- Manuals

- Brands

- Rosemount Manuals

- Measuring Instruments

- 1151

- Product manual

-

Bookmarks

Quick Links

LCD Meter

Product Manual

Analog

Bar Graph

Left Configuration Button

00809-0100-4691

Right Configuration Button

English

Rev. AA

Related Manuals for Rosemount 1151

Summary of Contents for Rosemount 1151

-

Page 1

00809-0100-4691 English Rev. AA LCD Meter Product Manual Analog Bar Graph Left Configuration Button Right Configuration Button… -

Page 2

The Rosemount ® LCD meter is designed to be used with the Rosemount Model 1151 Smart and Analog Pressure Transmitters, the Model 1144 Pressure Transmitter, the Model 751 Field Signal Indicator, the Model 444 Temperature Transmitter, and the Model 1135 Pressure-to-Current Converter. -

Page 3

Figure 1 shows the mounting hardware required to properly install the LCD meter on a transmitter or in the field signal indicator. This mounting hardware may also be used with the Rosemount universal (analog) meter. LCD METER CONFIGURATION The LCD meter may be configured to meet specific requirements by using the left and right configuration buttons located on the meter face as shown on the cover. -

Page 4

Remove the cover 1. Unscrew the retaining ring shown on the cover and lift the transparent cover off of the housing. Position the decimal point and select the meter function 2. Press the left and right configuration buttons simultaneously and release them immediately. 3. -

Page 5

numbers, press the right configuration button. Set the numbers between –999 and 9999. The sum of the 4 mA point and the span must not exceed 9999. 11. To store the information, press both configuration buttons simultaneously for two seconds. Note that the meter displays “—-”… -

Page 6

LCD METER SPECIFICATIONS Input Signal 4–20 mA dc. Meter Indication 4-digit LCD showing –999 to 9999. A 20-segment bar graph directly represents the 4–20 mA current. Digital Display Resolution 0.05% of range ±1 digit. Analog Bar Graph Resolution 1 mA or 5% of input range. Indication Accuracy 0.25% of range ±1 digit. -

Page 7

Input current < 3.5 mA: Display blank. Input current > 22.0 mA: Display flashes 112.5% of full scale value or 9999, whichever is less. Hazardous Locations Approved for use with Rosemount Models 444, 751, 1135, 1144, and 1151. Meter Size -inch diameter face with… -

Page 8

Rosemount Inc. 8200 Market Boulevard Chanhassen, MN 55317 USA Tel 1-800-999-9307 Telex 4310012 Fax (612) 949-7001 © Rosemount Inc. 1997. All rights reserved. http://www.rosemount.com ¢00809-0100-4691S¤ 00809-0100-4691, Rev. AA… -

Page 9

Mounting Screw into Housing Strap Washer Retaining Straps Mounting Screws Mounting Screw into Mounting Plate Terminal Screws (Mount into Transmitter “Test” Terminal Block) Mounting Plate Meter (Meter May Be Rotated in 90° Increments) Cover Bushing Cover Foam Spacer FIGURE 1. LCD Meter Exploded View.

00809-0100-4360

English

Rev. AA

Model 1151

Alphaline® Pressure

Transmitters

Product Manual

Model 1151 Alphaline® Pressure

Transmitters

NOTICE

Read this manual before working with the prod uc t. For perso nal and system

safety, and for optimum product performance, make sure you thoroughly

understand the conten ts before installing, using, or maintaining this product.

Within the United States, Rosemount Inc. ha s two tol l-free assistance numbers.

Customer Central: 1-800-999-9307 (

Technical support, quoting, and order-related questions.

North American 1-800-654-7768 (

Response Center: Equipment service needs.

For equipment s ervice or s upport n eeds outs ide th e United State s, cont act your

local Rosemount representative.

7:00 a.m. to 7:00 p.m. CST)

24 hours a day – Includes Canada)

Rosemount In c.

8200 Market Boulevard

Chanhassen, MN 55317 USA

Tel 1-800-999-9307

Telex 4310012

Fax (612) 949-7001

© 1997 Rosemount, Inc.

http://www.rosemount.com

The products described in this document are NOT designed for nuclearqualified applications.

Using non-nuclear qua lifi ed products in applications that require nuclearqualified hardware or products may cause inaccurate readings.

For information on Rosemount nucle ar-qualified products, contact you r local

Rosemount Sales Representative.

May be protected by one or more of the following U.S. Patent Nos. 3,195 ,028; 3,271,669; 3,318,15 3;

3,618,390; 3,646,538; 3,793,885; 3,800,413; 3,854,039; 3,859,594; 3,975,719; 4,339,750; 5,237,285;

Re. 30,603. May Depend on Model. Other U.S. and Foreign Patents Issued and Pending.

Rosemount, the Rosemount logotyp e, Alphaline, and SMART FAMILY are registered trademarks of

Rosemount Inc.

HART is a registered trademark of the HART Communication Foundation.

d

-Cell is a trademark of Rosemount Inc.

Hastelloy, Hastelloy C, and Hastelloy C-276 are registered trademarks of Cabot Corp.

Monel is a registered trademark of International Nickel Co.

Teflon is a registered trademark of E.I. du Pont de Nemours & Co.

Aflas is a registered trademark of Asahi Glass Co., Ltd.

Kynar is a trademark of Pennwalt Inc.

Flourolube is a registered trademark of Hooker Chemical Co.

Loctite is a registered trademark of Loctite Corporation.

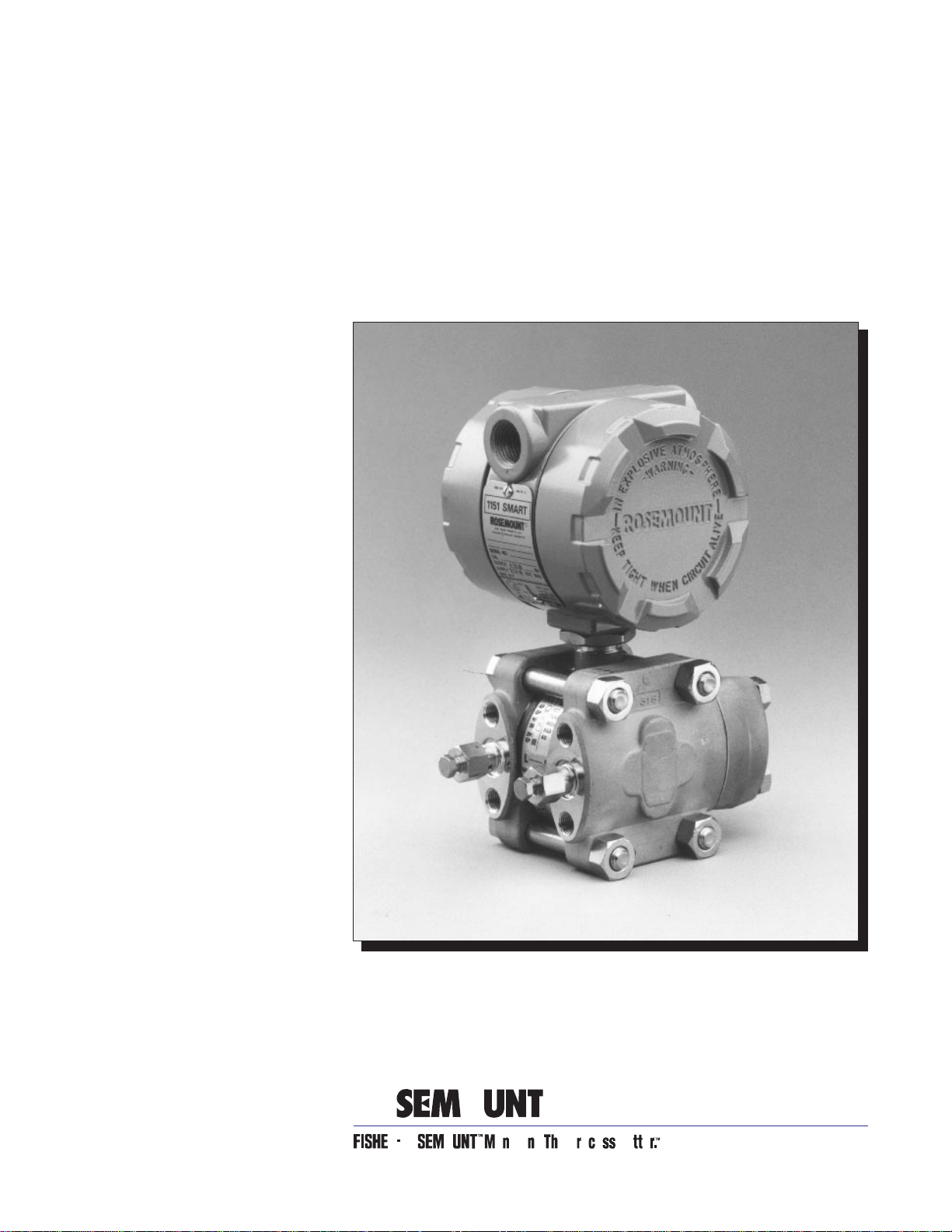

Cover Photo: 1151-001AB

Fisher-Rosemount satisfies all obligations coming from legislation

to harmonize product requ ireme n ts in th e Euro pe a n Union.

T

N

I

E

D

R

P

IN

U.

A.

S.

SNF-0004

Table of Contents

Introduction

Installation

Using This Manua. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Model 1151 Alphaline® Pressure Transmitters . . . . . . . . . . . . . . 9

Transmitter overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

General Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Mechanical Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Environmental Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Access Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Process Flange Orientation . . . . . . . . . . . . . . . . . . . . . . . 13

Housing Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Terminal Side of Electronics Housing . . . . . . . . . . . . . . . 13

Circuit Side of Electronics Housing . . . . . . . . . . . . . . . . . 13

Exterior of Electronics Housing . . . . . . . . . . . . . . . . . . . 13

Mounting Effects. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Process Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Mounting Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Mounting Requirements (for Steam, Liquid, Gas) . . . . . . . . 17

Taps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Drain/Vent Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Impulse Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Electrical Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Conduit Sealing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Signal Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Transmitter Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Grounding Effects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Hazardous Locations Certifications. . . . . . . . . . . . . . . . . . . . 24

Liquid Level Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Open Vessels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Closed Vessels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Dry Leg Condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Wet Leg Condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Bubbler System in Open Vessel . . . . . . . . . . . . . . . . . . . . 26

Calibration

Quick Calibration Procedure (for E, G, and J Electronics). . . . . 29

Quick Calibration Procedure (For L and M Electronics) . . . . . . 29

Data Flow with Calibration Options . . . . . . . . . . . . . . . . . . . . . . 31

Span Adjustment Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Zero Adjustment Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Zero and Span Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Elevated or Suppressed Zeros . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Linearity Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Damping Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Static Pressure Span Correction Factor . . . . . . . . . . . . . . . . . . . . 37

i

Options

Mounting Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

(Option Codes B1–B7 and B9) . . . . . . . . . . . . . . . . . . . . . 39

Analog Meters (4–20 ma only) . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

LCD Meters (4–20 ma only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

LCD Meter Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Remove the Cove . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .r 42

Position the Decimal Point and Select the Meter Function 42

Store the Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Set the Display Equivalent to a 4 mA Signal . . . . . . . . . 43

Set the Display Equivalent to a 20 mA Signal. . . . . . . . 43

Replace the Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

LCD Meter Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

LCD Meter Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Terminal Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Filter Terminal Block (Option Code R2) . . . . . . . . . . . . . . . . 46

Transient Protection and Filter Terminal Block

(Option Code R1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Retrofitable Transient Terminal Block(Option Code R9). . . 46

R9 Terminal Block Installation . . . . . . . . . . . . . . . . . . . . 47

Terminal Block Specifications (for R1, R2, and R9) . . . . . . . 49

Maintenance and

Troubleshooting

Specifications and

Reference Data

Hardware Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Transmitter Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

54

Process Sensor Body Removal 55

Removing the Sensor from the Electrical Housing . . . . 56

Sensor Module Checkout . . . . . . . . . . . . . . . . . . . . . . . . . 57

Reassembly Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Preliminary Precaution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Connecting the Electrical Housing to the Sensor. . . . . . . . . 58

Backup Ring and O-ring Installation . . . . . . . . . . . . . . . . . . 58

Optional Plug-in Meter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .s 60

Return of Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Performance Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Physical Specifications (Standard Configuration). . . . . . . . . . . . 68

ii

Section

1 Introduction

USING THIS MANUAL

This manual is designed to assist in installing, operating, and

maintaining the Rosemount Model 1151 Analog Pressure Transmitter

Family.

Section 2 Installation

provides mechanical and electrical installation instructions.

Section 3 Calibration

explains technique for calibration of the device.

Section 4 Options

explains the options available for the Model 1151, including mounting

brackets, LCD meters, custom configuration, transient protection, and

filter terminal blocks.

Section 5 Maintenance and Troubleshooting

describes trim procedures and offers troubleshooting instructions for

dealing with potential mechanical or electrical difficulties.

Section 6 Specifications and Reference Data

lists functional, performance, and physical specifications data as well

as ordering information for the transmitter.

Appendix A Approval Drawings

contains approval drawings for Canadian Standards Association (CSA)

and Factory Mutual (FM) intrinsic safety drawings.

Glossary

provides brief definitions of the terms use d in this manual and tells

where to find more information.

MODEL 1 151 ALPHALINE®

PRESSURE

TRANSMITTERS

Index

contains a comprehensive, standard index.

