Настройка уровнемера достаточно кропотливое занятие. Существует очень много видов уровнемеров, а так же их производителей. Для их настройки используются различные программы а так же способы их подключения к ноубуку. С каждым прибором идет инструкция по настройке прибора. Но используя только инструкцию по настройке, сложно правильно настроить прибор. На данной странице предлагаю рассмотреть настройку уровнемера Rosemount5300 в том числе с разделом фаз. Как подключиться к прибору с помощью программы PACTware можно посмотреть на странице на странице «Насторйка приборов программой PACTware». На данной странице рассмотрим вариант подключения уровнемера с протоколом связи Foundation fieldbus.

- Как установить программу Radar Master.

- Как подключиться к прибору по протоколу Foundadation Fieldbas.

- Проверка и сохранение настроек уровнемера.

- Виды резервуаров.

- Как замерить уровень и раздел фаз в резервуаре электронной рулеткой.

- Как замерить уровень и раздел фаз в резервуаре механической рулеткой.

- Внесение измеренных значений уровня в программу Radar Master

- Определение уровня в резервуаре по эхосигналу уровнемера.

- Возможные причины некорректных показаний уровнемера.

Скачать программу Radar Master для настойки уровнемеров бесплатно не получиться. Данная программа поставляется на CD диске вместе с уровнемером. При желании можно купить программу на сайте разработчика. Сколько стоит, не знаю. Для получения информации необходимо отправить запрос, заполнив свои данные. При установке программы по протоколу HART у вас должен быть установлен драйвер на имеющийся у вас модем. Как установить драйвер на HART-модем можно посмотреть на странице «Настройка приборов программой PACTware». Каких либо проблем при установке программы Radar Master не возникает. Для подключения по протоколу Foundadation Fieldbas (далее FF) необходимо иметь Модем USB полевой шины Fieldbus . Например производителя Emerson. Модем поставляется вместе с программным обеспечением. Подробная инструкция по установке программы и подключения к прибору имеется в инструкции по эксплуатации.

2. Как подключиться к прибору по протоколу Foundadation Fieldbas

В инструкции по эксплуатации на модем FF имеется рисунок подключения ноутбука к прибору.

При подключении к прибору в лабораторных условиях данная схема конечно применима. Предлагаемая схема подключения в полевых условиях предполагает подключение прибора к ноутбуку в полевых условиях, что не всегда возможно. По требованиям безопасности, ноутбук при использовании во взрывоопасной зоне должен быть взрывобезопасного исполнения. Не всегда удобно носить ноутбук в «поле», особенно в непогоду, или мороз. При настройке прибора может выключиться питание ноутбука от батареи, и прибор может уйти «в ошибку». Потеряются показания прибора. Т.к. обычно для настройки прибора оперативным персоналом выделяется очень небольшой промежуток времени, то длительное отсутствие показаний может повлечь за собой нарушение технологического процесса. Для возможности настройки прибора и контроля его работы в течение длительного времени я подключаю FF-модем в кроссовом шкафу. Прежде чем производить какие либо действия с любым прибором по протоколу FF как обычно необходимо все свои действия согласовать с оперативным персоналом. Прибор обязательно должен быть выведен в «сервисный режим». Т.е. инженер АСУ ТП должен программно перевести в режим «Out of Service». При подключении в «рабочем режиме» «Auto» к прибору может произойти программный сбой, и могут потеряться показания («зависнуть») всех приборов одного «сигмента FF».

В кросовом шкафу находим провода полевой шины сигмента, к которым подключен прибор. Подключаем параллельно FF-модем. Для FF-протокола «полярность» значения не имеет. Запускаем программу Radar Master.

Для подключения к уровнемеру при запуске программы выбираем вид протокола связи Foundadation Fieldbas

Запускается программа. Открывается окно настройки уровнемера. Производим поиск приборов. В окошке «Список приборов» будет отображаться список приборов подключенных к программе приборов.

Выбираем необходимый нам прибор. Подключаем его

Заходим в меню «Общие настройки». Проверяем, переведен ли прибор в режим «Out of Service». Если блок находиться в режиме «Auto», переводим в режим «Out of Service».

3.Проверка и сохранение настроек уровнемера.

Нажимая кнопку «Прочитать» считываем настройки прибора.

Конфигурацию прибора сохраняем в отдельной папке.

Запускаем мастер настройки прибора. Кнопкой «Вперед» просматриваем и сохраняем для себя все настройки прибора.

Заходим в меню настройки резервуара. Считываем их. Данные сохраняем. Обычно все настройки я сохраняю в виде скриншотов в отдельной папке, созданной для данного уровнемера.

В данной вкладке есть меню «Условия работы». Необходимо проверить, правильно выставлен диапазон диэлектрической проницаемости среды.

4.Виды резервуаров

Самое сложное возникает с настройкой параметров резервуара. Для правильной настройки необходимо правильно провести замер базовой высоты резервуара, уровня жидкости, уровня раздела фаз. Конечно же, эти замеры не производят специалисты КИПиА. Обычно эти замеры проводит технологический персонал, с соблюдением всех мер безопасности. Но для уверенности в правильности замеров зачастую приходиться лично присутствовать при замерах. При коммерческих учетах измерение уровня в резервуаре проводят после отстоя нефти продолжительностью не менее двух часов с момента окончания заполнения. Резервуары бывают разного типа.

- РВС- резервуар вертикальный стальной со стационарной крышей без понтона;

- РВСП- резервуар вертикальный стальной со стационарной крышей с понтоном;

- РВСПК — резервуар вертикальный стальной с плавающей крышей;

Всем кому интересно более подробное устройство резервуаров могут ознакомиться с их устройством в ГОСТ 31385-2016 «РЕЗЕРВУАРЫ ВЕРТИКАЛЬНЫЕ ЦИЛИНДРИЧЕСКИЕ СТАЛЬНЫЕ ДЛЯ НЕФТИ И НЕФТЕПРОДУКТОВ». Нас интересуют данные, которые необходимо внести в уровнемер. Технология замеров уровня в резервуарах так же разная. Рассмотрим вариант измерения уровня в стальном цилиндрическом резервуаре с разделом фаз вода/нефтепродукты.

5.Как замерить уровень и раздел фаз в резервуаре электронной рулеткой

Возможно провести измерения уровня и уровня раздела фаз в резервуаре, электронной измерительной рулеткой — например «HERMetic Gtex 2000».

Электронная рулетка применяется для проведения измерений уровня в резервуарах, без контакта работника, с измеряемой средой. Рулетка имеет быстросъемное соединение с патрубком, смонтированном на измерительном фланце. При проведении измерений необходимо соблюдать все меры предосторожности прописанные в инструкции по эксплуатации. До проведения замеров рулетку необходимо заземлить.

После соединения с фланцем открывается шаровый кран, и производиться замер. При соприкосновении с поверхностью жидкости изменяется звуковой сигнал издаваемый рулеткой на более короткие сигналы. При достижении электродами рулетки уровня раздела фаз, звуковой сигнал изменяется на прерывистый.

Более подробно порядок проведения измерения электронной рулеткой можете почитать в инструкции по эксплуатации по ссылке. При измерении электронной рулеткой следует учитывать длину всех монтажных элементов до отметки базовой высоты резервуара. До начала измерения, при полностью смотанной на катушку ленте, показания измерительной рулетки уже будут 474 мм.

К этому значению необходимо прибавить значение равному Ln от ответного измерительного фланца рулетки до базовой высоты резервуара (обычно это край фланца измерительного люка). Сумма двух значений будет составлять величину Lnr. Эту величину вычитаем от показаний рулетки до уровня D1 в резервуаре и до уровня раздела фаз D2.

Получаем 2 значения. D1- дистанция от базовой высоты до уровня в резервуаре. D2- дистанция от базовой высоты до уровня раздела фаз. Вычитая эти значения от базовой высоты Lб получим значения уровня жидкости в резервуаре L1и уровень раздела фаз L2. Базовую высоту придется брать из паспорта резервуара.

Очень редко бывает так, что фланец измерительного люка и фланец, на котором размещен уровнемер, находятся на одном уровне. Для каждого патрубка на резервуаре в паспорте указывается разница по высоте между базовой высотой Lб и высотой расположения патрубка уровнемера d1 и d2.

Прибавляя значения d1 и d2 к базовой высоте резервуара мы получим значения базовой высоты для каждого уровнемера.

Останется только правильно внести все значения в соответствующие проведенным замерам, уровнемеры. В результате вычислений уровнемеры должны показывать реальные значения уровня в резервуаре. При этом разность показаний между уровнемерами должна совпадать с разностью измеренных значений рулеткой между уровнем в резервуаре L1 и уровнем раздела фаз L2. Данное значение отображается так же на мониторе АРМ оператора.

Очень удобно проводить замеры электронной рулеткой. Но иногда провести замеры электронной рулеткой не получается. На фотографии ниже вы увидите, что электроды рулетки расположенные в нижней части лота забиваются нефтепродуктами. Раздел фаз при этом определить не представляется возможным. В этом случае приходиться пользоваться обычной механической рулеткой с лотом.

