-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

Operation & Maintenance

Manual

ATTENTION

Unsafe use of this machine may cause serious injury

or death. Operators and maintenance personnel

must read this manual before operating or

maintaining this machine.

This manual should be kept inside the cab for

reference and periodically reviewed by all personnel

who will come into contact with the machine.

WB93R

BACKHOE-LOADER

SERIAL NUMBER

WB93R-5 F50003

WEAM006000

-5

and up

Chapters

Summary of Contents for Komatsu WB93R-5

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

Operation & Maintenance

Manual

ATTENTION

Unsafe use of this machine may cause serious injury

or death. Operators and maintenance personnel

must read this manual before operating or

maintaining this machine.

This manual should be kept inside the cab for

reference and periodically reviewed by all personnel

who will come into contact with the machine.

WB93R

BACKHOE-LOADER

SERIAL NUMBER

WB93R-5 F50003

WEAM006000

-5

and up

Chapters

Summary of Contents for Komatsu Utility WB93R-5

This manual is also suitable for:

F50003

WEAM002304

Operation & Maintenance

Manual

WB91R-2

WB93R-2

BACKHOE-LOADER

SERIAL NUMBER

WB91R-2 91F20250 WB93R-2 93F25184

WARNING

Unsafe use of this machine may cause serious injury or death. Operators and maintenance personnel must read this manual before operating or maintaining this machine.

This manual should be kept inside the cab for reference and periodically reviewed by all personnel who will come into contact with the machine.

FOREWORD

1.1 FOREWORD

•This manual has been carried out by Komatsu Utility in order to supply their customers with all the necessary information on the machine and the safety regulations related to it, together with the use and maintenance instructions that enable the operator to exploit the capacity of the machine with optimal results and to keep the machine efficient over time.

•The operation manual, together with the spare parts catalogue, is an integral part of the machine and must accompany it, even when it is resold, until its final disposal.

•The manual must be handled with the greatest care and always kept on board the machine, so that it can be consulted at any moment; it must be placed in the appropriate compartment behind the seat, where also the ownership documents and the logbook are usually kept (see “3.5.10 TECHNICAL DOCUMENTATION”).

•This manual must be given to the persons who have to use the machine and carry out the routine maintenance operations; they must read the contents carefully more than once, in such a way as to clearly understand what are the correct operating conditions and the dangerous conditions that must be avoided.

In case of loss or damage, request a new copy to Komatsu Utility or your Komatsu Utility Dealer.

•The illustrations contained in this manual may represent machine configurations available upon request. Komatsu Utility machines are constantly improved in order to increase their efficiency and reliability; this manual sums up all the information regarding the most recent techniques applied at the moment in which the machine is marketed.

For any further and/or updated information, contact your Komatsu Utility Dealer.

•Punctual periodic annotations regarding the maintenance operations that have been carried out are important to have a clear prospect of the situation and to know exactly what has been done and what has to be done after the next maintenance interval. Therefore, it is advisable to consult the hour meter and the maintenance plan frequently.

•Over the years Komatsu Utility Dealers have gathered considerable experience in customer service.

If more information is needed, do not hesitate to contact your Komatsu Utility Dealer: he always knows how to get the best performance from the machine, he can suggest the use of the equipment that is most suitable for specific needs and can provide the technical assistance necessary for any change that may be required to conform the machine to the safety standards and traffic rules.

Furthermore, Komatsu Utility Dealers also ensure their assistance for the supply of Komatsu Utility genuine spare parts, which alone guarantee safety and interchangeability.

•The table included in this manual must be filled in with the machine data, which are the data that must always be indicated to the Dealer when requiring assistance and ordering spare parts.

•The incorrect use of the machine and inappropriate maintenance operations may cause serious injuries and even death.

•Operators and maintenance personnel must carefully read this manual before using the machine or performing maintenance operations.

•Any serious accident that may occur during the use of the machine or during maintenance operations is due to failure to comply with the instructions given herein.

•The procedures and precautions described in this manual are valid for application to the machine only when it is used correctly.

If the machine is used for any purpose or in any way other than those described herein, the operator shall be responsible for his own safety and for the safety of any other person involved.

1

INFORMATION ON SAFETY

1.2 INFORMATION ON SAFETY

Many accidents are caused by insufficient knowledge of and failure to comply with the safety regulations prescribed for the maintenance operations that must be performed on the machine.

In order to avoid accidents, before starting work and before carrying out any maintenance operation, carefully read and be sure to understand all the information and warnings contained in this manual and given on the plates applied onto the machine, so that you can follow the instructions without making mistakes.

To identify the messages regarding safety that are included in this manual and written on the machine plates, the following words have been used.

|

DANGER |

• This word is used in the safety warnings in the manual and on the plates when |

||||||

|

the situation is dangerous and it may possibly result in serious injuries or even |

|||||||

|

death. |

|||||||

|

These messages describe the safety precautions to be taken in order to avoid |

|||||||

|

any risk. Non-compliance with these instructions may also result in serious |

|||||||

|

damage to the machine. |

|||||||

|

CAUTION |

• This word is used in the safety warnings in the manual and on the plates to sig- |

||||||

|

nal risks that may cause moderate damage or injuries. |

|||||||

|

The message can be used even to indicate the risk of damage to the machine |

|||||||

|

only. |

|||||||

|

• This word is used when precautions are indicated, which must be taken to avoid |

|||||||

|

IMPORTANT |

|||||||

|

actions that may shorten the life of the machine. |

|||||||

Komatsu Utility cannot reasonably predict every circumstance that might involve a potential hazard during the operation or maintenance of the machine; for this reason, the safety messages included in this manual and applied onto the machine may not include all possible safety precautions.

If all the procedures and operations prescribed for this machine are kept to, you can be sure that the operator and the persons in the vicinity can work in total safety, with no risk of damaging the machine. In case of doubt regarding the safety measures necessary for some procedures, contact Komatsu Utility or your local Dealer.

•Before starting any maintenance operation, position the machine on firm and level ground, engage the safety locks of the equipment and of the controls, stop the engine and apply the parking brake.

•To make the information clearer, some illustrations in this manual represent the machine without safety guards. Do not use the machine without guards and do not start the engine when the engine protection casing is open, if this is not expressly prescribed for some specific maintenance operations.

2

INFORMATION ON SAFETY

•It is strictly forbidden to modify the setting of the hydraulic system safety valves; Komatsu Utility cannot be held liable for any damage to persons, property or the machine, if this has been tampered with by modifying the standard setting of the hydraulic system.

•Before carrying out any electrical welding, disconnect the battery and the alternator (See “2.8.13 PRECAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR”).

DANGER

• Install only authorized additional equipment (See “6.1 AUTHORIZED OPTIONAL EQUIPMENT”).

•The machine can travel on roads only if provided with homologated equipment; before travelling on roads, make sure that the equipment with which the machine is provided is homologated and that the safety locks are correctly.

3

INTRODUCTION

1.3 INTRODUCTION

1.3.1 INTENDED USES

The Komatsu Utility BACKHOE LOADERS described in this manual have been designed and constructed to be used mainly for the following functions:

•LOADER

•EXCAVATOR

Through the installation of optional equipment, the machine can also be used for the following applications:

•HANDLING OF MATERIALS (4IN1 BUCKET — PALLET FORKS)

•SNOWPLOUGH (ANGLEDOZER BLADE — SNOWPLOUGH)

•DEMOLITION (HAND HAMMER — HAMMER ON THE BACKHOE)

•DITCH CLEANING AND DIGGING (SPECIAL BUCKETS)

1.3.2 IMPROPER OR UNAUTHORIZED USES

•This paragraph describes some of the improper or unauthorized uses of the machine; since it is impossible to predict all the possible improper uses, if the machine happens to be used for particular applications, contact your Komatsu Utility Dealer before carrying out the work.

IMPORTANT

•The instructions regarding the authorized optional equipment are given in the relevant operation and maintenance manuals; if the equipment is supplied by Komatsu Utility, these publications are enclosed to this manual.

•The instructions regarding the assembly of the authorized equipment, the controls requiring special arrangement on the machine and the hydraulic couplings necessary for the operation of the equipment are grouped in the final section of this manual.

