- Manuals

- Brands

- BMW Manuals

- Motorcycle

- K 1200RS

- Repair manual

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Related Manuals for BMW k 1200 rs

Summary of Contents for BMW k 1200 rs

-

Page 1

Repair Manual K 1200 RS BMW Motorrad After Sales… -

Page 2

Issued by © BMW Motorrad After Sales UX-VS-2 All rights reserved. Not to be reprinted, translated or duplicated either wholly or in part without prior written permission. Errors and omissions excepted; subject to technical amendment. Printed in Germany 03/01 Order number 01 79 0 137 531… -

Page 3

A new issue of this repair manual will be published if amendments or additions (supplements) are needed. All information in both text and illustrations refers to motorcycles in standard condition or with genuine BMW accessories installed, and not to motorcycles which have been modified in any way to depart from the manufacturer’s specification. -

Page 4: Tightening Torques

The list of contents is followed by the Technical Data table. Key to symbols In this Repair Manual for the K 1200 RS model, the following symbols are used; their meanings are ex- plained in the table. Special instructions aimed at improving the work procedures…

-

Page 5

Read out the fault memory BMW MoDiTeC unit [Integral ABS] perform bleed test with BMW MoDiTeC Check throttle cable play, adjust if necessary Change engine oil while at operating temperature If the motorcycle is ridden only for short distances or at outside temperatures below 0 °C (32 °F), this work must be… -

Page 6: Pre-Delivery Check

BMW Motorrad Pre-delivery check K 1200 RS as of model year 01, Integral ABS Customer Licence plate No. Pre-delivery check Order No. Mechanic’s signature Check the shipping crate for damage Unpacking the motorcycle – unpack – inspect for damage –…

-

Page 7: Engine

BMW Motorrad Service data K 1200 RS as of model year 01, Integral ABS Unit of measure- Item Desired value ment Oil capacities Engine (with filter) 3.5 (6.2) litres (Imp. pints) Gearbox Initial filling about 0.6 (1 .0) litres (Imp. pints)

-

Page 8: 12 Engine Electrics

Contents << Back Group / Chapter 00 Tightening torques, operating fluids 00 Pre-delivery check 00 Maintenance 11 Engine 12 Engine electrics 13 Fuel preparation and control 16 Fuel tank and lines 17 Radiator 18 Exhaust system 21 Clutch 23 Gearbox 31 Front forks 32 Steering >>…

-

Page 9

>> Continuation Group / Chapter 33 Rear wheel drive 34 Brake 36 Wheels and tyres 46 Frame 51 Equipment 52 Dualseat 61 General electrical equipment 62 Instruments 63 Lights << Back… -

Page 10: Table Of Contents

00 Tightening torques, operating fluids Contents Page Tightening torques ……………………3 11 Engine ……………………….3 12 Engine electrics ……………………4 13 Fuel preparation and control ………………..5 16 Fuel tank and lines ……………………5 17 Radiator ……………………….6 18 Exhaust system …………………….6 21 Clutch ……………………….6 23 Transmission ……………………..7 31 Front fork ……………………….8…

-

Page 11

Contents Page 00.2… -

Page 12: Tightening Torques

Tightening torques Model K 1200 RS Connection 11 Engine Cylinder head Cylinder head bolts 20 Oiled before installation Wrench angle ° Cylinder head cover Temperature sensor Coolant stub pipe Shield plate Split conrods Split-conrod bearing cap Wrench angle ° Engine block…

-

Page 13: Engine Electrics

Model K 1200 RS Connection 11 Engine Timing chain Slider rail to camshaft bearing cap Timing case cover Chain tensioner to cover of timing case Screw plug for chain tensioner Timing case cover Oil/water pump Oil pressure switch to oil pump intermediate flange…

-

Page 14: Fuel Preparation And Control

Model K 1200 RS Connection 12 Engine electrics Starter motor Starter motor to gearbox, M6 Positive lead to starter motor, M6 Earth (ground) lead to cross-tube Model K 1200 RS Connection 13 Fuel preparation and control Temperature sensor to intake air silencer…

-

Page 15: 17 Radiator

Model K 1200 RS Connection 17 Radiator Expansion tank to frame Fan to radiator 2 Clean thread + Loctite 243 Coolant hose clips hand-tight Model K 1200 RS Connection 18 Exhaust system Exhaust system to cylinder head Retaining hoop to silencer (muffler)

-

Page 16: 23 Transmission

Model K 1200 RS Connection 23 Transmission Housing Oil drain plug Oil filler plug Housing cover to housing Gearshift linkage Selector lever to selector shaft Gearshift pedal to transverse tube 8 Staburags NBU 30 PTM pivot bushing Gearshift lever, M6, adjustable…

-

Page 17: 31 Front Fork

Model K 1200 RS Connection 31 Front fork Fork leg Oil drain plug, sliding tube Screw plug in fixed tube Leading link Leading link to sliding tube bridge 130 Clean thread and Loctite 2701 Leading link to frame 107 Clean thread and Loctite 243…

-

Page 18: 32 Steering

Model K 1200 RS Connection 32 Steering Fastener for brake lever fitting Fastener for clutch lever fitting Cover for cable guide Pivot screw, handlebar lever Clean thread and Loctite 243 Model K 1200 RS Connection 33 Rear wheel drive Rear wheel drive…

-

Page 19: Brakes [Integral Abs]

Model K 1200 RS Connection 34 Brakes [Integral ABS] Front brake Brake caliper to fork tube Grub screw in front brake caliper Brake disc to front wheel 21 Clean thread and Loctite 243 Brake hose/line/banjo bolt Brake fluid distributor to holder…

-

Page 20: Brakes [Optional Extras, Without Integral Abs]

Model K 1200 RS Connection 34 Brakes [Optional extras, without Integral ABS] Front brake Brake caliper to fork tube Brake disc to front wheel 21 Clean thread and Loctite 243 Brake hose/line/banjo bolt Brake fluid distributor to holder Holder to sliding tube…

-

Page 21

Model K 1200 RS Connection 46 Frame Fairing Front mudguard, front (with rear section) to upper sliding tube Fairing holder Oil cooler to fairing bracket Fairing bracket, left/right, to frame Centre fairing bracket to frame Windscreen mount 6 Staburags NBU 30 PTM… -

Page 22: Frame

Model K 1200 RS Connection 46 Frame Rear frame Rear of frame to main frame, top Rear of frame to main frame, bottom Battery carrier to rear of frame, right Fuse box holder Seat tray support Grab handle Lock mount…

-

Page 23: 61 General Electrical Equipment

Model K 1200 RS Connection 61 General electrical equipment Horn to fairing bracket Ground (earth) strap to engine block Electrics box to main frame Cables to main frame Temperature sensor to cylinder head Fastener, side stand switch, M6 5 Clean thread and Loctite 243…

-

Page 24: Table Of Operating Fluids

Table of operating fluids Item Order number Quantity Lubricant Staburags NBU 30 PTM High-performance lubricating paste 07 55 9 056 992 75 g tube Optimoly MP 3 High-performance lubricating paste 07 55 9 062 476 100 g tube Optimoly TA High-temperature assembly paste 18 21 9 062 599 100 g tube Silicone grease 300, heavy…

-

Page 25

83 19 9 407 855 500 ml spray housings Crack testing agent for aluminium Developer MR 70 81 22 9 407 495 500 ml spray housings Installation aid BMW chilling spray Cooling spray 83 19 9 407 762 300 ml spray 00.16… -

Page 26

00 Pre-delivery check Contents Page General view of crated motorcycle ………………19 Checking the shipping crate for damage …………..20 Damage discovered in Germany ………………..20 Damage discovered in importer markets …………….20 Unpacking the motorcycle ………………..21 General instructions …………………….21 Pushing the motorcycle onto a workshop platform …………21 Inspecting motorcycle for damage ………………21… -

Page 27

Contents Page Adjusting footrests left/right …………………28 Adjusting gearshift lever ………………….28 [Integral ABS] Performing bleed test with BMW MoDiTeC ………29 Final inspection and function check …………….29 Final cleaning ……………………..29 Handover ……………………….30 00.18… -

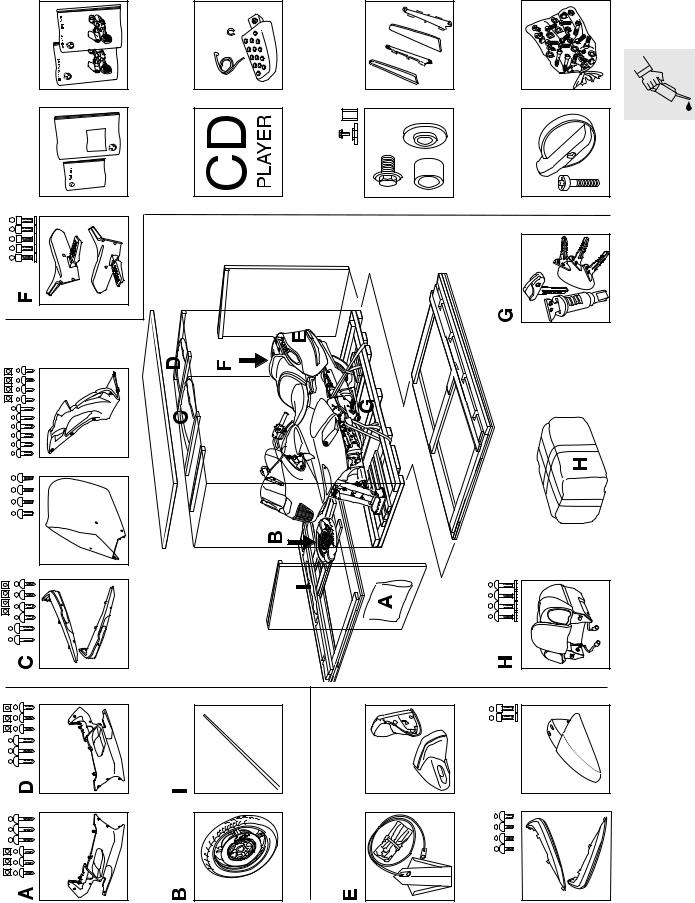

Page 28: General View Of Crated Motorcycle

General view of crated motorcycle 00.19…

-

Page 29: Checking The Shipping Crate For Damage

Checking the shipping crate for 00 00 damage • When the motorcycle arrives, check the crate im- mediately for damage and if necessary examine the contents for consequential damage. Damage discovered in Germany 00 00 • Note the damage on the delivery slip. •…

-

Page 30: Unpacking The Motorcycle

Cut the plastic sheet open and pull it off. Check for damage. • • Take out the separate pack of items: “Express message” to – Windscreen BMW Motorrad, UX-VS-1 – Mirrors, right/left Fax number 089-382-33220 • – Engine spoiler Rectify the fault.

