ROR

Axle & Brake Service Manual

TM Series Axles including Disc and Drum Brake variants

1

2

3

4

5

APPENDIX

INDEX

Section Description

QUICK REFERENCE WARRANTY CHART

IDENTIFYING THE AXLE

Identifying the Axle Type, Identifying the Serial Number

INTRODUCTION TO THE TM AXLE RANGE

AXLE INSTALLATION

TM MAINTENANCE SCHEDULE

TECHNICAL DATA TABLES

Table 1: Fastener Torque Values

Table 2: Recommended Lubricants

Table 3: Hub Bearing Grease Fill Volumes

TM DRUM BRAKE SERVICE

TM DISC BRAKE SERVICE

TM HUB SERVICE FOR DRUM BRAKES

TM HUB SERVICE FOR DISC BRAKES

ADDITIONAL PROCEDURES

AXLE & BRAKE SERVICE FAULTS

Page

3

8

12

13

9

8

13

23

33

39

41

46

2

TM Service

TM Hubs

Any component not referred to below is covered by a 1 yr / 100,000 km warranty for mechanical failure only.

Labour costs can only be claimed at an agreed rate with ArvinMeritor Service Department prior to work commencing.

For full warranty terms and conditions see ‘ArvinMeritor Warranty Terms and Conditions’ Publication No 4.84.1

TM

1 yr / 100,000 km

Hub cap & screws

1 yr / 100,000 km

Hub cap gasket.

Mechanical failure only

1 yr / 100,000 km

Oil seal.

Mechanical failure only

TM DX195

1 yr / 100,000 km

Hub cap & screws

1 yr / 100,000 km

Hub cap & screws

3 yr / 300,000 km

Axle end fixings

3 yr / 300,000 km

TM Hub assembly

1 yr / 100,000 km

Hub cap gasket.

Mechanical failure only

1 yr / 100,000 km

Oil seal.

Mechanical failure only

1 yr / 100,000 km

Hub cap & screws

3 yr / 300,000 km

Axle end fixings

3 yr / 300,000 km

TM Hub assembly

3

TM Service

DX 195 Disc Brake for TM Axles

Any component not referred to below is covered by a 1 yr / 100,000 km warranty for mechanical failure only.

Labour costs can only be claimed at an agreed rate with ArvinMeritor Service Department prior to work commencing.

For full warranty terms and conditions see ‘ArvinMeritor Warranty Terms and Conditions’ Publication No 4.84.1

2 yrs/200,000 km

Caliper assembly

1 yr / 100,000 km

Brake retaining clips.

4

1 yr / 100,000 km

Brake pad assemblies.

Mechanical failure only

1 yr / 100,000 km

ABS components

1 yr / 100,000 km

ABS components

2 yr / 200,000 km

Brake rotor.

Mechanical Failure only

TM Service

TM Axle shown

Any component not referred to below is covered by a 1 yr / 100,000 km warranty for mechanical failure only.

Labour costs can only be claimed at an agreed rate with ArvinMeritor Service Department prior to work commencing.

For full warranty terms and conditions see ‘ArvinMeritor Warranty Terms and Conditions’ Publication No 4.84.1

1 yr / 100,000 km

Brake shoe assemblies.

Mechanical failure only 1 yr / 100,000 km

Assister spring

1 yr / 100,000 km

Retaining spring

2 yr / 200,000 km

Anchor pin assembly

1 yr / 100,000 km

ABS components

2 yr / 200,000 km

Cam bearing

1 yr / 100,000 km

ABS components

2 yr / 200,000 km

Camshaft

1 yr / 100,000 km

Return spring

5 yr / 500,000 km

Axle beam weld assembly, Ex works.

Including Flexair spring seat.

(3 yr / 300,000 km

TM beam non-

ArvinMeritor welded)

1 yr / 100,000 km

Brake shoe assemblies.

Mechanical failure only

2 yr / 200,000 km

Cam roller assembly

3 yr / 300,000 km

Brake drum. Mechanical failure only

1 yr / 100,000 km

Dust covers & screws

5

TM Service

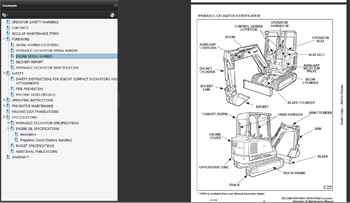

Identifying the Axle Type

Anti-Lock Type

(Table D)

Steer Axle

Self (S)/Command (C)

T M

Axle series loading

(Table A)

Wheel fixing to suit single (S) or twin wheels (T)

Brake size and type denoted by letters

(Table B)

Number of wheel bolts either 8 or 10

Type of wheel bolts

(Table C)

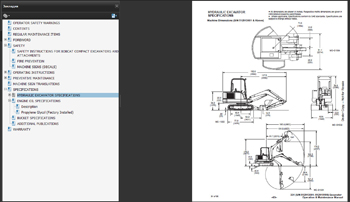

Table A – TM Loading – Standard and Low Loader

Axle

Series

20,000

22,500

25,000

Nominal

Highway Axle

Rating kg

9,500

10,170

11,690

Maximum

Offset mm

460

490

490

The axle ratings shown are for normal highway applications and any special application for installation must be approved by ArvinMeritor Design Engineering.

Track – spring centres

NB: Offset =

2

TABLE C – TM WHEEL FIXING CODING CHART

Axle Letter

Code

S

M

J

MX

MXA

B

Wheel Mounting

7 ⁄

8

” BSF (SMMT)

M22mm x 1.5mm metric (DIN)

‘Trilex’ type

ISO 4107 type with M22mm x 1.5mm

wheel bolts

ISO 4107 type with M22mm x 1.5mm

wheel bolts for alloy wheels

Japanese M20 x 1.5mm

TABLE B – TM BRAKE CODING CHART

Axle Letter

Code

P

Q

ZA

Z

AA

AC

B

O

Brake

310mm x 190mm

350mm x 200mm

394mm x 180mm

420mm x 150mm

420mm x 180mm

420mm x 200mm

420mm x 220mm

380mm x 180mm Stopmaster

TABLE D – TYPE OF ANTI-LOCK SENSING

Axle Letter

Code

A

Exciter Type

60/45T

Pressed Steel

Suitable For

Grau MGX2 & MGX2E

Bendix MDR & MDRA

W 100/80T

Solid Ring

Wabco

Bosch

Grau DGX & MGX100

Bendix AL-4T

Note: Please refer to relevant anti-lock manufacturers service manual for specific service and replacement instructions.

Identifying the Serial Number

Brake Lining Type Build Month

Sequential Number

Build Year

Order Number

6

TM Service

Introduction to the TM Axles Range

AXLE BEAMS

The ROR Mark III TM Series Axle is manufactured to a very high standard of beam engineering. The beam material is heat treated to provide an excellent yield strength whilst maintaining a good ductility.

The carbon equivalent of the beam material is controlled to ensure that pre-heating is not necessary when welding per the provisions of BS

5135.

It is advisable to have ArvinMeritor Engineering Department review the application of any welded bracketry if not previously approved.

The Beam Spindles are forged and heat treated to high strength.

Quality is built-in; the whole process is self monitoring with 100% checks of critical dimensions.

All ROR beams are manufactured to ensure the beam is straight and in line. Some slight distortion will occur when spring seats are welded to the beam but in general this is negligible. If cambered beams are required – these must be ordered specially.

AIR CHAMBER BRACKETS AND CAM BRACKETS

All Mark III beams come equipped with air chamber brackets and cam brackets welded in the correct position to ensure brake actuators operate in the optimum way. Replacement beams are normally supplied without air chamber brackets or spring seats.

SPRING SEATS AND AIR SUSPENSION AXLE

ADAPTERS

ArvinMeritor can supply axles with the above components welded to individual customer requirements.

ANTI-LOCK OPTIONS

Axles can be ordered with anti-lock sensor equipment already installed and tested.

BRAKING

ArvinMeritor offers S cam brakes in three diameters – 420mm diameter as standard available in three widths, 350 and 310mm diameter for low loader applications. The brake design incorporates

ROR patented quick change brake shoes. The 380mm diameter

Stopmaster is also available.

ROR’s Mark III axles are fitted with non-asbestos brake linings.

(Effective from 1st January 1992.) Materials are capable of meeting

UK/EEC braking regulations.

As a general guide, ArvinMeritor recommends:-

TANDEM AXLE TRAILER (Normal Use)

TRI-AXLE TRAILER (Normal Use)

TANDEM AXLE TRAILER (Heavy Duty Use)

420×180 brakes

420×180 brakes

420×220 brakes

BRAKE SHOES

ROR quick-change design shoe is accurately produced by manufacturing processes ensuring all shoes are capable of being relined several times. When relined with the ROR original part the necessity to machine the linings on the axle is eliminated.

The anchor pin and roller areas are induction hardened to prevent wear.

Each shoe is coated with a rust inhibiting finish.

Every ROR shoe is marked with an ROR logo – look for this guarantee to avoid being the recipient of non-genuine lower quality shoes.

