- Manuals

- Brands

- Puritan Bennett Manuals

- Fan

- 840

- Service manual

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

840

Service Manual

V e n t i l a t o r S y s t e m

4-070496-00 Rev K

August 2010

Related Manuals for Puritan Bennett 840

Summary of Contents for Puritan Bennett 840

-

Page 1

Service Manual V e n t i l a t o r S y s t e m 4-070496-00 Rev K August 2010… -

Page 3

Nothing in this manual shall limit or restrict in any way Puritan Bennett’s right to revise or otherwise change or modify the equipment (including its software) described herein, without notice. In the absence of an express, written agreement to the contrary, Puritan Bennett has no obligation to furnish any such revisions, changes, or modifications to the owner or user of the equipment (including its software) described herein. -

Page 4

In case of fire or a burning smell, immediately disconnect the ventilator from the oxygen supply, facility power, and BPS. • When handling any part of the Puritan Bennett 840 Ventilator System, always follow your hospital infection control guidelines for handling infectious material. -

Page 5

• Patients on life-support equipment should be appropriately monitored by competent medical personnel and suitable monitoring devices. • The Puritan Bennett 840 Ventilator System is not intended to be a comprehensive monitoring device and does not activate alarms for all types of dangerous conditions for patients on life-support equipment. -

Page 6

While this manual covers the ventilator configurations currently supported by Puritan Bennett, it may not be all-inclusive and may not be applicable to your ventilator. You should ensure you have the most current applicable version of this manual; if in doubt, contact Puritan Bennett or visit the Puritan Bennett product manual Web page at http://www.puritanbennett.com/serv/manuals.aspx… -

Page 7: Table Of Contents

2.3.3 Exhalation module………………… 2-38 2.3.3.1 Exhalation module components …………. 2-39 2.3.3.2 Exhalation module operation …………..2-40 2.3.4 806 Compressor Unit ………………2-43 2.3.4.1 806 Compressor unit components …………2-43 2.3.4.2 806 Compressor unit operation………….. 2-46 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 8

2.6.3 Pressure transducer autozero…………….2-115 2.6.4 Power monitoring and power fail handling …………. 2-117 2.6.4.1 Loss of power source …………….2-117 2.6.4.2 Supply voltage monitoring …………..2-118 2.7.1 Safety valve open (SVO) state…………….2-118 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 9

4.2.10.2 External Test Control: Performing remote ventilator testing ….. 4-9 4.2.10.3 Exp Valve Calibration …………….4-9 4.2.10.4 Vent Inop Test………………4-12 4.2.10.5 Flow Sensor Calibration…………….4-13 4.2.10.6 Atmospheric Pressure Transducer calibration………. 4-15 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 10

6.12 How to troubleshoot GUI LCD screen messages ……….. 6-109 6.12.1 Example 1: Missing data key information …………6-109 6.12.2 Example 2: No communication between the GUI and BDU……6-111 6.12.3 Example 3: POST or Background check errors ……….6-112 viii Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 11

8.13 Repairing the 10.4-inch GUI ………………8-8 8.13.1 Removing or installing the 10.4-inch GUI when mounted on RTA cart….8-8 8.13.2 Removing or installing the 10.4-inch GUI when mounted on Puritan Bennett 800 Series Ventilator Compressor Mount Cart or Puritan Bennett 800 Series Ventilator Pole Cart……………. -

Page 12

8.15 Breath delivery unit (BDU) ………………8-50 8.15.1 Removing BDU from RTA cart …………….. 8-53 8.15.2 Removing BDU from Puritan Bennett 800 Series Ventilator Compressor Mount Cart or Puritan Bennett 800 Series Ventilator Pole Cart..8-53 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 13

8.15.4 Installing BDU onto RTA cart …………….8-55 8.15.5 Installing BDU onto Puritan Bennett 800 Series Ventilator Compressor Mount Cart or Puritan Bennett 800 Series Ventilator Pole Cart ..8-55 8.15.6 Analog interface (AI) PCB and breath delivery (BD) CPU PCB……8-56 8.15.6.1 Removing AI PCB or BD CPU PCB ………… -

Page 14

8.17.17 Compressor assembly …………….. 8-121 8.17.17.1 Removing the compressor assembly ………… 8-121 8.17.17.2 Replacing the coalescing filter element ……….8-122 8.17.18 Replacing the compressor panels …………..8-123 8.17.19 Reinstalling the plenum assembly…………..8-124 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 15

8.19.4.2 Installing casters on RTA cart …………..8-151 8.19.5 Removing casters from Puritan Bennett 800 Series Ventilator Compressor Mount Cart or Puritan Bennett 800 Series Ventilator Pole Cart … 8-151 8.19.6 Installing casters on Puritan Bennett 800 Series Ventilator Compressor Mount Cart or Puritan Bennett 800 Series Ventilator Pole Cart ..8-152 8.19.7 Removing/installing GUI mount on all carts……….. -

Page 16

Contents Parts list 9.1 How to use this parts list ………………… 9-1 9.2 Puritan Bennett 840 Ventilator System patient system and accessories ……. 9-3 9.2.1 Puritan Bennett 840 Ventilator System NeoMode patient system and accessories ………………..9-6 9.3 Flex arm assembly, oxygen and air hose assemblies, power cords ……9-8 9.3.1 Flex arm assembly ……………….. -

Page 17

RTA cart, Puritan Bennett 800 Series Ventilator Compressor Mount Cart, and Puritan Bennett 800 Series Ventilator Pole Cart ……2-6 Figure 2-8. -

Page 18

AC panel …………. 2-63 Figure 2-47. Puritan Bennett 840 Ventilator System interconnect diagram – AC panel … . 2-64 Figure 2-48. -

Page 19

/CAL In Progress indicator……… 4-20 Figure 5-1. Puritan Bennett 840 ventilator side view — PTS 2000 port ……5-9 Figure 5-2. -

Page 20

Adding ferrites to air and oxygen transducer harnesses ……8-66 xviii Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 21

Removing existing brackets ……….8-128 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 22

Bennett 800 Series Ventilator Pole Cart ……..8-154 Figure 9-1. Puritan Bennett 840 Ventilator System patient system and accessories ….9-5 Figure 9-2. -

Page 23

Puritan Bennett 800 Series Ventilator Pole Cart ……. . 9-92… -

Page 24

Figures This page is intentionally blank. xxii Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 25

Recommended separation distances between portable and mobile RF communications equipment and the Puritan Bennett 840 Ventilator System ……1-14 Table 1-7. -

Page 26

Table 6-2. Puritan Bennett 840 Ventilator System diagnostic codes ……6-7 Table 6-3. -

Page 27: General Information

BPS, which is located in the BDU shelf. The Puritan Bennett 800 Series Ventilator Pole Cart can also be used with a one-hour battery or an optional four-hour battery, located in the cart base. The Puritan Bennett 800 Series Ventilator Pole Cart cannot be used with a compressor.

-

Page 28: Configuration Information

An external air source is required when performing service mode calibrations and performance verification testing. 1.3 Configuration information The Puritan Bennett 840 Ventilator System is available in a variety of versions, intended to meet differing needs and regulations throughout the world. The major differences in configuration among ventilators are listed below: Electrical requirements: Available in 100 V, 50/60 Hz;…

-

Page 29: Accessories

“Part numbers” appendix of the Puritan Bennett 800 Series Ventilator System Operator’s and Technical Reference Manual for patient circuit ordering information. Humidification device: The Puritan Bennett 840 Ventilator System supports the use of an optional humidification device, including a heated humidifier, heat and moisture exchanger (HME), or heated wire.

-

Page 30: Specifications

(41 in. high x 27 in. wide x 33 in. deep with wheels in outermost position) Puritan Bennett 800 Series Ventilator Pole Cart: 1041mm high x 686 mm wide x 839 mm deep (41 in. high x 27 in. wide x 33 in. deep with wheels in outermost position) 804 Compressor: 417 mm high x 458 mm wide x 362 mm deep (16.4 in.

-

Page 31

, 50 cmH O; P , 3 cmH O. Input power specifications are for ventilators with Fisher & Paykel MR730 MEAN SENS humidifiers. (Humidifier connection only available on 100 – 120 V ventilators.) Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 32

Every 2 months when storage temperature is 41 to 50 C (105 to122 F) NOTE: BPS battery life specifications are approximate. To ensure maximum battery life, maintain full charge and minimize the number of complete discharges. Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 33: Figure 1-1. Remote Alarm (Nurse’s Call) Port Pinout (View From Back Of Gui)

The remote alarm port is a 4-pin female connector. Allowable current is 500 mA at 30 V DC (maximum). Signal Normally closed (NC) Relay common Normally open (NO) Not connected Figure 1-1. Remote alarm (nurse’s call) port pinout (view from back of GUI) Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 34: Figure 1-2. Puritan Bennett 840 Ventilator System Rs-232 Serial Port Pinout

RS-232 (serial) port (Figure 1-2). A 9-pin male connector configured as data terminal equipment capabilities (cont) (DTE). Allowable current is 0.2 A at 10 V DC (maximum). Figure 1-2. Puritan Bennett 840 Ventilator System RS-232 serial port pinout Signal Not connected…

-

Page 35: Compliance And Approvals

General information 1.6 Compliance and approvals The Puritan Bennett 840 Ventilator System was developed in accordance with pertinent North American and International standards (Table 1-2). The manufacturing facility for this product is certified to EN ISO 13485:2000 (ISO 13485:1996) Quality Systems — Medical Devices — Particular Requirements for the Application of ISO 9001:1994.

-

Page 36

220 – 240 V, 60 Hz EN 60601-1:1990 EN 60601-1 Amendment 1:1993 EN 60601-1 Amendment 11:1993 EN 60601-1 Amendment 12:1993 EN 60601-1 Amendment 2:1995 EN 60601-1 Amendment 13:1996 IEC 60601-2-12:2001 EN 60601-1-2:2001+A1:2006 Manufacturer self- certification 1-10 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 37: Manufacturer’s Declaration

Puritan Bennett 800 Series Ventilator System Operator’s and Technical Reference Manual. Warning • The Puritan Bennett 840 Ventilator System should not be used adjacent to or stacked with other equipment, except as specified in this manual and the Puritan Bennett 800 Series Ventilator System Operator’s and Technical Reference Manual.

-

Page 38: Table 1-4. Electromagnetic Immunity

Table 1-4: Electromagnetic Immunity The Puritan Bennett 840 Ventilator System is intended for use in the electromagnetic environment specified below. The customer or the user of the Puritan Bennett 840 Ventilator System should ensure it is used in such an environment.

