Combine harvesters

TUCANO

450 440 430 420 340 320

Time to grow.

The new TUCANO.

Healthy growth is the basis of every successful harvest. It was with this principle in mind that we developed the new TUCANO. As well as growing to incorporate the intelligence and comfort of the large combine segment, it has a design which immediately announces a new dimension of excellence and gives you the capacity you need for the future:

Time to grow.

tucano400-300.claas.com

2

TUCANO

3

TUCANO 450 / 440 / 430 / 420 / 340 / 320.

4

Contents

|

Cab |

6 |

|

|

EASY |

11 |

|

|

CEBIS |

12 |

|

|

CEBIS, multifunction control lever, |

||

|

CMOTION |

14 |

|

|

TELEMATICS |

16 |

|

|

Yield mapping, job management |

18 |

|

|

Automatic guidance systems |

20 |

|

|

Front attachments |

22 |

|

|

Cutterbar |

25 |

|

|

VARIO cutterbar, rapeseed cutterbar |

26 |

|

|

VARIO 930 / 770, CERIO cutterbars |

28 |

|

|

CONSPEED, CONSPEED LINEAR |

30 |

|

|

SUNSPEED, SWATH UP |

32 |

|

|

Rice cutterbar, FLEX |

34 |

|

|

Automated cutterbar control |

36 |

|

|

Threshing system |

38 |

|

|

APS threshing system |

40 |

|

|

CLAAS threshing system |

42 |

|

|

Straw walker technology |

44 |

|

|

Crop cleaning |

46 |

|

|

Grain tank, QUANTIMETER, |

||

|

PROFI CAM |

48 |

|

|

Straw management |

50 |

|

|

CLAAS POWER SYSTEMS |

52 |

|

|

Engine, drive train |

54 |

|

|

All-wheel drive, |

||

|

central lubrication system |

56 |

|

|

Tyres, maintenance |

58 |

|

|

First CLAAS Service |

60 |

|

|

Technology in detail |

62 |

|

|

Benefits |

66 |

|

|

Technical data |

67 |

|

5

Well-being at work.

Deluxe comfort in your working environment.

At CLAAS, comfort and convenience mean that everything is designed to enable you to work with optimal efficiency. From the flawless 360° view to the smallest action.

6

Cab

7

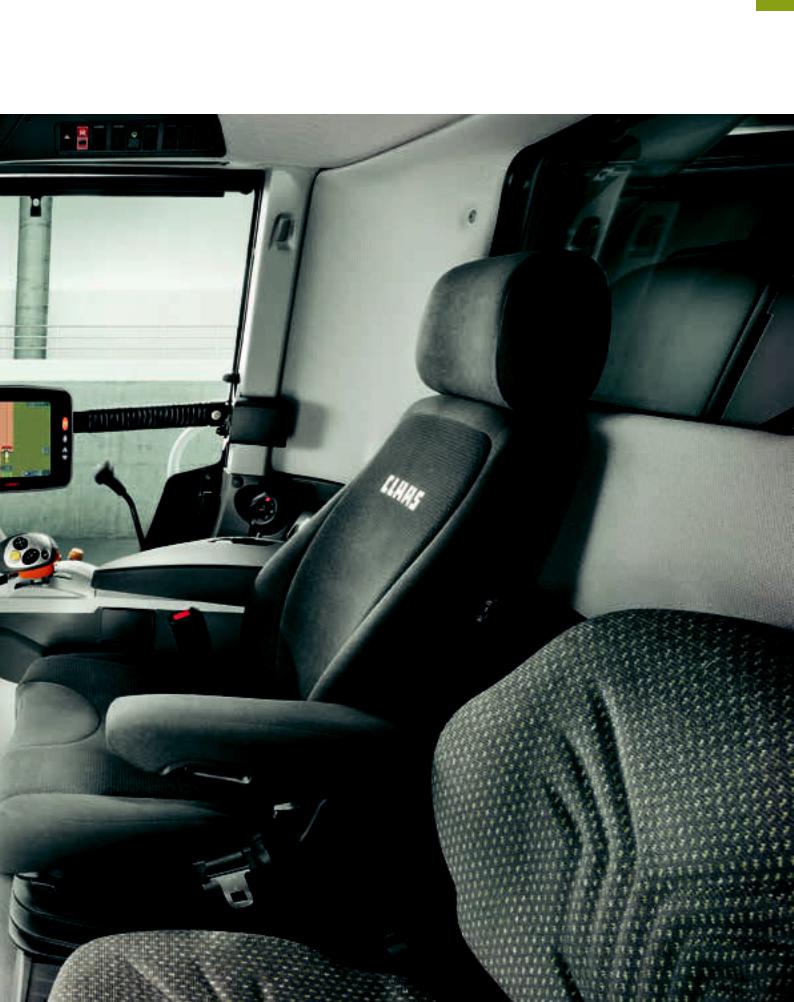

More space. More comfort.

A more productive workplace.

For optimal working conditions.

The TUCANO gives the operator freedom of movement, a clear control layout and excellent visibility on all sides. The air conditioning maintains a consistent, comfortable atmosphere, which together with superb soundproofing and a threeposition adjustable steering column provides first-class working conditions.

The steering column is adjustable three ways.

8

Cab

Cushions, supports, ventilates and keeps you warm: the deluxe operator’s seat.

Full support for dynamic, active work while seated. Active comfort control ensures optimal ventilation and sweat removal without subjecting the operator to unhealthy draughts. The air suspension seat with automatic height control adjusts automatically to the operator’s weight and effectively attenuates vibrations by up to 40%. A pneumatic, two-part lumbar support keeps your back in shape while the automatic thermostat for the seat’s heating keeps you warm and comfortable.

