Руководство на английском языке по техническому обслуживанию и ремонту двигателей Hino моделей W06D-TI и W06D-TI-II.

- Автор: —

- Издательство: Hino Motors

- Год издания: —

- Страниц: 236

- Формат: PDF

- Размер: 3,4 Mb

Руководство на английском языке по техническому обслуживанию и ремонту двигателей Hino моделей W04C-T, W04C-TI, W04D.

- Автор: —

- Издательство: Hino Motors

- Год издания: —

- Страниц: 216

- Формат: PDF

- Размер: 5,2 Mb

Руководство на английском языке по техническому обслуживанию и ремонту двигателей Hino модели W04D.

- Автор: —

- Издательство: Hino Motors

- Год издания: —

- Страниц: 205

- Формат: PDF

- Размер: 4,4 Mb

Руководство по техническому обслуживанию и ремонту двигателей Hino моделей H06, H06C-T, H06C, H07C-T, H07D, EH700, EH700-TI, EP100-TI.

- Автор: —

- Издательство: Легион-Автодата

- Год издания: —

- Страниц: 144

- Формат: —

- Размер: —

Руководство по техническому обслуживанию и ремонту двигателей Hino моделей J08C-TP, J08C-TR, J05C, J05C-TD, J05D, J05E-TE, J05E-TC, J05E-TD, S05C, S05C-B, S05C-TA, S05C-TB, S05D.

- Автор: —

- Издательство: Легион-Автодата

- Год издания: —

- Страниц: 190

- Формат: —

- Размер: —

Руководство по техническому обслуживанию и ремонту двигателей Hino моделей J05C, S05C, S05C-B, S05C-TA, S05C-TB, S05D.

- Автор: —

- Издательство: Легион-Автодата

- Год издания: —

- Страниц: 120

- Формат: —

- Размер: —

Руководство по техническому обслуживанию и ремонту двигателей Hino моделей W04 и W06.

- Автор: —

- Издательство: Легион-Автодата

- Год издания: —

- Страниц: 134

- Формат: —

- Размер: —

Diesel Injection Pump

SERVICE MANUAL

Common Rail System for HINO Dutro / TOYOTA Dyna N04C-T# Type Engine

OPERATION

November, 2003

00400058E

|

TABLE OF CONTENTS |

|||

|

1. |

Product Application List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

|

|

1-1. |

Vehicle Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

|

|

1-2. |

Component Part Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

|

|

2. |

Common Rail System Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

|

|

2-1. |

Background to Development . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

|

|

2-2. |

System Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

|

|

2-3. Comparison to The Conventional System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3 |

||

|

3. |

Outline of TOYOTA / HINO Small Truck Common Rail System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 |

|

|

3-1. |

Main System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 |

|

|

3-2. Outline of Composition and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 |

||

|

3-3. Fuel System and Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

||

|

4. |

Description of Main Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

|

|

4-1. |

Supply Pump (HP3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

|

|

4-2. |

Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

14 |

|

|

4-3. |

Injector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

16 |

|

|

4-4. Engine ECU (Electronic Control Unit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

19 |

||

|

4-5. EDU (Electronic Driving Unit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

19 |

||

|

5. |

Description of Control System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

20 |

|

|

5-1. |

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

20 |

|

|

5-2. |

Description of Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

21 |

|

|

6. |

Various Types of Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

26 |

|

|

6-1. Common Rail System Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

26 |

||

|

6-2. Fuel Injection Quantity Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

27 |

||

|

6-3. Fuel Injection Timing Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

30 |

||

|

6-4. Fuel Injection Rate Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

31 |

||

|

6-5. Fuel Injection Pressure Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

31 |

||

|

7. |

Other (ECU Related) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

32 |

|

|

7-1. ECU External Wiring and Terminal Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

32 |

||

|

7-2. |

Diagnostic Trouble Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

38 |

|

1. |

Product Application List |

|||

|

1-1. |

Vehicle Specifications |

|||

|

Vehicle Name |

Engine Model |

Exhaust Volume |

||

|

HINO DUTRO / TOYOTA DYNA |

N04C-TF |

4.0L |

||

1-2. Component Part Numbers |

||||

|

Product Name |

HINO Part Number |

DENSO Part Number |

||

|

Supply Pump |

22730-1261B |

294000-0191 |

||

|

Rail |

22760-1170A |

095440-0490 |

||

|

Injector |

23910-1271A |

095000-5321 |

||

|

Engine ECU |

89660-37460 |

101758-6580 |

||

|

EDU |

89870-37030 |

101310-5391 |

||

|

APM (Accelerator Pedal Module) |

78100-37550 |

198800-3150 |

||

|

NE Sensor |

89411-1630A |

029600-1361 |

||

|

TDC Sensor |

89410-1570A |

949979-1310 |

||

|

Coolant Temperature Sensor |

83420-1250A |

071560-0110 |

||

|

AFM (Mass Airflow Meter) |

22204-21010 |

197400-2000 |

||

|

Intake Air Temperature Sensor |

89441-4310A |

071500-2490 |

||

|

Turbo Pressure Sensor |

89390-1080A |

079800-5890 |

||

|

EGR-V |

17350-1170A |

135000-7051 |

||

|

Exhaust Gas Temperature Sensor |

89441-37020 (IN) |

265600-0600 (IN) |

||

|

89441-37030 (OUT) |

265600-0530 (OUT) |

|||

-1-

2. Common Rail System Outline

2-1. Background to Development

•The common rail system was developed primarily to cope with exhaust gas regulations for diesel engines, and is a diesel injection control system with the following aims:

•To further improve fuel economy;

•To reduce noise;

•To achieve high power output.

2-2. System Characteristics

•The common rail system uses a type of accumulation chamber called a rail to store pressurized fuel, and injectors that contain electronically controlled solenoid valves to inject the pressurized fuel into the cylinders. Because the engine ECU controls the injection system (injection pressure, injection rate, and injection timing), the injection system is independent, and thus unaffected by the engine speed or load. This ensures a stable injection pressure at all times, particularly in the low engine speed range, and dramatically decreases the amount of black smoke ordinarily emitted by a diesel engine during start-up and acceleration. As a result, exhaust gas emissions are cleaner and reduced, and higher power output is achieved.

A.Injection Pressure Control

•Enables high-pressure injection even at low engine speeds.

•Optimizes control to minimize particulate matter and NOx emissions.

B.Injection Timing Control

•Enables finely tuned optimized control in accordance with driving conditions.

C.Injection Rate Control

•Pilot injection control injects a small amount of fuel before the main injection.

