РУКОВОДСТВО ПО

ЭКСПЛУАТАЦИИ

Эксплуатация

Техническое обслуживание

Технические характеристики

Вся информация в настоящем Руководстве по эксплуатации приведена по

состоянию на момент публикации.

Компания Hyundai оставляет за собой право в любое время вносить изменения

в рамках постоянно действующей программы модернизации продукции.

Настоящее Руководство применимо для всех моделей автомобилей Hyundai и

содержит описания как дополнительного, так и стандартного оборудования, а

также соответствующие пояснения. Поэтому в данном Руководстве Вы сможете

обнаружить материалы, не имеющие отношения к конкретной модели Вашего

автомобиля.

Руководство на английском языке по кузовному ремонту автомобилей Hyundai Coupe и Hyundai Tiburon.

- Автор: —

- Издательство: Hyundai Motor Company

- Год издания: —

- Страниц: 131

- Формат: PDF

- Размер: 12,7 Mb

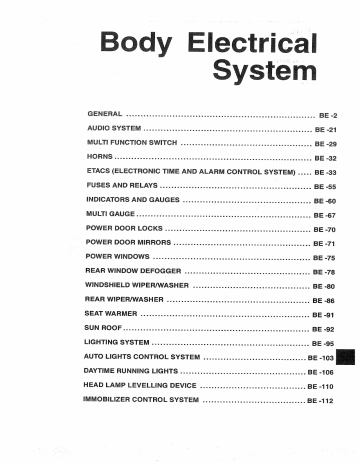

Руководство на английском языке по ремонту электрооборудования автомобилей Hyundai Coupe и Hyundai Tiburon.

- Автор: —

- Издательство: Hyundai Motor Company

- Год издания: 2001

- Страниц: —

- Формат: PDF

- Размер: 87,3 Mb

Руководство на английском языке по техническому обслуживанию и ремонту автомобилей Hyundai Coupe и Hyundai Tiburon.

- Автор: —

- Издательство: Hyundai Motor Company

- Год издания: 2001

- Страниц: —

- Формат: PDF

- Размер: 115,6 Mb

Руководство по эксплуатации Hyundai Coupe.

- Автор: —

- Издательство: Hyundai Motor Company

- Год издания: —

- Страниц: 237

- Формат: PDF

- Размер: 11,8 Mb

- Manuals

- Brands

- Hyundai Manuals

- Automobile

- coupe 2002

- Owner’s manual

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

SA000A1-E

This Owners Manual should be considered a part of the car and remain with it when it is sold for the use

of the next owner.

ORIGINAL:

NAME:

ADDRESS:

STREET:

TOWN:

COUNTY:

P.CODE:

DATE OF SALE:

SUBSEQUENT:

NAME:

ADDRESS:

STREET:

TOWN:

COUNTY:

P.CODE:

TRANSFER DATE:

OWNER I.D.

Related Manuals for Hyundai coupe 2002

Summary of Contents for Hyundai coupe 2002

-

Page 1

SA000A1-E This Owners Manual should be considered a part of the car and remain with it when it is sold for the use of the next owner. OWNER I.D. ORIGINAL: NAME: ADDRESS: STREET: TOWN: COUNTY: P.CODE: DATE OF SALE: SUBSEQUENT: NAME: ADDRESS: STREET:… -

Page 2

This manual applies to all markets and includes descriptions and explanations of optional as well as standard equipment. As a result, some of the equipment operating descriptions referred to may not apply to the particular vehicle with which this manual is supplied. Please refer to the nearest franchised Hyundai dealer for information regarding current standard and optional equipment levels. -

Page 3

It is recommended that all maintenance operations and repairs are entrusted to a franchised Hyundai dealer to ensure that the latest repair methods, specialized tooling and genuine Hyundai parts are used to ensure the continued reliability and safety of the vehicle. -

Page 4

Page 9-3 in the Vehicle Specifications section of the Owner’s Manual. Copyright 2002 Hyundai Motor Company. All rights reserved. No part of this publication may be reproduced, stored in any retrieval system or transmitted in any form or by any means without the prior written permission of Hyundai Motor Company. -

Page 5

It is possible for incorrectly installed two way radio equipment including mobile telephones to adversely affect these systems. Before radio equipment of this kind is installed, please contact your Hyundai dealer for recommendation regarding the suitability of the particular radio equipment concerned and the recommended method of installation and equip- ment location. -

Page 6

SA070A1-F SAFETY AND VEHICLE DAMAGE WARNING This manual includes information titled as WARNING, CAUTION and NOTE. These titles indicate the following: WARNING: This indicates that a condition may result in harm or injury to you or other persons if the warning is not heeded. -

Page 7: Table Of Contents

TABLE OF CONTENTS SECTION PAGE 1. CONTROLS AND EQUIPMENT …………….1-1 2. DRIVING YOUR HYUNDAI …………….. 2-1 3. IN CASE OF EMERGENCY …………….3-1 4. APPEARANCE CARE ………………4-1 5. VEHICLE MAINTENANCE REQUIREMENTS ………… 5-1 6. OWNER MAINTENANCE ………………6-1 7.

-

Page 8

Logo on the package (see below). and built to meet rigid original manu- The export specifications are written facturing requirements. Using imita- in English only. tion, counterfeit or used salvage parts A100A03L is not covered under the Hyundai New A100A02L A100A04L A100A01L… -

Page 9: Controls And Equipment

4) Never allow the engine to labour. Use the PETROLS FOR CLEANER AIR gearbox freely and avoid large throttle open- To help contribute to cleaner air, Hyundai recom- ings when the engine speed is below 1500 mends that you use petrols treated with deter- B010A02GK rpm.

-

Page 10

AX10020A-1 keys arises. New keys are available from any All of the locks fitted to the vehicle are operated Hyundai dealer by quoting the relevant key num- by the same key. However, since it is possible to ber. lock the doors without the use of the key, care… -

Page 11

CONTROLS AND EQUIPMENT SB040B1-F B040C01S-AAT B040D01S-AAT Locking, unlocking front doors with a Locking From the Outside Locking From the Inside UNLOCK UNLOCK LOCK LOCK HGK208-D HGK099-D HGK101-D To lock the doors from the inside, simply close The doors can be locked without a key. o The door can be locked or unlocked with a key. -

Page 12

CONTROLS AND EQUIPMENT 3) Once the system is armed, only the B040G01GK-GAT B070A01A-AAT Central Door Lock THEFT-ALARM SYSTEM hatchabck door may be unlocked using the key without disarming the system. (Not all models) 4) If you don’t open any doors within 30 This system is designed to provide protection seconds after locked the all doors by the from unauthorized entry into the car. -

Page 13

CONTROLS AND EQUIPMENT B070D01GK-AAT B070E01GK-GAT Disarmed Stage Replacing the battery When the transmitter’s battery begins to get weak, it may take several pushes on the button to lock or unlock the doors, and the LED will not light. Replace the battery as soon as possible. Battery type : CR2032 Battery Replacement instructions:… -

Page 14

CONTROLS AND EQUIPMENT B050A01GK-AAT DOOR WINDOWS Power window (Not all models) B050A02GK-D HGK097-D WARNING: CAUTION: o Be careful that head, hands and body are Never try to operate the main switch and sub- HGK096-D not trapped by a closing window. switch in opposing directions at the same o If passengers remain in the car when you time. -

Page 15

CONTROLS AND EQUIPMENT SB070A1-E SB070C1-E SB070D1-E FRONT SEAT ADJUSTMENT Front seat recline adjustment Head restraint adjustment WARNING: Front seat adjustments must not be under- taken whilst the vehicle is in motion. Loss of control of the vehicle may result if seat ad- justments are made whilst the vehicle is in motion. -

Page 16

CONTROLS AND EQUIPMENT SB070E1-E FB070F1-F The seat warmer is provided to warm the front Lumbar support adjustment Seat Cushion Height Adjustment seats during cold weather. With the ignition key (Not all models) in the «ON» position, push either of the switches (Driver’s seat only) (Not all models) to warm the driver’s seat or the passenger’s seat. -

Page 17

CONTROLS AND EQUIPMENT B130A01GK-DAT B099A01F-AAT REAR SEAT ENTRY (Walk in device) BEFORE FOLDING THE REAR SEATS The driver and front passenger’s seatback should be tilted to enter the rear seat. HGK240-D By pulling up the walk in device lever (1) at the B099A01GK left-up side of the passenger side seatback, the seatback will tilt forward. -

Page 18

CONTROLS AND EQUIPMENT SB480A1-E SB090C1-E WARNING: FOLDING REAR SEAT (Not all models) Larger Children The folding rear seats are intended to allow Larger children should occupy the rear seat and the carriage of longer objects than could be restrained at all times. The restraint may take otherwise be accommodated. -

Page 19

Additional questions concerning seat unable to afford maximum protection if the front WARNING: belt operation should be directed to a Hyundai seats are at or near the fully reclined position. o The height adjuster must be in the locked Dealer. -

Page 20

CONTROLS AND EQUIPMENT SB090P1-E nism by allowing a small amount of webbing to be SB090R1-F SEAT BELTS (3-Point Type) To Release the Seat Belt retracted and the belt withdrawn again. To Fasten The Seat Belt SB090Q1-F Adjusting Your seat Belt FUD1090R The seat belt is released by pressing the release FUD1090P… -

Page 21

CONTROLS AND EQUIPMENT WARNING: shoulder belt must always be positioned B230A02GK-EAT CHILD RESTRAINT SYSTEM o A child restraint system must be placed in as low as possible on the child’s hips and Children riding in the car should sit in the rear the rear seat. -

Page 22

If the seat belt does not operate as de- scribed, have the system checked imme- Cover, Child Restraint diately by your authorized Hyundai dealer. Hook Holder (4 door only) Bolt, Holder (5/16″-30 mm) WARNING: Do not install any child restraint system in the… -

Page 23

Front of Vehicle requirements of ECE-R44. For your Hyundai, B230E01GK the Hyundai ISOFIX GR1 / Hyundai Duo / Römer Two child restraint hook holders are located on ISOFIX GR1 and the Römer Duo ISOFIX / Britax the vertical back panel. -

