-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

ST 3000 Smart Transmitter

Release 300 with HART

Communications Option

User Manual

Doc. No.:

34-ST-25-17

Revision Date:

10/05

Related Manuals for Honeywell ST 3000

Summary of Contents for Honeywell ST 3000

-

Page 1

ST 3000 Smart Transmitter Release 300 with HART Communications Option User Manual Doc. No.: 34-ST-25-17 Revision Date: 10/05… -

Page 2: Patent Notice

In no event is Honeywell liable to anyone for any indirect, special or consequential damages. The information and specifications in this document are subject to change without notice.

-

Page 3: About This Document

Updated with STA info. 10/05 Updated bolt torque and write protect. Contacts World Wide Web The following lists Honeywell’s World Wide Web sites that will be of interest to our industrial automation and control customers. Honeywell Organization WWW Address (URL) Corporate http://www.honeywell.com…

-

Page 4: Symbol Definitions

About This Document Technical Assistance If you encounter a problem with your ST 3000 Smart Transmitter, check to see how your transmitter is currently configured to verify that all selections are consistent with your application. If the problem persists, you can reach Honeywell’s Solution Support Center for technical support by telephone during normal business hours.

-

Page 5: Table Of Contents

Mounting ST 3000 Transmitter………………….17 Piping ST 3000 Transmitter…………………..28 Wiring ST 3000 Transmitter ………………….33 5— Getting Started………………..39 Overview……………………….39 Establishing Communications ………………….39 Making Initial Checks…………………….42 6— Configuration ………………… 45 Overview……………………….45 Configuration Overview ……………………46 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 6

Saving and Restoring a Configuration Database …………….93 9— Maintenance …………………. 97 Introduction……………………….97 Preventive Maintenance ……………………97 Inspecting and Cleaning Barrier Diaphragms ……………….97 Replacing Printed Wiring Assembly (PWA)………………100 Replacing Meter Body ……………………103 10— Calibration ………………… 107 ST 3000 HART Transmitter Release 300 User Manual 10/05… -

Page 7

Setting smart meter display using the HART communicator…………160 Typical smart meter indications…………………..163 Operation error codes……………………164 Meter/transmitter interaction………………….165 Appendix B— Configuration Record Sheet …………167 ST 3000 R300 Smart Transmitter with HART Communications ……………………………167 Appendix C – Freeze Protection of Transmitters………… 169 Possible Solutions/Methods ………………….169 10/05… -

Page 8

Contents Appendix D —Hazardous Area Classifications …………179 Introduction……………………….179 North American Hazardous Location Standards…………….179 International Electrotechnical Commission (IEC) Classifications…………184 Enclosure Ratings ………………………187 Index ……………………189 viii ST 3000 HART Transmitter Release 300 User Manual 10/05… -

Page 9

Table 4 Operating Temperature Limits (Transmitters with Silicone Fill Fluid DC200) ……….15 Table 5 Transmitter Maximum Allowable Working Pressure (MAWP) Ratings…………16 Table 6 Mounting ST 3000 Transmitter to a Bracket ………………..18 Table 7 Zero Corrects Procedure for Transmitters with a Small Differential Pressure Span ……..21 Table 8 Flush Mount Transmitter Installation ………………….24… -

Page 10

Tables Table 53 Major ST 3000 Smart Transmitter Parts Reference………………123 Table 54 Parts Identification for Callouts in Figure 42 and Figure 43 …………..125 Table 55 Parts Identification for Callouts in Figure 44…………………126 Table 56 Parts Identification for Callouts in Figure 45…………………129 Table 57 Parts Identification for Callouts in Figure 46. -

Page 11

Figure 3 Typical Communication Interface……………………7 Figure 4 Typical ST 3000 Transmitter Order Components……………….8 Figure 5 ST 3000 with Local Smart Meter Option………………….9 Figure 6 Typical Mounting Area Considerations Prior to Installation……………..14 Figure 7 Typical Bracket Mounted and Flange Mounted Installations…………….18 Figure 8 Leveling Transmitters ………………………21… -

Page 12

Figure C-8 Piping Installation for Differential Pressure Transmitter and Impulse Piping with Steam Heating..175 Figure C-9 Piping Installation for Process Pressure Transmitter and Impulse Piping with Steam Heating….176 Figure 1 ST 3000 Model STD110, STD120, STD125, STD130, STD170, STD924, STD930 (Rev S or greater)…………………………..201… -

Page 13

Section 13 provides additional wiring diagrams showing alternate wiring methods. Electronics Electronics Terminal Terminal Housing Housing Block Block Internal Internal Ground Ground Terminal Terminal 3-Screw Terminal Block 5-Screw Terminal Block 10/05 ST 3000 HART Transmitter Release 300 User Manual xiii… -

Page 15: 1- Introduction — First Time Users Only

1— Introduction — First Time Users Only Overview About this section This section is intended for users who have never worked with our ST 3000 Smart Transmitter with HART communications. It provides some general information to acquaint you with the ST 3000 transmitter and the HART communications interface.

-

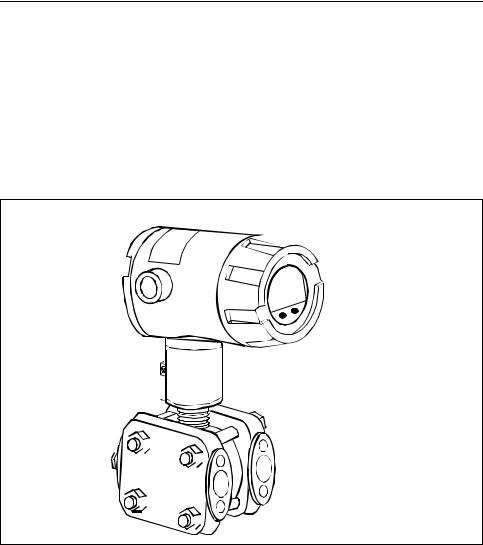

Page 16: St 3000 Smart Transmitters

1— Introduction — First Time Users Only — ST 3000 Smart Transmitters ST 3000 Smart Transmitters About the transmitter The ST 3000 Smart Transmitter comes in a variety of models for measurement applications involving one of these basic types of pressure: •…

-

Page 17: Figure 2 Functional Block Diagram For Transmitter In Analog Mode Of Operation

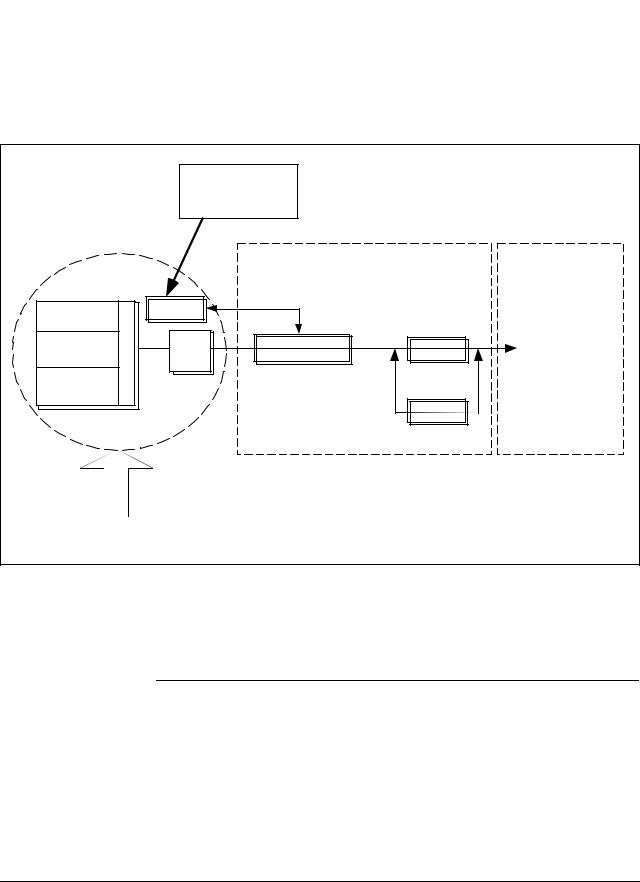

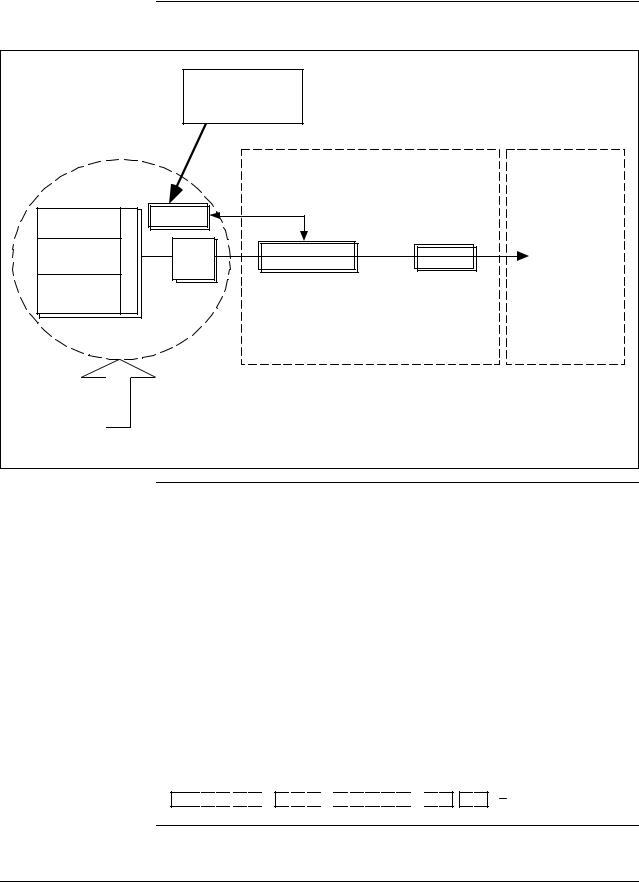

1— Introduction — First Time Users Only — ST 3000 Smart Transmitters Functional block diagram Besides the process variable (PV) output, the transmitter also provides its meter body temperature as a secondary variable (SV) which is only available as a read-only parameter through the communicator interface.

