Комментарии

10

Войдите или зарегистрируйтесь, чтобы писать комментарии, задавать вопросы и участвовать в обсуждении.

Войти

Зарегистрироваться

AutoBOTT

Я езжу на Nissan X-Trail I

Можете закинут на Яндекс диск мануал на Xtrail T30, не как не разберусь с Dropbox…

5 месяцев

Romanov-86

Я езжу на Nissan X-Trail II

спасибо. скачал.

6 лет

kyrok84

Я езжу на Jeep Grand Cherokee (WK2)

Есть книга Эксплуатация, обслуживание и ремонт Хитрого с 2007 г. и рестал 2011 г., кому надо пишите, залью куда-нить типа Яндекс диска…

7 лет

ComeAgain

Я езжу на Honda Fit (3G)

отличные ссылки. скачал — спасибо!

7 лет

toor76

Автор

Я езжу на Nissan X-Trail II

Пожалуста)

7 лет

Energy73RUS

Я езжу на Volkswagen Tiguan (2G)

Спасибо, в закладки!

7 лет

SKORPIONCIK

Я езжу на Nissan X-Trail II

а че подругому нельзя скачать?

7 лет

toor76

Автор

Я езжу на Nissan X-Trail II

Черкни куда залить и что именно)

7 лет

sibers42

Я езжу на Honda Stream

Спасибо)

7 лет

toor76

Автор

Я езжу на Nissan X-Trail II

Всегда рад помочь)

7 лет

- Модель Т30 год 2000 — 2009

- Модель Т31 год 2007 — 2014

- Модель Т32 год 2013 — …

Для общего представления о технических возможностях автомобилей Nissan X-Trail воспользуйтесь разделом,

где в одном месте собраны наиболее полные данные о всех моделях данного кроссовера:

-

Ниссан Х Трейл технические характеристики

Книги для модели Т30: год 2000 — 2009

Ниссан Х-Трейл. Руководство по ремонту моделей с 2000 года

выпуска.

Автомобили серии T30 с двигателями QR20DE / QR25DE / YD22DDTi. Обслуживание,

эксплуатация, ремонт. 476 страниц.

Книга Nissan X-Trail Т30

Nissan X-Trail. Руководство по эксплуатации, ремонту и

техническому обслуживанию

Для автомобилей с бензиновым двигателем QR20DE (2.0 л), QR25DE (2.5 л) и с

дизельным двигателем YD22DDTi (2.2 л), выпускавшихся с 2001 по 2007 гг. 448 страниц.

Книга Nissan X-Trail Т30

Nissan X-Trail. Модели выпуска с 2000 года с бензиновым

двигателем.

Руководство по эксплуатации, устройство, техническое обслуживание и ремонт

автомобилей с двигателем QR20DE (2.0 л). 400 страниц.

Книга Nissan X-Trail Т30

Nissan X-Trail. Ремонт моделей с 2001 года

выпуска.

Весь ряд двигателей серии T30 2001 — 2007 года выпуска. Полное описание по

эксплуатации, ремонту и обслуживанию. 576 страниц.

Книга Nissan X-Trail Т30

Книги для модели Т31 год 2007 — 2014

Модель Nissan X-Trail T31 с 2007 года

Подробные инструкции по эксплуатации и ремонту для всех типов бензиновых

двигателей. Серия Автолюбитель. 376 страниц.

Книга Nissan X-Trail Т31

Nissan X-Trail (Rogue). Модели T31 с 2007 года выпуска

Бестселлер. Руководство для автомобилей с бензиновыми и дизельными двигателями 2,0

и 2,5 л. 430 страниц.

Книга Nissan X-Trail Т31

Цветное руководство для Nissan X-Trail T31

Ремонт и эксплуатация Ниссан Икс-трэйл для всех типов двигателей выпускаемых с 2007

года. Достоверно и доступно. 320 страниц.

Книга Nissan X-Trail Т31

Руководство Nissan X-Trail T31 с бензиновыми двигателями

Серия Профессионал. Самое подробное руководство для модели T31. 752 страниц.

Книга Nissan X-Trail Т31

Книги для модели Т32 год 2013 — …

Nissan X-Trail Т32 c 2014 года

Техническое обслуживание, инструкции по эксплуатации, диагностика и ремонт. 700

страниц. Самое объемное руководство в технической серии.

Книга Nissan X-Trail Т32

Nissan X-Trail (Rogue). Модели T32 с 2014 года выпуска

Бестселлер. Руководство для автомобилей с бензиновыми и дизельными двигателями

MR20DD (2.0 л), QR25DE (2,5 л), dCi (1,6 л). 526 страниц.

Книга Nissan X-Trail Т32

Nissan X-Trail III (Ниссан Икс-Трэйл 3). Руководство по

ремонту

Модели с 2015 года выпуска с бензиновыми и дизельным двигателями. Серия ремонтирую

я сам. 384 страниц.

Книга Nissan X-Trail Т32

Руководство по самостоятельному обслуживанию и ремонту Nissan

X-Trail Т32 c 2013 года

Пошаговые инструкции по ремонту. Помощь в дороге и гараже. Технологии

само-диагностики. Электрические схемы. 300 страниц.

Книга Nissan X-Trail Т32

Мультимедийное руководство на английском языке по техническому обслуживанию и ремонту автомобиля Nissan X-Trail серии T30 с 2001 года выпуска.

- Автор: —

- Издательство: Nissan

- Год издания: 2006

- Страниц: —

- Формат: —

- Размер: 266,9 Mb

Мультимедийное руководство на английском языке по техническому обслуживанию и ремонту автомобиля Nissan X-Trail серии T31 с 2007 года выпуска.

- Автор: —

- Издательство: Nissan

- Год издания: 2007

- Страниц: —

- Формат: —

- Размер: 365,6 Mb

Руководство на английском языке по техническому обслуживанию и ремонту автомобиля Nissan X-Trail серии T32.

- Автор: —

- Издательство: Nissan

- Год издания: —

- Страниц: —

- Формат: —

- Размер: 196,7 Mb

Мультимедийное руководство на английском языке по техническому обслуживанию и ремонту автомобиля Nissan X-Trail серии T31.

- Автор: —

- Издательство: Nissan

- Год издания: —

- Страниц: —

- Формат: ISZ

- Размер: 197,3 Mb

Руководство по техническому обслуживанию и ремонту автомобиля Nissan X-Trail серии T30 2000-2007 годов выпуска с бензиновыми двигателями объемом 2,0/2,5 л.

- Автор: —

- Издательство: Автонавигатор

- Год издания: —

- Страниц: 480

- Формат: —

- Размер: —

Руководство по эксплуатации и ремонту автомобилей Nissan Roque и Nissan X-Trail серии T31 с 2007 года выпуска с бензиновыми и дизельными двигателями.

- Автор: —

- Издательство: Монолит

- Год издания: —

- Страниц: 430

- Формат: —

- Размер: —

Руководство по эксплуатации и ремонту автомобиля Nissan X-Trail с 2014 года выпуска с бензиновыми и дизельными двигателями.

- Автор: —

- Издательство: Монолит

- Год издания: —

- Страниц: 526

- Формат: —

- Размер: —

Руководство по эксплуатации и техническому обслуживанию автомобиля Nissan X-Trail 2000-2007 годов выпуска.

- Автор: —

- Издательство: MoToR

- Год издания: —

- Страниц: 240

- Формат: —

- Размер: —

Руководство по эксплуатации и техническому обслуживанию автомобиля Nissan X-Trail 2007-2015 годов выпуска.

- Автор: —

- Издательство: MoToR

- Год издания: —

- Страниц: 337

- Формат: —

- Размер: —

Руководство по эксплуатации и техническому обслуживанию автомобиля Nissan X-Trail с 2007 года выпуска.

- Автор: —

- Издательство: Nissan

- Год издания: —

- Страниц: 325

- Формат: PDF

- Размер: 12,0 Mb

Руководство по эксплуатации, техническому обслуживанию и ремонту автомобиля Nissan X-Trail 2001-2007 годов выпуска с бензиновыми и дизельными двигателями.

- Автор: —

- Издательство: Арго-Авто

- Год издания: —

- Страниц: 448

- Формат: —

- Размер: —

Руководство по эксплуатации, техническому обслуживанию и ремонту автомобиля Nissan X-Trail с 2000 года выпуска с бензиновыми двигателями.

- Автор: —

- Издательство: Автонавигатор

- Год издания: 2005

- Страниц: 484

- Формат: PDF

- Размер: 54,0 Mb

Руководство по эксплуатации, техническому обслуживанию и ремонту автомобиля Nissan X-Trail серии T30 с 2000 года выпуска с бензиновым двигателем объемом 2,0 л.

- Автор: —

- Издательство: Автонавигатор

- Год издания: —

- Страниц: 400

- Формат: —

- Размер: —

Руководство по эксплуатации, техническому обслуживанию и ремонту автомобиля Nissan X-Trail серии T31 с 2007 года выпуска с бензиновыми двигателями.

- Автор: —

- Издательство: Автонавигатор

- Год издания: 2008

- Страниц: 375

- Формат: DjVu

- Размер: 12,7 Mb

Руководство по техническому обслуживанию и ремонту автомобиля Nissan X-Trail серии T31 2007-2014 годов выпуска с бензиновыми двигателями объемом 2,0/2,5 л

- Автор: —

- Издательство: Автонавигатор

- Год издания: —

- Страниц: 376

- Формат: —

- Размер: —

Руководство по техническому обслуживанию и ремонту автомобиля Nissan X-Trail серии T31 2007-2010 годов выпуска с бензиновыми двигателями объемом 2,0/2,5 л.

