Материал из BikesWiki — энциклопедия японских мотоциклов

Перейти к: навигация, поиск

Yamaha FZR250

Ниже представлены прямые ссылки на скачку сервисной документации.

Для Yamaha FZR250 / Yamaha FZR400

- Каталог запчастей (микрофиши) на Yamaha FZR 250 (2KR, 1986-1988)

- Каталог запчастей (микрофиши) на Yamaha FZR 250 (3LN, 1989-1994)

- Каталог запчастей (микрофиши) на Yamaha FZR 400 (1988)

- Сервисный мануал (Service Manual) на Yamaha FZR 400 (1988)

- Сервисный мануал (Service Manual) на Yamaha FZR400RR SP-1 (1992)

Обзор модели

- Yamaha FZR 250

- Yamaha FZR 400

Источник — «https://bikeswiki.ru/index.php?title=Yamaha_FZR250-400:_мануалы&oldid=9966»

Категория:

- Сервисная документация

- Manuals

- Brands

- Yamaha Manuals

- Motorcycle

- FZR400 1988-1989

- Service manual

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

Yamaha

FZR400

Service

Manual

1988-1989 Models

Related Manuals for Yamaha FZR400 1988-1989

Summary of Contents for Yamaha FZR400 1988-1989

-

Page 1

Yamaha FZR400 Service Manual 1988-1989 Models… -

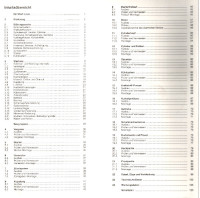

Page 3: Table Of Contents

CONTENTS CHAPTER 1. GENERAL INFORMATION IDENTIFICATION ……. . l — l MOTORCYCLE NUMBER .

-

Page 4: Periodic Inspection And Adjustment

CHAPTER 3. PERIODIC INSPECTION AND ADJUSTMENT INTRODUCTION………., 3-1 MAINTENANCE INTERVALS CHART .

-

Page 5

ELECTRICAL……….3-44 INSPECTION . -

Page 6

BEARING AND OIL SEAL ……..YAMAHA EXHAUST VARIABLE VALVE (For California only) ..4-48 ENGINE ASSEMBLY AND ADJUSTMENT. -

Page 7: Cooling System

CHAPTER 5. COOLING SYSTEM INSTALLATION ……….5-4 WATER PUMP AND THERMOSTATIC VALVE.

-

Page 8

FRONT AND REAR BRAKE……..7-10 BRAKE PAD REPLACEMENT . -

Page 9

CHAPTER 8. ELECTRICAL ……CIRCUIT DIAGRAM ELECTRICAL COMPONENTS……..CHECKING OF SWITCHES. -

Page 10

YAMAHA EXHAUST VARIABLE VALVE SYSTEM (For California only)……… . -

Page 11: Motorcycle Identification

CONTENTS INFORMATION ……..GENERAL IDENTIFICATION .

-

Page 12: Engine Serial Number

MOTORCYCLE IDENTIFICATION GENERAL INFORMATION MOTORCYCLE IDENTIFICATION VEHICLE IDENTIFICATION NUMBER The vehicle identification number @ is stemped into the right side of the steering head. Starting serial number: NOTE: The vehicle identification number is used to identify your motorcycle and may be used to register your motorcycle with the licensing authority in your state.

-

Page 13: Specifications

SPECIFICATIONS JSPECII GENERAL SPECIFICATIONS GENERAL SPECIFICATIONS Model Model Code Number: Vehicle Identification Number: Engine Starting Number: Basic Weight: With Oil and Full Fuel Tank 188 kg (414 lb) (FZR400A) 191 kg (421 lb) (FZR400SAC) Tire: Front Rear Tubeless Tubeless Size Manufacture (Type) BRIDGESTONE…

-

Page 14: Maintenance Specifications

92 mm (3.62 in) Bellow the top of inner fork tube without fork spring Oil Grade Yamaha Fork Oil 10WT or equivalent Front Disc Brake: Dual 282 x 4 mm (11 .lO x 0.16 in) Disc Outside Diameter x Thickness…

-

Page 15: Tightening Torque

MAINTENANCE SPECIFICATIONS -1 TIGHTENING TORQUE Tightening torque Part to be tightened Thread size Front Axle and Outer Tube Ml6 x 1.5 10.7 Rear Axle and Nut M8 x I.25 Handlebar Crown and Inner Tube Handlebar Crown and Steering Stem M22 x 1.0 11.0 Brake Caliper (Front/Rear) M8 x 1.25…

-

Page 16: General Torque Specifications

GENERAL TORQUE SPECIFICATIONS Is4 TORQUE GENERAL This chart specifies torque for standard fasteners with standard I.S.O. pitch threads. Torque specifications for special components or assem- blies are included in the applicable sections of this book. To avoid warpage, tighten multi- fastener assemblies in a crisscross fashion, in progressive stages, until full torque is reached.

-

Page 17: Periodic Inspections And Adjustments

DRIVE CHAIN SLACK ADJUSTMENT PERIODIC INSPECTIONS AND ADJUSTMENTS CHASSIS DRIVE CHAIN SLACK ADJUSTMENT NOTE: Before checking and/or adjusting the chain slack, rotate the rear wheel several revolutions. Check the chain slack several times to find the point where the chain is the tightest. Check and/or adjust the chain slack where the rear wheel is in this “tight chain”…

-

Page 18

DRIVE CHAIN SLACK ADJUSTMENT ADJ m Clockwise Counterclockwise decreased. NOTE: Turn each adjuster exactly the same amount to maintain correct axle alignment. (There marks on each side of swingarm; use them to check for proper alignment.) Tighten the locknut. Tighten the axle nut to specification, while pushing up or down on the chain to zero slack. -

Page 19: Chassis

REAR WHEEL -1 CHASSIS REAR WHEEL @ C o l l a r @ C o l l a r WEAR LIMIT: 1 .O mm (0.04 in) RIM SIZE: MT4.00 x 18 RIM RUNOUT LIMIT: RADIAL: 2.0 mm (0.08 in) LATERAL:…

-

Page 20: Rearwheel

REAR WHEEL -1 REMOVAL 1. Place the motorcycle on a level place. Securely support the motorcycle so there is no danger of it falling over. 2. Elevate the rear wheel by placing a suitable stand under the swingarm. 3. Remove: Bolts (brake caliper) @ NOTE: Do not depress the brake pedal while the caliper…

-

Page 21: Inspection

REAR WHEEL INSPECTION 1. Inspect: Tire Rear wheel axle Wheel Wheel bearings Refer to the “FRONT WHEEL — INSPEC- TION”. 2. Measure: Wheel runout Refer to the “FRONT WHEEL — INSPEC- . TION”. 3. Check: Wheel balance Refer to the “FRONT WHEEL — INSPEC- TION”.

-

Page 22: Static Wheel Balance Adjustment

REAR WHEEL lctf=l &x31 Do not loosen the axle nut after torque tighten- ing. If the axle nut groove is not aligned with the wheel shaft cotter pin hole, align groove with the hole by tightening up on the axle nut. 4.

-

Page 23: Front And Rear Brake

FRONT AND REAR BRAKE pqzq FRONT AND REAR BRAKE The arrow mark @ on the pad spring must pointing the disc rotating direction. @Brake pad 2 Nm (0.2 rn. kg, 1.4 ftslb) If DOT #4 is not available, 20 Nm (2.0 ma kg,…

-

Page 24

FRONT AND REAR BRAKE @Brake caliper @Diaphragm @ P i s t o n @Piston seal @Brake disc… -

Page 25: Brake Pad Replacement

FRONT AND REAR BRAKE pi$q Disc brake components rarely require disassem- bly. DO NOT: Disassembly components unless absolutely nec- essary. Use solvents on internal brake component. Use contaminated brake fluid for cleaning. Use only clean brake fluid. ?? AIIOW brake fluid to come in contact with the eyes otherwise eye injury may occur.

-

Page 26

FRONT AND REAR BRAKE -1 Remove: Brake pads @ NOTE: Replace the pad spring if the pad replacement is required. Replace the pads as a set if either is found to be worn to the wear limit. 0.5 mm (0.02 in) 4. -

Page 27

FRONT AND REAR BRAKE -1 6. Inspect: Brake fluid level Refer to the “BRAKE FLUID INSPEC- TION” section in the CHAPTER 3. 7. Check: Brake lever operation A softy or spongy filling + Bleed brake system. Refer to the “Al R BLEEDING” section in the CHAPTER 3. -

Page 28

FRONT AND REAR BRAKE b-l &I 4. Remove: Brake pads (with shims) @ Pad spring @ NOTE : Replace the pad spring if the pad replacement is required. Replace the pads as a set if either is found to be worn to the wear limit. Replace the pad shim if the pad replacement is required. -

Page 29

FRONT AND REAR BRAKE -1 6. Install: Retaining bolts @ Retaining bolts: 10 Nm (1.0 ma kg, 7.2 ft. lb) 7. Install: Bolts (brake caliper) @ Bolts (brake caliper): 35 Nm (3.5 rn- kg, 25 ft. lb) 8. Inspect: Brake fluid level Refer to the “BRAKE FLUID INSPEC- TION”… -

Page 30: Caliper Disassembly

FRONTANDREARBRAKE CALIPER DISASSEMBLY NOTE: Before disassembling the front or rear brake master cylinders, drain the brake hose, master cylinder, brake caliper and reservoir tank of their brake fluid. Securely support the motorcycle so there is no danger of it falling over. Front brake 1.

-

Page 31

FRONT AND REAR BRAKE -1 4. Remove: Pistons 0 Dust seals @ Piston seals @I Remove steps: *Blow compressed air into the tube joint opening to force out the piston from the caliper body. Never try to pry out the piston. Cover the piston with a rag. -

Page 32: Master Cylinder Disassembly

FRONT AND REAR BRAKE pi&E&l Remove steps: Blow compressed air into the tube joint opening to force out the piston from the caliper body. Never try to pry out the piston. Cover the piston with a rag. Use care so that piston does not cause injury as it is expelled from the cylinder.

-

Page 33

FRONT AND REAR BRAKE 3. Remove: Master cylinder @ 4. Remove: Cap (master cylinder) 6) Diaphragm @ . Dust boot @ Circlip 0 Master cylinder kit @ Rear brake 1. Remove: Side cover (right) 2. Remove: Cotter pin @ Washer @ Disconnect: Reservoir hose @ Place the open hose end into a container… -

Page 34: Inspection And Repair

FRONT AND REAR BRAKE ICHASl &I 7. Remove: Reservoir tank @ (from flame) Cap (reservoir tank) @ Holder (diaphragm) @ Diaphragm @ INSPECTION AND REPAIR All internal parts should be cleaned in new brake fluid only. Do not use solvents will cause seals to swell and distort.

