Предложите, как улучшить StudyLib

(Для жалоб на нарушения авторских прав, используйте

другую форму

)

Ваш е-мэйл

Заполните, если хотите получить ответ

Оцените наш проект

1

2

3

4

5

REVISED GUIDELINES FOR THE MAINTENANCE AND INSPECTION OF FIRE PROTECTION SYSTEMS AND APPLIANCES

3 This circular supersedes MSC/Circ.850.

ANNEX

REVISED GUIDELINES FOR THE MAINTENANCE AND INSPECTION OF FIRE PROTECTION SYSTEMS AND APPLIANCES

7 Annual testing and inspections

Annual inspections should be carried out to ensure that the indicated actions are taken for the specified equipment:

7.1 Fire mains, fire pumps, hydrants, hoses and nozzles

.4 pressure test a sample of fire hoses at the maximum fire main pressure, so that all fire

hoses are tested within five years;

Российский Морской Регистр Судоходства, 2013

ПРАВИЛА КЛАССИФИКАЦИОННЫХ ОСВИДЕТЕЛЬСТВОВАНИЙ СУДОВ В ЭКСПЛУАТАЦИИ

2.4.4 Противопожарная защита.

2.4.4.5 Противопожарное снабжение. Запасные части и инструмент.

2.4.4.5.3 Все пожарные рукава подвергаются гидравлическим испытаниям рабочим давлением водопожарной системы. При освидетельствовании шкафов (ящиков) для пожарных рукавов необходимо удостовериться в целостности конструкции, наличии

дренажа и отсутствии коррозии. Дополнительные указания по освидетельствованиям пожарных рукавов и соединительных головок и оценке их состояния —

см. 2.2.4.2.1 части I I «Проведение классификационных освидетельствований судов» Руководства.

Российский Морской Регистр Судоходства, 2014

РУКОВОДСТВО ПО ТЕХНИЧЕСКОМУ НАБЛЮДЕНИЮ ЗА СУДАМИ В ЭКСПЛУАТАЦИИ

2.2.4 Противопожарная защита.

2.2.4.2 Объем освидетельствования приведен в 2.2.4 части II «Периодичность и объемы освидетельствований» Правил.

Ниже, в 2.2.4.2.1 — 2.2.4.2.4, приводятся дополнительные указания и рекомендации по проводимым при ежегодных и очередных освидетельствованиях проверкам и осмотрам пожарных рукавов, соединительных головок и ручных стволов, пенообразователей, автономных дыхательных аппаратов и переносных огнетушителей.

2.2.4.2.1.4 При определении объема контроля пожарных рукавов при ежегодных и очередных освидетельствованиях необходимо учитывать сроки их поставки на судно, время хранения в складских условиях, места расположения и включать в объем контроля наружный осмотр состояния поверхности, обвязки, уплотнительных колец.

Гидравлические испытания должны проводиться рабочим давлением водопожарной системы. Необходимость их проведения следует устанавливать в каждом конкретном случае с учетом результатов наружного осмотра. Рукава должны испытываться не реже 1 раза в 3 года, а также при очередном освидетельствовании (в случае их соответствия требованиям правила 10 гл. П-2, п. 2.3 Конвенции СОЛАС-74/78/88). Существующие пожарные рукава, не соответствующие этим требованиям, до их замены на соответствующие рукава подлежат наружному осмотру и гидравлическим испытаниям ежегодно.

Результаты освидетельствований должны отражаться в актах (формы 6.3.7, 6.3.12). При выдаче указанных актов можно учитывать документы, оформленные специализированными станциями, признанными Регистром, членами МАКО или морскими администрациями (в том числе ими могут быть специальные пожарные части).

РД 31.21.44-86

РУКОВОДСТВО ПО ПРОВЕДЕНИЮ ПОЖАРНО-ПРОФИЛАКТИЧЕСКОЙ РАБОТЫ НА СУДАХ МИНИСТЕРСТВА МОРСКОГО ФЛОТА, НАХОДЯЩИХСЯ В ЭКСПЛУАТАЦИИ

ПРИЛОЖЕНИЕ 2 (обязательное)

ПЕРЕЧЕНЬ ДОКУМЕНТАЦИИ, ПОДЛЕЖАЩЕЙ ПРОВЕРКЕ ИИС ПТС ВОХР ММФ НА СУДАХ

1. № п/п: 2.

2. Наименование проверяемого документа (его раздела): Пожарно-контрольный

формуляр, разделы: в) учет проведения проверок, технического обслуживания,

ремонта: системы водяного пожаротушения;

3. Объект проверки: наличие записи даты: перекатки на новый шов пожарных рукавов

4. Периодичность проверок экипажем или компетентными организациями: 1 раз в месяц

«Правила пожарной безопасности на судах флота рыбной промышленности СССР и рыболовецких колхозов«

(утв. Минрыбхозом СССР 25.11.1988 N 527)

3. ТРЕБОВАНИЯ К СОДЕРЖАНИЮ НА СУДАХ ПРЕДМЕТОВ ПРОТИВОПОЖАРНОГО СНАБЖЕНИЯ И ОБОРУДОВАНИЯ

3.8. ПОЖАРНЫЕ РУКАВА И СТВОЛЫ

3.8.5. Пожарные рукава для воды и пены в комплекте с присоединительной арматурой следует периодически подвергать наружным осмотрам и гидравлическим испытаниям на прочность. Наружные осмотры имеющихся на судне рукавов, в том числе и хранящихся в запасе, требуется производить ежемесячно и каждый раз после применения их на пожаре или учении. При осмотрах проверяют целостность рукавов и резиновых уплотнительных колец в присоединительной арматуре, исправность рукавных гаек, легкость и надежность их присоединения. Внешне поверхность рукава не должна иметь местных изменений цвета, масляных пятен и следов плесени. Каждые 6 мес. при очередном осмотре производится перекатка рукавов по новым складкам с таким расчетом, чтобы новая складка не находилась в непосредственной близости от старой.

Гидравлические испытания пожарных рукавов на прочность следует производить ежегодно на рабочее давление судовой водо-пожарной системы. Результаты осмотров и акты гидравлических испытаний записывают в журнал технического состояния.

Revised Guidelines for the maintenance and inspection of fire protection systems and appliances

| dd-mm-yyyy = Entry into force | ||

| Document | MSC.1/Circ.1432 | 31-05-2013 |

| Supersedes | MSC.1/Circ.850 | |

| Amended by | MSC.1/Circ.1516 | 08-06-2015 |

Revised Guidelines for the maintenance and inspection of fire protection systems and appliances

- The Maritime Safety Committee, at its ninetieth session (16 to 25 May 2012), having considered a proposal by the Sub-Committee on Fire Protection, at its fifty-fifth session, and recognizing the need to include maintenance and inspection guidelines for the latest advancements in fire-protection systems and appliances, approved the Revised Guidelines for the maintenance and inspection of fire protection systems and appliances, as set out in the annex.

