-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

C200H-AD002/DA002

Analog I/O Units

Operation Guide

Revised July 2000

Related Manuals for Omron C200H

Summary of Contents for Omron C200H

-

Page 1

C200H-AD002/DA002 Analog I/O Units Operation Guide Revised July 2000… -

Page 3

OMRON. No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without notice. -

Page 5: Table Of Contents

SECTION 2 C200H-AD002 Analog Input Unit ….Before Operation …………

-

Page 6

C200H or C200HS PC. The C200H-AD002 can convert up to eight analog inputs into digital form. The operator can select from four input ranges: 1 to 5 V, 0 to 10 V, –10 to 10 V, and 4 to 20 mA. Useful functions, such as scaling, mean value, peak value, and square root, are built-in. -

Page 7

PRECAUTIONS This section provides general precautions for using the Programmable Controller (PC) and Analog I/O Units. The information contained in this section is important for the safe and reliable application of the Analog I/O Units. You must read this section and understand the information contained before attempting to set up or operate a PC system and Analog I/O Units. -

Page 8: Intended Audience

It is extremely important that a PC and all PC Units be used for the specified purpose and under the specified conditions, especially in applications that can directly or indirectly affect human life. You must consult with your OMRON representative before applying a PC System to the above-mentioned applications.

-

Page 9: Operating Environment Precautions

Application Precautions Operating Environment Precautions Caution Do not operate the control system in the following places: • Locations subject to direct sunlight. • Locations subject to temperatures or humidity outside the range specified in the specifications. • Locations subject to condensation as the result of severe changes in tempera- ture.

-

Page 10

Application Precautions • Interlock circuits, limit circuits, and similar safety measures in external circuits (i.e., not in the Programmable Controller) must be provided by the customer. • Always use the power supply voltage specified in this manual. An incorrect voltage may result in malfunction or burning. •… -

Page 11: System Design

SECTION 1 System Design This section describes the basic uses of Analog I/O Units in a control system and illustrates the type of applications in which they might be found. Introduction …………. Safety Precautions .

-

Page 12: Introduction

Section 1-2 Introduction The C200H-AD002 Analog Input Unit is used to convert the output of analog field devices, usually sensors, to a digital form that the PC can read. The C200H-DA002 Analog Output Unit converts the digital output of the PC to ana- log signals which drive analog field devices.

-

Page 13: Basic Configuration

For example, a preamplifier may amplify the output of a pres- sure gauge to the level required for the Analog Input Unit and a regulator may interface a heating system to control temperature. C200H-AD002 C200H-DA002 Analog Input Unit…

-

Page 14: Example Configurations

Below are two examples of how Analog I/O Units can be used in control systems. The first diagram shows a temperature regulating system and the second shows a servomotor positioning system. C200H-AD002 Analog Input Unit C200H-DA002 Analog Output Unit Transducer SYSMAC C200HS, C200H, C200HX/HG/HE Temperature sensing element Valve controller Fuel Sensor Encoder Ç…

-

Page 15: System Considerations

For details regarding data area allocations, refer to 2-2 and 3-2 IR and DM Bit Allocations . With the C200H, do not mount an Analog I/O Unit in the two slots adjacent to the CPU. Doing so would prevent peripheral devices such as the Programming Console from being connected.

-

Page 16

System Considerations Section 1-5 To reduce the risk of malfunctioning due to electrical noise, wire input and output lines in separate ducts from high-voltage and power lines. For further wiring precautions, refer to the respective sections on wiring for Ana- log Input Units and Analog Output Units. -

Page 17: C200H-Ad002 Analog Input Unit

C200H-AD002 Analog Input Unit This section provides the information required to install and operate a C200H-AD002 Analog Input Unit. Before Operation …………

-

Page 18: Before Operation

Lit when an input signal wire is disconnected. This indicator operates only when the input range is set to 1 to 5 V/4 to 20 mA. Functions The following table briefly outlines the basic functions of the C200H-AD002. These functions are covered in more detail in 2-3 Functions and Programming . Function…

-

Page 19

(AR0100 to AR0109) is turned ON and then OFF again. 4. The unit number can be set to between A and F Hex (10 to 15 decimal) only when a C200H-AD002 with a lot number jj16 or later (January 1996 or later) is used with a C200HG-CPU53/CPU63 or C200HX-CPU54/CPU64 CPU Unit. -

Page 20

Section 2-1 Before Operation Pin Allocation Name Name Name Common (–) Input 7 — Common (–) Input 8 Current input (+) Current input (+) Voltage/Current input (+) Analog ground (AG) Voltage/Current input (+) Common (–) Input 5 21 Shield Common (–) Input 6 Current input (+) Shield… -

Page 21

Section 2-1 Before Operation Input Wiring Diagram Voltage input C200H-AD002 1 MΩ 1 MΩ Shield 10 kΩ Current input 1 MΩ 250 Ω 1 MΩ Shield 10 kΩ and V/I : Voltage/current input (+) : Current input (+) : Common (–) -

Page 22

Section 2-1 Before Operation Wiring Methods Use the connectors provided with the Unit to wire input lines. (Connec- tor: MR-34FG; Cover: MR-34L; both manufactured by Honda Communications; Connector/Cover Set: MR-34LFG). Be sure to tighten the lock screws whenever attaching the connector to the Unit. Use wires with a diameter of 0.3 mm maximum. -

Page 23

Section 2-1 Before Operation Input Wiring When wiring inputs, apply the following points to avoid noise interference and Considerations optimize Analog Input Unit performance. • Use shielded twisted-pair cable for external connections and power lines. • Route input cables separately from the AC cable, and do not run the Unit’s cables near a main circuit cable, high voltage cable, or a non-PC load cable. -

Page 24: Bit And Dm Area Allocations

UNIT OVER error will be generated and operation will be stopped. 2. The unit number can be set to between A and F Hex (10 to 15 decimal) only when a C200H-AD002 with a lot number jj16 or later (January 1996 or later) is used with a C200HG-CPU53/CPU63 or C200HX-CPU54/CPU64…

-

Page 25

Note The unit number can be set to between A and F Hex (10 to 15 decimal) only when a C200H-AD002 with a lot number jj16 or later (January 1996 or later) is used with a C200HG-CPU53/CPU63 or C200HX-CPU54/CPU64 CPU Unit. -

Page 26

Bit and DM Area Allocations Section 2-2 Note When the input range is set to –10 V to +10 V, the 15 bit indicates the sign. A bit status of 0 indicates “+” and a bit status of 1 indicates “–.” There is no sign bit when the scaling or square root function is being executed. -

Page 27

Bit and DM Area Allocations Section 2-2 word word Input 1 scaling: lower-limit value Input 1 scaling: upper-limit value Input 2 scaling: lower-limit value Input 2 scaling: upper-limit value Input 3 scaling: lower-limit value Input 3 scaling: upper-limit value m+10 Input 4 scaling: lower-limit value m+11 Input 4 scaling: upper-limit value… -

Page 28

Bit and DM Area Allocations Section 2-2 DM Contents DM word(s) Bits Item Data contents 15 to 10 Not used. Limit warning mode Sets the operating mode for the limit warning function. This setting applies to all 8 inputs. 0: Mode 1 (normal warning) 1: Mode 2 (sequence warning) Refer to 2-3-8 Limit Warning Function for more details. -

Page 29: Functions And Programming

Be sure to perform one or the other of these steps whenever new data has been set or data has been changed. • Turning ON → OFF → ON the power to the C200H, C200HS, C200HX/HG/HE CPU.

