-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

Operation &

Maintenance Manual

PC210

PC210LC

PC210

PC210LC

HYDRAULIC EXCAVATOR

SERIAL NUMBERS

PC210-10

— K60001

PC210LC-10 — K60001

PC210-10

— 450120

PC210LC-10 — 450120

WARNING

Unsafe use of this machine may cause serious injury or

death. Operators and maintenance personnel must read

this manual before operating or maintaining this

machine. This manual should be kept inside the cab for

reference and periodically reviewed by all personnel who

will come into contact with the machine.

-10

-10

-10

DEMOLITION BASE SPEC

-10

and up

and up

and up

and up

DEMOLITION BASE SPEC

ORIGINAL INSTRUCTIONS

UENAM00902

.

.

Chapters

Summary of Contents for Komatsu PC210-10

ОТПРАВИТЬ ЗАЯВКУ:

Нажимая кнопку «ОТПРАВИТЬ ЗАЯВКУ», Вы соглашаетесь на обработку Ваших данных Подробнее

НАШИ ПРЕИМУЩЕСТВА

Выезд

к заказчику

Собственная

ремзона

Дополнительное

оборудование

Гарантийное

постгарантийное

сезонное ТО

Запчасти

в наличии

Шиномонтаж

МЫ РЕМОНТИРУЕМ:

- Manuals

- Brands

- Komatsu Manuals

- Excavators

- PC210LC-8

Manuals and User Guides for Komatsu PC210LC-8. We have 2 Komatsu PC210LC-8 manuals available for free PDF download: Shop Manual, Operation & Maintenance Manual

Komatsu PC210LC-8 Shop Manual (1201 pages)

