-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

DigitalFlow™ XGF868i

Panametrics flare gas

flow transmitter

Programming manual

Related Manuals for Baker Hughes Panametrics DigitalFlow XGF868i

Summary of Contents for Baker Hughes Panametrics DigitalFlow XGF868i

-

Page 1

DigitalFlow™ XGF868i Panametrics flare gas flow transmitter Programming manual… -

Page 3

DigitalFlow™ XGF868i Panametrics flare gas flow transmitter Programming manual 910-198P Rev. C February 2015… -

Page 4

[no content intended for this page]… -

Page 5

Information paragraphs Safety issues Note: These paragraphs provide information that provides a WARNING! deeper understanding of the situation, but is not essential to It is the responsibility of the user to make sure the proper completion of the instructions. all local, county, state and national codes, regulations, rules and laws related to safety IMPORTANT: and safe operating conditions are met for… -

Page 6

Environmental compliance Waste Electrical and Electronic Equipment (WEEE) directive Panametrics is an active participant in Europe’s Waste Electrical and Electronic Equipment (WEEE) take-back initiative, directive 2012/19/EU. The equipment that you bought has required the extraction and use of natural resources for its production. It may contain hazardous substances that could impact health and the environment. -

Page 7: Table Of Contents

Contents Chapter 1. Programming site data …………1 Introduction .

-

Page 8

Chapter 3. Logging data …………. . . 29 Introduction . -

Page 9

C.6 Entering data in the global menu …………. . . 64 C.6.1 Entering global-system data . -

Page 11: Chapter 1. Programming Site Data

Chapter 1. Programming site data Introduction Programming methods The XGF868i flow transmitter must be properly installed You can program the XGF868i via either the keypad on the and programmed, as described in the Startup guide, lower part of the glass window, or PanaView™, a PC-based, before it can provide accurate flow rate measurements.

-

Page 12: The Xgf868I Keypad

The XGF868i keypad Keypad program Along with the 2-line, 16-character LCD, the XGF868i Six keys on the keypad enable users to program includes a 6-key magnetic keypad. The decal cutout for the XGF868i: each key contains a hall effect sensor, pushbutton switch •…

-

Page 13: Activating A Channel

Activating a channel Entering system data for the channel The channelx-ACTIV submenu permits selection of the desired measurement method. In addition, it is used The channelx-system submenu is used to enter to activate/deactivate one or both of the channels in a system parameters for the channel.

-

Page 14: Selecting Totalizer Units

1.5.3 Selecting totalizer units 1.5.4 Selecting mass flow units 1. Scroll to the desired totalizer units for a totalized 1. Scroll to the desired mass flow units for the flow rate flow rate display and press [enter]. Table 1 on page 3 display and press [enter].

-

Page 15: Entering Transducer And Pipe Parameters

Entering transducer and pipe parameters 1.6.2 Pipe data Enter the transducer and pipe parameters via the pipe submenu. While following the programming instructions, If either a standard or a special transducer is being used, refer to Figure 28 on page 40. the programming sequence should be rejoined at this point.

-

Page 16

1.6.2a Path and axial lengths Procedure options 7. To enter the path length: After entering the calibration factor, the XGF868i returns to a. Use the [] arrow key to highlight the path length the channel program. Do one of the following: unit type at the right of the screen. -

Page 17: Entering Zero Cutoff And Setting Up Inputs

Entering zero cutoff and setting up inputs Enter the zero cutoff value and set up the temperature and actual temperature is used to calculate the pressure inputs via the I/O submenu. While programming standard mass flow rate. these parameters, refer to Figure 28 on page 40. 2.

-

Page 18: Entering Setup Data

Entering setup data The signal limits, response times, mass flow and multiple CAUTION! K factors for the XGF868i are specified via the setup The signal default settings are suitable for submenu. The following four submenus are included most applications. Consult with Panametrics in this section: before changing any of these parameters.

-

Page 19

Table 4: Transducer signal settings Transducer signal Default Range Description parameters value The E6: CYCLE SKIP error message appears when the calculated fluid 0 to 250 ft/s 15 ft/s velocity changes by more than the programmed ACCELERATION LIMIT Acceleration limit (0 to 76 m/s) (5 m/s) value from one reading to the next. -

Page 20: Initializing Setup Parameters — Default Setup

1.8.2 Initializing setup parameters — 1.8.3 Setting response time — V averaging default setup Use this option to specify the number of readings that occur before the meter will respond to a step change in Use this option to initialize (reset) all of the parameters flow rate.

-

Page 21: Using Advanced Features

1.8.4 Using advanced features 1.8.4c Activating mass flow This option enables you to access the more advanced features of the meter. In this option you can do the following: Use this option to calculate mass flow from a static • Enter a table of K factors — to compensate for non-linear fluid density.

-

Page 22: Entering Global Data

Entering global data 1.9.1a Selecting volumetric units The global menu is used to enter information that is not specific to either of the individual channels. Information 1. Scroll to the desired volumetric units for the flow rate programmed via this menu is used to compute parameters display and press [enter].

-

Page 23: Setting Up Inputs And Outputs

1.9.1c Selecting mass flow units 1.9.2 Setting up inputs and outputs 1. Scroll to the desired mass flow units for the flow rate Set up the XGF868i inputs and outputs via the I/O submenu. display and press [enter]. The available units for this While following the programming instructions, refer to Figure prompt are determined by the selection made at 30 on page 42 and Figure 31 on page…

-

Page 24

Procedure options Table 7: Error response options After completing the above steps, the XGF868i returns to the global I/O window. Do one of the following: Option Output response Totalizer response • To continue programming, refer to Appendix A. Menu Maps on page 39, to navigate to the desired menu. Continues to totalize, Holds the last HOLD… -

Page 25

Table 9: Available measurement parameters Option bar Description Good Displays the flow velocity. N.A. N.A. VOLUM Displays the volumetric flow. N.A. N.A. +TOTL Displays the forward totalized volume flow. N.A. N.A. -TOTL Displays the reverse totalized volume flow. N.A. N.A. TIME Displays the total flow measurement time. -

Page 26

Table 9: Available measurement parameters Option bar Description Good PRESR Displays the gas pressure (from 0/4-20 mA input). N.A. N.A. Displays the molecular weight. N.A. N.A. Displays the compressibility. N.A. N.A. AcVOL Displays actual volumetric flow. N.A. N.A. StVOL Displays standard volumetric flow. N.A. -

Page 27

5. Use the arrow keys to enter a value (a temperature 1.9.2f Frequency outputs value for special inputs) for the low end of the analog The frequency output issues a continuous signal with a input range and press [enter]. frequency proportional to the selected measurement. 6. -

Page 28: Configuring The Communications Port

1.9.3 Configuring the communications port 1.9.3b Setting up MODBUS communications The XGF868i flowmeter is equipped with an RS232 serial interface. The meter can be configured with a When equipped with an optional MODBUS output card, the MODBUS option card for MODBUS communications, a XGF868i can transmit flow data serially to a flow computer, Foundation Fieldbus option card for Foundation Fieldbus or SCADA, using a Gould-type RTU protocol.

-

Page 29: Requesting Parameters Using Modbus

1.9.4 Requesting parameters using MODBUS To request specific parameters from the XGF868i via the MODBUS, the control system must enter the appropriate register number. Only registers 1 through 90 are available for MODBUS communications, while registers 508 through 512 are used by the XGF868i to store the MODBUS parameters.

