- Manuals

- Brands

- Rotax Manuals

- Engine

- 582 UL series

- Operator’s manual

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

AIRCRAFT ENGINES

OperatOrs Manual

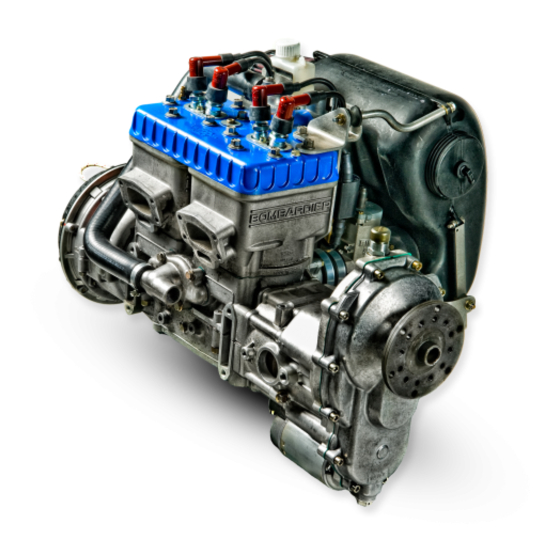

FOr rOtax® EnginE tYPE 582 UL SERIES

rOtaX® 582 ul dCdI Mod. 99

with OPtiOnS

rOtaX® 582 ul dCdI Mod. 17

with OPtiOnS

ref. no.: OM-582 UL | part no.: 899122

picture: rOtax® 582 UL DCDi Mod. 99 with options

Related Manuals for Rotax 582 UL series

Summary of Contents for Rotax 582 UL series

-

Page 1

FOr rOtax® EnginE tYPE 582 UL SERIES rOtaX® 582 ul dCdI Mod. 99 with OPtiOnS rOtaX® 582 ul dCdI Mod. 17 with OPtiOnS ref. no.: OM-582 UL | part no.: 899122 picture: rOtax® 582 UL DCDi Mod. 99 with options… -

Page 2

These technical data and the information embodied therein are the property of BRP-Rotax GmbH & CO KG, Austria, acc, BGBI 1984 no. 448, and shall not, without prior written permission of BRP-Rotax GmbH & Co KG, be disclosed in whole or in part to third parties. -

Page 3: Table Of Contents

4 – Abnormal operation Chapter 5 – Performance and Fuel consumption Chapter 7 – System Description Chapter 8 – Checks Chapter 9 – Supplement Chapter 10 – Proper disposal BRP-Rotax Page Content-1 Effectivity: 582 UL Edition 3 / Rev. 0 January 01/2018…

-

Page 4

NOTES Page Notes-2 BRP-Rotax Effectivity: 582 UL January 01/2018 Edition 3 / Rev. 0… -

Page 5

INTRO) Introduction Topics in this chapter Foreword BRP-Rotax GmbH & Co KG (hereinafter “BRP-Rotax”) provides “Instructions of Continued Airworthiness”, which are based on the design, the tests and certification of the engine and its components. These instructions apply only to engines and components supplied by BRP-Rotax. -

Page 6

NOTES Page Notes-2 BRP-Rotax Effectivity: 582 UL January 01/2018 Edition 3 / Rev. 0… -

Page 7

Jan. 01 2018 Jan. 01 2018 Jan. 01 2018 Jan. 01 2018 Jan. 01 2018 Jan. 01 2018 Jan. 01 2018 Jan. 01 2018 Jan. 01 2018 Effectivity: 582 UL BRP-Rotax Page LEP-1 Edition 3 / Rev. 0 January 01/2018… -

Page 8

Chapter Page Date Chapter Page Date rear Jan. 01 2018 page Page LEP-2 BRP-Rotax Effectivity: 582 UL January 01/2018 Edition 3 / Rev. 0… -

Page 9: Toa) Table Of Amendments

INTRO Jan. 01 2018 DOA* Jan. 01 2018 DOA* Jan. 01 2018 DOA* 1 up to Jan. 01 2018 DOA* BRP-Rotax Page TOA-1 Effectivity: 582 UL Edition 3 / Rev. 0 January 01/2018…