HYDRAULIC EXCAVATOR

Brand: Komatsu

|

Category: Excavators

|

Size: 69.18 MB

Table of Contents

-

Table of Contents

6

-

Table of Contents

17

-

Foreword and General Information

18

-

Safety Notice

18

-

General Precautions

18

-

Preparations for Work

18

-

Precautions for Sling Work and Making Signs

20

-

Precautions for Using Mobile Crane

21

-

Precautions for Using Overhead Hoist Crane

21

-

Selecting Wire Ropes

21

-

Wire Ropes

21

-

-

How to Read the Shop Manual

22

-

Filing Method

23

-

Symbols

23

-

Units

23

-

-

Explanation of Terms for Maintenance Standard

24

-

Standard Size and Tolerance

24

-

Standard Clearance and Standard Value

25

-

Standard Interference

25

-

Repair Limit and Allowable Value

25

-

Clearance Limit

25

-

-

Handling Electric Equipment and Hydraulic Component

26

-

Main Failures Occurring in Wiring Harness

26

-

Disconnections in Wiring

27

-

High-Pressure Water Entering Connector

27

-

Oil or Dirt Stuck to Connector

27

-

Disconnecting Connectors

28

-

When Removing from Clips

28

-

Connecting Connectors

29

-

Connecting DT Connectors

29

-

Drying Wiring Harness

30

-

Handling Controller

31

-

Points to Remember When Troubleshooting Electric Circuits

31

-

Points to Remember When Handling Hydraulic Equipment

32

-

Flushing Operations

33

-

Cleaning Operations

33

-

-

How to Read Electric Wire Code

34

-

Type, Symbol, and Material

34

-

Dimensions

35

-

Colour Codes Table

36

-

Types of Circuits and Colour Codes

36

-

-

Method of Disassembling and Connecting Push-Pull Type Coupler

37

-

Standard Tightening Torque Table

40

-

Table of Tightening Torques for Bolts and Nuts

40

-

Table of Tightening Torques for Split Flange Bolts

41

-

Table of Tightening Torques for O-Ring Boss Piping Joints

41

-

Table of Tightening Torques for O-Ring Boss Plugs

41

-

Table of Tightening Torques for Hoses

42

-

Table of Tightening Torques for 102, 107 and 114 Engine Series

42

-

-

Conversion Table

44

-

Millimetres to Inches

44

-

Kilogram to Pound

45

-

Litres to U.S. Gallons

45

-

Litres to U.K. Gallons

46

-

Temperature

48

-

Hydraulic Excavator

51

-

Specification and Technical Data

51

-

-

Specification Dimension Drawings

52

-

Specification and Technical Data

52

-

Working Range Diagram

53

-

Weight Table

58

-

Table of Fuel, Coolant and Lubricants

62

-

Structure, Function and Maintenance Standard

65

-

Engine and Cooling System

66

-

Engine Related Parts

66

-

Structure, Function and

66

-

Radiator, Oil Cooler, Aftercooler and Fuel Cooler

67

-

Diesel Particulate Filter

68

-

Diesel Particulate Filter — Component Parts

69

-

System Description

70

-

Regeneration

70

-

Power Train

73

-

Structure, Function and

74

-

Power Train

74

-

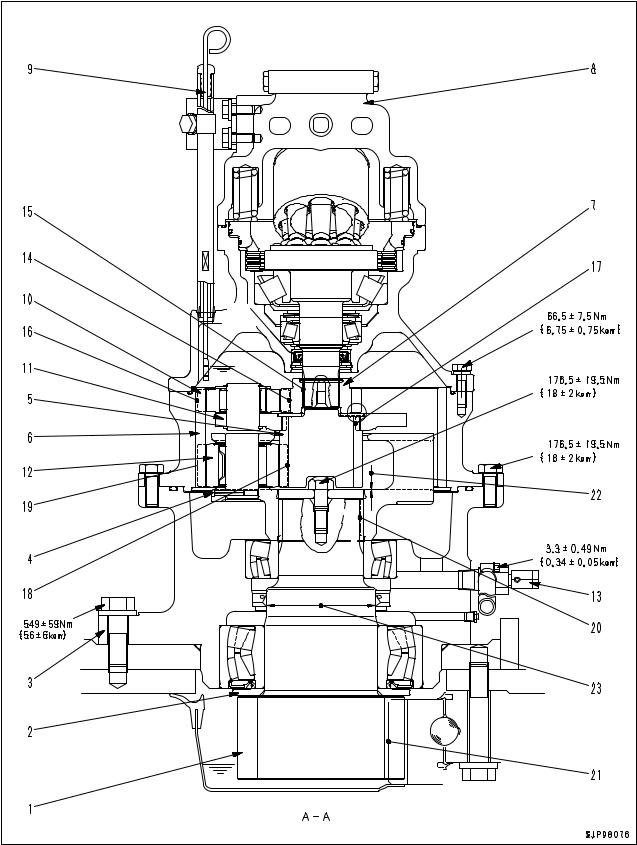

Final Drive

76

-

Swing Machinery

78

-

Swing Circle

82

-

Undercarriage and Frame

85

-

Track Frame and Recoil Spring

86

-

Structure, Function and

86

-

Undercarriage and Frame

86

-

Standard Shoe

87

-

Idler

88

-

Carrier Roller

90

-

Track Roller

91

-

Track Shoe

92

-

Triple Grouser Shoe

96

-

Swamp Shoe

96

-

Road Liner

96

-

Hydraulic System

99

-

-

Hydraulic Equipment Layout Drawing

100

-

Structure, Function and

100

-

Hydraulic System, Part 1

100

-

Hydraulic Tank and Filter

102

-

Hydraulic Pump

103

-

Operation of Pump

109

-

Control of Delivery

110

-

LS Valve

111

-

When the Control Valve Is Situated at Neutral

112

-

Action for the Direction of Maximizing the Pump Delivery

113

-

Action for the Direction of Minimizing the Pump Delivery

114

-

When Servo Piston Is Balanced

115

-

PC Valve

116

-

When Pump Controller Is Normal

117

-

Action of PC-EPC Valve Solenoid

117

-

Action of Spring

118

-

When the Main Pump Is under Heavy Load

123

-

LS (PC)-EPC Valve

124

-

When Signal Current Is 0

125

-

When Signal Current Is very Small

126

-

When Signal Current Is Maximum

126

-

-

Pilot Oil Filter

127

-

Control Valve

130

-

General View

131

-

Sectional View

134

-

Arm Valve

139

-

R.H. Travel Valve

139

-

Swing Valve

139

-

Boom Valve

141

-

Bucket Valve

141

-

L.H. Travel Valve

141

-

Outline of CLSS

143

-

Basic Principle

144

-

Pump Swash Plate Angle Control

144

-

LS Differential Pressure

144

-

Pressure Compensation Control

145

-

Functions and Operation by Valve

148

-

Hydraulic Circuit Diagram and the Name of Valves

148

-

Unload Valve

150

-

When the Unload Valve Is Actuating

150

-

Operation of Relief Valve

151

-

Introduction of LS Pressure

152

-

LS Bypass Valve

153

-

Pressure Compensation Valve

154

-

Integrated Pressure Compensation Valve

154

-

When Compensated

155

-

Pressure Compensation Valve Area Ratio

156

-

Pressure Compensation Valve Inner Shuttle Valve

157

-

In the Case of Travel

158

-

Boom Regeneration Circuit

159

-

Arm Regeneration Circuit

161

-

If the Cylinder Head Pressure Is Lower than the Bottom Pressure

162

-

Merge-Divider Valve

163

-

LS Select Valve

165

-

Self Pressure Reducing Valve

166

-

During Neutral and When Load Pressur (P2) Is Low

167

-

When Load Pressure (P2) Is High

167

-

When Abnormally High Pressure Is Generated

168

-

Travel Junction Valve

169

-

When Pilot Pressure Is Turned on

169

-

When Pilot Pressure Is Turned off

170

-

Travel PPC Shuttle Valve

171

-

Hydraulic Drift Prevention Valve

174

-

When the Piping Is Free of Burst

176

-

If the Piping Is Bursted

176

-

Quick Return Valve

179

-

When Arm out

179

-

When the Arm Is in Neutral

180

-

Lift Check Valve

181

-

While Engine Is Stopped

181

-

While Engine Is Running

181

-

Main Relief Valve

182

-

2-Stage Safety-Suction Valve

183

-

If Pilot Pressure Is on

184

-

-

Swing Motor

189

-

Hydraulic System, Part 3

189

-

Swing Holding Brake

192

-

Relief Valve Portion

193

-

Reverse Prevention Valve

194

-

Explanatory Drawing of Effects

195

-

-

Centre Swivel Joint

198

-

Travel Motor

201

-

Operation of Motor

204

-

At Slow Speed

204

-

At High Speed

205

-

Operation of Parking Brake

206

-

Brake Valve

208

-

Counterbalance Valve and Check Valve

208

-

Operation When Pressurized Oil Is Supplied

208

-

Operation of Brake During Travelling Downhill

209

-

Safety Valve

210

-

The Pump Pressure Rises, Providing a Large

211

-

-

PPC Valve

212

-

Work Equipment and Swing PPC Valve

212

-

Travel PPC Valve

216

-

Pressure Reducing Valve Function

219

-

Travel Signal

220

-

Steering Signal

220

-

-

Service PPC Valve (with EPC Valve)

225

-

EPC Valve

227

-

Service PPC Valve

230

-

Valve Control

232

-

ATT EPC Valve Assembly

234

-

Solenoid Valve

236

-

PPC Accumulator

238

-

Return Oil Filter

239

-

Attachment Circuit Selector Valve

240

-

Quick Coupler Control Valve

242

-

K50001~K50303

242

-

Function

245

-

Hydraulic Cylinder

246

-

Boom Cylinder

248

-

Arm Cylinder

248

-

Bucket Cylinder

248

-

Work Equipment

251

-

Dimensions of Components

252

-

Dimension of Arm

254

-

Dimension of Bucket

256

-

Cab and Its Attachments

259

-

Air Conditioner Piping

260

-

Electrical System

263

-

-

Engine Control

264

-

Starting Engine

264

-

Electrical System

264

-

Fuel Control Dial

265

-

Engine Controller

267

-

Coolant Temperature Sensor

269

-

Oil Pressure Switch

269

-

Rotation Sensor

270

-

Boost Pressure and Temperature Sensor

270

-

WIF (Water-In-Fuel Detection) Sensor

271

-

Engine Oil Level Sensor

271

-

-

Electrical Control System

272

-

Machine Control System Diagram

274

-

Engine and Pump Composite Control Function

276

-

Pump and Valve Control Function

280

-

LS Control Function

281

-

2-Stage Relief Function

281

-

Cut-Off Function

281

-

Power Maximizing Function

282

-

Auto-Deceleration Function

283

-

Auto-Warm-Up and Overheat Prevention Function

284

-

Auto-Warm-Up Function

285

-

Overheat Prevention Function

285

-

Swing Control Function

286

-

Swing Lock and Swing Holding Brake Function

287

-

Travel Control Function

288

-

Function to Control Pump During Travel

289

-

Travel Speed Change Function

289

-

System Component Parts

293

-

PPC Oil Pressure Switch

293

-

Oil Pressure Sensor

294

-

Pump Pressure Sensor

295

-

Quick Coupler Low Pressure Warning Switch

296

-

Auto Grease Pressure Switch

297

-

-

Monitor System

298

-

Machine Monitor

299

-

Input and Output Signals

300

-

Monitor Control, Display Portion

303

-

Monitor Items and Display

305

-

Switches

309

-

Buzzer Cancel Switch

309

-

Auto-Deceleration Switch

309

-

Guidance Icon and Function Switch

309

-

Working Mode Selector Switch

311

-

Travel Speed Selector Switch

311

-

Window Washer Switch

311

-

Air Conditioner Control Switch

311

-

Camera Screen Display Function

312

-

Maintenance Function

315

-

User Mode

317

-

Breaker/Attachment 1 Setting

317

-

Changing Breaker Mode Setting

318

-

Changing Attachment Mode 1 Setting

319

-

Attachment Setting Selection Screen

320

-

Attachment Flow Rate Setting Screen

320

-

Changing Attachment Mode 2 Setting

321

-

Message Display

323

-

Clock Adjustment

324

-

Time Setting

324

-

12/24 Display Mode

324

-

Language Setting

325

-

Economy Mode Adjustment

325

-

Summer Time

325

-

Idle Stop Guidance Function

326

-

Service Meter Check Function

327

-

Display LCD Check Function

327

-

User Code/Failure Code Display

328

-

-

Sensor

329

-

Hydraulic Oil Level Sensor

329

-

Fuel Level Sensor

330

-

Air Cleaner Clogging Sensor

330

-

Coolant Level Sensor

331

-

-

PPC Levers

332

-

LH PPC Lever

332

-

RH PPC Lever

333

-

-

KOMTRAX Terminal System

334

-

KOMTRAX Communication Modem

335

-

Auto Grease System

337

-

-

Outline of Auto Grease System

338

-

The Relief Valve

339

-

The Minimum-Level Switch

339

-

The Test Push-Button

339

-

-

Assembly

339

-

Components

339

-

Distribution Blocks and Metering Units

340

-

Grease Pressure Switch

341

-

The Display

341

-

-

The Greasing Cycle

342

-

The Pumping Phase

342

-

The Re-Grease Phase

342

-

The Pressure Decrease Phase

342

-

Greasing Cycle B

343

-

Pump Unit

343

-

Pump Unit Assembly

343

-

Magnetic Valve

344

-

Metering Units

345

-

Principle of Operation of the Metering Unit — First Phase

345

-

Principle of Operation of the Metering Unit — Second Phase

345

-

Principle of Operation of the Metering Unit — Third Phase

346

-

Principle of Operation of the Metering Unit — Fourth Phase

346

-

-

Introduction

348

-

The Length of the Greasing Cycles

349

-

Maximum Length of the Pumping Phase

349

-

Length of the Re-Grease and Pressure Decrease Phases

349

-

Reaction of the System to Grease Pressure Malfunctions

350

-

Display

350

-

Standard Service Value Table

353

-

Standard Value Table for Engine Related Parts

354

-

Standard Value Table for Chassis Related Parts

356

-

Hydraulic Drift of Travel

371

-

Boom Speed

371

-

Bucket Speed

371

-

Boom Time Lag

371

-

Arm Time Lag

372

-

Bucket Time Lag

372

-

Testing and Adjusting

375

-

-

Tools for Testing, Adjusting, and Troubleshooting

377

-

30 Testing and Adjusting

377

-

Testing and Adjusting, Part 1

377

-

Measuring Engine Speed

380

-

Preparation Work

380

-

Measuring Low Idle Speed

380

-

Measuring High Idle Speed

380

-

-

Measuring Intake Air Pressure (Boost Pressure)