-

Page 30

Table 10: MODBUS registers for a 2-channel XGF868i MODBUS DPR hex Scaling Description Size in bytes Reg # addr (decimal places) Ch2 std volumetric #Q DIGITS 4 (IEEE 32 bit) Ch2 fwd totals #T DIGITS 4 (2 16 bit int) Ch2 rev totals #T DIGITS 4 (2 16 bit int) -

Page 31

Table 10: MODBUS registers for a 2-channel XGF868i MODBUS DPR hex Scaling Description Size in bytes Reg # addr (decimal places) Avg rev mass totals #MT DIGITS 4 (2 16-bit int) Avg #mass tot digits Avg timer 4 (2 16-bit int) 5Avg error code Avg sound speed 4 (2 16-bit int) -

Page 32: Exiting The User Program

1.9.5 Activating security 1.10 Exiting the user program In order to prevent unauthorized tampering with the After completing the COMM option, the XGF868i returns to flowmeter’s programming, the XGF868i is equipped with the global program prompt. press [escape] twice to return a security feature that locks all the keys except [prog] to the keypad program, and a third time to return to the meter display.

-

Page 33: Chapter 2. Displaying Data

Chapter 2. Displaying data Introduction The OFF setting switches the measurement display off, while the KEY setting enables users to change the measurement display via the arrow keys, without accessing the keypad This chapter explains how to display measurement data program.

-

Page 34: Displaying Data On A Computer Terminal

2.3 Displaying data on a computer terminal The flow rate data collected by the XGF868i may be displayed in various formats on a remote computer terminal via the meter’s RS232 serial port. This requires the use of the optional PanaView software. Refer to the instructions below to display data via PanaView.

-

Page 35: Graphing The Output

6. If the [continuous] option was selected in step 5 above, 2.3.3 Graphing the output click on the [stop] option button, which has replaced To collect data from the instrument and display it the original [continuous] option button, to terminate graphically in a new format, complete the following steps: data collection.

-

Page 36: Displaying Transducer Signals

2.3.2b Graphing data 2.3.3 Displaying transducer signals The PanaView network tree has already been described, and Along with flow rate data, PanaView enables XGF868i users the display pane shows only a graph in the default style with to read and plot transducer signals from the XGF868i. no data points.

-

Page 37

2.3.3a Reading transducer signals 2.3.3b Plotting transducer signals 3. To read a signal from the meter, click on the [read To plot the selected signal, click on [plot]. A graphical signals] button. (If the meter is a multi-channel window opens, as shown in Figure 8 below. instrument, open the channel drop-down menu and click on the desired channel.) After a moment, the properties window appears similar to Figure 7 below. -

Page 39: Chapter 3. Logging Data

Chapter 3. Logging data Introduction PanaView can create PC log files for the XGF868i for storage on the PC’s hard drive. This chapter explains how to use the XGF868i data logging capability with PanaView. 3.2 Logging with PanaView PanaView is capable of creating and viewing log files of the following types: •…

-

Page 40: Creating Meter Logs

3.3 Creating meter logs To create a new meter log, complete the following steps: d. Type the desired log message in the right window, and click [next item]. 1. From the new meter browser in PanaView, expand the network tree and open the edit functions option e.

-

Page 41: Creating An Error Log

each parameter, type the desired number in the • If you select edit, PanaView asks first for the desired right window, (or scroll to and click on the desired year, then for the month, and finally for the day. For month) and click [next item] (or simply click [next each parameter, type the desired number in the item] to step through the parameters).

-

Page 42: Creating Pc Logs

3.4 Creating PC logs PC logs are created in a different menu from the meter logs 3. Double click on PC logs to advance to the dialog box described in the last section. To create a new PC log: shown in Figure 16. below. 1.

-

Page 43: Viewing Meter Log Files

NOTE: Start time and stop time cannot be specified NOTE: To add all the channel parameters to a given log, for PC logs. These options are inactive in the right-click on the desired channel. A pop-up button, PC log window. “add group to log,”…

-

Page 44: Viewing Pc Log Files

3.6 Viewing PC log files After one or more PC log files have been created, the logs You can monitor the progress of an ongoing log in several may be viewed by using PanaView as follows: ways: 1. You can access PC logs in two ways: •…

-

Page 45: Chapter 4. Printing Data

Chapter 4. Printing data Data types for printing The XGF868i flowmeter has no ability to print any of its data directly. However, any of the data stored in its memory may be printed via the built-in RS232 communications port, using a computer terminal. In order to use the capability, the XGF868i must be linked to the computer terminal with the optional PanaView software.

-

Page 46

[no content intended for this page]… -

Page 47: Chapter 5. Clearing Data

Chapter 5. Clearing data Introduction This chapter explains how to purge totalized measurements, site data and/or log files from the XGF868i memory. NOTE: For detailed information on creating a log file, see Chapter 3. Logging data on page 29. For detailed information on programming site data, see Chapter 1.

-

Page 48: Clearing The Xgf868I Memory

5.2 Clearing the XGF868i memory If the XGF868i available memory becomes nearly full, it may be necessary to purge some or all of the existing data from memory, before any additional data can be stored. In order to accomplish this task, proceed to the appropriate section for step-by-step instructions.

-

Page 49: Appendix A. Menu Maps

Appendix A. Menu maps The following Menu Maps are included in this appendix: • Figure 28 on page 40, “PROG > CHx > ACTIV, SYSTM, PIPE & I/O Menus” • Figure 29 on page 41, “PROG > CHx > SETUP Menu” •…

-

Page 50

Figure 28: PROG > CHx > ACTIV, SYSTM, PIPE and I/O menus… -

Page 51

Figure 29: PROG > CHx > SETUP menu… -

Page 52

Figure 30: PROG > GLOBL > SYSTM, I/O and COMM menus… -

Page 53

Figure 31: PROG > GLOBL > I/O > OPTIONS menu… -

Page 55: Appendix B. Data Records

Appendix B. Data records Available option cards The XGF868i can hold one option card in slot 1 and one in slot 2. The available configurations are listed in Table 12 below. Table 12: Option card configurations Card # Slot # Configuration 1473-02 OI — 2 current inputs…

-

Page 56: Setup Data

B.3 Setup data After the XGF868i flow transmitter has been installed, setup data must be entered via the user program prior to operation. record that information in Table 14 below. Table 14: Setup data General information Model # Serial # Software version Setup date Channel — status…

-

Page 57

Table 14: Setup data Channel — pipe parameters Channel 1 Channel 2 Transducer type SPEC Transducer type Transducer # Transducer # Spec. trans. freq. Spec. trans. freq. Spec. trans. Tw Spec. trans. Tw Pipe O.D. Pipe O.D. Pipe wall Pipe wall Path length (P) Path length (P) Axial length (L) -

Page 58

Table 14: Setup data Channel — SETUP — advanced features — multi K factors K-factor # Velocity K-factor K-factor # Velocity K-factor… -

Page 59

Table 14: Setup data Channel — SETUP — advanced features — mass flow calculation Mass flow Mass flow Density type Fluid dens. Mol. wt. Density type Fluid dens. Mol. wt. or Q Actual Standard or Q Actual Standard Fluid density Fluid density Mole. -

Page 61: Appendix C. Programming The Xgf868I With Panaview

Appendix C. Programming the XGF868i with PanaView™ C.1 Introduction The XGF868i flow transmitter must be properly installed and programmed, as described in the Startup guide, before it can provide accurate flow rate measurements. After completing the installation and initial setup, use this chapter to program the advanced features of the model XGF868i’s via the PanaView™…

-

Page 62: Programming With Panaview

C.2 Programming with PanaView™ You can program the XGF868i with PanaView™, a Panametrics PC-based, non-resident software program that communicates with the XGF868i via its RS232 serial port. C.2.1 Preparing for PanaView programming Before you attempt to communicate with the XGF868i, be sure you have linked your PC to the XGF868i via an RS232 interface.

