Руководство по ремонту Cummins ISBE, ISB, QSB

Руководство по ремонту (4960496)

Двигатели серии ISBe, ISB и QSB (топливная система с общим топливопроводом высокого давления)

Bulletin Number 4960496

© 2000-2010 Cummins Inc. С сохранением всех прав.

Запчасти

Двигатели Cummins, Запчасти, Корейские запчасти, Двигатель, Автобус, Экскаватор, Спецтехника, Hyundai Robex, Daewoo-Doosan, Volvo, Samsung MX, MX132, MX202, MX8, MX6, Robex1300, Robex130, Robex2000, Cummins b3.9, Cummins 4BT, Cummins b5.9, Cummins 6BT, Cummins isf2.8, Cummins isf3.8, Cummins 4isbe, Cummins 6isbe, Cummins M11, Cummins KTA19, Cummins qsb6.7, Cummins EQB5.9, Cummins 6isl8.9, Cummins NT855, Cummins LTA10, Грузовик, Автозапчасти, МКПП, Коробка передач, Раздатка, Прокладка, Стартер, Двигатель, Запчасти, Карданный вал, Мост, Редуктор, Поршня, Гильза, Кольца, Коленвал, Шатун, Гидроцилиндр, ТНВД, Форсунка, Радиатор, Сальник, Амортизатор, Фильтр, Топливный, Масляный, Воздушный, Коронки, Зубы, Ремкомплект, ДВС, Насос, ГУР, Подрезы, Выжимной, Подшипник, Корзина, Сцепления, Диск, Сцепление, Коробка Передач, Поршень, Средний, мост, Шкворень, Шкворня, Сайлентблок, Сальник, Рулевая, Колонка, Кардан, Амортизатор, Рессора, Рессорный Лист, Поросёнок, Вкладыши, Коренные, Шатунные, Турбина, Компрессор, ПГУ, Подушка, Палец, МКПП, Тормоз, Ступица, Шестерня, Колодки, Тормозные, Накладка, Hyndai, Daewoo, Samsung, Doosan, Cosmos, KIA, Aero City, Aero Space, GRANBIRD, GRANTO, Aero Town, Transtar, ULTRA, Самсунг, ASIA, AM 937, Хундай, L6, L7, LX, ДЭУ, Гранбёрд, КИЯ, Аэротаун, АэроСити, 6BT, 4BT, Корея, 6BT 5.9, Каминз, Каминс, Камминз, Cummins, Cumins, 4BT 3.9, EF750, F17E, D1146, DE12, dv15, DE08TIS, DV11, D6BR, D6AU, D6AV, H07C, D6AB, D6AC, D6CA, D6CB, D6DA, D2366, D8AY, D8AB, DC23, JT, VM39, Am 948, BS 106, BM 090, BH 115, BH 117, BH 120, D8AB

Срочная Доставка во все города России, Казахстана

Абакан, Алмата, Альметьевск, Армавир, Архангельск, Астрахань, Ачинск, Байкальск, Балаково, Барнаул, Белгород, Белогорск, Березники, Бийск, Биробиджан, Благовещенск, Бодайбо, Братск, Брянск, Великий Новгород, Вихоревка, Владивосток, Владимир, Волгоград, Волжский, Вологда, Воронеж, Глазов, Екатеринбург, Иваново, Ижевск, Иркутск, Йошкар-Ола, Железногорск-Илимский, Зима, Казань, Калуга, Канск, Кемерово, Киров, Комсомольск-на-Амуре, Кострома, Краснодар, Красноярск, Курган, Курск, Липецк, Магадан, Магистральный, Магнитогорск, Махачкала, Миасс, Москва, Мурманск, Набережные, Челны, Находка, Нерюнгри, Нефтекамск, Нижневартовск, Нижнеудинск, Нижний Новгород, Нижний Тагил, Новая Игирма, Новокузнецк, Новороссийск, Новосибирск, Новый Уренгой, Ноябрьск, Омск, Орел, Оренбург, Орск, Пенза, Пермь, Петрозаводск, Петропавловск-Камчатский, Псков, Пятигорск, Ростов-на-Дону, Рубцовск, Рязань, Самара, Санкт-Петербург, Саранск, Саратов, Саянск, Слюдянка, Смоленск, Сочи, Ставрополь, Стерлитамак, Сургут, Сыктывкар, Таганрог, Тайшеь, Тамбов, Тверь, Тольятти, Томск, Тула, Тулун, Тюмень, Улан-Удэ, Улькан, Ульяновск, Усть-Илимск, Усть-Кут, Уфа, Хабаровск, Ханты-Мансийск, Чайковский, Чебоксары, Челябинск, Черемхово, Череповец, Чита, Чунский, Южно-Сахалинск, Якутск, Ярославль, Алупка, Алушта, Армянск, Бахчисарай, Белогорск, Джанкой, Евпатория, Инкерман, Керчь, Красноперекопск, Саки, Севастополь, Симферополь, Старый Крым, Судак, Феодосия, Щёлкино, Ялта

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Related Manuals for CUMMINS ISB

Summary of Contents for CUMMINS ISB

-

Page 1

Service Manual , ISB, and QSB (Common Rail Fuel System) Volume 1… -

Page 2

Service Manual , ISB, and QSB (Common Rail Fuel System) Volume 1 Copyright© 2014 Bulletin 4021271 Cummins Inc. Printed 29-OCTOBER-2014 All rights reserved To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 3

The specifications and rebuild information in this manual are based on the information in effect at the time of printing. Cummins Inc. reserves the right to make any changes at any time without obligation. If differences are found between your engine and the information in this manual, contact a Cummins Authorized Repair Location or call 1-800-DIESELS (1-800-343-7357) toll free in the U.S. -

Page 4

Cylinder Block — Group 01 ……………………..Cylinder Head — Group 02 ……………………..Rocker Levers — Group 03 ……………………..Cam Followers/Tappets — Group 04 ……………………. Back …………………………….back To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 5

To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 6: Table Of Contents

General Safety Instructions ……………………….i-8 Important Safety Notice………………………….i-8 How to Use the Manual …………………………i-2 General Information…………………………i-2 Illustrations ……………………………..i-7 General Information…………………………i-7 Symbols …………………………….i-3 General Information…………………………i-3 To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com…

-

Page 7

ISB, ISBe and QSB (Common Rail […] Page i-b Section i — Introduction This Page Left Intentionally Blank… -

Page 8: About The Manual

Additionally the manual is intended to aid mechanics in disassembly, inspecting parts for reuse, rebuilding and assembly of components. The manual is divided into sections. Each section is equivalent to a group used in Cummins’ filmcard system. Some sections contain reference numbers and procedure numbers. Reference numbers provide general information, specifications, diagrams, and service tools where applicable.