-

Page 30

Functions and Programming Section 2-3 Setting Method The conversion prohibit setting is made in bits 00 to 07 of DM word m. Set the corresponding bit to “1” to prohibit conversion for that input. Bit 07 0: Conversion enabled DM m 1: Conversion disabled Sampling Period The “sampling period”… -

Page 31

Functions and Programming Section 2-3 Inputs Input signal range Bit settings Inputs 1 to 4 +1 to +5 V Inputs 5 and 6 –10 to +10 V Inputs 7 and 8 0 to +10 V Bit 15 DM (m + 1) Set DM word m+1 to “50AA”… -

Page 32

Functions and Programming Section 2-3 BCD Data Conversion 0 to +10 V –10 to +10 V +1 to +5 V/+4 to +20 mA –10 V +10 V +10 V Input signal +1 V +5 V +4 mA +20 mA Input signal Sign bit (15 bit) Note… -

Page 33

Functions and Programming Section 2-3 2-3-5 Scaling Function The scaling function converts the digital output values to the scale defined by the specified lower-limit and upper-limit values, then outputs the scaled data. The lower-limit value is the digital output value corresponding to the minimum input value. -

Page 34

Functions and Programming Section 2-3 Note 1. The resolution is fixed at 1/4000 if the (upper limit – lower limit) term is great- er than 4000. 2. The resolution will be lower if the (upper limit – lower limit) term is less than 4000. -

Page 35

Functions and Programming Section 2-3 For example, the scaled data for –2 V is calculated as follows: (* 2) * (* 10) BCD conversion value for * 2 V + 4000 + 4000 + 1600 10 * (* 10) 7000 * 1000 * 2 V scaled data + 1600 ) 1000 + 3400 4000… -

Page 36

Functions and Programming Section 2-3 2-3-7 Peak Value Function Function The peak value function holds the maximum output value for every input. This function can be used in combination with the scaling, mean value, and square root functions. These functions are performed in the following order: A/D conversion →… -

Page 37

Functions and Programming Section 2-3 1, 2, 3… 1. The limit warning mode is set with bit 09 of DM word m. This mode setting applies to all 8 inputs. Bit 15 É É DM (m) 0: Mode 1 (normal warning) 1: Mode 2 (sequence warning) Mode 1 The output values are compared to the upper/lower limits from startup. -

Page 38

Functions and Programming Section 2-3 DM word Data m+33 Input 3 upper-limit value m+34 Input 4 lower-limit value m+35 Input 4 upper-limit value m+36 Input 5 lower-limit value m+37 Input 5 upper-limit value m+38 Input 6 lower-limit value m+39 Input 6 upper-limit value m+40 Input 7 lower-limit value m+41… -

Page 39

Functions and Programming Section 2-3 Mean Value Processing and The following diagram shows how a disconnection detection affects the results Disconnection Detection (output data) produced by the mean value function. (n+1) time time time Mean value É É É É… -

Page 40: Data Setting And Programming Examples

Data Setting and Programming Examples Section 2-4 Data Setting and Programming Examples 2-4-1 Data Settings The following settings are used in this example. Basic Settings Item Setting Unit number 0 (allocated words: IR 100 to IR 109 and DM 1000 to DM 1043) Inputs used Inputs 1 to 5 (The conversion prohibit bits for inputs 6 to 8 are turned ON.) conversion…

-

Page 41

Data Setting and Programming Examples Section 2-4 2-4-2 Programming Reading Output Data The converted data (or the results of calculations performed on it) can be read from the output words IR n+1 to IR n+8 and moved to other words in memory using MOV(21) and/or XFER(70). -

Page 42: Troubleshooting

Troubleshooting Section 2-5 Troubleshooting Error Detection When an error occurs in an input or in the Unit itself, the error is indicated by an output to a flag in the IR, SR, or AR area. The following tables show the various errors that may occur, along with their probable causes and remedies.

-

Page 43

Troubleshooting Section 2-5 Special I/O Unit Error Flags (AR) Item Function AR 0000 Unit #0 Error Flag When one of the CPU errors described above occurs, the AR bit turns ON for the Unit where the h AR bi ON f h U i AR 0001 Unit #1 Error Flag… -

Page 44: C200H-Da002 Analog Output Units

C200H-DA002 Analog Output Units This section provides the information required to install and operate a C200H-DA002 Analog Output Unit. Before Operation …………

-

Page 45: Before Operation

Section 3-1 Before Operation Before Operation 3-1-1 Nomenclature and Functions Model label Display Unit number panel setting switch External output terminal block connectors Backplane connector Indicators Indicator Color Function Green Lit when the Analog Input Unit is operating correctly. If operation is not normal, this indicator turns OFF and Unit operation is stopped.

-

Page 46

The following diagram shows the basic internal configuration of the Analog Out- put Unit. Switch Voltage output – Outputs 1 to 4 Photocoup- D/A con- I/O bus verter Current C200H ROM/ output – Analog DC/DC power converter supply 3-1-2 Switch Settings Unit Number Unit number setting switch The switch notch points to the unit number. -

Page 47

(AR0100 to AR0109) is turned OFF → ON → OFF. 4. The unit number can be set to between A and F Hex (10 to 15 decimal) only when a C200H-DA002 with a lot number jj16 or later (January 1996 or later) is used with a C200HG-CPU53/CPU63 or C200HX-CPU54/CPU64 CPU Unit. -

Page 48

Section 3-1 Before Operation Output Wiring The following diagram shows the external wiring of outputs for the C200H-DA002. C200H-DA002 Load Voltage output 1 – Output 1 Current output 1 – Voltage output 2 – Output 2 Current output 2 –… -

Page 49

Section 3-1 Before Operation Output Wiring When wiring outputs, apply the following points to avoid noise interference and Considerations optimize Analog Output Unit performance. • Use shielded twisted-pair cable for external connections and power lines. • Route output cables separately from the AC cable, and do not run the Unit’s cables near a main circuit cable, high voltage cable, or a non-PC load cable. -

Page 50: Bit And Dm Allocations

OVER error will be generated and operation will be stopped. 2. The unit number can be set to between A and F Hex (10 to 15 decimal) only when a C200H-AD002 with a lot number jj16 or later (January 1996 or later) is used with a C200HG-CPU53/CPU63 or C200HX-CPU54/CPU64 CPU Unit.

-

Page 51

Troubleshooting Section 3-3 Note When the –10 to +10 V range is being used, the 15 bit serves as the sign bit. A value of 0 indicates “+” and a value of 1 indicates “–.” 3-2-1 Programming Use the MOV(21) instruction to write output data (binary data) from the CPU to the Analog Output Unit. -

Page 52

Troubleshooting Section 3-3 CPU error Probable causes and operations Possible remedies • The Special I/O Unit is defective. • Replace the defective Special I/O Unit. CPU waiting • The PC hasn’t begun to run. • The defective Unit should appear as $ signs only in the I/O table read opera- tion. -

Page 53

Troubleshooting Section 3-3 Special I/O Unit Restart Bits (AR) Turn OFF → ON → OFF the Special I/O Unit Restart Bits in the following circumstances: • After DM data has been set or replaced. • To restart Unit operation after clearing an error. The same effect can be achieved by turning ON →… -

Page 54

Appendix A Standard Models Analog Input Unit Model C200H, C200HS, C200HX/HG/HE C200H-AD002 Analog Output Unit Model C200H, C200HS, C200HX/HG/HE C200H-DA002… -

Page 55

Appendix B Specifications C200H-AD002 Analog Input Unit General Specifications All general specifications of the C200H-AD002 Analog Input Unit conform to those of the C Series. Performance Specifications Item Specifications Number of analog inputs 8 max. Input signal range (note 1) Voltage input –10 to +10 V… -

Page 56

Appendix B Specifications Input Specifications Converted output data (Top: Binary Parentheses: BCD) 0FA0 (4000) 0 to 10 V 1 to 5 V/4 to 20 mA –10 to +10 V 07D0 (2000) 0000 (8001) (–0001) 87D0 (A000) (–2000) 8FA0 10 V –5 V 0 V 1 V 10 V… -

Page 57

Appendix B Specifications C200H-DA002 Analog Output Unit All general specifications of the C200H-DA002 Analog Output Unit conform to those of the C Series. Item Specifications Number of analog outputs Output signal range Voltage outputs –10 to +10 V Current outputs 4 to 20 mA Voltage output: 0.5 Ω… -

Page 58

Appendix B Specifications Output Specifications Output signal +10 V (+20 mA) –10 to +10 V +4 to +20 mA (+4 mA) –10 V Digital input data (Top: Binary Parentheses: BCD) Sign bit (15 bit) Note 1. If a digital signal is input that exceeds the output signal range (max. value of +10 V or +20 mA, or min. value of –10 V or +4 mA), the analog output will remain fixed at its maximum or minimum value. -

Page 59

Appendix B Specifications External Dimensions Unit: mm C200H-AD002 Analog Input Unit C200H-DA002 Analog Output Unit… -

Page 60

Appendix B Specifications Installation Dimensions (Unit: mm) C200H-AD002 Analog Input Unit Connecting cable Approx. 200… -

Page 61

Appendix C Data Memory Coding Sheet C200H-AD002 Analog Input Unit Data Settings C200H-AD002 Unit number: Item Input 8 Input 7 Input 6 Input 5 Input 4 Input 3 Input 2 Input 1 Conversion prohibit setting A/D conversion data Binary or BCD… -

Page 62

Appendix C Data Memory Coding Sheet Data Memory Coding Sheet C200H-AD002 Unit number: DM1_00 to DM1_43 DM address Data Usage (rightmost digits) Bit 09: Limit warning mode Conversion prohibit setting (Mode 2 = 1) (prohibit = 1) Bit 08: Data type setting (BCD = 1) Input signal range (00 specifies –10 to +10 V, 01 specifies 0 to… -

Page 63

Appendix C Data Memory Coding Sheet C200H-AD002 Unit number: DM1_00 to DM1_43 DM address Data Usage (rightmost digits) Input 8 mean value processing: number of samples Input 1 limit warning: lower-limit value Input 1 limit warning: upper-limit value Input 2 limit warning: lower-limit value… -

Page 64

C200H-AD002, data type setting, C200H-DA002, protective seal, dimensions external, installation, disconnection detection, DM area allocation, C200H-AD002, , scaling function, DM area contents, C200H-AD002, Slave Racks, specifications, square root function, switches C200H-AD002, error detection C200H-DA002,… -

Page 65

Date Revised content June 1993 Original production January 1994 Pages ix, 2, 3, 26, and 31: Information added to reflect that the C200H-AD002 can also be used with the C200HS. October 1995 Completely revised. July 2000 Pages 3, 4, 5, 9, 13, 14, 15, 18, 32, 35,, 39, 41, and 43: Information added to reflect that the C200H-AD002 and C200H-DA002 can also be used with the C200HX/HG/HE.

