-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

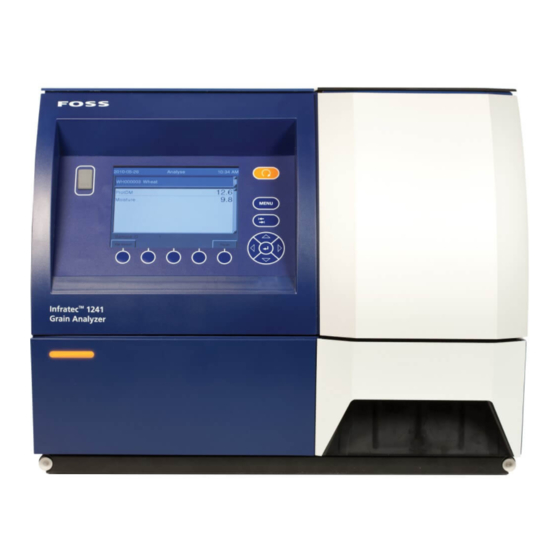

Infratec™ 1241 Grain Analyzer

Service Manual

1001 5015 / Rev. 4

Copyright 2011 / All rights reserved

FOSS Analytical A/S, Foss Allé 1, DK-3400 Hillerød, Denmark

Tel Int +45 7010 3370, Fax +45 7010 3371, E-mail info@foss.dk

Related Manuals for Foss Infratec 1241

Summary of Contents for Foss Infratec 1241

-

Page 1

Infratec™ 1241 Grain Analyzer Service Manual 1001 5015 / Rev. 4 Copyright 2011 / All rights reserved FOSS Analytical A/S, Foss Allé 1, DK-3400 Hillerød, Denmark Tel Int +45 7010 3370, Fax +45 7010 3371, E-mail info@foss.dk… -

Page 2

Infratec™ 1241 Grain Analyzer Information may be changed or updated without notice. The latest version is found at www.foss.dk. Rev. Date of Issue Revised Material 2011-03-18 First issue 2012-11-09 Service procedure updated 2015-05-18 General update 2016-09-26 Minor changes in section 1, 4 and 5… -

Page 3: Table Of Contents

Software Description ……….2:22 Installation ……….General ……………. 3:1 Installation of Test Weight Module on Infratec 1241 Generation 2 ……..3:1 3.2.1 Preparation of the Infratec for assembly ….3:1 3.2.2 Preparation of the Test Weight Module for assembly 3:4 3.2.3…

-

Page 4

Infratec™ 1241 Grain Analyzer Mosaic Connection ……….3:22 Diagnostics and Troubleshooting ….. General …………….. 4:1 4.1.1 Poor Results …………..4:2 4.1.2 User Problems …………..4:2 4.1.3 Poor Calibrations …………4:2 4.1.4 Outliers …………….4:2 4.1.5 Poor Reference Data …………. 4:3 4.1.6 Instrument Problems …………. -

Page 5

Infratec™ 1241 Grain Analyzer 4.7.2 Software …………..4:29 4.7.3 BIOS …………….4:29 4.7.4 Monochromator Constants ……..4:29 4.7.5 Operating Temperature ……….4:29 4.7.6 Volume Information ……….. 4:29 4.7.7 Voltage Information ……….. 4:29 Clone Instrument ………… 4:29 Settings …………..4:30 4.9.1 Default Settings ………… -

Page 6

Infratec™ 1241 Grain Analyzer 5.2.4 Replacement of Monochromator Complete ….5:9 5.2.5 Replacement of Halogen Lamp for Monochromator 5:11 5.2.6 Use of the Aperture Kit (p/n 60023539) ….5:13 5.2.7 Replacement of Power Supply Board ……5:16 5.2.8 Replacement of Interface Complete ……5:18 5.2.9 Replacement of PC Module Complete w/o Flash Disc ………….. -

Page 7

Infratec™ 1241 Grain Analyzer Preventive Maintenance Procedures ….5:72 5.7.1 Measuring Unit Adjustment of Path Length …. 5:72 5.7.2 TWM Balance Calibration ………. 5:74 5.7.3 TWM balance Control ……….5:77 Technical Specifications……Schematics ……….Document References …….. Service Manual 1001 5015 / Rev. 4… -

Page 8: Service Manual 1001 5015 /

Infratec™ 1241 Grain Analyzer Service Manual 1001 5015 / Rev. 4…

-

Page 9: Important Instructions

Contacting Customer Support For support on this product, please contact the responsible Technical Support engineer at FOSS or file a support request in the Global HelpDesk on FOSS EXTRAnet. ESD Information Parts of this instrument, e.g. PCBs, are sensitive to Electro Static Discharge (ESD).

-

Page 10: Precautions

Infratec™ 1241 Grain Analyzer The following ESD protection material is available from FOSS: • 436220 Field-ESD service kit including wrist band • 463238 Blue table mat with wrist strap and ground wire • 436246 Coiled wire, 360 cm with stretch-wrist band •…

-

Page 11: Technical Description

Technical Description History The Infratec 1241 was first launched in the year 2000. It was then equipped with a black & white display and a diskette drive as means of importing and exporting data to the instrument. These instruments are now referred to as Generation 1.

-

Page 12

Infratec™ 1241 Grain Analyzer Related Information Service personnel should be familiar with the following documentation: • User Manual; for function descriptions, maintenance and operating instructions • Spare Parts Manual; for spare part illustrations and spare part numbers • Quick Guide; for a quick start instruction Also see chapter 8 Document References. -

Page 13: Component Descriptions

Infratec™ 1241 Grain Analyzer Component Descriptions Compatibility with previous version Module Compatible Comments All versions Detector All versions Monochromator All versions All versions All versions (TN 1234) LCD Display See Spare Parts Manual PC module Requires OS vers 5.01 or higher PC- board Requires OS vers 5.01 or higher Compact Flash…

-

Page 14: Pc-Module

Infratec™ 1241 Grain Analyzer 2.2.1 PC-Module The PC-module is a PC104 embedded hardware platform with QNX real-time operating system (RTOS). PC104 is a popular standardized form-factor for small computing modules typically used in embedded system. A system composed of PC/ 104 modules is often referred to as a «stack».

-

Page 15: Processor Board

Infratec™ 1241 Grain Analyzer 2.2.2 Processor Board The processor board is a single board processor (SBC) with an onboard CPU processor. Processor board acts as a controller for the peripheral components. The processor board communicates with the DSP board via the PC/104 bus. The processor board has three main interfaces: •…

-

Page 16: Dsp Board

Infratec™ 1241 Grain Analyzer The Processor Board has replaceable external CMOS battery. Fig. 2:4 Processor Board 2.2.3 DSP Board The DSP module is accessed from the ISW via the PC/104 bus interface (P3) and acts as slave under the ISW. The DSP software acts as an extension of the ISW and is also used as an I/O system.

-

Page 17

Infratec™ 1241 Grain Analyzer Fig. 2:6 DSP Board Keypad Detector PC/104 Bus I2C Bus Power Supply I2C Bus Inverter Interface Board DSP running (red LED) Monochromator Monochromator (red LED) Monochromator Power On (green LED) Monochromator I2C communication (red LED) DSP Board From Designation Keypad overlay… -

Page 18: Compactflash Disk

2.2.5 Monochromator The Monochromator is developed and manufactured by FOSS. It is to be considered a closed, factory calibrated box. There is under no circumstance any reason to open it for maintenance, inspection or other purpose. On the contrary an opened monochromator will not be covered by warranty, neither will it be accepted in the exchange part system.

-

Page 19

This PCB is therefore a unique part dedicated for each monochromator and cannot be changed. NOTE: The Monochromator is sealed and it is absolutely forbidden to open it by other than FOSS personnel. Fig. 2:7 Lamp fiber… -

Page 20: Lamp Module

Infratec™ 1241 Grain Analyzer 2.2.6 Lamp Module The Infratec 1241 light source solution is accommodated in a heat sink aluminium housing. It has no internal electronics other than the power supply cable and light bulb. The module includes: • Aluminium housing as heat sink •…

-

Page 21: Detector

Infratec™ 1241 Grain Analyzer 2.2.7 Detector The detector converts light energy input to digital data output. It is constructed in a sealed and shielded box with a window for light input and a connector for digital input and output. The analog electronics inside the box are galvanic isolated (opto coupled) from all I/O signals.

-

Page 22: Power Supply

Infratec™ 1241 Grain Analyzer 2.2.8 Power Supply The Power Supply takes the 24V AC power it receives from the transformer and converts it to a variety of DC voltages (+ 5.5V, +5V, +12V, -12V, and +10.5V). These voltages are used by a variety of instrument components, including the PC module, measuring unit, lamp, display, and optional equipment (TWM, STM etc.).

-

Page 23

Infratec™ 1241 Grain Analyzer Fig. 2:11 Power Supply Board LCD Backlight Measuring Unit Power Fuse 6.3 AT M I2C Bus Fuse 1.25 AT T Remote I/O Power (optional) Fuse 4.0 AT From Transformer Fuse 500 mAT Lamp Fuse 4.0 AT DSP Board Power Service Manual 1001 5015 / Rev. -

Page 24: Lcd Display

Infratec™ 1241 Grain Analyzer 2.2.9 LCD Display The display is a 6.4 inch color active matrix LCD module, VGA 640 x 480 pixel resolution, incorporating amorphous silicon TFT (Thin Film Transistor). It is composed of a color TFT-LCD panel, driver ICs, control circuits, power circuits and a backlight unit.

-

Page 25: Display Interconnection Board

Infratec™ 1241 Grain Analyzer 2.2.10 Display Interconnection Board The Display Interconnection Board is connected between the Power Supply Board, DSP Board and the Display. It functions as a switch whereby ISW controls LCD Backlight and LCD Display by on/off function. Fig.

-

Page 26: Twm (Optional)

The instrument handles both metric units and imperial units making it possible to present test weight in both kg/hl and lbs/bu. More information can be found in the User Manual for Infratec 1241 Modules, p/n 60043623. 2:16 Service Manual 1001 5015 / Rev. 4…

-

Page 27

At start-up the wiper arm moves between the physical end positions. Then a couple of pulses are taken away in each end. The calculated positions are HOME and FAR positions. Below is a description of the weighing process for Infratec 1241 Test Weight Module: Activate the Test Weight Unit. -

Page 28: Stm (Optional)

DSP. The position of the cuvette is detected by two magnet sensors in the elevator unit. Electrically the STM is connected to either of the two ports on the measuring Unit. For installation and usage see the User Manual for Infratec 1241 Modules, p/n 60043623 2:18…

-

Page 29: Remote I/O (Optional)

This document describes the I/O Interface and specifies the physical interfaces used for connecting it to an Infratec 1241 or Infratec 1256. The Infratec is assumed to be prepared for this hardware such that the back plate has got place for a High Density DSUB15 connector for this purpose.

