-

8/9/2019 ABB REL 511 Technical Reference Manual

1/272

-

8/9/2019 ABB REL 511 Technical Reference Manual

2/272

COPYRIGHT

WE RESERVE ALL RIGHTS TO THIS DOCUMENT, EVEN IN THE EVENT THAT A

PATENT IS ISSUED AND A DIFFERENTCOMMERCIAL PROPRIETARY RIGHT IS REGISTERED. IMPROPER USE, IN

PARTICULAR REPRODUCTION AND DIS-SEMINATION TO THIRD PARTIES, IS NOT

PERMITTED.THIS DOCUMENT HAS BEEN CAREFULLY CHECKED. IF THE USER

NEVERTHELESS DETECTS ANY ERRORS, HE ISASKED TO NOTIFY US AS SOON AS POSSIBLE.

THE DATA CONTAINED IN THIS MANUAL IS INTENDED SOLELY FOR THE

PRODUCT DESCRIPTION AND IS NOT TO BEDEEMED TO BE A STATEMENT OF GUARANTEED PROPERTIES. IN THE

INTERESTS OF OUR CUSTOMERS, WE CON-STANTLY SEEK TO ENSURE THAT OUR PRODUCTS ARE DEVELOPED TO THE

LATEST TECHNOLOGICAL STAN-DARDS. AS A RESULT, IT IS POSSIBLE THAT THERE MAY BE SOME

DIFFERENCES BETWEEN THE HW/SW PRODUCTAND THIS INFORMATION PRODUCT.

Manufacturer:

ABB Automation Products AB

Substation Automation Division

SE-721 59 Västerås

Sweden

Tel: +46 (0) 21 34 20 00

Fax: +46 (0) 21 14 69 18

Internet: http://www.abb.se

-

8/9/2019 ABB REL 511 Technical Reference Manual

3/272

Contents

PageChapter

Chapter 1 Introduction

……………………………………………………………

1Introduction to the technical reference manual

……………………………… 2About the complete set of

manuals to a terminal………………………. 2Design of the

Technical reference manual (TRM) ……………………..

3Related

documents……………………………………………………………….

6Chapter 2

General…………………………………………………………………..

7Terminal

identification………………………………………………………………..

8General terminal parameters

…………………………………………………. 8Basic

protection parameters

…………………………………………………..

8Calendar and clock

……………………………………………………………..

12Technical data

………………………………………………………………………..

13Case dimensions

………………………………………………………………..

13Weight

………………………………………………………………………………

17Unit

…………………………………………………………………………………..

17Environmental

properties……………………………………………………..

17Chapter 3 Common functions

………………………………………………. 21Time synchronisation

(TIME)…………………………………………………….

22Application

…………………………………………………………………………

22Function block

……………………………………………………………………

22Input and output signals

………………………………………………………

22Setting parameters

……………………………………………………………..

23Setting group selector

(GRP)…………………………………………………….

24Application

…………………………………………………………………………

24Logic diagram

…………………………………………………………………….

24Function block

……………………………………………………………………

24Input and output signals

………………………………………………………

25Setting lockout (HMI)

……………………………………………………………….

26Application

…………………………………………………………………………

26Function block

……………………………………………………………………

26Logic diagram

…………………………………………………………………….

26Input and output signals

………………………………………………………

27Setting parameters

……………………………………………………………..

27I/O system configurator (IOP)

…………………………………………………… 28Application

…………………………………………………………………………

28Logic diagram

…………………………………………………………………….

28Function block

……………………………………………………………………

29Input and output signals

………………………………………………………

29Self supervision (INT)

………………………………………………………………

30Application

…………………………………………………………………………

30Function block

……………………………………………………………………

30 -

8/9/2019 ABB REL 511 Technical Reference Manual

4/272

Contents

Logic diagram

…………………………………………………………………….

31Input and output

signals……………………………………………………….

33Technical data

……………………………………………………………………

33Logic function blocks

……………………………………………………………….

34Application

…………………………………………………………………………

34Inverter function block (INV)

………………………………………………… 34OR

function block

(OR)………………………………………………………..

34AND function block (AND)

……………………………………………………

35Timer function block (TM)

…………………………………………………….

36Timer long function block (TL)

……………………………………………… 37Pulse

timer function block

(TP)……………………………………………..

38Extended length pulse function block

(TQ)…………………………….. 38Exclusive OR function

block (XO)………………………………………….

39Set-reset function block

(SR)………………………………………………..

40Set-reset with memory function block (SM)

……………………………. 41Controllable gate function

block (GT) ……………………………………. 41Settable timer function block

(TS)…………………………………………. 42Technical

data

……………………………………………………………………

43Blocking of signals during test

…………………………………………………..

44Application

…………………………………………………………………………

44Function

block…………………………………………………………………….

44Input and output

signals……………………………………………………….

44Chapter 4 Line impedance

…………………………………………………….

45Distance protection

(ZM)…………………………………………………………..

46Application

…………………………………………………………………………

46Functionality……………………………………………………………………….

48Function block, zone 1-

3……………………………………………………..

50Function block, zone

4…………………………………………………………

51Function block, zone

5…………………………………………………………

52Logic diagram

…………………………………………………………………….

52Input and output signals, zone

1-3………………………………………… 55Input and

output signals, zone

4…………………………………………… 56Input and

output signals, zone

5…………………………………………… 57Setting

parameters, general

………………………………………………… 57Setting

parameters, zone 1-3

………………………………………………. 58Setting

parameters, zone

4…………………………………………………..

60Setting parameters, zone

5………………………………………………….. 62Setting parameters, directional measuring element

………………… 64Technical data

……………………………………………………………………

64Automatic switch onto fault logic

(SOTF)……………………………………. 66Application

…………………………………………………………………………

66Functionality……………………………………………………………………….

66Function

block…………………………………………………………………….

66Logic diagram

…………………………………………………………………….

67Input and output

signals……………………………………………………….

67Setting parameters

……………………………………………………………..

67Technical data

……………………………………………………………………

68Local acceleration logic

(ZCLC)…………………………………………………

69Application

…………………………………………………………………………

69 -

8/9/2019 ABB REL 511 Technical Reference Manual

5/272

Contents

Functionality

………………………………………………………………………

69Function block

……………………………………………………………………

69Logic diagram

…………………………………………………………………….

70Input and output signals

………………………………………………………

70Setting parameters

……………………………………………………………..

71General fault criteria (GFC)

………………………………………………………

72Application

…………………………………………………………………………

72Functionality

………………………………………………………………………

72Function block

……………………………………………………………………

73Logic diagram

…………………………………………………………………….

73Input and output signals

………………………………………………………

77Setting parameters

……………………………………………………………..

78Technical data

……………………………………………………………………

80Power swing detection (PSD)

……………………………………………………

82Application

…………………………………………………………………………

82Functionality

………………………………………………………………………

82Function block

……………………………………………………………………

83Logic diagram

…………………………………………………………………….

84Input and output signals

………………………………………………………

85Setting parameters

……………………………………………………………..

85Technical data

……………………………………………………………………

87Scheme communication logic for distanceprotection functions

(ZCOM) …………………………………………………..

89Application

…………………………………………………………………………

89Functionality

………………………………………………………………………

89Function block

……………………………………………………………………

90Logic diagram

…………………………………………………………………….

90Input and output signals

………………………………………………………

92Setting parameters

……………………………………………………………..

93Technical data

……………………………………………………………………

93Current reversal and WEI logic for distance protection

(ZCAL)……… 94Application

…………………………………………………………………………

94Functionality

………………………………………………………………………

94Function block

……………………………………………………………………

95Logic diagram

…………………………………………………………………….

96Input and output signals

………………………………………………………

97Setting parameters

……………………………………………………………..

99Technical data

……………………………………………………………………

99Chapter 5 Current

……………………………………………………………….

101Instantaneous overcurrent protection (IOC)

……………………………… 102Application

……………………………………………………………………….

102Functionality

…………………………………………………………………….

102Function block

………………………………………………………………….

102Logic diagram

…………………………………………………………………..

103Input and output signals

…………………………………………………….

103Setting parameters

……………………………………………………………

104Technical data

………………………………………………………………….

105Time delayed overcurrent protection (TOC)

……………………………… 106Application

……………………………………………………………………….

106 -

8/9/2019 ABB REL 511 Technical Reference Manual

6/272

Contents

Functionality……………………………………………………………………..

106Function

block…………………………………………………………………..

106Logic diagram

…………………………………………………………………..

107Input and output

signals……………………………………………………..

107Setting parameters

……………………………………………………………

108Technical data

………………………………………………………………….

109Two step time delayed phase overcurrent protection (TOC2)

……… 110Application

……………………………………………………………………….

110Functionality……………………………………………………………………..

110Function

block…………………………………………………………………..

110Logic diagram

…………………………………………………………………..

