Информация

- О Нас

- Скачать каталоги

Интернет-Магазин Электрооборудования Вигор-Энерго. Работаем с 2008 года. Более 100 тысяч наименований. Заказать можно на сайте по выгодной цене с доставкой по России.

Данный веб-сайт носит исключительно информационный характер и ни при каких условиях не является публичной офертой, определяемой положениями Статьи 437 (часть 2) ГК РФ.

По всем возникающим вопросам звоните по телефону +7 (351) 776-93-51 в Челябинске

ИНН 7453194460, КПП 745301001, ОГРН 1087453003329

Our Brands

Register today

- Get custom product tools and services

- Access training

- Manage support cases

- Create and manage your orders (authorized partners only)

Create account

Log in

Read more benefits

0

item count of documents is

Item count in cart is

0

My Products

My Documents

Login/Register opens in new window

Schneider Electric USA Website

Welcome to our website.

V5.1IE57

Date : 05/06/2016

Type : User guide

Languages : English

Version : 04

Document Number : BBV46385

Date : 05/06/2016

Type : User guide

Languages : English

Version : 04

Document Number : BBV46385

Download

Files

| File Name |

ATV312_programming_manual_EN_BBV46385_04

(1.8 mb)

Document title

Date

Version

Languages

Document title

Product Ranges:

Altivar 312 Variable Frequency Drives VFD,

Altivar 312 Solar

Need help?

Start here!

Find answers now. Search for a solution on your own, or connect with one of our experts.

Contact Support

Reach out to our customer care team to receive more information, technical support, assistance with complaints and more.

Where to buy?

Easily find the nearest Schneider Electric distributor in your location.

Search FAQs

Search topic-related frequently asked questions to find answers you need.

Contact Sales

Start your sales inquiry online and an expert will connect with you.

2354235 11/2008

Altivar 312

Variable speed drives for asynchronous motors

Modbus communication manual

04/2009

www.schneider-electric.com

Contents

Important Information __________________________________________________________________________________________ 4

Before you begin _____________________________________________________________________________________________ 5

Documentation structure________________________________________________________________________________________ 6

Presentation _________________________________________________________________________________________________ 7

Connection to RS485 bus ______________________________________________________________________________________ 8

Configuration of the Modbus serial port ____________________________________________________________________________ 9

Modbus protocol ____________________________________________________________________________________________ 11

Appendix: Non-standard RS485 schematics _______________________________________________________________________ 16

BBV52816 04/2009

3

4

Important Information

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the device before trying to install, operate, or maintain it. The following special messages may appear throughout this documentation or on the equipment to warn of potential hazards or to call attention to information that clarifies or simplifies a procedure.

The addition of this symbol to a Danger or Warning safety label indicates that an electrical hazard exists, which will result in personal injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this symbol to avoid possible injury or death.

DANGER

DANGER indicates an imminently hazardous situation, which, if not avoided, will result in death or serious injury.

WARNING

WARNING indicates a potentially hazardous situation, which, if not avoided, can result in death, serious injury or equipment damage.

CAUTION

CAUTION indicates a potentially hazardous situation, which, if not avoided, can result in injury or equipment damage.

CAUTION

CAUTION, used without the safety alert symbol, indicates a potentially hazardous situation which, if not avoided,

can result in equipment damage.

PLEASE NOTE

The word «drive» as used in this manual refers to the controller portion of the adjustable speed drive as defined by NEC.

Electrical equipment should be installed, operated, serviced, and maintained only by qualified personnel. No responsibility is assumed by

Schneider Electric for any consequences arising out of the use of this product.

© 2009 Schneider Electric. All Rights Reserved.

BBV52816 04/2009

Before you begin

Read and understand these instructions before performing any procedure with this drive.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Read and understand this manual before installing or operating the Altivar 312 drive. Installation, adjustment, repair, and maintenance must be performed by qualified personnel.

• The user is responsible for compliance with all international and national electrical code requirements with respect to grounding of all equipment.

• Many parts of this drive, including the printed circuit boards, operate at the line voltage. DO NOT TOUCH. Use only electrically insulated tools.

• DO NOT touch unshielded components or terminal strip screw connections with voltage present.

• DO NOT short across terminals PA/+ and PC/– or across the DC bus capacitors.

• Before servicing the drive:

— Disconnect all power, including external control power that may be present.

— Place a “DO NOT TURN ON” label on all power disconnects.

— Lock all power disconnects in the open position.

— WAIT 15 MINUTES to allow the DC bus capacitors to discharge. Then follow the “Bus Voltage Measurement Procedure”, see

Installation manual, to verify that the DC voltage is less than 42 V. The drive LEDs are not indicators of the absence of DC bus voltage.

• Install and close all covers before applying power or starting and stopping the drive.

Failure to follow these instructions will result in death or serious injury.

DANGER

UNINTENDED EQUIPMENT OPERATION

• Read and understand this manual before installing or operating the Altivar 312 drive.

• Any changes made to the parameter settings must be performed by qualified personnel.

Failure to follow these instructions will result in death or serious injury.

WARNING

DAMAGED DRIVE EQUIPMENT

Do not operate or install any drive or drive accessory that appears damaged.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

WARNING

LOSS OF CONTROL

• The designer of any control scheme must

— consider the potential failure modes of control paths and, for certain critical control functions,

— provide a means to achieve a safe state during and after a path failure.

Examples of critical control functions are emergency stop and overtravel stop.

• Separate or redundant control paths must be provided for critical control functions.

• System control paths may include communication links. Consideration must be given to the implications of unanticipated transmission delays or failures of the link.

a

Failure to follow these instructions can result in death, serious injury, or equipment damage.

a. For additional information, refer to NEMA ICS 1.1 (latest edition), “Safety Guidelines for the Application, Installation, and Maintenance of Solid State Control” and to

NEMA ICS 7.1 (latest edition), “Safety Standards for Construction and Guide for Selection, Installation and Operation of Adjustable-Speed Drive Systems.”

5

BBV52816 04/2009

6

Documentation structure

The following Altivar 312 technical documents are available on the Schneider Electric website ( www.schneider-electric.com

) as well as on

DVD-ROM (reference VW3A8200).

Installation manual

This manual describes how to install and wire the drive.

Programming manual

This manual describes the functions, parameters and use of the drive terminal (integrated display terminal, optional graphic display terminal and optional remote terminal).

The communication functions are not described in this manual, but in the manual for the bus or network used.

Simplified manual

This manual is a simplified version of the User manual. This manual is delivered with the drive.

Quick Start sheet

The Quick Start describes how to wire and configure the drive to start motor quickly and simply for simple applications. This document is delivered with the drive.

Communication manuals: Modbus, CANopen, …

These manuals describe the assembly, connection to the bus or network, signaling, diagnostics, and configuration of the communicationspecific parameters.

They also describe the communication protocol services.

Communication variables manual

The Communication variables manual defines the drive control processes and the drive variables which can be accessed by the communication buses: Modbus, CANopen, …

BBV52816 04/2009

Presentation

The Modbus socket on the Altivar 312 can be used for the following functions:

• Configuration

• Settings

• Control

• Monitoring

The ATV312 drive supports:

• The 2-wire RS485 physical layer

• The RTU transmission mode

This guide contains information on installation and describes the Modbus services available. The «communication variables» guide describes the operating modes, as well as the Altivar 312 variables and parameters which can be accessed via the communication bus.

BBV52816 04/2009

7

Connection to RS485 bus

Connection to ATV312

Connection accessories should be ordered separately (please consult our catalogues).

Connect the RJ45 cable connector to the ATV312 connector.

Pin out of the ATV312 RJ45 Connector

View from underneath

8

8……………………1

5

6

3

4

7

8

Pin Signal

1

CANopen signal reserved

2

CANopen signal reserved

CANopen signal reserved

D1 Modbus signal

D0 Modbus signal

Not connected

VP (1)

Common Modbus signal

(1) Supply for RS232 / RS485 converter or a remote terminal

Protection against interference

• Use the Telemecanique cable with 2 pairs of shielded twisted conductors (reference: TSXCSA100, TSXCSA200, TSXCSA500).

• Keep the Modbus cable from the power cables (30 cm minimum).

• Make any crossovers of the Modbus cable and the power cables at right-angles, if necessary.

• Connect the cable shielding to the ground of each device.

For more information, please refer to the TSX DG KBL E guide: «Electromagnetic compatibility of industrial networks and fieldbuses».

RS485 bus schematic

The RS485 standard allows variants of different characteristics:

• polarisation

• line terminator

• distribution of a reference potential

• number of slaves

• length of bus

The new Modbus specification published on the Modbus.org site in 2002 contains precise details of all these characteristics. They are also summarised in the next paragraph (Standard schematic). The new Telemecanique devices conform to this specification.

Some devices comply with earlier specifications. The two most common networks are described in the appendices:

• «Uni-Telway schematic» page

16

• «Jbus schematic» page

17

Requirements enabling different types of protocol to coexist are given in the appendix:

• «Mixed schematic» page

18

In case of coexistence of different types of protocol, see the appendix page 21.

BBV52816 04/2009

Configuration of the Modbus serial port

Communication Menu Structure

The communication parameters are part of the COM- and FLt- menus.

These parameters are accessible as follows:

Communication configuration — Parameters decription

Parameter description

Modbus Address

Add

Modbus baud rate tbr

Important: only 19.2 kbps baud rate allows to communicate with the remote display)

Modbus format tFO

Range or listed values

1 to 247

4.8 kbps

9.6 kbps

19.2 kbps

8O1: 8 bits, odd parity, 1 stop bit.

8E1: 8 bits, even parity, 1 stop bit.

