-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Quick Links

SERVICE

Samsung Color Laser Printer

CLP-310N

Color Laser Printer

CLP-315/XAZ

Basic Model : CLP-310N,CLP-315

Manual

The keynote of Product

The smallest / The lowest noise

High Quality Muti-path CLBP

— Model : CLP-31x series

— Speed(Color/Mono) : 4/16 ppm(A4). 4/17ppm(Let)

— Printing resolution : Max. 2,400 x 600 dpi

— Emulation : SPL-C

— Memory : 32 MB (Network model : 32MB )

— Processor : 360MHz

— Interface : IEEE 802.3,Ethernet(10/100Mbps)

Wireless: Not Supported

— Toner Cartridge :

1.5K Toner(K), 1K toner(C, M, Y each)

— Printer Life : 100,000 pages

Monthly Max. Duty : 20,000 pages/month

Troubleshooting

Summary of Contents for Samsung CLP-310N

Окончание поддержки: драйверы для принтеров в Windows 7, 8, 8.1, Server 2008, 2008R2.

HP больше не поддерживает эти драйверы принтеров с 1 ноября 2022 г. HP рекомендует обновить операционную систему до поддерживаемой версии. Подробнее

Color Laser Printer

CLP-31x Series

CLP-310/315/310N/315W

Basic Model : CLP-310,CLP-315

SERVICE Manual

Samsung Clolr Laser Printer

CLP-310N

The keynote of Product

The smallest / The lowest noise

High Quality Muti-path CLBP

— Model series : CLP-310/315

CLP-310N (Network model) CLP-315W (Wireless model)

—Speed(Color/Mono) : 4/16 ppm(A4). 4/17ppm(Let)

—Printing resolution : Max. 2,400 x 600 dpi

—Emulation : SPL-C

—Memory : 32 MB (Network model : 32MB)

64 MB (Wireless model : 64MB)

—Processor : Jupiter 360MHz (CLP-310/315/310N) Chorus 360MHz (CLP-315W)

—Interface : IEEE 802.3,Ethernet(10/100Mbps) Wireless: IEEE 802.11b/g(Only wireless model)

—Toner Cartridge

•Initial : 1K Toner(K), 0.7K Toner(C,M,Y, each)

•Sales : 1.5K Toner(K), 1K toner(C, M, Y each)

—Printer Life : 100,000 pages

Monthly Max. Duty : 20,000 pages/month

GSPN (Global Service Partner Network)

North America : service.samsungportal.com Latin America : latin.samsungportal.com CIS : cis.samsungportal.com

Europe : europe.samsungportal.com China : china.samsungportal.com Asia : asia.samsungportal.com

