Комментарии

10

Войдите или зарегистрируйтесь, чтобы писать комментарии, задавать вопросы и участвовать в обсуждении.

Прикольно, а что за файл?

Нашел как-то на просторах. Сюда не получается выгрузить, поэтому ссылка диск. Попробуйте может получится себе скачать.

Хорошо, а что за файл-то?

Файл расширение .pdf. Мануал на паф дорест. Не открывается чтоли?

Я и не качал, просто потом только тему увидел а из тела поста не ясно что за файл )

Sobol102

Нашел как-то на просторах. Сюда не получается выгрузить, поэтому ссылка диск. Попробуйте может получится себе скачать.

Мануал к патику чтоль?

Welcome to the growing family of new NISSAN

owners. This vehicle is delivered to you with

confidence. It was produced using the latest

techniques and strict quality control.

This manual was prepared to help you under-

stand the operation and maintenance of your

vehicle so that you may enjoy many miles (kilome-

ters) of driving pleasure. Please read through this

manual before operating your vehicle.

A separate Warranty Information Booklet

explains details about the warranties cov-

ering your vehicle. The “NISSAN Service

and Maintenance Guide” explains details

about maintaining and servicing your ve-

hicle. Additionally, a separate Customer

Care/Lemon Law Booklet (U.S. only) will

explain how to resolve any concerns you

may have with your vehicle, as well as

clarify your rights under your state’s lemon

law.

Your NISSAN dealership knows your vehicle

best. When you require any service or have any

questions, they will be glad to assist you with the

extensive resources available to them.

Before driving your vehicle please read this Own-

er’s Manual carefully. This will ensure familiarity

with controls and maintenance requirements, as-

sisting you in the safe operation of your vehicle.

WARNING

IMPORTANT SAFETY INFORMATION RE-

MINDERS FOR SAFETY!

Follow these important driving rules to

help ensure a safe and comfortable trip

for you and your passengers!

● NEVER drive under the influence of al-

cohol or drugs.

● ALWAYS observe posted speed limits

and never drive too fast for conditions.

●

ALWAYS give your full attention to driving

and avoid using vehicle features or taking

other actions that could distract you.

● ALWAYS use your seat belts and appro-

priate child restraint systems. Pre-teen

children should be seated in the rear

seat.

● ALWAYS provide information about the

proper use of vehicle safety features to

all occupants of the vehicle.

● ALWAYS review this Owner’s Manual

for important safety information.

For descriptions specified for four-wheel drive

models, a

mark is placed at the begin-

ning of the applicable sections/items.

As with other vehicles with features for

off-road use, failure to operate four-wheel

drive models correctly may result in loss of

control or an accident. Be sure to read

“Driving safety precautions” in the “Start-

ing and driving” section of this manual.

ON-PAVEMENT AND OFF-ROAD

DRIVING

This vehicle will handle and maneuver

differently from an ordinary passenger

car because it has a higher center of

gravity for off-road use. As with other

vehicles with features of this type, fail-

ure to operate this vehicle correctly may

result in loss of control or an accident.

Be sure to read “On-pavement and off-

road driving precautions”, and “Avoid-

ing collision and rollover”, and “Driving

safety precautions”, in the “Starting and

driving” section of this manual.

FOREWORD READ FIRST—THEN DRIVE SAFELY

Z REVIEW COPY—

2008 Pathfinder (pat)

Owners Manual—USA_English (nna)

09/29/07—debbie

X

Смотреть руководство для Nissan Pathfinder (2008) ниже. Все руководства на ManualsCat.com могут просматриваться абсолютно бесплатно. Нажав кнопку «Выбор языка» вы можете изменить язык руководства, которое хотите просмотреть.

MANUALSCAT | RU

Вопросы и ответы

У вас есть вопрос о Nissan Pathfinder (2008), но вы не можете найти ответ в пользовательском руководстве? Возможно, пользователи ManualsCat.com смогут помочь вам и ответят на ваш вопрос. Заполните форму ниже — и ваш вопрос будет отображаться под руководством для Nissan Pathfinder (2008). Пожалуйста, убедитесь, что вы опишите свои трудности с Nissan Pathfinder (2008) как можно более детально. Чем более детальным является ваш вопрос, тем более высоки шансы, что другой пользователь быстро ответит на него. Вам будет автоматически отправлено электронное письмо, чтобы проинформировать вас, когда кто-то из пользователей ответит на ваш вопрос.

Задать вопрос о Nissan Pathfinder (2008)

- Бренд:

- Nissan

- Продукт:

- автомобили

- Модель/название:

- Pathfinder (2008)

- Тип файла:

- Доступные языки:

- английский

Сопутствующие товары Nissan Pathfinder (2008)

