Mitsubishi Colt Mark VI (Z30, CZ3/CZT) с бензиновыми двигателями: 3A90/134910 1.1 л (1124 см³) 75 л.с./55 кВт, 4G19 1.3 л (1343 см³) 90 л.с./66 кВт, 4А90/135930 1.3 л (1332 см³) 92-95 л.с./68-70 кВт, 4G15/4G15T 1.5 л (1468 см³) 98-110-150-154-166 л.с./72-81-110-113-122 кВт, 4А91/135950 1.5 л (1499 см³) 105-106-109-111 л.с./77-78-80-81 кВт и дизельными OM639 1.5 л (1493 см³) 68-95 л.с./50-70 кВт; Руководство по эксплуатации, техническому обслуживанию и ремонту, регулярные и периодические проверки, помощь в дороге и гараже, уникальная система определения неисправностей, технические характеристики, цветные электросхемы, контрольные размеры кузова. Производственно-практическое издание компактный легковой автомобиль малого (субкомпактного) Б-класса Мицубиси Кольт с цельнометаллическими несущими кузовами трех- и пятидверный хэтчбек передне- и полноприводные модели шестого поколения выпуска (включая праворульные) с 2002 по 2008 год

ЕСЛИ ВЫ ВИДИТЕ ОШИБКУ 406 Not Acceptable и не видите документ, то скорей всего у Вас IP РФ и его надо сменить, на любой другой страны, с помощью VPN ( Scribd и SlideShare блокируют посетителей с Российским IP).

Видео Mitsubishi Colt mk6 замена тяги (солдатиков) стабилизатора и передних тормозных колодок (Мицубиси Кольт 02-08)

Mitsubishi Colt Mark VI общая информация (Мицубиси Кольт 2002-2008)

Проверка передних дисковых тормозов

Проверка и замена тормозных колодок

Примечание: при уменьшении толщины накладки тормозной колодки до 2 мм индикатор износа соприкасается с тормозным диском и во время движения издает визжащий звук для предупреждения водителя о необходимости срочной замены тормозных колодок.

1. Через специальное сервисное отверстие в тормозном суппорте измерьте толщину накладки тормозной колодки.

Номинальное значение …………. 10 мм

Предельно допустимое значение …………. 2 мм

Внимание;

— Если толщина накладки любой колодки меньше предельно допустимого значения, то замените тормозные колодки комплектом, кроме того, одновременно замените тормозные колодки на противоположном колесе данной оси.

— Если есть заметная разница в толщине накладок тормозных колодок с левой и с правой сторон суппорта, то проверьте плавность перемещения суппорта по направляющим пальцам.

2. Выверните нижний направляющий палец. Поднимите суппорт в сборе и подвесьте его на проволоке.

Внимание: не удаляйте специальную смазку с направляющего и стопорного пальцев и не допускайте попадания загрязнений на направляющий палец.

3. Снимите следующие детали со скобы суппорта:

— прокладки:

— тормозную колодку;

— тормозную колодку и индикатор износа в сборе;

— фиксаторы колодок.

Примечание: при установке деталей нанесите специальную консистентную смазку.

4. Измерьте сопротивление вращению ступицы колеса при снятых тормозных колодках.

5. Установите тормозные колодки и суппорт, затем измерьте сопротивление вращению ступицы колеса.

Проверка тормозного диска

Внимание: для обеспечения нормальной работы дисковых тормозов необходимо уделять особое внимание соблюдению технических требований при обслуживании дисковых тормозов.

Примечание: перед восстановительными операциями (перед механической обработкой) тормозного диска необходимо проверить указанные ниже параметры.

1. Отсутствие царапин, ржавчины, износа и пропитки поверхности диска продуктами износа накладок.

а) Если автомобиль некоторое время не эксплуатировался, то часть поверхности диска, не контактировавшая с накладками тормозных колодок, покроется ржавчиной, что приведет к повышенному шуму и вибрации.

б) Если перед установкой новых тормозных колодок не удалить канавки и царапины, появившиеся на поверхности диска в результате интенсивного износа, то нормальный контакт между диском и накладками тормозных колодок обеспечен не будет.

2. Отсутствие биения или выработки тормозного диска. Повышенное биение или выработка диска приведет к увеличению сопротивления нажатию на педаль тормоза из-за пульсации поршня колесного тормозного цилиндра.

3. Изменение толщины (непараллельность) тормозного диска. Если толщина тормозного диска не одинакова по периметру, то это приведет к вибрации педали тормоза.

4. Коробление (неплоскостность) тормозного диска.

Неправильное обслуживание либо перегрев приведет к короблению тормозного диска (неплоскостности).

Проверка толщины тормозных дисков

1. Используя микрометр, измерьте толщину тормозного диска в восьми точках приблизительно через каждые 45° на расстоянии 10 мм от наружного края диска.

Толщина тормозного диска:

Передние тормоза, модели с задними барабанными тормозами:

Номинальное значение …………. 20 мм

Предельно допустимое значение …………. 18,4 мм

Передние тормоза, модели с задними дисковыми тормозами:

Номинальное значение …………. 24,0 мм

Предельно допустимое значение …………. 22,4 мм

Задние тормоза:

Номинальное значение …………. 10,0 мм

Предельно допустимое значение …………. 8,4 мм

Примечание: разность толщины тормозного диска между любыми двумя точками измерений не должна превышать 0,015 мм.

2. Если толщина тормозного диска меньше предельно допустимого значения, то снимите его и установите новый. Если разность толщины тормозного диска между различными точками измерений превышает предельно допустимое значение, то необходимо либо заменить тормозной диски либо обработать его на специальной токарном станке.

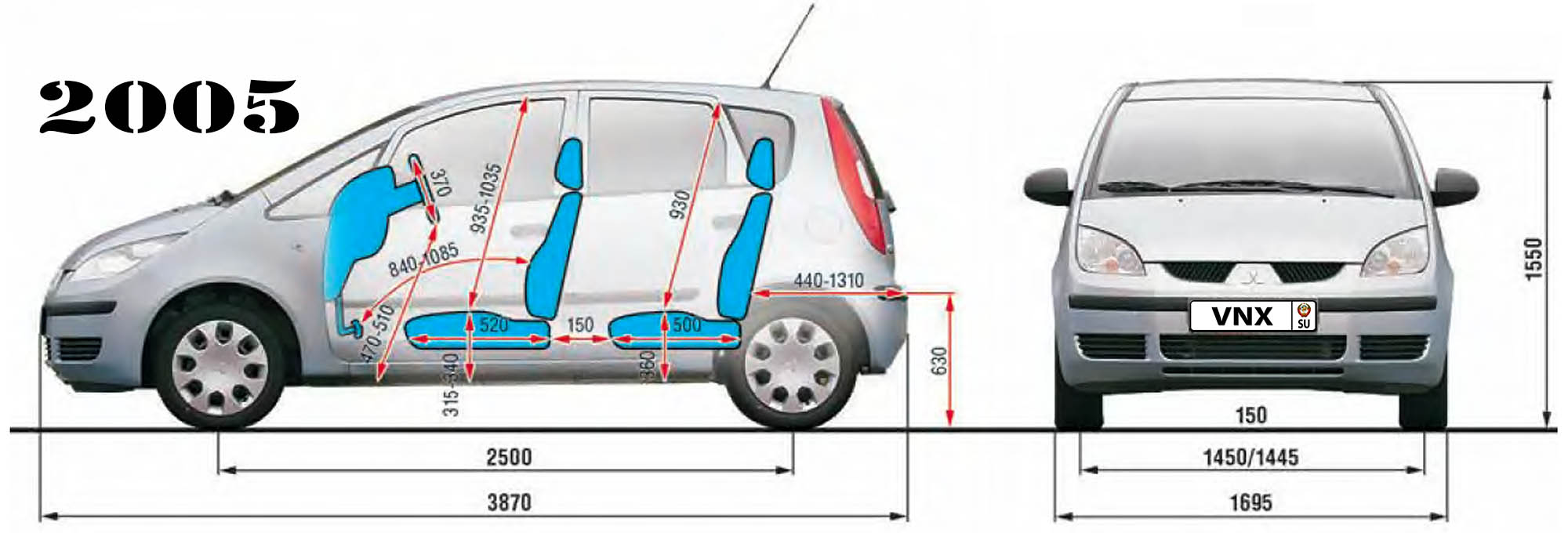

| № | Спецификация / Specs | Данные |

| Габариты (мм/mm) и масса (кг/kg) / Dimensions and Weight | ||

| 1 | Длина / Length | 3870 |

| 2 | Ширина (без/с зеркалами) / Width | 1695 |

| 3 | Высота (загружен/пустой) / Height | 1550 |

| 4 | Колёсная база / Wheelbase | 2500 |

| 5 | Дорожный просвет (клиренс) / Ground clearance | 150 |

| 6 | Снаряжённая масса / Total (curb) weight | 970 |

| Полная масса / Gross (max.) weight | 1450 | |

|

Двигатель / Engine |

||

| 7 | Тип / Engine Type, Code | Бензиновый, жидкостного охлаждения, четырехтактный, 3A90 |

| 8 | Количество цилиндров / Cylinder arrangement: Total number of cylinders, of valves | 3-цилиндровый, рядный, 12V, DOHC с верхним расположением двух распределительных валов |

| 9 | Диаметр цилиндра / Bore | 75.0 мм |

| 10 | Ход поршня / Stroke | 84.8 мм |

| 11 | Объём / Engine displacement | 1124 см³ |

| 12 | Система питания / Fuel supply, Aspiration | Распределенный впрыск топлива |

| Атмосферный | ||

| 13 | Степень сжатия / Compression ratio | 10.5:1 |

| 14 | Максимальная мощность / Max. output power kW (HP) at rpm | 55 кВт (75 л.с.) при 6000 об/мин |

| 15 | Максимальный крутящий момент / Max. torque N·m at rpm | 100 Нм при 3500 об/мин |

|

Трансмиссия / Transmission |

||

| 16 | Сцепление / Clutch type | 200×140 мм Однодисковое, сухое, с диафрагменной нажимной пружиной и гасителем крутильных колебаний, постоянно замкнутого типа |

| 17 | КПП / Transmission type | F5MGA МКПП 5 пятиступенчатая механическая, двухвальная, с синхронизаторами на всех передачах переднего хода |

О Книге

- Название: Mitsubishi Colt/ Colt CZ3/ Colt CZT Руководство по ремонту и эксплуатации

- Бензиновые двигатели: 3A90 1.1 л (1124 см³) 75 л.с./55 кВт, 4G19 1.3 л (1343 см³) 90 л.с./66 кВт, 4А90 1.3 л (1332 см³) 92-95 л.с./68-70 кВт, 4G15/4G15T 1.5 л (1468 см³) 98-110-150-154-166 л.с./72-81-110-113-122 кВт, 4А91 1.5 л (1499 см³) 105-106-109-111 л.с./77-78-80-81 кВт и дизельными OM639 1.5 л (1493 см³) 68-95 л.с./50-70 кВт

- Выпуск с 2002 года

- Серия: «Золотая»

- Год издания: 2010

- Автор: Коллектив авторов

- Издательство: «Ассоциация независимых издателей»

- Формат: PDF

- Страниц в книге: 292

- Размер: 50.99 МБ

- Язык: Русский

- Количество электросхем: 27

Привет всем! Готов поделиться книгами mitsu colt совершенно бесплатно, чисто символически за подпись на мой Colt! Извиняйте, но ничего интересного у меня нет, так как машина куплена недавно!