Komatsu Utility backhoe loaders are constructed exclusively for the handling, excavation and treatment of inert materials; therefore, the following uses are absolutely forbidden:

•USE OF THE MACHINE BY MINORS OR INEXPERIENCED PERSONS.

•USE OF THE MACHINE FOR LIFTING PERSONS OR OBJECTS.

•TRANSPORTATION OF PERSONS even if they are in the operator’s cab.

•TRANSPORTATION OF CONTAINERS with fluids, flammable fluids, loose material, without the appropriate slinging equipment.

•TRANSPORTATION AND LIFTING (EVEN IF IN EXCEPTIONAL CASES) OF EQUIPMENT OR MATERIALS THAT PROTRUDE FROM THE BUCKET OR ARE NOT SECURED TO THE BUCKET BY MEANS OF ROPES OR CHAINS.

•USE OF THE BUCKET FOR DRIVING OR EXTRACTING PILES.

•USE OF THE MACHINE FOR TOWING DAMAGED VEHICLES ON ROADS.

•USE OF THE MACHINE FOR LIFTING DAMAGED VEHICLES.

4

INTRODUCTION

1.3.3 MAIN CHARACTERISTICS

•Simple and easy operation.

•Servo-assisted steering with priority hydraulic system.

•4-gear mechanical gearshift and transmission with hydraulic converter; reversal controlled by a lever positioned under the steering wheel.

•Loader control through a single lever ensuring also combined movements that can be modulated proportionally and continually.

•Backhoe controls with two levers ensuring also combined movements that can be modulated proportionally and continually.

•Complete series of instruments visible from the two operating positions (loader or backhoe).

•Separate accelerator controls for the two operating positions.

•Foot brake control.

•Easy maintenance with simplified intervals.

1.3.4 RUNNING-IN

Every machine is scrupulously adjusted and tested before delivery.

A new machine, however, must be used carefully for the first 100 hours, in order to ensure proper running-in of the various components.

If the machine is subjected to excessive work load at the beginning of operation, its potential yield and its functionality will be shortly and untimely reduced.

Every new machine must be used carefully, paying special attention to the following indications:

•After the start, let the engine idle for 5 minutes, in such a way as to warm it up gradually before actual operation.

•Avoid operating the machine with the limit loads allowed or at high speed.

•Avoid abrupt starts or accelerations, useless sudden decelerations and abrupt reversals.

•After the first 250 hours, carry out the following operations, in addition to those to be performed every 250 hours:

1 — Change the hydraulic transmission oil and filter.

2 — Change the differential unit oil (front and rear axle).

3 — Change the oil in the final reduction gears (front and rear axle). 4 — Check and adjust the engine valve clearance.

5 — Change the hydraulic circuit oil filter.

SYNTHETIC BIODEGRADABLE OIL TYPE HEES

On machines in which the synthetic biodegradable oil type HEES is used, the following operations are to be performed besides the standard maintenance operations:

•After the first 50 hours of operation, change the hydraulic circuit drain filter.

•After the first 500 hours of operation, change the hydraulic circuit oil.

IMPORTANT

•When changing the oil filters (cartridges), check their innner part to make sure that there are no deposits.

If considerable deposits are observed, find out what may have caused them before starting the machine.

•The number of operation hours is indicated by the hour meter.

5

INTRODUCTION

1.4 PRODUCT IDENTIFICATION

The Komatsu Utility backhoe loader and its main components are identified by serial numbers stamped on the identification plates.

The serial number and the identification numbers of the components are the only numbers that must be indicated to the Dealer when requiring assistance and ordering spare parts.

1.4.1 MACHINE SERIAL NUMBER

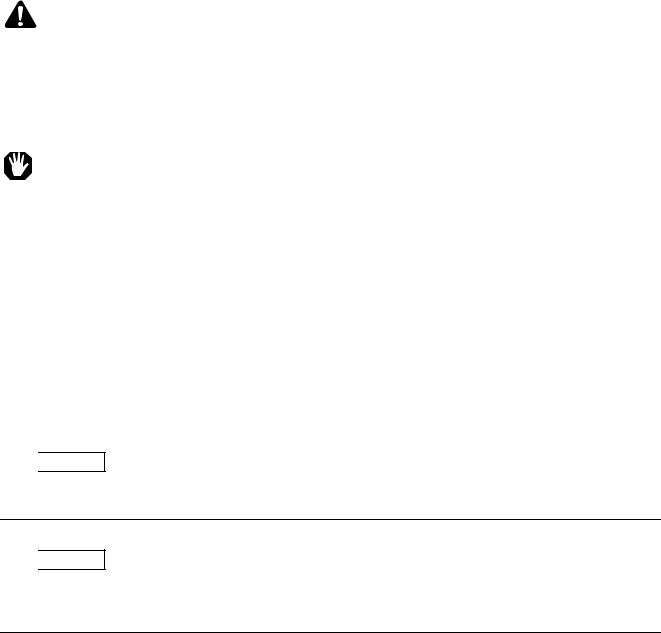

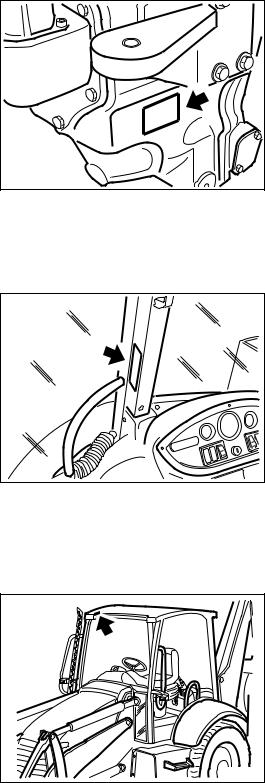

The machine serial number is stamped on the front part of the main frame, on the right side.

