Терморегулятор Omron E5CC относится к новому поколению устройств контроля температуры. Установка этого оборудования гарантирует точность регулировки и поддержание работы обжиговых и лабораторных печей.

Содержание

-

- Как правильно подключить терморегулятор Omron E5CC к муфельной печи

- Почему стоит установить терморегулятор Omron E5CC на муфельную печь

Регулятор Omron способен работать даже в условиях повышенной влажности

Японские терморегуляторы не зря считаются самыми высокоточными в мире. Достаточно посмотреть на перечень их достоинств:

- Жидкокристаллический дисплей. Монитор этой модели отличается увеличенными размерами, наличием подсветки и повышенной контрастностью изображения. Благодаря этому информация будет видна с большого расстояния и под разными углами.

- Производительность работы. Главные характеристики регуляторов – это скорость и точность измерения. Иногда от колебания температуры всего в несколько градусов может зависеть конечный результат исследований. Алгоритм работы регулятора Omron E5CC позволяет поддерживать выставленные параметры в пределах 0,5°С.

- Легкость управления. Автоматическая настройка намного уменьшит затраты времени, а также максимально упростит регулирование температуры во время работы.

- Компактность. Данный прибор можно устанавливать на любые муфельные электропечи SNOL.

Цитата: Во время устранения загрязнений после работы печи, регулятор также можно очищать. Для этого используются неагрессивные моющие средства

Как правильно подключить терморегулятор Omron E5CC к муфельной печи

Изучив инструкцию на русском про терморегулятор Omron E5CC, можно сделать вывод, что это устройство не сложное в эксплуатации. Для любых этапов работы – подключения, настройки или пользования достаточно сделать всего несколько простых шагов. Все операции проводятся путем нажатия клавиш с интуитивно понятными значениями.

Оптимальная температура окружающей среды во время работы прибора – не выше 45 градусов Цельсия

Для регулятора Omron E5CC инструкция на русском языке предусматривает возможность установки на разное оборудование – промышленное, бытовое и лабораторное. В их число входят, в том числе, муфельные печи и сушильные шкафы. При первичном подключении руководством по эксплуатации предусмотрены такие меры:

- Убедиться, что упаковка и сам прибор не носят следы повреждений.

- Осмотреть вентиляционные отверстия вокруг места для монтажа терморегулятора – они должны оставаться свободными для отвода тепла.

- Не стоит сильно затягивать клеммные зажимы.

- Необходимо правильно подсоединить входы питания.

- В месте установки обеспечить отсутствие жидкостей и посторонних предметов.

Если терморегулятор будет подвергаться постоянному нагреву, нужно позаботиться о дополнительном охлаждении или вентиляции

Опишем процесс монтажа на панель электропечи и особенности настройки Omron E5CC:

- Вставить устройство в специальное отверстие.

- Для обеспечения водонепроницаемости использовать прокладку.

- Предварительно закрепить регулятор, надев переходник от клеммного блока.

- Поочередно затянуть два крепежных винта.

Для подключения терморегулятора к компьютеру используется стандартный кабель USB

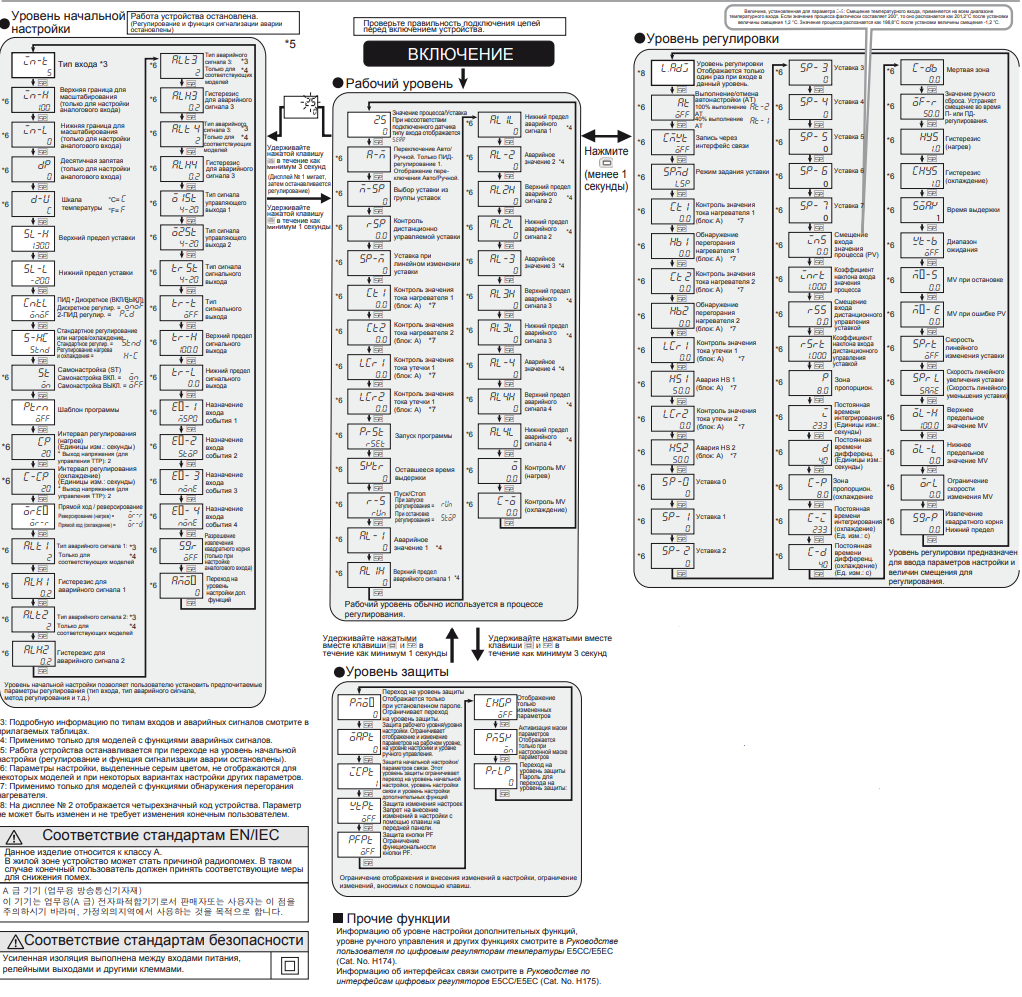

После включения питания на дисплее автоматически отображается эксплуатационный уровень. Чтобы изменить параметры, нужно перейти на одну из таких систем настроек:

- Первоначальной подготовки.

