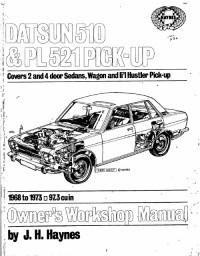

Руководство на английском языке по эксплуатации, техническому обслуживанию и ремонту Datsun 510 серии и Datsun PL521 Pick-Up 1968-1973 годов выпуска.

- Автор: J.H. Haynes

- Издательство: Haynes Publishing

- Год издания: 1974

- Страниц: 250

- Формат: PDF

- Размер: 11,0 Mb

Подборка руководств на английском языке по техническому обслуживанию и ремонту Datsun Pick-Up 620 серии.

- Автор: —

- Издательство: Nissan Motor Co., Ltd

- Год издания: 1974/1977

- Страниц: 438/537

- Формат: PDF

- Размер: 69,6 Mb

Подборка руководств на английском языке по техническому обслуживанию и ремонту Datsun Pick-Up 720 серии.

- Автор: —

- Издательство: Nissan Motor Co., Ltd

- Год издания: 1981

- Страниц: 564

- Формат: PDF

- Размер: 45,1 Mb

Подборка руководств на английском языке по техническому обслуживанию и ремонту Datsun Pick-Up 520 серии.

- Автор: —

- Издательство: Nissan Motor Co., Ltd

- Год издания: —

- Страниц: —

- Формат: PDF

- Размер: 27,7 Mb

Руководство на английском языке по эксплуатации, техническому обслуживанию и ремонту Datsun 510 серии и Datsun Pick-Up 1968-1972 годов выпуска.

- Автор: —

- Издательство: Clymer Publications

- Год издания: —

- Страниц: 252

- Формат: PDF

- Размер: 8,5 Mb

|

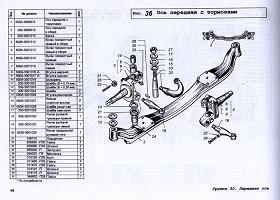

Инструкция NISSAN Pickup (1985-94гг) на русском языке в формате pdf для устройства: внедорожник. |

Описание к файлу:Тип устройства: внедорожник Фирма производитель: NISSAN Модель: NISSAN Pickup (1985-94гг) Инструкция на русском языке Формат файла: pdf, размер: 15.98 MB Обслуживание, устройство, ремонт

|

Для ознакомления с инструкцией необходимо нажать на ссылку «ЗАГРУЗИТЬ», чтобы скачать pdf файл. Если есть кнопка «ПРОСМОТР», то можно просто посмотреть документ онлайн.

Для удобства, Вы можете сохранить данную страницу с файлом руководства по эксплуатации в свой список «избранное» прямо на сайте (доступно для зарегистрированных пользователей).

Смотрите инструкцию для похожих моделей:

Вы можете задать вопрос посетителям сайта по модели NISSAN Pickup (1985-94гг). Если Вы являетесь её пользователем, то пожалуйста оставьте, по возможности развёрнутый отзыв:

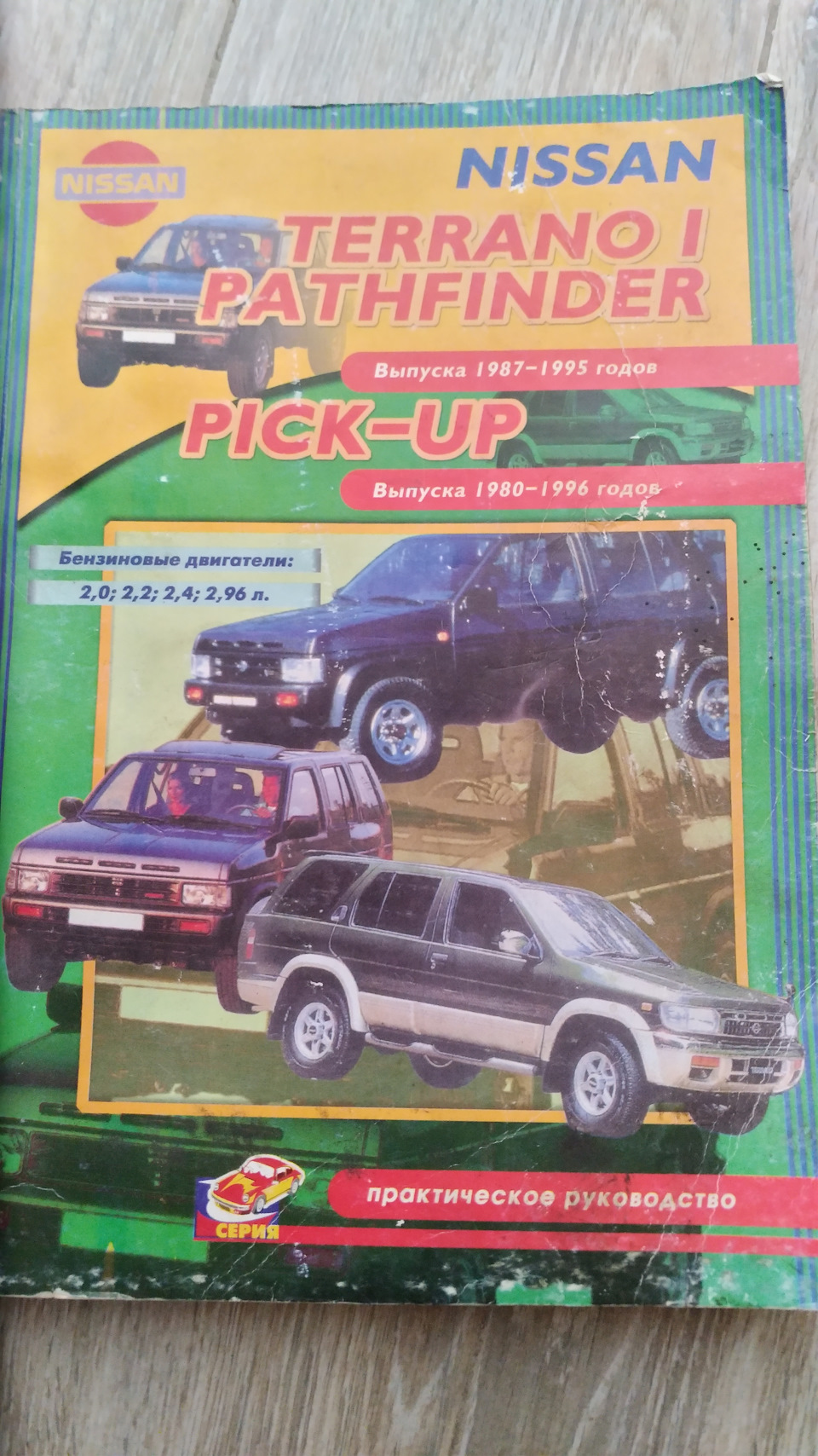

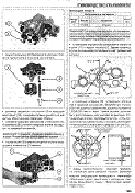

В общем, задумался я о приобретении полезной книжки для ремонта. Но цены на новые смутили, полез на авито. Там тоже люди не стесняются в ценах за б/у. И тут попалось объявление, что дяденька отдает такое руководство бесплатно. Правда живет он в Нижегородской обл. Списались, оказался пожилой дальнобойщик. Он посетовал, что рейсов нет в мою сторону, поэтому, в итоге, он просто сходил на почту и отправил мне книжку. Расходы он оплатил сам — все на полном доверии.

Полный размер

Книга 97 года, но состояние неплохое.

Через несколько дней я ее получил. Отправил ему 300 за отправку и 300 сверху. Книга обошлась мне в 600р., но засада была в том, что книга для авто с бензиновыми движками)). На авитовском фото этого было не разобрать и я не уделил этому внимания.

Полный размер

Издательство ПОНЧик)

Но зато по ходовке и прочему мне подходит.

Полный размер

Перевод нормальный, иллюстрации четкие.

В общем, если кому че отсканировать (в пределах 2-3х страниц) обращайтесь…

Цена вопроса: 600 ₽

Техническая документация по ремонту автомобилей Nissan Datsun ( все годы выпуска) Бесплатно, без регистрации и СМС

Руководство по ремонту, эксплуатации и техническому обслуживанию Nissan Datsun

— полные технические характеристик

-особенности эксплуатации

— устранение неисправностей Nissan Datsun

— цветные электросхемы Nissan Datsun

СКАЧАТЬ / СКАЧАТЬ С ЗЕРКАЛА

Руководство по эксплуатации Nissan Datsun

— полные технические характеристики Nissan Datsun

— особенности эксплуатации

— устранение неисправностей

— цветные электросхемы

СКАЧАТЬ / СКАЧАТЬ С ЗЕРКАЛА

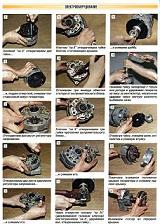

Руководство по ремонту Nissan Datsun в фотографиях

— полные технические характеристики

— особенности эксплуатации Nissan Datsun

— устранение неисправностей

в фотографиях своими руками

— более 1980 фотографий процесса ремонта

СКАЧАТЬ / СКАЧАТЬ С ЗЕРКАЛА

Каталог деталей и сборочных единиц Nissan Datsun

— таблица взаимозаменяемости деталей автомобилей

— предназначен для работников СТО и владельцев автомобилей Nissan Datsun

— каталог деталей Nissan Datsun

СКАЧАТЬ / СКАЧАТЬ С ЗЕРКАЛА

Подробная электросхема Nissan Datsun

— полное описание электрооборудования Nissan Datsun , подробная интерактивная электрическая схема Nissan Datsun

— подробно описан алгоритм поиска неисправностей электрооборудования (стартер, генератор, система зажигания, впрыск, инжектор)

— подробная схема электрооборудования ( электро схема ) Nissan Datsun

— распиновка разъемов электрических, распиновка электро проводки Nissan Datsun

СКАЧАТЬ / СКАЧАТЬ С ЗЕРКАЛА

Руководство по ремонту двигателя Nissan Datsun

— полные технические характеристики двигателя Nissan Datsun

— особенности конструкции и ремонта двигателя Nissan Datsun

— подробное описание процессов разборки, дефектовки и сборки двигателя с фотографиями, ГРМ

СКАЧАТЬ / СКАЧАТЬ С ЗЕРКАЛА

Руководство по ремонту коробок передач Nissan Datsun

— полные технические характеристики КПП

— особенности конструкции и ремонта КПП Nissan Datsun

— устранение неисправностей КПП трансмиссия, валы, шестерни, ШРУС

— подробное описание процессов разборки, дефектовки и сборки КПП с фотографиями

СКАЧАТЬ / СКАЧАТЬ С ЗЕРКАЛА

а вот здесь можно заработать на новую машину, и тогда старую не придется ремонтировать!!!

