руководство по ремонту

У кого-нибудь есть эл вариант книги «Mitsubishi Pajero IV. Модели с 2006 года выпуска с бензиновыми двигателями 6G72 (3,0) и 6G75 (3,8). Включая рестайлинговые модели с 2010 года выпуска. Руководство по ремонту и техническому обслуживанию» ?

Комментарии

17

Войдите или зарегистрируйтесь, чтобы писать комментарии, задавать вопросы и участвовать в обсуждении.

Есть ссылка на авто с бензиновым 6G75 и дизельным 4M41. И отдельная ссылка на движки 6G72. Интересует в таком наборе?

Zurabchik

Есть ссылка на авто с бензиновым 6G75 и дизельным 4M41. И отдельная ссылка на движки 6G72. Интересует в таком наборе?

спасибо

решил тоже глянуть, вдруг что интересно … порадовало название «модели с 2006 года выпуска с бензиновым 6G75 и дизельным 4M41. Устройство техническое обслуживание и ремонт», про 6G72 ни слова ! в него и лазить не надо и не ломается 🤘🤣

Ведь реально, в нем масла/фильтра/свечи/ремни меняй и будет ходить долго и счастливо)да и схожи они с 6G75)

AMAXSPB

решил тоже глянуть, вдруг что интересно … порадовало название «модели с 2006 года выпуска с бензиновым 6G75 и дизельным 4M41. Устройство техническое обслуживание и ремонт», про 6G72 ни слова ! в него и лазить не надо и не ломается 🤘🤣

все просто, на момент выпуска книги, 6G72 в России официально не продавался )) во втором издании книги он уже есть 😉

Да и в этой книге косяк, представлен 6g75 с гидрачами на впуске😐. А на некотрых картинках вообще с другим коллектором.

Угу, у меня 2е издание, там уже все правильно и даже бензин и дизель по разным книгам разделили, чтоб холивара не было 😂

Почему у меня такой нет ? Делись

Вот, только бумага, только хардкор 😆

Amorphis

Угу, у меня 2е издание, там уже все правильно и даже бензин и дизель по разным книгам разделили, чтоб холивара не было 😂

Если есть ссылочка, я бы тоже не отказался)

Увы, в электронном варианте не встречал 🤷🏻♂️

Все комментарии

-

Vad

- Сообщения: 1668

- Зарегистрирован: 03 сен 2003, 12:03

- Откуда: г.Волжский,Волгоградская область

- Благодарил (а): 1 раз

- Поблагодарили: 2 раза

Руководство по ремонту 6G72

Есть у кого в электронном виде Руководство по ремонту 6G72 24 клапана?

Pajero-II,97г,МКПП,SS,5дв,6G72(24 кл),демпфер ProComp,лифт 2″,шноркель Safari,

BFG 33х12.5х15 MUD,СВ Alan 48 Exсel,COME UP 9000

Subaru Tribeca B9

Квадрик СF Moto 500

-

Mossy

- Сообщения: 150

- Зарегистрирован: 29 авг 2009, 12:42

- Двигатель:: 6G72

- Мой автомобиль(и):: MPS GLS АКПП 2000 — (продан), Outlander XL 2,4i (2008).

- Откуда: ЯНАО, Надым [89]

- Поблагодарили: 1 раз

Re: Руководство по ремонту 6G72

Сообщение

Mossy » 20 сен 2010, 21:38

MPS 3.0 GLS 6G72 АКПП 2000г. — (продан)

Outlander XL 2,4i АКПП 2008г.

-

DenVer

- Модератор

- Сообщения: 19700

- Зарегистрирован: 29 сен 2009, 16:21

- Двигатель:: бэнзин

- Мой автомобиль(и):: TLC-200

- Откуда: Краснодар

- Благодарил (а): 132 раза

- Поблагодарили: 471 раз

Re: Руководство по ремонту 6G72

Сообщение

DenVer » 23 сен 2010, 19:09

-

Vad

- Сообщения: 1668

- Зарегистрирован: 03 сен 2003, 12:03

- Откуда: г.Волжский,Волгоградская область

- Благодарил (а): 1 раз

- Поблагодарили: 2 раза

Re: Руководство по ремонту 6G72

Сообщение

Vad » 23 сен 2010, 20:48

спасибки

Pajero-II,97г,МКПП,SS,5дв,6G72(24 кл),демпфер ProComp,лифт 2″,шноркель Safari,

BFG 33х12.5х15 MUD,СВ Alan 48 Exсel,COME UP 9000

Subaru Tribeca B9

Квадрик СF Moto 500

Mitsubishi Pajero Mark II (V20) руководство по ремонту и техническому обслуживанию с бензиновыми двигателями V6: 6G72 12V/24V SOHC 3.0 л (2972 см³) 148-150-152-185 л.с./109-110-112-136 кВт и 6G74 24V SOHC/DOHC 3.5 л (3497 см³) 189-194-208 л.с./139-143-153 кВт; Инструкция по эксплуатации, каталог запасных частей, технические характеристики, 117 электросхем и 31 система, характерные неисправности, проверка и замена, моменты затяжки, техобслуживание, периодичность, объемы и жидкости диагностика — 64 кодов dtc/5 систем, устройство, особенности конструкции. Производственно-практическое издание легковой автомобиль повышенной проходимости Мицубиси Паджеро полноразмерный рамный внедорожник с кузовами пяти- и трехдверный универсал повышенной вместимости полноприводные модели второго поколения выпуска с 1991 по 2000 год

ЕСЛИ ВЫ ВИДИТЕ ОШИБКУ 406 Not Acceptable и не видите документ, то скорей всего у Вас IP РФ и его надо сменить, на любой другой страны, с помощью VPN ( Scribd и SlideShare блокируют посетителей с Российским IP).

Видео Mitsubishi Pajero mk2 замена передних: тормозных дисков, подшипников ступицы и наконечников рулевой рейки (Мицубиси Паджеро 91-00)

Mitsubishi Pajero Mark II общая информация (Мицубиси Паджеро 1991-2000)

РЫЧАГИ И ТЯГИ РУЛЕВОГО УПРАВЛЕНИЯ

СНЯТИЕ И УСТАНОВКА

Последовательность снятия:

1. Боковая рулевая тяга в сборе

2. Внешний наконечник боковой тяги

3. Внутренний наконечник боковой тяги

4. Регулировочная муфта

5. Защитный чехол шарового шарнира

6. Демпфер рулевого управления

7. Средняя рулевая тяга

8. Маятниковый рычаг в сборе

9. Маятниковый рычаг

10. Защитный чехол шарового шарнира

11. Опора маятникового рычага

Заключительные операции:

• Проверка и регулировка углов установки колес (Регулировка схождения).

ОСНОВНЫЕ ОПЕРАЦИИ ПО СНЯТИЮ

1. ОТСОЕДИНЕНИЕ БОКОВОЙ РУЛЕВОЙ ТЯГИ

Внимание

1. Для предотвращения отскакивания съемника, необходимо предварительно привязать его шнуром.

2. Не отворачивайте полностью гайку с пальца шарового шарнира.

7. ОТСОЕДИНЕНИЕ СРЕДНЕЙ РУЛЕВОЙ ТЯГИ

«Со стороны рулевой сошки»

Внимание

1. Для предотвращения отскакивания съемника, необходимо предварительно привязать его шнуром.

2. Не отворачивайте полностью гайку с пальца шарового шарнира.

«Со стороны маятникового рычага»

С помощью специального инструмента и молотка снимите среднюю тягу с маятникового рычага.

Внимание

Не отворачивайте полностью гайку с пальца шарового шарнира.

9. СНЯТИЕ МАЯТНИКОВОГО РЫЧАГА

С помощью специального приспособления (пресс с верстаком) снимите маятниковый рычаг.

Внимание

Не отворачивайте полностью гайку с пальца шарового шарнира.

ПРОВЕРКА

МОМЕНТ НАЧАЛА ВРАЩЕНИЯ ШАРОВОГО ШАРНИРА

Номинальные значения:

Наконечник боковой рулевой тяги: 1 – 3 Нм

Маятниковый рычаг: 0.5 – 2.0 Нм

МОМЕНТ НАЧАЛА ВРАЩЕНИЯ МАЯТНИКОВОГО РЫЧАГА

Номинальное значение: 0.3 – 2.0 Нм (2.3 – 15.4 Н)

ОСНОВНЫЕ ОПЕРАЦИИ ПО УСТАНОВКЕ

4. Установка регулировочной муфты

3. Установка внутреннего наконечника боковой тяги

2. Установка внешнего наконечника боковой тяги

1. Установите наконечники и регулировочную муфту боковой тяги.

ПРИМЕЧАНИЕ

На рисунке показана левая боковая рулевая тяга в сборе. Правая боковая рулевая тяга собирается симметрично. (2) Поворотом регулировочной муфты отрегулируйте расстояния «a» и «b» так, чтобы разница между ними была 1.5 мм или меньше, после чего предварительно затяните контргайки регулировочной муфты.

ПРИМЕЧАНИЕ

Окончательная затяжка контргаек проводится после установки боковых рулевых тяг в сборе на автомобиль и регулировки схождения передних колес.

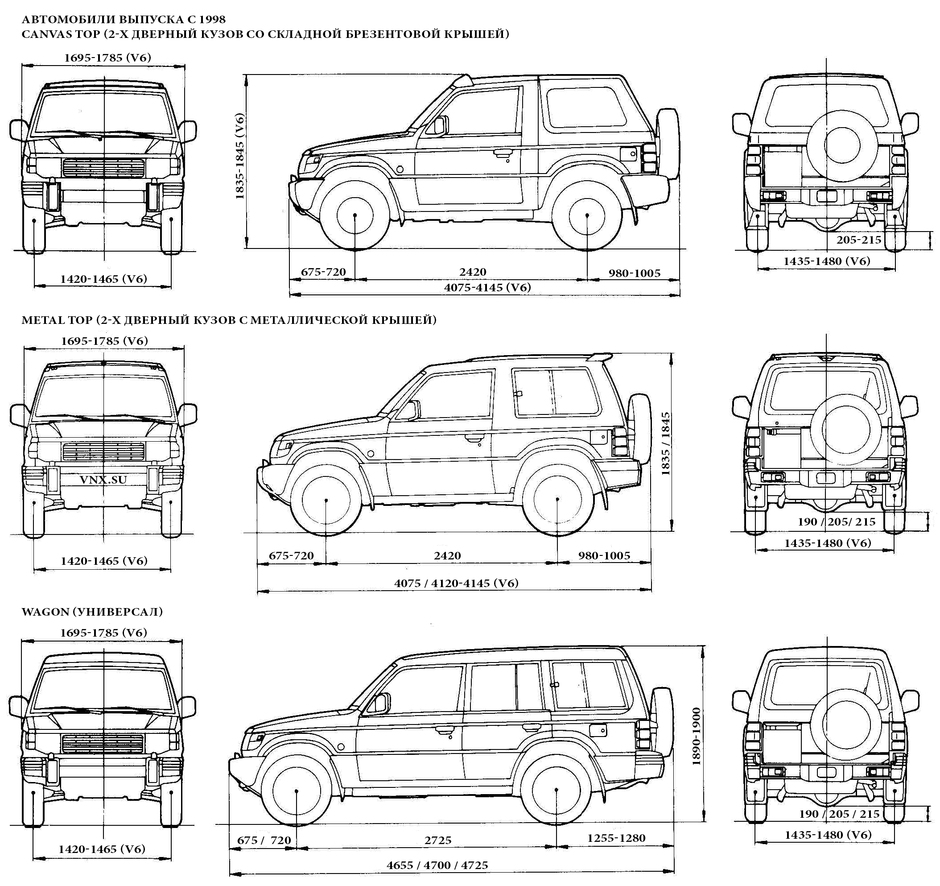

| № | Спецификация / Specs | Данные |

| Габариты (мм/mm) и масса (кг/kg) / Dimensions and Weight | ||

| 1 | Длина / Length | 4145 с запасным колесом |

| 2 | Ширина (без/с зеркалами) / Width | 1785 |

| 3 | Высота (загружен/пустой) / Height | 1845 |

| 4 | Колёсная база / Wheelbase | 2420 |

| 5 | Дорожный просвет (клиренс) / Ground clearance | 215 |

| 6 | Снаряжённая масса / Total (curb) weight | 1800-1925 (в зависимости от комплектации) |