-

Page 9: How To Use The Manual

How to Use the Manual General Information This manual is divided into the same group system used for previous manuals and the Cummins’ filmcard system. Section 00 is organized into a logical sequence of engine disassemble/assemble, all other sections are in numerical sequence.

-

Page 10: Symbols

Minor personal injury can result or a part, and assembly, or the engine can be damaged if the caution instructions are not followed. Indicates a REMOVAL or Dissassembly step. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com…

-

Page 11

Section i — Introduction Indicates an INSTALLATION or ASSEMBLY step. INSPECTION is required. CLEAN the part or assembly. PERFORM a mechanical or time MEASUREMENT. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 12

LUBRICATE the part or assembly. Indicates that a WRENCH or TOOL SIZE will be given. TIGHTEN to a specific torque. PERFORM an electrical MEASUREMENT. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 13

The component weighs 23kg [50 lbs] or more. To reduce the possibility of personal injury, use a hoist or get assistance to lift the component. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 14: Illustrations

The illustrations are intended to show repair or replacement procedures. The procedure will be the same for all applications, although the illustration can differ. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com…

-

Page 15: General Safety Instructions

All fasteners must be replaced on re-fitting the guards. • Do not perform any repair when fatigued or after consuming alcohol or drugs that can impair your functioning. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com…

-

Page 16

California Proposition 65 Warning — Diesel engine exhaust and some of its constituents are known to the State of California to cause cancer, birth defects, and other reproductive harm. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 17: General Repair Instructions

• Perform the inspections specified in the procedures • Replace all components or assemblies which are damaged or worn beyond the specifications To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com…

-

Page 18: Welding On A Vehicle With An Electronic Controlled Fuel System

The assembly instructions have been written to use again as many components and assemblies as possible. When it is necessary to replace a component or assembly, the procedure is based on the use of new Cummins or Cummins ReCon® components. All of the repair services described in this manual are available from all Cummins Distributors and most Dealer locations.

-

Page 19: General Cleaning Instructions

Cummins Inc. does not recommend sanding or grinding the carbon ring at the top of cylinder liners until clean metal is visible. The liner will be ruined and any signs of a problem at the top ring reversal point (like a dust-out) will be destroyed.

-

Page 20: Gasket Surfaces

The object of cleaning gasket surfaces is to remove any gasket material, not refinish the gasket surface of the part. Cummins Inc. does not recommend any specific brand of liquid gasket remover. If a liquid gasket remover is used, check the directions to make sure the material being cleaned will not be harmed.

-

Page 21: Plastic Bead Cleaning

Plastic Bead Cleaning Cummins Inc. does not recommend the use of glass bead blast or walnut shell media on any engine part. Cummins Inc. recommends using only plastic bead media, Part Number 3822735 or equivalent on any engine part. Never use sand as a blast media to clean engine parts.

-

Page 22: Fuel System

Cummins Inc. now recommends glass bead media NOT used to clean any engine parts. Glass media is too easily embedded into the material particularly in soft materials and when air pressures greater than media manufacturer’s recommend are used.

-

Page 23

Clean and dry the tools before returning them to the tool box. • If possible, store fuel system tools in sealed containers. • Make sure fuel system tools are clean before use. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 24: Acronyms And Abbreviations

Liquified Petroleum Gas Low Temperature Aftercooling MCRS Modular Common Rail System Malfunction Indicator Lamp Megapascal Miles Per Hour Miles Per Quart N•m Newton-meter To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com…

-

Page 25

Selective Catalytic Reduction Step Timing Control Subsystem Identification Descriptions Top Dead Center Volts of Direct Current Variable Geometry Turbocharger Variable Speed Vehicle Speed Sensor To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 26

Cummins® Service Engine Model Product Identification ………………E-45 General Information…………………………E-45 Engine Diagrams …………………………..E-6 Engine Views…………………………..E-6 Engine Identification …………………………E-1 Cummins® Engine Nomenclature……………………..E-3 ECM Dataplate…………………………..E-4 Engine Dataplate…………………………..E-1 Fuel Injection Pump Dataplate………………………E-4 To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 27

ISB, ISBe and QSB (Common Rail […] Page E-b Section E — Engine and System Identification This Page Left Intentionally Blank… -

Page 28: Engine Identification

1 Engine serial number 2 Control parts list (CPL) 3 Model 4 Horsepower and rpm rating. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com…

-

Page 29

(CPL) provide information for service and for ordering parts. The engine dataplate must not be changed unless approved be changed unless approved by Cummins Inc. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 30

Marine Applications The Cummins MerCruiser Diesel engine nomenclature provides the engine model, displacement in liters and horsepower rating. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 31: Fuel Injection Pump Dataplate

NOTE: The presence of an ECM dataplate depends on the manufacturing plant andthe date the engine was manufactured. If an ECM dataplate was not installed by the manufacturing plant, calibration data can be found on the engine dataplate. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com…

-

Page 32

If an ECM dataplate was not installed by the manufacturing plant, calibration data can be found on the engine dataplate. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