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Related Manuals for Omron SYSMAC C200H-AD003

Summary of Contents for Omron SYSMAC C200H-AD003

-

Page 1

Cat. No. W325-E1-04 SYSMAC C200H-AD003/DA003/DA004/MAD01 Analog I/O Units… -

Page 2

C200H-AD003/DA003/DA004/MAD01 Analog I/O Units Operation Manual Revised June 2003… -

Page 4

OMRON. No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without notice. -

Page 6: Table Of Contents

TABLE OF CONTENTS PRECAUTIONS ……. . . 1 Intended Audience .

-

Page 7

About this Manual: This manual describes the installation and operation of the C200H-AD003 Analog Input Unit, the C200H-DA003/DA004 Analog Output Unit, and the C200H-MAD01 Analog I/O Unit and includes the sec- tions described below. The C200H-AD003 Analog Input Unit converts analog sensor output to digital format and transmits it to C200H, C200HS and C200HX/HG/HE PCs. -

Page 8

PRECAUTIONS This section provides general precautions for using the Programmable Controller (PC) and Analog I/O Units. The information contained in this section is important for the safe and reliable application of the Analog I/O Unit. You must read this section and understand the information contained before attempting to set up or operate a PC system and Analog I/O Unit. -

Page 9: Intended Audience

It is extremely important that a PC and all PC Units be used for the specified purpose and under the specified conditions, especially in applications that can directly or indirectly affect human life. You must consult with your OMRON representative before applying a PC System to the above-mentioned applications.

-

Page 10: Operating Environment Precautions

Application Precautions such problems, external safety measures must be provided to ensure safety in the system. • When the 24-VDC output (service power supply to the PC) is overloaded or short-circuited, the voltage may drop and result in the outputs being turned OFF.

-

Page 11

Application Precautions • Mounting or dismounting Power Supply Units, I/O Units, CPU Units, Memory Cassettes, or any other Units. • Assembling the Units. • Setting DIP switch or rotary switches. • Connecting or wiring the cables. • Connecting or disconnecting the connectors. Caution Failure to abide by the following precautions could lead to faulty operation of the PC or the system, or could damage the PC or PC Units. -

Page 12

Application Precautions • Changing the operating mode of the PC. • Force-setting/force-resetting any bit in memory. • Changing the present value of any word or any set value in memory. • Resume operation only after transferring to the new CPU Unit the contents of the DM Area, HR Area, and other data required for resuming operation. -

Page 13: System Design

SECTION 1 System Design This section describes the features and system configuration of the C200H-AD003 Analog Input Unit, the C200H-DA003 and C200H-DA004 Analog Output Units, and the C200H-MAD01 Analog I/O Unit, and explains the operations that they have in common. Features and Functions .

-

Page 14: Features And Functions

Features and Functions Section Features and Functions Analog Input Unit Analog I/O Unit Analog Output Units C200H-AD003 C200H-DA003 C200H-DA004 C200H-MAD01 Units for C200H, C200HS, These special-purpose Units enable highly accurate analog input and output at and C200HX/HG/HE PCs a resolution of 4,000, for C200H, C200HS, and C200HX/HG/HE PC systems. The C200H-AD003 Analog Input Unit converts analog sensor output to digital format and transmits it to C200H, C200HS and C200HX/HG/HE PCs.

-

Page 15

Features and Functions Section Peak Value Function The peak value function holds the maximum digital conversion value for every input (including mean value processing). This function can be used with analog input. The following diagram shows how digital conversion values are affected when the peak value function is used. -

Page 16: Basic Configuration

Basic Configuration Section Basic Configuration The basic system configuration is shown in the following diagram, using the C200H-AD003 Analog Input Unit and the C200H-DA003 Analog Output Unit as examples. Analog Input Unit Analog Output Unit CPU Unit Sensor Regulator Temperature (Temperature control) Preamp Pressure…

-

Page 17

Basic Configuration Section The Units that belong to the various Special I/O Unit groups are shown in the following table. Their usage is limited according to the maximum current pro- vided for the Rack and the amount of current consumed by each Unit. For de- tails, refer to the C200H, C200HS, or C200HX/HG/HE Installation Guide. -

Page 18

Basic Configuration Section Mounting Analog I/O Units Use the following procedure to mount an Analog I/O Unit to the Backplane. 1, 2, 3… 1. Lock the top of the Analog I/O Unit into the slot on the Backplane and rotate the Unit downwards as shown in the following diagram. -

Page 19: Setting The Unit Number

Setting the Unit Number Section When wiring a Unit, place a cover over the top of the Unit to prevent wire clip- pings and so on from getting inside. When the wiring has been completed, the cover must be removed to prevent heat radiation. Remove the cover after the wiring has been completed.

-

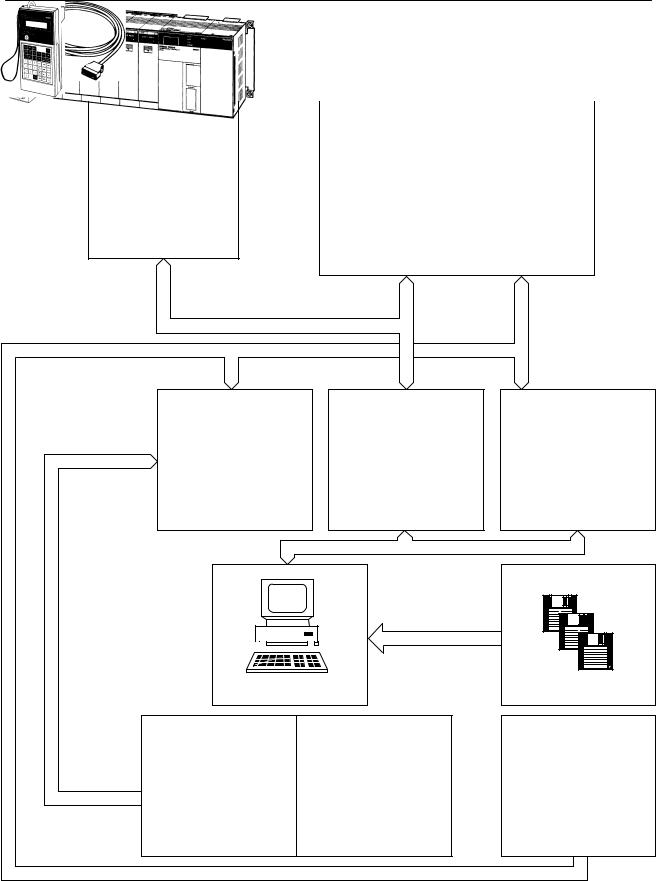

Page 20: Operating Procedure

Operating Procedure Section Operating Procedure Follow the procedure outlined below when using Analog I/O Units. Installation and Settings 1, 2, 3… 1. Set the DIP switch on the rear panel of the Unit to normal mode. 2. Wire the Unit. 3.

-

Page 21: Section 2 C200H-Ad003 Analog Input Unit

SECTION 2 C200H-AD003 Analog Input Unit This section provides the information required to install and operate a C200H-AD003 Analog Input Unit. Specifications …………2-1-1 General Specifications .

-

Page 22: Specifications

Specifications Section Specifications 2-1-1 General Specifications All general specifications of the C200H-AD003 Analog Input Unit conform to those of the C200H, C200HS, and C200HX/HG/HE Series. 2-1-2 Performance Specifications Item C200H-AD003 Voltage input Current input Number of analog inputs Input signal range (note 1) 0 to 10 V 4 to 20 mA –10 to 10 V…

-

Page 23: Input Specifications

Specifications Section 2-1-3 Input Specifications Range: 1 to 5 V (4 to 20 mA) Conversion value (16-bit binary data) 1068 0FA0 Resolution: 4,000 0000 FF38 1 V (4 mA) 5 V (20 mA) 5.2 V (20.8 mA) 0.8 V (3.2 mA) Analog input signal Range: 0 to 10 V Conversion value (16-bit binary data)

-

Page 24: Nomenclature And Functions

Nomenclature and Functions Section Range: –10 to 10 V Conversion value (16-bit binary data) 0898 07D0 Resolution: 4,000 0000 F830 F768 –10 V +10 V –11 V +11 V Analog input signal Nomenclature and Functions Front Back Model label Indicators Unit number setting switch Operation mode switch Terminal block mounting…

-

Page 25: Indicators

Nomenclature and Functions Section The terminal block is attached by a connector. It can be removed by loosening the black mounting screw. When removing the terminal block after wiring, re- move the wire connected to the top terminal of the right column. Check to be sure that the black terminal block mounting screw is securely tight- ened to a torque of 0.5 N S m.

