Skip to content

NC750X

faq & Forum

Документация

1. Руководства по эксплуатации

NC700S: NC700SA

NC700X: instrukciyanc700xaxd

NC750: instrukciyanc750xa-xd-sa

NC750XD/XA: download

NM-04: nm4

2. Сервисные мануалы

NC700: servicemanualnc700 servicemanualnc700rus

NC750 (Рест): https://disk.yandex.ru/i/NZhZ6L7RdYHJSA

NC750X 2016-2017: скачать

CTX: CTX Service Manual

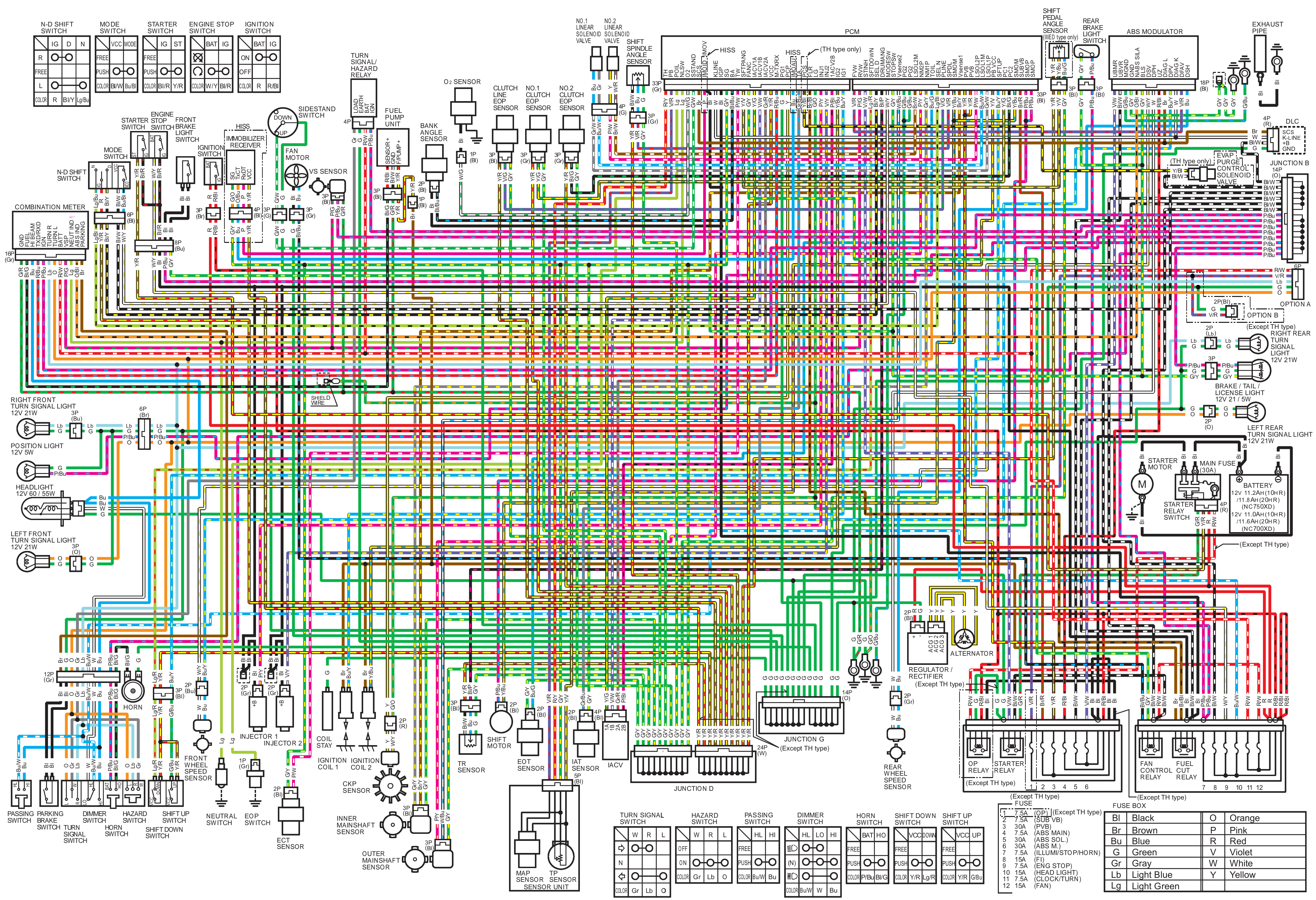

3. Электрическая схема

Сборник схем: скачать

PDF: elshema2021

4. Моменты затяжки

Скачать PDF: momentyzatyajki

5. Parts

NC700: nc700xnew

NC750: nc750parts

6. Схема (распиновка) разъема мозгов

7. Инициализация (адаптация) DCT

Скачать PDF: dctclutchinitializelearning

8. Рекомендации Honda по вождению

Скачать PDF: rekomendaciihonda

Материал из BikesWiki — энциклопедия японских мотоциклов

Перейти к: навигация, поиск

Honda NC700X (NC750X)

Ниже представлены прямые ссылки на скачку сервисной документации.

Для Honda NC700 (NC750)

- Схемы электропроводки для Honda NC700X (XA,XD) и Honda NC700S (SA,SD)

- Сервисный мануал на Honda NC700X и Honda NC700S

- Каталог запчастей (микрофиши) на Honda NC700X (XA,XD)

- Руководство пользователя (Owners Manual) на Honda NC700S (SA,SD)

- Руководство пользователя (Owners Manual) на NC700X (XA,XD)

- Руководство пользователя (Owners Manual) на Honda NC750S (SA) и Honda NC750X (XA,XD)

Обзор модели

- Honda NC700 (NC750)

Источник — «https://bikeswiki.ru/index.php?title=Honda_NC700(750):_мануалы&oldid=12974»

Категория:

- Сервисная документация

|

Detail Specifications: 1917/1917228-nc750x.pdf file (29 Jan 2023) |

Accompanying Data:

Honda NC750X Motorcycle PDF Manual (Updated: Sunday 29th of January 2023 07:22:09 AM)

Rating: 4.5 (rated by 17 users)

Compatible devices: 954, CR85 Expert, GL 1000 GOLD WING 1975, CB250N DELUXE, CBR6OOF, V 45 SABRE-VF750S 1982, 2004 CRF250R, ST1100 Police.

Recommended Documentation:

Text Version of Manual

(Ocr-Read Summary of Contents, UPD: 29 January 2023)

-

112, 2. Remove the reserve tank cap and add fluid while monitoring the coolant level. u Do not overfill above the UPPER level mark. u Make sure no foreign objects enter the reserve tank opening. 3. Securely reinstall the reserve tank cap. 4. Install the lower cowl. 3WARNING Removing the radiator cap while the engine is hot can cause the coolant to spray out, potentially scalding you. Alway…

-

8, If You are Involved in a Crash Personal safety is your first priority. If you or anyone else has been injured, take time to assess the severity of the injuries and whether it is safe to continue riding. Call for emergency assistance if needed. Also follow applicable laws and regulations if another person or vehicle is involved in the crash. If you decide to continue…

-

98, Clip # Removal 1. Press down on the center pin to release the lock. 2. Pull the clip out of the hole. # Installation 1. Slightly open the retaining pawls and then push them out. 2. Insert the clip into the hole. 3. Lightly press down on the center pin to lock the clip. Removing & Installing Body Components u Clip Maintenance 96

… -

55, Honda NC750X Operation Guide 53 Continued N-D switch To shift between Neutral and AT MODE. (P.65) Start button Ignition Switch Switches the electrical system on/off, locks the steering. u Key can be removed when in the OFF or LOCK position. Steering Lock: (P.54) AT/MT switch To shift between the AT MODE and MT MODE. (P.65) Engine stop switch Should normally remain in the (Run) position. u In an em…

-

10, Safety Labels Safety and information labels on your motorcycle provide important safety information and may warn you of potential hazards that could cause serious injury. Read these labels carefully and don’t remove them. If a label comes off or becomes hard to read, contact your dealer for a replacement. Safety Labels Motorcycle Safety 8

… -

110, Honda NC750X 3. Install the new clutch oil filter with the rubber seal facing in, toward the engine. You will see “OUT-SIDE” mark on the clutch oil filter body, toward the filter cover. 4. Replace the O-ring and apply a thin coat of engine oil to the new O-ring before installing it. 5. Install the spring and the clutch oil filter cover. 6. Install the clutch oil filter cover bolts and tighten. 7. App…

-

62, Shifting Gears NC750X/XA Your motorcycle transmission has 6 forward gears in a one-down, five-up shift pattern. If you put the motorcycle in gear with the side stand down, the engine will shut off. # Recommended Shift Points Shifting Up From 1st to 2nd 12 mph (20 km/h) From 2nd to 3rd 19 mph (30 km/h) From 3rd to 4th 25 mph (40 km/h) From 4th to 5th 31 mph (50 km/h) From 5th to 6th 37 mph…

-

74, Tool Kit The tool kit is located on the maintenance lid (in the luggage box) by the rubber strap. # Opening the luggage box. (P.70) Document Bag The document bag is located in the owner’s manual box (in the luggage box). Opening the owner’s manual Box a Remove the clip. (P.96) b Open the owner’s manual box lid. Closing owner’s manual Box a Close the owner’s man…

-

70, Honda NC750X Refueling This motorcycle must be opened the rear seat for refueling. Rear Seat Open a Insert the ignition key into the lock, and turn the key counterclockwise. b Pull up the front of the rear seat. Close a Pull up the rod upward. b Push down the front of the rear seat until it locks in place. u Make sure that the tabs are locked securely in position to pull up the front …

Recommended Instructions:

INT 2702A+, KBD-USB-TB50 Series, VMA Series, InfiniteStorage 3500

-

Contents Motorcycle Safety P. 2 Operation Guide P. 16 Maintenance P. 42 Troubleshooting P. 88 Information P. 110 Specifications P. 133 Index P. 137Contents31MGE601.indb 1 2010/03/08 18:05:09 …

VFR1200F 143

-

K5July ’04 Printed in Japan (TK) 0299505-01095-01EFOREWORDThis motorcycle has been designed and produced utilizing Suzuki’s most moderntechnology. The finest product, however, cannot perform properly unless it is cor-rectly assembled and serviced. This set-up manual has been produced to aid you inproperly assembling and servicing this motorcycle.Please review this set-up …

RM85/LK5 28

-

PIAGGIO DESIDERA RINGRAZIARLAper aver scelto uno dei suoi prodotti. Abbiamo preparato questo manuale per consentirLe di apprezzarne a pieno le qualità. Le raccomandiamo dileggerlo in tutte le sue parti prima di accingersi per la prima volta alla guida. In esso sono contenute informazioni, consigli ed avvertenze diretti all’utilizzodel Suo veicolo; scoprirà altresì caratteristiche, part …

MP3 LT 500 i.e. Series 160

-

PREFACEThis booklet is your guide to the basic operation and maintenance of your new Hero MotoCorp MAESTRO scooter. Please take time to read it carefully. As with any fine machine, proper care and maintenance is essential for trouble-free operation and optimum performance.Let us make this world a safer, healthier and more environment friendly place. We …

MAESTRO 86

Popular Right Now:

Operating Impressions, Questions and Answers:

Table of contents :

Honda 2012-2015 NC700 / NC750 Service Manual

Table of Contents

General Information

Frame / Body Panels / Exhaust System

Maintenance

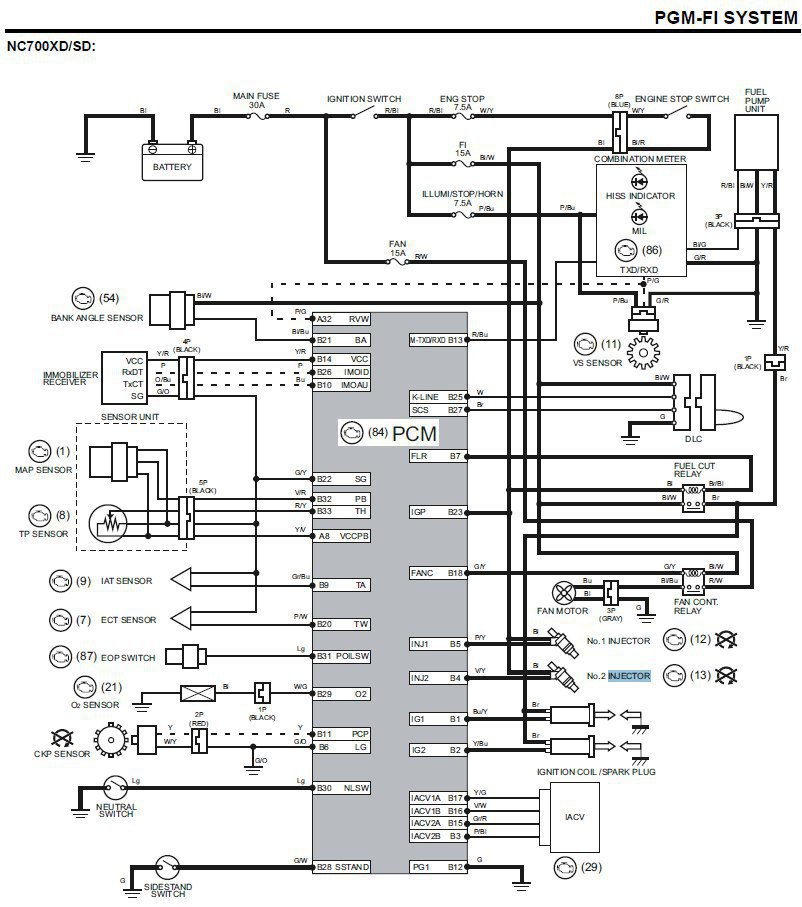

PGM-FI System

Ignition System

Electric Starter

Fuel System

Cooling System

Lubrication System

Cylinder Head / Valves

Clutch / Gearshift Linkage

Dual Clutch Transmission

Alternator / Starter Clutch

Crankcase / Transmission / Balancer

Crankshaft / Piston / Cylinder

Engine Removal / Installation

Front Wheel / Suspension / Steering

Rear Wheel / Suspension

Hydraulic Brake

Anti-Lock Brake System (ABS)

Battery / Charging System

Lights / Meters / Switches

Wiring Diagram

Index

HOW TO USE THIS MANUAL

How To Use This Manual This manual describes the service procedures for the NC?OOX/XNXD/SA-C, NC700X/XD-E, NC750XNSA-E. Sections 1, 2 and 3 apply to the whole motorcycle. Section 2 illustrates procedures for removal/installation of components that may be required to perform service described in the following sections. Section 4 through 22 describe parts of the motorcycle, grouped according to location. If you are not familiar with this motorcycle, read Technical Feature in Section 1. Follow the Maintenance Schedule (Section 3) recommendations to ensure that the motorcycle is in peak operating condition and the emission levels are within the standards set by the U.S . Environmental Protection Agency (EPA) and California Air Resources Board (CARB) and Environment Canada . Performing the first scheduled maintenance is very important. It compensates for the initial wear that occurs during the break-in period . Find the section you want on this page, then turn to the table of contents on the first page of the section. Most sections start with an assembly or system illustration, service information and troubleshooting for the section. The subsequent pages give detailed procedure. Refer to the troubleshooting in each section according to the malfunction or symptom . In case of an engine trouble, refer to PGM-FI section troubleshooting first.

Your safety, and the safety of others, is very important. To help you make informed decisions we have provided safety messages and other information throughout this manual. Of course, it is not practical or possible to warn you about all the hazards associated with servicing this vehicle. You must use your own good judgement. ‘ You will find important safety information in a variety of forms including: • Safety Labels — on the vehicle • Safety Messages — preceded by a safety alert symbol a~ and one of three signal words , DANGER, WARNING , or CAUTION. These signal words mean :

f1i f#[tj§;i You WILL be KILLED or SERIOUSLY HURT if you don ‘t follow instructions. 1

rrW4j;@i(il You CAN be KILLED or SERIOUSLY HURT if you don ‘t follow instructions. f11ft;11jj[t}@ You CAN be HURT if you don’t follow instructions. • Instructions — how to service this vehicle correctly and safely.

As you read this manual, you will find information that is preceded by a CWilID symbol. The purpose of this message is to help prevent damage to your vehicle, other property, or the environment.

HOW TO USE THIS MANUAL

SYMBOLS The symbols used throughout this manual show specific service procedures. If supplementary information is required pertaining to these symbols, it would be explained specifically in the text without the use of the symbols.

/

I

, s

~

71 -~

,. ~

~

cw .;1~

I I

Replace the part(s) with new one(s) before assembly.

Use the recommended engine oil , unless otherwise specified.

Use molybdenum oil solution (mixture of the engine oil and molybdenum grease in a ratio of 1:1).

Use multi-purpose grease (lithium based multi-purpose grease NLGI #2 or equivalent). Use molybdenum disulfide grease (containing more than 3% molybdenum disulfide, NLGI #2 or equivalent). Example: Molykote® BR-2 plus manufactured by Dow Corning U.S.A. Multi-purpose M-2 manufactured by Mitsubishi Oil, Japan Use molybdenum disulfide paste (containing more than 40% molybdenum disulfide, NLGI #2 or equivalent). Example: Molykote® G-n Paste manufactured by Dow Corning U.S.A. Honda Moly 60 (U.S.A. only) Rocol ASP manufactured by Rocol Limited, U.K. Rocol Paste manufactured by Sumico Lubricant, Japan

..

.. ..

Use silicone grease.

Apply locking agent. Use a medium strength locking agent unless otherwise specified.

Apply sealant.

Use DOT 4 brake fluid. Use the recommended brake fluid unless otherwise specified.

Use fork or suspension fluid .

CONTENTS GENERAL INFORMATION FRAME/BODY PANELS/EXHAUST SYSTEM MAINTENANCE PGM-FI SYSTEM ~

(40.9 cu-in) 670 cm 3 (40.9 cu-in) 745 cm> (45.4 cu-in) 10.7:1 Chain driven , OHC with rocker arm No.1: — 20° BTDC No.2: — 25° BTDC 27° ABDC 30° BBDC No.1: -15° ATDC No.2: — 20° ATDC Forced pressure and wet sump Trochoid Liquid cooled Paper element 60.5 kg (133.4 lbs) 67.3 kg (148.4 lbs) 60.5 kg (133.4 lbs) 67.3 kg (148.4 lbs) 62 .6 kg (138.0 lbs) 1-2 PGM-FI (Programmed Fuel Injection) 36 mm (1.4 in)