В наличии:

Mitsubishi COLT с 2004 г.в. c бенз. дв. 4A90 и 4А91

Mitsubishi COLT & COLT PLUS праворульные модели 2WD&4WD с двиг. 4G19, 4A90, 4G15 и 4A91

Ссылки на скачивание:

yadi.sk/i/I2F5bwj5uqSJW «правша»

yadi.sk/i/zQ1kFLOFuqSHY «евро»

Не забывайте подписываться на машину!

Удачи с кольтами!

Цена вопроса: 0 ₽

Войдите или зарегистрируйтесь, чтобы писать комментарии, задавать вопросы и участвовать в обсуждении.

Все комментарии

Сборник электросхем на английском языке автомобилей Mitsubishi Colt 1994-2001 и Mitsubishi Lancer 1994-2000 годов выпуска.

- Автор: —

- Издательство: Mitsubishi Motors Corp.

- Год издания: 1993-2000

- Страниц: —

- Формат: PDF

- Размер: 33,9 Mb

Сборник руководств на английском языке по техническому обслуживанию и ремонту автомобилей Mitsubishi Colt и Mitsubishi Lancer 1992-1996 годов выпуска.

- Автор: —

- Издательство: Mitsubishi Motors Corp.

- Год издания: —

- Страниц: —

- Формат: PDF

- Размер: 41,2 Mb

Руководство на английском языке по техническому обслуживанию и ремонту автомобилей Mitsubishi Colt и Mitsubishi Lancer 1993 года выпуска.

- Автор: —

- Издательство: Mitsubishi Motors Corp.

- Год издания: —

- Страниц: —

- Формат: PDF

- Размер: 99,9 Mb

Сборник руководств на английском языке по техническому обслуживанию и ремонту автомобилей Mitsubishi Colt и Mitsubishi Lancer 1996-2001 годов выпуска.

- Автор: —

- Издательство: Mitsubishi Motors Corp.

- Год издания: 1995-2000

- Страниц: —

- Формат: PDF

- Размер: 26,5 Mb

Сборник мультимедийных руководств на английском языке по техническому обслуживанию и ремонту автомобиля Mitsubishi Colt 2005-2011 годов выпуска.

- Автор: —

- Издательство: Mitsubishi Motors Corp.

- Год издания: —

- Страниц: —

- Формат: —

- Размер: 1,8 Gb

Сборник руководств на английском языке по техническому обслуживанию и ремонту автомобиля Mitsubishi Colt 2007 года выпуска.

- Автор: —

- Издательство: Mitsubishi Motors Corp.

- Год издания: 2006

- Страниц: —

- Формат: PDF

- Размер: 174,4 Mb

Руководство по ремонту автомобилей Mitsubishi Colt и Mitsubishi Lancer 1991-1995 годов выпуска с бензиновыми и дизельными двигателями.

- Автор: —

- Издательство: СверчокЪ

- Год издания: 2005

- Страниц: 279

- Формат: PDF

- Размер: 38,2 Mb

уководство по ремонту автомобилей Mitsubishi Colt и Mitsubishi Lancer 1991-2004 годов выпуска с бензиновыми и дизельными двигателями.

- Автор: В. Покрышкин

- Издательство: СверчокЪ

- Год издания: 2005

- Страниц: 279

- Формат: DjVu

- Размер: 19,9 Mb

Мультимедийное руководство по эксплуатации и ремонту автомобилей Mitsubishi Colt/Lancer/Mirage/Cordia/Tredia/Precis 1983-1993 годов выпуска.

- Автор: —

- Издательство: —

- Год издания: —

- Страниц: —

- Формат: ISO

- Размер: 196,8 Mb

Сборник руководств по техническому обслуживанию и ремонту автомобилей Mitsubishi Colt и Mitsubishi Lancer 1996-2001 годов выпуска.

- Автор: —

- Издательство: Mitsubishi Motors Corp.

- Год издания: 1995-2000

- Страниц: —

- Формат: PDF

- Размер: 54,0 Mb

Руководство по эксплуатации, техническому обслуживанию и ремонту автомобилей Mitsubishi Colt/Lancer/Mirage 1991-1996 и Mitsubishi Libero 1992-2002 годов выпуска с бензиновыми и дизельными двигателями.

- Автор: —

- Издательство: Легион-Автодата

- Год издания: —

- Страниц: 448

- Формат: —

- Размер: —

Руководство по эксплуатации, техническому обслуживанию и ремонту + каталог расходных запчастей автомобиля Mitsubishi Colt 2004-2012 годов выпуска с бензиновыми двигателями объемом 1,3/1,5 л.

- Автор: —

- Издательство: Легион-Автодата

- Год издания: —

- Страниц: 410

- Формат: —

- Размер: —

Руководство по эксплуатации и ремонту автомобилей Mitsubishi Colt и Mitsubishi Lancer/Lancer Wagon с 1992 года выпуска с бензиновыми и дизельными двигателями.

- Автор: —

- Издательство: Монолит

- Год издания: —

- Страниц: 326

- Формат: —

- Размер: —

Руководство по эксплуатации и ремонту автомобиля Mitsubishi Colt с 2002 года выпуска с бензиновыми и дизельными двигателями.

- Автор: —

- Издательство: Монолит

- Год издания: 2010

- Страниц: 292

- Формат: —

- Размер: —

Руководство по эксплуатации, техническому обслуживанию и ремонту автомобилей Mitsubishi Colt/Lancer/Mirage/Cordia/Tredia/Precis/Galant/Sigma/Eterna/Magna/Sapporo 1983-1993 годов выпуска с бензиновыми и дизельными двигателями.

- Автор: —

- Издательство: Техно-BOOK

- Год издания: 2005

- Страниц: 273

- Формат: PDF

- Размер: 34,7 Mb

Руководство по эксплуатации, техническому обслуживанию и ремонту автомобилей Mitsubishi Colt и Mitsubishi Lancer 1993-2003 годов выпуска с бензиновыми и дизельными двигателями.

- Автор: —

- Издательство: Автомастер

- Год издания: 2003

- Страниц: 281

- Формат: PDF

- Размер: 16,4 Mb

Руководство по техническому обслуживанию и ремонту автомобилей Mitsubishi Mirage/Lancer/Colt/Galant/Eterna/Sapporo/Sigma/Cordia/Tredia/Precis 1983-1993 годов выпуска.

- Автор: —

- Издательство: MoToR

- Год издания: 1996

- Страниц: 183

- Формат: —

- Размер: —

Руководство по техническому обслуживанию и ремонту автомобилей Mitsubishi Colt и Mitsubishi Lancer 1984-1992 годов выпуска.

- Автор: Г.Р. Этцольд

- Издательство: Arinas

- Год издания: 1994

- Страниц: 339

- Формат: DjVu

- Размер: 10,4 Mb

Руководство по техническому обслуживанию и ремонту автомобилей Mitsubishi Colt с 2002 и Mitsubisi Colt Plus с 2004 года выпуска с бензиновыми двигателями объемом 1,3/1,5 л.

- Автор: —

- Издательство: Легион-Автодата

- Год издания: 2012

- Страниц: 376

- Формат: —

- Размер: —

27.04.2014

20 882 просмотров

Представляем руководство по ремонту и эксплуатации автомобиля Mitsubishi Colt, Mitsubishi Colt CZ3, Mitsubishi Colt CZT которые выпускались с 2004 по 2008 годы. Рекомендации и советы приведенные в руководстве помогут провести ремонт, выполнить обслуживание как в гаражных условиях так и на автосервисах. Поэтому данная книга по ремонту Mitsubishi Colt будет полезна как владельцам Mitsubishi Colt, так и работникам различных СТО.

Представляем руководство по ремонту и эксплуатации автомобиля Mitsubishi Colt, Mitsubishi Colt CZ3, Mitsubishi Colt CZT которые выпускались с 2004 по 2008 годы. Рекомендации и советы приведенные в руководстве помогут провести ремонт, выполнить обслуживание как в гаражных условиях так и на автосервисах. Поэтому данная книга по ремонту Mitsubishi Colt будет полезна как владельцам Mitsubishi Colt, так и работникам различных СТО.

Представлены моторы:

Бензиновые — 1,1 л (134), 1,3 л, 1,5 л (135), 1,5 л (4 G1)

Дизельные: 1,5.л (639)

Скачать книгу

Дорогие друзья!

Если представленный материал принес Вам пользу — поделитесь ссылкой в своих социальных сетях.

Будем Вам бесконечно благодарны.

Иллюстрированное руководство по ремонту Мицубиси Кольт, устройство, а также руководство по эксплуатации и техническому обслуживанию Mitsubishi Colt, которые сходят с конвейера с 2004 года и оборудуются бензиновыми двигателями 4A90 и 4A91 рабочим объемом 1,3 и 1,5 л. соответственно.

В настоящее руководство включены подробные данные по диагностике, регулировке и ремонту различных систем и элементов двигателя, систем впрыска топлива MPI, изменения фаз газораспределения MIVEC, зажигания, запуска и зарядки, инструкции по использованию систем самодиагностики двигателя, роботизированной коробки передач (РКПП), антиблокировочной тормозной системы (ABS), электронной системы распределения усилий тормоза (EBD), системы курсовой устойчивости (ASC), противобуксовочной системы (TCL), электроусилителя рулевого управления (EPS), системы пассивной безопасности (SRS), системы мультиплексной связи (LIN), шины передачи данных (CAN), иммобилайзера, системы кондиционирования, а также рекомендации и советы по регулировке механических и роботизированных КП, регулировке и ремонту элементов системы тормозов (включая ABS, EBD, TCL и ASC), подвески и рулевого управления.