- Автор: —

- Издательство: Автонавигатор

- Год издания: —

- Страниц: 752

- Формат: PDF

- Размер: 95,9 Mb

Руководство по техническому обслуживанию и ремонту автомобиля Nissan X-Trail серии T31 с 2007 года выпуска с бензиновыми двигателями объемом 2,0/2,5 л.

- Автор: —

- Издательство: Автонавигатор

- Год издания: —

- Страниц: 752

- Формат: —

- Размер: —

Руководство по техническому обслуживанию и ремонту автомобиля Nissan X-Trail серии T32 с 2014 года выпуска с бензиновыми и дизельными двигателями.

- Автор: —

- Издательство: Автонавигатор

- Год издания: —

- Страниц: 700

- Формат: —

- Размер: —

Руководство по эксплуатации, техническому обслуживанию и ремонту автомобиля Nissan X-Trail с 2007 года выпуска с бензиновыми двигателями объемом 2,0/2,5 л.

- Автор: —

- Издательство: Мир Автокниг

- Год издания: 2012

- Страниц: 511

- Формат: PDF

- Размер: 104,9 Mb

Руководство по эксплуатации, техническому обслуживанию и ремонту автомобиля Nissan X-Trail с 2015 года выпуска.

- Автор: —

- Издательство: Мир Автокниг

- Год издания: —

- Страниц: 384

- Формат: —

- Размер: —

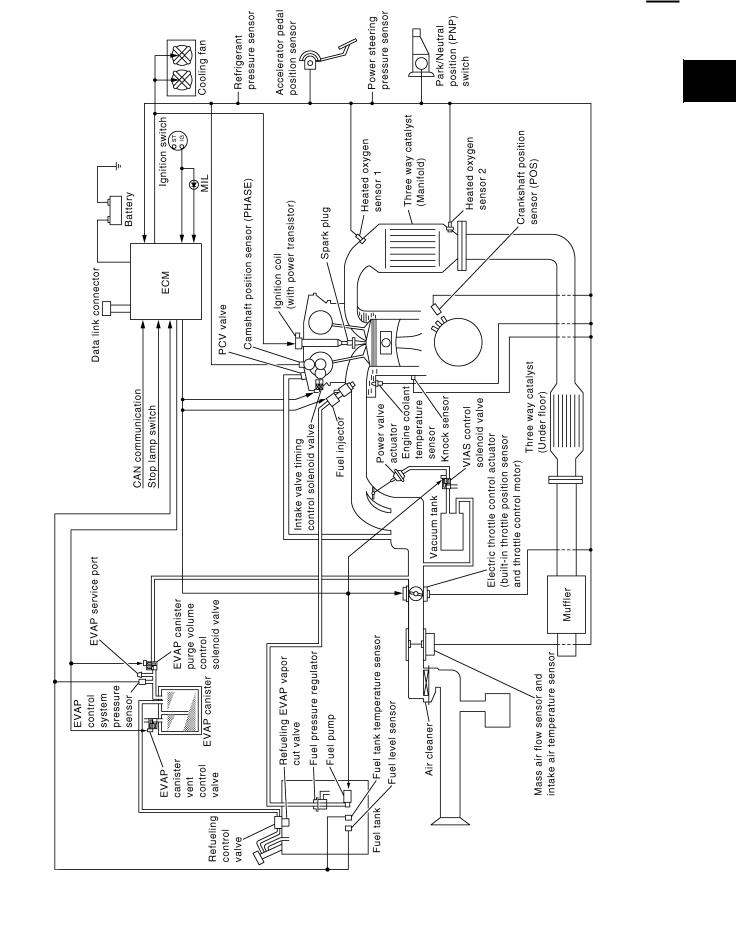

B ENGINE

SECTION EC

ENGINE CONTROL SYSTEM

CONTENTS

|

INDEX FOR DTC ………………………………………………. |

8 |

|

DTC No. Index ……………………………………………….. |

8 |

|

Alphabetical Index ………………………………………….. |

11 |

|

PRECAUTIONS ………………………………………………. |

14 |

|

Precautions for Supplemental Restraint System |

|

|

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN- |

|

|

SIONER” ……………………………………………………… |

14 |

|

On Board Diagnostic (OBD) System of Engine and |

|

|

A/T ………………………………………………………………. |

14 |

|

Precaution ……………………………………………………. |

14 |

|

PREPARATION ……………………………………………….. |

18 |

|

Special Service Tools …………………………………….. |

18 |

|

Commercial Service Tools ………………………………. |

19 |

|

ENGINE CONTROL SYSTEM …………………………… |

21 |

|

System Diagram ……………………………………………. |

21 |

|

Multiport Fuel Injection (MFI) System ………………. |

22 |

|

Electronic Ignition (EI) System ………………………… |

24 |

|

Fuel Cut Control (at No Load and High Engine |

|

|

Speed) …………………………………………………………. |

25 |

|

AIR CONDITIONING CUT CONTROL ……………….. |

26 |

|

Input/Output Signal Chart ……………………………….. |

26 |

|

AUTOMATIC SPEED CONTROL DEVICE (ASCD)… |

27 |

|

System Description ……………………………………….. |

27 |

|

Component Description …………………………………… |

28 |

|

CAN COMMUNICATION ………………………………….. |

29 |

|

System Description ……………………………………….. |

29 |

|

EVAPORATIVE EMISSION SYSTEM …………………. |

30 |

|

Description …………………………………………………… |

30 |

|

Component Inspection …………………………………… |

33 |

|

Removal and Installation ………………………………… |

34 |

|

How to Detect Fuel Vapor Leakage …………………. |

34 |

|

ON BOARD REFUELING VAPOR RECOVERY |

|

|

(ORVR) …………………………………………………………… |

37 |

|

System Description ……………………………………….. |

37 |

|

Diagnostic Procedure …………………………………….. |

38 |

|

Component Inspection …………………………………… |

41 |

|

POSITIVE CRANKCASE VENTILATION ……………. |

44 |

|

Description …………………………………………………… |

44 |

|

Component Inspection …………………………………… |

44 |

|

NVIS (NISSAN VEHICLE IMMOBILIZER SYSTEM- |

|

NATS) …………………………………………………………….. |

46 |

|

Description ……………………………………………………. |

46 |

|

ON BOARD DIAGNOSTIC (OBD) SYSTEM ……….. |

47 |

|

Introduction …………………………………………………… |

47 |

|

Two Trip Detection Logic ………………………………… |

47 |

|

Emission-Related Diagnostic Information ………….. |

48 |

|

Malfunction Indicator Lamp (MIL) …………………….. |

61 |

|

OBD System Operation Chart …………………………. |

65 |

|

BASIC SERVICE PROCEDURE ………………………… |

70 |

|

Basic Inspection ……………………………………………. |

70 |

|

Idle Speed and Ignition Timing Check ………………. |

75 |

|

VIN Registration ……………………………………………. |

77 |

|

Accelerator Pedal Released Position Learning ….. |

77 |

|

Throttle Valve Closed Position Learning ……………. |

78 |

|

Idle Air Volume Learning ………………………………… |

78 |

|

Fuel Pressure Check ……………………………………… |

80 |

|

TROUBLE DIAGNOSIS ……………………………………. |

83 |

|

Trouble Diagnosis Introduction ………………………… |

83 |

|

DTC Inspection Priority Chart ………………………….. |

89 |

|

Fail-Safe Chart ……………………………………………… |

91 |

|

Symptom Matrix Chart ……………………………………. |

92 |

|

Engine Control Component Parts Location ……….. |

96 |

|

Vacuum Hose Drawing …………………………………. |

101 |

|

Circuit Diagram ……………………………………………. |

102 |

|

ECM Harness Connector Terminal Layout ………. |

104 |

|

ECM Terminals and Reference Value ……………… |

104 |

|

CONSULT-II Function (ENGINE) ……………………. |

112 |

|

Generic Scan Tool (GST) Function …………………. |

125 |

|

CONSULT-II Reference Value in Data Monitor …. |

127 |

|

Major Sensor Reference Graph in Data Monitor |

|

|

Mode ………………………………………………………….. |

131 |

|

TROUBLE DIAGNOSIS — SPECIFICATION VALUE. 133 |

|

|

Description ………………………………………………….. |

133 |

|

Testing Condition …………………………………………. |

133 |

|

Inspection Procedure ……………………………………. |

133 |

|

Diagnostic Procedure …………………………………… |

134 |

|

TROUBLE DIAGNOSIS FOR INTERMITTENT INCI- |

|

|

DENT ……………………………………………………………. |

143 |

|

Description ………………………………………………….. |

143 |

|

Diagnostic Procedure …………………………………… |

143 |

|

Revision: 2006 July |

EC-1 |

2006 X-Trail |

|

POWER SUPPLY AND GROUND CIRCUIT ………. |

144 |

|

Wiring Diagram ……………………………………………. |

144 |

|

Diagnostic Procedure …………………………………… |

145 |

|

Component Inspection ………………………………….. |

151 |

|

Ground Inspection ……………………………………….. |

151 |

|

DTC U1000, U1001 CAN COMMUNICATION LINE. 152 |

|

|

Description ………………………………………………….. |

152 |

|

On Board Diagnosis Logic …………………………….. |

152 |

|

DTC Confirmation Procedure ………………………… |

152 |

|

Wiring Diagram ……………………………………………. |

153 |

|

Diagnostic Procedure …………………………………… |

154 |

|

DTC P0011 IVT CONTROL ……………………………… |

155 |

|

Description ………………………………………………….. |

155 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

. 155 |

|

|

On Board Diagnosis Logic …………………………….. |

156 |

|

DTC Confirmation Procedure ………………………… |

156 |

|

Diagnostic Procedure …………………………………… |

157 |

|

Component Inspection ………………………………….. |

158 |

|

Removal and Installation ………………………………. |

158 |

|

DTC P0031, P0032 HO2S1 HEATER ……………….. |

159 |

|

Description ………………………………………………….. |

159 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

. 159 |

|

|

On Board Diagnosis Logic …………………………….. |

159 |

|

DTC Confirmation Procedure ………………………… |

160 |

|

Wiring Diagram ……………………………………………. |

161 |

|

Diagnostic Procedure …………………………………… |

163 |

|

Component Inspection ………………………………….. |

165 |

|

Removal and Installation ………………………………. |

165 |

|

DTC P0037, P0038 HO2S2 HEATER ……………….. |

166 |

|

Description ………………………………………………….. |

166 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

. 166 |

|

|

On Board Diagnosis Logic …………………………….. |

166 |

|

DTC Confirmation Procedure ………………………… |

167 |

|

Wiring Diagram ……………………………………………. |

168 |

|

Diagnostic Procedure …………………………………… |

170 |

|

Component Inspection ………………………………….. |

172 |

|

Removal and Installation ………………………………. |

172 |

|

DTC P0075 IVT CONTROL SOLENOID VALVE … |

173 |

|

Component Description ………………………………… |

173 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

. 173 |

|

|

On Board Diagnosis Logic …………………………….. |

173 |

|

DTC Confirmation Procedure ………………………… |

173 |

|

Wiring Diagram ……………………………………………. |

174 |

|

Diagnostic Procedure …………………………………… |

176 |

|

Component Inspection ………………………………….. |

177 |

|

