- Manuals

- Brands

- SDLG Manuals

- Compact Loader

- LG6210E

- Maintenance manual

-

Bookmarks

Quick Links

LG6210E

Maintenance Manual

山东临工工程机械有限公司

Shandong Lingong Construction Machinery Co, Ltd

Related Manuals for SDLG LG6210E

Summary of Contents for SDLG LG6210E

-

Page 1

LG6210E Maintenance Manual 山东临工工程机械有限公司 Shandong Lingong Construction Machinery Co, Ltd… -

Page 2

Maintenance Manual──LG6210E Hydraulic Excavator Forward This maintenance manual includes the Safety specifications, function information of systems and units, maintenance instructions, checking and adjustment methods, schematic diagrams and wiring diagrams. Please refer to «Safety” for safety notes for Overall maintenance operation on the machine. -

Page 3

Service Manual──LG6210E Hydraulic Excavator PREFACE …………………………..I SECURITY …………………………..1 Common precaution ……………………… 1 Security precautions …………………………1 Safety Devices …………………………… 1 Clothing and Personal Protective Items……………………1 Emergency matters preparation ……………………..2 Fire Prevention for Oil and Fuel ……………………..2 Properly dispose of scrap liquid …………………….. -

Page 4

Maintenance Manual──LG6210E Hydraulic Excavator Rotary gear ring,specifications ……………………33 Regulator, specifications ……………………….. 34 Cab specifications …………………………34 Operator seat specifications ……………………..35 Recommended hydraulic oil specifications ………………….. 35 Hydraulic oil, specifications ……………………..36 Hydraulic pressure,specifications ……………………36 Hydraulic tank, specifications ……………………..36 Air conditioning unit,specifications ……………………. -

Page 5

Maintenance Manual──LG6210E Hydraulic Excavator Draining …………………………..69 Filling oil …………………………..70 Fuel filter, replacing ……………………….. 70 Additional fuel filter (oil-water separator core), checking / draining …………… 71 Water separator filter element, replacing ………………….71 Fuel tank sediment, draining ……………………..72 Fuel tank ventilation filter, replacing …………………… -

Page 6

Maintenance Manual──LG6210E Hydraulic Excavator ……………………..107 VERVIEW OF THE ENGINE BF6M2012C Engine ……………………….107 Engine characteristics curves ……………………… 110 BF6M2012C engine ……………………….110 Basic examination, engine ……………………..110 Purpose of the basic examination ……………………110 Testing of the basic examination ……………………111 Troubleshooting ………………………… -

Page 7

Maintenance Manual──LG6210E Hydraulic Excavator 5.1 Overview ……………………….142 Cooling System,instruction ……………………..142 Cooling system, operating ……………………..143 Coolant …………………………..143 Draining the cooling system ……………………..145 5.2 Radiator, including assembly and connection …………….145 Coolant, replacing ………………………… 145 Draining the coolant ……………………….145 Filling the coolant in the cooling system …………………. -

Page 8

Maintenance Manual──LG6210E Hydraulic Excavator 2.1 Hydraulic motor 1, travel motor …………………. 197 Travel motor,instruction ………………………. 197 Operating, the hydraulic motor ……………………200 Operating, brake valve……………………….. 201 Operating, parking brake ……………………..202 Operating, displacement conversion valve …………………. 203 Travel motor, operation precautions …………………… 205 Installing ………………………….. -

Page 9

Maintenance Manual──LG6210E Hydraulic Excavator Rotating joints description ………………………. 262 Rotary joints,assembly ……………………….263 Rotary joints, tools ……………………….. 264 Common tools …………………………264 Special tools …………………………265 Rotary joint soft hose (valve — rotary joints), replacing ………………. 266 Rotary joint hose (Rotary joints — motor), replacing ………………267 Rotary joints, dismantling …………………….. -

Page 10

Maintenance Manual──LG6210E Hydraulic Excavator Installation …………………………..311 2.5 Bottom roller ……………………….. 312 Bearing wheel specification ……………………..312 Bearing wheel,wear limitation ……………………… 313 Measure the wear of outside diameter of roller thread………………. 314 Measure the wear of flange width of roller ………………….. 314 Bearing wheel, installing ……………………… -

Page 11

Maintenance Manual──LG6210E Hydraulic Excavator Actuator, air mixing valve driver ……………………356 Water temperature sensor ……………………..357 Pipe temperature sensor ……………………… 358 Temperature sensor inside the vehicle ………………….359 Air conditioning units, maintenance……………………. 359 Periodic inspection ……………………….359 Inspection items …………………………359 Ambient temperature sensor …………………….. -

Page 12

Maintenance Manual──LG6210E Hydraulic Excavator Solenoid valve troubleshooting ……………………407 ) …………..407 AIN CONTROL VALVE IRECTIONAL VALVE CONTROL VALVE Hydraulic circuit, valve ……………………….407 Description of the main control valve………………….. 409 Main control valve, partial view ……………………413 General notes …………………………416 Notice for disassembly ……………………….. -

Page 13

Maintenance Manual──LG6210E Hydraulic Excavator Pump instructions ………………………… 460 Pump, partial view ……………………….462 Pump, exploded view……………………….463 Operation principle of pump ……………………..464 Maximum oil flow adjustment ……………………… 466 Minimum oil flow adjustment ……………………..466 Pumps, maintenance standards ……………………466 Precaution for use ………………………. -

Page 14

Maintenance Manual──LG6210E Hydraulic Excavator Troubleshooting …………………………513 4. R ) …………….514 EMOTE CONTROL VALVE ONTROL PRESSURE VALVE 4.1 Remote control valve(Operation lever)………………. 514 Remote control valve(Operation lever),specification ………………514 Remote control valve (Operation lever), instruction ………………515 Maintenance standard of remote valve(operation lever) …………….522 Remote control valve(operation lever),removing ……………… -

Page 15

Maintenance Manual──LG6210E Hydraulic Excavator Check valve …………………………… 624 6.2 Machinery Equipment / Additional Equipment …………….624 Hydraulic Quick Installation, instruction ………………….624 Hydraulic quick installation, adjusting ………………….629 ) …………..631 ROUBLESHOOTING ORKING HYDRAULIC SERVO HYDRAULIC Troubleshooting diagnostics procedures ………………….631 Examples of hydraulic system failure …………………. -

Page 16

Maintenance Manual──LG6210E Hydraulic Excavator ……………………….709 TARTING SYSTEM 4.1Overview …………………………… 709 Starting operations …………………………. 709 4.2 Starting motor including coil …………………… 711 Starting engine , indication ……………………… 711 Battery relay instructions ……………………….711 Safety starting relay, instructions …………………….. 712 Starting relay, replacing ……………………….712 4.3 Electronic air preheater, not including components Warm-up, indication …….. -

Page 17

Maintenance Manual──LG6210E Hydraulic Excavator SCH14 ……………………………. 752 SCH15 ……………………………. 754 SCH16 ……………………………. 755 SCH17 ……………………………. 758 SCH18 ……………………………. 759 ……………………760 RELAY CIRCUIT CUT 2.1 Fuse …………………………760 Fuse,instruction …………………………760 Slow-melt fuse,instruction ……………………..761 Replacement process of fuse …………………….. 762 Relay box,specification………………………. -

Page 18

Service Manual──LG6210E Hydraulic Excavator Preface Repair Manual contains specification, function introduction of the system and components, repair instruction, the method to check and adjust, Security diagram and circuits. ⅠWhole machine instruction The safety regulations about maintaining on the Ⅱ Repair and maintenance machine refer to SAFE PART. -

Page 19

Maintenance Manual──LG6210E Hydraulic Excavator Security Common precaution Warning! Please comply with the following rules for the security. Security precautions l If you have been drinking, eating some pills or other narcotics, do not operate the machine. l Only trained and authorized people can be permitted to Conform to safety operate and maintain the machine. -

Page 20

Maintenance Manual──LG6210E Hydraulic Excavator Emergency matters preparation l Know the position of fire-fighting equipmentsand how to use them. l Keep the emergency box and the tool used to wash the eyes in the working site. l Keep the phone number of doctor, emergency car,hospital and the fire department. -

Page 21

Maintenance Manual──LG6210E Hydraulic Excavator Working in the dusty environmental Dust impurities in the work environment • After the machine works in the environmetn containing asbestos dust, or other hazardous impurities, put the used cab and engine air filter into a sealed bag before placing it… -

Page 22

Maintenance Manual──LG6210E Hydraulic Excavator Reasonably and safely use of tools • Only use the tools in accordance with the designed purpose of tools • Keep all tools in good condition, and understand their proper uses. • Set a place at the repair site used to store special tools and removed parts. -

Page 23

Maintenance Manual──LG6210E Hydraulic Excavator .Use handrails or ladders l Never jump on or off the machine. Never get on or off a moving machine. l When getting on or off the machine, face the machine and use the handrails and pedals to ensure that you support yourself. -

Page 24

Maintenance Manual──LG6210E Hydraulic Excavator all the pipes leading to the engine and heater. Contacting with these parts can cause serious burns. • Hot coolant can cause burns. • Only the engine is stopped and the temperature of the radiator pressure cap is so low that it can be removed by hand, you can check the coolant level. -

Page 25

Maintenance Manual──LG6210E Hydraulic Excavator The assembly position of the components should be right. l Use a crane or a crane slowly to prevent the compoments from hitting other parts. l When disassembling or assembling, use wedges, jack and frames to support the machine. -

Page 26

Maintenance Manual──LG6210E Hydraulic Excavator l Do not make fire, lit matches and open flames near the top of the battery, in case that the battery (hydrogen) is exploded. l If the battery electrode or wire touch with metal objects, short circuit may occur, which may cause your harm. -

Page 27

Maintenance Manual──LG6210E Hydraulic Excavator 3 Do not weld near the ring near the welded joints in the cylinder.Dsitance between the ring and the welding point of welding plates is 100 mm. 4 Do not weld at the bend part of a metal plate. -