|

Common Rail System |

||||||||||

|

Injection Pressure Control |

Injection Timing Control |

Injection Rate Control |

||||||||

|

Optimization, High Pressurization |

Optimization |

Rate |

Pilot |

After-Injection |

||||||

|

Injection |

||||||||||

|

Post-Injection |

||||||||||

|

Injection Pressure |

Common Rail System |

Common Rail |

Injection |

Main |

||||||

|

System |

||||||||||

|

Injection |

||||||||||

|

Particulate |

||||||||||

|

NOx |

Crankshaft Angle |

|||||||||

|

Injection Quantity Control |

||||||||||

|

Conventional |

Conventional |

Cylinder Injection |

||||||||

|

Quantity Correction |

||||||||||

|

Pump |

TimingInjection |

|||||||||

|

Pump |

||||||||||

|

Speed |

Injection Pressure |

Speed |

Speed |

|||||||

|

1 |

3 |

4 |

2 |

|||||||

|

Q000518E |

||||||||||

|

-2- |

2-3. Comparison to The Conventional System |

||||

|

In-Line & VE Pumps |

Common Rail System |

|||

|

High-Pressure Pipe |

||||

|

Momentary High Pressure |

Supply |

Rail |

||

|

Timer |

Pump |

|||

|

Nozzle |

Normally High Pressure |

|||

|

Governor |

||||

|

System |

Delivery Valve |

|||

|

In-Line Pump |

||||

|

Feed |

SCV (Suction Control Valve) |

|||

|

Pump |

||||

|

Injector |

||||

|

Fuel Tank |

||||

|

VE Pump |

||||

|

Injection Quantity Control |

Pump (Governor) |

Engine ECU, Injector (TWV)*1 |

||

|

Injection Timing Control |

Pump (Governor) |

Engine ECU, Injector (TWV)*1 |

||

|

Rising Pressure |

Pump |

Engine ECU, Supply Pump |

||

|

Distributor |

Pump |

Engine ECU, Rail |

||

|

Injection Pressure Control |

Dependent upon speed and injection quantity |

Engine ECU, Supply Pump (SCV)*2 |

||

|

*1 TWV: Two Way Valve |

||||

|

*2 SCV: Suction Control Valve |

||||

|

Q000387E |

-3-

3. Outline of TOYOTA / HINO Small Truck Common Rail System

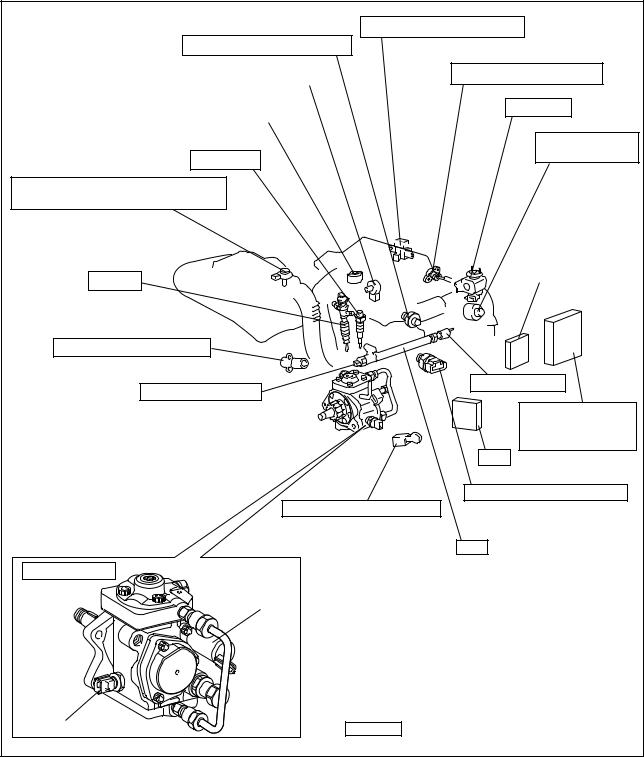

3-1. Main System Components

|

Accelerator Position Sensor |

|

|

Intake Air Temperature Sensor |

|

|

Variable Nozzle Type Turbo Opening Sensor |

Intake Air Pressure Sensor |

|

Variable Nozzle Type Turbo Motor |

EGR Valve |

|

Intake Restriction |

|

|

Glow Plug |

Step Motor |

|

Airflow Meter (With Integrated Ambient |

|

|

Air Temperature Sensor) |

|

|

Variable Nozzle |

|

|

Injector |

Controller |

|

Crankshaft Position Sensor |

|

|

Rail Pressure Sensor |

Pressure Limiter |

|

Engine ECU (With |

|

|

Built-In Atmospheric |

|

|

Pressure Sensor) |

|

|

EDU |

|

|

Coolant Temperature Sensor |

|

|

Cylinder Recognition Sensor |

|

|

Rail |

|

|

Supply Pump |

|

|

SCV |

|

|

Fuel Temperature Sensor |

Items are DENSO products |

|

Q000569E |

|

|

-4- |

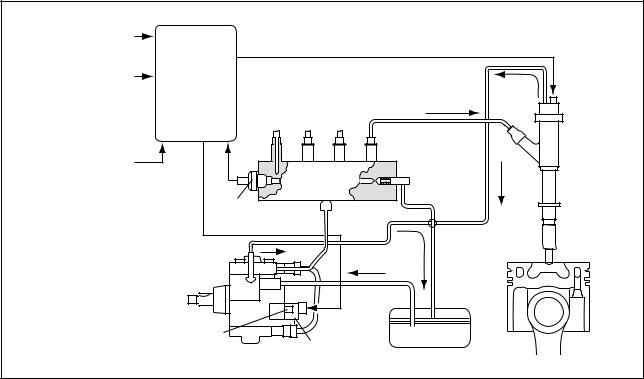

3-2. Outline of Composition and Operation A. Composition

The common rail system consists primarily of a supply pump, rail, injectors, and engine ECU.

Fuel Temperature

Vehicle Speed

Accelerator Opening

Intake Air Pressure

Intake Air Temperature

Coolant Temperature

Crankshaft Position

Cylinder Recognition Signal

|

Intake Airflow Rate |

|||

|

Rail |

Pressure |

Injector |

|

|

Limiter |

|||

|

Rail |

|||

|

Pressure Sensor |

Fuel Temperature Sensor

|

Supply Pump |

SCV (Suction |

Fuel Tank |

|

|

Control Valve) |

|||

Q000144E

B. Operation

a.Supply Pump (HP3)

The supply pump draws fuel from the fuel tank, and pumps the high pressure fuel to the rail. The quantity of fuel discharged from the supply pump controls the pressure in the rail. The SCV (Suction Control Valve) in the supply pump effects this control in accordance with commands received from the engine ECU.

b.Rail

The rail is mounted between the supply pump and the injector, and stores the high-pressure fuel.

c.Injector (G2 Type)

This injector replaces the conventional injection nozzle, and achieves optimal injection by effecting control in accordance with signals from the engine ECU. Signals from the engine ECU determine the duration and timing in which current is applied the injector. This in turn, determines the quantity, rate and timing of the fuel that is injected from the injector. QR codes noting the characteristics of each vehicle are inscribed on the injector, and this data is sent to the ECU when the engine ECU or injectors are replaced. This enables software to be adjusted to the mechanical characteristics of each injector.

d.Engine ECU

The engine ECU calculates data received from the sensors to comprehensively control the injection quantity, timing and pressure.

-5-

3-3. Fuel System and Control System A. Fuel System

This system comprises the route through which diesel fuel flows from the fuel tank via the rail to the supply pump, and is injected through the injector, as well as the route through which the fuel returns to the tank via the overflow pipe.

B. Control System

In this system, the engine ECU controls the fuel injection system in accordance with signals received from various sensors. The components of this system can be broadly divided into the following three types: (a) sensors; (b) ECU; and (c) actuators.

a.Sensors

Detect the engine and driving conditions, and convert them into electrical signals.

b.Engine ECU

Performs calculations based on the electrical signals received from the sensors, and sends them to the actuators in order to achieve optimal conditions.

c.Actuators

Operate in accordance with electrical signals received from the ECU. Injection system control is undertaken by electronically controlling the actuators. The injection quantity and timing are determined by controlling the duration and timing in which current is applied to the TWV (Two-Way Valve) in the injector. Injection pressure is determined by controlling the SCV (Suction Control Valve) in the supply pump.

|

Sensor |

Actuator |

|||||||

|

Crankshaft Position Sensor NE |

Engine Speed |

|||||||

|

Injector |

||||||||

|

· Injection Quantity Control |

||||||||

|

Cylinder Recognition |

· Injection Timing Control |

|||||||

|

Cylinder Recognition Sensor G |

· Injection Pressure Control |

|||||||

|

Load |

Engine |

|||||||

|

Accelerator Position Sensor |

||||||||

|

ECU |

Supply Pump (SCV) |

|||||||

|

· Fuel Pressure Control |

||||||||

|

Rail Pressure Sensor |

||||||||

|

EGR, Air Intake Control |

||||||||

|

Relay, Light |

||||||||

|

Other Sensors and Switches |

||||||||

|

Q000390E |

||||||||

-6-

4. Description of Main Components

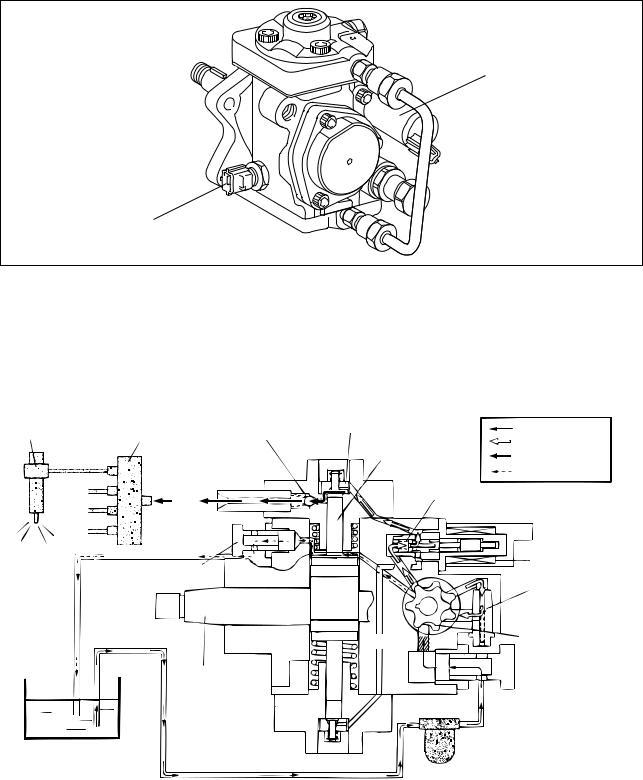

4-1. Supply Pump (HP3)

A.Outline

•The supply pump consists primarily of the pump body (camshaft (eccentric cam), ring cam, and plungers), SCV (Suction Control Valve), fuel temperature sensor, and feed pump.

SCV

Fuel Temperature Sensor

Q000570E

•The two plungers are positioned vertically on the outer ring cam for compactness.

•The engine drives the supply pump at a ratio of 1:1. The supply pump has a built-in feed pump (trochoid type), and draws the fuel from the fuel tank, sending it to the plunger chamber.

•The internal camshaft drives the two plungers, and they pressurize the fuel sent to the plunger chamber and send it to the rail. The quantity of fuel supplied to the rail is controlled by the SCV, using signals from the engine ECU. The SCV is a normally open type (the intake valve opens during de-energization).

|

Injector |

Rail |

Intake Valve |

Intake Pressure |

|||

|

Discharge Valve |

Feed Pressure |

|||||

|

Plunger |

High Pressure |

|||||

|

Return |

||||||

|

Return Spring |

||||||

|

Return |

||||||

|

Fuel Overflow |

SCV |

|||||

|

Regulating Valve |

||||||

|

Feed Pump |

||||||

|

Filter |

||||||

|

Camshaft |

Fuel Inlet |

|||||

|

Fuel Tank |

Intake Fuel Filter |

|||||

|

(With Priming Pump) |

||||||

|

Q000392E |

• The supply pump in the common rail system with DPNR has a fuel cut valve (FCV). The FCV is provided to enable manual shut-off if a fuel leak occurs in the fuel addition valve passage.