-

Page 39: Table 1-5. Electromagnetic Immunity — Conducted And Radiated Rf

Table 1-5: Electromagnetic immunity – conducted and radiated RF The Puritan Bennett 840 Ventilator System is intended for use in the electromagnetic environment specified below. The customer or the user of the Puritan Bennett 840 Ventilator System should ensure it is used in such an environment. Immunity test…

-

Page 40: Table 1-6. Recommended Separation Distances Between Portable And Mobile Rf Communications Equipment And The Puritan Bennett 840 Ventilator System

If the measured field strength in the location in which the Puritan Bennett 840 Ventilator System is used exceeds the applicable RF compliance level above, the Puritan Bennett 840 Ventilator System should be observed to ver- Puritan Ben- ify normal operation.

-

Page 41

General information Table 1-6: Recommended separation distances between portable and mobile RF communications equipment and the Puritan Bennett 840 Ventilator System (continued) For transmitters rated at a maximum output power not listed above, the recommended separation distance d in meters (m) can be determined using the equation applicable to the frequency of the transmitter, where P is the maximum output power rating of the transmitter in watts (W) according to the transmitter manufacturer. -

Page 42: Table 1-7. Compliant Cables

General information Table 1-7: Compliant cables Puritan Bennett does not supply remote alarm (nurse call) or serial port cables. In order to maintain compliance to International Electromagnetic Compatibility (EMC) standards, Puritan Bennett recommends using shielded cables for these applications. Warning…

-

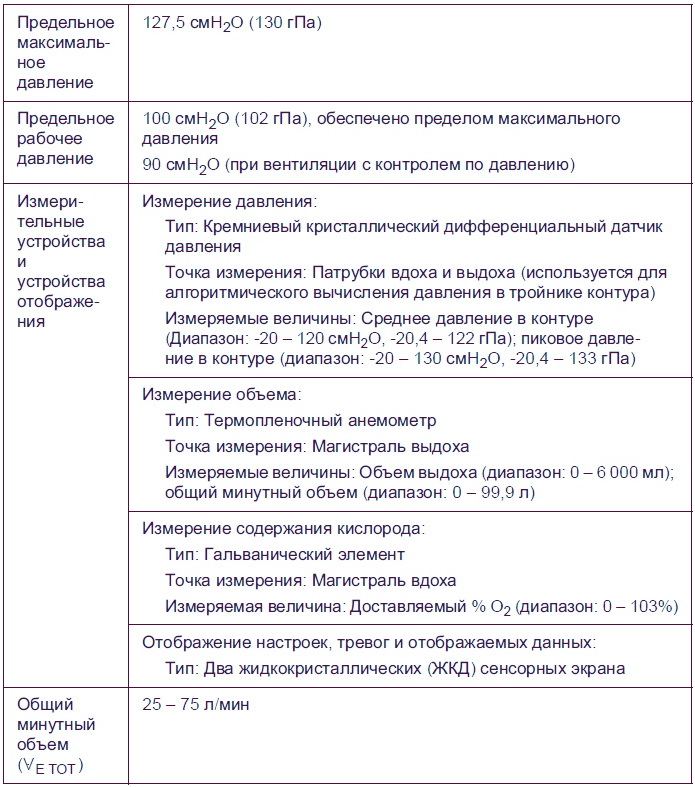

Page 43: Technical Information

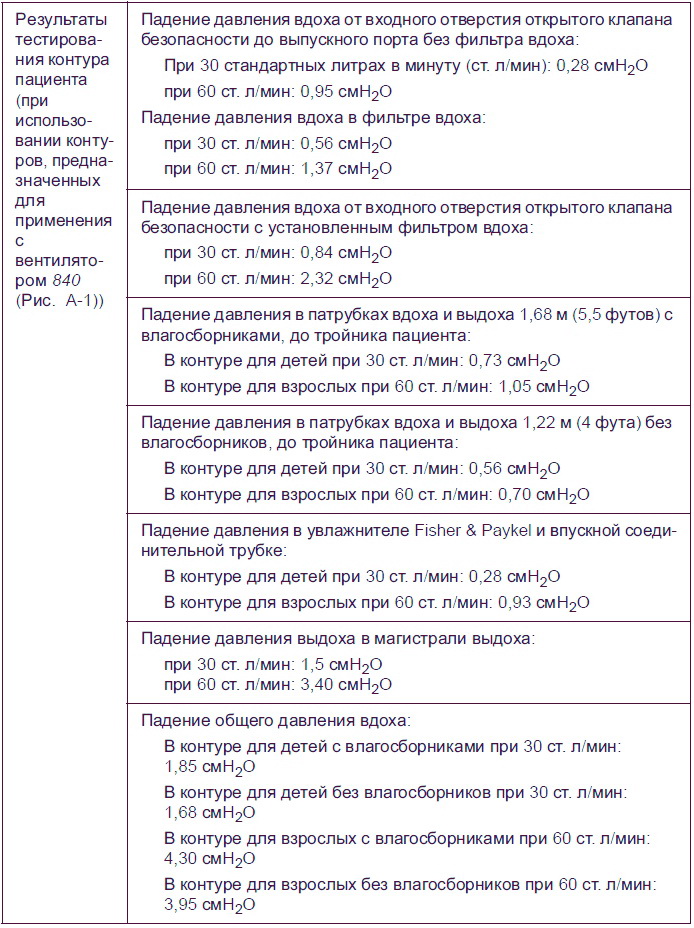

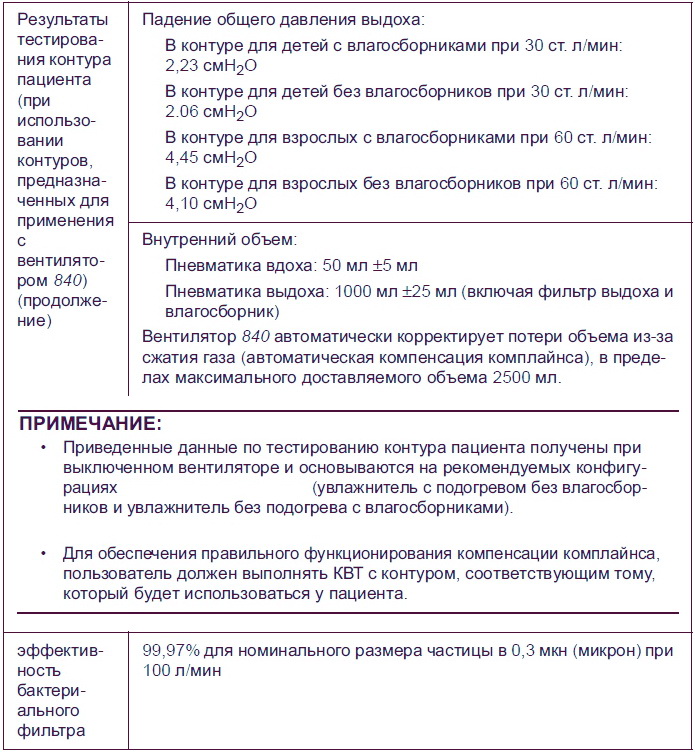

General information 1.7 Technical information Refer to Table 1-8 for Puritan Bennett 840 Ventilator System miscellaneous technical information. NOTE: When pressure units are set to hPa, pressure delivery and spirometry are subject to an additional 2% error. Table 1-8: Technical information Maximum limited pressure 127.5 cmH…

-

Page 44

Inspiratory pneumatics: 50 mL 5 mL Expiratory pneumatics: 1000 mL 25 mL (including expiratory filter and collector vial) The Puritan Bennett 840 Ventilator System automatically adjusts for volume losses due to gas compressibility (that is, automatic compliance compensation), subject to a maximum delivered volume of 2500 mL. -

Page 45: Range, Resolution, Accuracy, And New Patient/Default Settings

Pediatric: 15 s Adult: 20 s Apnea mandatory type Range: VC or PC Resolution: N/A Accuracy: N/A New patient: PC with NEONATAL patient circuit VC with PEDIATRIC or ADULT patient circuit 1-19 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 46

New patient: Maximum of 3* mL or (7.25 x IBW); with NEONATAL patient circuit (7.25 x IBW); with PEDIATRIC or ADULT patient circuit *Assumes NeoMode 2.0 software option is installed Normal (non-apnea) ventilation 1-20 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 47

Range: HME, non-heated expiratory tube, or heated expiratory tube Resolution: Not applicable Accuracy: Not applicable New patient value: previous setting Humidifier volume Range: 100 mL to 1000 mL Resolution: 10 mL New patient value: previous setting 1-21 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 48

VC with PEDIATRIC or ADULT patient circuit Mode Range: A/C, SIMV, SPONT, or BILEVEL Resolution: Not applicable Accuracy: Not applicable New patient: SIMV with NEONATAL patient circuit A/C with PEDIATRIC or ADULT patient circuit 1-22 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 49

Accuracy: 0.1 + 0.6% of setting)/min averaged over 60 seconds or 5 breaths, whichever occurs last New patient: 20/min with NEONATAL patient circuit 14/min with PEDIATRIC patient circuit 10/min with ADULT patient circuit 1-23 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 50

*Assumes NeoMode 2.0 software option is installed Trigger type Range: Flow (V-TRIG) NEONATAL patient circuit Pressure or flow (P-TRIG or V-TRIG) with PEDIATRIC or ADULT patient circuit Resolution: Not applicable Accuracy: Not applicable New patient: Flow (V-TRIG) 1-24 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 51

SUPP MEAN is rejected. Refer to the Technical Reference section of part of the Puritan Bennett 800 Series Ventilator System Operator’s and Technical Reference Manual for more details. Vent type Range: INVASIVE or NIV (non-invasive) -

Page 52

Resolution: 1 mL for 1 to 100 mL; 5 mL for 100 to 400 mL; 10 mL for 400 to 2500 mL New patient: 7.25 x IBW x 0.70 when vent type is INVASIVE; OFF when vent type is NIV 1-26 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 53

O for PEEP 20 cmH 1.0 cmH Sensor Range: Enabled, Disabled, or Calibration Resolution: Not applicable New patient value: Enabled NOTE: The O sensor must be for the High/Low delivered O Enabled alarm to function. 1-27 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 54

O for 10 to 130 cmH MEAN (formerly P CIRC Accuracy: ± (3 + 4% of reading) cmH O relative to pressure measured at the exhalation side of the patient wye. 1-28 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 55: Tools, Equipment, And Service Materials

1.9 Tools, equipment, and service materials The tools, equipment, and service materials listed in Table 1-10 are used to service the Puritan Bennett 840 Ventilator System. Refer to Chapter 5 for a list of required tools, equipment, and service materials specific to performance verification.

