- Manuals

- Brands

- Yamaha Manuals

- Offroad Vehicle

- YFM660FS

- Supplementary service manual

-

Contents

-

Table of Contents

-

Troubleshooting

-

Bookmarks

Related Manuals for Yamaha YFM660FS Grizzly 4×4

Summary of Contents for Yamaha YFM660FS Grizzly 4×4

-

Page 1

YFM660FS SUPPLEMENTARY SERVICE MANUAL LIT-11616-17-14 5KM-28197-E2… -

Page 2

YFM660FP SERVICE MANUAL: LIT-11616-15-01 (5KM-28197-E0) YFM660FR SUPPLEMENTARY SERVICE MANUAL: LIT-11616-16-34 (5KM-28197-E1) YFM660FS SUPPLEMENTARY SERVICE MANUAL ©2003 by Yamaha Motor Corporation, U.S.A. First Edition, April 2003 All rights reserved. Any reproduction or unauthorized use without the written permission of Yamaha Motor Corporation, U.S.A. -

Page 3: Important Information

EB001000 NOTICE This manual was produced by the Yamaha Motor Company primarily for use by Yamaha dealers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manual, so it is assumed that anyone who uses this book to perform maintenance and repairs on Yamaha machine has a basic understanding of the mechanical ideas and the procedures of machine repair.

-

Page 4

EB002000 HOW TO USE THIS MANUAL MANUAL ORGANIZATION This manual consists of chapters for the main categories of subjects. (See “Illustrated symbols”) 1st title 1: This is the title of the chapter with its symbol in the upper right corner of each page. 2nd title 2: This title indicates the section of the chapter and only appears on the first page of each section. -

Page 5

EB003000 ILLUSTRATED SYMBOLS Illustrated symbols 1 to 0 are printed on the SPEC INFO top right of each page and indicate the subject of each chapter. 1 General information 2 Specifications 3 Periodic checks and adjustments 4 Engine 5 Cooling system 6 Carburetion 7 Drive train COOL… -

Page 6: Table Of Contents

CONTENTS GENERAL INFORMATION …………….1 FEATURES ………………..1 OVERRIDE SWITCH (DEACTIVATING THE SPEED LIMITER WHEN THE DIFFERENTIAL IS LOCKED) ………..1 SPECIFICATIONS ………………..3 GENERAL SPECIFICATIONS …………..3 MAINTENANCE SPECIFICATIONS …………4 ENGINE ………………..4 CHASSIS ………………..5 ELECTRICAL ………………5 CHASSIS ………………….6 STEERING SYSTEM …………….6 INSTALLING THE REAR BRAKE LEVER ……….6 ELECTRICAL ………………..7 CHECKING THE SWITCH …………….7 CHECKING THE SWITCH CONTINUITY ……….7…

-

Page 7: General Information

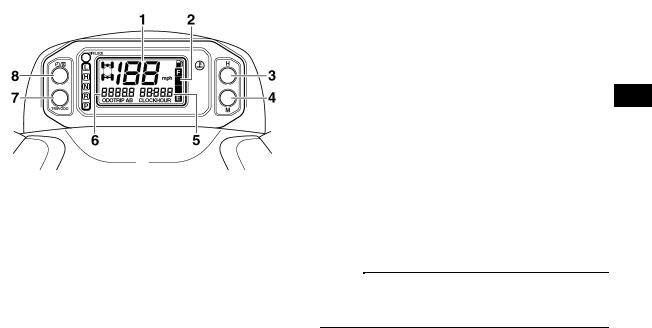

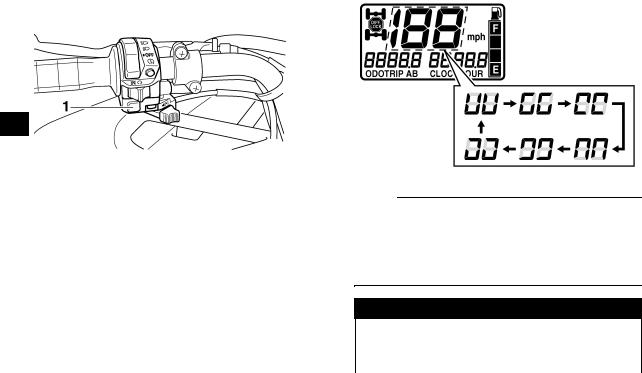

FEATURES INFO GENERAL INFORMATION FEATURES OVERRIDE SWITCH (DEACTIVATING THE SPEED LIMITER WHEN THE DIFFERENTIAL IS LOCKED) This model is equipped with a speed limiter system (35 km/h [22 mph]) that operates when the dif- ferential is locked and the ATV is traveling forward. If additional engine power is required (e.g., to free the ATV from mud) when the ATV is traveling forward and the differential is locked, the speed limiter can be temporarily deactivated by pressing the override switch.

-

Page 8

FEATURES INFO CAUTION: If the segments of the speedometer digits show the override display when the override switch is not pressed, the speed limiter system is malfunctioning. Check the override switch and ignition system, and then repair if necessary. – 2 –… -

Page 9: Specifications

SPEC GENERAL SPECIFICATIONS SPECIFICATIONS GENERAL SPECIFICATIONS Item Standard Model code: 5KMH 5KMM 5KMN 5KMP Transmission: Primary reduction system V-belt Secondary reduction system Shaft drive 41/21 × 24/18 × 33/9 (9.544) Secondary reduction ratio Transmission type V-belt automatic Operation Left hand operation Single speed automatic 2.45 ~ 0.70 : 1 Sub transmission ratio…

-

Page 10: Maintenance Specifications

SPEC MAINTENANCE SPECIFICATIONS MAINTENANCE SPECIFICATIONS ENGINE Item Standard Limit Carburetor: I. D. mark 5KMA 10 —- Main jet (M.J) #153.8 —- Main air jet (M.A.J) —- Jet needle (J.N) 6JPH9-53-2 —- Needle jet (N.J) O-0M —- Pilot air jet (P .A.J.1) —- Pilot air jet (P .A.J.2)

-

Page 11: Chassis

SPEC MAINTENANCE SPECIFICATIONS CHASSIS Item Standard Limit Front suspension: Shock absorber travel 86 mm (3.39 in) —- Fork spring free length 296.5 mm (11.67 in) 290.6 mm (11.44 in) Spring fitting length 237 mm (9.33 in) —- Spring rate (K1) 20 N/mm —- (2.04 kg/mm, 114.2 lb/in)

-

Page 12: Chassis

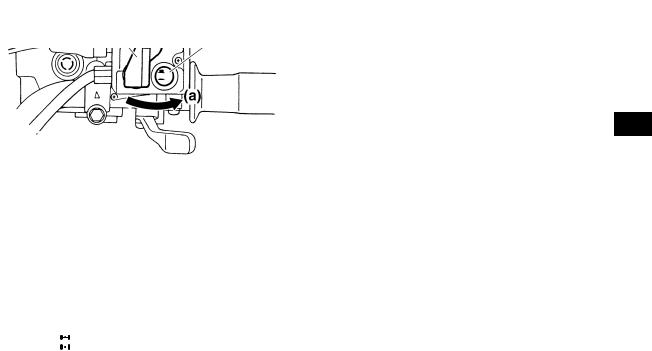

CHAS STEERING SYSTEM CHASSIS STEERING SYSTEM INSTALLING THE REAR BRAKE LEVER 1.Install: Handlebar switch 1 Rear brake lever Lever bracket 2 NOTE: Install the lever bracket as shown. a 74.5 mm (2.9 in) – 6 –…

-

Page 13: Electrical

– ELEC CHECKING THE SWITCH ELECTRICAL CHECKING THE SWITCH CHECKING THE SWITCH CONTINUITY Refer to “CHECKING THE SWITCH” in CHAPTER 9 (Manual No.: 5KM-28197-E0) and check for continuity between lead terminals. Poor connection, no continuity → Correct or replace. The coupler locations are circled. Br L Y G R/B R/W PUSH…

-

Page 14

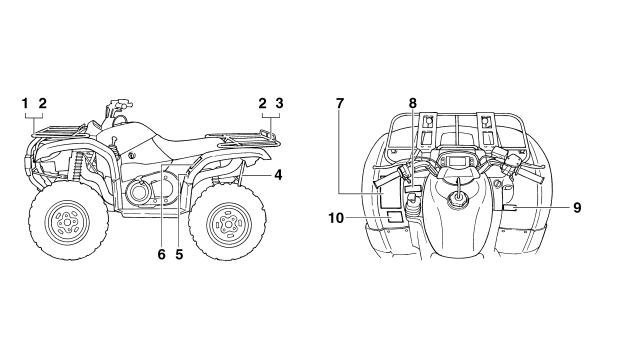

– ELEC CHECKING THE SWITCH 1 Light switch 2 Engine stop switch 3 Start switch 4 Override switch 5 On-command four-wheel drive switch and differential gear lock switch 6 Main switch 7 Rear brake light switch 8 Front brake light switch 9 Rear brake switch 0 Gear position switch A Reverse switch… -

Page 15: Signal System

– ELEC SIGNAL SYSTEM EB806000 SIGNAL SYSTEM CIRCUIT DIAGRAM – 9 –…

-

Page 16

– ELEC SIGNAL SYSTEM 3 Main switch 4 Backup fuse 5 Battery 6 Main fuse 9 Reverse switch 0 CDI unit D Speed sensor F Multi-function meter G Differential gear lock indicator light H Coolant temperature indicator light I Reverse indicator light J Neutral indicator light K Park indicator light L High-range indicator light… -

Page 17

YAMAHA MOTOR CO., LTD. 2500 SHINGAI IWATA SHIZUOKA JAPAN PRINTED IN U.S.A. -

Page 18: Yfm660Fs Wiring Diagram

YFM660FS WIRING DIAGRAM 1 AC magneto 2 Rectifier/regulator 3 Main switch R/B Br/B Br/B 4 Backup fuse (GRAY) (GRAY) R/B L/W G/W W/B B/Y R B/R Lg 5 Battery WIRE HARNESS SUB-WIRE HARNESS WIRE HARNESS SUB-WIRE HARNESS WIRE HARNESS IGNITION COIL LEAD (BLACK) (BLACK) (BLACK)

-

Page 72

YFM660FP SERVICEMANUAL LIT-11616-15-01 5KM-28197-E0… -

Page 73

YFM660FP SERVICE MANUAL ©2001 by Yamaha Motor Corporation, U.S.A. First edition, May 2001 All rights reserved. Any reproduction or unauthorized use without the written permission of Yamaha Motor Corporation, U.S.A. is expressly prohibited. Printed in U.S.A. LIT-11616-15-01… -

Page 74

EB001000 NOTICE This manual was produced by the Yamaha Motor Company primarily for use by Yamaha dealers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manual, so it is assumed that anyone who uses this book to perform maintenance and repairs on Yamaha machine has a basic understanding of the mechanical ideas and the procedures of machine repair. -

Page 75

EB002000 HOW TO USE THIS MANUAL MANUAL ORGANIZATION This manual consists of chapters for the main categories of subjects. (See “Illustrated symbols”) 1st title 1: This is the title of the chapter with its symbol in the upper right corner of each page. 2nd title 2: This title indicates the section of the chapter and only appears on the first page of each section. -

Page 76: Cooling System

EB003000 ILLUSTRATED SYMBOLS Illustrated symbols 1 to 0 are printed on the SPEC INFO top right of each page and indicate the subject of each chapter. 1 General information 2 Specifications 3 Periodic checks and adjustments 4 Engine 5 Cooling system 6 Carburetion 7 Drive train COOL…

-

Page 77

TABLE OF CONTENTS GENERAL INFORMATION INFO SPECIFICATIONS SPEC PERIODIC CHECKS AND ADJUSTMENTS ENGINE COOLING SYSTEM COOL CARBURETION CARB DRIVE TRAIN DRIV CHASSIS CHAS – ELECTRICAL ELEC TROUBLESHOOTING TRBL SHTG… -

Page 78: General Information

CONTENTS CHAPTER 1. GENERAL INFORMATION MACHINE IDENTIFICATION ……………. 1-1 VEHICLE IDENTIFICATION NUMBER ……….1-1 MODEL LABEL ………………1-1 FEATURES ………………..1-2 FRONT DIFFERENTIAL ……………. 1-2 TRANSMISSION ………………. 1-9 IMPORTANT INFORMATION …………..1-10 PREPARATION FOR REMOVAL PROCEDURES ……1-10 REPLACEMENT PARTS …………..1-10 GASKETS, OIL SEALS AND O-RINGS ……….

