Информация, представленная на Сайте, носит информационный характер и ни при каких условиях не является публичной

офертой, определяемой положениями статьи 437 Гражданского кодекса Российской Федерации. Все содержащиеся на

Сайте сведения носят исключительно информационный характер и не являются исчерпывающими. Все условия

приобретения мототехники, цены, спецпредложения и комлектации мототехники указаны с целью ознакомления.

Комплектации и цены действительны на момент публикации и могут быть изменены без предварительного оповещения.

Представленная на Сайте мототехника может быть укомплектована дополнительным оборудованием, не входящим в

стандартную версию, но доступным за дополнительную плату. Сведения о продукции, касающиеся объёмов поставки,

внешнего вида, характеристик, габаритов и веса, эксплуатационных затрат и т.д. не являются обязательными,

рассматриваются как приблизительные и указаны с условием того, что могут возникнуть ошибки при печати, настройке

и/или наборе текста. Такая информация может быть изменена без предварительного уведомления. Чтобы получить

полную информацию о продукции, услугах, дополнительном оборудовании и спецпредложениях, интересных для Вас,

обращайтесь к менеджерам Дилерского центра

- Manuals

- Brands

- KTM Manuals

- Motorcycle

- 250 EXC

Manuals and User Guides for KTM 250 EXC. We have 13 KTM 250 EXC manuals available for free PDF download: Owner’s Manual, Repair Manual, Owner’s Handbook Manual, Manual

KTM 250 EXC Owner’s Manual (410 pages)

Brand: KTM

|

Category: Motorcycle

|

Size: 23.71 MB

Table of Contents

-

Table of Contents

5

-

Important Limited Warranty and Limited Guarantee Information

4

-

Table of Contents

5

-

-

Engine Number, Engine Type

6

-

Serial Number Locations

6

-

Chassis Number

6

-

Operation Instruments

7

-

Clutch Lever

7

-

Hand Decompression Lever

7

-

Hand Brake Lever

7

-

Combination Switch (EXC)

7

-

Short Circuit Button (SX/MXC)

7

-

Flasher Switch

8

-

Starter Button (EXC)

8

-

Emergency off Switch (EXC Australia)

8

-

Digital Speedometer, Indicator Lamps

8

-

Electronic Speedometer

9

-

Setting the Clock

13

-

Overview of Electronic Speedometer Functions

13

-

-

Hot Start Device (450/525 SX)

14

-

Filler Cap

14

-

Choke

14

-

Fuel Tap

14

-

Shift Lever

15

-

Kickstarter

15

-

Foot Brake Pedal

15

-

Side Stand

15

-

Steering Lock

15

-

Compression Damping of Fork

16

-

Rebound Damping of Fork

16

-

Damping Action During Compression of Shock Absorber (SX)

16

-

Compression Damping of Shock Absorber (MXC, EXC)

17

-

Rebound Damping of Shock Absorber (SX, MXC, EXC)

17

-

General Tips and Warnings for Starting the Motorcycle

18

-

Instructions for Initial Operation

18

-

Running in the Racing Models

18

-

Driving Instructions

19

-

Check the Following before each Start

19

-

Starting When the Engine Is Warm

20

-

What to Do When the Engine Is «Flooded

20

-

Starting off

20

-

Shifting/Riding

20

-

Starting When the Engine Is Cold

20

-

Braking

21

-

Stopping and Parking

21

-

Fuel

21

-

Periodic Maintenance

22

-

Maintenance Work on Chassis and Engine

26

-

Changing the Spring Preloading of the Shock Absorber

26

-

Pivot Bearing

26

-

Determining the Static Sag of the Shock Absorber

27

-

Determining the Riding Sag of the Shock Absorber

27

-

Checking the Shock Absorber and Spring

27

-

Basic Suspension Setup for the Weight of the Driver

27

-

Checking the Basic Setup of the Telescopic Fork

28

-

Changing the Spring Preload on the Telescopic Fork (SX Models)

28

-

Changing the Spring Preload on the Telescopic Fork (MXC/EXC Models)

28

-

Replacing Fork Springs

28

-

Checking and Adjusting the Steering Head Bearing

29

-

Cleaning the Dust Sleeves of the Telescopic Fork

29

-

Breather Plug Front Fork

29

-

Changing the Fork Offset (Caster) (SX)

30

-

Checking and Adjusting the Steering Head Bearing

31

-

Check Chain Tension

32

-

Correct Chain Tension

32

-

Chain Maintenance

33

-

Chain Wear

33

-

General Information about KTM Disc Brakes

34

-

Checking the Front Brake Pads

35

-

Refilling the Front Brake Fluid Reservoir

35

-

Checking the Brake Fluid Level — Front Brake

35

-

Adjusting the Free Travel at the Hand Brake Lever

35

-

Replacing the Front Brake Pads

36

-

Changing the Basic Position of the Foot Brake Pedal

36

-

Checking the Rear Brake Fluid Level

36

-

Refilling the Rear Brake Fluid Reservoir

36

-

Checking the Rear Brake Pads

37

-

Replacing the Rear Brake Pads

37

-

Dismounting and Mounting the Front Wheel

37

-

Dismounting and Mounting the Rear Wheel

38

-

Checking Spoke Tension

38

-

Tires, Air Pressure

39

-

Check/Set Distance of the Magnetic Sensor

39

-

Replacing the Battery of the Digital Speedometer

39

-

Battery (MXC/EXC)

40

-

Charging the Battery

40

-

Fuse (MXC/EXC)

41

-

Replacing Headlight Lamp/Parking Light Lamp

41

-

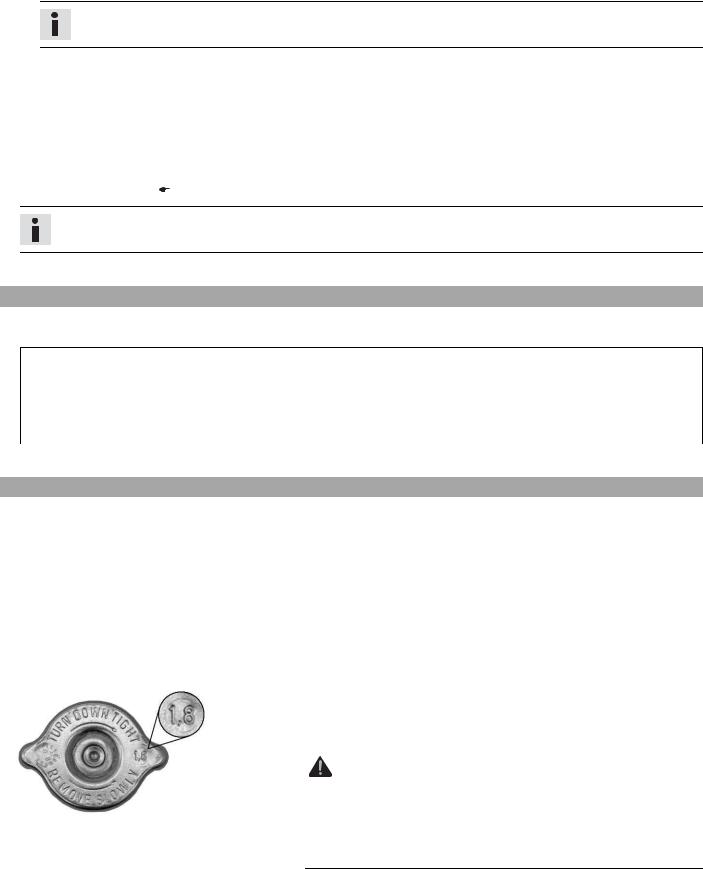

Cooling System

42

-

Checking the Coolant Level

42

-

Bleeding the Cooling System

42

-

Replacing the Glassfiber Yarn Packing of the Silencer

43

-

Cleaning the Spark Arrester (MXC/EXC USA)

43

-

Cleaning the Air Filter

44

-

Checking the Adjustment of the Hand Decompression Release Cable

44

-

Adjusting the Throttle Cables

44

-

Changing the Original Position of the Clutch Lever

45

-

Checking the Oil Level of the Hydraulic Clutch

45

-

Bleeding of the Hydraulic Clutch

45

-

CARBURETOR — Adjust Idling (Keihin-FCRMX 37/39/41)

46

-

Adjusting the Mixture Control Screw

46

-

Checking the Float Level (Float Height)

46

-

Checking the Engine Oil Level

47

-

Oil Circuit

47

-

Draining the Float Chamber of the Carburetor

47

-

Engine Oil

48

-

Changing the Engine Oil

48

-

Changing Oil Filters

49

-

-

Troubleshooting

50

-

Storage

52

-

Conservation for Winter Operation

52

-

Use after a Period of Storage

52

-

Cleaning

52

-

Technical Data — Engine

53

-

Technical Data — Chassis

56

-

Cylinder Head

127

-

Checking Charging Voltage

162

-

Ignition Coil

163

-

Troubleshooting in Ignition System

163

-

Basic Carburator Setting

207

-

-

Advertisement

KTM 250 EXC Owner’s Manual (154 pages)