-

Page 18

Specification and Model Selection Guide that is provided as a separate document. ATTENTION Be aware that previous vintages of the ST 3000 transmitter with designations of Series 100, Series 100e, Series 600, and Series 900 have been supplied at various times since the ST 3000 was introduced in 1983. -

Page 19: Table 1 St 3000 Pressure Transmitter Family

1— Introduction — First Time Users Only — ST 3000 Smart Transmitters ST 3000 transmitter family Table 1 illustrates the various ST 3000 Release 300 pressure transmitters that are presently available. Table 1 ST 3000 Pressure Transmitter Family Transmitter Type…

-

Page 20

1— Introduction — First Time Users Only — ST 3000 Smart Transmitters Transmitter Type Series 100 Model Series 900 Model STG1xx STG9xx Gauge and Absolute Pressure STA1xx STA9xx STF1xx STF9xx Flange-Mount Liquid Level Differential Pressure STR1xx STR9xx with Remote Diaphragm Seals… -

Page 21: Hart Communicator

HART Communicator Transmitter adjustments Except for optional local zero and span adjustments, the ST 3000 has no physical adjustments. You need a HART communicator to make any adjustments in a ST 3000 with the HART communications option. Transmitter operator interface The HART communicator (Model 275) is connected to the loop wiring of the ST 3000 transmitter for direct communication with the transmitter.

-

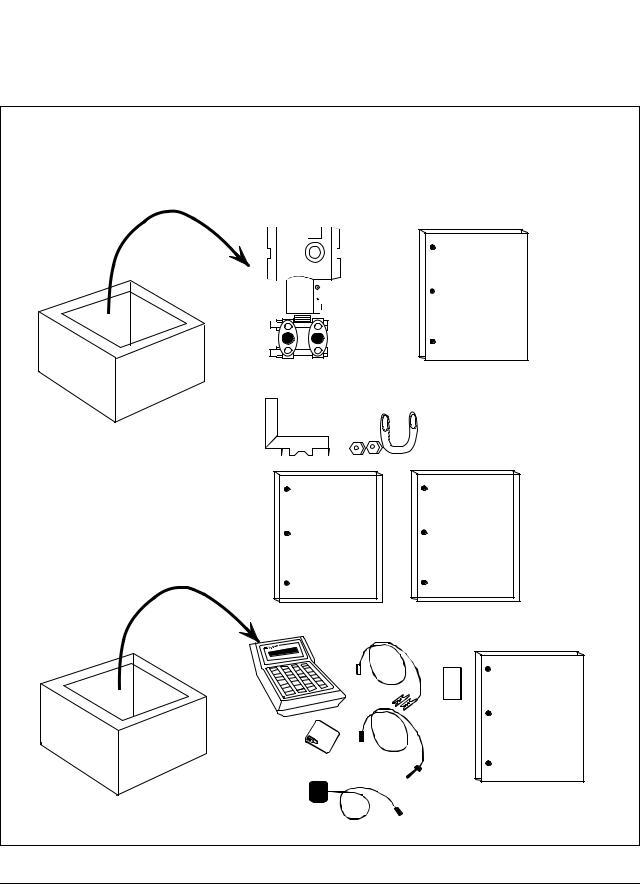

Page 22: Transmitter Order

1— Introduction — First Time Users Only — Transmitter Order Transmitter Order Order components Figure 4 shows the components that would be shipped and received for a typical ST 3000 transmitter order. Ordered ST 3000 Series 100 HART differential pressure transmitter…

-

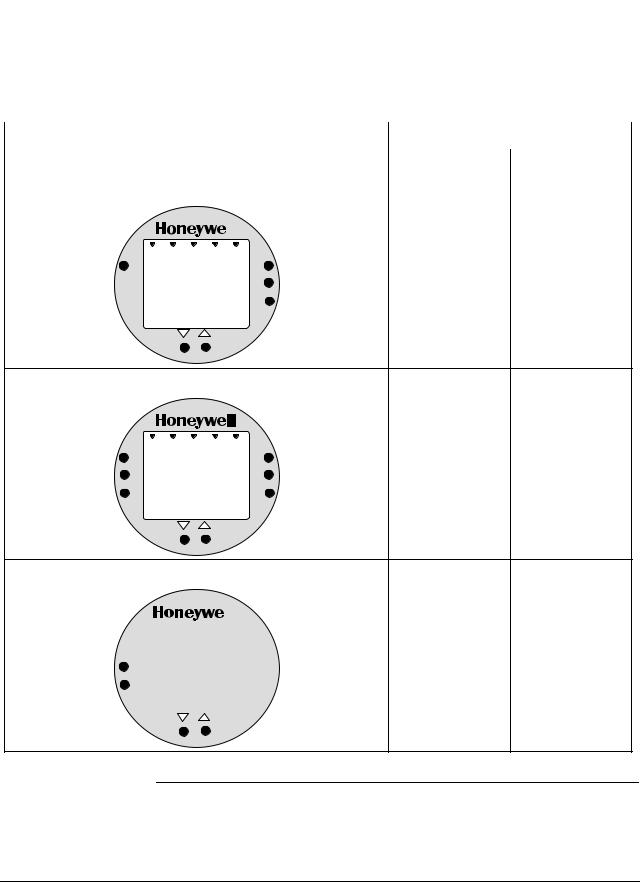

Page 23: Local Smart Meter Option

See Figure 5. Electronics Housing Local Smart Meter Option Figure 5 ST 3000 with Local Smart Meter Option. 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 24: Table 2 Local Smart Meter Options

Local Smart Meter with Zero and Span Adjustments UPPER SEL. VALUE Yes * SPAN UNITS ZERO LOWER VALUE Local Zero and Span Adjustments only Yes * SPAN ZERO * Except draft range, Model STD110. ST 3000 HART Transmitter Release 300 User Manual 10/05…

-

Page 25: 2- Quick Start Reference

This section assumes that the ST 3000 transmitter has been installed and wired correctly, and is ready to be put into operation. It also assumes that you are somewhat familiar with using the HART communicator and that the transmitter has been configured correctly for your application.

-

Page 26: Getting St 3000 Transmitter On-Line Quickly

Getting ST 3000 Transmitter On-Line Quickly Quick start-up tasks Table 3 lists common start-up tasks for an ST 3000 transmitter using a HART communicator and gives an appropriate section in this manual to reference for more information about how to do the task. The start-up tasks are listed in the order they are commonly completed.

-

Page 27: 3- Preinstallation Considerations

HART communicator interface conditions. • Operating conditions for transmitters equipped with the smart meter option. Of course, if you are replacing an existing ST 3000 transmitter you may skip this section. CE Conformity (Europe) Notice About conformity and special conditions This product is in conformity with the protection requirements of 89/336/EEC, the EMC Directive.

-

Page 28: Considerations For St 3000 Transmitter

Considerations for ST 3000 Transmitter Evaluate conditions The ST 3000 transmitter is designed to operate in common indoor industrial environments as well as outdoors. To assure optimum performance, evaluate these conditions at the mounting area relative to published transmitter specifications and accepted installation practices for electronic pressure transmitters.

-

Page 29: Table 4 Operating Temperature Limits (Transmitters With Silicone Fill Fluid Dc200)

3— Preinstallation Considerations — Considerations for ST 3000 Transmitter Table 4 Operating Temperature Limits (Transmitters with Silicone Fill Fluid DC200) Transmitter Type and Model Ambient Temperature Process Interface Temperature °C °F °C °F Draft Range STD110 -40 to 70 -40 to 158…

-

Page 30: Considerations For Hart Communicator

If your transmitter is to be installed and operated with one of the integral smart meter options, please note the Smart meter specifications and operating conditions for the meter located in Appendix A of this manual. ST 3000 HART Transmitter Release 300 User Manual 10/05…

-

Page 31: 4- Installation

4— Installation — Overview 4— Installation Overview About this section This section provides information about installing the ST 3000 transmitter. The topics in this section include: • Mounting the ST 3000 transmitter — various mounting methods are described and can be used depending upon the transmitter type.

-

Page 32: Table 6 Mounting St 3000 Transmitter To A Bracket

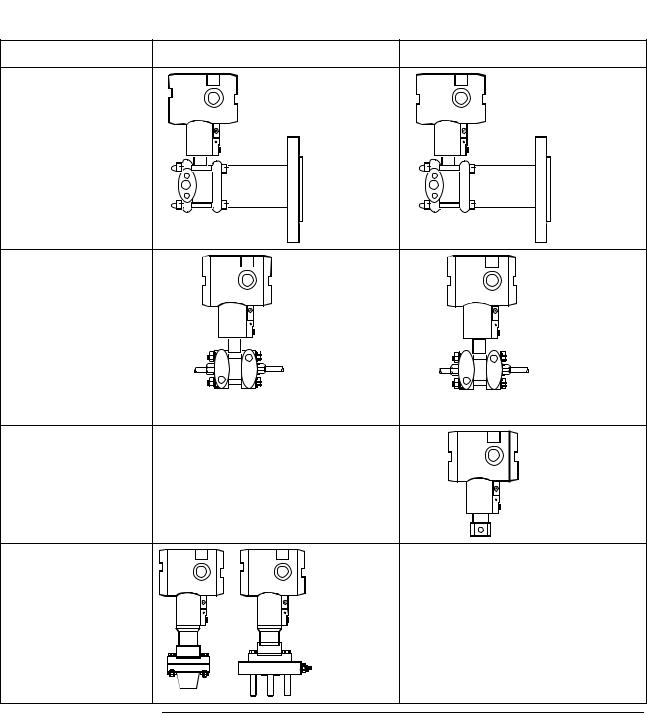

Flange Figure 7 Typical Bracket Mounted and Flange Mounted Installations Bracket mounting Table 6 summarizes typical steps for mounting a transmitter to a bracket. Table 6 Mounting ST 3000 Transmitter to a Bracket Step Action If you are using an……

-

Page 33

Loosen set screw on outside neck of transmitter one full turn. Rotate electronics housing in maximum of 180 degree increment in left or right direction from center to position you require 10/05 ST 3000 HART Transmitter Release 300 User Manual… -

Page 34

You do this by leveling the transmitter side-to-side and front-to-back. See Figure 8 for suggestions on how to level the transmitter using a spirit balance. Absolute pressure models Center Section Process Head Position spirit balance on center section of meter body only. ST 3000 HART Transmitter Release 300 User Manual 10/05… -

Page 35: Table 7 Zero Corrects Procedure For Transmitters With A Small Differential Pressure Span

Attach the transmitter to the mounting bracket but do not completely tighten the mounting bolts. Connect a tube between the input connections in the high pressure (HP) and low pressure (LP) heads to eliminate the affects of any surrounding air currents. 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 36

Press OK to initiate zero input corrects. You will be prompted to return the loop to automatic control. Press OK Remove the tube from between the input connections, the power, and the milliammeter and ST 3000 HART Transmitter Release 300 User Manual 10/05… -

Page 37: Figure 9 Typical Flange Mounted Transmitter Installation

Maximum Level Variable Reference Head H1 Minimum Level HP Side LP Side vented mounted to atmosphere to tank Figure 9 Typical Flange Mounted Transmitter Installation 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 38: Table 8 Flush Mount Transmitter Installation

Flush mounting ST 3000 flush mount transmitters (model STG9xx) are mounted directly to the process pipe or tank using a 1 inch weld nipple. Figure 10 shows a typical installation for a transmitter with a flush mount on a pipe.

