Operating Instructions

Proline Prosonic Flow 92F

HART

Ultrasonic Flow Measuring System

6

BA00121D/06/EN/13.10

71124139

Valid as of version V1.01.XX (device software)

|

Proline Prosonic Flow 92F |

Table of contents |

Table of contents

|

1 |

Safety instructions . . . . . . . . . . . . . . . . |

5 |

|

1.1 |

Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 |

|

1.2 |

Installation, commissioning and operation . . . . . . . . |

5 |

|

1.3 |

Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 |

|

1.4 |

Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

|

1.5 |

Notes on safety conventions and icons . . . . . . . . . . . |

6 |

|

2 |

Identification . . . . . . . . . . . . . . . . . . . . |

7 |

|

2.1 |

Device designation . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

|

2.1.1 Nameplate of the transmitter . . . . . . . . . . . . |

7 |

|

|

2.1.2 Nameplate of the sensor . . . . . . . . . . . . . . . |

8 |

|

|

2.1.3 Nameplate for connections . . . . . . . . . . . . . |

8 |

|

|

2.2 |

Certificates and approvals . . . . . . . . . . . . . . . . . . . . |

9 |

|

2.3 |

Registered trademarks . . . . . . . . . . . . . . . . . . . . . . . |

9 |

|

3 |

Installation . . . . . . . . . . . . . . . . . . . . . |

10 |

|

|

3.1 |

Incoming acceptance, transport, storage . . . . . . . . . |

10 |

|

|

3.1.1 |

Incoming acceptance . . . . . . . . . . . . . . . . . |

10 |

|

|

3.1.2 |

Transport . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

|

|

3.1.3 |

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

|

|

3.2 |

Installation conditions . . . . . . . . . . . . . . . . . . . . . . |

11 |

|

|

3.2.1 |

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . |

11 |

|

|

3.2.2 |

Mounting location . . . . . . . . . . . . . . . . . . . |

11 |

|

|

3.2.3 |

Orientation . . . . . . . . . . . . . . . . . . . . . . . . |

12 |

|

|

3.2.4 |

Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . |

12 |

|

|

3.2.5 |

Thermal insulation . . . . . . . . . . . . . . . . . . |

13 |

|

|

3.2.6 Inlet and outlet run . . . . . . . . . . . . . . . . . . |

13 |

||

|

3.2.7 |

Limiting flow . . . . . . . . . . . . . . . . . . . . . . . |

13 |

|

|

3.3 |

Installation instructions . . . . . . . . . . . . . . . . . . . . . |

14 |

|

|

3.3.1 |

Mounting the sensor . . . . . . . . . . . . . . . . . |

14 |

|

|

3.3.2 Turning the transmitter housing . . . . . . . . |

14 |

||

|

3.3.3 Turning the local display . . . . . . . . . . . . . . |

14 |

||

|

3.3.4 Mounting the remote version . . . . . . . . . . |

15 |

||

|

3.4 |

Post-installation check . . . . . . . . . . . . . . . . . . . . . . |

15 |

|

4 |

Wiring . . . . . . . . . . . . . . . . . . . . . . . . |

16 |

|

4.1 Connecting the remote version . . . . . . . . . . . . . . . |

16 |

4.1.1Connecting cable for sensor/transmitter . . 16

4.1.2 Cable specification for connecting cable . . . 16 4.2 Connecting the measuring unit . . . . . . . . . . . . . . . 17 4.2.1 Connecting the transmitter . . . . . . . . . . . . 17 4.2.2 Terminal assignment . . . . . . . . . . . . . . . . . 19 4.2.3 HART connection . . . . . . . . . . . . . . . . . . . 20

4.3 Degree of protection . . . . . . . . . . . . . . . . . . . . . . . 21 4.4 Post-connection check . . . . . . . . . . . . . . . . . . . . . . 22

|

5 |

Operation . . . . . . . . . . . . . . . . . . . . . . |

23 |

|

5.1 |

Display and operating elements . . . . . . . . . . . . . . . |

23 |

|

5.2 |

Operation via the function matrix . . . . . . . . . . . . . |

24 |

|

5.2.1 General notes . . . . . . . . . . . . . . . . . . . . . . |

25 |

|

|

5.2.2 Enabling the programming mode . . . . . . . . |

25 |

|

|

5.2.3 Disabling the programming mode . . . . . . . |

25 |

|

|

5.3 |

Communication . . . . . . . . . . . . . . . . . . . . . . . . . . |

26 |

Endress+Hauser

5.3.1 Operating options . . . . . . . . . . . . . . . . . . . 27 5.3.2 Current device description files . . . . . . . . . 28

5.3.3Device variables and process variables . . . . 29

5.3.4 Universal/common practice HART commands . . 30 5.3.5 Device status/diagnosis code messages . . . . 35

5.3.6Switching HART write protection on/off . . 37

6 Commissioning . . . . . . . . . . . . . . . . . . 38

6.1 Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . 38 6.2 Switching on the measuring device . . . . . . . . . . . . 38 6.3 Quick Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39 6.3.1 «Commissioning» Quick Setup . . . . . . . . . . 39