- Member Governments are invited to apply the annexed Guidelines when performing maintenance, testing and inspections in accordance with SOLAS regulation II-2/14.2.2.1 on or after 31 May 2013 and bring the annexed Guidelines to the attention of shipowners, shipmasters, ships’ officers and crew and all other parties concerned.

- This circular supersedes MSC/Circ.850.

Annex

1 Application

These Guidelines apply to all ships and provide the minimum recommended level of maintenance and inspections for fire protection systems and appliances. This information may be used as a basis for the ship’s onboard maintenance plan required by SOLAS regulation II-2/14. These Guidelines do not address maintenance and inspection of fixed carbon dioxide systems or portable fire extinguishers. Refer to the comprehensive instructions provided in the Guidelines for the maintenance and inspections of fixed carbon dioxide fire-extinguishing systems (MSC.1/Circ.1318) for fixed carbon dioxide systems, and in the Improved Guidelines for marine portable fire extinguishers (resolution A.951(23)) for portable fire extinguishers.

2 Operational readiness

All fire protection systems and appliances should at all times be in good order and readily available for immediate use while the ship is in service. If a fire protection system is undergoing maintenance, testing or repair, then suitable arrangements should be made to ensure safety is not diminished through the provision of alternate fixed or portable fire protection equipment or other measures. The onboard maintenance plan should include provisions for this purpose.

3 Maintenance and testing

3.1 Onboard maintenance and inspections should be carried out in accordance with the ship’s maintenance plan, which should include the minimum elements listed in sections 4 to 10 of these Guidelines.

3.2 Certain maintenance procedures and inspections may be performed by competent crew members who have completed an advanced fire-fighting training course, while others should be performed by persons specially trained in the maintenance of such systems. The onboard maintenance plan should indicate which parts of the recommended inspections and maintenance are to be completed by trained personnel.

3.3 Inspections should be carried out by the crew to ensure that the indicated weekly, monthly, quarterly, annual, two-year, five-year and ten-year actions are taken for the specified equipment, if provided. Records of the inspections should be carried on board the ship, or may be computer-based. In cases where the inspections and maintenance are carried out by trained service technicians other than the ship’s crew, inspection reports should be provided at the completion of the testing.

3.4 In addition to the onboard maintenance and inspections stated in these guidelines, manufacturer’s maintenance and inspection guidelines should be followed. The quality of water in automatic sprinkler systems is of particular importance and should be maintained in accordance with manufacturer guidelines. Records of water quality should be maintained on board in accordance with the manufacturer’s guidelines

3.5 Where particular arrangements create practical difficulties, alternative testing and maintenance procedures should be to the satisfaction of the Administration.

4 Weekly testing and inspections

4.1 Fixed fire detection and alarm systems

Verify all fire detection and fire alarm control panel indicators are functional by operating the lamp/indicator test switch.

4.2 Fixed gas fire-extinguishing systems

- verify all fixed fire-extinguishing system control panel indicators are functional by operating the lamp/indicator test switch; and

- verify all control/section valves are in the correct position.

4.3 Fire doors

Verify all fire door control panel indicators, if provided, are functional by operating the lamp/indicator switch.

4.4 Public address and general alarm systems

Verify all public address systems and general alarm systems are functioning properly.

4.5 Breathing apparatus

Examine all breathing apparatus and EEBD cylinder gauges to confirm they are in the correct pressure range.

4.6 Low-location lighting

Verify low-location lighting systems are functional by switching off normal lighting in selected locations.

4.7 Water mist, water spray and sprinkler systems

- verify all control panel indicators and alarms are functional;

- visually inspect pump unit and its fittings; and

- check the pump unit valve positions, if valves are not locked, as applicable.

5 Monthly testing and inspections

Monthly inspections should be carried out to ensure that the indicated actions are taken for the specified equipment.

5.1 Fire mains, fire pumps, hydrants, hoses and nozzles

- verify all fire hydrants, hose and nozzles are in place, properly arranged, and are in serviceable condition;

- operate all fire pumps to confirm that they continue to supply adequate pressure; and

- emergency fire pump fuel supply adequate, and heating system in satisfactory condition, if applicable.

5.2 Fixed gas fire-extinguishing systems

Verify containers/cylinders fitted with pressure gauges are in the proper range and the installation free from leakage.

5.3 Foam fire-extinguishing systems

Verify all control and section valves are in the proper open or closed position, and all pressure gauges are in the proper range.

5.4 Water mist, water spray and sprinkler systems

- verify all control, pump unit and section valves are in the proper open or closed position;

- verify sprinkler pressure tanks or other means have correct levels of water;

- test automatic starting arrangements on all system pumps so designed;

- verify all standby pressure and air/gas pressure gauges are within the proper pressure ranges; and

- test a selected sample of system section valves for flow and proper initiation of alarms.

(Note – The valves selected for testing should be chosen to ensure that all valves are tested within a one-year period.)

5.5 Firefighter’s outfits

Verify lockers providing storage for fire-fighting equipment contain their full inventory and equipment is in serviceable condition.

5.6 Fixed dry chemical powder systems

Verify all control and section valves are in the proper open or closed position, and all pressure gauges are in the proper range.

5.7 Fixed aerosol extinguishing systems

- verify all electrical connections and/or manual operating stations are properly arranged, and are in proper condition; and

- verify the actuation system/control panel circuits are within manufacturer’s specifications.

5.8 Portable foam applicators

Verify all portable foam applicators are in place, properly arranged, and are in proper condition.

5.9 Wheeled (mobile) fire extinguishers

Verify all extinguishers are in place, properly arranged, and are in proper condition.

5.10 Fixed fire detection and alarm systems

Test a sample of detectors and manual call points so that all devices have been tested within five years. For very large systems the sample size should be determined by the Administration.

6 Quarterly testing and inspections

Quarterly inspections should be carried out to ensure that the indicated actions are taken for the specified equipment:

6.1 Fire mains, fire pumps, hydrants, hoses and nozzles

Verify international shore connection(s) is in serviceable condition.

6.2 Foam fire-extinguishing systems

Verify the proper quantity of foam concentrate is provided in the foam system storage tank.

6.3 Ventilation systems and fire dampers

Test all fire dampers for local operation.

6.4 Fire doors

Test all fire doors located in main vertical zone bulkheads for local operation.

6.5 Water mist, water spray and sprinkler systems

Assess system water quality in the header tank and pump unit against the manufacturer’s water quality guidelines.

7 Annual testing and inspections

Annual inspections should be carried out to ensure that the indicated actions are taken for the specified equipment:

7.1 Fire mains, fire pumps, hydrants, hoses and nozzles

- visually inspect all accessible components for proper condition;

- flow test all fire pumps for proper pressure and capacity. Test emergency fire pump with isolation valves closed;

- test all hydrant valves for proper operation;

- pressure test a sample of fire hoses at the maximum fire main pressure, so that all fire hoses are tested within five years;

- verify all fire pump relief valves, if provided, are properly set;

- examine all filters/strainers to verify they are free of debris and contamination; and

- nozzle size/type correct, maintained and working.