- Регулирования.

- Расширенной функциональности.

- Передачи информационных данных.

При выставлении настроек не забудьте выбрать единицы измерения температуры — ºC или °F

Какие функции еще входят в инструкцию по программированию Omron E5CC, наглядно можно посмотреть в представленном видео:

Почему стоит установить терморегулятор Omron E5CC на муфельную печь

Как видим, терморегулятор Omron E5CC способен контролировать множественные рабочие функции лабораторных печей. Его отличительными особенностями являются:

- 2Пид-регулирование.

- Наличие аналоговых входов.

- Небольшие габариты.

- Возможность использования интерфейса RS-485.

- Датчики сигналов о неисправностях.

- Работа с термопарами разных типов.

- Простая инструкция по настройке и управлению.

- Контрастный ЖК-дисплей с крупноразмерными цифрами, видными издалека.

Любые лабораторные исследования или работа с образцами предусматривают точное соблюдение температурных параметров. Использование терморегуляторов Omron E5CC дает возможность обеспечить необходимые условия для проведения опытов.

Производитель обеспечивает техническую поддержку для устройств любого типа. Сотрудники более 200 сервисных центров по всему миру помогут быстро устранить неисправности и произвести замену нужных деталей.

Еще один бонус – гарантия единой цены на устройства во всех странах

По всем вопросам эксплуатации и приобретения терморегуляторов обращайтесь в компанию «Лабор».

Предписание

В этом руководстве описаны функции, рабочие параметры и области применения для оптимального использования продукта. Пожалуйста, соблюдайте следующие правила при использовании этого продукта:

• Этот продукт предназначен для использования только квалифицированным персоналом, знакомым с электрическими системами.

• Внимательно прочтите и усвойте содержание данного руководства перед использованием оборудования, чтобы обеспечить правильную работу оборудования.

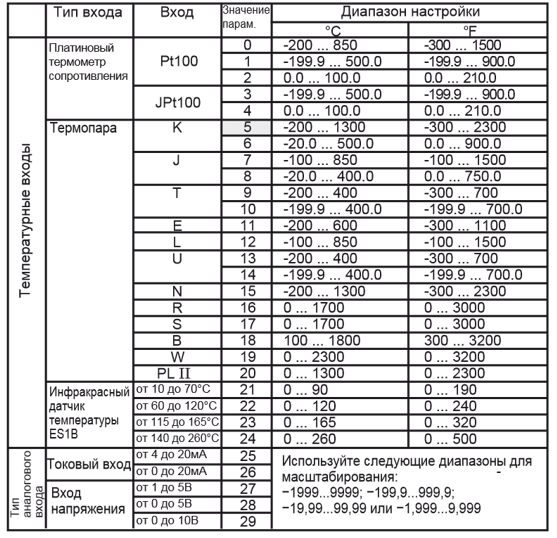

Типы подключаемых датчиков и входов

Примечание:

- Значение по умолчанию: 5.

- S.ERR отображается, если при подключении платинового термометра сопротивления

соответствующим образом не будет настроен тип входа. Для снятия отображения S.ERR необходимо правильно выполнить подсоединения при этом выключить и снова включить

питание.

Программирование и настройка прибора

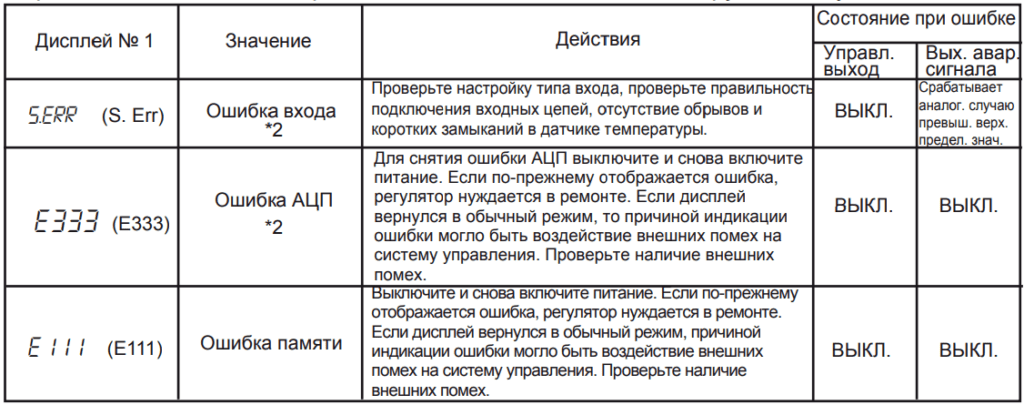

Список возможных ошибок

В случае возникновения ошибки на дисплее № 1 отображается код ошибки.

Примите необходимые меры в соответствии с кодом ошибки, руководствуясь таблицей ниже.

Примечание:

Если входной сигнал находится в пределах диапазона регулирования, но выходит за диапазон отображения значений на дисплее (-1999…9999), на дисплее отобразится [[[[, если значение меньше -1999, и ]]]], если значение больше 9999. При такой индикации выходы управления и сигнализации аварий работают в своем обычном режиме.

*2: Ошибка отображается только в режиме «Значение процесса / Уставка».

В других режимах ошибка не отображаются.