-

Page 79

LUBRICATION POINTS AND LUBRICANT TYPES ……..2-21 ENGINE ………………..2-21 COOLANT FLOW DIAGRAMS …………..2-22 OIL FLOW DIAGRAMS …………….2-24 CABLE ROUTING ………………2-27 CHAPTER 3. PERIODIC CHECKS AND ADJUSTMENTS INTRODUCTION ………………. 3-1 PERIODIC MAINTENANCE/LUBRICATION INTERVALS ……3-1 SEAT, CARRIERS, FENDERS AND FUEL TANK ……..3-3 SEAT AND SIDE PANELS ………….. -

Page 80: Engine

CHASSIS ………………..3-39 ADJUSTING THE REAR BRAKE …………3-39 CHECKING THE BRAKE FLUID LEVEL ……….3-41 CHECKING THE FRONT BRAKE PAD ……….3-43 CHECKING THE REAR BRAKE PAD ……….3-43 CHECKING THE BRAKE HOSE …………3-43 BLEEDING THE HYDRAULIC BRAKE SYSTEM ……. 3-44 ADJUSTING THE SELECT LEVER CONTROL CABLE AND SHIFT ROD …………….

-

Page 81

ROCKER ARMS ………………4-12 REMOVING THE ROCKER ARM …………4-14 CHECKING THE ROCKER ARM …………4-14 INSTALLING THE ROCKER ARM …………4-15 CAMSHAFT AND CYLINDER HEAD …………4-16 REMOVING THE CAMSHAFT AND CYLINDER HEAD ….. 4-18 CHECKING THE CAMSHAFT …………. 4-19 CHECKING THE CAMSHAFT SPROCKET …….. -

Page 82

CHECKING THE BALANCER DRIVE ……….4-49 INSTALLING THE BALANCER DRIVE GEAR AND BALANCER DRIVEN GEAR ……….. 4-49 PRIMARY AND SECONDARY SHEAVES ……….4-51 PRIMARY SHEAVE …………….4-53 SECONDARY SHEAVE …………..4-54 REMOVING THE PRIMARY AND SECONDARY SHEAVES ….. 4-55 DISASSEMBLING THE SECONDARY SHEAVE …….. 4-55 CHEKING THE PRIMARY SHEAVE ……….. -

Page 83: Cooling System

TRANSMISSION ………………4-78 REMOVING THE TRANSMISSION ………… 4-81 CHECKING THE SHIFT FORK …………4-81 CHECKING THE SHIFT CAM …………. 4-82 CHECKING THE DRIVE AXLE …………4-82 CHECKING THE HIGH WHEEL GEAR AND MIDDLE DRIVE GEAR …………4-82 CHECKING THE SECONDARY SHAFT AND DRIVEN SPROCKET …………..

-

Page 84: Carburetion

CHAPTER 6. CARBURETION CARBURETOR ………………… 6-1 DISASSEMBLING THE CARBURETOR ……….6-4 CHECKING THE CARBURETOR …………6-4 ASSEMBLING THE CARBURETOR …………. 6-6 ADJUSTING THE FUEL LEVEL …………6-7 CHAPTER 7. DRIVE TRAIN TROUBLESHOOTING ……………… 7-1 FRONT CONSTANT VELOCITY JOINTS AND DIFFERENTIAL GEAR …………..7-4 DISASSEMBLING THE UNIVERSAL JOINT ……..

-

Page 85: Chassis

CHAPTER 8. CHASSIS FRONT WHEELS AND BRAKE DISCS …………8-1 FRONT WHEELS ……………… 8-1 CHECKING THE FRONT WHEEL …………8-3 CHECKING THE FRONT WHEEL HUB ……….8-3 CHECKING THE FRONT BRAKE DISC ……….8-4 INSTALLING THE FRONT WHEEL HUB ……….8-4 INSTALLING THE FRONT WHEEL …………

-

Page 86

STEERING SYSTEM ……………… 8-36 HANDLEBAR ………………8-36 REMOVING THE REAR BRAKE SWITCH ……… 8-37 CHECKING THE HANDLEBAR …………8-37 INSTALLING THE HANDLEBAR …………8-37 INSTALLING THE REAR BRAKE LEVER ………. 8-37 INSTALLING THE MASTER CYLINDER ASSEMBLY ……8-38 STEERING STEM …………….8-39 REMOVING THE BEARING RETAINER ………. -

Page 87

CHAPTER 9. ELECTRICAL ELECTRICAL COMPONENTS …………..9-1 CHECKING THE SWITCH …………….9-2 CHECKING THE SWITCH …………..9-2 CHECKING A SWITCH SHOWN IN THE MANUAL ……9-2 CHECKING THE SWITCH CONTINUITY ……….9-4 CHECKING THE BULBS AND BULB SOCKETS ……..9-6 TYPES OF BULBS ……………. -

Page 88: Troubleshooting

COOLING SYSTEM ………………9-47 CIRCUIT DIAGRAM …………….9-47 TROUBLESHOOTING …………… 9-48 2WD/4WD SELECTING SYSTEM ………….. 9-52 CIRCUIT DIAGRAM …………….9-52 TROUBLESHOOTING ……………. 9-53 CHAPTER 10. TROUBLESHOOTING STARTING FAILURE/HARD STARTING ……….. 10-1 FUEL SYSTEM ………………10-1 ELECTRICAL SYSTEM …………… 10-1 COMPRESSION SYSTEM …………..10-2 POOR IDLE SPEED PERFORMANCE …………

-

Page 89

SHOCK ABSORBER MALFUNCTION …………10-6 MALFUNCTION ………………. 10-6 UNSTABLE HANDLING …………….10-6 UNSTABLE HANDLING …………..10-6 LIGHTING SYSTEM ………………10-6 HEADLIGHT DARK …………….10-6 BULB BURNT OUT …………….10-6… -

Page 90: Gen Info

MACHINE IDENTIFICATION INFO GENERAL INFORMATION MACHINE IDENTIFICATION VEHICLE IDENTIFICATION NUMBER The vehicle identification number 1 is stamped into the left side of the frame. MODEL LABEL The model label 1 is affixed to the frame. This information will be needed to order spare parts.

-

Page 91: Features

FEATURES INFO FEATURES FRONT DIFFERENTIAL 1 Adapter 7 Drive pinion gear 2 Drive clutch 8 Gear motor 3 Differential side gear (left) 4 Differential pinion gear È To front wheel 5 Ring gear É From the middle gear 6 Differential side gear (right) 1 — 2…

-

Page 92

FEATURES INFO Power is transmitted as follows: middle gear → front drive shaft → drive pinion gear 7 → ring gear 5 → differential pinion gear 4. In the 2WD mode, the left differential side gear 3 and the drive clutch 2 are not engaged, therefore, the left side gear runs idle and does not transmit power to the left front constant velocity joint. -

Page 93

FEATURES INFO When the 4WD mode is selected, the gear motor is operated, and the drive clutch 2 moves to the right and engages with the left differential side gear 3. Accordingly, power is transmitted as follows: ring gear 5 → differential pinion gear 4 → left differential side gear 3 → drive clutch 2 → adapter 1 →… -

Page 94

FEATURES INFO 4WD (Diff-Lock) When the 4WD (Diff-Lock) mode is selected, the gear motor moves the drive clutch 2 further to the right, which causes the ring gear 5 and the drive clutch 2 to engage. As a result, power is transmit- ted directly from the ring gear 5 to the drive clutch 2, then to the left front constant velocity joint via the adapter 1. -

Page 95

FEATURES INFO In addition, the 4WD (Diff-Lock) mode can be engaged only when the ATV is stopped. Even if an attempt is made to select this mode when the ATV is traveling, it will only result in a standby condi- tion (i.e., when the differential lock select switch and the differential gear are not matched). -

Page 96

FEATURES INFO Shift mechanism A new shift mechanism with a parking position has been added to the YFM660F. 1.Shift cam 2.Shift fork guide bar 3.Drive axle 4.Stopper lever shaft 1 — 7… -

Page 97

FEATURES INFO Parking (1) L (Low), H (High), N (Neutral), and R (Reverse) positions The end of the stopper lever is held by the return spring 1. Then, the stopper lever tab is sepa- rated from the drive axle stopper to free the drive axle. (2) P (Park) position When the drive select lever is shifted to the “P”… -

Page 98: Transmission

FEATURES INFO TRANSMISSION To create a compact, 3-axle transmission, a chain drive has been adopted for the reverse transmis- sion. 1 Secondary shaft 2 Drive axle 3 Middle drive shaft 4 Low wheel gear 5 Chain 1 Secondary shaft 2 Drive axle L (Low) or H (High) mode When the transmission is in either the low or high mode, the drive axle is driven via the sec-…

-

Page 99: Important Information

5.Keep all parts away from any source of fire. EB101010 REPLACEMENT PARTS 1.Use only genuine Yamaha parts for all replacements. Use oil and grease recom- mended by Yamaha for all lubrication jobs. Other brands may be similar in function and appearance, but inferior in quality.

-

Page 100: Lock Washers/Plates And Cotter Pins

IMPORTANT INFORMATION INFO EB101030 LOCK WASHERS/PLATES AND COTTER PINS 1.Replace all lock washers/plates 1 and cotter pins after removal. Bend lock tabs along the bolt or nut flats after the bolt or nut has been tightened to specification. EB101040 BEARINGS AND OIL SEALS 1.Install bearings and oil seals so that the manufacturer’s marks or numbers are visible.

-

Page 101: Checking Of Connections

CHECKING OF CONNECTIONS INFO EB801000 CHECKING OF CONNECTIONS Check the connectors for stains, rust, mois- ture, etc. 1.Disconnect: Connector 2.Check: Connector Moisture → Dry each terminal with an air blower. Stains/rust → Connect and disconnect the terminals several times. 3.Check: Connector leads Looseness →…

-

Page 102: Special Tools

SPECIAL TOOLS INFO EB102001 SPECIAL TOOLS The following special tools are necessary for complete and accurate tune-up and assembly. Use only the appropriate special tools; this will help prevent damage caused by the use of inappropriate tools or improvised techniques. Special tools may differ by shape and part number from country to country.