Mideast & Africa : mea.samsungportal.com

Samsung Electronics Co.,Ltd. January. 2008

|

Printed in Korea. |

|

|

VERSION NO. : 1.00 |

CODE : 0310-C0SEE |

Contents

1.Precautions

1.1Safety Warning••••••••••••••••••••••••••••••••••••••••••••••••••••••••1-1

1.2Caution for safety•••••••••••••••••••••••••••••••••••••••••••••••••••••1-2

1.3ESD Precautions••••••••••••••••••••••••••••••••••••••••••••••••••••••1-5

2.Product spec and feature

2.1Product Specifications•••••••••••••••••••••••••••••••••••••••••••••••2-1

2.1.1Product Overview•••••••••••••••••••••••••••••••••••••••••••••••2-1

2.1.2Prouduct Specification•••••••••••••••••••••••••••••••••••••••••2-2

2.1.3Model Comparison Table••••••••••••••••••••••••••••••••••••2-10

2.2System Overview••••••••••••••••••••••••••••••••••••••••••••••••••• 2-11

2.2.1System Structure•••••••••••••••••••••••••••••••••••••••••••••• 2-11

2.2.2Main PBA Description••••••••••••••••••••••••••••••••••••••••2-18

2.2.3CRUM•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••2-25

2.3S/W Structure and Descriptions••••••••••••••••••••••••••••••••••2-26

2.3.1Architecture•••••••••••••••••••••••••••••••••••••••••••••••••••••2-26

2.3.2Language Monitor•••••••••••••••••••••••••••••••••••••••••••••2-26

2.3.3Status Monitor••••••••••••••••••••••••••••••••••••••••••••••••••2-26

2.3.4Network Interface••••••••••••••••••••••••••••••••••••••••••••••2-27

2.3.5Printer Driver <-> Status Monitor•••••••••••••••••••••••••••2-27

2.3.6System F/W Flow••••••••••••••••••••••••••••••••••••••••••••••2-28

2.3.7Alarm Shortage••••••••••••••••••••••••••••••••••••••••••••••••2-29

2.3.8Error status•••••••••••••••••••••••••••••••••••••••••••••••••••••2-29

2.3.9CRUM Overview•••••••••••••••••••••••••••••••••••••••••••••••2-30

2.3.10FW Upgrade••••••••••••••••••••••••••••••••••••••••••••••••••2-30

2.3.11Initailize Flow•••••••••••••••••••••••••••••••••••••••••••••••••2-31

Continued

3.Disassembly and Reassembly

3.1Precautions when replacing parts•••••••••••••••••••••••••••••••••3-1

3.1.1Precautions when assembling and disassembling•••••••3-1

3.1.2Preautions when handling PBA•••••••••••••••••••••••••••••••3-1

3.1.3Releasing Plastic Latches•••••••••••••••••••••••••••••••••••••3-1

3.2Parts for Maintenance and Repair•••••••••••••••••••••••••••••••••3-2

3.2.1Replacement interval for parts with a limited life••••••••••3-2

3.2.2Printer Cleaning•••••••••••••••••••••••••••••••••••••••••••••••••3-3

3.3Information Related to Disassembly and Assembly••••••••••••3-4

3.3.1Special service parts••••••••••••••••••••••••••••••••••••••••••••3-4

3.3.2Screws used in the printer•••••••••••••••••••••••••••••••••••••3-5

3.4Disassembly Procedure•••••••••••••••••••••••••••••••••••••••••••••3-7

3.4.1Cover••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••3-7

3.4.2ITB••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••3-9

3.4.3Fuser•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••3-9

3.4.4HVPS board••••••••••••••••••••••••••••••••••••••••••••••••••••3-10

3.4.5Main PBA•••••••••••••••••••••••••••••••••••••••••••••••••••••••3-10

3.4.6SMPS board•••••••••••••••••••••••••••••••••••••••••••••••••••• 3-11

3.4.7LSU Unit••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 3-11

3.4.8Holder Pad••••••••••••••••••••••••••••••••••••••••••••••••••••••3-12

3.4.9Transfer roller••••••••••••••••••••••••••••••••••••••••••••••••••3-12

3.4.10OPE PBA••••••••••••••••••••••••••••••••••••••••••••••••••••••3-13

3.4.11Pick up roller••••••••••••••••••••••••••••••••••••••••••••••••••3-13

3.4.12Wireless PBA (only CLP-315W)••••••••••••••••••••••••••3-14

4.Alignment & Troubleshooting

4.1Alignment and Adjustments•••••••••••••••••••••••••••••••••••••••••4-1

4.1.1Control Panel•••••••••••••••••••••••••••••••••••••••••••••••••••••4-1

4.1.2Function•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••4-2

4.1.3Jam Removal••••••••••••••••••••••••••••••••••••••••••••••••••••4-5

Continued

4.1.4Sample Pattern••••••••••••••••••••••••••••••••••••••••••••••••••4-8

4.1.5Periodic Defective Image••••••••••••••••••••••••••••••••••••4-10

4.1.6How to use EDC (Engine Diagnostic Control) Mode••• 4-11

4.2Troubleshooting•••••••••••••••••••••••••••••••••••••••••••••••••••••4-17

4.2.1Procedure of Checking the Symptoms••••••••••••••••••••4-17

4.2.2Troubleshooting Checklist•••••••••••••••••••••••••••••••••••4-18

4.2.3Solving General Printing Problems••••••••••••••••••••••••4-19

4.2.4Solving Print Quality Problems•••••••••••••••••••••••••••••4-30

4.2.5Common Windows Problems•••••••••••••••••••••••••••••••4-48

4.2.6Common Macintosh Problems••••••••••••••••••••••••••••••4-49

4.2.7Common Linux Problems••••••••••••••••••••••••••••••••••••4-50

4.2.8Major Problems Trouble shooting••••••••••••••••••••••••••4-54

5.System Diagram

5.1Block Diagram•••••••••••••••••••••••••••••••••••••••••••••••••••••••••5-1

5.2Connection Diagram•••••••••••••••••••••••••••••••••••••••••••••••••5-2

6.Reference Information

6.1Tool for Troubleshooting•••••••••••••••••••••••••••••••••••••••••••••6-1

6.2Acronyms and Abbreviations•••••••••••••••••••••••••••••••••••••••6-2

6.3Select a location for the printer•••••••••••••••••••••••••••••••••••••6-4

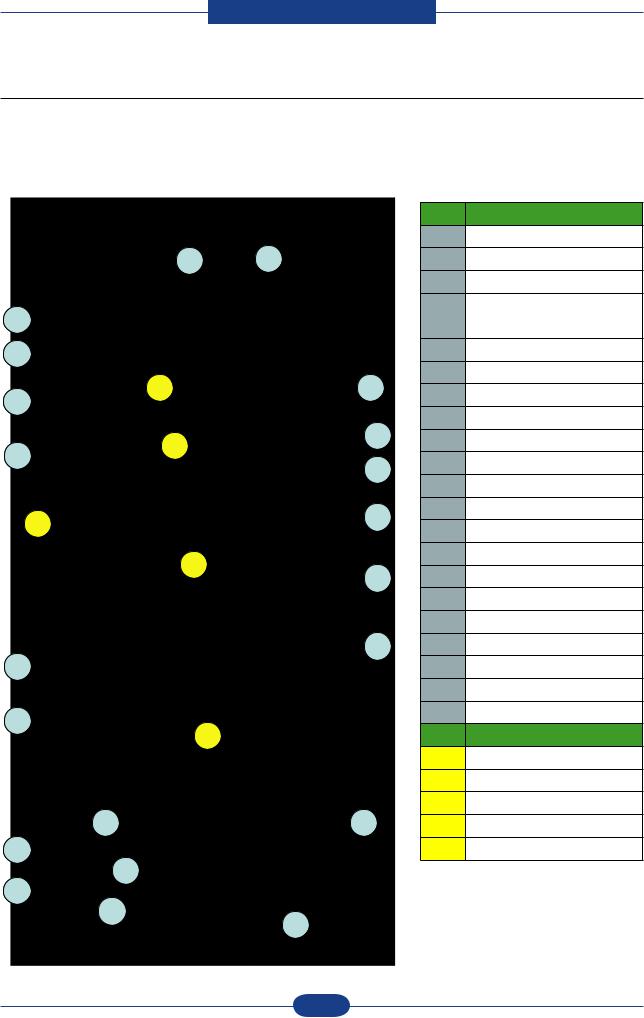

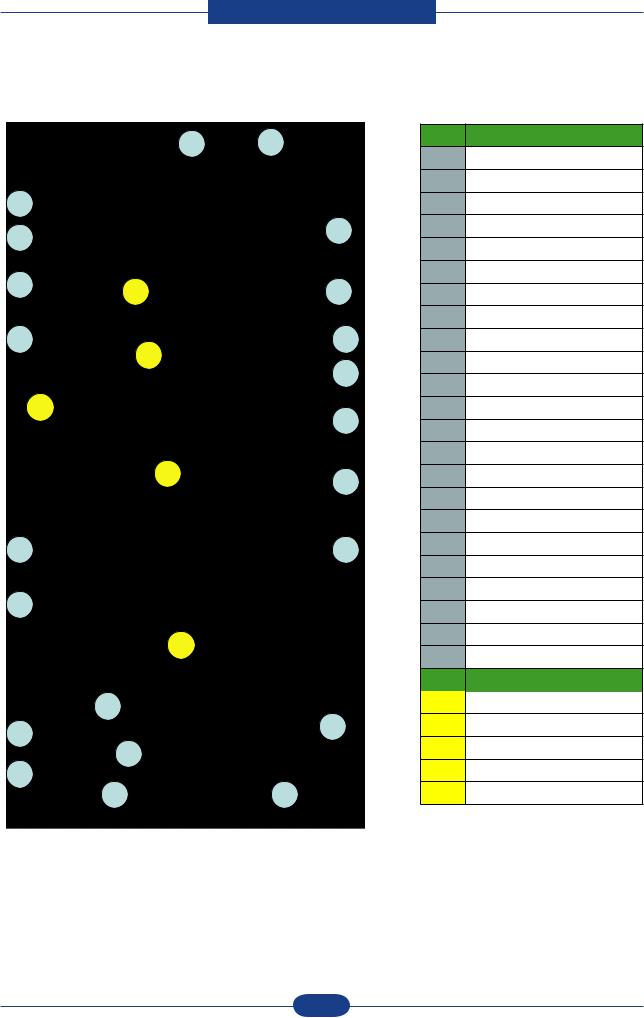

6.4A4 ISO 19798 Standard Pattern•••••••••••••••••••••••••••••••••••6-5

Continued

Parts Catalog

Power Cord•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 2

Thumbnail•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 3

1.Main••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 4

2.Cover Front•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 7

3.Cover Top•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••• 9

4.Rear Cover•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••11

5.Transfer Unit••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••13

6.Frame1••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••15

7.Frame2••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••17

8.Main Drive1•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••19

9.Main Drive2•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••21

10.Fuser Unit••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••23

11.Tank Waste Unit•••••••••••••••••••••••••••••••••••••••••••••••••••••••••25

12.Cassette•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••27

13.Frame Sub Unit 1 (MEA UNIT-PICK UP ROLL)•••••••••••••••••29

14.Frame Sub Unit 2 (MEA UNIT-FRAME EXIT)••••••••••••••••••••31

15.Frame Sub Unit 3 (MEA UNIT-GUIDE PICK UP)••••••••••••••••33

Precautions

1. Precautions

In order to prevent accidents and to prevent damage to the equipment please read the precautions listed below carefully before servicing the printer and follow them closely.

1.1 Safety Warning

(1)Only to be serviced by appropriately qualified service engineers.

High voltages and lasers inside this product are dangerous. This printer should only be serviced by a suitably trained and qualified service engineer.

(2)Use only Samsung replacement parts

There are no user serviceable parts inside the printer. Do not make any unauthorized changes or additions to the printer, these could cause the printer to malfunction and create electric shock or fire hazards.

(3)Laser Safety Statement

The Printer is certified in the U.S. to conform to the requirements of DHHS 21 CFR, chapter 1 Subchapter J for Class 1(1) laser products, and elsewhere, it is certified as a Class I laser product con-forming to the requirements of IEC 825. Class I laser products are not considered to be hazardous. The laser system and printer are designed so there is never any human access to laser radiation above a Class I level during normal operation, user maintenance, or prescribed service condition.

Warning >> Never operate or service the printer with the protective cover removed from Laser/

Scanner assembly. The reflected beam, although invisible, can damage your eyes. When using this product, these basic safety pre-cautions should always be followed to reduce risk of fire, electric shock, and injury to persons.

|

Service Manual |

1-1 |

Samsung Electronics |

Precautions

1.2 Caution for safety

1.2.1 Toxic material

This product contains toxic materials that could cause illness if ingested.

(1)If the LCD control panel is damaged it is possible for the liquid inside to leak. This liquid is toxic. Contact with the skin should be avoided, wash any splashes from eyes or skin immediately and contact your doctor. If the liquid gets into the mouth or is swallowed see a doctor immediately.

(2)Please keep Drum cartridge and Toner Cartridge away from children. The toner powder contained in the Drum cartridge and Toner Cartridge may be harmful and if swallowed you should contact a doctor.

1.2.2 Electric Shock and Fire Safety Precautions

Failure to follow the following instructions could cause electric shock or potentially cause a fire.

(1)Use only the correct voltage, failure to do so could damage the printer and potentially cause a fire or electric shock.

(2)Use only the power cable supplied with the printer. Use of an incorrectly specified cable could cause the cable to overheat and potentially cause a fire.

(3)Do not overload the power socket, this could lead to overheating of the cables inside the wall and could lead to a fire.

(4)Do not allow water or other liquids to spill into the printer, this can cause electric shock. Do not allow paper clips, pins or other foreign objects to fall into the printer these could cause a short circuit leading to an electric shock or fire hazard.

(5)Never touch the plugs on either end of the power cable with wet hands, this can cause electric shock.

When servicing the printer remove the power plug from the wall socket.

(6)Use caution when inserting or removing the power connector. The power connector must be inserted completely otherwise a poor contact could cause overheating possibly leading to a fire. When removing the power connector grip it firmly and pull.

(7)Take care of the power cable. Do not allow it to become twisted, bent sharply round corners or other wise damaged. Do not place objects on top of the power cable. If the power cable is damaged it could overheat and cause a fire or exposed cables could cause an electric shock. Replace a damaged power cable immediately, do not reuse or repair the damaged cable. Some chemicals can attack the coating on the power cable, weakening the cover or exposing cables causing fire and shock risks.

(8)Ensure that the power sockets and plugs are not cracked or broken in any way. Any such defects should be repaired immediately. Take care not to cut or damage the power cable or plugs when moving the machine.

(9)Use caution during thunder or lightening storms. Samsung recommend that this machine be disconnected from the power source when such weather conditions are expected. Do not touch the machine or the power cord if it is still connected to the wall socket in these weather conditions.

(10)Avoid damp or dusty areas, install the printer in a clean well ventilated location. Do not position the machine near a humidifier. Damp and dust build up inside the machine can lead to overheating and cause a fire.

(11)Do not position the printer in direct sunlight. This will cause the temperature inside the printer to rise possibly leading to the printer failing to work properly and in extreme conditions could lead to a fire.

(12)Do not insert any metal objects into the machine through the ventilator fan or other part of the casing, it could make contact with a high voltage conductor inside the machine and cause an electric shock.

|

Service Manual |

1-2 |

Samsung Electronics |

Precautions

1.2.3 Handling Precautions

The following instructions are for your own personal safety, to avoid injury and so as not to damage the printer

(1)Ensure the printer is installed on a level surface, capable of supporting its weight. Failure to do so could cause the printer to tip or fall.

(2)The printer contains many rollers, gears and fans. Take great care to ensure that you do not catch your fingers, hair or clothing in any of these rotating devices.

(3)Do not place any small metal objects, containers of water, chemicals or other liquids close to the printer which if spilled could get into the machine and cause damage or a shock or fire hazard.

(4)Do not install the machine in areas with high dust or moisture levels, beside on open window or close to a humidifier or heater. Damage could be caused to the printer in such areas.

(5)Do not place candles, burning cigarettes, etc on the printer, These could cause a fire.

1.2.4 Assembly / Disassembly Precautions

Replace parts carefully, always use Samsung parts. Take care to note the exact location of parts and also cable routing before dismantling any part of the machine. Ensure all parts and cables are replaced correctly. Please carry out the following procedures before dismantling the printer or replacing any parts.

(1)Check the contents of the machine memory and make a note of any user settings. These will be erased if the mainboard or network card is replaced.

(2)Ensure that power is disconnected before servicing or replacing any electrical parts.

(3)Disconnect printer interface cables and power cables.

(4)Only use approved spare parts. Ensure that part number, product name, any voltage, current or temperature rating are correct.

(5)When removing or re-fitting any parts do not use excessive force, especially when fitting screws into plastic.

(6)Take care not to drop any small parts into the machine.

(7)Handling of the OPC Drum

—The OPC Drum can be irreparably damaged if it exposed to light.

Take care not to expose the OPC Drum either to direct sunlight or to fluorescent or incandescent room lighting. Exposure for as little as 5 mins can damage the surface? photoconductive properties and will result in print quality degradation. Take extra care when servicing the printer. Remove the OPC Drum and store it in a black bag or other lightproof container. Take care when working with the covers(especially the top cover) open as light is admitted to the OPC area and can damage the OPC

Drum.

—Take care not to scratch the green surface of OPC Drum Unit.

If the green surface of the Drum Cartridge is scratched or touched the print quality will be compromised.

|

Service Manual |

1-3 |

Samsung Electronics |

Precautions

1.2.5 Disregarding this warning may cause bodily injury

(1)Be careful with the high temperature part.

The fuser unit works at a high temperature. Use caution when working on the printer. Wait for the fuser to cool down before disassembly.

(2)Do not put finger or hair into the rotating parts.

When operating a printer, do not put hand or hair into the rotating parts (Paper feeding entrance, motor, fan, etc.). If do, you can get harm.

(3)When you move the printer

—The equipment weighs approximately 11 Kg (including consumables), therefore pay attention when handling it.

—Be sure not to hold the movable parts or units (e.g. the control panel, DADF) when transporting the equipment.

—Be sure to use a dedicated outlet with 110V/220Vpower input.