-

Page 10

Summary of the relevant amendments in this context, but without any claim to completeness. page current no. chapter date of comments change 1 up to 10 Jan. 01 2018 new layout and change of company name BRP-Rotax Effectivity: 582 UL Page TOA-2 January 01/2018 Edition 3 / Rev. 0… -

Page 11: General Note

………………15 1.9 Technical data ………………16 1.9.1 Dimensions ………………16 1.9.2 Weights ……………….. 16 1.9.3 Fuel consumption …………….16 1.9.4 Direction of rotation …………….17 Effectivity: 582 UL BRP-Rotax Page 1-1 Edition 3 / Rev. 0 January 01/2018…

-

Page 12: General

For additional information on engines, maintenance or parts, you can also contact your nearest ROTAX® authorized aircraft engines distributor or their independent Service Center. Engine serial When making inquiries or ordering parts, always indicate the number engine serial number.

-

Page 13: Abbreviations And Terms

General Aviation Manufacturers Association g/kWh Gram per kilowatt hour High Altitude Compensation Horsepower Inch in³ Cubic inch in³/h Cubic inch per hour INTRO Introduction International Standard Atmosphere Effectivity: 582 UL BRP-Rotax Page 1-3 Edition 3 / Rev. 0 January 01/2018…

-

Page 14

Newtonmeter Pounds per square inch Power Take Off Rev. Revision Research Octane Number ROTAX® Is a trademark of BRP-Rotax GmbH & Co KG Revolutions per minute Society of Automotive Engineers Service Bulletin Service Instruction Service Letter Type certificate Table Of Amendment… -

Page 15: Safety

The information and descriptions of components and systems contained in this Manual are correct at the time of publication. BRP-Rotax maintains a policy of continuous improvement of its products without imposing upon itself any obligation to retrofit products previously manufactured.

-

Page 16

ENVIRONMENTAL NOTE Environmental notes give you tips on environmental protection. A revision bar outside the page margin indicates a change to text or graphic. Page 1-6 BRP-Rotax Effectivity: 582 UL January 01/2018 Edition 3 / Rev. 0… -

Page 17: Safety Information

Never fly the aircraft equipped with this engine at locations, air speeds, altitudes or in other situations which do not allow a success- ful no-power landing after sudden engine stoppage. Effectivity: 582 UL BRP-Rotax Page 1-7 Edition 3 / Rev. 0 January 01/2018…

-

Page 18

• Due to the varying designs, equipment and types of aircraft, BRP-Rotax grants no warranty on the suitability of its engines use on any particular aircraft. Further, BRP-Rotax grants no warranty on this Engine’s suitability with any other part, com- ponents or system which may be selected by the aircraft manufacturer, assembler or user for aircraft application. -

Page 19

• Select and use proper aircraft instrumentation. This instru- Instrumentation mentation is not included in the ROTAX® engine package. Only approved instrumentation may be installed. Engine log book • Keep an engine log book and respect engine and aircraft maintenance schedules. Keep the engine in top operating condition at all times. -

Page 20

• To eliminate the risk of injury or damage, ensure any loose equipment or tools are properly secured before starting the engine. • Allow the engine to cool at idle for several minutes before turning off the engine. Page 1-10 BRP-Rotax Effectivity: 582 UL January 01/2018 Edition 3 / Rev. 0… -

Page 21

Reference Any reference to a document refers to the latest edition issued by BRP-Rotax if not stated otherwise. Illustrations The illustrations in this Manual are merely sketches and show typical arrangements. -

Page 22

This number (e.g. AE 2St_001) is of no significance for the content. 1.6) Description of design Figure 1 Page 1-12 BRP-Rotax Effectivity: 582 UL January 01/2018 Edition 3 / Rev. 0… -

Page 23: 582 Ul Dcdi Mod. 99 / Mod. 17

• Radiator (one-piece or two-piece radiator set). NOTE 582 UL DCDI mod. 99 and 582 UL DCDI mod. 17 are only avail- able as 48 kW version. Effectivity: 582 UL BRP-Rotax Page 1-13 Edition 3 / Rev. 0 January 01/2018…