-

Page 30

12V supply to external sensor Sensor Trigger IN Trigger input used to start analysis GND to external sensor Indicates that the Infratec 1241/1256 is busy IO0 — Busy analysing Indicates that the Infratec 1241/1256 is con- IO1 — Connected nected… -

Page 31

12/24V from the outside. One pin on the connector is connected to the Infratec 1241/1256 12V supply to enable connection of an external sensor without extra hardware. -

Page 32: Software Description

Infratec™ 1241 Grain Analyzer Software Description The operative system used in the instrument is QNX which is a commercial Unix- like real-time operating system (RTOS), aimed primarily at the embedded systems market. The DSP software acts as an extension of the instrument software (ISW) and is located as an IO module to the PC board.

-

Page 33

Infratec™ 1241 Grain Analyzer SW 7: Sample Transport Module (STM) microcontroller software PIC microcontroller software to control the STM functions. IF 1: Instrument Software/DSP gen II (10014320) Interface between the Instrument software and the DSP software. IF 2: DSP/Monochromator I2C interface between the DSP and the monochromator microcontroller. IF 3: DSP/Detector Module I2C interface between the DSP and the detector module E2PROM, I2C expander and temperature sensor. -

Page 34

Infratec™ 1241 Grain Analyzer 2:24 Service Manual 1001 5015 / Rev. 4… -

Page 35: Installation

The site preparation is intended to be carried out prior to the installation of the instrument at the customer site. The site preparation documents can be found at FOSS Intranet – Customer Support Toolbox. Filling Out Installation Documents Each instrument is delivered with an Owners Guide binder where you will find all installation documents to be filled out.

-

Page 36

Infratec™ 1241 Grain Analyzer Disconnect the collection drawer sensor cable connector (1) from the Measuring Unit, see Fig. 3:2 below. 1241298a Fig. 3:2 Collection drawer sensor cable, Measuring Unit Gen. I (left) and Measuring Unit Gen. II (right) The next step requires that the instrument be tilted on its left side. Before this can be done, there must be adequate workbench space and a soft padding (or equivalent) must be laid where the instrument will be tilted on its side. -

Page 37

Infratec™ 1241 Grain Analyzer Remove the bottom plate by loosening the four screws with a 3 mm allen wrench, see Fig. 3:4 below. Fig. 3:4 Bottom plate Remove the collection drawer guides (two on each side). This is done by unscrewing the screws with a 4 mm allen wrench, see Fig. -

Page 38: Preparation Of The Test Weight Module For Assembly 3:4

Infratec™ 1241 Grain Analyzer 3.2.2 Preparation of the Test Weight Module for assembly To prepare the Test Weight Module for assembly, perform the following: Place the Test Weight Module on a workbench. The workbench should be as level as possible. The workbench should also be as free from vibrations as possible.

-

Page 39

Infratec™ 1241 Grain Analyzer Loosen the two letter screws on the Back Transport Securing Device and grip the Test Weight Module at the same time so that it will not fall, see Fig. 3:8 below. Use the two letter screws to fasten the Front Transport Securing Device on the block situated behind the Test Weight Module. -

Page 40: Final Assembly Of Infratec And Test Weight Module Into A Complete Assembly

Infratec™ 1241 Grain Analyzer 3.2.3 Final assembly of Infratec and Test Weight Module into a complete assembly The Infratec and Test Weight Module should be assembled into a complete assembly as follows: Tilt the Test Weight Module so that it can be introduced in the Infratec. Caution Extreme caution should be used when mounting the Test Weight Module to the Infratec.

-

Page 41

Infratec™ 1241 Grain Analyzer Fasten the guiding bracket on the right side of the Test Weight Module. Use the holes market with arrows in Fig. 3:12 below and Fig. 3:13 on page 3:7. Attach bracket with two short screws using a 3 mm allen wrench. Fig. -

Page 42

Infratec™ 1241 Grain Analyzer Position the cover plate assembly in the collection drawer opening of the Infratec, see Fig. 3:14 below. Fasten the cover plate assembly with two long screws using a 3 mm allen wrench. Note: Fasten a toothed plate connector in the plane counter- sinked hole. -

Page 43

Infratec™ 1241 Grain Analyzer 11. Connect the drawer sensor cable and the Test Weight Module power cable to the Measuring Unit, see Fig. 3:16 below. The Test Weight Module power cable can be connected in either of the two optional contacts 2 or 3. 1241298a 1. -

Page 44: Installation Of Test Weight Module On

Infratec™ 1241 Grain Analyzer Installation of Test Weight Module on Infratec 1241 Generation 3 Remove the two plastic slides for the drawer. They should be moved to the TWM later. Fig. 3:17 Remove the metal plate covering the drawer sensor by loosen the four screws.

-

Page 45

Infratec™ 1241 Grain Analyzer Fig. 3:19 Turn the Infratec on the left side. Place some soft material on the table to prevent scratches. Fig. 3:20 Service Manual 1001 5015 / Rev. 4 3:11… -

Page 46

Infratec™ 1241 Grain Analyzer Remove three of the four feet. Fig. 3:21 Remove the two beams 1 and 2 by loosen the screws. Fig. 3:22 3:12 Service Manual 1001 5015 / Rev. 4… -

Page 47

Infratec™ 1241 Grain Analyzer Remove the bottom plate by removing the three screws 1. Keep the screws because they are needed later. Fig. 3:23 Disconnect the drawer sensor and remove the sensor plate by removing the two screws 1. Fig. 3:24 Service Manual 1001 5015 / Rev. -

Page 48

Infratec™ 1241 Grain Analyzer Prepare the grain deflector (p/n 60039237) by putting the adhesive (p/n 10014399) on the outside of the right part of the deflector (see arrow below). It is used to hold it in place before it is fasten by the screws later in the assembly. Mount the grain deflector at the front by using four screws (p/n 55320017). -

Page 49

Infratec™ 1241 Grain Analyzer 11. Fasten the cover plate to the deflector and adjust. Then fasten the screws holding the deflector. Fig. 3:27 12. Use the three screws that were holding the bottom plate to cover the screw holes (one screw is not shown below). Fig. -

Page 50

Infratec™ 1241 Grain Analyzer 13. Prepare the Test Weight Unit by mounting the two plastic slides from the Infratec. Fig. 3:29 14. Transfer the drawer sensor from the holder that you have taken out from the Infratec (removed in step 7) to the holder for TWM (p/n 60039395). Put the sensor as much to the left as possible. -

Page 51

Infratec™ 1241 Grain Analyzer 15. Put in the holder into the TWM. Note that the cable from the drawer sensor should be placed between the rubber sealing and the chassis. Fasten with three screws (p/n 55320017). Fig. 3:31 16. Loosen the three letter screws 1 on the Front Transport Securing Device. Store them in the extra holes on the Front Transport Securing Device. -

Page 52

Infratec™ 1241 Grain Analyzer 17. Loosen the two letter screws 1 on the Back Transport Securing Device and grip the Test Weight Module at the same time so that it will not fall. Store them as well in the holes in the Front Transport Securing Device. Fig. -

Page 53

Infratec™ 1241 Grain Analyzer 19. Use the enclosed labels 1 (p/n 10009083) to cover the two holes from the letter screws. Fig. 3:35 20. Take the Test Weight Unit and connect it to the Infratec. Place the balance behind the deflector so that the level sensors don’t touch the deflector. Fig. -

Page 54

Infratec™ 1241 Grain Analyzer 21. Secure the TWM to the Infratec by using eight screws 1 (p/n 55320017) (six screws are not shown below). Fig. 3:37 22. Refit the two beams 1 and 2 and the three feet. Place the Infratec into standing position. -

Page 55: Installation Of Sample Transport Module

23. Connect the TWM to the measuring unit. Make sure that no cables are touching the balance. Fig. 3:39 24. Swich on the Infratec. 25. Enable the TWM function of the Infratec 1241 according to User Manual Infratec 1241 Modules (p/n 60043623). Installation of Sample Transport Module Software Options In the Service Menu there is an option in “3 Manual Tests”…

-

Page 56: Mosaic Connection

Infratec™ 1241 Grain Analyzer Mosaic Connection Assigning Instrument type to Network The instrument type must be assigned to the Network. Right click on Network Name. Select “Assign instrument types” from the context menu. Fig. 3:40 Highlight the instrument type that should be assigned and click “OK”. Fig.

-

Page 57

Add an instrument group to the instrument type by right clicking on instrument type, select New Group from the context menu. In the example a New Group is added to Infratec 1241. Fig. 3:42 New instrument group will show up: Fig. -

Page 58

Infratec™ 1241 Grain Analyzer Right click on the New instrument group and select Properties from the context menu. Fig. 3:44 Give the Instrument group a new Name, for example customer name, site, factory or similar. Click OK. Fig. 3:45 3:24 Service Manual 1001 5015 / Rev. -

Page 59

Infratec™ 1241 Grain Analyzer The new Instrument Group Name will appear under the instrument type. Fig. 3:46 Connect Infratec 1241 to the Mosaic Server Fig. 3:47 Service Manual 1001 5015 / Rev. 4 3:25… -

Page 60

Infratec™ 1241 Grain Analyzer In analyze mode click on the Menu button. Select 1 Main Menu. Fig. 3:48 Enter password. The default password is “123456”. Fig. 3:49 3:26 Service Manual 1001 5015 / Rev. 4… -

Page 61

Infratec™ 1241 Grain Analyzer 10. Select “5 Instrument Settings”. Fig. 3:50 11. Select “2 Setup”. Fig. 3:51 12. Select “1 Communication”. Fig. 3:52 Service Manual 1001 5015 / Rev. 4 3:27… -

Page 62

Infratec™ 1241 Grain Analyzer 13. Select “2 LAN Settings”. Fig. 3:53 The customer IT department will assign if Static or Dynamic IP should be used. The IT department should also supply all information needed. 14. If the instrument will have a Static IP select “1 Static IP”. If using Dynamic IP please select “2 Dynamic IP”. -

Page 63

Infratec™ 1241 Grain Analyzer 15. Static IP: Enter at least the Instrument IP No., Subnet Mask and Gateway which the customer IT department has assigned for the instrument. Press Activate. Fig. 3:55 16. Dynamic IP: Enter Instrument Name assign by Customer IT department. Press Activate. -

Page 64

Infratec™ 1241 Grain Analyzer 17. Select “3 Network Information” to check the LAN settings is correct in Infratec. Fig. 3:57 18. Select “2 LAN Settings”. Fig. 3:58 19. Select “4 Mosaic Settings” to enter the Mosaic server settings. Fig. 3:59 3:30 Service Manual 1001 5015 / Rev. -

Page 65

Infratec™ 1241 Grain Analyzer 20. Type in the IP number to the Mosaic Server in Mosaic Host field. Remember that Infratec software cannot resolve DNS name, therefore use IP number to Mosaic server. Enter the right port for the Infratec to connect. Select Update type On Command or On Timer. -

Page 66

“Instrument is waiting registration by Mosaic Manager” will appear if the synchronization was successful. Continue to register the instrument in Mosaic. Fig. 3:62 Connect Infratec to Network in Mosaic 23. In Unassigned Instrument the newly synchronized Infratec 1241 will appear. Fig. 3:63 3:32 Service Manual 1001 5015 / Rev. 4… -

Page 67

Infratec™ 1241 Grain Analyzer 24. Right click on the Instrument and select “Register…” from the context menu. Fig. 3:64 25. Select the Network and Instrument group that the instrument should be assigned to and click OK. Fig. 3:65 Service Manual 1001 5015 / Rev. 4 3:33… -

Page 68

Infratec™ 1241 Grain Analyzer Fig. 3:66 3:34 Service Manual 1001 5015 / Rev. 4… -

Page 69: Diagnostics And Troubleshooting

For the Infratec 1241 ALWAYS supply the complete set of log files from the instrument. This chapter helps you to quickly find the explanation and likely cause to most of the error messages and faults.