| Полная масса / Gross (max.) weight | 2510 | |

|

Двигатель / Engine |

||

| 7 | Тип / Engine Type, Code | Бензиновый, жидкостного охлаждения, четырехтактный, 6G74 |

| 8 | Количество цилиндров / Cylinder arrangement: Total number of cylinders, of valves | 6-цилиндровый, V-образный, 24V, DOHC с верхним расположением двух распределительных валов |

| 9 | Диаметр цилиндра / Bore | 93.0 мм |

| 10 | Ход поршня / Stroke | 85.8 мм |

| 11 | Объём / Engine displacement | 3497 см³ |

| 12 | Система питания / Fuel supply, Aspiration | Распределенный впрыск топлива MPI |

| Атмосферный | ||

| 13 | Степень сжатия / Compression ratio | 9.5:1 |

| 14 | Максимальная мощность / Max. output power kW (HP) at rpm | 153 кВт (208 л.с.) при 5000 об/мин |

| 15 | Максимальный крутящий момент / Max. torque N·m at rpm | 300 Нм при 3000 об/мин |

|

Трансмиссия / Transmission |

||

| 16 | Сцепление / Clutch type | 250×160 мм Однодисковое, сухое, с диафрагменной нажимной пружиной и гасителем крутильных колебаний, постоянно замкнутого типа |

| 17 | КПП / Transmission type | V5M31 МКПП 5 пятиступенчатая механическая, двухвальная, с синхронизаторами на всех передачах переднего хода, с двухступенчатой раздаткой и блокировкой межосевого дифференциала |

О Книге

- Название: Mitsubishi Pajero II Руководство по ремонту и техническому обслуживанию

- Бензиновые двигатели: 6G72 12V/24V SOHC 3.0 л (2972 см³) 148-150-152-185 л.с./109-110-112-136 и 6G74 24V SOHC/DOHC 3.5 л (3497 см³) 189-194-208 л.с./139-143-153 кВт

- Выпуск с 1991 года

- Серия: «Профессионал»

- Год издания: 2015

- Автор: Коллектив авторов

- Издательство: «Ассоциация независимых издателей»

- Формат: PDF

- Страниц в книге: 411

- Размер: 674.86 МБ и 115.21 МБ оптимизированный

- Язык: Русский

- Количество электросхем: 117

ENGINE6672

CONTENTS

BRACKET ………………………………………………………. 122

CAMSHAFT, ROCKER ARMS ANDBEARING CAPS ……………………………………………. 87

CRANKSHAFT, FLYWHEEL ANDDRIVE PLATE ……….. . …………………………………….. 115

CYLINDER HEAD AND VALVES — SOHC …….. 91

CYLINDER HEAD AND VALVES — DOHC …….. 98EXHAUST MANIFOLD …………………………………. 67

GENERAL INFORMATION … ……………………….. 2

GENERAL SPECIFICATIONS ………………………. 12

GENERATOR AND DRIVE BELT …………………… 27

IGNITION SYSTEM ……………………… . ……………. 44

INTAKE MANIFOLD AND FUEL PARTS …….. 62

INTAKE MANIFOLD PLENUM ANDTHROTTLE BODY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

OIL PAN AND OIL PUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

PISTON AND CONNECTING ROD . . . . . . . . . . . . . . . . . . . . 108

ROCKER ARMS AND CAMSHAFTS . . . . . . . . . . . . . . . . 77

SEALANT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23. . . . . . . . . . .SERVICE SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

THROTTLE BODY . . . . . . . . . . . . . . . . . . . . . . . …*….. . . . . . . . . . . . . . 37. . .

TIMING BELT — SOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

TIMING BELT- DOHC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

TORQUE SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

TURBOCHARGER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

‘HE-2 6G7 ENGINE — General Information

GENERAL INFORMATIONSECTIONAL VIEW — SOHC ENGINE for DIAMANTE

7EN0323

TSB Revision

6G7 ENGINE — General Information llE-3

TEN0324

1% Revis ion

IIE-4 6G7 ENGINE — General Information

SECTIONAL VIEW — SOHC ENGINE for MONTERO AND TRUCK

TSB Revision7EN0135

I

667 ENGINE — General Information

TSB Revision

7EN0120

I

WE-6 6G7 ENGINE — General Information

SECTIONAL VIEW — DOHC NON-TURBO ENGINE

TSB Revision

7EN0325

IIE-8 6G7 ENGINE — General Information

SECTIONAL VIEW — DOHC TURBO ENGINE

1 TSB Revision

7EN0335

667 ENGINE — General Information IIE-9

TSB Revision

7EN0334

IIE-10 6G7 ENGINE — General Information

JJBRICATION SYSTEM — SOHC

/

Oil pressureswitch

n t

Oil pressuregauge unit

Oil cooler by-passvalve — MONTERO only

RockeLash adjuster

7LUOO34

TSB Revision

667 ENGINE — General Information llE41

UBRICATION SYSTEM — DOHC

Toturbo-

Oil pressure switch charger

-turboonly

is

Oil pressuregauge unit

Las

To oil cooler -Turbo only

II

Oil cooler by-passvalve -Turbo only

Relief valve

TSB Revision

WE-12 6G7 ENGINE — General Specifications

GENERAL SPECIFICATIONSSOHC

Description Specifications

Type 6O”V, SOHC (per bank)Number of cylinders 6Combustion chamber Compact typeTotal displacement cm3 (cu.in.1 2,972 (181.4)Cylinder bore x stroke mm (in.) 91 .I x 76.0 (3.59 x 2.99)Compression ratio

Front wheel drive vehicle 10.0Rear wheel drive vehicle 8.9

Valve timing: Front wheel driveIntake valve

Opens 16” BTDCCloses 66” ABDC

Exhaust valveOpens 56” BBDCCloses 26” ATDC

Valve timing: Rear wheel driveIntake valve

Opens 19” BTDCCloses 59” ABDC

Exhaust valveOpens 59” BBDCCloses 19” ATDC

Lubrication system Pressure feed, full-flow filtration3il pump type Trochoid typeCooling system Water-cooled forced circulation

JVater pump type Centrifugal impeller type

EG R type Single typenjector type and number Electromagnetic, 6njector identification mark For MONTERO and TRUCK B210H

For DIAMANTE and TRUCK N21 OHThrottle bore mm (in.) 60 (2.362)rhrottle position sensor Variable resistor typeIosed throttle position switch Movable contact type

TSB Revision

667 ENGINE — General Specifications

DOHC

Description

TypeNumber of cylindersCombustion chamberTotal displacement cm3 (cu.in.1Cylinder bore x stroke mm (in.)Compression ratio Non-turbo

TurboValve timing-Non-turbo

Intake valve

OpensCloses

Exhaust valveOpensCloses

Valve timing -Turbo

Intake valve

OpensCloses

Exhaust valve

OpensCloses

Lubrication systemOil pump typeCooling systemtiater pump typeEGR typeInjector typenjector identification mark Non-turbo

TurboThrottle bore mm (in.)Throttle position sensorClosed throttle position switch

Specifications

6O”V. DOHC (per bank)6Compact type2,972 (181.4)91.1 x 76.0 (3.59 x 2.99)10.08.0

16” BTDC55” ABDC

48” BBDC15” ATDC

16” BTDC55” ABDC

50” BBDC17” ATDCPressure feed, full-flow filtrationTrochoid typeWater-cooled forced circulationCentrifugal impeller typeSingle type

Electromagnetic, 6BDH210BDL36060 (2.362)Variable resistor typeMovable contact type

1 TSB Revision I

IIE-14 6G7 ENGINE — Service Specifications

SERVICE SPECIFICATIONSmm (in.)

Standard Limit

Cylinder head — SOHCFlatness of gasket surface Less than 0.05 (.0019) 0.2 (.008)

Grinding limit of gasket surface *0.2 (.008)

* Total resurfacing depth of bothcylinder head and cylinder block

Overall height 84 (3.31)Oversize rework dimensions of valve guide hole(both intake and exhaust)

0.05 (.002) 13.05- 13.07 (.5138- .5147)0.25 (.OlO) 13.25 — 13.27 (5217 — .5224)0.50 (.020) 13.50 — 13.52 (.5315 — .5323)

Oversize rework dimension of valve seat holeIntake 0.3 (.012) 44.30 — 44.33 (1.7441 — 1.7453)

0.6 (.024) 44.60 — 44.63 (1.7559 — 1.7571)

Exhaust 0.3 (.012) 38.30 — 38.33 (1.5079 — 1.5091)0.6 (.024) 38.60 — 38.63 (1.5197 — 1.5209)

Cylinder head — DOHCFlatness of gasket surface Less than 0.03 (.0012) 0.2 (.008)Grinding limit of gasket surface “0.2 (008).* Total resurfacing depth of both

cylinder head and cylinder block3verall height 132 (5.20)Dversize rework dimensions of valve guide holeIboth intake and exhaust)

0.05 (.002) 12.05 — 12.07 (.4744- .4752)0.25 (.OlO) 12.25 — 12.27 (4823 — .4831)0.50 (.020) 12.50 — 12.52 l.4921 — .4929)

3versize rework dimension of valve seat holeIntake 0.3 (.012) 36.30 — 36.33 (1.4291 — 1.4303)

0.6 (.024) 36.60 — 36.63 (1.4409 — 1.4421)Exhaust 0.3 (.012) 33.30-33.33(1.3110-1.3122)

0.6 (.024) 33.60 — 33.63 (1.3228 — 1.3240)

Camshaft- SOHCZam height

Intake 41.25 (1.6240) 40.75 (1.6043)Exhaust 41.25 (1.6240) 40.75 (1.6043)

lournal diameter 34 (1.34)Iii clearance 0.05 — 0.09 (.0020 — .0035)dentification mark for DIAMANTE

for MONTERO and TRUCK !

TSB Revision

667 ENGINE — Service SDecifications

mm (in.)

Camshaft — DOHCCam height

Intake

Exhaust

Journal diameterOil clearance

Rocker arm — SOHCI.D.Rocker arm-to-shaft clearance

Rocker shaft — SOHC3.D.Dverall length

Valve — SOHC3verall length

IntakeExhaust

jtem diameterIntakeExhaust

-ace anglestem-to guide clearance

IntakeExhaust

-hickness of valve head (Margin)IntakeExhaust

lalve — DOHCIverall length

IntakeExhaust

item diameterIntakeExhaust

ace angleitem-to guide clearance

IntakeExhaust

hickness of valve head (Margin)IntakeExhaust

Standard

35.49(1.3972)*‘,34.91 (1.3744)**

35.20(1.3858)*’,34.91 (1.3744)*’

26(1.02)0.05-0.09(.020-.0035)

18.91 -18.93(.7445-.7453)0.01 -0.04(.0004-.0016)

18.89-18.90 (.7437-.7441)333.5(13.130)

102.97 (4.0539)102.67 (4.0421)

7.96-7.98(.3134-.3142)7.93-7.95 (.3122-.3130)45″-45.5″

0.03-0.06(.0012-.0024)0.05-0.09(.0020-.0035)

1.2 (.047)2.0 i.079)

106.28(4.1842)105.40(4.1496)

6.57-6.58(.2587-.2591)6.53-6.55(.2571 -.2579)45″-45.5″

0.02-0.05(.0008-.0020)0.05-0.09 (.0020-.0035)

1 .o l.039)1.5 (.059)

Limit

34.99(1.3776)*’34.41 (1.3547)»‘34.70 (1.3661)»‘34.41 (1.3!%7)»2

0.10(.004)’

.