6.Как замерить уровень и раздел фаз в резервуаре механической рулеткой.

При проведении замера уровня и раздела фаз в резервуаре с помощью обычной измерительной рулетки с лотом, приходиться замеры производить по другой схеме.

Рулетка с лотом так же позволяет определить раздел фаз в резервуаре. Для этого необходима водочувствительная индикаторная паста для нефтепродуктов. На участок стальной ленты, где предположительно должен находиться уровень раздела фаз наносится водочувствительная паста. Длина участка с нанесенной пастой может быть и 1 и 2 метра. Водочувствительную пасту наносят тонким слоем (0,2¸0,3) мм на поверхность лота полосками с двух противоположных сторон.

В замерных люках резервуаров, имеется специальная направляющая канавка для стальной лены рулетки. Опускать и поднимать ленту следует по этой направляющей канавке. Лот очень осторожно необходимо опустить на дно резервуара. При этом показания рулетки должны совпадать с базовой высотой в паспорте резервуара. При отклонении от паспортных данных базовой высоты, следует понимать, что в резервуаре имеются донные отложения. Разница между паспортным значением и измеренным значением будет уровнем донных отложений. При различных значениях измеренной рулеткой и паспортными данными, значений базовой высоты резервуара, необходимо ориентироваться на дистанцию от базовой высоты резервуара до уровня нефтепродуктов и уровня раздела фаз. При отсутствии донных отложений можно замерить уровень и раздел фаз прямым методом.

Поднимают ленту рулетки строго вверх, без смещения в сторону, чтобы избежать искажения линии смачивания на ленте рулетки. На ленте рулетки после появления смоченной части определяют высоту уровня жидкости в резервуаре либо дистанцию до уровня нефтепродуктов от базовой высоты.

При дальнейшем подъеме измерительной лены, необходио определить уровень раздела фаз. Нанесенная на ленте водочувствительная паста, изменит свой цвет, на уровне раздела фаз нефть/ вода. Определяем уровень воды в резервуаре, или дистанцию до уровня раздела фаз от базовой высоты. Измерение уровня в резервуаре проводят дважды. Если результаты измерений отличаются на 1 мм, то в качестве результата измерения принимается их среднее значение. Если полученное расхождение измерений более 1 мм, измерения повторяют еще дважды и берут среднее по трем наиболее близким измерениям.

При проведении замеров, необходимо соблюдать требования техники безопасности.

Останется только правильно внести измеренные показания, в данные резервуара в программе Radar Master уровнемера.

В инструкции по эксплуатации на уровнемер описано все подробно. При настройке уровнемера, инструкция по настройке у вас должна быть под рукой. Либо как минимум вы должны ее прочитать хотя бы один раз.

После внесения данных в настройки уровнемера с помощью программы Radar Master иногда могут не соответствовать показания уровнемера измеренным данным. В этом случае необходимо будет выяснить причину отклонения показаний уровнемера.

7. Внесение измеренных значений уровня в программу Radar Master

Останется только правильно внести измеренные показания, в данные резервуара в программе Radar Master уровнемера.

В инструкции по эксплуатации на уровнемер описано все подробно. При настройке уровнемера, инструкция по настройке у вас должна быть под рукой. Либо как минимум вы должны ее прочитать хотя бы один раз.

8. Определение уровня в резервуаре по эхосигналу уровнемера.

После внесения данных в настройки уровнемера с помощью программы Radar Master иногда могут не соответствовать показания уровнемера измеренным данным. В этом случае необходимо будет выяснить причину отклонения показаний уровнемера.

Рассмотрим на примере резервуара пластовой воды приведенного выше.

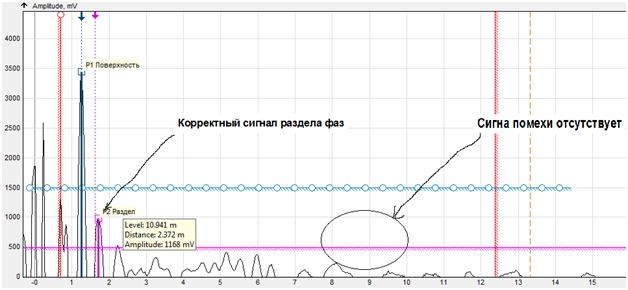

При измерении уровня взлива в резервуаре, показания уровнемера совпадают с измеренным рулеткой значением. Показания же уровнемера раздела фаз не соответствуют измеренному значению. Для выяснения причины необходимо зайти в меню «Эхосигнал». В данном меню отображается кривая эхосигнала.

Для того, что бы настроить уровнемер, нужно понять, что такое кривая эхосигнала. Попытаюсь объяснить очень примитивно. От передатчика по волноводу или по воздуху (в зависимости от излучателя) отправляется сигнал. Этот сигнал начинает отражаться от всех имеющихся на пути препятствий. Основным параметром при построении кривой, является диэлектрическая проницаемость среды. В зависимости от изменения диэлектрической проницаемости среды изменяется и величина отраженного сигнала. В итоге мы получаем кривую эхосигнала с различной амплитудой. Программа уровнемера производит вычисление уровня в резервуаре, в зависимости от внесенных в уровнемер данных и от отраженного эхосигнала. Эта программа у каждого производителя является собственной разработкой. Поэтому у различных производителей могут быть разные параметры, которые необходимо внести в программу настройки уровнемера. Но принцип отражения кривой эхосигнала практически одинаковый для всех производителей и для различных излучателей.

Поняв один раз, что отражается на кривой эхосигнала, можно всегда представить, что происходит в резервуаре (емкости). Сигнал исходит из верхней точки отсчета — Upper Reference Point. Первым препятствием для эхосигнала конечно же будет сам фланец и соединения преобразователя с зондом. Величина отраженного от фланца и соединений сигнала большая. Так же помехи для измерения создает сам патрубок, на котором смонтирован уровнемер. Поэтому отраженный от фланца сигнал отсекается программно — Distance Offset . Этот сигнал уже не учитывается при вычислении уровня. Далее следует отраженный от поверхности жидкости отраженный сигнал — Поверхность. Его амплитуда будет самая большая. Так как среда при переходе из слоя нефти в слой воды не однородная, можно увидеть на кривой эхосигнала несколько различных отраженных сигналов помех. Но в области перехода фазы нефти в фазу воды будет самый высокий отраженный сигнал – Раздел фаз. Далее на кривой эхосигнала отображаются различные сигналы помехи. Это могут быть помехи от измеряемой среды – неоднородность заполняемой в резервуар жидкости, различные налипания на зонд. Так же это могут быть помехи создаваемые самим измерительным зондом. Это могут быть повреждения тросового зонда, перемычки на двойном жестком или коаксиальном зонде и т.д.

Для понимания вида помех, вносимых самим зондом необходимо демонтировать уровнемер, хорошо промыть, почистить волновод. При подключении к уровнемеру программой Radar Master можно увидеть все сигналы помех волновода. Ниже представлена кривая эхосигнала чистого тросового волновода длиной 12350 мм. Помехи имеются. Сигнал помех не превышает значения 500 mV. Но эти помехи, говорят о том, что тросовый волновод имеет повреждения. В местах повреждений может скапливаться различные отложения. Это могут быть как нефтепродукты, так и различные солевые отложения.

Сигнал помех может значительно вырасти, и уровнемер будет искажать показания. Поэтому с волноводами надо обращаться очень бережно, не повредить их.

9. Возможные причины некорректных показаний уровнемера.

Иногда возникают ситуации, когда сигнал помех вносимых измеряемой средой, гораздо больше сигнала рздела фаз. Рассмотрим такой пример.

На резервуаре смонтированы два уровнемера. Первый уровнемер измеряет уровень взлива. Уровнемер без функции измерения раздела фаз. Он прекрасно работает. Его показания совпадают с измеренным рулеткой уровнем.

На этом же резервуаре смонтирован второй уровнемер с функцией измерения раздела фаз.

Показания уровня раздела фаз не соответствуют измеренному значению. Согласно проведенным измерениям уровень раздела фаз вода/нефть находиться в районе дистанции D2 около 5,5метра. В промежутке дистанции 9…10 метров имеется сигнал помехи большой величины. Такой же сигнал помехи можно увидеть и на первом уровнемере. Никакими рекомендованными в инструкции по настройке уровнемера, способами, отсечь данный сигнал помехи не получилось. Была ли эта помеха от внутренних конструкций резервуара, так же не представилось возможным. На данный резервуар не было паспорта.

Этот уровнемер временно был смонтирован на фланец измерительного патрубка.

Сигнал помехи на кривой эхосигнала отсутствует. Уровень раздела фаз уровнемер показывает корректно. Было принято решение смонтировать уровнемер на замерном патрубке. Вопрос некорректного показания уровня раздела фаз был решен.