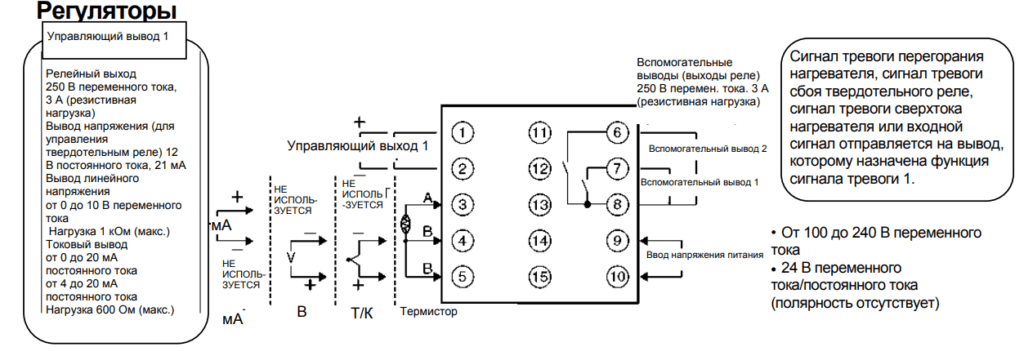

Схема подключения прибора

Внимание!

Выход напряжения (выход управления срабатыванием твердотельного реле) не изолирован гальванически от внутренних цепей. При использовании заземленной термопары не подключайте к земле какие-либо управляющие выходные клеммы. Если клеммы выхода управления подключен к земле, измеренные значения температуры будут неправильными из-за тока утечки.

Скачать полную документацию.

RU

E5CC

Digital Controller

EN

INSTRUCTION MANUAL

Thank you for purchasing the OMRON E5CC Digital Controller.

This manual describes the functions, performance, and

application methods needed for optimum use of the product.

Please observe the following items when using the product.

• This product is designed for use by qualified personnel with

a knowledge of electrical systems.

• Before using the product, thoroughly read and understand

this manual to ensure correct use.

• Keep this manual in a safe location so that it is available for

reference whenever required.

OMRON Corporation

©All Rights Reserved

Refer to the E5□C Digital Controllers User’s Manual (Cat. No. H174)

for detailed application procedures.

Safety Precautions

Key to Warning Symbols

Indicates a potentially hazardous situation which, if

not avoided, is likely to result in minor or moderate

injury or property damage. Read this manual

CAUTION

carefully before using the product.

5377443-6A

CC1

Wiring

Dimensions

Dimensions (mm)

Solderless terminal size

(64)

4

60

48×48

1

* Do not remove the terminal block. Doing so may result in failure or malfunction.

* A Setup Tool port is provided on the upper of the product. Use this port to connect a personal computer to the product when using

the Setup Tool. E58-CIFQ2 USB-Serial Conversion Cable is required to connect the personal computer to the product. (Do not use

the product with the USB-Serial Conversion Cable left permanently connected.)

Refer to the instruction manual provided with the USB-Serial Conversion Cable for details on connection methods.

Names of Parts on Front Panel

• °C / °F : temperature unit

The temperature unit is displayed when the displayed value

is a temperature. Either C or F is displayed according to

the set value of the temperature unit.

•

Level key

Use this key to change levels:

•

Mode key

Press this key to change the contents of the display.

Press this button for 1 s or longer for reverse scroll.

• Press the O key and the M key together for at

least 3 seconds to switch to protect level.

• Shift key (PF key)

The default PF Setting parameter is for shifting the digit.

This is a function key. When it is pressed, the function

set for the PF Setting parameter will operate.

Operation Menu

Input Type

Input type

Input

Setting

Setting range

°C

°F

0

-200 to 850

-300 to 1500

Platinum

Pt100

1

resistance

-199.9 to 500.0

-199.9 to 900.0

thermometer

2

0.0 to 100.0

0.0 to 210.0

3

-199.9 to 500.0

-199.9 to 900.0

JPt100

4

0.0 to 100.0

0.0 to 210.0

K

5

-200 to 1300

-300 to 2300

Thermocouple

6

-20.0 to 500.0

0.0 to 900.0

J

7

-100 to 850

-100 to 1500

8

-20.0 to 400.0

0.0 to 750.0

T

9

-200 to 400

-300 to 700

10

-199.9 to 400.0

-199.9 to 700.0

11

-200 to 600

-300 to 1100

E

L

12

-100 to 850

-100 to 1500

U

13

-200 to 400

-300 to 700

14

-199.9 to 400.0

-199.9 to 700.0

N

15

-200 to 1300

-300 to 2300

R

16

0 to 1700

0 to 3000

S

17

0 to 1700

0 to 3000

B

18

100 to 1800

300 to 3200

W

19

0 to 2300

0 to 3200

PL II

20

0 to 1300

0 to 2300

21

0 to 90

0 to 190

Infrared

10 to 70°C

22

Thermosensor

60 to 120°C

0 to 120

0 to 240

ES1B

115 to 165°C

23

0 to 165

0 to 320

140 to 260°C

24

0 to 260

0 to 500

4 to 20mA

25

Current input

0 to 20mA

Use the following ranges for scaling: -1999

26

to 9999, -199.9 to 999.9, -19.99 to 99.99,

1 to 5V

27

Voltage input

0 to 5V

28

-1.999 to 9.999

0 to 10V

29

*The default is»5″.

*s. e rr will be displayed when a platinum resistance thermometer is mistakenly connected

while input type is not set for it. To clear the s. e rr display, correct the wiring and cycle the

power supply.

Alarms

Alarm output function

Alarm type

Setting

Positive alarm value (X) Negative alarm value (X)

0

No alarm function

Output off

Vary with

*1

Deviation upper/lower limit

1

«L», «H» values

X

X

Deviation upper limit

ON

ON

2

OFF

OFF

SP

SP

X

ON

Deviation lower limit

ON

3

OFF

OFF

SP

SP

L H

Vary with

ON

*1

Deviation upper/lower range

4

«L», «H» values

OFF

SP

Deviation upper/lower limit

L H

Vary with

*1

5

ON

«L», «H» values

standby sequence ON

OFF

SP

X

X

Deviation upper limit

ON

ON

6

OFF

standby sequence ON

OFF

SP

SP

X

Deviation lower limit

ON

ON

7

standby sequence ON

OFF

OFF

SP

SP

X

X

ON

ON

8

Absolute value upper limit

OFF

OFF

0

X

X

ON

ON

9

Absolute value lower limit

OFF

OFF

0

X

Absolute value upper limit

ON

ON

10

OFF

OFF

standby sequence ON

0

X

Absolute value lower limit

ON

11

ON

standby sequence ON

OFF

OFF

0

12

LBA (only for alarm 1)

13

PV Change Rate Alarm

X

ON

ON

14

SP absolute value upper limit

OFF

OFF

0

X

ON

15

SP absolute value lower limit

ON

OFF

OFF

0

X

ON

ON

16

MV absolute value upper limit

OFF

OFF

0

X

ON

MV absolute value lower limit

ON

17

OFF

OFF

0

X

ON

ON

18

RSP absolute value upper limit

OFF

OFF

0

X

ON

19

RSP absolute value lower limit

ON

OFF

OFF

0

*1: Upper and lower limits can be set for parameters 1, 4 and 5 to

provide for different types of alarm. These are indicated by the

letter «L» and «H».