-

Page 24: Type Description

1.7) Type description The type description consists of the following: e.g. mod. ROTAX 99 / DCDI mod. type ignition model certification Designation Designation Description Type Two stroke engine, 2 cylinder in line with ro- tary valve inlet. Certifica- Non-certified aircraft engines…

-

Page 25: Engine Components, Engine Views, Cylinder Designation

1.8) Engine components, engine views, cylinder designation 582 UL DCDI Figure 2 Engine serial number Propeller gearbox Electric starter Magneto side Power take off side Effectivity: 582 UL BRP-Rotax Page 1-15 Edition 3 / Rev. 0 January 01/2018…

-

Page 26: Technical Data

582 UL DCDI / mod. 99 / mod. 17 at take-off performance 26.5 l/h (7 US gal/h) at 75 % continuous performance 20.5 l/h (5.4 US gal/h) specific fuel consumption 425 g/kWh (0.7 lb/hph) Page 1-16 BRP-Rotax Effectivity: 582 UL January 01/2018 Edition 3 / Rev. 0…

-

Page 27: Direction Of Rotation

1.9.4) Direction of rotation Direction of Direction of rotation on propeller shaft: clockwise, viewed from rotation the front. Figure 3: Normal direction of propeller rotation Effectivity: 582 UL BRP-Rotax Page 1-17 Edition 3 / Rev. 0 January 01/2018…

-

Page 28

NOTES Page Notes-18 BRP-Rotax Effectivity: 582 UL January 01/2018 Edition 3 / Rev. 0… -

Page 29: Operating Instructions

2.3 Operating media – Fuel…………….4 2.4 Operating media — Lubricants …………..6 Introduction This chapter of the Operators Manual contains the operating limits that must be observed to ensure the ROTAX® aircraft engine and standard systems operate safely. 2.1) Operating limits Speed Take-off speed 6800 rpm (max.

-

Page 30

-25 °C (-13 °F) Coolant temperature Max. 80 °C (175 °F) Min. 65 °C (150 °F) Fuel pressure Max. 0.4 bar (5.8 psi) Min. 0.2 bar (2.9 psi) Page 2-2 BRP-Rotax Effectivity: 582 UL January 01/2018 Edition 3 / Rev. 0… -

Page 31

At verification of the coolant level replenish coolant at radiator cap (radiator or expansion tank). The coolant level in the over- flow bottle should be between min. and max. mark. Effectivity: 582 UL BRP-Rotax Page 2-3 Edition 3 / Rev. 0 January 01/2018… -

Page 32

Risk of vapor formation when using winter fuel for summer operation. ATTENTION If the engine is not equipped with injection lubrication, a 2 % Super two stroke oil must be added to the fuel. Page 2-4 BRP-Rotax Effectivity: 582 UL January 01/2018 Edition 3 / Rev. 0… -

Page 33

Non-compliance can result in serious injuries or death! At refueling use only metal containers and ground the aircraft in ac- cordance with the grounding specifications to avoid electrostatic charging. Effectivity: 582 UL BRP-Rotax Page 2-5 Edition 3 / Rev. 0 January 01/2018… -

Page 34

Gear oil API-GL5 or GL6, SAE 140 EP, or 85 W — 140 EP. lubrication Rotary valve drive Super two stroke oil (same as used for engine lubrication). lubrication Page 2-6 BRP-Rotax Effectivity: 582 UL January 01/2018 Edition 3 / Rev. 0… -

Page 35: Standard Operation

The control elements mentioned in this chapter are only symbolic and should support the understanding of the procedures. The execution of control elements is in the responsibility of the aircraft manufacturer. Effectivity: 582 UL BRP-Rotax Page 3-1 Edition 3 / Rev. 0 January 01/2018…

-

Page 36: Daily Checks

• Verify oil tank content (oil injection engines) • Inspect for coolant leaks • Inspect engine and gearbox for oil leaks Ignition system • Verify spark plug connectors for security Page 3-2 BRP-Rotax Effectivity: 582 UL January 01/2018 Edition 3 / Rev. 0…