Зачастую, к неправильным показаниям уровнемера приводит нарушение оперативным персоналом технологического режима. Например появление раздела фаз в емкости, где раздела фаз быть не должно.

Например, емкость для сбора серной кислоты. Используется бесконтактный радарный уровнемер. При нарушении технологического режима в емкость попадает алкилат. Появляется раздел фаз. В принципе уровнемеру должно быть все равно. Он должен показывать общий уровень. Но чем больше алкилата на поверхности серной кислоты, тем меньше уровня в емкости показывает уровнемер. Никакие попытки настроить программно правильность показаний уровнемера не дали результата. Рекомендации производителя были заменить уровнемер, на другой, с функцией раздела фаз. Так как конечно никто не купит новый уровнемер, оперативному персоналу приходилось соблюдать технологический режим. Уровнемер стал работать корректно.

Настройка уровнемеров, работающих с программой PactWare производится аналогично. Подключение уровнемеров программой PactWare описана на странице «Настройка приборов программой PactWare«.

Пишите в форуме. Делитесь опытом как решались проблемы с уровнемерами.

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

Reference Manual

00809-0100-4530, Rev DD

May 2016

™

Rosemount

5300 Series

Superior Performance Guided Wave Radar

Related Manuals for Rosemount 5300 Series

Summary of Contents for Rosemount 5300 Series

-

Page 1

Reference Manual 00809-0100-4530, Rev DD May 2016 ™ Rosemount 5300 Series Superior Performance Guided Wave Radar… -

Page 3: Table Of Contents

Reference Manual Introduction 00809-0100-4530, Rev DD May 2016 Contents 1Section 1: Introduction Using this manual …………1 Product recycling/disposal .

-

Page 4

Reference Manual Contents 00809-0100-4530, Rev DD May 2016 3.2.11 Installation and configuration considerations for ESD systems..34 Mounting …………35 3.3.1 Flange connection . -

Page 5

Basic configuration using a Field Communicator ……95 Basic configuration using Rosemount Radar Master ….. . .98 5.6.1… -

Page 6

7.3.1 Using Rosemount Radar Master ……. . . 153 7.3.2 Using the echo curve analyzer with a Field Communicator . -

Page 7

Reference Manual Introduction 00809-0100-4530, Rev DD May 2016 7.22.4 Measurement status ……… . . 188 7.22.5 Interface status. -

Page 8

Reference Manual Contents 00809-0100-4530, Rev DD May 2016 A.1.9 Ambient temperature ……… . 221 A.1.10Storage temperature. -

Page 9

Reference Manual Introduction 00809-0100-4530, Rev DD May 2016 B.4.4 Brazilian certifications ……… . 289 B.4.5 Chinese certifications . -

Page 10

Configure the AI Block ……….372 ® ® JAppendix J: Rosemount 5300 Series with HART to Modbus Converter Safety messages . -

Page 11

Troubleshooting ……….. . 407 J.13 HMC firmware upgrade in Rosemount Radar Master ….408 J.14 Specifications . -

Page 12

Reference Manual Contents 00809-0100-4530, Rev DD May 2016 Contents… -

Page 13

Title Page 00809-0100-4530, Rev DD May 2016 ™ Rosemount 5300 Series Guided Wave Radar Level and Interface Transmitters NOTICE Read this manual before working with the product. For personal and system safety, and for optimum product performance, make sure you thoroughly understand the contents before installing, using, or maintaining this product. -

Page 14

High voltage that may be present on leads could cause electrical shock. Avoid contact with leads and terminals. Make sure the main power to the Rosemount 5300 Transmitter is off and the lines to any other external power source are disconnected or not powered while wiring the gauge. -

Page 15: Using This Manual

Section 5: Configuration provides instructions on configuration of the transmitter using the ™ Field Communicator, the Rosemount Radar Master software, AMS Device Manager, and ™ DeltaV . Information on software functions and configuration parameters are also included.

-

Page 16: Product Recycling/Disposal

Appendix I: Analog-Input Block describes the operation and parameters of the analog input transducer block. Appendix J: Rosemount 5300 Series with HART® to Modbus® Converter describes the operation of the HART to Modbus Converter (HMC). Product recycling/disposal Recycling of equipment and packaging should be taken into consideration and disposed of in accordance with local and national legislation/regulations.

-

Page 17

Reference Manual Transmitter Overview 00809-0100-4530, Rev DD May 2016 Section 2 Transmitter Overview Theory of operation …………page 4 Applications . -

Page 18: Theory Of Operation

Theory of operation ™ The Rosemount 5300 Series Radar Transmitter is a smart, two-wire continuous level transmitter based on Time Domain Reflectometry (TDR) principles. Low power nano-sec- ond-pulses are guided along an immersed probe. When a pulse reaches the surface, part of…

-

Page 19: Applications

00809-0100-4530, Rev DD May 2016 Applications The Rosemount 5300 Series Radar Transmitter series is suited for aggregate (total) level measurements on most liquids, semi-liquids, solids, and liquid/liquid interfaces. Guided microwave technology offers the highest reliability and precision to ensure measurements are virtually unaffected by temperature, pressure, vapor gas mixtures, density, turbulence, bubbling/boiling, low level, varying dielectric media, pH, and viscosity.

-

Page 20

The Rosemount 5302 measures both level and interface level in a separator tank. Water The Rosemount 5300 Series is a good choice for underground tanks. It is installed on the top of the tank with the radar pulse concentrated near the probe. It… -

Page 21

It measures independently of dust, angled surfaces etc. The Rosemount 5300 Series with Dynamic Vapor Compensation will automatically compensate for dielectric changes in high pressure steam applications and maintain the level accuracy. -

Page 22: Components Of The Transmitter

May 2016 Components of the transmitter The Rosemount 5300 Series Radar Transmitter has an aluminum or stainless steel (SST) transmitter housing containing advanced electronics and software for signal processing. SST housing is preferred for harsh environment applications, such as off-shore platforms or other locations where the housing can be exposed to corrodents, such as salt solutions and caustics.

-

Page 23

Reference Manual Transmitter Overview 00809-0100-4530, Rev DD May 2016 Remote housing allows for the transmitter head to be mounted separately from the probe. Figure 2-4. Remote Housing Components A. Dual compartment housing B. Cable remote connection C. U-bolt D. Bracket E. -

Page 24: System Architecture

With the HART protocol multidrop configuration is possible. In this case, communication is restricted to digital, since current is fixed to the 4 mA minimum value. The transmitter can be connected to a Rosemount 751 Field Signal Indicator, or it can be equipped with an integral display.

-

Page 25

A. Rosemount 5300 F. PC 5300 Setup in Rosemount Radar Master B. Power G. Control System C. 475 Field Communicator H. RS-232/RS-485 Converter D. Modbus, Levelmaster Emulation/RS-485 I. PC 5300 Setup in Rosemount Radar Master via Tunneling E. HART modem Transmitter Overview… -

Page 26: Probe Selection Guide

Reference Manual Transmitter Overview 00809-0100-4530, Rev DD May 2016 Probe selection guide The following guidelines should be used to choose the appropriate probe for the Rosemount 5300 Series Transmitter: Rigid single Flexible Coaxial Rigid twin Flexible twin lead, single lead…

-

Page 27

Reference Manual Transmitter Overview 00809-0100-4530, Rev DD May 2016 Rigid single Flexible Coaxial Rigid twin Flexible twin lead, single lead lead lead segmented rigid single lead G = Good NR = Not Recommended AD = Application Dependent (consult your local Emerson Process Management representative) Turbulence… -

Page 28: Measuring Range

Reference Manual Transmitter Overview 00809-0100-4530, Rev DD May 2016 Measuring range The measuring range depends on probe type, dielectric constant of the product and installation environment, and is limited by the Blind Zones at the very top and bottom of the probe.

-

Page 29: Process Characteristics

May 2016 Process characteristics The Rosemount 5300 Series has high sensitivity because of its advanced signal processing and high signal to noise ratio. This makes it able to handle various disturbances, however, the following circumstances should be considered before mounting the transmitter.

-

Page 30: Interface

2.7.6 Interface Rosemount 5302 is the ideal choice for measuring the level of oil, and the interface of oil and water, or other liquids with significant dielectric differences. Rosemount 5301 can also be used for interface measurement in applications where the probe is fully submerged in the liquid.

-

Page 31: Vessel Characteristics

2.8.1 Heating coils, agitators Because the radar signal is transmitted along a probe, the Rosemount 5300 Radar Transmitter is generally not affected by objects in the tank. Avoid physical contact with metallic objects when twin lead or single lead probes are used.

-

Page 32: Installation Procedure

Reference Manual Transmitter Overview 00809-0100-4530, Rev DD May 2016 Installation procedure Follow these steps for proper installation: Review mounting considerations (see page Mount the transmitter (see page Wire the transmitter (see Section 4: Electrical Installation) Make sure covers and cable/conduit connections are tight Power up the transmitter…

-

Page 33: Safety Messages

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 Section 3 Mechanical Installation Safety messages …………page 19 Mounting considerations .