-

Page 56: Table 1-10. Tools, Equipment, And Service Materials

Digital multimeter patch cords G-061567-00 Performance verification (optional) * These parts may be purchased individually or by ordering a Puritan Bennett 840 VTS Accessories Kit, P/N 4-076599-00. Disinfectant/cleaner The following solutions are acceptable General cleaning for disinfecting/cleaning the Puritan…

-

Page 57

Filter, expiratory bacteria filter DAR 351P19005 Performance verification * These parts may be purchased individually or by ordering a Puritan Bennett 840 VTS Accessories Kit, P/N 4-076599-00. Filter, expiratory bacteria filter, 4-070305-00 Performance verification reusable (Re/X800) Filter, inspiratory, Re/Flex… -

Page 58

• One available TCP/IP network port with BNC connector (if software download desired) * These parts may be purchased individually or by ordering a Puritan Bennett 840 VTS Accessories Kit, P/N 4-076599-00. Pneumatic calibration analyzer or Puritan Bennett PTS 2000 Performance… -

Page 59

Test lung, 4 L 4-075578-00 Performance verification Tie wraps 4-000003-00 (small) Various places 4-000004-00 (large) * These parts may be purchased individually or by ordering a Puritan Bennett 840 VTS Accessories Kit, P/N 4-076599-00. 1-33 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 60: Series Ventilator Compressor Mount Cart, And Puritan Bennett 800 Series Ventilator Pole Cart

N-4800168 Replacing casters (RTA cart) Wye, patient circuit *4-000338-00 SST, performance verification * These parts may be purchased individually or by ordering a Puritan Bennett 840 VTS Accessories Kit, P/N 4-076599-00. 1-34 Puritan Bennett 800 Series Ventilator System Service Manual…

-

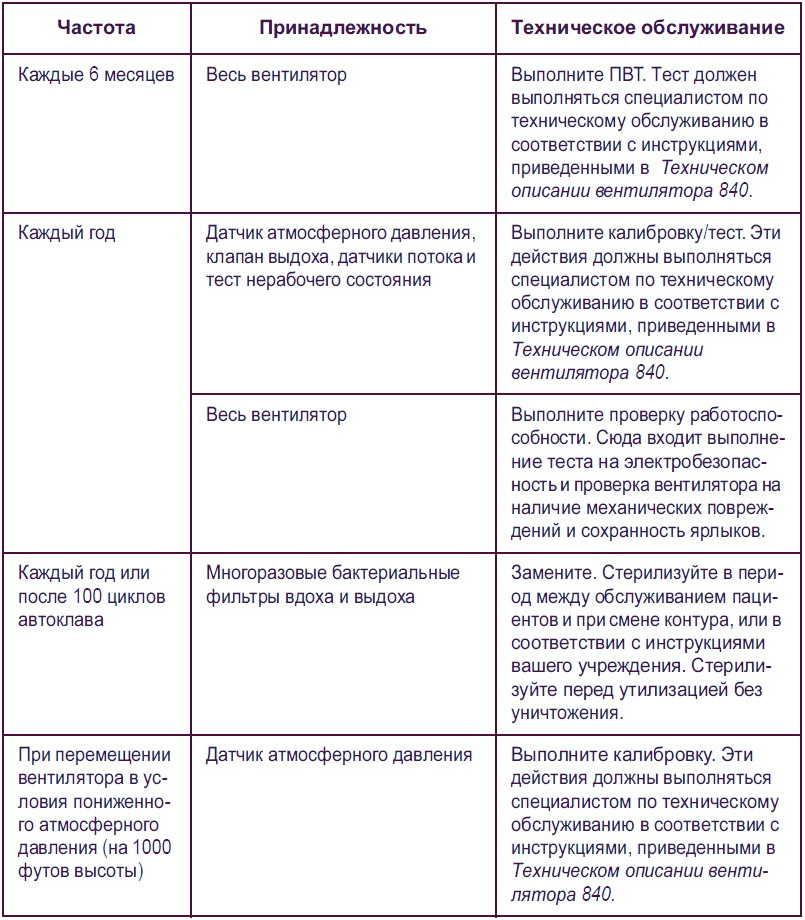

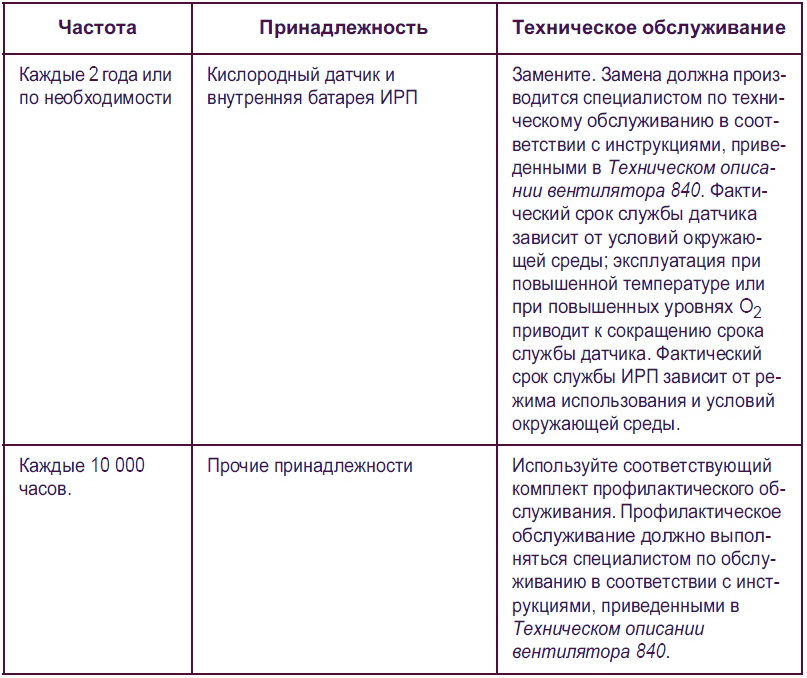

Page 61: Periodic Maintenance

Table 1-11 lists the periodic maintenance activities required for the Puritan Bennett 840 Ventilator System. See the Ventilator Information screen for total hours of operation for the ventilator and compressor. For details on patient system maintenance, refer to the Puritan Bennett 800 Series Ventilator System Operator’s and Technical Reference Manual.

-

Page 62

Use appropriate preventive maintenance kit (see Table 1-12). Every 15,000 hours NOTE: If any part found in a preventive maintenance kit requires replacement before the recommended interval elapses, consider installing the entire kit anyway. 1-36 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 63: Service Kits

General information 1.11 Service kits Table 1-12 lists the Puritan Bennett 840 Ventilator System service kits. Chapter 9 lists the mounting kits available for the ventilator. Table 1-12: Service kits Interval Description Part no. Kit contents 10,000 hours 9.4“ GUI and BDU…

-

Page 64

Filter element for water trap assembly Main inlet filter Outlet filter for solenoid assembly Tie wrap, large, for air dryer assembly Tie wraps, small for fan harnesses (qty. 2) Tinnerman clips (qty. 6) 1-38 Puritan Bennett 800 Series Ventilator System Service Manual… -

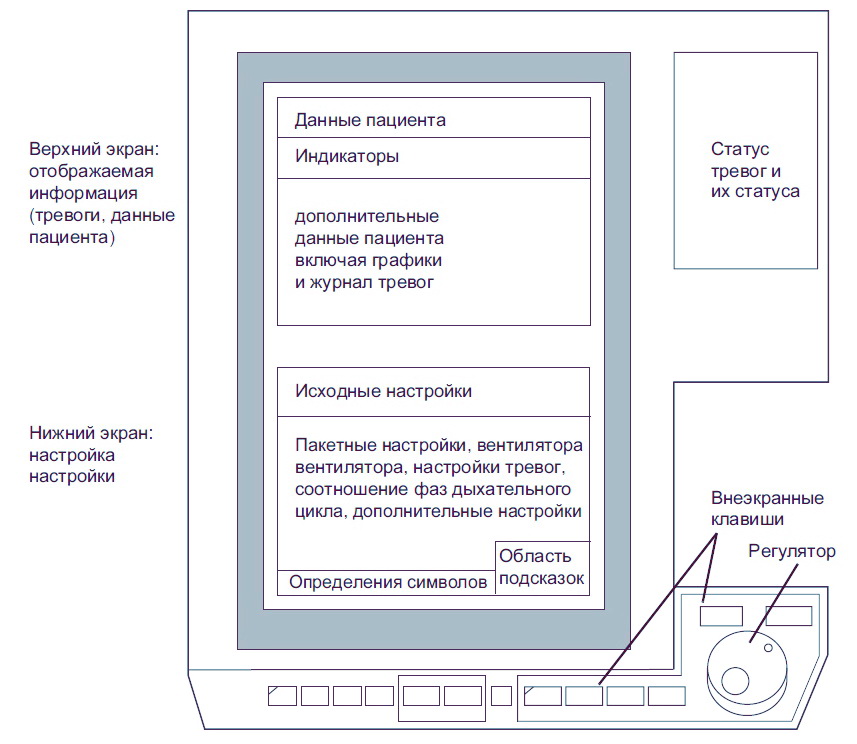

Page 65: Controls And Indicators

1.12 Controls and indicators Refer to Figure 1-3 through Figure 1-10 and Table 1-13 through Table 1-20 for ventilator controls and indicators. 10 11 Figure 1-3. Monochrome GUI front view (showing all keys) 1-39 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 66: Table 1-13. Gui Front View

Color GUI (9.4 inch screen): Key present but inactive Monochrome GUI: Display brightness key. Allows you to adjust screen brightness when you hold down this key while turning the knob. (US version only) 1-40 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 67

You cannot reset a DEVICE ALERT alarm. Displays basic operating information about the ventilator. US version only 1-41 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 68

0.5 and 2 seconds. Pressing and holding this key initiates a manual inspiratory pause extending inspiration up to 7 seconds. Cancels a proposed setting. 1-42 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 69

Gray normal ventilator operation indicator. Indicator appears unilluminated when no ventilator inoperative condition exists. non-US version US version text is not visible when no ventilator inoperative condition exists. US version 1-43 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 70

Red safety valve open (SVO) indicator. Illuminates when the ventilator has entered its safe state and opened its safety valve to allow the patient to breathe unassisted from room air. non-US version US version 1-44 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 71

(battery symbol) is lit, ventilator is operating on BPS, and AC power is insufficient to support ventilator operation. During BPS operation, power to the compressor unit and the humidifier outlet (if available) is off. BATTERY US version only 1-45 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 72

Green normal ventilator operation indicator steadily lit. This indicator is off if the ventilator is not in a ventilation mode, for example, during service mode or short self test (SST). 1-46 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 73: Figure 1-4. 10.4-Inch Gui Rear View

10.4-inch GUI only: Two serial ports with 9-pin male connector configured as data terminal equipment (DTE). NOTE: Allowable current is 0.2 A at 10 V DC (maximum). RS-232 NULL Null modem port (9.4-inch and 10.4-inch GUI) 1-47 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 74: Figure 1-5. Bdu Front View

Index Labeling Function (Figure 1-5) EXHAUST port BDU exhaust port. Gas is vented to atmosphere. Ventilator operation indicators Red ventilator inoperative indicator. (See Table 1-13, item 15.) non-US version US version 1-48 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 75

Gray normal GUI indicator. Indicator appears unilluminated when no loss of GUI condition exists. non-US version US version text is not visible when no loss of GUI condition exists. US version 1-49 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 76

2.3 A (270 VA) with a maximum leakage current of 50 A. To patient port Ventilator outlet From patient port Expiratory limb connector on exhalation filter (Collector vial drain port) Collector vial drain port. Use to attach drainage bag. 1-50 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 77: Figure 1-6. Bdu I/O Panel

BDU, the ventilator is placed into service mode (for example, to run EST). PTS 2000 Puritan Bennett PTS 2000 Performance Test System connection. Data key connection Caution Do not remove the data key. The data key cover can only be removed with a screwdriver.