Page 28

Maintenance Manual──LG6210E Hydraulic Excavator Be careful when removing or installing the track of the machine. When removing the track pin, the track will be suddenly separated, so do not let anyone stand on either side of track. Always do good protection at both ends of the track, in case of suddenly controlled actions to cause unnecessary harm. -

Page 29

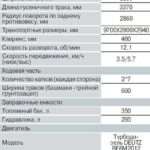

Maintenance Manual──LG6210E Hydraulic Excavator Ⅰ.Whole machine description 1. Summary Components position Fig.1 Components position Boom Engine hood Tension spring Bucket arm cylinder Balancing weight Guiding wheel Boom cylinder Hydraulic pump Control panel(Forward) Operation lever Track motor and gears Operator seat… -

Page 30

Maintenance Manual──LG6210E Hydraulic Excavator 2. Specification Standard tightening torque The following table offers the standard tightening torque of the screws and the nuts. Additional circumstance will be shown in “Disassembly or assembly”. Table1 Tightening torque (m) Grade 4.8T 8.8T 10.9T,12.9 T… -

Page 31

Maintenance Manual──LG6210E Hydraulic Excavator Table2.Tghtening torque(inch) Grade 4.8T 8.8T 10.9T,12.9 T Size Tightening torque Tightening torque Tightening torque 9.80 ±0.98 23.53±2.35 16.67 ±1.96 5/16 11.76±1.17 19.61±1.96 29.42±2.94 19.61±1.96 40.20±3.92 54.91±4.90 7/16 31.38±3.13 59.82 ±5.88 87.27 ± 8.82 46.09±4.60 100.02 ±9.80 131.40 ±12.74… -

Page 32

Maintenance Manual──LG6210E Hydraulic Excavator Tightening torque of hydraulic plug with O ring Fig.2 Hydraulic plug with O ring 1. O ring 2. Plug Pf screw Table 4. Tghtening torque (Hydraulic plug) Thread Plug number Tightening torque Nm 9415–11012 24.51 ±1.96 9415–11022… -

Page 33

Maintenance Manual──LG6210E Hydraulic Excavator Table 5.Tghtening torque of rotating nut device with O ring Outer diameter of pipe Screw size(inch) Tightening torque Nm UN 13/16 – 16 93.16 ±9.31 UN 1 3/16 – 12 176.52 ±17.65 UN 1 7/16 – 12 205.94 ±20.59… -

Page 34

Maintenance Manual──LG6210E Hydraulic Excavator Engine, specifications Table 7 Specification Program Unit Specification Fuel injection pump BOSCH Fuel pump setup, B.T.D.C Injector,starting pressure Oil consumption ratio g/kW·h 216 at1900 r/min Fuel tank Capacity Filter Valve clearance, specifications Table 8 Specification Engine model… -

Page 35

Maintenance Manual──LG6210E Hydraulic Excavator Coolant, specifications Table11. Specification Items Unit Specification Radiator Axle core model 4-CF(Wave-shape plates) Radiator core volume(W × H × 720 × 293 × 145.4 D) Dry weight Hydraulic Axle core model 1-CF(Wave-shape cooler plates) Radiator core volume(W × H ×… -

Page 36

Maintenance Manual──LG6210E Hydraulic Excavator Engine control, specifications Table14. -

Page 37

Maintenance Manual──LG6210E Hydraulic Excavator Gauge control unit I-ECU, specifications Table15. Gauge control unit, I-ECU connector, specification Connector Attached connector House:AMP 174657-2 House:AMP 174655-2 Terminal:AMP 171661-1 Terminal:AMP 171662-1 Wire sealing:AMP 172888-2 Wire sealing:AMP 172888-2 Connecting pins, specifications Table15. Gauge control unit, I-ECU connector, specification No. -

Page 38

Maintenance Manual──LG6210E Hydraulic Excavator Engine control unit E-ECU (EMR2 ), specification Table15. E-ECU (EMR2 ) pin, specification Specifications Specifications No connection ECU grounding No connection ECU grounding No connection No connection No connection No connection No connection No connection No connection… -

Page 39

Maintenance Manual──LG6210E Hydraulic Excavator Vehicle control unit V-ECU, specifications (I-ECU has been assembled.) Table18. Vehicle control unit , V-ECU,, specification Item Connector Housing Tiny timer & JPT 70Pin AMP 1-963484-1,Terminal JPT(X10) connector AMP 929939-1,JPT Wire sealing AMP 828904-1,Terminal MT-2(X60) AMP 962876-1,MT-2 Wire sealing… -

Page 40

Maintenance Manual──LG6210E Hydraulic Excavator Fig.6 VECU, connector Table20. Connector (JB) pins , specification specifications No. specifications No connecting No connecting flow control proportional valve Attached pressure sensor grounding EMR2 power checking Hammer pressure switch Floating position pressure switch No connecting… -

Page 41

Maintenance Manual──LG6210E Hydraulic Excavator specifications No. specifications High speed selecting switch Rapid assembly ending switch Preheating relay grounding No connecting Speed solenoid valve No connecting Preheating relay Overloading warning selecting switch Speed control signal 1 Speed control signal 2 Speed control signal 3… -

Page 42

Maintenance Manual──LG6210E Hydraulic Excavator Battery, specifications Table21.Battery, specifications Items Specifications Number 2 series Voltage of battery(Rated) Min12.65V / .Battery Max12.95V / .Battery Capacity 150A/h, .Battery Battery disconnector Connecting to “-” Density of sour liquid at 27°C(81°F) MIN 1.265 g/ccm MAX1.300 g/ccm AC generator, specifications Table22. -

Page 43

Maintenance Manual──LG6210E Hydraulic Excavator Battery relay, specifications Table24. Specifications Items Specifications Rated voltage DC 24V Rated loading 100A (Continuous), 1000 A (30s) Exciting current 0.5A or less(24 V,20°C) Voltage of open circuit DC 9V or less Min. working voltage DC 20V or less ≥1 MΩ… -

Page 44

Maintenance Manual──LG6210E Hydraulic Excavator Traveling warning, specifications Table28. Specifications Items Specifications Working voltage DC 18~32V Current 0.4A Sound pressure 115 ± 5Hz Operating temperature -20 — 50 °C Upper wiper motor, specifications Table29. Specifications without loading Items Specifications <2.5kgNm Starting torque… -

Page 45

Maintenance Manual──LG6210E Hydraulic Excavator Security lever switch, specifications Table32. AC generator, specifications Items Specifications Manufacuturer OMRON Model and name D2VW-5L2A-1M Operating force 230 gf Reaction force 20 gf Rated voltage DC 30 V,5 A Environmental -40 — 90 °C temperature Rated current 1500 rpm—为… -

Page 46

Maintenance Manual──LG6210E Hydraulic Excavator Fuse specifications Capacity and marks related to circuits. Energy Application/circuit Energy Application/circuit 10 A I-ECU F 16 15 A Starting switch 10 A Working lamp(Cab roof) F 17 Cab lamps 15 A Working lamp(Boom) F 18… -

Page 47

Maintenance Manual──LG6210E Hydraulic Excavator Relay box, specifications Table 35.Relay code of relay box Relay Name Description Type number RE3611 Speaker Always open, NO RE3501 Front work lights Always open, NO RE3301 Starter Always closed, NC RE9106 X3/quick install safety devices Always open, NO… -

Page 48

Maintenance Manual──LG6210E Hydraulic Excavator Radio with cassette or CD player specifications CD and MP3 player with recorder Table 39.Specifications Items Specifications Rated voltage DC 14V(negative grounding) Operating temperature -30 — 75℃ Output 20W×2EA Frequency range EU:MW531-1602KHZ/FM87.5-108MHZ/LW153-279KHZ NA:FM87.7-107.9MHZ/AM530-1710KHZ 80PF 75 W… -

Page 49

Maintenance Manual──LG6210E Hydraulic Excavator Travel motor, specifications Table 43.Travel motor, specifications Items Unit specifications Travel Model EM140V Motor Type Variable swash plate piston hydraulic motor Displacement cm³/rev 82.4/140.5 Pressure reducing (Standard value / 39.2+2.9/-1 when 15 l/min reconstructed value) Pressure reducing (Maintenance limit 39.2+2.9/-2 when 15 l/min… -

Page 50

Maintenance Manual──LG6210E Hydraulic Excavator Rotary unit specifications Table 44. Specifications Items Unit Specification Model M5X130CHB Fixed swash plate , Type piston motor Pressure reducing valve— model KRD22EK10C Rebound damping valve— model 2KAR6P72 Displacement cm³/rev 121.6 Rated pressure 34.3 Theoretical output torque… -

Page 51

Maintenance Manual──LG6210E Hydraulic Excavator Attention! For contact pressure of the ground,refer to the Operator Manual Rotary gear ring,specifications Table 46. Specifications Items Unit Specification Type Ball bearings with internal gear Teeth Weight Outer diameter 1327 Height Bearing Material SUJ-2 Outer ball diameter 31.75… -

Page 52

Maintenance Manual──LG6210E Hydraulic Excavator Regulator, specifications Table.47. Specifications Items Unit specifications Model KR3G-9N2A Maximum input torque kef m 60.9 Maximum oil output rate L/min 2×200 Minimum oil output rate L/min 2×38 Cab specifications Table.48 specifications Items Unit Specifications Length 1800… -

Page 53

Maintenance Manual──LG6210E Hydraulic Excavator Operator seat specifications Table.49 specifications Items Unit Specification suspension , tilt Type Adjustable backrest handrail with backrest 。 Base Setting Headrest Forward 。 Backrest Forward back 。 Handrail below Height below Suspension Stroke ±35 Load 50~130… -

Page 54

Maintenance Manual──LG6210E Hydraulic Excavator Attention! I *:is installed at the factory * ISO:International Organization for Standardization *HV:High viscosity Hydraulic oil, specifications Table 51:Specification Items Unit Specification Type Anti-wear mineral oil used in high-pressure hydraulic system Level ISO VG46 Viscosity at 40℃… -

