Руководство

пользователя

Программирование

открытым текстом

HEIDENHAIN

iTNC 530

Программное обеспечение NC

340 490-05

340 491-05

340 492-05

340 493-05

340 494-05

Русский (ru)

3/2009

- Manuals

- Brands

- HEIDENHAIN Manuals

- Control Unit

- ITNC 530 — CONVERSATIONAL PROGRAMMING

- User manual

-

Contents

-

Table of Contents

-

Bookmarks

Related Manuals for HEIDENHAIN iTNC 530

Summary of Contents for HEIDENHAIN iTNC 530

-

Page 1

User’s Manual DIN/ISO Programming iTNC 530 NC software 606 420-02 606 421-02 606 424-02 English (en) 12/2011… -

Page 2

Controls of the TNC Program/file management, TNC functions Keys on visual display unit Function Function Select or delete programs and files, external data transfer Split screen layout Define program call, select datum and point tables Toggle the display between machining and programming modes Select MOD functions Soft keys for selecting functions on… -

Page 3

Tool functions Coordinate axes and numbers: Entering and editing Function Function Define tool data in the program Select coordinate axes or . . . enter them into the program Call tool data Numbers . . . Decimal point / Reverse algebraic sign Programming path movements Function Polar coordinate input / Incremental… -

Page 5: About This Manual

Would you like any changes, or have you found any errors? We are continuously striving to improve documentation for you. Please help us by sending your requests to the following e-mail address: tnc-userdoc@heidenhain.de. HEIDENHAIN iTNC 530…

-

Page 6

TNC have the following limitations: Simultaneous linear movement in up to 4 axes HSCI (HEIDENHAIN Serial Controller Interface) identifies the new hardware platform of the TNC controls. HeROS 5 identifies the operating system of HSCI-based TNC controls. -

Page 7

User’s Manual for Cycle Programming: All of the cycle functions (touch probe cycles and fixed cycles) are described in a separate manual. Please contact HEIDENHAIN if you require a copy of this User’s Manual. ID: 670 388-xx smarT.NC user documentation: The smarT.NC operating mode is described in a separate… -

Page 8

Software options The iTNC 530 features various software options that can be enabled by you or your machine tool builder. Each option is to be enabled separately and contains the following respective functions: Software option 1 Cylinder surface interpolation (Cycles 27, 28, 29 and 39) -

Page 9

CAD Viewer software option Description Opening of 3-D models on the NC control. Page 255 Remote Desktop Manager software Description option Remote operation of external computer units Page 630 (e.g. a Windows PC) via the user interface of the TNC HEIDENHAIN iTNC 530… -

Page 10

Cross Talk Compensation software option Description (CTC) Compensation of axis couplings Machine Manual Position Adaptive Control (PAC) software Description option Changing control parameters Machine Manual Load Adaptive Control (LAC) software Description option Dynamic changing of control parameters Machine Manual… -

Page 11

Cycles full contact with the workpiece PLANE function: Entry of axis angle Page 420 User documentation as a Page 158 context-sensitive help system smarT.NC: Programming of smarT.NC Page 117 and machining can be carried out simultaneously HEIDENHAIN iTNC 530… -

Page 12

FCL 3 functions Description smarT.NC: Contour pocket on point smarT.NC Pilot pattern smarT.NC: Preview of contour smarT.NC Pilot programs in the file manager smarT.NC: Positioning strategy for smarT.NC Pilot machining point patterns FCL 2 functions Description 3-D line graphics Page 150 Virtual tool axis Page 519 USB support of block devices (memory… -

Page 13

DCM: Tool carrier management (see “Tool Holder Management (DCM Software Option)” on page 366) In the Test Run mode, the working plane can now by defined manually (see “Setting a tilted working plane for the test run” on page 544) HEIDENHAIN iTNC 530… -

Page 14

In Manual mode the RW-3D mode for position display is now also available (see “Position Display Types” on page 581) Entries in the tool table TOOL.T (see “Tool table: Standard tool data” on page 170) New DR2TABLE column for definition of a compensation table for tool radius compensation depending on the tool’s contact angle New LAST_USE column, into which the TNC enters the date and time of the last tool call… -

Page 15

In Cycle 241 «Single-Fluted Deep-Hole Drilling» it is now possible to define a dwell depth (see User’s Manual for Cycle Programming) The approach and departure behavior of Cycle 39 «Cylinder Surface Contour» can now be adjusted (see User’s Manual for Cycle Programming) HEIDENHAIN iTNC 530… -

Page 16

New Functions with 606 42x-02 New function for opening 3-D data (software option) directly on the TNC (see «Open 3-D CAD data (software option)» page 255 ff) Improvement of Dynamic Collision Monitoring (DCM): The display of stepped tools has been improved When you select tool carrier kinematics, the TNC now displays a graphical preview of the carrier kinematics (see “Assigning the tool-carrier kinematics”… -

Page 17

Exporting of tool data in CSV format (see “Export the tool data” on page 199) Marking and deleting of selectable tool data (see “Delete marked tool data” on page 200) Inserting of tool indices (see “Operating the tool management” on page 195) HEIDENHAIN iTNC 530… -

Page 18

New cycle 225 Engraving (see User’s Manual for Cycle Programming) New cycle 276 Contour Train (see User’s Manual for Cycle Programming) New cycle 290 Interpolation Turning (software option, see User’s Manual for Cycle Programming) In the thread milling cycles 26x a separate feed rate is now available for tangential approach to the thread (see User’s Manual for Cycle Programming) The following improvements were made to the KinematicsOpt… -

Page 19

(see “Position display” on page 407) The approach behavior during side finishing with Cycle 24 (DIN/ISO: G124) was changed (see User’s Manual for Cycle Programming). HEIDENHAIN iTNC 530… -

Page 20

Changed functions with 606 42x-02 Tool names can now be defined with 32 characters (see “Tool numbers and tool names” on page 168) Improved and simplified operation by mouse and touchpad in all graphics windows (see “Functions of the 3-D line graphics” on page 150) Various pop-up windows have been redesigned If you do a Test Run without calculating the machining time, the TNC… -

Page 21: Heidenhain Itnc 530

Table of Contents First Steps with the iTNC 530 Introduction Programming: Fundamentals, File Management Programming: Programming Aids Programming: Tools Programming: Programming Contours Programming: Data Transfer from DXF Files or Plain-language Contours Programming: Subprograms and Program Section Repeats Programming: Q-Parameters Programming: Miscellaneous Functions…

-

Page 23: Table Of Contents

1 First Steps with the iTNC 530 ..47 1.1 Overview ..48 1.2 Machine Switch-On ..49 Acknowledge the power interruption and move to the reference points ..49 1.3 Programming the First Part ..50 Select the correct operating mode ..50 The most important TNC keys ..

-

Page 24

Additional status displays ..77 2.5 Window Manager ..85 Soft-key row ..86 2.6 SELinux security software ..87 2.7 Accessories: HEIDENHAIN 3-D Touch Probes and Electronic Handwheels ..88 3-D touch probes ..88 HR electronic handwheels ..89… -

Page 25

Actual position capture ..101 Editing a program ..102 The TNC search function ..106 3.3 File Management: Fundamentals ..108 Files ..108 Show externally created files on the TNC ..110 Data backup ..110 HEIDENHAIN iTNC 530… -

Page 26

3.4 Working with the File Manager ..111 Directories ..111 Paths ..111 Overview: Functions of the file manager ..112 Calling the file manager ..114 Selecting drives, directories and files ..115 Creating a new directory (only possible on the drive TNC:) ..118 Creating a new file (only possible on the drive TNC:) .. -

Page 27

Calling the TNCguide help system ..156 Generating service files ..157 4.8 The Context-Sensitive Help System TNCguide (FCL3 Function) ..158 Function ..158 Working with the TNCguide ..159 Downloading current help files ..163 HEIDENHAIN iTNC 530… -

Page 28

5 Programming: Tools ..165 5.1 Entering Tool-Related Data ..166 Feed rate F ..166 Spindle speed S ..167 5.2 Tool Data ..168 Requirements for tool compensation ..168 Tool numbers and tool names ..168 Tool length L ..168 Tool radius R .. -

Page 29

Zero point for polar coordinates: pole I, J ..230 Straight line at rapid traverse G10 Straight line with feed rate G11 F ..230 Circular path G12/G13/G15 around pole I, J ..231 Circular path G16 with tangential connection ..232 Helical interpolation ..233 HEIDENHAIN iTNC 530… -

Page 30

7 Programming: Data Transfer from DXF Files or Plain-language Contours ..237 7.1 Processing DXF Files (Software Option) ..238 Function ..238 Opening a DXF file ..239 Basic settings ..240 Layer settings ..241 Specifying the reference point ..242 Selecting and saving a contour .. -

Page 31

Calling any program as a subprogram ..261 8.5 Nesting ..263 Types of nesting ..263 Nesting depth ..263 Subprogram within a subprogram ..264 Repeating program section repeats ..265 Repeating a subprogram ..266 8.6 Programming Examples ..267 HEIDENHAIN iTNC 530… -