• The default alarm type is «2»

Conformance to EN/IEC Standards

This is a class A product.

In residential areas it may cause radio interference, in which case the user

may be required to take adequate measures to reduce interference.

A 급 기기 (업무용 방송통신기자재)

이 기기는 업무용(A 급) 전자파적합기기로서 판매자또는 사용자는 이 점을

주의하시기 바라며, 가정외의지역에서 사용하는 것을 목적으로 합니다.

Warning Symbols

CAUTION

Minor injury due to electric shock may occasionally occur.

Do not touch the terminals while power is being supplied.

Electric shock, fire, or malfunction may occasionally occur. Do not allow metal objects, conductors,

cuttings from installation work, or moisture to enter the Digital Controller, the Setup Tool ports, or

between the pins on the connectors on the Setup Tool cable.

Do not use the product where subject to flammable or explosive gas. Otherwise, minor injury from

explosion may occasionally occur.

Never disassemble, modify, or repair the product or touch any of the internal parts. Minor electric

shock, fire, or malfunction may occasionally occur.

CAUTION — Risk of Fire and Electric Shock

a) This is the product UL listed as Open Type Process Control Equipment. It must be mounted in an enclosure

that does not allow fire to escape externally.

b) More than one disconnect switch may be required to de-energize the equipment before servicing.

c) Signal inputs are SELV, limited energy.

d) Caution: To reduce the risk of fire or electric shock, do not interconnect the outputs of different Class 2 circuits.

If the output relays are used past their life expectancy, contact fusing or burning may occasionally occur.

Always consider the application conditions and use the output relays within their rated load and

electrical life expectancy. The life expectancy of output relays varies considerably with the output load

and switching conditions.

Loose screws may occasionally result in fire. Tighten the terminal screws to the specified torque of 0.43

to 0.58 N•m.

Set the parameters of the product so that they are suitable for the system being controlled. If they are

not suitable, unexpected operation may occasionally result in property damage or accidents.

A malfunction in the Digital Controller may occasionally make control operations impossible or prevent

alarm outputs, resulting in property damage. To maintain safety in the event of malfunction of the Digital

Controller, take appropriate safety measures, such as installing a monitoring device on a separate line.

Suitability for Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations which

apply to the combination of the Product in the Buyer’s application or use of the Product.

At Buyer’s request, Omron will provide applicable third party certification documents identifying ratings and

limitations of use which apply to the Product. This information by itself is not sufficient for a complete

determination of the suitability of the Product in combination with the end product, machine, system, or

other application or use. Buyer shall be solely responsible for determining appropriateness of the particular

product with respect to Buyer’s application, product or system. Buyer shall take application responsibility in

all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Installation

Individual mounting (mm)

M3

In the pack:

44.8×44.8

*Main unit

*Instruction manual

*Watertight packing (Y92S-P8):

*Adapter (Y92F-49):

*Terminal cover (Provided only for

+0.6

□□□□

□

models with E5CC-

5

):

45

0

Sold Separately

*Terminal cover (E53-COV23)

*USB-Serial Conversion Cable

(E58-CIFQ2)

• Insert the main unit through the mounting hole in the panel (1 to 5 mm thickness). Insert the

mounting brackets (supplied) into the fixing slots located on the top and bottom of the rear

case.

• Tighten the two mounting screws on the top and bottom of the adapter to keep them

balanced, and finally tighten them to a torque of between 0.29 and 0.39 N·m.

• When more than one machine is installed, make sure that the ambient temperature does

not exceed the specified limit.

Operation indicators

•

• SUB1: Auxiliary output 1 indicator

No.1 display

• SUB2: Auxiliary output 2 indicator

Process value or set data type

• SUB3: Auxiliary output 3 indicator

• OUT1: Control output 1 indicator

•

• OUT2: Control output 2 indicator

No.2 display

Set point, set data read-out value or changed input

•

RSP: Remote SP indicator

value

Lit when the assigned function is ON.

•

Up and Down keys

•

Each press of U key increments or advances the

TUNE:

values displayed on the No.2 display.

Flashing during self-tuning.

Each press of D key decrements or returns the

Lit during auto-tuning.

values displayed on the No.2 display.

Operation stopped.

Initial Setting Level

(Control/alarm are both stopped.)

alt3

in-t

Alarm 3

Input Type *3

*6

2

Type

5

M

M

Scaling Upper Limit

in-h

alh3

Alarm 3

(only when setting

*6

*6

Hysteresis

100

0.2

analog input)

M

M

Scaling Lower Limit

alt4

in-l

Alarm 4

(only when setting

*6

*6

Type

0

2

analog input)

M

M

Decimal Point

dp

alh4

Alarm 4

(only when setting

*6

*6

Hysteresis

0

0.2

analog input)

M

M

c

°C=

o1st

d-u

Temperature

Control Output 1

f

*6

*6

°F=

Unit

Signal

c

4-20

M

M

trst

sl-h

Transfer

*6

SP Upper Limit

Output Signal

4-20

1300

M

M

tr-t

sl-l

Transfer

SP Lower Limit

*6

Output Type

off

-200

M

M

PID•ON/OFF

tr-h

cntl

Transfer Output

onof

In ON/OFF control =

*6

100.0

onof

Upper Limit

pid

In 2-PID control =

M

M

Standard or Heating/Cooling

tr-l

s-hc

Transfer Output

stnd

*6

Standard control =

Lower Limit

0.0

stnd

h-c

Heating and cooling control =

M

M

ev-1

st

ST (Self-Tuning)