-

Page 35

FRONT AND REAR BRAKE 3. Inspect : Master cylinder @ Wear/Scratches -+ Replace. Master cylinder body @ Cracks/Damage Blow out with compressed air. 4. Inspect: Master cylinder kit @ Scratches/Wear/Damage Replace. Front 5. Inspect: Diaphragm (front) @ Diaphragm (rear) @ Wear/Damage -+ Replace. -

Page 36

FRONT AND REAR BRAKE 6. Inspect: Brake hoses @ Cracks/Wear/Damage Replace. Front 7. Measure: Brake pads (thickness) @ Out of specification + Replace. Wear limit: 0.5 mm (0.02 in) NOTE: Replace the pad spring as a set if pad replace- ment is required. -

Page 37: Assembly

FRONT AND REAR BRAKE ASSEMBLY brake fluid only. Internal parts should be lubricated with brake fluid when installed. Replace the piston seal and dust seal whenever a caliper is disassembled. Securely support the motorcycle so there is no danger of it falling over. Brake fluid: DOT #4…

-

Page 38

FRONT AND REAR BRAKE bHAsi @@d 4. Install: Copper washers @ Brake hose @ (onto brake caliper) Union bolt: 26 Nm (2.6 m — kg, 19 ft. lb) When installing the brake hose to the caliper tion @ on brake caliper. Proper hose routing is essential to insure safe Refer to “CABLE motorcycle operation. -

Page 39

FRONT AND REAR BRAKE 7. Install: Brake hose @ Copper washers @ Union bolts @ 26 Nm (2.6 m — kg, 19 ft- lb) *Proper hose routing is essential to insure safe motorcycle operation. Refer to the “CABLE ROUTING”. Always use new copper washers. 8. -

Page 40

FRONT AND REAR BRAKE 10. Install: Diaphragm @ Master cylinder cap @ Screws (master cylinder cap): 2 Nm (0.2 m — kg, 1.4 ft. lb) 11. Air bleed: @Brake system Refer to the “AIR BLEEDING” section in the CHAPTER 3. 12. -

Page 41

FRONT AND REAR BRAKE pi$q 3. Install: Brake caliper 0 Bolts (brake caliper): 35 Nm (3.5 m — kg, 25 ft. lb) 4. Install: Master cylinder kit @ Push rod @ 5. Install: Master cylinder assembly @ Bolts (master cylinder assembly): 35 Nm (3.5 m — kg, 25 ft. -

Page 42

FRONT AND REAR BRAKE lct-~ ebbi 8. Install: Brake hose Copper washers Union bolts Reservoir hose Union bolts: 26 Nm (2.6 rn- kg, 19 ft. lb) When installing the brake hose, lightly touch the brake pipe @ with the projections @ on the caliper and master cylinder. -

Page 43

FRONT AND REAR BRAKE [iiiqq Use only the designated quality brake fluid: otherwise, the rubber seals may deteriorate, causing leakage and poor brake performance. Refill with the same type of brake fluid; mixing fluids may result in a harmful chem- ical reaction and lead to poor performance. -

Page 44

CONTENTS CHAPTER 1. GENERAL INFORMATION IDENTIFICATION ……. . l — l MOTORCYCLE NUMBER . -

Page 45

CHAPTER 3. PERIODIC INSPECTION AND ADJUSTMENT INTRODUCTION………., 3-1 MAINTENANCE INTERVALS CHART . -

Page 46

ELECTRICAL……….3-44 INSPECTION . -

Page 47

BEARING AND OIL SEAL ……..YAMAHA EXHAUST VARIABLE VALVE (For California only) ..4-48 ENGINE ASSEMBLY AND ADJUSTMENT. -

Page 48

CHAPTER 5. COOLING SYSTEM INSTALLATION ……….5-4 WATER PUMP AND THERMOSTATIC VALVE. -

Page 49

FRONT AND REAR BRAKE……..7-10 BRAKE PAD REPLACEMENT . -

Page 50

CHAPTER 8. ELECTRICAL ……CIRCUIT DIAGRAM ELECTRICAL COMPONENTS……..CHECKING OF SWITCHES. -

Page 51

YAMAHA EXHAUST VARIABLE VALVE SYSTEM (For California only)……… . -

Page 52: Motorcycle Identification

MOTORCYCLE IDENTIFICATION INFO 6% ” ‘ ” GENERAL MOTORCYCLE IDENTIFICATION VEHICLE IDENTIFICATION NUMBER The vehicle identification number @ is stemped into the right side of the steering head. NOTE: The vehicle identification number is used to identify your motorcycle and may be used to register your motorcycle with the licensing authority in your state.

-

Page 53: Important Information

5. Keep away from fire. ALL REPLACEMENT PARTS 1. Use only genuine Yamaha parts for all re- placements. Use oil and/or grease recom- mended by Yamaha for assembly and adjust- ment. Other brands may be similar in func- tion and appearance, but inferior in quality.

-

Page 54: Lock Washers/Plates And Cotter Pins

IMPORTANT INFORMATION INFO 8% LOCK WASHERS/PLATES AND COTTER PINS 1. All lock washers/plates @ and cotter pins must be replaced when they are removed. Lock tab(s) should be bent along the bolt or nut flat(s) after the bolt or nut has been pro- perly tightened.

-

Page 55: Special Tools

SPECIAL TOOLS SPECIAL TOOLS The proper special tools are necessary for com- plete and accurate tune-up and assembly. Using the correct special tool will help prevent damage caused by the use of improper tools or impro- vised techniques. FOR TUNE UP 1.

-

Page 56: For Engine Service

SPECIAL TOOLS INFO df@ 5. Vacuum Gauge YU-08030 This gauge is needed for carburetor synchroniza- tion. FOR ENGINE SERVICE 1. Cam Chain Cutter P/N Y M-01 112 This tool is used when cutting the cam chain. 2. Piston Pin Puller YU-01304 This tool is used to remove the piston pin.

-

Page 57

SPECIAL TOOLS INFO d!@ 5. Universal Rotor Holder YU-01235 This tool is used when loosening or tightening the A.C. magneto securing bolt. 6. Heavy Duty Puller P/N Y U-33270 This tool is used to remove the starter clutch. 7. Camshaft Wrench YM-04115 This tool is used to turn the camshaft. -

Page 58

SPECIAL TOOLS INFO IO. Valve Guide Installer P/N YM-041 I7 This tool is needed to install the valve guides properly. 1 I. Valve Guide Reamer (4.5 mm) P/N YM-041 I8 This tool is used to rebore the new valve guide. 12. -

Page 59: For Chassis Service

SPECIAL TOOLS INFO d@@ 15. Piston Base P/N Y M-01 067 Use 4 of these to hold the piston during cylinder installation. 16. Radiator Cap Tester P/N Y U-24460-01 Adaptor P/N Y U-33984 This tester is needed for checking the cooling system.

-

Page 60: For Electrical Components

SPECIAL TOOLS INFO FOR ELECTRICAL COMPONENTS 1. Dynamic Coil Tester P/N Y M-34487 This tester is necessary for checking the ignition system components. 2. Pocket Tester P/N Y U-031 12 This instrument is invaluable for checking the electrical system.

-

Page 61: Chapter 2. Specifications

GENERAL SPECIFICATIONS (SPECII SPECIFICATIONS GENERAL SPECIFICATIONS Model 3BF (FZR400U) Model Code Number: 3 F H (FZR400SUC) Vehicle Identification Number: Engine Starting Number: Dimensions: Overall Length 2,070 mm (81.5 in) Overall Width 690 mm (27.2 in) Overall Height 1,125 mm (44.3 in) Seat Height 785 mm (30.9 in) Wheelbase…

-

Page 62: General Torque Specifications

GENERAL SPECIFICATIONS (,,,,I1 Model Unleaded fuel recommended 18.0 L (3.94 Imp gal, 4.8 US gal) Tank capacity 3.0 L (0.66 Imp gal, 0.79 US gal) Reserve Amoun BDS32 x 4 Type x Quantity Manufacturer Type (Manufacture) 0.7 — 0.8 mm (0.028 — 0.032 in) Wet, multiple-disc Transmission: Spur gear…

-

Page 63

GENERAL SPECIFICATIONS ISPECp(y Model Brake: Dual disc brake Front Brake Type Right hand operation Operation Single disc brake Rear Brake Type Right foot operation Operation Suspension: Telescopic fork Front Suspension Rear Suspension Shock Absorber: Coil spring/Oil damper Front Shock Absorber Coil gas spring/Oil damper Rear Shock Absorber Wheel Travel:… -

Page 64

MAINTENANCE SPECIFICATIONS (,,,,I1 MAINTENANCE SPECIFICATIONS Engine Model Cylinder Head: Warp Limit* 0.03 mm (0.0012 in) , *Lines indicate straightedge measurement Cylinder: Bore Size 56.000 — 56.005 mm (2.2047 — 2.2049 ir Drive Method Chain drive (Center) Cam Cap Inside Dia. 23.000 — 23.021 mm (0.9055 — 0.9063 ir Camshaft Outside Dia. -

Page 65

MAINTENANCE SPECIFICATIONS Model “A” Head Dia. 21.9 — 22.1 mm (0.8622 — 0.8701 in) 18.9 — 19.1 mm (0.7441 — 0.7520 in) 1.6 — 2.4 mm (0.0630 — 0.0945 in) 1.6 — 2.4 mm (0.0630 — 0.0945 in) “C” Seat Width 0.9 — 1 .l mm (0.0354 — 0.0433 in) 0.9 — 1 .l mm (0.0354 — 0.0433 in) <… -

Page 66

MAINTENANCE SPECIFICATIONS piqjqJ Model 55.945 — 55.960 mm (2.2026 — 2.2031 in) Piston Size “D” 5 mm (0.197 in) Measuring Point “H” (From bottom line of piston skirt) — — — — — — — — 0.04 — 0.06 mm (0.0016 — 0.0024 in) Piston-to-Cylinder Clearance <… -

Page 67

MAINTENANCE SPECIFICATIONS piqjq Model FZ R400U/FZR400SUC Main Journal Oil Clearance 0.025 — 0.043 mm (0.0010 — 0.0017 in) Bearing Size No. Color Code 1. Blue 2. Black 3. Brown 4. Green 5. Yellow Clutch: 2.9 — 3.1 mm (0.114 — 0.122 in) x 8 Friction Plate Thickness x Quantity Wear Limit 2.8 mm (0.11 in) -

Page 68

MAINTENANCE SPECIFICATIONS pqjq Model Lubrication System: Oil Filter Type Paper Trochoid pump Oil Pump Type 0.09 — 0.15 mm (0.0035 — 0.0060 in) Tip Clearance < 0.2 mm (0.008 in) > < Limit > Side Clearance 0.03 — 0.08 mm (0.0012 — 0.0031 in) <… -

Page 69

MAINTENANCE SPECIFICATIONS Model Lubrication chart: Pressured feed Main journal bearing Main journal bearing Oil pan Crankcase (Lower) Crankcase (Upper) 8 mm Bolt: 24 Nm (2.4 m-kg, 17 ft.lb) mm Bolt: 12 Nm (1.2 m-kg, 8.7 ft*Ib) -

Page 70: Maintenance Specifications

MAINTENANCE SPECIFICATIONS (SPECI] Tightening torque Part to be tightened Part name Remarks size 1 .o Flange bol Camshaft Cap Cylinder Head M l 0 Spark Plug Bolt 1 .o Cylinder Head Cover Blind Plug (Sand) Screw M l 2 Screw Blind Plug (Water) Connecting Rod Cam Chain Sprocket…

-

Page 71: Chassis

Oil Capacity 92 mm (3.62 in) Oil Level (Fully Compression) Bellow the top of inner fork tube without fork spring Oil Grade Yamaha Fork Oil IOWT or equivalent Rear Suspension: 50 mm (I .97 in) Shock Absorber Travel Spring Free Length 196.5 mm (7.74 in)

-

Page 72

MAINTENANCE SPECIFICATIONS Model Dual Disc Outside Diameter x Thickness 5.5 mm (0.22 in) Inner Pad Thickness 0.5 mm (0.02 in) < L i m i t >* 5.5 mm (0.22 in) Outer Pad Thickness < L i m i t >* 0.5 mm (0.02 in) 15.87 mm (0.62 in) Master Cylinder Inside Diameter… -

Page 73

MAINTENANCE SPECIFICATIONS (SPECII Tightening torque Part to be tightened Thread size Front Axle and Outer Tube Rear Axle and Nut 10.7 Handlebar Crown and Inner Tube Handlebar Crown and Steering Stem M22 x 1.0 1 1 0 11.0 Brake Caliper (Front/Rear) Bleed Screw and Brake Caliper Brake Hose and Union Bolt Front Master Cylinder and Master Cylinder Holder… -

Page 74: Electrical

MAINTENANCE SPECIFICATIONS -1 Electrical Model Voltage: Ignition System: IO” at 1,300 r/min Ignition Timing (B.T.D.C.) 48” at 6,500 r/min (3BF), 38” at 3,500 r Advanced Timing (B.T.D.C.) Electrical Advancer Type 3FH: 3BF: 9 1 0 1 1 1 2 1 314 15 1 0 1 1 1 2 1 3 1 4 1 5 Engine Speed (x IO3 r/min)

-

Page 75

MAINTENANCE SPECIFICATIONS Model Electrical Starter System: Constant mesh type Starter Motor: SM-7/M ITSUBA Model/Manufacturer output Armature Coil Resistance 11 mm (0.43 in) Brush — Overall Length 5 mm (0.20 in) < Limit > 540 — 660 g (19.05 — 23.28 oz) 23 mm (0.91 in) Commutator Dia. -

Page 76: General Torque Specifications

GENERAL TORQUE SPECIFICATIONS [+q-jqq GENERAL TORQUE General torque specifications This chart specifies torque for standard fasteners 10 mm with standard I.S.O. pitch threads. Torque specifications for special components or assem- 12mm blies are included in the applicable sections of 14 mm 10 mm this book.