Page 24

Do not mis- law. Please ask your Hyundai dealer in this Hyundai. use the ISOFIX anchors by attempting to respect. -

Page 25

Driver’s side airbag Child Seat Restraint Suitability For Seat Pre-tensioner Seat Belt (Not all models) Passenger’s Your Hyundai vehicle is equipped with driver’s Position side airbag and front passenger’s pre-tensioner seat belts. Use child safety seats that have been officially The purpose of the pre-tensioner is to make sure approved and are appropriate for your children. -

Page 26

Do not attempt to inspect or replace the dent in which the pre-tensioner seat belts pre-tensioner seat belts yourself. This Your Hyundai is equipped with a Supplemental were activated. must be done by an authorized Hyundai Restraint (Airbag) System. The indications of the dealer. -

Page 27

If the airbags inflate, they must be re- light collisions in which protection can be forcefully contact the occupant causing placed by an authorized Hyundai dealer. provided by the seat belt. serious or fatal injuries. o Do not tamper with or disconnect SRS… -

Page 28

CONTROLS AND EQUIPMENT B240B01GK-AAT The airbag modules are located both in the SRS Components and Functions centre of the steering wheel and in the front passenger’s panel above the glove box. When the SRSCM detects a considerable impact to the front of the vehicle, it will automatically deploy the airbags. -

Page 29

B990B01L.DAG erly worn seat belt slows the driver’s or the continuously when the ignition key is Your Hyundai is equipped with a side airbag in passenger’s forward motion, thus reducing the turned to «ON», or continuously remains each front seat. The purpose of the airbag is to risk of head and chest injury. -

Page 30

SRS supplemental side air bag inflates. wheel must be performed by a qualified Hyundai system. Doing so could result in injury, o To prevent unexpected deployment of the technician. -

Page 31

If your car was flooded and has soaked carpeting or water on flooring, you shouldn’t try to start engine; have car towed to authorized Hyundai dealer. 1- 23… -

Page 32

CONTROLS AND EQUIPMENT B250A01GK-EAT INSTRUMENTS AND CONTROLS 3 4 5 6 1213 1. Passenger’s side Drink Holder 2. Passenger’s Side Air Bag (Not all models) 3. Multi Guage (Not all models) 4. Front Fog Light Switch (Not all models) 5. Rear fog Light Switch 6. -

Page 33

CONTROLS AND EQUIPMENT B260A01GK-EAT INSTRUMENT CLUSTER AND INDICATOR LIGHTS 2 3 4 HGK026B 9 10 11 12 13 151617 18 1920 22 23 1. Speedometer 9. Traction Control Indicator Light 17. Malfuction Indicator Light (Not all models) 2. Turn Signal Indicator Light (Not all models) 18. -

Page 34

The high beam indicator lamp will illuminate ignition is turned «on», contact the nearest Hyundai come on when the key is turned to the «ON» whenever the headlamps are switched to high dealer before further operating the vehicle. -

Page 35

9 litres and that the vehicle should be The Hyundai Lantra is equipped with a diagonally the advice of a Hyundai dealer should be sought. refuelled. If the vehicle is driven for an extended split dual braking system which will ensure that in… -

Page 36

The indicator light does not illuminate when the rized Hyundai dealer and have the system The fuel gauge indicates the quantity of fuel cruise control main switch is pushed a second checked. -

Page 37

The speedometer indicates the vehicle speed in be readily established, the assistance of a both miles and kilometres per hour. Hyundai dealer should be sought. WARNING: The engine cooling system is pressurized and removal of the radiator cap when the… -

Page 38

CONTROLS AND EQUIPMENT B310B01GK-EAT B400B01GK-EAT 1. Odometer ODOMETER/TRIP ODOMETER TRIP COMPUTER The odometer records the total driving distance in miles, and is useful for keeping a record for maintenance intervals. A Type NOTE: Any alteration of the odometer may void your warranty coverage. -

Page 39

If the distance to empty is indicated «- -«, DISTANCE TO EMPTY have the trip computer system checked by A Type your authorized Hyundai dealer. o The distance to empty can differ from the actual tripmeter according to driving con- AVERAGE SPEED ditions. -

Page 40

CONTROLS AND EQUIPMENT B330C01GK-GAT SB220A1-E Instantaneous Fuel Consumption gauge MULTI GAUGE (Not all models) MULTI FUNCTION SWITCH It shows instantaneous fuel consumption ac- Multi gauge is consists of torque gauge, instan- Turn Signal Operation cording to the driving condition. The more indi- taneous fuel consumption gauge and volt gauge. -

Page 41

CONTROLS AND EQUIPMENT To indicate an intention to change lanes, moving SB220D1-E SB220E1-E HIGH AND LOW BEAM HEADLAMP FLASH the lever slightly towards the direction of the relevant turn signal will cause the turn signal To turn on the headlight high beams, push the lamps to flash. -

Page 42

CONTROLS AND EQUIPMENT B350A01GK-EAT The variable intermittent wipe facility is operated Mist Wiper Operation WINDSCREEN WIPER/WASHER by moving the windscreen wiper switch to the first position. The time period between wipes is SWITCH adjusted by moving the rotary control on the windscreen wiper switch barrel. -

Page 43

CONTROLS AND EQUIPMENT o In icy or snowy weather, ensure that the SB240A1-E SB250A1-E HAZARD WARNING SYSTEM HEATED REAR WINDOW wiper blades are not frozen to the glass prior to operating the wipers. A Type B350A01O-EAT Hatchback door Wiper And Washer Switch B Type HGK140… -

Page 44

When this is done: Do not use electric accessories or equipment Pressing «R» between 10 : 30 and 11 : 29 changes other than the Hyundai genuine parts in the the readout to 11 : 00 Pressing «R» between 11 : socket. -

Page 45

CONTROLS AND EQUIPMENT B430A01GK-AAT B450A01GK-GAT SB320A2-F FRONT ASHTRAY DRINK HOLDER (Not all models) HEADLIGHT LEVELING DEVICE SYS- Passenger’s Driver’s HGK146-D HGK149-D HGK157-D The front ashtray may be opened by pushing and The drink holder is used for holding cups or cans. releasing the ashtray door at its top edge. -

Page 46

HGK029 FB330A1-E HGK030 SUNROOF (Not all models) Your HYUNDAI is equipped with a sliding sun- The sunroof can be electrically opened or closed The electrically operated sunroof may be used shade which you can manually adjust to let in with the ignition key in the «ON» position. The only whilst the ignition switch is at the «ON»… -

Page 47

CONTROLS AND EQUIPMENT CAUTION: B460D02GK-AAT 3. Push and turn the wrench counterclockwise Manual Operation of Sunroof o Do not open the sunroof in severely cold to open or clockwise to close the sunroof. temperature or when it is covered with ice If the sunroof does not electrically operate: or snow. -

Page 48

CONTROLS AND EQUIPMENT B480A01GK-GAT FB340B1-F B500A01A-EAT MAP LIGHT SPECTACLE CASE (Not all models) GLOVE BOX (1) (2) HGK036 HGK034 HGK147-D The spectacle case is located on the front over- (1) Push in the map light switch to turn the driver WARNING: head console. -

Page 49

CONTROLS AND EQUIPMENT CAUTION: YB270B2-A the switch for the rear window defroster. The EXTERIOR REAR VIEW MIRROR o Do not operate the switch continuously rearview mirror glass will be heated for defrost- for an unnecessary length of time. ing or defogging and will give you improved rear Electric Type o Scraping ice from the mirror face could vision in inclement weather conditions. -

Page 50

CONTROLS AND EQUIPMENT SB370A1-E B520B01O-GAT SB380A1-E INTERIOR REAR VIEW MIRROR DAY/NIGHT REAR VIEW MIRROR PARKING BRAKE (Electric type) (Not all models) Sensor B520A01GK HGK178 The parking brake must always be set when the The interior mirror is of the day/night type to B520B01GK vehicle is to be left unattended. -

Page 51

CONTROLS AND EQUIPMENT YB800A2-A B360B01GK-GAT B550A02S-DAT FRONT FOG LIGHT SWITCH REAR FOG LIGHT SWITCH HIGH-MOUNTED REAR STOPLIGHT (Not all models) (Not all models) A Type B Type B550A02GK HGK142 In addition to the lower-mounted rear stoplights HGK183 on either side of the car, the high mounted rear To turn on the rear fog lights, push the switch. -

Page 52

CONTROLS AND EQUIPMENT SB410A1-E B570A01GK-EAT FRONT DOOR EDGE WARNING LAMP BONNET RELEASE HGK098 WARNING: Bonnet Release Lever B620A01GK-D HGK106-D o Always double check to be sure that the 1. Pull the release knob to unlatch the bonnet. bonnet is firmly latched before driving The red door edge warning lamp which serves to 2. -

Page 53

Do a Genuine Hyundai replacement part should not pry on the lid. If necessary, spray around be used to prevent fuel leakage. -

Page 54

CONTROLS AND EQUIPMENT SB450C2-E B540D01GK-GAT SB500A1-E To Unlock Using the Key When you close the hatchback door REAR PARCEL SHELF B140A01GK B540C01GK HGK226 Large or heavy items must not be placed upon To open the hatchback door using the ignition the rear parcel shelf to prevent the possibility of key, insert the key into the lock barrel and turn injury arising from such items in the event of… -

Page 55

CONTROLS AND EQUIPMENT SB510A1-E B600A01HP-AAT SB530B1-F SUNVISOR STEERING WHEEL TILT LEVER HORN (Not all models) Working Zone Vanity mirror HGK141 HGK145-D HGK127-D Press the pad on the steering wheel to sound the Sun visors are fitted to both the driver and pas- horn. -

Page 56

CONTROLS AND EQUIPMENT WARNING: Some objects can be kept in the net at the B660B01E-AAT To Set the Cruise Speed luggage compartment. To avoid accidental cruise control engage- Use the luggage net on the floor(Not all models) ment, keep the cruise control main switch off or at the back of the luggage compartment to when not using the cruise control prevent the objects from slipping. -

