-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

OWNER’S/OPERATOR’S MANUAL

LH400ATV-2B

08.0

1. Introduction

Congratulations on the purchase of your ALL Terrain Vehicle (ATV). We take

pride in offering you this product engineered and manufactured to the highest

performance and quality standards. We are sure that you will enjoy superior

levels of performance, reliability, riding comfort, and safety.

This manual is provided to help the owner and operators of this ATV become

familiar with the operating characteristic, and the many features offered on the

ATV. The manual also covers information on the care and maintenance of your

ATV.

Please read this manual carefully. The information contained in this Owner’s

Manual, the Warning Labels supplied with this product will help you to

understand the safe use and maintenance of your ATV. Make sure that you

understand and follow all Warnings and Instructions in this material.

If you did not receive any of the material listed above, please call your dealer

and request to have them sent to you.

Important Safety Notice

Never make any modifications to the engine, drive system, mechanical or

electrical systems of your ATV. Never install aftermarket parts or accessories

intended to increase the speed or power of your ATV.

Failure to follow these warnings increases the possibility of accidents leading

to DEATH or SERIOUS INJURY!

Additionally, failure to follow these requirements will void the Warranty on your

ATV.

NOTE

The addition and use of certain accessories including, (but not limited to)

mowers, blades, sprayers, winches and windshields will change the handling

characteristics and the performance of your ATV.

Practice Responsible ATV Riding

Make sure that you understand and follow all local, state/province, and

federal/national riding laws and requirements.

Remember……Respect your vehicle, respect the environment and respect the

property of others. You are responsible for your safety and the safety of others

around you when you ride!

AN ATV CAN BE HAZARDOUS TO OPERATE. An ATV handles

differently from other vehicles including motorcycles and cars. A collision

1-1

Troubleshooting

Summary of Contents for Linhai LH400ATV-2B

- Manuals

- Brands

- Linhai Manuals

- Offroad Vehicle

- LH400CUV-2

- Service manual

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

LH400CUV-2

SERVICE MANUAL

Related Manuals for Linhai LH400CUV-2

Summary of Contents for Linhai LH400CUV-2

-

Page 1

LH400CUV-2 SERVICE MANUAL… -

Page 2: Important Information

NOTICE This manual was produced by the Linhai Group primarily for use by Linhai dealers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manual, so it is assumed that anyone who uses this book to perform maintenance and repairs on Linhai vehicle has a basic understanding of the mechanical ideas and the procedures of vehicle repair.

-

Page 3

Failure to follow WARNING instructions could result in severe injury or death to the vehicle operator, passenger, a bystander, or a person checking or repairing the vehicle. CAUTION: A CAUTION indicates special precautions that must be taken to avoid damage to the vehicle. NOTE: A NOTE provides key information to make procedures easier or clearer. -

Page 4

Never run an engine in an enclosed area. Carbon monoxide exhaust gas is poisonous and can cause severe injury or death. Always start engines outdoors. Gasoline is extremely flammable and explosive under certain conditions. Battery electrolyte is poisonous. It contains sulfuric acid. Serious burns can result from contact with skin, eyes or clothing. -

Page 5: General Information

CHAPTER 1 GENERALINFORMATION CUV SERVICE MANUAL 09.0 CHAPTER 1 GENERAL INFORMATION The parts of different types/ variants/ versions maybe un-interchangeable, even some parts have almost same appearance. Always refer to Parts Manual of each CUV model for spare parts information and service. 1.1 IMPORTANT INFORMATION 1.2 V.I.N AND ENG INE SERIAL NUMB ER 1.3 VEHICLE DIMENSIONS…

-

Page 6

CHAPTER 1 GENERALINFORMATION CUV SERVICE MANUAL 09.0 1.1 IMPORTANT INFORMATION PREPARATION FOR REMOVAL PROCEDURES 1. Remove all dirt, mud, dust and foreign material before removal and disassembly. 2. Use proper tools and cleaning equipment. 3. When disassembling the machine, always keep mated parts together. This includes gears, cylinders, pistons and other parts that have been ”mated ”through normal wear. -

Page 7

CHAPTER 1 GENERALINFORMATION CUV SERVICE MANUAL 09.0 Replace distorted circlips. When installing a circlip ①, make sure that the sharp-edged corner ② is positioned opposite the thrust ③ it receives. See sectional view. ④Shaft CHECKING OF CONNECTIONS Dealing with stains, rust, moisture, etc. on the connector. -

Page 8

CHAPTER 1 GENERALINFORMATION CUV SERVICE MANUAL 09.0 CONVERSION TABLE How to use the CONVERSION TABLE Use this table to convert METRIC unit data to IMPERIAL unit data. METRIC MULIPLIER **mm 0. 3937 **in **cm 0.03937 **in CONVERSION TABLE METRIC TO IMP Known Multiplier Result… -

Page 9

CHAPTER 1 GENERALINFORMATION CUV SERVICE MANUAL 09.0 V.I.N AND ENGINE SERIAL NUMBER The vehicle identification number ○ is stamped into the front of the frame tube. The engine serial number ○ is stamped into left side of engine crankcase. PAGE. 1- 5 CHAPTER 1 GENERAL… -

Page 10: Vehicle Dimensions

CHAPTER 1 GENERALINFORMATION CUV SERVICE MANUAL 09.0 VEHICLE DIMENSIONS Note. The on-road equipments (rear view mirror, turn lights, etc.) are not Standard Equipment for USA. CHAPTER 1 GENERAL PAGE. 1- 6…

-

Page 11

CHAPTER 1 GENERALINFORMATION CUV SERVICE MANUAL 09.0 NOTES PAGE. 1- 7 CHAPTER 1 GENERAL… -

Page 12: Maintenance

CHAPTER 2 MAINTENANCE CUV SERVICE MANUA 09.0 CHAPTER 2 MAINTENANCE The parts of different types/ variants/ versions maybe un-interchangeable, even some parts have almost same appearance. Always refer to Parts Manual of each CUV model for spare parts information and service. 2.1 PERIODIC MAI NTENANCE 2.2 THROTTLE PEDAL INSPECTION 2.3 CHOKE ADJUS TMETN…

-

Page 13: Periodic Maintenance

CHAPTER 2 MAINTENANCE CUV SERVICE MANUA 09.0 2.1 PERIODIC MAINTENANCE GENARAL CAUTION Mark on the following chart DL :Due to the nature of the adjustments marked with a DL on the following chart, it is recommended that service be performed by an authorized dealer. ▲:…

-

Page 14: Engine

CHAPTER 2 MAINTENANCE CUV SERVICE MANUA 09.0 Headlamp Inspection Daily apply dielectric grease to connector when replaced Tail lamp inspection Daily apply dielectric grease to socket when replaced ▲ Air Filter-Main Element Weekly Replace if necessary ▲ Transmission Oil Level Monthly change annually Battery Terminals…

-

Page 15: Transmission

CHAPTER 2 MAINTENANCE CUV SERVICE MANUA 09.0 Shift linkage 50 hrs 6 months I A R if necessary Transmission belt 50 hrs 6 months if necessary ▲ Steering 50 hrs 6 months T if necessary ▲ Front Suspension 50 hrs 6 months T if necessary ▲…

-

Page 16: Brakes

CHAPTER 2 MAINTENANCE CUV SERVICE MANUA 09.0 Brake fluid 200 hrs 24 months Change every two years Idle Speed As Required Toe adjustment As Required Periodic inspection, adjust when parts are replaced Headlight Aim As Required Adjust if necessary ▲ Ball joint (A arm- strut) 10 hrs monthly…

-

Page 17

CHAPTER 2 MAINTENANCE CUV SERVICE MANUA 09.0 CHAPTER 2 MAINTENANCE PAGE. 2-… -

Page 18

CHAPTER 2 MAINTENANCE CUV SERVICE MANUA 09.0 LUBRICATION RECOMMENDATIONS NOTE: 1.More often under severe use, such as wet or dusty conditions. 2.Grease: Light weight lithium-soap grease. 3.Grease M:Molybdenum disulfide (MoS ) grease (water resistant). 4.When suspension action becomes stiff or after washing. 5.Hours are based on 10 mph(16Km/h) average. -

Page 19: Fuel System

CHAPTER 2 MAINTENANCE CUV SERVICE MANUA 09.0 2.3 CHOKE ADJUSTMETN If the choke knob does not stay out when pulled, adjust the choke tension by tightening (clockwise) the chock cable boot until the choke slider freely but stays out when pulled. If smooth choke operation is not obtainable, inspect choke cable for kinks or sharp bends in routing 2.4 FUEL SYSTEM…

-

Page 20: Toe Alignment

CHAPTER 2 MAINTENANCE CUV SERVICE MANUA 09.0 VENT LINES AND ROLL OVER VALVE 1. Check fuel tank, oil tank, carburetor, battery and transmission vent lines for signs of wear, deterioration, damage of leakage. Replace every two years. 2. Be sure vent lines are routed properly and secured with cable ties.

-

Page 21

CHAPTER 2 MAINTENANCE CUV SERVICE MANUA 09.0 Always pay attention to tie rods assembly, Both ends must screw in same and enough threads length. 2.6 BRAKING SYSTEM INSPECTION The following checks are recommended to keep the braking system in good operating condition. Service life of braking system components depends on operating conditions. -

Page 22

CHAPTER 2 MAINTENANCE CUV SERVICE MANUA 09.0 is obtained. Turning in: Free play is increased. Turning out: Free play is decreased. 3. Tighten the locknut ADJUSTING THE PARKING BRAKE Although the parking brake has been adjusted at the factory, the brake should be checked for proper operation. The mechanical brake must be maintained to be full functional. -

Page 23

CHAPTER 2 MAINTENANCE CUV SERVICE MANUA 09.0 2.7 SUSPENSION SPRING RPELOAD ADJUSTMENT Operator weight and vehicle loading affect suspen- ents. Adjust as sary. sion spring preload requirem neces FRONT SUSPENSION Compress and release front suspension. Damping should be smooth throughout the range of travel. Check all front suspension components for wear or damage. -

Page 24

CHAPTER 2 MAINTENANCE CUV SERVICE MANUA 09.0 3. Elevate the side of the vehicle by placing a suitable stand under the footrest frame. 4. Remove the wheel nuts and remove the wheel. WHEEL INSTALLATION 1. With the transmission in gear and the parking Brake locked, place the wheel in the correct Position on the wheel hub. -

Page 25

CHAPTER 2 MAINTENANCE CUV SERVICE MANUA 09.0 TIRE TREAD DEPTH Always replace tires when tread depth is worn to 1/8″ (3mm ) or less. Operating an CUV with worn tires will increase the possibility of the vehicle skidding easily with possible loss of control. -

Page 26

CHAPTER 2 MAINTENANCE CUV SERVICE MANUA 09.0 NOTES CHAPTER 2 MAINTENANCE PAGE. 2- 15… -

Page 27: Chapter 3 Engine Atv Service Manual 2005/ Version Number

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 CHAPTER 3 ENGINE 3.1 MAINTENANCE SPECIFICATIONS 3.1.1 SPECIFICATIONS 3.1.2 TIGHTENING TORQUES 3.2 PARTS INSPECTION AND SERVICE 3.2.1 VALVE CLEARANCE ADJUSTMENT 3.2.2 IDLING SPEED ADJUSTMENT 3.2.3 SPARK PLUG INSPECTION 3.2.4 COMPRESSION PRESSURE 3.2.5 ENGINE OIL LEVEL INSPECTION 3.2.6 COOLANT LEVEL INSPECTION 3.3 CYLINDER HEAD…

-

Page 28: Chapter 3 Engine

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 3.1 MAINTENANCE SPECIFICATIONS 3.1.1SPECIFICATIONS Item Standard Limit Cylinder head : 0.03 mm Warp limit Cylinder: 80.000- 80.014 mm 80.025 mm Bore size Out of round limit 0.03 mm Camshaft: Cam dimensions Intake «A»…

-

Page 29

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 Standard Limit I te m Stem-to-guide clearance 0.010- 0.037 mm 0.08 mm 0.025-0.052 mm 0.1 mm … Stem runout limit 0.01 mm Valve seat width 0.9-1.1 mm 1.6 mm 0.9-1.1 mm 1.6 mm Valve spring : Free length (Inner) -