-

Page 103

SPECIAL TOOLS INFO Tool No. Tool name/How to use Illustration Piston pin puller 90890-01304 YU-01304 This tool is used to remove the piston pin. Tappet adjusting tool (3 mm) 90890-01311 YU-08035 This tool is necessary for adjusting the valve clearance. Fuel level gauge 90890-01312 YM-01312-A… -

Page 104

SPECIAL TOOLS INFO Tool No. Tool name/How to use Illustration Ring nut wrench 90890-01430 This tool is needed to removing and YM-38404 installing the middle driven shaft bearing retainer. Gear lash measurement tool 90890-01467 YM-01467 This tool is used to measure the gear lash. -

Page 105

SPECIAL TOOLS INFO Tool No. Tool name/How to use Illustration Adapter Adapter 90890-04059 Spacer (crankshaft installer) YM-90069 Spacer These tools are used to install the crank- 90890-04081 YM-91044 shaft. Universal joint holder 90890-04062 YM-04062 This tool is needed when removing or installing the universal joint yoke nut. -

Page 106

INFO Tool No. Tool name/How to use Illustration Ignition checker 90890-06754 This instrument is necessary for checking the ignition system components. Yamaha bond No. 1215 ® Bond Sealant (Quick Gasket 90890-85505 Sealant This sealant (bond) is used on crankcase ACC-11001-05-01 mating surfaces, etc. -

Page 107: Chapter 2. Specifications

SPEC GENERAL SPECIFICATIONS SPECIFICATIONS GENERAL SPECIFICATIONS Item Standard Model code: 5KM1 5KM5 Dimensions: Overall length 2,085 mm (82.1 in) Overall width 1,150 mm (45.3 in) Overall height 1,210 mm (47.6 in) Seat height 880 mm (34.6 in) Wheelbase 1,275 mm (50.2 in) Minimum ground clearance 275 mm (10.83 in) Minimum turning radius…

-

Page 108

SPEC GENERAL SPECIFICATIONS Item Standard Differential gear case oil Periodic oil change 0.28 L (0.25 lmp qt, 0.30 US qt) Total amount 0.33 L (0.29 lmp qt, 0.35 US qt) Radiator capacity (including all routes) 1.8 L (1.58 lmp qt, 1.90 US qt) Air filter: Wet type element Fuel:… -

Page 109

SPEC GENERAL SPECIFICATIONS Item Standard Tire pressure (cold tire): Maximum load* 220 kg (485 lb) Off-road riding front 32 ~ 38 kPa (0.32 ~ 0.38 kg/cm , 4.6 ~ 5.5 psi) rear 27 ~ 33 kPa (0.27 ~ 0.33 kg/cm , 3.9 ~ 4.8 psi) *Load in total weight of rider accessories Brake:… -

Page 110: Maintenance Specifications

SPEC MAINTENANCE SPECIFICATIONS MAINTENANCE SPECIFICATIONS ENGINE Item Standard Limit Cylinder head: Warp limit —- 0.03 mm (0.0012 in) Cylinder: Bore size 100.005 ~ 100.055 mm 100.1 mm (3.9372 ~ 3.9392 in) (3.94 in) Measuring point 50 mm (1.97 in) —- Camshaft: Drive method Chain drive (Left)

-

Page 111

SPEC MAINTENANCE SPECIFICATIONS Item Standard Limit Cam chain: Cam chain type/No. of links 92RH2010J/126M —- Cam chain adjustment method Automatic —- Rocker arm/rocker arm shaft: Bearing inside diameter 12.000 ~ 12.018 mm —- (0.4724 ~ 0.4731 in) Shaft outside diameter 11.976 ~ 11.991 mm —- (0.4715 ~ 0.4721 in) -

Page 112

SPEC MAINTENANCE SPECIFICATIONS Item Standard Limit Stem runout limit —- 0.01 mm (0.0004 in) Valve seat width 0.9 ~ 1.1 mm —- (0.0354 ~ 0.0433 in) 0.9 ~ 1.1 mm —- (0.0354 ~ 0.0433 in) Valve spring: Inner spring Free length 32.63 mm (1.28 in) 31.0 mm (1.22 in) -

Page 113

SPEC MAINTENANCE SPECIFICATIONS Item Standard Limit Piston: Piston to cylinder clearance 0.05 ~ 0.07 mm 0.15 mm (0.0020 ~ 0.0028 in) (0.0059 in) Piston size “D” 99.945 ~ 99.995 mm —- (3.9348 ~ 3.9368 in) Measuring point “H” 2.5 mm (0.10 in) —- Piston off-set 1.0 mm (0.0394 in) -

Page 114

SPEC MAINTENANCE SPECIFICATIONS Item Standard Limit 2nd ring Type Taper —- Dimensions (B × T) 1.2 × 4.0 mm —- (0.0472 × 0.1575 in) End gap (installed) 0.30 ~ 0.45 mm 0.80 mm (0.0118 ~ 0.0177 in) (0.0315 in) Side clearance 0.03 ~ 0.07 mm 0.13 mm (0.0012 ~ 0.0028 in) -

Page 115

SPEC MAINTENANCE SPECIFICATIONS Item Standard Limit Transmission: Main axle deflection limit —- 0.06 mm (0.0024 in) Drive axle deflection limit —- 0.06 mm (0.0024 in) Shifter: Shifter type Shift cam and guide bar —- Air filter oil grade: Engine oil —- Carburetor: I. -

Page 116

SPEC MAINTENANCE SPECIFICATIONS Item Standard Limit Radiator cap opening pressure 93.3 ~ 122.7 kPa (0.933 ~ —- 1.227 kg/cm , 13.53 ~ 17.79 psi) Radiator capacity 0.78 L (0.69 Imp qt, 0.82 US qt) —- Coolant reservoir Capacity 0.3 L (0.26 Imp qt, 0.32 US qt) —- From low to full level 0.165 L (0.15 Imp qt, 0.17 US qt) -

Page 117

SPEC MAINTENANCE SPECIFICATIONS Item Standard Cylinder head tightening sequence: 2 — 11… -

Page 118

SPEC MAINTENANCE SPECIFICATIONS Tightening torques Tightening torque Part Thread Part to be tightened Q’ty Remarks name size m·kg ft·lb Cylinder head (exhaust pipe) Stad bolt Cylinder head Bolt Bolt Bolt Spark plug — Cylinder head cover Bolt Camshaft end cap Bolt Oil check bolt Union bolt… -

Page 119

SPEC MAINTENANCE SPECIFICATIONS Tightening torque Part Thread Part to be tightened Q’ty Remarks name size m·kg ft·lb Primary sheave assembly 12.0 Secondary sheave assembly 10.0 Secondary sheave spring retainer Clutch carrier assembly 16.0 Balancer driven gear 11.0 Middle driven shaft bearing retainer Screw Middle driven shaft drive pinion 14.5… -

Page 120: Chassis

SPEC MAINTENANCE SPECIFICATIONS CHASSIS Item Standard Limit Steering system: Steering bearing type Ball and race bearing —- Front suspension: Shock absorber travel 86 mm (3.39 in) —- Fork spring free length 295 mm (11.61 in) —- Spring fitting length 235.5 mm (9.27 in) —- Spring rate (K1)

-

Page 121

SPEC MAINTENANCE SPECIFICATIONS Item Standard Limit Front disc brake: Type Dual —- Disc outside diameter × thickness 220.0 × 3.5 mm (8.66 × 0.14 in) —- Pad thickness inner 4.2 mm (0.17 in) 1 mm (0.04 in) Pad thickness outer 4.2 mm (0.17 in) 1 mm (0.04 in) -

Page 122

SPEC MAINTENANCE SPECIFICATIONS Tightening torques Tightening torque Part to be tightened Thread size Remarks m·kg ft·lb Engine bracket and engine Engine bracket and rubber damper (front) Engine bracket and rubber damper (front) Engine and rubber damper (rear) Engine and rubber damper (rear) Rubber damper and frame Front wheel and front wheel hub Front wheel hub and constant velocity joint… -

Page 123

SPEC MAINTENANCE SPECIFICATIONS Tightening torque Part to be tightened Thread size Remarks m·kg ft·lb Rear knuckle and rear frame (upper) Rear knuckle and rear frame (lower) Rear shock absorber and frame Rear shock absorber and rear arm (lower) Rear arm (upper) and frame Rear arm (lower) and frame Differential gear case and frame Differential gear case filler bolt… -

Page 124: Electrical

Rotor ratation direction sensing coil resis- —- tance/color Red – White/Blue C.D.I. unit model/manufacturer F8T36472/MITSUBISHI —- Ignition coil: Model/manufacturer 2JN/YAMAHA —- Minimum spark gap 6 mm (0.24 in) —- 0.18 ~ 0.28 Ω at 20 °C (68 °F) Primary winding resistance —- Secondary winding resistance 6.32 ~ 9.48 kΩ…

-

Page 125

SPEC MAINTENANCE SPECIFICATIONS Item Standard Limit Starter relay Model/manufacturer MS5F-561/JIDECO —- Amperage rating 180 A —- 4.18 ~ 4.62 Ω at 20 °C (68 °F) Coil winding resistance —- Electric fan: Running rpm 2,880 r/min —- Thermostat switch: Thermostat switch 1 Model/manufacturer 5KM/DENSO —-… -

Page 126: How To Use The Conversion Table

HOW TO USE THE CONVERSION TABLE/ SPEC GENERAL TORQUE SPECIFICATIONS EB201000 EB202001 HOW TO USE THE CONVERSION GENERAL TORQUE TABLE SPECIFICATIONS All specification data in this manual are listed This chart specifies torque for standard fasten- in SI and METRIC UNITS. ers with standard I.S.O.

-

Page 127: Lubrication Points And Lubricant Types

Shift lever (select lever)/shift guide Shift cam lever Stopper lever Clutch carrier assembly One-way bearing Drive chain/sprocket Sealant (Quick Gasket Crankcase mating surfaces Yamaha Bond No.1215 Stater lead grommet Sealant (Quick Gasket (left side crankcase) Yamaha Bond No.1215 2 — 21…

-

Page 128: Coolant Flow Diagrams

SPEC COOLANT FLOW DIAGRAMS COOLANT FLOW DIAGRAMS 1 Radiator 2 Radiator cap 3 Thermo switch 4 Radiator inlet hose 5 Thermostat assembly breather hose 6 Water pump outlet pipe 7 Water pump outlet hose 8 Radiator outlet hose B — B 2 — 22…

-

Page 129

SPEC COOLANT FLOW DIAGRAMS 1 Thermostat 2 Radiator inlet hose 3 Radiator 4 Radiator outlet hose 2 — 23… -

Page 130: Oil Flow Diagrams

SPEC OIL FLOW DIAGRAMS OIL FLOW DIAGRAMS 1 Camshaft 2 Oil delively pipe 2 3 Oil delively piep 3 4 Crankshaft 2 — 24…

-

Page 131

SPEC OIL FLOW DIAGRAMS 1 Oil delively pipe 1 2 Oil delively pipe 2 3 Oil delively pipe 3 4 Oil pump 5 Oil strainer 2 — 25… -

Page 132

SPEC OIL FLOW DIAGRAMS 1 Oil filter 2 Oil delively pipe 2 3 Oil delively pipe 1 4 Drive axle 5 Relief valve 6 Oil pump 7 Oil strainer 2 — 26… -

Page 133: Cable Routing

SPEC CABLE ROUTING CABLE ROUTING 1 Rear brake light switch 9 Rear brake light switch lead 2 Rear brake cable 0 Fan motor lead 3 Starter cable A Sub-wire harness (to gear motor) 4 Front brake hose B Differential gear case breather hose 5 Throttle cable 6 On-command four-wheel drive switch and differ- È…

-

Page 134

SPEC CABLE ROUTING É Fasten the front brake light switch lead, and the Ì Fasten the thermo switch 2 lead, fan motor lead, on-command four-wheel drive switch and differ- coolant reservoir breather hose, coolant reser- ential gear lock switch lead behind the handle- voir hose, gear motor lead and differential gear bar with a plastic band. -

Page 135

SPEC CABLE ROUTING Î Pass the brake hose through the hose guide. Ï Fasten the on-command four-wheel drive switch and differential gear lock switch lead, front brake light switch lead, handlebar switch lead, and rear brake light switch lead on the front side on the steering stem with a plastic locking tie. -

Page 136

SPEC CABLE ROUTING 1 Park brake light switch È To the front brake light switch, on-command four- 2 On-command four-wheel drive switch and differ- wheel drive switch and differential gear lock switch, ential gear lock switch lead handlebar switch, and rear brake light switch. 3 Headlight lead É… -

Page 137

SPEC CABLE ROUTING Ì Pass the fan motor breather hose through the guide on the front fender. Í Pass the headlight lead through the guide on the front fender. É È Ê Í Ë Ì 2 — 31… -

