector Cover

367

Install Injector Cover

368

Connect Fuel Return Hose to Fuel Pressure Regulator

368

Connect Fuel Inlet Hose to Delivery Pipe

368

Injectors (5S-FE)

369

Inspect Injector Operation

369

Inspect Injector Resistance

369

Removal of Injectors

370

Remove Accelerator Brackets

370

Disconnect Engine Wire

370

Disconnect Fuel Return Hose from Return Pipe

370

Remove Delivery Pipe and Injectors

371

Inspect Injector Injection

372

Installation of Injectors

373

Install Injectors and Delivery Pipe

373

Connect Fuel Return Hose to Return Pipe

375

Connect Engine Wire

375

Connect Injector Connectors

375

Install Accelerator Brackets

375

Injectors (3S-GE)

376

Disconnect Hoses from Throttle Body and Air Intake Chamber

376

Disconnect Hoses from Air Pipe

377

Disconnect Connectors and Grand Strap

377

Remove Air Control Valve Assembly

378

Remove Cold Start Injector Pipe from Delivery Pipe

378

Inspection of Injectors

379

Connect Wire Harness Protector

381

Connect Four Injector Connectors

381

Install Cold Start Injector Pipe

382

Install Air Control Valve Assembly

382

Connect Connectors and Grand Strap

382

Connect Hoses to Air Pipe

382

Connect Hoses to Throttle Body and Air Intake Chamber

383

Injectors (3S-GTE)

385

Disconnect Injector Connectors

385

If Necessary, Replace Injectors

387

Air Flow Meter (3S-GTE Only)

390

Inspect Resistance of Air Flow Meter

390

Removal of Air Flow Meter

390

Remove Air Flow Meter from Air Cleaner Cap

391

Install Air Flow Meter to Air Cleaner Cap

391

Throttle Body (5S-FE W/O ECT)

392

Inspect Throttle Body

392

Inspect Throttle Position Sensor

392

Inspect Throttle Opener

393

Removal of Throttle Body

394

Disconnect Hoses from Throttle Body

394

Remove Throttle Body

395

Inspection of Throttle Body

395

Clean Throttle Body

395

Inspect Throttle Valve

395

If Necessary, Adjust Throttle Position Sensor

396

Installation of Throttle Body

397

Install Throttle Body

397

Connect Hoses to Throttle Body

397

Throttle Body (5S-FE W/Ect)

398

Throttle Body (3S-GE)

400

Throttle Body (3S-GTE)

404

Remove Air Connector

405

Remove Air Connector Stay

405

Install Air Connector Stay

407

Install Air Connector

408

Idle Speed Control (ISC) Valve (5S-FE)

409

Inspect ISC Valve Operation

409

Inspect ISC Valve Resistance

410

Removal of ISC Valve

410

Installation of ISC Valve

410

Idle Speed Control (ISC) Valve (3S-GE)

411

Remove ISC Valve

412

Install ISC Valve

412

Idle Speed Control (ISC) Valve (3S-GTE)

413

Location of Electronic Control Parts

415

ECU and Circuit Opening Relay

415

Other Control Parts (5S-FE)

415

Other Control Parts (3S-GE)

416

Other Control Parts (3S-GTE)

416

5S-Fe

417

3S-Gte

418

EFI Main Relay

419

Inspect Relay Continuity

419

Inspect Relay Operation

419

Circuit Opening Relay

420

Inspection of Circuit Opening Relay

420

Solenoid Resistor (3S-GTE Only)

421

Inspection of Solenoid Resistor

421

Cold Start Injector Time Switch

422

Inspection of Cold Start Injector Time Switch

422

Water Temperature Sensor

423

Inspection of Water Temperature Sensor

423

Fuel Pump Relay and Resistor (3S-GTE Only)

424

Inspection of Fuel Pump Relay and Resistor

424

Intake Air Temperature Sensor (5S-FE and 3S-GE Only)

425

Inspect Resistance of Intake Air Temperature Sensor

425

Vacuum Sensor (5S-FE and 3S-GE Only) (Manifold Absolute Pressure Sensor)