Page 30

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 Standard Limit I te m Automatic centrifugal clutch: 3.0 mm 2.0 mm Clutch shoe thickness 135 mm 135.5 mm Clutch hosing inside diameter … 28.1 mm Clutch shoe spring free length 20 mm 19 .5 mm W eight outside diameter… -

Page 31

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 Standard Limit I te m Radiator: … Type Cooling fin with electric fan … Width/height/thickness 360/246/68 mm … Radiator cap opening pressure 110-140kPa (1.1-1.4kg/cm 1.1-1.4bar) … Radiator capacity … Reservoir tank capacity 0.35 L Thermostatic valve: Valve opening temperature… -

Page 32

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 3.1.2TIGHTENING TORQUES Tightening Q’ty Part name Thread Part to be tightened Remarks Torque size m.kg Oil check bolt Exhaust pipe stud bolt Spark plug Cam sprocket cover Bolt Cylinder head and cylinder 2 .2 Cylinder head and cylinder Bolt… -

Page 33

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 Tightening Part to be tightened Part name Thread Q’ty Remarks torque size m.kg Cover (oil pump) Bolt P lug 0 .8 Timing check plug One way clutch Bolt Clutch housing 0 .3 Grease stopper (Primary sheave) Primary fixed sheave… -

Page 34

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 3.2 PARTS INSPECTION AND SERVICE 3.2.1VALVE CLEARANCE ADJUSTMENT NOTE: Valve clearance adjustment should be made with the engine cool, at room temperature. When the valve clearance is to be measured or adjusted, the piston must be at Top Dead Center (T.D.C.) on the compression. -

Page 35

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 Measure the valve clearance. If the clearance is incorrect, repeat above steps until specified clearance is obtained. 7. Install: Valve cover (intake side) O-ring 8 . Install: Valve cover(exhaust side) O-ring Spark plug Timing check window screw… -

Page 36

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 Turning in → Idling speed is increased. Turning out → Idling speed is decreased. 3.2.3SPARK PLUG INSPECTION 1.Remove : Spark plug cap Spark plug CAUTION: Before removing spark plug, compressed blow… -

Page 37

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 3.2.4COMPRESSION PRESSURE MEASUREMENT NOTE : Insufficient compression pressure will result in performance loss. 1. Check: Valve clearance Out of specification Adjust. Refer to “CALCE CLEARANCE ADJUSTMENT” section. 2. Start the engine and let it warm up for several minutes. -

Page 38

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 Standard: 1,400 kPa (14Kg/cm , 14 bar) Minimum : 1,120 kP a (11.2 kg /cm , 11.2 bar) Measurement steps : Crank the engine with the throttle wide open until reading on the compression gauge stabilizes. -

Page 39

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 minutes. 5. Turn off the engine. NOTE: Wait a few minutes until the oil settles before inspecting the oil level. ENGINE OIL REPLACEMENT 1. Start the engine and let it warm up for several minutes . -

Page 40

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 or leakage. Start the engine after solving the problem (s), and recheck the oil pressure. Tighten the oil check bolt to specification. CAUTION: Start the engine and check the oil pressure with the oil check bolt loosened. -

Page 41

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 2. Remove: Hose (reservoir tank) Drain the reservoir tank of its coolant. 3. Remove: Drain bolt Radiator cap WARNING: Do not remove the radiator cap when the engine and radiator are hot. Scalding hot fluid and steam may be blown out under pressure, which could cause serious injury. -

Page 42

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 Fill the coolant slowly, until the coolant comes out from the head hose. Reservoir tank ( to maximum level ○ Recommended coolant: High quality ethylene glycol anti-freeze containing corrosion inhibitors aluminum engine. -

Page 43: Cylinder Head

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 Fill the coolant slowly to the specified level. 10. Install: Radiator cap 11. Start the engine and let it warm up for several minutes. 12. Stop the engine and inspect the level. NOTE: Wait a few minutes until the coolant settles before inspecting the coolant level.

-

Page 44

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 Q ’ty Order Job name / Part name Remarks Cylinder head removal Remove the parts in order. Drain the coolant. Side panel Footrest board Carburetor Thermo unit lead Refer to «CARBURETOR» Plug cap section . -

Page 45

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 CYLINDER HEAD REMOVAL 1. Align: «I» mark ○ on the rotor (with stationary pointer ○ on the crankcase cover ) NOTE: If any special mark found, contact the ATV manufacture via the agent for the parts and special instruction. -

Page 46

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 NOTE: Do not use a sharp instrument to avoid damaging or scratching: Spark plug threads Valve seats 2. Inspect: Cylinder head Scratches/damage → Replace. 3. Measure: Cylinder head warpage Out of secification → Resurface . Cylinder head warpage : Less than 0.03 mm Warpage measurement and resurfacement… -

Page 47

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 the TDC mark ○ matches the stationary pointer ○ Align the «I» mark ○ on the cam sprocket with the stationary pointer ○ on the cylinder head. NOTE: If any special mark found, contact the ATV manufacture via the agent for the parts and special instruction. -

Page 48: Camshaft And Rocker Arms

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 6. Tighten: Bolt (cam sprocket) 7. Check: Valve timing Out of alignment → Adjust. 8. Check: Valve clearance Out of specification → Adjust. Refer «VALVE CLEARANCE ADJUSTMENT»section. 3.4CAMSHAFT AND ROCKER ARMS Q ’ty Order Job name / Part…

-

Page 49

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 Rocker arm shaft (intake) SHAFT REMOVAL AND INSTALLATION» Rocker arm shaft (exhaust) section.. Rocker arm Camshaft Refer to «CAMSHAFT INSTALLATION» Locknut section . Adjuster O-ring Reverse the removal procedure for installation ROCKER ROCKER… -

Page 50

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 compressed air. ROCKER ARMS AND ROCKER ARM SHAFTS INSPECTION 1. Inspect: Cam lobe contact surface Adjuster surface Wear/Pitting/Scratches/Blue discoloration→ Replace. Inspection steps: Inspect the two contact areas on the rocker arms for signs of unusual wear. -

Page 51

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 NOTE: Bend the lockwasher tabs along the bolt falts. 3. Apply: Molybdenum disulfide oil onto the rocker arm and rocker arm shaft. Molybdenum disulfide oil 4. Install: Rocker arm Rocker arm shaft … -

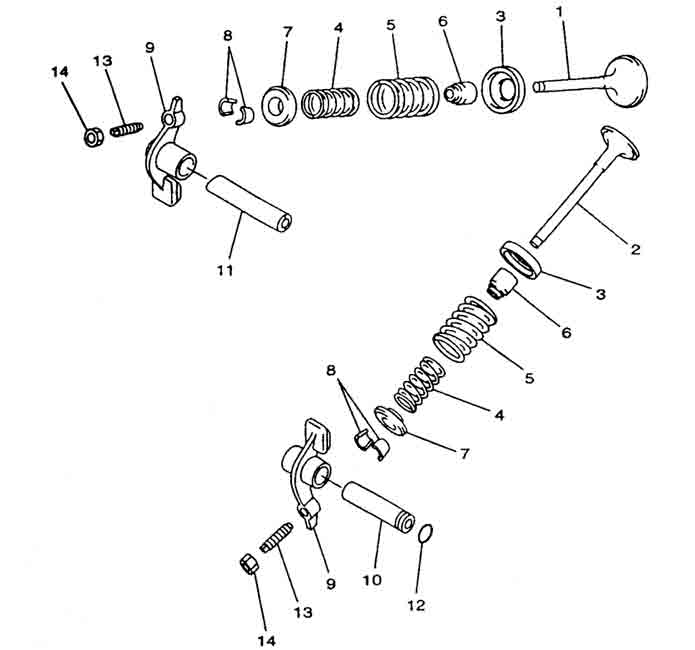

Page 52: Valves And Valve Springs

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 3.5VALVES AND VALVE SPRINGS Q ’ty Order Job name / Part name Remarks Valves and valve springs removal Remove the parts in order. Cylinder head Refer to «CYLINDER HEAD » section . Rocker arm , rocker arm shaft Refer to «ROCKER ARM SHAFT AND ROCKER ARMS»…

-

Page 53

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 VALVES AND VALVE SPRINGS REMOVAL 1. Remove: Valve cotters NOTE: Attach a valve spring compressor and attachment between the valve spring retainer and cylinder head to remove the valve cotters. CAUTION: Do not compress so much as to avoid damage to the valve spring. -

Page 54

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 4. Measure: Spring tilt Out of specification → Replace. Spring tilt limit: 1.7mm (2.5º) 5. Inspect: Spring contact face Wear/Pitting/Scratches → Replace. 6. Measure: Valve guide inside diameter Out of specification → Replace. Valve guide inside diameter: Intake: 6.000-6.012 mm… -

Page 55

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 3. Measure: Valve seat width ○ Out of specification → Reface the valve seat. Valve seat width: Intake: 0.9-1.1mm <Limit:1.6mm> Exhaust: 0.9-1.1mm <Limit:1.6mm> Measurement step: Apply Mechanic’s blueing dye (Dykem) to the valve face. -

Page 56

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 For best lapping results, lightly tap the valve seat while rotating the valve back and forth between your hand. Apply a fine lapping compound to the valve face and repeat the above steps. NOTE: Make sure to clean off all compound from the valve face and valve seat after every lapping… -

Page 57

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 4. Instal: Valve cotters NOTE: Install the valve cotters while com pressing the valve spring with a valve spring compressor and attachment . 5. Secure the valve cotters onto the valve stem by tapping lightly with a piece of wood. -

Page 58: Cylinder And Piston

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 3.6CYLINDER AND PISTON Q ’ty Order Job name / Part name Remarks Cylinder and piston removal Remove the parts in order. Cylinder head Refer to » CYLINDER HEAD » Joint section .

-

Page 59

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 Side rail/Spacer INSTALLATION » section . Reverse the removal procedure for installation . PISTON AND PISTON RINGS REMOVAL 1. Remove: Piston pin circlip Piston pin Piston NOTE: Before removing the piston pin circlip, cover the crankcase opening with a clean tow el or rag to prevent the circlip from falling into the crankcase… -

Page 60

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 PISTON AND PISTON PIN INSPECTION 1. Measure: Piston skirt diameter Out of specification → Replace . ○ 5.0mm from the piston bottom edge. Valve skirt diameter: 69.965-69.980 mm 2. Calculate: Piston-to-cylinder clearance Piston-to-cylinder clearance= Cylinder bore-Piston skirt diameter… -

Page 61

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 PISTON RINGS INSPECTION 1. Measure: Side clearance ○ Out of specification → Replace the piston and the piston rings as a set. NOTE: Eliminate the carbon deposits from the piston ring grooves and rings before measuring the side clearance. -

Page 62

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 2nd ring Side rails (oil ring) Expander spacer (oil ring) NOTE: Make sure to install the piston rings so that the manufacturer’s m arks or numbers are located on the upper side of the rings. -

Page 63: Engine Oil

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 5. Lubricate: Piston outer surface Piston ring Cylinder inner surface Engine oil 6. Install: Cylinder NOTE: Install the cylinder with one hand while com pressing the piston rings with the other hand. Pass the timing chain and timing chain guide (exhaust side) through the timing chain cavity.