-

Page 31: Installing Remaining Items On Motorcycle

K41UB0020 Installing remaining items on Installing mirrors, left/right 00 00 00 00 motorcycle Installing the windscreen 00 00 Note: The windscreen can be set manually to two posi- tions. • Raise the windscreen holder. • Push the bushings (arrows) into the holes at the sides of the windscreen (1).

-

Page 32: Installing Bracket For Engine Spoiler

Installing bracket for engine Installing the engine spoiler 00 00 00 00 spoiler KR460110 KR460120 • Secure the engine spoiler to the lower bracket. • • Fit the rubber support (1). Secure the engine spoiler to the left and right •…

-

Page 33: Filling And Charging The Battery

Filling and charging the battery 00 00 Remove the battery Filling and charging the battery • Pull off the battery breather hose (3). Warning: Battery sulphuric acid ……Density 1.28 Battery acid is highly caustic. • Protect your eyes, face, hands, clothing and the Top up the battery acid to the MAX mark.

-

Page 34: Checking Tyre Pressures

Checking tyre pressures 00 00 Front tyre pressure one-up ……..2.5 bar (36.26 psi) two-up ……..2.5 bar (36.26 psi) two-up with luggage….2.5 bar (36.26 psi) Rear tyre pressure one-up ……..2.9 bar (42.06 psi) two-up ……..2.9 bar (42.06 psi) two-up with luggage….

-

Page 35: Checking And Adjusting The Motorcycle

Checking and adjusting the 00 00 motorcycle Checking the function of side 00 00 stand contact switch • Switch off the engine. • Place motorcycle on its centre stand. • Select a gear and switch on the ignition. – Temperature gauge warning light lights up. •…

-

Page 36: Installing The Seat

Installing the seat Adjusting the handlebars, left/ 00 00 00 00 right Attention: When installing, make sure that the seat is retained Warning: firmly. Do not twist the handlebars, because this leads to air getting into the brake circuit or hydraulic circuit •…

-

Page 37: Adjusting Footrests Left/Right

Adjusting footrests left/right Adjusting gearshift lever 00 00 00 00 Warning: If the motorcycle is to be ridden by a sporty rider, fit the footrests in the upper position. • Remove the left/right footrest support. • Install the left/right footrest support in the alter- native position.

-

Page 38: [Integral Abs] Performing Bleed Test With Bmw Moditec

Brake light (operate front and rear brakes) Warning: – Turn signals left/right When performing maintenance and repair work on – Hazard warning flashers the BMW Integral ABS, avoid rapid and forceful – Horn pumping of the brakes. – Telltale and warning lights •…

-

Page 39: Handover

How to adjust the mirrors – Controls – Instruments and telltale and warning lights – Procedure and noises of BMW Integral ABS self- diagnosis Note: Starting on gradients: Always switch on the ignition with gear engaged and both brake levers released. Self-diagnosis cannot be performed successfully if you do not follow this procedure.

-

Page 40

Pushing the motorcycle onto a workshop platform ( 00.21) …………35 Reading the BMW MoDiTeC fault code memory …………35 (Inspections I, II, III and IV) …………………….35 [Integral ABS] Perform bleed test with BMW MoDiTeC ………35 (Inspections II and III) …………………….35 Checking throttle cable play, adjusting if necessary ……….36 (Inspections I and III) …………………….36… -

Page 41

[Integral ABS] Filling brake-fluid reservoir for rear wheel circuit and rear control circuit ( 00.50) ………………..56 [Integral ABS] Performing bleed test with BMW MoDiTeC ( 00.35) ….56 (Inspection IV) annual ……………………56 [Option without Integral ABS] Checking brake fluid level front and rear ..57… -

Page 42

Contents Page [Option without Integral ABS] Changing brake fluid and bleeding the brake system ……………………..58 (Inspection IV) annual ……………………58 Front brake ……………………….58 Force back the brake pistons………………….58 Change and bleed the front brake circuit……………….58 Bleeding the front left brake caliper ………………..59 Bleeding the front right brake caliper ………………..59 Rear brake ……………………….60… -

Page 43

Checking swinging arm bearings, adjusting if necessary ……..73 (Inspections I and III) …………………….73 [Option without BMW Integral ABS] Cleaning inductive signal transmitter at rear wheel ……………………..73 Clean the inductive sensor at the rear wheel every 40,000 km (24,000 miles) or every 2 years at the latest ……………………….73… -

Page 44: Maintenance

Reading the BMW MoDiTeC Maintenance intervals consist of the first Inspection 00 00 (after the first 1,000 km / 600 miles), the BMW Ser- fault code memory vice, BMW Inspection and BMW Annual Service. (Inspections I, II, III and IV) Inspection 1,000 km (600 miles) •…

-

Page 45: Checking Throttle Cable Play, Adjusting If Necessary

Checking throttle cable play, 13 00 adjusting if necessary (Inspections I and III) • With the handlebars turned to various angles, open the throttle twistgrip fully and allow it to clo- se again. – When released, the twistgrip must return to the closed position by itself.

-

Page 46: [Cruise Control] Models With Cruise Control

[Cruise control] Models with • 13 00 Back off adjusting screw (3) of the closer cable (4) until total play of the two cables (opener cruise control. and closer cables) is approx. 1…max. 1.5 mm (0.0394 in… max. 0.0591 in). •…

-

Page 47: [Cruise Control] Turning Throttle Twistgrip Relative To Throttle-Valve Shaft

[Cruise control] Turning throttle 13 00 twistgrip relative to throttle-valve shaft Note: cruise-control system does not switch off • The throttle twist grip must be turned relative to the Increase opener cable play. • throttle-valve shaft if the switch for the cruise control Reduce play of the closer cable by the same on the throttle valve is not functioning correctly.

-

Page 48: Changing Engine Oil, Replacing Oil Filter Element

• Drain the oil completely. • Remove the screws (2) holding the oil filter cover. • Unscrew the oil filter with special wrench (3), BMW No. 11 4 650. • Unscrew and remove the oil filter. BMW recommends Castrol 00.39…

-

Page 49: Gearbox Oil Change

Gearbox oil change Rear wheel drive oil change 23 00 33 00 (every 40,000 km/24,000 miles) (Inspection III) (Inspections I and III) – Drain the oil from the gearbox only at regular – Drain the oil from the gearbox only at regular operating temperature.

-

Page 50: [Integral Abs] Checking Brake Pads/Brake Discs For Wear/Replacing If Necessary

[Integral ABS] Checking brake [Integral ABS] Checking rear 34 00 34 00 pads/brake discs for wear/replacing brake pads for wear if necessary (Inspections II and III) [Integral ABS] Checking front 34 00 brake pads for wear K41000030 • Remove the cover from the brake caliper. •…

-

Page 51: [Integral Abs] Replacing Brake Pads

• Fit new outer pad. Note: After switching on the ignition, always wait for the BMW Integral ABS to complete its self-diagnosis. Do not operate the brake lever until self-diagnosis has completed. • After replacing the pads of a caliper, bed in the new pads with the ignition switched on.

-

Page 52: Replacing Rear Brake Pads

…………MIN Note: (top edge of the marking ring) After switching on the ignition, always wait for the BMW Integral ABS to complete its self-diagnosis. Brake fluid ………..DOT 4 Do not operate the brake lever until self-diagnosis has completed.

-

Page 53: [Integral Abs] Checking Operation Of Brake System And Freedom From Leaks; Repairing If Necessary

Do not operate the brake lever until self-diagnosis has completed. Warning: When performing maintenance and repair work on the BMW Integral ABS, avoid rapid and forceful pumping of the brakes. • Apply the brake hard and hold on in this position for a short time.

-

Page 54: [Integral Abs] Changing Brake Fluid In Wheel Circuit/Bleeding

Do not scrape the wheel – mask it off if necessary. • Use resetting tool, BMW No. 34 1 531, and loca- tor, BMW No. 34 1 532, to force the pistons in the left and right brake calipers all the way back and hold them in this position.

-

Page 55: Change The Front Brake Fluid/Bleeding

Close the bleed screw. • • Slowly fill the filler bottle, BMW No. 34 1 581, to Release the brake and switch off the ignition. • approximately 1/2 its capacity with new brake Disconnect the brake bleeding device from the fluid.

-

Page 56: [Integral Abs] Reservoir Filling Instructions For Front Wheel Circuit

00.42). 34 1 533 34 1 531 K41000090 • Screw the filler bottle, BMW No. 34 1 581, onto 34 1 532 the front wheel circuit reservoir. • Remove the adapter, BMW No. 34 1 533, and press back the pistons with the reset device until the brake pads can be inserted.

-

Page 57: [Integral Abs] Replacing Brake Fluid In The Rear Wheel Circuit/Bleeding

• Remove cap (3) of rear wheel-circuit Attention: reservoir (4). Install piston resetting tool, BMW No. 34 1 531, • Draw off the old brake fluid from the wheel-circuit only when the cap has been removed from the reservoir (4).

-

Page 58: Change The Rear Brake Fluid/Bleeding

Screw the filler bottle, BMW No. 34 1 581, onto BMW MoDiTeC! the rear wheel circuit reservoir. • • Slowly fill the filler bottle, BMW No. 34 1 581, to Perform bleed test with BMW MoDiTeC approximately 1/3 its capacity with new brake 00.35). fluid.