Page 138

SPEC CABLE ROUTING 1 Coolant reservoir hose È Connect the ignition coil coupler under the front 2 Fan motor lead fender. 3 Ignition coil coupler É Pass the starter cable through the cable guide at 4 Starter cable the front of plastic cover. 5 Fuel tank breather hose Ê… -

Page 139

SPEC CABLE ROUTING Í Slacken the coolant reservoir hose, and then Ð Fasten the gear motor lead and differential gear case insert it between the frame and the water pump breather hose with a plastic band. Be sure not to inlet. -

Page 140

SPEC CABLE ROUTING 1 Fuel sender lead B Starter cable 2 Differential gear case breather hose C Fuel hose 3 Vacuum chamber breather hose D Thermo switch 1 lead 4 Starter motor lead E Reverse switch lead 5 Wireharness F AC magneto coupler 6 Gear position switch lead G Gear position switch coupler 7 Final drive gear case breather hose… -

Page 141

SPEC CABLE ROUTING È Fasten the final drive gear case breather hose, speed sensor lead, ground lead, gear position switch lead, AC magneto lead, wire harness, and reverse indicator light lead with a plastic locking tie. Be careful not to pinch the breather hose. -

Page 142

SPEC CABLE ROUTING Ï Pass the vacuum chamber breather hose through the plastic cover hole. Ð Insert a clamp into the third hole from the top of the rectifier/regulator bracket, and then clamp the final drive gear case breather hose with the clamp. È… -

Page 143

SPEC CABLE ROUTING 1 Gear position switch B Rear brake hose 2 Reverse switch 3 Crankcase breather hose È Pass the rear brake cable and throttle cable 4 Select lever control cable through the cable guide. 5 Rear brake cable É… -

Page 144

SPEC CABLE ROUTING Ê Clamp the spark plug lead and radiator inlet hose with a plastic clamp. Ë When installing the ignition coil, face the spark lead to the right side of the frame. Ì To the rear fender hole Í… -

Page 145

SPEC CABLE ROUTING 1 Negative battery lead È Pass the tail/brake light lead through the lead 2 Tail/brake light lead guide. 3 Fuse box É Position the wire harness tape at the end of the 4 Four-wheel drive relay 3 rear fender guide. -

Page 146

SPEC CABLE ROUTING 1 Front brake hose È Pass the thermo sensor 1 lead through the lead 2 Throttle cable guide. 3 Thermo switch 1 lead É Pass the crankcase breather hose through the 4 Crankcase breather hose hose guide. 5 Fuel sender lead Ê… -

Page 147

SPEC CABLE ROUTING Î Fasten the speed sensor coupler, thermo switch 1 lead, reverse switch lead, ground lead, gear position switch lead, and AC magneto couplers with a band. Í A — A Ì Ë Î È É C — C Ê… -

Page 148: Chapter 3. Periodic Checks And Adjustments

INTRODUCTION/PERIODIC MAINTENANCE/ LUBRICATION INTERVALS EB300000 PERIODIC CHECKS AND ADJUSTMENTS INTRODUCTION This chapter includes all information necessary to perform recommended inspections and adjust- ments. These preventive maintenance procedures, if followed, will ensure more reliable vehicle operation and a longer service life. The need for costly overhaul work will be greatly reduced. This information applies to vehicles already in service as well as to new vehicles that are being prepared for sale.

-

Page 149

• Check for cracks or damage. Fittings and Fasten- • Check all chassis fittings and fasteners. ers* • Correct if necessary. It is recommended that these items be serviced by a Yamaha dealer. ** Lithium-soap-based grease NOTE: Recommended brake fluid: DOT 4 Brake fluid replacement: 1.When disassembling the master cylinder or caliper, replace the brake fluid. -

Page 150: Seat, Carriers, Fenders And Fuel Tank

SEAT, CARRIERS, FENDERS AND FUEL TANK SEAT, CARRIERS, FENDERS AND FUEL TANK SEAT AND SIDE PANELS Order Job name/Part name Q’ty Remarks Removing the seat and side panels Remove the parts in the order below. Seat NOTE: Pull up the seat lock lever, then pull up on the rear of the seat.

-

Page 151: Front Carrier, Front Bumper And Front Grill

SEAT, CARRIERS, FENDERS AND FUEL TANK FRONT CARRIER, FRONT BUMPER AND FRONT GRILL 33 Nm (3.3 m kg, 24 ft • • 33 Nm (3.3 m kg, 24 ft • • 9 Nm (0.9 m kg, 6.5 ft • • Order Job name/Part name Q’ty…

-

Page 152: Handlebar Cover, Fuel Tank Cover And Front Fender

SEAT, CARRIERS, FENDERS AND FUEL TANK HANDLEBAR COVER, FUEL TANK COVER AND FRONT FENDER 12 10 Order Job name/Part name Q’ty Remarks Removing the handlebar cover, fuel Remove the parts in the order below. tank cover and front fender Seat and fuel tank side panels Refer to “SEAT AND SIDE PANELS”.

-

Page 153

SEAT, CARRIERS, FENDERS AND FUEL TANK 12 10 Order Job name/Part name Q’ty Remarks Rear brake switch coupler Disconnect. Front brake light switch coupler Disconnect. Rear brake light switch coupler Disconnect. Main switch coupler Disconnect. Auxiliary DC jack coupler Disconnect. Fan motor breather hose Differential gear case breather hose Coolant reservoir breather hose… -

Page 154: Rear Carrier And Rear Fender

SEAT, CARRIERS, FENDERS AND FUEL TANK REAR CARRIER AND REAR FENDER 7 Nm (0.7 m kg, 5.1 ft • • Order Job name/Part name Q’ty Remarks Removing the rear carrier and rear Remove the parts in the order below. fender Seat and fuel tank side panels Refer to “SEAT AND SIDE PANELS”.

-

Page 155

SEAT, CARRIERS, FENDERS AND FUEL TANK 7 Nm (0.7 m kg, 5.1 ft • • Order Job name/Part name Q’ty Remarks Battery Starter relay ground lead Disconnect. Taillight connector Disconnect. Crankcase breather hose Clamp screw Loosen. Air filter case Rear fender For installation, reverse the removal procedure. -

Page 156: Engine Skid Plate (Center) And Engine Skid Plate (Rear)

SEAT, CARRIERS, FENDERS AND FUEL TANK ENGINE SKID PLATE (CENTER) AND ENGINE SKID PLATE (REAR) 9 Nm (0.9 m kg, 6.5 ft • • Order Job name/Part name Q’ty Remarks Removing the engine skid plate Remove the parts in the order below. (center) and engine skid plate (rear) Engine skid plate (center) Engine skid plate (rear)

-

Page 157: Fuel Tank

SEAT, CARRIERS, FENDERS AND FUEL TANK FUEL TANK Order Job name/Part name Q’ty Remarks Removing the fuel tank Remove the parts in the order below. Seat and side panels Refer to “SEAT AND SIDE PANELS”. Fuel tank cover Refer to “HANDLEBAR COVER, FUEL TANK COVER AND FRONT FENDER”.

-

Page 158

SEAT, CARRIERS, FENDERS AND FUEL TANK Order Job name/Part name Q’ty Remarks Clamp Vacuum chamber breather hose Differential gear case breather hose Crankcase breather hose Plastic band Bushing Plastic cover For installation, reverse the removal procedure. 3 — 11… -

Page 159: Footrest Boards

FOOTREST BOARDS FOOTREST BOARDS 9 Nm (0.9 m kg, 6.5 ft • • (12) (12) 33 Nm (3.3 m kg, 24 ft • • Order Job name/Part name Q’ty Remarks Removing the footrest boards Remove the parts in the order below. Fuel tank side panels Refer to “SEAT AND SIDE PANELS”.

-

Page 160: Engine

ADJUSTING THE VALVE CLEARANCE ENGINE ADJUSTING THE VALVE CLEARANCE NOTE: The valve clearance must be adjusted when the engine is cool to the touch. Adjust the valve clearance when the piston is at the Top Dead Center (T.D.C.) on the com- pression stroke.

-

Page 161

ADJUSTING THE VALVE CLEARANCE 6.Remove: Timing plug 1 7.Check: Valve clearance Out of specification → Adjust. Valve clearance (cold): Intake: 0.10 ~ 0.15 mm (0.0039 ~ 0.0059 in) Exhaust: 0.15 ~ 0.20 mm (0.0059 ~ 0.0079 in) ***************************************************** Checking steps: Turn the crankshaft counterclockwise with a wrench. -

Page 162

ADJUSTING THE VALVE CLEARANCE 8.Adjust: Valve clearance ***************************************************** Adjustment steps: Loosen the locknut 1. Insert a feeler gauge 2 between the adjuster end and the valve end. Turn the adjuster 3 clockwise or counter- clockwise with the tappet adjusting tool 4 until the proper clearance is obtained. -

Page 163: Adjusting The Timing Chain

ADJUSTING THE VALVE CLEARANCE/ADJUSTING THE TIMING CHAIN/ ADJUSTING THE IDLING SPEED 11.Install: Engine side cover Fuel tank Front fender Front carrier Seat Refer to “SEAT, CARRIERS, FENDERS AND FUEL TANK”. ADJUSTING THE TIMING CHAIN Adjustment free. ADJUSTING THE IDLING SPEED 1.Start the engine and let it warm up for sev- eral minutes.

-

Page 164: Adjusting The Idling Speed

ADJUSTING THE IDLING SPEED/ ADJUSTING THE THROTTLE LEVER FREE PLAY 5.Adjust: Engine idling speed ***************************************************** Adjustment steps: Turn the throttle stop screw 1 in or out until the specified idling speed is obtained. Idling speed becomes Turning in higher. Idling speed becomes Turning out lower.

-

Page 165

ADJUSTING THE THROTTLE LEVER FREE PLAY 1.Check: Throttle lever free play a Out of specification → Adjust. Throttle lever free play: 3 ~ 5 mm (0.12 ~ 0.20 in) 2.Remove: Seat Fuel tank side panel (right) Refer to “SEAT, CARRIERS, FENDERS AND FUEL TANK”. -

Page 166: Adjusting The Speed Limiter

ADJUSTING THE THROTTLE LEVER FREE PLAY/ ADJUSTING THE SPEED LIMITER Second step: Pull back the adjuster cover 4. Loosen the locknut 5. Turn the adjuster 6 in or out until the correct free play is obtained. Turning in Free play is increased. Turning out Free play is decreased.

-

Page 167

ADJUSTING THE SPEED LIMITER 2.Adjust: Speed limiter length ***************************************************** Adjustment steps: Loosen the locknut 1. Turn the adjuster 2 in or out until the speci- fied speed limiter length is obtained. Speed limiter length is Turning in decreased. Speed limiter length is Turning out increased. -

Page 168: Adjusting The Starter Cable

ADJUSTING THE STARTER CABLE/ CHECKING THE SPARK PLUG ADJUSTING THE STARTER CABLE 1.Remove: Seat Fuel tank side panel (left) 2.Adjust: ***************************************************** Adjustment steps: Disconnect the starter cable 1 from the car- buretor body. NOTE: Do not remove the starter plunger 2 from the starter cable.

-

Page 169: Checking The Ignition Timing

CHECKING THE SPARK PLUG/ CHECKING THE IGNITION TIMING CHECKING THE SPARK PLUG 1.Remove: Spark plug 2.Check: Spark plug type Incorrect → Replace. Standard spark plug: DPR8EA-9/NGK 3.Check: Electrode 1 Wear/damage → Replace. Insulator 2 Abnormal color → Replace. Normal color is a medium-to-light tan color. 4.Clean the spark plug with a spark plug cleaner or wire brush.