-

Page 34: Mounting Considerations

Mounting. 3.2.1 Process connection The Rosemount 5300 Series has a threaded connection for easy mounting on a tank roof. It can also be mounted on a nozzle by using different flanges. Threaded connection Figure 3-1. Mounting on Tank Roof Using Threaded Connection…

-

Page 35

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 Flange connection on nozzles Figure 3-2. Mounting in Nozzles Avoid nozzles with reducer Hold Off Distance/UNZ (unless using coaxial probe). Make sure the nozzle does not extend into the tank. The transmitter can be mounted in nozzles by using an appropriate flange. The nozzle sizes given in Table 3-1 show the recommended dimensions. -

Page 36: Installation In Non-Metallic Tanks And Open-Air Applications

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 A long stud — 9.8 in. (250 mm) — is recommended for single flexible probes in a tall nozzle. Figure 3-3. A Single Flexible Probe with a Long Stud Long Stud (9.8 in./250 mm) Note For single lead probes, avoid 10-in.

-

Page 37: Installation In Concrete Silos

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 For clean liquids, use a coaxial probe to reduce effect of potential electrical disturbances. Figure 3-5. Coaxial Probe in an Open-Air Application For optimal single lead probe performance in non-metallic tanks, the probe must be mounted with a metal flange, or screwed in to a metal sheet (d >…

-

Page 38: Considerations For Solid Applications

Tensile strength is minimum 6519 lb (29 kN) Collapse load is maximum 7868 lb (35 kN) Keep the following in mind when planning installation of the Rosemount 5300 in solid applications: There might be considerable down-pull forces on silo roofs caused by the media, so …

-

Page 39: Mounting In Chamber/Still Pipe

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 Table 3-2. Pulling Force on Probe Installed in Tanks with Different Products Tensile load for 0.16 in. (4 mm) Tensile load for 0.24 in. (6 mm) flexible single lead probe, lb (kN) flexible single lead probe, lb (kN) Material Probe length 49 ft (15 m)

-

Page 40

The single probe creates a virtual coaxial probe with the chamber as the outer tube. The extra gain provided by the twin and coaxial probes is not necessary; the electronics in the Rosemount 5300 Series is very sensitive and is not a limiting factor. -

Page 41

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 The probe must not touch the chamber wall, should extend the full height of the chamber, but not touch the bottom of the chamber. Probe type selection depends on probe length: Less than 20 ft (6 m): Rigid single probe is recommended. -

Page 42

00809-0100-4530, Rev DD May 2016 When mounting in a Rosemount 9901 chamber, see Table 3-4 for information on probe length determination. Table 3-4. Probe Length Determination for Rosemount 9901 Chambers Probe length Chamber Side-and-side chamber Side-and-bottom chamber Rosemount 9901 B + 19 in. (480 mm) B + 4 in. -

Page 43: Replacing A Displacer In An Existing Displacer Chamber

Considerations when changing to Rosemount 5300 When changing from a displacer to a Rosemount 5300 Series Transmitter, make sure to correctly match the Rosemount 5300 Series flange choice and probe length to the chamber. Both standard ANSI and EN (DIN), as well as proprietary chamber flanges are available.

-

Page 44: Free Space

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 3.2.7 Free space For easy access to the transmitter, make sure it is mounted with sufficient service space. For maximum measurement performance, the transmitter should not be mounted close to the tank wall or near other objects in the tank.

-

Page 45: Recommended Mounting Position For Liquids

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 3.2.8 Recommended mounting position for liquids Tank conditions are recommended to be carefully considered when finding the appropriate mounting position for the transmitter. The transmitter should be mounted so the influence of disturbing objects is reduced to a minimum.

-

Page 46: Recommended Mounting For Solids

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 3.2.9 Recommended mounting for solids Figure 3-15. Recommended Mounting for Solids Consider the following guidelines when mounting the transmitter: Do not mount near inlet pipes in order to avoid product filling on the probe. …

-

Page 47: Insulated Tanks

May 2016 3.2.10 Insulated tanks When the Rosemount 5300 is installed in high temperature applications, consider the maximum ambient temperature. Tank insulation should not exceed 4 in. (10 cm) above the top of the process connection. Figure 3-16. Tank Insulation A.

-

Page 48: Installation And Configuration Considerations For Esd Systems

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 3.2.11 Installation and configuration considerations for ESD systems Figure 3-18 shows a common example of an Emergency Shutdown (ESD) system in a separator. High-high and low-low transmitters act as redundant safeguards. They will trigger emergency shutdowns or redirect flow of the application.

-

Page 49: Mounting

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 Low-low unit The distance from flange to upper inlet must be at least 20 in. (500 mm). If this requirement is not met, a spool piece can be added. When the requirement of 20 in. (500 mm) is met, an Upper Null Zone (UNZ) of 14 in.

-

Page 50: Flange Connection

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 3.3.1 Flange connection Figure 3-21. Tank Connection with Flange A. Transmitter head B. Nut C. Bolts D. Flange E. Probe F. Gasket G. Tank flange H. PTFE covered probe with protective plate The transmitter is delivered with head, flange, and probe assembled into one unit.

-

Page 51

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 Figure 3-22. Tank Connection with Loose Flange (“Plate Design”) A.Flange nut B.Bolts C.Probe D.Tank flange E.Transmitter head F. Nut G.Flange H.Gasket Transmitters delivered with alloy probes featuring plate design are mounted as described below: Place a gasket on top of the tank flange. -

Page 52: Threaded Connection

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 3.3.2 Threaded connection Figure 3-23. Threaded Tank Connection A.Tank connection B.Probe C.Nut D.Sealant on threads or gasket (for BSP/G threads) For tank connections with BSP/G threads, place a gasket on top of the tank flange, or use a sealant on the threads of the tank connection.

-

Page 53: Tri Clamp Connection

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 3.3.3 Tri Clamp connection Figure 3-24. Tri Clamp Tank Connection A. Nut B.Probe C.Gasket D.Tank E.Transmitter head F. Tri Clamp G.Clamp Place a gasket on top of the tank flange. Lower the transmitter and probe into the tank. Fasten the Tri Clamp to the tank with a clamp.

-

Page 54: Bracket Mounting

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 3.3.4 Bracket mounting On pipe Mount the bracket to the pipe. Put the two U-bolts through the holes of the bracket. Vertical pipe Horizontal pipe b. Put the clamping brackets on the U-bolts and around the pipe. Use the supplied nuts to fasten the bracket to the pipe.

-

Page 55

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 Mount the transmitter with probe to the bracket. On wall Mount the bracket directly to the wall with screws suitable for the purpose. Mount the transmitter with probe to the bracket. Mechanical Installation… -

Page 56: Shortening The Probe

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 3.3.5 Shortening the probe Note HTHP coaxial and PTFE probes must not be shortened. Flexible twin/single lead Minimum: 1.6 in./40 mm Spacer Allen screws Mark off the required probe length. Add at least 1.6 in. (40 mm) to the required probe length to be inserted into the weight.

-

Page 57

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 Rigid single lead Cut the single lead probe to the desired length. The minimum probe length is 15.7 in. (400 mm). If a centering disc is used, follow the instructions on page Update the transmitter configuration to the new probe length, see “Tank and… -

Page 58

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 Coaxial Note The HTHP coaxial probe must not be cut in field. To cut a coaxial probe: Insert the centering piece. The centering piece is delivered from factory and should be used to prevent the spacers centering the rod from coming loose. -

Page 59: Using A Segmented Probe

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 3.3.6 Using a segmented probe Figure 3-26. Segmented Probe Parts 15.2 (385) 31.5 (800) Dimensions are in inches (mm). A. Safety ring B. Screw C. Top segment D. Split pin E. PTFE washer (optional) F.