111Input and output

signals……………………………………………………..

111Setting parameters

……………………………………………………………

112Technical data

………………………………………………………………….

113Two step time delayed directional phaseovercurrent protection

(TOC3) ………………………………………………..

115Application

……………………………………………………………………….

115Functionality……………………………………………………………………..

115Function

block…………………………………………………………………..

116Logic diagram

…………………………………………………………………..

116Input and output

signals……………………………………………………..

120Setting parameters

……………………………………………………………

121Technical data

………………………………………………………………….

122Definite and inverse time-delayed residualovercurrent protection

(TEF) …………………………………………………..

124Application

……………………………………………………………………….

124Functionality……………………………………………………………………..

124Function

block…………………………………………………………………..

125Logic diagram

…………………………………………………………………..

126Input and output

signals……………………………………………………..

127Setting parameters

……………………………………………………………

127Scheme communication logic for residualovercurrent protection

(EFC) …………………………………………………

129Application

……………………………………………………………………….

129Functionality……………………………………………………………………..

129Function

block…………………………………………………………………..

129Logic diagram

…………………………………………………………………..

130Input and output

signals……………………………………………………..

130Setting parameters

……………………………………………………………

131Technical data

………………………………………………………………….

131Current reversal and weak end infeed logic for

residual overcurrent protection (EFCA)

……………………………………. 132Application

……………………………………………………………………….

132Design……………………………………………………………………………..

132Function

block…………………………………………………………………..

133Logic diagram

…………………………………………………………………..

133Input and output

signals……………………………………………………..

134Setting parameters

……………………………………………………………

135Technical data

………………………………………………………………….

135 -

8/9/2019 ABB REL 511 Technical Reference Manual

7/272

Contents

Chapter 6 Voltage

……………………………………………………………….

137Time delayed undervoltage protection (TUV)

……………………………. 138Application

……………………………………………………………………….

138Function block

………………………………………………………………….

138Logic diagram

…………………………………………………………………..

138Input and output signals

…………………………………………………….

139Setting parameters

……………………………………………………………

139Technical data

………………………………………………………………….

140Time delayed overvoltage protection (TOV)

……………………………… 141Application

……………………………………………………………………….

141Functionality

…………………………………………………………………….

141Function block

………………………………………………………………….

141Logic diagram

…………………………………………………………………..

142Input and output signals

…………………………………………………….

142Setting parameters

……………………………………………………………

143Technical data

………………………………………………………………….

144Chapter 7 Secondary system supervision

…………………………… 145Fuse failure supervision

(FUSE)………………………………………………

146Application

……………………………………………………………………….

146Functionality

…………………………………………………………………….

146Function block

………………………………………………………………….

146Logic diagram

…………………………………………………………………..

147Input and output signals

…………………………………………………….

148Setting parameters

……………………………………………………………

148Technical data

………………………………………………………………….

149Chapter 8 Control

……………………………………………………………….

151Synchrocheck (SYN)

……………………………………………………………..

152Application

……………………………………………………………………….

152Functionality

…………………………………………………………………….

152Function block

………………………………………………………………….

153Logic diagram

…………………………………………………………………..

154Input and output signals

…………………………………………………….

155Setting parameters

……………………………………………………………

156Technical data

………………………………………………………………….

158Automatic reclosing function (AR)

…………………………………………… 159Application

……………………………………………………………………….

159Functionality

…………………………………………………………………….

159Function block

………………………………………………………………….

160Input and output signals

…………………………………………………….

160Setting parameters

……………………………………………………………

163Technical data

………………………………………………………………….

165 -

8/9/2019 ABB REL 511 Technical Reference Manual

8/272

Contents

Chapter 9

Logic…………………………………………………………………..

167Trip logic (TR)

……………………………………………………………………….

168Application

……………………………………………………………………….

168Functionality……………………………………………………………………..

168Function

block…………………………………………………………………..

169Logic diagram

…………………………………………………………………..

169Input and output

signals……………………………………………………..

173Setting parameters

……………………………………………………………

174Technical data

………………………………………………………………….

175High speed binary output logic (HSBO)

……………………………………. 176Application

……………………………………………………………………….

176Functionality……………………………………………………………………..

176Function

block…………………………………………………………………..

176Logic diagram

…………………………………………………………………..

177Input and output

signals……………………………………………………..

178Setting parameters

……………………………………………………………

179Serial

communication……………………………………………………………..

181Application, common

…………………………………………………………

181Design,

common……………………………………………………………….

181Serial communication, SPA (SPA-bus V 2.4

protocol)………………… 183Application

……………………………………………………………………….

183Design……………………………………………………………………………..

183Setting parameters

……………………………………………………………

183Technical data

………………………………………………………………….

184Serial communication, IEC (IEC 60870-5-103 protocol)

……………… 185Application

……………………………………………………………………….

185Design……………………………………………………………………………..

185IEC 60870-5-103 information types

…………………………………….. 185Function

block…………………………………………………………………..

192Input and output

signals……………………………………………………..

192Setting parameters

……………………………………………………………

193Technical data

………………………………………………………………….

193Serial communication, LON

…………………………………………………….

194Application

……………………………………………………………………….

194Design……………………………………………………………………………..

194Technical data

………………………………………………………………….

194Event function (EV)

………………………………………………………………..

195Application

……………………………………………………………………….

195Design……………………………………………………………………………..

195Function

block…………………………………………………………………..

196Input and output

signals……………………………………………………..

197Setting parameters

……………………………………………………………

198Chapter 10

Monitoring…………………………………………………………..

201Disturbance report (DRP)

……………………………………………………….

202Application

……………………………………………………………………….

202Functionality……………………………………………………………………..

202Function

block…………………………………………………………………..

203Input and output

signals……………………………………………………..

204 -

8/9/2019 ABB REL 511 Technical Reference Manual

9/272

Contents

Setting parameters

……………………………………………………………

204Technical data

………………………………………………………………….

207Indications…………………………………………………………………………….

208Application

……………………………………………………………………….

208Functionality

…………………………………………………………………….

208Disturbance recorder

……………………………………………………………..

209Application

……………………………………………………………………….

209Functionality

…………………………………………………………………….

209Technical data

………………………………………………………………….

210Event recorder

………………………………………………………………………

211Application

……………………………………………………………………….

211Design

…………………………………………………………………………….

211Technical data

………………………………………………………………….

211Fault locator (FLOC)

………………………………………………………………

212Application

……………………………………………………………………….

212Functionality

…………………………………………………………………….

212Function block

………………………………………………………………….

213Input and output signals

…………………………………………………….

213Setting parameters

……………………………………………………………

214Technical data

………………………………………………………………….

215Monitoring of AC analogue measurements

………………………………. 216Application

……………………………………………………………………….

216Functionality

…………………………………………………………………….

216Function block

………………………………………………………………….

216Input and output signals

…………………………………………………….

217Setting parameters

……………………………………………………………

218Technical data

………………………………………………………………….

228Monitoring of DC analogue measurements

………………………………. 229Application

……………………………………………………………………….

229Function block

………………………………………………………………….

229Input and output signals

…………………………………………………….

229Setting parameters

……………………………………………………………

230Technical data

………………………………………………………………….

233Chapter 11 Hardware

modules………………………………………………

235Modules

……………………………………………………………………………….

236Transformer input module (TRM)

……………………………………………. 238Design

…………………………………………………………………………….

238Technical data

………………………………………………………………….

238A/D-conversion module (ADM)

……………………………………………….. 240Design

…………………………………………………………………………….

240Binary I/O capabilities

…………………………………………………………….

241Application

……………………………………………………………………….

241Design

…………………………………………………………………………….

241Technical data

………………………………………………………………….

241Binary input module (BIM)

………………………………………………………

243Application

……………………………………………………………………….

243Design

…………………………………………………………………………….

243Function block

………………………………………………………………….

243Input and output signals

…………………………………………………….

243 -

8/9/2019 ABB REL 511 Technical Reference Manual

10/272

Contents

Binary output module (BOM)

…………………………………………………..

245Application

……………………………………………………………………….

245Design……………………………………………………………………………..

245Function

block…………………………………………………………………..

246Input and output

signals……………………………………………………..

246Power supply module (PSM)

…………………………………………………..

247Application

……………………………………………………………………….

247Design……………………………………………………………………………..

247Function

block…………………………………………………………………..

247Input and output

signals……………………………………………………..

247Technical data

………………………………………………………………….

248Human-machine-interface modules (HMI)

………………………………… 249Application

……………………………………………………………………….

249Design……………………………………………………………………………..

249Technical data

………………………………………………………………….

250Serial communication modules

(SCM)……………………………………… 251Design, SPA/IEC

………………………………………………………………

251Design, LON

…………………………………………………………………….

251Technical data

………………………………………………………………….

251Chapter 12 Diagrams

…………………………………………………………….