Page 32

9 Programming: Q-Parameters ..273 9.1 Principle and Overview ..274 Programming notes ..276 Calling Q-parameter functions ..277 9.2 Part Families—Q Parameters in Place of Numerical Values ..278 Function ..278 9.3 Describing Contours through Mathematical Operations ..279 Function .. -

Page 33

Tilting the working plane with mathematical angles: rotary axis coordinates calculated by the TNC ..311 Measurement results from touch probe cycles (see also User’s Manual for Touch Probe Cycles) ..312 9.11 Programming Examples ..314 HEIDENHAIN iTNC 530… -

Page 34

10 Programming: Miscellaneous Functions ..321 10.1 Entering Miscellaneous Functions M and STOP ..322 Fundamentals ..322 10.2 Miscellaneous Functions for Program Run Control, Spindle and Coolant ..323 Overview ..323 10.3 Miscellaneous Functions for Coordinate Data ..324 Programming machine-referenced coordinates: M91/M92 .. -

Page 35

Activating/deactivating a function ..372 Basic rotation ..374 Swapping axes ..375 Superimposed mirroring ..376 Additional, additive datum shift ..376 Axis locking ..377 Superimposed rotation ..377 Feed rate override ..377 Handwheel superimposition ..378 HEIDENHAIN iTNC 530… -

Page 36

11.6 Adaptive Feed Control Software Option (AFC) ..380 Application ..380 Defining the AFC basic settings ..382 Recording a teach-in cut ..384 Activating/deactivating AFC ..387 Log file ..388 Tool breakage/tool wear monitoring ..390 Spindle load monitoring ..390 11.7 Creating Text Files .. -

Page 37

Selecting tilting axes: M138 ..436 Compensating the machine’s kinematics configuration for ACTUAL/NOMINAL positions at end of block: M144 (software option 2) ..437 12.5 Peripheral milling: 3-D radius compensation with workpiece orientation ..438 Function ..438 HEIDENHAIN iTNC 530… -

Page 38

13 Programming: Pallet Editor ..439 13.1 Pallet Editor ..440 Application ..440 Selecting a pallet table ..442 Leaving the pallet file ..442 Pallet datum management with the pallet preset table ..443 Executing the pallet file ..445 13.2 Pallet Operation with Tool-Oriented Machining .. -

Page 39

Managing more than one block of calibrating data ..498 14.8 Compensating Workpiece Misalignment with a 3-D Touch Probe ..499 Introduction ..499 Basic rotation using 2 points: ..501 Determining basic rotation using 2 holes/studs: ..503 Workpiece alignment using 2 points ..504 HEIDENHAIN iTNC 530… -

Page 40

14.9 Datum Setting with a 3-D Touch Probe ..505 Overview ..505 Datum setting in any axis ..505 Corner as datum – using points that were already probed for a basic rotation ..506 Corner as datum—without using points that were already probed for a basic rotation..506 Circle center as datum .. -

Page 41: Heidenhain Itnc 530

15 Positioning with Manual Data Input ..521 15.1 Programming and Executing Simple Machining Operations ..522 Positioning with Manual Data Input (MDI) ..522 Protecting and erasing programs in $MDI ..525 HEIDENHAIN iTNC 530…

-

Page 42

16 Test Run and Program Run ..527 16.1 Graphics ..528 Application ..528 Overview of display modes ..530 Plan view ..530 Projection in 3 planes ..531 3-D view ..532 Magnifying details ..535 Repeating graphic simulation ..536 Displaying the tool .. -

Page 43

Application ..581 17.11 Unit of Measurement ..582 Application ..582 17.12 Selecting the Programming Language for $MDI ..583 Application ..583 17.13 Selecting the Axes for Generating G01 Blocks ..584 Application ..584 HEIDENHAIN iTNC 530… -

Page 44

17.14 Entering the Axis Traverse Limits, Datum Display ..585 Application ..585 Working without additional traverse limits ..585 Find and enter the maximum traverse ..585 Datum display ..586 17.15 Displaying HELP Files ..587 Application ..587 Selecting HELP files .. -

Page 45

Selecting general user parameters ..598 List of general user parameters ..599 18.2 Pin Layouts and Connecting Cables for the Data Interfaces ..614 RS-232-C/V.24 interface for HEIDENHAIN devices ..614 Non-HEIDENHAIN devices ..615 RS-422/V.11 interface ..616 Ethernet interface RJ45 socket .. -

Page 46

19 Industrial PC 6341 with Windows 7 (Option) ..629 19.1 Introduction ..630 Functionality ..630 Specifications of the IPC 6341 ..630 End User License Agreement (EULA) for Windows 7 ..631 Switch to Windows interface ..631 Exiting Windows .. -

Page 47: First Steps With The Itnc 530

First Steps with the iTNC 530…

-

Page 48: Overview

The following topics are included in this chapter Machine Switch-On Programming the First Part Graphically Testing the Program Tool Setup Workpiece Setup Running the First Program First Steps with the iTNC 530…

-

Page 49: Machine Switch-On

The TNC is now ready for operation in the Manual Operation mode. Further information on this topic Traversing the reference marks: See “Switch-on” on page 460 Operating modes: See “Programming and Editing” on page 73 HEIDENHAIN iTNC 530…

-

Page 50: Programming The First Part

Soft keys on the screen with which you select functions appropriate to the active state Further information on this topic Writing and editing programs: See “Editing a program” on page 102 Overview of keys: See “Controls of the TNC” on page 2 First Steps with the iTNC 530…

-

Page 51: Create A New Program/File Management

The TNC automatically generates the first and last blocks of the program. Afterwards you can no longer change these blocks. Further information on this topic File management: See “Working with the File Manager” on page Creating a new program: See “Creating and Writing Programs” on page 97 HEIDENHAIN iTNC 530…

-

Page 52: Define A Workpiece Blank

Example NC blocks %NEW G71 * N10 G30 G17 X+0 Y+0 Z-40 * N20 G31 X+100 Y+100 Z+0 * N99999999 %NEW G71 * Further information on this topic Defining the workpiece blank: (see page 98) First Steps with the iTNC 530…

-

Page 53: Program Layout

N40 G00 G40 G90 Z+250 * Further information on this topic: N50 G200… * Cycle programming: See User’s Manual for Cycles N60 X… Y… * N70 G79 M13 * N80 G00 Z+250 M2 * N99999999 BSBCYC G71 * HEIDENHAIN iTNC 530…

-

Page 54: Program A Simple Contour

Move to contour point 3: Enter the X coordinate 95 and save your entry with the END key Define the chamfer at contour point 3: Enter the chamfer width 10 mm and save with the END key First Steps with the iTNC 530…

-

Page 55

Departure” on page 212 Programming contours: See “Overview of path functions” on page Tool radius compensation: See “Tool radius compensation” on page Miscellaneous functions (M): See “Miscellaneous Functions for Program Run Control, Spindle and Coolant” on page 323 HEIDENHAIN iTNC 530… -

Page 56: Create A Cycle Program

Confirm Radius comp.: RL/RR/no comp? by pressing the ENT key: Do not activate the radius compensation Miscellaneous function M? Enter M2 to end the program and confirm with the END key: The TNC saves the entered positioning block First Steps with the iTNC 530…

-

Page 57

N100 G00 Z+250 M2 * Retract in the tool axis, end program N99999999 %C200 G71 * Further information on this topic Creating a new program: See “Creating and Writing Programs” on page 97 Cycle programming: See User’s Manual for Cycles HEIDENHAIN iTNC 530… -

Page 58: Graphically Testing The First Program

S and is therefore active for the Test Run Press the END key: Leave the file manager Further information on this topic Tool management: See “Entering tool data in the table” on page 170 Testing programs: See “Test Run” on page 539 First Steps with the iTNC 530…

-

Page 59: Choose The Program You Want To Test

Further information on this topic Running a test run: See “Test Run” on page 539 Graphic functions: See “Graphics” on page 528 Adjusting the test speed:See “Setting the speed of the test run” on page 529 HEIDENHAIN iTNC 530…

-

Page 60: Tool Setup

To leave the tool table, press the END key Further information on this topic Operating modes of the TNC: See “Operating Modes” on page 72 Working with the tool table: See “Entering tool data in the table” on page 170 First Steps with the iTNC 530…

-

Page 61: The Pocket Table Tool_P.tch

To leave the pocket table, press the END key Further information on this topic Operating modes of the TNC: See “Operating Modes” on page 72 Working with the pocket table: See “Pocket table for tool changer” on page 182 HEIDENHAIN iTNC 530…

-

Page 62: Workpiece Setup

If you do not have a 3-D touch probe available, you have to align the workpiece so that it is fixed with its edges parallel to the machine axes. First Steps with the iTNC 530…

-

Page 63: Align The Workpiece With A 3-D Touch Probe System

NO ENT key (no transfer) Further information on this topic MDI operating mode: See “Programming and Executing Simple Machining Operations” on page 522 Workpiece alignment: See “Compensating Workpiece Misalignment with a 3-D Touch Probe” on page 499 HEIDENHAIN iTNC 530…

-

Page 64: Set The Datum With A 3-D Touch Probe

Set to 0: Press the SET DATUM soft key Press the END to close the menu Further information on this topic Datum setting: See “Datum Setting with a 3-D Touch Probe” on page 505 First Steps with the iTNC 530…

-

Page 65: Running The First Program

File management: See “Working with the File Manager” on page Start the program Press the NC start button: The TNC executes the active program Further information on this topic Running programs: See “Program Run” on page 545 HEIDENHAIN iTNC 530…

-

Page 66

First Steps with the iTNC 530… -

Page 67: Introduction

Introduction…

-

Page 68: The Itnc 530

The TNC can run all part programs that were written on HEIDENHAIN controls TNC 150 B and later. In as much as old TNC programs contain OEM cycles, the iTNC 530 must be adapted to them with the PC software CycleDesign. For more information, contact your machine tool builder or HEIDENHAIN.