8N1, 8 bits, no parity, 1 stop bit

8N2: 8 bits, no parity, 2 stop bits.

Adjustable from 0.1 to 30s Modbus time out ttO

Modbus fault mgt

SLL

(This parameter is not a communication management parameter)

No action.

Freewheel stop

Ramp stop

Fast stop»

default

1

Long name

[Modbus Address]

19.2 kbps [Modbus baud rate]

8E1

10 s

—

[8 odd 1 stop]

[8 even 1 stop]

[8 no 1 stop]

[8 no 2 stop]

[Modbus time out]

[No]

[Freewheel ]

[Ramp Stop]

[Fast Stop]

Short name @

Add

—

—

4.8

9.6

19.2

801

8E1

8n1

8n2 ttO nO

YES rNP

FSt

—

—

—

WARNING

LOSS OF CONTROL

If Modbus fault management

SLL

is set to nO, communication control will be inhibited. For safety reasons, inhibition of communication fault should only be used for adjustment or special applications purpose.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

BBV52816 04/2009

9

Connection to RS485 bus

Standard schematic

The standard schematic corresponds to the Modbus specification published on the Modbus.org

site in 2002

(Modbus_over_serial_line_V1.pdf, Nov 2002) and in particular to the schematic of the 2-wire multidrop serial bus.

The ATV312 drive conforms to this specification.

Schematic diagram:

Master

R

650

Ω

0 V

T

5 V

650

Ω

D1

120

Ω

1n F

120

Ω

1n F

D0

Common

R

T

R

T

Type of trunk cable

Maximum length of bus

Maximum number of stations (without repeater)

Maximum length of tap links

Bus polarisation

Line terminator

Common polarity

Shielded cable with 1 twisted pair and at least a third conductor

1000 m at 19200 bps with the Telemecanique TSX CSA ppp

cable

32 stations, ie. 31 slaves

20 m for one tap link

40 m divided by the number of tap links on a multiple junction box

One 450 to 650

Ω

pulldown resistor at 5 V (650

Ω

recommended)

One 450 to 650 Ω pulldown resistor at the Common (650 Ω recommended)

This polarisation is recommended for the master.

One 120 Ω 0.25 W resistor in series with a 1nF 10 V capacitor

Yes (Common), connected to the protective ground at one or more points on the bus

10

BBV52816 04/2009

Modbus protocol

Configuration of the serial link

Configuration of the serial link parameters can be accessed from the Communication menu

COM-

Parameters

Address

Add

Speed tbr

Possible values

1 to 247

Terminal display

001

to

247

Format tFO

4800 bps

9600 bps

19200 bps (1)

8 data bits, odd parity, 1 stop bit

8 data bits, even parity, 1 stop bit (1)

8 data bits, no parity, 1 stop bit

8 data bits, no parity, 2 stop bits

4.8

9.6

19.2

8O1

8E1

8n1

8n2

(1) The display terminal will only work with these values.

RTU mode

The transmission mode used is RTU mode. The frame contains no message header byte, nor end of message bytes.

It is defined as follows:

Default value

1

19200 bps

8E1

Slave address

Request code Data CRC16

The data is transmitted in binary code.

CRC16: cyclical redundancy check.

The end of the frame is detected on a silence greater than or equal to 3 characters.

Principle

The Modbus protocol is a master-slave protocol.

Master

Only one device can transmit on the line at any time.

The master manages the exchanges and only it can take the initiative.

It interrogates each of the slaves in succession.

No slave can send a message unless it is invited to do so.

The master repeats the question when there is an incorrect exchange, and declares the interrogated slave absent if no response is received within a given time period.

If a slave does not understand a message, it sends an exception response to the master. The master may or may not repeat the request.

Slave j

Slave i

Direct slave-to-slave communications are not possible.

Slave k

For slave-to-slave communication, the application software must therefore be designed to interrogate a slave and send back data received to the other slave.

Two types of dialogue are possible between master and slaves:

• the master sends a request to a slave and waits for its response

• the master sends a request to all slaves without waiting for a response (broadcasting principle)

Addresses

• The drive Modbus address can be configured from 1 to 247.

• Address 0 coded in a request sent by the master is reserved for broadcasting. ATV 312 drives take account of the request, but do not respond to it.

BBV52816 04/2009

11

Modbus protocol

Modbus functions

The following table indicates which Modbus functions are managed by the Altivar 312, and specifies their limits.

The “read” and “write” functions are defined from the point of view of the master.

Code

(decimal)

3

6

16

43

Function name

Read N output words

Write one output word

Write N output words

Identification

Broadcasting

NO

YES

YES

NO

Max. value of N

29 words max.

–

27 words max.

–

Modbus standard name

Read Holding Registers

Preset Single Register

Preset Multiple Regs

Read Device Identification

Read N output words: function 3

Note: Hi = high order byte, Lo = low order byte.

This function can be used to read all ATV 312 words, both input words and output words.

Request

Slave no.

1 byte

03

1 byte

No. of first word

Hi

2 bytes

Lo

Number of words

Hi

2 bytes

Lo Lo

CRC16

2 bytes

Hi

Response

Slave no.

1 byte

03

1 byte

Number of bytes read

1 byte

First word value

Hi Lo

2 bytes

——Last word value

Hi Lo

2 bytes

Example: read 4 words W3102 to W3105 (16#0C1E to 16#0C21) in slave 2, using function 3, where:

• SFr = Switching frequency = 4 kHz (W3102 = 16#0028)

• tFr = Maximum output frequency = 60 Hz (W3103 = 16#0258)

• HSP = High speed = 50 Hz (W3104 = 16#01F4)

• LSP = Low speed = 0 Hz (W3105 = 16#0000)

Request 02 03 0C1E 0004 276C

Response 02 03

Value of:

Parameters:

08 0028

W3102

SFr

0258

W3103 tFr

01F4

W3104

HSP

0000

W3105

LSP

CRC16

Lo

2 bytes

Hi

52B0

Write one output word: function 6

Request and response (the frame format is identical)

06 Slave no.

1 byte 1 byte

Hi

Word number

Lo

2 bytes

Hi

Value of word

Lo

2 bytes

Example: write value 16#000D in word W9001 (16#2329) in slave 2 (ACC = 13 s).

Request and response 02 06 2329 000D 9270

Lo

CRC16

2 bytes

Hi

12

BBV52816 04/2009

Modbus protocol

Identification: Function 43 (16#2B)

Request

2B Slave no.

1 byte 1 byte

Type of MEI

0E

1 byte

ReadDeviceId

01

1 byte

Response

Slave no.

1 byte

2B

1 byte

Type of MEI

0E

1 byte

ReadDeviceId

01

1 byte

Object Id

00

1 byte

Lo

CRC16

2 bytes

Hi

Degree of conformity

02

1 byte

——-

——-

——-

Number of additional frames

00

1 byte

Id of object no. 1

00

1 byte

Length of object no. 1

0D

1 byte

Next object Id

00

1 byte

Value of object no. 1

“Telemecanique”

13 bytes

Number of objects

03

1 byte

——-

——-

——Id of object no. 2

01

1 byte

Length of object no. 2

0F

1 byte

Value of object no. 2

“ATV31HU09M3S232”

15 bytes

——-

——Id of object no. 3

02

1 byte

Length of object no. 3

04

1 byte

Value of object no. 3

“0201”

0 4 bytes

——-

——-

Lo

1 byte

CRC16

Hi

1 byte

The total response size equals 48 bytes

The three objects contained in the response correspond to the following objects:

• Object no

. 1:

• Object no

. 2:

• Object no

. 3:

Manufacturer name (always “Telemecanique”, ie. 13 bytes).

Device reference (ASCII string; for example: “ATV31HU09M3S232”, ie. 15 bytes).

Device version, in “MMmm” format where “MM” represents the determinant and “mm” the subdeterminant (4-byte ASCII string; for example: “0201” for version 2.1).

Note: The response to function 43 may be negative; in this case, the response located at the top of the next page is sent by the Altivar 312 rather than the response described above.

BBV52816 04/2009

13

Modbus protocol

Negative response

Slave no.

1 byte

2B + 80

AB

1 byte

Error code:

Type of MEI

0E

1 byte

Error code

00 to 02

1 byte

Lo

1 byte

CRC16

Hi

1 byte

• 16#0

0 =

• 16#0

1 =

• 16#0

2 =

No error

The “Request code” (16#2B), the “Type of MEI” (16#0E) or the “ReadDeviceId” (16#01) contained in the request is incorrect

The “Object Id” (16#00) contained in the request is incorrect

Example: Following the request from the Modbus master, slave 2 identifies itself as follows:

• Manufacturer name = “Telemecanique” (13 bytes)

• Device name = “ATV31HU09M3S232” (15 bytes)

• Device version = “0201” (4 bytes)

Request 02 2B 0E 01 00 3477

Response 02 2B 0E 01 02 00 00 03 ——-

——00 0D

——01 0F

54 45 4C 45 4D 45 43 41 4E 49 51 55 45 ——-

41 54 56 33 31 48 55 30 39 4D 33 53 32 33 32 ——-

——02 04 30 32 30 31 A80F

Write N output words: function 16 (16#10)

Request

No.

slave

1 byte

10

1 byte

No. of first word

Hi Lo

2 bytes

Number of words

Number of bytes

2 bytes 1 byte

Response

Slave no.

1 byte

10 No. of first word

Hi Lo

2 bytes

Number of words

Hi Lo

2 bytes 1 byte

Example: write values 20 and 30 in words W9001 and W9002 in slave 2

(ACC = 20 s and DEC = 30 s)

Request 02 10 2329 0002 04 0014

Value of first word

Hi Lo

2 bytes

Lo

CRC16

2 bytes

Hi

001E 517F

Response 02 10 2329 0002 8FED

——-

Lo

CRC16

Hi

2 bytes

14

BBV52816 04/2009

Modbus protocol

Exception responses

An exception response is returned by a slave when it is unable to perform the request which is addressed to it.