6.3.2Data backup with the T–DAT SAVE/LOAD

|

function . . . . . . . . . . . . . . . . . . . . . . . |

. . . . 41 |

||

|

6.4 |

Adjust |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . 42 |

|

6.4.1 |

Zero point adjustment . . . . . . . . . . . . |

. . . . 42 |

|

|

6.5 |

Data storage device (HistoROM) . . . . . . . . . . |

. . . . 43 |

|

|

6.5.1 |

HistoROM/T-DAT (transmitter–DAT) |

. . . . 43 |

|

7 |

Maintenance . . . . . . . . . . . . . . . . |

. . . . 44 |

|

|

7.1 |

Exterior cleaning . . . . . . . . . . . . . . . . . . . . . |

. . . . . 44 |

|

|

7.2 |

Cleaning with pigs . . . . . . . . . . . . . . . . . . . . . |

. . . . 44 |

|

|

8 |

Accessories . . . . . . . . . . . . . . . . . . |

. . . 45 |

|

|

8.1 |

Device-specific accessories . . . . . . . . . . . . . . . |

. . . . 45 |

|

|

8.2 |

Measuring principle-specific accessories . . . . . |

. . . . 45 |

|

|

8.3 |

Communication-specific accessories . . . . . . . . |

. . . . 45 |

|

|

8.4 |

Service-specific accessories . . . . . . . . . . . . . . . |

. . . . 46 |

|

|

9 |

Troubleshooting . . . . . . . . . . . . . . |

. . . 47 |

|

|

9.1 |

Troubleshooting instructions . . . . . . . . . . . . . |

. . . . 47 |

|

|

9.2 |

Diagnosis code messages . . . . . . . . . . . . . . . . |

. . . . 48 |

|

|

9.2.1 |

Category F diagnosis code messages . . |

. . . . 48 |

|

|

9.2.2 |

Category C diagnosis code messages |

. . . . . 49 |

|

|

9.2.3 |

Category S diagnosis code messages . . |

. . . . 50 |

|

|

9.3 |

Process errors without messages . . . . . . . . . . |

. . . . 51 |

|

|

9.4 |

Response of outputs to errors . . . . . . . . . . . . . |

. . . . 52 |

|

|

9.5 |

Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . 53 |

|

|

9.5.1 |

Installing and removing electronics boards . 54 |

||

|

9.6 |

Return |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . 58 |

|

9.7 |

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . 58 |

|

|

9.8 |

Software history . . . . . . . . . . . . . . . . . . . . . . . |

. . . . 58 |

|

|

10 |

Technical data . . . . . . . . . . . . . . . . |

. . . 59 |

|

|

10.1 |

Technical data at a glance . . . . . . . . . . . . . . . |

. . . . 59 |

|

|

10.1.1 |

Application . . . . . . . . . . . . . . . . . . . . |

. . . . 59 |

|

|

10.1.2 |

Function and system design . . . . . . . . |

. . . . 59 |

|

|

10.1.3 |

Input . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . 59 |

|

|

10.1.4 |

Output . . . . . . . . . . . . . . . . . . . . . . . |

. . . . 60 |

|

|

10.1.5 |

Power supply . . . . . . . . . . . . . . . . . . . |

. . . . 62 |

|

|

10.1.6 |

Performance characteristics . . . . . . . . |

. . . . 62 |

|

|

10.1.7 |

Operating conditions: Installation . . . . |

. . . . 62 |

|

|

10.1.8 |

Operating conditions: Environment . . |

. . . . 63 |

|

|

3 |

|

Proline Prosonic Flow 92F |

Table of contents |

||||

|

10.1.9 |

Operating conditions: Process |

64 |

|||

|

10.1.10 Mechanical construction . . . . . . . . . . . . |

. . 64 |

||||

|

10.1.11 Human interface . . . . . . . . . . . . . . . . . . |

. . 66 |

||||

|

10.1.12 Certificates and approvals . . . . . . . . . . . |

. . 66 |

||||

|

10.1.13 Ordering information . . . . . . . . . . . . . . |

. . 67 |

||||

|

10.1.14 Accessories . . . . . . . . . . . . . . . . . . . . . . . |

. 67 |

||||

|

10.1.15 Documentation . . . . . . . . . . . . . . . . . . |

. . 67 |

||||

|

11 Description of device functions . . . . . |

. 68 |

||||

|

11.1 |

Illustration of the function matrix . . . . . . . . . . . . . |

. 68 |

|||

|

11.2 |

Group MEASURING VALUES . . . . . . . . . . . . . . |

. . 70 |

|||

|

11.3 |

Group |

. . . . . . . . . . . . . . . . . . . . . SYSTEM UNITS 71 |

|||

|

11.4 |

Group QUICK SETUP . . . . . . . . . . . . . . . . . . . . |

. . 75 |

|||

|

11.5 |

Group OPERATION . . . . . . . . . . . . . . . . . . . . . |

. . 76 |

|||

|

11.6 |

Group USER INTERFACE . . . . . . . . . . . . . . . . . |

. . 77 |

|||

|

11.7 |

Group TOTALIZER . . . . . . . . . . . . . . . . . . . . . . |

. . 79 |

|||

|

11.7.1 Function group TOTALIZER 1 (TOTALIZER 2) |

. 79 |

||||

|

11.7.2 Group HANDLING TOTALIZER . . . . . . |

. . 81 |

||||

|

11.8 |

Group CURRENT OUTPUT . . . . . . . . . . . . . . . . |

. . 82 |

|||

|

11.9 |

Group PULSE, FREQUENCY, STATUS . . . . . . . . |

. . 85 |

|||

|

11.10 |

Information on the response of the status output |

. . 98 |

|||

|

11.11 |

Group COMMUNICATION . . . . . . . . . . . . . . . . |

. 100 |

|||

|

11.12 |

Group PROCESS PARAMETER . . . . . . . . . . . . . |

. 101 |

|||

|

11.13 |

Group SYSTEM PARAMETER . . . . . . . . . . . . . . |

. 103 |

|||

|

11.14 |

Group SENSOR DATA . . . . . . . . . . . . . . . . . . . . |

. 104 |

|||

|

11.15 |

Group SUPERVISION . . . . . . . . . . . . . . . . . . . . |

. 106 |

|||

|

11.16 |

Group SIMULATION SYSTEM . . . . . . . . . . . . . |

. 108 |

|||

|

11.17 |

Group SENSOR VERSION . . . . . . . . . . . . . . . . . |

. 108 |

|||

|

11.18 |

Group AMPLIFIER VERSION . . . . . . . . . . . . . . . |

. 108 |

|||

|

12 |

Factory settings . . . . . . . . . . . . . . . . . |

109 |

|||

|

12.1 |

Metric system units (not for USA and Canada) . . |

. 109 |

|||

|

12.1.1 |

Low flow cut off, fullscale value, pulse value, |

||||

|

totalizer → Page 71 . . . . . . . . . . . . . . . |

. 109 |

||||

|

12.1.2 |

Language → Page 76 . . . . . . . . . . . . . . |

. 109 |

|||

|

12.1.3 |

Unit totalizer 1 + 2 → ä 79 . . . . . . . . . . |

109 |

|||

|

12.2 |

US units (only for USA and Canada) . . . . . . . . . . |

. 110 |

|||

|

12.2.1 |

low flow cut off, full scale value, pulse value, |

||||

|

totalizer → ä 71 . . . . . . . . . . . . . . . . . |

. 110 |

||||

|

Index . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . |

111 |

|||

|

Proline Prosonic Flow 92F |

Safety instructions |

1 Safety instructions

1.1Designated use

The measuring device described in these Operating Instructions is to be used only for measuring the flow rate of liquids in closed pipes, e.g.:

•Acids, alkalis, paints, oils

•Liquefied gas

•Ultrapure water with a low conductivity, water, wastewater

In addition to measuring the volume flow, the measuring device also always measures the sound velocity of the fluid. In this way, different fluids can be distinguished or the fluid quality can be monitored.

Resulting from incorrect use or from use other than that designated the operational safety of the measuring devices can be suspended. The manufacturer accepts no liability for damages being produced from this.

1.2Installation, commissioning and operation

Note the following points:

•Installation, connection to the electricity supply, commissioning and maintenance of the device must be carried out by trained, qualified specialists authorized to perform such work by the facility’s owner operator. The specialist must have read and understood these Operating Instructions and must follow the instructions they contain.

•The device must be operated by persons authorized and trained by the facility’s owner-operator. Strict compliance with the instructions in these Operating Instructions is mandatory.

•In the case of special fluids (incl. fluids for cleaning), Endress+Hauser will be happy to assist in clarifying the corrosion resistance properties of wetted materials. Slight changes to the temperature, concentration or degree of contamination in the process can, however, alter the corrosion resistance. Consequently, Endress+Hauser does not accept any guarantee or liability with regard to the corrosion resistance of wetted materials in a specific application. The user is responsible for the choice of suitable wetted materials in the process.

•If carrying out welding work on the piping, the welding unit may not be grounded by means of the measuring device.

•The installer must ensure that the measuring system is correctly wired in accordance with the wiring diagrams. The transmitter must be grounded, unless the power supply is galvanically isolated.

•Invariably, local regulations governing the opening and repair of electrical devices apply.

1.3Operational safety

•Measuring systems for use in hazardous environments are accompanied by separate «Ex documentation», which is an integral part of these Operating Instructions. Strict compliance with the installation instructions and ratings as listed in this supplementary documentation is mandatory. The symbol on the front of this supplementary Ex documentation indicates the approval and the inspection authority (0 Europe, 2 USA, 1 Canada).

•The measuring device complies with the general safety requirements in accordance with EN 61010, the EMC requirements of IEC/EN 61326 and NAMUR recommendations NE 21 and NE 43.

•The manufacturer reserves the right to modify technical data without prior notice. Your Endress+Hauser distributor will supply you with current information and updates to these Operating Instructions.

|

Safety instructions |

Proline Prosonic Flow 92F |

1.4Return

•Do not return a measuring device if you are not absolutely certain that all traces of hazardous substances have been removed, e.g. substances which have penetrated crevices or diffused through plastic.

•Costs incurred for waste disposal and injury (burns, etc.) due to inadequate cleaning will be charged to the owner-operator.

•Please note the measures on → ä 58

1.5Notes on safety conventions and icons

The devices are designed to meet state-of-the-art safety requirements, have been tested, and left the factory in a condition in which they are safe to operate. The devices comply with the applicable standards and regulations in accordance with EN 61010 «Protection Measures for Electrical Equipment for Measurement, Control, Regulation and Laboratory Procedures». The devices can, however, be a source of danger if used incorrectly or for anything other than the designated use. Consequently, always pay particular attention to the safety instructions indicated in these Operating Instructions by the following symbols:

#Warning!«Warning» indicates an action or procedure which, if not performed correctly, can result in injury or a safety hazard. Comply strictly with the instructions and proceed with care.

«Caution!«Caution» indicates an action or procedure which, if not performed correctly, can result in incorrect operation or destruction of the device. Comply strictly with the instructions.

!Note!«Note» indicates an action or procedure which, if not performed correctly, can have an indirect effect on operation or trigger an unexpected response on the part of the device.

|

Proline Prosonic Flow 92F |

Identification |

2 Identification

2.1Device designation

The «Prosonic Flow 92» flowmeter system consists of the following components:

•Prosonic Flow 92 transmitter

•Prosonic Flow F Inline sensor

Two versions are available:

•Compact version: transmitter and sensor form a single mechanical unit.