For TM Series Axles fitted with the option of Q+ brake assemblies, refer to Axle & Brake Service Manual, LM Series.

ANCHOR PINS AND BUSHES

The Mark III axle has new sealed anchor pins with indented greased bronze bushes. This unique feature keeps the pin working, providing consistent brake performance. The ‘O’ ring seals keep contaminants away from the bush area. From June 1991 all axles using 420mm brakes have a fabricated anchor bracket which has a stainless steel anchor pin bush.

CAMSHAFTS – CAMSHAFT BUSHES & SPHERICAL

BEARING ASSEMBLIES

The Mark III axle camshaft is an induction hardened one piece forging with an SAE 10 spline. It runs in bushes that are grease packed. The cam bush is bronze whilst the spherical bearing is glass-filled nylon encased in a heavy gauge steel housing. From June 1991 axles with

420 dia brakes have used a pressed steel anchor bracket with a bolton spherical bearing at the cam head end of the camshaft.

SEALS

All ROR axles contain unitized seals. These seals are suitable for either grease filled or oil filled operation. Low Loader axles use special high temperature synthetic seals to prevent leakage even when operating at elevated temperatures.

HUBS

Hubs are normally grease filled but are available oil-filled on request.

HUBODOMETERS

Available on request. Specify tyre size and Kilometers or Miles.

SLACK ADJUSTERS

ArvinMeritor will supply their own automatic slack adjuster on request.

RUBBER SEALING

From June 1991 all axles with 420mm brakes have camshaft rubber seals fitted as standard. For other brake sizes the camshaft sealing kit is available as an option.

7

TM Service

Introduction to ROR DX195

Disc Brake

The ROR DX195 Air Disc Brake is one of a family of modular high performance, low weight, high efficiency brakes designed for Trailers,

Trucks, Coaches, Buses and other Commercial vehicles.

The brake has a cast caliper, which straddles the brake rotor and houses two lining pads. Clamping force is produced by a standard industry air chamber, amplified via a high efficiency shallow throw eccentric and balance beam assembly.

The caliper is carried on a saddle which is a fixed support bolted to a torque plate on the axle beam.

Equalised clamping action on the inner and outer pads is generated by allowing the caliper to “float” on the two slide pins fixed to the saddle.

Clamping force created by the primary actuation is applied to the inner pad, which forces it into contact with the rotor. Reactive force through the caliper body applies equal clamping force to the outer “Fixed” pad.

The slide pins also allow the caliper to freely position itself on the saddle to compensate for the reduction in lining pad thickness due to wear.

Lining wear would result in correspondingly longer actuation lever throw and excessive chamber stroke. To eliminate the problem, the brake incorporates an inbuilt automatic adjustment mechanism.

The auto-adjuster operates on each clamping action to sense excessive pad-rotor clearance, and reduces excessive clearance by a fixed proportion with each actuation.

For brake set up and new lining installation, the brake incorporates provision for manual adjustment, easily made using a standard

Hexagon key.

8

TM Service

Axle Installation

INTRODUCTION

The following notes and recommendations are offered as a guide to the trailer manufacturer and service engineer. They are based on experience gained from both the manufacture and the servicing of single and multiple axle installations.

STRESSES ON AXLE BEAMS

The stresses on the axle beam under the load take two forms. The upper portion of the beam is subjected to a COMPRESSION stress equal to the TENSION stress of the lower portion. Along the beam centre is a zone of minimum stress, often named the neutral stress zone area.

Fig. 1 is a simplified sketch of the transverse section of a tubular axle and spring showing these three zones. Fig. 2 is a graphic representation of the degree of stress in the wall of the tube when the beam is under load.

When an air suspension is assembled to the axle beam of a design which uses the beam as a torsional member of the air suspension, then an additional allowance must be added to determine overall beam strength. In this application beam strength is composed of maximum load, air suspension torsional stress and braking stress. In general the

22,500 Series axle beam should be applied as a minimum rating.

ArvinMeritor Engineering should be contacted for written approval of application.

The length of the arrows “X” represents the amount of stress at a given point. From this illustration it is evident that the two opposite stresses diminish as the horizontal centre line is approached. The stress imparted by the action of braking is taken into consideration in rating axle capacity. The axle beam strength is computed by adding together the maximum load and braking stress to which the beam will be subjected. A reasonable allowance of both is then added as a safety factor.

When the axle beam is suddenly relieved of its load and torsional stresses, then torsion, compression and brake stresses are momentarily relaxed. These stresses are re-applied and reversed many times during normal axle life. For this reason, the steel from which the beam is manufactured must have certain qualities of ductility which will permit it to absorb shock, and to flex whilst retaining its calculated strength.

COMPRESSION

STRESS

NEUTRAL STRESS

AREA

TENSION STRESS

FIG. 1

X

X

X

X

FIG. 2

HOW WELDING AFFECTS BEAM MATERIAL

All welds made on the beam create, in effect, an extreme local heat treatment. The heat generated by the weld causes the material immediately adjacent to the weld to become hardened, substituting the undesirable characteristic of brittleness for the original and desirable quality of ductility. This small hardened area becomes the weakest part of the tube creating a notch effect.

Since the same characteristics of relative stress apply in both cases it can be seen that the loss of strength at the weld area can cause failure. The notch can be at the bottom of the beam as well as at the top. Either case is at the maximum stress location.

Some welding tips to minimise the notch effect:

1. Make all “tack” welds at least one inch long.

2. Keep the number of tack welds to a minimum – if possible clamp the bracket tightly to the beam and eliminate tack welds.

3. If more than one bead of weld is required make the second run

(third etc) runs with different start points and BEFORE the first run cools down (descaling between runs of course).

4. Remove oil, and if possible paint from surfaces to be joined.

RECOMMENDED LOCATION OF WELDS

Fig. 3 illustrates the recommended location of the weld fillet for round beams. All welds should be located in the area of minimum stress. The direction of welding should be as near the horizontal as possible.

Welding around the corners of brackets or spring seats should be avoided. It is important that all welds should be excluded from an area of 50º of either side of the bottom vertical centre line of the beam.

Avoid welds of a circumferential nature on the lower half of the beam.

Where the brackets fit down the side of the beam they should have a corner radius of approximately 1” (25mm). The purpose of this radius is to avoid local concentration of stress.

The illustrations show the recommended weld location for the various parts to be attached to the axle beam. None of these parts has been welded to the beam at points of maximum stress.

The welding rod used should meet BS 639 and BS 1719 (British

Standard) specification. They should not be broken at the end of the fillet, instead the electrode should be “backed-up” to fill the crater that would otherwise remain.

9

TM Service

Use the voltage and amperage recommended by the electrode manufacturers. This will provide the best fusion and strongest weld and will minimise the detrimental side effects such as localised hardening and residual stress. Deposit the required amount of metal with the least number of passes practicable – one pass to be preferred. If a second pass is required first thoroughly clean the weld.

MOST IMPORTANT

1. Do not test the arc on the axle beam or springs.

2. Fillet welds up to 12mm (1⁄2”) can be used on round axle beams and the attachment should fit as close as possible to avoid excessive welding – minimum recommended fitted weld 8mm

(5⁄16”) where practicable. It is important to remove all scale in fillet welds prior to painting. If this is not adhered to it will precipitate corrosion in these important weld areas.

MIN

50°

50°

MIN

3.75” (95mm)

NO WELD

NO WELD

MAX

WELD

AREA

FIG. 3

10

TM Service

TM Axle Maintenance Schedule

SERVICE ROUTINE

TM – Disc & Drum

CHECK BRAKE ADJUSTMENT AND

CHECK WHEEL NUT TORQUES

TM – Drum

LUBRICATE CAMSHAFT BEARINGS

CHECK BRAKE ADJUSTMENT

CHECK OIL LEVEL (OIL FILLED HUBS)

TM – Drum

BRAKE INSPECTION & SERVICE

TM – Disc

BRAKE INSPECTION & SERVICE

TM – Disc & Drum

HUB AND BEARING INSPECTION:

INCLUDING OIL SEAL REPLACEMENT,

HUB CAP GASKET REPLACEMENT AND

HUB OIL RENEWAL (WHERE APPLICABLE)

TM – Disc & Drum

MAJOR HUB SERVICE

FREQUENCY

• Before entering service.

• After 150 km.

• After 1500 km.

• Every 3 months.

• After any wheel fixing removal.

• After any brake service.

• Recommended maximum at 3 monthly intervals.

Note: If other than ROR Brake Lubricant Total Fina is used or where vehicles are in contact with severe abrasives a max of 6 week interval necessary.

• Linings should be inspected every 6 weeks or 25,000 kms and must be replaced as an axle set if worn down to the wear indicator (8mm).

Full stripdown should be prior to 2nd annual test or at 1st reline, whichever is soonest.

THEN

Annually or at every subsequent brake reline. Whichever is most frequent.

• Pads, caliper and rotor should be inspected every 50,000 kms or

3 months. Pads must be replaced when worn to a minimum lining thickness of 3mm. Always replace pads as an axle set.