-

Page 26: Operation Mode Switch

Wiring Section Note 1. Switches A to F can be set for the C200HX/HG-CPU5j-E/6j-E. Setting numbers A to F for C200H, C200HS, C200HE, or C200HX/HG- CPU3j-E/4j-E PCs will cause an I/O UNIT OVER error and the Unit will not operate. 2.

-

Page 27: Internal Circuitry

Wiring Section 2. The input signal ranges for individual inputs are set in the Data Memory (DM). They can be set in units of analog input numbers. 3. The COM terminal is connected to the 0-V analog circuit in the Unit. Con- necting shielded input lines can improve noise resistance.

-

Page 28: Input Wiring Example

Wiring Section If the line breakage occurs at point A or B as shown in the preceding diagram while power is shared by the connected devices, a short-circuit line will be formed as indicated by the dotted line in the above illustration, thus generating a voltage of approximately one-third to two-thirds of the voltage output from the connected device.

-

Page 29: Input Wiring Considerations

IR and DM Areas Section 2-3-5 Input Wiring Considerations When wiring inputs, apply the following points to avoid noise interference and optimize Analog Input Unit performance. • Use shielded twisted-pair cable for external connections and power lines. • Route input cables separately from the AC cable, and do not run the Unit’s cables near a main circuit cable, high voltage cable, or a non-PC load cable.

-

Page 30

IR and DM Areas Section Allocation for Normal For normal mode, set the operation mode switch on the rear panel of the Unit as Mode shown in the following diagram. The allocation of IR words and bits is shown in the following table. Bits Word Output… -

Page 31

IR and DM Areas Section Allocation for For adjustment mode, set the operation mode switch on the rear panel of the Adjustment Mode Unit as shown in the following diagram. When the Unit is set for adjustment mode, the RUN indicator on the front panel of the Unit will flash. The allocation of IR words and bits is shown in the following table. -

Page 32: Dm Allocation And Contents

IR and DM Areas Section 2-4-2 DM Allocation and Contents DM Allocation SYSMAC C200H/C200HS/C200HX/HG/HE PC C200H-AD003 Analog Input Unit Data Memory (DM) Fixed data area DM words DM 1000 to 1099 Unit #0 DM (m) Use designation DM 1100 to 1199 Unit #1 Input signal range Data is automatically…

-

Page 33: Using The Functions

Using the Functions Section Set Values and Stored Values Item Contents Use designation Do not use. Use. Input signal range 00: –10 to 10 V 01: 0 to 10 V 10: 1 to 5 V/4 to 20 mA (See note.) Same as for setting “10”…

-

Page 34: Reading Conversion Values

Using the Functions Section For the DM word addresses, m = 1000 + 100 x unit number (Units #A to #F = Unit numbers 10 to 15). Note After making the DM settings from a Peripheral Device, it will be necessary to either power up the PC again or turn ON the Special I/O Unit Restart Bit in order to transfer the contents of the DM settings to the Special I/O Unit.

-

Page 35: Mean Value Processing

Using the Functions Section 2-5-3 Mean Value Processing The Analog Input Unit can compute the mean value of the conversion values of analog inputs that have been previously sampled. Mean value processing in- volves an operational mean value in the history buffers, so it has no affect on the data refresh cycle.

-

Page 36

Using the Functions Section The history buffer operational means are calculated as shown below. (In this ex- ample there are four buffers.) 1, 2, 3… 1. With the first cycle, the data is stored with Data 1 being in all the history buff- ers. -

Page 37: Peak Value Function

Using the Functions Section 2-5-4 Peak Value Function The peak value function holds the maximum digital conversion value for every input (including mean value processing). This function can be used with analog input. The following diagram shows how digital conversion values are affected when the peak value function is used.

-

Page 38

Using the Functions Section The input disconnection detection signals for each input number are stored in bits 00 to 07 of IR word n+9. Specify these bits as execution conditions in order to use disconnection detection in the user’s program. Word n+9 The respective bit turns ON when a disconnection is detected for a given… -

Page 39: Offset And Gain Adjustment

Offset and Gain Adjustment Section Offset and Gain Adjustment This function is designed to calibrate inputs depending on the devices to be con- nected. 2-6-1 Adjustment Mode Operational Flow The following diagram shows the flow of operations when using the adjustment mode for adjusting offset and gain.

-

Page 40: Offset And Gain Adjustment Procedures

Offset and Gain Adjustment Section Note Input adjustments can be performed more accurately in conjunction with mean value processing. 2-6-2 Offset and Gain Adjustment Procedures Specifying Input Number To specify the input number to be adjusted, write the value to the rightmost byte to be Adjusted of IR word n as shown in the following diagram.

-

Page 41

Offset and Gain Adjustment Section The following example uses input number 1 adjustment for illustration. (The unit number is 0.) 1, 2, 3… 1. Turn ON bit 00 (the Offset Bit) of IR word n+1. (Hold the ON status.) 00000 CONT SHIFT MONTR… -

Page 42

Offset and Gain Adjustment Section While the Offset Bit is ON, the offset value will be saved to the Unit’s EE- PROM when the Set Bit turns ON. 5. To finish the offset adjustment, turn OFF bit 00 (the Offset Bit) of IR word n+1. -

Page 43

Offset and Gain Adjustment Section 2. Check whether the input devices are connected. Voltage input – Input 1 Current input – Input 1 3. Input the voltage or current so that the conversion value is maximized (0FA0 or 07D0). The following table shows the the gain adjustment voltages and currents to be input according to the input signal range. -

Page 44

Offset and Gain Adjustment Section Caution Do not turn OFF the power supply or restart the Unit while the Set Bit is ON (data is being written to the EEPROM). Otherwise, illegal data may be written in the Unit’s EEPROM and “Special I/O Unit Errors” may occur when the power supply is turned ON or when the Unit is restarted, causing a malfunction. -

Page 45: Error Processing

Error Processing Section Note The EEPROM can be overwritten 50,000 times. Error Processing 2-7-1 Troubleshooting Procedure Use the following procedure for troubleshooting Analog Input Unit errors. 1, 2, 3… 1. Error occurs. 2. Is the ERROR indicator lit? Yes: Error detected by Analog Input Unit (Refer to 2-7-2 Errors Detected by Analog Input Unit.) No: Go to the next step.

-

Page 46: Errors Detected By Cpu Unit

Error Processing Section Note Disconnection detection (82) operates for input numbers used with a range of 1 to 5 V (4 to 20 mA). Errors indicated with 8j codes are automatically reset when proper counter- measures are taken. The errors indicated with Fj codes are cleared when the power is turned on after making the correct settings and when the Special I/O Unit Restart Bit is turned OFF, ON, and OFF again.

-

Page 47: Troubleshooting

Error Processing Section Special I/O Unit Restart Bits Bits Functions C200HX/HG/HE C200H/HS Turning the Restart Bit 28100 AR 0100 Unit #0 Restart Bit for any Unit ON and U i ON 28101 AR 0101 Unit #1 Restart Bit then OFF again then OFF again 28102 AR 0102…

-

Page 48

Error Processing Section Conversion Values are Probable cause Countermeasure Page Inconsistent The input signals are being Change the shielded cable affected by external noise. connection to the Unit’s COM terminal. Insert a 0.01-µF to 0.1-µF ceramic capacitor or film capacitor between the input’s (+) and (–) terminals. -

Page 49: Section 3 C200H-Da003 And C200H-Da004 Analog Output Units

SECTION 3 C200H-DA003 and C200H-DA004 Analog Output Units This section provides the information required to install and operate a C200H-DA003 or C200H-DA004 Analog Output Unit. Specifications …………3-1-1 General Specifications .