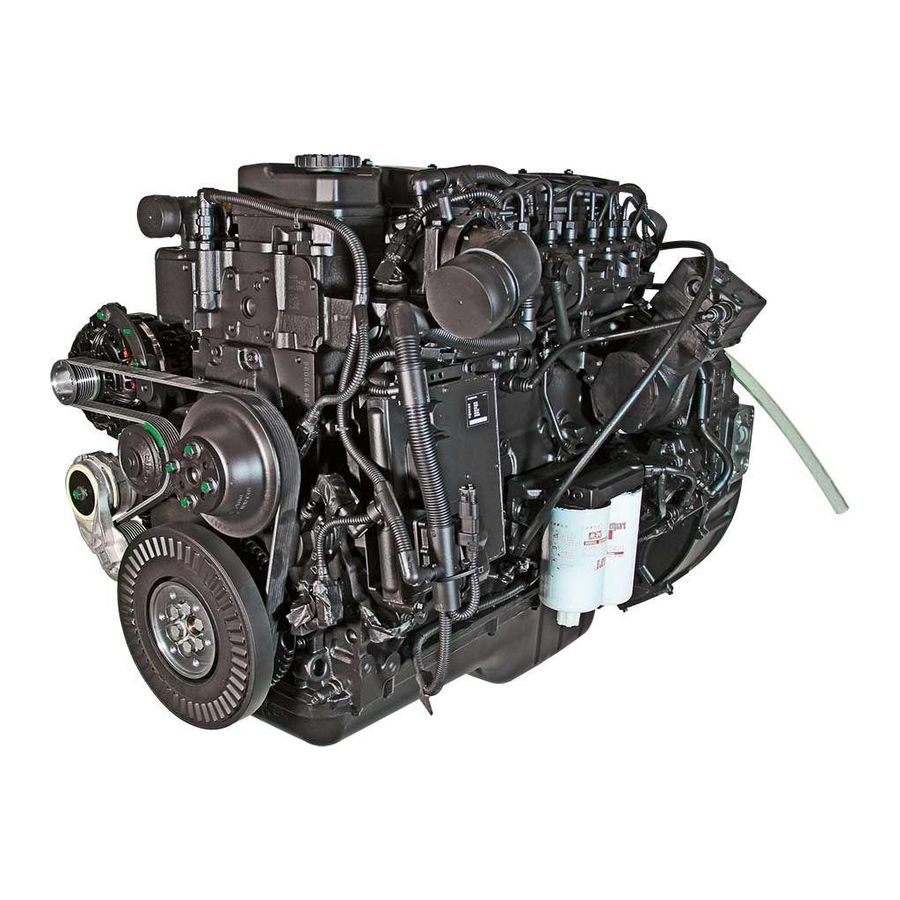

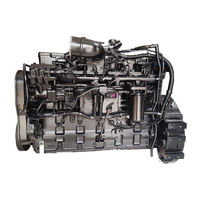

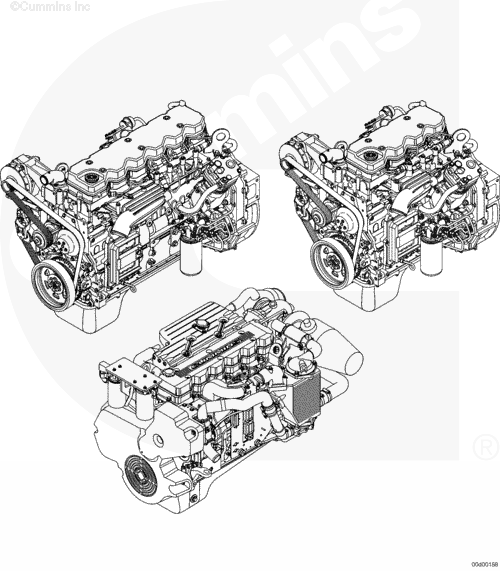

Page 33: Engine Views

Some external components will be at different locations for different engine models. NOTE: The illustrations are only a reference to show a typical engine. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com…

-

Page 34

15 Ambient air pressure sensor (internal to ECM) 16 Fuel inlet to cooling plate 17 Air intake inlet 18 Coolant outlet 19 Rail pressure sensor 20 Fuel rail. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 35

15 Ambient air pressure sensor (internal to ECM) 16 Fuel inlet to cooling plate 17 Air intake inlet 18 Coolant outlet 19 Rail pressure sensor 20 Fuel rail. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 36

8 Fan or PTO drive flange mounting 9 Starter 10 Water pump 11 Coolant inlet 12 Belt tensioner 13 Alternator 14 Coolant outlet 15 Coolant temperature sensor. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 37

8 Fan or PTO drive flange mounting 9 Starter 10 Water pump 11 Coolant inlet 12 Belt tensioner 13 Alternator 14 Coolant outlet 15 Coolant temperature sensor. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 38

2 Air outlet from turbocharger 3 Air inlet to turbocharger 4 Flywheel 5 Flywheel housing 6 Crankcase breather tube 7 Fuel return line 8 Engine lifting brackets. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 39

2 Air outlet from turbocharger 3 Air inlet to turbocharger 4 Flywheel 5 Flywheel housing 6 Crankcase breather tube 7 Fuel return line 8 Engine lifting brackets. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 40

4 Coolant inlet 5 Oil filter 6 Oil pan drain plug 7 Turbocharger exhaust outlet 8 Starter 9 Flywheel housing 10 Turbocharger compressor inlet. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 41

4 Coolant inlet 5 Oil filter 6 Oil pan drain plug 7 Turbocharger exhaust outlet 8 Starter 9 Flywheel housing 10 Turbocharger compressor inlet. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 42

12 Engine speed sensor (crankshaft) 13 Tone wheel 14 Coolant temperature sensor 15 Vibration damper 16 Coolant outlet 17 Alternator 18 Oil pressure/temperature sensor 19 Exhaust manifold. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 43

12 Engine speed sensor (crankshaft) 13 Tone wheel 14 Vibration damper 15 Coolant temperature sensor 16 Coolant outlet 17 Alternator 18 Oil pressure/temperature sensor 19 Exhaust manifold. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 44

9 Engine speed sensor (crankshaft) 10 Electronic control module (ECM) 11 Engine position sensor (camshaft) 12 Air intake inlet 13 Rail pressure sensor 14 Dipstick To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 45

7 Vibration damper 8 Water pump 9 Starter 10 Belt tensioner 11 Alternator 12 Coolant outlet 13 Coolant temperature sensor 14 Turbocharger air outlet To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 46

1 Rear engine lifting bracket 2 Turbocharger exhaust outlet 3 Clutch mounting holes 4 Flywheel housing 5 Flywheel/flexplate 6 Crankcase breather tube 7 Injector drain line To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 47

4 Lubricating oil cooler 5 Oil filter 6 Oil pan drain plug 7 Turbocharger exhaust outlet 8 Starter 9 Flywheel housing 10 Turbocharger compressor inlet. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 48

8 Tone wheel 9 Vibration damper 10 Coolant temperature sensor 11 Coolant outlet 12 Alternator 13 Exhaust manifold 14 Rail pressure relief valve To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 49

12 Dipstick/oil level sensor 13 Electronic control module (ECM) 14 Air intake inlet 15 Coolant outlet 16 Fuel rail pressure relief valve 17 Fuel rail. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 50

7 Fan or PTO drive flange mounting 8 Starter mounting location 9 Coolant inlet 10 Water pump 11 Belt tensioner 12 Alternator 13 Coolant outlet 14 Coolant temperature sensor. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 51

2 Air outlet from turbocharger 3 Air inlet to turbocharger 4 Flywheel 5 Flywheel housing 6 Crankcase breather tube 7 Fuel return line 8 Engine lifting brackets. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 52

4 Coolant inlet 5 Oil filter 6 Oil pan drain plug 7 Turbocharger exhaust outlet 8 Starter 9 Flywheel housing 10 Turbocharger compressor inlet. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 53

9 High-pressure fuel lines 10 Oil fill cap 11 Tone wheel 12 Coolant temperature sensor 13 Vibration damper (Optional) 14 Coolant outlet 15 Exhaust manifold. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 54

16 Electronic control module (ECM) 17 Engine speed sensor (camshaft) 18 Air intake inlet 19 EGR temperature sensor 20 Fuel heater 21 Rail pressure sensor. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 55

14 Starter 15 Coolant inlet 16 Belt tensioner 17 Water pump 18 Freon compressor 19 Alternator 20 Coolant outlet 21 Coolant temperature sensor. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 56

7 Flywheel 8 Gear housing 9 Crankcase breather 10 Fuel out (return to tank) 11 Coolant connection for air compressor 12 Fuel return line. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 57