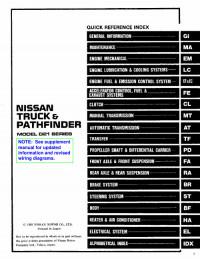

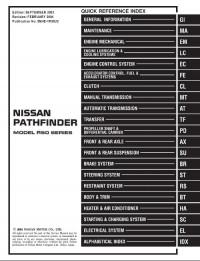

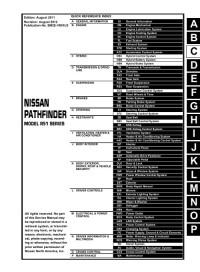

TRANSMISSION & DRIVELINE

SECTION DLN

DRIVELINE

CONTENTS

|

TRANSFER: ATX14B |

|

|

BASIC INSPECTION …………………………….. |

8 |

|

DIAGNOSIS AND REPAIR WORKFLOW ……… |

8 |

|

Work Flow ………………………………………………………. |

8 |

|

Preliminary Check ……………………………………………. |

9 |

|

FUNCTION DIAGNOSIS ………………………… |

12 |

|

4WD SYSTEM …………………………………………… |

12 |

|

System Diagram …………………………………………….. |

12 |

|

System Description …………………………………………. |

13 |

|

Component Parts Location ………………………………. |

18 |

|

CAN Communication ………………………………………. |

19 |

|

DIAGNOSIS SYSTEM (TRANSFER CON- |

|

|

TROL UNIT) ………………………………………………. |

20 |

|

CONSULT-III Function (ALL MODE AWD/4WD) …. |

20 |

|

NOISE, VIBRATION AND HARSHNESS |

|

|

(NVH) TROUBLESHOOTING ……………………… |

24 |

|

NVH Troubleshooting Chart …………………………….. |

24 |

|

COMPONENT DIAGNOSIS ……………………. |

25 |

|

P1811 POWER SUPPLY CIRCUIT FOR |

|

|

TRANSFER CONTROL UNIT ……………………… |

25 |

|

Description ……………………………………………………. |

25 |

|

DTC Logic …………………………………………………….. |

25 |

|

Diagnosis Procedure ………………………………………. |

25 |

|

Component Inspection ……………………………………. |

26 |

|

P1802 – P1804, P1809 TRANSFER CON- |

|

|

TROL UNIT ……………………………………………….. |

27 |

|

Description ……………………………………………………. |

27 |

|

DTC Logic …………………………………………………….. |

27 |

|

Diagnosis Procedure ………………………………………. |

27 |

|

P1807 VEHICLE SPEED SENSOR (A/T) ……… |

29 |

|

Description ……………………………………………………. |

29 |

|

DTC Logic …………………………………………………….. |

29 |

|

Diagnosis Procedure ………………………………………. |

29 |

|

P1808 VEHICLE SPEED SENSOR (ABS) ……. |

30 |

|

Description …………………………………………………….. |

30 |

|

DTC Logic ……………………………………………………… |

30 |

|

Diagnosis Procedure ………………………………………. |

30 |

|

P1810 NEUTRAL-4LO SWITCH ………………….. |

31 |

|

Description …………………………………………………….. |

31 |

|

DTC Logic ……………………………………………………… |

31 |

|

Diagnosis Procedure ………………………………………. |

31 |

|

Component Inspection …………………………………….. |

33 |

|

P1813 4WD SHIFT SWITCH ……………………….. |

34 |

|

Description …………………………………………………….. |

34 |

|

DTC Logic ……………………………………………………… |

34 |

|

Diagnosis Procedure ………………………………………. |

34 |

|

Component Inspection …………………………………….. |

36 |

|

P1814 WAIT DETECTION SWITCH …………….. |

38 |

|

Description …………………………………………………….. |

38 |

|

DTC Logic ……………………………………………………… |

38 |

|

Diagnosis Procedure ………………………………………. |

38 |

|

Component Inspection …………………………………….. |

40 |

|

P1816 PNP SWITCH ………………………………….. |

41 |

|

Description …………………………………………………….. |

41 |

|

DTC Logic ……………………………………………………… |

41 |

|

Diagnosis Procedure ………………………………………. |

41 |

|

P1817 ACTUATOR MOTOR ……………………….. |

42 |

|

Description …………………………………………………….. |

42 |

|

DTC Logic ……………………………………………………… |

42 |

|

Diagnosis Procedure ………………………………………. |

42 |

|

Component Inspection …………………………………….. |

46 |

|

P1818 ACTUATOR POSITION SWITCH ………. |

48 |

|

Description …………………………………………………….. |

48 |

|

DTC Logic ……………………………………………………… |

48 |

|

Diagnosis Procedure ………………………………………. |

48 |

|

Component Inspection …………………………………….. |

50 |

A

B

C

DLN

E

F

G

H

I

J

K

L

M

N

O

P

DLN-1

|

P1819 TRANSFER CONTROL DEVICE ………. |

51 |

|

Description ……………………………………………………. |

51 |

|

DTC Logic …………………………………………………….. |

51 |

|

Diagnosis Procedure ……………………………………… |

51 |

|

P1820 ENGINE SPEED SIGNAL ………………… |

55 |

|

Description ……………………………………………………. |

55 |

|

DTC Logic …………………………………………………….. |

55 |

|

Diagnosis Procedure ……………………………………… |

55 |

|

P1822 CLUTCH PRESSURE SOLENOID …….. |

56 |

|

Description ……………………………………………………. |

56 |

|

DTC Logic …………………………………………………….. |

56 |

|

Diagnosis Procedure ……………………………………… |

56 |

|

Component Inspection ……………………………………. |

58 |

|

P1823 2-4 SOLENOID ……………………………….. |

60 |

|

Description ……………………………………………………. |

60 |

|

DTC Logic …………………………………………………….. |

60 |

|

Diagnosis Procedure ……………………………………… |

60 |

|

Component Inspection ……………………………………. |

63 |

|

P1824 TRANSFER MOTOR ……………………….. |

64 |

|

Description ……………………………………………………. |

64 |

|

DTC Logic …………………………………………………….. |

64 |

|

Diagnosis Procedure ……………………………………… |

64 |

|

Component Inspection ……………………………………. |

68 |

|

P1826 TRANSFER FLUID TEMPERATURE … 70 |

|

|

Description ……………………………………………………. |

70 |

|

DTC Logic …………………………………………………….. |

70 |

|

Diagnosis Procedure ……………………………………… |

70 |

|

Component Inspection ……………………………………. |

71 |

|

P1827 CLUTCH PRESSURE SWITCH ………… |

73 |

|

Description ……………………………………………………. |

73 |

|

DTC Logic …………………………………………………….. |

73 |

|

Diagnosis Procedure ……………………………………… |

73 |

|

Component Inspection ……………………………………. |

74 |

|

P1828 LINE PRESSURE SWITCH ………………. |

76 |

|

Description ……………………………………………………. |

76 |

|

DTC Logic …………………………………………………….. |

76 |

|

Diagnosis Procedure ……………………………………… |

76 |

|

Component Inspection ……………………………………. |

78 |

|

P1829 THROTTLE POSITION SIGNAL (ECM) |

|

|

… 79 |

|

|

Description ……………………………………………………. |

79 |

|

DTC Logic …………………………………………………….. |

79 |

|

Diagnosis Procedure ……………………………………… |

79 |

|

P1830 ABS OPERATION SIGNAL (ABS) ……. |

80 |

|

Description ……………………………………………………. |

80 |

|

DTC Logic …………………………………………………….. |

80 |

|

Diagnosis Procedure ……………………………………… |

80 |

|

P1831 VDC OPERATION SIGNAL (ABS) ……. |

81 |

|

Description ……………………………………………………. |

81 |

|

DTC Logic …………………………………………………….. |

81 |

|

Diagnosis Procedure ……………………………………… |

81 |

|

P1832 TCS OPERATION SIGNAL (ABS) …….. |

82 |

|

Description ……………………………………………………. |

82 |

|

DTC Logic ……………………………………………………… |

82 |

|

Diagnosis Procedure ………………………………………. |

82 |

|

ECU DIAGNOSIS ………………………………… |

83 |

|

TRANSFER CONTROL UNIT …………………….. |

83 |

|

Reference Value ……………………………………………. |

83 |

|

Wiring Diagram ……………………………………………… |

91 |

|

DTC Index …………………………………………………… |

101 |

|

SYMPTOM DIAGNOSIS ……………………… |

106 |

|

4WD SYSTEM SYMPTOMS ………………………. |

106 |

|

Symptom Table ……………………………………………. |

106 |

|

4WD SHIFT INDICATOR LAMP AND 4LO IN- |

|

|

DICATOR LAMP DO NOT TURN ON …………. |

107 |

|

Description ………………………………………………….. |

107 |

|

Diagnosis Procedure …………………………………….. |

107 |

|

4WD WARNING LAMP DOES NOT TURN ON..110 |

|

|

Description ………………………………………………….. |

110 |

|

Diagnosis Procedure …………………………………….. |

110 |

|

4WD SHIFT INDICATOR LAMP OR 4LO INDI- |

|

|

CATOR LAMP DO NOT CHANGE ……………… |

113 |

|

Description ………………………………………………….. |

113 |

|

Diagnosis Procedure …………………………………….. |

113 |

|

ATP WARNING LAMP DOES NOT TURN ON..115 |

|

|

Description ………………………………………………….. |

115 |

|

Diagnosis Procedure …………………………………….. |

115 |

|

4WD SHIFT INDICATOR LAMP KEEPS |

|

|

FLASHING ………………………………………………. |

117 |

|

Description ………………………………………………….. |

117 |

|

Diagnosis Procedure …………………………………….. |

117 |

|

4WD WARNING LAMP FLASHES RAPIDLY..118 |

|

|

Description ………………………………………………….. |

118 |

|

Diagnosis Procedure …………………………………….. |

118 |

|

4WD WARNING LAMP FLASHES SLOWLY .. |

119 |

|

Description ………………………………………………….. |

119 |

|

Diagnosis Procedure …………………………………….. |

119 |

|

HEAVY TIGHT-CORNER BRAKING SYMP- |

|

|

TOM OCCURS …………………………………………. |

120 |

|

Description ………………………………………………….. |

120 |

|

Diagnosis Procedure …………………………………….. |

120 |

|

ATP SWITCH …………………………………………… |

122 |

|

Description ………………………………………………….. |

122 |

|

Diagnosis Procedure …………………………………….. |

122 |

|

4WD SYSTEM DOES NOT OPERATE ……….. |

124 |

|

Description ………………………………………………….. |

124 |

|

Diagnosis Procedure …………………………………….. |

124 |

|

PRECAUTION ……………………………………. |

125 |

DLN-2

|

PRECAUTIONS ……………………………………….. |

125 |

|