1-7

GENERAL INFORMATION ITEM

DRIVE TRAIN

Clutch system

X/XA/SA XO XIXA!SA XO

Clutch operation system Transmission Primary reduction Final reduction

’12 — ’13 model After ’13 model

Gear ratio

’12- ’13 model After ’13 model After ’13 model

X/XA/SA XO NC700X/XA/SA NC700XD NC700X NC700XD NC750XA/SA NC700X/XA/SA NC700X NC750XA/SA

’12 — ’13 model NC700XD After ’13 model NC700XD

Gearshift pattern

X/XA/SA

XO

ELECTRICAL

Ignition system

Starting system Charging system Regulator/rectifier Lighting system

1-8

1st 2nd 3rd 4th 5th 6th 1st 2nd 3rd 4th 5th 6th

SPECIFICATIONS Multi-plate, wet 2 Multi-plate wet clutches Cable operating Automatic Constant mesh, 6-speeds 1.731 (71/41) 1.921 (73/38) 2.687 (43/16) 2.437 (39/16) 2.687 (43/16) 2.437 (39/16) 2.529 (43/17) 2.812 (45/16) 1.894 (36/19) 1.454 (32/22) 1.200 (30/25) 1.033 (31/30) 0.837 (31/37) 2.666 (40/15) 1.904 (40/21) 1.454 (32/22) 1.200 (30/25) 1.033 (31/30) 0.837 (31 /37) Left foot operated return system , 1-N-2-3-4-5-6 Automatic and electric shift (left hand operated) return system , N-1-2-3-4-5-6 Computer-controlled digital transistorized with electric advance Electric starter motor Triple phase output alternator FET shorted/triple phase full wave rectification Battery

GENERAL INFORMATION PGM-FI SPECIFICATIONS ITEM IAT sensor resistance (at 20°C/68 °F) ECT sensor resistance (at 40°C/104°F) Fuel injector resistance (at 20°C/68°F)

SPECIFICATIONS 2.2-2.7 kO 1.0-1 .3 kO 11-130

IGNITION SYSTEM SPECIFICATIONS ITEM Spark plug (Iridium) Spark plug gap Ignition coil peak voltage CKP sensor peak voltage (at 20°C/68°F) Ignition timing («F» mark)

SPECIFICATIONS IFR6G-11 K (NGK) 1.00 — 1.10 mm (0 .039 — 0.043 in) 100 V minimum 0.7 V minimum 12° BTDC at idle

ELECTRIC STARTER SPECIFICATION ITEM

Starter motor brush length

STANDARD 12.0 -13.0 (0.47 — 0.51)

Unit: mm (in) SERVICE LIMIT 6.5 (0.26)

FUEL SYSTEM SPECIFICATIONS ITEM Throttle body identification number Idle speed Throttle grip freeplay Fuel pressure at idle Fuel pump flow (at 12 V)

SPECIFICATIONS GQ3UA 1,200 ± 100 rpm 2-6 mm (1/16-1 /4 in) 343 kPa (3 .5 kgf/cm 2 , 50 psi) 230 cmJ (7 .8 US oz, 8.1 Imp oz) minimum/10 seconds

COOLING SYSTEM SPECIFICATIONS ITEM

Coolant capacity

Radiator cap relief pressure Thermostat

Recommended antifreeze Standard coolant concentration

Radiator and engine At draining Reserve tank Begin to open Fully open Valve lift

SPECIFICATIONS 1.69 liters (1 .79 US qt, 1.49 Imp qt) 1.41 liters (1.49 US qt, 1.24 Imp qt) 0.13 liter (0.14 US qt, 0.11 Imp qt) 108 — 137 kPa (1 .1 — 1.4 kgf/cm’, 16 — 20 psi) 80 — 84°C (176 — 183°F) 95°C (203°F) 8 mm (0 .3 in) minimum Pro Honda HP Coolant or an equivalent high quality ethylene glycol antifreeze containing silicate-free corrosion inhibitors 1: 1 (mixture with distilled water)

1-9

GENERAL INFORMATION LUBRICATION SYSTEM SPECIFICATIONS Engine oil capacity

ITEM X/XNSA

XD

At draining At oil filter change At disassembly At draining At oil filter change At disassembly

Recommended engine oil

Oil pressure at engine oil filter Oil pump rotor (X/XA/SA)

Engine oil pump rotor (XD)

Clutch oil pump rotor (XD)

Tip clearance Body clearance Side clearance Tip clearance Body clearance Side clearance Tip clearance Body clearance Side clearance

STANDARD 3.1 liters (3.3 US qt, 2.7 Imp qt)

Unit: mm (in) SERVICE LIMIT —

3.4 liters (3 .6 US qt, 3.0 Imp qt)

—

3.7 liters (3.9 US qt, 3.3 Imp qt) 3.2 liters (3.4 US qt, 2.8 Imp qt)

—

3.4 liters (3 .6 US qt, 3.0 Imp qt)

—

4.1 liters (4 .3 US qt, 3.6 Imp qt) Pro Honda GN4 4-stroke oil (U .S.A. and Canada) or equivalent motor oil API service classification : SG or Higher JASO T 903 standard: MA Viscosity: SAE 1OW-30 470 kPa (4.8 kgf/cm’, 68 psi) at 5,000 rpm/(80°C/176°F) 0.15 (0.006) 0.15 — 0.21 (0 .006 — 0.008) 0.04 — 0.09 (0.002 — 0.004) 0.15 (0.006) 0.15 — 0.21 (0.006 — 0.008 ) 0.04 — 0.09 (0.002 — 0.004 ) 0.15 (0.006) 0.15 — 0.21 (0.006 — 0.008) 0.04- 0.09 (0.002 — 0.004)

—

—

0.20 0.35 0.12 0.20 0.35 0.12

(0 .008) (0.014) (0.005) (0 .008) (0.014) (0 .005)

—

CYLINDER HEADNALVES SPECIFICATIONS ITEM Cylinder compression at 470 rpm Valve clearance

IN EX

Rocker arm l.D . Rocker arm , rocker arm Rocker arm shaft O.D. shaft Rocker arm-to-shaft clearance Cam chain tensioner wedge B length Cam lobe height Camshaft IN EX Runout Camshaft journal O.D. IN Valve stem O.D. Valve , valve guide EX IN/EX Valve guide l.D . IN Stem-to-guide clearance EX IN Valve guide projection above EX cylinder head IN Valve seat width EX Valve spring free length Cylinder head warpage Cylinder head camshaft journal l.D. Cylinder head-to-camshaft clearance

1-10

STANDARD 1,775 kPa (18.1kgf/cm’,257 psi) 0.17 ± 0.02 (0 .007 ± 0.001) 0.28 ± 0.02 (0 .011 ± 0.001) 20.012 — 20.030 (0.7879- 0.7886) 19.972-19.993 (0.7863 — 0.7871) 0.019 — 0.058 (0 .0007 — 0.0023)

34.7897 — 35.0297 (1 .36967 — 1.37912) 34.9227- 35.1627 (1 .37491 -1 .38436)

41 .935 — 41 .950 (1.6510 — 1.6516) 4.975 — 4.990 (0 .1959 — 0.1965) 4.965 — 4.980 (0.1955- 0.1961) 5.000 — 5.012 (0.1969 — 0.1973) 0.010 — 0.037 (0 .0004 — 0.0015) 0.020 — 0.047 (0.0008 — 0.0019) 17.7 -18.0 (0 .70- 0.71) 19.6 — 19.9 (0 .77 — 0.78) 0.90 — 1.10 (0.035 — 0.043) 1.30 — 1.50 (0 .051 — 0.059) 49.07 (1 .932) —

41.995 — 42 .019 (1.6533 — 1.6543) 0.045 — 0.084 (0.0018 — 0.0033)

Unit: mm (in) SERVICE LIMIT —

20.041 (0 .7890) 19.961 (0 .7859) 0.08 (0.003) 6.0 (0 .24) 34.7697 (1.36888) 34.9027 (1 .37412) 0.04 (0.002) 41 .927 (1 .6507) 4.965 (0 .1955) 4.955 (0 .1951) 5.04 (0.198) 0.075 (0 .0030) 0.085 (0 .0033) —

1.5 (0.06) 1.9 (0.07) 48.1 (1 .89) 0.10 (0.004) 42.027 (1 .6546) 0.10 (0 .004)

GENERAL INFORMATION CLUTCH/GEARSHIFT LINKAGE SPECIFICATIONS (X/XA/SA) ITEM

Clutch lever freeplay Clutch Spring free length

I I

’12 — ’13 model After ’13 model

Disc thickness Plate warpage Clutch outer 1.0. guide 0 .0 . Mainshaft 0.0. at clutch outer guide Clutch outer guide-to-mainshaft clearance Primary driven gear 1.0. Primary driven gear-to-clutch outer guide clearance

STANDARD 10 — 20 (3/8-13/16) 43.2 (1.70) 43.5 (1 .71) 2.62 — 2.78 (0.103 — 0.109)

21 .991 — 22.016 (0.8658 — 0.8668) 31 .959 — 31.975 (1 .2582 — 1.2589) 21.967 — 21 .980 (0.8648 — 0.8654) 0.011 — 0.049 (0 .0004 — 0.0019) 32.000 — 32.025 (1 .2598 — 1.2608) 0.025 — 0.066 (0.0010 — 0.0026)

Unit: mm (in) SERVICE LIMIT

41 .7 (1 .64) 41.9 (1 .65) 2.3 (0.09) 0.30 (0.012) 22 .03 (0.867) 31 .92 (1 .257) 21 .95 (0.864) 0.08 (0.003) 32.09 (1.263) 0.10 (0.004)

DUAL CLUTCH TRANSMISSION SPECIFICATIONS (XO) ITEM

STANDARD 0.9 — 1.1 (0.035 — 0.043) 2.5 — 2.8 kQ

Clutch clearance EOT sensor resistance (20°C/68°F)

Unit· mm (in) SERVICE LIMIT 2.0 (0.08) —

ALTERNATOR/STARTE R CLUTCH SPECIFICATIONS ITEM Starter driven gear boss 0.0. Starter clutch outer 1.0.

