TNC 620

Руководство пользователя

«Диалог открытым текстом

HEIDENHAIN»

Программное обеспечение с ЧПУ

817600-02

817601-02

817605-02

Русский (ru)

5/2015

-

Contents

-

Table of Contents

-

Bookmarks

Quick Links

TNC 620

User’s Manual

Setup, Testing and Running

NC Programs

NC Software

817600-16

817601-16

817605-16

English (en)

01/2022

Related Manuals for HEIDENHAIN TNC 620

Summary of Contents for HEIDENHAIN TNC 620

-

Page 1

TNC 620 User’s Manual Setup, Testing and Running NC Programs NC Software 817600-16 817601-16 817605-16 English (en) 01/2022… -

Page 2

Function Program Run, Single Block Define tool data in the NC program Program Run, Full Sequence Call tool data Programming modes Function Programming Test Run HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 3

Potentiometer for feed rate and spindle speed Navigate down one page Feed rate Spindle speed Select the next tab in forms Up/down one dialog box or button HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 4

Contents HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 5: Table Of Contents

Tools……………………….127 Setup……………………….165 Testing and running……………………245 Special functions……………………311 Pallets……………………….317 MOD functions…………………….. 339 10 HEROS functions……………………369 11 Operating the touchscreen………………….471 12 Tables and overviews………………….. 489 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 6

Contents HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 7

Contents Basic information……………………25 About this manual……………………..26 Control model, software and features………………..28 Software options…………………………..30 New functions 81760x-16……………………….34 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 8

Machining the workpiece……………………. 54 Selecting the Program run, single block or Program run, full sequence operating mode……54 Selecting the NC program……………………….54 Starting an NC program………………………… 54 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 9

Additional tools for management of external file types………………93 Error messages and help system………………..101 Error messages…………………………..101 TNCguide: context-sensitive help……………………..107 NC fundamentals……………………..113 Position encoders and reference marks………………….. 113 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 10

Contents Programmable axes…………………………113 Reference systems…………………………114 Accessories: HEIDENHAIN 3-D touch probes and electronic handwheels……..124 3-D touch probes (option 17)……………………..124 HR electronic handwheels……………………….125 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 11

Available tool types…………………………155 Importing and exporting tool data……………………..157 Tool carrier management………………….. 160 Fundamentals…………………………..160 Saving tool carrier templates………………………160 Parameterizing tool carriers………………………..161 Assigning a tool carrier……………………….. 164 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 12

Recording measured values from the touch probe cycles…………….212 Writing measured values from the touch probe cycles to a datum table…………213 Writing measured values from the touch probe cycles to the preset table………..214 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 13

Limitations on working with the tilting function………………..241 Activating manual tilting……………………….242 Setting the tool-axis direction as the active machining direction…………..244 Setting a preset in a tilted coordinate system…………………244 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 14

Scrollbar…………………………….269 6.10 Program run……………………… 270 Application…………………………….270 Running an NC program……………………….270 Structuring NC programs……………………….271 Checking and changing Q parameters……………………272 Interrupting, stopping or aborting machining…………………..274 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 15

Superimposing handwheel positioning during program run: M118 (option 21)……….. 308 Deleting basic rotation: M143……………………..309 Lifting off the tool automatically from the contour at NC stop: M148…………310 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 16

Contents Special functions……………………311 Active Chatter Control (ACC) (option 145)………………312 Application…………………………….312 Activating ACC…………………………..313 Defining a counter……………………..314 Application…………………………….314 Defining FUNCTION COUNT………………………. 315 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 17

Mid-program startup with block scan……………………329 Batch Process Manager (option 154)………………… 330 Application…………………………….330 Fundamentals…………………………..330 Opening Batch Process Manager……………………… 334 Creating a job list…………………………. 336 Editing a job list…………………………..337 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 18

9.11 Configuring the HR 550FS radio handwheel……………….362 Application…………………………….362 Assigning the handwheel to a specific handwheel holder…………….362 Setting the transmission channel……………………… 363 Selecting the transmitter power……………………..363 Statistical data…………………………..364 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 19

Set the system time…………………………365 9.13 Diagnostic functions……………………366 Bus diagnosis…………………………..366 TNCdiag…………………………….366 Drive diagnosis…………………………..366 Hardware configuration……………………….366 HeROS information…………………………366 9.14 Displaying operating times………………….367 Application…………………………….367 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 20

Settings for network drives……………………….421 10.7 SELinux security software………………….426 10.8 User administration……………………427 Introduction…………………………….427 Configuring the user administration……………………428 Local LDAP database…………………………432 LDAP on remote computer……………………….433 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 21

IT Security…………………………….462 Machine configuration………………………….463 Setting up the connection……………………….463 Application development……………………….465 Access to directories…………………………466 PKI Admin…………………………….467 10.10 Changing the HEROS conversational language…………….469 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 22

Operating the simulation……………………….478 Using the HEROS menu……………………….479 Operating the CAD viewer……………………….480 11.3 Functions in the taskbar…………………….486 Icons of the taskbar…………………………486 Touchscreen Configuration……………………….487 Touchscreen Cleaning………………………….487 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 23

12.2 Pin layout and cables for data interfaces………………507 V.24/RS-232-C interface for HEIDENHAIN devices……………….. 507 Ethernet interface RJ45 socket……………………..507 12.3 Specifications……………………..508 User functions…………………………..511 Accessories…………………………….514 Keycaps for keyboard units and machine operating panels…………….514 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 25: Basic Information

Basic information…

-

Page 26: About This Manual

Type and source of hazard Consequences of ignoring the hazard, e.g.: «There is danger of collision during subsequent machining operations» Escape – hazard prevention measures HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 27