-

Page 64

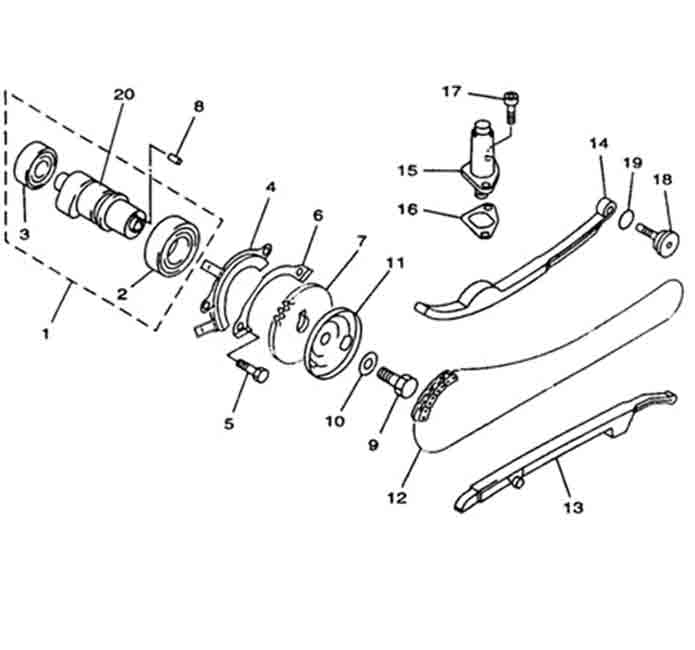

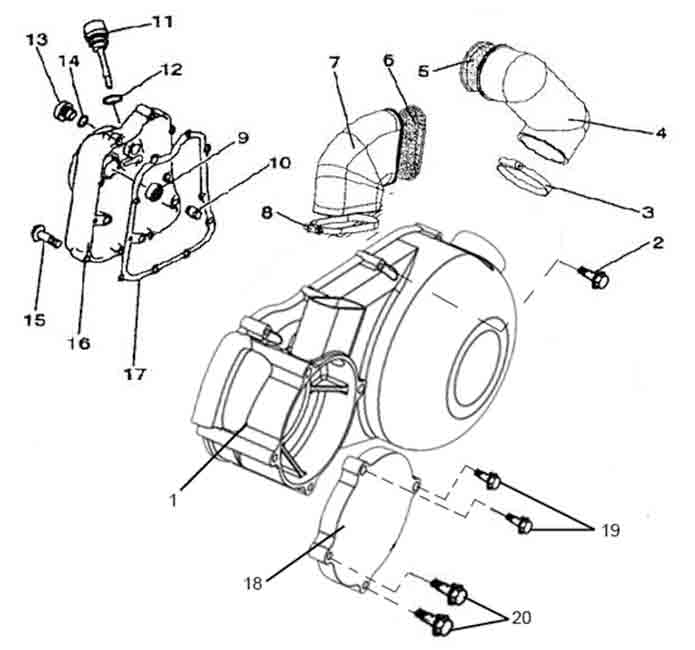

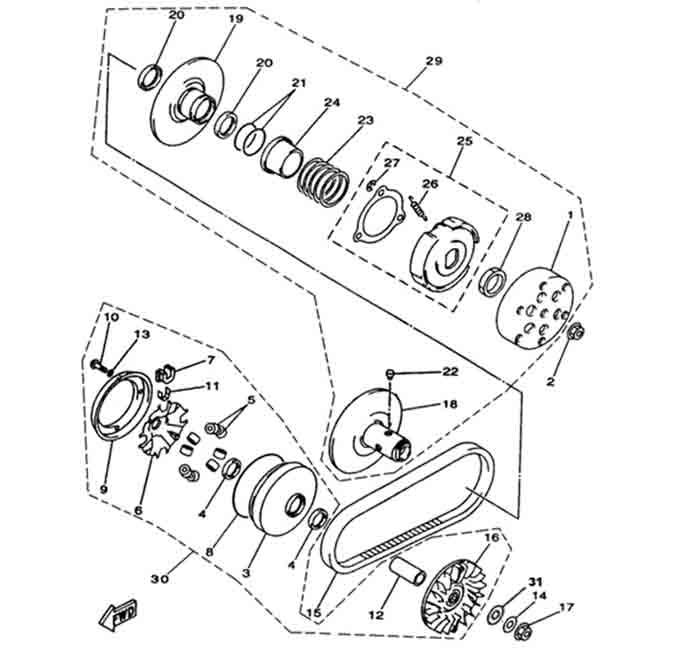

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 3.7V-BELT,CLUTCH AND SECONDARY/PRIMARY SHEAVE CRANKCASE COVER (LEFT) Q ’ty Order Job name / Part name Remarks Crankcase cover (left) Remove the parts in order. removal Crankcase cover (left) Hose clamp B Joint B Air strainer B Hose clamp A… -

Page 65

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 Air strainer A Reverse the removal procedure for installation . PRIMARY SHEAVE *Apply molybdenum disulfide grease Q ’ty Order Job name / Part name Remarks V-belt, clutch and secondary/ Remove the parts in order primary sheave removal Nut/Plain washer Refer to «PRIMARY SHEA VE… -

Page 66

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 ASSEMBLY» section. Weight Slider Refer to «PRIMARY SHEAVE ASSEMBLY» section. Spacer Oil seal Reverse the removal Procedure for installation. SECONDARY SHEAVE **Apply lightweight lithium-soap base grease Q ’ty Order Job name / Part name Remarks Secondary sheave disassembly Disassemble the parts in order. -

Page 67

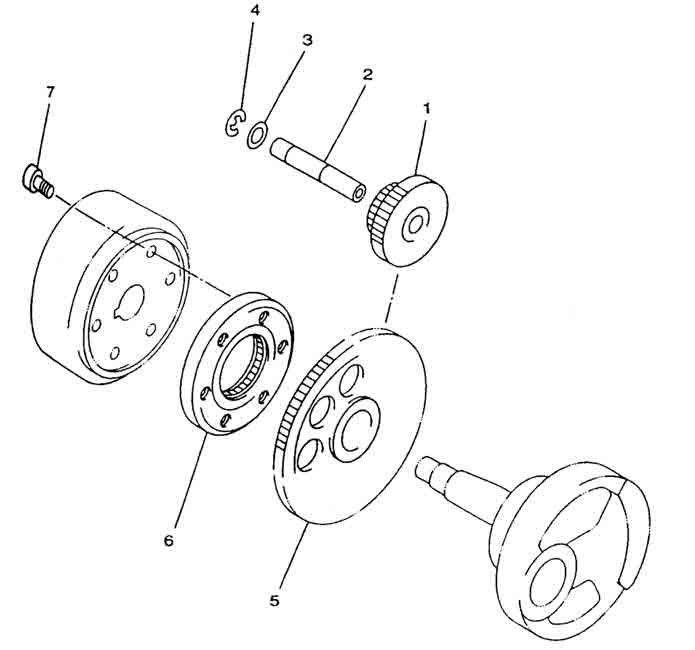

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 Reverse the disassembly procedure for assembly. PRIMARY SHEAVE REMOVAL 1. Remove: Nut (primary sheave) Plate washer Primary fixed sheave NOTE: Loosen the nut (primary fixed sheave) while holding the primary fixed sheave with the rotor holder. -

Page 68

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 SECONDARY SHEAVE DISASSEMBLY 1. Remove: Nut (secondary sheave) NOTE: Loosen the nut while attaching the clutch spring compressor and clutch spring holder arm and release the compressed spring after removing the nut. -

Page 69

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 V-belt width: 22.6mm (Limit:21.0mm) WEIGHT INSPECTION 1. Inspect: Weight minimum outside diameter Cracks/Wear /Scaling /Chipping → Replace. Out of specification → Replace Weight out side diameter: 20.0 mm <Limit: 19.5mm> SECOMDARY SHEAVE INSPECTION 1. -

Page 70

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 3. Install: Spacer Slider Cam Primary sliding sheave cap. SECOMDARY SHEAVE INSTALLATION 1. Apply: Lightweight lithium-soap base grease (to the secondary sliding sheave inner surface, grease nipple groove, and oil seals) … -

Page 71

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 NOTE: Temporarily tighten the nut while attaching the clutch spring holder and clutch spring holder arm and compress the spring. CAUTION: Use the spacer (30mm, thickness: 2-3mm). 6. -

Page 72

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 V- belt NOTE: Move the V-belt to minimum diameter of the primary sheave , maximum diameter of the secondary sheave and make the V-belt tense. 3.8A.C. MAGNETO AND STARTER CLUTCH MAGNETO COVER AND STATOR COIL Order Job name/ Part name… -

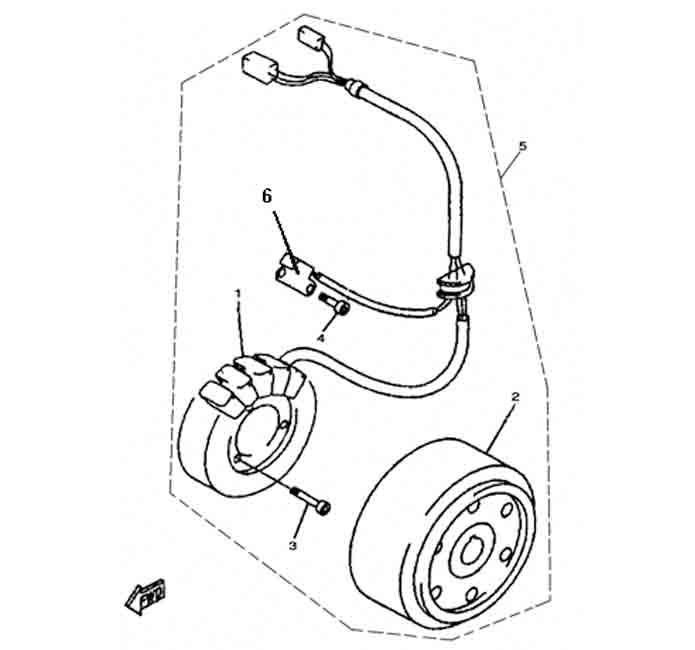

Page 73

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 Magneto cover Gasket (magneto cover) Dowel pins Stator coil Pick up coil Reverse the removal procedure for installation. A. C. MAGNETO AND STARTER CLUTCH Order Job name/ Part name Q’ty Remarks CHAPTER 3 ENGINE PAGE. -

Page 74

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 A.C. magneto and starter clutch Remove the parts in order. removal Rotor Refer to «A.C. MAGNETO ROTOR REMOVAL /INSTALLATION» section. Shaft (idle gear) Idler gear Starter one way clutch assembly Woodruff key Refer to «ROTOR INSTALLATION»… -

Page 75

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 2. Check: Starter clutch operation Push the dowel pins to the arrow direction. Unsmooth operation → Replace. Checking steps: Hold the starter clutch. When turning the starter wheel gear clockwise, the starter clutch and the starter wheel gear should be engaged. -

Page 76: Oil Pump

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 3.9OIL PUMP Order Job name/ Part name Q’ty Remarks CHAPTER 3 ENGINE PAGE. 3- 50…

-

Page 77

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 Oil pump removal Remove the parts in order. A.C. magneto Refer to «A.C. MAGNETO AND STARTER Cover CLUTCH» section. Pump driven gear Dowel pin Oil pump assembly Gasket Impeller shaft gear Dowel Pin Shaft Reverse the removal procedure for… -

Page 78

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 3.10CRANKCASE AND CRANKSHAFT CHAPTER 3 ENGINE PAGE. 3- 52… -

Page 79

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 Order Job name/ Part name Q’ty Remarks Remove the parts in the order. Crankcase and crankshaft removal Refer to «ENGINE REMOVAL» section. Engine removal Refer to «CYLINDER HEAD» section. Cylinder head Refer to «CYLINDER AND PISTION»… -

Page 80

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 Order Job name/ Part name Q’ty Remarks Timing chain guide (intake) Crankcase (right) Refer to «CRANKSHAFT INSTALLATION» section. Dowel pin Crankshaft assembly Refer to «CRANKSHAFT REMOVAL/ Timing chain INSTALLATION» section. Crankcase (left) Oil seal Oil seal… -

Page 81

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 0.35-0.85 mm 3. Measure: Crank width Out of specification → Replace crankshaft. Crank width: 59.95-60.00 mm 4. Inspect: Crankshaft sprocket Wear/ Damage → Replace crankshaft. Bearing Wear/ Crack /Damage → Replace crankshaft. Pump drive gear … -

Page 82

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 Dowel pins Timing chain NOTE: Install the timing chain not to be seen through the crankshaft hole○ on the crankcase (left). 3.11COOLING SYSTEM 3.11.1RADIATOR Remarks Order Job name/ Part name Q’ty CHAPTER 3 ENGINE PAGE. -

Page 83

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 Radiator removal Remove the parts in order. Drain the coolant. Refer «COOLANT REPLACEMENT» section. Fan motor leads Thermo switch leads hose (radiator) Outlet hose (radiator) Inlet hose (radiator) Radiator Radiator cap Radiator filler neck Reverse the removal… -