Precaution for Supplemental Restraint System |

|

|

(SRS) «AIR BAG» and «SEAT BELT PRE-TEN- |

|

|

SIONER» …………………………………………………….. |

125 |

|

Precaution for Transfer Assembly and Transfer |

|

|

Control Unit Replacement ……………………………… |

125 |

|

Precaution …………………………………………………… |

126 |

|

Service Notice ……………………………………………… |

126 |

|

PREPARATION …………………………………. |

128 |

|

PREPARATION ……………………………………….. |

128 |

|

Special Service Tool …………………………………….. |

128 |

|

Commercial Service Tool ………………………………. |

131 |

|

ON-VEHICLE MAINTENANCE …………….. |

132 |

|

TRANSFER FLUID …………………………………… |

132 |

|

Replacement ……………………………………………….. |

132 |

|

Inspection ……………………………………………………. |

132 |

|

TRANSFER OIL FILTER …………………………… |

133 |

|

Removal and Installation ……………………………….. |

133 |

|

ON-VEHICLE REPAIR ………………………… |

135 |

|

TRANSFER CONTROL UNIT ……………………. |

135 |

|

Removal and Installation ……………………………….. |

135 |

|

FRONT OIL SEAL ……………………………………. |

136 |

|

Removal and Installation ……………………………….. |

136 |

|

REAR OIL SEAL ……………………………………… |

138 |

|

Removal and Installation ……………………………….. |

138 |

|

SIDE OIL SEAL ……………………………………….. |

140 |

|

Removal and Installation ……………………………….. |

140 |

|

TRANSFER CONTROL DEVICE ……………….. |

141 |

|

Removal and Installation ……………………………….. |

141 |

|

AIR BREATHER HOSE …………………………….. |

142 |

|

Removal and Installation ……………………………….. |

142 |

|

TRANSFER MOTOR ………………………………… |

147 |

|

Removal and Installation ……………………………….. |

147 |

|

REMOVAL AND INSTALLATION ………… |

148 |

|

TRANSFER ASSEMBLY ………………………….. |

148 |

|

Removal and Installation ……………………………….. |

148 |

|

DISASSEMBLY AND ASSEMBLY ……….. |

149 |

|

TRANSFER ASSEMBLY ………………………….. |

149 |

|

Disassembly and Assembly …………………………… |

149 |

|

SERVICE DATA AND SPECIFICATIONS |

|

|

(SDS) ………………………………………………… |

186 |

|

SERVICE DATA AND SPECIFICATIONS |

|

|

(SDS) ……………………………………………………… |

186 |

|

General Specification ……………………………………. |

186 |

|

Inspection and Adjustment …………………………….. |

186 |

||

|

TRANSFER: TX15B |

A |

||

|

BASIC INSPECTION ………………………….. |

188 |

||

|

DIAGNOSIS AND REPAIR WORKFLOW |

188 |

B |

|

|

Work Flow ……………………………………………………. |

188 |

||

|

FUNCTION DIAGNOSIS ……………………… |

190 |

C |

|

|

4WD SYSTEM …………………………………………. |

190 |

||

|

……………………………………………System Diagram |

190 |

DLN |

|

|

System Description |

191 |

||

|

Component Parts Location |

193 |

||

|

CAN Communication …………………………………….. |

194 |

E |

|

|

Cross-Sectional View ……………………………………. |

194 |

||

|

Power Transfer …………………………………………….. |

195 |

||

|

DIAGNOSIS SYSTEM (TRANSFER CON- |

F |

||

|

TROL UNIT) |

197 |

||

|

CONSULT-III Function (ALL MODE AWD/4WD) .. |

197 |

||

|

NOISE, VIBRATION AND HARSHNESS |

G |

||

|

(NVH) TROUBLESHOOTING ……………………. |

200 |

||

|

NVH Troubleshooting Chart …………………………… |

200 |

||

|

COMPONENT DIAGNOSIS |

201 |

H |

|

|

P1801, P1811 POWER SUPPLY CIRCUIT |

|||

|

FOR TRANSFER CONTROL UNIT ……………. |

201 |

I |

|

|

Description …………………………………………………… |

201 |

||

|

DTC Logic ……………………………………………………. |

201 |

||

|

Diagnosis Procedure …………………………………….. |

201 |

J |

|

|

Component Inspection …………………………………… |

203 |

||

|

P1802 – P1804, P1809 TRANSFER CON- |

K |

||

|

TROL UNIT ……………………………………………… |

204 |

||

|

Description …………………………………………………… |

204 |

||

|

DTC Logic ……………………………………………………. |

204 |

L |

|

|

Diagnosis Procedure …………………………………….. |

204 |

||

|

P1807 VEHICLE SPEED SENSOR (A/T) ……. |

206 |

||

|

Description …………………………………………………… |

206 |

M |

|

|

DTC Logic |

206 |

||

|

Diagnosis Procedure …………………………………….. |

206 |

||

|

P1808 VEHICLE SPEED SENSOR (ABS) ….. 207 |

N |

||

|

Description …………………………………………………… |

207 |

||

|

DTC Logic ……………………………………………………. |

207 |

||

|

Diagnosis Procedure …………………………………….. |

207 |

O |

|

|

P1810 4 LO SWITCH ……………………………….. |

208 |

||

|

Description …………………………………………………… |

208 |

||

|

DTC Logic ……………………………………………………. |

208 |

P |

|

|

Diagnosis Procedure …………………………………….. |

208 |

||

|

Component Inspection …………………………………… |

210 |

||

|

P1813 4WD SHIFT SWITCH ……………………… |

211 |

||

|

Description …………………………………………………… |

211 |

||

|

DTC Logic ……………………………………………………. |

211 |

||

|

Diagnosis Procedure …………………………………….. |

211 |

DLN-3

|

Component Inspection …………………………………… |

213 |

|

P1814 WAIT DETECTION SWITCH …………… |

214 |

|

Description …………………………………………………… |

214 |

|

DTC Logic ……………………………………………………. |

214 |

|

Diagnosis Procedure …………………………………….. |

214 |

|

Component Inspection …………………………………… |

216 |

|

P1816 PNP SWITCH ……………………………….. |

217 |

|

Description …………………………………………………… |

217 |

|

DTC Logic ……………………………………………………. |

217 |

|

Diagnosis Procedure …………………………………….. |

217 |

|

P1817 ACTUATOR MOTOR …………………….. |

218 |

|

Description …………………………………………………… |

218 |

|

DTC Logic ……………………………………………………. |

218 |

|

Diagnosis Procedure …………………………………….. |

218 |

|

Component Inspection …………………………………… |

223 |

|

P1818 ACTUATOR POSITION SWITCH ……. |

225 |

|

Description …………………………………………………… |

225 |

|

DTC Logic ……………………………………………………. |

225 |

|

Diagnosis Procedure …………………………………….. |

225 |

|

P1819 TRANSFER CONTROL DEVICE …….. |

228 |

|

Description …………………………………………………… |

228 |

|

DTC Logic ……………………………………………………. |

228 |

|

Diagnosis Procedure …………………………………….. |

228 |

|

P1820 ENGINE SPEED SIGNAL ………………. |

231 |

|

Description …………………………………………………… |

231 |

|

DTC Logic ……………………………………………………. |

231 |

|

Diagnosis Procedure …………………………………….. |

231 |

|

ECU DIAGNOSIS ……………………………….. |

232 |

|

TRANSFER CONTROL UNIT ……………………. |

232 |

|

Reference Value …………………………………………… |

232 |

|

Wiring Diagram …………………………………………….. |

237 |

|

DTC Index …………………………………………………… |

245 |

|

SYMPTOM DIAGNOSIS ……………………… |

248 |

|

4WD SYSTEM SYMPTOMS ……………………… |

248 |

|

Symptom Table ……………………………………………. |

248 |

|

4WD WARNING LAMP DOES NOT TURN ON. 249 |

|

|

Description …………………………………………………… |

249 |

|

Diagnosis Procedure …………………………………….. |

249 |

|

4WD SHIFT INDICATOR LAMP AND 4LO IN- |

|

|

DICATOR LAMP DO NOT TURN ON ………… |

251 |

|

Description …………………………………………………… |

251 |

|

Diagnosis Procedure …………………………………….. |

251 |

|

4WD SHIFT INDICATOR LAMP OR 4LO INDI- |

|

|

CATOR LAMP DO NOT CHANGE …………….. |

253 |

|

Description …………………………………………………… |

253 |

|

Diagnosis Procedure …………………………………….. |

253 |

|

ATP WARNING LAMP DOES NOT TURN ON. 255 |

|

|

Description …………………………………………………… |

255 |

|

Diagnosis Procedure …………………………………….. |

255 |

|

4WD SHIFT INDICATOR LAMP KEEPS |

|

|

FLASHING ………………………………………………. |

257 |

|

Description ………………………………………………….. |

257 |

|

Diagnosis Procedure …………………………………….. |

257 |

|

4WD WARNING LAMP FLASHES SLOWLY .. |

258 |

|

Description ………………………………………………….. |

258 |

|

Diagnosis Procedure …………………………………….. |

258 |

|

ATP SWITCH …………………………………………… |

259 |

|

Description ………………………………………………….. |

259 |

|

Diagnosis Procedure …………………………………….. |

259 |

|

Component Inspection ………………………………….. |

260 |

|

PRECAUTION ……………………………………. |

262 |

|

PRECAUTIONS ……………………………………….. |

262 |

|

Precaution for Supplemental Restraint System |

|

|

(SRS) «AIR BAG» and «SEAT BELT PRE-TEN- |

|

|

SIONER» …………………………………………………….. |

262 |

|

Precaution for Transfer Assembly and Transfer |

|

|

Control Unit Replacement ……………………………… |

262 |

|

Precaution …………………………………………………… |

264 |

|

Service Notice ……………………………………………… |

264 |

|

PREPARATION ………………………………….. |

266 |

|

PREPARATION ……………………………………….. |

266 |

|

Special Service Tool …………………………………….. |

266 |

|

Commercial Service Tool ………………………………. |

268 |

|

ON-VEHICLE MAINTENANCE …………….. |

269 |

|

TRANSFER FLUID …………………………………… |