426

Inspect Power Source Voltage of Vacuum Sensor

426

Inspect Power Output of Vacuum Sensor

426

Variable Resistor (3S-GE (W/O TWC) Only)

427

Inspect Power Source Voltage of Variable Resistor

427

Inspect Power Output of Variable Resistor

427

Inspect Resistance of Variable Resistor

428

ACIS VSV (3S-GE Only)

429

Inspection of ACIS VSV

429

T-VIS VSV (3S-GTE Only)

431

Inspection of T-VIS VSV

431

EGR VSV (5S-FE and 3S-GTE Only)

433

Inspection of EGR VSV (5S-FE)

433

Inspection of EGR VSV (3S-GTE)

434

Turbocharging Pressure Sensor (3S-GTE Only)

435

Inspection of Turbocharging Pressure Sensor

435

Turbocharging Pressure VSV (3S-GTE Only)

436

Inspection of Turbocharging Pressure VSV

436

Oxygen Sensor (W/Twc Only)

438

Inspection of Oxygen Sensor

438

Inspect Feedback Voltage

438

Inspect Heater Resistance of Oxygen Sensor (3S-GE and 3S-GTE Only)

440

Engine (and ЕСТ) Electronic Controlled Unit (ECU)

441

Inspection of Engine (and ECT) ECU

441

Voltage at Engine ECU Wiring Connectors (5S-FE (W/O ECT))

442

Voltage at Engine (and ECT) ECU

443

Wiring Connectors (5S-FE (W/Ect))

443

Voltage at Engine ECU Wiring Connectors (3S-GE)

444

Resistance of Engine ECU Wiring Connectors (5S-FE W/O ECT)

446

Resistance of Engine ECU Wiring Connectors (5S-FE W/Ect)

447

Resistance of Engine ECU Wiring Connectors (3S-GE)

447

Resistance of Engine ECU Wiring Connectors (3S-GTE)

448

Fuel Cut RPM

449

Inspection of Fuel Cut RPM

449

Fuel Pressure Control System (3S-GE Only)

450

Inspection of Fuel Pressure Control System

450

Cooling System

452

Radiator

455

Radiator Cap

455

Reservoir Tank

455

Thermostat

455

Check and Replacement of Engine Coolant

457

Water Pump

458

Removal of Water Pump

458

Remove Alternator Belt Adjusting Bar (5S-FE)

459

Remove Idler Pulley Bracket (3S-FE, 3S-GTE)

459

Disconnect Oil Cooler Water By-Pass Hose (3S-GTE)

459

Remove Water Pump and Water Pump Cover Assembly

459

Separate Water Pump and Water Pump Cover

460

Inspection of Water Pump

460

Assemble Water Pump and Water Pump Cover

460

Connect Oil Cooler Water By-Pass Hose (3S-GTE)

462

Install Alternator Belt Adjusting Bar (5S-FE)

462

Install Idler Pulley Bracket (3S-GE, 3S-GTE)

462

Removal of Thermostat

463

Remove Alternator Bracket (3S-GE, 3S-GTE)

463

Remove Water Inlet and Thermostat

463

Inspection of Thermostat

463

Installation of Thermostat

464

Cleaning of Radiator

465

Inspection of Radiator

465

Electric Cooling Fans

466

System Circuit

466

Turn Ignition Switch «On»

467

Disconnect Water Temp. Switch Connector

467

Connect Water Temp. Switch Connector

467

Start Engine

467

Inspect No.1 Water Temp. Switch

468

Inspect No.2 Water Temp. Switch (3S-GE EUROPE)

468

Inspect No.1 Cooling Fan Relay

468

Inspect No.2 Cooling Fan Relay (3S-GE EUROPE)