-

Page 59: Control Circuit

BMW No. 34 1 531, in the brake caliper. • Install 23 adapter, BMW No. 34 1 534, in reset- • ting tool, BMW No. 34 1 531, in the brake cali- Perform bleed test with BMW MoDiTeC per. 00.35).

-

Page 60: [Integral Abs] Replacing Brake Fluid In The Control Circuit/Bleeding

(Inspection IV) every 2 years Warning: When performing maintenance and repair work on Warning: the BMW Integral ABS, avoid rapid and forceful All repair and maintenance work on the pumping of the brakes. BMW Integral ABS should be carried out by •…

-

Page 61: [Integral Abs] Replacing Brake Fluid In The Front Control Circuit/Bleeding

[Integral ABS] Replacing brake 34 00 fluid in the front control circuit/ Warning: When performing maintenance and repair work on bleeding the BMW Integral ABS, avoid rapid and forceful pumping of the brakes. • In sequence, bleed the: – Filler adapter (1), –…

-

Page 62: Bleeding The Control Circuit At The Filler Adapter

When changing and bleeding the control circuit bra- • ke fluid, do not use vacuum extraction. Bleed system using the ring spanner, BMW No. 34 2 532, in accordance with • Tighten the bleed screw up to the stop in the filler instructions for bleeding.

-

Page 63: Front Control Circuit

34 00 circuit to specified level 13 3 010 KR340850 • Remove special ring spanner, BMW No. 34 2 531 and silicon hose with hose K41000060 clip, BMW No. 13 3 010. • Screw in the battery tray. • Turn the handlebars to the left.

-

Page 64: [Integral Abs] Replacing Brake Fluid In The Rear Control Circuit/Bleeding

Same procedure via other bleed screws as on front • control circuit, metering cylinder and integral Use special ring spanner BMW No. 34 2 532 circuits. and connect silicon hose with brake bleeding device to bleed screw (1), but do not switch on.

-

Page 65: Rear Integral Circuit

Fit the protective caps on the bleed screws. KL000590 • Connect special ring spanner, BMW No. 34 2 532, and silicon hose with blee- ding unit to bleed screw (2), but do not switch • Bleed system using the ring spanner, BMW No.

-

Page 66: [Option Without Integral Abs] Checking Brake Fluid Level Front And Rear

[Option without Integral ABS] Checking the rear brake fluid level 34 00 34 00 Checking brake fluid level front and rear Note: The volume of the brake fluid (MIN/MAX) is suf- (Inspections II and III) ficient for pad thicknesses from new to the wear li- mit.

-

Page 67: [Option Without Integral Abs] Changing Brake Fluid And Bleeding The Brake System

Use resetting tool, BMW No. 34 1 531, and loca- During brake bleeding, make sure that the fluid rep- tor, BMW No. 34 1 532, to force the pistons in lenishing hole is always below the level of the brake the left and right brake calipers all the way back fluid, or else air will be drawn into the brake system.

-

Page 68: Bleeding The Front Left Brake Caliper

Bleeding the front left brake caliper Bleeding the front right brake caliper • Connect the brake bleeding device to the bleed screw on the right brake caliper. • Open the bleed screw by half a turn. • Draw off brake fluid until it emerges clear and free from air bubbles.

-

Page 69: Rear Brake

Dispose of old brake fluid in an environmentally-fri- endly manner. KR340820 Brake fluid ………..DOT 4 • Using resetting tool, BMW No. 34 1 531, force the pistons fully back. Tightening torque: Change and bleed the rear brake circuit. Bleed screw ……….10 Nm –…

-

Page 70: Checking Clutch Fluid Level, Correcting If Necessary

Checking clutch fluid level, cor- 21 00 recting if necessary (Inspections II and III) Attention: Do not allow brake fluid to come into contact with painted parts of the motorcycle, because brake fluid destroys paint. – Place the motorcycle on its centre stand so that it is level.

-

Page 71: Changing The Clutch Fluid/Bleeding The Clutch System

Changing the clutch fluid/blee- 21 00 ding the clutch system (Inspection IV) every 2 years – Place the motorcycle on its main (centre) stand. • Turn the handlebars to the right. Attention: Do not allow brake fluid to come into contact with painted parts of the motorcycle, because brake fluid destroys paint.

-

Page 72: Renewing Fuel Filter (Every 40,000 Km/24,000 Miles)

16 1 710 K41160020 Renewing fuel filter Removing/installing fuel-pump 16 00 16 00 (every 40,000 km/24,000 miles) unit • Remove seal (6) and union nut (7). • (Inspection III) Pull fuel pump unit (5) far enough out of the fuel tank to enable the clips on drain hose (3) and breather hose (4) to be undone with pliers.

-

Page 73: Removing/Installing Fuel Filter

Connect drain hose (3) and breather hose (4). Open fasteners (8) with pliers. • Close fasteners with pliers, BMW No. 13 1 500. Disconnect fuel hoses (12) and (9) from fuel • Install gasket (6) and union nut (7) and tighten.

-

Page 74: Removing/Installing Fuel Pump

• Pull fuel pump (15) with pump inlet vibration Offer up the new intake filter and secure it with damper (17) off holder (19). pliers, BMW No. 13 1 500. • • Pull pump inlet vibration damper (17) off fuel Further installation is the reverse of the removal pump (15).

-

Page 75: Checking Coolant Level And Concentration; Topping Up If Necessary; Checking Cooling System For Leaks If Necessary

KR170080 Checking coolant level and 17 00 concentration; topping up if neces- Attention: sary; checking cooling system for Anti-freeze protection must be guaranteed to at leaks if necessary least -30 °C (-22 °F). Use only nitrite-free long-term antifreeze and corrosion inhibitor. (Inspections I and III) Do not top up expansion tank over the MAX mark (arrow).

-

Page 76: Changing Coolant

Changing coolant 17 00 Draining coolant 17 00 – Remove left side section of fairing, right rear sec- tion and engine spoiler ( 46.10). • Open the filler cap on the left radiator. KR170010 • Slacken fastener (2) for breather hose. •…

-

Page 77: Adding Coolant

Adding coolant 17 00 • Install the expansion tank and tighten screw (1). Attention: Ensure that the breather hose is free of kinks and constrictions. • Connect coolant hose to oil/water pump. Positi- on the clip screw (arrow) at the front and tighten •…

-

Page 78: Checking Battery

Checking battery 61 00 Attention: (Inspections III and IV) Reconnect the battery only when the ignition is swit- ched off. To avoid short-circuits: Check battery acid level and add distilled water Connect the positive battery lead (+) first, if necessary; inspect battery terminals and clean position the protective cap over the positive battery and grease them if necessary terminal,…

-

Page 79: Adding Distilled Water

Replacing intake air filter ele- • Installation is the reverse of the removal proce- 13 00 dure. Pay particular attention to the following: ment (Inspection III) Note: If the motorcycle is used in very dusty or dirty con- ditions, replace the intake air filter every 10,000 km (6,000 miles) or even more frequently.

-

Page 80: Checking Function Of Side-Stand Switch

46 5 710 KR460550 • Retract the centre stand. • Using spring tensioner, BMW No. 46 5 710, ten- sion the springs until they can be detached from KL000410 the pivot mount (arrow). • Release the spring tensioner and take off the pla- •…

-

Page 81: Checking The Steering Damper

KR460270 Checking the steering damper 31 00 Attention: Mounting bolts (1) are secured with a thread-locking compound. Do not overheat the O-rings (3) when (Inspections II and III) softening the thread-locking compound. • Place the handlebars in full left-hand lock. •…

-

Page 82: Checking Tightness Of Rear Wheel Studs

[Option without BMW Integral Checking tightness of rear 36 00 33 00 ABS] Cleaning inductive signal wheel studs transmitter at rear wheel (Inspection I) • Tighten the rear wheel studs with a torque wrench. Clean the inductive sensor at the rear wheel…

-

Page 83: Checking Valve Clearances, Adjusting If Necessary

Prevent the chain tensioner from moving in the ti- Attention: ming case cover with chain tensioner pin, Never unscrew the spark plugs before measuring BMW No. 11 6 740. valve clearances. Particles of oily soot could beco- me lodged behind the exhaust valve head and falsify the measurement.

-

Page 84

When turning the crankshaft, make sure that the ti- • Take out the camshafts. ming chain does not come away from the crankshaft • Use a rubber extractor, BMW No. 11 3 251, to sprocket. withdraw the relevant bucket tappets from the • cylinder head. -

Page 85: Replace The Lining Of The Chain Tensioning Rail, Chain Guide Rail And Thrust Piece

• • Turn the engine over and check the relative po- Tighten all screws until sealed. • sitions of the camshaft chain sprockets and the Tighten the screws in diagonally opposite se- crankshaft (at TDC). quence, working from the inside outwards. •…

-

Page 86: Replacing Spark Plugs

• • Unscrew and remove spark plugs (3) with spark Handbrake and foot brake, Integral ABS • plug wrench, BMW No. 12 3 500. Lights and signalling equipment • • Installation is the reverse of the removal proce- Telltale and warning lights •…

-

Page 87

11 Engine Contents Page Technical Data ……………………..5 Preparatory work with engine installed …………….. 11 …for removal of combined oil/water pump ……………. 11 …for removal of timing case cover, removal of timing chain ……..11 …for removal of cylinder head, removal of piston with conrod ……… -

Page 88

Contents Page Removing, disassembling and assembling cylinder head ……….19 Removing camshafts …………………….19 Removing bucket-type tappets ………………….19 Removing cylinder head ……………………19 Removing valves ……………………..19 Remachining valve seat ……………………20 Installing valve and valve stem seal ………………..20 Removing/installing coolant sealing cap at top of cylinder head …………21 Removing crankshaft ……………………22 Removing big end bearings …………………..22… -

Page 89

Contents Page Assembling engine ……………………36 Installing output shaft ……………………36 Assembling the crankcase ……………………36 Installing oil mesh strainer …………………….37 Installing oil filter ……………………..37 Installing oil sump ……………………..37 Installing intermediate flange ………………..38 Installing freewheel ……………………..38 Installing countershaft ……………………38 Installing intermediate flange ………………….38 Installing output shaft sealing ring …………………38 Installing clutch housing ……………………39 Installing driver ……………………..39… -