0.10 (.0039)0.15 (.0059)

0 . 7 (.028)1 . 5 (.059)

0.10 i.0039)0.15 i.0059)

0.5(.019)1 .o i.039)

NOTE*I = Up to 1992 models“2 = from 1993 models

TSB RevisionI

IIE-16 667 ENGINE — Service SDecifications

mm (in.)

Standard Limit

Valve spring — SOHCFree length 49.8 (1.961) 48.8 (1.921)

Load/Installed height N/mm (Ibs./in.) 329/40.4 (725/l .591)Out-of-squareness Less than 2” 4”

Valve spring — DOHCFree length 45.2 (1.780)*‘, 46.4 (1.827)“’ 44.2 (1.740)*’

45.4 (1.787)“’Load/installed height N/mm (Ibs.in.1 240/37.9 (52.911.492)Out-of-squareness Less than 2” 4”

Valve guide — SOHCOverall length

Intake 44 (1.73)Exhaust 48 (1.89)

I.D. 8.00 — 8.02 i.315 — .316)O.D. 13.06- 13.07 (.5142-.5146)Service size 0.05 (.002), 0.25 LO1 0)

0.50 (.020) Oversize

Valve guide — DOHCOverall length

IntakeExhaust

I.D.O.D.Service size

45.5(1.791)50.5 (1.988)6.60 — 6.62 (.2598 — .2607)12.06 — 12.07 (.4748 — .4752)0.05 (.002), 0.25 LO1 0)0.50 (.020) Oversize

Valve seatSeat anglevalve contact widthSinkageService size

Piston — SOHC3.D.‘iston-to-cylinder clearanceService size

44- 44.5”0.9 — 1.3 (035 — ,051)

0.30 (.012), 0.60 t.024) Oversize

91 .I (3.587)0.02 — 0.04 (.0008 — .0016)0.25 (.OlO), 0.50 (.020)0.75 (.030), 1 .OO l.039) Oversize

0.2

‘iston — DOHC3.D.‘iston-to-cylinder clearanceService size

91 .I (3.587)0.02 — 0.04 (.0008 — .0016)0.25 LOlO), 0.50 f.020)0.75 (.030), 1 .OO (039) Oversize

NOTEO.D. = Outer DiameterI.D. = Inner Diameter*I = Up to 1992 models“2 = From 1993 models

1 TSB Revision

6G7 ENGINE — Service Specifications ,llE-17mm (in.)

Piston ring — SOHCEnd gap

No. 1 ringNo. 2 ring

Front wheel drive vehicleRear wheel drive vehicle

Oil ringFront wheel drive vehicleRear wheel drive vehicle

Ring to ring groove clearanceNo.1 ring

Front wheel drive vehicleRear wheel drive vehicle

No.2 ring

Piston ring — DOHCEnd gap

No. 1 ringNo. 2 ringOil ring

?ing to ring groove clearanceNo. 1 ringNo. 2 ring

‘iston pinI.D.‘Tess-in load N (Ibs.)‘Tess-in temperature

Connecting rod3ig end center-to-small end center length3end‘wistjig end side clearance

Crankshaft!nd playournal O.D.‘in O.D.jut-of-roundness of journal and pin

Two-camshaft engineFour-camshaft engine

aper of journal and pin)il clearance of journal)il clearance of pin

NOTEO.D. = Outer Diameter

Standard

0.30-0.45(.0118-.0177)

0.45 — 0.60 (.0177 — .0236)0.25 — 0.45 LOO98 — .0177)

0.20 — 0.60 LOO79 — .0236)0.20 — 0.70 (.0079 — .0276)

0.03 — 0.07 LOOI 2 — .0028)0.05 — 0.09 (0020 — .0035)0.02 — 0.06 (.0008 — .0024)

0.30 — 0.45 (.0118 — .0177)0.45 — 0.60 (.0177 — .0236)0.20 — 0.70 (.0079 — .0276)

0.03 — 0.07 (.0012 — .0028)0.02 — 0.06 (.0008 — .0024)

22.001 — 22.007 (8662 — .8664)75.00 — 175.00 (1,653 — 3,858)Room temperature

Limit

0.8 (.031)

0.8 (.031)0.8 (.031)

‘I .o (.039)1 .o (.039)

0.1 (004)0.1 (004)0.1 (.004)

0.8 (.031)1 .o (.039)1 .o (039)

0.1 (.004)0.1 (.004)

140.9- 141 .o0.05 (0020) or less0.1 (004) or less0.10 — 0.25 (.0039 — .0098)

0.05 — 0.25 (0020 — .0098)60 (2.36)50 (I .97)

Less than 0.005 (.0002)Less than 0.003 (.OOOl)Less than 0.005 (.0002)0.020 — 0.050 t.0008 — .0020)0.020 — 0.050 (0008 — .0020)

0.4 (.016)

0.3 (.012)

0.1 (.004)0.1 (.004)

1 TSB Revision

IIE-18 6G7 ENGINE — Service SDecifications

mm (in.)

Cylinder blockCylinder boreFlatness of gasket surfaceGrinding limit of top surface* Total resurfacing depth of both

cylinder head and cylinder block

Standard

91.1 (3.587)0.05 (.002)

Limit

“0.2 (.008)

Oil pumpTip clearance 0.03 — 0.08 (0012 — .0031) 0.35 (0138)Side clearance 0.04-0.10 (.0016- .0039)Body clearance 0.10 — 0.18 (0040 — .0070)

Drive belt — SOHC for DIAMANTEDeflection

New belt 4.0-5.0(.157-,197)Used belt 7.0 (276)

Tension gauge N (Ibs.)New belt 700 — 900 (154 — 198)Used belt 500 (I IO)

Drive belt — SOHC for MONTERO and TRUCKDeflection

New belt 6.5 — 8.0 (.256 — ,315)Used belt 9.0 (.354)

Tension gauge N (Ibs.)New belt 500-700(110-154)Used belt 400 (88)

Irive belt — DOHCIeflection

New belt 3.5-4.0(.138-,157)Used belt 4.0-5.0(.157-,197)

rension N (Ibs.)New belt 650 — 850 (143 — 187)Used belt 450 — 500 (99 — 132)

njectorZoil resistance

Non-turbo R 13 — 16 at 20°C (68°F)T u r b o R 2 — 3 at 20°C (68°F)

dle air control motorIoil resistance R 28 — 33 at 20°C (68°F)

-hrottle position sensortesistance kS1 3.5 — 6.5

rccelerator pedal position sensorlesistance kR 3.5-6.5

‘ariable induction control motor(esistance fi 5 — 35 at 20°C (68°F)

TSB Revision

667’ ENGINE — Torque Specifications

TORQUE SPECIFICATIONS

Generator and drive beltCooling fan bolt

Nm

11

ftlbs.

8 .<Fan pulley bolt 11 8Tensioner pulley nut

SOHC DIAMANTE, DOHC 50 36SOHC MONTERO AND TRUCK 45 33

Tensioner bracket boltSOHC DIAMANTE 42 30SOHC MONTERO AND TRUCK Ml0 24 17.

Ml2 42 30DOHC 19 14 ,,.’

Idler pulley bolt ,’

SOHC MONTERO AND TRUCK 45 33DOHC 50 36

Cooling fan bracket bolt 42 30Tensioner bracket stay bolt 24 17Generator pivot nut 23 17Generator brace bolt .F-’

SOHC DIAMANTE 14 IOSOHC MONTERO AND TRUCK- Side bolt 10 7

— Exhaust manifold tightening side bolt 13 9Generator bracket bolt 24 17

45 33lrankshaft bolt SOHC 155 122

DOHC 185 134.

ntake manifold plenum and throttle bodyiGR pipe bolt 18 13ntake manifold plenum stay bolt 18 13!GR valve bolt 22 16-hrottle body bolt 12 8

SOHC MONTERO AND TRUCK 14 10gnition coil bolt 2.5 1.8gnition power transistor bolt 5 3.6

-hrottle body‘hrottle position sensor bolt 2 1.4Ye air control motor bolt 3.5 2.5

SOHC DIAMANTE DOHC Non-TURBO 2.5 1.8ccelerator pedal position sensor bolt 2 1.4‘acuum actuator bolt 3.5 2.5

1 TSB Revision

IIE-20 6G7 ENGINE — Torque Specifications

Ignition systemCenter cover boltSpark plugDistributor nut

Ignition coil boltSOHC MONTERO AND TRUCKDOHC

Ignition power transistor boltDIAMANTE3000GT

Crankshaft position sensor nut

Timing belt — SOHCEngine support bracket bolt Ml0

Ml2Tensioner lock boltCamshaft sprocket boltZenerator stay bolt3enerator bracket bolt

riming belt — DOHC

Engine support bracket bolt Ml0Ml2

ZrankshaftKamshaft position sensor bolts4uto tensioner boltrensioner pulley boltrensioner arm assembly boltdler pulley boltdler pulley bracket boltjocker cover boltCamshaft sprocket bolt

ntake manifold and fuel partsnjector and fuel rail bolt:uel regulator boltpressure-uel pipe boltleat pipe boltngine coolant temperature gauge unitngine coolant temperature sensor

SOHC DIAMANTEhermo switchdater outlet fitting boltltake manifold nutJater inlet fitting bolthermostat housing bolt

. .

N m ft.Ibs.

3 225 1814 10

25 1813 9

22 1613 912 7

60 43110 8029 1990 6525 1825 18

70 ‘51110 809 724 1749 3542 3055 4042 303 290 65

12 99 79 712 930 2211 88 68 619 1418 1319 1419 14

—

ITSB Revision 1

6G7 ,ENGlNE — Torque Specifications

Exhaust manifoldOil level guide boltgauge

Heat protector boltEngine hanger bolt

SOHC DIAMANTESOHC MONTERO AND TRUCKDOHC NON-TURBO

Exhaust manifold nut

SOHCDOHC NON-TURBODOHC TURBO

Heater pipe boltdater pipe bolt

SOHC MONTERO AND TRUCKdater boltpump

ieat protector CTurbocharger stay boltixhaust fitting bolt3il pipe bolteye

Yare nutNater pipe eye boltXl return pipe bolt

rurbocharger‘urbocharger waste gate actuator bolt

locker arms and camshafts — SOHC>il filler boltlocker cover boltIistributor adaptor boltlocker arm shaft and bearing cap bolt

Camshafts, rocker arms and bearing caps- DOHClrankshaft position sensor adaptor boltlearing caps, front and rear boltrearing cap bolts No. 2, 3,4

lylinder head and valve- SOHC:ylinder head bolt

:ylinder head and valve — DOHC:ylinder head bolt

NON-TURBOTURBO

Nm ft.lbs.