Page 57

CONTROLS AND EQUIPMENT o During cruise-control driving with a manual B660D01E-AAT B660F01E-AAT To Resume the Preset Speed To Reset at a Slower Speed transaxle vehicle, do not shift into neutral without depressing the clutch pedal, or the engine will be overrevved. If this happens, depress the clutch pedal or release the main switch. -

Page 58

CONTROLS AND EQUIPMENT B710A01GK-EAT B710A01S-AAT HEATING AND COOLING CONTROL VENTILATION To operate the ventilation system: o Set the air intake control on «Fresh» mode o To direct all intake air to the dashboard vents, set the airflow control to «Face». o Adjust the fan speed control to the desired speed. -

Page 59

CONTROLS AND EQUIPMENT B670A01GK-GAT B670B01A-AAT B670E01A-AAT Fan Speed Control (Blower Control) ROTARY TYPE (Not all models) Temperature Control Cool Warm HGK006 HGK002 HGK007 1. Air Conditioning switch This is used to turn the blower fan on or off and This is used to turn the heating system on and off to select the fan speed. -

Page 60

CONTROLS AND EQUIPMENT B670C01FC-EAT With the «Recirculation» mode selected, air from B670D01GK-EAT Air Intake Control Air Flow Control within the passenger compartment will be drawn through the heating system and heated or cooled according to the function selected. NOTE: o It should be noted that prolonged opera- tion of the heating in «Recirculation»… -

Page 61

CONTROLS AND EQUIPMENT If the «Floor-Defrost» mode is selected, the A/C will be on automatically and it will be changed to «Fresh» mode. HGK021-D HGK023-D Face-Level Floor-Level Selecting the «Face» mode will cause air to be Air is discharged through the floor vents, HGK025-D discharged through the face level vents. -

Page 62

CONTROLS AND EQUIPMENT B740A01S-AAT B740B01S-AAT B690A01S-AAT AIR CONDITIONING SYSTEM Air Conditioning Operation HEATING CONTROLS For normal heating operation, set the air intake (Not all models) Cooling control to the «Fresh» position and the air flow Air Conditioning Switch control to «Floor». For faster heating, the air intake control should be in the «Recirculation»… -

Page 63

CONTROLS AND EQUIPMENT NOTE: B720A01FC-EAT DEFROSTING/DEFOGGING When the A/C is operated continuously on the floor-defrost level ( ) or defrost level ( ), it may cause fog to form on the exterior windscreen by the temperature differential. At this time set the air flow control to the face level position ( )and fan speed control to the low position. -

Page 64

CONTROLS AND EQUIPMENT B970A01Y-EAT AUTOMATIC HEATING AND COOLING CONTROL SYSTEM (Not all models) Your Hyundai is equipped with an automatic heating and cooling control system controlled by simply setting the desired temperature. B970B01GK-EAT Heating and Cooling Controls TYPE A (Without Air Quality System) -

Page 65

CONTROLS AND EQUIPMENT NOTE: B970C02E-AAT Automatic Operation If the battery has been discharged or discon- nected, the temperature mode will reset as centigrade degrees. This is a normal condition and you can change the temperature mode from centigrade to farenheit as follows; Press the TEMP button down 3 seconds or more with the OUTSIDE… -

Page 66

CONTROLS AND EQUIPMENT B995A01Y-GAT B980B01Y-AAT B670C01GK-EAT AMBIENT SWITCH Fan Speed Control Switch Air Intake Control Switch (Without A.Q.S) HGK015 HGK009 The fan speed can be set to the desired speed by Pressing the OUTSIDE button displays the amb- HGK008 TEMP pressing the appropriate fan speed control but- ient temperature on the LCD. -

Page 67

CONTROLS AND EQUIPMENT With the «Recirculation» mode selected, and air B980C01GK-EAT Exhaust gas cutoff mode : Air Intake Control Switch (With A.Q.S) from within the passenger compartment will be Air enters the vehicle from the outside. drawn through the heating system and heated or (Not all models) But if exhaust gas enters the vehicle from the cooled according to the function selected. -

Page 68

CONTROLS AND EQUIPMENT B980D01Y-AAT makes it possible to have cooler air from the Heating and Cooling System Off dashboard vents and warmer air from the floor Press the «OFF» button to stop the operation of outlets at the same time. the heating and cooling system. -

Page 69

CONTROLS AND EQUIPMENT B760A02GK-EAT Floor-Defrost Level AIR FILTER When selecting the «Floor-Defrost» mode, the (IN FRONT OF BLOWER UNIT) indicator light will come on and the air will be discharged through the windscreen defrost Outside air Inside air nozzle, the floor vents, side defroster nozzle, Filter side ventilator. -

Page 70

CONTROLS AND EQUIPMENT B750A02A-AAT AM reception FM radio station STEREO SOUND SYSTEM Ionosphere Unobstructed How Car Audio Works area FM reception Ionosphere Mountains Obstructed area Buildings SSAR011A Iron bridges SSAR012A AM broadcasts can be received at greater dis- FM broadcasts are transmitted at high frequency tances than FM broadcasts. -

Page 71

CONTROLS AND EQUIPMENT B750B02Y-AAT Using a cellular phone or a two-way radio When a cellular phone is used inside the vehicle, noise may be produced from the audio equip- ment. This does not mean that something is wrong with the audio equipment. In such a case, use the cellular phone at a place as far as possible from the audio equipment. -

Page 72

CONTROLS AND EQUIPMENT JB580B1-A Do not grip or pull out the disc with your hand SR040B1-F CARE OF DISC Care of Cassette Tapes while the disc is being pulled into the unit by the Self Loading mechanism. Proper Handling Do not pull the unit from the dash immediately after a disc is inserted or the Eject Switch has been pressed. -

Page 73

CONTROLS AND EQUIPMENT Head Cotton applicator SSAR042B FUAR053B HGK062-D o Be sure that the cassette label is not loose or o The playback head, capstan and pinch rollers NOTE: peeling off or tape ejection may be difficult. will develop a coating of tape residue that can Look at a tape before you insert it. -

Page 74

CONTROLS AND EQUIPMENT B870A01A-GAT ANTENNA Fixed Rod Antenna B870A01F Your car uses a fixed rod antenna to receive both AM and FM broadcast signals. This antenna is a removable type. To remove the antenna, turn the antenna counterclockwise. To install the antenna, turn the antenna clockwise. CAUTION: Be sure to remove the antenna before wash- ing the car in an automatic car wash or the… -

Page 75: Driving Your Hyundai

DRIVING YOUR HYUNDAI SC000A1-E 2. DRIVING YOUR HYUNDAI C010A01O-EAT WARNING: ENGINE EXHAUST CAN BE DANGEROUS! Engine exhaust gases are potentially lethal. If at any time engine exhaust gas is detected within the passenger compartment, move the vehicle to an open area and open all windows.

-

Page 76

SC040A1-F COMBINATION IGNITION SWITCH AND STEERING LOCK To Start the Engine o If your Hyundai is equipped with a manual START transaxle, place the shift lever in neutral and depress the clutch pedal fully. o If your Hyundai has an automatic transaxle, C040A01E place the shift lever in «P»… -

Page 77

Avoid cruising at unnecessary high speeds. o Always ensure that the periodic maintenance LOCK CAUTION: services are performed by a Hyundai dealer Do not leave the vehicle unattended whilst at the time and/or mileage intervals speci- idling. Never allow the vehicle to idle or fied. -

Page 78

DRIVING YOUR HYUNDAI SC090D1-F C070A02GK-EAT CAUTION: To Remove the Ignition Key MANUAL TRANSMISSION o Do not attempt to engage reverse gear when the car is in motion. o To avoid damaging the selector mecha- nism, do not use the gear shift lever as a hand rest. -

Page 79

35 mph (55 km/h) mature wear of the transaxle shift forks. HGK174-D 45 mph (75 km/h) The highly efficient Hyundai automatic transaxle has four forwards speeds and one reverse speed. The individual speeds are selected au- SC090B1-F Using the Clutch tomatically, depending on the position of the speed selector lever. -

Page 80

DRIVING YOUR HYUNDAI The first few shifts on a new vehicle, or if the C090B01A-AAT C090E01O-AAT The function of each position is as o D(Drive): battery has been disconnected, may be somewhat abrupt. This is a normal condi- Use for normal driving. The transaxle will auto-… -

Page 81

DRIVING YOUR HYUNDAI SKIP : By rapidly moving the selector forwards o Before driving away from a stop on a C090I01L-GAT CAUTION: or backwards twice, it is possible to skip one slippery road, push the selector lever gear, i.e. 1st to 3rd or 3rd to 1st . -

Page 82

Use only genuine Hyundai replacement o Always wear your seat belts. brake pads and shoes to ensure consistent o The risk of rollover is greatly increased if NOTE: friction characteristics and wear rates. -

Page 83

DRIVING YOUR HYUNDAI WARNING: CAUTION: C300A03Y-EAT TRACTION CONTROL SYSTEM (TCS) ABS will not prevent accidents due to im- When the TCS indicator blinks, SLIP control (Not all models) proper or dangerous driving manoeuvres. has been activated. It also means that the… -

Page 84

DRIVING YOUR HYUNDAI 3) When the engine starts, a click is heard 2) This warning function is not provided o Take care of your tires. Keep them inflated from the engine compartment; however, when the driver choose the TCS-OFF to the recommended pressure. Incorrect infla- this is only the sound of traction control mode. -

Page 85

DRIVING YOUR HYUNDAI o Remember, your car does not require ex- ZC170B1-E ZC170D1-E Electrical System Door Locks tended warm-up. As soon as the engine is running smoothly, you can drive away. In Winter conditions impose severe demands upon Should the door lock mechanism become fro-… -

Page 86

TOWING ATTACHMENTS windscreen wiper blades may fail to clear the screen properly due to the formation of It is strongly recommended that only an Hyundai ice upon the blade edge. It will therefore be Approved towing attachment is used to ensure… -

Page 87

DRIVING YOUR HYUNDAI sure rather than as a result of the distances gradients are encountered. Improved accelera- Lbs.(kg) towed. The inside walls of the tyres should be tion performance will be available by selecting Maximum inspected along with the outside walls for crack- «Overdrive Off»,»2″, or «1»… -

Page 88

DRIVING YOUR HYUNDAI o The maximum permissible static vertical fifth gear (manual transmission) or overdrive 13.Avoid holding the brake pedal down too long load on the coupling device : (automatic transmission). or too frequently. This could cause the brakes Lbs.(kg) 5. -

Page 89: In Case Of Emergency

In 3. Check fuel line in the engine room. addition, if the vehicle is equipped with an 4. If engine still refuses to start, call a Hyundai exhaust catalyst, damage to the catalyst may dealer or seek other qualified assistance.