Brand: KTM

|

Category: Motorcycle

|

Size: 7.42 MB

Table of Contents

-

Table of Contents

4

-

1 Means of Representation

7

-

Symbols Used

7

-

Formats Used

7

-

-

2 Safety Advice

8

-

Use Definition — Intended Use

8

-

Degrees of Risk and Symbols

8

-

Tampering Warning

8

-

Safe Operation

9

-

Protective Clothing

9

-

Work Rules

9

-

Environment

9

-

Owner’s Manual

9

-

-

3 Important Notes

10

-

Guarantee, Warranty

10

-

Operating and Auxiliary Substances

10

-

Spare Parts, Accessories

10

-

Service

10

-

Figures

10

-

Customer Service

10

-

-

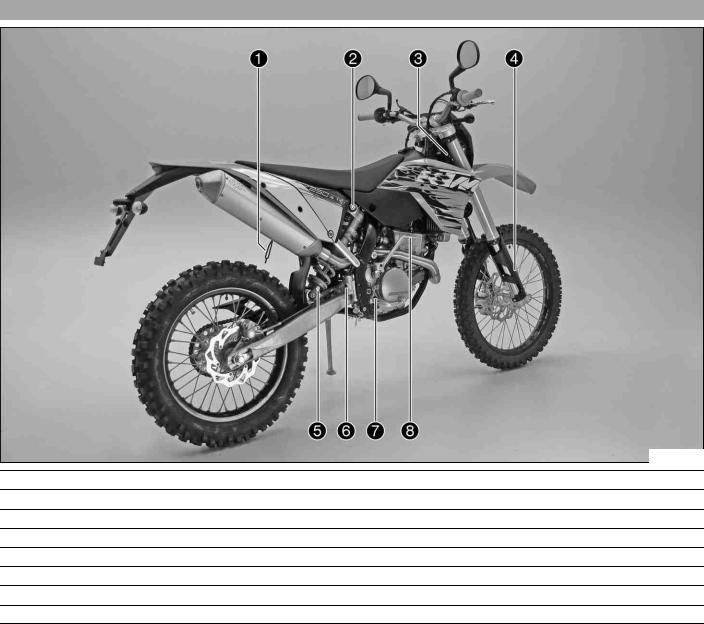

4 View of Vehicle

11

-

View of Vehicle, Front Left (Example)

11

-

View of Vehicle, Rear Right (Example)

12

-

-

5 Serial Numbers

13

-

Chassis Number

13

-

Type Label

13

-

Key Number (All EXC Models)

13

-

Engine Number

13

-

Fork Part Number

13

-

Shock Absorber Part Number

14

-

-

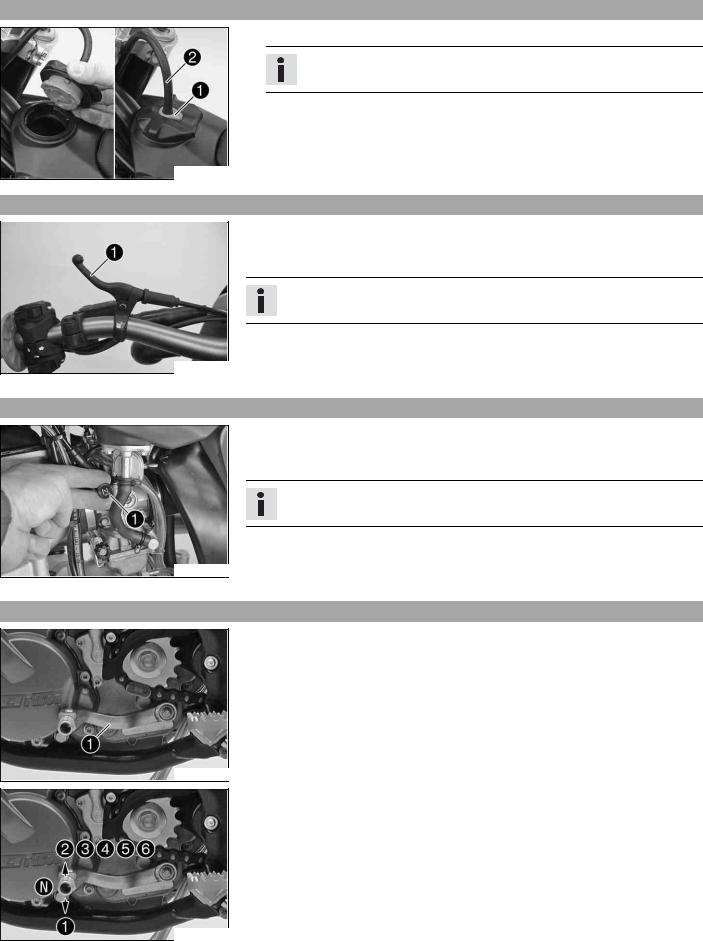

6 Controls

15

-

Clutch Lever

15

-

Hand Brake Lever

15

-

Throttle Grip

15

-

Kill Switch (All EXC Models)

15

-

Kill Switch (All XC-W Models)

16

-

Horn Button (All EXC Models)

16

-

Light Switch (All EXC Models)

16

-

Light Switch (All XC-W Models)

16

-

Turn Signal Switch (All EXC Models)

16

-

Emergency off Switch (EXC AU)

17

-

Electric Starter Button (All 200/250/300 EU/US Models, 300 EXC BR)

17

-

Electric Starter Button (EXC AU)

17

-

Overview of Indicator Lamps (All EXC Models)

17

-

Overview of Indicator Lamps (All XC-W Models)

17

-

Opening the Filler Cap

18

-

Closing the Filler Cap

18

-

Fuel Tap

19

-

Choke

19

-

Shift Lever

19

-

Kick Starter

20

-

Foot Brake Lever

20

-

Side Stand

20

-

Steering Lock (All EXC Models)

20

-

Locking the Steering (All EXC Models)

21

-

Unlocking the Steering (All EXC Models)

21

-

-

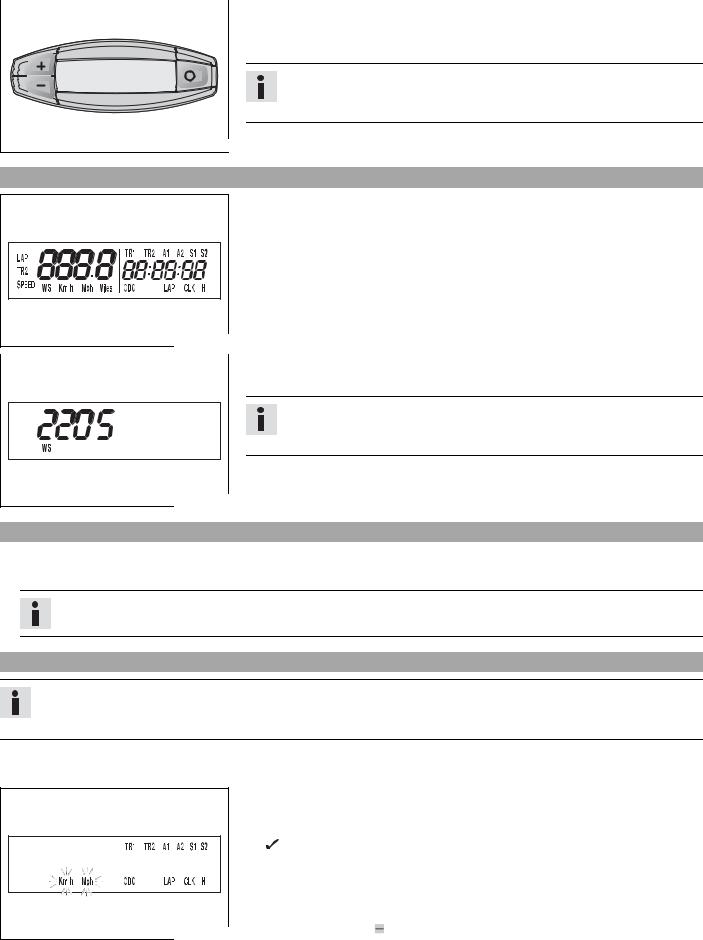

7 Speedometer

22

-

Speedometer Overview

22

-

Activation and Test

22

-

Setting Kilometers or Miles

22

-

Setting the Speedometer Functions

23

-

Setting the Clock

23

-

Viewing the Lap Time

23

-

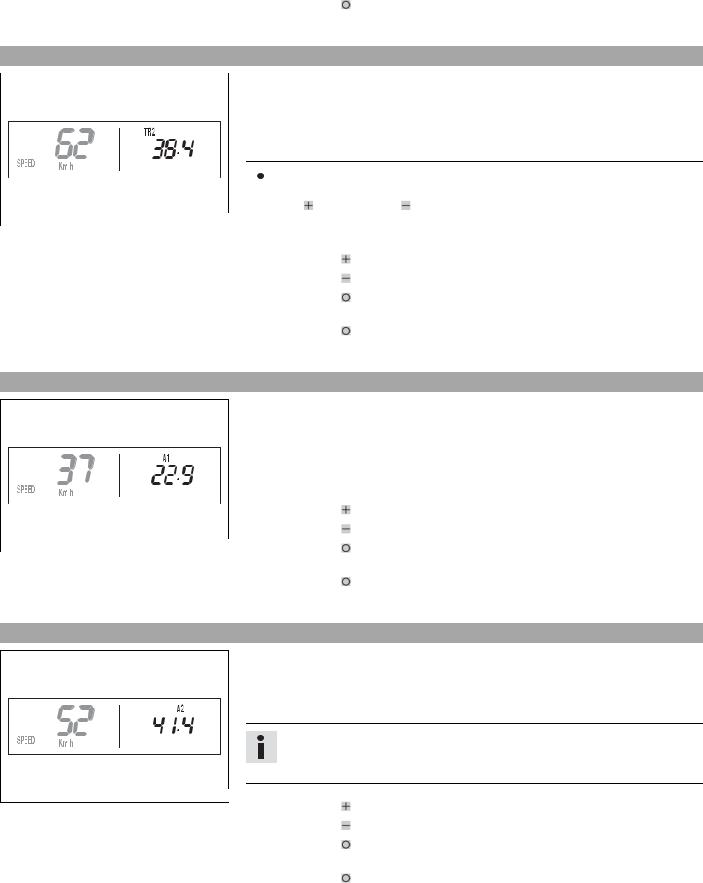

Display Mode SPEED (Speed)