Page 55

Maintenance Manual──LG6210E Hydraulic Excavator Size: Height×width×depth mm 399×732×19 Compressor Model SD7H15WZ8045 Type Swing plate Number cylinders-diameter 7-φ29.3×39.8 stroke, mm Displacement,cc 154.9 Pressure of e pressure reducing 38±2 valve Maximum permissible continuous 5000r/min speed Maximum downshift speed 5000r/min Lubricating oil capacity, cc… -

Page 56

Maintenance Manual──LG6210E Hydraulic Excavator Table 54.Tightening torque Items kgf.m nut , electromagnetic Central clutch (SD7H15) Install screws of valve cover Oil filling plug Hose connector Expansion valve Proportional solenoid calve specifications Table 55. Specification Category Unit Value Conditions of Maximum supply pressure kgf/cm²… -

Page 57

Maintenance Manual──LG6210E Hydraulic Excavator Table 57.Specification limit , Component Mode Standard/reconstruction Maintenance value,unit:Mpa unit:Mpa Main Main pressure 32.4+1.5/-1 at 200l/min 32.4+1.5/-2 control reducing valve 200l/min valve High 34.3+1.5/-1 at 200l/min 34.3+1.5/-2 200l/min Boom throttle Raising 35.8+1.5/-1 at 28l/min 35.8+1.5/-2 at 28l/min… -

Page 58

Maintenance Manual──LG6210E Hydraulic Excavator machine.When the measured pressure value does not meet the maintenance tolerance limit, the worn or defective parts should be checked, or adjusted the pressure. 4 Main throttle pressure reducing valve is affected by the following 5 factors, so the pressure measurement conditions should be ensured strictly.And if measured… -

Page 59

Maintenance Manual──LG6210E Hydraulic Excavator Servo pump specifications Table 59.Specification Items Unit Model ZX10LGRZ1-07A Type Fixed gear Displacement cc/rev Oil flow l/min Release pressure kgf/cm² Accumulator specifications Table 60.Specification Description Unit Specification Type of gas Gas volume Boost pressure of gas 1.47±0.1… -

Page 60

Maintenance Manual──LG6210E Hydraulic Excavator Solenoid valve, specifications X1, solenoid valve 3 section Fig.9 X1, solenoid valve 3 section Table 61. X1, solenoid valve 3 section, specifications Instructions Unit Specification Maximum operating kgf/cm² pressure Maximum flow l/min ℃ Range of temperature -20~95… -

Page 61

Maintenance Manual──LG6210E Hydraulic Excavator Remote control valve (lever)specifications Table 62. Specification Items Unit Specification Remote control valve(bar),left type Hydraulic Remote control valve (bar) ,right Type hydraulic Operating angle Degree 19(throttle 1-3),25(throttle 2-4) Hydraulic oil Mineral hydraulic oil ℃ Engine oil temperature range -20~95… -

Page 62

Maintenance Manual──LG6210E Hydraulic Excavator Table 64. Straight moving pedal, specification Items Unit Instruction Type Mineral hydraulic oil Operating angle Degree Backward:12.4,forward: 12.4 ℃ Engine oil temperature range -20~90 Main operating pressure 3.2+0.2 Weight Hydraulic oil cooling system, specifications Refer to cooling systems, specifications… -

Page 63

Maintenance Manual──LG6210E Hydraulic Excavator Table 65.Specification,2 pump oil flow selector valve Instruction Unit Specification Normal operating pressure 34.32 Normal flow l/min Maximum oil flow at 140 kgf/cm² in section C cc/min Maximum pressure loss when flow rate is 0.07 100lpm Minimum cracking pressure of spool 0.69… -

Page 64

Maintenance Manual──LG6210E Hydraulic Excavator Rotary solenoid valve Fig. 12 Rotary solenoid valve Table 67.Specification,solenoid valve Instruction Unit Specification Maximum operating pressure kgf/cm² Operating flow Allowed regressive pressure kgf/cm² Internal leakage at pressure 140 kgf/cm² and Cc/min viscosity 20 cSt ℃… -

Page 65

Maintenance Manual──LG6210E Hydraulic Excavator Solenoid valve, specifications Table 68.Solenoid valve block 1 Items Specification Maximum pressure 50 kgf/cm² Maximum oil flow and The direction of oil flow Maximum oil Pressure loss pressure loss (viscosity flow l/min kgf/cm² P1→A1 20 cSt) 5 maximum (A1→T)… -

Page 66

Maintenance Manual──LG6210E Hydraulic Excavator Table 70. Specification,boom Items Unit 5.7m HD Length 5700 5910 1585 Width Weight 1890 Boom cylinder specifications Table 71. Specification Items Unit Specification Boom cylinder Quantity Φ125×φ80×1235 Inner diameter ×live bar × stroke Align the center Fully retracted(A)… -

Page 67

Maintenance Manual──LG6210E Hydraulic Excavator Bucket arm, specifications Fig.15 Bucket arm Table 72. Size,arm Items Unit 2.9 m HD Length 2900 3910 Width Weight 1085 Bucket arm cylinder, specifications Table 73.Specification Items Unit Specification Stick cylinder Quantity φ135×φ95×1540 Internal diameter ×live lever ×… -

Page 68

Maintenance Manual──LG6210E Hydraulic Excavator Fig. 16 Cylinder length A Retracted length B Stretched length Bucket cylinder, specifications Table 74. Specification Items Unit Specification Bucket cylinder Quantity φ120×φ80×1065 Internal diameter ×live lever × stroke Make the center Fully retracted(A) 1655±2 distance of the pin Fully stretched(B)… -

Page 69

Maintenance Manual──LG6210E Hydraulic Excavator Fig.17.Cylinder length A Retracted length B Stretched length 3 Tools NET 8940-00200 remote control valve connector replacement tools Fig. 18 Remote control valve connector replacement tools Items Quantity Name remarks Socket wrench SAE 4130(QT) Baffle SAE 4130(QT)… -

Page 70

Maintenance Manual──LG6210E Hydraulic Excavator NET 8940-00190 Moving motor guide pins Fig. 9 Moving motor guide pins Items Quantity Name Remarks Guide bar SAE 4130(25~35 HRC) Screw M8×16 NET 8940-00270 rotating ring replacement tool Fig. 20 Rotary ring replacement tool Items… -

Page 71

Maintenance Manual──LG6210E Hydraulic Excavator NET 8940-00290 alignment pins of track motor Fig. 21 Track motor, pins Items Quantity Name Remarks Guide bar SAE 4130(25~35 HRC) Screw M8×16 NET 8940-00300 Rotary gear alignment pins Fig.22 Rotating gear ring, guide pin Items… -

Page 72

Maintenance Manual──LG6210E Hydraulic Excavator 4 Maintenance instructions;Security instructions Maintenance position Park the machine in a horizontal solid place. The appropriate positions of machine are described in a variety of maintenance instructions. Fig.23 Maintenance position A Fig.24 Maintenance position B Fig. 25 Maintenance position C… -

Page 73

Maintenance Manual──LG6210E Hydraulic Excavator Fig. 27 Maintenance position E Fig. 28 Maintenance position F… -

Page 74

Maintenance Manual──LG6210E Hydraulic Excavator Ⅱ Repair and maintenance 1 Lubricating; fuel; other liquids 1.1 Overview Recommend lubricants Note! 1) Recommended engine oil level (VDS-3, or Global DHD-1 +VDS-2, or ACEA-E5 + VDS-2, or API CH-4 + VDS-2) Note! *: is installed in the factory. -

Page 75

Maintenance Manual──LG6210E Hydraulic Excavator • ISO: International Organization for Standardization • API: American Petroleum Institute Table 2. Filling capacity Tank Type of fluid About filling capacity Liters Engine oil disc with filter Engine oil 19.5 Hydraulic oil tank Hydraulic oil… -

Page 76

Maintenance Manual──LG6210E Hydraulic Excavator adaptation temperature requirements), ASTM D 975 No 1D and 2D, JIS KK 2204. Note! Please use the API level of CF or CG as the engine oil. If the API Level is CD, then the replacement intervals of engine oil should be half. -

Page 77

Maintenance Manual──LG6210E Hydraulic Excavator 10 Battery status, checking 11 Seat belts and tension of seat belt, checking, replacing it if necessary 12 Coolant freezing point, checking 13 Lubrication, refer to the lubrication chart 14 Oil level of rotating gearbox, checking… -

Page 78

Maintenance Manual──LG6210E Hydraulic Excavator 23 Rotary gearbox oil level, checking 24 Rotary motor gear box, changing the oil 25 Rotating ring gear bearings, lubrication 26 Rotary oil bath grease, checking 27 Cab; door, lid, hinges, fittings and locks, lubricating 28 Track board bolts, checking… -

Page 79

Maintenance Manual──LG6210E Hydraulic Excavator 2 Machine, check the external damage, cracking and worn damage 3 Cleanser level, checking 4 Coolant level, checking 5 Additional fuel filter (oil-water separator core), checking / draining 6 Track plate bolts, checking 7 Engine, oil level, checking Maintenance every 50 hours Maintenance points marked as «Optional equipment»… -

Page 80

Maintenance Manual──LG6210E Hydraulic Excavator 8 Main filter element of air filter, cleaning 9 Battery status, checking 10.Cab,pre-filter,cleaning 11 Lubrication, refer to the lubrication chart 12 Rotary gearbox oil level, checking 13 Rotating ring gear bearings, lubricating 15 X1 oil return filter (optional equipment), replacing Maintenance every 500 hours Maintenance points marked as «Optional equipment»… -

Page 81

Maintenance Manual──LG6210E Hydraulic Excavator 2 Machine, check the external damage, cracking and worn damage 3 Cleanser level, checking 4 Coolant level, checking 5 Hydraulic oil level, checking 6 Replace the fuel of engine. 7.Fuel filter,replacing 8 Oil-water separator filter element, replacing 9. -

