-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

Belt-Way Scales, Inc.

Conveyor Belt Scale

Product Manual

Belt-Way Scales, Inc.

1 Beltway Rd.

Rock Falls, IL 61071 USA

Phone: (815) 625-5573

www.beltwayscales.com

Phone: (815) 625-5573

beltwayscales.com

sales@beltwayscales.com

Related Manuals for Belt-Way Scales Conveyor Belt Scale

Summary of Contents for Belt-Way Scales Conveyor Belt Scale

-

Page 1

Belt-Way Scales, Inc. Conveyor Belt Scale Product Manual Belt-Way Scales, Inc. 1 Beltway Rd. Rock Falls, IL 61071 USA Phone: (815) 625-5573 www.beltwayscales.com Phone: (815) 625-5573 beltwayscales.com sales@beltwayscales.com… -

Page 2

Conveyor Belt Scale Product Manual This page intentionally left blank Page 2 of 44 Phone: (815) 625-5573 beltwayscales.com sales@beltwayscales.com… -

Page 3

Conveyor Belt Scale Product Manual Safety and Warnings All Belt-Way components MUST be used as described in this manual! Please note the labels on the integrator and in the manual denote dangerous voltage. Failure to take safety precautions may result in serious injury or death. -

Page 4: Table Of Contents

Conveyor Belt Scale Product Manual Table of Contents Scale Accessories …………..6 Integrator Specifications …………7-9 Mechanical Installation …………10-16 Integrator Installation …………17-22 Integrator Board ………………………. 18 Sensor and Power Wiring ……………………19 Sensor Board ……………………….20 Terminal Board with AC Power Supply ………………..21 Terminal Board with DC Power Supply………………..

-

Page 5

Product Manual Introduction The Belt-Way conveyor belt scale is a highly accurate and cost effective in — motion weighing system. It is designed to measure material flow over a conveyor belt in real-time. The primary components are the integrator (AKA, controller, display, indicator), load cell assemblies, and speed sensor. -

Page 6: Scale Accessories

Conveyor Belt Scale Product Manual Scale Accessories The Belt-Way conveyor belt scale works with a range of accessories designed to maximize accuracy, efficiency, and safety. Visit beltwayscales.com or call us today for a complete list of all the accessories that Belt-Way has to offer.

-

Page 7: Integrator Specifications

Conveyor Belt Scale Product Manual Integrator Specifications Replacement Part Number: BWINT 100-240 AC Power Supply Factory Installed Part Number: BWPS -AC 100-240 AC Power Supply Field Installation Kit Part Number: BWPSKIT IO Option Board Part Number: BWIO (Factory Installed) IO Option Board Kit Part Number: BWIOKIT (Field Installed) Display: 4.3″…

-

Page 8

Conveyor Belt Scale Product Manual Electrical Ratings Input Power to 12-30 VDC, 24 VDC 2.25A Max Belt-Way Integrator: AC Power option: Input:100-240VAC 50/60Hz, 1A Max Output: 24VDC, 2.25A Max Use of the factory supplied AC Power option is recommended. AC control power over-current protection with isolated circuit, and disconnect point such as a breaker or switch box, is recommended Conformance to local electrical codes is required. -

Page 9

Conveyor Belt Scale Product Manual Scale Components The single idler scale consists of the following components 1 — Integrator 2 — Load Cell 2 — Mounting pipes 1 — Speed Sensor with Assemblies 1- Hardware Kit mounting arm The dual idler scale consists of the following components… -

Page 10: Mechanical Installation

Conveyor Belt Scale Product Manual Mechanical Installation V-Block MODIFIED CEMA IDLER MOUNTING PIPE LOAD CELL ASSEMBLIES LEVELING PLATES SPEED CONVEYOR SENSOR FRAME 2D component and installation drawings are available at beltwayscales.com 3D drawings are available by request. Recommended Tools ▪…

-

Page 11

Conveyor Belt Scale Product Manual Scale Placement ▪ Install the scale where it is easily accessible for maintenance purposes. ▪ Choose a very rigid section of conveyor such as an idler over a brace. ▪ Avoid curves in the conveyor. -