12 Turbocharger speed sensor 13 Turbocharger exhaust outlet 14 Starter 15 Flywheel housing 16 Gear housing 17 EGR cooler 18 EGR valve 19 EGR actuator. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 58

13 EGR differential pressure sensor 14 Tone wheel 15 Vibration damper 16 Oil fill cap 17 Coolant temperature sensor 18 Coolant outlet 19 Alternator 20 Oil filter. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 59

Engine Diagrams ISB, ISBe and QSB (Common Rail […] Page E-32 Section E — Engine and System Identification To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 60

10 Mounting brackets 11 Oil pan 12 Lubricating oil drain 13 Belt and pulley guards 14 Lubricating oil filter 15 Lubricating oil filter head inlet. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 61

19 Fuel return from high pressure fuel pump 20 Crankshaft speed sensor 21 Camshaft speed sensor 22 Oil pressure sensor 23 Fuel pump 24 Fuel cooler 25 Sea water pump. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 62

18 Closed crankcase breather oil drain line 19 Flywheel housing 20 Heat exchanger engine coolant outlet 21 Heat exchanger sea water inlet 22 Marine gear oil cooler 23 Turbocharger To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 63

9 Flywheel housing 10 Flywheel 11 Aftercooler air inlet 12 Aftercooler zinc anode 13 Marine gear oil cooler 14 Air cleaner and filter. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 64

18 Exhaust outlet connection 19 Closed crankcase breather blow-by connection 20 Air inlet restriction indicator 21 Air cleaner connection 22 Closed crankcase breather/air cleaner assembly To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 65

4 Exhaust elbow 5 Tailstock assembly 6 Driveshaft 7 Trim cylinder zinc anode 8 Ventilation plate zinc anode 9 Sterndrive™ 10 Trim cylinder. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 66

4 Bearing support assembly 5 Tailstock assembly 6 Driveshaft 7 Trim cylinder 8 Ventilation plate zinc anode (bottom of ventilation plate) 9 Trim cylinder zinc anode. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 67

5 Gear oil drain plug 6 Sea water outlet valve 7 Transmission drain 8 Steering and transmission oil cooler 9 Exhaust outlet connection. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 68

6 Propeller shaft 7 Drive skeg 8 Gear housing 9 Sea water inlet and seacock 10 Drive shaft (under shield) 11 Drive shaft shield. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 69

Section E — Engine and System Identification Zeus™ 3500 (Top View) 1 Transmission dipstick 2 Steering and transmission fluid reservoir fill 3 Transmission filter. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 70

Engine Diagrams Section E — Engine and System Identification Page E-43 Zeus™ 3500 Drop Box (Starboard View) 1 Exhaust riser 2 Transmission drop box. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 71

ISB, ISBe and QSB (Common Rail […] Page E-44 Section E — Engine and System Identification Zeus™ 3500 Drop Box (Port View) 1 Drop box drain plug To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 72

If the engine operates on a fuel type other than diesel, the type will be identified after the liter size. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 73

Example: 1 On-Highway automotive «X» 15 liter engine 2 Control system number 871 3 Technology supported; Electric EGR and Diesel Particulate Filter To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 74

Modular Common Rail System Used only on QSK19, 38, 50 , 60 MCRS HHP Engines Integrated Dosing Control Unit Not Used None Integrated To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 75

Cummins® Service Engine Model Product Identification ISB, ISBe and QSB (Common Rail […] Page E-48 Section E — Engine and System Identification Notes… -

Page 76

Fuel System — Overview ………………………..F-6 General Information…………………………F-6 Injectors and Fuel Lines — Overview ……………………F-14 General Information…………………………F-14 Lubricating Oil System — Overview …………………….F-16 General Information…………………………F-16 To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 77

ISB, ISBe and QSB (Common Rail […] Page F-b Section F — Familiarization This Page Left Intentionally Blank… -

Page 78

General Information Connecting Rods This familiarization section helps to identify and orient the various styles of ISB connecting rods for installation. These details are important because some connecting rods are not marked with a part number and identification can be difficult. -

Page 79

ISB 4.5, ISB 6.7 Connecting Rod Joint: Machined Cylinder Bore: 107 mm [4.212 in] Cylinder Stroke: 124 mm [4.881 in] Orientation: Through hole toward camshaft To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 80

ISB 4.5, ISB 6.7 Connecting Rod Joint: Fractured Cylinder Bore: 107 mm [4.212 in] Cylinder Stroke: 124 mm [4.881 in] Orientation: Blind hole toward camshaft To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 81

Use the following illustrations to identify 3.9 Liter, 4.5 Liter, 5.9 Liter, and 6.7 Liter (6 cylinder) connecting rods. Note: Lead-free bushings (10) Part Numbers 4983518 and 5257363 are not serviceable. Connecting Rod Characteristics 1 Balancer 2 Machined surface To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 82

9 Oil grooves in leaded bushing Part Number 4891178 5 Smooth 10 Oil grooves in lead-free bushings Part Numbers 4983518/5257363. (These bushings 6 Single dimple serviceable) 7 Three dimple To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 83

The fuel that enters the high-pressure fuel pump is pressurized between 250 and 1800 bar [3626 to 26107 psi] by three radial pumping chambers. An M-Prop valve, or electronic fuel control (EFC) valve, at the inlet to the three radial To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 84

Exceeding the maximum capacity will cause the gauge to read incorrectly. If the maximum is exceeded, check the gauge against a reference gauge. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 85

NOTE: Always use the same size and material of line or hoses that were originally supplied with the gauge. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 86

Tools required to troubleshoot the common rail system include: • M10 Compuchek® fittings • Orificed diagnostic fuel line, 0.043 mm [.002 in] To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 87

Maximum high pressure pump leakage 300 cc [.32 quart] per 30 seconds @ 1500 rpm 300 cc [.32 quart] per 30 seconds @ cranking To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 88

NOTE: * Engines are either equipped with an air cooled or fuel cooled ECM. If an air cooled ECM is used, the fuel enters the engine from the OEM connection at the gear pump inlet. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 89

14 High-pressure connector to fuel injector 15 Fuel injector 16 Injector return line 17 Pressure relief return line 18 Fuel pump return line 19 Fuel return manifold. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 90

18 Injector return line 19 Fuel pump to fuel manifold return 20 Fuel manifold to fuel cooler 21 Fuel cooler 22 Fuel return to tank. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 91

NOTE: The edge filters are not a substitute for cleaning and covering all fuel system connections during repair. Edge filters are not a substitute for maintaining the recommended engine mounted fuel filter. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 92

Exceeding the maximum capacity will cause the gauge to read incorrectly. If the maximum is exceeded, check the gauge against a reference gauge. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 93

This is due to the fact that all B series engines use sliding tappets. NOTE: If CI/SK oils are not available, see the appropriate Operation and Maintenance manual for your engine for alternatives. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 94