-

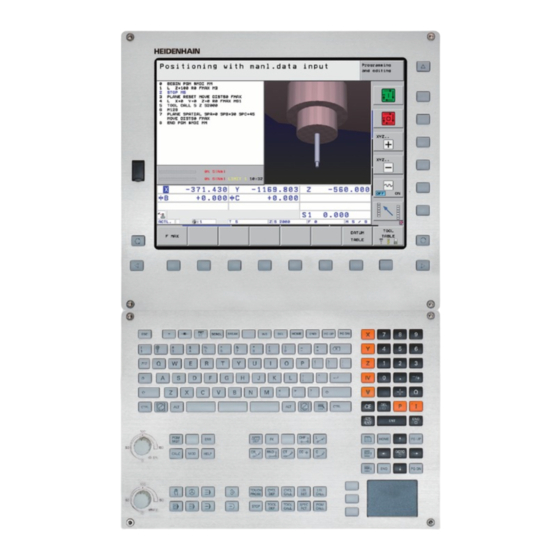

Page 69: Visual Display Unit And Keyboard

Shift key for switchover between machining and programming modes Soft-key selection keys for machine tool builder soft keys The15-inch screen has 6 soft keys, the 19-inch screen has 18 soft keys. Switches soft-key rows for machine tool builders HEIDENHAIN iTNC 530…

-

Page 70: Sets The Screen Layout

Sets the screen layout You select the screen layout yourself: In the PROGRAMMING AND EDITING mode of operation, for example, you can have the TNC show program blocks in the left window while the right window displays programming graphics. You could also display the program structure in the right window instead, or display only program blocks in one large window.

-

Page 71: Operating Panel

The functions of the individual keys are described on the inside front cover. Some machine manufacturers do not use the standard operating panel from HEIDENHAIN. Please refer to your machine manual in these cases. Machine panel buttons, e.g. NC START or NC STOP, are also described in the manual for your machine tool.

-

Page 72: Operating Modes

2.3 Operating Modes Manual Operation and Electronic Handwheel The Manual Operation mode is required for setting up the machine tool. In this mode of operation, you can position the machine axes manually or by increments, set the datums, and tilt the working plane. The Electronic Handwheel mode of operation allows you to move the machine axes manually with the HR electronic handwheel.

-

Page 73: Programming And Editing

TNC takes into account all permanent machine components defined by the machine manufacturer as well as all measured fixtures. Soft keys for selecting the screen layout: see «Program Run, Full Sequence and Program Run, Single Block», page 74. HEIDENHAIN iTNC 530…

-

Page 74: Program Run, Full Sequence And Program Run, Single Block

Program Run, Full Sequence and Program Run, Single Block In the Program Run, Full Sequence mode of operation the TNC executes a part program continuously to its end or to a manual or programmed stop. You can resume program run after an interruption. In the Program Run, Single Block mode of operation you execute each block separately by pressing the machine START button.

-

Page 75: Status Displays

F and active M functions. Program run started. Axis is locked. Axis can be moved with the handwheel. Axes are moving under a basic rotation. Axes are moving in a tilted working plane. The M128 function or TCPM FUNCTION is active. HEIDENHAIN iTNC 530…

-

Page 76

Symbol Meaning The Dynamic Collision Monitoring function (DCM) is active. The Adaptive Feed Function (AFC) is active (software option). One or more global program settings are active (software option) Number of the active presets from the preset table. If the datum was set manually, the TNC displays the text MAN behind the symbol. -

Page 77: Additional Status Displays

With the soft keys or switch-over soft keys, you can choose directly between the available status displays. Please note that some of the status information described below is not available unless the associated software option is enabled on your TNC. HEIDENHAIN iTNC 530…

-

Page 78

Overview After switch-on, the TNC displays the Overview status form, provided that you have selected the PROGRAM+STATUS screen layout (or POSITION + STATUS). The overview form contains a summary of the most important status information, which you can also find on the various detail forms. -

Page 79

Active subprogram numbers with block number in which the subprogram was called and the label number that was called Information on standard cycles (CYC tab) Soft key Meaning No direct Active machining cycle selection possible Active values of Cycle G62 Tolerance HEIDENHAIN iTNC 530… -

Page 80

Active miscellaneous functions M (M tab) Soft key Meaning No direct List of the active M functions with fixed meaning selection possible List of the active M functions that are adapted by your machine manufacturer Introduction… -

Page 81

Oversizes (delta values) from the tool table (TAB) and the TOOL CALL (PGM) Tool life, maximum tool life (TIME 1) and maximum tool life for TOOL CALL (TIME 2) Display of the active tool and the (next) replacement tool HEIDENHAIN iTNC 530… -

Page 82

Tool measurement (TT tab) The TNC only displays the TT tab if the function is active on your machine. Soft key Meaning No direct Number of the tool to be measured selection possible Display whether the tool radius or the tool length is being measured MIN and MAX values of the individual cutting edges and the result of measuring the rotating… -

Page 83

Global program settings 2 (GPS2 tab, software option) The TNC only displays the tab if the function is active on your machine. Soft key Meaning No direct Locked axes selection possible Superimposed basic rotation Superimposed rotation Active feed rate factor HEIDENHAIN iTNC 530… -

Page 84

Adaptive Feed Control (AFC tab, software option) The TNC only displays the AFC tab if the function is active on your machine. Soft key Meaning No direct Active mode in which adaptive feed control is selection running possible Active tool (number and name) Cut number Current factor of the feed potentiomenter in percent… -

Page 85: Window Manager

The TNC shows a star in the upper left of the screen if an application of the window manager or the window manager itself has caused an error. In this case, switch to the window manager and correct the problem. If required, refer to your machine manual. HEIDENHAIN iTNC 530…

-

Page 86: Soft-Key Row

In the task bar you can also select other applications that you have started together with the TNC (switch for example to the PDF viewer or TNCguide) Click the green HEIDENHAIN symbol to open a menu in which you can get information, make settings or start applications. The following functions are available:…

-

Page 87: Selinux Security Software

Files created anew by other programs must basically not be run. There are only two procedures permitted to run new files: Starting a software update A HEIDENHAIN software update can replace or change system files. Starting the SELinux configuration The configuration of SELinux is usually password-protected by your machine tool builder.

-

Page 88: Accessories: Heidenhain 3-D Touch Probes And Electronic Handwheels

2.7 Accessories: HEIDENHAIN 3-D Touch Probes and Electronic Handwheels 3-D touch probes With the various HEIDENHAIN 3-D touch probe systems you can: Automatically align workpieces Quickly and precisely set datums Measure the workpiece during program run Measure and inspect tools All of the touch probe functions are described in the User’s Manual for Cycles.

-

Page 89: Hr Electronic Handwheels

Electronic handwheels facilitate moving the axis slides precisely by hand. A wide range of traverses per handwheel revolution is available. Apart from the HR130 and HR150 integral handwheels, HEIDENHAIN also offers the HR 520 and HR 550 FS portable handwheels. You will find a detailed description of HR 520 in Chapter 14 of this manual (see “Traversing with electronic handwheels”…

-

Page 90

Introduction… -

Page 91: Programming: Fundamentals, File Management

Programming: Fundamentals, File Management…

-

Page 92: Fundamentals

3.1 Fundamentals Position encoders and reference marks The machine axes are equipped with position encoders that register the positions of the machine table or tool. Linear axes are usually equipped with linear encoders, rotary tables and tilting axes with angle encoders.

-

Page 93: Reference System On Milling Machines

X direction, and the index finger in the positive Y direction. The iTNC 530 can control up to 18 axes. The axes U, V and W are secondary linear axes parallel to the main axes X, Y and Z, respectively.

-

Page 94: Polar Coordinates

Polar coordinates If the production drawing is dimensioned in Cartesian coordinates, you also write the NC program using Cartesian coordinates. For parts containing circular arcs or angles it is often simpler to give the dimensions in polar coordinates. While the Cartesian coordinates X, Y and Z are three-dimensional and can describe points in space, polar coordinates are two-dimensional and describe points in a plane.