253Terminal diagrams

…………………………………………………………………

254Terminal diagram, REL 511-C1

………………………………………….. 254 -

8/9/2019 ABB REL 511 Technical Reference Manual

11/272

1

About this chapter Chapter 1

Introduction

Chapter 1 Introduction

About this chapter

This chapter introduces you to the manual as such.

-

8/9/2019 ABB REL 511 Technical Reference Manual

12/272

2

Introduction to the technical referencemanual

Chapter 1

Introduction

1 Introduction to the technical reference manual

1.1 About the complete set of manuals to a terminal

The complete package of manuals to a terminal is named users

manual (UM). The Us-ers manual consists of four different manuals:

The Application Manual (AM) contains descriptions, such as

application and func-tionality descriptions as well as setting calculation examples

sorted per function. Theapplication manual should be used when designing and engineering

the protection ter-minal to find out where and for what a typical protection

function could be used. Themanual should also be used when calculating settings and

creating configurations.The Technical Reference Manual (TRM) contains technical

descriptions, such asfunction blocks, logic diagrams, input and output signals,

setting parameter tables andtechnical data sorted per function. The technical reference

manual should be used as atechnical reference during the

engineering phase, installation and commissioning phaseand during the normal service phase.

The Operator´s Manual (OM) contains instructions on how to

operate the protectionterminal during normal service (after commissioning and before

periodic maintenancetests). The operator´s manual could be used to find out how to

handle disturbances orhow to view calculated and measured network data in order to

determine the reason ofa fault.

The Installation and Commissioning Manual (ICM) contains

instructions on how toinstall and commission the protection terminal. The manual can

also be used as a refer-ence if a periodic test is performed. The manual covers

procedures for mechanical andelectrical installation, energising and checking of external

circuitry, setting and config-uration as well as verifying settings and performing a

directionality test. The chaptersand sections are organised in the chronological order (indicated

by chapter/sectionnumbers) the protection terminal should be installed and

commissioned.Application

manual

Technical

reference

manual

Installation and

commissioning

manual

Operator´s

manual

en01000044.vsd

-

8/9/2019 ABB REL 511 Technical Reference Manual

13/272

3

Introduction to the technical referencemanual

Chapter 1

Introduction

1.2 Design of the Technical reference manual (TRM)

The description of each terminal related function follows the

same structure (where ap-plicable):

Application

States the most important reasons for the implementation of a

particular protectionfunction.

Functionality/Design

Presents the general concept of a function.

Function block

Each function block is imaged by a graphical symbol.

Input signals are always on the left side, and output signals on

the right side. Settingsare not displayed. A special kind of settings are sometimes

available. These are sup-posed to be connected to constants in the configuration scheme,

and are therefore de-picted as inputs. Such signals will be found in the signal list

but described in the settingstable.

Figure 1: Function block symbol example

Logic diagram

The description of the design is chiefly based on simplified

logic diagrams, which useIEC symbols, for the presentation of different functions,

conditions etc. The functionsare presented as a closed block with the most important internal

logic circuits and con-figurable functional inputs and outputs.

Completely configurable binary inputs/outputs and functional

inputs/outputs enable theuser to prepare the REx 5xx with his own configuration of

different functions, accord-ing to application needs and standard

practice.TUV

BLOCK

BLKTR

VTSU

TRIP

STL1

STL2

STL3

START

xx00000207.vsd

-

8/9/2019 ABB REL 511 Technical Reference Manual

14/272

4

Introduction to the technical referencemanual

Chapter 1

Introduction

Figure 2: Function block diagram example

The names of the configurable logic signals consist of two parts

divided by dashes. Thefirst part consists of up to four letters and presents the

abbreviated name for the corre-sponding function. The second part presents the functionality of

the particular signal.According to this explanation, the meaning of the signal

TUV—BLKTR is as follows.• The first part of the signal, TUV- represents the adherence to

the Time delayed Un-der-Voltage function.

• The second part of the signal name, BLKTR informs the user

that the signal willBLocK the TRip from the under-voltage function, when its value

is a logical one (1).Different binary signals have special symbols with the following

significance:• Signals drawn to the box frame to the left present functional

input signals. It is pos-sible to configure them to functional output signals of other

functions as well as tobinary input terminals of the REx 5xx terminal. Examples are

TUV—BLKTR, TUV--BLOCK and TUV—VTSU.Signals in frames with a shaded area on

their right sidepresent the logical setting signals. Their values are high (1)

only when the corre-sponding setting parameter is set to the symbolic value

specified within the frame.Example is the signal Operation = On. These signals are not

configurable. Their log-ical values correspond automatically to the selected setting

value.The internal sig-nals are usually dedicated to a certain function. They are

normally not available forTUV—BLKTR

TUV—BLOCK

TUV—VTSU >1

STUL1

STUL2

&

&

&STUL3

Operation = On

>1& t

tt

15 msTUV—TRIP

TUV—START

TUV—STL1

TUV—STL2

TUV—STL3

t15 ms

t

15 ms

t

15 ms

t

15 ms

TRIP — cont.

xx01000170.vsd

-

8/9/2019 ABB REL 511 Technical Reference Manual

15/272

5

Introduction to the technical referencemanual

Chapter 1

Introduction

configuration purposes. Examples in are signals STUL1, STUL2 and

STUL3.Thefunctional output signals, drawn to the box frame to the right,

present the logical out-puts of functions and are available for configuration purposes.

The user can config-ure them to binary outputs from the terminal or to inputs of

different functions.Typical examples in are signals TUV—TRIP,

TUV—START etc.Other internal signals configurated to other function blocks are

written on a line with anidentity and a cont. reference. An example is the signal TRIP —

cont. The signal can befound in the corresponding function with the same identity.

Input and output signals

The signal lists contain all available input and output signals

of the function block, onetable for input signals and one for output signals.

Table 1: Input signals for the TUV (TUV—) function block

Table 2: Output signals for the TUV (TUV—) function block

Setting parameters

The setting parameters table contains all available settings of

the function block. If afunction consists of more than one block,

each block is listed in a separate table.Signal Description

BLOCK Block undervoltage function

BLKTR Block of trip from time delayed undervoltage function

VTSU Block from voltage transformer circuit supervision

Signal DescriptionTRIP Trip by time delayed undervoltage

functionSTL1 Start phase undervoltage phase L1

STL2 Start phase undervoltage phase L2

STL3 Start phase undervoltage phase L3

START Start phase undervoltage

-

8/9/2019 ABB REL 511 Technical Reference Manual

16/272

6

Introduction to the technical referencemanual

Chapter 1

Introduction

Table 3: Setting parameters for the time delayed undervoltage

protection TUV(TUV—) functionTechnical data

The technical data specifies the terminal in general, the

functions and the hardwaremodules.

1.3 Related documents

Parameter Range Default Unit Description

Operation Off, On Off — Operating mode for TUV function

UPE< 10-100

Step: 1

70 % of

U1b

Operate phase voltage

t 0.000-

60.000

Step: 0.001

0.000 s Time delay

Documents related to REL 511-C1*2.3 Identity number

Operator’s manual 1MRK 506 096-UEN

Installation and commissioning manual 1MRK 506 098-UEN

Technical reference manual 1MRK 506 097-UEN

Application manual 1MRK 506 116-UEN

Technical overview brochure 1MRK 506 095-BEN

-

8/9/2019 ABB REL 511 Technical Reference Manual

17/272

7

About this chapter Chapter 2

General

Chapter 2 General

About this chapter

This chapter describes the terminal in general.

-

8/9/2019 ABB REL 511 Technical Reference Manual

18/272

8

Terminal identification Chapter 2

General

1 Terminal identification

1.1 General terminal parameters

Use the terminal identifiers to name the individual terminal for

identification purposes.Use the terminal reports to check serial numbers of the terminal

and installed modulesand to check the firmware version.

Identifiers and reports are accessible by using the HMI as well

as by SMS or SCS sys-tems.