•Remote version: transmitter and sensor are installed separately.

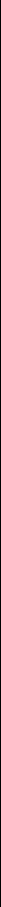

2.1.1Nameplate of the transmitter

|

Prosonic Flow 92 |

||||

|

Order Code: |

92FXX-XXXXXXXXXXX |

IP67 / NEMA/Type4X |

||

|

1 |

Ser.No.: |

12345678901 |

||

|

TAG No.: |

ABCDEFGHJKLMNPQRST |

|||

|

2 |

12-35VDC |

1.2W |

||

|

3 |

4…20mA, HART |

|||

|

i |

||||

|

-40°C<Ta<+60°C |

Ta+10°C/18°F |

|||

|

-40°F<Ta<+140°F |

||||

|

N12895 |

||||

|

4 |

5 |

|||

|

a0006111 |

Fig. 1: Nameplate specifications for the «Prosonic Flow» transmitter (example)

1Order code / serial number: See the specifications on the order confirmation for the meanings of the individual letters and digits

2Power supply: 12 to 35 V DC Power consumption: 1.2 W

3Available outputs

4Permitted ambient temperature range

5Degree of protection

|

Identification |

Proline Prosonic Flow 92F |

2.1.2Nameplate of the sensor

|

Prosonic Flow F |

||||

|

1 |

Order Code: |

92FXX-XXXXXXXXXXXXX |

i |

|

|

Ser.No.: |

XXXXXXXXXXX |

|||

|

2 |

K-factor: |

1.000/0000 |

5P-CAL |

|

|

3 |

DN100/4″ DIN/EN PN16 |

|||

|

4 |

Materials: |

CF3M / 1.4404 / F316L / F316 |

||

|

5 |

TM: |

-40°C(-40°F)…+150°C(+302°F) |

||

|

N12895 |

||||

|

8 |

||||

|

6 |

IP67 / NEMA/Type4X |

|||

|

7 |

-40°C <Tamb< +80°C |

4153 Reinach |

||

|

-40°F <Tamb< +176°F |

Switzerland |

|||

|

a0006107 |

Fig. 2: Nameplate specifications for the Prosonic Flow F sensor (example)

1Order code/serial number: See the specifications on the order confirmation for the meanings of the individual letters and digits

2Calibration factor with zero point

3Device nominal diameter/nominal pressure

4Measuring tube material

5Medium temperature range

6Degree of protection

7Permitted ambient temperature range

8Additional information (examples):

– 5P-CAL: with 5-point calibration

2.1.3Nameplate for connections

|

1 |

4..20mA |

||

|

max. 36VDC |

|||

|

2 |

|||

|

3 |

|||

|

max. 36VDC |

|||

|

4 |

max. 15mA |

||

|

Plug |

Optional |

||

|

Connector |

|||

|

ATEX II3G / Zone 2: |

|||

|

Do not separate when energized! |

|

Seeoperatingmanual. |

Betriebsanleitungbeachten. |

Observermanueld’Instruction. |

a0006110

Fig. 3: Nameplate specifications for Proline transmitter (example)

|

Proline Prosonic Flow 92F |

Identification |

2.2Certificates and approvals

The devices are designed in accordance with good engineering practice to meet state-of-the-art safety requirements, have been tested, and left the factory in a condition in which they are safe to operate.

The measuring device complies with the general safety requirements in accordance with EN 61010, the EMC requirements of IEC/EN 61326 and NAMUR recommendations NE 21 and NE 43. The measuring system described in these Operating Instructions thus complies with the statutory requirements of the EC Directives. Endress+Hauser confirms successful testing of the device by affixing to it the CE mark.

The measuring system complies with the EMC requirements of the Australian Communications and Media Authority (ACMA).

!Note!A detailed list of all the certificates and approvals is provided in the technical data on Page 66.

2.3Registered trademarks

HART®

Registered trademark of the HART Communication Foundation, Austin, USA

HistoROM™ T-DAT ®, FieldCare ®, Fieldcheck®, FieldXpert™, Applicator®

Registered or registration-pending trademarks of Endress+Hauser Flowtec AG, Reinach, CH

|

Installation |

Proline Prosonic Flow 92F |

3 Installation

3.1Incoming acceptance, transport, storage

3.1.1Incoming acceptance

On receipt of the goods, check the following points:

•Check the packaging and the contents for damage.

•Check the shipment, make sure nothing is missing and that the scope of supply matches your order.

3.1.2Transport

Please note the following when unpacking or transporting to the measuring point:

•The devices must be transported in the container supplied.

•The covers or caps fitted to the process connections prevent mechanical damage to the sealing faces and the ingress of foreign matter to the measuring tube during transportation and storage. Consequently, do not remove these covers or caps until immediately before installation.

•Devices with nominal diameters > DN 40 (> 1½») may not be lifted at the transmitter housing or at the connection housing of the remote version when transporting. Use carrier slings when transporting and put the slings around both process connections. Avoid chains as these could damage the housing.

#Warning!Risk of injury if the measuring device slips. The center of gravity of the entire measuring device might be higher than the points around which the slings are slung.

Therefore, when transporting, make sure that the device does not unintentionally turn or slip.

a0005765

Fig. 4: Instructions for transporting sensors with a nominal diameter > DN 40 (> 1½»)

3.1.3Storage

Note the following points:

•Pack the measuring device in such a way as to protect it reliably against impact for storage (and transportation). The original packaging provides optimum protection.

•The permissible storage temperature is –40 to +80 °C (–40 °F to 176 °F), preferably +20 °C (68 °F).

•Do not remove the protective covers or caps on the process connections until you are ready to install the device.

•The measuring device must be protected against direct sunlight during storage in order to avoid unacceptably high surface temperatures.

|

Proline Prosonic Flow 92F |

Installation |

3.2Installation conditions

Note the following points:

•No special measures such as supports are necessary. External forces are absorbed by the construction of the instrument.

•The flowmeter flanges must be coplanar with connecting flanges and free from tension.

•The maximum permitted ambient temperatures (→ ä 63) and fluid temperatures (→ ä 63) must be observed.

•Pay particular attention to the notes on orientation and piping insulation on the following pages.

•The correct operation of the measuring system is not influenced by pipe vibrations.

3.2.1Dimensions

All the dimensions and lengths of the sensor and transmitter are provided in the separate documentation «Technical Information». → ä 67

3.2.2Mounting location

Accumulated gas bubbles in the measuring tube can result in measuring errors.

Avoid the following locations:

•Highest point of a pipeline. Risk of gas accumulating.

•Directly upstream of a free pipe outlet in a vertical pipeline.

a0006081

Fig. 5: Mounting location

The proposed configuration in the following diagram, however, permits installation in a vertical pipeline. Pipe restrictors or the use of an orifice plate with a smaller cross section than the nominal diameter prevent the sensor from running empty during measurement.

1

2

3

4

5

a0006082

Fig. 6: Installation in a vertical pipe (e.g. for batching applications)

1 = Supply tank , 2 = Sensor, 3 = Orifice plate, pipe restriction , 4 = Valve, 5 = Batching tank

|

Installation |

Proline Prosonic Flow 92F |

System pressure

No additional pressure loss results from installing the device. It is important to ensure that cavitation or degassing does not occur at fittings upstream from the measuring device as this can affect sound transmission in the fluid.

No special measures need to be taken for fluids which have properties similar to water under normal conditions.

In the case of liquids with a low boiling point (hydrocarbons, solvents, liquefied gases) or in suction lines, it is important to ensure that pressure does not drop below the vapor pressure and that the liquid does not start to boil. It is also important to ensure that the gases that occur naturally in many liquids do not outgas. Such effects can be prevented when system pressure is sufficiently high.

For this reason, preference should be given to the following mounting locations:

•Downstream from pumps (no danger of vacuum)

•At the lowest point in a vertical pipe

3.2.3Orientation

Make sure that the direction of the arrow on the nameplate of the sensor matches the direction of flow (direction in which the fluid flows through the pipe).

A

a0005971

Fig. 7: Orientations A, B and C recommended, orientation D only recommended under certain circumstances

3.2.4Heating

Some fluids require heat to be transfered at the sensor. Heating can be electric, e.g. with heated elements, or by hot water or steam.