This manual describes the following Model 1151 Alphaline® Pressure

Transmitters.

• Model 1151DP— Differential Pressure Transmitter

measures differential pressure from 6 inH

(1.493 to 6895 kPa).

• Model 1151HP— Differential Pressure Transmitter

for High Line Pressures measures high line pressures from

25 inH

• Model 1151GP— Gage Pressure Transmitter

measures gage pressure from 6 inH

41369 kPa).

• Model 1151AP— Absolute Pressure Transmitter

measures absolute pressure from 25 inH

6895 kPa).

O to 300 psi (6.22 to 2668 kPa).

2

2

O to 6,000 psi (1.493 to

O to 1,000 psi

2

O to 1,000 psi (6.22 to

2

1-1

Model 1151 Alphaline® Pressure Transmitters

TRANSMITTER OVERVIEW

The Rosemount Model 1151 Alphaline® series of pressure transmitters

has set an industry standard as the largest-selling transmitter in the

world. It brings true precision to the measurement of flow, level, gage

and absolute pressures, vacuum, and specific gravity.

With proven performance, quality, and reliability, the Model 1151

provides accurate measurement using the variable capacitance

principle. It is virtually unaffected by changes in temperature, static

pressure, vibration, and power supply voltage.

Installation, calibration, and commissioning are simplified by the

transmitter’s compact design, integral junction box, and local span and

zero adjustments. Its modular design and high degree of

interchangeability result in a minimal investment for spare parts.

1-2

Section

2 Installation

This section covers areas to consider when installing the Model 1151

Analog Transmitter:

• General Considerations

• Mechanical Considerations

• Environmental Requirements

• Electrical Considerations

• Liquid Level Measurement

GENERAL

CONSIDERATIONS

MECHANICAL

CONSIDERATIONS

The accuracy of a flow, pressure, or level measurement depends on

proper installation of the transmitter and impulse piping. The piping

between the process and transmitter must accurately transmit process

pressure to the transmitter. Mount the transmitter close to the process

and use a minimum of piping to achieve best accuracy. Keep in mind,

however, the need for easy access, safety of personnel, practical field

calibration, and a suitable transmitter environment. In general, install

the transmitter so as to minimize vibration, shock, and temperature

fluctuations.

Installations in food, beverage, and pharmaceutical processes may

require sanitary seals and fittings. Regulations may dictate special

installation requirements needed to maintain sanitation and

cleanability considerations. See Product Data Sheet 00813-0100-4016

for more information about sanitary pressure instruments from

Rosemount Inc.

Rosemount Model 1151DP, GP, HP, and AP transmitters may be

mounted in several ways. They may be panel-mounted, wall-mounted,

or attached to a 2-inch pipe through an optional mounting bracket.

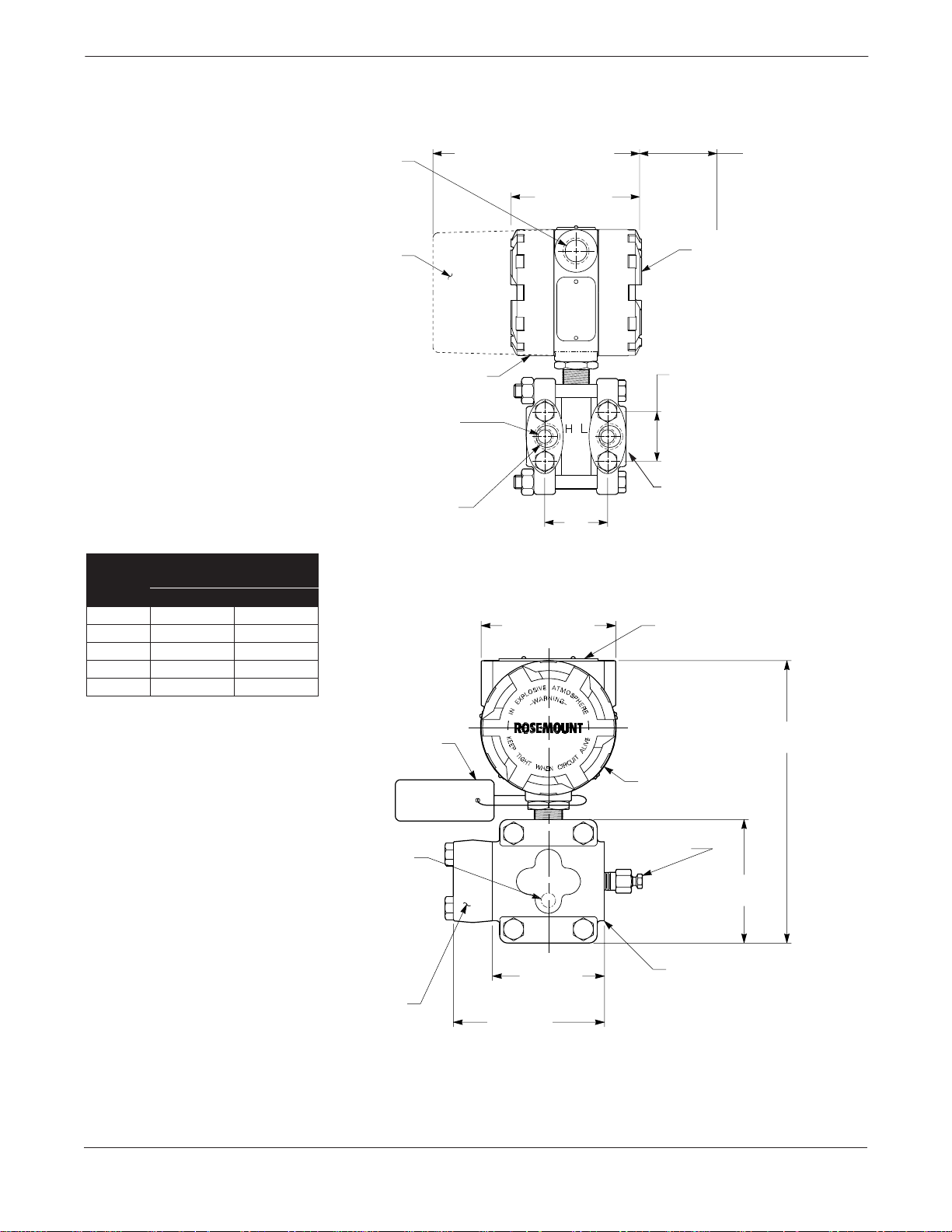

Figure 2-1 shows the transmitter dimensions. The following

paragraphs discuss factors necessary for a successful transmitter

installation.

2-1

Model 1151 Alphaline® Pressure Transmitters

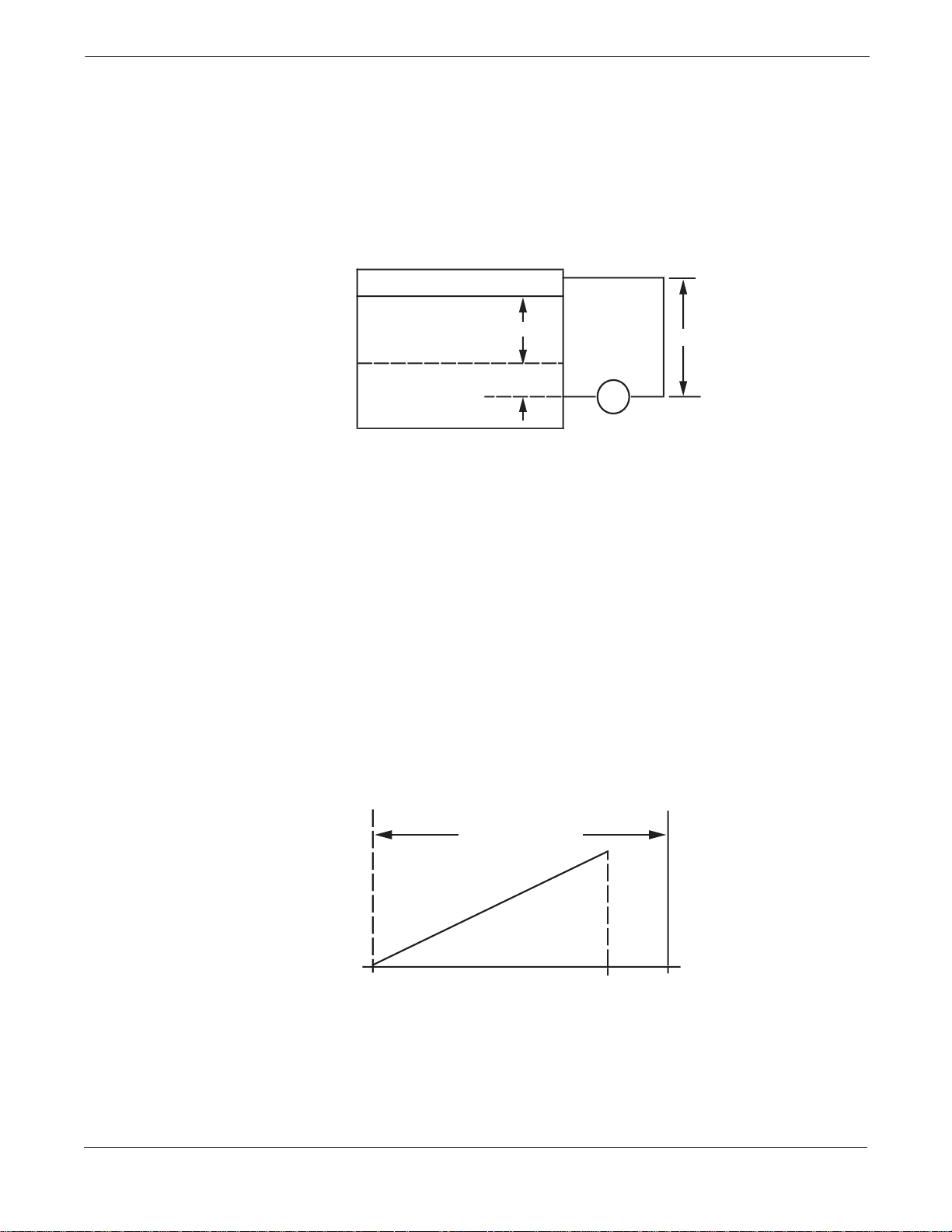

FIGURE 2-1. Dimensional Drawing

for Model 1151 Transmitter.

Flange Distance “A”

Range

3, 4, 5 2.125 54

6, 7 2.188 56

82.250 57

92.281 58

02.328 59

Center to Center

inches mm

½–14 NPT

Conduit

Connection

(2 Places)

Meter

Housing

Terminal Connections

This Side

¼–18 NPT on

Flanges for Pressure

Connection without

Flange Adapters

½–14 NPT on

Flange

Adapters

7.5 (191) Max.

with Optional Meter

4.5 (114)

Max.

A

(See Table)

4.5 (114)

Max.

0.75 (19)

Clearance for

Cover Removal

(Typical)

Transmitter

Circuitry

This Side

1.625

(41)

Blank Flange

Used on

AP and GP

Transmitters

Permanent

Tag (Optional)

NOTE

Dimensions are in inches (millimeters).

2-2

Wired-on

(Standard)

¼–18 NPT for

Side Drain/Vent

(Optional Top

or Bottom)

Flange

Adapter

Tag

4.5 (114)

3.375

(86)

9.0 (229) Max.

Nameplate

Drain/Vent

Valve

3.69

(94)

Flanges Can

Be Rotated

1151-1151A,B05A

Installation

ENVIRONMENTAL

REQUIREMENTS

Mount the transmitter to minimize ambient temperature changes. The

transmitter electronics temperature operating limits are –40 to 200 °F

(–40 to 85 °C) for “E” output options, –20 to 150 °F (–29 to 66 °C) for “J”

output options, and –20 to 200 °F (–29 to 93 °C) for G, L, and M output

options. Section 5 Maintenance and Troubleshooting lists the

sensing element operating limits. Mount the transmitter to avoid

vibration and mechanical shock, and to avoid external contact with

corrosive materials.

Access Requirements

When choosing an installation location and position, take into account

the need for access to the transmitter.

Process Flange Orientation Orient the process flanges to enable process connections to be made.

For safety reasons, orient the drain/vent valves so that process fluid is

directed down and away from technicians when the valves are used.

This can be accomplished by pointing the hole in the outside valve body

downward and away. In addition, consider the need for a testing or

calibration input.

Do not rotate the transmitter housing more than 90 degrees

without disconnecting the header board. Exceeding 90

degrees rotation will damage the internal sensor module

wiring. Refer to Removing the Sensor from the Electrical

Housing on page 5-6 for further information.

Housing Rotation The electronics housing may be rotated up to 90 degrees to improve

field access to the two housing compartments. T o rotate the housing less

than 90 degrees, loosen the housing lock nut and turn the housing not

more than 90 degrees from the orientation shown in Figure 2-1. To

rotate the housing more than 90 degrees, follow th e transmitter

disassembly procedures in Section 5 Maintenance and

Troubleshooting.

Terminal Side of

Electronics Housing

Make wiring connections through the conduit openings on the top side

of the housing. The terminal side of the housing is marked on the

nameplate located on the side of the transmitter. Mount the transmitter

so that the terminal side is accessible. A ¾-inch clearance is required

for cover removal with no meter. A 3-inch clearance is required for cover

removal if a meter is installed. If practical, provide approximately 6

inches clearance so that a meter may be installed later.