|

RWAB0070 |

|

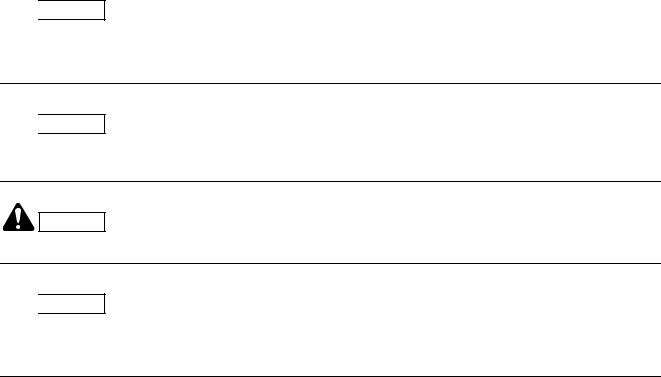

1.4.2 MACHINE IDENTIFICATION PLATE |

|

|

The Komatsu Utility backhoe loaders described in this manual |

|

|

are provided with the CE mark, which certifies that they are in |

|

|

compliance with the CE harmonized standards. |

|

|

The plate with the mark is applied inside the operator’s cab, on |

|

|

the left vertical wall of the frame, in correspondence with the |

|

|

brake pedals. |

|

|

RWA04680 |

|

|

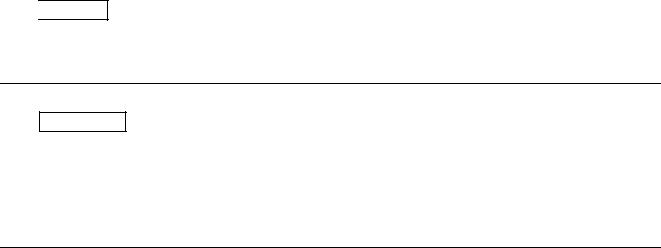

MODELLO |

— MODEL |

|

TYP |

— MODELE |

MATRICOLA N˚ — SERIAL N˚

|

FABR. NR. |

— SERIE NR. |

|

|

ANNO |

— YEAR |

|

|

BAUJAHR |

— ANNEE |

|

|

MASSA TOTALE MAX |

— TOTAL MAX WEIGHT |

|

|

ZUL. GESAMTGEWICHT |

— POIDS TOTAL MAX |

|

|

POTENZA MOTORE |

— ENGINE POWER |

|

|

LEISTUNG |

— PUISSANCE MOTEUR |

|

|

MASSA MAX ASSE ANT. — MAX WEIGHT FRONT AXLE |

||

|

ZUL. ACHSLAST VORN |

— POIDS MAX ESSIEU AV |

MASSA MAX ASSE POST. — MAX WEIGHT REAR AXLE ZUL. ACHSLAST HINTEN — POIDS MAX ESSIEU AR

MANUFACTURED BY KOMATSU UTILITY EUROPE S.p.A. 36025 NOVENTA VICENTINA (VI) ITALY

|

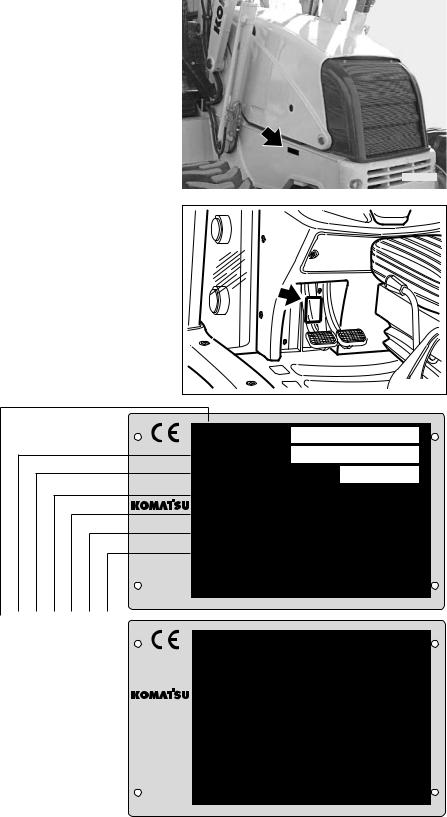

21D-98-12580 |

||||||||||||

|

RWA34270 |

||||||||||||

|

MODEL |

||||||||||||

|

SERIAL N |

||||||||||||

|

YEAR |

||||||||||||

|

TOTAL MAX WEIGHT |

kg |

|||||||||||

|

ENGINE POWER |

kw |

|||||||||||

|

MAX WEIGHT FRONT AXLE |

kg |

|||||||||||

|

MAX WEIGHT REAR AXLE |

kg |

|||||||||||

MANUFACTURED BY KOMATSU UTILITY EUROPE S.p.A. 36025 NOVENTA VICENTINA (VI) ITALY

6

INTRODUCTION

1.4.3ENGINE SERIAL NUMBER AND EXHAUST GAS EMISSION PLATE

The engine serial number is stamped on the plate positioned on the rear side of the tappet cover.

RWAB0480

The plate regarding the exhaust emission regulations is applied to the front side of the tappet cover.

RWAB0620

1.4.4 FRONT AXLE SERIAL NUMBER

The serial number of the front axle is stamped on the plate positioned on the right side of the axle body.

1.4.5 REAR AXLE SERIAL NUMBER

The serial number of the rear axle is stamped on the plate positioned on the right side of the axle body.

INTRODUCTION

1.4.6 TRANSMISSION SERIAL NUMBER

The transmission serial number is stamped on the plate postioned on the right side of the transmission case.

RWA02540

1.4.7 CAB SERIAL NUMBER

The cab serial number is stamped on the plate positioned on the right center pillar.

1.4.8CANOPY SERIAL NUMBER (if provided)

The serial number is stamped on the plate positioned inside the canopy, on the front right part.

8

INTRODUCTION

1.4.9 SERIAL NUMBERS AND DEALER’S ADDRESS

|

Machine n. |

Model |

||||||||

|

Engine n. |

|||||||||

|

Front axle n. |

|||||||||

|

Rear axle n. |

|||||||||

|

Transmission n. |

|||||||||

|

Cab n. |

|||||||||

|

Canopy n. |

|||||||||

|

Dealer: |

|||||||||

Address:

Tel.

Person to contact:

NOTES:

9

THIS PAGE WAS INTENTIONALLY LEFT EMPTY

10

TABLE OF CONTENTS

|

Page |

|||

|

TABLE OF CONTENTS |

|||

|

1.1 |

FOREWORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1 |

|

|

1.2 |

INFORMATION ON SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2 |

|

|

1.3 |

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 |

|

|

1.3.1 |

INTENDED USES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 |

|

|

1.3.2 |

IMPROPER OR UNAUTHORIZED USES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 |

|

|

1.3.3 |

MAIN CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 |

|

|

1.3.4 |

RUNNING-IN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 |

|

|

1.4 |

PRODUCT IDENTIFICATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

|

|

1.4.1 |

MACHINE SERIAL NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

|

|

1.4.2 |

MACHINE IDENTIFICATION PLATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

|

|

1.4.3 |

ENGINE SERIAL NUMBER AND EXHAUST GAS EMISSION PLATE. . . . . . . . . . . . . . . . . . |

7 |

|

|

1.4.4 |

FRONT AXLE SERIAL NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

|

|

1.4.5 |

REAR AXLE SERIAL NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

|

|

1.4.6 |

TRANSMISSION SERIAL NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

|

|

1.4.7 |

CAB SERIAL NUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

|

|

1.4.8 |

CANOPY SERIAL NUMBER (if provided) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

|

|

1.4.9 |

SERIAL NUMBERS AND DEALER’S ADDRESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

9 |

|

|

SAFETY AND ACCIDENT PREVENTION |

|||

|

2.1 SAFETY, NOISE AND VIBRATION PLATES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

20 |

||

|

2.1.1 |

POSITION OF THE SAFETY PLATES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

20 |

|

|

2.1.2 |

PICTOGRAMS AND RELEVANT MEANINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

22 |

|

|

2.1.3 |

POSITION OF THE NOISE PLATES ON MACHINES WITH CAB (model WB91R-2) . . . . . . |

26 |

|

|

2.1.4 |

POSITION OF THE NOISE PLATES ON MACHINES WITH CAB (model WB93R-2) . . . . . . |

27 |

|

|

2.1.5 |

VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED . . . . . . . . . . . . . . . . . . . . . . . . |

28 |

|

|

2.2 |

GENERAL PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

29 |

|

|

2.2.1 |

GENERAL SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

29 |

|

|

2.2.2 |

SAFETY DEVICES AND GUARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

29 |

|

|

2.2.3 |

CLOTHING AND PERSONAL PROTECTION ITEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

29 |

|

|

2.2.4 |

UNAUTHORIZED MODIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

30 |

|

|

2.2.5 |

LEAVING THE OPERATOR’S SEAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

30 |

|

|

2.2.6 |

GETTING ON AND OFF THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

31 |

|

|

2.2.7 |

CHECKING THE REAR-VIEW MIRRORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

31 |

|

|

2.2.8 |

PREVENTING FIRES DUE TO FUEL AND OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

31 |

|

|

2.2.9 |

PREVENTING BURNS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

32 |

|

|

2.2.10 |

PREVENTING DAMAGE DUE TO ASBESTOS POWDER . . . . . . . . . . . . . . . . . . . . . . . . . . |

32 |

|

|

2.2.11 |

PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT . . . . . . . . . . . . . . . . . . . . |

33 |

|

|

2.2.12 |

FIRE EXTINGUISHERS AND FIRST AID KIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

33 |

|

|

2.2.13 |

PRECAUTIONS CONCERNING THE CAB STRUCTURE . . . . . . . . . . . . . . . . . . . . . . . . . . . |

33 |

|

|

2.2.14 |

PRECAUTIONS CONCERNING THE EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

33 |

|

|

2.3 PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . |

34 |

||

|

2.3.1 |

SAFETY ON THE WORK SITE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

34 |

|

|

2.3.2 |

FIRE PREVENTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

34 |

|

|

2.3.3 |

PRECAUTIONS TO BE TAKEN FOR THE OPERATOR’S CAB . . . . . . . . . . . . . . . . . . . . . |

. 34 |

|

|

2.3.4 |

ROOM VENTILATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

35 |

2.3.5CLEANING WINDOWS, MIRRORS AND LIGHTS — CHECKING THE WINDSHIELD

|

WIPER BLADES AND THE BULBS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

35 |

11

TABLE OF CONTENTS

|

Page |

|||

|

2.4 PRECAUTIONS TO BE TAKEN WHEN WORKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

36 |

||

|

2.4.1 |

STARTING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

36 |

|

|

2.4.2 |

RULES FOR ROAD TRAVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

36 |

|

|

2.4.3 |

CHECKS FOR TRAVELLING IN REVERSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