Format of an exception response:

Slave no.

1 byte

Response

code

1 byte

Error code

1 byte

Lo

CRC16

2 bytes

Hi

Response code: request function code + 16#80.

Error code:

1 = The function requested is not recognized by the slave

2 = The bit or word addresses indicated in the request do not exist in the slave

3 = The bit or word values indicated in the request are not permissible in the slave

4 = The slave has started to execute the request but cannot continue to process it completely

CRC16 calculation

The CRC16 is calculated on all the message bytes by applying the following method:

Initialize the CRC (16-bit register) to 16#FFFF.

Enter the first to the last byte of the message:

CRC

Enter

XOR

8 times

<byte> —> CRC

Move the CRC one bit to the right

If the output bit = 1, enter CRC XOR 16#A001—> CRC

End enter

End enter

The CRC obtained will be transmitted with the low order bytes sent first, followed by the high order ones (unlike the other data contained in

Modbus frames).

XOR = exclusive OR.

BBV52816 04/2009

15

Appendix: Non-standard RS485 schematics

Uni-Telway schematic

The Uni-Telway bus schematic has been used by Telemecanique for its drives and soft starters (ATV58, ATV28, etc).

Schematic diagram:

Master

R

4.7 k

Ω

0 V

T

5 V

4.7 k

Ω

D(B)

120

Ω

1 nF

120

Ω

1 nF

D(A)

0VL

4.7 k

Ω

0 V

5 V

4.7 k

Ω

R

T

Slave 1

4.7 k

Ω

0 V

R

T

5 V

4.7 k

Ω

Slave n

Type of trunk cable

Maximum length of bus

Maximum number of stations (without repeater)

Maximum length of tap links

Bus polarisation

Line terminator

Common polarity

Cable with 2 twisted pairs shielded in pairs

1000 m at 19200 bps

29 stations, ie. 28 slaves

• 20 m

• 40 m divided by the number of tap links on a multiple junction box

For the master and each slave:

• One 4.7 k

Ω pulldown resistor at 5 V

• One 4.7 k

Ω pulldown resistor at 0 VL

One 120

Ω 0.25 W resistor in series with a 1 nF 10 V capacitor

Yes (0 VL) and high impedance placed between 0 VL and the ground in each station

16

BBV52816 04/2009

Appendix: Non-standard RS485 schematics

Jbus schematic

Schematic diagram:

Master

R

470

Ω

0 V

T

5 V

470

Ω

L- (B/B’)

150

Ω

L+ (A/A’)

150

Ω

R

T

Slave 1

R

T

Slave n

Type of trunk cable

Maximum length of bus

Maximum number of stations (without repeater)

Maximum length of tap links

Bus polarisation

Line terminator

Common polarity

Cable with 1 shielded twisted pair

1300 m at 19200 bps

32 stations, ie. 31 slaves

3 m

One 470

Ω pulldown resistor at 5 V

One 470

Ω pulldown resistor at 0 V

This polarisation is often provided in the master.

One 150

Ω resistor

No

BBV52816 04/2009

17

Appendix: Non-standard RS485 schematics

Mixed schematic

Slaves with 4.7 k

Ω polarisation can be integrated into a standard schematic. Suitable polarisation (Rp) must be calculated.

Schematic diagram:

Master

R

T

5 V

Rp

Rp

0 V

D1

120

Ω

1 nF

120

Ω

1 nF

D0

Common

4.7 k

Ω

0 V

5 V

4.7 k

Ω

R

T

R

T

Type of trunk cable

Maximum length of bus

Maximum number of stations

(without repeater)

Maximum length of tap links

Bus polarisation

Line terminator

Common polarity

Slave 1

Shielded cable with 1 twisted pair and at least a 3

1000 m at 19200 bps

Slave n

rd

conductor

At most 32 stations ie. 31 slaves (depending on Rp and the number of 4.7 k

Ω resistors)

• 20 m for a single tap link

• 40 m divided by the number of tap links on a multiple junction box

• One pulldown resistor at 5 V (Rp)

• One pulldown resistor at the Common (Rp)

This polarisation can be provided in the master.

The value of Rp should be validated (or determined) by calculating the equivalent polarisation (Re) according to the polarisation of the master and slave stations.

The value of Re must be between 162

Ω and 650 Ω (recommended value: 650 Ω).

One 120

Ω 0.25 W resistor in series with a 1 nF 10 V capacitor

Yes (Common)

• To calculate the polarisation (Rp), all station polarisations must be deemed to be connected in parallel.

Example:

If the bus Rp polarisation is 470

Ω (installed in the master) and 2 slaves have 4700 Ω polarisation, the equivalent polarisation is:

1/Re = 1/470 + 1/4700 + 1/4700 ie. Re = 1/ (1/470 + 1/4700 + 1/4700) and therefore Re = 390

Ω.

390

Ω is greater than 162 Ω, and the schematic is correct.

For an ideal equivalent polarisation (650

Ω), Rp bus polarisation can be installed so that:

1/650 = 1/Rp + 1/4700 + 1/4700 ie. Rp = 1/(1/650 — 1/4700 — 1/4700) and therefore Rp = 587

Ω.

• If the master is fitted with a 470

Ω polarisation, it is possible to connect a maximum of 18 slaves with 4.7 kΩ polarisation.

18

BBV52816 04/2009

Appendix: Non-standard RS485 schematics

Recommendations for setting up a Modbus network using non-standard devices

1. Identify polarities D0 and D1.

They are labeled in a variety of ways according to the specification used:

Modbus

EIA/TIA-485

UNI-TELWAY

Jbus

D0

A / A’

D(A)

RD + / TD +

L +

D1

B / B’

D(B)

RD — / TD —

L —

Common

C / C’

0VL

However, certain RS485 electronic components are labeled in the opposite way to the EIA/TIA-485 standard.

It may be necessary to perform a test by connecting a master to a slave, then reversing the connection in the event of failure.

2. Check polarizations.

Study the documentation supplied with the devices to determine the polarization resistance.

If there is one, check that the value is correct (see Mixed schematic page 18

)

Polarization is not always possible. For example, in the event of the 5 V not being available in the master.

3. Select a line terminator.

In the case of polarization, select an RC line terminator (R = 120

Ω, C = 1 nF).

If polarization is not possible, select an R line terminator (R = 150

Ω).

BBV52816 04/2009

19

BBV52816

ATV312_Modbus_EN_V1.pdf

04/2009

2354235 11/2008

Altivar 312

Variable speed drives

for asynchronous motors

CANopen® communication manual

09/2009

BBV52819

www.schneider-electric.com

Contents

Important Information __________________________________________________________________________________________ 4

Before you begin______________________________________________________________________________________________ 5

Documentation structure________________________________________________________________________________________ 6

Presentation _________________________________________________________________________________________________ 7

Hardware setup CANopen

Hardware setup CANopen

Configuration _______________________________________________________________________________________________ 17

Signalling __________________________________________________________________________________________________ 18

Software setup ______________________________________________________________________________________________ 19

Software setup with PL7 and SyCon _____________________________________________________________________________ 22

Description of the services _____________________________________________________________________________________ 31

Object dictionary_____________________________________________________________________________________________ 45

®

daisy chain — option VW3A31208 __________________________________________________________ 8

®

tap — option VW3CANTAP2 ______________________________________________________________ 12

BBV52819 09/2009 3

Important Information

The addition of this symbol to a Danger or Warning safety label indicates that an electrical hazard exists, which will result in

personal injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow

this symbol to avoid possible injury or death.

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the device before trying to install, operate, or maintain

it. The following special messages may appear throughout this documentation or on the equipment to warn of potential hazards or to call

attention to information that clarifies or simplifies a procedure.

DANGER

DANGER indicates an imminently hazardous situation, which, if not avoided, will result in death or serious injury.

WARNING

WARNING indicates a potentially hazardous situation, which, if not avoided, can result in death, serious injury or

equipment damage.

CAUTION

CAUTION indicates a potentially hazardous situation, which, if not avoided, can result in injury or equipment

damage.

CAUTION

CAUTION, used without the safety alert symbol, indicates a potentially hazardous situation which, if not avoided,

can result in equipment damage.

PLEASE NOTE

The word «drive» as used in this manual refers to the controller portion of the adjustable speed drive as defined by NEC.

Electrical equipment should be installed, operated, serviced, and maintained only by qualified personnel. No responsibility is assumed by

Schneider Electric for any consequences arising out of the use of this product.

© 2009 Schneider Electric. All Rights Reserved.

4 BBV52819 09/2009

Before you begin

Read and understand these instructions before performing any procedure with this drive.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Read and understand this manual before installing or operating the Altivar 312 drive. Installation, adjustment, repair, and

maintenance must be performed by qualified personnel.

• The user is responsible for compliance with all international and national electrical code requirements with respect to grounding of

all equipment.

• Many parts of this drive, including the printed circuit boards, operate at the line voltage. DO NOT TOUCH. Use only electrically

insulated tools.

• DO NOT touch unshielded components or terminal strip screw connections with voltage present.

• DO NOT short across terminals PA/+ and PC/– or across the DC bus capacitors.

• Before servicing the drive:

— Disconnect all power, including external control power that may be present.

— Place a “DO NOT TURN ON” label on all power disconnects.

— Lock all power disconnects in the open position.

— WAIT 15 MINUTES to allow the DC bus capacitors to discharge.