Circuit Side of

Electronics Housing

The circuit compartment should not routinely need to be opened when

the unit is in service; however, provide 6 inches clearance if possible to

allow access for on-site maintenance. The circuit side of the housing is

marked on the nameplate located on the side of the transmitter.

Exterior of Electronics Housing The analog Model 1151 uses local span and zero screws, which are

located under the nameplate on the side of the transmitter . Please allow

6 inches clearance if possible to allow access for on-site maintenance.

2-3

Model 1151 Alphaline® Pressure Transmitters

Mounting Effects

The analog Model 1151 weighs 12 lb (5.4 kg) for AP, DP, GP, and HP

transmitters, excluding options. This weight must be securely

supported; see Figure 2-2 on page 2-6 for mounting bracket

information. The transmitter is calibrated in an upright position at the

factory. If this orientation is changed during mounting, the zero point

will shift by an amount equivalent to the liquid head caused by the

mounting position. Zero and Span Adjustment on page 3-6 describes

how to correct this shift.

Process leaks can cause death or serious injury. Only use

bolts supplied with the transmitter or sold by Rosemount

Inc. as a spare part. Using unauthorized bolts may reduce

pressure retaining capabilities and render the instrum ent

dangerous.

Do not plug the low side with a solid plug. Plugging the low

side will cause an output shift.

Process Connections

Model 1151AP, DP, GP, and HP process connections on the transmitter

flanges are ¼–18 NPT. Flange adapter unions with ½–14 NPT

connections are supplied as standard. These are Class 2 threads; use

plant-approved lubricant or sealant when making the process

connections. The flange adapters allow users to disconnect from the

process by removing the flange adapter bolts. Figure 2-1 on page 2-2

shows the distance between pressure connections. This distance may be

1

varied ±

/8 inch (3.2 mm) by rotating one or both of the flange adapters.

To ensure a tight seal on the flange adapters or three-valve manifold,

first finger-tighten both bolts, then wrench-tighten the first bolt to

approximately 29 ft-lbs (34 Nm). Wrench-tighten the second bolt to

approximately 29 ft-lbs (34 Nm).

2-4

Process leaks can cause death or serious injury. Install and

tighten all four flange bolts before applying pressure, or

process leakage may result. When properly installed, the

flange bolts will protrude through the top of the module

housing. Attempting to remove the flange bolts while the

transmitter is in service may cause process fluid leaks.

Failure to install flange adapter O-rings can cause process

leaks, which can result in death or serious injury.

There are two styles of Rosemount flange adapters, each

requiring a unique O-ring, as shown below. Each flange

adapter is distinguished by its unique groove.

MODEL 3051/2024/3001/3095

Flange Adapter

O-ring

Installation

Unique O-ring

Grooves

Flange Adapter

O-ring

MODEL 1151

Use only the O-ring designed to seal with the corresponding

flange adapter.

Refer to the Spare Parts List on page 6-13 for the part

numbers of the flange adapters and O-rings designed for

the Model 1151 Pressure Transmitter.

NOTE

If Teflon O-rings are used, they should be replaced if the f lange adapter

is removed.

The low-side process flange has a ¼–18 NPT connection. A flange

adapter union is supplied for ½–14 NPT process connections. The

flange adapter allows the transmitter to be easily disconnected from the

process by removing the flange adapter bolts. On open vessels the lowside process flange is open to atmosphere and should be mounted with

the threaded hole pointed down. On closed vessels this connection is

used for the dry or wet leg.

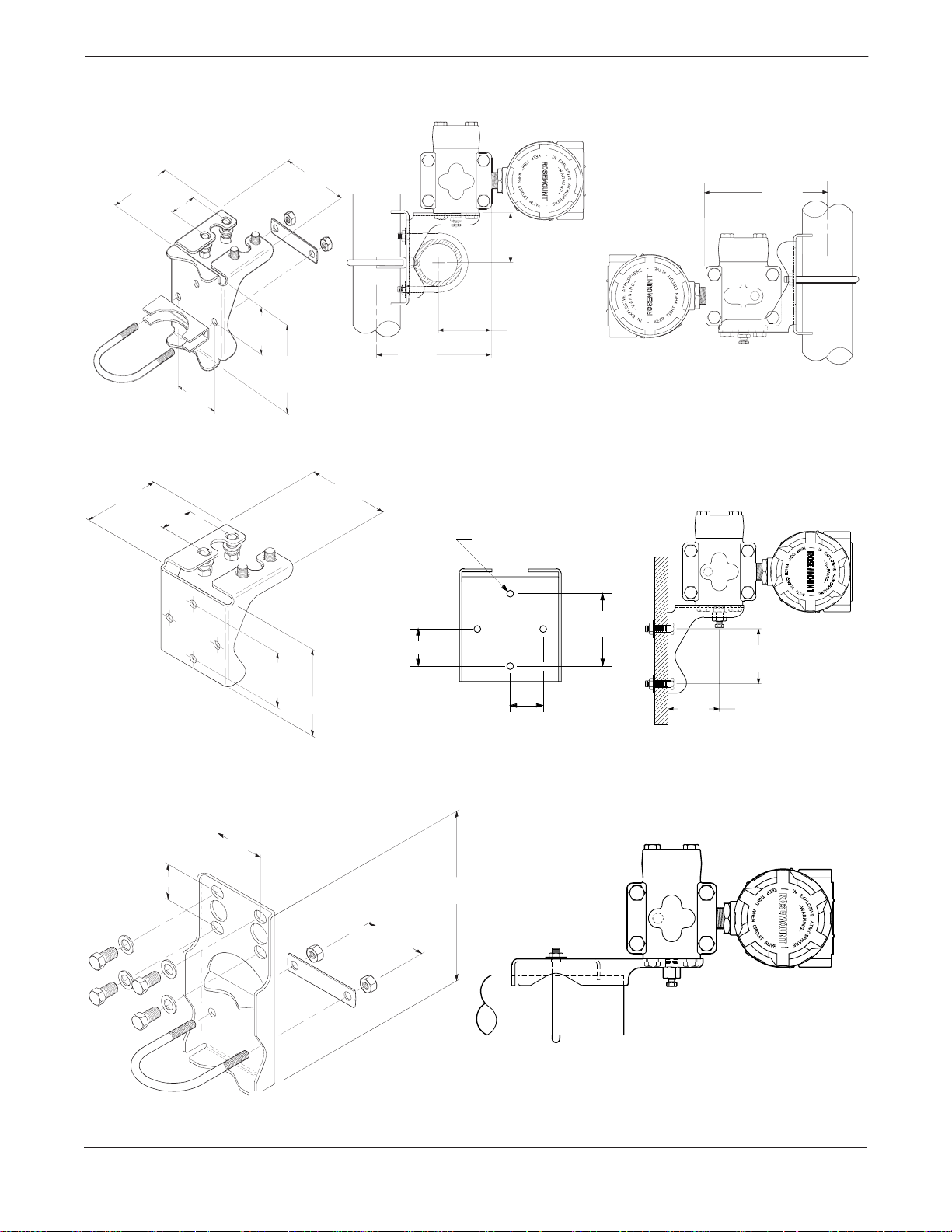

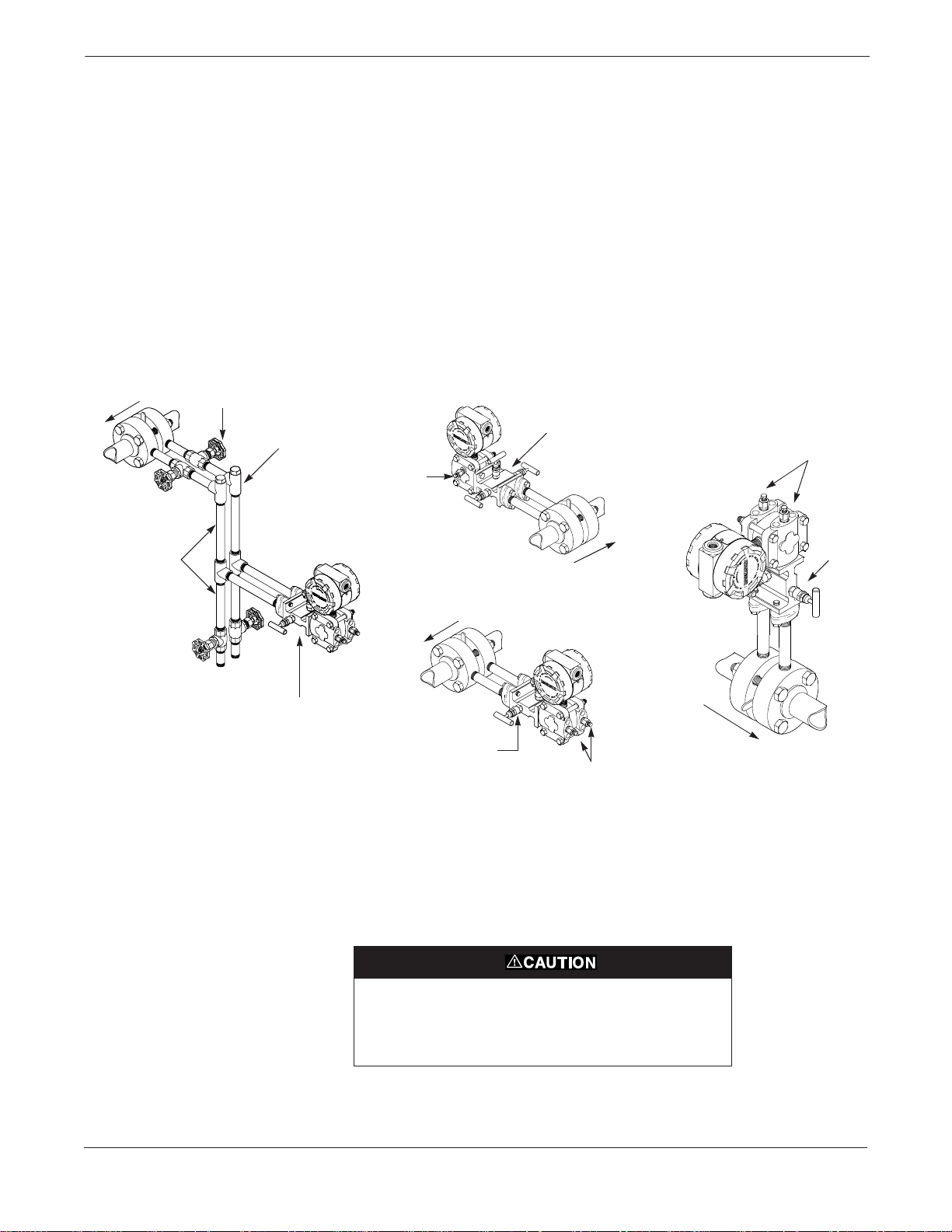

Mounting Brackets

An optional mounting bracket permits mounting the transmitter to a

wall, a panel, or a 2-inch horizontal or vertical pipe. Figure 2-2

illustrates some typical configurations using these mounting brackets.

2-5

Model 1151 Alphaline® Pressure Transmitters

FIGURE 2-2. Mounting Bracket

Options.

3.75

(95)

3.75 (95)

1.65 (42)

2.81

(71)

1.65 (42)

3.87

(98)

2.625 (67)

2.62

(67)

4.97

(127)

5.625

(143)

2.625

(67)

PIPE MOUNTING BRACKET OPTION CODES B1, B4, AND B7

3.87 (98)

Mounting Holes

0.375 Diameter

(10)

2.81 Typ.

(71)

1.40 (46)

2.81 Typ.

(71)

4.5 (114)

1.40

(36)

PANEL MOUNTING BRACKET OPTION CODES B2 AND B5

5.625

(143)

3051-3051D19A, 1151-1151D,B06C

2.81 Typ.

(71)

2.625

(67)

3051-3051B19A, 1151-0244A, 1151-1151E06A

2.125 (54)

1.62 (41)

NOTE

Dimensions are in inches (millimeters).

2-6

8 (203)

2.81 (71)

FLAT MOUNTING BRACKET OPTION CODES B3, B6, AND B9

3051-3051H19B, 1151-1151F06B

Installation

Mounting Requirements

The following information applies to steam, liquid, and gas installations.

(for Steam, Liquid, Gas)

Taps Different measurement conditions call for different piping

configurations. For liquid flow measurement, place taps to the side of

the line to prevent sediment deposits, and mount the transmitter beside

or below these taps so gases can vent into the process line. For gas flow

measurement, place taps in the top or side of the line and mount the

transmitter beside or above the taps so liquid will drain into the process

line. For steam flow measurement, place taps to the side of the line with

the transmitter mounted below them to ensure that the impulse piping

stays filled with condensate. See Figure 2-3 for a diagram of these

arrangements.