Page 90

Contents Page 11.4… -

Page 91: Technical Data

Technical Data K 1200 RS (72 kW) K 1200 RS (96 kW) Engine, general Engine design Inline four-stroke engine installed longitudinally, with double overhead camshafts and four valves per cylinder, liquid cooling and electronic fuel in- jection. Location of engine number…

-

Page 92

Technical Data K 1200 RS (72 kW) K 1200 RS (96 kW) Oil pump Oil pump Gear-type Valves Included angle between valves Inlet ° 20.5 Exhaust ° 19.5 Valve clearances with engine cold (max. 35 °C/95 °F) Inlet valve mm (in) 0.15…0.20 (0.0059…0.0079) Exhaust valve mm (in) 0.25…0.30 (0.0098…0.0118) -

Page 93

Technical Data K 1200 RS (72 kW) K 1200 RS (96 kW) Valve seat Valve seat angle Inlet ° 45 Exhaust ° 45 Valve seat width Inlet mm (in) 0.95…1.25 (0.0374…0.0492) Wear limit mm (in) 2.5 (0.0984) Exhaust mm (in) 1.15…1.45 (0.0452…0.0570) Wear limit mm (in) 3.0 (0.1181) -

Page 94

Technical Data K 1200 RS (72 kW) K 1200 RS (96 kW) Camshaft Inlet camshaft ° 284 Exhaust camshaft ° 284 Guide bearing dia. mm (in) 29.970…30.000 (1.1799…1.1811) Wear limit mm (in) 29.95 (1.1791) Guide bearing bore mm (in) 30.020…30.041 (1.1819…1.1827) Camshaft bearing bore mm (in) 24.020…24.041 (0.9457…0.9465) -

Page 95

Technical Data K 1200 RS (72 kW) K 1200 RS (96 kW) Connecting rod Big end bearing with bearing shell Radial clearance mm (in) 0.030…0.066 (0.0012…0.0026) Wear limit mm (in) 0.130 (0.0051) Piston pin bore dia. with bushing mm (in) 17.000…17.021 (0.6693…0.6701) Distance between centers mm (in) 130.9…131.1 (5.1535…5.1614) -

Page 96

Technical Data K 1200 RS (72 kW) K 1200 RS (96 kW) Piston rings 1st groove: square-section ring Height mm (in) 0.975…0.990 (0.0383…0.0389) Wear limit mm (in) 0.90 (0.0354) mm (in) 0.20…0.40 (0.0079…0.0157) Wear limit mm (in) 1.50 (0.0590) Float mm (in) 0.040…0.075 (0.0016…0.0030) -

Page 97: Preparatory Work With Engine Installed

Preparatory work with engine …for removal of crankshaft 1100 1100 installed – Remove the right side section of the fairing 46.8). …for removal of combined oil/ 1100 water pump …for removal of intermediate flange, removal of output shaft – Remove the right side section of the fairing 46.8).

-

Page 98: Removing/Installing Engine

– Remove left/right radiators with fans ( 17.7). Connect cables and connectors for engine and • Secure lifter, BMW No. 00 1 510, to oil sump. gearbox, and secure them with cable ties. • – Remove exhaust system ( 18.5).

-

Page 99: Disassembling Engine

Removing the oil/water pump Drive out slipring seal (7) and shaft sealing • Disconnect oil pressure warning and water pump ring (6) with a drift, BMW No. 11 6 721. temperature sensor cables from switch. • Withdraw cables through hole in pump housing.

-

Page 100: Removing The Oil Pressure Switch And Regulating Element

Insert pump shaft (5) (lightly oiled) into the hous- ing. • • Remove greased sealing ring (14), regulating Place sliding sleeve, BMW No. 11 6 722, on element (13) and coil spring (12). pump shaft. • Insert shaft sealing ring (6) into the guide sleeve Installing oil pressure switch and regulating ele- of pressing-in tool, BMW No.

-

Page 101: Removing Timing Chain Cover

KR110200 Removing timing chain cover 1100 Removing cylinder head cover Remove the crankcase cover. KL000010 • Remove heat shield (7). KR110210 • Pull off spark plug caps (6) with flat pliers. • Remove cylinder head cover (8). Removing ignition trigger Note: •…

-

Page 102: Removing Timing Case Cover

Turn or press the camshaft in the normal direction of er with slip-over sleeve, BMW No. 11 6 771/772. rotation (for about 20 to 30 seconds if the engine is •…

-

Page 103: Removing/Installing Shaft Sealing Ring In Timing Case Cover

BMW thinners. 11 6 771 KL110410 • Using assembly sleeve, BMW No. 11 6 772, slip the shaft sealing ring with wording as indicated (arrow) over assembly sleeve, BMW No. 11 6 771. •…

-

Page 104: Removing The Timing Chain

KR110260 Removing the timing chain 1100 Removing chain tensioner rail • Remove the keeper and washer. • Take off tensioner rail (4). Important: Removing chain guide rail • Set the piston to the centre of the cylinder Remove keepers (1) and washers (2) from pivot (cylinder 1 approx.

-

Page 105: Removing, Disassembling And Assembling Cylinder Head

Turn the camshafts until the tips of the cams are clear. KR110280 • Install support plate, BMW No. 11 1 749, for the valve spring clamping device at the rear of the cylinder head (not the timing end). 11 1 740 KR110270 •…

-

Page 106: Remachining Valve Seat

Place a shrink-fit tube approx. 20 mm (0.7874 in) long, on the valve stem and heat it up. • Drive in valve stem seal (1) with the assembly tool, BMW No. 11 1 602, until resistance is felt. Important: Remove the shrink-fit sleeve from the valve stem. •…

-

Page 107: Removing/Installing Coolant Sealing Cap At Top Of Cylinder Head

(2) until it is at a right angle in its bore. • Drive in coolant sealing caps (1) and (2) until seated below bevel, using hammer and drift, BMW No. 11 6 761. • Fill the cooling system. – Check cooling system for leaks ( 17.11).

-

Page 108: Removing Crankshaft

Removing crankshaft 1100 Removing main bearings (engine installed) Note: Remove the driver first if the intermediate flange is also to be removed after the crankshaft. Removing big end bearings • Bring pistons 1 and 4 to BDC position. KR110330 • Loosen all but one (arrow) of the main bearing bolts.

-

Page 109: Removing, Disassembling And Assembling Piston With Conrod

• Remove the circlip (3) at one side. • Press out piston pin (2) with pressing-out tool, KR110360 BMW No. 11 6 710. • Carefully remove piston rings (1) with piston-ring • pliers. Measure piston diameter with a micrometer at distance “A”.

-

Page 110: Assembling Pistons

Assembling pistons Checking that conrod bores are parallel 0,06 KR110371 KR110400 • • Install piston rings, using piston-ring pliers. The difference over the reference length “P” must not exceed 0.06 mm (0.0024 in). Note: Reference length “P” ….150 mm (5.9055 in) The “Top”…

-

Page 111: Assembling Pistons And Conrods

• Assembling pistons and conrods Only install pistons of the same weight group. Important: It should be possible to push the piston pin through the small end bushing with only slight pressure. • Note weight tolerances when replacing conrods: use only conrods of the same weight class. Weight tolerance ……

-

Page 112: Removing/Installing Crankshaft Gear And Rotor Flange

– Remove alternator ( 12.10). • Secure dial-guage holder, BMW No. 00 2 500, to gearbox intermediate flange. • Use the clamping screw to secure the clamp, BMW No. 11 5 510, to the first vane of the driver. 11.26…

-

Page 113: Removing Intermediate Flange

KL110231 • Pull the driver off by hand. • If necessary, use a puller, BMW No. 00 8 400, • Install the retaining device (arrow), with the pressure head from puller-separator, BMW No. 11 2 821, in the position illustrated.

-

Page 114: Removing Intermediate Flange

KR110090 Removing clutch housing Removing intermediate flange • Use Torx socket T30, BMW No. 00 2 600, to re- lease the screws. • Important: Remove the intermediate flange. After unscrewing nut (1), do not strike the output shaft or turn the engine over, so that output shaft endplay cannot cause damage to the crankcase or pump housing.

-

Page 115: Disassembling/Assembling Intermediate Flange

Remove thrust plate (1). • Take off cup spring (2). • Remove ball bearing (3) with puller, BMW No. 00 8 570, and internal puller 21/3, BMW No. 00 8 574. • Remove snap ring (4). Installing driver bearing •…

-

Page 116: Removing/Installing Shaft Sealing Ring For Driver

BMW No. 00 7 500. Note: Clean the sealing ring seat. • Pre-shape the sealing ring with your thumbs and drive it in dry with a drift, BMW No. 11 1 620, and handle, BMW No. 00 5 500. 11.30…

-

Page 117: Disassembling/Assembling Freewheel

• Pull off freewheel cage (3). • Take out cup spring (2). KR110170 • Pull needle roller bearing out of freewheel gear with a puller, BMW No. 00 8 570, and internal puller 21/3, BMW No. 00 8 574. 11.31…

-

Page 118: Assembling Freewheel

(x) is the same at both sides. • Place support ring, BMW No. 11 6 731, in posi- Distance “X” ..0.2…0.6 mm (0.0079…0.0236 in) tion and remove bearing with puller, BMW No. 00 8 570, and internal puller 21/3, •…

-

Page 119: Removing Output Shaft

Coat the sealing face of the new oil level sight glass with tyre assembly paste and drive it in with Removing the oil mesh strainer and oil filter drift, BMW No. 00 5 550. • Take out the screw and pull off oil mesh strainer (1).

-

Page 120: Disassembling/Assembling Output Shaft

Disassembling/assembling output • 1100 Remove retaining ring (4) with suitable pliers. • Insert a puller, BMW No. 00 8 400, in the oppo- shaft site cutout of the gearwheel and pull ball Disassembling output shaft bearing (5) off with pressure block, •…

-

Page 121: Assembling Tensioning Gear

• Attach the tensioning spring to the pin in the ten- sioning gear and turn it clockwise with the coun- ter-holder, BMW No. 12 4 600 until the pin of the tensioning gear engages the hole in the gear. •…

-

Page 122: Installing Dampers

KR110451 Installing dampers Assembling the crankcase • Insert the rubber dampers (7) into the damper housing (6). Note: New parts must be oiled lightly. • Push the retaining plate (4) onto the output shaft (3), slightly heat the inner part of the damper (5) and press it into position on the shaft.