-7-

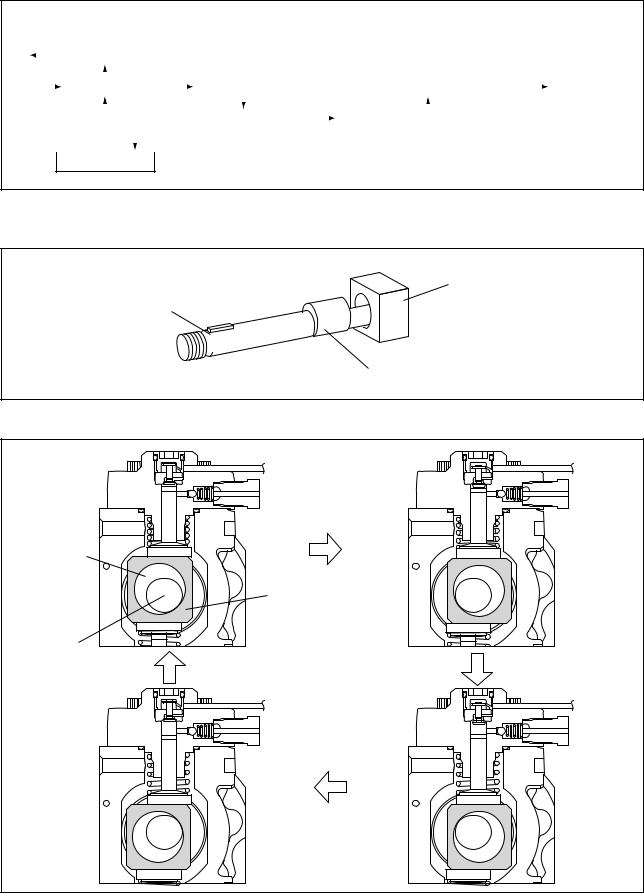

a.Supply Pump Exploded Diagram

|

SCV |

|

|

(Suction Control Valve) |

|

|

Plunger |

|

|

Pump Body |

Feed Pump |

|

Ring Cam |

Regulating Valve |

|

Filter |

|

|

Camshaft |

|

|

Plunger |

|

|

Fuel Temperature Sensor |

|

|

Q000393E |

|

|

-8- |

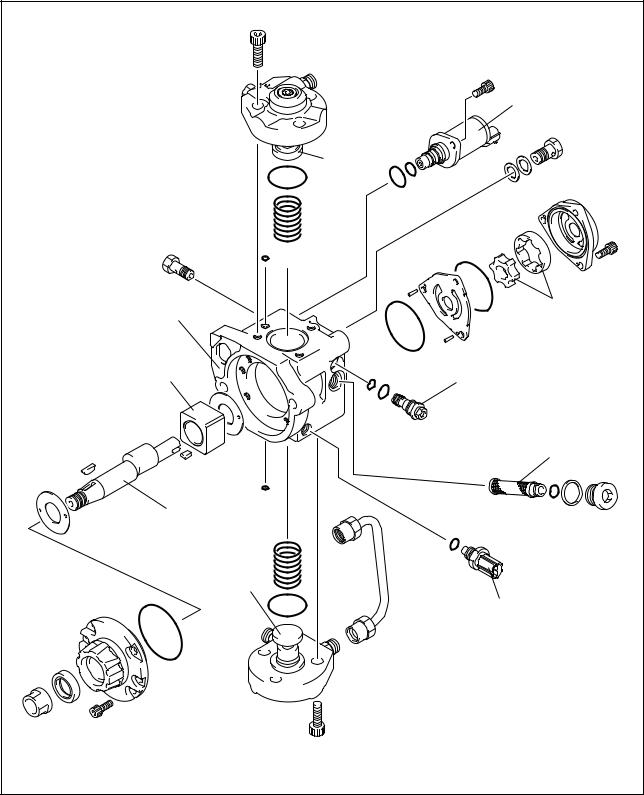

B. Supply Pump Internal Fuel Flow

Fuel drawn from the fuel tank passes through the route in the supply pump as illustrated, and is fed into the rail.

|

Supply Pump Interior |

|||||||||||||||||||||||

|

Regulating Valve |

|||||||||||||||||||||||

|

Feed Pump |

SCV (Suction Control Valve) |

Discharge Valve |

Rail |

||||||||||||||||||||

|

Overflow |

|||||||||||||||||||||||

|

Intake Valve |

Pumping Portion (Plunger) |

||||||||||||||||||||||

Fuel Tank

Q000394E

C.Construction of Supply Pump

•The eccentric cam is formed on the camshaft and is attached to the ring cam.

Ring Cam

Camshaft

Eccentric Cam

Q000395E

• As the camshaft rotates, the eccentric cam rotates eccentrically, and the ring cam moves up and down while rotating.

Eccentric Cam

Ring Cam

Camshaft

Q000396E

-9-

•The plunger and the suction valve are mounted on top of the ring cam. The feed pump is connected to the rear of the camshaft.

Plunger A

Ring Cam

Feed Pump

Plunger B

QD0728E

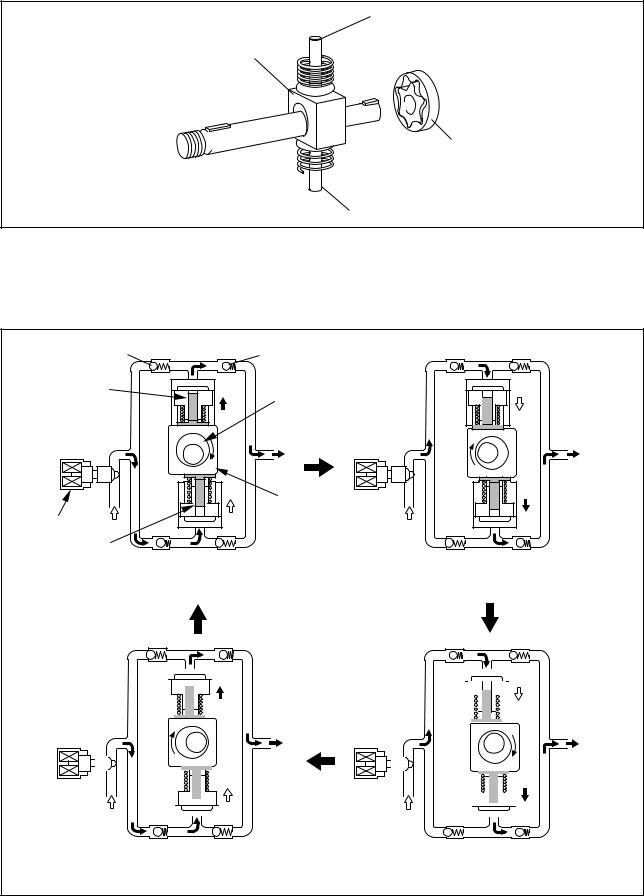

D. Supply Pump Operation

As shown in the illustration below, the rotation of the eccentric cam causes the ring cam to push Plunger A upwards. Due to the spring force, Plunger B is pulled in the opposite direction to Plunger A. As a result, Plunger B draws in fuel while Plunger A pumps it to the rail.

Suction Valve Delivery Valve

Plunger A

Eccentric Cam

Ring Cam

SCV

Plunger B

|

Plunger A: Finish Compression |

Plunger A: Begin IntakePlunger |

|

Plunger B: Finish Intake |

B: Begin Compression |

|

Plunger A: Begin Compression |

Plunger A: Finish Intake |

||||||||||||||||||||||||||

|

Plunger B: Begin Intake |

Plunger B: Finish Compression |

QD0707E

-10-

E. Description of Supply Pump Components

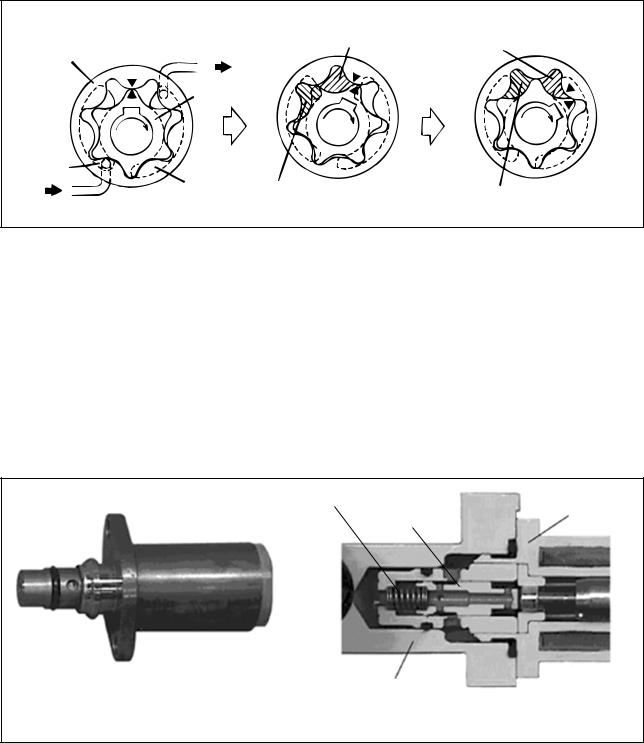

a.Feed Pump

The trochoid type feed pump integrated into the supply pump, draws fuel from the fuel tank and feeds it to the two plungers via the fuel filter and the SCV (Suction Control Valve). The feed pump is driven by the camshaft. With the rotation of the inner rotor, the feed pump draws fuel from its suction port and pumps it out through the discharge port. This is done in accordance with the space that increases and decreases with the movement of the outer and inner rotors.