-

Page 78

General information Table 1-16: BDU I/O panel (continued) Index Labeling Function (Figure 1-6) Compressor data cable connection Compressor US version GUI cable connection Display (GUI) US version 1-52 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 79: Figure 1-7. Bdu Right-Side Panel

Labeling Function (Figure 1-7) Ventilator circuit breaker for compressor and humidifier NOTE: A humidifier connection is only available on 100 – 120 V ventilators. Compressor & humidifier circuit breaker US version 1-53 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 80

A common grounding point for the entire ventilator. Maximum allowed output to auxiliary mains socket (compressor electrical connection) Compressor outlet: 5.6 A max US version 1-54 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 81: Figure 1-8. Bdu Rear View

(High-pressure air fitting) DISS male, DISS female, NIST, Air Liquide, or SIS fitting (High-pressure oxygen DISS male, DISS female, NIST, Air Liquide, or SIS fitting fitting) Figure 1-9. GUI rear view 1-55 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 82: Table 1-19. Gui Rear View

Labeling Function (Figure 1-9) (Warning label) Warns user of hazards associated with the operation of the Puritan Bennett 840 Ventilator System and GUI (Serial number label) Unique assigned number. Must be the same as the GUI serial number stored on the data key.

-

Page 83: Figure 1-10. 802 Bps Controls And Indicators

General information Figure 1-10. 802 BPS controls and indicators Figure 1-11. 803 BPS controls and indicators 1-57 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 84: Figure 1-12. Puritan Bennett 800 Series Ventilator Compressor Mount Cart Charging Status And

General information Figure 1-12. Puritan Bennett 800 Series Ventilator Compressor Mount Cart charging status and battery indicator labels 1-58 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 85: Figure 1-13. Puritan Bennett 800 Series Ventilator Pole Cart Charging Status And

General information Figure 1-13. Puritan Bennett 800 Series Ventilator Pole Cart charging status and battery indicator labels Table 1-20: BPS controls and indicators Labeling Function Index (Figure 1-10) 802 BPS charging status. When the ventilator is operating on mains power, the top symbol (green LED next to gray battery icon) indicates that the BPS is charged, and the bottom symbol (yellow LED next to gray battery icon) indicates that the BPS is charging.

-

Page 86

All countries Index (Figure 1-12) Charging status on Puritan Bennett 800 Series Ventilator Compressor Mount Cart: Indicates the charging status of the BPS. A yellow LED next to the partially full battery icon indicates the battery is charging. A green LED next to the full battery icon indicates the battery is charged. -

Page 87: Onscreen Symbols And Abbreviations

Manual to interpret these. 1.14 Ventilator serial numbers and software version The Puritan Bennett 840 Ventilator System serial numbers and software versions can be displayed on the GUI upper subscreen. On the GUI upper screen, select the VENT CONFIG button. The ventilator configuration subscreen displays the current software revisions for the BDU, GUI, compressor, and audible alarm subsystem.

-

Page 88

General information This page intentionally blank. 1-62 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 89: Theory Of Operation

ECTION H A PT ER Theory of operation This chapter details the operational theory of the Puritan Bennett™ 840 Ventilator System and contains the following information: • description of major ventilator assemblies • overview of ventilator operation • description of the pneumatic system •…

-

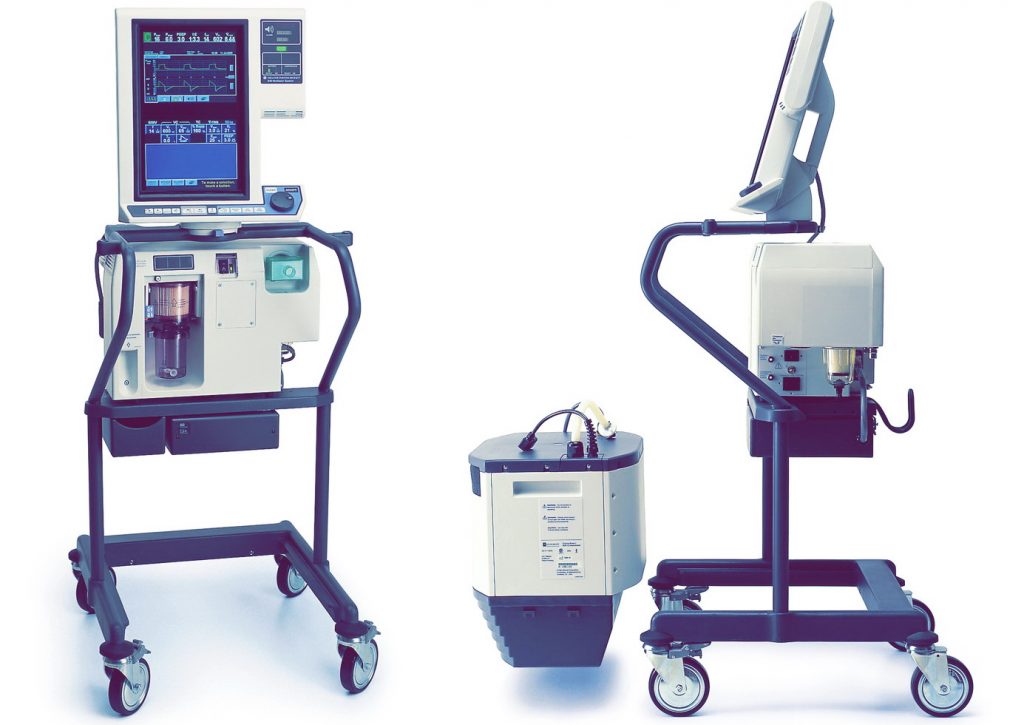

Page 90: Breath Delivery Unit (Bdu)

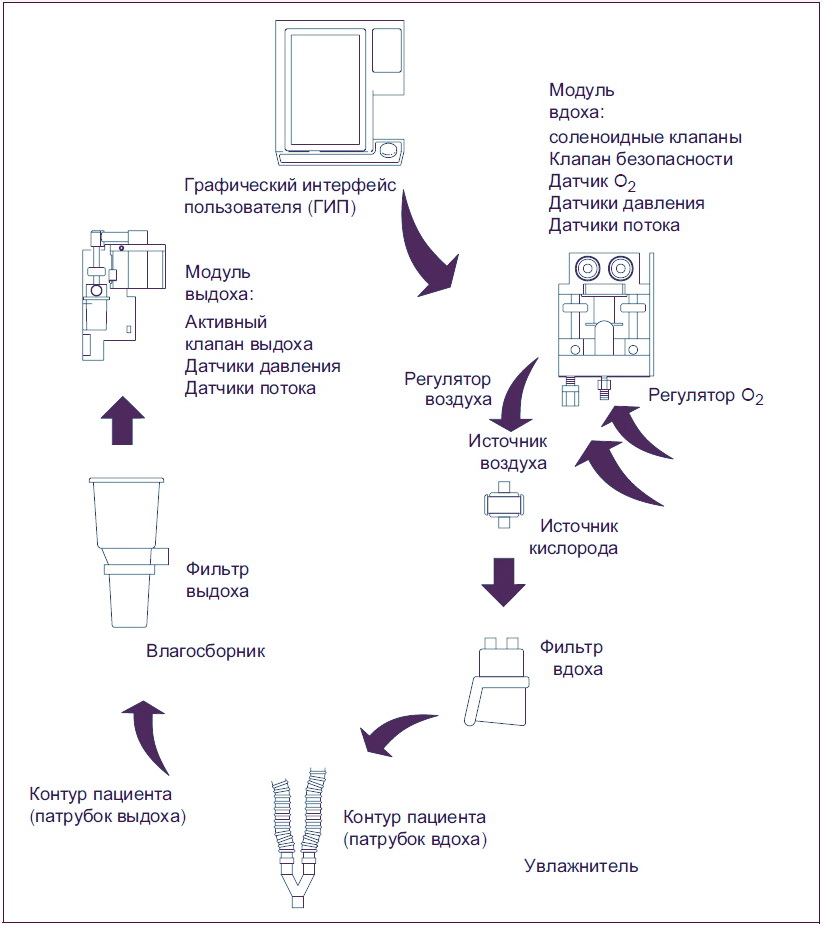

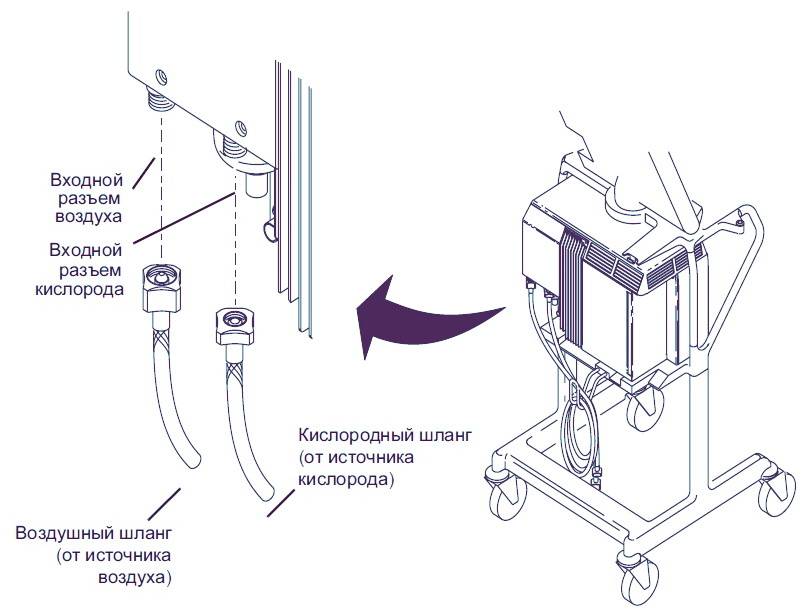

Ventilator Compressor Mount Cart, and Puritan Bennett 800 Series Ventilator Pole Cart 2.1.1 Breath delivery unit (BDU) The BDU, shown in Figure 2-2, is the core of the Puritan Bennett 840 Ventilator System. Its pneumatic system, under control of the breath delivery (BD) central processing unit (CPU), mixes oxygen and air and controls gas flow to the patient.