Page 12

Conveyor Belt Scale Product Manual Attach Load Cell Assemblies to idler ▪ Bolt the load cell assemblies to the idler as shown using the “V-Block”. ▪ The load cell cable should point downhill. ▪ Leave plenty of clearance between the load cell assembly and conveyor frame. -

Page 13

Conveyor Belt Scale Product Manual Install Scale Support Pipes This step is extremely important to ensure long term scale accuracy. ▪ The mounting pipe must touch the strap on the uphill side of load cell assembly. ▪ The strap on the downhill side must create an oval opening. -

Page 14

Conveyor Belt Scale Product Manual Drill U-bolt Holes ▪ Use the leveling plate as a drill template for the U -bolts. ▪ The centers of the leveling plates and pipes should measure 15” apart. ▪ The holes should be at least 7/16” to clear the 3/8” -16 U-bolts. -

Page 15

Conveyor Belt Scale Product Manual String-Line Idlers to level the Weighbridge: This is an extremely important step in the insta llation process. ▪ The empty belt must rest uniformly on all idlers within the weighbridge. ▪ Use a minimum of three strings to align all 5 or 6 weighbridge idlers. -

Page 16

Conveyor Belt Scale Product Manual Install Hose Clamps: ▪ Install the hose clamps on the outside of the load cell assembly. ▪ Leave clearance so the clamps don ’t bind between the pipe and load cell bracket. ▪ Rotate the screw barrels away from the gaps between the hanger brackets and the pipes. -

Page 17: Integrator Installation

Conveyor Belt Scale Product Manual WARNING! Always disconnect power before servicing the integrator! Make sure you LOCK OUT, TAG OUT TRY OUT the electrical system before any maintenance or service. Please follow all Federal, State and Company Safety procedures and policies when working with this product.

-

Page 18: Integrator Board

Conveyor Belt Scale Product Manual A. Integrator Board The scale firmware and programmable settings are stored in the integrator board. MAKE SURE THE USB IS INSTALLED BEFORE PROCEEDING WITH SCALE SETUP. The scale will function without the USB but it records Important calibration and operating data.

-

Page 19: Sensor And Power Wiring

Conveyor Belt Scale Product Manual B. Wiring the scale sensors and power Use a small screwdriver to carefully remove each connector. Shield Wire Grounding Load Cell, Speed Sensor, and Angle Sensor wires MUST be connected as shown below. Properly terminating the shield wire is required to reduce electrical interference.

-

Page 20: Sensor Board

Conveyor Belt Scale Product Manual C. Sensor Board oad cells, the speed sensor, and angle sensor connect to the sensor board. 1.25 A Fuse Speed Sensor Wiring SIGA – GREEN +5V – RED GND – BLACK & WHITE Angle Sensor Wiring SIG –…

-

Page 21: Terminal Board With Ac Power Supply

Conveyor Belt Scale Product Manual D. Terminal Board with 110 / 240 AC Power Supply All power wiring must conform to local and national electrical codes. Always disconnect power before servicing the integrator. The AC Power supply is installed below the Sensor Board. It converts 110/240 AC to 24 VDC.

-

Page 22: Terminal Board With Dc Power Supply

Conveyor Belt Scale Product Manual E. Terminal Board with DC Power Supply The DC Power supply is installed below the Sensor Board. It boosts 9-24 VDC up to 24 VDC and regulates the voltage during engine cranking. 9-24 VDC Landing Board…

-

Page 23: Integrator Configuration

Conveyor Belt Scale Product Manual Integrator Configuration and Scale Calibration A. Integrator Navigation and Data Entry Returns to the Run Screen HOME: Displays the Main Menu MAIN MENU: Moves to previous screen only BACK: Initiate the Zero Calibration process ZERO CALIBRATION: Print ticket or save a screenshot to USB when no printer is installed.