«Caution!• Danger of electronics overheating!

Make sure that the adapter between the sensor and transmitter and the connection housing of the remote version always remain free of insulating material.

•When using electrical heat tracing whose heat is regulated using phase control or by pulse packs, it cannot be ruled out that the measured values are influenced by magnetic fields which may occur, (i.e. at values greater than those permitted by the EC standard (Sinus 30 A/m)). In such cases, the sensor must be magnetically shielded.

|

Proline Prosonic Flow 92F |

Installation |

3.2.5Thermal insulation

Some fluids require suitable measures to avoid loss of heat at the sensor. A wide range of materials can be used to provide the required thermal insulation.

a0005763-ae

Fig. 8: A maximum insulation thickness of 20 mm (0.8 inch) must be observed in the area of the electronics/neck.

If the device is installed horizontally (with transmitter head pointing upwards), an insulation thickness of min. 10 mm (0.4″) is recommended to reduce convection. The maximum insulation thickness of 20 mm (0.8″) must not be exceeded.

3.2.6Inlet and outlet run

If possible, install the sensor well clear of fittings such as valves, T-pieces, elbows, etc. As a minimum, the inlet and outlet runs shown below must be observed to achieve the specified accuracy of the device. The longest inlet run shown must be observed if two or more flow disturbances are present.

|

5 × DN |

3 × DN |

15 × DN |

3 × DN |

||

|

1 |

A |

B |

2 |

A |

B |

|

5 × DN |

3 × DN |

4 |

10 × DN |

3 × DN |

|

|

A |

B |

A |

B |

||

|

3 |

|||||

|

A0006267 |

Fig. 9: Minimum inlet and outlet runs with various flow obstructions (values given for 3 and 4 path versions)

A = Inlet run, B = Outlet run, 1 = 90° elbow or T-piece, 2 = Pump, 3 = 2 × 90° elbow, 3-dimensional, 4 = Control valve

3.2.7Limiting flow

Information on limiting flow is provided under «Measuring range» in the technical data section.

|

Installation |

Proline Prosonic Flow 92F |

3.3Installation instructions

3.3.1Mounting the sensor

•Prior to installing the measuring device in the piping, remove all traces of transport packaging and any protective covers from the sensor.

•Make sure that the internal diameters of seals are the same as, or greater than, those of the measuring device and piping. If seals with a smaller internal diameter are used, this affects the flow and results in inaccurate measurement.

•Ensure that the arrow on the measuring tube matches the direction of flow in the piping.

•For Carbon steel option remove transport protection coating using mineral spirit (optional).

3.3.2Turning the transmitter housing

1.Loosen the safety screw.

2.Turn the transmitter housing to the desired position (max. 180° in each direction to the stop).

! Note!

There are recesses in the rotating groove at 90° stages (only compact version). These help you align the transmitter easier.

3.Retighten the securing screw.

180°

180°

a0005766

Fig. 10: Turning the transmitter housing

3.3.3Turning the local display

1.Unscrew the cover of the electronics compartment from the transmitter housing.

2.Remove the display module from the transmitter retainer rails.

3.Turn the display to the desired position (max. 4 x 45° in each direction) and reset it onto the retaining rails.

4.Screw the cover of the electronics compartment firmly back onto the transmitter housing.

|

Proline Prosonic Flow 92F |

Installation |

3.3.4Mounting the remote version

The transmitter can be mounted in the following ways:

•Wall mounting

•Pipe mounting (with separate mounting kit, accessories) → ä 45

«Caution!When mounting on a pipe, the ambient temperature range may not be exceeded. → ä 63

The transmitter and the sensor must be mounted separate in the following circumstances:

•Poor accessibility

•Lack of space

•Extreme ambient temperatures

Mount the transmitter as illustrated in the diagram.

|

232 |

(9.13) |

227 |

(8.94) |

|

|

*226 |

(*8.90) |

*221 |

(*8.70) |

|

ANSCHLUSSKLEMMEN |

— |

FIELD TERMINALS |

||

|

ANSCHLUSSKLEMMEN |

— |

FIELD TERMINALS |

mm (inch)

a0005947-ae

Fig. 11: Mounting the transmitter (remote version)

ADirect wall mounting

BPipe mounting

* Dimensions for version without local display

3.4Post-installation check

Perform the following checks after installing the measuring device:

|

Device condition and specifications |

Notes |

|

Is the device damaged (visual inspection)? |

— |

|

Do the process temperature/pressure, ambient temperature, measuring range etc. correspond to the |

→ ä 5 |

|

specifications of the device? |

|

|

Installation |

Notes |

|

Does the arrow on the sensor or sensor neck match the direction of flow through the pipe? |

— |

|

Are the measuring point number and labeling correct (visual inspection)? |

– |

|

Process environment / process conditions |

Notes |

|

Is the measuring device protected against direct sunlight? |

-→ ä 63 |

|

Wiring |

Proline Prosonic Flow 92F |

4 Wiring

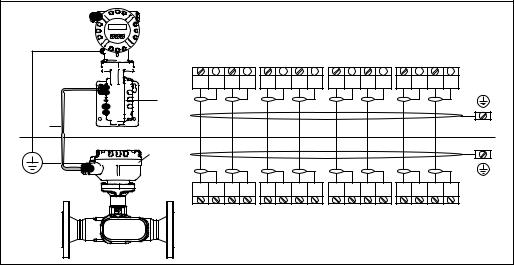

4.1Connecting the remote version

4.1.1 Connecting cable for sensor/transmitter

!Note!• The remote version must be grounded. In doing so, the sensor and transmitter must be connected

to the same potential matching (see Fig. 12, d).

•You may only connect the sensor to the transmitter with the same serial number (see nameplate). Communication errors can occur if this is not observed when connecting the devices.

Procedure

1.Remove the covers of the connection compartments (a/b).

2.Feed the connecting cable (c) through the appropriate cable entries.

3.Wire the sensor and transmitter in accordance with the electrical connection diagram: see Fig. 12 or the wiring diagram in the cover of the connection compartment.

4.Connect the appropriate cable shield (e/f).

5.Firmly tighten the glands of the cable entries.

6.Screw the covers of the connection compartments (a/b) back on.

|

1 |

GROUND |

2 |

GROUND |

3 |

GROUND |

4 |

GROUND |

5 |

GROUND |

6 |

GROUND |

7 |

GROUND |

8 |

GROUND |

|

|

1 G 2 G 3 G 4 G 5 G 6 G 7 G 8 G |

||||||||||||||||

|

a |

||||||||||||||||

|

e |

||||||||||||||||

|

c |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

||||||||

|

d |

b |

f |

||||||||||||||

|

1 G 2 G 3 G 4 G 5 G 6 G 7 G 8 G |

||||||||||||||||

|

1 |

GROUND |

2 |

GROUND |

3 |

GROUND |

4 |

GROUND |

5 |

GROUND |

6 |

GROUND |

7 |

GROUND |

8 |

GROUND |

|

|

a0005764 |

Fig. 12: Connecting the remote version

aCover of the connection compartment (transmitter)

bCover of the connection compartment (sensor)

cConnecting cable (signal cable)

dIdentical potential matching for sensor and transmitter

eConnect the shielding to the ground terminal in the transmitter

fConnect the shielding to the ground terminal in the connection

housing and keep it as short as possible housing

4.1.2Cable specification for connecting cable

Only use the cables supplied by Endress+Hauser and pre-terminated at the factory. The cables are available with a fixed length of 10 m (30 feet) and 30 m (90 feet) and optionally available with variable lengths ranging from 1 m (3 feet) to max. 50 m (150 feet). The cable sheathing is made of PVC.

|

Proline Prosonic Flow 92F |

Wiring |

4.2Connecting the measuring unit

4.2.1 Connecting the transmitter

#Warning!When connecting Ex-certified devices, see the notes and diagrams in the Ex-specific supplement to these Operating Instructions. Please do not hesitate to contact your Endress+Hauser representative if you have any questions.

!Note!• Observe national regulations governing the installation of electrical equipment.

•The remote version must be grounded. In doing so, the sensor and transmitter must be connected to the same potential matching.

•When connecting the transmitter, use a connecting cable with a continuous service temperature range between –40 °C (–40 °F) and the permitted max. ambient temperature plus 10 °C (plus 18 °F)

Connecting the transmitter, non-Ex/Ex-i version (→ å 13)

1.Unscrew the cover (a) of the electronics compartment from the transmitter housing.