7.2 Fixed fire detection and fire alarm systems

- test all fire detection systems and fire detection systems used to automatically release fire-extinguishing systems for proper operation, as appropriate;

- visually inspect all accessible detectors for evidence of tampering obstruction, etc., so that all detectors are inspected within one year; and

- test emergency power supply switchover.

7.3 Fixed gas fire-extinguishing systems

- visually inspect all accessible components for proper condition;

- externally examine all high pressure cylinders for evidence of damage or corrosion;

- check the hydrostatic test date of all storage containers;

- functionally test all fixed system audible and visual alarms;

- verify all control/section valves are in the correct position;

- check the connections of all pilot release piping and tubing for tightness;

- examine all flexible hoses in accordance with manufacturer’s recommendations;

- test all fuel shut-off controls connected to fire-protection systems for proper operation;

- the boundaries of the protected space should be visually inspected to confirm that no modifications have been made to the enclosure that have created uncloseable openings that would render the system ineffective; and

- if cylinders are installed inside the protected space, verify the integrity of the double release lines inside the protected space, and check low pressure or circuit integrity monitors on release cabinet, as applicable.

7.4 Foam fire-extinguishing systems

- visually inspect all accessible components for proper condition;

- functionally test all fixed system audible alarms;

- flow test all water supply and foam pumps for proper pressure and capacity, and confirm flow at the required pressure in each section (Ensure all piping is thoroughly flushed with fresh water after service.);

- test all system cross connections to other sources of water supply for proper operation;

- verify all pump relief valves, if provided, are properly set;

- examine all filters/strainers to verify they are free of debris and contamination;

- verify all control/section valves are in the correct position;

- blow dry compressed air or nitrogen through the discharge piping or otherwise confirm the pipework and nozzles of high expansion foam systems are clear of any obstructions, debris and contamination. This may require the removal of nozzles, if applicable;

- take samples from all foam concentrates carried on board and subject them to the periodical control tests in MSC.1/Circ.1312, for low expansion foam, or MSC/Circ.670 for high expansion foam.

(Note: Except for non-alcohol resistant foam, the first test need not be conducted until 3 years after being supplied to the ship.); and

- test all fuel shut-off controls connected to fire-protection systems for proper operation.

7.5 Water mist, water spray and sprinkler systems

.1 verify proper operation of all water mist, water-spray and sprinkler systems using the test valves for each section;

.2 visually inspect all accessible components for proper condition;

.3 externally examine all high pressure cylinders for evidence of damage or corrosion;

.4 check the hydrostatic test date of all high pressure cylinders;

.5 functionally test all fixed system audible and visual alarms;

.6 flow test all pumps for proper pressure and capacity;

.7 test all antifreeze systems for adequate freeze protection;

.8 test all system cross connections to other sources of water supply for proper operation;

.9 verify all pump relief valves, if provided, are properly set;

.10 examine all filters/strainers to verify they are free of debris and contamination;

.11 verify all control/section valves are in the correct position;

.12 blow dry compressed air or nitrogen through the discharge piping of dry pipe systems, or otherwise confirm the pipework and nozzles are clear of any obstructions. This may require the removal of nozzles, if applicable;

.13 test emergency power supply switchover, where applicable;

.14 visually inspect all sprinklers focusing in areas where sprinklers are subject to aggressive atmosphere (like saunas, spas, kitchen areas) and subject to physical damage (like luggage handling areas, gyms, play rooms, etc.) so that all sprinklers are inspected within one year. Sprinklers with obvious external damage, including paint, should be replaced and not included in the number of sprinklers tested in subparagraph .17;

.15 check for any changes that may affect the system such as obstructions by ventilation ducts, pipes, etc.;

.16 test a minimum of one section in each open head water mist system by flowing water through the nozzles. The sections tested should be chosen so that all sections are tested within a five-year period;

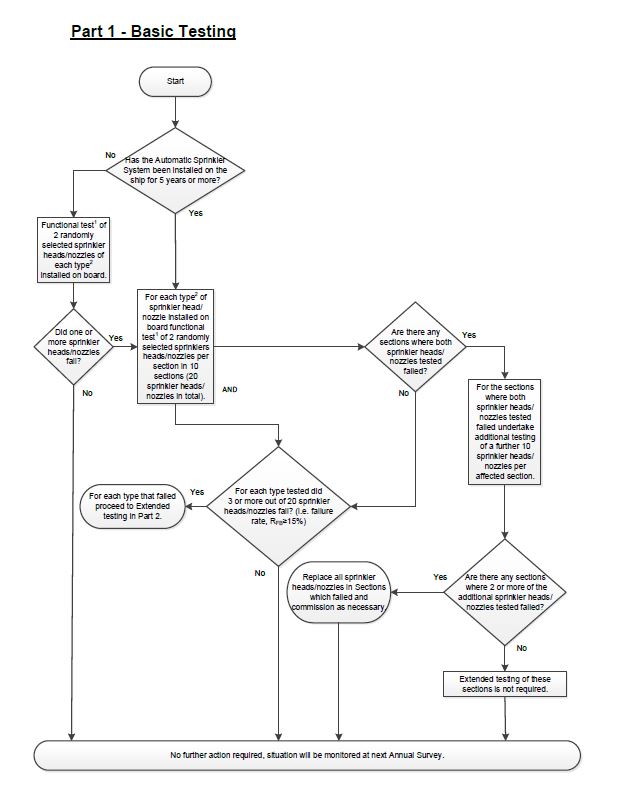

.17 test automatic sprinklers and automatic water mist nozzles in accordance with the following flow chart:

Explanatory notes to the flow chart

- Functional test is defined as a test that demonstrates the operation and flow ofwater from sprinkler head/nozzle.

- Type is defined as each different manufacturer model of sprinkler head/nozzle.

- Static/standby pressure is defined as the constant pressure maintained in the system at all times prior to activation.

- All testing should be carried out at static/standby pressure.

- Failure rate (RFB) is the number of sprinkler heads/nozzles to fail testing divided by test sample size multiplied by 100; and

.18 during basic testing, and extended testing when applicable, of automatic sprinkler heads/nozzles as outlined in subparagraph .17, water quality testing should be conducted in each corresponding piping section. Note – should a tested sprinkler fail, assessing the corresponding water quality at that time would assist in determining the cause of failure.»

7.6 Ventilation systems and fire dampers

- test all fire dampers for remote operation;

- verify galley exhaust ducts and filters are free of grease build-up; and

- test all ventilation controls interconnected with fire-protection systems for proper operation.

7.7 Fire doors

Test all remotely controlled fire doors for proper release.

7.8 Breathing apparatus

- check breathing apparatus air recharging systems, if fitted, for air quality;

- check all breathing apparatus face masks and air demand valves are in serviceable condition; and

- check EEBDs according to maker’s instructions.

7.9 Fixed dry chemical powder systems

- visually inspect all accessible components for proper condition;

- verify the pressure regulators are in proper order and within calibration; and

- agitate the dry chemical powder charge with nitrogen in accordance with system manufacturer’s instructions.

(Note: Due to the powder’s affinity for moisture, any nitrogen gas introduced for agitation must be moisture free.)

