Материал из BikesWiki — энциклопедия японских мотоциклов

Перейти к: навигация, поиск

Kawasaki Ninja ZX-6R 636

Ниже представлены прямые ссылки на скачку сервисной документации.

Для Kawasaki ZX-6R

- Сервисный мануал (Service Manual) на Kawasaki ZX-6R (1995-1997)

- Сервисный мануал (Service Manual) на Kawasaki ZX-6R (1998-1999)

- Сервисный мануал (Service Manual) на Kawasaki ZX-6R (2001-2002)

- Сервисный мануал (Service Manual) на Kawasaki ZX-6R, ZX-6RR (2003-2004)

- Сервисный мануал (Service Manual) на Kawasaki ZX-6R (2005-2006)

- Сервисный мануал (Service Manual) на Kawasaki ZX-6R (2007-2008)

- Сервисный мануал (Service Manual) на Kawasaki ZX-6R (2009-2011)

- Сервисный мануал (Service Manual) на Kawasaki ZX-6R 636 (2013), оригинал англ.

- Сервисный мануал (Service Manual) на Kawasaki ZX-6R 636 (2013), русский перевод

Обзор модели

- Kawasaki ZX-6R

Источник — «https://bikeswiki.ru/index.php?title=Kawasaki_ZX-6R:_мануалы&oldid=9740»

Категория:

- Сервисная документация

Посмотреть инструкция для Kawasaki Ninja ZX-6R (2007) бесплатно. Руководство относится к категории мотоциклы, 13 человек(а) дали ему среднюю оценку 8.9. Руководство доступно на следующих языках: английский. У вас есть вопрос о Kawasaki Ninja ZX-6R (2007) или вам нужна помощь? Задайте свой вопрос здесь

Главная

Не можете найти ответ на свой вопрос в руководстве? Вы можете найти ответ на свой вопрос ниже, в разделе часто задаваемых вопросов о Kawasaki Ninja ZX-6R (2007).

Как перевести мили в километры?

В чем разница между топливом E10 и E5?

Какова рекомендуемая частота замены масляного фильтра в двигателе Kawasaki?

Как часто следует менять масло в двигателе Kawasaki?

Как удалить ржавчину с устройства Kawasaki мотоцикл?

Инструкция Kawasaki Ninja ZX-6R (2007) доступно в русский?

Не нашли свой вопрос? Задайте свой вопрос здесь

Руководство на английском языке по техническому обслуживанию и ремонту мотоциклов Kawasaki серий KZ, ZX и ZN 1981-2002 годов выпуска с двигателями объемом 1000-1100 cc.

- Издательство: Clymer

- Год издания: 2003

- Страниц: 378

- Формат: PDF

- Размер: 43,5 Mb

Руководство на английском языке по техническому обслуживанию и ремонту мотоциклов Kawasaki Ninja ZX-6R.

- Издательство: Kawasaki Heavy Industries, Ltd.

- Год издания: 1997

- Страниц: 370

- Формат: PDF

- Размер: 64,3 Mb

Руководство на английском языке по техническому обслуживанию и ремонту мотоциклов Kawasaki Ninja ZX-6R 2000-2002 годов выпуска.

- Издательство: Kawasaki Heavy Industries, Ltd.

- Год издания: —

- Страниц: 332

- Формат: PDF

- Размер: 19,1 Mb

Руководство на английском языке по техническому обслуживанию и ремонту мотоциклов Kawasaki Ninja ZX-6R.

- Издательство: Kawasaki Heavy Industries, Ltd.

- Год издания: 2007

- Страниц: 663

- Формат: PDF

- Размер: 12,0 Mb

Руководство на английском языке по техническому обслуживанию и ремонту мотоциклов Kawasaki Ninja ZX-6R и ZX-6RR 2003-2004 годов выпуска.

- Издательство: Kawasaki Heavy Industries, Ltd.

- Год издания: —

- Страниц: 514

- Формат: PDF

- Размер: 42,5 Mb

Руководство на английском языке по техническому обслуживанию и ремонту мотоциклов Kawasaki Ninja ZX-6RR.

- Издательство: Kawasaki Heavy Industries, Ltd.

- Год издания: 2004

- Страниц: 519

- Формат: PDF

- Размер: 10,1 Mb

Руководство на английском языке по подготовке к гонкам мотоциклов Kawasaki ZX-6RR.

- Издательство: Kawasaki Heavy Industries, Ltd.

- Год издания: 2005

- Страниц: 63

- Формат: PDF

- Размер: 7,5 Mb

Руководство на английском языке по техническому обслуживанию и ремонту мотоциклов Kawasaki Ninja ZX-7R и ZX-7RR.

- Издательство: Kawasaki Heavy Industries, Ltd.

- Год издания: —

- Страниц: 364

- Формат: PDF

- Размер: 38,7 Mb

Руководство на английском языке по подготовке к гонкам мотоциклов Kawasaki ZX-7R м ZXR750R 1992 года выпуска.

- Издательство: Kawasaki Heavy Industries, Ltd.

- Год издания: 1991

- Страниц: 69

- Формат: PDF

- Размер: 148,4 Mb

Руководство на английском языке по подготовке к гонкам мотоциклов Kawasaki ZX-7RR 1998 года выпуска.

- Издательство: Kawasaki Heavy Industries, Ltd.

- Год издания: 1997

- Страниц: 107

- Формат: PDF

- Размер: 138,0 Mb

Руководство на испанском языке по эксплуатации и техническому обслуживанию мотоциклов Kawasaki Ninja ZX-9R.

- Издательство: —

- Год издания: —

- Страниц: 174

- Формат: PDF

- Размер: 3,3 Mb

Сборник руководств на английском языке по техническому обслуживанию и ремонту мотоциклов Kawasaki Ninja ZX-9R.

- Издательство: Kawasaki Heavy Industries, Ltd.

- Год издания: —

- Страниц: 307/322

- Формат: PDF

- Размер: 161,3 Mb

Руководство на английском языке по техническому обслуживанию и ремонту мотоциклов Kawasaki ZX-10 и Ninja ZX-10.

- Издательство: Kawasaki Heavy Industries, Ltd.

- Год издания: 1989

- Страниц: 231

- Формат: PDF

- Размер: 162,0 Mb

Руководство на английском языке по техническому обслуживанию и ремонту мотоциклов Kawasaki Ninja ZX-10R.

- Издательство: Kawasaki Heavy Industries, Ltd.

- Год издания: 2008

- Страниц: 694

- Формат: PDF

- Размер: 14,7 Mb

Руководство на английском языке по подготовке к гонкам мотоциклов Kawasaki ZX-10R 2006 года выпуска.

- Издательство: Kawasaki Heavy Industries, Ltd.

- Год издания: 2006

- Страниц: 82

- Формат: PDF

- Размер: 2,5 Mb

Руководство по эксплуатации и техническому обслуживанию мотоциклов Kawasaki Ninja ZX-10R.

- Издательство: Kawasaki Heavy Industries, Ltd.

- Год издания: 2011

- Страниц: 207

- Формат: PDF

- Размер: 6,4 Mb

Руководство на английском языке по техническому обслуживанию и ремонту мотоциклов Kawasaki Ninja ZX-11 и ZZ-R1100 1993-2001 годов выпуска.

- Издательство: Kawasaki Heavy Industries, Ltd.

- Год издания: —

- Страниц: —

- Формат: JPG

- Размер: 62,4 Mb

Руководство на английском языке по техническому обслуживанию и ремонту мотоциклов Kawasaki Ninja ZX-12R.

- Издательство: Kawasaki Heavy Industries, Ltd.

- Год издания: 2004

- Страниц: 613

- Формат: PDF

- Размер: 11,3 Mb

Руководство на немецком языке по техническому обслуживанию и ремонту мотоциклов Kawasaki Ninja ZX-12R (ZX1200-A).

- Издательство: Kawasaki Motoren GmbH

- Год издания: 2000

- Страниц: 431

- Формат: PDF

- Размер: 149,8 Mb

Руководство на немецком языке по техническому обслуживанию и ремонту мотоциклов Kawasaki ZX-12R (ZX1200B).

- Издательство: Kawasaki Motors Europe

- Год издания: 2002

- Страниц: 451

- Формат: PDF

- Размер: 38,7 Mb

Руководство на английском языке по техническому обслуживанию и ремонту мотоциклов Kawasaki Ninja ZX-14 и ZZR1400.

- Издательство: Kawasaki Heavy Industries, Ltd.

- Год издания: 2006

- Страниц: 703

- Формат: PDF

- Размер: 13,6 Mb

Руководство на английском языке по техническому обслуживанию и ремонту мотоциклов Kawasaki ZX400-H2

- Издательство: Kawasaki Heavy Industries, Ltd.

- Год издания: —

- Страниц: —

- Формат: PDF

- Размер: 46,6 Mb

Руководство на немецком языке по техническому обслуживанию и ремонту мотоциклов Kawasaki ZX500-A1 и ZX600-A1.

- Издательство: —

- Год издания: —

- Страниц: 234

- Формат: PDF

- Размер: 19,9 Mb

Руководство на английском языке по техническому обслуживанию и ремонту мотоциклов Kawasaki KZ500/KZ550/ZX550 1979-1985 годов выпуска.

- Издательство: Clymer

- Год издания: —

- Страниц: 341

- Формат: PDF

- Размер: 12,0 Mb

Руководство на английском языке по техническому обслуживанию и ремонту мотоциклов Kawasaki ZX600/ZZR600/Ninja ZX-6 1990-2000 годов выпуска.

- Издательство: Haynes Publishing

- Год издания: 2001

- Страниц: —

- Формат: JPG

- Размер: 57,7 Mb

Руководство на английском языке по техническому обслуживанию и ремонту мотоциклов Kawasaki ZX600/ZX636 (ZX-6R) 1995-2002 годов выпуска.

- Издательство: Haynes Publishing

- Год издания: 2003

- Страниц: 272

- Формат: PDF

- Размер: 171,0 Mb

Руководство на английском языке по техническому обслуживанию и ремонту мотоциклов Kawasaki GPX600R/GPX750R/GPZ600R/Ninja 600R/Ninja 600RX/Ninja 750R/ZX600/ZX750 1985-1987 годов выпуска.

- Издательство: Haynes Publishing

- Год издания: 1999

- Страниц: 265

- Формат: PDF

- Размер: 77,0 Mb

Руководство на английском языке по техническому обслуживанию и ремонту мотоциклов Kawasaki ZX750 (ZXR750) 1989-1996 и ZX750 (Ninja ZX-7) 1989-1995 годов выпуска.

- Издательство: Haynes Publishing

- Год издания: 1998

- Страниц: 341

- Формат: PDF

- Размер: 36,7 Mb

Руководство на немецком языке по техническому обслуживанию и ремонту мотоциклов Kawasaki ZX750J/ZX750K/ZXR750/ZXR750R.