-

Page 77: Lubrication Point And Grade Of Lubricant

LUBRICATION POINT AND GRADE OF LUBRICANT piqjqq LUBRICATION POINT AND GRADE OF LUBRICANT ENGINE Symbol Lubrication Point Oil seal lip O-Ring Bearing Piston surface Piston pin Cylinder head bolt Crankshaft pin Crankshaft journal Connecting rod bolt/Nut Camshaft cam lobe/Journal Valve stem (IN, EX) Valve stem end (IN, EX) Valve lifter Water pump impeller shaft…

-

Page 78

LUBRICATION POINT AND GRADE OF LUBRICANT l=l CHASSIS Lubrication Point Steering bearing (Upper/Lower) Wheel bearing/Axle Front wheel oil seal (Right/Left) Rear wheel oil seal Clutch hub oil seal Clutch hub fitting area Rear brake pedal shaft Change pedal Side stand sliding surface Tube guide (Throttle grip) inner surface Brake lever bolt, sliding surface Clutch lever bolt, sliding surface… -

Page 79: Lubrication Diagram

LUBRICATION DIAGRAM LUBRICATION DIAGRAM…

-

Page 80: Coolant Diagram

COOLANT DIAGRAM @Thermostatic valve 2-20…

-

Page 81

CABLE ROUTING CABLE ROUTING (‘I) Insert the clutch cable into the frame inner hole. 2-21… -

Page 82

CABLE ROUTING bpEcl CABLE ROUTING (2) Pass the handlebar switch lead (Left) behind the inner tube •I To headlight unit To flasher light (Left) To flasher light (Right) -

Page 83

CABLE ROUTING CABLE ROUTING (3) -

Page 84

CABLE ROUTING -1 To handlebar switch (Left) @Speedometer assembly To clutch lever Pass the speedometer cable outside the inner tube. @ H o r n To air filter case @Brake hose To fuel tank To fuel pump @Front brake caliper (Left) Pass the sidestand switch lead inside the water pipe. -

Page 85

CABLE ROUTING CABLE ROUTING (4) 2-26… -

Page 86

CABLE ROUTING To radiator cap assembly @Brake hose (Right) Pass the spark lead and fan motor lead along the air @ C l a m p guide groove. Pass the recovery tank hose on the fuel tank bracket. @Spark lead (Right) Pass on the inside of the water pipe the carburetor @Air guide… -

Page 87

CABLE ROUTING ISPEC(l CABLE ROUTING (5) -

Page 88: Cable Routing

CABLE ROUTING (SPECII To fuel pump Pass the starter motor lead under the starter motor. Pass on the inside of the water pipe the carburetor motor air vent hose on the side of the #I and #2 cylinders, @ C l a m p and clamp this hose together with the carburetor air vent hose on the side of the # 3 and #4 cylinders.

-

Page 89: Maintenance Intervals Chart

INTRODUCTION/MAINTENANCE INTERVALS CHART ADJ PERIODIC INSPECTIONS ADJUSTMENTS INTRODUCTION This chapter includes all information necessary to perform recommended inspections and adjustments. These preventive maintenance procedures, if followed, will ensure more reliable vehicle operation and a longer service life. The need for costly overhaul work will be greatly reduced. This information ap- plies to vehicles already in service as well as new vehicles that are being prepared for sale.

-

Page 90

Check chain condition. D r i v e Adjust and Every 500 km (300 mi) lubricate chain motor oil. chain thoroughly. Yamaha chain Apply chain and cable Control lube or SAE and meter lube thoroughly. 1 OW30 motor cable oil. -

Page 91

Check and Sidestand clean or switch replace if necessary. *It is recommended that these items be serviced by a Yamaha dealer or other qualified mechanic. NOTE: the above maintenance at the period established, ““1: Every odometer reading, repeat 6,000 km (3,800 mi), **2:… -

Page 92: Cowling Removal And Installation

COWLINGS REMOVAL AND INSTALLATION COWLING REMOVAL AND INSTALLATION REMOVAL 1. Remove: Lower cowling (Left) 2. Remove: Lower cowling (Right) 3. Remove: Center cowling (Left) 4. Remove: Center cowling (Right)

-

Page 93

5. Remove: Rear view mirrows (Left and right) 9. Remove:… -

Page 94

COWLINGS REMOVAL AND INSTALLATION Remove: Seat NOTE: To open the seat lock, insert the key in the lock and turn it clockwise. 11. Remove: Top cover INSTALLATION Reverse the “REMOVAL” procedure. Note the following points. 1. install: Seat NOTE: Make sure that the seat is securely fitted. ?? When reinstalling the seat, insert the lobes on the seat front into the receptacles on the frame, then push down the seat. -

Page 95: Engine

2. Remove: Valve cover @ 3. Turn on the main switch. NOTE: If does not operate EXUP servo motor, refer to the “YAMAHA EXHAUST VARIABLE VALVE SYSTEM” section in the CHAPTER 8. 4. Check: Alignment mark @ Not aligned + Adjust EXUP cables.

-

Page 96: Valve Clearance Adjustment

VALVE CLEARANCE ADJUSTMENT AD J @!!!iii 7. Install: (Valve Cover): 10 Nm (1.0 m-kg, 7.2 ft.lb) VALVE CLEARANCE ADJUSTMENT The engine must be cool before servicing the valve clearance. NOTE: Measure and adjust valve clearance when piston is at TDC on compression stroke. REMOVAL 1.

-

Page 97

J @iii VALVE CLEARANCE ADJUSTMENT AD 5. Remove: Radiator cap @ 6. Drain: ‘“COOLANT REPLACE. Refer to the MENT” section. 7. Disconnect: Fan motor coupler @ 8. Disconnect: Hose (Radiator — Inlet) Hose (Radiator — Outlet) 9. Remove: Radiator 10. Remove: Spark plug leads Cylinder head cover Generator cover… -

Page 98: Valve Clearance Adjustment

VALVE CLEARANCE ADJUSTMENT UOTE: T.D.C. can be found when the : a m l o b e s a r e a p a r t f r o m e a c h o t h e r , a s Gauge @ .

-

Page 99

J @iii VALVE CLEARANCE ADJUSTMENT AD Refer to the “ENGINE DISASSEMBLY CAM- SHAFT AND CYLINDER HEAD — Procedure Fasten the wire to the cam chain to prevent it from falling into the crankcase. Remove: Use valve lapper @ Record the installed pad number. NOTE: Place a piece of rug in the cam chain room to prevent the pad from falling into the… -

Page 100

VALVE CLEARANCE ADJUSTMENT AD EXAMPLE: Installed pad number = 148 (1.48 mm) Rounded off digit = 150 NOTE: Pads can only be selected in 0.05 mm (0.002 in) increments. Locate the “Rounded off Pad Number” on the chart, and then find the measured valve clearance. -

Page 101

VALVE CLEARANCE ADJUSTMENT INTAKE 235 240 220 225 225 230 VALVE CLEARANCE (cold): 0.11 — 0.20 mm (0.004 — 0.008 in) Example: Installed is 170 Measured clearance is 0.24 mm (0.009 in) Replace 170 pad with 180 pad EXHAUST 180118511901195 205 210~215~220~225~230~23E VALVE CLEARANCE… -

Page 102

VALVE CLEARANCE ADJUSTMENT ADJ m NOTE: Refer to the “ENGINE ASSEMBLY AND AD- J U S T M E N T H E A D A N D CAMSHAFT” section in the CHAPTER 4. Turn the carnkshaft counterclockwise several turns for the installed parts to settle into the correct position. -

Page 103: Carburetor Synchronization

CARBURETOR SYNCHRONIZATION Recheck: Align the matching marks @ . 4. Install: Chain guide (Upper) @ Chain guide (Exhaust side) @I Bolts (Chain Guide): 10 Nm (1.0 m-kg, 7.2 ft.lb) 5. Install: Cylinder head cover Bolts (Cylinder Head Cover): 10 Nm (1.0 m-kg, 7.2 ft-lb) 6.

-

Page 104

CARBURETOR SYNCHRONIZATION AD 1. Remove: Refer to the “COWLING REMOVAL AND section. INSTALLATION — REMOVAL” 2. Remove: Fuel tank R e f e r t o t h e “ C A R B U R E T O R — R E — MOVAL”… -

Page 105: Idle Speed Adjustment

IDLE SPEED ADJUSTMENT AD *Racing the engine for less than a second, two or three times, and check the syn- chronization again. Vacuum Pressure at Idle Speed: 21.33 f 0.6 kPa (160 * 5 mmHg, 6.30 f 0.2 inHg) Vacuum Synchronous Difference: 1.33 kPa (10 mmHg, 0.4 inHg) carburetor No.

-

Page 106: Throttle Cable Free Play Adjustment

THROTTLE CABLE FREE PLAY ADJUSTMENT T H R O T T L E C A B L E F R E E P L A Y A D J U S T — M E N T NOTE: Before adjusting the throttle cable free play, the engine idle speed should be adjusted.

-

Page 107: Spark Plug Inspection

SPARK PLUG INSPECTION Throttle Cable Free Play (Throttle Grip) @ : 2 — 5 mm (0.08 — 0.20 in) Tighten the locknut @ . NOTE: Normally, once the throttle cable length adjuster (carburetor) is properly set; the only adjustment required is maintenance of free play at the throttle cable length adjuster (Throttle grip).

-

Page 108: Ignition Timing Check

IGNITION TIMING CHECKS AD 4. Measure: *Spark plug gap Out of specification * Regap. Use a wire gauge. Spark Plug Gap: mm (0.028 — 0.032 in) 0.7 — 0.8 5. Tighten: NOTE: Before installing a spark plug, clean the gasket surface and plug surface.

-

Page 109: Compression Pressure Measurement

COMPRESSION PRESSURE MEASUREMENT AD 4. Warm up the engine and allow it to idle at the specified speed. Engine Idle Speed: 1,250 — 1,350 r/min Check: Visually check the crankcase end @ is within the firing range @ on the magneto. Out of firing range -+ Check pickup as- sembly.

-

Page 110

COMPRESSION PRESSURE MEASUREMENT (be sure the battery is fully charged) with the throttle wide open until the compression reading on the gauge stabilizes. *Check readings with specified levels (See chart). Compression Gauge: Compression Pressure (At sea level) : Standard : 950 kPa (9.5 kg/cm2, 138 psi) Minimum: 750 kPa (7.5 kg/cm2, 109 psi) -

Page 111: Engine Oil Level Inspection

ENGINE OIL LEVEL INSPECTION/ ENGINE OIL REPLACEMENT ENGINE OIL LEVEL INSPECTION 1. Place the motorcycle on its centerstand and warm up the engine for several minutes. NOTE: Position motorcycle straight up when checking oil level, a slight tilt to the side can produce false readings.