37 |

|

|

2.4.4 |

MOVING THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

37 |

|

|

2.4.5 |

WORKING ON SLOPES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

38 |

|

|

2.4.6 |

PREVENTING ELECTROCUTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

39 |

|

|

2.4.7 |

VISIBILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

40 |

|

|

2.4.8 |

WORKING ON ICY OR SNOW-COVERED SURFACES . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

40 |

|

|

2.4.9 |

PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT . . . . . . . . . . . . . . . . . . . . |

40 |

|

|

2.4.10 |

WORKING ON LOOSE GROUND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

40 |

|

|

2.4.11 |

PARKING THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

41 |

|

|

2.5 TRANSPORTING THE MACHINE ON MOTOR VEHICLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

42 |

||

|

2.5.1 |

LOADING AND UNLOADING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

42 |

|

|

2.5.2 |

TRANSPORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

42 |

|

|

2.6 |

BATTERY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

43 |

|

|

2.6.1 |

PREVENTING RISKS THAT MAY BE DUE TO THE BATTERY . . . . . . . . . . . . . . . . . . . . . |

43 |

|

|

2.6.2 |

STARTING WITH BOOSTER CABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

43 |

|

|

2.7 PRECAUTIONS FOR THE REMOVAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

44 |

||

|

2.8 |

PRECAUTIONS FOR MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

45 |

|

|

2.8.1 |

WARNING PLATES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

45 |

|

|

2.8.2 |

TOOLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

45 |

|

|

2.8.3 |

PERSONNEL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

45 |

|

|

2.8.4 |

EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

46 |

|

|

2.8.5 |

WORKING UNDER THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

46 |

|

|

2.8.6 |

CLEANING THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

46 |

|

|

2.8.7 |

USE OF THE ENGINE DURING MAINTENANCE OPERATIONS . . . . . . . . . . . . . . . . . . . . . |

47 |

|

|

2.8.8 |

PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY . . . . . . . . . . |

47 |

2.8.9STOP THE ENGINE BEFORE CARRYING OUT ANY MAINTENANCE OPERATION

|

OR INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

48 |

|

2.8.10 RULES TO BE FOLLOWED DURING FUEL OR OIL TOPPING UP . . . . . . . . . . . . . . . . . . . |

49 |

|

2.8.11 CHECKING THE COOLANT LEVEL IN THE RADIATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . |

49 |

|

2.8.12 USING LAMPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

49 |

|

2.8.13 PRECAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR . . . . . . . . . . . . . |

50 |

|

2.8.14 PRECAUTIONS CONCERNING THE STARTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

50 |

|

2.8.15 HANDLING HIGH-PRESSURE PIPES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

51 |

|

2.8.16 PRECAUTIONS TO BE TAKEN WHEN HANDLING HIGH-PRESSURE OIL . . . . . . . . . . . . . |

51 |

|

2.8.17 PRECAUTIONS FOR MAINTENANCE OPERATIONS AT HIGH TEMPERATURES |

|

|

AND HIGH PRESSURE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

51 |

|

2.8.18 COOLING FAN AND BELT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

52 |

|

2.8.19 WASTE MATERIALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

52 |

|

2.8.20 PRECAUTIONS TO BE TAKEN WHEN INFLATING TYRES . . . . . . . . . . . . . . . . . . . . . . . . . |

52 |

|

2.8.21 PRECAUTIONS FOR THE INSTALLATION OF THE EXHAUST SYSTEM TAILPIPE . . . . . . |

53 |

|

2.8.22 PRECAUTIONS FOR THE USE OF THE SYNTHETIC BIODEGRADABLE OIL |

|

|

TYPE HEES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

53 |

12

|

TABLE OF CONTENTS |

|||

|

Page |

|||

|

DESCRIPTION AND USE OF THE MACHINE |

|||

|

3.1 |

SAFETY LOCKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . . 56 |

|

|

3.1.1 |

FRONT LOADER LOCKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . 56 |

|

|

3.1.2 |

BACKHOE LOCKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . 58 |

|

|

3.2 |

GENERAL VIEWS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . . . . . . . . . . 59 |

3.2.1 FRONT GENERAL VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59 3.2.2 BACKHOE GENERAL VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 3.2.3 CAB INSIDE GENERAL VIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61 3.2.3.1 CAB INSIDE GENERAL VIEW (Standard version) . . . . . . . . . . . . . . . . . . . . . . . . 61

3.2.3.2CAB INSIDE GENERAL VIEW (Version with servcontrols available on request) . 62

|

3.3 |

INSTRUMENTS AND CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

63 |

||

|

3.3.1 |

FRONT INSTRUMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

63 |

||

|

3.3.2 |

SIDE INSTRUMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

67 |

||

|

3.3.2.1 SIDE INSTRUMENTS (Standard version) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

67 |

|||

|

3.3.2.2 SIDE INSTRUMENTS (Version with servo controls available on request) . . . . . . |

68 |

|||

|

3.3.3 |

PUSH BUTTONS ON THE FRONT LOADER CONTROL LEVER . . . . . . . . . . . . . . . . . . . . . |

75 |

||

|

3.3.4 |

PUSH BUTTON ON THE GEARSHIFT LEVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

75 |

||

|

3.3.5 |

ELECTRICAL ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

76 |

||

|

3.3.6 |

MACHINE CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

77 |

||

|

3.3.6.1 MACHINE CONTROLS (Standard version) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

77 |

|||

|

3.3.6.2 |

MACHINE CONTROLS (Version with servo controls available upon request) . . . |

78 |

||

|

3.4 |

FUSES AND RELAYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

106 |

||

|

3.4.1 |

EQUIPMENT FUSES AND RELAYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

106 |

||

|

3.4.1.1 |

FUSES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

107 |

||

|

3.4.1.2 |

RELAYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

108 |

||

|

3.4.2 |

ENGINE FUSES AND RELAYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

108 |

||

|

3.4.2.1 |

FUSES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

109 |

||

|

3.4.2.2 |

RELAYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

109 |

||

|

3.4.3 |

SIDE DASHBOARD RELAYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

110 |

||

|

3.4.4 |

SIDE DASHBOARD RELAYS AND FUSES (Only with servo controls) . . . . . . . . . . . . . . . . . |

110 |

||

|

3.4.2.1 |

FUSES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

110 |

||

|

3.5 GUARDS, CAB AND DRIVER’S SEAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

111 |

|||

|

3.5.1 |

ENGINE HOOD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

111 |

||

|

3.5.2 |

CANOPY (if provided) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

111 |

||

|

3.5.3 |

CAB . . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

112 |

|

|

3.5.4 |

VENTILATION AND HEATING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

115 |

||

|

3.5.5 |

AIR CONDITIONER (if installed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

116 |

||

|

3.5.6 |

SEAT . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

118 |

|

|

3.5.6.1 |

SEAT (STANDARD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

118 |

||

|

3.5.6.2 |

SEAT (OPTIONAL). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

119 |

||

|

3.5.7 |

SAFETY BELT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

120 |

||

|

3.5.8 |

FIRE EXTINGUISHER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

120 |

||

|

3.5.9 |

FIRST AID KIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

120 |

||

|

3.5.10 |

TECHNICAL DOCUMENTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

120 |

||

|

3.5.11 |

ADDITIONAL TOOL BOX (if provided) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