-

Page 24: Setup Wizard

Conveyor Belt Scale Product Manual B. Setup Wizard The Setup Wizard is a step by step guide for the the initial setup of the Integrator. Use the following page to record important values before starting the Setup Wizard. ▪ Number of weigh idlers (1 for single idler scale and 2 for dual idler scale) ▪…

-

Page 25

Conveyor Belt Scale Product Manual Dealer Contact Information Dealer Name: Contact Name: Contact Phone: Contact Email: Address: City, State, Zip Scale Information Serial Number: BWINT- Date of Install: Conveyor Type: Stationary Stacker Mobile (track mounted) Conveyor Make: Conveyor Model: Scale Setup Parameters… -

Page 26: Scale Setup

Conveyor Belt Scale Product Manual C. Scale Setup View or edit scale parameters at the Scale Setup Menu. Default Settings Options Run Mode: Weight / Rate, Loadout, Rate Control, Blending Number of Idlers: 1,2,3,4 Load Cell: 45,50,100,150,200,350,500,1000 kg 1000 lb, Custom…

-

Page 27: Scale Calibration

Conveyor Belt Scale Product Manual D. Scale Calibration Navigate to Main Menu > Calibration i. Perform Length and Zero (if not completed during the setup wizard) The Length and Zero measures the belt length and weight of the empty belt.

-

Page 28: Test Weight Calibration

Conveyor Belt Scale Product Manual iii. Test Weight Calibration The Test Weight Calibration adjusts the Trim Value to properly calibrate the scale. The calibration should be performed at startup and several times per year on a stationary conveyor. A portable conveyor should be calibrated each time it is moved.

-

Page 29

Conveyor Belt Scale Product Manual Navigate to Main Menu > Calibration > Test Weight. Enter the test weight amount. Start the belt running empty and follow the instructions on the screen. The calibration will run for several belt revolutions and then stop. -

Page 30: Material Test Calibration

Conveyor Belt Scale Product Manual iv. Perform Material Test Calibration The Material Test Calibration verifies the belt scale against a certified scale. The calibration is typically performed with a legal for trade truck scale. It is also possible to do a material test comparison with a loader scale, rail scale, barge draft, or other very accurate weight.

-

Page 31: Totals And Diagnostics

Conveyor Belt Scale Product Manual v. Digital Calibration The digital calibration resets the Trim Factor to the default of 1.000. Navigate to Calibration > Digital Calibration and follow the instructions. E. Totals and Diagnostics Totals & Diagnostics contains additional scale totals and other scale information.

-

Page 32

Conveyor Belt Scale Product Manual iii. Diagnostics Navigate to Totals & Diagnostics > Diagnostics Calibration Navigate to Totals & Diagnostics > Diagnostics > Calibration ▪ Trim Factor (Calibration Multiplier) Should be close to 1.000 ▪ Zero Value (Empty Belt Weight) Typically, 75 –… -

Page 33

Conveyor Belt Scale Product Manual Sensors Navigate to Totals & Diagnostics > Diagnostics > Sensors ▪ Load cells 1-8 ▪ Speed Sensor ▪ Angle Sensor Load Cell mV signal diagnostics. ▪ Each load cell should show 1.0 — 7.0 mV when the belt is empty. -

Page 34: Device Setup

Conveyor Belt Scale Product Manual F. Device Setup Navigate to Main Menu > Device Setup CONTACT BELT-WAY FOR SPECIFIC DOCUMENTATION COVERING THE PRINTER, SCOREBOARD DISPLAY, IO BOARD, AND PLANT CONNECT USB Data Logging The integrator saves to a periodic_log.txt file once per minute. It syncs new data to the USB drive once per hour.