269 |

|

Replacement ……………………………………………….. |

269 |

|

Inspection ……………………………………………………. |

269 |

|

ON-VEHICLE REPAIR ………………………… |

270 |

|

TRANSFER CONTROL UNIT ……………………. |

270 |

|

Removal and Installation ……………………………….. |

270 |

|

FRONT OIL SEAL ……………………………………. |

271 |

|

Removal and Installation ……………………………….. |

271 |

|

REAR OIL SEAL ……………………………………… |

273 |

|

Removal and Installation ……………………………….. |

273 |

|

TRANSFER CONTROL DEVICE ……………….. |

275 |

|

Removal and Installation ……………………………….. |

275 |

|

AIR BREATHER HOSE …………………………….. |

277 |

|

Removal and Installation ……………………………….. |

277 |

|

PLANETARY CARRIER ……………………………. |

279 |

|

Disassembly and Assembly …………………………… |

279 |

|

FRONT DRIVE SHAFT ……………………………… |

283 |

|

Disassembly and Assembly …………………………… |

283 |

|

SHIFT CONTROL …………………………………….. |

285 |

DLN-4

|

Disassembly and Assembly …………………………… |

285 |

|

REMOVAL AND INSTALLATION ………… |

287 |

|

TRANSFER ASSEMBLY ………………………….. |

287 |

|

Removal and Installation ……………………………….. |

287 |

|

DISASSEMBLY AND ASSEMBLY ……….. |

288 |

|

TRANSFER ASSEMBLY ………………………….. |

288 |

|

Disassembly and Assembly …………………………… |

288 |

|

SERVICE DATA AND SPECIFICATIONS |

|

|

(SDS) ………………………………………………… |

304 |

|

SERVICE DATA AND SPECIFICATIONS |

|

|

(SDS) ……………………………………………………… |

304 |

|

General Specification ……………………………………. |

304 |

|

Inspection and Adjustment …………………………….. |

304 |

|

PROPELLER SHAFT: 2F1310 |

|

|

PREPARATION …………………………………. |

305 |

|

PREPARATION ……………………………………….. |

305 |

|

Commercial Service Tool ………………………………. |

305 |

|

FUNCTION DIAGNOSIS ……………………… |

306 |

|

NOISE, VIBRATION, AND HARSHNESS |

|

|

(NVH) TROUBLESHOOTING ……………………. |

306 |

|

NVH Troubleshooting Chart …………………………… |

306 |

|

ON-VEHICLE REPAIR ………………………… |

307 |

|

PROPELLER SHAFT ……………………………….. |

307 |

|

On-Vehicle Service ………………………………………. |

307 |

|

REMOVAL AND INSTALLATION ………… |

308 |

|

PROPELLER SHAFT ……………………………….. |

308 |

|

Removal and Installation ……………………………….. |

308 |

|

DISASSEMBLY AND ASSEMBLY ……….. |

310 |

|

PROPELLER SHAFT ……………………………….. |

310 |

|

Disassembly and Assembly …………………………… |

310 |

|

SERVICE DATA AND SPECIFICATIONS |

|

|

(SDS) ………………………………………………… |

312 |

|

SERVICE DATA AND SPECIFICATIONS |

|

|

(SDS) ……………………………………………………… |

312 |

|

General Specification ……………………………………. |

312 |

|

Snap Ring …………………………………………………… |

312 |

|

PROPELLER SHAFT: 2S1330 |

|

|

PREPARATION …………………………………. |

313 |

|

PREPARATION ……………………………………….. |

313 |

|

Commercial Service Tool ………………………………. |

313 |

|

FUNCTION DIAGNOSIS ……………………… |

314 |

|

NOISE, VIBRATION, AND HARSHNESS |

||

|

(NVH) TROUBLESHOOTING ……………………. |

314 |

A |

|

NVH Troubleshooting Chart …………………………… |

314 |

|

ON-VEHICLE REPAIR ………………………… |

315 |

B |

|

|

PROPELLER SHAFT ……………………………….. |

315 |

||

|

On-Vehicle Service ……………………………………….. |

315 |

||

|

REMOVAL AND INSTALLATION |

316 |

C |

|

|

PROPELLER SHAFT |

316 |

||

|

DLN |

|||

|

Removal and Installation |

316 |

||

|

DISASSEMBLY AND ASSEMBLY |

318 |

||

|

PROPELLER SHAFT |

318 |

E |

|

|

Disassembly and Assembly ……………………………. |

318 |

||

|

SERVICE DATA AND SPECIFICATIONS |

F |

||

|

(SDS) ………………………………………………… |

320 |

||

|

SERVICE DATA AND SPECIFICATIONS |

G |

||

|

(SDS) |

320 |

||

|

General Specification ……………………………………. |

320 |

||

|

Snap Ring ……………………………………………………. |

321 |

H |

|

|

PROPELLER SHAFT: 2S1350 |

|||

|

PREPARATION …………………………………. |

322 |

I |

|

|

PREPARATION |

|||

|

322 |

|||

|

Commercial Service Tool ………………………………. |

322 |

||

|

FUNCTION DIAGNOSIS |

323 |

J |

|

|

NOISE, VIBRATION, AND HARSHNESS |

|||

|

(NVH) TROUBLESHOOTING ……………………. |

323 |

K |

|

|

NVH Troubleshooting Chart …………………………… |

323 |

||

|

ON-VEHICLE REPAIR ………………………… |

324 |

L |

|

|

PROPELLER SHAFT ……………………………….. |

324 |

||

|

On-Vehicle Service ……………………………………….. |

324 |

||

|

REMOVAL AND INSTALLATION |

325 |

M |

|

|

PROPELLER SHAFT ……………………………….. |

325 |

N |

|

|

Removal and Installation |

325 |

||

|

DISASSEMBLY AND ASSEMBLY ……….. |

327 |

||

|

PROPELLER SHAFT |

327 |

O |

|

|

Disassembly and Assembly ……………………………. |

327 |

||

|

SERVICE DATA AND SPECIFICATIONS |

P |

||

|

(SDS) ………………………………………………… |

329 |

||

|

SERVICE DATA AND SPECIFICATIONS |

|||

|

(SDS) ……………………………………………………… |

329 |

||

|

General Specification ……………………………………. |

329 |

||

|

Snap Ring ……………………………………………………. |

330 |

||

|

FRONT FINAL DRIVE: R180A |

DLN-5

|

PRECAUTION ……………………………………. |

331 |

|

PRECAUTIONS ………………………………………. |

331 |

|

Precaution for Servicing Front Final Drive ………… |

331 |

|

PREPARATION ………………………………….. |

332 |

|

PREPARATION ………………………………………. |

332 |

|

Special Service Tool ……………………………………… |

332 |

|

Commercial Service Tool ………………………………. |

334 |

|

FUNCTION DIAGNOSIS ……………………… |

336 |

|

NOISE, VIBRATION AND HARSHNESS |

|

|

(NVH) TROUBLESHOOTING ……………………. |

336 |

|

NVH Troubleshooting Chart …………………………… |

336 |

|

DESCRIPTION ………………………………………… |

337 |

|

Cross-Sectional View ……………………………………. |

337 |

|

ON-VEHICLE MAINTENANCE …………….. |

338 |

|

DIFFERENTIAL GEAR OIL ………………………. |

338 |

|

Changing Differential Gear Oil ………………………… |

338 |

|

Checking Differential Gear Oil ………………………… |

338 |

|

ON-VEHICLE REPAIR ………………………… |

339 |

|

FRONT OIL SEAL …………………………………… |

339 |

|

Removal and Installation ……………………………….. |

339 |

|

SIDE OIL SEAL ………………………………………. |

341 |

|

Removal and Installation ……………………………….. |

341 |

|

CARRIER COVER …………………………………… |

342 |

|

Removal and Installation ……………………………….. |

342 |

|

REMOVAL AND INSTALLATION …………. |

343 |

|

FRONT FINAL DRIVE ASSEMBLY …………… |

343 |

|

Removal and Installation ……………………………….. |

343 |

|

DISASSEMBLY AND ASSEMBLY ……….. |

345 |

|

FRONT FINAL DRIVE ……………………………… |

345 |

|

Disassembly and Assembly ……………………………. |

345 |

|

SERVICE DATA AND SPECIFICATIONS |

|

|

(SDS) ………………………………………………… |

364 |

|

SERVICE DATA AND SPECIFICATIONS |

|

|

(SDS) ……………………………………………………… |

364 |

|

General Specification ……………………………………. |

364 |

|

Inspection and Adjustment …………………………….. |

364 |

|

FRONT FINAL DRIVE: M205 |

|

|

PRECAUTION ……………………………………. |

366 |

|

PRECAUTIONS ………………………………………. |

366 |

|

Precaution for Servicing Front Final Drive ………… |

366 |

|

PREPARATION ………………………………….. |

367 |

|

PREPARATION ……………………………………….. |

367 |

|

Special Service Tool …………………………………….. |

367 |

|

Commercial Service Tool ………………………………. |

369 |

|

FUNCTION DIAGNOSIS ……………………… |

370 |

|

NOISE, VIBRATION AND HARSHNESS |

|

|

(NVH) TROUBLESHOOTING …………………….. |

370 |

|

NVH Troubleshooting Chart …………………………… |

370 |

|

ON-VEHICLE MAINTENANCE …………….. |

371 |

|

DIFFERENTIAL GEAR OIL ……………………….. |

371 |

|

Changing Differential Gear Oil ……………………….. |

371 |

|

Checking Differential Gear Oil ……………………….. |

371 |

|

ON-VEHICLE REPAIR ………………………… |

372 |

|

SIDE OIL SEAL ……………………………………….. |

372 |

|

Removal and Installation ……………………………….. |

372 |

|

FRONT OIL SEAL ……………………………………. |

373 |

|

Removal and Installation ……………………………….. |

373 |

|

CARRIER COVER ……………………………………. |

375 |

|

Removal and Installation ……………………………….. |

375 |

|

REMOVAL AND INSTALLATION …………. |

376 |

|

FRONT FINAL DRIVE ………………………………. |

376 |

|

Removal and Installation ……………………………….. |

376 |

|

DISASSEMBLY AND ASSEMBLY ……….. |

378 |

|

FRONT FINAL DRIVE ………………………………. |

378 |

|

Disassembly and Assembly …………………………… |

378 |

|

SERVICE DATA AND SPECIFICATIONS |

|

|

(SDS) ………………………………………………… |

395 |

|

SERVICE DATA AND SPECIFICATIONS |

|

|

(SDS) ……………………………………………………… |

395 |

|

General Specification ……………………………………. |

395 |

|