Removal and Installation ………………………………. |

177 |

|

DTC P0101 MAF SENSOR ……………………………… |

178 |

|

Component Description ………………………………… |

178 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

. 178 |

|

|

On Board Diagnosis Logic …………………………….. |

178 |

|

DTC Confirmation Procedure ………………………… |

178 |

|

Overall Function Check ………………………………… |

180 |

|

Wiring Diagram ……………………………………………. |

181 |

|

Diagnostic Procedure …………………………………… |

182 |

|

Component Inspection ………………………………….. |

185 |

|

Removal and Installation ……………………………….. |

186 |

|

DTC P0102, P0103 MAF SENSOR …………………… |

187 |

|

Component Description ………………………………… |

187 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

.187 |

|

|

On Board Diagnosis Logic …………………………….. |

187 |

|

DTC Confirmation Procedure …………………………. |

187 |

|

Wiring Diagram ……………………………………………. |

189 |

|

Diagnostic Procedure ……………………………………. |

190 |

|

Component Inspection ………………………………….. |

193 |

|

Removal and Installation ……………………………….. |

194 |

|

DTC P0112, P0113 IAT SENSOR ……………………… |

195 |

|

Component Description ………………………………… |

195 |

|

On Board Diagnosis Logic …………………………….. |

195 |

|

DTC Confirmation Procedure …………………………. |

195 |

|

Wiring Diagram ……………………………………………. |

197 |

|

Diagnostic Procedure ……………………………………. |

198 |

|

Component Inspection ………………………………….. |

200 |

|

Removal and Installation ……………………………….. |

200 |

|

DTC P0117, P0118 ECT SENSOR ……………………. |

201 |

|

Component Description ………………………………… |

201 |

|

On Board Diagnosis Logic …………………………….. |

201 |

|

DTC Confirmation Procedure …………………………. |

202 |

|

Wiring Diagram ……………………………………………. |

203 |

|

Diagnostic Procedure ……………………………………. |

204 |

|

Component Inspection ………………………………….. |

206 |

|

Removal and Installation ……………………………….. |

206 |

|

DTC P0122, P0123 TP SENSOR ……………………… |

207 |

|

Component Description ………………………………… |

207 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

.207 |

|

|

On Board Diagnosis Logic …………………………….. |

207 |

|

DTC Confirmation Procedure …………………………. |

208 |

|

Wiring Diagram ……………………………………………. |

209 |

|

Diagnostic Procedure ……………………………………. |

211 |

|

Component Inspection ………………………………….. |

214 |

|

Remove and Installation ……………………………….. |

214 |

|

DTC P0125 ECT SENSOR ………………………………. |

215 |

|

Description ………………………………………………….. |

215 |

|

On Board Diagnosis Logic …………………………….. |

215 |

|

DTC Confirmation Procedure …………………………. |

215 |

|

Diagnostic Procedure ……………………………………. |

216 |

|

Component Inspection ………………………………….. |

217 |

|

Removal and Installation ……………………………….. |

217 |

|

DTC P0127 IAT SENSOR ………………………………… |

218 |

|

Component Description ………………………………… |

218 |

|

On Board Diagnosis Logic …………………………….. |

218 |

|

DTC Confirmation Procedure …………………………. |

218 |

|

Diagnostic Procedure ……………………………………. |

219 |

|

Component Inspection ………………………………….. |

220 |

|

Removal and Installation ……………………………….. |

220 |

|

DTC P0128 THERMOSTAT FUNCTION ……………. |

221 |

|

On Board Diagnosis Logic …………………………….. |

221 |

|

DTC Confirmation Procedure …………………………. |

221 |

|

Diagnostic Procedure ……………………………………. |

221 |

|

Component Inspection ………………………………….. |

222 |

|

Removal and Installation ……………………………….. |

222 |

|

DTC P0132 HO2S1 ………………………………………… |

223 |

|

Revision: 2006 July |

EC-2 |

2006 X-Trail |

|

Component Description ………………………………… |

223 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

. 223 |

|

|

On Board Diagnosis Logic ……………………………. |

223 |

|

DTC Confirmation Procedure ………………………… |

224 |

|

Wiring Diagram …………………………………………… |

225 |

|

Diagnostic Procedure …………………………………… |

227 |

|

Component Inspection …………………………………. |

228 |

|

Removal and Installation ………………………………. |

230 |

|

DTC P0133 HO2S1 ………………………………………… |

231 |

|

Component Description ………………………………… |

231 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

. 231 |

|

|

On Board Diagnosis Logic ……………………………. |

231 |

|

DTC Confirmation Procedure ………………………… |

232 |

|

Overall Function Check ………………………………… |

233 |

|

Wiring Diagram …………………………………………… |

234 |

|

Diagnostic Procedure …………………………………… |

236 |

|

Component Inspection …………………………………. |

240 |

|

Removal and Installation ………………………………. |

241 |

|

DTC P0134 HO2S1 ………………………………………… |

242 |

|

Component Description ………………………………… |

242 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

. 242 |

|

|

On Board Diagnosis Logic ……………………………. |

242 |

|

DTC Confirmation Procedure ………………………… |

243 |

|

Overall Function Check ………………………………… |

244 |

|

Wiring Diagram …………………………………………… |

245 |

|

Diagnostic Procedure …………………………………… |

247 |

|

Component Inspection …………………………………. |

249 |

|

Removal and Installation ………………………………. |

250 |

|

DTC P0137 HO2S2 ………………………………………… |

251 |

|

Component Description ………………………………… |

251 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

. 251 |

|

|

On Board Diagnosis Logic ……………………………. |

251 |

|

DTC Confirmation Procedure ………………………… |

252 |

|

Overall Function Check ………………………………… |

252 |

|

Wiring Diagram …………………………………………… |

254 |

|

Diagnostic Procedure …………………………………… |

256 |

|

Component Inspection …………………………………. |

258 |

|

Removal and Installation ………………………………. |

259 |

|

DTC P0138 HO2S2 ………………………………………… |

260 |

|

Component Description ………………………………… |

260 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

. 260 |

|

|

On Board Diagnosis Logic ……………………………. |

260 |

|

DTC Confirmation Procedure ………………………… |

261 |

|

Overall Function Check ………………………………… |

262 |

|

Wiring Diagram …………………………………………… |

263 |

|

Diagnostic Procedure …………………………………… |

265 |

|

Component Inspection …………………………………. |

270 |

|

Removal and Installation ………………………………. |

271 |

|

DTC P0139 HO2S2 ………………………………………… |

272 |

|

Component Description ………………………………… |

272 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

. 272 |

|

|

On Board Diagnosis Logic ……………………………. |

272 |

|

DTC Confirmation Procedure ………………………… |

273 |

|

Overall Function Check ………………………………… |

273 |

|

Wiring Diagram ……………………………………………. |

275 |

|

Diagnostic Procedure …………………………………… |

277 |

|

Component Inspection ………………………………….. |

279 |

|

Removal and Installation ………………………………. |

280 |

|

DTCP0171FUELINJECTIONSYSTEMFUNCTION. 281 |

|

|

On Board Diagnosis Logic …………………………….. |

281 |

|

DTC Confirmation Procedure ………………………… |

281 |

|

Wiring Diagram ……………………………………………. |

283 |

|

Diagnostic Procedure …………………………………… |

285 |

|

DTCP0172FUELINJECTIONSYSTEMFUNCTION. 289 |

|

|

On Board Diagnosis Logic …………………………….. |

289 |

|

DTC Confirmation Procedure ………………………… |

289 |

|

Wiring Diagram ……………………………………………. |

291 |

|

Diagnostic Procedure …………………………………… |

293 |

|

DTC P0181 FTT SENSOR ………………………………. |

296 |

|

Component Description ………………………………… |

296 |

|

On Board Diagnosis Logic …………………………….. |

296 |

|

DTC Confirmation Procedure ………………………… |

296 |

|

Wiring Diagram ……………………………………………. |

298 |

|

Diagnostic Procedure …………………………………… |

299 |

|

Component Inspection ………………………………….. |

301 |

|

Removal and Installation ………………………………. |

301 |

|

DTC P0182, P0183 FTT SENSOR ……………………. |

302 |

|

Component Description ………………………………… |

302 |

|

On Board Diagnosis Logic …………………………….. |

302 |

|

DTC Confirmation Procedure ………………………… |

302 |

|

Wiring Diagram ……………………………………………. |

303 |

|

Diagnostic Procedure …………………………………… |

304 |

|

Component Inspection ………………………………….. |