Page 84

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 and make sure there is no pressure drop. 4. Inspect: Fan motor assembly Damage → Replace. Malfunction → Check and repair. Refer to «COOLING SYSTEM «. 5. Inspect: Pipes Cracks/damage → Replace. 3.11.2WATER PUMP CHAPTER 3 ENGINE PAGE. -

Page 85

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 Remarks Order Job name/ Part name Q’ty Water pump removal Remove the parts in order. Drain the coolant. Refer to «COOLANT REPLACEMENT» section. A.C. magneto Refer to «A.C. MAGNETO AND STARTER CLUTCH»… -

Page 86

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 Order Job name/Part name Q’ty Remarks Impeller shaft Refer to “WATER PUMPINSTALLATION” O-ring section. O-ring Reverse the removal procedure for installation. NOTE: It is not necessary to disassemble the water pump, unless there is an abnormality such as excessive change in coolant temperature and/ or level, discoloration of coolant, or milky… -

Page 87

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 1. Install: Mechanical seal Installation steps: Apply the bond to the outside of the mechanical seal. Install the mechanical seal by using the mechanical seal installer and middle shaft bearing driver … -

Page 88

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 7. Install: Shaft Align the slot on the impeller shaft with the projection on the shaft when installing. 3.11.3THERMOSTAT CHAPTER 3 ENGINE PAGE. 3- 62… -

Page 89

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 Remarks Order Job name/ Part name Q’ty Remove the parts in order. Thermostat removal Refer «COOLANT REPLACEMENT» Drain the coolant section. Clip Hose Hose clamp Inlet hose (radiator) Thermostatic cover Refer to «THERMOSTAT INSTALLATION»… -

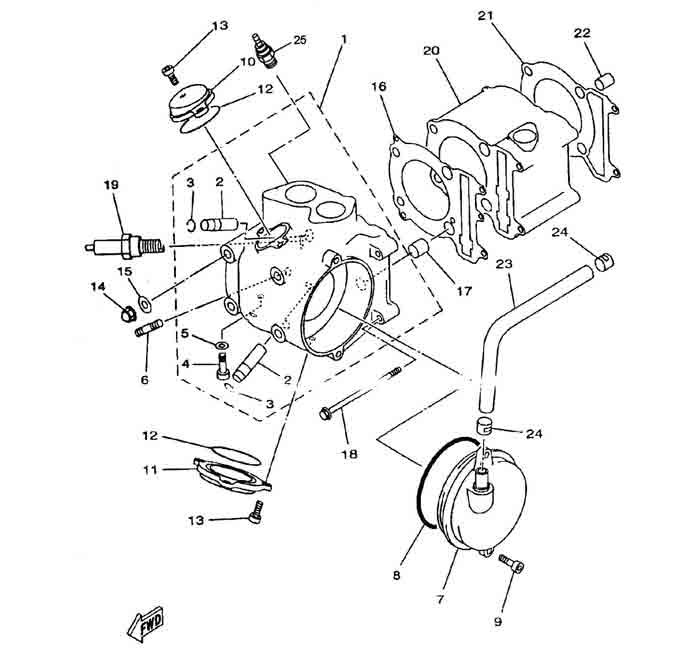

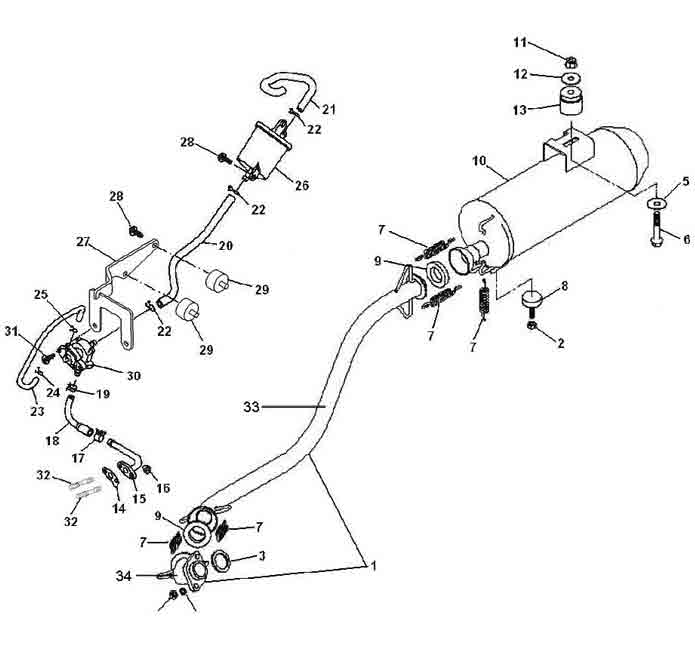

Page 90

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 Thermostatic valve Thermostatic cover 3.12CARBURETOR 1. Remove: Fuel hose 2. Remove: Manual enriching starter rope① 3. Remove: Nut② Throttle cable 4.Lossen: Bolt③ Bolt④ 5. Remove: Carburetor assy 6.Remove: Cover① 7.Remove: Diaphragm spring①… -

Page 91

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 8.Inspect: Jet needle Wear→Replace. Piston valve Wear→Replace. 9.Remove: Float chamber① Float② Needle valve③ 10.Inspect: Needle valve Wear→Replace. 11.Remove: Idling jet CHAPTER 3 ENGINE PAGE. 3- 65… -

Page 92

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 12.Remove: Pilot jet 13.Remove: Main jet 14.Remove: Main nozzle 15.Remove Mixture adjusting screw CHAPTER 3 ENGINE PAGE. 3- 66… -

Page 93

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 16. Remove Nut① Throttle valve mounting arm② Torsion-bar spring③ Gasket④ 17.Remove: Screws①&② Throttle valve mounting bracket③ 18. Reverse the removal procedure for installation. CHAPTER 3 ENGINE PAGE. 3- 67… -

Page 94

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 NOTES CHAPTER 3 ENGINE PAGE. 3- 68… -

Page 95

CHAPTER 3 ENGINE ATV SERVICE MANUAL 2005/ version number 0501 CHAPTER 3 ENGINE PAGE. 3- 69… -

Page 96

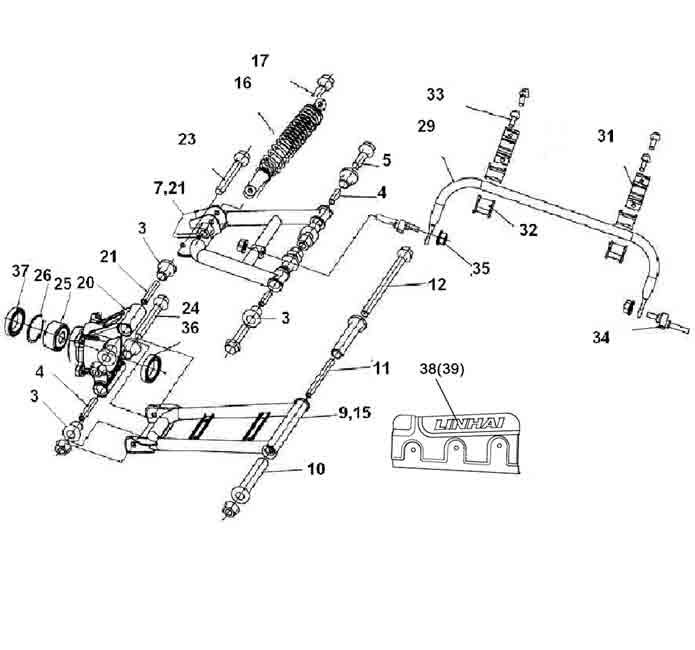

CHAPTER 4 CHASSIS CUV SERVICE MANUAL 09.0 CHAPTER 4 CHASSIS WARNING The parts of different types/ variants/ versions maybe un-interchangeable, even some parts have almost same appearance. Always refer to Parts Manual of each CUV model for spare parts information and service. 4.1 FRONT A-ARM REPLACEMENT 4.2 REAR A-ARM REPLACEMENT 4.3 REAR STABILIZER BAR REMOVA L/INSTALLATION… -

Page 97

CHAPTER 4 CHASSIS CUV SERVICE MANUAL 09.0 4.1 FRONT A-ARM REPLACEMENT 1. Elevate and safely support vehicle with weight removed from front wheel(s). 2. Remove cotter pin from ball joint stud at wheel end of A- arm and loosen nut until it is flush with end of stud. -

Page 98

CHAPTER 4 CHASSIS CUV SERVICE MANUAL 09.0 Upon A-arm installation completion, test vehicle at low speeds before putting into regular service. 4.2 REAR A-ARM REPLACEMENT CHAPTER 4 CHASSIS PAGE. 4-… -

Page 99

CHAPTER 4 CHASSIS CUV SERVICE MANUAL 09.0 1. Elevate and safely support vehicle with weight removed from the rear wheel(s). 2. Remove the wheel nuts and wheel. NOTE: To ease the removal of the spindle bolt, remove the hub cap and loosen the spindle bolts before removing the wheel. -

Page 100

CHAPTER 4 CHASSIS CUV SERVICE MANUAL 09.0 4. Remove the brake caliper. Suspend the brake caliper from the frame with a wire. NOTE: Do not let the brake caliper hand from the brake line or damage may occur. 5. Loosen two bolts that secure the rear knuckle to the A-arm. -

Page 101

CHAPTER 4 CHASSIS CUV SERVICE MANUAL 09.0 11. Insert new A-arm bushings and new A-arm shaft into new A-arm. 12. Install new A-arm assembly onto vehicle frame. Apply Loctite™ 242 to screw threads of the A arm bolts and torque bolts to 44 ft. lbs. (60 Nm ). DO NOT reuse old bolts. -

Page 102

CHAPTER 4 CHASSIS CUV SERVICE MANUAL 09.0 1. Elevate and safely support vehicle with weight removed from the rear wheel(s). 2. Remove the rear wheel to gain access to the stabilizer bar, each side. 3. Remove the stabilizer bar nut from the lower A-arm, each side. -

Page 103

CHAPTER 4 CHASSIS CUV SERVICE MANUAL 09.0 4.4 FRONT STRUT REPLACEMENT 1. Hold strut rod with wrench and remove top nut. 2. Compress spring. 3. Remove upper strut pivot assembly. 4. Remove coil spring and collapse strut body. 5. Remove two pinch bolts from strut body. 6. -

Page 104

CHAPTER 4 CHASSIS CUV SERVICE MANUAL 09.0 seated fully. 10. Torque strut rod nut to specification. Do not over torque nut. Strut Rod Nut Torque :15 ft. lbs. (21 Nm) 4.5 FRONT STRUT BALL JOINT REPLACEMENT 1. Loosen front wheel nuts. 2. -

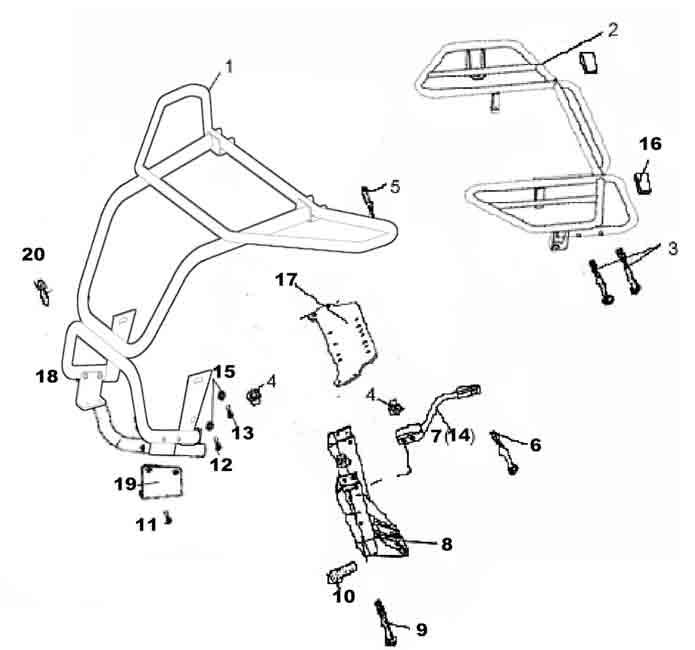

Page 105

CHAPTER 4 CHASSIS CUV SERVICE MANUAL 09.0 4.6 BOX REMOVAL/INSTALLATION Box Removal 1. Disconnect the license light coupler. 2. Lift the box into the dump position. 3. Remove the box shock pin from the frame (both sides). 4. Remove the shocks from the shock brackets. Let the shocks fully extend. -