-

Page 35

Conveyor Belt Scale Product Manual web-based production monitoring: iPhone / Android App Unlimited Scales Unlimited Users Historical Data Realtime Dashboard Production Reports Contact Belt-Way for more information about how to sign up! Page 35 of 44 Phone: (815) 625-5573 beltwayscales.com… -

Page 36: Administration

Conveyor Belt Scale Product Manual G. Administration Navigate to Main Menu > Administration Security Navigate to Administration > Security Create a password to restrict access to any desired scale function. Any locked item requires the password. Set the Time and Date Navigate to Administration >…

-

Page 37: Routine Maintenance

Conveyor Belt Scale Product Manual Routine Maintenance Checklist The scale will only perform as well as the surrounding envirnment allows. Inspect the scale, belt, idlers, etc on a regular basis to ensure all components are functioning properly. Maintenance Task Item…

-

Page 38: Troubleshooting

Conveyor Belt Scale Product Manual Troubleshooting Belt Speed Problems If there is no belt speed: ▪ Check if the belt is stopped. ▪ Check to confirm the speed sensor wheel is touching the belt and turning. ▪ Confirm the wheel is not excessivley worn or bouncing.

-

Page 39

Conveyor Belt Scale Product Manual Power Problems The integrator requires a minimum of 12 VDC to operate properly. Underpowered AC transformers will not work. We strongly suggest use of the Belt-Way AC power supply. AC Power Supply Spec: ▪ Input: 100-240 VAC 50/60 Hz. -

Page 40: Product Warranty

Belt-Way Scales, Inc., or to bind Belt-Way Scales, Inc., in any manner whatsoever. Products manufactured by Belt-Way are warranted to be free of manufacturing defects for a one year period after the original date of purchase.

-

Page 41

NOT AUTHORIZE ANYONE TO MAKE ANY OTHER WARRANTY EXCEPT AS STATED HEREIN. Exclusion of Consequential Damages BELT-WAY SCALES, INC. SHALL IN NO EVENT BE RESPONSIBLE FOR SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES CAUSED BY ANY PRODUCT SOLD HEREUNDER, WHETHER ON THEORIES OF BREACH OF EXPRESS OR IMPLIED WARRANTIES UNDER THE UNIFORM… -

Page 42

Conveyor Belt Scale Product Manual This page intentionally left blank Page 42 of 44 Phone: (815) 625-5573 beltwayscales.com sales@beltwayscales.com… -

Page 43

Conveyor Belt Scale Product Manual This page intentionally left blank Page 43 of 44 Phone: (815) 625-5573 beltwayscales.com sales@beltwayscales.com… -

Page 44

Conveyor Belt Scale Product Manual Belt-Way Scales, Inc. 1 Beltway Rd. Rock Falls, IL 61071 USA Phone: (815) 625-5573 sales@beltwayscales.com www.beltwayscales.com Page 44 of 44 Phone: (815) 625-5573 beltwayscales.com sales@beltwayscales.com…

Спасибо! Ваша заявка отправлена.

Мы свяжемся с вами в течение 24 часов.

Извините, при отправке заявки произошла ошибка.

Попробуйте позже.

Заполните форму обратной связи, выбрав тип обращения.

Вы сможете прикрепить фото или обращение на бланке предприятия

ФИО:

*

Некорректный формат ввода ФИО

Телефон:

*

Некорректный формат ввода телефона

E-mail:

*

Некорректный формат ввода E-mail

Название организации:

Некорректный формат ввода названия организации

Прикрепить реквизиты организации

(формат файла: doc, xls, pdf, rtf)

Некорректный формат файла или размер больше 3МБ

Нажимая на кнопку «Отправить», я даю согласие на обработку моих персональных данных согласно политике компании