Nissan Datsun

Мой сайт. Ниссан датсун пикап устройство и ремонт

Все для ремонта Nissan Datsun

скачать бесплатно

|

Руководство по ремонту Nissan Datsun Руководство ремонту, эксплуатации и техническому обслуживанию Nissan Datsun Ремонт в фотографиях Nissan Datsun |

|

||

|

Скачать bonar |

Скачать turbobit |

Скачать bitoman |

|

|

Электросхема Nissan Datsun Схема электрооборудования Nissan Datsun Подробная электросхема Nissan Datsun |

|

||

|

Скачать bonar |

Скачать turbobit |

Скачать bitoman |

|

|

Каталог деталей Nissan Datsun Каталог деталей и сборочных единиц Nissan Datsun Каталог деталей Nissan Datsun |

|

||

|

Скачать bonar |

Скачать turbobit |

Скачать полная версия bitoman |

|

Недостатки / достоинства Nissan Datsun / преимущества / плюсы / минусы / особенности / неисправности генератор, стартер, свечи, Nissan Datsun зажигание, электропроводка, КПП, дифференциал, трансмиссия, ступицы, ШРУС, капот, двери, Nissan Datsun кузов, приборная панель, контрольные приборы, шины, диски, колеса, сиденье, тормоза, колодки, диски, шланги, прокладки, пыльники, манжеты, литература, мануалы, книги, схемы, пособие, стойки, пружины амортизаторы, руль, наконечник, рейка, лонжерон, балка, подрамник Nissan Datsun

Техническая документация Nissan Datsun

avtoo.ucoz.ru

Nissan-datsun пикап 1988 год ремонт. Советы, отзывы, фото

Содержание статьи:

Владивосток. 1988 год, 2400 куб. см., Дизель, Коробка, Полный привод. В салоне тепло. До этого владел пикапами Датсун 94 г.в с и Хайлюксом 98 г.в. с дизелем 2,8. В них зимой Отзывы владельцев Nissan Datsun о своих машинах.

Руководства по эксплуатации, обслуживанию и ремонту Datsun Pick — Up. Автор: Издательство: Nissan Motor Co., Ltd Год издания: Страниц: Формат: PDF Размер: 69,6 Mb.

Паспортные данные.

Мучаю их постоянно, ни одного толком не замучил. Агрегаты не доставляют хлопот. В каталоге нет его квалификации. Содержание Габаритные размеры Технические характеристики Коробка передач и тормозная система Последняя модель двадцатого века Фото.

Nissan Datsun в кузове Пикап, I выпускаемый с 1988 по Список модификаций Nissan Datsun в кузове Пикап, I VERcity.

Japanese Used Cars Portal. Search by Car Make. Search for Make, Model, Chassis, Year, Fuel, Transmission etc. JUMVEA Japan Used Motor Vehicle Exporters Association is approved by the Ministry of International Trade and Industry MITI , presently the Ministry of Economy, Trade and Industry METI in Japan. JUMVEA certified member compnay is a legally registered company in Japan and have a license to buy, sell the second-hand vehicles and an exporter of the used motor vehicles.

For More information, please Click Here. What is JUMVEA SAFE TRADE Membership? Bank information will be provided by supplier in proforma invoice. Disclaimers All Right Reserved. Search by Car Type.

Search by Car Fuel. Search by Car Model. Search by Car Sub Type. Search by Car Steering. Search by Car Price. Search by Car Mileage. Search by Car MFG Year. Price Low to High. Price High to Low. Year New to Old. Year Old to New. Make A to Z. Make Z to A. Model A to Z. Model Z to A. Select All Clear All. Save as my search. PHOTO YEAR MAKE MODEL JCT REF. ID KM Steering DEALER FOB PRICE.

1996 Datsun/Nissan pickup 2.7L turbodiesel

rfautoinfo.ru

MAХИНА — Nissan DATSUN

Электронные книги Nissan DATSUN для автомобилистов бесплатно

Руководство по ремонту, эксплуатации и техническому обслуживанию Nissan DATSUN СКАЧАТЬ 194 Мб(Руководство по ремонту Nissan DATSUN полная версия)

Руководство по ремонту Nissan DATSUN в фотографиях СКАЧАТЬ 116 Mб(Ремонт Nissan DATSUN в фотографиях)

Секреты ремонта Nissan DATSUN СКАЧАТЬ 51 Мб(подробное описание особенностей ремонта Nissan DATSUN )

Подробная схема электрооборудования Nissan DATSUN СКАЧАТЬ 72 Мб ( электросхема Nissan DATSUN )

Каталог деталей Nissan DATSUN СКАЧАТЬ 101 Мб( Nissan DATSUN Каталог деталей и сборочных единиц )

Руководство по ремонту двигателя Nissan DATSUN СКАЧАТЬ 73 Мб(ремонт двигателя Nissan DATSUN своими руками в фотографиях)

Руководство по ремонту трансмиссии Nissan DATSUN СКАЧАТЬ 104 Мб(ремонт КПП и дифференциала Nissan DATSUN своими руками в фотографиях)

Коды неисправностей Nissan DATSUN СКАЧАТЬ 15 Мб( Nissan DATSUN коды ошибок инжектора, распиновка, самодиагностика )

Мультимедийное Руководство по тюнингу Nissan DATSUN СКАЧАТЬ 115 Мб(тюнинг Nissan DATSUN своими руками с фотографиями)

ТЕГИ: Руководства по ремонту Nissan DATSUNбесплатно, без регистрации и СМС Nissan DATSUN Бесплатно, без регистрации и СМС Nissan DATSUN

Nissan DATSUN

maxina.ucoz.net

loveavto — Nissan Datsun

Техническая документация по ремонту автомобилей Nissan Datsun ( все годы выпуска) Бесплатно, без регистрации и СМС

Руководство по ремонту, эксплуатации и техническому обслуживанию Nissan Datsun

— полные технические характеристик

-особенности эксплуатации

— устранение неисправностей Nissan Datsun

— цветные электросхемы Nissan DatsunСКАЧАТЬ / СКАЧАТЬ С ЗЕРКАЛА

Руководство по эксплуатации Nissan Datsun- полные технические характеристики Nissan Datsun- особенности эксплуатации

— устранение неисправностей

— цветные электросхемыСКАЧАТЬ / СКАЧАТЬ С ЗЕРКАЛА

Руководство по ремонту Nissan Datsun в фотографиях- полные технические характеристики

— особенности эксплуатации Nissan Datsun- устранение неисправностей в фотографиях своими руками- более 1980 фотографий процесса ремонтаСКАЧАТЬ / СКАЧАТЬ С ЗЕРКАЛА

Каталог деталей и сборочных единиц Nissan Datsun- таблица взаимозаменяемости деталей автомобилей

— предназначен для работников СТО и владельцев автомобилей Nissan Datsun- каталог деталей Nissan DatsunСКАЧАТЬ / СКАЧАТЬ С ЗЕРКАЛА

Подробная электросхема Nissan Datsun- полное описание электрооборудования Nissan Datsun , подробная интерактивная электрическая схема Nissan Datsun- подробно описан алгоритм поиска неисправностей электрооборудования (стартер, генератор, система зажигания, впрыск, инжектор)- подробная схема электрооборудования ( электро схема ) Nissan Datsun- распиновка разъемов электрических, распиновка электро проводки Nissan DatsunСКАЧАТЬ / СКАЧАТЬ С ЗЕРКАЛА

Руководство по ремонту двигателя Nissan Datsun- полные технические характеристики двигателя Nissan Datsun- особенности конструкции и ремонта двигателя Nissan Datsun- подробное описание процессов разборки, дефектовки и сборки двигателя с фотографиями, ГРМСКАЧАТЬ / СКАЧАТЬ С ЗЕРКАЛА

Руководство по ремонту коробок передач Nissan Datsun- полные технические характеристики КПП- особенности конструкции и ремонта КПП Nissan Datsun- устранение неисправностей КПП трансмиссия, валы, шестерни, ШРУС- подробное описание процессов разборки, дефектовки и сборки КПП с фотографиямиСКАЧАТЬ / СКАЧАТЬ С ЗЕРКАЛА

а вот здесь можно заработать на новую машину, и тогда старую не придется ремонтировать!!!

