Руководство по ремонту блока питания Antminer APW8 [EN]

Version date: 2010.7.23

File Category: Maintenance Plan

Content of this Volume: It mainly describes the troubleshooting of various faults of the power supply APW8, and how to use the test tool for accurate positioning.

※ The copyright of this article belongs to Bitmaintech Pte.Ltd. (Bitmain). The article shall solely be reprinted, extracted or used in any other ways with the permission of the copyright owner. Please contact Bitmain official customer service if there is any need of reprinting or quoting.

I. Requirements on the Maintenance Platform

1. The constant temperature soldering iron above 80W (soldering temperature: 300-350°C). The tip soldering iron head is used for soldering chip resistors and capacitors. The blade type soldering iron head is used for soldering and replacement of plug-in components (soldering temperature: 380-420°C)

2. The thermal chimney is used for chip disassembly and soldering, be careful not to heat for a long time to avoid PCB foaming (soldering temperature: 260°C ±2 °C).

3. The AC controllable power supply voltage regulator (output 200-250V, can limit 0-20A current) is used for APW8 power-on inspection. If there is no such condition, a 100W ordinary light bulb can also be strung on the AC fire line with mains. Be careful.

4. For electronic load (power 2KW, meet the voltage 0-50V), if there is no such condition, a resistive load that matches the APW8 can also be made.

5. The fluke 15b+ multimeter, suction gun, tweezers, V9-1.2 test jig and special power test card firmware (if there is condition, an oscilloscope can be configured).

6. Flux, lead-free tin wire, water for cleaning panel with anhydrous alcohol; water for cleaning panel is used to clean flux residue and appearance after maintenance.

7. Thermally conductive silicone grease (2500) is used to repair the thermal conduction between the MOS and the cooling fin, thermal conductive silicone (704 silica gel) is used for fixing and covering the glue damage at the original after the repair of the PCBA components

II. Requirements on Maintenance Operations

1. The maintenance personnel must have certain electronic knowledge, more than one year of maintenance experience, and a certain understanding of the working principle of switching power supply, and well master the soldering technology.

2. Before the product is opened and the PCBA panel is repaired, the large capacitor must be discharged, and the voltage must be measured with a multimeter (less than 5V discharge), and then the soldering operation can be performed! Be sure to confirm to avoid electric shock.

3. Pay attention to the working method when judging the circuit components. After replacing any device, the PCB panel has no obvious deformation, the soldering of bonding pad is reliable, and the replacement parts and the surrounding area have no problem such as insufficient parts, open circuit or short circuit.

4. After replacing the key components, the main circuit shall have no short circuit and other obvious abnormalities before the AC voltage test, otherwise there is a hidden danger of explosion.

5. It needs AC220V voltage to judge the circuit signal; pay attention to operational protection.

The following: Notes, key slogans

● Maintenance personnel qualifications must meet the specified requirements;

● Instruments and equipment used for maintenance must meet the specified requirements;

● The instruments and equipment for maintenance must be effectively grounded, and the maintenance environment must comply with anti-static requirements; Of course, it is better to wear an anti-static wrist strap.

● Materials used for maintenance must meet the specified requirements; in order to guarantee the accuracy and traceability of the materials used for maintenance, the materials used for maintenance must be the production materials for the corresponding models, and the material replacement must be confirmed;

1. In order to prevent possible electric shock hazard, non-professionals should not disassemble the enclosure:

2. The maintenance personnel shall use a special enclosure opener to open the enclosure of power adapter and repair, to avoid damage to the internal components of the product:

3. After the product is opened, it is required to discharge the high voltage capacitor;

4. E-waste waste generated during product maintenance cannot be arbitrarily dropped:

5. Bad products must have a repair process card and indicate the cause of the failure, and placed separately;

6. The repaired products must be well marked to distinguish.

7. The repaired products must be placed in the repaired area and shall be systematically tested before they can be stored.

III. The Principle and Structure of the Power Supply

1. Principle overview

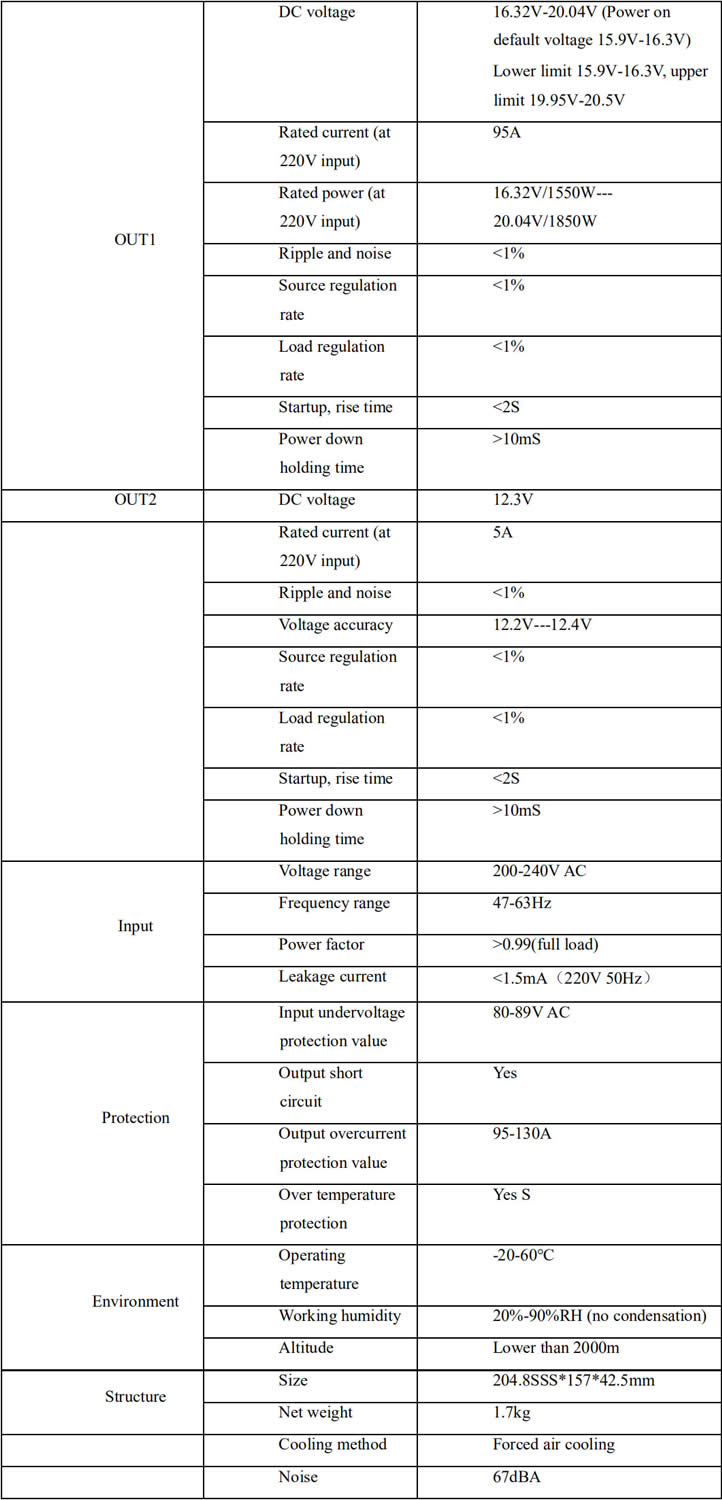

1.1 APW8 consists of 1 large panel, 2 fans and the upper and lower enclosures. The normal input AC220V has two DC output voltages, which are SB 12V respectively. The main voltage output is controlled by the PIC port and the miner communication, and different models’ DC voltage range is (8V-9.2V, 10V-11V, 16.32V-20.04V)

1.2 Performance characteristics and scope of use: S15, T15 with APW8 power supply 16.32V-20.04V as follows:

APW8 power supply is a high-efficiency DC power supply designed and manufactured by our company. It has single-phase AC input and two DC outputs:

1>. 16.32V-20.04V voltage adjustable output, the maximum current can reach 95A;

2>. 12V voltage fixed output, the current can reach 5A.

The adjustable output part of voltage can meet the common DC load use within 95A current of the adjustable voltage range, especially suitable for circumstances with strict requirements for power supply of servers and miners; the 12V voltage’s fixed output part can meet the use of control panel and cooling fin.

1.21 The are following characteristics:

●200-240V voltage input

●There is protection for undervoltage, short circuit, overload, over temperature, with

automatic recovery after fault removal

●The use of high-quality devices ensures stable and reliable products through reasonable

design, and can work at full load for a long time in a high temperature environment at 60°C or lower.