-

Page 39: Figure 11 Typical Flange And Pipe Mounted Installations

Once the transmitter is mounted, the electronics housing can be rotated to the desired position. See Table 6, step 4. Tank Wall Flange Transmitter Connection Flange Process Pipe 1/2″ NPT Connection Figure 11 Typical Flange and Pipe Mounted Installations 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 40: Table 9 Mounting Remote Diaphragm Seal Transmitter

4— Installation — Mounting ST 3000 Transmitter Remote seal mounting ST 3000 transmitters furnished with remote diaphragm seals (models STRxxx) can be mounted using the optional mounting brackets. (See procedure in Table 6 in this section for bracket mounting.) Follow the guidelines below to determine the mounting position of the remote seals for the given fill fluid and then use the procedure in Table 9 to mount the remote seals to the process connections.

-

Page 41: Figure 12 Typical Remote Diaphragm Seal Transmitter Installation

Maximum Level Variable Fixed Head H1 Ref. Leg Minimum Level HP Side — Model STR93D — Model STR12D LP Side — Model STR13D Figure 12 Typical Remote Diaphragm Seal Transmitter Installation. 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 42: Piping St 3000 Transmitter

Figure 13 Typical 3-Valve Manifold and Blow-Down Piping Arrangement. Another piping arrangement uses a block-off valve and a tee connector in the process piping to the transmitter as shown in Figure 14. ST 3000 HART Transmitter Release 300 User Manual 10/05…

-

Page 43: Table 10 Suggested Transmitter Location For Given Processes

As a general rule there is a 56 degree C drop (100 degree F) in the temperature of the process for every foot of 1/2″ uninsulated piping. 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 44: Table 11 Process Connections

(See Table 12) on High Pressure Side*. See model selection guide for description of available flanged, threaded, Remote Diaphragm chemical tee, saddle, and sanitary process connections. Seals * Reference side has standard differential pressure process head. ST 3000 HART Transmitter Release 300 User Manual 10/05…

-

Page 45: Table 12 Flange Description

(where possible) before connecting these lines to the transmitter’s meter body. • Be sure all the valves in the blow-down lines are closed tight after the initial blow-down procedure and each maintenance procedure after that. 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 46: Table 13 Installing Flange Adapter

Apply an anti-seize compound on the stainless steel bolts prior to threading them into the process head. Evenly torque flange adapter bolts to a torque of 27,1 Nm +/- 1,4 Nm (20 ft lbs +/- 1.0 ft lbs) ST 3000 HART Transmitter Release 300 User Manual 10/05…

-

Page 47: Wiring St 3000 Transmitter

Operating Voltage (Vdc) 21012 Figure 15 Operating Range for ST 3000 Transmitters. The positive and negative loop wires are connected to the positive (+) and negative (–) SIGNAL terminals on the terminal block in the transmitter’s electronics housing as shown in Figure 16.

-

Page 48: Figure 16 St 3000 Transmitter Terminal Blocks

If you will be using the transmitter in a hazardous area, be sure to review the hazardous location reference data included in Appendix D of this manual before wiring and operating the transmitter. ST 3000 HART Transmitter Release 300 User Manual 10/05…

-

Page 49: Table 14 Wiring The Transmitter

• Double wound mains transformer per BS 3535 or equivalent. • An adequately rated zener diode whose voltage is not significantly higher than the rated voltage. • An adequately rated semiconductor voltage regulator. 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 50: Figure 17 Ground Connection For Lightning Protection

When installed as nonincendive equipment in a Division 2 Hazardous Location, disconnect power to the transmitter in the non-hazardous area, or determine that the location is non-hazardous prior to disconnecting or connecting the transmitter wires. ST 3000 HART Transmitter Release 300 User Manual 10/05…

-

Page 51

4— Installation — Wiring ST 3000 Transmitter Output meter options The ST 3000 transmitter can be equipped with any of these three optional output indicating meters that provide a 0 to 100% indication of the transmitter’s output. Meter type Wiring Connections to Transmitter Integral smart meter connections —… -

Page 52

SM 3000 remote meter in conjunction with a new smart meter that is configured to display readings in custom or flow units, the indications of the two meters will be displayed in different units. ST 3000 HART Transmitter Release 300 User Manual 10/05… -

Page 53: 5- Getting Started

5— Getting Started Overview About this section This section tells you how to establish communications with the ST 3000 and make initial checks of the transmitter’s settings and configuration using a HART hand-held communicator. This section includes these topics: •…

-

Page 54: Figure 18 Typical Communicator Connections

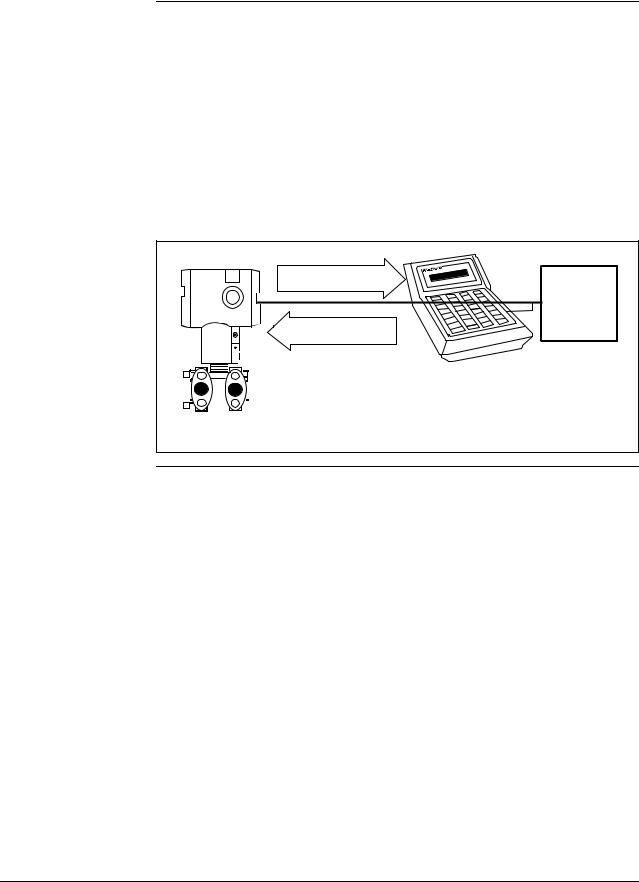

4 to 20 milliampere loop wiring. (Polarity of the communicator connection does not matter.) WARNING When the transmitter’s end-cap is removed, the housing is not explosionproof. Figure 18 shows typical communicator connections across loop wiring to a ST 3000 transmitter. ST 3000 Power Supply…

-

Page 55: Table 15 Starting Communications With Transmitter

Starting communications Once you connect the communicator to the transmitter, you are ready to start communicating with the transmitter. The procedure in Table 15 outlines the steps for starting communications with an ST 3000 transmitter without an assigned tag number.

-

Page 56: Making Initial Checks

* This information is fixed and cannot be changed by reconfiguring the transmitter. ** Alarm option and transmitter security are jumper-selectable on the electronics board. After reviewing the transmitter data, press EXIT which takes you back to the “Device setup” display. ST 3000 HART Transmitter Release 300 User Manual 10/05…

-

Page 57: Figure 19 Write Protection And Failsafe Direction Jumper Location

5— Getting Started — Making Initial Checks Transmitter write protection option The ST 3000 transmitters have a transmitter security option, also known as a “write protect option,” which is jumper-selectable. When the write protect option is ordered, transmitters are shipped with a default jumper position for read-only.

-

Page 58: Figure 20 Smart Meter Display With All Indicators Lit

Local smart meter display indications If your ST 3000 transmitter is equipped with the smart meter option, you can check the status of all the indicators on the local smart meter LCD display by cycling power to the transmitter. The meter runs a brief self-test whenever power is applied to the transmitter.

-

Page 59: 6- Configuration

6— Configuration Overview About this section This section introduces you to ST 3000 transmitter configuration. It identifies the parameters that make up the transmitter’s configuration database and provides procedures for entering values/selections for the given configuration parameters. This section also provides an overview of the HART communicator, including data on menus and keyboard, descriptions of display selections and symbols, and information on making changes using the communicator.

-

Page 60: Configuration Overview

Communicator and ST 3000 transmitter memories As shown in Figure 22, both the communicator and the ST 3000 transmitter have working memories. They serve as temporary storage areas for data exchanged between them during communications.

-

Page 61: Figure 22 Communicator And St 3000 Transmitter Memories

Figure 22 Communicator and ST 3000 Transmitter Memories Copying transmitter configuration into nonvolatile memory When setting up or configuring a ST 3000, whether you are changing one value or a configuration database, all configuration data must be copied into the transmitter’s non-volatile memory to ensure the security of the data.

-

Page 62: Table 17 Summary Of Pressure Transmitter Configuration Parameters

6— Configuration — Configuration Overview What to configure Table 17 summarizes the parameters that are included in the configuration database for a ST 3000 pressure transmitter. Table 17 Summary of Pressure Transmitter Configuration Parameters Configuration Data Setting or Selection Key in a tag identification up to eight characters in length.

-

Page 63

Information available through the communicator is accessed through menus. The procedures in this manual give the shortest path from the “Online” (or HOME) menu. There are alternate paths which, depending on your starting point, may be better suited. 10/05 ST 3000 HART Transmitter Release 300 User Manual… -

Page 64: Figure 23 Online (Or Home) Menu Summary

PV Unit PV URV PROM ID Final assembly Poll address PV URL PV LRV number Number of PV LRL Date Device id request preambles Figure 23 Online (or HOME) Menu Summary ST 3000 HART Transmitter Release 300 User Manual 10/05…

-

Page 65: Figure 24 Hart Communicator Menu Summary

Please refer to the communicator product manual or use the online help Configure Communicator for details on these menu options. System Information Listen for PC Polling Storage Location Contrast Simulation Off Time Ignore diagnostics Delete Configuration Figure 24 HART Communicator Menu Summary 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 66: Figure 25 Hart Communicator Keyboard

■ ■ ■ ■ ■ ■ ■ ■ ■ Arrow keys used to indicate position of characters that appear at top of buttons in keypad 22899 Figure 25 HART Communicator Keyboard ST 3000 HART Transmitter Release 300 User Manual 10/05…

-

Page 67

ATTENTION An alternate way of selecting a menu item, besides using the up and down arrows, is to press the key corresponding to the number left of the desired menu item. 10/05 ST 3000 HART Transmitter Release 300 User Manual… -

Page 68

See the example below to key in the word DATE. To key in a numeric character, merely press the key. ST 3000 HART Transmitter Release 300 User Manual 10/05… -

Page 69: Tag- Entering A Tag Number

Refer to “Making changes” in the previous section for information on keying in alphanumeric characters. Press ENTER. Either: • press SEND to download change to transmitter, or • go to another procedure and continue making changes. 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 70: Pv Unit- Selecting Unit Of Pressure Measurement

Since the engineering units affect the value of LRV and URV, it is recommended that you send the changed PV unit to the transmitter and then verify and change as required the values of LRV and URV. ST 3000 HART Transmitter Release 300 User Manual 10/05…

-

Page 71: Range Values- Setting Pv Urv And Pv Lrv

Table 19 to change it.) ATTENTION • ST 3000 Smart Transmitters are factory calibrated with inches of water ranges using inches of water pressure referenced to a temperature of 39.2˚F (4˚C).