Рассмотрены возможные неисправности машины, изучены методы устранения этих неполадок. Даны кузовные размеры, сопрягаемые размеры основных деталей, пределы их допустимого износа, предложены рекомендации для смазочных материалов и рабочих жидкостей.

|

HOW TO USE THIS MANUAL. . . . . . |

00-2 |

|

TARGETS OF DEVELOPMENT . . . . |

00-2 |

|

PRODUCT FEATURES . . . . . . . . . . . |

00-2 |

|

TECHNICAL FEATURES. . . . . . . . . . |

00-3 |

|

EXTERIOR . . . . . . . . . . . . . . . . . . . . . . . . . |

00-3 |

|

INTERIOR . . . . . . . . . . . . . . . . . . . . . . . . . . |

00-4 |

|

SPACIOUS CABIN . . . . . . . . . . . . . . . . . . . |

00-4 |

|

ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . |

00-5 |

|

TRANSMISSION. . . . . . . . . . . . . . . . . . . . . |

00-5 |

|

SUSPENSION. . . . . . . . . . . . . . . . . . . . . . . |

00-8 |

|

BRAKE . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

00-10 |

|

STEERING . . . . . . . . . . . . . . . . . . . . . . . . . |

00-11 |

|

LOCAL INTERCONNECT NETWORK (LIN) |

00-12 |

|

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

|

|

ACTIVE SAFETY. . . . . . . . . . . . . . . . . . . . . |

00-13 |

|

PASSIVE SAFETY . . . . . . . . . . . . . . . . . . . |

00-17 |

|

EQUIPMENTS . . . . . . . . . . . . . . . . . . . . . . . |

00-20 |

|

ENVIRONMENTAL PROTECTION . . . . . . . |

00-21 |

|

SERVICEABILITY AND RELIABILITY . . . . |

00-21 |

|

VEHICLE IDENTIFICATION . . . . . . . . |

00-22 |

|

MAJOR SPECIFICATIONS . . . . . . . . |

00-23 |

|

00-2 |

GENERAL |

|

HOW TO USE THIS MANUAL |

HOW TO USE THIS MANUAL

MODEL INDICATIONS

The following abbreviations are used in this manual for identification of model types.

1100: Indicates models equipped with the 1,124 mL <134910> petrol engine.

1300: Indicates models equipped with the 1,332 mL <135930> petrol engine.

M2000029000242

1500: Indicates models equipped with the 1,499 mL <13590> petrol engine.

DOHC: Indicates an engine with the double overhead camshaft.

MIVEC: Indicates Mitsubishi innovative valve timing electronic control system.

MPI: Indicates the multipoint injection. M/T: Indicates the manual transmission. A/C: Indicates the air conditioner.

TARGETS OF DEVELOPMENT

M2000004000342

COLT has been developed as entry model of Mitsubishi model line-up, as compact passenger car with space MPV versatility.

PRODUCT FEATURES

ADVANCED AND FASHIONABLE STYLING

The one motion silhouette which consists of roominess and stylish appearance.

NEWLY DEVELOPED ENGINE WITH GOOD FUEL EFFICIENCY AND EXCELLENT POWER-DRIVEN PERFORMANCE

•134910-DOHC MIVEC* engine with 3-cylinder

•135930-DOHC MIVEC engine and

135950-DOHC MIVEC engine with 4-cylinder

NOTE: *MIVEC: Mitsubishi Innovative Valve timing Electronic Control system is a generic term for the engine with variable valve timing mechanism.

M2000005000174

HIGH LEVEL OF SAFETY

•Reinforced Impact Safety Evolution (RISE) chassis adopted

•Driver’s SRS airbag equipped as standard

•Front passenger’s SRS airbag, SRS side airbag, and SRS curtain airbag adopted <Optional>

•ISO FIX child seat fixing bar equipped as standard

EXCELLENT PRACTICABILITY AND SPACE UTILITY

•Multi function box storage as cup holder, ashtray, small item holder, etc.

•6:4 separate sliding, tumbling and removable rear seat.

|

GENERAL |

00-3 |

|

TECHNICAL FEATURES |

TECHNICAL FEATURES

EXTERIOR

M2000017000331

DESIGN FEATURES

1

2

5

OVERALL

•Dynamic one motion line connects chamfered front end.

•Simple body side section emphasis the wheel arches.

•Dynamic DLO (day light opening) creates car is motion even when car is stop.

•Front lights on the chamfered surface follows one of the Mitsubishi identity.

•Inside of the light reflectors given high-tech image of Japanese product.

•Simple exterior design emprises car’s functionality.

•Door cut’s matching the lines of the DLO and rear light.

1

6

AC311182AC

1. SIDE SILHOUETTE

Simple and dynamic one motion curve from the front nose to the roof end.

2. BODY SIDE SURFACE

Take simple and clean surface to emphasize wheel arches.

3. MITSUBISHI MARK

New Mitsubishi front face which designed every elements connects from three diamonds.

4. FRONT END CORNER

Apply the chamfer shape for easy handling.

5. HEAD LAMP

Create the high-tech image of Japanese product.

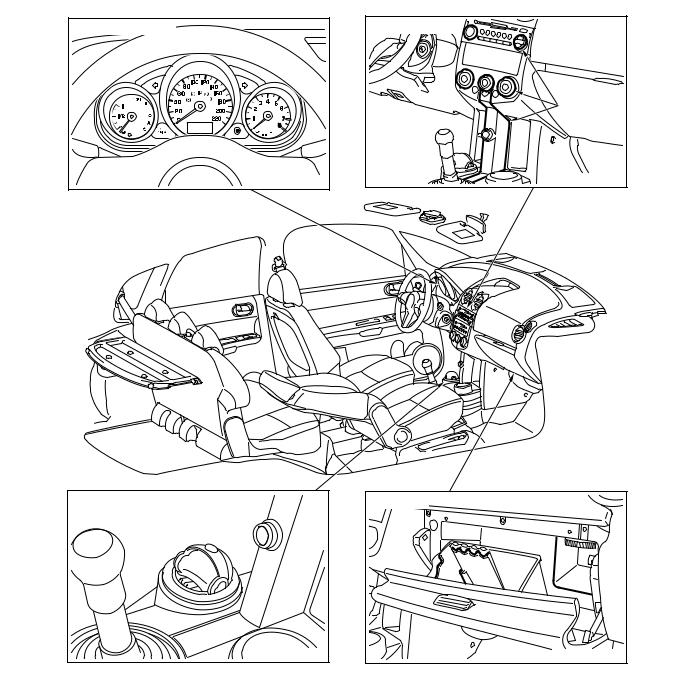

FLOOR CONSOLE AND DOOR TRIM

• Multi cup holder.

• Removable ashtray (This ashtray can be set in all cup holders).

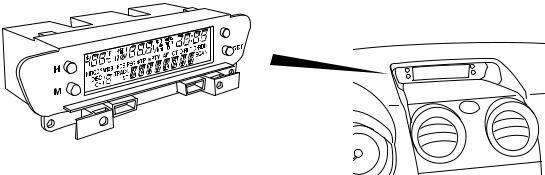

COMBINATION METER

• Easy to recognize, independent function meters.

SPACIOUS CABIN

M2000000400025

|

00-4 |

GENERAL |

|

TECHNICAL FEATURES |

|

|

6. TAIL LAMP |

INTERIOR |

Apply long vertical type to easy to recognize from outside.

M2000018000312

DESIGN FEATURES

|

Combination meter |

Instrument panel |

|

Translucent |

|

|

parts |

|

|

AC312521AB |

|

|

Cup holder and ashtray |

Glove box |

OVERALL

• Sporty elegance feeling with comfortable space.

• The maximum roominess in the limited package.

INSTRUMENT PANEL

• Illumination systems presented by translucent parts of audio and A/C control panel

• Searchlight system from translucent parts.

• Useful glove box (card holder, pen holder, coin holders and bottle holder).

By the adoption of the long wheelbase, it realizes the interior length of the top-class.

|

GENERAL |

00-5 |

|

TECHNICAL FEATURES |

4 5

|

1 |

2 |

||||

|

3 |

|||||

|

AC311954AB |

|||||

|

No. |

Item |

Dimension mm |

No. |

Item |

Dimension mm |

|

1 |

Brake pedal room |

880 |

4 |

Front head room |

931 |

|

2 |

Hip point couple |

825 |

5 |

Rear head room |

862 |

|

3 |

Total leg room |

1,705 |

NOTE: Refer to P.00-23 for the body dimensions.

ENGINE

M2000020000223

The following three types of newly developed engines have been adopted to realize light weight, small size, and good fuel efficiency. Those engines are complied with Step 4 in European emissions regulations.

|

Item |

134910 |

135930 |

135950 |

||

|

Total displacement mL |

1,124 |

1,332 |

1,499 |

||

|

Bore × stroke mm |

75 × 84.8 |

75 × 75.4 |

75 × 84.8 |

||

|

Compression ratio |

10.5 |

||||

|

Combustion chamber |

Pentroof-type |

||||

|

Valve |

Intake opening |

BTDC 41° − ATDC 9° |

BTDC 41° − ATDC 9° |

BTDC 41° − ATDC 9° |

|

|

timing |

|||||

|

Intake closing |

ABDC 19° − ABDC 69° |

ABDC 3° − ABDC 53° |

ABDC 11° − ABDC 61° |

||

|

Exhaust opening |

BBDC 35° |

BBDC 35° |

BBDC 39° |

||

|

Exhaust closing |

ATDC 5° |

ATDC 5° |

ATDC 5° |

||

|

Maximum |

output kW(PS)/rpm |

55(75)/6,000 |

70(95)/6,000 |

80(109)/6,000 |

|

|

Maximum torque |

100(10.2)/3,500 |

125(12.7)/4,000 |

145(14.8)/4,000 |

||

|

N m(kg-m)/rpm |

|||||

TRANSMISSION

M2000021000226

The following two types of newly developed transmissions with light weight and small-size design have been adopted to realize good fuel efficiency.

•F5MGA 5-speed manual transmission

•F6SGA 6-speed automated manual transmission

|

00-6 |

GENERAL |

|

TECHNICAL FEATURES |

MANUAL TRANSMISSION

SECTIONAL VIEW

|

5th gear |

2nd gear |

Reverse gear |

1st gear |

Input shaft

Output shaft

4th gear

3rd gear

Differential

AC311790 AC

|

GENERAL |

00-7 |

|

TECHNICAL FEATURES |

AUTOMATED MANUAL TRANSMISSION

OUTSIDE VIEW

Shift actuator assembly

Drum position sensor

Clutch actuator

AC311791AB

|

As automated manual transmission is designed |

SCHEMATIC DIAGRAM |

||

|

based on 6-speed manual gearbox and driven by |

|||

|

electric actuators (motors) via sophisticated |

|||

|

twin-drum shift mechanism, it gives our customers |

|||

|

«easy to drive as A/T», «fun to drive and high fuel effi- |

|||

|

ciency as M/T». |

|||

|

Shift actuator Automated manual transmission |

Clutch actuator |

||

|

assembly |

|||

Engine

Engine automated manual transmission electronic control unit (Engine-A-M/T-ECU)

|

Accelerator pedal |

N |

Allshift lever |

|

A |

||

|

Brake pedal |

DRIVING MODE

Driving mode provides either manual mode (like sequential M/T) or automatic mode (like conventional A/T), by tipping shift lever toward «A» or «+» or «−» from «s.b.» position.