-

Page 95: Absolute And Incremental Workpiece Positions

G91 Y = 10 mm G91 Y = 10 mm Absolute and incremental polar coordinates Absolute polar coordinates always refer to the pole and the reference axis. Incremental coordinates always refer to the last programmed nominal position of the tool. HEIDENHAIN iTNC 530…

-

Page 96: Setting The Datum

The fastest, easiest and most accurate way of setting the datum is by using a 3-D touch probe from HEIDENHAIN. See “Setting the Datum with a 3-D Touch Probe” in the Touch Probe Cycles User’s Manual.

-

Page 97: Creating And Writing Programs

The last block of a program is identified by N99999999 the program name and the active unit of measure. Danger of collision! After each tool call, HEIDENHAIN recommends always traversing to a safe position, from which the TNC can position the tool for machining without causing a collision!

-

Page 98: Creating A New Part Program

Creating a new part program You always enter a part program in the Programming and Editing mode of operation. An example of program initiation: Select the Programming and Editing operating mode. Press the PGM MGT key to call the file manager. Select the directory in which you wish to store the new program: FILE NAME = OLD.H Enter the new program name and confirm your entry…

-

Page 99

Working spindle axis X/Y/Z by pressing the DEL key! The TNC can display the graphics only if the shortest side is at least 50 µm long and the longest side is no longer than 99 999.999 mm. HEIDENHAIN iTNC 530… -

Page 100: Programming Tool Movements In Din/Iso Format

Programming tool movements in DIN/ISO format To program a block, select a DIN/ISO function key on the alphabetic keyboard. You can also use the gray contouring keys to get the corresponding G code. You only need to make sure that capitalization is active. Example of a positioning block Start block.

-

Page 101: Actual Position Capture

(e.g. for radius compensation), then the TNC also closes the soft-key row for axis selection. The actual-position-capture function is not allowed if the tilted working plane function is active. HEIDENHAIN iTNC 530…

-

Page 102: Editing A Program

Editing a program You cannot edit a program while it is being run by the TNC in a machine operating mode. The TNC allows you to place the cursor in the block, but it does not save the changes and responds instead with an error message. While you are creating or editing a part program, you can select any desired line in the program or individual words in a block with the arrow keys or the soft keys:…

-

Page 103

To accept the change, press the END key. If you want to insert a word, press the horizontal arrow key repeatedly until the desired dialog appears. You can then enter the desired value. HEIDENHAIN iTNC 530… -

Page 104

Looking for the same words in different blocks To use this function, set the AUTO DRAW soft key to OFF. To select a word in a block, press the arrow keys repeatedly until the highlight is on the desired word. Select a block with the arrow keys. -

Page 105

To end the marking function, press the CANCEL SELECTION soft key. Function Soft key Switch the marking function on. Switch the marking function off. Delete the marked block. Insert the block that is stored in the buffer memory. Copy the marked block. HEIDENHAIN iTNC 530… -

Page 106: The Tnc Search Function

The TNC search function With the search function of the TNC, you can search for any text within a program and replace it by a new text, if required. Searching for texts If required, select the block containing the word you wish to find. Select the search function.

-

Page 107

REPLACE soft key. To replace all text occurrences, press the REPLACE ALL soft key. To skip the text and move to its next occurrence press the DO NOT REPLACE soft key. End the search function HEIDENHAIN iTNC 530… -

Page 108: File Management: Fundamentals

3.3 File Management: Fundamentals Files Files in the TNC Type Programs In HEIDENHAIN format In DIN/ISO format smarT.NC files Structured unit program Contour descriptions Point tables for machining positions Tables for Tools Tool changers .TCH Pallets Datums Points .PNT Presets Cutting data .CDT…

-

Page 109

0 1 2 3 4 5 6 7 8 9 . _ — You should not use any other characters in file names in order to prevent any file transfer problems. The maximum limit for the path and file name together is 82 characters (see “Paths” on page 111). HEIDENHAIN iTNC 530… -

Page 110: Show Externally Created Files On The Tnc

We recommend saving newly written programs and files on a PC at regular intervals. The TNCremoNT data transmission freeware from HEIDENHAIN is a simple and convenient method for backing up data stored on the TNC. You additionally need a data medium on which all machine-specific data, such as the PLC program, machine parameters, etc., are stored.

-

Page 111: Working With The File Manager

AUFTR1 directory, the directory NCPROG was created and the part program PROG1.H was copied into it. The part program now has the following path: TNC:AUFTR1NCPROGPROG1.H The chart at right illustrates an example of a directory display with different paths. HEIDENHAIN iTNC 530…

-

Page 112: Overview: Functions Of The File Manager

Overview: Functions of the file manager If you want to use the old file management system, you must use the MOD function to switch to the old file manager (see “Changing the PGM MGT setting” on page 575). Function Soft key Page Copy (and convert) individual files Page 119…

-

Page 113

Function Soft key Page Manage network drives. Page 139 Copy a directory. Page 122 Update the directory tree, e.g. to be able to see if a new directory was created while the file manager was opened. HEIDENHAIN iTNC 530… -

Page 114: Calling The File Manager

Calling the file manager Press the PGM MGT key: The TNC displays the file management window (see figure for default setting. If the TNC displays a different screen layout, press the WINDOW soft key.) The narrow window on the left shows the available drives and directories.

-

Page 115: Selecting Drives, Directories And Files

To select a drive, press the SELECT soft key, or Press the ENT key. Step 2: Select a directory Move the highlight to the desired directory in the left-hand window— the right-hand window automatically shows all files stored in the highlighted directory HEIDENHAIN iTNC 530…

-

Page 116

Step 3: Select a file Press the SELECT TYPE soft key Press the soft key for the desired file type, or Press the SHOW ALL soft key to display all files, or Use wild card characters, e.g. to show all files of the 4*.H file type .H that begin with 4 Move the highlight to the desired file in the right window:… -

Page 117

Shift the soft-key row. Select the submenu for selecting the editor. Open the .HU or .HC program with the conversational editor. Open the .HU program with the smarT.NC editor. Open the .HC program with the smarT.NC editor. HEIDENHAIN iTNC 530… -

Page 118: Creating A New Directory (Only Possible On The Drive Tnc:)

Creating a new directory (only possible on the drive TNC:) Move the highlight in the left window to the directory in which you want to create a subdirectory. Enter the new directory name, and confirm with ENT. CREATE NEW DIRECTORY? Press the YES soft key to confirm, or Abort with the NO soft key.

-

Page 119: Copying A Single File

ENT key or the OK soft key: the TNC copies the file to the selected directory. The original file is retained. When the copying process has been started with ENT or the OK soft key, the TNC displays a pop-up window with a progress indicator. HEIDENHAIN iTNC 530…

-

Page 120: Copying Files Into Another Directory

Copying files into another directory Select a screen layout with two equally sized windows. To display directories in both windows, press the PATH soft key. In the right window Move the highlight to the directory into which you wish to copy the files, and display the files in this directory with the ENT key.

-

Page 121: Copying A Table

Or, if you press the REPLACE FIELDS soft key, the TNC merely overwrites the first 10 lines of the number, length and radius columns in the TOOL.T file. The data of the other lines and columns is not changed. HEIDENHAIN iTNC 530…

-

Page 122: Copying A Directory

Copying a directory In order to copy directories, you must have set the view so that the TNC displays directories in the window on the right (see “Adapting the file manager” on page 128). Please note that when copying directories, the TNC only copies those files that are displayed by the current filter settings.

-

Page 123: Deleting A File

To select the erasing function, press the DELETE soft key. The TNC inquires whether you really intend to delete the directory and all its subdirectories and files To confirm, press the YES soft key; To cancel deletion, press the NO soft key. HEIDENHAIN iTNC 530…

-

Page 124: Marking Files

Marking files Marking function Soft key Move cursor upward Move cursor downward Tag a single file Tag all files in the directory Untag a single file Untag all files Copy all tagged files Programming: Fundamentals, File Management…

-

Page 125

To mark further files, press the TAG FILE soft key, etc. To copy the tagged files, press the COPY TAG soft key, or Delete the tagged files by pressing END to end the marking function, and then the DELETE soft key to delete the tagged files. HEIDENHAIN iTNC 530… -

Page 126: Renaming A File

Tagging files with shortcuts Move the highlight to the first file Press and hold the CTRL key. Use the arrow keys to move the cursor frame to other files Press the spacebar to tag a file. When you have tagged all desired files: release the CTRL key and perform the desired file operation.