7.10 Fixed aerosol extinguishing systems

Verify condensed or dispersed aerosol generators have not exceeded their mandatory replacement date. Pneumatic or electric actuators should be demonstrated working, as far as practicable.

7.11 Portable foam applicators

- verify all portable foam applicators are set to the correct proportioning ratio for the foam concentrate supplied and the equipment is in proper order;

- verify all portable containers or portable tanks containing foam concentrate remain factory sealed, and the manufacturer’s recommended service life interval has not been exceeded;

- portable containers or portable tanks containing foam concentrate, excluding protein based concentrates, less than 10 years old, that remain factory sealed can normally be accepted without the periodical foam control tests required in MSC.1/Circ.1312 being carried out;

- protein based foam concentrate portable containers and portable tanks should be thoroughly checked and, if more than five years old, the foam concentrate should be subjected to the periodical foam control tests required in MSC.1/Circ.1312, or renewed; and

- the foam concentrates of any non-sealed portable containers and portable tanks, and portable containers and portable tanks where production data is not documented, should be subjected to the periodical foam control tests required in MSC.1/Circ.1312.

7.12 Wheeled (mobile) fire extinguishers

- perform periodical inspections in accordance with the manufacturer’s instructions;

- visually inspect all accessible components for proper condition;

- check the hydrostatic test date of each cylinder; and

- for dry powder extinguishers, invert extinguisher to ensure powder is agitated.

7.13 Galley and deep fat cooking fire-extinguishing systems

Check galley and deep fat cooking fire-extinguishing systems in accordance with the manufacturer’s instructions.

8 Two-year testing and inspections

Two-year inspections should be carried out to ensure that the indicated actions are taken for the specified equipment.

8.1 Fixed gas fire-extinguishing systems

- all high pressure extinguishing agents cylinders and pilot cylinders should be weighed or have their contents verified by other reliable means to confirm that the available charge in each is above 95 per cent of the nominal charge. Cylinders containing less than 95 per cent of the nominal charge should be refilled; and

- blow dry compressed air or nitrogen through the discharge piping or otherwise confirm the pipe work and nozzles are clear of any obstructions. This may require the removal of nozzles, if applicable.

8.2 Fixed dry chemical powder systems

- blow dry nitrogen through the discharge piping to confirm that the pipe work and nozzles are clear of any obstructions;

- operationally test local and remote controls and section valves;

- verify the contents of propellant gas cylinders (including remote operating stations);

- test a sample of dry chemical powder for moisture content; and

- subject the powder containment vessel, safety valve and discharge hoses to a full working pressure test.

9 Five-year service

At least once every five years, the following inspections should be carried out for the specified equipment.

9.1 Fixed gas fire-extinguishing systems

Perform internal inspection of all control valves.

9.2 Foam fire-extinguishing systems

-

flush all ro-ro deck deluge system piping with water, drain and purge with air;

-

perform internal inspection of all control/section valves; water quality testing should be conducted in all corresponding piping sections, if not previously tested as outlined in paragraph 7.5.18 within the last five years;

- check all nozzles to prove they are clear of debris; and

- test all foam proportioners or other foam mixing devices to confirm that the mixing ratio tolerance is within +30 to -10% of the nominal mixing ratio defined by the system approval.

9.3 Water mist, water spray and sprinkler systems

-

flush all ro-ro deck deluge system piping with water, drain and purge with air;

-

perform internal inspection of all control/section valves; water quality testing should be conducted in all corresponding piping sections, if not previously tested as outlined in paragraph 7.5.18 within the last five years;

-

check condition of any batteries, or renew in accordance with manufacturer’s recommendations; and

-

for each section where the water is refilled after being drained or flushed, water quality should meet manufacturer’s guidelines. Testing of the renewed water quality should be conducted and recorded as a new baseline reference to assist future water quality monitoring for each corresponding section.

9.4 Breathing apparatus

Perform hydrostatic testing of all steel self-contained breathing apparatus cylinders. Aluminium and composite cylinders should be tested to the satisfaction of the Administration.

9.5 Low-location lighting

Test the luminance of all systems in accordance with the procedures in resolution A.752(18).

9.6 Wheeled (mobile) fire extinguishers

Visually examine at least one extinguisher of each type manufactured in the same year and kept on board.

10 Ten-year service

At least once every 10 years, the following inspections should be carried out for the specified equipment:

10.1 Fixed gas fire-extinguishing systems

- perform a hydrostatic test and internal examination of 10 per cent of the system’s extinguishing agent and pilot cylinders. If one or more cylinders fail, a total of 50 per cent of the onboard cylinders should be tested. If further cylinders fail, all cylinders should be tested;

- flexible hoses should be replaced at the intervals recommended by the manufacturer and not exceeding every 10 years; and

- if permitted by the Administration, visual inspection and NDT (non-destructive testing) of halon cylinders may be performed in lieu of hydrostatic testing.

10.2 Water mist, water spray and sprinkler systems

Perform a hydrostatic test and internal examination for gas and water pressure cylinders according to flag Administration guidelines or, where these do not exist, EN 1968:2002 + A1.

10.3 Fixed dry chemical powder systems

Subject all powder containment vessels to hydrostatic or non-destructive testing carried out by an accredited service agent.

10.4 Fixed aerosol extinguishing systems

Condensed or dispersed aerosol generators to be renewed in accordance with manufacturer’s recommendations.

10.5 Wheeled (mobile) fire extinguishers

All extinguishers together with propellant cartridges should be hydrostatically tested by specially trained persons in accordance with recognized standards or the manufacturer’s instructions.

Life Saving Appliances

Weekly

Equipment/Requirement Regulation Ship Type

Interval

By Remark

Emergency escape breathing devices (EEBDs)

Examine cylinder gauges toconfirmthey are in the correct pressure range

MSC.1/Circ.1432, para. 4.5 All Weekly Crew

Falls used in launching appliances

Maintenance SOLAS III/20.4MSC.1/Circ.1206/Rev.1

All Weekly SER (or Crew) Inspections according to makersmaintenance guidelines;Special concern to hidden areas and areasof end terminations;Ships crew only if properly trained andfamiliar with these works.

Lifeboats (except free-fall lifeboats)

Moving from stowed position

SOLAS III/20.6.3 All Weekly Crew

Test run of life- and rescue boat engines SOLAS III/20.6.2MSC.1/Circ.1206/Rev.1

All Weekly Crew it should be demonstrated that the gear box and gear box trainare engaging satisfactorily.

Testing of public address systems and general alarm systems

SOLAS III/20.6.4MSC.1/Circ.1432, para. 4.4

All Weekly Crew

Visual inspection of survival craft, rescue boats and launching appliances (davit , winch)

SOLAS III/20.6.1 All Weekly Crew The inspection shall include, but is not limited to, the condition of hooks,their attachment to the lifeboat and the on-load release gear being properly and completely reset

Monthly

Equipment/Requirement Regulation Ship Type

Interval

By Remark

Means of Embarkation on and Disembarkation from ships (Gangways, accommodation laddersincl. winch and fittings as well as usefor pilot transfer)

Maintenance and inspection SOLAS II-1/3-9.3SOLAS III/20.4SOLAS III/20.7.2MSC.1/Circ.1331, Annex, para. 4

All Monthly Crew In accordance with manufacturer’sinstructions. Maintenance of wires acc.To SOLAS III/20.4.