|

00-8 |

GENERAL |

|

TECHNICAL FEATURES |

+: Up shifting

s.b.: Stand by (manual selection of gear) : Down shifting

A: Switch automatic

N: Neutral

R: Reverse gear

|

AC312516AB |

|||

|

Position |

Operation |

Function |

Further explanation |

|

«N» |

In «N» |

Neutral |

Engine start possible only at «N». |

|

«R» |

«N» → «R» |

Reverse drive |

No creeping. |

|

s.b. (stand |

«N» → s.b. |

Forward drive |

Creeping starts (with brake pedal depress). |

|

by) |

|||

|

Auto mode or Manual |

Starts from auto mode. <135950> |

||

|

mode |

|||

|

Starts from manual mode. <135930> |

|||

|

«A» |

s.b. → «A» |

Mode change |

Auto mode or Manual mode comes alternatively. |

|

(tip) |

(Auto mode → Manual mode → Auto mode → Manual |

||

|

mode) |

|||

|

«+», «−» |

s.b. → «+» |

+: Manual up shifting |

Higher gear will be selected. *1, *2 |

|

(tip) |

|||

|

−: Manual down shifting |

Lower gear will be selected. *1, *3 |

||

|

s.b. → «−» |

|||

|

*1: After «+» or «−» tip action, mode becomes manual mode. |

|||

|

(tip) |

|||

|

*2: If vehicle speed is too low, some up shifts neglected. |

|||

|

*3: If engine speed is too high, down shifting neglected. |

|||

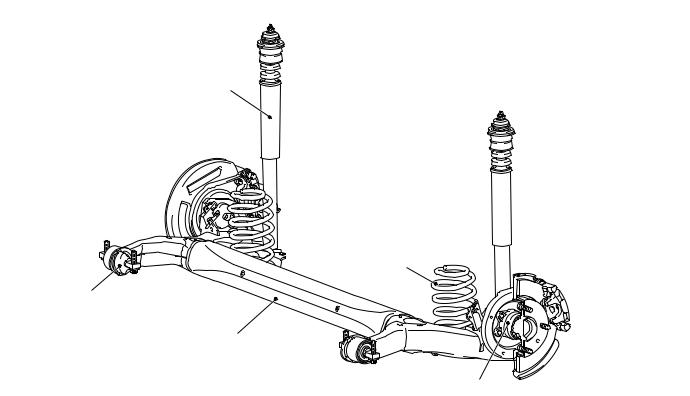

SUSPENSION

M2000023000211

FRONT SUSPENSION

The newly developed MacPherson Strut suspension with compatible characteristics of high rigidity and light weight has been adopted for the front suspension to realize sufficient driving comfort and driving stability.

|

GENERAL |

00-9 |

|

TECHNICAL FEATURES |

Strut assembly

Coil spring

Stabilizer bar

Lower arm

Crossmember

AC310151AB

REAR SUSPENSION

The torsion beam suspension has been adopted for the rear suspension to realize a large suspension stroke and excellent driving comfort. The suspension with small-size design has provided ample interior space.

|

00-10 |

GENERAL |

|

TECHNICAL FEATURES |

Shock absorber

Coil spring

Arm bushing

Torsion beam and arm assembly

|

Unit type bearing |

AC310152AB |

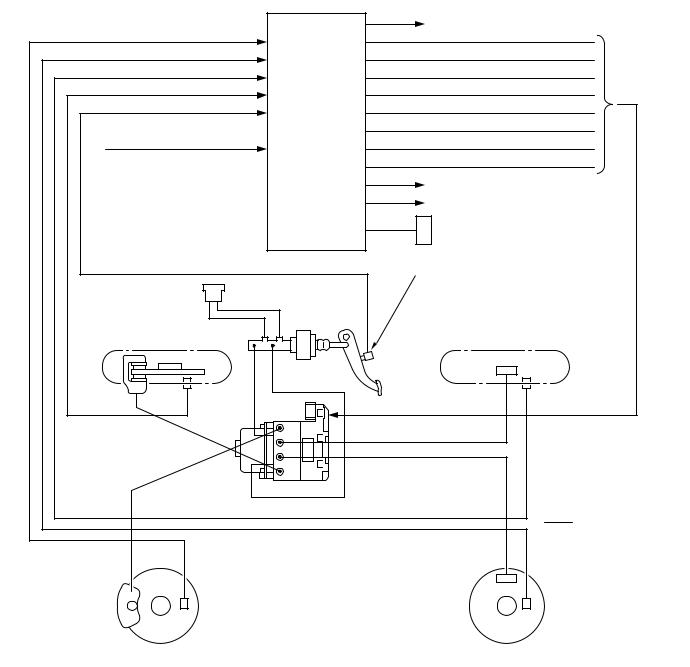

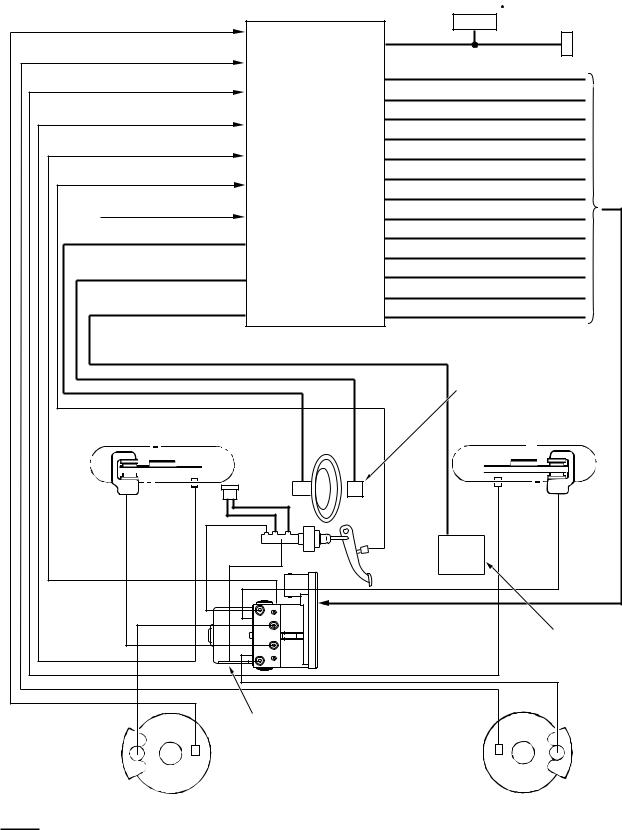

BRAKE

M2000024000043

14-inch ventilated disk brake for the front, 8-inch leading trailing drum brake or 14-inch solid disk brake for the rear have been installed to realize high reliability and durability along with excellent braking performance.

|

GENERAL |

00-11 |

|

TECHNICAL FEATURES |

<Vehicle with rear drum brake>

Brake booster

Hydraulic unit

(Integrated with ABS-ECU/Active Stability Control System-ECU)

Rear drum brake

Master cylinder

Parking brake lever

|

Front disc brake |

AC311564 |

<Vehicle with rear disc brake>

Brake booster

Hydraulic unit

(Integrated with ABS-ECU/Active Stability Control System-ECU)

|

Master cylinder |

Rear disc brake |

|

|

Parking brake lever |

||

|

Front disc brake |

AC311651 |

|

|

AC311650AB |

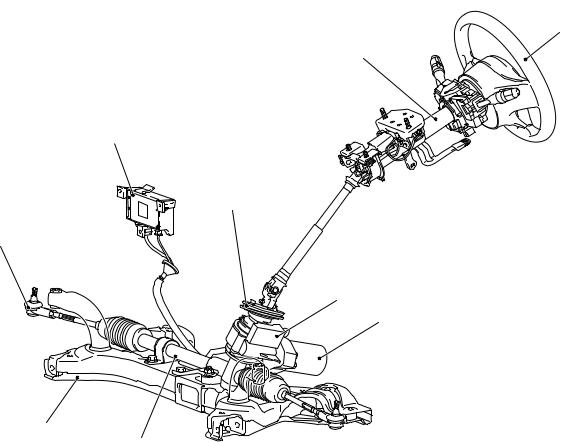

STEERING

M2000040000010

Due to the adoption of electric power steering driven by newly developed pinion shaft, effortless steering wheel manoeuvring at the low speed as well as stable steering wheel manoeuvring at the mid to high speed has been achieved.

|

00-12 |

GENERAL |

|

TECHNICAL FEATURES |

Steering wheel

Steering column assembly

Electric power steering-ECU

Dash panel cover

Tie rod end

Torque sensor

Motor

Crossmember

LOCAL INTERCONNECT NETWORK (LIN)

M2000041000013

LIN refers to «Local Interconnect Network», a global

standard of serial multiplex communication protocol*1 administrated by LIN consortium. A communication circuit employing the LIN protocol connects each ECU, and switch data can be shared among ECUs, which enables more reduction in wiring. Transmission speed is 19.2 kbps.

For COLT, ETACS*2-ECU can receive some input

NOTE: *1: The regulations have been decided in detail, from software matters such as the necessary transmission rate for communication, the system, data format, and communication timing control method to hardware matters such as the harness type and length and the resistance values.

NOTE: *2: ETACS (Electronic Time and Alarm Control System)

NOTE: *3: CAN (Controller Area Network)

signals through CAN*3 communication in addition to the LIN communication.

|

GENERAL |

00-13 |

|

TECHNICAL FEATURES |

ACTIVE SAFETY

M2000031000216

BRAKING SYSTEM

ABS warning lamp

Brake warning lamp

AC311642

Hydraulic unit and

ABS-ECU

Diagnosis connector

|

Stop lamp switch |

Wheel speed sensor |

|

Wheel speed sensor |

AC311643 |

|

AC311644AC |

|

00-14 |

GENERAL |

|

TECHNICAL FEATURES |

|

Engine-ECU <M/T> or Engine-A-M/T-ECU* |

|||

|

Front-left wheel speed sensor |

<Automated manual transmission> |

||

|

Front right solenoid valve (out) |

|||

|

Rear-left wheel speed sensor |

Front right solenoid valve (in) |

||

|

Rear-right wheel speed sensor |

Front left solenoid valve (out) |

||

|

Front-right wheel speed sensor |

Front left solenoid valve (in) |

||

|

Stop lamp switch |

Rear right solenoid valve (out) |

||

|

ABS-ECU |

Rear right solenoid valve (in) |

||

|

ABS-ECU power supply |

Rear left solenoid valve (out) |

||

|

Rear left solenoid valve (in) |

|||

|

Brake warning lamp |

|||

|

ABS warning lamp |

|||

|

Diagnosis connector |

|||

|

Stop lamp switch |

|

Front-right wheel (FR) |

Rear-right wheel (RR) |

|

Front-right |

Rear-right wheel |

|

|

wheel |

speed sensor |

|

|

speed |

||

|

sensor |

Note |

|

|

*Engine-A-M/T-ECU: |

||

|

Hydraulic |

Engine automated manual |

|

|

transmission electronic |

||

|

unit (HU) |

||

|

control unit |

||

|

: CAN-bus line |

|

Front-left wheel |

Rear-left wheel |

|

speed sensor |

speed sensor |

|

Front-left wheel (FL) |

Rear-left wheel (RL) |

AC311645AC

4-WHEEL ANTI-SKID BRAKING SYSTEM (4ABS)

A 4-wheel anti-skid braking system (4ABS) has been adopted to prevent slipping caused by the vehicle wheels locking up, in order to minimize braking distance, and also to maintain a stable vehicle posture and steering performance.