-

Page 127: Additional Functions

Search for a USB device. In order to remove the USB device, move the cursor to the USB device. Remove the USB device. For more information: See “USB devices on the TNC (FCL 2 function)” on page 140. HEIDENHAIN iTNC 530…

-

Page 128

Adapting the file manager You open the menu for adapting the file manager either by clicking the path name or with soft keys: Select the file manager: Press the PGM MGT key Select the third soft-key row Press the MORE FUNCTIONS soft key Press the OPTIONS soft key: the TNC displays the menu for adapting the file manager Use the arrow keys to move the highlight to the desired setting… -

Page 129: Working With Shortcuts

Disconnect USB device (see also ”USB devices on the TNC (FCL 2 function)” on page 140) SHIFT + UP or DOWN arrow key: Mark several files or directories (see also ”Marking files” on page 124) ESC key: Cancel the function. HEIDENHAIN iTNC 530…

-

Page 130: Archive Files

Archive files You can use the TNC archiving function to save files and directories in a ZIP archive. You can open the ZIP archives externally using standard programs. The TNC packs all the marked files and directories into the desired ZIP archive. TNC packs TNC-specific files (e.g. plain-language programs) in an internal format (binary format), so you must observe the points below: You might not be able to open packed files with an…

-

Page 131: Extract Files From Archive

Select the desired target directory Confirm with the OK soft key and the TNC extracts the archive The TNC always extracts the files to the target directory you have selected. If the archive contains directories, the TNC creates subdirectories for them. HEIDENHAIN iTNC 530…

-

Page 132: Additional Tools For Management Of External File Types

Additional tools for management of external file types With the additional tools you can display or edit various externally created file types on the TNC. File types Description PDF files (pdf) Page 132 Excel tables (xls, csv) Page 133 Internet files (htm, html) Page 133 ZIP archive (zip) Page 134…

-

Page 133

Mozilla Firefox is provided under Help. To exit Mozilla Firefox, proceed as follows: Use the mouse to select the File menu item. Select the menu item Quit: The TNC returns to the file manager. HEIDENHAIN iTNC 530… -

Page 134

Working with ZIP archives To open ZIP archives with the extension zip directly on the TNC, proceed as follows: Call the file manager Select the directory in which the archive file is saved Move the highlight to the archive file Press ENT: The TNC opens the archive file in its own application using the Xarchiver additional tool With the key combination ALT+TAB you can always return to the TNC… -

Page 135

(STRG+C, STRG+V,…), are available within Mousepad. To exit Mousepad, proceed as follows: Use the mouse to select the File menu item. Select the menu item Quit : The TNC returns to the file manager. HEIDENHAIN iTNC 530… -

Page 136

Displaying Image Files To open image files with the extension bmp, gif, jpg or png directly on the TNC, proceed as follows: Call the file manager Select the directory in which the image file is saved Move the highlight to the image file Press ENT: The TNC opens the image file in its own application using the ristretto additional tool With the key combination ALT+TAB you can always return to the TNC… -

Page 137: Data Transfer To Or From An External Data Medium

Moves the highlight from the left to the right window, and vice versa. If you wish to copy from the TNC to the external data medium, move the highlight in the left window to the file to be transferred. HEIDENHAIN iTNC 530…

-

Page 138

If you wish to copy from the external data medium to the TNC, move the highlight in the right window to the file to be transferred. To select another drive or directory: press the soft key for choosing the directory. The TNC opens a pop-up window. -

Page 139: The Tnc In A Network

TNC displays [READ DIR] to indicate that a connection is being established. The maximum transmission speed is 2 to 5 Mbps, depending on the type of file being transferred and how busy the network is. HEIDENHAIN iTNC 530…

-

Page 140: Usb Devices On The Tnc (Fcl 2 Function)

In theory, you should be able to connect all USB devices with the file systems mentioned above to the TNC. If you nevertheless encounter problems, please contact HEIDENHAIN. The USB devices appear as separate drives in the directory tree, so you can use the file-management functions described in the earlier chapters correspondingly.

-

Page 141

TNC removes the USB device from the directory tree. Exit the file manager. In order to re-establish a connection with a USB device that has been removed, press the following soft key: Select the function for reconnection of USB devices. HEIDENHAIN iTNC 530… -

Page 142

Programming: Fundamentals, File Management… -

Page 143: Programming: Programming Aids

Programming: Programming Aids…

-

Page 144: Adding Comments

4.1 Adding Comments Function You can add comments to any desired block in the part program to explain program steps or make general notes. If the TNC cannot show the entire comment on the screen, the >> sign is displayed. The last character in a comment block must not have any tilde (~).

-

Page 145: Functions For Editing Of The Comment

Jump to end of comment. Jump to the beginning of a word. Words must be separated by a space. Jump to the end of a word. Words must be separated by a space. Switch between insert mode and overwrite mode. HEIDENHAIN iTNC 530…

-

Page 146: Structuring Programs

4.2 Structuring Programs Definition and applications This TNC function enables you to comment part programs in structuring blocks. Structuring blocks are short texts with up to 37 characters and are used as comments or headlines for the subsequent program lines. With the aid of appropriate structuring blocks, you can organize long and complex programs in a clear and comprehensible manner.

-

Page 147: Integrated Pocket Calculator

Superimpose the on-line calculator by pressing the CALC key and perform the desired calculation Press the actual-position-capture key for the TNC to transfer the calculated value into the active input box and to close the calculator HEIDENHAIN iTNC 530…

-

Page 148: Programming Graphics

4.4 Programming Graphics Generating / not generating graphics during programming While you are writing the part program, you can have the TNC generate a 2-D pencil-trace graphic of the programmed contour. To switch the screen layout to displaying program blocks to the left and graphics to the right, press the SPLIT SCREEN key and PGM + GRAPHICS soft key.

-

Page 149: Block Number Display On/Off

Enlarge the frame overlay—press and hold the soft key to magnify the detail Confirm the selected area with the WINDOW DETAIL soft key. With the WINDOW BLK FORM soft key, you can restore the original section. HEIDENHAIN iTNC 530…

-

Page 150: D Line Graphics (Fcl2 Function)

4.5 3-D Line Graphics (FCL2 Function) Function Use the 3-D line graphics to have the TNC show the programmed traverse paths in three dimensions. A powerful zoom function is available for recognizing details quickly. You should especially use the 3-D line graphics to inspect programs created externally for irregularities before machining, in order to avoid undesirable traces of the machining process on the workpiece.

-

Page 151

Show workpiece in the last active view Show/hide programmed end points with a dot on the line Do or do not highlight the selected NC block of the 3-D line graphics in the left window Do or do not show block numbers HEIDENHAIN iTNC 530… -

Page 152: Highlighting Nc Blocks In The Graphics

You can also use the mouse with the 3-D line graphics. The following functions are available: In order to rotate the wire model shown in three dimensions: Hold the right mouse button down and move the mouse. The TNC displays a coordinate system showing the currently active orientation of the workpiece.

-

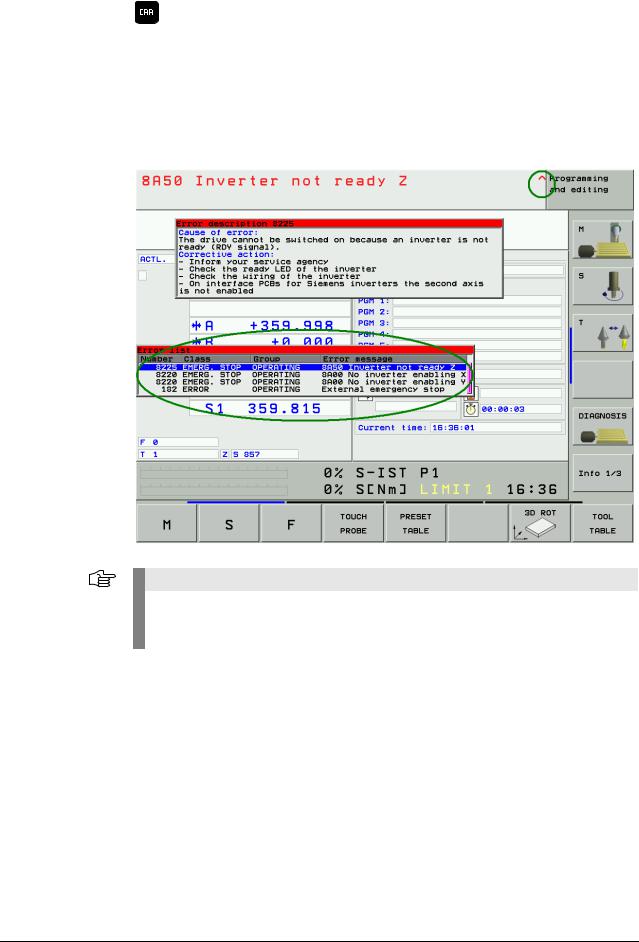

Page 153: Immediate Help For Nc Error Messages

Read the cause of error and any suggestions for possible remedies. The TNC may show additional information that can be helpful to trained HEIDENHAIN personnel during troubleshooting. Close the Help window with the CE key, thus canceling the error message.