Event Input

*6

*6

on

Assignment 1

ST ON =

msp0

on

ST OFF =

off

M

M

ev-2

ptrn

Event Input

Program Pattern

*6

Assignment 2

stop

off

M

M

cp

Control Period (Heating)

ev-3

Event Input

*6

*6

(Unit: Seconds)

Assignment 3

none

20

*Voltage output (for driving SSR): 2

M

M

ev-4

c-cp

Control Period (Cooling)

Event Input

*6

*6

(Unit: Seconds)

Assignment 4

none

20

*Voltage output (for driving SSR): 2

X

M

M

Extraction of Square

orev

Direct/Reverse Operation

sqr

Root Enable

or-r

*6

In Reverse operation (Heating) =

(Only when analog

or-r

off

input is set)

or-d

In Direct operation (Cooling) =

M

M

alt1

amov

Move to Advanced

Alarm 1 Type:

*3

*6

Function Setting

*6

Specified models only

2

*4

0

Level

M

M

alh1

X

Alarm 1 Hysteresis

*6

0.2

M

alt2

Alarm 2 Type:

0

*3

*6

Specified models only

2

*4

M

0

X

alh2

Alarm 2 Hysteresis

*6

0

0.2

X

M

0

Initial setting level enables users to specify their preferred

operating conditions (input type, alarm type, control method, etc.)

*3: Refer to the adjoining tables for details of input types and alarm types.

X

*4: Applicable only to models with alarm functions.

*5: Operation is stopped when moved to the initial setting level.

0

(control/alarm are both stopped.)

X

*6: The grayed-out setting items are not displayed for some models and

0

some settings of other setting items.

X

*7: Applicable only to models with heater burnout functions.

0

*8: The four numeric digits of the product code are displayed in the No. 2

X

display. The setting cannot be changed and there is nothing that you

need to set.

0

X

0

Conformance to Safety Standard

X

0

Reinforced insulation is provided between input power

supply, relay outputs, and between other terminals.

Due to UL Listing requirements, use the E54-CT1L or E54-CT3L

current transformer with the factory wiring (internal wiring).

Use a UL category XOBA or XOBA7 current transformer that is UL

Listed for field wiring (external wiring) and not the factory wiring

(internal wiring).

Always externally connect the recommended fuse that is specified

in the Instruction Manual before you use the Digital Controller.

Analog Input

• If you input an analog voltage or current, set the Input Type

parameter to the correct input type.

• Do not use the Digital Controller to measure a circuit with

Measurement Category II, III, or IV.

• Do not use the Digital Controller to measure an energized circuit to

which a voltage that exceeds 30 Vms or 60 VDC is applied.

The protection provided by the Digital Controller may be impaired if the

Digital Controller is used in a manner that is not specified by the

manufacturer.

Precautions for Safe Use

Be sure to observe the following precautions to prevent operation failure, malfunction, or adverse affects on the

performance and functions of the product. Not doing so may occasionally result in unexpected events.

Use the product within specifications.

(1) The product is designed for indoor use only. Do not use the product outdoors. Do not use or store the product

in any of the following locations.

•Places directly subject to heat radiated from heating equipment.

•Places subject to splashing liquid or oil atmosphere.

•Places subject to direct sunlight.

•Places subject to dust or corrosive gas (in particular, sulfide gas and ammonia gas).

•Places subject to intense temperature change.

•Places subject to icing and condensation.

•Places subject to vibration and large shocks.

(2) Use/store within the rated temperature and humidity ranges. Provide forced-cooling if required.

(3) To allow heat to escape, do not block the area around the product.

Do not block the ventilation holes on the product.

(4) Be sure to wire properly with correct polarity of terminals.

(5) Use the specified size of crimped terminals (M3, width 5.8 mm or less) for wiring. To connect bare wires to the

terminal block, use copper braided or solid wires with a gage of AWG24 to AWG18 (equal to cross- sectional

area of 0.205 to 0.8231 mm

2

). (The stripping length is 6 to 8 mm.) Up to two wires of same size and type, or

two crimped terminals can be inserted into a single terminal.

(6) Do not wire the terminals which are not used.

(7) Allow as much space as possible between the controller and devices that generate a powerful high- frequency

or surge. Separate the high-voltage or large-current power lines from other lines, and avoid parallel or

common wiring with the power lines when you are wiring to the terminals.

(8) Use this product within the rated load and power supply.

(9) Make sure that the rated voltage is attained within two seconds of turning ON the power using a switch or relay

contact. If the voltage is applied gradually, the power may not be reset or output malfunctions may occur.

(10) Make sure that the Digital Controller has 30 minutes or more to warm up after turning ON the power before

starting actual control operations to ensure the correct temperature display.

(11) When executing self-tuning, turn the load and the unit ON simultaneously, or turn the load ON before you turn

the controller ON.

(12) A switch or circuit breaker should be provided close to this unit. The switch or circuit breaker should be within

easy reach of the operator, and must be marked as a disconnecting means for this unit.

(13) Wipe off any dirt from the Digital Controller with a soft dry cloth. Never use thinners, benzine, alcohol, or any

cleaners that contain these or other organic solvents. Deformation or discoloration may occur.

(14) Design system (control panel, etc) considering the 2 second of delay that the controller’s output to be set after

power ON.

(15) The output will turn OFF when you move to the Initial Setting Level. Take this into consideration when

performing control.

(16) The number of non-volatile memory write operations is limited. Therefore, use RAM write mode when

frequently overwriting data during communications or other operations.

(17) When disassembling the Temperature Controller for disposal, use suitable tools.

(18) Do not exceed the communications distance that is given in the specifications and use the specified

communications cable. Refer to the E5□C Digital Controllers User’s Manual (Cat. No.H174) for the

communications distance and cable specifications.

(19) Do not turn the power supply to the Digital Controller ON or OFF while the USB-Serial Conversion Cable is

connected. The Digital Controller may malfunction.

(20) The maximum terminal temperature is 75°C. Use wires with heat resistance of 75°C min to wire the terminals.

Side-by-side mounting (mm)

+1

(48 x number of units — 2.5)

0

Waterproofing is impossible

with side-by-side

installation. When

waterproofing is required, fit

watertight packing on the

backside of front panel.