When the diagnosing lubricating system malfunctions, check all obvious items related to oil pressure, such as gauges, high level, excessive contamination, and oil viscosity. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 95

To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 96

The engine will have low pressure or no oil pressure during starting, followed by normal oil pressure. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 97

Coolant in the oil can be caused by: • Expansion plugs leaking • Oil cooler element leaking • Damaged cylinder head or gasket • Cracked engine block • Casting porosity. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 98

Lubricating oil drain plug. Refer to Procedure Procedure 007-037. Leaks indicate defective oil cooler, cylinder head gasket, or cracked cylinder head or block. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 99

An injector leak will also cause the engine to run rough and have low power. Remove and repair, or replace leaking injectors. Refer to Procedure Procedure 006-026 To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 100

NOTE: If the engine experiences a turbocharger failure or any other occasion where oil or debris is put into the charge air cooler, the charge air cooler must be cleaned. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 101

Also, a failed air compressor head gasket or cylinder head gasket can allow oil to leak into the coolant or coolant to leak into the oil during a hot shutdown. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 102

10 Filter bypass valve open 11 To lubricating oil filter 12 Full-flow lubricating oil filter 13 From lubricating oil filter 14 Main lubricating oil rifle. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 103

© Cummins Inc. © Cummins Inc. 07d00074 Lubrication for the Turbocharger, Non Marine Engines 1 Turbocharger lubricating oil supply 2 Turbocharger lubricating oil drain. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 104

2 Filtered oil supply to main oil rifle 3 Lubricating oil cooler 4 Unfiltered lubricating oil to filter 5 Turbocharger lubricating oil supply 6 Turbocharger lubricating oil drain. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 105

6 To camshaft 7 Crankshaft main journal 8 Oil supply to rod bearings 9 Directed piston-cooling nozzle 10 To internal lubrication of air compressor. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 106

1 Main lubricating oil rifle 2 Rocker lever support 3 Transfer slot 4 Rocker lever shaft 5 Rocker lever bore 6 Rocker lever. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 107

Lubrication for the Accessory Drive 1 Oil feed from block 2 Oil supply to accessory drive. NOTE: Oil returns to pan through the gear housing. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 108

On engines with EGR, the vent pipe plug located in the EGR cooler bundle return must be removed any time the engine is filled with coolant. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 109

Refer to Procedure Procedure 007-999 (Lubricating Oil System- Overview). NOTE: Transmission fluid can also leak into the coolant through radiator bottom tank transmission oil coolers. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 110

8 Coolant bypass passage 9 Coolant flow back to radiator 10 Bypass open 11 Coolant bypass in cylinder head 12 Coolant flow to water pump inlet. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 111

8 Coolant flow from cylinder block to turbocharger bearing housing 9 Coolant flow return from turbocharger bearing housing back to the rear of the cylinder head. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 112

12 Turbocharger vent line 13 Cylinder head vent line 14 Exhaust manifold vent line 15 Coolant recovery bottle 16 Heat exchanger zinc anode. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 113

11 Turbocharger with Water Cooled Turbine Housing 12 Turbocharger Coolant Outlet 13 Engine Coolant Outlet to Thermostat Housing 14 Coolant Outlet to Keel Cooler. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 114

3 Fuel cooler 4 Aftercooler zinc anode 5 Aftercooler housing 6 Marine gear oil cooler 7 Heat exchanger 8 Exhaust outlet 9 Sea water discharge To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 115

The combustion air system on Marine engines consists of the following: • Air cleaner with oil separator system • Water-cooled turbocharger • Aftercooler • Air piping • Wet exhaust manifold. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 116

1 Intake air inlet to turbocharger 2 Turbocharger air to aftercooler 3 Aftercooler 4 Intake manifold 5 Intake valve. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 117

See the corresponding Operation and Maintenance, or Owner’s Manual for the engine being serviced. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 118

Low-boost pressures can cause excessive smoke and low power. High-boost pressures can cause major engine damage. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 119

NOTE: If this occurs, it is necessary to flush the charge air cooler to clean oil from the intake system. Refer to Procedure 010-027 and Refer to Procedure 010-023 To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 120

If suspect, check for turbocharger blade damage and bearing clearance. Refer to Procedure 010-033 If leaks, blade damage, or improper clearances are found, replace the turbocharger. Refer to Procedure 010-033 To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 121

NOTE: The long-term integrity of the charge air cooling system is the responsibility of the vehicle and component manufacturers. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 122

2 Turbocharger air to charge air cooler 3 Charge air cooler 4 Intake manifold (integral part of the cylinder head) 5 Intake valve. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 123

2 Turbocharger air to charge air cooler 3 Charge air cooler 4 EGR mixer 5 Intake manifold (integral part of the cylinder head) 6 Intake valve. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 124

© Cummins Inc. © Cummins Inc. © Cummins Inc. 10d00197 1 Intake air inlet 2 Turbocharger 3 Aftercooler 4 Intake manifold 5 Intake valve To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 125

© Cummins Inc. © Cummins Inc. © Cummins Inc. © Cummins Inc. 11d00018 1 Exhaust valve 2 Exhaust manifold 3 Turbocharger 4 Turbocharger exhaust outlet. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 126

6 Exhaust gas from EGR valve to EGR cooler connection 7 EGR cooler 8 Cooled exhaust gas to EGR connection tube and EGR mixer. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 127

© Cummins Inc. © Cummins Inc. © Cummins Inc. 11d00095 1 Exhaust valve 2 Exhaust manifold (wet) 3 Turbocharger (water cooled) 4 Exhaust outlet. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 128

The intake air would be approximately equal ambient air pressure. Various brands of compressors can be used on the ISB and QSB (4 and 6 cylinder) engines. Troubleshooting procedures are very similar for these air compressors but refer to the compressor manufacturer’s manual for information including detailed repair information and torque values. -

Page 129

3 Coolant in 4 Coolant out 5 Lubricating oil in (internal to the gear housing) 6 Lubricating oil out (internal to the gear housing). To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 130

All necessary wiring. All components must be carefully matched. The accompanying illustrations show typical parallel and series battery connections: • Parallel connection • Series connection. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 131

50 percent indicate that something is wrong. The engine test must be discontinued until the cause has been determined and corrected. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 132

Driveability/Low Power/Excessive Fuel Consumption — Checklist…………….TS-8 Engine Noise Diagnostic Procedures — General Information………………TS-3 Fuel Consumption — Customer Complaint Form…………………TS-10 Fuel Consumption — General Information…………………….TS-9 To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 133

ISB, ISBe and QSB (Common Rail […] Page TS-b Section TS — Troubleshooting Symptoms Main Bearing Noise…………………………TS-3 Oil Consumption…………………………TS-11 Piston Noise…………………………..TS-3 To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 134