-

Page 50: Specifications

Specifications Section Specifications 3-1-1 General Specifications All general specifications of the C200H-DA003/DA004 Analog Output Units conform to those of the C200H, C200HS, and C200HX/HG/HE Series. 3-1-2 Performance Specifications Item C200H-DA003 C200H-DA004 Number of analog outputs Output signal range (note 1) 0 to 10 V 4 to 20 mA –10 to 10 V 1 to 5 V…

-

Page 51: Output Specifications

Specifications Section 3-1-3 Output Specifications Range: 1 to 5 V (4 to 20 mA) Analog output signal 5.2 V (20.8mA) 5 V (20mA) 1 V (4mA) 0.8 V (3.2mA) 0000 OFA0 1068 FF38 Resolution: 4,000 Set value (16-bit binary data) Range: 0 to 10 V Analog output signal +10.5 V…

-

Page 52: Nomenclature And Functions

Nomenclature and Functions Section Range: –10 to 10 V Analog output signal +11 V +10V –10 V –11 V 0000 F830 07D0 Resolution: 4,000 0898 F768 Set value (16-bit binary data) Nomenclature and Functions The model shown here is the C200H-DA003 Front Back Model label…

-

Page 53: Indicators

Nomenclature and Functions Section Check to be sure that the black terminal block mounting screw is securely tight- ened to a torque of 0.5 N S m. Fasten the mounting screw. 3-2-1 Indicators The RUN and ERROR indicators show the operating status of the Unit. The fol- lowing table shows the meanings of the indicators.

-

Page 54: Operation Mode Switch

Wiring Section 2. If two or more Special I/O Units are assigned the same unit number, an I/O UNIT OVER error will be generated and the PC will not operate. 3-2-3 Operation Mode Switch The operation mode switch on the back of the Unit is used to set the operation mode to either normal mode or adjustment mode (for adjusting offset and gain).

-

Page 55: Internal Circuitry

Wiring Section Current Output Model (C200H-DA004) Current output 1 (–) Current output 2 (–) Current output 1 (+) Current output 2 (+) Current output 3 (–) Current output 4 (–) Current output 3 (+) Current output 4 (+) Current output 5 (–) Current output 6 (–) Current output 5 (+) Current output 6 (+)

-

Page 56: Output Wiring Examples

Wiring Section 3-3-3 Output Wiring Examples Voltage Output Model (C200H-DA003) C200H-DA003 (Output device) (Output device) Output 1 Output 2 Output 3 Output 4 Output 5 Output 6 Output 7 Output 8 Current Output Model (C200H-DA004) (Output device) C200H-DA004 (Output device) Output 1 Output 2 Output 3…

-

Page 57: Output Wiring Considerations

Wiring Section Note Crimp-type terminals must be used for terminal connections, and the screws must be tightened securely. Use M3 screws and tighten them to a torque of 0.5 N S m. Fork Type M3 screw 6.0 mm max. Round Type 6.0 mm max.

-

Page 58: Ir And Dm Areas

IR and DM Areas Section IR and DM Areas The IR and DM word addresses that each Analog Output Unit occupies are set by the unit number switch on the front panel of the Unit. (For details on setting the unit number, refer to 3-2-2 Unit Number Switch.) 3-4-1 IR Area Allocation and Contents IR Area Allocation…

-

Page 59

IR and DM Areas Section Allocation for Normal For normal mode, set the operation mode switch on the rear panel of the Unit as Mode shown in the following diagram. The allocation of IR words and bits is shown in the following table. Bits Word Output… -

Page 60

IR and DM Areas Section Allocation for For adjustment mode, set the operation mode switch on the rear panel of the Adjustment Mode Unit as shown in the following diagram. When the Unit is set for adjustment mode, the RUN indicator on the front panel of the Unit will flash. The allocation of IR words and bits is shown in the following table. -

Page 61: Dm Allocation And Contents

IR and DM Areas Section 3-4-2 DM Allocation and Contents DM Allocation SYSMAC C200H/C200HS/C200HX/HG/HE PC C200H-DA003/DA004 Analog Output Unit Fixed data area Data Memory (DM) DM words DM 1000 to 1099 Unit #0 DM (m) Use designation DM 1100 to 1199 Unit #1 Output signal Data is automatically…

-

Page 62: Using The Functions

Using the Functions Section 2. For the DM word addresses, m = 1000 + 100 x unit number (Units #A to #F = Unit numbers 10 to 15). Set Values and Stored Values Item Contents Use designation Do not use. Use.

-

Page 63: Output Hold Function

Using the Functions Section For the DM word addresses, m = 1000 + 100 x unit number (Units #A to #F = Unit numbers 10 to 15). This setting is not valid for the C200H-DA004 (current output model). The output signal range for the C200-DA004 is 4 to 20 mA, regardless of the settings.

-

Page 64: Writing Set Values

Using the Functions Section 3-5-3 Writing Set Values Analog output set values are written to IR words n+1 through n+8. Word Function Stored value 16-bit binary data Output 1 set value Output 2 set value Output 3 set value Output 4 set value Output 5 set value Output 6 set value Output 7 set value…

-

Page 65: Output Setting Errors

Using the Functions Section The analog output when conversion is stopped will differ depending on the out- put signal range setting. (Refer to 3-5-1 Setting Outputs and Signal Ranges.) Conversion will not begin under the following conditions even if the Conversion Enable Bit is turned ON.

-

Page 66: Offset And Gain Adjustment

Offset and Gain Adjustment Section Offset and Gain Adjustment This function is designed to calibrate outputs depending on devices to be con- nected. 3-6-1 Adjustment Mode Operational Flow The following diagram shows the flow of operations when using the adjustment mode for adjusting offset and gain.

-

Page 67: Offset And Gain Adjustment Procedures

Offset and Gain Adjustment Section 3-6-2 Offset and Gain Adjustment Procedures Specifying Output To specify the output number to be adjusted, write the value to the rightmost byte Number to be Adjusted of IR word n as shown in the following diagram. (Rightmost) (Leftmost) Word n…

-

Page 68

Offset and Gain Adjustment Section The following example uses output number 1 adjustment for illustration. (The unit number is 0.) 1, 2, 3… 1. Turn ON bit 00 (the Offset Bit) of IR word n+1. (Hold the ON status.) 00000 CONT SHIFT MONTR… -

Page 69

Offset and Gain Adjustment Section Change the set value, using the Up Bit (bit 03 of word n+1) and the Down Bit (bit 02 of word n+1). Word n+1 Up Bit Down Bit While the Up Bit is ON, the resolution will be increased by 1 every 0.5 seconds. -

Page 70

Offset and Gain Adjustment Section 6. To finish the offset adjustment, turn OFF bit 00 (the Offset Bit) of IR word n+1. CONT SHIFT MONTR 10100 10104 ^ ON ^OFF 10100 10104 OFF ^OFF RESET Caution Do not turn OFF the power supply or restart the Unit while the Set Bit is ON (data is being written to the EEPROM). -

Page 71

Offset and Gain Adjustment Section 2. Check whether the output devices are connected. Voltage output Output 1 Current output Output 1 3. Monitor IR word n+8 and check the set value while the Gain Bit is ON. 00000 SHIFT MONTR c108 0FA0 4. -

Page 72

Offset and Gain Adjustment Section CONT SHIFT MONTR 10102 c108 ^OFF 0FA0 The bit will remain ON until the output becomes an appropriate value, at which time, it will turn OFF. 10102 c108 PLAY 0F9F 10102 c108 0F9F RESET 5. Check the 10V/5V/20mA output, and then turn bit 04 (the Set Bit) of IR word n+1 OFF, ON, and then OFF again. -

Page 73

Offset and Gain Adjustment Section Clearing Offset and Gain Follow the procedure outlined below to return the offset and gain adjusted val- Adjusted Values ues to their default settings. The following example uses output number 1 adjustment for illustration. (The unit number is 0.) 1, 2, 3… -

Page 74: Error Processing

Error Processing Section Error Processing 3-7-1 Troubleshooting Procedure Use the following procedure for troubleshooting Analog Input Unit errors. 1, 2, 3… 1. Error occurs. 2. Is the ERROR indicator lit? Yes: Error detected by Analog Output Unit (Refer to 3-7-2 Errors Detected by Analog Output Unit.) No: Go to the next step.

-

Page 75: Errors Detected By Cpu Unit

Error Processing Section 3-7-3 Errors Detected by CPU Unit When the CPU Unit detects an error at a Special I/O Unit, it outputs to the CPU’s SR and AR areas as shown below. Special I/O Unit Error Flag Error Contents CPU Unit status LED indicators 25415…

-

Page 76: Troubleshooting

Error Processing Section Special I/O Unit Restart Bits Bits Functions C200HX/HG/HE C200H/HS Turning the Restart Bit 28100 AR 0100 Unit #0 Restart Bit for any Unit ON and U i ON 28101 AR 0101 Unit #1 Restart Bit then OFF again then OFF again 28102 AR 0102…

-

Page 77: Section 4 C200H-Mad01 Analog I/O Unit

SECTION 4 C200H-MAD01 Analog I/O Unit This section provides the information required to install and operate a C200H-MAD01 Analog I/O Unit. Specifications …………4-1-1 General Specifications .