-

Page 170

CHECKING THE IGNITION TIMING CHECKING THE IGNITION TIMING NOTE: Engine idling speed and throttle cable free play should be adjusted properly before checking the ignition timing. 1.Remove: Seat Fuel tank side panel (left) Engine side cover Refer to “SEAT, CARRIERS, FENDERS AND FUEL TANK”. -

Page 171: Measuring The Compression Pressure

CHECKING THE IGNITION TIMING/ MEASURING THE COMPRESSION PRESSURE 4.Detach: Timing light Tachometer 5.Install: Engine side cover Fuel tank side panel (left) Seat Refer to “SEAT, CARRIERS, FENDERS AND FUEL TANK”. MEASURING THE COMPRESSION PRESSURE NOTE: Insufficient compression pressure will result in a loss of performance.

-

Page 172

MEASURING THE COMPRESSION PRESSURE 6.Measure: Compression pressure Above the maximum pressure: Inspect the cylinder head, valve surfaces, and piston crown for carbon deposits. Below the minimum pressure: Squirt a few drops of oil into the affected cyl- inder and measure again. Refer to the table below. -

Page 173: Checking The Engine Oil Level

CHECKING THE ENGINE OIL LEVEL CHECKING THE ENGINE OIL LEVEL 1.Place the machine on a level surface. 2.Remove: Engine side panel Refer to “SEAT, CARRIERS, FENDERS AND FUEL TANK”. 3.Check: Engine oil level Oil level should be between the maximum 1 and minimum 2 marks.

-

Page 174: Changing The Engine Oil

CHANGING THE ENGINE OIL CHANGING THE ENGINE OIL 1.Start the engine and let it warm up for sev- eral minutes. 2.Stop the engine and place an oil pan under the engine. 3.Remove: Seat Fuel tank side panel (left) Engine side cover Refer to “SEAT, CARRIERS, FENDERS AND FUEL TANK”.

-

Page 175

CHANGING THE ENGINE OIL 6.Install: Engine oil drain bolt 1 30 Nm (3.0 m • kg, 22 ft • lb) 7.Fill: Crankcase (with sufficient oil to reach the specified level) Refer to “CHECKING THE ENGINE OIL LEVEL”. Oil quantity: Periodic oil change: 1.9 L (1.7 Imp qt, 2.0 US qt) With oil filter replacement: 2.0 L (1.8 Imp qt, 2.1 US qt) -

Page 176

CHANGING THE ENGINE OIL Start the engine after solving the problem(-s) and check the engine oil pressure again. Tighten the oil gallery bolt to specification. Oil gallery bolt: 7 Nm (0.7 m • kg, 5.1 ft • lb) ***************************************************** 12.Install: Engine side cover Fuel tank side panel (left) Seat… -

Page 177: Cleaning The Air Filter

CLEANING THE AIR FILTER 3.Remove: Air filter element assembly 1 Air filter element cap Air filter element NOTE: When removing the air filter element, rotate the air filter element cap 1/4 of a turn and remove the element. 2 Air filter element cap 3 Air filter element CAUTION: Never operate the engine with the air filter…

-

Page 178: Checking The Coolant Level

CLEANING THE AIR FILTER/ CHECKING THE COOLANT LEVEL Squeeze the excess solvent out of the ele- ment and let it dry. CAUTION: Do not twist or wring out the element. This could damage the foam material. Apply engine oil to the element. Squeeze out the excess oil.

-

Page 179: Changing The Coolant

CHECKING THE COOLANT LEVEL/ CHANGING THE COOLANT 3.Check: Coolant level The coolant level should be between the minimum level mark a and maximum level mark b. Below the minimum level mark → Add the recommended coolant to the proper level. CAUTION: Adding water instead of coolant lowers the antifreeze content of the coolant.

-

Page 180

CHANGING THE COOLANT 2.Remove: Plastic band 1 Coolant reservoir bolts 2 Coolant reservoir cap 3 3.Disconnect: Coolant reservoir breather hose 4 4.Drain: Coolant (from the coolant reservoir) 5.Connect: Coolant reservoir breather hose 6.Install: Coolant reservoir bolts Plastic band 7.Remove: Radiator cap 1 WARNING A hot radiator is under pressure. -

Page 181

CHANGING THE COOLANT 10.Check: Copper washer 1 Coolant drain bolt 2 Damage → Replace. 11.Install: Coolant drain bolt (water pump) 10 Nm (1.0 m • kg, 7.2 ft • lb) 12.Fill: Cooling system (with the specified amount of the recom- mended coolant) Recommended antifreeze High-quality… -

Page 182

CHANGING THE COOLANT CAUTION: Adding water instead of coolant lowers the antifreeze content of the coolant. If water is used instead of coolant, check, and if necessary, correct the antifreeze concentration of the coolant. Use only distilled water. However, soft water may be used if distilled water is not available. -

Page 183: Checking The Coolant Temperature Warning Light

CHECKING THE COOLANT TEMPERATURE WARNING LIGHT/CHECKING THE V-BELT CHECKING THE COOLANT TEMPERATURE WARNING LIGHT 1 Coolant temperature indicator light CHECKING THE V-BELT 1.Remove: Right footrest board Crankcase cover (right) Refer to “PRIMARY AND SECONDARY SHEAVES” in CHAPTER 4. 2.Check: V-belt 1 Cracks/wear/scaling/chipping →…

-

Page 184: Checking The V-Belt

CHECKING THE V-BELT/ CLEANING THE SPARK ARRESTER 4.Replace: V-belt ***************************************************** Replacing steps: Install the bolts 1 (90101-06016) into the secondary fixed sheave hold. NOTE: Tightening the bolts 1 will push the secondary sliding sheave away, causing the gap between the secondary fixed and sliding sheaves to widen.

-

Page 185

CLEANING THE SPARK ARRESTER Tap the tailpipe lightly with a soft-face ham- mer or suitable tool, then use a wire brush to remove any carbon deposits from the spark arrester portion of the tailpipe and the inner contact surfaces of the muffler. Insert the tailpipe 2 into the muffler and align the bolt holes. -

Page 186: Chassis

ADJUSTING THE REAR BRAKE CHASSIS ADJUSTING THE REAR BRAKE WARNING Always adjust both the brake pedal and the rear brake lever whenever adjusting the rear brake. 1.Check: Rear brake lever free play b Out of specification → Adjust. Rear brake lever free play: 0.5 ~ 2 mm (0.02 ~ 0.08 in) 2.Check: Rear brake pedal height a…

-

Page 187

ADJUSTING THE REAR BRAKE Loosen the locknut 4. Turn the adjusting bolt 5 until the brake pedal height is within the specified limits. Rear brake pedal height: 45 mm (1.77 in) Tighten the locknut 4. NOTE: When adjusting the brake pedal height make sure the locknut-to-adjusting bolt clearance b does not exceed 2 mm (0.08 in). -

Page 188: Checking The Brake Fluid Level

ADJUSTING THE REAR BRAKE/ CHECKING THE BRAKE FLUID LEVEL Adjust the select lever control cable. Refer to “ADJUSTING THE SELECT LEVER CONTROL CABLE AND SHIFT ROD”. Install the rear brake master cylinder cover. WARNING After this adjustment is performed, lift the front and rear wheels off the ground by placing a block under the engine, and spin the rear wheels to ensure there is no brake…

-

Page 189

CHECKING THE BRAKE FLUID LEVEL WARNING Use only the designed quality brake fluid: otherwise, the rubber seals may deterio- rate, causing leakage and poor brake per- formance. Refill with the same type of brake fluid; mixing fluids may result in a harmful chemical reaction and lead to poor perfor- mance. -

Page 190: Checking The Front Brake Pad

CHECKING THE FRONT BRAKE PAD/CHECKING THE REAR BRAKE PAD/CHECKING THE BRAKE HOSE CHECKING THE FRONT BRAKE PAD 1.Remove: Front wheels 2.Check: Brake pad Wear indicators 1 almost touch the brake disc → Replace the brake pads as a set. Refer to “FRONT AND REAR BRAKES” in CHAPTER 8.

-

Page 191: Checking The Brake Hose

CHECKING THE BRAKE HOSE/ BLEEDING THE HYDRAULIC BRAKE SYSTEM 2.Check: Front brake hoses 1 Rear brake hoses 2 Cracks/wear/damage → Replace. Fluid leakage → Replace the hose. Refer to “FRONT AND REAR BRAKES” in CHAPTER 8. NOTE: Hold the machine in an upright position and apply the front or rear brake.

-

Page 192

BLEEDING THE HYDRAULIC BRAKE SYSTEM 1.Bleed: È Brake system ***************************************************** Air bleeding steps: a. Add the proper brake fluid to the reservoir. b. Install the diaphragm. Be careful not to spill any fluid or allow the reservoir to overflow. c. Connect the clear plastic hose 1 tightly to the caliper bleed screw 2. -

Page 193: Adjusting The Select Lever Control Cable And Shift Rod

ADJUSTING THE SELECT LEVER CONTROL CABLE AND SHIFT ROD ADJUSTING THE SELECT LEVER CONTROL CABLE AND SHIFT ROD 1 NEUTRAL 2 HIGH 3 LOW 4 REVERSE 5 PARK 6 Control cable 7 Select lever shift rod WARNING Before moving the select lever, bring the machine to a complete stop and return the throttle lever to its closed position.

-

Page 194: Adjusting The Rear Brake Light Switch

ADJUSTING THE SELECT LEVER CONTROL CABLE AND SHIFT ROD/ ADJUSTING THE REAR BRAKE LIGHT SWITCH Check that locknuts 2 are tightened cor- rectly. If the operation of the select lever is incor- rect, adjust the select lever control cable 3 with the adjuster 4.

-

Page 195: Checking The Final Gear Oil Level

CHECKING THE FINAL GEAR OIL LEVEL/ CHANGING THE FINAL GEAR OIL CHECKING THE FINAL GEAR OIL LEVEL 1.Place the machine on a level place. 2.Loosen: Oil check bolt 1 NOTE: Loosen the slightly. Do not remove the bolt, otherwise the gear oil may come out.

-

Page 196: Checking The Differential Gear Oil

CHANGING THE FINAL GEAR OIL/ CHECKING THE DIFFERENTIAL GEAR OIL 6.Fill: Final gear case Periodic oil change: 0.28 L (0.25 Imp qt, 0.30 US qt) Total amount: 0.33 L (0.29 Imp qt, 0.35 US qt) Recommended oil: SAE 80 API “GL-4” Hypoid gear CAUTION: Take care not to allow foreign material to enter the final gear case.

-

Page 197: Changing The Differential Gear Oil

CHANGING THE DIFFERENTIAL GEAR OIL CHANGING THE DIFFERENTIAL GEAR OIL 1.Place the machine on a level surface. 2.Place a receptacle under the differential gear case. 3.Remove: Oil filler bolt Drain plug 1 4.Drain: Differential gear oil 5.Install: Drain plug 10 Nm (1.0 m • kg, 7.2 ft • lb) NOTE: Check the gasket (drain plug).

-

Page 198: Checking The Constant Velocity Joint Dust Boot

CHECKING THE CONSTANT VELOCITY JOINT DUST BOOT/CHECKING THE STEERING SYSTEM/ADJUSTING THE TOE-IN CHECKING THE CONSTANT VELOCITY JOINT DUST BOOT 1.Check: Dust boots 1 Damage → Replace. Refer to “FRONT CONSTANT VELOCITY JOINTS AND DIFFERENTIAL GEAR” in CHAPTER 7. CHECKING THE STEERING SYSTEM 1.Place the machine on a level surface.

-

Page 199: Adjusting The Toe-In

ADJUSTING THE TOE-IN ***************************************************** Measurement steps: NOTE: Before measuring the toe-in, make sure that the tire pressure is correct. Mark both front tire tread centers. Face the handlebar straight ahead. Measure the width È between the marks. Rotate the front tires 180° until the marks are exactly opposite one another.