468

Inspect Engine Main Relay

469

Inspect Cooling Fan

469

Check Engine Coolant Level at Reserve Tank

472

Check Engine Coolant Quality

472

Replacement of Engine Coolant

473

Engine Coolant Circuit

473

Drainage of Engine Coolant

474

Refill of Engine Coolant

475

Set Service Hoses

475

Fill with Engine Coolant

475

Water Pump Components

478

Install Water Pump and Water Pump Cover Assembly

480

Inspect Thermostat

482

Place Thermostat in Water Pump

483

Install Water Inlet

483

Inspect Radiator (Water Filler) Cap

484

Inspect Cooling System for Leaks

484

Removal of Radiator

485

Remove Upper Radiator Support Seal

485

Disconnect Radiator Hoses

486

Remove Front Hood Lock

486

Remove Radiator and Cooling Fans

486

Remove No.1 and No.2 Cooling Fans from Radiator

486

Install No.1 and No.2 Cooling Fans to Radiator

487

Install Radiator and Cooling Fans

487

Install Front Hood Lock

488

Connect Radiator Hoses

488

Install Upper Radiator Support Seal

488

Install Front Luggage under Covers

488

Radiator Cooling Fans (W/A/C)

489

Location of Radiator Cooling Fan Components

489

Disconnect Radiator Water Temperature Sensor Connector

490

Inspect A/C Amplifier for Circuit

490

Inspect No.1 Cooling Fan Relay («Fan No.1»)

491

Inspect No.2 Cooling Fan Relay («Fan No.2»)

491

Inspect No.3 Cooling Fan Relay («Fan No.3»)

492

Inspect Radiator Water Temperature Sensor

492

Inspect No.1 and No.2 Radiator Cooling Fans

492

Removal of Radiator Cooling Fans

493

Disconnect Radiator Cooling Fan Connectors

493

Remove Radiator Cooling Fans

493

Remove Fan

494

Remove Fan Motor

494

Assembly of Radiator Cooling Fans

494

Install Radiator Cooling Fans

495

Radiator Cooling Fan (W/O A/C)

496

Disconnect Water Temperature Switch Connector

497

Inspection of Radiator Cooling Fan Components

497

Inspect Radiator Water Temperature Switch

497

Inspect No.1 Radiator Cooling Fan

498

Engine Compartment Cooling Fan (3S-GTE)

499

Location of Engine Compartment Cooling Fan Components

499

Disconnect Engine Compartment Temperature Sensor Connector

500

Connect Engine Compartment Temperature Sensor Connector

500

Inspection of Engine Compartment Cooling Fan Components

501

Inspect Cooling Fan ECU for Circuit

501

Inspect Engine Compartment Temperature Sensor

501

Inspect Engine Compartment Cooling Fan

501

Removal of Engine Comparment Cooling Fan

502

Disassembly of Engine Compartment Cooling Fan

503

Installation of Engine Compartment Cooling Fan

504

Lubrication System

505

Oil Pump

508

Oil Pressure Regulator

508

Oil Filter

508

Oil Pressure Check

509

Check Oil Quality

509

Check Engine Oil Level

509

Check Oil Pressure

510

Install Oil Pressure Gauge

510

Replacement of Engine Oil and Oil Filter

511

Drain Engine Oil

511

Replace Oil Filter

511

Fill with Engine Oil

512

Removal of Oil Pump

513

Remove Stiffener Plate

513

Disconnect Turbocharger Oil Outlet Hose from Oil Pan (3S-GTE)

513

Remove Oil Pan

514

Remove Oil Strainer and Baffle Plate

514

Remove Oil Pump

514

Disassembly of Oil Pump

515

Remove Relief Valve

515

Remove Drive and Driven Rotors

515

Inspection of Oil Pump

516

Inspect Relief Valve

516

Inspect Drive and Driven Rotors

516

Replacement of Oil Pump Oil Seal

517

Install Drive and Driven Rotors

517

Install Relief Valve

517

Install Oil Pump

518

Install Baffle Plate and Oil Strainer

518

Install Oil Pan

518

Connect Turbocharger Oil Outlet Hose to Oil Pan (3S-GTE)

519

Install Stiffener Plate

519

Oil Cooler (5S-FE, 3S-GE) Components

520

Removal of Oil Cooler

520

Remove Water By-Pass Hose Heat Protector (5S-FE)

520

Disconnect Water By-Pass Hoses from Oil Cooler

521

Remove Oil Cooler

521

Inspect Oil Cooler

521

Install Oil Cooler

522

Connect Water By-Pass Hoses

522

Install Water By-Pass Hose Heat Protector (5S-FE)