STANDARD 57.749 — 57.768 (2.2736- 2.2743) 74.412 — 74.442 (2.9296 — 2.9308)

Unit: mm (in) SERVICE LIMIT 57.73 (2 .273) 74.46 (2.931)

CRANKCASE/TRANSMISSION/BALANCER SPECIFICATIONS XJXA/SA

Transmission

ITEM Gear 1.0.

Gear bushing 0.0. Gear-to-bushing clearance Gear bushing 1.0.

Shift fork, fork shaft

Mainshaft 0.0. Countershaft 0 .0 . Bushing-to-shaft clearance Fork 1.0. Claw thickness Shift fork shaft 0 .0.

M5, M6, C1 C2 , C3 , C4 M5, M6 C2 C3, C4 M5, M6 C2 C3, C4 M5 C2 At M5 bushing At C2 bushing M5 C2

STANDARD 28.000 — 28.021 (1.1024 — 1.1032) 31.000- 31.025 (1 .2205-1 .2215) 27.959-27.980 (1 .1007-1.1016) 30.955- 30.980 (1.2187-1 .2197) 30.950 — 30.975 (1.2185 — 1.2195) 0.020 — 0.062 (0.0008 — 0.0024) 0.020 — 0.070 (0.0008 — 0.0028) 0.025 — 0.075 (0.0010 — 0.0030) 25.000- 25.021(0.9843-0.9851) 27.985 — 28.006 (1 .1018 — 1.1026) 24.972 — 24.993 (0.9831 — 0.9840) 27.967 — 27.980 (1.1011 — 1.1016) 0.007 — 0.049 (0.0003 — 0.0020) 0.005 — 0.039 (0.0002 — 0.0015) 12.000 — 12.018 (0.4724 — 0.4731) 5.93 — 6.00 (0.233 — 0.236) 11.957-11 .968 (0.4707-0.4712)

Unit: mm (in) SERVICE LIMIT 28.04 (1.104) 31 .04 (1.222) 27.94 (1.100) 30.93 (1 .218) 30.93 (1.218) 0.08 (0.003) 0.10 (0.004) 0.11 (0.004) 25.04 (0.986) 28 .02 (1 .103) 24.95 (0.982) 27.95 (1 .100) 0.09 (0.004) 0.06 (0.002) 12.03 (0.474) 5.9 (0.23) 11 .95 (0.470)

1-11

GENERAL INFORMATION XO

Transmission

ITEM Gear l.D.

Gear bushing O.D.

Gear-to-bushing clearance

Gear bushing l.D.

Inner mainshaft O.D. Outer mainshaft O.D. Countershaft O.D. Bushing-to-shaft clearance

Shift fork, fork shaft

M5 M6 C1 C2 C3 , C4 M5 M6 C1 C2 C3, C4 M5 M6 C1 C2 C3, C4 M5 M6 C1 C2

STANDARD 33.000 — 33.025 (1 .2992 — 1.3002) 43 .000 — 43.025 (1.6929 — 1.6939) 31.010 — 31 .035 (1 .2209 — 1.2218) 25.000 — 25.021 (0.9843 — 0.9851) 31 .000 — 31 .025 (1 .2205 — 1.2215) 32 .955 — 32.980 (1 .297 4 — 1.2984) 42.950 — 42.975 (1 .6909 — 1.6919) 30.970 — 30.995 (1 .2193 — 1.2203) 24.959 — 24.980 (0.9826 — 0.9835) 30.950 — 30.975 (1.2185 — 1.2195) 0.020 — 0.070 (0 .0008 — 0.0028) 0.025 — 0.075 (0.0010 — 0.0030) 0.015 — 0.065 (0 .0006 — 0.0026) 0.020 — 0.062 (0 .0008 — 0.0024) 0.025 — 0.075 (0 .0010 — 0.0030) 29.985- 30.006 (1 .1805-1 .1813) 40.007 — 40.028 (1 .5751 — 1.5759) 28.000 — 28.021 (1 .1024 — 1.1032) 21 .985 — 22.006 (0 .8655 — 0.8664)

Unit: mm (in) SERVICE LIMIT 33.04 (1 .301) 43.04 (1 .694) 31.06 (1.223) 25.03 (0.985) 31.04 (1 .222) 32 .93 (1 .296) 42 .93 (1.690) 30.94 (1 .218) 24.94 (0.982) 30.93 (1.218) 0.10 (0 .004) 0.11 (0 .004) 0.10 (0 .004) 0.09 (0.004) 0.11 (0 .004) 30.03 (1.182) 40.038 (1.5763) 28.04 (1.104) 22.02 (0.867)

At M5 bushing

29.957 — 29.970 (1.1794 — 1.1799)

29.93 (1 .178)

At M6 bushing

39.975 — 39.991 (1 .5738 — 1.5744)

39.965 (1 .5734)

At C1 bushing At C2 bushing M5 M6 C1 C2

27.967-27.980(1.1011-1 .1016) 21.952 — 21.965 (0 .8643 — 0.8648) 0.015 — 0.049 (0.0006 — 0.0019) 0.016 — 0.053 (0 .0006 — 0.0021) 0.020 — 0.054 (0.0008 — 0.0021) 0.020 — 0.054 (0.0008 — 0.0021) 12.000-12.018 (0.4724 — 0.4731) 5.93 — 6.00 (0.233 — 0.236) 11.957 — 11 .968 (0.4707 — 0.4712)

27.95 (1 .100) 21 .94 (0 .864) 0.09 (0 .004) 0.10 (0 .004) 0.08 (0.003) 0.08 (0.003) 12.03 (0.474) 5.9 (0 .23) 11 .95 (0.470)

Fork l.D. Claw thickness Shift fork shaft O.D.

CRANKSHAFT/PISTON/CYLINDER SPECIFICATIONS ITEM Connecting rod side clearance Right side Runout Left side Main journal bearing oil clearance NC700 l.D. Cylinder NC750 Out-of-round Taper Warpage NC700 Piston O.D . at 13 Piston, piston mm (0.5 in) from rings NC750 bottom Piston pin bore l.D. Piston pin O.D. Piston-to-piston pin clearance Top Piston ring end gap Second Oil (side rail) Top Piston ring-to-ring groove clearance Second Cylinder-to-piston clearance Connecting rod small end l.D. Crankpin bearing oil clearance

Crankshaft

1-12

72 .976 — 72.990 (2 .8731 — 2.8736)

Unit: mm (in) SERVICE LIMIT 0.45 (0.018) 0.03 (0.001) 0.03 (0.001) 0.05 (0 .002) 73.07 (2 .877) 77.07 (3.034) 0.10 (0.004) 0.10 (0.004) 0.10 (0 .004) 72 .970 (2.8728)

76.976 — 76.990 (3.0305 — 3.0311)

76.970 (3 .0303)

18.010- 18.013 (0.7091 — 0.7092) 17.996 — 18.000 (0.7085 — 0.7087) 0.010 — 0.017 (0.0004 — 0.0007) 0.15 — 0.30 (0 .006 — 0.012) 0.30 — 0.42 (0.012 — 0.017) 0.20 — 0.70 (0 .008 — 0.028) 0.035 — 0.080 (0 .0014 — 0.0032) 0.030 — 0.055 (0 .0012 — 0.0022) 0.010 — 0.039 (0 .0004 — 0.0015) 17.964-17.977 (0.7072 — 0.7078) 0.026 — 0.044 (0 .0010 — 0.0017)

18.023 (0 .7096) 17.988 (0 .7082) 0.035 (0 .0014) 0.6 (0.02) 0.6 (0.02) 0.8 (0.03) 0.15 (0 .006) 0.13 (0.005) 0.05 (0.002) 17.985 (0.7081) 0.05 (0.002)

STANDARD 0.15 — 0.35 (0.006 — 0.014)

0.019 — 0.037 (0 .0007 — 0.0015) 73.000- 73.015 (2 .8740- 2.8746) 77.000- 77.015 (3 .0315-3.0321)

—

GENERAL INFORMATION FRONT WHEEL/SUSPENSION/STEERING SPECIFICATIONS ITEM

STANDARD

Minimum tire tread depth Cold tire Up to 90 kg (200 lb) load pressure Up to maximum weight capacity Axle runout Wheel rim runout Radial Axial Wheel balance weight Fork

—

250 kPa (2.50 kgf/cm’, 36 psi) 250 kPa (2 .50 kgf/cm», 36 psi)

—

Spring free X/XA/XD length SA Tube runout Recommended fork fluid Fluid level Fluid capacity

Unit: mm (in) SERVICE LIMIT 1.5 (0.06)

394.9 (15 .55) 357.0 (14 .06)

Pro Honda Suspension Fluid SS-47 (10W) 104 (4 .1) 103 (4 .1) 514 ± 2.5 cm 0 (17.4 ± 0.08 US oz, 18.1 ± 0.09 Imp oz) 518 ± 2.5 cm» (17.5 ± 0.08 US oz, 18.2 ± 0.09 Imp oz)

X/XA/XD SA X/XA/XD SA

—

0.2 (0.01) 2.0 (0 .08) 2.0 (0.08) 60g(2.1oz) max. 387.0 (15.24) 349.9 (13 .78) 0.20 (0.008) —

—

REAR WHEEL/SUSPENSION SPECIFICATIONS ITEM Minimum tire tread depth Cold tire pressure

Axle runout Wheel rim runout

STANDARD

Up to 90 kg (200 lb) load Up to maximum weight capacity

290 kPa (2.90 kgf/cm», 42 psi) 290 kPa (2 .90 kgf/cm 2 , 42 psi) —

Radial Axial

—

Wheel balance weight Drive chain

Size/link

Slack

’12-’13 model

X/XA/ SA XO

After ’13 model

X/XA/ SA XO X/XA/XD SA

DID RK DID RK DID RK DID RK

DID520V0-114LE RK520MK0 -114LE DID520V0-112LE RK520MK0 -112LE DID520V0-114LE RK520KH0-114LE DID520V0-112LE RK520KH0-112LE 30 — 40 (1.2 — 1.6) 25- 35 (1.0-1.4)