Fully featured: trainee’s seat with integrated cooler.

−−Integrated armrest at left on door

−−Foldable backrest as a table

−−Large in-cab refrigerator, with capacity of 43 litres and a bottle holder

−−Many other stowage compartments

Turns night into day at the flick of a switch.

The lighting systems ensure the best visibility for the entire work area and machine parts even at night. Intelligent features, such as the afterlight function, make for a complete package. Powerful H9 and xenon lights turn night into day.

−−Up to ten work lights

−−Lighting for folding front attachments

−−Side lights, stubble lights, steering axle lights

−−Automatic lighting of the discharge auger tube

−−Automatic reversing lights

−−Lighting for the cleaning system, grain tank and returns

−−Service lights below the side panels

−−Mobile work light

|

The operating panel gives a good |

|

|

overview and enables simple control |

|

|

of the working lights. The light |

|

|

Refrigerator box integrated in |

settings can be adjusted easily in |

|

trainee’s seat |

CEBIS. |

9

EASY. Simply more.

10

EASY – Efficient Agriculture Systems by CLAAS

The name says it all.

All the electronics expertise of CLAAS can be summarised in a word: EASY.

That stands for Efficient Agriculture Systems, and it lives up to the name. Equipment settings, guidance systems, software solutions and more: EASY makes it all simple. Your systems can be matched perfectly with each other, enabling you to get the best performance from your combines and top results for your operation.

Go on. Go easy.

The EASY concept is made up of four components, each providing specialist competence and together forming a strong team.

−−on board – Control and performance optimisation of the combine from the cab

−−on field – Increased productivity directly in the field

−−on track – Equipment monitoring and remote diagnostics

−−on farm – Software solutions for your operation

11

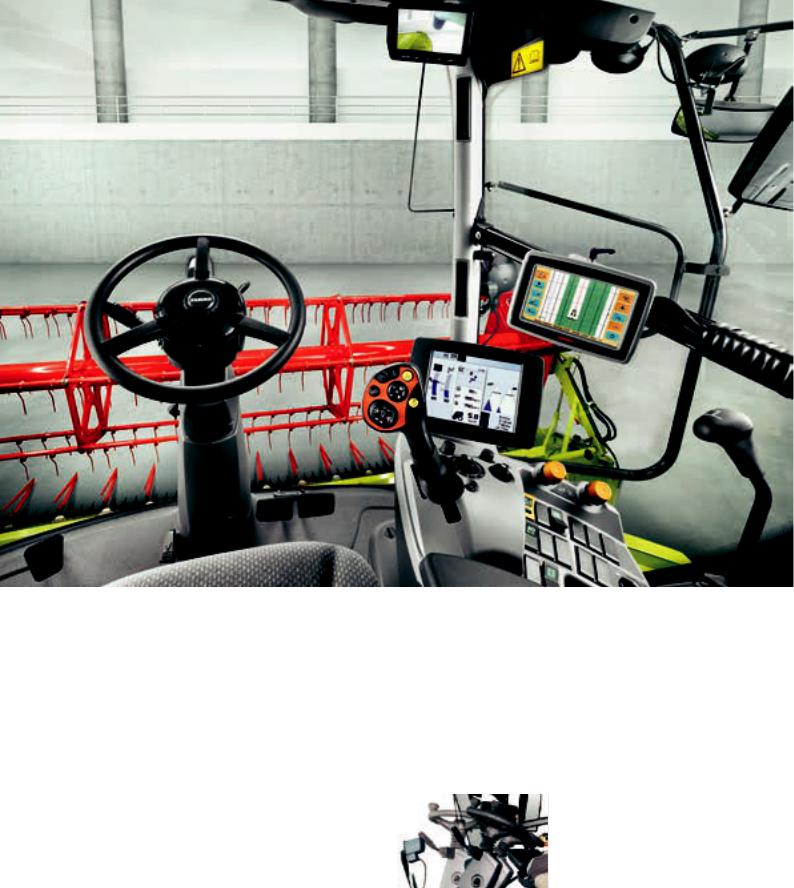

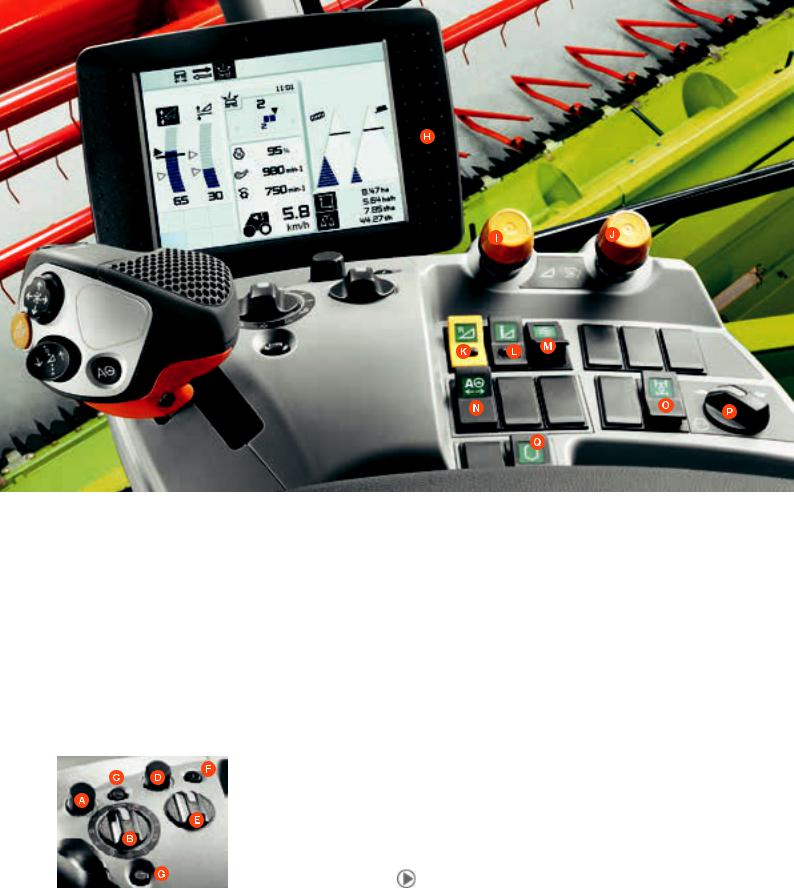

More informed, more monitoring.