2.Remove the display module (b) from the retaining rails (c) and refit onto the right retaining rail with the left side of the display (this secures the display module).

3.Loosen screw (d) of the cover of the connection compartment and fold the cover down.

4.Push the cable for the power supply current output through the cable gland (e).

Optional: push the cable for the pulse output/frequency output through the cable gland (f).

5.Pull the terminal connector (g) out of the transmitter housing and connect the cable for the power supply/current output. (→ Fig. 14, A)

Optional: pull terminal connector (h) out of the transmitter housing and connect the cable for the pulse output/frequency output. (→ Fig. 14, B)

! Note!

The terminal connectors (g / h) are pluggable, i.e. they can be plugged out of the transmitter housing to connect the cables.

6.Plug the terminal connectors (g / h) into the transmitter housing.

! Note!

The connectors are coded so you cannot mix them up.

7.Only remote version:

secure the ground cable to the ground terminal (→ Fig. 14, C).

8.Tighten the cable glands (e / f) (see alsoPage 21).

9.Fold up the cover of the connection compartment and tighten the screws (d).

10.Remove the display module (b) and fit on the retaining rails (c).

11.Screw the cover of the electronics compartment (a) onto the transmitter housing.

|

Wiring |

Proline Prosonic Flow 92F |

|

d |

h |

g |

e |

|

|

c |

f |

|||

|

a |

d |

|||

|

b |

a0001895

Fig. 13: Connecting the transmitter, non-Ex/Ex i version

aCover of electronics compartment

bDisplay module

cRetaining rail for display module

dConnection compartment cover

eCable gland for power supply/current output cable

fCable gland for pulse output/frequency output cable (optional)

gTerminal connector for power supply/current output

hTerminal connector for pulse output/frequency output (optional)

Connecting the transmitter, Ex-d → å 14

1.Open the clamp (a) securing the cover of the connection compartment.

2.Unscrew the cover (b) of the connection compartment from the transmitter housing.

3.Push the cable for the power supply/current output through the cable gland (c).

Optional: push the cable for the pulse output/frequency output through the cable gland (d).

4.Pull the terminal connector (e) out of the transmitter housing and connect the cable for the power supply/current output. (→ Fig. 14, A)

Optional: pull terminal connector (f) out of the transmitter housing and connect the cable for the pulse output/frequency output. (→ Fig. 14, B)

! Note!

The terminal connectors (e/f) are pluggable, i.e. they can be plugged out of the transmitter housing to connect the cables.

5.Plug the terminal connectors (e / f) into the transmitter housing.

! Note!

The connectors are coded so you cannot mix them up.

6.Only remote version:

secure the ground cable to the ground terminal (→ Fig. 14, C).

7.Tighten the cable glands (c / d) (see alsoPage 21).

8.Secure the ground cable to the ground terminal (only remote version)

9.Screw the cover (b) of the connection compartment onto the transmitter housing.

10.Tighten the clamp (a) securing the cover of the connection compartment.

|

Proline Prosonic Flow 92F |

Wiring |

d

c

f

e

a

b

a0001896

Fig. 14: Connecting the transmitter, Ex d version

aClamp securing cover of connection compartment

bCover of connection compartment

cCable gland for power supply/current output cable

dCable gland for pulse output/frequency output cable (optional)

eTerminal connector for power supply/current output

fTerminal connector for pulse output/frequency output (optional)

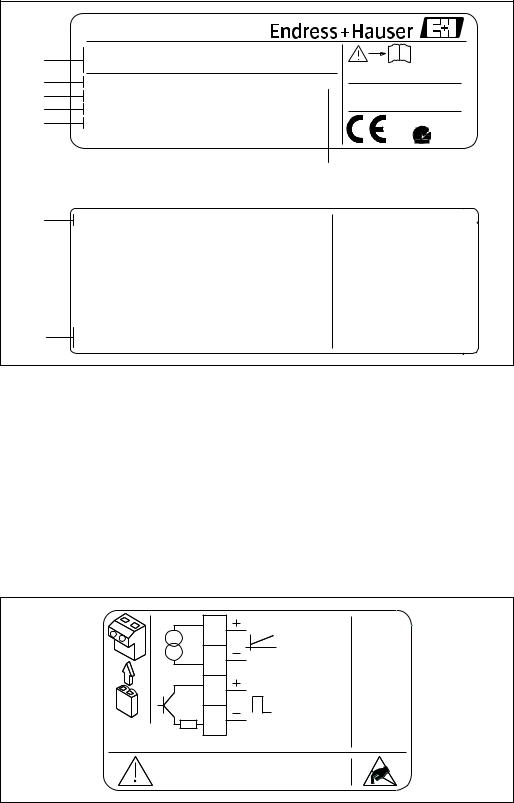

Wiring diagram

C

A0014635

Fig. 15: Assignment of terminals

APower supply/current output

BOptional pulse output/status output

CGround terminal (only relevant for remote version)

4.2.2Terminal assignment

|

Terminal No. (inputs/outputs) |

|||

|

Order version |

1 – 2 |

3 – 4 |

|

|

92***-***********W |

HART current output |

– |

|

|

92***-***********A |

HART current output |

Pulse/status output/ |

|

|

frequency output |

|||

HART current output

Galvanically isolated, 4 to 20 mA with HART

Pulse/status output

Open collector, passive, galvanically isolated, Umax = 30 V, with 15 mA current limiting, Ri = 500 Ω, can be configured as pulse output or status output

|

Wiring |

Proline Prosonic Flow 92F |

4.2.3HART connection

Users have the following connection options at their disposal:

•Direct connection to transmitter by means of terminals 1 (+) / 2 (−)

•Connection by means of the 4 to 20 mA circuit

!Note!• The measuring circuit’s minimum load must be at least 250 Ω .

•After commissioning, make the following setting:

Switch HART write protection on or off (see Page 38)→ Page 37

•For connecting, please refer also to the documentation issued by the HART Communication Foundation, in particular HCF LIT 20: «HART, a technical summary».

Connecting the HART handheld terminal

For the connection, also refer to the documentation issued by the HART Communication

Foundation, and in particular HCF LIT 20: «HART, a technical summary».

|

9 |

6 |

|

|

1 |

2 |

3 |

|

4 |

5 |

6 |

|

7 |

8 |

9 |

|

. |

0 |

— |

|

375 |

FIELD COMMUNICATOR

250

A0014632

Fig. 16: Electrical connection to the HART operating terminal

1HART operating terminal

2Power supply

3Shielding

4Additional switching units or PLC with passive input

Connecting a PC with operating software

A HART modem (e.g. «Commubox FXA195») is required for connecting a PC with operating software (e.g. «FieldCare»).

For the connection, also refer to the documentation issued by the HART Communication Foundation, and in particular HCF LIT 20: «HART, a technical summary».

A0014633

Fig. 17: Electrical connection of a PC with operating software

1PC with operating software

2Power supply

3Shielding

4Additional switching units or PLC with passive input

5HART modem e.g. Commubox FXA195

|

Proline Prosonic Flow 92F |

Wiring |

4.3Degree of protection

The devices fulfill all the requirements for IP 67 (optional IP 68) degree of protection. Compliance with the following points is mandatory following installation in the field or servicing in order to ensure that IP 67 protection is maintained:

•The housing seals must be clean and undamaged when inserted into their grooves. The seals must be dried, cleaned or replaced if necessary.

•All housing screws and screw caps must be firmly tightened.

•The cables used for connection must be of the specified outside diameter.

•Firmly tighten the cable entries.

•The cables must loop down before they enter the cable entries («water trap»).

This arrangement prevents moisture penetrating the entry. Always install the measuring device in such a way that the cable entries do not point up.

•Replace all unused cable entries with dummy plugs.

•Do not remove the grommet from the cable entry.

a0001914

Fig. 18: Installation instructions for cable entries

«Caution!The cable glands of the sensor housing must not be released as the degree of protection guaranteed by Endress+Hauser would no longer apply.