-

Page 70: Poor Results

Infratec™ 1241 Grain Analyzer 4.1.1 Poor Results The points listed below can be considered as a check list for trouble shooting “poor” results. The reasons for “poor” results can be divided into: • User problems • Poor calibrations • Outliers •…

-

Page 71: Poor Reference Data

The appropriate value for this parameter, as well as the appropri- ate values for A and B parameters, are determined when the calibration is developed. Values for the A,B, and C constants will be recommended for AMs supplied by Foss Analytical.

-

Page 72: Instrument Problems

4.1.7 C Trouble Shooting Infratec 1241 is basically a PC with some extra hardware to perform analysis. The hardware is connected to the PC via a two-wire bus called the I2C. This is a Phillips developed bus. All communication (commands, analytical data, error messages) is performed through the bus.

-

Page 73

Infratec™ 1241 Grain Analyzer This table gives the approximate times for these events. Service Manual 1001 5015 / Rev. 4… -

Page 74

Infratec™ 1241 Grain Analyzer If the bus is corrupted in any way, the communication will not work. It is therefore possible to have a black display, when the error is actually in the I2C communication. Display Monochromator PC/104 Processor Detector Flash Module External PC… -

Page 75

Infratec™ 1241 Grain Analyzer Fig. 4:2 Troubleshooting the I C communication Service Manual 1001 5015 / Rev. 4… -

Page 76

Infratec™ 1241 Grain Analyzer Fig. 4:3 I C Bus in Infratec 1241 Service Manual 1001 5015 / Rev. 4… -

Page 77

Infratec™ 1241 Grain Analyzer The following troubleshooting scheme is suggested. Situation: A black display or an error log with information pointing in different direc- tions. Disconnect all external equipment (STM, TWM) if present. Disconnect the i2c cable from the PSU, monochromator, detector and MU to the DSP board. -

Page 78: Service Menu

Service Menu. The Service Menu assume a more detailed knowledge about the In- fratec 1241 Grain Analyzer. The Service Menu is therefore password protected. Password is only given to personnel approved by FOSS. Most of the headings in the Service Menu have sub menus, see menu structure on next page.

-

Page 79

Infratec™ 1241 Grain Analyzer Level 1 Level 2 Level 3 Level 4 Comments 3 Measuring Unit 1 Position Setting 2 Sensors 3 Set Ambient Tem- perature 4 Display 5 Scan 6 Test Weight Greyed out if not installed 1 Position Settings 2 Calibrate 1 Balance Con- trol… -

Page 80: Quality Control

Infratec™ 1241 Grain Analyzer Level 1 Level 2 Level 3 Level 4 Comments 7 Settings 1 Default Settings Resets the instrument to its default settings 2 Scan Mode (Standard) 8 Read Disk Read contents of USB stick and install possible options e.g.

-

Page 81

Infratec™ 1241 Grain Analyzer PC Module System configuration verification These routines check the current system configuration against the values stored in the CMOS memory. If they do not match, the program outputs an error message. You will then need to run the BIOS setup program to set the configuration information in memory. -

Page 82

Infratec™ 1241 Grain Analyzer Checking hardware The check of communication and hardware is separated. Voltage check After checking the PSU hardware, a voltage check is performed. Min. Max. Line description including typical value Units limit limit SELFTEST/12411615/VoltageTest/+5=Number,4.96 Volt SELFTEST/12411615/VoltageTest/+5.5=Number,5.58 Volt SELFTEST/12411615/VoltageTest/+12=Number,11.95 Volt 11.2… -

Page 83

Infratec™ 1241 Grain Analyzer Detector ADC No Missing Codes This test checks the ADC unlinearity and the missing codes. The result is presented as «True» or «False». Min. Max. Line description including typical value Units limit limit SelfTest/1241xxxx/Detector/SerialNumber=String, 00000015 SelfTest/1241xxxx/Detector/ADCNo MissingCodes=Bool, True bool Detector Offset Test Measures the offset voltage at the ADC input with no light falling on the detector,… -

Page 84

Infratec™ 1241 Grain Analyzer Min. Max. Line description including typical value Units Comments limit limit SelfTest/1241xxxx/Detector/SerialNumber=String, 00000015 SelfTest/1241xxxx/Detector/gain1/Min=Number, 499 bits SelfTest/1241xxxx/Detector/gain1/Max=Number, 500 bits SelfTest/1241xxxx/Detector/gain1/Mean=Number, 500 bits 2000 SelfTest/1241xxxx/Detector/gain1/StdDev=Number, 0.4943 bits SelfTest/1241xxxx/Detector/gain1/Temp=Number, 24 real SelfTest/1241xxxx/Detector/gain2/Min=Number, 499 bits SelfTest/1241xxxx/Detector/gain2/Max=Number, 500 bits SelfTest/1241xxxx/Detector/gain2/Mean=Number, 500 bits 2000 SelfTest/1241xxxx/Detector/gain2/StdDev=Number, 0.4943… -

Page 85

Infratec™ 1241 Grain Analyzer Line description including typical value Units Min. Max. Comments SelfTest/1241xxxx/Detector/gain8/Min=Number, 495 bits SelfTest/1241xxxx/Detector/gain8/Max=Number, 505 bits SelfTest/1241xxxx/Detector/gain8/Mean=Number, 500 bits 2000 SelfTest/1241xxxx/Detector/gain8/StdDev=Number, 0.8220 bits SelfTest/1241xxxx/Detector/gain8/Temp=Number, 24 real SelfTest/1241xxxx/Detector/gain9/Min=Number, 495 bits SelfTest/1241xxxx/Detector/gain9/Max=Number, 505 bits SelfTest/1241xxxx/Detector/gain9/Mean=Number, 500 bits 2000 SelfTest/1241xxxx/Detector/gain9/StdDev=Number, 0.8220 bits SelfTest/1241xxxx/Detector/gain9/Temp=Number, 24 real… -

Page 86

Infratec™ 1241 Grain Analyzer Checksum test of detector EEPROM This test validates the serial number and gain settings. If the checksum does not match what is stored in the EEPROM, an error occur and the instrument disables analysis Min. Max. Line description including typical value Units limit… -

Page 87: Clean Measuring Unit

Infratec™ 1241 Grain Analyzer Test Results report Once the Self-test is completed a report line is given the overall «Passed/Failed» sta- tus of each of the communication, monochromator, detector, air stability and mono- chromator wave length tests. The date and time of the Self-test is also shown. There will be a report on the screen with the test result as below.

-

Page 88: Hardware Error Log

Infratec™ 1241 Grain Analyzer 4.3.5 Hardware Error Log Fig. 4:6 Displays the hardware Error log. When choosing the Disk option an “xxxxxxxx.hl” file is created. For decoding of the Hardware error log, see 4.12. 4.3.6 Export Logs and Configuration Exports the record of errors that occurred during analysis, and the instrument config- uration, to a USB memory stick.

-

Page 89: Automatic Tests

Infratec™ 1241 Grain Analyzer Automatic Tests From here all of the tests carried out in the Self-test routine can be executed individ- ually. The test results are presented in the same way as described in section Self-test, with an option to save to disk. Fig.

-

Page 90: Monochromator

Infratec™ 1241 Grain Analyzer 4.4.2 Monochromator Fig. 4:9 Monochromator Tests Grating System Identical to the «Grating System» test carried out in the Self-test routine. Air Stability Almost identical to the «Air stability test» test carried out in the Self test routine, with one exception: This test has an option to break the test by using the Stop function that makes it possible to go on measuring stability after the test has passed.

-

Page 91: I/0 (Input/Output)

Infratec™ 1241 Grain Analyzer the measuring unit when prompt for. Ten sub samples are taken and the 2 peak is detected and displayed on the screen. Line description including typical value Units Min. Max. SelfTest/1241xxxx/Monoch./SerialNumber=String, T9010017 SelfTest/1241xxxx/Monoch./E/Peak2Mean=Number, 879.82 real SelfTest/1241xxxx/Monoch./E/Peak2Min=Number, 879.61 real SelfTest/1241xxxx/Monoch./E/Peak2Max=Number, 879.90 real…

-

Page 92

Infratec™ 1241 Grain Analyzer The test runs the ports individually as chosen in the «I/0» menu. If any error occur this is reported to screen and Error log. Line description including typical value Units Min. Max. SelfTest/00000000/PCBoard/COMParallel=Bool, True bool SelfTest/00000000/PCBoard/COM1Serial=Bool, True bool SelfTest/00000000/PCBoard/COM2Serial=Bool, True bool… -

Page 93: Manual Tests

Infratec™ 1241 Grain Analyzer Manual Tests To exercise all of the instrument low-level hardware commands. All the tests below are addressed one by one and performed in manual order. Fig. 4:11 Manual Tests 4.5.1 Detector Available options: • Set Gain value •…

-

Page 94: Measuring Unit

Infratec™ 1241 Grain Analyzer 4.5.3 Measuring Unit Fig. 4:12 Measuring Unit Tests Position Setting Available options: • Set path length • Set bottom shutter Open/Closed • Set top shutter Open/Closed • Set conveyor belt On/Off Sensors Available options: • Read ambient temperature (Calculated using the ambient temp. sensor in the hood together with the detector temp.

-

Page 95: Test Weight

The result is stored in the EEPROM of the TWM. – Adjust Balance; Should only be used after discussion with Product specialist at FOSS. Test Weight Cycle This function runs a complete Test weight cycle (sequence) but with possibilities to check part sequences and continue.

-

Page 96: Manual Analysis

Infratec™ 1241 Grain Analyzer Manual Analysis Fig. 4:14 Manual Analysis 4.6.1 Settings The parameters used in the manual analysis sequence: • Set path length • Set fill speed • Set flush speed 4.6.2 Fill Sample Cell Fills the measuring unit sample cell at the speed pre-set in settings. 4.6.3 Scan Collects a scan at a gain and a shutter position chosen in the window popped up when…

-

Page 97: Instrument Info

Infratec™ 1241 Grain Analyzer Instrument Info Fig. 4:15 Instrument Info 4.7.1 Hardware Displays the following: • DSP software version • Monochromator software version and serial number • Detector serial number • Measuring unit software version • Optional module and serial number 4.7.2 Software Displays the different instrument software module versions.