— Measure the voltage of the DC bus between the PA/+ and PC/– terminals to ensure that the voltage is less than 42 Vdc.

— If the DC bus capacitors do not discharge completely, contact your local Schneider Electric representative. Do not repair or

operate the drive

• Install and close all covers before applying power or starting and stopping the drive.

Failure to follow these instructions will result in death or serious injury.

DANGER

UNINTENDED EQUIPMENT OPERATION

• Read and understand this manual before installing or operating the Altivar 312 drive.

• Any changes made to the parameter settings must be performed by qualified personnel.

Failure to follow these instructions will result in death or serious injury.

WARNING

DAMAGED DRIVE EQUIPMENT

Do not operate or install any drive or drive accessory that appears damaged.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

WARNING

LOSS OF CONTROL

• The designer of any control scheme must

— consider the potential failure modes of control paths and, for certain critical control functions,

— provide a means to achieve a safe state during and after a path failure.

Examples of critical control functions are emergency stop and overtravel stop.

• Separate or redundant control paths must be provided for critical control functions.

• System control paths may include communication links. Consideration must be given to the implications of unanticipated

transmission delays or failures of the link.

a

Failure to follow these instructions can result in death, serious injury, or equipment damage.

a. For additional information, refer to NEMA ICS 1.1 (latest edition), “Safety Guidelines for the Application, Installation, and Maintenance of Solid State Control” and to

NEMA ICS 7.1 (latest edition), “Safety Standards for Construction and Guide for Selection, Installation and Operation of Adjustable-Speed Drive Systems.”

BBV52819 09/2009 5

Documentation structure

The following Altivar 312 technical documents are available on the Schneider Electric website (www.schneider-electric.com) as well as on

DVD-ROM (reference VW3A8200).

Installation manual

This manual describes how to install and wire the drive.

Programming manual

This manual describes the functions, parameters and use of the drive terminal (integrated display terminal, optional graphic display terminal

and optional remote terminal).

The communication functions are not described in this manual, but in the manual for the bus or network used.

Simplified manual

This manual is a simplified version of the User manual. This manual is delivered with the drive.

Quick Start sheet

The Quick Start describes how to wire and configure the drive to start motor quickly and simply for simple applications. This document is

delivered with the drive.

Communication manuals: Modbus and CANopen

These manuals describe the assembly, connection to the bus or network, signaling, diagnostics, and configuration of the communicationspecific parameters.

They also describe the protocol communication services.

®

Communication variables guide

This manual defines the drive control processes and the drive variables which can be accessed by the communication buses: Modbus,

CANopen

®

, …

6 BBV52819 09/2009

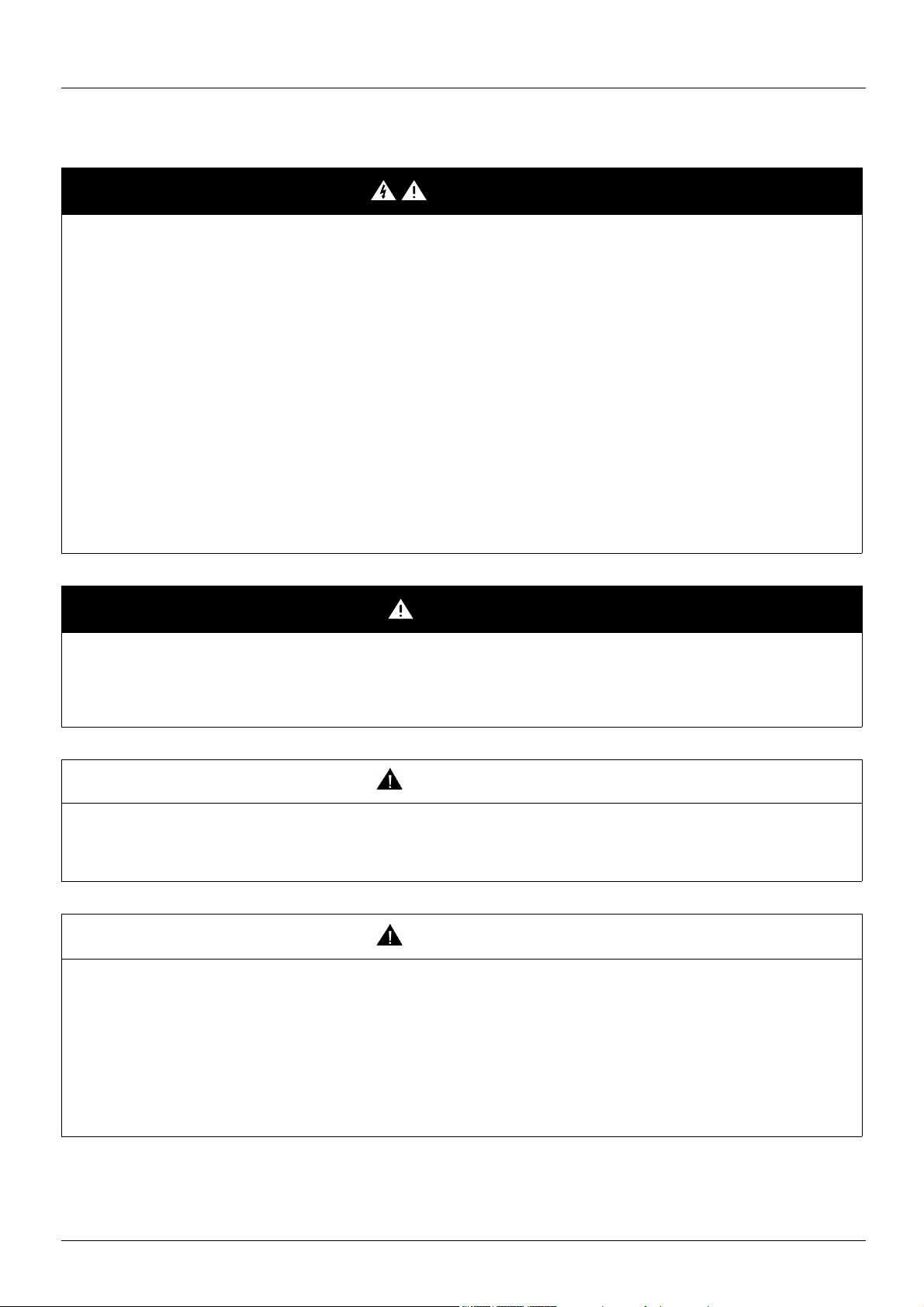

Presentation

The CANopen® socket on the Altivar 312 can be used for the following functions:

• Configuration

• Settings

• Control

• Monitoring

This guide contains information on installation and describes the CANopen

describes the operating modes, as well as the Altivar 312 variables and parameters which can be accessed via the communication bus.