121 |

||

|

3.6 USE OF THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

123 |

|||

|

3.6.1 |

CHECKS BEFORE STARTING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

123 |

||

|

3.6.1.1 |

VISUAL CHECKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

123 |

||

|

3.6.1.2 |

DAILY CHECKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

123 |

||

|

3.6.1.3 |

OPERATIONAL CHECKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

124 |

13

TABLE OF CONTENTS

|

Page |

||||

|

3.6.2 |

STARTING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

125 |

||

|

3.6.2.1 STARTING WITH WARM ENGINE OR IN TEMPERATE CLIMATES . . . . . . . . . |

125 |

|||

|

3.6.2.2 STARTING WITH COLD ENGINE OR IN COLD CLIMATES . . . . . . . . . . . . . . . . |

126 |

|||

|

3.6.3 |

WARMING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

127 |

||

|

3.6.4 |

HEATING THE HYDRAULIC OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

127 |

||

|

3.6.5 |

HOW TO MOVE THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

128 |

||

|

3.6.5.1 |

DIFFERENTIAL LOCKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

129 |

||

|

3.6.5.2 ENGAGING THE FOUR-WHEEL DRIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

129 |

|||

|

3.6.5.3 |

WORKING ON SLOPES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

130 |

||

|

3.6.5.4 |

MAXIMUM IMMERSION DEPTH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

131 |

||

|

3.7 |

PARKING THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

132 |

||

|

3.7.1 |

PARKING ON LEVEL GROUND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

132 |

||

|

3.7.2 |

PARKING ON SLOPES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

133 |

||

|

3.8 |

STOPPING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

134 |

||

|

3.9 |

TRANSPORTING THE MACHINE ON MOTOR VEHICLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

135 |

||

|

3.9.1 |

LOADING AND UNLOADING THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

135 |

||

|

3.9.2 |

TRANSPORT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

136 |

||

|

3.10 |

PRECAUTIONS TO BE TAKEN IN THE COLD SEASON. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

137 |

||

|

3.10.1 |

FUEL AND LUBRICANTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

137 |

||

|

3.10.2 |

COOLANT |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

137 |

|

|

3.10.3 |

BATTERY |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

137 |

|

|

3.10.4 |

OTHER PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

138 |

||

|

3.10.5 |

PRECAUTIONS TO BE TAKEN AT THE END OF WORK . . . . . . . . . . . . . . . . . . . . . . . . . . . |

138 |

||

|

3.11 |

PRECAUTIONS TO BE TAKEN IN THE WARM SEASON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

139 |

||

|

3.12 |

USING THE MACHINE AS A LOADER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

140 |

||

|

3.12.1 |

BUCKET POSITION INDICATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

140 |

||

|

3.12.2 |

ORGANIZING THE WORK AREA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

140 |

||

|

3.12.2.1 LOADING HEAPED AND LEVEL MATERIAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

141 |

|||

|

3.12.2.2 LOADING OPERATIONS ON SLOPES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

142 |

|||

|

3.12.3 |

CHANGING THE STANDARD FRONT BUCKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

142 |

||

|

3.13 USING THE MACHINE AS AN EXCAVATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

143 |

|||

|

3.13.1 POSITIONING THE BUCKET ACCORDING TO THE WORK |

||||

|

THAT MUST BE CARRIED OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

143 |

|||

|

3.13.2 |

POSITIONING THE MACHINE FOR DIGGING OPERATIONS . . . . . . . . . . . . . . . . . . . . . . |

144 |

||

|

3.13.3 |

SLIDING THE BACKHOE UNIT SIDEWARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

145 |

||

|

3.13.4 |

DIGGING METHOD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

146 |

||

|

3.13.5 |

CHANGING THE BACKHOE BUCKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

147 |

||

|

3.14 |

LONG PERIODS OF INACTIVITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

148 |

||

|

3.14.1 |

BEFORE THE PERIOD OF INACTIVITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

148 |

||

|

3.14.2 |

DURING THE PERIOD OF INACTIVITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

150 |

||

|

3.14.3 |

AFTER THE PERIOD OF INACTIVITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

150 |

||

|

3.15 |

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

151 |

||

|

3.15.1 |

HOW TO REMOVE THE MACHINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

151 |

||

|

3.15.2 |

AFTER THE FUEL HAS RUN OUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

151 |

||

|

3.15.3 |

IF THE BATTERY IS DOWN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

152 |

||

|

3.15.3.1 STARTING WITH BOOSTER CABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

153 |

|||

|

3.15.4 |

OTHER TROUBLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

154 |

||

|

3.15.4.1 |

ELECTRICAL CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

154 |

||

|

3.15.4.2 |

HYDRAULIC SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

154 |

||

|

3.15.4.3 |

BRAKING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

155 |

||

|

3.15.4.4 |

CONVERTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

155 |

||

|

3.15.4.5 |

ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

156 |

14

TABLE OF CONTENTS

Page

MAINTENANCE

|

4.1 |

GUIDE TO MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

158 |

||

|

4.2 |

MAINTENANCE NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

160 |

||

|

4.2.1 NOTES REGARDING THE ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

160 |

|||

|

4.2.1.1 |

ENGINE OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

160 |

||

|

4.2.1.2 |

COOLANT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

160 |

||

|

4.2.1.3 |

FUEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

161 |

||

|

4.2.2 NOTES REGARDING THE HYDRAULIC SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

161 |

|||

|

4.2.3 NOTES REGARDING THE ELECTRICAL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

162 |

|||

|

4.2.4 |

NOTES REGARDING LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

162 |

||

|

4.2.5 PARTS SUBJECT TO WEAR THAT PERIODICALLY NEED CHANGING . . . . . . . . . . . . . . |

163 |

|||

|

4.3 FUEL, COOLANT AND LUBRICANTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

164 |

|||

|

4.3.1 HOMOLOGATED HEES SYNTHETIC BIODEGRADABLE LUBRICANTS . . . . . . . . . . . . . . . |

166 |

|||

|

4.4 DRIVING TORQUES FOR SCREWS AND NUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

167 |

|||

|

4.4.1 |

STANDARD DRIVING TORQUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

167 |

||

|

4.4.2 |

SPECIFIC TIGHTENING TORQUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

167 |

||

|

4.5 |

LUBRICATION . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

168 |

|

|

4.5.1 |

LUBRICATION DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

168 |

||

|

4.5.2 LUBRICATION DIAGRAM (4in1 bucket and pallet forks) . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

169 |

|||

|

4.5.3 LUBRICATION DIAGRAM (Front bucket rapid couplings) . . . . . . . . . . . . . . . . . . . . . . . . . . . |

170 |

|||

|

4.5.4 LUBRICATION DIAGRAM (Telescopic arm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

171 |

|||

|

4.5.5 LUBRICATION DIAGRAM (Offset device) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

172 |

|||

|

4.6 PERIODICAL CHANGE OF THE COMPONENTS CONNECTED WITH SAFETY . . . . . . . . . . . . . . . |

173 |

|||

|

4.6.1 CRITICAL PARTS FOR SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

174 |

|||

|

4.7 |

MAINTENANCE PLAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

178 |

||

|

4.7.1 |

WHEN REQUIRED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

182 |

||

|

4.7.1.a |

CHECKING, CLEANING OR CHANGING THE AIR CLEANER CARTRIDGE . . . |

182 |

||

|

4.7.1.b |

CHECKING AND CLEANING THE CAB AIR FILTER . . . . . . . . . . . . . . . . . . . . . . |

183 |

||

|

4.7.1.c CHECKING AND CLEANING THE RECIRCULATING AIR FILTER |

||||

|

(only for machines with air conditioner) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

184 |

|||

|

4.7.1.d BLEEDING THE BRAKING CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

185 |

|||

|

4.7.1.e |

CLEANING THE WATER SEPARATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

186 |

||

|

4.7.1.f |

CHECKING AND ADJUSTING THE FRONT WHEEL TOE-IN . . . . . . . . . . . . . . |

186 |

||

|

4.7.1.g |

CHECKING AND ADJUSTING THE PARKING BRAKE . . . . . . . . . . . . . . . . . . . . |

187 |

||

|

4.7.1.h |

CHECKING THE BRAKING EFFICIENCY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

188 |

||

|

4.7.1.j |

CHECKING AND ADJUSTING THE BRAKE PEDAL STROKE . . . . . . . . . . . . . . |

189 |

||

|

4.7.1.k ADJUSTING THE AUTOMATIC RETURN-TO-DIG DEVICE |

||||

|

OF THE FRONT BUCKET (if installed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

189 |

|||

|

4.7.1.l |

CHECKING AND ADJUSTING THE STABILIZER SLACK . . . . . . . . . . . . . . . . . . |

190 |

||

|

4.7.2 MAINTENANCE INTERVALS IN CASE OF USE OF THE DEMOLITION HAMMER . . . . . . . |

191 |

|||

|

4.7.2.a |

CHANGING THE HYDRAULIC OIL FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