Have you found any errors or would you like to suggest changes? We continuously strive to improve our documentation for you. Please help us by sending your suggestions to the following e-mail address: tnc-userdoc@heidenhain.de HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 28: Control Model, Software And Features

All functions provided by the machining cycles are described in the User’s Manual for Programming of Machining Cycles. Please contact HEIDENHAIN if you need this User’s Manual. ID: 1303427-xx HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 29

User’s Manuals for Klartext Programming and ISO Programming. Please contact HEIDENHAIN if you need these User’s Manuals. ID for Klartext Programming: 1096883-xx ID for ISO Programming: 1096887-xx HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 30: Software Options

Advanced Programming Features (option 19) Expanded programming functions FK free contour programming: Programming in HEIDENHAIN conversational format with graphic support for workpiece drawings not dimensioned for NC HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 31

The OPC UA NC Server provides a standardized interface (OPC UA) for external access to the control’s data and functions These software options allow you to create up to six parallel client connections HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 32

Batch Process Manager (option 154) Batch process manager Planning of production orders Component Monitoring (option 155) Component monitoring without exter- Monitoring configured machine components for overload nal sensors HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 33

The manufacturer of the software that uses these communication interfaces is responsible for performing system tests. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 34: New Functions 81760X-16

The TRANS DATUM RESET function allows you to reset the rotation. The NC functions serve as an alternative to Cycle 10 ROTATION. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 35

If necessary, you can display the files with the SHOW FILES soft key. Further information: «Additional functions», Page 84 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 36

Further information: «Tool table fundamentals», Page 130 The control supports the TS 760 workpiece touch probe. Further information: «3-D touch probes (option 17)», Page 124 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 37

(option 17). Further information: «Functions in touch probe cycles», Page 209 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 38

The input range of machine parameter displayPace (no. 101000) has been extended. The minimum display step of the axes is 0.000001° or mm. Further information: «General status display», Page 68 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 39

This cycle allows you to define an extrusion. With an active extrusion, the control repeats the touch points along a direction over a defined length. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 40

The parameter Q370 TOOL PATH OVERLAP has been added to Cycle 208 BORE MILLING (ISO: G208, option 19). Use this parameter to define the lateral infeed. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 41

The following parameters have been added: Q342 ROUGHING DIAMETER Q253 F PRE-POSITIONING: If parameter Q342 is defined, feed rate for approaching the recessed starting point HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 42

If you defined the value 2 in parameter Q1125 CLEAR. HEIGHT MODE, the control positions the touch probe at rapid traverse FMAX from the touch probe table to the set-up clearance. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 43: First Steps

First steps…

-

Page 44: Overview

Workpiece setup Machining the workpiece The User’s Manuals for Klartext Programming and ISO Programming cover the following topics: Switching on the machine Programming the workpiece HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 45: Switching On The Machine

The control is now ready for operation in the Manual operation mode. Further information on this topic Approaching reference points Further information: «Switch-on», Page 166 Operating modes Further information: «Programming», Page 66 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 46: Graphically Testing The Workpiece (Option 20)

Further information on this topic Tool management Further information: «Entering tool data into the table», Page 135 Testing NC programs Further information: «Test run», Page 264 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 47: Selecting The Nc Program

3-D view Further information on this topic Graphic functions Further information: «Graphics (option 20)», Page 246 Performing a test run Further information: «Test run», Page 264 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 48: Starting The Test Run

Graphic functions Further information: «Graphics (option 20)», Page 246 Adjusting the simulation speed Further information: «Setting the speed of the Test Run mode «, Page 253 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 49: Setting Up Tools

When measuring on the machine: store the tools in the tool changer Further information: «Editing the TOOL_P.TCH pocket table», Page 51 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 50: Editing The Tool.t Tool Table

Working with the tool table Further information: «Entering tool data into the table», Page 135 Working with tool management Further information: «Calling tool management», Page 151 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 51: Editing The Tool_P.tch Pocket Table

Operating modes of the control Further information: «Modes of operation», Page 65 Working with the pocket table Further information: «Pocket table for tool changer», Page 141 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 52: Workpiece Setup

Enter the tool data Press the ENT key Enter the tool axis Z Press the ENT key Press the END key Press the NC Start key HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 53

Press the END soft key to close the menu Further information on this topic Presetting Further information: «Presetting with a 3-D touch probe (option number 17)», Page 230 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 54: Machining The Workpiece

Press the NC start key The control runs the active NC program. Further information on this topic Running NC programs Further information: «Program run», Page 270 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 55: Fundamentals

Fundamentals…

-

Page 56: The Tnc 620

TNC 150 B) may not always run on the TNC 620. If the NC blocks contain invalid elements, the control will mark these as ERROR blocks or with error messages when the file is opened. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 57: Data Security And Data Protection

Check any removable memory media for malicious software before using them Start the internal web browser only from within the sandbox HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 58

If you insist on using a virus scanner, you must operate the control in a protected network (with a gateway and a virus scanner). The subsequent installation of a virus scanner is not possible. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

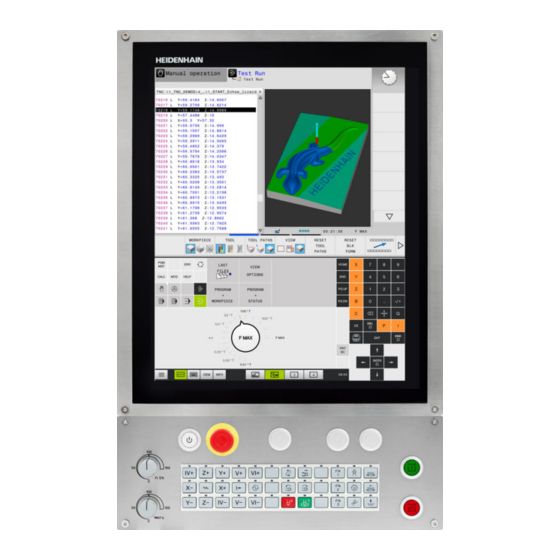

Page 59: Visual Display Unit And Operating Panel

USB connection If you are using a TNC 620 with touch control, you can replace some keystrokes with gestures. Further information: «Operating the touchscreen», Page 471 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 60: Setting The Screen Layout