®

services available. The «communication variables» guide

BBV52819 09/2009 7

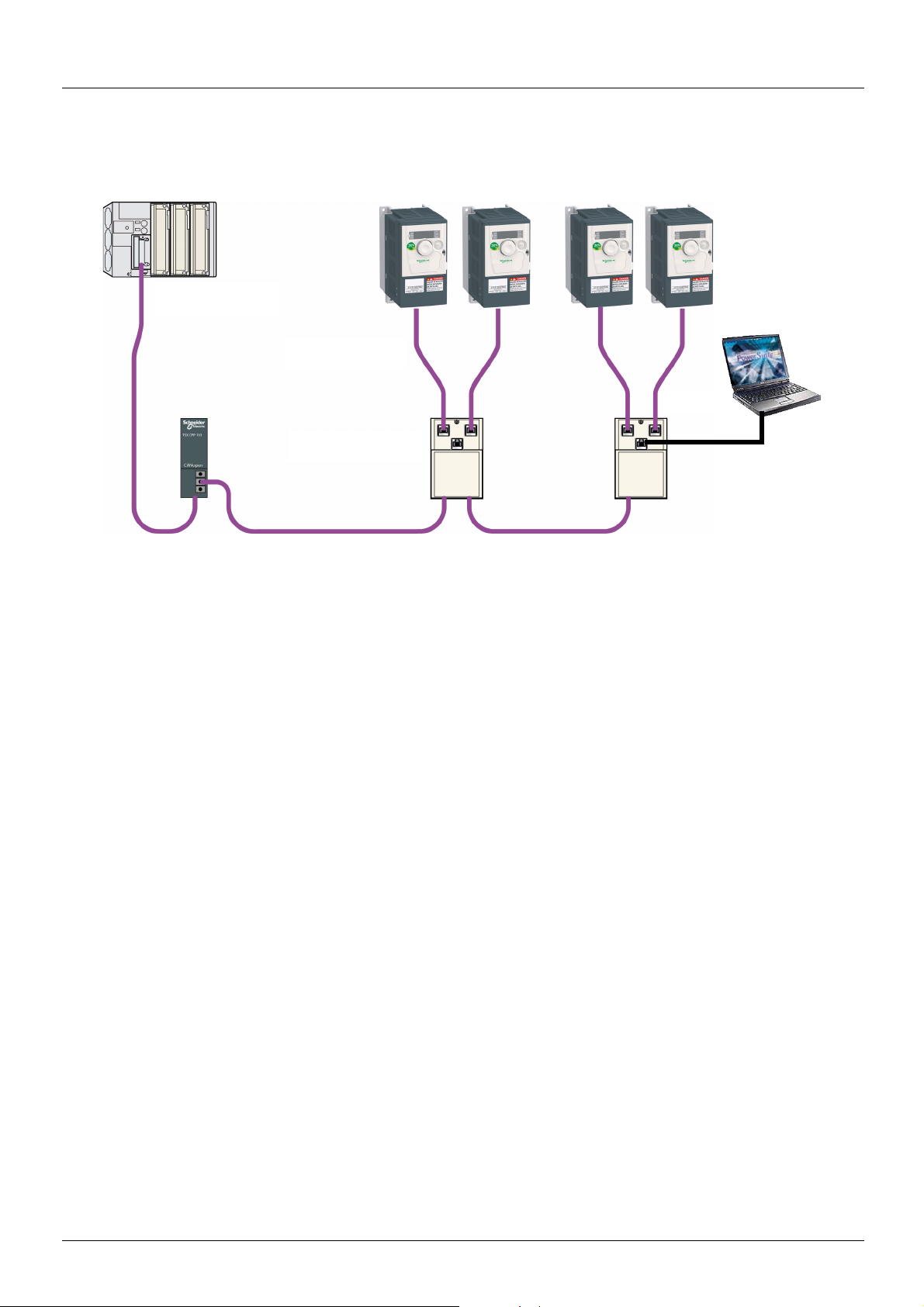

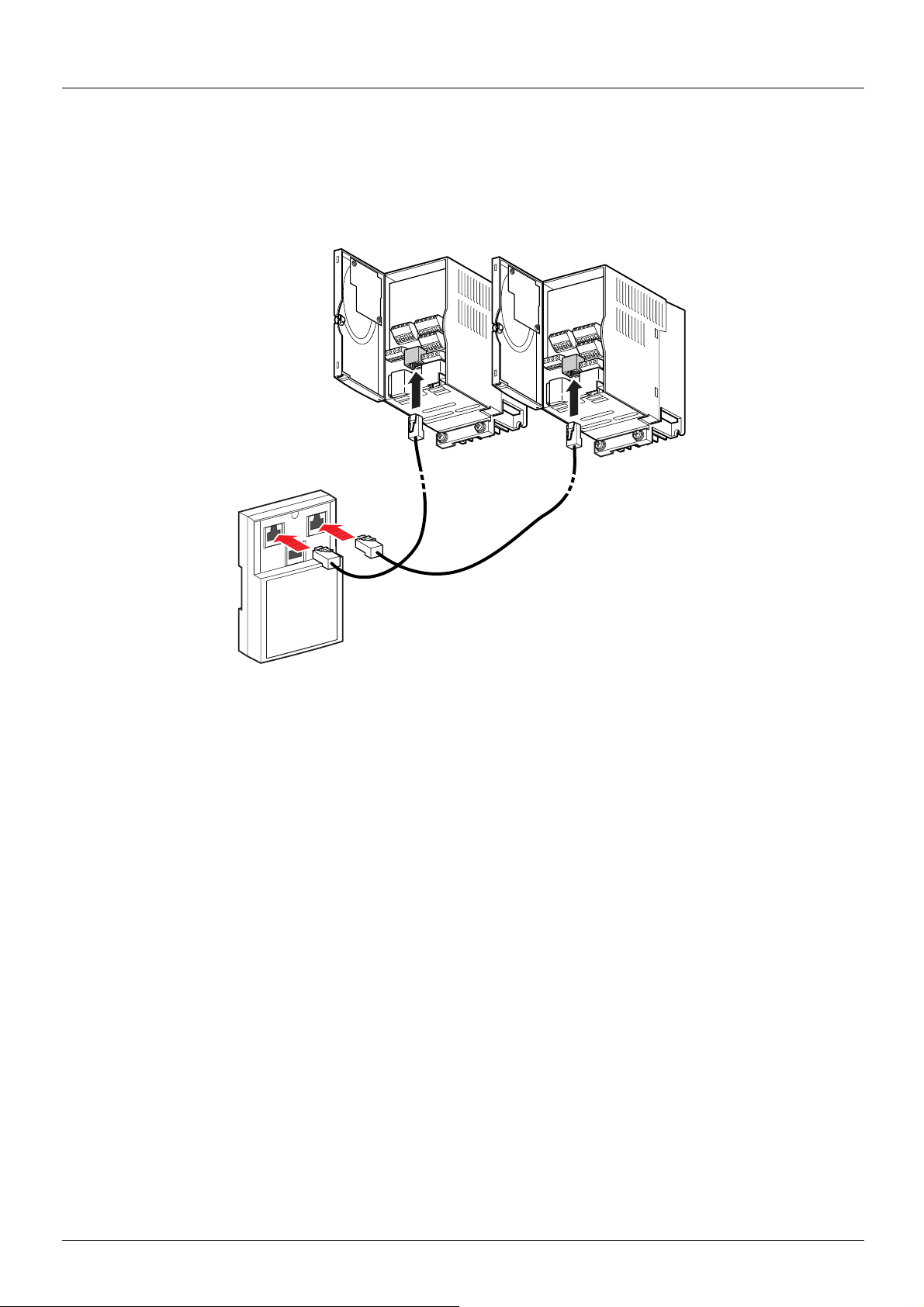

Hardware setup CANopen® daisy chain — option VW3A31208

PowerSuite

or SoMove

Line Termination

TCS CAR013M120

Modbus

Master PLC

M340 CANopen

®

ATV 312 drop cord

VW3 CAN CA RR

p

The following diagram shows an example of four ATV 312, with each one a CANopen® daisy chain module inside, and connected to M340.

®

ATV312 CANopen

• Two RJ45 connectors allow the creation of a CANopen

cord is a cable equipped with 2 RJ45 connectors. Two lengths are available: 0.3 m (0.98 ft), reference: VW3 CAN CA RR 03 and

1 m (3.28 ft), reference: VW3 CAN CA RR1.

• A third RJ45 connector to connect the ATV312 with the commissioning tools like : PowerSuite, SoMove, Bluetooth™ adaptor, Simpleloader and Multi-loader, or to connect Modbus devices (PLC, HMI, etc…).

daisychain option card (reference: VW3 A31208, supplied separately) provides:

®

network by using cables equipped with RJ45: ATV 312 CANopen® drop

The network termination is done by inserting on the last available RJ45 port of the last device on the network a line termination (reference

TCS CAR013M120). This line termination is fitted with a RJ45 to be directly inserted on the module.

As the VW3 A31208 replaces the base terminal card of the ATV312, it is also equipped with digital and analog IOs.

Note: maximum bus length are divided by 2 when an Altivar 312 is placed on a CANopen

See values page 17

.

®

bus with CANopen® daisychain VW3A31208.

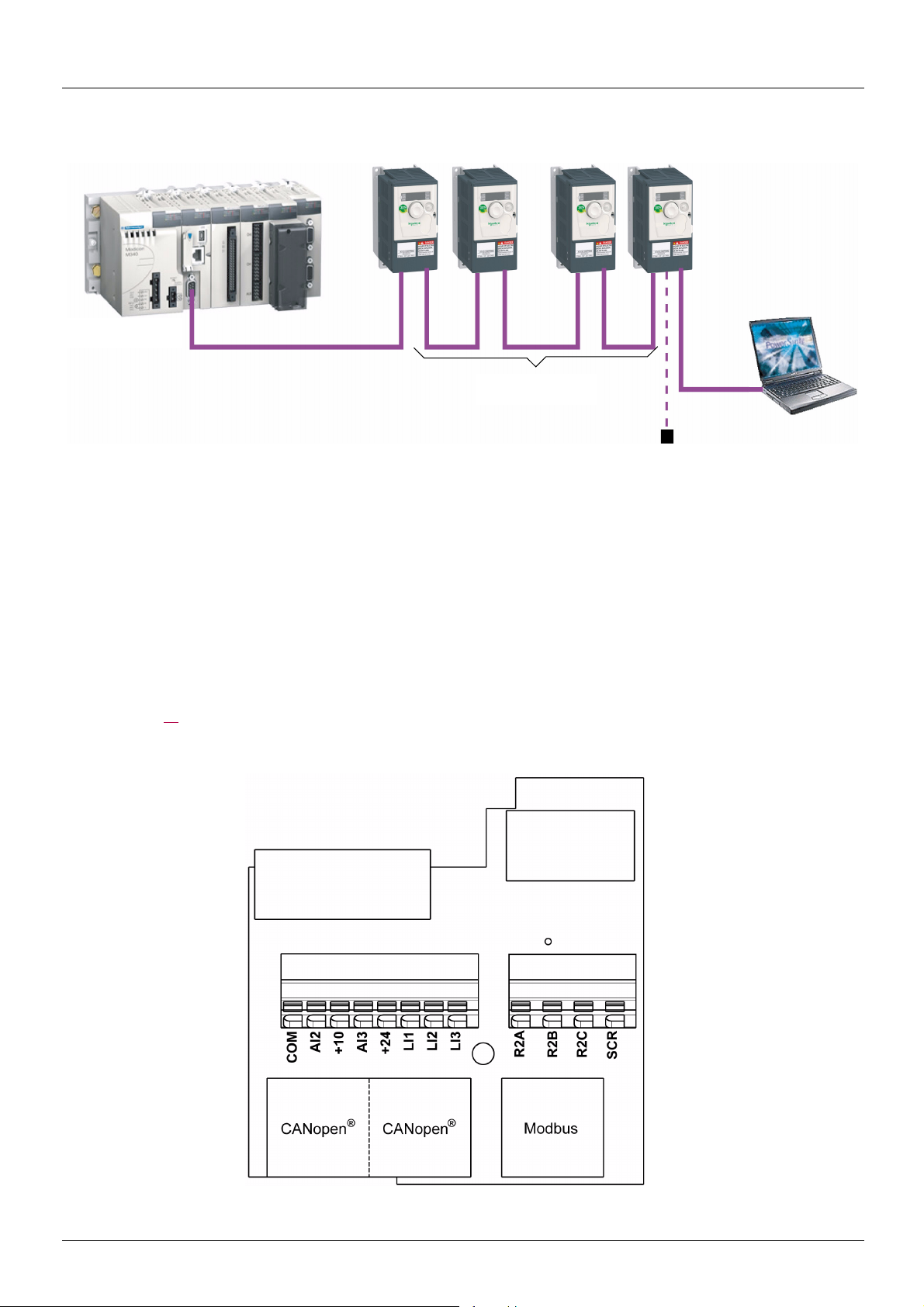

Presentation

8 BBV52819 09/2009

Hardware setup CANopen® daisy chain — option VW3A31208

Receipt

• Check that the card catalog number marked on the label is the same as that on the delivery note corresponding to the purchase order.