Page 106

CHAPTER 4 CHASSIS CUV SERVICE MANUAL 09.0 4.7 STEERING ASSEMBLY REMOVAL/INSTALLATION 1. With the steering wheel cover bolts removed, remove the steering wheel cover and the steering wheel. 2. With the steering wheel holder nut removed, remove the steering wheel holder. 3. -

Page 107

CHAPTER 4 CHASSIS CUV SERVICE MANUAL 09.0 NOTES CHAPTER 4 CHASSIS PAGE. 4- 12… -

Page 108

CHAPTER 5 FINAL DRIVE CUV SERVICE MANUAL 09.0 CHAPTER 5 FINAL DRIVE WARNING The parts of different types/ variants/ versions maybe un-interchangeable, even some parts have almost same appearance. Always refer to Parts Manual of each CUV model for spare parts information and service. -

Page 109

CHAPTER 5 FINAL DRIVE CUV SERVICE MANUAL 09.0 5.1 WH E E L , H U B , AND SPINDLE TORQUE TABLE Item Specification heel Nuts 59 Ft.Lbs 66 Nm Front W heel Nuts 59 Ft.Lbs 66 Nm Rear W Front Hub Nut on Spindle/ outer CV joint 101 Ft.Lbs 137 Nm Rear Hub Retaining Nut… -

Page 110

CHAPTER 5 FINAL DRIVE CUV SERVICE MANUAL 09.0 3. Grasp the top and bottom of the tire. The tire should rotate smoothly without binding or rough spots. 4. Remove wheel nuts and wheel. 5. Remove the two brake caliper mounting bolts. CAUTION: Do not hang the caliper by the brake line. -

Page 111

CHAPTER 5 FINAL DRIVE CUV SERVICE MANUAL 09.0 7. Rotate hub. It should rotate smoothly without binding or rough spots or side play. 8. Install brake caliper using new bolts. (Apply Loctite™ 242 to threads) Tighten bolts to 18 ft.lbs (24 Nm) CAUTION: New bolts have a pre-applied locking agent which is destroyed bolts upon removal. -

Page 112

CHAPTER 5 FINAL DRIVE CUV SERVICE MANUAL 09.0 5.6 FRONT DRIVE AXLE REMOVAL/INSPECTION (4X4) NOTE: The outer CV joint cannot be disassembled or repaired, if damage or faulty the drive axle assembly must be replace. 1. Drive Axle/Outer CV Joint Assembly. 2. -

Page 113

CHAPTER 5 FINAL DRIVE CUV SERVICE MANUAL 09.0 4. Place a tire lever between the inner CV joint and the differential housing, with a small piece of wood against the housing to help get «leverage» and protect the casting. «pop» the in inner CV joint out from the front gearcase. -

Page 114

CHAPTER 5 FINAL DRIVE CUV SERVICE MANUAL 09.0 groove. 4. Carefully install the outer CV joint (spindle) into the strut,install the front hub and wheel. 5. Install the ball joint on the A arm, the steering tie rods, the hubs and the wheels as described in this Chapter and Chapter 4. -

Page 115

CHAPTER 5 FINAL DRIVE CUV SERVICE MANUAL 09.0 3. Check for wear or damage to the inner splines of the bearing race. 4. If necessary, disassembly the bearing assembly for further inspection. Carefully remove the steel balls from the bearing cage then remove the bearing race from the bearing cage. -

Page 116

CHAPTER 5 FINAL DRIVE CUV SERVICE MANUAL 09.0 5.9 FRONT DRIVE AXLE ASSEMBLY (4X4) 1. The rubber boots are not identical and must be installed on the correct joint. The boots are marked as follows: a. Inner CV joint boot : “inner”, b. -

Page 117: Rear Hub Exploded View

CHAPTER 5 FINAL DRIVE CUV SERVICE MANUAL 09.0 joint cavity behind the bearing assembly with additional molybdenum disulfide grease. 12. Pack each boot with the following amounts of molybdenum disulfide grease: a. Inboard boot:35-55grams(1.2-1.9oz.). b. Outboard boot:30-50grams(1.1-1.8oz.). 13. Move the inboard boot onto the inner CV joint. 14.Move the inboard joint on the drive axle.

-

Page 118

CHAPTER 5 FINAL DRIVE CUV SERVICE MANUAL 09.0 5.11 RE AR HUB AND KNUCKLE REMOVAL/ INSPECTION 1. Elevate rear end and safely support machine under main frame area. C AUTIO N: Serious injury may result if machine tips or falls. Be sure machine is secure before beginning this service… -

Page 119

CHAPTER 5 FINAL DRIVE CUV SERVICE MANUAL 09.0 nut to 101 ft.lbs. (137 Nm). Install a new cotter key and the hub cap. 8. Install brake caliper using new bolts. (Apply Loctite™ 242 to threads) Tighten bolts to 18 ft.lbs (24 Nm) 5.13 RE AR DRIVE SHAFT REMOVAL 1. -

Page 120

CHAPTER 5 FINAL DRIVE CUV SERVICE MANUAL 09.0 2. Reinstall the rear driveshaft into the rear gearcase. Be sure the circlip is securely fit into the rear gearcase. Use a rubber mallet to tap on the outboard end of the driveshaft if necessary. 3. -

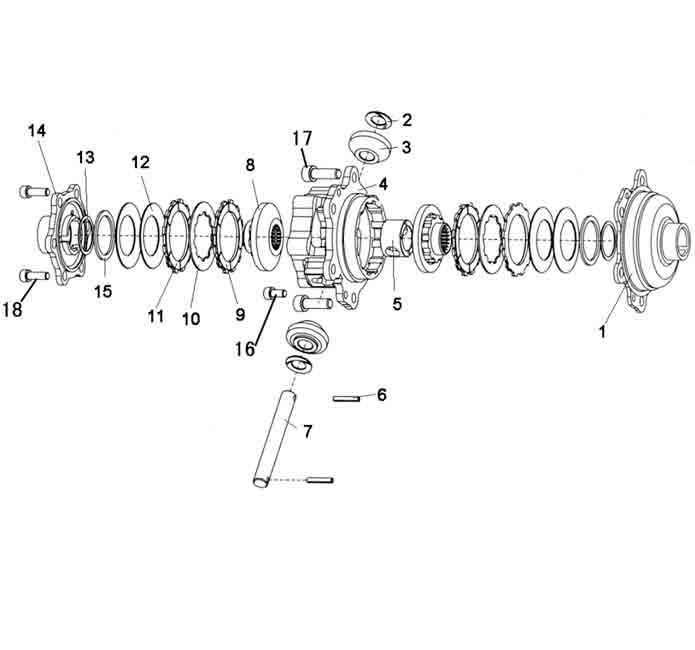

Page 121

CHAPTER 5 FINAL DRIVE CUV SERVICE MANUAL 09.0 5.15 RE AR GE ARCASE EXPLODED VIEW 1. REAR GEAR-BOX ASSY 2. DRIVE HOUSING 3. OUTPUT COVER 4. O-RING 160X2.65 5. BOLT M8X28 6. BOLT M10X1.25X28 7. WASHER 31 8. O-RING 20X3 9. -

Page 122

CHAPTER 5 FINAL DRIVE CUV SERVICE MANUAL 09.0 5.16 REAR GEARCASE DISASSEMBLY 1. Drain and properly dispose of used oil. 2. Loosen the cover bolts in a crisscross pattern in several steps and remove them. 3. Pry the cover at the prying points using a screw-driver and remove the output cover. -

Page 123

CHAPTER 5 FINAL DRIVE CUV SERVICE MANUAL 09.0 5.18 BACKLASH INSPECTION 1. Remove the oil filler cap. 2. Install the special tool into the pinion joint, and set the final drive assembly and tool in a vise. 3. Install the drive shaft into the final drive assembly and hold it. -

Page 124

CHAPTER 5 FINAL DRIVE CUV SERVICE MANUAL 09.0 NOTE: It is recommended to replace the FRONT DIFFRENTIAL as an assembly when out of specification. 5.20 FRONT GEARCASE DISASSEMBLY/ INSPECTION (4X4) 1. Drain and properly dispose of used oil. 2. Remove bolts, gasket and shift motor. 3. -

Page 125

CHAPTER 5 FINAL DRIVE CUV SERVICE MANUAL 09.0 5. Remove selector fork, splined dog and input shaft. 6. Remove bearing and seal. 7. Remove gear, screws, pinion shaft retainer plate and pinion shaft. 8. Remove seal from the case. CHAPTER 5 FINAL DRIVE. -

Page 126

CHAPTER 5 FINAL DRIVE CUV SERVICE MANUAL 09.0 9. Remove bolts, left cover and differential. → Differential 10. Remove seal from left cover. CHAPTER 5 FINAL DRIVE. 5- 19… -

Page 127

CHAPTER 5 FINAL DRIVE CUV SERVICE MANUAL 09.0 11. Clean all components and inspect for wear. Inspect gears for wear, cracks, chips or broken teeth. Inspect engagement dogs and detent ball housing, replace if edges are rounded. Inspect casting for crack. Inspect bearings for smooth operation. -

Page 128

CHAPTER 5 FINAL DRIVE CUV SERVICE MANUAL 09.0 7. Apply LocTite 518 to mating surfaces, reinstall cover and torque bolts. 8ft.lbs. (12Nm) 8. Reinstall gasket and shift motor and torque bolts. 2ft.lbs. (3Nm) 9. Install differential into case. Apply LocTiteTM 518 to mating surfaces, reinstall left cover and torque bolts. -

Page 129

CHAPTER 5 FINAL DRIVE CUV SERVICE MANUAL 09.0 5.22 FRONT DIFFRENTIAL DISASSEMBLY/ INSPECTION (4X4) 1. Remove bolts and bevel crownwheel. 2. Remove bolts and differential cap A. 3. Remove spring seat, springs, outer single clutch plate, differential plat, outer double clutch plate, bevel gear and gear axle washer. -

Page 130

CHAPTER 5 FINAL DRIVE CUV SERVICE MANUAL 09.0 5. Remove spring seat, springs, outer single clutch plate, differential plat, outer double clutch plate, bevel gear and gear axle washer. 6. Remove roll pin from center pin. 7. Remove center pin, bevel pinion washers, bevel pinions and center spacer from differential housing. -

Page 131

CHAPTER 5 FINAL DRIVE CUV SERVICE MANUAL 09.0 5.23 FRONT DIFFRENTIAL ASSEMBLY (4X4) 1. Install center pin, bevel pinion washers, bevel pinions and center spacer into differential housing. 2. Install bevel gear, gear axle washer, outer double clutch plate, differential plate, outer single clutch plate, springs, spring seat. -

Page 132

CHAPTER 5 FINAL DRIVE CUV SERVICE MANUAL 09.0 5. Install bevel crownwheel, Apply Loctite (red) to screw threads and torque bolts to 24ft.lbs. (32Nm) 6. Install bevel gear, gear axle washer, outer double clutch plate, differential plate, outer single clutch plate, springs, spring seat. -

Page 133

CHAPTER 5 FINAL DRIVE CUV SERVICE MANUAL 09.0 9. Apply Loctite 271(red) to screw threads and torque bolts to 16ft.lbs. (22Nm) CAUTION: Slip limit torque relate to the preload clearance on the differential, and affect the Steering Effort (heavy steering). Always field test the CUV carefully and thoroughly after front gearcase and differential service for vehicle maneuvers and operation. -

Page 134

CHAPTER 5 FINAL DRIVE CUV SERVICE MANUAL 09.0 5.25 REAR, FRONT PROP SHAFT REMOVAL Using roll pin remover, remove the roll pin from prop shaft Slide the prop shaft back and away from the gear case. (The rear gearcase must be disassembly from the frame before the rear prop shaft removal). -