Quantity Decrease

To Quantity Decrease (Fuel Discharge)

Pump Chamber

Outer Rotor

Inner Rotor

Intake Port

|

Discharge |

Quantity Increase |

Quantity Increase |

|

|

Port |

|||

|

From |

(Fuel Intake) |

||

|

Fuel Tank |

QD0708E |

||

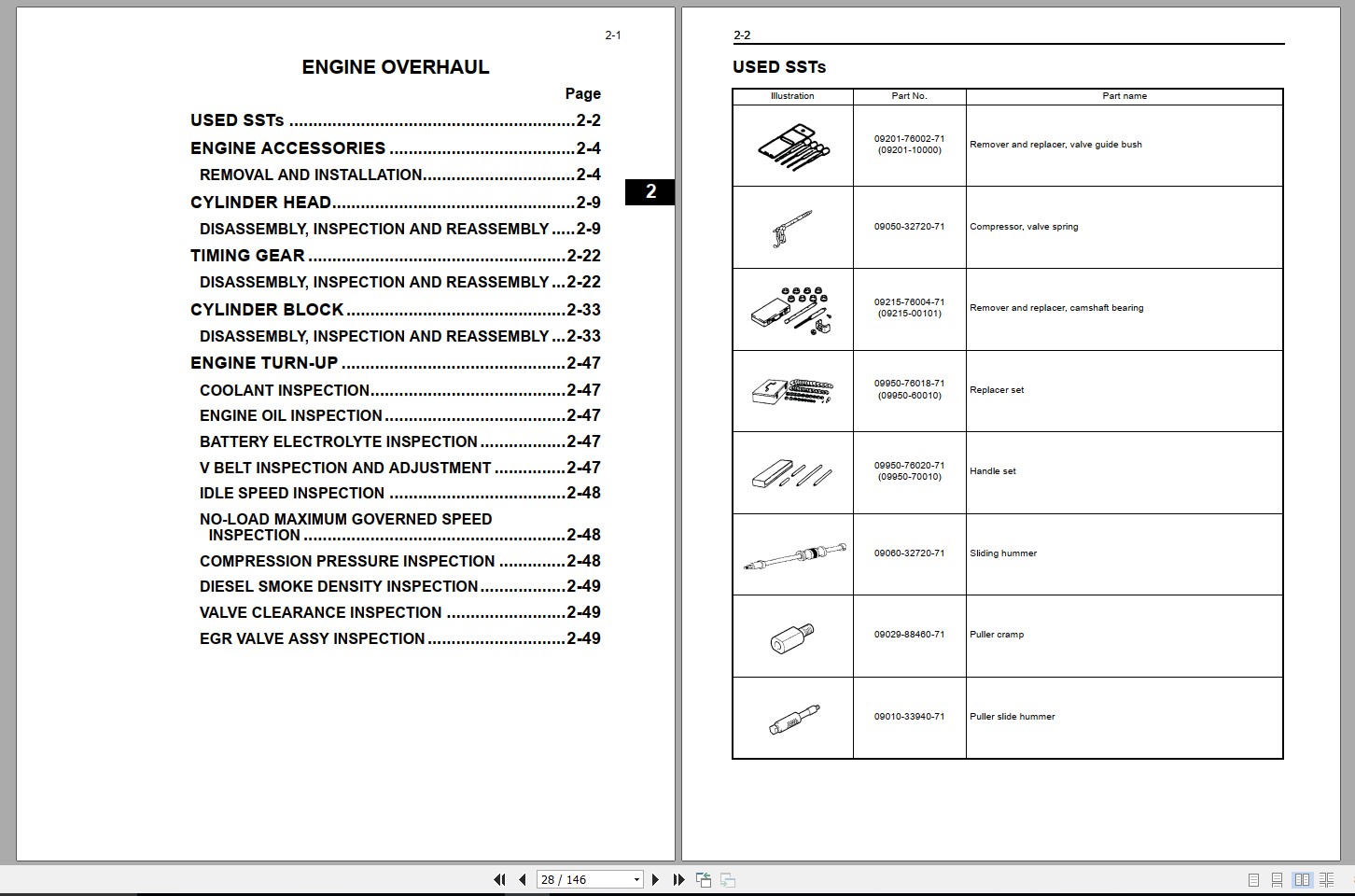

b.SCV (Suction Control Valve: Normally Open Type)

•A linear solenoid type valve has been adopted. The ECU controls the duty ratio (the duration in which current is applied to the SCV), in order to control the quantity of fuel that is supplied to the high-pressure plunger.

•The supply pump drive load decreases because intake fuel quantity is controlled to achieve the target rail pressure.

•When current flows to the SCV, the internal armature moves in accordance with the duty ratio. The fuel quantity is regulated by the cylinder, which moves in connection with the armature to block the fuel passage.

•With the SCV OFF, the return spring pushes the cylinder, completely opening the fuel passage and supplying fuel to the plungers. (Full quantity intake => full quantity discharge.)

•When the SCV is ON, the return spring contracts and closes the fuel passage.

•By turning the SCV ON/OFF, fuel is supplied in an amount corresponding to the drive duty ratio and then discharged by the plungers.

Return Spring

SCV

Cylinder

Pump Body

|

External View |

Cross-Section |

Q000050E

-11-

Регулировка зазоров клапанов на двигателе N04C, автомобиля HINO-300 производится на холодном двигателе.

Зазор впускного клапана 0.3мм

Зазор выпускного клапана 0.45мм

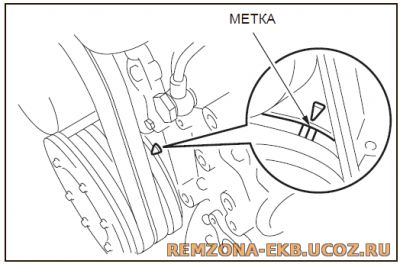

Снимаем клапанную крышку и выставляем метки на шкиве коленвала

!Метка на коленвале совпадает 2 раза через 360градусов, поэтому в зависимости от того, в каком цилиндре двигателя верхняя мертвая точка (1 или 4)

выбирается последовательность регулировки. Для того чтобы это понять достаточно убедится что впускные и выпускные клапана закрыты

Можно просто пошатать вверх вниз коромысла регулируемых клапанов чтобы понять последовательность по 1 или 4 цилиндру

они должны иметь свободный ход.

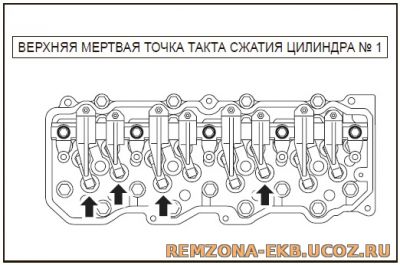

Последовательность регулировки клапанов если такт сжатия в первом цилиндре:

При таком порядке регулируются 1,2,3 и 6 клапаны (коромысла считаем от вентилятора)

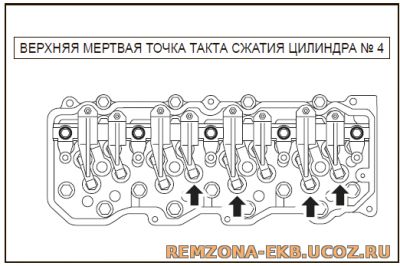

Если такт сжатия в 4 цилиндре, то регулируем в последовательности показанной на следующей картинке

В таком положении регулируются 4, 5, 7, 8 клапаны

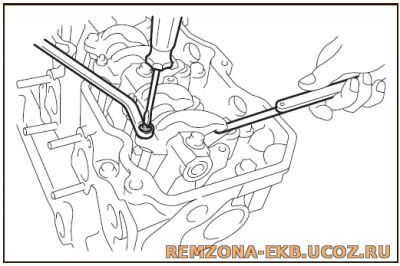

Зазор регулируется между носком коромысла и соединительным мостом клапанов, сразу для 2 клапанов

Контргайку регулировочного винта затянуть моментом 2.8-2.9 кгс*м

Прокладку клапанной крышки рекомендуется заменить новой. Вопросы задавайте в комментариях

Счета для вашей благодарности:

Яндекс-деньги 41001327031715

Карта сбербанка РФ 639002169074388980 (Красноперов Дмитрий Сергеевич)

Партнерка от Donation Alert http://www.donationalerts.ru/r/dmitrij_krasnoperov

Спонсор статьи человек с нашего сайта с ником БЕЛОВ, спасибо за поддержку проекта!

Руководство по ремонту HINO и другие только на нашем файлообменнике

COMMON RAIL SYSTEM (CRS) SERVICE MANUAL: Operation

N04C-# Engine

Applicable Vehicle :Manufacturer Vehicle Name

TOYOTADYNACOASTER

HINO DUTRO

Issued : March 2007Revised : December 2009

00400058EB

© 2009 DENSO CORPORATIONAll rights reserved. This material may not be reproduced or copied, in whole or in part, without the written permission of DENSO Corporation.

