Материал из BikesWiki — энциклопедия японских мотоциклов

Перейти к: навигация, поиск

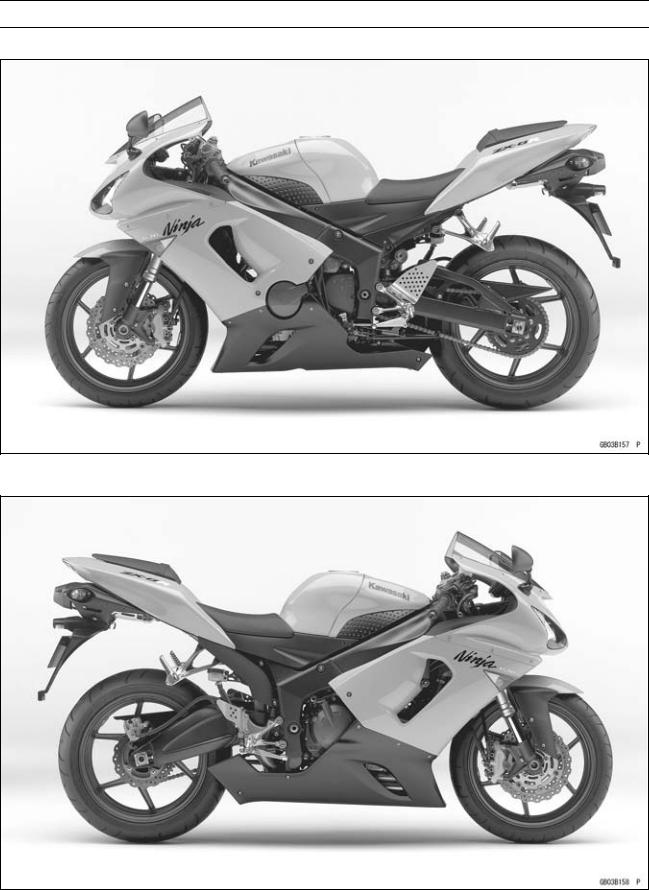

Kawasaki Ninja ZX-6R 636

Ниже представлены прямые ссылки на скачку сервисной документации.

Для Kawasaki ZX-6R

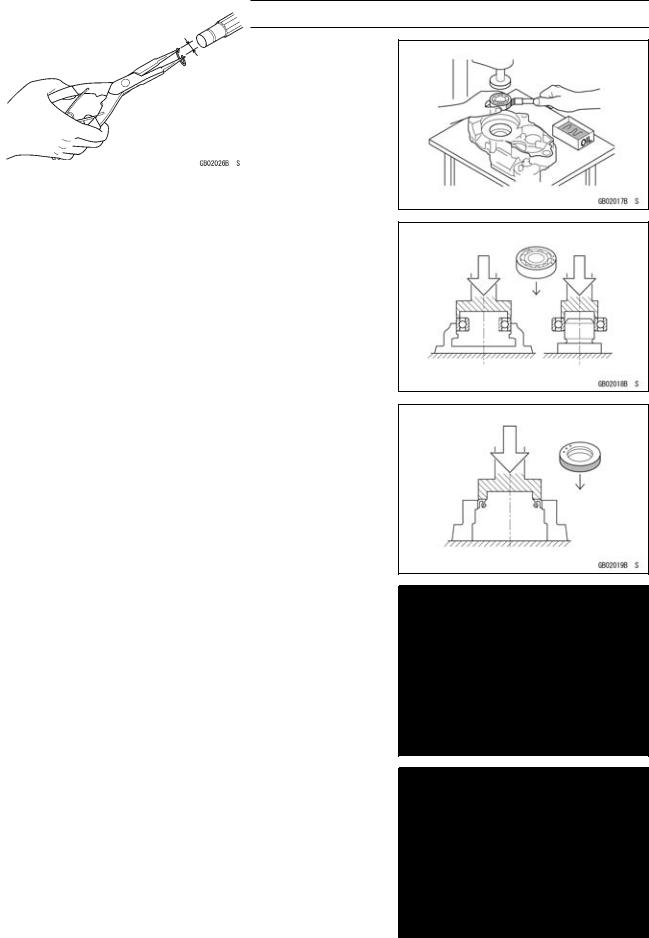

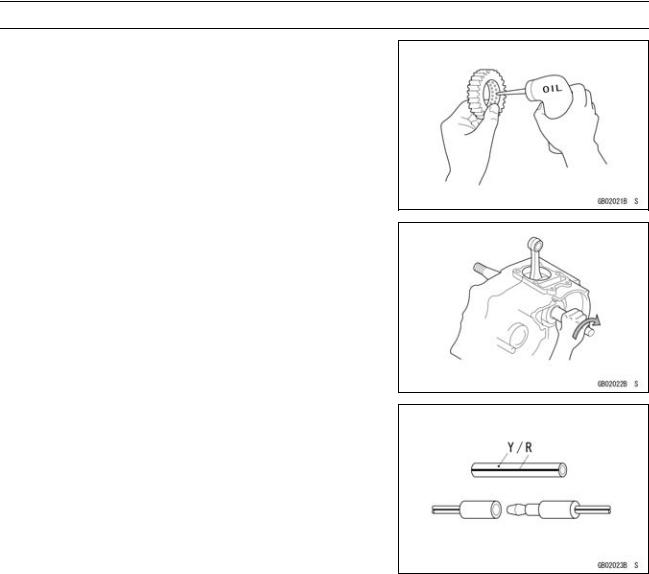

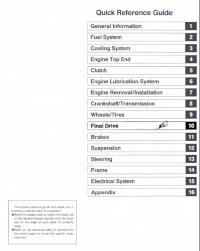

- Сервисный мануал (Service Manual) на Kawasaki ZX-6R (1995-1997)

- Сервисный мануал (Service Manual) на Kawasaki ZX-6R (1998-1999)

- Сервисный мануал (Service Manual) на Kawasaki ZX-6R (2001-2002)

- Сервисный мануал (Service Manual) на Kawasaki ZX-6R, ZX-6RR (2003-2004)

- Сервисный мануал (Service Manual) на Kawasaki ZX-6R (2005-2006)

- Сервисный мануал (Service Manual) на Kawasaki ZX-6R (2007-2008)

- Сервисный мануал (Service Manual) на Kawasaki ZX-6R (2009-2011)

- Сервисный мануал (Service Manual) на Kawasaki ZX-6R 636 (2013), оригинал англ.

- Сервисный мануал (Service Manual) на Kawasaki ZX-6R 636 (2013), русский перевод

Обзор модели

- Kawasaki ZX-6R

Источник — «https://bikeswiki.ru/index.php?title=Kawasaki_ZX-6R:_мануалы&oldid=9740»

Категория:

- Сервисная документация