Page 135

CHAPTER 5 FINAL DRIVE CUV SERVICE MANUAL 09.0 NOTES CHAPTER 5 FINAL DRIVE. 5- 28… -

Page 136

CHAPTER 6 TRANSMISSION CUV SERVICE MANUAL 07.0 CHAPTER 6 TRANSMISSION WARNING The parts of different types/ variants/ versions maybe un-interchangeable, even some parts have almost same appearance. Always refer to Parts Manual of each CUV model for spare parts information and service. 6.1 GEAR SHIFTER REMOVAL 6.2 GEAR SHIFT ER DISASSEMBLY 6.3 GEAR SHIFT ER ASSEM BLY… -

Page 137

CHAPTER 6 TRANSMISSION CUV SERVICE MANUAL 07.0 6.1 GEAR SHIFTER REMOVAL 1. Remove parts that interfere with access to shift selector (seat, cover etc.) 2. Disconnect the two linkage rods from transmission slides. 3. Remove four bolts attaching gear shift selector to the mounting bracket. -

Page 138

CHAPTER 6 TRANSMISSION CUV SERVICE MANUAL 07.0 2. Carefully pull the cover and shift lever from the shifter housing. 3. Set the shift cover lever assembly aside. 4. Remove the three springs from shifter housing. NOTE: Do not tip shifter housing upside down or detent bullets and stop pin may fall out. -

Page 139

CHAPTER 6 TRANSMISSION CUV SERVICE MANUAL 07.0 shifter on the CUV. Put a new sticker on the knob in correct direction NOTE: If moisture or corrosion is found in the shift rod the boot should be replaced. 6.4 SHIFTER INSTALL ATION Place shift rod back into the mounting bracket and replace five bolts. -

Page 140

CHAPTER 6 TRANSMISSION CUV SERVICE MANUAL 07.0 neutral position detents. 6. Be sure the shift linkage rod ends are firmly attached to the gear selector slides. Adjust the low range (inside) rod so the rod end is centered on the transmission bell crank. Install the lock nut to the rod end and torque to 35 in.lbs ( 4 Nm). -

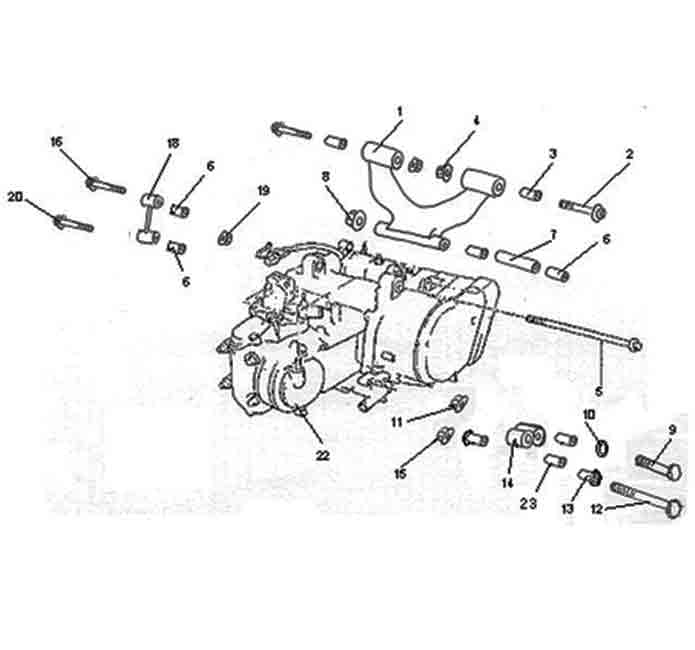

Page 141

CHAPTER 6 TRANSMISSION CUV SERVICE MANUAL 07.0 7. Loose all bolts on the brackets which connect the engine/ transmission between the frame, except the 2 brackets between the engine and transmission and left them on the transmission. See picture. 2 brackets between the engine and transmission 8. -

Page 142

CHAPTER 6 TRANSMISSION CUV SERVICE MANUAL 07.0 6.7 ENGINE AND TRANSMSSION INSTALL Transmission 1. Position transmission in frame, Align rear drive shaft and slide shaft into the yoke. 2. Install all brackets, loosely install new fasteners. 3. Tighten fasteners in “right -left– rear” order. NOTE: While tightening, it is important to turn the rear drive shaft by hand to check the position of transmission. -

Page 143: Transmission Disassembly

CHAPTER 6 TRANSMISSION CUV SERVICE MANUAL 07.0 6.8 TRANSMISSION DISASSEMBLY 1. Place gears in neutral. 2. Remove gear position indicator switches. IMPORTANT: The gear position indicator switches must be removed prior to disassembly. 3. Remove the transmission cover bolts. 4. Carefully remove the cover with a soft face hammer tap on the cover bosses.

-

Page 144: Transmission Assembly

CHAPTER 6 TRANSMISSION CUV SERVICE MANUAL 07.0 8. Remove front drive output housing cover screws. Carefully remove the cover with a soft face hammer tap on the cover bosses. 9. Note position of shim washers and thrust button. 10. Remove shafts as an assembly. 11.

-

Page 145

CHAPTER 6 TRANSMISSION CUV SERVICE MANUAL 07.0 3. a. (4X4) Install front and rear output shafts with chain as an assembly. b. (2X4) Install rear output shaft. 4. Before installing the cover make sure the sealing surfaces are clean and dry, and shafts are fully seated in the transmission case. -

Page 146

CHAPTER 6 TRANSMISSION CUV SERVICE MANUAL 07.0 11. Carefully install high/reverse shaft assembly and gear cluster as a unit into their respective bearing case areas. Tap with a soft face hammer to seat shaft assemblies. NOTE: Make sure shift shaft pins are properly positioned in the slot on selector arms. -

Page 147

CHAPTER 6 TRANSMISSION CUV SERVICE MANUAL 07.0 6.10 TROUBLE SHOOTING CHECKLIST Check the following items when shifting difficulty is encountered Idle speed adjustment Transmission oil type/quality Driven clutch (CVT) deflection Loose fasteners on rod ends Loose fasteners on gear shift box Worn rod ends, clevis pins, or pivot arm bushings Linkage rod adjustment and rod end positioning Shift selector rail travel… -

Page 148

CHAPTER 6 TRANSMISSION CUV SERVICE MANUAL 07.0 2X4 TRANSMISSION EXPLODED VIEW CHAPTER 6 TRANSMISSION PAGE. 6- 13… -

Page 149

CHAPTER 6 TRANSMISSION CUV SERVICE MANUAL 07.0 4X4 TRANSMISSION EXPLODED VIEW CHAPTER 6 TRANSMISSION PAGE. 6- 14… -

Page 150

CHAPTER 6 TRANSMISSION CUV SERVICE MANUAL 07.0 NOTES CHAPTER 6 TRANSMISSION PAGE. 6- 15… -

Page 151

CHAPTER 7 BRAKES CUV SERVICE MANUAL 09.0 CHAPTER 7 BRAKES WARNING The parts of different types/ variants/ versions maybe un-interchangeable, even some parts have almost same appearance. Always refer to Parts Manual of each ATV model for spare parts information and service. NOTE: Also See Chapter 2 for Maintenance Information. -

Page 152

CHAPTER 7 BRAKES CUV SERVICE MANUAL 09.0 7.1 SPECIFICATIONS Front Brake Caliper Item Standard Service Limit Brake Pad Friction material 0.157″/ 4mm 0.04″/ 1mm Thickness B rake Disc Thickness 0.150- 0.164″/3.810- 4.166mm 0.140″/ 3.556mm Brake Disc Thickness Variance 0.002 «/ .051m m Between Measurements Brake Disc Runout 0.005 «/ .127mm… -

Page 153

CHAPTER 7 BRAKES CUV SERVICE MANUAL 09.0 Check and adjust master cylinder reservoir fluid level after pad service. Make sure atmospheric vent on reservoir is unobstructed. Adjust foot brake after pad service. Test for brake drag after any brake system service and investigate cause if brake drag is evident. -

Page 154

CHAPTER 7 BRAKES CUV SERVICE MANUAL 09.0 This procedure should be used to change fluid or bleed brakes during regular maintenance. 1. Clean reservoir cover thoroughly. 2. Remove cover from reservoir. 3. If changing fluid, remove old fluid from reservoir with a brake fluid pump or similar tool. -

Page 155

CHAPTER 7 BRAKES CUV SERVICE MANUAL 09.0 calipers. 11. Add brake fluid to MAX level inside reservoir. Master Cylinder Fluid Level Between the MIN line and the MAX line of reservoir. 12. Install master cylinder reservoir cover. 13. Field test machine at low speed before putting into service. -

Page 156: Parking Brake Adjustment

CHAPTER 7 BRAKES CUV SERVICE MANUAL 09.0 2. Inspect the parking brake cable at the parking brake lever assembly on the brake caliper. 3. Inspect the brake lines and brake line connections for possible leaks or loose lines. 7.7 PARKING BRAKE ADJUSTMENT Parking Brake Inspection 1.

-

Page 157

CHAPTER 7 BRAKES CUV SERVICE MANUAL 09.0 7.8 PARKING BRAKE REAR CALIPER REMOVAL / INSTALL Park Brake Caliper Disassembly / Pad Inspection NOTE: Do not get oil, grease, or fluid on the park brake pads. Damage to the pads may cause the pads to function improperly. -

Page 158

CHAPTER 7 BRAKES CUV SERVICE MANUAL 09.0 CAUTION: Use care when supporting vehicle so that it does not tip or fall. Severe injury may occur if machine tips or falls. 2. Remove the front wheel. 3. Remove the two caliper bolts and caliper from mounting bracket. -

Page 159

CHAPTER 7 BRAKES CUV SERVICE MANUAL 09.0 INSTALLATION 1. Lubricate mounting bracket pins with a light film of All Season Grease, and install rubber dust boots. 2. Compress mounting bracket and make sure dust boots are fully seated. Install pads with friction material facing each other. -

Page 160

CHAPTER 7 BRAKES CUV SERVICE MANUAL 09.0 Brake Disc Thickness Variance Service Limit 0.002 » (0.051 mm) difference between measurements 3. Mount dial indicator as shown to measure disc runout on the dial indicator. Replace the disc if runout exceeds specifications. Brake Disc Runout Service Limit 0.005″… -

Page 161

CHAPTER 7 BRAKES CUV SERVICE MANUAL 09.0 INSPECTION Inspect caliper body for nicks, scratches or worn. Replace caliper as an assembly if any problem exists. INSTALLATION 1. Install caliper on hub strut, Apply Loctite™ 242 to screw threads and Install new bolts. Front Caliper Mounting Bolt Torque 18 ft. -

Page 162

CHAPTER 7 BRAKES CUV SERVICE MANUAL 09.0 Remove excess fluid from reservoir as required. 5. Remove the brake pads. 6. Clean the caliper with brake cleaner or alcohol. INSPECTION Measure the thickness of the pad friction material. Replace pads if worn beyond the service limit. Service Limit 0.3/64″(1 mm) INSTALLATION 1. -

Page 163

CHAPTER 7 BRAKES CUV SERVICE MANUAL 09.0 lines. 3. After the fluid has drained into the container, remove the caliper mounting bolts and remove caliper. 4. Remove brake pad as described above. 5. Inspect surface of caliper for nicks, scratches or damage and replace if necessary. -

Page 164

CHAPTER 7 BRAKES CUV SERVICE MANUAL 09.0 difference between measurements 3. Mount dial indicator as shown to measure disc runout on the dial indicator. Replace the disc if runout exceeds specifications. Brake Disc Runout Service Limit 0.005″ (0.127 mm) REMOVAL/ REPLACEMENT 1. -

Page 165

CHAPTER 7 BRAKES CUV SERVICE MANUAL 09.0 NOTES CHAPTER 7 BRAKES PAGE. 7- 15… -

Page 166

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 CHAPTER 8 ELECTRICAL PARTS INSPECTION AND SERVICE BATTERY IGNITION SYSTEM CHARGING SYSTEM ELECTRICS STARTING SYSTEM COOLING SYSTEM LIGHTING SYSTEM REVERSE LIMIT SYSTEM GEAR POSITION INDICATOR SWITCH TEST 8.10 SPEEDOMETER SYSTEM 8.11 MAIN SWITCH AND HANDLE SWITCH 8.12 FUEL GAUGE/ FUEL LEVEL SENSOR 8.13… -