- Издательство: —

- Год издания: —

- Страниц: 282

- Формат: PDF

- Размер: 23,4 Mb

Руководство на немецком языке по техническому обслуживанию и ремонту мотоциклов Kawasaki GPX750R/ZX750F.

- Издательство: Kawasaki Heavy Industries, Ltd.

- Год издания: —

- Страниц: 192

- Формат: PDF

- Размер: 11,4 Mb

Руководство на английском языке по техническому обслуживанию и ремонту мотоциклов Kawasaki ZX900-A1.

- Издательство: Kawasaki Heavy Industries, Ltd.

- Год издания: —

- Страниц: 293

- Формат: PDF

- Размер: 22,9 Mb

Руководство на английском языке по техническому обслуживанию и ремонту мотоциклов Kawasaki ZX900-C1 и ZX900-D1.

- Издательство: Kawasaki Heavy Industries, Ltd.

- Год издания: —

- Страниц: 307

- Формат: PDF

- Размер: 27,9 Mb

Руководство на немецком языке по техническому обслуживанию и ремонту мотоциклов Kawasaki GPZ1000RX (ZX1000-A1).

- Издательство: Kawasaki Heavy Industries, Ltd.

- Год издания: —

- Страниц: 130

- Формат: PDF

- Размер: 20,8 Mb

Руководство на немецком языке по техническому обслуживанию и ремонту мотоциклов Kawasaki GPZ1100 (ZX1100E).

- Издательство: Kawasaki Heavy Industries, Ltd.

- Год издания: —

- Страниц: 327

- Формат: PDF

- Размер: 10,9 Mb

#1

motogad

- Пол:Мужчина

- Город:Москва ВАО

- Мото:Kawasaki Ninja ZX6R

Отправлено 18 Август 2008 — 18:34

Все мануалы которые у нас есть ниже по теме

Сообщение отредактировал max232: 31 Январь 2014 — 13:53

- bktspro, Michaelgrorm, SCpraics и 2 другим это нравится

- Наверх

#2

max232

max232

- Пол:Мужчина

- Страна:Россия

- Город:Елец, Липецкая область

- Мото:zx-10r `08

Отправлено 09 Январь 2014 — 21:19

Просьба к обладателям мануалов которых нет в списке,

мы будем признательны если вы с нами поделитесь.

Руководство по ремонту демпфера Ohlins

Каталог з/ч Kawasaki

Руководство по эксплуатации Kawasaki Ninja H2 (ZX1000NF) 2014-

Руководство по эксплуатации Kawasaki Ninja H2 SX (ZX1000NF) 2017- (РУС) НОВОЕ! Спасибо Mikhail72

Руководство по ремонту KNinja H2 SX 2018- НОВОЕ! Спасибо belenkiy

Руководство по ремонту Kawasaki ZZR1400, ZZR1400 ABS, Ninja ZX-14 2012-2013 (РУС) НОВОЕ! Спасибо Назарий

Руководство пользователя Kawasaki ZZR1400, ZZR1400 ABS, Ninja ZX-14 2012- (РУС) НОВОЕ! Спасибо Ewil Dwarf

Руководство по ремонту Kawasaki ZZR1400, ZZR1400 ABS, Ninja ZX-14 2010-2011

Руководство по ремонту Kawasaki ZZR1400, ZZR1400 ABS, Ninja ZX-14 2008-2009

Руководство по ремонту Kawasaki ZZR1400, ZZR1400 ABS, Ninja ZX-14 2006-2007

Руководство по ремонту Ninja ZX-12R 2002-2005

Руководство по ремонту Ninja ZX-12R 2000-2001

Руководство по ремонту Kawasaki Ninja ZX-10R, Ninja ZX-10R ABS 2016-2017 НОВОЕ!

Руководство по ремонту Kawasaki Ninja ZX-10R, Ninja ZX-10R ABS 2013-2015

Руководство по ремонту Kawasaki Ninja ZX-10R, Ninja ZX-10R ABS 2011-2012

Руководство по эксплуатации (РУС) Kawasaki Ninja ZX-10R 2011-2012

Руководство по эксплуатации (EN) Kawasaki Ninja ZX-10R 2008-2010

Руководство по ремонту Kawasaki Ninja ZX-10R 2008-2010

Руководство по ремонту Kawasaki Ninja ZX-10R 2006-2007

Руководство по ремонту Kawasaki Ninja ZX-10R 2004-2005

Руководство по ремонту Kawasaki Ninja ZX-10 1988-1990

Руководство по ремонту Kawasaki ZX-9R 1998 — 1999

Руководство по ремонту Kawasaki ZX-9R 1998 — 1999 RUS

Руководство по ремонту Kawasaki ZX-9R 1994-1997

Руководство по ремонту Kawasaki ZX-9R (Ger) 2002-2003

Руководство по ремонту Kawasaki ZX750 (ZXR-750) 1989-1996, ZX750 (Ninja ZX-7)1989-1995

Руководство по ремонту Kawasaki Ninja ZX-7R, ZX-7RR 1996-2003

Руководство по ремонту Kawasaki Ninja ZX-6R, Ninja ZX-6R ABS 2013

Руководство по ремонту (РУС пер.Viktor72) Kawasaki Ninja ZX-6R, Ninja ZX-6R ABS 2013

Руководство по ремонту Kawasaki Ninja ZX-6R 2009-2011

Руководство по ремонту Kawasaki ZX-6R 2007-2008

Руководство по ремонту Kawasaki Ninja ZX-6R 2005-2006

Руководство по ремонту Kawasaki Ninja ZX–6R, ZX-6RR 2003-2004

Руководство по ремонту Kawasaki Ninja ZX-6R 2001-2002

Руководство по ремонту Kawasaki Ninja ZX-6R 2001-2002 (РУС) НОВОЕ! Спасибо Vjaceslav

Руководство по ремонту Kawasaki Ninja ZX–6R, 98-99

Руководство по ремонту Kawasaki Ninja ZX-6R 95-97

Руководство по ремонту Kawasaki ZXR400 (zx-4), ZX400-H2 1989-1990

Руководство по ремонту Kawasaki ZXR400 (zx-4), ZX400 L1-L8 1991-1998

Руководство по ремонту Kawasaki ZXR400(zx-4), ZX400 G1,G1A,G1B 1988

Руководство по ремонту Kawasaki Ninja 250 2008-2012

Руководство пользователя Kawasaki Ninja 250 (РУС) 2008-2012

Руководство по ремонту Kawasaki Ninja 300, Ninja 300 ABS 2013-

Руководство по эксплуатации (РУС) Kawasaki Ninja 300, Ninja 300 ABS 2013-

Дорожные мотоциклы Kawasaki. Общее руководство по эксплуатации (РУС) 2012-

Руководство по ремонту Kawasaki ER-6n, ER-6n ABS 2012-

Руководство по эксплуатации (РУС) Kawasaki ER-6n, ER-6n ABS 2012-

Руководство по ремонту Kawasaki ER-6n, ER-6n ABS 2009-2011

Руководство по ремонту Kawasaki ER-6n, ER-6n ABS 2006-2008

Руководство по ремонту Kawasaki Ninja 650, Ninja 650 ABS, ER-6f, ER-6f ABS 2012-

Руководство по эксплуатации (РУС) Kawasaki Ninja 650, Ninja 650 ABS, ER-6f, ER-6f ABS 2012-

Руководство по ремонту Kawasaki Ninja 650, Ninja 650 ABS, ER-6f, ER-6f ABS 2009-2011

Руководство по ремонту Kawasaki NINJA 650R, ER-6f, ER-6f ABS 2006-2008

Руководство по ремонту Kawasaki ER500 C1-C5

2001 ER500-C1 37Kw

2001 ER500-D1 25kw

2002 ER500-C2 37Kw

2003 ER500-C3 37Kw

2004 ER500-C4 катализатор -1Kw

2005 ER500-C5 модифицирован выхлоп, авто выключение/включение света

Руководство по ремонту Kawasaki Z1000, Z1000 ABS 2017- НОВОЕ! Спасибо Назарий

Руководство по ремонту Kawasaki Z1000SX Ninja 1000 2017- НОВОЕ! Спасибо Ghost1195

Руководство по ремонту Kawasaki Z1000SX, Z1000SX ABS, Ninja 1000, Ninja 1000 ABS 2014-2016 НОВОЕ! Спасибо alexus1313

Руководство по ремонту Kawasaki Z1000SX, Z1000SX ABS, Ninja 1000, Ninja 1000 ABS 2011-2013 НОВОЕ! Спасибо Glareone

Руководство по ремонту Kawasaki Z1000, Z1000 ABS 2014-2016

Руководство по ремонту Kawasaki Z1000, Z1000 ABS 2010-2013

Руководство по эксплуатации (РУС) Kawasaki Z1000SX, Z1000SX ABS 2010-2013

Руководство по ремонту Kawasaki Z1000, Z1000 ABS 2007-2009

Руководство по ремонту Kawasaki Z1000 2003-2006

Руководство по ремонту Kawasaki Z900, Z900 ABS, ZR900 2017- НОВОЕ! Спасибо ev6en!

Руководство по ремонту Kawasaki Z800 2013-

Инструкция по эксплуатации Kawasaki Z800 (РУС) 2013-

Инструкция по эксплуатации Kawasaki Z750R (РУС) 2011

Руководство по ремонту Kawasaki Z750S 2005-2006

Руководство по ремонту Kawasaki Z750 2003-2006

Руководство по ремонту Kawasaki Z750, Z750 ABS 2007-2010

Руководство по ремонту Kawasaki Z750R, Z750R ABS 2011- 2012 РОЗЫСК!

Инструкция по эксплуатации Kawasaki Z400 ABS (РУС) 2019- НОВОЕ! Спасибо Бродячий Кот!

Kawasaki 1400GTR, CONCOURS 14 ABS, CONCOURS 14 2010-2014 РОЗЫСК

Kawasaki 1400GTR, CONCOURS 14 ABS, CONCOURS 14 2008-2009

Руководство по эксплуатации (РУС) Kawasaki 1400GTR 2010

Руководство по ремонту Kawasaki VERSYS 650 VERSYS 650 ABS 2015-2016

Руководство по ремонту Kawasaki VERSYS 650 VERSYS 650 ABS 2010-2014

Руководство по ремонту Kawasaki VERSYS 650 2007-2009

Руководство по ремонту Kawasaki VERSYS 1000 2012-2014

Руководство по эксплуатации (РУС) Kawasaki VERSYS 1000 2012-2014

Руководство по эксплуатации (РУС) Kawasaki VERSYS 1000 SE 2019 — НОВОЕ!

Руководство по эксплуатации (РУС) Kawasaki VULCAN S VULCAN S ABS 2015- НОВОЕ! Спасибо offlineb!