Unit: mm (in) SERVICE LIMIT 2.0 (0.08)

0.2 (0 .01) 2.0 (0.08) 2.0 (0.08) 60 g (2 .1 oz) max. —

—

1-13

—

— — ·- — — — — — —

GENERAL INFORMATION HYDRAULIC BRAKE SPECIFICATIONS Front

Rear

ITEM Specified brake fluid Brake disc thickness Brake disc warpage Master cylinder 1.0. Master piston 0 .0 . Caliper cylinder 1.0. (’12 — ’13 model X) Caliper piston 0 .0 . (’12 — ’13 model X) Cylinder A Calipercylinderl.O. (’12’13 model XNXO/SA) Cylinder B Piston A Caliper piston 0.0. (’12 ’13 model XNXO/SA) Piston B Caliper cylinder 1.0. (After ’13 model) Caliper piston 0.0. (After ’13 model) Specified brake fluid Brake disc thickness Brake disc warpage Master cylinder l.D. Master piston 0 .0 . Caliper cylinder l.D. Caliper piston 0 .0. Brake pedal height

STANDARD

OOT4 4.8 — 5.2 (0.19 — 0.20)

11 .000 — 11 .043 10.957 — 10.984 27 .000 — 27.050 26 .918 — 26.968 22.650 — 22. 700 27 .000 — 27 .050 22 .585 — 22 .618 26.918 — 26.968 27 .000 — 27.050 26.918 — 26.968 OOT4 4.8 — 5.2 (0 .19 —

(0.4331 — 0.4348) (0.4314 — 0.4324) (1.0630 — 1.0650) (1.0598 — 1.0617) (0.8917 — 0.8937) (1.0630 — 1.0650) (0 .8892 — 0.8905) (1.0598 -1 .0617) (1 .0630 — 1.0650) (1.0598 — 1.0617)

Unit: mm (in) SERVICE LIMIT —

4.0 (0 .16) 0.30 (0.012) 11.055 (0.4352) 10.945 (0.4309) 27.060 (1.0654) 26.91 (1.059) 22.712 (0.8941) 27.060 (1 .0654) 22.56 (0.888) 26.91 (1.059) 27 .060 (1.0654) 26.91 (1 .059)

0.20)

14.000-14.043 (0 .5512 — 0.5529) 13.957 — 13.984 (0.5495 — 0.5506) 38.18 — 38.23 (1.503 — 1.505) 38.098 — 38.148 (1.4999 — 1.5019) 85.0 — 87.0 (3 .35 — 3.43)

4.0 (0 .16) 0.30 (0.012) 14.055 (0.5533) 13.945 (0.5490) 38.24 (1.506) 38.09 (1.500)

BATTERY/CHARGING SYSTEM SPECIFICATIONS ITEM

Battery

Type Capacity Current leakage Voltage (20°C/68°F) Charging current

Alternator

1-14

NC700 NC750 NC700 NC750 Fully charged Needs charging Normal Quick

Capacity Charging coil resistance (20°C/68°F)

SPECIFICATIONS YTZ12S YTZ14S 12 V — 11 .0 Ah (10 HR)/11.6 Ah (20HR) 12 V — 11.2 Ah (10 HR)/11.8 Ah (20HR) 1.2 mA maximum 13.0-13.2V

Below 12.4 V 1.1 N5 — 10 h 5.5 N1 h 0.42 kW/5,000 rpm 0.1 — 0.5 0

—

GENERAL INFORMATION LIGHTS/METERS/SWITCHES SPECIFICATIONS ITEM Headlight Brake/tail/license light Front turn signal/position light Rear turn signal light Instrument light Turn signal indicator High beam indicator Neutral indicator Engine oil pressure indicator High coolant temperature indicator MIL ABS indicator (XA/XD/SA) Parking brake indicator (XD) Fuse Main fuse PGM-FI fuse Sub fuse ABS fuse (XA/XD/SA) OCT fuse (XD) ECT sensor resistance 40°C (104°F) 100°c (212 °F) Fuel level sensor resistance Full Empty

Bulbs

SPECIFICATIONS 12 V- 60/55 W 12V-21 /5W 12V-21/5Wx2 12V-21Wx2 LED LED LED LED LED LED LED LED LED 30A 15 A 15Ax2, 7.5Ax4 30 Ax 2, 7.5 A 30A, 7.5A 1.0-1 .3 kQ 0.1 — 0.2 kQ 4-60 80-83 Q

1-15

GENERAL INFORMATION

TORQUE VALUES STANDARD TORQUE VALUES FASTENER TYPE 5 mm bolt and nut 6 mm bolt (Include SH flange bolt) and nut 8 mm bolt and nut 10 mm bolt and nut 12 mm bolt and nut

TORQUE N·m (kgf·m, lbf·ft) 5.2 (0.5 , 3.8) 10(1 .0, 7) 22 (2 .2, 16) 34 (3.5 , 25) 54 (5 .5, 40)

TORQUE N·m (kgf·m, lbf·ft) 4.2 (0.4, 3.1) 9.0 (0 .9, 6.6) 12 (1 .2, 9)

FASTENER TYPE 5 mm screw 6 mm screw 6 mm flange bolt (Include NSHF) and nut 8 mm flange bolt and nut 10 mm flange bolt and nut

27 (2.8, 20) 39 (4.0, 29)

ENGINE & FRAME TORQUE VALUES FRAME BODY PANELS/EXHAUST SYSTEM

2 1

THREAD DIA. (mm) 4 6

TORQUE N·m (kgf·m, lbf·ft) 0.9 (0 .1, 0.7) 6.0 (0 .6, 4.4)

1 2

5 6

1.7 (0 .2, 1.3) 4.0 (0.4 , 3.0)

3

6

12(1 .2, 9)

1 1

6 6

12(1 .2,9) 12(1.2,9)

1 1 3 3

6 8 8 8

10(1 .0,7) 17.5(1 .8, 13) 28 (2.9 , 21)

ITEM

Q’TY

Seat cowl assembly screw Brake/tail/license light mounting screw Reflector mounting nut Luggage box lid lock plate mounting screw Luggage box lid mounting socket bolt Luggage box lid hinge nut Gearshift arm pinch bolt (X/XNSA) Muffler cover socket bolt Muffler band bolt Exhaust pipe joint nut Exhaust pipe stud bolt

1-16

—

REMARKS

U-nut ALOC bolt; replace with a new one .

See page 2-33 See page 2-34

GENERAL INFORMATION MAINTENANCE

Air cleaner housing cover screw Spark plug Valve adjusting screw lock nut

6 2 8

THREAD DIA. (mm) 5 14 7

Camshaft maintenance cap Timing hole cap Crankshaft hole cap Engine oil drain bolt Engine oil filter cartridge Oil filter boss

1 1 1 1 1 1

36 14 30 12 20 20

4.0 (0.4 , 3.0) 10 (1 .0, 7) 15 (1.5, 11 ) 30 (3 .1, 22 ) 26 (2.7 , 19)

Rear axle nut Drive chain adjuster lock nut Drive sprocket bolt Driven sprocket nut Master cylinder reservoir cover screw Rear brake reservoir mounting bolt Rear master cylinder push rod lock nut Parking brake adjuster bolt lock nut (XD ) Sidestand pivot bolt

1 2 1 5 4

18 8 10 12 4

98 (10.0, 72) 21(2 .1, 15) 54 (5 .5, 40 ) 108 (11 .0, 80) 1.5 (0.2 , 1.1 )

1 1

6 8

10(1 .0, 7) 17(1.7, 13)

1

8

17(1.7, 13)

1

10

—

Sidestand pivot nut Sidestand switch bolt

1 1

10 6

39 (4 .0, 29) 10 (1 .0, 7)

THREAD DIA. (mm) 10 6 12

TORQUE N·m (kgf·m, lbf·ft) 12 (1.2 , 9) 10 (1.0 , 7) 24 .5 (2 .5, 18)

THREAD DIA. (mm) 14 6

TORQUE N·m (kgf·m, lbf·ft) 10 (1 .0, 7) 12 (1 .2, 9)

THREAD DIA. (mm) 6

TORQUE N·m (kgf·m , lbf·ft) 10 (1.0 , 7)

TORQUE N·m (kgf·m, lbf·ft) 12 (1 .2 , 9) 1.5(0.2 , 1.1)

—

ITEM

Q’TY

TORQUE N·m (kgf·m , lbf·ft) 1.1 (0.1 , 0.8) 22 (2.2 , 16) 14 (1.4 , 10)

—

REMARKS

Apply engine oil to the threads and seating surface . See page 3-14 Apply grease to the threads . Apply grease to the threads . Apply engine oil to the threads . See page 3-16 Apply locking agent to the threads. Coating width ; 6.5 ± 1.0 mm (0.26 ± 0.04 in) from tip U-nut

U-nut

See page 3-30 Apply grease to the sliding surface. U-nut ALOC bolt; replace with a new one .