-

Page 98: Default Settings

Infratec™ 1241 Grain Analyzer Settings 4.9.1 Default Settings To be able to return to a normal instrument status the «Default Settings» command sets the instrument to the following status: Monochromator lamp Grating motor Shutter Open Detector gain Initialise Measuring Unit Set Ambient temperature 4.9.2 Scan Mode (Standard)

-

Page 99: Error Codes In Software Log (Sl) And Hardware

Infratec™ 1241 Grain Analyzer 4.11 Error Codes in Software Log (SL) and Hard- ware Log (HL) When reviewing the SL and HL log files it’s a good idea to look at the two files simultaneously. Try to compare the entries using the time stamps. This way you will many times get a better understanding because you can see both what the customer reported (SL) and what command was sent at the same time.

-

Page 100

Infratec™ 1241 Grain Analyzer Message to the User (What possibly can be done before Comments Note Error Error contacting Service) 33538 0x8302 TWM operation mode switch. 33539 0x8303 TWM EEPROM error Problems to read/write the data in the PROM 33540 0x8304 TWM EEPROM error Slope data outside limits. -

Page 101: Error 4, Grating Motor Error

Infratec™ 1241 Grain Analyzer Message to the User (What possibly can be done before Comments Note Error Error contacting Service) 4243 0x1093 No cup detected. The speckle function is not used. The cup is detected by the difference in absorbance between the reference scan and the first sub-sample.

-

Page 102: Error 128, Path Length Error

These files will only be presented in Hex Code and you will need the HL Translator to be able to read the error as text. The HL Translator can be downloaded from the FOSS Intranet/Internal Knowledge. 4:34…

-

Page 103: Error 33292, Reference Scan Too Low

Infratec™ 1241 Grain Analyzer 4.11.8 Error 33292, Reference Scan too low During Start up Test or before analyse the lamp intensity is checked by setting the Detector Gain to 1*1 and performing a scan. The received value from the Detector should be more than 15000 bits.

-

Page 104: Error Word

Infratec™ 1241 Grain Analyzer 4.12 Hardware Error Log (xxxxxxxx.HL) 4.12.1 Error Word Presents the error that was received when the command was executed. Position in instrument Hardware Error Code in bold: E.g. «20 — 304/1ef3/201/20/0/0/0/450». Hardware Errors 0001 Instrument hardware communication error 0002 Detector ADC error 0004…

-

Page 105: Commands

Infratec™ 1241 Grain Analyzer 4.12.2 Commands Presents which command that was sent out before the error occurred. Position in instrument Hardware Error Code in bold: E.g. «20 — 304/1ef3/201/20/0/0/0/450». DSP Module Commands Id (hex) Name Note Read HW status and error words. Updates the 0001 GetDSPStatus TWM, STM, EID and ASTM installed bit.

-

Page 106

Infratec™ 1241 Grain Analyzer Monochromator module commands The communication between the DSP and the Monochromator module is done via an C bus interface to the Monochromator board PIC microcontroller. The Microcontroller handles the filter/shutter movement and the onboard E PROM, which can be accessed from the ISW. -

Page 107

Infratec™ 1241 Grain Analyzer 0305 RunMotor Run the conveyor motor. 0306 FireSolenoid Fire the MU solenoids Read the MU sensors: Speckle and Drawer 0307 GetMUSensors sensor 0308 MoveCell Move the adjustable cell. 030B GetMUTemp Read MU temperature sensor Open the bottom solenoid to empty the 030C EmptyMUCell sample cell. -

Page 108

Infratec™ 1241 Grain Analyzer Power Supply Module (PSM) commands The PSM has an I C expander on board that is accessed from the DSP and is used to set the values of the display, lamp and backlight controls. Support for new Power Supply Unit (PSU) was implemented 2002-10. The new PSU is identified with a ‘0’ in bit four of the PSM byte and the PSU has got new functionality such as 63 steps for display contrast and the ability to measure all voltages on the board. -

Page 109: Status Word 1

Infratec™ 1241 Grain Analyzer 4.12.3 Status Word 1 Presents the status of the system when the error occurred. Fig. 4:16 Position in instrument Hardware Error Code in bold: E.g. «20 — 304/1ef3/201/20/0/0/0/450». Id (hex) Specification Note Source 0001 ADCRunning ADC communication is OK 0002 GratingMotorEnable Grating motor: 0/1 — off/on…

-

Page 110: Status Word 2

Infratec™ 1241 Grain Analyzer 4.12.4 Status Word 2 «Sub-error», presents more detailed information about what went wrong when the error occurred. Position in instrument Hardware Error Code in bold: E.g. «20 — 304/1ef3/201/20/0/0/0/450». Id (hex) Specification Note Source 0001 MU board status 0/1 — old/new 0002 MU SW status…

-

Page 111: Error Word 1

Infratec™ 1241 Grain Analyzer 4.12.5 Error Word 1 «Main error», presents a more detailed information about what went wrong when the error occurred. Position in instrument Hardware Error Code in bold: E.g. «20 — 304/1ef3/201/20/0/0/0/450». Id (hex) Specification Note Source SystemCommunicationErr 0001 DSP communication error…

-

Page 112: Error Word 2

Infratec™ 1241 Grain Analyzer 4.12.6 Error Word 2 «Sub-error», presents a more detailed information about what went wrong when the error occurred. Position in instrument Hardware Error Code in bold: E.g. «20 — 304/1ef3/201/20/0/0/0/450». Id (hex) Specification Note Source 0001 SystemCommandFailed Unknown command All modules…

-

Page 113: Error Word 3

Infratec™ 1241 Grain Analyzer 4.12.7 Error Word 3 «Sub-error», presents a more detailed information about what went wrong when the error occurred. Position in instrument Hardware Error Code in bold: E.g. «20 — 304/1ef3/201/20/0/0/0/450». Id (hex) Specification Note Source Monochromator command 0001 MonochromatorFailed Monoch.

-

Page 114: Export Logs And Configuration

A customer can easily obtain the files and send them to you by email. When reporting an Infratec Support Incident into the Global Helpdesk at FOSS Analytical it’s mandatory to include the log files. The files will always be named xxxxxxxx.ext, where xxxxxxxx equals the 8 digit s/n of the Infratec instrument and ext equals the file extension according to the list below.

-

Page 115

Infratec™ 1241 Grain Analyzer Example: I/12416305/SerialNumber=String,»12416305″ I/12416305/OConstant=Number,1676.29 I/12416305/PConstant=Number,0.348120 I/12416305/LargeFont=Bool,False I/12416305/InstrumentModel=String,»1241 GA» I/12416305/SoftwareVersion=String,»v5.52″ I/12416305/InstrumentType=String,»1241 Standard» I/12416305/AnalyseCounter=Number,2168 I/12416305/Password=String,»123456″ I/12416305/ RestrictedPassword=String,»a3fd,0100080903080c030b0a150e0d0e090a08150b09 080914090014080e» I/12416305/DisplayOutlier=Number,0 I/12416305/Printer=String,»» I/12416305/PrinterTemplate=String,»» I/12416305/DailyPrinterTemplate=String,»» I/12416305/Modem=String,»» I/12416305/Contrast=Number,32 I/12416305/PrintResult=Bool,True I/12416305/Language=String,»Deutsch» I/12416305/DateTimeFormat=String,»» I/12416305/NumericFormat=String,»» I/12416305/SaveScanOverride=Bool,False I/12416305/SaveResultOverride=Bool,False I/12416305/DisableTWM=Bool,False I/12416305/SaveResultIfOutlierOverride=Bool,False I/12416305/MinOperatingTemp=Number,0.0 I/12416305/MaxOperatingTemp=Number,42.0 I/12416305/UseFlyback=Bool,True I/12416305/DumpMedia=String,»Serial» I/12416305/DumpIPAddress=String,»0.0.0.0″ I/12416305/DumpIPPort=String,»55556″ I/12416305/Operator=String,»» I/12416305/Font=String,»Swiss721 BT»… -

Page 116

I/12416305/Note8/Name=String,»Note 8″ I/12416305/Note9/Name=String,»Note 9″ I/12416305/Note10/Name=String,»Note 10″ BIOS Log (xxxxxxxx.BI) Information about the CPU BIOS version. Example: Phoenix — AwardBIOS v6.00PG GENE-5312 BIOS REV 1.41 for FOSS (04/10/2007) Ltd 10/02/2006-AMD-GX2-6A439ac9C-00 Hardware Versions Log (xxxxxxxx.HV) Information about the hardware modules. Example: HV/12416305/DSP/Version=String,»5.02″ HV/12416305/Monochromator/Version=String,»5.5″… -

Page 117

Infratec™ 1241 Grain Analyzer HV/12416305/TWM/SerialNumber=String,»21436587″ HV/12416305/Eid=String,»64e7780e00c0″ Software Log (xxxxxxxx.SL) Logs the messages shown on the display to the operator. Example: ;0019,0255,0019,1000 SL/12415238/2007-10-16 20:04:41/Name=String, «Errort Self test stopped. » SL/12415238/2007-10-18 13:34:09/Name=String, «Errort Sample in the cellt Empty and clean the cell using thet flush function on the taskbart More information in the user manual. -

Page 118

Infratec™ 1241 Grain Analyzer HL/12415238/2007-10-18 13:36:40/Name=String, «80 — 30d/1fc3/201/80/0/0/0/ 501» HL/12415238/2007-10-18 16:10:29/Name=String, «20 — 30c/1fc3/201/20/0/0/0/ 501» HL/12415238/2007-10-18 16:10:32/Name=String, «20 — 30c/1fc3/201/20/0/0/0/ 501» HL/12415238/2007-10-18 16:10:35/Name=String, «200 — 30d/1fc3/201/200/0/0/0/ 501» HL/12415238/2008-01-22 13:29:10/Name=String, «40 — 30e/1fc3/201/40/0/0/0/ 501» HL/12415238/2008-01-22 15:55:56/Name=String, «40 — 30e/1fc3/201/40/0/0/0/ 501» HL/12415238/2008-01-30 16:39:12/Name=String, «40 — 30e/1fc3/201/40/0/0/0/ 501″… -

Page 119

Infratec™ 1241 Grain Analyzer The five latest failed start-up tests will be saved and named xxxxxxxx.SU1 — xxxxxxxx.SU5. The files are automatically renamed so xxxxxxxx.SU1 is always the latest. The latest start-up test (failing or not) is named xxxxxxxx.SU. Example: SECTION 1 SUMMARY SELFTEST/12417132/START/2011-01-18 15:42:11 SELFTEST/12417132/Software/Version v5.11… -