Nissan Datsun

loveavto.ucoz.net

Смотрите также

Закрыть

Запись на тест-драйв

-

Aet tO

DATSUN TRUCK

MODEL 320

SfRVICE MANUAL

NISSAN

yNI55AN MOTOR CO LTD

OTEMACHI BLDG OTEMACHI CHIYODA KU

TOKYO JAPAN

CAlLI ADDRISS I NISMO TOKTO

HONU I 211 5281

c

fi 11t

lJ

l

E

t

Book Sale

-

MODEL 1IO U

NEW MODEL 1IO U

I

i

-

INTRODUCTION

ThIS manual has been comphes for purpose

of asslstmg DATSUN dIstnbutors and dealers

for effectIve serVIce and mamtenance of the

Model P L 320 U Each assembly of the major

components IS descnbed 10 detaIl In addItIOn

comprehenSIve mstructlOns are gIven for com

pIete dlsmanthng assembImg and mspectlOn of

these assembltes

It IS emphasIsed that only genuine DATSUN

Spare Parts should be used as replacements

l

cfi4

-

CONTENTS

SPEClFICA TION

ENGINE

1 6

1

1

3

1015

203435

38

3943444954

General SpecIftcatlOnsCOOLING SYSTEM

Lubncatlon

ServIce OperatIOns wIth EngIne In PosItionRocker Mechamsm

Removmg RefittIngOperatIOn WIth the Engme Removed

FUEL SYSTEM

The GasolIne TankFuel StrainerFuel PumpAdjustment and Inspection

of EngIneCarburetorBRAKER POINT AND IGNITION TIMING ADJUSTMENT

DlstnbutorAdjustIng the Igmtlon TImIngCheckIng the Spark

PlugsCLUTCH

Clutch

Descnptlon of Clutch Control

TRANSMISSION

TransmIssIOn

DIsassemblIng the CaseAssembhng the TransmISSIOnSelector Inner

Operatmg Lever Cross ShaftPROPELLER SHAFT UNIVERSAL JOINT

Propeller Shaft Umversal jomts

STEERING

FRONT AXLE

Front Axle

Settmg of TenSIon Rex

Page

59

596165

qit0 t

1

66

67

68

76

77818791

93

U1IJJ

l

rt

i1

94

97

106t

106 l114

-

uc

Page

REAR AXLE 117

Rear Axle 118AssemblIng Adjustment 122

BRAKE 138

IGNIfI0N SYSFEM 147

ELECTRICAL SYSTEM 150

Starter Motor 164

Battery 171

t

v

-

SPECIFICA TIONS

For Model 320 U

VEHICLE DIMENSIONS

Length overall approxWIdth overall approx

HeIght overall approxWheelbaseTread Front

Rear

Mm road clearance

CARGO SPACE DIMENSIONS

Intenor lengthlntenor wIdthlntenor height

WEIGHTS

Dry vehIcle weIght emptySeating capacItyMax cargo weIght

Model 320 UModel 320 UN

Model 320 UP

PERFORMANCE

Max speedGrade ablhty Sm 6Mm turnmg radIUs

ENGINE

NameKmd

Cyhnder No and arrdngementCyclevalve arrangementBore x

StrokeTotal piston dIsplacementCompressIOn ratioMax powerMax

torqueFInng order

4 185 mm 164 8 m1 515 mm 59 6 m1 50S mm 59 3 m2 470 mm 97 2 InI

170 mm 46 1 In1 187 mm 46 7 m177 mm 7 0 In

I 850 mm 72 8 m1 427 mm 56 2 In

406 mm 16 0 In r

945 kg 2 080 lbs 12

225 kg 500 lbs500 kg 1 000 lbs910 kg 2 000 lbs

J

120 KPH 75 MPH

t385 2 m 17 ft

Model E 1

Gasohne engme4 cvls m lme

4 cycleValve m head

73x7l mm 2 875 m x 2 796 m1 189 cc 72 5 cu m

8 2

60 HP at 5 000 r P m SAE

9 3 kg m 673ft lb at 3 600 r p m1 3 4 2

ir f

-

rValve tlmmgInlet opemngInlet closmgExhaust opemngExhaust

closmgValve clearance Both m1et and exhaust Hot

IGNITION SYSTEM

19mtlon tlmmgSpark plugsSpark plug gap

FUEL SYSTEM

CarburetorThrottle valve dlaVentlro dlaMam Jet dla

t Slow Jet dla

PQwer Jet dlaSlo economlzerSlow aIr FIrstSlow atr Second

Float levelFuel tanJlcapaclty

Llj RICA TION SYSTEM

OIl pan capacity

COOLING SYSTEMt

r

Coolmg water capacIty

BATTERY

TypeVoltage

Capacity

Termmal grounded

JGENERATOR

CapacityVoltage current regulator

2

14 deg B T C50 deg A B C52 deg B B C

12 deg A T C0 35 mm 0 014 m

10 deg B T C 600 rpmNGK Model B 6E 14 mm

0 7 0 8 mm

Pnmary28 mm

21 8 mm

9848

4Q145

100220

Secondary30mm25 14 7 mm

11540

19mm35 htres 9 3 U S gal

3 1 htres 0 86 U S gal

5 4 htres 1 4 U S gal

CF3 12K 14M2 M39 1212 volts2 SMS

40 amp hr 20 hr50 amp hr 20 hr

posltlve sIde

0 2 KWCarbon ptie type

-

STARTER MOTOR

Voltage and power 12 volts 14 hp

CLUTCH

TypeOperating systemMaster cyhnder mSlde dlaOperatmg cy1mder

mSlde dzaDry smgle plate typeHydrauhc

15 85 mm 5 8 m19 05mm 3 410

TRANSMISSION

Type Four forward speeds and one reverseSynchromesh on 2nd 3rd

and top gearsFor 320U320 UN For 320UP

3 94 4 942 40 3 01149 1731 00 1 005 16 6 46

2 0 lures 0 53 U S gal

Gear ratIOs

1st speed2nd speed3rcl speed4th speedReverse

all capacIty

REAR AXLE

TypeGear ratIo

all capacIty

Semi floatIng4 875 39T 8T for 320 U 320 UN 5 143 36T 7T for 320

UPfor other 320 senes as potIonalO 85 htres 0 22 U S gal

STEERING SYSTEM

Gear mechamsm

Gear ratIO

Warm and roller

17 3 I

FRONT AXLE

Toe mCamberCaster

Kmg pm mchnatIon

2 3 mm1 deg 30 mm4 deg 15 min6 deg

c

BRAKE SYSTEM

Type Foot brake FrontRear

Hydrauhc umservo typeHydrauhc duoservo type

Mechanical rear wheels brakedHand brake

3

-

Brake drum dla front and rearMaster cylmder boreWheel cyhnder

boreFront wheelsRear wheels

254 rom 10 1019 05 mm 0 77 10

19 05 mm 0 77 lD19 05 mm 0 77 lD

SUSPENSWN SYSTEM

Front suspensIOnFront spnngsDimensIOn Ola x LengthRear

spnngs111lckness numberWishbone type Independent suspensionTorsIOn bar spnng

20 5 x 604 5 mmParallel semlelltptic leaf spnng

7 mm x 2f 320 U

6 mm x 1or

6mm 412 mm 1

6mm

215 mm 212 mm 1for 320 UN

for 320 UP With

helper rubber

Shock absorbers FrontRear

smgle actionsmgle action

TIRES

Model Front Rear

320 U 5 60 14 6PL T 24 lb 5 60 14 6PL T 30 lb

320 UN 5 50 14 6PL T 22 lb 5 50 i4 6PL T 36 lb320 UP 6 00 14 6PL

T 22 lb 6 00 14 8PL T 60 lbI

4

-

FOT

RUNCH SEDAN U320 Double Seat 2 DOOR ST WAGON V320N320 Single

SeatVEHICLE DIMENSIONS

U320 V320 N320

Length overall 4 285 mm 4 155 mm 4 155 mmapprox 168 7 m 163 6 m

163 6 mWIdth overall 1 497 mm 1 497 mm 1 497 mm

approx 58 9 10 58 9 m 58 9 m

HeIght overall 1 520 mm 1 515 mm 1 530 mmapprox 59 8 m 59 6 m 60

3 mWheel base 2 470 mm 2 470 mm 2 470 mm97 2 10 97 2 m 97 2 m

CARGO SPACE DIMENSIONS

Intenor length 880 mm 2 1 555 mm 1 560 mm34 6 m 61 2 m 61 6 m

FIntenor wIdth 1 245 mm 5940 mm 1 254 mm49 m 1 180 10 49 4 m

tIntenor heIght 420 mm 905mm 430 mm

16 5 m 35 6 m 16 9 m

WEIGHTS

VehIcle weIght 1 000 kg 1 020 kg 955 kg2 200 lbs 2 255 lbs 2 100

lbsSeatmg and loadmgcapacIty 5 400 kg 2 SOO kg 2 500 kg

880 lbs 1 100 Ibs 1 100 1bs5 300 kg

660 lbs

TRANSMISSION

Gear tram HIgh gear 4 forward1 reverse

Gear ratIO Low 3 94 2nd 2 40 3rd 1 49 Low 3 94 2nd 2 40

hIgh 100 reverse 5 16 3rd 1 49 4th 1 000Reverse 5 16

5

-

FINAL GEAR

Gear ratIO 5 143 36T 7T 4 875 39T 8T

SUSPENSION

Front Wishbone type IndependentsuspensIOn wIth torsIOn bar

Rear thickness andnumber of spnngleaves 6 mm 4

12 mm I6 mm I12 mm 1

Supplemental Sp 108 mm 80 mm

Shock absorbers Front Single actingRear Single acting

Optional

Single actionSingle action

TIRE SIZE AND PRESSURE

Front

Rear5 50 l4 6PL T 22 lb5 50 14 6PL T 46 lb

5 50 14 6PL5 50 14 6PL

1 PERFORMANCE

iT Max speedGrade abilityMin turning

radIus

110 KPH 70 MPH0 30

120 KPH 74 6 MPH0 30

5 2 m 17 ft 5 2 m 17 ft

NOTE Other speclftcatlOns are same as Model 320 U

6

-

ENGINE

I

c

1

l

I

I

-

ENGINE

The engme IS of monobloc construction and IS fitted with

overheadvalvesoperated by rockers and push rods from the camshaft 011 seals

are fItted to thevalves Three steel backed beanngs support the

camshaft whIch IS cham dnvenThe OIl pump and dlstnbutor are dnven from the camshatt each

componenthavmg Its own dnve shaftThe pIstons are each htted with two

compressIOn rmgs and a slotted011

control nng Beanngs of the thm shell preformed type are fitted

to the connect109 rod bIg ends and to the malO beanngs A counter

blanced crankshaft IS fittedThe end thrust on this component IS

taken by specIal washers at the center malObeanng The centnfugal water pump and coolmg fan are dnven by the

dynamobeltGENERAL SPECIFICATIONS

No of Cyhnder 4

Bore 73 025 mm 2 875 m

Stroke 71 mm 2 796 m

Volume 1 189 cc

Max brake horse power 60 HP at 5000 r p m

Torque 9 3 kg m at 3600 r p m

Flnngorder 1 3 4 2

Valve arrangement Overhead valve push rod type

CompressIOn pressure 163 lbs per sq m 11 5 kg cmat 350 r p m

CompressIOn ratio 8 2 1

1

-

1Engine Rightside

Engine Leftside

2

-

COOLING SYSTEM

An effIcIent coohng system IS of major Importance to ensure the

satisfactoryrunmng of the engIne and It IS therefore necessary to

pay patlcular attention toIts maIntanceDescriptionThe coohng system IS maIntaIned by water pump

CIrculation combIned wIthan effIcient fan cooled radIator and thermostat

The system IS pressunsed and the rehef valve Incorporated 10 the

radIatorfIller cap controls the pressure at approxImately O 4 kg

per sq cm Do notremove the ftller cap If the temperature of the

coolant IS above IXJhng poInt orIf the engIne IS runmng ToppIng up should only be requIred

occasIOnally to replace water lost through the overflow pIpe Top up

when the engIne IS cold andIf pOSSIble use clean soft waterlij

l

Fig 1 Rmliator

FIll to wIthIn 1 2 of the bottom of the fIller plug well

OverfIlhng when theengIne IS cold may cause water to flow through the overflow pIpe