306 |

|

Removal and Installation ………………………………. |

306 |

|

DTC P0222, P0223 TP SENSOR ……………………… |

307 |

|

Component Description ………………………………… |

307 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

. 307 |

|

|

On Board Diagnosis Logic …………………………….. |

307 |

|

DTC Confirmation Procedure ………………………… |

308 |

|

Wiring Diagram ……………………………………………. |

309 |

|

Diagnostic Procedure …………………………………… |

311 |

|

Component Inspection ………………………………….. |

314 |

|

Remove and Installation ……………………………….. |

314 |

|

DTC P0300 — P0304 MULTIPLE CYLINDER MIS- |

|

|

FIRE, NO. 1 — 4 CYLINDER MISFIRE ……………….. |

315 |

|

On Board Diagnosis Logic …………………………….. |

315 |

|

DTC Confirmation Procedure ………………………… |

315 |

|

Diagnostic Procedure …………………………………… |

316 |

|

DTC P0327, P0328 KS …………………………………… |

322 |

|

Component Description ………………………………… |

322 |

|

On Board Diagnosis Logic …………………………….. |

322 |

|

DTC Confirmation Procedure ………………………… |

322 |

|

Wiring Diagram ……………………………………………. |

323 |

|

Diagnostic Procedure …………………………………… |

324 |

|

Component Inspection ………………………………….. |

326 |

|

Removal and Installation ………………………………. |

326 |

|

DTC P0335 CKP SENSOR (POS) ……………………. |

327 |

|

Component Description ………………………………… |

327 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

. 327 |

|

|

On Board Diagnosis Logic …………………………….. |

327 |

|

Revision: 2006 July |

EC-3 |

2006 X-Trail |

A

EC

C

D

E

F

G

H

I

J

K

L

M

|

DTC Confirmation Procedure ………………………… |

328 |

|

Wiring Diagram ……………………………………………. |

329 |

|

Diagnostic Procedure …………………………………… |

331 |

|

Component Inspection ………………………………….. |

334 |

|

Removal and Installation ………………………………. |

334 |

|

DTC P0340 CMP SENSOR (PHASE) ……………….. |

335 |

|

Component Description ………………………………… |

335 |

|

On Board Diagnosis Logic …………………………….. |

335 |

|

DTC Confirmation Procedure ………………………… |

336 |

|

Wiring Diagram ……………………………………………. |

337 |

|

Diagnostic Procedure …………………………………… |

338 |

|

Component Inspection ………………………………….. |

341 |

|

Removal and Installation ………………………………. |

342 |

|

DTC P0420 THREE WAY CATALYST FUNCTION . 343 |

|

|

On Board Diagnosis Logic …………………………….. |

343 |

|

DTC Confirmation Procedure ………………………… |

343 |

|

Overall Function Check ………………………………… |

344 |

|

Diagnostic Procedure …………………………………… |

345 |

|

DTC P0441 EVAP CONTROL SYSTEM ……………. |

348 |

|

System Description ………………………………………. |

348 |

|

On Board Diagnosis Logic …………………………….. |

348 |

|

DTC Confirmation Procedure ………………………… |

349 |

|

Overall Function Check ………………………………… |

349 |

|

Diagnostic Procedure …………………………………… |

350 |

|

DTC P0442 EVAP CONTROL SYSTEM ……………. |

354 |

|

On Board Diagnosis Logic …………………………….. |

354 |

|

DTC Confirmation Procedure ………………………… |

355 |

|

Diagnostic Procedure …………………………………… |

357 |

|

Component Inspection ………………………………….. |

363 |

|

DTC P0443 EVAP CANISTER PURGE VOLUME |

|

|

CONTROL SOLENOID VALVE ………………………… |

364 |

|

Description ………………………………………………….. |

364 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

. 364 |

|

|

On Board Diagnosis Logic …………………………….. |

365 |

|

DTC Confirmation Procedure ………………………… |

365 |

|

Wiring Diagram ……………………………………………. |

366 |

|

Diagnostic Procedure …………………………………… |

368 |

|

Component Inspection ………………………………….. |

370 |

|

Removal and Installation ………………………………. |

371 |

|

DTC P0444, P0445 EVAP CANISTER PURGE VOL- |

|

|

UME CONTROL SOLENOID VALVE ………………… |

372 |

|

Description ………………………………………………….. |

372 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

. 372 |

|

|

On Board Diagnosis Logic …………………………….. |

373 |

|

DTC Confirmation Procedure ………………………… |

373 |

|

Wiring Diagram ……………………………………………. |

374 |

|

Diagnostic Procedure …………………………………… |

376 |

|

Component Inspection ………………………………….. |

377 |

|

Removal and Installation ………………………………. |

378 |

|

DTC P0447 EVAP CANISTER VENT CONTROL |

|

|

VALVE ………………………………………………………….. |

379 |

|

Component Description ………………………………… |

379 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

. 379 |

|

|

On Board Diagnosis Logic …………………………….. |

379 |

|

DTC Confirmation Procedure ………………………… |

380 |

|

Wiring Diagram ……………………………………………. |

381 |

|

Diagnostic Procedure ……………………………………. |

382 |

|

Component Inspection ………………………………….. |

384 |

|

DTC P0448 EVAP CANISTER VENT CONTROL |

|

|

VALVE …………………………………………………………… |

386 |

|

Component Description ………………………………… |

386 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

.386 |

|

|

On Board Diagnosis Logic …………………………….. |

386 |

|

DTC Confirmation Procedure …………………………. |

387 |

|

Wiring Diagram ……………………………………………. |

388 |

|

Diagnostic Procedure ……………………………………. |

389 |

|

Component Inspection ………………………………….. |

391 |

|

DTCP0451EVAPCONTROLSYSTEMPRESSURE |

|

|

SENSOR ……………………………………………………….. |

393 |

|

Component Description ………………………………… |

393 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

.393 |

|

|

On Board Diagnosis Logic …………………………….. |

393 |

|

DTC Confirmation Procedure …………………………. |

394 |

|

Diagnostic Procedure ……………………………………. |

394 |

|

Component Inspection ………………………………….. |

395 |

|

DTCP0452EVAPCONTROLSYSTEMPRESSURE |

|

|

SENSOR ……………………………………………………….. |

396 |

|

Component Description ………………………………… |

396 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

.396 |

|

|

On Board Diagnosis Logic …………………………….. |

396 |

|

DTC Confirmation Procedure …………………………. |

397 |

|

Wiring Diagram ……………………………………………. |

398 |

|

Diagnostic Procedure ……………………………………. |

399 |

|

Component Inspection ………………………………….. |

402 |

|

DTCP0453EVAPCONTROLSYSTEMPRESSURE |

|

|

SENSOR ……………………………………………………….. |

403 |

|

Component Description ………………………………… |

403 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

.403 |

|

|

On Board Diagnosis Logic …………………………….. |

403 |

|

DTC Confirmation Procedure …………………………. |

404 |

|

Wiring Diagram ……………………………………………. |

405 |

|

Diagnostic Procedure ……………………………………. |

406 |

|

Component Inspection ………………………………….. |

410 |

|

DTC P0455 EVAP CONTROL SYSTEM ……………. |

411 |

|

On Board Diagnosis Logic …………………………….. |

411 |

|

DTC Confirmation Procedure …………………………. |

412 |

|

Diagnostic Procedure ……………………………………. |

413 |

|

DTC P0456 EVAP CONTROL SYSTEM ……………. |

419 |

|

On Board Diagnosis Logic …………………………….. |

419 |

|

DTC Confirmation Procedure …………………………. |

420 |

|

Overall Function Check …………………………………. |

421 |

|

Diagnostic Procedure ……………………………………. |

422 |

|

Component Inspection ………………………………….. |

429 |

|

DTC P0460 FUEL LEVEL SENSOR …………………. |

430 |

|

Component Description ………………………………… |

430 |

|

On Board Diagnostic Logic ……………………………. |

430 |

|

DTC Confirmation Procedure …………………………. |

430 |

|

Diagnostic Procedure ……………………………………. |

431 |

|

Removal and Installation ……………………………….. |

431 |

|

DTC P0461 FUEL LEVEL SENSOR …………………. |

432 |

|

Component Description ………………………………… |

432 |

|

Revision: 2006 July |

EC-4 |

2006 X-Trail |

|

On Board Diagnostic Logic …………………………… |

432 |

|

Overall Function Check ………………………………… |

432 |

|

Diagnostic Procedure …………………………………… |

433 |

|

Removal and Installation ………………………………. |

433 |

|

DTC P0462, P0463 FUEL LEVEL SENSOR ……… |

434 |

|

Component Description ………………………………… |

434 |

|

On Board Diagnostic Logic …………………………… |

434 |

|

DTC Confirmation Procedure ………………………… |

434 |

|