Руководство по эксплуатации (РУС) Kawasaki W800 2012-

Руководство по эксплуатации (РУС) Kawasaki KLX250

Руководство по эксплуатации (ENG) Kawasaki KLX150L 2014- НОВОЕ!Спасибо roy0864!

Руководство по эксплуатации (РУС) Kawasaki 1000GTR ZG1000-A1 1986

Все что у нас есть выложено здесь, и мы больше ничего от Вас не прячем. Затрудните себя хотя бы поиском в списке мануала для своей модели мотоцикла.

По этим ссылкам расположены 2 архива по гигабайту с мануалами которых нет в вышеуказанном списке.

http://yadi.sk/d/yrnnmcxJJ9wxG

http://yadi.sk/d/nxb6nuh_J9x52

Эта ссылка на теже мануалы с возможностью не скачивать архивы целиком https://yadi.sk/d/OzesQZ8RUrXPE

- mrkvch, EnergyControl, Walazar и еще 1 это нравится

- Наверх

#3

Smart

Smart

- Пол:Мужчина

- Страна:Россия

- Город:Митино

- Мото:9-ka 1999г—>9-ka 2001г

Отправлено 17 Январь 2014 — 11:26

По ссылке https://yadi.sk/d/I61_p9A6mdk6m находятся мануалы на следующие модели которые не вошли в список выложенный выше.

Kawasaki ZZR1100 & ZX11 1993-2001

Kawasaki NINJA 250 86-07

Kawasaki GPZ400-550 & Z400F-FII & Z500F-550F 83-85 Service Manual

Kawasaki GPZ-500,600,ZX-500-A1,ZX-600-A1 Service Manual

Kawasaki GPZ-500S 86-94 Service Manual

Kawasaki GPZ-600R/GPX-600R/Ninja 600R/RX/GPX-750R/Ninja 750R

Kawasaki GPZ-750 Turbo 1984 Service Manual

Kawasaki GPZ900R 1984-1990 Workshop Manual

Kawasaki GPZ-1000RX,GPZ-900R Service Manual

Kawasaki GPZ-1100E Service Manual

Kawasaki GTR-1400 2014 Service Manual

Kawasaki KDX200 89-94 Service Manual

Kawasaki KH250-400 72-76

Kawasaki KLV1000-A1 2004 Service Manual

Kawasaki KLX650

Kawasaki KR250

Kawasaki KX250F 2004 Service Manual

Kawasaki KX450F 2006 Service Manual

Kawasaki KZ400 1974 Service Manual

Kawasaki KZ440 Service Manual

Kawasaki VN1500 87-99 Service Manual

Kawasaki VN1600-A1&A2 2003 Service Manual

Kawasaki VN2000-A1 2003 Service Manual

Kawasaki VN750 Manual and Parts

Kawasaki ZZR250 90-96 Service Manual

Kawasaki A Series Rotary Valve Twins 250,350,500 69-71 Workshop Manual

Kawasaki EN450,EN500,EN454,LTD500 Vulcan 85-04 Service Manual

Kawasaki ER-5 2004 Service Manual

Kawasaki ER-5 1997 Service Manual(DE)

Kawasaki VN800 Vulcan 96-04 Service Manual

Kawasaki VN900 Vulcan Classic 2006 Service Manual

Kawasaki W650 ’99 Service Manual (German)

Kawasaki ZR1100A,Zephir-1100 Service Manual

Kawasaki ZRX1200R,ZRX1200S 2001-2007 Service Manual

Kawasaki ZR550,ZR750 Zephyr 1990 Service Manual

Kawasaki ZR-7S,ZR-750H1 Service Manual

Kawasaki ZXR400R Kit 1989 Service Manual

Kawasaki ZXR400L Service Manual

Kawasaki ZXR750R,ZXR750J,ZXR750K Service Manual

Kawasaki ZXR750 Racing Kit 1992 Service Manual

Kawasaki ZX-10 Ninja 1988-1990 Service Manual

Kawasaki ZZR1200 ’03 Service Manual (German)

Kawasaki Z1 1972 Service Manual

Kawasaki KLE500 Service Manual

Kawasaki ZRX1200 Service Manual(German)

Kawasaki KLX110 Service Manual

Kawasaki ZXR 250 Service Manual 1997

- sem01 и Walazar это нравится

- Наверх

#4

albert8121984

albert8121984

-

- Members

-

- 35 сообщений

Прохожий

- Пол:Мужчина

- Страна:Россия

- Город:Москва СВАО(Алтуфьево), (КБР г.Прохладный)

- Мото:Kawasaki Z1000SX, (Versys 650B-08г), (ZX-6R 636 05г.) (ZZR 400 — 2)

Отправлено 16 Октябрь 2015 — 14:29

Пользуюсь сайтом ManualsLib – Search For Manuals Online.

Если что-то не понятно с помощью googla можно перевести страничку.

- Cher Tannov это нравится

- Наверх

#5

Cher Tannov

Cher Tannov

-

Вконтакте:

- Пол:Мужчина

- Страна:Россия

- Город:Москва, Чер Танново

- Мото:ER-6F ’12

Отправлено 06 Апрель 2016 — 10:32

Каталог Hiflo по масляным и воздушным фильтрам: https://yadi.sk/i/8FAFZ19PqmkhH

Немало каталогов и мануалов на тайском сайте Кавасаки.

http://www.kawasaki….c&page=download

ONLINE КАТАЛОГИ

Каталоги производителей, представленных в наших магазинах. Ссылки открываются в новом окне.

HIFLOFILTRO — Воздушные и маслянные фильтры

MOTUL — Моторные масла и мотохимия

JTSPROKETS — Звёзды и цепи привода

LUCAS TRW — Тормозные колодки

FERODO — Тормозные колодки

NGK — Свечи зажигания

ARIETE — Сальники и пыльники вилки

ALL BALLS RACING — Подшипники рулевой колонки

Сообщение отредактировал Cher Tannov: 06 Май 2016 — 11:35

- Coreydus и gtaemblem.club это нравится

- Наверх

#6

max232

max232

- Пол:Мужчина

- Страна:Россия

- Город:Елец, Липецкая область

- Мото:zx-10r `08

Отправлено 19 Сентябрь 2019 — 15:43

Ребята, думаю навести в этом разделе порядок.

Если просто так скидывать ссылки, без указания точной модели для разных рынков,от какого года до какого года, сервисный мануал/руководство по эксплуатации, на каком языке.

Этот раздел очень быстро превратиться в помойку в котором невозможно ничего найти.

Зачастую люди кидают ссылки на то что у нас уже есть.

Очень много мото для разных рынков называются по разному.

Я вроде недалекий человек от мото, но и мне не просто разобраться какие модели одинаковые а какие нет.

Пожалуйста, если у вас есть чем поделиться указывайте как минимум следующую информацию:

1. точная модель мотоцикла

2. модельный год. (от какого года и ДО какого года)

3. Сервисный мануал или руководство по эксплуатации

4. На каком языке издание

5. Ссылка

БЕЗ УКАЗАНИЯ ЭТОЙ ИНФОРМАЦИИ Я БУДУ УДАЛЯТЬ ПОСТЫ

- Наверх

#7

ведьмак 24

ведьмак 24

-

- Читатели

- 1 сообщений

- Пол:Мужчина

- Страна:россия

- Город:иркутск

- Мото:кавасаки илиминатор VN250

Отправлено 22 Октябрь 2020 — 09:40

а не подскажеш где найти мануал на кавасаки илименатор вн 250,нигде найти не могу

- Наверх

#8

max232

max232

- Пол:Мужчина

- Страна:Россия

- Город:Елец, Липецкая область

- Мото:zx-10r `08

Отправлено 13 Апрель 2021 — 12:14

а не подскажеш где найти мануал на кавасаки илименатор вн 250,нигде найти не могу

https://www.ebay.com.au/p/2185422503

- Наверх

#9

Назарий

Назарий

-

- Читатели

- 6 сообщений

- Пол:Мужчина

- Страна:Россия

- Город:Москва

- Мото:Z1000

Отправлено 18 Август 2021 — 16:39

- Наверх

#10

max232

max232

- Пол:Мужчина

- Страна:Россия

- Город:Елец, Липецкая область

- Мото:zx-10r `08

Отправлено 19 Август 2021 — 00:27

- Наверх

#11

Lavarock

Lavarock

-

- Читатели

- 1 сообщений

- Пол:Мужчина

- Страна:Россия

- Город:Сочи

- Мото:z650

Отправлено 14 Декабрь 2021 — 21:53

Помогите найти мануал на Z650 2017 год

- Наверх

#12

advokat56

advokat56

-

- Читатели

- 1 сообщений

- Пол:Мужчина

- Страна:РФ

- Город:Оренбург

- Мото:Ninja 1000SX

Отправлено 25 Январь 2022 — 18:44

Доброе время суток! Поменял свой мот на Ninja 1000SX 2020 г. долго искал мануал на русском. Нашел делюсь. https://e-kawasaki.r…ba66894759a.pdf

- Наверх

#13

belenkiy

belenkiy

-

- Читатели

- 3 сообщений

- Пол:Мужчина

- Страна:Россия

- Город:Москва

- Мото:fz6r

Отправлено 15 Май 2022 — 18:50

Руководство по ремонту — Kawasaki h2 2018

https://1drv.ms/b/s!…-l2jLg?e=kLBago

К сожалени к SX не смог найти

- Наверх

#14

max232

max232

- Пол:Мужчина

- Страна:Россия

- Город:Елец, Липецкая область

- Мото:zx-10r `08

Отправлено 15 Май 2022 — 22:10

По вашей ссылке именно SX

Я добавил к списку. спасибо!

- Наверх

#15

Denisik

Denisik

-

- Читатели

- 1 сообщений

- Пол:Мужчина

- Страна:Россия

- Город:Вологда

- Мото:Z250

Отправлено 16 Сентябрь 2022 — 10:20

Руководство по эксплуатации Kawasaki Z250

https://disk.yandex…./zXaOezF2k7TSSQ

- Наверх

#16

L0ckhead

L0ckhead

-

- Members

-

- 20 сообщений

Прохожий

- Пол:Мужчина

- Страна:Россия

- Город:Краснознаменск

- Мото:Kawasaki Ninja 1000 sx

Отправлено 26 Март 2023 — 20:52

Мб кому пригодится мануал на ninja 1000 sx 2020+ Файл можно получить по ссылке:

Ninja 1000 sx.pdf

https://disk.yandex…./ddmFwjH-2Lc4Yg

- Наверх

#17

L0ckhead

L0ckhead

-

- Members

-

- 20 сообщений

Прохожий

- Пол:Мужчина

- Страна:Россия

- Город:Краснознаменск

- Мото:Kawasaki Ninja 1000 sx

Отправлено 26 Март 2023 — 20:53

Дубль

- Наверх

#18

AnDrRew

AnDrRew

-

- Читатели

- 4 сообщений

- Пол:Мужчина

- Страна:Russia

- Город:Moscow

- Мото:Ninja 1000

Отправлено 08 Апрель 2023 — 14:39

На manualslib больше нет наших мануалов((

Пока искал сервис мануал для своего мотоцикла нашёл:

Руководство пользователя z1000sx ninja1000 2017-19 на русском языке

https://docviewer.ya…m89MCJ9&lang=ru

- Наверх

#19

AnDrRew

AnDrRew

-

- Читатели

- 4 сообщений

- Пол:Мужчина

- Страна:Russia

- Город:Moscow

- Мото:Ninja 1000

Отправлено 08 Апрель 2023 — 14:40

На manualslib больше нет наших мануалов((

Пока искал сервис мануал для своего мотоцикла нашёл:

Руководство пользователя z1000sx ninja1000 2017-19 на русском языке

https://mot63.ru/upl…6e444596981.pdf

- Наверх

View a manual of the Kawasaki Ninja ZX-6R (2007) below. All manuals on ManualsCat.com can be viewed completely free of charge. By using the ‘Select a language’ button, you can choose the language of the manual you want to view.