Press the screen layout key: The soft-key row shows the available layout options Further information: «Modes of operation», Page 65 Select the desired screen layout with a soft key HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 61: Operating Panel

Some machine tool builders do not use the standard HEIDENHAIN operating panel. External keys, e.g. NC START or NC STOP, are described in your machine manual. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 62

Please observe the information for the cleaner. Carefully wipe the shell area clean with the cloth until all smears or stains have been removed HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 63

The seal must not be damaged; otherwise the IP54 protection rating cannot be guaranteed. Verify proper seating and correct functioning HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 64: Screen Keypad

SPECIAL CHARACTERS soft key and insert them. Use the BACKSPACE soft key to delete individual characters. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 65: Modes Of Operation

Soft keys for selecting the screen layout Soft key Window NC program Left: NC program, right: status display Left: NC program, right: workpiece (option 20) HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 66: Programming

Soft keys for selecting the screen layout Soft key Window NC program Left: NC program, right: status display Left: NC program, right: workpiece (option 20) Workpiece (Option 20) HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 67: Program Run, Full Sequence And Program Run, Single Block

Soft key Window Pallet table Left: NC program, right: pallet table Left: pallet table, right: status display Left: pallet table, right: graphics Batch Process Manager HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 68: Status Displays

Axis is locked Axis can be moved with the handwheel The machine parameter CfgPosDisplayPace (no. 101000) defines the display accuracy by the number of decimal places. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 69

Axes are moving, taking the basic rotation into account A 3-D basic rotation is active in the active preset Axes are moving, taking the setting in the 3-D ROT menu into account HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 70

X, Y, and Z because the PARAXMODE or POLARKIN function is active. An active PARAXMODE or POLARKIN icon hides the PARAXCOMP DISPLAY icon. The PARAXCOMP DISPLAY function is active HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 71: Additional Status Displays

Or by using the next tab key Please note that some of the status information described below is not available unless the associated software option is enabled on your control. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 72

Name and path of the active main program selection possible Actual/nominal value counters Circle center CC (pole) Dwell time counter Current machining time Current time Called NC programs HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 73

No direct List of the active M functions with fixed functional- selection possible List of the active M functions (adapted by your machine tool builder) HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 74

(TAB) and TOOL CALL (PGM) Tool life, maximum tool life (TIME 1) and maximum tool life for TOOL CALL (TIME 2) Display of programmed tool and replacement tool HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 75

(no. 114319). The control will determine the tilt angle automatically only if a tolerance is defined. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 76

Further information: User’s Manual for Programming of Machining Cycles Further information: User’s Manuals for Klartext Programming and ISO Programming HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 77

10 The display of QS parameters is restricted to the first 30 characters, i.e. the contents might be truncated. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 78

Alternatively, the machine tool builder can define only warning limits or error limits. If no limits have been defined, the corresponding red or yellow line is not displayed. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 79

In this case, you can use the CfgMonUser (no. 129400) machine parameter to influence the configured overload responses. Further information: «List of user parameter», Page 492 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 80: File Management

Depending on the setting, the control generates backup files with the extension *.bak after editing and saving of NC programs. This reduces the available memory space. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 81

The maximum permitted path length is 255 characters. The path length consists of the drive characters, the directory name and the file name, including the extension. Further information: «Paths», Page 82 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 82: Displaying Externally Generated Files On The Control

NC program PROG1.H was copied into it. The NC program now has the following path: TNC:AUFTR1NCPROGPROG1.H The chart at right illustrates an example of a directory display with different paths. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 83: Calling The File Manager

File is protected against deletion and editing, because it is being run Date that the file was last edited Date Time that the file was last edited Time HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 84: Additional Functions

Move the cursor to the left-hand window Press the MORE FUNCTIONS soft key Remove the USB device Further information: «USB devices on the control», Page 88 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 85

To show hidden files and folders: Press the MORE FUNCTIONS soft key Press the SHOW FILES soft key The control displays the files and folders. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 86: Selecting Drives, Directories And Files

Step 2: Select a directory Move the highlight to the desired directory in the left window The right-hand window automatically shows all files stored in the highlighted directory HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 87

The control will show all files of file type .h and .d. Any display filter you have set will remain effective even after a control restart, HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 88: Choosing One Of The Last Files Selected

The control automatically detects these USB devices when they are plugged in. If the file system is not supported, the control issues an error message as soon as the stick is plugged in. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 89

To remove a USB device, proceed as follows: Move the cursor to the left-hand window Press the MORE FUNCTIONS soft key Remove the USB device HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 90: Data Transfer To Or From An External Data Carrier

A status window appears on the control, informing about the copying progress. Alternative: Press the WINDOW soft key The control displays the standard file manager window again. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 91: The Control Within The Network

NC program. Undesirable machine movements or collisions may result. Copy the NC program and all called files to the TNC: drive HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 92: Data Backup

TNC 620 and saves the changes to the selected file. Further information: «Importing tool tables», Page 139 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 93: Additional Tools For Management Of External File Types

Mode tab). If you are using a TNC 620 with touch control, you can replace some keystrokes with gestures. Further information: «Operating the touchscreen», Page 471 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 94