The capacItyof the system IS approxImately 5 2 htres3

-

In order to ensure maxImum effIcIency It IS essential to keep

the engineoperating temperatures within certain hmlts To assist

this a bellows typethermostat IS fttted being located In the water

outlet at the front of the cyhnderhead The deVIce consIsts of

metalhc bellows fIlled WIth a volatile hqUledwhIch controls a

mushroom valve When the engine IS cold thIS valve IS closedand on

starting the engine the flow of water to the radiator IS temporanly

restnctedDue to thiS the temperature of the water In the cyhnder head and

cyhnderJackets wIll qUIckly nse thus ensunng rapid warnllng up The

heat so generatedwill gradually expand the bellows so opening the

valve and ultlmatelly permittinga full flow of water to the

radIatorThe thermostat Itself IS detachabletherefore should the occasIOn

anse Itcan be removed from ItS housmg and thehose reconnected to

aVOId laYing up thecar Should the thermostat be tightthere are two

tapped holes on the topwhIch may be utlhzed to ease It fromcasting When the system has been com

pletely emptied It IS essential to allowaIr to escape through

the thermostatvalve and then fmally top up The thermostat opening

IS set by the manufacturerand cannot be altered It open at a

temperature of 71 5 74 5 C Dunng decarbomslng It IS pohcy to test

thiS openlng by Immersing the thermostat In waterraIsed to the

reqUIsite temperature Thet lQ valve should open under these conditIOnsAr but If It fads

to open a new umt should befitted Fig 2Therm ostat

Overheating

r lt ffr i itl

J

J II

t

4Y 2Jr

0

J tc

J

nlustTahng the Removelof the Thermostat fromits Housing

Overheating may be caused by a slack fan belt excessIve carbon

depoSItIn the cyhnders runmng WIth the Igmtlon too far retarded

Incorrect carburetoradjustment falhre of the water to CIrculate or

loss of waterFan Belt Adjustment

The fan IS dnven from the crankshaft by a V belt thIS also

dnvlng thedynamoA New belt can be fitted by ftrst loosemng the clamp bolts FIg 3

whIchhold the dynamo m posltJon llld moving the dynamo towards the

engine Shdethe belt over the fan and onto the fan pulley4

-

Adjustment IS then made by bnngmg thedynamo away from the engme

The belt shouldbe sufftclently tight to prevent shp yet thebelt

should have 15 to 20 rnm 5 8 3 4 slackbetween the generator and crankshaft pulleywhen the mIdspan IS

pushed ftrmlyAs the dnve IS taken on the V of the

pulleys It IS not necessary to have the fan belttight to do so

may cause excessIve wear tothe dynamo and water pump beanngs

Afterthe correct tensIOn has been obtamed securelylock the dynamo m

pOSItiOn agamFIg 3 Fan Belt AdjustmentI Generator hmge bolt2 AdJustmg lmk

boltFrost Precautions 0

Freezmg may occur ftrst at the bottom of the radIator or m the

lower hoseconnectionsIce m the hose wIll stop water cIrculation and may

cause bOllmg A muffcan be used to advantage but care must be taken not to run wIth

the muff fullyclosed or bOlhng wIll result When frost IS expected

or when the car IS to beused m a very low temperature make sure

that the strength of the solution ISm fact up to the strength

adVIsed by the manufacturers The strength of thesolution must be

mamtamed by toppmg up WIth anti freeze solution as

necessaryExcessIve toppmg up with water reduces the degree of

protection affordedSolution must be made up m accordance WIth

mstructlons supphed WIth thecontamerRelations of freezmg temperatures of alchol water and

glycenne mIxturesratIO

co

5

10

15

lDIS

31

35

III

45

1

co

5

10

i5

ID

15

JOJ5

41

45

1

1

10 lOYJ 4Q 50 601lI a1 10 20 30 40 50 60 70 80

Glycenne Water mIxture roAlcohol Water ro

5

-

Top up when the system IS coldIf the coolmg system has to be

dramed run the mIxture mto a clear contamerand use agam

Protection by Draining

On cars where antI freeze IS not used the followmg precautions

must betaken dunng frosty weather to obvIate any damage due to

freezmg of the coohngsystemWhen heavy frost IS Immment the coohng system must be completely

dramedIt IS not suffIcient merely to cover the radiator and engme

wIth rugs and musksThere are two dram cocks one on the left hand

SIde of the cyhnder block and theother at the base of the radiator

block Both taps must be opened to dram the system and the car must

be on level ground while drammgThe dram taps should be tested at frequent mtervals by lOsertlng

a pIece ofwIre to ensure that they are cleare Tlus should be done

immedIately the tapsare opened so that any obstruction freed by the

wIre may be flushed out by thewater The drammg should be carned out

when the engme IS hotWhen completely dramed the engme should be run for a tImed mmute

to ensurethat all water has been cleaned from the systemA SUItable notice should be then affIxed to the radIator

mdIcatlng that thewater has been dramedI Flushing the Radiator

To ensure effICIent CIrculatIon of the coolant and to reduce the

fonnatIon ofscale and sedIment m the radIator the system should be

pencxhcally flushed Withclear runnmg water preferably before puttmg

m antI freeze m the wlOter andagam when takmg It out m the spnng

The water should be allowed to run throughuntIl It comes out clear

from the dralO taps At mtervals a stIff pIece ofWireshould be

mserted mto the taps durmg drammg to ensure that they are not

becommgclogged with sedImentTlus rnethod of radiator flushmg may serve well but m cases

where the furrlOg up is excessIve the operator Will find it more effiCIent

practIce to removethe radIator completely and flush m the reverse

way to the flow turn the radIatorupSIde down and let the water flow

m through the bottom hose connectIon and out ofthe top

connectIonWATER PUMP

After drammg the water from the radIator remove the pump unIt

from thecylInder block by takmg off the fan belt and releasmg the

setbolts WIth spnnpwashers and hmge bolts to dynamo4

6

-

WATER PUMP

Removing the Pump Shaft Assembly

DIsconnect the fan blades pulley and coverThe shaft and ball

beanngs IS combmed with one umtPut the pulley hub on the benchFIrst

press or knock the shaftend WIth a dnft hard bar and drawout the pulley hub on the U

typebenchTake out the set pm from thesht whIch locked the shaft

assemblyto the pump body See Fig 1Next turn the body upsIde downand press out the shaft

assemblyfrom the vane SIde on the U typebenchji

7

-

The shaft and ball beanng assembly can be drewout from the

bodyThus take out the vane floatmg seal and seal whIch remamed the

pump bodyReassem bly

The reassembhng of the pump IS a reversal of the disassembly

procedurebut a care should be taken to ensure that the shaft

assembly IS fItted correctlyfor a slIt a hole of set nng wIth a

groove of shaft so as to msert and set the saIdnng correctly

Pulley

Pulley hub

Set bol t

Shaft WJ thbearIngs

21035 OOO

Set rlDg plD

SPrIng washer

Body

Washer

Cover

Fig 1 Sectional View of the Water Pump

8

-

Adjusting the Clearance the Vane End and BodyFIrst press down

the shaft fIttmg wIth a groove lme to msert the set pmInsertmg

thIckness gauge fhlckness O 4 0 5 mm between the vane end onthe U block bench Take out the thickness gauge and fmd out good

condmonScrew up wIth the cover and cork washersere

Shaft bear1llgsassembly

Set p1ll 0Yf VaneFloatl llg seal

Insert herethlckness

gauge0 40 5 mm

9

-

LUBRICATION

Circulation

Pressure lubncatlon IS used throughout the umt and IS provIded

by gear 011pump The 011 pump IS bolted mto the left hand sIde of

the crankcase and IS dnven from the camshaft gear by a short

vertical shaftOllIS drawn mto the pump vIa the filter and IS dehvered through

mternal 011way The rehef valve dIrectly IS situated m the 011

filter bodyFrom the rehef valve the 011 passes Into the mam 011 way If

caused the elementfml to pass rhe 011 The flow then passes vIa

connectmg 011 ways to the mam bIgend and cam shaft beanngs through

dnllmgs m the crankshaft The connectmg rodends are dnlhng m the

cyhnder block and the rear rocker shaft bracket to lubncate the

rockers and then drams back Into the engme sump vIa the push rod

apertures all from the center camshaft beanng enters a gallery on

the left handsIde of the engme and lubncates the tappets through

mdlvldual dnlhngs As thecamshaft rotates two grooves m the front

Journal regIster WIth a small hole mthe camshaft thrust plate thus

allowmga small amount of 011 to pass mto thetlmmg case tWIce dunng case revolution of the camshaft to

provIdelubncatlOn for the tlmmg cham andgears From the tlmmg case

the011 returns VIa a dram hole back tothe engme sump The ftlter therefore forms part of the mam oJ

gallery and as such IS fIlled withoJ under pressure

The full of 011 enters the element through holes m the casmgand

passes through the element mtothe annular space round the

centerboltThIs space IS sealed top and

bottom so that the 011 can only escape through the hole mto the

hollow center bolt and from thIS pomtback Into the mlet passage

throughthe elementFlg 1 Checkmg the Oil FlUt

10

-

Draining the Sump Oil Pan

The sump IS a metal pressmg with the dram plugOne new and

reconditiOned engmes the sump must be dramed and refilled withnew 011 after the first 1000 km and subsequently atmtervals of

5000 kmDram the 011 when the engme IS hot smce warm Oil flows freely

and takeswith It any sludge or sediment whIch may have

accumulattedNever use petrol or paraffm for flushmg purposes Such cleamng

medlUmsare never completely dIspersed from the engme lubncatiOn

system and wIll remam to contammate any fresh Oll ThIs may cause

premature beanng faIlureOil Pressure

The normal operatmg OIl pressure IS 60 lb per sq m

The warmng lIght whIch IS emboclted 10 the mstrument panel hght

If the Oilpressure drops below 8 lbs sq m under these cIrcumstances

do not attemptto run the engme or serIOus damage may resultRefillig

When refllltng the sump do not pour the OIl m too qUIckly as It

may overflowfrom the fIller orifIce and mIslead the operator as to

the quantity of lubricant 10the engmeBefore testing the level of the Oil ensure that the

vehIcle IS as near levelas pOSSIble Always WIpe the dIp stick clean wIth a non fluffy

cloth before talangthe readmg It should be remembered that time

must be allowed for new 011 toreach to sump before readmg the

dIpstickCheck for Low Oil Pressure

Check the level of OIl m the engme sump by means of the dip

stIck and topup If nece sal v If the warnmg Itgiit IS still on

after reftllmg the sump switchoff and ascertam that the gauge

stramer m the ump IS clean and not chokedwith sludge ale that no aIr leakage eXIsts at the strainer uniOn

on the suctionSide of the Oil pump bemg defectIve remove the umt

and rectify the fault11

-

Removing the Filter

A new hlter element should be fitted every 6 000 km

The fIlter forms part of the mam 011 gallery of the engme To

remove thehlter It IS only necessary to unscrew the center bolt

when the bowl can be removedfrom the cylinder block complete wIth

the element For full flow type E1 engmeIt IS neceE sary to cover

wIth some of rugs to prevent from flow 011 on the generatorwhen

remove the body Take care not to lose the rubber seahng nng Remove

theelement and note the assembly of the componentsWash out the bowl WIth pettol so that It IS clean It IS