-

Page 90

1. Ensure that the booster battery is 12 volt type. coolant is leaking out, stop the engine imme- If the booster battery is installed in another diately and call the nearest Hyundai dealer SD040A1-E vehicle, ensure that the two vehicles are not for assistance. -

Page 91

CHANGING A FLAT TYRE checked as soon as possible by a Hyundai other car components may occur. dealer. 6. The temporary spare tyre pressure should be checked once a month while the tyre is stored. -

Page 92

IN CASE OF EMERGENCY D060K01FC-EAT 4. Reinstall the wheel cap by fitting the boss of the The jack is located in the right side of luggage Wheel Cap (Not all models) wheel cap in the groove of the wheel, hitting the trim. -

Page 93

IN CASE OF EMERGENCY SD070E1-E SD070F1-F D060F02E-EAT 3. Loosen Wheel Nuts 4. Put the Jack in Place 5. Raising the Car Wrench bar Wheel nut wrench HGK186 HGK193 HFC4022 The wheel nuts should be loosened slightly be- The base of the jack should be placed on firm, After inserting a bar into the wheel nut wrench, level ground. -

Page 94

IN CASE OF EMERGENCY D060G02Y-EAT D060H02Y-EAT 6. Changing Wheels 7. Reinstall Wheel Nuts STA3071H WARNING: HGK232 D060H01GK Wheels and wheel cover may have sharp To reinstall the wheel hold it on the studs put the Loosen the wheel nuts and remove them with edges. -

Page 95

IN CASE OF EMERGENCY SD070J1-E SD070K1-E SD080A1-E 8. Lower Vehicle and Tighten Nuts AFTER CHANGING WHEELS VEHICLE TOWING OR RECOVERY D080A01GK o OK FOR AUTOMATIC OR MANUAL TRANSAXLE EQUIPPED VEHICLE HGK195 HGK194 CAUTION: The pressure of the spare tyre should be checked Lower the car to the ground turning the wheel nut at the first available opportunity. -

Page 96

IN CASE OF EMERGENCY SD090A1-E since the steering lock is not designed to Manual Transmission Vehicle withstand the force required to hold the front wheels straight during the tow. o The vehicle must not be towed with the front wheels on the ground for more than thirty miles. -

Page 97: Appearance Care

By using the most advanced design and con- washing the underbody, the more vulnera- struction practices, every Hyundai is built to ble areas such as wheel arches should be dark body colours. The heat from the sun rays is absorbed by the paint film increasing the surface retain the original factory finish for many years.

-

Page 98

SEAT BELTS those used in manufacture. It is recommended Seat belts should be cleaned only with a mild that repairs are entrusted to a Hyundai dealer to soap solution. Strong detergents, solvens or SE040C1-E ensure that replacement parts used are of the… -

Page 99: Vehicle Maintenance Requirements

It is recommended that all maintenance opera- at your Hyundai dealer because of the need for tions with the exception of the daily operating specialized knowledge and tooling and to en- checks are entrusted to a Hyundai dealer to…

-

Page 100

Hyundai dealer to ensure that the manufacturers recommended procedures In order to ensure the continued safety, reliability and longevity of the vehicle, are employed and that only genuine Hyundai replacement parts are used. the following maintenance service operations should be performed at the time Incorrect maintenance techniques or the use of non genuine replacement parts or mileage intervals specified. -

Page 101

VEHICLE MAINTENANCE REQUIREMENTS F030C02GK-EAT R : REPLACE I : INSPECT AND, AFTER INSPECTION, CLEAN, ADJUST, REPAIR OR REPLACE IF NECESSARY MILES X 1000 DESCRIPTION MONTHS GENERAL MAINTENANCE COOLING SYSTEM COOLANT COOLANT SPECIFIC GRAVITY MANUAL TRANSAXLE OIL AUTOMATIC TRANSAXLE FLUID BRAKE PIPES, HOSES, AND CONNECTIONS BRAKE FLUID CLUTCH FLUID REAR BRAKE LININGS AND CYLINDERS… -

Page 102

VEHICLE MAINTENANCE REQUIREMENTS F040A02GK-EAT MAINTENANCE UNDER SEVERE USAGE CONDITIONS The following items must be serviced more frequently on cars normally used under severe driving conditions. Refer to the chart below for the appropriate maintenance intervals. R : Replace I : Inspect and, after inspection, clean, adjust, repair or replace if necessary MAINTENANCE MAINTENANCE DRIVING… -

Page 103

6ZF060H1-A damage and deformation. Replace any dam- o Air cleaner filter aged parts immediately. A Genuine Hyundai air cleaner filter is recom- 6ZF060B2-A mended when filter is replaced. o Drive belts Inspect all drive belts for evidence of cuts, cracks,… -

Page 104

VEHICLE MAINTENANCE REQUIREMENTS 6ZF070B1-A 6ZF070F1-A 6ZF070K1-A o Cooling system o Brake hoses and lines o Exhaust pipe and muffler Check the cooling system part, such as radiator, Visually check for proper installation, chafing, Visually inspect the exhaust pipes, muffler and coolant reservoir, hoses and connections for cracks, deterioration and any leakage. -

Page 105

VEHICLE MAINTENANCE REQUIREMENTS 6ZF070P1-A o Driveshafts and boots Check the drive shafts, boots and clamps for cracks, deterioration, or damage. Replace any damaged parts and, if necessary, repack the grease. 6ZF070Q1-A o Air conditioning refrigerant Check the air conditioning lines and connections for leakage and damage. -

Page 106: Owner Maintenance

OWNER MAINTENANCE SG000A1-E 6. OWNER MAINTENANCE G010A01GK-EAT ENGINE COMPARTMENT (1.6 DOHC) CAUTION: When inspecting or servicing the engine, you should handle tools and other heavy objects carefully so that the plastic rocker cover of the engine is not damaged. HGK238-D 1.

-

Page 107

OWNER MAINTENANCE G010A01GK-EAT ENGINE COMPARTMENT (2.0 DOHC VVT) CAUTION: When inspecting or servicing the engine, you should handle tools and other heavy objects carefully so that the plastic rocker cover of the engine is not damaged. HGK059-D 1. Clutch fluid reservoir (Not all models) 6. -

Page 108

OWNER MAINTENANCE G010B01GK-EAT ENGINE COMPARTMENT (2.7 V6) CAUTION: When inspecting or servicing the engine, you should handle tools and other heavy objects carefully so that the plastic rocker cover of the engine is not damaged. HGK209-D 11. Engine oil filler cap 1. -

Page 109

OWNER MAINTENANCE SG020B1-E SG030A1-E SG030B02GK-E DAILY OPERATING CHECKS ENGINE OIL Recommended Oil The following items should be checked on a daily The correct engine oil level is of paramount 2,7 L V6 basis or whenever the vehicle is refuelled, which- importance. -

Page 110

OWNER MAINTENANCE SG030C1-E SG030D1-E 2,0 L DOHC VVT Engine Oil Level ENGINE OIL REPLENISHMENT DOHC VVT DOHC VVT HGK259 See the lubrication chart on the page 9-3. HGK211 HGK210 NOTE: The engine oil level should be checked with the If the indicated oil level is at or below the lower o The use of a 5W-20 multi grade oil is not engine at normal operating temperature and the mark of the dipstick, oil should be added until the… -

Page 111

OWNER MAINTENANCE CAUTION: ZG030E1-A G040A02GK-EAT ENGINE OIL CONSUMPTION ENGINE OIL AND FILTER The oil being drained from the engine will be REPLACEMENT hot. Care should be exercised to prevent Function of engine oil scalding. Engine oil has the primary function of lubricating DOHC VVT and cooling the inside of the engine. -

Page 112

«LOW» mark on a regular basis despite sion inhibitor properties deteriorate with time. being topped up, consult a Hyundai dealer. SG050A1-E It is important to note that whilst an increase in the… -

Page 113

Use Engine 2.7L should be changed by an autho- extreme caution when working near the blades rized Hyundai dealer. of the cooling fan so that you are not injured by a rotating fan blade. As the engine coolant 2. -

Page 114

When replacing the spark plug, always use care should be exercised that the air flow the genuine parts recommended. sensor is not damaged during replacement of the element. To ensure maximum filtration performance and continued engine performance, only genuine Hyundai replacements should be used. -

Page 115

If the wipers continue to streak or smear the and in the concentration recommended by the glass, replace them with genuine Hyundai re- Recommended Oil manufacturer. The windscreen washer reservoir placement. -

Page 116

If the level is low and no Open the bonnet and remove the transmission Your Hyundai automatic transaxle is specially lubricant is seen to drip, add the required quantity dipstick, remembering that care must be exer- designed to operate with DIAMOND ATF SP-III, of lubricant and replace the plug. -

Page 117

Fluid level should be within this range essential to the safe operation of the vehicle and therefore, any maintenance operations other than those listed below should be en- trusted to a Hyundai dealer. SG120C2-E Brake Fluid Recommendations HGK249 Only brake fluid conforming to DOT 3 or DOT 4… -

Page 118

OWNER MAINTENANCE SG130A1-C SG130B2-E CHECKING THE CLUTCH FLUID Adding Fluid Recommended brake fluid conforming to DOT 3 (Not all models) or DOT 4 should be used. The reservoir cap must To Check the Clutch Fluid be fully tightened to avoid contamination from foreign matter or moisture. -