Page 82

Maintenance Manual──LG6210E Hydraulic Excavator 3 Cleanser level, checking 4 Coolant level, checking 5 Hydraulic oil level, checking 6 Replace the fuel and filter of engine. 7.Fuel filter,replacing 8 Oil-water separator filter element, replacing 9. Fuel tank, draining 10 Ventilation filter of fuel tank, replacing 11Hydraulic oil servo filter, replacing 12.Main filter of air filter, cleaning… -

Page 83

Maintenance Manual──LG6210E Hydraulic Excavator 1 Try to run and check 2 Machine, check the external damage, cracking and worn damage 3 Cleanser level, checking 4 Coolant level, checking 5 Hydraulic oil level, checking 6 Replace the fuel and filter of engine. -

Page 84

Maintenance Manual──LG6210E Hydraulic Excavator Maintenance every 6000 hours Maintenance points marked as «Optional equipment» is not included in the calculated maintenance interval. 1 Try to run and check 2 Machine, check the external damage, cracking and worn damage 3 Cleanser level, checking… -

Page 85

Maintenance Manual──LG6210E Hydraulic Excavator 33 Loose and missing bolts, checking 34 X1 oil return filter (optional equipment), replacing Test running and checking 1 Starting and stopping functions (including warm-up function) 2 Instruments 3 Lighting 4 Direction instruction 5 Danger flash lamp… -

Page 86

Maintenance Manual──LG6210E Hydraulic Excavator 2Check the cleanser level Add cleanser inside the cleaner. Fig.2 Engine oil level, checking 1 Open the hood. 2 Pull out the dipstick (1), wipe it with a clean cotton cloth. 3 Insert the dipstick, and then pull it out. -

Page 87

Maintenance Manual──LG6210E Hydraulic Excavator Hydraulic oil level, checking 1. Park the machine on hard ground. 2. Stop the machines in the repair location C. Refer to maintenance position. 3 Push the safety control lock lever down and fix it firmly in Fig.5… -

Page 88

Maintenance Manual──LG6210E Hydraulic Excavator 3 Open the right door on the machine. Fig.8 4 Replace oil filter with 9,996,672 wrench , fill the new oil filter with engine oil. Clean the base of filter housing. Make sure that all the old filter gaskets are removed. -

Page 89

Maintenance Manual──LG6210E Hydraulic Excavator 2 Use a 9,996,671 oil filter wrench to loosen the fuel filter, then remove it. 3 Clean the sealing surface of filter head. 4 Coat the new rubber seal of filter with a little oil, or make it wet with diesel fuel. -

Page 90

Maintenance Manual──LG6210E Hydraulic Excavator 2 Disconnect the cable connector (1). 3 Loosen the drain valve (2), and discharge the sediment from the oil-water separator tank (3). 4 Use an oil filter wrench to loosen 9996671 oil-water separator tank (3), then remove it. -

Page 91

Maintenance Manual──LG6210E Hydraulic Excavator 2 Remove the clamping screw (2) and air filter (1) of fuel tank. Fig.17 3 Install the new fuel tank air filter (1) and the rubber connector (2). 4 Install the clamping screw and the fuel tank air filter. -

Page 92

Maintenance Manual──LG6210E Hydraulic Excavator 3 Pull out the main filter element of air filter and place it in a soft, clean surface, Carefully beat the end of the main element. Fig.21 4 Use clean dry compressed air to clean the main filter,… -

Page 93

Maintenance Manual──LG6210E Hydraulic Excavator 5 Close the air filter cover and side door. Safety filter element of air filter, replacing Note! After replacing the main filter element every 3 times, security filter should be replaced, or at least once every two years. -

Page 94

Maintenance Manual──LG6210E Hydraulic Excavator 2 Remove the battery cover. Fig.28 Removing the battery 3 Remove the battery cover (1). Electrolyte level should be approximately exceeding the panels about 10 mm. 4 When necessary, use distilled water to fill. 5 Operate the machine after filling fully, so that water can be mixed in the battery electrolyte, which is even more important in cold weather. -

Page 95

Maintenance Manual──LG6210E Hydraulic Excavator External radiator / oil cooler outside, cleaning WARNING! Compress air. Do not point directly to exposed skin. Use protective equipment. 1 Open the left door on the machine. Fig.31 2 Remove the screws (1), and open the radiator cap (2). -

Page 96

Maintenance Manual──LG6210E Hydraulic Excavator 4 Pull up the filter mesh and remove it 5 Blow the outside of the radiator / hydraulic oil cooler and inflatable cooler with compressed air or water flow net cleanly. Fig. 34 Filter Hydraulic tank, oil returning filter, replacing Note! When using a hydraulic hammer, refer to the table to replace the oil return filter. -

Page 97

Maintenance Manual──LG6210E Hydraulic Excavator Hydraulic oil draining filter, replacing Note! After 500 operating hours, replace the filter element of hydraulic oil draining filter, and then replace it every 1000 operating hours. 1 Put a container under the oil draining filter, turn the filter counterclockwise to remove it. -

Page 98

Maintenance Manual──LG6210E Hydraulic Excavator Hydraulic tank, replacing the ventilation filter Removing 1 Release the residue pressure in the hydraulic tank from the respirator. 2 Remove the rubber cover (1) and nut (2). Fig.40 Remove the rubber cap and nut 1. Rubber nut 2. Nut 3 Remove the cover by rotating respirator cover (3), and remove the filter components (4) of respirator. -

Page 99

Maintenance Manual──LG6210E Hydraulic Excavator Hydraulic tank, hydraulic oil replacing Important! Use the same hydraulic oil in the system. If you mix different brands of hydraulic oil, hydraulic system may be damaged. Note! Refer to the table below to replace the hydraulic oil. -

Page 100

Maintenance Manual──LG6210E Hydraulic Excavator Valve clearance, checking / adjusting Tool 9,998,681 Rotary tool 885,812 Timing Tool WARNING! Risk of burns — stop diesel engine and let it cool, then make the necessary operations. 1. Park the machine in the maintenance position B. Refer to maintenance position 2 Open the engine hood. -

Page 101

Maintenance Manual──LG6210E Hydraulic Excavator 6 Remove the rocker cover (1). 7 Open the right side door on the machine. Fig.47 8 Removing gear cover (1) of camshaft, install the steering gear (2). Note! Steering gear must be fully meshed with the gear of camshaft. -

Page 102

Maintenance Manual──LG6210E Hydraulic Excavator Fig.50 Valve overlap Fig. 51 1,3,5,7,9 and 11 are exhaust valve 10 According to the black mark in the figure, adjust the valve clearance for each cylinder. Adjustment steps are as follows: 1 Loosen the locking bolts on the adjusting screw of the rocker. -

Page 103

Maintenance Manual──LG6210E Hydraulic Excavator Fig. 53 1 885 812 timing tool 2 Adjustment screws 11 Rotate the crankshaft one full circle until the valves of cylinder overlap. According to the black mark in the figures, adjust the valve clearance of each cylinder. -

Page 104

Maintenance Manual──LG6210E Hydraulic Excavator Coolant, replacing WARNING! Risk of burns — stop diesel engine and let it cool, then make the necessary operations. WARNING! When the expansion tank cap (cooler cover) is opened, because of the high pressure of cooler within the system, it has the risk of scalding. -

Page 105

Maintenance Manual──LG6210E Hydraulic Excavator Note! Do not fill the cold coolant when the engine is warming up, which may cause cracks of engine body and cylinder heads. Main filter of air conditioning, cleaning 1 Move driver’s seat to the front position and fold the backrest forward front. -

Page 106

Maintenance Manual──LG6210E Hydraulic Excavator Note! When removing the lid, refer to the method of top lid. Fig.62 6 Remove the filter and blow the filter with compressed air —- maximum pressure of 0.2 Mpa. 7 Restore the machine to the operating state. -

Page 107

Maintenance Manual──LG6210E Hydraulic Excavator 5 Disconnect the wiring harness (4) of air actuator. Remove the pipe (1) of air conditioning and the upper shell (3). . Fig. 67 1 Pipeline 2 Open method of housing 3 Upper shell 4 Wire harness Note! When removing the lid, refer to the method of top lid. -

Page 108

Maintenance Manual──LG6210E Hydraulic Excavator 3.Remove the filter and blow the filter with compressed air —- maximum pressure of 0.2 Mpa. Note! If the air filter is clogged, airflow reduces, and cooling and heating capacity will decrease. Therefore, clean regularly. Fig.71… -

Page 109

Maintenance Manual──LG6210E Hydraulic Excavator 2 Check the gear oil level and fill it fully as needed. Note! After adding gear oil, wait about 5 minutes, then check the gear oil level. Fig.75 Rotary motor gear box, changing the oil Important! Drain when the gear oil is heated to rush out the dirt. -

Page 110

Maintenance Manual──LG6210E Hydraulic Excavator 3 After lubrication, thoroughly clean the excessive grease. Rotary oil bath grease, checking 1 Open the battery cover on the right side of the machine. 2 Remove the lid. Fig.79 3 Check the grease level. Note! If the grease is contaminated, or water is under discoloration, grease should be replaced. -

Page 111

Maintenance Manual──LG6210E Hydraulic Excavator Fig.82 2 Rotate the superstructure to one side , and fall the boom to lift the track. Rotate the track plate forward and backward several times slowly. Check whether the track plates and screws are loose or missing or damaged. -

Page 112

Maintenance Manual──LG6210E Hydraulic Excavator Fig.85 2 Rotate the track plate forward and backward several times slowly. Check whether the track plates and screws are loose or missing or damaged. Stop the track when rotating back. 3 Measure the track tension between the track plate in the center of track frame and the assembling surface of track bearing wheel.. -

Page 113

Maintenance Manual──LG6210E Hydraulic Excavator Oil level of track gearbox, checking 1 Put the machine on a hard ground. 2 Rotate the gearbox as shown in the figure. Remove the cover on the plug (2), check if there is gear oil spilling. -

Page 114

Maintenance Manual──LG6210E Hydraulic Excavator 2 Check the loose and missing assembly bolts of the seal cap visually. 3 Check whether the bolts of the hydraulic pump, motor, main control valve are loose or missing. Hydraulic pressure, checking 1 Measure the hydraulic pressure with pressure gauge, and adjust it if necessary, refer to main pressure reducing valve adjustment. -