At intervals of 100,000 kms, or every 6 months, (preferably when changing pads), the opportunity should be taken to remove any accumulations of wear debris and rust from the edge of the rotor, and from the pad location points in the caliper. Check also condition and location of sealing boots.

The above service intervals are recommended maximums under normal operating conditions. Unusual ambient temperatures or adverse operating conditions (e.g. dusty atmospheres or severe gradients) will require more frequent service intervals. It is the responsibility of the vehicle operator to establish these intervals.

• Whenever hubs are removed from axle.

• Annually after 1st major hub overhaul.

• If a problem is found during inspection.

• Prior to 2nd annual test or after 200,000 km, whichever occurs first.

THEN

Annually or subsequent 100,000 km intervals, whichever is most frequent.

11

TM Service

Technical Data Tables

TABLE 1:

FASTENER TORQUE VALUES – DRUM/DISC BRAKE

Hub cap – grease . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-30 Nm

Hub cap – oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25-30 Nm

Dust covers – forged A/Bkt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-30 Nm

Dust covers – pressed A/Bkt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50-60 Nm

Spherical bearing (spline end) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50-60 Nm

Spherical bearing (cam head end) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50-60 Nm

ABS sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.5-11 Nm

ABS exciter ring (310-350 brakes) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7.5-11 Nm

Axle adjustment nut . . . . . . . . . . . . . . . . . . . . . .Refer to Setting Procedure, Section 3.11

Axle lock nut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .350-375 Nm

TABLE 2:

FASTENER TORQUE VALUES – DISC BRAKE ONLY

Rotor flange bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230/270 Nm

Caliper retaining bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280/320 Nm

Blanking plug adjuster access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10/17 Nm

Lever clamp bolt/nut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31/37 Nm

Air chamber nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175-200 Nm

TABLE 3:

RECOMMENDED LUBRICANTS

Manufacturer

ROR Hub Grease

Shell

Mobil

Castrol

Texaco

Total

B.P.

Esso

Silkoline

Eurol

Axel Christiernsson

Fina

SKF

GB Lubricants

Grease Filled Hub

Blue Lithium EP2

Shell Calithia EP2T

Shell Alvania EP (LF)2

Mobilux EP2

Spheerol EPL2

Multifak EP2

Multis EP2

L.S. EP2

Beacon EP2

Silkoline G62

Universalfett EP2

Lithac 162EP

Marson EPL2

LGEP2

GB Lithium EP2

Brake Components and Camshaft Bearings:

ROR Brake Lubricant – (Total Fina CERAN WRC2)

Spindle Bearing Journal:

Optimol Optimoly White Paste T

Oil Filled Hub

Spirax EP90

Mobilube GX90

Castrol Hypoy EP90

Multigear EP85W/90

Total EP90

Gear Oil 90EP

GX 85/90

TABLE 4:

HUB & BEARING GREASE FILL VOLUMES

Hub Cavity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200-250 gm

Inner Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45-50 gm

Outer Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45-50 gm

Hub Cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Nil

12

TM Service

Section 1

TM Drum Brake Service

13

TM Service

SECTION 1

Major Brake Service

Braking can be divided into sub-systems each requiring maintenance to ensure correct performance:

The Air System

The Foundation Brakes

The Brake Actuation

The Load Sensing/Anti-Lock System

The Air System

Since April 1983 it has been a legal requirement to fit air pressure test points at the following points in the air system.

1) Each side of the load sensing valve.

2) The slowest brake actuator to respond when the brakes are applied.

In addition to these some trailer manufacturers fit a test point close to the air reservoir.

With the aid of an air pressure test gauge (21214100) and connecting hose (21214101) the air pressure can be checked at the test points.

The air pressure, measured at the test point close to one of the brake chambers, should reach 6.5 to 7.5 bar with maximum application of the tractor brakes. If a load sensing valve is fitted it will be necessary to either have the trailer loaded to capacity or disconnect the load sensing valve linkage at the axle.

If the pressure reading is not reached then disconnect the trailer’s yellow line and with a suitable coupling measure the air pressure at the yellow coupling. If there is ample pressure at this point the fault lies in the trailer air system and must be traced and rectified.

The Foundation Brakes

420mm, 350mm, 310mm.

The Brake Actuation

1.1 REMOVING BRAKE SHOES – SERIES III

Using a screwdriver between brake shoe gussets ease out both retainer springs (Fig. 1).

Take hold of bottom shoe pulling it off the anchor pin, tilt forward and lift off camshaft head (Fig. 2).

Remove brake return spring.

Lift off top shoe.

1.2 INSPECTION

Inspect brake anchor pins and bushes for wear.

For Mark III anchor pins – check and replace ‘O’ rings as required.

Inspect cam rollers. If removed from the brake shoe, the roller-retainer clip must be replaced by a new unit.

FIG. 1

FIG. 2

Inspect brake shoes for wear at anchor pin and cam roller at location point.

Prior to re-assembly the following parts should be lightly coated with

ROR high perfomance brake lubricant.

(i) Bores of Camshaft Bushes.

(ii) Cam Rollers and camshaft head profile.

(iii) Brake Anchor Pin bearing surfaces and holes in Brake Shoe

Gussets.

Ensure pressure greasing is carried out to the four grease nipples on each axle. Use ROR high perfomance brake lubricant.

Check brake drums for cracks, scoring or other damage.

Replace all worn parts with genuine ROR parts. The use of non-Original

ROR parts will nullify all warranty and may substantially reduce service life.

14

TM Service

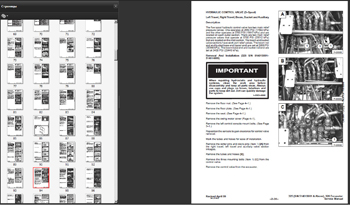

1.3 RE-FITTING BRAKE SHOES 420MM & 350MM

Fit spring pins and rollers, lubricate ‘D’ holes with ROR high perfomance brake lubricant (Fig. 3).

Attach bottom shoe to spring, push down and in towards cam head, and onto anchor pin (Fig. 6).

LUBRICATE

FIG. 3

Fit anchor pins applying ROR high perfomance brake lubricant inside the anchor pin bushes (Fig. 4).

Fit both retaining springs to top shoe, with screwdriver pull spring down and ease into bottom shoe (Fig. 7).

FIG. 6

Fit top shoe and hang return spring from pin (Fig. 5).

FIG. 4

FIG. 7

IMPORTANT:

If anchor pin bushes require replacement, ArvinMeritor recommends fitting the new bronze indented bushes 21016666A sealed anchor pins

No. 21205193G and ‘O’ rings No. 21220668 (see page 20). The use of tool 21205456 is recommended as demonstrated in Fig. 8.

FIG. 5 FIG. 8

15

TM Service

1.4 RE-FITTING BRAKE SHOES 310MM

Fit spring pins and cam rollers, lubricate ‘D’ holes with ROR high perfomance brake lubricant.

Fit top shoe and hang return spring from pin (Fig. 9).

Fit both retaining springs to both shoes (Fig. 11).

FIG. 9

Attach bottom shoe to spring, push down and in towards cam head

(Fig. 10).

Lift top shoe and fit anchor pin.

Lever down bottom shoe and fit anchor pin – do not over stretch springs (Fig. 12).

FIG. 11

FIG. 12

FIG. 10

16

TM Service

1.5 REFITTING BRAKE SHOES 420MM WITH

PRESSED STEEL ANCHOR BRACKET

Lubricate as on page 15 (Fig. 3 & 4).

Brake shoe fitted with rolled roll pin (Fig. 13).

Anchor bracket with anchor pins fitted (Fig. 14).

Offer both brake shoes together to anchor bracket (Fig. 15).

Lift lower shoe into place (Fig. 16).

Fit retainer spring (Fig. 17).

FIG. 13

FIG. 14

FIG. 15

FIG. 16

FIG. 17

17

TM Service

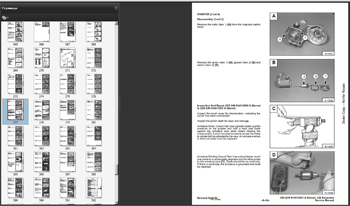

1.6 CAMSHAFT AND BUSHINGS

1.6.1 REMOVAL

With brake shoes removed as described in previous section.

Remove slack adjuster.

Remove circlip adjacent to brake anchor bracket and withdraw camshaft. The circlip will not be fully removable until the splined end is clear of the spherical bearing.

Inspect nylon bushes or bronze bush in the anchor bracket. Remove bushes if worn.

Inspect spherical bearing for serviceability. This is a sealed assembly containing no user serviceable components.

Unscrew the securing bolts and remove the spherical bearing.

1.6.2 REPLACEMENT CAMSHAFTS

Stepped Camshafts

In use on production axles with 350 dia. brakes from October 1984 and axles fitted with 420 and 394 dia. brakes from January 1985, the stepped camshaft is stiffer in torsion, making for improved brake times and reduced air consumption, both very important under EEC/ECE braking regulations, furthermore, it is fitted as standard with a thin walled phosphor bronze bush in the anchor bracket, having superior wear and temperature characteristics to the P.E.S. bushes used with earlier designs of camshafts.