●Small size, high power density

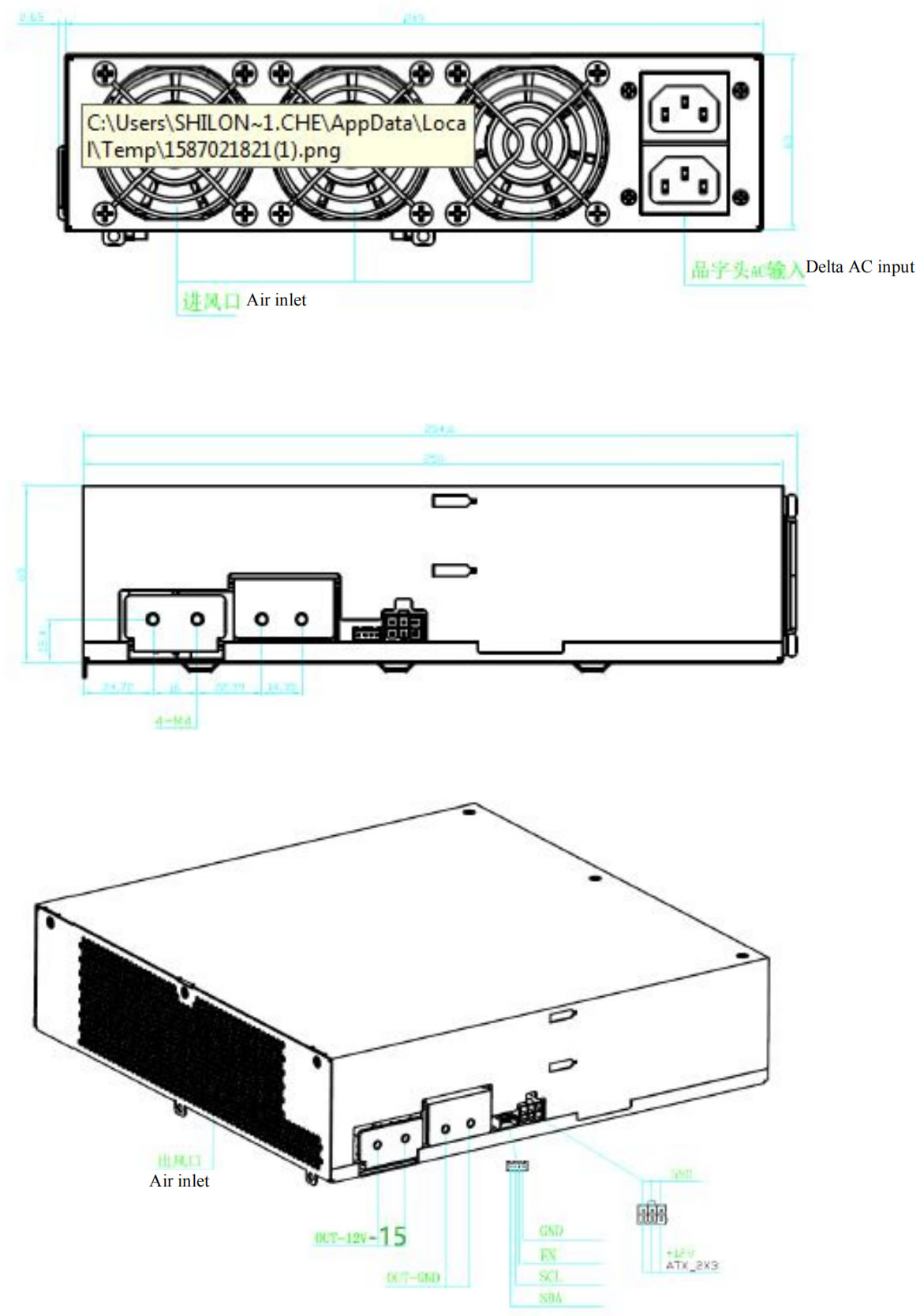

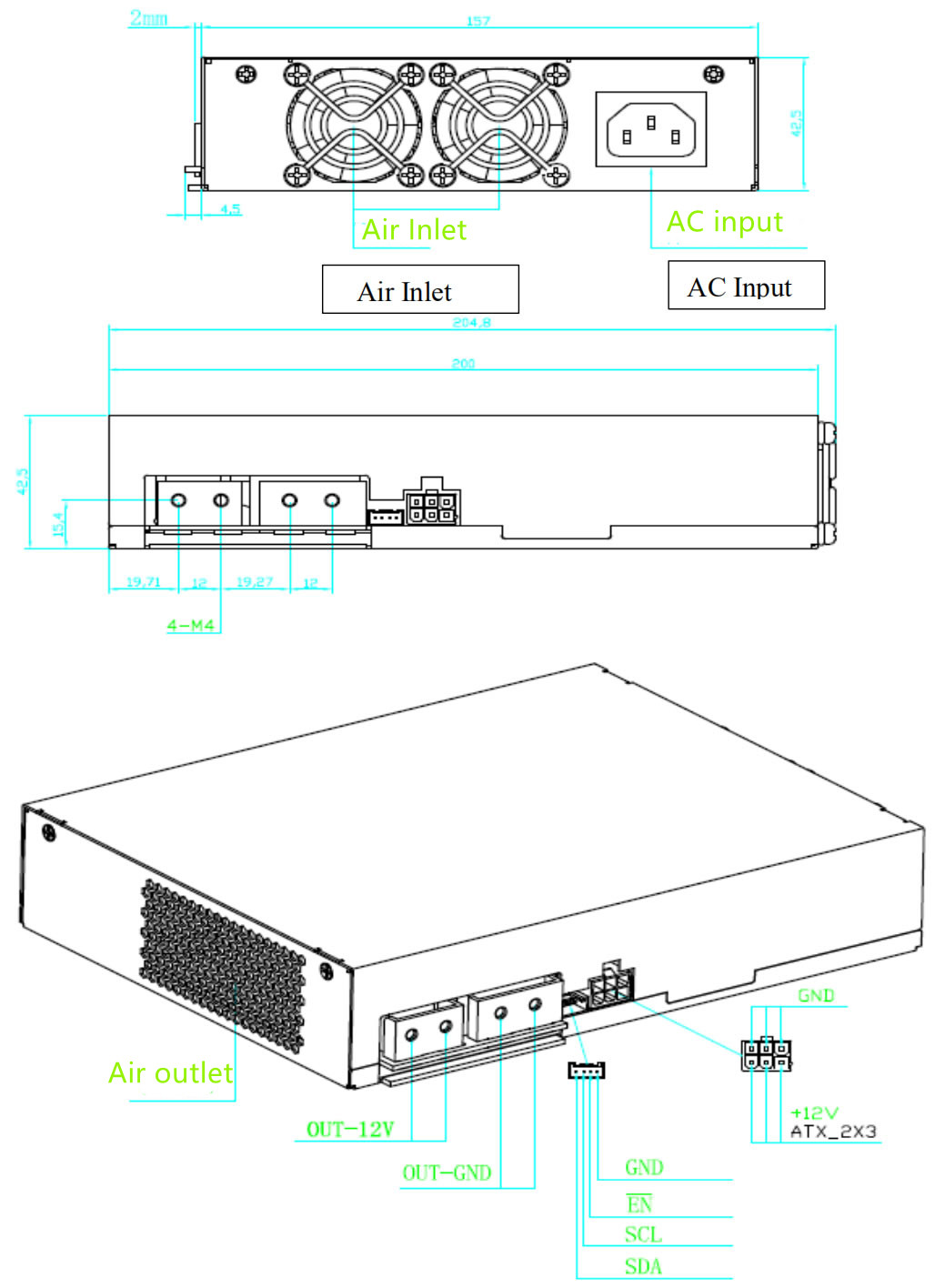

1.3 Appearance of APW8 Power Supply

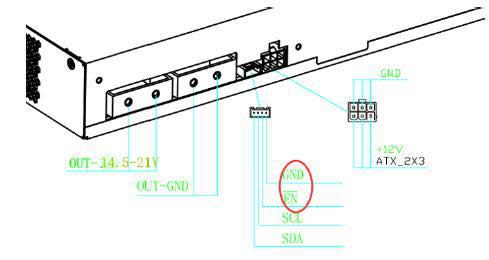

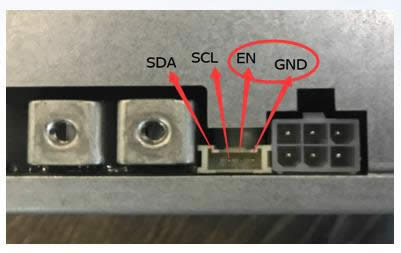

Note: If you need to turn on the default voltage 16.32V test, you can use the adapter cable to short connect the voltage Pin EN to GND.

● Distribution on the front panel of the power supply: one triangle-shape AC input interface two size-4028 high speed fans

●Distribution on the left side of the power supply: four PCB-33 copper soldering terminals with adjustable voltage output one 4Pin signal terminal one 12V fixed voltage output PCIE terminal

● Distribution on the rear panel of the power supply: 1 set of air outlets, forming the air outlet of the high-speed fan.

● The model of the AC input terminal on the power supply front panel is C14, and the AC input cable of the C13 interface is

required.

● The 4Pin signal terminal is the interface between the external control panel and the power supply. The SDA/SCL is the I2Cprotocol, and can adjust the output voltage of the power supply through I2C. EN is the enable signal of the power supply, and the control panel can enable the power supply through EN, which is effective in low level.

● The output part of the adjustable voltage adopts four PCB-33 copper soldering terminals, 90-degree side foot binding posts, M4 high current horizontal fixed seat; the 2 terminals close to the air outlet are output positive poles, and 2 near signal terminals are output negative poles, the output line or output copper bar can be fixed on terminal by M4 screw, which is convenient and flexible to use.

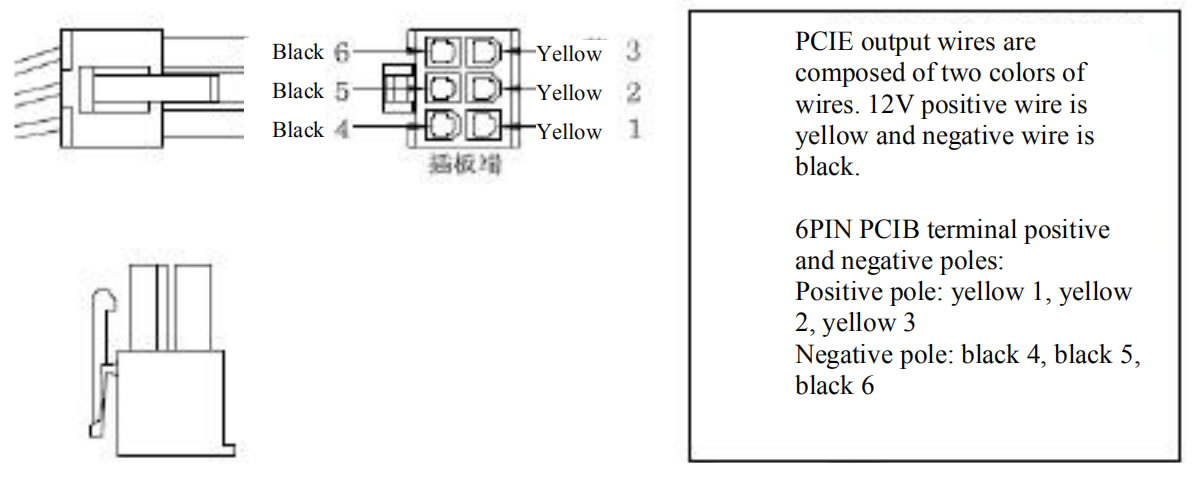

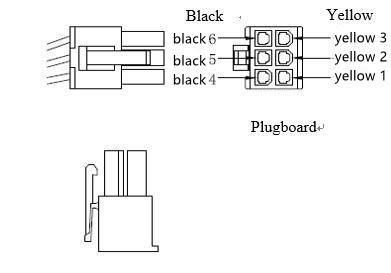

● The output part of the 12V fixed voltage uses the PCIE output terminal. The PCIE output terminal diagram is as follows:

The PCIE output line consists of two color lines, the 12V positive line is yellow, and the negatives line is black.

Definition of 6PIN PCIE terminal positive and negative poles:

Positive pole: yellow 1, yellow 2, yellow 3

Negative pole: black 4, black 5, black 6

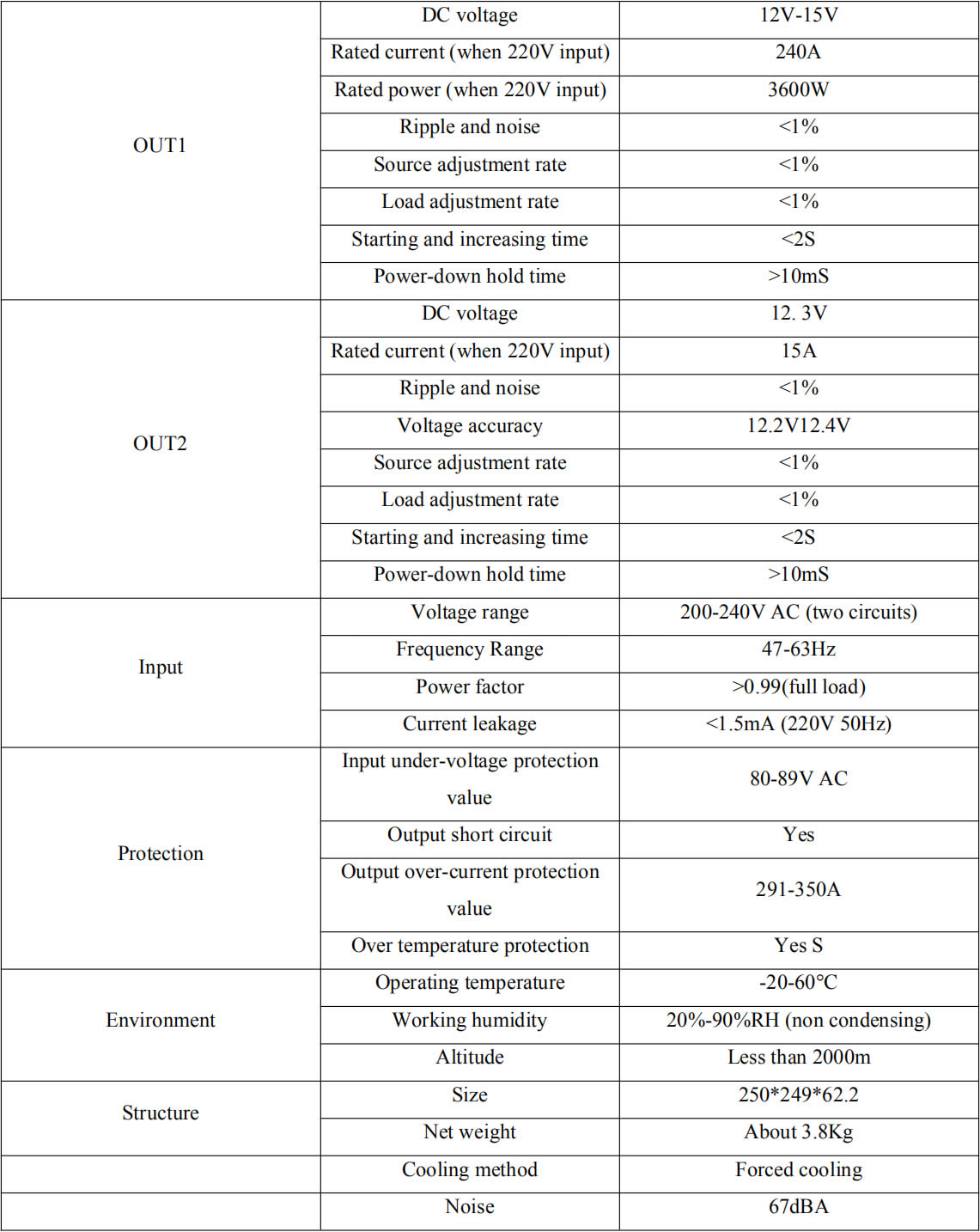

1.4 Parameters of APW8 Power Supply:

2. Maintenance ideas and cases of common faults

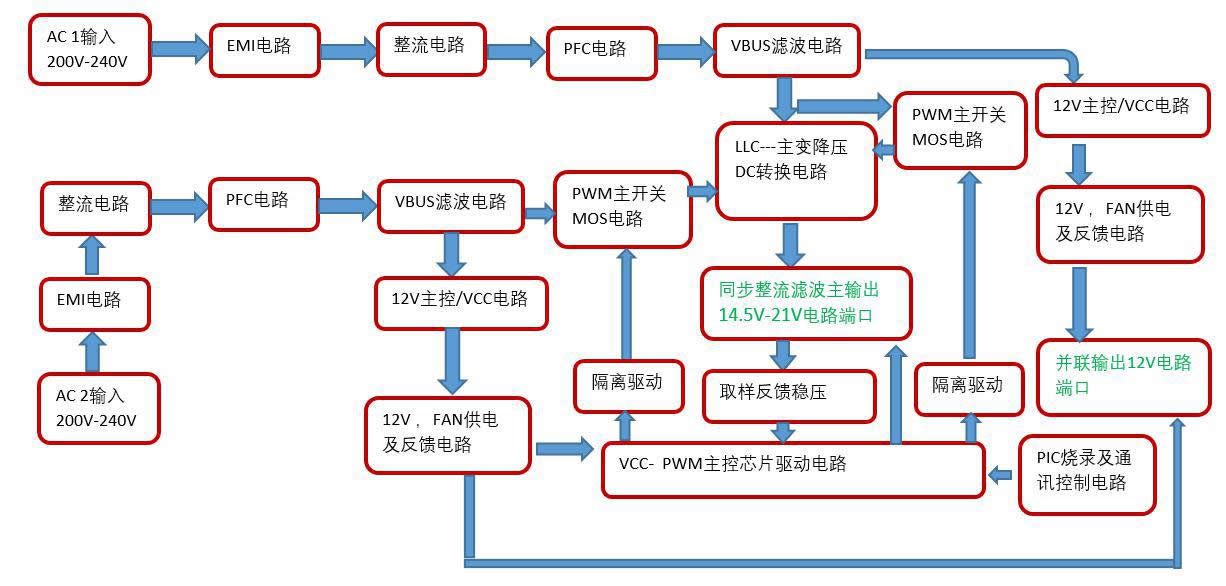

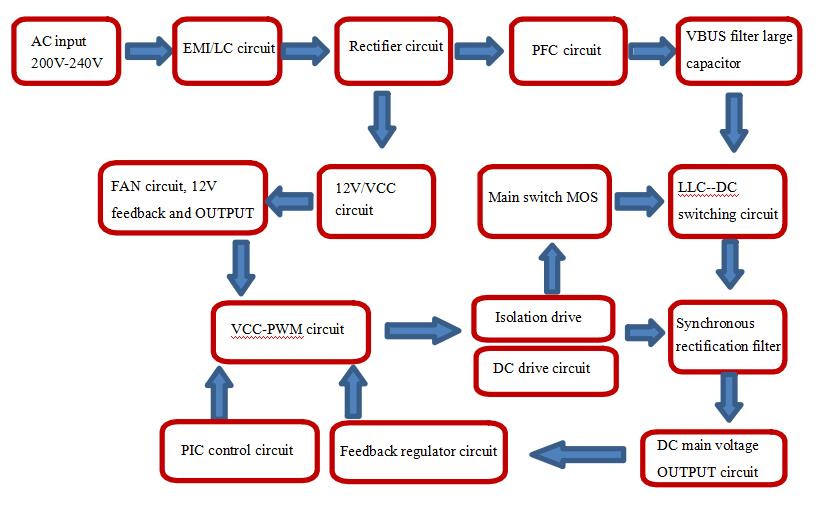

2.1 Block diagram for power basic principle

基本原理工作流程图: Basic principle work flow chart

AC 输入 200V- 240V: AC input of 200V-240V

EMI/LC 电路: EMI/LC circuit

整流电路: Rectifier circuit

PFC 电路: PFC circuit

VBUS 滤波大电容: VBUS filter large capacitor

FAN 电路、12V 反馈及 OUTPUT: FAN circuit, 12V feedback and OUTPUT

12V/VCC 电路: 12V/VCC circuit

主开关 MOS: Main switch MOS

LLC—DC 转换电路: LLC—DC switching circuit

VCC- PWM 电路: VCC-PWM circuit

隔离驱动: Isolation drive

DC 驱动电路: DC drive circuit

同步整流滤波: Synchronous rectification filter

PIC 控制电路: PIC control circuit

反馈稳压电路: Feedback regulator circuit

DC 主电压 OUTPUT 电路: DC main voltage OUTPUT circuit

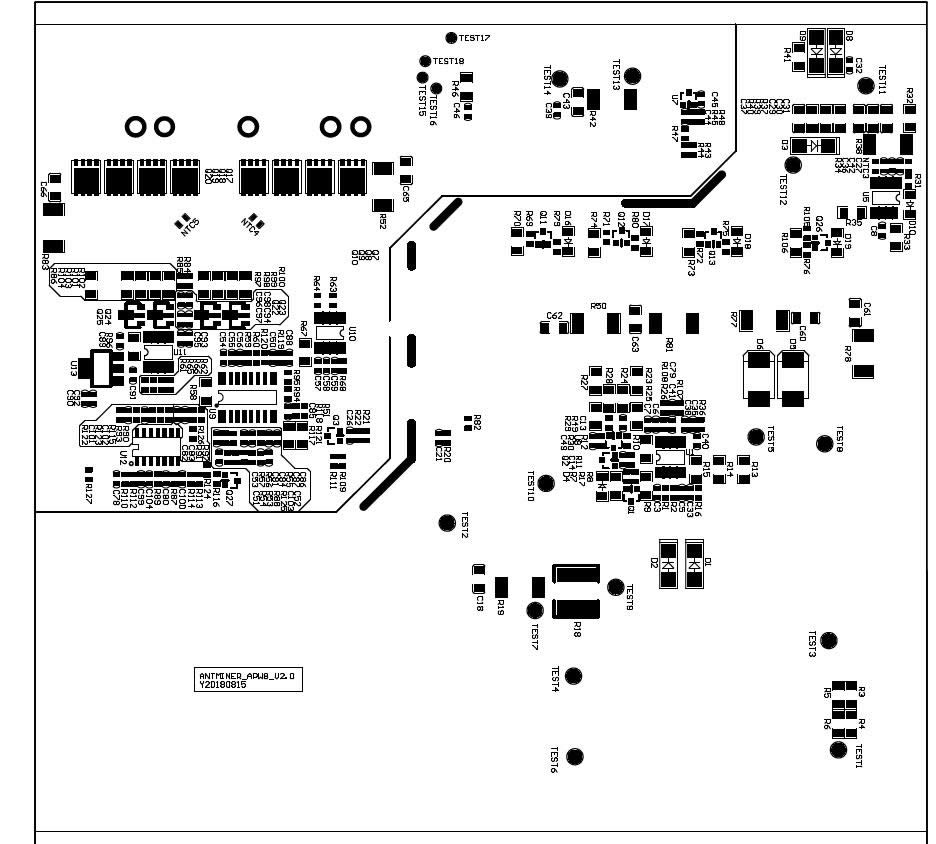

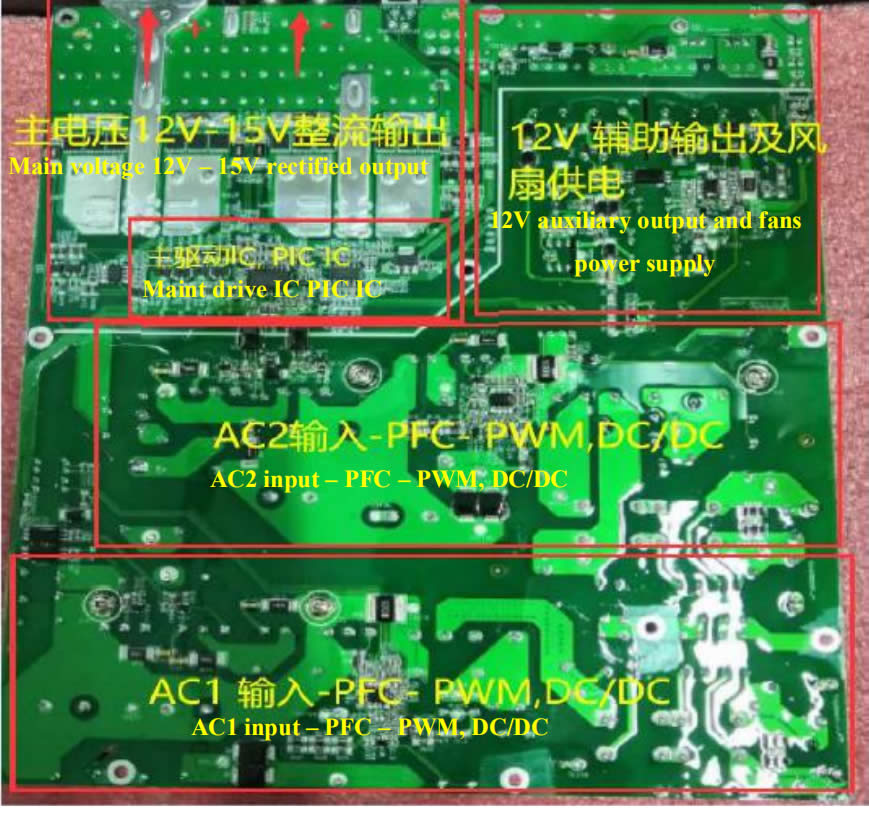

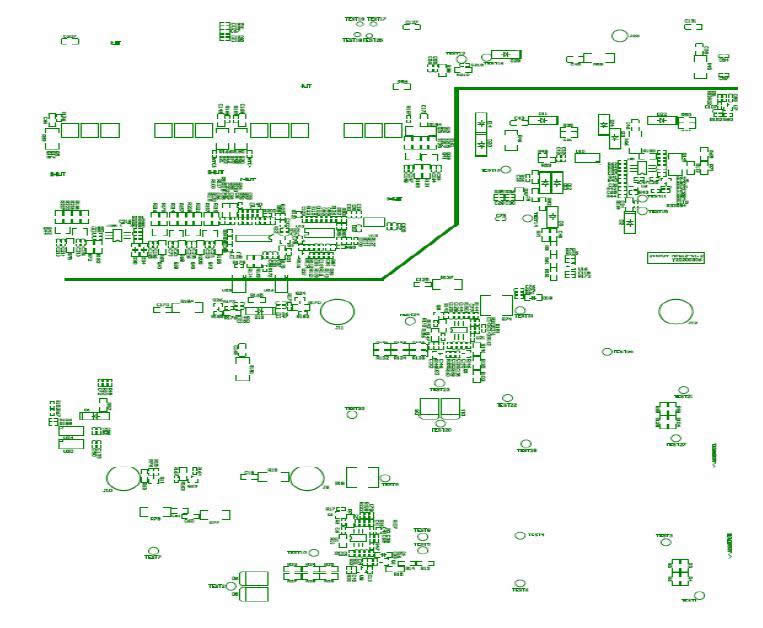

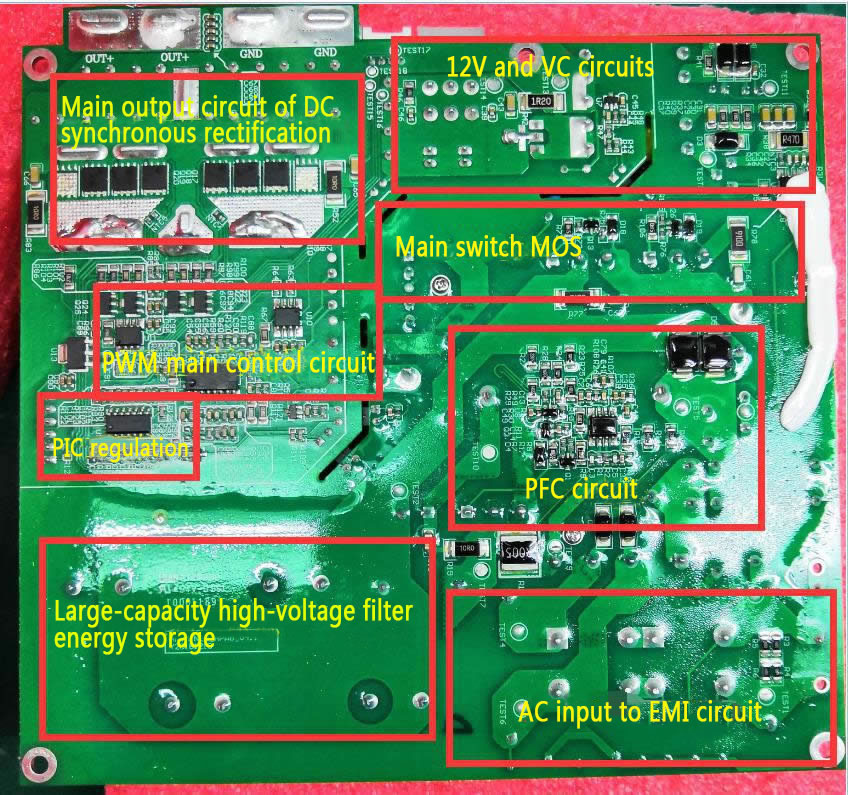

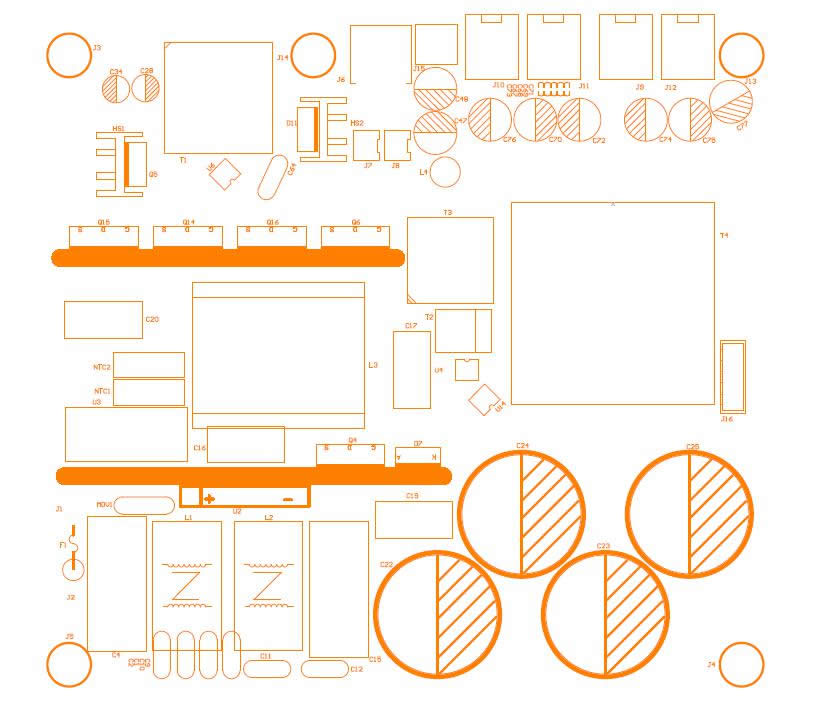

2.2 Power PCBA board layout

DC 同步整流主输出电路: Main output circuit of DC synchronous rectification

12V 及 VC 电路: 12V and VC circuits

主开关 MOS: Main switch MOS

PWM 主控电路: PWM main control circuit

PIC 调控: PIC regulation

PFC 电路: PFC circuit