-

Page 37: Engine Start

If the engine fails to start or operates only on one cylinder, check whether the ignition wiring is correctly connected to the spark plug connectors, check spark plugs and check the igni- tion is in ON position. Effectivity: 582 UL BRP-Rotax Page 3-3 Edition 3 / Rev. 0 January 01/2018…

-

Page 38

ATTENTION Ensure ignition switch is in correct position and wired correctly. Page 3-4 BRP-Rotax Effectivity: 582 UL January 01/2018 Edition 3 / Rev. 0… -

Page 39: After Engine Start

Operate the engine at 3000 to 3500 rpm. Alternately ignition system 1 and 2 must be switched off. Speed drop with only one ignition circuit must not ex- ceed 300 rpm. Effectivity: 582 UL BRP-Rotax Page 3-5 Edition 3 / Rev. 0 January 01/2018…

-

Page 40: Operation In Flight

A well designed and well maintained air intake system (e.g. RO- TAX® intake silencer with K & N oil impregnated air filter) will help to prevent water ingestion. Page 3-6 BRP-Rotax Effectivity: 582 UL January 01/2018 Edition 3 / Rev. 0…

-

Page 41

Be aware that modifications will require a different carburetor setting. Enquire at your dealer for more information, and consult author- ized ROTAX® aircraft engines distributor or their independent Service Center. Winter Winter can create additional problems such as carburetor icing, frozen fuel lines, higher air densities etc., which may affect car-… -

Page 42

NOTES Page Notes-8 BRP-Rotax Effectivity: 582 UL January 01/2018 Edition 3 / Rev. 0… -

Page 43: Abnormal Operation

Further checks — see Maintenance Manual. The following description of procedures depends on the respective type of installation in the aircraft and shall therefore only be seen functionally. Effectivity: 582 UL BRP-Rotax Page 4-1 Edition 3 / Rev. 0 January 01/2018…

-

Page 44

Any exceeding of the max. admissible exhaust gas temperature haust gas temper- must be entered by the pilot into the logbook, stating duration ature max. and extent of excess-temperature condition. Page 4-2 BRP-Rotax Effectivity: 582 UL January 01/2018 Edition 3 / Rev. 0… -

Page 45

4.4.1) Too low fuel pressure m WARNING Non-compliance can result in serious injuries or death! Repair as necessary all discrepancies and shortcoming before flight. Effectivity: 582 UL BRP-Rotax Page 4-3 Edition 3 / Rev. 0 January 01/2018… -

Page 46

Start by checking the supply (tank), fittings (loose?), filter (plugged?), float chamber (fouled?). Spark Try new spark plugs. Problems of a more complex nature are best left to a ROTAX® engine technician: See your ROTAX® Authorized Distributor or their independent Service Centers. Knocking under load… -

Page 47

Those values need to determined and provided by the aircraft manufacturer. Effectivity: 582 UL BRP-Rotax Page 5-1 Edition 3 / Rev. 0 January 01/2018… -

Page 48

5.1) Performance data 582 UL DCDI mod.99 / mod. 17 Figure 1 Page 5-2 BRP-Rotax Effectivity: 582 UL January 01/2018 Edition 3 / Rev. 0… -

Page 49: System Description

The design shown in this chapter does not represent a specified execution but should support the understanding of the system. Effectivity: 582 UL BRP-Rotax Page 7-1 Edition 3 / Rev. 0 January 01/2018…

-

Page 50

Radiator screw cap, with ex- Hose from cylinder head to cess pressure valve and re- radiator turn valve Temperature gauge for 10 Overflow hose cooling water Page 7-2 BRP-Rotax Effectivity: 582 UL January 01/2018 Edition 3 / Rev. 0… -

Page 51

For fuel refer to section 2.3. 7.3) Lubrication system Lubrication Generally the engines are designed to run on a gasoline-oil mixture of 50:1 unless equipped with optional ROTAX® oil in- jection system. For preparation of fuel-oil mixture refer to sec- tion 2.3. Oil injection… -