Page 115

Maintenance Manual──LG6210E Hydraulic Excavator Bucket arm cylinder • Bucket cylinder is completely extended. Fig.91 Measurement conditions, bucket arm cylinder A B→A: Arm is retracted B A→B: Arm is extended Bucket cylinder Fig.92 Measurement conditions, bucket arm cylinder A B→A: Bending out… -

Page 116

Maintenance Manual──LG6210E Hydraulic Excavator Measuring • Operate the control lever with full stroke • Measure the time of full stroke of cylinder with a watch. • Measure 3 times and calculate the mean. Operating Standar Allowable Remarks value Boom Lifting 2.6±0.3… -

Page 117

Maintenance Manual──LG6210E Hydraulic Excavator • After measurement, remove the tape and carefully clean Fig.94 Measurement conditions, peristaltic 1 Tape 3 Piston rod 5 Retracted (L = A — a) 2 Seal sleeve of cylinder 4 Starting position 6 Extending (H = b — A) -

Page 118

Maintenance Manual──LG6210E Hydraulic Excavator Fig. 95 Measurement conditions, rotation speed Rotation towards left/right at idle Preparation • Bucket is with full load. • Bucket arm cylinder is completely retracted. • Bucket cylinder is completely extended. • Make the mark (A) on the outer bearing sleeve of rotary bearing, and mark (B) on the chassis under it directly. -

Page 119

Maintenance Manual──LG6210E Hydraulic Excavator Fig.97 Moment of inertia A Mark position (bearings) C Stopping position of rotary device E Starting rotation device B Mark position (chassis frame) D Moment of inertia F 180 ° rotation Measuring clearance of bearing Removable status Standard 0.05 ~ 0.2… -

Page 120

Maintenance Manual──LG6210E Hydraulic Excavator Installation conditions Clean the bearing sleeve and lower part of chassis of outer rotary gear. Wear of rotary gear are uneven on the entire circumference. To obtain accurate results, measure twice and rotate the upper structure around the axis 90 °. -

Page 121

Maintenance Manual──LG6210E Hydraulic Excavator Allowed spacing Measure the gap twice in each location and record in the following table. Superstructure in the 1st At the 2nd reading of the reading of the gap position position superstructure A (1st measurement) B (2nd measurement) -

Page 122

Maintenance Manual──LG6210E Hydraulic Excavator Travel time Standard Allowed value Maximum 1 Speed 2 Speed Performance of moving straight Preparation • Bucket cylinder / bucket arm cylinder are fully extended • Fix the excavating device to the move gesture. Fig.102 Measurement conditions, performance of moving straight Measuring 1 Operate two travelling control lever with full-stroke. -

Page 123

Maintenance Manual──LG6210E Hydraulic Excavator Track running speed Preparation • Mark any of the track piece in the test side. • Top up the track to be tested. Fig.104 measurement conditions, track speed Measuring • Accelerate the engine to maximum speed. -

Page 124

Maintenance Manual──LG6210E Hydraulic Excavator • When another machine is starting, do not make two machines contact with each other. Connect the actuating cable as follows: 1 Connect the clamp (1) of the actuating cable (A) with (+) pole of battery on the machine that is started with actuator. -

Page 125

Maintenance Manual──LG6210E Hydraulic Excavator Ⅲ Engine system 1 Overview of the engine BF6M2012C Engine The engine is 4- stroke, six-cylinder, turbocharged, direct injection, water-cooled diesel engine, equipped with inflatable cooling and wet replaceable cylinder. The electronically controlled diesel engine is controlled by the electronic control unit (EMR2) software of engine. -

Page 126

Maintenance Manual──LG6210E Hydraulic Excavator Cylinder is coded from the flywheel end. Engine Rotation direction of engine is counterclockwise seen from the flywheel side. Fig. 2 Engine, side view of starting motor 1 Fuel intake throttle 2 Single injection pump 3 Fan drive… -

Page 127

Maintenance Manual──LG6210E Hydraulic Excavator Fig. 3 Engine, side view of air heater 1 Coolant inlet (from radiator) 2 Coolant exit (to the radiator) 3 Coolant supplement throttle 4 Air inlet (from the air filter) 5 Turbocharger 6 Intake manifold 7 Exhaust manifold… -

Page 128

Maintenance Manual──LG6210E Hydraulic Excavator Engine characteristics curves BF6M2012C engine Fig.4 Engine characteristics curve Basic examination, engine Note! Some testing and safety inspection is carried out when the lock lever is not locked. If the lock lever is not locked in a safe situation, ensure that the machine will not be operated accidentally. -

Page 129

Maintenance Manual──LG6210E Hydraulic Excavator Testing of the basic examination Basic examination divided into the following test items should be done after reading the fault code and checking parameters. Troubleshooting Troubleshooting overview If a function has been felt to fail, it is very important to identify the cause as soon as possible. -

Page 130

Maintenance Manual──LG6210E Hydraulic Excavator Contain design information of error code, all fault codes table and each fault code information. 5 Components, repair and specifications Contain troubleshooting methods and numerical measurements of components. Also contain some circuits and certain regulations 6 Parameters Wrong setting of parameters will result in the failure symptoms. -

Page 131

Maintenance Manual──LG6210E Hydraulic Excavator Fig.5 Valve • Each cylinder of engine has one intake valve and an exhaust valve. Guide lever of the valve guide is retracted in the cylinder cover. Valve embedded body is made of high-quality steel and also is retracted in the cylinder cover. -

Page 132

Maintenance Manual──LG6210E Hydraulic Excavator • Measuring projection of piston needs a dial indicator of locator. • Piston is located on the dead point position on the surface of the piston. Fig. 6 Measurement, piston projection 1 Dial indicator A. Set the dial indicator on the surface of cylinder to «zero». -

Page 133

Maintenance Manual──LG6210E Hydraulic Excavator • 3-hole = 1.4 mm Table 2 piston projection Piston projection Identification cylinder head gasket 0.33 ~ 0.55 mm 1 hole 0.56 ~ 0.65 mm 2 holes 0.66 ~ 0.76 mm 3 holes Installing cylinder cover… -

Page 134

Maintenance Manual──LG6210E Hydraulic Excavator 1.2 Pistons Piston, indication BF6M2012C Engine Piston is made from special aluminum alloy. Combustion chamber of position is located slightly off-center relative to the piston (eccentric). Piston is equipped with three rings. The first ring has a ring prop made of cast iron. -

Page 135

Maintenance Manual──LG6210E Hydraulic Excavator Piston cooling Piston is cooled by spraying the oil to the inner part of the piston. Plastic 2-hole piston cooling nozzle is installed in the main bearing base. Fig. 10 Piston cooling 1.3 Valves mechanery Valves, indication… -

Page 136

Maintenance Manual──LG6210E Hydraulic Excavator 1.Park the machine in the maintenance position B. Refer to maintenance position 2 Open the engine hood. 3 Remove the turbocharger inlet pipe (1). 4 Remove the ventilation pipe (1) of crankcase. Fig.13 5 Remove the cable bracket (1). -

Page 137

Maintenance Manual──LG6210E Hydraulic Excavator Note! Steering gear must be fully meshed with the teeth of camshaft gear. 9 Set the overlap angle of engine valve Rotate the crankshaft using the steering gear 1 until it reaches the overlap angle of cylinder valve. -

Page 138

Maintenance Manual──LG6210E Hydraulic Excavator 10 According to the black mark in the figure, adjust the valve clearance for each cylinder. Adjustment steps are as follows: 1 Loosen the locking bolts on the adjusting screw of the rocker. 2 Install the protractor on adjustment screws. -

Page 139

Maintenance Manual──LG6210E Hydraulic Excavator 13 After the maintenance work is completed, start the engine, check for leakage and operation state. 1.5 Engine Assembly Engine Assembly Table 3 tightening torque, unit: kgf· m Installation location Tightening torque Screws (fan and flywheel side) 70±7… -

Page 140

Maintenance Manual──LG6210E Hydraulic Excavator 2 Lubrication system Lubrication system, indication •By the forced lubrication through the oil pump, engine oil is supplied to the rotating parts, such as the turbocharger, crankshaft, camshaft, pistons, intake / exhaust valves, rocker arms and the contact surface of timing gear. -

Page 141

Maintenance Manual──LG6210E Hydraulic Excavator Diagram, oil circuit Table 4 Specifications Items Explain Remarks Oil Pump Rotary pumps: Volume flow in the n = 2500 min-1: 65 l / min Oil radiator Oil cooler bypass valve Opening pressure: p = 2.1 ± 0.35 bar… -

Page 142

Maintenance Manual──LG6210E Hydraulic Excavator the oil cooler to the oil filter. These two parts are mounted on the oil cooler on the crankcase with flange. Downstream from the filter, oil flows into the main oil and secondary pipeline. From here, the oil pipeline will be guided to the lubrication points. -

Page 143

Maintenance Manual──LG6210E Hydraulic Excavator Oil cooling tank Pressure relief valve of oil cooling tank and oil cooler, cooperate with each other. Table 6 oil cooling tank Item Explain Remarks Oil filter Components: the filter shell, oil filter and filter element. -

Page 144

Maintenance Manual──LG6210E Hydraulic Excavator 3 Fuel system 3.1 Overview Fuel system, indication Fuel supply system is composed of a low and a high pressure circuit. Low pressure circuit Fuel comes out from the fuel tank, goes into fuel filter 5… -

Page 145

Maintenance Manual──LG6210E Hydraulic Excavator through a large number of fuel, with automatic exhaust function. Fuel flow system diagram Fuel flows from the pump (9) to the tank (2) to the supply pipe of each cylinder injection pump on the crankcase through a filter (7). -

Page 146

Maintenance Manual──LG6210E Hydraulic Excavator Fuel level sensor is installed in the fuel tank. When the fuel level gauge shows EMPTY, the tank there is about 40 liters of fuel left. Fuel injection system, indication • BF6M2012C works according to direct injection. -