381

-

Checking Exhaust Gas Colour

382

-

Checking Tools for Exhaust Gas Colour

382

-

Adjusting Valve Clearance

383

-

Measuring Tools for Valve Clearance

383

-

Valve Arrangement Drawing

383

-

-

Measuring Compression Pressure

385

-

Measuring Blow-By Pressure

387

-

Measuring Engine Oil Pressure

388

-

Handling Fuel System Parts

389

-

Releasing Residual Pressure from Fuel System

389

-

Measuring Fuel Pressure

390

-

Measuring Fuel Return Rate and Leakage

392

-

Bleeding Air from Fuel Circuit

394

-

Air Bleeding Route of Fuel Circuit

395

-

Checking Fuel Circuit for Leakage

396

-

Checking and Adjusting Air Conditioner Compressor Belt Tension

397

-

Measuring Swing Circle Bearing Clearance

398

-

Checking and Adjusting Track Shoe Tension

399

-

Increasing Tension

399

-

Decreasing Tension

400

-

Measuring Swing Relief Pressure

403

-

Travel Relief Pressure

403

-

-

Measuring Control Circuit Basic Pressure

405

-

Measuring and Adjusting Oil Pressure in Pump PC Control Circuit

406

-

Measuring PC-EPC Valve Output Pressure

407

-

Adjusting Pump PC Valve

408

-

Loosen Locknut

409

-

-

Measuring and Adjusting Oil Pressure in Pump LS Control Circuit

410

-

Measuring LS Differential Pressure

411

-

Measuring Solenoid Valve Output Pressure

416

-

Operation Table of PPC Lock Solenoid Valve

418

-

Operation Table of 2-Stage Relief Solenoid Valve

418

-

Operation Table of Swing Holding Brake Solenoid Valve

418

-

Operation Table of Travel Speed Shifting Solenoid Valve

418

-

-

Measuring PPC Valve Output Pressure

419

-

Connecting Points of PPC Piping

419

-

Measuring Tools for PPC Valve Output Pressure

420

-

-

Adjusting Play of Work Equipment and Swing PPC Valves

421

-

Measuring and Adjusting Quick Coupler Control Valve Output Pressure

422

-

Checking Parts Which Cause Hydraulic Drift of Work Equipment

423

-

Checking Arm Cylinder

423

-

Checking PPC Valve

424

-

-

Releasing Residual Pressure from Hydraulic Circuit

425

-

Releasing Residual Pressure from Swing Motor Circuit

425

-

Releasing Residual Pressure from Travel Motor Circuit

425

-

-

Measuring Oil Leakage

426

-

Measuring Oil Leakage from Arm Cylinder

426

-

Measuring Oil Leakage from Bucket Cylinder

427

-

Measuring Oil Leakage from Swing Motor

427

-

Measuring Oil Leakage from Travel Motor

428

-

-

Bleeding Air from each Part

429

-

Bleeding Air from Hydraulic Pump

429

-

Starting

430

-

Bleeding Air from Cylinder

430

-

Bleeding Air from Swing Motor

431

-

Bleeding Air from Travel Motor

431

-

Checking Oil Level and Starting Work

431

-

-

Checking Cab Tipping Stopper

432

-

Adjusting Mirrors

434

-

Installing Positions of Mirrors

435

-

Adjusting Mirrors (A1) and (B1)

435

-

Adjusting Mirrors (C1) and (D1)

435

-

Special Functions of Machine Monitor

440

-

Air Conditioner Specification

440

-

Heater Specification

441

-

Upper Section of Machine Monitor

441

-

Lower Section of Machine Monitor

441

-

Ordinary Functions and Special Functions of Machine Monitor

442

-

Classification of Operator Mode

443

-

Operator Mode (Outline)

444

-

Display Pattern of Operator Mode

444

-

Display of KOMATSU Logo

444

-

Display of Inputting Password

445

-

Display of Check before Starting

445

-

Display of Check of Breaker Mode

445

-

Display of Warning after Check before Starting

446

-

Display of Ending of Maintenance Interval

446

-

Display of Check of Working Mode and Travel Speed

446

-

Display of Ordinary Screen

446

-

Display of End Screen

447

-

Selection of Working Mode

447

-

Selection of Auto-Deceleration

447

-

Selection of Travel Speed

448

-

Precautions for Selecting Breaker Mode

448

-

Operation to Stop Alarm Buzzer

448

-

Operation of Windshield Wiper

449

-

Operation of Air Conditioner/Heater

449

-

Operation of Window Washer

449

-

Operation to Display Camera Mode

450

-

Operation to Display Clock and Service Meter

450

-

Check of Maintenance Information

451

-

Setting and Display of User Mode

451

-

Display of Energy-Saving Guidance

453

-

Display of Caution Monitor

453

-

Display of Automatic Judgment of Breaker

454

-

Display of User Code and Failure Code

454

-

Function of Checking Display of LCD

456

-

Function of Checking Service Meter

456

-

Function of Changing Attachment/Maintenance Password

457

-

Service Mode

459

-

Selection of Service Menu

459

-

Monitoring

460

-

Selecting Menu

460

-

Selecting Monitoring Items

460

-

Deciding Monitoring Items

460

-

Executing Monitoring

461

-

Holding Monitoring Information

461

-

Changing Machine Setting Mode

461

-

Monitoring Items Table

462

-

Abnormality Record

465

-

Abnormality Record (Electrical Systems)

466

-

Resetting Abnormality Record

466

-

Failure Codes Table

468

-

User Code

472

-

Alarm Buzzer

472

-

Component in Charge

472

-

Category of Record

472

-

Change of Maintenance Mode

475

-

Contents of Setting of each Maintenance Item

476

-

Function of Initializing All Items

476

-

Default (Working Mode with Key ON)

478

-

Default (Setting of Unit)

479

-

Default (With/Without Attachment)

480

-

Default (Setting of ECO Display)

484

-

Default (Setting of Breaker Detect)

485

-

Adjustment (Setting of Travel lo Speed)

488

-

Cylinder Cut-Out Operation

494

-

No Injection Cranking

495

-

Starting no Injection Cranking

496

-

Finishing no Injection Cranking

496

-

Prohibiting no Injection Cranking

496

-

Display of Fuel Consumption

497

-

Starting Measurement

497

-

Display and Function During Measurement

497

-

Finishing Measurement

497

-

Display of KOMTRAX Message

502

-

-

Handling High-Voltage Circuit of Engine Controller

506

-

30 Testing and Adjusting

506

-

Testing and Adjusting, Part 3

506

-

Preparation Work for Troubleshooting of Electrical System

507

-

Procedure for Testing Diodes

511

-

When Using Analog Circuit Tester

511

-

When Using Digital Circuit Tester

511

-

-

Pm Clinic Service

513

-

Items Related to Engine

514

-

Items Related to Oil Pressure

515

-

Check Sheet (PC210/LC/NLC-8/PC230NHD-8)

516

-

General Information on Troubleshooting

527

-

-

General Information on Troubleshooting

528

-

Points to Remember When Troubleshooting

528

-

Sequence of Events in Troubleshooting

529

-

Check before Troubleshooting

530

-

Classification and Procedures for Troubleshooting

531

-

Phenomena Looking Like Troubles and Troubleshooting Nos.

532

-

How to Read Electric Wire Code

535

-

Connection Table for Connector Pin Numbers

538

-

T-Boxes and T-Adapters Table

569

-

Troubleshooting by Failure Code

575

-

Locations of Fusible Links

584

-

Location of Fuse Box and Fuse Nos.