Falls used in launching appliances

Maintenance SOLAS III/20.4MSC.1/Circ.1206/Rev.1

All Monthly SER (or Crew) Inspections according to makersmaintenance guidelines;Special concern to hidden areas and areas of end terminations;Ships crew only if properly trained andfamiliar with these works.

Immersion suits and anti-exposure Suits

Inspection SOLAS III/20.7.2SOLAS III/36.1MSC/Circ.1047

All Monthly Crew

Lifeboats (except free-fall lifeboats)

Turning out from stowed position

SOLAS III/20.7.1 All Monthly Crew

Inspection of lifeboat equipment SOLAS III/20.7.2 All Monthly Crew

Annually

Equipment/Requirement Regulation Ship Type

By Remark

Means of Embarkation on and Disembarkation from ships (Gangways, accommodation laddersincl. winch and fittings as well as use for pilot transfer)

Examination SOLAS II-1/3-9.3MSC.1/Circ.1331, Annex, para. 5

All Crew + GL

Emergency escape breathing devices (EEBDs)

Check according to maker’sinstructions

MSC.1/Circ.1432, para. 7.8.3

All Crew

Falls used in launching appliances

Maintenance SOLAS III/20.4MSC.1/Circ.1206/Rev.1

All SER or Crew Inspections according to makers maintenance guidelines; Special concern to hidden areas and areas of end terminations; Ships crew only if properly trained and familiar with these works.

Maintenance of hydrostatic release units (non disposable) SOLAS III/20.9.1 All SER Administration may extend this period to 17 months.Maintenance of inflatable liferafts, lifejackets SOLAS III/20.8.1.1 All SER Administration may extend this period to 17 months.

Inflatable liferafts: Administration can accept specific liferafts for extended service intervals acc. to SOLAS III/20.8.3 and MSC.1/Circ.1328.

Launching appliances Launching appliance annual thorough examination

SOLAS III/20.11.1.2MSC.1/Circ.1206/Rev.1/Appendix of Annex 1, para. 2.8 and 2.9 asapplicable

All Maker orMTP orSPF orSP + GL

Dynamic test of the winch brake SOLAS III/20.11.1.3MSC.1/Circ.1206/Rev.1/Appendix of Annex 1, para. 3.1

Applicable load: Weight of survival craft without persons on board.

and 3.3 asapplicableOn-load release gear/automatic release hooks thorough examination and operational testincl. freefalllifeboat release system

SOLAS III/20.11.2..2 + 20.11.3.2 MSC.1/Circ.1206/Rev.1/Appendixof Annex 1, para. 2.4 / 2.5 / 2.6 and 2.7

Examination of lifeboats MSC.1/Circ.1206/Rev.1 All Crew + Maker Engine, propulsion, manoeuvring and power supply system.

Examination of lifeboats with sprinkler system MSC.1/Circ.1206/Rev.1 Tanker (oil) Crew + MakerLifeboats with self-contained air support sytem

Examination MSC.1/Circ.1206/Rev.1 Tanker (chem/gas)

Crew + Maker Incl. external inspection of air cylinders.

Marine evacuation systems (MES)

Service SOLAS III/20.8.1.1 Passenger ships

SER Administration may extend this period to 17 months.

30 Months

Servicing of inflatable liferafts (30 months) Solas III/20.8.3 & MSC Circ.1328 Crew + SER

Immersion suits and anti-exposure suits MSC/Circ.1114 SBM or Crew By crew provided suitable equipment is available on board. Tests more frequently for suits older than 10 years.

5 Years

Means of Embarkation on and Disembarkation from ships (Gangways, accommodation ladders incl. winch and fittings as well as use for pilot transfer)

Examination and operational test with specified max. operational load

SOLAS II-1/3-9.3MSC.1/Circ.1331, Annex, para. 5

All Crew + GL Suitable test weights are to be provided.

Falls used in launching appliances

Renewal Latest after 5 yearsor earlier when

SOLAS III/20.4 All Maker orMTP orSPF or

necessary due todeterioration

SP + GL

Launching appliances Dynamic test of the winch brake

SOLAS III/20.11.1.3MSC.1/Circ.1206/Rev.1/Appendixof Annex 1, para. 3.2 and 3.3 asapplicable

All Maker + GL orMTP + GL orSP + GL orSPF

Applicable load: 1.1 x Weight of fullyequipped survival craft with equivalentweight of max. permitted number of persons.To be performed in connection with theannually required thorough examination.On-load release

gear/automatic release hooks five yearly overhaul and operational test incl. free-fall lifeboat release system.

SOLAS III/20.11.2.3 + 20.11.3.3MSC.1/Circ.1206/Rev.1/Appendixof Annex 1, para. 4

Liferaft Operational test under 1.1 xtotal mass of liferaft fullyequipped and loaded when release hook is overhauled.

Solas III/20.11.3.3 All Under Survey

Lifeboats with self-contained air

Hydrostatic test of air cylinders

IACS Rec. No.88 Tanker (chem/gas)

SER or ALS

Fire Protection and Fire Fighting Equipment

Weekly

Equipment/Requirement Regulation Ship Type

By Remark

Self-contained breathing apparatuses (SCBAs)

Examine cylinder gauges to confirm they are in the correct pressure range

MSC.1/Circ.1432, para. 4.5 All Crew

Fixed fire detection andalarm systems

Verify all fire detection and fire alarm control panel indicators are functional by operating the lamp/indicator test switch.

MSC.1/Circ.1432, para. 4.1 All Crew

Fire doors Verify that all fire door control panel indicators, if provided, are functional by operating the lamp/indicator switch.

MSC.1/Circ.1432, para. 4.3 All Crew

Monthly

Equipment/Requirement Regulation Ship Type

By Remark

Air recharging systemfor SCBAs

The compressed air equipment shall be inspected.

BCH Code, para. 3.16.8IGC Code, para. 14.2.6

Tanker (chem/gas)

Crew By a responsible officer.

Self-contained breathingapparatuses (SCBAs)

The breathing apparatus shall be inspected. BCH Code, para. 3.16.8IBC Code, para. 14.2.6IGC Code, para. 14.2.6

Tanker (chem/gas)

Crew By a responsible officer.

Fixed fire detection andalarm systems

Test a sample of detectors and manual call points so that all devices have been tested within five years.

MSC.1/Circ.1432, para. 5.10

All Crew For very large systems the sample size shall be determined by the Administration.

Wheeled (mobile) fireextinguishers

Verify that all are in place, properly arranged, and are in proper condition.

MSC.1/Circ.1432, para. 5.9

All Crew

Fire-fighter’s outfits Verify lockers providing storage for fire-fighting equipment contain their full inventory and equipment is in serviceable condition.

MSC.1/Circ.1432, para. 5.5

All Crew

Fire mains, fire pumps,hydrants, hoses andnozzles

Verify that all fire hydrants, hose and nozzles are in place, properly arranged, and are in serviceable condition.