-

Page 154: List Of All Current Error Messages

4.7 List of All Current Error Messages Function With this function you can show a pop-up window in which the TNC shows all current error messages. The TNC shows errors both from the NC as well as those from the machine tool builder. Show error list You can call the list as soon as at least one error message is present: To display the list, press the ERR key…

-

Page 155: Window Contents

Window contents Column Meaning Number Error number (–1: no error number defined), issued by HEIDENHAIN or your machine tool builder Error class. Defines how the TNC processes Class this error. ERROR Collective error class for errors that can cause various error reactions depending on…

-

Page 156: Calling The Tncguide Help System

MANUFACTURER soft key with which you can call this separate help system. There you will find further, more detailed information on the error message concerned. Call the help for HEIDENHAIN error messages. Call the help for HEIDENHAIN error messages, if available. Programming: Programming Aids…

-

Page 157: Generating Service Files

The service file contains all NC data needed for troubleshooting. By passing on the service file you declare your consent to your machine tool builder or DR. JOHANNES HEIDENHAIN GmbH to use these data for diagnostic purposes. The maximum size of a service file is 40 MB…

-

Page 158: The Context-Sensitive Help System Tncguide (Fcl3 Function)

The English and German documentation is shipped as standard with each NC software level. HEIDENHAIN provides the remaining conversational languages for cost-free download as soon as the respective translations are available (see “Downloading current help files”…

-

Page 159: Working With The Tncguide

Use the arrow keys to move the cursor to the block Press the HELP key: The TNC starts the help system and shows a description for the active function (does not apply to miscellaneous functions or cycles that were integrated by your machine tool builder) HEIDENHAIN iTNC 530…

-

Page 160: Table Of Contents

Navigating in the TNCguide It’s easiest to use the mouse to navigate in the TNCguide. A table of contents appears on the left side of the screen. By clicking the rightward pointing triangle you open subordinate sections, and by clicking the respective entry you open the individual pages. It is operated in the same manner as the Windows Explorer.

-

Page 161

The focus is switched internally to the TNC application so that you can operate the control when the TNCguide is open. If the full screen is active, the TNC reduces the window size automatically before the change of focus Close the TNCguide HEIDENHAIN iTNC 530… -

Page 162: Programming: Programming Aids

Subject index The most important subjects in the Manual are listed in the subject index (Index tab). You can select them directly by mouse or with the cursor keys. The left side is active. Select the Index tab Activate the Keyword input field Enter the word for the desired subject and the TNC synchronizes the index and creates a list in which you can find the subject more easily, or…

-

Page 163: Downloading Current Help Files

Downloading current help files You’ll find the help files for your TNC software on the HEIDENHAIN home page www.heidenhain.de under: Services and Documentation Documentation / Information User Documentation TNCguide Select the desired language, for example English: You will see a ZIP…

-

Page 164

Language TNC directory Chinese (simplified) TNC:tncguidezh Chinese (traditional) TNC:tncguidezh-tw Slovenian (software option) TNC:tncguidesl Norwegian TNC:tncguideno Slovak TNC:tncguidesk Latvian TNC:tncguidelv Korean TNC:tncguidekr Estonian TNC:tncguideet Turkish TNC:tncguidetr Romanian TNC:tncguidero Lithuanian TNC:tncguidelt Programming: Programming Aids… -

Page 165: Programming: Tools

Programming: Tools…

-

Page 166: Entering Tool-Related Data

5.1 Entering Tool-Related Data Feed rate F The feed rate F is the speed (in millimeters per minute or inches per minute) at which the tool center point moves. The maximum feed rates can be different for the individual axes and are set in machine parameters.

-

Page 167: Spindle Speed S

To program the spindle speed, press the S key on the alphabetic keyboard. Enter the new spindle speed. Changing during program run You can adjust the spindle speed during program run with the spindle- speed override knob S. HEIDENHAIN iTNC 530…

-

Page 168: Tool Data

5.2 Tool Data Requirements for tool compensation You usually program the coordinates of path contours as they are dimensioned in the workpiece drawing. To allow the TNC to calculate the tool center path—i.e. the tool compensation—you must also enter the length and radius of each tool you are using. Tool data can be entered either directly in the part program with G99 or separately in a tool table.

-

Page 169: Delta Values For Lengths And Radii

Tool radius: Compensation value for the tool radius In the programming dialog, you can transfer the value for tool length and tool radius directly into the input line by pressing the desired axis soft key. Example N40 G99 T5 L+10 R+5 * HEIDENHAIN iTNC 530…

-

Page 170: Entering Tool Data In The Table

When transferring tool tables to older software versions of the iTNC 530 or to older TNC controls, you must make sure that tool names are not longer than 16 characters, because otherwise they will be truncated accordingly by the TNC when read in. This can lead to errors in connection with the Replacement Tool function.

-

Page 171

Input range: 0 to 99999 minutes Comment on the tool. Tool description? Input range: 16 characters max. Information on this tool that is to be sent to the PLC. PLC status? Input range: 8 characters bit-coded HEIDENHAIN iTNC 530… -

Page 172

Abbr. Inputs Dialog PLC-VAL Value of this tool that is to be sent to the PLC. PLC value? Input range: -99999.9999 to +99999.9999 PTYP Tool type for evaluation in the pocket table. Tool type for pocket table? Input range: 0 to +99 NMAX Limits the spindle speed for this tool. -

Page 173

LAST_USE Date and time at which the TNC inserted the tool for the last time Date/time of last tool call? via TOOL CALL. Input range: 16 characters max., format internally specified: Date = yyyy.mm.dd, time = hh.mm HEIDENHAIN iTNC 530… -

Page 174

Tool table: Tool data required for automatic tool measurement For a description of the cycles for automatic tool measurement, see the User’s Manual for Cycle Programming. Abbr. Inputs Dialog Number of teeth (99 teeth maximum) Number of teeth? Input range: 0 to 99 Permissible deviation from tool length L for wear detection. -

Page 175

Permissible deviation from tool radius R for breakage detection. If Breakage tolerance: radius? the entered value is exceeded, the TNC locks the tool (status L). Input range: 0 to 0.9999 mm Input range in mm: 0 to 0.9999 Input range in inches: 0 to +0.03936 HEIDENHAIN iTNC 530… -

Page 176

Tool table: Tool data for automatic speed/feed rate calculation Abbr. Inputs Dialog TYPE Tool type: Press the ASSIGN TYPE soft key (3rd soft-key row); the Tool type? TNC superimposes a window where you can select the type of tool. Functions are currently only assigned to the DRILL and MILL tool types TMAT Tool material: Press the ASSIGN MATERIAL soft key (3rd soft-key… -

Page 177

Select previous page in table Select next page in table Look for the tool name in the table Show tool information in columns or show all information on one tool on one screen page Move to beginning of line HEIDENHAIN iTNC 530… -

Page 178

Editing functions for tool tables Soft key Move to end of line Copy highlighted field Insert copied field Add the entered number of lines (tools) at the end of the table Insert a line for the indexed tool number after the active line. -

Page 179

The target file must exist The file to be copied must contain only the columns (or lines) you want to replace To copy individual columns or lines, press the REPLACE FIELDS soft key (see “Copying a single file” on page 119). HEIDENHAIN iTNC 530… -

Page 180: Tool-Carrier Kinematics

HEIDENHAIN provides tool-carrier kinematics for HEIDENHAIN touch probes. If required, please contact HEIDENHAIN. Assigning the tool-carrier kinematics Follow the procedure below to assign carrier kinematics to a tool:…

-

Page 181: Using An External Pc To Overwrite Individual Tool Data

Using an external PC to overwrite individual tool data The HEIDENHAIN data transfer software TNCremoNT provides an especially convenient way to use an external PC to overwrite tool data (see “Software for data transfer” on page 567). This applies when you measure tool data on an external tool presetter and then want to transfer the data to the TNC.

-

Page 182: Pocket Table For Tool Changer

Pocket table for tool changer The machine tool builder adapts the functional range of the pocket table to the requirements of your machine. The machine tool manual provides further information. For automatic tool changing you need the pocket table TOOL_P.TCH. The TNC can manage several pocket tables with any file names.

-

Page 183

Lock the pocket at left? Box magazine: Lock the pocket at right LOCKED_RIGHT Lock the pocket at right? S1 … S5 Function is defined by the machine tool builder. The machine tool Value? documentation provides further information. HEIDENHAIN iTNC 530… -

Page 184

Editing functions for pocket tables Soft key Select beginning of table Select end of table Select previous page in table Select next page in table Reset pocket table Reset tool number column T Go to beginning of next line Reset column to original state. Only applies to the columns RSV, LOCKED_ABOVE, LOCKED_BELOW, LOCKED_LEFT and LOCKED_RIGHT Programming: Tools… -

Page 185: Calling Tool Data

Tool length oversize DL: Enter the delta value for the tool length. Tool radius oversize DR: Enter the delta value for the tool radius. Tool radius oversize DR2: Enter the delta value for the tool radius 2. HEIDENHAIN iTNC 530…

-

Page 186

Editing tool data in the selection window In the pop-up window for tool selection you can also edit the displayed tool data: Use the arrow keys to select the line and then the column of the value to be edited: The light-blue background marks the editable field Set the EDIT soft key to ON, enter the desired value and confirm with the ENT key… -

Page 187

Tool preselection with tool tables If you are working with tool tables, use G51 to preselect the next tool. Simply enter the tool number or a corresponding Q parameter, or type the tool name in quotation marks. HEIDENHAIN iTNC 530… -

Page 188: Tool Change

Tool change The tool change function can vary depending on the individual machine tool. The machine tool manual provides further information. Tool change position The tool change position must be approachable without collision. With the miscellaneous functions M91 and M92, you can enter machine- based (rather than workpiece-based) coordinates for the tool change position.