24

-

Display Mode SPEED/H (Service Hours)

24

-

Setup Menu

25

-

Setting the Unit of Measurement

25

-

Display Mode SPEED/CLK (Time)

26

-

Setting the Clock

26

-

Display Mode SPEED/LAP (Lap Time)

26

-

Viewing the Lap Time

27

-

Display Mode SPEED/ODO (Odometer)

27

-

Display Mode SPEED/TR1 (Trip Master 1)

27

-

Display Mode SPEED/TR2 (Trip Master 2)

28

-

Setting TR2 (Trip Master 2)

28

-

Display Mode SPEED/A1 (Average Speed 1)

28

-

Display Mode SPEED/A2 (Average Speed 2)

29

-

Display Mode SPEED/S1 (Stop Watch 1)

29

-

Display Mode SPEED/S2 (Stop Watch 2)

29

-

Table of Functions

30

-

Table of Conditions and Menu Activation

31

-

-

8 Preparing for Use

32

-

Advice on First Use

32

-

Running in the Engine

33

-

Preparing the Vehicle for Difficult Riding Conditions

33

-

Preparations for Riding on Dry Sand

34

-

Preparations for Riding on Wet Sand

34

-

Preparations for Riding on Wet and Muddy Surfaces

35

-

Preparations for Riding at High Temperatures and Low Speeds

35

-

Preparing for Riding at Low Temperatures or in Snow

36

-

-

9 Riding Instructions

37

-

Checks and Maintenance Work When Preparing for Use

37

-

Starting

37

-

Start off

38

-

Shifting, Riding

38

-

Braking

38

-

Stopping, Parking

39

-

Transport

39

-

Refueling

40

-

-

10 Service Schedule

41

-

Service Work (as Additional Order)

42

-

-

11 Tuning the Chassis

43

-

Checking the Basic Chassis Setting with the Rider’s Weight

43

-

Compression Damping of Shock Absorber

43

-

Adjusting the Low-Speed Compression Damping of the Shock Absorber

43

-

Adjusting the High-Speed Compression Damping of the Shock Absorber

44

-

Adjusting the Rebound Damping of the Shock Absorber

44

-

Measuring the Sag of the Unloaded Rear Wheel

45

-

Checking the Static Sag of the Shock Absorber

45

-

Checking the Riding Sag of the Shock Absorber

46

-

Adjusting the Spring Preload of the Shock Absorber

46

-

Adjusting the Riding Sag

47

-

Checking the Basic Setting of the Fork

47

-

Adjusting the Compression Damping of the Fork

48

-

Adjusting the Rebound Damping of the Fork

49

-

Adjusting the Spring Preload of the Fork (EXC, XC-W)

50

-

Handlebar Position

51

-

Adjusting the Handlebar Position

52

-

-

12 Service Work on the Chassis

54

-

Raising the Motorcycle with the Lift Stand

54

-

Removing the Motorcycle from the Lift Stand

54

-

Bleeding the Fork Legs

54

-

Cleaning the Dust Boots of the Fork Legs

55

-

Removing the Fork Protector

55

-

Installing the Fork Protector

56

-

Removing the Fork Legs

56

-

Installing the Fork Legs

57

-

Removing the Lower Triple Clamp (200 XC-W US, 250 XC-W US, 300 EXC BR, 300 XC-W US)

58

-

Removing the Lower Triple Clamp (EXC EU, EXC Six Days, EXC EU/AU, Six Days)

59

-

Installing the Lower Triple Clamp

59

-

(200 XC-W Us, 250 XC-W Us, 300 Exc Br, 300 XC-W Us)

59

-

Installing the Lower Triple Clamp (EXC EU, EXC Six Days, EXC EU/AU, Six Days)

61

-

Checking the Play of the Steering Head Bearing

64

-

Adjusting the Play of the Steering Head Bearing

65

-

Greasing the Steering Head Bearing

66

-

Removing the Front Fender

66

-

Installing the Front Fender

67

-

Removing the Shock Absorber

67

-

Installing the Shock Absorber

67

-

Removing the Seat

68

-

Mounting the Seat

68

-

Removing the Air Filter Box Lid

69

-

Installing the Air Filter Box Lid

69

-

Removing the Air Filter

69

-

Installing the Air Filter

70

-

Cleaning the Air Filter and Air Filter Box

70

-

Sealing the Air Filter Box

71

-

Removing the Main Silencer

71

-

Installing the Main Silencer

71

-

Changing the Glass Fiber Yarn Filling of the Main Silencer

71

-

Removing the Fuel Tank

72

-

Installing the Fuel Tank

73

-

Checking the Chain for Dirt

74

-

Cleaning the Chain

74

-

Checking the Chain Tension

74

-

Adjusting the Chain Tension

75

-

Checking the Chain, Rear Sprocket, Engine Sprocket and Chain Guide

76

-

Checking the Frame

77

-

Checking the Swingarm

78

-

Checking the Routing of the Throttle Cable

78

-

Checking the Rubber Grip

79

-

Additionally Securing the Rubber Grip

79

-

Adjusting the Basic Position of the Clutch Lever

79

-

Checking/Correcting the Fluid Level of the Hydraulic Clutch

80

-

Changing the Hydraulic Clutch Fluid

80

-

Removing the Engine Guard

82

-

Installing the Engine Guard

82

-

KTM 250 EXC Owner’s Manual (145 pages)

Brand: KTM

|

Category: Motorcycle

|

Size: 7.05 MB

Table of Contents

-

Table of Contents

4

-

Table of Contents 2

4

-

1 Means of Representation

7

-

Symbols Used

7

-

Formats Used

7

-

-

2 Safety Advice

8

-

Use Definition — Intended Use

8

-

Degrees of Risk and Symbols

8

-

Tampering Warning

8

-

Safe Operation

9

-

Protective Clothing

9

-

Work Rules

9

-

Environment

9

-

Owner’s Manual

9

-

-

3 Important Notes

10

-

Guarantee, Warranty

10

-

Operating and Auxiliary Substances

10

-

Spare Parts, Accessories

10

-

Service

10

-

Figures

10

-

Customer Service

10

-

-

4 View of Vehicle

11

-

View of Vehicle, Front Left (Example)

11

-

View of Vehicle, Rear Right (Example)

12

-

-

5 Serial Numbers

13

-

Chassis Number

13

-

Type Label

13

-

Key Number (All EXC Models)

13

-

Engine Number

13

-

Fork Part Number

13

-

Shock Absorber Part Number

14

-

-

6 Controls

15

-

Clutch Lever

15

-

Hand Brake Lever

15

-

Throttle Grip

15

-

Kill Switch (EXC EU/AU, EXC Factory Edition, 300 EXC BR)

15

-

Kill Switch (Six Days EU)

16

-

Kill Switch (All XC-W Models)

16

-

Horn Button (EXC EU/AU, EXC Factory Edition, 300 EXC BR)

16

-

Horn Button (Six Days EU)

16

-

Light Switch (EXC EU/AU, EXC Factory Edition, 300 EXC BR)

16

-

Light Switch (Six Days EU)

17

-

Light Switch (All XC-W Models)

17

-

Turn Signal Switch (EXC EU/AU, EXC Factory Edition, 300 EXC BR)

17

-

Turn Signal Switch (Six Days EU)

17

-

Emergency off Switch (EXC AU)

17

-

Electric Starter Button (All 200/250/300 EU/US Models, 300 EXC BR)

18

-

Electric Starter Button (EXC AU)

18

-

Overview of Indicator Lamps (All EXC Models)

18

-

Overview of Indicator Lamps (All XC-W Models)

18

-

Opening the Filler Cap

18

-

Closing the Filler Cap

19

-

Fuel Tap

19

-

Choke

20

-

Shift Lever

20

-

Kick Starter

20

-

Foot Brake Lever

20

-

Side Stand

21

-

Steering Lock (All EXC Models)

21

-

Locking the Steering (All EXC Models)

21

-

Unlocking the Steering (All EXC Models)

22

-

-

7 Speedometer

23

-

Speedometer Overview

23

-

Activation and Test

23

-

Setting Kilometers or Miles

23

-

Setting the Speedometer Functions

24

-

Setting the Clock

24

-

Viewing the Lap Time

24

-

Display Mode SPEED (Speed)

25

-

Display Mode SPEED/H (Service Hours)

25

-

Setup Menu

25

-

Setting the Unit of Measurement

26

-

Display Mode SPEED/CLK (Time)

26

-

Setting the Clock

27

-

Display Mode SPEED/LAP (Lap Time)

27

-

Viewing the Lap Time

27

-

Display Mode SPEED/ODO (Odometer)

28

-

Display Mode SPEED/TR1 (Trip Master 1)

28

-

Display Mode SPEED/TR2 (Trip Master 2)

28

-

Setting TR2 (Trip Master 2)

28

-

Display Mode SPEED/A1 (Average Speed 1)

29

-

Display Mode SPEED/A2 (Average Speed 2)

29

-

Display Mode SPEED/S1 (Stop Watch 1)

30

-

Display Mode SPEED/S2 (Stop Watch 2)