Inspection and Adjustment …………………………….. |

395 |

|

REAR FINAL DRIVE: R200 |

|

|

PRECAUTION ……………………………………. |

397 |

|

PRECAUTIONS ……………………………………….. |

397 |

|

Precaution for Servicing Rear Final Drive ………… |

397 |

|

PREPARATION ………………………………….. |

398 |

|

PREPARATION ……………………………………….. |

398 |

|

Special Service Tool …………………………………….. |

398 |

|

Commercial Service Tool ………………………………. |

401 |

|

FUNCTION DIAGNOSIS ……………………… |

402 |

|

NOISE, VIBRATION AND HARSHNESS |

|

|

(NVH) TROUBLESHOOTING …………………….. |

402 |

|

NVH Troubleshooting Chart …………………………… |

402 |

DLN-6

|

DESCRIPTION ………………………………………… |

403 |

|

Cross-Sectional View ……………………………………. |

403 |

|

ON-VEHICLE MAINTENANCE …………….. |

404 |

|

DIFFERENTIAL GEAR OIL ……………………….. |

404 |

|

Changing Differential Gear Oil ……………………….. |

404 |

|

Checking Differential Gear Oil ………………………… |

404 |

|

ON-VEHICLE REPAIR ………………………… |

405 |

|

FRONT OIL SEAL ……………………………………. |

405 |

|

Removal and Installation ……………………………….. |

405 |

|

SIDE OIL SEAL ……………………………………….. |

407 |

|

Removal and Installation ……………………………….. |

407 |

|

CARRIER COVER ……………………………………. |

409 |

|

Removal and Installation ……………………………….. |

409 |

|

REMOVAL AND INSTALLATION ………… |

410 |

|

REAR FINAL DRIVE ………………………………… |

410 |

|

Removal and Installation ……………………………….. |

410 |

|

DISASSEMBLY AND ASSEMBLY ……….. |

413 |

|

REAR FINAL DRIVE ………………………………… |

413 |

|

Disassembly and Assembly …………………………… |

413 |

|

SERVICE DATA AND SPECIFICATIONS |

|

|

(SDS) ………………………………………………… |

432 |

|

SERVICE DATA AND SPECIFICATIONS |

|

|

(SDS) ……………………………………………………… |

432 |

|

General Specification ……………………………………. |

432 |

|

Inspection and Adjustment …………………………….. |

432 |

|

REAR FINAL DRIVE: R230 (4WD) |

|

|

PRECAUTION ……………………………………. |

434 |

|

PRECAUTIONS ……………………………………….. |

434 |

|

Precaution for Servicing Rear Final Drive ………… |

434 |

|

PREPARATION …………………………………. |

435 |

|

PREPARATION ……………………………………….. |

435 |

|

Special Service Tool ……………………………………… |

435 |

||

|

Commercial Service Tool ………………………………. |

438 |

A |

|

|

FUNCTION DIAGNOSIS ……………………… |

439 |

||

|

NOISE, VIBRATION AND HARSHNESS |

B |

||

|

(NVH) TROUBLESHOOTING ……………………. |

439 |

||

|

NVH Troubleshooting Chart …………………………… |

439 |

||

|

DESCRIPTION |

440 |

C |

|

|

Cross-Sectional View ……………………………………. |

440 |

||

|

DLN |

|||

|

ON-VEHICLE MAINTENANCE …………….. |

441 |

||

|

DIFFERENTIAL GEAR OIL |

441 |

||

|

Changing Differential Gear Oil ………………………… |

441 |

E |

|

|

Checking Differential Gear Oil |

441 |

||

|

ON-VEHICLE REPAIR ………………………… |

442 |

F |

|

|

FRONT OIL SEAL |

|||

|

442 |

|||

|

Removal and Installation ……………………………….. |

442 |

||

|

SIDE OIL SEAL |

444 |

G |

|

|

Removal and Installation ……………………………….. |

444 |

||

|

CARRIER COVER ……………………………………. |

446 |

H |

|

|

Removal and Installation ……………………………….. |

446 |

||

|

REMOVAL AND INSTALLATION ………… |

447 |

I |

|

|

REAR FINAL DRIVE ………………………………… |

447 |

||

|

Removal and Installation ……………………………….. |

447 |

||

|

DISASSEMBLY AND ASSEMBLY |

450 |

J |

|

|

REAR FINAL DRIVE ………………………………… |

450 |

K |

|

|

Disassembly and Assembly ……………………………. |

450 |

||

|

SERVICE DATA AND SPECIFICATIONS |

|||

|

(SDS) ………………………………………………… |

466 |

L |

|

|

SERVICE DATA AND SPECIFICATIONS |

|||

|

(SDS) ……………………………………………………… |

466 |

M |

|

|

General Specification |

466 |

||

|

Inspection and Adjustment …………………………….. |

466 |

N

O

P

DLN-7

DIAGNOSIS AND REPAIR WORKFLOW |

[TRANSFER: ATX14B] |

|

< BASIC INSPECTION > |

|

BASIC INSPECTION |

|

|

DIAGNOSIS AND REPAIR WORKFLOW |

|

Work Flow |

INFOID:0000000001728331 |

WORK FLOW |

AWNIA0126GB

DETAILED FLOW

1.CUSTOMER INFORMATION

Interview the customer to obtain detailed information about the symptom.

>> GO TO 2

2.PRELIMINARY CHECK

Perform preliminary check. Refer to DLN-9, «Preliminary Check».

>> GO TO 3

3.SELF-DIAGNOSIS

Perform self-diagnosis. Refer to DLN-20, «CONSULT-III Function (ALL MODE AWD/4WD)».

DLN-8

|

DIAGNOSIS AND REPAIR WORKFLOW |

|

|

< BASIC INSPECTION > |

[TRANSFER: ATX14B] |

>> GO TO 4

4.SYMPTOM

Check for symptoms. Refer to DLN-106, «Symptom Table».

>> GO TO 5

5.MALFUNCTIONING PARTS

Repair or replace the applicable parts.

>> GO TO 6

6.SYSTEM OPERATION

Check system operation.

>> GO TO 7

7.SELF-DIAGNOSIS

Perform self-diagnosis.

Are any DTC’s displayed?

|

YES |

>> GO TO 5 |

|

NO |

>> Inspection End |

Preliminary Check

TRANSFER FLUID CHECK

Check for leaks and fluid level. Refer to DLN-132, «Inspection».

A

B

C

DLN

E

F

G

H

INFOID:0000000001728332

I

PREPARATION FOR ROAD TEST

The purpose of the test is to determine overall performance of transfer case and analyze causes of malfunctions.

When a malfunction is found in any part of transfer, perform the road test to locate the malfunction area and repair the malfunction parts. The road test consists of the following three parts.

1.CHECK BEFORE ENGINE IS STARTED

2.CHECK AT IDLE

3.CRUISE TEST

CHECK BEFORE ENGINE IS STARTED

1.CHECK 4WD SHIFT INDICATOR LAMP

1.Park vehicle on flat surface.

2.Turn ignition switch to OFF position.

3.Move A/T selector lever to P position.

4.Set 4WD shift switch to 2WD position.

5.Turn ignition switch to ON position. (Do not start engine.)

Does 4WD shift indicator lamp turn ON for approximately 1 second?

|

YES |

>> GO TO 2. |

|

NO |

>> GO TO DLN-107, «Diagnosis Procedure». |

2.CHECK 4WD WARNING LAMP

1.Turn ignition switch to OFF position.

2.Move A/T selector lever to P position.

3.Set 4WD shift switch to 2WD position.

4.Turn ignition switch to ON position. (Do not start engine.)

DLN-9

|

DIAGNOSIS AND REPAIR WORKFLOW |

[TRANSFER: ATX14B] |

|

|

< BASIC INSPECTION > |

||

|

Does 4WD warning lamp turn ON? |

||

|

YES |

>> GO TO CHECK AT IDLE. |

|

|

NO |

>> GO TO DLN-110, «Diagnosis Procedure». |

CHECK AT IDLE

1.CHECK 4WD SHIFT INDICATOR LAMP

1.Park vehicle on flat surface and engage the parking brake.

2.Turn ignition switch to OFF position.

3.Move A/T selector lever to P position.

4.Set 4WD shift switch to 2WD position.

5.Start engine.

Does 4WD shift indicator lamp turn ON?

|

YES |

>> GO TO 3. |

|

NO |

>> GO TO 2. |

2.CHECK 4WD WARNING LAMP

Check 4WD warning lamp state.

Is 4WD warning lamp turned ON?

|

YES |

>> Perform the self-diagnosis. Refer to DLN-20, «CONSULT-III Function (ALL MODE AWD/4WD)». |

|

NO |

>> Refer to DLN-113, «Diagnosis Procedure». |

3.CHECK 4WD SHIFT INDICATOR AND 4LO INDICATOR OPERATION

1.Brake pedal depressed.

2.Move A/T selector lever to N position.

3.Set 4WD shift switch to 2WD, AUTO, 4H, 4LO, 4H, AUTO and 2WD in order. (Stay at each switch position for at least 1 second.)

Do 4WD shift indicator and 4LO indicator lamps change properly?

Does buzzer sound?

|

YES |

>> GO TO CRUISE TEST. |

|

NO |

>> GO TO DLN-113, «Diagnosis Procedure». |

WDIA0136E

CRUISE TEST

1.CHECK INPUT SIGNAL

1.Warm up engine to normal operating temperature.

2.Park vehicle on flat surface.

3.Move A/T selector lever to P position.

4.Set 4WD shift switch to AUTO position.

5.Start engine.

6.Drive vehicle for at least 30 seconds at a speed higher than 20 km/h (12 MPH).

Is 4WD warning lamp turned ON?

On steady>>Perform the self-diagnosis. Refer to DLN-20, «CONSULT-III Function (ALL MODE AWD/4WD)».

DLN-10

|

DIAGNOSIS AND REPAIR WORKFLOW |

[TRANSFER: ATX14B] |

|

< BASIC INSPECTION > |

|

|

Flash rapidly>>Refer to DLN-118, «Diagnosis Procedure». |

|

|

Flash slowly>>Refer to DLN-119, «Diagnosis Procedure». |

|

|

NO >> GO TO 2. |

|

|

2.CHECK TIGHT CORNER BRAKING SYMPTOM (1) |

1.Set 4WD shift switch to AUTO position.

2.Drive vehicle at speed lower than 20 km/h (12 MPH) with steering wheel fully turned.