Page 147

Maintenance Manual──LG6210E Hydraulic Excavator hand, which avoids the start-up procedure of engine. (Starting protection). Note! Do not reduce cross-section of pipe and connect to pump (refer to installation instructions), which will cause the engine power loss. Fig. 30 Oil supply pump… -

Page 148

Maintenance Manual──LG6210E Hydraulic Excavator 4 Turn on the power, start the engine, run the engine at low idle for several minutes. If the engine is difficult to start, and then use the main pump to exhaust. Note! The main pump can not be used with the engine running. -

Page 149

Maintenance Manual──LG6210E Hydraulic Excavator 5 Remove the pipes(1), screws (3) and fuel supply pump (2). Fig.35 1 Fuel input / output pipeline Note! Cover the port of hose, to prevent debris from 2 Fuel supply pump entering the fuel system. -

Page 150

Maintenance Manual──LG6210E Hydraulic Excavator 5 Tighten screw on the filter by hand until the seal contacts tightly, then turn a half circle. 6 Perform to exhaust air. Refer to fuel system, oil leakage Additional extra oil filter, replacing Tool 9996671 oil filter wrench… -

Page 151

Maintenance Manual──LG6210E Hydraulic Excavator 3.3 Fuel Tank Description of the fuel tank Fig.39 Structure, fuel tank 1 fuel tank 2 mesh filter 3 fuel tank lid 4 emissions knob 5 handle 6 oil output throttle 7 screws 8 shims 9 flat gasket10 spring washers… -

Page 152

Maintenance Manual──LG6210E Hydraulic Excavator 3.4 Injectors; oil supply pipelines Injector, indication Injection nozzle has 6 holes, which is designed to provide a fixed standard of the injection surface shape, regardless of the angle of injector and injector nozzles. Fig. 40… -

Page 153

Maintenance Manual──LG6210E Hydraulic Excavator Injector, replacing one 1 Park the machine in the maintenance position B, refer to maintenance position Important! Note to keep clean as far as possible! 2 Open the engine hood. 3 Remove the cable bracket (1) from the valve cover. -

Page 154

Maintenance Manual──LG6210E Hydraulic Excavator Engine starting conditions Note! This test can only be used for engine has problems about starting. 4 Remove the injectors cover (1) from the engine, disconnect all the cables (2)of injector. Note! Do separate the disconnected cables. -

Page 155

Maintenance Manual──LG6210E Hydraulic Excavator Note! If test results are not normal, check the fuel pressure sensor and the engine electronic control unit (EMR2). 11 Stop the engine. 12 Store the operation cards. The engine is running, but without load. 13.Begin the testing of SIEDIA engine. -

Page 156

Maintenance Manual──LG6210E Hydraulic Excavator 4 Air intake system; exhaust system 4.1 Overview Air intake system, instruction • Air used for combustion is filtered by pre-filter, air filter, then provide into the combustion chamber of engine through the air cooler. • To provide convenience to the operator, blocking of the intake system will be perceived and start a warning light on the gauge. -

Page 157

Maintenance Manual──LG6210E Hydraulic Excavator Exhaust System, instruction BF6M2012C engine 1 The exhaust system is designed to make noise is significantly reduced when the waste air goes through exhaust manifold and the muffler. Fig. 49 Installing, the muffler 1 turbocharger 2 pipes… -

Page 158

Maintenance Manual──LG6210E Hydraulic Excavator 4.2 Air cleaner with the connecting pipe; air preheater Preheating coil, replacing WARNING! Risk of burns — stop diesel engine and let it cool, then make the necessary operations. 1 Open the hood. 2 Remove the outlet pipe (1) and hose (2)of boost air cooler. -

Page 159

Maintenance Manual──LG6210E Hydraulic Excavator Intercooler reduces the air temperature about 100 ° C (212 ° F), which can increase engine power by about 10%. Torque of engine will increase, and fuel consumption is also reduced. Turbo diesel engine with inflation cooling (intercooling) is the most efficient during all diesel engines. -

Page 160

Maintenance Manual──LG6210E Hydraulic Excavator 5 Cooling System 5.1 Overview Cooling System,instruction Chamber and boxes of cooling unit are made of aluminum. Hydraulic oil cooler and boost air cooler is installed on the radiator frame. As the fan rotates, the air goes through the radiator, oil cooler and inflatable cooler ,and then be absorbed into the engine. -

Page 161

Maintenance Manual──LG6210E Hydraulic Excavator Cooling system, operating Fig.55 Cooling System (1) 1 cooling fan 2 radiator 3 vent hose 4 outlet hose of coolant 5 thermostat6 fan belt 7 cylinder cooling chamber 8 filters of engine and oil cooler 9 inlet hose of coolant 10 water pump 11 additional hose Note! Tightening torque (clip): 0.5 ~ 0.6 kgf ·… -

Page 162

When filling and replacing the coolant, only use the coolant VCS of SDLG. Do not mix different coolants or corrosion protection agent, as this may cause damage to engine. If you use the VCS coolant and pure water, the mixture should contain 40-60% concentrated coolant and 60-40% water. -

Page 163

Maintenance Manual──LG6210E Hydraulic Excavator concentrated coolant. Do not mix with other premixed coolant, which may cause the damage to engine. Important! Refrigerant of cooling system must be disposed according to environmental regulations. Draining the cooling system Draining To drain the cooling system, remove screw on the left crankcase, use the appropriate container to collect the coolant. -

Page 164

Maintenance Manual──LG6210E Hydraulic Excavator 3 Open the left side door on the machine. Open the coolant drain valve (1), and drain the coolant into a suitable container. Note! Prepare a suitable container. Note! After emptying the cooling system, do not prevent freezing. -

Page 165

Maintenance Manual──LG6210E Hydraulic Excavator 4 Remove the screws (2), and remove the thermostat housing (1) at the outlet hose (3) of the radiator. 5 Remove the cover from the engine cylinder thermostat (1). Fig.60 6 Install a new thermostat with a new gasket (2). -

Page 166

Maintenance Manual──LG6210E Hydraulic Excavator 2. Heat when measuring the water temperature, then see actions listed in the table. About operating temperature, refer to thermostats, specifications. Note! Opening temperature of valve is engraved on the flange. 3 Put the thermostat in a container filled with antifreeze or oil. -

Page 167

Maintenance Manual──LG6210E Hydraulic Excavator 4 Loosen two mounting screws for 2 laps. Fig.66 5 Use the belt adjusting nut (3) to remove the compressor belt (1). Note! Belt tension of adjuster is very strong. Therefore, after removing the belt, pay attention to injury. -

Page 168

Maintenance Manual──LG6210E Hydraulic Excavator 6 Use a socket wrench handle (1 / 2 «) rotate belt tension (3)clockwise, remove the belt (4), then install a new belt. Note! Belt tension of adjuster is very strong. Therefore, after removing the belt, pay attention to injury. -

Page 169

Maintenance Manual──LG6210E Hydraulic Excavator 6.2 Speed control Engine speed control switch description · VECU automatic operating position, the operator can easily control operation mode, the engine speed and maximum horsepower by the engine speed control switch. · Switch can control engine speed and maximum horsepower according to the programs of each mode of VECU. -

Page 170

Maintenance Manual──LG6210E Hydraulic Excavator Ⅳ Power transmission 1 Gear box 1.1 Track gearbox Track gearbox, instruction Track gear box is made up of 2 -order planetary gear devices, which can turn the high speed of hydraulic motor to low speed, high torque rotational force in the centre of sprocket teeth. -

Page 171

Maintenance Manual──LG6210E Hydraulic Excavator Fig. 2 Port connector 1.Gear oil level checking throttle (PF 3 / 4) 2 Gear oil filling and discharge throttle (PF 3 / 4) 3 High-speed 4 Low-speed Table 1 Direction of rotation E-axis view Import… -

Page 172

Maintenance Manual──LG6210E Hydraulic Excavator Table 2 Throttle connection Throttle sign Dimension of the throttle Throttle (A)(B) PF 1 Oil supply(oil return) (P )(P ) PT1/4 Pressure checking (P) PF1/4 Displacement conversion valve —oil supply (D )(D ) PF1/4 Draining oil Fig.4 Track gear box, cross section… -

Page 173

Maintenance Manual──LG6210E Hydraulic Excavator Fig. 5 Track gearbox, exploded view Power from the output shaft of hydraulic motor will be delivered to prime epicyclic gear (27) → No.1 bracket rack (19) →secondary epicyclic gear (20) →secondary planetary gear (12) → ring gear (8). -

Page 174

Maintenance Manual──LG6210E Hydraulic Excavator Tightening torque Table 4 tightening torque Deceleration screws (A) Quantity Thread Torque, kgf · m M16(P2.0) 27±3 Sprocket bolt (B) M16(P2.0) 27±3 Note! The intensity level of screws must be greater than 10.9 KS. Lubricating oil Important! Before operating the travel function, fill the gearbox to the correct level with the gear oil. -

Page 175

Maintenance Manual──LG6210E Hydraulic Excavator Operation Checking • Check the oil level before operating the travel function • Check whether gear box assemblies is leaked. • Check whether the mounting screws are tight. • Check whether there is abnormal sound or vibration during the operation. -

Page 176

Maintenance Manual──LG6210E Hydraulic Excavator Table 5 Components, replacement standard Items No. Component Status Allow value Ring gear There is dents or uneven wear on the Area ratio: No.2, planetary gear teeth surface. No.2 epicyclic gear Gear is broken. No.1 planetary gear No.1 epicyclic gear… -

Page 177

Maintenance Manual──LG6210E Hydraulic Excavator Special tools Table 7. Special tools Explain Size Quantity Bearing shim adjustors Refer to the next figure Gasket thickness measurement fixtures Fig.11 Gasket thickness, measurement tool Track gear box, removing 1 Remove cover screws (2), and remove the cover (1). -

Page 178

Maintenance Manual──LG6210E Hydraulic Excavator Fig.13 Remove the hydraulic hose and screw 6 Entangle around the gear box with a rope, and then lift it. Remove the motor. Then, push the gearbox out with the screws in the thread hole of the chassis. -