522

Oil Cooler (3S-GTE) Components

523

Disconnect Water By-Pass Hose from Oil Cooler

523

Remove Oil Cooler Bracket

524

Inspection of Oil Cooler

524

Installation of Oil Cooler

525

Install Oil Cooler Bracket

525

Connect Water By-Pass Hose to Oil Cooler

526

Disconnect Oil Dipstick Guide from Water Inlet

528

Install Oil Dipstick Guide to Water Inlet

531

Oil Nozzles (3S-GTE) Components

532

Removal of Oil Nozzles

532

Inspection of Oil Nozzles

532

Installation of Oil Nozzles

532

Ignition System

533

Ignition System Circuit

536

Electronic Spark Advance (ESA)

536

Spark Test

537

Check that Spark Occurs

537

Disconnect High-Tension Cords from Spark Plugs

538

Inspect High-Tension Cord Resistance

538

Inspection of Spark Plugs (Conventional Type)

539

Inspection of Spark Plugs (Platinum Tipped Type)

540

Inspect Electrode Gap

541

Clean Spark Plugs

541

Inspection of Ignition Coil

542

Inspect Primary Coil Resistance

542

Inspect Secondary Coil Resistance

542

Inspection of Distributor

543

Inspect Air Gap

543

Inspect Signal Generator (Pickup Coil) Resistance

544

Distributor Components

545

Install Distributor

546

Starting System

547

Starting System Circuit

548

Starter Components

549

Disassembly of Starter

550

Remove Field Frame and Armature

550

Remove Starter Housing, Clutch Assembly and Gears

550

Remove Steel Ball

550

Remove Brush Holder

551

Remove Armature from Field Frame

551

Inspection and Repair of Starter

551

Inspect Commutator for Dirty and Burnt Surface

551

Inspect Commutator for Runout

552

Inspect Undercut Depth

552

Inspect Field Coil for Open Circuit

552

Inspect Field Coil for Ground

552

Inspect Brush Length

553

Inspect Brush Spring Load

553

Inspect Gear Teeth

553

Inspect Clutch Pinion Gear

553

If Necessary, Replace Clutch Assembly

554

Inspect Bearings

556

If Necessary, Replace Bearings

556

Perform Pull-In Coil Open Circuit Test

556

Perform Hold-In Coil Open Circuit Test

556

Assembly of Starter

557

Place Armature into Field Frame

557

Install Brush Holder

557

Insert Steel Ball into Clutch Shaft Hole

557

Install Clutch Assembly and Gears

558

Install Field Frame and Armature Assembly

558

Perform Pull-In Test

560

Perform Hold-In Test

560

Inspect Plunger Return

560

Perform No-Load Performance Test

560

Charging System

561

Charging System Circuit

562

Inspect Battery Specific Gravity and Electrolyte Level

563

Check Battery Terminals, Fusible Links and Fuses

563

Inspect Drive Belt

563

Visually Check Alternator Wiring and Listen for Abnormal Noises

564

Inspect Charge Warning Light Circuit

564

Inspect Charging Circuit Without Load

565

Inspect Charging Circuit with Load

565

Alternator Components

566

Disassembly of Alternator

567

Remove Air Duct (3S-GTE)

567

Remove Rear End Cover

567

Remove Brush Holder and IC Regulator

567

Remove Rectifier Holder

568

Remove Pulley

568

Remove Rectifier End Frame

569

Remove Rotor from Drive End Frame

569

Inspection and Repair of Alternator

570

Rotor

570

Stator (Drive End Frame)

570

Inspect Exposed Brush Length

571

If Necessary, Replace Brushes (5S-FE M/T)

571

Inspect Positive Rectifier

571

Inspect Negative Rectifier

572

Inspect Front Bearing

572

If Necessary, Replace Front Bearing

572

Всем доброго времени суток! ٩(●●)۶

Спасибо, что зашли на мою страницу и обратили внимание на мой автомобиль!

