Материал из BikesWiki — энциклопедия японских мотоциклов

Перейти к: навигация, поиск

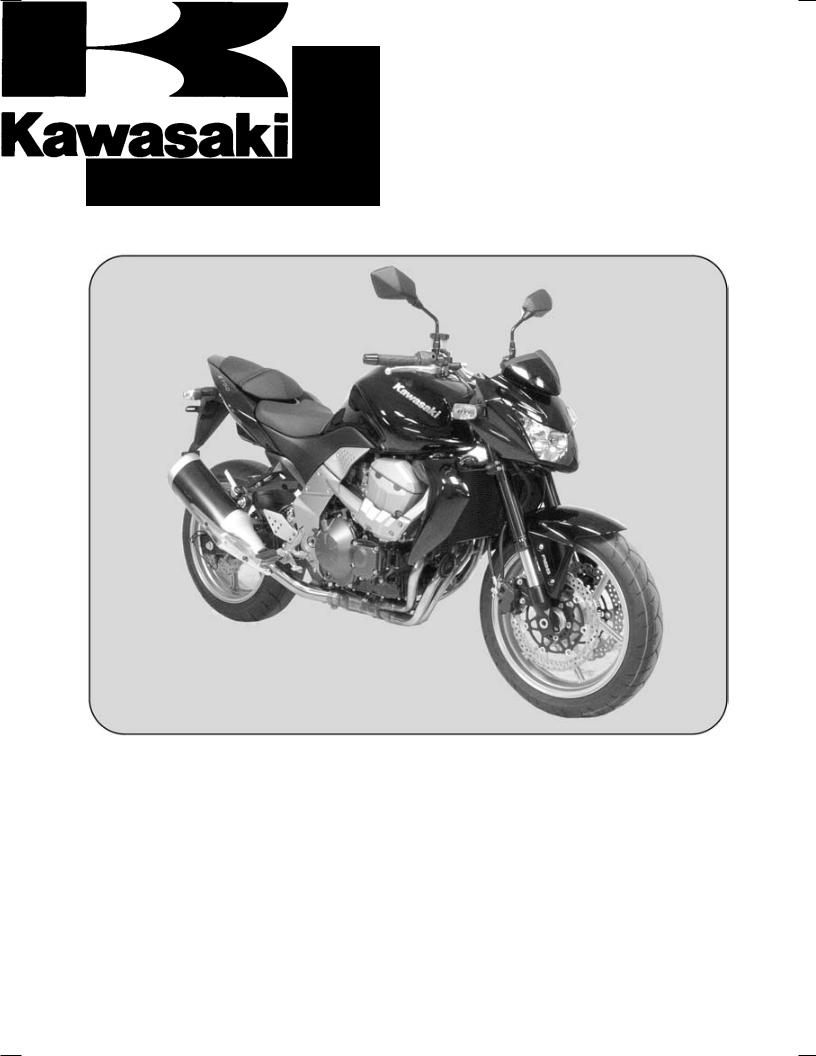

Kawasaki Z750

Ниже представлены прямые ссылки на скачку сервисной документации.

Для Kawasaki Z750

- Руководство пользователя (Owners Manual) на Kawasaki Z750R (на русском)

- Сервисный мануал (Service Manual) на Kawasaki Z750 (2003-2006)

- Сервисный мануал (Service Manual) на Kawasaki Z750 (2007-2010)

- Сервисный мануал (Service Manual) на Kawasaki Z750S (2005)

- Мануал по обслуживанию Kawasaki Z750R

Обзор модели

- Kawasaki Z750

Источник — «https://bikeswiki.ru/index.php?title=Kawasaki_Z750:_мануалы&oldid=9719»

Категория:

- Сервисная документация

#1

motogad

- Пол:Мужчина

- Город:Москва ВАО

- Мото:Kawasaki Ninja ZX6R

Отправлено 18 Август 2008 — 18:34

Все мануалы которые у нас есть ниже по теме

Сообщение отредактировал max232: 31 Январь 2014 — 13:53

- bktspro, Michaelgrorm, SCpraics и 2 другим это нравится

- Наверх

#2

max232

max232

- Пол:Мужчина

- Страна:Россия

- Город:Елец, Липецкая область

- Мото:zx-10r `08

Отправлено 09 Январь 2014 — 21:19

Просьба к обладателям мануалов которых нет в списке,

мы будем признательны если вы с нами поделитесь.

Руководство по ремонту демпфера Ohlins

Каталог з/ч Kawasaki

Руководство по эксплуатации Kawasaki Ninja H2 (ZX1000NF) 2014-

Руководство по эксплуатации Kawasaki Ninja H2 SX (ZX1000NF) 2017- (РУС) НОВОЕ! Спасибо Mikhail72

Руководство по ремонту KNinja H2 SX 2018- НОВОЕ! Спасибо belenkiy

Руководство по ремонту Kawasaki ZZR1400, ZZR1400 ABS, Ninja ZX-14 2012-2013 (РУС) НОВОЕ! Спасибо Назарий

Руководство пользователя Kawasaki ZZR1400, ZZR1400 ABS, Ninja ZX-14 2012- (РУС) НОВОЕ! Спасибо Ewil Dwarf

Руководство по ремонту Kawasaki ZZR1400, ZZR1400 ABS, Ninja ZX-14 2010-2011

Руководство по ремонту Kawasaki ZZR1400, ZZR1400 ABS, Ninja ZX-14 2008-2009

Руководство по ремонту Kawasaki ZZR1400, ZZR1400 ABS, Ninja ZX-14 2006-2007

Руководство по ремонту Ninja ZX-12R 2002-2005

Руководство по ремонту Ninja ZX-12R 2000-2001

Руководство по ремонту Kawasaki Ninja ZX-10R, Ninja ZX-10R ABS 2016-2017 НОВОЕ!

Руководство по ремонту Kawasaki Ninja ZX-10R, Ninja ZX-10R ABS 2013-2015

Руководство по ремонту Kawasaki Ninja ZX-10R, Ninja ZX-10R ABS 2011-2012

Руководство по эксплуатации (РУС) Kawasaki Ninja ZX-10R 2011-2012

Руководство по эксплуатации (EN) Kawasaki Ninja ZX-10R 2008-2010

Руководство по ремонту Kawasaki Ninja ZX-10R 2008-2010

Руководство по ремонту Kawasaki Ninja ZX-10R 2006-2007

Руководство по ремонту Kawasaki Ninja ZX-10R 2004-2005

Руководство по ремонту Kawasaki Ninja ZX-10 1988-1990

Руководство по ремонту Kawasaki ZX-9R 1998 — 1999

Руководство по ремонту Kawasaki ZX-9R 1998 — 1999 RUS

Руководство по ремонту Kawasaki ZX-9R 1994-1997

Руководство по ремонту Kawasaki ZX-9R (Ger) 2002-2003

Руководство по ремонту Kawasaki ZX750 (ZXR-750) 1989-1996, ZX750 (Ninja ZX-7)1989-1995

Руководство по ремонту Kawasaki Ninja ZX-7R, ZX-7RR 1996-2003

Руководство по ремонту Kawasaki Ninja ZX-6R, Ninja ZX-6R ABS 2013

Руководство по ремонту (РУС пер.Viktor72) Kawasaki Ninja ZX-6R, Ninja ZX-6R ABS 2013

Руководство по ремонту Kawasaki Ninja ZX-6R 2009-2011

Руководство по ремонту Kawasaki ZX-6R 2007-2008

Руководство по ремонту Kawasaki Ninja ZX-6R 2005-2006

Руководство по ремонту Kawasaki Ninja ZX–6R, ZX-6RR 2003-2004

Руководство по ремонту Kawasaki Ninja ZX-6R 2001-2002

Руководство по ремонту Kawasaki Ninja ZX-6R 2001-2002 (РУС) НОВОЕ! Спасибо Vjaceslav

Руководство по ремонту Kawasaki Ninja ZX–6R, 98-99

Руководство по ремонту Kawasaki Ninja ZX-6R 95-97

Руководство по ремонту Kawasaki ZXR400 (zx-4), ZX400-H2 1989-1990

Руководство по ремонту Kawasaki ZXR400 (zx-4), ZX400 L1-L8 1991-1998

Руководство по ремонту Kawasaki ZXR400(zx-4), ZX400 G1,G1A,G1B 1988

Руководство по ремонту Kawasaki Ninja 250 2008-2012

Руководство пользователя Kawasaki Ninja 250 (РУС) 2008-2012

Руководство по ремонту Kawasaki Ninja 300, Ninja 300 ABS 2013-

Руководство по эксплуатации (РУС) Kawasaki Ninja 300, Ninja 300 ABS 2013-

Дорожные мотоциклы Kawasaki. Общее руководство по эксплуатации (РУС) 2012-

Руководство по ремонту Kawasaki ER-6n, ER-6n ABS 2012-

Руководство по эксплуатации (РУС) Kawasaki ER-6n, ER-6n ABS 2012-

Руководство по ремонту Kawasaki ER-6n, ER-6n ABS 2009-2011

Руководство по ремонту Kawasaki ER-6n, ER-6n ABS 2006-2008

Руководство по ремонту Kawasaki Ninja 650, Ninja 650 ABS, ER-6f, ER-6f ABS 2012-

Руководство по эксплуатации (РУС) Kawasaki Ninja 650, Ninja 650 ABS, ER-6f, ER-6f ABS 2012-

Руководство по ремонту Kawasaki Ninja 650, Ninja 650 ABS, ER-6f, ER-6f ABS 2009-2011

Руководство по ремонту Kawasaki NINJA 650R, ER-6f, ER-6f ABS 2006-2008

Руководство по ремонту Kawasaki ER500 C1-C5

2001 ER500-C1 37Kw

2001 ER500-D1 25kw

2002 ER500-C2 37Kw

2003 ER500-C3 37Kw

2004 ER500-C4 катализатор -1Kw

2005 ER500-C5 модифицирован выхлоп, авто выключение/включение света

Руководство по ремонту Kawasaki Z1000, Z1000 ABS 2017- НОВОЕ! Спасибо Назарий

Руководство по ремонту Kawasaki Z1000SX Ninja 1000 2017- НОВОЕ! Спасибо Ghost1195

Руководство по ремонту Kawasaki Z1000SX, Z1000SX ABS, Ninja 1000, Ninja 1000 ABS 2014-2016 НОВОЕ! Спасибо alexus1313

Руководство по ремонту Kawasaki Z1000SX, Z1000SX ABS, Ninja 1000, Ninja 1000 ABS 2011-2013 НОВОЕ! Спасибо Glareone

Руководство по ремонту Kawasaki Z1000, Z1000 ABS 2014-2016

Руководство по ремонту Kawasaki Z1000, Z1000 ABS 2010-2013

Руководство по эксплуатации (РУС) Kawasaki Z1000SX, Z1000SX ABS 2010-2013

Руководство по ремонту Kawasaki Z1000, Z1000 ABS 2007-2009

Руководство по ремонту Kawasaki Z1000 2003-2006

Руководство по ремонту Kawasaki Z900, Z900 ABS, ZR900 2017- НОВОЕ! Спасибо ev6en!

Руководство по ремонту Kawasaki Z800 2013-

Инструкция по эксплуатации Kawasaki Z800 (РУС) 2013-

Инструкция по эксплуатации Kawasaki Z750R (РУС) 2011

Руководство по ремонту Kawasaki Z750S 2005-2006

Руководство по ремонту Kawasaki Z750 2003-2006

Руководство по ремонту Kawasaki Z750, Z750 ABS 2007-2010

Руководство по ремонту Kawasaki Z750R, Z750R ABS 2011- 2012 РОЗЫСК!

Инструкция по эксплуатации Kawasaki Z400 ABS (РУС) 2019- НОВОЕ! Спасибо Бродячий Кот!

Kawasaki 1400GTR, CONCOURS 14 ABS, CONCOURS 14 2010-2014 РОЗЫСК

Kawasaki 1400GTR, CONCOURS 14 ABS, CONCOURS 14 2008-2009

Руководство по эксплуатации (РУС) Kawasaki 1400GTR 2010

Руководство по ремонту Kawasaki VERSYS 650 VERSYS 650 ABS 2015-2016

Руководство по ремонту Kawasaki VERSYS 650 VERSYS 650 ABS 2010-2014

Руководство по ремонту Kawasaki VERSYS 650 2007-2009

Руководство по ремонту Kawasaki VERSYS 1000 2012-2014

Руководство по эксплуатации (РУС) Kawasaki VERSYS 1000 2012-2014

Руководство по эксплуатации (РУС) Kawasaki VERSYS 1000 SE 2019 — НОВОЕ!

Руководство по эксплуатации (РУС) Kawasaki VULCAN S VULCAN S ABS 2015- НОВОЕ! Спасибо offlineb!

Руководство по эксплуатации (РУС) Kawasaki W800 2012-

Руководство по эксплуатации (РУС) Kawasaki KLX250

Руководство по эксплуатации (ENG) Kawasaki KLX150L 2014- НОВОЕ!Спасибо roy0864!