584

-

Troubles that Occur When Power Supply of Pump Controller Is Defective

585

-

Information in Troubleshooting Table

588

-

Failure Code [AB00KE] Charge Voltage Low

592

-

Failure Code [B@BAZG] Eng Oil Press. Low

594

-

Failure Code [B@BCNS] Eng Water Overheat

595

-

Failure Code [B@HANS] Hydr Oil Overheat

596

-

Failure Code [CA111] EMC Critical Internal Failure

596

-

Failure Code [CA115] Eng Ne and Bkup Speed Sens Error

597

-

Failure Code [CA122] Chg Air Press Sensor High Error

598

-

Circuit Diagram Related to Boost Pressure/Temperature Sensor

599

-

Failure Code [CA123] Chg Air Press Sensor Low Error

600

-

Failure Code [CA131] Throttle Sensor High Error

602

-

Failure Code [CA132] Throttle Sensor Low Error

604

-

Failure Code [CA144] Coolant Temp Sens High Error

606

-

Failure Code [CA145] Coolant Temp Sens Low Error

608

-

Circuit Diagram Related to Coolant Temperature Sensor

609

-

Failure Code [CA153] Chg Air Temp Sensor High Error

610

-

Failure Code [CA154] Chg Air Temp Sensor Low Error

612

-

Failure Code [CA155] Chg Air Temp High Speed Derate

614

-

Failure Code [CA187] Sens Supply 2 Volt Low Error

616

-

Failure Code [CA221] Ambient Press Sens High Error

618

-

Failure Code [CA222] Ambient Press Sens Low Error

620

-

Failure Code [CA227] Sens Supply 2 Volt High Error

622

-

Failure Code [CA238] Ne Speed Sens Supply Volt Error

624

-

Failure Code [CA271] IMV/PCV1 Short Error

625

-

Failure Code [CA272] IMV/PCV1 Open Error

626

-

Failure Code [CA322] Inj #1 (L#1) Open/Short Error

628

-

Failure Code [CA323] Inj #5 (L#5) Open/Short Error

630

-

Circuit Diagram Related to No. 5 Injector

631

-

Failure Code [CA324] Inj #3 (L#3) Open/Short Error

632

-

Circuit Diagram Related to No. 3 Injector

633

-

Failure Code [CA325] Inj #6 (L#6) Open/Short Error

634

-

Failure Code [CA331] Inj #2 (L#2) Open/Short Error

636

-

Circuit Diagram Related to No. 2 Injector

637

-

Failure Code [CA332] Inj #4 (L#4) Open/Short Error

638

-

Circuit Diagram Related to No. 4 Injector

639

-

Failure Code [CA342] Calibration Code Incompatibility

643

-

Failure Code [CA351] Injectors Drive Circuit Error

644

-

Circuit Diagram Related to Engine Controller

645

-

Failure Code [CA352] Sens Supply 1 Volt Low Error

646

-

Circuit Diagram Related to Sensor Power Supply 1

647

-

Failure Code [CA386] Sens Supply 1 Volt High Error

648

-

Failure Code [CA428] Water in Fuel Sensor High Error

650

-

Circuit Diagram Related to Water-In-Fuel Sensor

651

-

Failure Code [CA429] Water in Fuel Sensor Low Error

652

-

Failure Code [CA435] Eng Oil Press Sw Error

654

-

Failure Code [CA441] Battery Voltage Low Error

655

-

Circuit Diagram Related to Engine Controller Power Supply

657

-

Failure Code [CA442] Battery Voltage High Error

658

-

Failure Code [CA449] Rail Press very High Error

660

-

Failure Code [CA451] Rail Press Sensor High Error

662

-

Circuit Diagram Related to Common Rail Pressure Sensor

663

-

Failure Code [CA452] Rail Press Sensor Low Error

664

-

Failure Code [CA488] Chg Air Temp High Torque Derate

666

-

Failure Code [CA553] Rail Press High Error

666

-

Failure Code [CA559] Rail Press Low Error

667

-

Failure Code [CA689] Eng Ne Speed Sensor Error

668

-

Circuit Diagram Related to Engine Ne Speed Sensor

669

-

Failure Code [CA731] Eng Bkup Speed Sens Phase Error

670

-

Failure Code [CA757] All Continuous Data Lost Error

672

-

Failure Code [CA778] Eng Bkup Speed Sensor Error

674

-

Circuit Diagram Related to Engine Bkup Speed Sensor

675

-

Failure Code [CA1633] KOMNET Datalink Timeout Error

676

-

Circuit Diagram Related to CAN Communication

677

-

Failure Code [CA2185] Throt Sens Sup Volt High Error

678

-

Failure Code [CA2186] Throt Sens Sup Volt Low Error

679

-

Failure Code [CA2249] Rail Press very Low Error

680

-

Failure Code [CA2311] IMV Solenoid Error

682

-

Circuit Diagram Related to Supply Pump Actuator (Metering Unit)

683

-

Failure Code [CA2555] Grid Htr Relay Volt High Error

684

-

Failure Code [CA2556] Grid Htr Relay Volt Low Error

686

-

Failure Code [D19JKZ] Personal Code Relay Abnormality

688

-

Failure Code [D862KA] GPS Antenna Discon

690

-

Failure Code [DA25KP] 5V Sensor 1 Power Abnormality

691

-

Overload Alarm Monitor Non-Display Specification

691

-

Overload Alarm Monitor Display Specification

695

-

Failure Code [DA29KQ] Model Selection Abnormality

698

-

Circuit Diagram Related to Model Selection Connector (PC210, 210LC-8)

699

-

Circuit Diagram Related to Model Selection Connector (PC240LC-8)

701

-

Failure Code [DA2RMC] CAN Discon (Pump con Detected)

706

-

Failure Code [DAFGMC] GPS Module Error

708

-

Failure Code [DAFRMC] CAN Discon (Monitor Detected)

710

-

Failure Code [DGH2KB] Hydr Oil Sensor Short

712

-

Failure Code [DHPAMA] F Pump Press Sensor Abnormality

714

-

Circuit Diagram Related to F Pump Pressure Sensor

715

-

Failure Code [DHPBMA] R Pump Press Sensor Abnormality

716

-

Circuit Diagram Related to R Pump Pressure Sensor

717

-

Failure Code [DHS3MA] Arm Curl PPC Press Sensor Abnormality

718

-

Circuit Diagram Related to Arm Curl PPC Pressure Sensor

719

-

Failure Code [DHS4MA] Bucket Curl PPC Press Sensor Abnormality

720

-

Circuit Diagram Related to Bucket Curl PPC Pressure Sensor

721

-

Failure Code [DHS8MA] Boom Raise PPC Press Sensor Abnormality

722

-

Circuit Diagram Related to Boom Raise PPC Pressure Sensor

723

-

Failure Code [DHSAMA] Swing RH PPC Press Sensor Abnormality

724

-

Circuit Diagram Related to Swing Right PPC Pressure Sensor

725

-

Failure Code [DHSBMA] Swing LH PPC Press Sensor Abnormality

726

-

Circuit Diagram Related to Swing Left PPC Pressure Sensor

727

-

Failure Code [DHSDMA] Bucket Dump PPC Press Sensor Abnormality

728

-

Circuit Diagram Related to Bucket Dump PPC Pressure Sensor

729

-

Failure Code [DHX1MA] Overload Sensor Abnormality (Analog)

730

-

Circuit Diagram Related to Overload Alarm Pressure Sensor

731

-

Failure Code [DW43KA] Travel Speed Sol Discon

732

-

Circuit Diagram Related to Travel Speed Shifting Solenoid

733

-

Failure Code [DW43KB] Travel Speed Sol Short

734

-

Failure Code [DW45KA] Swing Brake Sol Discon

736

-

Circuit Diagram Related to Swing Holding Brake Solenoid

737

-

Failure Code [DW45KB] Swing Brake Sol Short

738

-

Failure Code [DW91KA] Travel Junction Sol Discon

740

-

Circuit Diagram Related to Travel Junction Solenoid

741

-

Failure Code [DW91KB] Travel Junction Sol Short

742

-

Failure Code [DWA2KA] Service Sol Discon

744

-

Failure Code [DWA2KB] Service Sol Short

745

-

Failure Code [DWK0KA] 2-Stage Relief Sol Discon

746

-

Failure Code [DWK0KB] 2-Stage Relief Sol Short

748

-

Circuit Diagram Related to 2-Stage Relief Solenoid

749

-

Failure Code [DXA8KA] PC-EPC (F) Sol Discon

753

-

Circuit Diagram Related to PC-EPC (F) Solenoid and PC-EPC (R) Solenoid

754

-

Failure Code [DXA8KB] PC-EPC (F) Sol Short

755

-

Failure Code [DXA9KA] PC-EPC (R) Sol Discon

757

-

Failure Code [DXA9KB] PC-EPC (R) Sol Short

759

-

Failure Code [DXE0KA] LS-EPC Sol Discon

761

-

Failure Code [DXE0KB] LS-EPC Sol Short

763

-

Failure Code [DXE4KA] Service Current EPC Discon

765

-

Failure Code [DXE4KB] Service Current EPC Short

767

-

Failure Code [DXE5KA] Merge-Divider Main Sol Discon

769

-

Circuit Diagram Related to Merge-Divider Main EPC Solenoid

770

-

Failure Code [DXE5KB] Merge-Divider Main Sol Short

771

-

Failure Code [DXE6KA] Merge-Divider LS Sol Discon

773

-

Failure Code [DXE6KB] Merge-Divider LS Sol Short

775

-

Failure Code [DY20KA] Wiper Working Abnormality

777

-

Circuit Diagram Related to Windshield Wiper and Window Washer

778

-

Failure Code [DY20MA] Wiper Parking Abnormality

779

-

Failure Code [DY2CKA] Washer Drive Discon

781

-

Failure Code [DY2CKB] Washer Drive Short

783

-

Failure Code [DY2DKB] Wiper Drive (For) Short

785

-

Failure Code [DY2EKB] Wiper Drive (Rev) Short

787

-

Failure Code [DXEAKA] Service Current EPC1 Discon

789

-

Failure Code [DXEAKB] Service Current EPC1 Short

790

-

Failure Code [DXE7KA] Service Current EPC2 Discon

791

-

Failure Code [DXE7KB] Service Current EPC2 Short

792

-

Failure Code [DXE8KA] Service Current EPC3 Discon

793

-

Failure Code [DXE8KB] Service Current EPC3 Short

794

-

Failure Code [DXE9KA] Service Current EPC4 Discon

795

-

Failure Code [DXE9KB] Service Current EPC4 Short

796

-

Failure Code [DFB1KZ] Service Lever Potentio 1 Abnormality

799

-

Failure Code [DFB2KZ] Service Lever Potentio 2 Abnormality

801

-

Failure Code [DFB5KZ] Service Lever Sub Potentio 1 Abnormality

803

-

Failure Code [DFB6KZ] Service Lever Sub Potentio 2 Abnormality

805

-

Failure Code [DFB3L8] Service Lever 1 Potentio Error

807

-

Failure Code [DFB4L8] Service Lever 2 Potentio Error

808

-

Troubleshooting of Electrical System

813

-

Before Carrying out Troubleshooting of Electrical System

815

-

Connection Table of Fuse Box

816

-

E-1 When Starting Switch Turned ON, Machine Monitor Displays

820

-

Circuit Diagram Related to Machine Monitor Power Supply

821

-

When Starting Switch Turned on

822

-

Circuit Diagram Related to Radiator Coolant Level Switch

823

-

Engine Does Not Start (Engine Does Not Turn)