大电容高压滤波储能: Large-capacity high-voltage filter energy storage

AC 输入 EMI 电路: AC input to EMI circuit

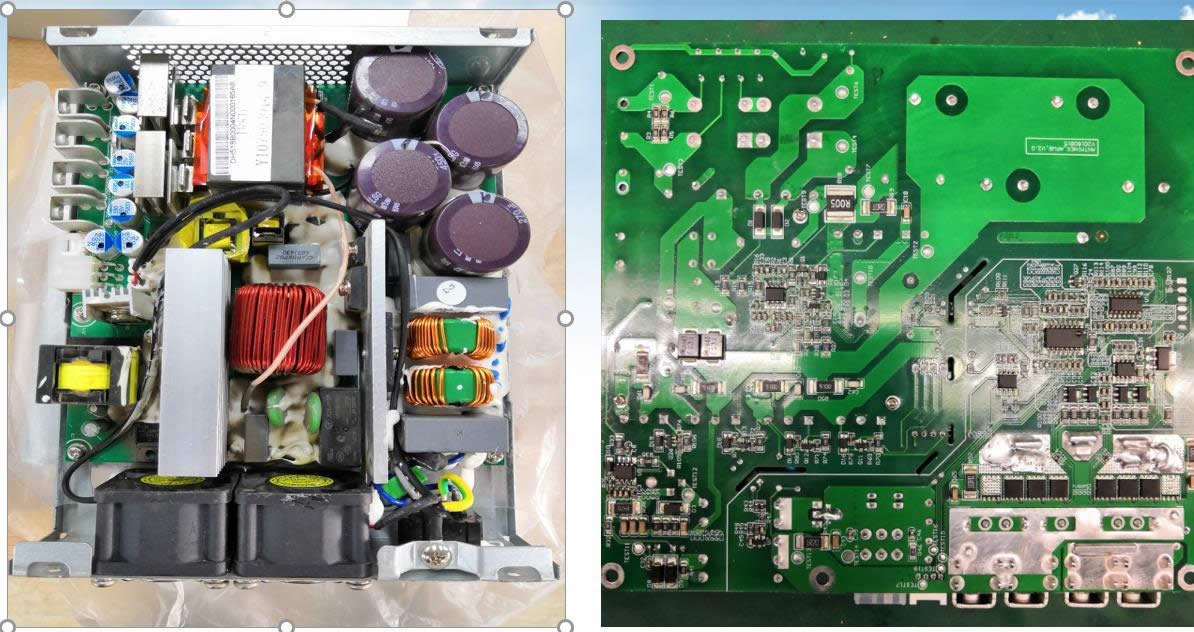

Physical picture, there will be small differences in product versions, but the principle is similar.

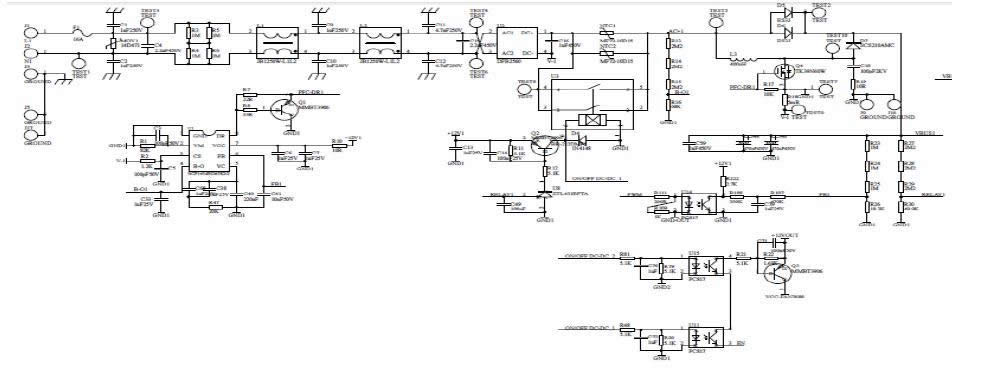

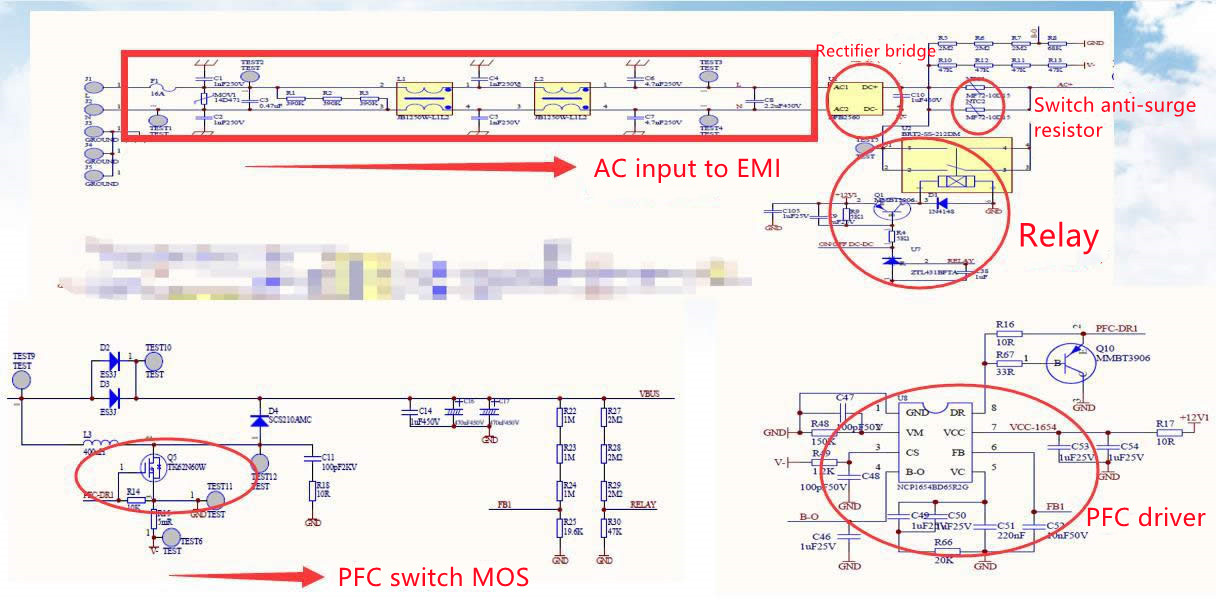

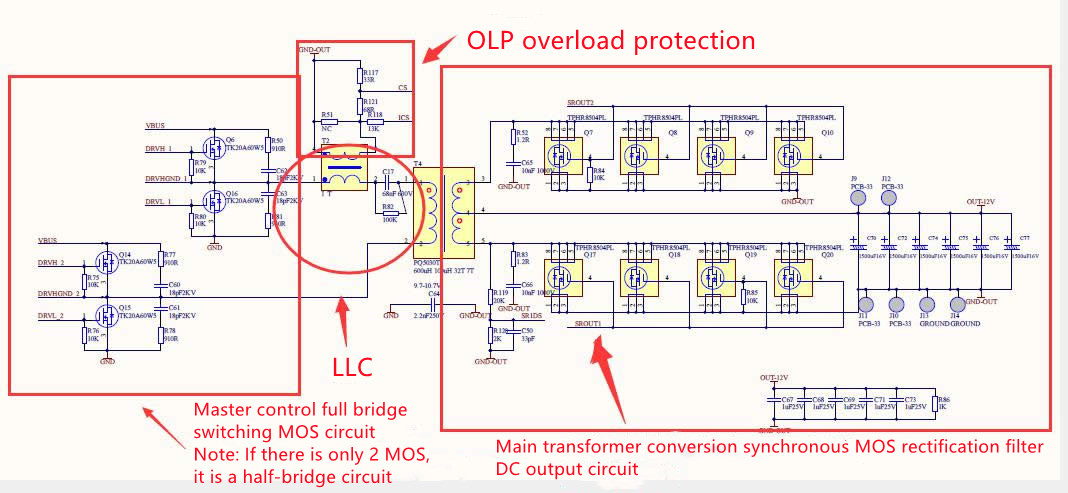

2.21 AC inputs EMI to PFC circuit schematic, focus on measuring whether F1 insurance, U2 rectifier bridge, Q4, D7, D5, D6 are damaged.

整流桥: Rectifier bridge

AC 输入EMI: AC input to EMI

开关防浪涌电阻: Switch anti-surge resistor

继电器: Relay

PFC 开关 MOS: PFC switch MOS

PFC 驱动: PFC driver

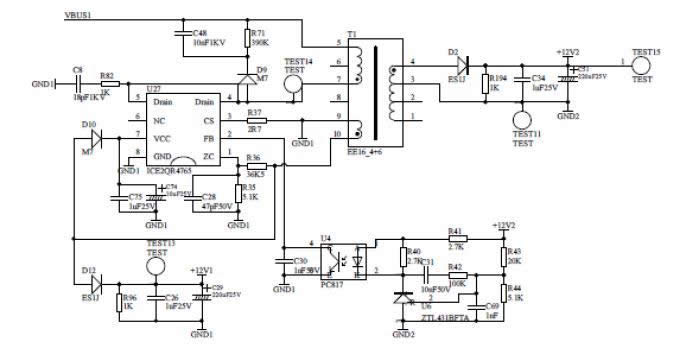

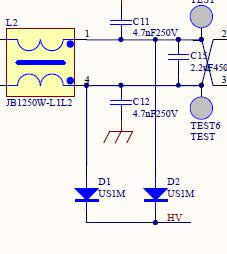

2.22 12V auxiliary circuit principle, focus on measuring whether voltage detection starts resistor R33, 47K and connecting with HV to D1, D2, and whether Q5, D8, D9, T1 is damaged.

高电压输入: High voltage input

电压检测启动: Voltage detection starts

12V 主开关 MOS: 12V main switch MOS

驱动 IC: Driver IC

VCC 12V 供电: VCC 12V power supply

风扇供电: Fan power supply

12V 变压器及整流输出: 12V transformer and rectifier output

12V 稳压反馈电路: 12V regulated feedback circuit

12V 正常时,PFC 大电容 370-380V 电压正常,自动开 VCC12V 主控制供电: When 12V is normal, the PFC large capacitor 370-380V voltage is normal, and the VCC12V main control power supply is automatically turned on.