30

-

Table of Functions

30

-

Table of Conditions and Menu Activation

31

-

-

8 Preparing for Use

32

-

Advice on First Use

32

-

Running in the Engine

33

-

Preparing the Vehicle for Difficult Riding Conditions

33

-

Preparations for Riding on Dry Sand

34

-

Preparations for Riding on Wet Sand

34

-

Preparations for Riding on Wet and Muddy Surfaces

35

-

Preparations for Riding at High Temperatures and Low Speeds

35

-

Preparing for Riding at Low Temperatures or in Snow

36

-

-

9 Riding Instructions

37

-

Checks and Maintenance Work When Preparing for Use

37

-

Starting

37

-

Start off

38

-

Shifting, Riding

38

-

Braking

38

-

Stopping, Parking

39

-

Transport

39

-

Refueling

40

-

-

10 Service Schedule

41

-

Service Work (as Additional Order)

42

-

-

11 Tuning the Chassis

43

-

Checking the Basic Chassis Setting with the Rider’s Weight

43

-

Compression Damping of Shock Absorber

43

-

Adjusting the Low-Speed Compression Damping of the Shock Absorber

43

-

Adjusting the High-Speed Compression Damping of the Shock Absorber

44

-

Adjusting the Rebound Damping of the Shock Absorber

44

-

Measuring the Sag of the Unloaded Rear Wheel

45

-

Checking the Static Sag of the Shock Absorber

45

-

Checking the Riding Sag of the Shock Absorber

46

-

Adjusting the Spring Preload of the Shock Absorber

46

-

Adjusting the Riding Sag

47

-

Checking the Basic Setting of the Fork

47

-

Adjusting the Compression Damping of the Fork

48

-

Adjusting the Rebound Damping of the Fork

49

-

Adjusting the Spring Preload of the Fork (EXC, XC-W, EXC Factory Edition)

50

-

Handlebar Position

50

-

Adjusting the Handlebar Position

51

-

Advertisement

KTM 250 EXC Repair Manual (154 pages)

KTM Automobile Parts User Manual

Brand: KTM

|

Category: Engine

|

Size: 5.51 MB

Table of Contents

-

Table of Contents

5

-

Updating Instructions

7

-

Explanation — Updating

9

-

General Information

14

-

Operating Ranges of the Carburetor

16

-

Basic Information on a Change of the Carburetor Setting

17

-

Basic Information on the Original Carburetor Setting

17

-

-

Carburetor Adjustment

17

-

Bleeding of the Hydraulic Clutch

18

-

Checking the Setting of the TVC System

18

-

Special Tools — Engine 250/300/380

19

-

-

Cleaning

20

-

Conservartion for Winter Operation

20

-

Storage

20

-

Removing and Refitting Engine

22

-

Dismounting the Engine

24

-

Filling in of Cooling Liquid

26

-

Filling in of Transmission Oil

26

-

Refitting the Engine

26

-

-

Disassembling the Engine

28

-

Dismounting of Cylinder Head, Cylinder and Piston

30

-

Dismounting of Sprocket and Shift Lever

30

-

Draining Gear Oil

30

-

Dismounting of Clutch Cover

31

-

Dismounting of Pressure Cap and Clutch Discs

32

-

Dismounting of the Primary Drive

32

-

Dismounting of Ignition Cover

33

-

Dismounting of Kickstarter

33

-

Dismounting of the Shift Lock

33

-

Dismounting of the Ignition (Kokusan)

34

-

Dismounting of the Ignition (SEM)

34

-

Dismounting of Gearshift Mechanism and Transmission

35

-

Dismounting of Intake Flange and Reed Valve Housing

35

-

Parting of Engine Housing Halves

35

-

Dismounting the Crankshaft

36

-

Servicing of Individual Components

37

-

Working on the Right-Hand Housing Half

39

-

Working on the Left-Hand Housing Half

40

-

-

Crankshaft

41

-

Crankshaft Webs – Measure Outer Dimension

41

-

Piston

41

-

Piston Ring End Gap

41

-

Checking Cylinder for Wear

42

-

Nikasil Coating of Cylinder

42

-

Recoated Cylinder

42

-

Cylinder Exhaust Control System

43

-

Cylinder Preassembly

43

-

Exhaust Control, Clutch Cover

45

-

Preassembly of Clutch Cover

45

-

Reed Valve Housing, Intake Flange

46

-

Clutch

47

-

Replace Outer Clutch Hub

48

-

Preassembly of Shift Shaft

49

-

Shift Mechanism

49

-

Check Stator and Pulse Generator (Kokusan)

50

-

Ignition (Kokusan)

50

-

Kokusan Ignition & Spark Plug

50

-

Check Stator (SEM)

51

-

Ignition (SEM)

51

-

SEM Ignition & Spark Plug

51

-

Assembly Mainshaft

52

-

Transmission

52

-

Assembly Countershaft

53

-

Assemble of Kickstarter Shaft

54

-

Assembling the Engine

55

-

Assembling the Engine Housing

58

-

Mounting Kickstarter

59

-

Mounting Shift Mechanism

59

-

Mount Primary Drive and Clutch

60

-

Mounting Clutch Discs and Pressure Cap

61

-

Adjusting Dimension „X“

62

-

Mounting Piston and Cylinder

62

-

Adjusting Control Flap (Dimension “Z“)

63

-

Mounting Cylinder Head

64

-

Mounting Reed Valve Housing and Intake Flange

64

-

Mounting Steering Covers

64

-

Mounting Engine Sprocket

65

-

Mounting the Ignition (Kokusan)

65

-

Adjusting Ignition Point (SEM)

66

-

Mounting Starting Lever and Shift Lever

66

-

Mounting the Ignition (SEM)

66

-

Electrical

67

-

Checking the Voltage Regulator (Kokusan)

69

-

Checking the Voltage Regulator (Tympanium)

69

-

Checking the Voltage Regulator-Rectifier (Shindengen)

69

-

CDI Unit

70

-

Checking the Capacitor

70

-

Ignition Coil (Kokusan)

70

-

Ignition Coil (SEM)

70

-

Checking the Voltage Regulator

71

-

Static Ignition Values 250-380 SX, EXC (Kokusan 2K-1, 2K-3, 2K-4)

72

-

Static Generator Values 250-380 EXC (Kokusan 2K-3) (Except 250 USA)

74

-

Static Ignition Values 250 MXC, EXC USA (Kokusan 2K-2)

76

-

Troubleshooting

79

-

-

Trouble Shooting

81

-

Technical Specifications

83

-

Technical Specifications — Engine 250/300/380 SX/MXC/EXC ‘99 (Only for USA)

85

-

Basic Carburetor Setting

86

-

Gasket Thicknesses

86

-

Tightening Torques

86

-

Tolerances and Fitting Clearances

86

-

Technical Specifications — Engine 250/300/380 SX/EXC/EGS ‘99 (All Models out of USA)

87

-

Standard Adjustment — Fork

89

-

Standard Adjustment — Shock Absorber

89

-

Technical Specifications Chassis 250/300/380 SX/MXC/EXC/EGS ‘99

89

-

Carburetor Setting KTM 250/300 MXC/EXC EU, USA‘99 KEIHIN PWK 38

90

-

Carburetor Setting KTM 250 SX Europe, USA ‘99 KEIHIN PWK 38

91

-

Carburetor Setting KTM 380 SX/MXC/EXC EU, USA ‘99 KEIHIN PWK 38

92

-

Technical Data — Engine 250/300/380 SX/MXC/EXC 2000 (Only USA)

93

-

Technical Data — Engine 250/300/380 SX/EXC 2000 (All Models out of USA)

95

-

Technical Specifications Chassis 250/300/380 SX, MXC, EXC 2000

97

-

Carburetor Setting G KTM 250 SX EUR/USA 2000 KEIHIN PWK 38AG PJ

98

-

Carburetor Setting KTM 250 MXC/EXC EUR/USA 2000 KEIHIN PWK 38 AG

99

-

Carburetor Setting KTM 300 MXC/EXC EUR/USA 2000 KEIHIN PWK 38 AG

100

-

Carburetor Setting KTM 380 SX/MXC/ EXC/EUR/USA 2000 KEIHIN PWK 38 AG

101

-

Technical Data — Engine 250/300/380 SX/MXC EXC 2001 (Only USA)

103

-

Technical Data — Engine 250/300/380 SX / EXC 2001 (All Models out of USA)

105

-

Technical Specifications Chassis 250/300/380 SX, MXC, EXC 2001

107

-

Carburetor Setting KTM 250 SX EUR/USA 2001 KEIHIN PWK 38AG PJ

108

-

Carburetor Setting KTM 250 MXC/EXC EUR/USA 2001 KEIHIN PWK 38 AG

109

-

Carburetor Setting KTM 300 MXC/EXC EUR/USA 2001 KEIHIN PWK 38 AG

110

-

Carburetor Setting KTM 380 SX / MXC / EXC EUR / USA 2001 KEIHIN PWK 38 AG

111

-

Technical Data — Engine 250/300/380 SX / MXC / EXC 2002 (Only USA)

112

-

Technical Data — Engine 250/300/380 SX / EXC 2002 (All Models out of USA)

114

-

Technical Specifications Chassis 250/300/380 SX, MXC, EXC 2002

116

-

Carburetor Setting KTM 250 SX EUR/USA 2002 KEIHIN PWK 38AG

117

-

Carburetor Setting KTM 250 MXC/EXC EUR/USA 2002 KEIHIN PWK 38 AG

118

-

Carburetor Setting KTM 300 MXC/EXC EUR/USA 2002 KEIHIN PWK 38 AG

119

-

Carburetor Setting KTM 380 SX / MXC / EXC EUR / USA 2002 KEIHIN PWK 38 AG

120

-

Technical Data — Engine 250/300 MXC/EXC 2003

121

-

Periodic Lubrication and Maintenance Schedule

131

-

Periodic Maintenance Schedule 2001/02

132

-

Important Chacks and Maintenance to be Carried by the Rider

133

-

Periodic Maintenance Schedule 2003

134

-

Recommended Inspection of the 250/300 EXC and MXC Engine Used for Enduro Competitions by Your KTM Workshop