Table 4: Set parameters for the general terminal parameters

function1.2 Basic protection parameters

Path in HMI-tree: Configuration/AnalogInputs/General

Table 5: Setting parameters for analogInputs — General

Path in HMI-tree: Configuration/AnalogInputs/U1-U5

Parameter Range Default Unit Description

Station Name 0-16 Station

Name

char Identity name for the station

Station No 0-99999 0 — Identity number for the station

Object Name 0-16 Object

Name

char Identity name for the protected

object

Object No 0-99999 0 — Identity number for the protected

object

Unit Name 0-16 Unit Name char Identity name for the terminal

Unit No 0-99999 0 — Identity number for the terminal

Parameter Range Default Unit Description

CTEarth In/Out Out — Direction of CT earthing

fr 50, 60, 16

2/3

50 Hz System frequency

-

8/9/2019 ABB REL 511 Technical Reference Manual

19/272

9

Terminal identification Chapter 2

General

Table 6: Analog Inputs — Voltage

Parameter Range Default Unit Description

U1r * 10.000 —

500.000

Step: 0.001

63.509 V Rated voltage of transformer on

input U1

U1b 30.000 —

500.000

Step:0.001

63.509 V Base voltage of input U1

U1Scale 1.000 —

20000.000

Step: 0.001

2000.000 — Main voltage transformer ratio, input

U1

Name_U1 0 — 13 U1 char User-defined name of input U1

U2r * 10.000 —

500.000

Step: 0.001

63.509 V Rated voltage of transformer on

input U2

U2b 30.000 —

500.000

Step: 0.001

63.509 V Base voltage of input U2

U2Scale 1.000 —

20000.000

Step: 0.001

2000.000 — Main voltage transformer ratio, input

U2

Name_U2 0 — 13 U2 char User-defined name of input U2

U3r * 10.000 —

500.000

Step: 0.001

63.509 V Rated voltage of transformer on

input U3

U3b 30.000 —

500.000

Step: 0.001

63.509 V Base voltage of input U3

U3Scale 1.000 —

20000.000

Step: 0.001

2000.000 — Main voltage transformer ratio, input

U3

Name_U3 0 — 13 U3 char User-defined name of input U3

-

8/9/2019 ABB REL 511 Technical Reference Manual

20/272

-

8/9/2019 ABB REL 511 Technical Reference Manual

21/272

11

Terminal identification Chapter 2

General

Table 7: Analog Inputs — Current

Parameter Range Default Unit Description

I1r * 0.1000 —

10.0000

Step:

0.0001

1.0000 A Rated current of transformer on

input I1

I1b 0.1 — 10.0

Step: 0.1

1.0 A Base current of input I1

I1Scale 1.000 —

40000.000

Step: 0.001

2000.000 — Main current transformer ratio,

input I1

Name_I1 0 — 13 I1 char User-defined name of input I1

I2r * 0.1000 —

10.0000

Step:

0.0001

1.0000 A Rated current of transformer on

input I2

I2b 0.1 — 10.0

Step: 0.1

1.0 A Base current of input I2

I2Scale 1.000 —

40000.000

Step:0.001

2000.000 — Main current transformer ratio,

input I2

Name_I2 0 — 13 I2 char User-defined name of input I2

I3r * 0.1000 —

10.0000

Step:

0.0001

1.0000 A Rated current of transformer on

input I3

I3b 0.1 — 10.0

Step: 0.1

1.0 A Base current of input I3

I3Scale 1.000 —

40000.000

Step: 0.001

2000.000 — Main current transformer ratio,

input I3

Name_I3 0 — 13 I3 char User-defined name of input I3

-

8/9/2019 ABB REL 511 Technical Reference Manual

22/272

12

Terminal identification Chapter 2

General

1.3 Calendar and clock

Table 8: Calendar and clock

I4r * 0.1000 —

10.0000

Step:

0.0001

1.0000 A Rated current of transformer on

input I4

I4b 0.1 — 10.0

Step: 0.1

1.0 A Base current of input I4

I4Scale 1.000 —

40000.000

Step: 0.001

2000.000 — Main current transformer ratio,

input I4

Name_I4 0 — 13 I4 char User-defined name of input I4

I5r * 0.1000 —

10.0000

Step:

0.0001

1.0000 A Rated current of transformer on

input I5

I5b 0.1 — 10.0

Step: 0.1

1.0 A Base current of input I5

I5Scale 1.000 —

40000.000

Step: 0.001

2000.000 — Main current transformer ratio,

input I5

Name_I5 0 — 13 I5 char User-defined name of input I5

*) Setting is done through the local HMI only

Parameter Range Default Unit Description

Parameter Range

Built-in calender 30 years with leap years

-

8/9/2019 ABB REL 511 Technical Reference Manual

23/272

13

Technical data Chapter 2

General

2 Technical data

2.1 Case dimensions

Figure 3: Hardware structure of the 1/2 of full width 19”

case -

8/9/2019 ABB REL 511 Technical Reference Manual

24/272

14

Technical data Chapter 2

General

Diagrams (Dimensions)

96000309.tif

96000310.tif

Case

size

A B C D E F G H I J K

6U x 1/2 223.7 205.7 203.7 — —

6U x 3/4 265.9 336 204.1 245.1 255.8 318 190.5 316 — 227.6 —

6U x 1/1 448.3 430.3 428.3 465.1

*)

482.6

*) equal to 19” (mm)

-

8/9/2019 ABB REL 511 Technical Reference Manual

25/272

15

Technical data Chapter 2

General

Panel cut-outs for REx 500 series

Flush mounting Semi-flush mounting

97000025.tif97000026.tif

Case size

Cut-out dimensions (mm)

A+/-1 B+/-1

6U x 1/2 210.1 259.3

6U x 3/4 322.4 259.3

6U x 1/1 434.7 259.3

C = 4-10 mm

D = 16.5 mm

E = 187.6 mm without protection cover, 228.6 mm with protection

coverF = 106.5 mm

G = 97.6 mm without protection cover, 138.6 mm with protection

cover -

8/9/2019 ABB REL 511 Technical Reference Manual

26/272

16

Technical data Chapter 2

General

The flush mounting kits are available in three designs, suitable

for 1/2, 3/4 or full widthterminals and consists of four fasteners (4) with appropriate

mounting details and a seal-ing strip (1) providing IP54 class protection for fastening to

the terminal (5). The semi-flush mounting kit adds a distance frame (2). An additional

sealing strip (3) can beordered for semiflush mounting to provide

IP54 class protection.Figure 4: The flush mounting kit

xx00000129.eps

1

2

3

4

5

6

xx01000049.vsden01000047.vsd

-

8/9/2019 ABB REL 511 Technical Reference Manual

27/272

17

Technical data Chapter 2

General

2.2 Weight

Table 9: Weight

2.3 Unit

Table 10: Unit

2.4 Environmental properties

Table 11: Temperature and humidity influence

Case size (mm) A B C D E

6U x 1/2 292 267.1

6U x 3/4 404.3 379.4 272.8 390 247

6U x 1/1 516 491.1

Case size Weight

6U x 1/2 ≤ 8.5 kg

6U x 3/4 ≤ 11 kg

6U x 1/1 ≤ 18 kg

Material Steel sheet

Front plate Aluminium profile with cut-out for HMI

Surface treatment Aluzink preplated steel

Finish Light beige (NCS 1704-Y15R)

Degree of protection Front side: IP40, IP54 with optional

sealing strip Rear side: IP20Parameter Rated value Nominal range Influence

Storage temperature — -40 °C to +70 °C —

Ambient temperature (duringoperation)

+20 °C -5 °C to +55 °C 0.01%/°C, within nomi-nal range

Correct function within

operative range

Relative humidity 10%-90% 10%-90% —

-

8/9/2019 ABB REL 511 Technical Reference Manual

28/272

18

Technical data Chapter 2

General

Table 12: Auxiliary DC supply voltage influence on functionality

during operationTable 13: Electromagnetic compatibility

Table 14: Insulation

Table 15: CE compliance

Dependence on: Within nominal

range

Within operative range

Ripple, max 12% or EL Negligible Correct function

Interrupted auxiliary

DC voltage

Without reset

-

8/9/2019 ABB REL 511 Technical Reference Manual

29/272

19

Technical data Chapter 2

General

Table 16: Mechanical tests

Test Type test values Reference standards

Vibration Class I IEC 60255-21-1

Shock and bump Class I IEC 60255-21-2

Seismic Class I IEC 60255-21-3

-

8/9/2019 ABB REL 511 Technical Reference Manual

30/272

20

Technical data Chapter 2

General

-

8/9/2019 ABB REL 511 Technical Reference Manual

31/272

21

About this chapter Chapter 3

Common functions

Chapter 3 Common functions

About this chapter

This chapter presents the common functions in the terminal.

-

8/9/2019 ABB REL 511 Technical Reference Manual

32/272

22

Time synchronisation (TIME) Chapter 3

Common functions

1 Time synchronisation (TIME)

1.1 Application

Use the time synchronization source selector to select a common

source of absolutetime for the terminal when it is a part of a protection system.

This makes comparison ofevents and disturbance data between all terminals in a system

possible.1.2 Function block

1.3 Input and output signals

Table 17: Input signals for the TIME (TIME-) function block

Table 18: Output signals for the TIME (TIME-) function block

xx00000171.vsd

TIME-

TIME

MINSYNC

SYNCSRC

RTCERR

SYNCERR

Signal Description

MINSYNC Minute pulse input

SYNCSRC Synchronization source selector input. See settings

fordetails.