Important to thoroughlydry the bowl to obVIate any contammatIon of

the lubncatmg 011rr

J

Flg 3 Components of Oil Rlter

Replacing the Filter4

Put the element WIth seat of It on the bracket Cover with the

filter body afterputtmg the element retamer spnng andthe gasket 10 posltlon

Insert the centershaft mto posltlon and screw up Itwith ughtmg torque 2 2 5 kg m

and secure mtoposttJon by means of the center bolt

12

-

Removing the Oil Pan0

The sump capacIty IS 3 1 htres Dram the 011 and replace the dram

plugRemove the set screw bolts whIch are mserted from the undersIde

of the secunng flange and the lower bolts from the bottom edge of the

bell housmg Lowerthe OIl pan from the engme takmg care not to

damage the Jomt washers m theprocessmoviDg the StrainerJ

i

l t

WIth the sump lowered It IS possIble to remove the OIl stramer

through whIch011 IS drawn mto the 011 pump To remove the stramer

unto the umon connectingthe 011 pIck up to the pump and unscrew the

secunng boltsThe stramer may be dIsmantled for cleamng purpose by removing

the dehvery pipe flange boltsNotice that there are the dowel pinS to the cover whICh must be

posItIOnedcorrectly when reftttmgRemoving the Oil Pump

Remove the 011 pan and pIck up strainer Three of the ftve bolts

secunng theOIl pump bottom cover are long enough to secure the pump

to the crankcaseFIg 4 Illustrates the pump In explosed form Unscrew

the long bolts and removethe pump with ItS dnve shaftDismantling the Oil PumpRemove the setscrews and spnng washers

whIch secure the cover to the b6dyand take off the cover On tlltmg the body upSide down the Inner

rotor with ItSdnve shaft and the outer rotor wIth shde outRefitting the Sump

Clean out the sump by washing It In paraffin the care to remove

any tracesof the paraffm before reflttmg the OIl pan to the engme

Pay patlcular attentIOnto the 011 pan and crank case JOint faces

and remove any traces of old Jomtlngmatenal Examme the JOint washer

and renew It If necessary The old JOintwasher can be used again If

It IS sound but It IS adVIsable to ftt a new oneSmear the faces of the JOint WIth grease and ftt the JOint

washer Lift the OIl panInto positIOn and Insert the setscrews Into

the flange tlghtlng them up evenlyReassembling the Oil Pump

The outer rotor FIg 4 has a chamfered edge It IS of great

Importance thattills chamfer be towards the base of the body ftlure to assemble

In thIS way Willresult In the cover IS tightened down Insert the

slotted end of the dnve shaft Intothe body and brmg the rotors Into

mesh13

-

Oil strainer ass y

Oil pump dnve spmdle 01l pump plalnwasher

Lock washer

Oil pump bolt

Oil pump gearshaft

ass y

I

eJV Dowel pinl Oil pump

Dcover

f

f i

Fig 4 Oil Pump

14

a

-

SERVICE OPERATIONSENGINE IN

WITHPOSITION

Removing Starting Nut and PulleyRemove the radIator Slacken the

dynamo attachment bolts and remove thefan beltBend back the tab on the startmg dog nut lockmg washer

Unscrew the startmg dog nut by usmg Heavy duty Shock type spannerA few sharp

blows m an ant1 clockwlse d1reCtIOn WIll slacken the nutPull off

the crankshaft pulleyRemoving the Timing Cover

The tImmg cover IS secured by set screw bolts each havmg

ashakeproofwasher and a special plam washer Note that the specIal

washer IS of elongatedshape and IS f1tted next to the tImmg cover

flangeThe spnng washers are Imme

dIately below the bolt headsTake out the set screw bolts

remove the cover and Its Jomt twasher Care should be taken notto

damage the washer when breakmgthe Jomt If damage does occur fita

new washer cleanmg of the facesof the JOint surfaces beforehandFag 1 Heavy Duty Shock TypeSpanner

Removing the Timing GearJI

The tImmg cham IS endless and It 1S necessary to remove both the

crankshaft and camshaft gears together Before domg thIS notIce the

tImmg markson both gears and theIr relatIonshIp to each otherDraw off both the gears a httle at a t1me hrst removmg the

crankshaft gearretaining nutAs the gears are w1thdrawn care must be taken not to lose the

packmgwashers from behind the crankshaft gear Between the camshaft

gear teeth IS arubber nng Wh1Ch acts as a tenslOner and ensures

SIlent operatIon of the chamdnve Examme the felt washer and renew

It If 011 has been lost be seepageRefitting the Timing Gear

ReplaCing the components of the tlmmg gear 1S largely a reversal

of the dISmantlmg process but spec1al attentlon should be pa1d to

the follOWing pomts15

-

FIt the crankshaft and camshaft gears mto theIr respective

shafts Ensurethe tlmmg marks are opposIte and mimeTurn the engme crankshaft until the keyway IS at T D C and the

camshaftWIth Its keyway m approximately the one 0 clock

posJtJonPlace the gears mto pOSitIOn ensunng that the keys are present m

keywayson the shafts Ensure that the tJmmg marks on the gears are

opposite to eachother and mime Dnve the gears homeThe same number of packmg washers taken from behmd the

crankshaft gearmust be replaced unless a new crank or camshaft has

been fitted In thIs case thealIgnment of the gear faces and

measuremg the alIgnment wIth a feeler gauge Toadjust the alIgnment

It Will be necessary to vary the number of packmg washersFIt the 011 thrower behmd the crankshaft gear so that Its

concave face It towards the front of the car and check that the

felt washer IS In posJtJonValve Rocker Cover Removal

Remove the aIr cleaner Unscrew the cap nuts secunng the engme

IIftmgbrackets Remove the rocker cover and the cork Jomt washerRemoving the Rocker Assembly

Dram the coolmg system If anti freeze IS m use use a clean

contamerfor the flUId If It IS to be used agamIt IS necessary to dram the system and slacken the cylmder head

nutsbecause four of the rocker shaft ftxmg nuts also secure the

cylmder headIf the cylmder head nuts are not slackened dlstonatlOn may

result and allowwater to find ItS way from the coolmg system mto

the cylmders and pumpNotice that under the nght hand rear rocker stud nut IS a

speCIal lockmgplate Completely unscrew the rocker shaft blacket

nuts and remove the rockerassembly Complete with brackets and

rockersDismantling the AssemblyTo dIsmantle the rocker shaft assembly

ftrst remove the grub screw andlockmg plate from the rear rocker bracketRemove the split pms

flat washers and spnng washers from each end of theshaft SlIde the rockers brackets and spnngs from the shaft

Unscrew the plugfrom the end of the shaft and clean out the OIl

wayThe two end rockers may be dIsmantled without the whole rocker

assemblybemg drawn out ThIS may be achlved by turmng the engme by

hand untIl No Ipush rod reacher Its lowest pOSItIOnUnlock the tappet adJustmg screw and screw It back as far as It

WIll goWithdraw the split pm flat and spnng washers and slide the

rocker off theshaftSometimes the valve spnng WIll have to be slIghtly

compressed by levennga screwdnvel under No 2 rocker thus allOWing the end rocker to

slIde off theshaft eaSily Repeat the procedure for No 8 rocker16

-

Frg 2 Rear Locking Plate 1 Plate 2 Locatmg Stud

Reassembling the Rocker

On reassembly tIghten the pedestal bracket secunng nuts a httle

at a timeworkmg dIagonally from nut to nut left nut of No 1

pedestal bracket nght nutof No 2 left of No 3 and so on returmng

from the left nut of No 4 bracket andrepeating the process until they are all tight If the rocker

assembly has beencompletely stnpped down and rebushed the OIl holes

wIll have to be rednlledand the bushes reamed down to sIze before

assembly on the shaftThe rockers and spnng must be replaced m theIr ongmal pOSJtJon

on theends of the shaft Remember to replace the rocker shaft

locating screw andlock plateReplace the spnng and flat washers wIth the spht pms on the ends

of theshaft Replace the rocker cover and gasket The vent pIpe

should be at thefront of the engme Secure the cover by means of the

two cap nuts ensunngthat the rubber bushed and engme hftlng plates

are m positIOn If the rockercover gasket or the rubber bushes are

found to be faulty they must be renewedotherwIse OIl leaks will

resultPush Rod Removal

If the valve rocker assembly has already been removed all that

remamsIS for the push rods to be hfted out They may on the other

hand be taken outWIthout detaclung the rocker assemblyRemove the aIr cleaner and rocker cover

Slacken all the tappet adJustmg screws to their full extent then

usmg ascrewdnver with the rocker shaft as a fulcrum depress the

valve sprmg17

-

sltde the rocker sIde ways and Itft out the push rodAll but the

end push rods can be withdrawn In thIs way These wIll have to

bewithdrawn after the removal of the two end rockers from the

shaft When replacingpush rods ensure that the ball ends regIster In

the tappet cups From here onwards reassembly IS a straIght forward

reversal of the dIsmantling processAdjusting Valve Rocker Cltarances

Remove the aIr cleaner and rocker coverThere should be a

clearance of O 014 In 0 3S mm fbetween the face of therocker and the base of the valve stem Whtlst checking the

clearances It IS lmportant to maintain pressure wIth a screw dnver

on the tappet adjusting screw todIsperse the fIlm of 011 from the

push rod cup Fallure to follow thIs procedureWIll result In a wrong

reading being takenTurn the engine over by hand Starting handle untll the push rod

stops fallingthe valve IS fully closedFig 3 Adjusting the Rocker Clearance

18

-

To adjust FIg 3 msert a screwdnver m the adJustmg screw slot and

slakenthe lock nut Then msert 014 m feeler gauge between the face

of the rocker andthe valve stem RaIse or lower the adJustmg screw until the

correct clearanceIS obtamedTIghten the lock nut and recheck the clearanceIt IS Important to

note that whIle the clearance IS bemg set the tappet of thevalve bemg adjusted must be on the back of the cam opposite to