-

Page 78: Specifications

Specifications Section Specifications 4-1-1 General Specifications All general specifications of the C200H-MAD01 Analog I/O Unit conform to those of the C200H, C200HS, and C200HX/HG/HE Series. 4-1-2 Performance Specifications C200H-MAD01 Item Voltage I/O Current I/O Input Number of analog inputs Input signal range (note 0 to 10 V 4 to 20 mA –10 to 10 V…

-

Page 79: Input Specifications

Specifications Section 4. A/D conversion time is the time it takes for an analog signal to be stored in memory as converted data after it has been input. It takes at least one cycle before the converted data is read by the CPU Unit. D/A conversion time is the time required for converting and outputting the PC data.

-

Page 80: Output Specifications

Specifications Section Range: –10 to 10 V Conversion value (16-bit binary data) 0898 07D0 Resolution: 4,000 0000 F830 F768 –10 V +10 V –11 V +11 V Analog input signal 4-1-4 Output Specifications Range: 1 to 5 V (4 to 20 mA) Analog output signal 5.2 V (20.8mA) 5 V (20mA)

-

Page 81

Specifications Section Range: 0 to 10 V Analog output signal +10.5 V +10 V –0.5 V 0000 OFA0 Resolution: 4,000 FF38 1068 Set value (16-bit binary data) Range: –10 to 10 V Analog output signal +11 V +10 V –10 V –11 V 0000 F830… -

Page 82: Nomenclature And Functions

Nomenclature and Functions Section Nomenclature and Functions Front Back Model label Indicators Unit number setting switch Operation mode switch Terminal block mounting screw (black M3) External input terminal block (M3) Backplane connector The terminal block is attached by a connector. It can be removed by loosening the black mounting screw.

-

Page 83: Unit Number Switch

Nomenclature and Functions Section 4-2-2 Unit Number Switch The CPU Unit and Analog I/O Unit exchange data via the IR area and the DM area. The IR and DM word addresses that each Analog Input Unit occupies are set by the unit number switch on the front panel of the Unit. Always turn off the power before setting the unit number.

-

Page 84: Wiring

Wiring Section Wiring 4-3-1 Terminal Arrangement The signal names corresponding to the connecting terminals are as shown in the following diagram. Voltage output 1 (+) Voltage output 2 (+) Voltage/current output 1 (–) Voltage/current output 2 (–) B1 Current output 1 (+) Current output 2 (+) Current input 1 Current input 2…

-

Page 85: Line Breakage While Using Voltage Input

Wiring Section Output Circuitry (Voltage Output) Output switch and Voltage conversion output (+) circuit Voltage output (–) AG (common to all outputs) Output Circuitry (Current Output) Internal power supply Output switch and conversion circuit Current output (+) Current output (–) AG (common to all outputs) 4-3-3 Line Breakage while Using Voltage Input Con-…

-

Page 86: I/O Wiring Example

Wiring Section If a line breakage occurs while using the voltage input, either separate the power supply from the connected device or use an isolator for each input to avoid the following problem. If the line breakage occurs at point A or B as shown in the preceding diagram while power is shared by the connected devices, a short-circuit line will be formed as indicated by the dotted line in the above illustration, thus generating a voltage of approximately one-third to two-thirds of the voltage output from the…

-

Page 87: I/O Wiring Considerations

Wiring Section 4. Crimp-type terminals must be used for terminal connections, and the screws must be tightened securely. Use M3 screws and tighten them to a torque of 0.5 N S m. Fork Type M3 screw 6.0 mm max. Round Type 6.0 mm max.

-

Page 88: Ir And Dm Areas

IR and DM Areas Section IR and DM Areas 4-4-1 IR Area Allocation and Contents IR Area Allocation SYSMAC C200H/C200HS/C200HX/HG/HE PC C200H-MAD01 Analog I/O Unit (I/O refresh data area) (Work area) Normal Mode Words IR n IR 100 to 109 Unit #0 OUT refresh IR n+4…

-

Page 89

IR and DM Areas Section Allocation for Normal For normal mode, set the operation mode switch on the rear panel of the Unit as Mode shown in the following diagram. The allocation of IR words and bits is shown in the following table. Bits Word Output… -

Page 90

IR and DM Areas Section Allocation for For adjustment mode, set the operation mode switch on the rear panel of the Adjustment Mode Unit as shown in the following diagram. When the Unit is set for adjustment mode, the RUN indicator on the front panel of the Unit will flash. The allocation of IR words and bits is shown in the following table. -

Page 91: Dm Allocation And Contents

IR and DM Areas Section 4-4-2 DM Allocation and Contents DM Allocation SYSMAC C200H/C200HS/C200HX/HG/HE PC C200H-MAD01 Analog I/O Unit (Work area) (Fixed data area) Word I/O conversion DM 1000 to 1099 DM (m) Unit #0 permission loop mode setting DM 1100 to 1199 Unit #1 Input signal range DM 1200 to 1299…

-

Page 92

IR and DM Areas Section DM Allocation Contents The following table shows the allocation of DM words and bits for both normal and adjustment mode. Bits DM word DM (m) Not used. Ratio conversion use Not used. Use desig- Not used. Use desig- designation nation… -

Page 93: Analog Input Functions

Analog Input Functions Section Analog Input Functions 4-5-1 Setting Inputs and Signal Ranges Input Numbers The Analog I/O Unit only converts analog inputs specified by input numbers 1 and 2. In order to specify the analog inputs to be used, turn ON from a Peripheral Device the DM bits shown in the following diagram.

-

Page 94: Reading Conversion Values

Analog Input Functions Section 4-5-2 Reading Conversion Values Analog input conversion values are stored for each input number, in IR words n+5 and n+6. Word Function Stored value Input 1 conversion value 16-bit binary data Input 2 conversion value For the IR word addresses, n = 100 + 10 x unit number. For Units #A to #F (10 to 15), n = 400 + 10 x (unit number –…

-

Page 95

Analog Input Functions Section When mean value processing is used together with the peak value function, the mean value will be held. To specify whether or not mean value processing is to be used, and to specify the number of history buffers for mean data processing, use a Peripheral Device to make the settings in DM m+6 and DM m+7 as shown in the following table. -

Page 96: Peak Value Function

Analog Input Functions Section 4. With the fourth cycle, the Data 4 data is stored in the first history buffer. Data 4 Data 3 (Mean value Conversion value processing) Data 2 Data 1 Mean value = (Data 4 + Data 3 + Data 2 + Data 1) B 4 5.

-

Page 97: Input Disconnection Detection Function

Analog Input Functions Section In the following example, the peak value function is in effect for input number 1, and the unit number is 0. Input condition The maximum 10004 conversion data value is held for input number 1. When mean value processing is used together with the peak value function, the mean value will be held.

-

Page 98: Analog Output Functions

Analog Output Functions Section Analog Output Functions 4-6-1 Setting Outputs and Signal Ranges Output Numbers The Analog Output Units only convert analog outputs specified by output num- bers 1 and 2. In order to specify the analog outputs to be used, use a Peripheral Device to turn ON the DM bits shown in the following diagram.

-

Page 99: Output Hold Function

Analog Output Functions Section 4-6-2 Output Hold Function The Analog I/O Unit stops conversion under the following circumstances, and output the value set by the output hold function. 1, 2, 3… 1. When the Conversion Enable Bit is OFF. (Refer to 4-4-1 IR Area Allocation and Contents and 4-6-4 Starting and Stopping Conversion.) 2.

-

Page 100: Starting And Stopping Conversion

Analog Output Functions Section Use MOV(21) or XFER(70) to write values in the user program. Example 1 In this example, the set value from only one input is read. (The unit number is #0.) Input condition The set value stored in DM 0001 MOV (21) is written to IR word 101 (output DM0001…

-

Page 101: Output Setting Errors

Ratio Conversion Function Section 4-6-5 Output Setting Errors If the analog output set value is outside of the range, a setting error signal will be stored in IR word n+9 (bits 00 and 02). To use disconnection detection with the user’s program, set these bits as execution conditions in the ladder program.

-

Page 102

Ratio Conversion Function Section Negative Gradient (Analog output) = F – A x (Analog input) + B Conversion ∆Y ∆X Analog output ∆Y ∆X Analog input F: Output range maximum A: Ratio set value 0 to 99.99 (BCD) B: Bias 8000 to 7FFF (16-bit binary data) Specifying I/O To specify the use of Loop 1 and Loop 2 and their I/O relationships, set bits 08 to… -

Page 103: Adjustment Mode Operational Flow

Offset and Gain Adjustment Section Offset and Gain Adjustment This function is designed to calibrate inputs or outputs depending on devices to be connected. 4-8-1 Adjustment Mode Operational Flow The following diagram shows the flow of operations when using the adjustment mode for adjusting offset and gain.

-

Page 104: Offset And Gain Adjustment

Offset and Gain Adjustment Section Caution Be sure to turn off the power to the PC before mounting or removing any Units. If the I/O table is registered in the PC, an I/O setting error may occur, not allowing any adjustment. In such a case, either cancel the I/O table or create the I/O table again.