-

Page 189

If the radii are not equal, the TNC displays an error message and does not replace the tool. On NC programs without radius compensation the TNC does not check the tool radius of the replacement tool during the change. HEIDENHAIN iTNC 530… -

Page 190: Tool Usage Test

Tool usage test The tool usage test function must be enabled by your machine manufacturer. Refer to your machine tool manual. The following are prerequisites for a tool usage test: Bit 2 of the machine parameter must be set to 7246=1 The machining timer must be active in the Test Run operating mode A simulation of the plain language program must have been completed in the Test Run mode…

-

Page 191

Tool name from the tool table Tool-usage time in seconds (feed time) TIME WTIME Tool-usage time in seconds (total usage time between tool changes) Tool radius R + Oversize of tool radius DR from the tool table. The unit is 0.1 µm. HEIDENHAIN iTNC 530… -

Page 192

Column Meaning BLOCK Block number in which the TOOL CALL block was programmed TOKEN = TOOL: Path name of the active main PATH program or subprogram TOKEN = STOTAL: Path name of the subprogram Tool number with tool index Maximum feed rate override that occurred OVRMAX during machining. -

Page 193: Tool Management (Software Option)

Select the tool table: Press the TOOL TABLE soft key Scroll through the soft-key row Select the TOOL MANAGEMENT soft key: The TNC goes into the new table view (see figure at right) HEIDENHAIN iTNC 530…

-

Page 194

In the new view, the TNC presents all tool information in the following four card registers: Tools: Tool specific information Tool pockets: Pocket-specific information Tooling list: List of all tools in the NC program that is selected in the Program Run mode (only if you have already created a tool usage file, see «Tool usage test», page 190). -

Page 195

Define the settings: SORT COLUMN active: Click the column header to sort the content of the column MOVE COLUMN active: The column can be shifted by drag and drop Reset manual settings (shifted columns) to original condition HEIDENHAIN iTNC 530… -

Page 196

In addition, you can perform the following functions by mouse: Sorting function By clicking a column of the table head, you sort the data in ascending or descending order (depending on the active setting). Moving columns You can arrange the columns in any sequence you want by clicking a column of the table head and then moving it with the mouse key pressed down. -

Page 197

Copy the tool data of the selected tool (2nd soft- key row) Insert the copied tool data in the selected tool (2nd soft-key row) Select/deselect check boxes (e.g. for TL line) Open selection lists of combo boxes (e.g. for AFC line) HEIDENHAIN iTNC 530… -

Page 198

Import tool data Using this function you can simply import tool data that you have measured externally on a presetting device, for example. The file to be imported must have the CSV format (comma separated value). The CSV file format describes the structure of a text file for exchanging simply structured data. -

Page 199

Start the export procedure with the START soft key: The TNC shows the status of the export procedure in a pop-up window Terminate the export procedure by pressing the END key or soft key The TNC always stores the exported CSV file in the TNC:systemtooltab directory. HEIDENHAIN iTNC 530… -

Page 200

Delete marked tool data You can use this function you can simply delete tool data that you no longer need. Follow the steps outlined below for deleting: In the tool management you use the arrow keys or mouse to mark the tool data that you wish to delete Select the DELETE MARKED TOOLS soft key and the TNC shows a pop-up window listing the tool data to be deleted… -

Page 201: Tool Compensation

L from the G99 block or tool table is the oversize for length DL in the T 0 block (not TOOL CALL taken into account by the position display). is the oversize for length DL in the tool table. HEIDENHAIN iTNC 530…

-

Page 202: Tool Radius Compensation

Tool radius compensation The NC block for programming a tool movement contains: G41 or G42 for radius compensation G43 or G44, for radius compensation in single-axis movements G40 if there is no radius compensation Radius compensation becomes effective as soon as a tool is called and is moved with a straight line block in the working plane with G41 or G42.

-

Page 203

G42/G41 or canceled with G40 the TNC always positions the tool perpendicular to the programmed starting or end position. Position the tool at a sufficient distance from the first or last contour point to prevent the possibility of damaging the contour. HEIDENHAIN iTNC 530… -

Page 204

Entering radius compensation Radius compensation is entered in a G01 block: To select tool movement to the left of the programmed contour, select function G41, or To select tool movement to the right of the contour, select function G42, or To select tool movement without radius compensation or to cancel radius compensation, select function G40… -

Page 205

Machining corners without radius compensation If you program the tool movement without radius compensation, you can change the tool path and feed rate at workpiece corners with the miscellaneous function M90. see «Smoothing corners: M90», page 327. HEIDENHAIN iTNC 530… -

Page 206

Programming: Tools… -

Page 207: Programming: Programming Contours

Programming: Programming Contours…

-

Page 208: Tool Movements

6.1 Tool Movements Path functions A workpiece contour is usually composed of several contour elements such as straight lines and circular arcs. With the path functions, you can program the tool movements for straight lines and circular arcs. Miscellaneous functions M With the TNC’s miscellaneous functions you can affect The program run, e.g., a program interruption The machine functions, such as switching spindle rotation and…

-

Page 209: Fundamentals Of Path Functions

The tool retains the Z coordinate and moves in the XY plane to the position X=70, Y=50 (see figure). Three-dimensional movement The program block contains three coordinates. The TNC thus moves the tool in space to the programmed position. Example: N50 G01 X+80 Y+0 Z-10 * HEIDENHAIN iTNC 530…

-

Page 210

Entering more than three coordinates The TNC can control up to 5 axes simultaneously (software option). Machining with 5 axes, for example, moves 3 linear and 2 rotary axes simultaneously. Such programs are too complex to program at the machine, however, and are usually created with a CAM system. -

Page 211

You cannot activate radius compensation in a circle block. Activate it beforehand in a straight-line block (see «Path Contours—Cartesian Coordinates», page 216). Pre-positioning Before running a part program, always pre-position the tool to prevent the possibility of damaging it or the workpiece. HEIDENHAIN iTNC 530… -

Page 212: Contour Approach And Departure

6.3 Contour Approach and Departure Starting point and end point The tool approaches the first contour point from the starting point. The starting point must be: Programmed without radius compensation Approachable without danger of collision Close to the first contour point Example Figure at upper right: If you set the starting point in the dark gray area, the contour will be damaged when the first contour element is…

-

Page 213

Example Figure at upper right: If you set the starting point in the dark gray area, the contour will be damaged when the first contour element is approached. HEIDENHAIN iTNC 530… -

Page 214: Tangential Approach And Departure

Tangential approach and departure With G26 (figure at top right), you can program a tangential approach to the workpiece, and with G27 (figure at lower right) a tangential departure. In this way you can avoid dwell marks. Starting point and end point The starting point and the end point lie outside the workpiece, close to the first and last contour points.

-

Page 215

Tangential approach with radius R = 5 mm . . . PROGRAM CONTOUR BLOCKS Last contour point . . . Tangential departure with radius R = 5 mm N210 G27 R5 * End point N220 G00 G40 X-30 Y+50 * HEIDENHAIN iTNC 530… -

Page 216: Path Contours—Cartesian Coordinates

6.4 Path Contours—Cartesian Coordinates Overview of path functions Function Path function key Tool movement Required input Page Line L Straight line Coordinates of the end Page 217 points of the straight line Chamfer CHF Chamfer between two Chamfer side length Page 218 straight lines Circle Center CC…

-

Page 217: Straight Line At Rapid Traverse G00 Straight Line With Feed Rate G01 F

TNC generates an L block with the actual position coordinates. In the MOD function, you define the number of axes that the TNC saves in a G01 block (see «Selecting the Axes for Generating G01 Blocks», page 584). HEIDENHAIN iTNC 530…

-

Page 218: Inserting A Chamfer Between Two Straight Lines

Inserting a chamfer between two straight lines The chamfer enables you to cut off corners at the intersection of two straight lines. The line blocks before and after the G24 block must be in the same working plane as the chamfer The radius compensation before and after the G24 block must be the same The chamfer must be machinable with the current tool…

-

Page 219: Corner Rounding G25

A feed rate programmed in the G25 block is effective only in that G25 block. After the G25 block, the previous feed rate becomes effective again. You can also use an RND block for a tangential contour approach. HEIDENHAIN iTNC 530…

-

Page 220: Circle Center I, J

Circle center I, J You can define a circle center for circles that you have programmed with the G02, G03 or G05 function. This is done in the following ways: Entering the Cartesian coordinates of the circle center in the working plane, or Using the circle center defined in an earlier block, or Capturing the coordinates with the ACTUAL-POSITION-CAPTURE…

-

Page 221: Circular Path C Around Circle Center Cc

For the end point, enter the same point that you used for the starting point. The starting and end points of the arc must lie on the circle. Input tolerance: up to 0.016 mm (selected with MP7431). Smallest possible circle that the TNC can traverse: 0.0016 µm. HEIDENHAIN iTNC 530…

-

Page 222: Circular Path G02/G03/G05 With Defined Radius

Circular path G02/G03/G05 with defined radius The tool moves on a circular path with the radius R. Direction of rotation In clockwise direction: G02 In counterclockwise direction: G03 Without programmed direction: G05. The TNC traverses the circular arc with the last programmed direction of rotation Coordinates of the arc end point Radius R Note: The algebraic sign determines the size of the…

-

Page 223

The maximum radius that can be entered directly is 99.9999 m, with Q parameter programming 210 m. You can also enter rotary axes A, B and C. HEIDENHAIN iTNC 530… -

Page 224: Circular Path G06 With Tangential Connection

Circular path G06 with tangential connection The tool moves on an arc that starts tangentially to the previously programmed contour element. A transition between two contour elements is called tangential when there is no kink or corner at the intersection between the two contours—the transition is smooth.