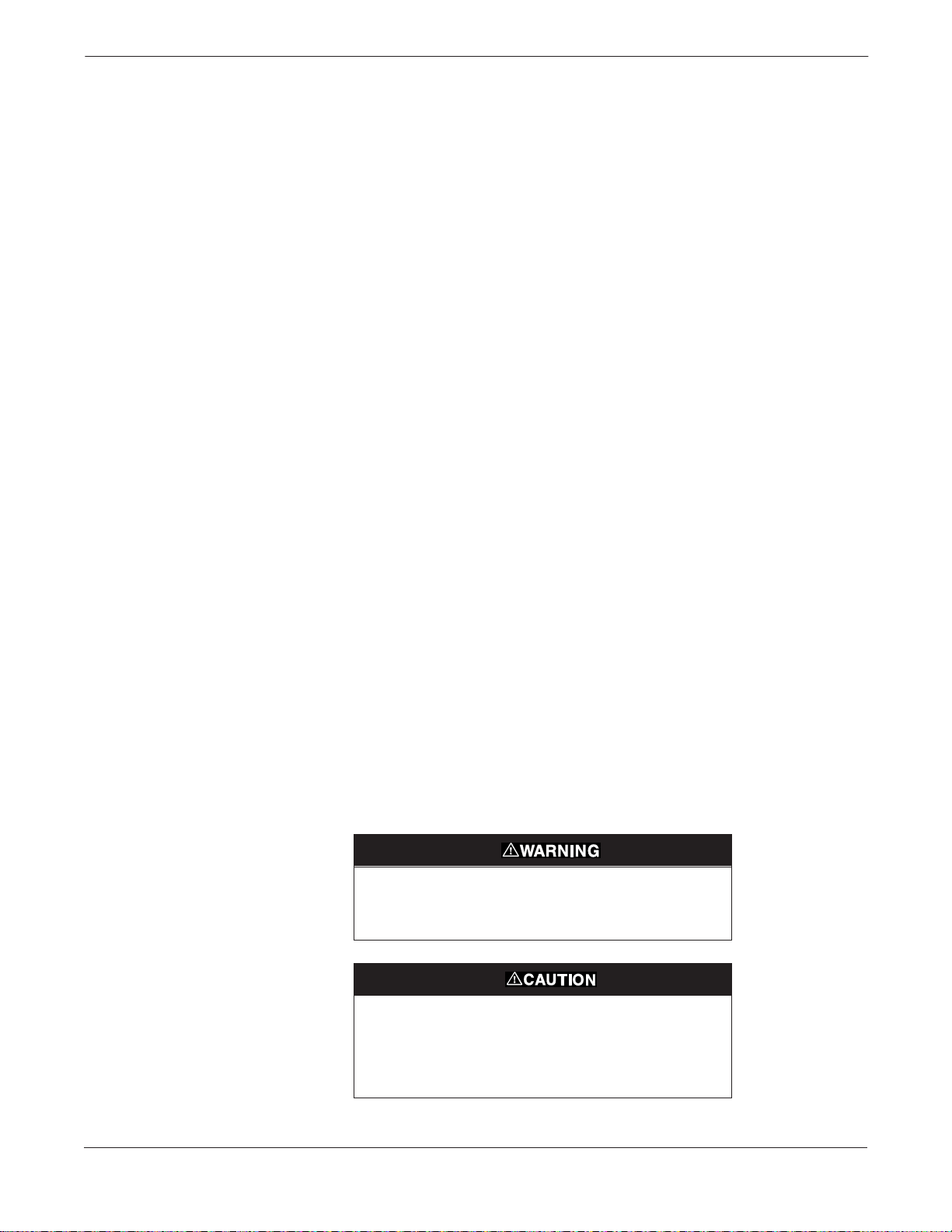

FIGURE 2-3. Steam, Liquid, and

Gas Service Installation Diagrams.

Blocking

Flow

Valves

Plugged Tee

for Steam Service

for Sealing Fluid

Optional Side-

mounted Drain/

Vent Valve

LIQUID SERVICE

L

H

3-valve

Manifold

GAS SERVICE

H

Vent/Drain

Valve

L

Sufficient

Length for

Cooling

H

L

STEAM SERVICE

3-valve

Manifold

NOTE

For steam service do not blow down impulse piping

through transmitter. Flush lines with blocking valves closed

and refill lines with water before resuming measurement.

Flow

3-valve

Manifold

Flow

Flow

H

L

Drain/Vent

Valve

3-valve

Manifold

Drain/Vent Valves For transmitters with side drain/vent valves, place taps to the side of

the line. For liquid service, mount the side drain/vent valve upward to

allow the gases to vent. For gas service, mount the drain/vent valve

down to allow any accumulated liquid to drain. T o change the drain/vent

valve orientation from top to bottom, rotate the process flange 180

degrees.

1151-1151D,A,B,C01A

Steam or other elevated temperature processes can cause

damage to the sensor. Do not allow the temperature inside

the process flanges to exceed the transmitter limit of 220 °F

(104 °C).

In steam service, lines should be filled with water to prevent contact of

the live steam with the transmitter.

2-7

Model 1151 Alphaline® Pressure Transmitters

Impulse Piping The piping between the process and the transmitter must accurately

transfer the pressure in order to obtain accurate measurements. In this

pressure transfer , there are five possible sources of error: leaks, friction

loss (particularly if purging is used), trapped gas in a liquid line, liquid

in a gas line, and temperature-induced or other density variation

between the legs.

The best location for the transmitter in relation to the process pipe

depends on the process itself. Co nsider th e f ollowing gene ral guidelines

in determining transmitter location and placement of impulse piping:

• Keep impulse piping as short as possible.

• Slope the impulse piping at least 1 inch per foot (8 centimeters

per meter) upward from the transmitter toward the process

connection for liquid.

• Slope the impulse piping at least 1 inch per foot (8 centimeters

per meter) downward from the transmitter toward the process

connection for gas.

• Avoid high points in liquid lines and low points in gas lines.

• Make sure both impulse legs are the same temperature.

• Use impulse piping large enough to avoid friction effects and

prevent blockage.

• Vent all gas from liquid piping legs.

• When using a sealing fluid, fill both piping legs to the same level.

• When purging is necessary, make the purge connection close to

the process taps and purge through equal lengths of the same size

pipe. Avoid purging through the transmitter.

• Keep corrosive or hot process material out of direct contact with

the sensor module and flanges.

• Prevent sediment deposits in the impulse piping.

• Keep the liquid head balanced on both legs of the impulse piping.

ELECTRICAL

CONSIDERATIONS

2-8

Before making any electrical connections to the Model 1151 analog,

consider the following standards and be sure to have proper power

supply, conduit, and other accessories. Make sure all electrical

installation is in accordance with national and local code requirements,

such as the NEC (NFPA 70).

Explosions can cause death or serious injury. Do not

remove the instrument cover in explosive atmospheres

when the circuit is alive.

Do not connect the power signal wiring to the test terminals.

Voltage may burn out the reverse-polarity protection diode

in the test connection. If the test diode is destroyed, then the

transmitter can still be operated without local indication by

jumping the test terminals.

High voltage (greater than 55 Volts for “E” electronics, 85

Volts for “G” electronics, 12 Volts for “L” electronics, and 14

Volts for “M” electronics.) can cause damage to the

transmitter. Do not apply high voltage to the test terminals.

Installation

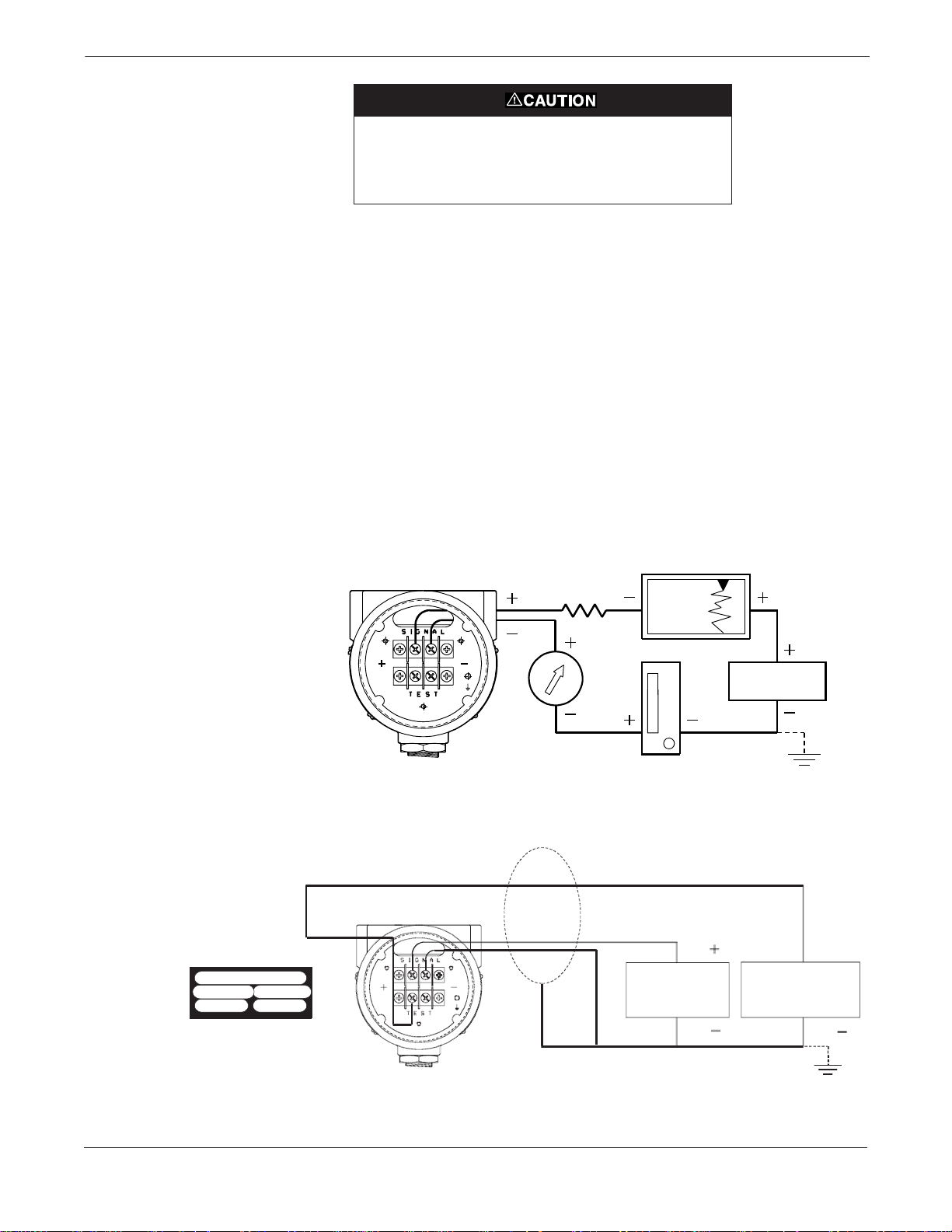

Wiring

FIGURE 2-4. Terminal Connections.

The signal terminals and test terminals are located in a compartment

of the electronics housing separate from the transmitter electronics.

The nameplate on the side of the transmitter indicates the locations of

the terminal and electronics compartments. The upper pair of

terminals are the signal terminals and the lower pair are the test

terminals. The test terminals have the same 4–20 mA output as the

signal terminals and are only for use with the optional integral meter

or for testing.

To make connections, remove the cover on the side marked “Terminal”

on the nameplate. All power to the transmitter is supplied over the

signal wiring. Connect the lead that originates at the positive side of

the power supply to the terminal marked “+” and the lead that

originates at the negative side of the power supply to the terminal

marked “–” as shown in Figure 2-4. No additional wiring is required.

Shielded cable should be used for best results in electrically noisy

environments.

POWER

SUPPL Y

FIGURE 2-5. Wiring Con nec tions for

Low Power Output Codes L and M.

Terminal

+

Common

Case

+ Power

Signal

Field Wiring

Label Detail

The signal loop may be grounded at

any point or left ungrounded.

Shield

Supply

Power

1151-1151G05A

A to D

Converter

1151-1151H05A

2-9

Model 1151 Alphaline® Pressure Transmitters

NOTE

An alternate location to connect an ammeter is on the set of terminals

labelled “TEST.” Connect the positive lead of the ammeter to the

positive test terminal, and the negative lead of the ammeter to the

negative test terminal.

NOTE

When conduit lines are used, signal wiring need not be shielded, but

twisted pairs should be used for best results. Wiring should be 12-24

AWG.