The control returns to the file manager. If you are using a TNC 620 with touch operation, the full-screen mode is automatically terminated after five seconds. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 95

Gnumeric opens the File select menu. Move the cursor to the Close menu item Press the ENT key The control returns to the file manager. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 96

You can update the web browser only if you deactivate the SELinux security software during this period and if a connection with the Internet is available. Reactivate SELinux again after the update. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 97

File selection menu Move the cursor to the Quit menu item Press the ENT key The control returns to the file manager. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 98

The Xarchiver opens the ARCHIVE select menu. Move the cursor to the Exit menu item Press the ENT key The control returns to the file manager. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 99

The paid-for Fluendo Codec Pack is required for other formats, such as for MP4 files. Any additional software will be installed by your machine tool builder. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 100

The control returns to the file manager. If you are using a TNC 620 with touch operation, the full-screen mode is automatically terminated after five seconds. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 101: Error Messages And Help System

When you open the error window, the complete information on all pending errors will be shown. Press the ERR key The control opens the error window and displays all accumulated error messages. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 102

Press the INTERNAL INFO soft key The control opens a window with internal information about the error. Exit the detailed information: Press the INTERNAL INFO soft key again HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 103

Press the STORE soft key If an error with the specified error number occurs, a service file will be saved automatically. Press the GO BACK soft key HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 104

Set the current error log if required: Press the CURRENT FILE soft key The oldest entry is at the beginning of the log file, and the most recent entry is at the end. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 105

The control deletes this information text with the next valid entry. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 106

Closing the error window To close the error window: Press the END soft key Alternative: Press the ERR key The control closes the error window. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 107: Tncguide: Context-Sensitive Help

.chm files are shown in one place. As an option, your machine manufacturer can embed machine-specific documentation in TNCguide. These documents then appear as a separate book in the main.chm file. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 108

The control opens the Help system and shows the description of the active function. This does not apply for miscellaneous functions or cycles from your machine tool builder. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 109

Select the page last shown Page forward if you have used the Select page last shown function Go back one page Go forward one page HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 110

To activate the function, use the mouse or select it and then press the space bar to confirm. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 111

TNC:tncguideit Spanish TNC:tncguidees Portuguese TNC:tncguidept Swedish TNC:tncguidesv Danish TNC:tncguideda Finnish TNC:tncguidefi Dutch TNC:tncguidenl Polish TNC:tncguidepl Hungarian TNC:tncguidehu Russian TNC:tncguideru Chinese (simplified) TNC:tncguidezh Chinese (traditional) TNC:tncguidezh-tw HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 112

Fundamentals | Error messages and help system Language TNC directory Slovenian TNC:tncguidesl Norwegian TNC:tncguideno Slovak TNC:tncguidesk Korean TNC:tncguidekr Turkish TNC:tncguidetr Romanian TNC:tncguidero HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 113: Nc Fundamentals

The number, designation and assignment of the programmable axes depend on the machine. Your machine tool builder can define further axes, such as PLC axes. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 114: Reference Systems

All reference systems build upon each other. They are subject to the kinematic chain of the specific machine tool. The machine coordinate system is the reference system. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 115

Refer to the machine tool builder’s documentation Use pallet presets only in conjunction with pallets Check the display of the PAL tab before you start machining HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 116

Z axis in the input coordinate system. The user can program positions related to the machine datum, e.g. by using the miscellaneous function M91. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 117

Refer to the machine tool builder’s documentation Use pallet presets only in conjunction with pallets Check the display of the PAL tab before you start machining HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 118

Cycle 19, the programmed transformations (mirroring, rotation, and scaling) do not affect the position of the tilt datum or the orientation of the rotary axes HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 119

Other transformations are of course possible in the working plane coordinate system Further information: «Working plane coordinate system WPL-CS», Page 120 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 120

3-axis machining. The BASE TRANSFORM. values of the active line of the preset table have a direct effect on the input coordinate system with this assumption. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 121

Orientation of the tool coordinate system can be performed in various reference systems. Further information: «Tool coordinate system T-CS», Page 122 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 122

7 L A+0 B+45 C+0 R0 F2500 7 LN X+48 Y+102 Z-1.5 NX-0.04658107 NY0.00045007 NZ0.8848844 TX-0.08076201 TY-0.34090025 TZ0.93600126 R0 M128 7 LN X+48 Y+102 Z-1.5 NX-0.04658107 NY0.00045007 NZ0.8848844 R0 M128 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 123

→ corner-radius cutter or toroidal cutter Without the TCPM function or miscellaneous function M128, orientation of the tool coordinate system and input coordinate system is identical. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 124: Accessories: Heidenhain 3-D Touch Probes And Electronic Handwheels

A wear-resistant optical switch generates the trigger signal. With the TT 160, signal transmission is by cable. The TT 460 supports infrared and radio transmission. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 125: Hr Electronic Handwheels

(HSCI: HEIDENHAIN Serial Controller Interface) serial interface for control components. Configuration is performed via the machine tool builder. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 127: Tools

Tools…

-

Page 128: Tool Data

With a gauge block With a calibration pin (inspection tool) Before you determine tool length, you have to set the preset in the spindle axis. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 129

Move the tool onto the flexible inner ring until the gauge displays The control displays the absolute tool length as the actual position in the position display. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 130: Tool Radius R

You can choose between a list view and a form view. Other settings, such as SORT/ HIDE COLUMNS, can be made after the file has been opened. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 131

(option 93), you can insert an indexed tool by means of the INSERT INDEX soft key. The control generates the index continuously and adopts all values of the original tool. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 132

Show all drills in the tool table Show all cutters in the tool table Show all taps/thread cutters in the tool table Show all touch probes in the tool table HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 133