-

Page 112: Engine Oil Filter Replacement

ENGINE OIL FILTER REPLACEMENT Fill: CAUTION: Do not allow foreign material to enter the crankcase. Periodic Oil Change: L (2.4 Imp qt. 2.9 US qt) Recommended Engine Oil: At 5°C (40” F) or Higher: Yamalube 4-cycle oil or SAE 2OW40 Type SE Motor Oil At 15°C (60°F) or Lower: SAE lOW30 Type SE Motor Oil 8.

-

Page 113

ENGINE OIL FILTER REPLACEMENT Remove: @Spring @ Check: Cracks/Damage —f Replace. 8. install: Shim To oil filter cover. Be sure the O-ring (ij is positioned properly. 9. Install: Bolt (Oil Filter Cover): 15 Nm (1.5 m-kg, 11 ft-lb) NOTE: Mesh the oil filter cover projection (0 with the crankcase slot. -

Page 114: Clutch Adjustment

J @!iii CLUTCH ADJUSTMENT AD CLUTCH ADJUSTMENT 1. Check: Clutch lever free play :a Out of specification —f Adjust. 2 — 3 mm (0.08 — 0.12 in) 2. Adjust: Clutch lever free play Adjustment steps: Loosen the locknut @ , Turn the adjuster @ in or out until the specified free play is obtained.

-

Page 115: Air Filter Cleaning

AIR FILTER CLEANING/CARBURETOR INSP JOINT INSPECTION/FUEL LINE INSPECTION AD AIR FILTE3 CLEANING 1. Remove: Seat Top cover “ C O W L I N G R E M O V A L R e f e r t o t h e A N D I N S T A L L A T I O N section.

-

Page 116: Crankcase Ventilation Hose Inspection

CRANKCASE VENTILATION HOSE INSPECTION/ EXHAUST SYSTEM INSPECTION 2. Inspect: Fuel pipes Cracks/Damage + Replace. Fuel filter Contamination/Damage + Replace. NOTE: Drain and flush the fuel tank if abrasive damage to any components is evident. CRANKCASE VENTILATION HOSE INSPEC- TION 1. Remove: Top cover Refer to the “COWLING REMOVAL AND STALLATION — REMOVAL”…

-

Page 117: Coolant Level Inspection

COOLANT LEVEL INSPECTION/COOLANT REPLACEMENT 3. Tighten: Nuts (Exhaust Pipe) : 10 Nm (1.0 m-kg, 7.2 ftmlb) Bolt (Muffler/Rear Footrest) : 20 Nm (2.0 m-kg, 14 ft*lb) Bolt (Muffler Star) : (For California only) 20 Nm (2.0 mekg, 14 ft. lb) COOLANT LEVEL INSPECTION 1.

-

Page 118: Coolant Replacement

COOLANT REPLACEMENT Place a thick rag, like a towel, over the radiator cap, slowly rotate the cap counterclockwise to the detent. This procedure allows any residual pressure to escape. When the hissing sound has stopped, press down on the cap while turning counterclockwise and remove it.

-

Page 119

J @!!ii COOLANT REPLACEMENT AD Coolant filling steps: the coolant into the radiator until the radiator is full. Start the engine (Coolant level decreases.) Always check coolant level, and check for coolant leakage before starting engine. Add the coolant while engine is running. Stop the engine when coolant level stabilizes. -

Page 120: Chassis

FRONT BRAKE ADJUSTMENT/REAR BRAKE ADJUSTMENT CHASSIS FRONT BRAKE ADJUSTMENT 1. Loosen: Adjuster locknut @ 2. Adjust: Free play Turn the adjuster @ until the free play @ is within the specified limits. Free play is decreased. Turn in Free play is increased. Turn out Front Brake Lever Free Play: 2 — 5 mm (0.08 — 0.20 in)

-

Page 121: Brake Fluid Inspection

BRAKE FLUID INSPECTION/BRAKE PAD INSPECTION REAR BRAKE LIGHT SWITCH ADJUSTMENT BRAKE FLUID INSPECTION *Brake fluid level Fluid at lower level + Replenish. brake fluid lower level Use only designated quality brake fluid to avoid poor brake performance. fluid; mixing fluids could result in poor brake performance.

-

Page 122: Brake Hose Inspection

BRAKE HOSE INSPECTION/DRIVE CHAIN SLACK CHECK/ AIR BLEEDING 2. Adjust: *Rear brake light switch Hold the switch body @ with your hand so it does not rotate and turn the adjuster 0. NOTE: Proper adjustment is achieved when the brake light comes on just before the brake begins to take effect.

-

Page 123: Drive Chain Slack Adjustment

DRIVE CHAIN SLACK ADJUSTMENT F r o n t tainer. al times. Hold the lever or pedal in position. or pedal to travel towards its limit. h. Tighten the bleed screw when the lever or pedal limit has been reached; then release the lever or pedal.

-

Page 124

DRIVE CHAIN SLACK ADJUSTMENT Remove: *Cotter pin @ Loosen: Nut (Rear axle) @ Locknut @ 5. Adjust: *Chain slack Turn the adjuster @ in or out. Turn in Chain slack is decreased. Turn out Chain slack is increased. NOTE: There are marks on each side of rear arm and on each chain puller;… -

Page 125: Drive Chain Lubrication

DRIVE CHAIN LUBRICATION/STEERING HEAD INSPECTION DRIVE CHAIN LUBRICATION The chain consists of many parts which work against each other. If the chain is not maintained properly, it will wear out rapidly, therefore, form the habit of periodically servicing the chain. This service is especially necessary when riding in dusty conditions.

-

Page 126

STEERING HEAD INSPECTION AD 6. Remove: Lock washer @ *Washer @ 7. Remove: Front fork Refer to the “FRONT FORK — REMO- VAL” section in the CHAPTER 7 8. Tighten: Ring nuts (Lower and upper) Ring nuts tightening steps: NOTE: Set the Torque Wrench to the Ring Nut Wrench so that they form a right angle. -

Page 127: Steering Head Inspection

STEERING HEAD INSPECTION If steering is binded, loosen the ring nut that there is no free play on bearing. If steering is loosened, repeat the adjustment steps. NOTE: The tapered side of ring nut must face down- ward. the slots of both ring nuts. If not aligned, hold the lower ring nut @ and tighten the other until they are aligned.

-

Page 128: Front Fork Inspection

FRONT FORK INSPECTION/ REAR SHOCK ABSORBER ADJUSTMENT FRONT FORK INSPECTION Securely support the motorcycle so there is no danger of it falling over. 1. Place the motorcycle on a level place. 2. Check: Inner tube Scratch/Damage + Replace. Oil seal Excessive oil leakage —f Replace.

-

Page 129: Tire Inspection

TIRE INSPECTION TIRE INSPECTION Tire pressure Out of specification -t Adjust. Tire inflation pressure should be checked and adjusted when the temperature of the tire euqals the ambient air temperature. Tire in- flation pressure must be adjusted according to total weight of cargo, rider, passenger, and accessories (fairing, saddlebags, etc.

-

Page 130: Wheel Inspection

WHEEL INSPECTION After extensive tests, the tires mentioned below have been approved by Yamaha motor Co., Ltd. for this model. No guarantee for handling characteristics can be given if tire combinations other than what is approved are used on this motorcycle.

-

Page 131: Cable Inspection

J @fii CABLE INSPECTION/LUBRICATION AD CABLE INSPECTION Inspect: @Throttle cables Cable sheaths Clutch cable Starter cable Check for damage to the cable insulation. Corrosion/Damage —f Replace. Obstruction -+ Reroute. Unsmoothness + Lubricate. LUBRICATION Throttle cables/Clutch cable/Starter cable Cable lubrication steps: Remove the two grip ends that secure throttle to handlebar.

-

Page 132: Electrical

BATTERY INSPECTION ELECTRICAL BATTERY INSPECTION 1. Remove: Refer to the “COWLING REMOVAL AN INSTALLATION — REMOVAL” section. 2. Inspect: Fluid level @ should be between upper 0 and lower @ marks. Incorrect+ Refill. Refill with distilles water only; tap water con tains minerals harmful to a battery.

-

Page 133: Battery Inspection

BATTERY INSPECTION Replace the battery if: Battery voltage will not rise to a specific value or bubbles fail to rise even after many hours of charging. Sulfation of one or more cells occurs, as in- dicated by the plates turning white, or an ac- cumulation of material exists in the bottom of the cell.

-

Page 134: Fuse Inspection

FUSE INSPECTION/HEADLIGHT BEAM ADJUSTMENT AD FUSE INSPECTION The fuse panel is located under the seat. 1. Inspect: Fuses Defective+ Replace. Blown fuse (New)+ Inspect circuit. Install new fuses of proper amperage. Amperage Quantity Description Main Headlight Signal Ignition Reserve Blown fuse replacement steps: *Turn off ignition and the circuit.

-

Page 135: Headlight Bulb Replacement

J @iii HEADLIGHT BULB REPLACEMENT AD 2. Adjust: @Vertical adjustment: To raise the beam, turn the adjusting screw To lower the beam, turn the screw @ counterclockwise. HEADLIGHT BULB REPLACEMENT 1. Remove: Headlight cover @ 2. Disconnect: Headlight bulb coupler @ Remove: Headlight bulb cover @ Remove:…

-

Page 136: Tail/Brake Bulb Replacement

TAIL/BRAKE BULB REPLACEMENT 7. Connect: Headlight bulb coupler 8. Install: Headlight cover. TAIL/BRAKE BULB REPLACEMENT 1. Remove: cowling Remove: Bulb socket Turn the bulb socket approximately 30” counterclockwise. Remove: Defective bulb 4. Install: Bulb socket 3-48…

-

Page 137: Lower Cowling, Center Cowling, Upper Cowling And Top Cover

ENGINE REMOVAL ENGINE OVERHAUL ENGINE REMOVAL NOTE: It is not necessary to remove the engine in order to remove the following components: Cylinder head Cylinder . Clutch A.C. magneto LOWER COWLING, CENTER COWLING, UPPER COWLING AND TOP COVER 1. Remove: Lower cowlings (Left and right) Center cowlings (Left and right) Top cover…

-

Page 138: Radiator

ENGINE REMOVAL RADIATOR 1. Disconnect: Hose (Radiator — Inlet) @ Hose (Radiator — Outlet) @ 2. Disconnect: Fan motor coupler 3. Remove: Radiator assembly Cover the cylinder head cover and the fender with rugs to prevent a scratching. 4. Disconnect: Pipes (Left and right) 5.

-

Page 139: Engine Disassembly

ENGINE DISASSEMBLY MUFFLER ASSEMBLY (For California only) 1. Remove: Nuts (Exhaust pipe) @ Cowling stays @ Bolt (Muffler bracket) @ 2. Remove: Bolt (Muffler stay) 3. Loosen: Lock nut @ Adjuster @ 4. Remove: Clips 0 5. Remove: Bracket @ Housing @ Gasket (Left side)

-

Page 140: Clutch Cable And Drive Chain

ENGINE REMOVAL CLUTCH CABLE AND DRIVE CHAIN 1. Remove: Shift arm Crankcase cover (Left) 2. Remove: Clutch cable 3. Straighten: Lock washer tab 4. Remove: Drive sprocket LEADS 1. Straighten: 2. Disconnect: Battery leads NOTE: Disconnect the negative lead @ first.