825

-

Preheater Does Not Operate

828

-

Automatic Warm-Up System Does Not Operate

830

-

Precaution Lights up While Engine Is Running

834

-

Circuit Diagram Related to Air Cleaner Clogging Switch

837

-

Emergency Stop Item Lights up While Engine Is Running

839

-

Engine Coolant Temperature Gauge Does Not Indicate Normally

840

-

Hydraulic Oil Temperature Gauge Does Not Indicate Normally

841

-

Circuit Diagram Related to Hydraulic Oil Temperature Sensor

841

-

Fuel Level Gauge Does Not Indicate Normally

843

-

Circuit Diagram Related to Fuel Level Sensor

843

-

Fuel Level Gauge and Fuel Level Monitor

844

-

Machine Monitor Does Not Display some Items

845

-

Function Switch Does Not Work

845

-

Auto-Decelerator Does Not Operate Normally

846

-

Working Mode Does Not Change

847

-

Travel Speed Does Not Change

848

-

Alarm Buzzer Cannot be Stopped

849

-

Circuit Diagram for Quick Coupler System

851

-

Windshield Wiper and Window Washer Do Not Operate

852

-

Power Maximising Function Does Not Operate Normally

854

-

Circuit Diagram Related to Left Knob Switch

854

-

Swing Holding Brake Does Not Operate Normally

858

-

Travel Alarm Does Not Sound or Does Not Stop Sounding

860

-

Air Conditioner Does Not Operate Normally

862

-

Circuit Diagram Related to Air Conditioner

873

-

Machine Monitor Cannot be Set in Service Mode

874

-

Circuit Diagram Related to Travel PPC Pressure Switch and Travel Alarm

879

-

KOMTRAX System Does Not Operate Normally

884

-

Troubleshooting of Hydraulic and Mechanical System (H-Mode)

887

-

System Diagram of Hydraulic and Mechanical System

890

-

Engine Speed Lowers Extremely or Engine Stalls

895

-

Work Equipment, Swing, and Travel Systems Do Not Work

896

-

Abnormal Sound Comes out from Around Hydraulic Pump

896

-

Auto-Decelerator Does Not Operate

897

-

Fine Control Performance or Response Is Low

897

-

Speed or Power of Boom Is Low

898

-

Speed or Power of Arm Is Low

899

-

Speed or Power of Bucket Is Low

900

-

Work Equipment Does Not Move Singly

900

-

Hydraulic Drift of Work Equipment Is Large

901

-

Time Lag of Work Equipment Is Large

903

-

Power Maximizing Function Does Not Work

904

-

Machine Deviates During Travel

906

-

Travel Speed Is Low

907

-

Machine Is Not Steered Well or Steering Power Is Low

908

-

Travel Speed Does Not Change or Travel Speed Is Low/High

909

-

Travel System Does Not Move (Only One Side)

910

-

Upper Structure Does Not Swing

911

-

Swing Acceleration or Swing Speed Is Low

913

-

Upper Structure Overruns Remarkably When It Stops Swinging

914

-

Large Shock Is Made When Upper Structure Stops Swinging

915

-

Large Sound Is Made When Upper Structure Stops Swinging

915

-

Hydraulic Drift of Swing Is Large

916

-

Attachment Circuit Is Not Changed

917

-

Oil Flow in Attachment Circuit Cannot be Controlled

917

-

Attachment Installation Specification

917

-

Quick Coupler

918

-

Troubleshooting of Engine (S-Mode)

925

-

Method of Using Troubleshooting Chart

927

-

Exhaust Gas Is Black

928

-

Starting Performance Is Poor

930

-

Engine Does Not Start

931

-

Engine Does Not Turn

931

-

Exhaust Smoke Comes but Engine Does Not Start

933

-

Engine Does Not Pick up Smoothly

934

-

General Causes Why Engine Does Not Pick up Smoothly

934

-

Engine Stops During Operations

935

-

General Causes Why Engine Stops During Operations

935

-

Engine Does Not Rotate Smoothly

936

-

General Causes Why Engine Does Not Rotate Smoothly

936

-

Engine Lack Output (or Lacks Power)

937

-

General Causes Why Engine Lacks Output

937

-

Exhaust Smoke Is Black (Incomplete Combustion)

939

-

General Causes Why Exhaust Smoke Is Black

939

-

Oil Consumption Is Excessive (or Exhaust Smoke Is Blue)

940

-

General Causes Why Oil Consumption Is Excessive

940

-

Oil Becomes Contaminated Quickly

941

-

Fuel Consumption Is Excessive

942

-

Oil Is in Coolant

943

-

General Causes Why Oil Is in Coolant

943

-

Oil Pressure Drops

944

-

General Causes Why Oil Pressure Drops

944

-

Oil Level Rises (Entry of Coolant/Fuel)

945

-

General Causes Why Oil Level Rises

945

-

Coolant Temperature Becomes too High (Overheating)

946

-

General Causes Why Coolant Temperature Becomes too High

946

-

Abnormal Noise Is Made

947

-

General Causes Why Abnormal Noise Is Made

947

-

Vibration Is Excessive

948

-

General Causes Why Vibration Is Excessive

948

-

Diesel Particulate Filter System

949

-

Troubleshooting of Auto Grease System

951

-

Recognising Malfunctions

952

-

Malfunction Reports of the Display

952

-

Malfunction Finding Procedures

955

-

Disassembly and Assembly Related Information

959

-

Removal and Installation of Assemblies

960

-

List of Adhesives

962

-

Special Tool List

965

-

Sketches of Special Tools

970

-

A8 Plate

970

-

F1 Push Tool

970

-

F3 Plate

971

-

J2 Push Tool

971

-

J6 Push Tool

972

-

S Push Tool

972

-

Engine Cooling Related

975

-

Removal and Installation of Fuel Supply Pump Assembly

976

-

Removal and Installation of Fuel Injector Assembly

978

-

Fuel Injector Assembly

982

-

Rocker Arm and Crosshead Assembly

983

-

High-Pressure Pipes and Common Rail

984

-

Removal and Installation of Engine Front Seal

985

-

Vibration Damper

987

-

Removal and Installation of Engine Rear Seal

988

-

Removal and Installation of Cylinder Head Assembly

991

-

Cylinder Head Assembly

997

-

Removal and Installation of Radiator Assembly

1003

-

Removal and Installation of Aftercooler Assembly

1008

-

Removal and Installation of Fuel Cooler Assembly

1010

-

Disassembly and Assembly of Final Drive Assembly

1026

-

-

427-1510 Push Tool

1026

-

Block T

1026

-

Rod T

1026

-

Puller (30 Ton) T

1026

-

Pump T

1026

-

Hub Assembly

1028

-

Nut

1030

-

No.2 Carrier Assembly

1031

-

-

Wrench T

1034

-

Installer T

1034

-

427-1220 Push Tool T

1034

-

Block T

1034

-

Washer T

1034

-

Jack T

1034

-

Hydraulic Pump T

1034

-

Under Carriage and Frame

1057

-

Disassembly and Assembly of Carrier Roller

1058

-

-

Installer T

1058

-

Disassembly and Assembly of Track Roller Assembly

1061

-

Installer T

1061

-

Disassembly and Assembly of Idler Assembly

1063

-

Installer T

1063

-

Disassembly and Assembly of Recoil Spring

1066

-

Compressor (A) T

1066

-

Compressor (B) T

1066

-

Spacer Extension T

1066

-

Cylinder

1066

-

(686Kn{70Ton})