14 1014 10

24 1719 1413 9

19 1445 3330 2212 914 1012 924 1730 2260 4314 1017 1225 1831 229 7

12 9

9 79 713 920 14

24 1720 1411 8

110 80

110 80125 + Back off 90 + Back off+ 125 .—* 90

TSB Revision I

11 E-22 667 ENGINE — Torque Specifications

Nm ft.lbs.

Oil pan and oil pumpTransmission stay bolt 75 54

Oil pressure switchDIAMANTE AND 3000GT 19 14

MONTERO AND TRUCK IO 7

Oil pressure gauge unitDIAMANTE AND 3000GT 10 7MONTERO 55 40

Oil cooler by-pass valve 55 40

Oil filter bracket stay bolt (10×20) 23 17(8×20) 13 IO

Oil filter bracket boltDIAMANTE AND 3000GT 24 17MONTERO AND TRUCK mark 4 24 17

mark 7 14 10Drain plug 40 29Oil boltpan 6 4Oil screen bolt 19 14Plug 45 33Oil case boltpump 14 10Oil cover boltpump 10 7

Piston and connecting rodConnecting rod cap nut 52 38

Crankshaft, flywheel and drive plate+wheel bolt 75 54Irive plate bolt 75 543ear plate bolt 11 83ell housing cover bolt 9 73il seal case bolt 11 83earing cap stay bolt 48 353earing cap bolt — SOHC 79 57

DOHC 93 671993 models DOHC -TURBO 74 54

knock sensor bracket bolt 29 21knock sensor 23 17

BracketKnock sensor — DIAMANTE and 3000GT 23 17knock sensor bracket bolt — DIAMANTE and 3000GT 29 21loll stopper bracket — M 10 42 30

Ml2 75 54

TSB Revision

667 ENGINE — Sealant

SEALANT ‘”,. )

Items Specified sealant

Auto tensioner bolt -Turbo 3M ATD Part No. 8660Engine coolant temperature sensor 3M NUT Locking Part No.41 71Engine coolant temperature gauge unit 3M ATD Part No.8660Rocker cover 3M ATD Part No.8660Bearing cap 3M NUT Locking Part No.41 71Oil pressure switch 3M ATD Part No.8660Oil pressure gauge unit 3M ATD Part No.8660Oil pan MITSUBISHI GENUINE Part No.MD970389Oil seal case MITSUBISHI GENUINE Part No.MD970389

Quantity

As requiredAs requiredAs requiredAs requiredAs requiredAs requiredAs requiredAs requiredAs required

,

TSB Revision

11 E-24 6G7 ENGINE — SDecial Tools

SPECIAL TOOLS

MD99871 9 orSOHC engine only

Leak-down tester

Air bleed wire

Camshaft oilseal installer

For SOHC engine only

ton and timing beltFor SOHC engine only

TSB Revision

8G7 ENGINE — Special Tools

Tool Number andtool name

Supersession

MD99871 7Crankshaftfront oil sealinstaller

IMD99871 8Crankshaftrear oil sealinstaller

MD998719Pulley holdingpins (2)

MD998727Oil panremover

M D998729Valve stemseal installer

MD998735Valve springcompressor

M D998754Pulley holdingpins (2)

MD998761 MD998761-01Camshaft oilseal installer

M D998762Circular packinginstaller

MD99871 7-01

MD998718-01Use with MB990938,01

MIT308239

MD998735-01

M IT308239

IInstallation of crankshaft rear oil seal

iolding camshaft sprocket when looseningx torquing bolt-or SOHC engine only

fqemoval of oil pan

nstallation of valve stem seal:or SOHC engine only

lemoval and installation of valve and re-jted parts

l-lolding crankshaft sprocket when loosen-irlg or torquing bolt

lstallation of camshaft oil sealor DOHC engine only

Application

Installation of crankshaft front oil seal

M D998762-01 Installation of circular packingFor DOHC engine only

TSB Revision

11 E-26 6G7 ENGINE — Special Tools

seal installer

compressor

Installation of flywheel

TSB Revision

667 ENGINE — Generator and Drive Belt

GENERATOR AND DRIVE BELTREMOVAL AND INSTALLATION — SOHC for DIAMANTE

1 3

2

30 ft.lbs.

il7

155 Nm112 ft.lbs.

23 Nm

8 I14 Nm10 ft.lbs.

Removal steps+A4 I. Drive belt

2. Tensioner pulley3. Adjusting bolt4. Adjusting stud5. Tensioner bracket6. Pivot bolt7. Generator8. Generator brace

QArJ +B4 9. Crankshaft bolt10. Special washer11. Crankshaft pulley

7EN0487

1 TSB Revision I

IIE-28 6G7 ENGINE — Generator and Drive Belt

tEMOVAL AND INSTALLATION — SOHC for MONTERO and TRUCK

1213 Nm9 ftlbs.

I

IIONm7 ftlbs.

Removal steps

13 Nm9 ftlbs.

13

1. Drive belt2. Cooling fan3. Fan clutch4. Fan pulley5. Idler pulley6. Tensioner pulley7. Adjusting bolt8. Adjusting stud9. Tensioner bracket0. Cooling fan bracket assembly1. Tensioner bracket stay2. Generator brace3. Generator4. Crankshaft bolt5. Special washer6. Crankshaft pulley

7EN0488

TSB Revision

6G7 ENGINE — Generator and Drive Belt

IEMOVAL AND INSTALLATION i DOHC

23 Nm17 ft.lby

24 Nm17 ftlbs.

24 Nm17 ft.lbs.

I

4 8 I45 Nm33 ft.lbs.

50 Nm2

36 klbs. 50 Nm

I165 Nm134ft.lbs.

Removal steps#A4 1. Drive belt

2. Idler pulley3. Tensioner pulley4. Adjusting bolt5. Adjusting stud6. Tensioner bracket7. Generator8. Generator bracket9. Bracket

(IA(J #64 IO. Crankshaft bolt11. Special washer12. Crankshaft pulley

7EN0489

TSB Revision

WE-30 6G7 ENGINE — Generator and Drive Belt

SOHC for DIAMANTE

NTERO and TRUCK

DOHC IOON

7EN0349

REMOVAL SERVICE POINT(JAO CRANKSHAFT BOLT LOOSENING(1) Using the special tool, hold the drive plate or flywheel.(2) Remove the crankshaft bolt.

INSTALLATION SERVICE POINT#A4 DRIVE BELT TENSION ADJUSTMENTDRIVE BELT — TENSION CHART

Generatordrive belt

SOHC for NewDIAMANTE USed

SOHC for NewMONTERO USedand TRUCK

DOHC NewUsed I

Deflectionmm (in.) I

TenEo;bt;uge

4.5 (.16-.20) 700-900(154-198)

7 l.28) 500 (110)

6.5-8.0(.26-.32) 500-700(110-154)9(.35) 400(88)

3.5-4.0(.14-.16) 650-850(143-187)4-5(.16-.20) 450-600(99-132)

TSB Revision

(1) Loosen the tensioner pulley locking nut.(2) Tighten the adjusting bolt to adjust the belt deflectbn to the

specification shown in the chart.

6G7 ENGINE — Generator and Drive Belt

SOHC for DIAMANTE-

wgaugeTension’ w7EN0399

SOHC for MONTERO and TRUCK

7EL0070

DOHC

(3) If you use a tension gauge, tighten the adjusting bblt toadjust the belt tension to the specification shown in thechart.

.:.

I)B4 CRANKSHAFT BOLT TIGHTENING(1) Using the special tool, hold the drive plate or flywheel.(2) Install the crankshaft bolt.

TSB Revision 1

11 E-32 6G7 ENGINE — Intake Manifold Plenum and Throttle Body

INTAKE MANIFOLD PLENUM AND THROTTLE BODYREMOVAL AND INSTALLATION — SOHC for DIAMANTE

8

18 Nm12 Nm8 ft.lbs.

I5Nm3.6 ft.lbs.

22 Nm16 ftlbs.

18Nm13 ft.lbs.

Removal steps1. EGRpipe2. Ignition coil

For California

3. High tension cable4. Intake manifold plenum stay, rear5. Intake manifold plenum stay, front6. EGR valve7. EGR valve aasket 1 For California8. Throttle body9. Throttle body gasket

10. Ignition power transistor11. Intake manifold plenum12. Intake manifold plenum gasket

7EN0405

TSB Revision

6G7 ENGINE — Intake Manifold Plenum and Throttle Body

IEMOVAL AND INSTALLATION — SOHC for MONTERO and TRUCK

14 Nm10 ft.lbs.

tr- 18 Nm13 ft.lbs.

18 Nm

Removal steps1. EGR pipe2. EGR pipe gasket I For California

3. Intake inariifold plenum stay, rear4. Intake manifold plenum stay, front5. EGR valve6. EGR valve gasket > For California

7. Throttle body8. Throttle body gasket9. Intake manifold plenum

10. Intake manifold plenum gasket

22 Nm16 ft.lbs.

7EN0408

TSB Revision

11 E-34 6G7 ENGINE — Intake Manifold Plenum and Throttle Body

{EMOVAL AND INSTALLATION — DOHC NON-TURBO

612 Nm8 ft.lbs.

I

8Nm3 ftlbs.

22 Nm16 ft.lbs.

18Nm13 ft.lbs.

318Nm13 ftlbs.

Removal steps1. EGR pipe For California2. Intake manifold plenum stay, rear3. Intake manifold plenum stay, front5. EGR valve6. EGR valve gasket I

For California

7. Throttle body8. Intake manifold plenum9. Intake manifold plenum gasket

Cb,18Nm13 fklbs.

TSB Revision

7EN0411

IEMOVAL AND FUEL SYSTEM — DOHC TURBO

m2-?& 18hm13 ftlbs. 18Nm

13 ft.lbs.

Removal steps1. EGRpipe2. EGR pipe gasket j For California

3. Intake manifold plenum stay, rear4. Intake manifold plenum stay, front5. EGR valve6. EGR valve aasket I For California

7. Throttle bo?iy8. Throttle body gasket9. Intake manifold plenum

10. Intake manifold plenum gasket

18 Nm13 ftlbs.

6G7 ENGINE — Intake Manifold Plenum and Throtiib B’ijdy qq-ps5

1 TSB Revision II . 1

11 E-36 6G7 ENGINE — Intake Manifold Plenum and Throttle Body

6EM0384

INSPECTIONEGR VALVE(1) Check the EGR valve for sticking or carbon deposits.

If such conditions exist, clean or replace the EGR valve.(2) Connect a hand vacuum pump to the nipple of the EGR

valve and plug other nipple.(3) If there is vacuum leakage, replace the EGR valve.(4) Blow air in from one passage of the EGR to check its

condition as follows.

TSB Revision

THROTTLE BODY

667 ENGINE — Throttle Body n-E-37

DISASSEMBLY AND REASSEMBLY — SOHC for DIAMANTE, DOHC NON-TURBO

2Nin1.4ft.lbs.

2.5 Nm1.8 ft.lbs.

Disassembly stepsQArJ +A4 1. Throttle position sensor

2. Idle air control [email protected] 3. Throttle body

7FU1282

DISASSEMBLY AND REASSEMBLY — For VEHICLES with TRACTION CONTROL

!Nm1.4 ft.lbs.-

4I ii+—

3.5 Nm2.5 ftlbs.

3.5 Nm2.5 ft.lbs.

5

Disassembly steps1. Water hose

#B4 6. Throttle body

1.4 ft.lbs.

sensor

7FU1283

TSB Revision

11 E-38 6G7 ENGINE — Throttle Body

DISASSEMBLY AND REASSEMBLY — DOHC TURBO

Disassembly steps

Up to 1992 models3. Vacuum valve4. Dash pot- From 1993 models

(IAO )A4 5. Throttle position sensor6. Idle air control motor

0 7. Throttle body

DISASSEMBLY AND REASSEMBLY — SOHC for MONTERO and TRUCK

3

I n

1

cz!J/T’Disassembly stepsOAO )B4 1. Throttle position sensor

(Within closed throttle position switch)2. Idle air control motor assembly3. Throttle body

3.5 Nm2.5 ftlbs.

2Nm1.4 ft.lbs.