-

Page 105: Input Offset And Gain Adjustment Procedures

Offset and Gain Adjustment Section Offset Adjustment The procedure for adjusting the analog input offset is explained below. As shown in the following diagram, the offset is adjusted by sampling inputs so that the conversion value becomes 0. 0FA0 Input signal range: –10 to 10 V 10 V Offset adjustment input range…

-

Page 106

Offset and Gain Adjustment Section 3. Input the voltage or current so that the conversion value becomes 0000. The following table shows the the offset adjustment voltages and currents to be input according to the input signal range. Input signal range Input voltage/current Input range 0 to 10 V… -

Page 107

Offset and Gain Adjustment Section Gain Adjustment The procedure for adjusting the analog input gain is explained below. As shown in the following diagram, the gain is adjusted by sampling inputs so that the con- version value is maximized. Gain adjustment input range 0FA0 Input signal range: 0 to 10 V… -

Page 108

Offset and Gain Adjustment Section 4. With the voltage or current having been input so that the conversion value for the Analog I/O Unit is maximized (0FA0 or 07D0), turn bit 04 (the Set Bit) of IR word n+1 ON and then OFF again. CONT SHIFT MONTR… -

Page 109

Offset and Gain Adjustment Section 2. Turn bit 04 of IR word n+1 ON and then OFF again. CONT SHIFT MONTR 10104 10105 ^OFF ^ ON 10104 10105 PLAY ^ ON 10104 10105 ^ ON RESET While the Clear Bit is ON, the default offset and gain values will be saved to the Unit’s EEPROM when the Set Bit turns ON. -

Page 110: Output Offset And Gain Adjustment Procedures

Offset and Gain Adjustment Section PRES VAL? c100 0000 ???? c100 0011 WRITE Bits Used for Adjusting The IR word n+1 bits shown in the following diagram are used for adjusting offset Offset and Gain and gain. Word n+1 Offset Adjustment The procedure for adjusting the analog output offset is explained below.

-

Page 111

Offset and Gain Adjustment Section 2. Check whether the output devices are connected. Voltage output Output 1 Current output Output 1 3. Monitor IR word n+8 and check the set value while the Offset Bit is ON. 00000 SHIFT MONTR c108 0000 4. -

Page 112

Offset and Gain Adjustment Section CONT SHIFT MONTR 10102 c108 ^OFF 0000 The bit will remain ON until the output becomes an appropriate value, at which time, it will turn OFF. 10102 c108 PLAY FFFF 10102 c108 FFFF RESET 5. Check the 0V/1V/4mA output, and then turn bit 04 (the Set Bit) of IR word n+1 ON and then OFF again. -

Page 113

Offset and Gain Adjustment Section Gain Adjustment The procedure for adjusting the analog output gain is explained below. As shown in the following diagram, the set value is adjusted so that the analog output is maximized (to 10V/5V/20mA). Gain adjustment output range 10 V Output signal range: 0 to 10 V… -

Page 114

Offset and Gain Adjustment Section 3. Monitor IR word n+8 and check the set value while the Gain Bit is ON. 00000 SHIFT MONTR c108 0FA0 4. Change the set value so that the output voltage and output current are as shown in the following table. -

Page 115

Offset and Gain Adjustment Section 5. Check the 10V/5V/20mA output, and then turn bit 04 (the Set Bit) of IR word n+1 ON and then OFF again. CONT SHIFT MONTR 10104 10102 c108 ^OFF ^ OFF 0F9F 10104 10102 c108 PLAY ^ OFF 0F9F 10104 10102 c108… -

Page 116: Troubleshooting Procedure

Error Processing Section 2. Turn bit 04 of IR word n+1 ON and then OFF again. CONT SHIFT MONTR 10104 10105 ^OFF ^ ON 10104 10105 PLAY ^ ON 10104 10105 ^ ON RESET While the Clear Bit is ON, the default offset and gain values will be saved to the Unit’s EEPROM when the Set Bit turns ON.

-

Page 117: Error Processing

Error Processing Section 4-9-2 Errors Detected by Analog I/O Unit When an error occurs at the Analog I/O Unit, the ERROR indicator on the front panel of the Unit lights and the error code is stored in bits 08 to 15 of IR word n+9. Word n+9 Error code Disconnection…

-

Page 118: Errors Detected By Analog I/O Unit

Error Processing Section 4-9-3 Errors Detected by CPU Unit When the CPU Unit detects an error at a Special I/O Unit, it outputs to the CPU Unit’s SR and AR areas as shown below. Special I/O Unit Error Flag Error Contents CPU Unit status LED indicators…

-

Page 119: Restarting Special I/O Units

Error Processing Section 4-9-4 Restarting Special I/O Units There are two ways to restart Special I/O Unit operation after having changed DM contents or having corrected the cause of an error. The first way is to power up the PC again, and the second way is to turn the Special I/O Unit Restart Bit ON and then OFF again.

-

Page 120

Error Processing Section Value Does Not Change Probable cause Countermeasure Page as Intended The input device’s signal range Check the specifications of the does not match the input signal input device, and match the range for the relevant input number settings for the input signal ranges. -

Page 121: A Dimensions

Appendix A Dimensions External Dimensions Unit: mm C200H-AD003 C200H-DA003 C200H-DA004 C200H-MAD01 100.7 34.5 126.2…

-

Page 122: B Changes From Earlier Models

Appendix B Changes From Earlier Models Differences Between C200H-AD003 and C200H-AD001/AD002 Functions Conversion Permission Setting With the C200H-AD003, in contrast to the C200H-AD001/002, use designation inputs must be set in advance to “1: Use.” A/D Conversion Data Identification Setting Only the C200H-AD002 has this function; the C200H-AD003 does not. Data is always output in 16-bit binary, and a BCD display can be created using a ladder program.

-

Page 123

Changes From Earlier Models Appendix B Error Codes Error codes have been provided for the C200H-AD003. DM area setting errors and errors during operation are stored in the IR area when the ERR indicator lights. (Refer to 2-7-2 Errors Detected by Analog Input Unit.) BROKEN WIRE Indicator The C200H-AD003 does not have a BROKEN WIRE indicator. -

Page 124: C Sample Programs

Appendix C Sample Programs Sample Program 1: Obtaining Analog Input Unit Conversion Values This is a program for obtaining the Analog Input Unit’s conversion values. Individual input values are obtained by MOV(21) when their Disconnection Detection Flags turn OFF. (With the C200H-AD003, there are no causes for errors in normal mode other than disconnections, so a disconnection can be determined merely by seeing that bit 15 of word 109 is ON.) Unit Settings…

-

Page 125

Sample Programs Appendix C Program Example Execution condition MOV(21) DM0000 Set value Reset condition 10915 Output Setting Error Flag Output Setting Error Flag Sample Program 3: Upper- and Lower-limit Alarm (Regular Monitoring) Comparisons are made to the upper and lower limits of the A/D conversion values or D/A output values from the beginning of operation. -

Page 126

Sample Programs Appendix C Program Example The following program can be executed only with the C200HS, C200HX/HG/HE CPU Units. Operation condition ZCP(88) Conversion value Lower limit (16-bit binary) DM0000 Upper limit (16-bit binary) DM0001 25506(=) 25503((ERR) Alarm Flag Sample Program 4: Upper- and Lower-limit Alarm (With Sequence) Comparisons are made to the upper and lower limits of the A/D conversion values or D/A output values after the value falls within the range between the upper limit and lower limit following the beginning of operation. -

Page 127

Sample Programs Appendix C Sample Program 5: Scaling A/D conversion values are converted into BCD data whose full scale is set by the lower-limit value data and upper- limit value data and retrieved as scaling data. The DM 0000 value will vary depending on the input signal range of the input number subject to scaling. -

Page 128

Sample Programs Appendix C • DM Area Setting Digital value for –5% DM0000: 00C8 DM0001: (Used for calculation) Conversion value +C8 (-5% portion) DM0002: 0000 Lower limit: BCD DM0003: 0000 Lower limit +C8 (-5% portion): BIN DM0004: 4400 Upper limit: BCD Used with SCL instruction DM0005: 1130 Upper limit +C8 (+5% portion): BIN… -

Page 129

Sample Programs Appendix C • DM Area Setting DM0000: 00C8 Digital value for –5% DM0001: (Used for calculation) Conversion value +C8 (-5% portion) DM0002: 0100 Lower limit: BCD DM0003: 0000 Lower limit +C8 (-5% portion): BIN DM0004: 0500 Upper limit: BCD Used with SCL instruction DM0005: 1130 Upper limit +C8 (-5% portion): BIN… -