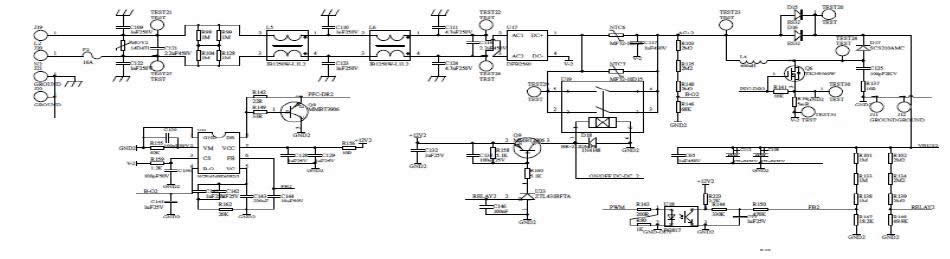

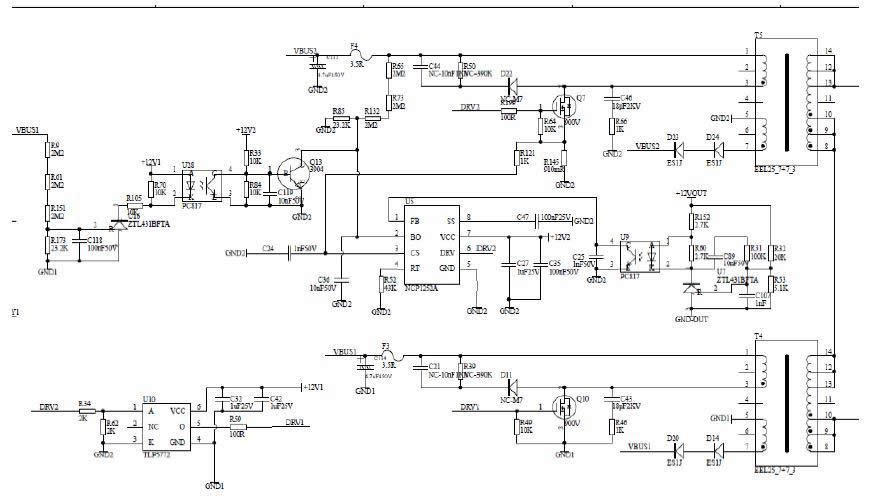

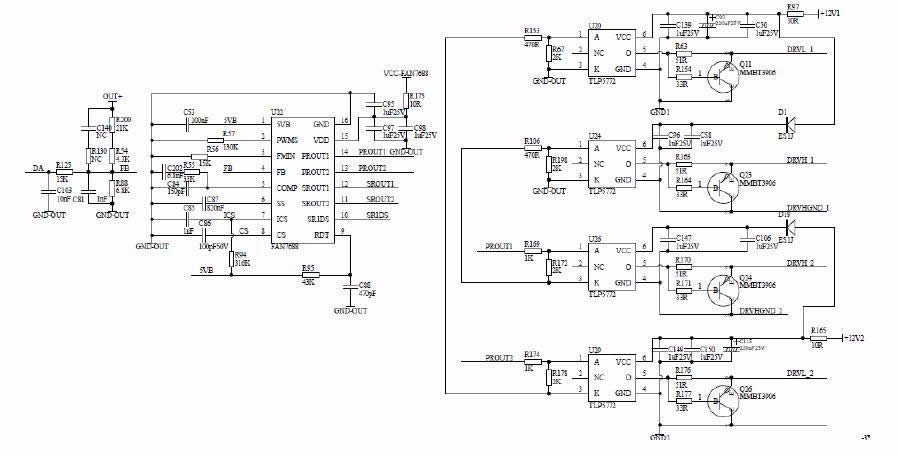

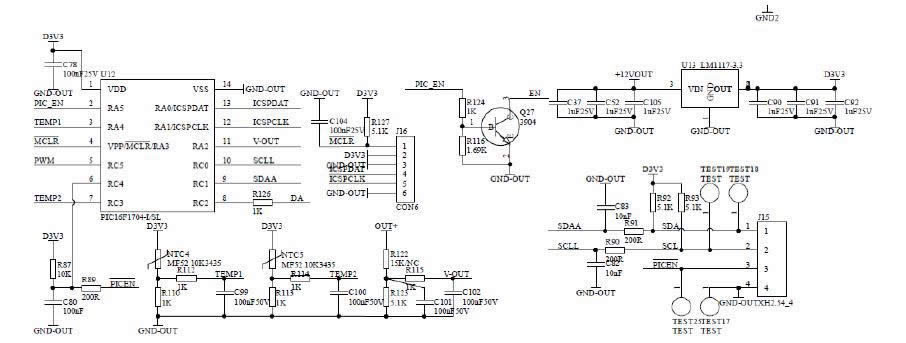

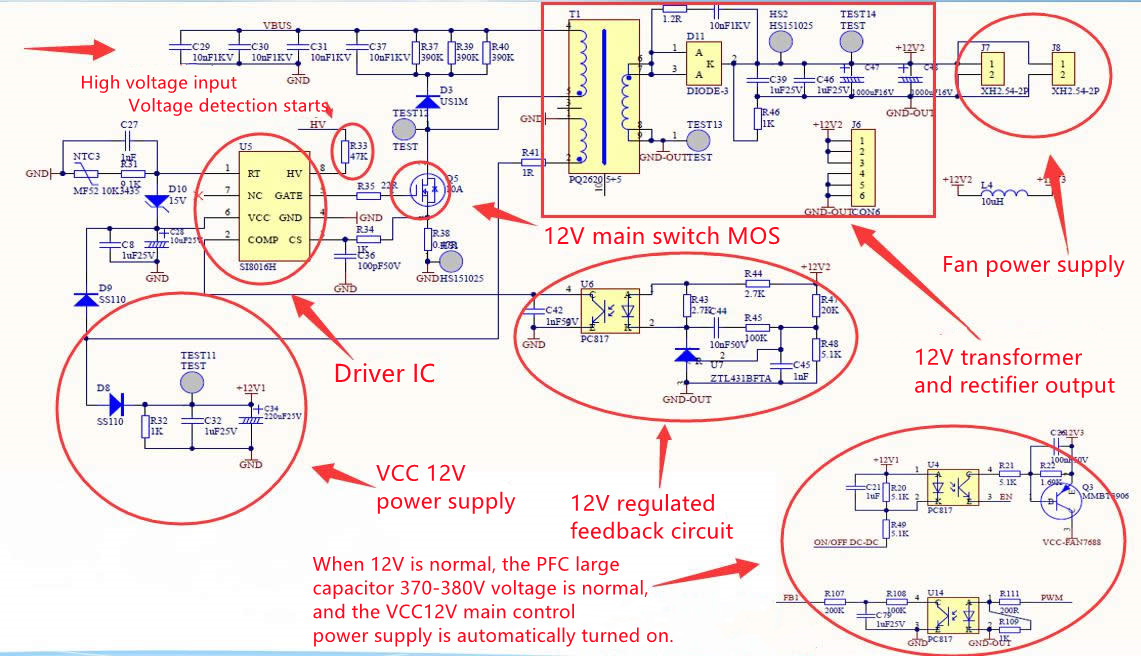

2.23 The main control PWM drive circuit, PIC control voltage regulation schematic diagram, focus on the main IC VCC power supply and drive transformer.

稳压反馈: Voltage regulation feedback

PWM 主驱动电路: PWM main drive circuit

PIC 芯片及控制电路: PIC chip and control circuit

PIC 烧录及通讯端口: PIC burning and communication port

输出端同步整流驱动: Synchronous rectification drive at output end

驱动信号隔离: Drive signal isolation

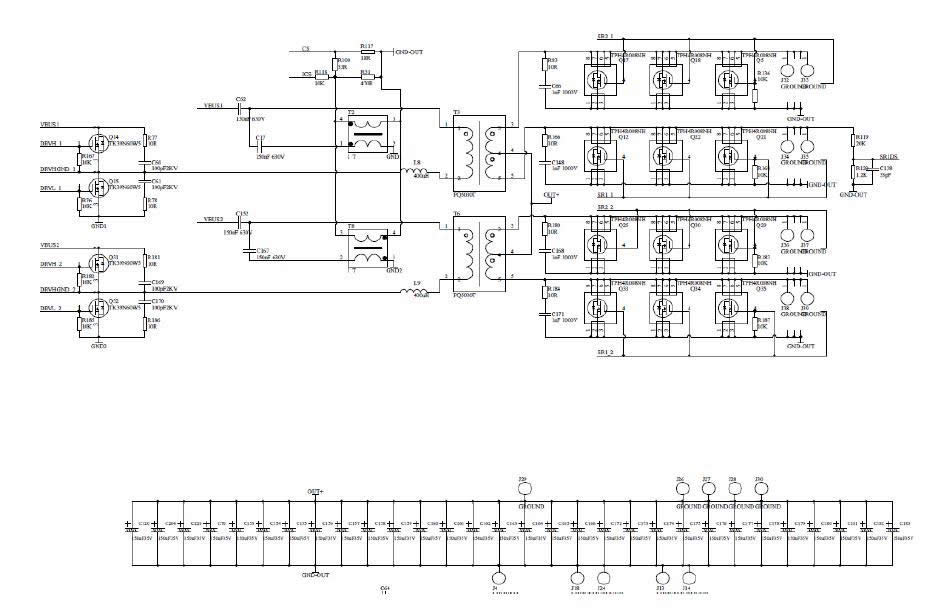

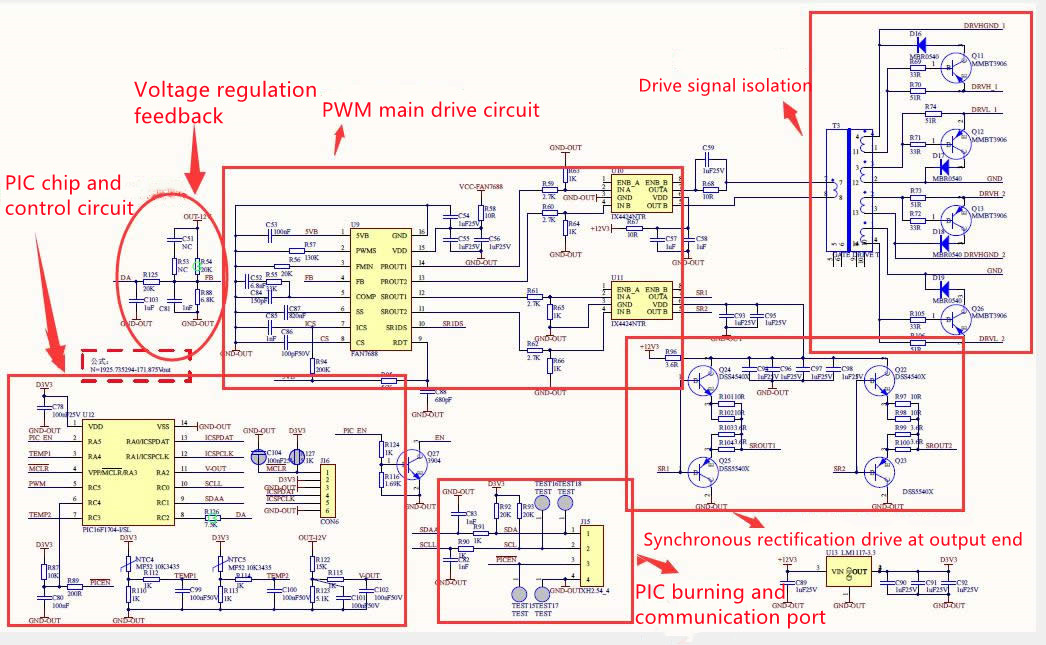

2.24 Main switch MOS and transformer conversion buck synchronous rectification DC filter output circuit, focus on the main switch MOS Q14, Q15, Q6, Q16, the output rectifier side positive and negative have no short circuit.

OLP 过载保护: OLP overload protection

主控全桥开关 MOS 电路: Master control full bridge switching MOS circuit

注:如只有 2 个 MOS 为半桥电路: Note: If there is only 2 MOS, it is a half-bridge circuit

主变压器转换同步 MOS 整 流 滤 波: Main transformer conversion synchronous MOS rectification filter

DC 输出电路: DC output circuit

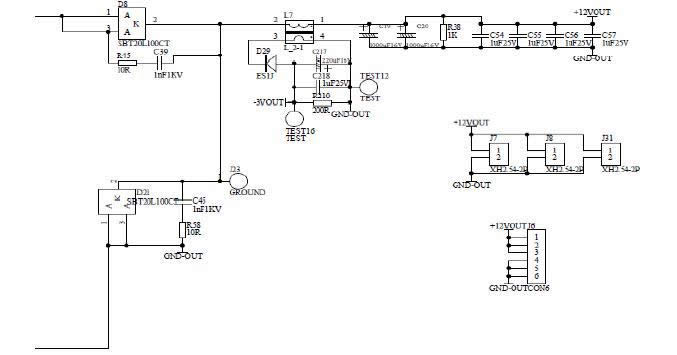

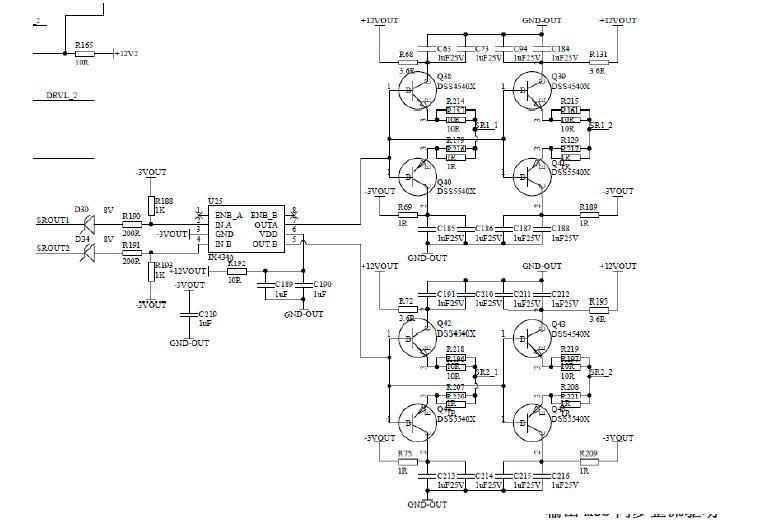

2.25 Location of A side of SMD patch and B side of plug-in

Figure 1 SMD patch side location

Figure 2 Plug-in side location

2.3 Maintenance steps

2.31. Check whether the appearance of the power supply is seriously damaged or deformed, and whether the DC fan and the AC socket are damaged.