136

-

Recommended Inspection of the 250/300 EXC and MXC Engine Used for Hobby Enduro by Your KTM Workshop

136

-

-

KTM 250 EXC Owner’s Manual (70 pages)

KTM Owner’s Manual Motorcycle 250 SX-F, 250 EXC, 400 EXC, 450 SX, XC, EXC, 525 SX, XC

Brand: KTM

|

Category: Motorcycle

|

Size: 5.62 MB

Table of Contents

-

Important Limited Warranty and Limited Guarantee Information

4

-

Table of Contents

5

-

Serial Number Locations

6

-

Chassis Number

6

-

Engine Number, Engine Type

6

-

-

Operation Instruments

6

-

Clutch Lever

6

-

Hot Start Lever (250 SX-F)

7

-

Hand Decompression Lever (450/525 SX)

7

-

Hand Brake Lever

7

-

Short Circuit Button (SX/XC)

7

-

Combination Switch (EXC)

7

-

Flasher Switch

8

-

Starter Button (EXC)

8

-

Emergency off Switch (EXC Australia)

8

-

Indicator Lamps

8

-

Electronic Speedometer

9

-

Setting the Clock

13

-

Filler Cap

13

-

Overview of Electronic Speedometer Functions

13

-

Fuel Tap

14

-

Choke

14

-

Hot Start Device (450/525 SX)

14

-

Shift Lever

15

-

Kickstarter

15

-

Foot Brake Pedal

15

-

Side Stand

15

-

Steering Lock

15

-

Compression Damping of Fork

16

-

Rebound Damping of Fork

16

-

Damping Action During Compression of Shock Absorber (SX)

16

-

Compression Damping of Shock Absorber (XC, EXC)

17

-

Rebound Damping of Shock Absorber (SX, XC, EXC)

17

-

-

General Tips and Warnings for Starting the Motorcycle

18

-

Instructions for Initial Operation

18

-

Running in the Racing Models

18

-

-

Driving Instructions

19

-

Check the Following before each Start

19

-

Starting When the Engine Is Cold

19

-

Starting When the Engine Is Warm

20

-

What to Do When the Engine Is „Flooded

20

-

Starting off

20

-

Shifting/Riding

20

-

Braking

21

-

Stopping and Parking

21

-

Fuel

21

-

-

Periodic Maintenance

22

-

Maintenance Work on Chassis and Engine

28

-

Changing the Spring Preloading of the Shock Absorber

28

-

Pivot Bearing

28

-

Basic Suspension Setup for the Weight of the Driver

29

-

Checking the Shock Absorber and Spring

29

-

Determining the Static Sag of the Shock Absorber

29

-

Determining the Riding Sag of the Shock Absorber

29

-

Checking the Basic Setup of the Telescopic Fork

30

-

Changing the Spring Preload on the Telescopic Fork (SX Models)

30

-

Changing the Spring Preload on the Telescopic Fork (XC/EXC Models)

30

-

Replacing Fork Springs

30

-

Breather Plug Front Fork

31

-

Cleaning the Dust Sleeves of the Telescopic Fork

31

-

Checking and Adjusting the Steering Head Bearing

31

-

Changing the Fork Offset (Caster) (SX)

32

-

Checking and Adjusting the Steering Head Bearing

33

-

Check Chain Tension

34

-

Correct Chain Tension

34

-

Chain Maintenance

35

-

Chain Wear

35

-

General Information about KTM Disc Brakes

36

-

Adjusting the Free Travel at the Hand Brake Lever

37

-

Checking the Brake Fluid Level — Front Brake

37

-

Refilling the Front Brake Fluid Reservoir

37

-

Checking the Front Brake Pads

37

-

Replacing the Front Brake Pads

38

-

Changing the Basic Position of the Foot Brake Pedal

38

-

Checking the Rear Brake Fluid Level

38

-

Refilling the Rear Brake Fluid Reservoir

38

-

Checking the Rear Brake Pads

39

-

Replacing the Rear Brake Pads

39

-

Dismounting and Mounting the Front Wheel

39

-

Dismounting and Mounting the Rear Wheel

40

-

Checking Spoke Tension

40

-

Tires, Air Pressure

41

-

Check/Set Distance of the Magnetic Sensor

41

-

Replacing the Battery of the Digital Speedometer

41

-

Battery (XC/EXC)

42

-

Charging the Battery

42

-

Fuse (XC/EXC)

43

-

Replacing Headlight Lamp/Parking Light Lamp

43

-

Cooling System

44

-

Checking the Coolant Level

44

-

Bleeding the Cooling System

44

-

Replacing the Glassfiber Yarn Packing of the Silencer

45

-

Cleaning the Spark Arrester (XC/EXC USA)

45

-

Cleaning the Air Filter

46

-

Checking the Adjustment of the Hand Decompression Release Cable

46

-

Adjusting the Throttle Cables

46

-

Changing the Original Position of the Clutch Lever

47

-

Checking the Oil Level of the Hydraulic Clutch

47

-

Bleeding of the Hydraulic Clutch

47

-

Carburetor — Adjust Idling (Keihin-FCRMX 37/39/41)

48

-

Adjusting the Mixture Control Screw

48

-

Checking the Float Level (Float Height)

48

-

Draining the Float Chamber of the Carburetor

49

-

Oil Circuit

49

-

Checking the Engine Oil Level

49

-

Engine Oil

50

-

Changing the Engine Oil

50

-

Changing the Oil Filters

51

-

KTM 250 EXC Owner’s Manual (74 pages)

KTM Owner’s Manual Motorcycle 125 EXC, EXC SIX DAYS 200 XC, XC-W, EXC 250 XC, XC-W, EXC, EXC SIX DAYS 300 XC, XC-W, EXC-E, EXC-E SIX DAYS

Brand: KTM

|

Category: Motorcycle

|

Size: 9.08 MB

Table of Contents

-

Table of Contents

5

-

Serial Number Locations

6

-

Chassis Number

6

-

Engine Number, Engine Type

6

-

-

Operation Instruments

6

-

Clutch Lever

6

-

Hand Brake Lever

6

-

Electronic Speedometer

7

-

Indicator Lamps (EXC)

11

-

Short Circuit Button

11

-

Combination Switch (EXC)

12

-

Headlamp Switch (XC-W)

12

-

Flasher Switch

12

-

Starter Button

12

-

Emergency off Switch (Australia)

12

-

Filler Cap

13

-

Fuel Tap

13

-

Choke Knob

13

-

Shift Lever

14

-

Kickstarter

14

-

Foot Brake Pedal

14

-

Side Stand

14

-

Steering Lock

14

-

Compression Damping of Fork

15

-

Rebound Damping of Fork

15

-

Spring Preload of the Fork

15

-

Shock Absorber Compression Damping

16

-

Shock Absorber Rebound Damping

16

-

-

General Tips and Warnings for Starting the Motorcycle

17

-

Instructions for Your First Ride

17

-

Running in

17

-

-

Driving Instructions

18

-

What You Should Check before each Start

18

-

Starting When the Engine Is Cold

19

-

Starting When the Engine Is Warm

19

-

What to Do When the Engine Is „Flooded

19

-

Starting off

19

-

Shifting/Riding

20

-

Braking

20

-

Stopping and Parking

20

-

Refueling, Fuel

20

-

-

Periodic Maintenance Schedule

21

-

Maintenance Work on Chassis and Engine

25

-

Changing the Spring Preloading of the Shock Absorber

25

-

Pivot Bearing

25

-

Basic Suspension Setup for the Weight of the Driver

26

-

Checking the Shock Absorber and Spring

26

-

Determining the Static Sag of the Shock Absorber

26

-

Determining the Riding Sag of the Shock Absorber

26

-

Changing the Spring Preload on the Telescopic Fork

27

-

Checking the Basic Setup of the Telescopic Fork

27

-

Breather Plug Front Fork

27

-

Cleaning the Dust Sleeves of the Telescopic Fork

28

-

Checking and Adjusting the Steering Head Bearing

28

-

Changing the Fork Offset (Caster) XC/EXC Six Days

29

-

How to Change the Handlebar Position

30

-

Adapting Chain Guide to the Rear Sprocket

31

-

Check Chain Tension

32

-

Correct Chain Tension

32

-

Chain Maintenance

32

-

Chain Wear

32

-

General Information about KTM Disc Brakes

33

-

Changing Basic Position of the Hand Brake Lever

34

-

Checking the Brake Fluid Level — Front Brake

34

-

Refilling the Front Brake Fluid Reservoir

34

-

Checking the Front Brake Pads

34

-

Replacing the Front Brake Pads

35

-

Checking the Rear Brake Fluid Level

35

-

Refilling the Rear Brake Fluid Reservoir

35

-

Changing the Basic Position of the Foot Brake Pedal

36

-

Checking the Rear Brake Pads

36

-

Replacing the Rear Brake Pads

36

-

Dismounting and Mounting the Front Wheel

37

-

Dismounting and Mounting the Rear Wheel

38

-

Tires, Air Pressure

38

-

Checking Spoke Tension

39

-

Replacing the Battery of the Digital Speedometer

39

-

Replacing the Headlight Lamp/Parking Light Lamp

39

-

Battery

40

-

Charging the Battery

40

-

Fuse

41

-

Cooling System

41

-

Checking the Coolant Level

42

-

Refilling/Bleeding the Cooling System

42

-

Cleaning the Air Filter

42

-

Checking the Oil Level of the Hydraulic Clutch

43

-

Exhaust System

43

-

Changing the Original Position of the Clutch Lever

43

-

Bleeding the Hydraulic Clutch

44

-

Carburetor Adjustment

44

-

Draining the Float Chamber of the Carburetor

46

-

Checking the Float Level

46

-

Adjusting the Engine Characteristic Via the Ignition Curve

46

-

Adjusting the Engine Characteristic Via the Auxiliary Spring

47

-

Check Transmission Oil Level

48

-

Changing the Transmission Oil

48

-

KTM 250 EXC Owner’s Manual (71 pages)