Signal Description

RTCERR Real time clock error

SYNCERR Time synchronisation error

-

8/9/2019 ABB REL 511 Technical Reference Manual

33/272

23

Time synchronisation (TIME) Chapter 3

Common functions

1.4 Setting parameters

Table 19: Setting parameters for the time synchronization source

selector func-tionParameter Range Default Unit Description

SYNCSRC 0-5 0 — Selects the time synchronization

source:

0: No source. Internal real time clock

is used without fine tuning.

1: LON bus

2: SPA bus

3: IEC 870-5-103 bus

4: Minute pulse, positive flank

5: Minute pulse, negative flank

-

8/9/2019 ABB REL 511 Technical Reference Manual

34/272

24

Setting group selector (GRP) Chapter 3

Common functions

2 Setting group selector (GRP)

2.1 Application

Use the four sets of settings to optimize the terminal’s

operation for different systemconditions. By creating and switching between fine tuned setting

sets, either from thehuman-machine interface or configurable binary inputs, results

in a highly adaptableterminal that can cope with a variety of system scenarios.

2.2 Logic diagram

Figure 5: Connection of the function to external circuits

2.3 Function block

GRP—ACTGRP1

GRP—ACTGRP2

GRP—ACTGRP3

GRP—ACTGRP4

IOx-Bly1

IOx-Bly2

IOx-Bly3

IOx-Bly4

+RL2

∅

∅

∅

∅

en01000144.vsd

ACTIVATE GROUP 4

ACTIVATE GROUP 3

ACTIVATE GROUP 2

ACTIVATE GROUP 1

xx00000153.vsd

GRP—

ACTIVEGROUP

ACTGRP1

ACTGRP2

ACTGRP3

ACTGRP4

GRP1

GRP2

GRP3

GRP4

-

8/9/2019 ABB REL 511 Technical Reference Manual

35/272

25

Setting group selector (GRP) Chapter 3

Common functions

2.4 Input and output signals

Table 20: Input signals for the ACTIVEGROUP (GRP—) function

blockTable 21: Output signals for the ACTIVEGROUP (GRP—) function

blockSignal Description

ACTGRP1 Selects setting group 1 as active

ACTGRP2 Selects setting group 2 as active

ACTGRP3 Selects setting group 3 as active

ACTGRP4 Selects setting group 4 as active

Signal Description

GRP1 Setting group 1 is active

GRP2 Setting group 2 is active

GRP3 Setting group 3 is active

GRP4 Setting group 4 is active

-

8/9/2019 ABB REL 511 Technical Reference Manual

36/272

26

Setting lockout (HMI) Chapter 3

Common functions

3 Setting lockout (HMI)

3.1 Application

Unpermitted or uncoordinated changes by unauthorized personnel

may cause severedamage to primary and secondary power circuits. Use the setting

lockout function toprevent unauthorized setting changes and to control when setting

changes are allowed.By adding a key switch connected to a binary input a simple

setting change control cir-cuit can be built simply allowing only authorized keyholders to

make setting changesfrom the built-in HMI.

3.2 Function block

3.3 Logic diagram

Figure 6: Connection and logic diagram for the BLOCKSET

functionxx00000154.vsd

SETTING RESTRICTION

BLOCKSET

SettingRestrict=BlockRESTRICT

SETTINGS

HMI—BLOCKSET

&SWITCH

WITH KEY

+

Rex 5xx

en01000152.vsd

-

8/9/2019 ABB REL 511 Technical Reference Manual

37/272

27

Setting lockout (HMI) Chapter 3

Common functions

3.4 Input and output signals

Table 22: Input signals for the SETTING RESTRICTION function

block3.5 Setting parameters

Table 23: Setting parameters for the setting lockout

functionSignal Description

BLOCKSET Input signal to block setting and/or configuration

changesfrom the local HMI. WARNING: Read the instructions

beforeuse. Default configuration to NONE-NOSIGNAL.

Parameter Range Default Unit Description

SettingRestrict Open,Block

Open — Open: Setting parameters can bechanged.

Block: Setting parameters can only

be changed if the logic state of the

BLOCKSET input is zero.

-

8/9/2019 ABB REL 511 Technical Reference Manual

38/272

28

I/O system configurator (IOP) Chapter 3

Common functions

4 I/O system configurator (IOP)

4.1 Application

The I/O system configurator must be used in order for the

terminal’s software to recog-nize added modules and to create internal address mappings

between modules and pro-tections and other functions.

4.2 Logic diagram

Figure 7: Example of an I/O-configuration in the graphical tool

CAP 531 for a REx 5xxwith two BIMs.

IOP1-

S11

S14

S15

S16

S17

S18

S13

S12

S19

S20

S21

S23

S22

I/OPosition

S24

S25

S26

S27

S28

S30

S32

S34

S36

IO01-

IO02-

I/O-module

I/O-module

POSITION ERROR

BI1

BI6

.

.

.

POSITION ERROR

BI1

BI6

.

.

.

en01000143.vsd

-

8/9/2019 ABB REL 511 Technical Reference Manual

39/272

29

I/O system configurator (IOP) Chapter 3

Common functions

4.3 Function block

4.4 Input and output signals

Table 24: Output signals for the I/OPOSITION (IOPn-) function

blockxx00000238.vsd

IOP1-

I/OPOSITION

S11

S12

S13

S14

S15

S16

S17

S18

S19

S20

S21

S22

S23

S24

S25

S26

S27S28

S29

S30

S31

S32

S33

S34

S35

S36

Signal Description

Snn Slot position nn (nn=11-39)

-

8/9/2019 ABB REL 511 Technical Reference Manual

40/272

30

Self supervision (INT) Chapter 3

Common functions

5 Self supervision (INT)

5.1 Application

Use the local HMI, SMS or SCS system to view the status of the

self-supervision func-tion. The self-supervision operates continuously and

includes:• Normal micro-processor watchdog function

• Checking of digitized measuring signals

• Checksum verification of PROM contents and all types of signal

communication5.2 Function block

xx00000169.vsd

INT—

INTERNSIGNALS

FAIL

WARNING

CPUFAIL

CPUWARN

ADC

SETCHGD

-

8/9/2019 ABB REL 511 Technical Reference Manual

41/272

31

Self supervision (INT) Chapter 3

Common functions

5.3 Logic diagram

Figure 8: Hardware self-supervision, potential-free alarm

contact.Power supply fault

WatchdogTX overflowMaster resp.Supply fault

ReBoot I/O

Checksum fault

Sending reports

DSP fault

Supply faultParameter check

Power supplymodule

I/O nodes

A/D conv.module

Main CPU

&

Fault

Fault

Fault

Fault

INTERNALFAIL

I/O nodes = BIM, BOM, IOM PSM, MIM or DCMDSP = Digital

Signal Processorxxxx = Inverted signal99000034.vsd

-

8/9/2019 ABB REL 511 Technical Reference Manual

42/272

32

Self supervision (INT) Chapter 3

Common functions

Figure 9: Software self-supervision, function block INTernal

signalsChecksum

Node reports

Synch error

NO RX Data

NO TX Clock

Check RemError

&

>1

>1

INT—ADC

Send Rem Error

OK

OK

>1TIME-RTCERR INT—CPUWARN

>1

TIME-SYNCERR

RTC-WARNING

INT—CPUWARN

INT—WARNING

Watchdog

Check CRC

RAM check

DSP Modules, 1-12

OK

OK

OK&

OKINT—CPUFAIL

Parameter check

Watchdog

Flow control

&

OK

OK

OK&

>1

INT—CPUFAIL

INT—ADC

I/O node FAILINT—FAIL

Start-up self-test Fault

MainCPU

Remoteterminal

communication

A/D Converter

Module

RTC-WARNING = DIFL-COMFAIL or RTC1-COMFAIL +

RTC2-COMFAIL

I/O node = BIM, BOM, IOM, PSM, MIM, DCM (described in the

hardware design)99000035.vsd

>1

RTC-WARNING

-

8/9/2019 ABB REL 511 Technical Reference Manual

43/272

33

Self supervision (INT) Chapter 3

Common functions

5.4 Input and output signals

Table 25: Output signals for the INTERNSIGNALS (INT—) function

block5.5 Technical data

Table 26: Internal event list

Signal Description

FAIL Internal fail status

WARNING Internal warning status

CPUFAIL CPU module fail status

CPUWARN CPU module warning status

ADC A/D-converter error

SETCHGD Setting changed

Data Value

Recording manner Continuous, event controlled

List size 40 events, first in-first out

-

8/9/2019 ABB REL 511 Technical Reference Manual

44/272

34

Logic function blocks Chapter 3

Common functions

6 Logic function blocks

6.1 Application

The user can with the available logic function blocks build

logic functions and config-ure the terminal to meet application specific requirements.

Different protection, control, and monitoring functions within

the REx 5xx terminalsare quite independent as far as their configuration in the

terminal is concerned. The usercan not change the basic algorithms for different functions. But

these functions com-bined with the logic function blocks can be used to create

application specific function-ality.