All’s clear on the operating panel!

Integrated with the operator’s seat, its flexible functions can be adapted as needed. Function switches include:

AMenu selection rotary/push switch

BCEBIS direct menu rotary switch

CEscape button

DHOTKEY rotary/push switch

EHOTKEY direct menu rotary switch

FInformation button

GDIRECT ACCESS button

HCEBIS screen

IFront attachment on/off

JThreshing unit on/off

KFront attachment reverser

LRapeseed knife, left, on/off

MLateral adjustment of cutterbar / changes to values in HOTKEY menu / longitudinal position of VARIO cutterbar table

NLASER PILOT left/right preselection

OAll-wheel drive

PDiesel engine speed (three steps)

QGrain tank cover open

|

CEBIS controls and HOTKEY |

For more information, please visit: tucano400-300.claas.com |

12

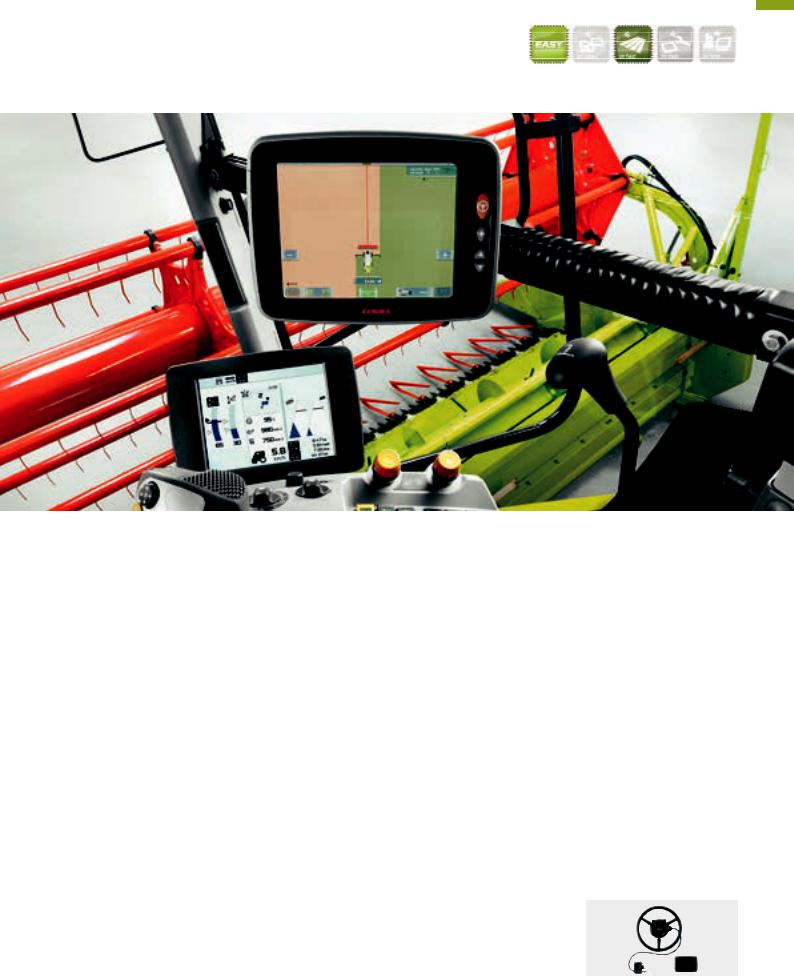

CEBIS

Keeping the operator in the picture at all times. Clear, simple and fast operation.

Information, registration, control and monitoring are the tasks of the CEBIS electronic on-board information system. It is distinguished by its clear, logical organisation of functions in the menu structure.

A brief glance at the CEBIS display gives an overview of the current processes and conditions: all the relevant information for driving or harvesting is summarised clearly on the screen. Warning messages are given audibly as a buzz tone and visually as icons and text.

An eye-catching 21 cm screen.

The 8.4″ colour CEBIS screen offers an ideal view thanks to its ball coupling mount which enables the monitor to be adjusted as required by the operator. It can be adjusted for angle as well as horizontally and vertically.

CEBIS on the road.

1Menu bar

2Travel speed and rpm

3Operating hours

4Fuel level and temperature display as well as AdBlue level

CEBIS in the field.