Page 52

Gearbox lubrication operates with its own oil filled into gearbox lubrication housing. ATTENTION Never operate engine with a dry gearbox. NOTE For lubricants refer to section 2.4. Page 7-4 BRP-Rotax Effectivity: 582 UL January 01/2018 Edition 3 / Rev. 0… -

Page 53

The secondary winding supplies the high voltage for the ignition spark. NOTE The grey cable is provided for a rev-counter signal. Figure 3 Effectivity: 582 UL BRP-Rotax Page 7-5 Edition 3 / Rev. 0 January 01/2018… -

Page 54

3.00 : 1 Crankshaft : propeller shaft 3.47: 1 4.00 : 1 NOTE This type of gearbox designated as EL is also available with an incorporated lighting generator. Page 7-6 BRP-Rotax Effectivity: 582 UL January 01/2018 Edition 3 / Rev. 0… -

Page 55: Checks

ATTENTION Carry out all directives of Service Bulletins (SB), according to their priority. Observe applicable Service Instructions (SI) and Service Letter (SL). Effectivity: 582 UL BRP-Rotax Page 8-1 Edition 3 / Rev. 0 January 01/2018…

-

Page 56

• Remove air filters and inject approx. 6 cm³ of preservation oil or equivalent oil into the air intake of each carburetor • Stop engine and secure against inadvertent engine start Page 8-2 BRP-Rotax Effectivity: 582 UL January 01/2018 Edition 3 / Rev. 0… -

Page 57

• Spray all external steel parts with engine oil or appropriate preservation oil Effectivity: 582 UL BRP-Rotax Page 8-3 Edition 3 / Rev. 0 January 01/2018… -

Page 58

NOTES Page Notes-4 BRP-Rotax Effectivity: 582 UL January 01/2018 Edition 3 / Rev. 0… -

Page 59: Supplement

9) Supplement Authorized Overview of ROTAX® Authorized Distributor or their Distributor independent Service Center. Refer to the official ROTAX® AIRCRAFT ENGINES Website www.FLYROTAX.com. Effectivity: 582 UL BRP-Rotax Page 9-1 Edition 3 / Rev. 0 January 01/2018…

-

Page 60

NOTES Page Notes-2 BRP-Rotax Effectivity: 582 UL January 01/2018 Edition 3 / Rev. 0… -

Page 61: Proper Disposal

ENVIRONMENTAL NOTE Work with the utmost care to ensure that no water pollutants can penetrate into the soil, water or the sewerage system. Effectivity: 582 UL BRP-Rotax Page 10-1 Edition 3 / Rev. 0 January 01/2018…

-

Page 62

Please return old/used parts (not periodic maintenance parts) Old/used parts from ROTAX® aircraft engines F.O.B to ROTAX® Authorized Distributors or their independent Service Centers. Chemical agents Please observe the safety and disposal instructions of the (cleaner, LOCTITE manufacturer. etc.) Page 10-2… -

Page 63

4 weeks up to 1 year……..2 Engine start ……. 2–3 Engine views …….15 Re-Start during flight ……2 Exceeding cylinder head temperature ………2 Exceeding engine speed ….2 Effectivity: 582 UL BRP-Rotax Page Index-1 Edition 3 / Rev. 0 January 01/2018… -

Page 64

Technical documentation ….11 Temperature ……..2 Safety notice ……5, 7 Trouble shooting ……4 Special operating conditions …6 Type description ……14 Table of amendments …..1 Weights……..16 Technical data ……16 Page Index-2 BRP-Rotax Effectivity: 582 UL January 01/2018 Edition 3 / Rev. 0… -

Page 68

AIRCRAFT ENGINES __________________________________________________________ Engine serial no. __________________________________________________________ Type of aircraft __________________________________________________________ Aircraft registration no. ROTAX® authorized distributor WWW.FLYROTAX.COM ® and TM are trademarks of BRP-Rotax GmbH & Co KG. © 2018 BRP-Rotax GmbH & Co KG. All rights reserved…