!Note!The Prosonic Flow 92F can be supplied with IP 68 rating (permanent immersion in water to a depth ot 3 meters /10 ft). In this case the transmitter must be installed remote from the sensor.

|

Wiring |

Proline Prosonic Flow 92F |

4.4Post-connection check

Perform the following checks after completing electrical installation of the measuring device:

|

Device condition and specifications |

Notes |

|

Are cables or the device damaged (visual inspection)? |

− |

|

Electrical connection |

Notes |

|

Does the supply voltage match the specifications on the nameplate? |

− |

|

• Non-Ex: 12 to 35 V DC (with HART: 18 to 35 V DC) |

|

|

• Ex i and Ex n: 12 to 30 V DC (with HART 18 to 30 V DC) |

|

|

• Ex d: 15 to 35 V DC (with HART 21 to 35 V DC) |

|

|

Do the cables used comply with the specifications? |

→ ä 16, → ä 62 |

|

Do the cables have adequate strain relief? |

− |

|

Are the cables for power supply/current output, frequency output (optional) and |

→ ä 17 |

|

grounding connected correctly? |

|

|

Remote version only: |

→ ä 16 |

|

Is the connecting cable between the sensor and transmitter connected correctly? |

|

|

Remote version only: |

→ ä 16 |

|

Are the sensor and transmitter connected to the same potential matching? |

|

|

Are all screw terminals firmly tightened? |

− |

|

Are all the cable entries installed, tightened and sealed? |

→ ä 21 |

|

Cable run with «water trap»? |

|

|

Are all the housing covers installed and tightened? |

− |

|

Proline Prosonic Flow 92F |

Operation |

5 Operation

5.1Display and operating elements

The local display enables you to read important parameters directly at the measuring point and configure the device using the «Quick Setup» or the function matrix.

The display consists of two lines; this is where measured values and/or status variables (e.g. bar graph) are displayed.

By means of local operation, you can change the assignment of the display lines to different variables to suit your needs and preferences. See Device Functions in the Appendix → ä 68

+48.25 xx/yy

1

+3702.6 x

Esc

— + E

a0001141

Fig. 19: Display and operating elements

1Liquid crystal display

The two-line liquid-crystal display shows measured values and diagnosis messages.

–Top line: shows main measured values, e.g. volume flow in [dm/h] or in [%].

–Bottom line: shows additional measured variables and status variables, e.g. totalizer reading in [dm], bar graph, tag name.

–During commissioning or in the event of a fault in normal measuring operation, a diagnosis message flashes on the screen.

The first line shows the diagnosis code beginning with the letters F, C, S or M and a short text containing the diagnosis message appears on the second line.

2Plus/minus keys

–Enter numerical values, select parameters

–Select different function groups within the function matrix

Press the +/- keys simultaneously to trigger the following functions:

–Exit the function matrix step by step → HOME position

–Press and hold down +/- keys for longer than 3 seconds → return directly to the HOME position

–Cancel data entry

3Enter key

–HOME position → enter the function matrix

–Save the numerical values you input or settings you changed

|

Operation |

Proline Prosonic Flow 92F |

5.2 Operation via the function matrix

!Note!• Please refer to the general notes → ä 25

• Function descriptions → see the «Description of Device Functions» manual

1. HOME position → F → enter the function matrix

2.Select a function group e.g. CURRENT OUTPUT

3.Select a function (e.g. TIME CONSTANT) Change parameter/enter numerical values:

P → select or enter enable code, parameters, numerical values F → save your entries

4.Exit the function matrix:

–Press and hold down the Esc key (X) for more than 3 seconds → HOME position

–Repeatedly press Esc key (X) → return step by step to HOME position

— + E

|

p |

|||

|

Esc |

Esc |

> 3 s |

|

|

m E |

– + |

– + |

|

o |

||||

|

E |

E |

E |

E |

E |

|

Esc |

||||

|

– |

+ |

n +–

E

E

E

E

a0001142

Fig. 20: Selecting and configuring functions (function matrix)

|

Proline Prosonic Flow 92F |

Operation |

5.2.1General notes

The Quick Setup menu is adequate for commissioning with the necessary standard settings. Complex measuring operations on the other hand necessitate additional functions that you can configure as necessary and customize to suit your process conditions. The function matrix, therefore, comprises a multiplicity of additional functions which, for the sake of clarity, are arranged in a number of function groups.

Comply with the following instructions when configuring functions:

•You select functions as described already.

•You can switch off certain functions (OFF). If you do so, related functions in other function groups will no longer be displayed.

•Certain functions prompt you to confirm your data entries. Press P to select «SURE [ YES ]» and press F to confirm. This saves your setting or starts a function, as applicable.

•Return to the HOME position is automatic if no key is pressed for 5 minutes.

•Programming mode is automatically disabled if you do not press a key within 60 seconds following return to the HOME position.

!Note!A detailed description of all the functions required for commissioning is provided in Section 11.1 «Description of device functions».

!Note!• The transmitter continues to measure while data entry is in progress, i.e. the current measured

values are output via the signal outputs in the normal way.

• If the power supply fails, all preset and configured values remain safely stored in the EEPROM.

5.2.2Enabling the programming mode

The function matrix can be disabled. Disabling the function matrix rules out the possibility of inadvertent changes to device functions, numerical values or factory settings. A numerical code (factory setting = 92) has to be entered before settings can be changed.

If you use a code number of your choice, you exclude the possibility of unauthorized persons accessing data ( → see «Description of Device Functions» manual).

Comply with the following instructions when entering codes:

•If programming is disabled and the P operating elements are pressed in any function, a prompt for the code automatically appears on the display.

•If «0» is entered as the private code, programming is always enabled.

•Your Endress+Hauser service organization can be of assistance if you are locked out of the device.

«Caution!Changing certain parameters influences numerous functions of the entire measuring device, and may effect measuring accuracy!

There is no need to change these parameters under normal circumstances and consequently, they are protected by a special service code known only to the Endress+Hauser service organization. Please contact Endress+Hauser if you have any questions.

5.2.3Disabling the programming mode

Programming mode is disabled if you do not press an operating element within 60 seconds following automatic return to the HOME position.

You can also disable programming by entering any number (other than the private code) in the ACCESS CODE function.

|

Operation |

Proline Prosonic Flow 92F |

5.3Communication

In addition to via local operation, the measuring device can also be configured and measured values obtained by means of the HART protocol. Digital communication takes place using the 4–20 mA current output HART.

The HART protocol allows the transfer of measuring and device data between the HART master and the field devices for configuration and diagnostics purposes. HART masters, such as a handheld terminal or PC-based operating programs (such as FieldCare), require device description (DD) files. They are used to access all the information in a HART device. Such information is transferred solely via «commands». There are three different command classes:

There are three different command classes:

•Universal commands

All HART devices support and use universal commands. The following functionalities are linked to them:

–Recognizing HART devices

–Reading off digital measured values (volume flow, totalizer, etc.)

•Common practice commands:

Common practice commands offer functions which are supported and can be executed by many but not all field devices.

•Device-specific commands:

These commands allow access to device-specific functions which are not HART standard. Such commands access individual field device information, (among other things), such as empty-pipe/ full-pipe adjustment values, low flow cutoff settings etc.

!Note!The measuring device has all three command classes.

List of all «Universal Commands» and «Common Practice Commands»: → ä 30

|

Proline Prosonic Flow 92F |

Operation |

5.3.1Operating options

For the complete operation of the measuring device, including device-specific commands, there are device description (DD) files available to the user to provide the following operating aids and programs:

!Note!• The HART protocol requires the «4 to 20 mA HART» setting (individual options see device

function) in the CURRENT SPAN function (current output 1).

HART Field Communicator Field Xpert

Selecting device functions with a HART Communicator is a process involving a number of menu levels and a special HART function matrix.

The HART operating instructions in the carrying case of the HART handheld terminal contain more detailed information on the device.

Operating program «FieldCare»

FieldCare is Endress+Hauser’s FDT-based plant asset management tool and allows the configuration and diagnosis of intelligent field devices. By using status information, you also have a simple but effective tool for monitoring devices.

Operating program «SIMATIC PDM» (Siemens)

SIMATIC PDM is a standardized, manufacturer independent tool for the operation, configuration, maintenance and diagnosis of intelligent field devices.

Operating program «AMS» (Emerson Process Management)

AMS (Asset Management Solutions): program for operating and configuring devices.

|

Operation |

Proline Prosonic Flow 92F |

5.3.2Current device description files

The following table illustrates the suitable device description file for the operating tool in question and then indicates where these can be obtained.