• Remove the option card from its packaging and check that it has not been damaged in transit.

Installing the card in the drive

DANGER

UNINTENDED EQUIPMENT OPERATION

• Do not plug or unplug the terminal board while drive is powered.

• Check the tightening of the fixing screw after any manipulation on the terminal board.

Failure to follow these instructions will result in death or serious injury.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Do not touch the terminal board before :

• removing power on the drive,

• removing any voltage on input and output terminals.

Failure to follow these instructions will result in death or serious injury.

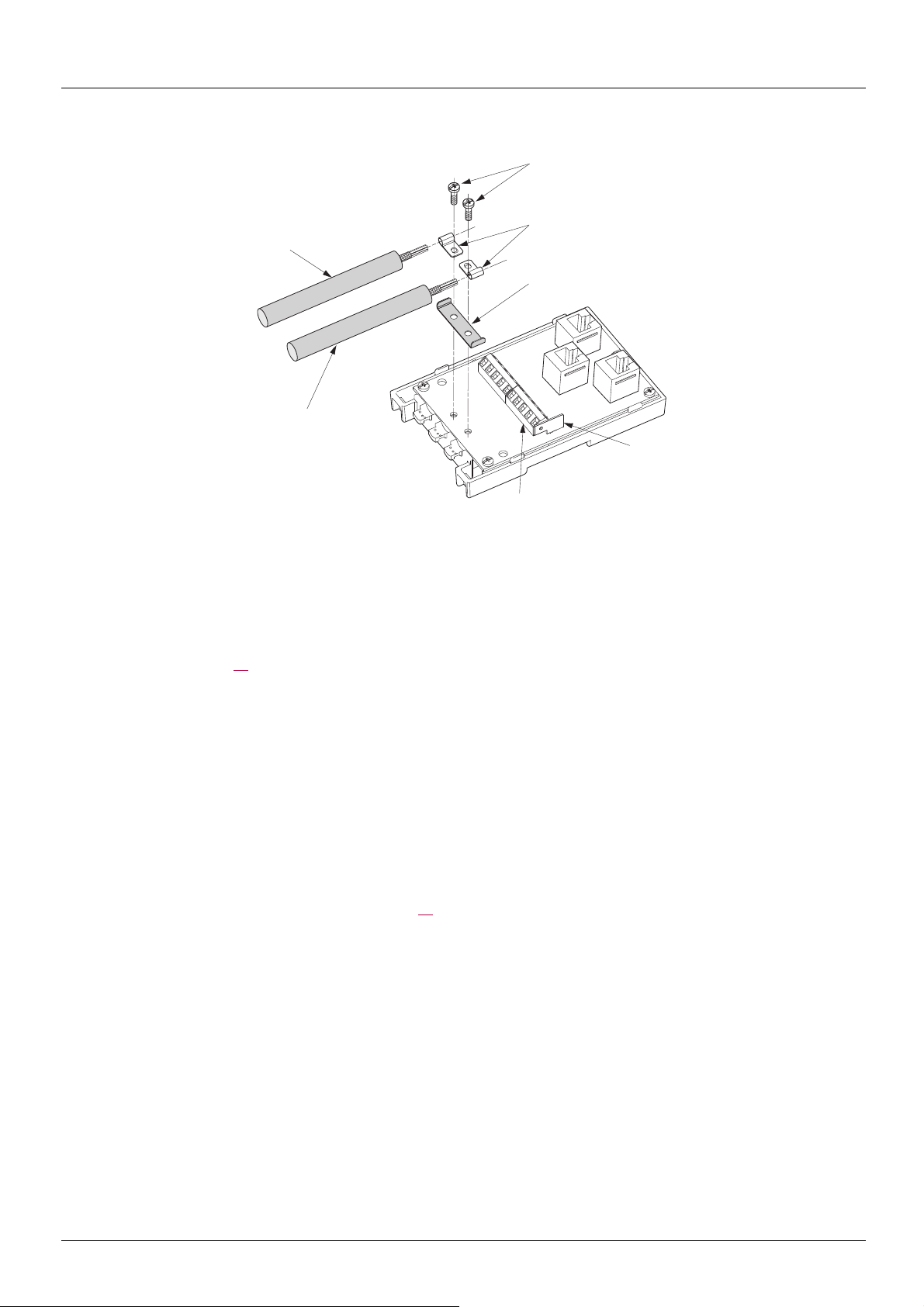

Install the CANopen® daisy chain card in ATV312 as follows:.

1. Open the ATV312 front cover.

2. Remove the terminal board fixing screw and take off the ATV312 standard terminal board.

(Be careful not to lose the terminal board fixing screw when removed since it may be used again.)

This step does not apply if you are using an ATV312…. B (product without standard IO terminal).

3. Perform wiring before installing CANopen

4. Install the CANopen

(M3 tapping screw tightening torque: 0.7 to 0.8Nm).

5. Stick the new cabling label on the reverse side of the ATV312 front cover.

6. Stick the CANopen® daisy chain card nameplate near the ATV312 nameplate. (Be careful not to cover slits on the ATV312 enclosure)

Note: To install or remove the terminal board, make it slide in or out in parallel with board to avoid mechanical stress on the board.

BBV52819 09/2009 9

®

daisy chain card and secure it with the board fixing screw

®

daisy chain card.

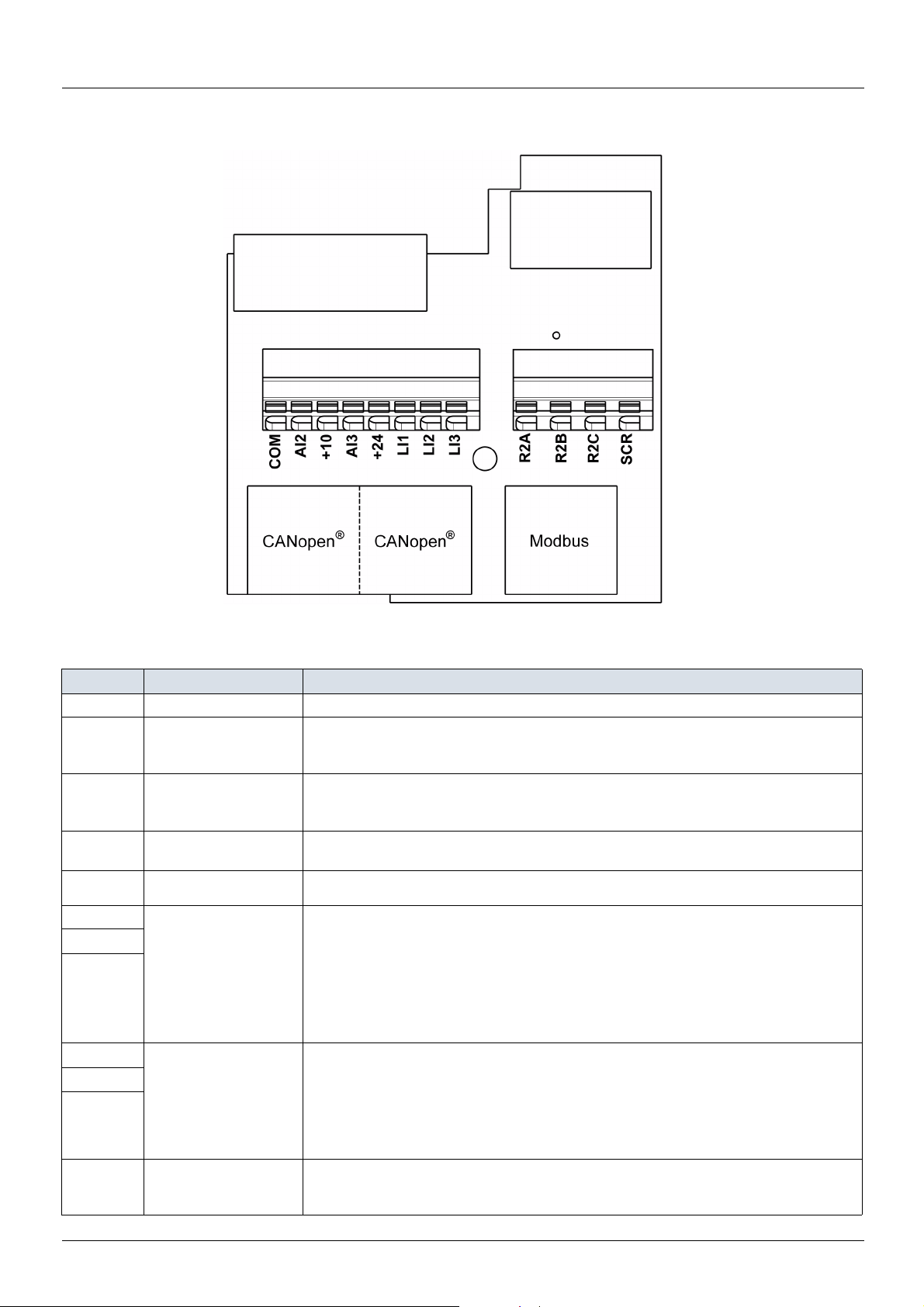

Hardware setup CANopen® daisy chain — option VW3A31208

Description of the terminals

Control terminals characteristics

Terminal Function Electrical characteristics

COM Analog I/O common 0 V

Analog bipolar voltage input ±10 V:

AI2 Analog voltage input

Power supply for the

10 V

AI3 Analog current input

24 V Logic input power supply

LI1

LI2

LI3

R2A

R2B

R2C

SCR (Screen)

reference potentiometer

(2.2 to 10 k

Logic inputs

Configurable relay

outputs 1 relay logic

output, one “N/C” contact

and one “N/O” contact

with common point.