Determine the cause of the problem and make a thorough repair • After repairs have been made, operate the engine to make sure the cause of the complaint has been corrected To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 135

Follow through the chart to identify the corrective action. WARNING Troubleshooting presents the risk of equipment damage, personal injury or death. Troubleshooting must be performed by trained, experienced technicians. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 136

To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 137

Engine-related poor acceleration or response can be caused by several different factors such as: Failed boost sensor, if equipped Excessive drainline restriction Accelerator deadband. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 138

After change in selected programmable parameters? Yes ________ No________ • If so, what was repaired and when?______________________________________________________________ • Does the vehicle also experience poor fuel economy? Yes ________No ________ To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 139

Troubleshooting Overview ISB, ISBe and QSB (Common Rail […] Page TS-6 Section TS — Troubleshooting Symptoms To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 140

POWER/EXCESSIVE FUEL CONSUMPTION CHECKLIST, AND GO TO THE POOR ACCELERATION/RESPONSE SYMPTOM TREE. Additional Comments: • ___________________________________________________________________________________________ ___________________________________________________________________________________________ ___________________________________________________________________________________________ _________ These Pages Can Be Copied for Your Convenience. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 141

Percent Asphalt Percent Concrete Additional Comments: ______________________________________________________________________________________________ ______________________________________________________________________________________________ __________________ NOTE: Use this information for VE/VMS® run. This Page Can Be Copied for Your Convenience To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 142

Additional vehicle factors, vehicle specifications, and axle alignment can also affect fuel consumption. For additional information on troubleshooting fuel consumption complaints, see Troubleshooting Excessive Fuel Consumption, Bulletin 3387245. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 143

ENVIRONMENTAL FACTORS, OR DRIVER TECHNIQUE, FILL OUT THE DRIVEABILITY/LOW-POWER/ EXCESSIVE FUEL CONSUMPTION CHECKLIST, AND GO TO THE FUEL CONSUMPTION EXCESSIVE TROUBLESHOOTING SYMPTOM TREE. This Page Can Be Copied for Your Convenience. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 144: Oil Consumption

KM PER KM PER FAMILY LITER QUART LITER IMPERIAL IMPERIAL QUART LITER IMPERIAL QUART QUART QUART 10.0 10.6 12.0 10.0 L, M, N To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com…

-

Page 145

Last Mileage/Hours/Kilometers_________________________ Minus Start Mileage/Hours/ Kilometers_________________________ Equals Test Mileage/Hours/Kilometers_________________________ Divided by Oil Added_________________________ Equals_________________________ Usage Rate_________________________ Customer Signature Cummins® Dealer Cummins® Distributor Cummins Inc. Form 4755 To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 146

Page TS-13 Oil Consumption OIL CONSUMPTION REPORT Customer Name: D/r: Engine Model: Mi/Km/Hr: Engine Serial Number: CPL Number: Vehicle Make/Model: Date: Signed: __________________________________________________ To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 147

Procedure 012-019 in Section 12 and the OEM ….. Air system leaks service manual. For vehicles equipped with air assisted aftertreatment components, check for leaks in the air supply lines. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 148

Procedure 012-019 in Section 12 and the OEM ….. Air system leaks service manual. For vehicles equipped with air assisted aftertreatment components, check for leaks in the air supply lines. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 149

Air compressor is excessively worn or internally ….. Refer to Procedure 012-014 in Section 12 and the damaged OEM service manual. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 150

Perform the oil carry-over test and inspect the ….. compressor passes the test, inspect the intake system for restriction. compressor intake system for restrictions. Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 151

Go To Next Step STEP 15 Inspect the air compressor. Refer to Procedure Air compressor is excessively worn or internally ….. 012-014 in Section 12. damaged To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 152

Procedure 012-019 in Section 12 and the OEM ….. Air system leaks service manual. For vehicles equipped with air assisted aftertreatment components, check for leaks in the air supply lines. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 153

Air system leaks service manual.. For vehicles equipped with air assisted aftertreatment components, check for leaks in the air supply lines. Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 154

Correction STEP 7 Inspect the air compressor. Refer to Procedure Air compressor is excessively worn or internally ….. 012-014 in Section 12. damaged To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 155

Procedure 012-019 in Section 12 and the OEM ….. Air system leaks service manual. For vehicles equipped with air assisted aftertreatment components, check for leaks in the air supply lines. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 156

Refer to ….. Alternator or voltage regulator is malfunctioning Procedure Procedure 013-001 and the OEM service manual. Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 157

Refer to the corresponding Electronic Control Electronic fault codes active or high counts of ….. System Troubleshooting and Repair Manual for inactive fault codes the engine being serviced. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 158

Go To Next Step STEP 5 Refer to boat manufacturer’s specification and ….. Battery isolator failed (if equipped) wiring. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 159

Gradual Overheat symptom tree or the Coolant ….. Engine is overheating Temperature is Above Normal — Sudden Overheat symptom tree . Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 160

Go To Next Step STEP 9 Pressure-test the coolant system. Refer to Wet exhaust manifold and turbine housing leaking ….. Procedure 008-020. coolant To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 161

Go To Next Step Inspect the cylinder block. Refer to Procedure STEP 9 ….. Cylinder block is cracked or porous 001-026 in Section 1. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 162

Fan shroud is damaged or missing or the air ….. Repair, replace, or install, if necessary. Refer to recirculation baffles are damaged or missing Procedure 008-038. Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 163

Refer to the Intake Manifold Air Temperature Intake manifold air temperature is above ….. Above Specification symptom tree . specification Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 164

STEP 25 ….. are using the correct components. Refer to the Vehicle cooling system is not adequate OEM service manual. Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 165

Check for air or combustion gases in the cooling Air or combustion gases are entering the cooling ….. system. Refer to Procedure 008-020. system To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 166

Test the temperature gauge. Repair or replace the STEP 8 ….. gauge, if necessary. Refer to the OEM service Coolant temperature gauge is malfunctioning manual. Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 167

Go To Next Step Perform the cooling system diagnostics test. Refer STEP 16 ….. Cooling system component is malfunctioning to Procedure 008-020. Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 168

Remove and inspect the cooler cores and o-rings. Torque converter cooler or hydraulic oil cooler is ….. Refer to the OEM service manual. malfunctioning To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 169: Coolant Temperature Below Normal

Fan drive or fan controls are malfunctioning the engine’s ECM. If OEM controlled, refer to the OEM service manual. Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com…

-

Page 170

OEM service manual Go To Next Step STEP 9 Perform the cooling system diagnostics test. Refer ….. Cooling system component is malfunctioning to Procedure 008-020. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 171: Coolant In The Lubricating Oil

Procedure 002-004. Go To Next Step Inspect the cylinder block. Refer to Procedure STEP 7 ….. Cylinder block is cracked or porous 001-026. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com…

-

Page 172

Go To Next Step Inspect the sea water pump impeller. Refer to STEP 6 ….. Sea water pump is not pumping water Procedure 008-057. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 173