HART protocol:

|

Valid for software: |

1.01.XX |

→ Function «Device software» |

|

|

Device data HART |

→ Function «Manufact ID» |

||

|

Manufacturer ID: |

11hex (ENDRESS+HAUSER) |

||

|

Device ID: |

61hex |

→ Function «Device ID» |

|

|

HART version data: |

Device Revision 6/ DD Revision 1 |

||

|

Software release: |

12.2010 |

||

|

Operating program: |

Sources for obtaining device descriptions: |

||

|

Handheld terminal Field Xpert |

• Use update function of handheld terminal |

||

|

FieldCare / DTM |

• www.endress.com → Download |

||

|

• CD-ROM (Endress+Hauser order number 56004088) |

|||

|

• DVD (Endress+Hauser order number 70100690) |

|||

|

AMS |

• www.endress.com → Download |

||

|

SIMATIC PDM |

• www.endress.com → Download |

||

|

Tester/simulator: |

Sources for obtaining device descriptions: |

||

|

Fieldcheck |

• Update by means of FieldCare via the Flow Device FXA193/291 DTM |

||

|

in the Fieldflash module |

|||

!Note!The «Fieldcheck» tester/simulator is used for testing flowmeters in the field. When used in conjunction with the «FieldCare» software package, test results can be imported into a database, printed out and used for official certification. Contact your Endress+Hauser representative for more information.

|

Proline Prosonic Flow 92F |

Operation |

5.3.3Device variables and process variables

Device variables:

The following device variables are available via the HART protocol:

|

ID (decimal) |

Device variable |

|

30 |

Volume flow |

|

40 |

Sound velocity |

|

43 |

Signal strength |

|

49 |

Flow velocity |

|

240 |

Totalizer 1 |

|

241 |

Totalizer 2 |

Process variables:

At the factory, the process variables are assigned to the following device variables:

•Primary process variable (PV) → volume flow

•Secondary process variable (SV) → totalizer

•Third process variable (TV) → sound velocity

•Fourth process variable (FV) → flow velocity

!Note!You can set or change the assignment of device variables to process variables using Command 51 → ä 33.

|

Operation |

Proline Prosonic Flow 92F |

5.3.4Universal/common practice HART commands

The following table contains all the universal commands supported by the device.