Я бы Вас попросил нажать «Нравится» и поделиться моими записями с Вашими подписчиками но это строго противоречит правилам сайта drive2.ru так, что сделать я этого не могу но буду очень благодарен))! (⊙_⊙)

Знаю, что в интернете полно мануалов по автомобилям:

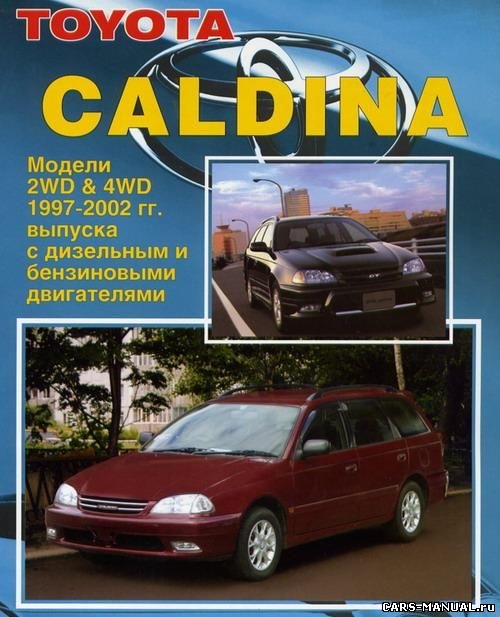

Toyota Caldina c 1997-2002

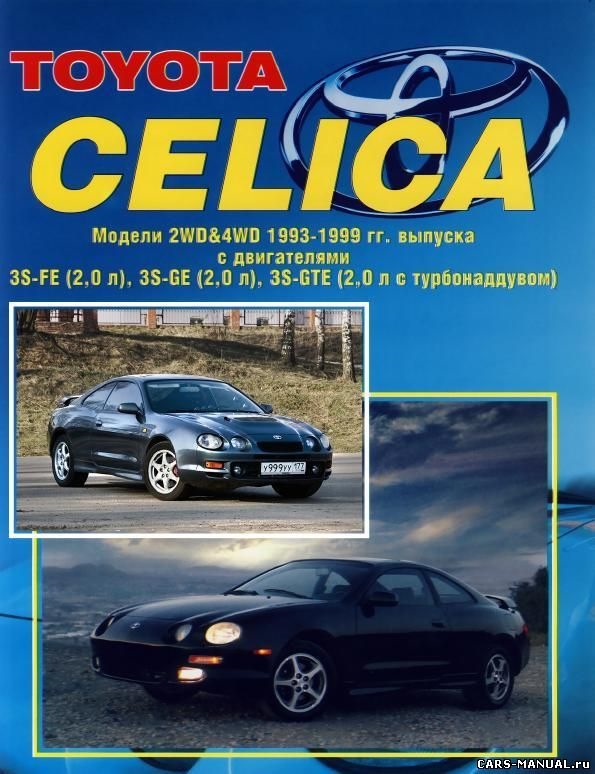

Toyota Celica c 1993-1999

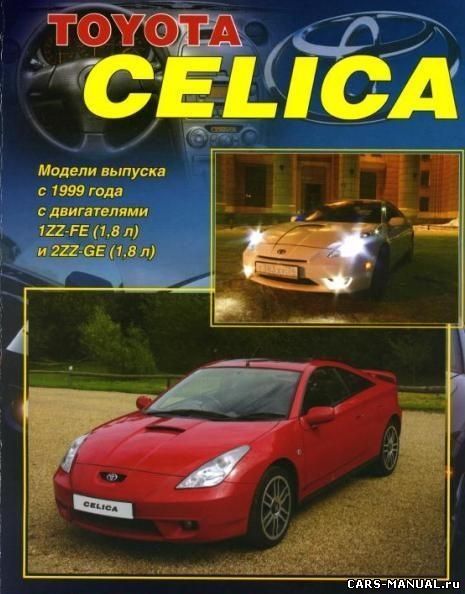

Toyota Celica с 1999

Но они все на английском языке или же просто напросто платные от 400рублей и выше!

Не справедливо это всё)

Выкладываю ссылки на книги и буду очень благодарен если Вам понравится данная запись!

Репост так же приветствуется всё таки проделан не малый труд по поиску)))

ССЫЛКИ НА СКАЧИВАНИЕ ПОД КАРТИНКАМИ!