-

Page 200: Adjusting The Front Shock Absorber

ADJUSTING THE TOE-IN/ ADJUSTING THE FRONT SHOCK ABSORBER ***************************************************** Adjustment steps: Mark both tie-rods ends. This reference point will be needed during adjustment. Loosen the locknuts (tie-rod end) 1 of both tie-rods. The same number of turns should be given to both the right and left tie-rods 2 until the specified toe-in is obtained.

-

Page 201: Adjusting The Rear Shock Absorber

TIRE CHARACTERISTICS 1)Tire characteristics influence the handling of ATV’s. The tires listed below have been approved by Yamaha Motor Co., Ltd. for this model. If other tire combinations are used, they can adversely affect your machine’s handling characteristics and are therefore not recommended.

-

Page 202

CHECKING THE TIRE TIRE PRESSURE 1)Recommended tire pressure Front 35 kPa (0.35 kg/cm , 5.0 psi) Rear 30 kPa (0.30 kg/cm , 4.3 psi) 2)Tire pressure below the minimum specifi- cation could cause the tire to dislodge from the rim under severe riding condi- tions. -

Page 203: Checking The Wheel

CHECKING THE TIRE/CHECKING THE WHEEL Cold tire Front Rear pressure 35 kPa 30 kPa Standard (0.35 kg/cm (0.30 kg/cm 5.0 psi) 4.3 psi) 32 kPa 27 kPa Minimum (0.32 kg/cm (0.27 kg/cm 4.6 psi) 3.9 psi) 38 kPa 33 kPa Maximum (0.38 kg/cm (0.33 kg/cm…

-

Page 204: Checking And Lubricating The Cable

Cable sheath Damage → Replace. 2.Check: Cable operation Unsmooth operation → Lubricate or replace. Recommended lubricant: Yamaha chain and cable lube or Engine oil NOTE: Hold the cable end up and apply several drops of lubricant to the cable. 3.Apply:…

-

Page 205: Electrical

CHECKING THE BATTERY EB305000 ELECTRICAL CHECKING THE BATTERY NOTE: Since the MF battery is a sealed type battery, it is not possible to measure the specific gravity of the electrolyte in order to check the charge state of the battery. Therefore the charge of the battery has to be checked by measuring the voltage at the battery terminals.

-

Page 206

CHECKING THE BATTERY Batteries generate explosive hydrogen gas. Always follow these preventive measures: Charge batteries in a well-ventilated area. Keep batteries away from fire, sparks or open flames (e.g., welding equipment, lighted cigarettes, etc.) DO NOT SMOKE when charging or han- dling batteries. -

Page 207

CHECKING THE BATTERY Check the condition of the battery using the Relationship between the open-circuit voltage and the charging time at 20 °C following charts. Example: Open-circuit voltage = 12.0 V Charging time = 6.5 hours Charge condition of the battery = 20 ~ 30% Charging method for MF batteries Charging time (hours) CAUTION:… -

Page 208

CHECKING THE BATTERY Charging method using a variable voltage charger NOTE: Leave the battery unused for more than 30 minutes before Measure the open-circuit measuring its open-circuit voltage. voltage prior to charging. Charger Ammeter NOTE: Set the charging voltage to Connect a charger and 16 ~ 17 V. -

Page 209

CHECKING THE BATTERY Charging method using a constant voltage charger NOTE: Leave the battery unused for Measure the open-circuit more than 30 minutes before voltage prior to charging. measuring its open-circuit voltage. Connect a charger and ammeter to the battery and start charging. -

Page 210

CHECKING THE BATTERY/CHECKING THE FUSE 5.Check: Battery terminals Dirty → Clean with a wire brush. Poor connection → Correct. NOTE: After cleaning the terminals, apply a light coat of grease. 6.Install: Battery 7.Connect: Battery leads CAUTION: First, connect the positive lead 1, then connect the negative lead 2. -

Page 211: Checking The Fuse

CHECKING THE FUSE NOTE: Set the tester to the “Ω × 1” position. Pocket tester: P/N. YU-03112, 90890-03112 If the tester indicates o, replace the fuse. ***************************************************** 3.Replace: Blown fuse ***************************************************** Replacement steps: Turn off the ignition. Install a new fuse of the proper amperage. Turn on switches to verify operation of the related electrical devices.

-

Page 212: Adjusting The Headlight Beam

CHECKING THE FUSE/ADJUSTING THE HEADLIGHT BEAM/ CHANGING THE HEADLIGHT BULB 4.Install: Seat Refer to “SEAT, CARRIERS, FENDERS AND FUEL TANK”. ADJUSTING THE HEADLIGHT BEAM 1.Adjust: Headlight beam (vertically) Turn the adjuster 1 in or out. Turning in Headlight beam raised. Turning out Headlight beam lowered.

-

Page 213: Changing The Headlight Bulb

CHANGING THE HEADLIGHT BULB 4.Remove: Cover 1 Bulb holder 2 Bulb NOTE: Turn the bulb holder counterclockwise and remove the defective bulb. WARNING Keep flammable products and your hands away from the bulb while it is on, since it will be hot. Do not touch the bulb until it cools down.

-

Page 214: Chapter 4. Engine

ENGINE REMOVAL ENGINE ENGINE REMOVAL AIR DUCTS, MUFFLER AND EXHAUST PIPE Order Job name/Part name Q’ty Remarks Removing the air ducts, muffler and Remove the parts in the order below. exhaust pipe Engine oil Drain. Refer to “CHANGING THE ENGINE OIL” in CHAPTER 3.

-

Page 215

ENGINE REMOVAL Order Job name/Part name Q’ty Remarks Air duct assembly 3 For installation, reverse the removal procedure. 4 — 2… -

Page 216: Select Lever Unit And Coolant Reservoir

ENGINE REMOVAL SELECT LEVER UNIT AND COOLANT RESERVOIR Order Job name/Part name Q’ty Remarks Removing the select lever unit and Remove the parts in the order below. coolant reservoir Coolant Drain. Refer to “CHANGING THE COOLANT” in CHAPTER 3. Shift arm Select lever shift rod Select lever unit Coolant reservoir breather hose…

-

Page 217: Hoses And Leads

ENGINE REMOVAL HOSES AND LEADS Order Job name/Part name Q’ty Remarks Removing the hoses and leads Remove the parts in the order below. Radiator inlet hose Refer to “THERMOSTAT” in CHAPTER 5. Water pump assembly Refer to “WATER PUMP” in CHAPTER 5. Spark plug lead Crankcase breather hose Thermo switch lead…

-

Page 218: Engine Mounting Bolts

ENGINE REMOVAL ENGINE MOUNTING BOLTS Order Job name/Part name Q’ty Remarks Removing the engine mounting bolt Remove the parts in the order below. Engine skid plate (front) Refer to “SEAT, CARRIERS, FENDERS Engine skid plate (center) AND FUEL TANK” in CHAPTER 3. Engine skid plate (rear) Rear wheels Refer to “REAR WHEELS AND BRAKE…

-

Page 219

ENGINE REMOVAL Order Job name/Part name Q’ty Remarks Rubber damper nut (front) NOTE: Engine mounting bolt (rear-upper) Remove the engine assembly from the Engine mounting bolt (rear-lower)/nut left side of the machine. Engine assembly Rubber damper nut (rear) CAUTION: Rubber damper (rear) Install all of the bolts/nuts and then Rubber damper (front) tighten them to full torque specifica-… -

Page 220: Installing The Engine

ENGINE REMOVAL INSTALLING THE ENGINE 1.Install: Engine mounting bolt (front) 1 Rubber damper (front) 2 Rubber damper nut (rear) 3 Engine assembly 4 Engine mounting bolt (rear lower)/nut 5 Engine mounting bolt (rear upper) 6 Rubber damper nut (front) 7 NOTE: Do not fully tighten the bolts and nuts.

-

Page 221: Cylinder Head Cover

CYLINDER HEAD COVER CYLINDER HEAD COVER Order Job name/Part name Q’ty Remarks Removing the cylinder head cover Remove the parts in the order below. Seat/front fender Refer to “SEAT, CARRIERS, FEND- Fuel tank/plastic cover ERS AND FUEL TANK” in CHAPTER 3. Recoil starter/timing plug Refer to “ADJUSTING THE VALVE CLEARANCE”…

-

Page 222

CYLINDER HEAD COVER Order Job name/Part name Q’ty Remarks Cylinder head cover Refer to “REMOVING/INSTALLING THE CYLINDER HEAD COVER”. Dowel pin For installation, reverse the removal procedure. 4 — 9… -

Page 223: Removing The Cylinder Head Cover

CYLINDER HEAD COVER REMOVING THE CYLINDER HEAD COVER 1.Align: “I” mark (with stationary pointer) ***************************************************** Checking steps: Turn the crankshaft counterclockwise with a wrench. Align the “I” mark 1 on the rotor with the sta- tionary pointer 2 on the crankcase cover. When the “I”…

-

Page 224: Checking The Tappet Cover

(to the mating surfaces of the cylinder head and cylinder head cover) ) 1: Sealant (Quick Gasket P/N. ACC-11001-05-01 Yamaha bond No. 1215: P/N. 90890-85505 2.Install: Cylinder head cover Washers 1 Bolts 10 Nm (1.0 m • kg, 7.2 ft • lb)

-

Page 225: Rocker Arms

ROCKER ARMS ROCKER ARMS Order Job name/Part name Q’ty Remarks Removing the rocker arm Remove the parts in the order below. Cylinder head cover Refer to “CYLINDER HEAD COVER”. Plug/O-ring Bolt Rocker arm shaft 2 Rocker arm 3 Rocker arm shaft 3/O-ring Refer to “REMOVING/INSTALLING THE Rocker arm 4 ROCKER ARM”.

-

Page 226

ROCKER ARMS Order Job name/Part name Q’ty Remarks Spring Locknut Valve adjuster For installation, reverse the removal procedure. 4 — 13… -

Page 227: Removing The Rocker Arm

ROCKER ARMS REMOVING THE ROCKER ARM 1.Remove: Rocker arm shafts 1 Rocker arms 2 NOTE: Use a slide hammer bolt 3 and weight 4 to remove the rocker arm shafts. Slide hammer set: P/N. YU-01083-A Slide hammer bolt (M6): P/N. 90890-01083 Weight: P/N.

-

Page 228: Installing The Rocker Arm

ROCKER ARMS Measure the outside diameter b of the rocker arm shafts. Out of specification → Replace. Rocker arm shaft outside diameter: 11.976 ~ 11.991 mm (0.4715 ~ 0.4721 in) Calculate the clearance by subtracting the rocker arm shaft outside diameter from the rocker arm inside diameter.

-

Page 229: Camshaft And Cylinder Head

CAMSHAFT AND CYLINDER HEAD CAMSHAFT AND CYLINDER HEAD Order Job name/Part name Q’ty Remarks Removing the camshaft and cylin- Remove the parts in the order below. der head Seat/front fender Refer to “SEAT, FENDERS AND FUEL TANK” in CHAPTER 3. Fuel tank/plastic covers Carburetors Refer to “CARBURETOR”…

-

Page 230

CAMSHAFT AND CYLINDER HEAD Order Job name/Part name Q’ty Remarks Camshaft Thermo switch Cylinder head Cylinder head gasket Dowel pin Carburetor joint For installation, reverse the removal procedure. 4 — 17… -

Page 231: Removing The Camshaft And Cylinder Head

CAMSHAFT AND CYLINDER HEAD REMOVING THE CAMSHAFT AND CYLINDER HEAD 1.Loosen: Camshaft sprocket bolts 1 2.Loosen: Timing chain tensioner cap bolt 3.Remove: Timing chain tensioner Timing chain guide (exhaust) Decompressor cam guide plates Camshaft sprocket Camshaft NOTE: Fasten a safety wire to the timing chain to prevent it from falling into the crankcase.