Page: 1

Ninja ZX-6R

Motorcycle

Service Manual

Page: 2

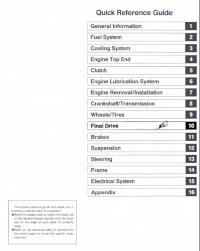

This quick reference guide will assist

you in locating a desired topic or pro-

cedure.

•Bend the pages back to match the

black tab of the desired chapter num-

ber with the black tab on the edge at

each table of contents page.

•Refer to the sectional table of contents

for the exact pages to locate the spe-

cific topic required.

Quick Reference Guide

General Information 1 j

Periodic Maintenance 2 j

Fuel System (DFI) 3 j

Cooling System 4 j

Engine Top End 5 j

Clutch 6 j

Engine Lubrication System 7 j

Engine Removal/Installation 8 j

Crankshaft/Transmission 9 j

Wheels/Tires 10 j

Final Drive 11 j

Brakes 12 j

Suspension 13 j

Steering 14 j

Frame 15 j

Electrical System 16 j

Appendix 17 j

Page: 3

Ninja ZX-6R

Motorcycle

Service Manual

All rights reserved. No parts of this publication may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means, electronic mechanical photocopying, recording or otherwise,

without the prior written permission of Quality Assurance Division/Consumer Products & Machinery

Company/Kawasaki Heavy Industries, Ltd., Japan.

No liability can be accepted for any inaccuracies or omissions in this publication, although every possible

care has been taken to make it as complete and accurate as possible.

The right is reserved to make changes at any time without prior notice and without incurring an obligation

to make such changes to products manufactured previously. See your Motorcycle dealer for the latest

information on product improvements incorporated after this publication.

All information contained in this publication is based on the latest product information available at the time

of publication. Illustrations and photographs in this publication are intended for reference use only and may

not depict actual model component parts.

© 2007 Kawasaki Heavy Industries, Ltd. First Edition (1): Jan. 30, 2007 (M)

Page: 4

LIST OF ABBREVIATIONS

A ampere(s) lb pound(s)

ABDC after bottom dead center m meter(s)

AC alternating current min minute(s)

ATDC after top dead center N newton(s)

BBDC before bottom dead center Pa pascal(s)

BDC bottom dead center PS horsepower

BTDC before top dead center psi pound(s) per square inch

°C degree(s) Celsius r revolution

DC direct current rpm revolution(s) per minute

F farad(s) TDC top dead center

°F degree(s) Fahrenheit TIR total indicator reading

ft foot, feet V volt(s)

g gram(s) W watt(s)

h hour(s) Ω ohm(s)

L liter(s)

COUNTRY AND AREA CODES

AU Australia MY Malaysia

CA Canada US United States

CAL California WVTA Whole Vehicle Type Approval

FR France

Page: 5

EMISSION CONTROL INFORMATION

To protect the environment in which we all live, Kawasaki has incorporated crankcase emis-

sion (1) and exhaust emission (2) control systems in compliance with applicable regulations of

the United States Environmental Protection Agency and California Air Resources Board. Addi-

tionally, Kawasaki has incorporated an evaporative emission control system (3) in compliance

with applicable regulations of the California Air Resources Board on vehicles sold in California

only.

1. Crankcase Emission Control System

This system eliminates the release of crankcase vapors into the atmosphere. Instead, the vapors

are routed through an oil separator to the inlet side of the engine. While the engine is operating,

the vapors are drawn into combustion chamber, where they are burned along with the fuel and air

supplied by the fuel injection system.

2. Exhaust Emission Control System

This system reduces the amount of pollutants discharged into the atmosphere by the exhaust

of this motorcycle. The fuel, ignition, and exhaust systems of this motorcycle have been carefully

designed and constructed to ensure an efficient engine with low exhaust pollutant levels.

The exhaust system of this model motorcycle manufactured primarily for sale in California in-

cludes a catalytic converter system.

3. Evaporative Emission Control System

Vapors caused by fuel evaporation in the fuel system are not vented into the atmosphere. In-

stead, fuel vapors are routed into the running engine to be burned, or stored in a canister when

the engine is stopped. Liquid fuel is caught by a vapor separator and returned to the fuel tank.

The Clean Air Act, which is the Federal law covering motor vehicle pollution, contains what is

commonly referred to as the Act’s “tampering provisions”.

“Sec. 203(a) The following acts and the causing thereof are prohibited…

(3)(A) for any person to remove or render inoperative any device or element of design installed

on or in a motor vehicle or motor vehicle engine in compliance with regulations under this

title prior to its sale and delivery to the ultimate purchaser, or for any manufacturer or dealer

knowingly to remove or render inoperative any such device or element of design after such

sale and delivery to the ultimate purchaser.

(3)(B) for any person engaged in the business of repairing, servicing, selling, leasing, or trading

motor vehicles or motor vehicle engines, or who operates a fleet of motor vehicles know-

ingly to remove or render inoperative any device or element of design installed on or in a

motor vehicle or motor vehicle engine in compliance with regulations under this title follow-

ing its sale and delivery to the ultimate purchaser…”

NOTE

○The phrase “remove or render inoperative any device or element of design” has been generally

interpreted as follows.

1. Tampering does not include the temporary removal or rendering inoperative of de-

vices or elements of design in order to perform maintenance.

2. Tampering could include.

a.Maladjustment of vehicle components such that the emission standards are ex-

ceeded.

b.Use of replacement parts or accessories which adversely affect the performance

or durability of the motorcycle.

c.Addition of components or accessories that result in the vehicle exceeding the stan-

dards.

d.Permanently removing, disconnecting, or rendering inoperative any component or

element of design of the emission control systems.

WE RECOMMEND THAT ALL DEALERS OBSERVE THESE PROVISIONS OF FEDERAL LAW,

THE VIOLATION OF WHICH IS PUNISHABLE BY CIVIL PENALTIES NOT EXCEEDING $10

000 PER VIOLATION.

Page: 6

TAMPERING WITH NOISE CONTROL SYSTEM PROHIBITED

Federal law prohibits the following acts or the causing thereof. (1) The removal or rendering

inoperative by any person other than for purposes of maintenance, repair, or replacement, of any

device or element of design incorporated into any new vehicle for the purpose of noise control

prior to its sale or delivery to the ultimate purchaser or while it is in use, or (2) the use of the

vehicle after such device or element of design has been removed or rendered inoperative by

any person.

Among those acts presumed to constitute tampering are the acts listed below.

•Replacement of the original exhaust system or muffler with a component not in compliance

with Federal regulations.

•Removal of the muffler(s) or any internal portion of the muffler(s).

•Removal of the air box or air box cover.

•Modifications to the muffler(s) or air inlet system by cutting, drilling, or other means if such

modifications result in increased noise levels.

Page: 7

Foreword

This manual is designed primarily for use by

trained mechanics in a properly equipped shop.

However, it contains enough detail and basic in-

formation to make it useful to the owner who de-

sires to perform his own basic maintenance and

repair work. A basic knowledge of mechanics,

the proper use of tools, and workshop proce-

dures must be understood in order to carry out

maintenance and repair satisfactorily. When-

ever the owner has insufficient experience or

doubts his ability to do the work, all adjust-

ments, maintenance, and repair should be car-

ried out only by qualified mechanics.

In order to perform the work efficiently and

to avoid costly mistakes, read the text, thor-

oughly familiarize yourself with the procedures

before starting work, and then do the work care-

fully in a clean area. Whenever special tools or

equipment are specified, do not use makeshift

tools or equipment. Precision measurements

can only be made if the proper instruments are

used, and the use of substitute tools may ad-

versely affect safe operation.

For the duration of the warranty period,

we recommend that all repairs and scheduled

maintenance be performed in accordance with

this service manual. Any owner maintenance or

repair procedure not performed in accordance

with this manual may void the warranty.

To get the longest life out of your vehicle.

•Follow the Periodic Maintenance Chart in the

Service Manual.

•Be alert for problems and non-scheduled

maintenance.

•Use proper tools and genuine Kawasaki Mo-

torcycle parts. Special tools, gauges, and

testers that are necessary when servicing

Kawasaki motorcycles are introduced by the

Service Manual. Genuine parts provided as

spare parts are listed in the Parts Catalog.

•Follow the procedures in this manual care-

fully. Don’t take shortcuts.

•Remember to keep complete records of main-

tenance and repair with dates and any new

parts installed.

How to Use This Manual

In this manual, the product is divided into

its major systems and these systems make up

the manual’s chapters. The Quick Reference

Guide shows you all of the product’s system

and assists in locating their chapters. Each

chapter in turn has its own comprehensive Ta-

ble of Contents.

For example, if you want stick coil information,

use the Quick Reference Guide to locate the

Electrical System chapter. Then, use the Table

of Contents on the first page of the chapter to

find the Stick Coil section.

Whenever you see these WARNING and

CAUTION symbols, heed their instructions!

Always follow safe operating and maintenance

practices.

WARNING

This warning symbol identifies special

instructions or procedures which, if not

correctly followed, could result in per-

sonal injury, or loss of life.

CAUTION

This caution symbol identifies special

instructions or procedures which, if not

strictly observed, could result in dam-

age to or destruction of equipment.

This manual contains four more symbols (in

addition to WARNING and CAUTION) which will

help you distinguish different types of informa-

tion.

NOTE

○This note symbol indicates points of par-

ticular interest for more efficient and con-

venient operation.

•Indicates a procedural step or work to be

done.

○Indicates a procedural sub-step or how to do

the work of the procedural step it follows. It

also precedes the text of a NOTE.

Indicates a conditional step or what action to

take based on the results of the test or inspec-

tion in the procedural step or sub-step it fol-

lows.

In most chapters an exploded view illustration

of the system components follows the Table of

Contents. In these illustrations you will find the

instructions indicating which parts require spec-

ified tightening torque, oil, grease or a locking

agent during assembly.