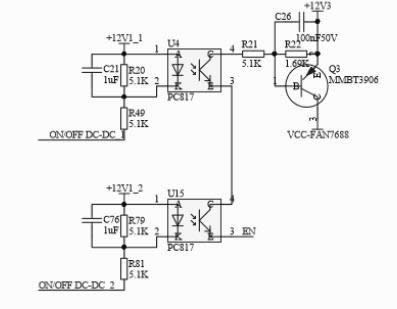

2.32. Power on AC220V, check whether the fan is rotating normally, and use the multimeter to measure whether the output J6 terminal’s voltage is 12V (12.1V-12.50) to eliminate measuring error

2.33. Open the enclosure to check whether the components and solder surface have sparking phenomenon (focus on whether the R33 resistor is damaged), use a multimeter to detect whether the AC input terminal’s F1 fuse has open circuit, whether the U2 rectifier bridge; PFC MOS Q1, D7, D5, D6 have short circuit, whether the PWM circuit’s main switches MOS Q6, Q14, Q15, Q16 and output patches MOS Q17, Q18, Q19, Q20 have short circuit; if there is a short circuit, the component position should be checked and replaced, pay attention to the circuit resistance around bad bit MOS tube; the transistor may be damaged and needs to be replaced.

2.34. Detect whether the auxiliary 12V circuits U5, T1, Q5, D11 have short circuit or open circuit, and whether the surrounding components are burned, etc., replace if necessary.

2.35. If there is no abnormality in the above locations, the F1 fuse path is normal. After the AC is powered on, the DC fan rotates (if there is no rotation, check whether the fan socket has voltage of 12V, if the voltage is normal, replace the fan); the output terminal J6 has 12V voltage, measure whether there is DC370V-380V at both ends of PFC large capacitor C16 or C17, otherwise check whether U1, pin 7V VCC power supply has 12V or judge material damage and replace, if there is no abnormality, it needs to detect PWM circuit U9, U10, U11, whether supply VCC has 12V voltage or judge material damage and replace, and whether the T4 drive transformer is damaged.

2.36. other bad needs to be further analyzed and judged according to the skills of maintenance personnel, After the above check, the single power supply test main circuit DC output needs to be short connected to the J15 PIN 4-5, as EN-GND pin shown in the figure. Note that short connection errors may damage the chip. After the defective device is replaced and the soldering is correct, the AC220V test can be performed.

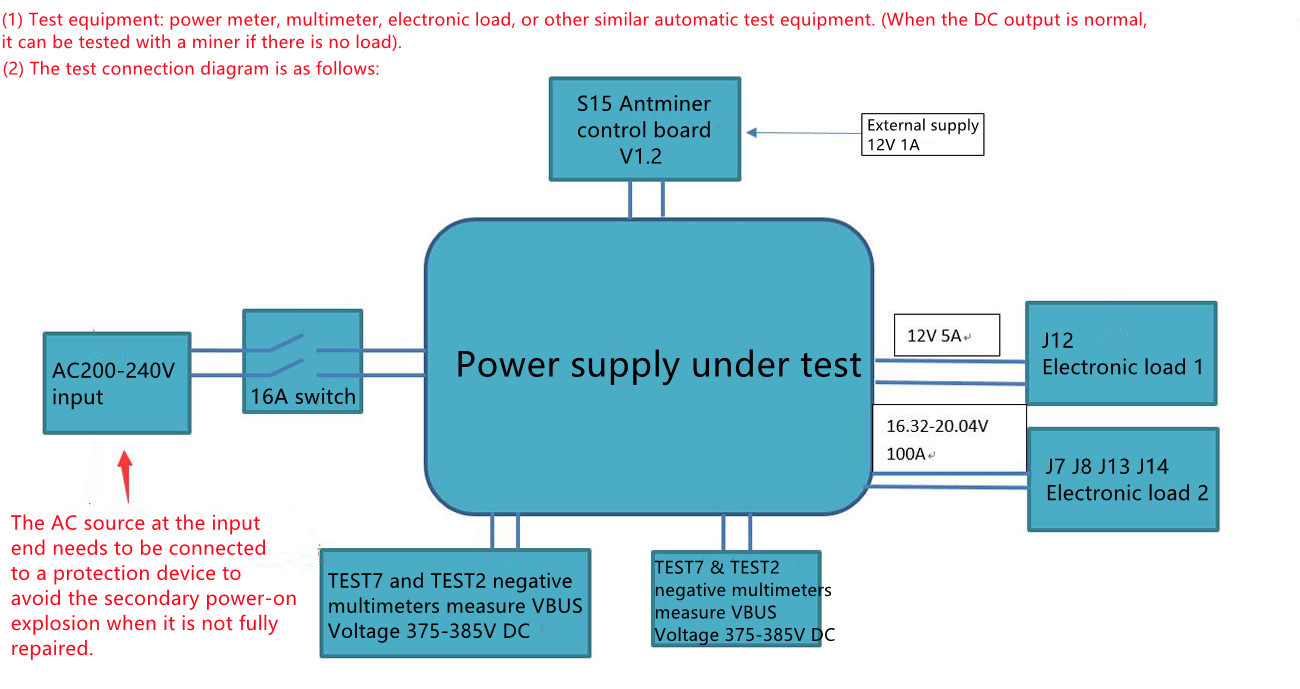

2.4 Diagram for electrical function test connection, PCBA main voltage measurement point.

(一)测试设备: 功率计、万用表、电子负载、或者其他同类型自动测试仪器。(DC输出正常时,如没有负载也可以用带矿机测试)。

(1) Test equipment: power meter, multimeter, electronic load, or other similar automatic test equipment. (When the DC output is normal, it can be tested with a miner if there is no load).

(二)测试连接图如下:

(2) The test connection diagram is as follows:

S15 矿机控制板: S15 miner control panel

外供 12V 1A: External supply 12V 1A.

AC200-240V 输入: AC200-240V input

16A 开关: 16A switch

被测电源: Power supply under test

电子负载 1: Electronic load 1

电子负载 2: Electronic load 2

输入端 AC 源需接保护装置,以免未完全修好的开关电源二次上电炸机。

The AC source at the input end needs to be connected to a protection device to avoid the secondary power-on explosion when it is not fully repaired.

TEST7 与 TEST2 负极万用表量测 VBUS: TEST7 and TEST2 negative multimeters measure VBUS

电压 375-385V DC: Voltage 375-385V DC

TEST11 与 TEST7 负极万用表量测 VCC 12-13V: TEST11 and TEST7 negative multimeters measure VCC 12-13V

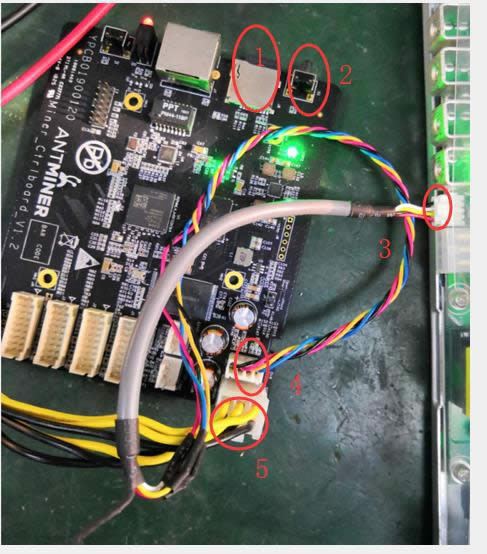

2.41 Diagram for S15 control panel V1.2 and APW8 power PIC port connection test, label 1 is the dedicated card test firmware, 2 is the DC voltage debugging high-low conversion button, 3 is the PIC communication port, 4 is the control panel socket, 5 is 12V power supply; note that yellow indicates positive and black indicates negative. Note: After the general power supply defective products are repaired, the power supply only needs to be short connected with the PIC communication J15 port EN-GND pin, and if there is voltage output 16V, it is normal, and the following single test for the control panel is not requried (when the PIC single chip is damaged, or when the firmware is abnormal, it needs to test a small panel before re-burning), and the corresponding miner test can be directly installed.

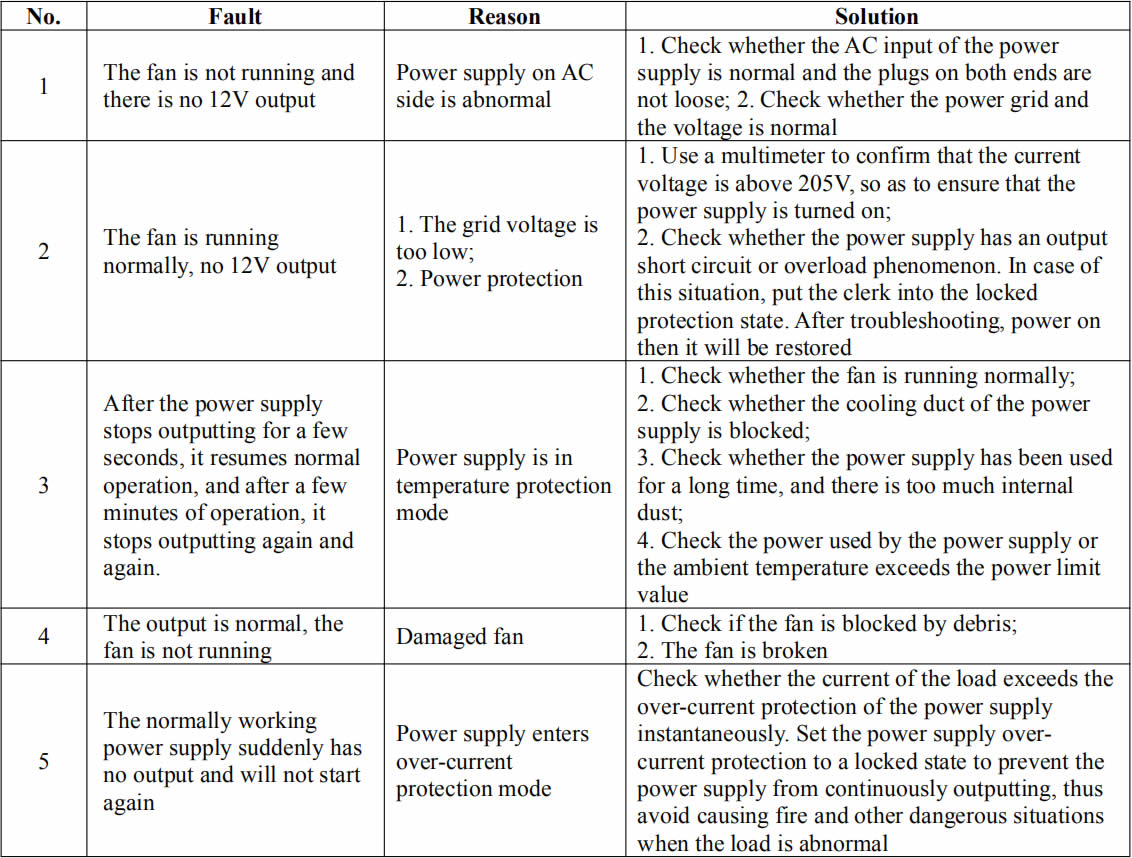

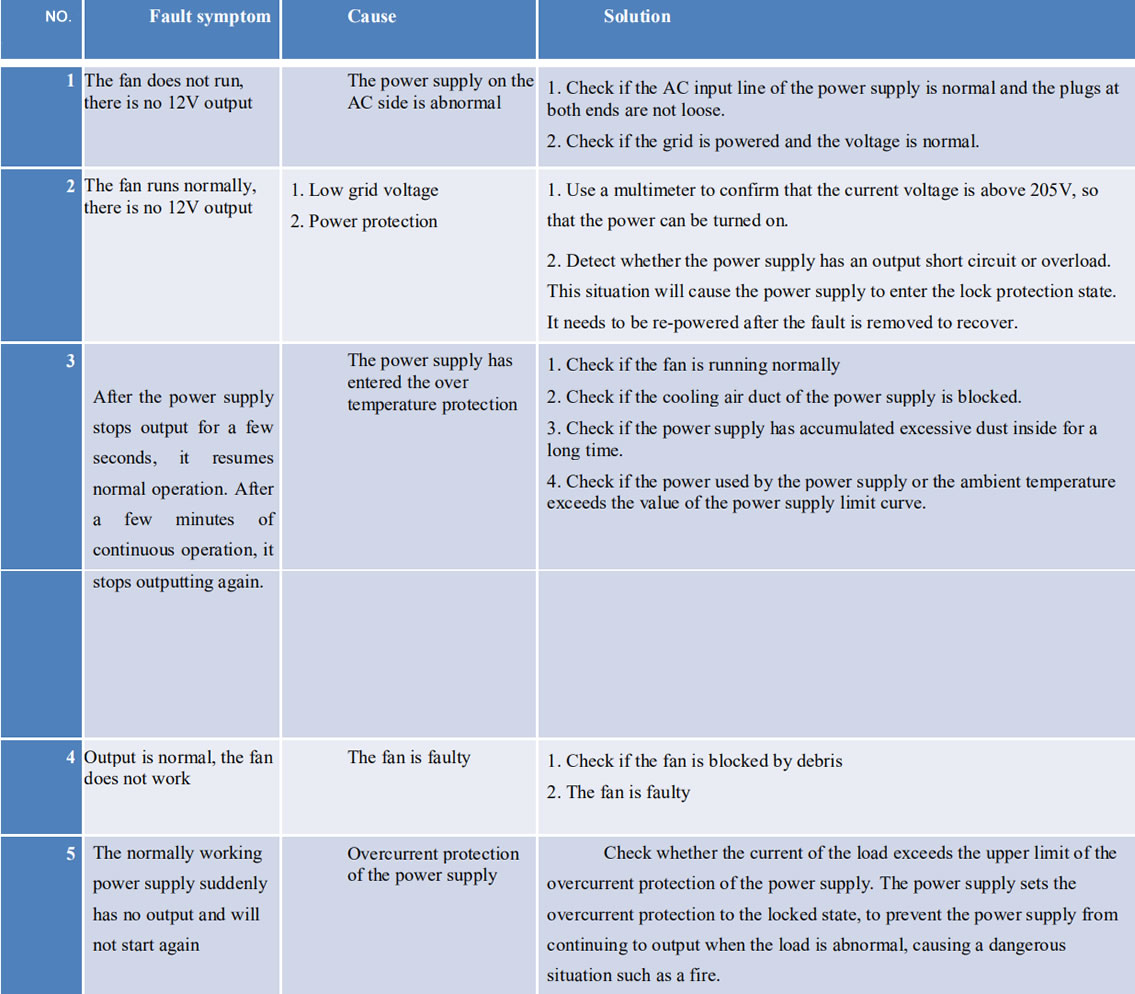

2.5 Simple judgment and maintenance of common faults of mine power supply

2.6 After the power supply maintenance test is normal, it is required to operate normally for 2 hours with the rated load of 80% (80A) or more before it can be used by the client.