•

STOP: Control stopped indicator

Lit when «Run/Stop» is stopped during operation.

During control stop, functions other than control output

are valid.

•

CMW: Communications writing

enabled/disabled indicator

Lit when communications writing is enabled and not lit

when it is disabled.

•

:Protection indicator

Lit when Setting Change Protect is

ON (disables the Up and Down Keys).

• MANU: Manual output indicator

Lit when the Auto/Manual Mode is set

to Manual Mode.

Check the wiring before turning ON the power supply.

*5

POWER ON

*3

*4

Operation Level

Process Value/Set Point

25

al1l

s.err is displayed when

*6

connected sensor is

*3

0

different from input type.

*4

M

Hold O down

a-m

al-2

Auto/Manual Switch

for at least

*6

*6

PID control only.

3 seconds

M

(No.1 display flashes,

then the control stops.)

m-sp

al2h

Multi-SP

*6

*6

Set Point Selection

0

M

Hold O down

rsp

al2l

for at least

*6

Remote SP Monitor

*6

0.0

1 second

M

sp-m

al-3

Set Point During

*6

*6

SP Ramp

0

M

ct1

Heater Current 1

al3h

*6

*6

Value Monitor

0.0

*7

(Unit: A)

M

ct2

Heater Current 2

al3l

*6

*6

Value Monitor

0.0

*7

(Unit: A)

M

lcr1

Leakage Current 1

al-4

*6

*6

Value Monitor

0.0

*7

(Unit: A)

M

lcr2

Leakage Current 2

al4h

*6

*6

Value Monitor

0.0

(Unit: A)

*7

M

prst

al4l

*6

Program Start

*6

rset

M

sktr

*6

Soak Time Remain

*6

0

M

r-s

RUN/STOP

c-o

run

*6

When control start =

*6

run

stop

When control stop =

M

al-1

*6

Alarm Value 1

*4

0

M

al1h

Alarm Value Upper Limit 1

*6

*4

0

M

Operation level should normally be used during operations.

Hold O and M keys

Hold O and M keys

down for at least

down for at least

1 second

3 seconds

Protect Level

Move to Protect Level

pmov

chgp

Displayed only when a

password is set. Restricts

0

off

moving to Protect Level.

M

Operation / Adjustment Protect

oapt

Restricts displaying and

pmsk

modifying menu items in

0

Operation, Adjustment,

and Manual Control Levels.

M

Initial Setting / Communication Protect

icpt

prlp

Restricts movement to the

Initial Setting, Communications

1

Setting, and Advanced Function

M

Setting Levels.

wtpt

Setting Change Protect

Restricts changes to settings

off

by operating the front panel keys.

M

pfpt

PF Key Protect

Restricts PF key operation.

off

M

Restricts which settings can be displayed or changed, and

restricts change by key operation.

Other functions

Refer to the E5□C Digital Controllers User’s Manual (Cat. No.

H174) for information on the Advanced Function Setting Level,

Manual Control Level, and other functions.

Refer to the E5□C Digital Controllers Communications Manual (Cat.

No. H175) for information on communications.

Specifications

Power supply voltage

Operating voltage range

Power consumption

Option 000:

All other specifications:

Indication accuracy

(Ambient temperature: 23°C)

Event input

Contact input

No-contact input

Remote SP input

Control output 1

Control output 2

Control method

Auxiliary outputs

Transfer output

Ambient temperature

Ambient humidity

Storage temperature

Altitude

Recommended fuse

Weight

Degree of protection

Installation environment

Memory protection

Temporary overvoltage

Connections

(The applicability of the electric terminals varies with the type of machine.)

Do not connect anything to the terminals that are shaded gray.

Control output 1

Control output 2

Auxiliary outputs 1, 2, and 3

Voltage output (for driving SSR)

Relay output

Current output

Relay outputs

12 VDC, 21 mA

250 VAC, 3 A (resistive load)

0 to 20 mA DC

two outputs 250 VAC: 3 A

4 to 20 mA DC

Voltage output (for driving SSR)

(resistive load)

Load: 500 Ω max.

12 VDC, 21 mA

three outputs 250 VAC: 2 A

(resistive load)

*1 Control Outputs 1 and 2

RX

QX

CX

CQ

One relay

One voltage output

One linear

Two voltage outputs

Linear current output/

output

(for driving SSR)

current output

(for driving SSR)

voltage output (for driving SSR)

OUT1

OUT1

OUT1

OUT1

1

1

1

1

1

+

+

+

R

Q

C

Q

−

−

−

2

2

2

2

2

OUT2

+ Q

3

3

3

3

3

1

2

3

*2 Sensor Temperature/Analog Input

4

TC

Pt

I

V

5

A

+

4

4

4

4

6

−

B

mA

−

5

5

5

5

−

B

V

6

6

6

6

+

+

*5 Options

001

002

003

004

Event inputs 1 and 2,

Communications

Communications

Communications (RS-485)

and event inputs 3 and 4

and CT1

(RS-485) and CT1

(RS-485), CT1, and CT2

(−)

B(+)

B(+)

B(+)

13

13

13

13

RS-485

RS-485

RS-485

14

14

14

14

EV1

A(−)

A(−)

A(−)

15

15

15

15

EV2

(−)

16

16

16

16

CT1

CT1

CT1

17

17

17

17

COM

EV3

CT2

18

18

18

18

EV4

* When complying with EMC standards, the line connecting the sensor must be 30 m or less.

If the cable length exceeds 30 m, compliance with EMC standards will not be possible.

* Use non-voltage inputs for the event inputs. The polarity for a non-contact input is indicated by «(-).»

Only the value set to the ins: Temperature Input Shift parameter is applied to the entire temperature input range.

When the process value is 200°C, the process value is treated as 201.2°C after input shift if the input shift value

is set to 1.2°C. The process value is treated as 198.8°C after input shift if the input shift value is set to -1.2°C.

Adjustment Level

l.adj

Adjustment Level

*8

Displayed only once when

entering Adjustment Level.