PGM-FI SYSTEM ITEM

Q’TY

ECT sensor Bank angle sensor mounting bolt 0 2 sensor

1 2 1

REMARKS

IGNITION SYSTEM ITEM

Q’TY

Timing hole cap Right crankcase cover wire clamp bolt (XD )

1 2

REMARKS Apply grease to the threads . Apply locking agent to the threads . Coating width; 6.5 ± 1.0 mm (0.26 ± 0.04 in ) except 2.0 ± 1.0 mm (0.08 ± 0.04 in ) from tip

ELECTRIC ST ARTER ITEM Starter motor terminal nut

Q’TY

1

REMARKS

FUEL SYSTEM ITEM

Q’TY

Fuel pump mounting nut Air cleaner connecting hose band screw Insulator band screw

6 1

THREAD DIA. (mm) 6 4

2

5

REMARKS For tightening sequence (page 7-15)

See page 7-20

1-17

GENERAL INFORMATION COOLING SYSTEM Q’TY

THREAD DIA. (mm)

TORQUE N·m (kgf·m, lbMt)

Water hose band screw

6

—

—

Fan motor shroud mounting bolt Fan motor mounting screw Cooling fan mounting nut

3 3 1

6 4 3

8.4 (0.9, 6.2) 2.7 (0 .3, 2.0) 1.0(0.1,0.7)

THREAD DIA. (mm) 20

TORQUE N·m (kgf·m, lbMt) 26 (2.7 , 19)

TORQUE N·m (kgf·m, lbf·ft) 10 (1 .0, 7) 29 (3 .0, 21)

ITEM

REMARKS See page 8-6 See page 8-8 See page 8-11

Apply locking agent to the threads .

LUBRICATION SYSTEM ITEM Engine oil filter cartridge

Q’TY 1

REMARKS Apply engine oil to the threads.

CYLINDER HEADNALVES

Cylinder head cover socket bolt Rocker arm shaft bolt

3 3

THREAD DIA. (mm) 6 8

Camshaft maintenance cap

1

36

4.0 (0.4 , 3.0)

Cam chain tensioner bolt Cam sprocket bolt

2 1

6 10

12 (1.2, 9) 56(5 .7, 41)

Water hose band screw Insulator band screw Cylinder head special bolt

6 1 6

—

—

ITEM

Q’TY

5 9

44 (4.5, 32)

TORQUE N·m (kgf·m, lbf·ft) 128 (13 .1, 94)

REMARKS Apply engine oil to the threads and seating surface. See page 10-10 See page 10-25 Apply engine oil to the threads and seating surface . See page 10-15 See page 10-24 Apply molybdenum oil solution to the threads and seating surface.

CLUTCH/GEARSHIFT LINKAGE (X/XA/SA)

Clutch center lock nut

1

THREAD DIA. (mm) 18

Clutch lifter plate bolt Primary drive gear mounting bolt

4 1

6 10

12 (1 .2, 9) 93 (9 .5, 69)

Shift drum stopper arm pivot bolt

1

6

12 (1.2, 9)

Shift drum center socket bolt

1

8

23 (2 .3, 17)

Gearshift pedal adjuster lock nut Gearshift pedal pivot bolt Gear position sensor holder bolt

2 1 3

6 8 6

10(1 .0, 7) 27 (2.8, 20) 14 (1.4 , 10)

ITEM

1-18

Q’TY

REMARKS Apply engine oil to the threads and seating surface . Lock nut; replace with a new one and stake . Apply engine oil to the threads and seating surface. Apply locking agent to the threads. Coating width ; 6.5 ± 1.0 mm (0 .26 ± 0.04 in) except 2.0 ± 1.0 mm (0 .08 ± 0.04 in) from tip Apply locking agent to the threads. Coating width; 6.5 ± 1.0 mm (0 .26 ± 0.04 in) except 2.0 ± 1.0 mm (0.08 ± 0.04 in) from tip

GENERAL INFORMATION DUAL CLUTCH TRANSMISSION (OCT) (XO)

Solenoid valve stopper plate bolt

1

THREAD DIA. (mm) 6

Right crankcase cover wire clamp bolt

2

6

12 (1 .2, 9)

Linear solenoid valve body mounting bolt Shift spindle angle sensor bolt Primary drive gear mounting bolt

6

6

—

1 1

6 10

12 (1 .2, 9) 93 (9.5, 69)

Reduction gear cover bolt TR sensor bolt Shift control motor bolt Shift drum center bolt

3 1 3 1

6 6 6 8

14 (1.4, 10) 12 (1 .2, 9) 14 (1.4, 10) 23 (2 .3, 17)

Drum shifter guide plate bolt

2

6

12(1.2, 9)

Clutch line EOP sensor EOT sensor

3 1

10 10

19.6 (2.0 , 14) 14(1.4,10)

TORQUE N·m (kgf·m, lbMt) 157 (16.0, 116)

ITEM

Q’TY

TORQUE N·m (kgf·m, lbMt) 12(1 .2, 9)

REMARKS

Apply locking agent to the threads. Coating width : 6.5 ± 1.0 mm (0.26 ± 0.04 in) except 2.0 ± 1.0 mm (0.08 ± 0.04 in) from tip Apply locking agent to the threads . Coating width : 6.5 ± 1.0 mm (0.26 ± 0.04 in) except 2.0 ± 1.0 mm (0.08 ± 0.04 in) from tip For tightening sequence (page 12-64) Apply engine oil to the threads and seating surface.

Apply locking agent to the threads . Coating width: 6.5 ± 1.0 mm (0.26 ± 0.04 in) except 2.0 ± 1.0 mm (0 .08 ± 0.04 in) from tip Apply locking agent to the threads. Coating width : 6.5 ± 1.0 mm (0.26 ± 0.04 in) except 2.0 ± 1.0 mm (0 .08 ± 0.04 in) from tip Apply engine oil to the threads and seating surface.

AL TERNATOR/ST ARTER CLUTCH

Flywheel mounting bolt

1

THREAD DIA. (mm) 12

Starter clutch socket bolt

6

8

30 (3 .1, 22 )

Alternator stator mounting bolt

4

6

10 (1.0, 7)

Alternator wire clamp bolt

1

6

10(1.0, 7)

ITEM

Q’TY

REMARKS

Left hand thread Apply engine oil to the threads and seating surface. Apply locking agent to the threads. Coating width ; 6.5 ± 1.0 mm (0.26 ± 0.04 in) except 2.0 ± 1.0 mm (0.08 ± 0.04 in) from tip Apply locking agent to the threads. Coating width; 6.5 ± 1.0 mm (0.26 ± 0.04 in) except 2.0 ± 1.0 mm (0.08 ± 0.04 in) from tip Apply locking agent to the threads . Coating width; 6.5 ± 1.0 mm (0 .26 ± 0.04 in) except 2.0 ± 1.0 mm (0 .08 ± 0.04 in) from tip

1-19

GENERAL INFORMATION CRANKCASE/TRANSMISSION/BALANCER TORQUE N·m (kgf·m, lbf·ft) 12(1 .2,9)

Mainshaft bearing set plate bolt

3

THREAD DIA. (mm) 6

Shift drum bearing set plate bolt

2

6

12(1 .2, 9)

Front balancer shaft bearing set plate bolt

3

6

12 (1 .2, 9)

Rear balancer shaft bearing set plate bolt (NC750 only)

2

6

12(1 .2, 9)

Crankcase main journal bolt (new)

6

9

20 (2.0, 15) + 150°

Crankcase 10 mm bolt Crankcase 8 mm bolt Crankcase 8 x 45 mm bolt

1 3 1

10 8 8

39 (4.0 , 29) 24 (2.4 , 18) 24 (2.4 , 18)

Crankcase 6 mm bolt

8

6

14(1.4, 10)

TORQUE N·m (kgf·m, lbf·ft) 10 (1.0 , 7) + 90°

ITEM

Q’TY

REMARKS Apply locking agent to the threads. Coating width; 6.5 ± 1.0 mm (0 .26 ± 0.04 in) except 2.0 ± 1.0 mm (0 .08 ± 0.04 in) from tip Apply locking agent to the threads . Coating width; 6.5 ± 1.0 mm (0.26 ± 0.04 in) except 2.0 ± 1.0 mm (0 .08 ± 0.04 in) from tip Apply locking agent to the threads . Coating width ; 6.5 ± 1.0 mm (0 .26 ± 0.04 in) except 2.0 ± 1.0 mm (0.08 ± 0.04 in) from tip Apply locking agent to the threads. Coating width; 6.5 ± 1.0 mm (0 .26 ± 0.04 in) except 2.0 ± 1.0 mm (0 .08 ± 0.04 in) from tip See page 14-29 Replace with a new one.

Apply locking agent to the threads. Coating width; 6.5 ± 1.0 mm (0 .26 ± 0.04 in) from tip

CRANKSHAFT/PISTON/CYLINDER

Crankpin bearing cap bolt

4

THREAD DIA. (mm) 6

Crankcase main journal bolt (retightening)

6

9

20 (2 .0, 15) + 120°

THREAD DIA. (mm) 12 12 12 12 8 10 6

TORQUE N·m (kgf·m, lbf·ft) 59 (6 .0, 44) 54 (5 .5, 40) 54 (5.5, 40) 54 (5.5, 40) 32 (3 .3, 24) 54 (5 .5, 40) 10(1 .0, 7)

—

—

ITEM

Q’TY

REMARKS See page 15-7 See page 15-12 Replace with a new one. Apply engine oil to the threads and seating surface . See page 15-9 Apply engine oil to the threads and seating surface .