-

Page 141: Engine Removal

ENGINE REMOVAL 3. Disconnect: Lead (Starter motor) Remove: 5. Disconnect: Coupler (Oil level Neutral switch) Coupler (A.C. generator) Coupler (Sidestand switch) Remove: Spark plug leads ENGINE REMOVAL 1. Remove: 2. Place a suitable stand under the engine. Remove: Down tube frames (Left and right) @ Bolt (Engine-mount) @…

-

Page 142

ENGINE REMOVAL Remove: Lower) @ Bolt (Engine-mounting Bolt (Engine-mounting Upper) @ Collars @ Remove: Engine assembly. From right side. -

Page 143: Engine Disassembly

ENGINE DISASSEMBLY ENGINE DISASSEMBLY CYLINDER HEAD COVER, CAMSHAFT AND CYLINDER HEAD NOTE: With the engine mounted, the cylinder head cover, camshaft and cylinder head can be maintained by removing the following parts. Lower cowlings (Left and right) Center cowlings (Left and right) Seat Top cover Radiator…

-

Page 144

ENGINE DISASSEMBLY 5. Remove: Cam chain tensioner @ Gasket (Cam chain tensioner) 6. Remove: Union bolts @ Oil delivery pipe @ 7. Remove: Cam chain guide (Upper) @ Cam chain guide (Exhaust side) @ NOTE: Select either of the two procedures explained in this manual, as follows: Procedure 1. -

Page 145

ENGINE DISASSEMBLY Procedure 1. Cam chain Use the Cam Chain Cutter @ . Cam Chain Cutter: YM-01112 2. Remove: Rubbers (Camshaft cap) @ 3. Remove: Nuts (Cylinder head) Use the Hexagon Wrench 6 mm (0.24 in)@. 4. Remove: Cylinder head Gasket (Cylinder head) 5. -

Page 146: Cylinder And Piston

ENGINE DISASSEMBLY 3. Remove: Nuts (Cylinder head) Use the Hexagon Wrench 6 mm (0.24 in)@. NOTE: Loosen the nuts in their proper loosening sequence. Follow numerical order shown in photo. Start by loosening each nut l/2 turn until all are loose. 4.

-

Page 147

ENGINE DISASSEMBLY 1. Remove: Cylinder Remove: Gasket (Cylinder) @ Dowel pins @ 3. Mark: With the piston number designations as shown. Remove: Circlips (Piston pin) @ NOTE: Before removing the piston pin circlip, cover the crankcase with a clean rag to prevent the circlip from falling into the crankcase cavity. -

Page 148: Starter Clutch

ENGINE DISASSEMBLY STARTER CLUTCH NOTE: With the engine mounted, the starter clutch can be maintained by removing the following parts. Lower cowling (Right) Starter clutch cover 1. Remove: clutch cover @ Gasket (Starter clutch cover) Dowel pens. Remove: Bolt (Starter clutch) @ Washer Attach: Heavy Duty Puller @…

-

Page 149: Clutch

ENGINE DISASSEMBLY CLUTCH NOTE: With the engine mounted, the starter clutch can be maintained by removing the following parts. Lower cowling (Right) Crankcase cover (Right) 1. Remove: Crankcase cover (Right) @ Gasket (Crankcase cover) Dowel pins NOTE: Working in a crisscross pattern, loosen bolts l/4 turn each.

-

Page 150: A.c. Magneto

ENGINE DISASSEMBLY 6. Remove: Lock washer @ 7. Remove: Spacer @ Bearing @ NOTE: Install the 5 mm (0.2 in) screw @ on the spacer screw. 9. Remove: Thrust washer @ *Collar @ A.C. MAGNETO NOTE: With the engine mounted, the A.C. Magneto can be maintained by removing the following parts.

-

Page 151: Water Pump

ENGINE DISASSEMBLY 1. Remove: Washer NOTE: Hold the magneto to loosen the nut by the Universal Rotor Holder 0. Universal Rotor Holder: P/N YU-01235 2. Attach: P/N YM-01080 Remove: 4. Remove: Starter coil assembly @ Pickup coil @ WATER PUMP NOTE: With the engine mounted, the water pump can be maintained by removing the following parts.

-

Page 152: Oil Pump And Shift Shaft

ENGINE DISASSEMBLY OIL PUMP AND SHIFT SHAFT NOTE: With the engine mounted, the oil pump and shift shaft can be maintained by removing the following parts. Lower cowling (Right) Crankcase cover (Right) Clutch housing 1. Remove: 2. Remove: Dowel pin @ 4-16…

-

Page 153: Oil Pan And Oil Strainer

ENGINE DISASSEMBLY Remove: Shift shaft assembly @ OIL PAN AND OIL STRAINER NOTE: With the engine mounted, the oil pan and oil strainer can be maintained by removing the following parts. Lower cowlings (Left and right) Muffler assembly stay 1. Disconnect: 0il level switch lead @ Neutral switch lead @ Remove:…

-

Page 154: Starter Motor

ENGINE DISASSEMBLY 4. Remove: Relief valve @ 5. Remove: Oil strainer assembly @ STARTER MOTOR NOTE: With the engine mounted, the starter motor, can be maintained by removing the following parts. Top cover Fuel tank 1. Remove: Starter motor 0 crankcase ventilation hose @ CRANKCASE DlSASSErVlBLY 1.

-

Page 155: Transmission, Shifter And Shift Cam

ENGINE DISASSEMBLY Remove: Bolts (Crankcase) NOTE: Remove the bolts starting with the highest numbered one. e m b o s s e d n u m b e r s i n t h e c r a n k c a s e designate the crankcase tightening sequence.

-

Page 156: Crankshaft

ENGINE DISASSEMBLY 4. Remove: Shift cam CRANKSHAFT 1. Remove: Crankshaft assembly 2. Remove: Main journal bearing NOTE: Identify each main journal bearing position very carefully so that it can be reinstalled in its original place. 4. Remove: Neutral switch 4 — 2 0…

-

Page 157: Valve Pad And Valve

ENGINE DISASSEMBLY 5. Remove: Breather hose VALVE PAD AND VALVE NOTE: With the engine mounted, the valve pad and valve can be maintained by removing the following parts. Lower cowlings (Left and right) @Center cowlings (Left and right) Fuel tank Carburetor Radiator @Generator cover…

-

Page 158

ENGINE DISASSEMBLY 2. Check: Leakage at valve seat + inspect the valve face, valve seat and valve seat width. Refer to the “INSPECTION AND REPAIR NOTE: Before removing the internal parts (valve, valve spring, spring seat, etc.) of the cylinder head, the valve sealing should be checked. -

Page 159: Connecting Rod

ENGINE DISASSEMBLY CONNECTING ROD 1. Remove: connecting rod @ Connecting rod bearing INNER ROTOR (OIL PUMP) 1. Remove: Pump housing 2. Remove: Washer @ Pump shaft @…

-

Page 160: Inspection And Repair

INSPECTION AND REPAIR INSPECTION AND REPAIR CYLINDER HEAD 1. Eliminate: Carbon deposit (from combustion chamber) Use rounded scraper. NOTE: Do not use a sharp instrument and avoid damag- ing or scratching: Spark plug threads Va Ive seat 2. Inspect: Cylinder head Scratches/Damage Replace.

-

Page 161: Valve

INSPECTION AND REPAIR VALVE Inspect: Wear/Pitting + Reface. Out of specification + Replace. Face Width @ : 1.6 — 2.4 mm (0.0630 — 0.0945 in) Seat Width @ : 0.9 — 1.1 mm (0.0354 — 0.0433 in) < Limit > 1.6 mm (0.063 in) Margin Thickness @ : 0.6 — 0.8 mm (0.0236 — 0.0315 in)

-

Page 162: Valve Guide

INSPECTION AND REPAIR 4. Measure: Out of specification + Replace. Maximum Runout: 0.02 mm (0.0008 in) VALVE GUIDE NOTE: Always replace the valve guide if the valve is replaced. Always replace the oil seal if the valve is removed. Valve guide Wear/Oil leakage into cylinder —f Replace.

-

Page 163: Valve Seat

INSPECTION AND REPAIR VALVE SEAT 1. Clean: Valve face Valve seat Remove carbon deposit. 2. Inspect: Valve seat Pitting/Wear + Reface valve seat. 3. Measure: Valve seat width @ Out of specification + Reface valve seat. Valve Seat Width Intake 0.9 — 1.1 m m (0.035 — 0.043 in) 0.9 — 1.1 m m (0.035 — 0.043 in) Exhaust…

-

Page 164

INSPECTION AND REPAIR Remove just enough material to achieve satis- factory seat. When twisting cutter, keep and even downward pressure to prevent chatter marks. Cut sections as follows Section Cutter 45” 60” Valve seat refacing steps: centered on valve face but is too wide. face but too narrow. -

Page 165

INSPECTION AND REPAIR 5. Lap: NOTE: After refacing the valve seat or replacing the valve and valve guide, the valve seat and valve face should be lapped. Valve lapping steps: Apply a coarse lapping compound @ to the valve face. CAUTION: Be sure no compound enteres the gap between the valve stem and guide. -

Page 166: Valve Spring

INSPECTION AND REPAIR Press the valve through the valve guide and onto the valve seat to make a clear pattern. the valve seat width @ again. If the valve seat width is out of specification, reface and lap the valve seat. VALVE SPRING 1.

-

Page 167: Camshaft, Cam Chain And Cam Sprocket

INSPECTION AND REPAIR VALVE LIFTER 1. I nspect: Scratches/Damage + Replace both lifters and camshaft case. CAMSHAFT, C A M C H A I N , A N D C A M SPROCKET Camshaft 1. I nspect : Pitting/Scratches/Blue discoloration Replace.

-

Page 168

INSPECTION AND REPAIR 3. Install: Dowel pins Camshaft caps 4. Tighten: camshaft cap bolts Bolts (Camshaft Cap) : 10 Nm (1.0 m-kg, 7.2 ftslb) NOTE: Tighten the camshaft caps in a crisscross pattern from innermost to outer caps. Do not turn the camshaft when measuring clearance with the Plastigage@. -

Page 169: Cylinder And Piston

INSPECTION AND REPAIR Cam Chain 1. Inspect: Chain stretch/Cracks —f Replace. Sprockets 1. Inspect: *Cam sprockets Wear/Damage + Replace. Cam Chain Guide 1. I nspect: Cam chain guide (Upper) @ Cam chain guide (Exhaust side) @ Cam chain guide (intake side) @ Wear + Replace.

-

Page 170

INSPECTION AND REPAIR Piston-to-cylinder clearance measurement steps: First step: Cylinder Bore Gauge. NOTE: Measure the-cylinder bore “C” in parallel to and at right angles to the crankshaft. Then, find the average of the measurements. Standard Wear Limit 56.05 mm Cylinder 56.000 — 56.005 mm (2.2067 in) bore “C”… -

Page 171: Piston Ring And Piston Pin

INSPECTION AND REPAIR If out of specification, rebore or replace cylinder, and replace piston and piston rings as a set. Piston-to-cylinder Clearance: Limit: 0.15 mm (0.006 in) PISTON RING AND PISTON PIN Piston Ring 1. Measure: Side clearance Use the Feeler Gauge 0. Out of specification + Replace the piston and/or rings.

-

Page 172

INSPECTION AND REPAIR End Gap (Installed) : Standard T o p ring 0.15 0.30 mm (0.0059 — 0.0118 in) 2nd ring 0.15 0.30 mm (0.0059 — 0.0118 in) Oil control 0.2 — 0.8 mm (Rails) (0.0079 — 0.0315 in) Piston Ring Oversize Oversize top and middle ring size is stamped on the top of ring. -

Page 173: Crankshaft And Connecting Rod

INSPECTION AND REPAIR Check: Free play When the pin is in place in the piston. Free play + Replace the piston pin and/or piston. CRANKSHAFT AND CONNECTING ROD Crankshaft Use the V-Blocks and Dial Gauge. Out of specification —t Replace. Out of specification + Replace.