1 TSB Revision7FUO532

I

6G7 ENGINE — Throttle Body

DISASSEMBLY SERVICE POINTSOAo THROlTLE POSITION SENSOR, ACCELERATOR

PEDAL POSITION SENSOR AND IDLE AIR CONTROLMOTOR REMOVAL

(1) Do not d’rsassemble the sensor and motor.(2) Do not clean the sensor and motor by dipping them into the

solvent. Clean them with shop towel.

7FU105i

(%r) THROlTLE BODY REMOVAL(1) Do not remove the throttle valve.(2) Check if the vacuum port or passage is clogged. Use

compressed air to clean the vacuum passage.

INSPECTIONDASH POT — DOHC TURBOUp to 1992 models(1) Push the rod of the dash pot all the way in and close the

nipple with the fingers,(2) If the rod does not protrude after releasing it, the dash pot is

functioning normally.(3) If the rod protrudes, a broken diaphragm is suspected.

Therefore, replace the dash pot.

From 1993 models(1) Push the dash pot rod in lightly and confirm the resistance.

NOTE1. Resistance increases as the rod is pushed harder.2. If the rod can be pushed in with no resistance, either

the diaphragm or check valve is faulty.(2) Release finger and confirm that the rod returns to its

original position quickly.NOTEIf the rod returns slowly, the check valve is faulty.

TSB Revision

IIE-40 6G7 ENGINE — Throttle Bodv

6EM069

Red

M D9984637FUO29(

Idle airmot01

MD998463 7FUOO71

VACUUM VALVE — DOHC TURBOUp to 1992 models(1) Remove the filter from the vacuum valve.(2) Connect a hand vacuum pump to the black nipple of the

vacuum valve.(3) With the other nipple closed by the finger, apply a negative

pressure of 500 mmHg (19.7 in.Hg.) to make sure that thenegative pressure is maintained.

(4) Let go your finger and make sure that the negative pressureleaks out gradually.

(5) Disconnect the hand vacuum pump and connect it to thegreen nipple.

(6) Make sure that the negative pressure leaks out as soon as itis applied.

(7) Remove the hand vacuum pump from the valve.(8) Install the filter onto the black nipple of the valve.

IDLE AIR CONTROL MOTORChecking the Coil Resistance(1) Connect Test Harness to the motor connector.(2) Measure the resistance between the white clip of Test

Harness and the red clip or blue clip.

Standard value: 28 — 33 LR at 20°C (68°F)

(3) Measure the resistance between the green clip of TestHarness and the yellow clip or black clip.

Standard value: 28 — 33 LR at 20°C (68°F)

Operational Check(1) Connect Test Harness to the idle air control motor

connector.(2) Connect the positive 0 terminal of 6 volt battery to the

white clip and the green clip of Test Harness.

1 TSB Revision I

6G7 ENGINE — Throttle Body 1 gs41

7FUO29f

w “’7FUlb3Z

I

(3) Hold the idle air control motor as shown in the illustration,connect the negative 0 terminal of the power supply toeach clip as described in the following steps, and checkwhether or not a vibrating feeling (a feeling of very slightvibration of the stepper motor) is generated as a result ofthe activation of the stepper motor.

@ Connect the negative 0 terminal of the power supply tothe red and black clip.

@ Connect the negative 0 terminal of the power supply tothe blue and black clip.

@ Connect the negative 0 terminal of the power supply tothe blue and yellow clip.

@ Connect the negative 0 terminal of the power supply tothe red and yellow clip.

@ Connect the negative 0 terminal of the power supply tothe red and black clip.

@ Repeat the tests in sequence from @ to 0.(4) If, as a result of these tests, vibration is detected, the

stepper motor can be considered to be normal.

CHECKING VACUUM ACTUATOR- VEHICLES with TRACTION CONTROL

(1) With the throttle valve opened, apply a vacuum of 200mmHg (7.9 in.Hg.) to the vacuum actuator to make surethat the throttle valve closes.

(2) Then lower the level of vacuum gradually to make sure thatthe vacuum actuator opens.

REASSEMBLY SERVICE POINTSI)A4 THROTTLE POSITION SENSOR (TPS)

INSTALLATION — SOHC for DIAMANTE, DOHC(1) Install the throttle position sensor to the throttle body as

shown in the illustration.

(2) Turn the throttle position sensor 90” clockwise to set it, andtighten the screws.

TSB Revision

11 E-42 6G7 ENGINE — Throttle Bodv

Throttle positionGround

I

Throttle positionsensor output

Closed throttleposition switch

7FU053E

7FUO53:

I I I 7FUO53L

Ground

Throttle positionsensor outmt

Closed throttleposition switch

Throttle positionsensor power

7FU053E

(3) Connect a circuit tester between 4 (ground) and 2 (output),or between 2 (output) and 1 (power). Then, make sure thatthe resistance changes smoothly when the throttle valve isslowly moved to the fully open position.

(4) Check for continuity across terminals 3 (closed throttleposition switch) and 4 (ground) with the throttle valve bothfully closed and fully open.

Throttle valve position

Fully closed

Continuity

Conductive

Fully open I Non-conductive I

If there is no continuity with the throttle valve fully closed,turn TPS counterclockwise, and then check again.

NOTESome throttle position sensors are not provided with theposition switch. In that case, the check described in step (4)cannot be accomplished.

(5) If the above specifications are not met, replace TPS.

I)B4 ;rNHslA~-EP$tSITION SENSOR (TPS)

— SOHC for MONTERO and TRUCK(1) Install the throttle position sensor to the throttle body as

shown in the illustration.

(2) Turn the throttle position sensor 90” counterclockwise toset it, and tighten the screws.

!I(3) Connect a circuit tester between @ (ground) and @

(output), or between @ (output) and @ (power). Then,make sure that the resistance changes smoothly when thethrottle valve is slowly moved to the fully open position.

(4) Check for continuity across terminals @ (closed throttleposition switch) and @ (ground) with the throttle valve bothfully closed and fully open.

TSB Revision 1

6G7 ENGINE — Throttle Body w43

7FU1071

7FU107:

Closed throttle Accelerator

pedal positionsensor output 7~~053~

)r”““-’If there is no continuity with throttle valve fully closed, turnthe throttle position sensor clockwise, and then checkagain.

(5) If the above specifications are not met, replace TPS.

I)c4 ACCELERATOR PEDAL POSITION SENSOR (APS)INSTALLATION

(1) Install the accelerator pedal position sensor to the throttlebody as shown in the illustration.

(2) Turn the accelerator pedal position sensor 90” clockwise toset it, and tighten the screws.

(3) Connect a circuit tester between (ground) and (output), orbetween (output) and (power). Then, make sure that theresistance changes smoothly when the throttle valve isslowly moved to the fully open position.

(4) Check for continuity across terminals (closed throttleposition switch) and (ground) with the throttle valve bothfully closed and fully open.

Throttle valve position Continuity

Fully closed Conductive

Fully open Non-conductive

If there is no continuity with the throttle valve fully closed,turn APS counterclockwise, and then check again.

(5) If the above specifications are not met, rep!ace APS.

1 TSB Revision

11 E-44 6G7 ENGINE — Ignition System

IGNITION SYSTEMSOHC for DIAMANTE

25 Nm18 ft.lbs.

Removal steps1. Spark plug cables2. Spark plug3. Distributor4. O-ring

7EN0406

TSB Revision I

6G7 ENGINE — Ignition Svstem

;OHC for MONTERO AND TRUCK

25 Nm18 ft.lbs.

Removal steps1. Spark plug cables2. Spark plugs3. High tension cable

*A4 4. Distributor5. O-ring6. Ignition coil

7EN0409

TSB RevisionI

11 E-46 667 ENGINE — Ignition System

IOHC for DIAMANTE AND 3000GT

13 Nm9 ft.lbs.

Removal steps1. Center cover2. Spark plug cables3. Soark oluas4. Ciamp’ um From5. Ignition

1993coil

models

6. Engine hanger7. Ignition power transistor- DIAMANTE

eB48. ignition power transistor _ 3000GT9. Crankshaft position sensor- Up to 1992 models

10. O-ring7EN0492

I

IL I1 TSB Revision

6G7 ENGINE — Ignition Svstem WE-47

INSTALLATION SERVICE POINTSI)A4 DISTRIBUTOR INSTALLATION — SOljC(1) Turn the crankshaft so that the No. 1 cylinder is at

compression top dead center.(2) Align the distributor housing and gear mating marks.(3) With the stud located in the center of the adjusting slot at

the distributor, install the distributor.

Mating mark7FI OOWi I

I)B4 ;;RAFKSHAFT POSITION SENSOR INSTALLATION —

(1) Turn the crankshaft so that the No. 1 cylinder is atcompressi,on top dead center.

(2) Install, lining up the matchmarks on the crankshaft positionsensor housing and the coupling.

TSB Revision

11 E-48 6G7 ENGINE — Timing Belt — SOHC

TIMING BELT — SOHCREMOVAL AND INSTALLATION — DIAMANTE

110 Nm80 ftlbs.

4F

6

I26 Nm19 ft.lbs.

Removal steps+D4 1. Engine support bracket

2. Access cover3. Timing belt front upper cover, right4. Timing belt cover cap5. Timing belt front upper cover, left6. Timing belt front lower cover7. Flange

4AO &CC 8. Timing beltiB4 9. Tensioner

10. Tensioner spring11. Crankshaft sprocket

QBrJ #A4 12. Camshaft sprocket bolt13. Camshaft sprocket14. Timing belt rear cover, left15. Timing belt rear cover, right

7EN0493

TSB Revision

6G7 ENGINE — Timing Belt — SOHC

IEMOVAL AND INSTALLATION — MONTERO AND TRUCK

11 Nm8 ftlbs.

25 Nm 1418 ft.lbs. I

19 ft.lbs.

4Removal steps

1. Access cover2. Timing belt front upper cover, right3. Timing belt front upper cover, left4. Timing belt front lower cover5. Flange

@IO #C4 6. Timing belteB4 7. Tensioner

8. Tensioner spring9. Crankshaft sprocket

(IBIJ +A4 10. Camshaft sprocket bolt11. Camshaft sprocket12. Timing belt rear upper cover, left13. Generator stay14. Generator bracket

7EN0494

TSB Revision

WE-50 6G7 ENGINE — Timing Belt — SOHC

MB990775-01

EJG000 008

,

REMOVAL SERVICE POINTS(IAO TIMING BELT REMOVAL(1) Mark the belt running direction for reference in reinstalla-

tion.

NOTE(1) Water or oil on the belt shortens its life drastically, so

the removed timing belt, sprocket, and tensioner mustbe kept free from oil and water. Do not immerse parts incleaning solvent.

(2) If there is oil or water on any part, check the front caseoil seal, camshaft oil seal and water pump for leaks.

~BI) CAMSHAFT SPROCKET BOLT REMOVAL

Abnormal wear(Fluffy strand)

INSPECTIONTIMING BELTReplace belt if any of the following conditions exist.