2007

Brand: KTM

|

Category: Motorcycle

|

Size: 5.14 MB

Table of Contents

-

Table of Contents

5

-

Serial Number Locations

6

-

Chassis Number

6

-

Engine Number, Engine Type

6

-

-

Operation Instruments

6

-

Clutch Lever

6

-

Hand Brake Lever

6

-

Electronic Speedometer

7

-

Indicator Lamps (EXC)

11

-

Combination Switch (EXC)

12

-

Headlamp Switch (XC-W)

12

-

Flasher Switch

12

-

Emergency off Switch (Australia)

12

-

Filler Cap

13

-

Filler Cap (XC, XC-W)

13

-

Fuel Tap

13

-

Choke Knob

13

-

Shift Lever

13

-

Kickstarter

14

-

Foot Brake Pedal

14

-

Side Stand

14

-

Steering Lock

14

-

Compression Damping of Fork

15

-

Rebound Damping of Fork

15

-

Spring Preload of the Fork(XC/EXC Six Days)

15

-

Compression Damping of Shock Absorber (XC-W, EXC)

16

-

Shock Absorber Compression Damping (XC-W/EXC)

16

-

Shock Absorber Rebound Damping XC-W, EXC)

16

-

-

General Tips and Warnings for Starting the Motorcycle

17

-

Instructions for Your First Ride

17

-

Running in

17

-

-

Driving Instructions

18

-

What You Should Check before each Start

18

-

Starting When the Engine Is Cold

19

-

Starting When the Engine Is Warm

19

-

What to Do When the Engine Is „Flooded

19

-

Starting off

19

-

Shifting/Riding

20

-

Braking

20

-

Stopping and Parking

20

-

Refueling, Fuel

20

-

-

Periodic Maintenance Schedule

21

-

Maintenance Work on Chassis and Engine

25

-

Changing the Spring Preloading of the Shock Absorber

25

-

Pivot Bearing

25

-

Basic Suspension Setup for the Weight of the Driver

26

-

Checking the Shock Absorber and Spring

26

-

Determining the Static Sag of the Shock Absorber

26

-

Determining the Riding Sag of the Shock Absorber

26

-

Changing the Spring Preload on the Telescopic Fork

27

-

Checking the Basic Setup of the Telescopic Fork

27

-

Replacing Fork Springs

28

-

Breather Plug Front Fork

28

-

Cleaning the Dust Sleeves of the Telescopic Fork

28

-

Changing the Fork Offset (Caster) (XC)

29

-

Checking and Adjusting the Steering Head Bearing

30

-

How to Change the Handlebar Position

31

-

Check Chain Tension

31

-

Correct Chain Tension

32

-

Chain Maintenance

32

-

Chain Wear

32

-

General Information about KTM Disc Brakes

33

-

Adjusting the Free Travel at the Hand Brake Lever

34

-

Checking the Brake Fluid Level — Front Brake

34

-

Refilling the Front Brake Fluid Reservoir

34

-

Checking the Front Brake Pads

34

-

Replacing the Front Brake Pads

35

-

Changing the Basic Position of the Foot Brake Pedal

35

-

Checking the Rear Brake Fluid Level

35

-

Refilling the Rear Brake Fluid Reservoir

35

-

Checking the Rear Brake Pads

36

-

Replacing the Rear Brake Pads

36

-

Dismounting and Mounting the Front Wheel

36

-

Dismounting and Mounting the Rear Wheel

37

-

Tires, Air Pressure

38

-

Checking Spoke Tension

38

-

Replacing the Battery of the Digital Speedometer

39

-

Check/Set Distance of the Magnetic Sensor

39

-

Replacing the Headlight Lamp/Parking Light Lamp

39

-

Cooling System

40

-

Checking the Coolant Level

40

-

Refilling/Bleeding the Cooling System

41

-

Cleaning the Air Filter

41

-

Checking the Oil Level of the Hydraulic Clutch

42

-

Exhaust System

42

-

Changing the Original Position of the Clutch Lever

42

-

Bleeding the Hydraulic Clutch

43

-

Carburetor Adjustment

43

-

Draining the Float Chamber of the Carburetor

45

-

Checking the Float Level

45

-

Adjusting the Engine Characteristic Via the Ignition Curve

45

-

Adjusting the Engine Characteristic Via the Auxiliary Spring

46

-

Check Transmission Oil Level (125/200)

47

-

Changing the Transmission Oil (125/200)

47

-

Check Transmission Oil Level (250/300)

47

-

Changing the Transmission Oil (250/300)

47

-

KTM 250 EXC Owner’s Manual (67 pages)

Brand: KTM

|

Category: Motorcycle

|

Size: 5.12 MB

Table of Contents

-

Table of Contents

5

-

Serial Number Locations

6

-

Chassis Number

6

-

Engine Number, Engine Type

6

-

-

Operation Instruments

6

-

Clutch Lever

6

-

Hand Brake Lever

6

-

Electronic Speedometer

7

-

Indicator Lamps (EXC)

11

-

Short Circuit Button (SX)

12

-

Combination Switch (EXC)

12

-

Headlamp Switch (EXC USA)

12

-

Flasher Switch

12

-

Emergency off Switch (Australia)

12

-

Filler Cap

13

-

Fuel Tap

13

-

Choke Knob

13

-

Shift Lever

13

-

Kickstarter

14

-

Foot Brake Pedal

14

-

Side Stand

14

-

Steering Lock

14

-

Compression Damping of Fork

15

-

Rebound Damping of Fork

15

-

Damping Action During Compression of Shock Absorber (SX)

15

-

Compression Damping of Shock Absorber (MXC, EXC)

16

-

Rebound Damping of Shock Absorber (SX, MXC, EXC)

16

-

-

General Tips and Warnings for Starting the Motorcycle

17

-

Instructions for Your First Ride

17

-

Running in

17

-

-

Driving Instructions

18

-

What You Should Check before each Start

18

-

Starting When the Engine Is Cold

19

-

Starting When the Engine Is Warm

19

-

What to Do When the Engine Is „Flooded

19

-

Starting off

19

-

Shifting/Riding

19

-

Braking

20

-

Stopping and Parking

20

-

Refueling, Fuel

20

-

-

Periodic Maintenance Schedule

21

-

Maintenance Work on Chassis and Engine

24

-

Changing the Spring Preload of the Shock Absorber

24

-

Pivot Bearing

24

-

Basic Suspension Setup for the Weight of the Driver

25

-

Checking the Shock Absorber and Spring

25

-

Determining the Static Sag of the Shock Absorber

25

-

Determining the Riding Sag of the Shock Absorber

25

-

Checking the Basic Setup of the Telescopic Fork

26

-

Changing the Spring Preload on the Telescopic Fork

26

-

Replacing Fork Springs

27

-

Breather Plug Front Fork

27

-

Cleaning the Dust Sleeves of the Telescopic Fork

27

-

Changing the Fork Offset (SX)

28

-

Checking and Adjusting the Steering Head Bearing

29

-

How to Change the Handlebar Position

30

-

Check Chain Tension

30

-

Correct Chain Tension

31

-

Chain Maintenance

31

-

Chain Wear

31

-

General Information about KTM Disc Brakes

32

-

Adjusting the Free Travel at the Hand Brake Lever

33

-

Checking the Brake Fluid Level — Front Brake

33

-

Refilling the Front Brake Fluid Reservoir

33

-

Checking the Front Brake Pads

33

-

Replacing the Front Brake Pads

34

-

Changing the Basic Position of the Foot Brake Pedal

34

-

Checking the Rear Brake Fluid Level

34

-

Refilling the Rear Brake Fluid Reservoir

34

-

Checking the Rear Brake Pads

35

-

Replacing the Rear Brake Pads

35

-

Dismounting and Mounting the Front Wheel

35

-

Dismounting and Mounting the Rear Wheel

36

-

Tires, Air Pressure

37

-

Checking Spoke Tension

37

-

Replacing the Battery of the Digital Speedometer

37

-

Check/Set Distance of the Magnetic Sensor

38

-

Replacing the Headlight Lamp/Parking Light Lamp

38

-

Cooling System

39

-

Radiator Cover for the Cold Season

39

-

Checking the Coolant Level

39

-

Refilling/Bleeding the Cooling System

40

-

Cleaning the Air Filter

40

-

Changing the Original Position of the Clutch Lever

41

-

Checking the Oil Level of the Hydraulic Clutch

41

-

Bleeding of the Hydraulic Clutch

41

-

Exhaust System

41

-

Cleaning the Spark Arrestor (EXC USA)

42

-

Carburetor Adjustment

42

-

Draining the Float Chamber of the Carburetor

43

-

Checking the Float Level

43

-

Engine Characteristic 250/300 SX/MXC/EXC

44

-

Check Transmission Oil Level (125/200)

45

-

Changing the Transmission Oil (125/200)

45

-

Check Transmission Oil Level (250/300)

45

-

Changing the Transmission Oil (250/300)

45

-

KTM 250 EXC Owner’s Manual (62 pages)

