Содержание

- автокаталог. программа автокаталог

- geodyna 4300

- Балансировочный стенд Hofmann Geodyna 4300-2p

- Описание балансировочного стенда

- Характеристики балансировочного стенда Hofmann Geodyna 4300-2p:

- Технические характеристики стенда балансировочного Hofmann Geodyna 4300-2p:

- Доставка по Ростову-на-Дону и области

- Доставка по России

- Цены сервисного обслуживания на Балансировочный стенд Hofmann Geodyna 4300-2p

- Балансировочный стенд Hofmann Geodyna 4300-2

- Описание балансировочного стенда

- Характеристики стенда балансировочного Hofmann Geodyna 4300-2:

- Технические характеристики стенда балансировочного Hofmann Geodyna 4300-2:

- Доставка по Ростову-на-Дону и области

- Доставка по России

- Цены сервисного обслуживания на Балансировочный стенд Hofmann Geodyna 4300-2

автокаталог. программа автокаталог

| Продажа запчастей на грузовые автомобили и трактора | |

| Ходовые агрегаты для гусеничной техники | |

| Проверка технического состояния | |

| Контроль, диагностика, регулировка | |

| Ремонт | |

| Очистительная техника | |

| Пуск, заряд | |

| Подъемники | |

| Шиноремонт | |

|

|

| Компрессоры | |

| Смазка, заправка | |

| Вытяжное оборудование |

geodyna 4300

| Цифровой балансировочный станок среднего класса с ЖК дисплеем (фирма HOFMANN, Германия) | 176200 RUB |

Техника VPM — виртуальные плоскости измерений. Снижает влияние дестабилизирующих факторов и повышает точность измерений.

Техника 2D — автоматический ввод расстояния от станка до колеса и диаметра обода.

KPS — измерительный рычаг с системой позиционирования клеевых грузиков. Измерительная рука запоминает выбранные места установки грузиков и находит их после измерения (акустический сигнал и индикация на дисплее).

HSP — патентованная программа установки грузиков за спицами.

8 вариантов установки грузиков, из них 7 ALU.

Программа балансировки аварийно-безопасных колес РАХ.

Автоматическая остановка колеса после измерения.

Монитороподобный большой ЖК дисплей.

Частота вращения 200 об/мин.

Время измерений 3 с.

Максимальный диаметр колеса 950 мм;

Ширина обода 1-20 дюймов.

Диаметр обода 8-24 дюйма.

Макс. ширина колеса 530 мм.

Макс. масса колеса 70 кг.

Погрешность измерений 1 г.

Электропитание 220 В.

Габариты (ВхШхГ) 1763х1213х1175 мм.

1. Анализ цен — рыночных, собственных, конкурентов.

2. Тендеры — проведение и участие.

3. Оптовая и розничная торговля и закупки.

4. Отслеживание процессов материально-технического обеспечения предприятия.

5. Каталоги товаров * и поставщиков.

*Грузовые автомобили и трактора: Автокаталог

Предлагаем оборудование для автосервиса: шиномонтажное оборудование, диагностическое оборудование (тестеры, сканеры, газоанализаторы, пьезодатчики), подъемники, оборудование для проверки технического состояния (мобильные и стационарные линии технического контроля, тестеры), оборудование для ремонта (обкаточные, рихтовочные стенды, станки, приспособления), очистительное оборудование (очистные установки, пылесосы), пускозарядное оборудование, компрессоры, оборудование для смазки и заправки.

Предлагаем запчасти для промышленной, сельскохозяйственной, железнодорожной техники, трелевочников, узлы сцепления, замки, радиаторы производства Чебоксарсого агрегатного завода.