Page 167

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 8.1 PARTS INSPECTION AND SERVICE A HEADLIGHT ADJUSTMENT 1. Use bulb 12V 35W/35W. 2. Pull the cable plug off the conducting strip in the socket, remove the clip① before dismounting the bulb. 3. Fit a new bulb into the socket, sitting properly in the three slots, install the clip as shown in the fig. -

Page 168

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 TAILLIGHT / BRAKELIGHT LAMP REPLACEMENT 1. From the rear of the taillight remove two screws holding lens cover in place and remove lens cover. 2. Remove lamp and replace it with recommended lamp. 3. -

Page 169

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 8.2 BATTERY Battery electrolyte is poisonous. It contains sulfuric acid. Serious burns can result from contact with skin, eyes or clothing Antidote: External: Flush with water. lnternal: Drink large quantities of water or milk. Follow with milk of magnesia, beaten egg, or vegetable oil. -

Page 170

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 level. Do not overfill the battery. To refill use only distilled water. Tap water contains minerals which are harmful to a battery. Do not allow cleaning solution or tap water to enter the battery. It will shorten the life of the battery. -

Page 171

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 IGNITION SYSTEM TROUBLESHOOTING No Spark, Weak or Intermittent Spark Spark plug gap incorrect Fouled spark plug Faulty spark plug cap or poor connection to high tension lead Related wiring loose, disconnected, shorted, or corroded Engine stop switch or ignition switch faulty … -

Page 172

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 CIRCUIT DIAGRAM CHAPTER 8 ELECTRICAL PAGE.8-… -

Page 173

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 IF THE IGNITION SYSTEM FAILS TO OPERATE Procedure Check: 1. Fuse (Main) 7.Pickup coil resistance 2. Battery 8.Main switch 3. Spark plug 9.Engine stop switch 4. lgnition spark gap 10.Wiring connection 5. Spark plug cap resistance (entire ignition system) 6. -

Page 174

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 4.lgnition spark gap Disconnect the spark plug cap from the spark plug Connect the ignition tester 1 as shown. 2 Spark plug Turn the main switch to «ON». Check the ignition spark gap . Check the spark by pushing the MEETS SPECIFICATION starter switch, and increase the spark… -

Page 175

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 Tester (+) lead Pink Terminal Tester ( ) lead B/Y 6. Ignition coil resistance Terminal Disconnect the ignition coil connector from the wire harness. Connect the pocket tester (1) to the ignition coil. … -

Page 176

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 7. Pickup coil resistance Disconnect the pickup coil coupler from the wire harness. Connect the pocket tester (Ω 100) to the pickup coil coupler. Tester (+) lead → BI/Y Terminal Tester (- ) lead→ B/R Terminal … -

Page 177: Charging System

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 8.4 CHARGING SYSTEM CHARGING SYSTEM CIRCUIT DIAGRAM CURRENT DRAW KEY OFF CAUTION: Do not connect or disconnect the battery cable or ammeter with the engine running. Damage will occur to light bulbs and speed limiter. Connect an ammeter in series with the negative battery cable.

-

Page 178

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 CHARGING SYSTEM Procedure Check: 1. Fuse (Main) 4.Stator coil resistance 2. Battery 5.Wiring system (entire charging system) 3.Charging voltage 1. fuse NO CONTINUITY Replace the fuse 2. Battery Check the battery condition. INCORRECT Refer to «BATTERY INSPECTION»… -

Page 179

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 4. Starter coil resistance Remove the A.C. magneto coupler from wire harness Connect the pocket tester (ΩX1) the stator coil Tester (+) lead –yellow terminal Tester (-) lead –yellow terminal OUT OF SPECITICATION Measure the stator coil resistance Stator coil resistance 0.5-0.8Ω(20℃)… -

Page 180

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 8.5 ELECTRICS STARTING SYSTEM D I A G R A M CHAPTER 8 ELECTRICAL CTRICAL PAGE 8- 15… -

Page 181

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 TROUBLESHOOTING IF THE STARTER MOTOR FAILS TO OPERATE Procedure Check: 7. Engine stop switch 1. Fuse (Main) 8. front/rear brake switch 2. Battery 9. starter switch 3. starter motor 10. wiring connection (entire starting system) 4. -

Page 182

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 WARNING 4.Starter relay A wire used as a jumper lead Disconnect the relay unit coupler from must have the equivalent the wire harness. capacity as that of the battery Connect the pocket tester (Ωx1) and lead or more, otherwise it battery (12V) to the relay unit coupler may burn. -

Page 183

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 6. Main switch CHECK SWITCHES NO CONTINUITY Replace the main switch 7. Engine stop switch NO CONTINUITY Replace the handlebar switch 8 Front /rear brake switch NO CONTINUITY CHECKING SWITCHES Replace the brake switch 9. -

Page 184

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 8.6 COOLING SYSTEM IF THE FAN MOTOR FAILS TO TURN Procedure Check: 1. Fuse (Main, Fan) 2. Battery 4. Fan motor (inspection) 3. Main switch 5. Thermo switch 6. Wiring connection (entire cooling system) CHAPTER 8 ELECTRICAL CTRICAL PAGE 8- 19… -

Page 185

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 1. fuse CHECK SWITCHES NO CONTINUITY Replace the fuse 2. Battery Check the battery condition. INCORRECT Refer to «BATTERY INSPECTION» section Clean battery terminals Recharge or replace the battery 3 Main switch CHECK SWITCHES NO CONTINUITY Replace the main switch 4. -

Page 186

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 6. Thermo switch Remove the thermo switch from the radiator. Connect the pocket tester (ΩX1) to the thermo switch. Immerse the thermo switch in the water Check the thermo switch for continuity. NOTE: Measure temperatures while heating the coolant with the temperature gauge… -

Page 187

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 IF THE HEAT ALARM UNIT WORKING When the main switch is turned on, the temperature of the engine begins to go up. As it comes to 88±3℃ the thermostat is connected and the fan starts to work, cooling the coolant, if the thermostat or the fan, fails to work;… -

Page 188

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 Handle the thermo unit with 4.Thermo unit special care. Drain the coolant and remove the Never subject it to strong thermo unit from the cylinder head. shocks or allow it to be Immerse the thermo unit in the dropped. -

Page 189: Lighting System

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 LIGHTING SYSTEM FOR USA MODEL CHAPTER 8 ELECTRICAL CTRICAL PAGE 8- 24…

-

Page 190

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 FOR EUROPE MODEL CHAPTER 8 ELECTRICAL CTRICAL PAGE 8- 25… -

Page 191

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 TROUBLESHOOTING Procedure Check: 1. Fuse (Main) 4.Lights switch 2. Battery 5.Dimmer switch 3. Main switch 6. Wiring connection (entire lighting system) 1.fuse refer ―CHECKING SWITCHES‖ NO CONTINUITY section Replace the fuse 2. Battery Check the battery condition. -

Page 192

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 POOR CONNECTIONS 6. Wiring connection Check the connection of the entire lighting system correct 7. check the condition of each of the lighting system’s circuits Refer to ―LIGHTING SYSTEM CHECK‖ LIGHT SYSTEM CHECK 1. -

Page 193

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 2. the taillight fails to come on 1. Bulb and bulb socket NO CONTINUITY CHECK SWITCHES Replace the bulb and /or bulb socket CONTINUITY 2. Voltage Connect the pocket tester (DC20V) to the bulb socket connector. -

Page 194

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 8.8 REVERSE LIMIT SYSTEM The limit set for the speed limiter by the manufacturer is 13~15 km/h, which can be reset in accordance with the user’s practice. Turning the adjusting bolt clockwise increase speed, while counterclockwise decrease it. -

Page 195

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 8.9 GEAR POSITION INDICATOR SWITCH TEST Switch table CHAPTER 8 ELECTRICAL CTRICAL PAGE 8- 30… -

Page 196

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 Switch schematic CHAPTER 8 ELECTRICAL CTRICAL PAGE 8- 31… -

Page 197

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 8.10 SPEEDMETER SYSTEM OPERATION OF SPPED SENSOR Speed Sensor is on the rear axle Operation Instructions of Electric Dial Meter and Speed Sensor/ Operation Instructions of LCD Meter and Speed Sensor Hall Sensor is a new type sensor used to measure speed, angle, revolution and length, etc by means of voltage pulse signals converted from sensing gear ratio of black metal gear or gear rack. -

Page 198

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 Speed Sensor on the Transmission Out Put Shaft. Operation Instructions of LCD Meter and Speed Sensor Main Technical Parameter: Item Code Vol value Unit Operating voltage 5-20 ≤15 Operating current Operating distance 1mm≤D≤8mm The following is the graphic illustration for sensor installation。… -

Page 199

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 1. Neutral indicator light 7. Engine rpm meter 2. High beam indicator light 8、9. The odometer 3. Turn indicator light 10.Engine working hour counter 4. Reverse indicator light 11. 2WD/4WD indicator* 5. Speedometer A: km/ mile selector Coolant temperature… -

Page 200

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 8.11 MAIN SWITCH AND HANDLE SWITCH CHAPTER 8 ELECTRICAL CTRICAL PAGE 8- 35… -

Page 201

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 8.12 FUEL GAUGE/ FUEL LEVEL SENSOR Removal Turn the ignition switch to“OFF”. Remove the fuel tank cover. Remove the three bolts, retaining plate and fuel level sensor from the fuel tank. Installation Install a new seal rubber onto the fuel level sensor. -

Page 202

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 Segment“RES”should blink. With the fuel level sensor float at the top (FULL) position, turn the ignition switch to “ON” and check the fuel gauge. All segments up to segment “F”should come on. If the fuel gauge does not function properly, check the fuel level sensor If the fuel level sensor is OK, replace the LCD Meter. -

Page 203

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 8.13 THE OPERATION PRINCIPLE OF THE ELECTRIC 4WD SHIFT (Fig 1) 1, The rider shifts 2WD to 4WD by the Switch on handlebar. 2. The Switch gives signal to Controller. 3, The controller gives power to the Shift Motor. 4, If the Splined Dog (Fig 2) is in right position, 4WD will engage immediately. -

Page 204

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 (Fig 2) (Fig 3)Page from owner’s manual CHAPTER 8 ELECTRICAL CTRICAL PAGE 8- 39… -

Page 205

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 (Fig 4) CHAPTER 8 ELECTRICAL CTRICAL PAGE 8- 40… -

Page 206

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 8.14 WIRING DIAGR CHAPTER 8 ELECTRICAL CTRICAL PAGE 8- 41… -

Page 207

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 CHAPTER 8 ELECTRICAL CTRICAL PAGE 8- 42… -

Page 208

CHAPTER 8 ELECTRICAL CUV SERVICE MANUAL 09.0 NOTES CHAPTER 8 ELECTRICAL CTRICAL PAGE 8- 43…

Главная | Руководства | Руководство по запчастям LH400ATV-2B (IRS) независимая задняя подвеска

ATV400-2B_PARTS_MANUAL_2012.6.18.xls

Размер: 8,75 МБ

Изменён: 23.02.2015 15:02:21

Скачан: 1814 раз

Здесь вы можете ознакомиться с руководством по запчастям для квадроцикла Linhai 400. Вы также можете скачать файл себе на компьютер.