191 |

||

|

4.7.2.b |

CHANGING THE HYDRAULIC OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

191 |

||

|

4.7.3 |

CHECKS BEFORE STARTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

192 |

||

|

4.7.3.a |

VARIOUS CHECKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

192 |

||

|

4.7.3.b |

CHECKING THE COOLANT LEVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

192 |

||

|

4.7.3.c |

CHECKING THE FUEL LEVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

193 |

||

|

4.7.3.d |

CHECKING THE ENGINE OIL LEVEL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

193 |

||

|

4.7.3.e |

CHECKING THE HYDRAULIC CIRCUIT OIL LEVEL . . . . . . . . . . . . . . . . . . . . . . |

194 |

||

|

4.7.3.f |

DRAINING THE WATER SEPARATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

195 |

||

|

4.7.4 MAINTENANCE EVERY 10 HOURS OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

196 |

|||

|

4.7.4.a |

LUBRICATING THE JOINTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

196 |

15

TABLE OF CONTENTS

Page

4.7.5MAINTENANCE AFTER THE FIRST 50 HOURS OF OPERATION

|

(Only for machines in which the synthetic biodegradable oil type HEES is used) . . . . . . . . . |

198 |

|

|

4.7.6 MAINTENANCE EVERY 50 HOURS OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

198 |

|

|

4.7.6.a |

CHECKING THE RADIATOR FLUID LEVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

198 |

|

4.7.6.b |

CHECKING THE BRAKING SYSTEM OIL LEVEL . . . . . . . . . . . . . . . . . . . . . . . . |

198 |

|

4.7.6.c |

LUBRICATING THE PROPELLER SHAFTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

199 |

|

4.7.6.d |

LUBRICATING THE FRONT AXLE JOINTS CENTRAL COUPLING . . . . . . . . . . |

200 |

|

4.7.6.e |

CHECKING THE TYRE PRESSURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

200 |

|

4.7.6.f |

CHECKING THE ELECTRICAL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

201 |

|

4.7.7 MAINTENANCE AFTER THE FIRST 250 HOURS OF OPERATION . . . . . . . . . . . . . . . . . . |

202 |

|

|

4.7.8 MAINTENANCE EVERY 250 HOURS OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

202 |

|

|

4.7.8.a |

ADJUSTING THE FAN BELT TENSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

202 |

|

4.7.8.b ADJUSTING THE A/C COMPRESSOR BELT TENSION |

||

|

(Only for machines with air conditioner) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

203 |

|

|

4.7.8.c |

CHECKING THE BATTERY ELECTROLYTE LEVEL . . . . . . . . . . . . . . . . . . . . . . |

204 |

|

4.7.8.d |

CHECKING THE FRONT AXLE OIL LEVELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

205 |

|

4.7.8.e |

CHECKING THE REAR AXLE OIL LEVELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

205 |

|

4.7.8.f |

CHECKING THE HYDRAULIC TRANSMISSION OIL LEVEL . . . . . . . . . . . . . . . . |

206 |

|

4.7.8.g |

CHECKING THE WHEEL NUT DRIVING TORQUE . . . . . . . . . . . . . . . . . . . . . . . |

206 |

4.7.9MAINTENANCE AFTER THE FIRST 500 HOURS OF OPERATION

|

(Only for machines in which the synthetic biodegradable oil type HEES is used) . . . . . . . . . |

207 |

|

|

4.7.10 MAINTENANCE EVERY 500 HOURS OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

207 |

|

|

4.7.10.a |

CHANGING THE ENGINE OIL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

207 |

|

4.7.10.b |

CHANGING THE ENGINE OIL FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

208 |

|

4.7.10.c |

CHANGING THE HYDRAULIC SYSTEM OIL FILTER . . . . . . . . . . . . . . . . . . . . . |

209 |

|

4.7.10.d |

CHANGING THE FUEL FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

210 |

|

4.7.10.e |

DRAINING THE FUEL TANK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

211 |

|

4.7.10.f |

DRAINING THE HYDRAULIC OIL TANK |

|

|

(Only for machines in which the synthetic biodegradable oil type HEES is used) . 212 |

||

|

4.7.10.g |

CLEANING THE OUTSIDE OF THE RADIATORS . . . . . . . . . . . . . . . . . . . . . . . . |

213 |

|

4.7.10.h |

CLEANING THE OUTSIDE OF THE A/C CONDENSER |

|

|

(Only for machines with air conditioner) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

214 |

|

|

4.7.11 MAINTENANCE EVERY 1000 HOURS OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . |

215 |

|

|

4.7.11.a |

CHANGING THE FRONT AXLE OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

215 |

|

4.7.11.b CHANGING THE REAR AXLE OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

216 |

|

|

4.7.11.c CHANGING THE HYDRAULIC TRANSMISSION OIL . . . . . . . . . . . . . . . . . . . . . |

217 |

|

|

4.7.11.d |

CHANGING THE HYDRAULIC TRANSMISSION FILTER . . . . . . . . . . . . . . . . . . |

218 |

|

4.7.11.e CHECKING AND ADJUSTING THE ENGINE VALVE CLEARANCE . . . . . . . . . . |

218 |

|

|

4.7.12 MAINTENANCE EVERY 2000 HOURS OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . |

219 |

|

|

4.7.12.a |

CHANGING THE HYDRAULIC SYSTEM OIL AND CLEANING THE SUCTION |

|

|

FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

219 |

|

|

4.7.12.b |

CHANGING THE COOLANT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

222 |

|

4.7.12.c |

CHANGING THE BRAKING SYSTEM OIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

224 |

|

4.7.12.d |

CHECKING THE ALTERNATOR AND THE STARTER. . . . . . . . . . . . . . . . . . . . . |

225 |

|

4.7.12.e CHECKING THE QUANTITY OF COOLANT IN THE A/C SYSTEM |

||

|

(Only for machines with air conditioner) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

225 |

|

|

4.7.13 MAINTENANCE EVERY 4000 HOURS OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . |

226 |

|

|

4.7.13.a |

CHANGING THE A/C DEHYDRATING FILTER |

|

|

(Only for machines with air conditioner) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

226 |

|

|

4.7.13.a |

CHECKING THE OPERATING CONDITIONS OF THE A/C COMPRESSOR |

|

|

(Only for machines with air conditioner) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

226 |

16

TABLE OF CONTENTS

Page

TECHNICAL SPECIFICATIONS

|

5.1 TECHNICAL DATA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

228 |

||

|

5.1.1 |

STANDARD OVERALL DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

228 |

|

|

5.1.1.1 STANDARD OVERALL DIMENSIONS WITH CENTERED BACKHOE . . . . . . . . . |

228 |

||

|

5.1.1.2 STANDARD OVERALL DIMENSIONS WITH FOLDED BACKHOE . . . . . . . . . . . |

228 |

||

|

5.1.2 |

TECHNICAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

229 |

|

|

5.1.2.1 |

TECHNICAL CHARACTERISTICS WB91R-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

229 |

|

|

5.1.2.2 |

TECHNICAL CHARACTERISTICS WB93R-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

230 |

|

|

5.1.3 |

LIFTING CAPACITIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

231 |

|

|

5.1.3.1 |

SYMBOL TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

231 |

|

|

5.1.3.2 LIFTING CAPACITY WB91R-2 (STANDARD BOOM) . . . . . . . . . . . . . . . . . . . . . . |

232 |

||

|

5.1.3.3 LIFTING CAPACITY WB91R-2 (OFFSET BOOM). . . . . . . . . . . . . . . . . . . . . . . . . |

233 |

||

|

5.1.3.4 LIFTING CAPACITY WB93R-2 (STANDARD BOOM) . . . . . . . . . . . . . . . . . . . . . |

234 |

||

|

5.1.3.5 LIFTING CAPACITY WB93R-2 (OFFSET BOOM). . . . . . . . . . . . . . . . . . . . . . . . . |

235 |

AUTHORIZED OPTIONAL EQUIPMENT

|

6.1 AUTHORIZED OPTIONAL EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

238 |

|

6.1.1 PRECAUTIONS REGARDING SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

238 |

|

6.1.2 CHARACTERISTICS OF THE OPTIONAL EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

239 |

|

6.1.2.1 CHARACTERISTICS OF THE OPTIONAL EQUIPMENT |

|

|

FOR MODEL WB91R-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

239 |

|

6.1.2.2 CHARACTERISTICS OF THE OPTIONAL EQUIPMENT |

|

|

FOR MODEL WB93R-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

240 |

|

6.2 FRONT EQUIPMENT QUICK COUPLING DEVICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

241 |

|

|

6.2.1 MANUAL CONTROL QUICK COUPLING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

241 |

|

|

6.2.2 |

HYDRAULIC CONTROL QUICK COUPLING FOR STANDARD BUCKET . . . . . . . . . . . . . . |

242 |

|

6.2.3 |

HYDRAULIC CONTROL QUICK COUPLING FOR 4IN1 BUCKET AND OPTIONAL |

|

|

EQUIPMENT WITH UNIDIRECTIONAL OIL FLOW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