Руководство по эксплуатации (РУС) Kawasaki 1000GTR ZG1000-A1 1986

Все что у нас есть выложено здесь, и мы больше ничего от Вас не прячем. Затрудните себя хотя бы поиском в списке мануала для своей модели мотоцикла.

По этим ссылкам расположены 2 архива по гигабайту с мануалами которых нет в вышеуказанном списке.

http://yadi.sk/d/yrnnmcxJJ9wxG

http://yadi.sk/d/nxb6nuh_J9x52

Эта ссылка на теже мануалы с возможностью не скачивать архивы целиком https://yadi.sk/d/OzesQZ8RUrXPE

- mrkvch, EnergyControl, Walazar и еще 1 это нравится

- Наверх

#3

Smart

Smart

- Пол:Мужчина

- Страна:Россия

- Город:Митино

- Мото:9-ka 1999г—>9-ka 2001г

Отправлено 17 Январь 2014 — 11:26

По ссылке https://yadi.sk/d/I61_p9A6mdk6m находятся мануалы на следующие модели которые не вошли в список выложенный выше.

Kawasaki ZZR1100 & ZX11 1993-2001

Kawasaki NINJA 250 86-07

Kawasaki GPZ400-550 & Z400F-FII & Z500F-550F 83-85 Service Manual

Kawasaki GPZ-500,600,ZX-500-A1,ZX-600-A1 Service Manual

Kawasaki GPZ-500S 86-94 Service Manual

Kawasaki GPZ-600R/GPX-600R/Ninja 600R/RX/GPX-750R/Ninja 750R

Kawasaki GPZ-750 Turbo 1984 Service Manual

Kawasaki GPZ900R 1984-1990 Workshop Manual

Kawasaki GPZ-1000RX,GPZ-900R Service Manual

Kawasaki GPZ-1100E Service Manual

Kawasaki GTR-1400 2014 Service Manual

Kawasaki KDX200 89-94 Service Manual

Kawasaki KH250-400 72-76

Kawasaki KLV1000-A1 2004 Service Manual

Kawasaki KLX650

Kawasaki KR250

Kawasaki KX250F 2004 Service Manual

Kawasaki KX450F 2006 Service Manual

Kawasaki KZ400 1974 Service Manual

Kawasaki KZ440 Service Manual

Kawasaki VN1500 87-99 Service Manual

Kawasaki VN1600-A1&A2 2003 Service Manual

Kawasaki VN2000-A1 2003 Service Manual

Kawasaki VN750 Manual and Parts

Kawasaki ZZR250 90-96 Service Manual

Kawasaki A Series Rotary Valve Twins 250,350,500 69-71 Workshop Manual

Kawasaki EN450,EN500,EN454,LTD500 Vulcan 85-04 Service Manual

Kawasaki ER-5 2004 Service Manual

Kawasaki ER-5 1997 Service Manual(DE)

Kawasaki VN800 Vulcan 96-04 Service Manual

Kawasaki VN900 Vulcan Classic 2006 Service Manual

Kawasaki W650 ’99 Service Manual (German)

Kawasaki ZR1100A,Zephir-1100 Service Manual

Kawasaki ZRX1200R,ZRX1200S 2001-2007 Service Manual

Kawasaki ZR550,ZR750 Zephyr 1990 Service Manual

Kawasaki ZR-7S,ZR-750H1 Service Manual

Kawasaki ZXR400R Kit 1989 Service Manual

Kawasaki ZXR400L Service Manual

Kawasaki ZXR750R,ZXR750J,ZXR750K Service Manual

Kawasaki ZXR750 Racing Kit 1992 Service Manual

Kawasaki ZX-10 Ninja 1988-1990 Service Manual

Kawasaki ZZR1200 ’03 Service Manual (German)

Kawasaki Z1 1972 Service Manual

Kawasaki KLE500 Service Manual

Kawasaki ZRX1200 Service Manual(German)

Kawasaki KLX110 Service Manual

Kawasaki ZXR 250 Service Manual 1997

- sem01 и Walazar это нравится

- Наверх

#4

albert8121984

albert8121984

-

- Members

-

- 35 сообщений

Прохожий

- Пол:Мужчина

- Страна:Россия

- Город:Москва СВАО(Алтуфьево), (КБР г.Прохладный)

- Мото:Kawasaki Z1000SX, (Versys 650B-08г), (ZX-6R 636 05г.) (ZZR 400 — 2)

Отправлено 16 Октябрь 2015 — 14:29

Пользуюсь сайтом ManualsLib – Search For Manuals Online.

Если что-то не понятно с помощью googla можно перевести страничку.

- Cher Tannov это нравится

- Наверх

#5

Cher Tannov

Cher Tannov

-

Вконтакте:

- Пол:Мужчина

- Страна:Россия

- Город:Москва, Чер Танново

- Мото:ER-6F ’12

Отправлено 06 Апрель 2016 — 10:32

Каталог Hiflo по масляным и воздушным фильтрам: https://yadi.sk/i/8FAFZ19PqmkhH

Немало каталогов и мануалов на тайском сайте Кавасаки.

http://www.kawasaki….c&page=download

ONLINE КАТАЛОГИ

Каталоги производителей, представленных в наших магазинах. Ссылки открываются в новом окне.

HIFLOFILTRO — Воздушные и маслянные фильтры

MOTUL — Моторные масла и мотохимия

JTSPROKETS — Звёзды и цепи привода

LUCAS TRW — Тормозные колодки

FERODO — Тормозные колодки

NGK — Свечи зажигания

ARIETE — Сальники и пыльники вилки

ALL BALLS RACING — Подшипники рулевой колонки

Сообщение отредактировал Cher Tannov: 06 Май 2016 — 11:35

- Coreydus и gtaemblem.club это нравится

- Наверх

#6

max232

max232

- Пол:Мужчина

- Страна:Россия

- Город:Елец, Липецкая область

- Мото:zx-10r `08

Отправлено 19 Сентябрь 2019 — 15:43

Ребята, думаю навести в этом разделе порядок.

Если просто так скидывать ссылки, без указания точной модели для разных рынков,от какого года до какого года, сервисный мануал/руководство по эксплуатации, на каком языке.

Этот раздел очень быстро превратиться в помойку в котором невозможно ничего найти.

Зачастую люди кидают ссылки на то что у нас уже есть.

Очень много мото для разных рынков называются по разному.

Я вроде недалекий человек от мото, но и мне не просто разобраться какие модели одинаковые а какие нет.

Пожалуйста, если у вас есть чем поделиться указывайте как минимум следующую информацию:

1. точная модель мотоцикла

2. модельный год. (от какого года и ДО какого года)

3. Сервисный мануал или руководство по эксплуатации

4. На каком языке издание

5. Ссылка

БЕЗ УКАЗАНИЯ ЭТОЙ ИНФОРМАЦИИ Я БУДУ УДАЛЯТЬ ПОСТЫ

- Наверх

#7

ведьмак 24

ведьмак 24

-

- Читатели

- 1 сообщений

- Пол:Мужчина

- Страна:россия

- Город:иркутск

- Мото:кавасаки илиминатор VN250

Отправлено 22 Октябрь 2020 — 09:40

а не подскажеш где найти мануал на кавасаки илименатор вн 250,нигде найти не могу

- Наверх

#8

max232

max232

- Пол:Мужчина

- Страна:Россия

- Город:Елец, Липецкая область

- Мото:zx-10r `08

Отправлено 13 Апрель 2021 — 12:14

а не подскажеш где найти мануал на кавасаки илименатор вн 250,нигде найти не могу

https://www.ebay.com.au/p/2185422503

- Наверх

#9

Назарий

Назарий

-

- Читатели

- 6 сообщений

- Пол:Мужчина

- Страна:Россия

- Город:Москва

- Мото:Z1000

Отправлено 18 Август 2021 — 16:39

- Наверх

#10

max232

max232

- Пол:Мужчина

- Страна:Россия

- Город:Елец, Липецкая область

- Мото:zx-10r `08

Отправлено 19 Август 2021 — 00:27

- Наверх

#11

Lavarock

Lavarock

-

- Читатели

- 1 сообщений

- Пол:Мужчина

- Страна:Россия

- Город:Сочи

- Мото:z650

Отправлено 14 Декабрь 2021 — 21:53

Помогите найти мануал на Z650 2017 год

- Наверх

#12

advokat56

advokat56

-

- Читатели

- 1 сообщений

- Пол:Мужчина

- Страна:РФ

- Город:Оренбург

- Мото:Ninja 1000SX

Отправлено 25 Январь 2022 — 18:44

Доброе время суток! Поменял свой мот на Ninja 1000SX 2020 г. долго искал мануал на русском. Нашел делюсь. https://e-kawasaki.r…ba66894759a.pdf

- Наверх

#13

belenkiy

belenkiy

-

- Читатели

- 3 сообщений

- Пол:Мужчина

- Страна:Россия

- Город:Москва

- Мото:fz6r

Отправлено 15 Май 2022 — 18:50

Руководство по ремонту — Kawasaki h2 2018

https://1drv.ms/b/s!…-l2jLg?e=kLBago

К сожалени к SX не смог найти

- Наверх

#14

max232

max232

- Пол:Мужчина

- Страна:Россия

- Город:Елец, Липецкая область

- Мото:zx-10r `08

Отправлено 15 Май 2022 — 22:10

По вашей ссылке именно SX

Я добавил к списку. спасибо!

- Наверх

#15

Denisik

Denisik

-

- Читатели

- 1 сообщений

- Пол:Мужчина

- Страна:Россия

- Город:Вологда

- Мото:Z250

Отправлено 16 Сентябрь 2022 — 10:20

Руководство по эксплуатации Kawasaki Z250

https://disk.yandex…./zXaOezF2k7TSSQ

- Наверх

#16

L0ckhead

L0ckhead

-

- Members

-

- 20 сообщений

Прохожий

- Пол:Мужчина

- Страна:Россия

- Город:Краснознаменск

- Мото:Kawasaki Ninja 1000 sx

Отправлено 26 Март 2023 — 20:52

Мб кому пригодится мануал на ninja 1000 sx 2020+ Файл можно получить по ссылке:

Ninja 1000 sx.pdf

https://disk.yandex…./ddmFwjH-2Lc4Yg

- Наверх

#17

L0ckhead

L0ckhead

-

- Members

-

- 20 сообщений

Прохожий

- Пол:Мужчина

- Страна:Россия

- Город:Краснознаменск

- Мото:Kawasaki Ninja 1000 sx

Отправлено 26 Март 2023 — 20:53

Дубль

- Наверх

#18

AnDrRew

AnDrRew

-

- Читатели

- 4 сообщений

- Пол:Мужчина

- Страна:Russia

- Город:Moscow

- Мото:Ninja 1000

Отправлено 08 Апрель 2023 — 14:39

На manualslib больше нет наших мануалов((

Пока искал сервис мануал для своего мотоцикла нашёл:

Руководство пользователя z1000sx ninja1000 2017-19 на русском языке

https://docviewer.ya…m89MCJ9&lang=ru

- Наверх

#19

AnDrRew

AnDrRew

-

- Читатели

- 4 сообщений

- Пол:Мужчина

- Страна:Russia

- Город:Moscow

- Мото:Ninja 1000

Отправлено 08 Апрель 2023 — 14:40

На manualslib больше нет наших мануалов((

Пока искал сервис мануал для своего мотоцикла нашёл:

Руководство пользователя z1000sx ninja1000 2017-19 на русском языке

https://mot63.ru/upl…6e444596981.pdf

- Наверх

Z750

Z750 ABS

Motorcycle

Service Manual

Quick Reference Guide

This quick reference guide will assist you in locating a desired topic or procedure.

•Bend the pages back to match the black tab of the desired chapter number with the black tab on the edge at each table of contents page.

•Refer to the sectional table of contents for the exact pages to locate the specific topic required.

|

General Information |

1 |

j |

|

Periodic Maintenance |

2 |

j |

|

Fuel System (DFI) |

3 |

j |

|

Cooling System |

4 |

j |

|

Engine Top End |

5 |

j |

|

Clutch |

6 |

j |

|

Engine Lubrication System |

7 |

j |

|

Engine Removal/Installation |

8 |

j |

|

Crankshaft/Transmission |

9 |

j |

|

Wheels/Tires |

10 |

j |

|

Final Drive |

11 |

j |

|

Brakes |

12 |

j |

|

Suspension |

13 |

j |

|

Steering |

14 |

j |

|

Frame |

15 |

j |

|

Electrical System |

16 |

j |

|

Appendix |

17 |

j |

Z750

Z750 ABS

Motorcycle

Service Manual

All rights reserved. No parts of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic mechanical photocopying, recording or otherwise, without the prior written permission of Quality Assurance Division/Consumer Products & Machinery Company/Kawasaki Heavy Industries, Ltd., Japan.

No liability can be accepted for any inaccuracies or omissions in this publication, although every possible care has been taken to make it as complete and accurate as possible.

The right is reserved to make changes at any time without prior notice and without incurring an obligation to make such changes to products manufactured previously. See your Motorcycle dealer for the latest information on product improvements incorporated after this publication.