Revision HistoryDate Revision Contents

2007.03 • Basic CRS content omitted, March, 2007 model CRS content added.Items added are as per the following:

APPLICABLE VEHICLES AND PRODUCT INFORMATIONMain components and SensorsEXHAUST GAS CONTROL SYSTEM (FEBRUARY 2007, JUNE 2009)“Engine ECU External Wiring Diagram” and “Connector Terminal Layout”ENGINE ECU DIAGNOSTIC TROUBLE CODES (DTC)

2009.12 • Basic CRS content omitted, June, 2009 model CRS content added.Items added are as per the following:

APPLICABLE VEHICLES AND PRODUCT INFORMATIONINJECTOR“Engine ECU External Wiring Diagram” and “Connector Terminal Layout”

Table of Contents

Operation Section

1. APPLICABLE VEHICLE AND PRODUCT INFORMATION1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Applicable Vehicles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.3 Applicable Product List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

2. SYSTEM OUTLINE2.1 Layout of Main Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

3. SUPPLY PUMP3.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

3.2 Suction Control Valve (SCV) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

3.3 Fuel Temperature Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

4. RAIL4.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

5. INJECTOR5.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

6. CONTROL SYSTEM6.1 Control System Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

6.2 Engine ECU. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

6.3 Electronic Drive Unit (EDU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

6.4 Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

7. EXHAUST GAS CONTROL SYSTEM (FEBRUARY 2007, AND JUNE 2009)7.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

7.2 E-EGR System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-23

7.3 DPF System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-24

8. ENGINE ECU DIAGNOSTIC TROUBLE CODES (DTC)8.1 DTC Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-26

9. CONTROL SYSTEM COMPONENTS9.1 Engine ECU External Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-33

9.2 Connector Terminal Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-57

Operation Section1–1

1. APPLICABLE VEHICLE AND PRODUCT INFORMATION

1.1 Introduction

This manual describes the Common Rail System (CRS) equipped with the NO4C-# engines used in the

HINO DUTRO, TOYOTA DYNA (both pickup trucks), as well as the TOYOTA COASTER (bus.)

For information on items common to all CRSs, refer to the previously published CRS general addition

manual (Doc ID: 00400076E). [Items common to all CRSs: CRS development process, system control,

construction and operation of main components (supply pump, rail, injectors.)]

1.2 Applicable Vehicles

November 2003

March 2007

June 2009

Vehicle Name Engine Model Remarks

DUTRO/DYNA N04C-TF

Vehicle Name Engine Model Destination Remarks

DUTRO/DYNA

N04C-TP

Europe

Vehicle power supply voltage: 24 V, EngineECU 12 V spec., with Diesel Particulate Filter(DPF), MT

N04C-TQ Vehicle power supply voltage: 24 V, MT withDPF

N04C-TR

GeneralVehicle power supply voltage: 24 V, EngineECU 12 V spec., MT

N04C-TS

N04C-TT

N04C-TU

Australia

Vehicle power supply voltage: 24 V, EngineECU 12 V spec., AT

N04C-TVVehicle power supply voltage: 24 V, EngineECU 12 V spec., MT

N04C-TW Europe, Hong KongVehicle power supply voltage: 24 V, EngineECU 12 V spec., with DPF, MT

COASTER

N04C-TQ Europe, Australia Vehicle power supply voltage: 24 V, with DPF,MT

N04C-TY China Vehicle power supply voltage: 24 V, MT

Vehicle Name Engine Model Remarks

DUTRO/DYNA/COASTER N04C-#

Operation Section1–2

1.3 Applicable Product List

November 2003

March 2007

Part Name DENSO Part Number Manufacturer Part Number Remarks

Supply Pump 294000-019# S2273-01264

Rail 095440-049# 22760-1170A

Injector 095000-532# 23910-1271A

Engine ECU 175800-658# 89660-37460

Electronic Drive Unit (EDU) 101310-539# 89870-37030

Accelerator Pedal Module 198800-315# 78100-37550

Crankshaft Position Sensor 029600-136# 89410-1630A

Camshaft Position Sensor 949979-131# 89410-1570A

Coolant Temperature Sensor 071560-011# 83420-1250A

Mass Air Flow (MAF) Meter 197400-200# 22204-21010

Intake Air Temperature Sensor 071500-249# 89441-4310A

Manifold Absolute Pressure(MAP) Sensor

079800-589# 89390-1080A

Exhaust Gas Recirculation(EGR) Valve

135000-705# 17350-1170A

Exhaust Gas TemperatureSensor

265600-060# (IN) 89441-37020 (IN)

265600-053# (OUT) 89441-37030 (OUT)

Part NameDENSO Part

Number

Manufacturer

Part NumberRemarks

Supply Pump 294000-059# 22100-E0060

294000-063# 22100-E0080 China Only

Rail 095440-098# 23810-E0010

Injector 095000-651# 23670-E0080

095000-652# 23670-E0090 General Only

095000-655# 23670-E0190 China Only

Operation Section1–3

EngineECU

DYNA/DUTRO

175800-799# 89661-37540 N04C-TQ, DPFVehicle power supplyvoltage: 24 V

175800-881# 89661-37590 N04C-TP, DPF

Vehicle power supply voltage: 24 V, Engine ECU 12 V specs.

175800-897# 89661-37600N04C-TW, DPF

175800-899# 89661-37610

175800-900# 89661-37620 N04C-TS

175800-902# 89661-37630 N04C-TT

175800-904# 89661-37640N04C-TV

175800-906# 89661-37650

175800-907# 89661-37550 N04C-TR

175800-909# 89661-37560 N04C-TS

175800-910# 89661-37570N04C-TU

175800-912# 89661-37580

EngineECU

COASTER 175800-863# 89661-36200N04C-TQ, DPF

Vehicle power supplyvoltage: 24 V175800-864# 89661-36210

175800-865# 89661-36180 N04C-TYVehicle power supplyvoltage: 12 V

175800-924# 89661-36220 N04C-TQ, DPFVehicle power supplyvoltage: 24 V

EDU 101310-539# 89870-37030 N04C-TQ

101310-571# 89870-37080

Accelerator PedalModule

198800-309# 78120-35460

198800-315# 78100-37750 N04C-TQ

EGR Valve 135000-721# 25620-E0010 Without N04C-TR, TS, TT

Camshaft PositionSensor

949979-131# 89410-1570A

Crankshaft PositionSensor

029600-136# 89410-1630A

MAF Meter 197400-200# 22204-21010

Exhaust GasTemperature Sensor

265600-053# 89425-37021 DPF, Upstream of Catalyst

265600-054# 89425-37031 DPF, Downstream of Catalyst

Differential PressureSensor

104990-102# 89480-37010DPF

Part NameDENSO Part

Number

Manufacturer

Part NumberRemarks

Operation Section1–4

June 2009

Part NameDENSO Part

Number

Manufacturer

Part NumberRemarks

Supply Pump 294000-059# 22100-E0060

Rail 095440-098# 23810-E0010

Injector095000-848# 23670-E0420 24 V use

095000-847# 23670-E0410 12V use

Engine ECU

275900-090# 89661-37540

175800-881# 89661-37590

175800-897# 89661-37600

175800-899# 89661-37610

175800-900# 89661-37620

175800-902# 89661-37630

EDU 101310-539# 89870-37030

Accelerator PedalModule

198800-309# 78120-35460 DUTRO right-hand driver vehicles

198800-326# 78100-37820 DUTRO left-hand driver vehicles

Accelerator PositionSensor

198300-815# 89281-26030 DYNA, COASTER

EGR Valve 135000-721# 25620-E0010

Camshaft PositionSensor

949979-131# 89410-1570A

Crankshaft PositionSensor

029600-136# 89410-1630A

Intake Air TemperatureSensor

072800-052# 89424-E0060

MAP Sensor 079800-740# 89420-37030

Differential PressureSensor

104990-102# 89480-37010

Operation Section1–5

2. SYSTEM OUTLINE

2.1 Layout of Main Components

Operation Section1–6

3. SUPPLY PUMP

3.1 Outline

The November 2003, and June 2009 model supply pumps are equipped with an SV1 type Suction Control

Valve (SCV). The March 2007 supply pump is equipped with an SV2 type SCV. Additionally, supply pumps

in the part number series 294000-059# are equipped with the SV1 type SCV as of June 2009. Supply pumps

in the part number series 294000-063# are equipped with the SV1 type SCV as of October 2007.

(1) November 2003 (294000-019#) , March 2007 (294000-063#*) and June 2009 (294000-059#)

* : Beginning from October 2007

(2) March 2007 (294000-059#, -063#)

Operation Section1–7

3.2 Suction Control Valve (SCV)

(1) November 2003 (294000-019#)

• The supply pumps in the part number series above are equipped with a conventional, normally open type SCV.

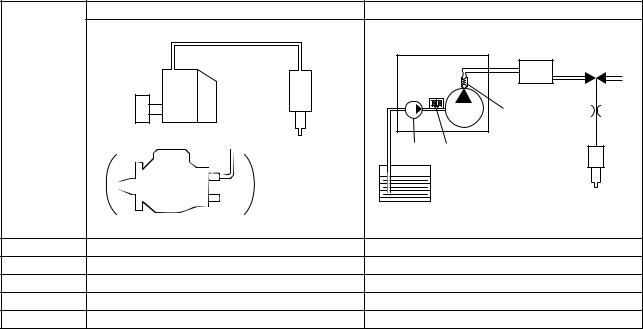

Operation Concept Diagram

Operation

Operation Section1–8

(2) March 2007 (294000-059#, -063#)

• The supply pumps in the part number series above are equipped with a compact, normally closed SCV.