1066

-

Guide Bolt T

1066

-

Push Tool Kit (B) Q

1066

-

Bolt

1066

-

Push Tool Kit

1066

-

Removal and Installation of Sprocket

1068

-

Expansion and Installation of Track Shoe Assembly

1069

-

Development of Track Shoe

1069

-

Installation of Track Shoe

1070

-

Removal and Installation of Revolving Frame Assembly

1071

-

Removal and Installation of Center Swivel Joint Assembly

1076

-

Disassembly and Assembly of Center Swivel Joint Assembly

1078

-

Removal and Installation of Hydraulic Tank Assembly

1079

-

Removal and Installation of Control Valve Assembly

1082

-

Disassembly and Assembly of Control Valve Assembly

1087

-

Assembly of Control Valve Assembly

1089

-

Removal and Installation of Hydraulic Pump Assembly

1091

-

Removal and Installation of Oil Seal in Hydraulic Pump Input Shaft

1096

-

Disassembly and Assembly of Travel PPC Valve Assembly

1098

-

Disassembly and Assembly of Hydraulic Cylinder Assembly

1099

-

Disassembly of Cylinder Head Assembly

1101

-

Disassembly of Piston Assembly

1101

-

Piston Rod Assembly

1102

-

Disassembly and Assembly of Quick Coupler Valve

1105

-

Removal of Pressure Regulating Valve

1105

-

Removal of Solenoid and Directional Control Valve

1105

-

Removal and Installation of the Work Equipment Assembly

1108

-

Cab Related

1113

-

Removal and Installation of Operator’s Cab Assembly

1114

-

Removal and Installation of Operator Cab Glass (Stuck Glass)

1117

-

Removal and Installation of Front Window Assembly

1127

-

Electric Components

1139

-

Removal and Installation of Air Conditioner Unit Assembly

1140

-

Removal and Installation of Monitor Assembly

1144

-

Removal and Installation of Pump Controller Assembly

1146

-

Removal and Installation of Engine Controller Assembly

1147

-

Hydraulic Diagrams and Drawings

1151

-

Hydraulic Circuit Diagram

1153

-

Electrical Diagrams and Drawings

1163

-

Electrical Circuit Diagram

1165

-

-

Advertisement

Komatsu PC210LC-8 Operation & Maintenance Manual (41 pages)

HYDRAULIC EXCAVATOR

Brand: Komatsu

|

Category: Excavators

|

Size: 1.15 MB

Table of Contents

-

Safety Information

5

-

Directions of Machine

11

-

Breaking-In the New Machine

12

-

Product Information

13

-

Service Meter Location

14

-

Machine Serial Plates

15

-

Location of Safety Labels

32

Advertisement

Related Products

-

Komatsu PC210LC-6K

-

Komatsu PC210LC-6

-

KOMATSU PC210LC-10 DEMOLITION BASE SPEC.

-

Komatsu PC210LC-11

-

Komatsu PC210LCI-11

-

Komatsu PC210LL-10

-

Komatsu PC210

-

Komatsu PC210NLC-8

-

Komatsu PC210NLC-11

-

Komatsu PC210-11

Komatsu Categories

Excavators

Trucks

Construction Equipment

Compact Loader

Tractor

More Komatsu Manuals

UEBM001701

PC210, 210LC, 210NLC PC240LC, 240NLC-7K

|

MACHINE MODEL |

SERIAL NUMBER |

|

PC210-7K |

K40001 AND UP |

|

PC210LC-7K |

K40001 AND UP |

|

PC210-NLC-7K |

K40001 AND UP |

|

PC240LC-7K |

K40001 AND UP |

|

PC240NLC-7K |

K40001 AND UP |

•This shop manual may contain attachments and optional equipment that are not available in your area. Please consult your local Komatsu distributor for those items you may require.

Materials and specifications are subject to change without notice.

©2002

|

All Rights Reserved |

00-1 |

|

Printed in Belgium 06-02 |

CONTENTS

No. of page

01 GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .01-1

10 STRUCTURE, FUNCTION AND MAINTENANCE STANDARD . . . . . . .10-1

20 TESTING AND ADJUSTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20-1

30 DISASSEMBLY AND ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30-1

90 OTHERS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90-1

00-2

LIST OF REVISED PAGES

The affected pages are indicated by the use of the following marks. It is requested that necessary actions be taken to these pages according to the table below.

|

Mark |

Indication |

Action required |

|

|

Page to be newly added |

Add |

||

|

Page to be replaced |

Replace |

||

|

( |

) |

Page to be deleted |

Discard |

Pages having no marks are those previously revised or made additions.