All information contained in this publication is based on the latest product information available at the time of publication. Illustrations and photographs in this publication are intended for reference use only and may not depict actual model component parts.

|

© 2007 Kawasaki Heavy Industries, Ltd. |

First Edition (1) : Feb. 28, 2007 (K) |

LIST OF ABBREVIATIONS

|

A |

ampere(s) |

lb |

pound(s) |

|

ABDC |

after bottom dead center |

m |

meter(s) |

|

AC |

alternating current |

min |

minute(s) |

|

ATDC |

after top dead center |

N |

newton(s) |

|

BBDC |

before bottom dead center |

Pa |

pascal(s) |

|

BDC |

bottom dead center |

PS |

horsepower |

|

BTDC |

before top dead center |

psi |

pound(s) per square inch |

|

°C |

degree(s) Celsius |

r |

revolution |

|

DC |

direct current |

rpm |

revolution(s) per minute |

|

F |

farad(s) |

TDC |

top dead center |

|

°F |

degree(s) Fahrenheit |

TIR |

total indicator reading |

|

ft |

foot, feet |

V |

volt(s) |

|

g |

gram(s) |

W |

watt(s) |

|

h |

hour(s) |

Ω |

ohm(s) |

|

L |

liter(s) |

COUNTRY AND AREA CODES

|

AT |

Austria |

GB |

United Kingdom |

|

AU |

Australia |

MY |

Malaysia |

|

CH |

Switzerland |

WVTA |

Whole Vehicle Type Approval |

|

DE |

Germany |

Foreword

This manual is designed primarily for use by trained mechanics in a properly equipped shop. However, it contains enough detail and basic information to make it useful to the owner who desires to perform his own basic maintenance and repair work. A basic knowledge of mechanics, the proper use of tools, and workshop procedures must be understood in order to carry out maintenance and repair satisfactorily. Whenever the owner has insufficient experience or doubts his ability to do the work, all adjustments, maintenance, and repair should be carried out only by qualified mechanics.

In order to perform the work efficiently and to avoid costly mistakes, read the text, thoroughly familiarize yourself with the procedures before starting work, and then do the work carefully in a clean area. Whenever special tools or equipment are specified, do not use makeshift tools or equipment. Precision measurements can only be made if the proper instruments are used, and the use of substitute tools may adversely affect safe operation.

For the duration of the warranty period, we recommend that all repairs and scheduled maintenance be performed in accordance with this service manual. Any owner maintenance or repair procedure not performed in accordance with this manual may void the warranty.

To get the longest life out of your vehicle.

•Follow the Periodic Maintenance Chart in the Service Manual.

•Be alert for problems and non-scheduled maintenance.

•Use proper tools and genuine Kawasaki Motorcycle parts. Special tools, gauges, and testers that are necessary when servicing Kawasaki motorcycles are introduced by the Service Manual. Genuine parts provided as spare parts are listed in the Parts Catalog.

•Follow the procedures in this manual carefully. Don’t take shortcuts.

•Remember to keep complete records of maintenance and repair with dates and any new parts installed.

How to Use This Manual

In this manual, the product is divided into its major systems and these systems make up the manual’s chapters. The Quick Reference

Guide shows you all of the product’s system and assists in locating their chapters. Each chapter in turn has its own comprehensive Table of Contents.

For example, if you want ignition coil information, use the Quick Reference Guide to locate the Electrical System chapter. Then, use the Table of Contents on the first page of the chapter to find the Ignition Coil section.

Whenever you see these WARNING and CAUTION symbols, heed their instructions! Always follow safe operating and maintenance practices.

This warning symbol identifies special instructions or procedures which, if not correctly followed, could result in personal injury, or loss of life.

CAUTION

This caution symbol identifies special instructions or procedures which, if not strictly observed, could result in damage to or destruction of equipment.

This manual contains four more symbols (in addition to WARNING and CAUTION) which will help you distinguish different types of information.

NOTE

○This note symbol indicates points of particular interest for more efficient and convenient operation.

•Indicatesdone. a procedural step or work to be ○Indicates a procedural sub-step or how to do the work of the procedural step it follows. It

also precedes the text of a NOTE.

In most chapters an exploded view illustration of the system components follows the Table of Contents. In these illustrations you will find the instructions indicating which parts require specified tightening torque, oil, grease or a locking agent during assembly.

GENERAL INFORMATION 1-1

|

General Information |

|

|

Table of Contents |

|

|

1 |

|

|

Before Servicing ……………………………………………………………………………………………………… |

1-2 |

|

Model Identification………………………………………………………………………………………………….. |

1-7 |

|

General Specifications……………………………………………………………………………………………… |

1-9 |

|

Unit Conversion Table ……………………………………………………………………………………………… |

1-12 |

1-2 GENERAL INFORMATION

Before Servicing

Before starting to perform an inspection service or carry out a disassembly and reassembly operation on a motorcycle, read the precautions given below. To facilitate actual operations, notes, illustrations, photographs, cautions, and detailed descriptions have been included in each chapter wherever necessary. This section explains the items that require particular attention during the removal and reinstallation or disassembly and reassembly of general parts.

Especially note the following.

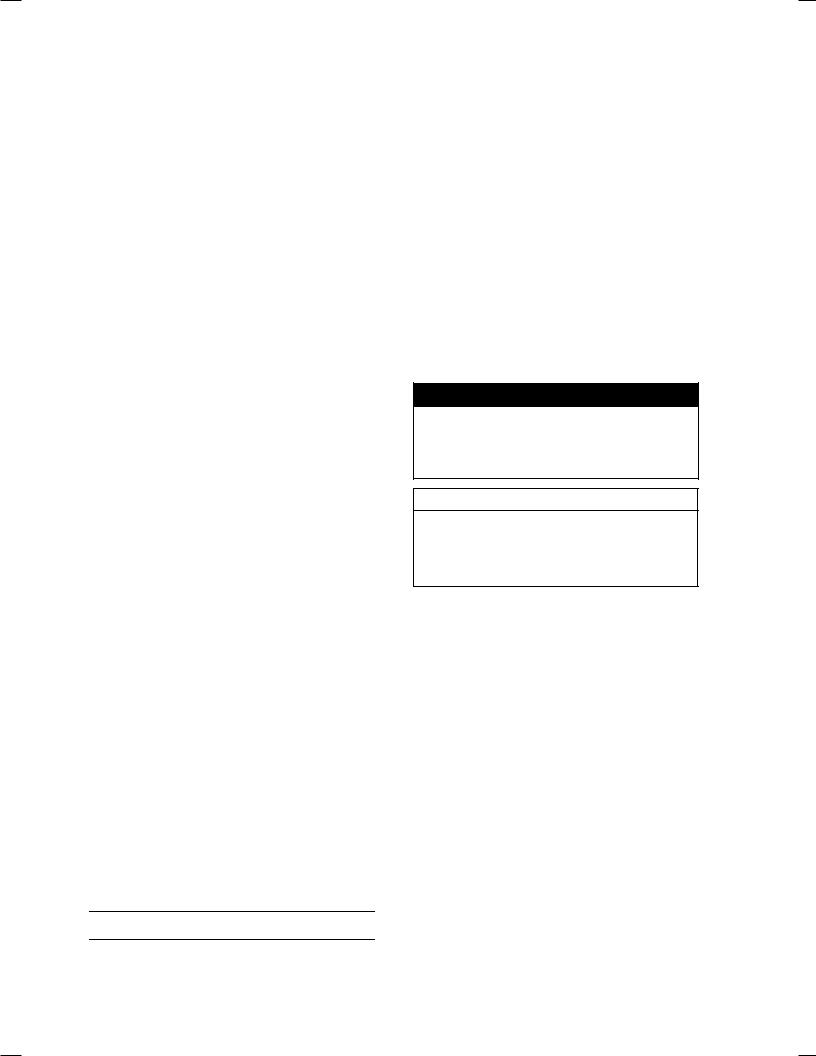

Battery Ground

Before completing any service on the motorcycle, disconnect the battery cables from the battery to prevent the engine from accidentally turning over. Disconnect the ground cable (–) first and then the positive (+). When completed with the service, first connect the positive (+) cable to the positive (+) terminal of the battery then the negative (–) cable to the negative terminal.

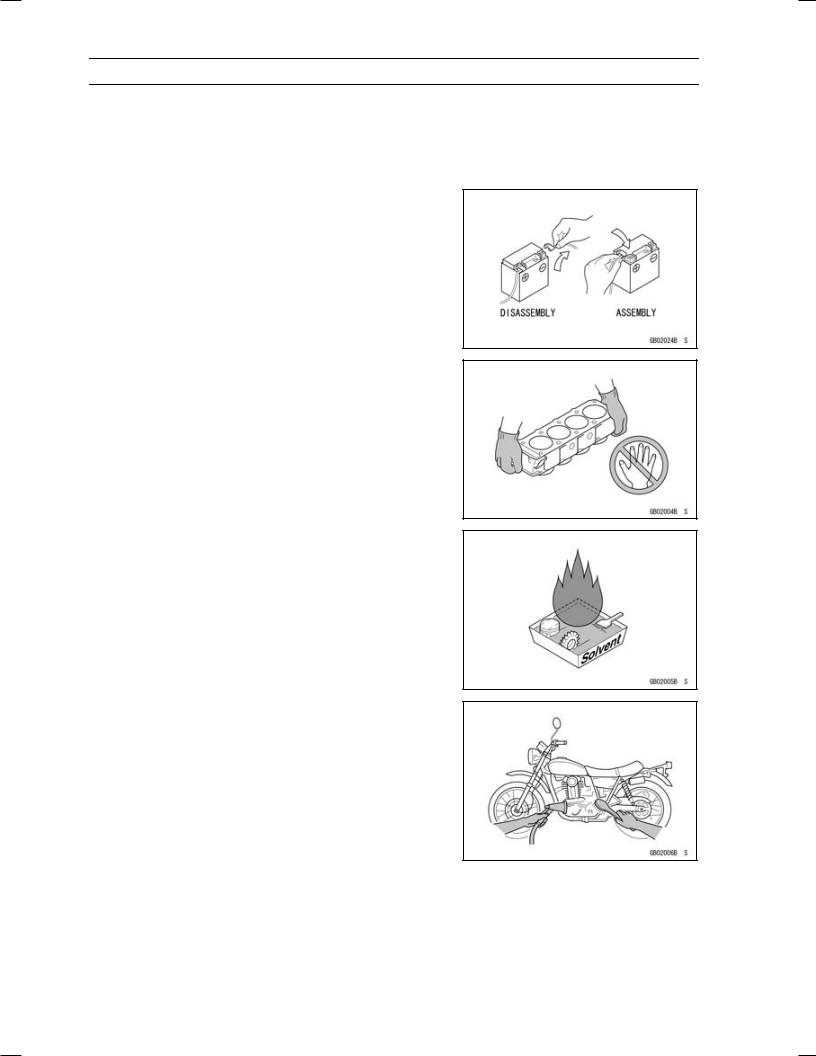

Edges of Parts

Lift large or heavy parts wearing gloves to prevent injury from possible sharp edges on the parts.

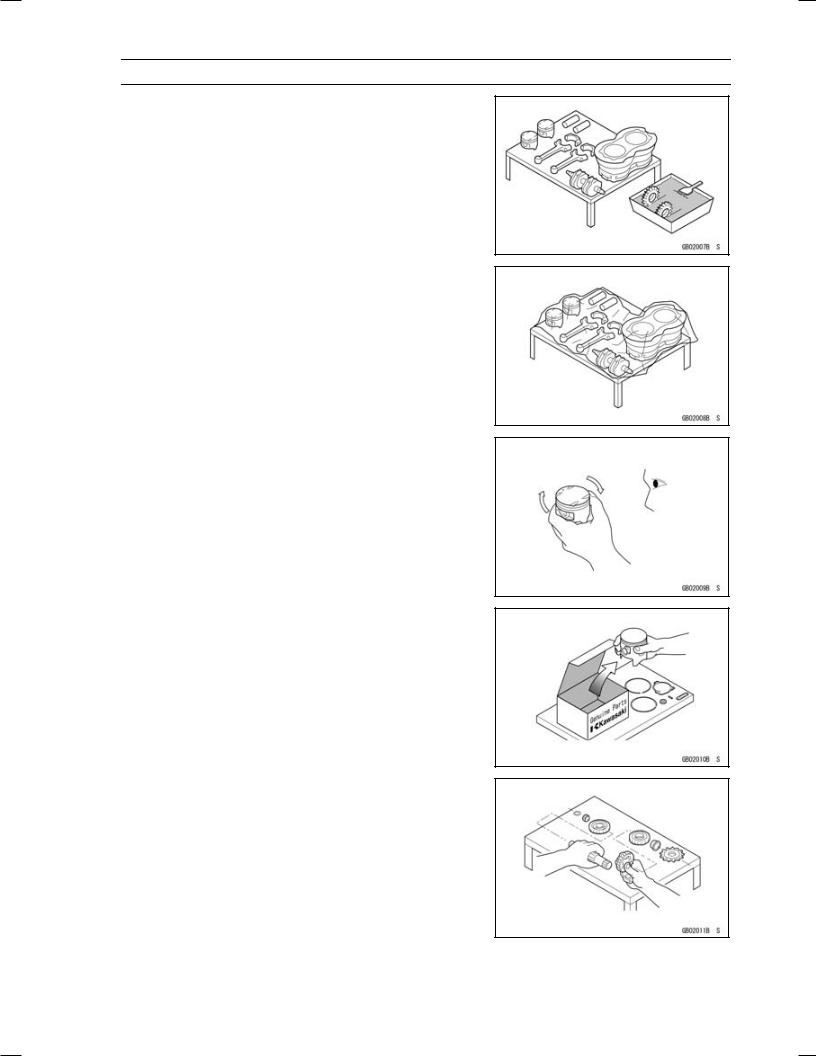

Solvent

Use a high-flush point solvent when cleaning parts. High -flush point solvent should be used according to directions of the solvent manufacturer.