5Throughput monitoring

6Area scaling and yield metering

7Driving information (up to 40 displays freely selectable)

8Message window (for alarms and information)

9Front attachment position (AUTO CONTOUR/ cutting height)

−The basic machine settings in working mode are made via the CEBIS rotary switch (B)

−An additional HOTKEY rotary switch allows fast access to other functions (E)

−The position of the rotary switch is shown on the CEBIS display (H)

−The CEBIS and HOTKEY rotary/push switches (A / D) are used for menu navigation and making changes to settings

−A Compact Flash Card makes data exchange particularly easy

−The DIRECT ACCESS button provides direct access to the last menu setting. It also offers fast access to the image from the camera

13

NEW

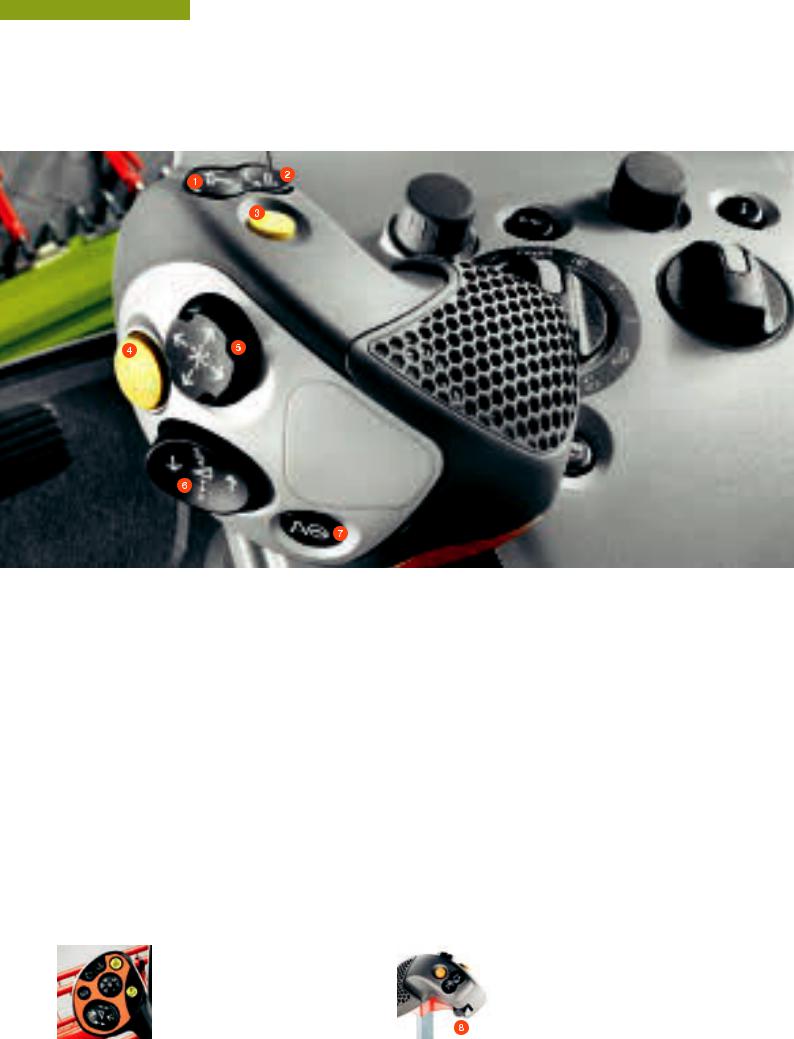

More functions at your fingertips.

CMOTION. Greater comfort.

The multifunction control lever, which is integrated in the right armrest of the operator’s seat, plays a key role in making the TUCANO so user-friendly and comfortable for the operator.

The CMOTION has been specially developed for ergonomic operation by the right hand. The innovative, three-finger control concept allows several functions to be controlled intuitively without having to reposition one’s hand.

1Extend grain tank discharge auger

2Retract grain tank discharge auger

3Grain tank offloading on / off

4Cutterbar stop

5Reel operation

6Front attachment height control

7AUTO PILOT, LASER PILOT, GPS PILOT

Another toggle switch (8) is situated on the back of the multifunction control lever. With three functions assigned to it, this switch enables manual lateral control of the cutterbar, changes to values in the HOTKEY menu or manual adjustment of the VARIO cutterbar table.

|

The choice is yours: multifunction control |

Three-function |

|

|

lever or CMOTION |

toggle switch (8) |

|

14

CEBIS | Multifunction control lever | CMOTION

Comprehensive information.

CEBIS is simple to use, allowing a wealth of equipment information to be displayed and printed in addition to performing full control and monitoring.

−−Automatic crop setting

−−GPS PILOT, LASER PILOT, AUTO PILOT – automatic guidance

−−Automated cutterbar control

−−QUANTIMETER – yield determination / moisture measurement

−−Area counter

−−Fuel consumption measurement

−−Yield mapping – crop log

−−Performance display – remaining diesel running time / range / grain tank fill level

−−Job management

−−Maintenance interval display and tasks

−−On-board diagnostics, alarm lists and alarm history

−−Speed monitoring, slippage display (for the threshing drum, for example)

NEW: Automatic machine setup.

Factory-programmed settings for over 35 crop types are available. In addition, users’ own settings based on experience (especially relating to specific varieties) can be stored and called up whenever required. Furthermore, favourite settings can be stored and recalled quickly by means of the hotkey rotary switch. The following machine parameters are set:

−−Threshing drum speed

−−Concave gap

−−Fan speed

−−Upper and lower sieve opening

−−Sieve throughput monitoring sensitivity

−−Residual grain separation throughput monitoring sensitivity

−−Specific crop weight (bulk density)

−−Crop-specific calibration factor

15

TELEMATICS.

Makes good operators even better.

|

A full overview with just a click of the mouse. |

Improve work processes. |

The CLAAS TELEMATICS feature enables you to access all the important data for your combine any time, anywhere via the internet. Enjoy the benefits of TELEMATICS.

Optimise your settings.

Use your personal access to the TELEMATICS web server to quickly compare the performance and harvesting data for your machines so that you can fine tune the settings for the best results under all conditions every day.

A report with the operating time analysis and other important evaluations of the machine is sent to you by e-mail each day. This enables you to review the specific data from the previous day and determine when and how efficiently the combine operated before you start work again. In addition, the working tracks of the machine can be viewed together with the event log in order to optimise the transport logistics. TELEMATICS enables planned fleet management and helps avoid unprofitable idle time.