-

Page 72: Table 21 Setting Lrv And Urv To Applied Pressures

You can also use the local zero and span adjustments on the new smart meter to set the lower and upper range values to applied pressures. See Appendix A for the procedure. ST 3000 HART Transmitter Release 300 User Manual 10/05…

-

Page 73: Device Information

Enter a new value, if desired and press ENTER. Note: Pressing ESC will cancel action without changing selection. Either: • press SEND to download change to transmitter, or • go to another procedure and continue making changes. 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 74: Pressure Transfer Function- Selecting Output Conformity

For differential pressure transmitters measuring the pressure drop across a primary element, the flow rate is directly proportional to the square root of the differential or pressure drop. The ST 3000 transmitter’s output is automatically converted to equal percent of flow when its output conformity is configured as square root.

-

Page 75: Figure 26 Square Root Dropout Point

70% • 16 + 4 = 15.2 mA dc Output Square root dropout To avoid unstable output at readings near zero, the ST 3000 transmitter automatically drops square root conformity and changes to linear conformity for low differential pressure readings. As shown in Figure 26, the point is near 0.5% of input for ST 3000 transmitters.

-

Page 76: Pv Damping- Adjusting Damping Time

If you do not want to change the damping value, press ABORT. Either: • press SEND to download change to transmitter, or go to another procedure and continue making changes. • ST 3000 HART Transmitter Release 300 User Manual 10/05…

-

Page 77: Sv Units- Selecting Secondary Variable Units

When the desired selection is highlighted, press ENTER. Pressing ESC will cancel procedure without changing unit selection. Either: • press SEND to download change to transmitter, or • go to another procedure and continue making changes. 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 78: Poll Addr- Selecting Poll Address

A device with a poll address of 0 (zero) will provide a 4 to 20 mA analog output as well as receive requests and respond to commands from the HART communicator. The steps in Table 26 show how set the poll address of the transmitter. ST 3000 transmitters are shipped from the factory with poll address 0.

-

Page 79: 7- Start-Up

DP transmitter with remote diaphragm seals in a liquid level measurement application ATTENTION All procedures in this manual assume a transmitter poll address of 0 (zero). See Section 6, for information about poll address. 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 80: Start-Up Tasks

These applications also apply for GP and AP type transmitters equipped with remote seals. However, you can only confirm that input pressure correlates with transmitter output in processes using remote seal connections. ST 3000 HART Transmitter Release 300 User Manual 10/05…

-

Page 81: Running Analog Output

If you have completed the loop test, then press OK and go to Step 8. Select 20mA to set output signal to 20 mA (5.0V or 100%). Press ENTER. The communicator notifies you that the transmitter ‘s output is fixed at 20 mA. 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 82: Figure 27 Typical Communicator And Meter Connections For Constant-Current Source (Output) Mode

Supply Black — Receiver HART hand-held Commnicator Differential Note: Polarity of the Communicator Pressure connection does not matter. Transmitter Figure 27 Typical Communicator and Meter Connections for Constant-Current Source (Output) Mode ST 3000 HART Transmitter Release 300 User Manual 10/05…

-

Page 83: Flow Measurement With Dp Transmitter

Refer to Figure 27 for sample communicator and meter connections in a typical analog loop with a differential pressure-type transmitter. 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 84

Check communicator and milliammeter readings again. If readings are still not correct, verify transmitter’s configuration data and change its range setting, if necessary. Remove communicator and milliammeter from loop. ST 3000 HART Transmitter Release 300 User Manual 10/05… -

Page 85: Pressure Measurement With Dp Transmitter

Open plug C and valve A to apply head pressure H to meter body. Then, open LP vent. Allow system to stabilize at head pressure At “Online” menu, read present LRV setting. 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 86

Check communicator and milliammeter readings again. If readings are still not correct, verify transmitter’s configuration data and change its range setting if needed. Remove communicator and milliammeter from loop. ST 3000 HART Transmitter Release 300 User Manual 10/05… -

Page 87: Liquid Level Measurement — Vented Tank

Refer to Figure 27 for sample communicator and meter connections in a typical analog loop with a differential pressure-type transmitter. Close block-off valve A. Refer to Figure 30 for sample piping arrangement. 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 88

URV can be set by filling the tank to the desired full scale level and then setting the URV through the communicator. See Range Values in Section 6 for details. ST 3000 HART Transmitter Release 300 User Manual 10/05… -

Page 89: Liquid Level Measurement — Pressurized Tank

Tap location at the minimum level to be measured Differential Pressure Transmitter HP side of transmitter Figure 31 Typical Piping Arrangement for Liquid Level Measurement with DP Type Transmitter and Pressurized Tank. 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 90: Table 32 Starting Up Dp Transmitter For Liquid Level Measurement In Pressurized Tank

When the following display appears, ST3000: PT 3011 Set the: 20mA Exit ABORT ENTER choose 4mA, then press ENTER. A display will prompt you to apply new 4 mA input. Press OK. ST 3000 HART Transmitter Release 300 User Manual 10/05…

-

Page 91

20mA, then press ENTER. A display will prompt you to apply new 20 mA input. Press OK. When “Current applied process value” display appears, choose “Set as 20mA value” then press ENTER. 10/05 ST 3000 HART Transmitter Release 300 User Manual… -

Page 92: Pressure Or Liquid Level Measurement With Gp Transmitter

Figure 27 for typical communicator and meter connections.. Pipe Block-off Union Plug valve no.1 Gauge Pressure Transmitter Block-off Process valve no.2 Tee connector Figure 32 Typical Piping Arrangement for Pressure Measurement with GP Type Transmitter ST 3000 HART Transmitter Release 300 User Manual 10/05…

-

Page 93: Table 33 Starting Up Gp Transmitter For Pressure Or Liquid Level Measurement

Optional (read output in % of range): From “Online” menu, step through the following menu selections: Device setup • Process variables • At “Process variables” display, read 0% output for corresponding input pressure. Check that milliammeter reading is 4 mA (0%) output 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 94

4mA, then press ENTER. A display will prompt you to apply new 4 mA input. Press OK. When “Current applied process value” display appears, choose “Set as 4mA value” then press ENTER. ST 3000 HART Transmitter Release 300 User Manual 10/05… -

Page 95: Pressure Measurement With Ap

Process For additional overrrange protection, use Sprague engineering type gauge saver or Fairchild model 95 gauge guard (style 1) Figure 34 Typical Piping Arrangement for Pressure Measurement with AP Type Transmitter 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 96: Table 34 Starting Up Ap Transmitter For Pressure Measurement

Check communicator and milliammeter readings again. If readings are still not correct, verify transmitter’s configuration data and change its range setting if needed. Remove communicator and milliammeter from loop. ST 3000 HART Transmitter Release 300 User Manual 10/05…

-

Page 97: Liquid Level Measurement With Dp Transmitter With Remote Seals

Refer to Figure 27 for sample communicator and meter connections in a typical analog loop with a differential pressure-type transmitter. 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 98

ENTER. LRV is set to fixed reference leg pressure H2 times density of remote seal fill fluid multiplied by –1 (pressure on low side of meter body). When the display above appears, choose Exit, then press ENTER. Return the loop to automatic control. ST 3000 HART Transmitter Release 300 User Manual 10/05… -

Page 99

From “Online” menu (if applicable, press HOME to get there), step through the following menu selections: • Device setup Diag/Service • • Calibration • Apply values You will be warned to remove the loop from automatic control. After doing so, press OK to continue. 10/05 ST 3000 HART Transmitter Release 300 User Manual… -

Page 100

Check communicator and milliammeter readings again. If readings are still not correct, verify transmitter’s configuration data and change its range setting if needed. Remove communicator and milliammeter from loop. ST 3000 HART Transmitter Release 300 User Manual 10/05… -

Page 101: 8- Operation

8— Operation Introduction About this section This section identifies how to access typical data associated with the operation of an ST 3000 transmitter. It also includes procedures for: changing the default failsafe direction of the transmitter’s output, changing the read/write access of the transmitter’s configuration database, and saving and/or restoring a transmitter’s configuration database.

-

Page 102: Table 36 Summary Of Keystrokes For Operation Data Access

PV LRL 0.00 inH2O PV URL 400.7 inH2O HELP You may need to select PV LRL and PV URL and press the right arrow key to view the values. (See Note.) ST 3000 HART Transmitter Release 300 User Manual 10/05…

-

Page 103

To view these values you must use the down arrow key to select the value and then press the right arrow key to display the value in detail. 10/05 ST 3000 HART Transmitter Release 300 User Manual… -

Page 104: Changing Default Failsafe Direction And Write Protect Jumpers

The procedure in Table 37 outlines the steps for cutting the failsafe jumper and/or repositioning the write protect jumper on the transmitter’s Printed Wiring Assembly (PWA). Figure 36 shows the location of the jumpers on the PWA of ST 3000 Release 300 transmitters. ESD HAZARD The nature of the integrated circuitry used in the transmitter’s PWA makes it susceptible to…

-

Page 105: Table 37 Changing Default Failsafe Direction Or Write Protect Jumper

90 degree increments. We recommend that you lubricate end-cap O-ring with silicon grease such as Dow Corning #33 or equivalent before you replace end cap. Turn ON transmitter power. 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 106: Writing Data In The Message Area

Press ENTER to save data in message area. (If you press ESC, you will exit message area without saving change.) When all desired changes have been made, press SEND to download changes from the communicator memory to the transmitter. ST 3000 HART Transmitter Release 300 User Manual 10/05…

-

Page 107: Saving And Restoring A Configuration Database

PT3011 Message Tank Pressure Message Tank Pressure Memory Module Working Working Memory Memory Data Pack SEND SAVE Communicator ST 3000 ST 3000 Figure 37 Summary of Save and Restore Database Function 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 108: Table 39 Saving A Configuration Database

A prompt may ask if you want to overwrite the existing configuration memory. Press YES or NO. The Online screen will appear when save is completed. Disconnect communicator from transmitter loop wiring and turn communicator off. ST 3000 HART Transmitter Release 300 User Manual 10/05…

-

Page 109: Table 40 Downloading A Configuration Database

The selected configuration is downloaded (sent) to the transmitter’s memory. Back out to “Offline” display, then choose Online. You can now change the tag number and other configuration data, as required. 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 110

ST 3000 HART Transmitter Release 300 User Manual 10/05… -

Page 111: 9- Maintenance

Preventive Maintenance Maintenance routines and schedules The ST 3000 transmitter itself does not require any specific maintenance routine at regularly scheduled intervals. However, you should consider carrying out these typical inspection and maintenance routines on a schedule that is dictated by the characteristics of the process medium being measured and whether blow- down facilities or purge systems are being used.