Page 120

Infratec™ 1241 Grain Analyzer SELFTEST/12417132/DSP Status, MUMode, Normal SELFTEST/12417132/DSP Status, TWMMode, Normal SELFTEST/12417132/DSP Status, Not aborted command indication SELFTEST/12417132/DSP Status, TWM, Not installed SELFTEST/12417132/DSP Status, MU board, New SELFTEST/12417132/DSP Status, MU software, Old SELFTEST/12417132/DSP Status, Monochromator board, Old SELFTEST/12417132/DSP Status, Monochromator software, Old SELFTEST/12417132/DSP Status, TWM board, Old SELFTEST/12417132/DSP Status, TWM software, Old SELFTEST/12417132/DSP Status, STM, Not installed… -

Page 121

Infratec™ 1241 Grain Analyzer SELFTEST/12417132/Monochromator/SerialNumber=String,E0113281 SELFTEST/12417132/Monochromator/PulseCount=Number,2884 (>2800 , <3400) SELFTEST/12417132/Monochromator/CycleTime=Number,2.74 (>2.0 , <3.2) SELFTEST/12417132/Monochromator/Min=Number,-4.7 (>-22) SELFTEST/12417132/Monochromator/Max=Number,5.6 (<22) SELFTEST/12417132/Monochromator/Diff=Number,10.3 (<50) SELFTEST/12417132/END MONOCHROMATOR TEST/2011-01-18 15:42:56 SELFTEST/12417132/START DETECTOR TEST/2011-01-18 15:43:03 SELFTEST/12417132/Detector/SerialNumber=String,001601 SELFTEST/12417132/Detector/Gain1/Min=Number,688 (>=5) SELFTEST/12417132/Detector/Gain1/Max=Number,689 SELFTEST/12417132/Detector/Gain1/Mean=Number,688.3450 (>50 , <2000) SELFTEST/12417132/Detector/Gain1/StdDev=Number,0.4754 (<= 2) SELFTEST/12417132/Detector/Gain1/Temp=Number,34.0 (>25.0 , <65.0) SELFTEST/12417132/2011-01-18 15:43:03 SELFTEST/12417132/Detector/Gain2/Min=Number,687 (>=5) SELFTEST/12417132/Detector/Gain2/Max=Number,688… -

Page 122

Infratec™ 1241 Grain Analyzer SELFTEST/12417132/Detector/Gain5/Min=Number,673 (>=5) SELFTEST/12417132/Detector/Gain5/Max=Number,675 SELFTEST/12417132/Detector/Gain5/Mean=Number,674.0966 (>50 , <2000) SELFTEST/12417132/Detector/Gain5/StdDev=Number,0.4810 (<= 2) SELFTEST/12417132/Detector/Gain5/Temp=Number,34.0 (>25.0 , <65.0) SELFTEST/12417132/2011-01-18 15:43:04 SELFTEST/12417132/Detector/Gain6/Min=Number,689 (>=5) SELFTEST/12417132/Detector/Gain6/Max=Number,690 SELFTEST/12417132/Detector/Gain6/Mean=Number,689.4406 (>50 , <2000) SELFTEST/12417132/Detector/Gain6/StdDev=Number,0.4965 (<= 2) SELFTEST/12417132/Detector/Gain6/Temp=Number,34.0 (>25.0 , <65.0) SELFTEST/12417132/2011-01-18 15:43:05 SELFTEST/12417132/Detector/Gain7/Min=Number,689 (>=5) SELFTEST/12417132/Detector/Gain7/Max=Number,690 SELFTEST/12417132/Detector/Gain7/Mean=Number,689.4748 (>50 , <2000) SELFTEST/12417132/Detector/Gain7/StdDev=Number,0.4994 (<= 2) SELFTEST/12417132/Detector/Gain7/Temp=Number,34.0 (>25.0 , <65.0) SELFTEST/12417132/2011-01-18 15:43:05… -

Page 123

Infratec™ 1241 Grain Analyzer SELFTEST/12417132/Detector/Gain10/Temp=Number,34.0 (>25.0 , <65.0) SELFTEST/12417132/2011-01-18 15:43:06 SELFTEST/12417132/Detector/Gain11/Min=Number,680 (>=5) SELFTEST/12417132/Detector/Gain11/Max=Number,693 SELFTEST/12417132/Detector/Gain11/Mean=Number,686.1520 (>50 , <2000) SELFTEST/12417132/Detector/Gain11/StdDev=Number,2.2264 (<= 5) SELFTEST/12417132/Detector/Gain11/Temp=Number,34.0 (>25.0 , <65.0) SELFTEST/12417132/2011-01-18 15:43:06 SELFTEST/12417132/Detector/Gain12/Min=Number,674 (>=5) SELFTEST/12417132/Detector/Gain12/Max=Number,694 SELFTEST/12417132/Detector/Gain12/Mean=Number,683.8184 (>50 , <2000) SELFTEST/12417132/Detector/Gain12/StdDev=Number,3.6825 (<= 9) SELFTEST/12417132/Detector/Gain12/Temp=Number,34.0 (>25.0 , <65.0) SELFTEST/12417132/2011-01-18 15:43:07 SELFTEST/12417132/Detector/Gain13/Min=Number,659 (>=5) SELFTEST/12417132/Detector/Gain13/Max=Number,700… -

Page 124

Infratec™ 1241 Grain Analyzer SELFTEST/12417132/START STABILITY TEST/2011-01-18 15:43:18 SELFTEST/12417132/Check Lamp and Grating Motor = Instrument No Error SELFTEST/12417132/Stability/Max=Number,47222 (>30000) SELFTEST/12417132/Stability/Max=Number,47124 (>30000) SELFTEST/12417132/Stability/Max=Number,47059 (>30000) SELFTEST/12417132/Stability/Max=Number,47014 (>30000) SELFTEST/12417132/Stability/Max=Number,46979 (>30000) SELFTEST/12417132/Stability/Max=Number,46951 (>30000) SELFTEST/12417132/Stability/Max=Number,46928 (>30000) SELFTEST/12417132/Stability/Max=Number,46910 (>30000) SELFTEST/12417132/Stability/Max=Number,46894 (>30000) SELFTEST/12417132/Stability/Max=Number,46879 (>30000) SELFTEST/12417132/Stability/Max=Number,46866 (>30000) SELFTEST/12417132/Stability/Max=Number,46854 (>30000) SELFTEST/12417132/Stability/Max=Number,46836 (>30000) SELFTEST/12417132/Stability/Diff=Number,-170.34 SELFTEST/12417132/Stability/Max=Number,46829 (>30000) -

Page 125

Infratec™ 1241 Grain Analyzer Example: SELFTEST/12417147/Monochromator/SerialNumber=String,E0103165 SELFTEST/12417147/Monochromator/PulseCount=Number,2884 SELFTEST/12417147/Monochromator/CycleTime=Number,2.72 SELFTEST/12417147/Monochromator/Min=Number,-5.2 SELFTEST/12417147/Monochromator/Max=Number,4.8 SELFTEST/12417147/Monochromator/Diff=Number,10.0 SELFTEST/12417147/Detector/SerialNumber=String,001594 SELFTEST/12417147/Detector/Gain1/Min=Number,684 SELFTEST/12417147/Detector/Gain1/Max=Number,685 SELFTEST/12417147/Detector/Gain1/Mean=Number,684.9628 SELFTEST/12417147/Detector/Gain1/StdDev=Number,0.1893 SELFTEST/12417147/Detector/Gain1/Temp=Number,54.5 SELFTEST/12417147/Detector/Gain2/Min=Number,683 SELFTEST/12417147/Detector/Gain2/Max=Number,684 SELFTEST/12417147/Detector/Gain2/Mean=Number,683.9352 SELFTEST/12417147/Detector/Gain2/StdDev=Number,0.2462 SELFTEST/12417147/Detector/Gain2/Temp=Number,54.5 SELFTEST/12417147/Detector/Gain3/Min=Number,681 SELFTEST/12417147/Detector/Gain3/Max=Number,682 SELFTEST/12417147/Detector/Gain3/Mean=Number,681.8420 SELFTEST/12417147/Detector/Gain3/StdDev=Number,0.3648 SELFTEST/12417147/Detector/Gain3/Temp=Number,54.0 SELFTEST/12417147/Detector/Gain4/Min=Number,676 SELFTEST/12417147/Detector/Gain4/Max=Number,678 SELFTEST/12417147/Detector/Gain4/Mean=Number,677.3968 SELFTEST/12417147/Detector/Gain4/StdDev=Number,0.4946 SELFTEST/12417147/Detector/Gain4/Temp=Number,54.0 SELFTEST/12417147/Detector/Gain5/Min=Number,668 SELFTEST/12417147/Detector/Gain5/Max=Number,670 SELFTEST/12417147/Detector/Gain5/Mean=Number,668.8676 SELFTEST/12417147/Detector/Gain5/StdDev=Number,0.4636 SELFTEST/12417147/Detector/Gain5/Temp=Number,54.0 SELFTEST/12417147/Detector/Gain6/Min=Number,685 SELFTEST/12417147/Detector/Gain6/Max=Number,687 SELFTEST/12417147/Detector/Gain6/Mean=Number,686.1154 SELFTEST/12417147/Detector/Gain6/StdDev=Number,0.3342 SELFTEST/12417147/Detector/Gain6/Temp=Number,54.0 SELFTEST/12417147/Detector/Gain7/Min=Number,685… -