(0-3) the control will freeze to the left border of the screen. These columns will remain visible when you navigate to the right within the table. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 134: Creating And Activating An Inch-Based Tool Table

The preset table is another table whose unit of measure is not adjusted automatically. Further information: «Creating and activating an INCH- based preset table», Page 193 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 135: Entering Tool Data Into The Table

Cutting material of the tool for the cutting data calculator TMAT Tool material? Cutting data table for the cutting data calculator CUTDATA Cutting data table? HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 136

(e.g., neck of end mills or side milling cutters) A neck radius RN that is shown in the graphic simulation is possible only if LU > LCUTS. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 137

(status L). Input range: 0 to 0.9999 mm Description of the cycles for automatic tool measurement. Further information: User’s Manual for Programming of Measuring Cycles for Workpieces and Tools HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 138

Select the end of the table Select the previous page in the table Select the next page in the table Find the text or number Go to beginning of line HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 139: Importing Tool Tables

ADAPT NC PGM / TABLE function. The control converts the contents of the imported tool table to a format valid for the TNC 620 and saves the changes to the selected file. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 140

When iTNC 530 tool tables are imported, all defined tool types are imported as well. Tool types not present are imported as type Undefined. Check the tool table after the import. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 141: Pocket Table For Tool Changer

Editing a pocket table in a Program Run operating mode Select the tool table: Press the TOOL TABLE soft Press the POCKET TABLE soft key If required, set the EDIT soft key to ON HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 142

Box magazine: Lock the pocket at left LOCKED_LEFT Lock the pocket at left? Box magazine: Lock the pocket at right LOCKED_RIGHT Lock the pocket at right? HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 143

Place the cursor in the current cell Sort the view Refer to your machine manual. The machine manufacturer defines the features, properties and designations of the various display filters. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 144: Tool Change

If the target position in the tool axis is above the current position, the tool axis is positioned first HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 145: Tool Usage Test

To conduct a tool usage test, you must activate Create tool usage files in the MOD menu. Further information: «Generating a tool usage file», Page 354 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 146

TOKEN = TOOL: Path name of the active PATH main program or subprogram TOKEN = STOTAL: Path name of the subprogram Tool number with tool index HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 147

The control closes the pop-up window. Alternative: Press the ENT key You can query the tool usage test with the FN 18 ID975 NR1 function. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 148: Touch Probe Table

The smaller this value is, the more exactly you must define the touch point position. Safety clearances defined in the touch probe cycle are added to this value. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 149: Editing The Touch Probe Table

Set the EDIT soft key to ON Select the desired value Perform desired changes You can also edit the touch probe table values in the tool management. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 150: Tool Management

If you edit a tool in tool management, the selected tool is locked. If this tool is required in the NC program being used, the control shows the message: Tool table locked. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 151: Calling Tool Management

If a pallet table is selected in the Program Run operating mode, the Tooling list and T usage order are calculated for the entire pallet table. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 152: Editing Tool Management

SHIFT COLUMN active: The column can be moved by drag and drop Reset the manually changed settings (move columns) to the original condition HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 153

EDIT ON/OFF soft key to ON HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 154

Discard all changes made since the form was called Add tool index Delete tool index Copy the tool data of the selected tool Insert the copied tool data in the selected tool HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 155: Available Tool Types

The following tool types are available: Icon Tool type Tool type number Undefined,**** Milling cutter,MILL Roughing cutter,MILL_R Finishing cutter,MILL_F Ball-nose cutter, BALL Toroid cutter, TORUS Drill,DRILL HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 156

Thread mill,GF Thread mill w/ countersink,GSF Thread mill w/ single thread,EP Thread mill w/ indxbl insert,WSP Thread milling drill,BGF Circular thread mill,ZBGF Grinding tool Dressing tool HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 157: Importing And Exporting Tool Data

ENT key The control shows a pop-up window with the content of the CSV file Start the import procedure with the EXECUTE soft key. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 158

Example Line 1 with column names T,L,R,DL,DR Line 2 with tool data 4,125.995,7.995,0,0 Line 3 with tool data 9,25.06,12.01,0,0 Line 4 with tool data 28,196.981,35,0,0 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 159

Terminate the export process by pressing the END key or soft key By default the control stores the exported CSV file in the TNC:systemtooltab directory. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 160: Tool Carrier Management

The tool carrier templates may consist of several sub- files. If the sub-files are incomplete, the control will display an error message. Do not use incomplete tool carrier templates! HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 161: Parameterizing Tool Carriers

ToolHolderWizard tool does not execute any function when the corresponding icons are activated. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 162

Output file area Press the GENERATE FILE button If required, reply to the message on the control Press the CLOSE icon The control closes the additional tool HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 163

Output file area Press the GENERATE FILE button If required, reply to the message on the control Press the CLOSE icon The control closes the additional tool HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 164: Assigning A Tool Carrier

Select the desired tool carrier using the preview Press the OK soft key The control copies the name of the selected tool carrier to the KINEMATIC column. Exit the tool table HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 165: Setup

Setup…

-

Page 166: Switching On/Off

If possible, reset tilting before shutting the system down Check the tilted condition when switching the machine back on HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 167

Only confirm the pop-up window with YES if the axis positions match Despite confirmation, at first only move the axis carefully If there are discrepancies or you have any doubts, contact your machine tool builder HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 168: Traversing Reference Points

Press and hold the axis direction button for each axis until the reference point has been traversed The control is now ready for operation in the Manual operation mode. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 169

The position shown in the pop-up window is the last position before the control was shut down. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 170: Switching Off

Always shut down the control Only operate the main switch after being prompted on the screen HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 171: Moving The Machine Axes