Page 119

SG140D1-E crankshaft pulleys. Adjustment of the belt should Off Season Maintenance be entrusted to a Hyundai dealer. The air conditioning must be run for ten minutes or so weekly during periods when the system would not normally be used to ensure that the compressor and seals are lubricated. -

Page 120

STEERING WHEEL FREEPLAY SSA6160A The clutch pedal freeplay should be checked against the specified value. If the freeplay is not correct, the clutch should be adjusted by a Hyundai dealer. 1.18in. (30 mm) HGK254 HGK218 4. Installation is the reverse order of disassem- Steering wheel freeplay should be checked to bly. -

Page 121

Hyundai dealer before a replace- should be performed by a Hyundai dealer. Pedal ment link is fitted. to floor clearance: 1.97 in. (50 mm) -

Page 122

The circuit which is corrosive and poisonous. Hydrogen even when the engine is not running. Use should be checked by a Hyundai dealer at the gas is emitted from the battery which is ex- extreme caution when working near the blades first available opportunity. -

Page 123

OWNER MAINTENANCE NOTE: The engine cooling fan should operate before the G270A02A-GAT HEADLIGHT BULB temperature gauge reaches the upper portion of Grinding noise from power steering pump Replacement instructions: the scale and the condenser fan should operate may be heard immediately after the engine is whenever the air conditioning is in use. -

Page 124

OWNER MAINTENANCE WARNING: 7. Adjust each cut-off line of the low beam to the High Beam The halogen bulb contains gas under pres- parallel line with a phillips screwdriver — VER- sure and if impacted could shatter, resulting TICAL AIMING. in flying fragments. -

Page 125

OWNER MAINTENANCE SPECIFICATION: «H» Horizontal centre line of headlights from ground: Low Beam: 26.7 in. (679mm) High Beam: 26.5 in. (672mm) «W» Distance between each headlight centre : Low Beam: 47.3 in. (1,202mm) High Beam: 38.0 in. (966mm) «L» Distance between the headlights and the wall that the lights are tested against : 118.11 in. -

Page 126

OWNER MAINTENANCE G280A02GK-EAT (Low) (High) 11 12 HGK035A Part Name Wattage Part Name Wattage High Mounted Without spoiler 2.4W (LED) Head Light (High/Low) 55/55 Stop LIght With spoiler 3.5W (LED) Map Light Rear Turn Signal Light Front Position Light Combination Stop/Tail Light Front Fog Light (Not all models) 21/5… -

Page 127

OWNER MAINTENANCE G200C01GK-GAT FUSE PANEL DESCRIPTION Engine Compartment PROTECTED COMPONENTS DESCRIPTION FUSE RATING Generator BATT 100A BATT Generator COND Condenser Fan Radiator Fan Engine Control, ECM. ATM Control Ignition, Start Relay ABS 1 ABS 2 BLOWER Blower Injector SNSR Sensor, ECM F/FOG Front fog Light TCM, ECM… -

Page 128

OWNER MAINTENANCE G200D01GK-GAT Inner Panel DESCRIPTION PROTECTED COMPONENTS FUSERATING IG COIL Ignition Coil, ECM AMP. Multi Gauge Unit B/UP LAMP B/Up Lamp A/BAG IND Air Bag Indicator A/BAG Air Bag HTD MIR Outside Mirror Defroster Hazard Warning Light HAZARD R/WIPER Rear Window Wiper TAIL-RH Taillight… -

Page 129: Emission Control System

JN70010A recommended that the vehicle is inspected and The purge control solenoid valve is controlled by Hyundai Coupe models are fitted with catalytic maintained by an authorized Hyundai dealer in the ECU; when the engine coolant temperature convertors which require special operating con-…

-

Page 130

(Note, it is impos- sible to push or tow start a Hyundai model equipped with fuel injection since the fuel pump safety interlock will prevent the pump from oper- ating under these conditions). -

Page 131: Consumer Information

CONSUMER INFORMATION SI010B1-E pressures can affect vehicle safety by causing SI000A1-E Engine Number reduced adhesion, steering response and tyre 8. CONSUMER failure through overheating. The tyre pressure DOHC VVT must only be checked when the tyres are cold. INFORMATION The correct tyre pressures are indicated on the label affixed to the drivers door pillar and below.

-

Page 132

CONSUMER INFORMATION I050A01GK-EAT I060A01GK-EAT TYRE CHAINS TYRE ROTATION Tyre chains should be installed on the front 15″, 16″ Tyre 17″ Tyre Sidewall wheels. Be sure that the chains are the proper size and that they are installed in accordance with the manufacturer’s instructions. Refer to the following information. -

Page 133

It is recommended that the tyres be balanced on The original wheels may only be replaced with the car for best results and that the tyres are Hyundai Approved Wheels. balanced whenever they have been removed from the wheel for repair. -

Page 134: Vehicle Specifications

VEHICLE SPECIFICATIONS J030A01GK-DAT SJ000A1-F TYPE 9. VEHICLE SPECIFICATIONS Standard 195/65 R15 Option 205/55 R16, 215/45 R17 J010A01GK-AAT MEASUREMENT in. (mm) Overall length 173(4395) J035A01GK-DAT SPARE TYRE Overall width 69.3(1760) Standard T125/70R 16 (Temporary) Overall height (unladen) 52.4(1330) Wheel base 99.6(2530) Wheel tread Front 58.7(1490)

-

Page 135

VEHICLE SPECIFICATIONS J070A03GK-EAT ENGINE SPECIFICATION ITEMS 1.6 L 2.0 L 2.7 L Engine Type 4-Cyl., In-line DOHC 2.7 6 Cylinder V6 DOHC Bore x Stroke 76.5 x 87 82 x 93.5 86.7 x 75 Displacement (cc) 1,599 1,975 2,656 Firing order 1 — 3 — 4 — 2 1 — 3 — 4 — 2 1 — 2 — 3 — 4 — 5 — 6… -

Page 136

MAX. 1L / 1500 Km Normal driving condition Engine Oil Consumption MAX. 1L / 1000 Km Severe driving condition Manual HYUNDAI GENUINE PARTS MTF 75W/90 (API GL-4) 1.86 (2.15, 2.3) Transaxle Auto DIAMOND ATF SP-III or SK ATF SP-III 6.9 (7.8, 8.2) -

Page 137: Index

INDEX JK000A2-EAT CARE OF CASSETTE TAPE …………1-64 10. INDEX CARE OF DISC …………….1-64 CARE OF SEAT BELTS …………..1-11 CATALYTIC CONVERTOR OPERATING PRECAUTIONS ..7-1~7-2 CENTRAL DOOR LOCK …………..1-4 AIR BAG ………………. 1-18 CHANGING A FLAT TYPE …………..3-3 AIR CONDITIONING SWITCH …………

-

Page 138

INDEX EFFECTIVE BRAKING …………… 2-8 GLOVE BOX ………………1-39 ELECTRIC COOLING FANS …………6-17 EMISSION CONTROL SYSTEMS …………. 7-1 ENGINE COMPARTMENT …………..6-1 HATCHBACK DOOR ……………. 1-45 ENGINE COOLANT CHECKING AND REPLACING ……6-7 HATCHBACK DOOR WIPER AND WASHER …….. 1-35 ENGINE COOLANT TEMPERATURE GUAGE ……. -

Page 139

POWER STEERING HOSES …………6-18 KEY POSITIONS …………….2-2 PRE-TENSIONER SEAT BELT ……….1-17 ~ 1-18 KEYS ………………..1-2 PROTECTING YOUR HYUNDAI FROM CORROSION ….4-1 LIGHTING SWITCH …………….1-33 REAR FOG LIGHT SWITCH …………1-43 LUGGAGE NET …………….1-47 REAR PARCEL SHELF ………….. -

Page 140

INDEX SEAT CUSHION HEIGHT ADJUSTMENT ……..1-8 TYRE PRESSURES …………….8-1 SEAT WARMER …………….. 1-8 TYRE BALANCING …………….8-3 SERVICE HISTORY …………….5-1 TYRE CHAINS ………………. 8-2 SMOOTH CORNERING …………..2-11 TYRE REPLACEMENT …………..8-3 SNOW TYRES ………………. 8-1 TYRE ROTATION …………….8-2 SPARE TYRE ………………

Валит ли Тибурон в жизни, так как валил в игре NFS.? (Hyundai tiburon)

Авто б/ушка — Hyundai Coupe 2.0 2008г.в

Тест драйв видео, обзор, отзыв Hyundai coupe, tiburon vs…, test drive over drive хундай купе

Hyundai Coupe как оно есть на самом деле, он же Tiburon, он же Tuscani, он же Turbulence ????????

Обзор hyundai tiburon / coupe Коплю на Феррари

Hyundai Tiburon АНТИтест / вся суть за 8 минут // АнтиТест-драйв tiburon / tuscani / coupe

![Видео [Автообзор] Hyundai Tiburon / Coupe / Tuscani. Безальтернативный бюджетный спорткар (автор: Гнутый Кардан)](https://i.ytimg.com/vi/bZxn0XA-_gs/mqdefault.jpg)

[Автообзор] Hyundai Tiburon / Coupe / Tuscani. Безальтернативный бюджетный спорткар

HYUNDAI COUPE | ТЕСТ ДРАЙВ

РУКОВОДСТВО ПО

ЭКСПЛУАТАЦИИ

Эксплуатация

Техническое обслуживание

Технические характеристики

Вся информация в настоящем Руководстве по эксплуатации приведена по

состоянию на момент публикации.

Компания Hyundai оставляет за собой право в любое время вносить изменения

в рамках постоянно действующей программы модернизации продукции.

Настоящее Руководство применимо для всех моделей автомобилей Hyundai и

содержит описания как дополнительного, так и стандартного оборудования, а

также соответствующие пояснения. Поэтому в данном Руководстве Вы сможете

обнаружить материалы, не имеющие отношения к конкретной модели Вашего

автомобиля.

Внесение любых изменений в конструкцию Вашего автомобиля Hy…

Страница 2

- Изображение

- Текст

F2

Внесение любых изменений в конструкцию Вашего автомобиля Hyundai не допускается.