Operation Concept Diagram

Operation

Operation Section1–9

(3) March 2007 (294000-063#*) and November 2009 (294000-059#)

• The supply pumps in the part number series above are equipped with a conventional, normally closed

type SCV

* : Beginning from October 2007

Operation Concept Diagram

Operation

Operation Section1–10

3.3 Fuel Temperature Sensor

A conventional sensor is used with the NO4C-# engine CRS. Sensor resistance values in relation to fuel

temperature are provided below.

Operation Section1–11

4. RAIL

4.1 Outline

Rails in the part number series 095440-049# have a flow damper to suppress fuel pulsations.

Since rails in the part number series 095440-098# have a built-in function to suppress fuel pulsations, there

is no flow damper.

(1) November 2003 (Rail: 095440-049#)

(2) March 2007, and June 2009 (Rail: 095440-098#)

Operation Section1–12

5. INJECTOR

5.1 Outline

The CRS detailed herein uses solenoid injectors with QR codes.

The injectors used in the June 2009 model CRS were designed to show improved responsiveness, as well

as to increase resistance against foreign material adherence to the nozzle.

(1) November 2003 (Injector: 095000-532#)

Operation Section1–13

(2) March 2007 (Injector: 095000-651#, -652#, -655#)

Operation Section1–14

(3) June 2009 (Injector: 095000-847#, -848#)

Operation Section1–15

6. CONTROL SYSTEM

6.1 Control System Diagram

Operation Section1–16

6.2 Engine ECU

General export vehicles for Europe, Oceania, and Asia use 12 V specification engine ECUs in relation to

the 24 V vehicle power supply (battery voltage). Accordingly, in the event that service such as repairs are

necessary, always verify the engine ECU specifications. To verify the specifications, look behind the

passenger seat back and check the engine ECU case, as well as whether or not there is a DC-DC converter.

< ATTENTION >When performing checks, do not apply vehicle power supply voltage to the engine ECU. If the

vehicle power supply voltage (24 V) is applied to a 12 V specification engine ECU, the ECU may be

damaged.

The figure below is an external view of the engine ECU. For the connector pin layout and external wiring

diagram: Refer to [Connector Terminal Layout] on P1-57.

Operation Section1–17

6.3 Electronic Drive Unit (EDU)

A conventional EDU is used with the NO4C-# engine CRS.

(1) Operation

• A high-voltage generating device converts the battery voltage into high voltage. The engine ECU sends signals to

terminals B through E of the EDU in accordance with the signals from each sensor. Upon receiving these signals, the

EDU outputs signals to the injectors from terminals K through N. At this time, terminal F outputs the IJf injection

verification signal to the ECU.

External Wiring Diagram

Operation Section1–18

6.4 Sensors

(1) Crankshaft position sensor and camshaft position sensor

• Conventional sensors are used as the crankshaft position sensor and camshaft position sensor. The crankshaft

position sensor is a Magnetic Pick Up (MPU) type sensor, while the camshaft position sensor is a Magnetic

Resistance Element (MRE) type.

Operation Section1–19

(2) Accelerator position sensor and accelerator pedal module

• A conventional hall element type sensor is used as the accelerator position sensor.

Accelerator Position Sensor: DYNA, COASTER

Operation Section1–20

Accelerator Pedal Module: DUTRO

Operation Section1–21

(3) Manifold Absolute Pressure (MAP) sensor

• The MAP sensor is used in the NO4C-TF engine. Sensor output voltage values in relation to absolute pressure are

provided below.

(4) Coolant temperature sensor

• The coolant temperature sensor is used in the NO4C-TF engine. Sensor resistance values in relation to coolant

temperature are provided below.

Operation Section1–22

(5) Mass Air Flow (MAF) meter

• A conventional sensor is used with the NO4C-# engine CRS.

Operation• When a heating element (heating coil) is placed in the air passage, the air absorbs heat and cools the heating

element. For this reason, the resistance value of the heating element decreases, and the current increases. As the

intake air volume increases, the cooling temperature of the heating element also increases. The hot-wire type airflow

meter utilizes the changes in the heating element.

One portion of the intake air passes by the heating element, and the temperature of the heating element resistor

changes in accordance with the intake air volume. The control circuit is used to ensure the temperature of the heating

element resistor is always constant. In other words, since the heating element becomes cooler as the airflow volume

increases, it is necessary to heat the element by increasing current flow through the resistor. This change in current

is converted into voltage by the control circuit IC.

However, even if the intake air volume is constant, the temperature of the heating element resistor changes according

to the intake air temperature. These changes result in errors when detecting the intake air volume. To correct these

errors, an additional intake air temperature compensator resistor (air thermometer) is used.

Operation Section1–23

7. EXHAUST GAS CONTROL SYSTEM (FEBRUARY 2007, AND JUNE 2009)

7.1 Outline

Both an Electric-Exhaust Gas Recirculation (E-EGR) and a Diesel Particulate Filter (DPF) system are used

to comply with Euro 4 emission regulations. The EGR valve, exhaust gas temperature sensor, and

differential pressure sensor are made by DENSO.

7.2 E-EGR System

The E-EGR system is an electronically controlled EGR system. The EGR system reduces NOx by lowering

the combustion temperature through re-circulating a portion of the exhaust gas to the intake manifold. Since

this system may also reduce engine output and decrease drivability, the EGR volume is controlled

electronically to an optimum level in accordance with driving conditions.

Both the electronically controlled EGR system and a high-capacity multipass system EGR cooler are used.

Engine performance has been increased through enabling high-volume exhaust gas recirculation.

A linear solenoid type valve is used as the actuator in the EGR valve. Simultaneous PM and NOx reduction

have been achieved by increasing EGR quantity adjustment precision.

An EGR valve lift sensor is also used. The EGR valve opening is fed back to the engine control computer

to enable optimal EGR control.

(1) Construction and operation

• To improve EGR exhaust gas purification performance, feedback control is performed using the EGR valve position.

Oxygen concentration in the intake air (which changes according to EGR) is controlled to a target value in accordance

with the engine state (engine speed, rising pressure, part temperatures, load and intake air volume.)

• To expand the EGR range, the lift sensor installed on the EGR valve performs feedback control of the

actual EGR quantity in relation to the pre-set target EGR quantity. Feedback control is based on the intake

restriction position and the variable nozzle turbo position.

Operation Section1–24

7.3 DPF System

A conventional DPF system is used with the NO4C-# engine CRS.

Operation Section1–25

(1) Exhaust gas temperature sensor

• A conventional sensor is used as the exhaust gas temperature sensor. Sensor resistance values in relation to exhaust

gas temperature are provided below.

(2) Differential pressure sensor

• A conventional sensor is used as the differential pressure sensor. Sensor output voltage values in relation to exhaust

gas differential pressure are provided below.

Operation Section1–26

8. ENGINE ECU DIAGNOSTIC TROUBLE CODES (DTC)

8.1 DTC Table

The following are Diagnostic Trouble Code (DTC) tables for November 2003, and March 2007 vehicles. The

«November 2003» DTC table is for conventional N04C-TF engines. The «March 2007» DTC table is for the

N04C-TP, Q, R, S, T, U, V, and W engines.

(1) November 2003

*1 : TCCS is the name designated by TOYOTA for DTCs resulting from the Malfunction Indicator Light(MIL). For details, refer to the CRS General Edition Manual (00400076E.)

*2 : The «A» in «A#» for TCCS represents a «10».

DTC Detection

Trip

Lamp

Output Detection Item

SAE TCCS*1 (CE)

P0030,P0031,P0130,P0131,P0132

21 1 A/F sensor (B1S1)

P0036,P0037,P0136,P0137,P0138

27 1 A/F sensor (B1S2)

P0087 49 1 Rail pressure abnormality (fixed output)

P0088 78 1 Suction Control Valve (SCV) abnormality (high-pressure in rail)

P0093 78 1 Fuel leak abnormality

P0095,P0097,P0098

23 1Intake air temperature sensor No. 2 (post-turbo intake airtemperature sensor)

P0100,P0102,P0103

31 1 Mass Air Flow (MAF) meter

P0105,P0107,P0108

35 1 Manifold Absolute Pressure (MAP) sensor

P0110,P0112,P0113

24 1 Intake air temperature sensor

Operation Section1–27

P0115,P0117,P0118

22 1 Coolant temperature sensor

P0120,P0122,P0123

41 1 Accelerator position sensor

P0168 39 1 Abnormally high fuel temperature

P0180,P0182,P0183

39 1 Fuel temperature sensor

P0190,P0192,P0193

49 1 Rail pressure sensor with back-up sensor

P0191 49 1 Rail pressure sensor with back-up sensor (out- of-range)

P0200 97 1 EDU abnormality (engine diagnostic)

P0234 34 1 VN turbo abnormality (closed-side abnormality)

P0263 78 1 Injector abnormality (FCCB abnormality) (No. 1 cylinder)

P0266 78 1 Injector abnormality (FCCB abnormality) (No. 2 cylinder)