-

Page 60

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 Verify probe length Segmented probe ordered with model code 4S Before installation, verify the probe length (L) on the label. If the probe length needs to be adjusted, see “Adjusting the probe length” on page Probe length Probe segments box Segmented probe ordered as spare part kit… -

Page 61

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 Pre-assemble the safety ring. Optional: If ordered, mount the centering disc on the bottom segment of the probe. Bottom Segment Insert the support tool. Bottom Segment Mechanical Installation… -

Page 62

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 Optional: If ordered, mount the centering disc. Note Maximum five pcs/probe Minimum two segments between each centering disc Mount a middle segment. Hand tighten Mechanical Installation… -

Page 63

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 Secure the split pin. Insert the second support tool. Mechanical Installation… -

Page 64

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 Remove the first support tool and lower the probe into the tank. Repeat steps until all segments are mounted. Make sure to finish with the top segment of the probe. Seal and protect threads. Only for NPT threaded tank connection. -

Page 65

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 Attach the probe to the device. Flange / Tri Clamp Threaded Sealant on threads (NPT) Gasket (BSP/G) Gasket Note For safety reasons, at least two people are needed when mounting the device. Make sure to hold the device above the tank. -

Page 66

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 Remove the support tool. Mount the device on the tank. Threaded Flange Tri Clamp Rotate the housing to the desired direction. Tighten the nut. The torque must be 30 Lbft (40 Nm). Connect the wiring. -

Page 67

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 Adjusting the probe length Determine L, the desired probe length. L, desired probe length: Determine n, the number of middle segments needed for the desired probe length. Table 3-7 Table 3-8 on page n, number of middle segments: Calculate Y, the length of the bottom segment. -

Page 68

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 Mark where to cut the bottom segment. Cut the bottom segment at the mark. Note Make sure the bottom segment is fixed while cutting. Optional: If a bottom centering disc is ordered, then drill two holes on the bottom segment using the drilling fixture. -

Page 69

11 pcs Y = L — 362.2 Y = L — 9200 Maximum probe length is 32 ft 9 in. (10 m) for the Rosemount 5300 Series. Table 3-8. Determination of Probe Segments for HTHP/HP/C Seal Desired probe length (L) -

Page 70: Anchoring

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 3.3.7 Anchoring In turbulent tanks, it may be necessary to fix the probe. Depending on the probe type, different methods can be used to guide the probe to the tank bottom. This may be needed to prevent the probe from hitting the tank wall or other objects in the tank, as well as preventing a probe from breaking.

-

Page 71

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 Coaxial probe The coaxial probe can be guided by a tube welded on the tank bottom. Tubes are customer supplied. Make sure that the probe can move freely in order to handle thermal expansion. The measurement accuracy will be reduced close to the tube opening. -

Page 72

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 Solid applications Pull the probe rope through a suitable anchoring point, e.g. a welded eye and fasten it with two clamps. It is 1cm/m recommended the probe is slack in order to prevent high tensile loads. -

Page 73: Mounting A Centering Disc For Pipe Installations

Table 3-10 shows which centering disc diameter to choose for a particular pipe and Table 3-11 shows which centering disc diameter to choose for a Rosemount 9901 Chamber. Table 3-10. Centering Disc Size Recommendation for Different Pipe Schedules Pipe size…

-

Page 74

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 Table 3-11. Centering Disc Size Recommendations for Rosemount 9901 Chambers Chamber size Chamber rating Centering disc Up to Class 600/PN 100 3 in. 3 in. Class 900, 1500/PN160, 250 2 in. -

Page 75

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 Mounting a centering disc on flexible single probes Note When using centering discs made of PTFE, note that the maximum temperature is 392 °F (200 °C). Figure 3-29. Centering Disc at the End of the Weight A. -

Page 76

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 Mounting a centering disc on rigid single probes Note Centering discs shall not be used with PTFE covered probes. Rigid single lead probe (8 mm) Drill one hole using the drilling fixture (included in your shipment). A. -

Page 77

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 Secure the split pin. Rigid single lead/segmented rigid single lead probe (13 mm) Drill two holes using the drilling fixture (included in your shipment). A. Drilling fixture B. Probe Mount the bushings and centering disc at the probe end. A. -

Page 78

Reference Manual Mechanical Installation 00809-0100-4530, Rev DD May 2016 Adjust distance by shifting hole for split pin in lower bushing. 0.16 in. (4 mm) 0.08 in. (2 mm) Insert the split pins through the bushings and the probe. Secure the split pins. Mechanical Installation… -

Page 79: Safety Messages

Reference Manual Electrical Installation 00809-0100-4530, Rev DD May 2016 Section 4 Electrical Installation Safety messages …………page 65 Cable/conduit entries .

-

Page 80: Cable/Conduit Entries

High voltage that may be present on leads could cause electrical shock. Avoid contact with leads and terminals. ™ Make sure the main power to the Rosemount 5300 Transmitter is off and the lines to any other external power source are disconnected or not powered while wiring the gauge.

-

Page 81: Cable Selection

Cable selection Use shielded twisted pair wiring for the Rosemount 5300 Series to comply with EMC regulations. The cables must be suitable for the supply voltage and approved for use in hazardous areas, where applicable. For instance, in the U.S., explosion-proof conduits must be used in the vicinity of the vessel.

-

Page 82: Connecting The Transmitter

Reference Manual Electrical Installation 00809-0100-4530, Rev DD May 2016 Connecting the transmitter Make sure the power supply is switched off. Remove the terminal block cover. Remove the plastic plugs. Pull the cable through the cable gland/conduit. Adapters are required if M20 glands are used. To connect the wires, see the illustrations on the following pages.

-

Page 83

Reference Manual Electrical Installation 00809-0100-4530, Rev DD May 2016 Use the enclosed metal plug to seal any unused port. Note Apply PTFE tape or other sealant to the threads. Tighten the cable gland. Note Apply PTFE tape or other sealant to the threads. Note Make sure to arrange the wiring with a drip loop. -

Page 84: Hart

Connect the power supply. ® HART 4.7.1 Power requirements Terminals in the transmitter housing provide connections for signal cables. The Rosemount 5300 Transmitter is loop-powered and operates with the following power supplies: Hazardous approval Current 3.75 mA 21.75 mA…

-

Page 85: Maximum Loop Resistance

Reference Manual Electrical Installation 00809-0100-4530, Rev DD May 2016 4.7.2 Maximum loop resistance The maximum current loop resistance (see Figure 4-5 Figure 4-6) is given by the following diagrams: Figure 4-2. Explosion-Proof / Flameproof Installations Operating External power region supply voltage Note This diagram is only valid if the load resistance is at the + side and if the — side is grounded, otherwise the maximum load resistance is limited to 435 .

-

Page 86: Non-Intrinsically Safe Output

Figure 4-5. Note Make sure the power supply is off when connecting the transmitter. Figure 4-5. Wiring Diagram for Non-Intrinsically Safe Installations (HART) Field Rosemount 5300 Series Communicator Radar Transmitter ™ Suite HART modem Load resistance 250 …

-

Page 87: Intrinsically Safe Output

Make sure the instruments in the loop are installed in accordance with intrinsically safe field wiring practices and system control drawings when applicable. Figure 4-6. Wiring Diagram for Intrinsically Safe Installations (HART) Field Rosemount 5300 Series Communicator Radar Transmitter AMS Suite…

-

Page 88: Foundation

™ Fieldbus OUNDATION 4.8.1 Power requirements Terminals in the transmitter housing provide connections for signal cables. The Rosemount 5300 Transmitter is powered over F Fieldbus with standard fieldbus power OUNDATION supplies. The transmitter operates with the following power supplies: Approval type…

-

Page 89: Foundation Fieldbus

Reference Manual Electrical Installation 00809-0100-4530, Rev DD May 2016 Connecting fieldbus devices Figure 4-7. Rosemount 5300 Radar Transmitter Field Wiring 6234 ft (1900 m) maximum (depending upon cable characteristics) Integrated power conditioner and filter Terminators Fieldbus segment (Trunk) Power supply…

-

Page 90: Non-Intrinsically Safe Output

Figure 4-8. Note Make sure that the power supply is off when connecting the transmitter. Figure 4-8. Wiring for Non-Intrinsically Safe Power Supply (F Fieldbus) OUNDATION Rosemount 5300 Series Radar Transmitter = 250 V Power supply Fieldbus modem Field Communicator…

-

Page 91: Intrinsically Safe Output

Make sure the instruments in the loop are installed in accordance with intrinsically safe field wiring practices. Figure 4-9. Wiring Diagram for Intrinsically Safe Power Supply (F Fieldbus) OUNDATION Rosemount 5300 Series Radar Transmitter Approved IS barrier Power supply Fieldbus modem…

-

Page 92: Optional Devices

Configure channels 1, 2, and 3 to reflect the units as well as upper range values and lower range values for your secondary, tertiary and fourth variables (variable assignment is configured in the Rosemount 5300). It is also possible to enable or disable a channel from this menu. See “Tri-Loop™…

-

Page 93: 751 Field Signal Indicator

Reference Manual Electrical Installation 00809-0100-4530, Rev DD May 2016 4.9.2 751 Field Signal Indicator Figure 4-11. Wiring Diagram for a Rosemount 5300 Transmitter with 751 Field Signal Indicator Rosemount 5300 Series Radar Transmitter Model 751 Field Signal Indicator Power supply…

-

Page 94

Reference Manual Electrical Installation 00809-0100-4530, Rev DD May 2016 Electrical Installation… -

Page 95: Safety Messages

Basic configuration using a Field Communicator …….page 95 Basic configuration using Rosemount Radar Master ……page 98 Basic configuration using AMS Suite (HART) .

-

Page 96: Overview

If the transmitter is pre-configured at the factory according to the ordering specifications in the Configuration Data Sheet, no further basic configuration is required unless tank conditions have changed. The Rosemount 5300 Series supports a set of advanced configuration options as well, which can be used to handle special tank conditions and applications.