6.2 Inverter function block (INV)

The inverter function block INV has one input and one output,

where the output is ininverse ratio to the input.

Table 27: Input signals for the INV (IVnn-) function block

Table 28: Output signals for the INV (IVnn-) function block

6.3 OR function block (OR)

The OR function is used to form general combinatory expressions

with boolean vari-ables. The OR function block has six inputs and two outputs. One

of the outputs is in-verted.

Signal Description

INPUT Logic INV-Input to INV gate

Signal Description

Out Logic INV-Output from INV gate

xx00000158.vsd

IV01-

INV

INPUT OUT

-

8/9/2019 ABB REL 511 Technical Reference Manual

45/272

35

Logic function blocks Chapter 3

Common functions

Table 29: Input signals for the OR (Onnn-) function block

Table 30: Output signals for the OR (Onnn-) function block

6.4 AND function block (AND)

The AND function is used to form general combinatory expressions

with boolean vari-ables.The AND function block has four inputs and two outputs.

One of the inputs andone of the outputs are inverted.

Signal Description

INPUT1 Input 1 to OR gate

INPUT2 Input 2 to OR gate

INPUT3 Input 3 to OR gate

INPUT4 Input 4 to OR gate

INPUT5 Input 5 to OR gate

INPUT6 Input 6 to OR gate

Signal Description

OUT Output from OR gate

NOUT Inverted output from OR gate

xx00000159.vsd

O001-

OR

INPUT1

INPUT2

INPUT3

INPUT4

INPUT5

INPUT6

OUT

NOUT

xx00000160.vsd

A001-

AND

INPUT1

INPUT2INPUT3

INPUT4N

OUT

NOUT

-

8/9/2019 ABB REL 511 Technical Reference Manual

46/272

36

Logic function blocks Chapter 3

Common functions

Table 31: Input signals for the AND (Annn-) function block

Table 32: Output signals for the AND (Annn-) function block

6.5 Timer function block (TM)

The function block TM timer has drop-out and pick-up delayed

outputs related to theinput signal. The timer has a settable time delay (parameter T)

between 0.000 and60.000 s in steps of 0.001 s.

Table 33: Input signals for the TIMER (TMnn-) function block

Table 34: Output signals for the TIMER (TMnn-) function

blockSignal Description

INPUT1 Input 1 to AND gate

INPUT2 Input 2 to AND gate

INPUT3 Input 3 to AND gate

INPUT4N Input 4 (inverted) to AND gate

Signal Description

OUT Output from AND gate

NOUT Inverted output from AND gate

Signal Description

INPUT Input to timer

T Time value. See setting parameters

Signal Description

OFF Output from timer, drop-out delayed

ON Output from timer , pick-up delayed

xx00000161.vsd

TM01-

TIMER

INPUTT

OFFON

-

8/9/2019 ABB REL 511 Technical Reference Manual

47/272

37

Logic function blocks Chapter 3

Common functions

6.5.1 Setting parameters

Table 35: Setting parameters for the Timer (TMnn-) function

6.6 Timer long function block (TL)

The function block TL timer with extended maximum time delay at

pick-up and at drop-out, is identical with the TM timer. The difference is the

longer time delay, settable be-tween 0.0 and 90000.0 s in steps of 0.1 s

Table 36: Input signals for the TIMERLONG (TLnn-) function

blockTable 37: Output signals for the TIMERLONG (TLnn-) function

block6.6.1 Setting parameters

Table 38: Setting parameters for the TimerLong (TLnn-)

functionParameter Range Default Unit Description

T 0.000-

60.000

Step: 0.001

0.000 s Delay for timer nn

Signal Description

INPUT Input to long timer

T Time value. See setting parameters

Signal Description

OFF Output from long timer, drop-out delayed

ON Output from long timer, pick-up delayed

xx00000162.vsd

TL01-

TIMERLONG

INPUT

T

OFF

ON

Parameter Range Default Unit Description

T 0.0-90000.0

Step:0.1

0.0 s Delay for TLnn function

-

8/9/2019 ABB REL 511 Technical Reference Manual

48/272

38

Logic function blocks Chapter 3

Common functions

6.7 Pulse timer function block (TP)

The pulse function can be used, for example, for pulse

extensions or limiting of opera-tion of outputs. The pulse timer TP has a settable length of a

pulse between 0.000 s and60.000 s in steps of 0.010 s.Table 39: Input signals for the TP (TPnn-) function block

Table 40: Output signals for the TP (TPnn-) function block

6.7.1 Setting parameters

Table 41: Setting parameters for the Pulse (TPnn-) function

6.8 Extended length pulse function block (TQ)

The function block TQ pulse timer with extended maximum pulse

length, is identicalwith the TP pulse timer. The difference is the longer pulse

length, settable between 0.0and 90000.0 s in steps of 0.1 s.

Signal Description

INPUT Input to pulse timer

T Pulse length. See setting parameters

Signal Description

OUT Output from pulse timer

xx00000163.vsd

TP01-

PULSE

INPUT

T

OUT

Parameter Range Default Unit Description

T 0.000-

60.000

Step:0.010

0.010 s Pulse length

-

8/9/2019 ABB REL 511 Technical Reference Manual

49/272

39

Logic function blocks Chapter 3

Common functions

Table 42: Input signals for the PULSELONG (TQnn-) function

blockTable 43: Output signals for the PULSELONG (TQnn-) function

block6.8.1 Setting parameters

Table 44: Setting parameters for the PulseLong (TQnn-)

function6.9 Exclusive OR function block (XO)

The exclusive OR function XOR is used to generate combinatory

expressions withboolean variables. The function block XOR has two inputs and two

outputs. One of theoutputs is inverted. The output signal is 1 if the input signals

are different and 0 if theyare equal.

Signal Description

INPUT Input to pulse long timer

T Pulse length. See setting parameters

Signal Description

OUT Output from pulse long timer

xx00000164.vsd

TQ01-

PULSELONG

INPUT

T

OUT

Parameter Range Default Unit Description

T 0.0-90000.0

Step: 0.1

0.0 s Pulse length

xx00000165.vsd

XO01-

XOR

INPUT1

INPUT2

OUT

NOUT

-

8/9/2019 ABB REL 511 Technical Reference Manual

50/272

40

Logic function blocks Chapter 3

Common functions

Table 45: Input signals for the XOR (XOnn-) function block

Table 46: Output signals for the XOR (XOnn-) function block

6.10 Set-reset function block (SR)

The Set-Reset (SR) function is a flip-flop that can set or reset

an output from two inputsrespectively. Each SR function block has two outputs, where one

is inverted.Table 47: Input signals for the SR (SRnn-) function block

Table 48: Output signals for the SR (SRnn-) function block

Signal Description

INPUT1 Input 1 to XOR gate

INPUT2 Input 2 to XOR gate

Signal Description

OUT Output from XOR gate

NOUT Inverted output from XOR gate

Signal Description

SET Input to SR flip-flop

RESET Input to SR flip-flop

Signal Description

OUT Output from SR flip-flop

NOUT Inverted output from SR flip-flop

xx00000166.vsd

SR01-

SR

SET

RESET

OUT

NOUT

-

8/9/2019 ABB REL 511 Technical Reference Manual

51/272

41

Logic function blocks Chapter 3

Common functions

6.11 Set-reset with memory function block (SM)

The Set-Reset function SM is a flip-flop with memory that can

set or reset an outputfrom two inputs respectively. Each SM function block has two

outputs, where one isinverted. The memory setting controls if the

flip-flop after a power interruption will re-turn the state it had before or if it will be reset.

Table 49: Input signals for the SRM (SMnn-) function block

Table 50: Output signals for the SRM (SMnn-) function block

Table 51: Setting parameters for the SRM (SMnn-) function

6.12 Controllable gate function block (GT)

The GT function block is used for controlling if a signal should

be able to pass from theinput to the output or not depending on a setting.