—The equipment must be grounded for safety.

—Select a suitable place for installation. Avoid excessive heat, high humidity, dust, vibration and direct sunlight.

—Provide proper ventilation since the equipment emits a slight amount of ozone.

—The equipment shall be installed near the socket outlet and shall be accessible.

—Be sure to fix and plug in the power cable securely after the installation so that no one trips over it.

|

Service Manual |

1-4 |

Samsung Electronics |

Precautions

1.3 ESD Precautions

Certain semiconductor devices can be easily damaged by static electricity. Such components are commonly called “Electrostatically Sensitive (ES) Devices” or ESDs. Examples of typical ESDs are: integrated circuits, some field effect transistors, and semiconductor “chip” components.

The techniques outlined below should be followed to help reduce the incidence of component damage caused by static electricity.

Caution >>Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

1.Immediately before handling a semiconductor component or semiconductor-equipped assembly, drain off any electrostatic charge on your body by touching a known earth ground. Alternatively, employ a

commercially available wrist strap device, which should be removed for your personal safety reasons prior to applying power to the unit under test.

2.After removing an electrical assembly equipped with ESDs, place the assembly on a conductive surface, such as aluminum or copper foil, or conductive foam, to prevent electrostatic charge buildup in the vicinity of the assembly.

3.Use only a grounded tip soldering iron to solder or desolder ESDs.

4.Use only an “anti-static” solder removal device. Some solder removal devices not classified as “anti-static” can generate electrical charges sufficient to damage ESDs.

5.Do not use Freon-propelled chemicals. When sprayed, these can generate electrical charges sufficient to damage ESDs.

6.Do not remove a replacement ESD from its protective packaging until immediately before installing it. Most replacement ESDs are packaged with all leads shorted together by conductive foam, aluminum foil, or a comparable conductive material.

7.Immediately before removing the protective shorting material from the leads of a replacement ESD, touch the protective material to the chassis or circuit assembly into which the device will be installed.

8.Maintain continuous electrical contact between the ESD and the assembly into which it will be installed, until completely plugged or soldered into the circuit.

9.Minimize bodily motions when handling unpackaged replacement ESDs. Normal motions, such as the brushing together of clothing fabric and lifting one’s foot from a carpeted floor, can generate static electricity sufficient to damage an ESD.

|

Service Manual |

1-5 |

Samsung Electronics |

Product spec and feature

2. Product spec and feature

2.1 Product Specifications

2.1.1 Product Overview

|

Item |

Descriptions |

|

|

Basic Model |

CLP-310/315 |

|

|

Series Model |

CLP-310N : Network Model |

|

|

CLP-315W : Wireless Model |

||

|

Main Specification |

1. Speed |

|

|

• Up to 16 ppm in A4 (17 ppm in Letter) |

||

|

• Up to 4 ppm in A4 (4 ppm in Letter) |

||

|

2. |

Printing Resolution |

|

|

• Max. 2400×600 dpi effective output |

||

|

3. |

Processor |

|

|

• Chorus3 (360Mhz, CLP-315W), Jupiter (360Mhz, CLP-310/315/310N) |

||

|

4. |

Printer Language Emulations |

|

|

• SPL-Color |

||

|

5. |

Memory |

|

|

• FLASH ROM 2MB : CLP-310/315 |

||

|

4MB : CLP-310N |

||

|

8MB : CLP-315W |

||

|

• DDR2 SDRAM 32MB : CLP-310/315/310N |

||

|

64MB : CLP-315W |

||

|

6. |

Interfaces |

|

|

• One USB port |

||

|

• One 10/100 BaseT network connector |

||

|

• One IEEE 802.11 b/g wireless LAN |

||

|

7. |

Control Panel |

|

|

• No LCD, 1 keys and 6 LEDs |

||

|

8. Toner cartridge |

||

|

• Black : 1K (initial) / 1.5K (sales) |

||

|

• Color : 0.7K (initial) / 1K (sales) |

||

|

9. |

Color |

|

|

• There are two kinds of colors. (Gray and Black) |

||

|

Service Manual |

2-1 |

Samsung Electronics |

Product spec and feature

2.1.2 Prouduct Specification

Specifications are correct at the time of printing. Product specifications are subject to change without notice. See below for product specifications.