Page 130

Sample Programs Appendix C Program Example The following program can be executed only with the C200HS, C200HX/HG/HE CPU Units. • Data Flow (Unit Number 0): Word 101 (AD Conversion Value) → Words 201 and 202 (Conversion Results) Execution condition MOV(21) 16-bit binary data DM0000 MOV(21) -

Page 131

Sample Programs Appendix C Program Example The following program can be executed only with the C200HS, C200HX/HG/HE CPU Units. • Data Flow (Unit Number 0): Word 101 (AD Conversion Value) → Word 200 (Calculation Result) Execution condition ADB(50) Conversion value + Negative number DM0000 DM0001… -

Page 132

Sample Programs Appendix C Program Example The following program can be executed only with the C200HS, C200HX/HG/HE CPU Units. • Data Flow (Unit Number 0): Word 101 (AD Conversion Value) → DM 0001 (Mean Value Result) Execution condition Conversion value #101 Number of samplings #0064… -

Page 133: D Data Memory Coding Sheet

Appendix D Data Memory Coding Sheet C200H-AD003 Setting contents DM word DM jj00 DM jj01 DM jj02 DM jj03 DM jj04 DM jj05 DM jj06 DM jj07 DM jj08 DM jj09…

-

Page 134

Data Memory Coding Sheet Appendix D Setting contents DM word Use designation Use Designation Input signal range setting Input 1: Mean value processing setting Input 2: Mean value processing setting 0: Do not use. Input 3: Mean value processing setting 1: Use. -

Page 135

Data Memory Coding Sheet Appendix D C200H-DA003/DA004 Setting contents DM word DM jj00 DM jj01 DM jj02 DM jj03 DM jj04 DM jj05 DM jj06 DM jj07 DM jj08 DM jj09… -

Page 136

Data Memory Coding Sheet Appendix D Setting contents DM word Use designation Use Designation Output signal range setting Output 1: Output status when con- version stopped Output 2: Output status when con- version stopped Output 3: Output 0: Do not use. status when con- 1: Use. -

Page 137

Data Memory Coding Sheet Appendix D C200H-MAD01 Setting contents DM word DM jj00 DM jj01 DM jj02 DM jj03 DM jj04 DM jj05 DM jj06 DM jj07 DM jj08 DM jj09 DM jj10 DM jj11 DM jj12 DM jj13… -

Page 138

Data Memory Coding Sheet Appendix D Use Designation Setting contents DM word 0: Do not use. 1: Use Loop use Input use Output use designation designation designation Input signal Output signal range setting range setting Output 1: Output status when conversion stopped Output 2: Output status 00: Do not use. -

Page 139: Index

Index CPU Unit, Special I/O Unit Error Flag C200H-AD003, 34 C200H-DA003, 63 A constant, 91 C200H-DA004, 63 C200H-MAD01, DM set value, 80 C200H-MAD01, 107 adjustment mode crimp-type terminals, torque C200H-AD003, IR area allocation, 19 C200H-AD003, 16 C200H-DA003, IR area allocation, 48 C200H-DA003, 45 C200H-DA004, IR area allocation, 48 C200H-DA004, 45…

-

Page 140

Index F–G C200H-AD003, 11 DM set value, 21 setting, 21 field devices, 4 C200H-MAD01, 67 DM set value, 80 gain adjustment function, 3 setting, 81 bits used C200H-AD003, 28 inputs C200H-DA003, 55 C200H-AD003 C200H-DA004, 55 IR adjustment mode set value, 19 C200H-MAD01 for input, 93 setting, 21 C200H-MAD01 for output, 99… -

Page 141

Index nomenclature output signal ranges C200H-AD003, 12 C200H-DA003, 39 C200H-DA003, 40 DM set value, 50 setting, 50 C200H-DA004, 40 C200H-DA004, 39 C200H-MAD01, 70 DM set value, 50 normal mode setting, 50 C200H-AD003, IR area allocation, 18 C200H-MAD01, 68 C200H-DA003, IR area allocation, 47 DM set value, 80 C200H-DA004, IR area allocation, 47 setting, 86… -

Page 142

Index settings, procedure, 8 troubleshooting C200H-AD003, 33, 35 signal names C200H-DA003, 62, 64 C200H-AD003, 14 C200H-DA004, 62, 64 C200H-DA003, 42 C200H-MAD01, 105, 108 C200H-DA004, 43 C200H-MAD01, 72 Slave Racks, 5 U–W Special I/O Unit Error Flags C200H-AD003, 34 unit number switch, 7 C200H-DA003, 63 C200H-AD003, 13 C200H-DA004, 63… -

Page 143: Revision History

Revision History A manual revision code appears as a suffix to the catalog number on the front cover of the manual. Cat. No. W325-E1-04 Revision code The following table outlines the changes made to the manual during each revision. Page numbers refer to the previous version.

-

Page 144

Wegalaan 67-69, NL-2132 JD Hoofddorp The Netherlands Tel: (31)2356-81-300/Fax: (31)2356-81-388 OMRON ELECTRONICS LLC 1 East Commerce Drive, Schaumburg, IL 60173 U.S.A. Tel: (1)847-843-7900/Fax: (1)847-843-8568 OMRON ASIA PACIFIC PTE. LTD. 83 Clemenceau Avenue, #11-01, UE Square, Singapore 239920 Tel: (65)6835-3011/Fax: (65)6835-2711… -

Page 145

Authorized Distributor: Cat. No. W325-E1-04 Note: Specifications subject to change without notice. Printed in Japan…

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- 61

- 62

- 63

- 64

- 65

- 66

- 67

- 68

- 69

- 70

- 71

- 72

- 73

- 74

- 75

- 76

- 77

- 78

- 79

- 80

- 81

- 82

- 83

- 84

- 85

- 86

- 87

Cat.No. W303–E1–4

Programmable Controllers

C200HX/C200HG/C200HE

OPERATION MANUAL

C200HX/C200HG/C200HE

Programmable Controllers

Operation Manual

Revised June 2000

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

! DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

! WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

! Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means “word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PC” means Programmable Controller and is not used as an abbreviation for anything else.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of information.

Note Indicates information of particular interest for efficient and convenient operation of the product.

1, 2, 3… 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

OMRON, 1996

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

v

TABLE OF CONTENTS

|

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xiii |

|

|

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xiv |

|

|

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xiv |

|

|

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xiv |

|

|

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xv |

|

|

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xv |

|

|

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

xvii |

|

|

SECTION 1 |

||

|

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

|

|

1-1 |

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

|

1-2 |

The Origins of PC Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

|

1-3 |

PC Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3 |

|

1-4 |

OMRON Product Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 |

|

1-5 |

Overview of PC Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 |

|

1-6 |

Peripheral Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 |

|

1-7 |

Available Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

|

1-8 |

C200HX/HG/HE Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

|

SECTION 2 |

||

|

Hardware Considerations . . . . . . . . . . . . . . . . . . . . . . . . . |

11 |

|

|

2-1 |

CPU Unit Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

12 |

|

2-2 |

PC Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

15 |

|

2-3 |

CPU Unit Capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

15 |

|

2-4 |

Memory Cassettes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

16 |

|

2-5 |

CPU Unit DIP Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

20 |

|

2-6 |

Operating without a Backup Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

21 |

|

SECTION 3 |

||

|

Memory Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

23 |

|

|

3-1 |

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

24 |

|

3-2 |

Data Area Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

25 |

|

3-3 |

IR (Internal Relay) Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

29 |

|

3-4 |

SR (Special Relay) Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

33 |

|

3-5 |

AR (Auxiliary Relay) Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

48 |

|

3-6 |

DM (Data Memory) Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

56 |

|

3-7 |

HR (Holding Relay) Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

68 |

|

3-8 |

TC (Timer/Counter) Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

68 |

|

3-9 |

LR (Link Relay) Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

69 |

|

3-10 |

UM Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

70 |

|

3-11 |

TR (Temporary Relay) Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

71 |

|

3-12 |

EM (Extended Data Memory) Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

71 |

|

SECTION 4 |

||

|

Writing and Inputting the Program . . . . . . . . . . . . . . . . . |

73 |

|

|

4-1 |

Basic Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

74 |

|

4-2 |

Instruction Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

74 |

|

4-3 |

Program Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

75 |

|

4-4 |

Basic Ladder Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

75 |

|

4-5 |

The Programming Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

88 |

|

4-6 |

Preparation for Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

91 |

|

4-7 |

Inputting, Modifying, and Checking the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

104 |

vii

TABLE OF CONTENTS

|

4-8 |

Controlling Bit Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

120 |

|

4-9 |

Work Bits (Internal Relays) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

122 |

|

4-10 |

Programming Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

124 |

|

4-11 |

Program Execution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

126 |

|

4-12 |

Special I/O Unit Interface Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

126 |

|

4-13 |

Analog Timer Unit Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

130 |

|

SECTION 5 |

||

|

Instruction Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

135 |

|

|

5-1 |

Notation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

138 |

|

5-2 |