-

Page 174

INSPECTION AND REPAIR 5. Install: *Bearings Into the lower crankcase. Crankcase (Lower) 6. Tighten: Tighten to full torque in torque sequence cast on the crankcase. Bolt @ — @ : 24 Nm (2.4 m-kg, 17 ft*lb) Bolt @ — @ : 12 Nm (1.2 m-kg, 8.7 ftalb) Remove: Reverse assembly procedure. -

Page 175

INSPECTION AND REPAIR Connecting Rod Oil Clearance 1. Clean all parts thoroughly. 2. Install: Connecting rod bearings Into the connecting rod and cap. 3. Attach: Onto the crank pin. 4. Install: Connecting rod Connecting rod cap NOTE: Be sure the “Y” marks @ on the connecting rods face toward left crankshaft end . -

Page 176

INSPECTION AND REPAIR Remove: connecting rod cap Use care in removing. 8. Measure: Width of Plastigage@ Out of specification + Replace the bearings and/or replace the crankshaft if necessary. Connecting Rod Oil Clearance: 0.043 — 0.0066 mm (0.0017 — 0.0026 in) Crankshaft Main Journal and Connecting Rod Bearing Selection… -

Page 177

INSPECTION AND REPAIR Example 1: Selection of the main journal bearings: are No. 4 and No. 1, respectively, the bearing size No. is: Bearing Size No. = C rankcase No. — Crankshaft No. = 4 — 1 = 3 (Brown) BEARING COLOR CODE No. -

Page 178

INSPECTION AND REPAIR 2. Lubricate: Pump shaft SAE lOW30 Motor Oil 3. Install: Reverse removal procedure. A l i g h n t h e p i n s i n t h e p u m p s h a f t a n d t h e groove on the inner rotors dualing assembly. -

Page 179: Starter Clutch

INSPECTION AND REPAIR STARTER CLUTCH 1. Check: Roller operation Push the roller to arrow direction. Unsmooth operation + Replace starter clutch. 2. Inspect: Burrs/Chips/Roughness/Wear -+ Replace. 3. Inspect: Contacting surfaces Pitting/Wear/Damage -+ Replace. 4. Check : Starter clutch operation Clutch operation checking steps: Install the starter clutch gear to the starter clutch, and hold the starter clutch.

-

Page 180: Clutch

INSPECTION AND REPAIR pqq CLUTCH Clutch Housing 1 . Inspect : Dogs on the housing Cracks/Wear/Damage —f Deburr or replace. Clutch housing bearing Chafing/Wear/Damage + Replace. NOTE: Wear on the friction plate dogs of the clutch housing will cause an erratic operation. Clutch Boss 1 .

-

Page 181

INSPECTION AND REPAIR 2. Inspect: Pressure plate Damage + Replace. Push Rod 1. I nspect : @Push rod 2 @ Wear/Cracks/Damage -+ Replace. Push Lever Assembly and Boll Screw Housing 1. I nspect : Push lever assembly Unsmooth + Replace. 2. -

Page 182: Transmission

INSPECTION AND REPAIR TRANSMISSION Shift Fork 1. Inspect: Shift fork cam follower @ Shift fork paw1 @ Wear/Chafing/Bends/Damage + Replace. 2. Check: Shift fork movement On its guide bar @ . Unsmooth operation + Replace the fork and/guide bar. Shift Cam 1.

-

Page 183: Relief Valve And Pipe

INSPECTION AND REPAIR -1 RELIEF VALVE AND PIPE 1. Check: Relief valve body @ Cover 0 *Spring @ O-ring @ Damage/Wear + Replace. 2. Check: Oii pipe 0 Damage + Replace. W a s h a n d b l o w o u t C o m t a m i n a t i o n + the passage.

-

Page 184

INSPECTION AND REPAIR YAMAHA EXHAUST VARIABLE VAiVE (For California Only) 1. I nspect : Shaft arm Wear/Cracks/Damage Replace. 2. Inspect: Wear -+ Replace. -

Page 185: Engine Assembly And Adjustment

ENGINE ASSEMBLY AND ADJUSTMENT ENGINE ASSEMBLY AND ADJUSTMENT INNER ROTOR (OIL PUMP) 1. Install: Pump shaft @ *Pin @ Outer rotor @ NOTE: Insert the inner rotor @ into the outer rotor 0. Then with the pump shaft dowel pin @ in the inner rotor slit.

-

Page 186: Crankshaft

ENGINE ASSEMBLY AND ADJUSTMENT CRANKSHAFT @Crankshaft @Connecting rod assembly @Connecting rod bolt @Connecting rod bearing @ N u t…

-

Page 187: Valve Pad And Valve

ENGINE ASSEMBLY AND ADJUSTMENT 5. Install: @Connecting rods NOTE: crankcase. Be sure the letter on both components align to form a perfect character. 6. Install: @Connecting rod bolts Align the bolt head and connecting rod cap. 7. Tighten : Connecting rod nuts Tighten to full torque specification without pausing.

-

Page 188

ENGINE ASSEMBLY AND ADJUSTMENT 2. Install: Oil seal @ 3. Install: NOTE: Apply molybdenum disulfide oil. 4. Install: NOTE: Install springs with wider-gapped coils facing upwards, as shown. @Smaller pitch Attach: Valve spring compressor @ Attachment @ 6. Install: 7. Settle the valve retainer by lightly patting the valve seat with a piece of wood @ in between. -

Page 189

ENGINE ASSEMBLY AND ADJUSTMENT 8. Install: NOTE: Apply molybdnum disulfide oil. 9. Install: CRANKSHAFT 1. Install: Oil baffle plate Breather hose Oil Baffle Plate Bolts: 10 Nm (1.0 m-kg, 7.2 ft.lb) 2. Install: Neutral switch assembly @ 3. Install: Cam chain guide (Intake side) @ O-ring @ Bolts (Chain… -

Page 190: Crankcase

ENGINE ASSEMBLY AND ADJUSTMENT CRANKCASE @Crankcase assembly @Crankcase ventilation hose 12 Nm (1.2 m-kg, 8.7 ft.lb) 24 Nm (2.4 m-kg, 17 ft. lb)

-

Page 191: Transmission

ENGINE ASSEMBLY AND ADJUSTMENT TRANSMISSION @Drive axle wheel gear wheel gear wheel gear @ W a s h e r C USE NEW ONE…

-

Page 192: Transmission, Shifter And Shift Cam

ENGINE ASSEMBLY AND ADJUSTMENT 4. Install: Main journal bearing @ To crankcase (Lower) @ NOTE: Apply molybedenum disulfide oil. 5. Install: Cam cabin @ Onto the crankshaft Crankshaft assembly @ NOTE: the left. *Pass the cam chain through the cam chain cavity.

-

Page 193: Crankcase Assembly

ENGINE ASSEMBLY AND ADJUSTMENT 2. Install: Stopper plate (Shift cam) @ Stopper lever @ Bolts (Stopper Plate) : 10 Nm (1.0 m-kg, 7.2 ftslb) Use LOCTI TE@ Bolt (Stopper Lever) : 10 Nm (1.0 m-kg, 7.2 ftslb) Use LOCTITE@ 3. Install: Circlip @ To crankcase ( Lower) NOTE:…

-

Page 194

ENGINE ASSEMBLY AND ADJUSTMENT Before tightening the crankcase bolts, check the following points: *Be sure the gear shifts correctly while hand- turning the shift cam. 2. Tighten: Upper crankcase bolt a (Follow the proper tightening sequence.) 24 Nm (2.4 m-kg, 17 ft*lb) 6mmBolt @ — @ @ — 8 : 12 Nm (1.2 m-kg, 8.7 ft*lb) NOTE:… -

Page 195: Starter Motor

ENGINE ASSEMBLY AND ADJUSTMENT STARTER MOTOR Check: Damage + Replace. 2. Install: Bolt (Starter Motor) : 10 Nm (1.0 m-kg, 7.2 ft.lb) OIL PAN AND OIL STRAINER 1. Install: Oil strainer assembly Bolts (Oil Strainer Assembly): 10 Nm (1.0 m-kg, 7.2 ft- lb) 2.

-

Page 196: Oil Pump And Shift Shaft

ENGINE ASSEMBLY AND ADJUSTMENT OIL PUMP AND SHIFT SHAFT 1. Install: Shift shaft NOTE: Insert the stopper between spring ends. 2. Install: *Gasket (New) @ 3. Install: NOTE: Align the oil pump arrow mark @ with crank- case arrow mark 0. WATER PUMP 1.

-

Page 197: A.c. Magneto

ENGINE ASSEMBLY AND ADJUSTMENT A.C. MAGNETO ST PSOR COlC REssT ANCE-. I 0.44 — 0.66R at 20°C (68’F) (White -White) PICKUP COIL RESISTANCE: 85 — 115R at 20°C (68°F) (White/Red -White/Black) 10 Nm (1.0 m-kg, 7.2 ftmlb) 80 Nm (8.0 m-kg, 58 ftelb) 4-61…

-

Page 198

ENGINE ASSEMBLY AND ADJUSTMENT A.C. MAGNETO 1. Install: Pickup coil @ *Woodruff key @ Bolts (Stator Coil Assembly): 10 Nm (1.0 m-kg, 7.2 ftslb) Use LOCTITE@ Screws (Pickup Coil): Nm (0.5 rn. kg, 3.6 ft. lb) NOTE: and magneto. When installing the magneto, make sure the woodruff key is properly seated in the key way of the crankshaft. -

Page 199: Clutch

ENGINE ASSEMBLY AND ADJUSTMENT CLUTCH @Primary driven gear @ O — r i n g @Thrust washer @ B o l l @Oil seal @Clutch plate @Push rod #2 @Push lever assembly @Clutch spring screw housing 0 ar SPRING FREE LENGTH LIMIT: 29.0 mm (1.142 in)

-

Page 200

ENGINE ASSEMBLY AND ADJUSTMENT CLUTCH 1. Install: *Collar 0 Bearing @ *Spacer @ Thrust washer @ Lock washer (New) @ NOTE: Install the bearing @ and spacer @after installa- tion of the clutch housing @ . 2. Tighten: Use the Universal Clutch Holder @ . NOTE: Hold the clutch boss to tighten the nut by Universal Clutch Holder @ . -

Page 201: Starter Clutch

ENGINE ASSEMBLY AND ADJUSTMENT 4. Install: Be sure the match mark @ on the clutch boss is aligned with the match mark @on the pressure plate. 5. Install: Bolts (Clutch spring) @ Bolts (Clutch Spring) : 6 Nm (0.6 m-kg, 4.3 ft. lb) 6.