ELECTRONIC BRAKE-FORCE DISTRIBUTION (EBD)

An electronic brake-force distribution (EBD) which makes it possible to maintain the maximum amount of braking force even when the vehicle’s load is varied has been adopted.

|

GENERAL |

00-15 |

|

TECHNICAL FEATURES |

ANTI-SKID BRAKE SYSTEM (ABS)/ACTIVE STABILITY CONTROL SYSTEM

Anti-skid Brake/Active stability control indicator lamp

Steering wheel sensor

Pressure sensor, Hydraulic unit and Anti-skid Brake/Active stability control system control unit (ABS/Active stability control system-ECU)

Diagnosis connector

Engine-ECU <M/T> or Engine-A-M/T-ECU (Engine automated manual transmission electronic control unit)

<Automated manual transmission>

G and yaw rate sensor

Wheel speed sensor

Stop lamp switch

|

Wheel speed sensor |

AC311649AC |

|

00-16 |

GENERAL |

|

TECHNICAL FEATURES |

Front-left wheel speed sensor

Rear-left wheel speed sensor

Rear-right wheel speed sensor

Front-right wheel speed sensor

Master cylinder pressure sensor

Stop lamp switch

Power supply to ABS/Active stability control system-ECU

Steering wheel sensor

G and yaw rate sensor

Engine-ECU <M/T> or engine-A- M/T-ECU <Automated manual transmission>

ABS/Active stability control system-ECU

Combination meter ABS/Active stability control indicator lamp

Diagnosis

Connector

Suction valve (FR)

Suction valve (FL)

Cut valve (FR)

Cut valve (FL)

Control solenoid valve (FR) IN

Control solenoid valve (FR) OUT

Control solenoid valve (FL) IN

Control solenoid valve (FL) OUT

Control solenoid valve (RR) IN

Control solenoid valve (RR) OUT

Control solenoid valve (RL) IN

Control solenoid valve (RL) OUT

Pamp motor

G and yaw rate sensor

|

Front-right wheel (FR) |

Rear-right wheel (RR) |

||

|

Steering |

||

|

Wheel |

wheel |

Wheel |

|

sensor |

||

|

speed |

speed |

|

|

sensor |

sensor |

|

|

Stop lamp |

||

|

switch |

||

|

Engine-ECU <M/T> or engine- |

||

|

A-M/T-ECU <Automated manual |

||

|

transmission> |

||

|

Hydraulic |

||

|

unit |

Wheel speed |

|

|

Wheel speed |

||

|

sensor |

sensor |

Front-left wheel (FL)

Rear-left wheel (RL)

Note

|

: CAN-bus line |

AC311782AC |

|

GENERAL |

00-17 |

|

TECHNICAL FEATURES |

The Anti-skid Brake System (ABS)/Active stability control system is a combination system of active stability control system and anti-skid brake control system. The active stability control system avoids a dangerous vehicle attitude by limiting the engine output and braking a set of wheels (left front and right rear, or right front and left rear) according to driving conditions. The anti-skid brake control system prevents wheel spinning at vehicle start.

ABS/Active stability control system is available for all models as optional equipment.

PASSENGER’S AIR BAG CUT OFF SWITCH

AC311721

AC311720

AC312760 AB

Passenger’s air bag cut off switch is located in the glove box.

The passenger’s air bag cut off switch can be used to disable the passenger’s (front) air bag.

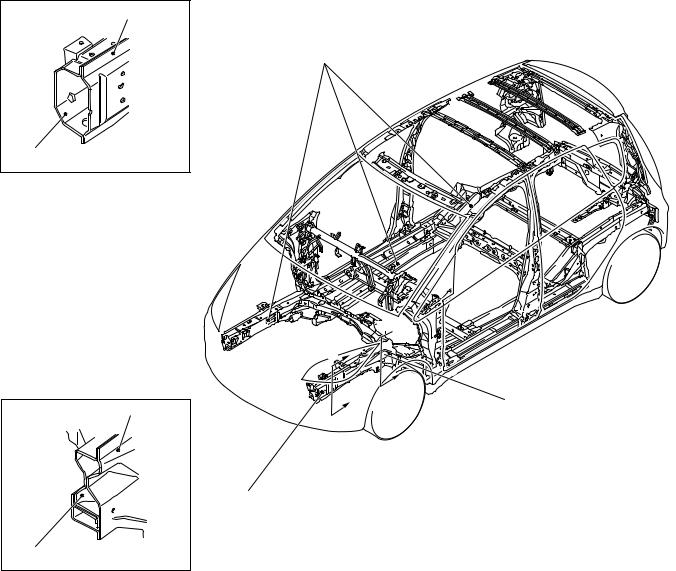

PASSIVE SAFETY

M2000032000208

IMPACT SAFETY BODY

The front and rear structures to absorb high energy, and the highly tough cabin structure reduce the risk of passenger injuries at front-, rear-, and side-impact collisions, secure the space for life protection, and facilitate rescuing passengers.

|

00-18 |

GENERAL |

|

TECHNICAL FEATURES |

Section A — A Front side member outer

Front side member

Section B — B Front side member outer

1

|

Front side member |

||

|

inner |

AB301791 |

AB301835AB |

1.The octagonal cross section for the front of the front sidemember and 8-shaped cross section for the rear of the front sidemember have been adopted for enlargement so that the applied structures can effectively absorb energy from the impact at the time of collision.

2.Due to the adoption of straightened front sidemember and the rear floor sidemember, the structure can effectively absorb energy from the impact at the time of collision.

|

GENERAL |

00-19 |

|

TECHNICAL FEATURES |

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) AND FRONT SEAT BELTS WITH PRE-TENSIONER

|

Driver’s air bag |

Curtain air bag modules |

|

|

module |

Passenger’s (front) |

|

|

Seat belt with |

||

|

air bag module |

||

|

pre-tensioner |

Side air bag modules

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

The SRS is designed to supplement the front seat belts. It eliminates or reduces injury to the front passenger(s) by deploying air bag(s) in case of a head-on collision.

AC313299AB

SEAT BELT WITH PRE-TENSIONER

The seat belts with pre-tensioner work simultaneously with the SRS. The pre-tensioner takes up seat belt slack immediately when a collision takes place, restraining the front passengers sooner than the SRS. This prevents the passengers from moving forward.

SRS SIDE AIR BAG

Side air bag systems in the front seats are activated when sideward impacts applied to the vehicle exceed a threshold to protect the occupants’ upper bodies.

SRS CURTAIN AIR BAG

The curtain air bag systems are activated when sideward impacts applied to the vehicle exceed a threshold, to protect the heads of the occupants in the front and rear seats.

STEERING SHAFT AND STEERING COLUMN

The impact absorption mechanism in combination of retractable steering shaft and steering column disengagement mechanism has been adopted to alleviate the impact from the steering wheel to the driver.

BRAKE PEDAL

The brake pedal backward movement restraint mechanism to restrain the backward movement of the brake pedal to the minimum at the time of frontal collision has been adopted so that the impact to the lower limbs of the driver can be alleviated.

|

00-20 |

GENERAL |

|

TECHNICAL FEATURES |

CHILD SEAT FIXING BAR COMPATIBLE WITH ISO FIX*

The anchor bar has been equipped as standard for easily and securely fixing the child seat compatible with ISO FIX.

NOTE: *ISO: International Organisation for Standardisation

REAR SEAT BELT WITH CHILD SEAT FIXING MECHANISM (ALR*)

The child seat fixing mechanism has been adopted to easily and securely fix the child seat that is not compatible with ISO FIX.

NOTE: *ALR: Automatic Locking Retractor

POWER WINDOW WITH SAFETY MECHANISM

The power window with safety mechanism has been adopted to automatically roll down and stop the door window glass as soon as the occurrence of jamming is detected at the time of rolling up the door window glass.

Multi-centre display

The multi-centre display to provide vehicle information in the text form has been equipped on the centre console as standard. The multi-centre display has the following functions:

• Clock

SUNROOF WITH SAFETY MECHANISM

The sunroof with safety mechanism has been adopted so that the roof lid glass can move in the reverse direction and stop when application of external force hinders the movement during the sliding to close or tilt down operation.

TRIMS AND HEADLINING

The head impact absorption structure has been adopted for the pillar trim, quarter trim, and headlining so that impact towards the head of a passenger can be reduced.

OTHER SAFETY FEATURES

•3-point ELR seat belts

•Child-protection rear door locks

•Front fog lamps <Optional>

•Rear fog lamp (Driver’s side)

EQUIPMENTS

M2000026000191

MULTI-CENTRE DISPLAY

AC311613 AB

•Outside temperature

•Vehicle information (average speed, instant fuel consumption, remaining distance)

•Audio information

|

GENERAL |

00-21 |

||

|

TECHNICAL FEATURES |

|||

|

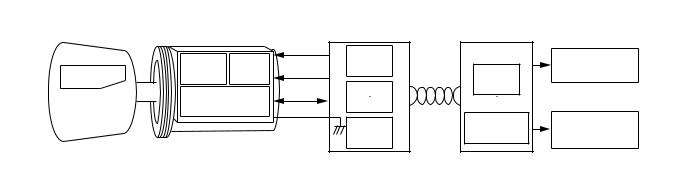

IMMOBILIZER SYSTEM |

|||

|

Ignition key |

Key ring antenna |

ETACS-ECU |

Engine-ECU <M/T> or Engine-A-M/T-ECU* |

|

(immobilizer-ECU) |

<Automated manual transmission> |

|

Power |

|||

|

Encrypted |

AMP |

SCI |

Clock |

|

code |

Data |

||

|

RF circuit |

|||

|

Transponder |

|||

|

Steering lock |

|

SCI |

CAN- |

CPU |

Ignition |

|

CPU |

Bus |

||

|

CAN- |

CAN-I/F |

Injection |

|

|

I/F |

|

Note |

|

|

*Engine-A-M/T-ECU: Engine automated manual transmission electronic control unit |

AC312166AC |

All models are equipped with the immobilizer system as standard. The immobilizer system is the theft prevention system designed for prohibiting the engine from fuel injection so that the vehicle cannot be started if someone tries to start the engine with something other than the ignition key encrypted for that vehicle.

ENVIRONMENTAL PROTECTION

M2000027000257

Mitsubishi has given careful consideration to protection of natural resources and the environment in the vehicle. Environmentally friendly features are shown below.