Скачать и просмотреть руководство по ремонту, запуску и обслуживанию асик майнеров AntMiner, Whatsminer, Innosilicon, Avalon онлайн

На этой странице вы можете прочесть и скачать все необходимые руководства.

Но, конечно, вы всегда можете связаться с нами по WhatsApp +79275104327, по электронной почте Этот адрес электронной почты защищен от спам-ботов. У вас должен быть включен JavaScript для просмотра. или оставить сообщение в чате, если у вас есть какие-либо (технические) вопросы о наших продуктах.

Руководство по ремонту [PDF] Antminer

Руководство по ремонту хэш-платы Antminer D3

Руководство по ремонту хэш-платы Antminer S9

Руководство по ремонту хэш-платы Antminer S9K

Руководство по ремонту хэш-платы Antminer S11

Руководство по ремонту хэш-платы Antminer S15 T15

Руководство по ремонту хэш-платы Antminer S17+

Руководство по ремонту хэш-платы Antminer S17E

Руководство по ремонту хэш-платы Antminer S17

Руководство по ремонту хэш-платы Antminer T9

Руководство по ремонту хэш-платы Antminer T17+

Руководство по ремонту хэш-платы Antminer T17

Руководство по ремонту хэш-платы Innosilicon miner

Руководство по ремонту хэш-платы Antminer WhatsMiner M10

Руководство по ремонту хэш-платы Antminer Whatsminer M20S

Инструкция по установке [PDF]

Antminer

Руководство Antminer D3

Руководство Antminer DR3

Руководство Antminer DR5

Руководство Antminer E3

Руководство Antminer L3

Руководство Antminer R4

Руководство Antminer S1

Руководство Antminer S2

Руководство Antminer S3

Руководство Antminer S4+

Руководство Antminer S5+

Руководство Antminer D3

Руководство Antminer S7

Руководство Antminer S9 Hydro

Руководство Antminer S9

Руководство Antminer S9k

Руководство Antminer S9SE

Руководство Antminer S11

Руководство Antminer S15

Руководство Antminer S17+

Руководство Antminer S17E

Руководство Antminer S17

Руководство Antminer S17Pro

Руководство Antminer T17

Руководство Antminer S19

Руководство Antminer S19Pro

Руководство Antminer T9

Руководство Antminer T15

Руководство Antminer T17+

Руководство Antminer T17E

Руководство Antminer T19

Руководство Antminer X3

Руководство Antminer Z9 Mini

Руководство Antminer Z9

Руководство Antminer Z11

Руководство Antminer Z15

Avalon

Avalonminer 1047 Manual

Avalonminer 1066 Manual

Avalonminer 1026 Manual

Avalonminer 1066 Pro Manual

Avalonminer 1146 Pro Manual

Innosilicon

Innosilicon A4+Manual

Innosilicon A6 Manual

Innosilicon A9 Manual

Innosilicon D9 DCR Manual

Innosilicon S11 Sia Manual

Innosilicon T2T 32T Manual

Innosilicon T2TZ 30T Manual

Innosilicon T3+57T Manual

Loveminer

Loveminer A1 Manual

Whatsminer

WhatsMiner D1 Manual

WhatsMiner M3 Manual

WhatsMiner M10 Manual

WhatsMiner M20S Manual

WhatsMiner M21 Manual

WhatsMiner M21S Manual

WhatsMiner M30S Manual

WhatsMiner M31S Manual

WhatsMiner M32 Manual

руководство по блоку питания и руководство по ремонту [PDF]

Руководство Antminer APW3

Руководство Antminer APW5

Руководство по ремонту блоков питания Antminer APW9 и APW9+

Руководства по Antminer, ремонт antminer , ремонт whatsminer, ремонт innosilicon, ремонт avalon, руководство по ремонту асиков

Руководство по ремонту [PDF]

Antminer

- Руководство по ремонту хэш-платы Antminer D3

- Руководство по ремонту хэш-платы Antminer S9

- Руководство по ремонту хэш-платы Antminer S9 K

- Руководство по ремонту хэш-платы Antminer S11

- Руководство по ремонту хэш-платы Antminer S15 T15

- Руководство по ремонту хэш-платы Antminer S17+

- Руководство по ремонту хэш-платы Antminer S17E

- Руководство по ремонту хэш-платы Antminer S17

- Руководство по ремонту хэш-платы Antminer T9

- Руководство по ремонту хэш-платы Antminer T17+

- Руководство по ремонту хэш-платы Antminer T17

- Руководство по ремонту хэш-платы Innosilicon miner

- Руководство по ремонту хэш-платы Antminer WhatsMiner M10

- Руководство по ремонту хэш-платы Antminer Whatsminer M20S

Инструкция по установке [PDF]

Antminer

- Руководство Antminer D3

- Руководство Antminer DR3

- Руководство Antminer DR5

- Руководство Antminer E3

- Руководство Antminer L3

- Руководство Antminer R4

- Руководство Antminer S1

- Руководство Antminer S2

- Руководство Antminer S3

- Руководство Antminer S4+

- Руководство Antminer S5+

- Руководство Antminer D3

- Руководство Antminer S7

- Руководство Antminer S9 Hydro

- Руководство Antminer S9

- Руководство Antminer S9 k

- Руководство Antminer S9 SE

- Руководство Antminer S11

- Руководство Antminer S15

- Руководство Antminer S17+

- Руководство Antminer S17 E

- Руководство Antminer S17

- Руководство Antminer S17 Pro

- Руководство Antminer T17

- Руководство Antminer S19

- Руководство Antminer S19 Pro

- Руководство Antminer T9

- Руководство Antminer T15

- Руководство Antminer T17+

- Руководство Antminer T17 E

- Руководство Antminer T19

- Руководство Antminer X3

- Руководство Antminer Z9 Mini

- Руководство Antminer Z9

- Руководство Antminer Z11

- Руководство Antminer Z15

Avalon

- Avalonminer 1047 Manual

- Avalonminer 1066 Manual

- Avalonminer 1026 Manual

- Avalonminer 1066 Pro Manual

- Avalonminer 1146 Pro Manual

Innosilicon

- Innosilicon A4+Manual

- Innosilicon A6 Manual

- Innosilicon A9 Manual

- Innosilicon D9 DCR Manual

- Innosilicon S11 Sia Manual

- Innosilicon T2T 32T Manual

- Innosilicon T2TZ 30T Manual

- Innosilicon T3+57T Manual

Loveminer

- Loveminer A1 Manual

Whatsminer

- WhatsMiner D1 Manual

- WhatsMiner M3 Manual

- WhatsMiner M10 Manual

- WhatsMiner M20S Manual

- WhatsMiner M21 Manual

- WhatsMiner M21S Manual

- WhatsMiner M30S Manual

- WhatsMiner M31S Manual

- WhatsMiner M32 Manual

руководство по блоку питания и руководство по ремонту [PDF]

- Руководство Antminer APW3

- Руководство Antminer APW5

- Руководство по ремонту блоков питания Antminer APW9 и APW9+

В 23.11.2020 в 20:49, DeathOfPower сказал:

Кто-нибудь ремонтировал хэшплаты Antminer T17 или S17? Долго ли они работают после ремонта?

У меня вот такой опыт:

Antminer T17После почти что года работы на стандартной прошивке сдохла одна хэшплата. При инициализации определялись только 24 чипа из 30. Асик стоял на балконе в шумопоглощающем ящике, что продают на Авито. От ящика до балконного окна с антикомариной сеткой были проложены 2 алюминиевые гофры чтобы горячий воздух выдувался за борт. Зимой при морозах асик тоже отлично работал. Остекление балкона хоть и есть но обычным одинарным стеклом, не стеклопакетами.

Сразу чинить не понёс — то некогда то отпуск. Потом сдохла вторая плата — в логе было что-то про питание, мол 0 вольт на плате. В итоге отнёс сразу 2 платы в ремонт. Забрал через неделю. Поставил — одна плата работает, на второй определяются 0 чипов. Тогда на улице было +5-7 градусов. Отнёс незаработавшую плату по гарантии (1 месяц). Пока её ремонтировали на той плате что сразу заработала через 2 дня 6 чипов перестали давать хэшрейт (после ремонта установил прошивку от Vnish — она позволяет задавать какую температуру чипов поддерживать ну и понижать напряжение чтоб меньше жрало электричества). При инициализации определяются все 30 а когда начинается майнинг у шести чипов хэшрейт — 0. Даже при стандартном напряжении и частоте.

Когда забирал одну плату из повторного ремонта отдал сразу вторую в повторный ремонт. В этот раз незаработавшая плата завелась и нормально работала. За это время сдохла 3-я плата — видит 24 чипа из 30.

Потом поехал забрал вторую плату из повторного ремонта. Привёз домой воткнул — не работает. При инициализации определяются то 17, то 24 то 6 то 1 чип. Отвёз её обратно. На следующий день звонят — мы подключили у нас работает. Повёз сам асик. У них подключили, вставили плату — работает. Привёз домой — в комнате включил — работает. Отнёс в ящик на балкон. Включаю — опять определяются то 17, то 24 то 6 то 1 чип.

Позвонил в сервис — говорят мол 17-я серия капризная им надо чтобы не меньше 15 градусов было в помещении. Но как это может быть? В инструкции пишут что рабочая температура окружающей среды от 0 до +25. Почему после ремонта надо вдруг не ниже 15 градусов?

В общем помайнил одной картой пару дней чтобы добраться до порога вывода намайненного с пула. Занёс опять домой. Постоял он часа 2, нагрелся. Включаю — та плата уже и в тепле не работает — определяются 24 чипа из 30. И что самое противное та плата что проработала дней 10 после ремонта тоже перестала запускаться — пишет 0 чипов из 30 найдено.

Вот и думаю — стоит ли пробовать ремонтировать 3-ю плату в другом месте, или лучше продать на запчасти. Блок питания то и управляющая плата в порядке. А с хэшплат можно повыпаивать чипы и отобрать нормальные.

у 17 серии есть проблемка в припое, он хрупкий. похоже на то, что микротрещины в пайке образовались. обычно лечится прогревом плат до 200 градусов, в течении пары минут

Руководство по ремонту блока питания Antminer APW12 [EN]

Как отремонтировать блок питания Antminer APW12?

Antminer APW12 Power Supply Repair Guide

Contents: Mainly describes how to troubleshoot various faults of the power supply APW12 and how to use testtools for accurate troubleshooting.

※The copyright of this article is owned by Bitmain. Without the permission of the copyright owner, no unit orindividual may reprint or extract this work, or use this work for other purpose. Please contact Bitmain officialcustomer service if there is any need of reprinting or extracting.

I. Requirements for Maintenance Platform

1. Constant temperature soldering iron, above 80W (soldering temperature is 300-350℃), pointed soldering iron tip is used to solder small patches such as resistors and capacitors, etc., knife-type soldering iron tip is used for replacing plug-in component by welding (welding temperature is 380-420 ℃).

2. The heat gun is used for chip disassembly and soldering. Be careful not to heat it for a long time to avoid PCB blistering (welding temperature is 260 ℃±2 ℃).

3. AC controllable power supply voltage regulator (output 200-250V, limit current 0-20A) is used for APW12 power-on inspection. If it’s not available, operator can also connect a 100W ordinary light bulb to the utility AC live wire, but shall pay attention to safety.

4. Electronic load (power 3.6KW, suitable voltage 0-50V); if it’s not available, operator can make a power resistance load matching APW12.

5. Fluke 15b+ Multimeter, suction pistol, tweezers, zj0001000001 or V9 1.2 hashboard testers and special power supply test card firmware (configure an oscilloscope if available).