2.1.2.1 General Print Engine

|

Item |

CLP-310/315 |

CLP-310N/CLP-315W |

|

|

Print Speed |

Simplex |

B&W : 17ppm@Letter |

B&W : 17ppm@Letter |

|

16ppm@A4 |

16ppm@A4 |

||

|

Color : 4ppm@A4,.Letter |

Color : 4ppm@A4,.Letter |

||

|

Duplex |

NA |

NA |

|

|

Print Emulation |

SPL-C |

SPL-C |

|

|

Auto Emulation Sensing |

NA |

NA |

|

|

Font |

Type |

NA |

NA |

|

Number |

NA |

NA |

|

|

Power Save |

Yes (5/10/15/30/60/120min.) |

Yes (5/10/15/30/60/120min.) |

|

|

Resolution |

Normal |

Up to 2400X600dpi Class |

Up to 2400X600dpi Class |

|

(Default 1200×600 dpi) |

(Default 1200×600 dpi) |

||

|

Optical: 600×600 Dpi |

Optical: 600×600 Dpi |

||

|

RET |

NA |

NA |

|

|

Toner Save |

NA |

NA |

|

|

FPOT |

From Ready |

Less than 26 sec ( Color ) |

Less than 26 sec ( Color ) |

|

Less than 14 sec ( B&W ) |

Less than 14 sec ( B&W ) |

||

|

From Idle |

Less than 57 sec ( Color ) |

Less than 57 sec ( Color ) |

|

|

Less than 45 sec (B&W) |

Less than 45 sec (B&W) |

||

|

From Cold Boot |

Less than 57 sec ( Color ) |

Less than 57 sec ( Color ) |

|

|

Less than 45 sec (B&W) |

Less than 45 sec (B&W) |

||

|

Duplex Print |

NA |

NA |

|

|

Printable Area |

210 x 297 mm (A4) |

210 x 297 mm (A4) |

|

|

216 x 279 mm (Letter) |

216 x 279 mm (Letter) |

||

|

216 x 355.6 mm (Legal) |

216 x 355.6 mm (Legal) |

||

|

Print Margin |

Side Margin: 4.23±2mm |

Side Margin: 4.23±2mm |

|

|

Top Margin: 4.23±3mm |

Top Margin: 4.23±3mm |

||

|

Service Manual |

2-2 |

Samsung Electronics |

Product spec and feature

2.1.2.2 Controller & S/W

|

Item |

CLP-310/315 |

CLP-310N/CLP-315W |

|

|

MPU |

Jupiter (360Mhz) |

310N : Jupiter (360Mhz) |

|

|

315W : Chorus3 (360Mhz) |

|||

|

Memory |

Standard / Max. |

32MB / 32MB |

32MB / 32MB |

|

Type |

DDR2 SDRAM |

DDR2 SDRAM |

|

|

Expand Memory Slot &Type |

NA |

NA |

|

|

Compression Technology |

YES |

YES |

|

|

Supporting OS |

Microsoft Windows: |

Microsoft Windows: |

|

|

2000/2003/XP(Include 64bit),Vista |

2000/2003/XP(Include 64bit),Vista |

||

|

Linux(Printer only)OS: |

MacOS:10.3,10.4 |

||

|

Red Hat 8~9, Fedora Core 1~4 |

MacOS:10.3,10.4 |

||

|

Mandrake 9.2~10.1 |

Linux(Printer only)OS: |

||

|

SuSE 8.2~9.2 |

Red Hat 8~9, Fedora Core 1~4 |

||

|

Mandrake 9.2~10.1 |

|||

|

SuSE 8.2~9.2 |

|||

|

Default Driver |

SPL-C |

SPL-C |

|

|

Driver feature |

Microsoft Windows: |

Microsoft Windows: |

|

|

-Watermark |

-Watermark |

||

|

-N-up printing |

-N-up printing |

||

|

-Poster printing |

-Poster printing |

||

|

-Manual Dulpex |

-Manual Dulpex |

||

|

-Quality(Best,Normal,Draft) |

-Quality(Best,Normal,Draft) |

||

|

-Color mode(Color, Gray scale) |

-Color mode(Color, Gray scale) |

||

|

-Device Color Support |

-Device Color Support |

||

|

-Color Management Support |

-Color Management Support |

||

|

[Mac] |

[Mac] |

||

|

-N-up printing |

-N-up printing |

||

|

-Quality(Best,Normal,Draft) |

-Quality(Best,Normal,Draft) |

||

|

-Color mode(Color, Gray scale) |

-Color mode(Color, Gray scale) |

||

|

[Linux] |

[Linux] |

||

|

— N-up printing |

— N-up printing |

||

|

-Quality(Best,Normal,Draft) |

-Quality(Best,Normal,Draft) |

||

|

[Common] |

[Common] |

||

|

-N/W Install |

-N/W Install |

||

|

during driver install |

during driver install |

||

|

WHQL |

Windows 2000 including vista |

Windows 2000 including vista |

|

|

Service Manual |

2-3 |

Samsung Electronics |

Product spec and feature

|

Item |

CLP-310/315 |

CLP-310N/CLP-315W |

|

Language Locallization |

[Windows] |

[Windows] |

|

— Korean,English,French,Germa |

— Korean,English,French,Germa |

|

|

N,Italian,Spanish,Russian,Dutch, |

N,Italian,Spanish,Russian,Dutch, |

|

|

E.Portuguese,B.Portuguese,Fi |

E.Portuguese,B.Portuguese,Fi |

|

|

Nish,Swedish,Norwegian,Danish |

Nish,Swedish,Norwegian,Danish |

|

|

S.Chinese,T.Chinese,Polish, |

S.Chinese,T.Chinese,Polish, |

|

|

Hungarian,Greek,Czech,Turkish |

Hungarian,Greek,Czech,Turkish |

|

|

[Mac] |

[Mac] |

|

|

— Korean,English,French,Germa |

— Korean,English,French,Germa |

|

|

N,Italian,Spanish |

N,Italian,Spanish |

|

|

[Linux] |

[Linux] |

|

|

— English Only |

— English Only |

|

|

Smart Panel |

USB |

310N : USB/Network |

|

315W : USB/Network/Wireless |

||

|

Network |

||

|

Default Install |

Default Install |

|

|

Network |

NA |

Set IP.SWAS &SWS (Linux, Mac |

|

Management |

not support, SWAS&SWS need I |

|

|

explorer 5.0 or Higher) |

||

|

NA Management |

||

|

Smart Thru |

NA |

Smart Thru 4 |

|

Service Manual |

2-4 |

Samsung Electronics |

Product spec and feature

2.1.2.3 Interface

|

Item |

CLP-310/315 |

CLP-310N/CLP-315W |

|

|

Interface |

Parallel |

NA |

NA |

|

USB |

USB 2.0 |

USB 2.0 |

|

|

Network |

NA |

Ethernet 10/100 base Tx |

|

|

Wireless |

NA |

802.11 b/g (only 315W) |

|

|

Network |

Protocol |

NA |

TCP/IP,IPP,SNMPv2 |

|

Interface |

|||

|

Network OS |

NA |

— Microsoft Windows: |

|

|

98/ME/2000/XP(32/64Bit) |

|||

|

2003 Server(32/64Bit)/ Vista |

|||

|

— Mac OS: 10.3,10.4(Printing |

|||

|

OnTCP/IP) |

|||

|

— Linux OS: Red Hat 8~9, |

|||

|

Fedora Core 1~4 |

|||

|

Mandrake 9.2~10.1 & Suse |

|||

|

8.2~9.2 |

|||

|

— Unix HP-UX, Solaris,SunOS |

|||

|

SCO UNIX |

|||

|

User |

LCD |

NA |

NA |

|

Interface |

OP UI |

Key 1 EA, LED 6EA |

Key 1 EA, LED 6EA |

|

Sound UI |

NA |

NA |

|

|

Service Manual |

2-5 |

Samsung Electronics |

Product spec and feature

2.1.2.4 Paper Handling

|

Item |

CLP-310/315 |

CLP-310N/CLP-315W |

|

|

Capacity |

Cassette |

150sheets@75g/ (Max) |

150sheets@75g/ (Max) |

|

Envelop ; 5 Sheets |

Envelop ; 5 Sheets |

||

|

Transparency ; 1 Sheets |

Transparency ; 1 Sheets |

||

|

Label , thick paper ; 10 Sheets |

Label , thick paper ; 10 Sheets |

||

|

MP Tray |

NA |

NA |

|

|

Option Cassette |

NA |

NA |

|

|

Output Capacity |

Face Down: 100Sheets/20lb |

Face Down: 100Sheets/20lb |

|

|

Envelop ; 5 Sheets |

Envelop ; 5 Sheets |

||

|

Transparency ; 1 Sheets |

Transparency ; 1 Sheets |

||

|

Label , thick paper ; 10 Sheets |

Label , thick paper ; 10 Sheets |

||

|

Output Full Sensing |

No |

No |

|

|

Duplex |

NA |

NA |

|

|

Paper Type |

Cassette |

A4, A5,A6, Letter, Legal, |

A4, A5,A6, Letter, Legal, |

|

Executive, Folio, ISO B5, JIS B5 |

Executive, Folio, ISO B5, JIS B5 |

||

|

Transparency;(Mono Print Only) |

Transparency;(Mono Print Only) |

||

|

MP Tray |

NA |

NA |

|

|

Option Tray |

NA |

NA |

|

|

Paper Weight |

Cassette |

16~43 lb. (60 to 163g/ ) |

16~43 lb. (60 to 163g/ ) |

|

Paper Path |

Standard output |

Bottom to Top Front (FIFO) |

Bottom to Top Front (FIFO) |

|

Straight Through |

NA |

NA |

|

|

Paper Size |

Max |

216 x 355.6mm(8.5”x14”) |

216 x 355.6mm(8.5”x14”) |

|

Min |

76 x 160mm(3”x6.3”) |

76 x 160mm(3”x6.3”) |

|

|

Jam Rate |

Cassette |

1/3,000 |

1/3,000 |

|

Multi-Feed Rate |

Cassette |

1/1,500 |

1/1,500 |

|

Printing Skew |

Top |

1.5/201.4mm (Cassette) |

1.5/201.4mm (Cassette) |

|

Side |

2.0/270.4mm (Cassette) |

2.0/270.4mm (Cassette) |

|

|

Service Manual |

2-6 |

Samsung Electronics |

Product spec and feature

2.1.2.5 Consumables

|

Item |

Image |

Pages Printed |

Part number |

Remark |

|

Black Toner |

Approx. Initial : 1,000 Pages* |

CLT-K409S(Black) |

CRU |

|

|

cartridge |

Sales : 1,500 Pages* |

|||

|

Color Toner |

Approx. Initial : 700 Pages* |

CLT-C409S(Cyan) |

||

|

cartridge |

Sales : 1,000 Pages* |

CLT-M409S(Magenta) |

||

|

CLT-Y409S(Yellow) |

||||

|

Imagine unit |

Approx. 24000 images* |

CLT-R409 |

||

|

Waste Toner |

Mono: Approx. 2500 images |

CLT-W409 |

||

|

Color: Approx. 2500 images |

||||

|

Pick-up roller |

Approx. 50,000 pages |

JC97-03028A |

FRU |

|

|

Fuser unit |

Approx. 100,000 black |

JC96-05492B(110V) |

||

|

pages or 50,000 color bages |

||||

|

JC96-05491B (220V) |

||||

|

T2 roller |

Approx. 10,000 pages |

JC97-03046A |

||

|

ITB |

Approx. 100,000 black |

JC96-04840A |

||

|

pages or 50,000 color bages |

||||

*Average A4-/letter-sized page count based on Std. ISO 19798 of individual colors on each page. Usage conditions and print patterns may cause results to vary.