Check the valve stems and seals. Refer to Valve stem clearance is excessive or the valve ….. Procedure 002-004 in Section 2. stem seals are damaged Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 174

001-043 in Section 1. For cylinder block inspection and reuse; Refer to Procedure 001-026 in Section 1. For piston ring inspection; Refer to Procedure 001-047 in Section 1. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 175

Check the fuel pump output pressure with INSITE™, an electronic service tool. Replace the STEP 9 ….. Fuel pump is malfunctioning fuel pump if necessary. Refer to Procedure 005-016. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 176: Engine Decelerates Slowly

STEP 6 ….. recommendations. Check the clutch for correct Clutch is malfunctioning or is not correct operation. Refer to the OEM service manual. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com…

-

Page 177

STEP 8 ….. Lubricating oil pressure is below specification is low, refer to the Lubricating Oil Pressure Low symptom tree. Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 178

Go To Next Step Check the torque converter. Refer to the OEM STEP 17 ….. Torque converter is loose service manual. Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 179

001-047. Analyze the lubricating oil and oil filters to Piston or piston rings are worn or damaged locate an area of probable damage and cause. Procedure 007-044 and Procedure Procedure 007-083. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 180

….. the orientation and tops of the pistons for debris. Piston is misassembled Procedure 001-054 for piston orientation and if necessary, piston removal. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 181

Inspect the connecting rod and bearings. Refer to ….. worn, are not assembled correctly, or are the Procedure 001-014. wrong bearings Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 182

Go To Next Step Inspect the crankshaft journals. Refer to Procedure STEP 10 ….. Crankshaft journals are damaged or out of round 001-016. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 183

Check the flywheel or flexplate and the mounting Flywheel or flexplate capscrews are loose or ….. capscrews. Refer to Procedures 016-004 and broken 016-005. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 184

Piston pin or bushing is loose, worn, or not ….. bushing for damage, wear, and correct installation. installed correctly Refer to Procedure 001-043 or 001-054. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 185

Check the turbocharger for damage. Measure the STEP 7 ….. turbine and compressor wheel clearances. Refer Turbocharger is worn or damaged to Procedure 010-033 in Section 10. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 186

Check for air in the fuel system. Refer to STEP 7 ….. Air in the fuel system Procedure 006-003. Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 187

Refer to OEM service manual and/or Procedure 019-085 in the corresponding Troubleshooting and Repair Manual for the engine being serviced. Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 188

STEP 19 ….. Fuel connector is leaking fuel that can cause fuel leaks. Refer to Procedures 006-026 and 006-052. Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 189

Inspect the turbocharger. Repair or Turbocharger wheel clearance is out of ….. replace the turbocharger if necessary. Refer to specification Procedure 010-033. Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 190

Analyze the oil and inspect the filters to locate an STEP 32 ….. area of probable damage. Refer to Procedure Internal engine damage 007-044. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 191

Battery cables are not the correct gauge or length manual. Go To Next Step STEP 9 ….. Disengage engine-driven units. Engine-driven units are engaged Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 192

Analyze the oil and inspect the filters to locate an STEP 14 ….. area of probable damage. Refer to Procedure Internal engine damage 007-083 in Section 7. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 193

….. shorter length cables. Refer to the OEM service Battery cables are not the correct gauge or length manual. Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 194

Analyze the oil and inspect the filters to locate an STEP 16 ….. area of probable damage. Refer to Procedure Internal engine damage 007-083 in Section 7. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 195

Fill the system to the ….. Lubricating oil level is above specification specified level. Refer to Procedures 007-009 and 007-043. Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 196

Analyze the oil and inspect the filters to locate an STEP 12 ….. area of probable damage. Refer to Procedure Internal engine damage 007-044. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 197

STEP 5 ….. the Electronic Control System Troubleshooting and Electronic control module (ECM) is malfunctioning Repair Manual for the engine being serviced . To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 198: Fuel Consumption Excessive

19 in the corresponding Electronic Control System Troubleshooting and Repair Manual for the engine being serviced. Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com…

-

Page 199

STEP 14 Vessel is malfunctioning or parasitics are ….. and driven accessories. Refer to the OEM service excessive manual. Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 200

Inspect the air intake and exhaust systems for air STEP 21 ….. leaks. Refer to Procedure Procedure 010-024 in Air intake or exhaust leaks Section 10. Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 201

Analyze the oil and inspect the filters to locate an STEP 28 ….. area of probable damage. Refer to Procedure Internal engine damage Procedure 007-044 in Section 7. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 202

Cylinder head is cracked or porous Pressure test the cooling system and look for coolant leaks. See Procedure 008-020. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 203: Fuel In The Lubricating Oil

STEP 8 ….. sealing washer thickness. Refer to Procedure Injector sealing washer is not correct 006-026 in Section 6. Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com…

-

Page 204

Analyze the oil and inspect the filters to locate an STEP 10 ….. area of probable damage. Refer to Procedure Internal engine damage 007-044 in Section 7. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 205

Control System Troubleshooting and Repair Manual for the engine being serviced, to monitor and check the manifold temperature sensor. Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 206

Refer to Procedure ….. Incorrect/Excessive exhaust brake operation 020-016 in Section 20 and/or the manufacturers instructions Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 207

Verify that the fan is the correct size. Refer to the ….. Fan is not an adequate size for the application OEM service manual. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 208

Turbocharger wastegate is damaged or is stuck ….. Inspect the wastegate for damage. Refer to open Procedure 010-050 in Section 10. Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 209

Go To Next Step Refer to the Engine Power Output Low STEP 11 ….. Engine power output is low troubleshooting symptom tree in Section TS. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 210: Lubricating Oil Consumption Excessive

QSB6.7 engines, use the following procedure in the QSB4.5 and QSB6.7 Engines Operation and Maintenance Manual, Bulletin 4021531. Refer to Procedure 102-002 in Section 2. Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com…

-

Page 211

Check the valve stems and seals. Refer to Valve stem clearance is excessive or the valve ….. Procedure 002-004 in Section 2. stem seals are damaged Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 212

Analyze the oil and inspect the filters to locate an STEP 16 ….. area of probable damage. Refer to Procedure Internal engine damage 007-044 and Procedure 007-083 in Section 7. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 213: Lubricating Oil Contaminated

Change the oil filters….Bulk oil supply is contaminated Refer to Procedure 007-013 and Procedure 007-037 in Section 7. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com…

-

Page 214: Lubricating Oil Pressure High

STEP 6 ….. is correct. Refer toProcedure Procedure 007-092 Lubricating oil filter plumbing not routed correctly in Section 7. Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com…

-

Page 215

STEP 8 Replace the main oil pressure regulator assembly….Main oil pressure regulator is malfunctioning Refer to Procedure 007-029 in Section 7. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 216: Lubricating Oil Pressure Low