-

Page 91: Graphic User Interface (Gui)

GUI. The GUI CPU monitors BDU communications. In turn, the GUI displays patient and ventilator performance information. Figure 2-3. 10.4-inch GUI Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 92: Compressor Unit

803 BPS will operate the ventilator for up to four hours with new, fully charged batteries. Neither BPS supplies the compressor unit or the humidifier with electrical power. The ventilator automatically switches back to AC power when facility power returns within the required limits. Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 93: Cart

The optional carts are shown in Figure 2-7. The cart mounts system components and accessories, including the compressor unit on the RTA and Puritan Bennett 800 Series Ventilator Compressor Mount Carts. They also provide mobility for the ventilator. Brakes on the front casters prevent the cart from rolling and turning.

-

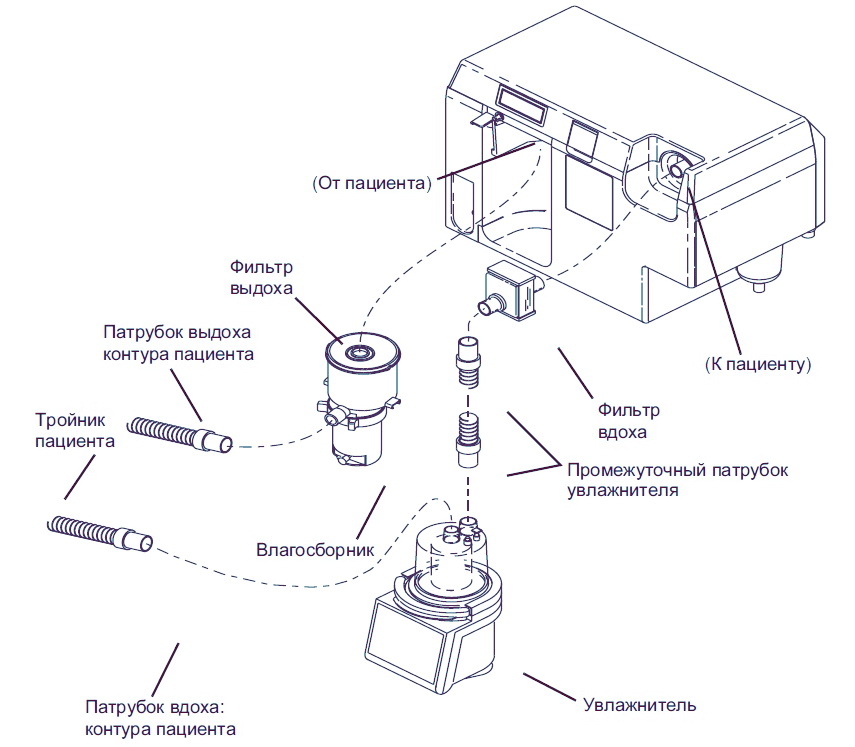

Page 94: Patient System

Theory of operation 8-01119 Figure 2-7. RTA cart, Puritan Bennett 800 Series Ventilator Compressor Mount Cart, and Puritan Bennett 800 Series Ventilator Pole Cart 2.1.6 Patient system The patient system (adult, reusable version shown in Figure 2-8) includes reusable or single- patient use tubing plus an inspiratory filter that prevents gas-borne particles from exiting the ventilator.

-

Page 95: Operational Overview

GUI: high circuit pressure limit, breath phase, breath mode, autozero offsets, inspiratory time, apnea interval, target pressure for pressure controlled breaths, breath phase start, and time stamp. Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 96: Figure 2-10. Puritan Bennett 840 Ventilator System Block Diagram

Figure 2-10. Puritan Bennett 840 Ventilator System block diagram The GUI logs an event in the diagnostic log and declares a ventilator inoperative condition if: • Any raw signal data from three BDU transmissions within 24 hours is corrupted.

-

Page 97

BDU CPU to control the PSOLs. As a result, the ventilator supplies mixed breathing gas to the patient according to operator-set variables. The mixed air and oxygen passes through the patient circuit external to the ventilator. Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 98

In case of a malfunction that prevents software from opening the safety valve, there is also an analog circuit that opens the safety valve if system pressure exceeds 100 to 120 cmH 2-10 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 99: Pneumatic System

Theory of operation 2.3 Pneumatic system This section describes the Puritan Bennett 840 Ventilator System pneumatics, as follows: • Inspiratory module: Contains the following pneumatic subsystems: – Gas supply conditioning subsystem – Flow control subsystem – Safety valve/inspiration monitoring subsystem •…

-

Page 100: Figure 2-12. Pneumatic System Diagram

Theory of operation Figure 2-12. Pneumatic system diagram 2-12 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 101: Table 2-1. Pneumatic Component Descriptions

Measures oxygen or air flow before PSOL. Regulator, oxygen/air Reduces input supply pressure (35 to 100 psig, flow up to 200 L/min REG1 BTPS) to output pressure (9 psig minimum to 12 psig maximum). REG2 2-13 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 102

Measures exhalation flow. Solenoid, autozero, expiratory +6 V, three-way solenoid valve. Energized (common to normally SOL2 pressure transducer closed) when transducer is autozeroed. De-energized (common to normally open) all other times. 2-14 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 103

Water trap Collects condensate as the compressed air cools in the heat exchanger. Automatically drains collected water to the housing base where it evaporates. 2-15 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 104: Inspiratory Module

The inspiratory module, which is part of the BDU, is shown in Figure 2-13 and Figure 2-14. It includes the gas supply conditioning, flow control, and safety valve/inspiration monitoring subsystems. Figure 2-15 is a diagram of the inspiratory module gas flow. Figure 2-13. Inspiratory module 2-16 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 105: Gas Supply Conditioning Subsystem

It does this by sending signals to the electronics when a gas source falls below a minimum pressure. Figure 2-17 illustrates the gas flow through gas supply conditioning subsytem. 2-17 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 106: Figure 2-16. Gas Supply Conditioning Subsystem

Figure 2-16. Gas supply conditioning subsystem Figure 2-17. Gas supply conditioning subsystem gas flow diagram 2.3.1.1.1 Gas supply conditioning subsystem components The oxygen side of the gas supply conditioning subsystem includes the following components: 2-18 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 107

• The oxygen pressure valve (TP1) checks the oxygen regulator setting (REG1). • The oxygen pneumatic noise filter (F7), housed in the flow sensor manifold, conditions gas flow by eliminating swirling of gas induced by elbows and restrictions. 2-19 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 108

• The air pressure valve (TP2) checks the oxygen regulator setting (REG2). • The air pneumatic noise filter (F6), housed in the flow sensor manifold, conditions gas flow by eliminating swirling of gas induced by elbows and restrictions. 2-20 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 109: Figure 2-18. Gas Supply Conditioning Subsystem Components

Theory of operation Oxygen inlet filter (F3) Oxygen impact filter (F1) Oxygen Filters (F1 and F3) Air inlet filter (F2) Oxygen/air pressure switches (PS1/PS2) Figure 2-18. Gas supply conditioning subsystem components 2-21 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 110

(F1), traps particles down to 65 m (microns) and the subsequent filter, the oxygen inlet filter (F3), traps particles down to 0.3 m (micron). The oxygen transfer tube directs oxygen to the check valve manifold. There is no check valve for oxygen. 2-22 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 111: Flow Control Subsystem

The flow control subsystem, shown in Figure 2-20 and Figure 2-19, controls the mixture and flow of oxygen and air to the patient. It is mounted on the gas supply conditioning subsystem. PSOL1 PSOL2 Figure 2-19. Flow control subsystem 2-23 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 112: Figure 2-20. Flow Control Subsystem Gas Flow Diagram

• Q1 and Q2 use a hot film (Figure 2-21) within each sensor to measure gas velocity (flow). The hot film constitutes one leg of a bridge circuit. The bridge is supplied by a constant 2-24 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 113: Figure 2-22. Flow Control Subsystem Components

Oxygen and air flow sensors (Q1 and Q2) with ferrites installed Oxygen and air proportional solenoid valves (PSOL1 and PSOL2) Figure 2-22. Flow control subsystem components 2-25 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 114: Safety Valve And Inspiration Monitoring Subsystem

• A safety valve section that, under certain circumstances, vents excessive ventilator pressure and lets the patient breathe room air. • An inspiration monitoring section that monitors the pressure and oxygen concentration of the inspiratory gas. 2-26 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 115: Figure 2-23. Safety Valve And Inspiration Monitoring Subsystem

The safety valve section includes the following components, shown in Figure 2-24: • The safety valve (SV) consists of a +12 V solenoid actuator that is normally energized (closed) while the ventilator operates. The closed valve prevents gas from escaping to the 2-27 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 116

• The absolute pressure transducer (PA), located on the inspiratory electronics PCB, measures atmospheric pressure (psia). One port is opened to the atmosphere and one port is connected to a sealed vacuum chamber. 2-28 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 117: Figure 2-25. Safety Valve And Inspiration Monitoring Subsystem Components

Theory of operation Safety valve (SV) Seat Leaf Check valve housing Oxygen sensor Oxygen sensor port 8-0112 Inspiratory outlet manifold Figure 2-25. Safety valve and inspiration monitoring subsystem components Oxygen sensor (OS) 2-29 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 118

O (measured at PE), components in the safety valve subsystem work together to relieve excess pressure. If pressure at the safety valve reaches nominal 115 cmH O, the valve is forced open. 2-30 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 119: Figure 2-26. Safety Valve Open Gas Flow Diagram

PEEP plus the effective working pressure for spontaneous, pressure-supported breaths. Ongoing diagnostics monitor ventilator pressures and check for severe occlusions and circuit disconnects by comparing pressure at PE and PI. 2-31 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 120: Inspiratory Module Operation

Check valve manifold Air check valve (CV2) Compressor check valve (CV4) Air impact screen filter (F4) Air regulator (REG2) Flow sensor manifold Air pressure valve (TP2) Air pneumatic noise filter (F6) 2-32 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 121

Inspiration monitoring. The oxygen concentration of the delivered gas is measured by the oxygen sensor (OS). The ventilator alarms if the monitored oxygen concentration is not within ±7% of the oxygen percentage setting. Pressure measurements are made by two differential pressure transducers. 2-33 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 122: Figure 2-28. Oxygen Flow Diagram

Check valve manifold Oxygen impact screen filter (F5) Oxygen regulator (REG1) Regulator vent Flow sensor manifold Oxygen pressure valve (TP1) Oxygen pneumatic noise filter (F7) Oxygen flow sensor (Q1) PSOL/SV manifold 2-34 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 123

REG1 reduces oxygen pressure from 35 – 100 psig to 9 – 12 psig (10.5 psig nominal). It vents at a maximum of 2 L/min (outside the BDU to prevent oxygen buildup). 2-35 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 124: Patient System

A variety of optional accessories can be used in the patient circuit. Figure 2-29 shows a typical patient system configuration. Inspiratory filter (F8) Humidification device Water trap (2 PL) Figure 2-29. Patient system (minus exhalation collector vial and expiratory filter) 2-36 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 125: Patient System Components

30 L/min with 99.99% efficiency. It has 22-mm ISO conical connections. The NeoMode DAR (PN 351919005) disposable expiratory filter and the Puritan Bennett Neo Re/x800 reusable expiratory filter are designed specifically for use with the NeoMode option.