KTM MotorCycle Owner’s Manual

Brand: KTM

|

Category: Motorcycle

|

Size: 3.41 MB

Table of Contents

-

Limited Guarantee Information

4

-

Table of Contents

5

-

Serial Number Locations

6

-

Chassis Number

6

-

Engine Number, Engine Type

6

-

-

Operation Instruments

6

-

Clutch Lever

6

-

Hand Decompression Lever

6

-

Hand Brake Lever

6

-

Digital Speedometer, Indicator Lamps

7

-

Electronic Speedometer

7

-

Tripmaster Switch

8

-

Overview of Tripmaster Functions

11

-

Short Circuit Button (SX/MXC)

12

-

Combination Switch (EXC)

12

-

Headlamp Switch (EXC USA)

12

-

Flasher Switch

12

-

Emergency off Button (EXC)

12

-

Emergency off Switch (EXC Australia)

13

-

Filler Cap

13

-

Fuel Tap

13

-

Choke

13

-

Hot Start Device

14

-

Shift Lever

14

-

Kickstarter

14

-

Foot Brake Pedal

14

-

Side Stand

14

-

Compression Damping of Fork

15

-

Rebound Damping of Fork

15

-

Damping Action During Compression of Shock Absorber (SX)

15

-

Compression Damping of Shock Absorber (MXC, EXC)

16

-

Rebound Damping of Shock Absorber (SX, MXC, EXC)

16

-

Steering Lock

16

-

-

General Tips and Warnings for Starting the Motorcycle

17

-

Driving Instructions

18

-

Stopping and Parking

20

-

Periodic Lubrication and Maintenance-Schedule

21

-

Maintenance Work on Chassis and Engine

25

-

Checking and Adjusting the Steering Head Bearing

25

-

Breather Plug Front Fork

26

-

Cleaning the Dust Sleeves of the Telescopic Fork

26

-

Adjusting the Spring Preload on the Fork (SX)

26

-

Basic Suspension Setup for the Weight of the Driver

27

-

Checking Shock Absorber/Spring

27

-

Determining Static/Riding Sag of Shock Absorber

27

-

Changing Spring Preload on Telescopic Fork

28

-

Replacing Fork Springs

28

-

-

How to Change the Handlebar Position

29

-

Changing the Spring Preload of the Shock Absorber

29

-

Pivot Bearing

29

-

Check Chain Tension

30

-

Correct Chain Tension

30

-

Chain Maintenance

31

-

Chain Wear

31

-

General Information about KTM Disc Brakes

32

-

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . .Appendix

33

-

Adjusting the Free Travel at the Hand Brake Lever

33

-

Checking the Brake Fluid Level — Front Brake

33

-

Refilling the Front Brake Fluid Reservoir

33

-

Checking the Front Brake Pads

33

-

Replacing the Front Brake Pads

34

-

Changing the Basic Position of the Brake Pedal

34

-

Checking the Rear Brake Fluid Level

34

-

Refilling the Rear Brake Fluid Reservoir

34

-

Checking the Rear Brake Pads

35

-

Replacing the Rear Brake Pads

35

-

Dismounting and Mounting the Front Wheel

35

-

Dismounting and Mounting the Rear Wheel

36

-

Tires-Air Pressure

37

-

Checking the Spoke Tension

37

-

Replacing the Battery of the Digital Speedometer

37

-

Setting the Clock

38

-

Kilometers or Miles

38

-

Checking/Setting Distance of the Magnetic Sensor

39

-

Battery (MXC/EXC)

40

-

Charging the Battery

40

-

Fuse (MXC/EXC)

41

-

Replacing the Headlight/Parking Light Lamp

41

-

Cooling System

42

-

Checking the Coolant Level

42

-

Bleeding the Cooling System

42

-

Replacing the Glassfiber Yarn Packing of the Silencer

43

-

Cleaning the Spark Arrestor (MXC/EXC USA)

43

-

Cleaning the Air Filter

44

-

Checking Adjustment of the Hand Decompression Release Cable

44

-

Adjusting the Throttle Cables

44

-

Changing the Original Position of the Clutch Lever

45

-

Checking the Oil Level of the Hydraulic Clutch

45

-

Bleeding of the Hydraulic Clutch

45

-

Carburetor Adjustment

46

-

Adjusting the Mixture Control Screw

46

-

CARBURETOR – Adjust Idling

46

-

Checking the Float Level

46

-

Draining the Float Chamber of the Carburetor

47

-

Oil Circuit

47

-

Checking the Engine Oil Level

47

-

Engine Oil

48

-

Changing the Engine Oil

48

-

Changing Oil Filters

49

-

KTM 250 EXC Owner’s Handbook Manual (45 pages)

Brand: KTM

|

Category: Motorcycle

|

Size: 3.46 MB

Table of Contents

-

Chassis Number

3

-

Engine Number

3

-

Table of Contents

5

-

Serial Number Locations

6

-

Chassis Number

6

-

Engine Number, Engine Type (125/200)

6

-

Engine Number, Engine Type (250/300/380)

6

-

-

Operation Instruments

6

-

Clutch Lever

6

-

Hand Brake Lever

6

-

Digital Speedometer, Indicator Lamp (EXC)

7

-

Digital Speedometer

7

-

Odometer (EXC USA)

7

-

Speedometer, Indicator Lamps (EXC — Australia)

7

-

Short Circuit Button (SX)

7

-

Combination Switch (EXC)

8

-

Headlamp Switch (EXC USA)

8

-

Flasher Switch

8

-

Emergency off Switch (Australia)

8

-

Filler Cap

8

-

Refueling, Fuel

9

-

Fuel Tap

9

-

Choke Knob

9

-

Shift Lever

10

-

Kickstarter

10

-

Foot Brake Pedal

10

-

Compression Damping of Fork

10

-

Rebound Damping of Fork

10

-

Compression Damping of Shock Absorber

11

-

Rebound Damping of Shock Absorber

11

-

Steering Lock

11

-

Side Stand

11

-

-

Driving Instructions

12

-

Starting off

13

-

Periodic Maintenance Schedule

14

-

-

Maintenance Work on Chassis and Engine

16

-

Changing the Original Position of the Clutch Lever

16

-

Checking and Adjusting the Steering Head Bearing

16

-

Breather Plug Front Fork

17

-

Cleaning the Dust Sleeves of the Telescopic Fork

17

-

How to Change the Handlebar Position

17

-

Changing the Spring Preloading of the Shock Absorber

18

-

Pivot Bearing

18

-

Check Chain Tension

18

-

Correct Chain Tension

19

-

Chain Maintenance

19

-

Chain Wear

19

-

General Informations about KTM Disc Brakes

20

-

Adjusting of Free Travel at the Hand Brake Lever

20

-

WIRING DIAGRAMME, CARBURETOR SETTING . . .Appendix

21

-

Checking of Brake Fluid Level — Front Brake

21

-

Refilling the Front Brake Fluid Reservoir

21

-

Checking the Front Brake Pads

21

-

Replacing the Front Brake Pads

21

-

Changing the Basic Position of the Foot Brake Pedal

22

-

Checking Rear Brake Fluid Level

22

-

Refilling the Rear Brake Fluid Reservoir

22

-

Checking the Rear Brake Pads

23

-

Replacing the Rear Brake Pads

23

-

Dismounting and Mounting the Front Wheel

23

-

Dismounting and Mounting the Rear Wheel

24

-

Tires-Air Pressure

25

-

Checking Spoke Tension

25

-

Replacing the Battery of the Digital Speedometer

25

-

Adjustin Digital Speedometer

27

-

Check/Set Distance of Magnetic Sensor

27

-

Replacing Headlight Lamp (H4)

28

-

Cooling System

28

-

Radiator Cover for the Cold Season

29

-

Checking the Coolant Level

29

-

Refilling/Bleeding the Cooling System

29

-

Cleaning the Air Filter

30

-

Exhaust System

30

-

Cleaning the Spark Arrestor (EXC USA)

30

-

Draining of Float Chamber of the Carburetor

30

-

Carburetor Adjustment

31

-

Checking the Float Level

32

-

Checking the Oil Level of the Hydraulic Clutch

32

-

Bleeding of the Hydraulic Clutch

32

-

Check Transmission Oil Level (125/200)

33

-

Changing the Transmission Oil (125/200)

33

-

Check Transmission Oil Level (250/300/380)

33

-

Changing the Transmission Oil (250/300/380)

33

-

KTM 250 EXC Owner’s Manual (39 pages)

Brand: KTM

|

Category: Motorcycle

|

Size: 4.82 MB

Table of Contents

-

Serial Number Locations

6

-

Frame Number

6

-

Engine Number, Engine Type (125/200)

6

-

Engine Number, Engine Type (250/300/380)

6

-

Operation Instruments

6

-

Clutch Control Lever (125/200)

6

-

Clutch Control Lever (250/300/380)

6

-

Table of Contents

5

-

Hand Brake Lever

7

-

Speedometer, Indicator Lamps (EXC)

7

-

Odometer (EXC USA)

7

-

Speedometer, Indicator Lamps (EGS)

7

-

Ignition Lock

7

-

Short Circuit Button (SX)

8

-

Combination Switch (EXC)

8

-

Headlamp Switch (EXC USA)

8

-

Flasher Switch

8

-

Emergency off Switch (Australia)

8

-

Filler Cap

9

-

Refueling, Fuel

9

-

Fuel Tap

9

-

Choke Knob

10

-

Shift Lever

10

-

Kickstarter

10

-

Foot Brake Pedal

10

-

Compression Damping of Fork

10

-

Rebound Damping of Fork

11

-

Compression Damping of Shock Absorber

11

-

Rebound Damping of Shock Absorber

11

-

Steering Lock

11

-

Side Stand

11

-

Driving Instructions

12

-

Starting When the Engine Is Cold

13

-

Starting When the Engine Is Warm

13

-

Starting off

13

-

Stopping and Parking

13

-

Periodic Lubrication and Maintenance Schedule

14

-

Maintenance Work on Chassis and Engine

15

-

Changing the Original Position of the Clutch Lever (125/200)