LIST OF REVISED PAGES

|

Mark Page |

Time of |

Mark Page |

Time of |

Mark |

Page |

Time of |

Mark Page |

Time of |

Mark Page |

Time of |

|

|

revision |

revision |

revision |

revision |

revision |

|||||||

|

00-1 |

10-1 |

10-29 |

10-57 |

10-85 |

|||||||

|

00-2 |

10-2 |

10-30 |

10-58 |

10-86 |

|||||||

|

00-2-1 |

10-3 |

10-31 |

10-59 |

10-87 |

|||||||

|

00-2-2 |

10-4 |

10-32 |

10-60 |

10-88 |

|||||||

|

00-2-3 |

10-5 |

10-33 |

10-61 |

10-89 |

|||||||

|

00-2-4 |

10-6 |

10-34 |

10-62 |

10-90 |

|||||||

|

10-7 |

10-35 |

10-63 |

10-91 |

||||||||

|

10-8 |

10-36 |

10-64 |

10-92 |

||||||||

|

01-1 |

10-9 |

10-37 |

10-65 |

10-93 |

|||||||

|

01-2 |

10-10 |

10-38 |

10-66 |

10-94 |

|||||||

|

01-3 |

10-11 |

10-39 |

10-67 |

10-95 |

|||||||

|

01-4 |

10-12 |

10-40 |

10-68 |

10-96 |

|||||||

|

01-5 |

10-13 |

10-41 |

10-69 |

10-97 |

|||||||

|

01-6 |

10-14 |

10-42 |

10-70 |

10-98 |

|||||||

|

01-7 |

10-15 |

10-43 |

10-71 |

10-99 |

|||||||

|

01-8 |

10-16 |

10-44 |

10-72 |

10-100 |

|||||||

|

01-9 |

10-17 |

10-45 |

10-73 |

10-101 |

|||||||

|

01-10 |

10-18 |

10-46 |

10-74 |

10-102 |

|||||||

|

01-11 |

10-19 |

10.47 |

10-75 |

10-103 |

|||||||

|

01-12 |

10-20 |

10-48 |

10-76 |

10-104 |

|||||||

|

01-13 |

10-21 |

10-49 |

10-77 |

10-105 |

|||||||

|

01-14 |

10-22 |

10-50 |

10-78 |

10-106 |

|||||||

|

10-23 |

10-51 |

10-79 |

10-107 |

||||||||

|

10-24 |

10-52 |

10-80 |

10-108 |

||||||||

|

10-25 |

10-53 |

10-81 |

10-109 |

||||||||

|

10-26 |

10-54 |

10-82 |

10-110 |

||||||||

|

10-27 |

10-55 |

10-83 |

10-111 |

||||||||

|

10-28 |

10-56 |

10-84 |

10-112 |

||||||||

LIST OF REVISED PAGES

|

Mark Page |

Time of |

Mark |

Page |

Time of |

Mark |

Page |

Time of |

Mark |

Page |

Time of |

Mark Page |

Time of |

|

revision |

revision |

revision |

revision |

revision |

||||||||

|

10-113 |

10-154 |

10-194 |

20-11 |

20-131 |

||||||||

|

10-114 |

10-155 |

10-195 |

20-12 |

20-132 |

||||||||

|

10-115 |

10-156 |

10-196 |

20-13 |

20-133 |

||||||||

|

10-116 |

10-157 |

10-197 |

20-14 |

20-134 |

||||||||

|

10-117 |

10-158 |

10-198 |

20-15 |

20-135 |

||||||||

|

10-118 |

10-159 |

10-199 |

20-16 |

20-136 |

||||||||

|

10-119 |

10-160 |

10-200 |

20-137 |

|||||||||

|

10-120 |

10-161 |

10-201 |

20-138 |

|||||||||

|

10-121 |

10-162 |

10-202 |

20-139 |

|||||||||

|

10-122 |

10-163 |

10-203 |

20-140 |

|||||||||

|

10-123 |

10-164 |

10-204 |

20-101 |

20-141 |

||||||||

|

10-124 |

10-165 |

10-205 |

20-102 |

20-142 |

||||||||

|

10-125 |

10-166 |

10-206 |

20-103 |

20-143 |

||||||||

|

10-126 |

10-167 |

10-207 |

20-104 |

20-144 |

||||||||

|

10-127 |

10-168 |

10-208 |

20-105 |

20-145 |

||||||||

|

10-128 |

10-169 |

10-209 |

20-106 |

20-146 |

||||||||

|

10-129 |

10-170 |

10-210 |

20-107 |

20-147 |

||||||||

|

10-130 |

10-171 |

10-211 |

20-108 |

20-148 |

||||||||

|

10-131 |

10-172 |

10-212 |

20-109 |

20-149 |

||||||||

|

10-132 |

10-173 |

10-213 |

20-110 |

20-150 |

||||||||

|

10-133 |

10-174 |

10-214 |

20-111 |

20-151 |

||||||||

|

10-134 |

10-175 |

10-215 |

20-112 |

20-152 |

||||||||

|

10-135 |

10-176 |

10-216 |

20-113 |

20-153 |

||||||||

|

10-136 |

10-177 |

10-217 |

20-114 |

20-154 |

||||||||

|

10-138 |

10-178 |

10-218 |

20-115 |

20-155 |

||||||||

|

10-139 |

10-179 |

10-219 |

20-116 |

20-156 |

||||||||

|

10-140 |

10-180 |

20-117 |

20-157 |

|||||||||

|

10-141 |

10-181 |

20-118 |

20-158 |

|||||||||

|

10-142 |

10-182 |

20-119 |

20-159 |

|||||||||

|

10-143 |

10-183 |

20-120 |

20-160 |

|||||||||

|

10-144 |

10-184 |

20-121 |

20-161 |

|||||||||

|

10-145 |

10-185 |

20-1 |

20-122 |

20-162 |

||||||||

|

10-146 |

10-186 |

20-2 |

20-123 |

20-163 |

||||||||

|

10-147 |

10-187 |

20-3 |

20-124 |

20-164 |

||||||||

|

10-148 |

10-188 |

20-4 |

20-125 |

20-165 |

||||||||

|

10-149 |

10-189 |

20-5 |

20-126 |

20-166 |

||||||||

|

10-150 |

10-190 |

20-6 |

20-127 |

20-167 |

||||||||

|

10-151 |

10-191 |

20-7 |

20-128 |

20-168 |

||||||||

|

10-152 |

10-192 |

20-8 |

20-129 |

20-169 |

||||||||

|

10.153 |

10-193 |

20-9 |

20-130 |

20-170 |

||||||||

LIST OF REVISED PAGES

|

Mark Page |

Time of |

Mark Page |

Time of |

Mark |

Page |

Time of |

Mark |

Page |

Time of |

Mark Page |

Time of |

|

revision |

revision |

revision |

revision |

revision |

|||||||

|

20-171 |

20-225 |

20-301 |

20-342 |

20-386 |

|||||||

|

20-172 |

20-226 |

20-302 |

20-343 |

||||||||

|

20-173 |

20-227 |

20-304 |

20-344 |

||||||||

|

20-174 |

20-228 |

20-305 |

20-345 |

||||||||

|

20-175 |

20-229 |

20-306 |

20-346 |

||||||||

|

20-176 |

20-230 |

20-307 |

20-347 |

||||||||

|

20-177 |

20-231 |

20-308 |

20-348 |

20-501 |

|||||||

|

20-178 |

20-232 |

20-309 |

20-349 |

20-502 |

|||||||

|

20-179 |

20-233 |

20-310 |

20-350 |

20-503 |

|||||||

|

20-180 |

20-234 |

20-311 |

20-351 |

20-504 |

|||||||

|

20-181 |

20-235 |

20-312 |

20-352 |

20-505 |

|||||||

|

20-182 |

20-236 |

20-313 |

20-353 |

20-506 |

|||||||

|

20-237 |

20-314 |

20-354 |

20-507 |

||||||||

|

20-238 |

20-315 |

20-355 |

20-508 |

||||||||

|

20-239 |

20-316 |

20-356 |

20-510 |

||||||||

|

20-240 |

20-317 |

20-357 |

20-511 |

||||||||

|

20-201 |

20-241 |

20-318 |

20-358 |

20-512 |

|||||||

|

20-202 |

20-242 |

20-319 |

20-359 |

20-513 |

|||||||

|

20-203 |

20-243 |

20-320 |

20-360 |

20-514 |

|||||||

|

20-204 |

20-244 |

20-321 |

20-362 |

20-515 |

|||||||

|

20-205 |

20-245 |

20-322 |

20-364 |

20-516 |

|||||||

|

20-206 |

20-246 |

20-323 |

20-365 |

20-517 |

|||||||

|

20-207 |

20-247 |

20-324 |

20-366 |

20-518 |

|||||||

|

20-208 |

20-248 |

20-325 |

20-367 |

20-519 |

|||||||

|

20-209 |

20-249 |

20-326 |

20-368 |

20-520 |

|||||||

|

20-210 |

20-250 |

20-327 |

20-369 |

20-521 |

|||||||

|

20-211 |

20-251 |

20-328 |

20-370 |

20-522 |

|||||||

|

20-212 |

20-252 |

20-329 |

20-372 |

20-523 |

|||||||

|

20-213 |

20-253 |

20-330 |

20-374 |

20-524 |

|||||||

|

20-214 |

20-254 |

20-331 |

20-375 |

20-525 |

|||||||

|

20-215 |

20-255 |

20-332 |

20-376 |

20-526 |

|||||||

|

20-216 |

20-256 |

20-333 |

20-377 |

20-527 |

|||||||

|

20-217 |

20-257 |

20-334 |

20-378 |

20-528 |

|||||||

|

20-218 |

20-335 |

20-379 |

20-530 |

||||||||

|

20-219 |

20-336 |

20-380 |

20-531 |

||||||||

|

20-220 |

20-337 |

20-381 |

20-532 |

||||||||

|

20-221 |

20-338 |

20-382 |

20-533 |

||||||||

|

20-222 |

20-339 |

20-383 |

20-534 |

||||||||

|

20-223 |

20-340 |

20-384 |

20-535 |

||||||||

|

20-224 |

20-341 |

20-385 |

20-536 |

||||||||

LIST OF REVISED PAGES

|

Mark Page |

Time of |

Mark |

Page |

Time of |

Mark |

Page |

Time of |

Mark |

Page |

Time of |

Mark |

Page |

Time of |

|

revision |

revision |

revision |

revision |

revision |

|||||||||

|

20-537 |

30-43 |

30-83 |

|||||||||||

|

20-538 |

30-44 |

30-84 |

|||||||||||

|

20-540 |

30-45 |

30-85 |

|||||||||||

|

20-541 |

30-1 |

30-46 |

30-86 |

||||||||||

|

20-542 |

30-2 |

30-47 |

30-87 |

||||||||||

|

20-543 |

30-3 |

30-48 |

30-88 |

||||||||||

|

20-544 |

30-4 |

30-49 |

30-89 |

||||||||||

|

20-545 |

30-5 |