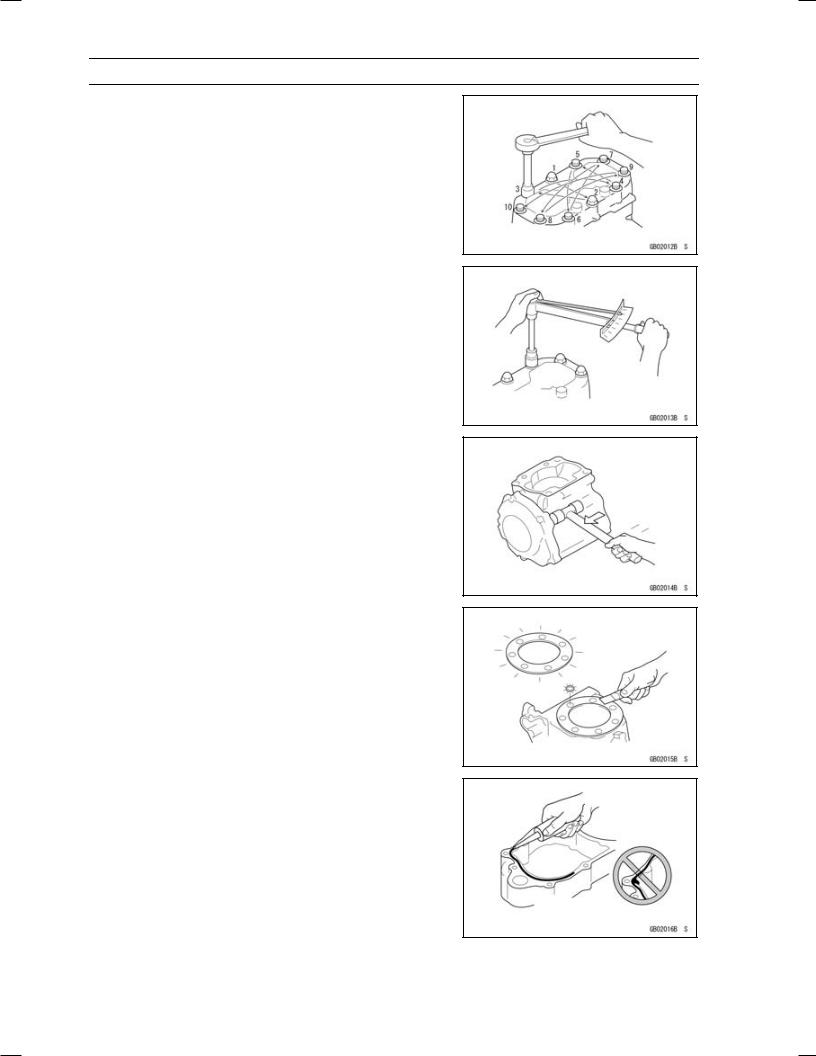

Cleaning Vehicle before Disassembly

Clean the vehicle thoroughly before disassembly. Dirt or other foreign materials entering into sealed areas during vehicle disassembly can cause excessive wear and decrease performance of the vehicle.

GENERAL INFORMATION 1-3

Before Servicing

Arrangement and Cleaning of Removed Parts

Disassembled parts are easy to confuse. Arrange the parts according to the order the parts were disassembled and clean the parts in order prior to assembly.

Storage of Removed Parts

After all the parts including subassembly parts have been cleaned, store the parts in a clean area. Put a clean cloth or plastic sheet over the parts to protect from any foreign materials that may collect before re-assembly.

Inspection

Reuse of worn or damaged parts may lead to serious accident. Visually inspect removed parts for corrosion, discoloration, or other damage. Refer to the appropriate sections of this manual for service limits on individual parts. Replace the parts if any damage has been found or if the part is beyond its service limit.

Replacement Parts

Replacement parts must be KAWASAKI genuine or recommended by KAWASAKI. Gaskets, O-rings, oil seals, grease seals, circlips or cotter pins must be replaced with new ones whenever disassembled.

Assembly Order

In most cases assembly order is the reverse of disassembly, however, if assembly order is provided in this Service Manual, follow the procedures given.

1-4 GENERAL INFORMATION

Before Servicing

Tightening Sequence

Generally, when installing a part with several bolts, nuts, or screws, start them all in their holes and tighten them to a snug fit. Then tighten them according to the specified sequence to prevent case warpage or deformation which can lead to malfunction. Conversely when loosening the bolts, nuts, or screws, first loosen all of them by about a quarter turn and then remove them. If the specified tightening sequence is not indicated, tighten the fasteners alternating diagonally.

Tightening Torque

Incorrect torque applied to a bolt, nut, or screw may lead to serious damage. Tighten fasteners to the specified torque using a good quality torque wrench.

Force

Use common sense during disassembly and assembly, excessive force can cause expensive or hard to repair damage. When necessary, remove screws that have a non -permanent locking agent applied using an impact driver. Use a plastic-faced mallet whenever tapping is necessary.

Gasket, O-ring

Hardening, shrinkage, or damage of both gaskets and O-rings after disassembly can reduce sealing performance. Remove old gaskets and clean the sealing surfaces thoroughly so that no gasket material or other material remains. Install the new gaskets and replace the used O-rings when re-assembling.

Liquid Gasket, Non-permanent Locking Agent

For applications that require Liquid Gasket or a Non-permanent Locking Agent, clean the surfaces so that no oil residue remains before applying liquid gasket or non-permanent locking agent. Do not apply them excessively. Excessive application can clog oil passages and cause serious damage.

GENERAL INFORMATION 1-5

Before Servicing

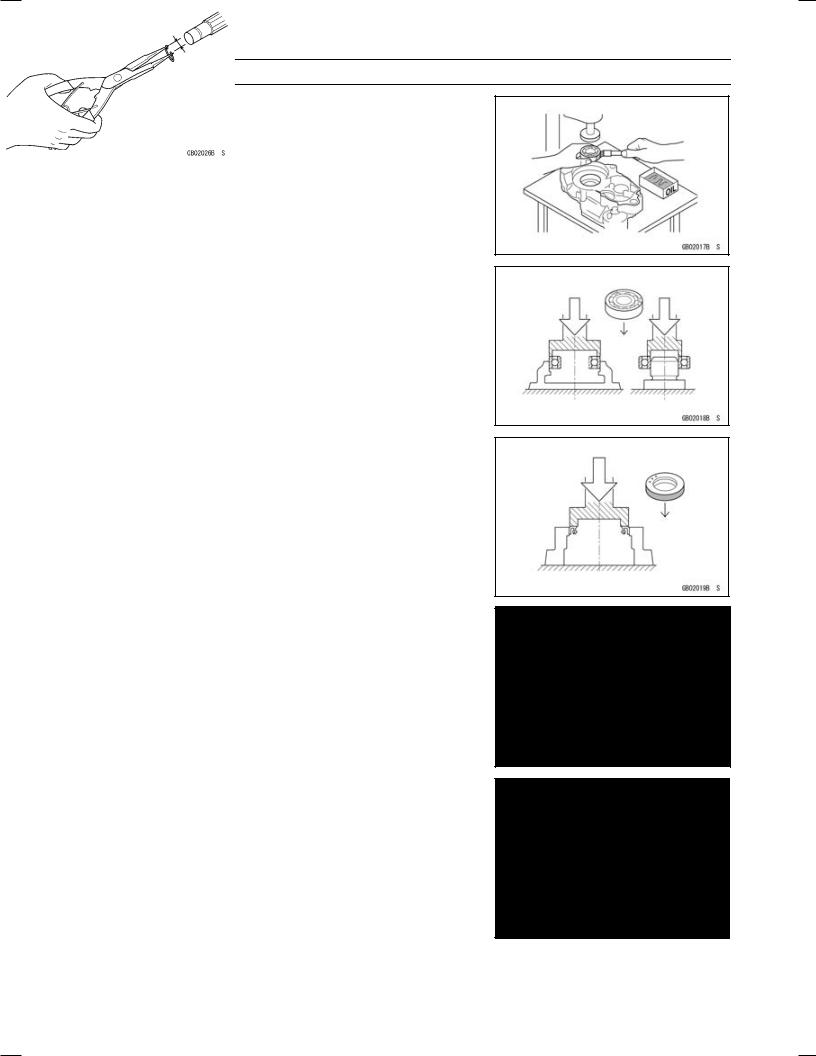

Press

For items such as bearings or oil seals that must be pressed into place, apply small amount of oil to the contact area. Be sure to maintain proper alignment and use smooth movements when installing.

Ball Bearing and Needle Bearing

Do not remove pressed ball or needle unless removal is absolutely necessary. Replace with new ones whenever removed. Press bearings with the manufacturer and size marks facing out. Press the bearing into place by putting pressure on the correct bearing race as shown.

Pressing the incorrect race can cause pressure between the inner and outer race and result in bearing damage.

Oil Seal, Grease Seal

Do not remove pressed oil or grease seals unless removal is necessary. Replace with new ones whenever removed. Press new oil seals with manufacture and size marks facing out. Make sure the seal is aligned properly when installing.

Apply specified grease to the lip of seal before installing the seal.

Circlips, Cotter Pins

Replace the circlips or cotter pins that were removed with new ones. Take care not to open the clip excessively when installing to prevent deformation.

1-6 GENERAL INFORMATION

Before Servicing

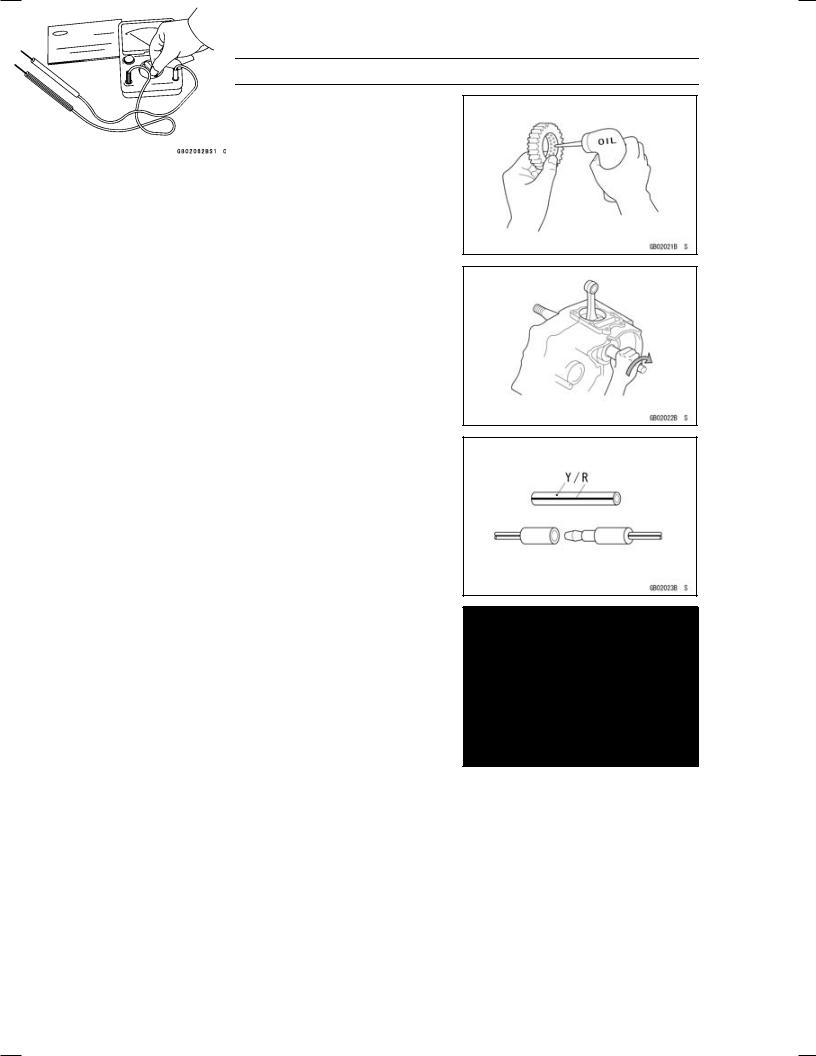

Lubrication

It is important to lubricate rotating or sliding parts during assembly to minimize wear during initial operation. Lubrication points are called out throughout this manual, apply the specific oil or grease as specified.