Signal Description

SET Input to SRM flip-flop

RESET Input to SRM flip-flop

Signal Description

OUT Output from SRM flip-flop

NOUT Inverted output from SRM flip-flop

Parameter Range Default Unit Description

Memory Off/On Off — Operating mode of the memory

function

xx00000382.vsd

SM01-

SRM

SET

RESET

OUT

NOUT

xx00000380.vsd

GT01-

GT

INPUT OUT

-

8/9/2019 ABB REL 511 Technical Reference Manual

52/272

42

Logic function blocks Chapter 3

Common functions

Table 52: Input signals for the GT (GTnn-) function block

Table 53: Output signals for the GT (GTnn-) function block

6.12.1 Setting parameters

Table 54: Setting parameters for the GT (GTnn-) function

6.13 Settable timer function block (TS)

The function block TS timer has outputs for delayed input signal

at drop-out and atpick-up. The timer has a settable time delay between 0.00 and

60.00 s in steps of 0.01 s.It also has an Operation setting On, Off that controls the

operation of the timer.Table 55: Input signals for the TS (TSnn-) function block

Table 56: Output signals for the TS (TSnn-) function block

Signal Description

INPUT Input to gate

Signal Description

Out Output from gate

Parameter Range Default Unit Description

Operation Off/On Off — Operating mode for GTn function

Signal Description

INPUT Input to timer

Signal Description

ON Output from timer, pick-up delayed

OFF Output from timer, drop-out delayed

xx00000381.vsd

TS01-

TS

INPUT ON

OFF

-

8/9/2019 ABB REL 511 Technical Reference Manual

53/272

43

Logic function blocks Chapter 3

Common functions

6.13.1 Setting parameters

Table 57: Setting parameters for the TS (TSn-) function

6.14 Technical data

Table 58: Available logic function blocks

Parameter Range Default Unit Description

Operation Off/On Off — Operating mode for TSn function

T 0.00-60.00

Step: 0.01

0.00 s Delay for settable timer n

Update rate Block Availability

6 ms AND 30 gates

OR 60 gates

INV 20 inverters

TM 10 timers

TP 10 pulse timers

SM 5 flip-flops

GT 5 gates

TS 5 timers

200 ms TL 10 timers

TQ 10 pulse timers

SR 5 flip-flops

XOR 39 gates

-

8/9/2019 ABB REL 511 Technical Reference Manual

54/272

44

Blocking of signals during test Chapter 3

Common functions

7 Blocking of signals during test

7.1 Application

The protection and control terminals have a complex

configuration with many includedfunctions. To make the testing procedure easier, the terminals

include the feature to in-dividually block a single, several or all functions.

This means that it is possible to see when a function is

activated or trips. It also enablesthe user to follow the operation of several related functions to

check correct functional-ity and to check parts of the configuration etc.

7.2 Function block

7.3 Input and output signals

Table 59: Input signals for the Test (TEST-) function block

Table 60: Output signals for the Test (TEST-) function block

TEST-

TEST

INPUT ACTIVE

en01000074.vsd

Signal Description

INPUT Sets terminal in test mode when active

Signal Description

ACTIVE Terminal in test mode

-

8/9/2019 ABB REL 511 Technical Reference Manual

55/272

45

About this chapter Chapter 4

Line impedance

Chapter 4 Line impedance

About this chapter

This chapter describes the line impedance functions in the

terminal. -

8/9/2019 ABB REL 511 Technical Reference Manual

56/272

46

Distance protection (ZM) Chapter 4

Line impedance

1 Distance protection (ZM)

1.1 Application

The ZM distance protection function provides fast and reliable

protection for overheadlines and power cables in all kinds of power networks. For each

independent distanceprotection zone, full scheme design provides continuous

measurement of impedanceseparately in three independent phase-to-phase measuring loops

as well as in three in-dependent phase-to-earth measuring loops.

Phase-to-phase distance protection is suitable as a basic

protection function againsttwo- and three-phase faults in all kinds of networks, regardless

of the treatment of theneutral point. Independent setting of the reach in the reactive

and the resistive directionfor each zone separately, makes it possible to create fast and

selective short circuit pro-tection in power systems.

Phase-to-earth distance protection serves as basic earth fault

protection in networkswith directly or low impedance earthed networks. Together with

an independent phasepreference logic, it also serves as selective protection

function at cross-country faults inisolated or resonantly earthed networks.

Independent reactive reach setting for phase-to-phase and for

phase-to-earth measure-ment secures high selectivity in networks with different

protective relays used for short-circuit and earth-fault protection.

R

jX

Rph-eRph-ph

Xph-e

Xph-ph

Zline

98000062.vmf

-

8/9/2019 ABB REL 511 Technical Reference Manual

57/272

47

Distance protection (ZM) Chapter 4

Line impedance

Figure 10: Schematic presentation of the operating

characteristic for one distance pro-tection zone in forward direction

Distance protection with simplified setting parameters is

available on request. It usesthe same algorithm as the basic distance protection function.

Simplified setting param-eters reduce the complexity of necessary setting procedures and

make the operatingcharacteristic automatically more adjusted to the needs in

combined networks.Where:

Xph-e = reactive reach for ph-e faults

Xph-ph = reactive reach for ph-ph faults

Rph-e = resistive reach for ph-e faults

Rph-ph = resistive reach for ph-ph faults

Zline = line impedance

R

xx00000713.vsd

jX

RFPERFPP

X

Zline

-

8/9/2019 ABB REL 511 Technical Reference Manual

58/272

48

Distance protection (ZM) Chapter 4

Line impedance

Figure 11: Schematic presentation of the operating

characteristic for one distance pro-tection zone in forward direction with simplified setting

parametersThe distance protection zones can operate, independently of each

other, in directional(forward or reverse) or non-directional mode. This makes it

suitable, together with dif-ferent communication schemes, for the

protection of power lines and cables in complexnetwork configurations, such as double-circuit, parallel lines,

multiterminal lines, etc.Zone 1, 2 and 3 can issue phase selective signals, such as start

and trip.The additional distance protection zones four and five have the

same basic functionalityas zone 1-3, but lack the possibility of issuing phase selective

output signals.Distance protection zone 5 has shorter operating time than other

zones, but also highertransient overreach. It should generally be used as a check zone

together with the SOTFswitch onto fault function or as a time delayed zone with time

delay set longer than100ms.

Basic distance protection function is generally suitable for use

in non-compensated net-works. A special addition to the basic functions is available

optionally for use on seriescompensated and adjacent lines where voltage reversals might

disturb the correct direc-tional discrimination of a basic distance protection.

1.2 Functionality

Separate digital signal processors calculate the impedance as

seen for different measur-ing loops in different distance protection zones. The results

are updated each millisec-ond, separately for all measuring loops and each distance

protection zone. Measurementof the impedance for each loop follows the differential

equation, which considers com-plete line replica impedance, as presented schematically in

figure 12.Where:

X = reactive reach for all kinds of faults

RFPP = resistive reach for phase-to-phase faults

RFPE = resistive reach for phase-to-earth faults

Zline = line impedance

u t( ) R l Rf+( ) i t( )Xlω——

∆i t( )∆t

————⋅+⋅=

-

8/9/2019 ABB REL 511 Technical Reference Manual

59/272

49

Distance protection (ZM) Chapter 4

Line impedance

Figure 12: Schematic presentation of impedance measuring

principle.Settings of all line parameters, such as positive sequence

resistance and reactance aswell as zero-sequence resistance and

reactance, together with expected fault resistancefor phase-to-phase and phase-to-earth faults, are independent

for each zone. The oper-ating characteristic is thus automatically adjusted to the line

characteristic angle, if thesimplified operating characteristic has not been especially

requested. The earth-returncompensation factor for the earth-fault measurement is

calculated automatically by theterminal itself.

Voltage polarization for directional measurement uses continuous

calculation and up-dating of the positive sequence voltage for each measuring loop

separately. This securescorrect directionality of the protection at different evolving

faults within the complexnetwork configurations. A memory retaining the pre-fault

positive-sequence voltage se-cures reliable directional operation

at close-up three-phase faults.Where:

Rl = line resistance

Rf = fault resistance

Xl = line reactance

ω 2πf

f = frequency

Rl

jXl

Rfu(t)

i(t)

98000063.vmf

-

8/9/2019 ABB REL 511 Technical Reference Manual

60/272

50

Distance protection (ZM) Chapter 4

Line impedance

The distance protection function blocks are independent of each

other for each zone.Each function block comprises a number of different functional

inputs and outputs,which are freely configurable to different external functions,

logic gates, timers and bi-nary inputs and outputs. This makes it possible to influence the

operation of the com-plete measuring zone or only its tripping

function by the operation of fuse-failurefunction, power swing detection function, etc.