ItS peakI

19

-

ROCKER MECHANISM

Rocker shaft

LengthOuter dIameter

Rocker arm bush

TypeOuter dIameter before

mountmgInner dIameter Reamer

flntshed dImensIOn after

mountIngThIckness before reamer

fmlshmgClearance

Rocker arm

Bore

Lever ratIo

355 63 mm 14 1 32 m15 850 15 875 mm 0 624 0 625 m

WhIte metal wIth steel hnmg

19075 19 101 mm 0 751 0 752 m

15 888 15 901 mm 0 625 1 2 0 626m

1 644 1 727 mm 0 065 1 2 0 068 m0 013 0 051 mm 0 0001 2 0 002

m19012 19 037 mm 0 7481 2

0 749 1 2 In25 003 to 35 719 mm

63 64 to 1 13 32 m

CYLINDER HEAD

Removing the Cylinder HeadDram the coohng system by openmg the

radIator and cylmder block dramtapsOne IS sItuated mlet tube at the backSIde of the radIator

and other at therear nght hand SIde of the engme If antI freeze mIxture IS m use

It should bedramed mto a SUItable contamer and retamed for future

useDIsconnect the negatIve cable from the battery be extractmg the

termmalscrew and removmg the lug from the battery term mal postSlacken both the retammg chps on the hose connectIng the

radIator to thethermostat housmg and remove the hoseExtract the termostat housmg securmg nuts and remove the housmg

andthermostatRemove the alrcleaner carburetor rocker cover and the mlet and

exhaustmamfo1dsDetach the Iugh tensIOn cables and remove the sparklOg plugs

also dISconnect the water temperature gauge connectIon from the

thermostat housmgTake off the rocker assembly not forgettmg to slacken the

external cyhnderhead nuts at the same tImeWithdraw the push rods keepmg them m the order of removal

I

i

20

-

The cylinder head can now be lifted off the cylinder block To

facIlitatebreadmg the cylmder head omt tap each sIde of the head

wIth a hammer usmga pIece of wood mterposed to take the blow Do not

use excessIve force Whenlifting the head a dIrect pull should be

gIven so that the head IS pulled evenly upthe studs Remove the

cylinder head gasketRemove the cylmder head WIth the valves still m posJtJon remove

thecarbon from the combustion chambers and the valve faces Leavmg

the valvesm positIOn for thIs operation ensures that damage cannot

be caused to the seatsby the wIre brush whIch should be used for

the removal of carbonIf the exhaust valve heads are coated with a very hard deposit

thIs may beremoved by usmg a chIsel shaped pIece of hardwoodRemove the valves and usmg the wIre brush clean out the carbon

from themlet and exhaust portsBlowout all traces of carbon dust with

compressed aIr or type pump andfmally clean the ports with gasolme and dry them out The carbon

should nowbe removed from the pIston crowns Rotate the engme until

the pIston to beworked on IS at T D C Protect the other cylinder bore from the

entry ofcarbon particles by pushmg a non fluffy rag mto themUsmg a chIsel shaped pIece of hardwood Carefully remove the

carbon fromthe pIston crowns A nng of carbon should be left round

the penphery of eachpIston and the deposIt round the top of the

cylinder bore should not be touchedAn mdlcatlon as to when

decarbomsatlOn IS requIred IS generally gIven by an allround loss

of power Cars used mamly on short runs WIll reqUIre thIS

attentIOnmore often than those used for longrunsDecarbonising

Removal and Replacementof a Valve

WhIlst the cylmder head ISremoved the valves can be taken

out To do thIS compress thevalve sprmg WIth the specIal

valvespnng compressor as shown mFIg 4

Removal

Remove the two cap retammgcollets Release the valve sprmgthe

valve spnng cap valve 011 sealInlet valve only and ItS retamerWIthdraw the valve from the

gUIdeKeep the valves m theIr relative posJtJons when removed from

the engme to ensure replacementm theIr ongmal valve guIdes

r 1

1

p t4T l

l

y

irlAf 1h

C

t

i

1 h

tJ

n

oyt t 5 r jL I r i4ldl

Fig 4 Valve pring Compressor

21

-

ReplacementNote that the dIameter of the exhaust valve heads are

smaller than the mletvalve To replace the valves msert each valve mto Its gUIde and

replace thesprmg OIl seal and retamer FIt 011 seal chamfered sIde

down wards The 011seals are more easIly fItted If they have been

soaked m engme 011 for a shortpenod before use The 011 seal IS used

for the mtake valve onlyReplace the valve spnng and compress the valve spnngRefIt the

cap retamers and secure them by means of the valve cottersRemove the compressor

Free length mmLength m use and loaded

mm kgTurnmng Nos of COIlEffectlve turn of COliDIa of COli

wireDIameter of COlIInner Sp50mm

Outer Sp52mm

36 9 13 1 t O 78 56 55 6 tO 2 mm24mm

38 9 29 t1 56 54 58 510 2 mm33 7 mm

VALVE SPRING

f

i x0

I

r1

i

r

A

O132j4 0 IOO

10N EH

00 I1320 o Jcj1 t f r

Fig 5 Valve Spring Valve Ass y

22

-

Valve GrindingBefore replacement of the cyhnder head the valves

and theIr seats should beexammed for SIgnS of pitting or burnt patches and dIstortionIf

these condItIOns are present the valve seats must be recut before

attempt109 to gnnd m the valves whtlst dIstorted valve heads should be

trued or the valverenewed Only the mmlmum amount of metal should be

removed 10 the turmngprocessWhen gnndmg a valve onto Its seahng the valve face should be

smeared hghtly WIth gnndmg paste and then lapped 10 WIth a suction

type gnndmg tool Thevalve must be ground to ItS seat WIth a semI

rotary motlron A ltght COIl spnngmterposed between the valve head

and the port WIll assIst consIderably when ltftmgthe valve m order

to rotate the face to a dIfferent posJtJon ThIs should be donefrequently to spread the gnndmg compound evenlyIt IS necessary

to contmue the gnndmg process until an even matt surface ISproduced on the seatmg and the valve faceOn completion the valve

seats and ports should be throughly cleaned WIthgasoltne soaked rag and dned and the subjected to a compressed

aIr blast Thevalves should be washed 10 gasoltne and all traces of

gnndmg compound removedVALVESJ

Valve head dIameter

Intake valveExhaust valve

Valve seat WIdth

Valve stem outer dIameter

both mtake and ex

Overall lengthIntake valveEx valve

34 7911 34 935 mm 1 370 1 375 m30 023 30 150 mm 1 182 1 187

m1 6310 015 mm

8 6805 8 6932 mm 0 341 3 4

0 342 1 4 m

109 54 mm 4 5 16 m108 74 mm 4 9 32 m

VAL VE GUIDE

f r

Length Intake valveExhaust valve

Outer dIameter both mtakeand exhaust

Inner dIameter both mtakeand exhaust

Inner dIameter at guIdemlet to msert both mtakeand exhaust

Clearance of valve stemand guIde both mtake andexhaust

47 63 mm 1 7 8 1057 94 mm 2 9 32 m

14 313 14 440 mm 0 5635 0 5685 m

8 733 8 860 mm 0 3438 0 3443m

14 3 mm 0 5634 m

0 0394 0 0648 mm 0 0015 0 0025m

I

23

-

Refitting the Cylinder Head

Ensure that the cyhnder head and cylInder block Jomt faces are

cleanThe cylInder head gasket IS marked Top so that It wIll be

placed headm correctly Place the gasket mto posltJon and lower the cyhnder

head mto placeFit the cylInder head securing nuts fmger tIghtInsert the push rods replacmg them m the posltJons from whIch

they weretakenScrew back all the tappet adJustmg screws Replace the rocker

assemblyand screw down the securing nuts finger tIght Evenly

tIghten the eleven cyhnderhead nuts a lIttle at a tIme m the order

gIven m FIg 6 fmally pullmg them downwith a torque wrench set to 45

Ibs 1ft5 7

oooo

o

D 10

8 4 2 6

Fig 6 The Order of Tighting the Cylinder Heag Nuts

1

Reset the valve clearances and fmally check them when the engme

IS nothot or cold The cyhnder head nuts may pull down shghtly more

after the engmehas attamea Its normal workmg temperature 10 whIch

case the valve clearancest will have to be checked agam and reset If necessaryRefit the

mlet and exhaust mamfoldsFIt the craburetor and reconnect the

control hnkage Reftt the IgmtIon advancesuctIon pIpe to the connectIon on the carburetter but do not at

thIs stage refit theair cleaner or It WIll have to be removed later

to check the valve clearances Replace the rocker cover takmg care to ftt the cork gasket

correctlyPlace the thermostat and Its housmg m posltJon and secure

wIth the three nutsReconnect the water temperature gauge wIre and fIt the radIator

hose to the thermostat housmg Connect the cables to the battery

Ensure that the radiator andcyhnder block dram tapes are closed and

reftll the radIatorClean and adjust the sparkmg plugs and reftt them chppmg on the

hlghtenslOnleads The flnng order of the engme IS 1 3 4 2 Replace

the chp wluch secures parr of the electrical whlnng harness to the

SIde of the headThe IgnltJon can now be switched on and the engme started When

the normaloperatmg temperature has been reached sWItch off and remove the

rocker coverso that the valve clearances may be rechecked Replace

the rocker cover and fitthe atr cleaner when the fmal check has

been madeWhilst the engifie IS runmng check that the water hose

connectIOns and fuelline umons do not leak TIghten them If

necessary24

-

Removing and Refitting Valve Guides

Remove the cyhnder headRemove the appropnate valve and

spnngRest the ylmder head with Its

machmed face downwards on a cleansurface and dnve the gUIde

downwardmto the combustion space wIth a dnftThIS should take the form of a hardened steel punch See Fig