15

-

Checking and Adjusting the Steering Head Bearing

15

-

Check Chain Tension

16

-

Correct Chain Tension

16

-

Chain Maintenance

16

-

Chain Wear

17

-

General Informations about KTM Disc Brakes

17

-

Adjusting of Free Travel at the Hand Brake Lever

17

-

Checking of Brake Fluid Level — Front Brake

18

-

Refilling the Front Brake Fluid Reservoir

18

-

Checking the Front Brake Pads

18

-

Replacing the Front Brake Pads

18

KTM 250 EXC Owner’s Handbook Manual (37 pages)

1999

Brand: KTM

|

Category: Motorcycle

|

Size: 5.75 MB

Table of Contents

-

Serial Number Locations

6

-

Chassis Number

6

-

Engine Number, Engine Type (125/200)

6

-

Engine Number, Engine Type (250/300/380)

6

-

Operation Instruments

6

-

Clutch Lever

6

-

Hand Brake Lever

6

-

Table of Contents

5

-

Speedometer, Indicator Lamp (EXC)

7

-

Odometer (EXC USA)

7

-

Speedometer, Indicator Lamps (EGS)

7

-

Ignition Lock

7

-

Short Circuit Button (SX)

8

-

Combination Switch (EXC)

8

-

Headlamp Switch (EXC USA)

8

-

Flasher Switch

8

-

Emergency off Switch (Australia)

8

-

Filler Cap

9

-

Refueling, Fuel

9

-

Fuel Tap

9

-

Choke Knob

10

-

Shift Lever

10

-

Kickstarter

10

-

Foot Brake Pedal

10

-

Compression Damping of Fork

10

-

Rebound Damping of Fork

11

-

Compression Damping of Shock Absorber

11

-

Rebound Damping of Shock Absorber

11

-

Steering Lock

11

-

Center Stand

11

-

Driving Instructions

12

-

Starting off

13

-

Periodic Lubrication and Maintenance Schedule

14

-

Maintenance Work on Chassis and Engine

15

-

Changing the Original Position of the Clutch Lever

15

-

Checking and Adjusting the Steering Head Bearing

15

-

Pivot Bearing

16

-

Check Chain Tension

16

-

Correct Chain Tension

16

-

Chain Maintenance

16

-

Chain Wear

17

-

General Informations about KTM Disc Brakes

17

-

Adjusting of Free Travel at the Hand Brake Lever

17

-

Checking of Brake Fluid Level — Front Brake

18

-

Refilling the Front Brake Fluid Reservoir

18

-

Checking the Front Brake Pads

18

-

Replacing the Front Brake Pads

18

-

Changing the Basic Position of the Brake Pedal

19

-

Checking Rear Brake Fluid Level

19

-

Refilling the Rear Brake Fluid Reservoir

19

KTM 250 EXC Manual (12 pages)

motor type 546

Brand: KTM

|

Category: Engine

|

Size: 10.69 MB

Table of Contents

-

Technical Data

1

-

Gear Ratios

2

-

Basic Carburetor Setting

2

-

Tolerances and Fitting Clearances

2

-

Gasket Thicknesses

2

-

Crank Case

3

-

Clutch Cover

4

-

Crankshaft, Piston

4

-

Cylinder

5

-

Twin Valve Control

5

-

Carburettor

6

-

Clutch

7

-

Kickstarter

7

-

Ignition System

8

-

Transmission

9

-

Shifting Mechanism

10

-

Cooling System

10

-

Special Tools

11

Advertisement

Related Products

-

KTM 250 EXC EU

-

KTM 250 EXC-F EU 2010

-

KTM 250 EXC EU 2010

-

KTM 250 EXC SIX DAYS EU 2010

-

KTM 250 EXC AUS 2010

-

KTM 250 EXC AUS

-

KTM 250 EXC Six days EU

-

KTM 250 EXC-F EU

-

KTM 250 EXC-F AUS

-

KTM 250 EXC-W USA

KTM Categories

Motorcycle

Motorcycle Accessories

Offroad Vehicle

Engine

Industrial Equipment

More KTM Manuals

Не можете найти ответ на свой вопрос в руководстве? Вы можете найти ответ на свой вопрос ниже, в разделе часто задаваемых вопросов о KTM 250 EXC (2012).

Как перевести мили в километры?

В чем разница между топливом E10 и E5?

Какова рекомендуемая частота замены масляного фильтра в двигателе KTM?

Как часто следует менять масло в двигателе KTM?

Как удалить ржавчину с устройства KTM мотоцикл?

Инструкция KTM 250 EXC (2012) доступно в русский?

Не нашли свой вопрос? Задайте свой вопрос здесь

owner’s Manuals

PowerWear & PowerParts Manuals

Here is your personal document

If you prefer a printed document to thumb through, or you would like to search for an older document, these are available in the Print on Demand portal.

In the portal, you can find owner’s and repair manuals for a wide variety of models.

You can choose between PDF downloads and printed copies.

To the Print on Demand portal

- Manuals

- Brands

- KTM Manuals

- Motorcycle

- 250 EXC

- Owner’s manual

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

BEDIENUNGSANLEITUNGEN

OWNER’S MANUAL

MANUALE O’USO

MANUEL D’UTILISATION

MANUAL DE INSTRUCCIONES

REPAIRMANUAL2005

REPARATURANLEITUNG

REPAIR MANUAL

MANUALE DI REPARAZIONE

MANUEL DE REPARATION

MANUAL DE REPARACION

FEDERBEIN

SHOCK ABSORBER

AMMORTIZZATORE

AMMORTISSEUR

AMORTIGUADOR

GABEL

FORK

FORCELLA

FOURCHE

HORQUILLA

Related Manuals for KTM 250 EXC RACING

-

-

-

-

Motorcycle KTM 125 EXC, EXC SIX DAYS, 200 XC, XC-W, EXC, 250 XC, XC-W, EXC, EXC SIX DAYS, 300 XC, XC-W, EXC-E, EXC-E SIX DAYS Owner’s Manual

Ktm owner’s manual motorcycle 125 exc, exc six days 200 xc, xc-w, exc 250 xc, xc-w, exc, exc six days 300 xc, xc-w, exc-e, exc-e six days (74 pages)

-

-

-

-

Summary of Contents for KTM 250 EXC RACING

-

Page 1

REPAIRMANUAL2005 BEDIENUNGSANLEITUNGEN REPARATURANLEITUNG FEDERBEIN GABEL OWNER’S MANUAL REPAIR MANUAL SHOCK ABSORBER FORK MANUALE O’USO MANUALE DI REPARAZIONE AMMORTIZZATORE FORCELLA MANUEL D’UTILISATION MANUEL DE REPARATION AMMORTISSEUR FOURCHE MANUAL DE INSTRUCCIONES MANUAL DE REPARACION AMORTIGUADOR HORQUILLA… -

Page 2

OWNER’S MANUAL 2005 250 EXC RACING 400 EXC RACING 450 SX, MXC, EXC RACING 525 SX, MXC, EXC RACING OWNER`S MANUAL MANUALE D`USO MANUEL D`UTILISATION MANUAL DE INSTRUCCIONES ART. NR. 3.211.39… -

Page 3

Take special care to follow the recommended run in, inspection, and maintenance intervals. Heeding these guidelines will significantly increase the life of your motorcycle. To ensure that all work to your KTM is performed properly and to avoid warranty conflicts, KTM recommends that you always have your KTM serviced by a recognized and qualified KTM dealer. -

Page 4: Important Limited Warranty And Limited Guarantee Information

» IMPORTANT LIMITED WARRANTY AND LIMITED GUARANTEE INFORMATION KTM sports motorcycles are designed and constructed to resist the usual wear and tear of normal use in competitions. The motorcycles comply with the regulations and categories currently in effect with the leading interna- tional motorcycle associations.

-

Page 5: Table Of Contents

Hand decompression lever …..6 General information about KTM disc brakes ..33 Hand brake lever ……6 Adjusting the free travel at the hand brake lever .

-

Page 6: Serial Number Locations

» SERIAL NUMBER LOCATIONS Chassis number The chassis number is stamped on the right side of the steering head tube. Enter this number in the field on page no 1. Engine number, engine type The engine number and the engine type are stamped into the left side of the engine below the engine sprocket.

-

Page 7: Operation Instruments

» OPERATION INSTRUMENTS Clutch lever The clutch lever [1] is located on the left side of the handlebar. The adjust- ing screw [A] is used to change the original position of the clutch lever (see maintenance work on chassis and engine). The clutch is hydraulically actuated and adjusts itself automatically.

-

Page 8: Flasher Switch

» OPERATION INSTRUMENTS Headlamp switch (EXC USA) In this model the headlamp is switched on with the pull switch [1]. Flasher switch The flasher switch is a separate unit and is mounted on the left portion of the handlebar. The wire harness is designed in a way that whenever you want to use your bike off-road, you can dismount the entire turn indicator system without affecting the function of the remaining electrical system.

-

Page 9: Electronic Speedometer

H displays the engine’s service hours. The service hour counter starts to count as soon as you start the engine. The displayed figure cannot be changed. Service intervals are indicated in service hours for some KTM offroad motor- cycles, making the service hour counter a very practical function.

-

Page 10

» OPERATION INSTRUMENTS Activating and deactivating display modes In the display mode SPEED/H, press and hold the button for 3 seconds to access the SETUP menu. The active functions will be displayed. The blink- ing function can be activated by pressing the + button and deactivated by pressing the –… -

Page 11