-

Page 202

ENGINE ASSEMBLY AND ADJUSTMENT STARTER CLUTCH 4 — 6 6… -

Page 203: Piston And Cylinder

ENGINE ASSEMBLY AND ADJUSTMENT m PISTON AND CYLINDER @ T o p r i n g @ D o w e l p i n @ O i l r i n g ( L o w e r ) @ C y l i n d e r @ O i l r i n g ( U p p e r ) @ S e c o n d…

-

Page 204

ENGINE ASSEMBLY AND ADJUSTMENT 3. Install: Dowel pins @Gasket (Stater clutch cover) (New) Stater clutch cover @ Bolts (Stater Clutch Cover): 10 Nm (1.0 m-kg, 7.2 ft-lb) PISTON AND CYLINDER 1. Install: NOTE: Be sure to install rings so that Manufacturer’s marks or numbers are located on the top side of the rings. -

Page 205

ENGINE ASSEMBLY AND ADJUSTMENT 3. Install: Gasket (Cylinder) @ Dowel pins 4. Lubricate: Cylinder NOTE: Apply a liberal coating of 4stroke engine oil. 5. Position: Offset the piston ring end gaps. Oil ring end (Lower) @ 2nd ring end @ 6. -

Page 206: Cylinder Head And Camshaft

ENGINE ASSEMBLY AND ADJUSTMENT CYLINDER HEAD AND CAMSHAFT Cylinder Head @ W a s h e r guide @Gasket (Cylinder head) head cover @Cylinder head assembly @ W a s h e r Nm (1.0 m-kg, 7.2 ft.lb) C 1 USE NEW ON4 4-70…

-

Page 207

ENGINE ASSEMBLY AND ADJUSTMENT Camshaft @Camshaft (Exhaust) @Camshaft (Intake) @Cam chain sprocket chain guide (Exhaust side) @Spring seat @Gasket (Cam chain tensioner) @Cam chain guide (Intake side) VALVE CLEARANCE (COLD): I N T A K E : 0.11 — 0.20 mm (0.004 — 0.008 in) EXHAUST: 0.21 — 0.30 mm… -

Page 208

ENGINE ASSEMBLY AND ADJUSTMENT CYLINDER HEAD AND CAMSHAFT 1. Install: @Gasket (Cylinder head) (New) @ Dowel pins @ NOTE: The gasket “HEAD” mark should face upward. NOTE: in this manual, as follows: Procedure 1. The cam chain is disconnected + Connect. @Procedure 2. -

Page 209

ENGINE ASSEMBLY AND ADJUSTMENT 4. Connect: Cam chain With the chain joint (New). Use the Cam Chain Cutter @ . Cam Chain Cutter: P/N YM-01112 NOTE: Keep the cam chain as tense as possible on the exhaust side. 5. Go to “CAM CHAIN TENSIONER”. Procedure 2. -

Page 210

ENGINE ASSEMBLY AND ADJUSTMENT pi&j Lubricate the camshaft bearing surfaces, cam lobes and cam journals. Molybdeum Disulfide Oil install the intake camshaft @ . Be sure the timing marks @I on the camshaft face upward. the exhaust side. Remove the retaining wire @ . Do not turn the camshaft separately or damage to the piston and valve will result. -

Page 211: Cam Chain Tensioner

ENGINE ASSEMBLY AND ADJUSTMENT CAM CHAIN TENSIONER 1. Position: Cam chain Exhaust side -+ Tense. Intake side + Slack. 2. Install: Cam chain tensioner Cam chain tensioner installation steps: Remove the tensioner end cap bolt and spring. Release the cam chain tensioner one-way cam @ and push the tension rod @ .

-

Page 212: Remounting Engine

ENGINE ASSEMBLY AND ADJUSTMENT 6 . I n s t a l l : Washers (New) Oil delivery pipe @ Union bolts @I 7. Install: Dowel pins Generator cover @ Bolts (Generator Cover): 10 Nm (1.0 m-kg, 7.2 ftslb) REMOUNTING ENGINE When remounting the engine, reverse the removal procedure.

-

Page 213

ENGINE ASSEMBLY AND ADJUSTMENT 3. Install: *Starter lever @ Bolt (Starter Lever) : 8 Nm (0.8 ma kg, 5.8 ft. lb) 4. Install: Drive chain @ Drive sprocket @ Lock washer (New) @ Nut (Drive sprocket) @ Nut (Drive Sprocket) : 70 Nm (7.0 me kg, 50 ft. -

Page 214: Yamaha Exhaust Variable Valve (For California Only)

ENGINE ASSEMBLY AND ADJUSTMENT YAMAHA EXHAUST VARIABLE VALVE (For California Only) Bracket Gasket (Exhaust pipe) @ W a s h e r Bush O i l s e a l Gasket Shaft arm Housing A USE NEW ONE 1.0 m-kg 7.2 ft.lb)

-

Page 215

ENGINE ASSEMBLY AND ADJUSTMENT 9. Install (For California only): Shaft arm *Gasket @ IO. Install (For California only): Washer Bracket Bolts (Bracket): 10 Nm (1.0 m-kg, 7.2 ftslb) Install (For California only): @Cables @ 12. Adjust (For California only): Cable Refer to the “EXUP CABLE ADJUST- MENT”… -

Page 216

ENGINE ASSEMBLY AND ADJUSTMENT 14. Adjust: Clutch Cable Free Play: 2 — 3 mm (0.08 — 0.12 in) Refer to the “CLUTCH ADJUSTMEI section in the CHAPTER 3. 15. Fill: Coolant Total Amount: 1.0 L (0.9 Imp qt, 1.1 US qt) Refertothe”COOLANT REPLACEME section in the CHAPTER 3. -

Page 217

R A D I A T O R COOL # COOLING SYSTEM RADIATOR @Outlet pipe @ O — r i n g @Hose (Radiator — Inlet) OPENING PRESSURE: (0.75 — 1.05 kg/cm’, 10.7 — 14.9 psi) COOLANT CAPACITY: 19 L (1.7 Imp qt, 2.0 US qt) lncludinq all routes 7 Nm (0.7 m.kg, 5.1 ftelh) -

Page 218

RADIATOR COOL % REMOVAL 1. Remove: Lower cowlings (Left and Right) Side cowlings (Left and Right) Refer to the “COWLING REMOVAL ANC I N S T A L L A T I O N — R E M O V A L ” sectiol in the CHAPTER 3. -

Page 219

6. Remove: Fan motor assembly INSPECTION 1. Inspect: Radiator core Obstruction + Blow out with compressed air through rear of the radiator. Flattened fin + Repair/replace. 2. Inspect: Hose (Radiator — Inlet) Cracks/Damage + Replace. Hose (Radiator — Outlet) Cracks/Damage + Replace. Cracks/Damage —f Replace. -

Page 220

Measurement steps: Adapter @ to the radiator cap @ . Cooling System Tester: Y U-24460-0 1 Adapter: Y U-33984 Apply the specified pressure for 10 seconds, and make sure there is no pressure drop. INSTALLATION Reverse the “REMOVAL” procedure. Note the following points. 1. -

Page 221

Inspection steps: @Attach the Cooling System Tester @ to the radiator. Cooling System Tester: Y U-24460-0 1 Apply 100 kPa (1 .O kg/cm*, 14 psi) pressure . @Measure the indicated pressure with the gauge. -

Page 222

WATER PUMP AND THERMOSTATIC VALVE COOL WATER PUMP AND THERMOSTATIC VALVE @ O — r i n g @Water pump cover @Pipe 1 @ O — r i n g @Water jacket joint Thermostatic pump housing @Water pipe THERMOSTATIC VALVE OPENING B USE NEW ONE… -

Page 223

WATER PUMP AND THERMOSTATIC VALVE COOL REMOVAL 1. Remove: Lower cowlings (Left and right) Center cowlings (Left and right) Top cover Refer to the “COWLING REMOVAL AND INSTALLATION REMOVAL” section in the CHAPTER 3. 2. Drain: Refer to the”COOLANT REPLACEMENT” section in the CHAPTER 3. -

Page 224

WATER PUMP AND THERMOSTATIC VALVE COOL 7. Disconnect: Thermo unit lead @ Thermo switch lead @ 8. Remove: Thermostatic housing 9. Remove: Thermostatic cover @ Thermostatic @ 10. Remove: Shift arm Crankcase cover (Left) 11. Remove: Water pipe 0 5 — 8… -

Page 225

WATER PUMP AND THERMOSTATIC VALVE I-f w Remove: pipe (Q Remove: Water pump housing @ @ O — r i n g INSPECTION 1. Inspect: Thermostatic valve Valve does not open at 80 — 84°C (176 — 183” F) + Replace. Inspection steps: *Suspend thermostatic valve @ in a vessel… -

Page 226

WATER PUMP AND THERMOSTATIC VALVE pqjiq 2. Inspect: Cracks/Wear/Damage + Replace. INSTALLATION Reverse the “REMOVAL” procedure. Note the following points. 1. Install: Crankcase cover (Left) Thermostatic cover Bolts (Water Pump 10 Nm (1.0 ma kg, 7.2 ftalb) Bolts (Pipe) : 10 Nm (1.0 ma kg, 7.2 ft*lb) Bolts (Crankcase Cover — Left): 10 Nm (1.0 me kg, 7.2 ft*lb) -

Page 227

CARBURETOR CARBURETOR CARBURETOR CATIONS Upper bracket ID Mark (Except for California), Lower bracket (For California) MAIN JET Float MAIN AIR JET PI LOT JET PILOT AIR JET NEEDLE PILOT SCREW T H R O T T L E V A L V E ENGINE IDLE SPEED 1,250 — 1,350 r/min FUEL… -

Page 228

CARBURETOR SECTION VIEW @Starter air bleed @Main air jet @Pilot outlet The pilot screw settings are adjusted fa screw maximum performance at the factory. @ A i r v e n t inlet @Main jet Any attempt to change these settings w @Float needle valve @Main bleed pipe II decrease engine performance. -

Page 229

CARBURETOR REMOVAL 1. Remove: Refer to the “COWLING REMOVAL AND INSTALLATION REMOVAL” section in the CHAPTER 3. 2. Turn the fuel cock to “OFF” position. Remove: Fuel cock lever @ 4. Disconnect: Fuel hose @ Remove: Fuel pump @ Gasoline is highly flammable. Avoid spilling fuel on the hot engine. -

Page 230

C A R B U R E T O R CARB # 8. Disconnect: Crankcase ventilation hose @ Air vent hose @ 9. Remove: Air filter case @ 10. Loosen : 11. Disconnect: Starter cable @ 12. Disconnect: Fuel hose @ 13. -

Page 231

CARBURETOR (CARBII DISASSEMBLY NOTE: The following parts can be cleaned and in- spected without carburetor separation. Throttle valve Float chamber components 1. Remove: *Bracket (Upper) @ (Lower) @ 2. Remove: ?????? ? 3. Remove: Vacuum chamber cover @ Spring @ Piston valve assembly @ 4. -

Page 232

CARBURETOR 5. Remove: 6. Remove: Float chamber cover *Gasket *Float pin @ *Float @ seat assembly @ 7. Remove: Main jet @ Holder (Main jet) @ Washer @ Needle jet @ Pilot air jet 8 INSPECTION 1. Inspect: Carburetor body Float chamber Fuel passage Contamination + Clean as indicated. -

Page 233

CARBURETOR 3. Inspect: *Float needle valve @ O-ring @ a set. 4. Inspect: *Throttle valve *Rubber diaphragm Tears+ Replace. 5. Inspect: Needle jet @ Main jet @ Holder @ Pilot adjust screw @ Bends/Wear/Damage Replace. Contamination + Blow out jets with a compressed air. -

Page 234

CARBURETOR ASSEMBLY To assemble the carburetor, reverse the disassem- bly procedures. Note the following points. Before reassembling, wash all parts in clean gasoline. Always use a new gasket. 1. Install: NOTE: Note position of tab @ on diaphragm. This tab must be placed in the cavity of the carburetor body during reassembly. -

Page 235

CARBURETOR 5. Installer: Screw (Upper Bracket): 3 Nm (0.3 m-kg, Screw (Lower Bracket): 5 Nm (0.5 m-kg, 3.6 ft.lb) INSTALLATION Reverse the “REMOVAL” procedure. Note the following points. 1. Install: Fuel tank @ Bolts (Fuel Tank): 14 Nm (1.4 ma kg, 10.2 ft- lb) 2. -

Page 236

CARBURETOR m ADJUSTMENT NOTE: Before adjusting the fuel level, the float heigl should be adlusted. The pilot screw settings are adjusted f maximum performance at the factory. A attempt to change these settings II decrease enaine performance. Fuel Level Adjustment 1. -

Page 237

CARBURETOR 2. Adjust: Fuel level Fuel level adjustment steps: *Remove the carburetor assembly. Refer to “REMOVAL” section. *Remove the float, valve seat and the needle valve. inspect the valve seat and the needle valve. If either is worn, replace as a set. *If both are fine, adjust the float height by bending the float tang 0. -

Page 238: Front Wheel

FRONT WHEEL pii&G CHASSIS FRONT WHEEL accessories. 1 lo/70 R17-53H WEAR LIMIT: 1.0 mm (0.04 in) i MT3.00 D / RIM RUNOUT LIMIT: /…