Page 126

Infratec™ 1241 Grain Analyzer SELFTEST/12417147/Detector/Gain7/Max=Number,688 SELFTEST/12417147/Detector/Gain7/Mean=Number,686.2666 SELFTEST/12417147/Detector/Gain7/StdDev=Number,0.4556 SELFTEST/12417147/Detector/Gain7/Temp=Number,54.5 SELFTEST/12417147/Detector/Gain8/Min=Number,685 SELFTEST/12417147/Detector/Gain8/Max=Number,688 SELFTEST/12417147/Detector/Gain8/Mean=Number,686.6090 SELFTEST/12417147/Detector/Gain8/StdDev=Number,0.6775 SELFTEST/12417147/Detector/Gain8/Temp=Number,54.5 SELFTEST/12417147/Detector/Gain9/Min=Number,684 SELFTEST/12417147/Detector/Gain9/Max=Number,690 SELFTEST/12417147/Detector/Gain9/Mean=Number,687.0134 SELFTEST/12417147/Detector/Gain9/StdDev=Number,1.1627 SELFTEST/12417147/Detector/Gain9/Temp=Number,54.0 SELFTEST/12417147/Detector/Gain10/Min=Number,683 SELFTEST/12417147/Detector/Gain10/Max=Number,695 SELFTEST/12417147/Detector/Gain10/Mean=Number,688.2688 SELFTEST/12417147/Detector/Gain10/StdDev=Number,2.3076 SELFTEST/12417147/Detector/Gain10/Temp=Number,54.0 SELFTEST/12417147/Detector/Gain11/Min=Number,662 SELFTEST/12417147/Detector/Gain11/Max=Number,685 SELFTEST/12417147/Detector/Gain11/Mean=Number,675.9810 SELFTEST/12417147/Detector/Gain11/StdDev=Number,3.7671 SELFTEST/12417147/Detector/Gain11/Temp=Number,54.5 SELFTEST/12417147/Detector/Gain12/Min=Number,649 SELFTEST/12417147/Detector/Gain12/Max=Number,690 SELFTEST/12417147/Detector/Gain12/Mean=Number,666.9090 SELFTEST/12417147/Detector/Gain12/StdDev=Number,6.9855 SELFTEST/12417147/Detector/Gain12/Temp=Number,54.5 SELFTEST/12417147/Detector/Gain13/Min=Number,608 SELFTEST/12417147/Detector/Gain13/Max=Number,702 SELFTEST/12417147/Detector/Gain13/Mean=Number,650.3872 SELFTEST/12417147/Detector/Gain13/StdDev=Number,14.4718 SELFTEST/12417147/Detector/Gain13/Temp=Number,54.5 SELFTEST/12417147/Detector/Gain14/Min=Number,531 SELFTEST/12417147/Detector/Gain14/Max=Number,685 SELFTEST/12417147/Detector/Gain14/Mean=Number,617.3802 SELFTEST/12417147/Detector/Gain14/StdDev=Number,26.1666 SELFTEST/12417147/Detector/Gain14/Temp=Number,54.0… -

Page 127

Infratec™ 1241 Grain Analyzer SELFTEST/12417147/Detector/Gain15/Min=Number,397 SELFTEST/12417147/Detector/Gain15/Max=Number,766 SELFTEST/12417147/Detector/Gain15/Mean=Number,552.2060 SELFTEST/12417147/Detector/Gain15/StdDev=Number,59.2260 SELFTEST/12417147/Detector/Gain15/Temp=Number,54.0 SELFTEST/12417147/Detector/SerialNumber=String,001594 SELFTEST/12417147/Detector/ADCNoMissingCodes=Bool,True SELFTEST/12417147/Monochromator/I/SerialNumber=String,E0103165 SELFTEST/12417147/Monochromator/I/Peak2Mean=Number,879.98 SELFTEST/12417147/Monochromator/I/Peak2Min=Number,879.97 SELFTEST/12417147/Monochromator/I/Peak2Max=Number,879.98 SELFTEST/12417147/Monochromator/I/Peak2Std=Number,0.00 SELFTEST/12417147/Monochromator/I/Peak2Diff=Number,-0.05 SELFTEST/12417147/VoltageTest/+5=Number,5.0 SELFTEST/12417147/VoltageTest/+5.5=Number,5.4 SELFTEST/12417147/VoltageTest/+12=Number,12.0 SELFTEST/12417147/VoltageTest/-12=Number,-11.7 SELFTEST/12417147/VoltageTest/+10.5=Number,10.4 SELFTEST/12417147/VoltageTest/Contrast=Number,-19.0 SELFTEST/12417147/VoltageTest/Input=Number,28.7 SELFTEST/12417147/VoltageTest/Passed=Bool,True SELFTEST/12417147/Name=Date,2011-01-26 14:38:15 SELFTEST/12417147/LampCheck/Passed=Bool,True SELFTEST/12417147/LampCheck/Measured value=Number,65535 SELFTEST/12417147/Name=Date,2011-01-26 14:37:25 SELFTEST/12417147/Monochromator/Comm=Bool,True SELFTEST/12417147/Monochromator/HardwareTest=Bool,True SELFTEST/12417147/Monochromator/Checksum=Bool,True SELFTEST/12417147/Detector/Comm=Bool,True SELFTEST/12417147/Detector/HardwareTest=Bool,True SELFTEST/12417147/Detector/Checksum=Bool,True SELFTEST/12417147/TempSensor/Comm=Bool,True SELFTEST/12417147/MU/Comm=Bool,True SELFTEST/12417147/MU/HardwareTest=Bool,True SELFTEST/12417147/PSM/Comm=Bool,True SELFTEST/12417147/PSM/Comm=Bool,True… -

Page 128

Infratec™ 1241 Grain Analyzer SELFTEST/12417147/Detector/ADCNoMissingCodes=Bool,True SELFTEST/12417147/LampCheck=Bool,True SELFTEST/12417147/WaveLengthStabilityTest=Bool,True 4:60 Service Manual 1001 5015 / Rev. 4… -

Page 129: Service And Maintenance

Infratec™ 1241 Grain Analyzer Service and Maintenance This chapter provides instructions for repair and guidance for maintenance of the Infratec 1241. Special Tools • P/N 1591 0019 Allen Key 2x225mm (For Monochromator feet) • P/N 1001 0661 Go no Go ball gauge •…

-

Page 130

Infratec™ 1241 Grain Analyzer Fig. 5:1 New Display Cable Ferrites Service Manual 1001 5015 / Rev. 4… -

Page 131

Infratec™ 1241 Grain Analyzer Disconnect the P1 cable from the DSP Board. Fig. 5:2 DSP Board Keypad Disconnect the display cable from CN1 on the LCD Display. Fig. 5:3 LCD Display Processor Board Service Manual 1001 5015 / Rev. 4… -

Page 132

Infratec™ 1241 Grain Analyzer Disconnect the JP1 and JP2 cables from the Display Interconnection Board. Fig. 5:4 Inverter Interface Board I2C Bus LCD Display Remove the two distance bolts together with the two nylon washers and carefully lift away the Display Interconnection Board. Service Manual 1001 5015 / Rev. -

Page 133

Infratec™ 1241 Grain Analyzer Remove the four distance bolts together with the two tooth lock washers and carefully lift away the LCD Display. Fig. 5:5 Removing LCD Display 10. Remove the two locking nuts 1 (one hidden) holding the PC Module and tilt down the PC Module. -

Page 134

Infratec™ 1241 Grain Analyzer 11. Remove the display cable from CN12 on the Processor Board. NOTE! Observe the display cable orientation. Fig. 5:7 Processor Board CN12 LCD Display 12. Fit the new display cable to CN12 on the Processor Board. NOTE! The display cable should be placed as before on the upper side of the PC Module. -

Page 135: Replacement Of Keyboard Overlay

Infratec™ 1241 Grain Analyzer 5.2.2 Replacement of Keyboard Overlay (P/N 1001 4765 Gen. 2 / P/N 6004 4142 Gen. 3) NOTE! Removing the keyboard overlay reduces the effectiveness of the adhesive. We strongly recommend that you do not reuse the keyboard overlay. Remove the Keyboard Overlay.

-

Page 136: Replacement Of Detector Unit Complete

Infratec™ 1241 Grain Analyzer Fig. 5:9 DSP Board Keypad 5.2.3 Replacement of Detector Unit Complete (P/N 1000 9777) Turn off the instrument and remove the mains cable. Lift up the hopper section and open the right-hand door. Disconnect the detector cable by unscrewing the screws on either side of the connector and pulling it straight backwards.

-

Page 137: Replacement Of Monochromator Complete

Infratec™ 1241 Grain Analyzer Fig. 5:10 Detector Remove the two screws which hold the spring plate over the detector. While holding the detector, remove the spring plate by pulling it straight upwards. Gently pull the detector straight outward towards you. Assemble the new detector in the reverse order.

-

Page 138

Infratec™ 1241 Grain Analyzer 3) Optional 4) Optional 5) Stop screw on protector 1241064 Fig. 5:11 Stop screw (pos 5) Now uncovered by the protector, loosen the stop screw to the fibre optic cable itself and remove it from the Measuring Unit. Pull from inside the compartment. Remove the four screws on the backside of the instrument which fasten the power supply module to the main chassis. -

Page 139: Replacement Of Halogen Lamp For Monochromator

Replace the halogen lamp as follows: Switch off the Infratec 1241 Grain Analyzer. Disconnect from mains. The cover plate to the lamp assembly is located on the top of the cooling flanges on the back side of the instrument, see Fig. 5:12. Unscrew the two screws 1 fastening the cover plate using the supplied 3 mm allen key.

-

Page 140

Infratec™ 1241 Grain Analyzer Fig. 5:12 Cover plate to lamp assembly Screws Use a flat bladed screwdriver to loose the two screws holding the lamp. Fig. 5:13 Removing lamp from holder Fit the new lamp and assemble in reverse order. After changing lamp let it burn in at least 2 hours. -

Page 141: Use Of The Aperture Kit (P/N 60023539)

Infratec™ 1241 Grain Analyzer 5.2.6 Use of the Aperture Kit (p/n 60023539) General The optical characteristics of each individual instrument are slightly different. Therefore it’s sometimes necessary to reduce the amount of light energy from the lamp onto the fibre bundle located just below the lamp. This describes the procedure to determine which aperture size to use and the way to fit it in the instrument.

-

Page 142

Infratec™ 1241 Grain Analyzer Procedure Aperture, Installation Switch off the instrument. Remove the screws securing the lamp cover and lift up the lamp and lamp holder assembly. Fig. 5:14 Inspect if an aperture already is fitted in the lamp housing. Usually not, which is the case in the picture below. -

Page 143

Infratec™ 1241 Grain Analyzer Usually the high limit is exceeded as described in the previous section and then you need to install a suitable aperture. In such a case we recommend to select the 6.5 mm size aperture as your first choice. When fitting the aperture, great care have to be taken not to touch or damage the surface of the fiber bundle. -

Page 144: Replacement Of Power Supply Board

Infratec™ 1241 Grain Analyzer 5.2.7 Replacement of Power Supply Board (P/N 1001 2810) Additional tools: Thermal paste (to be applied on transistors facing the heatsink) Removal of Power Supply Board Remove the Power Supply Module. Remove the Spring Plate 4 by unscrew screws 1 to 3. Unscrew the screws 5 and 6 and remove the Power Supply Board.

-

Page 145

Infratec™ 1241 Grain Analyzer Mounting Power Supply Board Mount the new Power Supply Board into pre-scored groove on the Cooling Flange. Insert right screw 5 and washer slightly for prepositioning purpose. Insert left screw 6 with earth cable shoe and washer for prepositioning. Fig. -

Page 146: Replacement Of Interface Complete

Infratec™ 1241 Grain Analyzer 5.2.8 Replacement of Interface Complete NOTE! Use ESD protection when handling circuit boards. Switch off the instrument. Carefully remove the covers for the five holes in the left-hand door with a screwdriver. Open the left-hand door. Disconnect the P1 cable from the DSP Board.