-

Page 97: Configuration Tools

Rosemount Radar Master (RRM). Note that RRM is recommended for advanced configuration features. “Basic configuration using Rosemount Radar Master” on page 98 information on how to use RRM for configuration of the Rosemount 5300 Series Field Communicator. “Basic configuration using a Field Communicator” on page 95…

-

Page 98: Host System Integration

2F0 or later 2A2 — 2E0 Firmware version is printed on the transmitter head label, e.g. SW 2E0 or can be found in Rosemount Radar Master (select Device > Properties). Device revision is printed on the transmitter head label, e.g. HART Dev Rev 4.

-

Page 99: Set Alarm Limits

Reference Manual Configuration 00809-0100-4530, Rev DD May 2016 5.3.2 Set alarm limits The alarm limits that are set in the host system need to be adjusted for the expected maximum product level rate and configured Damping Value. When setting the high alarm limit, a safety margin (see Figure 5-1) should be subtracted from the desired high alarm limit.

-

Page 100

Reference Manual Configuration 00809-0100-4530, Rev DD May 2016 To set the alarm limits, do the following: Identify maximum product level rate for the application. Note configured Damping Value. In RRM, select Setup > Advanced, and click the Echo Tracking tab. … -

Page 101

Reference Manual Configuration 00809-0100-4530, Rev DD May 2016 Example Maximum product level rate = 100 mm/min Damping Value = 10 s The Signal Quality Metrics is turned off in this example, so the safety margin is calculated by using Table 5-2. -

Page 102: Basic Configuration Parameters

Basic configuration parameters This section describes basic configuration parameters for a Rosemount 5300 Transmitter. Basic configuration is only needed for the Rosemount 5300 Series Transmitters which are not pre-configured at the factory. Factory configuration is normally specified in the Configuration Data Sheet.

-

Page 103

Reference Manual Configuration 00809-0100-4530, Rev DD May 2016 For the different tank connections the Upper Reference Point is located at the underside of the threaded adapter or at the underside of the welded flange, as illustrated in Figure 5-5: Figure 5-5. Upper Reference Point BSP/G Flange Tri Clamp… -

Page 104: Tank Environment

Tank environment Measurement mode Normally, the measurement mode does not need to be changed. The transmitter is pre-configured according to the specified model: Table 5-4. List of Measurement Modes for Different Rosemount 5300 Models Model Measurement mode Rosemount 5301 Liquid product level …

-

Page 105: Volume Configuration

Optimize the transmitter for measurement conditions where the level changes quickly due to filling and emptying of the tank. As a default standard, a Rosemount 5300 Transmitter is able to track level changes of up to 1.5 in./s (40 mm/s). When the Rapid Level Changes check-box is marked, the transmitter can track level changes of up to 8 in./s (200 mm/s).

-

Page 106

Reference Manual Configuration 00809-0100-4530, Rev DD May 2016 Tank type You can choose one of the following options: Strap table Vertical cylinder Horizontal cylinder Vertical bullet Horizontal bullet Sphere None Strapping table Use a strapping table if a standard tank type does not provide sufficient accuracy. Use most of the strapping points in regions where the tank shape is non-linear. -

Page 107

Reference Manual Configuration 00809-0100-4530, Rev DD May 2016 Standard tank shapes Figure 5-7. Standard Tank Shapes Vertical cylinder Vertical cylinder tanks are specified by diameter, height, and volume offset. Diameter Height Horizontal cylinder Horizontal cylinders are specified by Diameter diameter, height, and volume offset. Height Vertical bullet Vertical bullet tanks are specified by… -

Page 108: Analog Output (Hart)

Reference Manual Configuration 00809-0100-4530, Rev DD May 2016 5.4.5 Analog output (HART) The output source (Primary Value), range values, and alarm mode are specified for the analog output. Figure 5-8. Example of Range Value Settings Upper Reference Point Upper Blind Zone Reduced accuracy Upper Range Value (URV) = 100% 20 mA…

-

Page 109: Basic Configuration Using A Field Communicator

High 20.5 mA 22.5 mA Basic configuration using a Field Communicator This section describes how to configure the Rosemount 5300 Series Transmitter by using a Field Communicator. The menu tree with the various configuration parameters is shown in Figure 5-11. Section “Basic configuration parameters”…

-

Page 110

Select Finish, Device Specific Setup to see if there is any additional configuration that needs to be done. Restart the transmitter. HART command: [3, 2, 1, 1]. See also “Guided setup” on page 104 for further information on configuration of the Rosemount 5300 Transmitter. Configuration… -

Page 111

Reference Manual Configuration 00809-0100-4530, Rev DD May 2016 Figure 5-11. Field Communicator Menu Tree Corresponding to Device Revision 3 Process variables 1 Variable mapping 1 Primary variable 2 Probe 2 2nd 1 Primary variable 3 Geometry 3 3rd 2 2nd 4 Environment 4 4th 3 3rd… -

Page 112: Basic Configuration Using Rosemount Radar Master

Basic configuration using Rosemount Radar Master The Rosemount Radar Master (RRM) is a user-friendly software tool that allows the user to configure the Rosemount 5300 Series Transmitter. Choose either of the following methods to configure a Rosemount 5300 Series Transmitter with RRM: Guided Setup if you are unfamiliar with the Rosemount 5300 Transmitter (see …

-

Page 113: Installing The Rrm Software For Hart Communication

100. Getting started From the Start menu click Programs > Rosemount > Rosemount Radar Master or click the RRM icon in the Windows workspace. If the Search Device window did not appear automatically, choose menu option Device > Search.

-

Page 114: Specifying The Com Port

Reference Manual Configuration 00809-0100-4530, Rev DD May 2016 5.6.4 Specifying the COM port If communication is not established, open the Communication Preferences window and check that the correct COM Port is selected: In RRM, select View > Communication Preferences. Select the HART tab. Make sure that HART communication is enabled.

-

Page 115: Installing The Rrm Software For Foundation Fieldbus

Fieldbus is chosen as default protocol. OUNDATION Getting started Before starting RRM make sure that appropriate settings are made with the National Instruments Interface Configuration Utility: If only Rosemount Radar Master is connected to the bus: Device address = Fixed Configuration…

-

Page 116

Usage = NI-FBUS Start Rosemount Radar Master (RRM): from the Start menu click Programs > Rosemount > Rosemount Radar Master or click the RRM icon in the MS Windows workspace. If the National Instruments Communication Manager server is not running, click Yes when RRM displays a request for starting the server. -

Page 117: Specifying Measurement Units

Using the setup functions Use the setup function if you are already familiar with the configuration process for the Rosemount 5300 Series Transmitter or for changes to the current settings: Figure 5-12. Setup Functions in RRM 1. Start the RRM software.

-

Page 118: Guided Setup

HART commands (Field Communicator Fast Key Sequence) and F Fieldbus OUNDATION parameters are also shown. The Guided Setup is useful if you are unfamiliar with the Rosemount 5300 Series Transmitter. Start the Guided Setup. Start RRM. It automatically presents a list of available transmitters. Select the desired transmitter.

-

Page 119

Reference Manual Configuration 00809-0100-4530, Rev DD May 2016 Device properties Check the device properties. The first window in the configuration wizard presents general information stored in the transmitter database such as device model, serial number, communication protocol and device address. Check that the information complies with the ordering information. -

Page 120

Reference Manual Configuration 00809-0100-4530, Rev DD May 2016 Units Select the digital units of measurement for the device. HART command: [2, 1, 1]. Fieldbus parameters: OUNDATION TRANSDUCER 1100 > RADAR_LEVEL_RANGE TRANSDUCER 1100 > RADAR_LEVELRATE_RANGE TRANSDUCER 1100 > RADAR_VOLUME_RANGE TRANSDUCER 1100 > RADAR_INTERNAL_TEMPERATURE_RANGE Configuration… -

Page 121

Probe Type from the list. The Rosemount 5300 Series Transmitter automatically makes some initial calibrations based on the chosen Probe Type. The following probe types are… -

Page 122

When specifying the Tank Height, keep in mind that this value is used for all level and volume measurements performed by the Rosemount 5300 Series Transmitter. The Tank Height must be set in linear (level) units, such as feet or meters, regardless of primary variable assignment. -

Page 123

Reference Manual Configuration 00809-0100-4530, Rev DD May 2016 Tank environment Specify tank environment. HART command: [2, 1, 4]. Fieldbus parameter: OUNDATION TRANSDUCER 1100 > MEAS_MODE TRANSDUCER 1100 > PRODUCT_DIELEC_RANGE TRANSDUCER 1100 > UPPER_PRODUCT_DC Measurement mode Normally, the measurement mode does not need to be changed. The transmitter is pre-configured according to the specified model. -

Page 124

Reference Manual Configuration 00809-0100-4530, Rev DD May 2016 Rosemount Radar Master (RRM) includes tools to estimate the dielectric constant of the current product: The Dielectric Constant Chart lists the dielectric constant of a large number of products. The Dielectric Constant Chart can be opened with one of the following methods: — Select View >… -