Page: 8

GENERAL INFORMATION 1-1

1

General Information

Table of Contents

Before Servicing ……………………………………………………………………………………………………… 1-2

Model Identification………………………………………………………………………………………………….. 1-7

General Specifications……………………………………………………………………………………………… 1-9

Unit Conversion Table ……………………………………………………………………………………………… 1-12

Page: 9

1-2 GENERAL INFORMATION

Before Servicing

Before starting to perform an inspection service or carry out a disassembly and reassembly opera-

tion on a motorcycle, read the precautions given below. To facilitate actual operations, notes, illustra-

tions, photographs, cautions, and detailed descriptions have been included in each chapter wherever

necessary. This section explains the items that require particular attention during the removal and

reinstallation or disassembly and reassembly of general parts.

Especially note the following.

Battery Ground

Before completing any service on the motorcycle, discon-

nect the battery cables from the battery to prevent the en-

gine from accidentally turning over. Disconnect the ground

cable (–) first and then the positive (+). When completed

with the service, first connect the positive (+) cable to the

positive (+) terminal of the battery then the negative (–) ca-

ble to the negative terminal.

Edges of Parts

Lift large or heavy parts wearing gloves to prevent injury

from possible sharp edges on the parts.

Solvent

Use a high-flush point solvent when cleaning parts. High

-flush point solvent should be used according to directions

of the solvent manufacturer.

Cleaning vehicle before disassembly

Clean the vehicle thoroughly before disassembly. Dirt or

other foreign materials entering into sealed areas during ve-

hicle disassembly can cause excessive wear and decrease

performance of the vehicle.

Page: 10

GENERAL INFORMATION 1-3

Before Servicing

Arrangement and Cleaning of Removed Parts

Disassembled parts are easy to confuse. Arrange the

parts according to the order the parts were disassembled

and clean the parts in order prior to assembly.

Storage of Removed Parts

After all the parts including subassembly parts have been

cleaned, store the parts in a clean area. Put a clean cloth

or plastic sheet over the parts to protect from any foreign

materials that may collect before re-assembly.

Inspection

Reuse of worn or damaged parts may lead to serious ac-

cident. Visually inspect removed parts for corrosion, discol-

oration, or other damage. Refer to the appropriate sections

of this manual for service limits on individual parts. Replace

the parts if any damage has been found or if the part is be-

yond its service limit.

Replacement Parts

Replacement Parts must be KAWASAKI genuine or

recommended by KAWASAKI. Gaskets, O-rings, oil seals,

grease seals, circlips or cotter pins must be replaced with

new ones whenever disassembled.

Assembly Order

In most cases assembly order is the reverse of disassem-

bly, however, if assembly order is provided in this Service

Manual, follow the procedures given.

Page: 11

1-4 GENERAL INFORMATION

Before Servicing

Tightening Sequence

Generally, when installing a part with several bolts, nuts,

or screws, start them all in their holes and tighten them to

a snug fit. Then tighten them according to the specified se-

quence to prevent case warpage or deformation which can

lead to malfunction. Conversely when loosening the bolts,

nuts, or screws, first loosen all of them by about a quar-

ter turn and then remove them. If the specified tightening

sequence is not indicated, tighten the fasteners alternating

diagonally.

Tightening Torque

Incorrect torque applied to a bolt, nut, or screw may

lead to serious damage. Tighten fasteners to the specified

torque using a good quality torque wrench.

Force

Use common sense during disassembly and assembly,

excessive force can cause expensive or hard to repair dam-

age. When necessary, remove screws that have a non

-permanent locking agent applied using an impact driver.

Use a plastic-faced mallet whenever tapping is necessary.

Gasket, O-ring

Hardening, shrinkage, or damage of both gaskets and

O-rings after disassembly can reduce sealing performance.

Remove the old gaskets and clean the sealing surfaces

thoroughly so that no gasket material or other material re-

mains. Install the new gaskets and replace the used O-rings

when re-assembling

Liquid Gasket, Non-permanent Locking Agent

For applications that require Liquid Gasket or a

Non-permanent Locking Agent, clean the surfaces so

that no oil residue remains before applying liquid gasket or

non-permanent locking agent. Do not apply them exces-

sively. Excessive application can clog oil passages and

cause serious damage.

Page: 12

GENERAL INFORMATION 1-5

Before Servicing

Press

For items such as bearings or oil seals that must be

pressed into place, apply small amount of oil to the con-

tact area. Be sure to maintain proper alignment and use

smooth movements when installing.

Ball Bearing and Needle Bearing

Do not remove pressed ball or needle unless removal is

absolutely necessary. Replace with new ones whenever

removed. Press bearings with the manufacturer and size

marks facing out. Press the bearing into place by putting

pressure on the correct bearing race as shown.

Pressing the incorrect race can cause pressure between

the inner and outer race and result in bearing damage.

Oil Seal, Grease Seal

Do not remove pressed oil or grease seals unless removal

is necessary. Replace with new ones whenever removed.

Press new oil seals with manufacture and size marks facing

out. Make sure the seal is aligned properly when installing.

Apply specified grease to the lip of seal before installing

the seal.

Circlips, Cotter Pins

Replace the circlips or cotter pins that were removed with

new ones. Take care not to open the clip excessively when

installing to prevent deformation.

Page: 13

1-6 GENERAL INFORMATION

Before Servicing

Lubrication

It is important to lubricate rotating or sliding parts during

assembly to minimize wear during initial operation. Lubri-

cation points are called out throughout this manual, apply

the specific oil or grease as specified.

Direction of Engine Rotation

When rotating the crankshaft by hand, the free play

amount of rotating direction will affect the adjustment. Ro-

tate the crankshaft to positive direction (clockwise viewed

from output side).

Electrical Wires

A two-color wire is identified first by the primary color and

then the stripe color. Unless instructed otherwise, electrical

wires must be connected to those of the same color.

Instrument

Use a meter that has enough accuracy for an accurate

measurement. Read the manufacture’s instructions thor-

oughly before using the meter. Incorrect values may lead

to improper adjustments.

Page: 14

GENERAL INFORMATION 1-7

Model Identification

ZX600P7F (Europe) Left Side View

ZX600P7F (Europe) Right Side View

Page: 15

1-8 GENERAL INFORMATION

Model Identification

ZX600P7F (US and Canada) Left Side View

ZX600P7F (US and Canada) Right Side View

Page: 16

GENERAL INFORMATION 1-9

General Specifications

Items ZX600P7F (Ninja ZX-6R)

Dimensions

Overall Length 2 105 mm (82.9 in.)

Overall Width 720 mm (28.3 in.)

Overall Height 1 125 mm (44.3 in.)

Wheelbase 1 405 mm (55.3 in.)

Road Clearance 125 mm (4.7 in.)

Seat Height 820 mm (32.3 in.)

Dry Mass 167 kg (368 lb)

Curb Mass:

Front 101 kg (223 lb)

Rear 99 kg (218 lb)

Fuel Tank Capacity 17 L (4.5 US gal)

Performance

Minimum Turning Radius 3.4 m (11.2 ft)

Engine

Type 4-stroke, DOHC, 4-cylinder

Cooling System Liquid-cooled

Bore and Stroke 67.0 × 42.5 mm (2.6 × 1.7 in.)

Displacement 599 mL (36.6 cu in.)

Compression Ratio 13.3 : 1

Maximum Horsepower 91.9 kW (125 PS) @14 000 r/min (rpm),

(FR) 78.2 kW (106 PS) @14 000 r/min (rpm),

(MY) 80.0 kW (109 PS) @12 000 r/min (rpm),

(CA), (CAL), (US) – – –

Maximum Torque 66.0 N·m (6.7 kgf·m, 49 ft·lb) @11 700 r/min (rpm),

(FR) 58.4 N·m (6.0 kgf·m, 43 ft·lb) @11 700 r/min (rpm),

(MY) 64 N·m (6.5 kgf·m, 47 ft·lb) @12 000 r/min (rpm)

(CA), (CAL), (US) – – –

Carburetion System FI (Fuel injection)

Primary: KEIHIN TTK 38 × 4

Secondary: KEIHIN Multihole (8 holes) × 4

Starting System Electric starter

Ignition System Battery and coil (transistorized)

Timing Advance Electronically advanced (digital igniter in ECU)

Ignition Timing From 12.5° BTDC @1 300 r/min (rpm)

Spark Plug NGK CR9E

Cylinder Numbering Method Left to right, 1-2-3-4

Firing Order 1-2-4-3

Valve Timing:

Inlet:

Open 41° BTDC

Close 67° ATDC

Duration 288°

Exhaust:

Open 63° BBDC

Close 23° ATDC

Page: 17

1-10 GENERAL INFORMATION

General Specifications

Items ZX600P7F (Ninja ZX-6R)

Duration 266°

Lubrication System Forced lubrication (wet sump with cooler)

Engine Oil:

Type API SE, SF or SG

API SH, SJ or SL with JASO MA

Viscosity SAE10W-40

Capacity 3.8 L (4.0 US qt)

Drive Train

Primary Reduction System:

Type Gear

Reduction Ratio 1.900 (76/40)

Clutch Type Wet multi disc

Transmission:

Type 6-speed, constant mesh, return shift

Gear Ratios:

1st 2.714 (38/14)

2nd 2.200 (33/15)

3rd 1.850 (37/20)

4th 1.600 (32/20)

5th 1.421 (27/19)

6th 1.300 (26/20)

Final Drive System:

Type Chain drive

Reduction Ratio 2.688 (43/16)

Overall Drive Ratio 6.638 @Top gear

Frame

Type Tubular, diamond

Caster (Rake Angle) 25°

Trail 110 mm (4.3 in.)

Front Tire:

Type Tubeless

Size 120/70 ZR17 M/C (58 W)

Rear Tire:

Type Tubeless

Size 180/55 ZR17 M/C (73 W)

Rim Size:

Front 17 × 3.50

Rear 17 × 5.50

Front Suspension:

Type Telescopic fork (upside-down)

Wheel Travel 120 mm (4.7 in.)

Rear Suspension:

Type Swingarm (uni-trak)

Wheel Travel 133 mm (5.2 in.)

Page: 18

GENERAL INFORMATION 1-11

General Specifications

Items ZX600P7F (Ninja ZX-6R)

Brake Type:

Front Dual discs

Rear Single disc

Electrical Equipment

Battery 12 V 8 Ah

Headlight:

Type Semi-sealed beam

Bulb:

High 12 V 55 W + 65 W (quartz-halogen)

Low 12 V 55 W (quartz-halogen)

Tail/Brake Light 12 V 0.1/1.6 W (LED)

Alternator:

Type Three-phase AC

Rated Output 31 A/14 V @5 000 r/min (rpm)

Specifications subject to change without notice, and may not apply to every country.