Подобные изменения могут ухудшить работу автомобиля, его безопасность, или сократить

срок его службы, а также могут нарушить условия гарантийного обслуживания Вашего

автомобиля. Определенные изменения могут также нарушать положения, установленные

Министерством транспорта и другими исполнительными органами Вашей страны.

Ваш автомобиль оснащен системой электронного впрыска топлива и другими электронными

компонентами. Неправильная установка и настройка систем дуплексной радиосвязи или

сотового телефона могут отрицательно сказаться на работе электронных блоков автомобиля.

Поэтому, если Вы решили установить подобные устройства, мы рекомендуем Вам внимательно

следовать всем указаниям производителя этих систем или связаться с дилером Hyundai для

разъяснения мер предосторожности и особых инструкций.

ВНИМАНИЕ: ВНЕСЕНИЕ ИЗМЕНЕНИЙ В КОНСТРУКЦИЮ ВАШЕГО

АВТОМОБИЛЯ HYUNDAI

УСТАНОВКА СИСТЕМ ДУПЛЕКСНОЙ РАДИОСВЯЗИ ИЛИ

СОТОВОГО ТЕЛЕФОНА

В настоящее Руководство включена информация с заголовками О…

Страница 3

- Изображение

- Текст

F3

В настоящее Руководство включена информация с заголовками ОСТОРОЖНО, ВНИМАНИЕ и

К СВЕДЕНИЮ.

Данные заголовки означают следующее:

✽

✽ К СВЕДЕНИЮ

Информация, представленная под этим заголовком, может представить интерес для

владельца автомобиля или оказаться ему полезной.

ПРЕДУПРЕЖДАЮЩАЯ ИНФОРМАЦИЯ ОБ УГРОЗЕ

БЕЗОПАСНОСТИ И ПОВРЕЖДЕНИЯ АВТОМОБИЛЯ

ОСТОРОЖНО

Обозначенная под таким заголовком ситуация может привести к нанесению вреда,

причинению тяжелых травм владельцу автомобиля или другим лицам или их гибели

в случае игнорирования данного предупреждения. Необходимо следовать

рекомендациям, приведенным под данным заголовком.

ВНИМАНИЕ

Обозначенная под таким заголовком ситуация может привести к повреждению

автомобиля или его систем и оборудования в случае игнорирования данного

предупреждения. Необходимо следовать рекомендациям, приведенным под данным

заголовком.

ПРЕДИСЛОВИЕ Спасибо за то, что Вы выбрали автомобиль марки…

Страница 4

- Изображение

- Текст

F4

ПРЕДИСЛОВИЕ

Спасибо за то, что Вы выбрали автомобиль марки Hyundai. Мы рады приветствовать Вас в растущем сообществе

ценителей качества, сидящих за рулем наших автомобилей. Передовые идеи, заложенные при проектировании, и

высококачественное исполнение каждого автомобиля, созданного в нашей компании — это те ценности, которыми мы так

гордимся.

Настоящее Руководство по эксплуатации ознакомит Вас с особенностями конструкции и эксплуатации Вашего нового

автомобиля Hyundai. Мы предлагаем Вам детально изучить этот документ, поскольку находящаяся в нем информация

может существенно помочь Вам получить максимальное удовольствие от своего нового автомобиля.

Производитель также рекомендует проводить все работы по техническому обслуживанию и ремонту Вашего автомобиля

на предприятиях авторизованных дилеров компании Hyundai. Эти предприятия готовы предоставить высококачественное

техническое обслуживание автомобиля и оказать любые другие необходимые услуги.

КОМПАНИЯ HYUNDAI MOTORS

К сведению: Поскольку будущим владельцам автомобиля также потребуется информация, содержащаяся в данном

Руководстве, в случае продажи Вашего автомобиля Hyundai, пожалуйста, оставьте данное Руководство в

автомобиле. Спасибо.

Авторские права Hyundai Motor Company, 2008 г. Все права защищены. Никакая часть настоящего документа не может

быть воспроизведена, помещена в какую-либо информационно-поисковую систему или передана по каналам связи в

любой форме и любым способом без предварительного получения письменного разрешения компании Hyundai Motor

Company.

ВНИМАНИЕ

Использование топлива и смазочных материалов ненадлежащего качества, не соответствующих

требованиям компании Hyundai, может привести к серьезным повреждениям двигателя и трансмиссии.

Следует всегда использовать горюче-смазочные материалы высокого качества, которые соответствуют

требованиям, перечисленным в настоящем Руководстве на странице 8-4 в разделе “Технические

характеристики автомобиля”.

F5

Оpигинaльныe yзлы и

дeтaли кoмпaнии Hyundai

1. Что такое “оригинальные узлы и

детали Hyundai”?

Оригинальные узлы и детали Hyundai

— это узлы и детали, из которых

компания Hyundai Motor Company

производит автомобили.

При их разработке и испытаниях в

первую

очередь

учитывались

требования оптимального уровня

безопасности,

технических

характеристик и надежности для

наших клиентов.

2. Почему следует использовать

оригинальные узлы и детали?

Оригинальные

узлы

и

детали

компании Hyundai разработаны и

произведены в соответствии с

жесткими

производственными

стандартами.

Ограниченная гарантия компании

Hyundai на новый автомобиль или

любая

другая

гарантия,

предоставляемая компанией Hyundai,

не распространяется на узлы и

детали,

являющиеся

имитацией

оригинальных,

подделкой

под

оригинальные, или на узлы и детали,

снятые с автомобилей, бывших в

эксплуатации.

Кроме того, на любое повреждение

оригинальных узлов и деталей

Hyundai или их отказ, вызванные

установкой или отказом узлов и

деталей, являющихся имитацией

оригинальных,

подделкой

под

оригинальные, или узлов и деталей,

снятых с автомобилей, бывших в

эксплуатации, не распространяются

никакие гарантийные обязательства

Hyundai.

3. Как можно определить, являются

ли приобретаемые запасные

части оригинальными узлами и

деталями компании Hyundai?

Следует проверить наличие логотипа

оригинальных узлов и деталей

компании Hyundai на упаковке (см.

ниже). Экспортные оригинальные узлы

и детали компании Hyundai имеют

маркировку только на английском

языке. Оригинальные узлы и детали

компании Hyundai продаются только

через

авторизованных

дилеров

компании Hyundai.

A100A01L

A100A02L

A100A03L

A100A04L

I Введение Знакомство с вашим автомобилем Средства обеспече…

Страница 6

- Изображение

- Текст

1

2

3

4

5

6

7

8

I

Введение

Знакомство с вашим автомобилем

Средства обеспечения безопасности автомобиля

Характеристики автомобиля

Управление автомобилем

Действия в непредвиденных случаяхs

Техническое обслуживание

Технические характеристики & Информация для потребителя

Предметный указатель

СОДЕРЖАНИЕ

1

Как пользоваться настоящим руководством / 1-2

Требования к топливу / 1-3

Порядок обкатки автомобиля / 1-6

Условные обозначения на

cвeтoвыx индикaтopax приборной панели / 1-7

Введение

AHM Мы хотим помочь Вам получить максимально возможное удово…

Страница 8

- Изображение

- Текст

Введение

2

1

A010000AHM

Мы хотим помочь Вам получить

максимально

возможное

удовольствие от вождения данного

автомобиля. Настоящее Руководство

пользователя

может

оказать

содействие в этом различными

способами.

Мы

настойчиво

рекомендуем прочитать руководство

полностью. С целью уменьшения до

минимума вероятности гибели людей

и травматизма следует обязательно

прочитать

разделы,

отмеченные

заголовками

ОСТОРОЖНО

и

ВНИМАНИЕ, которые присутствуют во

всем руководстве.

Иллюстрации дополняют словесные

описания, приведенные в настоящем

руководстве,

для

того,

чтобы

наилучшим образом показать, как

получить удовольствие от данного

автомобиля.

Прочтя

данное

руководство, владелец автомобиля

ознакомится с его характерными

особенностями, важной информацией

о безопасности и с советами по его

эксплуатации в различных дорожных

условиях.

Общая

структура

руководства

приведена в содержании. Неплохим

местом для начала знакомства

является предметный указатель; в нем

приведен в алфавитном порядке

перечень

всей

информации,

содержащейся в руководстве.

Разделы: В настоящем руководстве

содержатся девять разделов и

предметный

указатель.

Каждый

раздел начинается с короткого

перечня

содержащейся

в

нем

информации, так что можно быстро

определить, есть ли в данном разделе

необходимые сведения.

В данном руководстве находятся

разнообразные

сведения

под

заголовками

ОСТОРОЖНО,

ВНИМАНИЕ и К СВЕДЕНИЮ. Они

были

подготовлены

с

целью

повышения

уровня

личной

безопасности владельца автомобиля.

Необходимо внимательно прочитать

ВСЕ процедуры и рекомендации,

приведенные

под

заголовками

ОСТОРОЖНО, ВНИМАНИЕ и К

СВЕДЕНИЮ, и соблюдать их.

✽

✽

К СВЕДЕНИЮ

Информация, представленная под

заголовком К СВЕДЕНИЮ, может

представить интерес для владельца

автомобиля или оказаться ему

полезной.

КАК ПОЛЬЗОВАТЬСЯ НАСТОЯЩИМ РУКОВОДСТВОМ

ОСТОРОЖНО

Обозначенная под заголовком

ОСТОРОЖНО ситуация может

привести к нанесению вреда,

причинению тяжелых травм или

к гибели людей в случае

игнорирования

данного

предупреждения.

ВНИМАНИЕ

Обозначенная под заголовком

ВНИМАНИЕ ситуация может

привести к нанесению вреда

автомобилю при игнорировании

данного предупреждения.

1 3

Введение

Автомобили с бензиновым

двигателем

A020101ABH

Неэтилированный бензин

Ваш новый автомобиль HYUNDAI

предназначается

только

для

использования

неэтилированного

бензина с октановым числом по

исследовательскому методу (RON) не

ниже

91 / антидетонационным

коэффициентом (AKI) не ниже 87.