Page 125

Reference Manual Configuration 00809-0100-4530, Rev DD May 2016 Tank length: TRANSDUCER 1300 > VOL_IDEAL_LENGTH Volume offset: TRANSDUCER 1300 > VOL_VOLUME_OFFSET To use volume calculation, choose a pre-defined calculation method based on the tank shape that best corresponds to the actual tank. See “Volume configuration”… -

Page 126

Reference Manual Configuration 00809-0100-4530, Rev DD May 2016 Analog output is not available for F Fieldbus. OUNDATION Typically, the Primary Variable (PV) is configured to be product level, interface level, or volume. Other variables like product distance, interface distance, upper product thickness, etc. -

Page 127

Reference Manual Configuration 00809-0100-4530, Rev DD May 2016 Device specific setup Select the Device specific setup button. This window will show if any additional configuration is needed. Proceed to step if no configuration is needed. Trim Near Zone is described further in “Handling of disturbances from nozzle”… -

Page 128

Reference Manual Configuration 00809-0100-4530, Rev DD May 2016 Restart the device Restart the device. When the transmitter is configured, it should be restarted to make sure that all configuration changes are properly activated and the transmitter performs as expected. It may take up to 60 seconds after the restart button is pressed until measurement values are updated. -

Page 129

Reference Manual Configuration 00809-0100-4530, Rev DD May 2016 A minor adjustment using Calibration Distance is normal. There may, for example be a deviation between the actual tank height and the configured value. Non-metallic (e.g. plastic) vessels and installation geometry may introduce an offset for the zero reference point. -

Page 130

When configuration is finished, it is recommended that the configuration is saved to a backup file. This information may be useful for: installing another Rosemount 5300 Series Transmitter in a similar tank since the file can be directly uploaded to a new device restoring the configuration, if for any reason, configuration data is lost or … -

Page 131

Reference Manual Configuration 00809-0100-4530, Rev DD May 2016 View live values from device Click View live values from device to view measurement values in order to verify that the transmitter works correctly. If the measured values seem incorrect, configuration settings may need to be adjusted. Configuration… -

Page 132: Basic Configuration Using Ams Suite (Hart)

00809-0100-4530, Rev DD May 2016 Basic configuration using AMS Suite (HART) The Rosemount 5300 Series Transmitter can be configured by using the AMS Suite software. Start the AMS Device Manager and make sure the transmitter connects. In the Device Connection View, right-click on the transmitter icon.

-

Page 133: Basic Configuration Using Deltav

This information is not required for the operation of the transmitter and can be left out if desired. General information such as device type (Rosemount 5300), manufacturer, device ID are presented. The Rosemount 5300 Series device ID consists of the following components: Manufacturer ID-Model-Serial Number.

-

Page 134

The Rosemount 5300 Series Transmitter automatically makes some initial calibrations based on the chosen probe type. The following probes are available: Rigid twin … -

Page 135

Reference Manual Configuration 00809-0100-4530, Rev DD May 2016 Select the TRANSDUCER1100 block and choose the Geometry tab. Tank height is the distance from the upper reference point to the tank bottom (see “Tank and probe geometry” on page 88). Make sure that this number is as accurate as possible. -

Page 136: Process Conditions

Reference Manual Configuration 00809-0100-4530, Rev DD May 2016 Submerged is used for applications where the probe is fully submerged in liquid. In this mode, the transmitter ignores the upper product level. See “Interface measurements with fully submerged probes” on page 162 for more information.

-

Page 137

Reference Manual Configuration 00809-0100-4530, Rev DD May 2016 To configure volume calculation, select the TRANSDUCER1300 block and then the Volume tab. Choose a pre-defined calculation method based on a tank shape that corresponds to the actual tank. Choose None if volume calculation is not desired. Use Volume offset if you do not want zero volume and zero level to match (for example if you want to include the product volume below the zero level). -

Page 138: Foundation

5.9.1 Assigning device tag and node address A Rosemount 5300 Series Transmitter is shipped with a blank tag and a temporary address (unless specifically ordered with both) to allow a host to automatically assign an address and a tag. If the tag or address need to be changed, use the features of the configuration tool.

-

Page 139: Foundation Fieldbus Block Operation

Reference Manual Configuration 00809-0100-4530, Rev DD May 2016 5.9.2 Fieldbus block operation OUNDATION Function blocks within the fieldbus device perform the various functions required for process control. Function blocks perform process control functions, such as Analog Input (AI) functions, as well as Proportional-Integral Derivative (PID) functions. The standard function blocks provide a common structure for defining function block inputs, outputs, control parameters, events, alarms, and modes, and combining them into a process that can be implemented within a single device or over the fieldbus network.

-

Page 140

Transducer Block, Appendix H: Resource Transducer Block, and Appendix I: Analog-Input Block. Function block summary The following function blocks are available for the Rosemount 5300 Series: Analog Input (AI) Proportional/Integral/Derivative (PID) Input Selector (ISEL) Signal Characterizer (SGCR) … -

Page 141: Configure The Ai Block

CHANNEL Select the channel that corresponds to the desired sensor measurement. The Rosemount 5300 measures Level (channel 1), Distance (channel 2), Level Rate (channel 3), Signal Strength (channel 4), Volume (channel 5), Internal Temperature (channel 6), Upper Product…

-

Page 142

Reference Manual Configuration 00809-0100-4530, Rev DD May 2016 temperature). The relationship between the transmitter measurement and the calculated measurement will be linear. Indirect square root Select indirect square root when the desired output is an inferred measurement based on the transmitter measurement and the relationship between the sensor measurement and the inferred measurement is square root (e.g. -

Page 143

Reference Manual Configuration 00809-0100-4530, Rev DD May 2016 Engineering units Note To avoid configuration errors, only select engineering units for XD_SCALE and OUT_SCALE that are supported by the device. The supported units are: Table 5-7. Length Display Description meter centimeter millimeter feet inch… -

Page 144

Reference Manual Configuration 00809-0100-4530, Rev DD May 2016 Table 5-11. Volume Display Description Cubic meter Liter Cubic inch Cubic feet Cubic yard Gallon US gallon ImpGall Imperial gallon Barrel (oil, 42 US gallons) Configuration… -

Page 145: Application Example 1

Reference Manual Configuration 00809-0100-4530, Rev DD May 2016 5.10.1 Application example 1 Radar level transmitter, level value A level transmitter is measuring the level in a 33 ft. (10 m) high tank. Figure 5-16. Situation Diagram 100% 33 ft (10 m) Solution Table 5-12 lists the appropriate configuration settings, and Figure 5-17 illustrates the correct function block configuration.

-

Page 146: Application Example 2

Reference Manual Configuration 00809-0100-4530, Rev DD May 2016 5.10.2 Application example 2 Radar level gauge, level value in percent (%) The maximum level in the tank is 46 ft. (14 m). The level value is displayed in percentage of the full span (see Figure 5-18).

-

Page 147: Application Example 3

Reference Manual Configuration 00809-0100-4530, Rev DD May 2016 5.10.3 Application example 3 Radar level transmitter, product level, and interface level value A level transmitter is measuring the product level and the interface level in a 33 ft. (10 m) high tank. The maximum interface level is 10 ft. (3 m). Figure 5-20.

-

Page 148

Reference Manual Configuration 00809-0100-4530, Rev DD May 2016 Figure 5-21. Analog Input Function Block Diagram for a Level and Interface Transmitter Level measurement OUT_D AI function block (product level) to another function block Interface level measurement OUT_D AI function block (interface level) to another function block… -

Page 149: Tri-Loop ™ Hart-To-Analog Converter

RRM: Setup > General/Communication Note Using a HART revision 7 device, the Rosemount 5300 Series supports up to 3 Burst messages. It can burst Cmd 1, 2, 3, 9, 33, 48. For command aggregation, Cmd78 is used. Supported burst trigger modes in HART 7: Continuous, Windowed, Falling, and Rising.

-

Page 150

Configure Tri-Loop channel 1: a. Assign variable: Tri-Loop HART command [1,2,2,1,1]. Make sure the SV, TV, and QV match the configuration of the Rosemount 5300 Series Transmitter. b. Assign units: Tri-Loop HART command [1,2,2,1,2]. Make sure that the same units are used as for the Rosemount 5300 Series Transmitter. -

Page 151: Hart Multi-Drop Configuration

HART address. Figure 5-23. Multidrop Connection The poll address can be changed by using a Field Communicator or by using the Rosemount Radar Master software. To change the poll address using a Field Communicator, choose HART command [2, 2, 4, 1].

-

Page 152

Reference Manual Configuration 00809-0100-4530, Rev DD May 2016 Select the Communication tab. Set the desired address for multidrop operation. HART 5: addresses between 1 and 15 HART 7: addresses between 1 and 63 Click the Store button to save the new address. Configuration… -

Page 153: Safety Messages

Reference Manual Operation 00809-0100-4530, Rev DD May 2016 Section 6 Operation Safety messages …………page 139 Viewing measurement data .