Page: 19

1-12 GENERAL INFORMATION

Unit Conversion Table

Prefixes for Units

Prefix Symbol Power

mega M × 1 000 000

kilo k × 1 000

centi c × 0.01

milli m × 0.001

micro µ × 0.000001

Units of Mass

kg × 2.205 = lb

g × 0.03527 = oz

Units of Volume

L × 0.2642 = gal (US)

L × 0.2200 = gal (imp)

L × 1.057 = qt (US)

L × 0.8799 = qt (imp)

L × 2.113 = pint (US)

L × 1.816 = pint (imp)

mL × 0.03381 = oz (US)

mL × 0.02816 = oz (imp)

mL × 0.06102 = cu in

Units of Force

N × 0.1020 = kg

N × 0.2248 = lb

kg × 9.807 = N

kg × 2.205 = lb

Units of Length

km × 0.6214 = mile

m × 3.281 = ft

mm × 0.03937 = in

Units of Torque

N·m × 0.1020 = kgf·m

N·m × 0.7376 = ft·lb

N·m × 8.851 = in·lb

kgf·m × 9.807 = N·m

kgf·m × 7.233 = ft·lb

kgf·m × 86.80 = in·lb

Units of Pressure

kPa × 0.01020 = kgf/cm²

kPa × 0.1450 = psi

kPa × 0.7501 = cmHg

kgf/cm² × 98.07 = kPa

kgf/cm² × 14.22 = psi

cmHg × 1.333 = kPa

Units of Speed

km/h × 0.6214 = mph

Units of Power

kW × 1.360 = PS

kW × 1.341 = HP

PS × 0.7355 = kW

PS × 0.9863 = HP

Units of Temperature

Page: 20

PERIODIC MAINTENANCE 2-1

2

Periodic Maintenance

Table of Contents

Periodic Maintenance Chart ……………………………………………………………………………………… 2-3

Torque and Locking Agent………………………………………………………………………………………… 2-6

Specifications …………………………………………………………………………………………………………. 2-12

Special Tools ………………………………………………………………………………………………………….. 2-14

Maintenance Procedure …………………………………………………………………………………………… 2-15

Fuel System (DFI)…………………………………………………………………………………………………. 2-15

Throttle Control System Inspection……………………………………………………………………….. 2-15

Engine Vacuum Synchronization Inspection…………………………………………………………… 2-15

Idle Speed Inspection …………………………………………………………………………………………. 2-18

Idle Speed Adjustment………………………………………………………………………………………… 2-19

Fuel Hose Inspection (fuel leak, damage, installation condition)……………………………….. 2-19

Evaporative Emission Control System (California Model) …………………………………………… 2-19

Evaporative Emission Control System Inspection …………………………………………………… 2-19

Engine Top End ……………………………………………………………………………………………………. 2-20

Valve Clearance Inspection …………………………………………………………………………………. 2-20

Valve Clearance Adjustment………………………………………………………………………………… 2-22

Air Suction System ……………………………………………………………………………………………….. 2-24

Air Suction System Damage Inspection…………………………………………………………………. 2-24

Cooling System…………………………………………………………………………………………………….. 2-25

Coolant Level Inspection……………………………………………………………………………………… 2-25

Radiator Hose Damage and Installation Condition Inspection…………………………………… 2-25

Clutch………………………………………………………………………………………………………………….. 2-26

Clutch Operation Inspection ………………………………………………………………………………… 2-26

Wheels/Tires………………………………………………………………………………………………………… 2-27

Air Pressure Inspection……………………………………………………………………………………….. 2-27

Wheel/Tire Damage Inspection…………………………………………………………………………….. 2-27

Tire Tread Wear Inspection …………………………………………………………………………………. 2-27

Wheel Bearing Damage Inspection ………………………………………………………………………. 2-28

Drive Train …………………………………………………………………………………………………………… 2-29

Drive Chain Lubrication Condition Inspection…………………………………………………………. 2-29

Drive Chain Slack Inspection……………………………………………………………………………….. 2-29

Drive Chain Slack Adjustment ……………………………………………………………………………… 2-30

Wheel Alignment Inspection ………………………………………………………………………………… 2-31

Drive Chain Wear Inspection ……………………………………………………………………………….. 2-31

Chain Guide Wear Inspection………………………………………………………………………………. 2-32

Brake System ………………………………………………………………………………………………………. 2-32

Brake Fluid Leak (Brake Hose and Pipe) Inspection ……………………………………………….. 2-32

Brake Hose Damage and Installation Condition Inspection………………………………………. 2-32

Brake Operation Inspection …………………………………………………………………………………. 2-33

Brake Fluid Level Inspection………………………………………………………………………………… 2-33

Brake Pad Wear Inspection …………………………………………………………………………………. 2-34

Brake Light Switch Operation Inspection……………………………………………………………….. 2-34

Suspensions ………………………………………………………………………………………………………… 2-35

Front Forks/Rear Shock Absorber Operation Inspection………………………………………….. 2-35

Front Fork Oil Leak Inspection……………………………………………………………………………… 2-35

Rear Shock Absorber Oil Leak Inspection……………………………………………………………… 2-36

Rocker Arm Operation Inspection…………………………………………………………………………. 2-36

Tie-Rod Operation Inspection ………………………………………………………………………………. 2-36

Steering System …………………………………………………………………………………………………… 2-36

Steering Play Inspection ……………………………………………………………………………………… 2-36

Page: 21

2-2 PERIODIC MAINTENANCE

Steering Play Adjustment…………………………………………………………………………………….. 2-37

Steering Stem Bearing Lubrication ……………………………………………………………………….. 2-38

Lights and Switches Operation Inspection……………………………………………………………… 2-38

Headlight Aiming Inspection ………………………………………………………………………………… 2-40

Side Stand Switch Operation Inspection………………………………………………………………… 2-41

Engine Stop Switch Operation Inspection………………………………………………………………. 2-42

Others…………………………………………………………………………………………………………………. 2-43

Chassis Parts Lubrication …………………………………………………………………………………… 2-43

Bolts, Nuts and Fasteners Tightness Inspection……………………………………………………… 2-44

Replacement Parts ……………………………………………………………………………………………….. 2-46

Air Cleaner Element Replacement………………………………………………………………………… 2-46

Fuel Hose Replacement ……………………………………………………………………………………… 2-47

Coolant Change…………………………………………………………………………………………………. 2-50

Radiator Hose and O-ring Replacement………………………………………………………………… 2-52

Engine Oil Change……………………………………………………………………………………………… 2-53

Oil Filter Replacement ………………………………………………………………………………………… 2-53

Brake Hose and Pipe Replacement………………………………………………………………………. 2-54

Brake Fluid Change ……………………………………………………………………………………………. 2-54

Master Cylinder Rubber Parts Replacement ………………………………………………………….. 2-56

Caliper Rubber Parts Replacement ………………………………………………………………………. 2-57

Spark Plug Replacement …………………………………………………………………………………….. 2-60

Page: 22

PERIODIC MAINTENANCE 2-3

Periodic Maintenance Chart

The scheduled maintenance must be done in accordance with this chart to keep the motorcycle in

good running condition.The initial maintenance is vitally important and must not be neglected.

Periodic Inspection

FREQUENCY Whichever

comes

first

* ODOMETER READING

× 1 000 km

(× 1 000 mile)

1 6 12 18 24 30 36

INSPECTION Every (0.6) (4) (7.5) (12) (15) (20) (24)

Fuel System

Throttle control system (play, smooth

return, no drag)-inspect

year • • • •

Engine vacuum synchronization-inspect • • •

Idle speed-inspect • • • •

Fuel leak (fuel hose and pipe)-inspect year • • • •

Fuel hose and pipe damage-inspect year • • • •

Fuel hose and pipe installation

condition-inspect

year • • • •

Evaporative Emission Control System

(California Model only)

Evaporative emission control system

function-inspect • • • • • • •

Cooling System

Coolant level-inspect • • • •

Coolant leak (radiator hose and

pipe)-inspect

year • • • •

Radiator hose damage-inspect year • • • •

Radiator hose installation condition

-inspect

year • • • •

Engine Top End

Valve clearance-inspect (United States

and Canada Models) •

Valve clearance-inspect (Other than

United States and Canada Models)

Every 42 000 km (26 000 mile)

Air Suction System

Air suction system damage-inspect • • •

Clutch

Clutch operation (play, disengagement,

engagement)-inspect • • • •

Wheels and Tires

Tire air pressure-inspect year • • •

Wheel/tire damage-inspect • • •

Tire tread wear, abnormal wear-inspect • • •

Wheel bearing damage-inspect year • • •

Drive Train

Drive chain lubrication condition-inspect # Every 600 km (400 mile)

Drive chain slack-inspect # Every 1 000 km (600 mile)

Page: 23

2-4 PERIODIC MAINTENANCE

Periodic Maintenance Chart

FREQUENCY Whichever

comes

first

* ODOMETER READING

× 1 000 km

(× 1 000 mile)

1 6 12 18 24 30 36

INSPECTION Every (0.6) (4) (7.5) (12) (15) (20) (24)

Drive chain wear-inspect # • • •

Drive chain guide wear-inspect • • •

Brake System

Brake fluid leak (brake hose and

pipe)-inspect

year • • • • • • •

Brake hose and pipe damage-inspect year • • • • • • •

Brake pad wear-inspect # • • • • • •

Brake hose installation condition-inspect year • • • • • • •

Brake fluid level-inspect 6 months • • • • • • •

Brake operation (effectiveness, play, no

drag)-inspect

year • • • • • • •

Brake light switch operation-inspect • • • • • • •

Suspensions

Front forks/rear shock absorber operation

(damping and smooth stroke)-inspect • • •

Front forks/rear shock absorber oil

leak-inspect

year • • •

Rocker arm operation-inspect • • •

Tie-Rods operation-inspect • • •

Steering System

Steering play-inspect year • • • •

Steering stem bearings-lubricate 2 years •

Electrical System

Lights and switches operation-inspect year • • •

Headlight aiming-inspect year • • •

Side stand switch operation-inspect year • • •

Engine stop switch operation-inspect year • • •

Others

Chassis parts-lubricate year • • •

Bolts and nuts tightness-inspect • • • •

*: For higher odometer readings, repeat at the frequency interval established here.

#: Service more frequently when operating in severe conditions; dusty, wet, muddy, high speed or

frequent starting/stopping.

CAL: California Model

Page: 24

PERIODIC MAINTENANCE 2-5

Periodic Maintenance Chart

Periodic Replacement Parts

FREQUENCY Whichever

come

first

* ODOMETER READING

× 1 000 km

(× 1 000 mile)

1 12 24 36 48

CHANGE/REPLACE ITEM Every (0.6) (7.5) (15) (24) (30)

Air cleaner element # Every 18 000 km (12 000 mile)

Fuel hose 4 years •

Coolant 3 years •

Radiator hose and O-ring 3 years •

Engine oil # year • • • • •

Oil filter year • • • • •

Brake hose and pipe 4 years •

Brake fluid 2 years • •

Rubber parts of master cylinder and caliper 4 years •

Spark plug • • • •

*: For higher odometer readings, repeat at the frequency interval established here.