-

Page 63: Setting Up Ethernet Communications

C.2.3 Setting up Ethernet communications C.2.4 Modifying Ethernet parameters If you have selected TCP/IP in step 6 on the previous page, To establish Ethernet communications with the XGF868i the setup communications window appears similar to or to modify its IP parameters, you will need to install the Figure 34 below.

-

Page 64: Adding The Xgf868I

C.3 Adding the XGF868i To add the XGF868i on the IDM-configured communications If the initialization is successful, the meter browser shows a port, complete the following steps: listing similar to Figure 37 below. 1. Highlight the communication port to which the meter will be added by clicking on it, and then open the edit menu on the menu bar (if the communication port is not highlighted first, the new meter option is not…

-

Page 65: Entering The User Program Using Panaview

C.4 Entering the user program using PanaView NOTE: Be sure to record all the programming data entered in this chapter in Appendix B. Data records on page 45. Programming of the status, system, and pipe submenus of the channel menu and the global-system menu are required for basic operation of the XGF868i.

-

Page 66

Figure 43: Site edit menu with current Settings Figure 42: Pipe parameters option in the site edit menu 6. When you have completed entering parameters in c. Do one of the following: a given option, click [exit page] to close the option. Click on [next item] to proceed to the next menu item, You can then double-click on another option, or click [close] to close the window. -

Page 67: Entering Data In The Channel Menu

C.5 Entering data in the channel menu C.5.2 Entering data in the channel system The channel menu is used to enter data specific to each channel. Refer to Figures D-1 through D-3 in Appendix option D. PanaView menu maps for the XGF868i on page 79, and 1.

-

Page 68: Entering Pipe Parameters

C.5.2a Programming the mass flow option C.5.3 Entering pipe parameters 1. Double-click on the desired mass flow units for flow rate Enter the transducer and pipe parameters via the pipe display (listed in Table 16 below). submenu. While following the programming instructions, see Figure 55 on page 80 of Appendix D, PanaView menu maps.

-

Page 69

C.5.3b Pipe OD C.5.3c Path and axial lengths 4. Click on the appropriate pipe OD unit type in the 6. Click on the appropriate path length unit type in the center pane from the list shown in Table 17 below. center pane. -

Page 70: Entering Input/Output Parameters

C.5.4 Entering input/output parameters C.5.4c Base temperature Enter the zero cutoff value and set up the temperature, pressure and quality inputs via the input/output submenu. 1. Enter the base temperature and click [next item]. While programming these parameters, refer to Figure 55 on The ratio of this value to the actual temperature is page 80 of Appendix D, PanaView menu maps.

-

Page 71: Entering Setup Parameters

C.5.5 Entering setup parameters C.5.5a The signal option Use this option to set the limits for the incoming signal The signal limits and response times for the XGF868i are and other parameters affecting the transducer signal. For specified via the SETUP submenu. While following the example, the programmed signal strength low limit may programming instructions, refer to Figure 57 on page be used to determine the trigger point for an alarm.

-

Page 72

Table 18: Transducer signal settings Transducer signal Default Range Description parameters value The amplitude discriminator measures the transducer signal received by the model XGF868i. The default value for the above parameter is 14, and values from 0 to 100 are acceptable. The Amplitude 0 to 100 E5: AMPLITUDE error message appears when the amplitude… -

Page 73

C.5.5b The default setup option 4. Double-click on yes to edit the K-factor table or on no to retain the current K-factor table (and return to Use this option to initialize (reset) all of the parameters the advanced features window). within the set up signal menu back to their default values. -

Page 74: Entering Data In The Global Menu

C.6 Entering data in the global menu C.6.1a Volumetric units The global menu is used to enter information that is not specific to any of the individual channels. Information 1. Double-click on the desired volumetric units for the flow programmed via this menu is used to enter several general rate display.

-

Page 75: Setting Up Inputs And Outputs

C.6.1c Programming mass flow data C.6.2 Setting up inputs and outputs 1. Double-click on the desired mass flow units for flow rate Set up the XGF868i inputs and outputs via the I/O submenu. display. The options are listed in Table 20 below. While following the programming instructions, see Figure 58 on page 83 in Appendix D, PanaView menu maps.

-

Page 76

Table 21: Error options and responses for a one-channel meter Option Output response Totalizer response Hold last value Holds the last “good” reading Holds the last “good” reading and continues to totalize, based on that reading Force low Forces the outputs to the low set point Stops totalizing Force high Forces the outputs to the high set point… -

Page 77

C.6.2c Setting up option cards The XGF868i has two built-in analog outputs, which are Table 24: Channel options assigned to slot 0. Also, a variety of input/output option cards may be installed in slot 1. See Chapter 1, Installation, Option Description of the Startup Guide for a complete description of the available option cards. -

Page 78

Table 25: Available measurement parameters Option bar Description Good Velocity Displays the flow velocity. N.A. N.A. Volumetric Displays the volumetric flow. N.A. N.A. FWD total Displays the forward totalized volume flow. N.A. N.A. REV total Displays the reverse totalized volume flow. N.A. -

Page 79

Table 25: Available measurement parameters Option bar Description Good DN +- peak Displays signal peaks for the downstream transducer. 100-2300 <100 or >2300 Temperature Displays the gas temperature (from 0/4-20 mA input). N.A. N.A. Pressure Displays the gas pressure (from 0/4-20 mA input). N.A. -

Page 80

7. Enter the units of measurement for input A and click 6. Enter a flow rate value for the full (high) end of the [next item]. frequency output range and click [next item]. 8. Enter a temperature value for the base (low) end 7. -

Page 81: Entering Communications Data

C.6.3 Entering communications data The XGF868i flowmeter is equipped with an RS232 serial NOTE: The XGF868i MODBUS communication settings interface. The serial port is used to transmit stored data and chosen in the next four steps must match those of the displayed readings to a personal computer by connecting MODBUS control system.

-

Page 82

Table 27: MODBUS registers MODBUS DPR hex MODBUS Description Scaling (decimal places) Size in bytes reg # addr reg # Ch1 rev totals #T DIGITS 4 (2 16 bit int) Ch1 #tot digits Ch1 mass flow #M DIGITS 4 (IEEE 32 bit) Ch1 Fwd mass totals #MT DIGITS 4 (2 16-bit int) -

Page 83

Table 27: MODBUS registers MODBUS DPR hex MODBUS Description Scaling (decimal places) Size in bytes reg # addr reg # Ch2 Fwd mass totals #MT DIGITS 4 (2 16-bit int) Ch2 rev mass totals #MT DIGITS 4 (2 16-bit int) Ch2 #mass tot digits Ch2 timer 4 (2 16-bit int) -

Page 84

Table 27: MODBUS registers MODBUS DPR hex MODBUS Description Scaling (decimal places) Size in bytes reg # addr reg # Avg timer 4 (2 16-bit int) 5Avg error code Avg sound s speed 4 (2 16-bit int) 2MODBUS baud rate Notes: 1. -

Page 85: Exiting The Site Edit Menu

C.7 Exiting the site edit menu After leaving the global submenu, PanaView returns to the site edit menu. Click [close] to exit the site edit menu. Then proceed to Chapter 3, Operation, of the Startup guide for instructions on taking measurements, or refer to the appropriate chapters of this manual for detailed instructions on using the other features of the XGF868i flow transmitter.

-

Page 86: Saving Site Data

C.9 Saving site data The XGF868i holds setup parameters for a single internal site, called Working. Through PanaView, users can store site file data in a PC and reload it into the XGF868i. To save or reload site data via PanaView: 1.