A range of packages to meet your requirements.

TELEMATICS is available in three different packages: basic, advanced and professional.

16

TELEMATICS

|

Simplify documentation. |

Automatic documentation. |

Use TELEMATICS to export the relevant data to your field catalogue and save valuable time. Transfer data on areaspecific yields, for example.

Faster service with CLAAS remote diagnostics.

With your consent, TELEMATICS can transmit maintenance and repair data to your CLAAS sales partner. This enables your CLAAS partner to carry out an initial analysis via

CDS Remote — when required — to find the causes of faults more quickly and to make optimum preparations to assist you on site as quickly as possible.

This function automatically documents and processes all process data. As an extension to TELEMATICS, automatic documentation transfers (without any intervention by the machine operator) the work data relating to the specific field deployment to the server, where they are interpreted and processed. Data interpretation and processing are based on the field boundaries previously uploaded from your system. Further processing is straightforward, as all machine-relevant data can be exported in IsoXML format.

17

More potential when you need it.

Fast data processing.

With its extremely fast on-board network, the TUCANO is already prepared to meet the far-reaching challenges of the future.

A wealth of information can be printed whenever required.

The working tracks picked up by GPS can also be displayed in CEBIS.

18

Yield mapping | Job management

|

Yield mapping. |

Job management. |

Building on the foundation of the job management functions, you can use your TUCANO to perform yield mapping. Sensors in the TUCANO measure the yield and grain moisture while CEBIS adds geographic coordinates using GPS satellite data.

All measurements are stored on portable chip cards to facilitate transfer. AGROCOM MAP START software is included to enable you to produce informative yield maps to use as a basis for your future production strategy.

You can manage your jobs with CEBIS. Moreover, with AGROCOM MAP START software from CLAAS you can prepare customer and parcel data to be run and processed with CEBIS.

−−All data is backed up when a specific task is completed or the working day comes to an end

−−The data can be printed out on the combine or transferred with a data card

−−All data can be viewed and processed further on a PC

−−Daily counts, crop counts and total counts can also be displayed and printed in CEBIS

19

More precise guidance.

LASER PILOT.

The electro-optical sensors of the LASER PILOT use pulses of light to scan between the crop and stubble and guide the TUCANO automatically along the edge.

The LASER PILOT can be folded away for transport and is available for both the left and right side of the cutterbar. Its optimal positioning on the cutterbar side close to the crop edge enables a good viewing angle and ensures high functional reliability even with laid crops and slopes.

Choose from three automatic guidance systems.

All the TUCANO models can be factory-fitted with three automatic guidance systems which can be selected as needed according to application.

−−GPS PILOT – the satellite-supported guidance system

−−LASER PILOT – the electro-optical guidance system

−−AUTO PILOT – the electro-mechanical guidance system

AUTO PILOT.

Two digital sensors, incorporated in one of the picker units, record the position of the TUCANO and automatically guide it on the best path through the rows of maize in all field conditions. In this way, AUTO PILOT contributes to greater performance and efficiency.

The way you want it.

Portable displays from CLAAS offer a flexible control option for ISOBUS and guidance systems. The terminal can also be moved from one tractor or self-propelled harvester to another, depending on the season or job in hand. Fit your TUCANO with the equipment you need, straight from the factory or as a retrofit option:

−−S10: high-resolution 10.4″ touchscreen terminal with guidance and ISOBUS functions: up to four cameras can be viewed

−−S7: high-resolution 7″ touchscreen terminal with guidance functions

20

Automatic guidance systems

|

Automatic steering at the headland. |

GPS PILOT FLEX. |

The AUTO TURN function takes care of turning manoeuvres at the headland. The direction of the turn and the next track to be worked are pre-selected on the terminal. The steering system does the rest.

How you benefit.

−High functional reliability and safety regardless of visibility conditions

−Optimal use of the full width of the cutterbar

−Greater precision for mapping areas and yields

−Reduced fuel consumption

−Reduced turning times

−Increased seasonal performance

−Significant reduction in workload for the operator, enabling greater concentration on threshing

The GPS PILOT can be used not only with hydraulically actuated steering, but also with the GPS PILOT FLEX automatic steering wheel. This steering wheel allows you to operate the machine with a high degree of accuracy. The great advantage of the GPS PILOT FLEX is its versatility.

−No need to touch the hydraulics

−Guidance system can quickly be moved between different machines

The electric steering wheel transfers steering commands from the terminal and navigation controller to the steering axle in order to steer the machine

GPS PILOT FLEX steering wheel

21

Приближается самая горячая пора – страда, успех которой во многом будет зависеть от эффективности работы зерноуборочных комбайнов. На сегодняшний день одной из самых часто встречаемых на полях Казахстана машин является TUCANO 450, выпускаемый немецким концерном CLAAS. О том, как правильно настроить и повысить эксплуатационную эффективность этого комбайна делятся специалисты по оптимизации машин компании CT AGRO, являющейся официальным дилером бренда CLAAS в Казахстане.

Как увеличить производительность комбайна? Какие резервы есть у машины для повышения ее производительности?

Чтобы машина отработала максимально производительно, она должна быть подготовлена. И здесь примерно на 75% эффективность работы комбайна зависит от настроек жатки, под которую с учетом климатических условий, рельефа местности и свойств убираемой культуры настраиваются все остальные агрегаты машины.

Если мы говорим про комбайн TUCANO 450, то гибкость настроек этой модели позволяет тонко корректировать работу систем обмолота и сепарации каждые пять минут. На разных участках поля может быть разная урожайность, объем соломенной массы, влажность, которая повышается или понижается в течение дня, в зависимости от погоды. Но далеко не всегда операторы все это учитывают – выставляются определенные настройки, с которыми машина работает и один, и второй и третий день, как будто задача – проехать поле от и до, а не собрать урожай. Поэтому главное – нужно просто знать и понимать имеющийся у машины функционал и грамотно этим пользоваться. Мы со своей стороны всегда стараемся помочь хозяйствам и обучить механизаторов грамотной эксплуатации современных комбайнов.