-

Page 126: Patient System Operation

• The mounting plate, used only with neonatal patient systems, allows the ventilator to accommodate the neonatal expiratory filter. Caution To protect the exhalation assembly, always use a Puritan Bennett expiratory filter or a recommended DAR expiratory filter. 2.3.2.2 Patient system operation A predetermined oxygen/air gas mixture flows from the ventilator, through F8, and the optional humidification device.

-

Page 127: Exhalation Module Components

• The exhalation flow sensor (Q3) provides flow information on exhaled gas. Flow sensor measurements are used to determine net gas flow to the patient and spirometry. 2-39 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 128: Exhalation Module Operation

The expiratory pressure transducer (PE), on the exhalation transducer PCB, and the exhalation flow sensor (Q3) provide readings used in breath delivery calculations. 2-40 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 129: Figure 2-33. Exhalation Module Components

Theory of operation Exhalation flow sensor (Q3) Figure 2-33. Exhalation module components NOTE: Exhalation module parts are shown here for reference only. For assembly illustration, refer to Figure 9-18 on page 9-53. 2-41 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 130

Theory of operation Expiratory pressure transducer autozero solenoid (SOL2) Exhalation check valve (CV5) Exhalation heater (EXH HTR) Exhalation module components (continued) 2-42 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 131: Compressor Unit

The optional, cart-mounted 806 compressor unit, shown in Figure 2-35, is the latest style compressor system available for use with the Puritan Bennett 840 Ventilator System. When AC power is present, the compressor system supplies air to the ventilator in the event that a hospital air source is unavailable or the source pressure drops below 26 psig.

-

Page 132: Figure 2-36. 806 Components

(F11) to prevent contaminants from entering the transducer. Pressure relief valve To heat exchanger Motor/compressor Silencer Cooling fans 0.3 micron filter Silencer Intake filter Filter foam Figure 2-36. 806 components 2-44 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 133: Figure 2-37. Heat Exchanger

Theory of operation Figure 2-37. Heat exchanger Water trap Filter element Figure 2-38. 806 water trap assembly 2-45 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 134: Compressor Unit Operation

Figure 2-40. 806 back panel 2.3.4.2 806 Compressor unit operation The 806 compressor is powered by and communicates with the Puritan Bennett 840 BDU. The BDU sends a signal to the compressor after completing POST, and the compressor enters either stand-by mode or run mode depending upon the state of the air-side pressure switch, PS2.

-

Page 135: Figure 2-41. 806 Cooling Fans

The air dryer also lowers the dew point to a temperature below ambient, preventing condensation from entering the ventilator. Figure 2-41. 806 cooling fans 2-47 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 136: Summary Of Electrical Components

Figure 2-84. Electrical system 2.4.1 Summary of electrical components The Puritan Bennett 840 ventilator electrical system, shown in Figure 2-42, includes the following: • AC distribution components, including power cord, AC panel (circuit breakers, AC filter PCB, power relay, and other components), and power switch •…

-

Page 137: Table 2-2. Electronic Component Descriptions

Output signals from the BPS PCB include charging*, charged*, BPS model, IBATT, VBATT, and E-BP. NOTE: When the ventilator is running on battery power, the compressor and humidifier are non-operational. * indicates signal is active low 2-49 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 138

Breath delivery (BD) CPU PCB Contains the electronics and software that control all breath delivery functions in the Puritan Bennett 840 Ventilator System. Communicates with the GUI CPU to respond to operator inputs and display ventilation parameters. Analog interface (AI) PCB Provides the interface for all analog signals in the ventilator. -

Page 139

Delivers a voltage proportional to the oxygen concentration. Ventilator alarms if the monitored oxygen concentration is not within 7% of the oxygen percentage setting. 2-51 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 140

Motor compressor AC powered and logic-controlled, supplies compressed air to the ventilator when adequate wall air pressure is unavailable. Contains internal over-temperature protection device. 2-52 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 141: Overview Of Electrical System Operation

PCB. 2.4.2 Overview of electrical system operation The Puritan Bennett 840 Ventilator System uses a dual-microprocessor architecture with an Ethernet network as the primary channel of communication between the two 68040 microprocessors. The BDU microprocessor handles the breath delivery control and monitoring functions;…

-

Page 142

Theory of operation This page intentionally blank. 2-54 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 143: Figure 2-42. Electrical System Block Diagram (10.4-Inch Gui-Trending-Enabled Cpu Pcb Shown)

Figure 2-42. Electrical system block diagram (10.4-inch GUI—Trending-enabled CPU PCB shown) Remove pages 2-55 and 2-56. (Page 2-56 is also printed on the reverse side of the foldout.) Figure 2-42. Electrical system block diagram (10.4-inch GUI—Trending-enabled CPU PCB shown) 2-55 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 144

Theory of operation This page intentionally blank. 2-56 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 145

CPU PCB shown) Remove pages 2-57 and 2-58. (Page 2-58 is also printed on the reverse side of the foldout.) Figure 2-43. Electrical system block diagram (10.4-inch GUI—Non-Trending-enabled CPU PCB shown) 2-57 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 146

Theory of operation This page intentionally blank. 2-58 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 147

Electrical system block diagram (9.4-inch GUI—Trending-enabled CPU PCB shown) Remove pages 2-59 and 2-60. (Page 2-60 is also printed on the reverse side of the foldout.) Figure 2-44. Electrical system block diagram (9.4-inch GUI—Trending-enabled CPU PCB shown) 2-59 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 148

Theory of operation This page intentionally blank. 2-60 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 149

Electrical system block diagram (older 9.4-inch GUI shown) Remove pages 2-61 and 2-62. (Page 2-62 is also printed on the reverse side of the foldout.) Figure 2-45. Electrical system block diagram (older 9.4-inch GUI shown) 2-61 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 150: Ac Distribution Components

2.4.3.1 Power cord The Puritan Bennett 840 Ventilator System includes a detachable power cord. The power cord has an IEC-standard, three-prong connector. The plug end varies, corresponding to different country requirements.

-

Page 151: Figure 2-46. Ac Panel

Potential equalization (compressor/ connector (J2) humidifier) circuit breaker Compressor (CB2) receptacle (J4) AC filter Main circuit breaker (CB1) Power relay (K1) Fuse Auxiliary (compressor/ humidifier circuit breaker (CB2) Figure 2-46. AC panel 2-63 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 152: Figure 2-47. Puritan Bennett 840 Ventilator System Interconnect Diagram — Ac Panel

Auxiliary mains circuit breaker Mains inlet To power supply Potential equalization point compartment Compressor outlet Power relay AC PANEL MODULE Figure 2-47. Puritan Bennett 840 Ventilator System interconnect diagram – AC panel 2-64 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 153: Power Switch

A cover protects the power switch and prevents it from accidentally being turned off. An LED indicator beside the power switch lights to indicate that power is available to the ventilator. Power switch Indicator (S1) Figure 2-48. Power switch (S1) and indicator 2-65 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 154: Power Supply

The power supply has no test points, and cannot be field-adjusted. Power supply voltages are displayed during the analog data display test in EST. Figure 2-49. Power supply assembly 2-66 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 155: Figure 2-50. Puritan Bennett 840 Ventilator System Interconnect Diagram — Power Distribution

To AC inspiratory panel module POWER SUPPLY To backup power supply (BPS) (This side is located adjacent to inspiratory module) Figure 2-50. Puritan Bennett 840 Ventilator System interconnect diagram – Power distribution 2-67 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 156: Bps

20 hours to recharge. The BPS contains a battery pack (Figure 2-53) (which includes two +12 V, lead-acid batteries and a 15 A fuse) and a PCB (Figure 2-54). Figure 2-51. 802 BPS 2-68 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 157: Figure 2-52. 803 Bps

Theory of operation Figure 2-52. 803 BPS Fuse Figure 2-53. 802 BPS battery pack 2-69 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 158: Figure 2-54. Bps Pcb

Theory of operation Figure 2-54. BPS PCB 2-70 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 159: Card Cage

The card cage, shown in Figure 2-55 and Figure 2-56, includes the motherboard PCB, the BD CPU PCB, and the AI PCB. BDU CPU PCB AI PCB Motherboard PCB Figure 2-55. Card cage with all PCBs installed 2-71 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 160: Figure 2-56. Puritan Bennett 840 Ventilator System Interconnect Diagram — Card Cage

UNIT (BDU) TEST switch (SW2) indicator GUI-to-BDU cable assy AI PCB PTS 2000 connection 9-pin BDU/compressor Data DC cable Figure 2-56. Puritan Bennett 840 Ventilator System interconnect diagram – Card cage 2-72 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 161: Motherboard Pcb

The motherboard PCB consists of a multilayer PCB, connectors for plug-in boards and I/O interface, and related electrical filters and protective devices. AI PCB connectors BD CPU PCB connectors Figure 2-57. Motherboard PCB 2-73 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 162: Figure 2-58. Motherboard Pcb In Place

Theory of operation Motherboard PCB Figure 2-58. Motherboard PCB in place 2-74 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 163: Figure 2-59. Motherboard Pcb Block Diagram

EXH MOD PWR & SENS TO/FROM EXHALATION MODULE BD ALARM +12 V EXH AZ EXH MODULE CTRL INSP MOD PWR & SENS TO/FROM INSPIRATORY INSP MODULE CTRL MODULE Figure 2-59. Motherboard PCB block diagram 2-75 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 164: Bdu Cpu Pcb

The BDU CPU PCB (Figure 2-60), in conjunction with the AI PCB, provides microprocessor control of all breath delivery functions for the Puritan Bennett 840 Ventilator System. It also communicates with the GUI CPU PCB for display and control information from the operator.