On the earlier design of camshaft (Fig. 18) both the cam and spherical bearing journals were the same diameter, with the shaft machined its full length. This camshaft was used in conjunction with two nylon cam bushes or single bronze cambush having integral ‘O’ ring seals.

The cam journal has been increased in diameter on the latest ‘stepped’ cam design (Fig. 19) specifically for use with a one piece phosphor bronze cam bush. In addition the camshaft now carries the ‘O’ ring seals (part number 21016721). This camshaft is not machined along its length with one exception, camshafts for use with the 310 x 190 brake when used with Neway air suspension. The camshaft number suffixed with an L or R for left and right hand is stamped into the shaft.

The new design can and should be used in preference to the earlier design when replacement becomes necessary. Only the phosphor bronze cam bush (part number 21209990) can be used with the new camshaft, this bush replacing the two nylon bushes.

In order to fit stepped camshafts in axles as a replacement for the earlier design of camshaft it will be necessary to use the following parts.

Camshaft bush kits containing these items are available.

Kit No. – AXL 131

1 ⁄

2 axle set suitable for T, U, TH and TM Axles pre May 1974.

Kit No. – AXL 132

1 ⁄

2 axle set suitable for TH and TM Axles after May 1974.

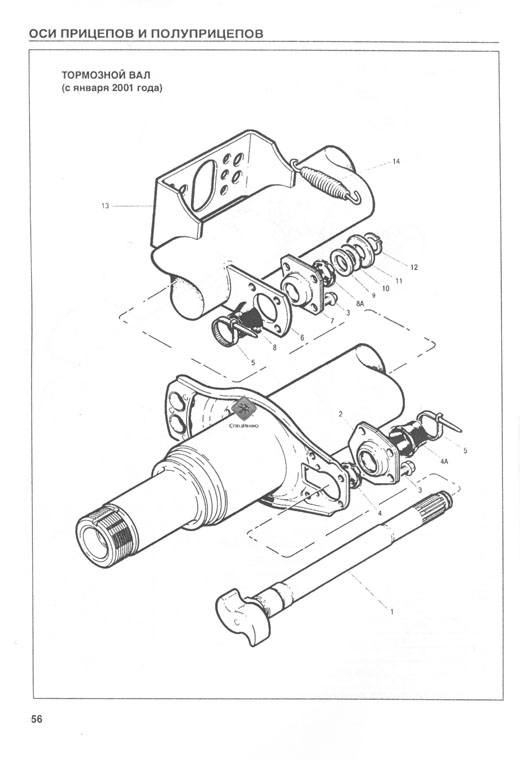

Fig. 20 shows the rolled spline camshaft used with 420mm brakes on axles produced from 1st January 1992 it has the pressed steel anchor braket with a bolt-on cam head spherical bearing.

This is identified by the snap ring groove in the centre of the cam head bearing journal.

Similar rolled spline camshafts without the snap ring groove were introduced on axles with 310mm and 350mm brakes.

FIG. 18

FIG. 19

FIG. 20

18

TM Service

REMOVAL OF THE 420mm CAMSHAFT

Having removed the slack adjuster the camshaft is released from the snap ring by tapping the spline end with a suitable soft faced hammer.

It is necessary for the phosphor bronze bush to be a tight press fit into the anchor bracket. Should the anchor bracket be worn (see Fig. 21) it will be necessary to machine the cam bore to accommodate the oversize phosphor bronze cam bush (part number 21213259). If it is necessary to fit oversize cam bushes the anchor bracket reamer tool should be used and is available as follows:

Part Number

21206670/1

21206670/2

21206670/4

21206670/5

21209271/1

21218572/1

21209272/1

21206670/3

Description

Cutter

Shaft

Sleeve

Pins (two required)

Jig for 310mm diameter brakes

Jig for 350mm diameter brakes

Jig for 394mm diameter brakes

Jig for 420mm diameter brakes

RECOMMENDED NOT RECOMMENDED

ArvinMeritor recommends replacing the plastic bushes with phosphor bronze. These bushes are available in four sizes.

PHOSPHOR BRONZE BUSHES

21204703 – old type camshafts

21209990 – new type “stepped” camshafts

21209623 – oversize bush for old type camshaft bores after reaming

21213259 – oversize bush for stepped camshaft

IMPORTANT:

When fitting cam bush the cross holes must be towards the cam head, as shown (Fig. 23).

FIG. 21

1.6.3 REFITTING

If it is necessary to replace the cam bushings, this can be easily done using special tool 21219919 (Fig. 22). Cam bush must be inserted from camhead side of anchor bracket.

FIG. 23

The camhead spherical bearing (Fig. 24) used on axles after June ‘91 with the pressed steel anchor bracket applies to 420mm brakes only.

Refit or replace bearing leaving bolts loose, fit the camshaft ensuring the snap ring has locked into the groove in the bearing journal. Rotate the camshaft to ensure free operation, tighten bearing bolts to the torque specified in table 1 page 12.

FIG. 22

FIG. 24

19

TM Service

1.8 ANCHOR PINS AND BUSHES

The Mark III Axle has a sealed anchor pin system. The anchor pin has two oil and heat resistant ‘O’ rings as shown in Fig. 26 and is coated with Dacromet – a zinc rich coating with excellent corrosion resistance.

The pin and ‘O’ rings are fitted into an indented bronze bush. The indents are designed to hold additional grease to lubricate the anchor pin over an extended period. An additional benefit is the ease of removing anchor pins whenever a major overhaul is carried out.

FIG. 25

Refit or replace spherical bearing leaving bolts loose. ArvinMeritor offers a new Mark III spherical bearing (Part No. 15213430) which retains its grease pack and is more durable (Fig. 25).

Fit the ‘O’ rings onto the camshaft (with old type cam fit ‘O’ ring into bush). Slide the cam head washer onto the camshaft. Slide the camshaft through the anchor bracket but not through the spherical bearing at this stage. Fit bevel washer (concave side facing anchor bracket) and circlip onto the shaft. Slide the camshaft through the spherical bearing simultaneously pushing the bevel washer and circlip up to the anchor bracket. Ensure the circlip is fitted correctly into the groove.

Rotate the cam to ensure correct alignment and free operation. Tighten the spherical bearing bolts or Powerlok screws to 50-60 Nm (30 lbf ft).

Rotate camshaft by hand to check that it moves freely. If it does not slacken spherical bearing bolts, realign camshaft and retighten bolts.

Check again for free rotation. Grease pack the spherical bearings through their grease nipples with Total Extemp or equivalent, until grease exudes from body.

1.7 SPRINGS

The return spring is an essential component for correct brake function.

It should be examined for any relaxation in the coils or any wear or notching in the hooks.

The retainer springs keep the shoes in contact with the anchorpins.

They should also be inspected for any relaxation and hook damage.

IMPORTANT:

It is strongly recommended that return and retainer springs are renewed as a matter of course during annual brake servicing.

FIG. 26

The sealed anchor pins and indented bushes are available in kit form from your ArvinMeritor Stockist and are interchangeable with earlier designs of anchor pin bushes used with quick change brake shoes.

Qty/Brake

2

4

2

Description

Anchor Pin

‘O’ Ring

Bush

Part Number

21205193G

21220668

21016666A

From June ‘91 axles with 420mm brake have a pressed steel anchor bracket which uses a stainless steel bush part number 21221028.

1.9 RELINING BRAKE SHOES

It is recommended that the correct lining be used to maintain the EEC performance levels designed and approved for your vehicle. A change in lining may substantially change the braking performance and could render the vehicle illegal. ROR linings are precisely contoured to fit ROR shoes and “bed-in” with the least number of stops.

The ROR shoe is coated with a rust inhibiting paint. When relining the shoe platform should be cleaned and recoated with a rust-proof primer.

The hardened anchor pin and cam roller location points must be inspected for damage. Renew shoe if these areas are damaged.

Part numbers for various components to suit the different camshafts are given in the following table.

Description

Cam Bush ‘O’ Ring

Cam Head Washer

Bevel Washer

Circlip

Qty/

Brake

1

1

2

2

1

Plastic Cam Bushes

OLD CAMSHAFT

Part No.

Qty/

Brake

1 21016720

21016721

21006593

21006624

99070006

1

1

1

Bronze Bush

Part No.

21016721

21006593

21006624

99070006

Qty/

Brake

2

NEW STEPPED

CAMSHAFT

Part No.

21016721

1

1

1

21202756

21202757

99070011

20

TM Service

The ROR patented series III shoe is capable of many relines. Make certain your stockist is giving you genuine ROR shoes when you exchange the original shoes. Look for the ROR logo and patent number on every shoe gusset.