-

Page 232: Checking The Camshaft

CAMSHAFT AND CYLINDER HEAD CHECKING THE CAMSHAFT 1.Check: Cam lobes Pitting/scratches/blue discoloration → Replace. 2.Measure: Cam lobes length a and b. Out of specification → Replace. Camshaft lobe limit: Intake: a 35.59 mm (1.4012 in) b 29.96 mm (1.1795 in) Exhaust: a 36.40 mm (1.4331 in) b 30.01 mm (1.1815 in)

-

Page 233: Checking The Timing Chain Guide

CAMSHAFT AND CYLINDER HEAD CHECKING THE TIMING CHAIN GUIDE 1.Check: Exhaust side timing chain guide Wear/damage → Replace. CHECKING THE TIMING CHAIN TENSIONER 1.Check: Timing chain tensioner Cracks/damage/rough movement → Replace. ***************************************************** a.Lightly press the timing chain tensioner rod into the timing chain tensioner housing by hand.

-

Page 234: Installing The Camshaft And Cylinder Head

CAMSHAFT AND CYLINDER HEAD 3.Measure: Cylinder head warpage Out of specification → Resurface. Cylinder head warpage: Less than 0.05 mm (0.002 in) ***************************************************** Measurement and resurfacing steps: Place a straightedge and a feeler gauge across the cylinder head. Use a feeler gauge to measure the warpage. If the warpage is out of specification, resur- face the cylinder head.

-

Page 235

CAMSHAFT AND CYLINDER HEAD 2.Install: Camshaft Camshaft sprocket ***************************************************** Installation steps: Turn the crankshaft counterclockwise with a wrench. Align the “I” mark 1 on the rotor with the sta- tionary pointer 2 on the crankcase cover. When the “I” mark is aligned with the station- ary pointer, the piston is at the Top Dead Center (T.D.C.). -

Page 236

CAMSHAFT AND CYLINDER HEAD Install the decompressor cam guide plates 9 and camshaft sprocket bolts 0. Camshaft sprocket bolt: 20 Nm (2.0 m • kg, 14 ft • lb) NOTE: Insert a screwdriver into the timing chain ten- sioner hole and push the timing chain guide inward. -

Page 237: Valves And Valve Springs

VALVES AND VALVE SPRINGS VALVES AND VALVE SPRINGS Order Job name/Part name Q’ty Remarks Removing the valve and valve Remove the parts in the order below. spring Cylinder head Refer to “CAMSHAFT AND CYLINDER HEAD”. Valve cotter Valve spring retainer Intake valve spring Exhaust valve spring Refer to “REMOVING/INSTALLING THE…

-

Page 238: Removing The Valve And Valve Spring

VALVES AND VALVE SPRINGS REMOVING THE VALVE AND VALVE SPRING 1.Check: Valve sealing Leakage at the valve seat → Inspect the valve face, valve seat and valve seat width. Refer to “CHECKING THE VALVE AND VALVE SPRING”. ***************************************************** Checking steps: Pour a clean solvent 1 into the intake and exhaust ports.

-

Page 239: Checking The Valve And Valve Spring

VALVES AND VALVE SPRINGS CHECKING THE VALVE AND VALVE SPRING 1.Measure: Stem-to-guide clearance Stem-to-guide clearance = valve guide inside diameter a – valve stem diameter b Out of specification → Replace the valve guide. Clearance (stem to guide): Intake: 0.010 ~ 0.037 mm (0.0004 ~ 0.0015 in) <Limit>: 0.08 mm (0.0031 in) Exhaust:…

-

Page 240

VALVES AND VALVE SPRINGS 3.Check: Valve face Pitting/wear → Grind the face. Valve stem end Mushroom shape or diameter larger than the body of the stem → Replace. 4.Measure: Margin thickness a Out of specification → Replace. Margin thickness: Intake: 0.85 ~ 1.15 mm (0.0335 ~ 0.0452 in) Exhaust:… -

Page 241

VALVES AND VALVE SPRINGS 8.Measure: Valve seat width a Out of specification → Reface the valve seat. Valve seat width: Intake: 0.9 ~ 1.1 mm (0.0354 ~ 0.0433 in) <Limit>: 1.6 mm (0.0630 in) Exhaust: 0.9 ~ 1.1 mm (0.0354 ~ 0.0433 in) <Limit>: 1.6 mm (0.0630 in) ***************************************************** Measurement steps:… -

Page 242

VALVES AND VALVE SPRINGS Install the valve into the cylinder head. Turn the valve until the valve face and valve seat are evenly polished, then clean off all of the compound. NOTE: For best lapping results, lightly tap the valve seat while rotating the valve back and forth between your hands. -

Page 243: Installing The Valve And Valve Spring

VALVES AND VALVE SPRINGS 11.Measure: Compressed spring force a Out of specification → Replace. b Installed length Compressed spring force: Intake: 100.0 ~ 115.7 N at 27.5 mm (10.20 ~ 11.80 kg, 22.48 ~ 26.01 lb at 1.08 in) Exhaust: 120.6 ~ 138.3 N at 31.0 mm (12.30 ~ 14.10 kg, 27.11 ~ 31.09 lb at 1.22 in)

-

Page 244

VALVES AND VALVE SPRINGS 3.Install: Valve cotters NOTE: Install the valve cotters while compressing the valve spring with the valve spring compressor 1 and valve spring compressor attachment Valve spring compressor: P/N. YM-04019, 90890-04019 Valve spring compressor attachment: P/N. 90890-01243 4.To secure the valve cotters onto the valve stem, lightly tap the valve tip with a piece of wood. -

Page 245: Cylinder And Piston

CYLINDER AND PISTON CYLINDER AND PISTON Order Job name/Part name Q’ty Remarks Removing the cylinder and piston Remove the parts in the order below. Water pump outlet hose Refer to “WATER PUMP” in CHAPTER 5. Cylinder head Refer to “CAMSHAFT AND CYLINDER HEAD”.

-

Page 246: Removing The Piston

CYLINDER AND PISTON REMOVING THE PISTON 1.Remove: Piston pin clips 1 Piston pin 2 Piston 3 NOTE: Put identification marks on each piston head for reference during reinstallation. Before removing each piston pin, deburr the clip groove and pin hole area. If the piston pin groove is deburred and the piston pin is still difficult to remove, use the piston pin puller 4.

-

Page 247

CYLINDER AND PISTON NOTE: Measure cylinder bore “C” in parallel to and at right angles to the cylinder matching surface. Then, find the average of the measurements. Standard Wear limit 100.005 ~ Cylinder 100.100 mm 100.055 mm bore “C” (3.9404 in) (3.9372 ~ 3.9392 in) If out of specification, rebore or replace the cylinder, and replace the piston and piston… -

Page 248: Checking The Piston Ring

CYLINDER AND PISTON CHECKING THE PISTON RING 1.Measure: Ring side clearance Use a feeler gauge. Out of specification → Replace the piston and rings as a set. NOTE: Clean carbon from the piston ring grooves and rings before measuring the side clearance. Side clearance Standard Limit…

-

Page 249: Checking The Piston Pin

CYLINDER AND PISTON CHECKING THE PISTON PIN 1.Check: Piston pin Blue discoloration/grooves → Replace, then inspect the lubrication system. 2.Measure: Piston pin-to-piston clearance ***************************************************** Measurement steps: Measure the piston pin outside diameter a. If out of specification, replace the piston pin. Outside diameter (piston pin): 21.991 ~ 22.000 mm (0.8658 ~ 0.8661 in)

-

Page 250: Installing The Cylinder

CYLINDER AND PISTON 2.Position: Top ring 2nd ring Oil ring Offset the piston ring end gaps as shown. a Top ring end b Oil ring end (lower) c Oil ring end (upper) d 2nd ring end 3.Install: Piston 1 Piston pin 2 Piston pin clips 3 NOTE: Apply engine oil onto the piston pin, piston…

-

Page 251: Recoil Starter And Ac Magneto

RECOIL STARTER AND AC MAGNETO RECOIL STARTER AND AC MAGNETO Order Job name/Part name Q’ty Remarks Removing the AC magneto Remove the parts in the order below. Engine oil Drain. Refer to “CHANGING THE ENGINE OIL” in CHAPTER 3. Coolant Drain.

-

Page 252

RECOIL STARTER AND AC MAGNETO Order Job name/Part name Q’ty Remarks Starter pulley Refer to “REMOVING/INSTALLING THE Crankcase cover (left)/gasket AC MAGNETO”. Dowel pin Lead holder Pickup coil Starter assembly CDI rotor Refer to “REMOVING/INSTALLING THE Woodruff key AC MAGNETO”. Starter wheel gear Washer Starter idle gear shaft… -

Page 253

RECOIL STARTER AND AC MAGNETO Order Job name/Part name Q’ty Remarks Disassembling the recoil starter Remove the parts in the order below. Starter handle Friction plate Pawl spring Refer to “DISASSEMBLING/ASSEM- Drive pawl BLING THE RECOIL STARTER”. Spring Sheave drum Rope Coil spring For assembly, reverse the disassembly… -

Page 254: Removing The Ac Magneto

RECOIL STARTER AND AC MAGNETO REMOVING THE AC MAGNETO 1.Remove: Starter pulley 1 NOTE: Use the rotor holding tool 2 to hold the starter pulley. Rotor holding tool: P/N. YU-01235, 90890-01235 2.Remove: Crankcase cover (left) Gasket Dowel pins NOTE: Working in a crisscross pattern, loosen each bolt 1/4 of a turn.

-

Page 255: Checking The Starter Clutch

RECOIL STARTER AND AC MAGNETO CHECKING THE STARTER CLUTCH 1.Check: Starter one-way clutch 1 Cracks/damage → Replace. Bolts 2 (starter clutch) Loose → Replace with a new one, and clinch the end of the bolt. NOTE: The arrow mark on the starter clutch must face inward, away from the CDI rotor.

-

Page 256: Checking The Starter Pulley

RECOIL STARTER AND AC MAGNETO CHECKING THE STARTER PULLEY 1.Check: Starter pulley Cracks/pitting → Deburr or replace. CHECKING THE RECOIL STARTER 1.Check: Rope 1 Sheave drum 2 Drive pawl 3 Wear/damage → Replace. Coil spring 4 Pawl spring 5 Spring 6 Fatigue →…

-

Page 257: Installing The Ac Magneto

Untie the knot 3 after making a knot 4 above the handle. INSTALLING THE AC MAGNETO 1.Apply: ® Sealant (Quick Gasket (into the slit) ® Sealant (Quick Gasket P/N. ACC-11001-05-01 Yamaha bond No. 1215: P/N. 90890-85505 4 — 44…

-

Page 258

RECOIL STARTER AND AC MAGNETO 2.Install: Woodruff key CDI rotor NOTE: Before installing the rotor, clean the outside of the crankshaft and the inside of the rotor. After installing the rotor, check that the rotor rotates smoothly. If not, reinstall the key and rotor. -

Page 259

RECOIL STARTER AND AC MAGNETO 5.Install: Select lever unit Select lever shift rod NOTE: Before installing the select lever shift rod, make sure that the select lever and shift cam is in the NEUTRAL position. 6.Adjust: Select lever shift rod Refer to “ADJUSTING THE SELECT LEVER CONTROL CABLE AND SHIFT ROD”… -

Page 260: Balancer Gears And Oil Pump Gears

BALANCER GEARS AND OIL PUMP GEARS BALANCER GEARS AND OIL PUMP GEARS Order Job name/Part name Q’ty Remarks Removing the balancer gears and oil Remove the parts in the order below. pump gears Starter wheel gear Refer to “RECOIL STARTER AND AC MAGNETO”.

-

Page 261: Removing The Balancer Drive Gear And Balancer Driven Gear

BALANCER GEARS AND OIL PUMP GEARS REMOVING THE BALANCER DRIVE GEAR AND BALANCER DRIVEN GEAR 1.Straighten the lock washer tabs. 2.Loosen: Balancer driven gear nut 1 NOTE: Place an aluminum plate 2 between the teeth of the balancer drive gear 3 and balancer driven gear 4.