-

Page 165: Figure 2-60. Bd Cpu Pcb

• A diagnostic LED array (with supporting circuitry) indicates the status of the BD CPU PCB. During POST, they indicate the current test step. A ninth LED displays the supervisory mode status of the CPU. 2-77 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 166

• The service mode switch is a push-button on the board edge used to activate this mode. The BD CPU PCB generates an NMI under any of these conditions: • Ethernet parity error detected • Power fail signal • A/D converter system error 2-78 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 167: Table 2-3. Novram Contents

Calculated during SST BD NOVRAM expiratory resistance Oxygen and air flow Calculated during EST BD NOVRAM sensor (Q1 and Q2) offsets Absolute pressure Calculated during PA calibration BD NOVRAM transducer (PA) offset 2-79 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 168: Analog Interface (Ai) Pcb

• The valve control and drive circuit provides drive signals for the PSOLs, EV, and the EV stabilizer device. PTS 2000 connector Data key connector Compressor connector AI LEDs Figure 2-61. AI PCB 2-80 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 169

The software reads this signal to determine whether the BPS is currently connected to the ventilator. • Other buffers provide conditioning for various ventilator signals. • The compressor interface circuit, in conjunction with the compressor PCB, controls and monitors the compressor operation. 2-81 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 170: Data Key Subsystem

Call your Puritan Bennett representative if the data key requires replacement due to loss or failure. The Puritan Bennett 840 Ventilator System uses a data key (Figure 2-62) to record data specific to a particular ventilator unit. The data key provides a way to retain data when PCBs or the battery are removed from the ventilator.

-

Page 171: Figure 2-63. 10.4″ Non-Te Gui Cpu Pcb

Theory of operation Figure 2-63. 10.4” Non-TE GUI CPU PCB compact flash component Figure 2-64. 10.4” TE GUI CPU PCB 2-83 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 172: Figure 2-65. 9.4″ Non-Te Gui Cpu Pcb And Backlight Inverter Pcb In Place

Theory of operation GUI CPU Backlight inverter PCB Figure 2-65. 9.4” Non-TE GUI CPU PCB and backlight inverter PCB in place compact flash component Figure 2-66. 9.4” GUI TE GUI CPU PCB 2-84 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 173

RAM contents. • The compact flash component, available only on the Trending-enabled GUI CPU PCB, provides additional memory required for use with the Puritan Bennett 840 Ventilator System Trending software option. • The real-time clock tracks the ventilator’s operational time and short-duration power losses (up to 60 minutes). -

Page 174: Figure 2-67. Puritan Bennett 840 Ventilator System Interconnect Diagram — Gui 10.4-Inch

To BDU RS-232 Remote alarm Keyboard cable assy Rear of keyboard Touch frame cable assy GUI MODULE Figure 2-67. Puritan Bennett 840 Ventilator System interconnect diagram – GUI 10.4-inch LCD panels 2-86 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 175

The GUI CPU PCB generates an NMI under any of these conditions: • GUI +5 V is high • GUI +12 V is out of range • Ethernet parity error detected • SAAS microcontroller failure 2-87 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 176: Figure 2-68. Puritan Bennett 840 Ventilator System Interconnect Diagram — Gui 9.4-Inch Lcd Panels (Non-Te Gui Cpu Pcb P/N 4-073200-Sp Shown)

Touch Frame Rear of keyboard cable assy GUI MODULE Figure 2-68. Puritan Bennett 840 Ventilator System interconnect diagram – GUI 9.4-inch LCD panels (Non-TE GUI CPU PCB P/N 4-073200-SP shown) 2-88 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 177: Lcd Panels (Te Gui Cpu Pcb Shown)

Remote alarm Keyboard Touch Frame Rear of keyboard cable assy GUI MODULE Figure 2-69. Puritan Bennett 840 Ventilator System interconnect diagram – GUI 9.4-inch LCD panels (TE GUI CPU PCB shown) 2-89 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 178: Touch Frame Pcb

During normal conditions, when all LEDs and IR detectors are functioning properly, the redundant detectors are used to provide a more accurate output by averaging the locations of the blocked beams. 2-90 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 179: Keyboard Assembly With Knob

The multiposition knob assembly, which is part of the keyboard assembly, permits ventilator setting selections or changes. Knob encoder/decoder circuitry on the GUI CPU PCB determines the direction and position of the shaft based on encoder outputs. 2-91 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 180: Figure 2-71. Keyboard Assembly

Theory of operation Figure 2-71. Keyboard assembly 2-92 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 181: Gui Led Pcb

The indicators are color-coded red, yellow, or green to show status. Each indicator (except «compressor operating» and «on BPS power») includes redundant LED strings so the indicators will stay lit if an LED bar burns out. Figure 2-72. GUI LED PCB 2-93 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 182: Backlight Inverter Pcb And Lcd Lamps

LCD panels simultaneously. The LCD lamps are part of the 10,000-hour preventive maintenance kit on the 9.4-inch GUI. Figure 2-73. 10.4” GUI LCD panels 2-94 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 183: Gui Alarm Assembly

Figure 2-74. 9.4-inch LCD panels and backlight tubes 2.4.8.6 GUI alarm assembly The GUI alarm assembly (Figure 2-75), the ventilator’s primary alarm, emits alarm sounds under control of the GUI CPU PCB. 2-95 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 184: Figure 2-75. Gui Alarm Assembly

Theory of operation Figure 2-75. GUI alarm assembly 2-96 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 185: Bdu Led Pcb

• The absolute pressure transducer (PA) senses absolute pressure in the inspiratory module. It is used to determine atmospheric pressure for volume delivery. • The oxygen sensor (OS) amplifier provides an interface for the oxygen concentration sensor mounted on the PCB. 2-97 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 186: Figure 2-78. Puritan Bennett 840 Ventilator System Interconnect Diagram — Inspiratory Module

4-071321-00 Press switch harness assy 4-071326-00 Air pressure Oxygen pressure switch (PS1) switch (PS2) 4-072206-00 4-072206-00 INSPIRATORY MODULE Figure 2-78. Puritan Bennett 840 Ventilator System interconnect diagram – Inspiratory module 2-98 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 187: Exhalation Transducer Pcb

(PE), which is on this PCB, senses the pressure difference in the exhalation circuit relative to ambient air pressure. The PCB uses a +10 V reference. Figure 2-79. Exhalation transducer PCB 2-99 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 188: Figure 2-80. Puritan Bennett 840 Ventilator System Interconnect Diagram — Exhalation Module

Exhalation Exhalation I/O module cable assy cable assy Expiratory Exhalation pressure transducer valve (PE) Exhalation transducer PCB EXHALATION MODULE Figure 2-80. Puritan Bennett 840 Ventilator System interconnect diagram – Exhalation module 2-100 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 189: Bd (Continuous-Tone) Alarm Assembly

Figure 2-81. BD alarm assembly 2.4.12 806 Compressor unit The 806 compressor unit’s electrical components include: AC power distribution components, a compressor motor, and a compressor PCB. The compressor unit is shown in Figure 2-82. 2-101 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 190

Theory of operation Figure 2-82. 806 compressor 2-102 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 191: Compressor Unit Ac Power Distribution Components And Motor

PCB’s primary function is to control the pressure of the air delivered to the ventilator when wall air is not present or is insufficient. Data cable Pressure transducer Power hose cord Solenoid cable Compressor cable cables Ground Figure 2-84. 806 compressor PCBA installed 2-103 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 192

Section 2.4.12.3 describes how this logic controls compressor component operation. This logic shuts off the compressor when AC is inadequate or the thermostat on the PCB detects overtemperature. 2-104 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 193: Figure 2-85. 806 Compressor Pcb Block Diagram

(PC) CKTS CAPACITOR MOTOR COMP COMPRESSOR CONTROL HOUSING CKTS TO/FROM AI PANEL EEPROM CKTS COMP OVER TEMP +5 V COMP THERMOSTAT +12 V COMP Figure 2-85. 806 compressor PCB block diagram 2-105 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 194: Figure 2-86. Puritan Bennett 840 Ventilator System Interconnect Diagram — Compressor Unit

Compressor unit Remove pages 2-106 and 2-107. (Page 2-107 is also printed on the reverse side of the foldout.) Figure 2-86. Puritan Bennett 840 Ventilator System interconnect diagram – Compressor unit 2-106 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 195: Compressor Unit Operation

If pressure in the accumulator drops below 22.5 psig (due to small leaks in the system or cooling of compressed air), the compressor starts and recharges the accumulator to 27 psig (see Figure 2-87). 2-107 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 196: Figure 2-87. Compressor Operational Sequence

After one second, a solid-state relay on the PCB is energized. After another 0.5 seconds, SOL3 is de-energized. 2-108 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 197: Breath Delivery

The ventilator does not autotrigger when pressure sensitivity is greater than 2 cmH O or when flow sensitivity is greater than 1 L/min for pediatric patients or 1.5 L/min for adult patients. 2-109 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 198: Figure 2-89. Inspiration Gas Flow Diagram

Theory of operation Figure 2-89. Inspiration gas flow diagram 2-110 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 199: Pressure Triggering

Backup limits (time, circuit pressure, and ventilator pressure) prevent inspirations of excessive duration or pressure. If a particular breath is subject to more than one backup limit, exhalation is triggered by whichever method goes into effect first. 2-111 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 200: Time-Cycling Method

2.5.2.6 High ventilator pressure limit The high ventilator pressure limit applies to volume-based mandatory breaths only. If the inspiratory pressure (measured at PI) equals or exceeds 100 cmH O, the ventilator transitions to exhalation. 2-112 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 201: Figure 2-90. Exhalation Gas Flow Diagram

Theory of operation Figure 2-90. Exhalation gas flow diagram 2-113 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 202: Other Hardware Operations

(exhaled tidal volume) to be transiently displayed as lower or higher than the actual exhaled volume. This is a result of initial spirometry calculations and does not reflect actual volume exhaled by the patient. 2-114 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 203: Pressure Transducer Autozero

Autozeroing is performed every minute for 20 minutes; every 2 minutes after 20 minutes, up to one hour; and every 5 minutes after 1 hour. 2-115 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 204: Figure 2-91. Pressure Transducer Autozero Mode Gas Flow Diagram

Theory of operation Figure 2-91. Pressure transducer autozero mode gas flow diagram 2-116 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 205: Power Monitoring And Power Fail Handling

802 BPS: 60 minutes minimum (30 minutes on ventilators built prior to July 2007) 803 BPS (Four-hour battery life with new fully charged battery) Figure 2-92. Power loss sequence 2-117 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 206: Supply Voltage Monitoring

• Displays the elapsed time since the loss of ventilatory support on the GUI • Does not display patient data, including waveforms, on the GUI • Does not detect patient circuit occlusion or disconnect conditions 2-118 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 207: Figure 2-93. Safety Valve Open Diagram

Theory of operation Figure 2-93. Safety valve open diagram 2-119 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 208: Occlusion Handling

During a severe occlusion, apnea detection, expiratory pause, manual inspirations, and maneuvers are suspended, and the P (high airway pressure) alarm limit is disabled. MEAN The GUI does allow you to change ventilator settings. 2-120 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 209: Figure 2-94. Pressure Release, Patient Circuit Occluded Diagram

Theory of operation Figure 2-94. Pressure release, patient circuit occluded diagram 2-121 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 210

Theory of operation This page intentionally blank. 2-122 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 211: Self Tests

TEST button while entering service mode. 3.3 Self tests and background checks The Puritan Bennett 840 Ventilator System has self test capabilities that include POST (power- on self test), SST (short self test), EST (extended self test), and background checks. These self test operations are described in Table 3-1, and Table 3-2 details the components tested by various self tests.