MSC.1/Circ.1432, para. 5.1.1

All Crew

Operate all fire pumps to confirm that they continue to supply adequate pressure.

MSC.1/Circ.1432, para. 5.1.2

Verify that emergency fire pump fuel supply is adequate and heating system in satisfactory condition, if applicable.

MSC.1/Circ.1432, para. 5.1.3

Portable foamapplicator units

Verify all portable foam applicators are in place,properly arranged, and are in proper condition.

MSC.1/Circ.1432, para. 5.8

All Crew

Verify that all portable foam applicators are set to the correct proportioning ratio for the foam concentrate supplied and the equipment is in proper order.

MSC.1/Circ.1432, para. 7.11.1

Verify that all portable containers or portable tanks containing foam concentrate remain factory sealed, and the manufacturer’s recommended service life interval has not been exceeded.

MSC.1/Circ.1432, para. 7.11.2

Portable containers or portable tanks containingfoam concentrate, excluding protein based

MSC.1/Circ.1432, para. 7.11.3

Foam control tests are to be conducted byan approved service supplier or an

concentrates, less than 10 year old, that remainfactory sealed can normally be accepted without the periodical foam control tests required in MSC.1/Circ.1312 being carried out.

accredited laboratory.

Protein based foam concentrate portable containers and portable tanks shall be thoroughly checked and, if more than five yearsold, the foam concentrate shall be subjected to the periodical foam control tests required in MSC.1/Circ.1312, or renewed.

MSC.1/Circ.1432, para. 7.11.4

The foam concentrates of any non-sealed portable containers and portable tanks, and portable containers and portable tanks where production datais not documented, shall be subjected to the periodical foam control tests required in MSC.1/Circ.1312.

MSC.1/Circ.1432, para. 7.11.5

Quarterly

Equipment/Requirement Regulation Ship Type

By Remark

Fire dampers Test all fire dampers for local operation. MSC.1/Circ.1432, para. 6.3

All Crew

Fire doors Test all fire doors located in main vertical zonebulkheads for local operation.

MSC.1/Circ.1432, para. 6.4

Passenger ships

Crew

Fire mains, fire pumps,hydrants, hoses andnozzles

Verify that international shore connection(s) is/are in serviceable condition.

MSC.1/Circ.1432, para. 6.1

All Crew

Annuanlly

Equipment/Requirement Regulation Ship Type

By Remark

Air recharging systemfor SCBAs

The equipment shall be inspected and tested. BCH Code, para. 3.16.8IGC Code, para. 14.2.6

Tanker (chem/gas)

Maker

Check breathing apparatus air recharging systems,if fitted, for air quality.

MSC.1/Circ.1432, para. 7.8.1

All ALS or Crew By crew provided a suitable measurement device is available on board. The test device is to be agreed with the maker of the air recharging system.

Self-contained breathingapparatuses (SCBAs)

The equipment shall be inspected and tested. BCH Code, para. 3.16.8IBC Code, para. 14.2.6IGC Code, para. 14.2.6

Tanker (chem/gas)

SER or Maker

Check all breathing apparatus face masks and air demand valves are in serviceable condition.

MSC.1/Circ.1432, para. 7.8.2

All Crew

Fixed fire detection andalarm systems

Test all fire detection systems and fire detectionsystems used to automatically release fire extinguishing systems for proper operation, as appropriate.

MSC.1/Circ.1432, para. 7.2.1

All Crew

Visually inspect all accessible detectors for evidence of tampering obstruction, etc., so that all detectors are inspected within one year

MSC.1/Circ.1432, para. 7.2.2

Test emergency power supply switchover. MSC.1/Circ.1432, para. 7.2.3

Fire dampers Test all fire dampers for remote operation. MSC.1/Circ.1432, para. 7.6 All CrewFire doors Test all remotely controlled fire doors for proper

release.MSC.1/Circ.1432, para. 7.7 All Crew

Portable fireextinguishers

Inspection in accordance with the manufacturer’s instruction and based on inspection guide in Res.A.951(23), table 9.1.3.

Res.A.951 (23), para. 9.1 Crew or SER By, or under supervision of, a person with demonstrable competence (e.g. advancedfire-fighting training course according to STCW Code, para. A-VI/3).

Wheeled (mobile) fireextinguishers

Inspection in accordance with the manufacturer’s instructions.

MSC.1/Circ.1432, para. 7.12.1

All Crew

Wheeled (mobile) fire extinguishers shall be visually inspected to check that all accessible components are in proper condition.

MSC.1/Circ.1432, para. 7.12.2

The hydrostatic test date of each cylinder is to be checked.

MSC.1/Circ.1432, para. 7.12.3

Dry powder wheeled (mobile) fire extinguishers areto be inverted to ensure that the powder is agitated.

MSC.1/Circ.1432, para. 7.12.4

Fire mains, fire pumps,hydrants, hoses andnozzles

Visually inspect all accessible components forproper condition.

MSC.1/Circ.1432, para. 7.1.1

All Crew

Flow test all fire pumps for proper pressure andcapacity. Test emergency fire pump with isolationvalves closed

MSC.1/Circ.1432, para. 7.1.2

Test all hydrant valves for proper operation. MSC.1/Circ.1432, para. 7.1.3

Pressure test a sample of fire hoses at themaximum fire main pressure, so that all fire hosesare tested within five years.

MSC.1/Circ.1432, para. 7.1.4

Verify all fire pump relief valves, if provided, areproperly set.

MSC.1/Circ.1432, para. 7.1.5

Examine all filters/strainers to verify they are free ofdebris and contamination.

MSC.1/Circ.1432, para. 7.1.6

Verify that the nozzle size/type is correct,maintained and working.

MSC.1/Circ.1432, para. 7.1.7

Galley exhaust ducts Verify galley exhaust ducts and filters are free ofgrease build-up.

MSC.1/Circ.1432, para. 7.6.2

All Crew

Ventilation systems Test all ventilation controls interconnected with fireprotection systems for proper operation.

MSC.1/Circ.1432, para. 7.6.3

All Crew

5 years

Equipment/Requirement Regulation Ship Type

By Remark

Self-contained breathingapparatuses (SCBAs)

Perform hydrostatic testing of all self-containedbreathing apparatus cylinders.

MSC.1/Circ.1432, para. 9.4 SER or ALS Aluminium and composite cylinders shall be tested to the satisfaction of theAdministration.

Portable fireextinguishers

At least one fire extinguisher of each typemanufactured in the same year and kept on board a ship shall be test discharged as part of a fire drill.

Res.A.951 (23), para. 9.1.1 Crew

Wheeled (mobile) fireextinguishers

Visually examination of at least one wheeled(mobile) extinguisher of each type manufactured inthe same year and kept on board.

MSC.1/Circ.1432, para. 9.6 Crew

10 years

Equipment/Requirement Regulation Ship Type

By Remark

Portable fireextinguishers

All fire extinguishers together with propellantcartridges shall be hydraulically tested inaccordance with the recognized standard or themanufacturer’s instruction.