-

Page 123: Installing Oil Mesh Strainer

Tighten oil filter (2) with the special oil filter Check that sealing face is clean and degreased wrench, BMW No. 11 4 650, by not more that and apply a thin coat of Omni VISC 1002, see half a turn once it has made contact.

-

Page 124: Installing Intermediate Flange

(arrow) projects upwards and is pre-loaded against Install the intermediate flange (with locating the freewheel gear. sleeves). • Use Torx socket T 30, BMW No. 00 2 600, to • Insert the countershaft into the crankcase with tighten the screws. the small gearwheel facing down.

-

Page 125: Installing Driver

• Slacken and then retighten the nut (50 Nm). • Use angle-of-rotation gauge, BMW No. 11 2 500, to tighten the nut fully. Tightening torque: 1. Nut for clutch housing ……140 Nm 2. Slacken off …………3. Retighten ……….50 Nm 4.

-

Page 126: Measuring Crankshaft Bearing Play

• Remove bearing cap. • Screw dial gauge holder (arrow), BMW No. 00 2 500, with dial gauge attached into the tapped hole for the timing case cover. • Move the crankshaft backwards and forwards as far as it will go and take the dial gauge readings.

-

Page 127: Installing Piston With Conrod

Use an angle-of-rotation gauge, • Carefully push the piston by hand out of the BMW No. 11 2 500, to tighten the big end bear- sleeve and into the cylinder. ings. Installing big end bearings…

-

Page 128: Checking Dimensions Of Crankshaft

• Use an angle-of-rotation gauge, BMW No. 11 2 500, to tighten the big end bearings. Tightening torque: Conrod bearings ………. 20 Nm Additional angle of rotation…….. 80°…

-

Page 129: Installing Cylinder Head

Set the piston in cylinder 1 to approx. 90° before Install angle-of-rotation gauge, top dead centre BMW No. 11 2 500, with two Torx inserts T 50, (cylinder 1 = at timing end of engine). BMW No. 00 2 630.

-

Page 130: Installing Camshafts

KL110120 • Important: Place aligning device, BMW No. 11 3 700 in po- Set the piston to the centre of the cylinder sition and secure it to the camshaft bearing (cylinder 1 approx. 90° before top dead centre), to caps.

-

Page 131

Install the snap rings (1) and washers (2) for the Tighten the bearing cap with sliding rail (7). • guide rail on the two bearing journals. Remove the aligning device, BMW No. 11 3 700. • Tighten the chain sprockets, counter-holding at hexagon of the camshaft. -

Page 132: Installing Timing Case Cover

• • Install chain tensioner in timing case cover. Use assembly sleeve, BMW No. 11 6 771, to po- • Prevent chain tensioner from moving with pin, sition the timing case cover on the rotor flange BMW No. 11 6 740.

-

Page 133: Installing Ignition Trigger

KR110710 Installing ignition trigger 1100 Installing ignition trigger cover • Run the cable to the ignition trigger through a • Install adjusting disc and rotor on crankshaft, rubber grommet in the timing case cover. • and tighten. Secure the cables for the oil pressure telltale and •…

-

Page 134: Installing Combined Oil/Water Pump

Installing combined oil/water 1100 pump Note: Turn the crankshaft to centre the gearwheels, tight- ening the screws further at the same time. Important: • Tighten the clutch housing before installing the oil/ Tighten the screws to specified torque. • water pump, so that the output shaft cannot dam- Check for any noticeable play at any position of age the pump housing.

-

Page 135: Installing Cylinder Head Cover

Installing cylinder head cover • 1100 Screw in all bolts until sealed. • Tighten the bolts in diagonally opposite se- • Install spark plugs and ignition leads ( 12.7). quence, working from the inside outwards. • Mount the heat shield on the cylinder head co- ver.

-

Page 136: Engine Electrics

12 Engine electrics Contents Page Technical Data ……………………..3 Renewing Hall-effect transmitter ………………5 Removing cover from Hall-effect transmitter ……………5 Removing magnetic gate ………………….5 Installing the magnetic gate …………………..6 Installing the cover of the Hall-effect transmitter ……………6 Replacing spark plugs/ignition leads …………….7 Removing/installing spark plugs ………………..7 Removing/installing ignition leads…

-

Page 137

Contents Page 12.2… -

Page 138: Technical Data

Technical Data K 1200 RS Starter motor Type Permanent-magnet motor Gear ratio 27:1 Power rating kW 0,7 Alternator Type Three-phase AC generator Gear ratio 1:1.5 Drive direct Maximum output rating W/V 840/14 Maximum current A 60 Three-phase generator speed for start of charge rpm 1,400 Max.

-

Page 139

12.4… -

Page 140: Renewing Hall-Effect Transmitter

KR110200 Renewing Hall-effect transmitter 12 11 – Remove the right side section of the fairing 46.10). – Remove the engine spoiler ( 46.14). – Drain coolant ( 00.67). – Disconnect the right-hand coolant hose. Removing cover from Hall-effect 12 11 transmitter •…

-

Page 141: Installing The Magnetic Gate

KR110200 Installing the magnetic gate Installing the cover of the Hall- 12 11 12 11 effect transmitter • Place adjusting disc (3) and rotor (2) on crank- shaft, and tighten. • Install magnetic gate (1) in the same position as previously marked.

-

Page 142: Replacing Spark Plugs/Ignition Leads

Pull off spark plug caps (2) with flat pliers. Removing/installing spark plugs 12 12 • Unscrew and remove spark plugs (1) with spark plug wrench, BMW No. 12 3 500. • Installation is the reverse of the removal proce- dure. Tightening torque: Spark plugs……….

-

Page 143: Timing The Ignition

Ignition firing point..6° before TDC = 0.24 mm Loosen the fasteners of magnetic gate (1) and ……….. (0.0094 in) before TDC turn it to the left or right until the BMW MoDiTeC displays the correct ignition firing point. •…

-

Page 144: Removing/Installing Coil

KR120110 Removing/installing coil 12 13 Important: Note positions of ignition leads on coil. Important: Switch off the ignition and disconnect and insulate the earth (ground) lead at the battery. – Remove left side section of fairing ( 46.10) • Disconnect the ignition lead plugs (6) from the coil.

-

Page 145: Replacing Three-Phase Generator

Replacing three-phase generator 12 31 Removing three-phase generator 12 31 Note: Important: For further information on the work described below, Unscrew the three fasteners uniformly and in diago- see brief version of instructions ( 46.29) or full de- nally opposite sequence. scription in the relevant chapters.

-

Page 146: Disassembling The Three-Phase Generator

Unlock the clips (1) and take off the housing cover (2). 12 4 600 KR120120 • Hold drive housing (3) with retaining device, BMW No. 12 4 600, to prevent it from turning, KR120140 release fastener (2) and take it off together with the spring washer. • •…

-

Page 147: Installing Generator

Installing generator 12 31 – Install the left/right radiators with fans ( 17.7). – Install the lower cross-tube ( 46.25). – Install drive shaft and swinging arm ( 33.21). – Install the rear wheel drive ( 33.19). – Remove lifter from engine sump. –…

-

Page 148: Replacing Starter Motor

Replacing starter motor 12 41 Removing starter motor 12 41 Note: Important: For further information on the work described below, Unscrew the three fasteners uniformly and in diago- see brief version of instructions ( 46.29) or full de- nally opposite sequence. scription in the relevant chapters.

-

Page 149: Disassembling And Reassembling Starter Motor

12 11 KR120090 Disassembling and reassembling 12 41 Removing/installing brush holder • Unscrew hex nut (6). starter motor • Take off outer insulating washer (5). • • Clamp the starter motor in the vise (with soft Take off brush holder plate (3) with carbon brush jaws) at its retaining lugs.

-

Page 150: Installing Starter Motor

Installing starter motor 12 41 – Install the left/right radiators with fans ( 17.7). – Reconnect plugs and cables for engine and gearbox. – Install the lower cross-tube ( 46.25). – Install drive shaft and swinging arm ( 33.21). – Install the rear wheel drive ( 33.19).

-

Page 151: Fuel Preparation And Control

13 Fuel preparation and control Contents Page Technical Data ……………………..3 Removing/installing Motronic control unit …………..5 Removing/installing intake air filter ( 00.70) ……………5 Replacing air temperature sensor ………………5 Removing/installing intake air silencer …………….6 Removing/installing fuel injection rail …………….7 Removing/installing injectors ………………..8 Removing/installing pressure regulator …………….8 Removing/installing throttle-valve rail…

-

Page 152

Contents Page 13.2… -

Page 153: Technical Data

Technical Data K 1200 RS Fuel grade Super (premium), unleaded, 95 octane (RON) Mixture preparation Motronic MA 2.4 Fuel pressure bar (psi) 3.5 (50.76) Throttle stub pipe intl. dia. mm (in) 38 (1.4960) Air filter Multi-layer paper element Intake stub pipe…

-

Page 154

13.4… -

Page 155: Removing/Installing Motronic Control Unit

Removing/installing Motronic Replacing air temperature sen- 13 61 13 62 control unit • Take off the left side section of the fairing Warning: 46.10). Comply with safety precautions when handling or working with fuel; note that the fuel lines are pressu- rised.

-

Page 156: Removing/Installing Intake Air Silencer

Pay particular attention to the following: • Secure non-reusable hose clips (2, 3) with pliers, KR170130 BMW No. 13 1 510. • Make sure that screw of hose clamp (4) on cylin- • Remove the fasteners (arrows). Take off the radi- der No.

-

Page 157: Removing/Installing Fuel Injection Rail

Comply with safety precautions when handling or working with fuel; note that the fuel lines are pressu- rised. • Use hose clamps, BMW No. 13 3 010, to close off fuel hoses (3). • Release hose clips of fuel hoses (3). Pull off the fuel hoses.