1.3 Function block, zone 1- 3

Figure 13: ZM1 function block for single, two and/or three phase

trippingFigure 14: ZM1 function block for three phase tripping

Figure 15: ZM2 function block for single, two and/or three phase

trippingxx00000173.vsd

ZM1—

ZM1

BLOCK

BLKTR

VTSZ

STCND

TRIP

TRL1

TRL2

TRL3

START

STL1

STL2

STL3

STND

xx00000702.vsd

ZM1—

ZM1

BLOCK

BLKTR

VTSZ

STCND

TRIP

START

STND

xx00000174.vsd

ZM2—

ZM2

BLOCK

BLKTR

VTSZ

STCND

TRIP

TRL1

TRL2

TRL3

START

STL1

STL2

STL3STND

-

8/9/2019 ABB REL 511 Technical Reference Manual

61/272

51

Distance protection (ZM) Chapter 4

Line impedance

Figure 16: ZM2 function block for three phase tripping

Figure 17: ZM3 function block for single, two and/or three phase

trippingFigure 18: ZM3 function block for three phase tripping

1.4 Function block, zone 4

Figure 19: ZM4 function block

xx00000703.vsd

ZM2—

ZM2

BLOCK

BLKTRVTSZ

STCND

TRIP

STARTSTND

xx00000175.vsd

ZM3—

ZM3

BLOCK

BLKTR

VTSZ

STCND

TRIP

TRL1

TRL2

TRL3

START

STL1STL2

STL3

STND

xx00000704.vsd

ZM3—

ZM3

BLOCK

BLKTR

VTSZ

STCND

TRIP

START

STND

xx00000176.vsd

ZM4—

ZM4

BLOCK

BLKTR

VTSZ

STCND

TRIP

START

STND

-

8/9/2019 ABB REL 511 Technical Reference Manual

62/272

52

Distance protection (ZM) Chapter 4

Line impedance

1.5 Function block, zone 5

Figure 20: ZM5 function block

1.6 Logic diagram

Figure 21: Conditioning by a group functional input signal

ZM1—STCNDxx00000177.vsd

ZM5—ZM5

BLOCK

BLKTR

VTSZ

STCND

TRIP

START

STND

99000557.vsd

ZM1L1L2

ZM1L2L3

ZM1L3L1

&

&

&

&

&

&

ZM1L1N

ZM1L2N

ZM1L3N

ZM1—STCND

STNDL1L2-cont.

STNDL2L3-cont.

STNDL3L1-cont.

STNDL1N-cont.

STNDL2N-cont.

STNDL3N-cont.

STZMPP-cont.

STNDPE-cont.

&ZM1—BLOCK

ZM1—VTSZ ZM1—STND

BLK-cont.

>1

>1

>1

>1

-

8/9/2019 ABB REL 511 Technical Reference Manual

63/272

53

Distance protection (ZM) Chapter 4

Line impedance

Figure 22: Composition of starting signals in non-directional

operating modeen00000488.vsd

STNDL1N-cont.

STNDL2N-cont.

STNDL3N-cont.

STNDL1L2-cont.

STNDL2L3-cont.

STNDL3L1-cont.

>1

>1

>1

>1

&

&

&

&

BLK-cont.

t15 ms

t15 ms

t15 ms

t15 ms

ZM1—START

ZM1—STL3

ZM1—STL2

ZM1—STL1

-

8/9/2019 ABB REL 511 Technical Reference Manual

64/272

54

Distance protection (ZM) Chapter 4

Line impedance

Figure 23: Composition of starting signals in directional

operating modeen00000489.vsd

STNDL1N-cont.

DIRL1N &

&

STNDL2N-cont.

DIRL2N

&

STNDL3N-cont.

DIRL3N

&STNDL1L2-cont.

DIRL1L2

&

STNDL2L3-cont.

DIRL2L3

&STNDL3L1-cont.

DIRL3L1

>1

>1

>1

>1

>1

&g

Page 1

Page 2

94

АНАЛИТИКА

СЕТИ РОССИИ

94

р

е

л

е

й

н

а

я

з

а

щ

и

т

а

и

а

в

т

о

м

а

т

и

к

а

релейная защит

а и автома

тика

ТЕРМИНАЛЫ

СЕРИИ

«REL-511»

В

микропроцессорных

терминалах

«REL-

511»

при

возникновении

неисправности

цепей

переменного

напряжения

«

звезды

»

срабатыва

—

ет

функция

контроля

исправности

цепей

пере

—

менного

напряжения

(FUSE).

При

этом

она

бло

—

кирует

срабатывание

всех

зон

ДЗ

и

их

пуски

.

В

таком

случае

возможен

отказ

функции

ДЗ

при

возникновении

КЗ

на

ЛЭП

.

Для

отключения

междуфазных

КЗ

на

ЛЭП

,

возникающих

при

наличии

неисправности

це

—

пей

переменного

напряжения

«

звезды

»

и

,

как

следствие

,

при

заблокированной

функции

ДЗ

,

по

факту

срабатывания

функции

FUSE

автома

—

тически

вводится

резервная

МТЗ

,

выполненная

при

помощи

функции

максимальной

токовой

за

—

щиты

(

рис

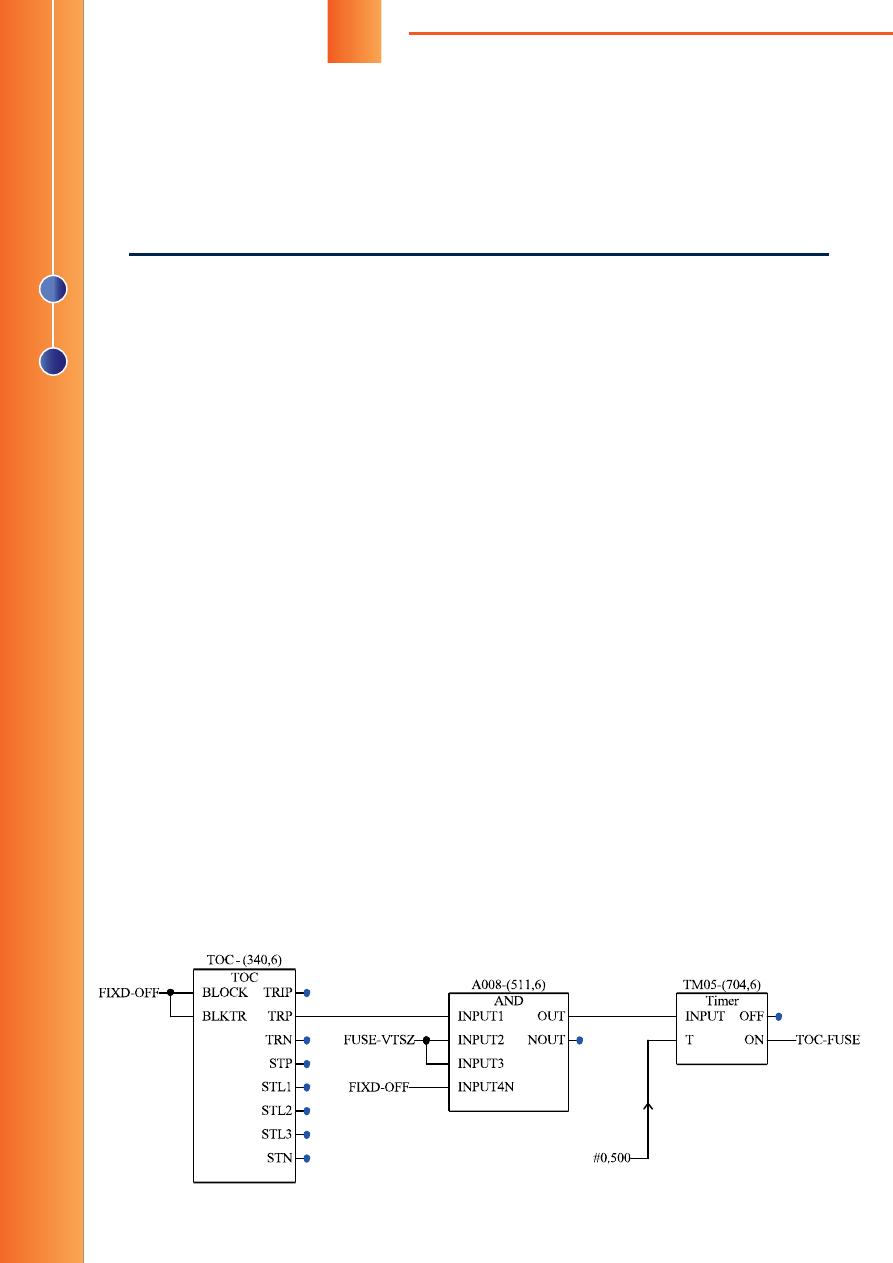

. 1).

Направленность

ТЗНП

реализована

по

сдви

—

гу

вектора

тока

нулевой

последовательности

3Io

относительно

виртуального

вектора

IN>DIR,

строящегося

программно

и

отстающего

от

векто

—

ра

напряжения

нулевой

последовательности

-U4

на

угол

65° (

задаётся

уставкой

функции

ТЗНП

),

подводимого

от

цепей

напряжения

разомкнуто

—

го

треугольника

ТН

(«

Н

», «

К

»).

Если

проекция

Рис

. 1.

Резервная

МТЗ

для

терминала

«REL-511»

FUSE-VTSZ —

сигнал

неисправности

цепей

переменного

напряжения

«

звезды

»

Работа терминалов «REL-511» и

«REL-670» при неисправности

цепей переменного напряжения

При возникновении неисправности во вторичных цепях переменного напря-

жения, используемых функциями направленной токовой защиты нулевой по-

следовательности (ТЗНП) и дистанционной защиты (ДЗ) в микропроцессорных

терминалах серий «REL-511» и «REL-670» производства ООО «АББ Силовые Ав-