Diagnostic Procedure …………………………………… |

435 |

|

Removal and Installation ………………………………. |

435 |

|

DTC P0500 VSS ……………………………………………. |

436 |

|

Description …………………………………………………. |

436 |

|

On Board Diagnosis Logic ……………………………. |

436 |

|

DTC Confirmation Procedure ………………………… |

436 |

|

Overall Function Check ………………………………… |

437 |

|

Diagnostic Procedure …………………………………… |

437 |

|

DTC P0506 ISC SYSTEM ……………………………….. |

438 |

|

Description …………………………………………………. |

438 |

|

On Board Diagnosis Logic ……………………………. |

438 |

|

DTC Confirmation Procedure ………………………… |

438 |

|

Diagnostic Procedure …………………………………… |

439 |

|

DTC P0507 ISC SYSTEM ……………………………….. |

440 |

|

Description …………………………………………………. |

440 |

|

On Board Diagnosis Logic ……………………………. |

440 |

|

DTC Confirmation Procedure ………………………… |

440 |

|

Diagnostic Procedure …………………………………… |

441 |

|

DTC P0550 PSP SENSOR ……………………………… |

442 |

|

Component Description ………………………………… |

442 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

. 442 |

|

|

On Board Diagnosis Logic ……………………………. |

442 |

|

DTC Confirmation Procedure ………………………… |

442 |

|

Wiring Diagram …………………………………………… |

443 |

|

Diagnostic Procedure …………………………………… |

444 |

|

Component Inspection …………………………………. |

446 |

|

Removal and Installation ………………………………. |

446 |

|

DTC P0603 ECM POWER SUPPLY …………………. |

447 |

|

Component Description ………………………………… |

447 |

|

On Board Diagnosis Logic ……………………………. |

447 |

|

DTC Confirmation Procedure ………………………… |

447 |

|

Wiring Diagram …………………………………………… |

448 |

|

Diagnostic Procedure …………………………………… |

449 |

|

DTC P0605 ECM …………………………………………… |

451 |

|

Component Description ………………………………… |

451 |

|

On Board Diagnosis Logic ……………………………. |

451 |

|

DTC Confirmation Procedure ………………………… |

451 |

|

Diagnostic Procedure …………………………………… |

452 |

|

DTC P0643 SENSOR POWER SUPPLY …………… |

454 |

|

On Board Diagnosis Logic ……………………………. |

454 |

|

DTC Confirmation Procedure ………………………… |

454 |

|

Wiring Diagram …………………………………………… |

455 |

|

Diagnostic Procedure …………………………………… |

457 |

|

DTC P0850 PNP SWITCH ………………………………. |

460 |

|

Component Description ………………………………… |

460 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

. 460 |

|

|

On Board Diagnosis Logic ……………………………. |

460 |

|

DTC Confirmation Procedure ………………………… |

460 |

|

Overall Function Check ………………………………… |

461 |

|

Wiring Diagram ……………………………………………. |

462 |

|

Diagnostic Procedure …………………………………… |

463 |

|

DTC P1143 HO2S1 ………………………………………… |

465 |

|

Component Description ………………………………… |

465 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

. 465 |

|

|

On Board Diagnosis Logic …………………………….. |

465 |

|

DTC Confirmation Procedure ………………………… |

466 |

|

Overall Function Check ………………………………… |

466 |

|

Diagnostic Procedure …………………………………… |

467 |

|

Component Inspection ………………………………….. |

469 |

|

Removal and Installation ………………………………. |

470 |

|

DTC P1144 HO2S1 ………………………………………… |

471 |

|

Component Description ………………………………… |

471 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

. 471 |

|

|

On Board Diagnosis Logic …………………………….. |

471 |

|

DTC Confirmation Procedure ………………………… |

472 |

|

Overall Function Check ………………………………… |

472 |

|

Diagnostic Procedure …………………………………… |

473 |

|

Component Inspection ………………………………….. |

475 |

|

Removal and Installation ………………………………. |

476 |

|

DTC P1148 CLOSED LOOP CONTROL …………… |

477 |

|

On Board Diagnosis Logic …………………………….. |

477 |

|

DTC Confirmation Procedure ………………………… |

477 |

|

Overall Function Check ………………………………… |

477 |

|

Diagnostic Procedure …………………………………… |

477 |

|

DTC P1211 TCS CONTROL UNIT ……………………. |

478 |

|

Description ………………………………………………….. |

478 |

|

On Board Diagnosis Logic …………………………….. |

478 |

|

DTC Confirmation Procedure ………………………… |

478 |

|

Diagnostic Procedure …………………………………… |

478 |

|

DTC P1212 TCS COMMUNICATION LINE ……….. |

479 |

|

Description ………………………………………………….. |

479 |

|

On Board Diagnosis Logic …………………………….. |

479 |

|

DTC Confirmation Procedure ………………………… |

479 |

|

Diagnostic Procedure …………………………………… |

479 |

|

DTC P1217 ENGINE OVER TEMPERATURE ……. |

480 |

|

Description ………………………………………………….. |

480 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

. 481 |

|

|

On Board Diagnosis Logic …………………………….. |

481 |

|

Overall Function Check ………………………………… |

481 |

|

Wiring Diagram ……………………………………………. |

484 |

|

Diagnostic Procedure …………………………………… |

485 |

|

Main 12 Causes of Overheating …………………….. |

491 |

|

Component Inspection ………………………………….. |

492 |

|

DTC P1225 TP SENSOR ………………………………… |

494 |

|

Component Description ………………………………… |

494 |

|

On Board Diagnosis Logic …………………………….. |

494 |

|

DTC Confirmation Procedure ………………………… |

494 |

|

Diagnostic Procedure …………………………………… |

495 |

|

Remove and Installation ……………………………….. |

495 |

|

DTC P1226 TP SENSOR ………………………………… |

496 |

|

Component Description ………………………………… |

496 |

|

On Board Diagnosis Logic …………………………….. |

496 |

|

DTC Confirmation Procedure ………………………… |

496 |

|

Diagnostic Procedure …………………………………… |

497 |

|

Remove and Installation ……………………………….. |

497 |

|

Revision: 2006 July |

EC-5 |

2006 X-Trail |

A

EC

C

D

E

F

G

H

I

J

K

L

M

|

DTC P1564 ASCD STEERING SWITCH …………… |

498 |

|

Component Description ………………………………… |

498 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

. 498 |

|

|

On Board Diagnosis Logic …………………………….. |

498 |

|

DTC Confirmation Procedure ………………………… |

499 |

|

Wiring Diagram ……………………………………………. |

500 |

|

Diagnostic Procedure …………………………………… |

502 |

|

Component Inspection ………………………………….. |

505 |

|

DTC P1572 ASCD BRAKE SWITCH ………………… |

506 |

|

Component Description ………………………………… |

506 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

. 506 |

|

|

On Board Diagnosis Logic …………………………….. |

506 |

|

DTC Confirmation Procedure ………………………… |

507 |

|

Wiring Diagram ……………………………………………. |

508 |

|

Diagnostic Procedure …………………………………… |

510 |

|

Component Inspection ………………………………….. |

516 |

|

DTC P1574 ASCD VEHICLE SPEED SENSOR …. |

517 |

|

Component Description ………………………………… |

517 |

|

On Board Diagnosis Logic …………………………….. |

517 |

|

DTC Confirmation Procedure ………………………… |

517 |

|

Diagnostic Procedure …………………………………… |

518 |

|

DTC P1720 VSS …………………………………………….. |

519 |

|

Description ………………………………………………….. |

519 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

. 519 |

|

|

On Board Diagnosis Logic …………………………….. |

519 |

|

DTC Confirmation Procedure ………………………… |

519 |

|

Diagnostic Procedure …………………………………… |

520 |

|

DTC P1800 VIAS CONTROL SOLENOID VALVE . 521 |

|

|

Component Description ………………………………… |

521 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

. 521 |

|

|

On Board Diagnosis Logic …………………………….. |

521 |

|

DTC Confirmation Procedure ………………………… |

521 |

|

Wiring Diagram ……………………………………………. |

522 |

|

Diagnostic Procedure …………………………………… |

523 |

|

Component Inspection ………………………………….. |

524 |

|

Removal and Installation ………………………………. |

525 |

|

DTC P1805 BRAKE SWITCH ………………………….. |

526 |

|

Description ………………………………………………….. |

526 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

. 526 |

|

|

On Board Diagnosis Logic …………………………….. |

526 |

|

DTC Confirmation Procedure ………………………… |

526 |

|

Wiring Diagram ……………………………………………. |

527 |

|

Diagnostic Procedure …………………………………… |