IMPROVEMENT ON RECYCLING EFFICIENCY

|

Category |

Part name |

Feature |

|

Recyclable materials |

Door handle |

Thermo plastics-easy recyclable |

|

Bumper |

||

|

Radiator grille |

||

|

Instrument panel |

||

|

Recycled materials |

Engine oil level gauge |

Recycled from other industries |

|

scrap |

||

|

REDUCTION OF MATERIAL BURDEN ON ENVIRONMENTt |

||

|

Category |

Part name |

Feature |

|

Elimination of hazardous |

Radiator core and heater core |

Lead free materials |

|

substances |

||

|

Windshield ceramic print |

||

|

Body electrodeposited coating |

||

|

Battery cable connector |

||

|

Wiring harness |

||

|

Water proof film |

Polyvinyl chloride (PVC) free |

|

|

material |

||

|

Prevention of ozone depletion |

Air conditioner refrigerant |

HFC134a refrigerant |

SERVICEABILITY AND RELIABILITY

M2000028000272

MUT-III (MULTI USE TESTER-III)

Comprehensive improvements have been made to the MUT-II, a tester for diagnosing problems with the electronic control system. For easier servicing, the newly developed MUT-III has greatly improved functions and is much easier to use. The MUT-III expands the functions of the MUT-II in the following

ways:

1.Interactive Error Diagnosis

•In response to the nature of the problem, the corresponding troubleshooting page from the maintenance manual is retrieved.

•Service data is displayed, and from the actuator test screen, the page of the maintenance manual is retrieved for a list of inspection reference values.

|

00-22 |

GENERAL |

|

VEHICLE IDENTIFICATION |

2.Service Manual Viewer

•The technical information manual and workshop manual can be displayed on a personal computer monitor.

3.CAN* bus diagnosis

•Auto diagnosis function for the CAN communications bus line.

NOTE: *CAN: Controller Area Network (for further details, refer to GROUP 54C P.54C-2).

IMPROVED SERVICEABILITY

•Since adoption of unvolatile memory (EEPROM*) helps the learned value not to be initialised when the battery terminal or connector of the control unit is disconnected, maintainability can be improved.

NOTE: *EEPROM: Electrical Erasable Programmable ROM (information to be memorised can be electronically written into and erased from ROM)

•Since the adoption of service hole at the quarter trim is designed for removal and installation of the rear shock absorber assembly, maintainability can be improved.

•Since the adoption of electric power steering makes hydraulic pipes and oil pumps unnecessary, maintainability can be improved.

•Since adoption of service hole at the splash shield helps for removal and installation of headlamp bulb (low beam) and front turn signal lamp bulb, maintainability can be improved.

•The instrument lower panel can be removed or installed without using tools at the time of fuse replacement in the junction block.

VEHICLE IDENTIFICATION

|

MODELS |

M2000001000644 |

||||||||||||||||||||||||||||||||||||

|

Model code |

Engine model |

Transmission model |

Fuel supply |

||||||||||||||||||||||||||||||||||

|

system |

|||||||||||||||||||||||||||||||||||||

|

Z32A |

XNLHL6 |

134910-DOHC MIVEC (1,124 mL) |

F5MGA <2WD, 5M/T> |

MPI |

|||||||||||||||||||||||||||||||||

|

XNLHR6 |

|||||||||||||||||||||||||||||||||||||

|

Z34A |

XNLHL6 |

135930-DOHC MIVEC (1,332 mL) |

|||||||||||||||||||||||||||||||||||

|

XNLHR6 |

|||||||||||||||||||||||||||||||||||||

|

XJLHL6 |

F6SGA <2WD, 6-speed |

||||||||||||||||||||||||||||||||||||

|

automated manual |

|||||||||||||||||||||||||||||||||||||

|

XJLHR6 |

|||||||||||||||||||||||||||||||||||||

|

transmission> |

|||||||||||||||||||||||||||||||||||||

|

Z36A |

XNLHL6 |

135950-DOHC MIVEC (1,499 mL) |

F5MGA <2WD, 5M/T> |

||||||||||||||||||||||||||||||||||

|

XNLHR6 |

|||||||||||||||||||||||||||||||||||||

|

XJLHL6 |

F6SGA <2WD, 6-speed |

||||||||||||||||||||||||||||||||||||

|

automated manual |

|||||||||||||||||||||||||||||||||||||

|

XJLHR6 |

|||||||||||||||||||||||||||||||||||||

|

transmission> |

|||||||||||||||||||||||||||||||||||||

|

MODEL CODE |

|||||||||||||||||||||||||||||||||||||

|

No. |

Item |

Content |

|||||||||||||||||||||||||||||||||||

|

1 |

Development |

Z3 |

MITSUBISHI COLT |

||||||||||||||||||||||||||||||||||

|

2 |

Engine type |

2 |

1,124 mL petrol engine |

||||||||||||||||||||||||||||||||||

|

Z3 |

2 |

A |

X |

N |

L |

H |

L |

6 |

4 |

1,332 mL petrol engine |

|||||||||||||||||||||||||||

|

6 |

1,499 mL petrol engine |

||||||||||||||||||||||||||||||||||||

|

3 |

Sort |

A |

Passenger car |

||||||||||||||||||||||||||||||||||

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

|||||||||||||||||||||||||||||

|

4 |

Body style |

X |

4-door hatchback |

||||||||||||||||||||||||||||||||||

|

AC311514 |

|||||||||||||||||||||||||||||||||||||

|

GENERAL |

00-23 |

|

MAJOR SPECIFICATIONS |

|

No. |

Item |

Content |

|

|

5 |

Transmission |

N |

5-speed manual |

|

type |

transmission |

||

|

J |

6-speed automated |

||

|

manual transmission |

|||

|

6 |

Trim level |

L |

L-line |

|

7 |

Specification |

H |

MPI-DOHC MIVEC |

|

engine feature |

|||

|

8 |

Steering wheel |

L |

Left hand drive |

|

location |

|||

|

R |

Right hand drive |

||

|

9 |

Destination |

6 |

For Europe |

MAJOR SPECIFICATIONS

|

M2000030000268 |

||||

|

8 |

||||

|

1 |

7 |

4 |

5 |

9 |

|

3 |

||||

|

2 |

6 |

|||

|

AC313517AB |

|

Item |

Z32A |

Z34A |

Z36A |

||||

|

XNLHL6/R6 |

XNLHL6/R6 |

XJLHL6/R6 |

XNLHL6/R6 |

XJLHL6/R6 |

|||

|

Vehicle |

Front track |

1 |

1,460 |

||||

|

dimensions |

|||||||

|

Overall width |

2 |

1,695 |

|||||

|

mm |

|||||||

|

Front overhang |

3 |

780 |

|||||

|

Wheel base |

4 |

2,500 |

|||||

|

Rear overhang |

5 |

590 |

|||||

|

Overall length |

6 |

3,870 |

|||||

|

Ground clearance |

7 |

154/169* |

|||||

|

Overall height |

8 |

1,550/1,565* |

|||||

|

Rear track |

9 |

1,445 |

|||||

|

00-24 |

GENERAL |

||||||||

|

MAJOR SPECIFICATIONS |

|||||||||

|

Item |

Z32A |

Z34A |

Z36A |

||||||

|

XNLHL6/R6 |

XNLHL6/R6 |

XJLHL6/R6 |

XNLHL6/R6 |

XJLHL6/R6 |

|||||

|

Vehicle |

Kerb weight |

965 |

970 |

975 |

990 |

995 |

|||

|

weight kg |

|||||||||

|

Max. gross vehicle |

1,450 |

1,460 |

1,465 |

||||||

|

weight |

|||||||||

|

Max. axle weight |

735 |

745 |

750 |

||||||

|

rating-front |

|||||||||

|

Max. axle weight |

745 |

||||||||

|

rating-rear |

|||||||||

|

Max. |

With brake |

1,000 |

|||||||

|

trailer |

|||||||||

|

Without |

500 |

||||||||

|

weight |

|||||||||

|

brake |

|||||||||

|

Max. trailer |

-nose |

50 |

|||||||

|

weight |

|||||||||

|

Seating capacity |

5 |

||||||||

|

Engine |

Model code |

134910 |

135930 |

135950 |

|||||

|

Total displacement mL |

1,124 |

1,332 |

1,499 |

||||||

|

Transmission |

Model code |

F5MGA |

F6SGA |

F5MGA |

F6SGA |

||||

|

Type |

5-speed manual |

6-speed |

5-speed |

6-speed |

|||||

|

transmission |

automated |

manual |

automated |

||||||

|

manual |

transmission |

manual |

|||||||

|

transmission |

transmission |

||||||||

|

Fuel system |

Fuel supply system |

MPI |

|||||||

NOTE: *: Vehicles with high ground suspension

11-1

GROUP 11

CONTENTS

ENGINE MECHANICAL <134>. . . . . . . . . . . . . . . . . . . . . . . . . . 11A ENGINE MECHANICAL <135>. . . . . . . . . . . . . . . . . . . . . . . . . . 11B

11A-1

GROUP 11A

ENGINE

MECHANICAL <134>

CONTENTS

|

GENERAL INFORMATION . . . . . . . . |

11A-2 BASE ENGINE . . . . . . . . . . . . . . . . . . |

11A-3 |

11A-2 ENGINE MECHANICAL <134>

GENERAL INFORMATION

GENERAL INFORMATION

The newly developed 1.1L 134910 engine features 3-cylinder, 12-valve, and double overhead camshafts (DOHC).

The engine family has the following features.

•Aluminum cylinder block

•A counter balance shaft

M2112000100404

•MIVEC (Mitsubishi Innovative Valve timing Electronic Control system)

•Selective valve tappet of direct acting valve system for valve clearance adjustment

•Timing chain

MAJOR SPECIFICATIONS

|

Item |

Specification |

|

|

Total displacement mL |

1,124 |

|

|

Bore × Stroke mm |

75 × 84.8 |

|

|

Compression ratio |

10.5 |

|

|

Compression chamber |

Pentroof-type |

|

|

Valve timing |

Intake opening |

BTDC 41° − ATDC 9° |

|

Intake closing |

ABDC 19° − ABDC 69° |

|

|

Exhaust opening |

BBDC 35° |

|

|

Exhaust closing |

ATDC 5° |

|

|

Maximum output kW (PS)/rpm |

55 (75)/6,000 |

|

|

Maximum torque Nm (kgm)rpm |

100 (10.2)/3,500 |

|

|

Fuel system |

Electronically controlled multipoint fuel injection |

|

|

Ignition system |

Electronic-controlled 3-coil |

|

|

ENGINE MECHANICAL <134> |

11A-3 |

|

BASE ENGINE |

BASE ENGINE

M2112001000325

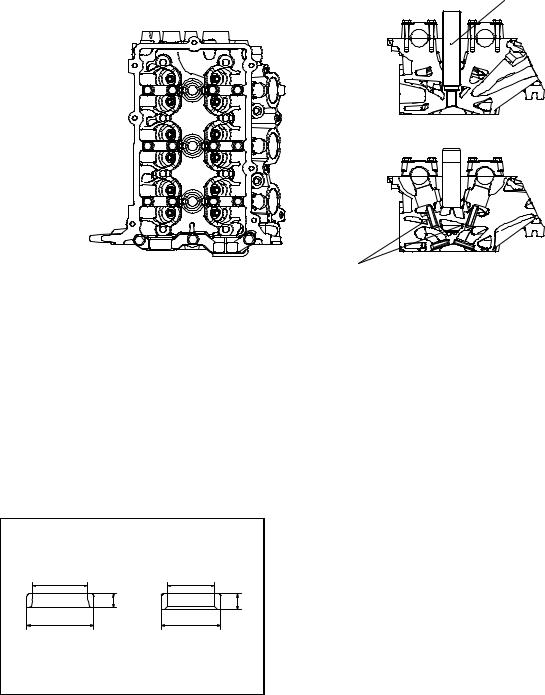

CYLINDER HEAD

Spark plug guide

Valve guide

AK305051AB

The cylinder head is made of aluminum alloy, which is lightweight and has an excellent cooling efficiency. The pentroof type combustion chamber has a spark plug in the center. The valve angle is relatively small, contributing to size reduction.