1.10 BRAKE DRUMS

If, upon inspection, drums are crazed and cracked it is an indication that the brake has been running excessively hot. Fitting new drums will not correct the cause of the problem. The following list are possible causes: a. The towing vehicle is fitted with a predominance valve and it is set to make the trailer brakes do most of the check braking.

b. Badly set or malfunctioning automatic slack adjuster.

c. Use of trailer brakes ONLY to check vehicle speed during long descents.

d. The use of a non approved lining.

e. Malfunction in air actuation system (see following Section).

In all cases the use of pressure test gauges at each test point will enable you to ascertain what is happening.

Light crazing of the braking surface indicates that the drum has been overheated but does not render the drum unserviceable. However brake drums with any other damage e.g. rivet grooving, must be rectified or replaced immediately.

Re-machining of drums is permissible if surface damage is slight with the exception of the 310mm brake drum which must always be replaced. The maximum bore diameters that the drums can be machined to are:

420 – 423mm

350 – 354mm

310 – No re-machining.

Oversize cam rollers (21006610A) must be used in conjunction with remachined drums.

Drums should be clean and dry before refitting. Care should be taken with loose dust as stated in The Garage Workers’ Asbestos Code (Page

45). Replacement brake drums from ArvinMeritor are supplied with a protective coating that does not need removing before fitting.

1.11 DUST COVERS

Dust Covers are provided with inspection apertures to assess lining wear. These apertures are closed with rubber plugs which must always be replaced.

Pre June 91 Dust Covers are fixed with six M8 x 1.25 tightened to the torque specified in table 1 page 12. If additional sealing is required –

ArvinMeritor offers an optional rubber sealing kit (Fig. 27).

Included:

1. U-Shaped moulded sealing strip to close the Dust Cover around the

Cam end of the Anchor Bracket.

2. Rubber Collar to close the end of the Camshaft bush (retained with a cable tie).

3. Outer rubber collar to close the Spherical bearing assembly

(retained with a cable tie).

FIG. 27

4. Inner rubber collar to close the Spherical bearing assembly (retained by the Slack Adjuster).

From June ‘91 axles fitted with pressed steel anchor brackets, 420mm brakes only, have dust covers retained by four M10 screws tightened to the torque specified in table 1, page 12.

From August ’97 TM Series axles with 420 diameter brakes are fitted with the “LM style” dust cover.

To refit with the camshaft removed: Ensure the filler plate locating tag is engaged around the end of the anchor bracket and secure with two

M10 screws. Tighten to the torque specified in table 1, page 12.

Fit the one piece dust cover ensuring it is correctly located onto the two filler plate studs. Tighten the two M10 screws and the two M8 nuts to the torque values specified in table 1, page 12.

If the camshaft is to be refitted prior to the dust cover: Clean the full length of the camshaft prior to assembly. Slide the under-head rubber boot onto the camshaft, lightly grease the cam head journal and slide the cam head bearing onto the camshaft towards the cam head until the spring clip is ready to engage in the groove (light resistance will be felt).

Slide the inner rubber boots, cover plate and spline end spherical bearing onto the camshaft.

Ensure the faces of the anchor bracket and camshaft bracket are clean.

Pass the cam head through the key hole slot in the brake anchor bracket and slide the spline end through the cam bracket slot. Fasten both camshaft bearings in position using the M10 screws. DO NOT

FULLY TIGHTEN THE BEARING SECURING SCREWS UNTIL THE BRAKE

SHOES ARE RE-ASSEMBLED.

Ensure the filler plate locating tag is engaged around the end of the anchor bracket and secure with two M10 screws. Tighten to the torque specified in table 1, page 12.

Fit the one piece dust cover ensuring it is correctly located onto the two filler plate studs. Tighten the two M10 screws and the two M8 nuts to the torque values specified in table 1, page 12.

21

TM Service

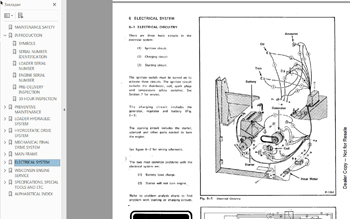

1.12 LOAD SENSING AND ANTI-LOCK SYSTEMS

1.12.1 GENERAL

All trailers manufactured to EEC Regulations are fitted with either load sensing, anti-lock, or both systems.

Although the legislation in the UK requires that only one of the above systems is fitted ArvinMeritor recommends the use of load sensing when anti-lock is fitted for two reasons:

1. to achieve a good brake balance unladen when used with load sensed towing vehicles.

2. to minimise the risk of trailer swing should the trailer antilock system fail and revert to full braking.

Many towing vehicles are fitted with “predominance” valves to boost the trailer coupling head pressure compared to the towing vehicle’s brake pressure: some trailer brake valves also incorporate this feature.

Fitting load sensing to the trailer will minimise the adverse effects of

too much predominance, especially at low brake pressures with an unladen or lightly laden trailer.

1.12.2 LOAD SENSING SYSTEMS

The basic purpose of load sensing is to reduce the likelihood of wheels locking with different loads being carried.

The load sensing valve adjusts the air pressure according to how much weight is being carried.

All new trailers fitted with load sensing are also fitted with a plate showing the setting pressures which correspond to the laden and unladen weights.

The load sensing valve setting should be checked periodically and corrections made as necessary.

Air pressure test points are provided in the brake lines each side of the load sensing valve so that both the input and output pressures can be measured, the test point on the output side of the load sensing valve may be located close to one of the brake actuators.

With the aid of test gauges connected to both test points the air pressures can be measured and checked against the values shown on the load sensing data plate for the corresponding axle weights.

When an annual Government inspection is performed and braking is measured against the axle design weights it is important that the load sensing valve is in the fully laden position during the test.

Normally in the fully laden position the load sensing valve output pressure will equal the input pressure which on a full brake application should be between 6.5 and 7.5 bar.

To achieve this the trailer must be fully loaded. If not, the load sensing valve must be disconnected which should only be done at the test station and must be reconnected before leaving the test station.

Whenever the trailer is tested on the ‘raised’ rollers it is essential that the load sensing valve is disconnected and set fully open: i.e. laden to ensure that full brake pressure is achieved for all axles.

Always disconnect the load sensing valve linkage at the axle and not at the valve control arm (see Fig. 28).

When testing an air suspended trailer on raised rollers, it is not readily possible to disconnect an air suspension load sensing valve. Instead, a fitting can be fabricated to accept both the input and output brake lines thus by-passing the load sensing valve.

22

FIG. 28

1.12.3 ANTI-LOCK SYSTEMS

Unlike load sensing systems that adjust the brake pressure proportional to the load being carried anti-lock systems monitor wheel speed and only modulate that brake pressure when the system detects that a sensed wheel is about to lock.

All anti-lock systems have sensors and exciter rings fitted to measure the speed of two or more wheels.

If the hub and drum are removed from an axle fitted with sensors it is important to remember to push the sensor fully outwards so that the exciter ring will push it back when the hub and drum are re-fitted. This will ensure that the correct gap is re-set between the sensor and exciter ring. Refer to page 36.

All anti-lock systems incorporate a warning light which should extinguish when the trailer is in motion. If it fails to do so then a fault has developed and the system must be thoroughly checked by trained personnel using specialised test equipment. Contact the supplier of your anti-lock equipment direct.

It should be possible to achieve between 6.5 and 7.5 bar pressure in the trailer actuators on a full brake application which can be checked with the aid of a test gauge connected to the test point close to one of the brake actuators.

In addition anti-lock systems are automatically switched off at very low vehicle speeds and should not be active during brake roller tests (3-5 mph).

TM Service

Section 2

TM Disc Brake Service

23

TM Service

SECTION 2

Brake and Servicing

2.1 NOMENCLATURE

Caliper Slide Pin

Adjuster Barrel

Manual Adjustment Port

Block

Over-Ride Clutch

Actuation Eccentric

Load Plate

Adjuster Barrel Gear

Adjuster Cassette

Adjuster Bevel Gear

One-Way Clutch

Spindle Screw

FIG. 1

Eccentricity

FIG. 3

All radial loads in the eccentric shaft and block are taken through precision needle roller assemblies maintaining an efficiency of around

97%, due to the complete absence of any sliding friction in the system.

Clamping:

The caliper assembly is free to “float” on the slide pins attached to the fixed saddle. Clamping force exerted on the inner pad by the eccentric action on the balance beam creates an equal and opposite reactive force in the caliper body (Fig. 4).

This reaction provides the clamping force for the outer pad, ensuring that both pads are loaded onto the rotor with an equal force.

2.2 OPERATING PRINCIPLES:

Actuation:

Linear force from the Air Chamber is translated by lever action to rotary torque on the main actuation shaft and eccentric.

The eccentric is located in a balance beam (actuation block) and rotation of the shaft causes the block to “lift” or travel forward (Fig. 2).

Bridge

FIG. 4

Linear Input Force

FIG. 2

24

TM Service

2.3 MAIN AUTO-ADJUST PARTS

Input shaft & eccentric

Main Block

Bevel gear

Adjuster gear and barrel

Cassette

(adjuster gear train)

Torque takes up clearance

Spindle Screw

Adjustment gear segment

Load Plate

FIG. 5

2.4 AUTOMATIC ADJUSTMENT MECHANISM

Step 1:

• Actuating lever moves and eccentric shaft rotates.