242 |

|

6.3 4in1 BUCKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

243 |

|

|

6.3.1 |

DESCRIPTION AND CONTROLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

243 |

|

6.3.2 |

SAFETY DEVICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

243 |

|

6.3.3 INSTALLING THE 4in1 BUCKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

244 |

|

|

6.3.4 USING THE 4in1 BUCKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

245 |

|

|

6.3.5 |

MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

245 |

|

6.4 |

PALLET FORKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

246 |

|

|

6.4.1 |

DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

246 |

|

|

6.4.2 |

SAFETY DEVICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

246 |

|

|

6.4.3 |

USING THE FORKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

247 |

|

|

6.4.3.1 PREPARING THE PALLET FORKS FOR USE . . . . . . . . . . . . . . . . . . . . . . . . . . |

247 |

||

|

6.4.3.2 OVERTURNING THE FORKS FOR TRAVEL ON ROADS . . . . . . . . . . . . . . . . . . |

248 |

||

|

6.4.4 |

REMOVING THE FORKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

249 |

|

|

6.4.5 |

INSTALLING THE FORKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

249 |

|

|

6.4.6 |

MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

249 |

|

|

6.5 |

BACKHOE TELESCOPIC ARM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

250 |

|

|

6.5.1 |

DESCRIPTION AND CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

250 |

|

|

6.5.1.1 VERSION WITH STANDARD CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

250 |

||

|

6.5.1.2 VERSION WITH SERVO CONTROLS (if installed) . . . . . . . . . . . . . . . . . . . . . . . |

250 |

17

TABLE OF CONTENTS

|

Page |

|||

|

6.5.2 |

SAFETY DEVICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

251 |

|

|

6.5.3 USING THE TELESCOPIC ARM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

251 |

||

|

6.5.4 |

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

252 |

|

|

6.5.4.1 ADJUSTING THE GUIDE SLACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

252 |

||

|

6.6 ARRANGEMENT FOR THE INSTALLATION OF THE DEMOLITION HAMMER. . . . . . . . . . . . . . . . |

254 |

||

|

6.6.1 |

DESCRIPTION AND CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

254 |

|

|

6.6.1.1 VERSION WITH STANDARD CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

254 |

||

|

6.6.1.2 VERSION WITH SERVO CONTROLS (if installed) . . . . . . . . . . . . . . . . . . . . . . . |

254 |

||

|

6.6.2 USE OF THE DEMOLITION HAMMER AND RULES TO BE OBSERVED. . . . . . . . . . . . . . . |

255 |

||

|

6.6.3 INSTALLING AND REMOVING THE DEMOLITION HAMMER . . . . . . . . . . . . . . . . . . . . . . . |

259 |

||

|

6.6.3.1 |

INSTALLING THE HAMMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

259 |

|

|

6.6.3.2 |

REMOVING THE HAMMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

261 |

|

|

6.6.4 |

USING THE HAMMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

261 |

|

|

6.6.5 |

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

261 |

|

|

6.7 APPLICATION OF THE OFFSET DEVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

262 |

||

|

6.7.1 |

DESCRIPTION AND CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

262 |

|

|

6.7.1.1 VERSION WITH STANDARD CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

262 |

||

|

6.7.1.2 VERSION WITH SERVO CONTROLS (if installed) . . . . . . . . . . . . . . . . . . . . . . . . |

263 |

||

|

6.7.2 |

MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

263 |

6.8ARRANGEMENT FOR THE OPERATION OF OPTIONAL EQUIPMENT WITH UNIDIRECTIONAL

|

OIL FLOW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

264 |

|

|

6.8.1 |

DESCRIPTION AND CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

264 |

|

6.8.1.1 VERSION WITH STANDARD CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

264 |

|

|

6.8.1.2 VERSION WITH SERVO CONTROLS (if installed) . . . . . . . . . . . . . . . . . . . . . . . |

264 |

|

|

6.8.2 INSTALLING AND CONNECTING THE EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

265 |

|

|

6.8.3 |

MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

265 |

|

6.9 ARRANGEMENT FOR THE INSTALLATION OF THE CLAMSHELL BUCKET . . . . . . . . . . . . . . . . |

266 |

|

|

6.9.1 |

DESCRIPTION AND CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

266 |

|

6.9.1.1 VERSION WITH STANDARD CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

266 |

|

|

6.9.1.2 VERSION WITH SERVO CONTROLS (if installed) . . . . . . . . . . . . . . . . . . . . . . . . |

267 |

|

|

6.9.2 INSTALLING THE CLAMSHELL BUCKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

268 |

|

|

6.9.3 USING THE CLAMSHELL BUCKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

269 |

|

|

6.9.4 |

MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

269 |

|

6.10 ARRANGEMENT FOR THE INSTALLATION OF THE MANUAL HYDRAULIC HAMMER . . . . . . . . |

270 |

||

|

6.10.1 |

DESCRIPTION AND CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

270 |

|

|

6.10.2 CONNECTING AND REMOVING THE HAMMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

271 |

||

|

6.10.2.1 |

CONNECTING THE HAMMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

271 |

|

|

6.10.2.2 |

REMOVING THE CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

271 |

|

|

6.10.3 |

USING THE HAMMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

272 |

|

|

6.10.4 |

MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

272 |

|

6.11 |

LOAD STABILIZER SYSTEM (LSS) (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

273 |

|

|

6.11.1 ACCUMULATOR OF THE LOAD STABILIZER SYSTEM (LSS) . . . . . . . . . . . . . . . . . . . . . . |

273 |

||

|

6.12 |

REAR EQUIPMENT RAPID COUPLING DEVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

274 |

|

|

6.12.1 |

EQUIPMENT COUPLING AND RELEASE PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . |

275 |

|

|

6.12.2 |

MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

277 |

18

SAFETY AND ACCIDENT PREVENTION

SAFETY, NOISE AND VIBRATION PLATES

2.1SAFETY, NOISE AND VIBRATION PLATES

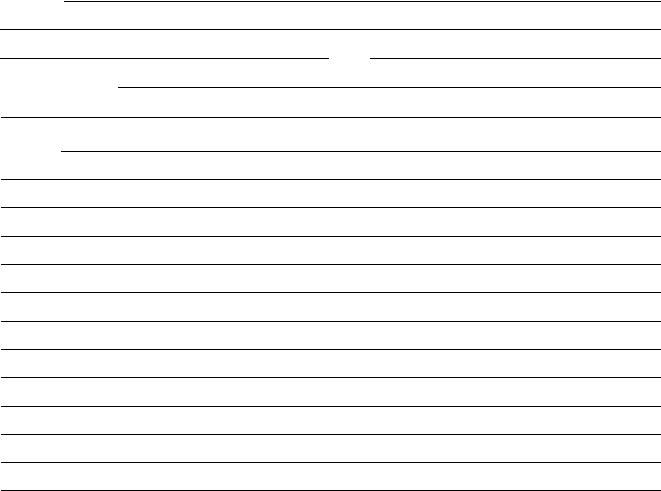

2.1.1 POSITION OF THE SAFETY PLATES

•The safety plates must always be legible and in good conditions; for this reason, if they are dirty with dust, oil or grease, it is necessary to clean them with a solution made of water and detergent.

Do not use fuel, petrol or solvents.