Второй фактор повышения производительности – это скорость движения комбайна. Данный параметр позволяет контролировать уровень загрузки систем обмолота и сепарации: не давать им работать вхолостую, но и не перезагружая. Здесь очень важно контролировать уровень соломенной массы и при его повышении скорость снижать.

Какие основные настройки комбайна TUCANO 450 значительнее всего влияют на производительность и экономичность этой машины?

В первую очередь, внимание следует обращать на высоту среза жатки. Во вторую – регулируются настройки мотовила и шнека жатки, и уже после этого смотрим на работу наклонной камеры. Важно, чтобы уже на входе срезаемой массы все цепные механизмы были настроены под определенную пропускную способность.

Следующий момент – это правильная, равномерная настройка системы APS и, в частности, зазора и оборотов подбарабанья, чтобы давать возможность машине работать на всю ширину молотильного аппарата и полностью загружать решетный стан системы очистки и сепарации зерна. Также следует обращать внимание на положение вентиляторных лотков и воздухонаправителей, обороты самого вентилятора и настройки решета.

В комбайнах CLAAS TUCANO есть дополнительное преимущество, позволяющее повышать эксплуатационную эффективность машины, — видимый из кабины колосовой элеватор. Механизатор в любой момент времени видит уровень его загрузки и то, насколько чистое зерно поступает в бункер. С учетом этого он может корректировать текущую загрузку машины.

Еще важный для производительности уборки момент – правильно настроенный измельчитель и вовремя замененные детали, которые влияют на качество резки материала. Если все эти запчасти и комплектующие исправны, имеют надлежащую заточку, то машина и в текущий момент будет работать экономично, и сохранит свой ресурс на будущее.

На что следует обратить особое внимание в конце каждого рабочего дня и какие работы помимо дефектовки следует выполнить по итогам всей уборочной кампании?

Прежде всего в конце рабочего дня необходимо зафиксировать результаты работы – посмотреть, сколько всего намолочено зерна. Исходя из этого составляется план на следующий день, чтобы, возможно, внести какие-то коррективы в настройки и добиться еще лучшего результата.

И здесь можно дать вторую рекомендацию – механизатору или кому-то из инженерного состава всегда необходимо поддерживать тесный контакт с сервисной службой дилера. В этом случае никаких проблем с эксплуатацией комбайна в хозяйстве не возникнет. Согласно имеющемуся опыту обслуживания техники, просто поддерживая с клиентом связь по телефону можно решать большинство вопросов, связанных с правильной настройкой машины и повышать до максимума ее производительность. По имеющейся у СТ AGRO статистике, за счет такой индивидуальной настройки производительность комбайна можно повышать на 20-30%, по сравнению с базовыми, заложенными в систему параметрами.

По итогам всей уборочной кампании дефектовка, разумеется, является обязательным условием. Перед постановкой комбайна на длительное хранение необходимо выявить степень износа всех деталей и сформировать два списка заявок. Первая – это те детали, которые обязательно должны быть заменены в машине до того, как она выйдет в поле. Второй список – это те комплектующие, износ которых составляет 50% и более. Они должны быть, заготовлены заранее, чтобы у хозяйства был определенный ресурс и уверенность, что машина будет работать бесперебойно. При этом здесь надо учитывать удаленность хозяйства от нашего дилерского центра и транспортную доступность, в целом. Как правило, если расстояние не превышает 300 км, мы готовы обеспечить доставку необходимых деталей в течение суток и необходимый на весь период уборки комплект деталей может храниться на нашем складе. В других случаях, мы рекомендуем аграриям создать необходимый запас непосредственно у себя в хозяйстве, чтобы минимизировать сроки простоя машины.

И в заключении следует обратить внимание на один нюанс, который, к счастью, встречается не так часто, но, тем не менее, бывает. Иногда комбайны оставляют на ночь с небольшим количеством недовымолоченного зерна. В этом случае утренняя роса влияет на сыпучесть материала и снижает производительность машины. Поэтому в конце дня 15-20 минут необходимо уделить тому, чтобы обдуть машину. Для этого у комбайнов CLAAS установлена специальная пневматическая система – это еще один плюс данной техники, о котором все знают, но далеко не всегда пользуются.

Marmion Collin

18 May 2023

Carlos Maldonado

19 May 2023

Massinissa Boudjemai

19 May 2023

Charles Healy

19 May 2023

Jordan Mighell

19 May 2023

Jaime L. Johnson

20 May 2023

Dennis G. Lee

20 May 2023

Valentine Fedorov

20 May 2023

Joseph M. Morley

20 May 2023

2008 Yamaha YFM250RX Raptor250 ATV Workshop Service Repair Manual

Tax included.

Claas TUCANO 450 840 Combine Operator’s Manual

Contents Of The Operator‘s Manual

Your Vehicle (Main Contents)

Driver And Passenger Safety (Seat Belts, Srs And Child Protection)

Instruments And Controls (Indicators, Gauges,information Display, Dashboard, And Steering Control)

Features (Climate Control, Audio, Steering Wheel, Security And Cruise Control

Before Driving (Fuel, Vehicle Break-in And Cargo Loading)

Driving (Engine And Transmission Operation)

Maintenance (Minder, Fluid Checking, Minor Services And Vehicle Storage)

Taking Care Of The Unexpected (Flat Tire, Dead Battery, Overheating Fuses)

Technical Information (Vehicle Specifications, Tires, And Emissions Controls)

Warranty And Customer Relations

Instant Download – After Payment.