528 |

|

Component Inspection ………………………………….. |

530 |

|

DTCP2100,P2103THROTTLECONTROLMOTOR |

|

|

RELAY ………………………………………………………….. |

531 |

|

Component Description ………………………………… |

531 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

. 531 |

|

|

On Board Diagnosis Logic …………………………….. |

531 |

|

DTC Confirmation Procedure ………………………… |

531 |

|

Wiring Diagram ……………………………………………. |

533 |

|

Diagnostic Procedure …………………………………… |

535 |

|

Component Inspection ………………………………….. |

537 |

|

DTC P2101 ELECTRIC THROTTLE CONTROL |

|

|

FUNCTION ……………………………………………………. |

538 |

|

Description ………………………………………………….. |

538 |

|

On Board Diagnosis Logic …………………………….. |

538 |

|

DTC Confirmation Procedure …………………………. |

538 |

|

Wiring Diagram ……………………………………………. |

539 |

|

Diagnostic Procedure ……………………………………. |

541 |

|

Component Inspection ………………………………….. |

545 |

|

Remove and Installation ……………………………….. |

545 |

|

DTC P2118 THROTTLE CONTROL MOTOR …….. |

546 |

|

Component Description ………………………………… |

546 |

|

On Board Diagnosis Logic …………………………….. |

546 |

|

DTC Confirmation Procedure …………………………. |

546 |

|

Wiring Diagram ……………………………………………. |

547 |

|

Diagnostic Procedure ……………………………………. |

549 |

|

Component Inspection ………………………………….. |

550 |

|

Removal and Installation ……………………………….. |

550 |

|

DTC P2119 ELECTRIC THROTTLE CONTROL |

|

|

ACTUATOR …………………………………………………… |

551 |

|

Component Description ………………………………… |

551 |

|

On Board Diagnosis Logic …………………………….. |

551 |

|

DTC Confirmation Procedure …………………………. |

551 |

|

Diagnostic Procedure ……………………………………. |

552 |

|

DTC P2122, P2123 APP SENSOR …………………… |

553 |

|

Component Description ………………………………… |

553 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

.553 |

|

|

On Board Diagnosis Logic …………………………….. |

553 |

|

DTC Confirmation Procedure …………………………. |

554 |

|

Wiring Diagram ……………………………………………. |

555 |

|

Diagnostic Procedure ……………………………………. |

557 |

|

Component Inspection ………………………………….. |

559 |

|

Removal and Installation ……………………………….. |

559 |

|

DTC P2127, P2128 APP SENSOR …………………… |

560 |

|

Component Description ………………………………… |

560 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

.560 |

|

|

On Board Diagnosis Logic …………………………….. |

560 |

|

DTC Confirmation Procedure …………………………. |

561 |

|

Wiring Diagram ……………………………………………. |

562 |

|

Diagnostic Procedure ……………………………………. |

564 |

|

Component Inspection ………………………………….. |

567 |

|

Remove and Installation ……………………………….. |

567 |

|

DTC P2135 TP SENSOR ………………………………… |

568 |

|

Component Description ………………………………… |

568 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

.568 |

|

|

On Board Diagnosis Logic …………………………….. |

568 |

|

DTC Confirmation Procedure …………………………. |

569 |

|

Wiring Diagram ……………………………………………. |

570 |

|

Diagnostic Procedure ……………………………………. |

572 |

|

Component Inspection ………………………………….. |

575 |

|

Remove and Installation ……………………………….. |

575 |

|

DTC P2138 APP SENSOR ………………………………. |

576 |

|

Component Description ………………………………… |

576 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

.576 |

|

|

On Board Diagnosis Logic …………………………….. |

576 |

|

DTC Confirmation Procedure …………………………. |

577 |

|

Revision: 2006 July |

EC-6 |

2006 X-Trail |

|

Wiring Diagram …………………………………………… |

578 |

|

Diagnostic Procedure …………………………………… |

580 |

|

Component Inspection …………………………………. |

583 |

|

Remove and Installation ……………………………….. |

583 |

|

ASCD BRAKE SWITCH …………………………………. |

584 |

|

Component Description ………………………………… |

584 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

. 584 |

|

|

Wiring Diagram …………………………………………… |

585 |

|

Diagnostic Procedure …………………………………… |

587 |

|

Component Inspection …………………………………. |

592 |

|

ASCD INDICATOR ………………………………………… |

594 |

|

Component Description ………………………………… |

594 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

. 594 |

|

|

Wiring Diagram …………………………………………… |

595 |

|

Diagnostic Procedure …………………………………… |

597 |

|

ELECTRICAL LOAD SIGNAL …………………………. |

598 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

. 598 |

|

|

Wiring Diagram …………………………………………… |

599 |

|

Diagnostic Procedure …………………………………… |

600 |

|

Wiring Diagram …………………………………………… |

605 |

|

Diagnostic Procedure …………………………………… |

606 |

|

Wiring Diagram …………………………………………… |

608 |

|

Diagnostic Procedure …………………………………… |

609 |

|

FUEL INJECTOR ……………………………………………. |

611 |

|

Component Description ………………………………….. |

611 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

..611 |

|

|

Wiring Diagram …………………………………………… |

612 |

|

Diagnostic Procedure …………………………………… |

613 |

|

Component Inspection …………………………………. |

616 |

|

Removal and Installation ………………………………. |

616 |

|

FUEL PUMP …………………………………………………. |

617 |

|

Description …………………………………………………. |

617 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

. 617 |

|

|

Wiring Diagram …………………………………………… |

618 |

|

Diagnostic Procedure …………………………………… |

619 |

|

Component Inspection …………………………………. |

622 |

|

Removal and Installation ………………………………. |

622 |

|

IGNITION SIGNAL …………………………………………. |

623 |

|

Component Description ………………………………… |

623 |

|

Wiring Diagram ……………………………………………. |

624 |

|

Diagnostic Procedure …………………………………… |

627 |

|

Component Inspection ………………………………….. |

632 |

|

Removal and Installation ………………………………. |

633 |

|

REFRIGERANT PRESSURE SENSOR …………….. |

634 |

|

Component Description ………………………………… |

634 |

|

Wiring Diagram ……………………………………………. |

635 |

|

Diagnostic Procedure …………………………………… |

636 |

|

Removal and Installation ………………………………. |

639 |

|

SNOW MODE SWITCH ………………………………….. |

640 |

|

Description ………………………………………………….. |

640 |

|

CONSULT-II Reference Value in the Data Monitor |

|

|

Mode ………………………………………………………….. |

640 |

|

Wiring Diagram ……………………………………………. |

641 |

|

Diagnostic Procedure …………………………………… |

643 |

|

Component Inspection ………………………………….. |

646 |

|

VIAS …………………………………………………………….. |

647 |

|

Description ………………………………………………….. |

647 |

|

CONSULT-IIReferenceValueinDataMonitorMode |

|

|

. 648 |

|

|

Wiring Diagram ……………………………………………. |

649 |

|

Diagnostic Procedure …………………………………… |

651 |

|

Component Inspection ………………………………….. |

655 |

|

Removal and Installation ………………………………. |

656 |

|

MIL AND DATA LINK CONNECTOR ………………… |

657 |

|

Wiring Diagram ……………………………………………. |

657 |

|

SERVICE DATA AND SPECIFICATIONS (SDS) … |

661 |

|

Fuel Pressure ……………………………………………… |

661 |

|

Idle Speed and Ignition Timing ………………………. |

661 |

|

Calculated Load Value ………………………………….. |

661 |

|

Mass Air Flow Sensor …………………………………… |

661 |

|

Intake Air Temperature Sensor ………………………. |

661 |

|

Engine Coolant Temperature Sensor ……………… |

661 |

|

Heated Oxygen Sensor 1 Heater …………………… |

661 |

|

Heated Oxygen Sensor 2 Heater …………………… |

661 |

|

Crankshaft Position Sensor (POS) …………………. |

661 |

|

Camshaft Position Sensor (PHASE) ………………. |

661 |

|

Throttle Control Motor …………………………………… |

662 |

|

Fuel Injector ………………………………………………… |

662 |

|

Fuel Pump ………………………………………………….. |

662 |

A

EC

C

D

E

F

G

H

I

J

K

L

M

|

Revision: 2006 July |

EC-7 |

2006 X-Trail |

INDEX FOR DTC

INDEX FOR DTC

DTC No. Index

NOTE:

If DTC U1000 or U1001 is displayed with other DTC, first perform the trouble diagnosis for DTC U1000, U1001. Refer to EC-152, «DTC U1000, U1001 CAN COMMUNICATION LINE» .