|

Command No. |

Command data |

Response data |

|||

|

HART command/access type |

(numeric data in decimal form) |

(numeric data in decimal form) |

|||

|

Universal commands |

|||||

|

0 |

Read the unique device identifier |

None |

The device identifier provides information on the device |

||

|

Access type = Read |

and manufacturer; it cannot be altered. |

||||

|

The response consists of a 12-byte device ID: |

|||||

|

– |

Byte 0: fixed value 254 |

||||

|

– |

Byte 1: manufacturer ID, 17 = E+H |

||||

|

– |

Byte 2: device type ID, e.g. 0x61 = Prosonic 92 |

||||

|

– |

Byte 3: number of preambles |

||||

|

– |

Byte 4: rev. no. universal commands |

||||

|

– |

Byte 5: rev. no. device-spec. Commands |

||||

|

– |

Byte 6: software revision |

||||

|

– |

Byte 7: hardware revision |

||||

|

– |

Byte 8: additional device information |

||||

|

– |

Byte 9-11: device identification |

||||

|

1 |

Read the primary process variable |

None |

– |

Byte 0: HART unit ID of the primary process variable |

|

|

Access type = Read |

– |

Byte 1-4: primary process variable |

|||

|

Factory setting: |

|||||

|

Primary process variable = volume flow |

|||||

|

! |

Note! |

||||

|

• |

You can set the assignment of device variables to |

||||

|

process variables using Command 51. |

|||||

|

• |

Manufacturer-specific units are represented using the |

||||

|

HART unit ID «240». |

|||||

|

2 |

Read the primary process variable as |

None |

– |

Byte 0-3: current current of the primary process |

|

|

current in mA and percentage of the |

variable in mA |

||||

|

set measuring range |

– |

Byte 4-7: percentage of the set measuring range |

|||

|

Access type = Read |

Factory setting: |

||||

|

Primary process variable = volume flow |

|||||

|

! |

Note! |

||||

|

You can set the assignment of device variables to process |

|||||

|

variables using Command 51. |

|||||

|

3 |

Read the primary process variable as |

None |

24 bytes are sent as a response: |

||

|

current in mA and four (preset |

– |

Byte 0-3: current of the primary process variable in |

|||

|

using command 51) dynamic |

mA |

||||

|

process variables |

– |

Byte 4: HART unit ID of the primary process variable |

|||

|

Access type = Read |

– |

Byte 5-8: primary process variable |

|||

|

– |

Byte 9: HART unit ID of the secondary process |

||||

|

variable |

|||||

|

– |

Byte 10-13: secondary process variable |

||||

|

– |

Byte 14: HART unit ID of the third process variable |

||||

|

– |

Byte 15-18: third process variable |

||||

|

– |

Byte 19: HART unit ID of the fourth process variable |

||||

|

– |

Byte 20-23: fourth process variable |

||||

|

Factory setting: |

|||||

|

• |

Primary process variable = volume flow |

||||

|

• |

Secondary process variable = totalizer 1 |

||||

|

• |

Third process variable = sound velocity |

||||

|

• |

Fourth process variable = flow velocity |

||||

|

! |

Note! |

||||

|

• |

You can set the assignment of device variables to |

||||

|

process variables using Command 51. |

|||||

|

• |

Manufacturer-specific units are represented using the |

||||

|

HART unit ID «240». |

|||||

|

Proline Prosonic Flow 92F |

Operation |

|||||

|

Command No. |

Command data |

Response data |

||||

|

HART command/access type |

(numeric data in decimal form) |

(numeric data in decimal form) |

||||

|

6 |

Set HART short-form address |

Byte 0: desired address (0 to 15) |

Byte 0: active address |

|||

|

Access type = Write |

Factory setting: |

|||||

|

0 |

||||||

|

! |

Note! |

|||||

|

With an address >0 (multidrop mode), the current |

||||||

|

output of the primary process variable is fixed to 4 mA. |

||||||

|

11 |

Read the unique device identifier |

Byte 0-5: TAG |

The device identifier provides information on the device |

|||

|

using the TAG |

and manufacturer; it cannot be altered. |

|||||

|

Access type = Read |

The response consists of a 12-byte device ID if the given |

|||||

|

TAG matches the one saved in the device: |

||||||

|

– |

Byte 0: fixed value 254 |

|||||

|

– |

Byte 1: manufacturer ID, 17 = E+H |

|||||

|

– |

Byte 2: device type ID, 0x61 = Prosonic 92 |

|||||

|

– |

Byte 3: number of preambles |

|||||

|

– |

Byte 4: rev. no. universal commands |

|||||

|

– |

Byte 5: rev. no. device-spec. Commands |

|||||

|

– |

Byte 6: software revision |

|||||

|

– |

Byte 7: hardware revision |

|||||

|

– |

Byte 8: additional device information |

|||||

|

– |

Byte 9-11: device identification |

|||||

|

12 |

Read user message |

None |

Byte 0-24: user message |

|||

|

Access type = Read |

! |

Note! |

||||

|

You can write the user message using command 17. |

||||||

|

13 |

Read TAG, TAG description and |

None |

– |

Byte 0-5: TAG |

||

|

date |

– |

Byte 6-17: TAG description |

||||

|

Access type = Read |

– |

Byte 18-20: date |

||||

|

! |

Note! |

|||||

|

You can write the TAG, TAG description and date using |

||||||

|

command 18. |

||||||

|

14 |

Read sensor information on the |

None |

– |

Byte 0-2: serial number of the sensor |

||

|

primary process variable |

– |

Byte 3: HART unit ID of the sensor limits and |

||||

|

measuring range of the primary process variable |

||||||

|

– |

Byte 4-7: upper sensor limit |

|||||

|

– |

Byte 8-11: lower sensor limit |

|||||

|

– |

Byte 12-15: minimum span |

|||||

|

! |

Note! |

|||||

|

• |

The data relate to the primary process variable (= |

|||||

|

volume flow). |

||||||

|

• |

Manufacturer-specific units are represented using the |

|||||

|

HART unit ID «240». |

||||||

|

15 |

Read output information of the |

None |

– |

Byte 0: alarm selection ID |

||

|

primary process variable |

– |

Byte 1: ID for transfer function |

||||

|

Access type = Read |

– |

Byte 2: HART unit ID for the set measuring range of |

||||

|

the primary process variable |

||||||

|

– |

Byte 3-6: end of measuring range, value for 20 mA |

|||||

|

– |

Byte 7-10: start of measuring range, value for 4 mA |

|||||

|

– |

Byte 11-14: attenuation constant in [s] |

|||||

|

– |

Byte 15: ID for write protection |

|||||

|

– |

Byte 16: ID for OEM dealer, 17 = E+H |

|||||

|

Factory setting: |

||||||

|

Primary process variable = volume flow |

||||||

|

! |

Note! |

|||||

|

• |

You can set the assignment of device variables to |

|||||

|

process variables using Command 51. |

||||||

|

• |

Manufacturer-specific units are represented using the |

|||||

|

HART unit ID «240». |

||||||

|

16 |

Read the device production number |

None |

Byte 0-2: production number |

|||

|

Access type = Read |

||||||

|

Operation |

Proline Prosonic Flow 92F |

||||

|

Command No. |

Command data |

Response data |

|||

|

HART command/access type |

(numeric data in decimal form) |

(numeric data in decimal form) |

|||

|

17 |

Write user message |

You can save any 32-character long text in the device |

Displays the current user message in the device: |

||

|

Access = Write |

with this parameter: |

Byte 0-23: current user message in the device |

|||

|

Byte 0-23: desired user message |

|||||

|

18 |

Write TAG, TAG description and |

You can save an 8-character TAG, a 16-character TAG |

Displays the current information in the device: |

||

|

date |

description and a date with this parameter: |

– |

Byte 0-5: TAG |

||

|

Access = Write |

– |

Byte 0-5: TAG |

– |

Byte 6-17: TAG description |

|

|

– |

Byte 6-17: TAG description |

– |

Byte 18-20: date |

||

|

– |

Byte 18-20: date |

||||

The following table contains all the common practice commands supported by the device.

|

Command No. |

Command data |

Response data |

|||||

|

HART command/access type |

(numeric data in decimal form) |

(numeric data in decimal form) |

|||||

|

Common practice commands |

|||||||

|

33 |

Read measured values |

Byte 0: device variable ID for channel 0 |

Byte 0: device variable ID for channel 0 |

||||

|

Byte 1: device variable ID for channel 1 |

Byte 1: unit ID for channel 0 |

||||||

|

Byte 2: device variable ID for channel 2 |

Byte 2-5: value of channel 0 |

||||||

|

Byte 3: device variable ID for channel 3 |

Byte 6: device variable ID for channel 1 |

||||||

|

Byte 7: unit ID for channel 1 |

|||||||

|

Byte 8-11: value of channel 1 |

|||||||

|

Byte 12: device variable ID for channel 2 |

|||||||

|

Byte 13: unit ID for channel 2 |

|||||||

|

Byte 14-17: value of channel 2 |

|||||||

|

Byte 18: device variable ID for channel 3 |

|||||||

|

Byte 19: unit ID for channel 3 |

|||||||

|

Byte 20-23: value of channel 3 |

|||||||

|

34 |

Write attenuation constant for |

Byte 0-3: attenuation constant of the primary process |

Displays the current attenuation constant in the device: |

||||

|

primary process variable |

variable in seconds |

Byte 0-3: attenuation constant in seconds |

|||||

|

Access = Write |

Factory setting: |

||||||

|

Primary process variable = flow |

|||||||

|

35 |

Write measuring range of the |

Write the desired measuring range: |

The measuring range currently set is shown as the |

||||

|

primary process variable |

– |

Byte 0: HART unit ID for the primary process variable |

response: |

||||

|

Access = Write |

– Byte 1-4: end of measuring range, value for 20 mA |

– Byte 0: HART unit ID for the set measuring range of |

|||||

|

– |

Byte 5-8: start of measuring range, value for 4 mA |

the primary process variable |

|||||

|

Factory setting: |

– |

Byte 1-4: end of measuring range, value for 20 mA |

|||||

|

– |

Byte 5-8: start of measuring range, value for 4 mA |

||||||

|

Primary process variable = flow |

|||||||

|

(is always at «0») |

|||||||

|

! |

Note! |

||||||

|

! |

Note! |

||||||

|

• |

You can set the assignment of device variables to |

||||||

|

process variables using Command 51. |

Manufacturer-specific units are represented using the |

||||||

|

HART unit ID «240». |

|||||||

|

• |

If the HART unit ID does not suit the process variable, |

||||||

|

the device will continue with the last valid unit. |

|||||||

|

36 |

Set full scale value |

None |

None |

||||

|

37 |

Set lower range value |

None |

None |

||||

|

38 |

Device status reset «configuration |

None |

None |

||||

|

changed» |

|||||||

|

Access = Write |

|||||||

|

40 |

Simulate output current of the |

Simulation of the desired output current of the primary |

The current output current of the primary process |

||||

|

primary process variable |

process variable. |

variable is displayed as a response: |

|||||

|

Access = Write |

An entry value of 0 exits the simulation mode: |

Byte 0-3: output current in mA |

|||||

|

Byte 0-3: output current in mA |

|||||||

|

Factory setting: |

|||||||

|

Primary process variable = flow |

|||||||

|

! |

Note! |

||||||

|

You can set the assignment of device variables to process |

|||||||

|

variables with Command 51. |

|||||||

|

42 |

Perform device reset |

None |

None |

||||

|

Access = Write |

|||||||

|

Proline Prosonic Flow 92F |

Operation |

||||||

|

Command No. |

Command data |

Response data |

|||||

|

HART command/access type |

(numeric data in decimal form) |

(numeric data in decimal form) |

|||||

|

44 |

Write unit of the primary process |

Specify the unit of the primary process variable. |

The current unit code of the primary process variable is |

||||

|

variable |

Only units which are suitable for the process variable are |

displayed as a response: |

|||||

|

Access = Write |

Byte 0: HART unit ID |

||||||

|

accepted by the device: |

|||||||

|

! |

|||||||

|

Byte 0: HART unit ID |

Note! |

||||||

|

Factory setting: |

Manufacturer-specific units are represented using the |

||||||

|

HART unit ID «240». |

|||||||

|

Primary process variable = flow |

|||||||

|

! |

Note! |

||||||

|

• |

If the written HART unit ID does not suit the process |

||||||

|

variable, the device will continue with the last valid |

|||||||

|

unit. |

|||||||

|

• |

If you change the unit of the primary process variable, |

||||||

|

this does not affect the system units. |

|||||||

|

45 |

Zero point adjustment at the |

Byte 0-3: measured current in mA |

The current output current of the primary process |

||||

|

current output |

variable is displayed as a response: |

||||||

|

Byte 0-3: output current in mA |

|||||||

|

46 |

Span adjustment (adjustment of the |

Byte 0-3: measured current in mA |

The current output current of the primary process |

||||

|

measuring range) at the current |

variable is displayed as a response: |

||||||

|

output |

Byte 0-3: output current in mA |

||||||

|

48 |

Read extended device status |

None |

The current device status is displayed in extended form |

||||

|

Access = Read |

as the response: |

||||||

|

Coding: see Table → Page 35 |

|||||||

|

50 |

Read assignment of the device |

None |

Display of the current variable assignment of the process |

||||

|

variables to the four process |

variables: |

||||||

|

variables |

– |

Byte 0: device variable ID to the primary process |

|||||

|

Access = Read |

variable |

||||||

|

– |

Byte 1: device variable ID to the secondary process |

||||||

|

variable |

|||||||

|

– |

Byte 2: device variable ID to the third process variable |

||||||

|

– |

Byte 3: device variable ID to the fourth process |

||||||

|

variable |

|||||||

|

Factory setting: |

|||||||

|

• |

Primary process variable: ID 1 for flow |

||||||

|

• |

Second process variable: code 250 for totalizer 1 |

||||||

|

• |

Third process variable: code 7 for sound velocity |

||||||

|

• |

Fourth process variable: code 9 for flow velocity |

||||||

|

! |