|

Service Manual |

2-7 |

Samsung Electronics |

Product spec and feature

2.1.2.6 Reliability & Service

|

Item |

CLP-310/315 |

CLP-310N/CLP-315W |

|

Max Monthly Duty |

20,000 image |

20,000 image |

|

(Color: 16,000/ Mono: 4,000) |

(Color: 16,000/ Mono: 4,000) |

|

|

SET Life Cycle |

100,000image or 5 years |

100,000image or 5 years |

|

whichever comes first |

whichever comes first |

|

|

MTBF |

40,000 images |

40,000 images |

|

(color 32,000 images and black |

(color 32,000 images and black |

|

|

8,000 images : total 40,000 |

8,000 images : total 40,000 image) |

|

|

image) |

||

|

MTTR |

<30 min. |

<30 min. |

|

Real-time Clock |

No |

No |

|

System record |

Total image count |

Total image count |

|

Total page count (color/mono) |

Total page count (color/mono) |

|

|

Imaging unit Information |

Imaging unit Information |

|

|

Transfer roller life |

Transfer roller life |

|

|

Transfer belt life |

Transfer belt life |

|

|

Toner information |

Toner information |

|

|

Tray roller life |

Tray roller life |

|

|

Minimum System Requirement |

Pentium400MHZ, 64MB RAM, |

Pentium400MHZ, 64MB RAM, |

|

300MB HDD, Internet Explorer 5.0 |

300MB HDD, Internet Explorer 5.0 |

|

|

Service Manual |

2-8 |

Samsung Electronics |

Product spec and feature

2.1.2.7 Environment

|

Item |

CLP-310/315 |

CLP-310N/CLP-315W |

|

|

Power |

Ready |

Less than 160W |

Less than 160W |

|

Consumption |

|||

|

Average |

Less than 350W |

Less than 350W |

|

|

(Currency:5A(110V)/3A(220V) |

(Currency:5A(110V)/3A(220V) |

||

|

Max/Peak |

700W/1KW |

700W/1KW |

|

|

Sleep/Power off |

Less than 8.4W |

Less than 8.4W |

|

|

Power Supply |

Input Voltage |

Low Voltage : 110 ~ 127VAC |

Low Voltage : 110 ~ 127VAC |

|

High Voltage : 220 ~ 240VAC |

High Voltage : 220 ~ 240VAC |

||

|

Input Frequency |

50 / 60Hz(+/- 3Hz) |

50 / 60Hz(+/- 3Hz) |

|

|

Noise |

Printing |

Mono : 46dBA |

Mono : 46dBA |

|

Color : 48dBA |

Color : 48dBA |

||

|

Standby |

Background noise level |

Background noise level |

|

|

Sleep |

Background noise level |

Background noise level |

|

|

Warm Up Time |

From Cold Status |

Less than 35 seconds |

Less than 35 seconds |

|

(At rated volt) |

|||

|

Temperature |

Operating |

10~32.5 |

10~32.5 |

|

Storage (Un-Packed) |

5~35 |

5~35 |

|

|

Storage (Packed) |

-20~50 |

-20~50 |

|

|

Humidity |

Operating |

20 ~ 80% RH |

20 ~ 80% RH |

|

Storage (Un-Packed) |

20 ~ 80% RH |

20 ~ 80% RH |

|

|

Storage (Packed) |

10~90% RH |

10~90% RH |

|

|

Altitude |

Normal: 0~3000ft (0~1000m) |

Normal: 0~3000ft (0~1000m) |

|

|

High: 3001~6600ft( ~2000m) |

High: 3001~6600ft( ~2000m) |

||

|

Higher: 6601~9900ft( ~3000m) |

Higher: 6601~9900ft( ~3000m) |

||

|

Highest;9901~13000ft( ~4000m) |

Highest;9901~13000ft( ~4000m) |

||

2.1.2.8 Accessory

|

Item |

CLP-310/315 |

CLP-310N/CLP-315W |

||

|

Quick setup guide |

Yes |

Yes |

||

|

Owner’s manual |

Yes |

Yes |

||

|

S/W CD ROM |

1 : for Driver |

1 |

: for Driver |

|

|

2 |

: for Network |

|||

|

S/W |

1 CD for Driver, SmarThru 4 |

1 CD for Driver, SmartThru 4, EUG |

1 CD for Driver, SmartThru 4, EUG |

|

|

Toner Cartridge |

4 EA (0.7K/0.5K yield ISO 19752 |

4 |

EA (0.7K/0.5K yield ISO 19752 |

|

|

5% Coverage) |

5% Coverage) |

|||

|

Power Cable |

1 EA |

1 EA |

||

|

Printer Cable |

1 EA |

1 |

EA |

|

Service Manual |

2-9 |

Samsung Electronics |

Product spec and feature

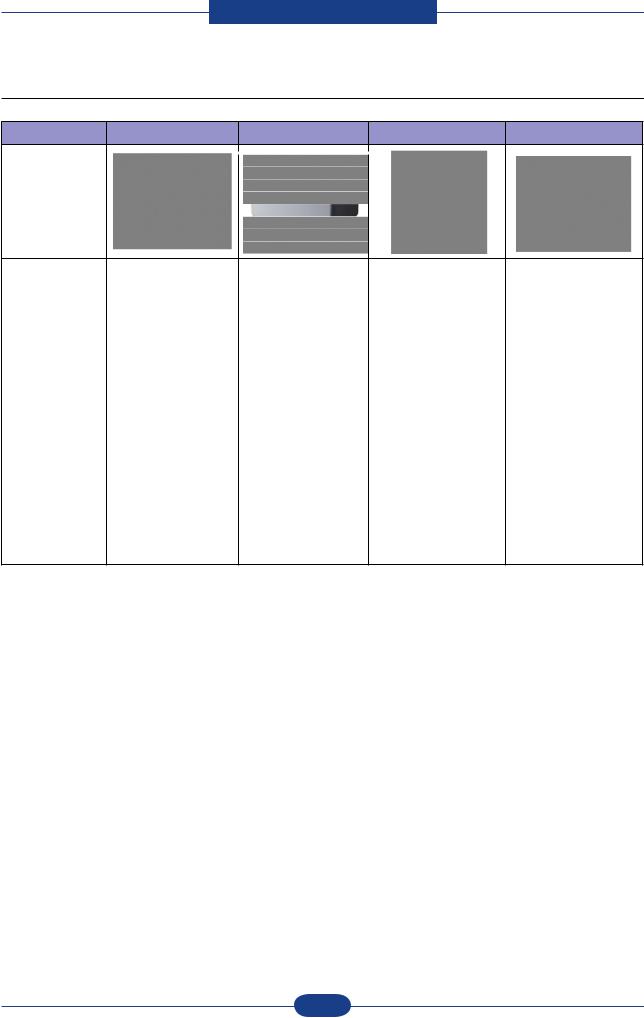

2.1.3 Model Comparison Table

|

Samsung CLP-310 Samsung CLP-300 |

HP CLJ 1600 |

HP LJ 1022 |

Image

|

Speed |

16/4 ppm |

16/4 ppm |

8/8 ppm -> 12/10 |

18 ppm |

|

ppm (E) |

||||

|

processor |

360 MHz |

300 MHz |

264 MHz |

266 MHz |

|

Memory |

32 MB |

32 MB |

16 MB |

8 MB |

|

Print Language |

SPL-C |

SPL-C |

GDI |

PCL5e |

|

Input |

150 sheets CST |

150 sheets CST |

250 sheets CST, 1 |

150 sheets MP, 10 |

|

Manual |

Manual |

|||

|

Duplex |

Manual |

Manual |

Manual |

Manual |

|

Interface |

USB 2.0 |

USB 2.0 |

USB 2.0 |

USB 2.0 |

|

Size (mm) |

388 x 314 x 237 |

350x315x250 |

407 x 453 x 370 |

370 x 245 x 241 |

|

Weight |

11 kg |

13 kg |

18.4 kg |

5.5 kg |

|

Noise |

45 dBA |

49 dBA |

47 dBA |

— |

|

Toner (Black/ |

1.5 K/1K |

2K/1K |

2.5 K/2K |

2K |

|

Color) |

|

Service Manual |

2-10 |

Samsung Electronics |

Product spec and feature

2.2 System Overview

This chapter describes the functions and operating principles of the main components.

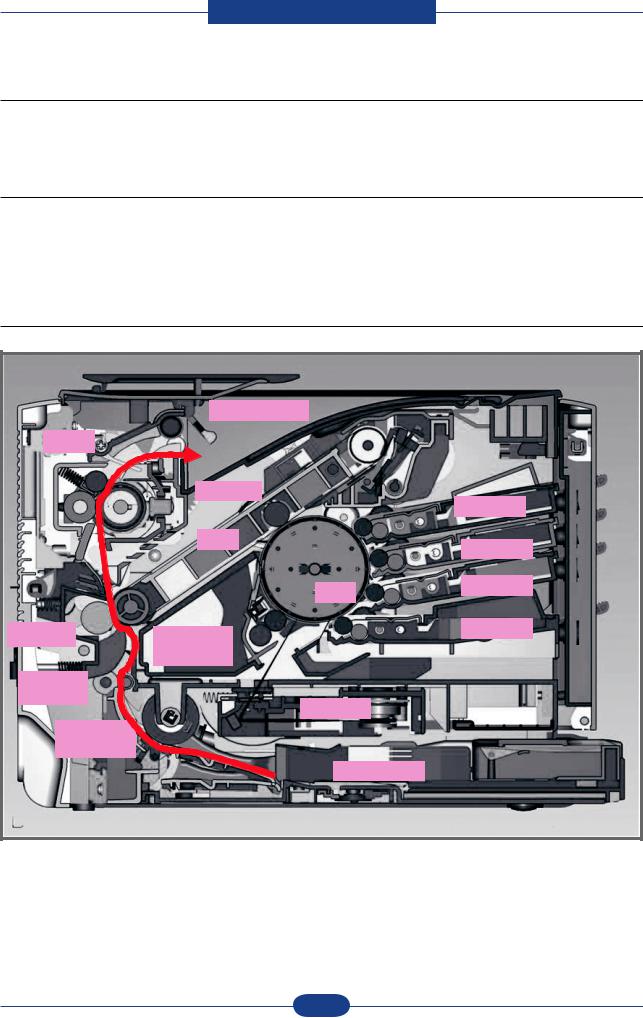

2.2.1 System Structure

The Printer function consists of the Engine part and the Main Controller part, and the Engine part consists of the Mechanical part comprising a Frame, Feeding, Developing, Driving, Transferring, Fusing, and Cabinet and the Electrical part comprising a SMPS, a HVPS, a LSU, and some facilities in the Main Controller to control the Engine part for printing.

2.2.1.1 Main Parts of System

Stacking Area

|

Fuser |

||

|

DEVE Y |

||

|

DEVE M |

||

|

OPC |

DEVE C |

|

|

T2 Roller |

DEVE K |

|

Regi.

Roller

LSU

Pick

Cassette

|

Service Manual |

2-11 |

Samsung Electronics |

Product spec and feature

Cassette

•Feeding Method : Cassette Type

•Feeding Standard : Center Loading

•Feeding Capacity : Cassette 150 Sheets(75g/ , 20lb Pa per Standard)

•No Manual Feeder

•Paper Detecting Sensor : Photo Sensor (Empty, Registration, Exit)

•Paper Size Sensor : None

LSU(Laser Scan Unit)

The LSU unit is controlled by video controller. It scans the video data received from video controller with laser beam by using the rotation principle of the polygon mirror to create the latent image on the OPC drum. It is the core part of LBP.

The OPC drum rotates as the same speed as the paper feeding speed. It creates the /HSYNC signal and sends it to the engine when the laser beam of the LSU reaches the end of the polygon mirror, and the engine detects the /HSYNC signal to arrange the vertical line of the image on the paper. After detecting the /HSYNC signal, the image data is sent to the LSU to arrange the its margin on the paper.

•Consisted of LD(Laser Diode) and Polygon Motor Control.

|

Error |

Phenomenon |

||

|

Polygon Motor Error |

The Rotation of Polygon Motor can not reach stable |

||

|

Hsync Error |

Though the rotation of Polygon Motor reach stable, the signal of Hsync is |

||

|

not occurred |

|||

|

Service Manual |

2-12 |

Samsung Electronics |

Product spec and feature

2nd Transfer Ass’y

•The life span: Print over 100,000 sheets (in 15~30 )

•Specification: Similar to CLP-300 Series

Fuser Ass’y

This unit consists of Heat Roller, a Thermostat and a Thermistor. It melts and fuses the toner, transferred by the transfer roller onto the paper, by applying pressure and high temperature to complete printing job.

* Heat Lamp : Kunckle Type

*Fusing system : 3-Roll Fusing type

—Heat roller : Pipe type (Lamp inside)

—Pressure roller

—Pressure roller Shaft

*Thermistor — Temperature-Measuring Device

*Thermostat — Critical Temperature-Detecting Device

*The life span – 100k(black)/color(25k)

Thermostat

When a heat lamp is overheated, a Thermostat cuts off the main power to prevent over-heating. — Non-Cotact type Thermostat

Heat roller

The heat roller transfers the heat from the lamp to apply a heat on the paper. The surface of a heat roller is coated with Teflon, so toner does not stick to the surface.

Pressure roller

A pressure roller mounted under a heat roller is made of a silicon resin, and the surface also is coated with Teflon. When a paper passes between a heat roller and a pressure roller, toner adheres to the surface of a paper permanently.

|

Service Manual |

2-13 |

Samsung Electronics |

Product spec and feature

& ITB(Intermediate Transfer Belt) & 1st Transfer Roller

•The life span: Print over 100,000 Images

•The ITB unit includes 1st Transfer Roller

& OPC(Organic Photo-Conductor) & Developer

•The life span: Print over 50,000 Images (Both)

•Imagine Unit consists of 4 kinds of Developer , OPC, and Deve. Main Frame

Toner Kits

•The life span: Color -> 1000 images (Std. ISO 19798 Print-Out) Black -> 1500 images (Std. ISO 19798 Print-Out)

Driver Ass’y

•It is a power delivery unit by gearing

•By driving the motor, it supplies the power to the feeding unit, the fusing unit, and the distributing unit.

•The Main Motor is similar to CLP-300 Series Main Motor.