-

Page 87: Saving New Site Data To The Xgf868I

C.9.2 Saving new site data to the XGF868i C.9.4 Clearing a site from the meter To save new site data to the meter: As the XGF868i has only one site loaded (working) at any time, it is not possible to remove this site. To change site 1.

-

Page 89: Appendix D. Panaview Menu Maps For The Xgf868I

Appendix D. PanaView menu maps for the XGF868i The following PanaView menu maps are included in this appendix: • Figure 55 on page 80, “PanaView prog > CHx > ACTIV, SYSTM, PIPE & I/O menus • Figure 56 on page 81, “PanaView prog > CHx > SETUP menu,”…

-

Page 90

Figure 55: PanaView PROG > CHx > ACTIV, SYSTM, PIPE and I/O menus… -

Page 91

Figure 56: PanaView PROG > CHx > SETUP menu… -

Page 92

Figure 57: PanaView PROG > GLOBL > SYSTM, I/O and COMM menus… -

Page 93

Figure 58: PanaView PROG > GLOBL > I/O > OPTIONS menu… -

Page 95: Appendix E. Foundation Fieldbus Communications

Appendix E. Foundation fieldbus communications Introduction Foundation fieldbus provides a means of communicating with the flowmeter. The patent numbers which apply are 5,909,363 and 6,424,872. This foundation fieldbus device supports six analog input (AI) blocks, which can be configured to supply the network measurements shown in Table 28 below.

-

Page 96: Configuration Utility Setup

E.2 Configuration utility setup E.3 Selecting the desired measurements The following is an example setup using National Instruments Configuration Utility v3.1. To set the measurement unit for each AI: Figure 59 below shows the configuration utility with a 1. Double click on the FLOW transducer block (in the tree flowmeter on the network (Panametrics flow-XGF).

-

Page 97: Selecting Units For Ai Blocks

E.4 Selecting units for AI blocks E.5 Resetting instrument totalizers To select the units for the individual AI blocks: To reset the instrument totalizers: 1. Double click on the AI block for which you wish to set 1. Double click on the FLOW transducer block (in the the units (ANALOG_INPUT_1 or ANALOG_INPUT_2 in the tree under GEFlow-XGF;…

-

Page 98: Function Block Application

E.6 Function block application Figure 63 below is an example setup using the function block application editor. The flowmeter AI blocks, along with the AO and PID of another device on the network, are displayed. We have connected the AI_1 OUT of the flowmeter to the CAS IN of the AO block.

-

Page 99

Warranty Return policy Each instrument manufactured by Panametrics is If a Panametrics instrument malfunctions within the warranted to be free from defects in material and warranty period, the following procedure must be workmanship. Liability under this warranty is limited to completed: restoring the instrument to normal operation or replacing 1. -

Page 100

Tel: +1 800 833 9438 (toll-free) E-mail: mstechsupport@bakerhughes.com Tel: +1 978 437 1000 E-mail: mstechsupport@bakerhughes.com Panametrics, a Baker Hughes Business, provides solutions in the toughest applications and environments for moisture, oxygen, liquid and gas flow measurement. Experts in flare management, Panametrics technology also reduces flare emissions and optimizes performance.

|

GE |

|

|

Measurement & Control |

Flow |

DigitalFlow™ XGF868i

Panametrics Flare Gas Flow Transmitter

Programming Manual

910-198P Rev. C

February 2015

DigitalFlow™ XGF868i

Panametrics Flare Gas Flow Transmitter

Programming Manual

910-198P Rev. C

February 2015

www.ge-mcs.com

©2015 General Electric Company. All rights reserved. Technical content subject to change without notice.

[no content intended for this page]

ii

Preface

Information Paragraphs

Note: These paragraphs provide information that provides a deeper understanding of the situation, but is not essential to the proper completion of the instructions.

IMPORTANT: These paragraphs provide information emphasizing instructions which are essential to proper setup of the equipment. Failure to follow these instructions carefully may cause unreliable performance.

WARNING! Indicates a potentially hazardous situation which can result in serious personal injury or death, if it is not avoided.

CAUTION! Indicates a potentially hazardous situation which can result in minor or moderate injury to personnel or damage to the equipment, if it is not avoided.

HIGH VOLTAGE! This symbol indicates the presence of high voltage. It calls your attention to situations or operations that could be dangerous to you and other persons operating the equipment. Read these messages and follow the instructions carefully.

Safety Issues

WARNING! It is the responsibility of the user to make sure all local, county, state and national codes, regulations, rules and laws related to safety and safe operating conditions are met for each installation.

Auxiliary Equipment

Local Safety Standards

The user must make sure that he operates all auxiliary equipment in accordance with local codes, standards, regulations, or laws applicable to safety.

Working Area

WARNING! Auxiliary equipment may have both manual and automatic modes of operation. As equipment can move suddenly and without warning, do not enter the work cell of this equipment during automatic operation, and do not enter the work envelope of this equipment during manual operation. If you do, serious injury can result.

WARNING! Make sure that power to the auxiliary equipment is turned OFF and locked out before you perform maintenance procedures on the equipment.

|

DigitalFlow™ XGF868i Programming Manual |

iii |

Preface

Qualification of Personnel

Make sure that all personnel have manufacturer-approved training applicable to the auxiliary equipment.

Personal Safety Equipment

Make sure that operators and maintenance personnel have all safety equipment applicable to the auxiliary equipment. Examples include safety glasses, protective headgear, safety shoes, etc.

Unauthorized Operation

Make sure that unauthorized personnel cannot gain access to the operation of the equipment.

Environmental Compliance

Waste Electrical and Electronic Equipment (WEEE) Directive

GE Measurement & Control Solutions is an active participant in Europe’s Waste Electrical and Electronic Equipment (WEEE) take-back initiative, directive 2012/19/EU.

The equipment that you bought has required the extraction and use of natural resources for its production. It may contain hazardous substances that could impact health and the environment.

In order to avoid the dissemination of those substances in our environment and to diminish the pressure on the natural resources, we encourage you to use the appropriate take-back systems. Those systems will reuse or recycle most of the materials of your end life equipment in a sound way.

The crossed-out wheeled bin symbol invites you to use those systems.

If you need more information on the collection, reuse and recycling systems, please contact your local or regional waste administration.

Visit http://www.ge-mcs.com/en/about-us/environmental-health-and-safety/weee.html for take-back instructions and more information about this initiative.

|

iv |

DigitalFlow™ XGF868i Programming Manual |

Contents

Chapter 1. Programming Site Data

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 1.2 Programming Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 1.3 The XGF868i Keypad. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 1.4 Activating a Channel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 1.5 Entering System Data for the Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.5.1 Accessing the Channelx-System Submenu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 1.5.2 Selecting Volumetric Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 1.5.3 Selecting Totalizer Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 1.5.4 Selecting Mass Flow Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 1.6 Entering Transducer and Pipe Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 1.6.1 Special Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 1.6.2 Pipe Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

1.7 Entering Zero Cutoff and Setting Up Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 1.7.1 Zero Cutoff Value. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 1.7.2 Temperature Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 1.7.3 Base Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 1.7.4 Pressure Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 1.7.5 Base Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 1.7.6 Low Pressure Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.8 Entering Setup Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 1.8.1 Setting Transducer Signal Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 1.8.2 Initializing Setup Parameters — Default Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 1.8.3 Setting Response Time — V Averaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 1.8.4 Using Advanced Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.9 Entering Global Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 1.9.1 Entering Global System Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 1.9.2 Setting Up Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 1.9.3 Configuring the Communications Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 1.9.4 Requesting Parameters Using MODBUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34 1.9.5 Activating Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