Conduit Sealing

Power Supply

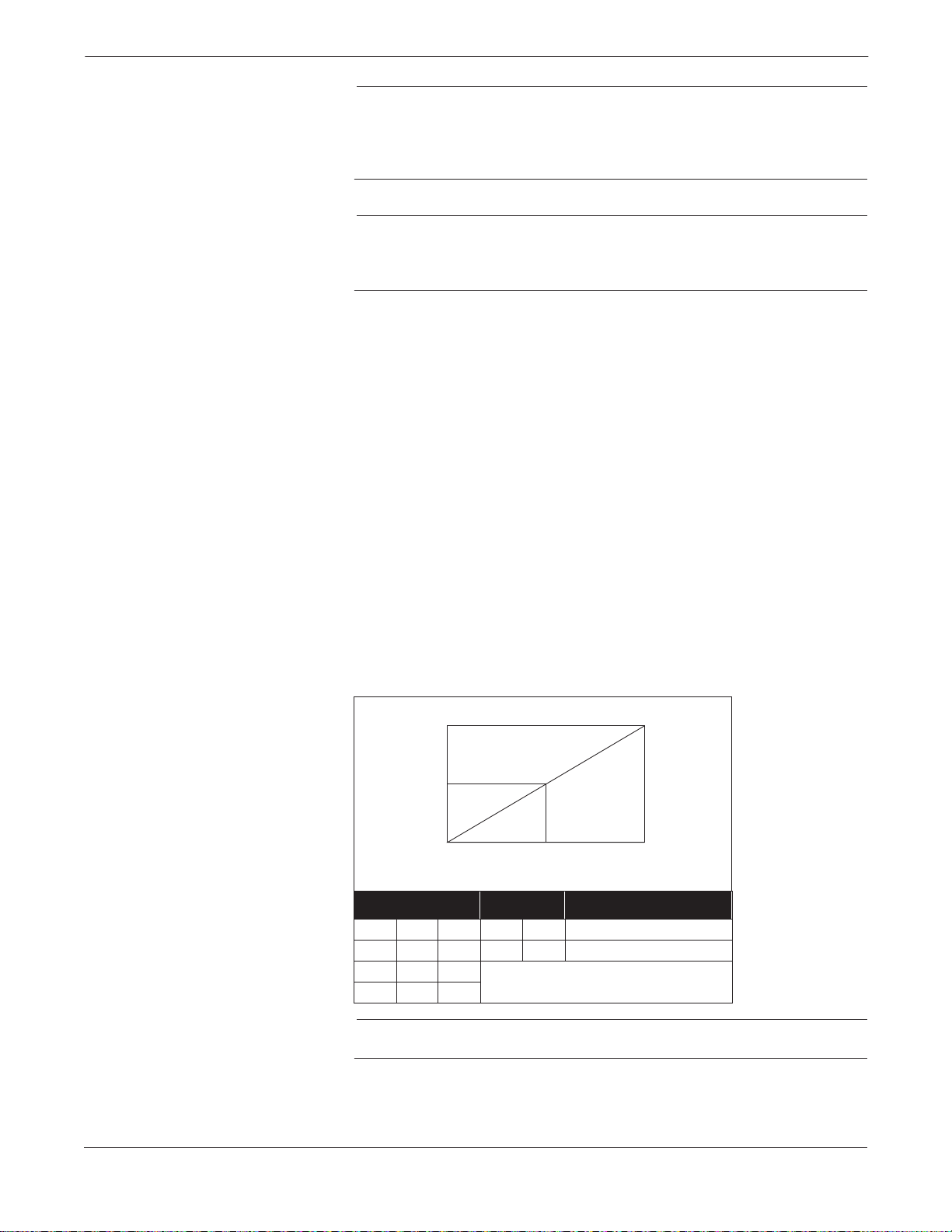

FIGURE 2-6. Power Supply Load

Limitations.

The 1151 has been rated as “Factory Sealed” by Factory Mutual (FM)

and Canadian Standards Association (CSA). It is therefore not

necessary to install conduit seals near the transmitter enclosure.

Do not run signal wiring in conduit or open trays with power wiring, or

near heavy electrical equipment. Signal wiring may be grounded at any

one point on the signal loop, or it may be left ung rounde d. The n egative

terminal of the power supply is a recommended grounding point. The

transmitter case must be grounded through the process or conduit

connections.

The dc power supply should provide power with less than 2 percent

ripple. The total resistance load is the sum of the resistance of the

signal leads and the load resistance of the controller, indicator, and

related pieces. Note that the resistance of intrinsic safety barriers, if

used, must be included.

To power the loop, connect the leads at the set of terminal screws

labeled “Signal.” Figure 2-6 illustrates power supply load limitations

for the transmitter:

R

max

2-10

R

L

R

min

V

min

Code V

E, J 12 45 0 1650 RL = 50 (VS – 12)

G 30 85 0 1100 R

L512

M814

minVmaxRminRmaxRL

Low Power Minimum Load Impedance:

V

S

Operating

Region

V

max

at Supply Voltage (VS)

= 20 (VS – 30)

L

100 kV

NOTE

For CSA Approvals (codes E and J), V

= 42.4 V dc.

max

FIGURE 2-7. Conduit Installat ion

Diagrams.

Installation

Possible

Conduit Line

Positions

1151-1 151D25A

Sealing

Compound

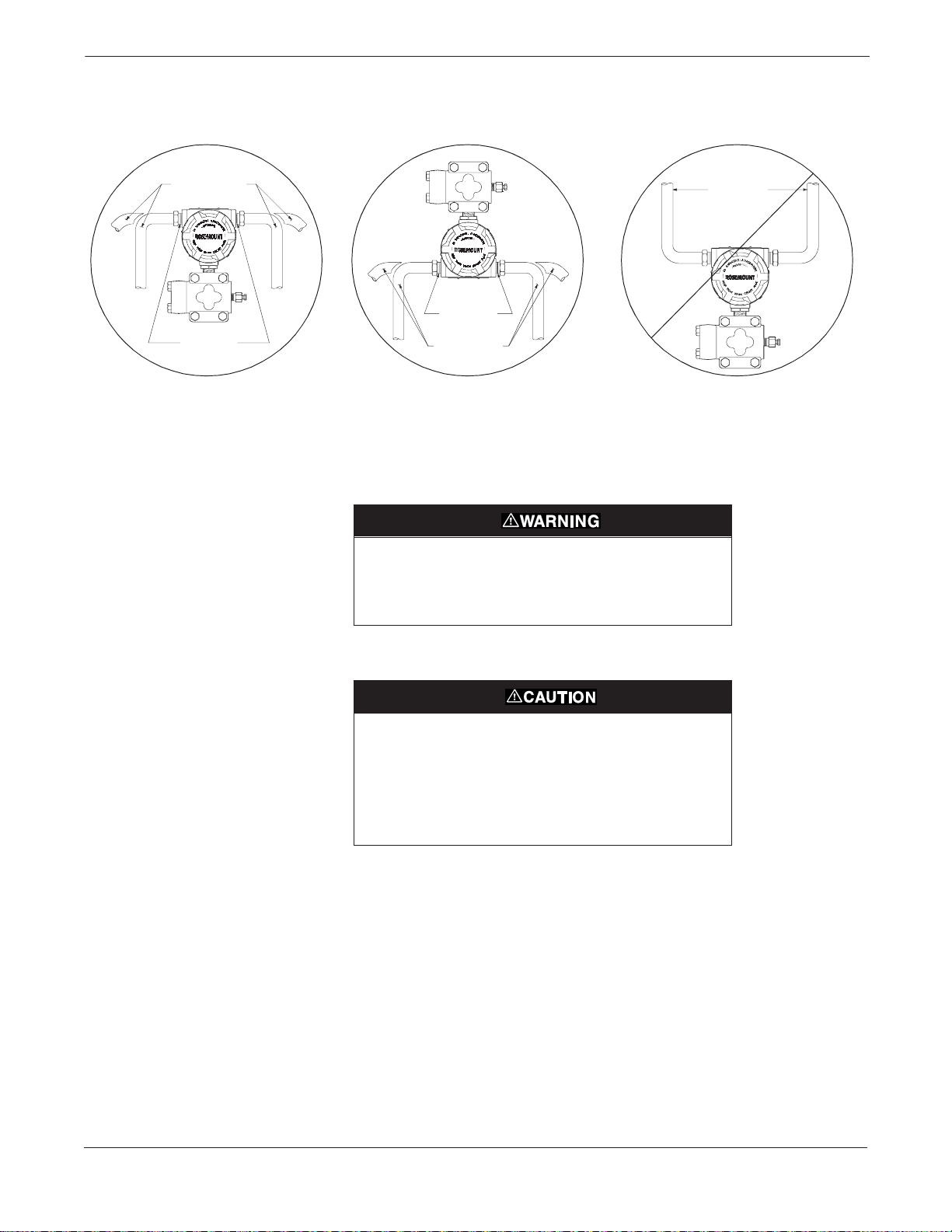

CORRECT CORRECT INCORRECT

Sealing

Compound

Possible

Conduit Line

Positions

1151-1151E25A

Conduit

Lines

Unused conduit connections on the transmitter housing should be

plugged and sealed to avoid moisture accumulation in the terminal side

of the housing. The recommended connections of conduit are shown in

Figure 2-7.

All explosion proof, flameproof, and dust-ign ition proof

installations require insertion of conduit plugs in all unused

openings with a minimum of 40 ft-lbs (54 N-m) of torque.

This will maintain five full threads of engagement.

1151-1151F25A

If all connections are not sealed, excess moisture

accumulation can damage the transmitter. Make sure to

mount the transmitter with the electrical housing positioned

downward for drainage. To avoid moisture accumulation in

the housing, install wiring with a drip loop, and ensure the

bottom of the drip loop is mounted lower than the conduit

connections or the transmitter housing.

Grounding

Use the following techniques to properly ground the transmitter signal

wiring and case:

Signal Wiring Do not run signal wiring in conduit or open trays with power wiring, or

near heavy electrical equipment. Signal wiring may be grounded at any

one point on the signal loop, or it may be left ung rounde d. The n egative

terminal of the power supply is a recommended grounding point.

Transmitter Case The transmitter case must be grounded in accordance with national

and local electrical codes. The most effective transmitter case

grounding method is a direct internal connection to earth ground with

minimal impedance.

2-11

Model 1151 Alphaline® Pressure Transmitters

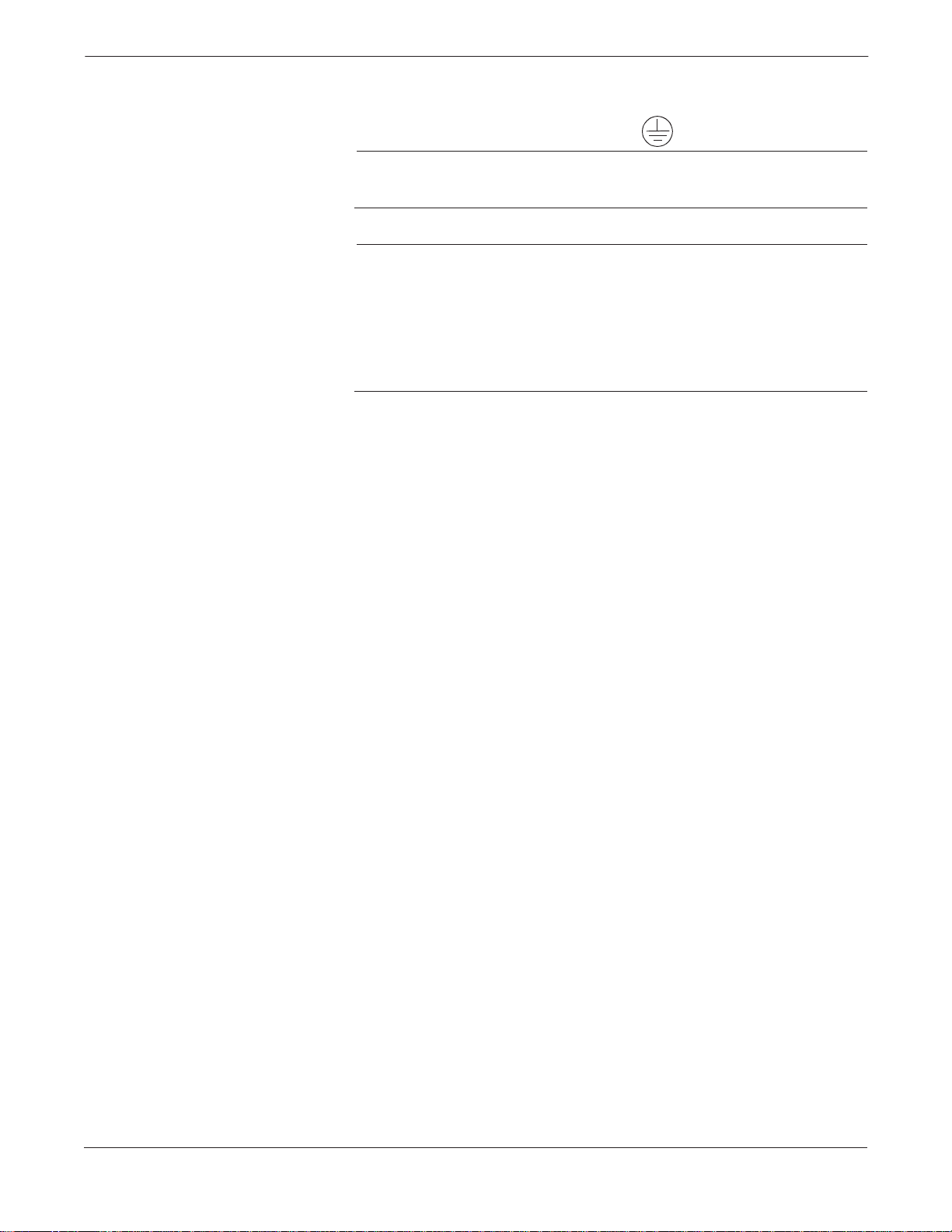

Internal Ground Connection: Inside the FIELD TERMINALS side of

the electronics housing is the Internal Ground Connection screw. This

screw is identified by a ground symbol: .

NOTE

Grounding the transmitter case via threaded conduit connection may

not provide sufficient ground continuity.

NOTE

The transient protection terminal block (See Figure 4-4 on page 4-8)

does not provide transient protection unless the transmitter case is

properly grounded. Use the preceding guidelines to ground the

transmitter case.

Do not run the transient protection ground wire with signal wiring as

the ground wire may carry excessive current if a lightning strike occurs.