Ω)

• impedance 30 k

• maximum safe voltage 30 V

+10 V (+ 8% — 0):

• 10 mA max

• protected against short-circuits and overloads

Analog current input X-Y mA by programming X and Y from 0 to 20 mA:

impedance 250

• + 24 V protected against short-circuits and overloads, min 19 V, max 30 V

• Maximum customer current available 100 mA

Programmable logic inputs:

• Impedance 3.5 k

• + 24 V internal or 24 V external power supply (min. 19 V, max. 30 V)

• Max. current: 100 mA

• Max. sampling time: 4 ms

Source position: Positive logic State 0 if < 5 V or logic input not wired, state 1 if > 11 V

Sink position: Negative logic State 0 if > 19 V or logic input not wired, state 1 if < 13 V

CLI position: Connection to PLC output

• Minimum switching capacity: 10 mA for 5 Vdc

• Maximum switching capacity on resistive load (cos ϕ = 1 and L/R= 0 ms).

5 A for 250 Vac and 30 Vdc

• Maximum switching capacity on inductive load (cos ϕ = 0.4 and L/R = 7 ms):

2 A for 250 Vac and 30 Vdc

• Sampling time 8 ms

• Service life: 100,000 operations at maximum switching power

CANopen

This terminal is not connected to other circuits in this board.

Ground this terminal in a location separated from the ground of power line.

®

Ω

Ω

Ω

communication shield terminal.

10 BBV52819 09/2009

Hardware setup CANopen® daisy chain — option VW3A31208

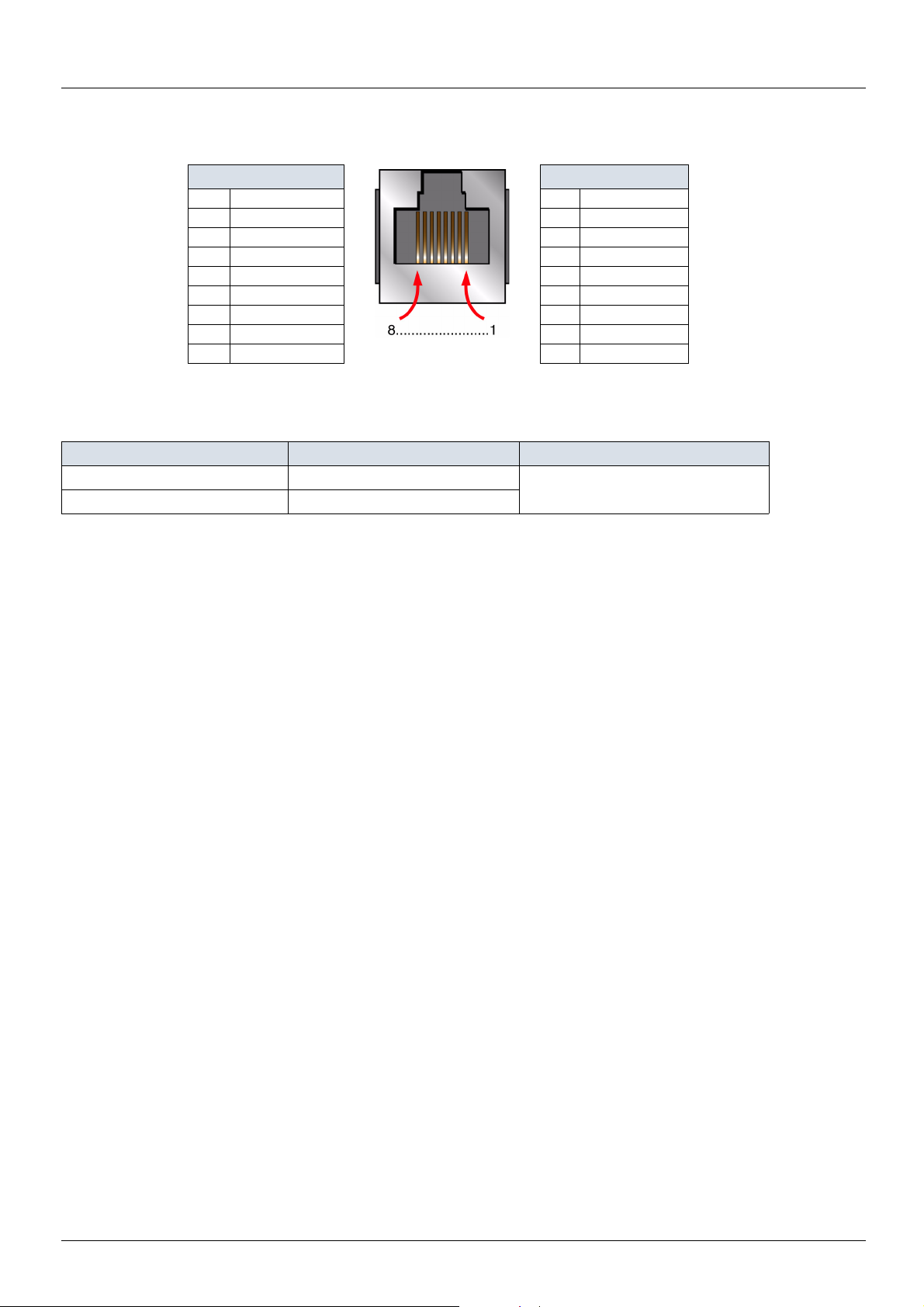

CANopen® and Modbus connectors

CANopen

Pin RJ 45 Signal Pin RJ 45 Signal

1 CAN_H 1 Not connected

2 CAN_L 2 Not connected

3 CAN_GND 3 Not connected

4 Not connected 4 D1

5 Not connected 5 D0

6 Not connected 6 Not connected

7 Not connected 7 VP (1)

8 Not connected 8 Common

®

Modbus

(1) Reserved for RS232/RS485 converter

Wire sizes

ATV312 Control terminals Applicable wire size mm² (AWG) (2) Tightening torque N·m (lb.in) (3)

R2A, R2B, R2C 0.75 to 1 (18 to 16) 0.5 to 0.6 (4.4 to 5.3)

Other terminals 0.14 to 0.5 (26 to 20)

(2)The value in bold corresponds to the minimum wire gauge to permit secureness.

(3)Recommended to maximum value.