-

Page 112: Table 41 Inspecting And Cleaning Barrier Diaphragms

22518 GP/AP Process Head • For process heads of a GP or AP transmitter with dual-head design, see illustration for differential pressure transmitters in Figure 38. 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 113: Figure 38 Disassembly Of Dp Transmitter Process Heads From Meter Body

See Overpressure ratings in Section 3 of this manual. Nuts O-ring Bolts Process head O-ring Center section Process head Figure 38 Disassembly of DP Transmitter Process Heads from Meter Body 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 114: Replacing Printed Wiring Assembly (Pwa)

About the PWA Electronics Board The circuitry in the ST 3000 Release 300 transmitters is of the single PWA design. The PWA contains connectors for the flex-tape conductor from the sensor, the loop power wires and a connector for the optional smart meter cable.

-

Page 115

PWA, and install retainers to hold screws in place. Plug meter cable into connector J4 on PWA and be sure cable is still 10/05 ST 3000 HART Transmitter Release 300 User Manual… -

Page 116

Return transmitter to service and turn ON power. If applicable, verify local smart meter configuration data. Reconfigure selected engineering units and lower and upper display range values as required. (See Appendix A for details.) 10/05 ST 3000 HART Transmitter Release 300 User Manual… -

Page 117: Replacing Meter Body

O-ring in the smaller/inner groove. On other models of GP and AP transmitters, use a large O-ring in the larger/outer groove. Never use both O-rings together. 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 118

Carefully assemble process head or heads and bolts to new meter body. Finger tighten nuts. Typical Series 100 DP Transmitter Meter Body Nuts Flex Tape O-ring O-ring Bolts Process head Meter Body Process head 10/05 ST 3000 HART Transmitter Release 300 User Manual… -

Page 119

Be sure to orient Local Smart Meter for proper viewing through end-cap window. You can rotate the meter mounting orientation in 90 degree increments. Return transmitter to service and turn ON power Verify transmitter’s configuration data. Restore saved database, if applicable. 10/05 ST 3000 HART Transmitter Release 300 User Manual… -

Page 120

10/05 ST 3000 HART Transmitter Release 300 User Manual… -

Page 121: 10- Calibration

Overview About calibration The ST 3000 Smart Transmitter does not require recalibration at periodic intervals to maintain accuracy. If a recalibration is required, we recommend that you do a bench calibration with the transmitter removed from the process and located in a controlled environment to get the best accuracy.

-

Page 122: Calibrating Analog Output Signal

If not equal, select No, press ENTER, then key in new meter value. (Returns to “Enter meter value” prompt until field device output equals reference meter.) − If equal, select Yes, press ENTER. Go to Step 4. 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 123: Calibrating Range

Prompt notifies you that the field device will be returned to its original output. Calibrating Range The ST 3000 Smart Transmitter has two-point calibration. This means when you calibrate two points in the range, all the points in that range adjust to that calibration.

-

Page 124: Figure 39 Typical Range Calibration Hookup

ST 3000 HART 24Vdc Power Supply 250 Ω Pressure Head Dead Weight Tester Precision Pressure Source Communicator NOTE: Polarity of communicator connection does not matter. Figure 39 Typical Range Calibration Hookup 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 125: Resetting Calibration

Resetting Calibration Background Every ST 3000 transmitter is factory-characterized. The characterization process calculates a mathematical model of the performance of the transmitter’s sensors and stores that data in the transmitter’s memory. Small residual errors result from the sensor data acquisition and modeling process. These errors can be eliminated through calibration, using either a zero offset or a span correction.

-

Page 126

10/05 ST 3000 HART Transmitter Release 300 User Manual… -

Page 127: 11- Troubleshooting

Troubleshooting Overview Diagnostics The communicator and ST 3000 transmitter are constantly running internal diagnostics to monitor the functions and status of the control loop and their communications link. When a diagnostic failure is detected, a corresponding message is generated for the communicator display.

-

Page 128: Diagnostic Messages

(PROM) fault PAC FAULT Currently not implemented. Once a critical fault has been corrected, you must clear the critical status from the transmitter. See Clearing Critical Status later in this section. 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 129: Table 49 Summary Of Diagnostic Messages For Non-Critical Failures

Table 50 Summary of Diagnostic Messages for Communication Errors Message Description Device Disconnected Communication with a device has been interrupted. No Device Found Communicator was unable to establish communications with any device upon power-up. 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 130: Interpreting Messages

Transmitter is operating as a Exit output mode (Loop test)-. In Output Mode current source. Perform Master reset, (or cycle power). Table continued on next page ⇒ 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 131

If no PWA problem. other diagnostic message is given, condition is most likely meter body related. Check installation and replace • meter body if condition persists. 10/05 ST 3000 HART Transmitter Release 300 User Manual… -

Page 132: Clearing Critical Status

When message “Master reset OK” appears, press OK. Previous calibration “CORRECTS” are removed and calibration is reset to default values. When prompted, return the loop to automatic control and press OK. 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

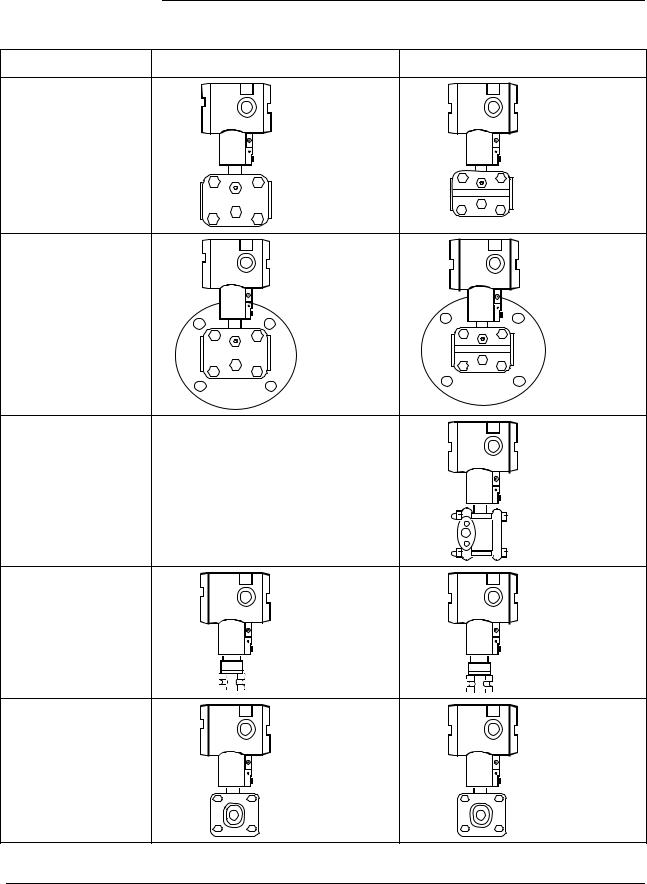

Page 133: 12- Parts List

Parts denoted with a “†” are recommended spares. See Table 64 for summary list of recommended spare parts. Figure 40 shows major parts for a given model with reference to parts list figures. 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 134: Figure 40 Major St 3000 Smart Transmitter Parts Reference

Attention: No replacement meter body is STF924 available for Remote Diaphragm Seal Models. STF932 STF92F STF93F High Temperature Models Figure STG14T STF14T Figure 40 Major ST 3000 Smart Transmitter Parts Reference. 10/05 ST 3000 HART Transmitter Release 300 User Manual…

-

Page 135: Figure 41 Major St 3000 Smart Transmitter Parts Reference

12— Parts List — Replacement Parts Angle Mounting Bracket Flat Mounting Bracket Figure 41 Major ST 3000 Smart Transmitter Parts Reference. Table 53 Major ST 3000 Smart Transmitter Parts Reference. Part Number Description Quantity Per Unit 30752770-003 Angle Bracket Mounting Kit for all models except LGP and Flush mount…

Скачать файл PDF «Honeywell ST 3000 Инструкция по эксплуатации» (2.87 Mb)

Популярность:

927 просмотры

Подсчет страниц:

126 страницы

Тип файла:

Размер файла:

2.87 Mb

Скачать

ST 3000 Smart Transmitter

Release 300 and SFC Smart Field

Communicator Model STS 103

Installation Guide

34-ST-33-39

2/05

ST 3000 Smart Transmitter

Release 300 and Smart Field

Communicator Model STS103

User’s Manual

34-ST-25-14 6/08

Honeywell Process Solutions

Copyright, Notices, and Trademarks

© Copyright 2008 by Honeywell Inc.

June 2008

While this information is presented in good faith and believed to be accurate, Honeywell disclaims the implied warranties of merchantability and fitness for a particular purpose and makes no express warranties except as may be stated in its written agreement with and for its customer.

In no event is Honeywell liable to anyone for any indirect, special or consequential damages. The information and specifications in this document are subject to change without notice.

This document was prepared using Information Mapping® methodologies and formatting principles.

TDC 3000, SFC, Smartline and ST 3000 are U.S. registered trademarks of Honeywell Inc.

Information Mapping is a trademark of Information Mapping Inc.

Honeywell Process Solutions

512 Virginia Drive

Fort Washington, PA 19034

|

ii |

ST 3000 Release 300 and SFC Model STS103 User’s Manual |

6/08 |

About This Publication

This manual is intended as a detailed “how to” reference for installing, piping, wiring, configuring, starting up, operating, maintaining, calibrating, and servicing Honeywell’s family of Release 300 Series 100 and Series 900 ST 3000® Smart Transmitters. It is based on using a model STS103 Smart Field Communicator (SFC®) as the operator interface for the ST 3000 transmitter. Be aware that data in this manual overlaps information in the ST 3000 Smart Transmitter Installation Guide and the Smart Field Communicator Model STS103 Operating Guide to minimize cross reference.