Page 179

Maintenance Manual──LG6210E Hydraulic Excavator Track gear box, replacing the lid 1.Park the machine in the maintenance position B, refer to maintenance position. Turn the gear box until the drain plug and level plug is located on the vertical axis. 2 Remove the two plugs (1,2)on the end cap and drain the gear oil into a suitable container. -

Page 180

Maintenance Manual──LG6210E Hydraulic Excavator Track gearbox removing Note •Before removing, completely clean the gear box components. • Choose a clean work area. • Make marks on the assembled components to note the correct position in order to facilitate assembly. • Be careful not to mix the secondary component parts, namely, the planetary gear bearings, gears and thrust washers. -

Page 181

Maintenance Manual──LG6210E Hydraulic Excavator 4 Remove No.1 planetary gear transmission equipment (18) from No.2 planetary gear (10). Remove No.1 planetary gear drive device. • Hit the spring pin (26) into the No. 1 pin (25). • Remove thrust washer (24), No.1 planetary(22) and needle roller bearings (23) gear from No.1 bracket (19). -

Page 182

Maintenance Manual──LG6210E Hydraulic Excavator 5 Remove No. 1 epicyclic gear (27) and coupling (9). Note! Remove 1 bracket (19) and remove the 2 and 1 star gear (20,27). WARNING! These parts are very heavy. Pay attention to the appropriate safety. -

Page 183

Maintenance Manual──LG6210E Hydraulic Excavator — Tools: Ring bolts (M10), plastic hammer Note! Mark the matching marks for the gear (12), pins (15) and bracket (11). Note! Do not mix gears, bearings, thrust washers and pin components. Note! Do not reuse the spring pin (16). -

Page 184

Maintenance Manual──LG6210E Hydraulic Excavator Note! When it is difficult to remove, lift of the parts vertically, and tap it with a plastic hammer. 10 Remove the seals (3) from the housing (1). Remove the seals (3) from motor housing (302 main shaft) on the removal of. -

Page 185

Maintenance Manual──LG6210E Hydraulic Excavator 1.Install the angular bearing (2) to the housing (1). — Tools: Plastic hammer, desktop presses. Note! Outer ring of angle of bearing should be completely aligned, full going to the bearing. Note! Press it with a hammer or press-fit. -

Page 186

Maintenance Manual──LG6210E Hydraulic Excavator Figure 36 Adjustment, shim 4 Install level pin (7) to the housing (1), calibrate the gear (8) correctly. — Tools: Plastic hammer Note! Coat the mating surface of ring gear (8)with Loctite # 5699 . Note! Temporary install four screws (30). -

Page 187

Maintenance Manual──LG6210E Hydraulic Excavator WARNING! These parts are very heavy. Pay attention to the appropriate safety notes. Note! Li pile technology: A solution using Loctite 6 No. 2 planetary gear transmission (10) is properly installed to the rack of the motor. -

Page 188

Maintenance Manual──LG6210E Hydraulic Excavator — Tools: plastic hammer Note! Align No. 1 bracket and hole of spring pin. Note! Piling technology: Note! Check whether the No. 1 planetary gears rotates smoothly. WARNING! These parts are very heavy. Pay attention to the appropriate safety notes. -

Page 189

Maintenance Manual──LG6210E Hydraulic Excavator 10 Insert a ring bolt into the oil level throttle and install the cover (28) to the ring gear (8). Install screws (31), screw (30) and tighten them to the specified torque. — Tools: Ring bolts (PT 1 / 2), L-shaped wrench 10 mm… -

Page 190

Maintenance Manual──LG6210E Hydraulic Excavator Track gearbox, troubleshooting Table 10 Troubleshooting of track gearbox Gearbox can’t Motor is overloading Reduce the load. rotate. Gearbox is damaged. Replace the gearbox. Mating surface Liquid washer is not Remove and reuse it. is leaking. -

Page 191

Maintenance Manual──LG6210E Hydraulic Excavator Abnormal Gear oil is not Refill the oil to the operating enough. specified level. temperature Bearing or gear is Replace the gearbox. damaged. Gear oil is mixed Replace the sealing with gear oil. ring of motor. -

Page 192

Maintenance Manual──LG6210E Hydraulic Excavator Rotary gear boxes, cross sections Fig.3 Rotary gear boxes, cross sections 1. No.2 planetary gear transmission 17 bearing 32 bearing 2. No.2 bracket 18 retaining ring 33 washers 3 No. 2 planetary gear 19 housing 34 washers 4 No. -

Page 193

Maintenance Manual──LG6210E Hydraulic Excavator Function 2—order planetary gear assembly converts speed / low output torque of the hydraulic motor into low speed / high torque, and then transfer to the inner gear of rotary ring through pinion gear to rotate upper structure. -

Page 194

Maintenance Manual──LG6210E Hydraulic Excavator Turn gearbox, lubricating Notes about lubrication • Before operating the rotary function, check the oil level. • Check whether the motor and gearbox assemblies leaks. • Check whether the mounting screws are tightened. • Check whether there is abnormal sound or vibration during rotation process. -

Page 195

Maintenance Manual──LG6210E Hydraulic Excavator Gear oil, replacing Note! Drain the gear oil when the oil can be decomposed into any impurities. • Open the cover (D) on the drain valve (C), and connect drain hose (E) to the drain valve (C), then drain the oil into a suitable container. -

Page 196

Maintenance Manual──LG6210E Hydraulic Excavator Table 11 standard replacement parts Item Part Name Status Standard values Allow the value epicyclic Erosion on the gear -Diameter Clearance: φ gear teeth. epicyclic 1mm (0.039 in) gear -Area ratio:<5% No.1 planetary gear No.2 planetary… -

Page 197

Maintenance Manual──LG6210E Hydraulic Excavator General Tools Table 12 General Tools Explain Size Quantity Wrench 17 × 19 mm 24 × 27 mm Socket wrench General wrench 10 mm 14 mm Torque Wrench 3923 ~ 17652 Nm 11768 ~ 47072 Nm φ… -

Page 198

Maintenance Manual──LG6210E Hydraulic Excavator Special tools Table 13 special tools Explain Part Number Number Bearing assembly fixtures 8920-00280 Bearing assembly fixtures 8932-00600 Oil seal assembly fixtures 8920-00550 Oil seal assembly guide fixtures 8920-00570 seal 8920-00560 assembly guide fixtures… -

Page 199

Maintenance Manual──LG6210E Hydraulic Excavator Rotary gear box, replacement 1 Park the machine in the maintenance position C, refer to maintenance position. 2 • When the engine is running, the hydraulic pipelines are under high pressure. Stop the machine, drain the… -

Page 200

Maintenance Manual──LG6210E Hydraulic Excavator 6 Remove the drain hose (2) of rotary motor. 7 Remove the feedback line hose (3)of rotary motor. 8 Remove the vice hose (4) of delay valve. 9 Remove the assembly screws (1) of rotary gear box, and remove the silica gel (2) from two rear holes. -

Page 201

Maintenance Manual──LG6210E Hydraulic Excavator 13 Transfer the drain hose (1) and pins (2) to the new rotary gear boxes. Fig.19 Transfer, oil drain hose and pins 1 oil drain hose 2 pin 14 Enhance the rotary units with the lifting device and install it on the machine. -

Page 202

Maintenance Manual──LG6210E Hydraulic Excavator 17 Install the vice delay hose (4) of valve. 18.Install drain hose (2 ) of rotary motor. 19.Install anti-cavitation hose (3). 20 Remove vacuum pump installed on the hydraulic tank. 21 Fill the gearbox oil from the oil filling pipe. -

Page 203

Maintenance Manual──LG6210E Hydraulic Excavator 5 Remove the screw (22). 6 Remove plate (23). Fig. 23 Removing, screws and plates 7 Remove No.1 epicyclic gear (37). Fig. 24 Removing, No.1 epicyclic gear 8 Remove the first planetary gear assembly (28) from the ring gear (20). -

Page 204

Maintenance Manual──LG6210E Hydraulic Excavator 9 Remove the ring gear (20) and connected pin (21). 10.Remove No.1 epicyclic gear (26) and thrust ring (25). Fig.27 Removing No.2 epicyclic gear 11 .Remove transmission device(1) of No.1 planetary gear from the shaft (10). -

Page 205

Maintenance Manual──LG6210E Hydraulic Excavator 16.Fix the reduction gear as shown in the picture. Press the shafts (10) from the boxes(19)out with press tool. Fig. 31 Removing, shaft 17 Remove the spherical bearing (16) and collar (11) from the shaft(10)with press tool. -

Page 206

Maintenance Manual──LG6210E Hydraulic Excavator 19 Push the spherical bearing (17) out of the tank (19) with the press tool. Note! Spherical bearing (17) can also be removed by work bench press tool. Fig. 34 Removing,, spherical Rotary gear box assembly Note •… -

Page 207

Maintenance Manual──LG6210E Hydraulic Excavator Assembly 1 Install the O-ring (13) to the collar (11), and then install it to the shaft (10). Note! Coat the O-ring (13) with grease (NLGI 2). Fig. 48 Installing, collar 2 Press the spherical bearing (16) down to the shaft (10) with press tool. -

Page 208

Maintenance Manual──LG6210E Hydraulic Excavator 3 Press the oil seal (14) into the cover (12) with press tool. Note! Coat the outer diameter of the oil seal with Loctite # 680. Be careful not to touch the oil seal lip chips. -

Page 209

Maintenance Manual──LG6210E Hydraulic Excavator 7.Fix the tank (19) as shown in the figure. 8 Press the spherical bearing (17) to the tank(19) with press tool. Note! Install the both internal and external bearing sleeve with press tool. Fig. 54 Installing, spherical bearings 9 Install spherical bearings (17), and install the retaining ring (18) on the shaft (10). -

Page 210

Maintenance Manual──LG6210E Hydraulic Excavator Note! Align the pin assembly (4) and spring pin hole of bracket(2). Install the thrust washers (8) attached with a small amount of grease to the gear (3). Install spring pin (9), with cutting edge towards the end of pin (5). -