M

AT Execute / Cancel

at

at-2

*6

100%AT Execute

off

at-1

40%AT Execute

Alarm Value

M

Lower Limit 1 *4

0

cmwt

Communications Writing

M

*6

off

Press O

Alarm Value 2 *4

M

(less than

0

spmd

1 second)

SP Mode

M

*6

lsp

Alarm Value

M

Upper Limit 2 *4

0

ct1

Heater Current 1 Value

M

*6

Monitor (Unit: A)

*7

0.0

Alarm Value

M

Lower Limit 2 *4

0

hb1

Heater Burnout Detection 1

M

*6

(Unit: A)

*7

0.0

Alarm Value 3 *4

M

0

ct2

Heater Current 2 Value

M

*6

Monitor (Unit: A)

*7

0.0

Alarm Value

M

Upper Limit 3 *4

0

hb2

Heater Burnout Detection 2

M

*6

(Unit: A)

*7

0.0

Alarm Value

M

Lower Limit 3 *4

0

lcr1

Leakage Current 1 Value

M

*6

Monitor (Unit: A)

*7

0.0

M

Alarm Value 4 *4

0

hs1

HS Alarm 1

M

*6

(Unit: A)

*7

50.0

Alarm Value

M

Upper Limit 4 *4

0

lcr2

Leakage Current 2 Value

M

*6

Monitor (Unit: A)

*7

0.0

Alarm Value

M

Lower Limit 4 *4

0

hs2

HS Alarm 2

*6

M

50.0

(Unit: A)

*7

o

MV Monitor

M

(Heating)

0.0

sp-0

SP 0

*6

M

0

MV Monitor

M

(Cooling)

0.0

sp-1

SP 1

M

*6

0

M

sp-2

SP 2

*6

0

M

Adjustment level is for entering set values and shift values for control.

Error Display (troubleshooting)

When an error has occurred, the No.1 display shows the error code. Take necessary measure

according to the error code, referring the table below.

No.1 display

Meaning

Check the setting of the Input Type parameter,

s.err

Input error

(S. Err)

check the input wiring, and check for broken or

*2

Changed

shorts in the temperature sensor.

Parameters Only

After the correction of A/D converter error, turn the

power OFF then back ON again. If the display

M

A/D converter error

remains the same, the controller must be repaired.

e333

Parameter Mask

(E333)

*2

If the display is restored to normal, then a

Enable

probable cause can be external noise affecting the

Displayed only

on

control system. Check for external noise.

when a parameter

mask is set.

M

Turn the power OFF then back ON again. If the

Password to Move

display remains the same, the controller must be

e111

Memory error

to Protect Level

repaired. If the display is restored to normal, then

(E111)

a probable cause can be external noise affecting

0

the control system. Check for external noise.

M

If the input value exceeds the display limit (-1999 to 9999), though it is within the control

range, [[[[ will be displayed under -1999 and ]]]] above 9999. Under these conditions,

control output and alarm output will operate normally.

Refer to the E5□C Digital Controllers User’s Manual (Cat. No. H174) for the controllable ranges.

*2: Error shown only for «Process value / Set point». Not shown for other status.

OMRON EUROPE B.V.

Wegalaan 67-69, NL-2132 JD Hoofddorp The Netherlands

Phone 31-2356-81-300

FAX 31-2356-81-388

OMRON ELECTRONICS LLC

One Commerce Drive Schaumburg, IL 60173-5302 U.S.A

Phone 1-847-843-7900

FAX 1-847-843-7787

OMRON ASIA PACIFIC PTE. LTD.

No. 438A Alexandra Road # 05-05/08 (Lobby 2),

Alexandra Technopark, Singapore 119967

Phone 65-6835-3011

FAX 65-6835-2711

OMRON Corporation

Shiokoji Horikawa, Shimogyo-ku, Kyoto 600-8530 JAPAN

100 to 240 VAC, 50/60 Hz or

24 VAC, 50/60 Hz / 24 VDC

85 to 110% of the rated voltage

5.2 VA max. (100 to 240 VAC)

3.1 VA max. (24 VAC)/1.6 W max. (24 VDC)

6.5 VA max. (100 to 240 VAC)

4.1 VA max. (24 VAC)/2.3 W max. (24 VDC)

Thermocouple:

(±0.3 % of indication value or ±1°C,

whichever is greater) ±1 digit max.

Platinum resistance thermometer:

(±0.2 % of indication value or ±0.8°C,

whichever is greater) ±1 digit max.

Analog input:

±0.2 % FS ±1 digit max.

Output current: approx. 7 mA per contact.

ON:1 kΩ max., OFF: 100 kΩ min.

ON: residual voltage 1.5 V max.,

OFF: leakage current 0.1 mA max.

4 to 20 mA DC or 0 to 20 mA DC

0 to 5 V DC or 1 to 5 V DC or 0 to 10 V DC

Relay output :SPST-NO

250VAC, 3A(resistive load)

Electrical life of relay: 100,000 operations

Voltage output (for driving SSR):

12 VDC ±20%, 21 mA

Current output: 4 to 20 mA DC, 0 to 20mA DC

Load: 500 Ω max.

Voltage output (for driving SSR):

12 VDC, 21 mA

ON/OFF or 2-PID control

Relay outputs:SPST-NO, 250 VAC,

two outputs: 3 A (resistive load),

three outputs: 2 A (resistive load),

Electrical life of relay: 100,000 operations

4 to 20 mA DC with load of 500 Ω max.

1 to 5 VDC with load of 1 kΩ min.

-10 to 55°C

(Avoid freezing or condensation)

25% to 85%

-25 to 65°C

(Avoid freezing or condensation)

Max. 2,000m

T2A, 250 VAC, time-lag, low-breaking capacity

Approx. 120 g (Digital Controller only)

Front panel: IP66

Rear case: IP20, Terminal section: IP00

Installation category II, pollution

degree 2 (as per IEC61010-1)

Non-volatile memory

(Number of write operations: 1,000,000)

Short term: 1200 V+ (power supply voltage)

Long term: 250 V+ (power supply voltage)

E5CC

1. Control outputs

5. Options

The E5CC is set for a K thermocouple (input type of 5)

by default. If a different sensor is used, an input error

(s.err) will occur.

Check the setting of the Input Type parameter.