Источник

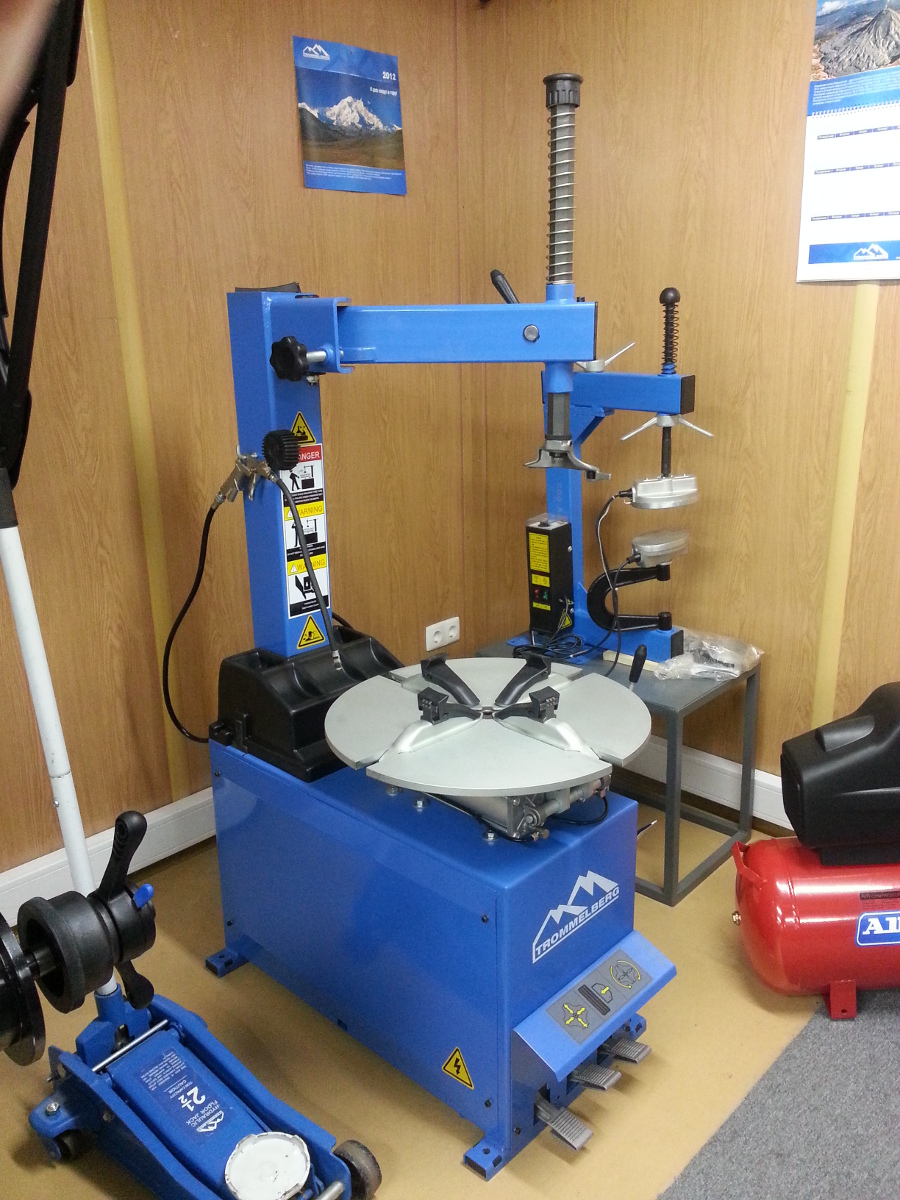

Балансировочный стенд Hofmann Geodyna 4300-2p

Цена: 252 750,00

БрендНазначениеТипНапряжениеГабаритные размерыВес изделия с упаковкойМакс. вес колеса до

| Наименование | Параметры |

|---|---|

| Hofmann | |

| Легковой | |

| Автомат | |

| 220 В | |

| 1756x1280x1080 мм | |

| 105 кг | |

| 70 кг |

Описание балансировочного стенда

- зажимное электромеханическое устройство колеса Power Clamp;

- большой жидкокристаллический дисплей;

- автоматический ввод расстояния от колеса до станка и ободного диаметра;

- функция блокировки Power Clamp до окончания балансировки колеса.

Характеристики балансировочного стенда Hofmann Geodyna 4300-2p:

- техника проведения измерений улучшенной точности VPM (плоскости измерения виртуальные (запатентовано)) — балансировочный узел сверхточный с повышенной устойчивостью к воздействиям извне;

- программа, оптимизирующая плавность хода (имеется патент);

- рычаг измерительный, оснащенный системой позиционирования (имеется патент) и зажимом для грузов;

- внесение дополнительных параметров колесного вращения при нажатой клавише (имеется патент);

- программы для размещения грузов за спицами;

- разнообразные операторские профили;

- тормоз колеса стопорного типа;

- после проведения диагностики колесо останавливается автоматически;

- защитный колесный кожух большого размера;

- счетчик колес отбалансированных;

- программа балансировки колес типа PAX;

- стол с удобными ячейками для грузов, конусов, инструментов;

- большой ассортимент дополнительных возможностей.