#: Service more frequently when operating in severe conditions; dusty, wet, muddy, high speed or

frequent starting/stopping.

Page: 25

2-6 PERIODIC MAINTENANCE

Torque and Locking Agent

The following tables list the tightening torque for the major fasteners requiring use of a

non-permanent locking agent or silicone sealant etc.

Letters used in the “Remarks” column mean:

AL: Tighten the two clamp bolts alternately two times to ensure even tightening torque.

G: Apply grease to the threads.

L: Apply a non-permanent locking agent to the threads.

MO: Apply molybdenum disulfide grease oil solution.

R: Replacement Parts

S: Follow the specified tightening sequence.

SI: Apply silicone grease.

SS: Apply silicone sealant.

Torque

Fastener

N·m kgf·m ft·lb

Remarks

Fuel System

Air Cleaner Housing Screws 1.1 0.11 9.7 in·lb

Air Cleaner Housing Clamp Bolts 2.0 0.20 17 in·lb

Air Cleaner Housing Mounting Bolt 6.9 0.70 61 in·lb

Air Inlet Duct Mounting Bolts 9.8 1.0 87 in·lb L

Camshaft Position Sensor Bolt 9.8 1.0 87 in·lb

Crankshaft Sensor Bolts 5.9 0.60 52 in·lb

Delivery Pipe Mounting Screws (Nozzle Assy) 3.4 0.35 30 in·lb

Delivery Pipe Mounting Screws (Throttle Body) 3.4 0.35 30 in·lb

Exhaust Butterfly Valve Actuator Mounting Bolts 6.9 0.70 61 in·lb

Exhaust Butterfly Valve Actuator Pulley Bolt 4.9 0.50 43 in·lb

Fuel Pump Bolts 9.8 1.0 87 in·lb L, S

Nozzle Assy Mounting Bolts 6.9 0.70 61 in·lb

Nozzle Assy Fuel Hose Screw 4.9 0.50 43 in·lb

Separator Bracket Mounting Bolt 0.8 0.08 7 in·lb

Throttle Body Assembly Holder Clamp Bolts 3.0 0.30 27 in·lb

Throttle Body Holder Bolts 12 1.2 106 in·lb L

Throttle Cable Holder Plate Bolt 3.9 0.40 35 in·lb L

Vehicle-down Sensor Bolts 5.9 0.60 52 in·lb

Water Temperature Sensor 25 2.5 18 SS

Cooling System

Coolant By-pass Fitting Bolt 8.8 0.90 78 in·lb L

Coolant Drain Bolt (Cylinder) 9.8 1.0 87 in·lb

Coolant Drain Bolt (Water Pump) 8.8 0.90 78 in·lb

Coolant Reserve Tank Mounting Bolts 7.0 0.70 61 in·lb

Impeller Bolt 9.8 1.0 87 in·lb

Oil Cooler Mounting Bolts 20 2.0 15

Radiator Bracket Mounting Bolt 9.8 1.0 87 in·lb

Radiator Lower Bolt 6.9 0.70 61 in·lb

Radiator Upper Bolts 9.8 1.0 87 in·lb

Thermostat Housing Cover Bolts 5.9 0.60 52 in·lb

Water Hose Clamp Screws 2.0 0.20 17 in·lb

Water Hose Fitting Bolts (Cylinder) 9.8 1.0 87 in·lb

Page: 26

PERIODIC MAINTENANCE 2-7

Torque and Locking Agent

Torque

Fastener

N·m kgf·m ft·lb

Remarks

Water Hose Fitting Bolts (Head Cover) 15 1.5 11 L

Water Pump Cover Bolts 12 1.2 106 in·lb L

Water Temperature Sensor 25 2.5 18 SS

Engine Top End

Air Suction Valve Cover Bolts 9.8 1.0 87 in·lb L

Camshaft Cap Bolts 12 1.2 106 in·lb S

Camshaft Chain Tensioner Cap Bolt 20 2.0 15

Camshaft Chain Tensioner Mounting Bolts 11 1.1 97 in·lb

Cam Sprocket Mounting Bolts 15 1.5 11 L

Cylinder Head Bolts (M9) 39 4.0 29 MO, S

Cylinder Head Bolts (M6) 12 1.2 106 in·lb S

Cylinder Head Cover Bolts 9.8 1.0 87 in·lb

Exhaust Butterfly Valve Actuator Mounting Nuts 6.9 0.70 61 in·lb

Exhaust Butterfly Valve Actuator Pulley Bolt 4.9 0.50 43 in·lb

Exhaust Butterfly Valve Cable Adjuster Locknuts 6.9 0.70 61 in·lb

Exhaust Butterfly Valve Cable Locknuts 6.9 0.70 61 in·lb

Exhaust Butterfly Valve Cover Bolt 6.9 0.70 61 in·lb

Exhaust Pipe Clamp Bolt 17 1.7 13

Exhaust Manifold Holder Nuts 17 1.7 13

Exhaust Pipe Mounting Bolt 28 2.8 21

Exhaust Manifold Holder Studs – – – (stopped)