•If the plates are damaged, ask for new ones to Komatsu Utility or to your Komatsu Utility Dealer.

•In case of replacement of a component provided with a safety plate, make sure that this plate is applied also on the new piece.

•The machine can be provided with other plates in addition to those indicated below; keep also to the instructions given in the additional plates, in any case.

|

RWA30450 |

|

RWA00020 |

|

RWA00010 |

|

RWA00020 |

|

20 |

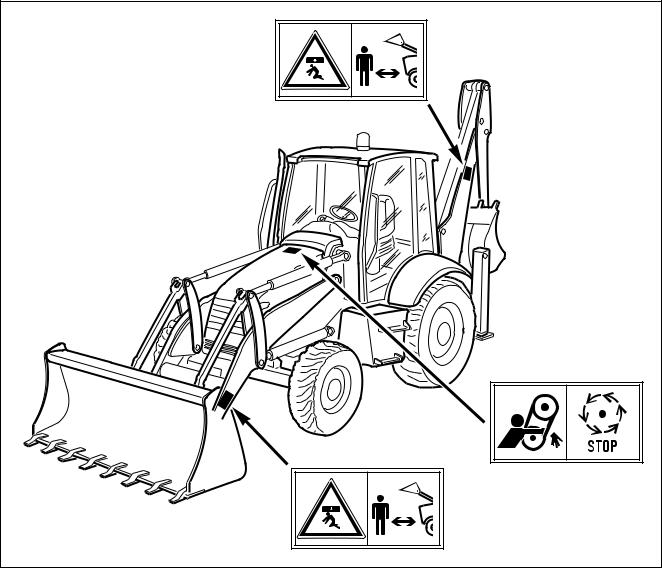

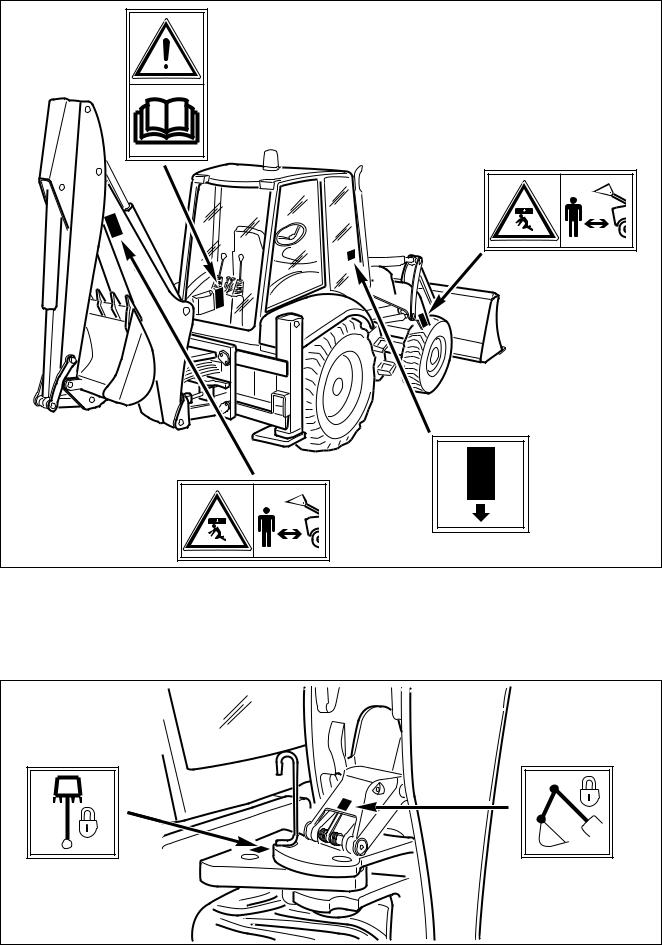

SAFETY, NOISE AND VIBRATION PLATES

|

RWA30460 |

|

RWA00030 |

|

RWA00020 |

|

RWA00190 |

|

RWA00020 |

|

RWA00150 |

RWA00160 |

|

RWA37700 |

|

|

21 |

SAFETY, NOISE AND VIBRATION PLATES

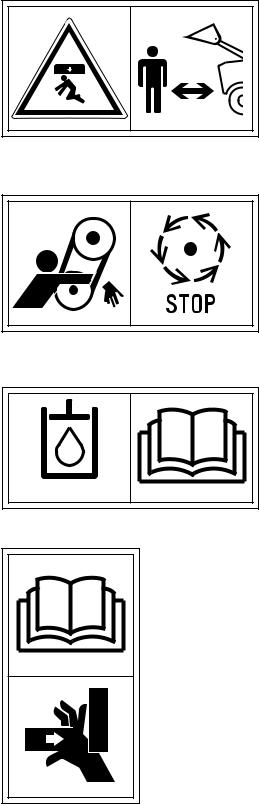

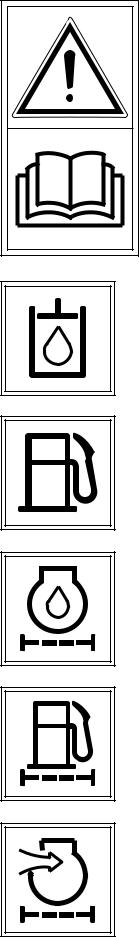

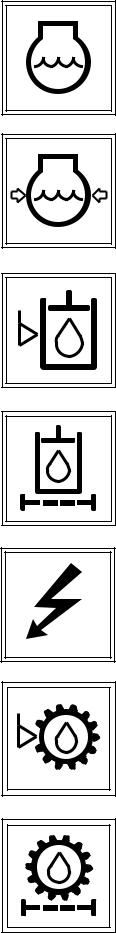

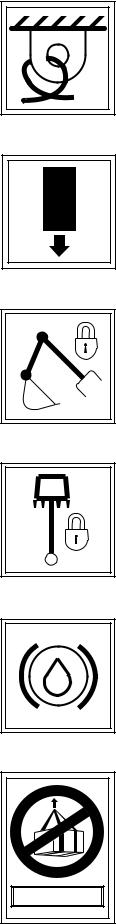

2.1.2 PICTOGRAMS AND RELEVANT MEANINGS

The warning and danger plates applied onto the machine are accompanied or represented by pictograms.

The personnel in charge with the operation and maintenance of the machine must know the symbols contained in the pictograms perfectly; the following description illustrates what they look like and their respective meanings.

DANGER IN THE WORK AREA

• Do not approach or stand in the equipment operating radius when the boom and the bucket are raised.

RWA00020

DO NOT OPEN THE HOOD

• Do not open or remove the hood when the engine is running.

FILLING THE HYDRAULIC SYSTEM WITH

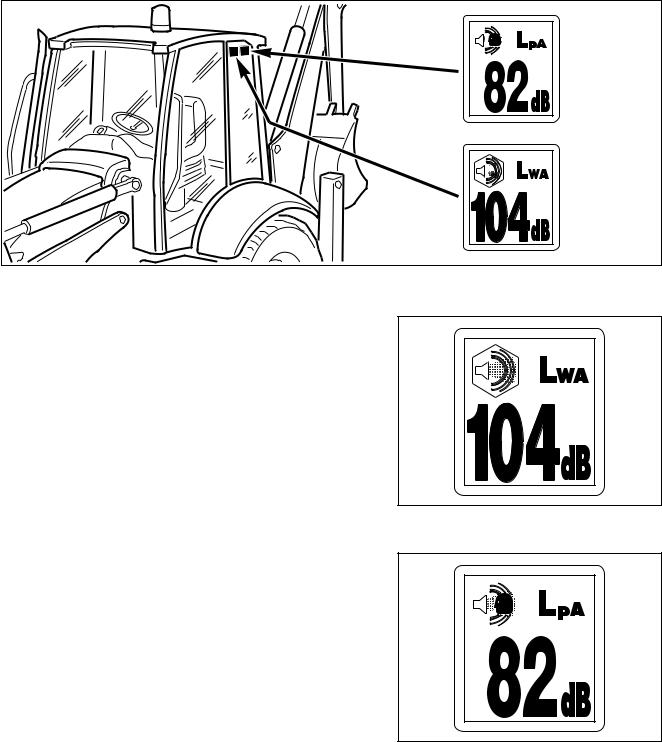

OIL