Res.A.951 (23), para. 9.1.2 SER or ALS

Wheeled (mobile) fireextinguishers

All fire extinguishers together with propellantcartridges shall be hydraulically tested inaccordance with the recognized standard or themanufacturer’s instruction.

MSC.1/Circ.1432, para. 10.5 SER or ALS

Fixed Fire Fighting Systems

Aerosol fire-extinguishing systems

Regulation Ship Type

Interval By Remark

Verify that all electrical connections and/or manual operating stations are properly arranged, and are in proper condition.

MSC.1/Circ.1432, para. 5.7 All Monthly Crew

Verify that the actuation system/control panel circuits are within manufacturer’s specifications.

MSC.1/Circ.1432, para. 5.7 All Monthly Crew

Verify that condensed or dispersed aerosol generators have not exceeded their mandatory replacement date. Pneumatic or electric actuators shall be demonstrated working, as far as practicable.

MSC.1/Circ.1432, para. 7.10 All Annually Crew

Maintenance by approved service supplier. Rules I-0, Sect. 3, C.1.1.4.2 All 2-yearly SER

Condensed or dispersed aerosol generators are to be renewed in accordance with manufacturer’s recommendations.

MSC.1/Circ.1432, para. 10.4 All 10-yearly SER

Alternative gas fire-extinguishing systems(e.g. FM200, NOVEC 1230 or HALON)

Regulation Ship Type

Interval By Remark

Verify that all fixed fire-extinguishing system control panel indicators ar functional by operating the lamp/indicator test switch.

MSC.1/Circ.1432, para. 4.2.1

All Weekly Crew

Verify that all control/section valves are in the correct position.

MSC.1/Circ.1432, para. 4.2.1

All Weekly Crew

Verify containers/cylinders fitted with pressure gauges are in the proper rangevand the installation free from leakage.

MSC.1/Circ.1432, para. 5.2 All Monthly Crew

Visually inspect all accessible components for proper condition.

MSC.1/Circ.1432, para. 7.3 All Annually

Externally examine all high pressure cylinders for evidence ofdamage or corrosion.Check the hydrostatic test date of all storage containers.Functionally test all fixed system audible and visual alarms.Verify all control/section valves are in the correct position.Check the connections of all pilot release piping and tubing for tightness.Examine all flexible hoses in accordance with manufacturer’s recommendations.

Test all fuel shut-off controls connected to fire-protection systems for proper operation.

The boundaries of the protected space shall be visually inspected to confirm that no modifications have been made tothe enclosure that have created uncloseable openings that would render the system ineffective.If cylinders are installed inside the protected space, verify theintegrity of the double release lines inside the protected space, and check low pressure or circuit integrity monitors onrelease cabinet, as applicable.Maintenance by approved service supplier. Rules I-0, Sect. 3, C.1.1.4.2 All 2-yearly SERAll high pressure extinguishing agents cylinders and pilot cylinders shall be weighed or have their contents verified by other reliable means to confirm that the available charge in each is above 95 per cent of the nominal charge. Cylinders containing less than 95 per cent of the nominal charge shall be refilled.

MSC.1/Circ.1432, para 8.1.1 All 2-yearly Crew or SER

Blow dry compressed air or nitrogen through the discharge piping or otherwise confirm the pipe work and nozzles are clear of any obstructions. This may require the removal of nozzles, if applicable.

MSC.1/Circ.1432, para 8.1.2

Perform internal inspection of all control valves. MSC.1/Circ.1432, para. 9.1 All 5-yearly SERPerform a hydrostatic test and internal examination of 10 per cent of the system’s extinguishing agent and pilot cylinders. Ifone or more cylinders fail, a total of 50 per cent of the onboard cylinders shall be tested. If further cylinders fail, all cylinders shall be tested.

MSC.1/Circ.1432, para. 10.1Rules I-0, Sect. 3, B.1.5.5.3

All 10-yearly SER + GL If permitted by the Administration, visualinspection and NDT (non-destructive testing) of halon cylinders may be performed in lieu of hydrostatic testing. GL HOis to be contacted prior to the NDT.

Flexible hoses shall be replaced at the intervals recommended by the manufacturer and not exceeding every 10 years.

MSC.1/Circ.1318, para 6.1.2Rules I-0,Sect.3 C.1.3.3.10.1

All At least 10-yearly Crew or SER Hose Assemblies are to be delivered on board with a GL testcertificate.

CO2 fire extinguishing system Regulation Ship Type

Interval By Remark

General visual inspection of the overall system condition for obvious signs of damage.

MSC.1/Circ.1318, para. 4.1

Monthly Crew

Verify that all stop valves are in the closed position. MSC.1/Circ.1318, para. 4.1.1

Monthly Crew

Verify that all releasing controls are in the proper position and readily accessible for immediate use

MSC.1/Circ.1318, para. 4.1.2

Monthly Crew

Verify that all discharge piping and pneumatic tubing is intact and has not been damaged.

MSC.1/Circ.1318, para. 4.1.3

Monthly Crew

Verify that all high pressure cylinders are in place and properly secured.

MSC.1/Circ.1318, para. 4.1.4

Monthly Crew

Verify that the alarm devices are in place and do not appear damaged. MSC.1/Circ.1318, para. 4.1.5

Monthly Crew

Verify that the pressure gauge is reading in the normal range. MSC.1/Circ.1318, para. 4.2.1

Monthly Crew

Verify that the liquid level indicator is reading within the proper level. MSC.1/Circ.1318, para. 4.2.2

Monthly Crew

Verify that the manually operated storage tank main service valve is secured in the open position.

MSC.1/Circ.1318, para. 4.2.3

Monthly Crew

Verify that the vapour supply line valve is secured in the open position. MSC.1/Circ.1318, para. 4.2.4

Monthly Crew

The boundaries of the protected space shall be visually inspected to confirm that no modifications have been made to the enclosure that have created uncloseable openings that would render the system ineffective.

MSC.1/Circ.1318, para. 5.1

Annually Crew

All storage containers shall be visually inspected for any signs of damage, rust or loose mounting hardware. Cylinders that are leaking, corroded, dented or bulging shall be hydrostatically retested or replaced.

MSC.1/Circ.1318, para. 5.2

Annually Crew

System piping shall be visually inspected to check for damage, loose supports and corrosion. Nozzles shall be inspected to ensure they have not been obstructed by the storage of spare parts or a new installation of structure or machinery.

MSC.1/Circ.1318, para. 5.3

Annually Crew

The manifold shall be inspected to verify that all flexible discharge hoses and fittings are properly tightened.

MSC.1/Circ.1318, para. 5.4

Annually Crew

All entrance doors to the protected space shall close properly and shall have warning signs, which indicate that the space is protected bya fixed carbon dioxide system and that personnel shall evacuate immediately if the alarms sound. All remote releasing controls shall be checked for clear operating instructions and indication as to the space served.