Does tight corner braking symptom occur?

|

YES |

>> GO TO DLN-120, «Diagnosis Procedure». |

|

NO |

>> GO TO 3. |

3.CHECK TIGHT CORNER BRAKING SYMPTOM (2)

1.Set 4WD shift switch to 4HI position.

2.Drive vehicle at speed lower than 20 km/h (12 MPH) with steering wheel fully turned.

Does tight corner braking symptom occur?

|

YES |

>> Inspection End. |

|

NO |

>> GO TO DLN-124, «Diagnosis Procedure». |

A

B

C

DLN

E

F

G

H

I

J

K

L

M

N

O

P

DLN-11

4WD SYSTEM |

|

|

< FUNCTION DIAGNOSIS > |

[TRANSFER: ATX14B] |

FUNCTION DIAGNOSIS |

|

|

4WD SYSTEM |

|

System Diagram |

INFOID:0000000001728333 |

|

WDIA0164E |

||||

COMPONENT DESCRIPTION |

||||

|

Components |

Function |

|||

|

Transfer control unit |

Controls transfer control device, control valves and shifts between 2WD/4WD and 4H/4LO. |

|||

|

Transfer control device |

Integrates actuator motor and actuator position switch. |

|||

|

2-4WD shift solenoid valve |

Controls oil pressure and allows shifting between 2WD and 4WD. |

|||

|

Clutch pressure solenoid valve |

Controls oil pressure and distributes torque between front and rear tires. |

|||

|

Line pressure switch |

Detects line pressure. |

|||

|

Clutch pressure switch |

Detects clutch pressure. |

|||

|

Transfer fluid temperature sensor |

Detects transfer fluid temperature. |

|||

|

Actuator motor |

Moves shift rods when signaled by transfer control unit. |

|||

|

Actuator position switch |

Detects actuator motor position. |

|||

|

Wait detection switch |

Detects whether or not 4WD lock gear is locked. |

|||

|

4LO switch |

Detects if transfer case is in 4LO. |

|||

|

ATP switch |

Detects if transfer case is in neutral. |

|||

|

4WD shift switch |

Allows driver to select from 2WD/4WD, 4H/4LO and AUTO. |

|||

|

• Illuminates if malfunction is detected in 4WD system. |

||||

|

4WD warning lamp |

• Flashes (1 flash / 2 seconds) if large difference in diameter of front and rear tires. |

|||

|

• Flashes (2 flashes / 1 second) if high transfer fluid temperature is detected. |

||||

|

ATP warning lamp |

Indicates that A/T parking mechanism does not operate when A/T selector lever is in P position |

|||

|

because transfer case is in neutral. |

||||

|

4WD shift indicator lamp |

Displays driving range selected by 4WD shift switch. |

|||

|

4LO indicator lamp |

Displays 4LO range. |

|||

DLN-12

|

4WD SYSTEM |

||||||

|

< FUNCTION DIAGNOSIS > |

[TRANSFER: ATX14B] |

|||||

|

Components |

Function |

A |

||||

|

ABS actuator and electric unit |

Transmits vehicle speed signal via CAN communication to transfer control unit. |

|||||

|

(control unit) |

||||||

|

Transmits the following signal via CAN communication to transfer control unit. |

B |

|||||

|

TCM |

• Output shaft revolution signal |

|||||

|

• A/T position indicator signal (PNP switch signal) |

||||||

|

Transmits the following signals via CAN communication to transfer control unit. |

||||||

|

ECM |

• Engine speed signal |

C |

||||

|

• Accelerator pedal position signal |

||||||

System Description |

INFOID:0000000001728334 |

|||||

|

DLN |

CONTROL SYSTEM

E

F

G

H

I

J

K

L

M

N

O

P

DLN-13

|

4WD SYSTEM |

|

|

< FUNCTION DIAGNOSIS > |

[TRANSFER: ATX14B] |

SDIA3396E

ALL-MODE 4WD Transfer Basic Control

DLN-14

|

4WD SYSTEM |

|

|

< FUNCTION DIAGNOSIS > |

[TRANSFER: ATX14B] |

LDIA0055E

Hydraulic Control Circuits

WDIA0163E

TRANSFER CONTROL UNIT

•Transfer control unit controls transfer control device and it directs shifts from 4H-4LO and 2WD-4WD.

•Self-diagnosis can be done.

A

B

C

DLN

E

F

G

H

I

J

K

L

M

TRANSFER SHIFT HIGH AND LOW RELAYS

Transfer shift high and low relays apply power supply to transfer control device (actuator motor).

TRANSFER SHUT OFF RELAY

Transfer shut off relay applies power supply to transfer motor relay.

4WD SHIFT SWITCH AND INDICATOR LAMPS

4WD Shift Switch

Able to select from 2WD, AUTO, 4H or 4LO.

4WD Shift Indicator Lamp

•Displays driving conditions selected by 4WD shift switch with 2WD, AUTO and 4H indicators while engine is running. (When 4WD warning lamp is turned on, all 4WD shift indicator lamps are turned off.)

•Turns ON for approximately 1 second when ignition switch is turned ON, for purpose of lamp check.

4LO Indicator Lamp

DLN-15

|

4WD SYSTEM |

|

|

< FUNCTION DIAGNOSIS > |

[TRANSFER: ATX14B] |

•Displays 4LO condition while engine is running. 4LO indicator lamp flashes if transfer gear does not shift completely under 2WD, AUTO, 4H 4LO. (When 4WD warning lamp is turned on, 4LO indicator lamp is turned off.)

•Turns ON for approximately 1 second when ignition switch is turned ON, for purpose of lamp check.

4WD WARNING LAMP

Turns on or flashes when there is a malfunction in 4WD system.

Also turns on when ignition switch is turned ON, for purpose of lamp check. Turns OFF approximately 1 second after the engine starts if system is normal.

4WD Warning Lamp Indication

|

Condition |

4WD warning lamp |

|

|

System normal |

OFF |

|

|

Lamp check |

Turns ON when ignition switch is turned ON. |

|

|

Turns OFF after engine start. |

||

|

4WD system malfunction |

ON |

|

|

During self-diagnosis |

Flashes malfunction mode. |

|

|

Large difference in diameter of front/ |

Flashes slow (1 flash / 2 seconds) |

|

|

rear tires |

(Continues to flash until the ignition switch is turned OFF) |

|

|

High fluid temperature in transfer case |

Flashes rapidly (2 flashes / 1 second) |

|

|

(Continues to flash until fluid temperature returns to normal) |

||

ATP WARNING LAMP

When the A/T selector lever is in P position, the vehicle may move if the transfer case is in neutral. ATP warning lamp is turned on to indicate this condition to the driver.

LINE PRESSURE SWITCH

•With the transfer system design, control of the oil pressure provides the transmission of drive torque to the front wheels. The main pressure to control the oil pressure is referred to as the line pressure.

•The line pressure switch determines whether or not adequate line pressure has built up under different operating conditions.

•The line pressure switch closes when line pressure is produced.

•The line pressure switch senses line pressure abnormalities and turns the 4WD warning lamp ON.

CLUTCH PRESSURE SWITCH

•The clutch pressure switch determines whether or not adequate clutch pressure has built up under different operating conditions.

•The clutch pressure switch closes when clutch pressure is produced.

•The clutch pressure switch senses clutch pressure abnormalities and turns the 4WD warning lamp ON.

WAIT DETECTION SWITCH

•The wait detection switch operates when there is circulating torque produced in the propeller shaft (L→H) or when there is a phase difference between 2-4 sleeve and clutch drum (H→L). After the release of the circulating torque, the wait detection switch helps provide the 4WD lock gear (clutch drum) shifts. A difference may occur between the operation of the 4WD shift switch and actual drive mode. At this point, the wait detection switch senses an actual drive mode.

•The wait detection switch operates as follows.

—4WD lock gear (clutch drum) locked: ON

—4WD lock gear (clutch drum) released: OFF

•The wait detection switch senses an actual drive mode and the 4WD shift indicator lamp indicates the vehicle drive mode.

ATP SWITCH

ATP switch detects if transfer case is in neutral by the position of the L-H shift fork.

NOTE:

Transfer case may be in neutral when shifting between 4H-4LO.

NEUTRAL-4LO SWITCH

The neutral-4LO switch detects that transfer gear is in neutral or 4LO (or shifting from neutral to 4LO) condition by L-H shift fork position.

DLN-16

|

4WD SYSTEM |

|

|

< FUNCTION DIAGNOSIS > |

[TRANSFER: ATX14B] |

TRANSFER FLUID TEMPERATURE SENSOR

The transfer fluid temperature sensor detects the transfer fluid temperature and sends a signal to the transfer A control unit.

TRANSFER MOTOR

• The transfer motor drives the sub-oil pump to provide proper lubrication and oil pressure control when the vehicle is at standstill, during low-speed operations or is being driven in reverse.

• The main oil pump is operated by the driving force of the mainshaft. In other words, sufficient oil pressure buildup does not occur when the vehicle is at standstill or during low-speed operations. While the vehicle is being driven in reverse, the main oil pump rotates in the reverse direction. Therefore the main oil pump does not discharge oil pressure. During any of the above vehicle operations, the transfer motor drives the sub-oil pump to compensate for insufficient oil pressure.

• The transfer motor operates as follows:

— The motor relay turns OFF in the 2WD mode.

— The motor relay operates as described in the table below in modes other than the 2WD mode.