Автомобиль

разработан

таким

образом,

чтобы

достигать

максимальных

эксплуатационных

характеристик при использовании

НЕЭТИЛИРОВАННОГО БЕНЗИНА, что

также приводит к минимизации

выхлопа

вредных

веществ

и

загрязнения свечей зажигания.

ТРЕБОВАНИЯ К ТОПЛИВУ

ВНИМАНИЕ

НИКОГДА НЕ ИСПОЛЬЗУЙТЕ

ЭТИЛИРОВАННОЕ

ТОПЛИВО.

Использование этилированного

топлива

наносит

ущерб

каталитическому

нейт-

рализатору

и

приведет

к

повреждению

кислородного

датчика системы управления

двигателя,

негативно

сказавшись

на

контроле

выброса вредных веществ.

Никогда не добавляйте какие-

либо присадки для очистки

топливной системы в топливо

за исключением тех, которые

были

рекомендованы

производителем автомобиля.

(За

дополнительной

информацией обратитесь к

авторизованному

дилеру

HYUNDAI.)

ОСТОРОЖНО

• Не доливайте топливо в бак по

верхнюю кромку заправочной

горловины после того, как

произойдет

автоматическое

отключение

заправочного

пистолета во время заправки.

• После завершения заправки

автомобиля

топливом

обязательно убедитесь в том,

что

крышка

заправочной

горловины плотно закрыта,

для того, чтобы топливо не

выплеснулось наружу в случае

д о р о ж н о т р а н с — п о р т н о г о

происшествия.

AUN Бензин, содержащий этиловый и метиловый спирт Бензоспирт…

Страница 10

- Изображение

- Текст

Введение

4

1

A020103AUN

Бензин, содержащий этиловый и

метиловый спирт

Бензоспирт, смесь, состоящая из

бензина и этилового спирта (также

известного под названием пищевой

спирт), и бензин или бензоспирт с

содержанием метилового спирта

(также известного под названием

древесный спирт) продаются на рынке

одновременно с этилированным или

неэтилированным

бензином

или

вместо них.

Не

допускается

использование

бензоспирта, содержащего более 10%

этилового спирта, и использование

бензина

или

бензоспирта,

содержащего

какую-либо

долю

метилового спирта. Все эти виды

топлива могут вызвать проблемы при

управлении автомобилем и привести к

повреждению топливной системы.

Прекратите использовать бензоспирт

любого типа при возникновении

проблем

при

управлении

автомобилем.

Повреждение

автомобиля

или

проблемы при управлении им могут не

покрываться гарантией производителя

в

случае,

если

они

вызваны

использованием следующих видов

топлива:

1. Бензоспирт, содержание этилового

спирта в котором превышает 10%.

2. Бензин

или

бензоспирт,

содержащие метиловый спирт.

3. Этилированное

топливо

или

этилированный бензин.

A020104AEN

Использование

метилтербутилэфира (MTBE)

Компания HYUNDAI не рекомендует

использовать в данном автомобиле

марки топлива, в которых объемная

доля метил-трет-бутилового эфира

(MTBE) превышает 15,0 % (при

весовой доле кислорода 2,7 %).

Использование топлив, объемная

доля метилтербутилэфира (MTBE) в

которых превышает 15,0% (весовая

доля кислорода — 2,7%), может

привести

к

снижению

эксплуатационных

характеристик

автомобиля и привести к образованию

паровых пробок или проблем при

запуске.

ВНИМАНИЕ

Никогда

не

используйте

бензоспирт,

содержащий

метиловый спирт. Прекратите

использовать любой продукт

типа бензоспирта, который

негативно

сказывается

на

управлении автомобилем.

Комментарии

POWER WINDOWS

REAR WINDOW DEFOGGER ....................... eenneninene nene... BETS

WINDSHIELD WIPER/W

REAR WIPER/W

SEAT WARMER .................eecccevececenonooeornarereeee reee eos

SUN ROOF.................. anrere sen sance decane see see anne ane cae

LIGHTING SYSTEM

AUTO LIGHTS CONTROL SYSTEM

DAYTIME RUNNING LIGHTS ...........eeeeocanrannenarooneonano nea ne

HEAD LAMP LEVELLING DEVICE .........e..eeooocnonaazacanencaneaa BE -110

IMMOBILIZER CONTROL SYSTEM ...........ereeeonn0necaconcorenvaoa ВЕ -112

SPECIFICATIO NS стосоово |

MULTIFUNCTION SWITCH —

BODY ELECTRICAL SYSTEM

Specifications

Rated Voltage

DC 12V

Operating temperature range

-30°C - +80°C (-22 - +176°F)

Rated load

Dimmer & passing switch

Lighting switch

Turn signal & lane change switch

Wiper switch

Wiper mist switch

Washer switch |

Variable intermittent wiper volume switch

Rear wiper & washer switch

Horn switch

High : 1A (Relay load)

Low : 1A (Relay load)

Passing : 1A (Relay load)

Lighting : 1A (Relay load)

6.6 + 0.5A (Lamp load)

Low, High : 4.5A (Motor load)

Int. : 0.22 + 0.05A (Relay load)

Lock : Max. 28A (Motor load)

4.5A (Motor load) ВЕ

4A (Motor load)

| Мах. 25mA — |

Rear wiper : 0.2A (Relay load)

Rear washer : 4A (Motor load)

1A (Relay load)

INSTRUMENTS AND WARNING SYSTEM

Warning lamps Bulb wattage (W) Color

High beam LED oo Blue

Low fuel LED - Amber

Turn signal (LH, RH) LED Green

Battery (charge) LED Red

Oil pressure LED CC Red

Air bag Bulb (1.4W) Red

Parking brake LED Red

Seat belt LED | Red

Check engine Bulb (1.4W) — Amber

ABS LED Amber

Door ajar LED Red

Trunk lid open LED Red

Cruise LED Green

TCS ~~ LED Amber

| TCS OFF LED ‘Amber

GENERAL

SERVICE SPECIFICATI

INDICATORS AND GAUGES

ETOCO100

items Specifications

Speedometer

- Type о Cross-coil type

Input spec. o Hall IC type : 4 pulses/rev.

Indication o Km/h : 637rpm x 4 pulses/rev. indicates 60Km/h

o MPH: 1026 rpm x 4 pulses/rev. indicates 60MPH

Standard values

Velocity (Km/h) 20 40 60 80 100 120 140

Tolerance (Km/h) | 20-24.4 40-43 | 60-64.4 | 80-85.5 | 100-105.5 | 120.5-126 | 140.5-146

Tolerance (Km/h)| 20-24.4 | 40-44.4 | 60-65.4 | 81-865 | 102-107.5 | 123-128.5 | 144-149.5

Velocity (Km/h) 160 180 200 220 240 Area

Tolerance (Km/h)| 160.5-166 | 181-186.5 | 201-206.5 | 221-226.7 | 241-246.7 Others

Tolerance (Km/h) | 165-170.5 | 186-191.5 | 207-212.5 [227.7-233.5248.5-254.3 EEC 8 General

Velocity (MPH) | 10 — 20 40 60 80

Tolerance (MPH)| 10-14.4 20-23 40-44.4 60-65.5 80-85.5

Tolerance (MPH) 8.5-11.5 18.5-21.5 38.5-41.5 58.3-61.7 178.3-81.7

Velocity (MPH) 100 120 140 160 Area —

Tolerance (MPH)| 100.5-106 120.5-126 140.5-147 - 160.5-167 Except USA

Tolerance (MPH)| 98.3-101.7 118.3-121.7 | 138.1-141.9 | 158.1-161.9 U.S.A

o Tap the speedometer to prevent hysterisis effects during inspection.

Tachometer — | a

Type | o Cross-coil type (4cyl : 2pulses/rev, 6cyl : 3pulses/rev)

Standard values Revolution (RPM) | 1,000 | 2,000 | 3,000 | 4,000 | 5,000 | 6,000 | 7,000 | 8,000

Tolerance (RPM) +100 +125 +150 +150 +150 +180 +210 +240

| o Tap the tachometer to prevent hysterisis e during inspection.

Fuel gauge |

Type o Cross - coil type (Fixed point type : Pointer should not fall into the "E" point but indicate remaining

fuel level when the ignition is off)

Standard values

Level - Gauge

Resistance (Q) Gauge angle (°)

E (Empty) 97 | =45 + 2.5

1/2 32.5 0+5.0

F (Full) 6 45 + 2.5

o inspection order: E >F >E

The level must be reached within 7 minutes after the resistance is set for Full or Empty.

o Point stability tolerance : Within +6°

Apply power for 10 minutes. Then turn off the power for an hour and read the position of the pointer.

ETOCO10A

DY ELECTRICAL SYSTEM

items Specifications

Temperature gauge

Type o Cross - coil type

Indication standard ;

Temperature Angle (*) Assembled tolerance (')

60°C O | -

85°C ~ 110°C 38 . | 15

Red zone (over 125°C) | 90 | +

o Inspection order: OFF>C—H

- Resistance of

Temperature (°C) 60 85 110 125

temperature sender |

| | Resistance (Q) 143.4+2 58.1+2 26.912 17.5+2

(NTC) *

Torque gauge |

Type o Stepper motor

Input spec. о ISO CAN 2.0A 500Kbps _

Standard values Indication (N.m) 0 50 100 150 200 ~400

| Tolerance (N.m) +5 +5 +5 +5 = +20

Instantaneous fuel |

consumption gauge | |

Type | o Stepper motor

Input spec. o Speed input (Hall IC)

Injection input from EMS.

Standard values Indication (£/100km) | O 5 | 10 | 15 | 20 | -Max. | Atide

Tolerance (£/100km) | — +2 +2 | +2 +2 3 +10 | Indicate "o"

Voltage gauge -

Type | | о Stepper motor

Input spec. o Battery input voltage |

Standard val

andard values Indication (V) Below 8.5V 10 12 14 16 Above 16V

Tolerance (V) Indicate "Min." | 0.5 | 0.5 +0.5 +0.5 | Indicate "Max."