Further information: «Spindle speed S, feed rate F and miscellaneous function M», Page 183 If a moving task is active on the machine, the control displays the control in operation symbol. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 172: Incremental Jog Positioning

Switch INCREMENT soft key to OFF If you are in the Jog increment menu, you can switch off incremental jog positioning with the SWITCH OFF soft key. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 173: Traversing With Electronic Handwheels

As soon as you have activated the handwheel with the handwheel activation key, the operating panel is locked. The control shows this status in a pop-up window on the screen. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 174

15 NC STOP key (machine-dependent function, key can be exchanged by the machine manufacturer) 16 Handwheel 17 Spindle speed potentiometer 18 Feed rate potentiometer 19 Cable connection, omitted with HR 550FS radio handwheel HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 175

12 STEP ON or OFF: Incremental jog active or inactive. If the function is active, the control additionally displays the current traversing step 13 Soft-key row: Selection of various functions, described in the following sections HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 176

HR 550FS sets off a vibrating alarm that is reliably noticed. If this happens you must reduce the distance to the handwheel holder in which the radio receiver is integrated. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 177

Select the END button The MOD menu includes a function for initial operation and configuration of the handwheel. Further information: «Configuring the HR 550FS radio handwheel», Page 362 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 178

Resulting handwheel sensitivity levels in in/revolution: 0.000127/0.000254/0.000508/0.00127/0.00254/0.00508/0.0127/0.0254/0.0508/0.127/0.254/0.508 Examples for resulting handwheel sensitivity values: Defined handwheel speed Speed level Resulting handwheel sensitivity 0.01 % 0.001 mm/revolution 0.01 % 0.001 degrees/revolution 0.0127 % 0.00005 in/revolution HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 179

In this case, you must turn the feed-rate potentiometer back to the previous value because the activated feed-rate potentiometer will only then be effective. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 180

10. By also pressing the CTRL key, you can increase the counting increment by a factor of 100 when pressing F1 or F2. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 181

Activate the handwheel Press the Generate NC block key on the handwheel The control inserts a complete traversing block containing all axis positions selected through the MOD function. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 182

Further information: «Returning to the contour», Page 289 On/off switch for the Tilt working plane function (handwheel soft keys MOP and then 3D) HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 183: Spindle Speed S, Feed Rate F And Miscellaneous Function M

The control shows the current spindle speed in the status display. If the spindle speed is less than 1000, the control also shows a decimal place that has been entered. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 184: Changing The Spindle Speed And Feed Rate

The feed-rate potentiometer only reduces the programmed feed rate and not the feed rate calculated by the control. The override for spindle speed is only functional on machines with infinitely variable spindle drive. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 185: Feed-Rate Limit F Max

Enter the desired maximum feed rate Press the OK soft key The control displays an exclamation mark behind the feed rate-value in the status display. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 186: Integrated Functional Safety (Fs)

In this chapter you will find explanations of the functions that are additionally available on a control with functional safety (FS). HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 187: Functional Safety (Fs) Status Displays

SOM_4 operating mode active Safe operating mode 4: This function must be enabled and Advanced manual intervention, process adapted by the machine manufacturer. monitoring, only for qualified users HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 188

S and feed rate F elements in the general status display. Symbol Meaning Feed rate when stopped Spindle when stopped Safe axis (not tested) HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 189

Further information: «Checking the axis positions», Page 190 The axis is not monitored by functional safety (FS) or is not configured as a safe axis. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 190: Checking The Axis Positions

Watch out for possible collisions Refer to your machine manual. The location of the test position is specified by your machine tool builder. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 191: Activating Feed-Rate Limits

SOM_1. Select the Manual operation mode Shift the soft-key row Switch on/off feed rate limit HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 192: Preset Management

If you work with pallets, please note that the presets stored in the preset table are relative to an activated pallet preset. Further information: «Pallets», Page 317 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 193: Creating And Activating An Inch-Based Preset Table

The tool table is another table where the unit of measure is not adjusted automatically. Further information: «Creating and activating an INCH- based tool table», Page 134 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 194: Saving Presets In The Table

To activate the preset table copied to another directory you have to copy it back. If you select a new preset table, you need to reactivate the preset. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 195

If needed, select the column in the preset table that you want to change Use the soft keys to select one of the available input options HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 196

If inch display is active: Enter the value in inches, and the control will inter- nally convert the entered values to mm HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 197

Reset the selected line: The control enters — into all columns. Insert a line as last line in the table Delete the last line in the table HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 198: Protecting Presets From Being Overwritten

Enter the password in the pop-up window Confirm with the OK soft key or with the ENT key: The control writes ### in the LOCKED column. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 199

Press the LOCK / UNLOCK PASSWORD soft key Enter the password in the pop-up window Confirm with the OK soft key or with the ENT key The control cancels the write-protection. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 200: Activating A Preset

Doc column that you want to activate. Further information: User’s Manual for Programming of Machining Cycles HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 201: Presetting Without A 3D Touch Probe

Preparation Clamp and align the workpiece Insert the zero tool with known radius into the spindle Ensure that the control is showing the actual positions HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 202: Presetting With An End Mill

The behavior of the control during presetting depends on the setting in the optional machine parameter chkTiltingAxes (no. 204601). Further information: «Introduction», Page 204 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 203: Using Touch Probe Functions With Mechanical Probes Or Measuring Dials

If you try to set a preset in a locked axis, the control will issue either a warning or an error message, depending on what the machine tool builder has defined. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 204: Using A 3-D Touch Probe (Option 17)

3D touch probe for presetting and the positions do not match. If the machine parameter has not been set, the control checks as if chkTiltingAxes: CheckAlways were set HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 205