• Block “lifts”, begins to move forward, carrying the adjuster sleeves and pistons (Fig. 6).

• Eccentric shaft turns within the gear plate segment – taking up clearance between tongue and shoulders (Fig. 7).

FIG. 7

NOTE:

This clearance governs the final pad/rotor running clearance, and is specific to each brake. It is vital that the correct (original) gear plate segment is retained matched to the eccentric shaft. Use of an unmatched gear plate segment, will alter the pad rotor running clearances perhaps outside of permissible limits.

STEP 2:

• Gear segment begins to turn.

• Main adjuster gear turns, in mesh with lower gear segment.

• Main adjuster drives through the one way clutch and the over-ride clutch to turn the central gear.

• Complete gear train turns, in mesh with the central gear. The adjuster barrels begin to turn.

At this stage one of two conditions will be encountered: SEE STEP 3A

OR 3B.

FIG. 6

25

TM Service

STEP 3A:

No Adjustment is required as clearance is correct

• At the point when the adjusters begin to turn, the pads contact the rotor and clamping force begins to build up.

• The clamping force generates friction in the screw threads between the adjuster sleeves and pistons, and friction under the flanged head of the adjuster sleeves. (Fig. 8).

Clamping Force

• The friction build up prevents further rotation of the adjuster sleeves – instead the over-ride clutch begins to slip. The adjuster drive train is locked by the friction in the system and no adjustment takes place. The main gear turns but does not transmit motion beyond the over-ride clutch into the adjuster train (Fig. 8).

STEP 4

Brakes Released

• When the pressure to the air chamber is relieved – the actuating lever will be retracted. The eccentric shaft and quadrant gear will reverse with the centre gear.

The one way clutch free-wheels preventing reverse transmission into the adjuster gear train and the adjuster sleeves do not move, thus holding the adjustment (Fig. 10).

Friction Build-up

Barrels Stationary

Bevel Gear Turns

Over-Ride Clutch Slips

FIG. 8

• The friction build up prevents rotation of the adjuster sleeves – instead the over-ride clutch begins to slip. The adjuster drive train is locked by the friction in the system and no adjustment takes place.

The main gear turns but does not transmit motion beyond the override clutch into the adjuster train.

STEP 3B

Adjustment is required as clearance is excessive.

• Before the pads contact the rotor, the adjuster sleeves are turned by the gear train. Rotation of the sleeves has the effect of unscrewing the adjuster piston within the sleeves thus increasing the effective length of the pistons and decreasing the travel required (Fig. 9).

Barrels Stationary

Adjustment Barrel Gears

Stationary

Bevel Gear Reverses

One-Way Clutch Slips

(No Gears Turn)

FIG. 10

Damping

• Compression springs ensure that the adjuster train has the necessary amount of predetermined friction, which prevents vibration in service from disturbing the clearance setting (Fig. 11).

Adjustment Plungers

Unscrew

Barrels Rotate

Adjustment Barrel Gears

Turn

Bevel Gear Turns

One-Way Clutch Turns

Gears

FIG. 9

• When the pads contact the rotor a clamping force is generated and this is fed back into the adjuster sleeves and pistons, generating friction in the adjuster screw threads, and friction under the flanged head of the adjuster sleeves. (Fig. 8).

26

Damping Springs

FIG. 11

TM Service

2.5 MANUAL ADJUSTMENT

Under normal operation the automatic adjustment mechanism will maintain correct pad to rotor clearance.

Provision is made for manual adjustment of the brake which may be required under the following conditions:

1) Where the pads cannot be removed due to wear on the rotor – in this case the pads will have to be retracted by back adjusting the brake.

2) Where new pads are to be fitted – it will be necessary to fully retract the adjusters to accommodate full thickness pads.

The brake is manually adjusted by turning one of the adjuster barrels by means of a 6mm standard hexagon key. The gear train will ensure that the other adjuster barrel will be turned by an equal amount.

Access for the hexagon key is gained by removal of the blanking plug

(Fig. 12) in the back plate.

FIG. 12

The adjustment direction depends on the particular installation of the brake – the handing of the eccentric, and the air chamber position.

In general, de-adjustment or “back adjustment” is achieved when the key is turned in the direction which produces load clicks. (This indicates that the torque limiter is working). Turning in the opposite direction will result in a smoother silent action, which will give positive adjustment and reduce pad to rotor clearance (Fig. 13).

NOTE:

Opening the adjusters from fully worn pad condition to fully retracted position requires approximately 20 turns.

CAUTION:

When backing the brake off stop turning the key when resistance is felt. This indicates that the adjuster pistons are fully retracted. Further turning could lock the adjuster pistons in the sleeves and cause damage to the internal components. When this resistance is felt, adjust the brake out 1/4 turn to ensure that Auto Adjustment will take place.

* DO NOT USE AN AIR GUN

2.6 BRAKE INSPECTION AND TROUBLE SHOOTING

WARNING:

Do not work under a vehicle supported only by jacks. Jacks can slip or fall over and cause serious personal injury. Support the vehicle with safety stands, block the wheels to prevent the vehicle from moving.

Inspection Schedules

Inspect the brake according to one of the following schedules. Use the schedule that gives the most frequent inspection.

• The schedule for chassis lubrication used by your fleet.

• The schedule for chassis lubrication recommended by the manufacturer of the chassis.

• At least every 3 months.

• During tyre replacement.

Inspection should include the following:

1. Stroke length: Check the adjusted chamber stroke as follows

(Fig. 14).

a. Measure the distance from the bottom of the air chamber to the centre of the large clevis pin while the brakes are released.

b. Have another person apply the brakes using 80-90 psi of air pressure.

MEASURE ADJUSTED CHAMBER STROKE

Measure this distance

FIG. 13

FIG. 14

NOTE

If the vehicle does not have an application pressure gauge, build tank pressure to 100 psi, shut off the engine, then make and hold a full brake application. This will give 80-90 psi in the air chamber.

27

TM Service

c. Measure the distance from the air chamber to the centre of the large clevis pin while the brakes are applied.

d. The difference between the measurement is the adjusted chamber stroke.

2. Pad wear: The pads must be replaced at or before the amount of pad material reaches a thickness of 2mm.

3. Anti-rattle springs: The pads have anti-rattle springs attached.

Inspect for bent, cracked or broken springs. If springs are damaged, replace with new. Refer to “Pad Removal and Replacement”.

6 Poor stopping power

• Long stopping distances

• Poor driver feel

• High brake pressures

• Lack of normal response

• Vehicle pulls to one side

7 Shimmey or brake pull

Vehicle air systems malfunction

Brakes out of adjustment

Vehicle overload

Contamination on pads

Companion brakes not working properly

Refer to 1, 2 and 6

Rotor run out and thickness variation

4. Seals: Caliper should be replaced if any of the seals are found to be cracked, torn or damaged in any way.

5. Caliper slides freely on slide pins: Clearance between the rotor and the pad should be transferred from the inboard rotor surface to the outboard rotor surface by sliding the caliper back and forth.

6. Disc (Rotor): Inspect the rotor for cracks, deep scores or other damage. Replace the rotor when necessary.

Inspection and Troubleshooting

CONDITION

1 Air Chamber exceeds 50mm maximum stroke requirement at 80 to 90 psi

2 Brake Drag

POSSIBLE CAUSES

Improper initial adjustment or inoperative automatic adjuster

Incorrect pad to rotor clearance

3 Short outboard/inboard pad life

CHECK FOR

Recheck chamber stroke after twenty brake applications.

CORRECTIONS

If the air chamber still overstrokes then replace the caliper/saddle assembly per

Section 2.9

Replace caliper/saddle assembly Minimum stroke at 80-90 psi to be

22mm

Improper initial adjustment

Vehicle air system malfunction

Readjust per Section 2.7

Repair or replace parts as required

Caliper seized or sticking on slide pins

Damaged slide pin seals

Caliper should move back and forth by hand with pads removed

Replace caliper/saddle assembly

4 Short pad life

5 Brake smoking

Refer to 2 and 3

Abusive use of brake system

Rotor surface

Non genuine pads

Vehicle overload

Companion brakes not working properly

High brake temperature

Contamination of pads

Refer to 2 and 3

Driver technique

Refer to 2 and 3

Train drivers

Cracks or heavy heat checking. Refer to Section 2.8

Refer to Section 2.8 for rotor inspection

See GAWR limitations on vehicle I.D.

plate.

Inspect companion vehicles brakes and air systems

Refer to 2, 3 and 4

Grease, oil etc., on pads

Fit ROR pads

Observe vehicle manufacturers load recommendations

Adjust or repair as required

Refer to 2, 3 and 4

Inspect hub seal. Replace as required. Clean rotor and caliper assembly. Replace pads per Section 2.7

Proper air pressure at the chamber inlet

Stroke exceeds 50mm requirement

Have the air system evaluated by a qualified brake system specialist

Replace caliper/saddle assembly.