-

Page 158: Removing/Installing Injectors

Take off the left side section of the fairing It is not necessary to open the cable ties (1). 46.10). • Use hose clamps, BMW No. 13 3 010, to close • Remove fuel injection rail. off fuel hoses at injection rail.

-

Page 159: Removing/Installing Throttle-Valve Rail

Removing/installing throttle- 13 54 valve rail – Take off the right side section of the fairing 46.10). KR170140 • Disconnect the plug (arrow) for the fan. Note: It is not necessary to open the cable ties when re- KR130260 moving the fuel injection rail. •…

-

Page 160: Removing/Installing Intake Stubs

Removing/installing intake 11 61 stubs • Remove throttle-valve rail. KL130030 • [Cruise control] Remove retainer (8). • [Cruise control] Disengage throttle-closer cable (5) from its pull at the throttle-valve rail and remove throttle-closer cable (5). KR130090 • [Cruise control] Disengage Bowden cable for cruise control.

-

Page 161: Replacing Fuel Hoses

Replacing fuel hoses 13 31 • Remove throttle-valve rail. KR130270 Important: KR130100 Make sure that the fuel hoses and protective sleeves are run correctly between the frame and the • Open the retaining clip (arrow). engine. • Insert the fuel hoses in the retaining clips. Note: Renew retaining clips if necessary.

-

Page 162: Removing/Installing Throttle-Valve Actuator

BMW MoDiTeC. • Mark the screw with paint. • • Remove the fasteners (arrows). Perform function test with BMW MoDiTeC, menu • Remove the throttle-valve actuator. item THROTTLE-VALVE POTENTIOMETER or throttle-valve actuator. Important: The throttle-valve actuator operates from the 5 volt Tightening torque: control-unit supply.

-

Page 163: Basic Throttle Cable Setting ( A 00.36)

Install the new throttle-valve potentiometer. Note: throttle-valve actuator must be installed and con- nected. Throttle-valve potentiometer must be con- nected. • Connect BMW MoDiTeC to diagnosis plug be- neath front seat. • Open the TOOLBOX menu and select THROT- TLE-VALVE POTENTIOMETER or throttle-valve actuator.

-

Page 164: [Cruise Control] Removing/Installing Throttle Cables

[Cruise control] Removing/ Removing/installing throttle- 32 73 32 72 installing throttle cables opener and throttle-closer cables Preparatory work for all Bowden cables – Remove left side panels ( 46.8). Warning: Comply with safety precautions when handling or working with fuel. –…

-

Page 165

K41130010 • Installation is the reverse of the removal proce- dure. Pay particular attention to the following: Important: Route Bowden cables so as to avoid tight bends and make sure they are not kinked or pinched. • Route the two cables parallel; the throttle-opener cable (1) with green mark always to the outside. -

Page 166: Removing/Installing Bowden Cable Of Cruise-Control System

K41130010 Removing/installing Bowden • 32 73 Installation is the reverse of the removal proce- dure. Pay particular attention to the following: cable of cruise-control system • Carefully pull apart sleeve (4) and lower cable shroud (arrow) and remove insert (3). Important: •…

-

Page 167: [Cruise Control] Removing/Installing Control Unit For Cruise Control

[Cruise control] Removing/ 65 71 installing control unit for cruise con- trol – Remove left side section of fairing ( 46.8). – Remove upper section of fairing ( 46.9). K41130030 • Disconnect plug (arrow). • Remove screws (4) securing retaining plate to fairing bracket.

-

Page 168: Checking Fuel Pressure

Comply with safety precautions when handling or working with fuel; note that the fuel lines are pressu- rised. • Connect a test pressure gauge, BMW No. 16 1 500, to the delivery side (lower line). • Start engine and allow to idle. Fuel pressure: Specification ……

-

Page 169: Troubleshooting

Troubleshooting Fault indication from BMW MoDiTeC: Leak in air intake line. Injector leaking? Renew injector/sealing ring. Intake air stub leaking? Renew intake air stub. 13.19…

-

Page 170

16 Fuel tank and lines Contents Page Technical Data ……………………..3 Removing/installing fuel tank ………………..5 Removing/installing fuel pump assembly, fuel filter and fuel pump ….6 Removing/installing fuel-pump unit ( 00.63) …………..6 Removing/installing fuel filter ( 00.64) ……………..7 Removing/installing fuel pump ………………..7 Removing/installing fuel filler pipe ………………7 Removing/installing fuel tank vent… -

Page 171

Contents Page 16.2… -

Page 172: Technical Data

Technical Data K 1200 RS Tank capacity 21 (4.62/5.55) (Imp. gal /US gal) including reserve of 4 (0.88/1.06) (Imp. gal /US gal) Fuel pump Type Gear-type Operating voltage V 12 Delivery volume 110 (24.21/29.06) (Imp. gal/ US gal/h) 16.3…

-

Page 173

16.4… -

Page 174: Removing/Installing Fuel Tank

K41160010 Removing/installing fuel tank • 16 11 Disconnect the plug for the immersed fuel level sensor (5). • Release the fasteners (4) at the left and right of Note: the fuel tank. Pull the fuel tank to the rear, away The immersion-tube sensor has to be calibrated if it from rubber mounting (7).

-

Page 175: Removing/Installing Fuel-Pump Unit

16 1 710 K41160020 Removing/installing fuel pump Removing/installing fuel-pump 16 11 16 14 assembly, fuel filter and fuel pump unit ( 00.63) • Remove fuel tank. Warning: Comply with safety precautions when handling or working with fuel. • Drain fuel tank. 16.6…

-

Page 176: Removing/Installing Fuel Filter ( A 00.64)

Removing/installing fuel filter Removing/installing fuel filler 16 12 16 11 00.64) pipe Removing/installing fuel pump 16 12 Warning: Comply with safety precautions when handling or • Disconnect connecting cable (10) from fuel working with fuel. pump. • Open hose clip (11) with pliers and pull off the hose.

-

Page 177: Removing/Installing Immersion-Tube Sensor

Removing/installing immersion- Renewing front left/right rubber 16 14 16 11 tube sensor mounting – Remove the right side section of the fairing 46.8). Important: Disconnect ground lead from battery and insulate. Warning: Comply with safety precautions when handling or working with fuel. KR160050 •…

-

Page 178

17 Radiator Contents Page Technical Data ……………………..3 Coolant circuit ……………………..5 Removing/installing radiator with fan …………….7 Removing/installing left radiator ………………..7 Removing/installing right radiator ………………..8 Removing/installing fan ………………….9 Removing/installing left fan ………………….9 Removing the right fan ……………………9 Removing/installing coolant hoses ………………10 Removing/installing thermostat ……………… -

Page 179

Contents Page 17.2… -

Page 180: Technical Data

Technical Data K 1200 RS Cooling system content (Imp. pint/ US quart) Coolant Use only nitrite-free long-term antifreeze and cor- rosion inhibitor. Thermostat opening temperature °C (°F) 85 Fan cut-in temperature °C (°F) 105 Cut-in temperature for coolant warning °C (°F) 115…

-

Page 181

17.4… -

Page 182: Coolant Circuit

Coolant circuit 17.5…

-

Page 183

17.6… -

Page 184: Removing/Installing Radiator With Fan

Removing/installing radiator 17 11 with fan Removing/installing left radiator 17 11 – Drain coolant ( 00.67). KR170130 • Release the retaining screws (arrows). Take off the radiator air outlet guide. KR170030 • Remove the fasteners (arrows). Take off the radi- ator air inlet guide.

-

Page 185: Removing/Installing Right Radiator

Note: Illustrations for the following work: b Remove left radiator. • Remove retaining clips with washers for radiator. • Loosen air outlet guide mountings. Take off air outlet guide. • Disconnect fan plug. KR170040 • Disconnect connecting hose (1) to right radiator, vapour discharge hose (2) and breather hose (3) at the top of the radiator.

-

Page 186: Removing/Installing Fan

Removing/installing fan Removing the right fan 17 11 17 11 Removing/installing left fan – Remove the right side section of the fairing 17 11 46.10). – Take off the left side section of the fairing 46.10) KR170050 KR170030 • Remove the fasteners (arrows). •…

-

Page 187: Removing/Installing Coolant Hoses

KR170080 Removing/installing coolant • 17 12 Installation is the reverse of the removal proce- dure. hoses – Drain coolant ( 00.67). Tightening torque: • Remove the corresponding coolant hose. Hose clips for coolant hose…..hand-tight – Connecting hose (1) between left and right radi- ators –…

-

Page 188: Removing/Installing Thermostat

• Screw pump, BMW No. 17 0 500, with adapter Checking thermostat 17 00 and threaded stub pipe, BMW No. 17 5 520, on to the filler pipe. • See “Troubleshooting” on Page 17.12 Pressure-test the cooling system; the pressure must remain unchanged for at least 5 minutes.

-

Page 189: Troubleshooting

Troubleshooting Coolant overheat warning light comes on. Check coolant in expansion tank. Is coolant Add coolant. level too low? Check thermostat. Thermostat does not open. Is the left radiator warmer than the right, and Replace thermostat. the coolant pipe to the water pump hot? Test the water pump.