Refer to the Lubricating Oil Contaminated STEP 7 ….. Lubricating oil is contaminated with coolant or fuel symptom tree . Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com…

-

Page 217

See the appropriate parts manual and /or the QuickServe® Online Internet Website. If necessary replace the oil pump. Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 218

Internal engine damage or internal lubricating oil ….. probable damage. Places for probable damage leak include internal cup plugs, main bearings, rod bearings, cam bushings and rocker levers. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 219: Lubricating Oil Sludge In The Crankcase Excessive

Go To Next Step STEP 8 Check for excessive blowby. Refer to Procedure ….. Crankcase pressure is excessive 014-010. Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com…

-

Page 220

Cause Correction STEP 9 Check the exhaust system for restriction. Refer to Exhaust system restriction is above or below ….. Procedure 011-009. specification To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 221: Lubricating Oil Temperature Above Specification

Analyze the oil and inspect the filters to locate an STEP 8 ….. area of probable damage. Refer to Procedure Internal engine damage 007-083 and Procedure 007-044. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com…

-

Page 222

Go To Next Step Replace the cylinder block. Refer to Procedure STEP 8 ….. Cylinder block is cracked or porous 001-026 in Section 1. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 223: Turbocharger Leaks Engine Oil Or Fuel

STEP 8 Check the exhaust system for restrictions. Refer to Exhaust system restriction is not within ….. Procedure 011-009. specification Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com…

-

Page 224

Check the valve stems and seals. Refer to Valve stem clearance is excessive or the valve ….. Procedures 002-004. stem seals are damaged To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 225

STEP 5 ….. catalyst. Repair as necessary. Refer to Procedure Urea leak (internal) Procedure 011-036, Exhaust Catalyst. Procedure 011-040, Aftertreatment Nozzle. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 226

Refer to Procedure 008-002 in Section 8 or the OEM service manual. Go To Next Step To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 227

STEP 9 belt alignment laser tool, Part Number 3163524, or ….. Accessory pulley is out of alignment equivalent. Refer to Procedure 008-002 in Section To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 228

Engine Performance Troubleshooting Tree — ISB, ISBe, and QSB engines without EGR (CM800 and CM850 Electronic Control System) ………………………..TT-1 Engine Performance Troubleshooting Tree for QSB5.9 Marine Engines with CM850 Electronic Control System ………………………………TT-49 Vibration Excessive ………………………..TT-141 To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 229

ISB, ISBe and QSB (Common Rail […] Page TT-b Section TT — Troubleshooting Symptoms (New Format) This Page Left Intentionally Blank… -

Page 230

Poor acceleration or response is difficult to troubleshoot, since it can be caused by several factors. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 231

STEP 3C: Monitor the engine speed during Is the engine speed greater than cranking. 150 rpm during cranking? To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 232

STEP 4K: Measure fuel drain line Is the drain line restriction less restriction. than specification? To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 233

STEP 7: Perform base engine mechanical checks. STEP 7A: Verify overhead adjustments are Are the overhead settings within correct. the lash check limits? To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 234

STEP 8I-1: Check the internal engine Is the internal engine balancer balancer. timing incorrect or is the balancer damaged? To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 235

• Verify there are no visible coolant leaks. • Verify the crankshaft position and the camshaft position sensors are correctly connected to the engine harness. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 236

Start or Will Not Start (With or Without Exhaust Smoke), Engine Shuts Off or Dies Unexpectedly or Dies During Deceleration, or Engine Starts but Will Not Keep Running? To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 237

Step 6 — Electronics Checks Step 7 — Base Engine Checks Is the engine symptom Excessive White Smoke and is the engine using coolant? To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 238

Coolant Loss coolant is being used. — Internal Troubleshoot Check the coolant level. ing Symptom (TS) Tree. Is the engine using coolant? 2D-2 To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 239

Perform the troubleshooting steps in the recommended order listed below: Step 4 — Fuel System Checks Step 7 — Perform Base Engine Mechanical Checks. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 240

Response Poor, Engine Power Output Low, Engine Decelerates Slowly, Intake Manifold Pressure (Boost) is Below Normal or Engine Will Not Reach Rated Speed (RPM)? To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 241

Is the engine symptom Engine Vibration Excessive? Is the engine symptom Engine Vibration For engine Excessive? related symptoms, see the correct troubleshooti ng symptom (TS) tree. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 242

Program the electronic features per the Protection. customer or OEM requirements. Are electronic features and programmable parameters the cause for the engine shutting down or the no-start complaint? To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 243

Consult the corresponding wiring diagram for the engine being serviced for connector pin identification. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 244

Check the battery connections and fuse terminals. Consult the corresponding wiring diagram for the engine being serviced for connector pin identification. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 245

ISC, QSC8.3, ISL, ISLe3, ISLe4, and QSL9 CM850 Electronic Control System Troubleshooting and Repair Manual, Bulletin 4021416. Refer to Procedure 019-115 in Section 19. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 246

If Fault Code 2215 or 559 becomes active, adequate fuel rail pressure is not being developed. Discontinue using this troubleshooting tree and troubleshoot Fault Code 2215 or 559. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 247

Is air present in the fuel supply? To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 248

• Fuel pressure range: 3 to 11 bar [44 to 160 psi]. Record the fuel filter inlet pressure measured. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 249

Procedure 005-016 in Section 5. minder can be checked to see if there is something on the OEM side causing an intermittent high restriction. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 250

It may be necessary to cut out multiple 006-026 in Section 6 cylinders at a time. Can the miss or excessive smoke be attributed to a single cylinder? To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 251

Attempt to start the engine or operate the engine smoke be attributed to a cylinder(s)? at idle. Repeat the above test, as necessary, with each cylinder blocked off. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 252

Fuels with low viscosity will result in higher injector leakage and greater drain flow rates. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 253

STEP 4I: Check the fuel pressure relief valve for excessive leakage. Condition: • Use the following procedure in the ISBe, ISB, and QSB (Common Rail Fuel System) Service Manual, Bulletin 4021271. Refer to Procedure 006-061 in Section 6. Action Specification/Repair Next Step Measure the fuel pressure relief valve drain flow. -

Page 254

STEP 4J: Measure the high-pressure fuel supply pump fuel drain flow. Condition: • Use the following procedure in the ISBe, ISB, and QSB (Common Rail Fuel System) Service Manual, Bulletin 4021271. Refer to Procedure 005-016 in Section 5. Action Specification/Repair… -

Page 255

Were any air intake system leaks found? air compressor intake line. The intake line supplies intake air from the intake of the engine to the air compressor. To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 256

Dirty Filter Is the air intake restriction greater than the specification? 635 mm-H O; [25 in-H Clean Filter 254 mm-H O; [10 in-H To buy Cummins Parts and Service Manuals, Training Guides, or Tools go to our website at https://store.cummins.com… -

Page 257