-

Page 154: Viewing Measurement Data

Using the display panel ™ The Rosemount 5300 Series Radar Transmitter uses an optional display panel for presentation of measurement data. When the transmitter is switched on, the display panel presents information such as transmitter model, measurement frequency, software ®…

-

Page 155

Reference Manual Operation 00809-0100-4530, Rev DD May 2016 Select the General option from the Setup menu, or select the General icon in the Device Configuration window. Device config General Select the LCD tab. Select the variables to be shown on the display panel. The LCD will alternate between the selected items. -

Page 156

Reference Manual Operation 00809-0100-4530, Rev DD May 2016 Select the transmitter icon in the Device Connection View window. Right click and select the Configure/Setup/Device option. Select the LCD tab and choose the desired LCD parameters and LCD measurement units. The available LCD parameters are listed in Table 6-1 on page 144. -

Page 157

Reference Manual Operation 00809-0100-4530, Rev DD May 2016 Using DeltaV Right click the transmitter icon and choose the Properties option. Select the Transducer1100 block. Select the LCD tab. Choose the variables you want to appear on the display panel and the corresponding measurement units. -

Page 158

Reference Manual Operation 00809-0100-4530, Rev DD May 2016 LCD parameters Table 6-1. LCD Parameters and Presentation on Display Parameter Presentation Description on display Level LEVEL Product level Distance DIST Distance from the upper reference point to the product surface Level rate LRATE The speed of level movement up or down Signal strength… -

Page 159: Viewing Measurement Data In Rrm

6.2.3 Viewing measurement data in RRM To view measurement data such as level, signal strength, etc. in Rosemount Radar Master, choose the Tools > Device Display option and select the Level tab. Figure 6-2. Presentation of Measurement Data in RRM To view the analog output signal, choose the Tools >…

-

Page 160: Viewing Measurement Data In Ams Suite

Reference Manual Operation 00809-0100-4530, Rev DD May 2016 6.2.4 Viewing measurement data in AMS Suite To view measurement data such as level, signal strength, etc. in the AMS Suite: Select the transmitter icon in the AMS Suite Device Connection View window. Right click and select the Process Variables option.

-

Page 161: Viewing Measurement Data In Deltav

Right click the transmitter icon and choose the Properties option. Select the Transducer1100 block. Select the Product Values tab. For interface measurement, select the Interface Values tab. Figure 6-5. Presentation of Measurement Data in DeltaV for the Rosemount 5300 Series Level values Interface level values…

-

Page 162

Reference Manual Operation 00809-0100-4530, Rev DD May 2016 Operation… -

Page 163

Reference Manual Service and Troubleshooting 00809-0100-4530, Rev DD May 2016 Section 7 Service and Troubleshooting Safety messages …………page 150 Analyzing the measurement signal . -

Page 164: Safety Messages

High voltage that may be present on leads could cause electrical shock. Avoid contact with leads and terminals. ™ Make sure the main power to the Rosemount 5300 Transmitter is off and the lines to any other external power source are disconnected or not powered while wiring the gauge.

-

Page 165: Analyzing The Measurement Signal

May 2016 Analyzing the measurement signal Rosemount Radar Master (RRM) and other tools using enhanced EDDL has powerful functions for advanced troubleshooting. Using the Echo Curve plot function, an instant view of the tank signal is shown. Measurement problems can be solved by studying the position and amplitude of the different pulses.

-

Page 166

-2000 Distance The following amplitude thresholds are used for the Rosemount 5300 Series Transmitter: Reference Threshold — Threshold to filter out noise in the echo curve for detection of the Reference peak. The reference peak is a strong negative echo very close to the device, see Figure 7-1 on page 151. -

Page 167: Using The Echo Curve Analyzer

May 2016 Using the echo curve analyzer The Echo Curve Analyzer in Rosemount Radar Master (RRM) shows the measurement signal amplitude from the top to the bottom of the tank. It includes functions for viewing and recording the Echo Curve, and advanced functions for configuration of amplitude thresholds 7.3.1…

-

Page 168

Reference Manual Service and Troubleshooting 00809-0100-4530, Rev DD May 2016 The configuration mode tab The Configuration Mode tab lets you adjust the different amplitude thresholds. When clicking the Echo Curve icon under Device Config/Setup, the Echo Curve Analyzer window appears with the Configuration Mode tab selected. Note By manually changing the amplitude thresholds in the Echo Curve plot, the Automatic mode is disabled for the corresponding threshold (see… -

Page 169

Reference Manual Service and Troubleshooting 00809-0100-4530, Rev DD May 2016 echoes with an amplitude smaller than the product surface echo. The ATC is adapted to the shape of the measurement signal as described in “Disturbance echo handling” on page 161. In the Echo Curve Analyzer/Configuration Mode window, select Learn and follow the … -

Page 170

Reference Manual Service and Troubleshooting 00809-0100-4530, Rev DD May 2016 Advanced The Advanced button opens a list below the Echo Curve plot with information about all echoes in the tank such as signal amplitude and position in the tank. Play When the Play button is clicked, the tank spectrum is continuously updated without being stored. -

Page 171: Using The Echo Curve Analyzer With A Field Communicator

Reference Manual Service and Troubleshooting 00809-0100-4530, Rev DD May 2016 7.3.2 Using the echo curve analyzer with a Field Communicator The Field Communicator supports the Electronic Device Description Language (EDDL) with enhancements that allows you to view the Echo Curve, create an Amplitude Threshold Curve (ATC) and specify amplitude thresholds such as the Surface Threshold, Interface Threshold, and Reference Threshold.

-

Page 172

Reference Manual Service and Troubleshooting 00809-0100-4530, Rev DD May 2016 Threshold settings To adjust the amplitude thresholds: Select HART command [2, 5, 2]. Fieldbus parameter: OUNDATION TRANSDUCER 1300 > PROBE_END_THRESH TRANSDUCER 1300 > REFERENCE_THRESH TRANSDUCER 1300 > INTERFACE_THRESH TRANSDUCER 1300 > FULL_TANK_THRESH_OFFSET The different threshold options appear on the display: Open the desired option. -

Page 173: Product Surface Peak Not Found

88). Normally no other threshold adjustment is needed, but if the transmitter still does not track the product surface correctly, it may be necessary to adjust the threshold values. Rosemount Radar Master (RRM) has a plot function showing the reflections along the probe (see “Using the echo curve analyzer” on page 153).

-

Page 174: Interface Peak Not Found

The Rosemount Radar Master (RRM) lets you view a waveform plot to analyze the measurement signal. The plot shows the signal and the thresholds used for the different amplitude peaks.

-

Page 175: Disturbance Echo Handling

When the Basic Configuration is done, the transmitter may need a fine-tuning to handle disturbing objects in the tank. The Amplitude Threshold Curve (ATC) function can be used for disturbance echo handling with the Rosemount 5300 Series Transmitter. 7.6.1 Amplitude threshold curve…

-

Page 176: Disturbances At The Top Of The Tank

324. Interface measurements with fully submerged probes The Rosemount 5300 Series has a measurement option which makes it possible to handle interface measurements when the probe is fully submerged into the upper product, see Figure 7-12, and only the interface level is detected by the transmitter. Even if the upper…

-

Page 177: Analog Output Calibration

Reference Manual Service and Troubleshooting 00809-0100-4530, Rev DD May 2016 Choose the Interface Level with Submerged Probe option. Measurement mode Interface Level with Submerged Probe can also be activated in the RRM software: In the RRM workspace, select the Tank icon. Select the Environment tab.

-

Page 178: Level And Distance Calibration

Reference Manual Service and Troubleshooting 00809-0100-4530, Rev DD May 2016 To calibrate the analog output current: Start RRM and make sure that the transmitter communicates with the PC (see Section 5: Configuration). In the Device Config/Setup toolbar, select the Output icon. Select the Analog Out 1 tab.

-

Page 179

Reference Manual Service and Troubleshooting 00809-0100-4530, Rev DD May 2016 A complete calibration is performed in two steps: Calibrate the Distance measurement by adjusting the Calibration Distance parameter. Calibrate the Level measurement by adjusting the Tank Height. Distance calibration Measure the actual distance between the Upper Reference Point and the product surface. -

Page 180: Logging Measurement Data

Reference Manual Service and Troubleshooting 00809-0100-4530, Rev DD May 2016 7.10 Logging measurement data By using the Log Device Registers function in the RRM software, you can log Input and Holding registers over time. It is possible to choose from different pre-defined sets of registers.

-

Page 181: Backing Up The Transmitter Configuration

Reference Manual Service and Troubleshooting 00809-0100-4530, Rev DD May 2016 7.11 Backing up the transmitter configuration Use this RRM option to make a backup copy of the configuration parameters in the transmitter database. The backup file can be used to restore the transmitter configuration. It can also be used for configuration of a transmitter in a similar application.

-

Page 182: Configuration Report