ENGINE REMOVAL/INSTALLATION ITEM

Q’TY

Rear lower engine hanger nut Front lower engine hanger bolt Upper engine hanger bolt Rear upper engine hanger nut Step holder mounting socket bolt Drive sprocket bolt Starter motor terminal nut Water hose band screw

1 2 2 1 4 1 1 2

1-20

REMARKS

See page 16-16 See page 16-23

GENERAL INFORMATION FRONT WHEEL/SUSPENSION/STEERING TORQUE N·m (kgf·m, lbMt) 22 (2 .2, 16) 2.5 (0.3, 1.8) 12(1 .2, 9) 10(1 .0,7)

ITEM

Q’TY

Handlebar holder bolt Handlebar switch housing screw Front master cylinder holder bolt Handlebar weight mounting screw

4 4 2 2

THREAD DIA. (mm) 8 5 6 6

Front brake disc mounting bolt Front axle Front axle pinch bolt Fork socket bolt Bottom bridge pinch bolt Fork cap Top bridge pinch bolt Front brake caliper mounting bolt Steering stem adjusting nut

5 1 1 2 2 2 2 2 1

8 18 8 8 10 37 8 8 26

Steering stem adjusting lock nut Steering stem nut Clutch lever pivot bolt (X/XA/SA) Clutch lever pivot nut (X/XA/SA)

1 1 1

26 24 6

103 (10.5, 76) 1.0(0.1,0.7)

1

6

6.0 (0 .6, 4.4)

THREAD DIA. (mm) 12 8 18 10 10 10 5 18 8 6

TORQUE N·m (kgf-m, lbMt) 108 (11 .0, 80) 42(4.3,31) 98 (10.0 , 72) 44 (4 .5, 32) 44 (4.5, 32) 44 (4.5, 32) 5.9 (0.6, 4.4) 98 (10.0 , 72) 32 (3.3, 24) 12 (1.2 , 9)

42 74 22 20 39 22 22 30 23

(4.3, (7.5, (2.2, (2.0, (4.0, (2.2, (2.2, (3 .1, (2.3,

31) 55) 16) 15) 29) 16) 16) 22) 17)

—

REMARKS

ALOC screw; replace with a new one. ALOC bolt; replace with a new one. Apply grease to the sliding surface. Apply locking agent to the threads .

ALOC bolt; replace with a new one. See page 17-37 Apply engine oil to the threads. See page 17-37 See page 17-37 Apply grease to the sliding surface.

REAR WHEEL/SUSPENSION ITEM

Q’TY

Driven sprocket nut Rear brake disc mounting bolt Rear axle nut Shock absorber mounting nut Shock arm nut Shock link nut Drive chain slider mounting screw Swingarm pivot nut Step holder mounting socket bolt Gearshift arm pinch bolt (X/XA/SA)

5 5 1 2 1 2 2 1 4 1

REMARKS U-nut ALOC bolt; replace with a new one. U-nut U-nut U-nut U-nut U-nut ALOC bolt; replace with a new one.

1-21

GENERAL INFORMATION HYDRAULIC BRAKE

2

THREAD DIA. (mm) 8

TORQUE N·m (kgf·m, lbHt) 5.4 (0.6, 4.0)

3

8

5.4 (0.6 , 4.0)

4

4

1.5(0.2, 1.1)

1 2 1 2 4

6 10 8 6 10

10(1 .0, 7) 17(1 .7,13) 22 (2 .2, 16) 12(1 .2, 9) 34 (3.5 , 25)

5

10

34 (3 .5, 25)

1 1

4 6

1.2 (0 .1, 0.9) 1.0(0.1, 0.7)

1 2

6 6

5.9 (0.6, 4.4) 12 (1 .2, 9)

4 1

8 4

32 (3.3 , 24) 1.5 (0.2, 1.1)

1

8

17(1 .7, 13)

1

8

22 (2 .2, 16)

Front brake caliper bracket pin

1

8

12 (1.2, 9)

Front brake caliper mounting bolt Rear brake caliper pin

2 1

8 12

30 (3 .1, 22) 27 (2 .8, 20)

caliper mounting

2

8

31 (3.2, 23)

Apply locking agent to the threads . Apply 0.4 g (0.01 oz) silicone grease to the sliding surface. Apply locking agent to the threads. Apply 0.4 g (0 .01 oz) silicone grease to the sliding surface . ALOC bolt; replace with a new one . Apply 0.4 g (0.01 oz) silicone grease to the sliding surface. ALOC bolt; replace with a new one .

caliper pin bolt

1

8

22 (2 .2, 16)

Apply locking agent to the threads.

pad pin (XO) adjuster bolt lock

2 1

8 8

17(1 .7, 13) 17(1 .7,13)

ALOC bolt; replace with a new one.

cable mounting nut

1

10

10 (1 .0, 7)

TORQUE N·m (kgf·m, lbMt) 32 (3 .3, 24) 14 (1.4 , 10)

ITEM

QTY

Brake caliper bleed valve (’12 ’13 model X, After ‘ 13 model) Brake caliper bleed valve (’12 — ’13 model XA/XD/SA) Master cylinder reservoir cover screw Rear brake reservoir mounting bolt Brake pad pin Rear brake caliper mounting bolt Front master cylinder holder bolt Brake hose oil bolt (‘ 12 — ‘ 13 model X, After ’13 model) Brake hose oil bolt (’12- ’13 model XA/XD/SA) Front brake light switch screw Front brake lever pivot bolt Front brake lever pivot nut Rear master cylinder mounting bolt Step holder mounting socket bolt Rear master cylinder hose joint screw Rear master cylinder push rod lock nut Front brake caliper pin

Parking brake bolt (XD) Parking brake (XD) Parking brake Parking brake nut (XD) Parking brake (XO)

REMARKS

ALOC bolt; replace with a new one .

Apply 0.10 g (0.004 oz) silicone grease to the sliding surface .

Apply locking agent to the threads.

ANTI-LOCK BRAKE SYSTEM (ABS) (XA/XD/SA) ITEM

Q’TY

Step holder mounting socket bolt Brake pipe joint nut (’12 — ’13 model) Brake pipe joint nut (After ’13 model) PCV mounting bolt (’12 — ’13 model) Delay valve mounting bolt (’12 — ’13 model)

4 14

THREAD DIA. (mm) 8 10

8

10

14(1.4,10)

2

6

12(1 .2, 9)

2

6

12(1 .2, 9)

1-22

REMARKS Apply brake fluid to the threads and sliding surface . Apply brake fluid to the threads and sliding surface.

GENERAL INFORMATION LIGHTS/METERS/SWITCHES ITEM

3

THREAD DIA. (mm) 5

TORQUE N·m (kgf·m, lbMt) 1.0 (0.1 , 0.7)

Q’TY

Combination meter mounting screw Combination meter back cover mounting screw (SA) EOP switch Ignition switch mounting bolt

4

3

0.3 (0.03, 0.2)

1 2

PT 1/8 8

18(1 .8, 13) 25 (2.5, 18)

Neutral switch Parking brake switch screw

1 1

10 4

12 (1.2, 9) 1.2 (0 .1, 0.9)

1

6

12(1.2, 9)

TORQUE N·m (kgf·m, lbMt) 12 (1 .2, 9)

30 (3.1, 22) 23 (2.3, 17) 5.1 (0.5, 3.8) 12 (1 .2, 9)

REMARKS

Apply sealant to the threads. One way bolt; replace with a new one.

(XO)

Gear position sensor bolt OTHERS ITEM

Q’TY

Cam chain tensioner set plate bolt

1

THREAD DIA. (mm) 6

Camshaft cap Gearshift spindle return spring pin Main step rubber mounting bolt Main step cap bolt

1 1 2 2

20 8 5 6

REMARKS Apply locking agent to the threads. Coating width; 6.5 ± 1.0 mm (0.26 ± 0.04 in) except 2.0 ± 1.0 mm (0.08 ± 0.04 in) from tip

ALOC bolt; replace with a new one.

1-23

GENERAL INFORMATION

LUBRICATION & SEAL POINTS ENGINE MATERIAL Liquid sealant (Three Bond 12078 or equivalent)

Molybdenum oil solution (a mixture of 1/2 engine oil and 1/2 molybdenum disulfide grease)

Engine oil

Multi-purpose grease Locking agent

Unirex N3 grease (Exxon Mobil)

1-24

LOCATION Oil pan mating surface Right crankcase cover mating surface CKP sensor wire grommet Linear solenoid valve wire grommet (XD) Alternator wire grommet Alternator cover mating surface Crankcase mating surface Rocker arm sliding surface Rocker arm shaft outer surface Camshaft lobes, journals and thrust surface Valve stem (valve guide sliding surface) and stem end Clutch outer guide sliding surface (X/XA/SA) Starter reduction and idle gear shaft outer surface M3/4, C5, C6 gear (shift fork grooves) (X/XA/SA) M3, M4, C5 , C6 gear (shift fork grooves) (XD) Each transmission spline collar outer surface Each transmission collar inner and outer surface Shift fork guide area and guide pin Shift fork shaft outer surface Main journal bearing sliding surface Crankpin bearing sliding surface Crankshaft thrust surface Oil filter cartridge 0-ring Oil filler cap 0-ring Timing hole cap 0-ring Crankshaft hole cap 0-ring Clutch oil filter cover 0-ring (XD) Oil joint pipe 0-ring (XD) Clutch oil guide collar 0-rings (XD) Oil strainer seal ring Starter motor 0-ring Fuel injector seal ring Water pump large 0-ring Valve stem seal Clutch disc entire surface (X/XA/SA) Clutch lifter rod A sliding surface (X/XA/SA) Clutch lifter rod B sliding surface (X/XA/SA) Mainshaft seal rings (XD ) Starter one-way clutch Piston sliding surface Piston ring sliding surface Piston pin outer surface Each bearing Each gear teeth and rotating surface Each 0-ring (except water sealing) Other rotating area and sliding surface Each oil seal lips CKP sensor mounting bolt threads

Electric shift reduction gear teeth and journal (XD)