*3 Auxiliary Outputs

Auxiliary outputs 1 and 2 Auxiliary outputs 1, 2, and 3

OUT1

+

C

7

7

—

OUT2

Auxiliary output 3

Auxiliary output 2

Q

+

8

8

Auxiliary output 2

9

9

Auxiliary output 1

Auxiliary output 1

10

10

13

7

14

8

Check for a single-fault condition of the COM t

erminal before use if auxiliary outputs 1,2 and 3

15

9

will be connected to different electrical potentials.

16

10

*4 Input Power Supply

17

11

100 to 240 VAC

24 VAC/DC

18

12

11

11

12

12

(no polarity)

005

006

007

Event inputs 1 to 4

Event inputs 1 and 2, and

Event inputs 1 and 2,

and remote SP

transfer output

(−)

(−)

(−)

13

13

13

14

14

14

EV1

EV1

EV1

15

15

15

EV2

EV2

EV2

(−)

+

16

16

+

16

+

V

V

+

17

17

17

m

EV3

A

I

18

−

−

18

18

EV4

c-db

sp-3

SP 3

Dead Band

*6

*6

0

0.0

M

M

sp-4

of-r

Manual Reset Value

SP 4

*6

Clears the offset

*6

0

50.0

during P or PD control.

M

M

sp-5

hys

SP 5

Hysteresis (Heating)

*6

*6

0

1.0

M

M

sp-6

chys

SP 6

Hysteresis (Cooling)

*6

*6

0

1.0

M

M

sp-7

soak

SP 7

*6

*6

Soak Time

0

1

M

M

ins

wt-b

PV

*6

*6

Wait Band

Input Shift

0.0

off

M

M

inrt

mv-s

PV input

*6

*6

MV at Stop

Slope Coefficient

1.000

0.0

M

M

rss

mv-e

Remote SP

*6

*6

MV at PV Error

Input Shift

0.0

0.0

M

M

rsrt

sprt

Remote SP input

*6

*6

SP Ramp Set Value

Slope Coefficient

1.000

off

M

M

p

sprl

Proportional

SP Ramp Set Value

*6

*6

Band

8.0

same

(SP Ramp Fall Value)

M

M

i

ol-h

Integral Time

MV Upper Limit

*6

*6

233

(Unit: Seconds)

100.0

M

M

d

ol-l

Derivative Time

*6

*6

MV Lower Limit

(Unit: Seconds)

40

0.0

M

M

c-p

orl

Proportional Band

MV Change

*6

*6

(Cooling)

8.0

Rate Limit

0.0

M

M

Integral Time

c-i

sqrp

Extraction of Square

*6

*6

(Cooling)

Root Low-cut Point

233

0.0

(Unit: Seconds)

M

M

c-d

Derivative Time

plcm

Communications

*6

*6

(Cooling)

Monitor

40

1234

(Unit: Seconds)

M

M

Status at error

Action

Control

Alarm

output

Operates

OFF

as above the

upper limit.

OFF

OFF

OFF

OFF

* Изображения служат только для ознакомления,

см. техническую документацию

Добавить в корзину 1 шт.

на сумму 50 130 руб.

Посмотреть альтернативные предложения2

Номенклатурный номер: 8002556088

Артикул: E5CC-RX3A5M-000

Страна происхождения: КИТАЙ

Бренд / Производитель: Omron

Описание

АвтоматикаРегулировка и управлениеРегуляторыРегуляторы температуры

Контроллер температуры цифровой серии E5CC, релейный выход, три вспомогательных выхода, напряжение питания 100..240 VAC, универсальный вход

Технические параметры

| Maximum Operating Temperature | +55°C |

| Minimum Operating Temperature | -10°C |

| Number of Outputs | 1 |

| Output Type | Relay |

| Series | E5CC |

| Size | 48x48mm |

| Supply Voltage | 100 → 240 V ac |

| Вес, г | 147.7 |

Техническая документация

Сроки доставки

Доставка в регион Курск

| Магазин «ЧИП и ДИП» | 5 июля1 | бесплатно |

| ПВЗ Boxberry | 3 июля1 | бесплатно |

| ПВЗ СДЭК | 4 июля1 | бесплатно |

| ПВЗ Л-Пост | 4 июля1 | бесплатно |

| ПВЗ 5Post | 5 июля1 | бесплатно |

| Почта России | 12 июля1 | бесплатно |

| Курьер | 4 июля1 | 416 руб.2 |

| ТК DPD | 3 июля1 | 546 руб.2 |

| ТК «Деловые линии» | 4 июля1 | 824 руб.2 |

Цена и наличие в магазинах

| ул. Карла Маркса, 68, ТЦ «Мега Гринн», 1 этаж | нет в наличии |

Термопара /Термосопротивление / По току / По напряжению

Дискретное вкл/выкл, 2-ПИД регулирование

K, J, E, T, L, N, U, R, S, B, C, P (PLII)

Вход термосопротивления (RTD):

JPt100, Pt100

Вход аналоговый по напряжению:

0-5 В, 1-5 В, 0-10 В

Диапазон регулировки температуры, °C:

-200…+2300

Количество контуров управления:

1

Количество аварийных выходов:

3

Температура эксплуатации Max, °C:

55

Температура эксплуатации Min, °C:

-10

Размер прямоугольного корпуса, мм:

48×48

2 11-сегментных светодиодных LED

Температура эксплуатации, °C:

-10…+55

Бесплатный самовывоз из пунктов выдачи заказов

г. Смоленск, 2-й Рославльский пер., 14 Б, Цокольный этаж, оф 6.

Пн — Пт 8 — 19

Суббота 10 — 17

Воскресенье выходной

Доставка по России

Транспортными компаниями (до терминала либо до двери)

СДЭК, Деловые Линии, ЕМС Почта России, DPD

Оперативная доставка в Санкт-Петербург, Екатеринбург, Новосибирск, Нижний Новгород, Краснодар, Самару, Челябинск, Казань, Пермь, Ростов-на-Дону, Уфу, Воронеж, Ижевск, Иркутск, Красноярск, Белгород.

Доставка в Казахстан и Беларусь

Отправляем товары транспортной компанией СДЭК

Доставка по Москве

Стоимость доставки 350 р. за исключением крупногабаритного товара (обговаривается отдельно)