1.10 Exiting the User Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Chapter 2. Displaying Data

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39 2.2 Displaying Data with the LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39 2.2.1 Adjusting LCD Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39 2.2.2 Programming the LCD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 2.3 Displaying Data on a Computer Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42 2.3.1 Preparing for PanaView Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42 2.3.1 The Text Display Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43 2.3.2 Graphing the Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46 2.3.3 Displaying Transducer Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

|

DigitalFlow™ XGF868i Programming Manual |

v |

Contents

Chapter 3. Logging Data

3.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51 3.2 Logging with PanaView. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51 3.3 Creating Meter Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52 3.3.1 Creating a Standard Meter Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53 3.3.2 Creating an Error Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55 3.4 Creating PC Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

3.5 Viewing Meter Log Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60 3.6 Viewing PC Log Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

Chapter 4. Printing Data

4.1 Data Types for Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Chapter 5. Clearing Data

5.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67 5.2 Clearing the XGF868i Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67 5.2.1 Clearing Site Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67 5.2.2 Clearing Log Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68 5.2.3 Clearing the Totalizers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Appendix A. Menu Maps

Appendix B. Data Records

B.1 Available Option Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77 B.2 Option Cards Installed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78 B.3 Setup Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

|

vi |

DigitalFlow™ XGF868i Programming Manual |

Contents

Appendix C. Programming the XGF868i With PanaView™

C.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83 C.2 Programming With PanaView™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83 C.2.1 Preparing for PanaView Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83 C.2.2 Setting Up the Communications Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84 C.2.3 Setting up Ethernet Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86 C.2.4 Modifying Ethernet Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87 C.3 Adding the XGF868i. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

C.4 Entering the User Program Using PanaView . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90 C.5 Entering Data in the Channel Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93 C.5.1 Selecting the Channel Measurement Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93 C.5.2 Entering Data in the Channel System Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94 C.5.3 Entering Pipe Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96 C.5.4 Entering Input/Output Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98 C.5.5 Entering Setup Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 C.6 Entering Data in the Global Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106 C.6.1 Entering Global-System Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107 C.6.2 Setting Up Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109 C.6.3 Entering Communications Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

C.7 Exiting the Site Edit Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122 C.8 Exiting the Site Edit Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124 C.9 Saving Site Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125 C.9.1 Saving Current Site Data to the Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126 C.9.2 Saving New Site Data to the XGF868i. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127 C.9.3 Saving a Site to the PC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127 C.9.4 Clearing a Site from the Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128 C.9.5 Saving Site Data in Text Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Appendix D. PanaView Menu Maps for the XGF868i Appendix E. Foundation Fieldbus Communications

E.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135 E.2 Configuration Utility Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136 E.3 Selecting the Desired Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136 E.4 Selecting Units for AI Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138 E.5 Resetting Instrument Totalizers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139 E.6 Function Block Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

|

DigitalFlow™ XGF868i Programming Manual |

vii |

Contents

|

viii |

DigitalFlow™ XGF868i Programming Manual |

Chapter 1. Programming Site Data

Chapter 1. Programming Site Data

1.1Introduction

The XGF868i flow transmitter must be properly installed and programmed, as described in the Startup Guide, before it can provide accurate flow rate measurements. After completing the installation and initial setup, use this chapter to program the advanced features of the XGF868i Keypad Program.

Step-by-step programming instructions are presented in this chapter. Also, as a programming aid, a complete set of menu maps for the XGF868i are included in Appendix A, Menu Maps. The specific figure numbers will be referenced throughout this chapter, as required.

Refer to the appropriate section for a discussion of the following Keypad Program features:

•Channelx-ACTIV — activate one or both channels and Scroll to the desired measurement method.

•Channelx-SYSTM — enter the individual channel parameters.

•Channelx-PIPE — enter the pipe geometry and other parameters.

•Channelx-I/O — set up the inputs and outputs.

•Channelx-SETUP — set the signal limits, response times and mass flow status.

•Global-SYSTM — scroll to system units (English or metric).

•Global-I/O — set up error handling, option cards and the display.

•Global-COMM — set the serial port parameters.

Note: The “x” in CHx represents the channel number.

To get the XGF868i up and running as quickly as possible you must, as a minimum, activate the channel(s), enter the channel and global system data and the pipe parameters. The Procedure Options section at the end of each menu will help you in programming the required (quick startup) and optional data.

Note: In this manual, only the programming of Channel 1 will be described. To program Channel 2 of a 2-channel meter, simply repeat the same procedure presented for Channel 1.

|

DigitalFlow™ XGF868i Programming Manual |

1 |

Chapter 1. Programming Site Data

1.2Programming Methods

You can program the XGF868i via either the keypad on the lower part of the glass window, or PanaView™, a PC-based, non-resident software program that communicates with the XGF868i via its RS232 serial port. PanaView supplements basic XGF868i functions with several additional capabilities. With PanaView, you can:

Load and save site file data

Create and save graph and log files

Display text output and graphs of live measurement data

Create custom templates for displaying text, graph and log data

Interface with multiple GE instruments.

Although the actual displays differ somewhat, the general procedures are the same for all three programming methods. This chapter provides detailed programming instructions for use with the magnetic keypad. If you are using PanaView™, see Appendix C, Programming the XGF868i via PanaView™, and/or the PanaView™ User’s Manual

(910-211) for detailed instructions.

IMPORTANT: This manual is for instruments using software version Y4AM or later.

|

2 |

DigitalFlow™ XGF868i Programming Manual |

Chapter 1. Programming Site Data

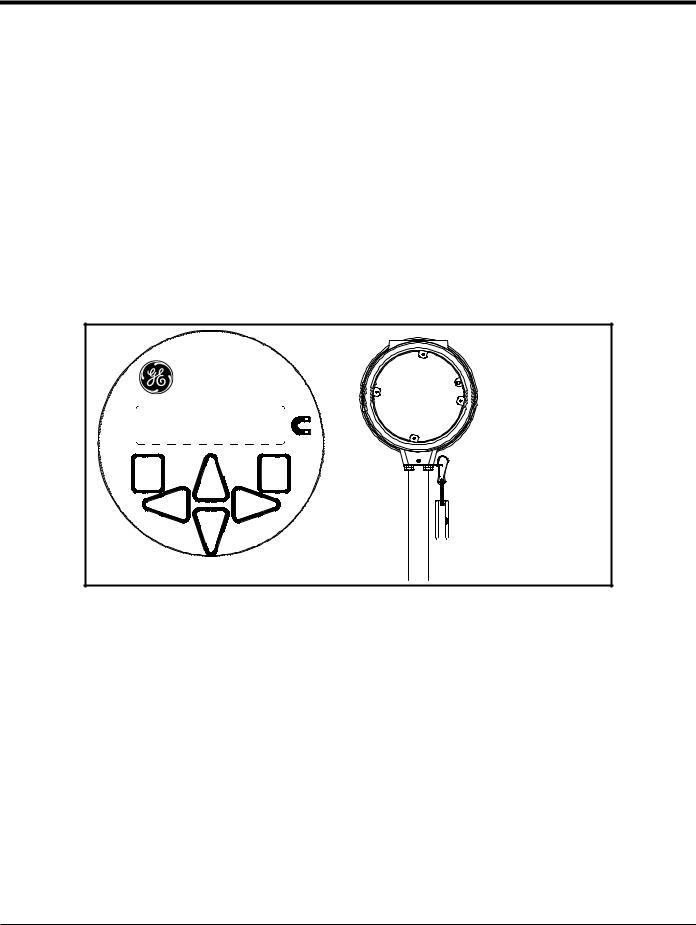

1.3The XGF868i Keypad

Keypad Program

Along with the 2-line, 16-character LCD, the XGF868i includes a 6-key magnetic keypad. The decal cutout for each key contains a hall effect sensor, pushbutton switch and visible red LED. The magnetic wand used to activate a magnetic key is found attached to the meter chassis below the front panel. An operator activates the key by pressing the magnetic wand up to the glass lid over the desired key. The LED will light indicating a successful key press.