-

Page 190

Excessive loss of coolant. Check coolant circuit. Coolant circuit is inter- Repair the fault. rupted Engine remains cold or warms up very slowly. Check thermostat. Thermostat does not close. Are both radiators equally warm and the cool- Replace thermostat. ant hose to the water pump cold? 17.13… -

Page 191: Exhaust System

18 Exhaust system Contents Page Technical Data ……………………..3 Removing/installing exhaust system ……………..5 Removing/installing oxygen sensor ………………5 Removing/installing exhaust system sleeve …………..6 18.1…

-

Page 192

Contents Page 18.2… -

Page 193

Technical Data K 1200 RS Exhaust system Silencer (muffler) Closed-loop catalytic converter 18.3… -

Page 194

18.4… -

Page 195

Before installing, lightly oil the thread of the oxygen sensor. • Coat the oxygen sensor with Optimoly TA and tighten by means of hex head using socket, BMW No. 11 7 020. Tightening torque: Oxygen sensor ……….45 Nm 18.5… -

Page 196

Removing/installing exhaust 18 30 system sleeve KR180050 KR180070 • • Remove fasteners (arrows) for cover. Pull the exhaust system sleeve away from the si- lencer with a turning movement (arrows). Note: When installing, push the sleeve on to the silencer with a turning movement, making sure that the holes in the sleeve and the silencer are aligned. -

Page 197

21 Clutch Contents Page Technical Data ……………………..3 Removing/installing clutch …………………5 Removing clutch ……………………..5 Removing clutch housing ………………….6 Installing clutch housing ………………….7 Installing clutch ……………………..8 Removing/installing clutch slave cylinder and pushrod ……….9 Removing/installing clutch slave cylinder ………………..9 Removing/installing clutch pushrod ………………..10 Removing/installing clutch lines ……………… -

Page 198

Contents Page 21.2… -

Page 199: Technical Data

Technical Data K 1200 RS Clutch Type Single dry plate clutch (asbestos-free) Operation hydraulic Clutch plate dia. mm (in) 180 (7.0866) Wear limit: Minimum clutch plate thickness mm (in) 4.5 (0.1771) 21.3…

-

Page 200

21.4… -

Page 201: Removing/Installing Clutch

(6) from the clutch housing (8). – Remove rear wheel ( 36.8). – [Without BMW Integral ABS] Remove inductive signal transmitter ( 61.15). – Remove brake caliper, fasten to the rear frame with the inductive sensor using a cable tie 34.5).

-

Page 202: Removing Clutch Housing

Move clutch housing (2) to and fro until O-ring (3) can be seen. • Cut through O-ring (3). • Pull off the clutch housing (2). • Take off thrust washer (1). 11 2 821 KR210030 • Attach the holder, BMW No. 11 2 821, as illus- trated. 21.6…

-

Page 203: Installing Clutch Housing

• Fit the clutch housing (2). Slacken and then retighten the nut. • Use angle-of-rotation gauge, BMW No. 11 2 500, to tighten the nut fully. • Remove the retaining fixture, BMW No. 11 2 821. Tightening torque: 1. Nut for clutch housing ……140 Nm 11 2 821 2.

-

Page 204: Installing Clutch

KR210010 Installing clutch 21 21 Important: Offset colour markings for residual imbalance by Important: 120°: yellow on clutch housing (8), white on thrust Always use new screws. plate (4) and clutch housing cover (2). • • Grease all lubrication points with Install wire ring (6), diaphragm spring (5), thrust Optimoly MP 3.

-

Page 205: Removing/Installing Clutch Slave Cylinder And Pushrod

– Remove swinging arm ( 33.21). • Centre clutch plate (3) with centering pin, BMW No. 21 2 673. • Tighten retaining screws (1) in succession, in di- agonally opposite sequence. Lubrication points: Splines on clutch plate and input shaft.

-

Page 206: Removing/Installing Clutch Pushrod

• Installation is the reverse of the removal proce- 21 52 Removing/installing clutch pushrod dure. Pay particular attention to the following: KR210050 KL210080 • Clean mating surfaces on the transmission case Note: and clutch slave cylinder, use new paper Pressure line (3) and bleed line (5) remain on the gasket (arrow).

-

Page 207: Removing/Installing Clutch Lines

KR210070 Removing/installing clutch lines 21 52 – Fill clutch system with brake fluid ( 00.62). – Bleed/adjust the clutch ( 00.62). – Install left side section of fairing ( 46.10). 21 52 Removing/installing clutch pressure line – Install the front section of the rear carrier –…

-

Page 208: Removing/Installing Bleed Line

KR210080 21 52 Removing/installing bleed line – Remove the front section of the rear carrier 46.7). • Cut through cable tie (1) at frame. • Remove banjo bolt (4), take off sealing rings (3), trap brake fluid in a suitable container and dis- pose of it in an environmentally acceptable man- ner.

-

Page 209

23 Gearbox Contents Page Technical Data ……………………..3 Gearbox — cutaway drawing ………………..5 Replacing the shaft sealing rings in the gearbox housing and gearbox cover ……………………7 Replacing input shaft sealing ring at input end ………………7 Replacing output shaft sealing ring …………………7 Replacing input shaft sealing ring at output side ……………..8 Replacing shaft sealing ring for selector drum ………………8 Replacing sealing ring for selector shaft ………………..8… -

Page 210

Contents Page Installing gearbox housing ………………….26 Aligning rubber mounts ………………….28 Aligning left-hand rubber mount ………………..28 Aligning right-hand rubber mount ………………29 23.2… -

Page 211: Technical Data

Technical Data K 1200 RS Type of gearbox 6-speed with sports ratios, claw shift and inte- grated shock damper acting in all gears Gearshift type Adjustable shift pedal, selector drum with overrun protection Gear ratios 1st gear 3.863 2nd gear 3.022 3rd gear 2.393…

-

Page 212

23.4… -

Page 213: Gearbox — Cutaway Drawing

Gearbox — cutaway drawing KR230000 23.5…

-

Page 214

23.6… -

Page 215: Replacing The Shaft Sealing Rings In The Gearbox Housing And Gearbox Cover

All shaft sealing rings can be replaced with the gear- • box installed, apart from the input-side shaft sealing Screw puller, BMW No. 00 8 750, into shaft seal- ring on the input shaft. Replace all shaft sealing ing ring and turn the hex bolt to remove the shaft rings if the gearbox is fully disassembled.

-

Page 216: Replacing Input Shaft Sealing Ring At Output Side

BMW No. 00 8 583. Install the new sealing ring with the sealing lip • Screw the pull rod, BMW No. 00 8 581, into the facing inwards, using assembly sleeve, pierced hole and use impact weight, BMW No. 23 4 612, and impact driver, BMW No.

-

Page 217: Removing/Installing Gearbox

KR230010 Removing/installing gearbox • 23 00 Cut through the cable tie (arrow) and disconnect the cable for the side stand switch. Removing gearbox • Remove clutch release rod (3) from the gearbox. 23 00 • Undo fasteners (4, 5) and remove the heat shield. •…

-

Page 218

KR230010 Installing gearbox 23 00 Important: • Insert gearbox into intermediate flange and push The alignment of the left-hand rubber mounts rela- on to reamed sleeves. tive to the frame is preset at the factory; do not slacken the securing screws. The rubber mounts do not have to be re-aligned un- Note: less the left-hand rubber mount has been replaced. -

Page 219: Disassembling Gearbox

Avoid damage to the housing cover and painted sur- faces. • Heat the bearing seats in the housing to 80 °C… 100 °C/176 °F…212 °F). • Use press-off tool, BMW No. 23 4 780, to sepa- rate the housing from the housing cover. 23.11…

-

Page 220: Removing Selector Drum

KR230040 Removing selector drum Disassembling/assembling selec- 23 31 23 31 tor shaft • Pull selector rails (1) out of selector forks. • Swing selector forks (2, 8, 9) out towards the edge of the cover. • Remove locking pin (5). •…

-

Page 221: Removing Gearbox Shafts

If the grooved ball bearings are replaced, the fully Pull off the grooved ball bearings with a universal assembled length must be re-adjusted. puller, BMW No. 00 7 500. • Press the output-side grooved ball bearing on to the intermediate shaft.

-

Page 222: Disassembling/Assembling Input Shaft

(3), thrust piece (2) and con- stant-speed gear (1). • Clamp input shaft (10) other way round in vise. • Use universal puller, BMW No. 00 7 500, and 00 7 500 pressure head (arrow) to pull off grooved ball bearing (11). KR230090 •…

-

Page 223: Assembling Input Shaft

KR230080 • 23 12 Assembling input shaft Check the fully-compressed length and adjust if • Lightly oil the bearing surface for constant-speed necessary ( 23.22). • gear (1) on input shaft (10), and install the con- Install spacing washer (8) of the calculated thick- stant-speed gear.

-

Page 224: Disassembling/Assembling Output Shaft

• Turn output shaft (6) other way round and clamp into the vise with soft jaws. • Use universal puller, BMW No. 00 7 500, to pull off grooved ball bearing (1). 00 7 500 • Remove shim washer (2), needle roller bearing (3), shift gearwheel for 2nd gear (4) and thrust washer (5).

-

Page 225

18 17 KR230120 23 12 Assembling output shaft Important: To avoid damaging the needle roller bearings on the Note: splines when installing, spread the rollers carefully Assembly starts at the shift at the end faces. gearwheel for 4th gear (9). Before assembly, oil all •… -

Page 226

18 17 KR230120 KR230140 • Reverse position of output shaft (16) in vise. • Install sliding gearwheel for 6th gear (17) with the recess for the selector fork facing the 2nd gear shift wheel (20). • Install backup washer (18) and needle roller bearing (19). -

Page 227: Checking Endplay

KR230150 Checking endplay 23 00 KR230190 • Secure dial gauge, BMW No. 00 2 510, to dial • gauge stand. Place spacing washer and both thrust washers • Position dial-gauge stylus on edge of the gear- on the selector drum.

-

Page 228: Checking/Adjusting Fully-Assembled Length Of Gearbox Shafts

Remove the spacing washer. ness on the intermediate shaft and press on the • Position dial gauge, BMW No. 23 4 762, in rear grooved ball bearing. locating bore of stand, BMW No. 23 4 761, and set to 0.2 mm (0.0079 in) preload.

-

Page 229: Checking/Adjusting Fully-Assembled Length Of Output Shaft

• Remove the spacing washer. Take off spacing washer, grooved ball bearing • Position dial gauge, BMW No. 23 4 762, in rear and reference washer. • locating bore of stand, BMW No. 23 4 761, and Place a spacing washer (1) of the correct thick- set to 0.2 mm (0.0079 in) preload.