|

DTC*1 |

Items |

|||

|

Reference page |

||||

|

CONSULT-II |

||||

|

ECM*3 |

(CONSULT-II screen terms) |

|||

|

GST*2 |

||||

|

NO DTC IS DETECTED. |

||||

|

No DTC |

Flashing*6 |

FURTHER TESTING |

EC-62 |

|

|

MAY BE REQUIRED. |

||||

|

U1000 |

1000*4 |

CAN COMM CIRCUIT |

EC-152 |

|

|

U1001 |

1001*4 |

CAN COMM CIRCUIT |

EC-152 |

|

|

NO DTC IS DETECTED. |

||||

|

P0000 |

0000 |

FURTHER TESTING |

— |

|

|

MAY BE REQUIRED. |

||||

|

P0011 |

0011 |

INT/V TIM CONT-B1 |

EC-155 |

|

|

P0031 |

0031 |

HO2S1 HTR (B1) |

EC-159 |

|

|

P0032 |

0032 |

HO2S1 HTR (B1) |

EC-159 |

|

|

P0037 |

0037 |

HO2S2 HTR (B1) |

EC-166 |

|

|

P0038 |

0038 |

HO2S2 HTR (B1) |

EC-166 |

|

|

P0075 |

0075 |

INT/V TIM V/CIR-B1 |

EC-173 |

|

|

P0101 |

0101 |

MAF SEN/CIRCUIT |

EC-178 |

|

|

P0102 |

0102 |

MAF SEN/CIRCUIT |

EC-187 |

|

|

P0103 |

0103 |

MAF SEN/CIRCUIT |

EC-187 |

|

|

P0112 |

0112 |

IAT SEN/CIRCUIT |

EC-195 |

|

|

P0113 |

0113 |

IAT SEN/CIRCUIT |

EC-195 |

|

|

P0117 |

0117 |

ECT SEN/CIRC |

EC-201 |

|

|

P0118 |

0118 |

ECT SEN/CIRC |

EC-201 |

|

|

P0122 |

0122 |

TP SEN 2/CIRC |

EC-207 |

|

|

P0123 |

0123 |

TP SEN 2/CIRC |

EC-207 |

|

|

P0125 |

0125 |

ECT SENSOR |

EC-215 |

|

|

P0127 |

0127 |

IAT SENSOR |

EC-218 |

|

|

P0128 |

0128 |

THERMSTAT FNCTN |

EC-221 |

|

|

P0132 |

0132 |

HO2S1 (B1) |

EC-223 |

|

|

P0133 |

0133 |

HO2S1 (B1) |

EC-231 |

|

|

P0134 |

0134 |

HO2S1 (B1) |

EC-242 |

|

|

P0137 |

0137 |

HO2S2 (B1) |

EC-251 |

|

|

P0138 |

0138 |

HO2S2 (B1) |

EC-260 |

|

|

P0139 |

0139 |

HO2S2 (B1) |

EC-272 |

|

|

P0171 |

0171 |

FUEL SYS-LEAN-B1 |

EC-281 |

|

|

P0172 |

0172 |

FUEL SYS-RICH-B1 |

EC-289 |

|

|

P0181 |

0181 |

FTT SENSOR |

EC-296 |

|

|

P0182 |

0182 |

FTT SEN/CIRCUIT |

EC-302 |

|

|

P0183 |

0183 |

FTT SEN/CIRCUIT |

EC-302 |

|

|

P0222 |

0222 |

TP SEN 1/CIRC |

EC-307 |

|

|

P0223 |

0223 |

TP SEN 1/CIRC |

EC-307 |

|

|

Revision: 2006 July |

EC-8 |

2006 X-Trail |

INDEX FOR DTC

|

DTC*1 |

Items |

A |

||||

|

Reference page |

||||||

|

CONSULT-II |

||||||

|

ECM*3 |

(CONSULT-II screen terms) |

|||||

|

GST*2 |

||||||

|

P0300 |

0300 |

MULTI CYL MISFIRE |

EC-315 |

EC |

||

|

P0301 |

0301 |

CYL 1 MISFIRE |

EC-315 |

|||

|

P0302 |

0302 |

CYL 2 MISFIRE |

EC-315 |

|||

|

C |

||||||

|

P0303 |

0303 |

CYL 3 MISFIRE |

EC-315 |

|||

|

P0304 |

0304 |

CYL 4 MISFIRE |

EC-315 |

|||

|

P0327 |

0327 |

KNOCK SEN/CIRC-B1 |

EC-322 |

D |

||

|

P0328 |

0328 |

KNOCK SEN/CIRC-B1 |

EC-322 |

|||

|

P0335 |

0335 |

CKP SEN/CIRCUIT |

EC-327 |

|||

|

E |

||||||

|

P0340 |

0340 |

CMP SEN/CIRC-B1 |

EC-335 |

|||

|

P0420 |

0420 |

TW CATALYST SYS-B1 |

EC-343 |

|||

|

P0441 |

0441 |

EVAP PURG FLOW/MON |

EC-348 |

F |

||

|

P0442 |

0442 |

EVAP SMALL LEAK |

EC-354 |

|||

|

P0443 |

0443 |

PURG VOLUME CONT/V |

EC-364 |

|||

|

P0444 |

0444 |

PURG VOLUME CONT/V |

EC-372 |

G |

||

|

P0445 |

0445 |

PURG VOLUME CONT/V |

EC-372 |

|||

|

P0447 |

0447 |

VENT CONTROL VALVE |

EC-379 |

|||

|

H |

||||||

|

P0448 |

0448 |

VENT CONTROL VALVE |

EC-386 |

|||

|

P0451 |

0451 |

EVAP SYS PRES SEN |

EC-393 |

|||

|

P0452 |

0452 |

EVAP SYS PRES SEN |

EC-396 |

I |

||

|

P0453 |

0453 |

EVAP SYS PRES SEN |

EC-403 |

|||

|

P0455 |

0455 |

EVAP GROSS LEAK |

EC-411 |

|||

|

J |

||||||

|

P0456 |

0456 |

EVAP VERY SML LEAK |

EC-419 |

|||

|

P0460 |

0460 |

FUEL LEV SEN SLOSH |

EC-430 |

|||

|

P0461 |

0461 |

FUEL LEVEL SENSOR |

EC-432 |

K |

||

|

P0462 |

0462 |

FUEL LEVL SEN/CIRC |

EC-434 |

|||

|

P0463 |

0463 |

FUEL LEVL SEN/CIRC |

EC-434 |

|||

|

L |

||||||

|

P0500 |

0500 |

VEH SPEED SEN/CIRC*5 |

EC-436 |

|||

|

P0506 |

0506 |

ISC SYSTEM |

EC-438 |

|||

|

P0507 |

0507 |

ISC SYSTEM |

EC-440 |

M |

||

|

P0550 |

0550 |

PW ST P SEN/CIRC |

EC-442 |

|||

|

P0603 |

0603 |

ECM BACK UP/CIRC |

EC-447 |

|||

|

P0605 |

0605 |

ECM |

EC-451 |

|||

|

P0643 |

0643 |

SENSOR POWER/CIRC |

EC-454 |

|||

|

P0705 |

0705 |

PNP SW/CIRC |

AT-95 |

|||

|

P0710 |

0710 |

ATF TEMP SEN/CIRC |

AT-100 |

|||

|

P0720 |

0720 |

VEH SPD SEN/CIR AT*5 |

AT-105 |

|||

|

P0725 |

0725 |

ENGINE SPEED SIG |

AT-111 |

|||

|

P0731 |

0731 |

A/T 1ST GR FNCTN |

AT-115 |

|||

|

P0732 |

0732 |

A/T 2ND GR FNCTN |

AT-120 |

|||

|

P0733 |

0733 |

A/T 3RD GR FNCTN |

AT-125 |

|||

|

P0734 |

0734 |

A/T 4TH GR FNCTN |

AT-130 |

|||

|

P0740 |

0740 |

TCC SOLENOID/CIRC |

AT-137 |

|||

|

Revision: 2006 July |

EC-9 |

2006 X-Trail |

|

INDEX FOR DTC |

||||

|

DTC*1 |

Items |

|||

|

Reference page |

||||

|

CONSULT-II |

||||

|

ECM*3 |

(CONSULT-II screen terms) |

|||

|

GST*2 |

||||

|

P0744 |

0744 |

A/T TCC S/V FNCTN |

AT-142 |

|

|

P0745 |

0745 |

L/PRESS SOL/CIRC |

AT-150 |

|

|

P0750 |

0750 |

SFT SOL A/CIRC |

AT-156 |

|

|

P0755 |

0755 |

SFT SOL B/CIRC |

AT-161 |

|

|

P0850 |

0850 |

P-N POS SW/CIRCUIT |

EC-460 |

|

|

P1143 |

1143 |

HO2S1 (B1) |

EC-465 |

|

|

P1144 |

1144 |

HO2S1 (B1) |

EC-471 |

|

|

P1148 |

1148 |

CLOSED LOOP-B1 |

EC-477 |

|

|

P1211 |

1211 |

TCS C/U FUNCTION |

EC-478 |

|

|

P1212 |

1212 |

TCS/CIRC |

EC-479 |

|

|

P1217 |

1217 |

ENG OVER TEMP |

EC-480 |

|

|

P1225 |

1225 |

CTP LEARNING |

EC-494 |

|

|

P1226 |

1226 |

CTP LEARNING |

EC-496 |

|

|

P1564 |

1564 |

ASCD SW |

EC-498 |

|

|

P1572 |

1572 |

ASCD BRAKE SW |

EC-506 |

|

|

P1574 |

1574 |

ASCD VHL SPD SEN |

EC-517 |

|

|

P1610 — P1615 |

1610 — 1615 |

NATS MALFUNCTION |

EC-46 |

|

|

P1705 |

1705 |

TP SEN/CIRC A/T |

AT-166 |

|

|

P1720 |

1720 |

V/SP SEN (A/T OUT) |

EC-519 |

|

|

P1760 |

1760 |

O/R CLTCH SOL/CIRC |

AT-171 |

|

|

P1800 |

1800 |

VIAS S/V CIRC |

EC-521 |

|

|

P1805 |

1805 |

BRAKE SW/CIRCUIT |

EC-526 |

|

|

P2100 |

2100 |

ETC MOT PWR |

EC-531 |

|

|

P2101 |

2101 |

ETC FUNCTION/CIRC |

EC-538 |

|

|

P2103 |

2103 |

ETC MOT PWR |

EC-531 |

|

|

P2118 |

2118 |

ETC MOT |

EC-546 |

|

|

P2119 |

2119 |

ETC ACTR |

EC-551 |

|

|

P2122 |

2122 |

APP SEN 1/CIRC |

EC-553 |

|

|

P2123 |

2123 |

APP SEN 1/CIRC |

EC-553 |

|

|

P2127 |

2127 |

APP SEN 2/CIRC |

EC-560 |

|

|

P2128 |

2128 |

APP SEN 2/CIRC |

EC-560 |

|

|

P2135 |

2135 |

TP SENSOR |

EC-568 |

|

|

P2138 |

2138 |

APP SENSOR |

EC-576 |

|

*1: 1st trip DTC No. is the same as DTC No. *2: This number is prescribed by SAE J2012.