Технические характеристики стенда балансировочного Hofmann Geodyna 4300-2p:

| Наименование параметра, единицы измерения | Значение параметра |

|---|---|

| Диаметр центрального дискового отверстия, мм | 43-116 |

| Валовый диаметр, мм | 40 |

| Частота валового вращения, об/мин | 200 |

| Дисковая ширина, дюймы | 1-20 |

| Дисковый диаметр, дюймы | 8-24 |

| Максимальная колесная ширина, мм | 530 |

| Максимальный колесный диаметр, мм | 950 |

| Максимальная колесная масса, кг | 70 |

| Измерительная точность, г | 1 |

| Время для проведения измерений, с | 6 |

| Размеры габаритные высота/ширина /глубина, мм | 1756/1280/1080 |

| Масса оборудования, кг | 105 |

| Электропитание балансировочного стенда, ф/В/Гц | 1/220/50 |

Купить балансировочный стенд Hofmann Geodyna 4300-2p можно у нас в компании «Кронвус-Юг», самостоятельно забрав товар со склада в Ростове-на-Дону. Если Вы не можете осуществить самовывоз, находясь в другом регионе, воспользуйтесь услугой доставки по регионам .

Москва

Санкт-Петербург

Краснодар

Сочи

Новороссийск

Анапа

Волгоград

Саратов

Самара

Невинномысск

Астрахань

Ставрополь

Владикавказ

Минеральные воды

Нальчик

Грозный

Пятигорск

Доставка по Ростову-на-Дону и области

Клиенты, которые находятся в Ростове-на-Дону, могут заказать доставку приобретаемого товара нашим грузовым транспортом. При этом сама доставка обойдется Вам в 1000 руб, вне зависимости от конечного места доставки, объема и веса товара (в пределах вместимости грузового автомобиля).

| Город | Километраж до города | Стоимость за 1км | Доставка по городу | Итог |

|---|---|---|---|---|

| Аксай | 24км | 15р | 700р | 1 060,00 |

| Батайск | 29км | 15р | 700р | 1 135,00 |

| Азов | 57км | 15р | 700р | 1 555,00 |

| Новочеркасск | 53км | 15р | 700р | 1 495,00 |

| Шахты | 89км | 15р | 700р | 2 035,00 |

| Таганрог | 70км | 15р | 700р | 1 750,00 |

Доставка по России

С открытием новых офисов продаж шиномонтажного оборудования в других регионах Южного федерального округа, наша компания осуществляет доставку купленного товара со склада, расположенного в Ростове-на-Дону, до любого терминала транспортной компании или конечного адреса клиента.

Приобретая оборудование в нашей компании, Вы можете не беспокоиться о его доставке, установке и подключении. Наличие собственной сервисной службы дает нам ряд преимуществ перед другими торгующими организациями.

Наши специалисты приедут к Вам на место, осуществят монтаж приобретенного оборудования, протестирует его на отсутствие заводских дефектов и, в случае необходимости, обучат Ваших сотрудников правильному обращению с изделием.

Цены сервисного обслуживания на Балансировочный стенд Hofmann Geodyna 4300-2p

Услугу сервисного обслуживания на Балансировочный стенд Hofmann Geodyna 4300-2p Вы можете заказать отдельно у наших менеджеров при оформлении заказа.

Подробно ознакомиться с информацией по сервисной службе, Вы можете в соответствующем разделе нашего сайта — Сервис.

Источник

Балансировочный стенд Hofmann Geodyna 4300-2

Цена: по запросу

БрендНазначениеТипНапряжениеГабаритные размерыВес изделия с упаковкойМакс. вес колеса до

| Наименование | Параметры |

|---|---|

| Hofmann | |

| Легковой | |

| Автомат | |

| 220 В | |

| 1756x1280x1080 мм | |

| 105 кг | |

| 70 кг |

Описание балансировочного стенда

- большой жидкокристаллический дисплей;

- ввод расстояния от стенда до колеса и диаметра обода автоматический.