BBV52819 09/2009 11

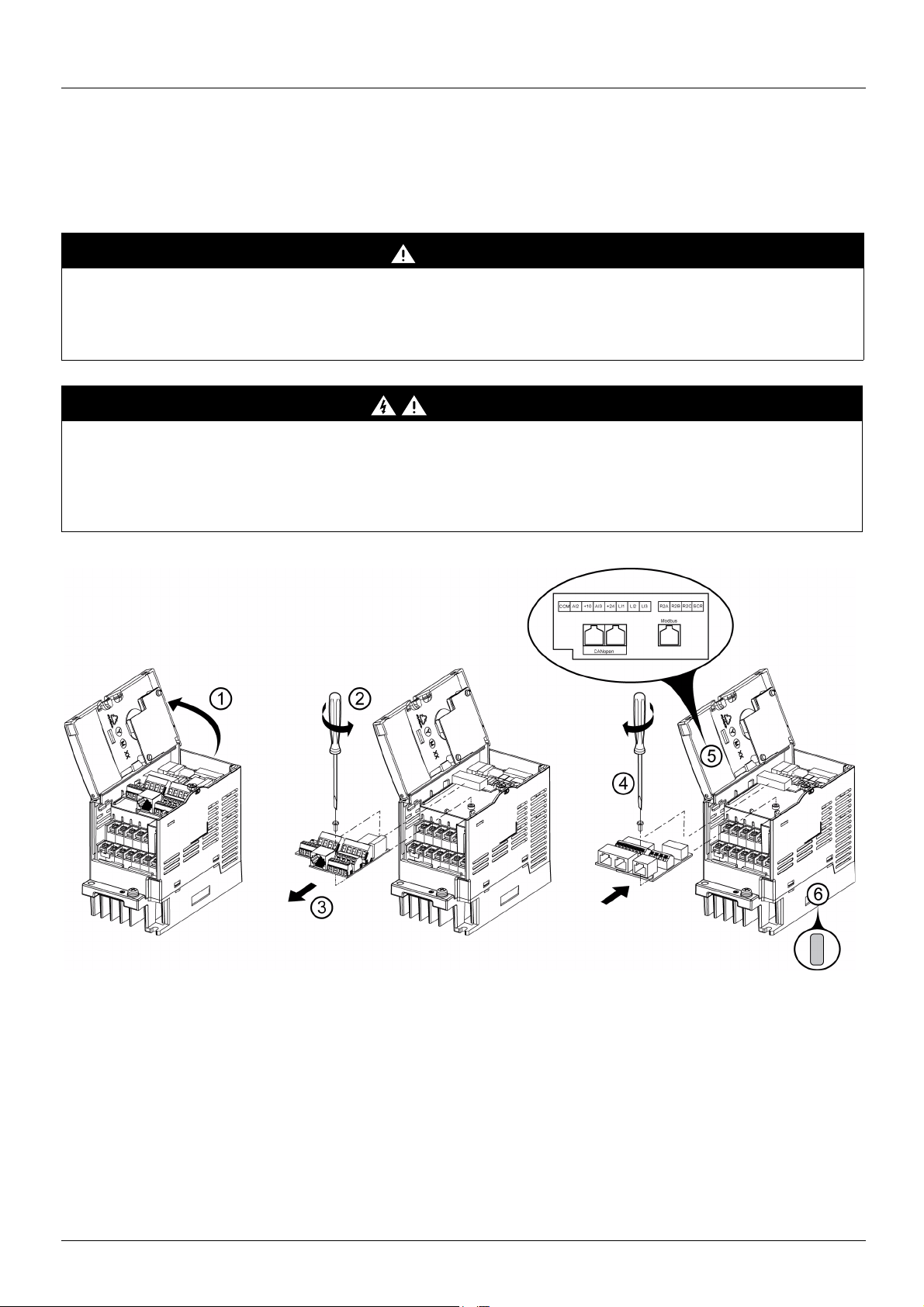

Hardware setup CANopen® tap — option VW3CANTAP2

PowerSuite

CANopen®

trunk cable

CANopen

®

trunk cable

ATV 312 CANopen®

tap VW3 CAN TAP 2

ATV 312 drop cord

VW3 CAN CA RR

p

Master PLC

+ TSX CPP 110

Modbus

Legacy CANopen® wiring solution for ATV 312

The following diagram shows an example of four ATV 312, connected to a master PLC Premium with a CANopen® master PCMCIA card

(TSX CPP 110).

Various accessories are available from the catalog to facilitate the connection of these devices.

ATV 312 CANopen

screw terminals embedded connectors. Two RJ45 connectors allow the connection of two Altivar 312 by ATV 312 CANopen

®

tap is a passive tap (reference: VW3CANTAP2) It can be connected on a CANopen® trunk cable, using the two 5-

®

drop cords.

One RJ45 connector is designed to interface these two Altivar 312 with PowerSuite (Commissioning software tool for PC or Pocket PC).

If only one ATV 312 is connected on the tap it should be on the connector labelled «ATV1». If two ATV 312 are connected, PowerSuite can

access the two drives in multidrop mode. The Modbus address of each drive must be different.

A remote terminal (VW3A31101) can also be connected to the «PowerSuite» connector, but in this case, only one ATV 312 drive can be

connected to the CANopen

ATV 312 CANopen

®

tap (on the plug labelled «ATV1»).

®

drop cord is a cable equipped with 2 RJ45 connectors. Two lengths are available: 0.3 m (0.98 ft), reference:

VW3CANCARR03) and 1 m (3.28 ft), reference: VW3CANCARR1.

Note: Only a 0.3 m (11.8 in.) drop cord can be used in a CANopen

®

network at a speed of 1 Mbits/s.

12 BBV52819 09/2009

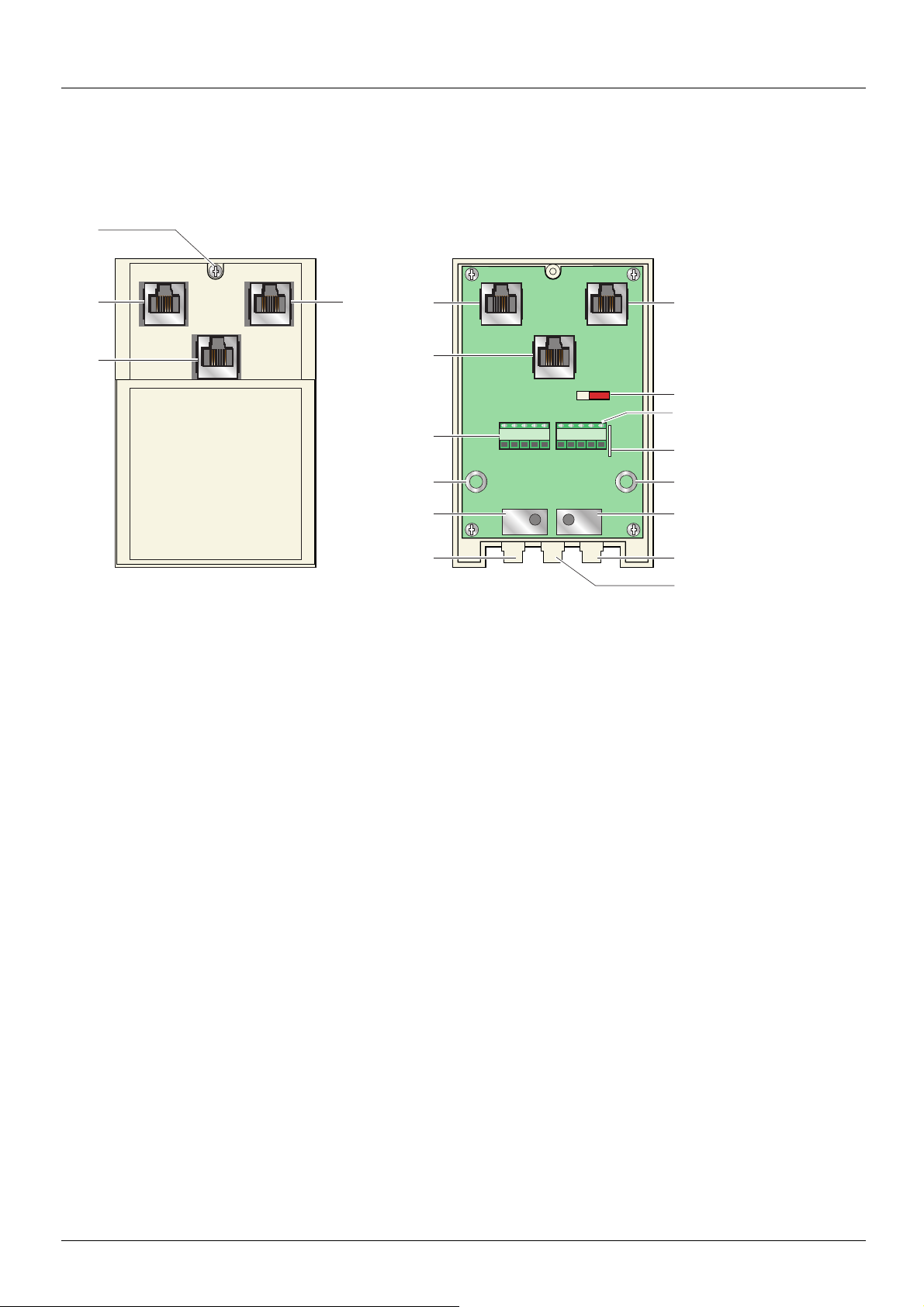

Hardware setup CANopen® tap — option VW3CANTAP2

1

ATV1 ATV2

PowerSuite

S1 S2

S3

ON

S4 S5

OFF

23

4

2

4

7

9

8

10

3

5

7

6

9

8

11

10

Description of the ATV 312 CANopen® tap

External view Internal view

1. Cover screw.

2. «ATV1» female RJ45 connector where the first Altivar 312 drive must be connected.

3. «ATV2» female RJ45 connector where the second, (if any), Altivar 312 drive must be connected. Do not use if a remote terminal is

connected to the «PowerSuite» connector.

4. «PowerSuite» female RJ45 connector, where PowerSuite (PC or Pocket PC) or a remote terminal can be connected.

5. Switch used to connect (ON) or disconnect (OFF) the internal line termination (120 Ω).

6. Lug for connecting the green/yellow grounding wire.

7. CANopen

8. Holes for Ø 4 screws used to mount the tap on a plate or panel, 60 mm (2.36 in.) mounting distance.

9. Ground plate for the trunk cable shield.

10. Openings for the CANopen

11. Opening for the green/yellow grounding wire.

®

terminal blocks, labelled S4 and S5 on the circuit board for wiring of the trunk cable.

®

trunk cable.

BBV52819 09/2009 13

Hardware setup CANopen® tap — option VW3CANTAP2

Connecting the drive to the ATV 312 CANopen® tap

Connect the cord with 2 RJ45 connectors (VW3 CAN CA RR 03 or VW3 CAN CA RR 1) to the RJ45 connector of the drive and to the «ATV1»

or «ATV2» female RJ45 connector located on the ATV 312 CANopen

If only one Altivar 312 is connected to the ATV 312 CANopen

®

tap (VW3 CAN TAP 2).

®

tap the «ATV1» connector must be used.

14 BBV52819 09/2009

Hardware setup CANopen® tap — option VW3CANTAP2

Setup of the CANopen® tap

Tools required:

• 2.5 mm flat screwdriver.

Procedure:

Note: the numbers shown below correspond to the numbers in the tap description.

• Unscrew screw 1 page 13

• Attach the tap base to its support:

— either to an AM1-DP200 or AM1-DE 200 DIN rail,

— or to a plate,

— or panel using 2 M4 screws at least 20 mm (0.8 in.) long.

• Prepare trunk cables 20 and 21, as shown on the following pages.

• Position grounding clamps 22 on the cables.

• Position ground connection 23.

• Connect the trunk cables to terminal blocks 7, as shown on the following pages. Use a 2.5 mm flat screwdriver. Thread torque on

terminal block screw

• Screw down the grounding clamps and connections using screws 19.

• Connect the green/yellow grounding wire to the connection lug 6.

• Immobilise the cables using nylon clamps.

• Position micro-switch to ON if line termination is required.

• Break the tabs on the cover so that the cables can pass through.

• Replace cover and fasten it in place with screw 1 page 13

. Open cover.

y 0.25 N·m (2.21 lb.in).

.

BBV52819 09/2009 15