6. Flux, lead-free solder wire, water for cleaning panel with anhydrous alcohol; water for cleaning panel is used to clean up the residue and appearance of the flux after maintenance.

7. Thermally conductive silicone grease (2500) is used to repair the heat conduction between the MOS and the heat sinks. The thermally conductive silicone (704 silicone) is used to fix the cover after the original glue of the PCBA component is damaged after repair.

II. Requirements for Maintenance Operations

1. Maintenance personnel must have certain electronic knowledge, more than one year of maintenance experience, have a certain understanding on the working principle of switching power supply, and master the welding technologies.

2. Before opening the shell and repairing the PCBA board, the large capacitor must be discharged. After the voltage is measured with a multimeter (if it’s less than 5V, discharge is completed), the welding operation can be performed! Please pay attention to confirm to avoid electric shocks.

3. Pay attention to the operation methods when judging circuit components. After replacing any device, there shall be no obvious deformation of the PCB board. The soldering of the bonding pad is reliable. Check the replacement parts and confirm whether there are few open and short circuits around them.

4. After the replacement of the key components, the main circuit is checked and measured to have no short circuit and other obvious abnormalities before the AC voltage test, otherwise there may be a hidden danger of miner explosion.

5. When AC220V voltage is needed to judge the circuit signal, please pay attention to operation protection. The following contents: Notes, key internal slogans

● The qualification of maintenance personnel must meet the specified requirements.

● The instruments and equipment used for maintenance must meet the specified requirements.

● The repaired instruments and equipment must be effectively grounded, and the maintenance environment requirements should meet anti-static requirements. Of course, it is better to wear an anti-static wrist strap.

● The materials used for maintenance must meet the specified requirements; in order to ensure the accuracy and traceability of the materials used for maintenance, the materials used for maintenance must be the production materials of the corresponding models, and the requirements for material replacement must be confirmed;

1. In order to prevent possible electric shock hazards, non-professionals are not allowed to disassemble the shell;

2. The maintenance personnel need to use a special shelling miner to repair the power adapter, so as not to damage the internal components of the product;

3. After the product is opened, it is required to discharge the high-voltage capacitor;

4. Electronic waste generated during product maintenance cannot be discarded at will;

5. Defective products must be marked on the repair process card and placed in a partition;

6. The repaired products must be marked to distinguish;

7. The repaired products must be placed in the repaired area and require systematic testing before they can be put into storage.

III. Principle and Structure of Power Supply

1. Overview of principles

1.1 APW12 is composed of a large board, three 60mm fans and a lower shell . Normally, two inputs are connected to AC220V. It has two DC output voltages, respectively including SB, 12V. The main voltage output 12V-15V is controlled by PIC port and miner communication.

1.2 The performance characteristics and scope of use are described as follows :

APW12 power supply is a high-efficiency DC power supply designed and produced by our company. It has two single-phase AC inputs and two DC outputs:

1) 12V-15V voltage output is adjustable, the maximum current can reach 12V/300A; 15V/240A

2) 12V voltage fixed output; current can reach 15A.

The adjustable voltage output part can meet the use of common DC loads within 240A current within the adjustable voltage range, especially is suitable for servers and miners that have strict power requirements; the 12V voltage fixed output part can meet the control board and cooling fan use.

1.21 Following characteristics:

It has the following characteristics:

♦ 200-240V wide voltage input

♦ There are under-voltage, short-circuit, overload, over-temperature protection inside, and it can automatically recover after the fault is removed.

♦ The selection of high-quality components ensures the stability and reliability of the product through reasonable design, and can work at full load for a long time in a high temperature environment within 50°C.

♦ Small size and high power density.

1.3 Introduction to the appearance of APW12 power supply

Note: If you need to test the default voltage of 15.2V at boot, please use an adapter cable to short-circuit the pin EN of the voltage regulator port with GND.

The following is APW12 shell and output port diagram

● Distribution on the front panel of the power supply: 2 delta-shaped AC input ports

3 medium-speed fans with a size of 60*60*25mm

● Distribution on the left side of the power supply: 2 PCB-33 copper solder terminals with adjustable voltage output

One PCIE terminal with 12 V fixed voltage output

● Distribution on the rear panel of the power supply: the heat dissipation, acting as the fan vents.

● The AC input terminal on the front panel of the power supply is C14 delta-shaped AC socket which is snap-in type, and the C13 AC input cable of the corresponding interface is required for use.

● The 4Pin signal terminal is the communication interface between the external control board and the power supply. SDA/SCL is the I2C protocol, and the output voltage of the power supply can be adjusted through I2C. EN is the enable signal of the power supply, and the control board can enable the power supply through EN, which is effective at low level.

● The adjustable voltage output part adopts 2 copper strip welding terminals, one copper strip terminal near the air outlet is the output positive pole, and the other one near the signal terminal is the output negative pole. The output wire or output copper strip can be fixed by M4 screws on the terminal. It is convenient and flexible to use.

● The 12V fixed voltage output part adopts PCIE output terminals. The schematic diagram of the PCIE output terminal is as follows:

1.4 APW12 power supply parameter table:

2. Maintenance ideas and cases of common faults

2.1. Block diagram of power supply basic principle

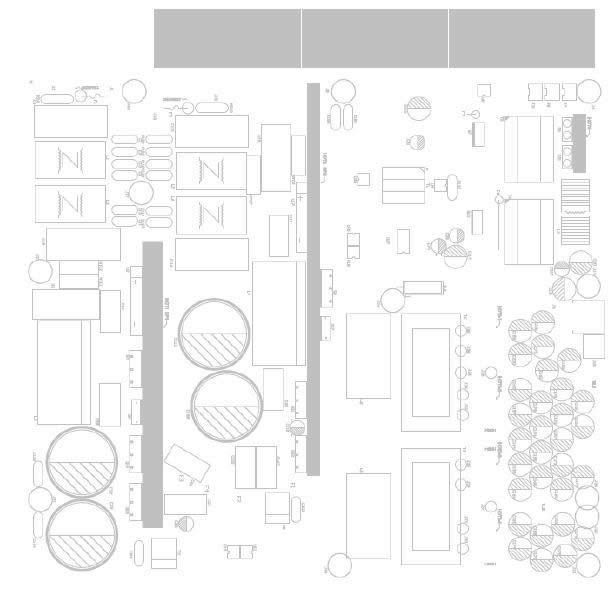

2.2 Power PCBA board layout

Layout marking instructions:

AC1 —the first circuit AC input and EMI circuit, — PFC and main switch MOS circuit, — 12V auxiliary and VCC circuit.

AC2 —the second circuit AC input and EMI circuit, — PFC and main switch MOS circuit, — 12V auxiliary and VCC circuit, —12V output port and PIC communication port

Main drive IC, PIC control chip — Main output

This figure is an actual picture. There may be small differences between different product versions, but the principle is similar.

2.21 Schematic diagram of two AC input EMI to PFC circuit, for example, for AC1 circuit, focus on measuring F1 safety circuit MOV1; for U2 rectifier bridge, confirm whether Q4, D7, D5, D6 are damaged (the same inspection method as the other circuit). Note that when the MOS is damaged, the drive resistance and circuit may be damaged simultaneously and need to be replaced. During normal operation, it can be judged that the DC voltage across the large capacitor is 410-420V.

2.22 Two-circuit 12V auxiliary circuit and fan power supply principle:

For VCC 12V circuit, the power supply judges that there is no short circuit abnormality. After powering on, this circuit needs to work normally to supply power to other ICs. Measure TEST15/TEST11 (11.98V-12.3V), TEST7/TEST13 (11.98V- 12.3V), and in case of any abnormal situations, check D12; D10; U7; D2; T1; etc.

12V auxiliary circuit and fan power supply, 12V output for miner supply control board and large fan, VBUS1 or VBUS2 voltage 420V, U5 chip 2 pin high level starting, if there is abnormal check, Q7; R66, R145, F4, R121 — Q10; R59; U10; check if F3 has any damage.

12V 0UTJ6 output for miner control board, J7, J8, J31 internal fan

For main PWM chip U9 VCC power supply control, pay attention to the front-end two PFC need to work normally.

2.23 Main control U22 PWM drive circuit, feedback control voltage regulation and voltage stabilization principle diagram, focusing on measuring the main IC U22 VCC power supply and drive photocoupling; resistance and transistor.

2.24 LLC circuit two-circuit main switch MOS and transformer conversion voltage-reduction synchronous rectification DC filter output circuit, focusing on testing the main switch MOS Q14, Q15, Q31, Q32, check whether there is a short circuit phenomenon at the positive and negative pole of the output rectifier chip MOS, over-current protection circuit T2, T8 transformer, etc.

2.25 For PIC control circuit, J15 voltage regulation communication port, J16 programming port, check TEST19- GND, TEST18-GND (3.2-3.3V)

2.26 SMD paster A side and plug-in B side device position screen printing diagram

Figure 1: SMD paster surface position

Figure 2: Plug-in surface position

2.31 Check whether the appearance of the power supply is seriously damaged or deformed, and whether the DC fan and AC outlet are damaged.

2.32 Power on AC220V and check whether the fan is rotating normally. Use a multimeter to measures and check whether the output voltage of the J6 terminal is 12V (12.1V-12.50).

2.33 Open the shell and check the components and soldering surface for sparking and scorching (focus on whether D1, D2, D21 and D22 are damaged, and whether 12V circuit chip capacitors are burning), use a multimeter to detect whether the AC input F1 fuse is open circuit, check U2 rectifier bridge and PFC MOS Q4; D7; D5; D6 to confirm whether there is short circuit (the same inspection method as the other circuit), measure the main switch of PWM circuit MOS Q31; Q32; Q15; Q16 and output chip MOS Q17; Q18; Q19; Q20; check whether there is a short circuit. If there is a short circuit, operator needs to check and replace the component position. Pay attention to the circuit resistance around the bad bit MOS tube; the transistor may be damaged and need to be replaced.

2.34 Check whether the auxiliary 12V circuit F3, U5; T1; Q5; D8, D9 and other components have short circuit or open circuit phenomenon and whether the surrounding components are burned, etc., if necessary, replace them.

2.35 If there is no abnormality in the above position, the F1 or F2 fuse circuit is normal, and the DC fan rotates after the two AC circuits are powered on (if it doesn’t rotate, please measure whether the fan socket is 12V; if it rotates normally, the fan shall be replaced normally), the output J6 is under 12V voltage. Measure and check whether there are DC410V-420V between the two ends of the two PFC large capacitance TEST20-TEST30 or TEST2-TEST7 measurement points, otherwise check the PFC chip U21 or U1, check the 7-pin VCC power supply has 12V or judge the material to be damaged and replace; if there is no abnormality, the PWM needs to be detected for circuit U9; U10; U24; power supply VCC has a voltage of 12V or judge that the material is damaged and replaced, and whether the T5 or T7 drive transformer is damaged.

2.36 Other defects need to be further analyzed and judged according to the skills of the maintenance personnel. After the above inspections are completed, the main DC output of the single power supply test needs to be about DC21.3V after short-circuiting the J15 PIN pin 4-5 pins, as shown in the EN-GND pin. Note that the short circuit error may damage the chip. Only after the replacement of the defective device is checked and the welding is correct, the AC220V test can be performed. Note: If other circuits are checked that the normal large capacitor is 420V, and there is no output after short-circuiting, it can also be judged that the PIC chip U12 firmware is reprogrammed or the IC is burned (generally there are fewer defects)

2.4 Available control board V1.2 and APW9 power PIC port connection test chart. Mark 1 is dedicated card test firmware, 2 is DC voltage debugging high and low conversion button, 3 is PIC communication port, 4 is control board letter socket, 5 is 12V power supply; please note that the yellow indicates positive and black indicates negative. Note: After the general power supply defective products are repaired, power on and short-circuit the PIC communication J15 port EN-GND pin, if there is a voltage output of about 21V as normal, it can be judged as normal and the control board test is not required (when the PIC microcontroller is broken, or the firmware is reprogrammed, then a small board test is required), and the corresponding miner can be directly installed for testing. After the power supply is repaired, if the current under 12V with a load is 12A and current under the main voltage DC21V with a load is 170A, it is qualified.

2.5 Simple judgment and maintenance of common faults in mine power supply.

2.6 After the maintenance test of the whole power supply is normal, it needs to operate for aging under more than 80% (140AA) of the rated load for 2 hours, and if it’s qualified, it can be used by the customers.

Источник

Файловый архив

Избранные файлы

-

Прошивка для тестов S17 — S17PRO

Автор:

Kowex

-

0 обзоров

-

55

-

0

ВАЖНО!

При применении тестера, тестер затирает информацию с ээпромки которая находится на хешплате. Прежде чем прогонять плату тестером, сохраните прошивку ээпром с платы. Если вы всё же затерли прошивку с платы то, скопируйте прошивку с соседней платы этого же майнера и залейте в него.

Лично я сделал переходник для программатора минипро и подав питание 3.3 вольта, считываю и заливаю прошивку как 24С02, смотрите фото.

Теперь по поводу тестера. Подключите по ТХ и РХ ТТЛ переходник

-

-

-