Direction of Engine Rotation

When rotating the crankshaft by hand, the free play amount of rotating direction will affect the adjustment. Rotate the crankshaft to positive direction (clockwise viewed from output side).

Electrical Wires

A two-color wire is identified first by the primary color and then the stripe color. Unless instructed otherwise, electrical wires must be connected to those of the same color.

Instrument

Use a meter that has enough accuracy for an accurate measurement. Read the manufacture’s instructions thoroughly before using the meter. Incorrect values may lead to improper adjustments.

GENERAL INFORMATION 1-7

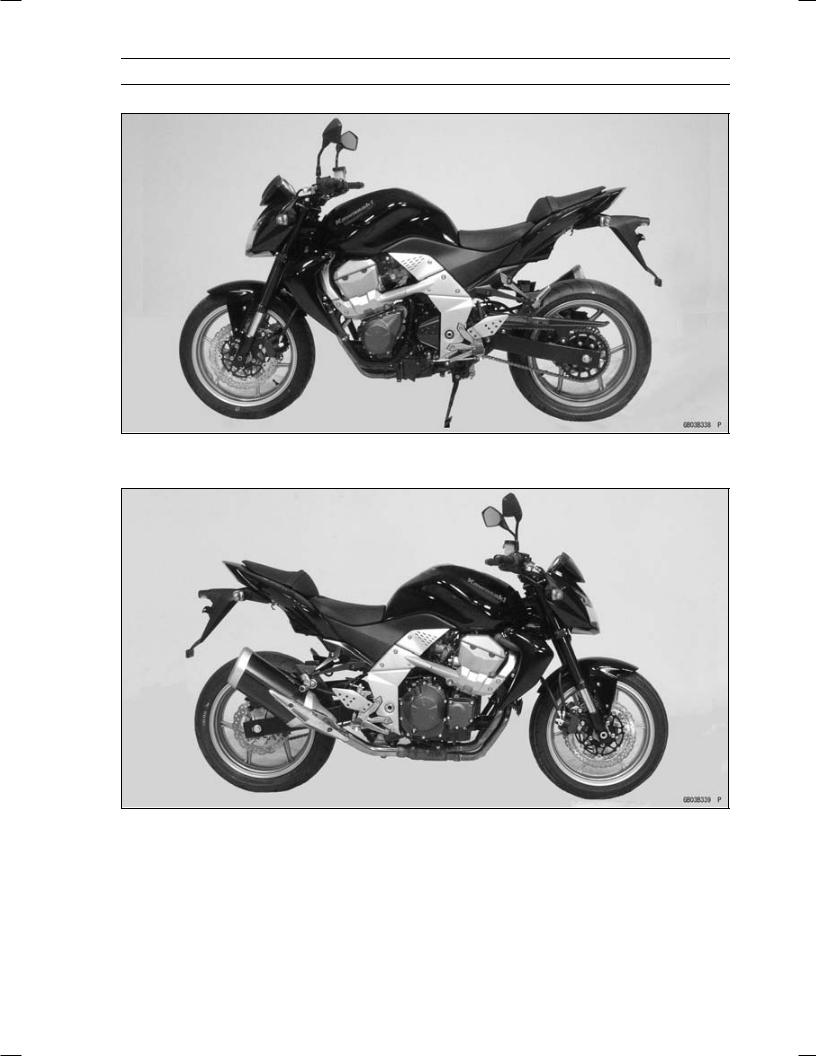

Model Identification

ZR750L7F (Europe) Left Side View

ZR750L7F (Europe) Right Side View

1-8 GENERAL INFORMATION

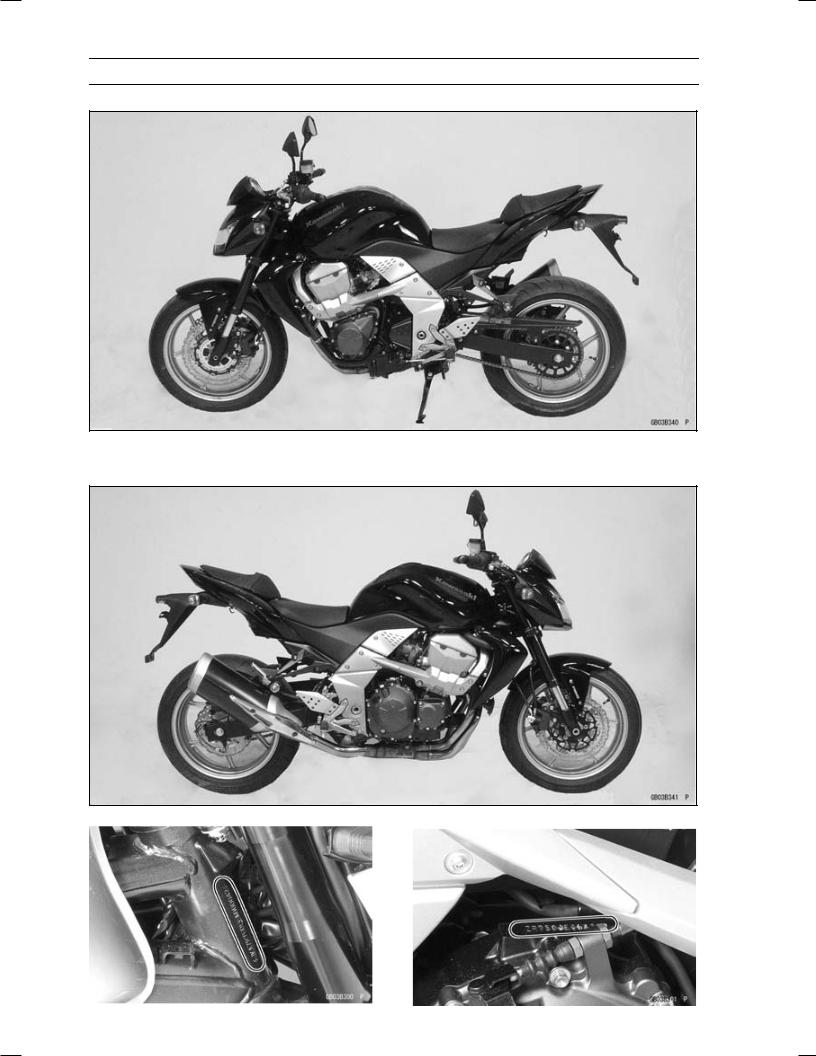

Model Identification

ZR750M7F Left Side View

ZR750M7F Right Side View

|

Frame Number |

Engine Number |

|

|

GENERAL INFORMATION 1-9 |

|

|

General Specifications |

|

|

Items |

ZR750L7F, ZR750M7F |

|

Dimensions |

|

|

Overall Length |

2 085 mm (82.09 in.) |

|

Overall Width |

805 mm (31.69 in.) |

|

Overall Height |

1 100 mm (43.31 in.) |

|

Wheelbase |

1 440 mm (56.69 in.) |

|

Road Clearance |

155 mm (6.10 in.) |

|

Seat Height |

815 mm (32.09 in.) |

|

Dry Mass: |

|

|

ZR750L7F |

203 kg (447.6 lb) |

|

ZR750M7F |

207 kg (456.4 lb) |

|

Curb Mass: |

|

|

Front: |

|

|

ZR750L7F |

113 kg (249.2 lb) |

|

ZR750M7F |

115 kg (253.6 lb) |

|

Rear: |

|

|

ZR750L7F |

113 kg (249.2 lb) |

|

ZR750M7F |

115 kg (253.6 lb) |

|

Fuel Tank Capacity |

18.5 L (4.9 US gal.) |

|

Performance |

|

|

Minimum Turning Radius |

3.0 m (9.8 ft) |

|

Engine |

|

|

Type |

4-stroke, DOHC, 4-cylinder |

|

Cooling System |

Liquid-cooled |

|

Bore and Stroke |

68.4 × 50.9 mm (2.69 × 2.00 in.) |

|

Displacement |

748 cm³ (45.64 cu in.) |

|

Compression Ratio |

11.3 : 1 |

|

Maximum Horsepower |

77.7 kW (106 PS) @10 500 r/min (rpm) |

|

(MY) 73.2 kW (100 PS) @9 000 r/min (rpm) |

|

|

Maximum Torque |

78.0 N·m (8.0 kgf·m, 57.5 ft·lb) @8 300 r/min (rpm) |

|

Carburetion System |

FI (Fuel Injection) KEIHIN TTK32 × 4 |

|

Starting System |

Electric starter |

|

Ignition System |

Battery and coil (transistorized) |

|

Timing Advance |

Electronically advanced (digital igniter) |

|

Ignition Timing |

From 10° BTDC @1 100 r/min (rpm) to 37.0° BTDC |

|

@5 000 r/min (rpm) |

|

|

Spark Plug |

NGK CR9EK |

|

Cylinder Numbering Method |

Left to right, 1-2-3-4 |

|

Firing Order |

1-2-4-3 |

|

Valve Timing: |

|

|

Inlet: |

|

|

Open |

38° BTDC |

|

Close |

66° ABDC |

|

Duration |

284° |

1-10 GENERAL INFORMATION

General Specifications

|

Items |

ZR750L7F, ZR750M7F |

|

|

Exhaust: |

||

|

Open |

51° BBDC |

|

|

Close |

25° ATDC |

|

|

Duration |

256° |

|

|

Lubrication System |

Forced lubrication (wet sump) |

|

|

Engine Oil: |

||

|

Type |

API SE, SF or SG |

|

|

API SH, SJ or SL with JASO MA |

||

|

Viscosity |

SAE 10W-40 |

|

|

Capacity |

3.8 L (4.0 US qt) |

|

|

Drive Train |

||

|

Primary Reduction System: |

||

|

Type |

Gear |

|

|

Reduction Ratio |

1.714 |

(84/49) |

|

Clutch Type |

Wet multi disc |

|

|

Transmission: |

||

|

Type |

6-speed, constant mesh, return shift |

|

|

Gear Ratios: |

||

|

1st |

2.571 |

(36/14) |

|

2nd |

1.941 |

(33/17) |

|

3rd |

1.556 |

(28/18) |

|

4th |

1.333 |

(28/21) |

|

5th |

1.200 |

(24/20) |

|

6th |

1.095 |

(23/21) |

|

Final Drive System: |

||

|

Type |

Chain drive |

|

|

Reduction Ratio |

2.867 |

(43/15) |

|

Overall Drive Ratio |

5.382 |

@Top gear |

|

Frame |

||

|

Type |

Tubular, diamond |

|

|

Caster (Rake Angle) |

24.5° |

|

|

Trail |

103 mm (4.06 in.) |

|

|

Front Tire: |

||

|

Type |

Tubeless |

|

|

Size |

120/70 ZR17 M/C (58W) |

|

|

Rim Size |

17 × 3.50 |

|

|

Rear Tire: |

||

|

Type |

Tubeless |

|

|

Size |

180/55 ZR17 M/C (73W) |

|

|

Rim Size |

17 × 5.50 |

|

|

Front Suspension: |

||

|

Type |

Telescopic fork |

|

|

Wheel Travel |

120 mm (4.72 in.) |

|

|

GENERAL INFORMATION 1-11 |

|

|

General Specifications |

|

|

Items |

ZR750L7F, ZR750M7F |

|

Rear Suspension: |

|

|

Type |

Swingarm (uni-trak) |

|

Wheel Travel |

125 mm (4.92 in.) |

|

Brake Type: |

|

|

Front |

Dual discs |

|

Rear |

Single disc |

|

Electrical Equipment |

|

|

Battery |

12 V 8 Ah |

|

Headlight: |

|

|

Type |

Semi-sealed beam |

|

Bulb |

12 V 55 W × 2/55 W (Hi/Lo) |

|

Tail/Brake Light |

12 V 0.5/4.1 W (LED) |

|

Alternator: |

|

|

Type |

Three-phase AC |

|

Rated Output |

24 A/14 V @5 000 r/min (rpm) |

Specifications are subject to change without notice, and may not apply to every country.