Page 211

Maintenance Manual──LG6210E Hydraulic Excavator WARNING! The parts are heavy. When operating these components, should take appropriate safety precautions. Note! — Coat the mating surface of the tank (19) with Loctite 5699 silicone rubber. — Support the tank (19). Fig. 61 Installing, No. 2 planetary 13 Transmission device of No.1 planetary gear and… -

Page 212

Maintenance Manual──LG6210E Hydraulic Excavator 14 Install the plate (23) to the ring gear (20), and then install the screws (22). Fig. 64 Installing, the board A Plug hole Note! Align the mating marks on tank(19), the ring gear (20) and plate (23). -

Page 213

Maintenance Manual──LG6210E Hydraulic Excavator 16 Tighten the drain valve (43) to the pipe (44), and then tighten the pipe (44) to the tank (19). 17 Install the pipe (40) to the motor, and then insert the level gauge (39). Note! Make the oil drain throttle of the pipe toward side. -

Page 214

Maintenance Manual──LG6210E Hydraulic Excavator Housing is Cracks or pin hole Replace the housing. leaking. leaks. Cover is damaged. Replace the cover. Shaft is Replace sealing O-ring is is worn. leaking. gasket. Contacting surface Replace or repair the of seal is damaged. -

Page 215

Maintenance Manual──LG6210E Hydraulic Excavator 2 Hydrostatic drive (Hydraulic motor, including the operating system) 2.1 Hydraulic motor 1, travel motor Travel motor,instruction • Hydraulic motor: the hydraulic motor is the design based on the variable impact and axial piston, including the paring brake valve assembly and the parking brake. -

Page 216

Maintenance Manual──LG6210E Hydraulic Excavator Fig.47 Travel motor structure 1 High-speed 2 Low-speed Table 11 Throttle connecting Throttle sign Throttle size Throttle (A), (B) Oil supply(oil return) (P1) ~ (P4) PT1 / 4 Pressure checking (P5) PT 1 / 8 Oil supply of displacement… -

Page 217

Maintenance Manual──LG6210E Hydraulic Excavator Fig.48 Travel motor, cylinder and piston 2-shaft 3 swash plate 4 cylinder 5 piston 6 piston sets 7 fixed plate 8 thrust ball 9 valve plate 10 washers 11 roller 12 brake piston 13 brake springs… -

Page 218

Maintenance Manual──LG6210E Hydraulic Excavator Operating, the hydraulic motor Pressurized oil is sent from the hydraulic pump through the control valve into the throttle on the rear flange (201) and flows to the half part of cylinder body (4) through the valve (9). -

Page 219

Maintenance Manual──LG6210E Hydraulic Excavator Operating, brake valve Operations (Brake release) When pressurized oil is supplied to the throttle (A), it opens the check valve (227) and flows into inlet throttle (C) of the hydraulic motor. Meanwhile, the pressurized oil goes into the chamber (b) through the channel (a) and through a small hole of the balance spool (223). -

Page 220

Maintenance Manual──LG6210E Hydraulic Excavator When the piston reaches the end of stroke, the pressure of chamber(g and f) begins to rise and react on the valve piston (101). At this point, open pressure of release valve is higher than the normal release set pressure. This process is used to buffer the pressure spikes when the valve is open. -

Page 221

Maintenance Manual──LG6210E Hydraulic Excavator When the oil pressure gets to about 6 kgf/cm , it starts to push brake piston (12) into the rear flange (201) to overcome the force of brake spring (13). At the same time, the piston moves away from the friction plate (15) and the mating piece (16) to separate them, and release the braking force of the control cylinder (4). -

Page 222

Maintenance Manual──LG6210E Hydraulic Excavator High speed When the solenoid valve is connected (ph), servo-hydraulic oil will flow to the throttle (D). Hydraulic flow (40kgf/cm2) of the throttle (D) overcomes the spring (266) force to move the spool (263) down and overcomes hydraulic oil pressure the throttle (A, B) to open the throttle (C). -

Page 223

Maintenance Manual──LG6210E Hydraulic Excavator Travel motor, operation precautions Installing • Check that the mating surface is clean. • Check that the motor is positioned in the frame correctly • If the gear that will be installed to the frame is very tight, install the components into frame evenly with the mounting screws. -

Page 224

Maintenance Manual──LG6210E Hydraulic Excavator The following standard about components maintenance capability can be decided according to the measurement before disassembly. However, they are general standards, and when the parts presents excessive external damage or discoloration, the primary thing is to determine the extent of replacement based on the average residual life span of parts and components. -

Page 225

Maintenance Manual──LG6210E Hydraulic Excavator kgf · m pieces Plate is bent. kgf • m Bearing Pitting / lobes appear on the bearing sleeve or ball or roller. Manual rotation is not smooth. Piston of Sliding surface is damaged. release valve Well Surface of base is damaged. -

Page 226

Maintenance Manual──LG6210E Hydraulic Excavator Table16.General tool Explain Size Quantity General wrench 5 mm、10 mm、8 mm、14 mm 1/2″ drive,3/4″ drive Torque Wrench About 280 n·m About 850 n·m Socket wrench 32、41 mm L-shape Socket 5、6、8、10、14、19 mm wrench Hammer Calibrated 12# Plastic hammer… -

Page 227

Maintenance Manual──LG6210E Hydraulic Excavator Table17.Special tool Instruction Quantity Quantity Ⅰ Fixer( ) 4Elevator Serial number:8932 — 00160 Ⅱ Fixer( ) Serial number:8932 — 00210 Serial number:8932 — 00150 Ⅲ Fixer( ) Serial number: 8933 — 00320 Pressure relief valve of travel motor, replacing 1. -

Page 228

Maintenance Manual──LG6210E Hydraulic Excavator 4 Remove pressure relief valve (1)of track motor. 5 Install the new pressure relief valve 6 Check pressure relief valve (1)of track motor, if necessary, adjust it. 7 Install the motor cover. Fig.60 Removing, valve Travel motor, disasembly Note •… -

Page 229

Maintenance Manual──LG6210E Hydraulic Excavator 3 Remove the screw (243). Fig.63 Screws, removing 4 Remove the flange (201) from the main shaft (302). Note! Be careful not to remove the shaft (2). Fig. 64 Rear flange, removing 5 Gearbox / hydraulic motor shaft and oil seal. -

Page 230

Maintenance Manual──LG6210E Hydraulic Excavator Brake valve 6 Removal of balanced spool. • Remove the plug (224) from rear flange (201). • Remove the O-ring (236) from the plug (224). Note! Do not reuse O-ring (236) after removal. • Remove the spring (228), locking device(225) and the balance spool (223)from rear flange (201). -

Page 231

Maintenance Manual──LG6210E Hydraulic Excavator 8 Double-speed valve, removing • Remove the plug (257) from rear flange (201). • Remove the spring (266) and spool (263)from rear flange (201). •Remove the O-ring (295) from the plug (257).. Fig. 70 Plug, removing Note! Do not reuse O-ring (295)after removal. -

Page 232

Maintenance Manual──LG6210E Hydraulic Excavator Fig. 75 Ball, removing 10. Release valve, removing • Remove the plug (104) and remove the well (102). Note! Do not replace two pressure relief valve with each other. •Remove the O-ring (110) from the plug (104). -

Page 233

Maintenance Manual──LG6210E Hydraulic Excavator Fig. 80 Release valve piston, removing Removing the hydraulic motor 11. Remove parking brake. WARNING! Sudden injection of compressed may result in pop-up of air piston. To ensure your safety, install a protective cover on the piston cover. -

Page 234

Maintenance Manual──LG6210E Hydraulic Excavator Note! Carefully remove the cylinder, do not let the piston and the needle (51) fall into the main shaft. •Grasp the cylinder (4) with two hands to remove it from the main shaft302). •Remove swash plate (3), ball (67) from the main shaft (302). -

Page 235

Maintenance Manual──LG6210E Hydraulic Excavator 16 Remove steel ball (67) and parallel pin (71)from the main shaft (302). WARNING! Sudden injection of compressed may result in pop-up of air piston. To ensure your safety, install a protective cover on the piston cover. -

Page 236

Maintenance Manual──LG6210E Hydraulic Excavator Note! Use a rubber pad to protect the sliding surface of the cylinder body. Note! Only it is needed to replace the spring (14). WARNING! Do not suddenly release the press tool. Spring may pop up and cause damage. -

Page 237

Maintenance Manual──LG6210E Hydraulic Excavator Brake, assembly 1.Check valve • Install the O-ring (237) to the plug (226). • Install the spring (230) and check valve (227) to the plug (226), then coat the springs and valve assembly with Fig. 93 Plug, installing grease. -

Page 238

Maintenance Manual──LG6210E Hydraulic Excavator • Tighten the plug (257) into the rear flange (201) to the required torque Torque (10±2 kgf·m). Fig. 97 Plug, installing 4 Impact release valve components. • Embed the ball (285) into the rear flange (201). -

Page 239

Maintenance Manual──LG6210E Hydraulic Excavator Note! Piston seals (120) includes O-ring and Teflon ring. Note! Coat the two side of the piston seal (120) withthe grease. Install O-ring, then Teflon ring. • Install the piston (101), spring (106), the spring positioning piece (103) and gasket (105) with a plug (104), then tighten to the required torque (10±2 kgf·m) -

Page 240

Maintenance Manual──LG6210E Hydraulic Excavator Note! Be careful, when shrunk to install ball bearing (49), do not heat the main shaft (2). 8 Assemble piston assembly (61), (62). •Coat the spring (93) with grease and install it on the piston assembly. -

Page 241

Maintenance Manual──LG6210E Hydraulic Excavator 11 Motor components. • Install needle (51) to the cylinder (4), and then put the collar (11) and thrust ball (8) into the cylinder. •Insert the piston assembly (5), (6) into the bearing plate (7). •Coat piston with hydraulic oil, and then install it into the cylinder body (4). -

Page 242