P0269 78 1 Injector abnormality (FCCB abnormality) (No. 3 cylinder)

P0272 78 1 Injector abnormality (FCCB abnormality) (No. 4 cylinder)

P0299 34 1 VN turbo abnormality (open-side abnormality)

P033513 1

Crankshaft position sensor (open circuit/phase difference/powerflicker)

P0335 12 1 Crankshaft position sensor (open circuit)

P0339 13 1 Crankshaft position sensor (NE power flicker)

P0340 12 1 Crankshaft position sensor (open circuit/power flicker)

P0340 12 1 Camshaft position sensor (during start-up)

P0400 71 1 Exhaust Gas Recirculation (EGR) flow malfunction

P0400 71 1 EGR valve

P0405,P0406

96 1 EGR lift sensor

P0488 15 1 Intake restriction motor control system

P0500 42 1 Vehicle speed sensor (MT)

P0504 51 1 Stop light switch

P0607 89 1 CPU abnormality

P0627 78 1 Pump abnormality (open/short circuit)

P1133 00 1 Exterior accelerator position No. 1 sensor high

P1143 19 1 Throttle knob high

DTC Detection

Trip

Lamp

Output Detection Item

SAE TCCS*1 (CE)

Operation Section1–28

P1229 78 1 Pump valve abnormality

P1238 78 2 Injector injection abnormality

P1251 34 1 VN turbo (power flicker)

P1530 92 1 Emergency stop switch system

P1601 89 1 Multiple-point injector correction (EEPROM abnormality)

P1611 17 1 Internal IC abnormality

P1611 17 1 RUN pulse abnormality

P1674 36 1 Exhaust brake VSV system

P2120,P2122,P2123,P2125,P2127,P2128,P2138

19 1 Accelerator position sensor

P2121 19 1 Accelerator position sensor (out-of-range)

P2226,P2228,P2229

A5*2 1 Accelerator position sensor (open circuit)

DTC Detection

Trip

Lamp

Output Detection Item

SAE TCCS*1 (CE)

Operation Section1–29

(2) March 2007, and June 2009

*1 : TCCS is the name designated by TOYOTA for DTCs resulting from the Malfunction Indicator Light(MIL). For details, refer to the CRS General Edition Manual (00400076E.)

*2 : The «A» in «A#» for TCCS represents a «10».

DTC Detection

Trip

Lamp

Output Detection Item Remarks

SAE TCCS*1 (CE)

P0045 34 1 VN turbo (open)

P0087 49 1Rail pressure abnormality (fixed output)

P0088 78 1Suction Control Valve (SCV) abnormality (high-pressure in rail)

P0093 78 1 Fuel leak abnormality

P0095,P0097,P0098

23 1Intake air temperature sensor No. 2 (post-turbo intake air temperature sensor)

P0100,P0102,P0103

31 1 Mass Air Flow (MAF) meter

P0101 31 2 MAF meter (out-of-range)

P0105,P0107,P0108

35 1 MAP Sensor

P0106 35 2 MAP Sensor (out-of-range)175800-799#, -863#, 864# only

P0110,P0112,P0113

24 1 Intake air temperature sensor

P0115,P0117,P0118

22 1 Coolant temperature sensor

P0116 22 2Coolant temperature sensor (hightemperature out-of-range)

P0116 22 1Coolant temperature sensor (hightemperature stuck)

175800-865#, -899#, -900#, -902#, -904#, -906#, -907#, -909#, -910#, -912# only

P0120,P0122,P0123

41 1 Accelerator position sensor

P0168 39 1 Abnormally high fuel temperature

P0180,P0182,P0183

39 1 Fuel temperature sensor

Operation Section1–30

P0190,P0192,P0193

49 1Rail pressure sensor with back-up sensor

P0191 49 1Rail pressure sensor with back-up sensor (out- of-range)

175800-799#, -863#, 864# only

P0200 97 1EDU abnormality (engine diagnostic)

P0234 34 1VN turbo abnormality (closed-side abnormality)

P0263 78 1Injector abnormality (FCCBabnormality) (No. 1 cylinder)

P0266 78 1Injector abnormality (FCCBabnormality) (No. 2 cylinder)

P0269 78 1Injector abnormality (FCCBabnormality) (No. 3 cylinder)

P0272 78 1Injector abnormality (FCCBabnormality) (No. 4 cylinder)

P0299 34 1VN turbo abnormality (open-sideabnormality)

P0335 13 1Crankshaft position sensor (opencircuit/phase difference/powerflicker)

P0335 12 1Crankshaft position sensor (opencircuit)

P0339 13 1Crankshaft position sensor (NEpower flicker)

P0340 12 1Crankshaft position sensor (opencircuit/power flicker)

P0340 12 1Camshaft position sensor (duringstart-up)

P0400 71 2 EGR flow malfunction

P0400 71 1 EGR system malfunction

P0405,P0406

96 1 EGR lift sensor

P0405,P0406

96 1 EGR lift sensor

P0488 15 1Intake restriction motor controlsystem

P0500 42 2 Vehicle speed sensor (MT)

P0504 51 1 Stop light switch

DTC Detection

Trip

Lamp

Output Detection Item Remarks

SAE TCCS*1 (CE)

Operation Section1–31

P0544,P0545,P0546

A3*2 1Exhaust temperature sensorcircuit malfunction (in)

P0607 89 1 CPU abnormality

P0617 43 1 Starter abnormally high

P0627 78 1Fuel pump abnormality (Open/ short circuit)

P0630 89 1Vehicle Identification Number(VIN) not read

P0863 17 1 EFI ECT communication fault175800-865#, -899#, -900#, -902#, -904#, -906#, -907#, -909#, -910#, -912# only

P1133 00 1Exterior accelerator positionsensor high

P1143 19 1 Throttle knob high

P1229 78 1Fuel pump abnormality (open/short circuit)

P1238 78 2 Injector injection abnormality

P1251 34 1 VN turbo (power flicker)

P1425,P1427,P1428

A4*2 1Differential pressure sensor (opencircuit)

P1426 A4*2 1Differential pressure sensor(incorrect piping)

P1530 92 1 Emergency stop switch system

P1601 89 1Multiple-point injector correction(EEPROM abnormality)

P1611 17 1 Internal IC abnormality

P1611 17 1 RUN pulse abnormality

P1674 36 1 Exhaust brake VSV system

P2002 94 1 DPF system abnormality

P2031,P2032,P2033

A3*2 1 Exhaust temperature sensor (out)

P2120,P2122,P2123,P2125,P2127,P2128,P2138

19 1 Accelerator position sensor

DTC Detection

Trip

Lamp

Output Detection Item Remarks

SAE TCCS*1 (CE)

Operation Section1–32

P2121 19 1Accelerator position sensor (out-of-range)

P2226,P2228,P2229

A5*2 1Atmospheric pressure sensor(open circuit)

P2227 A5*2 2Atmospheric pressure sensor(out-of-range)

U0293 A2*2 1CAN communication (HV ECU:communication disruption) 175800-865#, -899#, -900#, —

902#, -904#, -906#, -907#, -909#, -910#, -912# onlyU1123 A2*2 1

VNT ECU CAN communication(reception abnormality)

DTC Detection

Trip

Lamp

Output Detection Item Remarks

SAE TCCS*1 (CE)

Operation Section1–33

9. CONTROL SYSTEM COMPONENTS

9.1 Engine ECU External Wiring Diagram

(1) November 2003

175800-658# (1)

Operation Section1–34

175800-658# (2)

Operation Section1–35

(2) March 2007

175800-799# (1)

Operation Section1–36

175800-799# (2)

Operation Section1–37

175800-863#, -864# (1)

Operation Section1–38

175800-863#, -864# (2)

Operation Section1–39

175800-865# (1)

Operation Section1–40

175800-865# (2)

Operation Section1–41

175800-899# (1)

Operation Section1–42

175800-899# (2)

Operation Section1–43

175800-900#, -902#, -907#, -909# (1)

Operation Section1–44

175800-900#, -902#, -907#, -909# (2)

Operation Section1–45

175800-904#, -910# (1)

Operation Section1–46

175800-904#, -910# (2)

Operation Section1–47

175800-906#, -912# (1)

Operation Section1–48

175800-906#, -912# (2)

Operation Section1–49

(3) June 2009

275900-087# (1)

Operation Section1–50

275900-087# (2)

Operation Section1–51

275900-089# (1)

Operation Section1–52

275900-089# (2)

Operation Section1–53

275900-090# (1)

Operation Section1–54

275900-090# (2)

Operation Section1–55

275900-136# (1)

Operation Section1–56

275900-136# (2)

Operation Section1–57

9.2 Connector Terminal Layout

(1) November 2003

175800-658#

(2) March 2007

175800-799#

175800-863#, -864#

Operation Section1–58

175800-865#

175800-899#

175800-900#, -902#, -907#, -909#

175800-904#, -910#

Operation Section1–59

175800-906#, -912#

(3) June 2009

275900-087#

275900-089#

275900-090#

Operation Section1–60

275900-136#

Service Department DENSO CORPORATION1-1, Showa-cho, Kariya-shi, Aichi-ken, 448-8661, Japan