REMARKS See page 9-12 See page 11-5

See page 13-5 See page 14-29

Coating width ; 6.5 ± 1.0 mm (0 .26 ± 0.04 in) except 2.0 ± 1.0 mm (0 .08 ± 0.04 in) from tip 2 — 4 g (0.07 — 0.14 oz)

GENERAL INFORMATION FRAME MATERIAL Urea based multi-purpose grease with extreme pressure (example: Kyodo Yushi EXCELITE EP2, Shell Stamina EP2 or equivalent) Molybdenum disulfide grease

Multi-purpose grease

Cable lubricant

Honda bond A or Pro Honda Handgrip Cement (U.S.A. only) or equivalent Honda bond A or equivalent Silicone grease

DOT 4 brake fluid

Fork fluid Drive chain lubricant designed specifically for use with 0-ring chains , #80 — 90 gear oil or equivalent

LOCATION Steering head bearing sliding surface Steering head dust seal lips

REMARKS 3 — 5 g (0 .1 — 0.2 oz)

Shock arm needle bearings Rear shock absorber needle bearing Rear shock absorber dust seal lips Swingarm pivot needle bearings Swingarm pivot ball bearing Swingarm pivot dust seal lips Seat catch hook sliding area Luggage box lid catch sliding area Gearshift pedal pivot and dust seal lips (X/XNSA) Gearshift pedal tie-rod ball joint area (X/XNSA) Throttle cable end and throttle grip pipe flange groove Front wheel dust seal lips Rear wheel hub 0-ring Rear wheel dust seal lips Rear axle sliding surface Swingarm pivot sliding surface Rear brake pedal pivot sliding area Parking brake ratchet A, B teeth and sliding surface (XD) Parking brake lever, washer sliding surface (XD) Parking brake switch spring sliding surface (XD) Main step sliding area Pillion step sliding area Seat lock cable inside Luggage box lid lock cable inside Throttle cable A, B inside Clutch cable inside (X/XNSA) Parking brake cable inside (XD) Handlebar grip rubber inside

Brake pad retainer mating surface Front brake lever sliding surface and lever-to-master piston contacting area Rear brake master cylinder push rod sliding surface and boot fitting area Brake caliper dust seals Rear brake caliper boot inside Brake pad pin stopper ring Parking brake shaft outer surface (XD) Parking brake adjuster bolt threads and caliper piston sliding surface (XD) Parking brake shaft boot lips (XD) Parking brake caliper bracket pin sliding surface (XD) Parking brake caliper sleeve sliding surface (XD) Brake caliper piston and piston seals Brake master piston and cups Brake master cylinder inside Rear master cylinder reservoir hose joint 0-ring Fork cap 0-ring Fork dust seal and oil seal lips Drive chain whole surface

0.10 g (0 .004 oz)

0.4 g (0 .01 oz) 0.4 g (0 .01 oz) minimum 0.4 g (0.01 oz) minimum 0.4 g (0 .01 oz) minimum 0.4 g (0.01 oz) minimum 0.4 g (0.01 oz) minimum

1-25

GENERAL INFORMATION

CABLE & HARNESS ROUTING X/XA: CLUTCH SWITCH WIRE

XO: THROTTLE CABLE A

~ROTTLE CABLE B RIGHT HANDLEBAR SWITCH WIRE

1-26

GENERAL INFORMATION SA: CLUTCH SWITCH WIRE

BRAKE LIGHT SWITCH CONNECTOR

XJXAJXD: FRONT LEFT TURN SIGNAL/POSITION LIGHT 3P(ORANGE)CONNECTOR

FRONT SUB HARNESS

FRONT SUB HARNESS 6P (BROWN ) CONNECTOR

FRONT RIGHT TURN SIGNAL/POSITION LIGHT 3P (BLUE) CONNECTOR

1-27

GENERAL INFORMATION SA: FRONT SUB HARNESS

FRONT RIGHT TURN SIGNAL/POSITION LIGHT 3P(BLUE)CONNECTOR FRONT LEFT TURN SIGNAL/POSITION LIGHT 3P(ORANGE)CONNECTOR

1-28

GENERAL INFORMATION ’12 — ’13 model X:

MAIN WIRE HARNESS COMBINATION METER 16P (GRAY) CONNECTOR

CLUTCH CABLE

«&::»:—=—-

LEFT HANDLEBAR SWITCH 14P (GRAY) CONNECTOR

/0

f

~

I1

IGNITION SWITCH 2P (BROWN) CONNECTOR

FRONT SUB HARNESS 6P(BROWN)CO NNECTOR

HEADLIGHT 3P(BLACK)CON NECTOR

MAIN WIRE HARNESS

1-29

GENERAL INFORMATION After ’13 model X:

MAIN WIRE HARNESS

COMBINATION METER 16P (GRAY) CONNECTOR

BRAKE HOSE

LEFT HANDLEBAR SWITCH WIRE RIGHT HANDLEBAR SWITCH WIRE 14P (GRAY) CONNECTOR

IGNITION SWITCH ..,. — — — — 2P (BROWN ) CONNECTOR FRONT SUB HARNESS 6P (BROWN ) CONNECTOR OPTION B 2P (BLACK) CONNECTOR

Front side HEADLIGHT 3P(BLACK)CONNEC TOR

MAIN WIRE HARNESS

1-30

GENERAL INFORMATION ’12 — ’13 model XA:

MAIN WIRE HARNESS COMBINATION METER 16P (GRAY) CONNECTOR

CLUTCH CABLE

HEADLIGHT 3P(BLACK)CONNECTOR

+ MAIN WIRE HARNESS

1-31

GENERAL INFORMATION After ’13 model XA:

MAIN WIRE HARNESS COMBINATION METER 16P (GRAY) CONNECTOR

CLUTCH CABLE

LEFT HANDLEBAR SWITCH WIRE

14P(GRAY)CONNECTOR

~

IGNITION SWITCH • 3P (BROWN) CONNECTOR

FRONT SUB HARNESS 6P (BROWN) CONNECTOR OPTION B 2P (BLACK) CONNECTOR

side HEADLIGHT 3P (BLACK) CONNECTOR

MAIN WIRE HARNESS

1-32

GENERAL INFORMATION ’12 — ’13 model XD:

MAIN WIRE HARNESS

COMBINATION METER 16P(GRAY)CONNECTOR

~

—.,..,__ ,~ FRONT SUB HARNESS 6P (BROWN) CONNECTOR

IGNITION SWITCH 2P (BROWN) CONNECTOR

LEFT HANDLEBAR SWITCH 3P(BLACK)CONNECTOR

MAIN WIRE HARNESS

1-33

GENERAL INFORMATION After ’13 model XD:

COMBINATION METER 16P (GRAY) CONNECTOR MAIN WIRE HARNESS

PARKING BRAKE CABLE

LEFT HANDLEBAR SWITCH WIRE HAZARD DIODE LEFT HANDLEBAR SWITCH 3P(BLACK)CONNECTOR

FRONT SUB HARNESS 6P (BROWN) CONNECTOR OPTION B 2P (BLACK) CONNECTOR

HEADLIGHT 3P (BLACK)CONNECTOR

+ MAIN WIRE HARNESS

1-34

GENERAL INFORMATION ’12 — ’13 model SA: RIGHT HANDLEBAR SWITCH 8P(BLUE)CONNECTOR

IGNITION SWITCH 2P (BROWN) CONNECTOR

HEADLIGHT 3P(BLACK)CONNECTOR

I

‘I

FRONT WHEEL SPEED SENSOR WIRE

BRAKE SUB HOSE C (from DELAY VALVE)

After ’13 model SA: RIGHT HANDLEBAR SWITCH 8P(BLUE)CONNECTOR

FRONT SUB HARNESS 6P (BROWN) CONNECTOR

IGNITION SWITCH 2P(BLACK)CONNECTOR

LEFT HANDLEBAR SWITCH 14P(GRAY)CONNECTOR

HEADLIGHT 1 3P (BLACK) CONNECTOR —-ff—}7fift~fce

FRONT BRAKE HOSE D (from ABS MODULATOR)

FRONT WHEEL SPEED SENSOR WIRE

1-35

GENERAL INFORMATION SA: CLUTCH SWITCH CONNECTORS

THROTTLE CABLE A FRONT BRAKE HOSE A (to ABS MODULATOR)

CLUTCH CABLE THROTTLE CABLE B

LEFT HANDLEBAR SWITCH WIRE

IGNITION SWITCH WIRE

CLUTCH CABLE CLAMP (’12- ’13 MODEL ONLY)

1-36

GENERAL INFORMATION ’12

’13 model X/XA:

CLUTCH CABLE LEFT HANDLEBAR SWITCH WIRE

HAZARD DIODE COMBINATION METER 16P (GRAY)

Посмотреть инструкция для Honda NC750X (2023) бесплатно. Руководство относится к категории мотоциклы, 1 человек(а) дали ему среднюю оценку 7.5. Руководство доступно на следующих языках: английский. У вас есть вопрос о Honda NC750X (2023) или вам нужна помощь? Задайте свой вопрос здесь

Главная

| Honda | |

| NC750X (2023) | |

| мотоцикл | |

| английский | |

| Руководство пользователя (PDF) |

Не можете найти ответ на свой вопрос в руководстве? Вы можете найти ответ на свой вопрос ниже, в разделе часто задаваемых вопросов о Honda NC750X (2023).

Как перевести мили в километры?

В чем разница между топливом E10 и E5?

Какова рекомендуемая частота замены масляного фильтра в двигателе Honda?

Как часто следует менять масло в двигателе Honda?

Как удалить ржавчину с устройства Honda мотоцикл?

Инструкция Honda NC750X (2023) доступно в русский?

Не нашли свой вопрос? Задайте свой вопрос здесь