The intake and exhaust ports are arranged in a cross-flow construction. Each cylinder has a pair of intake ports on one side and a pair of exhaust ports on the other side.

Each of the intake and exhaust camshafts is supported by 4 bearings. On each camshaft, the thrust load is supported by No. 1 bearing. The No. 1 bearings for the intake and exhaust camshafts have a common bearing cap.

VALVE SEAT

|

Intake |

Exhaust |

|

d |

d |

|

h |

h |

|

D |

D |

Sintered alloy valve seat

|

Item |

Intake |

Exhaust |

|

D (Outer diameter) mm |

31.5 |

28 |

|

d (Inner diameter) mm |

26 |

22 |

|

h (height) mm |

6.6 |

7.3 |

AK305052AB

|

11A-4 |

ENGINE MECHANICAL <134> |

|

BASE ENGINE |

VALVE GUIDE

The intake and exhaust valves use the same-design valve guide.

|

Item |

Specification |

|

D (Outer diameter) mm |

10.5 |

|

d (Inner diameter) mm |

4.5 |

|

h (height) mm |

34.5 |

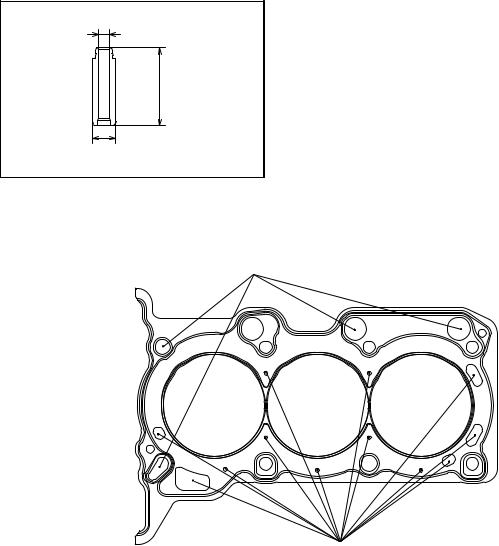

CYLINDER HEAD GASKET

Oil hole

Water hole

AK305055AB

The metal gasket having the one layer of wave stopper is used for the cylinder head gasket.

|

ENGINE MECHANICAL <134> |

11A-5 |

|

BASE ENGINE |

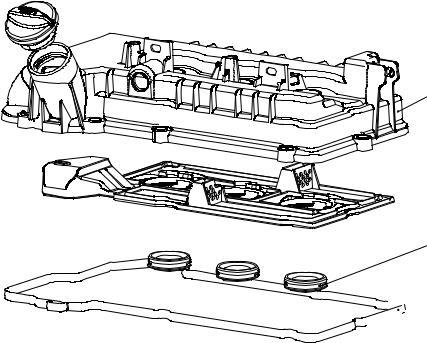

CYLINDER HEAD COVER

Cylinder head cover

Oil seal

Cylinder head

AK305057AB

A resin cylinder head cover is used for the cylinder head.

The oil plate and the oil seal are integrated with the cylinder head cover assembly.

|

11A-6 |

ENGINE MECHANICAL <134> |

|

BASE ENGINE |

|

|

CYLINDER BLOCK |

|

|

Right side view |

Front view |

Front

Nipple

|

Left side view |

Rear view |

|

Front |

|

Thermostat case installation position |

Oil filter installation position |

AK305060 AB |

The cylinder block is made of lightweight aluminum alloy.

The crankshaft journal is supported by 4 bearings. The crankshaft thrust load is supported by No. 3 bearing.

The water jacket is of a full-siamese design.

A nipple is provided at the front of the block to supply engine oil onto the timing chain.

|

Item |

Dimen |

|

sion |

|

|

Overall height mm |

280 |

|

Overall length mm |

292.1 |

|

Top face to crankshaft center mm |

205 |

|

Crankshaft center to bottom face mm |

75 |

|

Bore mm |

75 |

|

Bore pitch mm |

83 |

|

Stroke mm |

84.8 |

|

ENGINE MECHANICAL <134> |

11A-7 |

|

BASE ENGINE |

REAR OIL SEAL CASE

The rear oil seal case is a sheet-metal work. The case is installed with sealant applied onto the mounting face to prevent oil leakage.

A

AK305061AB

PISTON

AK305063AC

PISTON PIN

d D

h

AK305064AB

The piston is made of special aluminum alloy. Weight reduction is achieved by minimizing the overall height while maximizing the recess on both ends of the piston pin.

The center of the piston pin hole is offset by 0.5 mm from the center of the piston towards the thrust side. The piston skirt has a streak finish to enhance oil retention and anti-seizing property.

|

Item |

Dimension |

|

Base diameter mm |

75 |

|

Pin diameter mm |

18 |

|

Overall height mm |

46.04 |

The piston pin is of a semi-floating type, press-fitted into the connecting rod small end while capable of floating relative to the piston.

|

Item |

Dimension |

|

Outer diameter mm |

18 |

|

Inner diameter mm |

11 |

|

Overall length mm |

50 |

|

11A-8 |

ENGINE MECHANICAL <134> |

|

|

BASE ENGINE |

||

|

PISTON RING |

||

|

Piston ring No.1 |

Piston ring No.2 |

Piston ring No.1

Maker mark

Piston ring No.2

Oil ring

Oil ring

AK305365AB

Each piston is provided with No. 1 and No. 2 compression rings and an oil ring.

|

Item |

No. 1 piston ring |

No. 2 piston ring |

Oil ring |

|

Shape |

Barrel |

Tapered |

3-piece |

|

Surface treatment (Contact |

Nitride coated |

Parkerized |

Hard chrome plated |

|

face with cylinder) |

|||

|

Maker mark |

R |

2R |

No marking |

|

ENGINE MECHANICAL <134> |

11A-9 |

|

BASE ENGINE |

CONNECTING ROD

The connecting rod is made of highly rigid, forged carbon steel. The rod portion has an H-shaped cross section.

The connecting rod big end bearing is lubricated through an oil passage running from the main journal to the crankshaft pin.

|

Item |

Dimension |

|

d (Small end inner |

18 |

|

diameter) mm |

|

|

D (Large end inner |

43 |

|

diameter) mm |

|

|

L (Center distance) mm |

135.6 |

CONNECTING ROD BEARING

Identification color

H

AK305309AB

The upper and lower connecting rod bearing halves are identical.

The connecting rod bearing is equipped with back metal. While the bearing itself is made of aluminum alloy, the back metal is normally made of steel sheet. The connecting rod bearing is narrower than the bearing cap, this is to minimize wear.

|

Item |

Dimension |

|

H (Width) mm |

13.5 |

|

A (Thickness) mm |

1.5 |

|

11A-10 |

ENGINE MECHANICAL <134> |

|

BASE ENGINE |

CRANKSHAFT

Crankshaft sensing ring

Balance weight

Oil pump drive gear shaft

|

Crankshaft |

||

|

sprocket |

Oil hole |

|

|

Crankshaft |

Balance weight |

Crankshaft |

|

sprocket B |

||

AK305069AB

A casted crankshaft is used for the crankshaft. The crankshaft consists of 4 main bearings and 4 balance weights.

The crankshaft pins are arranged at 120° intervals. The oil hole supplies lubrication oil from the journal to the crank pin.

A crankshaft sprocket, an oil pump drive gear shaft, and crankshaft sprocket B are press-fitted onto the front of the crankshaft.

The crankshaft is also fitted with a crankshaft sensing ring.

CRANKSHAFT BEARING, THRUST BEARING

|

Front |

|

|

Upper bearing |

|

|

Thrust bearing |

Oil groove |

|

Oil hole |

|

|

Groove |

Identification |

|

color |

|

|

Lower bearing |

|

|

Identification |

|

|

color |

AK305071AB

The upper crankshaft bearing (with oil groove) is located on the cylinder block side while the lower bearing (without oil groove) is held by the bearing cap.

The crankshaft bearing is equipped with back metal. While the bearing itself is made of aluminum alloy, the back metal is made of steel sheet.

A thrust bearing is installed on both sides of the No. 3 crankshaft bearing.

|

ENGINE MECHANICAL <134> |

11A-11 |

|||

|

BASE ENGINE |

||||

|

Item |

Dimensio |

|||

|

n |

||||

|

Crankshaft bearing |

Width mm |

16 |

||

|

Thickness |

20 |

|||

|

mm |

||||

|

Crankshaft thrust bearing |

Thickness |

3.275 |

||

|

mm |

||||

CRANKSHAFT PULLEY

Timing mark

The crankshaft pulley is made of steel plate. The pulley has grooves to engage with a V-ribbed belt (5 ribs), which drives an alternator and a water pump.

AK305073AC

An ignition timing mark (notch) is stamped on the flange of the pulley.

|

11A-12 |

ENGINE MECHANICAL <134> |

|

BASE ENGINE |

FLYWHEEL

Flywheel

Ring gear

AK305074AB

The flywheel is made of cast-iron. A separate ring gear is mounted on it.

|

ENGINE MECHANICAL <134> |

11A-13 |

|

|

BASE ENGINE |

||

|

TIMING CHAIN TRAIN |

||

|

Timing chain mark |

Timing mark |

Timing chain mark |

|

link plate (bule) |

||

|

link plate (bule) |

||

|

Camshaft sprocket |

V.V.T. sprocket |

|

|

timing mark |

timing mark |

|

|

Camshaft sprocket |

V.V.T. sprocket |

|

|

Tensioner lever |

||

|

Chain guide |

||

|

Timing chain |

||

|

tensioner |

||

|

Timing mark |

Timing chain mark |

|

|

Crankshaft |

link plate (bule) |

|

|

sprocket |

||

|

timing mark |

||

|

Crankshaft sprocket |

||

|

AK305058AB |

The 2 camshafts are driven by the timing chain via the respective sprockets.

The timing chain, consisting of 122 links, is an endless chain, connecting the crankshaft sprocket with the camshaft and V.V.T. sprockets.

The timing chain is equipped with 3 mark link plates (blue) to correctly time the 3 sprockets with each other.