Wireless PBA (Only CLP-315W)

•CLP-315W model has a Wireless PBA to use wireless network.

|

Service Manual |

2-14 |

Samsung Electronics |

Product spec and feature

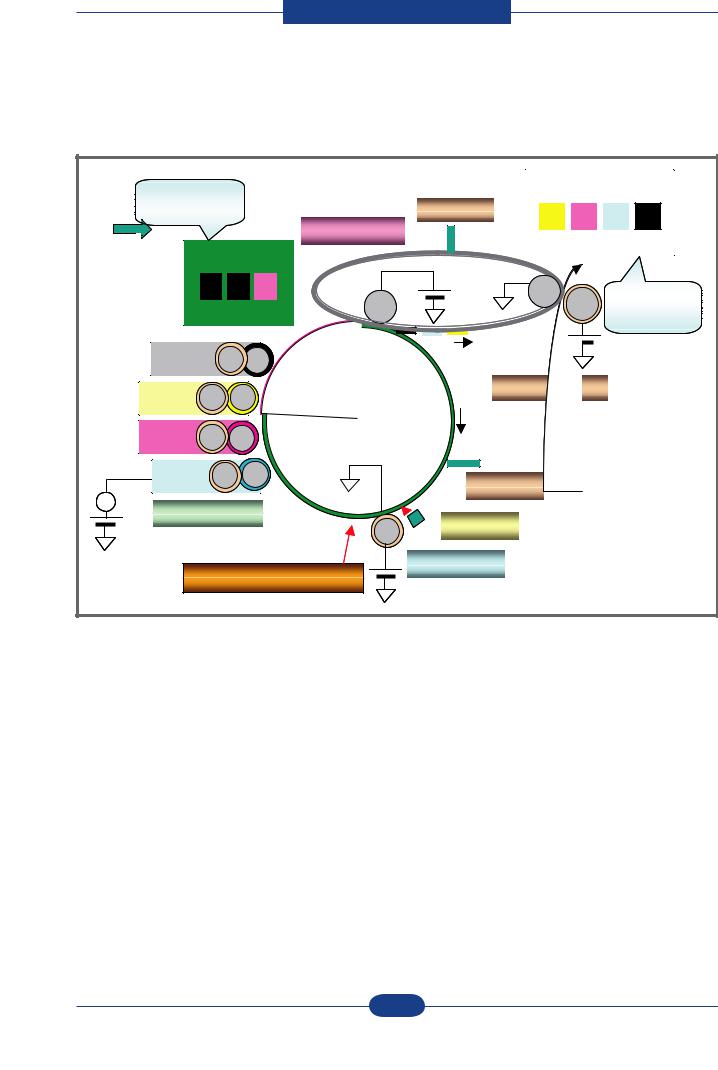

2.2.1.2 EP Process

— Structure of EP Process

|

P1: Image |

Blade |

|

|

on OPC |

||

|

ITB Unit |

||

|

P2: Image |

||

|

on Media |

||

|

Media Path |

||

|

OPC |

||

|

~ |

Blade |

|

|

Developer |

||

|

Eraser |

||

|

Laser Scanning Unit |

Charger |

|

|

Service Manual |

2-15 |

Samsung Electronics |

Product spec and feature

Charging

•Conductive Roller charging

•Applied voltage : -1.1kV

•Charge acceptance : -520V

•OPC coating thickness : 21um

•OPC diameter : Φ60mm

•Eraser system

1.Organic Photoconductor is charged to uniform voltage by conductive roll charging method

2.No ozone is produced because corona is not used

3.Charger roll is cleaned with cleaning roll

4.Toner remained on OPC after T1 process is cleaned by cleaning blade and retrieved into waste toner box by auger and belt driving mechanism

Exposing

•One polygon motor ( 6 facet )

•Single beam LD (1ea)

•LD wavelength : 785nm

•Polygon motor rpm : 29685

•LSU energy : 0.25uJ/cm^2

•OPC exposed potential : -50V

1.Exposing is implemented by laser striking on to OPC with uniform potential

2.Laser beam is modulated according to image to be printed that is from PC

3.Latent Image is formed on OPC, which is developed with toner

Developing

•Non-magnetic, mono component

•Non-contact development

•Developing bias : DC + AC

•AC peak to peak : 1.5 ~ 2.0kV

•Roller diameter : Φ10mm

•Process speed ratio : 1.2 (OPC=1.0)

•Color order : Y -> M -> C -> K

1.Only latent image formed by exposing process is developed with toner

2.AC + DC Voltage is being used to develop toner into latent image on OPC because non-contact developing method is adopted

3.Y, M, C, and K Images are sequentially developed onto OPC and transferred onto Intermediate Transfer Belt (hereafter ITB) to form a color image on ITB

4.Toner Bottles are used to supply toner into developer compartment

5.Toner level is being sensed to control toner supply from toner bottle to developer

|

Service Manual |

2-16 |

Samsung Electronics |

Product spec and feature

Transfer 1

•Multi-pass transfer

•Indirect transfer

•Transfer voltage : 0.5 ~ 2.0kV (controllable)

•Roller diameter : Φ14mm

•Transfer unit life : 100K images

1.Developed Image on OPC is transferred onto ITB by T1 Process

2.T1 Voltage is positive which attract toner to ITB

3.4 times of T1 process is required to make a color image on ITB, which means multi-pass process

4.ITB has a hole as a fiducial mark for timing. Engine control for color image is synchronous with it, ITB Home Sensing Signal

Transfer 2

•Indirect transfer

•Transfer voltage : 1 ~ 4.0kV (controllable)

•Roller diameter : Φ18.6mm

•Transfer unit life : 100 K images

1.Color image formed on ITB is transferred onto media by T2 process

2.T2 voltage is also positive to get color image moved onto media

3.Toner remained on ITB after T2 process is cleaning by ITB cleaning blade and collected and

4.Transported and retrieved into waste toner box by auger and belt driving system

5.T2 Roll is engaged when color image is being transferred onto media. Otherwise it is disengaged. Clutch is used for driving T2 Roll engagement and disengagement

Fusing

•3 Roll system

-> short warm-up time (35sec)

•Post Pressure Roll

1. Color Image on media is melted down and fixed into media by fusing process

|

Service Manual |

2-17 |

Samsung Electronics |

Product spec and feature

2.2.2 Main PBA Description

2.2.2.1 Main Controller PBA

— CLP-310N ( VE model )

14 16

9

7

A

12

2

B

15

1

24

3

13

18

NO. NAME

1Deve home CON.(3P)

2ITB CLT(3P)

3Deve CLT(2P)

7Fuser(2P)

8Regi CLT.(2P)

9Fuser CLT.(2P) 10 BLDC Motor(10P) 12 ITB Tension(3P) 13 HVPS(26P)

14 Wired N/W Con. (14P)

15 OPE & ITB (15P)

16 USB Con. (6P)

17 Key PTL(10P)

18 Cover OPEN (2P)

19 Pickup CLT (2P)

20 Pickup CLT. (3P)

21 SMPS (16P)

22 CRUM Con. (5P)

24 LSU Con.(16P)

30 Empty. (3P)

NO. NAME

A CPU(Jupiter5)

BDDR2 (32MB)

CNOR FLASH(2MB or 4MB)

D EEPROM

E PHY Chip

|

Service Manual |

2-18 |

Samsung Electronics |

Product spec and feature

|

— CLP-315W |

|||

|

14 |

16 |

||

|

9 |

|||

|

7 |

31 |

||

|

5 |

E |

4 |

|

|

10 |

C |

30 |

|

|

8 |

|||

|

D |

20 |

||

|

A |

17 |

||

|

12 |

22 |

||

|

2 |

|||

|

B |

|||

|

15 |

21 |

||

|

1 |

|||

|

24 |

|||

|

3 |

|||

|

13 |

18 |

||

NO. NAME

1Deve home CON.(3P)

2ITB CLT(3P)

3Deve CLT(2P)

4 Debug(4P)

5 T2 CLT(2P)

7Fuser(2P)

8Regi CLT.(2P)

9Fuser CLT.(2P) 10 BLDC Motor(10P) 12 ITB Tension(3P) 13 HVPS(26P)

14 Wired N/W Con. (14P)

15 OPE & ITB (15P)

16 USB Con. (6P)

17 Key PTL(10P)

18 Cover OPEN (2P)

19 Pickup CLT (2P)

20 Pickup CLT. (3P)

21 SMPS (16P)

22 CRUM Con. (5P)

24 LSU Con.(16P)

30 Empty. (3P)

31 W-LAN PBA

BDDR2 (64MB)

CNOR FLASH(8MB)

D EEPROM

E PHY Chip

|

Service Manual |

2-19 |

Samsung Electronics |

Product spec and feature

2.2.2.3 Main PBA Description

FLASH

CPU

Jupiter5 : 310/315/310N

Chorus3 : 315W

DDR SDRAM

Jupiter5(or Chorus3)

A Proprietary SoC, CHORUS3, executes and controls all jobs and functions to be required for printing. To do these all jobs, the CHORUS3 incorporates all H/W blocks as follows.

▪CPU Core ARM 926ESJ, I/D-Cache 16/16KB , Up to 400MHz

▪System Bus Internally 32-bit width, Up to 120MHz

▪MEM Controller DDR1/2, 16-bit width, 166MHz, 4-Bank, 128MB Space/bank

▪ROM Controller 16-bit width, 4-bank, 16MB Space/bank

▪CODEC Controller JBIG 4-ch Decoder and 2-ch Encoder, 1-ch JPEG

▪Image Processor Processing Scan Image

▪MAC Controller 10/100Mbps Full IEEE 802.3 Compatibility

▪USB Controller USB2.0, Device or Host

▪UART Controller

▪I2C Controller

▪Interrupt Controller

▪Misc. Controller ADC, DAC, PWM, Step Motor Control and so on

▪Voltage Core 1.0V, I/O 3.3V

▪Package 416PBGA

Flash Memory

Used to store System Programs including the Operating System.

▪Type NOR Flash

▪Bus 16-bit width

▪Size : 2MB (CLP-310/315) 4MB (CLP-310N) 8MB (CLP-315W)

|

Service Manual |

2-20 |

Samsung Electronics |

Product spec and feature

System Memory

Used as a Printing buffer for printing, a Scan buffer for scanning, a ECM Buffer for System Working Area.

▪Type DDR1 SDRAM

▪Bus 16-bit 166MHz

▪Size 32MB (310/315/310N) / 64MB(315W)

CRU Control

Used to store the printing and operating information into a Security EEPROM in 4 CRUs, Y,M,C and K Imaging Cartridge, respectively by the CHORUS3.

▪Access I2C Bus Ch.2 400KHz

▪Security Size 2K-bit

System Information Control

Used to store the system operating information needed at printing into a EEPROM in the Main Controller by the CHORUS3.

▪Access I2C Bus Ch.1 400KHz

▪EEPROM Size 64Kbit

OPE Interface

Used to control the OPE by the CHORUS3. Through CHORUS3’s GPIO pins, all LEDs and Keys in the OPE are controlled.

I/O Port

Used to receive or transmit some data from/to the Host.

▪USB Device USB2.0 High speed 480Mbps

▪Network Ethernet 10/100-Base Tx

(note) The Network only equipped at CLP-310N/315N, not CLP-310/315.