MSC.1/Circ.1318, para. 5.5

Annually Crew

Maintenance by approved service supplier. Rules I-0, Sect. 3, C.1.1.4.2

2-yearly SER

All high pressure cylinders and pilot cylinders shall be weighed or have their contents verified by other reliable means to confirm that the available charge in each is above 90% of the nominal charge. Cylinders containing less than 90% of the nominal charge shall be refilled. The liquid level of low pressure storage tanks shall be checkedto verify that the required amount of carbon dioxide to protect the largest hazard is available.

MSC.1/Circ.1318, para. 6.1.1

Passenger ships

2-yearly ± 3 months

Crew or SER

Cargo ships

2.5-yearly Crew or SER

The hydrostatic test date of all storage containers shall be checked. MSC.1/Circ.1318, para. 6.1.2

Passenger ships

2-yearly ± 3 months

Crew or SER

Cargo ships

2.5-yearly On the occasion of each intermediate,periodical and Class Renewal Survey.

The discharge piping and nozzles shall be tested to verify that they arenot blocked. The test shall be performed by isolating the discharge piping from the system and flowing dry air or nitrogen from test cylinders or suitable means through the piping.

MSC.1/Circ.1318, para. 6.1.3

Passenger ships

2-yearly ± 3 months

Crew or SER

Cargo ships

2.5-yearly On the occasion of each intermediate,periodical and Class Renewal Survey.

Where possible, all activating heads shall be removed from the cylinder valves and tested for correct functioning by applying full working pressure through the pilot lines.In cases where this is not possible, pilot lines shall be disconnected from the cylinder valves and blanked off or connected together and tested with full working pressure from the release station and checked for leakage.In both cases this shall be carried out from one or more release stations when installed.If manual pull cables operate the remote release controls, they shall be checked to verify the cables and corner pulleys are in good condition and freely move and do not require an excessive amount of travel to activate the system.

MSC.1/Circ.1318, para. 6.2.1

Passenger ships

2-yearly ± 3 months

SER

Cargo ships

At least 5-yearly

All cable components should be cleaned and adjusted as necessary, and the cable connectors shall be properly tightened. If the remote release controls are operated by pneumatic pressure, the tubing shall be checked for leakage, and the proper charge of the remote releasingstation pilot gas cylinders shall be verified.All controls and warning devices shall function normally, and the time delay, if fitted shall prevent the discharge of gas for the required time period.

MSC.1/Circ.1318, para. 6.2.2

Passenger ships

2-yearly ± 3 months

SER

Cargo ships

At least 5-yearly

After completion of the work, the system shall be returned to service. All releasing controls shall be verified in the proper position and connected to the correct control valves. All pressure switch interlocks shall be reset and returned to service. All stop valves shall be in the closed position.

MSC.1/Circ.1318, para. 6.2.3

Passenger ships

2-yearly ± 3 months

Cargo ships

At least 5-yearly

High pressure cylinders shall be subjected to periodical tests at intervals not exceeding 10 years. At the 10-year inspection, at least 10% of the total number provided shall be subjected to an internal inspection and hydrostatic test. If one or more cylinders fail, a total of 50% of the onboard cylinders shall be tested. If further cylinders fail, all cylinders shall be tested.

MSC.1/Circ.1318, para. 6.1.2Rules I-0, Sect. 3, B.1.5.5.3

All 10-yearly SER + GL

Flexible hoses shall be replaced at the intervals recommended by themanufacturer and not exceeding every 10 years.

MSC.1/Circ.1318, para. 6.1.2Rules I-0, Sect. 3, C.1.3.3.10.1

All At least 10-yearly SER orCrew Hose Assemblies are to be delivered onboard with a GL test certificate.

Low pressure CO2 bulk storage containers are subject to internal survey if the content has been released and the container is more than5 years old but not more frequently than once within five years.

Rules I-0, Sect. 3, B.1.5.5.4

All If the content hasbeen released.

SER + GL

Deep fat cooking fire-extinguishingsystems

Regulation Ship Type

Interval By Remark

Check in accordance with the manufacturer’s instructions. MSC.1/Circ.1432, para. 7.13

All Annually Crew

Maintenance by approved service supplier. Rules I-0, Sect. 3, C.1.1.4.2

All 2-yearly SER

Others

Equipment/Requirement Regulation Ship Type

Interval By Remark

Emergency escape breathing devices (EEBDs)

Hydrostatic test and internal inspectionof cylinders

IACS Rec. No.88 All As specified by themanufacturer

SER or ALS Intervals specified in recognized international standards (e.g. ISO, EN) are to be observed

Testing of emergency lighting SOLAS III/19.3.3.9 All At each abandonship drill

Crew

Lightweight survey SOLAS II-1/5.5IS Code VIII/8.1.5

Passenger ships 5-yearly SER or Crew + GL

Provided crew is properly trained.

Low-location lighting systems

Verify that the low-location lighting systems arefunctional by switching off normal lighting in selectedlocations

MSC.1/Circ.1432, para. 4.6 Passenger ships Weekly Crew

Test the luminance in accordance with the proceduresin resolution A.752(18).

MSC.1/Circ.1432, para. 9.5 Res.A.752(18)

5-yearly SER

Marine evacuation systems (MES)

Test SOLAS III/20.8.2 Passenger ships 6-yearly SER Deployment on rotational basis at intervals be agreed by Administration, however each system to be deployed at least once every six years.

Medical oxygen Replacement of oxygen. National pharmaceuticalregulations, if applicable

All According to nationalpharmaceuticalregulations

Maker

GL Recommendation Maker’s expiry date

Hydrostatic test and internal inspection of cylinders.

Flag State, if applicable According to FlagState requirements

SER or ALS Scope of inspection specified by the Flag State and/or recognized international standards (e.g. ISO, EN) are to be observed.

GL Recommendation According to maker’s instructions and/or internationalstandards (e.g. ISO,EN)

Float valves in

5

unit tank

Filters and

6

strainers

5.4

These guidelines apply to all ships and provide the minimum recommended level of maintenance

and inspection for fixed fire protection systems.

Onboard maintenance and inspection should be carried out in accordance with the vessels

maintenance plan, which should include the minimum elements listed in sections 4 to 10 in the

MSC.1/Circ. 1432 guidelines.

Weekly test and inspection

Verify all UCP indicators and alarms are functional (lamp test).

1

Visually inspect the pump unit and its fittings.

2

Check pump unit valve positions, if valves are not locked, as applicable.

3

4

Verify unit tank water level.

Monthly inspections should be carried out to ensure that indicated actions are taken for the specified

equipment.

Monthly test and inspection

Verify all unit control or stop valves are in proper condition, and in the right open or closed

1

position.

Test automatic starting arrangements on all unit pumps as designed.

2

Verify unit standby pressure.

3

4

Check unit audible and visual alarm devices for proper function.

In addition to the monthly test schedule, the following check and inspections should be carried out

at least every 12 months, to ensure that the indicated actions are taken for the specified equipment.

END USER MANUAL

OPERATION AND MAINTENANCE OF HIGH PRESSURE WATER MIST PUMP UNIT

REVISION 4, MAY 2016

Float valves supplying water the unit tank shall be checked for correct

function.

Filters in the water supply to the unit shall be inspected and cleaned as

necessary.

PAGE 45 / 48