-

Page 147

Infratec™ 1241 Grain Analyzer Remove the two locking nuts 1 (one hidden) holding the PC Module and tilt down the PC Module. Fig. 5:21 PC Module Locking Nut Service Manual 1001 5015 / Rev. 4 5:19… -

Page 148

Infratec™ 1241 Grain Analyzer Disconnect the four interface cables that are on the left side of the PC Module. Fig. 5:22 PC Module CN13 COM2 Interface (modem) CN18 Keyboard/Bar code Interface CN15 LAN/Ethernet Interface CN19 COM1 Interface (external PC) 5:20 Service Manual 1001 5015 / Rev. -

Page 149

Infratec™ 1241 Grain Analyzer Carefully disconnect the two interface cables from the Processor Board. Fig. 5:23 Processor Board Printer Interface CN5(1) USB Interface Service Manual 1001 5015 / Rev. 4 5:21… -

Page 150

Infratec™ 1241 Grain Analyzer Remove the six screws 1 together with the washers and lift away the Interface Module. Fig. 5:24 Interface Module Screw Fit the new Interface Module with the six screws together with the washers. 10. Carefully connect the two interface cables to the Processor Board. 11. -

Page 151: Replacement Of Pc Module Complete W/O Flash Disc

Infratec™ 1241 Grain Analyzer 5.2.9 Replacement of PC Module Complete w/o Flash Disc NOTE! Use ESD protection when handling circuit boards. Switch off the instrument. Carefully remove the covers for the five holes in the left-hand door with a screwdriver. Open the left-hand door.

-

Page 152

Infratec™ 1241 Grain Analyzer Remove the two cable ties 1 securing the USB cables. Remove the two locking nuts 2 (one hidden) holding the PC Module and tilt down the PC Module. Fig. 5:26 PC Module Cable Ties Locking Nut 5:24 Service Manual 1001 5015 / Rev. -

Page 153

Infratec™ 1241 Grain Analyzer Disconnect the four interface cables that are on the left side of the PC Module. Fig. 5:27 PC Module CN13 COM2 Interface (modem) CN18 Keyboard/Bar code Interface CN15 LAN/Ethernet Interface CN19 COM1 Interface (external PC) Service Manual 1001 5015 / Rev. 4 5:25… -

Page 154

Infratec™ 1241 Grain Analyzer Disconnect the eight cables from the DSP Board. Fig. 5:28 DSP Board Power Supply Monochromator Shutter Board Inverter Interface Board Detector Monochromator Encoder I2C Bus Monochromator Grating Motor I2C Bus 5:26 Service Manual 1001 5015 / Rev. 4… -

Page 155

Infratec™ 1241 Grain Analyzer Carefully disconnect the four cables from the Processor Board. NOTE! The display cable at CN12 is extremely sensitive. Do not pull the wires. Make sure you pull the connector. Fig. 5:29 Processor Board Printer Interface CN5(1) USB Interface CN5(0) USB Interface… -

Page 156

Infratec™ 1241 Grain Analyzer 10. Transfer Flash Disk from old to new PC Module or install a new Flash Disk. For localization of Flash Disk, see figure below. Fig. 5:30 PC Module 11. Fit the new PC Module. 12. Carefully connect the four cables to the Processor Board. 13. -

Page 157: Replacement Of Dsp Board

Infratec™ 1241 Grain Analyzer 5.2.10 Replacement of DSP Board NOTE! Use ESD protection when handling circuit boards. Switch off the instrument. Carefully remove the covers for the five holes in the left-hand door with a screwdriver. Open the left-hand door. Disconnect the P1 cable from the DSP Board.

-

Page 158

Infratec™ 1241 Grain Analyzer Remove the two cable ties 1 securing the USB cables. Remove the two locking nuts 2 (one hidden) holding the PC Module and tilt down the PC Module. Fig. 5:32 PC Module Cable Ties Locking Nut 5:30 Service Manual 1001 5015 / Rev. -

Page 159

Infratec™ 1241 Grain Analyzer Disconnect the four interface cables that are on the left side of the PC Module. Fig. 5:33 PC Module CN13 COM2 Interface (modem) CN18 Keyboard/Bar code Interface CN15 LAN/Ethernet Interface CN19 COM1 Interface (external PC) Service Manual 1001 5015 / Rev. 4 5:31… -

Page 160

Infratec™ 1241 Grain Analyzer Disconnect the eight cables from the DSP Board. Fig. 5:34 DSP Board Power Supply Monochromator Shutter Board Inverter Interface Board Detector Monochromator Encoder I2C Bus Monochromator Grating Motor I2C Bus 5:32 Service Manual 1001 5015 / Rev. 4… -

Page 161

Infratec™ 1241 Grain Analyzer Carefully disconnect the four cables from the Processor Board. NOTE! The display cable at CN12 is extremely sensitive. Do not pull the wires. Make sure you pull the connector. Fig. 5:35 Processor Board Printer Interface CN5(1) USB Interface CN5(0) USB Interface… -

Page 162

Infratec™ 1241 Grain Analyzer 10. Remove the two distance bolts 1 together with the two washers and carefully lift away the DSP Board. Fig. 5:36 DSP Board Distance Bolts 11. Fit the new DSP Board with the two distance bolts together with the two washers. -

Page 163: Replacement Of Compact Flash Disc

Infratec™ 1241 Grain Analyzer 5.2.11 Replacement of Compact Flash Disc NOTE! Use ESD protection when handling circuit boards. Switch off the instrument. Carefully remove the covers for the five holes in the left-hand door with a screwdriver. Open the left-hand door. Remove the Flash Disk 1.

-

Page 164: Measuring Unit

Infratec™ 1241 Grain Analyzer Measuring Unit 5.3.1 General The following pages describes how to maintain/clean and replace parts in the Measuring Unit module. Any kind of service that may affect the path length of the sample kuvette is after completion subject to a perfect control and possible adjustment of this path length.

-

Page 165

Infratec™ 1241 Grain Analyzer Loosen the Stop Screw to the Fibre Optic Cable Protector and slide it backwards, see fig below. 3) Optional 4) Optional 5) Stop screw on protector 1241064 Fig. 5:39 Stop screw (pos 5) 10. Now uncovered by the Protector, loosen the Stop Screw to the Fibre Optic Cable itself and remove it from the Measuring Unit. -

Page 166: Replacement Of Upper Solenoid

Infratec™ 1241 Grain Analyzer 5.3.3 Replacement of Upper Solenoid Note: The replacement is carried out with the Measuring Unit standing apart. Disconnect the Upper Solenoid Cable from the Measuring Unit Board. Remove the two screws holding the Upper Solenoid. Exchange the Upper Solenoid and assemble in reverse order. 5:38 Service Manual 1001 5015 / Rev.

-

Page 167: Replacement Of Lower Solenoid

Infratec™ 1241 Grain Analyzer 5.3.4 Replacement of Lower Solenoid Note: The replacement is carried out with the Measuring Unit standing apart. Disconnect the Lower Solenoid Cable from the Measuring Unit Board. Remove the two screws holding the Lower Solenoid. Exchange the Lower Solenoid and assemble in reverse order. Service Manual 1001 5015 / Rev.

-

Page 168: Replacement Of Lower Linkage Shutter Assembly

Infratec™ 1241 Grain Analyzer 5.3.5 Replacement of Lower Linkage Shutter Assembly Note: The replacement is carried out with the Measuring Unit standing apart. Note: You have to switch over the plunger. Disconnect the Lower Solenoid Cable from the Measuring Unit Board. Remove the two screws holding the Lower Solenoid and remove the Lower Shutter.

-

Page 169: Replacement Of Upper Linkage Shutter Assembly

Infratec™ 1241 Grain Analyzer 5.3.6 Replacement of Upper Linkage Shutter Assembly Note: The replacement is carried out with the Measuring Unit standing apart. Note: You have to switch over the plunger. Disconnect the Upper Solenoid Cable from the Measuring Unit Board. Remove the two screws holding the Upper Solenoid and remove the Upper Shutter.

-

Page 170: Replacement Of Connection Pcb Complete

Infratec™ 1241 Grain Analyzer 5.3.7 Replacement of Connection PCB Complete Note: The replacement is carried out with the Measuring Unit standing apart. Disconnect the Measuring Unit Card cable from the Measuring Unit Board. Remove the Measuring Unit Card by removing the two screws holding the Measuring Unit Card, see fig below.

-

Page 171: Replacement Of Measuring Unit Pcb

Infratec™ 1241 Grain Analyzer 5.3.8 Replacement of Measuring Unit PCB Note: The replacement is carried out with the Measuring Unit standing apart. Note: Use electrostatic discharge (ESD) protection when handling circuit boards. Disconnect cables and remove the Measuring Unit Board. Mount the new Measuring Unit Board and connect the cables according to fig below.

-

Page 172: Replacement Of Variable Motor

Infratec™ 1241 Grain Analyzer 5.3.9 Replacement of Variable Motor Note: The replacement is carried out with the Measuring Unit standing apart. Replacement is a factory repair. 1241113 Fig. 5:45 Nut and screws Exchange the Variable Cell Motor and assemble in reverse order. Fig.

-

Page 173: Replacement Of Conveyor Motor

Infratec™ 1241 Grain Analyzer 5.3.10 Replacement of Conveyor Motor Note: The replacement is carried out with the Measuring Unit standing apart. Disconnect the Conveyor Motor Cable from the Measuring Unit Board. Remove the three screws holding the Conveyor Motor. Exchange the Conveyor Motor and assemble in reverse order. Service Manual 1001 5015 / Rev.

-

Page 174: Replacement Of Cell Wall Front With Speckle Emitter Pcb

Infratec™ 1241 Grain Analyzer 5.3.11 Replacement of Cell Wall Front with Speckle Emitter Remove the two screws which hold the spring plate over the detector. While holding the detector, remove the spring plate by pulling it straight upwards. Gently pull the detector straight outward towards you. Disconnect the Speckle Emitter Board connector.

-

Page 175: Replacement Of Cell Block Complete And Path Length Encoder

Infratec™ 1241 Grain Analyzer 5.3.12 Replacement of Cell Block Complete and Path Length Encoder This is a factory repair and cannot be done in the field. Service Manual 1001 5015 / Rev. 4 5:47…

-

Page 176: Replacement Of Cell Cover Outer

Infratec™ 1241 Grain Analyzer 5.3.13 Replacement of Cell Cover Outer Remove the five screws according to the figure below. Fig. 5:48 Remove five screws Mount the new Cell Side with the three screws. 5:48 Service Manual 1001 5015 / Rev. 4…

-

Page 177: Checking Movement Of The Variable Cell

Infratec™ 1241 Grain Analyzer 5.3.14 Checking movement of the Variable Cell Use a Multi meter tool and check between pins 6 (brown) and pin 9 (grey). The reading should be low (close to 0 V). Issue a command to move the Cell via the Service Menu; Manual Tests /Meas- uring Unit/ Position Settings.