8When fIttmg new valve guides theseshould be dnven m from the top

of thecyhnder head

0

Fig 8 Hardened Steel Punch

Renewing a Valve Spring in Position

Fig 7 Renewmg a Valve Glade

In an emergency a new valve spnng can be fitted wIthout removmg

the cyhnderhead When domg thIS the apphcable pIston must be brought

to ItS T D C posltJonto ehmmate any posslblhty of the valve falhng

mto the cylmderRemove the spark plug from the cyhnder concerned Hold the valve

onto Itsseahng WIth the aId of a sUItable tool such as a bent

screwdnver WhICh WIll passthrough the sparkmg plug onftce and

locate on the valve head By usmg the rockershaft as a fulcrum pomt

the spnng can be compressed WIth two screwdnvers or afork ended

barWlthClraw the valve cotters and renew the valve spnng

25

-

rr

O ilt

l

Jt

J

r

tI 1

co

t

1

Nut

CotterPln

f

Washer

Washer

fldJust

screwnut

l

LocatIng

spnng

V

I

ker

iplate

outs

del

IliC1

a

ve

roc

S

II

5

crew

h

f

h

I

71

v

Jalve

rocker

IlJJ

shalt

i

Rockershaft

racket

t

9b

t

Sprm8retalner

TappetadjustIng

screw

Il

Rubberring

Pushrod

Outer

spnng

lnnerspnns

1

j

1Jl

Valverocker

ll

1

t

01

r

rI

ChaIntenSIon

Boltt

LOC

wasberlol

l

TImIngchan

CAMSHAFTVALVE

GEAR

-

rJ

11 1

A [email protected]

I

e

tJ 3

@ Q

[email protected]

eflelt o

00Or

e

Frg 9 Cylinder Head

I Engine slln2 011 fIll

g brdcket

1 Valver cap

4 was eercover

over JOint

n Thermostat6 JOint washer7 Cylmder head

ff

27

JA

rr

evh

I

rq

w

fcr

l

-

Jrit

Removing and Replacing the Tappets

Remove the carrWetor and therocker cover then tak off

themamfoldsDIsconnect the hIgh tensIOnleads from the sprkmg plugsremove the

rocker assembly andwIthdraw the push rods keepmgthem m theIr

respective pOSItIOnsso that they wIll be replaced ontothe same

tappetsRemove the tappet covers andhft out the tappets also keepmgthem

m same locations FIg 10New tappet should be fitted byselective assembly so that they

fallmto the gUJds under theIr ownwdlght when luorlcatedAssembly IS a reversal of theabove procedure but car should

betaken to see that tappet cover JOIntSare 011 tight and that the

rockersare adjusted to gIve the correctvalve clearance Fig 10

Removing a Tappet7

Piston and Connecting Rod Removal

Dram the coohng water from the engme and radIator Dram and

removethe sump from the engme then dIsconnect and remove the od

strainer Takeout the set screws and rock washers from the bIg ends

and WIthdraw the capsIt WIll be noted that the caps are off set

When used parts are replaced afterdlsmantlmg It IS essential they

are fItted mto theIr ongmal posltJons To ensure Qorrect refIttmg

mark the caps and connectmg rods on the SIdes to Identify them

together The pIston and connecting rods must be WIth drawn upwards

through the cyhnder boresRelease the connecting rod from the crankshaft and slowly push

the pIstonand rod upwards through the cyhnder boreNOTE

It may be necessary to remove the nng of carbon or hp from the

topof the cyhnder bore WIth a hand scraper to aVOId risk of pIston

nngbreakageRemove the assembly from the top of the cyhnder blockCheck the

crankpms for ovahty WIth a paIr of mIcro meter caltpersand examme the beanng surface for scoring eIther defect WIll

necesSItate the removal of the crankshaft for regnndmg28

-

CONNECTING ROD

pl

DIstance between center of

large end and small end

Large end beanng

Type

Overall lengthThICkness

Outer dIameterWidth of large endEnd play of large end

Fmlshmg dimensIOn of mnerdIameter of small end bush

Standard

1441 0 03 mm

Coppensh metal with steel llnmg upperSIde

WhIte metal with steel lmmg lowerSIde

25 273 25 527 mm 0 995 0 005 mI 8288 1 8352 mm 0 072 0 0725 m51

346 mm 2 015 m26 8 mm 1055 mo 203 0 305 mm 0 008 0 012 m

17 450 17 462 mm 0 6870 0 6875 m

CRANKSHAFT

Clearance of beanng penphery to cyhnder block hole

Matenal

Clearance of beanng mnerdtameter and crank Journal

DIameter of mam Journal

End play of crankshaftCrank pm dIameter

Standard

DIfference of crank pmdIameter

End play when flywheel wasmstalled

0 013 0 050 mm

Forged steell

o 0127 0 0508 mm 0 0005 0 0020 m i

50 183 50 825 mm 2 0005 2 001 m

o 051 0 076 mm 0 002 0 003 m

47 640 47 652 mm 1 875 1 876 m

Less than 0 012 mm 0 00048 m

Less than O 05 mm 0 002 m

The shell beanng are removable by hand The beanngs are reqUIre

nobeddmg m It IS bemg only necessary to ensure that the hOlsmgs

are scrupulously clean and dry and to place the beanngs mto

posltJon with the tangs locatedm theIr correspondmg slots Always

renew beanngs If they are scored or damaged m any way or followmg the regnndmg of the crankshaft beanng

surfacesIn the latter case underSIze beanngs Will be requIred and

the bnds of sIzes avaIlable are 0 010 0 020 0 030 and 0 040 etc29

-

ri II

h

J

q

l

l

ol

ilIdA5r

I Ir

t

I

Jc t

i t

J

7 8Jr1t

y

I

ConnectingrodasSY

tit

Dowelo

t

f

Crankshaftkey

lowerilo

PlSTONCRANK

SHAFT

-

ILI J

Fig 11 Crank Shaft

1f

PI STON

Replacing Pistons and Connecting Rods

Insert each pIston and connecting rod assembly Into the cyhnder

from whIch Itwas taken It IS essential that the splIt In the skIrt

of the pIston IS pObltJOned towards the camshaftCompress the piston rings WIth inserting pIston uSing tool FIg

12 and gentlytap the crown of the pIston With the wooden end ofa hammer handle until the pIstonIS clear of the pIston nng

clampI

Fig 12 PIston Adapter

if

l

t 1itJf J

l31

-

Now push the piston down the cylmder block until the big end of

the connectmgrod Just protrudes through the bottom of the cylmder

bore then posItIOn upper halfbeanng shellsNOTE Each upper lower beanng has two OIl holes there by

ensunngsuffIcient and It IS of the greatest Importance that the

correspondmg 011 hole m thebeanng shell regIsters with the 011 way

to provide an unobstructed passagePull the connecting rod onto the crankpm takmg care not to

injure the beanngsurface Insert the shell mto the connecting rod

cap posltlon the cap and the lockmg washers Insert the setscrews

and tighten with a torque wrench to 21 7 24 6lbs ftFmally knock back the lock washersCheck the connectmg rod bIg

end for side clearance 1 1000 m and see thatthe shell beanngs are not bmdmg on the crankpm when rotatmg the

crankshaftIf It IS dIffIcult to turn undo the bIg end and examme

the shell and seat for dIrtor gritBefore reassembhng always apply a httle clean Oil to the pIston

surfaces andmto the cyhnder bore Never ftle the connectmg rod caps

or theIr matmg surfacesas thiS creates ovallty m the beanngRemoving a Piston

Remove the clampmg bolt from the small end of the connectmg rod

and push outthe gudgeon pm The gudgeon pm IS a push ftt m pIston at

70 F 21 1 CWhen reassembhng ensure the gadgeon pm IS posItIoned m the

connectmg rodso that ItS groove IS mime with the clamp screw hole

Check that the spnng washerfttted under the head of the pitch bolt

IS not damagedCf

PISTON PIN

DIameter

10 1000 m

17 447 17 452mm0 6869 0 6871 m

17 574 17 579 mm0 6919 0 6921 m

17 701 17 706 mm0 6969 0 6971 m

17 828 17 833 mm0 7019 0 7021 In

64 20 64 45 mm2 568 2 578 m

Degree to be able to push It byfmger at 200C

o 003 0 010 mrn0 0001 0 0004 m

Over SIze 5 1000 m

2tt 15 1000 m

Length

Clearance of pm and pm hole

Clearance of pm and connectmgrod bush hole

32

-

PISTON AND BORES

There should be a clearance of O 0010 0 0016 m 0 025 0 040

mmPISTON RINGS

The pIston nng gap should be O 008 0 013 10 0 203 0 330 mm when

checked10 the cyhnder bore The clearance of tne compressJOn rlOgs

10 theIr groovesshould amount to 0 0015 0 0035 m 0 038 0 089 mm and

the 011 control nngo 0016 0 003610 0 041 0 092 mmHecause the pIston nngs do nor travel to the end of the cyhnder

bores a hpIS eventually formed due to wearThIs may be checked wIth a dIal gauge and must be removed If

thIs IS notdone there wIll be a tendency to nOIsy operation or a

fractured nng caused bythe top pIston nng stnklOg the hpPIston and nngs are avatlable 10 0 OlD 10 0 254 mm 0 020 10 0

508 mm0 030 10 0 762 mm and 0 04010 1 016 mm overslzes The pIston

nngsshould always be htted from the crown of the pIston and never

pushed upwardsover the skIrt Before httmg the nngs remove any

carbon deposit from thegrooves 10 the pIston When httIng note that

the second compressIOn IS taperedtype and 011 control nng IS slat

type processed by chromIUm platIng33

-

Jt REMOVING REFITTING

Experience has shown that It IS much easIer to remove the engine

and transmISSIOn as a smgle umt than to detach the engme by

ItselfTo remove the engme and transmISSIOn upwards proceed as

followsCompletely dram the coolmg system and the transmIsSIOn

dIsconnect andremove the battery and ItS supportmg trayRemove the upper and

lower radIator hoses by undonng the retammg clIpSDIsconnect the

capacitor lead at the dlstnbutor also the hIgh tenSIOn andswitch wIres at the COIlTake off the dynamo lead and dIsconnect

the starter motor cable at the motorend

Remove the 011 gauge and water temperature gauge leads from

theIr termmalson the engmeEngine Transmtsswn Assembly bemg ltfled from ChasSlS

The throttle and choke controls must be dIsconnected from the

carburetorDIsconnect the fuel pIpe from the fuel pumpNext remove the exhaust pipe from the mamfoldFrom below the

vehIcle remove the gear change selector rod from the leveron the transmISSIOn casmgDIsconnect the earth strap from the

starter motor Remove the hand brakecontrol rod supporting from transmISSIOnDIsconnect the speed

meter cable from the transmISSIOn Uncouple the propeller shaft pmIOn franges at rear axle and draw the shaft out

of the transmIssIonTo allow the engme and transmISSIOn to be drawn

forward the radIator mustbe removed by undomg the four secunng bolts

34

-

OPERA TION WITH THE ENGINE REMOVED

The followmg operations are best performed wIth the engme

removed fromthe carAlthough Itmay be found possIble to carry out cerram attentlons