• 4WD shift switch, PNP switch, Neutral-4LO switch, vehicle speed sensor and throttle position sensor are used in conjunction with the transfer motor.

Transfer Motor Relay Operation

|

4WD shift switch |

A/T selector lever position |

Vehicle speed |

Accelerator pedal position |

Motor relay drive |

|

|

(VSS) |

command |

||||

|

2WD |

— |

— |

— |

OFF |

|

|

N position |

0 |

— |

ON |

||

|

0 — 0.07/8 |

OFF* |

||||

|

P position |

0 |

0.07/8 — 1/8 |

HOLD |

||

|

1/8 — MAX |

ON |

||||

|

4H (LOCK) and 4LO |

|||||

|

0 < VSS ≤ 50 km/h (31 MPH) |

ON |

||||

|

Other than R position |

50 km/h (31 MPH) < VSS < 55 |

— |

HOLD |

||

|

km/h (34 MPH) |

|||||

|

55 km/h (34 MPH) ≤ VSS |

OFF |

||||

|

R position |

— |

— |

ON |

||

|

R position |

— |

— |

ON |

||

|

0 — 0.07/8 |

OFF* |

||||

|

0 |

0.07/8 — 1/8 |

HOLD |

|||

|

1/8 — MAX |

ON |

||||

|

P or N position |

|||||

|

0 < VSS ≤ 50 km/h (31 MPH) |

ON |

||||

|

AUTO |

50 km/h (31 MPH) < VSS < 55 |

— |

HOLD |

||

|

km/h (34 MPH) |

|||||

|

55 km/h (34 MPH) ≤ VSS |

OFF |

||||

|

0 < VSS ≤ 50 km/h (31 MPH) |

ON |

||||

|

Other than R, P and N posi- |

50 km/h (31 MPH) < VSS < 55 |

— |

HOLD |

||

|

tion |

km/h (34 MPH) |

||||

|

55 km/h (34 MPH) ≤ VSS |

OFF |

||||

*: After 2.5 seconds have elapsed.

CLUTCH PRESSURE SOLENOID VALVE

The clutch pressure solenoid valve distributes front and rear torque in AUTO mode.

2-4WD SHIFT SOLENOID VALVE

The 2-4WD shift solenoid valve operates to apply oil pressure to the wet-multiplate clutch, depending on the drive mode. The driving force is transmitted to the front wheels through the clutch so the vehicle is set in the 4WD mode. Setting the vehicle in the 2WD mode requires no pressure buildup. In other words, pressure force applied to the wet-multiplate clutch becomes zero.

TRANSFER CONTROL DEVICE

Integrates actuator motor and actuator position switch.

B

C

DLN

E

F

G

H

I

J

K

L

M

N

O

P

DLN-17

|

4WD SYSTEM |

|

|

< FUNCTION DIAGNOSIS > |

[TRANSFER: ATX14B] |

Actuator Motor

Moves shift rods when signaled by transfer control unit.

Actuator Position Switch

Detects actuator motor position and then sends signal to transfer control unit.

Component Parts Location |

INFOID:0000000001728335 |

WDIA0124E

DLN-18

|

4WD SYSTEM |

|

|

< FUNCTION DIAGNOSIS > |

[TRANSFER: ATX14B] |

CAN Communication |

INFOID:0000000001728336 |

A

Refer to LAN-10, «Self-Diagnosis».

B

C

DLN

E

F

G

H

I

J

K

L

M

N

O

P

DLN-19

DIAGNOSIS SYSTEM (TRANSFER CONTROL UNIT)

|

< FUNCTION DIAGNOSIS > |

[TRANSFER: ATX14B] |

|

DIAGNOSIS SYSTEM (TRANSFER CONTROL UNIT) |

|

CONSULT-III Function (ALL MODE AWD/4WD) |

INFOID:0000000001728337 |

FUNCTION

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

|

ALL MODE AWD/4WD diagnostic mode |

Description |

|

SELF-DIAG RESULTS |

Displays transfer control unit self-diagnosis results. |

|

DATA MONITOR |

Displays transfer control unit input/output data in real time. |

|

Supports inspections and adjustments. Commands are transmitted to the transfer control |

|

|

WORK SUPPORT |

unit for setting the status suitable for required operation, input/output signals are received |

|

from the transfer control unit and received data is displayed. |

|

|

CAN DIAG SUPPORT MNTR |

The results of transmit/receive diagnosis of CAN communication can be read. |

|

ECU PART NUMBER |

Transfer control unit part number can be read. |

SELF-DIAG RESULT MODE

Operation Procedure

1.Connect CONSULT-III.

2.With engine at idle, touch SELF-DIAG RESULTS.

Display shows malfunction experienced since the last erasing operation.

NOTE:

The details for TIME are as follows:

•0: Error currently detected with transfer control unit.

•Except for 0: Error detected in the past and memorized with transfer control unit.

Detects frequency of driving after DTC occurs (frequency of turning ignition switch ON/OFF).

How to Erase Self-diagnostic Results

1.Perform applicable inspection of malfunctioning item and then repair or replace.

2.Start engine and select SELF-DIAG RESULTS mode for ALL MODE AWD/4WD with CONSULT-III.

3.Touch ERASE on CONSULT-III screen to erase DTC memory.

CAUTION:

If memory cannot be erased, perform applicable diagnosis.

Description

If the engine starts when there is a malfunction in the 4WD system, the 4WD warning lamp turns ON or flickers in the combination meter. When the system functions properly, the warning lamp turns ON when the ignition switch is turned to ON, and it turns OFF after engine starts. To locate the cause of a malfunction, start the selfdiagnosis function. The 4WD warning lamp in the combination meter will indicate the malfunction area by flashing according to the self-diagnostic results. Refer to DLN-101, «DTC Index».

Diagnostic Procedure

1.Warn up engine.

2.Move A/T selector lever to P position.

3.Turn 4WD shift switch to 2WD position.

4.Turn ignition switch ON and OFF at least twice, and then turn ignition switch OFF.

5.Turn 4WD shift switch to AUTO position.

6.Turn ignition switch ON. (Do not start engine.)

7.4WD warning lamp ON.

8.Move A/T selector lever to R position.

9.Turn 4WD shift switch to 2WD, AUTO and 2WD in order.

10.Move A/T selector lever to D position.

11.Turn 4WD shift switch to 4H, AUTO and 4H in order.

DLN-20

DIAGNOSIS SYSTEM (TRANSFER CONTROL UNIT)

|

< FUNCTION DIAGNOSIS > |

[TRANSFER: ATX14B] |

12.Move A/T selector lever to N position.

13.Turn 4WD shift switch to AUTO position.

14.Move A/T selector lever to P position.

15.Read the flickering of 4WD warning lamp.

Self-diagnosis example

PDIA0227E

ERASE SELF-DIAGNOSIS

•In order to make it easier to find the cause of hard-to-duplicate malfunctions, malfunction information is stored into the control unit as necessary during use by the user. This memory is not erased no matter how many times the ignition switch is turned ON and OFF.

•However, this information is erased by turning ignition switch OFF after performing self-diagnostics or by erasing the memory using the CONSULT-III.

DATA MONITOR MODE

Operation Procedure

1.Connect CONSULT-III.

2.Touch DATA MONITOR.

3.Select from SELECT MONITOR ITEM, screen of data monitor mode is displayed.

NOTE:

When malfunction is detected, CONSULT-III performs REAL-TIME DIAGNOSIS. Also, any malfunction detected while in this mode will be displayed at real time.

Display Item List

|

×: Standard –: Not applicable |

|||||

|

Monitor item selection |

|||||

|

Monitored item (Unit) |

ECU INPUT |

MAIN |

SELEC- |

Remarks |

|

|

TION FROM |

|||||

|

SIGNALS |

SIGNALS |

||||

|

MENU |

|||||

|

Wheel speed calculated by ABS actuator and |

|||||

|

VHCL/S SEN·FR [km/h] or [mph] |

× |

– |

× |

electric unit (control unit). |

|

|

Signal input with CAN communication line. |

|||||

|

VHCL/S SEN·RR [km/h] or [mph] |

× |

– |

× |

Wheel speed calculated by TCM. |

|

|

Signal input with CAN communication line. |

|||||

|

ENGINE SPEED [rpm] |

× |

– |

× |

Engine speed calculated by ECM. |

|

|

Signal input with CAN communication line. |

|||||

|

× |

× |

Accelerator pedal position (APP) sensor sig- |

|||

|

THRTL POS SEN [V] |

– |

nal voltage is displayed. |

|||

|

Signal input with CAN communication line. |

|||||

|

FLUID TEMP SE [V] |

× |

– |

× |

Transfer fluid temperature sensor signal volt- |

|

|

age is displayed. |

|||||

|

BATTERY VOLT [V] |

× |

– |

× |

Power supply voltage for transfer control unit. |

|

|

2WD SWITCH [ON/OFF] |

× |

– |

× |

4WD shift switch status is displayed. |

|

|

AUTO SWITCH [ON/OFF] |

× |

– |

× |

4WD shift switch status is displayed. |

|

|

LOCK SWITCH [ON/OFF] |

× |

– |

× |

4WD shift switch status is displayed. |

|

|

(LOCK means 4H of 4WD shift switch.) |

|||||

DLN-21

DIAGNOSIS SYSTEM (TRANSFER CONTROL UNIT)