Engine Control

Used to control all parts to be required at printing by the CHORUS 3. ▪ Sensors Paper Empty

Paper Registration

Waste Toner Bottle Paper Exit

|

Temperature sensors |

|

|

Etc. |

|

|

▪ Clutches(Solenoid) Paper Pick Up |

|

|

Paper Registration |

|

|

Etc. |

|

|

▪ Motor |

1 BLDC |

|

▪ LSU |

|

|

▪ Fuser |

Control the Fuser’s temperature |

|

▪ HVPS |

Control the high voltage outputs |

|

▪ ADC |

Reading the Fuser’s temperature and the high voltage outputs’ feedback |

▪ Cover Open Sensing

|

Service Manual |

2-21 |

Samsung Electronics |

Product spec and feature

2.2.2.4 SMPS(Switching Mode Power Supply) PBA

SMPS is the power source of the entire system. It is assembled by an independent module, so it is possible to use for common use. It is mounted at the side of the set. It is consisted of the SMPS part which supplies the DC Power for driving the system and the AC Heater control part which supplies the AC Power to the Fuser. The SMPS has two DC output channels, +5V and +24V.

Fuse

AC input

Fuser

AC Input

|

Input Rated Voltage |

AC 110V~127V, AC 220V~240V |

|

AC 120V/AC 220V(EXP version) |

|

|

Input fluctuating range |

AC 99V~135V, AC 198V~264V |

|

Rated Frequency |

50/60 Hz |

|

Frequency Fluctuating |

47~63 Hz |

|

Input Current |

< 4.0Arms, 2.0Arms |

Rated Output Power

|

No |

Item |

CH1 |

CH2 |

Remark |

|

1 |

Channel Name |

+5V |

+24.0V |

|

|

2 |

Connector Pin |

CON 3 |

CON 3 |

|

|

5V Pin: 11,13,15 |

24V Pin:3,5,7,9 |

|||

|

GND Pin: 12,14,16 |

GND Pin:4,6,8,10 |

|||

|

3 |

Rated Output |

+5V ±5% |

+24V ±10% |

|

|

(4.75~5.25V) |

(21.6~26.4V) |

|||

|

4 |

Max. Output Current |

2 A |

2.4 A |

|

|

5 |

Peak Loading Current |

2.2 A |

2.7 A |

1ms |

|

6 |

Ripple Noise |

<100mVp-p |

<500mVp-p |

|

|

7 |

Maximum Output |

10.2W |

60W |

|

|

8 |

Peak Output |

11W |

64.8W |

1ms |

|

9 |

Protection for loading shortage and |

Shut down or Fuse |

Shut down or Output |

|

|

overflowing current |

Protection |

Voltage Drop |

||

|

Service Manual |

2-22 |

Samsung Electronics |

Product spec and feature

2.2.2.5 HVPS(High Voltage Power Supply) PBA

The HVPS creates the high voltages for T1(+), T2(+,-), Charger(-), DEV, and SUPPLY and then, supplies these voltages to the Developer part for making best condition to print. The HVPS part takes the 24V and outputs the high voltages and then, the high voltages are supplied to the Toner, OPC Cartridge, and Transfer

Belt and Roller.

BIAS AC +180V 3% BIAS DC -595V 3%

|

Waste |

||

|

CHARGER |

T1 |

OPC Waste & |

|

-1000V 3% |

+1000V 3% |

|

|

ITB Tension |

||

|

Nip Exit |

T2

+1550V 3% -1300V 20%

|

Service Manual |

2-23 |

Samsung Electronics |

Product spec and feature

1)Charger Voltage : Charger

•Function: voltage that charges OPC surface up to -500V~ -800V.

•Output voltage: -1.0KV ~ -2.0KV DC 3%

•Error type: if the voltage fails to be output to Charger Roll, OPC surface will not be charged, and the toner on the developer roller will be transferred to OPC Drum, printing black paper.

2)1st Transfer High Voltage : T1(+)

•Function: voltage necessary for transferring toner developed on OPC Drum surface onto ITB.

•Output voltage: Max +2.0KV 3%(Duty variable, no load)

•ERROR type: if T1(+) output fails, the toner on OPC drum will not be transferred to ITB normally and the image will be blurred.

3)2nd Transfer High Voltage : T2(+)

•Function: voltage used to transfer the toner primarily transferred on ITB again onto paper.

•Output voltage: Max +5.0KV 3%(Duty variable, no load)

•ERROR type: if T2(+) output fails, the toner on ITB will not be transferred to paper normally and the image will be blurred.

4)T2 Cleaning Voltage : Clean : T2(-)

•Function: prevent reverse side of paper from being dirtied, by recovering the negatively charged toner remaining at Transfer Roller and sending it onto ITB.

•Output voltage: with no feedback control, output fixed voltage(-1300V 15%)

•ERROR type: reverse side of paper will be dirtied.

5)Supplying Voltage : Supply AC+DC(-)

•Function: voltage that makes toner to develop on the area exposed by LSU by means of potential difference, output will be the voltage of AC+DC overlapped form.

•Output voltage: AC 600V ~ 2000V p-p 1.5%

DC -50V ~ -600V DC 3%

•ERROR type: 1. if supply is GND, density will be extremely low.

2.if supply is floating (for insecure terminal contact), density will be down so slightly that it is impossible to make out with naked eyes.

6)Developing Voltage : Deve AC+DC(-)

•Function: voltage that supplies toner to Developing Roller

•Output voltage: AC 250V ~ 1650Vp-p 1.5% (supply voltage is connected to ZENER Diode 350V)

DC -50V ~ -600V DC 3%

•ERROR type: 1. if Deve is GND, density will be extremely down.

2.if Deve is floating (for insecure terminal contact), density will be extremely down.

|

Service Manual |

2-24 |

Samsung Electronics |

Product spec and feature

2.2.3 CRUM

The CLP-310N engine will be equipped with electronics that can read and write data into NVRAMs otherwise known as CRUMs that reside within 1) C, M, Y, K Toner cartridges.

The CRUM has a company ID, and electronics logo.

The toner CRUM also identifies the type of toner cartridge (Standard or High Capacity). The CRUMs contain fixed data such as the low warning point, specified life point, and hard stop point (on toner)

and also store the current life count (pages count, pixels count, images count) and % of usage (gas gauge) data.

■ In the case of Refill Toner Install

1)Perception of Refill Cartridge (when power is on or the cover is closed) End of Life / life span data initialization -> judge to be Refill Cartridge

End of Life / life exhausted (simple refill) -> stop printing caused by life exhaustion

2)Operating

It is impossible to control appropriate development parameters, for there s no toner specification data. It runs with the setting of default development parameter. (Image quality will be degraded, for the lack of appropriate respond to the change of time and environment.)

■ Process after CRU life expiration

1)Record the information of End of Life.

2)Clear some information of Operation Area.

-> Supplier/Model Name/MFC date/Serial Number (Manufacture Information)

-> Let cartridge refiller initialize manufacture information and life span information.

|

Service Manual |

2-25 |

Samsung Electronics |

Product spec and feature

2.3 S/W Structure and Descriptions

2.3.1 Architecture

The belt CRUM interface board is a transmission belt CRUM interface board of the photoelectric Dry Color Laser Printer, mounted on the printer body, making it possible to physically combine the body and the belt CRUM board.

Printer Driver

Language Monitor

Status Monitor

|

Printer F/W |

Network Card F/W |

|||||

2.3.2 Language Monitor

Language Monitor is a part of the Printer Driver and the Windows Spool System. The main roll of the Language Monitor is that sends a job start message to the Status Monitor. Therefore the Status Monitor can start polling to get the printer status.

The second roll is that sends the job information such as User ID and Job ID to the Status Monitor and the Printer F/W. Hence the Status Monitor can stop polling because the Printer F/W informs the Status Monitor that printing job is complete.

2.3.3 Status Monitor

Status Monitor has no user interface. It shows only HTML help when any error occurs during printing jobs.

|

Service Manual |

2-26 |

Samsung Electronics |

Product spec and feature

2.3.4 Network Interface

Printer Driver

|

User ID + Job ID |

||||||||||

|

Language |

+ |

|||||||||

|

Printer Data |

Printer Data |

|||||||||

|

Monitor |

||||||||||

|

Printer Server |

||||||||||

|

(Kernel / NPC) |

||||||||||

|

Printer Name |

||||||||||

|

Port Name |

||||||||||

|

User ID |

||||||||||

|

Job ID |

||||||||||

|

Printer Server IP Addr |

SNMP |

|||||||||

|

Request Printer Status |

||||||||||

|

Printer Status |

||||||||||

|

Status Monitor |

Request Job Status |

|||||||||

|

Job Table |

||||||||||

Printer Server

(Kernel / NPC)

Job ID

Status Monitor Data Flow

After polling is started, Status Monitor has to know when it stops the polling. For this reason, the Network Printer Server should inform of completing job when the printing job is finished.

When Status Monitor requests a job status, the Printer Server returns the job table that contains user id, job id, and job status (printing or complete or canceled).

2.3.5 Printer Driver <-> Status Monitor

The Printer Driver and the Status Monitor can set/get some data to the system registry to share the Status Monitor information such as the polling interval.

When the user wants to set the option of the Status Monitor manually, he or she can set it using the Printer Driver User Interface. So, if the user set option that the Status Monitor is disabled, the Status Monitor can’s show HTML Help to the user although the error has occurred while printing.

|

Set option value |

|||||||||||

|

enable/disable |

|||||||||||

|

or |

|||||||||||

|

Set last error status |

System |

polling interval |

|||||||||

|

Status Monitor |

Printer Driver |

||||||||||

|

Registry |

|||||||||||

|

Get option value |

Get last error status |

||||||||||

|

enable/disable |

|||||||||||

|

or |

|||||||||||

|

polling interval |

|

Service Manual |

2-27 |

Samsung Electronics |

Product spec and feature

|

2.3.6 System F/W Flow |

||||

|

Process |

Output |

|||

|

Photo Sensor ( intensity |

PWM |

|||

|

of radiation ) |

LED |

|||

|

LED PWM Output |

||||

|

density |

||||

|

Density pattern |

||||

|

printing |

||||

|

LED PWM decision |

PWM |

|||

|

Comparator Threshold |

Comparator |

|||

|

voltage PWM decision |

||||

|

Color Registration measure |

||||

|

Auto Color Registration |

LSU |

|||

|

pattern printing |

||||

|

Color Registration adjustment |

Video data |

|||

|

P Sync. |

||||

|

Page Sync. modify |

||||

|

L Sync. |

Video signal |

|||

|

Line Sync. modify |

||||

|

generator |

||||

|

clock |

||||

|

Video Clock Freq. |

||||

|

LSU |

||||

|

modify |

||||

|

temperat |

ADC |

|||

|

ure |

LSU temperature control |

|||

|

sensor |

|

Service Manual |

2-28 |

Samsung Electronics |

Product spec and feature

2.3.7 Alarm Shortage

|

90 ~ 100 % |

100 ~ 110 % |

110 %~ |

|

|

Toner (C,M,Y,K) |

Ready Yellow Toner Low |

Replace Yellow Toner |

Yellow Toner Exhausted |

|

Transfer Belt |

Replace Transfer Belt Soon |

Replace Transfer Belt |

|

|

Fuser |

Replace Fuser Soon |

Replace Fuser |

|

|

Pickup Rollers |

Replace MP Pick-Roller |

||

|

(MP/Tray1/Tray2) |

2.3.8 Error status

1.Missing/Invalid Consumables

•Install Cyan (Magenta, Yellow, Black) Toner

•Install Transfer Belt

•Invalid Cyan (Magenta, Yellow, Black) Toner

•Invalid Transfer Belt

2.Paper JAM

•Jam 0 In MP(Tray1, Tray2)

•Jam Inside Printer

•Jam In Exit Area

3.Cover

•Cover Open : Message toggles between

“Cover Open” and “Install Transfer Belt”

•SCF Cove Open

4.Service Call : Unrecoverable Error

•Engine LSU Error

•Main Motor Error

•Engine Fuser Over(Low) Heat Error + Open Heat Error

•Transfer Belt Error

5.Others

•Ready IP Conflict

|

Service Manual |

2-29 |

Samsung Electronics |

Product spec and feature

2.3.9 CRUM Overview

—Stands for “Customer Replaceable Unit Monitor”

—EEPROM, SAMSUNG CRUM is used for CRUM Memory.