Отправить

| Автомобильные весы ВТА | |

|

Паспорт и руководство по эксплуатации

|

| Вагонные весы ВТВ | |

|

Паспорт и руководство по эксплуатации

|

| Вагонные весы ВТВ-C | |

|

Паспорт и руководство по эксплуатации

|

| Бортовая система взвешивания Monacs | |

|

Паспорт и руководство по эксплуатации

|

| Платформенные весы ВП | |

|

Паспорт и руководство по эксплуатации

|

|

| CI-6000A Руководство по эксплуатации | |

|

Устройство весоизмерительное типа CI-6000A

|

|

|

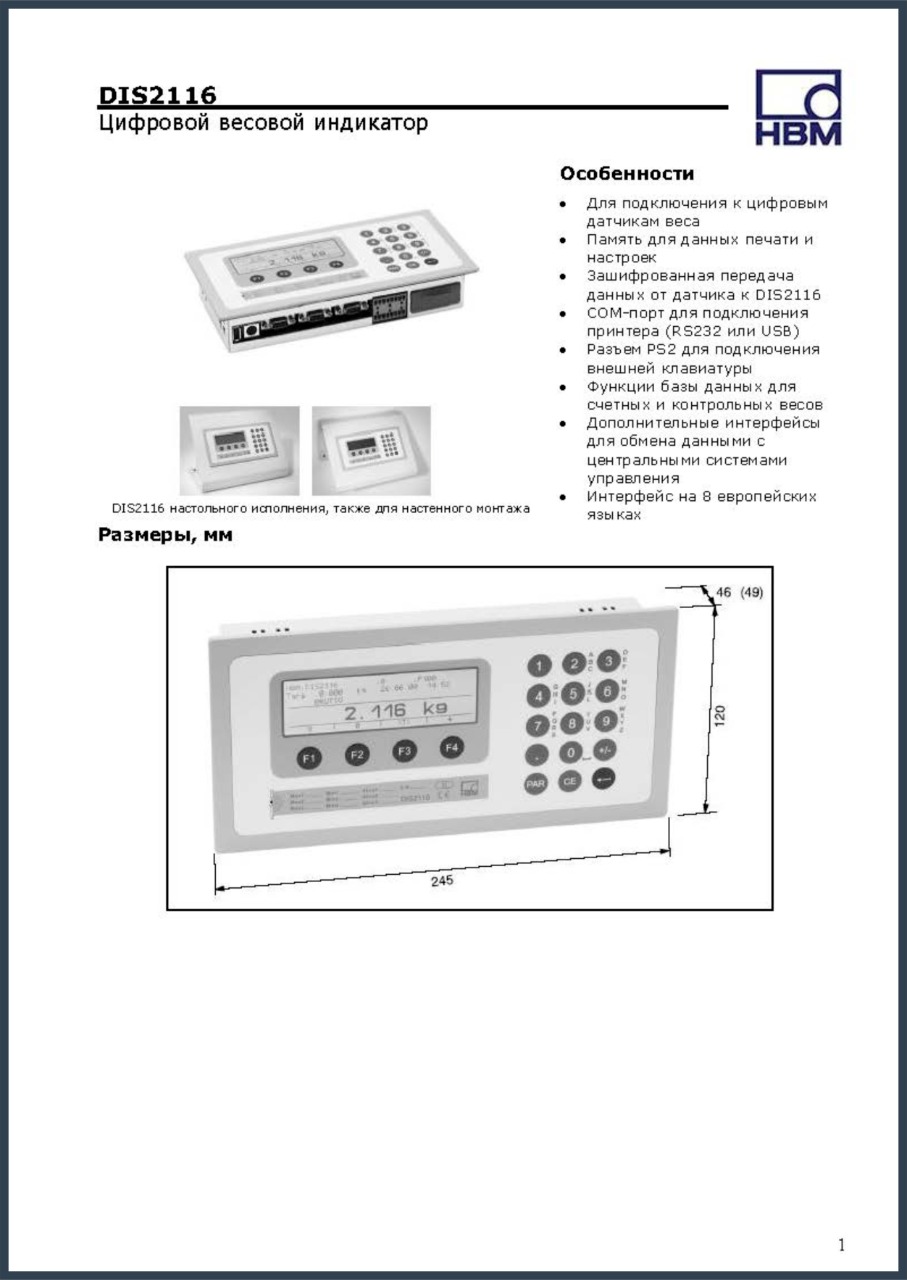

DIS2116 Техническое описание |

|

|

Техническое описание

|

|

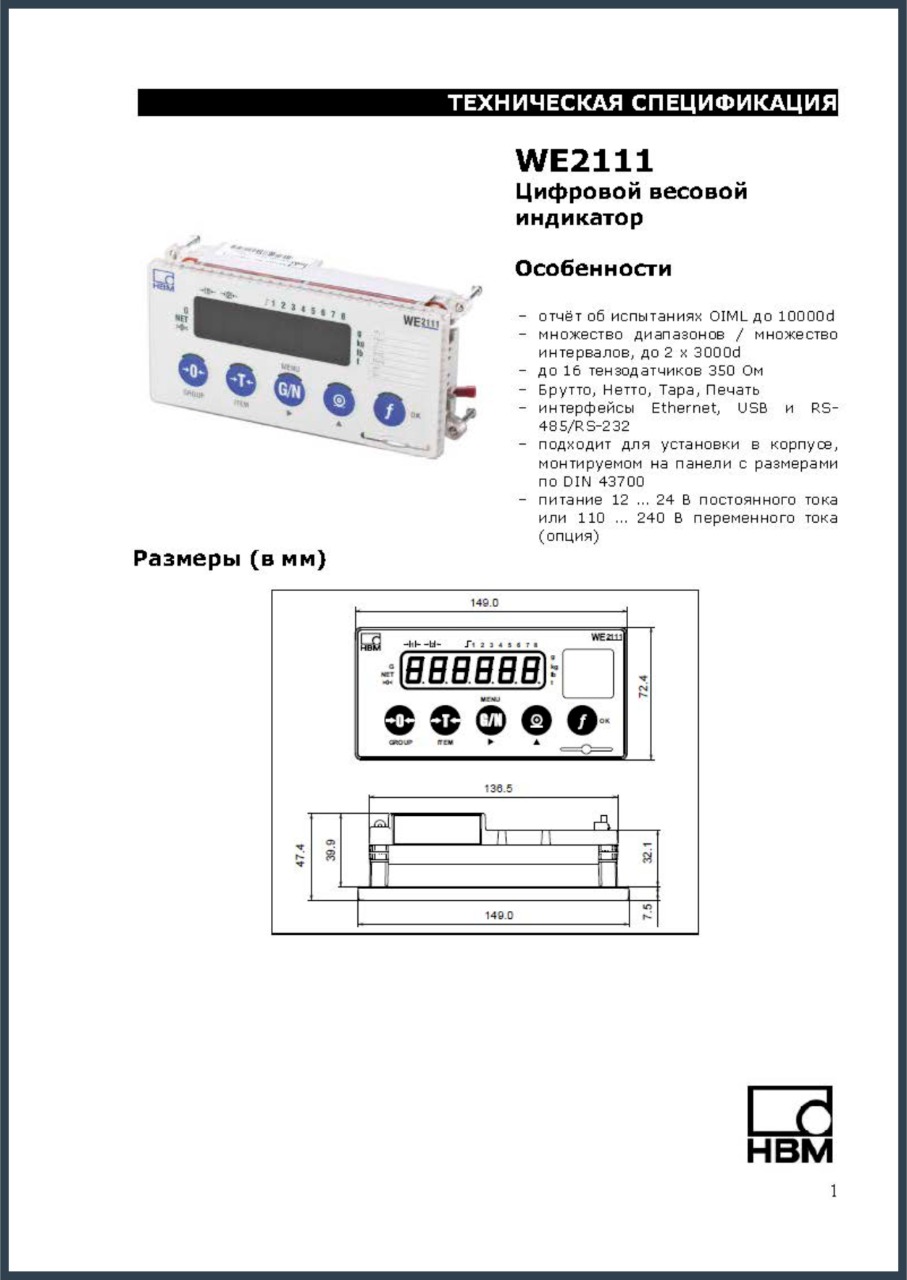

WE2111 Цифровой весовой индикатор |

|

|

Техническая спецификация WE2111

|

|

Электронный весовой терминал серии ВКА |

|

|

Электронный весовой терминал серии ВКА

|

|

|

Электронный цифровой весовой терминал ВКЦ |

|

|

Электронный цифровой весовой терминал ВКЦ

|

|

|

Нормирующий преобразователь ЦНП |

|

|

Нормирующий преобразователь ЦНП

|