Refer to Section 2.9

See GAWR limitations on vehicle I.D.

plate

Grease, oil etc., on pads

Observe vehicle manufacturer’s load recommendations

Inspect hub seal and replace pads per

Section 2.7

Adjust or repair as required Inspect companion vehicle brakes and air system

Refer to 1, 2 and 6 Refer to 1, 2 and 6

Replace hub and rotor assembly

28

TM Service

2.7 PAD REMOVAL AND REPLACEMENT

The pads must be replaced at or before the amount of pad materials reaches a thickness of 2mm.

WARNING:

Caution should be exercised in handling both asbestos and nonasbestos materials.

CAUTION:

Replace the pads on both brakes of a single axle, or all six brakes of a triaxle at the same time. If you do not replace all the pads at the same time, poor brake performance may occur.

1. Put blocks in front and behind the wheel so that the vehicle cannot roll.

WARNING:

Do not work under a vehicle supported only by jacks. Jacks can slip or fall over and cause serious personal injury. Support the vehicle with safety stands. Block the wheels to prevent the vehicle from moving.

2. Raise the vehicle enough to get clearance to remove the wheel and tyre. Support the axle with safety stands. Remove the wheel and tyre.

3. Remove the adjuster plug from the air chamber bracket

(Fig. 12).

4. Using a 6mm Allen key, carefully back off the brake.

(Fig. 13 and 14a). CAUTION – Read section 2.5, Manual

Adjustment.

RH BRAKE ASSEMBLY

FIG. 15 FIG. 16

10.Inspect for damaged boots and replace the caliper if boots are

damaged.

11.See Section 2.8 for rotor inspection and instructions.

12.Slide the caliper outboard then install the pad and spring assembly in the outboard side. If pads are to be reused, place the pad marked outboard (in Step 6) back in the outboard position. Take care to prevent the load plate hanging up on the saddle guides.

13.Slide the caliper inboard and install the inboard pad and spring assembly. If pads are to be reused, place the pad marked inboard

(in Step 6) back in the inboard position.

14.Pull down the stabiliser bar compressing the springs and install the stabiliser bar retainer pin and split pin bending its long leg.

15.To adjust the initial caliper clearance, adjust the caliper by reducing the caliper to rotor clearance to zero (See Fig. 14a for the adjusting direction). Make sure that the load plate is in full contact with the pad backing plate. Back-off the brake seven clicks to set the initial clearance.

16.Reinstall the adjuster plug and washer.(Fig. 12).

Tighten to the torque value specified in table 2, page 12.

Increase Clearance

Allen Wrench

Decrease Clearance

RH BRAKE ASSEMBLY

Allen Wrench

Decrease Clearance Increase Clearance

FIG. 14a

5. Remove the stabiliser bar split pin and stabiliser bar retainer pin.

Hinge the stabiliser bar up and out of the way. (Fig. 15 and 16).

6. Lift the inner pad out of the caliper assembly. If these pads are not to be replaced, mark the pads as inboard and outboard (Fig. 17).

7. Slide the caliper outward and remove the outboard pad.

8. Verify that the caliper will slide freely on the slide pins. The caliper can get jammed if moved past its working range. If this occurs use a rubber mallet to get the caliper back to its working range and verify that it will slide freely.

9. Remove any dirt or rust from the pad contact surfaces on the saddle.

FIG. 17

29

TM Service

2.8 ROTOR INSPECTION

Rotors should be examined in situ, whenever the brakes are serviced or new pads are fitted – or immediately if erratic braking performance is noted. The rotor condition should be visually checked for the following surface conditions, and replaced with a new rotor if suspect or defective.

A Surface Crazing (Fig 18a)

Light short random crazing surfaces are normal and acceptable.

B Radial Cracks (Fig 18a)

Short light cracks up to 0.5mm in width and a maximum of 1.0mm in depth are acceptable – providing they do not extend radially across more than 75% of the braking surface.

C Tangential Scoring (Fig 18a)

A series of light circular grooves is normal, and permissible if the maximum depth of the grooves is 0.5mm. Severe grooving indicated that skimming of the rotor is required – providing the minimum thickness of the rotor can be maintained (see skimming). Wear and grooving should be approximately equal on both surfaces. If the wear patterns differ significantly, the brake is not functioning correctly and should be examined.

D Heat Spotted Rotor (Fig 18a)

This condition indicates that the rotor has been subjected to extremely high temperatures that have caused a structural change in the rotor material and have caused the rotor to be more susceptible to cracking.

Rotors may be turned to remove hard raised areas (See skimming). If resurfacing does not remove the spots the rotor must be replaced.

Rotor Run Out

Use a Dial test Indicator (DTI) to check the run-out both axially and radially as in (Fig.

18b).

Axial

Run-out should not exceed 0.3mm over the rotor braking surface when the rotor is turned on properly adjusted wheel bearings. Excessive run-out may be due to incorrect mounting of the hub, fastener torque’s or mal-adjusted bearings.

Radial

Run out should not exceed 0.8mm total indicator reading.

Thickness

Rotor thickness must not vary by more than

0.13mm across any two points of the rotor faces.

Skimming

Resurfacing the rotor is permissible until the minimum thickness is reached 41mm.

Surface finish after machining should be 5 microns maximum.

Max length =

75% of ‘A’

A

C

‘A’

B

FIG. 18b

2.9 CALIPER REMOVAL AND REPLACEMENT

CAUTION:

Note to assist assembly on some axles. The two extreme fixings engage slots on the torque plate. Never leave the caliper with only these two fixings in place. Falling hazard! (Fig. 19a and Fig. 19b).

CAUTION:

Do not used the stabiliser bar for handling purposes. Damage to the bar could result.

D

FIG. 14

➨ ➨

FIG. 19a FIG. 19b

30

TM Service

Removing the caliper assembly: Refer to (Fig. 25)

1. Follow steps 1-7 of the lining change procedures (Section 2.7) to remove the linings.

2. Remove the ‘R’ clip and clevis pin from the lever (Fig. 20).

5. Lift the caliper away from the disc.

Installing the caliper assembly:

1. Lift the caliper over the rotor. Read CAUTION Page 30

Fig. 19a, Fig. 19b if assembly slots exist on the torque plate.

2. Align the bottom caliper bolt holes and hand start one of the inner fasteners, fitted with a hardened washer.

3. Hand start the remaining 5 bolts, starting on the top half of the torque plate.

4. Tighten the six fasteners to the torque value specified in table 2 using a 24mm 1/2” drive square socket. (Fig. 23)

FIG. 20

3. Remove the air chamber (Fig. 21).

FIG. 21

4. Remove the caliper mounting bolts. Take care not to allow the caliper to fall (Fig. 22). Remember that the caliper has a weight of

35kgs!

FIG. 23

Important

For 80mm levers, chamber fits lower (near) end of slot

For 90mm levers, chamber fits upper (far) end of slot

5. Mount the air chamber to the caliper assembly.(Fig. 24). Tighten the air chamber nuts and washers to to the torque value specified in table 2. (Page 12)

FAR

NEAR

FIG. 24

6. Install the clevis in and ‘R’ clip (Fig. 20).

7. Follow steps 12 to 16 described in Section 2.7 to fit the pads and adjust the brake.

FIG. 22

31

TM Service

Outboard Pad

Pad Backing Plate

Load Plate

Stabiliser Bar

Retainer Pin

Inboard Pad

Pad and Spring

Assembly

Pad Backing Plate

Stabiliser Bar

Split Pin

Adjuster

Plug Washer

Adjuster Plug

FIG. 25

2.10 FITTING A NEW ROTOR AND ABS RING

With the oil seal fitted, placed the hub, oil seal end upwards, on a clean, flat surface and cover the bore with a clean cloth to protect the bearings and grease from contamination. Check that the pole wheel mounting spigot on the hub is clean and free from rust using medium emery paper to clean it up if necessary. Ensure no emery dust or other debris contaminates the bearings or grease.

Drift the pole wheel onto the hub spigot using the TM oil seal driver

(ROR part no. 21218568) ensuring it bottoms out against the mounting shoulder. (Fig. 26).

Lower the rotor over the fitted pole wheel, aligning the M12 tapped holes in the rotor with the corresponding fixing locations in the hub flange.

NB: All rotor fixings must be tightened to the torque value specified in table 2, page 12

WARNING: ROTOR WEIGHT IS 32 KGS

32

FIG. 26

TM Service

Section 3

TM Hub Service for

Drum Brakes

33

TM Service

SECTION 3

Major Hub Service

3.1 GENERAL

Although inspection of brake lining thickness (min 8.25mm/0.325”) can be determined by the removal of rubber plugs in the dust covers, complete internal inspection and overhaul can only be achieved by the removal of the hub and drum assembly.

The number of re-usable parts will not be known until the assembly is stripped. Clean containers should be used to keep each set of hub components together and free from dirt.

When the hub is removed a full inspection of the internal components is advisable. Bearing in mind the length of time and/or mileage each component will have to endure until the hubs are again removed proceed as follows.

3.2 REMOVING THE HUB & DRUM

If oil filled, drain hub and remove hub cap.