While this manual provides detailed procedures to assist first time users, it also includes keystroke summaries for most procedures as a quick reference for experienced users.

If you will be digitally integrating the ST 3000 transmitter with our TotalPlant® Solution (TPS) system, you will need to supplement this information with data in the PM/APM Smartline® Transmitter Integration Manual which is supplied with the TDC 3000®X bookset. TPS is the evolution of TDC 3000X.

This manual does not apply for non Release 300 Series 100, Series 600, Series 100e and non Release 300 Series 900 transmitter models. If you have a non Release 300 Series 100 or Series 600 ST 3000 Smart Transmitter, refer to the Installation Guide 34-ST-33-28 and User’s Manual 34-ST-25-09 supplied with the transmitter for information. If you have a non Release 300 Series 900 or Series 100e Smart Transmitter, refer to the Installation Guide 34-ST-33-31 and User’s Manual 34-ST-25-11 supplied with the transmitter for information.

Patent Notice

This product is covered by one or more of the following U.S. Patents: 4,520,488; 4,567,466; 4,494,183; 4,502,335; 4,592,002; 4,553,104; 4,541,282; 4,806,905; 4,797,669; 4,735,090; 4,768,382; 4,787,250; 4,888,992; 5,811,690; 5,875,150; 5,765,436; 4,734,873; 6,041,659 and other patents pending.

|

6/08 |

ST 3000 Release 300 and SFC Model STS103 User’s Manual |

iii |

References

|

Publication |

Publication |

Binder |

Binder |

|

Title |

Number |

Title |

Number |

|

Smart Field Communicator |

34-ST-11-14 |

||

|

Model STS103 |

|||

|

Operating Guide |

|||

|

ST 3000 Smart Transmitter |

34-ST-33-39 |

||

|

Series 100 and Series 900 |

|||

|

Release 300 |

|||

|

Installation Guide |

|||

|

For R400 and later: |

|||

|

PM/APM Smartline Transmitter |

PM12-410 |

Implementation/ |

TDC 2045 |

|

Integration Manual |

PM/APM Optional Devices |

||

Symbol Definitions

This CAUTION symbol on the equipment refers the user to the Product Manual for additional information. This symbol appears next to required information in the manual.

This WARNING symbol on the equipment refers the user to the Product Manual for additional information. This symbol appears next to required information in the manual.

WARNING: risk of electrical shock. This symbol warns the user of a potential shock hazard where HAZARDOUS LIVE voltages greater than 30 Vrms, 42.4 Vpeak, or 60 VDC may be accessible.

ATTENTION, Electrostatic Discharge (ESD) hazards. Observe precautions for handling electrostatic sensitive devices

Protective Earth (PE) terminal. Provided for connection of the protective earth (green or green/yellow) supply system conductor.

Earth Ground. Functional earth connection. NOTE: This connection shall be bonded to Protective earth at the source of supply in accordance with national and local electrical code requirements.

|

iv |

ST 3000 Release 300 and SFC Model STS103 User’s Manual |

6/08 |

Table of Contents

|

References……………………………………………………………………………………………………………………………….. |

iv |

|

|

Technical Assistance ………………………………………………………………………………………………………………… |

xiii |

|

|

SECTION 1 —OVERVIEW — FIRST TIME USERS ONLY…………………………………………. |

1 |

|

|

1.1 |

Introduction ………………………………………………………………………………………………………………………. |

1 |

|

1.2 |

ST 3000 Smart Transmitters ………………………………………………………………………………………………. |

2 |

|

1.3 |

Smart Field Communicator…………………………………………………………………………………………………. |

8 |

|

1.4 |

Transmitter/SFC Order …………………………………………………………………………………………………….. |

11 |

|

1.5 |

Local Smart Meter Options……………………………………………………………………………………………….. |

13 |

|

SECTION 2 —QUICK START REFERENCE………………………………………………………… |

15 |

|

|

2.1 |

Introduction …………………………………………………………………………………………………………………….. |

15 |

|

2.2 |

Getting ST 3000 Transmitter On-Line Quickly …………………………………………………………………….. |

16 |

|

SECTION 3 —PREINSTALLATION CONSIDERATIONS ………………………………………. |

17 |

|

|

3.1 |

Introduction …………………………………………………………………………………………………………………….. |

17 |

|

3.2 |

CE Conformity (Europe) Notice…………………………………………………………………………………………. |

18 |

|

3.3 |

Considerations for ST 3000 Transmitter …………………………………………………………………………….. |

19 |

|

3.4 |

Considerations for SFC ……………………………………………………………………………………………………. |

22 |

|

3.5 |

Considerations for Local Smart Meter Option ……………………………………………………………………… |

24 |

|

SECTION 4 —INSTALLATION …………………………………………………………………………… |

25 |

|

|

4.1 |

Introduction …………………………………………………………………………………………………………………….. |

25 |

|

4.2 |

Mounting ST 3000 Transmitter………………………………………………………………………………………….. |

26 |

|

4.3 |

Piping ST 3000 Transmitter………………………………………………………………………………………………. |

38 |

|

4.4 |

Wiring ST 3000 Transmitter………………………………………………………………………………………………. |

43 |

|

SECTION 5 —GETTING STARTED ……………………………………………………………………. |

49 |

|

|

5.1 |

Introduction …………………………………………………………………………………………………………………….. |

49 |

|

5.2 |

Establishing Communications …………………………………………………………………………………………… |

50 |

|

5.3 |

Making Initial Checks……………………………………………………………………………………………………….. |

54 |

|

5.4 |

Changing Mode of Operation ……………………………………………………………………………………………. |

57 |

|

6/08 |

ST 3000 Release 300 and SFC Model STS103 User’s Manual |

v |

Table of Contents

|

SECTION 6 —CONFIGURATION ……………………………………………………………………….. |

59 |

|

|

6.1 |

Introduction ……………………………………………………………………………………………………………………. |

59 |

|

6.2 |

Overview ……………………………………………………………………………………………………………………….. |

60 |

|

6.3 |

Entering a Tag Number……………………………………………………………………………………………………. |

71 |

|

6.4 |

Selecting Output Form …………………………………………………………………………………………………….. |

73 |

|

6.5 |

Adjusting Damping Time………………………………………………………………………………………………….. |

76 |

|

6.6 |

Selecting Unit of Measurement…………………………………………………………………………………………. |

78 |

|

6.7 |

Setting Range Values Using SFC……………………………………………………………………………………… |

80 |

|

6.8 |

Setting Range Values Using Local Adjustments …………………………………………………………………. |

84 |

|

6.9 |

Selecting Output Signal Mode (DE Mode Only) ………………………………………………………………….. |

91 |

|

6.10 |

Selecting Message Format (DE Mode Only) ………………………………………………………………………. |

94 |

|

6.11 |

Configuring Smart Meter Using SFC …………………………………………………………………………………. |

96 |

|

6.12 |

Configuring Smart Meter Using Pushbuttons ……………………………………………………………………. |

103 |

|

6.13 |

Disconnecting SFC ……………………………………………………………………………………………………….. |

122 |

|

SECTION 7 —STARTUP………………………………………………………………………………….. |

123 |

|

|

7.1 |

Introduction ………………………………………………………………………………………………………………….. |

123 |

|

7.2 |

Startup Tasks ……………………………………………………………………………………………………………….. |

124 |

|

7.3 |

Running Analog Output Check ……………………………………………………………………………………….. |

125 |

|

7.4 |

Flow Measurement with DP Transmitter…………………………………………………………………………… |

128 |

|

7.5 |

Pressure Measurement with DP Transmitter…………………………………………………………………….. |

131 |

|

7.6 |

Liquid Level Measurement — Vented Tank ………………………………………………………………………… |

133 |

|

7.7 |

Liquid Level Measurement — Pressurized Tank …………………………………………………………………. |

136 |

|

7.8 |

Pressure or Liquid Level Measurement with GP Transmitter ………………………………………………. |

140 |

|

7.9 |

Pressure or Liquid Level Measurement with Flush Mount Transmitter …………………………………. |