1-12 GENERAL INFORMATION

Unit Conversion Table

|

Prefixes for Units: |

Units of Length: |

|

Prefix |

Symbol |

Power |

||

|

mega |

M |

× 1 000 |

000 |

|

|

kilo |

k |

× |

1 000 |

|

|

centi |

c |

× |

0.01 |

|

|

milli |

m |

× |

0.001 |

|

|

micro |

µ |

× 0.000001 |

Units of Mass:

|

kg |

× |

2.205 |

= |

lb |

|

g |

× |

0.03527 |

= |

oz |

Units of Volume:

|

L |

× |

0.2642 |

= |

gal (US) |

|

L |

× |

0.2200 |

= |

gal (imp) |

|

L |

× |

1.057 |

= |

qt (US) |

|

L |

× |

0.8799 |

= |

qt (imp) |

|

L |

× |

2.113 |

= |

pint (US) |

|

L |

× |

1.816 |

= |

pint (imp) |

|

mL |

× |

0.03381 |

= |

oz (US) |

|

mL |

× |

0.02816 |

= |

oz (imp) |

|

mL |

× |

0.06102 |

= |

cu in |

Units of Force:

|

N |

× |

0.1020 |

= |

kg |

|

N |

× |

0.2248 |

= |

lb |

|

kg |

× |

9.807 |

= |

N |

|

kg |

× |

2.205 |

= |

lb |

|

km |

× |

0.6214 |

= |

mile |

|

m |

× |

3.281 |

= |

ft |

|

mm |

× |

0.03937 |

= |

in |

Units of Torque:

|

N·m |

× |

0.1020 |

= |

kgf·m |

|

N·m |

× |

0.7376 |

= |

ft·lb |

|

N·m |

× |

8.851 |

= |

in·lb |

|

kgf·m |

× |

9.807 |

= |

N·m |

|

kgf·m |

× |

7.233 |

= |

ft·lb |

|

kgf·m |

× |

86.80 |

= |

in·lb |

Units of Pressure:

|

kPa |

× |

0.01020 |

= |

kgf/cm² |

|

kPa |

× |

0.1450 |

= |

psi |

|

kPa |

× |

0.7501 |

= |

cmHg |

|

kgf/cm² |

× |

98.07 |

= |

kPa |

|

kgf/cm² |

× |

14.22 |

= |

psi |

|

cmHg |

× |

1.333 |

= |

kPa |

Units of Speed:

km/h × 0.6214 = mph

Units of Power:

|

kW |

× |

1.360 |

= |

PS |

|

kW |

× |

1.341 |

= |

HP |

|

PS |

× |

0.7355 |

= |

kW |

|

PS |

× |

0.9863 |

= |

HP |

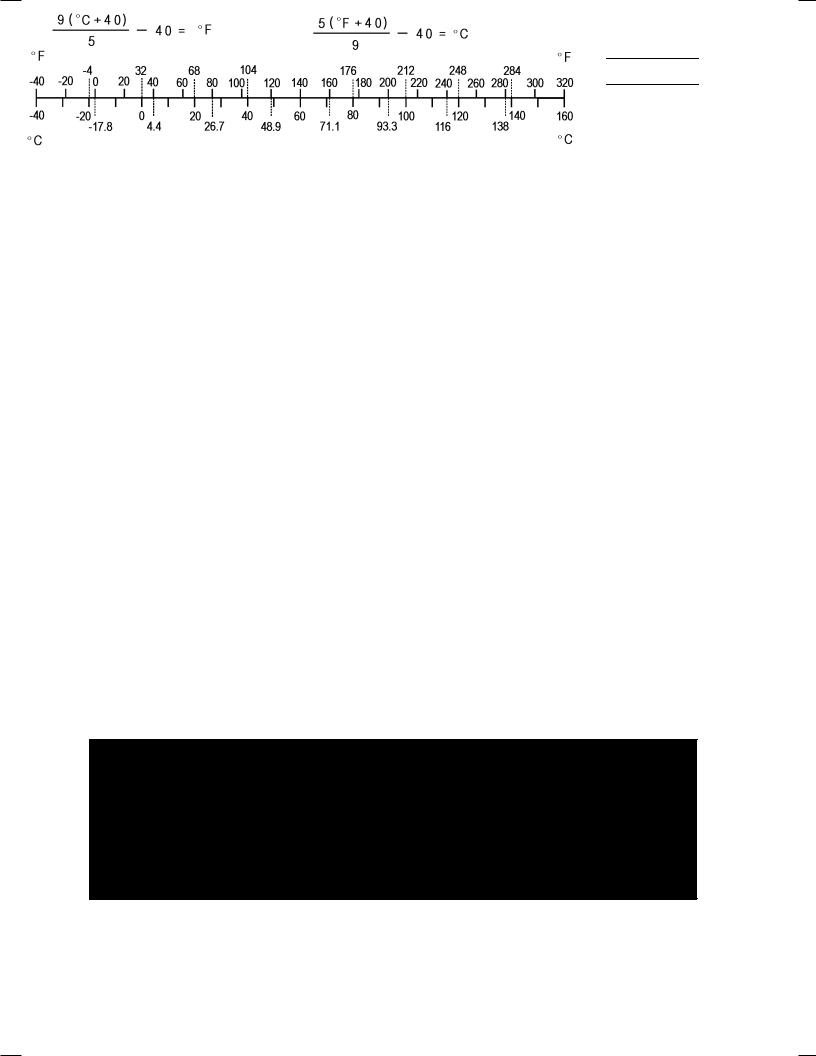

Units of Temperature:

PERIODIC MAINTENANCE 2-1

Periodic Maintenance

Table of Contents

|

Periodic Maintenance Chart ……………………………………………………………………………………… |

2-3 |

||

|

Torque and Locking Agent………………………………………………………………………………………… |

2-6 |

2 |

|

|

Specifications |

2-12 |

||

|

Special Tools ………………………………………………………………………………………………………….. |

2-14 |

||

|

Periodic Maintenance Procedures……………………………………………………………………………… |

2-15 |

||

|

Fuel System (DFI)…………………………………………………………………………………………………. |

2-15 |

||

|

Air Cleaner Element Cleaning………………………………………………………………………………. |

2-15 |

||

|

Throttle Control System Inspection……………………………………………………………………….. |

2-15 |

||

|

Engine Vacuum Synchronization Inspection…………………………………………………………… |

2-16 |

||

|

Idle Speed Inspection …………………………………………………………………………………………. |

2-19 |

||

|

Idle Speed Adjustment………………………………………………………………………………………… |

2-20 |

||

|

Fuel Hose Inspection (fuel leak, damage, installation condition) ……………………………….. |

2-20 |

||

|

Cooling System…………………………………………………………………………………………………….. |

2-22 |

||

|

Coolant Level Inspection……………………………………………………………………………………… |

2-22 |

||

|

Radiator Hose and Pipe Inspection (coolant leak, damage, installation condition) ………. |

2-22 |

||

|

Engine Top End ……………………………………………………………………………………………………. |

2-23 |

||

|

Valve Clearance Inspection …………………………………………………………………………………. |

2-23 |

||

|

Valve Clearance Adjustment………………………………………………………………………………… |

2-24 |

||

|

Exhaust Butterfly Valve Cable Inspection ………………………………………………………………. |

2-27 |

||

|

Exhaust Butterfly Valve Cable Adjustment……………………………………………………………… |

2-28 |

||

|

Air Suction System ……………………………………………………………………………………………….. |

2-31 |

||

|

Air Suction System Damage Inspection…………………………………………………………………. |

2-31 |

||

|

Clutch………………………………………………………………………………………………………………….. |

2-31 |

||

|

Clutch Operation Inspection…………………………………………………………………………………. |

2-31 |

||

|

Wheels/Tires………………………………………………………………………………………………………… |

2-32 |

||

|

Air Pressure Inspection……………………………………………………………………………………….. |

2-32 |

||

|

Wheel/Tire Damage Inspection…………………………………………………………………………….. |

2-33 |

||

|

Tire Tread Wear Inspection………………………………………………………………………………….. |

2-33 |

||

|

Wheel Bearing Damage Inspection ………………………………………………………………………. |

2-34 |

||

|

Drive Train …………………………………………………………………………………………………………… |

2-34 |

||

|

Drive Chain Lubrication Condition Inspection …………………………………………………………. |

2-34 |

||

|

Drive Chain Slack Inspection ……………………………………………………………………………….. |

2-35 |

||

|

Drive Chain Slack Adjustment ……………………………………………………………………………… |

2-35 |

||

|

Wheel Alignment Inspection ………………………………………………………………………………… |

2-36 |

||

|

Drive Chain Wear Inspection ……………………………………………………………………………….. |

2-37 |

||

|

Chain Guide Wear Inspection ………………………………………………………………………………. |

2-37 |

||

|

Brake System ………………………………………………………………………………………………………. |

2-38 |

||

|

Brake Fluid Leak (Brake Hose and Pipe) Inspection ……………………………………………….. |

2-38 |

||

|

Brake Hose and Pipe Damage and Installation Condition Inspection…………………………. |

2-39 |

||

|

Brake Operation Inspection …………………………………………………………………………………. |

2-39 |

||

|

Brake Fluid Level Inspection………………………………………………………………………………… |

2-39 |

||

|

Brake Pad Wear Inspection …………………………………………………………………………………. |

2-40 |

||

|

Brake Light Switch Operation Inspection ……………………………………………………………….. |

2-41 |

||

|

Suspensions ………………………………………………………………………………………………………… |

2-41 |

||

|

Front Forks/Rear Shock Absorber Operation Inspection ………………………………………….. |

2-41 |

||

|

Front Fork Oil Leak Inspection……………………………………………………………………………… |

2-42 |

||

|

Rear Shock Absorber Oil Leak Inspection ……………………………………………………………… |

2-42 |

||

|

Rocker Arm Operation Inspection…………………………………………………………………………. |

2-42 |

||

|

Tie-Rod Operation Inspection ………………………………………………………………………………. |

2-42 |

||

|

Steering System …………………………………………………………………………………………………… |

2-43 |

2-2 PERIODIC MAINTENANCE

|

Steering Play Inspection ……………………………………………………………………………………… |

2-43 |

|

Steering Play Adjustment…………………………………………………………………………………….. |

2-43 |

|

Steering Stem Bearing Lubrication ……………………………………………………………………….. |

2-44 |

|

Electrical System ………………………………………………………………………………………………….. |

2-45 |

|

Spark Plug Condition Inspection…………………………………………………………………………… |

2-45 |

|

Lights and Switches Operation Inspection……………………………………………………………… |

2-46 |

|

Headlight Aiming Inspection ………………………………………………………………………………… |

2-48 |

|

Sidestand Switch Operation Inspection …………………………………………………………………. |

2-49 |

|

Engine Stop Switch Operation Inspection………………………………………………………………. |

2-50 |

|

Others…………………………………………………………………………………………………………………. |

2-50 |

|

Chassis Parts Lubrication ……………………………………………………………………………………. |

2-50 |

|

Bolts, Nuts and Fasteners Tightness Inspection……………………………………………………… |

2-52 |

|

Replacement Parts ……………………………………………………………………………………………….. |

2-53 |

|

Air Cleaner Element Replacement………………………………………………………………………… |

2-53 |

|

Fuel Hose Replacement ……………………………………………………………………………………… |

2-54 |

|

Coolant Change …………………………………………………………………………………………………. |

2-56 |

|

Radiator Hose and O-ring Replacement………………………………………………………………… |

2-58 |

|

Engine Oil Change……………………………………………………………………………………………… |

2-58 |

|

Oil Filter Replacement ………………………………………………………………………………………… |

2-59 |

|

Brake Hose and Pipe Replacement………………………………………………………………………. |

2-60 |

|

Brake Fluid Change ……………………………………………………………………………………………. |

2-62 |

|

Master Cylinder Rubber Parts Replacement ………………………………………………………….. |

2-63 |

|

Caliper Rubber Parts Replacement ………………………………………………………………………. |

2-64 |

|

Spark Plug Replacement …………………………………………………………………………………….. |

2-67 |

PERIODIC MAINTENANCE 2-3

Periodic Maintenance Chart

The scheduled maintenance must be done in accordance with this chart to keep the motorcycle in good running condition.The initial maintenance is vitally important and must not be neglected.