*3: In Diagnostic Test Mode II (Self-diagnostic results), this number is controlled by NISSAN. *4: The troubleshooting for this DTC needs CONSULT-II.

*5: When the fail-safe operations for both self-diagnoses occur, the MIL illuminates. *6: When engine is running.

|

Revision: 2006 July |

EC-10 |

2006 X-Trail |

INDEX FOR DTC

Alphabetical Index |

ABS00D7Z |

NOTE:

If DTC U1000 or U1001 is displayed with other DTC, first perform the trouble diagnosis for DTC U1000, U1001. Refer to EC-152, «DTC U1000, U1001 CAN COMMUNICATION LINE» .

|

Items |

DTC*1 |

|||

|

Reference page |

||||

|

CONSULT-II |

||||

|

(CONSULT-II screen terms) |

ECM*3 |

|||

|

GST*2 |

||||

|

A/T 1ST GR FNCTN |

P0731 |

0731 |

AT-115 |

|

|

A/T 2ND GR FNCTN |

P0732 |

0732 |

AT-120 |

|

|

A/T 3RD GR FNCTN |

P0733 |

0733 |

AT-125 |

|

|

A/T 4TH GR FNCTN |

P0734 |

0734 |

AT-130 |

|

|

A/T TCC S/V FNCTN |

P0744 |

0744 |

AT-142 |

|

|

APP SEN 1/CIRC |

P2122 |

2122 |

EC-553 |

|

|

APP SEN 1/CIRC |

P2123 |

2123 |

EC-553 |

|

|

APP SEN 2/CIRC |

P2127 |

2127 |

EC-560 |

|

|

APP SEN 2/CIRC |

P2128 |

2128 |

EC-560 |

|

|

APP SENSOR |

P2138 |

2138 |

EC-576 |

|

|

ASCD BRAKE SW |

P1572 |

1572 |

EC-506 |

|

|

ASCD SW |

P1564 |

1564 |

EC-498 |

|

|

ASCD VHL SPD SEN |

P1574 |

1574 |

EC-517 |

|

|

ATF TEMP SEN/CIRC |

P0710 |

0710 |

AT-100 |

|

|

BRAKE SW/CIRCUIT |

P1805 |

1805 |

EC-526 |

|

|

CAN COMM CIRCUIT |

U1000 |

1000*4 |

EC-152 |

|

|

CAN COMM CIRCUIT |

U1001 |

1001*4 |

EC-152 |

|

|

CKP SEN/CIRCUIT |

P0335 |

0335 |

EC-327 |

|

|

CLOSED LOOP-B1 |

P1148 |

1148 |

EC-477 |

|

|

CMP SEN/CIRC-B1 |

P0340 |

0340 |

EC-335 |

|

|

CTP LEARNING |

P1225 |

1225 |

EC-494 |

|

|

CTP LEARNING |

P1226 |

1226 |

EC-496 |

|

|

CYL 1 MISFIRE |

P0301 |

0301 |

EC-315 |

|

|

CYL 2 MISFIRE |

P0302 |

0302 |

EC-315 |

|

|

CYL 3 MISFIRE |

P0303 |

0303 |

EC-315 |

|

|

CYL 4 MISFIRE |

P0304 |

0304 |

EC-315 |

|

|

ECM |

P0605 |

0605 |

EC-451 |

|

|

ECM BACK UP/CIRC |

P0603 |

0603 |

EC-447 |

|

|

ECT SEN/CIRC |

P0117 |

0117 |

EC-201 |

|

|

ECT SEN/CIRC |

P0118 |

0118 |

EC-201 |

|

|

ECT SENSOR |

P0125 |

0125 |

EC-215 |

|

|

ENG OVER TEMP |

P1217 |

1217 |

EC-480 |

|

|

ENGINE SPEED SIG |

P0725 |

0725 |

AT-111 |

|

|

ETC ACTR |

P2119 |

2119 |

EC-551 |

|

|

ETC FUNCTION/CIRC |

P2101 |

2101 |

EC-538 |

|

|

ETC MOT |

P2118 |

2118 |

EC-546 |

|

|

ETC MOT PWR |

P2103 |

2103 |

EC-531 |

|

|

ETC MOT PWR |

P2100 |

2100 |

EC-531 |

|

|

EVAP GROSS LEAK |

P0455 |

0455 |

EC-411 |

|

A

EC

C

D

E

F

G

H

I

J

K

L

M

|

Revision: 2006 July |

EC-11 |

2006 X-Trail |

INDEX FOR DTC

|

Items |

DTC*1 |

|||

|

Reference page |

||||

|

CONSULT-II |

||||

|

(CONSULT-II screen terms) |

ECM*3 |

|||

|

GST*2 |

||||

|

EVAP PURG FLOW/MON |

P0441 |

0441 |

EC-348 |

|

|

EVAP SMALL LEAK |

P0442 |

0442 |

EC-354 |

|

|

EVAP SYS PRES SEN |

P0451 |

0451 |

EC-393 |

|

|

EVAP SYS PRES SEN |

P0452 |

0452 |

EC-396 |

|

|

EVAP SYS PRES SEN |

P0453 |

0453 |

EC-403 |

|

|

EVAP VERY SML LEAK |

P0456 |

0456 |

EC-419 |

|

|

FTT SEN/CIRCUIT |

P0182 |

0182 |

EC-302 |

|

|

FTT SEN/CIRCUIT |

P0183 |

0183 |

EC-302 |

|

|

FTT SENSOR |

P0181 |

0181 |

EC-296 |

|

|

FUEL LEV SEN SLOSH |

P0460 |

0460 |

EC-430 |

|

|

FUEL LEVEL SENSOR |

P0461 |

0461 |

EC-432 |

|

|

FUEL LEVL SEN/CIRC |

P0462 |

0462 |

EC-434 |

|

|

FUEL LEVL SEN/CIRC |

P0463 |

0463 |

EC-434 |

|

|

FUEL SYS-LEAN-B1 |

P0171 |

0171 |

EC-281 |

|

|

FUEL SYS-RICH-B1 |

P0172 |

0172 |

EC-289 |

|

|

HO2S1 (B1) |

P0132 |

0132 |

EC-223 |

|

|

HO2S1 (B1) |

P0133 |

0133 |

EC-231 |

|

|

HO2S1 (B1) |

P0134 |

0134 |

EC-242 |

|

|

HO2S1 (B1) |

P1143 |

1143 |

EC-465 |

|

|

HO2S1 (B1) |

P1144 |

1144 |

EC-471 |

|

|

HO2S1 HTR (B1) |

P0031 |

0031 |

EC-159 |

|

|

HO2S1 HTR (B1) |

P0032 |

0032 |

EC-159 |

|

|

HO2S2 (B1) |

P0137 |

0137 |

EC-251 |

|

|

HO2S2 (B1) |

P0138 |

0138 |

EC-260 |

|

|

HO2S2 (B1) |

P0139 |

0139 |

EC-272 |

|

|

HO2S2 HTR (B1) |

P0037 |

0037 |

EC-166 |

|

|

HO2S2 HTR (B1) |

P0038 |

0038 |

EC-166 |

|

|

IAT SEN/CIRCUIT |

P0112 |

0112 |

EC-195 |

|

|

IAT SEN/CIRCUIT |

P0113 |

0113 |

EC-195 |

|

|

IAT SENSOR |

P0127 |

0127 |

EC-218 |

|

|

INT/V TIM CONT-B1 |

P0011 |

0011 |

EC-155 |

|

|

INT/V TIM V/CIR-B1 |

P0075 |

0075 |

EC-173 |

|

|

ISC SYSTEM |

P0506 |

0506 |

EC-438 |

|

|

ISC SYSTEM |

P0507 |

0507 |

EC-440 |

|

|

KNOCK SEN/CIRC-B1 |

P0327 |

0327 |

EC-322 |

|

|

KNOCK SEN/CIRC-B1 |

P0328 |

0328 |

EC-322 |

|

|

L/PRESS SOL/CIRC |

P0745 |

0745 |

AT-150 |

|

|

MAF SEN/CIRCUIT |

P0101 |

0101 |

EC-178 |

|

|

MAF SEN/CIRCUIT |

P0102 |

0102 |

EC-187 |

|

|

MAF SEN/CIRCUIT |

P0103 |

0103 |

EC-187 |

|

|

MULTI CYL MISFIRE |

P0300 |

0300 |

EC-315 |

|

|

NATS MALFUNCTION |

P1610 — P1615 |

1610 — 1615 |

EC-46 |

|

|

Revision: 2006 July |

EC-12 |

2006 X-Trail |

INDEX FOR DTC

|

Items |

DTC*1 |

|||

|

Reference page |

||||

|

CONSULT-II |

||||

|

(CONSULT-II screen terms) |

ECM*3 |

|||

|

GST*2 |

||||

|

NO DTC IS DETECTED. |

||||

|

FURTHER TESTING |

No DTC |

Flashing*6 |

EC-62 |