30-50 |

30-90 |

||||||||||

|

20-546 |

30-6 |

30-51 |

30-91 |

||||||||||

|

30-7 |

30-52 |

30-92 |

|||||||||||

|

30-8 |

30-53 |

30-93 |

|||||||||||

|

30-9 |

30-54 |

30-94 |

|||||||||||

|

30-10 |

30-55 |

30-95 |

|||||||||||

|

30-11 |

30-56 |

30-96 |

|||||||||||

|

20-601 |

30-12 |

30-57 |

30-97 |

||||||||||

|

20-602 |

30-13 |

30-58 |

|||||||||||

|

20-603 |

30-14 |

30-59 |

|||||||||||

|

20-604 |

30-15 |

30-60 |

|||||||||||

|

20-605 |

30-16 |

30-61 |

|||||||||||

|

20-606 |

30-17 |

30-62 |

|||||||||||

|

20-607 |

30-18 |

30-63 |

90-1 |

||||||||||

|

20-608 |

30-20 |

30-64 |

90-3 |

||||||||||

|

20-609 |

30-21 |

30-65 |

90-5 |

||||||||||

|

20-610 |

30-22 |

30-66 |

90-7 |

||||||||||

|

20-611 |

30-23 |

30-67 |

90-9 |

||||||||||

|

20-612 |

30-24 |

30-68 |

90-11 |

||||||||||

|

20-613 |

30-25 |

30-69 |

|||||||||||

|

20-614 |

30-26 |

30-70 |

|||||||||||

|

20-615 |

30-27 |

30-71 |

|||||||||||

|

20-616 |

30-28 |

30-72 |

|||||||||||

|

20-617 |

30-29 |

30-73 |

|||||||||||

|

20-618 |

30-30 |

30-74 |

|||||||||||

|

20-619 |

30-31 |

30-75 |

|||||||||||

|

20-620 |

30-32 |

30-76 |

|||||||||||

|

20-621 |

30-33 |

30-77 |

|||||||||||

|

20-622 |

30-34 |

30-78 |

|||||||||||

|

20-623 |

30-35 |

30-79 |

|||||||||||

|

20-624 |

30-36 |

30-80 |

|||||||||||

|

30-37 |

30-81 |

||||||||||||

|

30-38 |

30-82 |

||||||||||||

01 GENERAL

Specification Dimension Drawings

PC210, PC210LC, PC210NLC-7K . . . 01-2

PC240LC, PC240NLC-7K . . . . . . . . . . 01-4

Specifications

PC210, PC210LC, PC210NLC-7K . . . 01-6

PC240LC, PC240NLC-7K . . . . . . . . . . 01-8

Weight Table

PC210, PC210LC, PC210NLC-7K . . 01-10

PC240LC, PC240NLC-7K . . . . . . . . . 01-12

Fuel, Coolant, And Lubricants . . . . . . . . . . . 01-14

|

GENERAL |

SPECIFICATION DIMENSION DRAWINGS |

SPECIFICATION DIMENSION DRAWINGS

PC210-7K, PC210LC-7K, PC210NLC-7K

DIMENSIONS

WORKING RANGES

|

GENERAL |

SPECIFICATION DIMENSION DRAWINGS |

||||

|

DIMENSIONS |

|||||

|

Item |

Unit |

PC210-7K |

PC210LC-7K |

PC210NLC-7K |

|

|

A |

Overall length |

mm |

9,425 |

||

|

B |

Overall height |

mm |

3,000 |

||

|

C |

Overall width |

mm |

2,800 |

3,080 |

2,540 |

|

D |

Track shoe width |

mm |

600 |

700 |

500 |

|

E |

Height of cab |

mm |

3,000 |

||

|

F |

Tail swing radius |

mm |

2,750 |

||

|

G |

Track overall length |

mm |

4,080 |

4,450 |

4,450 |

|

H |

Length of track on ground |

mm |

3,270 |

3,640 |

3,655 |

|

Min. ground clearance |

mm |

440 |

|||

WORKING RANGES

|

Item |

Unit |

PC210-7K |

PC210LC-7K |

PC210NLC-7K |

|

|

A |

Max. digging reach |

mm |

9,875 |

||

|

B |

Max. digging depth |

mm |

6,620 |

||

|

C |

Max. digging height |

mm |

10,000 |

||

|

D |

Max. vertical wall depth |

mm |

5,980 |

||

|

E |

Max. dumping height |

mm |

7,110 |

||

|

F |

Min. dumping height |

mm |

2,645 |

||

|

G |

Max. reach at ground level |

mm |

2,645 |

||

|

GENERAL |

SPECIFICATION DIMENSION DRAWINGS |

PC240LC-7K, PC240NLC-7K

DIMENSIONS

WORKING RANGES

|

GENERAL |

SPECIFICATION DIMENSION DRAWINGS |

|||

|

DIMENSIONS |

||||

|

Item |

Unit |

PC240LC-7K |

PC240NLC-7K |

|

|

A |

Overall length |

mm |

9,885 |

9,885 |

|

B |

Overall height |

mm |

3,160 |

3,160 |

|

C |

Overall width |

mm |

2,980 |

3,280 |

|

D |

Track shoe width |

mm |

600 |

700 |

|

E |

Height of cab |

mm |

3,015 |

3,015 |

|

F |

Tail swing radius |

mm |

2,940 |

2,940 |

|

G |

Track overall length |

mm |

4,250 |

4,640 |

|

H |

Length of track on ground |

mm |

3,460 |

3,845 |

|

Min. ground clearance |

mm |

440 |

400 |

|

WORKING RANGES

|

Item |

Unit |

PC240LC-7K |

PC240NLC-7K |

|

|

A |

Max. digging reach |

mm |

10,180 |

10,180 |

|

B |

Max. digging depth |

mm |

6,920 |

6,920 |

|

C |

Max. digging height |

mm |

10,000 |

10,000 |

|

D |

Max. vertical wall depth |

mm |

6,010 |

6,010 |

|

E |

Max. dumping height |

mm |

7,035 |

7,035 |

|

F |

Min. dumping height |

mm |

2,530 |

2,530 |

|

G |

Max. reach at ground level |

mm |

10,020 |

10,020 |

SPECIFICATIONS

PC210-7K, PC210LC-7K, PC210NLC-7K

|

Machine model |

PC210-7K |

PC210LC-7K |

PC210NLC-7K |

||||

|

Serial Number |

K40001 and up |

||||||

|

Bucket capacity |

m³ |

0.8 |

|||||

|

Operating weight |

kg |

19,300 |

20,700 |

||||

|

Max. digging depth |

mm |

6,620 |

|||||

|

ranges |

Max. vertical wall depth |

mm |

5,980 |

||||

|

Max. digging reach |

mm |

9,875 |

|||||

|

Working |

Max. reach at ground level |

mm |

9,700 |

||||

|

Max. digging height |

mm |

10,000 |

|||||

|

Max. dumping height |

mm |

7,110 |

|||||

|

Performance |

Max. digging force |

kN {kg} |

138.3 {14,100} |

||||

|

(using power max. function) |

(149.1 {15,200}) |

||||||

|

Swing speed |

rpm |

12.4 |

|||||

|

Swing max. slope angle |

deg. |

20 |

|||||

|

Travel speed |

km/h |

Lo: 3.0 ( Mi: 4.1) |

|||||

|

Hi: 5.5 |

|||||||

|

Gradeability |

deg. |

35 |

|||||

|

Ground pressure |

kPa {kg/cm²} |

36.3 {0.37} |

|||||

|

[standard shoe width] |

[mm] |

[700] |

|||||

|

Overall length (for transport) |

mm |

9,425 |

9,425 |

9,425 |

|||

|

Overall width |

mm |

2,800 |

3,080 |

2,540 |

|||

|

Overall width of track |

mm |

2,800 |

3,080 |

2,540 |

|||

|

Overall height (for transport) |

mm |

3,000 |

3,000 |

3,000 |

|||

|

Overall height to chassis |

mm |

3,000 |

3,000 |

3,000 |

|||

|

Dimensions |

Ground clearance to bottom of upper structure |

mm |

1,085 |

1,085 |

1,085 |

||

|

Min. ground clearance |

mm |

440 |

440 |

440 |

|||

|

Tail swing radius |

mm |

2,750 |

2,750 |

2,750 |

|||

|

Min. swing radius of work equipment |

mm |

3,040 |

3,040 |

3,040 |

|||

|

Height of work equipment at min. swing radius |

mm |

8,005 |

8,005 |

8,005 |

|||

|

Length of track on ground |

mm |

3,270 |

3,655 |

3,655 |

|||

|

Track gauge |

mm |

2,200 |

2,380 |

2,040 |

|||

|

Height of machine cab |

mm |

2,335 |

2,335 |

2,335 |

|||

|

Machine model |

PC210-7K |

PC210LC-7K |

PC210NLC-7K |

||||||||||||

|

Serial Number |

K40001 and up |

||||||||||||||

|

Model |

SAA6D102E-2-A |

||||||||||||||

|

Type |

4-cycle, water-cooled, in-line, vertical, direct injection, with |

||||||||||||||

|

turbo charger |

|||||||||||||||

|

No. of cylinders — bore x stroke |

mm |

6 — 102 x 120 |

|||||||||||||

|

Piston displacement |

l {cc} |

5.883 {5,883} |

|||||||||||||

|

kW/rpm {HP/ |

|||||||||||||||

|

Performance |

Flywheel horsepower |

rpm} |

106.7/1,950 {143/1,950} |

||||||||||||

|

Engine |

Max. torque |

Nm/rpm {kgm/ |

610.0/1,500 {62.2/1,500} |

||||||||||||

|

Max. speed at no load |

rpm} |

2,150 |

|||||||||||||

|

Min. speed at no load |

rpm |

1,030 |

|||||||||||||

|

Min. fuel consumption |

rpm |

215 {160} |

|||||||||||||

|

g/kWh {g/HPh} |

|||||||||||||||

|

Starting motor |

24V, 4.5 kW |

||||||||||||||

|

Alternator |

24V, 35 A |

||||||||||||||

|

Battery |

12V, 110 Ah x 2 |

||||||||||||||

|

Radiator core type |

Corrugated CWX-4 |

||||||||||||||

|

Carrier roller |

2 on each side |

||||||||||||||

|

Undercarriage |

Track roller |

7 on each side |

9 on each side |

||||||||||||

|

Assembly-type |

Assembly-type triple grouser, 49 on |

||||||||||||||

|

Track shoe |

triple grouser, 45 |