Front Camshaft Chain Guide Bolt (Lower) 12 1.2 106 in·lb

Front Camshaft Chain Guide Bolt (Upper) 25 2.5 18

Muffler Body Clamp Bolt 17 1.7 12

Muffler Body Mounting Bolts 28 2.8 21

Muffler Rear Cover Bolts 6.9 0.70 61 in·lb

Muffler Slide Cover Bolts 6.9 0.70 61 in·lb

Muffler Upper Cover Bolts 6.9 0.70 61 in·lb

Upper Camshaft Chain Guide Bolt 25 2.5 18

Spark Plugs 13 1.3 113 in·lb

Oxygen Sensors 25 2.5 18

Throttle Body Assy Holder Clamp Bolts 2.9 0.30 26 in·lb

Throttle Body Holder Bolts 12 1.2 106 in·lb L

Water Passage Plugs 20 2.0 15 L

Clutch

Clutch Cover Bolts (M6, L = 40 mm) 9.8 1.0 87 in·lb

Clutch Cover Bolts (M6, L = 25 mm) 9.8 1.0 87 in·lb

Clutch Hub Nut 135 14 100 R

Clutch Lever Clamp Bolts 7.8 0.80 69 in·lb S

Clutch Spring Bolts 8.8 0.90 78 in·lb

Sub Clutch Hub Bolts 25 2.5 18 L

Engine Lubrication System

Oil Filler Cap 2.0 0.20 17 in·lb

Page: 27

2-8 PERIODIC MAINTENANCE

Torque and Locking Agent

Torque

Fastener

N·m kgf·m ft·lb

Remarks

Air Bleed Bolt 9.8 1.0 87 in·lb

Engine Oil Drain Bolt 29 3.0 22

Oil Cooler/Oil Filter Case Mounting Bolts 20 2.0 15 L

Oil Pump Gear Bolt 9.8 1.0 87 in·lb L

Oil Cooler Mounting Bolts 20 2.0 15

Oil Filter 31 3.2 23 G, R

Oil Filter Guard Bolts 4.0 0.41 35 in·lb L

Oil Filter Holder Bolt 25 2.5 18 L

Oil Pan Bolts 9.8 1.0 87 in·lb

Oil Passage Nozzle 4.9 0.50 43 in·lb

Oil Passage Plugs (Taper) 20 2.0 15 L

Oil Passage Plug (Left Side) 17 1.7 13

Oil Pressure Relief Valve 15 1.5 11 L

Oil Pressure Switch 15 1.5 11 SS

Oil Pressure Switch Terminal Bolt – – – Hand-tighten

Water Hose Clamp Screws 2.0 0.20 17 in·lb

Water Pump Cover Bolts 12 1.2 104 in·lb L

Engine Removal/Installation

Adjusting Collar Locknut 49 5.0 36 S

Adjusting Collar 9.8 1.0 87 in·lb S

Lower Engine Mounting Nut 44 4.5 33 S

Middle Engine Mounting Bracket Bolt 25 2.5 18 S

Middle Engine Mounting Nut 44 4.5 33 S

Upper Engine Mounting Bolts 44 4.5 33 S

Crankshaft/Transmission

Breather Plate Bolts 9.8 1.0 87 in·lb L

Connecting Rod Big End Nuts see the

text

see the

text

see the

text

MO

Crankcase Bolts (M8) (Lower) (First) 15 1.5 11 MO, S

Crankcase Bolts (M8) (Lower) (Final) 31 3.2 23 MO, S

Crankcase Bolts (M6, L = 50 mm) (Lower) 12 1.2 104 in·lb S

Gear Position Switch Screws 2.9 0.30 26 in·lb L

Crankcase Bolt (M8, L = 90 mm) (Upper) 27 2.8 20 S

Crankcase Bolts (M8, L = 75 mm) (Upper) 27 2.8 20 S

Crankcase Bolts (M6, L = 68 mm) (Upper) 12 1.2 104 in·lb S

Transmission Case Bolts (M8) 20 2.0 15

Transmission Case Bolts (M6) 9.8 1.0 87 in·lb

Piston Oil Nozzles 2.9 0.30 26 in·lb

Gear Positioning Lever Bolt 12 1.2 104 in·lb

Oil Passage Plugs (Taper Side) 20 2.0 15 L

Oil Passage Plug (Left Side) 17 1.7 13

Oil Pressure Switch 15 1.5 11 SS

Fitting (breather) 15 1.5 11 L

Page: 28

PERIODIC MAINTENANCE 2-9

Torque and Locking Agent

Torque

Fastener

N·m kgf·m ft·lb

Remarks

Oil Passage Nozzle 4.9 0.50 43 in·lb

Oil Pressure Switch Terminal Bolt – – – Hand-tighten

Bearing Holder Screws 4.9 0.50 43 in·lb L

Shift Drum Cam Holder Bolt 12 1.2 104 in·lb L

Shift Lever Bolt 6.9 0.70 61 in·lb

Shift Pedal Mounting Bolt 25 2.5 18

Shift Shaft Return Spring Pin 28 2.9 21 L

Shift Tie-Rod Locknuts 6.9 0.70 61 in·lb

Starter Clutch Bolt 49 5.0 36

Starter Clutch Bolt Cap – – – Hand-tighten

Timing Inspection Cap – – – Hand-tighten

Starter Clutch Cover Bolts 9.8 1.0 87 in·lb

Idle Gear Cover Bolts 9.8 1.0 87 in·lb

Wheels/Tires

Front Axle Clamp Bolts 20 2.0 15 AL

Front Axle Nut 127 13 94

Rear Axle Nut 127 13 94

Final Drive

Engine Sprocket Cover Bolts 9.8 1.0 87 in·lb

Engine Sprocket Nut 125 13 92 MO

Rear Sprocket Nuts 59 6.0 43

Chain Guide Bolts (Front) 9.8 1.0 87 in·lb L

Chain Guide Bolt (Rear) 4.9 0.50 43 in·lb L

Brakes

Caliper Bleed Valves 7.8 0.80 69 in·lb

Brake Hose Banjo Bolts 25 2.5 18

Brake Lever Pivot Bolt 1.0 0.10 9 in·lb Si

Brake Lever Pivot Bolt Locknut 5.9 0.60 52 in·lb

Brake Pedal Bolt 8.8 0.90 78 in·lb

Front Brake Light Switch Screw 1.2 0.12 10 in·lb

Front Brake Reservoir Cap Stopper Screw 1.2 0.12 10 in·lb

Front Brake Disc Mounting Bolts 27 2.8 20 L

Front Brake Pad Pins 17 1.7 13

Front Caliper Assembly Bolts 27 2.8 20

Front Caliper Mounting Bolts 34 3.5 25

Front Master Cylinder Bleed Valve 5.9 0.60 52 in·lb

Front Master Cylinder Clamp Bolts 8.8 0.90 78 in·lb S

Rear Brake Disc Mounting Bolts 27 2.8 20 L

Rear Caliper Mounting Bolts 25 2.5 18

Rear Master Cylinder Mounting Bolts 25 2.5 18

Rear Master Cylinder Push Rod Locknut 18 1.8 13

Suspension

Front Axle Clamp Bolts 20 2.0 15 AL

Page: 29

2-10 PERIODIC MAINTENANCE

Torque and Locking Agent

Torque

Fastener

N·m kgf·m ft·lb

Remarks

Front Fork Bottom Allen Bolts 35 3.5 26

Front Fork Clamp Bolts (Lower) 25 2.5 18 AL

Front Fork Clamp Bolts (Upper) 20 2.0 15

Front Fork Top Plugs 35 3.5 26

Piston Rod Nuts 20 2.0 15

Rear Shock Absorber Bracket Nut 59 6.0 43

Rear Shock Absorber Nut (Lower) 34 3.5 25

Rear Shock Absorber Nut (Upper) 34 3.5 25

Swingarm Pivot Adjusting Collar 20 2.0 15 S

Swingarm Pivot Adjusting Collar Locknut 98 10 72 S

Swingarm Pivot Shaft Nut 108 11 81 S

Tie-Rod Nuts 59 6.0 43

Uni-Trak Rocker Arm Nut 34 3.5 25

Steering

Front Fork Clamp Bolts (Lower) 25 2.5 18 AL

Front Fork Clamp Bolts (Upper) 20 2.0 15

Handlebar Bolts 25 2.5 18

Handlebar Position Bolts 9.8 1.0 87 in·lb L

Steering Stem Head Nut 78 8.0 58

Steering Stem Nut 20 2.0 15

Switch Housing Screws 3.5 0.36 31 in·lb

Frame

Front Fender Mounting Bolts 3.9 0.40 35 in·lb

Front Footpeg Bracket Bolts 25 2.5 18

Rear Footpeg Bracket Bolts 25 2.5 18

Rear Frame Bolts 44 4.5 32 L

Sidestand Bolt 44 4.5 32 G

Sidestand Bracket Bolts 49 5.0 36 L

Sidestand Switch Bolt 8.8 0.90 78 in·lb L

Windshield Mounting Bolts 0.4 0.04 4 in·lb

Electrical System

Alternator Cover Bolts 9.8 1.0 87 in·lb

Alternator Lead Holding Plate Bolt 9.8 1.0 87 in·lb L

Alternator Rotor Bolt 155 16 115

Camshaft Position Sensor Bolt 9.8 1.0 87 in·lb

Crankshaft Sensor Bolts 5.9 0.60 52 in·lb

Cylinder Head Cover Ground Bolt 9.8 1.0 87 in·lb

Front Brake Light Switch Screw 1.2 0.12 10 in·lb

Front Turn Signal Light Mounting Screws 1.2 0.12 10 in·lb

Headlight Mounting Screws 1.2 0.12 10 in·lb

Licence Light Assembly Screws 0.9 0.09 8 in·lb

Licence Light Mounting Screws 1.2 0.12 10 in·lb

Meter Mounting Screws 1.2 0.12 10 in·lb

Page: 30

PERIODIC MAINTENANCE 2-11

Torque and Locking Agent

Torque

Fastener

N·m kgf·m ft·lb

Remarks

Gear Position Switch Screws 2.9 0.30 26 in·lb L

Rear Turn Signal Light Lens Screws 1.0 0.10 9 in·lb

Rear Turn Signal Light Mounting Screws 1.2 0.12 10 in·lb

Regulator/Rectifier Bolts 6.9 0.70 61 in·lb

Regulator/Rectifier Bracket Nuts 6.9 0.70 61 in·lb

Side Stand Switch Bolt 8.8 0.90 78 in·lb L

Spark Plugs 13 1.3 113 in·lb

Speed Sensor Bolt 6.9 0.70 61 in·lb L

Stator Coil Bolts 12 1.2 106 in·lb L

Starter Motor Cable Terminal Bolt 2.9 0.30 26 in·lb

Starter Clutch Bolt 49 5.0 36

Starter Motor Mounting Bolts 9.8 1.0 87 in·lb

Starter Relay Cable Terminal Bolts 4.0 0.41 35 in·lb

Switch Housing Screws 3.5 0.36 31 in·lb

Tail/Brake Light Mounting Bolts 4.0 0.40 35 in·lb

Vehicle-down Sensor Bolts 5.9 0.60 52 in·lb

Water Temperature Sensor 25 2.5 18 SS

Idle Gear Cover Bolts 9.8 1.0 87 in·lb

Starter Clutch Cover Bolts 9.8 1.0 87 in·lb

Starter Clutch Bolt Cap – – – Hand-tighten

Timing Inspection Cap – – – Hand-tighten

The table below, relating tightening torque to thread diameter, lists the basic torque for the bolts and

nuts. Use this table for only the bolts and nuts which do not require a specific torque value. All of the

values are for use with dry solvent-cleaned threads.

Basic Torque for General Fasteners

Threads Torque

Diameter (mm) N·m kgf·m ft·lb

5 3.4 ∼ 4.9 0.35 ∼ 0.50 30 ∼ 43 in·lb

6 5.9 ∼ 7.8 0.60 ∼ 0.80 52 ∼ 69 in·lb

8 14 ∼ 19 1.4 ∼ 1.9 10 ∼ 13.5

10 25 ∼ 34 2.6 ∼ 3.5 19 ∼ 25

12 44 ∼ 61 4.5 ∼ 6.2 33 ∼ 45

14 73 ∼ 98 7.4 ∼ 10.0 54 ∼ 72

16 115 ∼ 155 11.5 ∼ 16.0 83 ∼ 115

18 165 ∼ 225 17.0 ∼ 23.0 125 ∼ 165

20 225 ∼ 325 23.0 ∼ 33.0 165 ∼ 240

Page: 31

2-12 PERIODIC MAINTENANCE

Specifications

Item Standard Service Limit

Fuel System (DFI)

Throttle Grip Free Play 2 ∼ 3 mm (0.08 ∼ 0.12 in.) – – –

Idle Speed 1 300 ±50 r/min (rpm) – – –

Throttle Body Vacuum 27.3 ±1.333 kPa (205 ±10 mmHg) at idle speed – – –

Air Cleaner Element Viscous paper element – – –

Cooling System

Coolant:

Type (Recommended) Permanent type antifreeze – – –

Color Green – – –

Mixed Ratio Soft water 50%, coolant 50% – – –

Freezing Point –35°C (–31°F) – – –

Total Amount 2.6 L (2.7 US qt) – – –

Engine Top End

Valve Clearance:

Exhaust 0.24 ∼ 0.31 mm (0.0094 ∼ 0.0122 in.) – – –

Inlet 0.13 ∼ 0.19 mm (0.0051 ∼ 0.0075 in.) – – –

Clutch

Clutch Lever Free Play 2 ∼ 3 mm (0.08 ∼ 0.12 in.) – – –

Engine Lubrication System

Engine Oil:

Type API SE, SF or SG

API SH, SJ or SL with JASO MA

– – –

Viscosity SAE 10W-40 – – –

Capacity 2.9 L (3.1 US qt) (when filter is not removed) – – –

3.2 L (3.4 US qt) (when filter is removed) – – –

3.8 L (4.0 US qt) (when engine is completely dry) – – –

Level Between upper and lower level lines (Wait 2 ∼ 3

minutes after idling or running)

– – –

Wheels/Tires

Tread Depth:

Front BRIDGESTONE: 3.6 mm (0.14 in.) 1 mm (0.04 in.),

(AT, CH, DE) 1.6

mm (0.06 in.)

Rear BRIDGESTONE: 4.8 mm (0.19 in.) Up to 130 km/h

(80 mph): 2 mm

(0.08 in.), Over

130 km/h (80

mph): 3 mm (0.12

in.)

Air Pressure (when Cold):

Front Up to 180 kg (397 lb) load:

250 kPa (2.5 kgf/cm², 36 psi)

– – –

Rear Up to 180 kg (397 lb) load:

290 kPa (2.9 kgf/cm², 42 psi)

– – –

Page: 32

PERIODIC MAINTENANCE 2-13

Specifications

Item Standard Service Limit

Final Drive

Drive Chain Slack 30 ∼ 40 mm (1.2 ∼ 1.6 in.) – – –

Drive Chain Wear (20-link

Length)

317.5 ∼ 318.2 mm (12.50 ∼ 12.53 in.) 323 mm (12.7 in.)

Standard Chain:

Make ENUMA – – –

Type EK520MVXL1 – – –

Link 112 links – – –

Brakes

Brake Fluid:

Grade DOT4 – – –

Brake Pad Lining

Thickness:

Front 4 mm (0.16 in.) 1 mm (0.04 in.)

Rear 5 mm (0.20 in.) 1 mm (0.04 in.)

Brake Light Timing:

Front Pulled ON – – –

Rear On after about 10 mm (0.39 in.) of pedal travel – – –

Page: 33

2-14 PERIODIC MAINTENANCE

Special Tools

Inside Circlip Pliers:

57001-143

Steering Stem Nut Wrench:

57001-1100

Jack:

57001-1238

Pilot Screw Adjuster, A:

57001-1239

Oil Filter Wrench:

57001-1249

Vacuum Gauge:

57001-1369

Extension Tube:

57001-1578

Jack Attachment:

57001-1608

Page: 34

PERIODIC MAINTENANCE 2-15

Maintenance Procedure

Fuel System (DFI)

Throttle Control System Inspection

•Check that the throttle grip [A] moves smoothly from full

open to close, and the throttle closes quickly and com-