Содержание руководства:

2438/2606

1856/2010

1749/1902

1981/2146

2026/2191

1729/1899

1637/1793

1532/1697

1700/1855

2129/2305

1443/1591

1788/1968

1798/1953

1877/2009

1712/1860

1724/1846

1485/1624

2323/2505

1983/2170

1396/1516

1373/1504

1542/1684

1717/1876

1541/1682

1529/1686

1589/1721

1518/1670

1555/1714

1678/1826

1784/1915

1664/1806

1814/1959

1673/1814

1663/1801

1553/1691

1582/1726

2317/2482

1423/1549

1618/1753

1531/1671

2128/2283

2109/2277

1728/1865

Руководства по эксплуатации и запчастям Linhai

Руководства по эксплуатации и запчастям Stels

НОВОСТИ

-

Cтильный Honda Shadow 750 Phantom

Дата: 10.10.19 4038/4361

Honda Shadow 750 Phantom. На нём можно нормально ездить в городе. Он не супер тяжелый, на нём можно выезжать куда-нибудь на дальняк. Если вы хотите средне кубатурный мотор, мотоцикл без большого количества хрома, то Phantom будет хорошим решением. Можно ра

-

Honda CBR 650F

Дата: 09.10.19 1718/1835

Honda cbr650f подойдет новичку и при этом будет дарить кучу позитивных эмоций не только 1 сезон, а также 2 и 3. Давайте же разберемся, что же это за такой мотоцикл, все мы знаем Honda cbr600rr, Hornet cb600. Ну это совсем другой мотоцикл. В четырнадцатом г

-

Polaris Sportsman XP 1000 High Lifter

Дата: 04.10.19 1697/1798

Cегодня мы раздобыли для обзора представителя знаменитой техники Polaris. Эту машину можно отнести к классу вездехода. Итак встречайте Sportsman XP 1000 High lifter Edition, создан для покорения наиболее сурового бездорожья. А у нас самый разгар лета, сто

Кредит

-

Уважаемые поситители сайта!

Всю представленную технику на нашем сайте можно приобрести в

кредит.

Узнать о кредите на мототехнику можно по телефону MТС:(029)707-25-11. Звоните и мы ответим

на все интересующие Вас вопросы.

|

Detail Specifications: 2161/2161904-archon_400.pdf file (11 Feb 2023) |

Accompanying Data:

Linhai ARCHON 400 Offroad Vehicle PDF Service Manual (Updated: Saturday 11th of February 2023 10:22:08 PM)

Rating: 4.6 (rated by 15 users)

Compatible devices: 2004 ATV 260, M565Li T3 EFI, M750L T3, M565Li, Landboss LH800U-2D, HY740STL 2018, ATV 500-D T3 EFI, LH400CUV-2.

Recommended Documentation:

Text Version of Service Manual

(Ocr-Read Summary of Contents, UPD: 11 February 2023)

-

13, Linhai ARCHON 400 CHAPTER 2 MAINTENANCE BUCK 450 SERVICE MANUAL 20.0 2.1 PERIODIC MAINTENANCE GENARAL CAUTION Mark on the following chart D :Due to the nature of the adjustments marked with a D on the f ollowing chart, it is recommended that service be performed by an authorized dealer. More often under severe use, such as dirty or wet c…

-

158, Linhai ARCHON 400 CHAPTER 6 TRANSMISSION BUCK 450 SERVICE MANUAL 20.0 CHAPTER 6 TRANSMISSION PAGE. 6- 2 6.1 GEAR SHIFTER REMOVAL 1. Remove parts that interfere with access to shift selector (seat, cover etc.) 2. Disconnect the two linkage rods from transmission slides. 3.Remove the …

-

110, CHAPTER 3 ENGINE BUCK 450 SERVICE MANUAL 20.0 2. Clear DTC Select ‘Clear DTC’ and press, it will display as right; 3. Data Stream Select ‘Data Stream’ and press , it will display as right; Press or key for page up/down to view more. Press key to exit. 4. Status Stream Select ‘Stat…

-

54, Linhai ARCHON 400 CHAPTER 3 ENGINE BUCK 450 SERVICE MANUAL 20.0 3. Measure: Valve seat width A○ aE Out of specification → Reface the valve seat. Valve seat width: Intake: 0.9-1.1mm <Limit:1.6mm> Exhaust: 0.9-1.1mm <Limit:1.6mm> Measurement step: Apply Mechanic�…

-

141, CHAPTER 5 FINAL DRIVE BUCK 450 SERVICE MANUAL 20.0 CHAPTER 5 FINAL DRIVE. 5- 19 pr Fig 1 2. Mount the adjust shim D in the shaft neck of the bevel gear comp.-driven E. Mount the bevel gear comp.-driven E in the bore of bearing A. Mount the adjust shim F in the other neck of the bevel gear comp.-driven E.…

-

108, Linhai ARCHON 400 CHAPTER 3 ENGINE BUCK 450 SERVICE MANUAL 20.0 ● Connect one end of the diagnostic main cable to the main unit, and the other end to diagnostic socket on the motor, tighten the screws. Normal Power – on Display When power is on normally, the unit will display: Seconds later, the unit …

-

41, CHAPTER 3 ENGINE BUCK 450 SERVICE MANUAL 20.0 3.3 CYLINDER HEAD CHAPTER 3 ENGINE PAGE. 3- 16

… -

213, CHAPTER 8 ELECTRICAL BUCK 450 SERVICE MANUAL 20.0 CHAPTER 8 ELECTRICAL PAGE 8- 29 LCD METER 1. Turn Left Indicator Light 10. The Odometer and Engine Working Hour Counter 2. Position Lamp Indicator 11. Km/ Mile Selector 3. High Beam Indicator Light 12. Gear Position Indicator 4. Parking Brake Indicate Lamp…

-

176, CHAPTER 7 BRAKES BUCK 450 SERVICE MANUAL 20.0 CHAPTER 7 BRAKES PAGE. 7- 7 7.8 PARKING BRAKE REAR CALIPER REMOVAL / INSTALL Park Brake Caliper Disassembly / Pad Inspection NOTE: Do not get oil, grease, or fluid on the park brake pads. Damage to the pads may cause the pads to function improperly. 1. Lo…

-

80, CHAPTER 3 ENGINE BUCK 450 SERVICE MANUAL 20.0 4. Inspect: Crankshaft sprocket Wear/ Damage → Replace crankshaft. Bearing Wear/ Crack /Damage → Replace crankshaft. Pump drive gear Wear/ Damage → Replace crankshaft. Balancer drive gear A○ 4E Wear/ Damage → Re…

-

51, CHAPTER 3 ENGINE BUCK 450 SERVICE MANUAL 20.0 3.5 VALVES AND VALVE SPRINGS Order Job name / Part name Q ’ty Remarks 1 2 3 4 5 6 7 8 Valves and valve springs removal Cylinder head Rocker arm , rocker arm shaft Valve cotters Spring retainer Valve spring (inner) Valve spring (Outer) Va…

-

101, CHAPTER 3 ENGINE BUCK 450 SERVICE MANUAL 20.0 ACTION REASON DO: The module heat sink and back plate must not be used as a connection point when jump starting the engine. The high level of voltage and current which the module could be subjected to, could cause module performance degradation or failure. DO: Connection of th…

Recommended Instructions:

PRO SERIES 11137, 102316, OCEO, CX205

-

45 HP MODELS: E265RC, j265RC © OUTBOARD MARINE CORPORATION 1974 ALL RIGHTS RESERVED SN MOBILE DIVISION/OUTBOARD MARINE CORPORATION, 3031 NORTH 114th STREET, MILWAUKEE, WISCONSIN 53222 OUTBOARD MARINE CORPORA-TION OF CANADA LTD., PETERBOROUGH, CANADA. . …

1975 E265RC 109

-

e Owner’s Manual with Assembly InstructionsPlease read this manual and save it with your original sales receipt. For Model M7246.Tools needed for assembly: Phillips Screwdriver and Slotted Screwdriver (both not included). Use only with a Power Wheels® 6 Volt (4.0 Amp/Hr.) Rechargeable Battery with Built-in Thermal Fuse and a Power Wheels® 6 Volt (4.0 Amp/Hr.) Charger (both …

M7246 32

-

FUJI HEAVY INDUSTRIES LTD. G1830GE42001 IMPREZA SERVICE MANUAL QUICK REFERENCE INDEXTRANSMISSION SECTIONThis service manual has been preparedto provide SUBARU service personnelwith the necessary information and datafor the correct maintenance and repairof SUBARU vehicles.This manual includes the proceduresfor maintenance, disassembling, reas-sembling, inspection and adjustment ofc …

2001 Impreza 49

-

2012-2016 KTM 250/350/450/500 XCW — PCV — 1I18-022.01 www.powercommander.comInstallation InstructionsPLEASE READ ALL DIRECTIONS BEFORE STARTING INSTALLATIONTHE IGNITION MUST BE TURNED OFF BEFORE INSTALLATION!YOU CAN ALSO DOWNLOAD THE POWER COMMANDER SOFTWARE AND LATEST MAPS FROM OUR WEB SITE AT:www.powercommander.com2191 Mendenhall Drive North Las Vegas, NV 89081 (800) 992-4993 …

PCV 5

Additional Information:

Popular Right Now:

Operating Impressions, Questions and Answers:

|

Title |

File Size |

Download Links |

|

Linhai 260 cc / SI 300 cc Part Book.pdf |

6.9Mb |

Download |

|

Linhai 260 Workshop Manual.pdf |

9.7Mb |

Download |

|

Linhai 550 Efi v Twin 4×4 Parts Manual.xls |

10.2Mb |

Download |

|

Linhai ATV 150CE Parts Catalogue.pdf |

2.8Mb |

Download |

|

Linhai ATV 260 Service Manual 2004.pdf |

— |

Download |

|

Linhai ATV 50/ 80/ 100/ 150 Service Manual.pdf |

26.6Mb |

Download |

|

Linhai ATV Service Manual 2007.pdf |

24.6Mb |

Download |

|

Linhai ATV300 Manual.pdf |

2.8Mb |

Download |

|

Linhai B-Type ATV 150/ 200 Service Manual.pdf |

24.6Mb |

Download |

|

Linhai B-Type ATV 260/ 300 Service Manual.pdf |

24.6Mb |

Download |

|

Linhai Landboss LH800U-2D Owner’s/ operator’s Manual.pdf |

4.2Mb |

Download |

|

Linhai LH 300 Parts Catalogue.pdf |

2.3Mb |

Download |

|

Linhai LH400CUV-2 Service Manual.pdf |

14.1Mb |

Download |

|

Linhai LH500ATV-D Owner’s/ operator’s Manual.pdf |

3.6Mb |

Download |

|

Linhai Scooter’s & ATVs Service Manual.rar |

19.8Mb |

Download |

Linhai ATVs are a joint project of two eastern giants: the Japanese YAMAHA Motor Co and the Chinese Jiangsu

Linhai Power Machinery Group Corporation. The transfer of part of the production to China allowed the use of cheaper labor and significant cost reductions while maintaining the Japanese level of

quality. YAMAHA technology and Linhai manufacturing capabilities together create a unique product that combines high quality and affordable price.

Linhai is a leader in the production of affordable high-quality motorcycle products. Linhai started with the production of power plants, gradually accumulating professional skills since 1956.

Mototechnics, in particular Linhai ATVs, is developed by the Jiangsu Linhai Group (LINHAI-YAMAHA Motor Co., Ltd), which was established in 1956 and has been developing and manufacturing engines

and equipment for more than 50 years.

Linhai’s acquired skills in engine and equipment manufacturing led to the launch of their first ATV in 2001. Designed for the North American market, the ATV is a 300cc liquid-cooled model that

was the forerunner of the current 300SE.

The high quality of the Linhai engine has gained worldwide recognition, “quality” and “reliability” have become synonymous with their name. Many Asian competing manufacturers tried to push LINHAI

to sell their engines. However, Linhai flatly disagrees with the sale of engines. They know that this can lead to a weakening of the LINHAI brand. The engine is the heart of every Linhai ATV, and

to build a trustworthy brand, you need to have a great engine.

Due to the high technological and financial potential, LINHAI have been able to create many successful companies, including Jiangsu LINHAI-YAMAHA Motor Co., Ltd .. This has expanded the influence

of Linhai Corporation by improving technology and product quality.

Linhai is committed to investing in advanced, sustainable technology. This commitment is reflected in their new 550EFI ATV. This ATV has Delphi electronic fuel injection technology. This

efficient system maximizes productivity and minimizes the environmental impact of this ATV. Expect to see Delphi EFI systems on many future LINHAI products.

Further development of the LINHAI product takes place in four main areas: Expansion of the ATV line (including models with a large engine displacement), Motorcycles (as well as scooters up to 400

cubic centimeters EFI), Electrical equipment (a full range of yard care products, including lawn mowers ), and products powered by electricity (including non-waste scooters, non-waste equipment

for yard maintenance etc.).