Lifetime Pdf And Access To Download (By Request)

Compatible With Windows, Mac, Ios, Android And Other Systems

Searchable Text And Built-in Index For Instant Information Search

Bookmarks

Printable – Pages Or Entire Manual

Zoomable – Detailed Exploded Diagrams, Picture

Back to CLAAS MANUAL DOWNLOAD PDF

- Manuals

- Brands

- Claas Manuals

- Farm Equipment

- TUCANO 2017

- Information and basic field settings

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

Information and Basic Field

Settings for TUCANO

2017

Related Manuals for Claas TUCANO 2017

Summary of Contents for Claas TUCANO 2017

-

Page 1

Information and Basic Field Settings for TUCANO 2017… -

Page 2: Table Of Contents

Contents Title Pages Introduction Safety Overview 4 — 5 Cab and controls 6– 9 CEBIS 10 — 18 Cutterbar 19 — 22 Threshing 23- 24 Separation 25- 27 Cleaning 28 — 29 Straw and Chaff Management Settings aid 31- 34 Maintenance Wet harvest recommendations 36 — 37…

-

Page 3: Introduction

This quick reference guide has been produced to aid operators with familiarisation and settings of CLAAS TUCANO combine harvesters. CLAAS combines are designed for output and efficiency but this can only be achieved with correct operation and maintenance of the machine.

-

Page 4: Safety

Safety Safety is of the utmost importance whilst you are operating and maintaining your combine harvester. Make sure that all of the risks are assessed to reduce the likelihood of an accident. Make sure you are familiar with the controls and operation of the machine and have read the operators manual The combine harvester has many moving parts, guards are designed to keep you safe, please ensure that all guards are kept in place and in good condition when operating…

-

Page 5: Overview

Overview Hybrid…

-

Page 6

Overview Walker… -

Page 7: Cab And Controls

Right Hand Consoles 1. CEBIS information screen 2. Storage box 3. Folding armrest 4. Ashtray 5. Groundspeed lever with multifunction handle 6. CEBIS control panel 7. Module slot for CF memory card 8. Module slot for CF memory card…

-

Page 8

9. Front attachment switch 14. Reverse front attachment switch 10. Threshing mechanism switch 15. Left rape cutter drive switch 11. CLAAS 4-TRAC system switch 16. Left side knife drive switch 12. Diesel engine speed switch 17. Fold front attachment switch (if fitted) 1. -

Page 9

Steering column 1. Urea minimum level 2. Diesel particulate filter loading condition Power reduction No function No function 6. No function 7. No function 8. Indicator 9. 24 V power supply 10. No function 11. Main beam 12. Hazard warning flasher 13. -

Page 10

C-MOTION Multifunction lever 1. Lower reel 11. Manual cross levelling, hot 2. Reel forward key adjustment, table in and out. 3. Raise reel 12. Grain tank unloading. 4. Reel Back 13. Swing out the unloading tube. 5. Auto pilot on 14. -

Page 11

CEBIS- Road Travel Display 1. Main menu 7. Ground speed units 2. Engine RPM 8. Vehicle control display 3. Speedometer 9. Drive status 4. Time 10. Message fields 5. Operating hours 11. Coolant temperature 6. Ground speed 12. Fuel/ urea level… -

Page 12

CEBIS – Harvest display Main Menus Ground speed Returns meter Drive status GRAINMETER 14-16 Variable display Separation performance monitor Message fields Cleaning performance monitor Cutting height control Area counter Pre-set cutting height Area work rate display 20/21 Variable display Yield display Time Yield output display… -

Page 13: Cebis

CEBIS Keys CEBIS Using the CEBIS rotary switch (1) the combine settings can be adjusted. The picture below shows the operating settings that can be adjusted. To navigate through the settings turn the CEBIS rotary switch (1). Inside the CEBIS display there are 2 large numbers, the top number (7) shows the desired value and the lower number (8) shows the actual value.

-

Page 14

HOTKEY HOTKEY The HOTKEY (2) is used to adjust the more frequently changing settings on the Combine for example straw chopper or LASER PILOT bias. To adjust any of the HOTKEY values turn the rotary switch (2) and the HOTKEY dial will appear on CEBIS which is shown in the picture below. -

Page 15

CEBIS Symbols Exits the menu and returns to CEBIS Manual reel speed adjustment Top sieve adjustment Bottom sieve adjustment Front attachment speed adjustment (if fitted) Rotor speed adjustment CEBIS screen brightness adjustment Drum speed adjustment Fan speed adjustment Concave clearance adjustment Cleaning performance monitor adjustment (Sieve loss) Separation performance monitor adjustments (Walker/rotor loss) -

Page 16

HOTKEY Symbols Cutting height, VARIO length, End snapping plate adjustment Partial working width adjustment LASER PILOT adjustment Hectolitre weight adjustment Flagging function for yield mapping Favourite crop settings Automatic Reel speed, Reel height, Reel fore & aft position… -

Page 17

CEBIS Menu Navigation To navigate through the CEBIS menu turn the switch (3) shown below and the different icons at the top of the CEBIS screen will be highlighted in black (8). When the desired menu is highlighted push switch (3) to enter it, with any menu turn switch (3) to select the required section and push it to enter it. -

Page 18

CEBIS Calibration To allow the machine to display accurate information certain parameters need to be ‘learnt’ either on a daily or seasonal basis. Daily zeroing This should be carried out with the machine running with threshing engaged at maximum no load speed. The following items should be zeroed on a daily basis. -

Page 19

If a problem occurs involving the AUTO CONTOUR response, always try learning the cutting height limits before contacting the service department of your preferred CLAAS dealer. Working Position Don’t forget to learn the working position of the cutterbar within CEBIS to avoid inaccurate yield measurements. -

Page 20: Cutterbar

Lifters It is recommended that lifters should be fitted to CLAAS cutterbars. The lifters should be fitted by placing the first one on the fifth finger from the RHS of the cutterbar and then on every fourth one thereafter.