Note: The pushbutton switch will also act as a key press but is done with the glass lid open. Do not use the pushbutton switch in a hazardous area where the lid needs to be installed.

Use the magnetic keypad to navigate through the user program. The menu map may be followed in sequence, or the four arrow keys may be used to scroll through the prompt screens. Figure 1 shows the front of the XGF868i, with magnetic keypad and magnetic wand.

DigitalFlowTM XGF868i

Figure 1: XGF868i Magnetic Keypad and Wand

IMPORTANT: The XGF868i keypad enables programming of the instrument through the glass faceplate without removing the cover. Thus, all programming procedures may be performed while the unit is installed in a hazardous area.

Six keys on the keypad enable users to program the XGF868i:

•[Enter] — confirms choice of a specific option and data entry within the option

•[Escape] — allows users to exit from a specific option without entering unconfirmed data

•[] and [] — enable users to highlight a specific window in the display option or to scroll through a list of options (parameters, letters, and numbers 0-9 as well as the negative sign and decimal point) in a menu

•[] and [] — enable users to scroll to a specific option, among choices in an option, or to a character in a text entry.

|

DigitalFlow™ XGF868i Programming Manual |

3 |

Chapter 1. Programming Site Data

1.3The XGF868i Enclosure Keypad (cont.)

When you power up the XGF868i, the display first shows the model and software version:

GE

XGF868i Y4DF.STD

The meter then starts to display measured parameters.

10.00Ft/s

To enter the Keypad Program, press the [Escape] key, followed by the [Enter] key, and the [Escape] key again. Each successive key must be entered within 10 seconds of the prior key.

As a guide in following the programming instructions in this chapter, the relevant portions of the XGF868i menu map have been reproduced in Figure 28 on page 73 and Figure 29 on page 74. Proceed to the following sections to enter data in the Channel or GLOBL menus.

IMPORTANT: If the keypad has not been pressed for 10 minutes, the XGF868i exits the Keypad Program and returns to displaying measurements. The meter retains any configuration changes that were confirmed with the [Enter] key, and restarts as if the operator had completed the programming cycle.

|

4 |

DigitalFlow™ XGF868i Programming Manual |

Chapter 1. Programming Site Data

1.4Activating a Channel

The Channelx-ACTIV submenu permits selection of the desired measurement method. In addition, it is used to activate/deactivate one or both of the channels in a 2-Channel XGF868i.

While following the programming instructions, refer to Figure 28 on page 73. To access the Channelx-ACTIV submenu:

1.In the Keypad Program, scroll to PROG and press [Enter].

2.In the PROG menu, scroll to CH1 or CH2 and press [Enter].

3.In the Channel PROGRAM menu, scroll to ACTIV and press [Enter].

4.Scroll to Burst to activate the channel/path, and press [Enter].

5.Scroll to one of the measurement methods described below and press [Enter].

•Skan Only is the preferred technique for locating the acoustic signal and for high velocity measurements. It is more robust in a noisy environment than the Measure technique.

•Skan/Measure is the preferred technique to use for low velocity measurements.

If Skan Only is selected at the above prompt, the meter uses this technique exclusively. However, if Skan/Measure is selected, the meter uses Skan Only to find the acoustic signal and then tries to use the Skan/Measure technique for the actual measurement.

Note: To change the Skan Only and Skan/Measure parameters, see the Signal submenu section on page 14 of this chapter.

Procedure Options

After completing the above step, the XGF868i returns to the Channel PROGRAM window. Do one of the following:

•To continue entering “quick startup” data, proceed to Step 3 in the following section.

•To continue regular programming, refer to Appendix A, Menu Maps, to navigate to the desired menu.

•To leave the Keypad Program, press [Escape] twice.

|

DigitalFlow™ XGF868i Programming Manual |

5 |

Chapter 1. Programming Site Data

1.5Entering System Data for the Channel

The Channelx-System submenu is used to enter system parameters for the channel. While following the programming instructions, refer to Figure 28 on page 73.

1.5.1 Accessing the Channelx-System Submenu

1.In the Keypad Program, scroll to PROG and press [Enter].

2.In the PROG menu, scroll to CH1 or CH2 and press [Enter].

3.In the Channel PROGRAM menu, scroll to SYSTM and press [Enter].

4.Use the arrow keys to enter the desired Channel Label (up to 5 characters) and press [Enter].

5.Use the arrow keys to enter the desired Site/Channel Message (up to 21 characters) and press [Enter].

1.5.2 Selecting Volumetric Units

1.Scroll to the desired Volumetric Units for the flow rate display and press [Enter]. Table 1 lists available units.

2.Scroll to the desired Volumetric Time units for the flow rate display and press [Enter].

3.Scroll to the desired number of Vol. Decimal Digits (digits to the right of the decimal point in the volumetric flow rate display) and press [Enter].

Table 1: Available Volumetric/Totalizer Units

|

English |

Metric |

|

ACF = Actual Cubic Feet |

ACM = Actual Cubic Meters |

|

KACF = Thousands of ACF |

KACM = Thousands of ACM |

|

MMACF = Millions of ACF |

MMACM = Millions of ACM |

|

SCF = Standard Cubic Feet |

SCM = Standard Cubic Meters |

|

KSCF = Thousands of SCF |

KSCM = Thousands of SCM |

|

MMSCF = Millions of SCF |

MMSCM = Millions of SCM |

1.5.3 Selecting Totalizer Units

1.Scroll to the desired Totalizer Units for a totalized flow rate display and press [Enter]. Table 1 above lists available units.

2.Scroll to the desired number of Tot Decimal Digits (digits to the right of the decimal point in the totalized flow rate display) and press [Enter].

3.Do one of the following:

•If MASS FLOW is ON, proceed to Selecting the Mass Flow Units on the following page.

•If MASS FLOW is OFF, the meter returns to the Channel PROGRAM. Go to Procedure Options on the next page.

Note: To activate mass flow, refer to page 19.

|

6 |

DigitalFlow™ XGF868i Programming Manual |

Chapter 1. Programming Site Data

1.5.4 Selecting Mass Flow Units

1.Scroll to the desired Mass Flow units for the flow rate display and press [Enter]. The available units for this prompt are determined by the selection made at System Units (see Table 2 below).

Table 2: Available Mass Flow Units

|

English |

Metric |

|

Pounds |

Kilograms |

|

Thousands of LB |

Metric Tons (1,000 KG) |

|

Millions of LB |

|

|

Tons (2,000 LB) |

|

2.Scroll to the desired Mass Flow Time units for the mass flow rate display and press [Enter].

3.Scroll to the desired number of Mdot Decimal Digits (digits to the right of the decimal point in the mass flow rate display) and press [Enter].

4.Scroll to the desired Mass (Totalizer) units for the totalized mass flow rate display and press [Enter]. The available units for this prompt are determined by the selection made at the System Units prompt.

5.Scroll to the desired number of Mass Decimal Digits (digits to the right of the decimal point in the totalized mass flow rate display) and press [Enter].

Procedure Options

After completing the steps on the previous page, the XGF868i returns to the Channel PROGRAM window. Do one of the following:

•To continue entering “quick startup” data, continue to Step 1 in Entering Transducer and Pipe Parameters on the next page.

•To continue regular programming, refer to Appendix A, Menu Maps, to navigate to the desired menu.