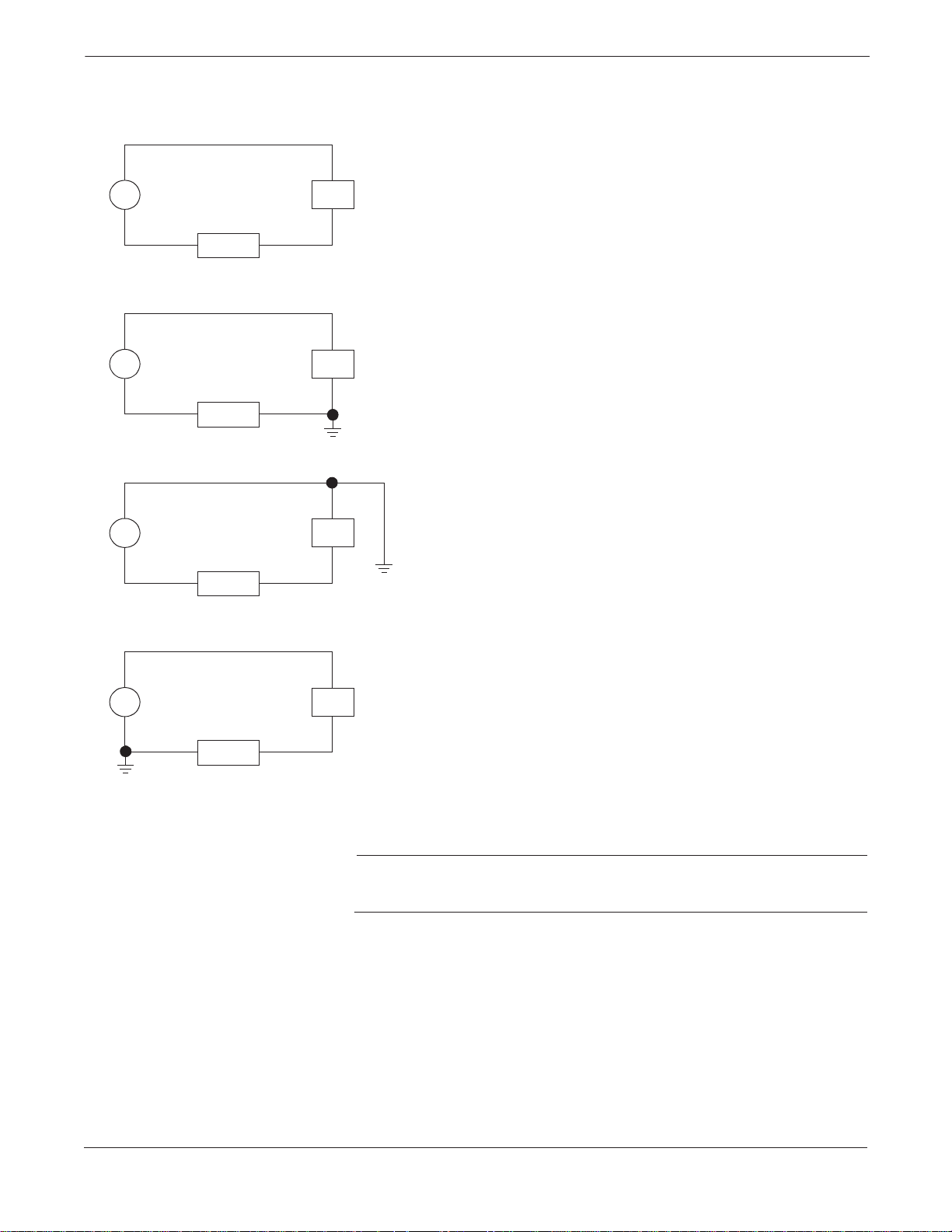

Grounding Effects The capacitance sensing module requires alternating current to

generate a capacitance signal. This alternating current is developed in

an oscillator circuit with a frequency of approximately 32 kHz. This

signal is capacitor-coupled to transmitter-case ground through the

sensing module. Because of this coupling, a voltage may be imposed

across the load, depending on the choice of grounding. See Figure 2-8.

Hazardous Locations

Certifications

This impressed voltage, which is seen as high frequency noise, will have

no effect on most instruments. Computers with short sampling times

will detect a significant noise signal, which should be filtered out by

using a large capacitor (1 µF) or by using a 32 kHz LC filter across the

load. Computers are negligibly affected by this noise and do not need

filtering

The Model 1151 was designed with an explosion-proof housing and

circuitry suitable for intrinsically safe and non-incendive operation.

Factory Mutual explosion-proof certification is standard for the Model

1151 Transmitter. Individual transmitters are clearly marked with a

tag indicating the approvals they carry. Transmitters must be installed

in accordance with all applicable codes and standards to maintain these

certified ratings. Refer to Hazardous Locations Certifications on

page 6-2 for information on the approvals associated with the analog

Model 1151.

.

2-12

FIGURE 2-8. T ypic al Ef fe ct s of Groundi ng

on Accuracy for Fast Sample Computers

(4-20 mA loops only).

Installation

PT

PT

PT

LOAD

LOAD

LOAD

+

PS

–

+

PS

Ungrounded System

Impressed Voltage: 12 to 22 mVp-p

32 kHz

Effect: 0.01% of span.

Ground Between Negative Sid e of Power Sup ply an d Load

Impressed Voltage: 35 to 60 mVp-p

32 kHz

Effect: 0.03% of span.

–

+

PS

–

Ground Between Positive Sid e of Transmitter and Power Supply

Impressed Voltage: 35 to 60 mVp-p

32 kHz

Effect: 0.03% of span.

PT

LOAD

+

PS

–

Ground Between Negative Terminal of Transmitter and Load

Impressed Voltage: 500 to 600 mVp-p

32 kHz

Effect: 0.27% of span.

NOTE

Typical effects caused by the impressed voltage on a computer with a

sampling time of 100 microseconds using a 2 to 10 volt signal.

2-13

Model 1151 Alphaline® Pressure Transmitters

LIQUID LEVEL

MEASUREMENT

Open Vessels

Closed Vessels

Differential pressure transmitters used for liquid level applications

measure hydrostatic pressure head. Liquid level and specific gravity of

a liquid are factors in determining pressure head. This pressure is

equal to the liquid height above the tap multiplied by the specific

gravity of the liquid. Pressure head is independent of volume or vessel

shape.

A pressure transmitter mounted near a tank bottom measures the

pressure of the liquid above.

Make a connection to the high pressure side of the transmitter, and

vent the low pressure side to the atmosphere. Pressure head e quals the

liquid’s specific gravity multiplied by the liquid height above the tap.

Zero range suppression is required if the transmitter lies below the zero

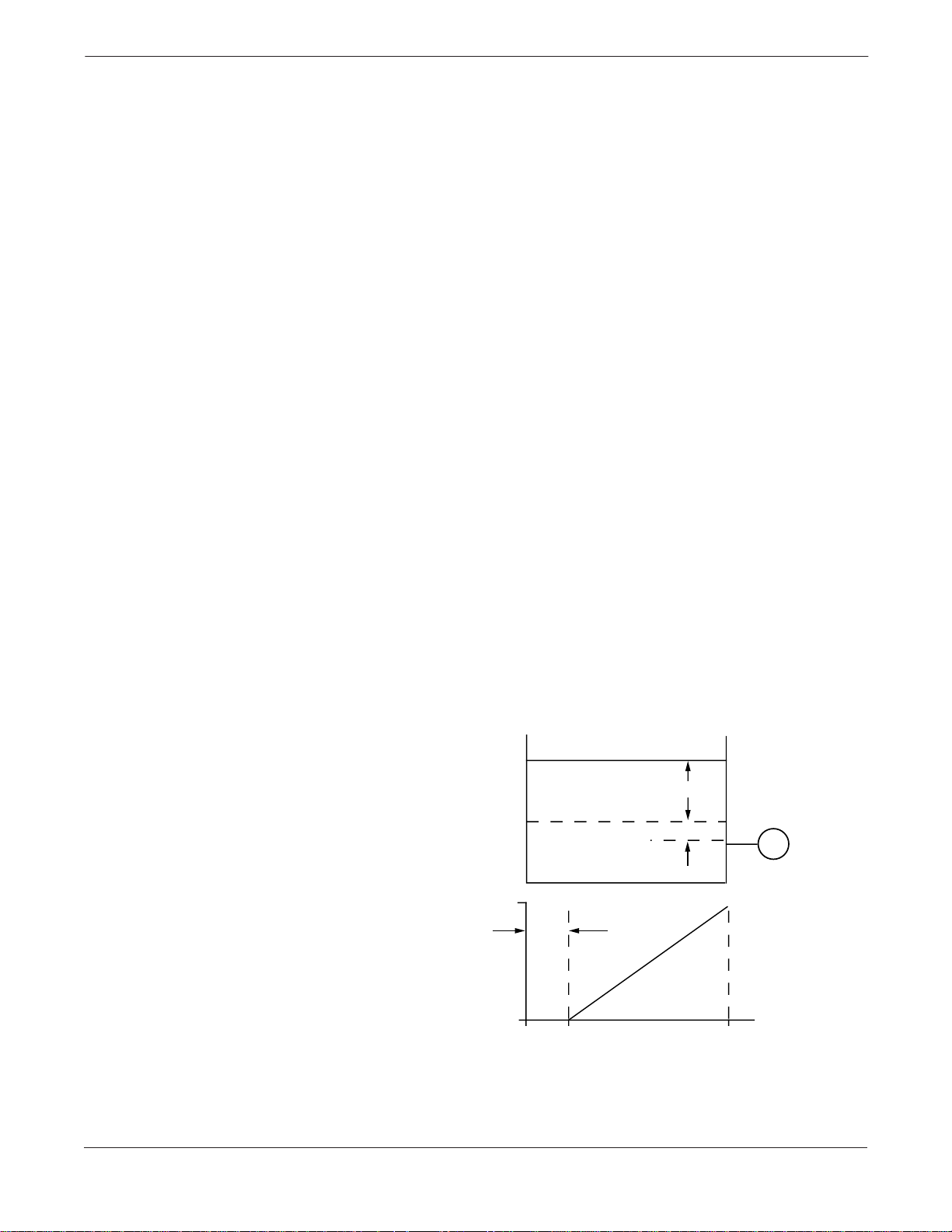

point of the desired level range. Figure 2-9 shows a liquid level

measurement example.

Pressure above a liquid affects the pressure measured at the bottom of

a closed vessel. The liquid specific gravity multiplied by the liquid

height plus the vessel pressure equals the pressure at the bottom of the

vessel.

To measure true level, the vessel pressure must be subtracted from the

vessel bottom pressure. T o do this, make a pressure tap at the top of the

vessel and connect this to the low side of the transmitter. Vessel

pressure is then equally applied to both the high and low sides of the

transmitter . The resulting diff eren tial pressure is pro portional to liquid

height multiplied by the liquid specific gravity.

Dry Leg Condition Low-side transmitter piping will remain empty if gas above the liquid

does not condense. This is a dry leg condition. Range determination

calculations are the same as those described for bottom-mounted

transmitters in open vessels, as shown in Figure 2-9.

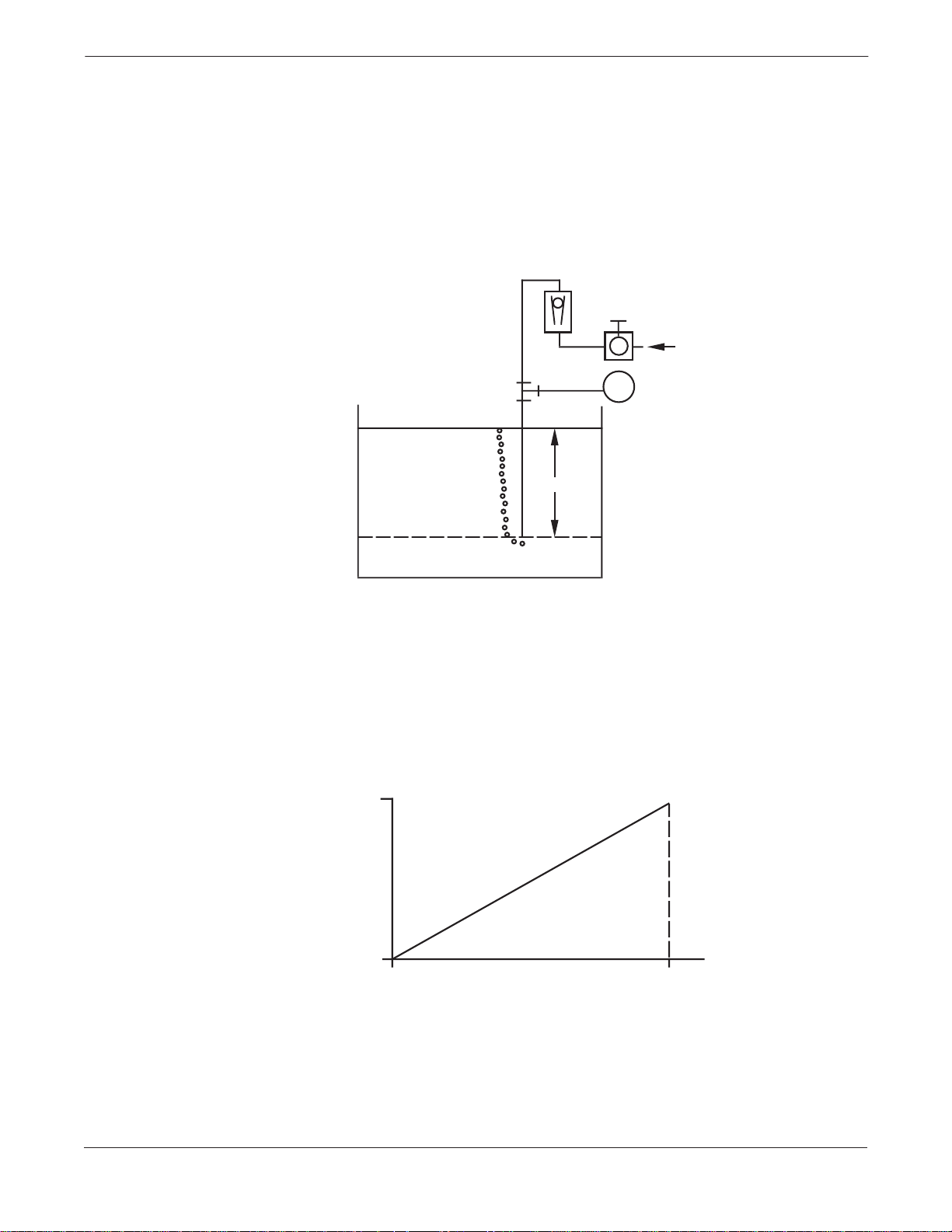

FIGURE 2-9. Liquid Level

Measurement Example.