Tilting can only be selected if you have set Manual Operation 3-D ROT to active. Further information: «Activating manual tilting», Page 242 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 206: Overview

Setting the preset on any axis Setting a corner as preset Setting a circle center as preset Setting the centerline as preset Touch probe system data management HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 207

Probe the second touch point If necessary, set the preset End the probing function If the handwheel is active, you cannot start the touch probe cycles. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 208: Suppressing Touch Probe Monitoring

There is a risk of collision if you choose the wrong direction of traverse! Carefully move the axes in the Manual operation operating mode HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 209: Functions In Touch Probe Cycles

Probe stud (outside circle) automatically Probe a model circle (center point of several elements) Select a paraxial probing direction for probing of holes, studs and model circles HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 210

Number of probing operations (3 toNumber of touch points? Probing a full circle (360°) or a circle Angular length? segment (angular length<360°) HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 211

After the last touching process and if the opening angle contains the value 360°, the control positions the workpiece touch probe back to the position it had prior to starting the probing function. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 212: Selecting The Probing Cycle

TCHPRMAN.html file directly under TNC:. Operating notes: If you run several touch probes cycles in a row, the control stores the measured values below each other. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 213: Writing Measured Values From The Touch Probe Cycles To A Datum Table

Enter the datum number in the Number in table? input field Press the ENTER IN DATUM TABLE soft key The control saves the datum in the indicated datum table under the entered number. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 214: Writing Measured Values From The Touch Probe Cycles To The Preset Table

The control displays a note if a table row cannot be written to because of disabling. The probing function itself is not interrupted. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 215: Calibrating 3-D Touch Probes (Option 17)

Measure the radius and the center offset using a stud or a calibration pin Measure the radius and the center offset using a calibration sphere HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 216: Calibrating The Effective Length

Press the OK soft key for the values to take effect Press the CANCEL soft key to terminate the calibrating function. The control logs the calibration process in the TCHPRMAN.html file. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 217: Calibrating The Effective Radius And Compensating Center Misalignment

180°, and then executes another probing routine. The center offset (CAL_OF in tchprobe.tp) is determined in addition to the radius by probing from opposite orientations. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 218

Refer to your machine manual. In order to be able to determine ball-tip center misalignment, the control needs to be specially prepared by the machine manufacturer. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 219

Refer to your machine manual. In order to be able to determine ball-tip center misalignment, the control needs to be specially prepared by the machine manufacturer. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 220: Displaying Calibration Values

This is regardless of whether you want to use a touch-probe cycle in automatic mode or in Manual operation mode. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 221: Compensating Workpiece Misalignment With 3-D Touch Probe (Option 17)

(3-D ROT menu) do not match, the working plane is inconsistent. Thus, the basic rotation is calculated in the workpiece coordinate system (W-CS), based on the tool axis. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 222

SET BASIC ROTATION or SET TABLE ROTATION soft key. The behavior of the control during presetting depends on the setting in the chkTiltingAxes machine parameter (no. 204601). Further information: «Introduction», Page 204 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 223: Measuring A Basic Rotation

If appropriate, the control opens the Overwrite active preset? menu. Press the OVERWRITE PRESET soft key The control saves the basic rotation in the preset table. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 224: Compensation Of Workpiece Misalignment By Rotating The Table

The control deletes the basic rotation from the preset table, and inserts the offset. Alternative: Press KEEP BASIC ROT. The control inserts the offset in the preset table, and the basic rotation also remains. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 225: Showing Basic Rotation And Offset

Apply with the SET BASIC ROTATION soft key Alternative: Apply with the SET TABLE ROTATION soft key Terminate the probing function: Press the END soft key HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 226: Determining A 3-D Basic Rotation

3rd point is on the minor axis, in a positive direction of the desired workpiece coordinate system The optional entry of a reference angle enables you to define the nominal direction of the probed plane. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 227

If a 3-D basic rotation is saved in the active preset, the control shows symbol for the 3-D basic rotation in the status display. The control moves the machine axes according to the 3-D basic rotation. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 228

PROBING PL soft key Enter 0 for all angles Press the SET BASIC ROTATION soft key Terminate the probing function: press the END soft key HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 229: Comparison Of Offset And 3-D Basic Rotation

The orientation is not The orientation is correct! correct! The next machining step will be correct. HEIDENHAIN recommends using 3D basic rotation because of its greater flexibility. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 230: Presetting With A 3-D Touch Probe (Option Number 17)

(possibly a manual preset defined in the Manual operation mode). The datum shift is taken into account in the position display. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 231: Presetting On Any Axis

Further information: «Writing measured values from the touch probe cycles to the preset table», Page 214 Terminate the probing function: Press the END soft key HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 232: Corner As Preset

Further information: «Writing measured values from the touch probe cycles to the preset table», Page 214 Terminate the probing function: Press the END soft key HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 233: Circle Center As Preset

More precise results are obtained with four touch points. If possible, always pre-position the touch probe to the center. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 234

Terminate the probing function: Press the END soft key Once the probing routine is completed, the control displays the current coordinates of the circle center and the circle radius. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 235

Further information: «Writing measured values from the touch probe cycles to the preset table», Page 214 Terminate the probing function: Press the END soft key HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 236: Setting A Center Line As Preset

This way you can determine the positions once, and then store them in the principal axis as well as in the secondary axis. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 237: Measuring Workpieces With A 3-D Touch Probe

Same axis but from the opposite direction Probe: Press the NC Start key The Measured value display shows the distance between the two points on the coordinate axis. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 238

Cancel the basic rotation, or restore the previous basic rotation Set the rotation angle to the value that you previously wrote down HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 239