•To leave the Keypad Program, press [Escape] twice.

|

DigitalFlow™ XGF868i Programming Manual |

7 |

Chapter 1. Programming Site Data

1.6Entering Transducer and Pipe Parameters

Enter the transducer and pipe parameters via the PIPE submenu. While following the programming instructions, refer to

Figure 28 on page 73.

1.From the Channel PROGRAM menu, scroll to the PIPE option and press [Enter].

2.The first prompt asks for the Transducer Number.

•For a standard transducer, use the arrow keys to enter the number engraved on the transducer head, and press

[Enter].

•If there is no number engraved on the transducer head, press the right arrow key to scroll to the STD option,

and use the up and down arrow keys to change to SPEC. Then use the arrow keys to enter an assigned number (from 91 to 99), and press [Enter].

IMPORTANT: Special transducers have no engraved number on the head and are rarely used. Examine the transducer head carefully for a number.

•If you entered the number for a standard transducer, proceed to the Pipe OD prompt in step 5.

•If you entered the number for a special transducer, proceed to step 3 below.

1.6.1 Special Transducers

Note: For special transducers, GE supplies a transducer data sheet with programming information.

3. Scroll to the transducer Frequency (supplied by the factory) and press [Enter].

Note: The frequency is required to transmit an excitation voltage at the transducer’s natural frequency.

4.Enter the special transducer Tw (time delay) value (supplied by the factory) and press [Enter].

Tw is the time required for the transducer signal to travel through the transducer and its cable. This time delay must be subtracted from the transit times of the upstream and downstream transducers to ensure an accurate flow rate measurement.

|

8 |

DigitalFlow™ XGF868i Programming Manual |

Chapter 1. Programming Site Data

1.6.2 Pipe Data

If either a standard or a special transducer is being used, the programming sequence should be rejoined at this point.

5.To select the appropriate Pipe OD Unit type from the list shown in Table 3, scroll to the right side of the screen, and use the up and down arrow keys to step through the list. Press [Enter]. Then use the arrow keys to enter the known pipe outside diameter or circumference on the left side and press [Enter].

Obtain the required information by measuring either the pipe outside diameter (OD) or circumference at the transducer installation site. The data may also be obtained from standard pipe size tables found in Sound Speeds and Pipe Size Data (914-004).

Table 3: Available Pipe Size Units

|

English |

Metric |

|

inches |

mm = millimeters |

|

feet |

m = meters |

|

in/PI = pipe circumference in inches |

mm/PI = pipe circumference in millimeters |

|

ft/PI= pipe circumference in feet |

m/PI = pipe circumference in meters |

6.Use the arrow keys to enter the known Pipe Wall Thickness (in inches or mm) and press [Enter]. If the pipe wall thickness is not available, look up the value in a table of standard pipe size data which can be found in the Sound Speeds and Pipe Size Data manual (914-004)

IMPORTANT: Because the units cannot be independently chosen for this parameter, the value must be entered in the same units used for the pipe OD/Circumference.

1.6.2a Path and Axial Lengths

7.To enter the Path Length:

a.Use the [] arrow key to highlight the path length unit type at the right of the screen.Then use the [] and [] arrow keys to scroll to the desired unit type.

b.Use the [] arrow key to return to the numeric entry on the left, and enter the path length of the ultrasonic signal. Press [Enter].

|

DigitalFlow™ XGF868i Programming Manual |

9 |

Chapter 1. Programming Site Data

1.6.2a Path and Axial Lengths (cont.)

Note: If a spoolpiece was ordered with the meter, the transducer signal path length (P) and the transducer signal axial length (L) are engraved on the flowcell and/or are included in the documentation supplied with the meter. For on-site transducer installations, refer to Appendix C, Measuring P and L Dimensions, in the Startup Guide.

8.In the same manner, enter the appropriate Axial Length L unit type and axial length of the ultrasonic signal, and press [Enter].

9.Scroll to the desired Fluid Type and press [Enter]. Then do one of the following:

•If OTHER was selected — proceed to Step 10.

•If AIR was selected — proceed to Step 11.

10.Use the arrow keys to enter the Fluid Soundspeed (in feet per second) in the gas to be measured and press [Enter].

11.Scroll to the appropriate choice to indicate whether you want Reynolds Correction, and press [Enter].

•If Off is selected, go to Step 12.

•If On is selected, the program asks for the Kinematic Viscosity. Use the arrow keys to enter the desired value, and press [Enter].

12.Use the arrow keys to enter a value for the flow Calibration Factor and press [Enter]. The default value is 1.00, but values between 0.50 and 2.0 may be entered.

Procedure Options

After entering the Calibration Factor, the XGF868i returns to the Channel PROGRAM. Do one of the following:

•To continue entering “quick startup” data, press [Escape] once and proceed to Step 1 in Entering Global System Data on page 21.

•To continue regular programming, refer to Appendix A, Menu Maps, to navigate to the desired menu.

•To leave the Keypad Program, press the [Escape] key twice.

|

10 |

DigitalFlow™ XGF868i Programming Manual |

Chapter 1. Programming Site Data

1.7Entering Zero Cutoff and Setting Up Inputs

Enter the zero cutoff value and set up the temperature and pressure inputs via the I/O submenu. While programming these parameters, refer to Figure 28 on page 73.

IMPORTANT: If an option card in Slot 1 fails to appear in this menu, it may be turned Off. See the Global-I/O-Options section on page 25 for setup instructions.

1.7.1 Zero Cutoff Value

Near a zero flow rate, the XGF868i’s readings may fluctuate due to small offsets caused by thermal drift or similar factors. To force a zero display reading when there is minimal flow, enter a zero cutoff value as described below.

1.In the Keypad Program, scroll to PROG and press [Enter].

2.In the PROG menu, scroll to CH1 or CH2 and press [Enter].

3.In the Channel PROGRAM menu, scroll to I/O and press [Enter].

4.Enter a value from 0 to 1 ft/sec (0 to 0.30 m/sec) for the Zero Cutoff and press [Enter]. The recommended setting is 0.0200 ft/sec (0.0009 m/sec).

1.7.2 Temperature Input

The XGF868i can use either a fixed temperature value or a live temperature input to calculate the density for the mass flow rate display.

1.Scroll to a Fixed temperature value or to set up the option card in Slot 1 that will supply the live temperature input and press [Enter].

Note: If Slot 1 contains an activated option card with an analog input assigned to Temperature or an RTD input, Slot 1 appears as an option at the above prompt. If the process temperature is stable, a fixed value may be used, but most applications require a live temperature input. If there is no active option card for temperature, the meter assumes you are using a fixed temperature.

2.Proceed to one of the following sections:

•If you selected Fixed — proceed to Step 3.

•If you selected Slot 1 — proceed to Step 4.

3.Enter the known Fixed Temp. (process temperature) and press [Enter]. The meter will accept values from –328° to 1832°F (–200° to 1000oC). Proceed to Base Temperature on the next page.

4.Scroll to Input A or Input B and press [Enter]. The inputs were labeled during setup.

Note: The set up of Input A is used as an example. Identical procedures would be used to set up Input B.

|

DigitalFlow™ XGF868i Programming Manual |

11 |

Chapter 1. Programming Site Data

1.7.3 Base Temperature

1.Use the arrow keys to enter the Base Temperature and press [Enter]. The ratio of this value to the actual temperature is used to calculate the standard mass flow rate.

2.Do one of the following:

•If you selected Pressure as the Input Type, proceed to Pressure Input below.

•If you selected Temperature as the Input Type, proceed to Base Pressure below.