144 |

|

7.10 |

Pressure Measurement with AP Transmitter …………………………………………………………………….. |

145 |

|

7.11 |

Liquid Level Measurement with DP Transmitter with Remote Seals…………………………………….. |

147 |

|

SECTION 8 —OPERATION ……………………………………………………………………………… |

151 |

|

|

8.1 |

Introduction ………………………………………………………………………………………………………………….. |

151 |

|

8.2 |

Accessing Operation Data ……………………………………………………………………………………………… |

152 |

|

8.3 |

Changing Default Failsafe Direction ………………………………………………………………………………… |

155 |

|

8.4 |

Writing Data in Scratch Pad Area ……………………………………………………………………………………. |

157 |

|

8.5 |

Saving and Restoring a Database …………………………………………………………………………………… |

159 |

|

8.6 |

Monitoring Local Smart Meter Display……………………………………………………………………………… |

163 |

|

SECTION 9 —MAINTENANCE …………………………………………………………………………. |

169 |

|

|

9.1 |

Introduction ………………………………………………………………………………………………………………….. |

169 |

|

9.2 |

Preventive Maintenance…………………………………………………………………………………………………. |

170 |

|

9.3 |

Inspecting and Cleaning Barrier Diaphragms ……………………………………………………………………. |

171 |

|

9.4 |

Replacing PWA …………………………………………………………………………………………………………….. |

175 |

|

9.5 |

Replacing Meter Body……………………………………………………………………………………………………. |

178 |

|

vi |

ST 3000 Release 300 and SFC Model STS103 User’s Manual |

6/08 |

Table of Contents

|

SECTION 10 —CALIBRATION…………………………………………………………………………. |

183 |

|

|

10.1 |

Introduction …………………………………………………………………………………………………………………… |

183 |

|

10.2 |

Overview………………………………………………………………………………………………………………………. |

184 |

|

10.3 |

Calibrating Analog Output Signal …………………………………………………………………………………….. |

185 |

|

10.4 |

Calibrating Range with SFC ……………………………………………………………………………………………. |

189 |

|

10.5 |

Resetting Calibration ……………………………………………………………………………………………………… |

192 |

|

SECTION 11 —TROUBLESHOOTING………………………………………………………………. |

195 |

|

|

11.1 |

Introduction …………………………………………………………………………………………………………………… |

195 |

|

11.2 |

Overview………………………………………………………………………………………………………………………. |

196 |

|

11.3 |

Clearing the “#” Symbol From SFC Display ………………………………………………………………………. |

197 |

|

11.4 |

Diagnostic Messages …………………………………………………………………………………………………….. |

199 |

|

11.5 |

Running Status Check……………………………………………………………………………………………………. |

202 |

|

11.6 |

Interpreting Messages ……………………………………………………………………………………………………. |

203 |

|

11.7 |

Checking SFC Display and Keyboard ………………………………………………………………………………. |

207 |

|

SECTION 12 —PARTS LIST ……………………………………………………………………………. |

209 |

|

|

12.1 |

Replacement Parts ………………………………………………………………………………………………………… |

209 |

|

SECTION 13 —REFERENCE DRAWINGS ………………………………………………………… |

231 |

|

|

13.1 |

Wiring Diagrams ……………………………………………………………………………………………………………. |

231 |

|

APPENDIX A – TABLE III OPTIONS IN MODEL NUMBER………………………………….. |

233 |

|

|

A.1 |

Table III Options Reference…………………………………………………………………………………………….. |

233 |

|

APPENDIX B – FREEZE PROTECTION OF TRANSMITTERS …………………………….. |

237 |

|

|

B.1 |

Possible Solutions/Methods ……………………………………………………………………………………………. |

237 |

|

APPENDIX C – CONFIGURATION RECORD SHEET …………………………………………. |

251 |

|

|

APPENDIX D – HAZARDOUS LOCATIONS REFERENCE ………………………………….. |

253 |

|

|

D.1 |

North American Classification of Hazardous Locations ………………………………………………………. |

253 |

|

D.2 |

International Electrotechnical Commission (IEC) Classification of Hazardous Locations ………… |

259 |

|

D.3 |

Enclosure Ratings …………………………………………………………………………………………………………. |

263 |

|

INDEX |

……………………………………………………………………………………………………………. |

266 |

|

6/08 |

ST 3000 Release 300 and SFC Model STS103 User’s Manual |

vii |

|

Figures |

||

|

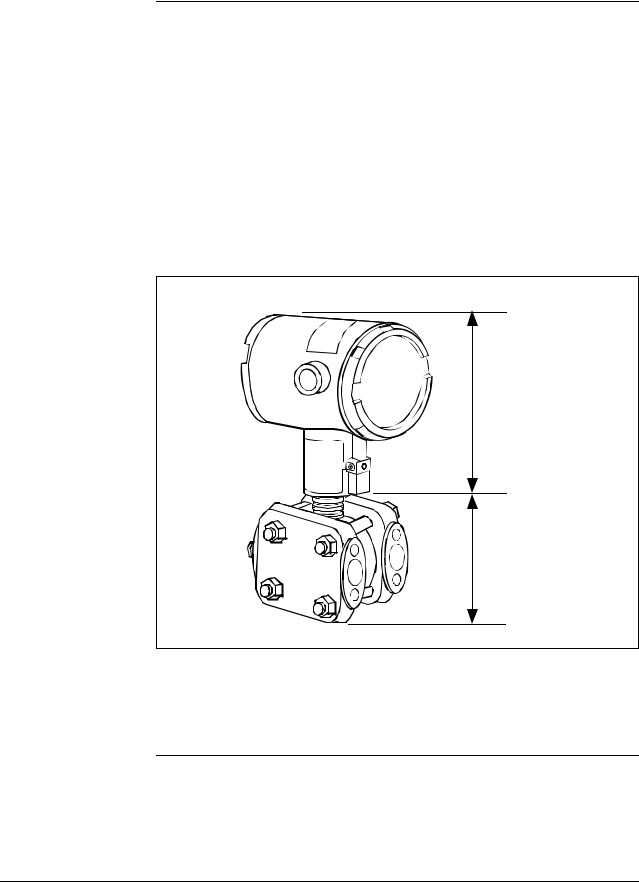

Figure 1 |

Typical ST 3000 Differential Pressure Transmitter…………………………………………………………………….. |

2 |

|

Figure 2 |

Functional Block Diagram for Transmitter in Analog Mode of Operation…………………………………….. |

3 |

|

Figure 3 |

Functional Block Diagram for Transmitter in Digital DE Mode of Operation. ………………………………. |

4 |

|

Figure 4 |

Typical SFC Communication Interface…………………………………………………………………………………….. |

8 |

|

Figure 5 |

Typical ST 3000 Transmitter and SFC Order Components. ………………………………………………………. |

11 |

|

Figure 6 |

ST 3000 with Local Smart Meter Option. ……………………………………………………………………………….. |

14 |

|

Figure 7 |

Typical Mounting Area Considerations Prior to Installation ……………………………………………………… |

19 |

|

Figure 8 |

Typical Bracket Mounted and Flange Mounted Installations……………………………………………………… |

26 |

|

Figure 9 |

Leveling a Model STA122 or 922 Absolute Pressure Transmitter. …………………………………………….. |

30 |

|

Figure 10 |

Typical Flange Mounted Transmitter Installation …………………………………………………………………….. |

33 |

|

Figure 11 |

Typical Flush Mounted Transmitter Installation ………………………………………………………………………. |

34 |

|

Figure 12 |

Typical Pipe and Flange Mounted Installations ……………………………………………………………………….. |

35 |

|

Figure 13 |

Typical Remote Diaphragm Seal Transmitter Installation. ………………………………………………………… |

37 |

|

Figure 14 |

Typical 3-Valve Manifold and Blow-Down Piping Arrangement. ……………………………………………… |

38 |

|

Figure 15 |

Typical Piping Arrangement for ½” NPT Process Connection…………………………………………………… |

39 |

|

Figure 16 |

Operating Range for ST 3000 Transmitters. ……………………………………………………………………………. |

43 |

|

Figure 17 |

ST 3000 Transmitter Terminal Block……………………………………………………………………………………… |

44 |

|

Figure 18 |

Ground Connection for Lightning Protection…………………………………………………………………………… |

46 |

|

Figure 19 |

Typical SFC Connections……………………………………………………………………………………………………… |

50 |

|

Figure 20 |

Write Protect Jumper Location and Selections…………………………………………………………………………. |

55 |

|

Figure 21 |

Display With All Indicators Lit……………………………………………………………………………………………… |

56 |

|

Figure 22 |

Keystroke Summary for Changing Mode of Operation. ……………………………………………………………. |

58 |

|

Figure 23 |

Summary of Configuration Process………………………………………………………………………………………… |

60 |

|

Figure 24 |

SFC and ST 3000 Transmitter Memories………………………………………………………………………………… |

61 |

|

Figure 25 |

Flowchart — ST 3000 Pressure Transmitter Configuration……………………………………………………….. |

66 |

|

Figure 26 |

Keystroke Summary for Entering Tag Number………………………………………………………………………… |

72 |

|

Figure 27 |

Keystroke Summary for Selecting Output Conformity. …………………………………………………………….. |

74 |

|

Figure 28 |

Square Root Dropout Points………………………………………………………………………………………………….. |

75 |

|

Figure 29 |

Keystroke Summary for Adjusting Damping Time…………………………………………………………………… |

77 |

|

Figure 30 |

Keystroke Summary for Keying in LRV and URV…………………………………………………………………… |

81 |

|

Figure 31 |

Keystroke Summary for Setting LRV and URV to Applied Pressures. ……………………………………….. |

83 |

|

Figure 32 |

Typical Setup for Setting Range Values Using Local Zero and Span Adjustments……………………….. |

90 |

|

Figure 33 |

Keystroke Summary for Selecting Mode of Output Signal Indication…………………………………………. |

93 |

|

Figure 34 |

Keystroke Summary for Selecting Message Format. ………………………………………………………………… |

95 |

|

Figure 35 |

Keystroke Summary for Configuring Local Smart Meter………………………………………………………… |

102 |

|

Figure 36 |

Button Pushing Summary for Selecting Engineering Units. …………………………………………………….. |

120 |

|

Figure 37 |

Button Pushing Summary for Setting Lower and Upper Display Limits. …………………………………… |

121 |

|

Figure 38 |

Typical SFC and Meter Connections for Constant-Current Source Mode………………………………….. |

127 |

|

Figure 39 |

Typical Piping Arrangement for Flow Measurement with DP Type Transmitter ………………………… |

128 |

|

Figure 40 |

Typical Piping Arrangement for Pressure Measurement with DP Type Transmitter……………………. |

131 |

|

Figure 41 |

Typical Piping Arrangement for Liquid Level Measurement with |

|

|

DP Type Transmitter and Vented Tank…………………………………………………………………………………. |

133 |

|

|

Figure 42 |

Typical Piping Arrangement for Liquid Level Measurement with |

|

|

DP Type Transmitter and Pressurized Tank…………………………………………………………………………… |

136 |

|

|

Figure 43 |

Typical Piping Arrangement for Pressure Measurement with GP Type Transmitter……………………. |

140 |

|

Figure 44 |

Typical Piping Arrangement for Liquid Level Measurement with GP TypeTransmitter………………. |

140 |

|

Figure 45 |

Typical Arrangement for Pressure Measurement with Flush Mount Transmitter………………………… |

144 |

|

Figure 46 |

Typical Arrangement for Liquid Level Measurement with Flush Mount Transmitter………………….. |

144 |

|

Figure 47 |

Typical Piping Arrangement for Pressure Measurement with AP Type Transmitter……………………. |

145 |

|

viii |

ST 3000 Release 300 and SFC Model STS103 User’s Manual |

6/08 |

|

Figures |

||

|

Figure 48 Typical Piping Arrangement for Liquid Level Measurement with |

||

|

DP Type Transmitter with Remote Seals ………………………………………………………………………………. |

147 |

|

|

Figure 49 Location of Failsafe Direction Jumper on PWA. ……………………………………………………………………. |

156 |

|

|

Figure 50 |

Summary of Save and Restore Database Function………………………………………………………………….. |

159 |

|

Figure 51 Display With All Indicators Lit……………………………………………………………………………………………. |

163 |

|

|

Figure 52 |

Typical Calibration Hookup………………………………………………………………………………………………… |

191 |

|

Figure 53 |

Major ST 3000 Smart Transmitter Parts Reference. ……………………………………………………………….. |

210 |

|

Figure 54 ST 3000 Transmitter Mounting Bracket Parts Reference. ……………………………………………………….. |

211 |

|

|

Figure 55 |

Series 100/900 Electronics Housing — Electronics/Meter End. …………………………………………………. |