-

Home

-

Truck & Heavy Truck Forum

-

Truck Workshop & Service Manuals

-

Hino Truck

-

Thread starter

Leonardobmt

-

Start date

Sep 23, 2020

-

Download this document, you need

350

Gallons

Download Now

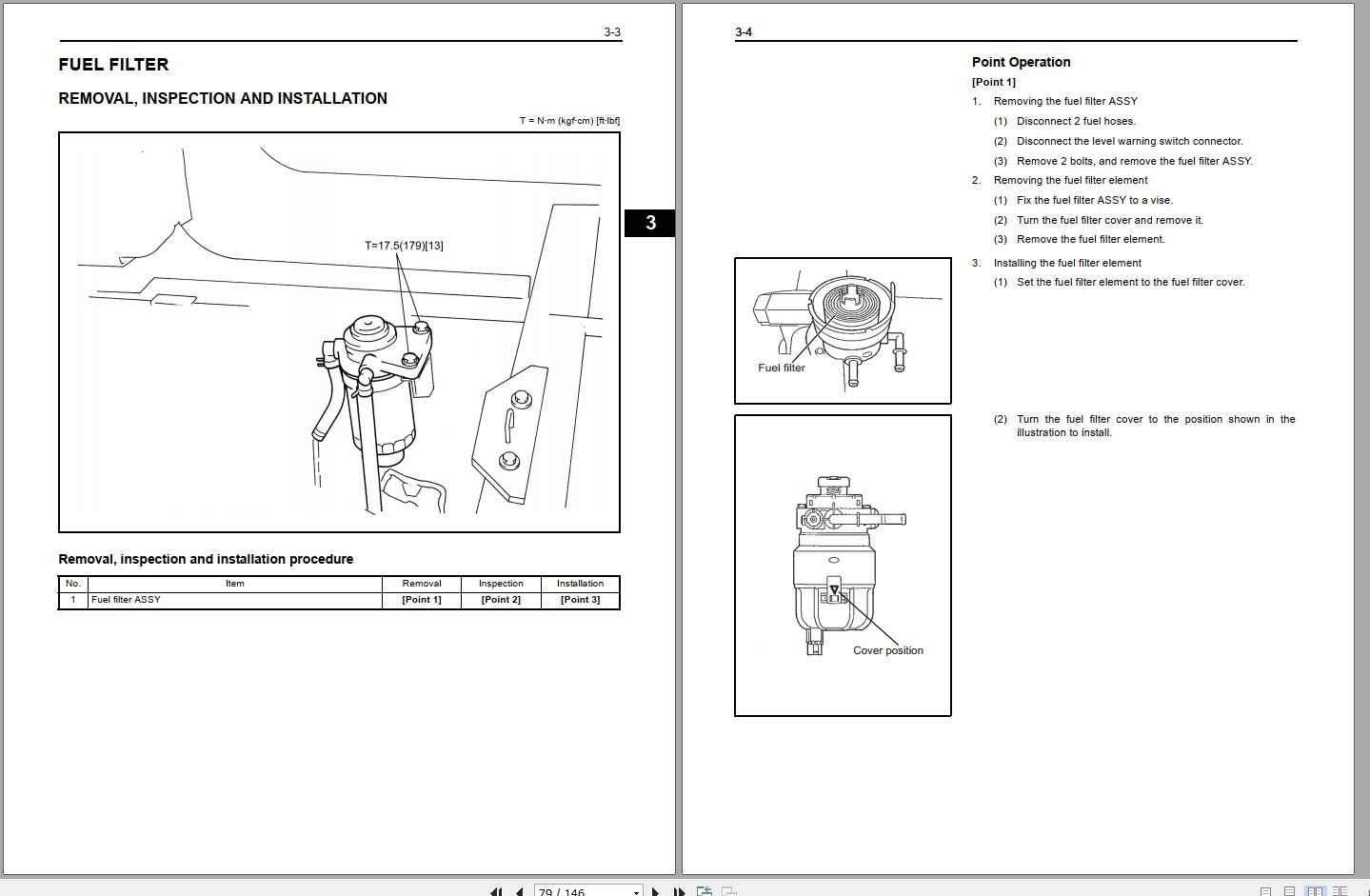

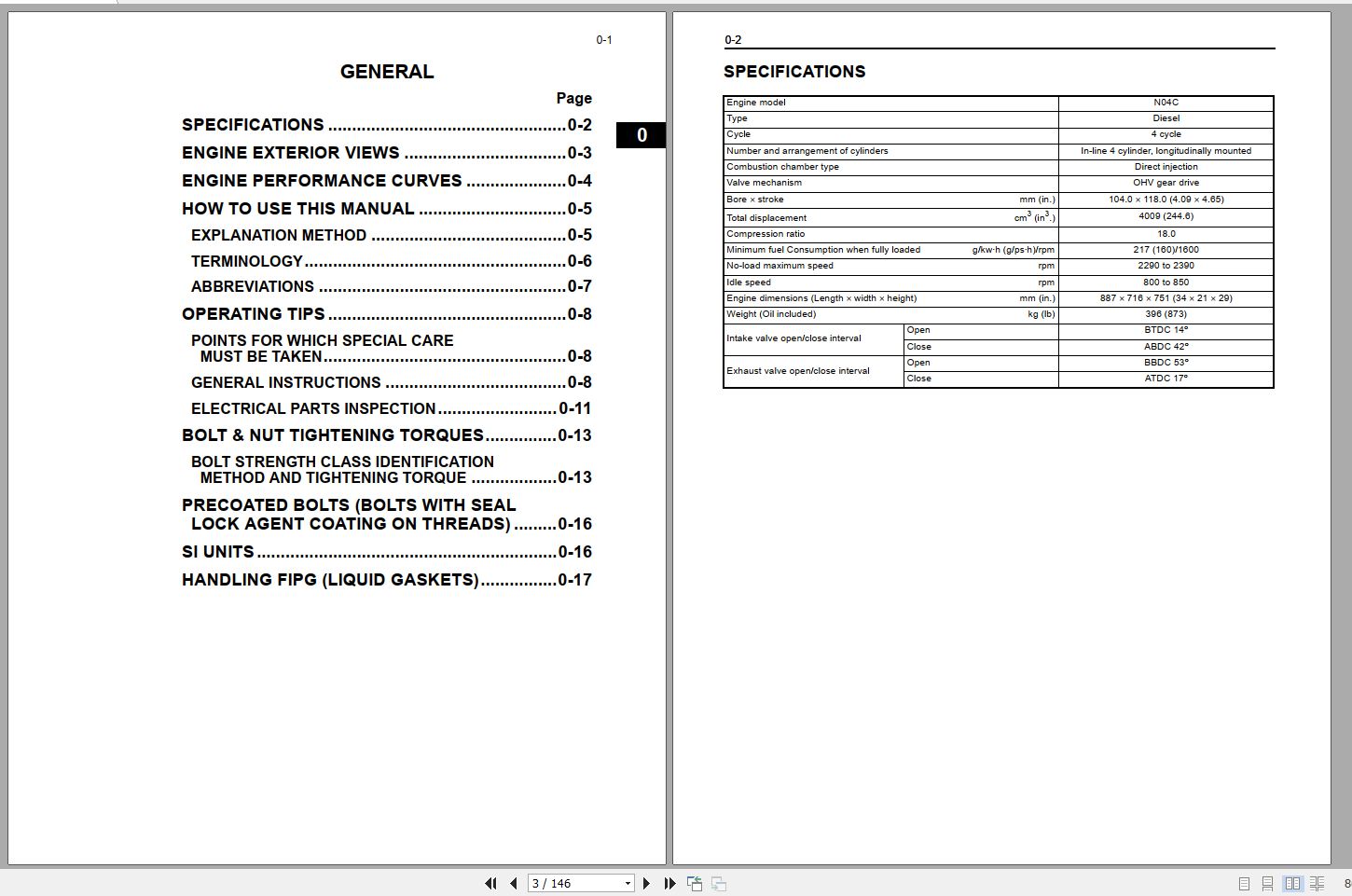

Hino Truck 300 Series Diesel N04C Engine Workshop Manual

Size: 7.87 MB

Format: PDF

Language: English

Brand: Hino

Type of machine: Hino Truck

Type of document: Workshop Manual

Model Type: Hino Truck 300 Series Diesel N04C

Number of Pages: 146 pages

More the random threads same category:

- Hino Dutro Workshop Repair manual(INCLUDING WIRING DIAGRAM/GEARBOX OVERHAUL)

- Hino Series 500 Workshop Manual

- Hino Series 300 Workshop Manual

- Hino FD, FE, FF, SG Engine Service Manual 2002

- Hino Series 700 Workshop Manual

- Hino 300 Dutro S05C Workshop Manual

- Hino Diesel Engine W04D,W04C,W04C-TI Workshop Manual

- Hino E13C Engine Electrical Circuits

- HINO 238, 258LP, 268, 338 SERIES WORKSHOP MANUALS

- Common Rail System for HINO Dutro / TOYOTA Dyna N04C-T# Type Engine

- Hino DUTRO WU & XZU Series Repair Manual

- Hino E13C Type Engine Service Manual

- Specification Technical Motor Hino SO5C-TAJ08C-TT

- Catalog Hino Series 300,500,600,700

- Hino Truck Model 700 Series ABS System (English)

-

Home

-

Truck & Heavy Truck Forum

-

Truck Workshop & Service Manuals

-

Hino Truck