X

Let X equal the vertical distance between the minimum and maximum

measurable levels (500 in.).

Let Y equal the vertical distance between the transmitter datum line and the

minimum measurable level (100 in.).

Let SG equal the specific gravity of the fluid (0.9).

Let h equal the maximum head pressure to be measured in inches of water.

Let e equal head pressure produced by Y expressed in inches of water.

Let Range equal e to e + h.

Then h = (X)(SG)

= 500 x 0.9

= 450 inH

e=(Y)(SG)

= 100 x 0.9

= 90 inH

Range = 90 to 540 inH

O

2

O

2

O

2

20

mA dc

ZERO

4

SUPPRESION

900

inH2O

Y

T

540

2024-0171A, 0172A

2-14

Installation

Wet Leg Condition Condensation of the gas above the liquid slowly causes the low side of

the transmitter piping to fill with liquid. The pipe is purposely filled

with a convenient reference fluid to eliminate this potential error. This

is a wet leg condition.

The reference fluid will exert a head pressure on the low side of the

transmitter . Z ero elevatio n of the range must then be made. See Figure

2-10.

FIGURE 2-10. Wet Leg Example.

X

Y

LT

Z

H L

Let X equal the vertical distance betwe en the minimum and max im um

measurable levels (500 in.).

Let Y equal the vertical distance between the transmitter datum line and the

minimum measurable level (50 in.).

Let z equal the vertical distance between the top of the liquid in the wet leg

and the transmitter datum line (600 in.).

Let SG

equal the specific gravity of the fluid (1.0).

1

Let SG

equal the specific gravity of the fluid in the wet leg (1.1).

2

Let h equal the maximum head pressure to be measured in inches of water.

Let e equal the head pressure produced by Y expressed in inches of water.

Let s equal head pressure produced by z expressed in inches of water.

Let Range equal e – s to h + e – s.

Then h = (X)(SG

= 500 x 1.0

= 500 in H

e=(Y)(SG

= 50 x 1.0

= 50 inH

s=(z)(SG

= 600 x 1.1

= 660 inH

Range = e – s to h + e – s.

= 50 – 660 to 500 + 50 – 660

= –610 to –110 inH

)

1

O

2

)

1

O

2

)

2

0

2

0

2

ZERO ELEVATION

inH2O

20

mA dc

4

-110-610

0

2024-0167A 2024-0168A

2-15

Model 1151 Alphaline® Pressure Transmitters

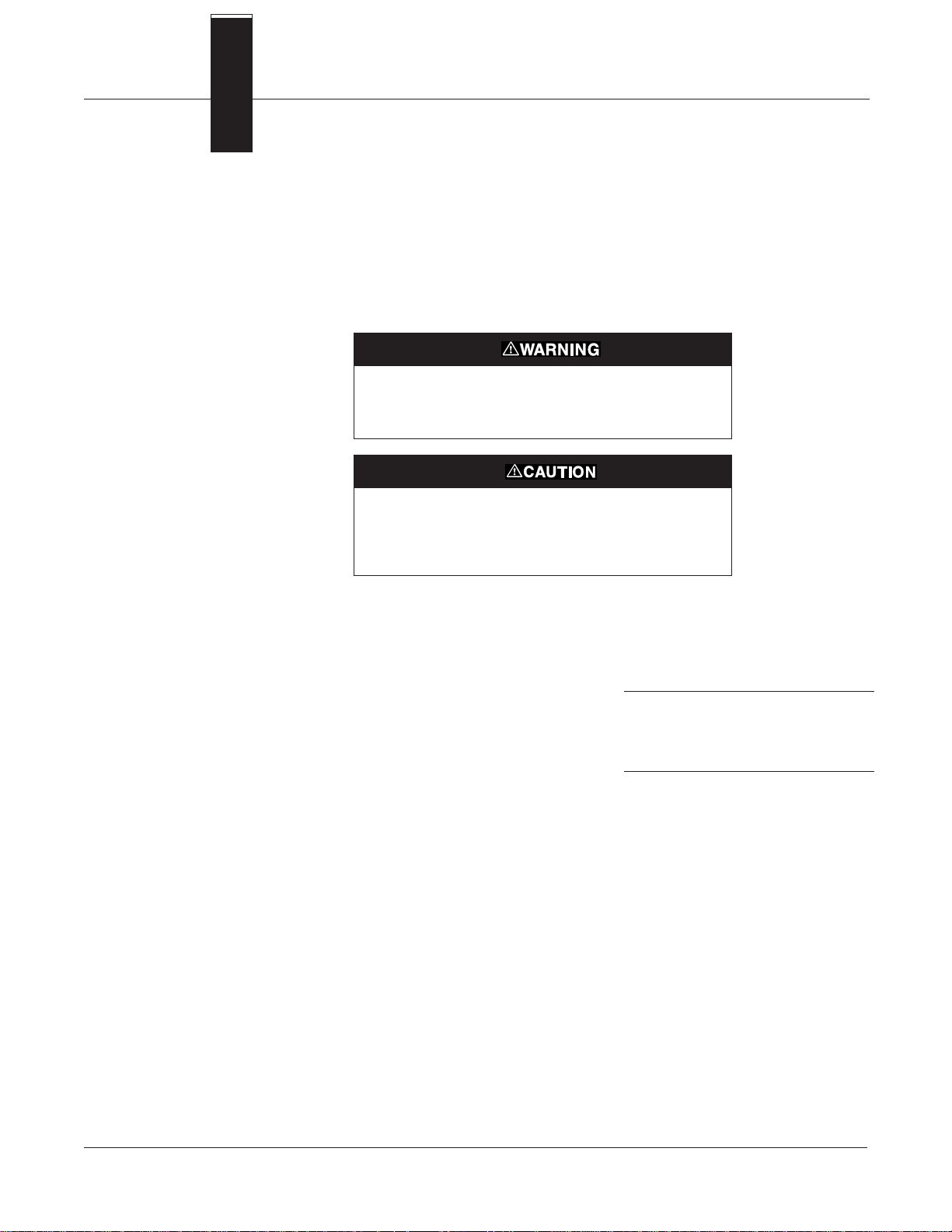

Bubbler System in Open Vessel A bubbler system that has a top-mounted pressure transmitter can be

used in open vessels. This system consists of an air supply, pressure

regulator, constant flow meter, pressure transmitter, and a tube that

extends down into the vessel.

Bubble air through the tube at a constant flow rate. The pressure

required to maintain flow equals the liquid’s specific gravity multiplied

by the vertical height of the liquid above the tube opening. Figure 2-11

shows a bubbler liquid level measurement example.

FIGURE 2-11. Bubbler Liquid Level

Measurement Example.

AIR

T

X

Let X equal the vertical distance betwe en the minimum and max im um

measurable levels (100 in.).

Let SG equal the specific gravity of the fluid (1.1).

Let h equal the maximum head pressure to be measured in inches of water.

Let Range equal zero to h.

Then h = (X)(SG)

= 100 x 1.1

= 110 inH

Range = 0 to 110 inH

20

mA dc

4

0

O

2

O

2

110

inH2O

2024-0165A

2024-0166A

2-16

Section

3 Calibration

Calibration of the Rosemount Model 1151 Pressure Transmitter is

simplified by its compact and explosion-proof design, external span and

zero adjustments, separate compartments for electronics and wiring,

and weatherproof construction. Descriptions of span, linearity, zero

adjustments, and damping follow.

Explosions can cause death or serious injury. Both

transmitter covers must be fully engaged to meet explosionproof requirements.

When replacing housing covers, tighten the covers enough

to make contact with the O-ring seals. If the covers are not

tightened enough, moisture can enter the housing and

cause transmitter failure.

QUICK CALIBRATION

PROCEDURE (FOR E, G,

AND J ELECTRONICS)

QUICK CALIBRATION

PROCEDURE (FOR L AND

M ELECTRONICS)

The following Quick Calibration Procedures are for those users who are

already familiar with the analog Model 1151.

NOTE

The zero and span adjustments are interactive. For applications

requiring large elevated or suppressed values, refer to Elevated or

Suppressed Zeros on page 3-7.

1. Apply 4 mA-point pressure and turn zero screw to output 4 mA.

2. Apply 20 mA-point pressure.

3. Subtract actual output from desired output.

4. Divide difference by 3.

5. Turn span screw above or below desired output by value in Step 4.

6. Repeat Steps 1 through 5 until calibrated.

1. Apply 1 V dc-point pressure for M electronics (0.8 V dc for L electronics)

and turn zero screw to output 1 V dc (0.8 V dc for L electronics).

2. Apply 5 V dc-point pressure (M electronics) or 3.2 V dc (L electronics).

3. Subtract actual output from desired output.

4. Divide difference by 3.

5. Turn span screw above or below desired output by value in Step 4.

6. Repeat Steps 1 through 5 until calibrated.

3-1

Model 1151 Alphaline® Pressure Transmitters

Example for a Model 1151DP Range 4: For a desired calibration of 0

to 100 inH

1. Adjust the zero. With zero input applied to the transmitter, turn

the zero adjustment screw until the transmitter reads 4 mA.

2. Adjust the span. Apply 100 inH

connection. Turn the span adjustment screw until the transmitter

output reads approximately 20 mA.

3. Release the input pressure and readjust the zero output to read 4

mA ±0.032 mA.

4. Re-apply 100 inH

greater than 20 mA, divide the difference by 3, and subtract the

result from 20 mA. Adjust the 100% output to this value.

If the output reading is less than 20 mA, divide the difference by 3 and

add the result to 20 mA. Adjust the 100% output to this value.

Example: The full scale transmitter output is 20.100 mA. Dividing

0.100 by 3.0 gives the product 0.033. Subtracting the product 0.033

from 20.00 mA gives the difference 19.967 mA. Adjust the 100% output

to this value.

5. Release input pressure and readjust the zero.

6. Apply 100% input and repeat Steps 3 through 5 if the full scale

output is not 20 ±0.032 mA.

O, use the following procedure:

2

O to the transmitter high side

2

O to the transmitter. If the output reading is

2

NOTE

Under operating conditions that subject the transmitter to temperature

extremes or significant vibration, mechanical backlash may occur in the

zero and span adjustment screws. To improve the stability of zero and

span settings in these circumstances, back off the adjustment screws

slightly after final adjustment to break contact between the

potentiometer blades and the adjustment screw slot surfaces.