-

Page 262: Checking The Balancer Drive

BALANCER GEARS AND OIL PUMP GEARS CHECKING THE BALANCER DRIVE 1.Check: Balancer drive gear 1 Balancer driven gear 2 Damage/wear → Replace the balancer drive gear and balancer driven gear as a set. Excessive noise during operation → Replace the balancer drive gear and balancer driven gear as a set.

-

Page 263

BALANCER GEARS AND OIL PUMP GEARS 3.Install: Lock washer Balancer driven gear nut 1 140 Nm (14.0 m • kg, 100 ft • lb) NOTE: Place an aluminum plate 2 between the teeth of the balancer drive gear 3 and bal- ancer driven gear 4. -

Page 264: Primary And Secondary Sheaves

PRIMARY AND SECONDARY SHEAVES PRIMARY AND SECONDARY SHEAVES 10 Nm (1.0 m kg, 7.2 ft • • 100 Nm (10.0 m kg, 72 ft • • 120 Nm (12.0 m kg, 85 ft • • 10 Nm (1.0 m kg, 7.2 ft •…

-

Page 265

PRIMARY AND SECONDARY SHEAVES 10 Nm (1.0 m kg, 7.2 ft • • 100 Nm (10.0 m kg, 72 ft • • 120 Nm (12.0 m kg, 85 ft • • 10 Nm (1.0 m kg, 7.2 ft • • 10 Nm (1.0 m kg, 7.2 ft •… -

Page 266: Primary Sheave

PRIMARY AND SECONDARY SHEAVES PRIMARY SHEAVE Order Job name/Part name Q’ty Remarks Disassembling the primary sheave Remove the parts in the order below. Primary pulley sheave cap Primary pulley slider Spacer Primary pulley cam Refer to “ASSEMBLING THE PRIMARY Primary pulley weight SHEAVE”.

-

Page 267: Secondary Sheave

PRIMARY AND SECONDARY SHEAVES SECONDARY SHEAVE Order Job name/Part name Q’ty Remarks Disassembly the secondary sheave Remove the parts in the order below. Spring seat Compression spring Spring seat Refer to “DISASSEMBLING/ASSEM- BLING SECONDARY SHEAVE”. Guide pin Secondary sliding sheave O-ring Secondary fixed sheave Oil seal…

-

Page 268: Removing The Primary And Secondary Sheaves

PRIMARY AND SECONDARY SHEAVES REMOVING THE PRIMARY AND SECONDARY SHEAVES 1.Loosen: Nut (secondary sheave) 1 Nut (primary sheave) 2 NOTE: Use the sheave holder 3 to hold the primary sheave. First, loosen the nut (secondary sheave) 2, then loosen the nut (primary sheave) 1. Sheave holder: P/N.

-

Page 269: Cheking The Primary Sheave

PRIMARY AND SECONDARY SHEAVES CHEKING THE PRIMARY SHEAVE 1.Check: Weight outside diameter a Out of specification → Replace the weight. Weight outside diameter: 30 mm (1.18 in) <Limit>: 29.5 mm (1.16 in) 2.Check: Primary puller slider Primary sliding sheave splines Wear/cracks/damage →…

-

Page 270: Assembling The Primary Sheave

Remove any excess grease. 2.Install: Weight 1 NOTE: Apply Yamaha Grizzly grease (90 g) to the whole outer surface of the weight and install. Apply Yamaha Grizzly grease to the inner surface of the collar. Apply Yamaha Grizzly grease to the inner surface of the primary sliding sheave.

-

Page 271

PRIMARY AND SECONDARY SHEAVES 3.Apply: ® BEL-RAY assembly lube (to the guide pin sliding groove 1, and O- ring 2 4.Install: Spring seat Compression spring Spring seat ***************************************************** Installing steps: Attach the sheave fixed block, locknut wrench and sheave spring compressor to the secondary sheave assembly. -

Page 272: Installing The Primary And Secondary Sheaves

PRIMARY AND SECONDARY SHEAVES INSTALLING THE PRIMARY AND SECONDARY SHEAVES 1.Install: Secondary sheave assembly V-belt Primary sheave assembly NOTE: Tightening the bolts 1 will push the second- ary sliding sheave away, causing the gap between the secondary fixed and sliding sheaves to widen.

-

Page 273: Clutch

CLUTCH CLUTCH Order Job name/Part name Q’ty Remarks Removing the clutch Remove the parts in the order below. Primary and secondary sheaves Refer to “PRIMARY AND SECONDARY SHEAVES”. Clutch housing assembly Gasket/dowel pin Refer to “REMOVING AND INSTALL- ING THE CLUTCH”. One-way clutch bearing Clutch carrier assembly For installation, reverse the removal…

-

Page 274

CLUTCH Order Job name/Part name Q’ty Remarks Disassembling the clutch housing Remove the parts in the order below. Oil seal Circlip Bearing housing Circlip Bearing Circlip Bearing Clutch housing For assembly, reverse the disassembly procedure. 4 — 61… -

Page 275: Removing The Clutch

CLUTCH REMOVING THE CLUTCH 1.Remove: Clutch housing assembly Gasket Dowel pins NOTE: Working in crisscross pattern, loosen each bolt 1/4 of a turn. Remove them after all of them are loosened. 2.Straighten: Punched portion of the nut 1. 3.Remove: Nut 1 NOTE: Use a clutch holding tool 2 to hold the clutch carrier assembly.

-

Page 276: Installing The Clutch

CLUTCH 2.Check: Clutch shoe Heat damage → Replace. 3.Measure: Clutch shoe thickness Out of specification → Replace. Clutch shoe thickness: 1.5 mm (0.06 in) Clutch shoe wear limit a: 1.0 mm (0.04 in) INSTALLING THE CLUTCH 1.Install: Collar Clutch carrier assembly Nut 1 160 Nm (16.0 m •…

-

Page 277

CLUTCH 4.Install: Dowel pins Gasket Clutch housing assembly 10 Nm (1.0 m • kg, 7.2 ft • lb) NOTE: Tighten the bolts in stages, using a criss- cross pattern. After tightening the bolts, check that the clutch housing assembly to counterclockwise rotates smoothly. -

Page 278: Crankcase

CRANKCASE CRANKCASE STARTER MOTOR, TIMING CHAIN AND OIL FILTER Order Job name/Part name Q’ty Remarks Remove the starter motor, timing Remove the parts in the order below. chain and oil filter Engine assembly Refer to “ENGINE REMOVAL”. Cylinder head Refer to “CAMSHAFT AND CYLINDER HEAD”.

-

Page 279: Crankcase

CRANKCASE Order Job name/Part name Q’ty Remarks Oil filter Speed sensor Shift cam stopper Gear position switch Reverse switch Oil filler cap Oil delivery pipe Drain plug For installation, reverse the removal procedure. 4 — 66…

-

Page 280

CRANKCASE CRANKCASE 10 Nm (1.0 m kg, 7.2 ft • • 10 Nm (1.0 m kg, 7.2 ft • • 14 Nm (1.4 m kg, 10 ft • • 10 Nm (1.0 m kg, 7.2 ft • • Order Job name/Part name Q’ty Remarks Separating the crankcase… -

Page 281: Crankcase Bearing

CRANKCASE CRANKCASE BEARING 10 Nm (1.0 m kg, 7.2 ft • • Order Job name/Part name Q’ty Remarks Removing the crankcase bearing Remove the parts in the order below. Crankshaft and oil pump Refer to “CRANKSHAFT AND OIL PUMP”. Transmission Refer to “TRANSMISSION”.

-

Page 282: Separating The Crankcase

CRANKCASE SEPARATING THE CRANKCASE È 1.Separate: Left crankcase Right crankcase ***************************************************** Separation steps: Remove the crankcase bolts. NOTE: Loosen each bolt 1/4 of a turn at a time and after all the bolts are loosened, remove É them. Loosen the bolts in stages, using a criss- cross pattern.

-

Page 283: Checking The Crankcase

Sealant (Quick Gasket (to the mating surfaces of both case halves) ® Sealant (Quick Gasket P/N. ACC-11001-05-01 Yamaha bond No. 1215: P/N. 90890-85505 2.Install: Dowel pin 2 3.Fit the left crankcase onto the right case. Tap lightly on the case with a soft hammer.

-

Page 284: Installating The Shift Lever

CRANKCASE 4.Tighten: È Crankcase bolts (follow the proper tightening sequence) 10 Nm (1.0 m • kg, 7.2 ft • lb) È Right crankcase É Left crankcase NOTE: Tighten the bolts in stages, using a crisscross pattern. É 5.Apply: 4-stroke engine oil (to the crank pin, bearing and oil delivery hole) 6.Check:…

-

Page 285: Crankshaft And Oil Pump

CRANKSHAFT AND OIL PUMP CRANKSHAFT AND OIL PUMP Order Job name/Part name Q’ty Remarks Removing the crankshaft and oil Remove the parts in the order below. pump Crankcase separation Refer to “CRANKCASE”. Oil strainer/O-ring Oil pump assembly/gasket Balancer Refer to “REMOVING THE CRANK- Plate SHAFT/INSTALLING THE CRANK- SHAFT AND BALANCER”.

-

Page 286: Oil Pump

CRANKSHAFT AND OIL PUMP OIL PUMP Order Job name/Part name Q’ty Remarks Disassembling the oil pump Remove the parts in the order below. Rotor cover Shaft Inner rotor Outer rotor Oil pump housing For assembly, reverse the disassembly procedure. 4 — 73…

-

Page 287: Removing The Crankshaft

CRANKSHAFT AND OIL PUMP REMOVING THE CRANKSHAFT 1.Remove: Crankshaft Use a crankcase separating tool 1. Crankcase separating tool: P/N. YU-01135-A, 90890-01135 CHECKING THE OIL PUMP 1.Check: Rotor housings Rotor cover Cracks/wear/damage → Replace. 2.Measure: Tip clearance a (between the inner rotor 1 and the outer rotor 2) Side clearance b (between the outer rotor 2 and the pump…

-

Page 288: Checking The Relief Valve

CRANKSHAFT AND OIL PUMP CHECKING THE RELIEF VALVE 1.Check: Relief valve body 1 Relief valve 2 Spring 3 O-ring 4 Damage/wear → Replace the defective parts(s). CHECKING THE OIL STRAINER 1.Check: Oil strainer 1 O-ring 2 Damage → Replace. Contaminants → Clean with engine oil. ASSEMBLING THE OIL PUMP 1.Install: Inner rotor…

-

Page 289: Checking The Crankshaft

CRANKSHAFT AND OIL PUMP CHECKING THE CRANKSHAFT 1.Measure: Crank width A Out of specification → Replace the crank- shaft. Crank width: 74.95 ~ 75.00 mm (2.9508 ~ 2.9528 in) Side clearance D Out of specification → Replace the crank- shaft. Big end side clearance: 0.35 ~ 0.65mm (0.0138 ~ 0.0256 in)

-

Page 290: Installing The Crankshaft And Balancer

CRANKSHAFT AND OIL PUMP INSTALLING THE CRANKSHAFT AND BALANCER 1.Install: Crankshaft Crankshaft installer pot 1: P/N. 90890-01274 Crankshaft installer bolt 2: P/N. 90890-01275 Crankshaft installer set 3: P/N. YU-90050 Adapter 4: P/N. YM-90069, 90890-04059 Spacer (crankshaft installer) 5: P/N. YM-91044, 90890-04081 Spacer 6: P/N.

-

Page 291: Transmission

TRANSMISSION TRANSMISSION Order Job name/Part name Q’ty Remarks Removing the transmission Remove the parts in the order below. Crankcase separation Refer to “CRANKCASE”. Middle driven gear Refer to “MIDDLE GEAR”. Low wheel gear Shift cam Shift fork assembly Short spring White painting.

-

Page 292