-

Page 212: Est (Extended Self Test)

EST requires a “gold standard” test circuit, available from Puritan Bennett. All required software support to perform an EST is resident on the ventilator. EST testing, excluding tests of optional equipment, such as the compressor, takes about 15 minutes to complete.

-

Page 213: Power On Self Test (Post)

3.4 Power on self test (POST) Table 3-2: Components tested by self tests Background Service mode Component tested POST checks calibrations Power supply/voltage checks AC monitor voltage Supply voltages (including BDU and GUI voltages) BPS supply voltage/current Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 214: Table 3-1. Self Tests

Table 3-2: Components tested by self tests (continued) Background Service mode Component tested POST checks calibrations BPS charging and discharging BPS model Patient system Patient circuit leak Patient circuit occlusions/resistance Patient circuit compliance Expiratory filter occlusion/resistance Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 215

Oxygen and air PSOL forward leak Oxygen and air PSOLs stuck open or stuck in other position Inspiration and exhalation pressure transducer autozero solenoids Inspiration pressure transducer Exhalation pressure transducer Inspiration and exhalation pressure transducer cross-check Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 216

Audio alarm and user interface sound- producing subsystem Alarm cable (BDU) Nurse’s call relay +10 V reference (used by ADCs and DACs) ADC/DAC functionality Power fail capacitor Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 217

POST routines are ordered so that each routine requires successively more operational hardware than the last. This sequence allows POST to systematically exclude electronic components as causes of system malfunctions. Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 218: Safety

POST’s memory test preserves all data necessary to determine ventilator settings and initializes the remaining memory to a predefined state. • Any other processors in the system initiates its own POST and reports the test results to the host processor. Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 219: Post Following Power Interruptions

POST. NOTE: Puritan Bennett recommends that a BPS is always installed on the ventilator. If there is a loss of AC power with a charged BPS installed, the ventilator will switch to the DC source and will not run POST upon restoration of AC power.

-

Page 220: Structure Of Post

Table 3-3 compares the BDU and GUI POST sequences, indicates the tests performed and shows which indicators are active during each phase. 3-10 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 221: Table 3-3. Post Structure

NOTE: Prior to the • BDU continuous tone alarm turned beginning of Phase 1, on and off twice all of the LEDs on the Trending-enabled GUI turn on for 200 to 350 ms. 3-11 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 222: Table 3-4. Post Outcomes

• POST continues to end. • Minor fault detected. • Check System Diagnostic Log for any associated error codes. • Ventilation proceeds. • Rerun POST/EST. • A DEVICE ALERT is annunciated. 3-12 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 223: Sst (Short Self Test)

10 minutes in service mode before running SST, to ensure accurate testing. • Puritan Bennett recommends that you run SST every 15 days, between patients, after a major service or repair (refer to Table 5-2 on page 5-6), and when you change the patient circuit.

-

Page 224: Hardware Requirements

1. If necessary, the compressor can be used as the only gas source. However, only the gas pathway, flow sensor, and PSOL of the single gas (air or O ) will be verified during SST. 3-14 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 225: Running Sst

SST can affect the accuracy of compliance calculation and the delivered and measured exhaled tidal volumes. You must rerun SST after changing the patient circuit type, installing a new patient circuit, or after adding or changing accessories. 3-15 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 226

To begin normal ventilation (if SST has not detected an ALERT or FAILURE), touch EXIT SST, then press ACCEPT. The ventilator reruns POST, then displays the Ventilator Startup screen. 3-16 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 227: Table 3-6. Sst Tests

Overriding an ALERT could cause inaccurate patient pressure estimation. FAILURE if test detects exhalation compartment occlusion, expiratory filter occlusion or damage, or you did not follow prompts to detach and reattach tubing correctly. 3-17 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 228: Table 3-7. Sst Individual Test Results

Exit SST in order to service ventilator or review error codes by condition is declared. pressing EXIT SST. OVERRIDDEN An ALERT status was overridden, Touch EXIT SST. and ventilation is authorized. 3-18 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 229: Est (Extended Self Test)

Table 3-10 lists the tests that comprise EST. For more details about these tests and associated diagnostic codes, see Chapter 6. For a theory of operation of EST, consult the Puritan Bennett 800 Series Ventilator System Operator’s and Technical Reference Manual.

-

Page 230: Hardware Requirements

The gold standard circuit connects to an ADULT expiratory filter installed at the From patient port. The other end of the gold standard circuit connects directly to the To patient port: Do not install an inspiratory filter. 3-20 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 231: Figure 3-2. Est Setup

You can touch EXIT EST during EST to halt testing. You can touch EXIT EST again to resume testing, or press ACCEPT to restart the ventilator (if EST has not detected an ALERT or FAILURE). 3-21 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 232

When all of the tests in EST are complete, the Extended Self Test screen displays all individual test results and EST outcome. Refer to Tables Table 3-10, Table 3-11, and Table 3-12 for additional information. 3-22 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 233: Figure 3-3. Est Screens During Testing

Self tests 08:28 18 Jul 2003 Figure 3-3. EST screens during testing 3-23 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 234

Self tests NOTE: The screens given above are intended as examples only. Your unit may vary slightly in appearance. 3-24 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 235: Table 3-10. Est Tests

Verifies that GUI LEDs are functioning by prompting the Observe GUI indicators and press operator to acknowledge that the LEDs are turned on. ACCEPT (if on) or CLEAR (if not on). 3-25 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 236

• If wall air is connected, disconnect wall air as directed. compressor pressure switch, and compressor operating states (run, standby, and disabled). • If AC is not connected, connect AC power as directed. 3-26 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 237: Table 3-11. Est Individual Test Results

Exit EST in order to service ventilator or review error codes by touching EXIT EST. In Single Test EST, touching “NEXT” allows you to choose another test to run 3-27 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 238: How To Run Single Test Est

Enter service mode and initiate single Test EST as follows: Turn on power to ventilator. (If power is already on, turn it off, then back on.) 3-28 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 239

If a test fails or completes with an ALERT outcome, REPEAT to retry the test, touch “NEXT” to choose another test, or exit Single Test EST by touching the EXIT button. 3-29 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 240

Self tests This page intentionally blank. 3-30 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 241: Service Mode

H A PT ER Service mode The Puritan Bennett™ 840 Ventilator System operates in two modes: Patient Ventilation and Service Mode. The Service Mode is intended for use by a trained service technician to aid in ventilator testing and troubleshooting and to perform system calibrations.

-

Page 242

Service mode Figure 4-1. Service Mode screens Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 243: Service Mode Functions

DATE/TIME Adjusts current date and time and allows the user to select a date format. EXIT Exits Service Mode. Other Screens Performs miscellaneous service, test, and calibration functions. Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 244: Figure 4-2. Service Mode Functions

Transducer Test Calibration (10.4 GUI only) Compact Flash Test* External Nominal Pressure Control Line Voltage Unit Baud Rate *Only available if Trending option is installed. LOWER SCREEN Figure 4-2. Service Mode functions Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 245: Sst Result: Displaying Sst Results

System Diagnostic Information and EST/SST Diagnostic logs can only be erased by using the Puritan Bennett 840 VTS Breath Labs Software. The alarm log is automatically erased each time a new patient is setup is selected and when EST is run.

-

Page 246: Figure 4-4. System Information Log

Service mode Figure 4-4. System Information Log Figure 4-5. EST/SST Diagnostic Log Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 247: Alarm Log: Displaying The Alarm History

The date formats shown in parentheses appear in the Trending graph and table screens if the Puritan Bennett 840 Trending software option is installed. If you make a change to the date format while viewing the SST Result Log or Test Summary, the time stamps do not update until the screen is closed and re-opened.

-

Page 248: Exit: Exiting Service Mode

O or hPa). External Test Control Lets you test the ventilator using a computer, Breath Labs 840 VTS Software, and PTS 2000 tester, to run performance verification. Also used to download new application software to the Puritan Bennett 840 ventilator.

-

Page 249: Service Mode Setup

Enter Service Mode and select the Other Screens button. Ensure air and oxygen are connected to the ventilator. Connect the gold standard circuit between the To Patient and From Patient ports. (Do not use a patient filter.) Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 250: Table 4-4. Exhalation Valve Calibration Errors

Exhalation valve temperature out of 1. Verify that the ventilator has temperature out of range range. warmed up for at least 10 minutes in Service Mode. 2. Replace exhalation valve. 3. Replace AI PCB. 4-10 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 251

(5, 25, 50, 75, and 100 2. Verify adequate supply pressure. 3. Replace inspiratory pressure trans- ducer. 4. Replace expiratory pressure trans- ducer. 4-11 Puritan Bennett 800 Series Ventilator System Service Manual… -

Page 252: Vent Inop Test

Service Mode will invoke the normal Service Mode. Troubleshoot as indicated in Table 4-6. You must repeat the Vent Inop Test and pass it with no failures before ventilation is allowed. 4-12 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 253: Flow Sensor Calibration

4.2.10.5.1 Running Flow Sensor Calibration Enter Service Mode. Ensure both air and oxygen are connected to the ventilator. Connect the gold standard circuit between the To Patient and From Patient ports. 4-13 Puritan Bennett 800 Series Ventilator System Service Manual…

-

Page 254: Table 4-7. Flow Sensor Calibration Errors

4. Try installing a known good inspi- ratory module. If calibration passes, replace inspiratory elec- tronics PCB. If calibration fails, replace inspiratory module blind- mate cable. 5. Replace expiratory flow sensor (Q3). 6. Replace AI PCB. 4-14 Puritan Bennett 800 Series Ventilator System Service Manual…

-