ЕТОСО10В

LIGHTING SYSTEM |

Items | | Bulb wattage(W)

Head lamp a | 55W / 55W (High / Low beam)

Front turn signal lamp 21W

Front position lamp a a | 5W

Front fog lamp | 51W

Rear combination lamps a

Tail/stop lamp 5W / 21W

Back up lamp 21W

Turn signal lamp 21W

Luggage lamp 5W

GENERAL

[tems

Bulb wattage(W)

Center high mounted stop lamp

Internal type : 2.4W (LED)

External spoiler type : 3.5W (LED)

Overhead console lamp 10W x 2

License plate lamp 5W x 2

AUDIO

items H250 H260

Rated output Max. 20W x 4 Max. 20W x 4

Load impedance 492 x 4 40 x 4

Band

AM/FM, LW/MW/FM

AM/FM, LW/MW/FM

Tuning type

PLL Synthesized type

PLL Synthesized type

Dark current

Max. 2mA

Max. 3.8mA

AM : 531-1602KHZ/9KHZ

AM : 531-1602KHZ/9KHZ

FM : 87.5-108MHZ/100KHZ

FM © 87.5~108MHZ/100KHZ

Frequency range / Channel

LW : 153-279KHZ/1KHZ

LW : 153~279KHZ/1KHZ

MW : 531-1602KHZ/9KHZ

MW : 531-1602KHZ/9KHZ

FM : 87.5-108MHZ/50KHZ

FM : 87.5-108MHZ/50KHZ

WINDSHIELD WIPER AND WASHER

ltems Specifications

Wiper motor _ | В

Rated voltage DC 12V

Operating voltage range DC 10-15V

Insulation resistance Min. 1MQ |

Speed/current at 1Nm load test Low : 44-52rpm/3.5A or less

| High : 64-78rpm/4.5A or less

Speed/current at 4Nm load test Low : 39-47rpm/5.5A or less

| High : 56-68rpm/7.0A or less

Torque/current when parking Low : 28Nm/24A or less

High : 23Nm/28A or less

Windshield washer

Motor type DC ferrite magnet

Pump type Centrifugal

Rated voltage 12V

Discharge pressure 1.8kg/cm? or more

Flow rate 1,450cc/min. or more

Current 5.0A or less

Overload capacity (Continuous operation)

With water 60sec. or less

Without water (Racing) 20sec. or less

Rear wiper motor

Speed/current at no load test

Speed/current at 1Nm load test

Torque/current when parking

Wiping angle at no load

35rpm/2.2A or less

30-40rpm/3.5A or less

ENM/T4A or less

170° x 3°

TROU BLESHOOTING — ETOCO150

INSTRUMENTS AND WARNING SYSTEM

BODY ELECTRICAL SYSTEM

| Symptom

Possible cause

Remedy

Tachometer does not operate

No.17 fuse (10A) blown

Tachometer faulty

Wiring faulty

Check for short and replace fuse _

Check tachometer

Repair if necessary

Fuei gauge does not operate

No.17 fuse (10A) blown

Fuel gauge faulty

Fuel sender faulty

Wiring faulty

Check for short and replace fuse

Check gauge

Check fuel sender

Repair if necessary

Low fuel warning lamp does not light

No.17 fuse (10A) blown

Bulb burned out

Fuel level sensor faulty

Wiring or ground faulty

Check for short and replace fuse

Replace bulb

Check sensor

Repair if necessary

Water temperature gauge does

not operate |

| No.17 fuse (10A) blown

Water temperature gauge faulty

Water temperature sender faulty

Wiring or ground faulty

Check for short and replace fuse

Check gauge

Check sender

Repair if necessary

Oil pressure warning lamp

does not light

No.17 fuse (10A) blown -

Bulb burned out

Oil pressure sender faulty

Wiring or ground faulty

Check for short and replace fuse

Replace bulb

Check sender

Repair if necessary

Low brake fluid warning lamp

does not light

No.17 fuse (10A) blown

Bulb burned out

Brake fluid level warning switch faulty

Parking brake switch faulty

Wiring or ground faulty

Check for short and replace fuse

Replace bulb

Check switch

Check switch

Repair if necessary

Open door warning lamp does

not light

No.18 fuse (10A) blown

Bulb burned out

Door switch faulty

Wiring or ground faulty

Check for short and replace fuse =

Replace bulb a

Check switch

Repair if necessary

Seat belt warning lamp does not light

No.17 fuse (10A) blown

Bulb burned out

Buckle switch faulty

Wiring or ground faulty

Check for short and replace fus

Replace bulb: a В

Check switch

Repair if necessary

GENERAL

LIGHTING SYSTEM

BE -7

Symptom

Possible cause

Remedy

One lamp does not light

(all exterior)

Bulb burned out |

Socket, wiring or ground faulty

Replace bulb

Repair if necessary

Head lamps do not light

Bulb burned out

Head lamp fuse (15A) blown

No.21 fuse (10A) blown

Head lamp relay faulty

Lighting switch faulty

Wiring or ground faulty

Replace bulb

Replace fuse and check for short

Check for short and replace fuse

Check relay

Check switch

Repair if necessary

Tail lamps and license plate

lamps do not light

No.9, No.14 fuse (10A) blown

Battery fusible link {50A) blown

Tail lamp relay faulty

Lighting switch faulty

Wiring or ground faulty

| Replace fuse and check for short

| Replace the fusible link

Repair if necessary

Check relay

Check switch

Stop lamps do not light

No.13 fuse (15A) blown

| Stop lamp switch faulty

Wiring or ground faulty

Repair if necessary

Replace fuse and check for short

Adjust or replace switch

Stop lamps stay on

Stop lamp switch faulty

Adjust or replace switch

instrument lamps do not light

(Tail lamps light)

Rheostat faulty

Wiring or ground faulty

Check rheostat

Repair if necessary

Turn signal lamp does not flash

on one side

Bulb burned out Е

Turn signal switch faulty

| Wiring or ground fauity

Replace bulb

Check switch

Repair if necessary

Turn signal lamps do not operate

No.7 fuse (10A) blown

Body control module faulty

Hazard relay faulty

Turn signal switch faulty

| Wiring or ground faulty

Replace fuse and check for short

Check body control module

Replace relay

Check switch

Repair if necessary

Hazard warning lamps do not operate

No.7 fuse (10A) blown

Body control module faulty

‘Hazard switch faulty

| Hazard relay faulty

Wiring or ground faulty

Replace relay -

Repair if necessary

Replace fuse and check for short

Check body control module

Check switch o

Flasher rate too slow or too fast

Lamps' wattages are smaller or

larger than specified

Defective body control module

| Replace lamps

Check body control module

Back up lamps do not light up

No.3 fuse (10A) blown

Back up lamp switch faulty

Wiring or ground faulty

Replace fuse and check for short

Check switch

Repair if necessary

Overhead console lamp does

not light up

No.18 fuse (10A) blown

Wiring or ground faulty

Replace fuse and check for short

Repair if necessary

BE -8 BODY ELECTRICAL SYSTEM

AUDIO

There are six areas where a problem can occur: wiring

harness, the radio, the cassette tape deck, the CD player,

the speaker, and antenna. Troubleshooting enables you to

confine the problem to a particular area. |

Turn ignition key to

ACC position

Turn on the radio or the

tape player 1) Place balance and fader control

| to center position.

|| 2) Set volume control to proper

Verify customer com- position.

plaint or identify symptom

| Sound | | Radio _ | | Cassette player| | Noise | | CD player | | Miscellaneous

See CHART1 See CHART2 See CHARTS See CHART4 See CHARTS |

Faint reception Poor volume problem ating" tape otor antenna

See CHART 6 See CHART 7 See CHART 8 See CHART 9 See CHART 10

ETJA315A

GENERAL

CHART 1

Sound

1. Radio and tape player

have no sound at all.

BE -9

All speakers

lumination lights ?

|

Yes| No | Blown Blownagain —___—

Check audio Check audio | | Replace | Check short

fuse (10A) fuse (10A) fuse | circuit

| О.К. | Check fuse of radio

unit.

Are all connectors behind

radio and tape player prop- -N2] Connect

erly connected ? properly

Yes

Is there voltage (12V) be- | o

tween terminal 16 of the — Ne Check

M16 and body ground ?

Yes

Are radio and player prop- | No | Reinstall |

erly connected ? properly

Yes

Check connection between

output connector of radio

and car.

О.К.

Replace radio unit

| One speaker

| Check speaker harness - —

О.К.

Check speaker (NG.

connector - |

| OK.

~~ | Connect |

“correctly |

Temporarily install OK. |

another speaker. = | В

o Replace

speaker

Replace radio unit |

ETNCO15A

Sr

a

| 2. Tape player OK but no sound from radio

Check that the antenna is

pluged into the radio.

Yes

No

Insert properly

CHART 2

Reinsert plug, O.K. ?

BODY ELECTRICAL SYSTEM

О.К.

Not O.K.

Does radio alone work ?

Yes

Inspect antenna plug

No

Temporarily install

another antenna. O.K. ?

О.К.

Replace radio

Not O.K.

Replace radio

Radio problem

Weak

Poor tone

| Check antenna

(extend antenna fully)

Tune correctly. Still poor a

Yes

Check connection of ~~

antenna plug |

Check for shorts in speaker

harness

Not O.K.

Inspect antenna and

antenna cable, and

replace if necessary

— ETA9010C

OK

Temporarily install another

antenna. O.K. ?

Check for object lying on

speaker and rattling

Not O.K.

Repair harness

О.К.

— INotO.K.-

OK

Extend antenna. Still poor ?

Replace radio

Yes

Replace antenna

Check antenna and lead-in

for broken connectors.

Does the tester indicate an

open circuit ?

Yes

Remove object

No

Is the broadcast quality the

cause of poor tone quality ?

Yes

Replace antenna

Replace radio unit

ETA9010D

we

que

8

ERAL

CHART 3

UN oipe. aoe|dey Jun ope’ eoe|dey

sinoy Qo | uey alow

OU 10 SjeAIQIUI Je UBISdED