Характеристики стенда балансировочного Hofmann Geodyna 4300-2:

- техника проведения измерений улучшенной точности VPM (плоскости измерения виртуальные (запатентовано)) — балансировочный узел сверхточный с повышенной устойчивостью к воздействиям извне;

- программа, оптимизирующая плавность хода ( имеется патент);

- рычаг измерительный, оснащенный системой позиционирования (имеется патент) и зажимом для грузов;

- внесение дополнительных параметров колесного вращения при нажатой клавише (имеется патент);

- программы для размещения грузов за спицами;

- разнообразные операторские профили;

- тормоз колеса стопорного типа;

- после проведения диагностики колесо останавливается автоматически;

- защитный колесный кожух большого размера;

- счетчик колес отбалансированных;

- программа балансировки колес типа PAX;

- стол с удобными ячейками для грузов, конусов, инструментов;

- большой ассортимент дополнительных возможностей.

Технические характеристики стенда балансировочного Hofmann Geodyna 4300-2:

| Наименование параметра, единицы измерения | Значение параметра |

|---|---|

| Диаметр центрального дискового отверстия, мм | 43-116 |

| Валовой диаметр, мм | 40 |

| Частота валового вращения, об/мин | 200 |

| Дисковая ширина, дюймы | 1-20 |

| Дисковый диаметр, дюймы | 8-24 |

| Максимальная колесная ширина, мм | 530 |

| Максимальный колесный диаметр, мм | 950 |

| Максимальная колесная масса, кг | 70 |

| Измерительная точность, г | 1 |

| Время для проведения измерений, с | 6 |

| Размеры габаритные высота/ширина /глубина, мм | 1756/1280/1080 |

| Масса стенда, кг | 105 |

| Электропитание балансировочного стенда, ф/В/Гц | 1/220/50 |

Купить балансировочный стенд Hofmann Geodyna 4300-2 можно у нас в компании «Кронвус-Юг», самостоятельно забрав товар со склада в Ростове-на-Дону. Если Вы не можете осуществить самовывоз, находясь в другом регионе, воспользуйтесь услугой доставки по регионам .

Москва

Санкт-Петербург

Краснодар

Сочи

Новороссийск

Анапа

Волгоград

Саратов

Самара

Невинномысск

Астрахань

Ставрополь

Владикавказ

Минеральные воды

Нальчик

Грозный

Пятигорск

Доставка по Ростову-на-Дону и области

Клиенты, которые находятся в Ростове-на-Дону, могут заказать доставку приобретаемого товара нашим грузовым транспортом. При этом сама доставка обойдется Вам в 1000 руб, вне зависимости от конечного места доставки, объема и веса товара (в пределах вместимости грузового автомобиля).

| Город | Километраж до города | Стоимость за 1км | Доставка по городу | Итог |

|---|---|---|---|---|

| Аксай | 24км | 15р | 700р | 1 060,00 |

| Батайск | 29км | 15р | 700р | 1 135,00 |

| Азов | 57км | 15р | 700р | 1 555,00 |

| Новочеркасск | 53км | 15р | 700р | 1 495,00 |

| Шахты | 89км | 15р | 700р | 2 035,00 |

| Таганрог | 70км | 15р | 700р | 1 750,00 |

Доставка по России

С открытием новых офисов продаж шиномонтажного оборудования в других регионах Южного федерального округа, наша компания осуществляет доставку купленного товара со склада, расположенного в Ростове-на-Дону, до любого терминала транспортной компании или конечного адреса клиента.

Приобретая оборудование в нашей компании, Вы можете не беспокоиться о его доставке, установке и подключении. Наличие собственной сервисной службы дает нам ряд преимуществ перед другими торгующими организациями.

Наши специалисты приедут к Вам на место, осуществят монтаж приобретенного оборудования, протестирует его на отсутствие заводских дефектов и, в случае необходимости, обучат Ваших сотрудников правильному обращению с изделием.

Цены сервисного обслуживания на Балансировочный стенд Hofmann Geodyna 4300-2

Услугу сервисного обслуживания на Балансировочный стенд Hofmann Geodyna 4300-2 Вы можете заказать отдельно у наших менеджеров при оформлении заказа.

Подробно ознакомиться с информацией по сервисной службе, Вы можете в соответствующем разделе нашего сайта — Сервис.

Источник

This document contains important information to use and/or repair your appliance.

Depending on the nature of the manual (use, installation, service, parts list), it provides instructions that you can’t ignore.

We provide PDF manuals : easy to download, the documents can be displayed on any equipment like mobile, tablet and computer.

This is an official document edited by the manufacturer or a local distributor.