-

Page 230

Take the input shaft out of the measuring fixture. • • Position dial gauge, BMW No. 23 4 762, in front Remove the adapter disc, spacing washer, locating bore of stand, BMW No. 23 4 761, and grooved ball bearing and reference washer. -

Page 231: Assembling Gearbox

• Align the input, output and intermediate shafts so that their gearwheels mesh. • Insert slip-over sleeve for input shaft, BMW No. 23 4 712, into cover. • Heat bearing points in cover to 80…100 °C (176…212 °F). • Insert input shaft (2), output shaft (3) and interme- diate shaft (1) together, at the same time.

-

Page 232: Shimming Selector Shaft

23 00 Shimming selector shaft Important: If the housing or the complete selector shaft is re- placed, the selector shaft must be measured and shimmed. KL230380 • Measure distance “C” from the shoulder on the selector shaft to the back of the sleeve. •…

-

Page 233: Installing Selector Drum

KR23250 23 31 Installing selector drum • Place a spacing washer of the determined thick- ness and the input-side thrust washer on selec- tor drum (7) and secure with a small amount of grease. • Swing locking lever (6) out towards the edge of the cover and install the selector drum.

-

Page 234: Installing Gearbox Housing

Using the metering device, apply Loctite 574 23 4 700 surface sealant to the mating face of the cover. • Place assembly sleeve, BMW No. 23 4 732, on the output shaft. KR230030 • Place assembly sleeve, BMW No. 23 4 712, on the input shaft.

-

Page 235

KR230020 • Insert screws (7) and tighten in diagonally oppo- site sequence. • Install gear indicator (2) and clip cable (arrow) into position. • Install breather (1). Important: Clean metal particles off the magnet in drain plug (5). • Install oil drain plug (5). •… -

Page 236: Aligning Rubber Mounts

KL230050 Aligning rubber mounts 23 00 Aligning left-hand rubber mount 23 00 Important: The alignment of the left-hand rubber mounts rela- tive to the frame is preset at the factory. Do not slacken the paint-marked Torx screws (1) unless the rubber mount has to be replaced. KL230060 –…

-

Page 237: Aligning Right-Hand Rubber Mount

Aligning right-hand rubber mount 23 00 Important: It is not necessary to re-align the right-hand rubber mount unless the gearbox, the frame or the left- hand rubber mount has been replaced. • Install the right-hand bearing bushing, but do not tighten the securing screws.

-

Page 238: Front Forks

31 Front forks Contents Page Technical Data ……………………..3 Removing/installing telescopic fork ………………5 Removing telescopic fork ………………….5 Installing telescopic fork ………………….7 Removing/installing fork bridge ……………….9 Renewing ball joint ……………………10 Removing/installing slider tube bridge …………….11 Removing/installing ball joint ………………..12 Disassembling/reassembling telescopic fork …………13 Disassembling telescopic fork ………………..

-

Page 239

Contents Page 31.2… -

Page 240: Technical Data

Technical Data K 1200 RS Front suspension Type Telelever with leading link pivoted centrally on main frame. Telescopic fork Fixed fork tube surface Hard chrome plated Fixed tube extl. dia. mm (in) 34.96 f8 (1.3764) Maximum permissible fixed fork tube runout mm (in) 0.4 (0.0157)

-

Page 241

31.4… -

Page 242: Removing/Installing Telescopic Fork

Remove the engine spoiler and holder end screws (1) on fixed fork tube (4) at left/right. 46.14). Screws are secured with a thread-locking com- • Secure lifter, BMW No. 00 1 510, to oil sump. pound. • Loosen the left/right handlebar holder clamp (3). •…

-

Page 243

Unscrew the fastener for the leading link at the the Allen screw when removing. fork slider tube bridge, using socket wrench in- sert and internal hexagon, BMW No. 31 5 600. • • Unscrew the fastener (arrow) for the left brake Pull the telescopic fork down to remove. -

Page 244: Installing Telescopic Fork

Tighten left and right handlebar clamps (1). • • Secure the leading link fastener to fork slider Tighten left and right fork bridge clamps (4). • tube bridge, using socket wrench insert and in- Compress the telescopic fork. ternal hexagon, BMW No. 31 5 600. 31.7…

-

Page 245

If the telescopic fork was disassembled, fill each leg with specified quantity of oil. Capacity per fork leg …… 0.51 l (0.90 Imp. pint/0.54 US quart) Oil grade ……BMW telescopic-fork oil Tightening torque: Oil drain plug……….13 Nm • From this point on, installation is the reverse of the removal procedure, note the following points in particular. -

Page 246: Removing/Installing Fork Bridge

Screw is secured with a thread-locking compound. • Undo the fork bridge fastener (3) at the frame with socket wrench insert and internal hexagon, BMW No. 31 5 600. • Take off fork bridge (10). • Installation is the reverse of the removal proce- dure.

-

Page 247: Renewing Ball Joint

Coat the ball joint fastener with Optimoly TA and • Tighten left and right fork bridge clamps (4). secure it to the fork bridge with 46 mm (1.8110 in) socket wrench insert, BMW No. 31 5 630. Important: Install screw (3) with Loctite 243. Tightening torque: Ball joint to fork bridge …….

-

Page 248: Removing/Installing Slider Tube Bridge

– Remove the engine spoiler and holder 46.14). • Secure lifter, BMW No. 00 1 510, to oil sump. Important: Do not operate the handbrake lever when the brake calipers have been removed. Protect painted parts from scratching: apply adhesive masking tape if necessary.

-

Page 249: Removing/Installing Ball Joint

31 5 630 31 5 620 KR310080 • Secure sliding tube fork bridge (1) in retaining fix- ture, BMW No. 31 5 620. Warning: Note that high torque has to be applied to loosen the ball joint fastener. • Release the ball joint fastener with the 46 mm (1.8110 in) socket wrench…

-

Page 250: Disassembling/Reassembling Telescopic Fork

KR310091 Disassembling/reassembling 31 42 telescopic fork – Before removing the telescopic fork, slacken the end plug (5). Important: – Remove telescopic fork. Avoid damage to fixed fork tube (4). Disassembling telescopic fork • 31 42 Remove fixed fork tube (4). •…

-

Page 251: Assembling Telescopic Fork

Oil shaft sealing ring lightly and press it home on sliding tube (1), using the combined weight (ar- row) of drift, BMW No. 31 5 610, reducing adapt- er with lugs, BMW No. 31 5 613, and sleeve, BMW No. 31 5 614.

-

Page 252: Removing/Installing Front Suspension Strut

Removing/installing front sus- 31 42 pension strut – Remove the engine spoiler and holder 46.14). • Secure lifter, BMW No. 00 1 510, to oil sump. – Remove fuel tank ( 16.5). KR310140 • Unscrew fastener (arrow) for suspension strut on frame.

-

Page 253

• Installation is the reverse of the removal proce- dure. Pay particular attention to the following: Note: If the telescopic fork was extended too far, loosen the fixed fork tube clamps and push the fixed tube into the fork tube, turning it at the same time. Note the correct projection when securing the fixed fork tube. -

Page 254: Removing/Installing Steering Damper

Removing/installing steering 31 42 damper Checking the steering damper – Remove front wheel ( 36.5). • – Remove left side section of fairing With the steering turned to the left, move the 46.8). front end of the piston rod radially to and fro and –…

-

Page 255: Removing/Installing Leading Link

– Remove the engine spoiler and holder 31 5 694 46.14). • Secure lifter, BMW No. 00 1 510, to oil sump. – Remove the right-hand air intake pipe ( 46.17). • Detach the right radiator from its holder and 31 5 693 press it forward.

-

Page 256: Installing Leading Link

M 12 threaded rod, BMW No. 31 5 691, equipment box. • M 12 nut with mount, BMW No. 31 5 692, Secure the electronic equipment box and wiring and puller sleeve, BMW No. 31 5 697, harness to the frame.

-

Page 257: Removing Left Leading Link Pivot Mount

M12 threaded rod, BMW No. 31 5 691, • Remove angular-contact ball bearing and spacer M 12 nut with mount, BMW No. 31 5 692, sleeve, using M12 threaded rod, spacer, BMW No. 31 5 695, BMW No. 31 5 691, support, BMW No.

-

Page 258: Measuring The Leading Link

BMW No. 31 5 682, into leading link (3). • • Undo the fastener (arrow) for the steering Stylus of gauge, BMW No. 31 5 682, must be lo- damper (2) at the leading link. cated in punch mark (arrow) in leading link on •…

-

Page 259

32 Steering Contents Page Technical Data ……………………..3 Removing/installing left grip tube ………………5 Removing/installing right grip tube ………………6 Removing/installing clutch lever fitting …………….7 Removing/installing brake lever fitting …………….8 Removing/installing left handlebar tube ……………..9 Removing/installing right handlebar tube …………..10 Removing/installing left and right handlebar levers ………. -

Page 260

Contents Page 32.2… -

Page 261: Technical Data

Technical Data K 1200 RS Type One-piece forged stub handlebars, adjustable from lower front to upper rear position; without anti-vibration weights Handlebar tube diameter mm (in) 22 (0.8661) Steering lock angle ° 32 Handlebar width with grip tube mm (in) 720 (28.3464)

-

Page 262

32.4… -

Page 263: Removing/Installing Left Grip Tube

K41320010 Removing/installing left grip 32 72 tube • [Option with heated grip] Undo cable tie. • [Option with heated grip] Separate plug connector (2) for the heated grip. • [Option with heated grip] Release cable shoes (3) from plug connector (2). •…

-

Page 264: Removing/Installing Right Grip Tube

K41320020 Removing/installing right grip 32 72 tube • Installation is the reverse of the removal proce- • [Option with heated grip] Undo cable tie. dure. • [Option with heated grip] Separate plug – Adjust the basic throttle cable setting ( 00.36).

-

Page 265: Removing/Installing Clutch Lever Fitting

K41320010 Removing/installing clutch 32 72 lever fitting • Installation is the reverse of the removal proce- – Take off mirror ( 00.22). dure. Pay particular attention to the following: – Remove grip tube ( 32.5). Important: Important: Make sure that lines and cables are correctly routed. Do not allow brake fluid to come into contact with painted parts of the motorcycle, because brake fluid destroys paint.

-

Page 266: Removing/Installing Brake Lever Fitting