-

Page 178: Drawer Sensor Cable, Rerouting

Infratec™ 1241 Grain Analyzer 5.3.15 Drawer Sensor Cable, rerouting NOTE: It is very important that the test weight balance assembly is free from cables. Switch off the instrument. Lift up the hopper section and open the right-hand door. Disconnect the drawer sensor cable 1 from the lower socket. Fig.

-

Page 179

Infratec™ 1241 Grain Analyzer Wrap the drawer sensor cable around the other cables according to figure and connect the drawer sensor cable. Check that the test weight balance assembly is free from cables. Fig. 5:50 Test Weight Balance Assembly Service Manual 1001 5015 / Rev. 4 5:51… -

Page 180: Test Weight Module

Test Weight Control Kit P/N 1001 1779 Disconnect the TWM from the Infratec. Use the installation description in User Manual for Infratec 1241 Modules, p/n 60043623, in the reverse order. Unfortu- nately it is necessary to do this due to two constraints;…

-

Page 181: Replacement Of Wiper Arm Complete

Infratec™ 1241 Grain Analyzer 5.4.2 Replacement of Wiper Arm Complete (P/N 6002 4272) Additional tools: • 2 mm allen key • 2.5 mm allen key • Test Weight Control Kit P/N 1001 1779 NOTE: It is very important not to put weight on the load cell in the TWM balance.

-

Page 182

Infratec™ 1241 Grain Analyzer Remove the old wiper arm together with the screw 1 using a 2 mm allen key. Fig. 5:52 Removing old wiper arm Screw Fit the new wiper arm with the screw 1 using a 2.5 mm allen key. Fig. -

Page 183

Infratec™ 1241 Grain Analyzer Adjust so the wiper arm is moving just above the edge of the red cuvette without any noise. Operate the wiper arm from the Service Menu; 3 Manual Tests/ 6 Test Weight/ 1 Position Setting. Fit the wiper arm with the two screws 1. NOTE: It is important that the wiper arm lies flat without scraping. -

Page 184: Replacement Of Twm Pcb

Infratec™ 1241 Grain Analyzer 5.4.3 Replacement of TWM PCB Test Weight Control Kit P/N 1001 1779 Warning Disconnect the incoming mains supply before removing any cover. NOTE! Use electrostatic discharge (ESD) protection when handling circuit boards. Separating the Infratec and the Test Weight Module On the rear of the instrument, remove the top screw from the plate connecting the Infratec and the TWM.

-

Page 185

Infratec™ 1241 Grain Analyzer Fig. 5:56 Fig. 5:57 Slide the TWM out from the instrument. Remove the four screws holding the TWM balance. Changing the TWM PCB Remove the six screws holding the black roofcover of the TWM balance and slide it off. -

Page 186: Replacement Of Wiper/Shutter Motor

Infratec™ 1241 Grain Analyzer 5.4.4 Replacement of Wiper/Shutter Motor Test Weight Control Kit P/N 1001 1779 Instruction for wiper motor replacement in the 1241 TWM Separate the TWM from the Infratec. Take out the TWM module. Don’t stress the load cell and handle the module with care.

-

Page 187

Infratec™ 1241 Grain Analyzer Remove the two Philips screws and lift out the motor. Fig. 5:59 Move the motor bracket to the new motor. The orientation is not important. Fix the new motor assembly. Make sure the cable falls behind the interconnect PCB. -

Page 188

Infratec™ 1241 Grain Analyzer Instruction for shutter motor replacement in the 1241 TWM Take out the TWM module. Don’t stress the load cell and handle the module with care. Remove the three screws 1 (2.5mm) on both sides (see picture). Fig. -

Page 189: Replacement Of Locking Guide

Infratec™ 1241 Grain Analyzer 5.4.5 Replacement of Locking Guide Test Weight Control Kit P/N 1001 1779 Additional tools: • 2 mm allen key • 2.5 mm allen key Remove the drawer. Remove the old locking guide together with the screw 1 using a 2.5 mm allen key.

-

Page 190

Infratec™ 1241 Grain Analyzer Place the 0.1 mm shim between the bottom shutter and the locking guide, press the locking guide to the bottom shutter and tighten the screw 1. NOTE! It is very important that the bottom shutter lies flat with a 0.1 mm gap when closed. -

Page 191: Checking/Adjusting Twm Level Sensors

Infratec™ 1241 Grain Analyzer 5.4.6 Checking/Adjusting TWM Level Sensors (P/N 6002 3294) Level Sensor Centring Tool TWM P/N 6002 3294 Test Weight Control Kit P/N 1001 1779 Remove the two screws and lift away the cover plate. Fig. 5:64 Removing cover plate Check the position of the two level sensors using the special tool.

-

Page 192

Infratec™ 1241 Grain Analyzer If the level sensor is in a wrong position — loosen the screws 1. Adjust the level sensor to correct position and tighten the screws 1. Fig. 5:66 Adjusting level sensor Screws Assemble in reverse order. Start up the instrument and let it go through the Startup Test. -

Page 193: Sample Transport Module

Infratec™ 1241 Grain Analyzer Sample Transport Module 5.5.1 Replacement of Cuvette Glass Kit Applicable to: 1001 2122 Cuvette bottom part 1001 2123 Cuvette top part 6 mm 1001 2124 Cuvette top part 10 mm 1001 2125 Cuvette top part 18 mm 1001 2126 Cuvette top part 25 mm 1001 2127…

-

Page 194: Replacement Of Stm Cuvette Cam Thread

Infratec™ 1241 Grain Analyzer 5.5.2 Replacement of STM Cuvette Cam Thread This instruction is valid for STM cuvette part no: • 10012592 (type 1) • 10013213 (type 1) • 10014163 (type 1) • 10011075 (type 2) Replacement — type 1 Remove the two grub screws 1, see Fig.

-

Page 195

Infratec™ 1241 Grain Analyzer Slide in the new cam thread through the open end. The lower end of the new cam thread should align with the groove in the cuvette see Fig. 5:69. Fig. 5:69 Installing cam thread Fit the two grub screws. Be careful not to overtighten the screws since the cam thread is made of a soft material. -

Page 196

Infratec™ 1241 Grain Analyzer The lower end of the new cam thread 2 should be placed 191mm from the top part of the cuvette see Fig. 5:70. Refit the bottom plate 3 and tighten the grub screws 1. Be careful not to over tighten the screws since the cam thread is made of a soft material. -

Page 197: Checking Stm Cuvette Cam Thread

Infratec™ 1241 Grain Analyzer 5.5.3 Checking STM Cuvette Cam Thread There are no parts that require regular maintenance. It is recommended though that the blue Cam Thread is checked for wear and positioning. The two sensors on the left side of the Elevator Unit should be lit when the Cuvette Holder is in place and they should have a tolerance of a few millimetre when moving the Cuvette Holder up and down.

-

Page 198: Corrective Maintenance Procedures

An upgrade Cable Stalk kit P/N 60028013 is introduced for replacement of I cabling in existing Cable Stalk. Infratec 1241-002 delivered prior to 2008-01-01 is subject for upgrading existing cables.

-

Page 199

• TWM 1241-050 delivered after 2008-01-01 is updated with HW described in this TN. Affected versions: • Infratec 1241-002 model delivered prior 2008-01-01, to be updated with below listed HW (Ref TN 1234): — P/N 60023758 DSP Board — P/N 60028013 Cable stalk Kit •… -

Page 200: Preventive Maintenance Procedures

Infratec™ 1241 Grain Analyzer Preventive Maintenance Procedures Preventive Maintenance of the Infratec 1241 consists of a series of checks that are performed periodically to detect and prevent impending failures, see PM Protocol part no. 1001 4569. 5.7.1 Measuring Unit Adjustment of Path Length After any change or repair to the Measuring unit the path length must be checked us- ing the Go/No Go ball gauge.

-

Page 201

If adjustment is required then follow the instruction under «Adjustment», herein. From the Infratec 1241 Service Menu (Manual Tests/Measuring Unit/Position Settings) set the path length to home position at 33 mm. Now, set the path length to 6 mm. -

Page 202: Twm Balance Calibration

Fig. 5:75 Log in on the Service menu. The password is 3677 . A hint to remember this password is to type «FOSS» on you mobile phones keyboard. Select Manual Tests/ Test weights/ Calibration/ Mass calibration (3.6.2.2). Basically just follow the instructions given on the display.

-

Page 203

Infratec™ 1241 Grain Analyzer Fig. 5:77 Fig. 5:78 Fig. 5:79 Service Manual 1001 5015 / Rev. 4 5:75… -

Page 204

Infratec™ 1241 Grain Analyzer Fig. 5:80 The next picture is taken from the emulator software. The normal slope is close to 1 and the Calculated weight is close to 400. Fig. 5:81 5:76 Service Manual 1001 5015 / Rev. 4… -

Page 205: Twm Balance Control

Infratec™ 1241 Grain Analyzer 5.7.3 TWM balance Control Select Manual Tests/ Test weights/ Calibration/ Balance Control (3.6.2.1). Fig. 5:82 Follow the instructions on the display. After completion the Software will answer the question «Balance OK?» with either Yes or No. If the Expected and Calculated value differs more than +/- 0.2 the answer is No.

-

Page 206

Infratec™ 1241 Grain Analyzer 5:78 Service Manual 1001 5015 / Rev. 4… -

Page 207: Technical Specifications

Infratec™ 1241 Grain Analyzer Technical Specifications See User Manual — Infratec™ 1241 Grain Analyzer. ™ Infratec 1241 Fuses T 8.0 AT (pos. F1 on PSU) TT 1.25 AT (pos. F2 on PSU) 4 AT (pos. F3 on PSU) Internal fuses 500 mAT (pos.

-

Page 208

Infratec™ 1241 Grain Analyzer Service Manual 1001 5015 / Rev. 4… -

Page 209

Infratec™ 1241 Grain Analyzer Schematics Service Manual 1001 5015 / Rev. 4… -

Page 210

Infratec™ 1241 Grain Analyzer Service Manual 1001 5015 / Rev. 4… -

Page 211

• 6004 3623 User Manual Infratec™ 1241 Modules (Gen. 2 and 3) • 1001 0694 Software Manual Infratec™ File Tool • 6002 2638 Installation Manual Infratec™ Data Logger • 6003 9725 Software Manual FOSS Data Link Service Manual 1001 5015 / Rev. 4… -

Page 212

Infratec™ 1241 Grain Analyzer Service Manual 1001 5015 / Rev. 4…

|

Detail Specifications: 1431/1431031-infratec_1241.pdf file (15 Nov 2022) |

Accompanying Data:

Foss Infratec 1241 Measuring Instruments PDF Service Manual (Updated: Tuesday 15th of November 2022 05:05:59 AM)

Rating: 4.2 (rated by 27 users)

Compatible devices: pH 5/6, WXT520, Aztec AWT440, SpectroDens, AR600E, FM-300, TDS & EC METER 2.0, XDS OptiProbe.

Recommended Documentation:

Text Version of Service Manual