|

< FUNCTION DIAGNOSIS > |

[TRANSFER: ATX14B] |

|||||

|

Monitor item selection |

||||||

|

Monitored item (Unit) |

ECU INPUT |

MAIN |

SELEC- |

Remarks |

||

|

TION FROM |

||||||

|

SIGNALS |

SIGNALS |

|||||

|

MENU |

||||||

|

4L SW [ON/OFF] |

× |

– |

× |

4WD shift switch status is displayed. |

||

|

(4L means 4LO of 4WD shift switch.) |

||||||

|

N POSI SW TF [ON/OFF] |

× |

– |

× |

Neutral-4LO switch signal status is displayed. |

||

|

ATP SWITCH [ON/OFF] |

× |

– |

× |

ATP switch signal status is displayed. |

||

|

WAIT DETCT SW [ON/OFF] |

× |

– |

× |

Wait detection switch status is displayed. |

||

|

LINE PRES SW [ON/OFF] |

× |

– |

× |

Line pressure switch status is displayed. |

||

|

CL PRES SW [ON / OFF] |

× |

– |

× |

Clutch pressure switch status is displayed. |

||

|

× |

× |

N position signal of A/T PNP switch status is |

||||

|

N POSI SW AT [ON/OFF] |

– |

displayed. |

||||

|

Signal input with CAN communication line. |

||||||

|

R position signal of A/T PNP switch status is |

||||||

|

R POSI SW AT [ON/OFF] |

× |

– |

× |

displayed. |

||

|

Signal input with CAN communication line. |

||||||

|

P position signal of A/T PNP switch status is |

||||||

|

P POSI SW AT [ON/OFF] |

× |

– |

× |

displayed. |

||

|

Signal input with CAN communication line. |

||||||

|

ABS OPER SW [ON/OFF] |

× |

– |

× |

ABS operation signal status is displayed. |

||

|

Signal input with CAN communication line. |

||||||

|

VDC OPER SW [ON/OFF] |

× |

– |

× |

VDC operation signal status is displayed. |

||

|

Signal input with CAN communication line. |

||||||

|

TCS OPER SW [ON/OFF] |

× |

– |

× |

TCS operation signal status is displayed. |

||

|

Signal input with CAN communication line. |

||||||

|

THROTTLE POSI [0.0/8] |

– |

× |

× |

Thottle position status is displayed. |

||

|

Signal input with CAN communication line. |

||||||

|

4WD MODE [AUTO/LOCK/2WD/4L] |

– |

× |

× |

Control status of 4WD recognized by transfer |

||

|

control unit. (AUTO, 4H, 2WD or 4LO) |

||||||

|

VHCL/S COMP [km/h] or [mph] |

– |

× |

× |

Vehicle speed recognized by transfer control |

||

|

unit. |

||||||

|

COMP CL TORQ [kgm] |

– |

× |

× |

Calculated torque recognized by transfer con- |

||

|

trol unit. |

||||||

|

DUTY SOLENOID [%] |

– |

× |

× |

Control value of clutch pressure solenoid. |

||

|

2-4WD SOL [ON/OFF] |

– |

× |

× |

Output condition to 2-4WD solenoid. |

||

|

2-4WD SOL MON [ON/OFF] |

– |

– |

× |

Check signal for transfer control unit signal |

||

|

output. |

||||||

|

MOTOR RELAY [ON/OFF] |

– |

× |

× |

Transfer motor relay signal status is dis- |

||

|

played. |

||||||

|

MOTOR RELAY MON [ON/OFF] |

– |

– |

× |

Check signal for transfer control unit signal |

||

|

output. |

||||||

|

4WD FAIL LAMP [ON/OFF] |

– |

× |

× |

Control status of 4WD warning lamp is dis- |

||

|

played. |

||||||

|

2WD IND [ON/OFF] |

– |

– |

× |

Control status of 4WD shift indicator lamp |

||

|

(2WD indicator lamp) is displayed. |

||||||

|

AUTO IND [ON/OFF] |

– |

– |

× |

Control status of 4WD shift indicator lamp |

||

|

(2WD and AUTO indicator lamp) is displayed. |

||||||

|

LOCK IND [ON/OFF] |

– |

– |

× |

Control status of 4WD shift indicator lamp |

||

|

(2WD, AUTO and Lock indicator) is displayed. |

||||||

|

4L IND [ON/OFF] |

– |

– |

× |

Control status of 4LO indicator lamp is dis- |

||

|

played. |

||||||

DLN-22

DIAGNOSIS SYSTEM (TRANSFER CONTROL UNIT)

|

< FUNCTION DIAGNOSIS > |

[TRANSFER: ATX14B] |

|||||

|

Monitor item selection |

||||||

|

Monitored item (Unit) |

ECU INPUT |

MAIN |

SELEC- |

Remarks |

||

|

TION FROM |

||||||

|

SIGNALS |

SIGNALS |

|||||

|

MENU |

||||||

|

ATP IND [ON/OFF] |

– |

– |

× |

Control status of ATP warning lamp is dis- |

||

|

played. |

||||||

|

SHIFT POS SW1 [ON/OFF] |

× |

– |

× |

Actuator position switch 1 (Low) signal status |

||

|

is displayed. |

||||||

|

SHIFT POS SW2 [ON/OFF] |

× |

– |

× |

Actuator position switch 2 (high) signal status |

||

|

is displayed. |

||||||

|

SHIFT ACT1 [ON/OFF] |

– |

× |

× |

Output condition to actuator motor (clockwise) |

||

|

SHIFT AC MON1 [ON/OFF] |

× |

– |

× |

Check signal for transfer control unit signal |

||

|

output |

||||||

|

SHIFT ACT2 [ON/OFF] |

– |

× |

× |

Output condition to actuator motor (counter- |

||

|

clockwise) |

||||||

|

SHIFT AC MON2 [ON/OFF] |

× |

– |

× |

Check signal for transfer control unit signal |

||

|

output |

||||||

|

T/F F SPEED [km/h] or [mph] |

× |

– |

× |

Displayed, but do not use. |

||

|

Output shaft revolution signal (Revolution |

||||||

|

A/T R SPEED [km/h] or [mph] |

× |

– |

× |

sensor) calculated by TCM. |

||

|

Signal input with CAN communication line. |

||||||

|

AT GEAR POSI [1/2/3/4/5] |

× |

– |

× |

A/T actual gear position is displayed. |

||

WORK SUPPORT

When there is no malfunction with transfer and 4WD system, the following symptoms in AUTO mode may be claimed by a customer: vibration when accelerating on a low road (snow-covered or icy road) or a slight shock is felt at a few hertz as if it were being pushed lightly from behind.

It is possible to deal with these symptoms by changing the CLUTCH FORCE RELEASE LIMIT VALUE. However, be careful when changing the value because it may adversely affect driving performance.

Operation Procedure

1.Connect CONSULT-III.

2.Touch WORK SUPPORT.

3.Select from CLUTCH/F RLS LIM ADJ, screen of data monitor mode is displayed.

Clutch Force Release Limit Adjustment

1.Initial CLUTCH FORCE RELEASE LIMIT value 0.3 kgm appears under CONDITION SETTING on CON- SULT-III display.

1.2 kg-m : Tight corner braking symptom is alleviated. However, vibration may occur when accelerating on a low road (icy road, etc.).

0.3 kg-m : Initial set value.

0.2 kg-m : Do not set to this value because the tight corner braking symptom will get worse.

2.Touch 1.2 on the display.

3.Display changes to NOW ADJUSTING in a short time.

4.When clutch force release limit value is set to 1.2 kgm, current value 0.3 kgm shown on display will be replaced by 1.2 kgm and ADJUSTMENT COMPLETE will appear at the same time. Clutch force release limit value setting is now complete.

A

B

C

DLN

E

F

G

H

I

J

K

L

M

N

O

P

DLN-23

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

|

< FUNCTION DIAGNOSIS > |

[TRANSFER: ATX14B] |

|

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING |

|

NVH Troubleshooting Chart |

INFOID:0000000001282210 |

Use the chart below to help you find the cause of the symptom. The numbers indicate the order of the inspection. If necessary, repair or replace these parts.

|

Reference page |

DLN-132 |

DLN-149 |

DLN-149 |

DLN-149 |

DLN-149 |

|||||||||||

|

SUSPECTED PARTS |

TRANSFER FLUID (Level low) |

TRANSFER FLUID (Wrong) |

TRANSFER FLUID (Level too high) |

LIQUID GASKET (Damaged) |

O-RING (Worn or damaged) |

OIL SEAL (Worn or damaged) |

SHIFT FORK (Worn or damaged) |

GEAR (Worn or damaged) |

BEARING (Worn or damaged) |

|||||||

|

(Possible cause) |

||||||||||||||||

|

Noise |

1 |

2 |

3 |

3 |

||||||||||||

|

Symptom |

Transfer fluid leakage |

3 |

1 |

2 |

2 |

2 |

||||||||||

|

Hard to shift or will not shift |

1 |

1 |

2 |

|||||||||||||

DLN-24

P1811 POWER SUPPLY CIRCUIT FOR TRANSFER CONTROL UNIT

|

< COMPONENT DIAGNOSIS > |

[TRANSFER: ATX14B] |

COMPONENT DIAGNOSIS

P1811 POWER SUPPLY CIRCUIT FOR TRANSFER CONTROL UNIT

A

Description |

INFOID:0000000001728338 B |