-

Page 225

N160 G27 R5 F500 * Tangential exit N170 G40 X-20 Y-20 F1000 * Retract tool in the working plane, cancel radius compensation N180 G00 Z+250 M2 * Retract in the tool axis, end program N99999999 %LINEAR G71 * HEIDENHAIN iTNC 530… -

Page 226

Example: Circular movements with Cartesian coordinates %CIRCULAR G71 * Define blank form for graphic workpiece simulation N10 G30 G17 X+0 Y+0 Z-20 * N20 G31 G90 X+100 Y+100 Z+0 * Call tool in the spindle axis and with the spindle speed S N40 T1 G17 S4000 * N50 G00 G40 G90 Z+250 * Retract tool in the spindle axis at rapid traverse… -

Page 227

Depart the contour on a circular arc with tangential connection N190 G40 X-20 Y-20 F1000 * Retract tool in the working plane, cancel radius compensation N200 G00 Z+250 M2 * Retract tool in the tool axis, end of program N99999999 %CIRCULAR G71 * HEIDENHAIN iTNC 530… -

Page 228

Example: Full circle with Cartesian coordinates %C-CC G71 * N10 G30 G17 X+0 Y+0 Z-20 * Definition of workpiece blank N20 G31 G90 X+100 Y+100 Z+0 * N40 T1 G17 S3150 * Tool call N50 G00 G40 G90 Z+250 * Retract the tool N60 I+50 J+50 * Define the circle center… -

Page 229: Path Contours—Polar Coordinates

Helical interpolation Combination of a circular and Polar radius, polar angle of Page 233 a linear movement the arc end point, coordinate of the end point in the tool axis HEIDENHAIN iTNC 530…

-

Page 230: Zero Point For Polar Coordinates: Pole I, J

Zero point for polar coordinates: pole I, J You can define the pole CC anywhere in the part program before blocks containing polar coordinates. Set the pole in the same way as you would program the circle center. Coordinates: Enter Cartesian coordinates for the pole or, if you want to use the last programmed position, enter G29.

-

Page 231: Circular Path G12/G13/G15 Around Pole I, J

Polar-coordinates angle H: Angular position of the arc end point between –99 999.9999° and +99 999.9999° Direction of rotation DR Example NC blocks N180 I+25 J+25 * N190 G11 G42 R+20 H+0 F250 M3 * N200 G13 H+180 * HEIDENHAIN iTNC 530…

-

Page 232: Circular Path G16 With Tangential Connection

Circular path G16 with tangential connection The tool moves on a circular path, starting tangentially from a preceding contour element. Polar coordinate radius R: Enter the distance from are end point to the pole I, J Polar coordinates angle H: Angular position of the arc end point Example NC blocks N120 I+40 J+35 *…

-

Page 233: Helical Interpolation

The table below illustrates in which way the shape of the helix is determined by the work direction, direction of rotation and radius compensation. Work Direction of Radius Internal thread direction rotation comp. Right-handed Left-handed Right-handed Z– Left-handed Z– External thread Right-handed Left-handed Right-handed Z– Left-handed Z– HEIDENHAIN iTNC 530…

-

Page 234

Programming a helix Always enter the same algebraic sign for the direction of rotation and the incremental total angle G91 H. The tool may otherwise move in a wrong path and damage the contour. For the total angle G91 H you can enter a value of -99 999.9999°… -

Page 235

N170 G27 R5 F500 * N180 G40 R+60 H+180 F1000 * Retract tool in the working plane, cancel radius compensation N190 G00 Z+250 M2 * Retract in the spindle axis, end of program N99999999 %LINEARPO G71 * HEIDENHAIN iTNC 530… -

Page 236

Example: Helix %HELIX G71 * N10 G30 G17 X+0 Y+0 Z-20 * Definition of workpiece blank N20 G31 G90 X+100 Y+100 Z+0 * N40 T1 G17 S1400 * Tool call N50 G00 G40 G90 Z+250 * Retract the tool Pre-position the tool N60 X+50 Y+50 * Transfer the last programmed position as the pole N70 G29 *… -

Page 237: Programming: Data Transfer From Dxf Files Or Plain-Language Contours

Programming: Data Transfer from DXF Files or Plain-language Contours…

-

Page 238: Processing Dxf Files (Software Option)

7.1 Processing DXF Files (Software Option) Function DXF files created in a CAD system can be opened directly by the TNC, in order to extract contours or machining positions, and save them as conversational programs or as point files. Plain-language programs acquired in this manner can also be run by older TNC controls, since these contour programs contain only L and CC/C blocks.

-

Page 239: Opening A Dxf File

Select the desired DXF file, and load it with the ENT key. The TNC starts the DXF converter and shows the contents of the DXF file on the screen. The TNC shows the layers in the left window, and the drawing in the right window. HEIDENHAIN iTNC 530…

-

Page 240: Basic Settings

Basic settings The third soft-key row has various possibilities for settings: Setting Soft key COLOR NORMAL/INVERTED: Changing the color scheme 3-D MODE/2-D MODE: Change between 2-D and 3-D mode UNIT OF MEASURE MM/INCH: Enter the unit of measurement of the DXF file. The TNC then outputs the contour program in this unit of measurement.

-

Page 241: Layer Settings

To hide a layer, select the layer with the left mouse button, and click its check box to hide it To show a layer, select the layer with the left mouse button, and click its check box again to show it HEIDENHAIN iTNC 530…

-

Page 242: Specifying The Reference Point

Specifying the reference point The datum of the drawing for the DXF file is not always located in a manner that lets you use it directly as a reference point for the workpiece. Therefore, the TNC has a function with which you can shift the drawing datum to a suitable location by clicking an element.

-

Page 243

If the TNC cannot calculate an intersection, it rescinds the marking of the first element. Element information At the bottom left of the screen, the TNC shows how far the reference point you haven chosen is located from the drawing datum. HEIDENHAIN iTNC 530… -

Page 244: Selecting And Saving A Contour

Selecting and saving a contour You must use the touchpad on the TNC keyboard or a mouse attached via the USB port in order to select a contour. If you are not using the contour program in the smarT.NC operating mode, you must specify the machining sequence when selecting the contour that it matches the desired machining direction.

-

Page 245

The TNC only saves elements that have actually been selected (blue elements), which means that they have been given a check mark in the left window. HEIDENHAIN iTNC 530… -

Page 246

Dividing, extending and shortening contour elements If contour elements to be selected in the drawing connect poorly, then you must first divide the contour element. This function is automatically available if you are in the mode for selecting a contour. Proceed as follows: The poorly connecting contour element is selected, so it is colored blue. -

Page 247: Selecting And Storing Machining Positions

Quick selection of hole positions by entering a diameter: By entering a hole diameter, you can select all hole positions with that diameter in the DXF file (see “Quick selection of hole positions by entering a diameter” on page 250) HEIDENHAIN iTNC 530…

-

Page 248

Individual selection Select the mode for choosing a machining position. The TNC hides the layers shown in the left window, and the right window becomes active for position selection. In order to select a machining position, click the desired element with the left mouse button. The TNC indicates possible locations for machining positions on the selected element with stars. -

Page 249

DXF file is also saved. If you want to select more machining positions in order to save them in a different file, press the CANCEL SELECTED ELEMENTS soft key and select as described above HEIDENHAIN iTNC 530… -

Page 250

Quick selection of hole positions by entering a diameter Select the mode for choosing a machining position. The TNC hides the layers shown in the left window, and the right window becomes active for position selection. Select the last soft-key row. Open the dialog for diameter input: enter any diameter in the pop-up window displayed by the TNC. -

Page 251

With the apply path optimization option on (default setting), the TNC sorts the selected machining positions for the most efficient possible tool path. You can have the tool path displayed by clicking the SHOW TOOL PATH soft key (see “Basic settings” on page 240). HEIDENHAIN iTNC 530… -

Page 252

Element information At the bottom left of the screen, the TNC displays the coordinates of the machining position that you last selected via mouse click in the left or right window. Undoing actions You can undo the four most recent actions that you have taken in the mode for selecting machining positions. -

Page 253: Zoom Function

The zooming center is the location of the mouse pointer. Alternatively you can zoom by selecting a zoom area with the left mouse button. A double-click with the right mouse button resets the view to the default setting. HEIDENHAIN iTNC 530…

-

Page 254: Data Transfer From Plain-Language Programs