Toyota Celica c 1993-1999

TOYOTA CELICA (1993-1999) Руководство по ремонту, эксплуатации и техническому обслуживанию

vk.com/doc38663475_406261853

Toyota Celica с 1999

TOYOTA CELICA Руководство по ремонту, эксплуатации и техническому обслуживанию

vk.com/doc38663475_407106739

Toyota Caldina c 1997-2002

TOYOTA CALDINA (1997-2002) Руководство по эксплуатации, техническому обслуживанию и ремонту

vk.com/doc38663475_407104996

Всем мир!

33 Мб

-

Год:

2013

-

Страниц:

185

-

Формат:

pdf

-

Язык:

русский

-

Размер:

33 Мб

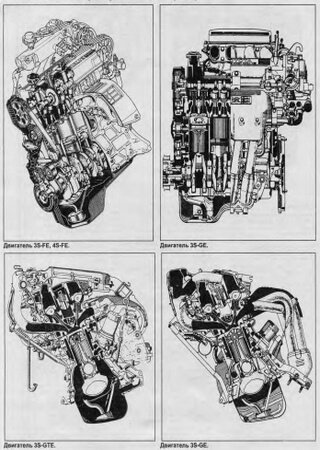

Руководство по ремонту двигателей Toyota 3S-FE, 3S-GE, 3S-GTE, 4S-Fi, 4S-FE и 5S-FE Скачать Бесплатно

Скачать33 Мб

ПОКАЗАТЬ ВСЕСВЕРНУТЬ

Toyota 3S-GTE: List of Available Documents

Note for Owners:

Guidesimo.com webproject is not a service center of Toyota trademark and does not carries out works for diagnosis and repair of faulty Toyota 3S-GTE equipment. For quality services, please contact an official service center of Toyota company. On our website you can read and download documentation for your Toyota 3S-GTE device for free and familiarize yourself with the technical specifications of device.

More Engine Devices:

-

Saito FG-21

Φ32.0mm 26.0mm 20.9cc15”x8“~16”x6”・Filterwithweight[G36-154] ・DurabletubeforGasoline(1m)[G36-155] ・Aluminumspinnernut[100-30]・Tappetadjustingkit[30-161] ・Digitaltachometer[G17-167]Bore Body:690g/Muffler:83g/Ignitionsystem:100g/Enginemount:156gStroke Disp. Weight(Approx.)RPMRan …

FG-21 Engine, 2

-

Zenoah G230PU

OWNER’S MANUALMODEL : G230PU — for AirplaneG230PUH — for HelicopterG230PUM — for BoatG230PUG230PUHG230PUMApril 20021155-93110(204)• Do not modify any parts of the engine.• This engine is designed to be used to Radiocontrolled products.• In case any modification by customer, KOMATSUZENOAH shall not bear any responsibility fromthe damage caused by such modification.• Keep ignition syst …

G230PU Engine, 4

-

Siemens MASTERDRIVES MC 1FK7

VLPRGULYHPDVWHUGULYHV&RQILJXUDWLRQ0DQXDO(GLWLRQ).6QFKURQRXV0RWRUV6,02’5,9(0$67(5’5,9(60& …

MASTERDRIVES MC 1FK7 Engine, 166

-

Parker 3Z Series

WARNINGThis product can expose you to chemicals including lead and DEHP, which are known to the State of California to cause cancer, and birth defects or other reproductive harm. For more information go to www.p65warnings.ca.govHY13-1597-01/US3Z Motor Series Service ProcedureEective: September20203ZGLowSpeed,HighTorqueHydraulicMotors …

3Z Series Engine, 24

Recommended Documentation:

Toyota Manuals and Guides:

The main types of Toyota 3S-GTE instructions: user guide — rules of useing and characteristics, service manual — repair, diagnostics, maintenance, operation manual — description of the main functions of Toyota 3S-GTE equipment, etc.

Most of the instructions, that you can see on the site are uploaded by our users. If you have available a manual or document for Toyota 3S-GTE, which is currently not on the site or present in a different language version, we ask you to upload your document on website, using the «uploading form» available to all registered users.