-

Page 239

FRONT WHEEL Ml REMOVAL 1. Place the motorcycle on a level place. Securely support the motorcycle so there is no danger of it falling over. 2, Remove: Speedometer cable @ 3. Remove: Brake calipers (Right/Left) 4. Loosen: Pinch bolt (Front axle) @ Axle (Front) @ 5. -

Page 240

FRONT WHEEL -1 3. Inspect: Wheel 4. Measure: Wheel runout Over specified limit + Repalce. Rim Runout Limits: Radial @ : 2.0 mm (0.08 in) Lateral @ : 2.0 mm (0.08 in) allow proper tire to rim seating. Failure to do so may cause an accident resulting in motor- cycle damage and possible operator injury. -

Page 241

FRONT WHEEL -1 NOTE: Use a socket @ that matches the outside diameter of the race of the bearing. CAUTION: Do not strike the center race or balls of the bearing. Contact should be made only with the outer race. 6. -

Page 242

FRONT WHEEL 3. Install: Front wheel NOTE: Be sure that the projecting portion (torque stopper) 0 of the gear unit housing is position- ed correctly. 4. Tighten: Front axle Pinch bolt (Front axle) Brake calipers (Right/Left) Speedometer cable Front Axle: 58 Nm (5.8 rn. -

Page 243

FRONT WHEEL 2. Set the wheel on a suitable stand. 3. Find: Heavy spot Procedure: a. Spin the wheel and wait for it to rest. b. Put an “X ” mark on the wheel bottom spot. c. Turn the wheel so that the “XI” mark is d. -

Page 244

REAR WHEEL -1 REAR WHEEL Collar 1 .O mm (0.04 in) RIM RUNOUT LIMIT: R A D I A L : 2.0 mm (0.08 in) L A T E R A L : 2.0 mm (0.08 in) 28 Nm (2.8 m — kg… -

Page 245

REAR WHEEL ~ REMOVAL 1. Place the motorcycle on a level place. Securely support the motorcycle so there is nc danger of it falling over. 2. Elevate the rear wheel by placing a suitabk stand under the swing arm. 3. Remove: Brake caliper NOTE: Do not depress the brake pedal while the calipe… -

Page 246

REAR WHEEL -1 INSTALLATION When installing the rear wheel, reverse the re- moval procedure. Note the following points. 1. Lubricate: Bearings Lithium — Soap Base Grease 2. Adjust: Drive chain slack Drive Chain Slack: mm (0.4 — 0.8 in) Refer to the “DRIVE CHAIN ADJUST- MENT”… -

Page 247

FRONT AND REAR BRAKE FRONT AND REAR BRAKE The arrow mark @ on the pad spring must pointing the disc rotating direction. Joint BRAKE FLUID TYPE: 2 Nm (0.2 m-kg, If DOT #4 is not available, BRAKE PAD WEAR LIMIT: 0.5 mm (0.02 in) BRAKE DISC WEAR LIMIT: 3.5 mm (0.14 in) -

Page 248

FRONT AND REAR BRAKE @Brake caliper @ P i s t o n @Brake @Brake disc BRAKE FLUID TYPE: If DOT #4 is not available, kg, 4.3 ( R e p l a c e s e t ) 7 — 1 1… -

Page 249

BRAKE PAD REPLACEMENT NOTE:… -

Page 250

FRONT AND REAR BRAKE piqzq… -

Page 251

FRONT AND REAR BRAKE 8 Inspect: . Brake fl”,d level BRAKE… -

Page 252

FRONT AND REAR BRAKE… -

Page 253

FRONT AND REAR BRAKE pi&q CALIPER DISASSEMBLY Before disassembling the front brake caliper or rear brake caliper, drain the brake system of its brake fluid. Front Brake 1. Remove: Pad spring Refer to the “BRAKE PAD REPLACE MENT” section. 2. Remove: Brake hose @ Place the open hose end into a container and pump the old fluid out carefully. -

Page 254

FRONT AND REAR BRAKE (CHASJ ebbI Remove steps: Blow compressed air into the tube joint opening to force out the piston from the caliper body. Never try to pry out the piston. Cover the piston with a rag. Use care so that piston does not cause injury as it is expelled from the cylinder. -

Page 255

FRONT AND REAR BRAKE Removal steps: *Blow compressed air into the tube joint opening to force out the piston from the caliper body. Never try to pry out the piston. Cover the piston with a rag. Use care so that piston does not cause injury as it is expelled from the cylinder. -

Page 256

FRONT AND REAR BRAKE Remove: (Master cylinder cap) @ Master cylinder cap @ Rubber seal @ Union bolt @ Copper washer @ Bolt (Master cylinder bracket) @ Master cylinder bracket 0 Master cylinder 8 Dust boot @ Circlip @ Master cylinder kit @ Rear Brake *Cotter pin @ Plain washer @… -

Page 257

FRONT AND REAR BRAKE ICHASl &I 2. Measure: Brake pad thickness @ Out of specification + Replace. Pad Wear Limit: 0.5 mm (0.02 in) NOTE: Replace the pads as a set if either is found to be worn to the wear limit. 3. -

Page 258

FRONT AND REAR BRAKE ASSEMBLY All internal parts should be cleaned in new brake fluid only. Internal parts should be lubricated with brake fluid when installed. Brake Fluid: DOT #4 If DOT #4 is not available, can be used. Replace the piston seals whenever a caliper is disassembled. -

Page 259

FRONT AND REAR BRAKE (CHASI &‘&I 4. Install: Master cylinder kit @ . Dust boot @ 5. Install: Master cylinder NOTE: Tighten first the upper bolt, then the lower bolt. Bolts (Master Cylinder Bracket): 9 Nm (0.9 me kg, 6.5 ft. lb) 6. -

Page 260

FRONT AND REAR BRAKE piqq 8. Fill: Brake fluid Recommended Brake Fluid: If DOT # 4 is not available, # 3 can be used. Brake fluid may erode painted surfaces or plastic parts. Always clean up spilled fluid immediately. Use only the designated quality brake fluid. otherwise, the rubber seals may deteriorate, causing leakage and poor brake performance. -

Page 261

FRONT AND REAR BRAKE Inspect: Brake fluid level Fluid level is under “LOWER” level line Refer to the “BRAKE FLUID INSPEC- TION” section in the CHAPTER 3. Rear Brake 1. Install: Dust seal @ 2. Install: Brake caliper Bolts (Brake Caliper): 35 Nm (3.5 m — kg, 25 ft. -

Page 262

FRONT AND REAR BRAKE -1 4. Install: Master cylinder kit @ Adjusting rod @ Master cylinder @ *Bolt (Master Cylinder) @ Plain washer @ Bolt (Master Cylinder): 20 Nm (2.0 m- kg, 14 ft. lb) Always use new cotter pin. 5. -

Page 263

FRONT AND REAR BRAKE 8. Install: Brake hose Copper washers Union bolts Union Bolts: Nm (2.6 m- kg, 19 ft- lb) Master cylinder Brake caliper A CAUT1QN: When installing the brake hose , lightly touch the brake pipe the caliper and master cylinder. Always use new copper washers. -

Page 264

FRONT AND REAR BRAKE pii@q Use only the designated quality brake fluid: otherwise, the rubber seals may deteriorate, causing leakage and poor brake performance. Refill with the same type of brake fluid; mixing fluids may result in a harmful chem- ical reaction and lead to poor performance. -

Page 265: Front Fork

FRONT FORK ICHASl ebbI FRONT FORK @Outer tube @Gasket @Gasket A F O R K O I L ( E A C H ) : CAPACITY: (15.6 imp oz, 15.0 US oz) LEVEL: 92 mm (3.62 in) From top of inner fork tube Fully compression without spring Fork oil 10WT or equivalent…

-

Page 266

FRONT FORK REMOVAL Securely support the motorcycle so there is no danger of it falling over. 1. Elevate the front wheel by placing a suitable stand under the engine. 2. Remove: Front wheel Refer to the “FRONT WHEEL — REMO- VAL”… -

Page 267

FRONT FORK 7. Loosen: Pinch bolt (Handlebar crown) @ Pinch bolt (Steering stem) @ Support the fork before loosening the pinch bolts. 8. Remove: Front fork DISASSEMBLY 1. Remove: *Cap bolt @ *Collar @ Fork spring @ Drain the fork oil 2. -

Page 268

FRONT FORK (cHns(f 4. Remove: Damper rod @ Rebound spring @ 5. Remove: Inner tube Inner tube removal steps: Hold fork leg horizontally. the caliper mounting boss of the outer tube securely in a vise with soft jaws. Pull out the inner tube from the outer tube by forcefully, but carefully, with drawing the inner tube. -

Page 269

FRONT FORK lons]l 2. Inspect: Outer tube Scratches/Bends/Damage + Replace. 3. Measure: Fork spring Over specified limit + Replace. Fork Spring Free Length (Limit) @ : mm (16.1 in) 4. I nspect : Damper rod @ Wear/Damage —f Replace. Contamination + Blow out all oil passages with compressed air. -

Page 270

FRONT FORK piq&q 2. Tighten: Bolt (Damper rod) Use the Damper Rod Holder T-Handle @ to lock the damper rod. Bolt (Damper Rod): 40 Nm (4.0 m — kg, 29 ft. lb) Apply LOCTITE @ 3. Install: Guide bushing @ (New) Into the outer tube @ . -

Page 271

FRONT FORK Each Fork: 444 cm3 (15.6 Imp oz, 15.0 US oz) Fork Oil IOWT or equivalent After filling, slowly pump the fork up and down to distribute oil. Oil Level @ : 92 mm (3.62 in) From the top of inner fork tube fully compressed without spring. -

Page 272

FRONT FORK (CHASII Pinch bolt (Handlebar crown) @ Pinch bolt (Steering stem) @ 3. Install: Handlebar boss NOTE: Insert the pin on the spacer into the correspond- ing hole on the handlebar. Bolts (Handlebar Boss) : 23 Nm (2.3 m-kg, 17 ft-lb) 4. -

Page 273

STEERING HEAD AND HANDLEBAR STEERING HEAD AND HANDLEBAR Handlebar 23 Nm (2.3 m-kg, 17 ft-lb) 25 Nm (2.5 m-kg, 18 ft.lb) 7-36… -

Page 274

STEERING HEAD AND HANDLEBAR Steering Head @Bearing cover @Bearing (Upper) @Steering stem (11 m-ks.BOft-lb) 26 Nm (2.6 m*kg, 19 ft.lb) 52 Nm (5.2 m-kg, 37 ft.lb) 2 N D : LOOSEN IT COMPLETELY 3 R D : 3 Nm (0.3 m-kg, 2.2 ft.lb) 7-37… -

Page 275

STEERING HEAD AND HANDLEBAR REMOVAL Securely support the motorcycle so there is no danger of it falling over. 1. Elevate the front wheel by placing a suitable stand under the engine. 2. Remove: Front wheel Refer to the “FRONT WHEEL — RE- MOVAL”… -

Page 276

STEERING HEAD AND HANDLEBAR Remove: Throttle cable 0 Handlebar grip (Right) @ Remove: Handlebar switch (Left) @ Remove: Handlebar grip end (Left) @ Handlebar grip (Left) @ Clutch lever holder @ 9. Remove: Handlebar (Right) Handlebar bosses (Left and right) @ with handlebar (Left). -

Page 277

STEERING HEAD AND HANDLEBAR piqq Remove: Horn @ Joint (Brake hose) @ Remove: Handlebar crown Remove: Lock washer @ Ring nut (Upper) @ Use Ring Nut Wrench Ring Nut Wrench: P/N Y U-33975 Remove: Washer @ Ring nut (Lower) @ Bearing cover @ Support the steering shaft so that it may not fall down. -

Page 278