wIth theengme m posItIOn It IS more convement to do the work on the

benchWithdrawing Camshaft

The camshaft IS pOSJtJoned by a locatmg plate held by three

screws andshakeproof washers Note the posJtJon of the small

lubncatlng 011 hole m thelocating plate when replacmg should be to the nght of the

engmeEnd play of O 003 0 007 m 0 076 0 178 mm IS controlled by the

thIcknessof the locating plate and can be checked WIth a dIal mdlcator

set agamst the camshaft gearBefore wlthdrawmg the camshaft the dlstnbutor and ItS dnvmg

spmdle pushrods and tappet WIll have to be removed Remove the 011

pump and ItS dnveshaft and take off the tlmmg cover and gears The engme front

mountmg plateIS now accessIble and may be removed by wlthdrawmg the

setscrew and lockmgplates The dynamo swmgmg Itnk must be

removedTake out the setscrews secunng the camshaft locatmg plate when

the camshaft can be WIthdrawn from the cyltnder blockCAMSHAFT BEARINGS

Wlute metal beanngs with steel lmmg are used for the camshaft

They canbe taken out renewed when necessary It bemg usual to do

thIS when the cyltnderblock IS bemg recondJtJonedThe beanngs can be removed by dnftmg them out of theIr

hosmgsWhen fitting new beanngs care must be taken to lme up the 011

holes WIth thecorrespondmg holes m the cylmder blockTap the new beanngs mto

pOSItIOn and ream them to gIve a runmng clearanceof O 001 0 002 m 0 025 0 051 mm

Refitting the Camshaft

Tlus IS a reversal of the lOtroductlons for removal Care should

be takenhowever to ahgn and engage the dnve pm m the rear end of the

camshaft WIththe slot m the 011 pump dnve shaft

35

-

Main Bearing Caps

Remove the flywheel and clutchTake off the tJmmg cham the sump

and stramer and the engme rear mountmg plate Unlock and remove the bolts secunng the mam beanng caps

to thecyhnder block also the two bolts secunng the front cap to the

engme front bearerplateNote that a thrust washer IS fitted on each sIde of the centre

mam beanng totake the crankshaft end thrust These thrust washers

each consIst of two semIcIrcular valves one half havmg a lug whIch

IS located m a recess m the detachable half of the beanng the other

bemg plamWhen flttmg new beanngs no scrapmg IS reqUIred as they are

machmed togIVe the correct runmng clearance of 0 0005 0 002 m 0

0127 0 0508 nnEnsure that the locating tangs are properly engaged m theIr

recessesHandle the new beanngs carefully so as not to damage the

fme surface ftmshRemove all traces of dIrt and 011 from the housmgs

and throughly dry themWIth a non fluffy rag Make sure that the Oil ways are clear When

flttmg thebearmg caps ensure that they are replaced the nght way

round Each cap IS punchmarked and the marks should face the

camshaft SIde of the engmefJ

I

Engine Rear Slde

36

-

CautionNever file the beanng caps to take up excessIve playas

thIs wIll causeovalttyAlways cover the beanng surfaces wIth engine OIl when

they are replacedThe main beanng caps are held In posJt1on by set

screws and lock washersPull the set screws up tight WIth a torque wrench set to a

loading of 75 80Ibs ft10 36 11 05 kgmWhen refItting the mam beanng caps tIghten the center one ftrst

after eachcap IS tighten rotate the crankshaft to ascertam that It

revalues freelyIf It IS tight remove the last cap tightened and examme the

beanng and ItSseating for foreIgn matterCheck the crankshaft end play by means of a dIal gauge ThIS

should be 0 002m 0 051 mmIf a beanng has run It IS essential to clean out all OIl ways m

the crankshaft and block Wash out the engme sump and the

stramerThe OIl pump sho lld be dIsmantled and cleaned Ensure that no

particles ofbeanng metal are left wlthm the engme lubncatlon

systemFIg 15 Remarmlg a Mcnn Bearing Cap Extractor

37

-

FUEL SYSTEM

38

1627508100

16119 08100

-

The fuel tank has a capacIty of 31 0 Ittres and IS sItuated at

the rear of theluggage compartmentThe fuel pump operated off the camshaft draws

fuel from the tank and forcesIt mto the carburetor float chamber A large and effIcIent air

cleaner fIlters theaIr supply to the carburetorTHE GASOLINE TANK

Drainin the Tank and Fuel Gauge

The fuel tank IS dramed by tummg the wrench operated dram

cockFuel Tank Gauge Unit

Fig 1 Fuel Tank Securing

SItuated on the top face of the tank IS the gauge unIt To remove

wIthrawthe set screws whIch secure the Unit to the tank not

forgettmg to dIsconnect theelectncallead beforehand Care must be

taken not to stram or bend the floatlever as thIS may serously effect subsequent gauge readmgs

Remember thISalso appltes when eftttmg the UnitExamme the Jomt washer to ensure that It IS m pOSItion and

undamageThIs IS essential as the JOInt between the tank and gauge

Unit must be fuel tight39

-

o2

11

o1

i coOg

sl

S

0

-

Troubles and Repairs of Gasoline Tank

A When Fuel Leaks from Gasoline Tank

When a crack dIstortion or damage IS found In the tank repaIr or

replace ItTo make repaIrs put marks with chalk at the leakIng

pOInts and even afterthe fuel In the tank has been draIned out blow with compressed

aIr through thetank to force out stagnant gasolIne vapor completely

RepaIrs should be done onlywhen the tank IS completely dryLeakage IS ordInanly mended by soldenng When weldIng IS

necessary theabove precaution must be stnctly observed OtherWIse

there WIll be danger ofexploslOnB When Gasoline Fails to Reach Gasoline Strainer

If the fuel fatls to reach the gasohne strainer when there IS

some fuel left Inthe gasoline tank and the operation of fuel pump

IS known to be satisfactory checkthe follOWIng pOintsWhen It IS dlfftcult to confIrm the dehvery of fuel at the

strainer loosen theconnector at the fuel Intake of the

carburetor1 Check to see If gasohne pIpe ISclogged with dust and dIrt ThIS

canbe eastly checked by dIsconnectingthe connector of the pIpe and

blowIng WIth compressed aIr toward thedIrection of the tank Then

from thetank end blow the pipe again andclean the pIpeIn many cases the tip of gasohneIntake pIpe of tank umt IS

cloggedwith dust and waterTherefore together with cleaningof the pIpe the Intenor of the

tankshould be cleaned by removmg thedrain plug at the bottom of the

tankCheck to see If the gasohne pIpeof the tank umt IS so bent as to

fallto reach the fuel surfaceThe standard posJtJon of the bottom

end of pIpe IS about 3 4 m apart from

the bottom m order to prevent ItS

suckIng up sedIments on the tank bottom

If not normal remove tank umtand adjust the bend of the pIpe

Check too seelf the vent hole of the

ftller cap IS clogged WIth dust and dIrtnot supplymg aIr to the

tankAccordIng to the degree of vacuumwlthm the tank fuel cannot be

drawnup even by the operatlOn of fuel pump

j

Fig 2 Wtring of Fuel Gauge1 Umt Gauge 4 19mtlon Switch2 Fuse 5

Ammeter3 Fuel Gauge 6 Battery41

-

So be sure to clean the aIr vent of the capIf you should lose

the cap and substitute a wooden plug for It a measurewhIch is sometimes wirnessed the condItIOn mSIde of the tank

becomes the sameas though It were sealed up Always use only the

standard capOperation and Repairs of Fuel GaugeAs shown m FIg 2 the fuel

gauge consIsts of the dash Unit and tank UnitThe dash Unit whIch is

mstalled on the mstrument panel has two cotls thatcross each other at nght angles whose magnetic forces control

the movementof a keeper iron pIece with a hand mdlcatorOn the tank Unit a contact arm shdes over a resIstance m

response to thefloat levelAs shown m FIg 2 If the IgnJtJon switch IS turned on when the

tank IS emptyelectnc current WIll flow from the battery through the

ammeter mto COIl A andthen through the contact arm to the

groundCotl A IS then magnetized attracts the Iron pIece and the

mdlcator pomtsto EAs the float IS raIsed and the contact arrn moves tank unit

mcreases resIstance m the CIrcuit and thus the current wluch

traveled through COIl A then flowsthIs time both contact arm and

COIl B and fmally to the groundAs both A and B cils are so wound as to have theIr magnetic

poles m the samedIreCtiOn the iron pIece wtll rotate to the

directIOn where the magnetic power ofthe two COIls can be balanced

WIth the mdlcator deflectmg m the dlrecnon of FThat IS this IS a gauge of electnc resIstance control type E

sIgnifIesEmpty level and F Full levelTroubles with Fuel Gauge and their Remedies

When somethmg IS wrong with the readmgs of the fuel gauge fIrst

diSconnect the wlnng at the Unit and turnm on the IgnitIOn SWItch

ground and unground the termmal end of the saId wlnng to the body

of the carIf the mdIcator of the dash Unit swmgs acnvely between E and F

the wIrmgbetween the dash Unit and the saId termmal end IS m good

condltJon WIth the defect eXlstmg either m tank Unit Itself or m

poor ground of thIS UnitIn the test mentIOned m the preceedmg secnon If the mdlcator

does not swmgbut Itmoves moves to E when the dash UDlt end of the

wlnng from the tank UnitIS grounded the wlnng between the dash Unit

and tank Unit IS def ctJveTherefore rewlnng or repalrmg is reqUIredIf when mdlcator flals

to swmg but sparkmg is observed when the wlnngconnectmg the battery with the termmal on the dash Unit IS

dIsconnected at thedash Unit end and grounded It proves the wlrmg

IS satisfactory and the troubleIS m the dash Unit ItselfIf sparkmg does not occur the wlrmg whIch IS thus mdlcated to be

out oforder should be repaIred or replacedIncorrect readmgs of the mdlcator probably means that the heIght

of the floatof the tank Unit is m errorIn thIS case adJust the heIght of the float by bendmg the

rodTroubles with the Unit are dIffIcult to repaIr so it should be

replaced by a newUnit

42

-

In checlang the tank Untt be sure to Insert a fuel gauge In the

CIrcuitbetween the battery and the unitFUEL STRAINER

Instruction for Disassembly

To remove the bowl from the body loosen the strainer nut and

remove thewIre to a SIde Take off the bolt nut and washer from the wIre

and remove bowlgasket and screenThe strainer body IS made of aluminum alloy

Take good care not to breakthreads of each connectIOn

Pay attention not to tighten the strainer nut so excessIvely

that the gasket andbowl are brokenWhen mstalhng the stramer assembly the strainer bracket should