—CRUM stores various information on consumables (including consumables’ life).

—In CLP-31x Series, total four CRUM’s are used (four on toner cartridges)

CRUM stores the following information

•Model Name

•Supplier ID

•Serial Number

•Company ID

•MFG Date

•Capacity

•Page Count

—Toner Cartridge and Transfer Belt

—Indicates how many pages are printed by using the consumable

•Dot Count

—Toner Cartridge Only

—Indicates how many dots are printed by using the toner cartridge

•Image Count

•Model ID

2.3.10 FW Upgrade

•Via USB or Network (SWS/SWAS)

•You can upgrade F/W via USB or Network whenever the printer is “Ready”

•Make sure connecting Printer to the computer with a USB cable

•Via Using F/W Download Mode :

Step 1) Power on while pressing the STOP Key

Step 2) Press STOP Key more time and the status LED is on as Green. Step 3) Download F/W via USB

|

Service Manual |

2-30 |

Samsung Electronics |

||

Product spec and feature

2.3.11 Initailize Flow

|

Service Manual |

2-31 |

Samsung Electronics |

Product spec and feature

|

Service Manual |

2-32 |

Samsung Electronics |

Disassembly and Reassembly

3. Disassembly and Reassembly

3.1 Precautions when replacing parts

3.1.1 Precautions when assembling and disassembling

*Use only approved Samsung spare parts. Ensure that part number, product name, any voltage, current or temperature rating are correct. Failure to do so could result in damage to the machine, circuit overload, fire or electric shock.

*Do not make any unauthorized changes or additions to the printer, these could cause the printer to malfunction and create electric shock or fire hazards.

*Take care when dismantling the unit to note where each screw goes. There are 19 different screws. Use of the wrong screw could lead to system failure, short circuit or electric shock.

*Do not disassemble the LSU unit. Once it is disassembled dust is admitted to the mirror chamber and will seriously degrade print quality. There are no serviceable parts inside.

*Regularly check the condition of the power cord, plug and socket. Bad contacts could lead to overheating and firfe. Damaged cables could lead to electric shock or unit malfunction.

3.1.2 Preautions when handling PBA

Static electricity can damage a PBA, always used approved anti-static precautions when handling or storing a PBA.

>> Precautions when moving and storing PBA

1. Please keep PBA in a conductive case, anti-static bag, or wrapped in aluminum foil. 2. Do not store a PBA where it is exposed to direct sunlight.

>> Precautions when replacing PBA

1. Disconnect power connectors first, before disconnecting other cables

2. Do not touch any soldered connections, connector terminals or other electronic parts when handling insulated parts.

>> Precautions when checking PBA

1.Before touching a PBA, please touch other grounded areas of the chassis to discharge any static electrical charge on the body.

2.Take care not to touch the PBA with your bare hands or metal objects as you could create a short circuit or get an electric shock. Take extra care when handling PBAs with moving parts fitted such as sensors, motors or lamps as they may get hot.

3.Take care when fitting, or removing, screws. Look out for hidden screws. Always ensure that the correct screw is used and always ensure that when toothed washers are removed they are refitted in their original positions.

3.1.3 Releasing Plastic Latches

Many of the parts are held in place with plastic latches. The latches break easily; release them carefully.

To remove such parts, press the hook end of the latch away from the part to which it is latched.

|

Service Manual |

3-1 |

Samsung Electronics |

Новости

Самые популярные статьи

-

Принтеры и МФУ -

-

Epson с СНПЧ и ПЗК -

Прошитый Samsung -

Принтер и МФУ HP -

Oki принтеры и мфу -

Ручной принтер -

Прошитый МФУ, принтер Pantum

-

-

СНПЧ -

-

СНПЧ Epson -

СНПЧ Canon -

СНПЧ Hp -

СНПЧ Brother -

СНПЧ Конструктор ( комплектующие )

-

-

Принтеры в разборе -

-

Epson струйные и лазерные принтеры и мфу -

HP струйные и лазерные принтеры и мфу -

Canon струйные и лазерные принтеры и мфу -

Samsung лазерные принтеры и мфу -

Brother струйные и лазерные принтеры и мфу -

OKI струйные и лазерные принтеры и МФУ -

Panasonic лазерные принтеры и мфу -

Xerox лазерные принтеры и МФУ -

Sharp лазерные принтеры и МФУ -

Ricoh лазерные принтеры и МФУ -

Kyocera лазерные принтеры и МФУ

-

-

ПЗК -

-

ПЗК Epson -

ПЗК HP -

ПЗК Canon -

ПЗК Brother

-

-

Чернила -

-

Чернила Epson -

Чернила Canon -

Чернила HP -

Чернила Brother -

Чернила Epson, Canon, HP в канистре

-

-

Фотобумага -

-

Фотобумага глянцевая -

Фотобумага матовая -

Фотобумага фактурная. Дизайнерская -

Рулонная фотобумага -

Фотобумага мелованная (2-х сторонний глянец для струйной печати) -

Оригинальная фотобумага HP, Canon, Epson

-

-

Термобумага для терминалов и банкоматов -

Тонер -

-

Тонер HP -

Тонер Samsung -

Тонер Canon -

Тонер Epson -

Тонер Xerox -

Тонер Brother -

Тонер Panasonic -

Тонер Kyocera -

Тонер OKI -

Тонер Ricoh -

Тонер Toshiba -

Тонер Konica -

Тонер Sharp -

Тонер Handan -

Тонер Lexmark

-

-

Лазерные картриджи -

-

Картридж Epson -

Картридж Canon -

Картридж HP -

Картридж Samsung -

Картридж Xerox -

Картридж Brother -

Картридж Panasonic -

Картридж Kyocera -

Картридж OKI -

Картридж Toshiba, Sharp, Lexmark, Ricoh

-

-

ЗИП для картриджа -

-

ЗИП картриджа Canon -

ЗИП картриджа HP -

ЗИП картриджа Samsung -

ЗИП картриджа Xerox -

ЗИП картриджа Brother -

ЗИП картриджа Panasonic -

ЗИП картриджа Lexmark -

ЗИП картриджа Ricoh, Kyocera, Sharp -

Пакеты для картриджей

-

-

Комплектующие (ЗИП) для принтера -

-

ЗИП Epson -

-

Print Head ( Печатающая головка ) -

Pump Assy ( Узел подачи чернил в сборе ) -

Board Assy ( Электронная плата ) -

DAMPER ( Демпер ) -

Cable Assy ( Шлейф в сборе ) -

Belt, Scale ( ремень каретки, лента позиционирования ) -

Motor Assy ( двигатель ) -

Paper feed unit ( узел подачи бумаги ) -

Gear ( Шестерня ) -

Scaner unit ( блок сканера ) -

Power Assy ( блок питания ) -

Разное Epson

-

-

ЗИП Canon -

-

Печатающая головка Canon -

Электронная плата Canon -

Узел термозакрепления Canon -

Узел подачи бумаги Canon -

Ремни, ленты позиционирования, диски энкодера Canon -

Шлейфы Canon -

Узел подачи чернил Canon -

Шестеренки Canon -

Блоки питания Canon -

Электродвигатели и соленоиды Canon -

Датчики Canon -

Разное Canon

-

-

ЗИП HP -

-

Печатающая головка HP -

Электронная плата HP -

Узел термозакрепления HP -

Узел подачи бумаги HP -

Ремни, ленты позиционирования, диски энкодера HP -

Шлейфы HP -

Узел подачи чернил HP -

Модули памяти HP -

Шестеренки HP -

Подшипники (бушинги) HP -

Блоки питания HP -

Электродвигатели и соленоиды HP -

Узел сканирования HP -

Датчики HP -

Разное HP

-

-

ЗИП Samsung -

-

Электронная плата Samsung -

Узел термозакрепления Samsung -

Узел подачи бумаги Samsung -

Шлейфы Samsung -

Шестеренки Samsung -

Подшипники (бушинги) Samsung -

Блоки питания Samsung -

Электродвигатели и соленоиды Samsung -

Узел сканирования Samsung -

Блок лазера Samsung -

Датчики Samsung -

Разное Samsung. Товары, не вошедшие в предыдущие категории

-

-

ЗИП Xerox -

-

Печатающая головка Xerox -

Электронная плата Xerox -

Узел термозакрепления Xerox -

Узел подачи бумаги Xerox -

Ремни, ленты позиционирования, диски энкодера Xerox -

Шлейфы Xerox -

Узел подачи чернил Xerox -

Шестеренки Xerox -

Электродвигатели и соленоиды Xerox -

Блоки питания Xerox -

Узел сканирования Xerox -

Датчики Xerox -

Блок лазера Xerox -

Разное Xerox

-

-

ЗИП Brother -

-

Печатающая головка Brother -

Электронная плата Brother -

Узел термозакрепления Brother -

Узел подачи бумаги Brother -

Ремни, ленты позиционирования, диски энкодера Brother -

Шлейфы Brother -

Узел подачи чернил Brother -

Шестеренки Brother -

Блоки питания Brother -

Электродвигатели и соленоиды Brother -

Датчики Brother -

Узел сканирования Brother -

Блок лазера Brother -

Разное Brother

-

-

ЗИП Kyocera -

-

Электронная плата Kyocera -