(1) Hardening of back rubber-back side is glossy withoutresilience and leaves no indent when pressed with finger-nail.

(2) Cracks on rubber back(3) Cracks or peeling of canvas(4) Cracks on tooth bottom(5) Cracks on belt

(6) Abnormal wear of belt sides. The sides are normal if theyare sharp as if cut by a knife.

TSB Revision

6G7 ENGINE — Timing Belt — SOHC

Rubber exposed

Tooth missing andcanvas fiber exposed

01w70:

(7) Abnormal wear on teeth(8) Tooth missing and canvas fiber exposed.

INSTALLATION SERVICE POINTS+A4 CAMSHAFT SPROCKET BOLT INSTALLATION

I)B4 TIMING BELT TENSIONER INSTALLATION(1) Insert a screwdriver into the hole of the timing belt

tensioner arm, move it all the way in the direction of thearrow, and tighten the tensioner lock bolt to temporarilyhold this position.

1 TSB Revision I

11 E-52 6G7 ENGINE — Timina Belt — SOHC

I)cg TIMING BELT INSTALLATION(1) Align the timing marks of the camshaft sprockets and the

crankshaft sprocket.(2) Install the timing belt on the crankshaft sprocket first and

while keeping the belt tight on the tension side, install thebelt on the left camshaft sprocket.

(3) Then, install on the water pump pulley and on the rightcamshaft sprocket and finally on the timing belt tensioner.

Timing mark(on belt cover)

Timing mark(on rear cover orgenerator bracket)

/Camshaft sprocket(wht)

Timing belt tensioner

(on front case)

Crankshaft sprocket (on sprocket)

side

I ImIng maw(on sprocket)

Camshaft(left)

sprocket

(4) Install the flange onto the front end of the crankshaft.(5) Install the special tool onto the crankshaft.(6) Loosen the tensioner lock bolt one or two turns and allow

the spring to tension the timing belt.(7) Turn the crankshaft two full turns clockwise. Turn smoothly

and in clockwise direction only.(8) Again line up the timing marks on the sprockets and tighten

the tensioner lock bolt to the specified torque.

TSB Revision

6G7 ENGINE — Timing Belt — SOHC

ad,I mark

7EN024: il

I)D4 ENGINE SUPPORT BRACKET INSTALLATION- DIAMANTE

(I) Tighten the engine support bracket bolts in the order shownin the illustration.

NOTEThe bolt used at the location shown in the illustration is areamer bolt (head mark “R”).

TSB Revision

11 E-54 6G7 ENGINE — Timing Belt — DOHC

TIMING BELT — DOHCREMOVAL AND INSTALLATION — Up to 1992 models

3Nm2 ft.lbs.

2417

90 Nm65 ftlbs.

RS.15 A

/ 6

49 Nm35 ft.lbs. i 30 ft.lbs.

55 Nm40 ftlbs.

Removal stepsI)E4 1. Engine support bracket

2. Timing belt front upper cover, right3. Timing belt front upper cover, left4. Timing belt front lower cover

4AO $04 5. Timing belt+C4 6. Auto tensioner

7. Tensioner pulley8. Tensioner arm assembly9. Idler pulley

10. Idler pulley bracket

11. Crankshaft sprocket#B4 12. Rocker cover

13. Rocker cover gasket, A14. Rocker cover gasket, B

(IB~J *A4 15. Camshaft sprocket bolt16. Camshaft sprocket17. Timing belt rear cover, right18. Timing belt rear cover, left19. Bracket20. Timing belt rear cover, center 7EN0497

TSB Revision I

667 ENGINE — Timing Belt — DOHC

tEMOVAL AND INSTALLATION — From 1993 models

3Nm2 klbs.

3Nm2 ft.lbs.

24 Nm17 ft.lbs.

25

1015

r 11455 Nm

42 Nm46Nm 30 ft.lbs.35 ft.lbs. 40 ft.lbs.

IlONm60 ft.lbs.

ap+C4 9. Auto tensioner

IO. Tensioner nrrllev11. Tensioner arm assembly12.

5Idler pulley

13. Idler pulley bracket2 14. Crankshaft sprocket

15. Sensing plate16. Washer

Removal stepseE4 1. Engine support bracket

2. Crankshaft position sensor bracket3. Timing belt front upper cover, right4. Timing belt front upper cover, left5. Timing belt front lower cover

OAo eD4 6. Timing belt7. Crankshaft position sensor8. Camshaft position sensor

#B4 17. Rocker cover18. Rocker cover gasket, A19. Rocker cover gasket, B

(rBr) +A4 20. Camshaft sprocket bolt21. Camshaft sprocket22. Camshaft sprocket23. Timing belt rear cover, right24. Timing belt rear cover, left25. Bracket26. Timing belt rear cover, center

7ENO498

r

1 TSB Revision

6G7 ENGINE — Timina Belt — DOHC

7EN0224

7ENO775

REMOVAL SERVICE POINTSaA0 TIMING BELT REMOVAL

(1) Mark the belt running direction for reference in reinstalla-tion.

NOTE(1) Water or oil on the belt shortens its life drastically, so

the removed timing belt, sprocket, and tensioner mustbe kept free from oil and water. Do not immerse parts incleaning solvent.

(2) If there is oil or water on any part, check the front caseoil seal, camshaft oil seal and water pump for leaks.

OBr) CAMSHAFT SPROCKET BOLT REMOVAL(1) Hold the hexagonal portion of the camshaft with a wrench,

when removing the camshaft sprocket bolt.

INSPECTIONTIMING BELT

Refer to “INSPECTION” on page IIE-50.

AUTO-TENSIONER(1) Check for oil leaks. If oil leaks are evident, replace the

auto-tensioner.(2) Check the rod end for wear or damage and replace the

auto-tensioner if necessary.(3) Measure the rod projection length. If the reading is outside

the standard value, replace the auto tensioner.Standard value: 11.7 — 12.3 mm (.461 — .484 in.)

(4) Use a vice to force the auto tensioner rod in. If the rodslides in easily, replace the tensioner. If there is nothingwrong, the rod will offer considerable resistance.

TSB Revision

6G7 ENGINE — Timing Belt — DOHC ljl51;_,

Apply sealant

7-G 7EN024

7EN024’ I

II I 7EN022E

Spark plug holes

7EN022i

INSTALLATION SERVICE POINTSI)A4 CAMSHAFT SPROCKET BOLT TIGHTENING(1) Hold the hexagonal portion of the camshaft with a wrench

when tightening the camshaft sprocket bolt. Tighten thebolt to the specified torque.

+B4 ROCKER COVER INSTALLATION(1) Apply sealant to the areas shown in the illustration.

Specified sealant: 3M ATD Part No.8660 or equivalent.

(2) Tighten the rocker cover bolts in the sequence shown in theillustration.

I)c4 AUTO-TENSIONER INSTALLATIONIf the auto-tensioner rod is fully extended, set it in the retractedposition with the following procedure.

(1) Set the auto tensioner in a vice.

(2) Slowly close the vice to force the rod in until the set hole (A)of the rod is lined up with the set hole (B) of the cylinder.

(3) Insert a wire [I .4 mm (.055 in.) in diameter] into the setholes.

(4) Remove the auto tensioner from the vice.(5) On engines with turbocharger, apply sealant to the threads

of the auto tensioner mounting bolt.Specified sealant: 3M ATD Part No.8660 or equivalent.

TSB Revision

11 E-58 6G7 ENGINE — Timing Belt — DOHC

I)04 TIMING BELT INSTALLATION(1) Using the special tool, line up the crankshaft sprocket

timing marks, and then rotate the sprocket one toothcounterclockwise.

(2) Line up the timing marks of the camshaft sprockets for leftbank.

(3) Using two wrenches, line up the timing marks of thecamshaft sprockets for right bank.

Caution1. Since valve spring force can turn the camshaft

sprocket, be careful not to catch your finger.2. If either camshaft sprocket is rotated one complete

turn clockwise or counterclockwise after lining upthe timing marks of the other camshaft sprocket,the intake and exhaust valves might interfere.Consequently, if a camshaft sprocket was turnedtoo far in lining up the timing marks, be sure torotate it back from that position to line up again thetiming marks.

(4) Install the timing belt on the exhaust side camshaftsprocket for right bank and hold it with a paper clip at theposition shown in the illustration.

(5) Install the timing belt on the intake side camshaft sprocketand hold it with a paper clip at the positions shown in theillustration.CautionSince the camshaft sprocket turns easily, avoid exces-sive pulling on the timing belt.

TSB Revision

6G7 ENGINE — Timing Belt — DOHC

(6) Check that the timing marks of the camshaft sprockets forleft bank are in alignment. Then install the timing belt onthese sprockets and hold it with a paper clip at the positionsshown in the illustration.

(7) Install the timing belt on the idler pulley.(8) Install the timing belt on the crankshaft sprocket.(9) Install the timing belt on the tensioner pulley.

(1O)Using the special tool, rotate the tensioner pulley clockwiseto tighten the center bolt.

(1 l)Remove the four paper clips.

(12)Using the special tool, turn the crankshaft a quarter turncounterclockwise. Then rotate it clockwise to line up thetiming marks and check that all the timing marks are inalignment.

1 TSB Revision

11 E-60 6G7 ENGINE — Timing Belt — DOHC

Timing marks(on rightrocker cover)

Camshaft sprocket Timing marks(on left rocker cover)

Auto tensionerTiming mark (on oil pump case)

(on sprocket)

Timing mark(on sprocket)

Crankshaft sprocket ’

7EN0235

(13)Loosen the center bolt of the auto-tensioner pulley, andinstall the special tool and a torque wrench on the pull’ey.While holding the pulley with approximately 10 Nm (7ftlbs.) torque to prevent it from turning, tighten the centerbolt to the specified torque.

(14)Turn the crankshaft two turns clockwise, and leave it alonefor about five minutes. Then move in and out theauto-tensioner setting metal wire to check that the wiremoves smoothly.NOTEIf the metal wire does not move smoothly, repeat step (12)until it does move smoothly.

(15)Remove the auto tensioner setting metal wire.

TSB Revision

6G7 ENGINE — Timing Belt — DOHC

ad markI,

7EN024:

(16)Check that the spacing between the tensioner arm antfaulotensioner is within the standard limit.

*.Standard value: 3.8 — 4.5 mm (.I50 — .I77 ‘in.)

r)E4 ENGINE SUPPORT BRACKET INSTALLATION(1) Tighten the engine support bracket bolts in the order shown

in the illustration.

NOTEThe bolt used at the location shown in the illustration is areamer bolt (head mark “R”).

TSB Revision I

11 E-62 6G7 ENGINE — Intake Manifold and Fuel Parts

INTAKE MANIFOLD AND FUEL PARTSREMOVAL AND INSTALLATION — SOHC for DIAMANTE

I/9Nm7 ftlbs.

[email protected] I2 __/J8Nm

/8 ftlbs.

,I5 c119 Nm14 ftlbs.

16

18

Removal steps1. injector harness2. Injector and fuel rail3. insulator

eG4 4. Fuel pressure regulator5. O-ring6. Insulator

eF4 87. lnj;e;rs

9: Gromet10. Fuel pipe11. O-ring12. Fuel rail

*D4 13. Engjne coolant temperature gauge unit+C4 14. Engrne coolant temperature sensor*I34 15. Therm0 switch

16. Water outlet fitting17. Water outlet fitting gasket18. Thermostat19. Intake manifold20. Intake manifold gasket

7EN0499

1 TSB Revision 7

6G7 ENGINE — Intake Manifold and Fuel Parts

IEMOVAL AND INSTALLATION — SOHC for MONTERO AND TRUCK

19Nm14 ft.lbs.