-

Page 21

Cutterbar Adjustments Knife Check that the knife is in good condition in order for it to work effectively. This involves replacing damaged or broken sections, removing vertical movement by adjusting the keeps, and making sure that the fingers are not rounded or bent. Regular checks/adjustments will aid cleaner cutting and reduced stress on the knife drive system. -

Page 22

Cutterbar Adjustments 2. Check the height of the auger within the trough of the cutterbar. There should be a minimum gap of 20mm between the trough and the auger flights. 3. Remove the intermediate retractable fingers along the length of the auger leaving just the middle ones. -

Page 23

Side Knife/Divider Installations Both the side knife and the divider use the new fork locating and locking device (2). Simply slide into the lock and ¼ turn the handle to lock in place (1). The side knife is easily attached with a simple twist lock turnbuckle. -

Page 24: Threshing

Threshing Hybrid To obtain initial settings it is recommended that the suggested settings in the Operators Manual are used, these are to only be used as a starting point, then adjustments should be made from there. Often changing one thing can change another. Only make one adjustment at a time.

-

Page 25

Threshing Walker To obtain initial settings it is recommended that the suggested settings in the Operators Manual are used, these are to only be used as a starting point, then adjustments should be made from there. Often changing one thing can change another. Only make one adjustment at a time. -

Page 26

Pre-Separation De-awning On the TUCANO 400 Series de-awning can be carried by out operating the lever (1), by the right hand front wheel of the machine into position A, which in turn installs a set of plates under the APS concave. This gives the crop an extra ‘rub’ which in turn threshes it harder. -

Page 27: Separation

Separation (Hybrid) It is important that the rotor speed is set correctly. The rotor separates the remaining grains from the straw and the rotor speed will have an effect on straw quality. If the rotor speed is too fast, broken straw and chaff is produced which could lead to overloading of the sieves.

-

Page 28

Separation (Walker) Straw curtain As the crop leaves the beater a straw retarding curtain is fitted to control the throw of the material on the walkers. A handle on the LHS of the machine body allows the angle of this to be altered. In normal conditions it should be left to hang freely but in damp conditions it may be a benefit to raise the curtain slightly to allow the material to remain loose and ensure an easier passage through the machine. -

Page 29: Cleaning

Cleaning Preparation pan The preparation pan is the first part of the cleaning system that the grain will come into contact with. It’s function is to separate the grain and the chaff. The grain is heavier and therefore goes to the bottom, the lighter chaff goes to the top. It is important that this is kept clean, to allow this to happen effectively.

-

Page 30

Cleaning Sieves On machines with manual sieve adjustment the sieve adjustment can be made at the back of the sieves by operating levers. To close the sieves the levers needs moving to the right, to open the sieves the levers need moving to the left. On machines with electronic sieve adjustment, both the top and bottom sieves are adjustable from 0 –… -

Page 31: Straw And Chaff Management

Straw and Chaff Management Chaff spreader The chaff spreader is situated at the back of the top sieve. The angle of the spreader can be adjusted to alter the spread width of the chaff spreader. Straw chopper 1. To move from chopping to rowing up, make sure that the engine is switched off and the chopper has stopped turning.

-

Page 32: Settings Aid

Settings Aid (Hybrid) The following pages are designed as quick reference flow chart to aid with settings. For further and more detailed instruction refer to the operators manual…

-

Page 33

Settings Aid (Hybrid) The following pages are designed as quick reference flow chart to aid with settings. For further and more detailed instruction refer to the operators manual… -

Page 34

Settings Aid (Walker) The following pages are designed as quick reference flow chart to aid with settings. For further and more detailed instruction refer to the operators manual… -

Page 35

Notes… -

Page 36: Maintenance

Maintenance A full maintenance schedule is provided in the relevant section of the operators book and this should be followed to ensure reliable operation of the combine. When checking belt tensions there are three main types of tensioner that are fitted to TUCANO Combines: 1.

-

Page 37: Wet Harvest Recommendations

Wet Harvest Recommendations With wet and laid crops, it is even more important to get a good cut and feed into the combine. Check the knife and fingers regularly, paying particular attention to the knife to finger gap (keep adjustment). To allow the cutterbar close to the ground when picking up laid crops, the skids under the bar must be raised into their highest position.

-

Page 38

Wet Harvest Recommendations Some dirt can usually be removed from both the cross auger covers, and the bottom covers on both the clean grain and returns elevators. When unloading wet grain, reduce the flow into the unloading auger by shutting down the slides on the cross auger in the grain tank. This will reduce the load on the unloading system, bringing it down to a ‘normal’… -

Page 39

Notes… -

Page 40

CLAAS Telematics CLAAS CEMOS Advisor CLAAS U.K. Ltd Saxham Bury St. Edmunds Suffolk IP28 6QZ Tel: 01284 763100 Fax: 01284 769839 www.claas.co.uk…

|

|

|

|

Корзина | |||

Заказать |

Производитель

|

Claas Tucano 450-430 / 340-320 Service ManualСкриншоты

Документация по ремонту и эксплуатации комбайнов Claas Tucano 450-430 / 340-320. Fitting Instructions Electric sieve adjustment Fitting Instructions 3-D cleaning system Fitting Instructions Auto-Contour Fitting Instructions Outline lighting Fitting Instructions High-end work lights Technical Systems Похожие товары

|