The timing chain is tensioned by the timing chain tensioner, which has a built-in plunger with plunger springs.

|

Item |

No. of |

|

teeth |

|

|

Camshaft sprocket |

36 |

|

V.V.T. sprocket |

36 |

|

Crankshaft sprocket |

18 |

TIMING CHAIN TENSIONER

Coil spring 1

Plunger

Ball sheet

|

Ball |

Retainer |

Cam |

|

|

Coil spring 2 |

|||

|

AK305388AB |

The plunger in the timing chain tensioner directly pushes the tension lever, and the pressure automatically adjusts the timing chain tension.

A cam is provided to lock the plunger in place after the engine stops. This helps prevent the timing chain from wobbling just after the engine starts.

With the timing chain tensioner installed, do not crank the engine in the reverse direction. This will force the plunger to overcome the cam, or even cause other problems.

|

11A-14 |

ENGINE MECHANICAL <134> |

|

BASE ENGINE |

VALVE MECHANISM

Exhaust camshaft

Spark plug guide

|

Exhaust valve |

Intake valve |

The valve mechanism is based on a 4-valve DOHC (Double Over Head Camshaft) design having the camshaft on the upper valve. Each cylinder has 2 intake valves and 2 exhaust valves, arranged in a V-shape pattern.

AK305077AB

Camshaft rotation is transmitted via valve tappets to the respective valves which open and close accordingly.

|

ENGINE MECHANICAL <134> |

11A-15 |

|

BASE ENGINE |

VALVE

Intake

L

The valves have heat-resistance. The entire valve surface is treated with gas nitriding.

VALVE STEM SEAL

Valve stem seal

AK305079AB

Exhaust

L

|

AK305078AB |

||

|

Item |

Intake valve |

Exhaust valve |

|

Head diameter |

30.5 |

25.5 |

|

mm |

||

|

Stem diameter |

5.0 |

5.0 |

|

mm |

||

|

Overall length |

89.61 |

90.94 |

|

mm |

||

The valve stem seal employs springs to enhance sealing performance, minimizing oil passing down to the port.

VALVE SPRING

h

The valve spring has a dual pitch spring to prevent surging in the high speed range.

|

Item |

Specification |

|

Free length mm |

43.1 |

|

No. of spring turns |

8.49 |

AK300721AB

|

11A-16 |

ENGINE MECHANICAL <134> |

|||||

|

BASE ENGINE |

||||||

|

VALVE TAPPET |

Valve tappets are available in 31 thicknesses, at 0.02 |

|||||

|

Thickness |

mm intervals between 2.70 mm and 3.30 mm, to |

|||||

|

ensure correct valve clearance. |

Identification mark

AK300722AB

MIVEC (MITSUBISHI INNOVATIVE VALVE TIMING ELECTRONIC CONTROL SYSTEM)

Oil control valve

A

Oil control

valve filter

Oil control

valve filter

bolt

V.V.T.sprocket bolt

|

Cylinder head |

||

|

A |

Cylinder block |

A-A |

AK300856AB

MIVEC (Mitsubishi Innovative Valve timing Electronic Control system) consists of the components illustrated above.

The intake valve timing is optimally controlled (continuously variable) under the changing driving conditions to improve power in the entire speed range.

V.V.T. SPROCKET (VARIABLE VALVE TIMING SPROCKET)

|

Timing mark |

Vane housing |

||

|

Advance oil chamber |

Stopper pin |

||

|

Vane roter |

|||

|

Vane bushing |

|||

|

V.V.T.sprocket |

|||

|

bolt |

|||

|

Sprocket |

Retard oil chamber |

||

AK300857AB

|

ENGINE MECHANICAL <134> |

11A-17 |

|

BASE ENGINE |

Oil from the oil control valve is sent to the V.V.T. sprocket, moving the vane rotor and thus regulating the valve timing.

CAMSHAFT

Intake camshaft

|

Advance |

|

|

Retard |

oil channel |

|

Dowel pin |

|

|

oil channel |

Exhaust camshaft

The lightweight camshaft is achieved by the hollow design.

Oil channels run through the intake camshaft, through which oil is sent from the oil control valve to the V.V.T. sprocket.

A cam position sensing ring is press-fitted onto the rear portion of the intake camshaft.

|

Hollow section |

Sensing bean |

|

Sealing cap |

|

AK305000AB |

||

|

Item |

Dimensio |

|

|

n |

||

|

Overall length mm |

Intake |

324.5 |

|

Exhaust |

278.9 |

|

|

Journal mm |

26 |

|

|

Valve lift mm |

Intake |

8.5 |

|

Exhaust |

7.6 |

|

OIL CONTROL VALVE (OCV)

|

Bobbin |

Enameled copper wire |

||

|

Insulation coilar |

|||

|

Spool |

|||

|

Plunger spring |

Pressure |

Default |

Terminal |

|

pressure |

Tape |

||

|

chamber |

chamber |

||

|

Valve sleeve |

|||

|

Spring guide |

Shaft |

Drain

Pump O-ring

Stator Bracket Yoke

|

11A-18 |

ENGINE MECHANICAL <134> |

|

BASE ENGINE |

The oil control valve is essentially a solenoid valve, regulated by the engine-ECU or engine-A-M/T-ECU signals to feed oil to the V.V.T. sprocket assembly to move the vane rotor.

TIMING CHAIN CASE

Engine support bracket

AK305244AB

The engine support bracket, the oil pump and the relief valve are integrated as well as water chamber of the water pump.

|

ENGINE MECHANICAL <134> |

11A-19 |

|

BASE ENGINE |

BALANCER

The 3-cylinder engine has three throws distributed at equal intervals. The motion of No. 1 and No. 3 pistons generates pitching moment around the No. 2 cylinder. This unbalancing moment is canceled out by the following system.

The crank webs for No. 1 and No. 3 cylinders are fitted with overbalance weights.

A counterbalance shaft is provided in parallel with the crankshaft that rotates at the same speed but in the opposite direction from the crankshaft.

The counterbalance shaft is fitted with weights that are balanced in mass with the overbalance weights fitted on the No. 1 and No. 3 cylinder crank webs.

The inertia force generated by the pistons and overbalance weights are cancelled out by the counterbalance weights, minimizing the pitching moment.

NOTE: The numbers shown in the drawings indicate the inertia forces expressed in ratio to «1.»

|

Mark to match with |

|||

|

balancer sprocket |

|||

|

Balancer |

|||

|

A |

Balancer chain mark |

shaft sprocket |

|

|

link plate (yellow) |

Balancer |

||

|

Counter |

chain |

||

|

balance |

|||

|

shaft |

A |

Timing mark |

|

|

Balance |

Tensioner B |

||

|

lever Assy |

|||

|

shaft driven |

Balance |

||

|

gear |

shaft sprocket |

Balance |

|

|

shaft drive |

Crankshaft |

||

|

gear |

|||

|

sprocket B Balancer chain mark |

|||

|

Counter |

link plate (yellow) |

||

|

balance |

|||

|

shaft |

A-A

AK304445AC

The counterbalance shaft is driven by the crankshaft via crankshaft sprocket B, the balancer chain B, the balance shaft sprocket, the balance shaft drive gear, and the balance shaft driven gear.

The balancer chain B, made up of 48 links, is an endless chain, connecting the crankshaft sprocket B with the balance shaft sprocket.

The balancer chain is provided with a mark link plate (yellow) at two locations to ensure the sprockets are timed correctly with each other.

|

Item |

No. of |

|

teeth |

|

|

Crankshaft sprocket B |

22 |

|

Balance shaft sprocket |

25 |

|

Balance shaft drive gear |

25 |

|

Balance shaft driven gear |

22 |

|

11A-20 |

ENGINE MECHANICAL <134> |

|

BASE ENGINE |

BALANCE SHAFT

Rear view

The cast-iron counterbalance shaft and the integrated driven gear are driven together by the chain B.

11B-1

GROUP 11B

CONTENTS

|

GENERAL INFORMATION . . . . . . . . |

11B-2 BASE ENGINE . . . . . . . . . . . . . . . . . . |

11B-2 |

|

11B-2 |

ENGINE MECHANICAL <135> |

|

GENERAL INFORMATION |

GENERAL INFORMATION

The unit is powered by the newly developed 135930 / 135950 engine. The total displacement is 1.3L for the 135930, and 1.5L for the 135950. Both engines are a 4-cylinder 16-valve DOHC (Double Over Head Camshaft) design.

The engine family has the following features.

M2112000100415

•Aluminum cylinder block

•MIVEC (Mitsubishi Innovative Valve timing Electronic Control system)

•Selective valve tappet of direct acting valve system for valve clearance adjustment

•Timing chain

MAJOR SPECIFICATIONS

|

Item |

135930 |

135950 |

||

|

Total displacement mL |

1,332 |

1,499 |

||

|

Bore × Stroke mm |

75 × 75.4 |

75 × 84.8 |

||

|

Compression ratio |

10.5 |

|||

|

Compression chamber |

Pentroof-type |

|||

|

Valve timing |

Intake opening |

BTDC 41° − ATDC 9° |

BTDC 41° − ATDC 9° |

|

|

Intake closing |

ABDC 3° − ABDC 53° |

ABDC 11° − ABDC 61° |

||

|

Exhaust opening |

BBDC 35° |

BBDC 39° |

||

|

Exhaust closing |

ATDC 5° |

ATDC 5° |

||

|

Maximum output kW (PS)/rpm |

70 (95)/6,000 |

80 (109)/6,000 |

||

|

Maximum torque Nm (kgm)/rpm |

125 (12.7)/4,000 |

145 (14.8)/4,000 |

||

|

Fuel system |

Electronically controlled |

multipoint fuel injection |

||

|

Ignition system |

Electronic-controlled 4-coil |

|||

BASE ENGINE

CYLINDER HEAD

The cylinder head is made of aluminum alloy, which is lightweight and has an excellent cooling efficiency. The pentroof type combustion chamber has a spark plug in the center. The valve angle is relatively small, contributing to size reduction.

The intake and exhaust ports are arranged in a cross-flow construction. Each cylinder has a pair of intake ports on one side and a pair of exhaust ports on the other side.

M2112001000336

Each of the intake and exhaust camshafts is supported by 5 bearings. On each camshaft, the thrust load is supported by No. 1 bearing. The No. 1 bearings for the intake and exhaust camshafts have a common bearing cap.

|

ENGINE MECHANICAL <135> |

11B-3 |

|

BASE ENGINE |

Spark plug guide

Valve guide

AK305050AB

VALVE SEAT

|

Sintered alloy valve seat |

|||||

|

Intake |

Exhaust |

Item |

Intake |

Exhaust |

|

|

D (Outer |

31.5 |

28 |

|||

|

d |

d |

||||

|

diameter) mm |

|||||

|

h |

h |

||||

|

d (Inner |

26 |

22 |

|||

|

D |

D |

diameter) mm |

|||

|

h (height) mm |

6.6 |

7.3 |

|||

|

AK305052AB |

VALVE GUIDE

|

The intake and exhaust valves use the same-design |

||||

|

d |

valve guide. |

|||