Periodic Inspection

|

FREQUENCY |

Whichever |

* ODOMETER READING |

|||||||||||||

|

comes |

× 1 000 km |

See |

|||||||||||||

|

first |

(× 1 000 mile) |

||||||||||||||

|

Page |

|||||||||||||||

|

1 |

6 |

12 |

18 |

24 |

30 |

36 |

|||||||||

|

INSPECTION |

Every |

(0.6) |

(4) |

(7.5) |

(12) |

(15) |

(20) |

(24) |

|||||||

|

Fuel System |

|||||||||||||||

|

Air cleaner element — clean |

• |

• |

2-15 |

||||||||||||

|

Throttle control system (play, smooth return, |

year |

• |

• |

• |

• |

2-15 |

|||||||||

|

no drag) — inspect |

|||||||||||||||

|

Engine vacuum synchronization — inspect |

• |

• |

• |

2-16 |

|||||||||||

|

Idle speed — inspect |

• |

• |

• |

• |

2-19 |

||||||||||

|

Fuel leak (fuel hose and pipe) — inspect |

year |

• |

• |

• |

• |

2-20 |

|||||||||

|

Fuel hose and pipe damage — inspect |

year |

• |

• |

• |

• |

2-20 |

|||||||||

|

Fuel hose and pipe installation condition — |

year |

• |

• |

• |

• |

2-20 |

|||||||||

|

inspect |

|||||||||||||||

|

Cooling System |

|||||||||||||||

|

Coolant level — inspect |

• |

• |

• |

• |

2-22 |

||||||||||

|

Coolant leak (radiator hose and pipe) — |

year |

• |

• |

• |

• |

2-22 |

|||||||||

|

inspect |

|||||||||||||||

|

Radiator hose damage — inspect |

year |

• |

• |

• |

• |

2-22 |

|||||||||

|

Radiator hose installation condition — inspect |

year |

• |

• |

• |

• |

2-22 |

|||||||||

|

Engine Top End |

|||||||||||||||

|

AU Model |

• |

2-23 |

|||||||||||||

|

Valve clearance — inspect |

|||||||||||||||

|

Other than AU |

Every 42 000 km (26 000 mile) |

2-23 |

|||||||||||||

|

Model |

|||||||||||||||

|

Exhaust butterfly valve cable — inspect |

• |

• |

• |

• |

• |

• |

• |

2-27 |

|||||||

|

Air Suction System |

|||||||||||||||

|

Air suction system damage — inspect |

• |

• |

• |

2-31 |

|||||||||||

|

Clutch |

|||||||||||||||

|

Clutch operation (play, disengagement, |

• |

• |

• |

• |

2-31 |

||||||||||

|

engagement) — inspect |

|||||||||||||||

|

Wheels and Tires |

|||||||||||||||

|

Tire air pressure — inspect |

year |

• |

• |

• |

2-32 |

||||||||||

|

Wheel/tire damage — inspect |

• |

• |

• |

2-33 |

|||||||||||

|

Tire tread wear, abnormal wear — inspect |

• |

• |

• |

2-33 |

|||||||||||

|

Wheel bearing damage — inspect |

year |

• |

• |

• |

2-34 |

||||||||||

|

Drive Train |

|||||||||||||||

|

Drive chain lubrication condition — inspect # |

Every 600 km (400 mile) |

2-34 |

|||||||||||||

|

Drive chain slack — inspect # |

Every 1 000 km (600 mile) |

2-35 |

|||||||||||||

|

Drive chain wear — inspect # |

• |

• |

• |

2-37 |

|||||||||||

|

Drive chain guide wear — inspect |

• |

• |

• |

2-37 |

2-4 PERIODIC MAINTENANCE

Periodic Maintenance Chart

|

FREQUENCY |

Whichever |

* ODOMETER READING |

|||||||||||

|

comes |

× 1 000 km |

See |

|||||||||||

|

first |

(× 1 000 mile) |

||||||||||||

|

Page |

|||||||||||||

|

1 |

6 |

12 |

18 |

24 |

30 |

36 |

|||||||

|

INSPECTION |

Every |

(0.6) |

(4) |

(7.5) |

(12) |

(15) |

(20) |

(24) |

|||||

|

Brake System |

|||||||||||||

|

Brake fluid leak (brake hose and pipe) — |

year |

• |

• |

• |

• |

• |

• |

• |

2-38 |

||||

|

inspect |

|||||||||||||

|

Brake hose and pipe damage — inspect |

year |

• |

• |

• |

• |

• |

• |

• |

2-39 |

||||

|

Brake hose and pipe installation condition — |

year |

• |

• |

• |

• |

• |

• |

• |

2-39 |

||||

|

inspect |

|||||||||||||

|

Brake operation (effectiveness, play, no |

year |

• |

• |

• |

• |

• |

• |

• |

2-39 |

||||

|

drag) — inspect |

|||||||||||||

|

Brake fluid level — inspect |

6 |

• |

• |

• |

• |

• |

• |

• |

2-39 |

||||

|

months |

|||||||||||||

|

Brake pad wear — inspect # |

• |

• |

• |

• |

• |

• |

2-40 |

||||||

|

Brake light switch operation — inspect |

• |

• |

• |

• |

• |

• |

• |

2-41 |

|||||

|

Suspensions |

|||||||||||||

|

Front forks/rear shock absorber operation |

• |

• |

• |

2-41 |

|||||||||

|

(damping and smooth stroke) — inspect |

|||||||||||||

|

Front forks/rear shock absorber oil leak — |

year |

• |

• |

• |

2-42 |

||||||||

|

inspect |

|||||||||||||

|

Rocker arm operation — inspect |

• |

• |

• |

2-42 |

|||||||||

|

Tie-rods operation — inspect |

• |

• |

• |

2-42 |

|||||||||

|

Steering System |

|||||||||||||

|

Steering play — inspect |

year |

• |

• |

• |

• |

2-43 |

|||||||

|

Steering stem bearings — lubricate |

2 years |

• |

2-44 |

||||||||||

|

Electrical System |

|||||||||||||

|

Spark plug condition — inspect |

• |

• |

• |

2-45 |

|||||||||

|

Lights and switches operation — inspect |

year |

• |

• |

• |

2-46 |

||||||||

|

Headlight aiming — inspect |

year |

• |

• |

• |

2-48 |

||||||||

|

Sidestand switch operation — inspect |

year |

• |

• |

• |

2-49 |

||||||||

|

Engine stop switch operation — inspect |

year |

• |

• |

• |

2-50 |

||||||||

|

Others |

|||||||||||||

|

Chassis parts — lubricate |

year |

• |

• |

• |

2-50 |

||||||||

|

Bolts and nuts tightness — inspect |

• |

• |

• |

• |

2-52 |

#: Service more frequently when operating in severe conditions; dusty, wet, muddy, high speed or frequent starting/stopping.

*: For higher odometer readings, repeat at the frequency interval established here.

PERIODIC MAINTENANCE 2-5

Periodic Maintenance Chart

Periodic Replacement Parts

|

FREQUENCY |

Whichever |

* ODOMETER READING |

|||||||||

|

comes |

× 1 000 km |

See |

|||||||||

|

first |

(× 1 000 mile) |

||||||||||

|

Page |

|||||||||||

|

1 |

12 |

24 |

36 |

48 |

|||||||

|

CHANGE/REPLACE ITEM |

Every |

(0.6) |

(7.5) |

(15) |

(24) |

(30) |

|||||

|

Air cleaner element # |

• |

2-53 |

|||||||||

|

Fuel hose |

4 years |

• |

2-54 |

||||||||

|

Coolant |

3 years |

• |

2-56 |

||||||||

|

Radiator hose and O-ring |

3 years |

• |

2-58 |

||||||||

|

Engine oil # |

year |

• |

• |

• |

• |

• |

2-58 |

||||

|

Oil filter |

year |

• |

• |

• |

• |

• |

2-59 |

||||

|

Brake hose and pipe |

4 years |

• |

2-60 |

||||||||

|

Brake fluid |

2 years |

• |

• |

2-62 |

|||||||

|

Rubber parts of master cylinder and caliper |

4 years |

• |

2-63, |

||||||||

|

2-64 |

|||||||||||

|

Spark plug |

• |

• |

• |

• |

2-67 |

#: Service more frequently when operating in severe conditions; dusty, wet, muddy, high speed or frequent starting/stopping.

*: For higher odometer readings, repeat at the frequency interval established here.

2-6 PERIODIC MAINTENANCE

Torque and Locking Agent

The following tables list the tightening torque for the major fasteners requiring use of a non-permanent locking agent or silicone sealant etc.

Letters used in the “Remarks” column mean:

AL: Tighten the two clamp bolts alternately two times to ensure even tightening torque. EO: Apply engine oil.

G: Apply grease.

HG: Apply high-temperature grease.

L: Apply a non-permanent locking agent.

MO: Apply molybdenum disulfide grease oil solution.

(mixture of the engine oil and molybdenum disulfide grease in a weight ratio 10 : 1)

R:Replacement Parts

S:Follow the specified tightening sequence. Si: Apply silicone grease (ex. PBC grease).

SS: Apply silicone sealant.