Cancel the basic rotation, or restore the previous basic rotation by setting the rotation angle to the value that you wrote down previously HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 240: Tilting The Working Plane (Option

ISO Programming The control functions for tilting the working plane are coordinate transformations. The working plane is always perpendicular to the direction of the tool axis. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 241: Position Display In A Tilted System

The Actual-position capture function is not allowed if the Tilt working plane function is active PLC positioning (determined by the machine tool builder) is not possible. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 242: Activating Manual Tilting

The traverses are effective in the WPL-CS working plane coordinate system. Further information: «Working plane coordinate system WPL-CS», Page 120 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 243

Even if the 3D ROT dialog in the Manual operation operating mode is set to Active, resetting the tilting (PLANE RESET) with an active basic transformation will still work correctly. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 244: Setting The Tool-Axis Direction As The Active Machining Direction

The behavior of the control during presetting depends on the setting in the optional machine parameter chkTiltingAxes (no. 204601): Further information: «Introduction», Page 204 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 245: Testing And Running

Testing and running…

-

Page 246: Graphics (Option 20)

Further information: «Graphic settings», Page 348 If you are using a TNC 620 with touch control, you can replace some keystrokes with gestures. Further information: «Operating the touchscreen», Page 471 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 247

Positioning w/ Manual Data Input The PROGRAM + WORKPIECE and WORKPIECE soft keys appear dimmed. The line graphic in Programming operating mode also functions without option 20. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 248: View Options

Further information: User’s Manual for Klartext Programming or ISO Programming Show the block numbers of the tool paths Show the end points of the tool paths HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 249

(prior to machining), you can test externally created NC programs for corresponding irregularities by displaying the tool paths. The control saves the state of the soft keys in non- volatile memory. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 250: Tool

No movements If you move at rapid traverse inside a workpiece, both the movement and the workpiece are shown in red at the respective location. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 251: View

The high-resolution 3-D view enables you to display the surface of the machined workpiece in greater detail. Using a simulated light source, the control creates realistic light and shadow conditions. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 252: Rotating, Zooming And Moving A Graphic

To return to the standard display: Press the shift key and simultaneously double-click with the right mouse key. The rotation angle is maintained if you only double-click with the right mouse key HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 253: Setting The Speed Of The Test Run Mode

A part program can be graphically simulated as often as desired. To do so you can reset the graphic to the workpiece blank. Soft key Function Show the unmachined workpiece blank HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 254: Shifting The Sectional Plane

The sectional plan is automatically reset when the control is restarted. Proceed as follows to move the sectional plane to the default position: Press the soft key for resetting the sectional planes soft key HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 255: Monitoring For Collisions

Programming To activate extended collision monitoring, proceed as follows: Set the soft key to ON The control performs extended collision monitoring during a test run. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 256: Measurement Of Machining Time (Option 20)

Clear the displayed time Machining time in the machine operating modes Time display from program start to program end. The timer stops whenever machining is interrupted. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 257: Showing The Workpiece Blank In The Working Space (Option 20)

Use the current machine status Display the current traverse range Selecting the traverse range The ranges of traverse are config- ured by the machine manufactur- HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 258

For blank in work space, the control depicts the BLK FORM only schematically. With BLK FORM CYLINDER, a cuboid is depicted as the workpiece blank With BLK FORM ROTATION, no workpiece blank is depicted HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 259: Measuring

The corresponding information is displayed in a blue text field. The MEASURING soft key is available in the following views: Plan view 3-D view Further information: «View», Page 251 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 260: Optional Program-Run Interruption

Test Run at NC blocks that contain an M1. Set the M01 soft key to ON The control interrupts the Program run or Test Run at NC blocks with M1. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 261: Skipping Nc Blocks

The control inserts a slash (/). To show NC blocks again in the Programming mode: Select the hidden NC block Press the REMOVE soft key The control removes the slash (/). HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 262: Positioning W/ Manual Data Input

To show NC blocks again in the Positioning w/ Manual Data Input operating mode, proceed as follows: Select the hidden NC block Press the Backspace key The control removes the slash (/). HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 263: Exporting A Finished Part

Press the EXPORT WORKPIECE soft key The control opens a pop-up window. Enter the desired file name Select the desired target directory Confirm the data entered HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 264: Test Run

The graphical representation functions and the quality of the represented model depend on the settings in the Graphic settings MOD function. Further information: «Graphic settings», Page 348 HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 265

Test Run operating mode. This macro will simulate the exact behavior of the machine. In doing so, the machine tool builder often changes the simulated tool change position. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022… -

Page 266: Test Run Execution

Selecting another NC block with the arrow keys or the GOTO key Making changes to the NC program Selecting another NC program HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 267: Executing A Test Run Up To A Certain Nc Block

Modification before the interruption point: The simulation restarts at the beginning Modification after the interruption point: Positioning at the interruption point is possible with GOTO HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 268: Using The Goto Key

When the control provides a selection menu, you can use the GOTO key to open the selection window. This allows you to view the available entries. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 269: Scrollbar

Screen content can be shifted with the mouse using the scroll bar at the right edge of the program window. In addition, the size and position of the scrollbar indicates program length and cursor position. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 270: 6.10 Program Run

This reduction affects all rapid traverse and feed movements, even after the control has been restarted. Program Run, Full Sequence Start the NC program with the NC start key HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 271: Structuring Nc Programs

NC blocks in the program window. This way you can quickly skip large program sections. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 272: Checking And Changing Q Parameters

1399, because there might be interferences with machine manufacturer-specific functions. All of the parameters with displayed comments are used by the control within cycles or as transfer parameters. HEIDENHAIN | TNC 620 | User’s Manual for Setup, Testing and Running NC Programs | 01/2022…

-

Page 273