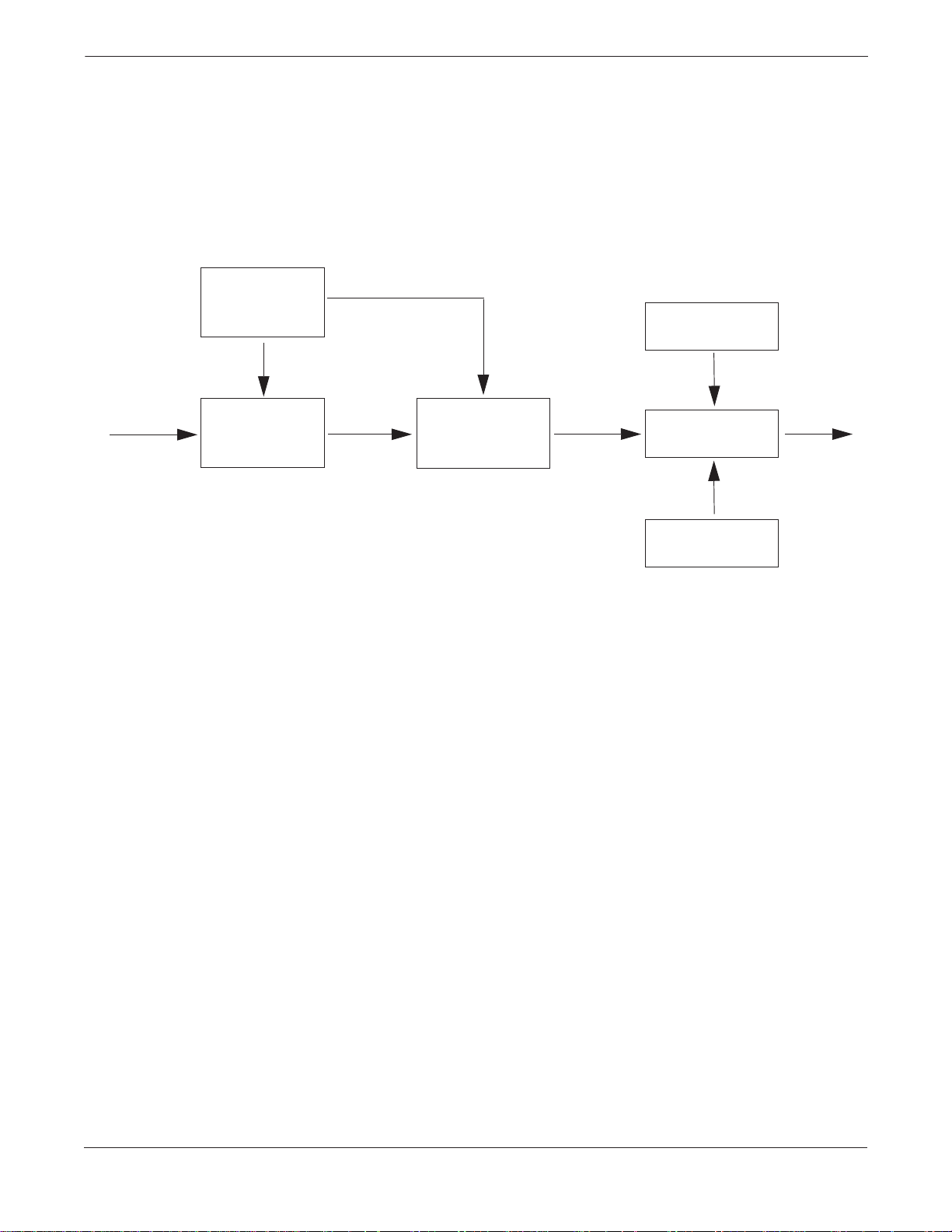

3-2

Calibration

DATA FLOW WITH

CALIBRATION OPTIONS

FIGURE 3-1. Model 1151 Transmitter

Data Flow with Calibration Options.

Sensor

Excitation

➀ Pressure

➁

Sensor

Figure 3-1 illustrates the Model 1151 Transmitter data flow with

calibration tasks.

Zero

Adjustment

➂

Signal

Conditioning

➃

Output

Span

Adjustment

Output

This data flow can be summarized in four major steps:

1. Pressure is applied to the sensor.

2. A change in pressure is measured by a change in the sensor

output.

3. The sensor signal is conditioned for various parameters.

4. The conditioned signal is converted to an appropriate analog

output.

3-3

Model 1151 Alphaline® Pressure Transmitters

SPAN ADJUSTMENT

RANGE

ZERO ADJUSTMENT

RANGE

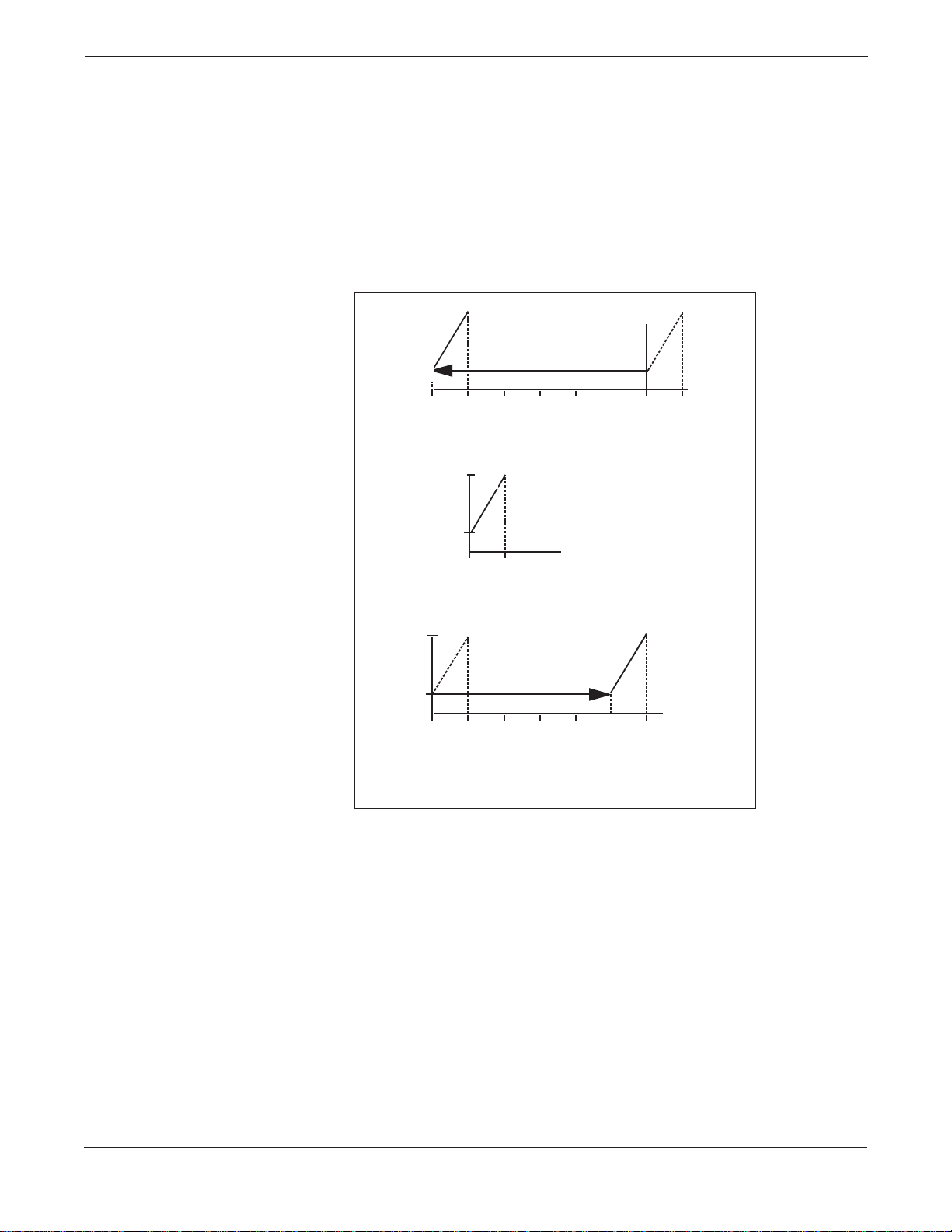

FIGURE 3-2. Zero Adjustment Range.

The span on a Model 1151 with E, G, and J output options is

continuously adjustable to allow calibration anywhere between

maximum span and one-sixth of maximum span. For example, the span

on a Range 4 transmitter can be adjusted between 25 and 150 inH

O

2

(6.2 and 37.2 kPa).

The zero on a Model 1151 with the E or G output options can be

adjusted for up to 500% suppression or 600% elevation. See Figure 3-2.

Output

(mA)

20

Pressure

O)

(inH

2

–150 –125 –100

Output

(mA)

20

Output

(mA)

600% Zero Elevation

–75

–50 –25 0

600% Zero Elevation*

20

4

0 25

No Zero Elevation or Suppression*

Pressure

O)

(inH

2

4

25

500% Zero Elevation

4

25

0

*Graphs based on a range 4 (0-25 inH2O to 0-150 inH2O) 1151

with a calibrated span of 25 inH

50

500% Zero Suppression*

75

100

O.

2

125

150

1151-0193A

The zero may be elevated or suppressed to these extremes with the

limitation that no pressure within the calibrated range exceeds the fullrange pressure limit. For example, a Range 4 tr ansmitt er cannot be

calibrated for 1 00 to 200 i nH

suppression) because 200 inH

O (24.8 to 49.7 kPa) (only 100% zero

2

O exceeds the 150 inH2O full-range

2

pressure limit of a Range 4.

To make large elevation or suppression adjustments, it is necessary to

move the jumper on the component side of the amplifier board. Figure

3-3 on page 3-5 shows elevation and suppression jumper settings. The

jumper has three positions. The middle position allows normal levels of

elevation or suppression. For larger adjustm ents, move the jumper to

the ELEVATE ZERO (EZ) or SUPPRESS ZERO (SZ) as marked.

3-4

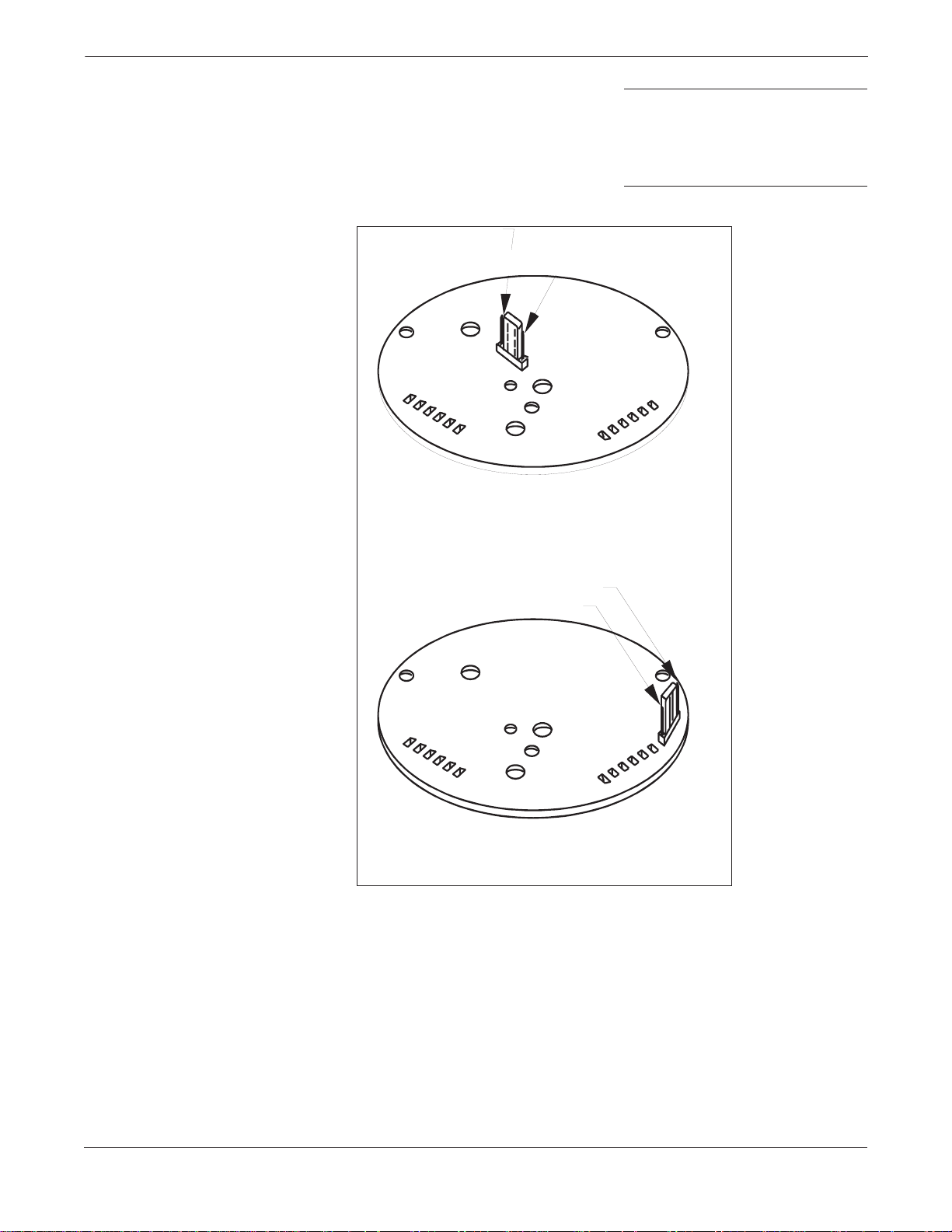

FIGURE 3-3. Elevation and

Suppression Jumper Settings.

Calibration

NOTE

Always make sure that the jumper is fully seated on its pins. If the

jumper has not been placed in any of the three positions, the amplifier

board will provide normal levels of elevation or suppression. A slide

switch replaces the jumper pin on some versions of the amplifier board.

E Output Option

(4–20 mA)

Elevate Zero

Suppress Zero

G Output Option

(10–50 mA)

Suppress Zero

Elevate Zero

NOTE: The jumper is located on the co mpon en t sid e of the

amplifier board. Jumper positions may vary from those shown. The

board must be unplugged from the transmitter to gain acce ss to

the component.

1151-0194A

3-5

- Manuals

- Brands

- Rosemount Manuals

- Measuring Instruments

- 1151

Manuals and User Guides for Rosemount 1151. We have 1 Rosemount 1151 manual available for free PDF download: Product Manual

На этой странице вы можете совершенно бесплатно скачать Инструкция по эксплуатации Emerson Rosemount 1151 Pressure Transmitter.

У документа PDF Инструкция по эксплуатации 22 страниц, а его размер составляет 1.15 Mb.

Читать онлайн Средства личной гигиены Emerson Rosemount 1151 Pressure Transmitter Инструкция по эксплуатации

Скачать файл PDF «Emerson Rosemount 1151 Pressure Transmitter Инструкция по эксплуатации» (1.15 Mb)

Популярность:

1935 просмотры

Подсчет страниц:

22 страницы

Тип файла:

Размер файла:

1.15 Mb