18

30 Nm22 c.lbs.

11 Nm8 ftlbs.8Nm — 47-6lklbs. d

12Nm

g )f~~bs~

Removal steps1. Injector and fuel rail 12. Heat pipe2. Insulator 13. Heat pipe gasket

eG4 3. Fuel pressure regulator 14. Water hose4. O-ring eD4 15. Engine coolant temperature gauge unit5. Insulator eC4 16. Engine coolant temperature sensor

)F4 6. Injectors eB4 17. Therm0 switch7. O-ring 18. Water outlet fitting8. Gromet 19. Water outlet fitting gasket9. Fuel rail 20. Thermostat

10. Water hose A 21. Intake manifoldIl. Water hose B 22. Intake manifold gasket 7EN0500

1 TSB Revision

11 E-64 6G7 ENGINE — Intake Manifold and Fuel Parts

{EMOVAL AND INSTALLATION — DOHC

IY Nrnldft Ihe

-318 Nm13 ft.lbs. —$j

19 Nm14 ft.lbs.

11 Nm8 ftlbs. 19 Nm

14 ft.lbs.

Removal steps

1. Injector harness2. Injector and fuel rail3. Insulator

+G4 4. Fuel pressure regulator5. O-ring6. Insulator7.

eF4Injector clip

8. Injectors9. O-ring

10. Gromet11. Fuel pipe12. O-ring13. Fuel rail

*E4 14. Intake manifold

15. Intake manifold gasketI)Dg 16. Engine coolant temperature gauge uniteC4 17. Engine coolant temperature sensor+B4 18. Therm0 switch

TE

19. Water hose20. Water hose A21. Water outlet fitting — 3000GT22. Water outlet fitting-23. Water outlet fitting gasket

DIAMAN

24. Water inlet fitting#A4 25. Thermostat

26. Thermostat housing27. Thermostat housing gasket 7EN0501

TSB Revision

667 ENGINE — Intake Manifold and Fuel Parts

6FU192C

Alignment mark Jiggle valve

II II 7COOO42

I

Sealant

1 EN0338

Sealant

9cooo91

Sealant

INSPECTIONINJECTORS(1) Measure the resistance between the terminals of the

injectors using a circuit tester. If the resistance is out of?hespecification, replace the injector.

Standard value:Non Turbo 13 — 16 R at 20°C (68°F)Turbo 2 — 3 IR at 20°C (68°F)

INSTALLATION SERVICE POINTS+A4 THERMOSTAT INSTALLATION — DOHC(1) install the thermostat and line up the jiggle valve with the

alignment mark on the thermostat housing.

I)B4 SEALANT APPLICATION TO THERM0 SWITCHSpecified sealant: 3M Part No. 8660 or equivalent

+c+ SEALANT APPLICATION TO ENGINE COOLANTTEMPERATURE SENSOR

Specified sealant:3M Nut Locking No. 4171 or equivalent

eD4 SEALANT APPLICATION TO ENGINE COOLANTTEMPERATURE GAUGE UNIT

Specified sealant: 3M Part No. 8660 or equivalent

IIE-66 6G7 ENGINE — Intake Manifold and Fuel Parts

_ Front

71 NO090

7FUO61′

r)E4 INTAKE MANIFOLD INSTALLATION — DOHC(1) Tighten the nuts on the right bank to 4 Nm (2.2 ft.lbs.).(2) Tighten the nuts on the left bank to the specified torque.

Then tighten the nuts on right bank to the specified torque.(3) Tighten the nuts on the left bank and those on the right

bbnk again in that order.

I)Fg INSTALLATION OF INJECTOR(1) Before installing the injector, the rubber O-ring must be

lubricated with a drop of clean engine oil for easyinstallation.

(2) Insert the injector top end into the fuel rail. Be careful not todamage O-ring during installation.

(3) Install the injector clip by sliding the open ends onto bothinjector and fuel rail.

I)G4 FUEL PRESSURE REGULATOR INSTALLATION(1) Before installing the pressure regulator, the O-ring must be

lubricated with a drop of clean engine oil for easyinstallation.

TSB Revision

667 ENGINE — Exhaust Manifold [email protected]

EXHAUST MANIFOLDREMOVAL AND INSTALLATION — SOHC for DIAMANTE

14 NmIOfLlbs. m

-I’” /(/ 1 6 III

24 Nm

l7 ft-‘?m 14 NmIO ft.lbs.

6.4&-

14

5—K-a , &

Removal steps1. Oil level gauge2. Oil level gauge guide3. O-ring4. Heat protector5. Engine hanger, right6. Exhaust manifold, right

)BC 7. Exhaust manifold gasket8. Heat protector, right9. Bracket

10. Exhaust manifold, left+B4 11. Exhaust manifold gasket

12. Water hose13. Water hose14. Water by-pass hose

[email protected]

14 ft.lbs.

+A4 15. Water inlet pipe B+A4 16. O-ring For M/l)A4 17. Water inlet pipe A*A4 18. Water inlet pipe*A4 19. O-ring For A/T

20. Water pump21. Water pump gasket

7EN0502

I

TSB Revision

6G7 ENGINE — Exhaust Manifold

IEMOVAL AND INSTALLATION — SOHC for MONTERO AND TRUCK

19 Nm

6 — I/‘,“/ I

I 1812Nm9 ft.lbs.

14 Nm10 ft.lbs.

Removal steps1. Oil level gauge2. Oil level gauge guide3. O-ring4. Heat protector, right5. Engine hanger6. Exhaust manifold, right

eB4 7. Exhaust manifold gasket8. Heat protector, left9. Bracket

10. Exhaust manifold, left$B4 11. Exhaust manifold gasket

12. Water hose13. Water hose A14. Heater pipe15. Heater pipe gasket16. Water pipe

+A4 17. O-ring*A4 18. Water inlet pipe

19. Water inlet fitting gasket20. Water pump21. Water pump gasket

7ENO360

TSB Revision

667 ENGINE — Exhaust Manifold

IEMOVAL AND INSTALLATION — DOHC NON-TURBO

914 Nm

c 1 2 14 10 1 ft.lbs. Nm

911m

10 ft.lbs.

13 Nm9 ft.lbs.

14 NmIO ftlbs.

45 Nm33 ft.lbs.

Removal steps1. Oil level gauge2. Oil level gauge guide3. O-ring4. Heat protector, right5. Engine hanger6. Exhaust manifold, right7. Exhaust manifold gasket8. Heat protector, left9. Exhaust manifold, left0. Exhaust manifold gasket1. O-ring2. Water inlet pipe3. O-ring4. Water pump

15. Water pump gasket7EN0503

IIE-70 667 ENGINE — Exhaust Manifold

REMOVAL AND INSTALLATION — DOHC TURBO

14 Nm10 ftlbs. —

Removal steps1. Oil level gauge2. Oil level gauge guide3. O-ring

*A4 4. O-ring+A4 5. Water inlet pipe

17 ftlbs. #A4 6. O-ring7. Water pump8. Water pump gasket

7EN0504

TSB RevisionI

6G7 ENGINE — Exhaust Manifold TIE-71

14 Nm10 ftlbs.

60 Nm

60 Nm44 ft.lbs.

14Nm __BIO ft.lbs.

31 Nm22 ft Ibs. “Nm

klbs.

43 ftlbs.

a

9. Heat protector B10. Heat protector A11. Turbocharger stay12. Exhaust fitting13. Exhaust fitting gasket14. Oil pipe15. Water pipe A, right16. Water hose17. Water pipe B, right18. Water hose

19. Turbocharger, right20. Turbocharger gasket21. Ring22. Oil return pipe, right23. Oil return pipe gasket24. Exhaust manifold sta , right

+C4 25. Exhaust manifold, rig): t26. Exhaust manifold gasket

71N0120

TSB Revision

11 E-72 6G7 ENGINE — Exhaust Manifold

4

%-35 IlNm

4%8 klbs.

31 Nm22 ftlbs./

14 NmIO ftlbs.

25 Nm18 ft.lbs. -9

—ml

Vm

10 Nm

28

14Nm &IO ft.lbs.

27 3im

27. Heat protector D28. Exhaust fitting, left29. Exhaust fitting gasket, left30. Heat protector C31. Oil return pipe32. Oil return pipe gasket33. Oil pipe34. Water pipe 6, left35. Water hose

7lN0121i

TSB Revision /’

6G7 ENGINE — Exhaust Manifold WE-73I

O-ringI Water pump I

Water in’let pipe6EN0594 I

For right bank

Front

c3

7lNOOlCI

Fronte

For left bankCylinder No.

7FNWi11

Cylinder No.

E

Groove

INSTALLATION SERVICE POINTS+A4 O-RING AND WATER PIPE INSTALLATION(I) Wet the O-ring (with water) to facilitate assembly.

CautionKeep the O-ring free of oil or grease.

I)B4 EXHAUST MANIFOLD GASKET IDENTIFICATION -SOHC

(1) Install gaskets with cylinder number 0, @ and @ embos-sed on their top side to the right bank and install those withcylinder number 0, @ and @J to the left bank.

I)c4 RIGHT EXHAUST MANIFOLD INSTALLATION -DOHC TURBO

Tighten the nuts in the following order.

(1) Tighten five nuts @ to 30 Nm (22 ftlbs.).(2) Tighten nuts @ to 50 Nm (36 ft.lbs.).(3) Back off nuts @I until a torque value of 10 Nm (7 ft.lbs.) is

achieved.(4) Tighten nuts @ to 30 Nm (22 ft.lbs.).

NOTE(1) Fit the cone disc spring with the grooved side facing the

nut.(2) Install the nut, cone disc spring and washer in the order

shown in the illustration.

7lNOl l!

TSB Revision

11 E-74 6G7 ENGINE — Exhaust Manifold

I Groove /

7lNOll

I)D4 LEFT EXHAUST MANIFOLD INSTALLATION — DOHCTURBO

Tighten the nuts in the following order.

(1) Tighten four nuts @ to 30 Nm (22 ft.lbs.).(2) -TT;.poranly tighten the turbocharger to the exhaust man-

(3) Tighten nut @ to 30 Nm (22 ft.lbs.).(4) Tighten nuts @ and @ to 50 Nm (36 ftlbs.).(5) Back off nuts @ and @ until a torque value of 10 Nm (7

ft.lbs.) is achieved.(6) Tighten nuts @ and @ to 30 Nm (22 ftlbs.).

NOTE(1) Fit the cone disc spring with the grooved side facing the

nut.(2) Install the nut, cone disc spring and washer in the order

shown in the illustration.

TSB Revision

6G7 ENGINE — Turbocharger

TURBOCHARGERDISASSEMBLY AND REASSEMBLY

Xsassembly steps1. Snap pin2. Turbocharger waste gate actuator3. Coupling

eD4 4. Turbine housing*C4 5. Snap ring*Bg 6. Turbine wheel assemblybAC 7. 0-rinar 1

8. Combressor cover71N0098

O-ring

3EN019C

INSPECTIONTURBOCHARGER(1) Manually open and close the waste gate valve to make sure

it operates freely.(2) Inspect the oil passage in the cartridge for signs of deposits

or blockage.(3) Clean the inlet section of the compressor cover with a rag.

Inspect it for signs of contact with the compressor turbine.If worn, replace it.

REASSEMBLY SERVICE POINTS#A4 O-RING INSTALLATION(1) Apply a light coat of engine oil to a new O-ring and fit it in

the groove of the turbine wheel assembly.