212 |

|

Figure 56 |

Series 100/900 Electronics Housing — Terminal Block End……………………………………………………… |

212 |

|

Figure 57 |

Series 100 and Series 900 DP Meter Body for Models STD924 & STD930 C, D, G, |

|

|

H, K, and L and STD974 ……………………………………………………………………………………………………. |

214 |

|

|

Figure 58 |

Series 900 DP Meter Body for Models Models STD924 & STD930 A, B, E, F, and J………………… |

217 |

|

Figure 59 |

Series 100 GP and AP Meter Bodies and Series 900 AP Meter Body……………………………………….. |

219 |

|

Figure 60 |

Series 900 Dual-Head GP Meter Bodies……………………………………………………………………………….. |

221 |

|

Figure 61 |

Series 100 and Series 900 LGP Meter Body………………………………………………………………………….. |

222 |

|

Figure 62 |

Series 900 Flush Mount Meter Body. …………………………………………………………………………………… |

223 |

|

Figure 63 |

Series 100 and Series 900 Flange Mounted Meter Body. ………………………………………………………… |

224 |

|

Figure 64 |

High Temperature Meter Body. …………………………………………………………………………………………… |

226 |

|

Figure 65 SFC Smart Field Communicator and Accessories. …………………………………………………………………. |

228 |

|

|

Figure B-1 |

Piping Installation for Sealing Liquid With Specific Gravity Heavier Than Process Fluid…………… |

238 |

|

Figure B-2 |

Piping Installation for Sealing Liquid with Specific Gravity Lighter Than Process Fluid…………….. |

239 |

|

Figure B-3 |

Piping Installation for Gas Flow. …………………………………………………………………………………………. |

240 |

|

Figure B-4 |

Piping Installation for Differential Pressure Transmitter with Metal Diaphragm Seals………………… |

241 |

|

Figure B-5 |

Piping Installation for Process Pressure Transmitter with Metal Diaphragm Seal……………………….. |

242 |

|

Figure B-6 |

Piping Installation for Differential Pressure Transmitter and |

|

|

Impulse Piping with Electric Heating and Control………………………………………………………………….. |

243 |

|

|

Figure B-7 |

Piping Installation for Process Pressure Transmitter and |

|

|

Impulse Piping with Electric Heating Control. ………………………………………………………………………. |

244 |

|

|

Figure B-8 |

Piping Installation for Differential Pressure Transmitter and Impulse Piping with Steam Heating… |

247 |

|

Figure B-9 |

Piping Installation for Process Pressure Transmitter and Impulse Piping with Steam Heating. …….. |

248 |

|

6/08 |

ST 3000 Release 300 and SFC Model STS103 User’s Manual |

ix |

|

Tables |

||

|

Table 1 |

ST 3000 Pressure Transmitter Family. ……………………………………………………………………………………. |

6 |

|

Table 2 |

SFC Model Differences………………………………………………………………………………………………………… |

9 |

|

Table 3 |

Local Smart Meter Available Options…………………………………………………………………………………… |

13 |

|

Table 4 |

Start-up Tasks Reference…………………………………………………………………………………………………….. |

16 |

|

Table 5 |

Operating Temperature Limits (Transmitters with Silicone Fill Fluids) …………………………………….. |

20 |

|

Table 6 |

Transmitter Overpressure Ratings………………………………………………………………………………………… |

21 |

|

Table 7 |

Installing and Charging SFC Battery Pack…………………………………………………………………………….. |

22 |

|

Table 8 |

Local Smart Meter Specifications. ……………………………………………………………………………………….. |

24 |

|

Table 9 |

Mounting ST 3000 Transmitter to a Bracket………………………………………………………………………….. |

27 |

|

Table 10 |

Zero Corrects Procedure for STD110……………………………………………………………………………………. |

32 |

|

Table 11 |

Mounting Remote Diaphragm Seal Transmitter……………………………………………………………………… |

36 |

|

Table 12 |

Suggested Transmitter Location for Given Process ………………………………………………………………… |

39 |

|

Table 13 |

Process Connections…………………………………………………………………………………………………………… |

40 |

|

Table 14 |

Flange Description …………………………………………………………………………………………………………….. |

41 |

|

Table 15 |

Installing Flange Adapter ……………………………………………………………………………………………………. |

42 |

|

Table 16 |

Wiring the Transmitter ……………………………………………………………………………………………………….. |

45 |

|

Table 17 |

Starting Communications with Transmitter……………………………………………………………………………. |

51 |

|

Table 18 |

Confirming Mode of Operation and Identifying Software Versions………………………………………….. |

54 |

|

Table 19 |

Changing Mode of Operation………………………………………………………………………………………………. |

57 |

|

Table 20 |

Summary of Pressure Transmitter Configuration Parameters …………………………………………………… |

63 |

|

Table 21 |

Entering Tag Number…………………………………………………………………………………………………………. |

71 |

|

Table 22 |

Selecting Output Conformity ………………………………………………………………………………………………. |

73 |

|

Table 23 |

Adjusting Damping Time ……………………………………………………………………………………………………. |

76 |

|

Table 24 |

Pre-Programmed Engineering Units for Selection ………………………………………………………………….. |

78 |

|

Table 25 |

Keying in LRV and URV……………………………………………………………………………………………………. |

80 |

|

Table 26 |

Setting LRV and URV to Applied Pressures………………………………………………………………………….. |

82 |

|

Table 27 |

Setting Range Values Using Local Zero and Span Adjustments ………………………………………………. |

84 |

|

Table 28 |

Selecting Mode of Output Signal Indication ………………………………………………………………………….. |

91 |

|

Table 29 |

Selecting Message Format…………………………………………………………………………………………………… |

94 |

|

Table 30 |

Setting Up Local Smart Meter Configuration Using an SFC ……………………………………………………. |

97 |

|

Table 31 |

Smart Meter Pushbutton Description ………………………………………………………………………………….. |

103 |

|

Table 32 |

Smart Meter Engineering Units Code …………………………………………………………………………………. |

105 |

|

Table 33 |

Selecting Engineering Units ………………………………………………………………………………………………. |

106 |

|

Table 34 |

Smart Meter Restrictions for Setting Display Values…………………………………………………………….. |

109 |

|

Table 35 |

Setting Lower Display Values for Smart Meter Display………………………………………………………… |

110 |

|

Table 36 |

Setting Upper Display Value for Smart Meter Display………………………………………………………….. |

114 |

|

Table 37 |

Startup Procedure Reference ……………………………………………………………………………………………… |

124 |

|

Table 38 |

Using Transmitter in Constant-Current Source Mode……………………………………………………………. |

125 |

|

Table 39 |

Starting Up DP Transmitter for Flow Measurement With SFC ………………………………………………. |

128 |

|

Table 40 |

Starting Up DP Transmitter for Pressure Measurement With SFC………………………………………….. |

131 |

|

Table 41 |

Starting Up DP Transmitter for Liquid Level Measurement in Vented Tank ……………………………. |

134 |

|

Table 42 |

Starting Up DP Transmitter for Liquid Level Measurement in Pressurized Tank ……………………… |

137 |

|

Table 43 |

Starting Up GP Transmitter for Pressure or Liquid Level Measurement With SFC…………………… |

141 |

|

Table 44 |

Starting Up AP Transmitter for Pressure Measurement With SFC………………………………………….. |

145 |

|

Table 45 |

Starting Up DP Transmitter with Remote Seals for Liquid Level Measurement with SFC…………. |

148 |

|

Table 46 |

Summary of Keystrokes for Operation Data Access……………………………………………………………… |

152 |

|

Table 47 |

Cutting Failsafe Direction Jumper………………………………………………………………………………………. |

156 |

|

Table 48 |

Writing Data in Scratch Pad Area ………………………………………………………………………………………. |

157 |

|

Table 49 |

Saving and Restoring a Database ……………………………………………………………………………………….. |

160 |

|

x |

ST 3000 Release 300 and SFC Model STS103 User’s Manual |

6/08 |

|

Tables |

||

|

Table 50 |

Description of Display Indicators Shown in Figure 51………………………………………………………….. |

163 |

|

Table 51 |

Summary of Typical Local Smart Meter Indications. ……………………………………………………………. |

165 |

|

Table 52 |

Possible Smart Meter Error Codes. …………………………………………………………………………………….. |

166 |

|

Table 53 |

Inspecting and Cleaning Barrier Diaphragms ………………………………………………………………………. |

171 |

|

Table 54 |

Process Head Bolt Torque Ratings……………………………………………………………………………………… |

174 |

|

Table 55 |

Replacing PWA……………………………………………………………………………………………………………….. |

175 |

|

Table 56 |

Replacing Meter Body Only………………………………………………………………………………………………. |

178 |

|

Table 57 |

Calibrating Output Signal for Transmitter in Analog Mode …………………………………………………… |

185 |

|

Table 58 |

Calibrating Measurement Range With SFC …………………………………………………………………………. |

189 |

|

Table 59 |

Resetting Calibration Data With SFC …………………………………………………………………………………. |

193 |

|

Table 60 |

Clearing the # Symbol from the SFC Display………………………………………………………………………. |

197 |

|

Table 61 |

Summary of Diagnostic Messages for Non-Critical Failures………………………………………………….. |

199 |

|

Table 62 |

Summary of Diagnostic Messages for Critical Failures…………………………………………………………. |

200 |

|

Table 63 |

Summary of Diagnostic Messages for Communication Errors ……………………………………………….. |

200 |

|

Table 64 |

Summary of Diagnostic Messages for Invalid Key Entry Errors…………………………………………….. |

201 |

|

Table 65 |

Summary of Interrupt Messages For SFC Display………………………………………………………………… |

201 |

|

Table 66 |

Running a Status Check With SFC …………………………………………………………………………………….. |

202 |

|

Table 67 |

Diagnostic Message Interpretation Table…………………………………………………………………………….. |

203 |

|

Table 68 |

Running SFC Display and Keyboard Test …………………………………………………………………………… |

207 |

|

Table 69 |

Major ST 3000 Smart Transmitter Parts Reference. ……………………………………………………………… |

211 |

|

Table 70 |

Parts Identification for Callouts in Figures 55 and 56……………………………………………………………. |

213 |

|

Table 71 |

Parts Identification for Callouts in Figure 57……………………………………………………………………….. |

215 |

|

Table 72 |

Parts Identification for Callouts in Figure 58……………………………………………………………………….. |

218 |

|

Table 73 |

Parts Identification for Callouts in Figure 59……………………………………………………………………….. |

219 |

|

Table 74 |

Replacement GP and AP Process Head Part Numbers for Narrow Profile Meter Body……………… |

220 |

|

Table 75 |

Parts Identification for Callouts in Figure 60……………………………………………………………………….. |

221 |

|

Table 76 |