Remove bearing locknut, lockwasher and adjusting nut using suitable

ROR hub nut box spanner.

Slacken off brakes by use of the slack adjuster .

Withdraw hub/drum ensuring outer bearing does not fall out of the hub.

If difficulty is experienced in withdrawing the hub it may be necessary to use withdrawal tool No. 21200141 as shown in Fig. 1.

FIG. 2

NOTE

ArvinMeritor recommends the use of a wheel dolly No. 21217493 to remove the wheels, hub, and drum assembly. This service aid will speed up the work, can be used easily by one man – and most important – will prevent seal and bearing damage.

The wheel dolly (Fig. 2) is available through ArvinMeritor Commercial

Vehicle Aftermarket Division.

The wheel dolly and hub puller have proven to pay for themselves in substantially reduced downtime and unnecessary damage to components such as seals and bearings.

FIG. 1

34

TM Service

3.3 HUB SEALS (GREASE OR OIL)

3.3.1 REMOVAL

As a rule oil seals should be replaced whenever the hub and drum are removed. Special care must be taken not to damage the inner bearing.

Two types of seal are found on ROR axles:

1. Unitised seal – NO WEAR SLEEVE FITTED.

2. Grease seal with wear sleeve fitted to axle. From July 1980, all

ROR axles are fitted with unitized seals and therefore NO wear sleeves are required.

3.3.2 FITTING NEW SEALS

ArvinMeritor specifies Unitized seals, which do not require wear sleeves.

Seals must be installed in the hub using service tool No. 21218568 as shown in Fig. 3. The use of the seal tool will ensure that seals are positioned squarely. Avoid problems – use the proper tool.

✓

✗

FIG. 4

FIG. 3

3.3.3 REMOVAL OF WEAR SLEEVE

To remove the wear sleeve carefully tap with a ball hammer, taking care not to damage the spindle.

NOTE 1

Prior to installing any seal in the hub make certain that the seal bore is free of any nicks, gouges or other damage. This will prevent any leakage around the seal’s outer diameter.

NOTE 2

Unitized seals are directly interchangeable with the older grease seal after removal of the wear sleeve.

3.4 GREASE FILLED HUBS

Fill hub cavity with correct grease quantity (see Fig. 4). Specification in table 4 Page 12.

Pack hub cap with correct grease quantity (see Fig. 5). Specification in table 4 Page 12.

Pressure pack or carefully hand pack each bearing. The two bearings together should contain 80gm.

FIG. 5

3.5 OIL FILLED HUBS

Fill to a level between the rings found on the hub cap window (380ml approx.).

3.6 CONVERTING FROM GREASE TO OIL

Oil filled bearings are better lubricated and have proven to be necessary when running in hot conditions to give long life. Should you wish to convert to oil filled:-

1. Remove hub and drum, if original bearings are to be re-used ensure they are refitted in the original hubs.

2. Clean out the grease from the hub cavity and wash out both bearings with a suitable cleaner. If the bearings are dried with the use of an air jet avoid rotating the bearings at high speed.

3. Refit inner bearing into hub and fit new unitized oil seal.

4. Refit hub and drum assembly, refit outer bearing and adjust bearings as per previous instructions and instructions on page 37.

5. Fit new oil filled hub cap and gasket.

Standard Oil Filled ………………………………………………….. 21200624

Hubodometer Oil Filled ……………………………………………. 21204834

Gasket Oil Filled ……………………………………………………… 21021002

6. Fill to level marked in hub cap window with EP90 oil.

7. Readjust brakes.

35

TM Service

3.7 BEARINGS

All ROR axles come with a built-in bearing end float that is pre-set.

There should be no need to adjust this setting. However, if any hubs are disassembled it is important that the adjustment procedure for hub and drum replacement is followed (see page 37).

The bearings used in ROR axles are selected to give the user maximum service life. To ensure the long life of these bearings, the following procedures are recommended.

3.7.1 BEARING REMOVAL AND INSPECTION

Remove hub and drum, this releases the outer bearing cone.

Remove oil seal, this releases the inner bearing cone.

Clean all the old grease from the hub, bearing cones and hub cap with clean paraffin or diesel fuel oil. DO NOT USE PETROL, HOT SOLUTION

OR STEAM CLEANING. Dry the parts using an air jet or with clean absorbent cloth or paper. Care must be taken not to rotate bearings at high speed when using an air jet.

After thoroughly cleaning, hold up the bearing between the light and eyes and turn the cage slowly inspecting each roller and raceway for:

(i) Pitting.

(ii) Flaking.

(iii) Discolouring.

(iv) Corrosion.

If there is any doubt as to the condition of the bearing, discard it and fit a replacement. At this stage it will be necessary to remove bearing cups from hubs.

Four cut-outs in the casting allow a soft steel drift to be used to remove inner cup, using each cut-out alternately. The bearing will be removed with relative ease and without damage.

NOTE:

Hardened steel drifts or brass bars must not be used.

3.7.2 BEARING REPLACEMENT

Ensure hub is thoroughly cleaned.

Insert inner bearing cup into hub, then using tool No. 21205452 drive cup into hub ensuring cup fits squarely to its shoulder. Tool No.

21205451 is used for outer bearing cup.

Thoroughly pack the inner bearing cone with grease (see table 4, page

12) ensuring grease reaches the inner raceway. For oil filled hubs a light coating of oil should be applied to the rollers.

Fit the seal in accordance with instructions on page 16. This will keep the bearing in position until the hub is fitted to spindle.

Pack hub cavity with correct quantity of grease specified in table 4

Page 12. of grease. As a guide, grease should not be above the level of outer bearing cup’s smallest diameter (see table 4, page 12 for approved grease).

Thoroughly pack outer bearing cone and place on clean surface ready for re-assembly.

3.8 SPINDLE END INSPECTION

Before replacing the hub and drum assembly it is good practice to inspect the spindle end.

Although bearings are designed to creep on journal in order to distribute the load evenly – excessive journal wear may require beam replacement. The lower limit of journal sizes are: Inner bearing

89.91mm, Outer bearing 64.91mm.

3.9 ANTI-LOCK OPTION

If the hub and drum being serviced is fitted with an anti-lock sensor – make certain the sensor is clean and pushed outwards in its housing before refitting hub and drum assembly (Fig. 6).

FIG. 6

3.10 PLASTIC SENSORS

If the sensor is excessively worn (see Fig. 7), it must be replaced. Refer to manufacturers instructions.

Examine the Exciter Ring and renew if any damage is found. When fitted to 420mm diameter brakes the pressed steel exciter ring (for use with the plastic sensor) is held in place by the wheel bolts – for removal see page 42 on wheel bolts.

The action of replacing the hub and drum assembly will correctly position the sensor against the Exciter Ring.

For any other problems with the anti-lock system contact the anti-lock supplier.

✓ ✗

COIL CASING

FIG. 7

36

TM Service

3.11 HUB AND DRUM REPLACEMENT

Correct setting of bearing end float is essential. The following procedure has been proven to provide correct end float.

CAUTION:

Noticeable end float in the cold (standing) condition will decrease when hub reaches normal operating temperature.

Feed hub/drum assembly onto spindle until inner bearing reaches shoulder.

Fit outer bearing and adjusting nut (Fig. 8).

FIG. 10

FIG. 8

Tighten adjusting nut to lightly pinch bearings – AT THE SAME TIME

ROTATING THE HUB & DRUM TO SEAT THE BEARINGS (Fig. 9).

FIG. 11

FIG. 9

Tighten adjusting nut to 70Nm with special pre-set torque wrench (Part

No. 21206783), adaptor (21218567) and box spanner (21218566)

Fig. 10.

Back off adjusting nut 2 1 ⁄

2

-3 flats.

Assemble Lock Washer and Locknut, tighten to torque specified in table

1 page 12 using torque wrench (Fig. 11).

Check that hub and drum rotate freely (Fig. 12).

The above sequence must be strictly observed.

FIG. 12

8. Pack hub cap with quantity of grease specified in table 4 page 12.

9. Fit new gasket and attach hub cap. Tighten hub cap screws to torque specified in table 1 page 12.

37

TM Service

38

TM Service

Section 4

TM Hub Service for

Disc Brakes

39

TM Service

SECTION 4

Hub and Bearing Removal and

Inspection

The hub removal, service and re-fitting procedures are similar to those described in Section 3. However, in the case of disc brake installations, the following additional procedures are required.

4.1 SLACKEN WHEEL NUTS:

Before lifting the axle it is advisable to slacken the wheel nuts.

Lift axle enough to get clearance to remove wheel. Support axle with safety stands and remove wheel and tyre.

Warning:

Do not work under a vehicle supported only by jacks. Jacks can slip or fall over and cause serious personal injury. Support the vehicle with safety stands and block the wheels ro prevent the vehicle from moving.

4.2 DE-ADJUST BRAKES

Release trailer brakes and de-adjust caliper and remove pads. (See section 2.7 Pad Removal and Replacement).

4.3 REMOVE CALIPER