1.7.4 Pressure Input

1.Scroll to a Fixed pressure value or to set up the option card in Slot 1 that will supply the live pressure input and press [Enter].

Note: If Slot 1 contains an activated option card with an input assigned to Pressure, Slot 1 appears as an option at the above prompt. If the process pressure is stable, a fixed value may be used, but most applications require a live pressure input. If there is no active option card for pressure, the meter assumes you are using a fixed pressure.

2.Proceed to one of the following steps:

•If you selected Fixed — proceed to Step 3.

•If you selected Slot 1 — proceed to Step 4.

3.Enter the known Fixed process Pressure and press [Enter]. The meter will only accept values from 0 to 5,000 psia. Proceed to Base Pressure below.

4.Scroll to Input A or Input B and press [Enter]. The inputs were labeled during setup.

Note: The set up of Input A is used as an example. Identical procedures would be used to set up Input B.

1.7.5 Base Pressure

1.Enter the Base Pressure and press [Enter]. The ratio of this value to the actual pressure is used to calculate the standard mass flow rate.

|

12 |

DigitalFlow™ XGF868i Programming Manual |

Chapter 1. Programming Site Data

1.7.6 Low Pressure Switch

1.Scroll to Yes or No to activate or deactivate the Low Pressure Switch software function and press [Enter].

2.Proceed to one of the following steps:

•If you selected Yes — proceed to Step 3.

•If you selected No — go to Procedure Options below.

3.Enter the Pressure Limit, the low pressure switch set point, and press [Enter]. The acceptable range is 0 to 5000 psia. The meter will stop taking readings if the pressure drops below this value.

Procedure Options

After completing the above steps, the XGF868i returns to the Channel PROGRAM window. Do one of the following:

•To continue programming, refer to Appendix A, Menu Maps, to navigate to the desired menu.

•To leave the Keypad Program, press [Escape] three times.

|

DigitalFlow™ XGF868i Programming Manual |

13 |

Chapter 1. Programming Site Data

1.8Entering Setup Data

The signal limits, response times, mass flow and multiple K factors for the XGF868i are specified via the Setup submenu. The following four submenus are included in this section:

Signal — set the parameters related to the transducer signal (see below).

Default Setup — reset all parameters to default values (page 17).

V averaging — specify the response of the meter to step changes (page 17).

Advanced Features — enable mass flow and enter K factors (page 18).

While following the programming instructions, refer to Figure 29 on page 74. Record all programmed data in Appendix B, Data Records.

1.8.1 Setting Transducer Signal Parameters

Use this option to set the limits for the incoming signal and other parameters affecting the transducer signal. For example, the programmed signal strength low limit may be used to determine the trigger point for an alarm.

CAUTION! The Signal default settings are suitable for most applications. Consult with GE before changing any of these parameters.

Only after consulting the factory, complete the following steps to program the signal parameters:

1.In the Keypad Program, scroll to PROG and press [Enter].

2.In the PROG menu, scroll to CH1 or CH2 and press [Enter].

3.In the Channel PROGRAM menu, scroll to Setup and press [Enter].

4.Scroll to SIGNL and press [Enter].

5.Use Table 4 on page 15 to choose the desired values. Use the arrow keys to enter a value (or scroll to a value for a parameter with menu options) and press [Enter].

Procedure Options

After completing the above steps, the XGF868i returns to the Channel SET UP window. Do one of the following:

•To continue programming, refer to Appendix A, Menu Maps, to navigate to the desired menu.

•To leave the Keypad Program, press [Escape] three times.

|

14 |

DigitalFlow™ XGF868i Programming Manual |

|

Chapter 1. Programming Site Data |

|||

|

1.8.1 Setting Transducer Signal Parameters (cont.) |

|||

Table 4: Transducer Signal Settings |

|||

|

Transducer |

|||

|

Signal |

Default |

||

|

Parameters |

Range |

Value |

Description |

|

Signal Low |

-20 to 100 |

20 |

The E1:LOW SIGNAL error message appears when the signal strength falls |

|

Limit |

below the programmed SIGNAL LOW LIMIT value. See Chapter 2 in the |

||

|

Service Manual for a discussion of error codes. |

|||

|

Correlation |

0 to 500 |

100 |

The E4: SIGNAL QUALITY error message appears when the signal quality |

|

Peak Limit |

falls below the programmed COR. PEAK LIMIT value. See Chapter 2 in the |

||

|

Service Manual for a discussion of error codes |

|||

|

Soundspeed+- |

1 to 50% |

20% |

The E2:SOUNDSPEED error message appears when the calculated fluid |

|

Limit |

sound speed differs from the fluid sound speed entered in the |

||

|

Channelx-System menu by more than the programmed SOUNDSPEED +- |

|||

|

LIMIT value. See Chapter 2 in the Service Manual for a discussion of error |

|||

|

codes. |

|||

|

Velocity Low |

-500 to |

-150 ft/sec |

The E3: VELOCITY RANGE error messages appears when the calculated |

|

Limit |

500 ft/sec |

(-46 m/sec) |

fluid velocity is less than the programmed VELOCITY LOW LIMIT value. |

|

(-150 to |

See Chapter 2 in the Service Manual for a discussion of error codes. |

||

|

150 m/sec) |

|||

|

Velocity High |

-500 to |

150 ft/sec |

The E3: VELOCITY RANGE error messages appears when the calculated |

|

Limit |

500 ft/sec |

(46 m/sec) |

fluid velocity exceeds the programmed VELOCITY HIGH LIMIT value. |

|

(-150 to |

See Chapter 2 in the Service Manual for a discussion of error codes. |

||

|

150 m/sec) |

|||

|

Acceleration |

0 to 250 ft/s (0 |

15 ft/s |

The E6: CYCLE SKIP error message appears when the calculated fluid |

|

Limit |

to 76 m/s) |

(5 m/s) |

velocity changes by more than the programmed ACCELERATION LIMIT |

|

value from one reading to the next. See Chapter 2 in the Service |

|||

|

Manual for a discussion of error codes. |

|||

|

Amplitude |

0 to 100 |

14 |

The amplitude discriminator measures the transducer signal received by |

|

Discriminator |

the Model XGF868i. The default value for the above parameter is 14, and |

||

|

Low |

values from 0 to 100 are acceptable. The E5: AMPLITUDE error message |

||

|

appears when the amplitude discriminator falls below the programmed |

|||

|

AMP. DISCRIM LOW value. See Chapter 2 in the Service Manual for a |

|||

|

discussion of error codes. |

|||

|

Amplitude |

0 to 100 |

34 |

The amplitude discriminator measures the transducer signal received by |

|

Discriminator |

the Model XGF868i. The default value for the above parameter is 34, and |

||

|

High |

values from 0 to 100 are acceptable. The E5: AMPLITUDE error message |

||

|

appears when the amplitude discriminator exceeds the programmed |

|||

|

AMP. DISCRIM HIGH value. See Chapter 2 in the Service Manual for a |

|||

|

discussion of error codes. |

|||

|

Delta T Offset |

-1000 to |

0 μsec |

An offset between the upstream and downstream transit times is specified |

|

1000 μsec |

at this prompt. |

||

|

Skan T Offset |

–500 to |

58 μsec |

At this prompt, specify a time measurement offset that compensates for |

|

500 μsec |

any shift resulting from cross-correlation. Set to 0 for active Skan T Offset. |

||

|

DigitalFlow™ XGF868i Programming Manual |

15 |

Chapter 1. Programming Site Data

Table 4: Transducer Signal Settings (cont.)

|

Transducer |

|||

|

Signal |

Default |

||

|

Parameters |

Range |

Value |

Description |

|

% of Peak |

1 to 100% |

50% |