TSB RevisionI

11 E-76 6G7 ENGINE — Turbocharger

Chamfered

T&ink wheelassembly I

CompressoBcover

664 TURBINE WHEEL ASSEMBLY INSTALLATION

il ) Install the turbine wheel assembly to the compressor coverwhile aligning the dowel pin and the hole.

CautionUse care not to damage the blades of the turbine wheeland compressor wheel.

+cg SNAP RING INSTALLATION(1) Fit the snap ring with its chamfered side facing up.

I)04 TURBINE HOUSING INSTALLATION(1) Install the turbine housing while aligning the dowel pin and

the hole.CautionUse care not to damage the blades of the turbinewheel.

TSB Revision-I

667 ENGINE — Rocker Arms and Camshaft — SOHC “14 E~77

ROCKER ARMS ANI) CAMSHAFTS — SOHCREMOVAL AND INSTALLATION — DIAMANTE

9Nm97 ft.lbs.

@

7

30

7

Removal steps#E4 ;. Fi;,c:;; cover

elII4 3. Circular packing+C4 4. Camshaft oil seal

5. Distributor adaptor6. O-ring

#B4 7. Rocker arms, shafts and bebring capsOAO +A4 98: pa,Smhs;W$er

7EN0362

TSB Revision

IIE-78 6G7 ENGINE — Rocker Arms and Camshaft — SOHC

REMOVAL AND INSTALLATION — MONTERO AND TRUCK

13Nm t9 ft.lbs. ——d

9NmQ- 7 ft.lbs.

9Nm

I — -7 ft.lbs.

08

Removal steps1 Oil filler2. Oil filler tube

eE4 3. Rocker cover4. Gasket

#D4 5. Circular packingI)C4 6. Camshaft oil seal

7. Distributor adaptor8. O-ring ’

#B4 9. Rocker arms, shafts and bearing capsaA0 *A4 ; 7: p&dfutster

7EN0363

TSB Revision

6G7 ENGINE — Rocker Arms and Camshaft — SOHC 1 TE39

REMOVAL SERVICE POINTflo ROCKER ARM, SHAFT AND BEARING CAP

REMOVAL

(1) Install the special tools to the rocker arm to hold the lashadjuster.

(2) Loosen the camshaft bearing cap bolt. Do not remove thebolts from the cap.

(3) Remove the rocker arm, shaft and bearing cap as anassembly.

INSPECTIONCAMSHAFT(1) Inspect the camshaft bearing journals for damage and

binding. If the journals are binding, also check the cylinderhead for damage. Also check the cylinder head oil holes forclogging.

(2) Check the tooth surface of the distributor drive gear teethof the camshaft and replace if abnormal wear is evident.

(3) Check the cam surface for abnormal wear and damage andreplace if defective. Also measure the cam height andreplace if out of limit.

Standard value: 41.25 mm (1.6240 in.)Limit: 40.75 mm (1.6643 in.)

LASH ADJUSTER LEAK DOWN TESTCaution1. The lash adjuster is a precision part. Keep it free

from dust and other foreign matters.2. Do not disassemble the lash adjusters.3. When cleaning the lash adjusters, use clean diesel

fuel only.

TSB Revision

11 E-80 667 ENGINE — Rocker Arms and Camshaft — SOHC

6EN057

I

Division = 1 mm (.04 in.)

7EN043t

6EN0421

3

M D998443-0 1 1

!ILash adjust&7EN0174

(1) Immerse the lash adjuster in clean diesel fuel.(2) While lightly pushing down the inner steel ball using the

small wire, move the plunger up and down four or fivetimes to bleed air.Use of the Retainer facilitates the air bleeding of the rockerarm mounted type lash adjuster.

(3) Remove the small wire and press the plunger. If the plungeris hard to be pushed in, the lash adjuster is normal. If theplunger can be pushed in all the way readily, bleed the lashadjuster again and test again. If the plunger is still loose,replace the lash adjuster.

CautionUpon completion of air bleeding, hold the lash adjusterupright to prevents the inside diesel fuel from spilling.

(4) After air bleeding, set the lash adjuster on the special tool(Leak down tester MD998440).

(5) After the plunger has gone down somewhat 0.2 — 0.5 mm(.008 — .020 in.), measure the time taken for it to go down 1mm (.04 in.). Replace if the measured time is out ofspecification.

Standard value: 4 — 20 seconds / 1 mm (.04 in.)[Diesel fuel at 15 — 20°C (50 — 68”F)]

INSTALLATION SERVICE POINTS*A4 LASH ADJUSTER INSTALLATION(1) Immerse the lash adjuster in clean diesel fuel.(2) Using a small wire, move the plunger up and down 4 or 5

times while pushing down lightly on the check ball in orderto bleed out the air.

(3) Insert the lash adjuster to rocker arm, being careful not tospill the diesel fuel. Then use the special tool to prevent theadjuster from falling while installing it.

TSB Revision

‘I

667 ENGINE — Rocker Arms and Camshaft — SOHC

+64 ROCKER ARM, SHAFT AND BEARING CAPINSTALLATION

(1) Apply a minimum amount of the specified sealant on thefour places of the cylinder head.

NOTEBe sure the sealing agent does not swell out onto the camjournal surface of the cylinder head. If it swells out,immediately wipe it off before it can dry.Specified sealant:

3M NUT Locking No. 4171 or equivalent

Apply sealantApply sealant* No. 1 and No.4 bearing cap mating surfaceof cylinder head

(2) Install the rocker arms, shafts and bearing caps such thatthe arrow mark on the bearing cap faces in the samedirection as the arrow mark on the cylinder head.

TSB Revision

11 E-82 667 ENGINE — Rocker Arms and Camshaft — SOHC

Rocker arm shaftassembly(B)

Arrow mark (bearing cap)

Arrow mark (cylinder head)c7Timing belt side

Rocker arm shaf t — — — — -assembly (A)

Arrow mark-(bearing cap)

7EN0176

(3) Tighten the bearing cap bolts to the specified torque.(4) Remove the special tools from all rocker arms.

ec4 CAMSHAFT OIL SEAL INSTALLATION(1) Apply a slight amount of engine oil all over the circumfer-

ence of the camshaft oil seal lip.(2) Using the special tool, insert the oil seal.

TSB RevisionI

667 ENGINE — Rocker Arms and Camshaft — SOHC

MD998714-01

/ \/ / 7EN0441

0.5 mm (020 in.)

I — -Spacer 7

/ IMD998714-01 7EN0131

#D4 C I R C U L A R P A C K I N G I N S T A L L A T I O N(1) Install a 1.3 to 1.5 mm (.052 to .059 in.) thick spacer to the

special tool and drive in the circular packing.NOTEUse of MD724328 spacer for transmission is recom-mended.

CautionThe packing is overdriven if no spacer is fitted to thespecial tool.

I)E4 ROCKER COVER INSTALLATION(1) Apply specified sealant on the area specified in the

illustration.

Specified sealant:3M ATD Part No. 6660 or equivalent

1 TSB Revision

IIE-84 6G7 ENGINE — Rocker Arms and Rocker Shafts — SOHC

DISASSEMBLY AND REASSEMBLY

Disassembly steps1. Bearing cap No.4

0 2. Rocker arm3. Spring4. Bearing cap No. 35. Bearing cap No. 2

*A4 6. Rocker arm shaft “B”$A4 7. Rocker arm shaft “A”

8. Bearing cap No. 1

DISASSEMBLY SERVICE POINTOAo ROCKER ARM REMOVAL(1) Before disassembly, identify the original location of each

rocker arm by a symbol.For example, put symbols as shown below.

1 IN: For No.1 cylinder intake6EX: For No.6 cylinder exhaust __

TSB Revision

667 ENGINE — Rocker Arms and Rocker Shafts — SOHC

7EN006r

Notch Rocker arm shaft “6”

Cap No.

Rockerarmshaft “A”

P 7EN0015

Jiew P Rocker armOil hole shaft (A)

/— — — -‘ao’&-,—-

Rocker arm shaft (B)7ENOOlE

INSPECTIONROCKER ARM(1) Check the roller surface and replace the rocker arm if

recesses, damage or heat seizure is observed.(2) Check roller rotation and replace the rocker arm if uneven

rotation or roller backlash is observed.(3) Check the inside diameter and replace the rocker arm if

damage or seizure is observed.

ROCKER ARM SHAFT(1) Check the rocker arm mounting portions of the rocker arm

shafts for wear or damage. Replace as necessary.(2) Check to ensure that the oil holes are clear.

REASSEMBLY SERVICE POINT#A4 ROCKER ARM SHAFT INSTALLATION(1) Install the rocker arm shafts “A” and “B” to the camshaft

bearing cap No.1 and insert the bolts into the holes of thebearing cap and shafts.

(2) Install the rocker arm shafts with the notched side facingthe bearing cap No.1 and the oil grooved side facingdownward. The shaft with a smaller oil hole is the rockerarm shaft “A”.

r&B Revision I

11 E-86 6G7 ENGINE — Rocker Arms and Rocker Shafts — SOHC

(3) Install the rocker arms, springs and camshaft bearing capsas illustrated. The rocker arms are all equally shaped.Assemble the rocker arms according to the symbols putbefore disassembly. The bearing caps are also equallyshaped. Assemble the caps according to the identificationmarks as to right and left banks put before disassembly.

Front mark

Camshaft bearing

Camshaft bearing cap No.1

Camshaft bearing cap No.2

cap No.4

Cap No.

7EN0079

TSB Revision I

6G7 ENGINE — Camshafts, Rocker Arms and Bearing Caps — DOHC 1 P:E187

CAMSHAFTS, ROCKER ARMS AND BEARING CAPS — DOHCREMOVAL AND INSTALLATION

20 Nm

Removal steps1. Crankshaft position sensor

#E4 2. Circular packingeD4 3. Camshaft oil seal

4. Bearing cap, front5. Bearing cap, rear6. Bearing cap No. 27. Bearing cap No. 48. Bearing cap No. 3W

)B( 9. Camshaft10. Rocker arm

#A4 11. Lash adjuster

adaptor-Up to- F r o m

1992 models1993 models

7EN0505

1 TSB Revision I

IIE-88 6G7 ENGINE — Camshafts, Rocker Arms and Bearing Caps — DOHC

MD998440Scale = 1 mm l.039 in.)

I n

6EN035:

Small wire

INSPECTIONCAMSHAFTMeasure the cam height (longer diameter of the cam). If itexceeds the limit, replace the camshaft.

Standard value:Up to 1992 models

Intake side 35.49 mm (1.3972 in.)Exhaust side 35.20 mm (1.3858 in.)

From 1993 modelsIntake side 34.91 mm (1.3744 in.)Exhaust side 34.91 mm (1.3744 in.)

Limit:Up to 1992 models

Intake side 34.99 mm (1.3778 in.)Exhaust side 34.70 mm (1.3661 in.)

From 1993 modelsIntake side 34.41 mm (1.3547 in.)Exhaust side 34.41 mm (1.3547 in.)

LASH ADJUSTER LEAK DOWN TESTRefer to “LASH ADJUSTER LEAK DOWN TEST” on pages11 E-79 and 11 E-80. Also note the following:When the lash adjuster is set on a tester, remove the adjustingscrew of the tester and adjust it to the height of the lashadjuster as shown in the illustration.

INSTALLATION SERVICE POINTSI)A4 LASH ADJUSTER INSTALLATION(1) Immerse the lash adjuster in clean diesel fuel.(2) Using a small wire, move the plunger up and down 4 or 5