|

Fastener |

Torque |

Remarks |

|||

|

N·m |

kgf·m |

ft·lb |

|||

|

Fuel System (DFI) |

|||||

|

Air Cleaner Duct Screws |

3.8 |

0.39 |

34 in·lb |

||

|

Air Cleaner Housing Mounting Bolts |

9.8 |

1.0 |

87 in·lb |

||

|

Air Cleaner Housing Tapping Screws |

1.2 |

0.12 |

11 in·lb |

||

|

Air Duct Clamp Bolts |

2.0 |

0.20 |

18 in·lb |

||

|

Bypass Screws |

0.2 |

0.02 |

1.8 in·lb |

||

|

Camshaft Position Sensor Bolt |

12 |

1.2 |

106 in·lb |

||

|

Crankshaft Sensor Bolts |

5.9 |

0.60 |

52 in·lb |

||

|

Delivery Pipe Assy Mounting Screws |

3.4 |

0.35 |

30 in·lb |

||

|

Exhaust Butterfly Valve Actuator Bracket Bolt |

6.9 |

0.70 |

61 in·lb |

||

|

Exhaust Butterfly Valve Actuator Mounting Bolts |

6.9 |

0.70 |

61 in·lb |

||

|

Exhaust Butterfly Valve Actuator Pulley Bolt |

5.0 |

0.51 |

44 in·lb |

||

|

Fuel Pump Bolts |

9.8 |

1.0 |

87 in·lb |

L, S |

|

|

Idle Adjusting Cable Clamp Screw |

3.4 |

0.35 |

30 in·lb |

||

|

Oxygen Sensor (Equipped Models) |

44.1 |

4.50 |

32.5 |

||

|

Speed Sensor Bolt |

12 |

1.2 |

106 in·lb |

||

|

Throttle Body Assy Holder Bolts |

13 |

1.3 |

115 in·lb |

||

|

Throttle Body Assy Holder Clamp Bolts |

2.0 |

0.20 |

18 in·lb |

||

|

Throttle Cable Plate Bolt |

5.9 |

0.60 |

52 in·lb |

||

|

Throttle Link Holder Screws |

2.0 |

0.20 |

18 in·lb |

||

|

Vehicle-down Sensor Bolts |

6.0 |

0.61 |

53 in·lb |

||

|

Water Temperature Sensor |

25 |

2.5 |

18 |

||

|

Cooling System |

|||||

|

Coolant Drain Bolt (Cylinder) |

9.8 |

1.0 |

87 in·lb |

||

|

Coolant Drain Bolt (Water Pump) |

11 |

1.1 |

97 in·lb |

||

|

Radiator Bracket Mounting Bolt |

6.9 |

0.70 |

61 in·lb |

||

|

Radiator Lower Bolt |

6.9 |

0.70 |

61 in·lb |

||

|

Radiator Upper Bolts |

6.9 |

0.70 |

61 in·lb |

||

|

Radiator (Water) Hose Clamp Screws |

3.0 |

0.31 |

27 in·lb |

||

|

Reserve Tank Bolts |

9.8 |

1.0 |

87 in·lb |

PERIODIC MAINTENANCE 2-7

Torque and Locking Agent

|

Fastener |

Torque |

Remarks |

|||

|

N·m |

kgf·m |

ft·lb |

|||

|

Thermostat Bracket Bolt |

6.9 |

0.70 |

61 in·lb |

||

|

Thermostat Housing Ground Bolt |

6.9 |

0.70 |

61 in·lb |

||

|

Thermostat Housing Screws |

5.9 |

0.60 |

52 in·lb |

||

|

Water Pipe Bolts |

11 |

1.1 |

97 in·lb |

L |

|

|

Water Pump Cover Bolts |

11 |

1.1 |

97 in·lb |

||

|

Water Pump Impeller Bolt |

9.8 |

1.0 |

87 in·lb |

||

|

Water Temperature Sensor |

25 |

2.5 |

18 |

||

|

Engine Top End |

|||||

|

Air Suction Valve Cover Bolts |

9.8 |

1.0 |

87 in·lb |

||

|

Camshaft Cap Bolts (L = 45 mm) |

12 |

1.2 |

106 in·lb |

S |

|

|

Camshaft Cap Bolts (L = 40 mm) |

12 |

1.2 |

106 in·lb |

S |

|

|

Camshaft Chain Tensioner Cap Bolt |

20 |

2.0 |

15 |

||

|

Camshaft Chain Tensioner Mounting Bolts |

11 |

1.1 |

97 in·lb |

||

|

Coolant Drain Bolt (Cylinder) |

9.8 |

1.0 |

87 in·lb |

||

|

Cylinder Head Bolts (M10 New Bolts) |

54 |

5.5 |

40 |

S |

|

|

Cylinder Head Bolts (M10 Used Bolts) |

49 |

5.0 |

36 |

S |

|

|

Cylinder Head Bolts (M6) |

12 |

1.2 |

106 in·lb |

S |

|

|

Cylinder Head Cover Bolts |

9.8 |

1.0 |

87 in·lb |

S |

|

|

Cylinder Head Jacket Plugs |

22 |

2.2 |

16 |

L |

|

|

Exhaust Butterfly Valve Actuator Bracket Bolt |

6.9 |

0.70 |

61 in·lb |

||

|

Exhaust Butterfly Valve Actuator Mounting Bolts |

6.9 |

0.70 |

61 in·lb |

||

|

Exhaust Butterfly Valve Actuator Pulley Bolt |

5.0 |

0.51 |

44 in·lb |

||

|

Exhaust Butterfly Valve Cable Adjuster Locknuts |

6.9 |

0.70 |

61 in·lb |

||

|

Exhaust Butterfly Valve Cable Locknuts |

6.9 |

0.70 |

61 in·lb |

||

|

Exhaust Butterfly Valve Cover Bolts |

6.9 |

0.70 |

61 in·lb |

||

|

Exhaust Pipe Manifold Holder Nuts |

17 |

1.7 |

13 |

S |

|

|

Front Camshaft Chain Guide Bolt (Lower) |

12 |

1.2 |

106 in·lb |

||

|

Front Camshaft Chain Guide Bolt (Upper) |

25 |

2.5 |

18 |

||

|

Muffler Body Clamp Bolt |

15 |

1.5 |

11 |

S |

|

|

Muffler Body Mounting Bolt |

4.9 |

0.50 |

43 in·lb |

S |

|

|

Muffler Body Mounting Nut |

34 |

3.5 |

25 |

S |

|

|

Muffler Body Side Cover Bolts |

6.9 |

0.70 |

61 in·lb |

||

|

Rear Camshaft Chain Guide Bolt |

25 |

2.5 |

18 |

||

|

Spark Plugs |

13 |

1.3 |

115 in·lb |

||

|

Throttle Body Assy Holder Bolts |

13 |

1.3 |

115 in·lb |

||

|

Throttle Body Assy Holder Clamp Bolts |

2.0 |

0.20 |

18 in·lb |

||

|

Clutch |

|||||

|

Clutch Cover Mounting Bolts |

11 |

1.1 |

97 in·lb |

||

|

Clutch Hub Nut |

135 |

13.8 |

99.6 |

R |

|

|

Clutch Lever Clamp Bolts |

7.8 |

0.80 |

69 in·lb |

S |

|

|

Clutch Spring Bolts |

8.8 |

0.90 |

78 in·lb |

||

|

Oil Filler Plug |

2.0 |

0.20 |

18 in·lb |

||

2-8 PERIODIC MAINTENANCE

Torque and Locking Agent

|

Fastener |

Torque |

Remarks |

|||

|

N·m |

kgf·m |

ft·lb |

|||

|

Engine Lubrication System |

|||||

|

Coolant Drain Bolt (Water Pump) |

11 |

1.1 |

97 in·lb |

||

|

Engine Oil Drain Bolt |

29 |

3.0 |

21 |

||

|

Oil Filter |

17 |

1.7 |

13 |

G, R |

|

|

Oil Filter Holder |

78 |

8.0 |

58 |

EO |

|

|

Oil Filler Plug |

2.0 |

0.20 |

18 in·lb |

||

|

Oil Jet Nozzle Bolts |

6.9 |

0.70 |

61 in·lb |

L |

|

|

Oil Pan Bolts |

11 |

1.1 |

97 in·lb |

||

|

Oil Pan Side Dummy Bolts |

6.9 |

0.70 |

61 in·lb |

||

|

Oil Passage Plugs |

20 |

2.0 |

15 |

L |

|

|

Oil Pipe Holder Bolts |

13 |

1.3 |

115 in·lb |

L |

|

|

Oil Pressure Relief Valve |

15 |

1.5 |

11 |

L |

|

|

Oil Pressure Switch |

15 |

1.5 |

11 |

SS |

|

|

Oil Pressure Switch Terminal Bolt |

2.0 |

0.20 |

18 in·lb |

HG |

|

|

Water Pump Cover Bolts |

11 |

1.1 |

97 in·lb |

||

|

Water Pump Impeller Bolt |

9.8 |

1.0 |

87 in·lb |

||

|

Engine Removal/Installation |

|||||

|

Adjusting Collar Lock Bolt |

34 |

3.5 |

25 |

S |

|

|

Adjusting Collar Locknut |

49 |

5.0 |

36 |

S |

|

|

Engine Ground Cable Terminal Bolt |

9.8 |

1.0 |

87 in·lb |

||

|

Front Engine Mounting Bolts |

44 |

4.5 |

32 |

S |

|

|

Lower Engine Mounting Nut |

44 |

4.5 |

32 |

S |

|

|

Middle Engine Mounting Nut |

44 |

4.5 |

32 |

S |

|

|

Rear Engine Bracket Bolts |

25 |

2.5 |

18 |

S |

|

|

Subframe Bolts |

25 |

2.5 |

18 |

S |

|

|

Upper Engine Bracket Bolts |

44 |

4.5 |

32 |

S |

|

|

Crankshaft/Transmission |

|||||

|

Breather Plate Bolts (M6) |

9.8 |

1.0 |

87 in·lb |

L |

|

|

Breather Plate Bolts (M5) |

5.9 |

0.60 |

52 in·lb |

L |

|

|

Connecting Rod Big End Nuts |

see the text |

← |

← |

MO |

|

|

Crankcase Bolts (M9) |

42 |

4.3 |

31 |

MO, S |

|

|

Crankcase Bolts (M8) |

27 |

2.8 |

20 |

S |

|

|

Crankcase Bolts (M7) |

20 |

2.0 |

15 |

S |

|

|

Crankcase Bolts (M6) |

12 |

1.2 |

106 in·lb |

S |

|

|

Front Footpeg Bracket Bolts |

25 |

2.5 |

18 |

||

|

Gear Positioning Lever Bolt |

12 |

1.2 |

106 in·lb |

||

|

Neutral Switch |

15 |

1.5 |

11 |

||

|

Oil Jet Nozzle Bolts |

6.9 |

0.70 |

61 in·lb |

L |

|

|

Oil Passage Plugs |

20 |

2.0 |

15 |

L |

|

|

Oil Pipe Holder Bolts |

13 |

1.3 |

115 in·lb |

L |

|

|

Shift Drum Bearing Holder Bolt |

13 |

1.3 |

115 in·lb |

L |

|

|

Shift Drum Bearing Holder Screw |

5.9 |

0.60 |

52 in·lb |

L |

|

|

Shift Drum Cam Holder Bolt |

12 |

1.2 |

106 in·lb |

L |

PERIODIC MAINTENANCE 2-9

Torque and Locking Agent

|

Fastener |

Torque |

Remarks |

|||

|

N·m |

kgf·m |

ft·lb |

|||

|

Shift Lever Bolt |

6.9 |

0.70 |

61 in·lb |

||

|

Shift Pedal Mounting Bolt |

34 |

3.5 |

25 |

L |

|

|

Shift Shaft Return Spring Pin |

29 |

3.0 |

21 |

L |

|

|

Starter Motor Clutch Bolts |

12 |

1.2 |

106 in·lb |

L |

|

|

Tie-Rod Locknuts |

6.9 |

0.70 |

61 in·lb |

||

|

Wheels/Tires |

|||||

|

Front Axle |

108 |

11.0 |

79.7 |

||

|

Front Axle Clamp Bolt |

20 |

2.0 |

15 |

||

|

Rear Axle Nut |

108 |

11.0 |

79.7 |

||

|

Final Drive |

|||||

|

Engine Sprocket Cover Bolts |

9.8 |

1.0 |

87 in·lb |

||

|

Engine Sprocket Cover Plate Bolts |

9.8 |

1.0 |

87 in·lb |

||

|

Engine Sprocket Nut |

125 |

12.7 |

92.2 |

MO |

|

|

Rear Axle Nut |

108 |

11.0 |

79.7 |

||

|

Rear Sprocket Nuts |

59 |

6.0 |

44 |

||

|

Brakes |

|||||

|

Bleed Valves |

7.8 |

0.80 |

69 in·lb |

||

|

Brake Hose Banjo Bolts |

25 |

2.5 |

18 |

||

|

Brake Lever Pivot Bolt |

1.0 |

0.10 |

9 in·lb |

Si |

|

|

Brake Lever Pivot Bolt Locknut |

5.9 |

0.60 |

52 in·lb |

||

|

Brake Pedal Bolt |

34 |

3.5 |

25 |

L |

|

|

Brake Pipe Joint Nuts (ABS Equipped Models) |

18 |

1.8 |

13 |

||

|

Front Brake Disc Mounting Bolts |

27 |

2.8 |

20 |

L |

|

|

Front Brake Light Switch Screw |

1.2 |

0.12 |

11 in·lb |

||

|

Front Brake Pad Pin Plugs |

2.5 |

0.25 |

25 in·lb |

||

|

Front Brake Pad Pins |

17.2 |

1.8 |

13 |

||

|

Front Brake Reservoir Cap Stopper Screw |

1.2 |

0.12 |

11 in·lb |

||

|

Front Caliper Holder Pin Bolt |

22 |

2.2 |

16 |

L, Si |

|

|

Front Caliper Mounting Bolts |

25 |

2.5 |

18 |

||

|

Front Master Cylinder Clamp Bolts |

8.8 |

0.90 |

78 in·lb |

S |

|

|

Rear Brake Disc Mounting Bolts |

27 |

2.8 |

20 |

L |

|

|

Rear Brake Pad Pin |

17.2 |

1.8 |

13 |

||

|

Rear Brake Pad Pin Plug |

2.5 |

0.25 |

25 in·lb |

||

|

Rear Caliper Mounting Bolt |

22 |

2.2 |

16 |

||

|

Rear Caliper Pin Bolt |

27 |

2.8 |

20 |

Si |

|

|

Rear Master Cylinder Mounting Bolts |

25 |

2.5 |

18 |

||

|

Rear Master Cylinder Push Rod Locknut |

17.2 |

1.8 |

13 |

||

|

Suspension |

|||||

|

Front Axle Clamp Bolt |

20 |

2.0 |

15 |

||

|

Front Fork Bottom Allen Bolts |

40 |

4.1 |

30 |

L |

|

|

Front Fork Top Plugs |

23 |

2.3 |

17 |

||

|

Lower Front Fork Clamp Bolts |

21 |

2.1 |

15 |

AL |

|

|

Piston Rod Nuts |

15 |

1.5 |

11 |

2-10 PERIODIC MAINTENANCE

Torque and Locking Agent

|

Fastener |

Torque |

Remarks |

|||

|

N·m |

kgf·m |

ft·lb |

|||

|

Rear Shock Absorber Nut (Lower) |

34 |

3.5 |

25 |

||

|

Rear Shock Absorber Nut (Upper) |

34 |

3.5 |

25 |

||

|

Swingarm Pivot Shaft |

9.8 |

1.0 |

87 in·lb |

||

|

Swingarm Pivot Shaft Locknut |

98 |

10.0 |

72.3 |

||

|

Swingarm Pivot Shaft Nut |

108 |

11.0 |

79.7 |

||

|

Tie-Rod Nuts |

59 |

6.0 |

44 |

||

|

Uni-Trak Rocker Arm Nut |

34 |

3.5 |

25 |

||

|

Upper Front Fork Clamp Bolts |

20 |

2.0 |

15 |

||

|

Steering |

|||||

|

Handlebar Holder Bolts |

25 |

2.5 |

18 |

S |

|

|

Handlebar Lower Clamp Nuts |

34 |

3.5 |

25 |

||

|

Lower Front Fork Clamp Bolts |

21 |

2.1 |

15 |

AL |

|

|

Steering Stem Head Bolt |

108 |

11.0 |

79.7 |

||

|

Steering Stem Nut |

27 |

2.8 |

20 |

||

|

Switch Housing Screws |

3.5 |

0.36 |

31 in·lb |

||

|

Upper Front Fork Clamp Bolts |

20 |

2.0 |

15 |

||

|

Frame |

|||||

|

Front Fender Bolts |

3.9 |

0.40 |

35 in·lb |

||

|

Front Footpeg Bracket Bolts |

25 |

2.5 |

18 |

||

|

Rear Footpeg Bracket Bolts |

25 |

2.5 |

18 |

||

|

Sidestand Bolt |

44 |

4.5 |

32 |

||

|

Sidestand Switch Bolt |

8.8 |

0.90 |

78 in·lb |

L |

|

|

Electrical System |

|||||

|

Alternator Cover Bolts |

11 |

1.1 |

97 in·lb |

||

|

Alternator Lead Holding Plate Bolt |

12 |

1.2 |

106 in·lb |

L |

|

|

Alternator Rotor Bolt |

155 |

15.8 |

114 |

S |

|

|

Camshaft Position Sensor Bolt |

12 |

1.2 |

106 in·lb |

||

|

Crankshaft Sensor Bolts |

5.9 |

0.60 |

52 in·lb |

||

|

Crankshaft Sensor Cover Bolts |

11 |

1.1 |

97 in·lb |

||

|

Engine Ground Cable Terminal Bolt |

9.8 |

1.0 |

87 in·lb |

||

|

Front Brake Light Switch Screw |

1.2 |

0.12 |

11 in·lb |

||

|

Fuel Level Sensor Bolts |

6.9 |

0.70 |

61 in·lb |

L |

|

|

License Plate Light Cover Mounting Screws |

0.9 |

0.09 |

8 in·lb |

||

|

License Plate Light Mounting Screws |

1.2 |

0.12 |

11 in·lb |

||

|

Meter Mounting Screws |

1.2 |

0.12 |

11 in·lb |

||

|

Neutral Switch |